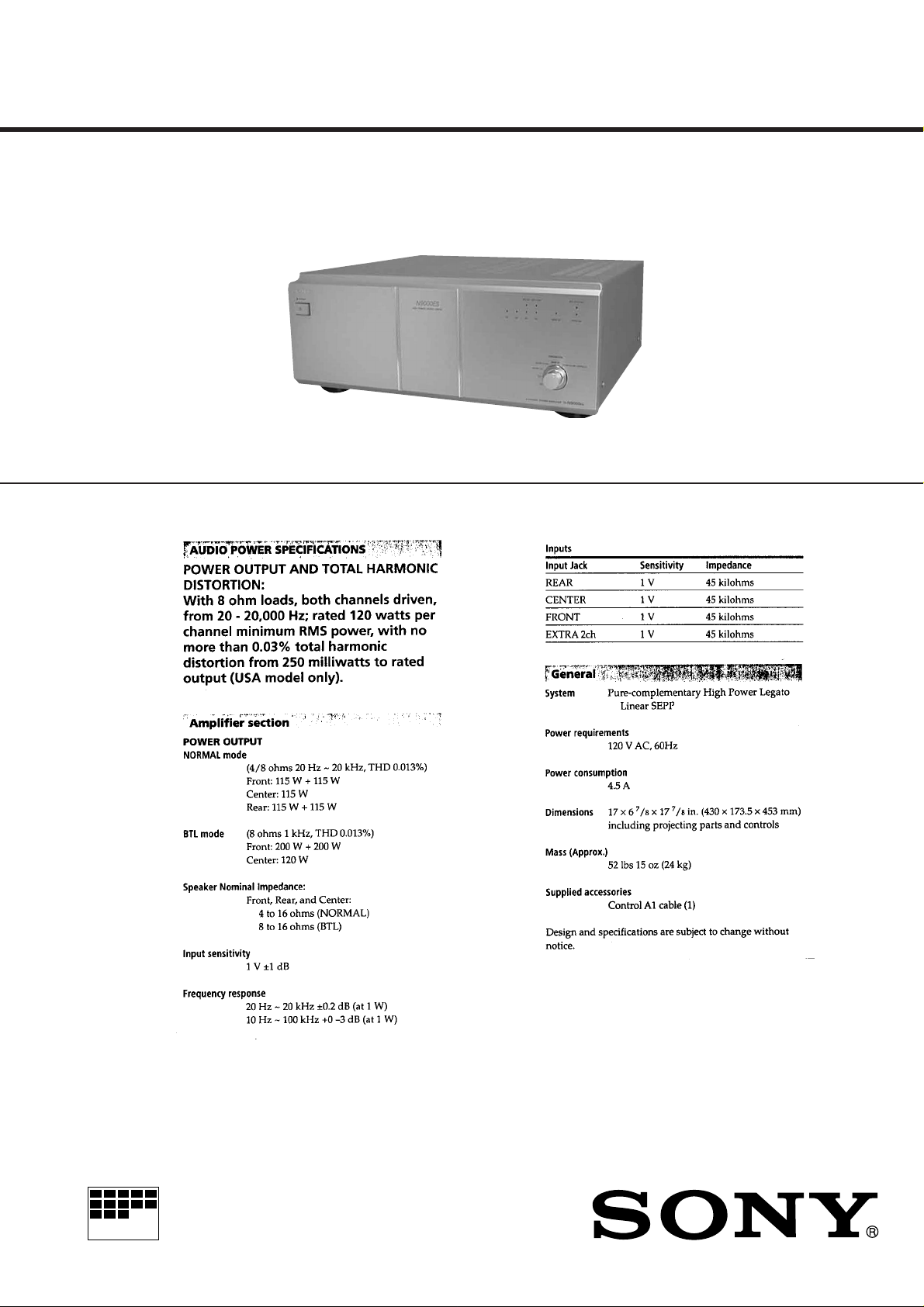

Sony TAN-9000-ES Service manual

TA-N9000ES

SERVICE MANUAL

Photo: GOLD model

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Chinese Model

MICROFILM

5 CHANNEL POWER AMPLIFIER

T ABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY ......................................................... 5

4. ELECTRICAL ADJUSTMENTS......................... 7

5. DIAGRAMS................................................................. 8

5-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 9

5-2. Printed Wiring Boards – MAIN Section – .................... 11

5-3. Schematic Diagram – MAIN Section (1/3) –................ 13

5-4. Schematic Diagram – MAIN Section (2/3) –................ 15

5-5. Schematic Diagram – MAIN Section (3/3) –................ 17

5-6. Printed Wiring Boards – CONTROL Section – ............ 19

5-7. Schematic Diagram – CONTROL Section –................. 21

5-8. Printed Wiring Boards – POWER Section – ................. 23

5-9. Schematic Diagram – POWER Section – ..................... 25

5-10. IC Pin Function Description ........................................... 27

6. EXPLODED VIEWS ................................................ 28

7. ELECTRICAL PARTS LIST ............................... 30

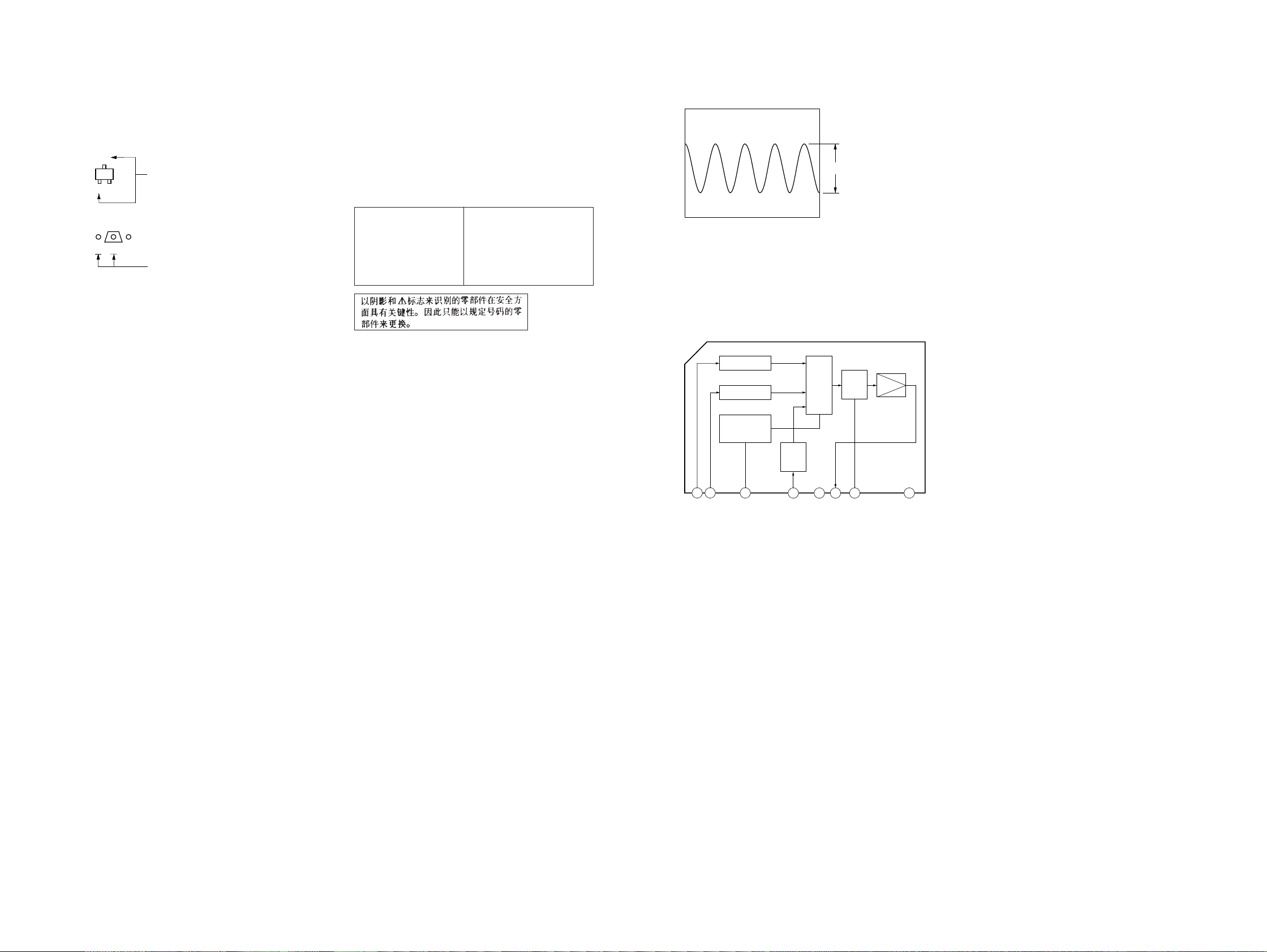

SAFETY-RELA TED COMPONENT W ARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY .

A TTENTION A U COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

SECTION 1

8

SERVICING NOTES

MODEL IDENTIFICATION

– Rear view –

234567

PART No.

MODEL PART No.

US, Canadian models 4-211-114-1π

Except US, Canadian models 4-211-114-2π

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

AC

voltmeter

(0.75 V)

– 3 –

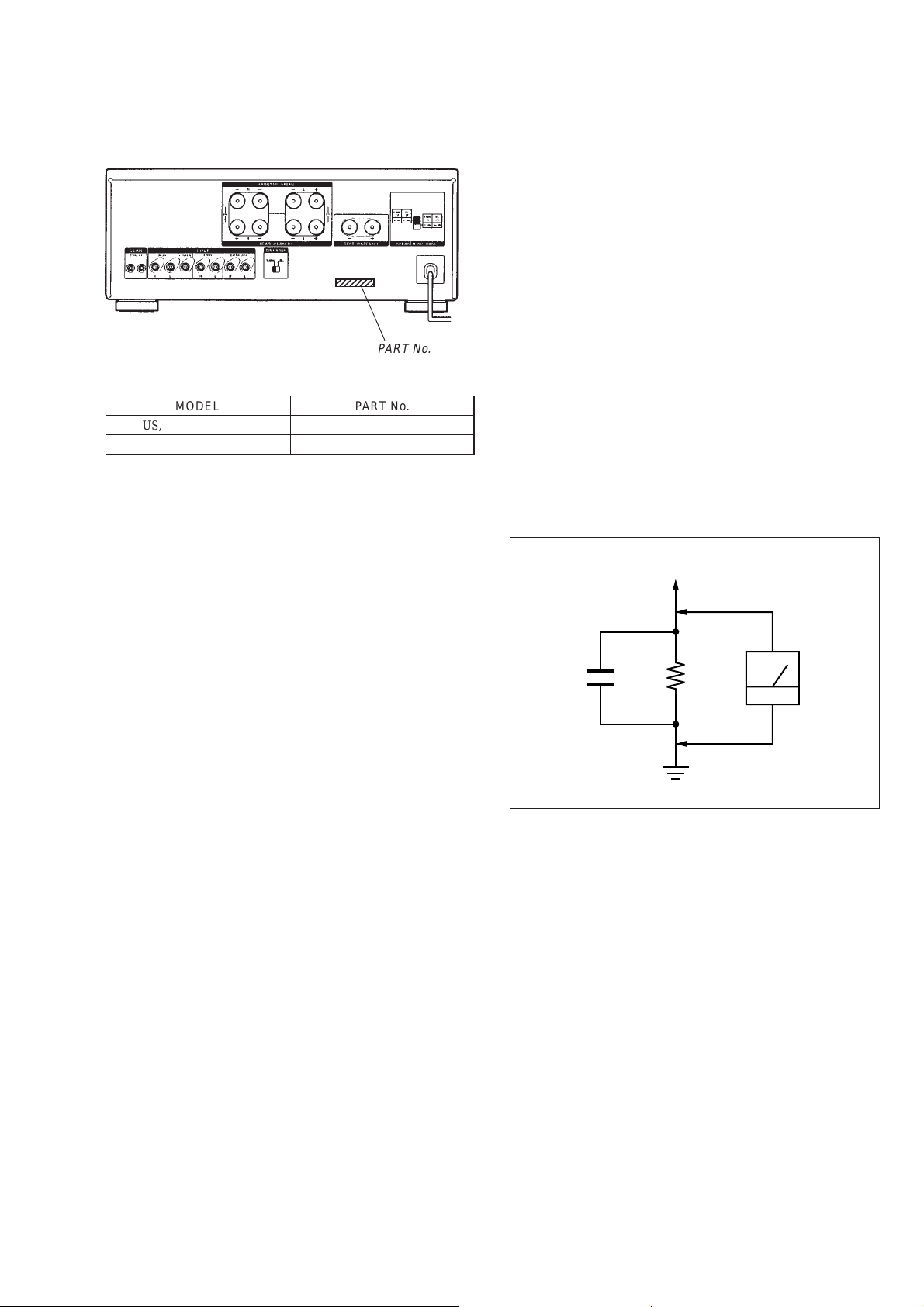

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 4 –

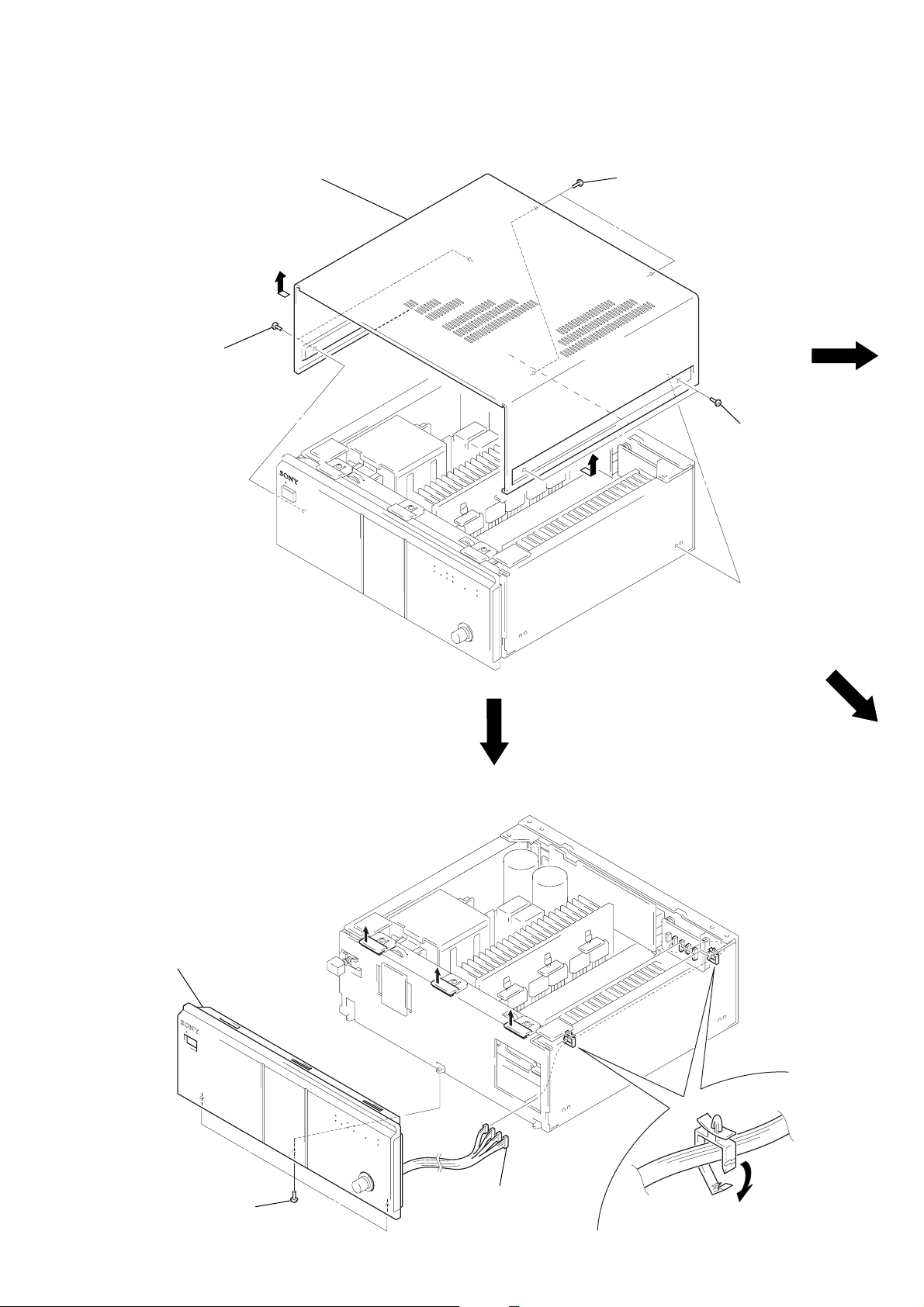

SECTION 3

s

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

3

case

2

two flat head screws

1

two screws

(BV3 x 8B)

2

two flat head screw

FRONT PANEL SECTION

front panel section

5

3

three screws

(BV3

×

8B)

4

4

4

2

four connectors

(CN152, 153, 154, 155)

1

Unlock each claw of the saddle wire.

– 5 –

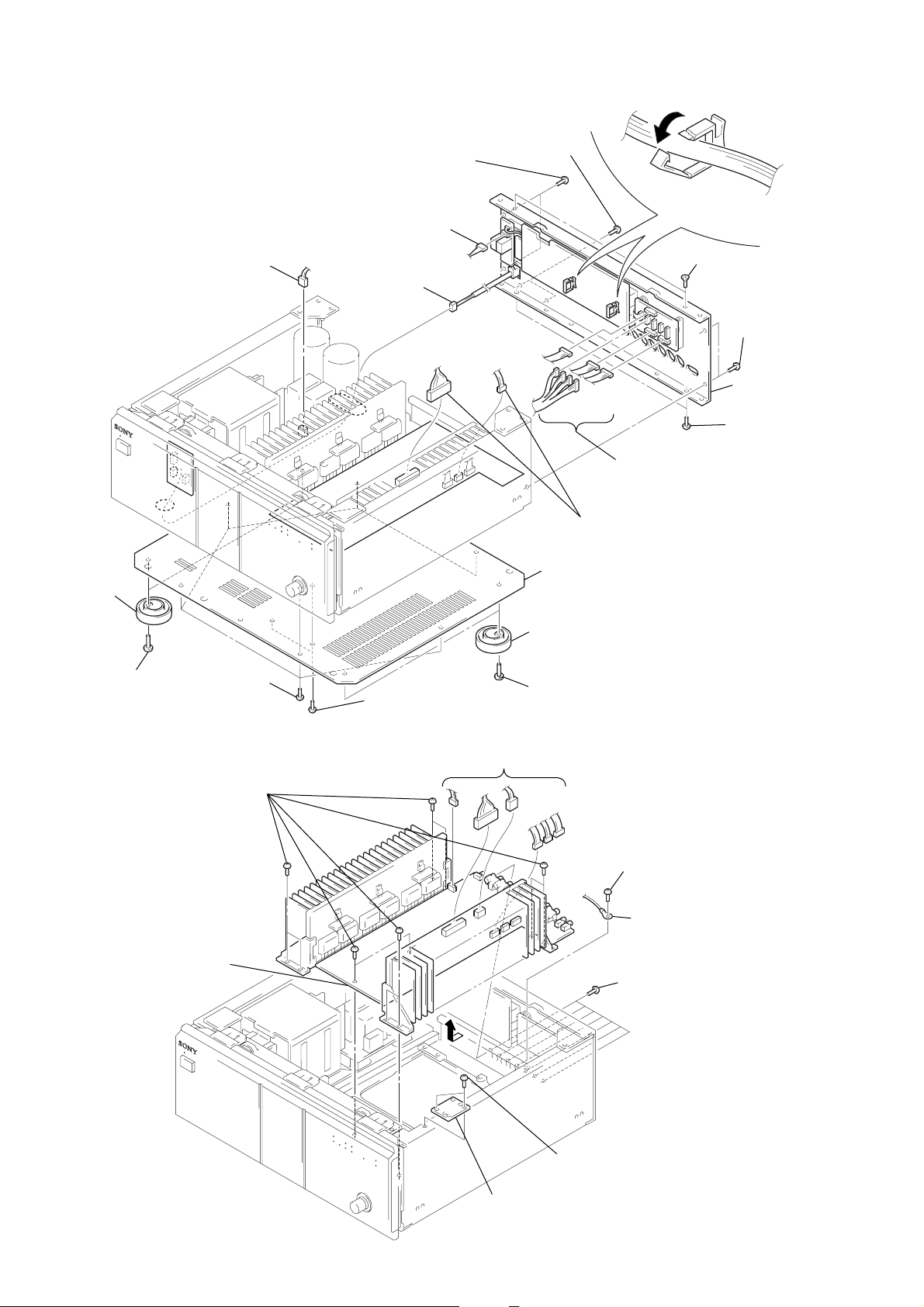

BOTTOM PLATE, BACK PANEL SECTION

6

connector

(CN808)

6

connector

(CN812)

8

6

connector

(CN809)

two screws

(BV3

×

8B)

9

two screws

(P4

×

8)

6

two connectors

(CN201, 205)

5

Unlock each claw of

the saddle wire.

7

6

seven connectors

(CN152, 153, 154,

155, 156, 157, 158)

two screws

(K3

×

8)

8

two screws

(BV3

0

back panel

section

8

two screws

(BV3

×

×

8B)

8B)

2

two foot assy’s

1

two screws

(B4

MAIN BOARD

×

16)

7

3

six screws

(BV3

6

ten screws

(BV3

MAIN board

×

×

8B)

8B)

3

two screws

(BV3

4

bottom plate

2

two foot assy’s

1

two screws

×

8B)

1

six connectors

(CN101, 201, 202, 203, 204, 205)

(B4

×

16)

4

screw

(BV3

5

lug

6

seven screws

(BV3

×

×

8B)

8B)

– 6 –

3

bracket

2

two screws

(BV3

×

8B)

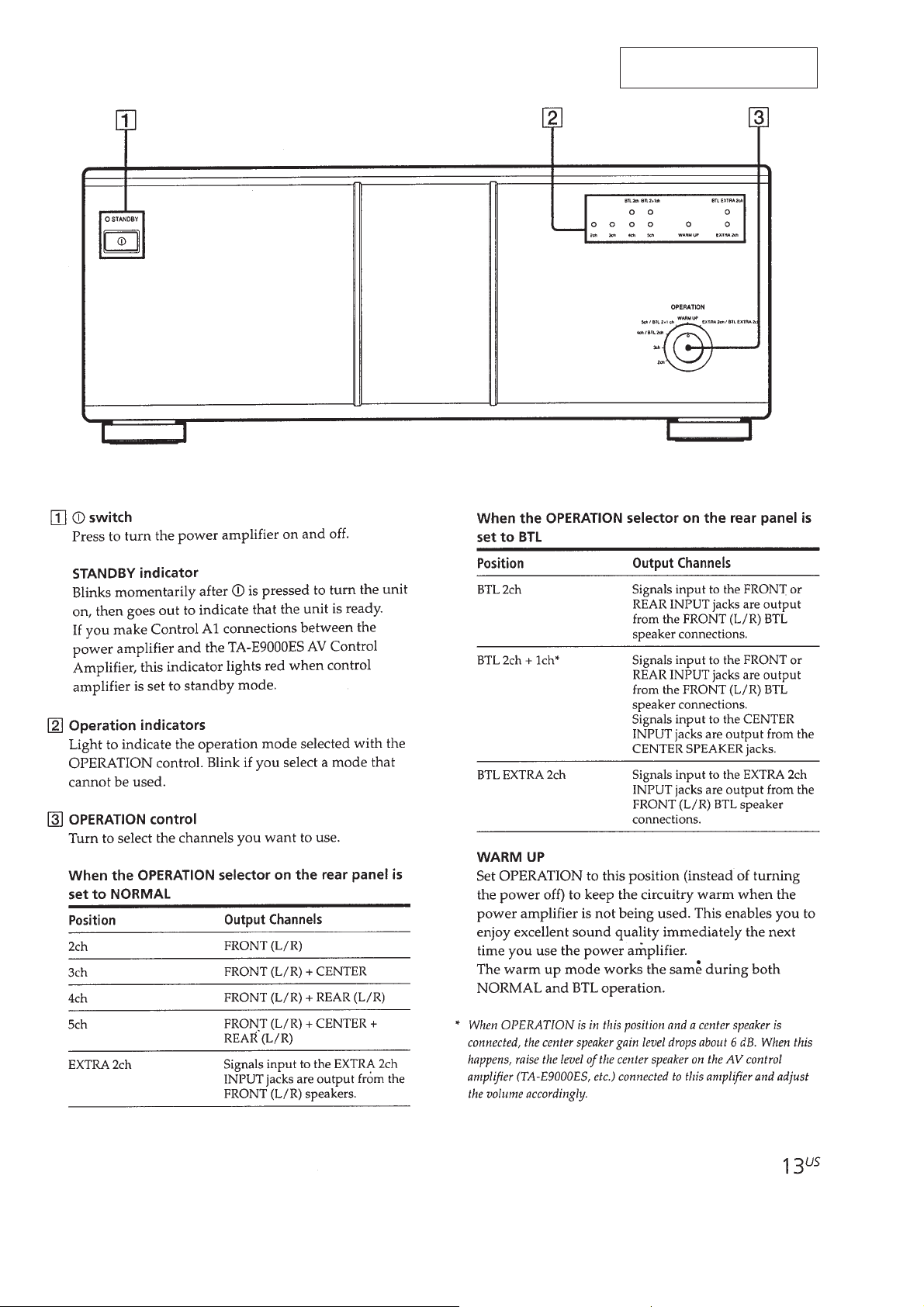

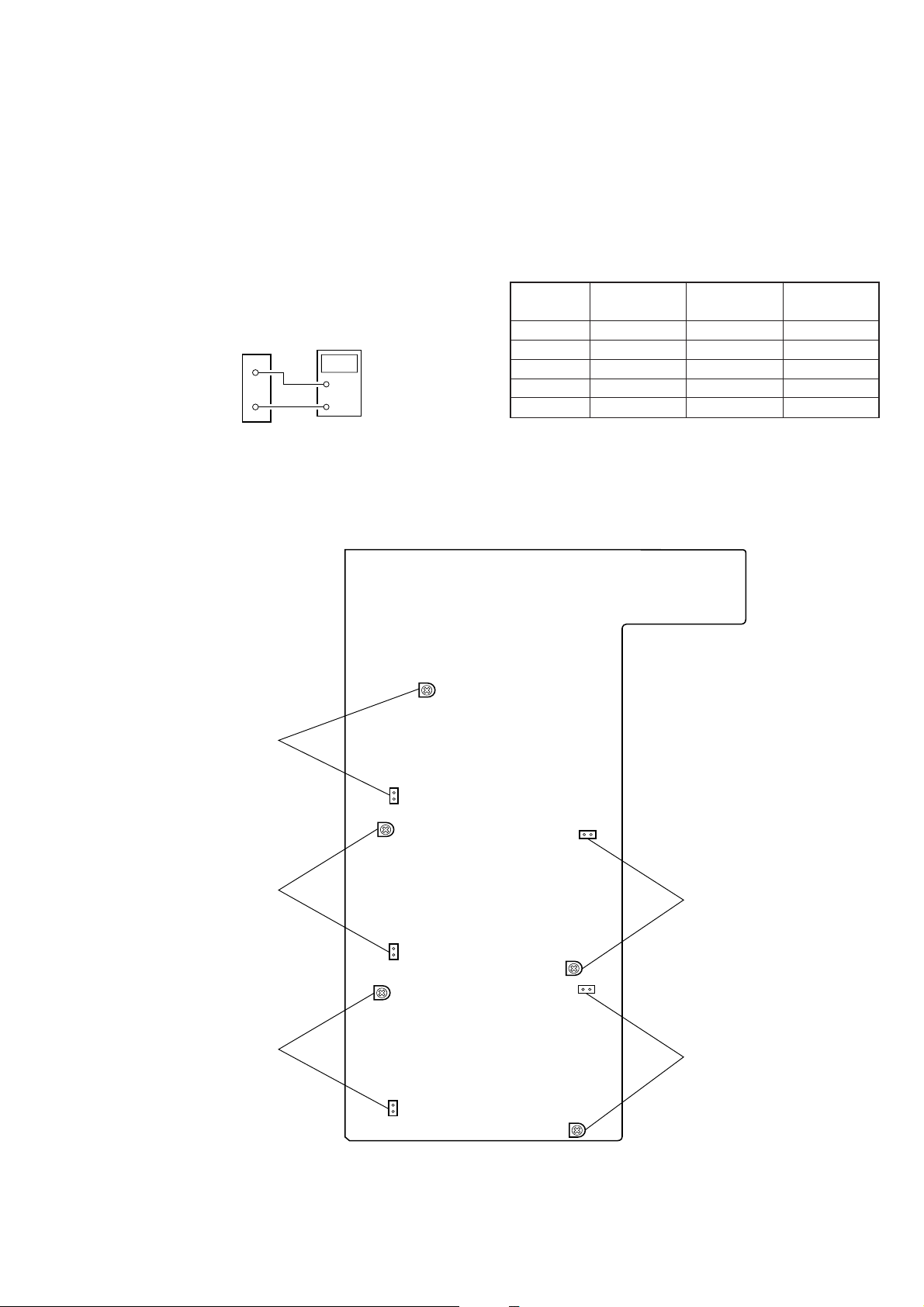

SECTION 4

ELECTRICAL ADJUSTMENTS

DC BIAS CURRENT Adjustment

(with no signal input)

After replacing the power transistors, DC BIAS CURRENT adjustments should be perfomed.

Setting:

SPEAKER IMPEDANCE switch (S801): 8 Ω MIN (NORMAL

USE)

Procedure:

MAIN BOARD

(CN301, 401, 501,

601, 701)

2

1

Note: After adjustment, check five connecting points.

Tester

+

–

Adjustment Location:

[MAIN Board]

(Component Side)

Connecting Adjustment Reading on

point part the tester

FRONT Lch CN601 RV601 11 ±1 mA

FRONT Rch CN701 RV701 11 ±1 mA

CENTER CN501 RV501 11 ±1 mA

REAR Lch CN301 RV301 11 ±1 mA

REAR Rch CN401 RV401 11 ±1 mA

RV601

FRONT Lch

CENTER

FRONT Rch

RV501

RV701

1

CN601

2

1

CN501

2

1

CN701

2

CN401

1

RV401

1

CN301

RV301

2

REAR Rch

2

REAR Lch

– 7 –

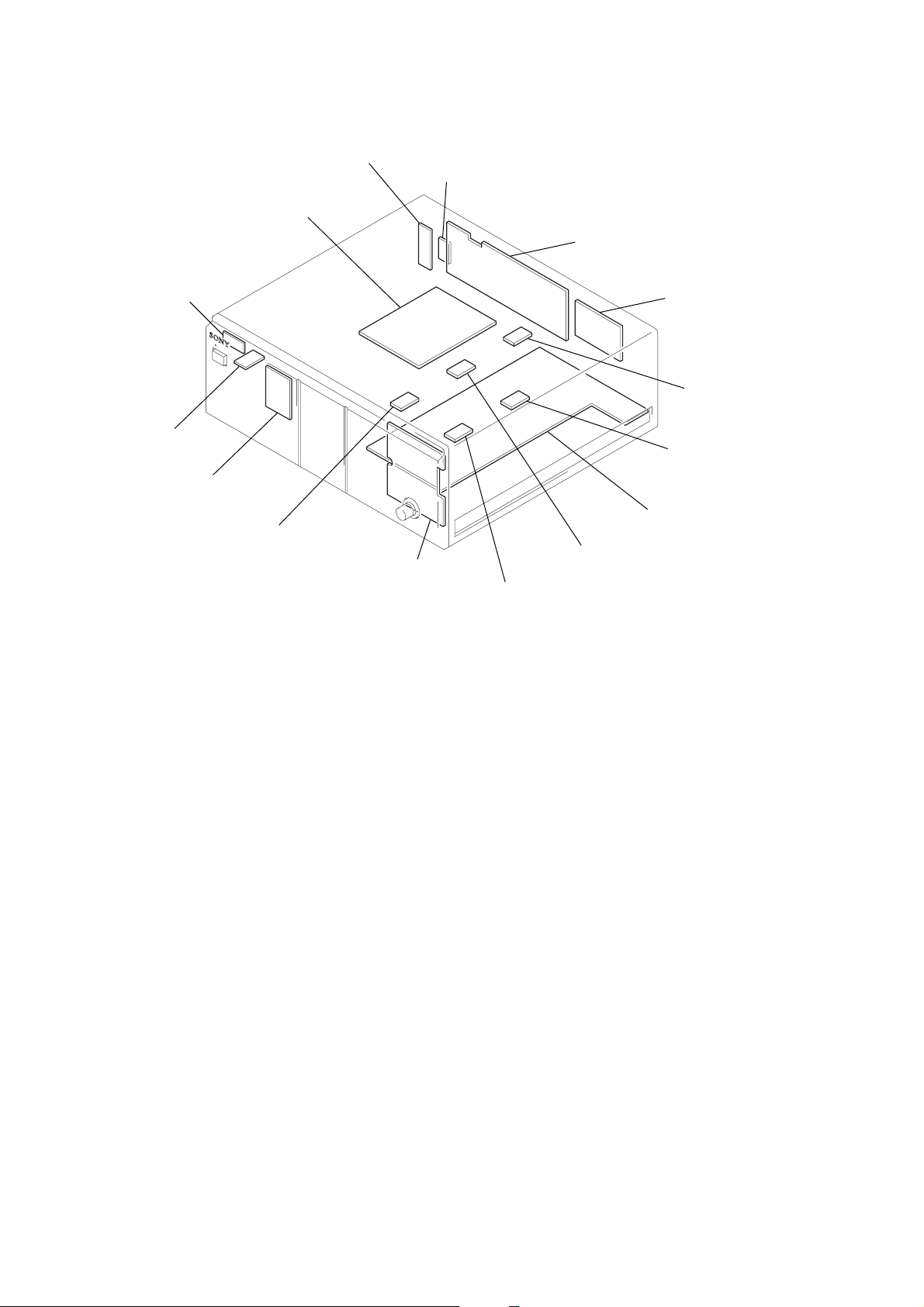

• Circuit Boards Location

d

SECTION 5

DIAGRAMS

RY board

SW board

PS board

SP board

LED board

AC-SW board

AC board

BIAS-FL board

CONTROL board

JOINT board

BIAS-FR boar

BIAS-RR board

MAIN board

BIAS-C board

BIAS-RL board

– 8 –

TA-N9000ES

3.8 Vp-p

8 MHz

5-1. NOTE FOR PRINTED WIRING BOARDS AND SCHEMA TIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

• Indication of transistor.

C

Q

B

E

These are omitted.

Q

B

CE

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

: internal component.

4

W or less unless otherwise

• 5 : fusible resistor.

• C : panel designation.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages and waveform are dc with respect to ground

under no-signal conditions.

• Voltages and waveforms are taken with a VOM (Input

impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

• Abbreviation

CND : Canadian model.

• Waveform

1 IC901 @º (X-OUT)

• IC Block Diagram

– MAIN BOARD –

IC201 µPC1237HA

OVER LOAD DET

OFFSET DET

LATCH/

AUTORESET

1 2 3

V

CC

MUTE

ON

F/F

AC OFF

DET

4 5 6 7 8

V

CC

– 9 – – 10 –

Loading...

Loading...