Page 1

SURVEY PRO

for Windows® CE

User’s Manual

2002 Tripod Data Systems, Inc.

All Rights Reserved

Page 2

TRIPOD DATA SYSTEMS SOFTWARE LICENSE AGREEMENT

IMPORTANT: BY OPENING TH E SEALED MEDIA PACKAGE, YOU ARE AGREEIN G TO BE BO UND BY THE TERMS AND CO NDITIO NS OF

THE LICENSE AGREEMENT AND LIMITATIONS OF LIABILITY ("Agreement"). THIS AGREEMENT CONSTITUTES THE COMPLETE

AGREEMENT BETWEEN YOU AND TRIPOD DATA SYSTEMS, INC. ("Licensor"). CAREFULLY READ THE AGREEMENT AND IF YOU DO

NOT AGREE WITH THE TERMS, RETURN THE UNOPENED MEDIA PACKAGE AND THE ACCOMPANYING ITEMS (including written

materials and binders or other containers) TO THE PLACE WHERE YOU OBTAINED THEM FOR A FULL REFUND.

LICENSE. LICENSOR grants to you a limited, non-exclusive license to (i) install and operate the copy of the computer program contained in this

package ("Program") on a single computer (one central processing unit and associated monitor and keyboard) and (ii) make one archival copy of the

Program for use with the same computer. LICE NSOR retains all rights to the Program not expressly granted in this Agreement.

OWNERSHIP OF PROGRAMS AND COPIES. This license is not a sale of the original Program or any copies. LICENSOR retains the ownership of

the Program and all subsequent cop ies of the Program made by you, regardless of the form in which the copies may exist. The Program and

accompanying manuals ("Documentation") are copyrighted works of authorship and contain valuable trade secrets and confidential information

proprietary to LICENSOR. You agree to exercise reasonable efforts to protect LICENSOR'S proprietary interest in the Program and Documentation

and maintain them in strict confidence.

USER RESTRICTIONS. You may physically transfer some Programs from one computer to another provided that the Program is operated only on

one computer. Other Programs will operate only with the computer that has the same security code and cannot be physically transferred to another

computer. You may not electronically transfer the Program or operate it in a time-sharing or service bureau operation. You agree not to translate,

modify, adapt, disassemble, de-compile, or reverse engin eer the Program, or create derivative works based on the Program or Documentation or any

portions thereof.

TRANSFER. The Program is provided for use in your internal commercial business operations and must remain at all times upon a single computer

owned or leased by you. You may not rent, lease, sublicense, sell, assign, pledge, transfer or otherwise dispose of the Program or Documentation, on

a temporary or permanent basis, without the prio r written consent of LICENSOR.

TERMINATION. This License is effective until terminated. This License will terminate automatically without notice from LICENSOR if you fail to

comply with any provision of this License. Upon termination you must cease all use of the Program and Documentation and return them, and any

copies thereof, to LICENSOR.

GENERAL. This License shall be governed by and construed in accordance with the laws of the State of Oregon, United States of America.

LICENSOR grants solely to you a limited warranty that (i) the media on which the Program is distributed shall be substantially free from material

defects for a period of NINETY (90) DAYS, and (ii) the Program will perform substantially in accordance with the material descriptions in the

Documentation for a period of NINETY (90) DAYS. These warranties commence on the day you first obtain the Program and extend only to you, the

original customer. These limited warranties give you specific legal rights, and you may have other rights, which vary from state to state.

Except as specified above, LICENSOR MAKES NO WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING THE

PROGRAM, MEDIA OR DOCUMENTATION AND HEREBY EXPRESSLY DISCLAIMS THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOS E. LICENSOR d oes not warran t the Program will meet your requirements or that its operations will be

uninterrupted or error-free.

If the media, Program or Documentation are not as warranted above, LICENSOR will, at its option, repair or replace the nonconforming item at no

cost to you, or refund your money, provided you return the item, with proof of the date you obtained it, to LICENSOR within TEN (10) DAYS after

the expiration of the applicable warranty period. If LICENSOR determines that the particular item has been damaged by accident, abuse, misuse or

misapplication, has been modified without the written permission of LICENSOR, or if any LICENSOR label or serial number has been removed or

defaced, the limited warranties set forth above do not apply and you accept full responsibility for the product.

The warranties and remedies set forth above are exclusive and in lieu of all others, oral or written, express or implied. Statements or

representations which add to, extend or modify these warranties are unauthorized by LICENSOR and should not be relied upon by you.

LICENSOR or anyone involved in the creation or delivery of the Program or Documentation to you shall have no liability to you or any third party

for special, incidental, or consequential damages (including, but not limited to, loss of profits or savings, downtime, damage to or replacement of

equipment and property, or recovery or replacement of programs or data) arising from claims based in warranty, contract, tort (including

negligence), strict liability, or otherwise even if LICENSOR has been advised of the possibility of such claim or damage. LICENSOR'S liability for

direct damages shall not exceed the actual amount paid for this copy of the Program.

Some states do not allow the exclusion or limitation of implied warranties or liability for incidental or consequential damages, so the above

limitations or exclusions may not apply to you.

If the Program is acquired for use by or on behalf of a unit or agency of the United States Government, the Program and Documentation are provided

with "Restricted Rig hts". Use, dup lication, or d isclosure by th e Government i s subject to restrictio ns as set forth in subparagraph (c)(1)(ii) of the

Rights in Technical Data and Computer Software clause at DFARS 252.227-7013, and to all other regulations, restrictions and limitations applicable

to Government use of Commercial Software. Contractor/manufacturer is Tripod Data Systems, Inc., PO Box 947, Corvallis, Oregon, 97339, United

States of America.

Should you have questions concerning the License Agreement or the Limited Warranties and Limitation of Liability, please contact in writing:

Tripod Data Systems, Inc., PO Box 947, Corvallis, Oregon, 97339, United States of America.

LIMITED WARRANTIES AND LIMITATION OF LIABILITY

U.S. GOVERNMENT RESTRICTED RIGHTS

Survey Pro is a registered trademark of Tripod Data Systems, Inc. Windows and Windows CE are registered trademarks of Microsoft Corporation.

TRADEMARKS

.MAN-CESURVEYPRO 10112002

ii

Page 3

Table of Contents

Getting Started __________________________________________ 1

Manual Conventions ________________________________1

Installation and Upgrading __________________________2

Angle and Time Conventions ________________________4

Azimuths _________________________________________________ 4

Bearings___________________________________________________ 4

Time______________________________________________________ 4

Starting the Program and Creating a New Job __________5

Navigating Within the Program ______________________7

Hotkeys ___________________________________________9

Parts of a Screen ___________________________________10

Input Fields_______________________________________________ 10

Output Fields _____________________________________________ 10

Input Shortcuts ___________________________________________ 12

The Map View ____________________________________14

The Settings Screen ________________________________15

Navigating to the Screens___________________________________ 16

Instrument Settings Page ___________________________________ 16

Units Settings_____________________________________________ 18

Format Settings ___________________________________________ 18

Files Settings______________________________________________ 19

Surveying Settings_________________________________________ 20

Stakeout Settings __________________________________________ 21

Repetition Settings_________________________________________ 24

Date/Time Settings________________________________________ 25

General Settings___________________________________________ 26

Required Files_____________________________________28

Job Files__________________________________________________ 28

Raw Data Files ____________________________________________ 29

Control Files ______________________________________30

Control File Example ______________________________________ 31

Description Files___________________________________32

Description Files Without Codes_____________________________ 32

Description Files With Codes________________________________ 33

Opening a Description File__________________________________ 34

Feature Codes_____________________________________35

Features__________________________________________________ 36

iii

Page 4

Attributes_________________________________________________36

Using Feature Codes in Survey Pro___________________________37

Layers____________________________________________38

Layer 0 ___________________________________________________38

Other Special Layers _______________________________________38

Managing Layers __________________________________________ 39

2D / 3D Points ____________________________________ 40

Polylines _________________________________________41

Alignments _______________________________________41

Creating an Alignment _____________________________________42

Fieldwork ______________________________________________47

Scenario One______________________________________________48

Scenario Two______________________________________________48

Scenario Three_____________________________________________49

Scenario Four _____________________________________________50

Summary _________________________________________________50

Data Collection Example____________________________51

Setup_____________________________________________________52

Performing a Side Shot _____________________________________55

Performing a Traverse Shot _________________________________56

Data Collection Summary___________________________________58

Stakeout Example__________________________________59

Set Up____________________________________________________60

Staking Points_____________________________________________61

Point Staking Summary_____________________________________64

Surveying with True Azimuths ______________________65

Road Layout ____________________________________________67

Overview_________________________________________67

Horizontal Alignment (HAL)________________________________67

Vertical Alignment (VAL)___________________________________67

Templates ________________________________________________67

POB______________________________________________________69

Road Component Rules ____________________________69

Alignments _______________________________________________69

Templates ________________________________________________69

Widenings and Super Elevations. ____________________________70

Road Rules Examples_______________________________________72

Creating Templates ________________________________75

Building an Alignment _____________________________77

Putting the Road Together __________________________78

iv

Page 5

Staking the Road __________________________________83

Slope Staking the Road _____________________________84

DTM Stakeout__________________________________________ 87

Create a DTM or DXF File __________________________87

Set Up the Job _____________________________________88

Select Your Layers_________________________________________ 90

Select a Boundary (optional) ________________________________ 90

Select any Break-lines (optional)_____________________________ 91

Stake the DTM ____________________________________93

View the DTM ____________________________________________ 94

Screen Examples ________________________________________ 97

Import / Export Coordinates________________________97

Importing *.JOB Coordinates________________________________ 98

Importing *.CR5 Coordinates _______________________________ 98

Exporting Coordinates _____________________________________ 99

Repetition Shots __________________________________100

Repetition Settings Screen _________________________________ 100

Repetition Shots Screen____________________________________ 102

Shoot From Two Ends_____________________________104

Offset Shots______________________________________105

Distance Offset Screen ____________________________________ 105

Horizontal Angle Offset Screen_____________________________ 106

Vertical Angle Offset Screen _______________________________ 107

Resection ________________________________________108

Performing a Resection____________________________________ 108

Solar Observations________________________________110

Performing a Sun Shot ____________________________________ 110

What to Do Next _________________________________________ 113

Remote Control __________________________________115

The Remote Control Screen ________________________________ 115

Taking a Shot in Remote Mode _____________________________ 116

Stake Out in Remote Mode ________________________________ 117

Slope Staking in Remote Mode _____________________________ 118

Slope Staking ____________________________________119

Defining the Road Cross-Section____________________________ 120

Staking the Catch Point____________________________________ 122

Intersection ______________________________________125

Map Check ______________________________________126

Entering Boundary Data___________________________________ 126

Editing Boundary Data____________________________________ 127

v

Page 6

Adding Boundary Data to the Current Project ________________127

Predetermined Area ______________________________128

Hinge Method____________________________________________128

Parallel Method __________________________________________129

Horizontal Curve Layout __________________________131

PC Deflection ____________________________________________131

PI Deflection _____________________________________________131

Tangent Offset____________________________________________132

Chord Offset _____________________________________________132

Parabolic Curve Layout ___________________________133

Spiral Layout_____________________________________134

Curve and Offset _________________________________135

Define Your Curve________________________________________135

Setup Your Staking Options ________________________________136

Aim the Total Station______________________________________136

Stake the Point ___________________________________________137

Scale Adjustment _________________________________138

Translate Adjustment _____________________________139

Translate by Distance and Direction _________________________139

Translate by Coordinates __________________________________140

Rotate Adjustment________________________________141

Traverse Adjust __________________________________142

Angle Adjust_____________________________________________142

Compass Rule____________________________________________142

Adjust Sideshots__________________________________________143

Performing a Traverse Adjustment __________________________144

vi

Page 7

Getting Started

TDS Survey Pro for Windows C E is available with different options

and sold under the names, Survey Standard, Survey Pro, Survey

Pro Robotic, Survey Pro GPS, and Survey Pro Max. Throughout

the manual and software, it is simply called Survey Pro. For a listing

of which features are included in each product, contact your local TDS

dealer.

This manual covers the routines that are available in all of the

different software packages except for the GPS routines , which are

included with Survey Pro GPS and Survey Pro Max. The GPS

routines are covered in a separate manual.

Manual Conventions

Throughout the Survey Pro Manual, certain text formatting is used

that represents different parts of the software. The formatting used

in the manual is explained below.

Fields

When referring to a particular field, the

Corresponding Value

would see in the software.

is shown with text that is similar to what you

Field Label

, or its

Screens and Menus

When referring to a particular screen or menu, the text is underlined.

Buttons

When referring to a particular button, the text is shown in a

%XWWRQ )RUPDW

, similar to that found in the software.

1

Page 8

User’s Manual

Installation and Upgrading

The Survey software that you purchased is shipped pre-installed on

the data collector. Upgrading the software is simply a matter of

purchasing a registration code that is specifically generated for your

data collector. Once entered in the data collector, it will activate the

appropriate add-on module.

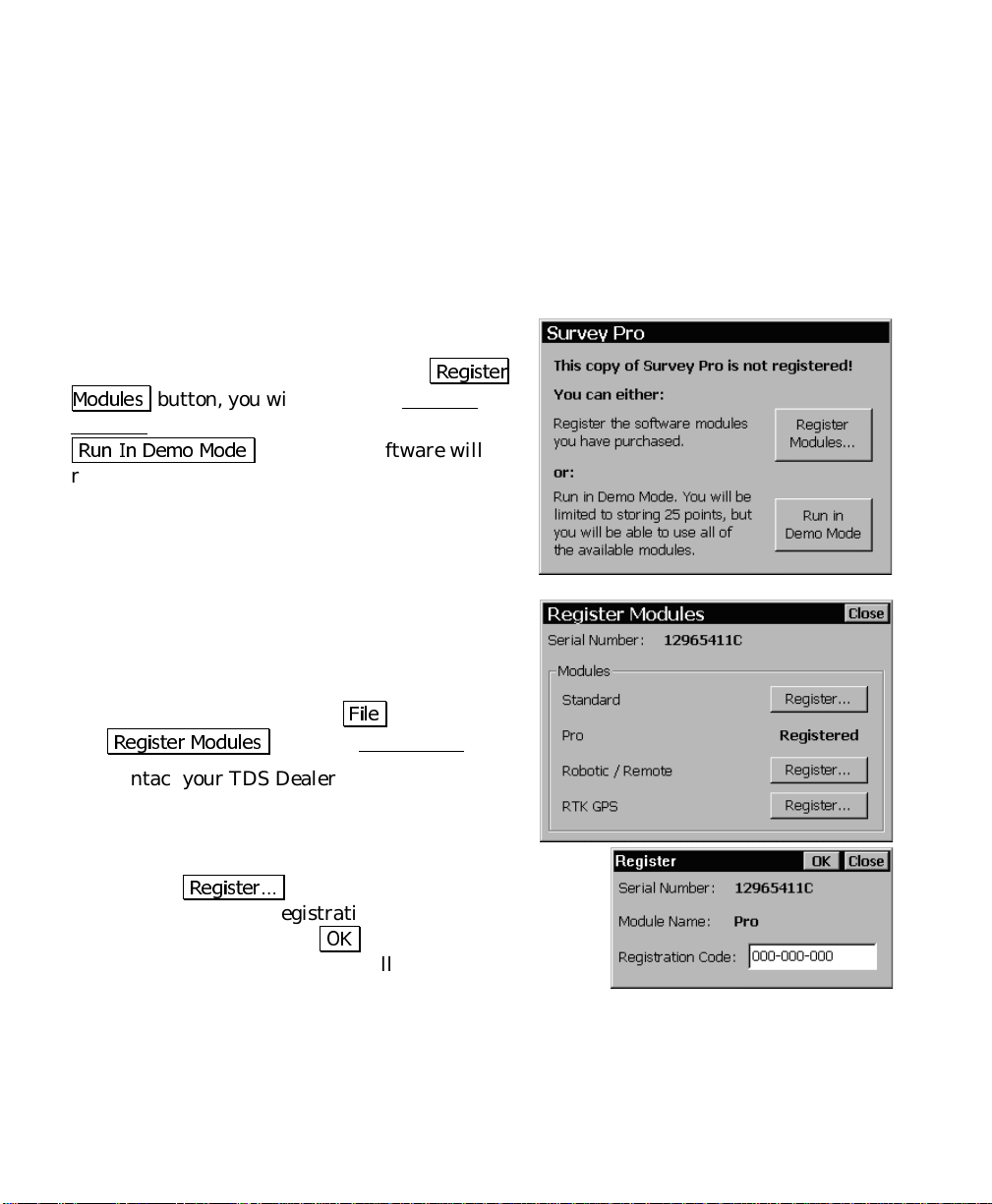

If you start Survey Pro and the Standard Module

has not yet been registered, the first screen

shown here will open. If you select the

0RGXOHV

Modules screen, described next. If you select the

5XQ ,Q 'HPR 0RGH

run in demo mode. When running in this special

mode, all areas of the software are available.

The only limitation is, a job cannot exceed 25

points. If a job is s tored on the data collector

that exceeds this limit, it cannot be opened.

Add-on modules can be purchased from your local

TDS dealer to upgrade your TDS Survey

Software. Upgrading is a quick and easy process

and described below.

button, you will access the Register

button, the software will

5HJLVWHU

1. On the data collector, tap

5HJLVWHU 0RGXOHV

2. Contact your TDS Dealer and give him your

unique serial number that is displayed on

your screen. He will give you a registration

number for the module that you purchased.

3. Tap the

module, enter the registration number in the dialog

box that opens and tap

module that you purchased will now be available.

2

5HJLVWHU«

from the Main Menu

button for the appropriate

)LOH

,

.

2.

. All the features for the

Page 9

Getting Started

Note: You should keep a record of all registration codes purchased in

case they need to be reentered at some point.

Upgrading from Version 1.x or 2.x to Version 3.0

or later is a chargeable upgrade. Once the new

software is installed, the screen shown here will

be displayed. A new registration code must be

purchased and entered in the

software will only run in Demo Mode, as

described above. Only one upgrade code is

required to upgrade all of the earlier-version

modules that were previously registered.

Users that are upgrading to Version 3.0 or later

from Version 1.x or 2.x must consider the

following limitations before installing the new software:

• You should have a Ranger with at least 32-MB of onboard

memory. The 16-MB models are not sufficient to run the

program and store a large job.

field or the

Code

• The Ranger must have Version 2.1 or later of Windows CE

installed before installing the new Survey Pro software.

3

Page 10

User’s Manual

Angle and Time Conventions

Throughout the software, the following conventions are followed

when inputting or outputting angles and time:

Azimuths

Azimuths are entered in degree-minut es-seconds format and are

represented as DD.MMSSsss, where:

• DD One or more digits representing the degrees.

• MM Two digits representing the minutes.

• SS Two digits representing the seconds.

• sss Zero or more digits representing the decimal fraction

part of the seconds.

For example,

seconds.

212.5800

Bearings

would indicate 212 degrees, 58 minutes, 0

Bearings can be entered in either of the following formats:

•

S32.5800W

seconds West.

•

3 32.5800

quadrant 3.

to indicate South 32 degrees, 58 minutes, 0

to indicate 32 degrees, 58 minutes, 0 seconds in

Time

When a field accepts a time for its input, the time is entered in hoursminutes-seconds format, which is represented as HH.MMSSsss

where:

• HH One or more digits representing the hours.

• MM Two digits representing the minutes.

• SS Two digits representing the seconds.

• sss Zero or more digits representing the decimal fraction

part of the seconds.

4

Page 11

Getting Started

Starting the Program and

Creating a New Job

Since Survey Pro runs in the Windows CE operating system,

selections and cursor control can be made by simply tapping the

screen with your finger or a stylus.

Note: You can temporarily disable the touch-screen if you need to

clean it by tapping

touch-screen and return to Survey Pro.

You can start the Survey Pro program by double tapping the icon

located on the desktop.

- [ ] (space). Tap [ESC] to reactivate the

Ctrl

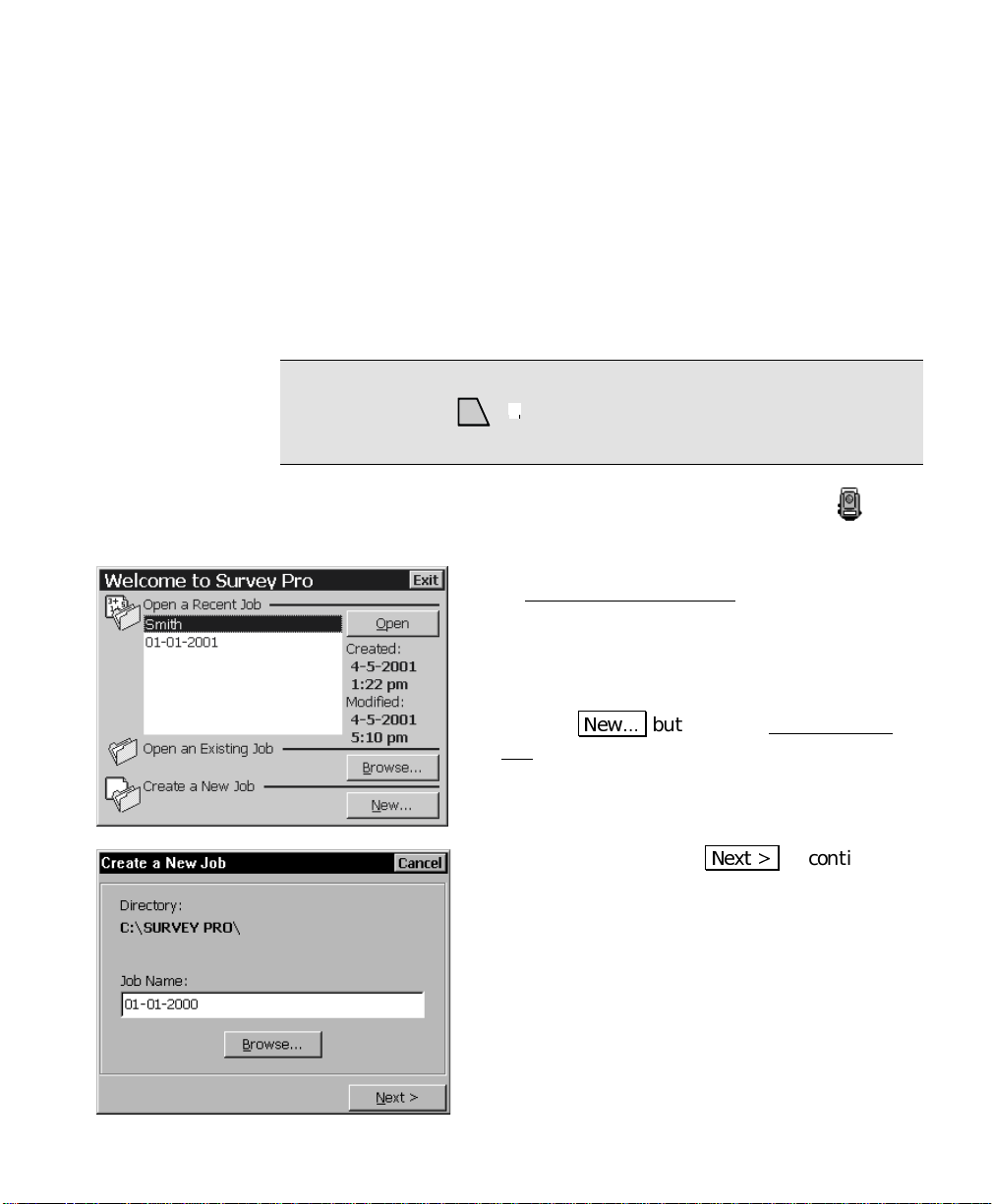

Survey Pro cannot start without a job being open

so the Welcome to Survey Pro

you want to open a recently opened job, open an

existing job, or create a new job. For this

example we will create a new job so you can begin

exploring the software.

screen will ask if

1. Tap the

Job dialog box will open, which prompts you

for a job name where the current date is the

default name.

2. Either type in a new name or accept the

default name and tap

1HZ«

button. The Create a New

1H[W !

to continue.

5

Page 12

User’s Manual

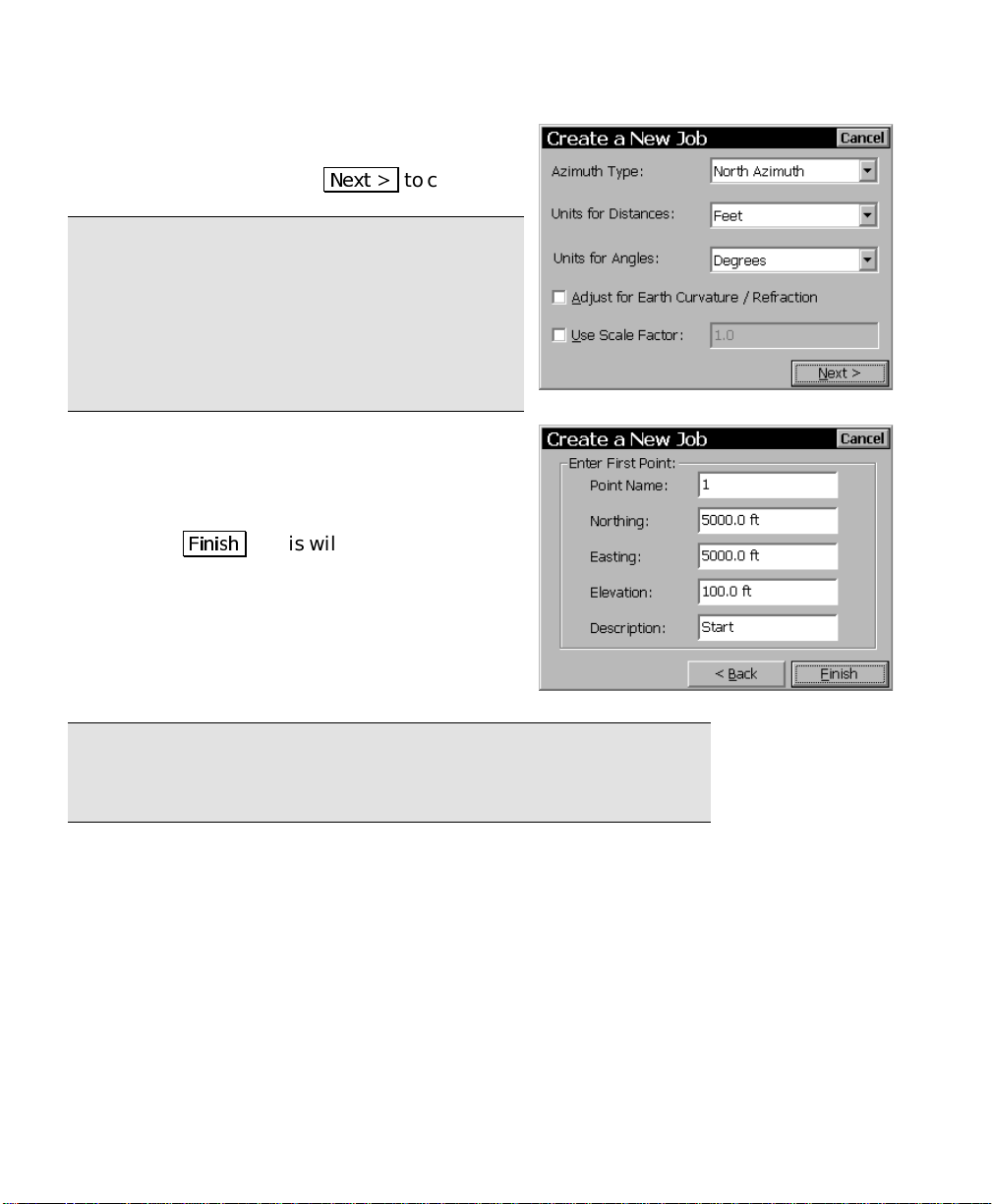

3. Another screen will open where you select

some of the job settings. Select the settings

that you desire and tap

Note: When creating a new job, it is important

that the

correct units. This allows you to seamlessly

switch between different units in mid-job.

Problems can arise if these units are

inadvertently set to the incorrect units when new

data is collected.

4. Since all jobs must have at least one point to

Units for Distances

start with, the final screen displays the

default point name and coordinates for the

first point. Accept the default values by

tapping

the new job. You are now ready to explore

the software.

)LQLVK

. This will create and store

1H[W !

field be set to the

to continue.

Note: The settings and values entered for a new job become the

default values for any subsequent new jobs with the exception of the

Use Scale Factor

6

setting, which always defaults to off.

Page 13

Getting Started

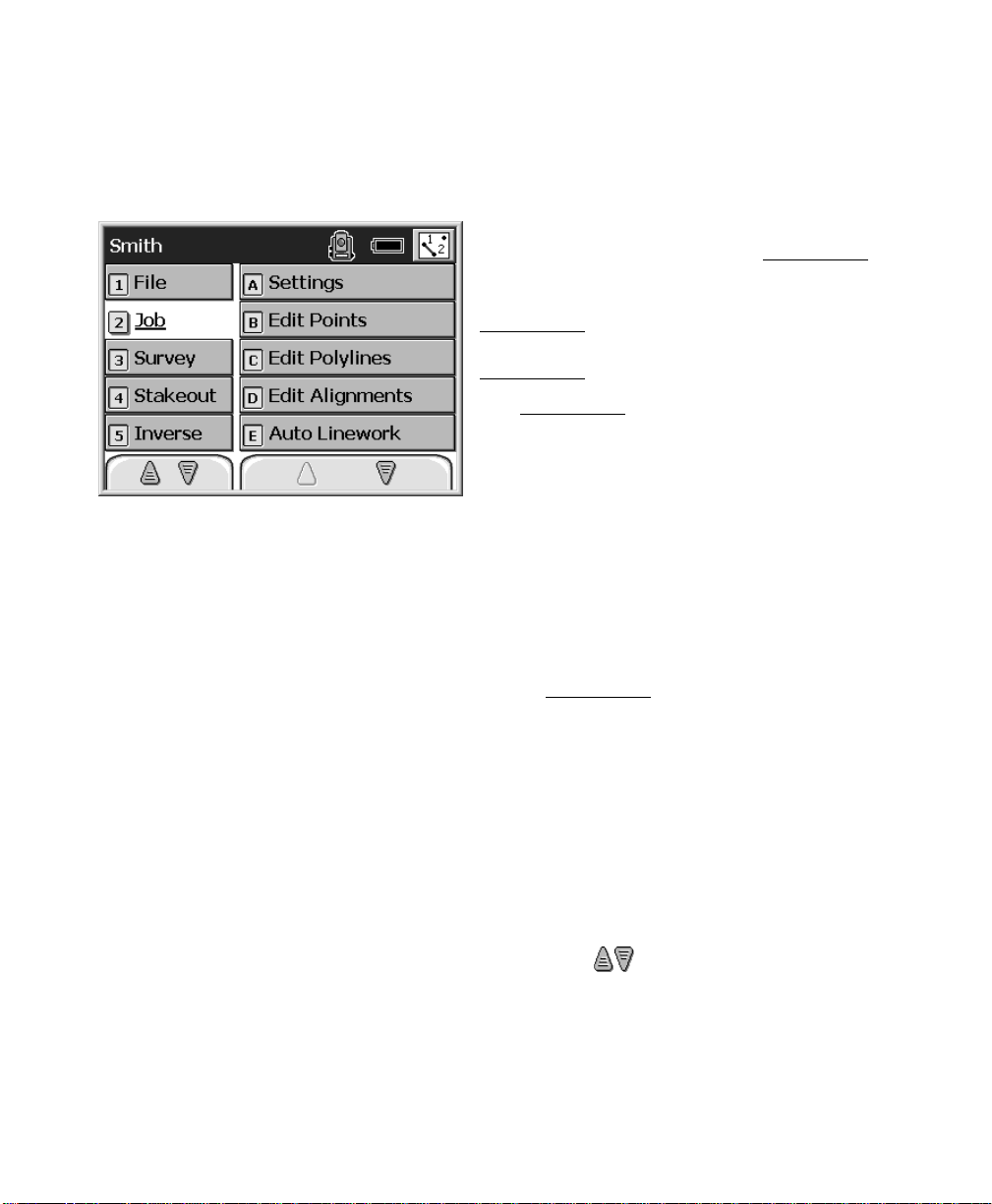

Navigating Within the Program

The starting point in Survey Pro, which appears

once a job is open, is called the Main Menu

shown here. All the screens that are available

in Survey Pro are accessed starting from the

Main Menu

Survey Pro will eventually take you back to the

Main Menu

. Likewise, closing the screens in

.

,

The Main Menu

left column contains all of the available menus

and the column on the right contains the menu

items associat ed with the active menu.

When a menu is selected from the left column, the corresponding

menu items will become available in the right hand column. When a

menu item is activated from the right hand column, the

corresponding screen will open. It is from these screens where you do

your work.

Navigation through the menus and menu items can be done using

any of the methods described below. The best way to become familiar

with navigating through the Main Menu

Each menu has a number associated with it, whereas the menu items

have letters associated with them. Pressing the associated number or

letter on the data collector’s keypad will activate the corresponding

menu or menu item.

You can scroll through the list of menus and menu items by using the

arrow keys on the keypad. The up and down arrow keys will scroll up

and down through the selected column. The other column can be

selected by using the horizontal arrow keys.

You can also scroll through the list of menus and menu items by

tapping the special arrow buttons

bottom of each column. If one of these buttons appears blank, it

indicates that you can scroll no further in that direction.

consists of two columns . The

is to simply try each method.

on the screen located at the

When the desired menu item is selected, it can be activated by

tapping it or pressing t h e [ Enter] key on the keypad.

7

Page 14

User’s Manual

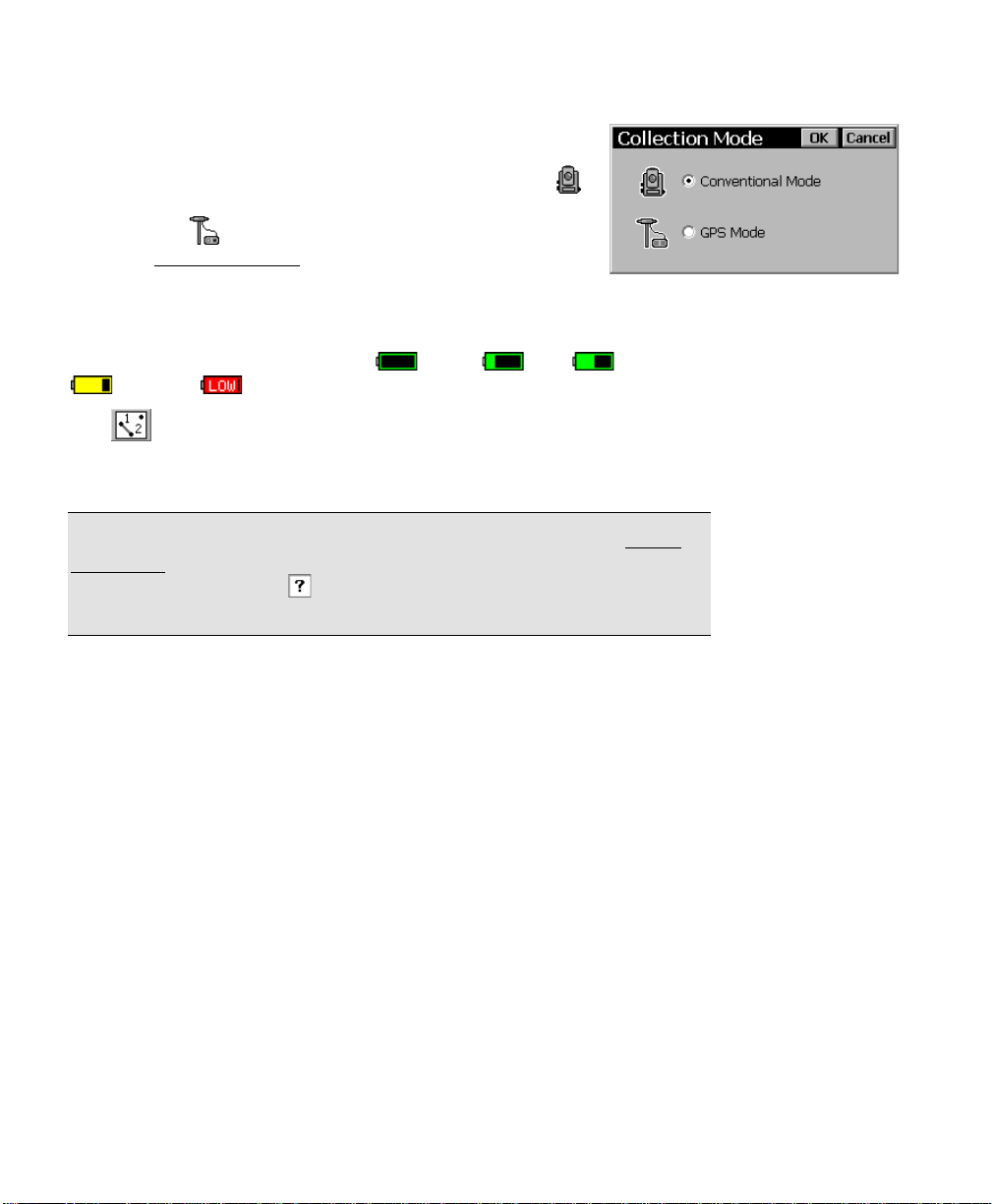

There are three icons in t he Main Menu’s title bar. The

first icon indicates which collection mode the software is

running in. When surveying with a total station, the

icon is displayed and when surveying with a GPS

receiver, the

open the Collection Mode

can be switched to the other mode.

The battery icon indicates the condition of the data collector’s

rechargeable battery. The icon has five variations depending on the

level of charge that is remaining:

25% and 5%.

icon is displayed. Tapping this icon will

dialog box where the software

100%, 75% 50%,

The

current job when it is tapped. The map view is available from most

screens and is discussed later.

Note: Tapping the battery icon is a shortcut to the Microsoft Power

Properties screen, which is normally accessed from the Windows CE

Control Panel. Tap the button in the title bar of this screen to

view the online help.

button in the title bar will access the map view of the

8

Page 15

Getting Started

Hotkeys

There are several shortcuts available to qui ckly access a variety of

screens no matter where you are at in the software. These shortcuts

are called hotkeys. Each hotkey is activated by holding down the

key as you press the associated hotkey on the keypad. Each hotkey is

listed below.

Disable Touch-Screen

A Calculator

B Enter Note

D View Points

E View Raw Data

F View Map

G Inverse Point to Point

H Corner Angle

I Triangle Solutions

Ctrl

J Past Results

K Manage Layers

L Auto Linework

M Horizontal Curve Solution

N Vertical Curve Solution

O Distance Offset

P Horizontal Angle Offset

Q Vertical Angle Offset

R Traverse / Sideshot

S Where is Next Point?

Y Remote Control

9

Page 16

User’s Manual

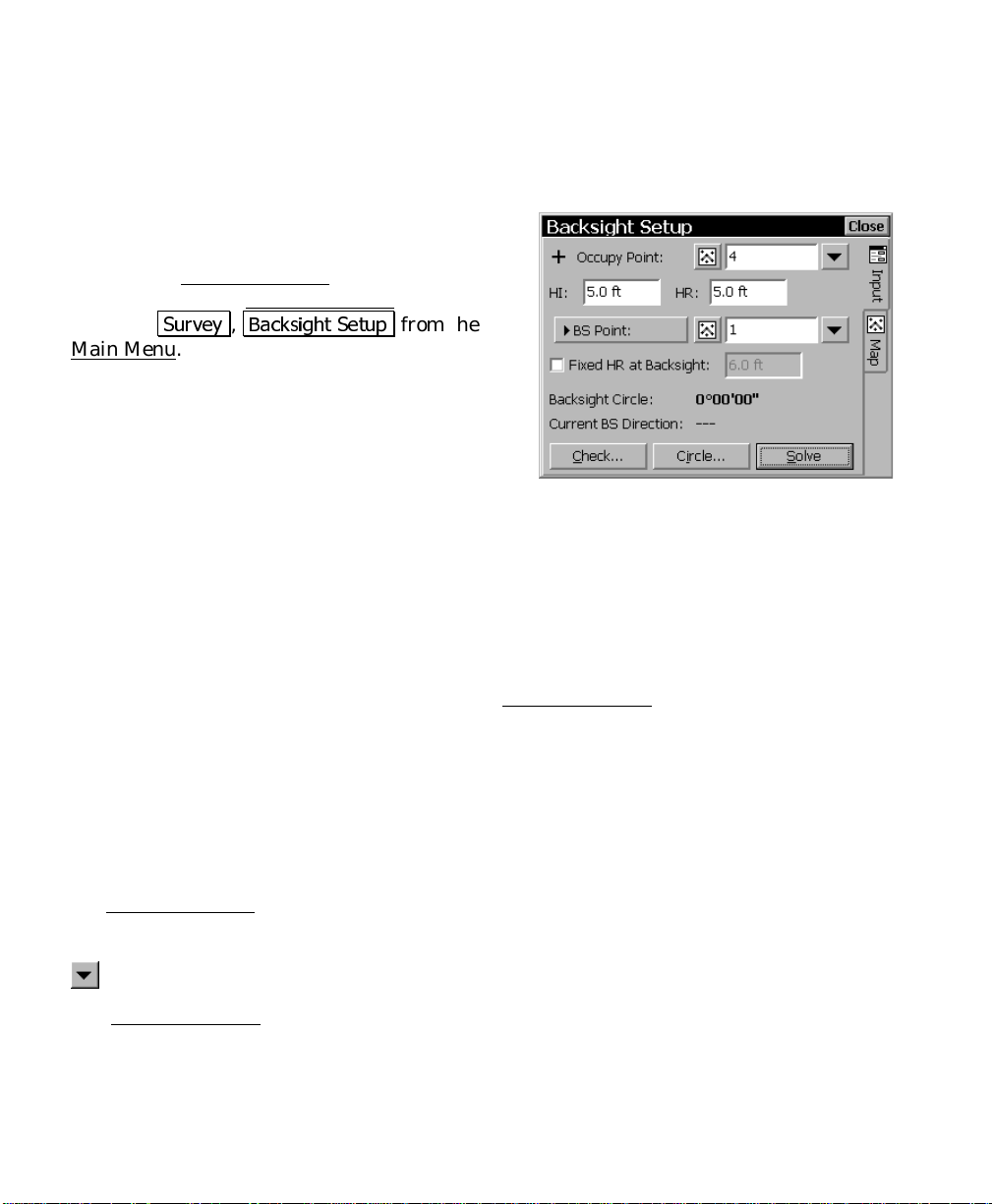

Parts of a Screen

Many screens share common features. To

illustrate some of these features, we will examine

parts of the Backsight Setup

You can access the Backsight Setup

selecting

Main Menu.

6XUYH\, %DFNVLJKW 6HWXS

Input Fields

An input field is an ar ea where a specific value is entered by the user.

An input field consists of a point label, which identifies the data that

is to be entered in that field. It has a rectangular area with a white

background, where the data is entered. A field must first be selected

before data can be entered in it. You can select a field by tapping on

it or pressing the [Tab] key on the data collector repeatedly until it is

selected. When a field is selected, a dark border is drawn around it

and a blinking cursor is inside the field. In the Backsight Setup

screen above, the

Occupy Point

screen, shown here.

screen by

from the

field is selected.

Output Fields

Output fields only display information. These fields typically display

values in

value cannot be changed from the current screen. For example, in

the Backsight Setup

field.

bold text

Power Buttons

The Backsight Setup screen contains two power buttons. Power

buttons are typically used to provide alternate methods of entering or

modifying data in an associated field. To use a power button, simply

tap it. Once tapped, a dropdown list will appear with several choices.

10

, do not have a special colored background, and the

screen, the

Backsight Circle

value is an output

Page 17

Getting Started

The choices available vary depending on with which field the power

button is associated. Simply tap the desired choice from the

dropdown list.

Tapping the first power button in the Backsight Setup

you to specify an occupy point using other methods or view the details

of the currently selected point. You should experiment with the

options available with various power buttons to become familiar with

them.

screen allows

Choose From Map Button

The Choose From Map But ton is always associated with a field where

an existing point is required. When the button is tapped, a map view

is displayed. To select a point for the required field, just tap it from

the map.

Note: If you tap a point from the map view that is located next to

other points, another screen will open that displays all of the points

in the area that was tapped. Tap the desired point from the list to

select it.

Scroll Buttons

When a button label i s preceded with thesymbol, it indicates that

the button label can be changed by tapping it, thus changing the type

of value that would be entered in the associated field. A s you

continue tapping a scroll button, the label will cycle through all the

available choices.

%XWWRQ

In the Backsight Setup

point or a direction by toggling the scroll button between

%6 3RLQW

and %6 'LUHFWLRQ

screen, the backsight can be defined by a

.

Special Point Symbols

Some field labels are preceded with a special symbol. For example,

the

Occupy Point

Occupy Point

represented as a plus symbol when viewing it in the Map View

Other symbols are also used to represent other types of points.

field in the Backsight Setup

” The plus symbol indicates that the occupy point is

screen is displayed as “

.

+

11

Page 18

User’s Manual

Index Cards

Many screens actuall y consist of multiple screens. The different

screens are selected by tapping on various tabs, which look like the

tabs on index cards. Because of this, each individual screen is

referred to as a card. The tabs can appear along the top of the screen

or the right edge.

The Backsight Setup

and the other is titled

The Settings

accessing several screens and is discussed in more detail starting on

Page 15.

screen has a variant of the Index Card format for

screen consists of two cards. One is titled

.

Map

Input

,

Input Shortcuts

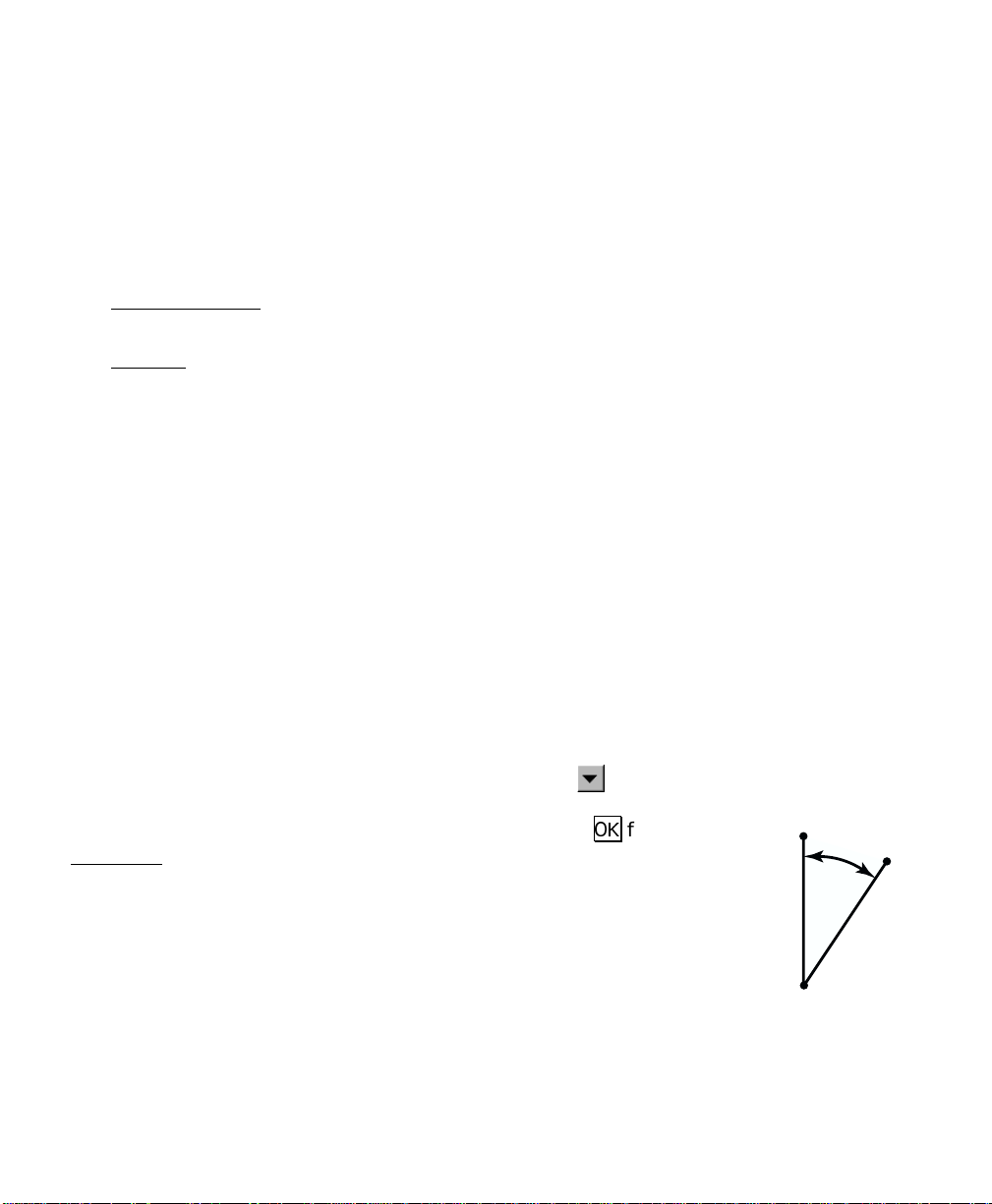

Distances and angles are normally entered in the appropriate fields

simply by typing the value from the keypad, but there is a shortcut

that can simplify th e entry of a distance or angle.

If you want to enter the distance between two points in a particular

field, but you do not know offhand what that distance is, you can

enter the two point names that define that distance separated by a

hyphen. For example, entering

the horizontal distance from Point 1 to Point 2. As soon as the cursor

is moved from that field, the horizontal distance between the points

will be computed and entered in that field.

An alternate method to using this shortcut is to tap the

button, select

define the distance that you want to enter. Once you tap 2. from the

Map View, the horizontal distance between the two tapped points will

appear in the corresponding field.

Choose from map…

in a distance field would compute

1-2

power

and then tap the two points that

1

α

3

Likewise, there is a similar shortcut to enter angles in fields that

accept them. If you wanted to enter the angle, α, from the

illustration shown here, you would simply enter

appropriate field. As soon as the cursor is moved from that field, the

angle formed by the three points entered will be entered in that field.

As with specifying a distance, you could also use the power button as

described above and tap the poi n ts of the angle in the correct order.

12

1-2-3

in the

2

Page 19

Getting Started

Entering Distances in Other Units

When a distance is entered in a particular field, it is normally entered

using the same units that are configured for the current job, but

distances can also be entered that are expressed in other distance

units.

When entering a distance that is expressed in units that do not match

those configured for the job, you simpl y append the entered distance

with the abbreviation for the type of units entered. For example, if

the distance units for your current job were set to

wanted to enter a distance in meters , you would simply append the

distance value with an m or M for meters. As soon as the cursor is

moved to another field, the meters that were entered will be

converted to feet.

The abbreviations can be entered in lower case or upper case

characters. They can also be entered directly after the distance

value, or separated with a space. The following abbreviations can be

appended to an entered distance:

Feet

and you

• Feet:

• US Survey Feet:

• Inches:

• Meters:

• Centimeters:

• Millimeters:

• Chains:

or

ft

f

or

usft

usf

in

m

cm

mm

or

c

ch

13

Page 20

User’s Manual

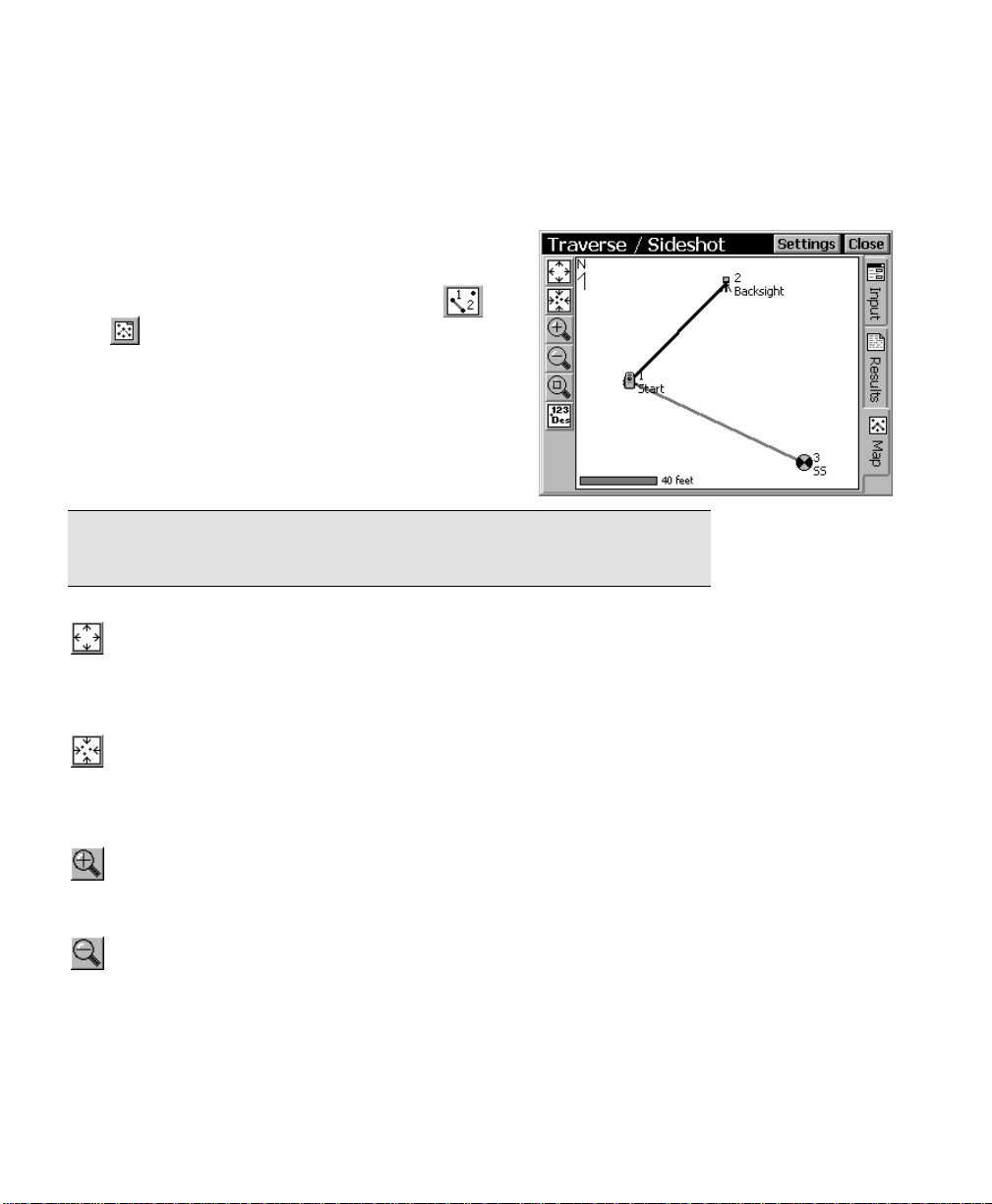

The Map View

Many screens provide access to a map view. The

map view is a graphical repres entation of the

points and other useful informat ion in the

current job and can be accessed with the

and

that indicates the scale of the map view.

The buttons along th e left edge of the screen

allow you to manipulate the map view so that it

displays what you want to see.

Some map views also display a vertical profile.

Tip: You can pan around your map by dragging your finger or stylus

across the screen.

This button will change the scale of the screen so that all the points

in the current job will fit on the screen.

buttons. A bar is shown at the bottom

Zoom Extents Button

Zoom Preview Button

When this button is available, it will display only the points that are

currently in use.

Zoom In Button

This button will zoom the current screen in by approximately 25%.

Zoom Out Button

This button will zoom the current screen out by approximately 25%.

14

Page 21

Getting Started

Zoom Window Button

After tapping this button, a box can be dragged across the screen.

When your finger or stylus leaves the screen, the map will zoom to

the box that was drawn.

Increase Vertical Scale

This button is only available when viewing a vertical profile. Each

time it is tapped, the vertical scale of t h e view is increased.

Decrease Vertical Scale

This button is only available when viewing a vertical profile. Each

time it is tapped, the vertical scale of t h e view is decreased.

Display / Hide Labels Button

In some screens, this button will simply toggle the point names and

descriptions on and off in a Ma p View

open the Map Display Options

control over what is displayed in the Map View

, but in other screens it will

screen, which gives you even more

.

The Settings Screen

The Settings screen is used to control all of the settings available for

your total station, data collector, current job, and Survey Pro

software.

Most of the settings remain unchanged unless you deliberately

change them, meaning the default settings are whatever they were

set to last. For example, if you create a new job where you change the

direction units from azimuths to bearings and then create another

new job, the default direction units for the new job will be bearings.

Survey Pro behaves in thi s way since most people use t he same

settings for a majority of their jobs. This way, once the settings are

set, they become the default settings for all new jobs and current jobs.

Some settings are considered critical and are therefore stored within

the job. The following settings are stored within a job and will

15

Page 22

User’s Manual

override the corresponding settings in the Settings

opened:

screen when it is

•

Scale Factor

•

Earth Curvature On

•

Units for Survey Data

•

•

•

or

North

Angle Units

GPS setup information

etc. (Requires GPS Module)

– Surveying Settings Card

or

– Surveying Settings Card

Off

(distances) – Units Settings Card

South Azimuth

– Units Settings Card

– Units Settings Card

such as localization, mapping plane,

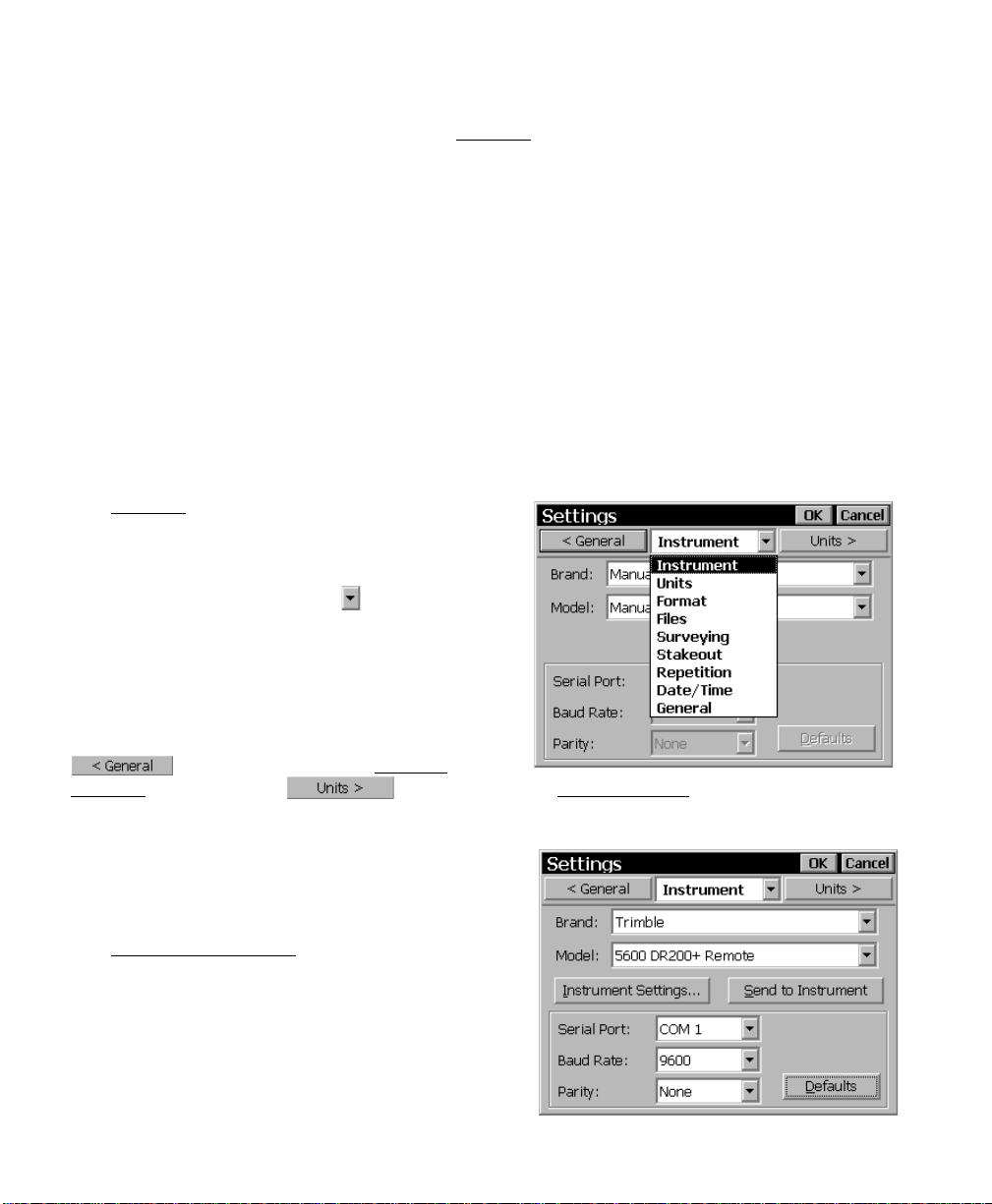

Navigating to the Screens

The Settings screen actually consists of several

separate screens where each indivi dual screen

contains different types of settings. There are

two ways to navigate to the various screens.

The first method is to tap the

down the list of available screens and then tap

on the desired screen from the list to open it.

The second method is to tap the buttons to the

side of the screen title, which will open the

previous or next screen respectively. For

example in the screen shown, you could tap

to open the previous (General

Settings) screen, or tap to open the next (Units Settings)

screen. Repeatedly tapping either of these buttons will cycle through

all the available screens.

button to drop

Instrument Settings Page

The Instrument Settings are used to define the

type of total station that is being used so it can

communicate with the data collector. When your

data collector is connected to a total station, the

and

Brand

your total station. If your exact model is not

16

should be selected to match

Model

Page 23

Getting Started

listed, you should select from the models that are available until you

find one that works.

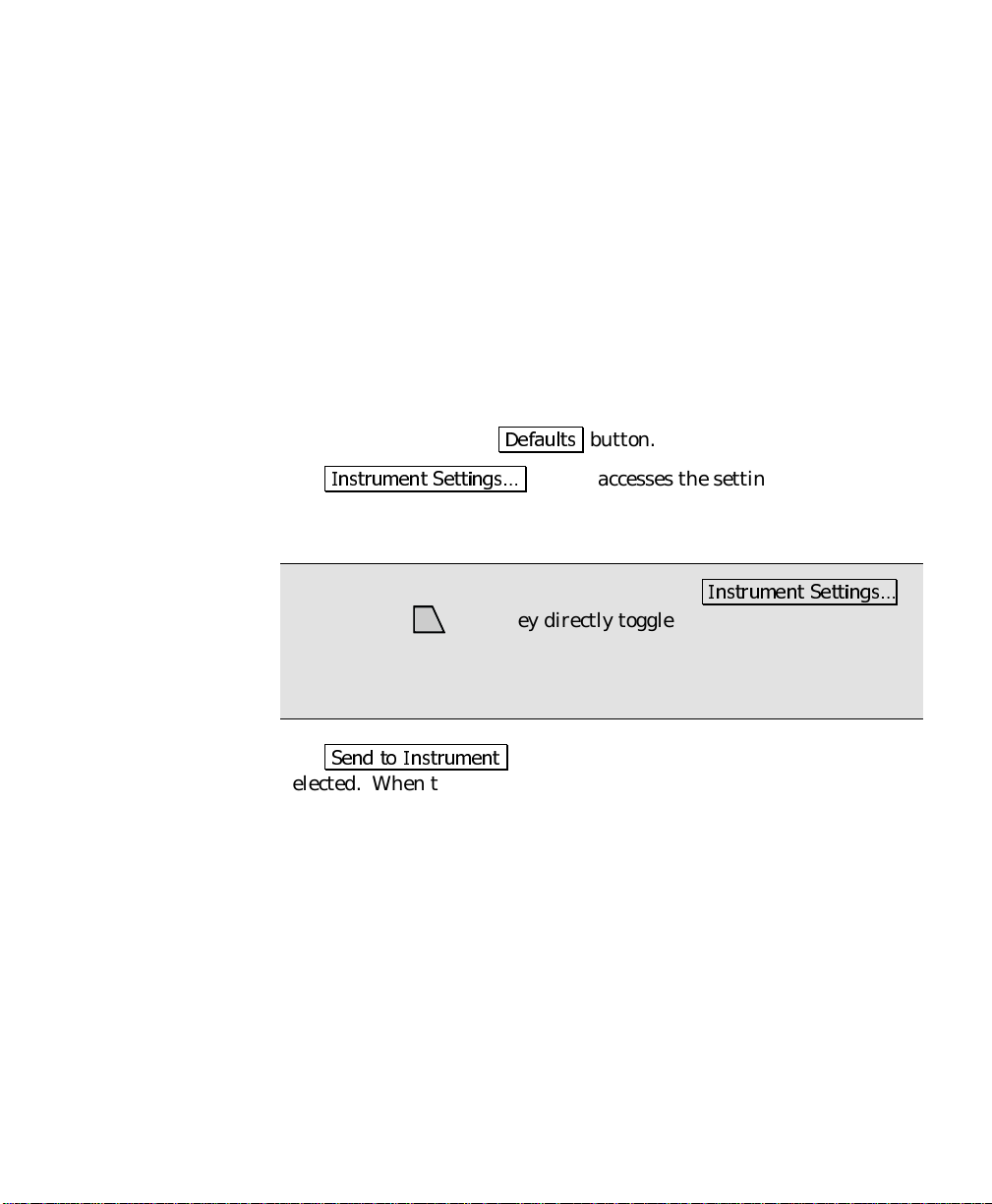

When set to

Manual Mode

, the data collector will not communicate

with a total station. Instead, when a button is pressed that would

normally trigger the total station to take a shot; a dialog box will open

where you enter the shot data manually from the keypad. When you

are learning the software in an office environment, it is usually

easiest to set the software to manual mode.

: is where you specify the model of the total station that you are

Model

using from a dropdown list. When a particular model is selected, the

default settings for that model are automatically selected. If those

setting are changed manually, you can switch back to the default

settings by tapping the

The

,QVWUXPHQW 6HWWLQJV«

'HIDXOWV

button.

button accesses the settings that are

specific for the selected total station model. This screen can also

quickly be accessed from anywhere in the program by using the.

Note: The options available after tapping the

button, or the

-W hotkey directly toggle settings that are built into

Ctrl

,QVWUXPHQW 6HWWLQJV«

your particular total station. These settings are explained in your

total station’s documentation and are not explained in the Survey Pro

Manual.

The

6HQG WR ,QVWUXPHQW

button is available when certain models are

selected. When this button is available, it should be tapped after

turning the total station on. This will send an initializing string to

the instrument that will make certain robotic functions work more

smoothly.

17

Page 24

User’s Manual

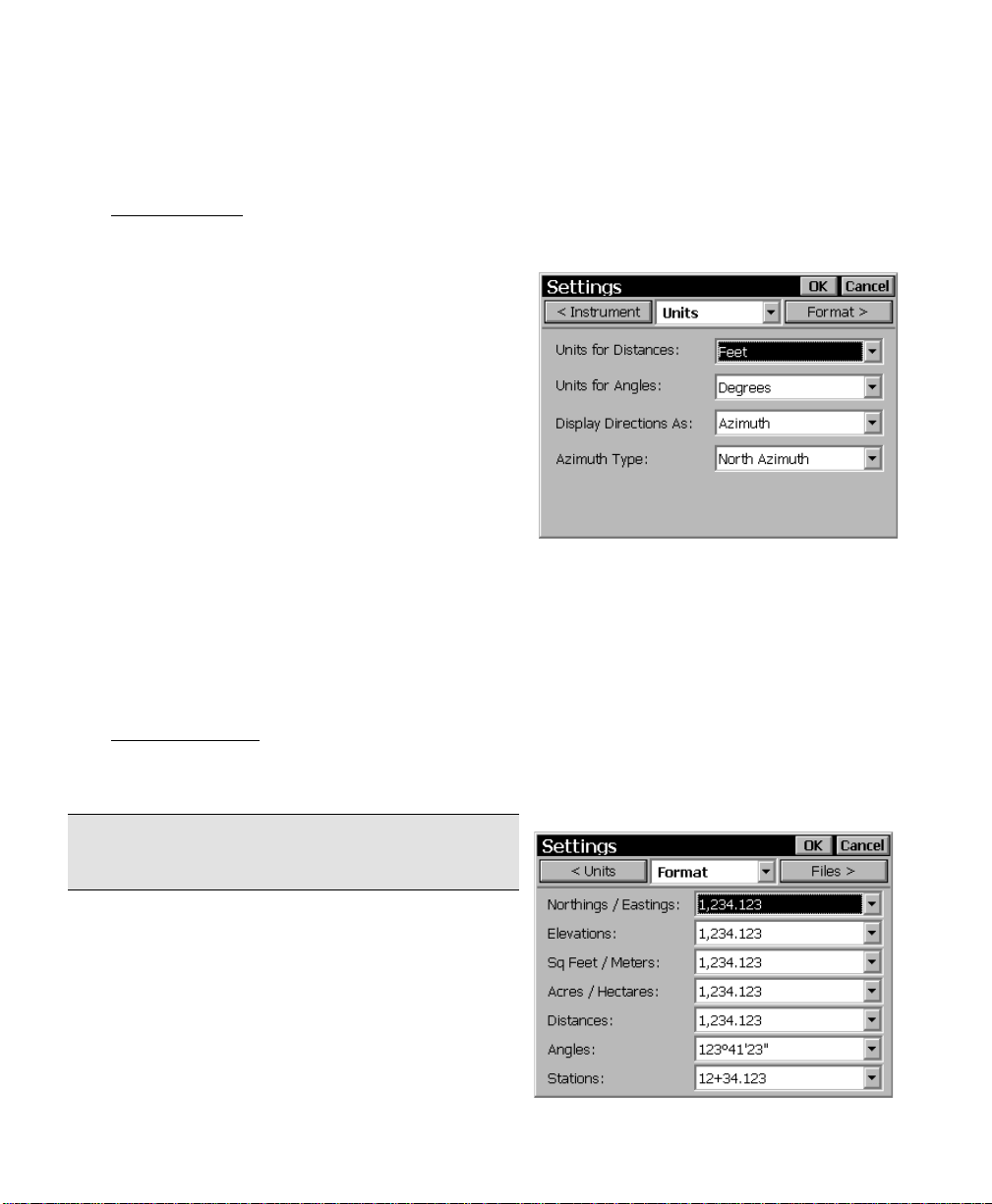

Units Settings

The Units Settings defines the units that are used within the

software, including those that are sent from the total station, entered

from the keypad and displayed on the screen. You can select the

following settings for your job.

Units for Distances

distances as

Units for Angles

angles as

Display Directions As

a

Bearing

Azimuth Type

Azimuth

Meters, Feet

Degrees

or

Azimuth

or a

South Azimuth

: defines the units used for

, or

International Feet

: defines the units used for

or

.

: defines if you are using a

.

Grads

: will display directions as

.

North

.

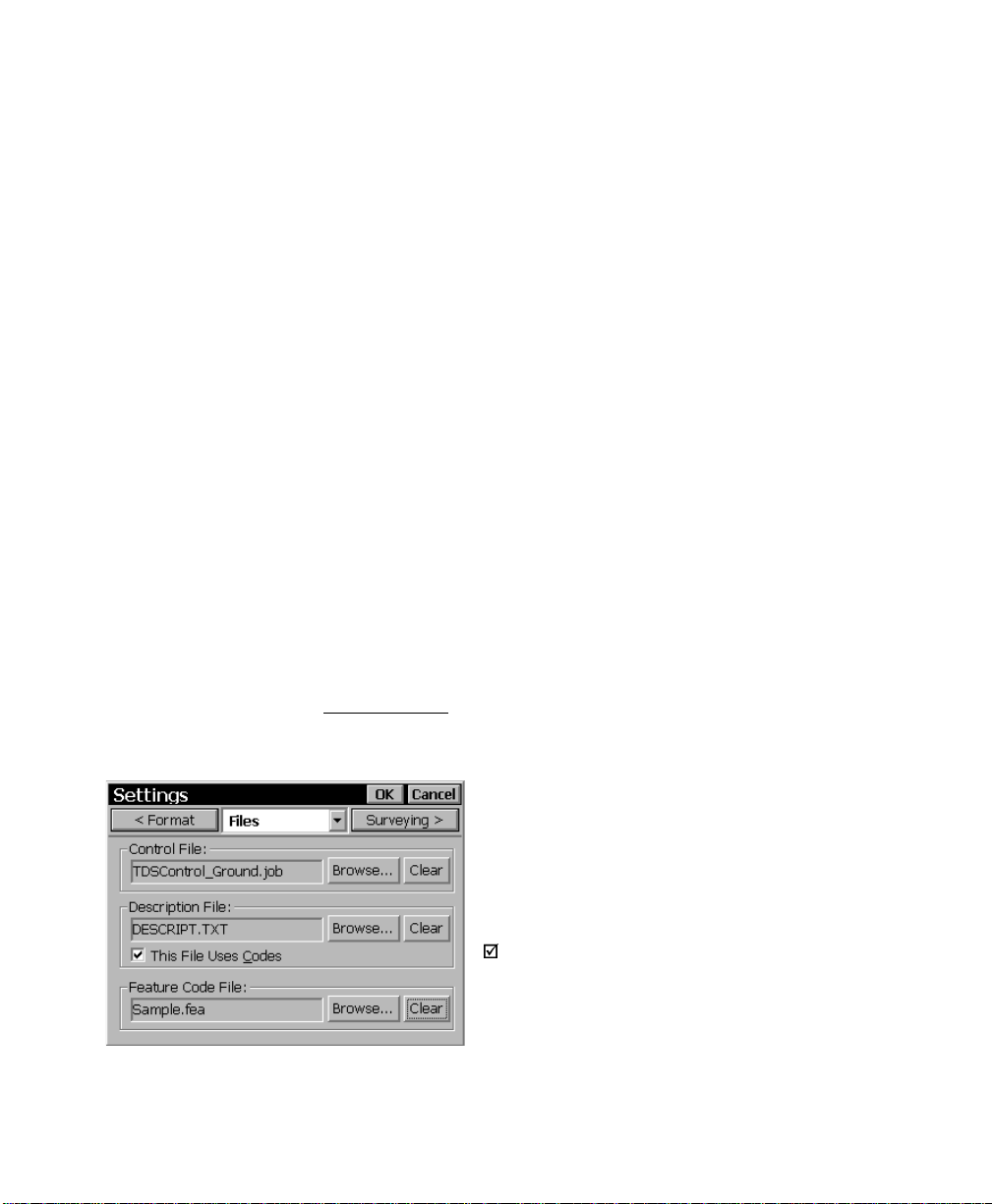

Format Settings

The Format Settings defines the precision (the number of places

beyond the decimal point) that is displayed for various values in all

screens, and how stations are defined.

Note: All internal calculations are performed

using full precision.

Northings / Eastings

from zero to six places passed the decimal point

for northing and easting values.

Elevations

places passed the decimal point for elevations.

Sq Feet / Meters

to four places passed the decimal point for

18

: allows you to display from zero to six

: will allow you to display

: allows you to display from zero

Page 25

square feet or square meter values.

Getting Started

Acres / Hectares

passed the decimal point for acre or hectare values.

Distances

decimal point for distances.

Angles

with angle values.

Stations

formats:

: allows you to display from zero to six places passed the

: allows you to include from zero to four fractional seconds

: allows you to display stations in any of the following

•

12+34.123

the + advances after traveling 100 feet or meters.

•

1+234.123

the + advances after traveling 1,000 feet or meters.

•

1,234.123

: allows you to display from zero to four places

: displays stations where the number to the left of

: displays stations where the number to the left of

: displays standard distances rather than stations.

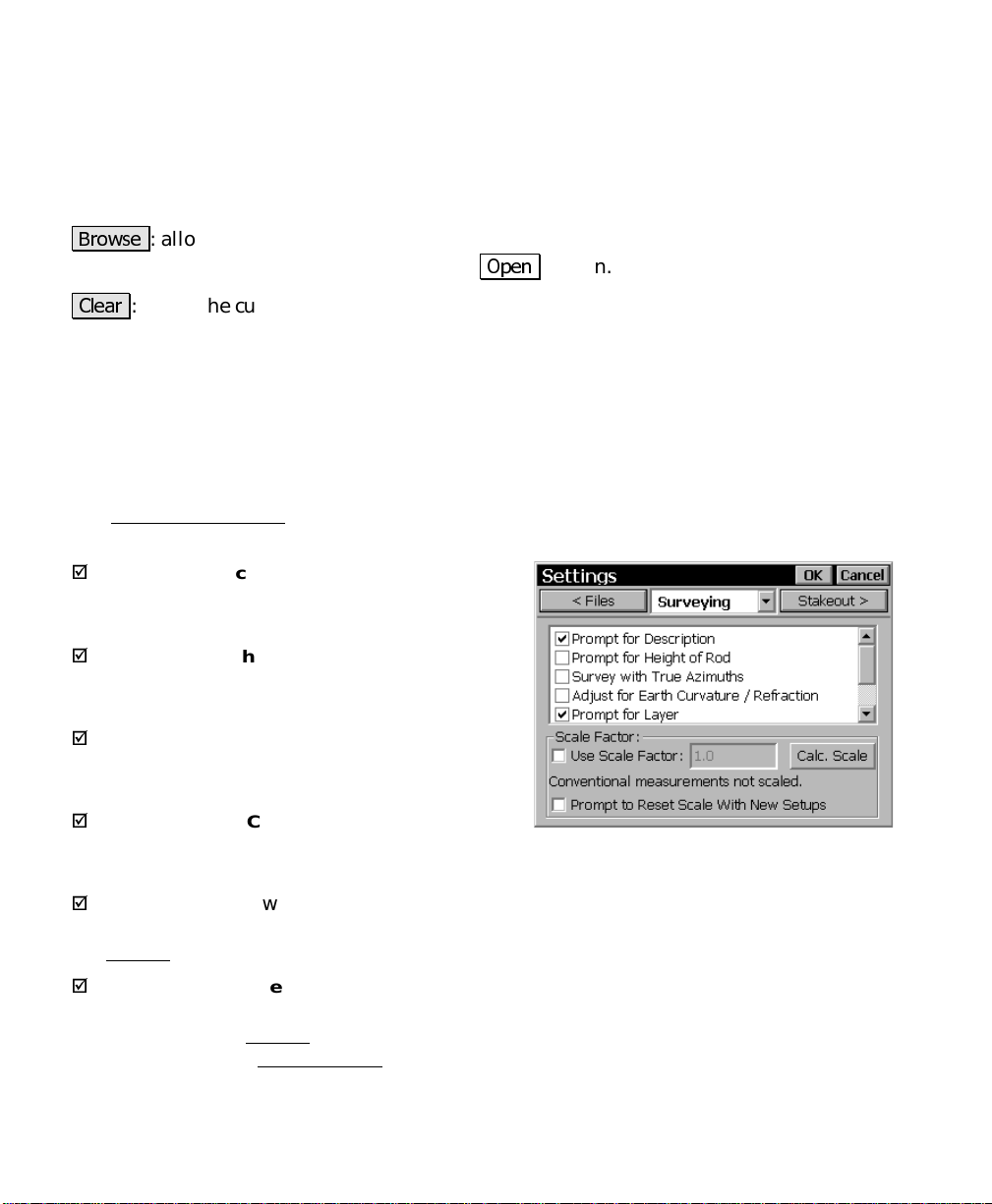

Files Settings

The Files Settings allow you to select a control file or description file

to use with the current job.

Control File

: allows you to select a control file to use with the current

job. Control files are discussed in more detail on

Page 28.

Description File

description file to use with the current job.

Description files are discussed in more detail on

Page 32.

This File Uses Codes

;

description file contains codes and associated

descriptions. Leave the b ox unchecked if the

description only contains descriptions (no

codes).

: allows you to select a

: Check this box if the

19

Page 26

User’s Manual

Feature Code File

the current job. You can switch b etween different feature code files in

mid-job, but if a collected attribute does not match an attribute in the

feature code file, it can only be viewed, but not edited.

: allows you to select a feature code file to use with

%URZVH

Simply tap on the filename and then tap the

&OHDU

with the current job.

: allows you to select a file to use with the current job.

2SHQ

button.

: closes the currently selected file so that it is no longer used

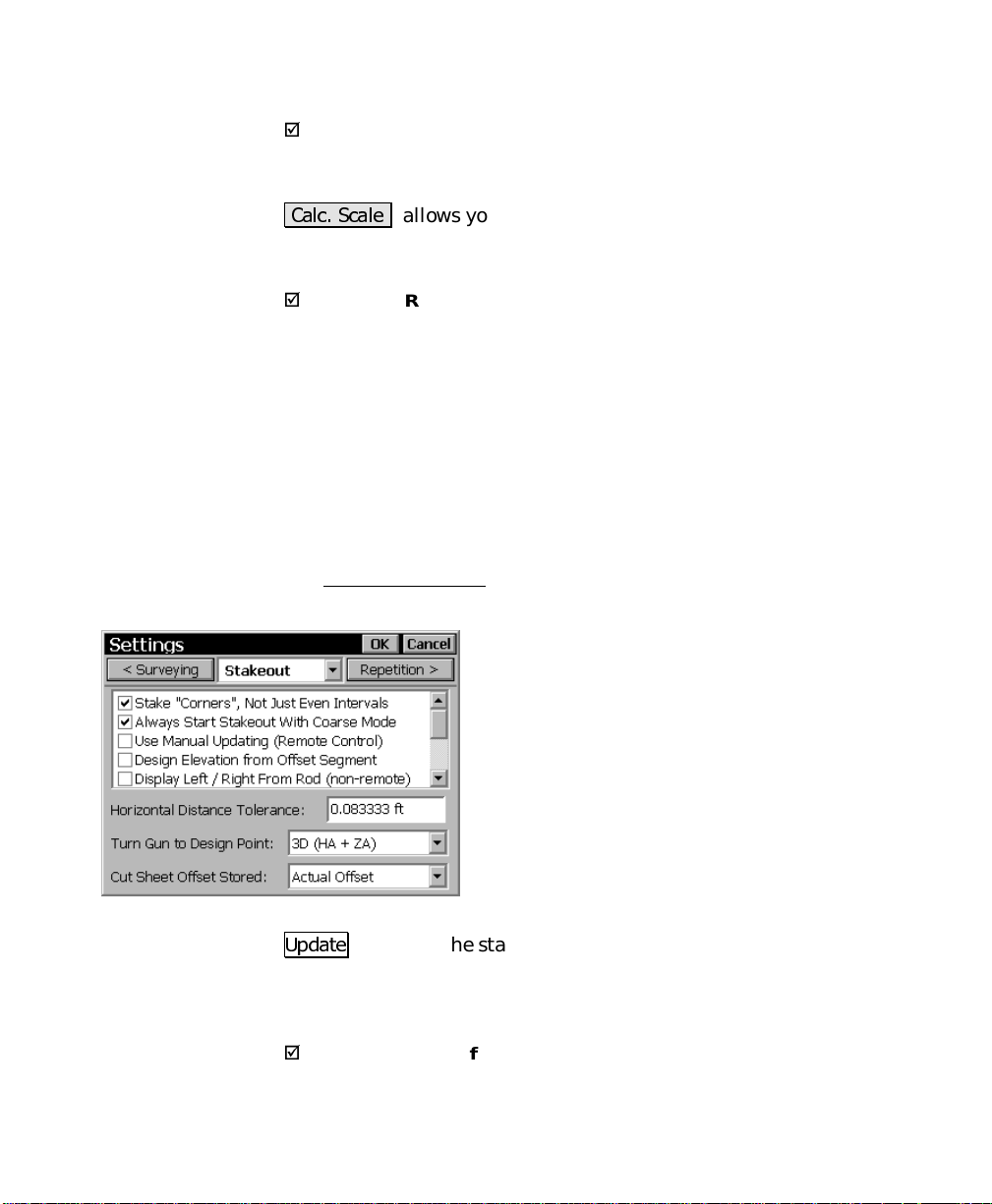

Surveying Settings

The Surveying Settings allows you to select various options that

affect how data collection is performed.

Prompt for Description

;

prompt for a point description will appear before

any new point is stored.

Prompt for Height of Rod

;

prompt for the rod height will appear before any

new point is stored.

Survey with True Azimuths

;

angle rights will be referenced from true north

when traversing.

: when checked, a

: when checked, a

: when checked,

Adjust for Earth Curvature / Refraction

;

checked, the elevations for new points are adjusted to compensate for

the curvature of the earth and refract ion.

Prompt for Layer

;

appear before any new point is stored from only the routines under

the Survey

Prompt for Attributes

;

information will appear before any new point is stored from only the

routines under the Survey

be selected from the Files Settings

20

menu.

: when checked, a prompt to select a layer will

: when checked, a prompt to select feature

menu. This also requires that a feature file

card, described above.

: when

Page 27

Getting Started

Use Scale Factor

;

points will be scaled by the factor entered here. Elevations are not

affected.

: when checked, horizontal distances to all new

&DOF 6FDOH

from a selected map projection. If a mapping plane is not already

selected, you will fist be prompted to select one.

Prompt to Reset Scale on New Setups

;

projection is selected and you setup over a new location, the specified

scale factor is compared to the scale factor defined for your current

location in the mapping plane. If the scale factor is different, you will

be prompted to use the new scale factor.

: allows you to automatically compute the scale factor

: if checked when a map

Stakeout Settings

The Stakeout Settings contains the setting that control how stakeout

is performed.

Stake “Corners,” Not Just Even Intervals

staking by stations, locations where a line

segment changes, such as from a straight

section to a curve, will also be staked when this

is checked.

Always Start Stakeout With Coarse Mode

when checked, the

checkbox found in all stakeout screens will

initially be checked. This instructs the total

station to measure distances faster, but with

slightly less accuracy.

Coarse EDM (fast shot)

: when

:

Use Manual Updating (Remote Control)

8SGDWH

When this not checked, shots are continuously taken in the stakeout

screens. (This is only valid when running in remote mode using a

robotic total station.)

;

offset or road stakeout, cut and fill information will be computed from

button in the stakeout screens must be pressed to take a shot.

Design Elevation from Offset Segment

: When this is checked, an

: When checked during

21

Page 28

User’s Manual

the design elevation at the node furthest from the centerline of the

current segment. When unchecked, cut and fill information will be

computed from the design elevation of the segment at the current rod

location.

Note: If staking extends beyond the end of th e cross section, the cut /

fill information will always be computed from the design elevation at

the node furthest from the centerline of the current segment.

Write Cut Sheet Data Only (No Store Point)

;

built points are not stored to the JOB file when staking points; only

the raw data is written to the RAW file.

Display Left / Right From Rod (non-remote)

;

move left or right information will be presented from the rod person’s

point of view. When unchecked, it will be presented from the total

station’s point of view. (This option only applies when a robotic total

station is selected in the Instrument Settings

Display Left / Right From Rod (remote)

;

left or right information will be presented from the rod person’s point

of view. When unchecked, it will be presented from the total station’s

point of view. (This option only applies when a non-robot total station

is selected in the Instrument Settings

Prompt for Layer

;

appear before any new point is stored from only the routines under

the Stakeout

Prompt for Attributes

;

information will appear before any new point is stored from only the

routines under the Stakeout

file be selected from the Files Settings

Note: There is no

Settings because you will always be prompted for a description when

storing a point from a stakeout routine.

menu.

: when checked, a prompt to select a layer will

: when checked, a prompt to select feature

menu. This also requires that a feature

Prompt for Description

.)

card, described earlier.

: When checked, as-

: When checked, the

.)

: When checked, the move

checkbox as in the Survey

Horizontal Distance Tolerance

Staking and Stake to Line routines. When staking to a line and the

prism is located at a perpendicular distance to the specified line that

22

: this setting affects the Remote

Page 29

Getting Started

is within the range set here, a message will state that you are on the

line. When performing Remote Stak eout, the final graphic screen

that is displayed when you are near the stake point will occur when

you are within the distance to the stake point specified here.

Turn Gun To Design Point

The following options are available:

•

Yes: 2D (HA only)

horizontally toward the design point.

•

Yes: 3D (HA and ZA)

horizontally and vertically toward the design point.

•

Cut Sheet Offset stored

stored to the raw data fi le in either of the following formats when

performing any offset staking routine:

•

•

: The total station must be turned manually.

No

Design Offset

design-offset values.

Actual Offset

measured-offset values.

: when selected, a cut sheet report will list the

: only applies to motorized total stations.

: The total station will automatically turn

: The total station will automatically turn

: The cut sheet offset information can be

: when selected, a cut sheet report will list the

23

Page 30

User’s Manual

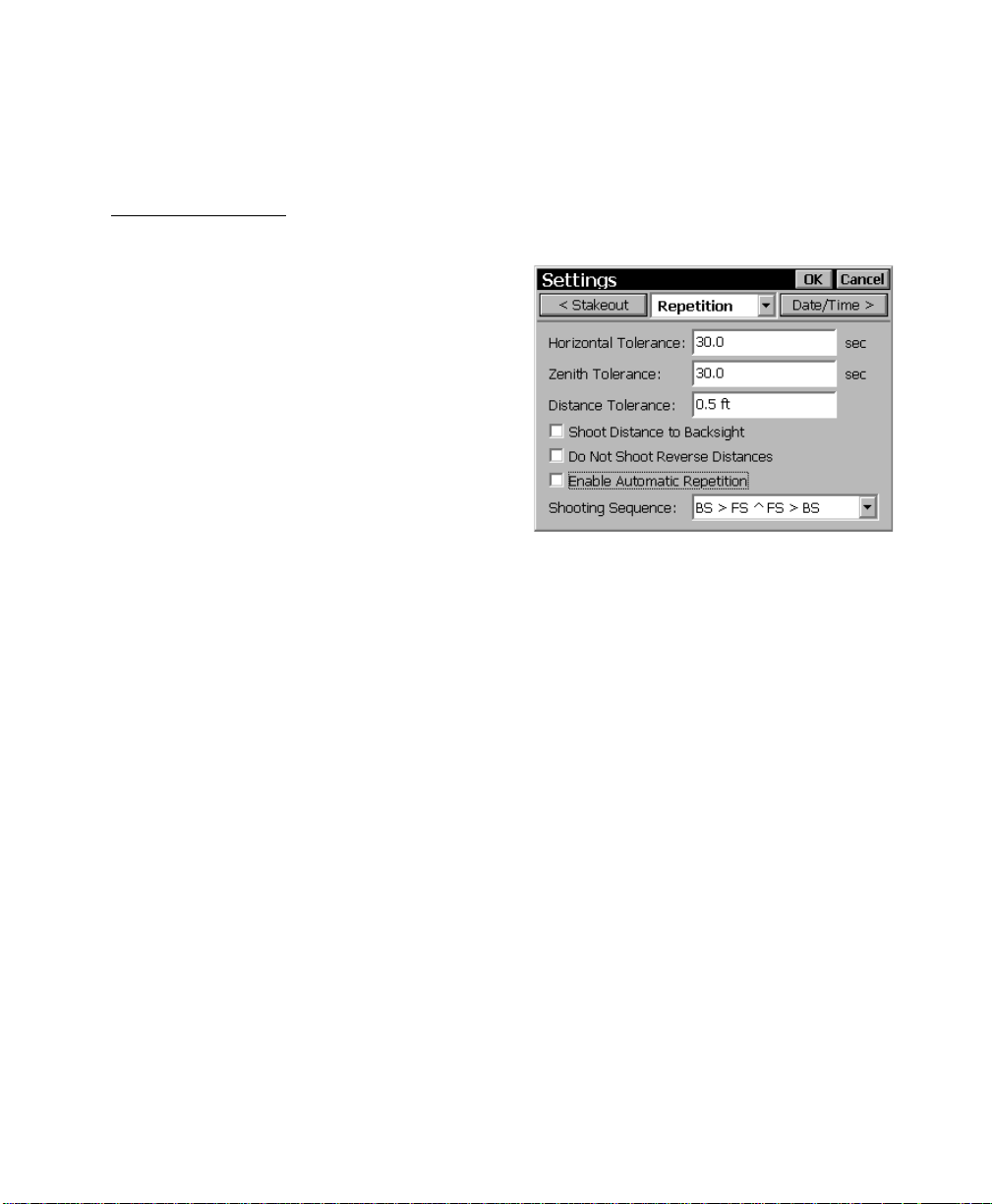

Repetition Settings

The Repetition Settings contains the settings that control how

repetition shots are performed and the acceptable tolerances.

Horizontal Tolerance

displayed if a horizontal angle exceeds the

tolerance entered here during a repetition shot.

Zenith Tolerance

displayed if a vertical angle exceeds the

tolerance entered here during a repetition shot.

Distance Tolerance

displayed if a distance exceeds the tolerance

entered here during a repetition shot.

Shoot Distance To Backsight

distance will be measured to each shot to the

backsight. When uncheck ed, only the angles are measured.

Do Not Shoot Reverse Distances

measured during reverse shots.

Enable Automatic Repetition

after the first shot to the backsight and foresight will occur

automatically when using a motorized instrument.

Shooting Sequence

the following options:

•

BS > FS ^ FS > BS

Backsight

: a warning message will be

: a warning message will be

: a warning message will be

: when checked, a

: when checked, distances are not

: when checked, all remaining shots

: specifies the order that the shots are taken from

: Backsight, Foresight, flop, Foresight

24

•

BS > FS ^ > BS > FS

Foresight

•

BS ^ BS > FS ^ FS

Foresight

•

FS ^ FS > BS ^ BS

Backsight

•

FS > BS ^ BS > FS

Foresight

: Backsight, Foresight, flop, Backsight,

: Backsight, flop, Backsight, Foresight, flop,

: Foresight, flop, Foresight, Backsight, flop,

: Foresight, Backsight, flop, Backsight,

Page 31

•

FS > BS ^ > FS > BS

Backsight

Getting Started

: Foresight, Backsight, flop, Foresight,

•

BS ^ BS ^ > FS ^ FS ^

Foresight, flop, Foresight, flop

: Backsight, flop, Backsight, flop,

Date/Time Settings

The Date/Time Settings is used to set the date and time in the data

collector.

: displays the current date.

Date

: displays the current time.

Time

Format

or

Note: The date, time and UTC are computed

using Windows CE’s Date/Time properties.

date that is entered.

: Select

to display Coordinated Universal Time.

UTC

6HW 'DWH

: will set the system date with the

to display your local time,

Local

6HW 7LPH

6\QFKURQL]H

current time and advance to the nearest second so that the time can

be set more accurately.

Set DUT

convert UTC to UT1. (UT1=UT C+DUT)

: will set the system time with the time entered.

: when pressed, will zero the fractional portion of the

: is the polar wandering correction factor, in seconds, used to

25

Page 32

User’s Manual

General Settings

The General Settings contains the following settings:

Use Enter Key to Move Between Fields

;

when checked, the [Enter] key will move the

cursor to the next field in all screens. When

unchecked, the [Enter] key will perform a

different function depending on the field

selected.

Note: The arrow keys and the [Tab] key can

also be used to move the cursor between fields.

Allow Alphanumeric Point Names

;

checked alphanumeric point names can be assigned to any point.

When unchecked, all point names must be numeri c .

Always Prompt for Backsight Check

;

prompted if you attempt to exit the Backsight Setup

first performing a backsight check.

Beep When Storing Points

;

whenever a new point is stored.

Prompt for Description

;

will appear before any new point is stored from any routine other

than those included in t he Survey

: when checked, a beep will sound

: when checked, a prompt for a description

and Stakeout menus.

:

: when

: when checked, you will be

screen without

Prompt for Layer

;

appear before any new point is stored from any routine other than

those included in the Survey

Prompt for Attributes

;

information will appear before any new point is stored from any

routine other than those included in the Survey

This also requires that a feature file be selected from the Files

Settings card, described earlier.

Prompt to Backup When Closing Job

;

will open to backup the current job prior to closing it.

26

: when checked, a prompt to select a layer will

and Stakeout menus.

: when checked, a prompt to select feature

and Stakeout menus.

: when checked, a reminder

Page 33

Getting Started

Write Point Attributes to Raw Data

;

and attribute information will be written to the raw data file.

: when checked, point feature

Auto time stamp every ___ min

;

record to the raw data file containing the current date and time each

time the specified number of minutes passes. This is useful for

tracking down when specific raw data records were written to the file.

Remind to backup job every ___ hrs

;

reminder to backup the current job after every specified number of

hours passes.

: when checked, will store a note

: when checked, will open a

27

Page 34

User’s Manual

Required Files

Every job that is used with TDS Survey Pro actually consists of at

least two separate files; a job file and a raw data file. Each file

performs a different role within the software.

A job file can be created in the data collector, or on a PC using TDS

Survey Link and then transferred to the data collector. A raw data

file is automatically generated once the job file is open in the data

collector. A raw data file cannot be created using any other method.

There are two other optional types of files that can be used with

Survey Pro called control files and description files. Job files and raw

data files are explained below. Control files and description files are

explained, starting on Page 28 and 32, respectively and include

examples to illustrate their use.

Job Files

A job file is a binary file that has a file name that is the same as the

job name, followed by a *.JOB extension. A job file is similar to the

older TDS-format coordinate file, except in addition to storing point

names and their associated coordinates, a job file also contains all of

the line work as well.

When you specify points to use for any reason within Survey Pro, the

software will read the coordinates for the specified points from the job

file. Whenever you store a new point within Survey Pro, the point is

added to this file.

A job file can be edited on the data collector when using the Edit

Points screen. Since a job file is binary, it requires special software

for editing on a PC, such as TDS Survey Link. It can also be

converted to or from an ASCII file using Survey Link. (Refer to the

Survey Link documentation for this procedure.)

When a job file is converted to an ASCII file, the resulting file is

simply a list of points and coordinates. Each line consists of a point

name, northing or latitude, easting or longitude, elevation or elliptical

height, and a note where each value is separated by a comma.

28

Page 35

Getting Started

Raw Data Files

A raw data file is an ASCII text file that is automatically generated

whenever a new job is created on the data collector. It has the same

file name as the job file (t he job name), followed by the *.RAW

extension.

A raw data file is a log of everything that occurred in the field. All

activity that can create or modify a point is written to a raw data file.

Survey Pro never “reads” from the raw data file – it only writes to the

file. Since a raw data file stores all of the activity that takes place in

the field, it can be used to regenerate the original job file if the job file

was somehow lost. This process requires the TDS Survey Link

software.

A raw data file is considered a legal document and editing it can

invalidate all of its contents and is not supported in any way by TDS.

TDS Survey Link allows you to edit some fields of a raw data file, but

other fields cannot be edited since those fields typically tie into other

fields in a complex way. Editing these fields in a text editor is

possible, but likely to corrupt the contents of t h e raw data file.

When viewing a raw data file on a PC using a simple text editor or on

Survey Pro using the View R aw Data

unaltered, which can appear somewhat cryptic. When viewing the file

from within Survey Link, the codes are automatically translated on

the screen to a format that is easier to understand.

screen, the file is shown

Refer to the TDS Web site for a downloadable document that explains

the meaning of the codes used in a raw data file.

29

Page 36

User’s Manual

Control Files

A Control File is simply an existing job that is optionally opened

within the current job so that the points from the control file are also

available for use in the current job. The points stored in a control file

are called Control Points.

Some users prefer to keep a set of known points in a separate control

file when repeatedly working on new jobs in the same general area.

That way when they return to the job site, they can create a new job,

but select the control file to easily have access to the known control

points.

Once a control file is selected in the current job, the control points can

be used in the same way as the job’s points with the following

exceptions:

• A control file has read only attributes. This means that the

points in a control file cannot be modified or deleted; they can

only be read. For example, you can select a control point to

use as an occupy point during data collection or as a design

point during stake out, bu t you could not use a control point

for a foresight where you intend to overwrite the existing

coordinates with new coordinates. You would also be unable

to modify a control point from the Edit Points

screen.

• Since the points in a control file are essentially merged with

the points in the current job, you cannot open a control file if

any of the point names used in it are also used in the current

job. If you attempt to do so, a dialog will tell you that a

duplicate point name was encountered and the control file

will not be opened.

• Only points are used from a control file. If a control file

contains other objects, such as polylines or alignment s, they

will be ignored.

30

Page 37

Getting Started

Control File Example

The following general example explains one scenario where a control

file is used. In this example, a new job is created with a point that has

arbitrary coordinates . The control file is selected and used to replace

the arbitrary coordinates with coordinates that are in the same

coordinate system as those in the control file. The steps in this

example can be modified to fit your specific situation.

Assume that you already have a job that contains several known

points for an area where you intend to work. You want to create a

new job and select the existing job as a control file to make the control

points available in the new job. Also, assume that the control file

contains points named 1 through 10.

1. Create a new job by selecting

Menu.

2. Enter a point name for the first point in the job that will not

conflict with the names that are in the control file. In this

example, you could enter either any alphanumeric name or any

numeric name that is above 10. (Accept the default coordinates

for now – they will be overwritten later.)

3. Select the

4. Tap the

and select the job that you want to use as a control file.

5. Define your

control file and enter the point name that was just created as the

Foresight

6. Take a side s h ot or traverse shot and overwrite the original

coordinates with the new coordinates. This will tie in the

coordinates for the new point with the coordinates in the control

file.

7. Continue your survey.

tab from the Settings

Files

%URZVH

.

button in the

Occupy

and

)LOH, 2SHQ1HZ

Control File

Backsight

points using points from the

from the Main

screen.

section of the screen

31

Page 38

User’s Manual

Description Files

A Description File is used to automate the task of entering

descriptions for points that are stored in a job. They are especially

useful when the same descriptions are frequently used in the s ame

job.

A description file is a text file containing a list of the descriptions that

you will want to use with a particular job. The file itself is usually

created on a PC, using any ASCII text editor such as Notepad, which

is included with Microsoft Windows. It is then saved using any file

name and the

It is important to realize that when you use a more sophisticated

application, such as a word processor to create a description file, you

must be careful how the file is saved. By default, a word processor

will store additional non-ASCII data in a file making it incompatible

as a description file. However this can be avoided if you use the

Save As…

format as the type of document to save. For more information on

creating a text file using a word processor, refer to the your word

processor’s documentation.

routine from your word processor and choose a

extension and then transferred to the data collector.

.txt

Text Only

File

|

Description files can be creat ed in two different formats; one includes

codes and the other does not. The chosen format determines how

descriptions are entered. Each format is described below.

Description Files Without Codes

A description file that does not contain codes is simply a list of the

descriptions that you will want to use in a job. The content of a

sample description file, without codes, is shown here.

The following rules apply to des cription files without codes:

• Each line in the file contains a separate description.

• A description can be up to 16 characters in lengt h (including

spaces).

• A description can contain any characters included on a

keyboard.

32

Page 39

Getting Started

• Descriptions do not need to be arranged in alphabetical order.

(Survey Pro does that for you.)

• Descriptions are case sensitive.

To use a description from a description file,

simply start typing that description in any

Description

descriptions in the

screen.) Once you start typing a description, a

dropdown list will appear displaying all of the

descriptions in the descriptor file along with all

the descriptors that have been used in the

current job in alphabetical order. If the first

letter(s) that you typed match the first letters of

a description in the descriptor file, that

description will automatically be selected in the

dropdown list. Once it is selected, you can have that description

replace what you have typed by pressing [Enter] on the keypad. You

can also use the arrow keys to scroll through the dropdown list to

make an alternate selection.

field. (You can experiment with

6XUYH\, 7UDYHUVH 6LGHVKRW

If you wanted

file used here, you would have to start typing with lower case

characters since descriptions are case sensitive. (Typing

not work.)

douglas fir

to be selected with the sample description

… would

Dou

Description Files With Codes

A description file that uses codes is similar to those without codes,

except a code precedes each description in the file. A sample

description file with codes is shown here.

The following rules apply to des cription files that use codes:

• Each line in a description file begins with a code, followed

by a single space, and then the description.

• A description code can consist of up to seven characters

with no spaces.

• Description codes are case sensitive.

• The description is limited to 16 characters.

33

Page 40

User’s Manual

• Descriptions can include any character included on a

keyboard.

To use a description from a description file with codes simply t ype the

code associated with the desired description in any

As soon as soon as the cursor moves out of the

code is replaced with the corresponding description. For example, if

you typed lo in a description field while using the description file

shown above, lo would be replaced with

cursor was moved to another field.

You can combine a description with any other text, or combine two

descriptions by using an ampersand (&). For example, entering

Tall&do

b&oa

works when spaces are included with the & character. For example,

entering

would result in a description of

would result in a description of

would have the same result as entering

b&oa

Lodgepole Pine

Tall Douglas Fir

Big Oak Tree

Description

Description

once the

. Entering

. This method also

b & oa

field.

field, the

.

Note: Remember to check the

opening a description file that contains codes, described next.

This File Uses Codes

checkbox when

Opening a Description File

Once a description file is created and stored in the data collector, it is

activated with the following steps:

1. Select

2. Select the

File

3. All of the files with a

file that you want to use and tap

4. If the description file contains codes, check the

Codes

-RE, 6HWWLQJV

tab and tap the

Files

section of the screen.

checkbox.

from the Main Menu

.txt

.

%URZVH

extension will be displayed. Select the

button in the

2SHQ

.

Description

This File Uses

34

Page 41

Getting Started

Feature Codes

As explained above, a description or descriptor codes can be used to

help describe a point prior to storing it, but this can be a limited

solution for describing certain points.

Survey Pro also allows you to describe any object using feature codes.

Feature codes can be used to describe objects quickly and in more

detail than a standard text description, particul arly when data is

collected for several points that fit into the same category. For

example, if the locations for all the utility poles in an area were being

collected, a single feature code could be used to separately describe

the condition of each utility pole.

When describing an object using feature codes, a selection is made

from any number of main categories called features. Once a

particular feature is selected, any number of descriptions can be

made from sub-categories to the selected feature called attributes.

In general, a feature describes what an object is and attributes are

used to describe the details of that object.

To take advantage of feature codes, a feature file must first be created

using the TDS Survey Attribute Manager, which is included in

Version 7.2, or later of the TDS Survey Link software.

The TDS Survey Attrib ute Manager can also be used to view or

modify the selected features in a particular job and to export them to

any of several different file formats for use in other popular software

packages.

Note: You can switch between different feature code files in mid-job,

but if a collected attribute does not match an attribute in the current

feature code file, it can still be viewed, but not edited.

For more information on creating a feature file, refer to the Survey

Attribute Manager section of the Survey Link manual.

35

Page 42

User’s Manual

Features

The primary part of a feature code is called a feature. Features

generally describe what an object is. Two types of features are used

in Survey Pro: points and lines, which are described below.

When assigning a feature to data that was collected in Survey Pro,

only features of the same type are available for selection. For

example, if selecting a feature to describe a point in a job, only the

point features are displayed. Likewise, if selecting a feature to

describe a polyline, only the line features in the feature file are

displayed.

•

Point Features

A point feature consists of a single independent point.

Examples of a point feature would be objects such as a tree, a

utility pedestal, or a fire hydrant.

•

Line Features

A line feature consists of two or more points that define a linear object,

such as a fence or a waterline. In Survey Pro, these are stored as

polylines, but line features can also be used to describe alignments.

Attributes

A feature, by itself, would not be useful in describing a point or line

with much detail since a feature only helps describe what the stored

point is. Attributes are used to help describe the details of the object.

Attributes are ei ther typed in from the keyboard or selected from a

pull-down menu and fall into the following three categories.

•

String Attributes

A string attribute consists of a title and a field where the user can type

any characters from the data collector’s keypad up to a specified

maximum length. An example of a string attribute is an attribute titled

36

Notes where the user would type anything to describe a feature.

•

Value Attributes

A value attribute accepts only numbers from the keypad. These

attributes are setup to accept numbers that fall in a specified range.

Some examples of a numeric attribute would be the height of a tree or a

utility pole’s ID number.

Page 43

Getting Started

•

Menu Attributes

A menu attribute is an attribute that is selected from a pull-down menu

rather than typed in from the keypad. Menu items can also have submenu items. For example, you could have a feature labeled Utility with

a pull-down menu labeled Type containing Pole and Pedestal. There

could also be sub-menu items available that could be used to describe

the pole or pedestal in more detail. Menus can only be two levels deep,

but there is no limit to the number of items that can be listed in a pulldown menu.

Using Feature Codes in Survey Pro

Before you can use features and attributes to describe points in

Survey Pro, you must select a valid feature file to use with the

current job.

To select a feature file, open the

screen and then select Files Settings. Tap the

bottom

the appropriate *.FEA feature file.

Once a feature file is selected for the current

job, you can configure Survey Pro to prompt for

attributes whenever a point, line, or alignment

is stored. There are three screens within the

-RE 6HWWLQJV

There is a ;

the Surveying Settings

and the General Settings

attributes only when an object is stored from the routi n es within the

Survey

the routines in the Stakeout

Settings affects if you are prompted for attribut es when an object is

stored from any other routines, such as the COGO

The features and attributes for existing points, polylines, and

alignments can also be edited using the Edit Points

Polylines and Edit Alignments screens, respectively.

menu. Likewise, the second affects only objects stored from

%URZVH«

. The first affects if you are prompted for

menu. The prompt in the General

button then locate and select

screen to configure this prompt.

Prompt for Attributes

, the Stakeout Settings

-RE, 6HWWLQJV

checkbox in

routines.

and Edit

37

Page 44

User’s Manual

Layers

Survey Pro uses layers to help manage the data in a job. Any number

of layers can exist in a job and any new objects can be assigned to any

particular layer. For example, a common set of points can be stored

on one layer and another set can be stored on a different layer.

The visibility of any layer can be toggled on and off, which gives full

control over the data that is displayed in a map view. This is useful

to reduce clutter in a job that contains several objects. The objects

that are stored on a layer include points, polylines, and alignments.