Page 1

XR-C5500T

y

SERVICE MANUAL

SPECIFICATIONS

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.08 % (WRMS)

Frequency response 30 – 18,000 Hz

Signal-to-noise ratio 58 dB

Saudi Arabia Model

Model Name Using Similar Mechanism XR-C5604X

T ape Transport Mechanism Type MG-25F-136

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 50 W × 4 (at 4 ohms)

(sure seal connectors)

Tuner section

FM

Tuning range 87.5 – 108.0 MHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

MW

Tuning range 531 – 1,602 kHz

SW

Tuning range SW tuning interval:

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivit

72 dB (mono)

0.6 % (stereo),

0.3 % (mono)

SW1: 2,940 – 7,735 kHz

SW2: 9,500 – 18,135 kHz

(except for 10,140 – 11,575

kHz)

30 µV

General

Outputs Audio output

Tone controls Bass ±9 dB at 100 Hz

Power requirements 12 V DC car battery

Dimensions Approx. 178 × 50 × 183 mm

Mounting dimensions Approx. 182 × 53 × 162 mm

Mass Approx. 1.2 kg

Supplied accessories Front panel case (1)

Design and specifications are subject to change

without notice.

Power aerial relay control

lead

Power amplifier control

lead

Treble ±9 dB at 10 kHz

(negative earth)

(w/h/d)

(w/h/d)

FM/MW/SW CASSETTE CAR STEREO

Page 2

TABLE OF CONTENTS

1. GENERAL

Location of Controls ....................................................... 3

Setting the Clock ............................................................. 3

2. DISASSEMBLY ......................................................... 4

3. ASSEMBLY OF MECHANISM DECK........... 6

4. MECHANICAL ADJUSTMENTS ....................... 9

5. ELECTRICAL ADJUSTMENTS

Tape Deck Section .......................................................... 9

Tuner Section .................................................................. 9

6. DIAGRAMS

6-1. Block Diagram – TUNER/TAPE/MAIN Section – ....... 11

6-2. Block Diagram – DISPLAY/KEY CONTROL/

BUS CONTROL/POWER SUPPLY Section – .............. 12

6-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 13

6-4. Schematic Diagram – MAIN Board (1/2) – ................... 14

6-5. Schematic Diagram – MAIN Board (2/2) – ................... 15

6-6. Printed Wiring Board – MAIN Board – ......................... 16

6-7. Printed Wiring Board – SUB Board – ........................... 17

6-8. Schematic Diagram – SUB Board – ............................... 17

6-9. Printed Wiring Board – KEY Board –........................... 18

6-10. Schematic Diagram – KEY Board – .............................. 19

6-11. IC Pin Function Description ........................................... 21

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

7. EXPLODED VIEWS................................................ 24

8. ELECTRICAL PARTS LIST ............................... 27

2

Page 3

SECTION 1

y

GENERAL

This section is extracted from

instruction manual.

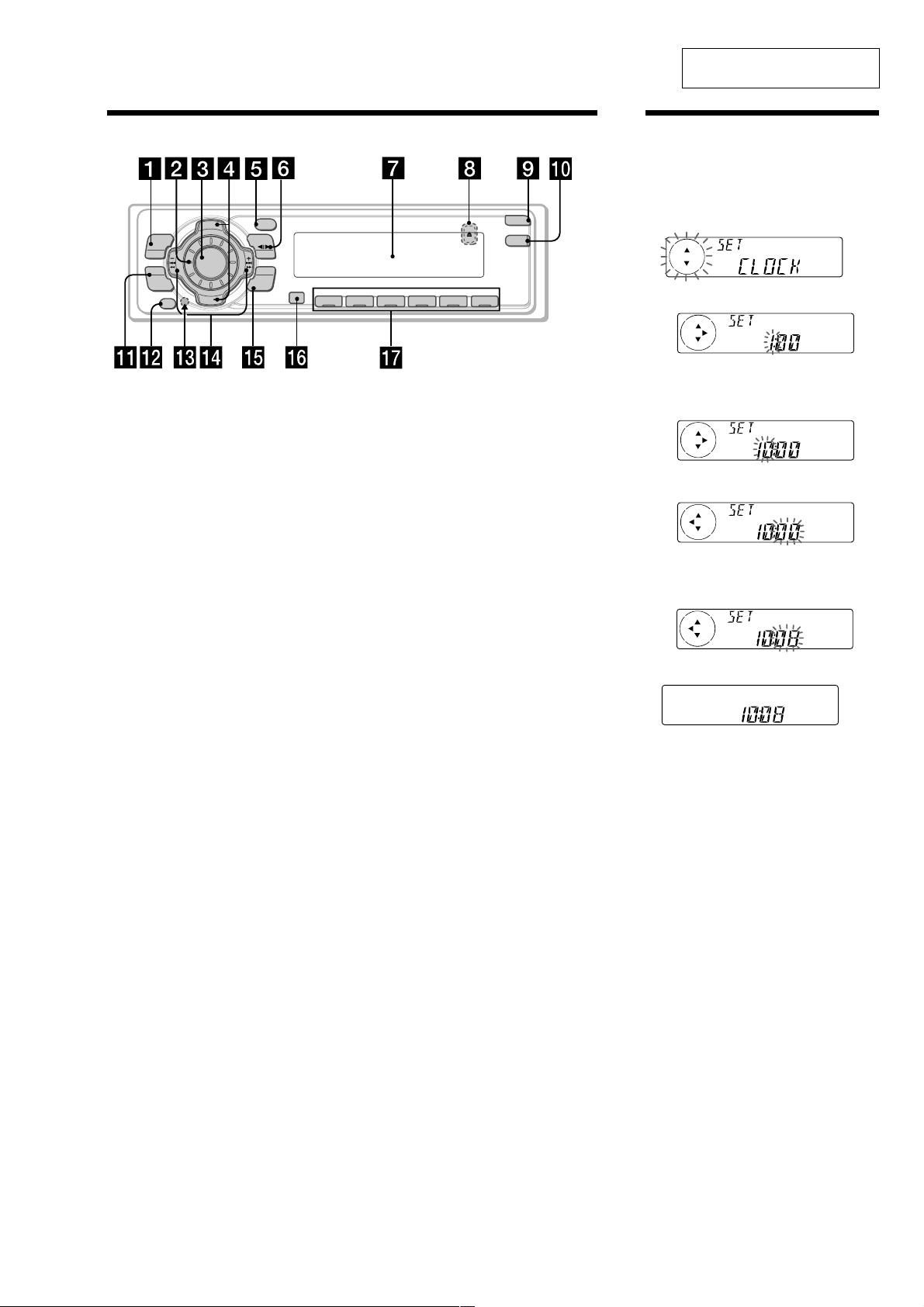

Location of controls

S

+

C

I

D

MENU

SOURCE

SOUND

P

R

S

T

—

D

I

S

OFF

Refer to the pages listed for details.

1 MENU button 8, 10, 11, 12, 13, 15

2 Volume control dial

3 SOURCE (TUNER/TAPE/CD/MD) button

7, 9, 11, 14

4 PRST/DISC +/– (cursor up/down) buttons

7, 8, 10, 11, 12, 13, 15

During radio reception:

Preset stations select 11

During CD/MD playback:

Disc change 15

5 DSPL (display mode change) button

10, 14, 15

6 MODE button 9, 10, 11, 14

During tape playback:

Playback direction change 9

During radio reception:

BAND select 11

During CD/MD playback:

CD/MD unit select 14

7 Display window

8 Z (eject) button (located on the front side

of the unit behind the front panel) 9

9 OPEN button 6, 9, 17

q; D-BASS button 14

qa SOUND button 13

qs OFF button* 6, 7, 9

DSPL

P

R

S

T

+

MODE

SEEK/AMS

ENTER

—

C

REP SHUF

1 2 3 4 56

OPEN

D-BASS

XR-C5500T

qd Reset button (located on the front side

of the unit behind the front panel) 6

qf SEEK/AMS –/+ (cursor left/right) buttons

7, 8, 9, 10, 11, 12, 13, 15

Seek 12

Automatic Music Sensor 9, 15

Manual search 12, 15

qg ENTER button 8, 10, 11, 12, 13, 15

qh

Receptor for the optional card remote

commander

qj Number buttons

During radio reception:

Preset number select 11

During tape playback:

(1) REP 10

During CD/MD playback:

(1) REP 16

(2) SHUF 16

* Warning when installing in a car

without ACC (accessory) position on

the ignition key switch

Be sure to press (OFF) on the unit for two

seconds to turn off the clock display after

turning off the engine.

When you press (OFF) only momentarily,

the clock display does not turn off and this

causes battery wear.

Setting the clock

The clock uses a 12-hour digital indication.

Example: To set the clock to 10:08

1

Press (MENU), then press either side of

(PRST/DISC) repeatedly until “CLOCK”

appears.

1 Press (ENTER).

The hour indication flashes.

2 Press either side of (PRST/DISC) to set

the hour.

3 Press (+) side of (SEEK/AMS).

The minute indication flashes.

4 Press either side of (PRST/DISC) to set

the minute.

2

Press (ENTER).

The clock starts.

After the clock setting is complete, the

display returns to normal playback mode.

Tip

When the D.INFO mode is set to ON, the time is

alwa

s displayed (page 13).

3

Page 4

e

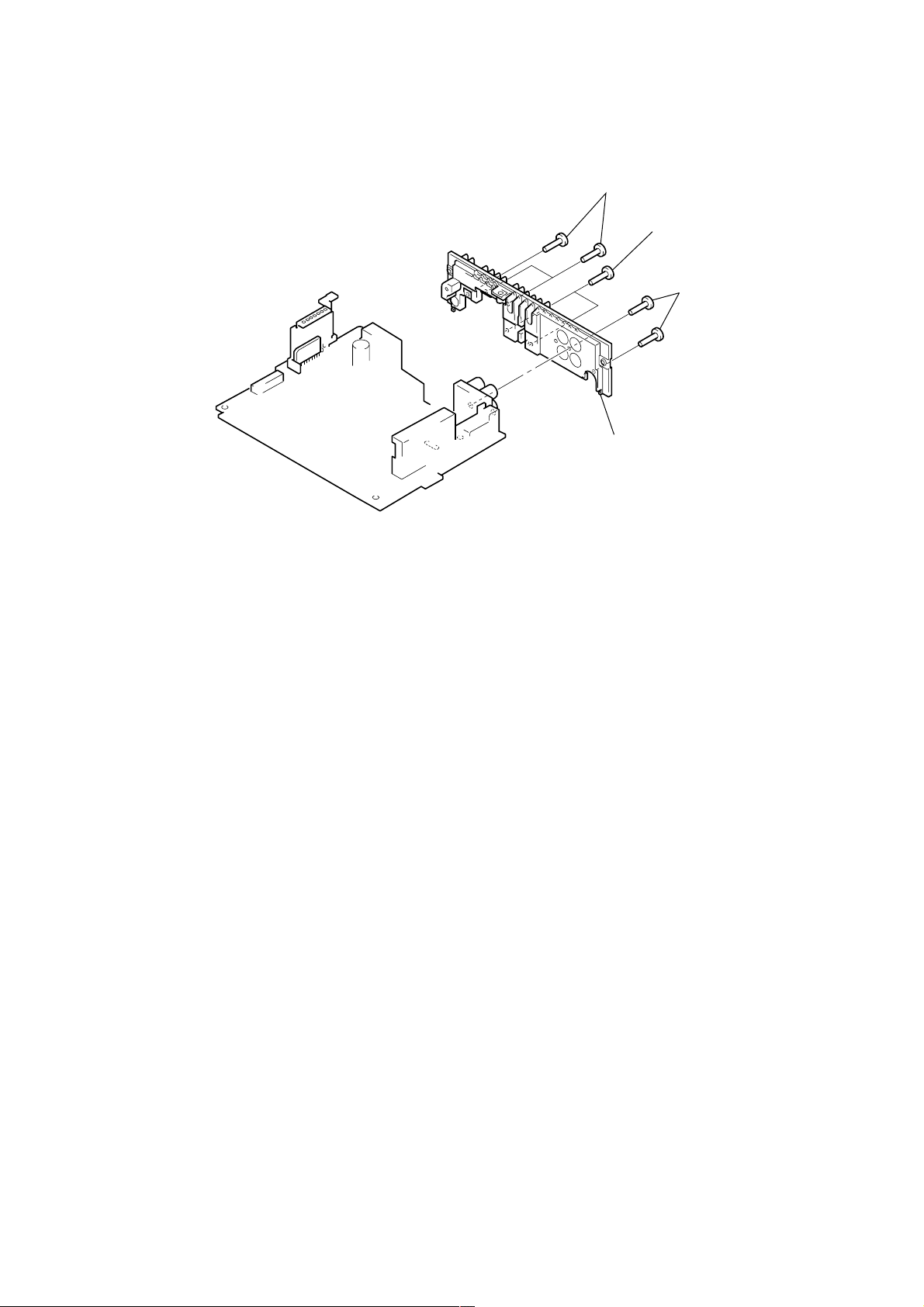

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

SUB PANEL, MECHANISM DECK (MG-25F-136)

0

mechanism deck

(MG-25F-136)

8

connector (CN351)

5

sub panel assy

3

screw

(PTT2.6 × 6)

9

screw

(P2.6 × 10)

7

flexible flat cabl

(CN301)

2

two screws

(PTT2.6 × 6)

MAIN BOARD

4

2

main board

1

two screws

(PTT2.6 × 6)

two ground point screws

6

flexible flat cable (14 core)

(CN701)

4

screw (PTT2.6 × 6)

3

rubber cap (25)

2

ground point screw

1

three screws

(PTT2.6

×

8)

5

insulated

plate

6

chassis

4

Page 5

HEAT SINK

1

three screws

(PTT2.6

3

heat sink

×

8)

2

two screws

(PTT2.6

1

×

12)

two screws

(PTT2.6

×

8)

5

Page 6

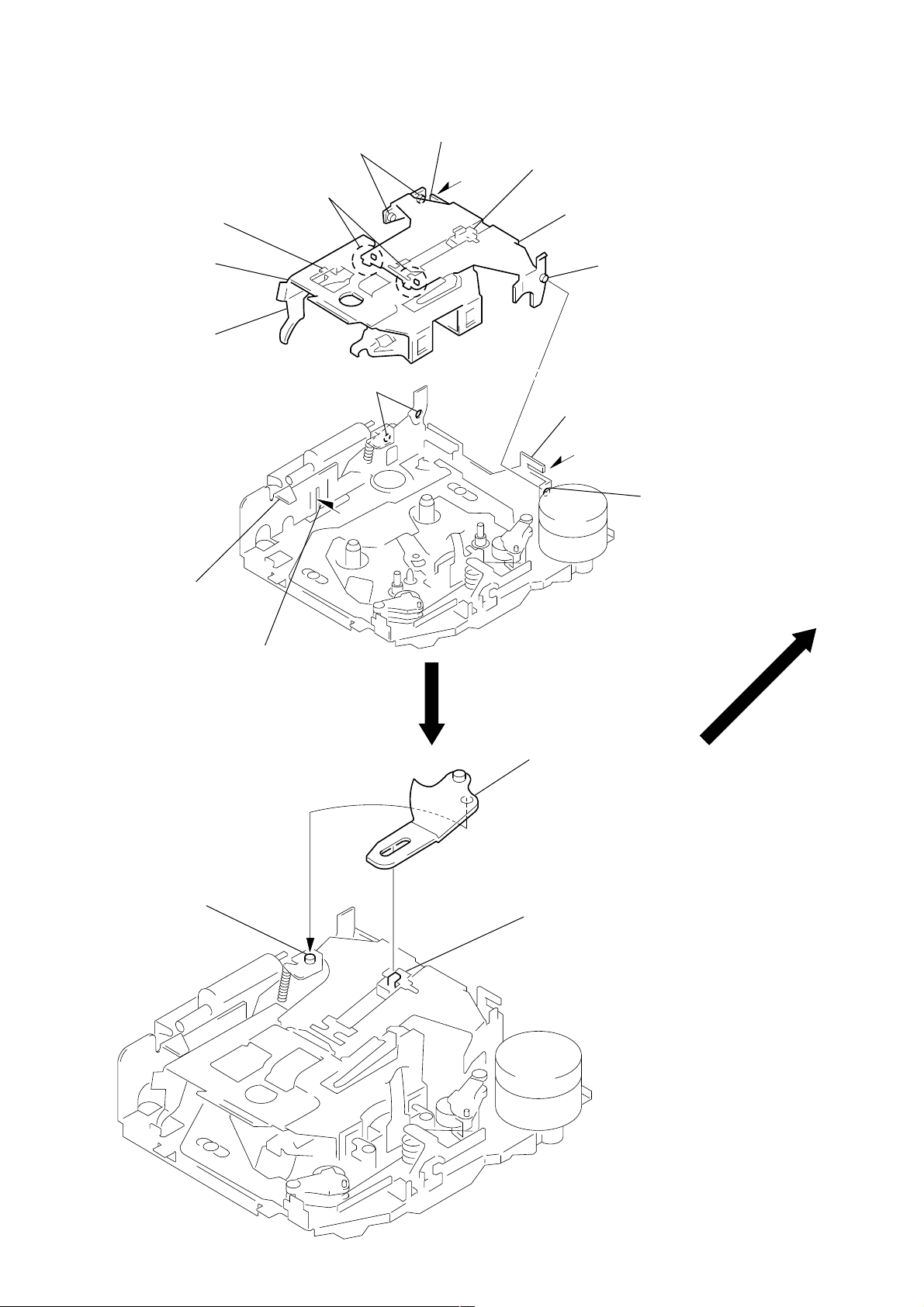

SECTION 3

w

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

5

HOUSING

4

Fit claw on B part.

3

Put the housing

under A part.

2

Install the hanger onto

two claws of the housing.

housing

Fit projection on C part.

C

part

7

Holder the hanger by bending the claw.

1

Install the catch to the hanger.

hanger

6

Fit projection on D part.

8

Hold the hanger by

bending the claw.

D

part

ARM (SUCTION)

A

part

projection

B

part

2

Move the arm (suction) in the arro

direction and fit on projection.

1

Fit the arm (suction) on the shaft.

6

Page 7

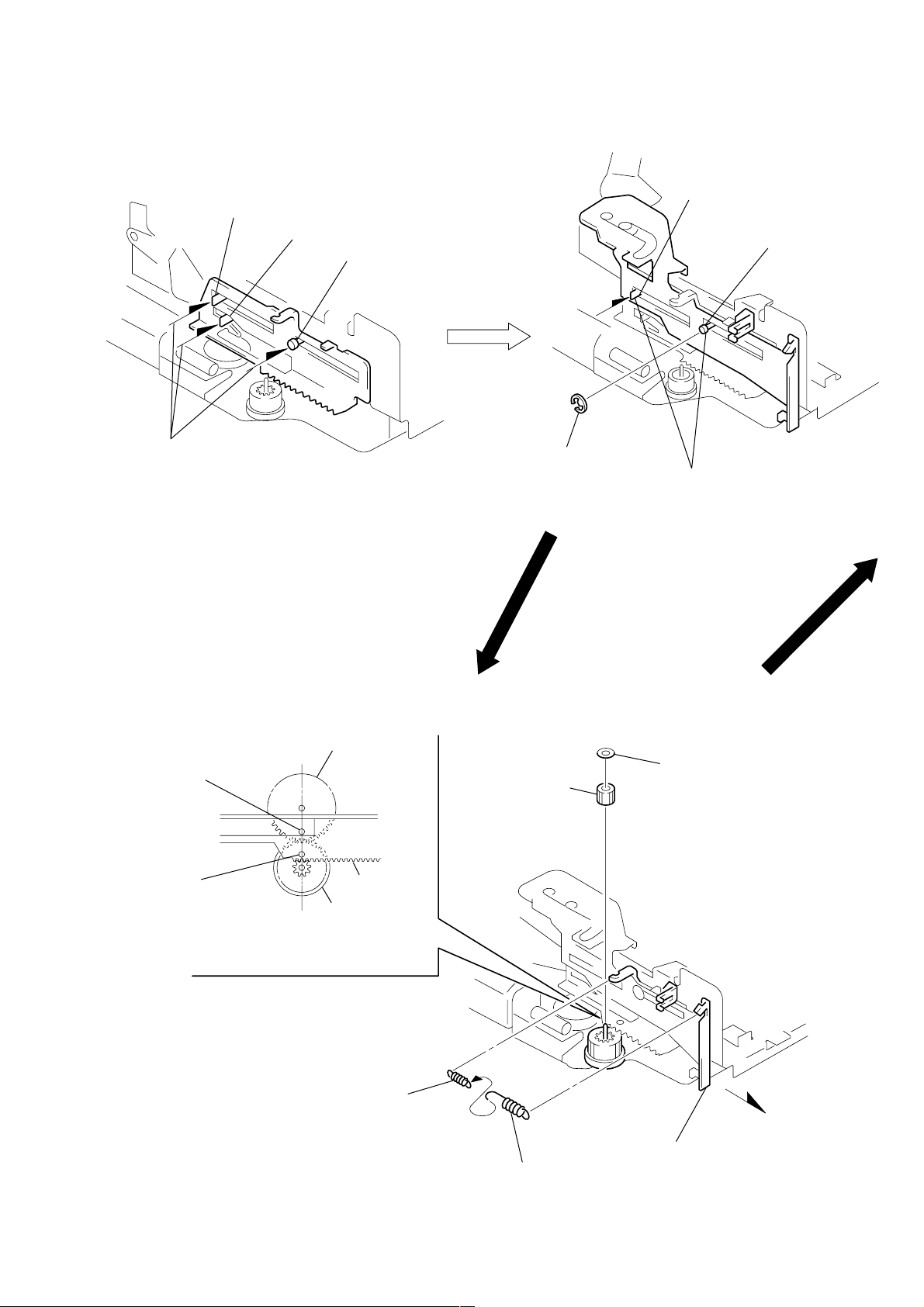

LEVER (LDG-A) / (LDG-B)

)

shaft

A

shaft

1

Fit the lever (LDG-A) on

shafts

A

– C and install it.

B

shaft

C

3

type-E stop ring 2.0

shaft

A

Fit the lever (LDG-B) on

2

shafts

install it.

A

and B and

shaft

B

GEAR (LDG-FT)

hole

hole

gear (LDG-D)

lever (LDG-A)

gear (LDG-FB)

4

Align hole in the gear (LDG-D)

with hole the lever (LDG-A).

2

tension spring (LD-2)

5

gear (LDG-FT)

1

6

polyethylene washer

2

tension spring (LD-1)

3

Move the lever (LDG-B

in the arrow direction.

7

Page 8

GUIDE (C)

s

2

guide (C)

1

three claws

MOUNTING POSITION OF CAPSTAN/REEL MOTOR (M901)

Note: Mount the motor so that the

angle between of the

motor and the hole for the

screw becomes 30

shown in this figure.

°

as

two precision screw

(P2 × 2)

capstan/reel motor

(M901)

30˚

8

Page 9

Tape Speed Adjustment

– SET UPPER VIEW –

SECTION 4

r

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

1. Clean the follo wing parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idler

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the power supply

voltage (14.4 V) unless otherwise noted.

• T orque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C (30 – 65 g•cm)

Forward

Back Tension

Reverse CQ-102RC (30 – 65 g•cm)

Reverse

Back Tension

FF, REW CQ-201B (60 – 200 g•cm)

CQ-102C (0.5 – 4.5g•cm)

CQ-102RC 0.05 – 0.44 mN•m

2.95 – 6.37 mN•m

(0.42 – 0.90 oz•inch)

0.05 – 0.44 mN•m

(0.01 – 0.06 oz•inch)

2.95 – 6.37 mN•m

(0.42 – 0.90 oz•inch)

(0.5 – 4.5g•cm)

(0.01 – 0.06 oz•inch)

5.89 – 19.61 mN•m

(0.83 – 2.78 oz•inch)

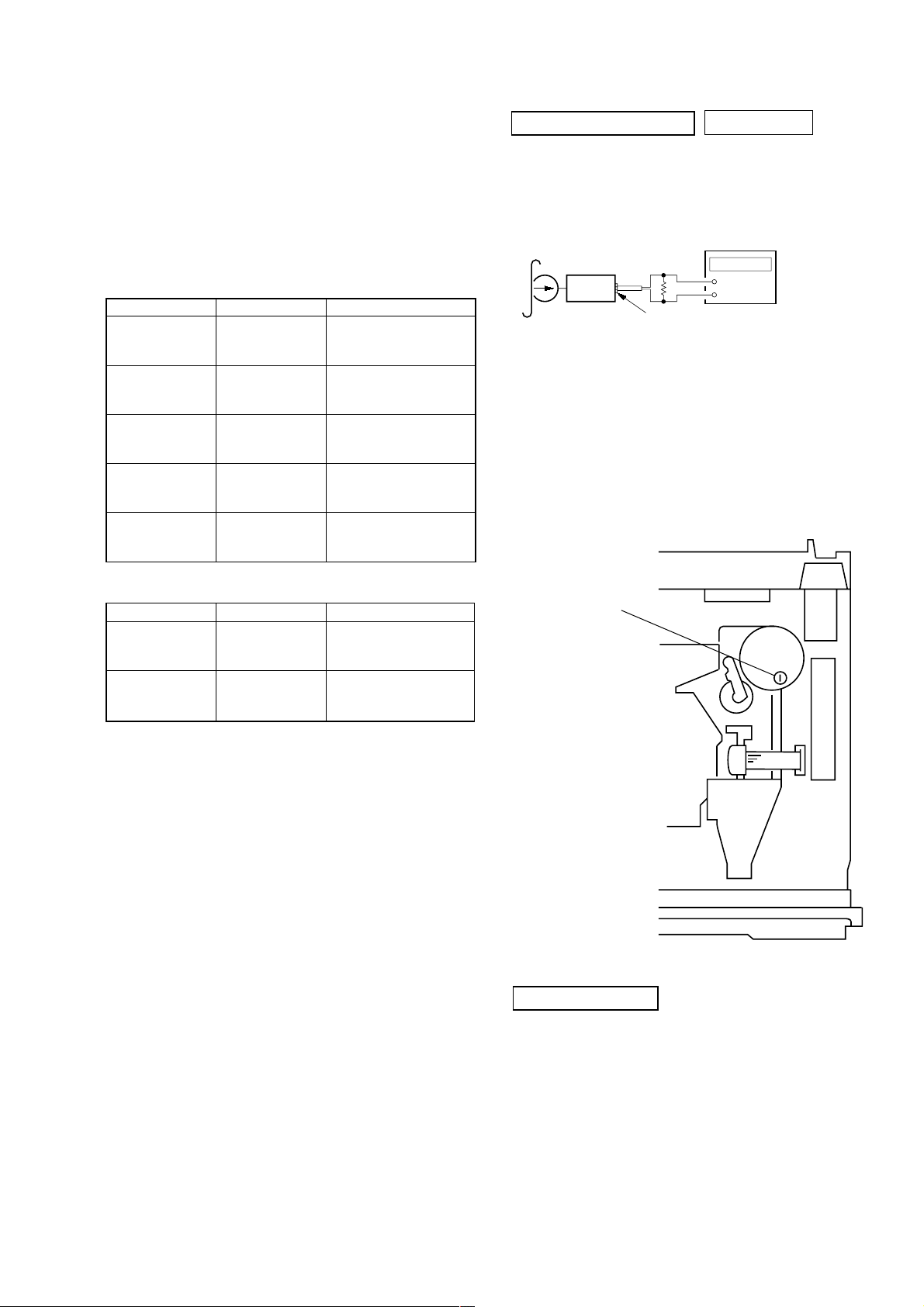

TAPE DECK SECTION

0 dB=0.775 V

Tape Speed Adjustment

Setting:

test tape

WS-48A

(3 kHz, 0 dB)

set

AUDIO OUT REAR jack (J331)

10 k

Ω

frequency counte

+

–

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust adjustment resistor for inside capstan motor so that the

reading on the frequency counter becomes in 3,015 Hz.

Specified Value: 2,955 to 3,075 Hz

Adjustment Location:

• T ape Tension Measurement

Forward CQ-403A (more than 90 g)

Reverse CQ-403R (more than 90 g)

Mode Tension Meter Meter Reading

more than 8.83 mN•m

(more than 3.18 oz)

more than 8.83 mN•m

(more than 3.18 oz)

TUNER SECTION

Tuner section adjustments are done automatically in this set.

9

Page 10

MEMO

10

Page 11

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM – TUNER/T APE/MAIN Section –

J331 (1/2)

BUS

AUDIO IN

L

10511

R-CH

VDD

S-METER

DATA

TAPE

IN2

4

BU B+

TUNER +8V

TUNER +5V

SDA

SCL

131214

CLOCK

+

MUTE

R

FM/MW/SW

HP901

(PLAYBACK)

FWD

L-CH

FWD

R-CH

REV

L-CH

REV

R-CH

J1

ANTENNA

R-CH

1

2

TAPE EQUALIZER AMP, AMS

PBF

IN2

37

R-CH

39

PBR

IN2

R-CH

FM/MW/SW TUNER UNIT

TU1

AM-ANT

FM-ANT

SDA-EEP

SIO

IC301

EQ AMP

R-CH

DRSW

19

TAPESW

18

SCL-EEP

CKO

OUT2

R-CH

FMAGC

PB

EEP VDD

FM-AGC

2

VCC

SW SHIFT

741817

SWSHIFT

INSW

17

AM-IF

R-CH

MPX

NR AMP

8AM-DET

10

19

DOLBY

DOLBY

16 20

R-CH

AMS

DET

MSSW

LINE

OUT2

MS

OUT

XR-C5500T

INPUT SELECT,

ELECTRICAL VOLUME

IC331

SE1L

1

AM

11

SE2L

4

AM-IF

12

13

DATA

CLOCK

7

14

SIO

CKO

FMAGC

MPX

SWSHIFT

AM/FM NOISE

L.P.F

DIGITAL

CONTROL

IIC BUS

SDA

20 21

INPUT

MULTIPLEXER

BLANKER

SCL

LOUDNESS

VOLUME

MUTE

PILOT

CANCELATION

PILOT DET

PLL

SOFT

MUTE

18

DEMODULATOR

STEREO ADJUST

STEREO BLEND

EXT-ATT

TONE

CONTROL

LOUDNESS

OUTPUT

SELECTOR

L.P.F.

D/A

CONVERTER

MPIN

S-METER

1514

MONO

FADER

S & H

BATT B+

OUTLF

MIXER

OUTLR

HIGH-

CUT

D622

MUTING

CONTROL SWITCH

Q622

R-CH

30

29

CONTROL SWITCH

MUTING

Q621

R-CH

R-CH

D625

D621

MUTING

Q171

MUTING

Q271

MUTING

Q181

MUTING

Q281

12

14

11

15

POWER AMP

FL-IN

FR-IN

RL-IN

RR-IN

16

AUX

IC751

22

R-CH

MUTE

FL+

FL–

FR+

FR–

RL+

RL–

RR+

RR–

STNBY

4

5

3

21

23

9

7

17

19

J331(2/2)

L

R

CN781 (1/2)

(POWER CONNECTOR)

1

FRONT L (+)

9

FRONT L (–)

4

FRONT R (+)

12

FRONT R (–)

2

REAR L (+)

10

REAR L (–)

3

REAR R (+)

11

REAR R (–)

AUDIO OUT

(LINE OUT) REAR

LOADING/TAPE

OPERATION

M901

(CAPSTAN/REEL)

05

REEL SENSOR B+

M

M

NROUT

OUT1

9

OUT2

7

LOADING/TAPE OPERATION

CAPSTAN/REEL

MOTOR DRIVE

MOTOR

DRIVE

MOTOR DRIVER

IC351

Q354

MTLON

1

VCC

Q353

IN1

IN2

BATT B+

TAPATT

LMEJ

LMLOD

90 89 91 92

REGULATOR

Q351

REGULATOR

CONTROL SWITCH

3

4

Q352

TAPON

AMSON

BATT B+

74 75 3 77

5752555453

AMSIN

E2P SIO

E2P CKO

MASTER CONTROLLER

IC501 (1/2)

CMON

POS0 – POS3

TAPE OPERATION

EJECT/FF/REW/

REV/FWD MODE DETECT

FMAGC

85 – 88

SWITCH

45

SWSHIFT

I2C SIO

I2C CKO

TAPE

DETECT

REEL SENSOR BOARD

TAKE-UP

REEL

SENSOR

84

BUFFER

4647

REL

SUPPLY

SENSOR

VOLATT

REEL

50

2

VSM

ATT

BEEP

AMPATT

AMPON

35

49

48

BATT B+

• SIGNAL PATH

: FM

: MW/SW

: TAPE PLAY

: BUS AUDIO IN

• R-ch is omitted due to same as L-ch.

1111

Page 12

XR-C5500T

6-2. BLOCK DIAGRAM – DISPLAY/KEY CONTROL/BUS CONTROL/POWER SUPPLY Section –

LIQUID CRYSTAL DISPLAY DRIVER

21

23

22

IC901

64

DI

63

CL

62

CE

60

OSC

4 – 51

S04 – S51

52 – 55

COM1 – COM4

REMOTE CONTROL

RECEIVER

IC951

OSC

C953, R957

LIQUID CRYSTAL

DISPLAY

LCD901

J561

REMOTE IN

LSW801, 901 – 907,

LSW909, 912 – 917,

S901 – 904

RE901

(VOLUME CONTROL)

ROTARY

ENCODER

RE901

D501

D553

24

RCIN1

7

RCIN0

5

KEYIN0

4

KEYIN1

81

REIN0

80

REIN1

MASTER CONTROLLER

IC501 (2/2)

LCDSO

LCDCKO

LCDCE

RST

DATA-OUT

DATA-IN

CLK

BUS ON

BUIN

SIRCS BUFFER

SONY BUS INTERFACE

RST

13

DATA IN

9

DATA OUT

8

CLK IN

11

BUS

ON IN

12

BATT

CHECK

10

Q582

IC581

RESET

SWITCH

BUS ON

SWITCH

BATTERY

SWITCH

RST

DATA

IN/OUT

CLK OUT

BUS ON

OUT

BATT

D587

2

6

4

1

3

CN581

BUS CONTROL IN

(FOR SONY BUS)

3

SIRCS

2

RESET

5

DATA

4

CLK

6

BUS ON

7

BATT

CN901

(FRONT PANEL SIDE)

BU B+

1

RESET SIGNAL

GENERATOR

IC551

KEY ACTIVE

SWITCH

Q551

9

CN701

(MAIN BODY SIDE)

S552

(NOSE DETECT)

BU B+

S551

(RESET)

7

Q601

D581

D572

D582

BATT B+

POWER AMP

(IC751) B+

29

SIRCS

6

8

11

10

9

5

AMP+B

ANT+B

TU+B (8V)

TU+B (5V)

COM8V

BU+B

BATTERY DETECT

Q581

REGULATOR

IC611

TUNER8.7

TUNER5.6

23 4

ILL B+

ACCESSORY CHECK

Q571

VCC

STB

REGULATOR

20

SYSRST

42

UNICKO

BUSON

DOORIND

TUNON

PW ON

OSCOUT

12 13

UNISO

UNISI

UNICLI

BUIN

ILLON

ACCIN

OSCIN

43

44

41

19

28

79

34

36

83

38

82

AD ON

26

KEYACK

78

DOORSW

18

NOSESW

33

RESET

XOUT

XIN

05

16 17

RST

DATA-OUT

DATA-IN

CLK

BUS ON

BUIN

LED801

(TAPE WINDOW),

LSW801

Z

LED DRIVE

Q631

BATT B+

FM/MW/SW TUNER UNIT

(TU1) B+

(AUDIO CIRCUIT B+)

TUNER +8V

TUNER +5V

COM +8V

BU B+

LSW901 – 907, 909, 912 – 917

(ILLUMINATION)

(LCD BACK LIGHT)

REGULATOR

CONTROL SWITCH

D1, 5

D551

LED901 – 904,

LED910 – 913

Q602

TH501

(POWER CONNECTOR)

D610

D611

CN781 (2/2)

6

5

16

7

BATT B+

ANT REM

AMP REM

BATT

ACC

X502

32.768kHz

X501

18.432MHz

1212

Page 13

6-3. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

• C : panel designation.

• U : B+ Line.

• Power voltage is dc 14.4V and fed with regulated dc po wer

supply from ACC and BATT cords.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

( ) : AM (MW/SW)

< > : TAPE PLA Y

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : AM (MW/SW)

E : TAPE PLAY

L : BUS AUDIO IN

: Impossible to measure

∗

1

4

/

W or less unless otherwise

• Waveforms

– MAIN Board –

1 IC501 qd (OSCIN)

54.2 ns

2 IC501 qg (XIN)

1.1 Vp-p

2.2 Vp-p

– KEY Board –

1 IC901 y; (OSC)

27

µ

s

2.7 Vp-p

30.5

µ

s

1313

Page 14

XR-C5500T

6-4. SCHEMATIC DIAGRAM – MAIN Board (1/2) – • See page 13 for waveforms. • See page 20 for IC Block Diagrams.

1414

Page 15

6-5. SCHEMATIC DIAGRAM – MAIN Board (2/2) – • See page 20 for IC Block Diagrams.

XR-C5500T

(Page

17)

1515

Page 16

XR-C5500T

6-6. PRINTED WIRING BOARD – MAIN Board –

• Semiconductor

Location

Ref. No. Location

D1 E-9

D51 E-13

D351 I-12

D352 G-13

D501 J-7

D551 F-12

D553 J-10

D571 D-9

D572 D-9

D581 E-11

D582 D-12

D585 B-13

D587 F-10

D588 E-9

D601 J-13

D610 E-10

D611 E-9

D613 D-10

D614 D-10

D621 E-6

D622 D-7

D625 D-7

D701 J-4

D702 J-5

D703 J-5

D704 J-5

D705 J-3

D706 K-5

D707 J-3

D708 J-3

D709 J-3

D710 K-4

D722 D-8

D781 D-12

65

8 7

321

(FRONT VIEW)

4

RR+ RR–

CN781

VIO

TO

GRN

WHT

GRN

VIO

GRY

BLU/WHT

BLU

RED

BLK

GRY

WHT

RED

YEL

2

1

NC

3

NC

4

RL+ RL–

5 6

1 9

2 10

3 11

4 12

5 13

6 14

7 15

8 16

FR+

FR–

1 2

FL+

FL–

3 4

GND

5

AMP REM

6

ACC ANT REM

7

8

BATT NC

9 10

VIO/BLK

GRN/BLK

WHT/BLK

GRN/BLK

VIO/BLK

GRY/BLK

YEL

GRY/BLK

WHT/BLK

BLK

BLU/WHT

BLU

IC301 H-4

IC331 E-4

IC351 I-13

IC501 H-8

IC551 K-11

IC581 D-11

IC611 F-14

IC751 B-7

Q171 C-4

Q181 C-5

Q271 C-5

Q281 D-5

Q351 H-12

Q352 H-12

Q353 H-12

Q354 G-12

Q551 I-11

Q571 D-8

Q581 E-11

Q582 G-10

Q583 E-9

Q601 J-13

Q602 J-13

Q621 E-6

Q622 E-7

Q631 K-6

(Page 17)

1616

Page 17

6-7. PRINTED WIRING BOARD – SUB Board – 6-8. SCHEMATIC DIAGRAM – SUB Board –

(Page 19)

XR-C5500T

(Page 18)

(Page 15)

(Page 16)

1717

Page 18

XR-C5500T

• Semiconductor

Location

Ref. No. Location

IC901 C-6

LED901 A-2

LED902 C-2

LED903 C-3

LED904 A-3

LED910 B-12

LED911 A-12

LED912 A-5

LED913 B-5

6-9. PRINTED WIRING BOARD – KEY Board –

• Semiconductor

Location

Ref. No. Location

D901 A-11

D902 B-10

D903 B-10

D904 B-10

D951 C-4

D952 B-6

IC951 B-8

(Page 17)

1818

Page 19

6-10. SCHEMATIC DIAGRAM – KEY Board – • See page 13 for waveform.

(Page

17)

XR-C5500T

1919

Page 20

• IC Block Diagrams

– MAIN Board –

IC301 CXA2509AQ-T4 IC351 LB1930M-TLM

VCC

1

BUFFER

NC

IN1

IN2

S-GND

2

3

4

BUFFER

5

CONTROL

CIRCUIT

PBFB2

PBRIN2

PBREF2

PBFIN2

VCT

PBGND

PBFIN1

PBREF1

PBRIN1

PBFB1

MSSW

NC

NC

LINEOUT2

MSLPF

25

NR BIAS

TAPE/AUX

TAPE EQ

FWD/RVS

VCC

+

–

F3

–

+

LINEOUT1

DIREF

24dB

NC

10

24dB

G2FB

21222326

MS

MODE

DETECT

MS ON/

OFF

20

19

18

17

16

15

14

13

12

11

MSMODE

DRSW

TAPESW

INSW

NC

NC

MSOUT

DGND

MSTC

G1FB

24

+

–

NC

AUXIN2

PBEQ2

–

31

32

33

34

35

VCT

36

37

38

39

40

F1

1

PBEQ1

TAPEIN2

PBOUT2

GND

282930

27

120µ/70µ

+

F2

–

+

120µ/70µ

345 6 7 8 9

2

VCC

PBOUT1

X1

+

X1

TAPEIN1

T2

LPF

T1

AUXIN1

IC581 BA8270F-E2 IC611 BA4908-V3

BUS ON

1

2

RST

BATT

3

4

CLK

5

VREF

6

DATA

GND

7 8

BUS ON

SWITCH

RESET

SWITCH

BATTERY

SWITCH

14

13

12

11

10

9

VCC

RST

BUS ON

CLK IN

BU IN

DATA IN

DATA OUT

REGULATOR

OVER VOLTAGE

PROTECT

–

+

–

+

MOTOR

DRIVE

CIRCUIT

–

+

IC331 TDA7402TR

NC

10

OUT1

9

8

NC

7

OUT2

P-GND

6

34

ACINLF

35

SWINR

36

SWINL

37

ACOUTR

38

ACOUTL

39

CREF

LP

HP

BASS

TREBLE

VOLUME

SOFTMUTE

LOUDNESS

MUX

40

+

IN-GAIN

+AUTO ZERO

MAIN SOURCE

SELECTOR

MD1

41

MD1G

MD2

MD2G

–

+

MAIN

42

43

PHONO

44

MAIN CH0 AUX

1 2 3 4 5 6 7 8 9 10 11

SEL

SER

ACINLR

ACINRF

ACINRR

33 32 31 30 29 28 27 26 25

LOUDNESS

IN-GAIN

MUTE

SELECTOR

FD2L–

FD2R+

FD2R–

FRONT

REAR

SW

FM

AM

AM

VOICE

BANDPASS

COMPANDER

MIXING

SELECTOR

MULTIPLEXER

FD1L+

FD1L–

ACIN

MAIN

INPUT

FD1R+

SELECTOR

SECOND

FD1R–

OUTPUT

SECOND SOURCE

FD2L+

MONO-

FADER

DIGITAL CONTROL IIC-BUS

OUTLF

MONOFADER

OUTLR

MIXER

MONO-

FADER

BEEP

AM/FM

NOISE BLANKER

OUTRF

OUTRR

MONOFADER

HIGH-CUT

S&H

25kHz

LP

DEMODULATOR

+STEREO ADJUST

+STEREO BLAND

PILOT

CANCELATION

OUTSWL

MONOFADER

SUBWOOFER

+PHASE

CONTROL

PIL DET

PLL

MONO-

FADER

OUTSWR

SUPPLY

PULSE

FORMER

QUAL

MULTIPATH

DETECTOR

D/A

CONVERTER

80kHz

LP

OUTSSL

24 23

OUTSSR

22

VDD

21

SCL

20

SDA

19

GND

18

SM

17

QUAL

16

MPOUT

15

MPIN

14

LEVEL

13

MPX

12

AMIF

2 3

1

NC

TUNER8.7 ANT SW

4

STB

TUNER5.6 SW

5 6 7 8 9 10 1211

ANT

VCC

AMP

VDD5.6V

COM8.7V

TUNER5.6V

GND

TUNER8.7V

2020

Page 21

6-11. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC501 MN101C49KTA2 (MASTER CONTROLLER)

Pin No. Pin Name I/O Description

1 VREF I Reference voltage (0V) input terminal (for A/D converter)

2 VSM I

3 FMAGC I FM AGC level detection signal input from the FM/MW/SW tuner unit (TU1) (A/D input)

4 KEYIN1 I

5 KEYIN0 I

6 DSTSEL I Destination setting terminal (fixed at “L” in this set)

7 RCIN0 I Rotary remote commander key input terminal (A/D input)

8 QUALITY I Noise level detection signal input at SEEK mode (A/D input) Not used (open)

9 — O Not used (open)

10 VREF I Reference voltage (+5V) input terminal (for A/D converter)

11 VDD — Power supply terminal (+5V) (for A/D converter)

12 OSCOUT O Main system clock output terminal (18.432 MHz)

13 OSCIN I Main system clock input terminal (18.432 MHz)

14 VSS — Ground terminal (for A/D converter)

15 XIN I Sub system clock input terminal (32.768 kHz)

16 XOUT O Sub system clock output terminal (32.768 kHz)

17 MMOD I Not used (fixed at “L”)

18 NOSESW I

19 BUSON O Bus on/off control signal output to the SONY bus interface (IC581) “L”: bus on

20 SYSRST O Reset signal output to the SONY bus interface (IC581) “L”: reset

21 LCDSO O Serial data output to the liquid crystal display driver (IC901)

22 LCDCE O Chip enable signal output to the liquid crystal display driver (IC901) “H” active

23 LCDCKO O Serial data transfer clock signal output to the liquid crystal display driver (IC901)

24 RCIN1 I Rotary remote commander shift key input terminal “L”: shift

25 RAMBU I

FM and AM signal meter voltage detection input from the FM/MW/SW tuner unit (TU1)

(A/D input)

Key input terminal (A/D input) (LSW801, LSW909, LSW912 to LSW917)

Z, D-BASS, 6, 5, 4, 3, SHUF 2, REP 1 keys input

Key input terminal (A/D input) (LSW901 to LSW907, S901 to S904)

OFF, SOURCE, SOUND, MENU, DSPL, MODE o, ENTER, SEEK/AMS – . m,

PRST + DISC +, SEEK/AMS + > M, PRST – DISC – keys input

Front panel block remove/attach detection signal input

“L”: front panel is attached, “H”: front panel is removed

Internal RAM reset detection signal input terminal

Input terminal to check that RAM data are not destroyed due to low voltage

This checking is made within 50 msec after reset Not used (fixed at “L”)

26 KEYACK I

27 — O Not used (open)

28 BUIN I

29 SIRCS I Sircs remote control signal input form the remote control receiver (IC951)

30, 31 — O Not used (open)

32 MTLIN I Auto metal detection signal input terminal “H”: auto metal Not used (fixed at “L”)

33 RESET I

34 TUNON O

35 BEEP O Beep sound drive signal output to the power amplifier (IC751)

36 PW ON O Main system power supply on/off control signal output to the BA4908 (IC611) “H”: power on

37 COLSEL I Setting terminal for the illumination color “L”: amber, “H”: green Fixed at “H” in this set

Input of acknowledge signal for the key entry Acknowledge signal is input to accept function

and eject keys in the power off status On at input of “H”

Battery detect signal input from the SONY bus interface (IC581) and battery detect circuit

“L” is input at low voltage

System reset signal input from the reset signal generator (IC551) and reset switch (S551)

“L”: reset “L” is input for several 100 msec after power on, then it changes to “H”

Tuner system power supply on/off control signal output to the BA4908 (IC611)

“H”: tuner power on

21

Page 22

Pin No. Pin Name I/O Description

38 ACC IN I Accessory detection signal input “L”: accessory on

39 TESTIN I Setting terminal for the test mode “H”: test mode, Normally: fixed at “L”

40 TELATT I Telephone muting signal input terminal At input of “H”, the signal is attenuated by –20 dB

41 UNICLI I Serial data transfer clock signal input from the SONY bus interface (IC581)

42 UNISO O Serial data output to the SONY bus interface (IC581)

43 UNISI I Serial data input from the SONY bus interface (IC581)

44 UNICKO O Serial data transfer clock signal output to the SONY bus interface (IC581)

45 I2C SIO I/O Two-way data bus with the electrical volume (IC331) and FM/MW/SW tuner unit (TU1)

46 VOLATT O Muting on/off control signal output to the electrical volume (IC331) “L”: muting on

47 I2C CKO O Clock signal output to the electrical volume (IC331) and FM/MW/SW tuner unit (TU1)

48 AMPON O

49 AMPATT O Muting on/off control signal output to the power amplifier (IC751) “L”: muting on

50 ATT O Audio line muting on/off control signal output “H”: muting on

51 TU ATT O

Standby on/off control signal output to the power amplifier (IC751)

“L”: standby mode, “H”: amplifier on

Muting on/off control signal output of the FM and AM tuner signal “H”: muting on

Not used (open)

52 AMSON O

53 NROUT O

54 MTLON I/O

55 TAPATT O

56 DOLON I/O

57 AMSIN I

58 4VPRE I 4VPREOUT model setting terminal “L”: 4VPREOUT model Fixed at “H” in this set

59 to 73 — O Not used (open)

74 E2P SIO I/O Two-way data bus with the FM/MW/SW tuner unit (TU1)

75 E2P CKO O Clock signal output to the FM/MW/SW tuner unit (TU1)

76 — O Not used (open)

77 SWSHIFT O AM filter control signal output to the FM/MW/SW tuner unit (TU1) “L”: SW mode

78 DOORSW I Front panel open/close detection signal input “L” is input when the front panel is closed

79 DOORIND O

80 REIN1 I

81 REIN0 I

82 AD ON O

Tape auto music sensor control signal output to the CXA2509AQ (IC301)

“L” is output to lower the gain for audio level at FF/REW mode

Forward/reverse direction control signal output to the CXA2509AQ (IC301)

“L”: forward direction, “H”: reverse direction

METAL control in/out terminal

At initial mode: auto/manual mode selection input of METAL function (manual at “L” input)

At manual mode: METAL on/off control signal output terminal (METAL on at “H” output)

At auto mode: input at MTLIN (pin es)

Tape muting on/off control signal output to the CXA2509AQ (IC301) “H”: muting on

Active at ATA, FF/REW mode

Dolby control in/out terminal

At initial mode: valid/invalid selection input of dolby function (valid at “L” input)

At normal mode: dolby on/off control signal output terminal (dolby on at “H” output)

Not used this function (fixed at “H”)

Whether a music is present or not from CXA2509AQ (IC301) is detected at auto music sensor

“L”: music is present, “H”: music is not present

LED drive signal output of the tape window and Z indicator (LED801, LSW801)

“H”: LED on “H” is output to turn on LED when front panel is opened

Dial pulse input of the rotary encoder (RE901) (for volume control)

A/D converter power control signal output

When the KEYACK (pin wh) that controls reference voltage power for key A/D conversion input

is active, “L” is output from this terminal to enable the input

83 ILLON O

22

Power on/off control signal output of the illumination LED and liquid crystal display driver

(IC901) “H”: power on

Page 23

Pin No. Pin Name I/O Description

84 REL I

85 POS3 I

86 POS2 I

87 POS0 I

88 POS1 I

89 LMLOD O

Rotation detection signal input from supply reel sensor and take-up reel sensor on the deck

mechanism

Tape position (EJECT/FF/REW/

REV/FWD mode) detection signal

input from the tape operation switch

on the deck mechanism

Motor drive signal output to the loading/tape operation motor driver (IC351) “H” active

(For the loading direction and forward side operation) *1

POS0: “L”: EJECT mode, “H”: others mode

POS1: “L”: FF and FWD mode, “H”: others mode

POS2: “L”: REW mode, “H”: others mode

POS3: “L”: REV and EJECT mode, “H”: others mode

90 LMEJ O

91 TAPON O Tape system power supply on/off control signal output “H”: tape on

92 CMON O Capstan/reel motor (M901) drive signal output “H”: motor on

93, 94 — O Not used (open)

95 DAVSS — Ground terminal (for D/A converter) Not used (open)

96 NS MASK O Discharge control signal output terminal “H”: discharge Not used (open)

97 to 99 — O Not used (open)

100 DAVDD — Power supply terminal (+5V) (for D/A converter) Not used (open)

*1 Loading/tape operation motor control

Mode

Terminal

LMLOD (pin il)

LMEJ (pin o;)

Motor drive signal output to the loading/tape operation motor driver (IC351) “H” active

(For the eject direction and reverse side operation) *1

STOP

“L”“H”“L”“H”

“L”“L”“H”“H”

LOADING/

FORWARD

EJECT/

REVERSE

BRAKE

23

Page 24

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) CHASSIS SECTION

16

10

not supplied

11

12

27

7

25

#2

#1

#2

#2

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

#5

20

MG-25F-136

22

#2

F781

19

21

TU1

#4

16

1

8

9

6

5

4

#10

14

13

3

15

18

#3

#3

#3

#9

17

#3

#3

#3

23

#1

24

Front panel section

Ref. No. Part No. Description Remark

* 1 A-3326-181-A MAIN BOARD, COMPLETE

* 2 3-040-994-01 CHASSIS

* 3 3-045-878-01 PLATE (TU), GROUND

4 X-3377-621-1 LOCK ASSY

5 3-040-990-01 BUTTON (EJECT) (Z)

* 6 1-676-603-11 SUB BOARD

7 3-027-437-11 DOOR, CASSETTE

8 3-935-003-01 SPRING, TORSION

* 9 3-045-877-01 CUSHION (TU)

10 X-3376-699-1 GEAR ASSY

11 3-030-909-01 DAMPER, OIL

12 3-713-786-51 SCREW +P 2X3

* 13 3-045-828-01 INSULATED PLATE

* 14 3-040-996-11 HEAT SINK (2P)

15 3-012-859-01 CAP (25), RUBBER

#2

26

2

Ref. No. Part No. Description Remark

16 3-915-923-01 SCREW, GROUND POINT

17 1-777-184-11 CORD (WITH CONNECTOR) (POWER)

* 18 3-046-991-01 SPACER (COVER R)

* 19 3-046-990-01 SPACER (COVER L)

* 20 3-040-995-01 COVER

* 21 3-040-998-01 BLACKET (IC)

* 22 3-041-262-01 HEAT SINK (REG/XR)

23 1-792-195-11 CABLE, FLEXIBLE FLAT (14 CORE)

24 X-3378-397-1 PANEL ASSY, SUB

25 3-224-530-01 SHEET (L)

26 3-224-529-01 SHEET (R)

27 3-224-528-01 CUSHION

F781 1-532-877-11 FUSE (BLADE TYPE) (AUTO FUSE) (10A)

TU1 A-3220-812-A FM/MW/SW TUNER UNIT (TUX-020)

24

Page 25

(2) FRONT PANEL SECTION

not supplied

(KEY board)

#6

65

66

60

LCD901

61

62

63

64

56

#6

59

58

57

52

51

Ref. No. Part No. Description Remark

51 3-040-980-01 BUTTON (SOURCE)

52 3-040-981-11 KNOB (VOL)

53 3-041-005-11 BUTTON (D) (D-BASS)

54 3-221-784-01 BUTTON (OPEN)

55 3-037-267-01 SPRING (OPEN)

56 3-040-987-01 BUTTON (OFF)

57 3-040-988-01 BUTTON (1-6) (1. 2. 3. 4. 5. 6)

58 3-040-985-01 BUTTON (DIR/ENTER) (MODE o. ENTER)

59 3-040-986-01 BUTTON (MENU/SOUND)

67

55

54

53

Ref. No. Part No. Description Remark

* 60 3-040-997-01 PLATE (LCD), GROUND

* 61 3-041-371-11 SHEET (REFLECTOR)

* 62 3-040-993-01 PLATE (LCD), LIGHT GUIDE

63 1-694-660-11 CONDUCTIVE BOARD, CONNECTION

* 64 3-040-992-01 HOLDER (LCD)

65 X-3378-398-1 PANEL ASSY, FRONT BACK

66 3-045-596-01 CUSHION (OFF)

67 X-3378-581-1 PANEL SUB ASSY

LCD901 1-803-907-11 DISPLAY PANEL, LIQUID CRYSTAL

25

Page 26

(3) MECHANISM DECK SECTION

(MG-25F-136)

153

154

#7

155

158

152

159

157

156

A

A

160

161

163

HP901

162

M901

164

not supplied

168

151

Ref. No. Part No. Description Remark

151 A-3291-667-A CLUTCH (FR) ASSY

* 152 3-019-130-01 LEVER (LDG-A)

* 153 3-019-131-01 LEVER (LDG-B)

154 3-020-539-01 SPRING (LD-1), TENSION

155 3-020-540-01 SPRING (LD-2), TENSION

156 3-020-542-01 GEAR (LOADING FT)

157 3-341-753-11 WASHER, POLYETHYLENE

158 3-020-533-01 HOUSING

* 159 3-020-532-01 ARM (SUCTION)

160 3-020-534-01 HANGER

#8

168

166

167

165

Ref. No. Part No. Description Remark

161 3-933-346-01 CATCHER

162 3-933-344-01 GUIDE (C)

163 3-014-798-01 SCREW (HEAD), SPECIAL

164 3-364-151-01 WASHER

165 A-3220-610-A MECHANISM DECK ASSY

166 3-017-302-01 BELT (25)

167 3-026-636-01 FLYWHEEL (F)

168 3-701-437-21 WASHER

HP901 1-500-157-21 HEAD, MAGNETIC (PLAYBACK)

M901 A-3291-665-A MOTOR ASSY, MAIN (CAPSTAN/REEL)

26

Page 27

SECTION 8

ELECTRICAL PARTS LIST

KEY

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

KEY BOARD

**********

1-694-660-11 CONDUCTIVE BOARD, CONNECTION

* 3-040-992-01 HOLDER (LCD)

* 3-040-993-01 PLATE (LCD) , LIGHT GUIDE

* 3-040-997-01 PLATE (LCD) , GROUND

* 3-041-371-11 SHEET (REFLECTOR)

< CAPACITOR >

C951 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C952 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C953 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C954 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C955 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

LED913 8-719-078-19 LED LWA673-R1S2*1 (LCD BACK LIGHT)

LSW901 1-771-609-11 SWITCH, TACT (WITH LED) (OFF)

LSW902 1-762-619-21 SWITCH, KEY BOARD (WITH LED) (SOURCE)

LSW903 1-762-619-21 SWITCH, KEY BOARD (WITH LED) (SOUND)

LSW904 1-762-619-21 SWITCH, KEY BOARD (WITH LED) (MENU)

LSW905 1-762-619-21 SWITCH, KEY BOARD (WITH LED) (DSPL)

LSW906 1-762-619-21 SWITCH, KEY BOARD (WITH LED)

LSW907 1-762-619-21 SWITCH, KEY BOARD (WITH LED) (ENTER)

LSW909 1-762-737-11 SWITCH, KEYBOARD (LED) (D-BASS)

LSW912 1-771-609-11 SWITCH, TACT (WITH LED) (6)

LSW913 1-771-609-11 SWITCH, TACT (WITH LED) (5)

When indicating parts by reference

number, please include the board.

< SWITCH >

(MODE o)

C956 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

< CONNECTOR >

CN901 1-794-065-22 PLUG, CONNECTOR 14P

< DIODE >

D901 8-719-158-49 DIODE RD12SB2

D902 8-719-056-82 DIODE UDZ-TE-17-6.2B

D903 8-719-056-82 DIODE UDZ-TE-17-6.2B

D904 8-719-056-82 DIODE UDZ-TE-17-6.2B

D951 8-719-976-99 DIODE DTZ5.1B

D952 8-719-976-99 DIODE DTZ5.1B

< IC >

IC901 8-759-366-34 IC LC75824E

IC951 8-749-012-25 IC RS-170-TU

< LIQUID CRYSTAL DISPLAY >

LCD901 1-803-907-11 DISPLAY PANEL, LIQUID CRYSTAL

< LED >

LED901 8-719-038-07 LED CL-190PG-CD-T (ILLUMINATION)

LED902 8-719-038-07 LED CL-190PG-CD-T (ILLUMINATION)

LED903 8-719-038-07 LED CL-190PG-CD-T (ILLUMINATION)

LED904 8-719-038-07 LED CL-190PG-CD-T (ILLUMINATION)

LED910 8-719-078-19 LED LWA673-R1S2*1 (LCD BACK LIGHT)

LED911 8-719-078-19 LED LWA673-R1S2*1 (LCD BACK LIGHT)

LED912 8-719-078-19 LED LWA673-R1S2*1 (LCD BACK LIGHT)

LSW914 1-771-609-11 SWITCH, TACT (WITH LED) (4)

LSW915 1-771-609-11 SWITCH, TACT (WITH LED) (3)

LSW916 1-771-609-11 SWITCH, TACT (WITH LED) (SHUF 2)

LSW917 1-771-609-11 SWITCH, TACT (WITH LED) (REP 1)

< RESISTOR >

R901 1-216-647-11 METAL CHIP 680 0.5% 1/10W

R902 1-216-647-11 METAL CHIP 680 0.5% 1/10W

R903 1-216-647-11 METAL CHIP 680 0.5% 1/10W

R904 1-216-651-11 METAL CHIP 1K 0.5% 1/10W

R905 1-216-655-11 METAL CHIP 1.5K 0.5% 1/10W

R906 1-216-655-11 METAL CHIP 1.5K 0.5% 1/10W

R907 1-216-659-11 METAL CHIP 2.2K 0.5% 1/10W

R908 1-216-663-11 METAL CHIP 3.3K 0.5% 1/10W

R909 1-216-667-11 METAL CHIP 4.7K 0.5% 1/10W

R910 1-216-671-11 METAL CHIP 6.8K 0.5% 1/10W

R911 1-208-806-11 RES-CHIP 10K 2% 1/10W

R912 1-216-647-11 METAL CHIP 680 0.5% 1/10W

R913 1-216-647-11 METAL CHIP 680 0.5% 1/10W

R914 1-216-647-11 METAL CHIP 680 0.5% 1/10W

R915 1-216-651-11 METAL CHIP 1K 0.5% 1/10W

R916 1-216-655-11 METAL CHIP 1.5K 0.5% 1/10W

R917 1-216-655-11 METAL CHIP 1.5K 0.5% 1/10W

R918 1-216-659-11 METAL CHIP 2.2K 0.5% 1/10W

R919 1-216-663-11 METAL CHIP 3.3K 0.5% 1/10W

R920 1-216-667-11 METAL CHIP 4.7K 0.5% 1/10W

R921 1-216-807-11 METAL CHIP 68 5% 1/16W

R923 1-216-809-11 METAL CHIP 100 5% 1/16W

R925 1-216-021-00 METAL CHIP 68 5% 1/10W

R927 1-216-029-00 METAL CHIP 150 5% 1/10W

27

Page 28

KEY MAIN

Ref. No. Part No. Description Remark

R929 1-216-029-00 METAL CHIP 150 5% 1/10W

R931 1-216-813-11 METAL CHIP 220 5% 1/16W

R932 1-216-813-11 METAL CHIP 220 5% 1/16W

R933 1-216-808-11 METAL CHIP 82 5% 1/16W

R935 1-216-809-11 METAL CHIP 100 5% 1/16W

R938 1-216-809-11 METAL CHIP 100 5% 1/16W

R951 1-216-819-11 METAL CHIP 680 5% 1/16W

R952 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R953 1-216-857-11 METAL CHIP 1M 5% 1/16W

R954 1-216-049-11 RES-CHIP 1K 5% 1/10W

R955 1-216-049-11 RES-CHIP 1K 5% 1/10W

R956 1-216-821-11 METAL CHIP 1K 5% 1/16W

R957 1-216-851-11 METAL CHIP 330K 5% 1/16W

R958 1-216-033-00 METAL CHIP 220 5% 1/10W

R970 1-216-815-11 METAL CHIP 330 5% 1/16W

R971 1-216-815-11 METAL CHIP 330 5% 1/16W

R972 1-216-864-11 METAL CHIP 0 5% 1/16W

R975 1-216-815-11 METAL CHIP 330 5% 1/16W

R976 1-216-815-11 METAL CHIP 330 5% 1/16W

R981 1-216-864-11 METAL CHIP 0 5% 1/16W

R999 1-216-864-11 METAL CHIP 0 5% 1/16W

< ROTARY ENCODER >

RE901 1-475-014-12 ENCODER, ROTARY (VOLUME CONTROL)

Ref. No. Part No. Description Remark

C102 1-163-263-11 CERAMIC CHIP 330PF 5% 50V

C103 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C104 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C105 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C106 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C109 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C110 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C111 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C112 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C141 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C142 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C171 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C172 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C174 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C181 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C182 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C183 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C184 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C191 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C201 1-163-263-11 CERAMIC CHIP 330PF 5% 50V

C202 1-163-263-11 CERAMIC CHIP 330PF 5% 50V

C203 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C204 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C205 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C206 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

< SWITCH >

S901 1-771-884-11 SWITCH, TACTILE (SEEK/AMS – . m)

S902 1-771-884-11 SWITCH, TACTILE (DISC +, PRST +)

S903 1-771-884-11 SWITCH, TACTILE (SEEK/AMS + > M)

S904 1-771-884-11 SWITCH, TACTILE (DISC –, PRST –)

**************************************************************

* A-3326-181-A MAIN BOARD, COMPLETE

*********************

* 3-040-996-11 HEAT SINK (2P)

* 3-040-998-01 BRACKET (IC)

* 3-041-262-01 HEAT SINK (REG/XR)

7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

7-685-793-09 SCREW +PTT 2.6X8 (S)

7-685-795-09 SCREW +PTT 2.6X12 (S)

< CAPACITOR >

C1 1-163-233-11 CERAMIC CHIP 18PF 5% 50V

C2 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C3 1-104-664-11 ELECT 47uF 20% 16V

C5 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C6 1-104-664-11 ELECT 47uF 20% 16V

C8 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C11 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C13 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C21 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C22 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C23 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C41 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C44 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C52 1-124-234-00 ELECT 22uF 20% 16V

C101 1-163-263-11 CERAMIC CHIP 330PF 5% 50V

C209 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C210 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C211 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C212 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C241 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C242 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C271 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C272 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C274 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C281 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C282 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C283 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C284 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C301 1-124-234-00 ELECT 22uF 20% 16V

C302 1-131-353-00 TANTALUM 10uF 10% 35V

C303 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C304 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C305 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C306 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C307 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C331 1-163-263-11 CERAMIC CHIP 330PF 5% 50V

C332 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C333 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C335 1-124-233-11 ELECT 10uF 20% 16V

C336 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C337 1-124-584-00 ELECT 100uF 20% 10V

C340 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C341 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C351 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C352 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C353 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C354 1-124-233-11 ELECT 10uF 20% 16V

C355 1-124-234-00 ELECT 22uF 20% 16V

28

Page 29

MAIN

Ref. No. Part No. Description Remark

C356 1-126-934-11 ELECT 220uF 20% 16V

C357 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C358 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C501 1-124-589-11 ELECT 47uF 20% 16V

C502 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C503 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C504 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C505 1-163-234-11 CERAMIC CHIP 20PF 5% 50V

C506 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C508 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C509 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C511 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C551 1-125-710-11 DOUBLE LAYER 0.1F 5.5V

C552 1-104-665-11 ELECT 100uF 20% 10V

C553 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C556 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C571 1-126-163-11 ELECT 4.7uF 20% 50V

C581 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C582 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C584 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C601 1-164-346-11 CERAMIC CHIP 1uF 16V

C602 1-164-346-11 CERAMIC CHIP 1uF 16V

C611 1-124-233-11 ELECT 10uF 20% 16V

C612 1-124-233-11 ELECT 10uF 20% 16V

C614 1-124-233-11 ELECT 10uF 20% 16V

C615 1-124-233-11 ELECT 10uF 20% 16V

C616 1-124-233-11 ELECT 10uF 20% 16V

C617 1-124-233-11 ELECT 10uF 20% 16V

C618 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C621 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C622 1-124-589-11 ELECT 47uF 20% 16V

C623 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C702 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C703 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C752 1-107-682-11 CERAMIC CHIP 1uF 10% 16V

C753 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C755 1-124-233-11 ELECT 10uF 20% 16V

C756 1-164-506-11 CERAMIC CHIP 4.7uF 16V

C758 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C781 1-107-885-31 ELECT 3300uF 20% 16V

C782 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C783 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C784 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C785 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

Ref. No. Part No. Description Remark

D551 8-719-073-01 DIODE MA111-(K8).S0

D553 8-719-073-01 DIODE MA111-(K8).S0

D571 8-719-057-80 DIODE MA8180-M-TX

D572 8-719-420-14 DIODE MA8082-M

D581 8-719-057-80 DIODE MA8180-M-TX

D582 8-719-017-62 DIODE MA8068-L-TX

D585 8-719-072-70 DIODE MA2ZD14001S0

D587 8-719-911-19 DIODE 1SS119-25

D588 8-719-911-19 DIODE 1SS119-25

D601 8-719-423-23 DIODE MA8110-M

D610 8-719-970-02 DIODE 1SR139-400

D611 8-719-970-02 DIODE 1SR139-400

D613 8-719-970-02 DIODE 1SR139-400

D614 8-719-970-02 DIODE 1SR139-400

D621 8-719-422-12 DIODE MA8039

D622 8-719-073-01 DIODE MA111-(K8).S0

D625 8-719-422-49 DIODE MA8056-L

D701 8-719-035-74 DIODE MA4062-M (TA)

D702 8-719-035-74 DIODE MA4062-M (TA)

D703 8-719-977-12 DIODE DTZ6.8B

D704 8-719-977-12 DIODE DTZ6.8B

D705 8-719-056-82 DIODE UDZ-TE-17-6.2B

D706 8-719-423-23 DIODE MA8110-M

D707 8-719-056-82 DIODE UDZ-TE-17-6.2B

D708 8-719-056-82 DIODE UDZ-TE-17-6.2B

D709 8-719-056-82 DIODE UDZ-TE-17-6.2B

D710 8-719-056-82 DIODE UDZ-TE-17-6.2B

D722 8-719-079-42 DIODE 1ZB22 (TPA3)

D781 8-719-049-38 DIODE 1N5404TU

< IC >

IC301 8-752-079-78 IC CXA2509AQ-T4

IC331 8-759-653-27 IC TDA7402TR

IC351 8-759-527-33 IC LB1930M-TLM

IC501 8-759-688-36 IC MN101C49KTA2

IC551 8-759-682-69 IC XC61CN4302MR

IC581 8-759-449-89 IC BA8270F-E2

IC611 8-759-661-47 IC BA4908-V3

IC751 8-759-690-99 IC TA8268HS

< JACK >

J1 1-764-808-21 JACK (ANT) (FM/MW/SW ANTENNA)

J331 1-774-699-12 JACK, PIN 4P(BUS AUDIO IN,

AUDIO OUT (LINE OUT) REAR)

J561 1-566-822-41 JACK (REMOTE IN)

< CONNECTOR >

CN301 1-785-694-11 CONNECTOR, FFC/FPC 7P

* CN351 1-506-995-11 PIN, CONNECTOR (PC BOARD) 13P

CN581 1-580-907-31 PLUG, CONNECTOR (BUS CONTROL IN)

CN701 1-784-456-11 CONNECTOR, FFC/FPC 14P

CN781 1-774-701-11 PIN, CONNECTOR 16P

< DIODE >

D1 8-719-420-51 DIODE MA729

D51 8-719-420-51 DIODE MA729

D351 8-719-977-22 DIODE DTZ9.1

D352 8-719-970-02 DIODE 1SR139-400

D501 8-719-820-05 DIODE 1SS181

< SHORT >

JC51 1-216-295-11 SHORT 0

JC171 1-216-295-11 SHORT 0

JC181 1-216-295-11 SHORT 0

JC191 1-216-295-11 SHORT 0

JC192 1-216-296-00 SHORT 0

JC193 1-216-296-00 SHORT 0

JC194 1-216-295-11 SHORT 0

JC195 1-216-296-00 SHORT 0

JC271 1-216-295-11 SHORT 0

JC281 1-216-295-11 SHORT 0

JC282 1-216-295-11 SHORT 0

29

Page 30

MAIN

Ref. No. Part No. Description Remark

JC283 1-216-296-00 SHORT 0

JC301 1-216-295-11 SHORT 0

JC302 1-216-295-11 SHORT 0

JC303 1-216-295-11 SHORT 0

JC304 1-216-295-11 SHORT 0

JC351 1-216-295-11 SHORT 0

JC502 1-216-295-11 SHORT 0

JC503 1-216-295-11 SHORT 0

JC504 1-216-295-11 SHORT 0

JC507 1-216-295-11 SHORT 0

JC582 1-216-295-11 SHORT 0

JC583 1-216-296-00 SHORT 0

< COIL >

L51 1-410-750-41 INDUCTOR 0.47uH

L501 1-410-750-41 INDUCTOR 0.47uH

L781 1-419-476-11 COIL, CHOKE 250uH

< TRANSISTOR >

Q171 8-729-920-21 TRANSISTOR DTC314TKH04

Q181 8-729-920-21 TRANSISTOR DTC314TKH04

Q271 8-729-920-21 TRANSISTOR DTC314TKH04

Q281 8-729-920-21 TRANSISTOR DTC314TKH04

Q351 8-729-015-11 TRANSISTOR 2SD1802FAST-TL

Q352 8-729-020-67 TRANSISTOR XN1A312-TX

Q353 8-729-900-53 TRANSISTOR DTC114EK

Q354 8-729-106-60 TRANSISTOR 2SB1115A-YQ

Q551 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q571 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q581 8-729-900-53 TRANSISTOR DTC114EK

Q582 8-729-027-38 TRANSISTOR DTA144EKA-T146

Q583 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q601 8-729-423-99 TRANSISTOR 2SD2137-OP

Q602 8-729-020-67 TRANSISTOR XN1A312-TX

Q621 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q622 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q631 8-729-020-67 TRANSISTOR XN1A312-TX

< RESISTOR >

R1 1-216-025-11 RES-CHIP 100 5% 1/10W

R2 1-216-025-11 RES-CHIP 100 5% 1/10W

R11 1-216-295-11 SHORT 0

R12 1-216-089-11 RES-CHIP 47K 5% 1/10W

R21 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R22 1-216-085-00 METAL CHIP 33K 5% 1/10W

R101 1-216-041-00 METAL CHIP 470 5% 1/10W

R102 1-216-109-00 METAL CHIP 330K 5% 1/10W

R103 1-216-077-00 RES-CHIP 15K 5% 1/10W

R104 1-216-079-00 METAL CHIP 18K 5% 1/10W

R141 1-216-073-00 METAL CHIP 10K 5% 1/10W

R142 1-216-025-11 RES-CHIP 100 5% 1/10W

R171 1-216-025-11 RES-CHIP 100 5% 1/10W

R172 1-216-081-00 METAL CHIP 22K 5% 1/10W

R173 1-216-025-11 RES-CHIP 100 5% 1/10W

R175 1-216-085-00 METAL CHIP 33K 5% 1/10W

R181 1-216-025-11 RES-CHIP 100 5% 1/10W

R182 1-216-081-00 METAL CHIP 22K 5% 1/10W

R183 1-216-025-11 RES-CHIP 100 5% 1/10W

Ref. No. Part No. Description Remark

R185 1-216-085-00 METAL CHIP 33K 5% 1/10W

R191 1-216-089-11 RES-CHIP 47K 5% 1/10W

R192 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R201 1-216-041-00 METAL CHIP 470 5% 1/10W

R202 1-216-109-00 METAL CHIP 330K 5% 1/10W

R203 1-216-077-00 RES-CHIP 15K 5% 1/10W

R204 1-216-079-00 METAL CHIP 18K 5% 1/10W

R241 1-216-073-00 METAL CHIP 10K 5% 1/10W

R242 1-216-025-11 RES-CHIP 100 5% 1/10W

R271 1-216-025-11 RES-CHIP 100 5% 1/10W

R272 1-216-081-00 METAL CHIP 22K 5% 1/10W

R273 1-216-025-11 RES-CHIP 100 5% 1/10W

R275 1-216-085-00 METAL CHIP 33K 5% 1/10W

R281 1-216-025-11 RES-CHIP 100 5% 1/10W

R282 1-216-081-00 METAL CHIP 22K 5% 1/10W

R283 1-216-025-11 RES-CHIP 100 5% 1/10W

R285 1-216-085-00 METAL CHIP 33K 5% 1/10W

R301 1-208-812-11 RES-CHIP 18K 2% 1/10W

R302 1-216-097-11 RES-CHIP 100K 5% 1/10W

R303 1-216-065-00 RES-CHIP 4.7K 5% 1/10W

R304 1-216-077-00 RES-CHIP 15K 5% 1/10W

R305 1-216-001-00 METAL CHIP 10 5% 1/10W

R306 1-216-105-00 RES-CHIP 220K 5% 1/10W

R331 1-216-001-00 METAL CHIP 10 5% 1/10W

R332 1-216-089-11 RES-CHIP 47K 5% 1/10W

R333 1-216-025-11 RES-CHIP 100 5% 1/10W

R334 1-216-025-11 RES-CHIP 100 5% 1/10W

R351 1-216-049-11 RES-CHIP 1K 5% 1/10W

R352 1-249-383-11 CARBON 1.5 5% 1/6W

R353 1-216-065-00 RES-CHIP 4.7K 5% 1/10W

R354 1-216-073-00 METAL CHIP 10K 5% 1/10W

R501 1-216-105-00 RES-CHIP 220K 5% 1/10W

R502 1-216-097-11 RES-CHIP 100K 5% 1/10W

R503 1-216-081-00 METAL CHIP 22K 5% 1/10W

R507 1-216-065-00 RES-CHIP 4.7K 5% 1/10W

R508 1-216-065-00 RES-CHIP 4.7K 5% 1/10W

R509 1-216-065-00 RES-CHIP 4.7K 5% 1/10W

R510 1-216-025-11 RES-CHIP 100 5% 1/10W

R511 1-216-073-00 METAL CHIP 10K 5% 1/10W

R512 1-216-097-11 RES-CHIP 100K 5% 1/10W

R513 1-216-073-00 METAL CHIP 10K 5% 1/10W

R514 1-216-025-11 RES-CHIP 100 5% 1/10W

R517 1-216-105-00 RES-CHIP 220K 5% 1/10W

R518 1-216-097-11 RES-CHIP 100K 5% 1/10W

R519 1-216-097-11 RES-CHIP 100K 5% 1/10W

R520 1-216-049-11 RES-CHIP 1K 5% 1/10W

R521 1-216-049-11 RES-CHIP 1K 5% 1/10W

R523 1-216-049-11 RES-CHIP 1K 5% 1/10W

R526 1-216-097-11 RES-CHIP 100K 5% 1/10W

R527 1-216-097-11 RES-CHIP 100K 5% 1/10W

R528 1-216-097-11 RES-CHIP 100K 5% 1/10W

R529 1-216-097-11 RES-CHIP 100K 5% 1/10W

R530 1-216-097-11 RES-CHIP 100K 5% 1/10W

R531 1-216-081-00 METAL CHIP 22K 5% 1/10W

R532 1-216-097-11 RES-CHIP 100K 5% 1/10W

R535 1-249-417-11 CARBON 1K 5% 1/4W

R538 1-216-033-00 METAL CHIP 220 5% 1/10W

30

Page 31

MAIN SUB

Ref. No. Part No. Description Remark

R540 1-216-097-11 RES-CHIP 100K 5% 1/10W

R541 1-216-097-11 RES-CHIP 100K 5% 1/10W

R542 1-216-097-11 RES-CHIP 100K 5% 1/10W

R543 1-216-097-11 RES-CHIP 100K 5% 1/10W

R544 1-216-049-11 RES-CHIP 1K 5% 1/10W

R545 1-216-025-11 RES-CHIP 100 5% 1/10W

R546 1-216-097-11 RES-CHIP 100K 5% 1/10W

R547 1-216-049-11 RES-CHIP 1K 5% 1/10W

R548 1-216-049-11 RES-CHIP 1K 5% 1/10W

R551 1-216-097-11 RES-CHIP 100K 5% 1/10W

R552 1-216-105-00 RES-CHIP 220K 5% 1/10W

R553 1-216-097-11 RES-CHIP 100K 5% 1/10W

R554 1-216-097-11 RES-CHIP 100K 5% 1/10W

R555 1-208-806-11 RES-CHIP 10K 0.5% 1/10W

R556 1-208-806-11 RES-CHIP 10K 0.5% 1/10W

R557 1-216-049-11 RES-CHIP 1K 5% 1/10W

R558 1-216-033-00 METAL CHIP 220 5% 1/10W

R560 1-216-089-11 RES-CHIP 47K 5% 1/10W

R561 1-216-073-00 METAL CHIP 10K 5% 1/10W

R562 1-208-806-11 RES-CHIP 10K 0.5% 1/10W

R563 1-216-025-11 RES-CHIP 100 5% 1/10W

R564 1-216-025-11 RES-CHIP 100 5% 1/10W

R569 1-216-105-00 RES-CHIP 220K 5% 1/10W

R571 1-216-089-11 RES-CHIP 47K 5% 1/10W

Ref. No. Part No. Description Remark

R781 1-216-081-00 METAL CHIP 22K 5% 1/10W

R782 1-216-081-00 METAL CHIP 22K 5% 1/10W

< SWITCH >

S501 1-571-478-11 SWITCH, SLIDE (FREQUENCY SELECT)

S551 1-692-431-21 SWITCH, TACTILE (RESET)

S552 1-771-540-11 SWITCH, PUSH (1 KEY) (NOSE DETECT)

< THERMISTOR >

TH501 1-803-350-21 THERMISTOR, POSITIVE

< TUNER >

TU1 A-3220-812-A FM /MW/SW TUNER UNIT (TUX-020)

< VIBRATOR >

X501 1-781-294-21 VIBRATOR, CRYSTAL (18.432MHz)

X502 1-567-098-41 VIBRATOR, CRYSTAL (32.768kHz)

**************************************************************

* 1-676-603-12 SUB BOARD

**********

1-792-195-11 CABLE, FLEXIBLE FLAT (14 CORE)

R572 1-216-089-11 RES-CHIP 47K 5% 1/10W

R573 1-249-421-11 CARBON 2.2K 5% 1/4W

R574 1-216-081-00 METAL CHIP 22K 5% 1/10W

R576 1-216-105-00 RES-CHIP 220K 5% 1/10W

R580 1-216-025-11 RES-CHIP 100 5% 1/10W

R581 1-216-049-11 RES-CHIP 1K 5% 1/10W

R582 1-216-073-00 METAL CHIP 10K 5% 1/10W

R583 1-216-025-11 RES-CHIP 100 5% 1/10W

R584 1-216-017-00 RES-CHIP 47 5% 1/10W

R585 1-216-089-11 RES-CHIP 47K 5% 1/10W

R586 1-216-073-00 METAL CHIP 10K 5% 1/10W

R587 1-216-073-00 METAL CHIP 10K 5% 1/10W

R588 1-216-097-11 RES-CHIP 100K 5% 1/10W

R589 1-216-085-00 METAL CHIP 33K 5% 1/10W

R594 1-216-049-11 RES-CHIP 1K 5% 1/10W

R601 1-249-387-11 CARBON 3.3 5% 1/4W

R603 1-216-041-00 METAL CHIP 470 5% 1/10W

R604 1-216-041-00 METAL CHIP 470 5% 1/10W

R621 1-216-065-00 RES-CHIP 4.7K 5% 1/10W

R624 1-216-121-11 RES-CHIP 1M 5% 1/10W

R625 1-249-421-11 CARBON 2.2K 5% 1/4W

R631 1-249-417-11 CARBON 1K 5% 1/4W

R632 1-249-417-11 CARBON 1K 5% 1/4W

R701 1-216-049-11 RES-CHIP 1K 5% 1/10W

R702 1-216-025-11 RES-CHIP 100 5% 1/10W

< CONNECTOR >

CNP801 1-794-064-12 SOCKET, CONNECTOR 14P

< LED >

LED801 8-719-038-07 LED CL-190PG-CD-T (TAPE WINDOW)

< SWITCH >

LSW801 1-771-609-11 SWITCH, TACT (WITH LED) (Z)

**************************************************************

MISCELLANEOUS

**************

17 1-777-184-11 CORD (WITH CONNECTOR) (POWER)

23 1-792-195-11 CABLE, FLEXIBLE FLAT (14 CORE)

63 1-694-660-11 CONDUCTIVE BOARD, CONNECTION

F781 1-532-877-11 FUSE (BLADE TYPE) (AUTO FUSE) (10A)

HP901 1-500-157-21 HEAD, MAGNETIC (PLAYBACK)

LCD901 1-803-907-11 DISPLAY PANEL, LIQUID CRYSTAL

M901 A-3291-665-A MOTOR ASSY, MAIN (CAPSTAN/REEL)

************************************************************

**************

HARDWARE LIST

**************

R703 1-216-025-11 RES-CHIP 100 5% 1/10W

R704 1-216-025-11 RES-CHIP 100 5% 1/10W

R705 1-216-025-11 RES-CHIP 100 5% 1/10W

R706 1-216-025-11 RES-CHIP 100 5% 1/10W

R707 1-216-025-11 RES-CHIP 100 5% 1/10W

R708 1-216-025-11 RES-CHIP 100 5% 1/10W

R710 1-216-001-00 METAL CHIP 10 5% 1/10W

R751 1-216-049-11 RES-CHIP 1K 5% 1/10W

R753 1-216-073-00 METAL CHIP 10K 5% 1/10W

#1 7-621-772-20 SCREW +B 2X5

#2 7-685-792-09 SCREW +PTT 2.6X6 (S)

#3 7-685-793-09 SCREW +PTT 2.6X8 (S)

#4 7-685-647-79 SCREW +BVTP 3X10 TYPE 2 N-S

#5 7-685-791-09 SCREW +PTT 2.6X5 (S)

#6 7-685-106-19 SCREW +P 2X10 TYPE 2 NON-SLIT

#7 7-624-104-04 STOP RING 2.0 TYPE-E

#8 7-627-553-17 PRECISION SCREW +P 2X2 TYPE 3

#9 7-685-795-09 SCREW +PTT 2.6X12 (S)

31

Page 32

XR-C5500T

Ref. No. Part No. Description Remark

#10 7-627-553-28 PRECISION SCREW +P 2X2.5

************************************************************

ACCESSORIES & PACKING MATERIALS

*******************************

3-227-562-11 MANUAL, INSTRUCTION (ENGLISH, ARABIC)

************************************************************

501 1-777-184-11 CORD (WITH CONNECTOR) (POWER)

502 3-023-953-11 SCREW, +T (5X8) TAPPING

X-3378-490-1 CASE (PANEL) ASSY

PARTS FOR INSTALLATION AND CONNECTIONS

**************************************

501 502

POWER CORD

+T5 × 8

(× 4)

Ref. No. Part No. Description Remark

9-870-229-11

32

Sony Corporation

Audio Entertainment Group

Printed in Japan C 2000. 12

2000L05XXX3-1

Published by General Engineering Dept.

Loading...

Loading...