Page 1

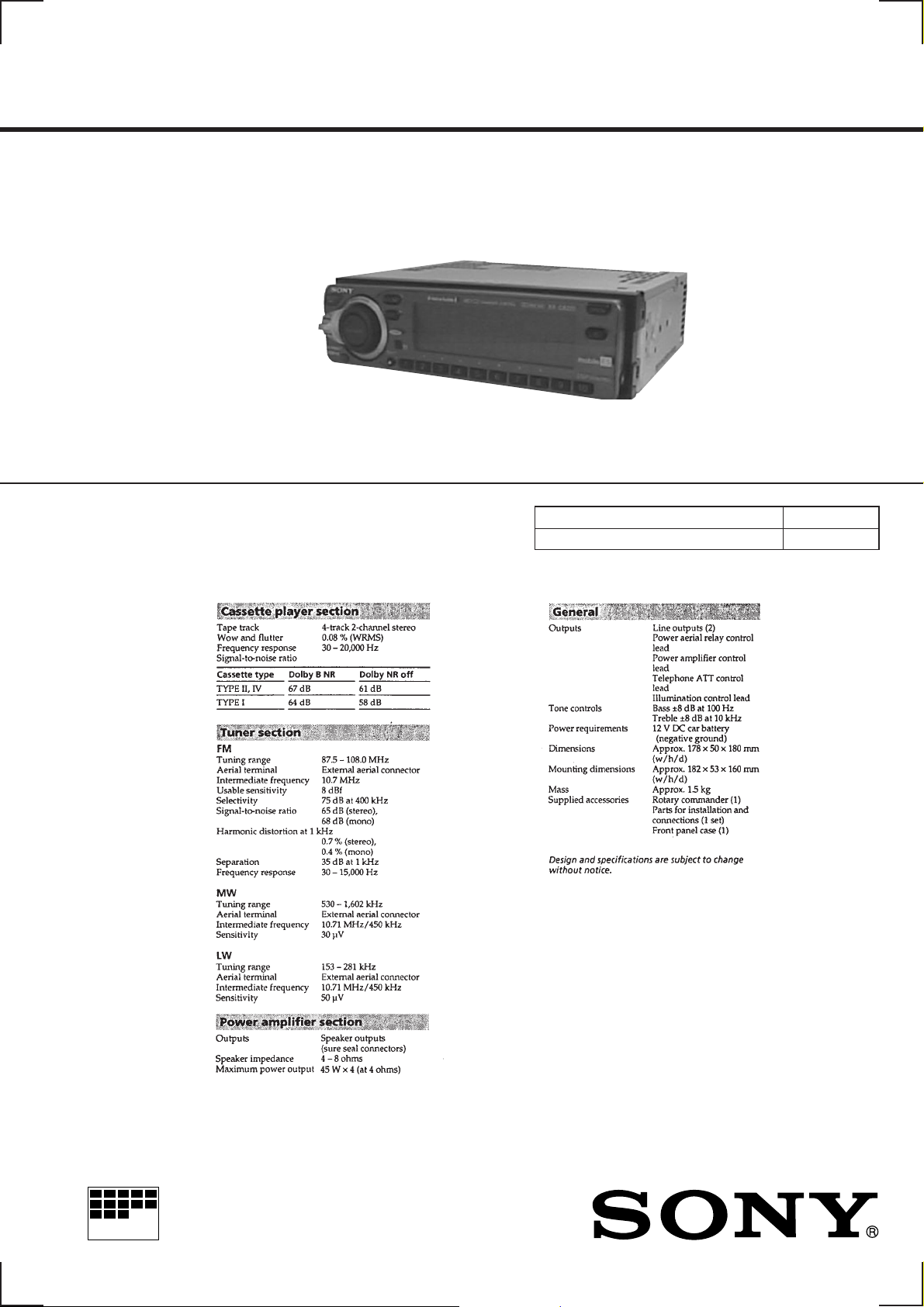

XR-C8220R

SERVICE MANUAL

For RM-X4S (Remote Commander),

please refer to RM-X4S Service Manual

(9-925-698-∏) previously issued.

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

SPECIFICA TIONS

AEP Model

UK Model

Model Name Using Similar Mechanism XR-C8100R

T ape Transport Mechanism Type MG-25D-136

MICROFILM

FM/MW/LW CASSETTE CAR STEREO

Page 2

SECTION 1

SERVICE NOTE

TABLE OF CONTENTS

1. SERVICE NOTE....................................................... 2

2. GENERAL

Location of Controls ....................................................... 3

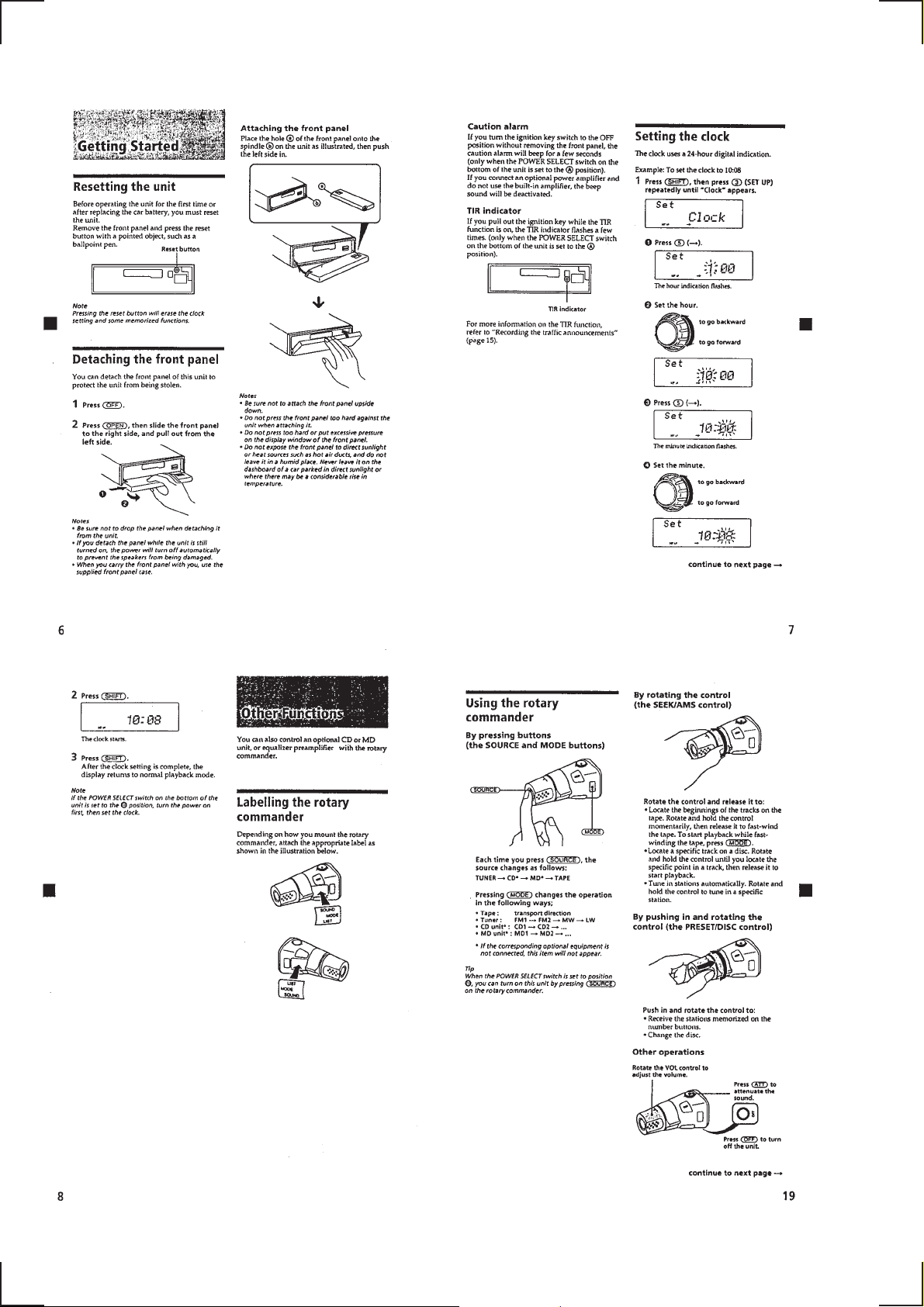

Resetting the Unit ........................................................... 4

Setting the Clock ............................................................. 4

Other Functions............................................................... 4

Installation....................................................................... 6

Connections ..................................................................... 7

3. DISASSEMBLY ......................................................... 12

4. ASSEMBLY OF MECHANISM DECK........... 14

5. MECHANICAL ADJUSTMENTS....................... 17

6. ELECTRICAL ADJUSTMENTS

Test Mode........................................................................ 18

Tape Deck Section .......................................................... 18

Tuner Section .................................................................. 19

7. DIAGRAMS

7-1. Block Diagram – TUNER Section – .............................. 23

7-2. Block Diagram – TAPE Section – .................................. 25

7-3. Block Diagram – MAIN Section – ................................. 27

7-4. Block Diagram

– DISPLAY/KEY CONTROL Section –........................ 29

7-5. Block Diagram

– BUS CONTROL/POWER SUPPLY Section –........... 31

7-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 33

7-7. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 35

7-8. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 37

7-9. Schematic Diagram – MAIN Board (1/4) – ................... 39

7-10. Schematic Diagram – MAIN Board (2/4) – ................... 41

7-11. Schematic Diagram – MAIN Board (3/4) – ................... 43

7-12. Schematic Diagram – MAIN Board (4/4) – ................... 45

7-13. Printed Wiring Board – KEY Board –............................ 47

7-14. Schematic Diagram – KEY Board – .............................. 49

7-15. Printed Wiring Boards – SUB/INVERTER Boards – .... 51

7-16. Schematic Diagram

– SUB/INVERTER Boards –.......................................... 52

7-17. IC Pin Function Description ........................................... 58

• Model Identification

The destination is expressed with the model according to the language of CSV (Computer Sound Voice) mounted in the set.

How to identify the model is described below.

– MAIN BOARD (Component Side) –

IC650

MSM6656A-687GS-KR1 (TYPE A: ENGLISH, FRENCH)

MSM6656A-688GS-KR1 (TYPE B: ENGLISH, GERMAN)

MSM6656A-689GS-KR1 (TYPE C: ENGLISH, SPANISH)

MSM6656A-690GS-KR1 (TYPE D: ENGLISH, ITALIAN)

8. EXPLODED VIEWS ................................................ 62

9. ELECTRICAL PARTS LIST ............................... 65

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 2 –

Page 3

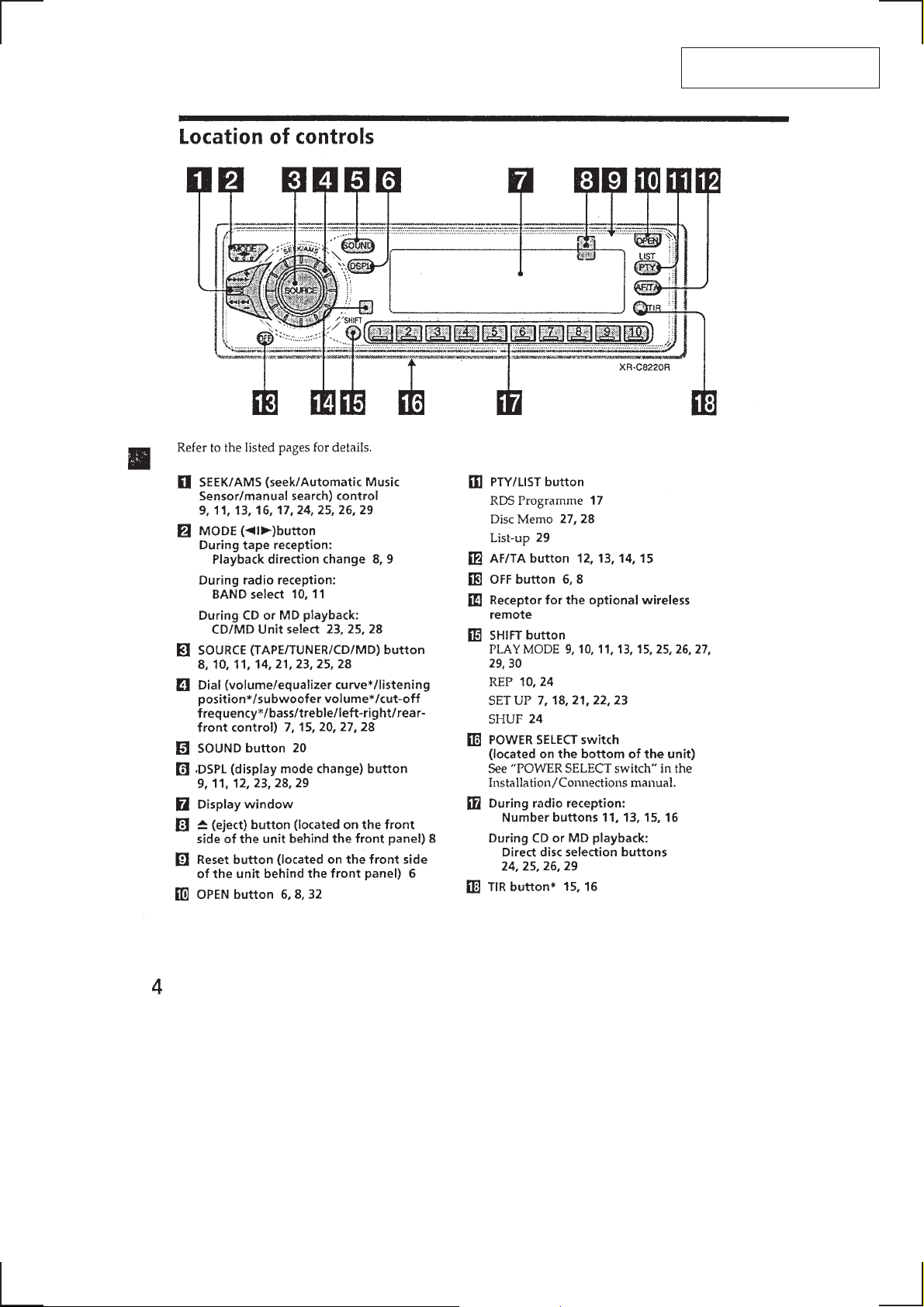

SECTION 2

GENERAL

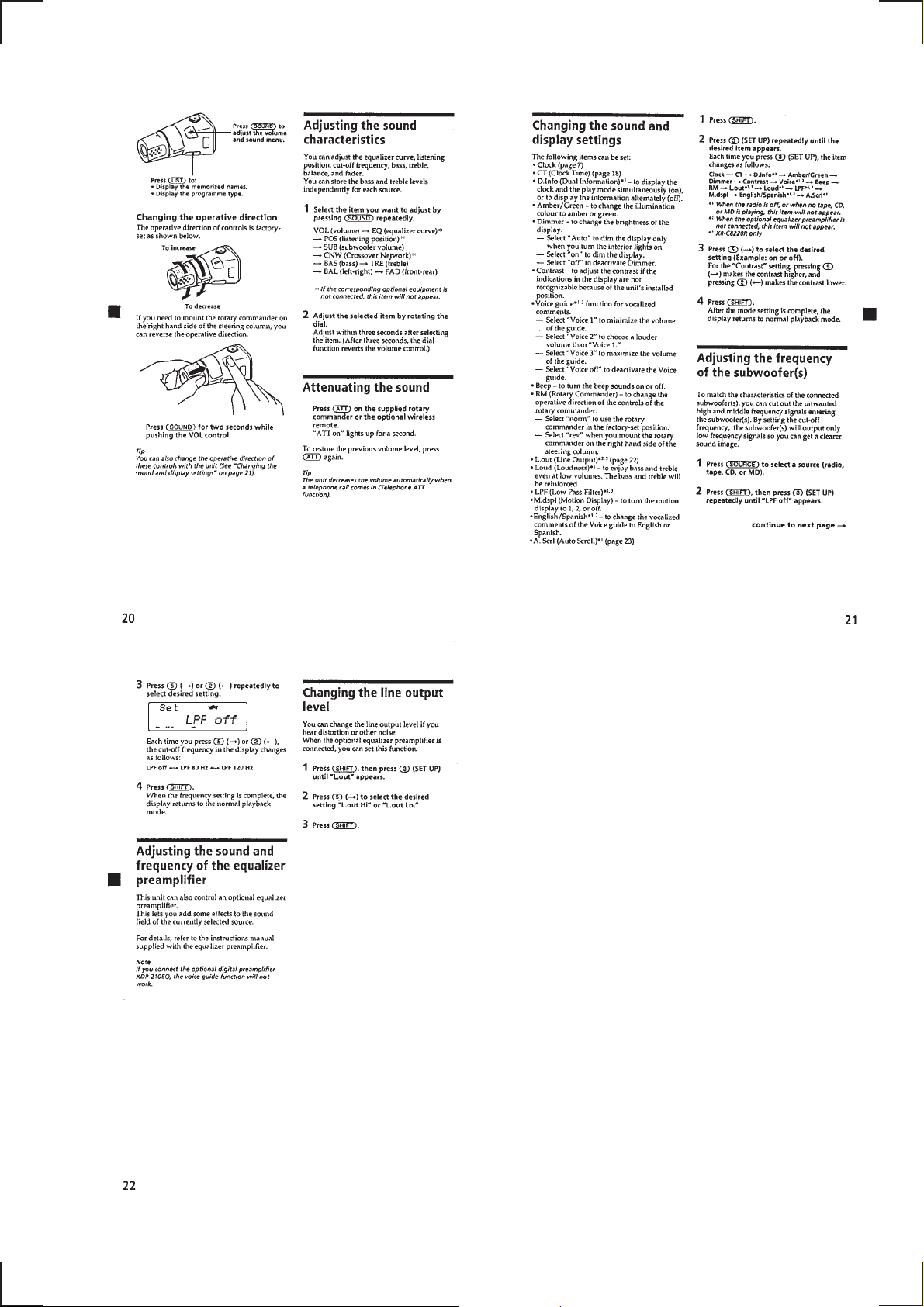

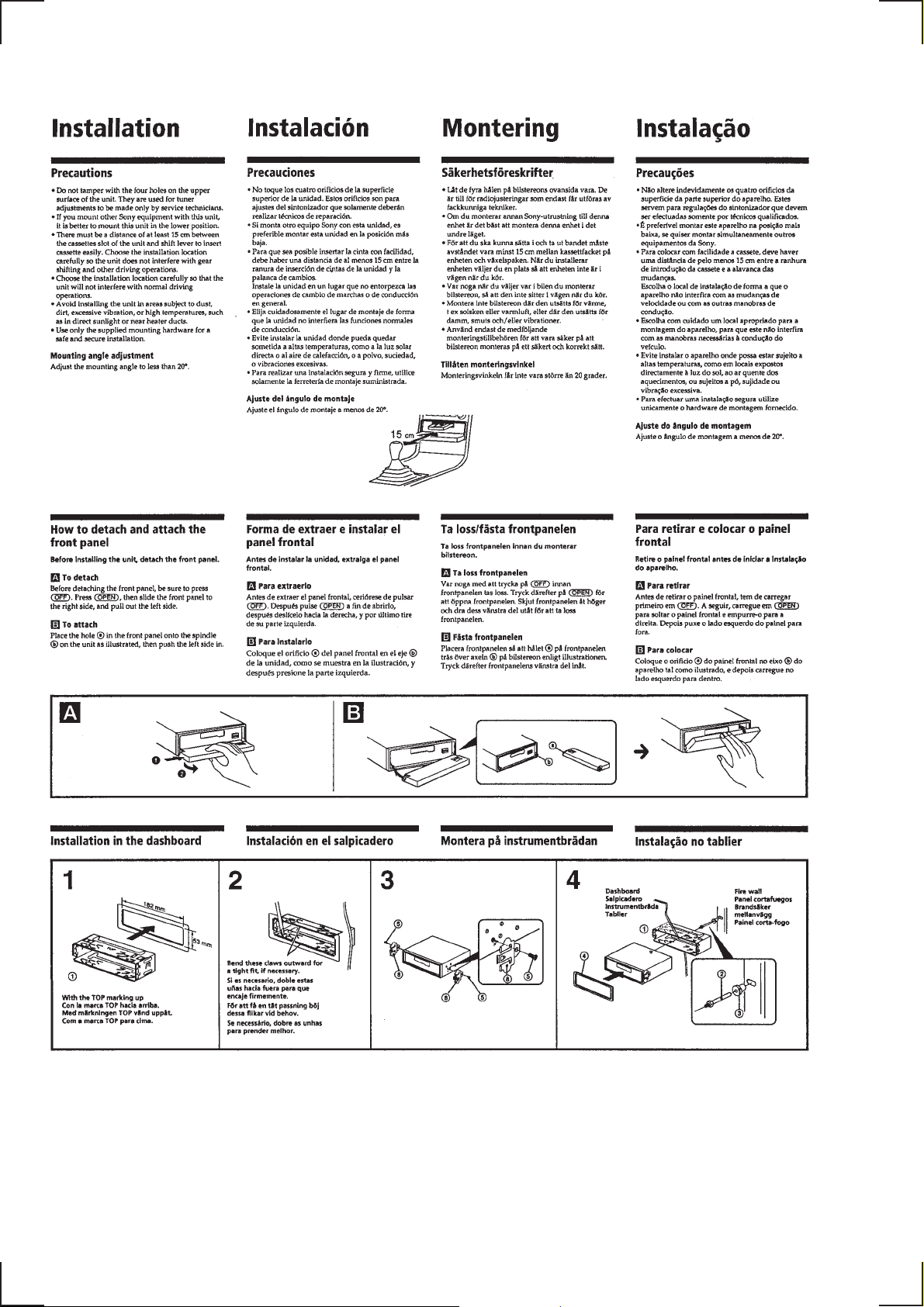

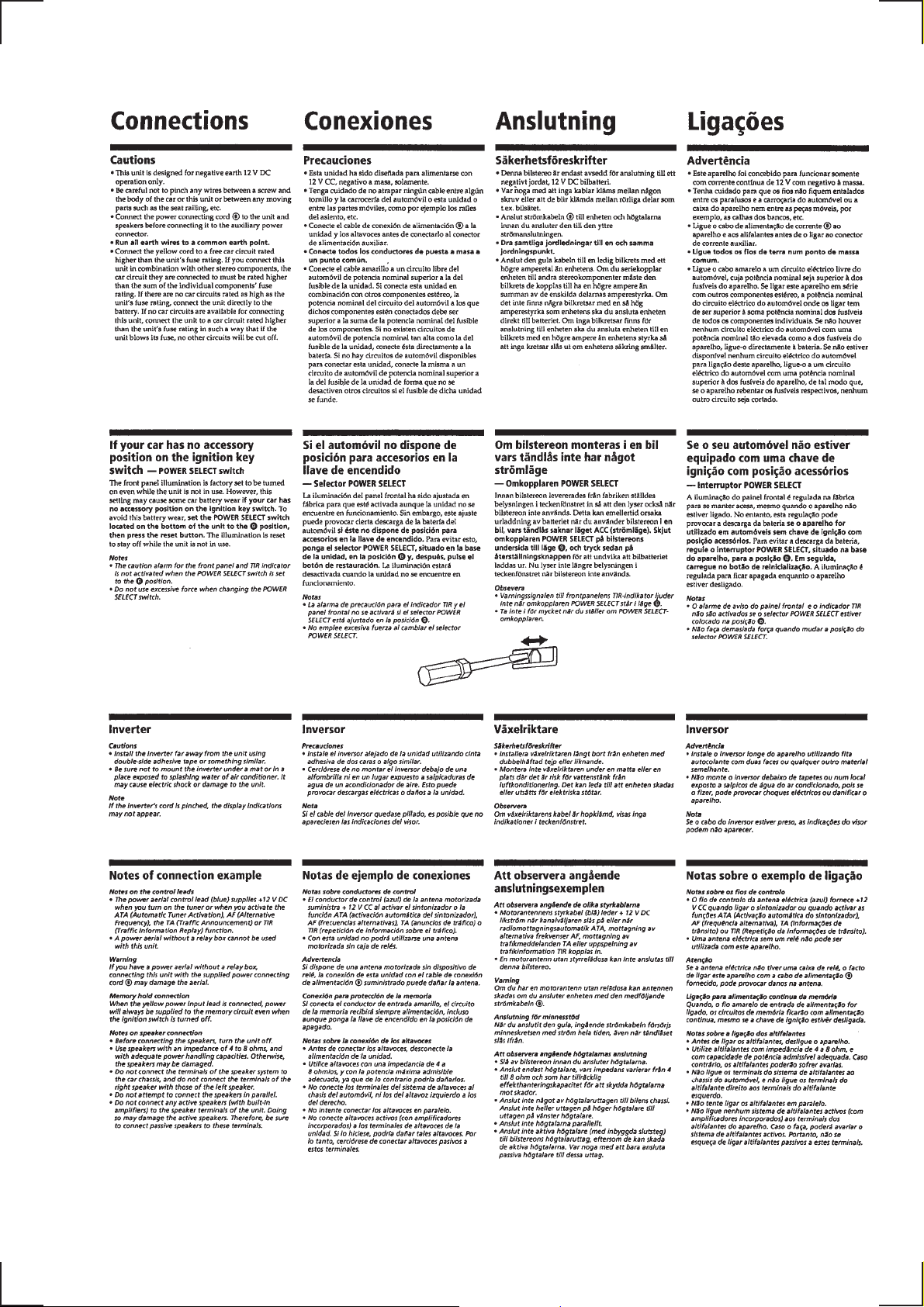

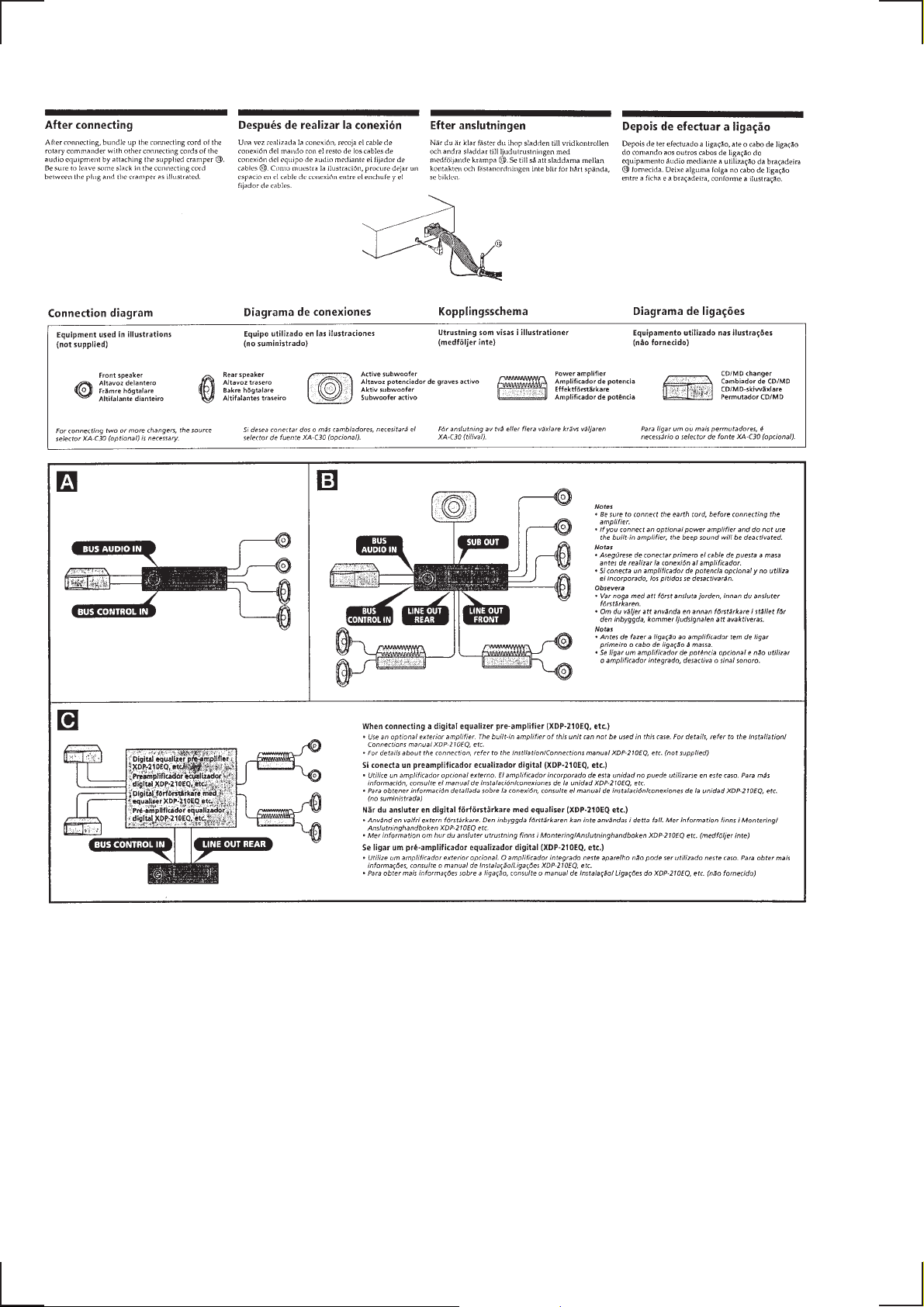

This section is extracted from

instruction manual.

– 3 –

Page 4

– 4 –

Page 5

– 5 –

Page 6

– 6 –

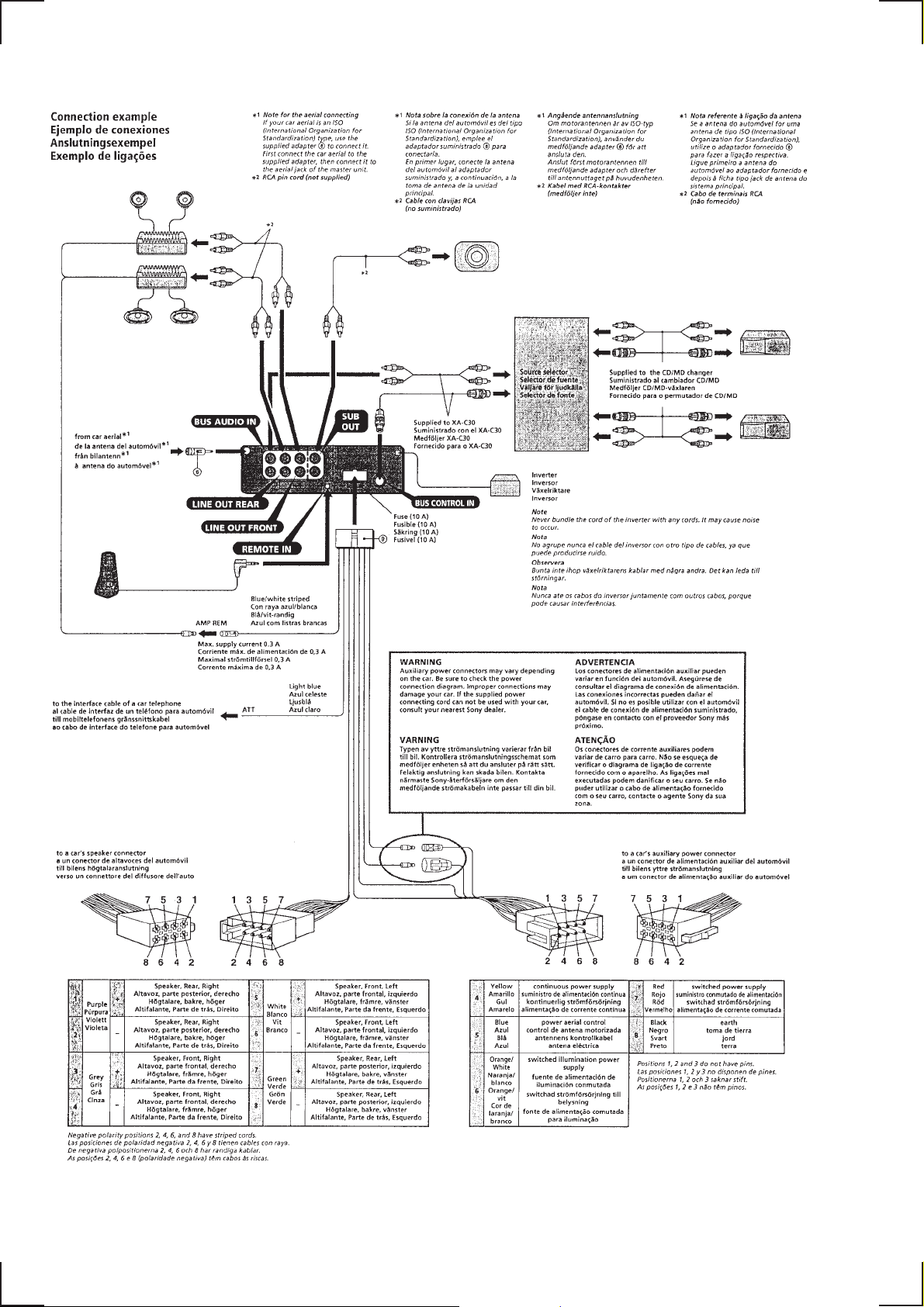

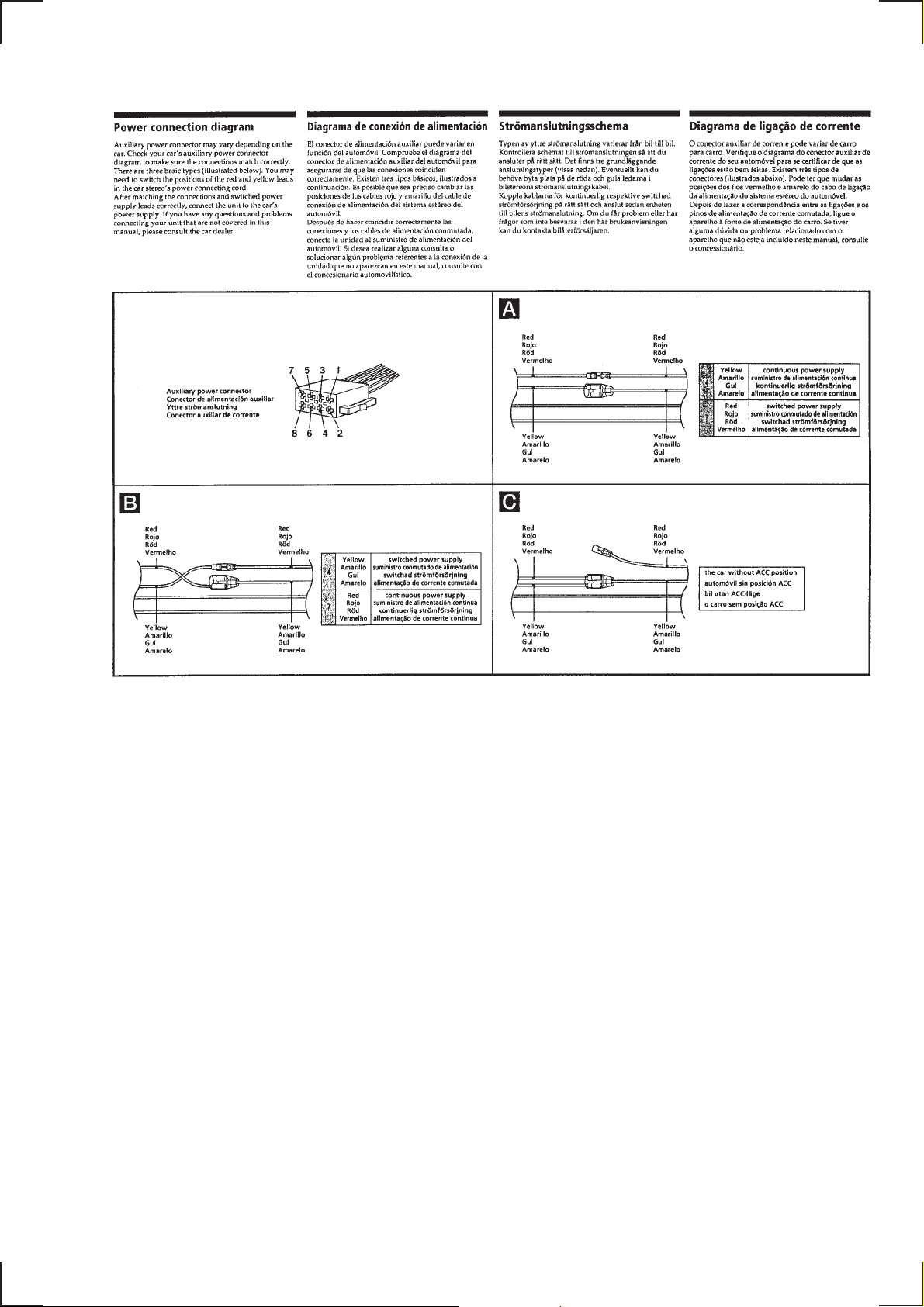

Page 7

– 7 –

Page 8

– 8 –

Page 9

– 9 –

Page 10

– 10 –

Page 11

– 11 –

Page 12

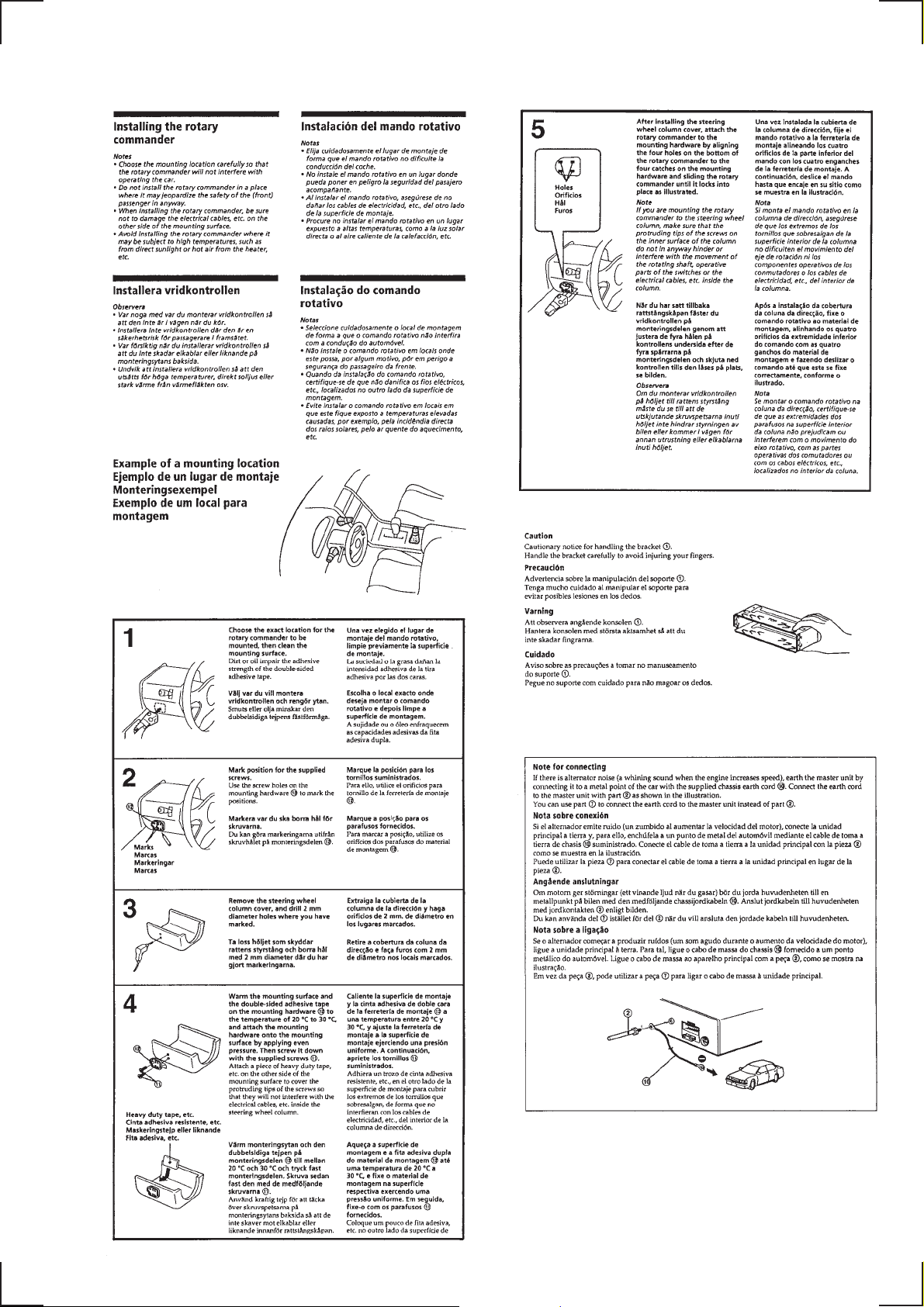

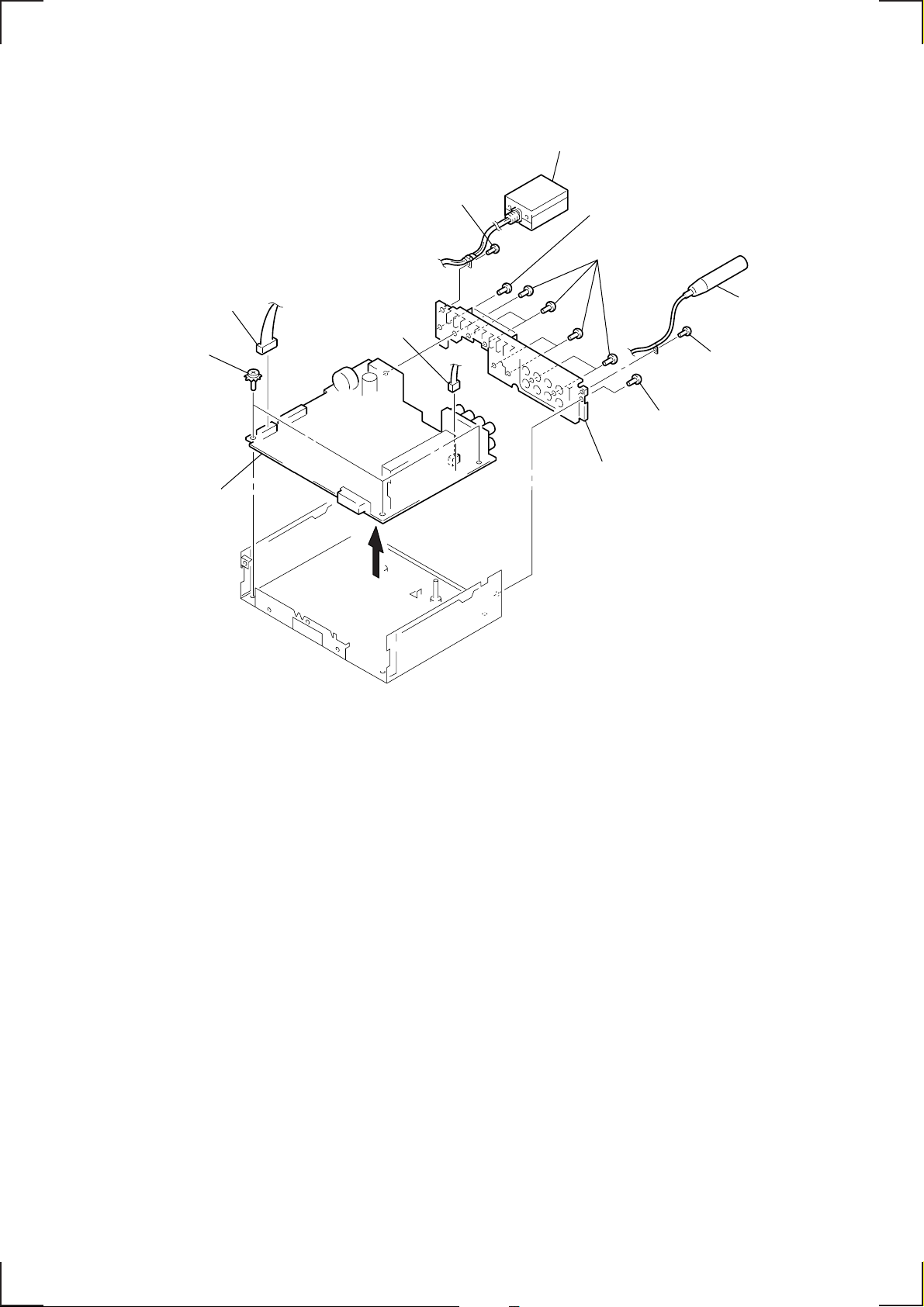

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

SUB PANEL ASS’Y

3

two claws

2

three screws

(PTT2.6 × 6)

1

connector

(CN802)

3

claw

4

connector

(CN500)

MECHANISM DECK (MG-25D-136)

1

connector

(CN201)

5

sub panel ass’y

3

two screws

(2.6 × 6)

4

2

lag

2

screw

(PTT2.6 × 6)

5

mechanism deck

(MG-25D-136)

flexible flat cable

(CN250)

– 12 –

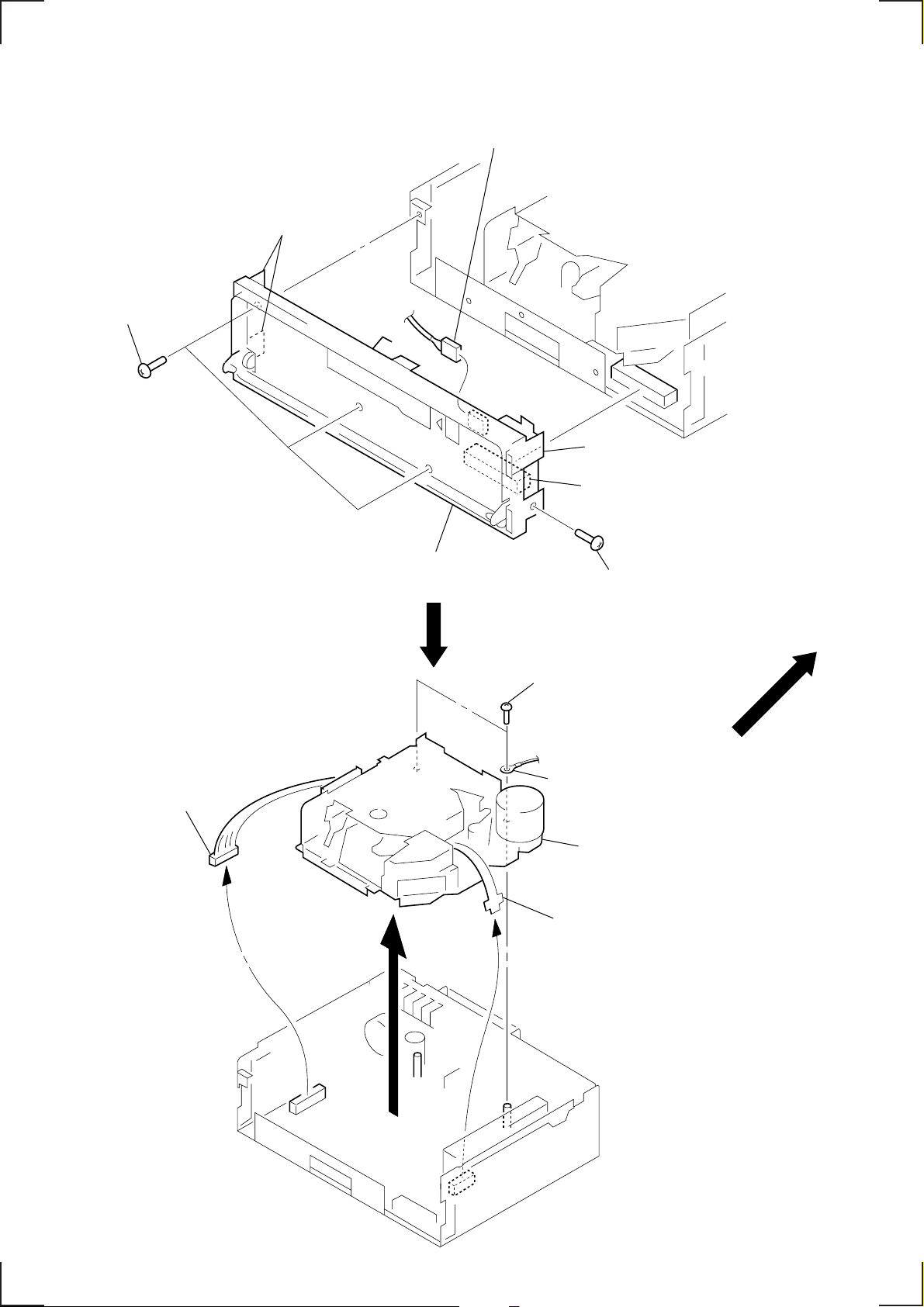

Page 13

MAIN BOARD, HEAT SINK

4

main board

2

three ground point

screws

1

connector

(CN553)

1

connector

(J10)

5

screw

(PTT2.6 × 10)

3

screw

(PTT2.6 × 10)

7

screw

(PTT2.6 × 10)

9

seven screws

(PTT2.6 × 10)

8

cord (with connector)

(ANT)

6

inverter ass’y

3

screw

(PTT2.6 × 10)

0

heat sink

– 13 –

Page 14

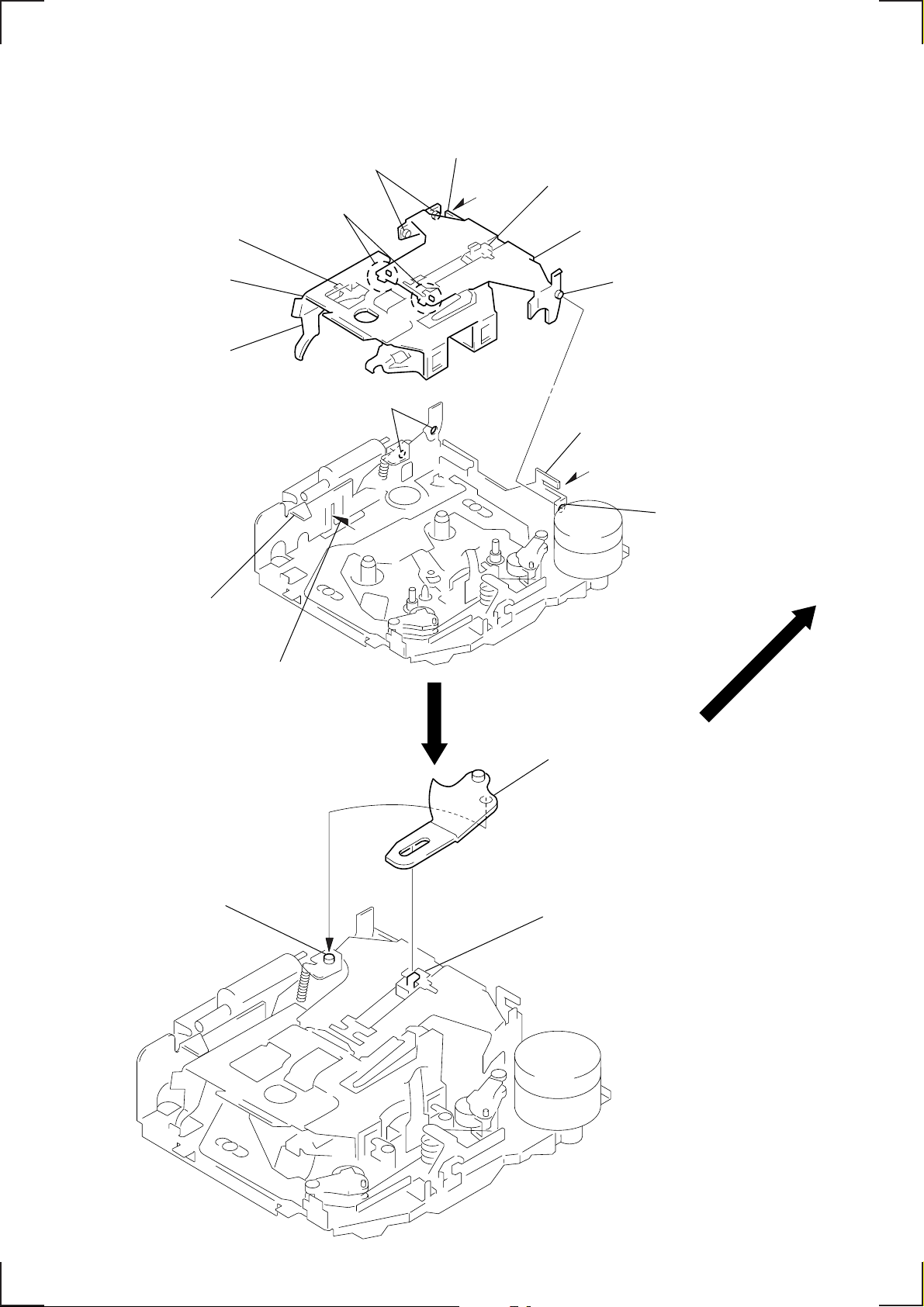

SECTION 4

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

HOUSING

4

Fit claw on B part.

3

Put the housing

under A part.

housing

2

Install the hanger onto

two claws of the housing.

5

Fit projection on C part.

C

part

7

Holder the hanger by bending the claw.

1

Install the catch to the hanger.

hanger

6

Fit projection on D part.

8

Hold the hanger by

bending the claw.

ARM (SUCTION)

A

part

projection

B

part

D

part

2

Move the arm (suction) in the arrow

direction and fit on projection.

1

Fit the arm (suction) on the shaft.

– 14 –

Page 15

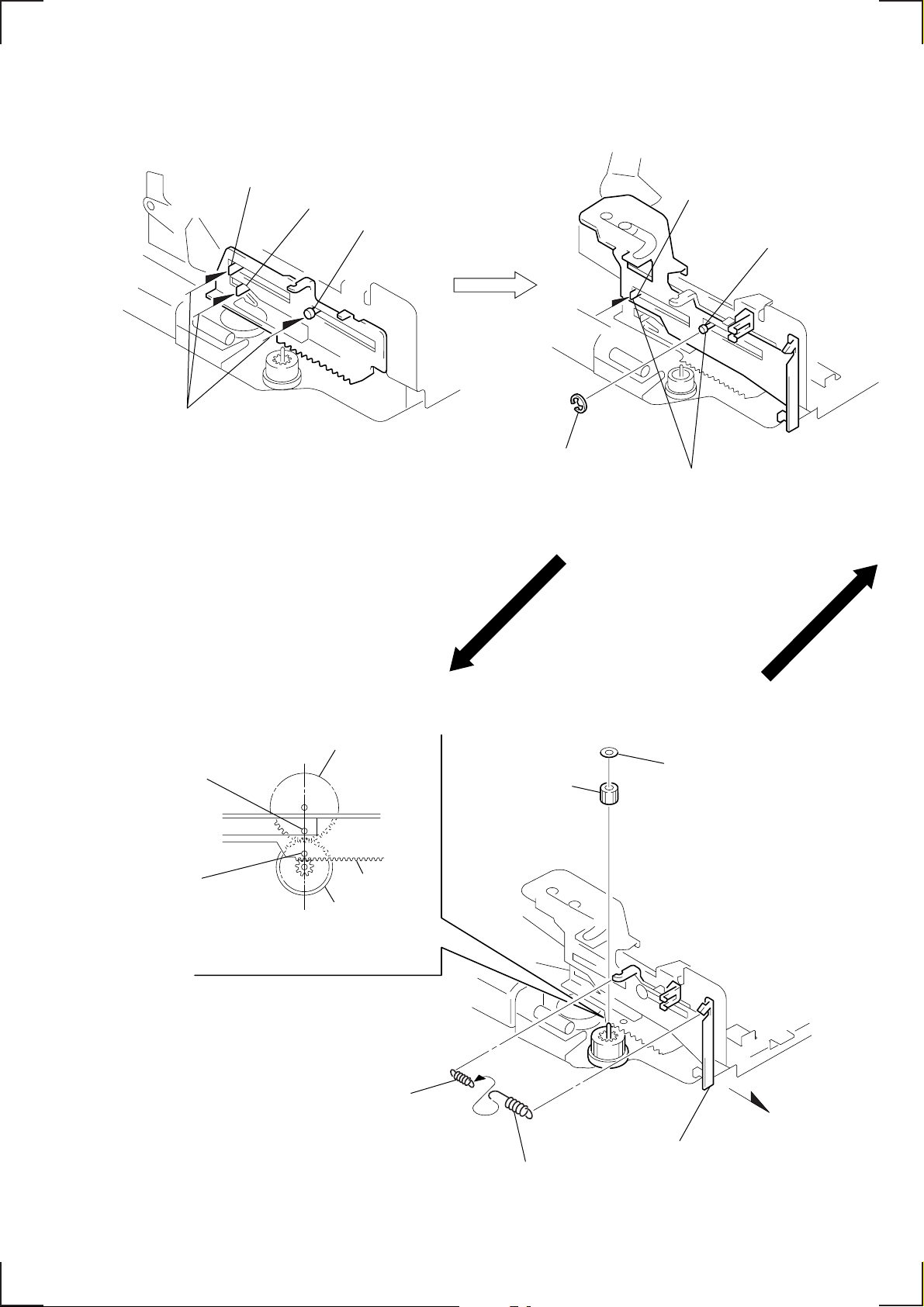

LEVER (LDG-A)/(LDG-B)

shaft

A

1

Fit the lever (LDG-A) on

shafts A – C and install it.

shaft

B

shaft

C

3

type-E stop ring 2.0

shaft

A

Fit the lever (LDG-B) on

2

shafts

install it.

A

and B and

shaft

B

GEAR (LDG-FT)

hole

hole

gear (LDG-D)

lever (LDG-A)

gear (LDG-FB)

4

Align hole in the gear (LDG-D)

with hole the lever (LDG-A).

2

tension spring (LD-2)

5

gear (LDG-FT)

1

6

polyethylene washer

2

tension spring (LD-1)

– 15 –

3

Move the lever (LDG-B)

in the arrow direction.

Page 16

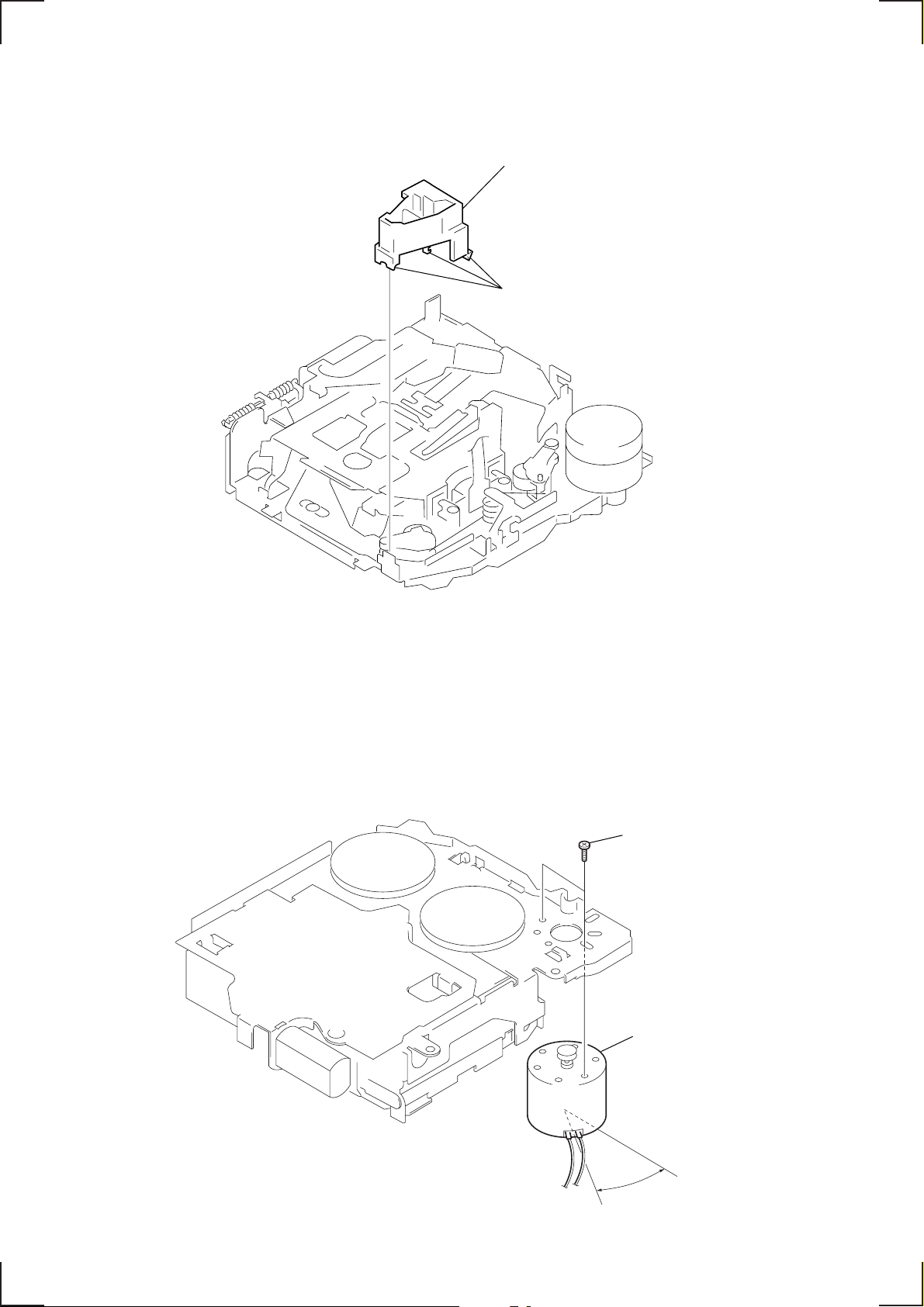

GUIDE (C)

2

guide (C)

1

three claws

MOUNTING POSITION OF CAPSTAN/REEL MOTOR (M901)

two precision screws

×

2)

(P2

capstan/reel motor

(M901)

30˚

– 16 –

Page 17

SECTION 5

MECHANICAL ADJUSTMENTS

1. Clean the follo wing parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idler

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the power supply

voltage unless otherwise noted.

• T orque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension (0.01 – 0.06 oz•inch)

Reverse CQ-102RC

Reverse

Back Tension (0.01 – 0.06 oz•inch)

FF, REW CQ-201B

CQ-102C

CQ-102RC

30 – 65 g•cm

(0.42 – 0.90 oz•inch)

0.5 – 4.5g•cm

30 – 65 g•cm

(0.42 – 0.90 oz•inch)

0.5 – 4.5g•cm

60 – 200 g•cm

(0.83 – 2.78 oz•inch)

• T ape Tension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A

Reverse CQ-403R

(more than 3.18 oz)

(more than 3.18 oz)

more than 90 g

more than 90 g

– 17 –

Page 18

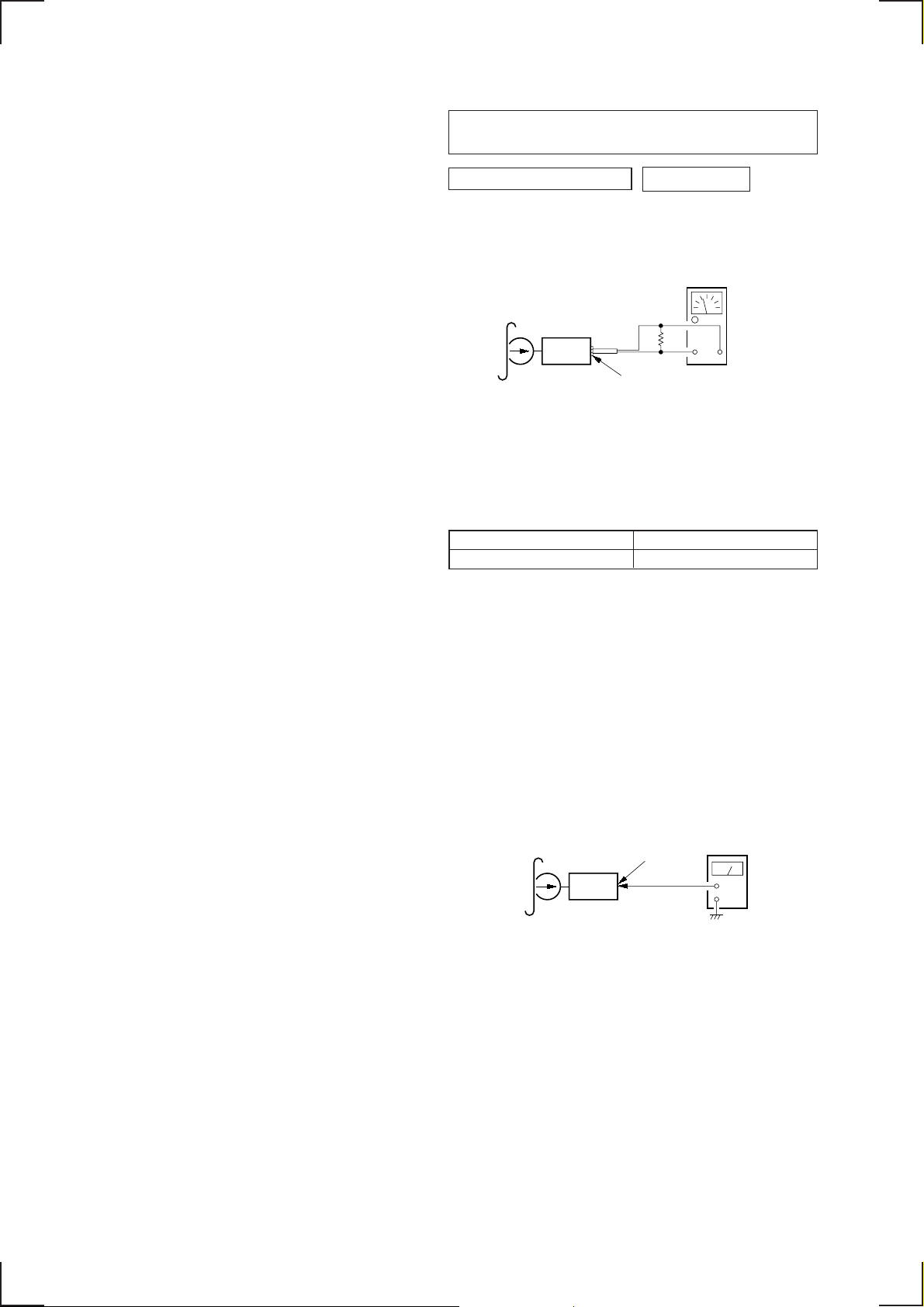

set

+

–

test tape

P-4-D400

(400Hz, 0 dB) level meter

MAIN board

TP (DOLBY-L)/

TP (DOLBY-R)

SECTION 6

ELECTRICAL ADJUSTMENTS

TEST MODE

This set have the test mode function. In the test mode, FM Auto

Scan/Stop Level and MW Auto Scan/Stop Level adjustments can

be performed easier than it in ordinary procedure.

<Set the Test Mode>

1. Set the “power select” switch (S600) is “A (ON)” position.

2. Turn ON the regulated power supply. (The clock is displayed)

Note: Press the [OFF] button, if the clock is not displayed.

3. Push the preset [4] button.

4. Push the preset [5] button.

5. Press the preset [1] button for more than two seconds.

6. Then the display indicates all lights, the test mode is set.

<Release the Test mode>

1. Push the [OFF] button.

2. Return the “power select” switch (S600) to initially set position.

See the adjustment location from on page 22 for the

adjustment.

TAPE DECK SECTION

0 dB=0.775 V

Tape Speed Adjustment

Setting:

speed checker

or

test tape

WS-48A

(3 kHz, 0 dB)

LINE OUT REAR jack (CN780)

set

frequency counter

10 k

Ω

+–

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust adjustment resistor for inside capstan motor so that the

reading on the speed checker or frequency counter becomes in

specification.

Specification: Constant speed

Speed checker Frequency counter

–1.5 to +2.5% 2,955 to 3,075 Hz

Adjustment Location: See page 22.

Dolby Level Adjustment

Setting:

[SHIFT] button : ON (light up SET UP and

PLAY MODE)

Preset [4] (PLAY MODE)

n [5] (n) buttons : NR off

SOUND (BAS) button : Center

SOUND (TRE) button : Center

SOUND (BAL) button : Center

SOUND (FAD) button : Center

SOUND (VOL) button : Maximum

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust RV230 (L-CH) and RV240 (R-CH) so that the level

meter reading is –6±0.5 dB (0.37 to 0.41 V).

Adjustment Location: See page 22.

– 18 –

Page 19

TUNER SECTION

)

FM RF signal

generator

Carrier frequency : 98.00 MHz

Output level : 70 dB (3.2 mV)

Mode : stereo

Modulation : main: 1 kHz, 33.75 kHz deviation (45%)

sub : 1 kHz, 33.75 kHz deviation (45%)

: 19 kHz pilot: 7.5 kHz deviation (10%)

0.01 µF

set

antenna jack

+

–

LINE OUT REAR jack

(CN780)

level meter

10 k

Ω

0 dB=1 µV

Cautions during repair

When the tuner unit is defective, replace it by a new one because its internal block is difficult to repair.

Note: Adjust the tuner section in the sequence shown below.

1. FM Auto Scan/Stop Level Adjustment

2. FM Stereo Separation Adjustment (Wide)

3. FM Stereo Separation Adjustment (Narrow)

4. FM RDS S-Meter Adjustment

5. MW Auto Scan/Stop Level Adjustment

FM Auto Scan/Stop Level Adjustment

Setting:

[SOURCE] button : FM

FM RF signal

generator

Carrier frequency : 98.00 MHz

Output level : 22 dB (12.6

Mode : mono

Modulation : 1 kHz, 22.5 kHz deviation (30%

Procedure:

1. Set to the test mode. (See page 18)

2. Push the [SOURCE] button and set to FM.

Display

0.01 µF

antenna jack

µ

V)

set

FM Stereo Separation Adjustment (Wide)

Setting:

[SOURCE] button : FM

[SHIFT] button : ON (light up SET UP and

PLAY MODE)

Preset [4] (PLAY MODE)

n [5] (n) buttons : WIDE mode

Procedure:

FM Stereo

signal generator

output channel

L-CH L-CH A

R-CH L-CH Adjust RV3 on TUX10

R-CH R-CH C

L-CH R-CH Adjust RV3 on TUX10

Level meter Level meter

connection reading (dB)

B

for minimum reading.

D

for minimum reading.

SHUF

3. Push the preset [3] button.

Display

SHUF

4. Adjust with the v olume R V2 on TUX10 so that the “FM” indication turns to “FM0” indication on the display window.

But, in case of already indicated “FM0”, turn the RV2 so that

put out light “0” indication and adjustment.

Display

SHUF

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

Specification: Separation more than 24 dB

Adjustment Location: See page 22.

Adjustment Location: See page 22.

– 19 –

Page 20

FM Stereo Separation Adjustment (Narrow)

Setting:

[SOURCE] button : FM

[SHIFT] button : ON (light up SET UP and

PLAY MODE)

Preset [4] (PLAY MODE)

n [5] (n) buttons : NARROW mode

FM RF signal

generator

Carrier frequency : 98.00 MHz

Output level : 70 dB (3.2 mV)

Mode : stereo

Modulation : main: 1 kHz, 20 kHz deviation (26.7%)

antenna jack

0.01 µF

set

sub : 1 kHz, 20 kHz deviation (26.7%)

: 19 kHz pilot: 7.5 kHz deviation (10%)

10 k

LINE OUT REAR jack

(CN780)

Procedure:

FM Stereo

signal generator

output channel

L-CH L-CH A

R-CH L-CH Adjust RV4 on TUX10

R-CH R-CH C

L-CH R-CH Adjust RV4 on TUX10

Level meter Level meter

connection reading (dB)

for minimum reading.

for minimum reading.

level meter

Ω

B

D

FM RDS S-Meter Adjustment

Setting:

[SOURCE] button: FM

FM RF signal

generator

0.01 µF

Carrier frequency : 98.00 MHz

Output level : 35 dB (56.2

Mode : mono

+

–

Procedure:

Modulation : no modulation

1. Set to the test mode. (See page 18)

2. Push the [SOURCE] button and set to FM.

Display

3. Push the

[10] button.

4. Adjust RV10 so that the display indication is “13.2”.

Display

SHUF

SHUF

antenna jack

µ

V)

set

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

Specification: Separation more than 18 dB

Adjustment Location: See page 22.

Specification: Display indication: 13.0 to 13.4

Adjustment Location: See page 22.

– 20 –

Page 21

MW Auto Scan/Stop Level Adjustment

µ

Setting:

[SOURCE] n [MODE] buttons : MW

AM RF signal

generator

AM dummy antenna

(50 Ω)

Carrier frequency : 999 kHz

30% amplitude

modulation by

1 kHz signal

Output level : 33 dB (44.7

V)

30

Ω

15 pF

65 pF

set

antenna jack

Adjustment Location:

– SET UPPER VIEW –

Tape Speed Adjustment

TUX10

RV1 MW Auto Scan/Stop Level Adjustment

Procedure:

1. Set to the test mode. (See page 18)

2. Push the [SOURCE] button and set to FM.

3. Push the [MODE] button and set to MW.

Display

SHUF

TP

4. Push the preset

[3] button.

Display

SHUF

TP

5. Adjust with the volume RV1 on TUX10 so that the “MW”

indication turns to “MW0” indication on the display window.

But, in case of already indicated “MW0”, turn the R V1 so that

put out light “0” indication and adjustment.

RV240

(R-CH)

– SET BOTTOM VIEW –

RV230

(L-CH)

Dolby Level

Adjustment

RV2 FM Auto Scan/Stop Level Adjustment

RV3 FM Stereo Separation Adjustment (Wide)

RV4 FM Stereo Separation Adjustment (Narrow)

RV10 FM RDS S-Meter Adjustment

Display

SHUF

TP

Adjustment Location: See page 22.

– 21 –

TP (DOLBY-L)

TP (DOLBY-R)

– 22 –

Dolby Level

Adjustment

Page 22

XR-C8220R

7-1. BLOCK DIAGRAM – TUNER Section –

SECTION 7

DIAGRAMS

FM/AM

ANTENNA

FM/AM TUNER UNIT

TUX10

FM-ANT

2

1

AM-ANT

VCO (FM/AM)21FM-IF-COUNT11AM-IF-COUNT (SEEK)

LO/DX

4

6

9 16 13

15

LO/DX

FM OSC

AM OSC

+

VT (FM/AM)

5

IF IN

LOW-PASS

FILTER

Q17

FM/AM PLL

IC10

TIME CONSTANT

SWITCH

18 7

PD

IC11

FM B+

FORCED WIDE/

24

AM B+

WIDE/NARROW

SWITCH

Q15

NARROW

FM +B

NARROW

AM B+

D10

AM +B

AF SEEK SWITCH

Q16

WIDE/NARROW

SWITCH

Q14

9108

+B (FM/AM)

RECEIVE/SEEK

13

20SD22

ST/MONO

FM/AM SIGNAL

METER BUFFER

S-METER

19

Q13

RV10

FM RDS

S-METER

S-METER

(RDS)

15

FM L-OUT

FM R-OUT

AM-DET

FM-DET

BAND-PASS

FILTER

IC51

SWITCH

REGISTER

STATUS

IC50

MUTING

CONTROL SWITCH

Q51

7

3

ADPCM

ADDRESS

ANALYZER/

SYNTHESIZER

CONTROLLER

Q52

CONTROLLER

DATA I/O

TIMING

SADX

REGISTER

CONTROLLER

RWCK

OSC

CS1

CS2

TAS

SAS

WE

D-IN/

OUT

Q53

MUTING

Q60

AM/TIR SIGNAL SELECT

IC100

CONVERTER

ADIN

CONVERTER

D50

2 1

5 6

D/A

A/D

R-CH

18

16

R-CH

12

23

BUFFER

Q12

LIN

AM

ON

202619

FIN

L.P.F.

MUTING

Q50

TRAFFIC INFORMATION REPLAY

18

AOUT

17

FOUT

16

CPU INTERFACE

FM-L

A

(Page 27)

AM/TIR

B

(Page 27)

SERIAL REGISTER

IC101

40

41

39

37

36

46

50

44

17

CS

SAD

23

TAS

18

22

SAS

16

WE

2

RWCK

DIN

11

DOUT

15

• SIGNAL PATH

: FM

: AM (MW/LW)

XIN

X10

7.2MHz

XOUT

DOUT

DIN

61 520 4 2

252627 28

PLLSI

PLLSO

CLK

CE

PLLCE

PLLCKO

3

WIDE

2

1 53

20

4

SD-IN

AF-SEEK

SEEKOUT

ST-MONO

VSM

PDWN

35

TIR-PDOWN

XT

48

X100

4.19MHz

47

5

60

TIR-PLAY

TUNMUTE

96

TIR-RD

TIR-WR

BUSY

82 – 85

–

TIR-D0

TIR-D3

RESET

5355455

95

99

TIR-BUSY

100

TIR-RES

CE

11

56

TIR CE0

TIR CE1

RDS DECODER

IC150

PATH

SC

OUT

MPTH

SYSTEM CONTROLLER

18

2

CIN

19

X150

4.332MHz

52

MTP

IC600 (1/5)

CLOCKED

COMPARATOR

OSCILLATOR

& CLOCK

OSCI

OSCO

4

5

MPX

LVIN

57 kHz

BAND-PASS

FILTER

MULTI

DETECTOR

16

20

SIGNAL

QUALITY

DECODER

RDS/RDBS

DEMODULATOR

& DECODER

DAVN

8

75

DAVN

5

4

INTERFACE

REGISTER

IIC BUS

SLAVE

TRANSCEIVER

SDA

9

70

I2C SIO

SCL

10

71

I2C CKO

RDWRCE

TIR RD

TIR WR

TIR D0 –

97

TIR-CE0

D0 – D3

1 – 4

TIR D3

98

TIR-CE1

101

XT

05

– 23 – – 24 –

Page 23

7-2. BLOCK DIAGRAM – TAPE Section –

TAPE EQUALIZER AMP,

DOLBY NR AMP, AMS

(PLAYBACK)

FWD

L-CH

FWD

R-CH

REV

L-CH

REV

R-CH

HP901

R-CH

R-CH

FWD

IN (L)

34

32

REV

IN (L)

IC250

R-CH R-CH

FWD/REV

19

EQ AMP

MTL/NORMAL

18

EQ

OUT

29 27

RV230

DOLBY LEVEL (L)

R-CH

TAPE

IN (L)

XR-C8220R

LCH

R-CH

DOLBY

NR AMP

MUTE

+

MUTE/TAPE

17

NR.ON

16 20

R-CH

AMS

DET

AMS/PLAY

OUT

AMS

OUT

24

14

TAPE-L

C

(Page 27)

LOADING/TAPE

OPERATION

M901

(CAPSTAN/REEL)

REEL SENSOR B+

M

M

(METAL DETECT)

D200

113 102 116 114

N-ROUT

9

7

CAPSTAN/REEL

MOTOR DRIVE

MTLIN

3

VCC

OUT1

MOTOR

OUT2

DRIVE

LOADING/TAPE OPERATION

MOTOR DRIVE

IC201

Q204

IN1

IN2

BATT B+

LM-EJ

LM-LOD

110 109

2

4

Q250

MUTE SWITCH

REGULATOR

Q203

REGULATOR

CONTROL SWITCH

Q202

DOLBY

SYSTEM CONTROLLER

IC600 (2/5)

TAPEON

112

BATT B+

AMSON

CM-ON

111

103

AMSIN

POS0 – POS3

TAPE OPERATION

SWITCH

EJECT/FF/REW/

REV/FWD MODE DETECT

TAKE-UP

REEL

SENSOR

TAPE

DETECT

REEL SENSOR BOARD

104105 – 108

BUFFER

REEL

SUPPLY

SENSOR

REEL

05

Q201

– 25 –

• SIGNAL PATH

: TAPE PLAY

– 26 –

Page 24

XR-C8220R

7-3. BLOCK DIAGRAM – MAIN Section –

(Page 24)

(Page 24)

(Page 25)

CN780 (1/2)

BUS

AUDIO IN

L

R

A

B

C

FM-L

AM/TIR

TAPE-L

R-CH

R-CH

INPUT SELECT,

ELECTRICAL VOLUME

IC301

AUX-IN-L

42

FM-IN-L

40

AM-IN-L

39

TAPE-IN-L

41

36 – 38

VR

VOLUME

SUB CUT

SWITCH

Q360, 362

IN1

CONTROL

CIRCUIT

LOUDNESS

CONTROL

CIRCUIT

R-CH

INAO1 VOUT

INPUT

GAIN

33 32 31

SELECTOR

R-CH

D351 D350

REFERENCE VOLTAGE

GENERATOR (FOR BIAS)

IC302

ELECTRICAL VOLUME

(FOR SUBWOOFER)

IC350

BUFFER

INP1

INAO1

SHIFT

REGISTER &

LATCH

CLK

DATA

CLK

DATA

TONE

TIN1

30 26 25

VR

IN1

16

1720

ZC

DET

CE

78 9

SUBCE

CONTROL

CIRCUIT

VCT

BUFFER

VCT

COM +8V

R-CH

TCO1

VOLUME

CONTROL

CIRCUIT

OUT1

• SIGNAL PATH

: FM

: AM (MW/LW)

: TAPE PLAY

: BUS AUDIO IN

LINE DRIVER

IC310

FD

IN1

+

REGISTER &

15

FADER

CONTROL

CIRCUIT

SHIFT

LATCH

CLK

DATA

CLK

DATA

CE

2216 2117

VOLCE

FNTO1

REO1

24

23

2

7

IN1

IN2

BUFFER

IC383

OUT1

OUT2

13

12

R-CH

R-CH

R-CH

12

POWER AMP

IN2

IC700

MUTING

Q340

MUTING

Q430

MUTING

Q330

MUTING

Q440

MUTING

Q361

MUTING

Q461

OUT2+

OUT2–

(POWER CONNECTOR)

5

3

CN700 (1/2)

1

9

L

CN781 (1/2)

FRONT

LINE OUT

R

L

CN780 (2/2)

REAR

LINE OUT

R

L

CN781 (2/2)

SUB OUT

R

FRONT L (+)

FRONT L (–)

R-CH

BUFFER

IC320

CLK

DATA

VOLCE

SUBCE

62

61

CSV

IC650

SUB-SW1

SUB-SW0

23

AOUT

05

2 3

4.19MHz

XT

X650

NAR

RESET

XT

SD

SI

8

ST

22

2115

2214

23

117

917

CSV-SO

CSV-CKO

CSV-CE

CSV-NAR

CSV-RST

67

64

66

68

VOLCE

SUBCE

VOLSO/SUBSO

VOLCKO/SUBCKO

SYSTEM CONTROLLER

IC600 (3/5)

MUTE

DOLBC

TESTIN

TEL-ATT

65

115

58

79

MUTING

CONTROL SWITCH

Q700, 701

D717

POWER AMP

MUTE SWITCH

LEVEL SHIFT

– 27 – – 28 –

Q603

Q702

R-CH

R-CH

D715

21

IN4

14

11

IN1

15

IN3

22

MUTE

4

ST-BY

OUT4+

OUT4–

OUT1+

OUT1–

OUT3+

OUT3–

23

9

7

17

19

4

12

2

10

3

11

15

13

FRONT R (+)

FRONT R (–)

REAR L (+)

REAR L (–)

REAR R (+)

REAR R (–)

TEST MODE

TEL-ATT

Page 25

7-4. BLOCK DIAGRAM – DISPLAY/KEY CONTROL Section –

RE900

VOLUME/BASS/TREBLE/

BALANCE/FADER CONTROL

D510

J500

REMOTE IN

LSW900 – 918,

S900, SW801

D506

ROTARY

ENCODER

RE900

LED800

(TAPE WINDOW)

LED802

6

LED800, 802

XR-C8220R

LED801

TIR

48 72

RC-IN0

X1

93

X600

3.68MHz

RC-IN1

KEY ACTIVE

SWITCH

Q510, 511

35

AD-ON

LCD SO13LCD CKO

RE-IN1

76

KEYACK

46

47

KEYIN1

KEYIN0

X1A

73

X601

32.768kHz

X0A

74

X0

92

36 37

RE-IN0

14 16

LCD CE

LCD INH

32

BACKUP +5V

SYSTEM CONTROLLER

IC600 (4/5)

LSW900, 901, 903,

LSW904, 906 – 910,

LSW912 – 918

SW500

(NOSE DETECT)

80

NOSESW

LED DRIVE

Q901

BUZZER

DRIVE

Q601

15

BEEP

BZ600

(BUZZER)

LED DRIVE

Q900

LED DRIVE

Q501

59

LED900 – 907,

LSW902, 905, 911

PACK-IND

P-ON +10V

LCD +10V

LED DRIVE

Q502

31

TIR-IND

LCDANG

41

CONTRAST

SWITCHING

R952

OSC

21

OSC-OUT

05

20

OSC-IN

18

17

LCD-DATA

14

19

LCD-CE

LCD-CLK

LIQUID CRYSTAL DISPLAY DRIVER

LCD-INH

SEG101 – SEG165

IC900

26 – 90

LIQUID CRYSTAL DISPLAY

COM100 – COM107

LCD900

Q903

2

AMBER

100 – 93

1

GREEN

Q902

11 – 6

VLC0 – VLC5

Q508, 509

LCD +10V

– 29 –

– 30 –

Page 26

XR-C8220R

7-5. BLOCK DIAGRAM – BUS CONTROL/POWER SUPPLY Section –

SYSTEM CONTROLLER

IC600 (5/5)

CN600

BUS CONTROL IN

(FOR SONY BUS)

3

SIRCS

D604

BACKUP +5V

SIRCS BUFFER

Q602

BACKUP +5V

RESET SIGNAL

GENERATOR

IC500

REMOTE CONTROL

RECEIVER

IC901

D523

SW800

RESET

SONY BUS INTERFACE

IC602

RAM RESET

IC501

55

RAMBU

90

RESET

86

HSTX

24

SIRCS

POWSEL

56

S600

POWER SELECT

B (OFF)

A (ON)

TUNER ON +5V

(TUNER CIRCUIT B+)

+9V

(FOR VT)

+5V

REGULATOR

Q10

+9V

REGULATOR

Q11

(AUDIO CIRCUIT B+)

FM B+

(FM CIRCUIT B+)

AM B+

(AM CIRCUIT B+)

COM +8V

CN700 (2/2)

(POWER CONNECTOR)

D719

BATT B+

POWER AMP

8

ANT+B

STB

VCC

7

11

FM+B

REGULATOR

AM+B

COM8V

IC502

MODE1

23 4

MODE2

10

9

(IC700) B+

6

ANT REM

RESET

DATA

CLK

BUS ON

BATT

BATT B+

2

5

4

6

7

TH600

D606

2

6

4

1

3

D601

RST

DATA

CLK

BUS ON

OUT

BATT

SWITCH

BUS ON

SWITCH

BATTERY

SWITCH

BATTERY DETECT

RESET

DATA IN

DATA OUT

CLK IN

ON IN

BU IN

Q600

RST

BUS

13

9

8

11

12

10

11

18

17

19

10

77

SYSRST

UNISO

UNISI

UNICKO

BUS-ON

BU-IN

FM-ON

TU-ON

POWON

LEDON

DOORSW

ILL-ON

DIMMER

6

7

120

P-ON +10V

LCD +10V

REGULATOR

IC550, Q553

D532 – 534

BACKUP +5V

OSC

Q556

Q557

REGULATOR

CONTROL SWITCH

Q505

REGULATOR

CONTROL SWITCH

Q507

CURRENT

CONTROL SWITCH

Q554, 555

118

12

29

30

CN900

(FRONT PANEL SIDE)

10

D524

D525

EL900

(LCD BACK LIGHT)

CONTROL SWITCH

5

D553

Q503

POWER ON/OFF

SWITCHING

T550

INVERTER

TRANSFORMER

DIMMER

Q552

OSC OFF

SWITCH

+6V

REGULATOR

IC503

TH700

B+ SWITCH

Q703, 704

+10V

REGULATOR

Q504

+10V

REGULATOR

Q506

B+ SWITCH

Q550, 551

F701

5

16

7

14

AMP REM

BATT

ACC

ILL

CN500

(MAIN BODY SIDE)

ACC IN

81

05

ILL IN

78

ACCESSORY CHECK

Q705

D713

ILLUMINATION

LINE DETECT

Q512

– 31 – – 32 –

D507

Page 27

XR-C8220R

3.8 Vp-p

236 ns

7-6. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

r

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Component Side) the parts face are indicated.

: Through hole.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• C : panel designation.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 14.4V and fed with regulated dc po wer

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• Abbreviation

: internal component.

supply from ACC and BATT cords.

under no-signal (detuned) conditions.

no mark : FM

( ) : AM (MW/LW)

〈〈 〉〉 : TAPE PLA Y

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM (MW/LW)

L : BUS AUDIO IN

E : TAPE PLAY

TAPE A : ENGLISH, FRENCH

TAPE B : ENGLISH, GERMAN

TAPE C : ENGLISH, SPANISH

TAPE D : ENGLISH, ITALIAN

4

W or less unless otherwise

• Waveforms

– MAIN Board –

1 IC10 @º (XOUT)

139 ns

2 IC100 $¶ (XT)

240 ns

3 IC150 4 (OSCO)

3.8 Vp-p

4.3 Vp-p

5 IC600 (£ (X1)

272 ns

6 IC650 2 (XT)

5.8 Vp-p

– KEY Board –

1 IC900 @º (OSC-IN)

µ

s

5.5

2 IC900 @¡ (OSC-OUT)

3.3 µs

– INVERTER Board –

1 Q556 (EMITTER)

2 Vp-p

6.8 Vp-p

230 ns

4 IC600 &¢ (X0A)

30.6

3.6 Vp-p

10 Vp-p

1.1 ns

3.6 Vp-p

µ

s

– 33 –

– 34 –

Page 28

XR-C8220R

7-7. PRINTED WIRING BOARD – MAIN Board (Component Side) –

• Semiconductor Location

(Component Side)

Ref. No. Location

D10 F-13

D200 H-4

D201 F-2

D202 F-3

D350 F-6

D351 F-6

D506 J-12

D508 B-9

D509 B-10

D510 C-9

D513 J-13

D514 K-13

D517 K-10

D519 K-10

D523 I-7

D524 J-4

D525 K-11

D526 K-10

D527 K-8

D528 K-6

D530 F-2

D601 E-2

D604 D-3

D605 D-2

D606 D-2

D701 C-7

D702 B-7

D703 B-7

D704 B-6

D705 B-7

D712 D-4

D715 B-5

D717 D-7

D718 C-3

D719 C-3

IC10 F-11

IC11 E-12

IC50 J-11

IC51 I-11

IC100 J-7

IC101 J-9

IC201 G-3

IC250 H-11

Ref. No. Location

IC301 G-8

IC302 F-10

IC310 D-12

IC320 G-7

IC350 E-7

IC383 D-8

IC410 D-10

IC500 D-5

IC600 H-5

IC602 D-2

IC650 E-4

Q11 E-9

Q14 G-13

Q15 G-12

Q16 E-12

Q17 E-12

Q50 I-12

Q51 J-12

Q60 I-12

Q80 I-12

Q201 F-3

Q202 G-3

Q250 H-10

Q330 B-12

Q340 B-11

Q361 B-10

Q430 B-11

Q440 B-12

Q461 B-10

Q502 K-10

Q507 K-6

Q508 K-10

Q509 K-9

Q510 J-11

Q511 J-12

Q600 E-2

Q602 D-3

Q603 E-5

Q700 B-9

Q702 D-7

Q703 D-4

Q704 D-5

– 35 – – 36 –

Page 29

7-8. PRINTED WIRING BOARD – MAIN Board (Conductor Side) –

• Semiconductor Location

(Conductor Side)

Ref. No. Location

D11 E-10

D12 E-10

D50 J-12

D501 K-7

D502 K-6

D503 K-10

D504 K-7

D507 F-4

D512 J-12

D515 J-12

D516 J-12

D518 J-12

D520 J-12

D521 K-10

D522 J-12

D532 E-2

D533 E-2

D534 E-2

D550 I-1

D602 B-1

D603 B-1

D608 B-1

D706 C-6

D707 C-6

D708 C-6

D709 D-2

D710 B-3

D711 B-9

D713 E-4

D714 E-3

D716 B-9

XR-C8220R

IC150 J-9

IC501 D-6

IC502 E-1

IC503 G-1

IC700 A-7

Q10 F-10

Q12 I-14

Q13 I-14

Q52 I-11

Q53 I-11

Q203 G-3

Q204 G-3

Q360 E-6

Q362 E-6

Q460 E-6

Q462 E-6

Q501 J-7

Q503 J-4

Q504 K-6

Q505 J-6

Q506 K-6

Q512 F-5

Q550 H-3

Q551 I-4

Q601 I-3

Q701 C-9

Q705 E-4

(Page 51)

(Page 51)

– 37 –

(Page 51)

(Page 51)

– 38 –

Page 30

XR-C8220R

7-9. SCHEMATIC DIAGRAM – MAIN Board (1/4) – • See page 34 for Waveforms. • See page 53 for IC Block Diagrams.

(Page

41)

(Page

45)

– 39 – – 40 –

(Page 44)

Page 31

7-10. SCHEMATIC DIAGRAM – MAIN Board (2/4) – • See page 55 for IC Block Diagrams.

(Page

40)

XR-C8220R

(Page

44)

– 41 –

(Page 46)

– 42 –

Page 32

XR-C8220R

7-11. SCHEMATIC DIAGRAM – MAIN Board (3/4) – • See page 34 for Waveforms. • See page 54 for IC Block Diagrams.

(Page 40)

(Page

41)

(Page

45)

– 43 – – 44 –

Page 33

7-12. SCHEMATIC DIAGRAM – MAIN Board (4/4) – • See page 56 for IC Block Diagrams.

(Page

40)

XR-C8220R

(Page 42)

(Page

44)

(Page 52)

(Page 52)

(Page

52)

(Page 52)

– 45 –

– 46 –

Page 34

XR-C8220R

7-13. PRINTED WIRING BOARD – KEY Board –

• Semiconductor

Location

(Component Side)

Ref. No. Location

IC901 C-4

LED900 C-4

LED901 A-4

LED902 A-2

LED903 A-2

LED904 C-2

LED905 C-2

LED906 B-2

LED907 B-2

• Semiconductor

Location

(Conductor Side)

Ref. No. Location

D901 C-5

D903 B-10

IC900 B-9

Q900 B-11

Q901 B-11

Q902 B-10

Q903 B-10

(Page 51)

– 47 – – 48 –

Page 35

7-14. SCHEMATIC DIAGRAM – KEY Board – • See page 34 for Waveforms.

XR-C8220R

(Page 52)

– 49 –

– 50 –

Page 36

XR-C8220R

7-15. PRINTED WIRING BOARDS – SUB/INVERTER Boards –

7-16. SCHEMATIC DIAGRAM – SUB/INVERTER Boards – • See page 34 for Waveform.

(Page 38) (Page 48)

(Page 46)

(Page 49)

(Page 38)

(Page 37)

(Page 46)

(Page 46)

(Page 38)

(Page 46)

– 51 – – 52 –

Page 37

• IC Block Diagrams

– MAIN Board –

IC10 BU2624FV-E2

CTL

I/O

REFERENCE

DIVIDER

SHIFT REGISTER LATCH

XIN

1

2

CE

CK

4

DA

5

CD

6

7

P0

9

P1

10

P3

MAIN

COUNT

PRESCALER

IF COUNT

CTL

20BIT COUNT

PHASE

DET

XOUT

20

19

VSS

18

PD

17

VDD

FMIN

16

AMIN

15

P2

14

13

IFIN

12

SD

P4

11

IC100 MSM6688GS-2K

CEWRRD

RESET

5253545556

1

D0

2

BUSY

RPM

VPM

ACON

TEST

MCUM

TEST

TEST

TEST

D1

3

D2

4

D3

5

6

7

8

9

10

CE

11

12

13

14

MCU I/F

STATUS

REGISTER

TEST

CIRCUIT

12BIT

ADC

NAR

MON

51 46

TIMING

CONTROLLER

LPF

RWCK

DVDDXTXT

OSC

ADDRESS

CONTROLLER

ADPCM

ANALYZER/

SYNTHESIZER

12BIT

DAC

SG

CIRCUIT

WE

DROM

DATA

I/O

DI/0

+

REGISTER

CONTROLLER

-

CS4

43444547484950

42

CS3

41

CS2

40

CS1

39

SADX

SADY

38

37

TAS

36

SAS

35

PDWN

34

TEST

33

TEST

RSEL2

32

RSEL1

31

30

DGND

29

AGND

-

+

15 16 17 18 19 20 21 22 23 24 25 26 27 28

TEST

ADIN

FOUT

AOUT

FIN

AMON

DVDD

AVDD

SG

SGC

LOUT

LINE

MOUT

– 53 –

MIN

Page 38

IC101 MSM6684JSDR1

TEST

RWCK

TEST

TEST

TEST

TEST

DIN

VSS

1

2

NC

3

4

5

9

10

11

NC

12

13

I/O CONTROL

WRITE CLOCK

GENERATOR

TIMING

GENERATOR

8,388,608DATA

REGISTER

COLUMN DECODER

COLUMN ADDRESS

COUNTER

ROW

DECODER

ADDRESS

MULTIPLEXER

REFRESH TIMER

REFRESH ADDRESS

COUNTER

ROW ADDRESS

COUNTER

ROW ADDRESS

REGISTER

26

VCC

25

RS/A

24

RFSH

SAD

23

22

SAS

18

TAS

CS

17

WE

16

DOUT

15

14

NC

IC150 SAA6588T-118

SCOUT

CIN

LVIN

20

MULTI

PATH

DETECTOR

2

1

MRO

MPTH

CLOCKED

COMPARATOR

RDS/RDBS

DEMODULATOR

TEST

CONTROL

3

19

TCON

18

BAND-PASS FILTER

OSCILLATOR

& CLOCK

4 5

OSCO

57kHz

8th ORDER

RDS/RDBS

DECODER

6

OSCI

VSSD

CLOCK

DATA

VDDD

VREF

17

87

DAVN

MPX

POWER SUPPLY

SIGNAL QUALITY

DECODER

445

INTERFACE

REGISTER

VSSA

15

& RESET

VDDA

14

CLOCK

DATA

IIC BUS SLAVE

TRANSCEIVER

9 10

SDA

AFIN

1316

PAUSE

DETECTOR

SCL

IC201 LB1638M

10

1

MAD

PSWN

11

12

GND

2

IN1

VCC

3

4

IN2

5 6

GND

CONTROL LOGIC

N.C.

9

OUT1

VS

8

7

OUT2

N.C.

– 54 –

Page 39

IC250 CXA2510AQ-T4

PBEQ1

PBOUT1

GND

120µ/

70µ

+

–

PBFB1

31

32

PBRIN1

1

VCT

PBEQ2

F2

F1

–

+

120µ/

70µ

345 6 7 8 9 10

2

VCC

PBOUT2

PBREF1

PBFIN1

VCT

PBGND

PBFIN2

PBREF2

PBRIN2

PBFB2

33

34

35

36

37

38

39

40

TAPEIN1

X1

+

X1

TAPEIN2

AUXIN1

T1

AUXIN2

DIREF

2425

T2

LPF

MSLPF

NR BIAS

TAPE/AUX

TAPE EQ

FWD/RVS

VCC

+

–

F3

–

+

LINEOUT2

+

OFF/B

NR

–

TCH2

2122232627282930

NR

OFF/B

MS

MODE

NR

MODE

DETECT

NC

PLAY

MS ON/

OFF

20

19

18

17

16

15

14

13

12

11

MSMODE

DRSW

TAPESW

INSW

NRSW

NC

MSOUT

DGND

MSTC

FF

MSSW

NC

TCH1

LINEOUT1

IC301 CXA1946BQ-T6

GAIN12

GAIN11

IN14

IN13

IN12

IN11

IN21

IN22

IN23

IN24

GAIN21

GAIN22

GAIN134

36

37

38

39

40

41

42

43

44

45

46

47

48

INPUT SW

ZCDET

INPUT SW

LDLC134LDHC133INAO132VRIN1

35

LOUD

LOUD

VOLUME

8dB STEP

LATCH

SHIFT

REGISTER

VOLUME

8dB STEP

VOUT130TIN129TCLC128TCLC1127TCLC1226TCO125FDIN1

31

VOLUME

1dB STEP

VCTBUFF

VCTBUFF

VCTBUFF

LATCH

CONTROL

VCTBUFF

VCTBUFF

VCTBUFF

VOLUME

1dB STEP

TONE FADER

TONE FADER

45k

45k

24

23

22

21

20

19

18

17

16

15

14

13

FNTO1

REO1

CE

CLK

DGND

GND

VCC

VCT

DATA

TIMER

REO2

FNTO2

1

GAIN234

2

3

LDLC2

LDHC2

4

INAO25VRIN2

6

VOUT2

7

8

9

11

12

TIN2

TCLC2

TCLC2110TCLC22

TCO2

FDIN2

– 55 –

Page 40

IC310, 410 TDA8574 (T)

1

VCCL

2

INL

SVRL

3

BUFFER

BUFFER

VCCL

LIFT

AMP

IC350 CXA1846BN-T4

VRIN 1

OUT 1

N.C.

GND

INP 1

INN 1

VCT 1

20 19 18 17 16 15 14 13 12 11

CL+

16

CL–

15

–

+

INAO 1

8dB STEP

VOLUME

1dB STEP

VOLUME

VCT

VCC

REFERENCE

4

INML

INMR

5

REFERENCE

SVRR

INR

VCCR

6

7

8

BUFFER

BUFFER

IC502 BA3918-V3

VCCL

VCCR

VCCR

SIGNAL

AMP

SIGNAL

AMP

LIFT

AMP

VCT 2

LATCH

CONTROL

INAO 2

8dB STEP

VOLUME

LGND

14

OUTL

13

12

OUTR

RGND

11

CR–

10

9

CR+

LATCH

SHIFT

REGISTER

+

–

1 2 3 4 5 6 7 8 9 10

INP 2

INN 2

VRIN 2

ZC

DET

1dB STEP

VOLUME

OUT 2

CE

DATA

VCT

BUFFER

CLK

INIT

IC602 BA8270F-E2

BUS ON

1

REGULATOR

OVER VOLTAGE

PROTECT

–

+

2 3

4

1

NC

STB

MODE2

MODE1

5 6 7 8 9 10 1211

VCC

AMP

ANT

COM

VDD

–

+

AM

–

+

FM

–

+

GND

2

RST

BATT

3

4

CLK

5

VREF

6

DATA

GND

7 8

BUS ON

SWITCH

RESET

SWITCH

BATTERY

SWITCH

14

13

12

11

10

9

VCC

RST

BUS ON

CLK IN

BU IN

DATA IN

DATA OUT

– 56 –

Page 41

IC650 MSM6656A-687GS-KR1 (TYPE A)

IC650 MSM6656A-688GS-KR1 (TYPE B)

IC650 MSM6656A-689GS-KR1 (TYPE C)

IC650 MSM6656A-690GS-KR1 (TYPE D)

1

VDD

2

XT

3

CMD

XT

NC

4

OSC

5

NC

6

7

NC

8

ST

TIMMING

CONTROLLER

I/O

INTERFACE

17 BIT

ADDRESS

COUNTER

BEEP TONE

GENARATOR

MELODY

GENARATOR

DATA

CONTROLLER

LPF

12 BIT

DAC

12

PCM

SYNTHSIZER

ADPCM

SYNTHESIZER

24

GND

23

AOUT

22

NAR

21

NC

20

BUSY

19

NC

18

NC

17

RESET

12/PoRT0

13/PoRT1

1M BIT ROM

17 BIT

MULTIPLEXER

7

9

10

10

11

11

12

ADDRESS

&

COMMAND

CONTROLLER

EDITING ROM &

ADDRESS ROM

CONTAINS 22KBIT

8

16

CH

15

16/SD

15/SI

14

14

13

– 57 –

Page 42

7-17. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC600 MB90574PFV-G-209-BND (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Function

Seek control signal output to the FM/AM tuner unit (TUX10)

1 SEEKOUT O

2 AF-SEEK O

3

4 ST-MONO I/O

5 TUNMUTE O

6

7

8 VCC —

9

10 BUS-ON

11 SYSRST O

12 DOORSW I

13 LCD SO

14 LCD CKO

15

16 LCD CE

17 UNISI

18 UNISO

19 UNICKO

20 SD-IN

21

22

23

24

25 PLLSI I

26 PLLSO O

27 PLLCKO O

28 PLLCE O

29

WIDE

FM-ON O

TU-ON O

CSV-RST

BEEP O Beep sound drive signal output terminal

CSV-SO

CSV-CKO

CSV-CE

SIRCS

ILL-ON O

AM mode: Used for IF count output/SD output request/AGC cut at SEEK or BTM

FM mode: Used for SD speed up at SEEK, BTM, or AF

“L” is output at tuner off

PLL low-pass filter time constant selection signal output at AF SEEK

“H” is output when AF SEEK

IF band select signal output to the FM/AM tuner unit (TUX10) “H”: wide mode

In receiving FM signals, interference noise from adjacent stations is removed by narrowing the

O

IF band automatically in the tuner unit so as to raise the selectivity, but in this case, the distortion

may increase and accordingly, the IF band is widened forcibly

FM stereo broadcasting detection signal input from the FM/AM tuner unit (TUX10), or forced

monaural control signal output to the FM/AM tuner unit (TUX10)

“L” is input in the FM stereo mode, or “L” is output in the forced monaural mode

Muting on/off control signal output of the FM and AM tuner signal “H”: muting on

FM system power supply on/off control signal output to the BA3918 (IC502)

“L”: AM power on, “H”: FM power on

Tuner system power supply on/off control signal output to the BA3918 (IC502)

“H”: tuner power on

Power supply terminal (+5V)

O

Reset signal output to the CSV (IC650) “L”: reset

O Bus on/off control signal output to the SONY bus interface (IC602) “L”: bus on

Reset signal output to the SONY bus interface (IC602) “L”: reset

Front panel open/close detection signal input “L” is input when the front panel is closed

O Serial data output to the liquid crystal display driver (IC900)

O Serial data transfer clock signal output to the liquid crystal display driver (IC900)

O Chip enable signal output to the liquid crystal display driver (IC900) “H” active

I Serial data input from the SONY bus interface (IC602)

O Serial data output to the SONY bus interface (IC602)

O Serial data transfer clock signal output to the SONY bus interface (IC602)

Station detector detect input from the FM/AM tuner unit (TUX10)

I

Stop level for SEEK, BTM, etc. is determined SD is present at input of “H”

O

Serial data output to the CSV (IC650)

O

Serial data transfer clock signal output to the CSV (IC650)

O

Chip enable signal output to the CSV (IC650) “L” active

I

Sircs remote control signal input from the remote control receiver (IC901)

PLL serial data input from the FM/AM PLL (IC10)

PLL serial data output to the FM/AM PLL (IC10)

PLL serial data transfer clock signal output to the FM/AM PLL (IC10)

PLL chip enable signal output to the FM/AM PLL (IC10) “H” active

Power on/off control signal output of the illumination LED and liquid crystal display driver

(IC900) “H”: power on Depends on initial setting of power select switch (S600)

Power select switch (S600) on: “H” output at the accessory on

Power select switch (S600) off: “H” output at the power on

30 DIMMER I/O

31 TIR-IND O

Dimmer control in/out terminal

At initial mode: The presence of dimmer select function is set (if this status, if “L” is input, the

dimmer select function is present)

At normal mode: LCD back light brightness control signal output

LED drive signal output of the TIR indicator (LED801) “H”: LED on

– 58 –

Page 43

Pin No. Pin Name I/O Function

32 LCD INH O

33

34 C —

35 AD-ON

36 RE-IN0

37 RE-IN1

38 DVCC —

39 DVSS —

40 — I

41 LCDANG

42 AVCC —

43 AVRH

44 AVRL

45 AVSS —

46 KEYIN0

47 KEYIN1

48 RC-IN0

49 DSTSEL0 I

50 DSTSEL1 I

51 DSTSEL2

52 MTP

53

54 VCC —

55 RAMBU I

56 POWSEL

57 EQ-SEL I

58 TESTIN

59 PACK-IND

60 TIR-PLAY O

61 SUB-SW1 O

62 SUB-SW0 O

63 VSS —

64 VOLCE

65 MUTE

66

67

68 SUBCE

VSS

VSM I

VOLSO/

SUBSO

VOLCKO/

SUBCKO

Blank indicate control signal output to the liquid crystal display driver (IC900) “L”: no display

—

Ground terminal

Connected to coupling capacitor for the power supply

A/D converter power control signal output terminal

O

When the KEYACK (pin &§) that controls reference voltage power for key A/D conversion input

is active, “L” is output from this terminal to enable the input

I

Dial pulse input of the rotary encoder (RE900)

(for VOLUME/BASS/TREBLE/BALANCE/FADER control)

I

Power supply terminal (+5V) (for D/A converter)

Ground terminal (for D/A converter)

Not used (fixed at “L”)

View field angle control signal is output when front panel is fully opened

O

“H”: front panel is fully opened

Power supply terminal (+5V) (for A/D converter)

I Reference voltage (+5V) input terminal (for A/D converter)

I Reference voltage (0V) input terminal (for A/D converter)

Ground terminal (for A/D converter)

Key input terminal (A/D input) (LSW900, S900, LSW901 to LSW908) OFF, SEEK/AMS +

I

+ ) = 0 – , MODE *, SOURCE, SOUND, DSPL, SHIFT, 1, 2, 3 keys input

Key input terminal (A/D input) (SW801, LSW909 to LSW918)

I

6, LIST, AF/TA, PTY LIST, 10, 9, 8, 7, 6, 5, 4 keys input

I Rotary remote commander key input terminal (A/D input)

Destination setting terminal (fixed at “L”)

Destination setting terminal (fixed at “H”)

Destination setting terminal (Type 1: fixed at “L”, Type 2: fixed at 1/4 voltage, Type 3: fixed at

I

1/2 voltage, Type 4: fixed at 3/4 voltage)

I Multi-path detection signal input from the RDS decoder (IC150)

FM and AM signal meter voltage detection input from the FM/AM tuner unit (TUX10)

(A/D input)

Power supply terminal (+5V)

Internal RAM reset detection signal input from the RN5VD33AA (IC501)

Input terminal to check that RAM data are not destroyed due to low voltage

This checking is made within 100 msec after reset

I Power select switch (S600) input terminal “L”: off (halt mode), “H”: on (operation mode)

Not used (fixed at “H”)

I Setting terminal for the test mode “L”: test mode, Normally: fixed at “H”

LED drive signal output of the tape window illumination and 6 indicators (LED800, 802)

O

“H”: LED on “H” is output to turn on LED when front panel is opened

AM/TIR selection signal output to the TC4W66F (IC51) “L”: AM signal, “H”: TIR signal

Sub woofer output cut-off frequency select signal output terminal

Sub woofer output cut-off frequency select signal output terminal

Ground terminal

O Chip enable signal output to the main electrical volume (IC301) “H”: active

O Audio line muting on/off control signal output terminal “H”: muting on

O Serial data output to the main electrical volume (IC301) and sub electrical volume (IC350)

Serial data transfer clock signal output to the main electrical volume (IC301) and sub electrical

O

volume (IC350)

O Chip enable signal output to the sub electrical volume (IC350) “H” active

– 59 –

Page 44

Pin No. Pin Name I/O Function

69

70 IIC SIO I/O

71 IIC CKO O

72 RC-IN1

73 X1A O

74 X0A I

75 DAVN I

76 KEYACK

77 BU-IN

78 ILL IN

79

80 NOSESW I

81 ACC IN

82 to 85

86 HSTX I

87 MD2 I

88 MD1 I

89 MD0 I

90 RESET I

91 VSS —

92 X0

93 X1

94 VCC —

95 TIR-BUSY I

96 TIR-WR O

FLASH-W

TEL-ATT I Telephone muting signal input terminal At input of “H”, the signal is attenuated by –20 dB

TIR-D0 to TIR-D3

Internal flash memory data write mode detection signal input terminal “L”: data write mode

I

Not used (fixed at “H” in this set)

Two-way data bus with the RDS decoder (IC150)

Bus clock signal output to the RDS decoder (IC150)

I Rotary remote commander shift key input terminal “L”: shift

Sub system clock output terminal (32.768 kHz)

Sub system clock input terminal (32.768 kHz)

Data transmit completed detect signal input from the RDS decoder (IC150) “H” active

Input of acknowledge signal for the key entry Acknowledge signal is input to accept function

I

and eject keys in the power off status On at input of “H”

Battery detect signal input from the SONY bus interface (IC602) and battery detect circuit

I

“L” is input at low voltage

Auto dimmer control illumination line detection signal input terminal

I

“L” is input at dimmer detection

Front panel block remove/attach detection switch (SW500) input terminal

“L”: front panel is attached

I Accessory detect signal input terminal “L”: accessory on

I/O

Two-way data bus with the MSM6688GS (IC100)

Hardware standby input terminal “L”: hardware standby mode Reset signal input in this set

Setting terminal for the CPU operational mode (fixed at “L” in this set)

Setting terminal for the CPU operational mode (fixed at “H” in this set)

Setting terminal for the CPU operational mode (fixed at “H” in this set)

System reset signal input from the reset signal generator (IC500) and reset switch (SW800)

“L”: reset “L” is input for several 100 msec after power on, then it changes to “H”

Ground terminal

I Main system clock input terminal (3.68 MHz)

O Main system clock output terminal (3.68 MHz)

Power supply terminal (+5V)

Busy detection signal input from the MSM6688GS (IC100)

“H” is output while MSM6688GS (IC100) is executing a command

Data write strobe signal output to the MSM6688GS (IC100)

“L” is output when data (D0 to D3) are output to the MSM6688GS (IC100)

97 TIR-CE0 O

98 TIR-CE1 O

99 TIR-RES O

100 TIR-PDOWN O

101 TIR-RD O

102 MTLIN I

103 AMSIN I

104 REEL I

105 POS0 I

106 POS1 I

107 POS2 I

108 POS3 I

Chip enable signal output to the MSM6688GS (IC100)

TIR-WR (pin (§) or TIR-RD (pin `⁄‚⁄) is accepted when CE is “L” or CE is “H” respectively

TIR-WR (pin (§) or TIR-RD (pin `⁄‚⁄) is not accepted when CE is “H” or CE is “L” respectively

Reset signal output to the MSM6688GS (IC100) “H”: reset

Power down control signal output to the MSM6688GS (IC100) “L”: power down

Data read strobe signal output to the MSM6688GS (IC100)

“L” is output when data (D0 to D3) are output to the MSM6688GS (IC100)

Metal detection signal input terminal “L”: normal position, “H”: metal position

Whether a music is present or not from CXA2510AQ (IC250) is detected at auto music sensor

“L”: music is present, “H”: music is not present

Rotation detect signal input from supply reel sensor and take-up reel sensor on the deck

mechanism

Tape position (EJECT/FF/REW/

REV/FWD mode) detect input from

the tape operation switch on the deck

mechanism

POS0: “L”: EJECT mode, “H”: others mode

POS1: “L”: FF and FWD mode, “H”: others mode

POS2: “L”: REW mode, “H”: others mode

POS3: “L”: REV and EJECT mode, “H”: others mode

– 60 –

Page 45

Pin No. Pin Name I/O Function

109 LM-EJ O

110 LM-LOD O

111 CM-ON O

112 TAPEON O

113 N-ROUT O

114 AMSON O

115 DOLBC O

116 DOLBY I/O

117

118 LEDON

119 VSS

120 POWON

CSV-NAR

Motor drive signal output to the loading/tape operation motor drive (IC201) “H” active

(For the eject direction and reverse side operation) *1

Motor drive signal output to the loading/tape operation motor drive (IC201) “H” active

(For the loading direction and forward side operation) *1

Capstan/reel motor (M901) drive signal output terminal “H”: motor on

Tape system power supply on/off control signal output terminal “H”: tape on

Forward/reverse direction control signal output to the CXA2510AQ (IC250)

“L”: forward direction, “H”: reverse direction

Tape auto music sensor control signal output to the CXA2510AQ (IC250)

“L” is output to lower the gain for audio level at FF/REW mode

Standby on/off control signal output to the power amplifier (IC700)

“L”: standby mode, “H”: amp on

Dolby control in/out terminal

At initial mode: valid/invalid selection input of dolby function (valid at “L” input)

At normal mode: dolby on/off control signal output to the CXA2510AQ (IC250)

(dolby on at “H” output)

I

“H” is input when CSV (IC650) sends data

O Power supply on/off control signal output of the illumination LED “H”: power on

—

Ground terminal

O Main system power supply on/off control signal output to the BA3918 (IC502) “H”: power on

*1 Loading/tape operation motor control

Mode

Terminal

LM-LOD (pin `⁄⁄‚)

LM-EJ (pin `⁄‚·)

STOP

“L” “H” “L” “H”

“L” “L” “H” “H”

LOADING/

FORWARD

EJECT/

REVERSE

BRAKE

– 61 –

Page 46

SECTION 8

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) CHASSIS SECTION

not

supplied

MG-25D-136

13

14

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

17

LUG1

16

19

18

A

15

not

supplied

16

23

21

• Abbreviation

TYPE A : ENGLISH, FRENCH

TYPE B : ENGLISH, GERMAN

TYPE C : ENGLISH, SPANISH

TYPE D : ENGLISH, ITALIAN

F701

22

#2

16

16

27

#3

24

25

26

28

12

11

10

9

7

31

4

3

8

5

#1

#2

#1

#2

2

Front panel section

Ref. No. Part No. Description Remark

1 3-022-310-01 COLLAR

2 X-3375-093-3 PANEL ASSY, SUB

3 3-022-338-01 BUTTON (EJECT) (6)

* 4 1-669-656-12 SUB BOARD

5 X-3375-068-1 LOCK ASSY

* 6 3-022-307-01 INSULATED PLATE

7 3-935-003-01 SPRING (C DOOR), TORSION

8 3-027-799-11 DOOR, CASSETTE

9 3-713-786-51 SCREW +P 2X3

10 3-953-235-01 DAMPER, OIL

1

#3

#3

#3

not

supplied

6

20

A

#3

#3

B

#3

29

#3

30

Ref. No. Part No. Description Remark

* 17 A-3317-692-A MAIN BOARD, COMPLETE (TYPE D)

* 17 A-3317-694-A MAIN BOARD, COMPLETE (TYPE A)

* 18 3-011-078-01 BRACKET (POWER IC)

* 19 3-022-317-01 BRACKET (AMP)

* 20 3-022-306-01 HEAT SINK

* 21 3-355-209-01 PLATE (B), GROUND

22 1-776-527-71 CORD (WITH CONNECTOR) (ISO) (POWER)

* 23 3-023-774-01 PLATE (LOCK), GROUND

24 3-937-282-03 CASE (UPPER)

* 25 3-034-264-01 SHEET (E)

B

11 3-341-752-11 WASHER, POLYETHYLENE

12 3-011-170-01 GEAR (HOLDER)

13 X-3375-066-2 BRACKET (GEAR) ASSY

* 14 3-022-316-01 COVER

15 3-919-171-01 SCREW (2.6X6) (C TIGHT)

16 3-915-923-01 SCREW, GROUND POINT

* 17 A-3317-686-A MAIN BOARD, COMPLETE (TYPE C)

* 17 A-3317-690-A MAIN BOARD, COMPLETE (TYPE B)

* 26 A-3313-646-A INVERTOR BOARD, COMPLETE

27 1-783-495-11 CORD (WITH CONNECTOR) (EL)

28 3-937-812-03 CASE (LOWER)

29 1-777-246-11 CORD (WITH CONNECTOR) (ANT)

* 30 X-3375-081-1 CHASSIS ASSY

* 31 3-025-352-01 PLATE (INV), SHIELD

F701 1-532-877-11 FUSE (BLADE TYPE) (AUTO FUSE) (10A)

* LUG1 1-537-738-21 TERMINAL, EARTH

– 62 –

Page 47

(2) FRONT PANEL SECTION

53

54

55

56

71

67

66

65

64

63

52

51

62

61

60

59

58

57

68

69

#4

not supplied

(KEY board)

not supplied

LCD900

EL900

68

70

70

70

Ref. No. Part No. Description Remark

51 X-3377-531-1 PANEL SUB ASSY, FRONT

52 3-022-332-01 BUTTON (10 KEY)

53 3-022-329-21 BUTTON (SOURCE)

54 3-033-667-02 KNOB (VOL)

55 3-022-323-24 LEVER (SHUTTLE)

56 3-022-324-02 PLATE (SHUTTLE), LIGHT GUIDE

57 3-022-330-01 BUTTON (MODE) (MODE *. OFF)

58 3-030-648-01 PLATE (RING), LIGHT GUIDE

59 3-022-331-01 BUTTON (SOUND) (SOUND. DSPL)

60 3-932-225-01 SPRING (OPEN)

61 3-022-333-01 BUTTON (OPEN)

(+ + ) . = 0 –. SEEK/AMS)

(SHIFT. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10)

Ref. No. Part No. Description Remark

62 3-022-308-12 BUTTON (PTY) (PTY. AF/TA. TIR)

* 63 3-022-327-01 PLATE (LCD), GROUND

64 1-694-414-11 CONDUCTOR BOARD, CONNECTION

* 65 3-034-558-01 ILUMINATOR (LCD)

* 66 3-022-326-03 PLATE (LCD), LIGHT GUIDE

67 3-017-984-01 TAPE (EL), DOUBLE STICK

68 3-327-119-01 SPACER (A)

69 3-023-554-01 SEET (EL), ADHESIVE

70 3-027-109-01 WASHER, POLYETHYLENE

71 X-3375-085-4 PANEL ASSY, FRONT BACK

EL900 1-517-766-11 LIGHT, ELECTRO LUMINESCENT

LCD900 1-803-504-11 DISPLAY PANEL, LIQUID CRYSTAL

– 63 –

Page 48

(3) MECHANISM DECK SECTION

(MG-25D-136)

154

153

#6

155

158

152

157

156

159

A

160

A

161

163

HP901

162

M901

164

165

168

151

Ref. No. Part No. Description Remark

151 A-3291-667-A CLUTCH (FR) ASSY

* 152 3-019-130-01 LEVER (LDG-A)

* 153 3-019-131-01 LEVER (LDG-B)

154 3-020-539-01 SPRING (LD-1), TENSION

155 3-020-540-01 SPRING (LD-2), TENSION

156 3-020-542-01 GEAR (LOADING FT)

157 3-341-753-11 WASHER, POLYETHYLENE

158 3-020-533-01 HOUSING

* 159 3-020-532-01 ARM (SUCTION)

160 3-020-534-01 HANGER

#7

168

166

167

Ref. No. Part No. Description Remark

161 3-933-346-01 CATCHER

162 3-933-344-01 GUIDE (C)

163 3-014-798-01 SCREW (HEAD), SPECIAL

164 3-364-151-01 WASHER

165 X-3375-625-1 CHASSIS (SV) ASSY (D)

166 3-017-302-01 BELT (25)

167 3-936-853-01 FLYWHEEL (F)

168 3-701-437-21 WASHER

HP901 1-500-157-21 HEAD, MAGNETIC (PLAYBACK)

M901 A-3291-665-A MOTOR ASSY, MAIN (CAPSTAN/REEL)

– 64 –

Page 49

SECTION 9

ELECTRICAL PARTS LIST

INVERTER KEY

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* A-3313-646-A INVERTER BOARD, COMPLETE

*************************

< CAPACITOR >

C551 1-126-157-11 ELECT 10uF 20% 16V

C552 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C553 1-126-934-11 ELECT 220uF 20% 10V

C554 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C555 1-124-257-00 ELECT 2.2uF 20% 50V

C556 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C557 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

< CONNECTOR >

* CN550 1-564-507-11 PLUG, CONNECTOR 4P

* CN551 1-564-505-11 PLUG, CONNECTOR 2P

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

R561 1-216-180-00 RES,CHIP 180 5% 1/8W

R562 1-216-097-00 RES,CHIP 100K 5% 1/10W

R563 1-216-097-00 RES,CHIP 100K 5% 1/10W

T550 1-431-831-11 TRANSFORMER, OSCILLATION (EL)

************************************************************

1-694-414-11 CONDUCTOR BOARD, CONNECTION

3-017-984-01 TAPE (EL), DOUBLE STICK

* 3-022-326-03 PLATE (LCD), LIGHT GUIDE

* 3-022-327-01 PLATE (LCD), GROUND

3-023-554-01 SHEET (EL), ADHESIVE

When indicating parts by reference

number, please include the board.

• Abbreviation

TYPE A : ENGLISH, FRENCH

TYPE B : ENGLISH, GERMAN

TYPE C : ENGLISH, SPANISH

TYPE D : ENGLISH, ITALIAN

< TRANSFORMER >

KEY BOARD

**********

< DIODE >

D550 8-719-422-49 DIODE MA8056-L

D551 8-719-422-80 DIODE MA8075-H-TX

D552 8-719-404-50 DIODE MA111-TX

D553 8-719-033-43 DIODE RB751H

D554 8-719-422-49 DIODE MA8056-L

< IC >

IC550 8-759-495-75 IC NJM317F

< TRANSISTOR >

Q552 8-729-421-22 TRANSISTOR UN2211

Q553 8-729-026-68 TRANSISTOR 2SD2525 (TP)

Q554 8-729-421-22 TRANSISTOR UN2211

Q555 8-729-903-46 TRANSISTOR 2SB1132-P

Q556 8-729-016-11 TRANSISTOR 2SD1507M

Q557 8-729-021-94 FET 2SK1657-T1B

< RESISTOR >

R552 1-216-198-00 RES,CHIP 1K 5% 1/8W

R553 1-216-198-00 RES,CHIP 1K 5% 1/8W

R555 1-216-158-00 RES,CHIP 22 5% 1/8W

R556 1-216-158-00 RES,CHIP 22 5% 1/8W

R557 1-216-001-00 METAL CHIP 10 5% 1/10W

* 3-034-558-01 ILLUMINATOR (LCD)

3-327-119-01 SPACER (A)

< CAPACITOR >

C900 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C901 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C902 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C903 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C904 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C905 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

< CONNECTOR >

CN900 1-778-183-11 PLUG, CONNECTOR 18P

< DIODE >

D901 8-719-420-90 DIODE MA8051-M

D903 8-719-420-90 DIODE MA8051-M

< ELECTRO LUMINESCENT LIGHT >

EL900 1-517-766-11 LIGHT, ELECTRO LUMINESCENT

< COIL >

FB901 1-414-233-22 INDUCTOR CHIP 0uH

R558 1-216-097-00 RES,CHIP 100K 5% 1/10W

R559 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R560 1-216-063-00 RES,CHIP 3.9K 5% 1/10W

< IC >

IC900 8-759-496-75 IC uPD16432BGC-018-9EU

– 65 –

Page 50

KEY MAIN

Ref. No. Part No. Description Remark

IC901 8-749-012-25 IC RS-170-TU

< LIQUID CRYSTAL DISPLAY >

LCD900 1-803-504-11 DISPLAY PANEL, LIQUID CRYSTAL

< LED >

LED900 8-719-987-45 LED CL-155Y/PG-CD (ILLUMINATION)

LED901 8-719-987-45 LED CL-155Y/PG-CD (ILLUMINATION)

LED902 8-719-987-45 LED CL-155Y/PG-CD (ILLUMINATION)

LED903 8-719-987-45 LED CL-155Y/PG-CD (ILLUMINATION)

LED904 8-719-987-45 LED CL-155Y/PG-CD (ILLUMINATION)

LED905 8-719-987-45 LED CL-155Y/PG-CD (ILLUMINATION)

LED906 8-719-033-13 LED CL-170Y-CD-T (ILLUMINATION)

LED907 8-719-033-14 LED CL-170PG-CD-T (ILLUMINATION)

< SWITCH >

LSW900 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (OFF)

LSW901 1-762-620-21 SWITCH, KEY BOARD (WITH LED)

(MODE, *)

LSW902 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (SOURCE)

LSW903 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (SOUND)

LSW904 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (DSPL)

LSW905 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (SHIFT)

LSW906 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (1)

LSW907 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (2)

LSW908 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (3)

LSW909 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (LIST)

LSW910 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (AF/TA)

LSW911 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (TIR)

LSW912 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (10)

LSW913 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (9)

LSW914 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (8)

LSW915 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (7)

LSW916 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (6)

LSW917 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (5)

LSW918 1-762-620-21 SWITCH, KEY BOARD (WITH LED) (4)

< TRANSISTOR >

Q900 8-729-904-66 TRANSISTOR DTD113EK

Q901 8-729-904-66 TRANSISTOR DTD113EK

Q902 8-729-424-08 TRANSISTOR UN2111

Q903 8-729-424-08 TRANSISTOR UN2111

Ref. No. Part No. Description Remark

R915 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R916 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R917 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R918 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R919 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R920 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R931 1-216-037-00 METAL CHIP 330 5% 1/10W

R932 1-216-041-00 METAL CHIP 470 5% 1/10W

R933 1-216-042-00 METAL CHIP 510 5% 1/10W

R935 1-216-182-00 RES,CHIP 220 5% 1/8W

R936 1-216-182-00 RES,CHIP 220 5% 1/8W

R937 1-216-037-00 METAL CHIP 330 5% 1/10W

R938 1-216-037-00 METAL CHIP 330 5% 1/10W

R939 1-216-048-00 METAL CHIP 910 5% 1/10W

R941 1-216-025-00 RES,CHIP 100 5% 1/10W

R942 1-216-041-00 METAL CHIP 470 5% 1/10W

R943 1-216-025-00 RES,CHIP 100 5% 1/10W

R944 1-216-037-00 METAL CHIP 330 5% 1/10W

R945 1-216-081-00 METAL CHIP 22K 5% 1/10W

R946 1-216-089-00 RES,CHIP 47K 5% 1/10W

R947 1-216-089-00 RES,CHIP 47K 5% 1/10W

R948 1-216-049-11 RES,CHIP 1K 5% 1/10W

R949 1-216-049-11 RES,CHIP 1K 5% 1/10W

R950 1-216-049-11 RES,CHIP 1K 5% 1/10W

R951 1-216-049-11 RES,CHIP 1K 5% 1/10W

R952 1-216-095-00 RES,CHIP 82K 5% 1/10W

R953 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R954 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R955 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R956 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R957 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R958 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

< ROTARY ENCODER >

RE900 1-475-014-11 ENCODER, ROTARY (VOLUME/BASS/TREBLE/

BALANCE/FADER CONTROL)

< SWITCH >

S900 1-771-290-11 SWITCH, SLIDE

(=0 –, + + ): SEEK/AMS)

************************************************************

< RESISTOR >

R901 1-216-045-00 METAL CHIP 680 5% 1/10W

R902 1-216-045-00 METAL CHIP 680 5% 1/10W

R903 1-216-045-00 METAL CHIP 680 5% 1/10W

R904 1-216-049-11 RES,CHIP 1K 5% 1/10W

R905 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R906 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R907 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R908 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R909 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R910 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R911 1-216-045-00 METAL CHIP 680 5% 1/10W

R912 1-216-045-00 METAL CHIP 680 5% 1/10W

R913 1-216-045-00 METAL CHIP 680 5% 1/10W

R914 1-216-049-11 RES,CHIP 1K 5% 1/10W

* A-3317-686-A MAIN BOARD, COMPLETE (TYPE C)

* A-3317-690-A MAIN BOARD, COMPLETE (TYPE B)

* A-3317-692-A MAIN BOARD, COMPLETE (TYPE D)

* A-3317-694-A MAIN BOARD, COMPLETE (TYPE A)

*********************

* 3-011-078-01 BRACKET (POWER IC)

* 3-022-306-01 HEAT SINK

* 3-022-317-01 BRACKET (AMP)

* 3-025-352-01 PLATE (INV), SHIELD

7-685-794-09 SCREW +PTT 2.6X10 (S)

< BUZZER >

BZ600 1-504-920-11 BUZZER

– 66 –

Page 51

MAIN

Ref. No. Part No. Description Remark

< CAPACITOR >

C10 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C11 1-104-665-11 ELECT 100uF 20% 10V

C12 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C13 1-104-665-11 ELECT 100uF 20% 10V

C14 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C15 1-104-665-11 ELECT 100uF 20% 10V

C16 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C17 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C18 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C19 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C20 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C21 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C22 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C23 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C24 1-126-157-11 ELECT 10uF 20% 16V

C25 1-124-234-00 ELECT 22uF 20% 16V

C27 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C28 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C29 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C31 1-124-589-11 ELECT 47uF 20% 16V

C32 1-126-157-11 ELECT 10uF 20% 16V

C33 1-163-234-11 CERAMIC CHIP 20PF 5% 50V

C34 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C35 1-124-234-00 ELECT 22uF 20% 16V

C36 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C37 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C38 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V