Sony UWP-V1,UWP-X8,UWP-V2,UWP-X7,UWP-V6 Service Manual

UHF WIRELESS MICROPHONE PACKAGE

UWP-V1

UWP-V2

UWP-V6

UWP-X7

UWP-X8

UHF SYNTHESIZED TRANSMITTER

UTX-B2

UHF SYNTHESIZED WIRELESS MICROPHONE

UTX-H2

UHF SYNTHESIZED TUNER UNIT

URX-M2

UHF SYNTHESIZED DIVERSITY TUNER

URX-P2

UHF SYNTHESIZED TRANSMITTER

UTX-P1

SERVICE MANUAL

1st Edition

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

UWP Series

Table of Contents

1. Service Overview

1-1. UTX-B2 .......................................................................... 1-1

1-1-1. Disassembly .......................................................... 1-1

1-1-2. Precaution for Reassembling ................................. 1-2

1-1-3. Precaution When Replacing EEPROM (IC611) ... 1-3

1-1-4. Error Messages ......................................................1-3

1-2. UTX-H2 ..........................................................................1-4

1-2-1. Disassembly .......................................................... 1-4

1-2-2. Precaution When Replacing EEPROM (IC401) ... 1-6

1-2-3. Error Messages ......................................................1-6

1-3. URX-M2 ......................................................................... 1-7

1-3-1. Removal/Installation ............................................. 1-7

1-3-2. URX-M2 Checking ............................................. 1-10

1-3-3. Error Messages ....................................................1-10

1-4. URX-P2 ........................................................................ 1-11

1-4-1. Disassembly ........................................................ 1-11

1-4-2. Precaution for Reassembling ............................... 1-12

1-4-3. Precaution When Replacing EEPROM (IC11) ... 1-13

1-4-4. Error Messages ....................................................1-13

1-5. UTX-P1 ......................................................................... 1-14

1-5-1. Disassembly ........................................................ 1-14

1-5-2. Precaution for Reassembling ............................... 1-15

1-6. Unleaded Solder ............................................................ 1-15

2. Electrical Alignment

2-1. UTX-B2 .......................................................................... 2-1

2-1-1. Equipment and Tools ............................................ 2-1

2-1-2. Adjustments ........................................................... 2-2

2-2. UTX-H2 ........................................................................2-13

2-2-1. Equipment and Tools .......................................... 2-13

2-2-2. Adjustments ......................................................... 2-14

2-3. URX-M2 ....................................................................... 2-26

2-3-1. Equipment and Tools .......................................... 2-26

2-3-2. Adjustments ......................................................... 2-27

2-4. URX-P2 ........................................................................ 2-40

2-4-1. Equipment and Tools .......................................... 2-40

2-4-2. Adjustments ......................................................... 2-41

2-5. UTX-P1 ......................................................................... 2-56

2-5-1. Equipment and Tools .......................................... 2-56

2-5-2. Adjustments ......................................................... 2-57

3. Spare Parts

3-1. Notes on Repair Parts ..................................................... 3-1

3-2. Exploded Views ..............................................................3-2

3-2-1. UTX-B2 ................................................................. 3-2

3-2-2. UTX-H2 ................................................................ 3-4

3-2-3. URX-M2 ................................................................ 3-6

3-2-4. URX-P2 .................................................................3-8

3-2-5. UTX-P1 ............................................................... 3-10

3-3. Electrical Parts List .......................................................3-12

3-3-1. UTX-B2 ............................................................... 3-12

3-3-2. UTX-H2 .............................................................. 3-17

3-3-3. URX-M2 .............................................................. 3-21

3-3-4. URX-P2 ...............................................................3-28

3-3-5. UTX-P1 ............................................................... 3-36

3-4. Accessories Supplied .................................................... 3-40

3-4-1. UWP-V1 ..............................................................3-40

3-4-2. UWP-V2 ..............................................................3-40

3-4-3. UWP-V6 ..............................................................3-41

3-4-4. UWP-X7 ..............................................................3-41

3-4-5. UWP-X8 ..............................................................3-41

4. Block Diagrams and Circuit Descriptions

4-1. UTX-B2 .......................................................................... 4-2

4-2. UTX-H2 ..........................................................................4-4

4-3. URX-M2 ......................................................................... 4-6

4-4. URX-P2 .......................................................................... 4-8

4-5. UTX-P1 ......................................................................... 4-10

5. Board Layouts

5-1. UTX-B2 .......................................................................... 5-1

5-2. UTX-H2 ..........................................................................5-2

5-3. URX-M2 ......................................................................... 5-3

5-4. URX-P2 .......................................................................... 5-4

5-5. UTX-P1 ........................................................................... 5-5

6. Schematic Diagrams

6-1. UTX-B2 .......................................................................... 6-1

6-2. URX-H2 .......................................................................... 6-4

6-3. URX-M2 ......................................................................... 6-5

6-4. URX-P2 .......................................................................... 6-9

6-5. UTX-P1 ......................................................................... 6-14

UWP Series

1

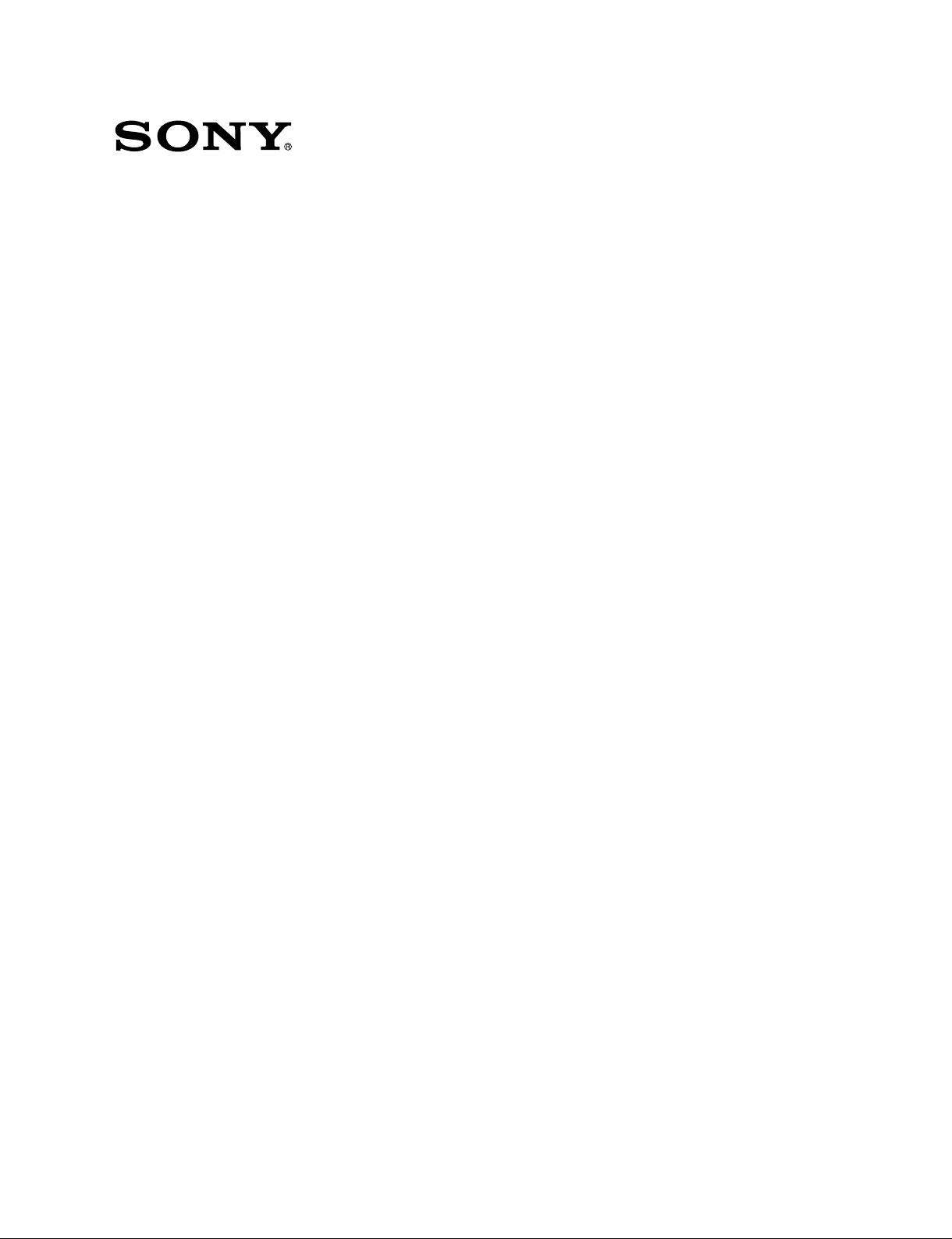

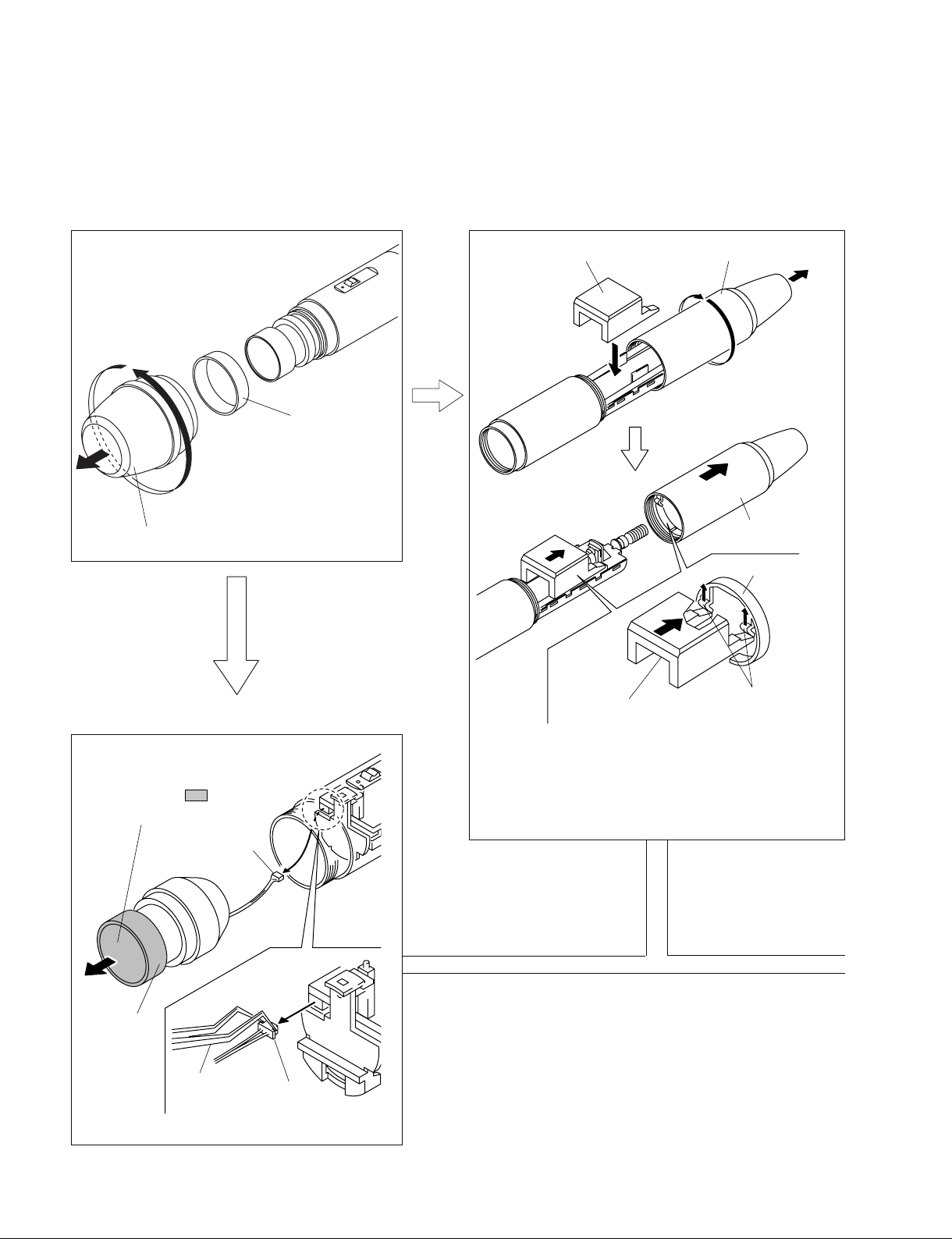

1-1. UTX-B2

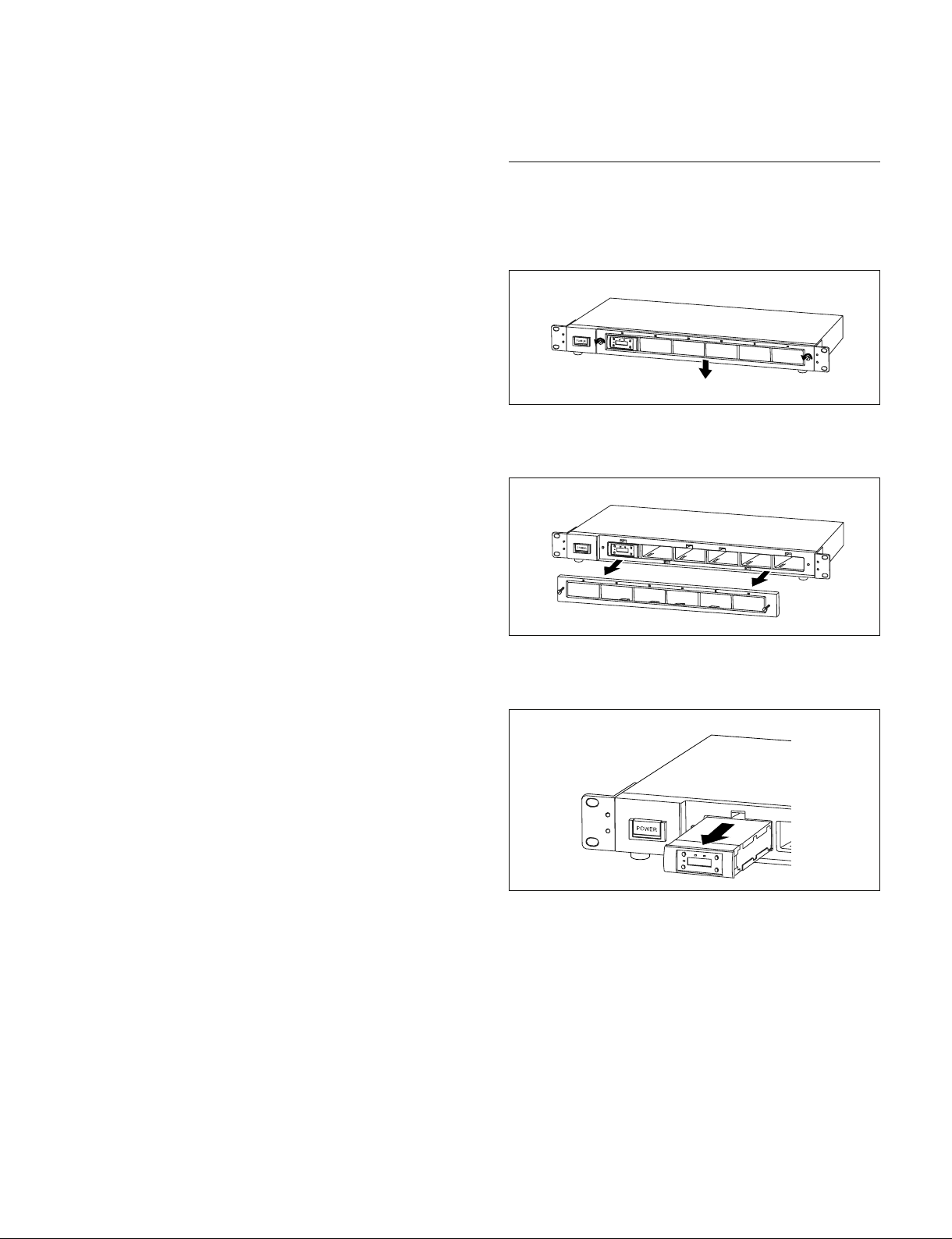

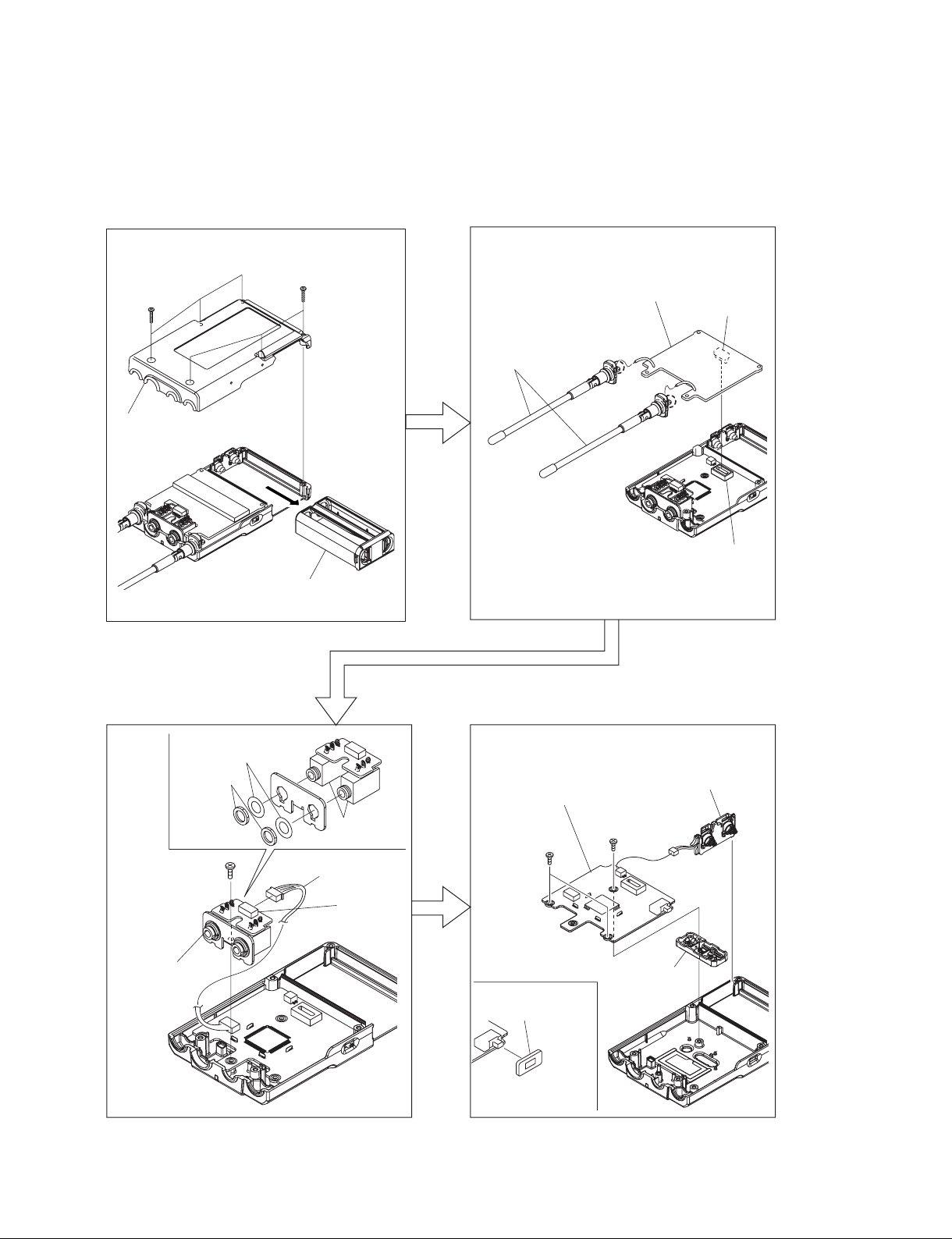

1-1-1. Disassembly

Section 1

Service Overview

Rear cabinet (TX)

M2 x 10

M2 x 10

Rear cabinet (TX)

M2 x 10

M2 x 10

Battery case assembly

Antenna/CPU-422 board

CPU422 board

Antenna

Mic sheet

Be careful not to

drop or lose this.

CN401

P2 x 5

CN2

Stereo miniature jack

UWP Series

P2 x 5

RF-131 boardStereo miniature jack

Battery spring plate

P2 x 5

RF-131 board

P2 x 5

Set button

Power protection

sheet

Be careful not to

drop or lose this.

1-1

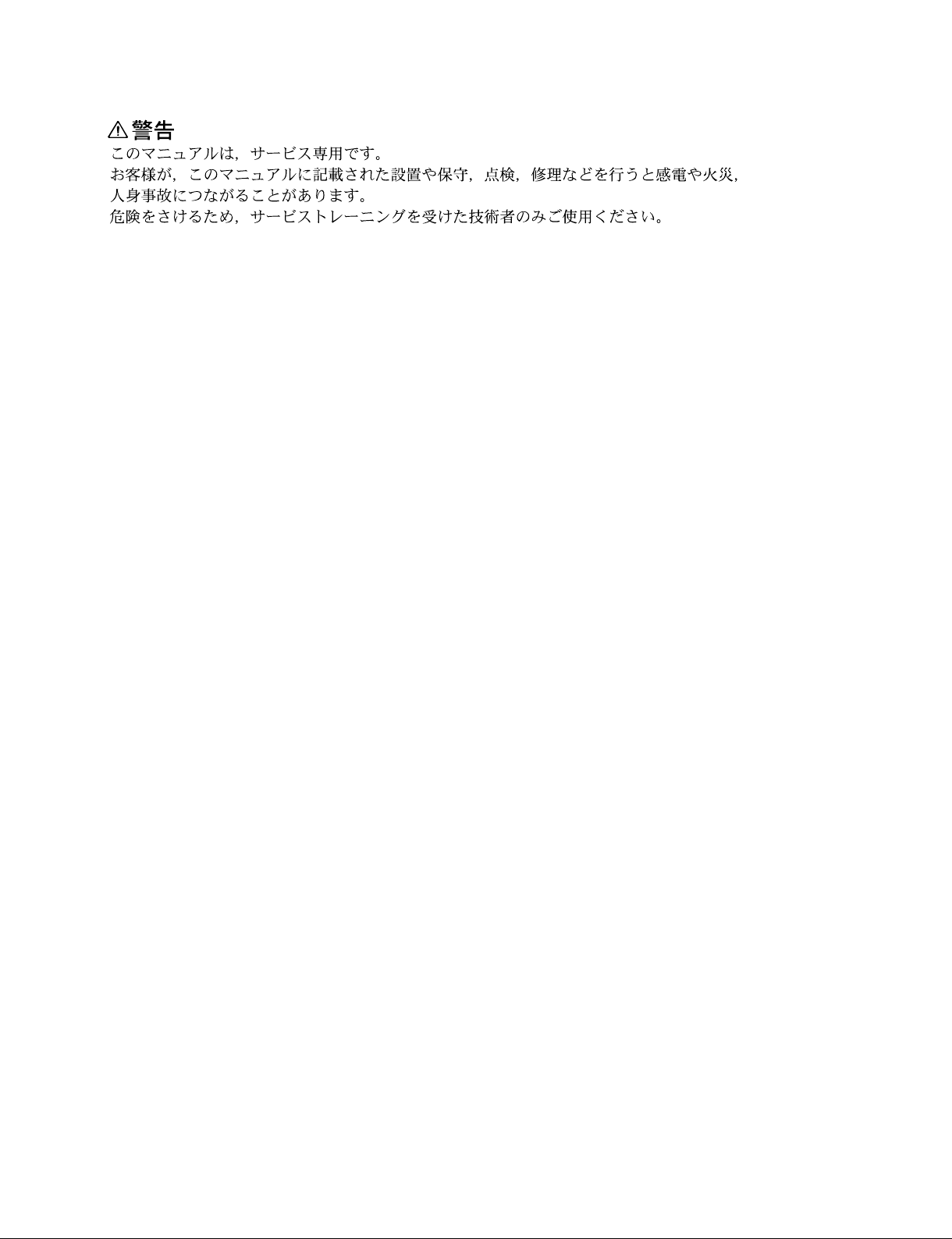

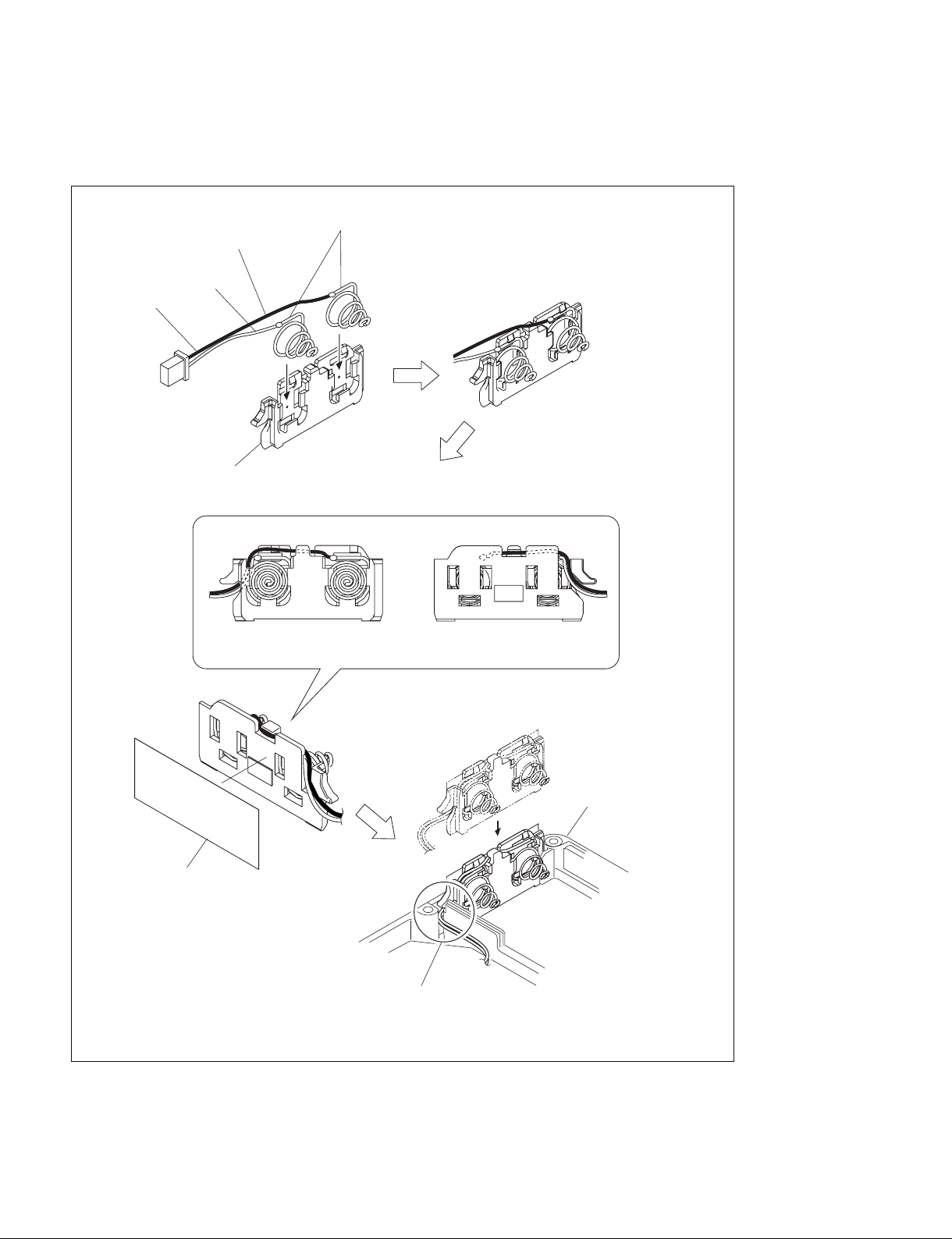

1-1-2. Precaution for Reassembling

When reassembling the UTX-B2, arrange the battery harnesses as shown in the following figures.

Battery spring

(Black)

(Red)

Harness

Battery spring plate

Arranging the harnesses as shown in the figures.

Tape for insulation

Front side Rear side

Front

cabinet

Note

When reassembling the UTX-B2, be careful that

the harness must not be pinched.

1-2

UWP Series

1-1-3. Precaution When Replacing EEPROM (IC611)

When the EEPROM (IC611) is replaced with the new EEPROM, the same data that have been stored in

the removed EEPROM must be written into the newly mounted EEPROM.

1-1-4. Error Messages

When an error occurs, any of the following error messages can be generated by the self-diagnostics

function that is built-in the UTX-B2 and can appear on the display section.

Message Error contents Remedial measure

Err01 An error occurs in the backup With “Err01” displayed, press and hold the “-“ button

Err02 An error occurs in the PLL Check the PLL synthesizer circuit (IC301, CP321 on

Err03 Power supply voltage has exceeded Use the equipment with the power supply of the

INIT The message is displayed when Do not press the “SET” button and the “_“ button.

memory data. for 20 seconds to read the backup data.

The data is successfully read when “RELOAD” is

displayed. If the data fails to be read, check the

EEPROM (IC661) and its peripheral circuits, and write

the frequency data to the EEPROM.

synthesizer circuit. the RF-131 board and its peripheral circuits).

the range of allowable limits. specified voltage range.

the power is turned on while the

“SET” button and the “_“ button are

pressed at the same time.

If the “SET” button and the “_“ button

are pressed at the same time, the

UTX-B2 enters the default setting mode.

UWP Series

1-3

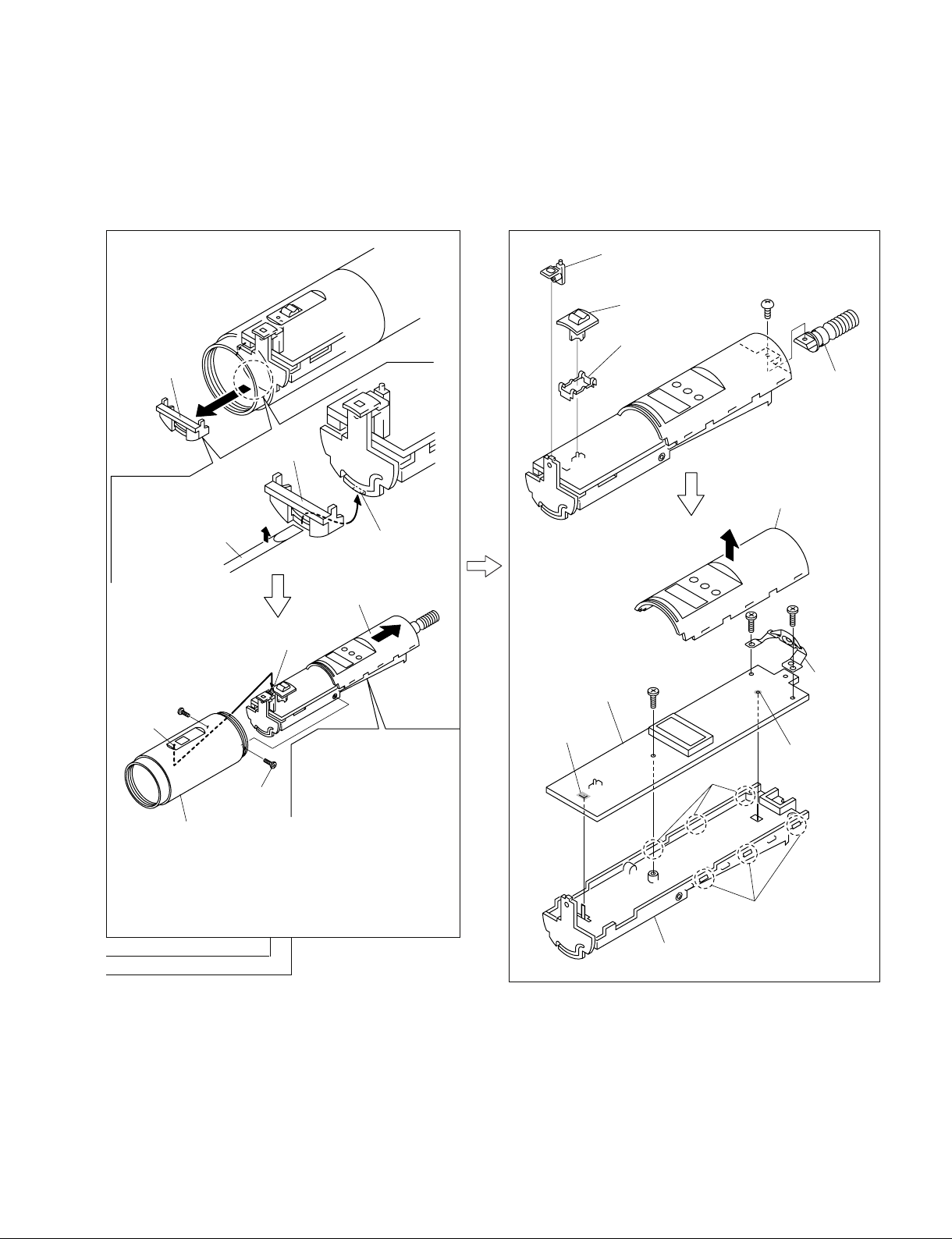

1-2. UTX-H2

1-2-1. Disassembly

Cage sub assembly

Cage sub assembly

Model cover

Grip (B)

*Grip removal fixture

Grip (B)

Grip (B)

Ring stopper

Dynamic unit

Do not touch the portion

during removing the unit.

Connector (3P)

Dynamic unit

Remove it using

tweezers.

Connector

(3P)

*Grip removal fixture

* : Tools required :

Grip removal fixture (J-6407-080-A)

Push up the claws.

(If difficult to remove,

unlock one claw

after another.)

Go to page 1-5

(Grip A)

1-4

UWP Series

Grip (A) Antenna/MB-1137 board

Indicator

Power button

Power lock

Precision

P2.6 x 5

Stopper

Disengage the claw of

the chassis (A) using

a flat head (_) screwdriver,

and remove the stopper.

Protruded portion

of the indicator

*LRT screw

(M2 x 4)

Hole

Precision

P2 x 3

Grip (A)

Stopper

Claw of

the chassis (A)

Chassis (A)

assembly

Remove the chassis (A)

assembly in the direction of

the arrow in the way as if

removing the protruded

portion of the indicator.

MB-1137 board

Unsolder.

Precision

P2 x 3

Antenna

Chassis (B) sub

assembly

Precision

P2 x 3

Precision

P2 x 3

Shield

Unsolder.

Three claws

UWP Series

*: Tools required :

LRT screwdriver (J-6402-350-A)

Three claws

Chassis (A) sub assembly

1-5

1-2-2. Precaution When Replacing EEPROM (IC401)

When the EEPROM (IC401) is replaced with the new EEPROM, the same data that have been stored in

the removed EEPROM must be written into the newly mounted EEPROM.

1-2-3. Error Messages

When an error occurs, any of the following error messages can be generated by the self-diagnostics

function that is built-in the UTX-H2 and can appear on the display section.

Message Error contents Remedial measure

Err01 An error occurs in the backup Check the EEPROM (IC401) and its peripheral

Err02 An error occurs in the PLL Check the PLL synthesizer circuit (IC102, CP101 on

Err03 Power supply voltage has exceeded Use the equipment with the power supply of the

memory data. circuits.

synthesizer circuit. the MB-5 board and its peripheral circuits).

the range of allowable limits. specified voltage range.

1-6

UWP Series

1-3. URX-M2

1. Tuner Base Unit MB-X6 / MB-806A

1-3-1. Removal/Installation

m

Before installing the URX-M2, make sure the MB-806A

.

into which the URX-M2 will be installed is turned off. Do

not install or uninstall the URX-M2 while the MB-806A is

turned on, as this may damage the connector or cause noise.

. The buttons and display on the front panel of the URX-

M2 may be damaged if they are gripped too strongly.

Always hold the URX-M2 by the side.

. Do not put your fingers on the connectors on the rear

panel of the URX-M2 or into the slot on the unit into

which the URX-M2 will be installed.

. Keep the URX-M2 away from static electricity.

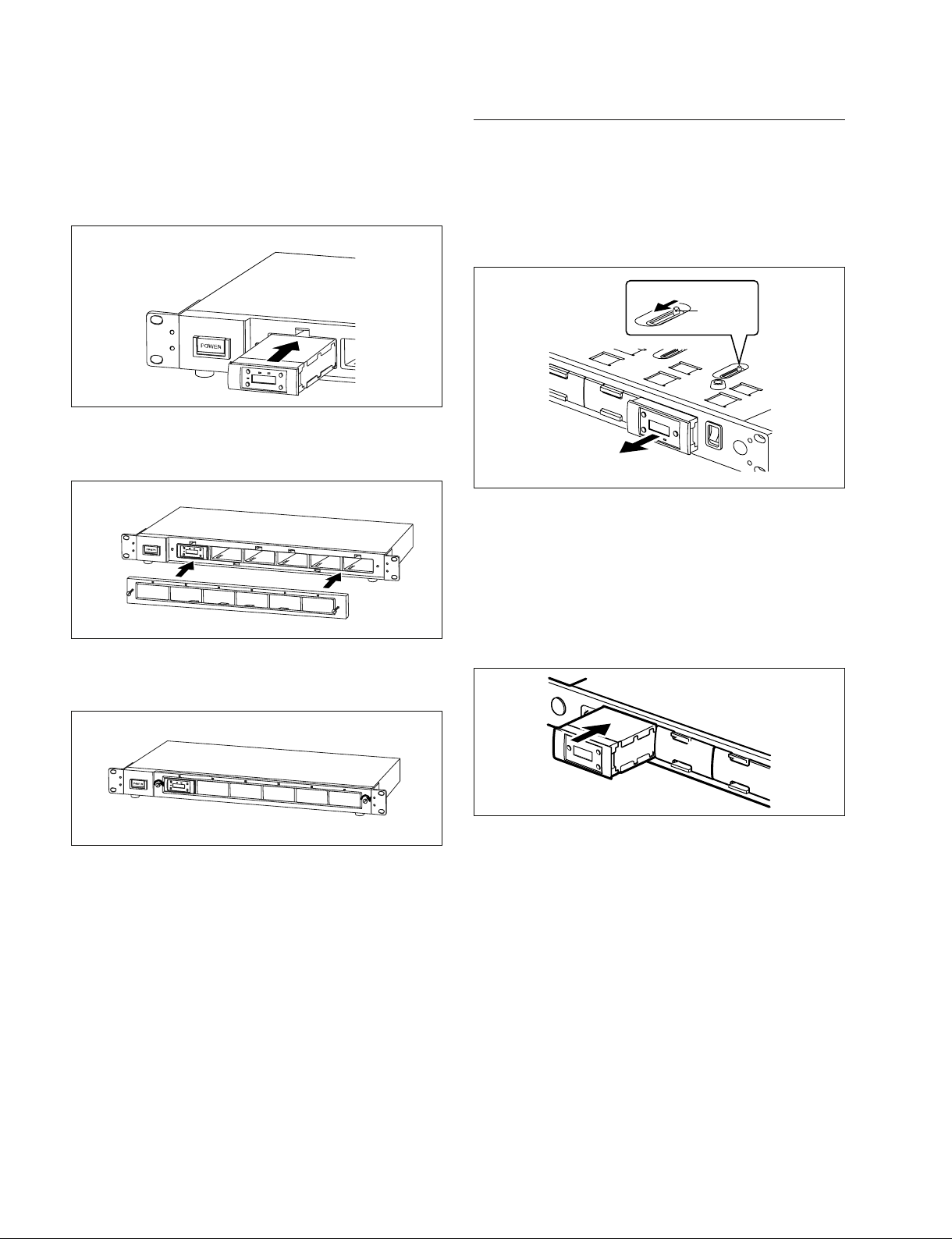

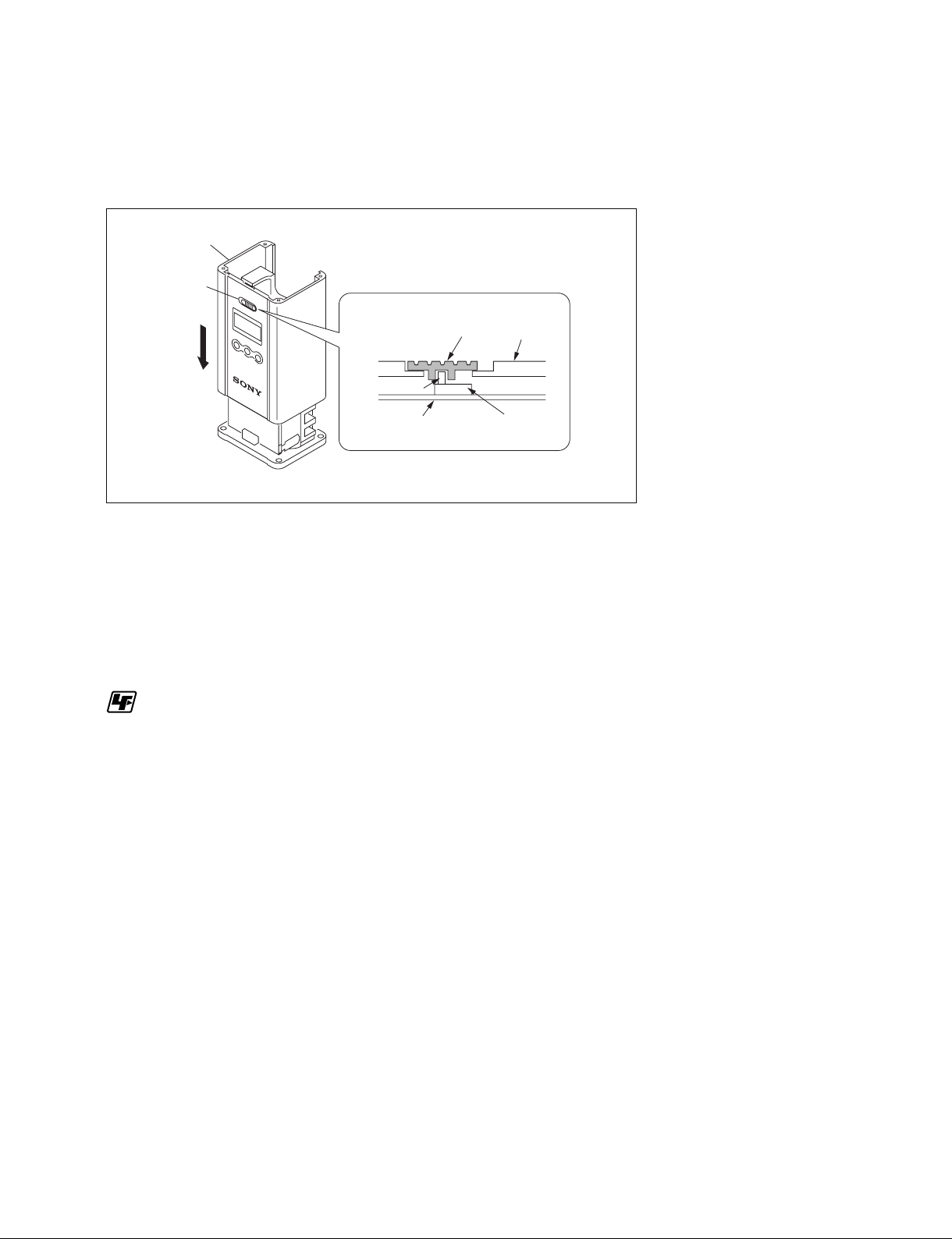

When using the MB-X6

Removal

1. Loosen the screws at both sides of the front cover, then

slide the front cover downward.

2. Hold the screws by the head and pull forward to

remove the front cover.

3. Remove the tuner unit URX-M2 from the slot in the

direction of the arrow.

UWP Series

1-7

Installation

When using the MB-806A

1. After removing the front cover, hold the tuner unit by

the top and bottom, then insert the tuner unit into the

slot.

2. Match the six latches with the six holes on the front

panel, then replace the front cover.

3. Tighten the screws on the front cover to secure it to the

front panel of the MB-X6.

Removal

1. On the bottom panel of the MB-806A, locate the lever

corresponding to the slot of the URX-M2 to be

removed and pull the lever forward. The URX-M2 is

ejected from the slot.

Lever

Installation

The MB-806A Tuner Base Unit can accommodate up to 6

URX-M2.

1. Inspect the top and bottom side of the URX-M2.

2. Holding both sides of the URX-M2, insert it into the

slot. Push it in until you hear a click.

1-8

UWP Series

GP

AF

R

F

GP

CH

B

ATT

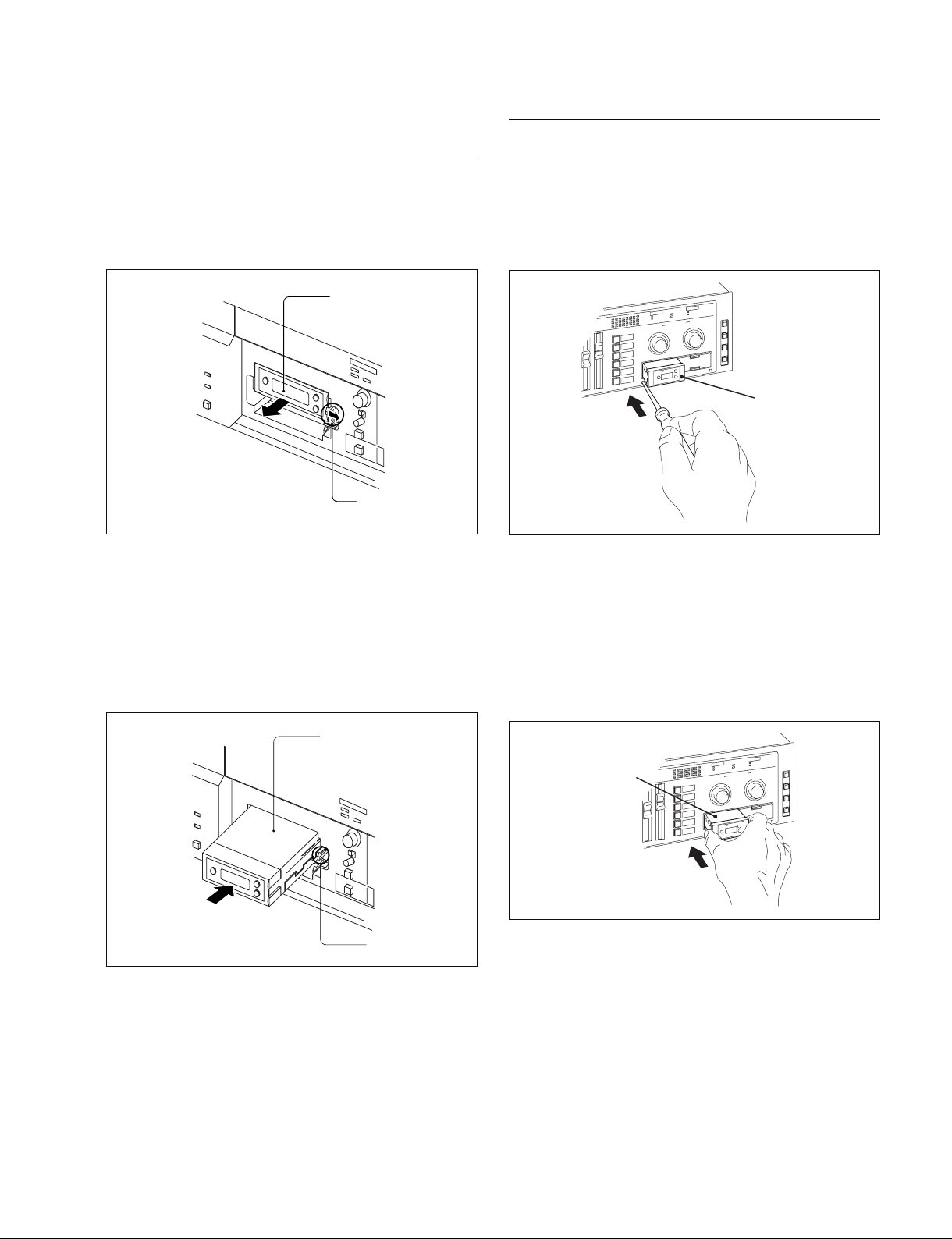

2. Powered Mixer SRP-X500P / SRP-X700P

When using the SRP-X700P

When using the SRP-X500P

Removal

1. Pull the latch securing the tuner unit to the side and

pull out the tuner unit URX-M2.

URX-M2

Latch

Installation

1. Check the top and bottom sides of the tuner unit, and

then insert it into the slot.

n

When installing the tuner unit, insert it fully into the

tuner slot of the SRP-X500P and secure it with the

latch on the slot.

Removal

1. Insert a screwdriver into the hole under the lower part

of the tuner slot and remove the URX-M2.

Screwdriver : Shaft diamter is between 2 to 4 mm

Shaft length is 30 mm or longer

SCENE

ECALL

R

B

MASTER

A

LINE 4 SELECT

A

B

C

D

E

F

ATT

B

RF

URX-M2

Installation

The SRP-X700P Powered Mixer can accommodate up to 2

URX-M2.

1. Remove the tuner slot cover from the SRP-X700P and

inspect the top and bottom sides of the URX-M2.

2. Holding the tuner module on both sides, insert it into

the slot.

URX-M2

URX-M2

LINE 4 SELECT

A

B

C

D

E

F

MASTER

A

TT

A

B

F

A

GP

F

R

H

C

P

G

SCENE

RECALL

B

Latch

UWP Series

1-9

1-3-2. URX-M2 Checking

The following procedures describe how to prove URX-M2 whether it needs to be required or not.

Equipment Required : MB-X6 (quality unit) / MB-806A (quality unit)

URX-M2 (quality unit)

1. Install the URX-M2 (repair unit) to be checked in an MB-X6 / MB-806A (quality unit).

2. Check if there is any fault using the MB-X6 / MB-806A (quality unit).

. If there is a fault, URX-M2 is defective.

Check the URX-M2 then fix a faulty section, and perform “2. Electrical Alignment”.

. If there is no fault, the URX-M2 (repair unit) is not defective. The original MB-X6 / MB-806A on

which the URX-M2 (repair unit) had been mounted is defective.

1-3-3. Error Messages

When an error occurs, any of the following error messages can be generated by the self-diagnostics

function that is built-in the URX-M2 and can appear on the display section.

Message

Err01

Err02

Err03

NOTONE

Sq OFF

Error contents

An error occurs in EEPROM data.

The PLL synthesizer circuit does not

lock.

Power supply voltage has exceeded

the range of allowable limits.

The tone signal does not exist, or

any tone signal radio wave other

than 32 kHz is received and the

audio signal is muted.

If you turn on the power while

pressing the “SET” button and the

“_” button at the same time, the

squelch function release mode is

set, and this message appears once

before the display of normal

operation appears.

Remedial measure

Take both of the following remedial measures.

. Write the frequency data that corresponds to the

desired destination location, into EEPROM.

. Perform the RF squelch adjustment and the RF

level indicator adjustment. (Refer to Section 2-3.)

If the frequency data that does not corresponds to

the desired reception frequency range is written:

Write the correct frequency data into the EEPROM.

If the error message is displayed even though the

frequency data is correct:

Check the PLL synthesizer circuit (IC301, X301,

Q305 and Q306 and its peripheral circuits on the

MB-1129 board).

Use the equipment with the power supply of the

specified voltage range.

An interference radio wave has occurred in the

frequency band in use.

. If an error is displayed while the power of the

transmitter is on:

Turn off the power of the transmitter.

. If the RF level indicator of the receiver LCD lights

even when the power of the transmitter is turned off:

Set the frequency of the transmit/receive channel

that is free from the interference radio wave.

When the error is not caused by the signal interference, the tone squelch circuit of receiver or transmitter

(both receiver and transmitter) is defective.

. Check the receiver : Check the tone squelch.

(Refer to Section 2-3.)

If the tone squelch does

not work well, check the

tone squelch circuit (IC406

and its peripheral circuit

on the MB-1129 board.)

. Check the transmitter : Refer to the Service

Manual of transmitter.

Turn off the power once and then back on without

pressing any button.

1-10

UWP Series

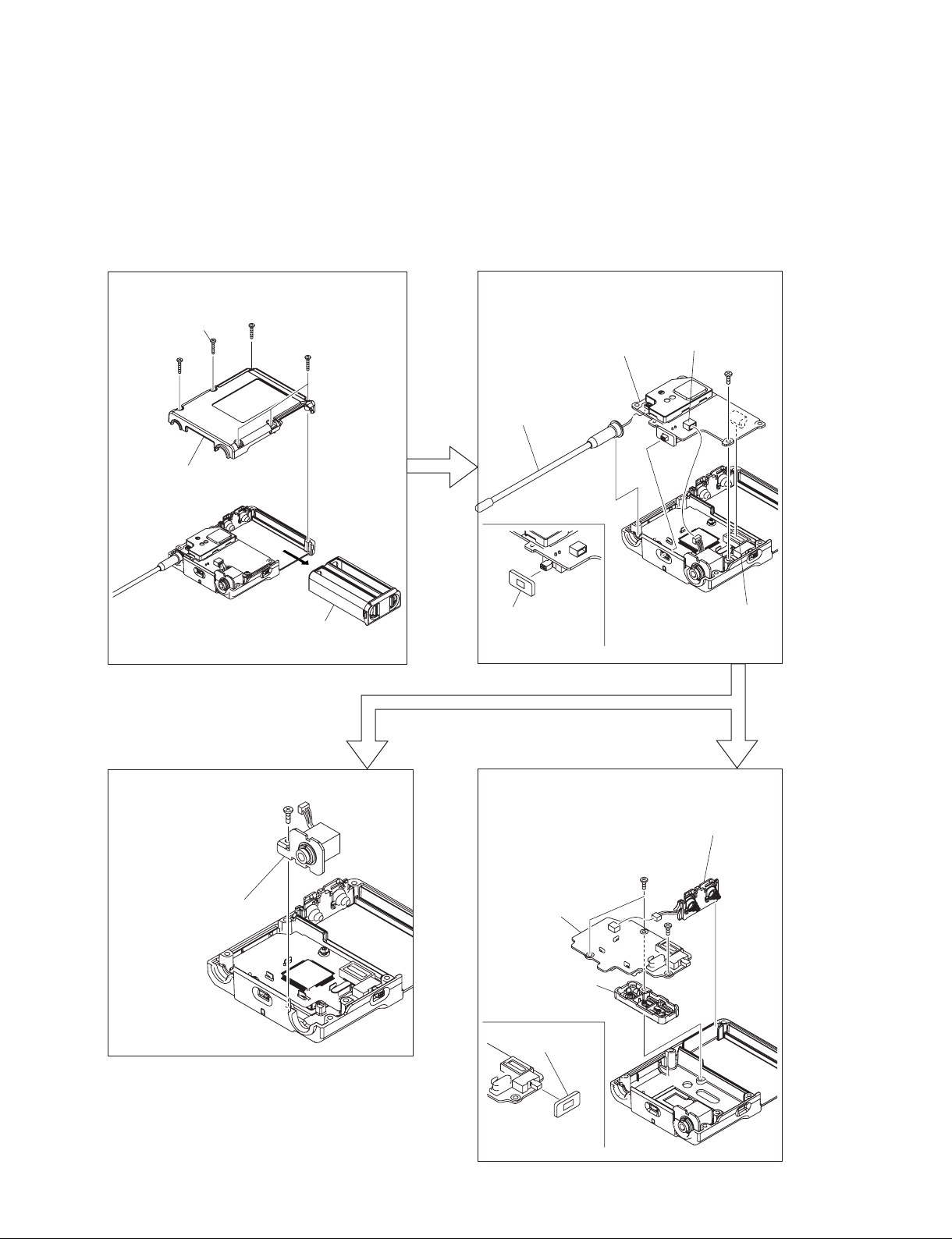

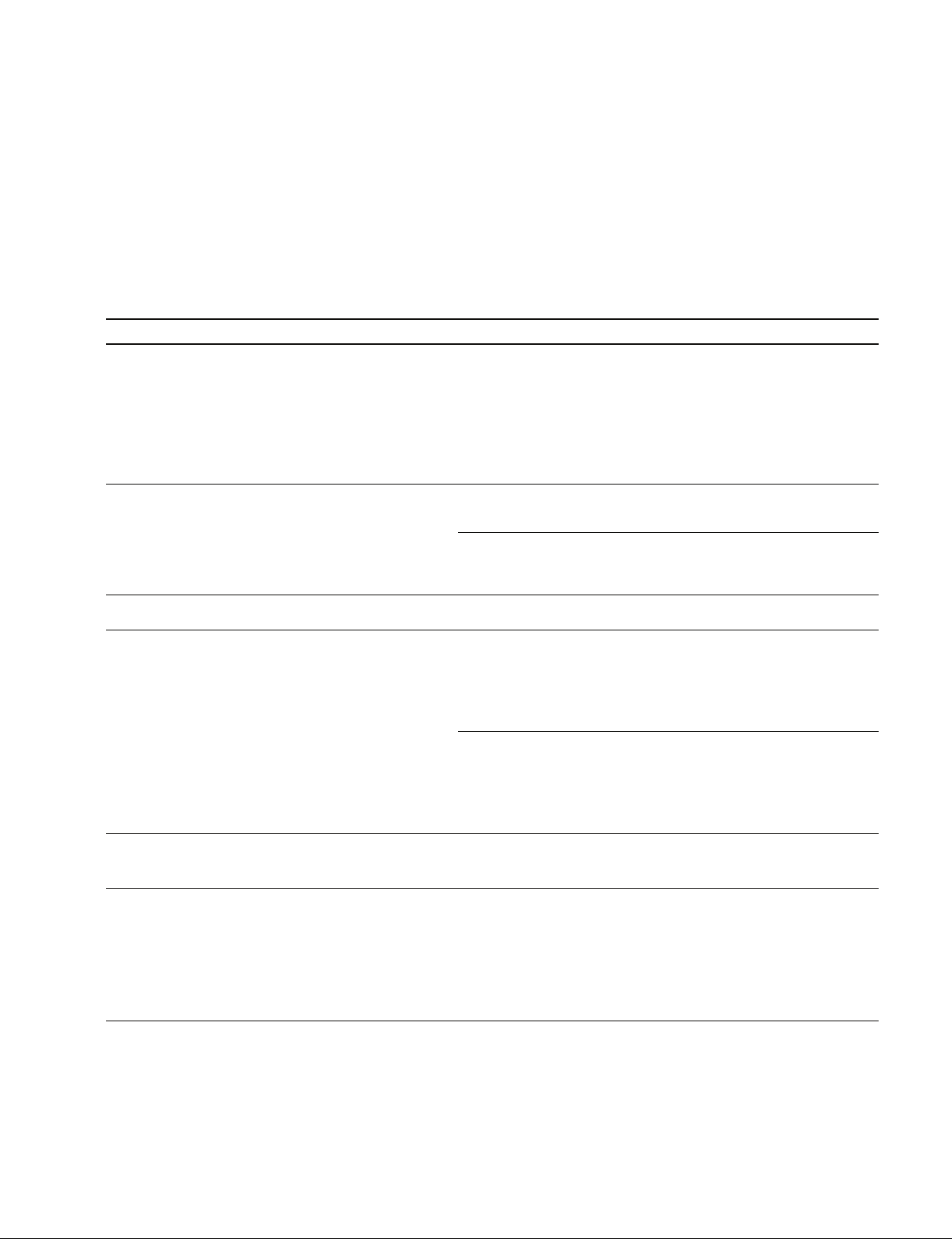

1-4. URX-P2

1-4-1. Disassembly

Rear cabinet Antenna/RF-130 board

M2 x 10

M2 x 10

Antenna

Rear cabinet (RX)

Battery case assembly

Stereo miniature jack CPU-421 board

RF-130 board

CN1

CN2

Stereo

miniature jack

UWP Series

Supplied washer

Supplied nut

P2 x 5

Stereo

miniature jack

Harness

CN1001

CPU-421 board

P2 x 5

Power supply

protection sheet

Do not drop or

lose this

Battery spring

plate

P2 x 5

Set button

1-11

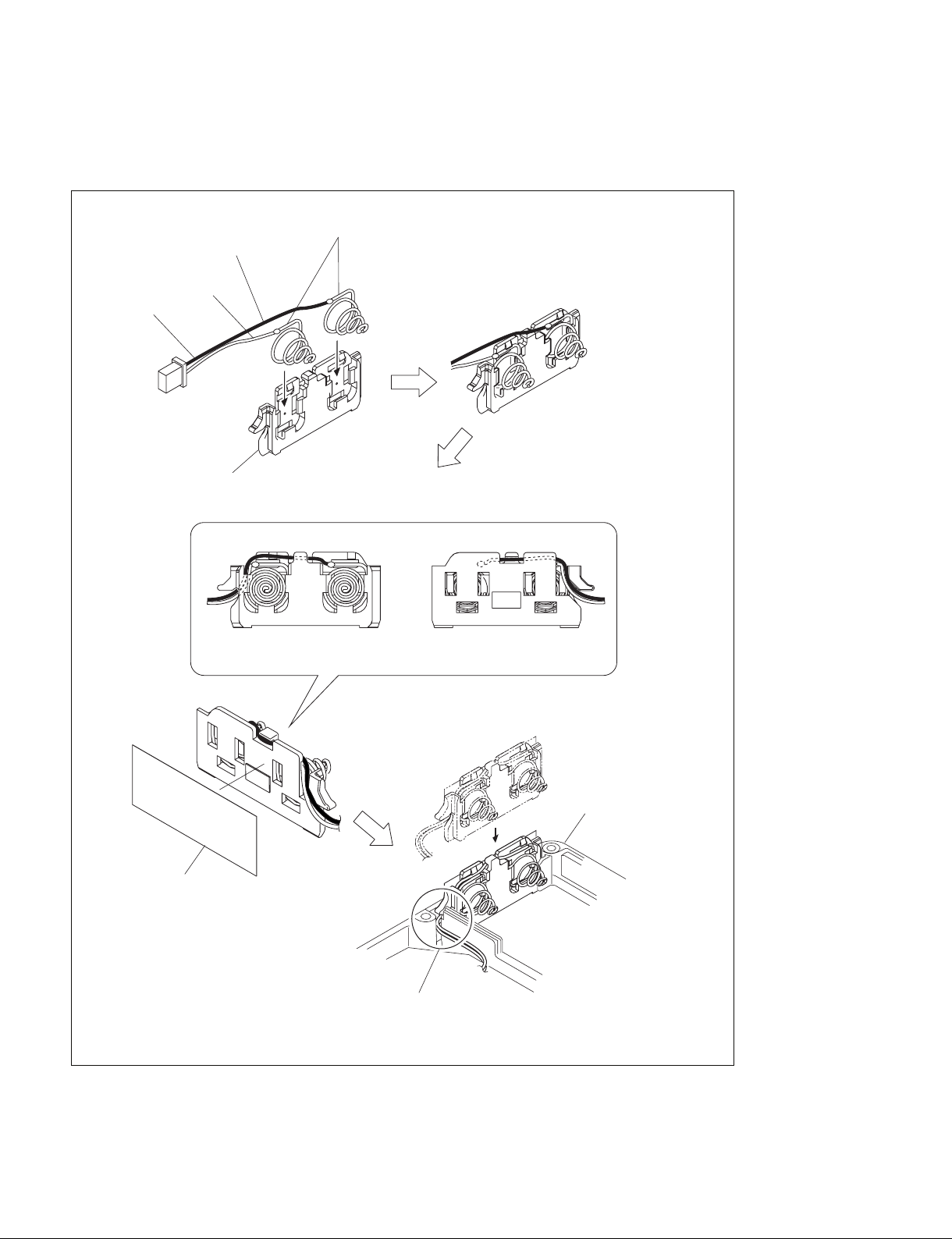

1-4-2. Precaution for Reassembling

When reassembling the UTX-P2, arrange the battery harnesses as shown in the following figures.

Battery spring

(Black)

(Red)

Harness

Battery spring plate

Arranging the harnesses as shown in the figures.

Tape for insulation

Front side Rear side

Front

cabinet

Note

When reassembling the UTX-B2, be careful that

the harness must not be pinched.

1-12

UWP Series

1-4-3. Precaution When Replacing EEPROM (IC11)

When the EEPROM (IC11) is replaced with the new EEPROM, the same data that have been stored in the

removed EEPROM must be written into the newly mounted EEPROM.

1-4-4. Error Messages

When an error occurs, any of the following error messages can be generated by the self-diagnostics

function that is built-in the URX-P2 and can appear on the display section.

Message

Err01

Err02

Err03

NOTONE

Sq OFF

INIT

Error contents

An error occurs in EEPROM data.

The PLL synthesizer circuit does not

lock.

Power supply voltage has exceeded

the range of allowable limits.

The tone signal does not exist, or

any tone signal radio wave other

than 32 kHz is received and the

audio signal is muted.

If you turn on the power while

pressing the “-“ button, the squelch

function release mode is set.

The message is displayed when the

power is turned on while the “SET”

button and the “_“ button are

pressed at the same time.

If the “SET” button and the “_“

button are pressed at the same time,

the UTX-P2 enters the default

setting mode.

Remedial measure

With “Error1” displayed, press and hold the “-“ button for 20 seconds to

read the backup data.The data is successfully read when “RELOAD” is

displayed. If the data fails to be read, check the peripheral circuits of

IC671, and perform the following measures.

. Write the frequency data that corresponds to the desired destination

location, into EEPROM.

. Perform the RF squelch adjustment and the RF level indicator

adjustment. (Refer to Section 2-4.)

If the frequency data that does not corresponds to the desired reception

frequency range is written:

Write the correct frequency data into the EEPROM.

If the error message is displayed even though the frequency data is

correct:

Check the PLL synthesizer circuit (IC321, X301, Q341 and Q342 and its

peripheral circuits on the RF-130 board).

Use the equipment with the power supply of the specified voltage range.

An interference radio wave has occurred in the frequency band in use.

. If an error is displayed while the power of the transmitter is on:

Turn off the power of the transmitter.

. If the RF level indicator of the receiver LCD lights

of the transmitter is turned off:

Set the frequency of the transmit/receive channel that is free from

the interference radio wave.

When the error is not caused by the signal interference, the tone squelch

circuit of receiver or transmitter (both receiver and transmitter) is defective.

. Check the receiver :

. Check the transmitter : Refer to the Service Manual of transmitter.

Turn off the power once and then back on without pressing any button.

Do not press the “SET” button and the “_“ button.

Check the tone squelch. (Refer to Section 2-4.)

If the tone squelch does not work well, check

the tone squelch circuit (IC441 and its

peripheral circuit on the CPU-421 board.)

even when the power

UWP Series

1-13

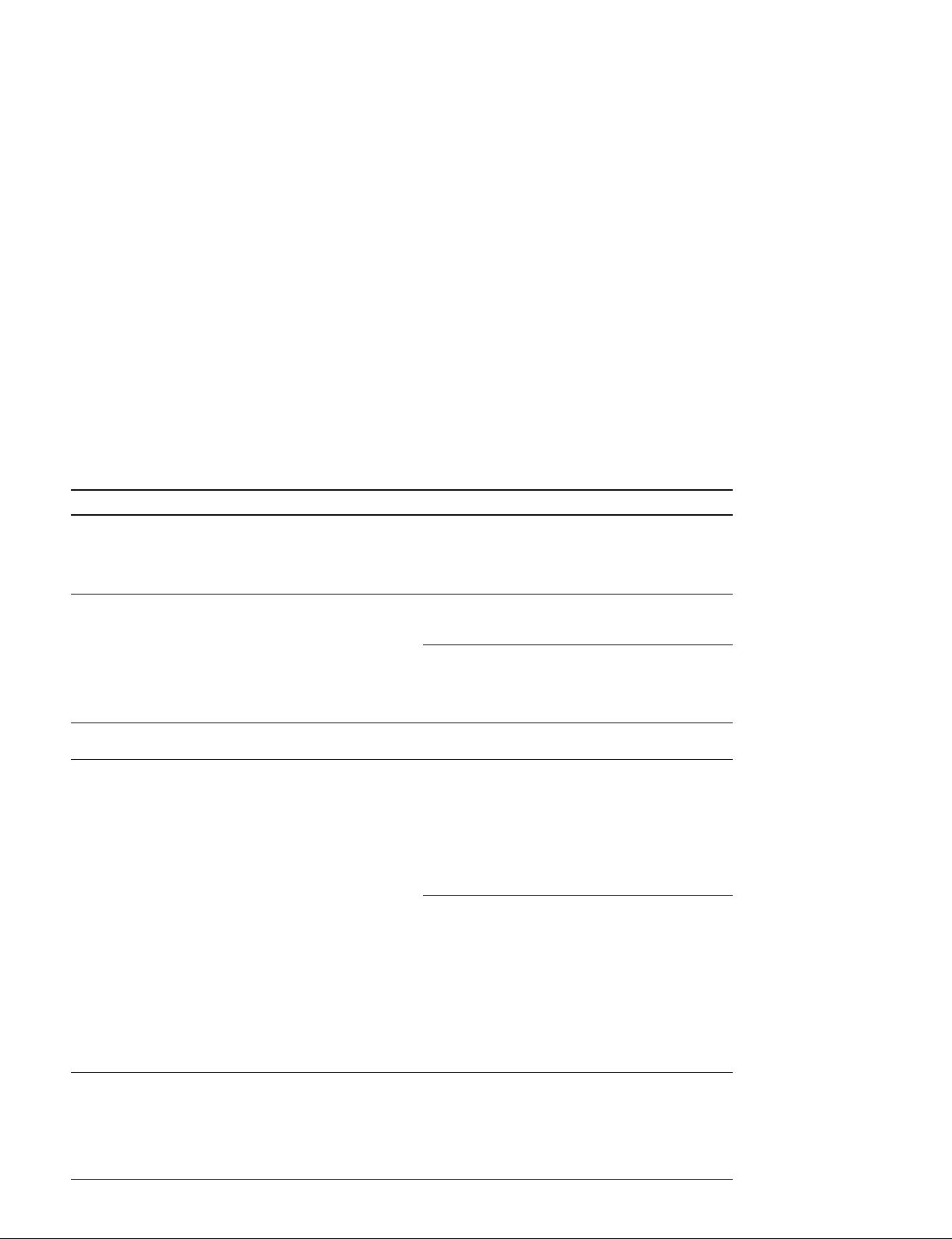

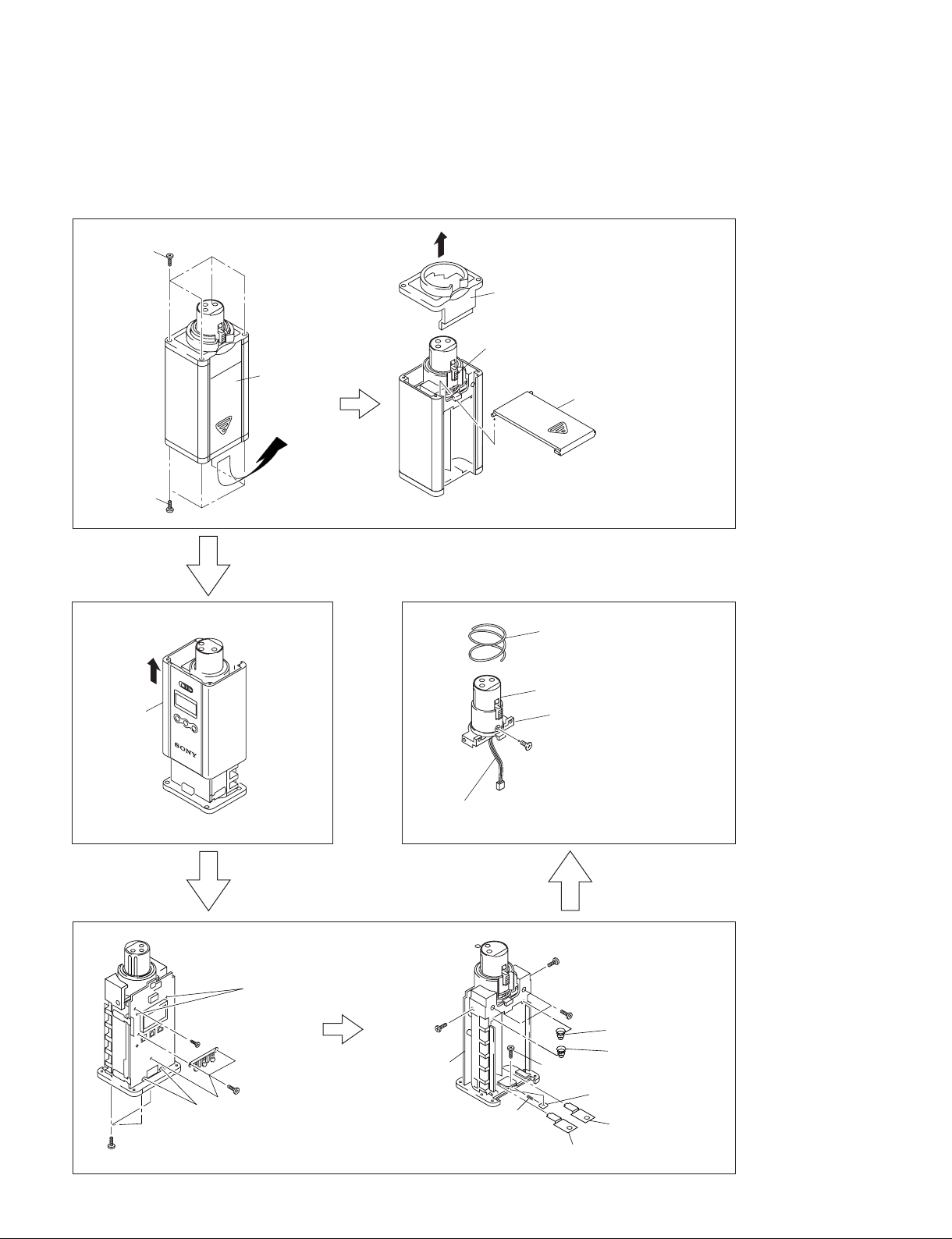

1-5. UTX-P1

1-5-1. Disassembly

Upper sub assembly

Four screws

P2 x 6

Four screws

P2 x 6

Battery

case

Upper sub assembly

Notch

Battery case

Press and hold the notch, and pull up the upper sub assembly.

Case

Case

MB-1094 board

Three screws

B2 x 6

*Remove the

solders.

Screw

P1.7 x 6

Three screws

B1.7 x 8

*Remove the

solders.

XLA connector

Coil spring

XLA connector

Connector holder

Screw

K2 x 5

Remove the solder, and disconnect the harness from

the XLA connector terminal.

Two screws

P2 x 6

Two screws

P2 x 6

MB-1094

board

Lower spring

Two screws

P2 x 6

Battery spring (_) L

Screw

P1.7 x 3

Battery spring (+)

Battery spring (_) R

Locking

Battery spring (+)

1-14

UWP Series

1-5-2. Precaution for Reassembling

When reassembling the UTX-P1, be sure that the knob on the case and the switch on the MB-1094 board

fit together correctly.

Case

Knob

Knob

Lever

MB-1094 board

1-6. Unleaded Solder

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

Panel

Switch

UWP Series

1-15

Section 2

Electrical Alignment

2-1. UTX-B2

2-1-1. Equipment and Tools

Equipment Required

Name Specifications Model Name

DC POWER SUPPLY Output regulated voltage : 0 to 5 V, 2 A –

DC AMMETER Measurement : 300 mA –

SPECTRUM ANALYZER Frequency : 10 kHz to 3 GHz ADVANTEST R3361B or equivalent

MODULATION ANALYZER RF input Frequency : 150 kHz to 3 GHz ANRITSU MS616A or equivalent

RF POWER METER Range : 3 uW to 100 mW HP 435B (Power sensor HP 8482A) or equivalent

WITH POWER SENSOR

AUDIO ANALYZER . Oscillator : 20 Hz to 100 kHz HP 8903B (with A-weight filter) or equivalent

FREQUENCY COUNTER Frequency : 10 Hz to 1000 MHz HP 5358A or equivalent

OSCILLOSCOPE Frequency : DC to 10 MHz –

DIGITAL VOLT METER Effective digits : 3 1/2 digits –

. DISTORTION ANALYZER

. S/N METER

. LEVEL METER

Effective digits: 10 digits

Tool

Name Part No. Remarks

MM-SMA conversion connector J-6402-490-A For RF signal output

SMA-BNC conversion connector J-6402-480-A For RF signal output

Adjustor (0.4 x 1.3 mm) 7-721-052-81 Screwdriver for adjustment

UWP Series

2-1

2-1-2. Adjustments

This section describes adjustments and checks which must be

completed to assure that the specifications are complied with.

Make adjustment and checks following the procedure below:

1. Power Supply Voltage Check

↓

2. Carrier Frequency Adjustment

↓

3. RF Power Output Adjustment

↓

4. Reference Frequency Deviation Adjustment

↓

5. Maximum Frequency Deviation Adjustment

↓

6. Distortion Ratio Check

↓

7. S/N Check

↓

8. Frequency Characteristics Check

9. Tone Signal Adjustment

10. Spurious Emissions Check

11. Occupied Band Width Check

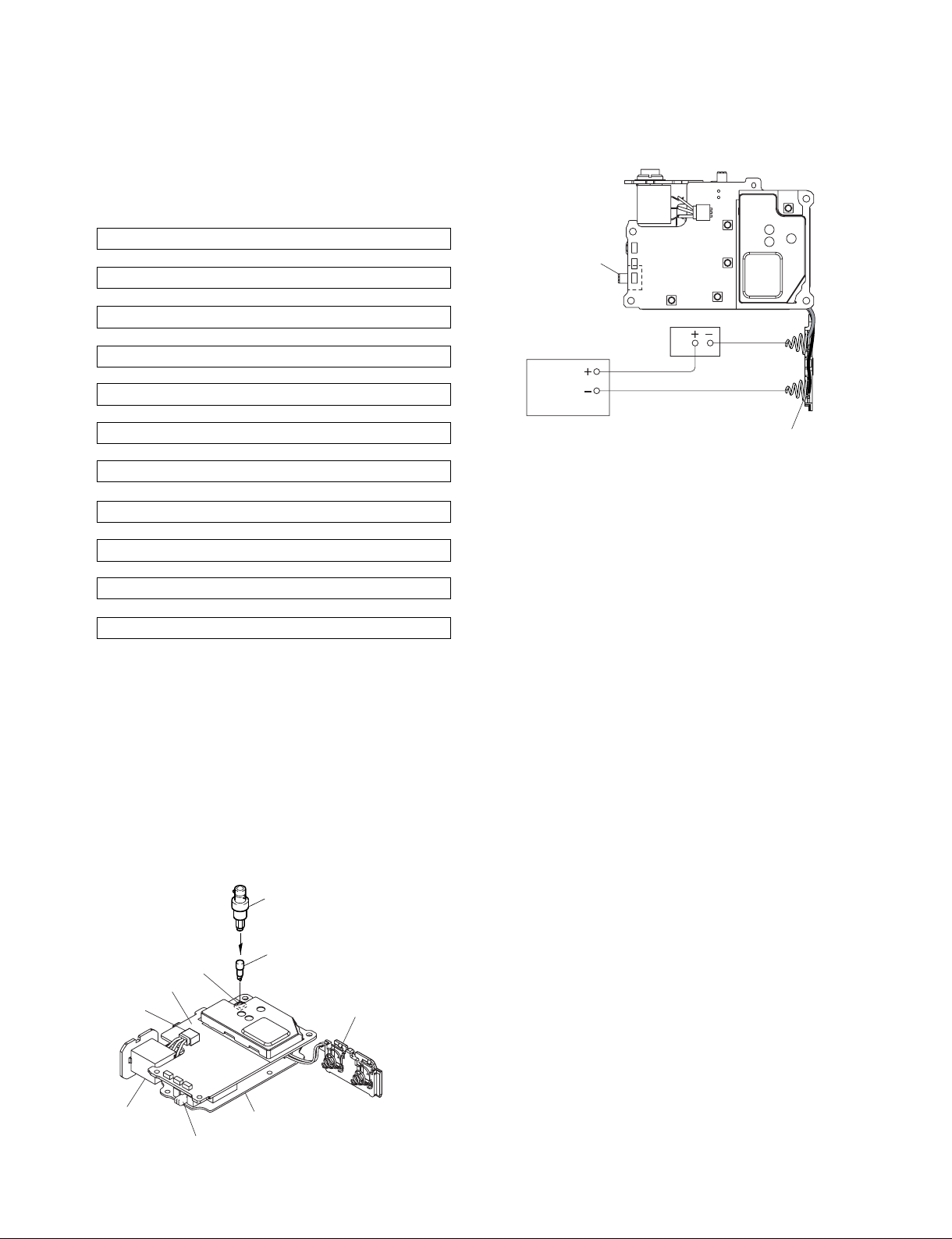

Preparation

1. Perform this adjustment after removing the front/rear

cabinets and battery case from the UTX-B2 unit, and

with the RF-131 board, battery terminal, and LINE/

MIC connector connected to the CPU-422 board.

(Refer to the Section 1-1-1. for removal.)

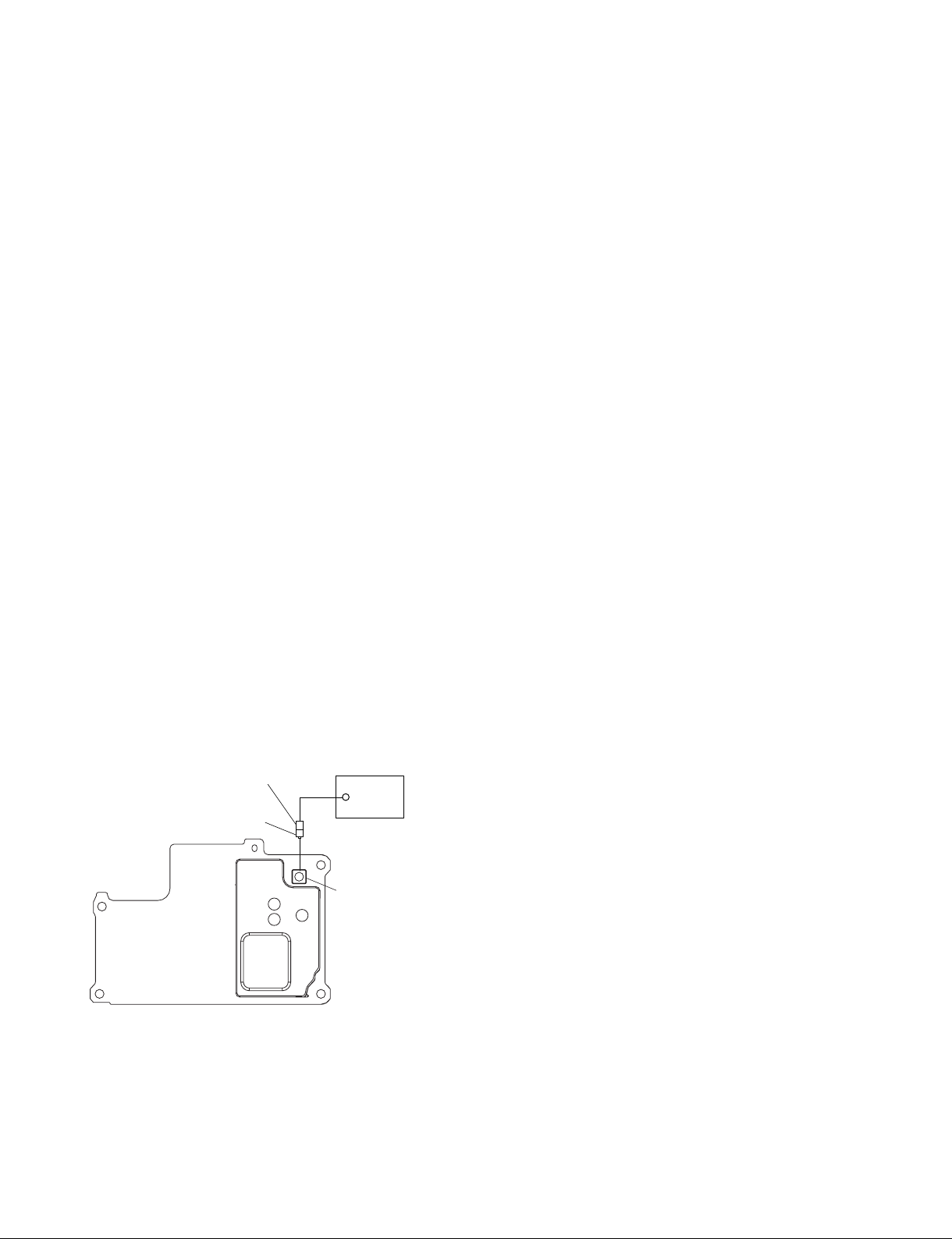

2. Connect the SMA-BNC conversion connector (J-6402480-A) and the MM-SMA conversion connector (J6402-490-A) to the antenna terminal (CN301) on the

RF-131 board as shown below.

↓

↓

↓

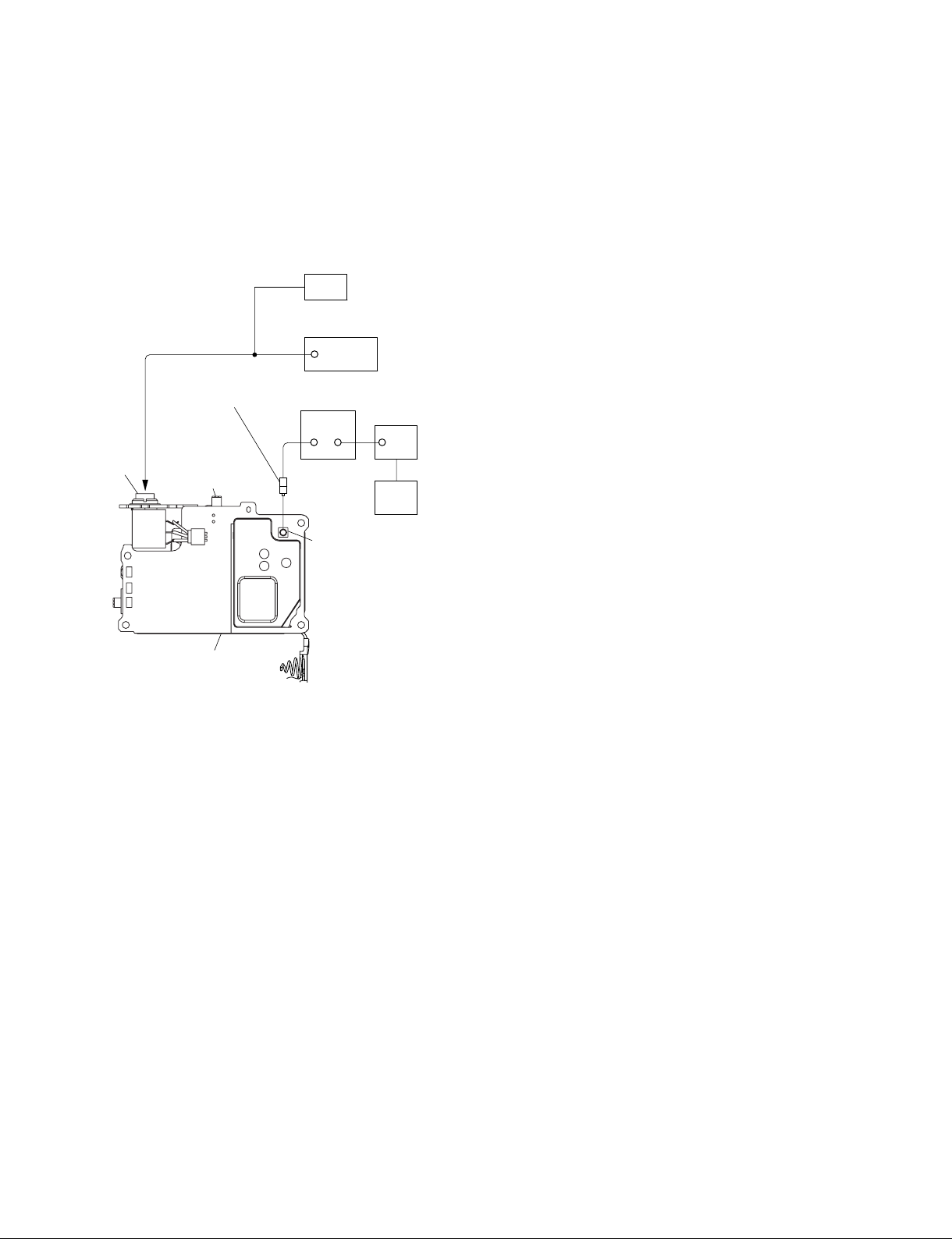

3. Connecting the DC power supply

Supply the DC power to the battery terminal as below.

POWER

switch

(S11/CPU-422 board)

DC ammeter

DC regulated power supply

(DC output voltage : + 3.0 ±0.1 V)

Battery terminal

Check

After the DC power supply connection is complete, set

the power switch (S11/CPU-422 board) to ON, and

check the level on DC ammeter.

DC ammeter indication level: 130 to 200 mA

Switch and Control Initial Setting

Switch and Control Setting

U30 model ; 30-01 channel (566.125 MHz)

U42 model ; 42-01 channel (638.125 MHz)

CE62 model ; Group 00, 62-01 channel (798.125 MHz)

CE67 model ; Group 00, 67-01 channel (838.125 MHz)

KR model ; 59-01 channel (740.125 MHz)

Attenuation setting : 0 dB

Accumulated time setting : “00 : 00”

n

Note down the setting position before the adjustment.

After the Adjustment complete, set the original position.

Red

+

Black

_

RF-131 board

CN401

MIC / LINE

input connector

2-2

SMA-BNC conversion connector

MM-SMA conversion connector

CN301

Battery terminal

CPU-422 board

POWER switch (S11)

UWP Series

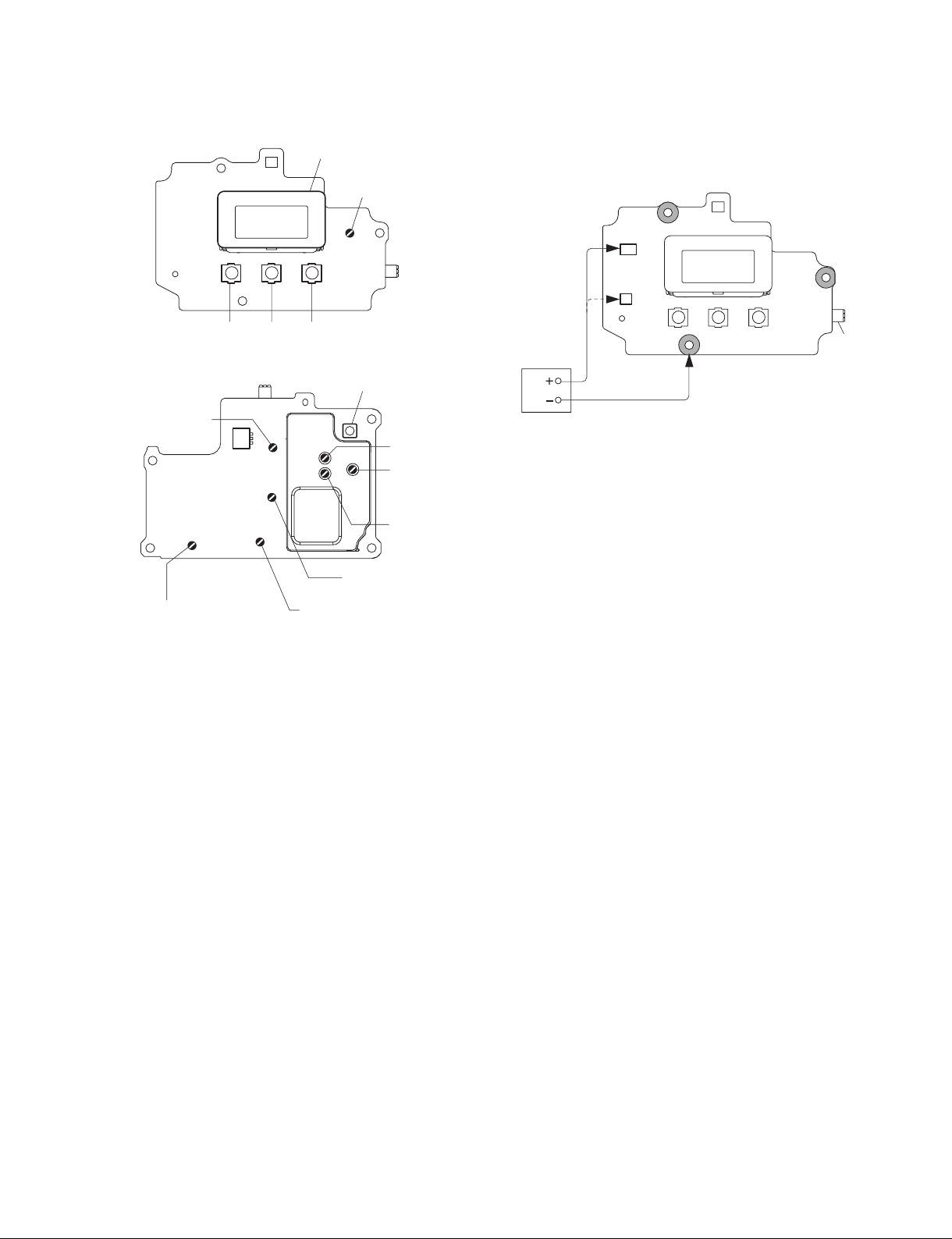

Adjustment Location

LCD

CT621

Connections

(For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.)

GND

C24 (+)

S673

S672_S671

RV521

(Reference frequency

deviation adjustment)

RV441

(AF limiter adjustment)

SET

CN401

+

CN301

RV491

(AF clipper adjustment)

RV511

(Tone signal level adjustment)

1. Power Supply Voltage Check

CPU-422 board

(B side)

RV351

(RF output "H"

adjustment)

CT361

(Output efficiency

optimization)

RV341

(RF output "L"

adjustment)

RF-131 board

(A side)

L12

GND

CPU-422 board (B side)

DC voltmeter

GND

S11

Procedure

1.

Set the POWER switch (S11/CPU-422 board) to ON.

2. Check the DC Voltage of the + terminal on the

CPU-422 board

Specification :

to the specified voltage as below :

C24 (

+ terminal) DC Voltage = +3.3

± 0.1Vdc

3. Check the DC voltage of the

L12/CPU-422 board

specified voltage as below :

Specification :

L12 terminal DC voltage = +5.0 ±0.1Vdc

C24/

to the

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ±0.1 Vdc

. DC ammeter

. Digital volt meter (or Digital multimeter)

Switch and Control Setting

CPU-422 board

Transmission channel

U30 model ; 30-01 channel (566.125 MHz)

U42 model ; 42-01 channel (638.125 MHz)

CE62 model ; Group 00, 62-01 channel (798.125 MHz)

CE67 model ; Group 00, 67-01 channel (838.125 MHz)

KR model ; 59-01 channel (740.125 MHz)

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

n

Take note of the settings before starting the confirmation

work.

After confirmation is completed, return the settings to

the original setting before change.

UWP Series

2-3

2. Carrier Frequency Adjustment

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ±0.1 Vdc

. DC ammeter

. Frequency counter

. Adjustor (SONY Part No. 7-721-052-81)

. MM-SMA conversion connector

(SONY Part No. J-6402-490-A)

.

SMA-BNC

(SONY Part No. J-6402-480-A)

Switch and Control Setting

Transmission channel

U30 model ; 32-01 channel (578.125 MHz)

U42 model ; 42-01 channel (650.125 MHz)

CE62 model ; Group 00, 63-32 channel (810.000 MHz)

CE67 model ; Group 00, 68-32 channel (850.000 MHz)

KR model ; 60-01 channel (746.125 MHz)

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

n

Note down the setting position before the adjustment.

After the Adjustment complete, set the original position.

conversion

connector

Procedure

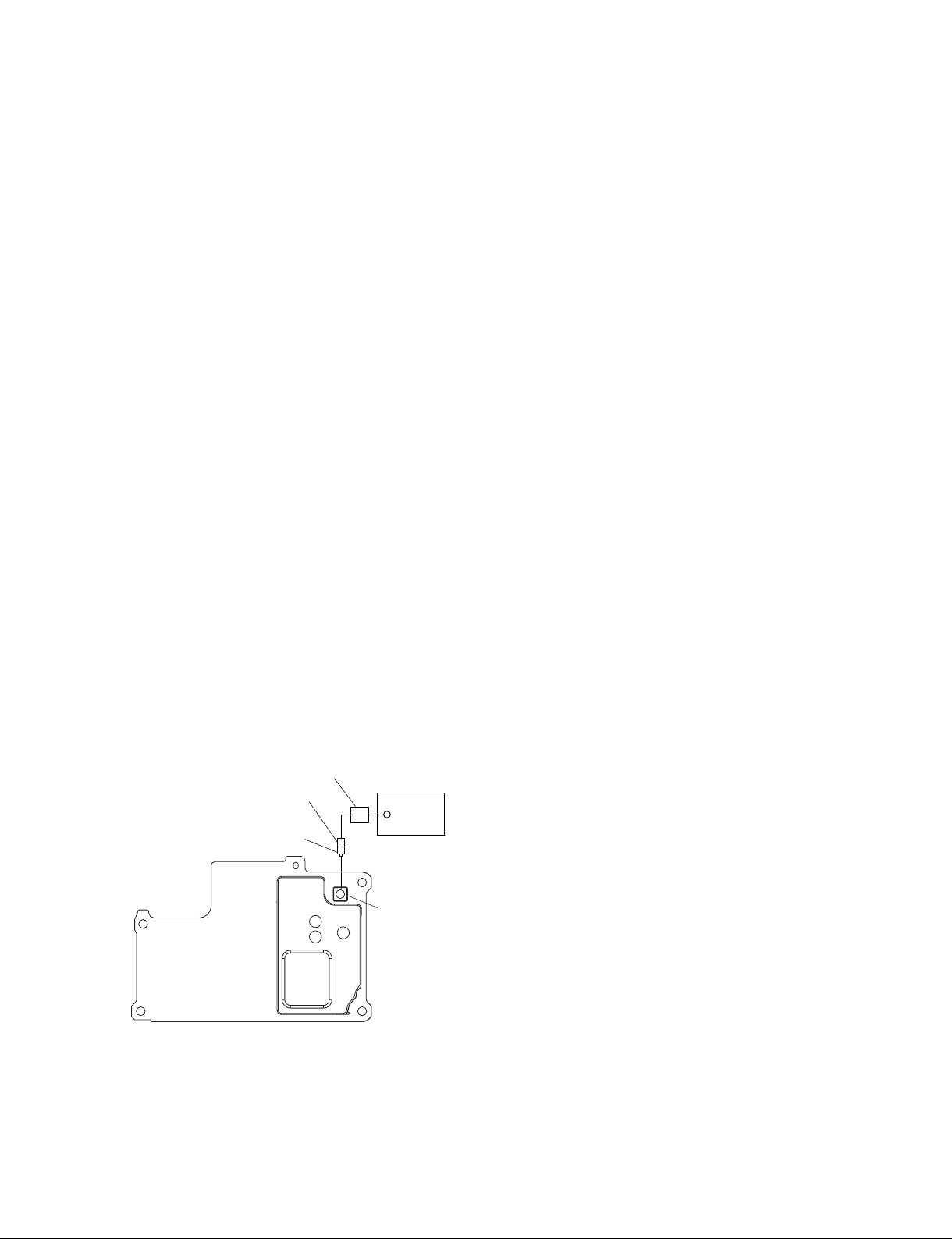

1. Connect a frequency counter to the antenna terminal

(CN301/RF-131 board) via the MM-SMA conversion

connector and the SMA-BNC conversion connector.

2. Adjust 1CT621 so that the frequency counter reading

meets the following specification.

Specification : Carrier frequency mentioned below.

U30 model ; 578.125 MHz ±1 kHz

U42 model ; 650.125 MHz ±1 kHz

CE62 model ; 810.000 MHz ± 1 kHz

CE67 model ; 850.000 MHz ± 1 kHz

KR model ; 746.125 MHz ± 1 kHz

Adjustment : 1CT621/CPU-422 board (B side)

(Refer to page 2-3 for the adjustment location.)

Connections

(For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.)

Frequency counter

SMA-BNC conversion connector

MM-SMA conversion connector

CN301

RF-131 board

(A side)

2-4

UWP Series

3. RF Power Output Adjustment

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ±0.1 Vdc

. DC ammeter

. Power meter (with power sensor)

. Adjustor (SONY Part No. 7-721-052-81)

. MM-SMA conversion connector

(SONY Part No. J-6402-490-A)

.

SMA-BNC

(SONY Part No. J-6402-480-A)

Switch and Control Setting

Transmission channel

U30 model ; 32-01 channel (578.125 MHz)

U42 model ; 42-01 channel (650.125 MHz)

CE62 model ; Group 00, 63-32 channel (810.000 MHz)

CE67 model ; Group 00, 68-32 channel (850.000 MHz)

KR model ; 60-01 channel (746.125 MHz)

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

RF power output : “H”

n

Note down the setting position before the adjustment.

After the Adjustment complete, set the original position.

Connections

(For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.)

conversion

connector

Procedure

1. Connect the power meter (with power sensor) to the antenna terminal (CN301/RF-131 board) via the MMSMA conversion connector and the

sion

connector

.

SMA-BNC

conver-

2. Adjust 1CT361 so that the power meter reading meets

the following specification.

Specification : power meter = Maximum

Adjustment : 1CT361/RF-131 board (A side)

(Refer to page 2-3 for the adjustment location.)

3. Adjust 1RV351 so that the power meter reading meets

the following specification.

Specification :

. U30, U42, CE62 and CE67 models :

Power meter = 28 ± 1 mW

. KR model :

Power meter = 9 mW

+0.5

_0.1

Adjustment : 1RV351/RF-131 board (A side)

(Refer to page 2-3 for the adjustment location.)

4. Set the transmission output to “L”.

5. Adjust 1RV341 so that the power meter reading meets

the following specification.

Specification :

. U30, U42, CE62 and CE67 models :

Power meter = 5 mW ±2 mW

. KR model :

Power meter = 1.6 ± 0.6 mW

Adjustment : 1RV341/RF-131 board (A side)

(Refer to page 2-3 for the adjustment location.)

SMA-BNC conversion connector

MM-SMA conversion connector

UWP Series

Power sensor

Power meter

CN301

RF-131 board

(A side)

2-5

4. Reference Frequency Deviation

Adjustment

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ±0.1Vdc

. DC ammeter

. Audio analyzer

. Modulation analyzer

MEASUREMENT : FM

MEASUREMENT RANGE : AUTO or ± 10 kHz

HPF : 50 Hz

LPF : 20 kHz or 15 kHz

DE EMPHASIS : 50 usec

. Adjustor (SONY part No. 7-721-052-81)

. MM-SMA conversion connector

(SONY Part No. J-6402-490-A)

.

SMA-BNC

(SONY Part No. J-6402-480-A)

Switch and Control Setting

Transmission channel

U30 model ; 32-01 channel (578.125 MHz)

U42 model ; 42-01 channel (650.125 MHz)

CE62 model ; Group 00, 63-32 channel (810.000 MHz)

CE67 model ; Group 00, 68-32 channel (850.000 MHz)

KR model ; 60-01 channel (746.125 MHz)

MIC/LINE change switch

(S401/RF-131 board) : MIC

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

n

Note down the setting position before the adjustment.

After the Adjustment complete, set the original position.

conversion

connector

Connections

(For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.)

Level meter

Audio analyzer

MM-SMA conversion connector and

SMA-BNC conversion connector

AF input

connector

MIC / LINE

change switch

(S401 / RF-131 board)

RF-131 board

analyzer

OscilloscopeModulation

CN301

Procedure

1. Input 1 kHz, _ 60 dBV (_57.8 dBm) signal to the AF

INPUT connector.

(0 dBV = 1 Vrms)

2. Connect a modulation analyzer to the antenna terminal

(CN301/RF-131 board) via the MM-SMA conversion

connector and the

SMA-BNC

conversion

connector

.

3. Adjust 1RV521 so that the frequency deviation for the

modulation analyzer reading meets the following specification.

Specification :

Frequency deviation = ±7 kHz ±0.1 kHz

Adjustment : 1RV521/RF-131 board (A side)

(Refer to page 2-3 for the adjustment location.)

2-6

UWP Series

5. Maximum Frequency Deviation

Adjustment

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ±0.1Vdc

. DC ammeter

. Audio analyzer

. Modulation analyzer

MEASUREMENT : FM

MEASUREMENT RANGE : AUTO or ± 100 kHz

HPF : 50 Hz

LPF : 15 kHz or 20 kHz

DE EMPHASIS : 50 usec

. Oscilloscope

. Adjustor (SONY part No. 7-721-052-81)

. MM-SMA conversion connector

(SONY Part No. J-6402-490-A)

.

SMA-BNC

(SONY Part No. J-6402-480-A)

Switch and Control Setting

Transmission channel

U30 model ; 32-01 channel (578.125 MHz)

U42 model ; 42-01 channel (650.125 MHz)

CE62 model ; Group 00, 63-32 channel (810.000 MHz)

CE67 model ; Group 00, 68-32 channel (850.000 MHz)

KR model ; 60-01 channel (746.125 MHz)

MIC/LINE change switch

(S401/RF-131 board) : MIC

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

n

Note down the setting position before the adjustment.

After the Adjustment complete, set the original position.

Connections

. Same as “4. Reference Frequency Division adjustments”.

. For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.

Procedure

1.

Input 1 kHz, _20 dBV (_17.8 dBm) signal to the AF INPUT connector (with Mic input cable). (0 dBV = 1 Vrms)

2. Adjust 1RV441/RF-131 so that the frequency devia-

tion for the modulation analyzer reading meets the following specification.

Specification : Frequency deviation = ±34.5 kHz ± 0.5 kHz

Adjustment :

3.

Input 1 kHz, _10 dBV (_7.8 dBm) signal to the AF INPUT connector (with Mic input cable). (0 dBV = 1 Vrms)

conversion

connector

1RV441/RF-131 board (A side)

4. Connect a modulation analyzer to the antenna terminal

(CN301/RF-131 board) via the MM-SMA conversion

connector and the

5.

Adjust 1RV491

SMA-BNC

/RF-131

conversion

connector

.

so that the frequency deviation

for the modulation analyzer reading meets the following

specification.

Specification :

Frequency deviation = ± 39.5 kHz ± 0.5 kHz

Adjustment : 1RV491/RF-131 board (A side)

6. Distortion Ratio Check

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ±0.1Vdc

. DC current meter

. Audio analyzer

. Modulation analyzer

MEASUREMENT : FM

MEASUREMENT RANGE : AUTO or ± 40 kHz

HPF : 50 Hz

LPF : 15 kHz or 20 kHz

DE EMPHASIS : 50 usec

. Oscilloscope

. MM-SMA conversion connector

(SONY Part No. J-6402-490-A)

.

SMA-BNC

(SONY Part No. J-6402-480-A)

Switch and Control Setting

Transmission channel

U30 model ; 32-01 channel (578.125 MHz)

U42 model ; 42-01 channel (650.125 MHz)

CE62 model ; Group 00, 63-32 channel (810.000 MHz)

CE67 model ; Group 00, 68-32 channel (850.000 MHz)

KR model ; 60-01 channel (746.125 MHz)

MIC/LINE change switch

(S401/RF-131 board) : MIC

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

n

Take note of the settings before starting the confirmation

work.

After confirmation is completed, return the settings to

the original setting before change.

conversion

connector

UWP Series

2-7

Connections

. For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.

. For the connection to the AF IN connector (CN1), refer

to the section “4. Reference Frequency Deviation

Adjustment”.

Level meter

Audio analyzer

Oscillator

MM-SMA conversion connector and

AF input

connector

SMA-BNC conversion connector

RFINAF

MIC / LINE

change switch

(S401 / RF-131 board)

RF-131 board

Modulation

analyzer

CN301

Distortion

analyzer

OUT

Oscilloscope

Procedure

1. Connect the audio analyzer (distortion analyzer) to the

AF OUT connector for the modulation analyzer.

2. Set the audio analyzer to distortion measurement

(DISTORTION mode).

3. Input 1 kHz, _60 dBV (_57.8 dBm) signal to the AF

INPUT connector from audio analyzer (oscillator).

(0 dBV = 1 Vrms)

4. Check that the distortion analyzer reading is less than

1.0%.

5. Input 1 kHz, _23 dBV (_20.8 dBm) signal to the AF

INPUT connector.

6. Check that the distortion analyzer reading is less than

1.0%.

2-8

7. S/N Check

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ± 0.1Vdc

. DC ammeter

. Audio analyzer

. Modulation analyzer

MEASUREMENT : FM

MEASUREMENT RANGE : ± 40 kHz

HPF : 50 Hz

LPF : 15 kHz or 20 kHz

DE EMPHASIS : 50 usec

. Oscilloscope

. MM-SMA conversion connector

(SONY Part No. J-6402-490-A)

.

SMA-BNC

(SONY Part No. J-6402-480-A)

Switch and Control Setting

Transmission channel

U30 model ; 32-01 channel (578.125 MHz)

U42 model ; 42-01 channel (650.125 MHz)

CE62 model ; Group 00, 63-32 channel (810.000 MHz)

CE67 model ; Group 00, 68-32 channel (850.000 MHz)

KR model ; 60-01 channel (746.125 MHz)

MIC/LINE change switch

(S401/RF-131 board) : MIC

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

n

Take note of the settings before starting the confirmation

work.

After confirmation is completed, return the settings to

the original setting before change.

Connections

. Same as “6. Distortion Ratio Check”.

. For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.

Procedure

1. Connect the audio analyzer (level meter) to the AF OUT

connector for the modulation analyzer.

2. Set the modulation analyzer.

3. Input 1 kHz, _ 60 dBV (_57.8 dBm) signal to the AF

INPUT connector from audio analyzer (oscillator).

(0 dBV = 1 Vrms)

4. Set the audio analyzer to S/N measurement (with Aweighting filter).

5. Check that the S/N reading is more than 30 dB.

n

Perform the checking with the AF INPUT connector

short-circuit.

conversion

connector

UWP Series

8. Frequency Characteristics Check

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ±0.1Vdc

. DC ammeter

. Audio analyzer

. Modulation analyzer

MEASUREMENT : FM

MEASUREMENT RANGE : ±40 kHz

HPF : 50 Hz

LPF : 15 kHz or 20 kHz

DE EMPHASIS : 50 usec

. Oscilloscope

. MM-SMA conversion connector

(SONY Part No. J-6402-490-A)

.

SMA-BNC

(SONY Part No. J-6402-480-A)

Switch and Control Setting

Transmission channel

U30 model ; 32-01 channel (578.125 MHz)

U42 model ; 42-01 channel (650.125 MHz)

CE62 model ; Group 00, 63-32 channel (810.000 MHz)

CE67 model ; Group 00, 68-32 channel (850.000 MHz)

KR model ; 60-01 channel (746.125 MHz)

MIC/LINE change switch

(S401/RF-131 board) : MIC

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

n

Take note of the settings before starting the confirmation

work.

After confirmation is completed, return the settings to

the original setting before change.

Connections

. Same as “6. Distortion Ratio Check”.

. For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.

conversion

connector

6.

Set the SENSITIVITY on the audio analyzer (level

meter) so that the audio analyzer (level meter) reads 0 dB.

7. Switch the oscillation frequency for the audio analyzer

(oscillator) from 1 kHz to 100 Hz.

8. Check that audio analyzer (level meter) reading is _1

± 2 dB.

9. Switch the oscillation frequency for the audio analyzer

(oscillator) from 100 Hz to 15 kHz.

10. Check that the reading for the audio analyzer (level

meter) is +3 ± 2 dB.

9. Tone Signal Adjustment

Equipment and Tools

. DC power supply

DC output voltage : +3.0 ±0.1Vdc

. DC current meter

. Frequency counter

. Spectrum analyzer

. Modulation analyzer

. RF adjusting cable (SONY part No. 7-721-052-81)

. MM-SMA conversion connector

(SONY Part No. J-6402-490-A)

.

SMA-BNC

(SONY Part No. J-6402-480-A)

Switch and Control Setting

Transmission channel

U30 model ; 32-01 channel (578.125 MHz)

U42 model ; 42-01 channel (650.125 MHz)

CE62 model ; Group 00, 63-32 channel (810.000 MHz)

CE67 model ; Group 00, 68-32 channel (850.000 MHz)

KR model ; 60-01 channel (746.125 MHz)

Attenuation setting : 0 dB

Accumulated time setting :“00 : 00”

n

Note down the setting position before the adjustment.

After the Adjustment complete, set the original position.

conversion

connector

Procedure

1. Connect the audio analyzer (level meter) to the AFOUT connector for the modulation analyzer.

2. Set the modulation analyzer.

3. Set the audio analyzer to level meter mode.

4. Input 1 kHz, _60 dBV (_57.8 dBm) signal to the AF

INPUT connector from audio analyzer (oscillator).

5.

Check the indication on the audio analyzer (level meter).

UWP Series

2-9

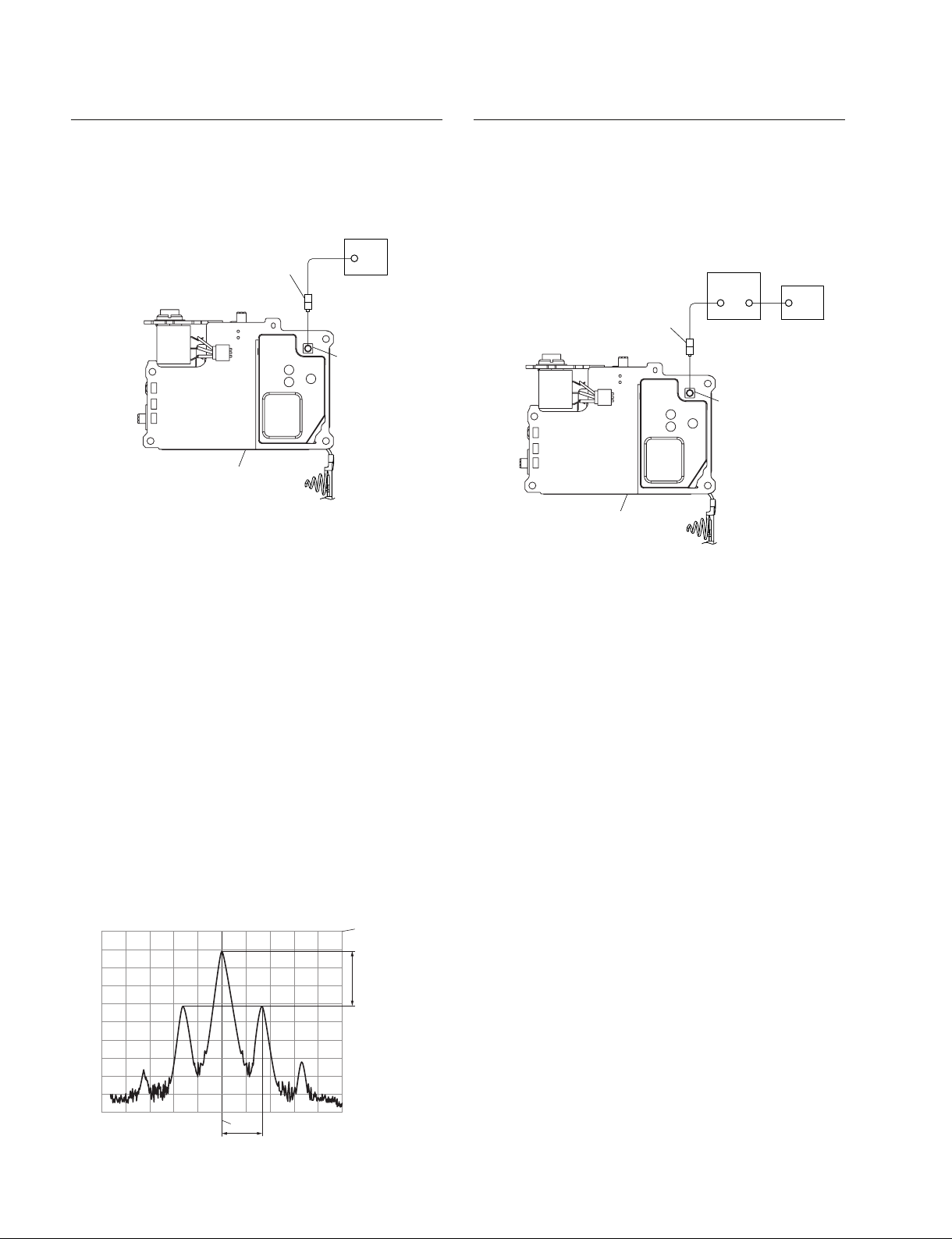

Frequency deviation adjustment

Frequency check

Connections

(For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.)

MM-SMA conversion connector and

SMA-BNC conversion connector

Spectrum analyzer

CN301

RF-131 board

Procedure

1. Connect the spectrum analyzer to the antenna terminal

(CN301/RF-131 board) via the MM-SMA conversion

connector and the

SMA-BNC

conversion

connector

.

2. Set the spectrum analyzer as below:

CENTER FREQUENCY (fc)

U30 model ; 578.125 MHz ± 1 kHz

U42 model ; 650.125 MHz ± 1 kHz

CE62 model ; 810.000 MHz ± 1 kHz

CE67 model ; 850.000 MHz ± 1 kHz

KR model ; 746.125 MHz ± 1 kHz

REFERENCE LEVEL : 20 dBm

FREQUENCY SPAN

: 200kHz (20 kHz/DIV)

RBW (resolution band width) : 3kHz

VBW (video band width) : 1kHz

ATT : 20 dB

3. Adjust 1RV511/RF-131 board (A side) so that level

between carrier frequency (frequency center level) on

spectrum analyzer and tone signal is within 29 dB ±1 dB.

Connections

(For connecting the DC power supply, refer to step

“3. Connecting the DC power supply” in Section 2-1-2.)

Modulation

analyzer

RF

AF

IN

MM-SMA conversion connector and

SMA-BNC conversion connector

RF-131 board

OUT

CN301

Frequency

counter

Procedure

n

Perform the checking with the AF INPUT connector shortcircuit.

1. Set the modulation analyzer as below:

MEASUREMENT : FM

MEASUREMENT RANGE : ± 40 kHz

HPF : 4 kHz

LPF : >20 kHz

DE EMPHASIS : OFF

2. Check that the frequency counter (resolution : 0.1 Hz

setting) reading is 32.000 kHz ± 1Hz.

2-10

20 dBm

29±1 dB

v:10 dB/div

H:20 MHz/div

fc

32.000 kHz

UWP Series

Loading...

Loading...