Sony XRC-7200 Service manual

XR-C7200/C7200W

SERVICE MANUAL

Photo: XR-C7200

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks

of Dolby Laboratories Licensing Corporation.

SPECIFICA TIONS

US Model

XR-C7200

E Model

XR-C7200/C7200W

Model Name Using Similar Mechanism NEW

Tape T ransport Mechanism T ype MG-25D-136

MICROFILM

– Continued on next page –

XR-C7200: US Model

FM/AM CASSET TE CAR STEREO

XR-C7200/C7200W: E Model

FM/MW/SW CASSET TE CAR STEREO

TABLE OF CONTENTS

1. GENERAL

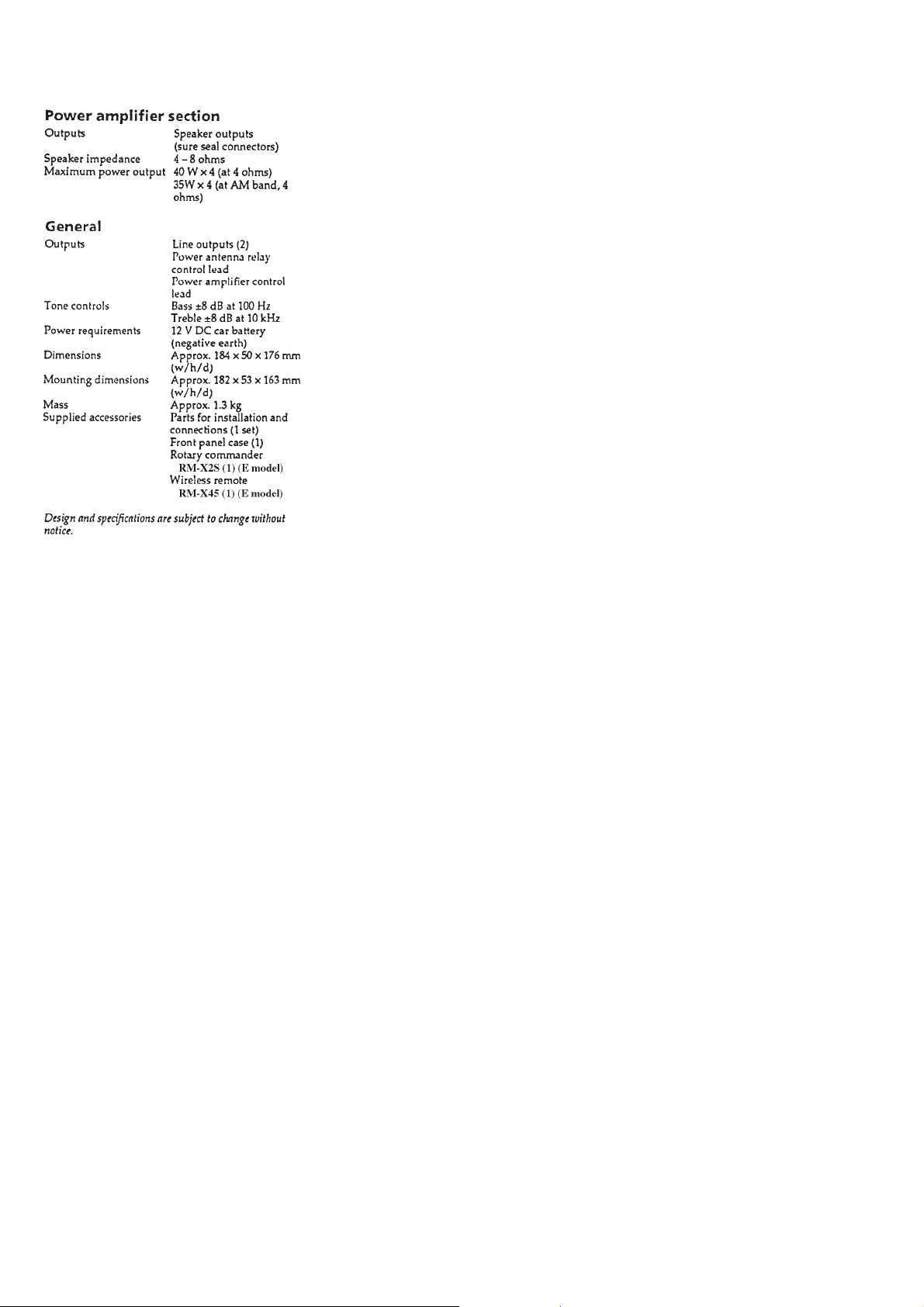

Location of Controls ....................................................... 3

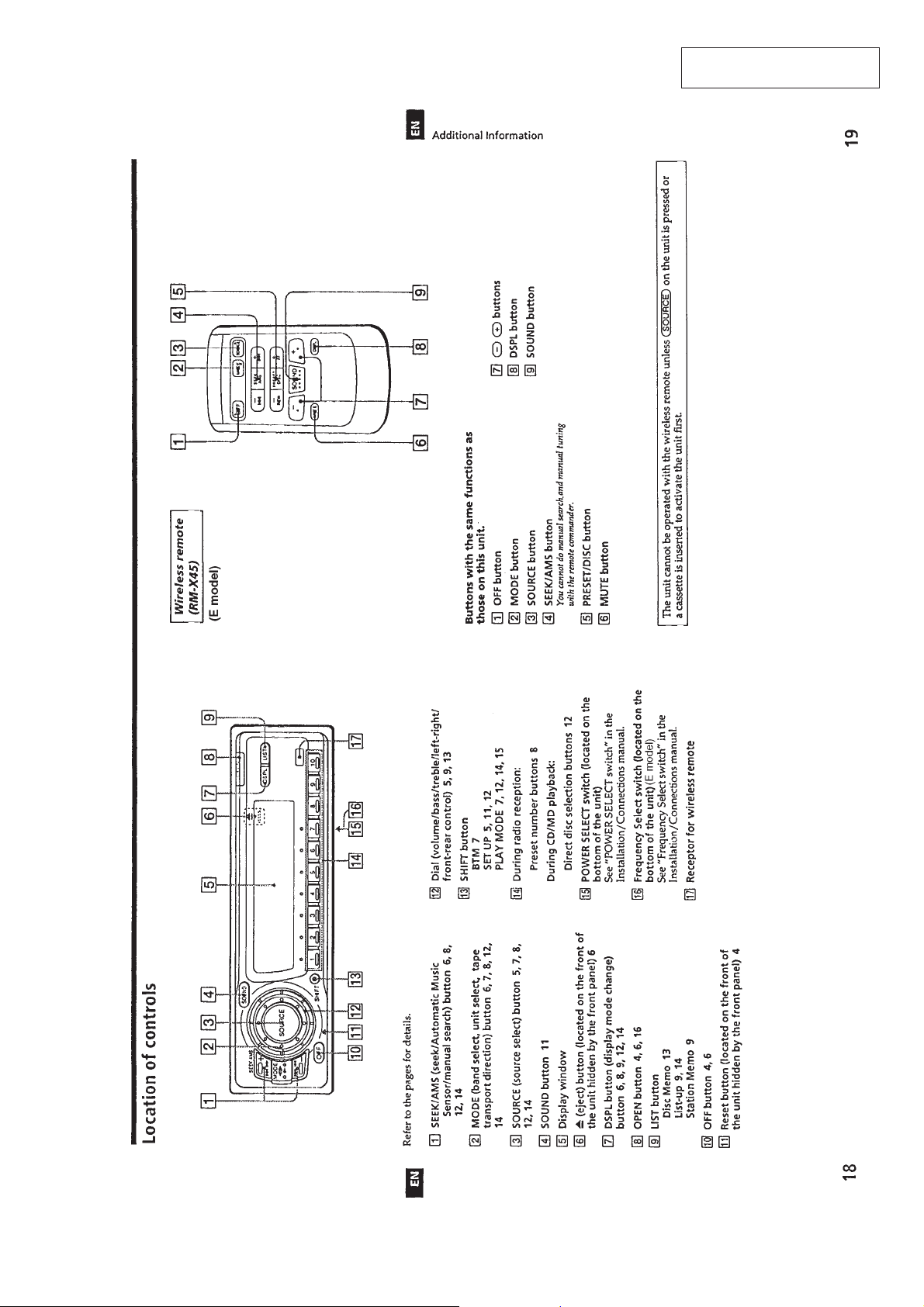

Resetting the Unit ........................................................... 4

Detaching the Front Panel............................................... 4

Setting the Clock ............................................................. 4

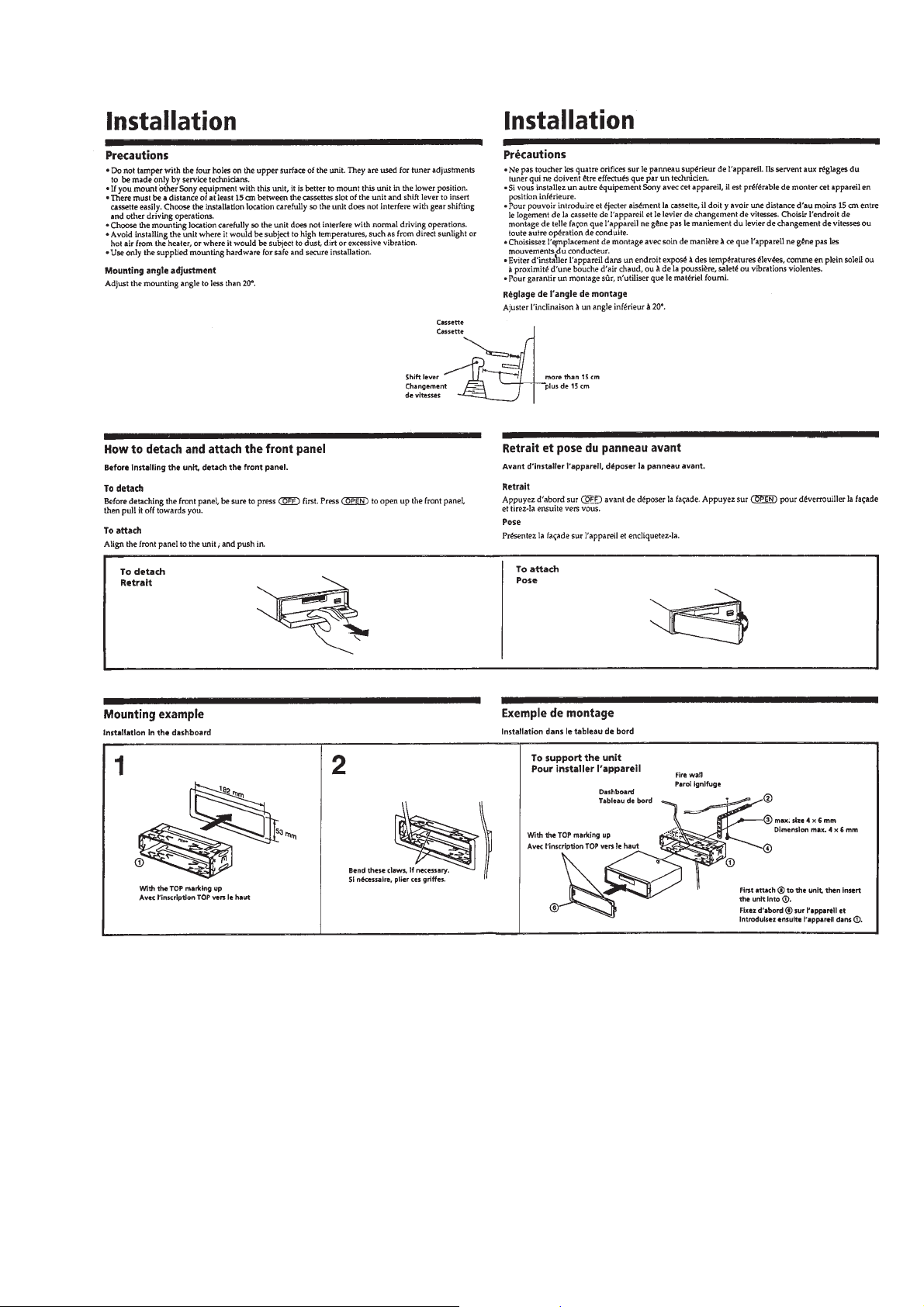

Installation....................................................................... 5

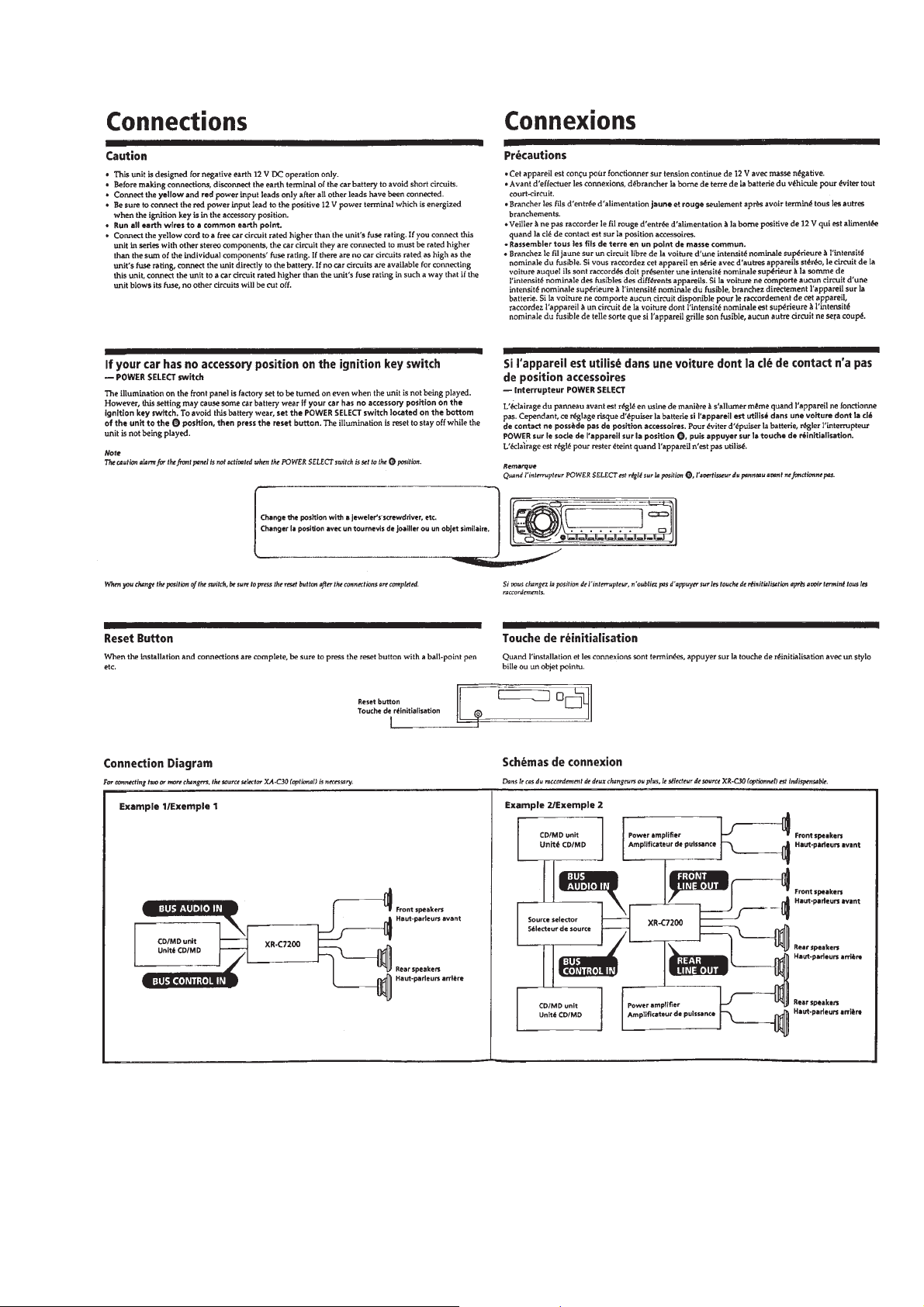

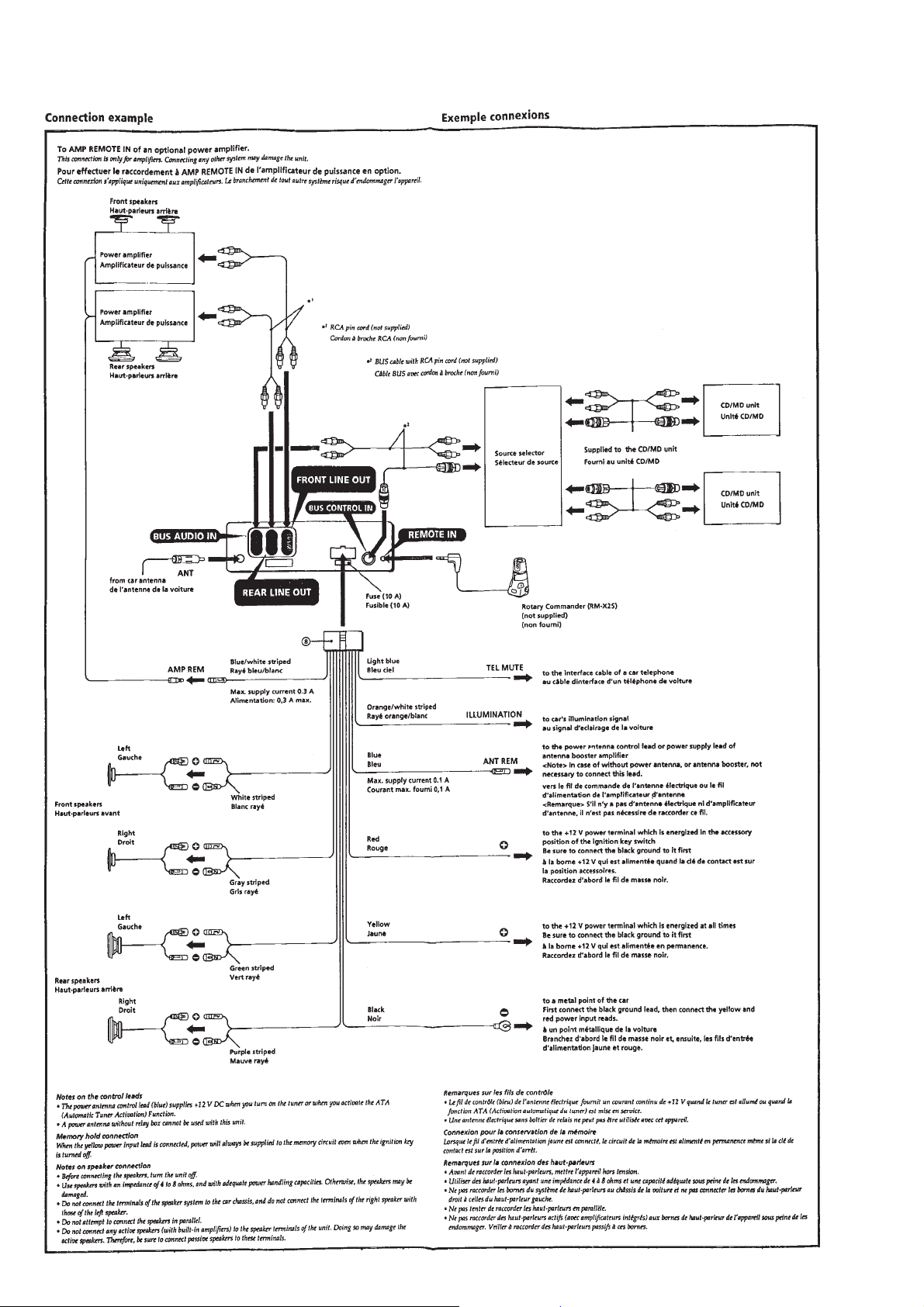

Connections ..................................................................... 7

2. DISASSEMBLY ......................................................... 9

3. ASSEMBLY OF MECHANISM DECK........... 12

4. MECHANICAL ADJUSTMENTS ....................... 15

5. ELECTRICAL ADJUSTMENTS

Test Mode........................................................................ 15

Tape Deck Section .......................................................... 15

Tuner Section .................................................................. 16

6. DIAGRAMS

6-1. Printed Wiring Board – MAIN Section –....................... 19

6-2. Schematic Diagram – MAIN Section –.......................... 23

6-3. Printed Wiring Boards – PANEL Section – ................... 28

6-4. Schematic Diagram – PANEL Section –........................ 30

6-5. IC Pin Function Description ........................................... 35

7. EXPLODED VIEWS ................................................ 38

8. ELECTRICAL PARTS LIST ............................... 41

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 2 –

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 3 –

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

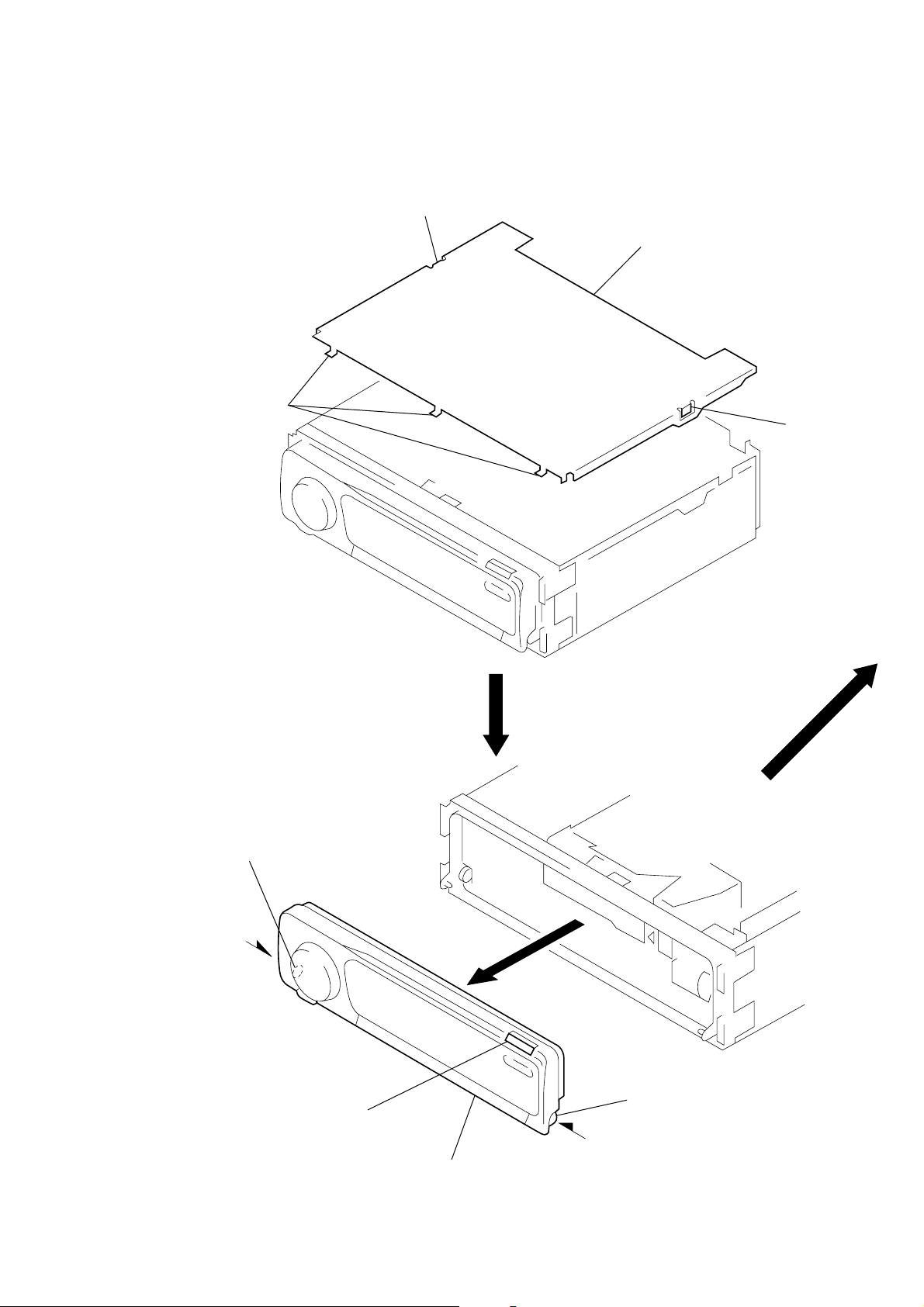

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER ASS’Y

1

claw

2

three claws

3

cover ass’y

1

claw

FRONT PANEL ASS’Y

3

Push the bearing (L).

1

Push the button (OPEN).

4

front panel ass’y

2

Push the bearing (R).

– 9 –

SUB PANEL ASS’Y

)

(

)

k

3

two screws

(PTT2.6

×

8)

4

2

two screws

(PTT2.6

two claws

×

8)

6

sub panel ass’y

5

claw

1

screw

(PTT2.6

×

8

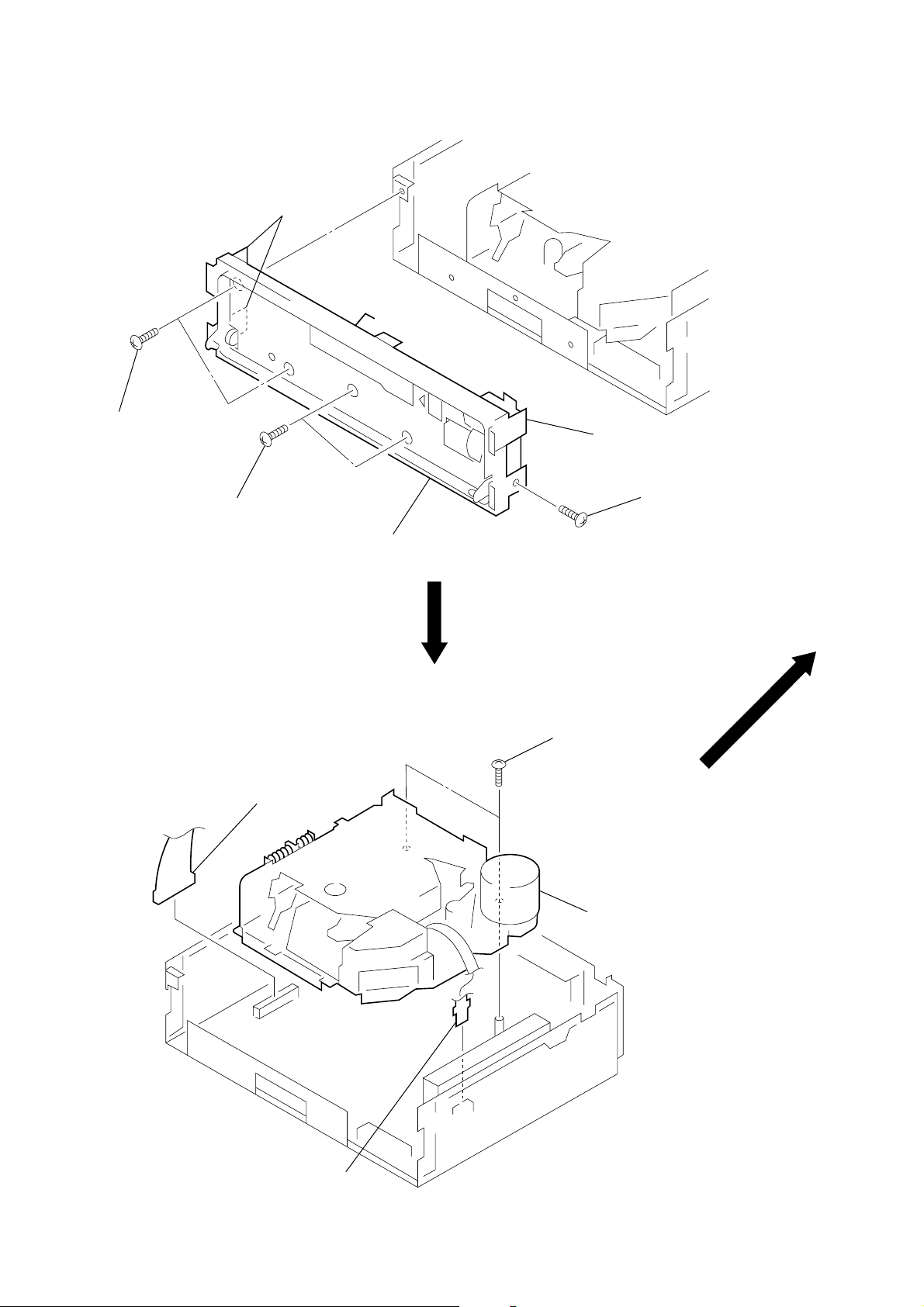

MECHANISM DECK (MG-25D-136)

2

connector

(CN201)

1

two screws

×

6)

(2.6

4

mechanism dec

(MG-25D-136)

3

flexible flat cable

CN231

– 10 –

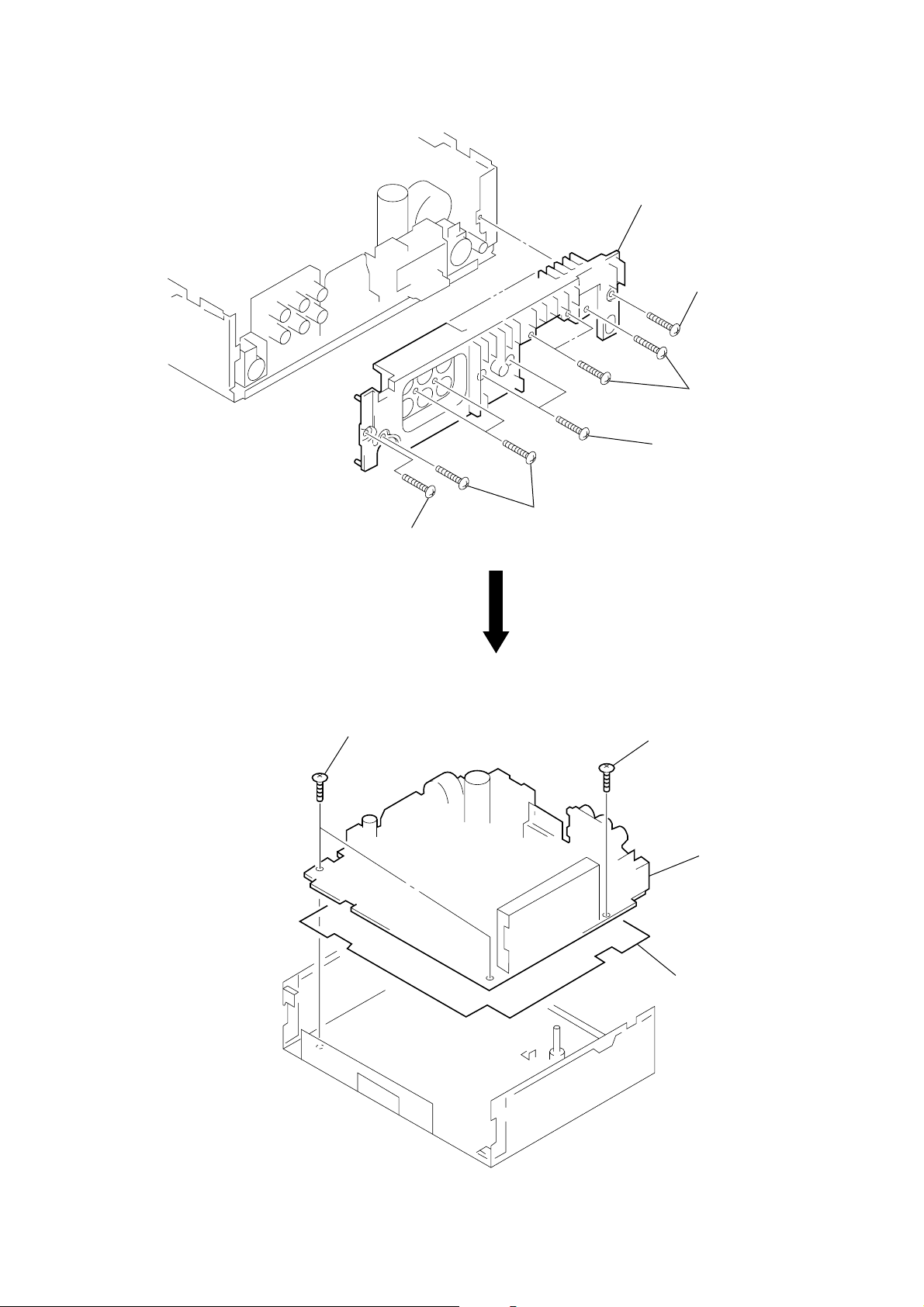

HEAT SINK

d

5

screw

(PTT2.6 × 8)

1

three screws

(PTT2.6 × 8)

6

heat sink

2

4

screw

(PTT2.6 × 8)

3

three screws

(PTT2.6 × 8)

two screws

(PTT2.6 × 8)

MAIN BOARD

2

two ground point screws

1

ground point screw

3

main boar

4

insulator

– 11 –

SECTION 3

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

HOUSING

4

Fit claw on B part.

3

Put the housing

under A part.

housing

2

Install the hanger onto

two claws of the housing.

5

Fit projection on C part.

C

part

7

Holder the hanger by bending the claw.

1

Install the catch to the hanger.

hanger

6

Fit projection on D part.

8

Hold the hanger by

bending the claw.

ARM (SUCTION)

A

part

projection

B

part

D

part

2

Move the arm (suction) in the arrow

direction and fit on projection.

1

Fit the arm (suction) on the shaft.

– 12 –

Loading...

Loading...