SONY XR-CA360 Service Manual

XR-CA360/CA360X

q

CA

SERVICE MANUAL

Ver 1.2 2003.12

Photo: XR-CA360

SPECIFICATIONS

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.13 % (WRMS)

Frequency response 30 – 15,000 Hz

Signal-to-noise ratio 55 dB

Tuner section

FM

Tuning range

(E model)

Tuning range

(Saudi Arabia model)

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 9 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 67 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

uency response 30 – 15,000 Hz

Fre

FM tuning interval:

50 kHz/200 kHz

switchable

87.5 – 108.0 MHz

(at 50 kHz step)

87.5 – 107.9 MHz

(at 200 kHz step)

87.5 – 108.0 MHz

69 dB (mono)

0.5 % (stereo),

0.3 % (mono)

AM (E model)

Tuning range AM tuning interval:

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

MW/SW (Saudi Arabia model)

Tuning range MW: 531 – 1,602 kHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 45 W × 4 (at 4 ohms)

XR-CA360/CA360X

Saudi Arabia Model

Model Name Using Similar Mechanism NEW

Tape T r ansport Mechanism Type MG-36SZ13-32

General

9 kHz/10 kHz switchable

531 – 1,602 kHz

(at 9 kHz step)

530 – 1,710 kHz

(at 10 kHz step)

SW1: 2,940 – 7,735 kHz

SW2: 9,500 – 18,135 kHz

(except for 10,140 – 11,575

kHz)

(sure seal connectors)

Outputs Audio output

Inputs BUS control input terminal

Tone controls Low:

Power requirements 12 V DC car battery

Dimensions Approx. 178 × 50 × 178 mm

Mounting dimensions Approx. 182 × 53 × 161 mm

Mass Approx. 1.2 kg

Supplied accessories Parts for installation and

Design and specifications are subject to change

without notice.

Power aerial relay control

lead

Power amplifier control

lead

BUS audio input terminal

Mid:

High:

(negative earth)

(w/h/d)

(w/h/d)

connections (1 set)

Front panel case (1)

E Model

XR-CA360

±10 dB at 60 Hz (Xplod)

±10 dB at 1 kHz (Xplod)

±10 dB at 10 kHz (Xplod)

E model

FM/AM/CASSETTE CAR STEREO

Saudi Arabia model

FM/MW/SW CASSETTE CAR STEREO

9-874-258-03 Sony Corporation

2003L05-1 e Vehicle Company

C 2003.12 Published by Sony Engineering Corporation

XR-CA360/CA360X

d

Ver 1.2

TABLE OF CONTENTS

SERVICING NOTES......................................................... 2

1. GENERAL

Location of Controls ....................................................... 3

Setting the Clock ............................................................. 3

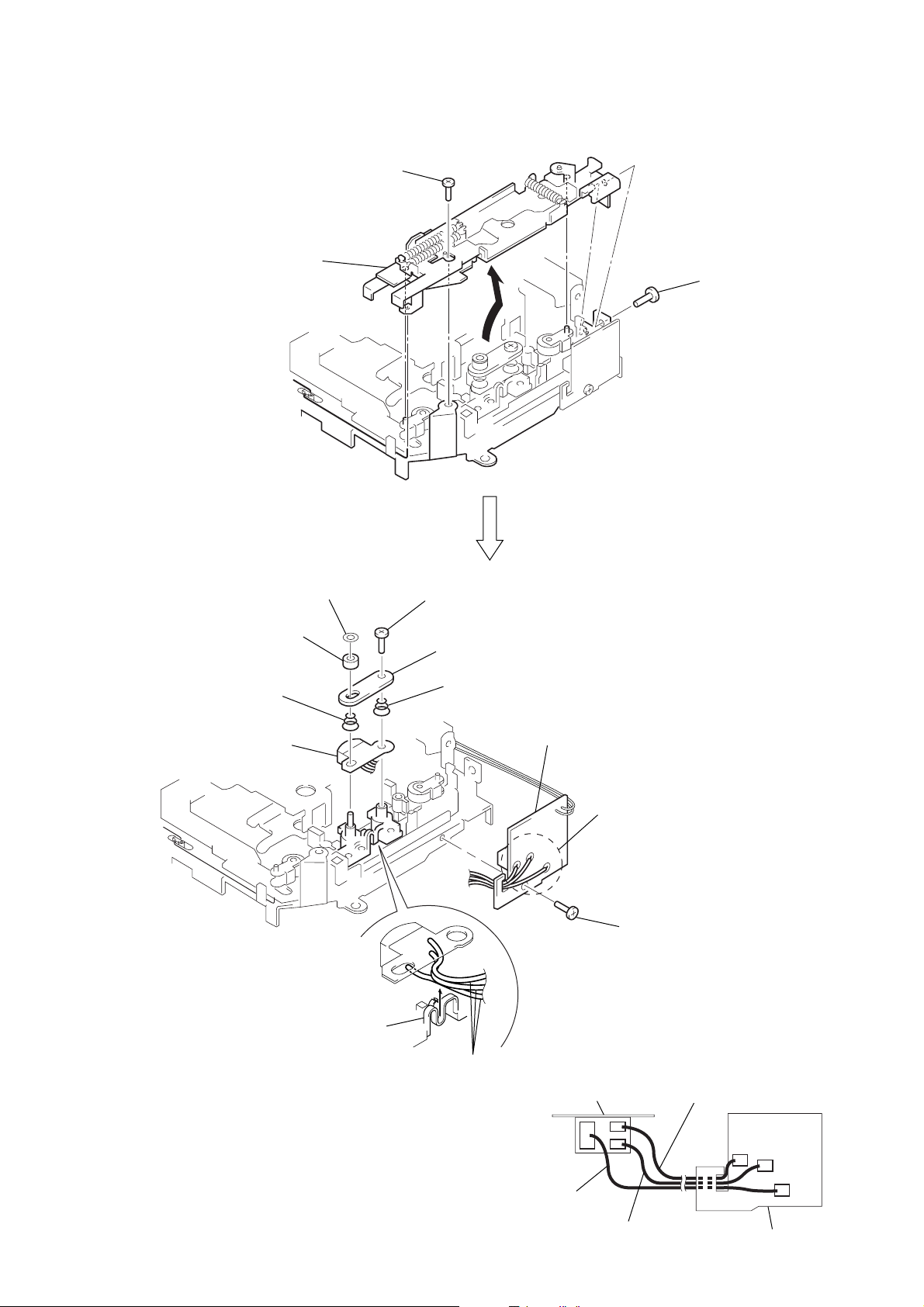

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 7

2-2. Sub Panel......................................................................... 7

2-3. Mechanism Deck (MG-36SZ13-32)............................... 8

2-4. MAIN Board ................................................................... 8

2-5. Heat Sink ......................................................................... 9

2-6. Bracket (MD) .................................................................. 9

2-7. DC Motor (Capstan/Reel) (M901) ................................. 10

2-8. Main Belt, Sub Belt (C) .................................................. 10

2-9. Magnetic Head (Playback) (HP901) .............................. 11

3. MECHANICAL ADJUSTMENTS....................... 12

4. ELECTRICAL ADJUSTMENTS

Tape Dec k Section .......................................................... 12

Tuner Section .................................................................. 13

5. DIAGRAMS

5-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 14

5-2. Printed Wiring Board – MAIN Board – ........................ 15

5-3. Schematic Diagram – MAIN Board (1/2) – .................. 16

5-4. Schematic Diagram – MAIN Board (2/2) – .................. 17

5-5. Printed Wiring Board – CONTROL Board – ................ 18

5-6. Schematic Diagram – CONTROL Board –................... 19

5-7. IC Pin Function Description ........................................... 21

SERVICING NOTES

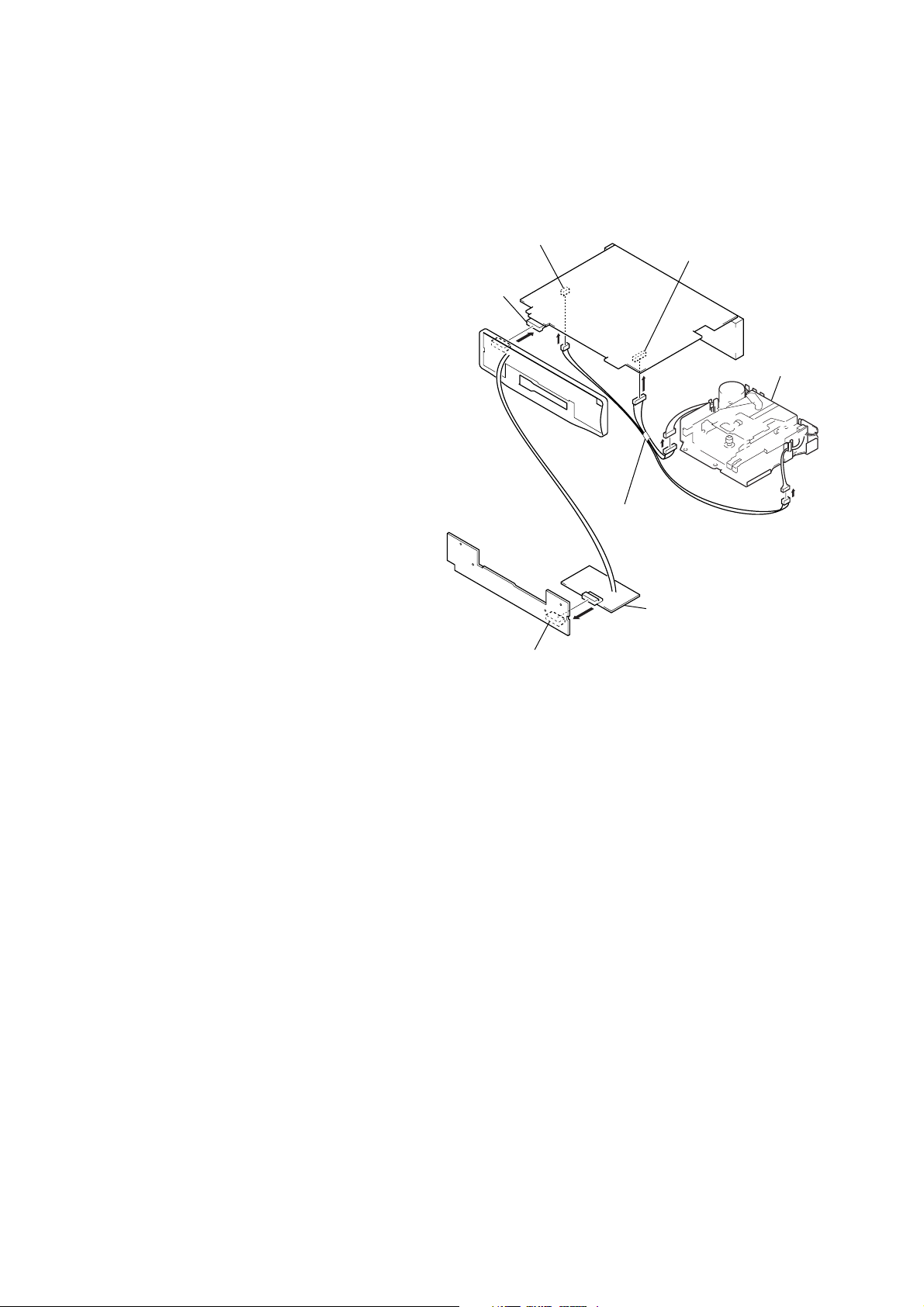

SERVICE POSITION

In checking the control board and main board, prepare two jigs

(extension (MD) cord J-2502-060-1 and

connection cable for F/P to main J-2502-072-1).

main board (CN300)

main board (CN350)

main board

(CN600)

mechanism deck

connect jig

(extention (MD) cord J-2502-060-1)

to the main board (CN300, CN350)

and mechanism deck.

connect jig

(connection cable

for F/P to main J-2502-072-1)

control board (CN900)

to the main board (CN600) an

control board (CN900).

6. EXPLODED VIEWS

6-1. General Section ............................................................... 23

6-2. Front Panel Section ......................................................... 24

6-3. MAIN Board Section ...................................................... 25

6-4. Mechanism Deck Section (MG-36SZ13-32) ................. 26

7. ELECTRICAL PARTS LIST ............................... 27

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Note of replacing of the IC1

In this set, the IC1 on the MAIN board is changed from the midway of the production.

When the replacing of the IC1, be sure to check the model name

printed by IC, and replace the IC1 by following the instructions

below.

• When replacing of the IC1 (MN101C49HAS)

Replace the IC1 with the MN101C49HEA (Part No.: 6-603178-01), and replace the TU101 (A-3220-944-A) simultaneously .

• When replacing of the IC1 (MN101C49HEA)

Perform the usual replacing.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

2

SECTION 1

y

play

GENERAL

XR-CA360/CA360X

This section is extracted from

instruction manual.

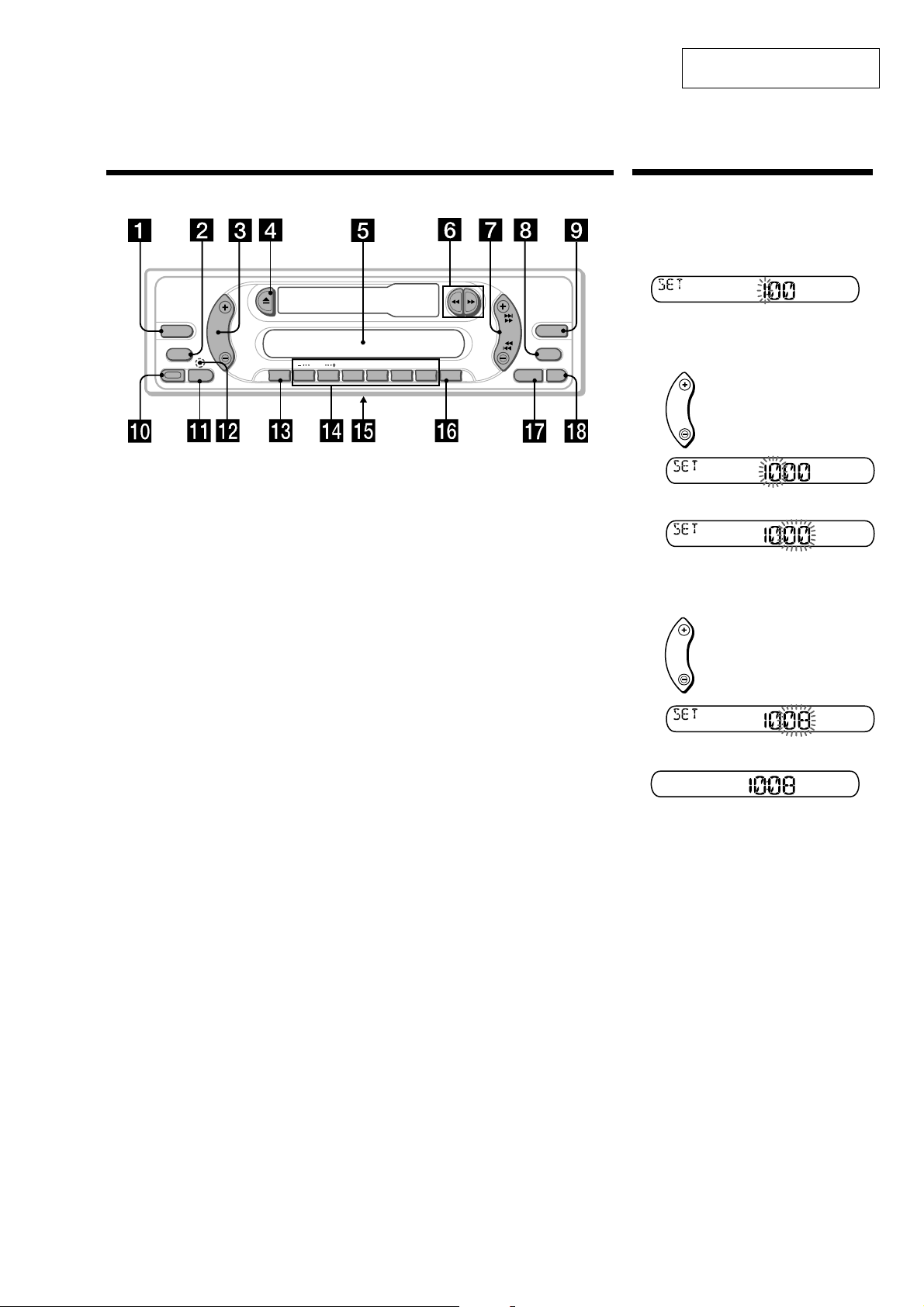

Location of controls

SOURCE

MODE

RELEASE

SEL

Refer to the pages listed for details.

1 SOURCE (Radio/CD/MD) button

2 MODE button

During radio reception:

Band select

During CD/MD playback:

CD/MD unit select

3 Volume +/– button

4 Z (eject) button

5 Display window

6 m/M (fast winding)/DIR (tape

transport direction change) buttons

7 SEEK button

Seek

Automatic Music Sensor

Manual search

8 DSPL (display mode change) button

9 EQ3 button

0 RELEASE (front panel release) button

qa SEL (select) button

qs RESET button (located on the front side

of the unit behind the front panel)

qd ATT (attenuate) button

DISC

ATT

123456

DIR

SEEK

REP

SHUF

ATA

BTM

XR-CA360X/CA360

qf Number buttons

During radio reception:

Preset number select

During CD/MD playback:

(1) DISC –

(2) DISC +

(3) REP

(4) SHUF

qg Frequency select switch (E model)

(located on the bottom of the unit)

See “Frequency select switch” in the

Installation/Connections manual.

qh BTM/ATA button

qj SENS button

qk OFF button*

* Warning when installing in a car

without ACC (accessory) position on

the ignition key switch

Be sure to press (OFF) on the unit for 2

seconds to turn off the clock display after

turning off the engine.

When you press (OFF) momentarily, the

clock display does not turn off and this

causes batter

wear.

EQ3

DSPL

Setting the clock

The clock uses a 12-hour digital indication.

Example: To set the clock to 10:08

1

Press (DSPL) for 2 seconds.

The hour indication flashes.

1 Press either side of the volume button

OFFSENS

to set the hour.

to go forward

to go back

2 Press (SEL).

The minute indication flashes.

3 Press either side of the volume button

to set the minute.

to go forward

to go back

2

Press (DSPL).

The clock starts.

After the clock setting is complete, the

returns to normal play mode.

dis

3

XR-CA360/CA360X

2

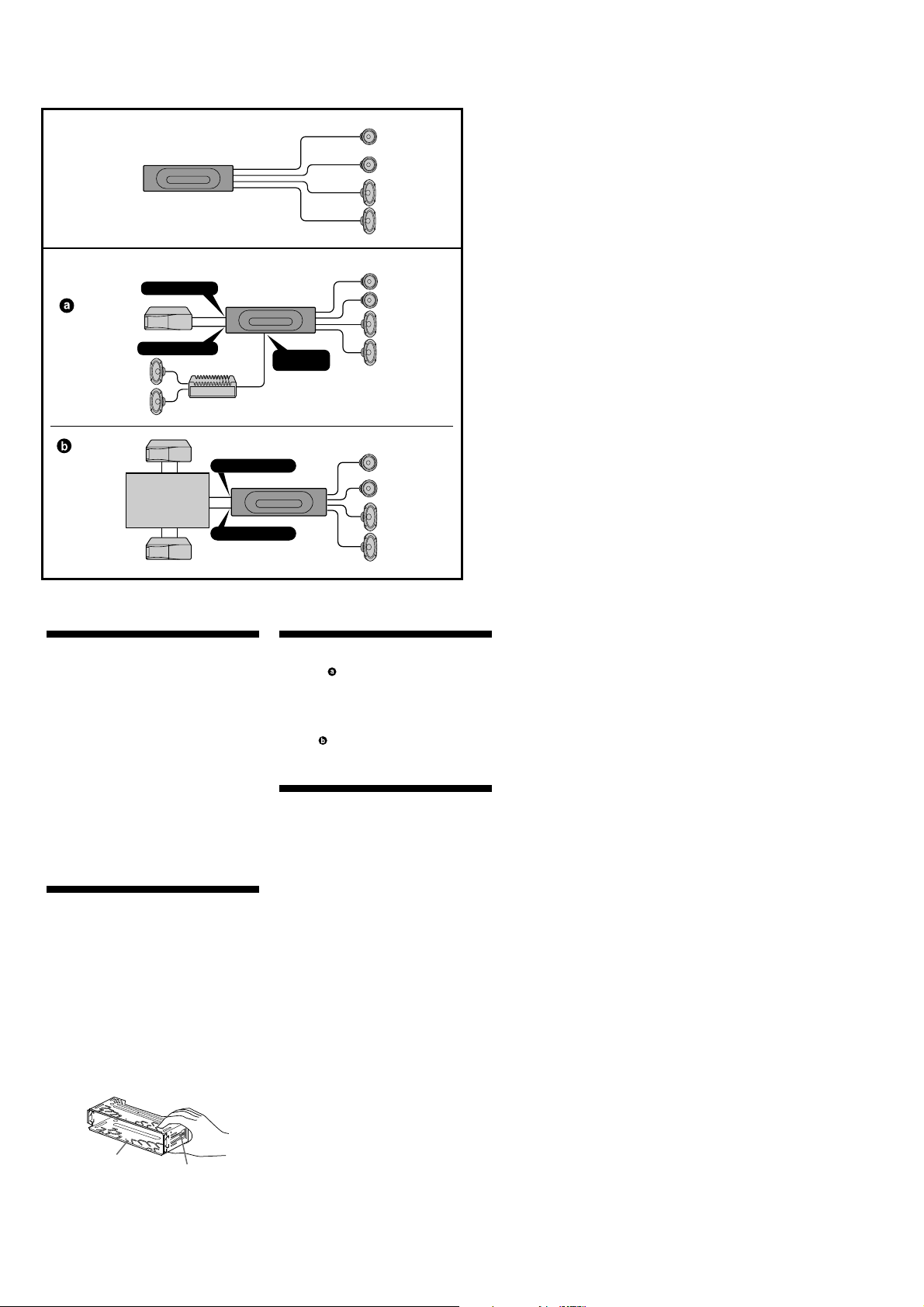

A

B

*not supplied

no suministrado

BUS AUDIO IN

BUS CONTROL IN

Source selector*

Selector de fuente*

XA-CA30

BUS AUDIO IN

BUS CONTROL IN

Cautions

•This unit is designed for negative earth 12 V DC

operation only.

•Do not get the wires under a screw, or caught in

moving parts (e.g. seat railing).

•Before making connections, turn the car ignition

off to avoid short circuits.

•Connect the yellow and red power input leads

only after all other leads have been connected.

•Run all earth wires to a common earth point.

•Be sure to insulate any loose unconnected wires

with electrical tape for safety.

Notes on the power supply cord (yellow)

•When connecting this unit in combination with

other stereo components, the connected car

circuit’s rating must be higher than the sum of

each component’s fuse.

•When no car circuits are rated high enough,

connect the unit directly to the battery.

Parts Iist (1)

•The numbers in the list are keyed to those in the

instructions.

•The bracket 1 and the protection collar 5 are

attached to the unit before shipping. Before

mounting the unit, use the release keys 7 to

remove the bracket 1 and the protection collar

5 from the unit. For details, see “Removing the

protection collar and the bracket (4)” on the

reverse side of the sheet.

•Keep the release keys 7 for future use as they

are also necessary if you remove the unit from

your car.

Caution

Handle the bracket 1 carefully to avoid injuring

your fingers.

AUDIO OUT

REAR

Connection example (2)

Notes (2-B- )

• Be sure to connect the earth cord before connecting

the amplifier.

•If you connect an optional power amplifier and do

not use the built-in amplifier, the beep sound will be

deactivated.

Tip (2-B-

For connecting two or more CD/MD changers, the

source selector XA-C30 (optional) is necessary.

)

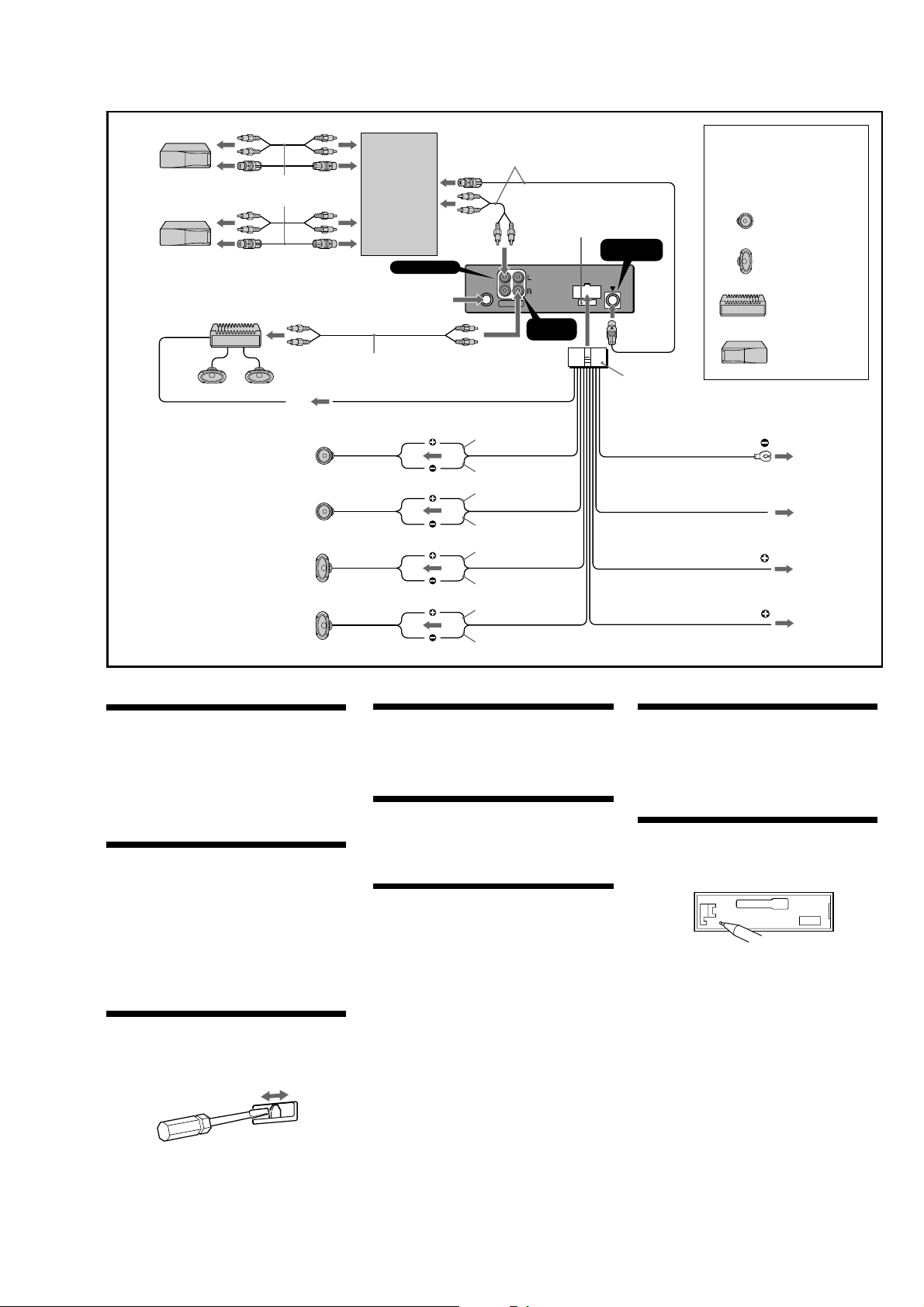

Connection diagram (3)

1 To a metal surface of the car

First connect the black earth lead, then connect the

yellow and red power input leads.

2 To the power aerial control lead or power supply

lead of aerial booster amplifier

Notes

•It is not necessary to connect this lead if there is no

power aerial or aerial booster, or with a manuallyoperated telescopic aerial.

•When your car has a built-in FM/AM aerial in the

rear/side glass, see “Notes on the control and

power supply leads.”

3 To AMP REMOTE IN of an optional power amplifier

This connection is only for amplifiers. Connecting

any other system may damage the unit.

4 To the +12 V power terminal which is energised in

the accessory position of the ignition key switch

Notes

•If there is no accessory position, connect to the +12

V power (battery) terminal which is energised at

all times.

Be sure to connect the black ground lead to a

metal surface of the car first.

•When your car has a built-in FM/AM aerial in the

rear/side glass, see “Notes on the control and

power supply leads.”

5 To the +12 V power terminal which is energised at

all times

Be sure to connect the black ground lead to a metal

surface of the car first.

Notes on the control and power supply leads

• The power aerial control lead (blue) supplies +12 V

DC when you turn on the tuner.

•When your car has built-in FM/AM aerial in the rear/

side glass, connect the power aerial control lead

(blue) or the accessory power input lead (red) to the

power terminal of the existing aerial booster. For

details, consult your dealer.

•A power aerial without relay box cannot be used with

this unit.

Memory hold connection

When the yellow power input lead is connected, power

will always be supplied to the memory circuit even

when the ignition key is turned off.

Notes on speaker connection

• Before connecting the speakers, turn the unit off.

• Use speakers with an impedance of 4 to 8 ohms, and

with adequate power handling capacities to avoid its

damage.

• Do not connect the speaker terminals to the car

chassis, or connect the terminals of the right speakers

with those of the left speaker.

• Do not connect the earth lead of this unit to the

negative (–) terminal of the speaker.

• Do not attempt to connect the speakers in parallel.

• Connect only passive speakers. Connecting active

speakers (with built-in amplifiers) to the speaker

terminals may damage the unit.

• To avoid a malfunction, do not use the built-in

speaker wires installed in your car if the unit shares a

common negative (–) lead for the right and left

speakers.

• Do not connect the unit’s speaker cords to each other.

1

Note

Before installing, make sure that the catches on both

sides of the bracket 1 are bent inwards 2 mm. If the

catches are straight or bent outwards, the unit will not

be installed securely and may spring out.

Catch

4

XR-CA360/CA360X

3

Supplied with the CD/MD changer

Suministrado con el cambiador de CD/MD

RCA pin cord (not supplied)

Cable con clavijas RCA (no suministrado)

AMP REM

3

Max. supply current 0.3 A

Corriente máx. de alimentación de 0,3 A

Left

Izquierdo

Right

Derecho

Left

Izquierdo

Right

Derecho

Source selector

(not supplied )

Selector de fuente

(no suministrado )

XA-C30

BUS AUDIO IN

from car aerial

de antena de automóvil

Supplied with XA-C30

Suministrado con el XA-C30

BUS

AUDIO

AUDIO IN

OUT

AUDIO

OUT REAR

Blue/white striped

Con raya azul/blanca

White

Blanco

White/black striped

Con raya blanca/negra

Grey

Gris

Grey/black striped

Con raya gris/negra

Green

Verde

Green/black striped

Con raya verde/negra

Purple

Púrpura

Purple/black striped

Con raya violeta/negra

Fuse (10 A)

Fusible (10 A)

BUS

CONTROL IN

6

Black

Negro

Blue

Azul

Corriente máx. de alimentación de 0,1 A

Red

Rojo

Yellow

Amarillo

Max. supply current 0.1 A

Equipment used in illustrations

(not supplied)

Equipo utilizado en las ilustraciones

(no suministrado)

Front speaker

Altavoces delanteros

Rear speaker

Altavoces traseros

Power amplifier

Amplificador de potencia

CD/MD

Cambiador de CD/MD

1

ANT REM

2

4

5

Precautions

•Choose the installation location carefully so that the unit will not

interfere with normal driving operations.

•Avoid installing the unit in areas subject to dust, dirt, excessive

vibration, or high temperatures, such as in direct sunlight or near

heater ducts.

•Use only the supplied mounting hardware for a safe and secure

installation.

Mounting angle adjustment

Adjust the mounting angle to less than 20°.

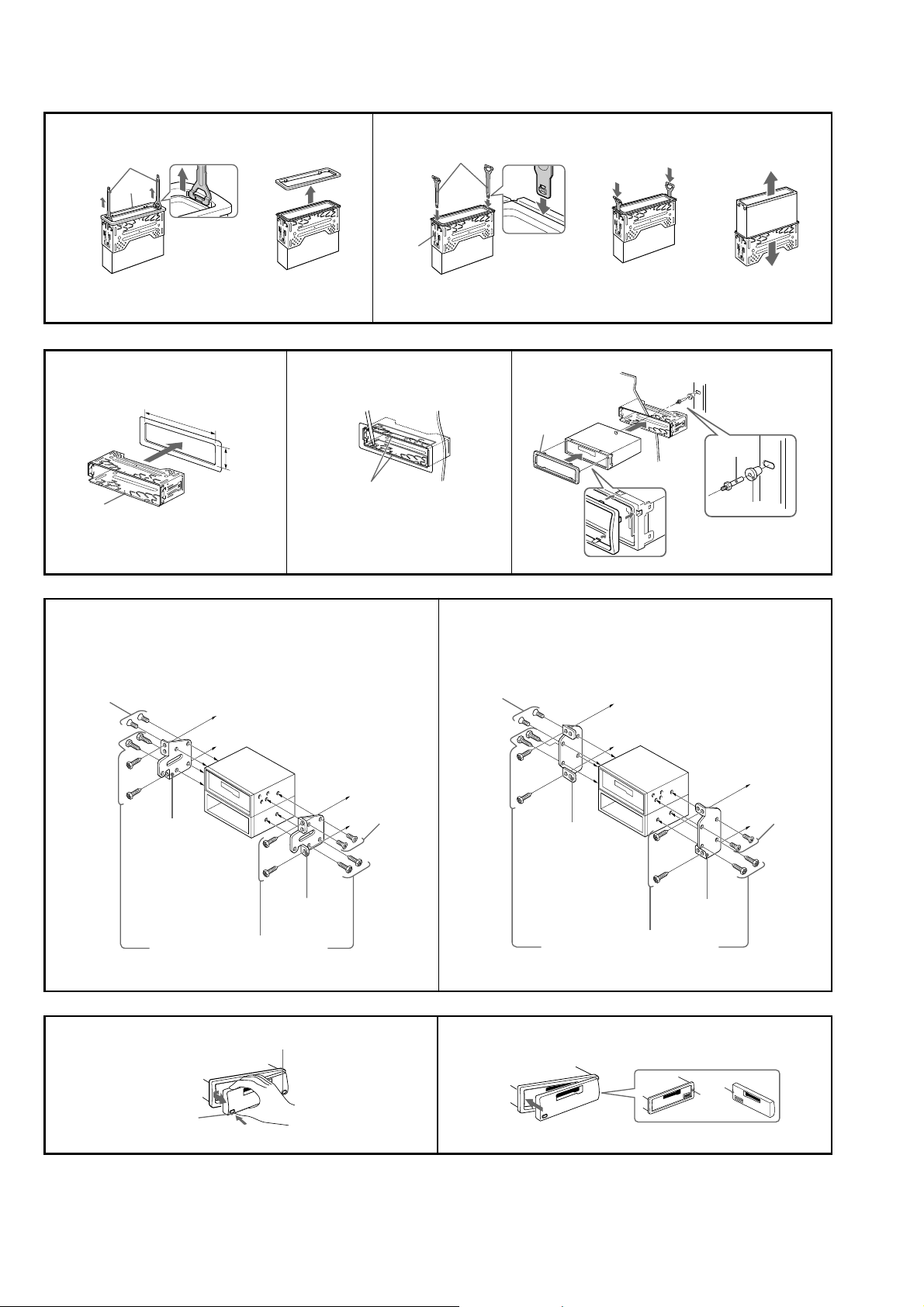

Removing the protection collar and the

bracket (4)

Before installing the unit, remove the protection collar 5 and

the bracket 1 from the unit.

1

Remove the protection collar 5.

1 Engage the release keys 7 together with the protection collar

5 .

2 Pull out the release keys 7 to remove the protection collar 5.

2

Remove the bracket 1.

1 Insert both release keys 7 together between the unit and the

bracket until they click.

2 Pull down the bracket 1, then pull up the unit to separate.

Frequency select switch (E model)

The AM (FM) tuning interval is factory-set to the 9 k (50 k) position.

If the frequency allocation system of your country is based on 10 kHz

(200 kHz) interval, set the switch on the bottom of the unit to the 10 k

(200 k) position before making connections.

Mounting example (5)

Installation in the dashboard

Notes

• Bend these claws outward for a tight fit, if necessary (5-2).

•Make sure that the 4 catches on the protection collar 5 are properly

engaged in the slots of the unit (5-3).

Mounting the unit in a Japanese car (6)

You may not be able to install this unit in some makes of Japanese

cars. In such a case, consult your Sony dealer.

Note

To prevent malfunction, install only with the supplied screws 4.

How to detach and attach the front panel

(7)

Before installing the unit, detach the front panel.

7-A To detach

Before detaching the front panel, be sure to press (OFF).

Press (RELEASE), then slide the front panel to the left, and pull it off

towards you.

7-B To attach

Attach part A of the front panel to part B of the unit as illustrated

and push the left side into position until it clicks.

Warning when installing in a car without ACC

(accessory) position on the ignition key

switch

Be sure to press (OFF) on the unit for two seconds to turn

off the clock display after turning off the engine.

When you press (OFF) only momentarily, the clock display does not

turn off and this causes battery wear.

RESET button

When the installation and connections are completed, be sure to

press the RESET button with a ballpoint pen, etc., after detaching the

front panel.

5

XR-CA360/CA360X

4

5

1

1

2

7

5

Orient the release key

correctly.

Oriente la llave de

liberación en la dirección

correcta.

c

2

182 mm

53 mm

Claws

1

Uñas

7

c

1

Face the hook inwards.

El gancho debe

encontrarse en la parte

interior.

3

5

Dashboard

Salpicadero

1

c

Fire wall

Panel cortafuegos

2

3

6

A

B

TOYOTA NISSAN

4

max. size

5 × 8 mm

Tamaño máx.

5 × 8mm

Bracket

Soporte

Existing parts supplied with your car

Piezas existentes suministradas con su automóvil

AB

7

to dashboard/centre console

al salpicadero/consola central

Bracket

Soporte

(OFF)

4

max. size

5 × 8 mm

Tamaño máx.

5 × 8mm

4

max. size

5 × 8 mm

Tamaño máx.

5 × 8mm

Bracket

Soporte

Existing parts supplied with your car

Piezas existentes suministradas con su automóvil

to dashboard/centre console

al salpicadero/consola central

Bracket

Soporte

4

max. size

5 × 8 mm

Tamaño máx.

5 × 8mm

A

B

(RELEASE)

6

SECTION 2

DISASSEMBLY

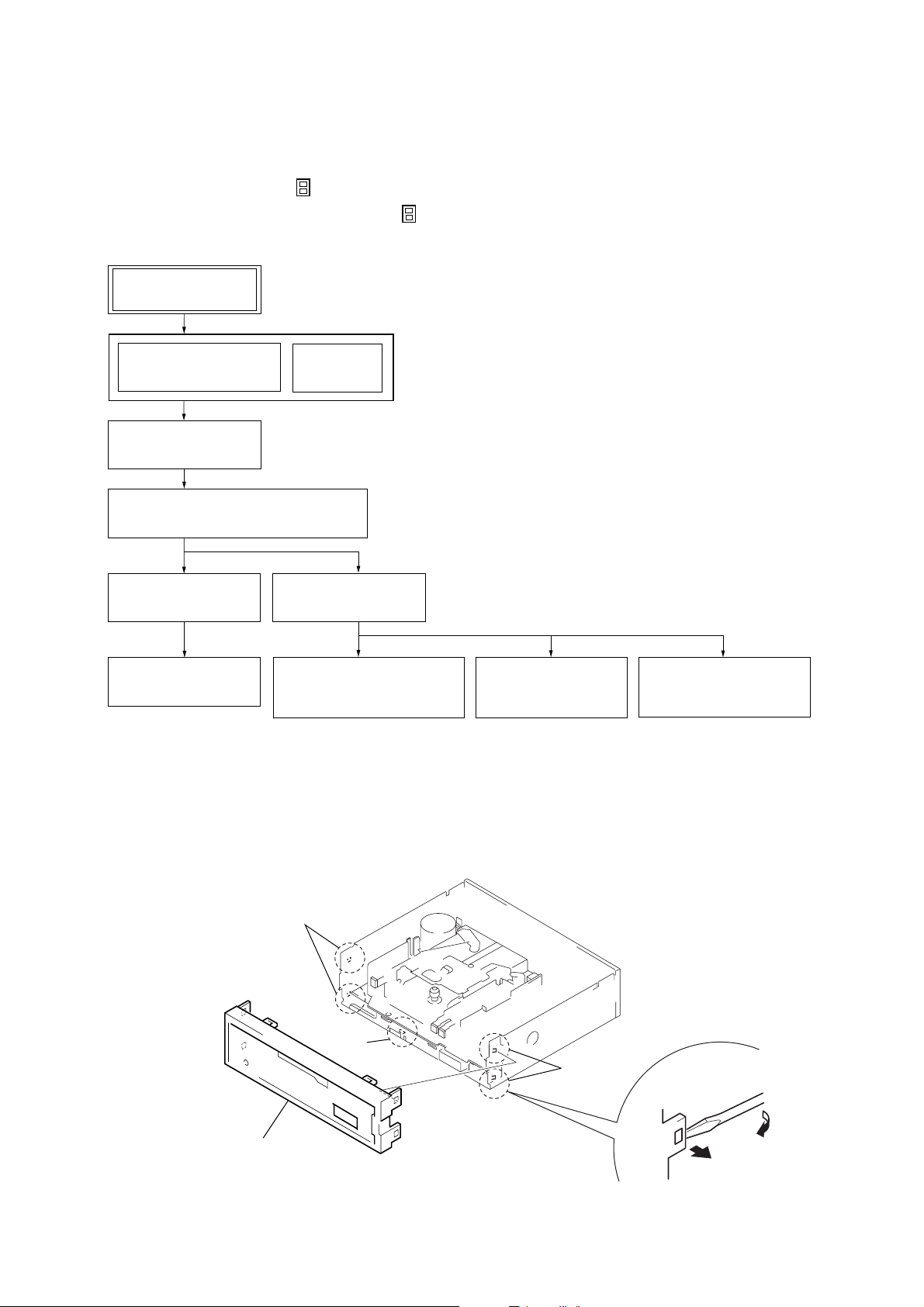

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

Note 3: Illustration of disassembly is omitted.

SET

XR-CA360/CA360X

FRONT PANEL SECTION

(Note 3)

2-2. SUB PANEL

(Page 7)

2-3. MECHANISM DECK (MG-36SZ13-32)

(Page 8)

2-4. MAIN BOARD

(Page 8)

2-5. HEAT SINK

(Page 9)

Note: Follow the disassembly procedure in the numerical order given.

COVER

(Note 3)

2-6. BRACKET (MD)

(Page 9)

2-7. DC MOTOR

(CAPSTAN/REEL) (M901)

(Page 10)

2-2. SUB PANEL

2-8. MAIN BELT,

SUB BELT (C)

(Page 10)

2-9. MAGNETIC HEAD

(PLAYBACK) (HP901)

(Page 11)

1

2

sub panel

two claws

1

claw

1

two claws

7

XR-CA360/CA360X

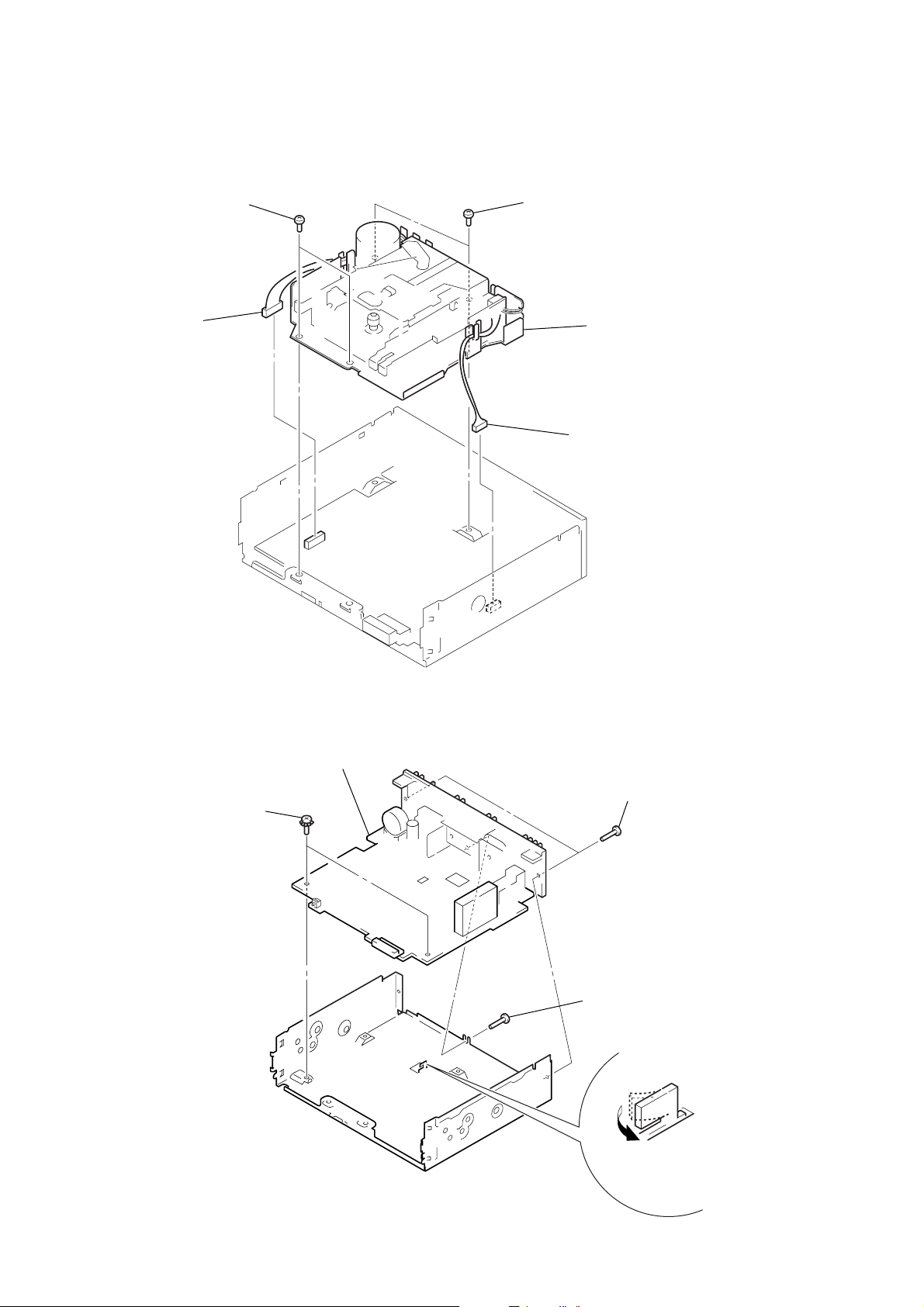

2-3. MECHANISM DECK (MG-36SZ13-32)

2

two screws

1

connector

(CN350)

(PTT2.6

×

6)

2

two screws

(PTT2.6

×

6)

3

mechanism deck (MG-36SZ13-32)

1

connector

(CN300)

2-4. MAIN BOARD

2

two ground point screws

(PTT2.6

×

6)

4

main board

3

3

screw

(PTT2.6

two screws

(PTT2.6

×

6)

×

6)

1

claw

8

2-5. HEAT SINK

)

2

heat sink

1

two screws

(PTT2.6 × 10)

XR-CA360/CA360X

1

five screws

(PTT2.6 × 10

2-6. BRACKET (MD)

1

claw

3

bracket (MD)

1

claw

2

four screws

(B2.6

1

claw

×

4)

9

XR-CA360/CA360X

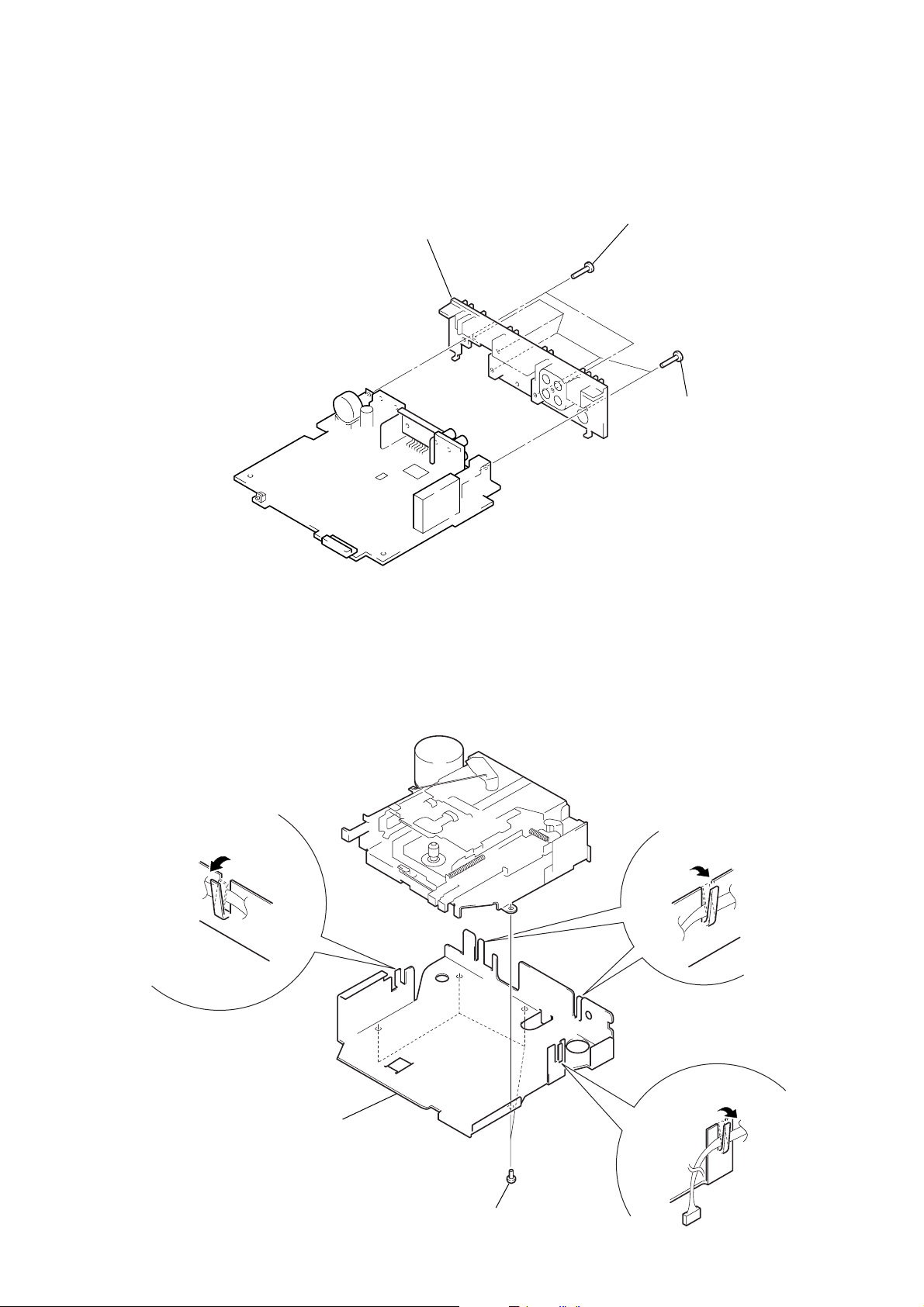

2-7. DC MOTOR (CAPSTAN/REEL) (M901)

2

main belt

3

sub belt (C)

1

two screws

(P2 × 2.5)

4

DC motor (capstan/reel) (M901)

2-8. MAIN BELT, SUB BELT (C)

1

main belt

2

screw

(PTP2

Note :When installing motor,

adjust the screw and

screw hole of motor.

×

3)

4

sub belt (c)

10

2

screw

(PTP2 × 3)

2

screw

(PTP2 × 3)

A

2

screw

(PTP2 × 3)

3

Lift up the bottom BKT (TS)

in the direction of arrow

(as far as the belt can be removed).

A

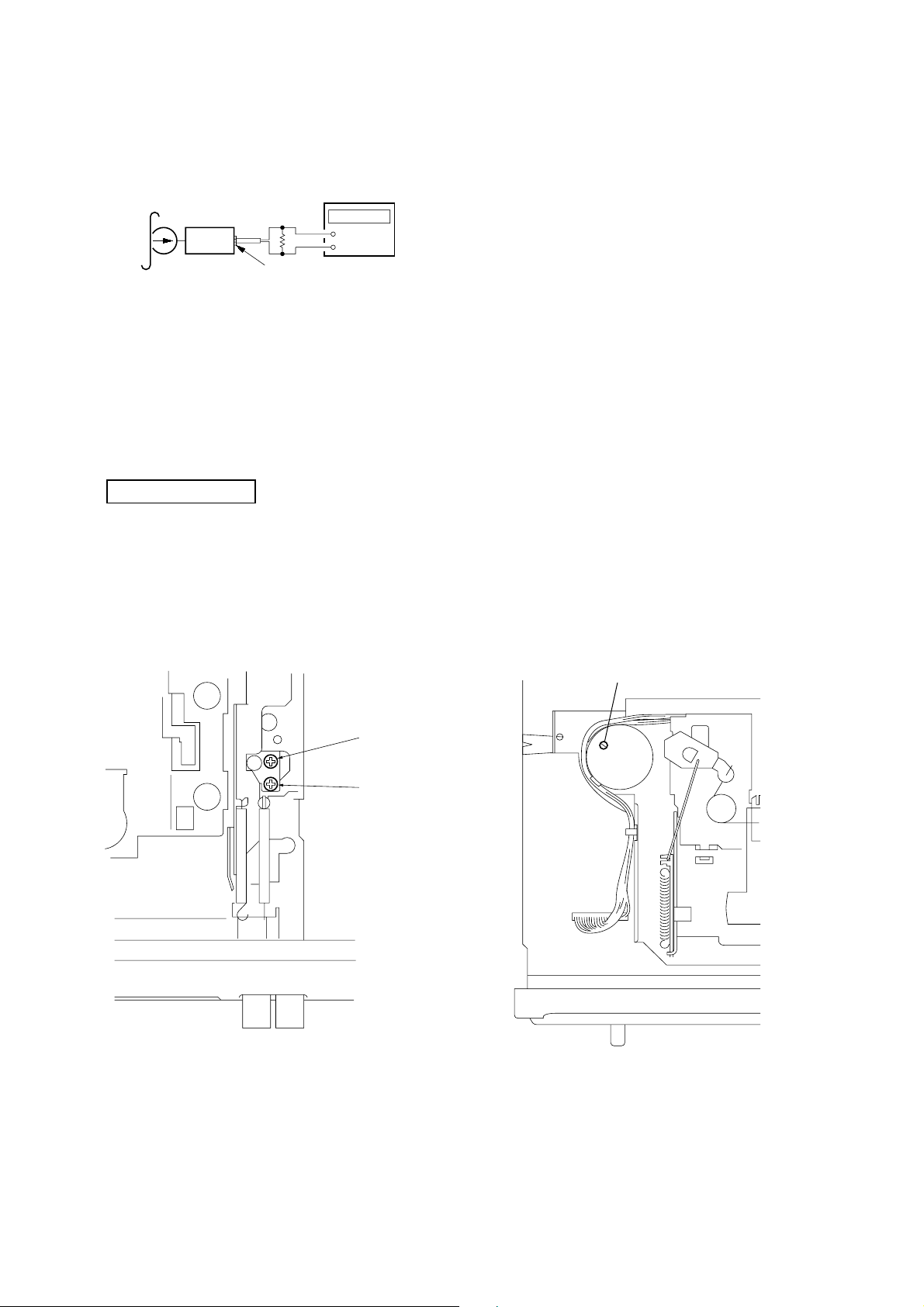

2-9. MAGNETIC HEAD (PLAYBACK) (HP901)

9

screw

(P2

×

4)

5

screw

(PTP2

×

3)

qd

Remove three magnetic

head lead wires from

the adjuster arm blue.

magnetic head

(HP901)

magnetic head lead wire

adjuster arm blue

•MAGNETIC HEAD LEAD WIRE COLOR INDICATION

ON HEAD (HP901) AND SLIDE SW BOARD.

0

SPG support plate

7

PSW (reel) B

8

HP roller (A)

qa

adjuster arm SPG (A)

qs

adjuster arm SPG (B)

qf

magnetic head (play back) (HP901)

6

slide SW board

4

Remove the three solders

of magnetic head lead wires.

yellow lead wire

black lead wire

red lead wire

slide SW board

2

screw

(PTT2 × 4)

3

FF/REV lever section

XR-CA360/CA360X

1

screw

(P2 × 3)

11

XR-CA360/CA360X

e

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idler

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the power supply

voltage (14.4 V) unless otherwise noted.

Note: With this set, it is not necessary to apply suitable locking

compound to the parts after the azimuth adjustment.

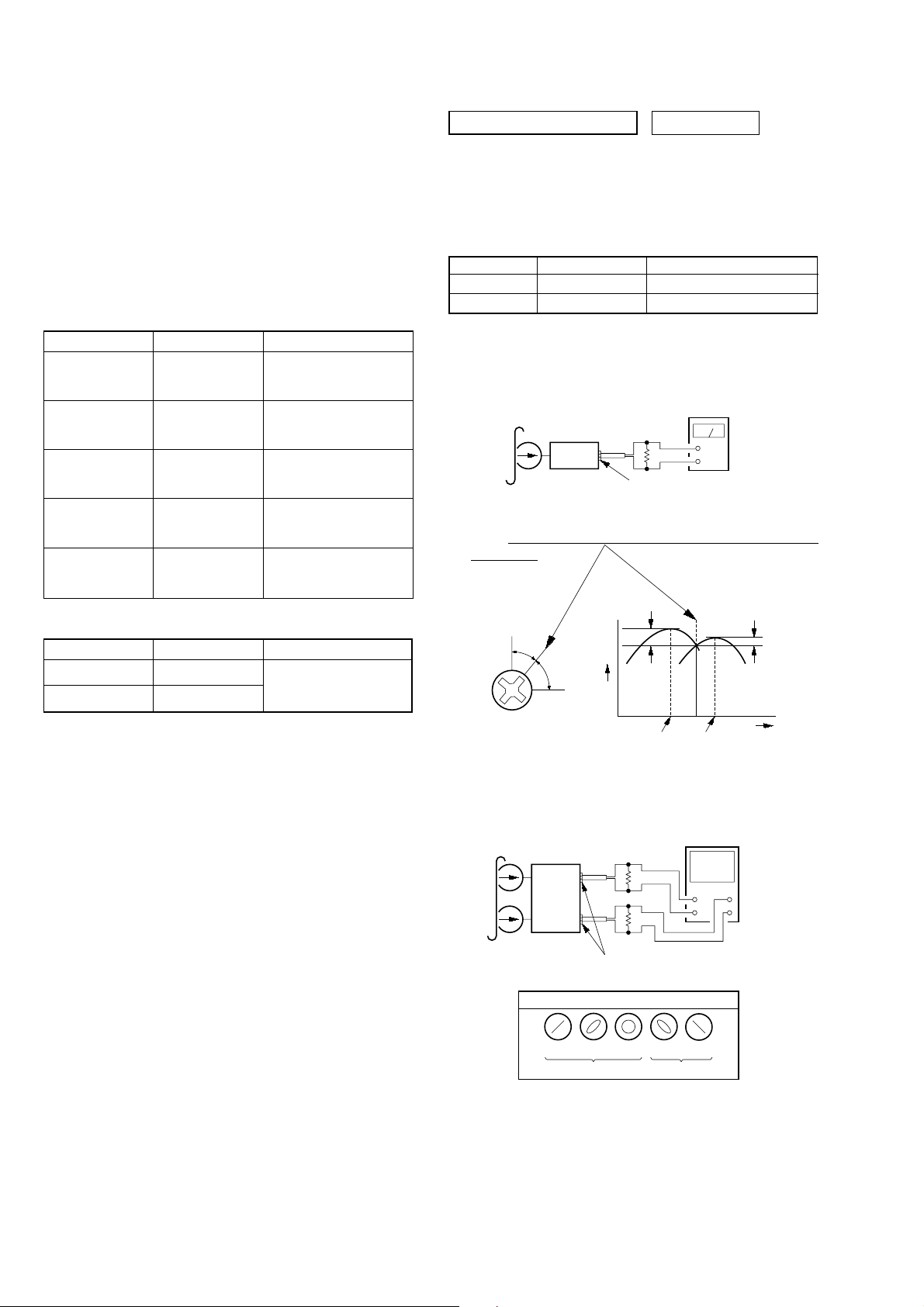

• TORQUE MEASUREMENT

Mode Torque Meter Meter Reading

Forward CQ-102C (25 – 55 g•cm)

Forward

Back Tension

Reverse CQ-102RC (25 – 55 g•cm)

Reverse

Back Tension

FF, REW CQ-201B (50 – 150 g•cm)

CQ-102C (1.5 – 4 g•cm)

CQ-102RC (1.5 – 4 g•cm)

2.46 – 5.39 mN•m

(0.35 – 0.76 oz•inch)

0.15 – 0.39 mN•m

(0.02 – 0.06 oz•inch)

2.46 – 5.39 mN•m

(0.35 – 0.76 oz•inch)

0.15– 0.39 mN•m

(0.02 – 0.06 oz•inch)

4.91 – 14.70 mN•m

(0.69 – 2.08 oz•inch)

• TAPE TENSION MEASUREMENT

Mode Tension Meter Meter Reading

Forward CQ-403A

Reverse CQ-403R

more than 5.89 mN•m

(more than 60 g)

(more than 2.12 oz)

TAPE DECK SECTION 0 dB= 0.775 V

1. The adjustments should be performed in the order given in

this service manual.

2. The adjustments should be performed for both L-CH and

R-CH.

TEST TAPE

Type Signal Used for

P-4-A063 6.3 kHz, –10 dB head azimuth adjustment

WS-48A 3 kHz, 0 dB tape speed adjustment

PB HEAD AZIMUTH ADJUSTMENT

Procedure:

1. Put the set into the FWD PB mode.

test tape

P-4-A063

(6.3 kHz, –10 dB)

set

4 Ω

speaker out terminal

2. Turn the screw and check the output peak value. Adjust the

screw so that the peak value in channels L and R coincides

within 3 dB.

output

level

within

3 dB

L-CH

peak

L-CH

peak

screw

position

R-CH

peak

level

meter

+

–

R-CH

peak

within

3 dB

angl

3. Check the phase in the FWD PB mode.

test tape

P-4-A063

(6.3 kHz, –10 dB)

L-CH

set

R-CH

in phase

4 Ω

4 Ω

speaker out terminal

Screen pattern

45 °

90 °

good wrong

oscilloscope

V

+

–

135 ° 180 °

H

+

–

4. Repeat the above adjustment for the REV PB mode.

5. Check that output level difference between FWD PB mode

and REV PB mode is within 4 dB.

Adjustment Location: PB head (See page 13)

12

r

TAPE SPEED ADJUSTMENT

Setting:

test tape

WS-48A

(3 kHz, 0 dB)

set

frequency counte

4 Ω

+

–

speaker out terminal

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust adjustment resistor for inside capstan motor so that the

reading on the frequency counter becomes in 3,015 Hz.

Specified Value: 2,940 to 3,090 Hz

Adjustment Location: DC motor

XR-CA360/CA360X

TUNER SECTION

Tuner section adjustments are done automatically in this set.

Adjustment Location: PB head

– Set Upper View –

FWD

adjustment

screws

REV

Adjustment Location: DC motor

– Set Upper View –

Tape Speed Adjustment

13

XR-CA360/CA360X

Ver 1.2

SECTION 5

DIAGRAMS

5-1. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

z

•

• : Pattern from the side which enables seeing.

•

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

•Abbreviation

• When replacing the IC1, refer to servicing note (Page 2 “When

: Through hole.

: Carbon pattern.

EA : Saudi Arabia model

replacing the IC1”).

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• C : panel designation.

• A : B+ Line.

•Power voltage is dc 14.4V and fed with regulated dc power

supply from ACC and BATT cords.

•Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

〈〈 〉〉 : TAPE PLAYBACK

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : AM

E : T APE PLAYBACK

L : BUS AUDIO IN

•Abbreviation

EA : Saudi Arabia model

• When replacing the IC1, refer to ser vicing note (Page 2

“When replacing the IC1”).

4

W or less unless otherwise

14

Loading...

Loading...