Sony TAMR-2-ES Service manual

TA-MR2ES

Continuous average power output (FTC):

35 W per channel min. RMS at 8 ohms,

both channels driven from 20 Hz to

20 kHz with no more than 0.09 %

THD.

40 W per channel min. RMS at 4 ohms,

both channels driven from 20 Hz to

20 kHz with no more than 0.09 %

THD.

Frequency responce: 5 Hz – 100 kHz + 0.5/–2 dB

Residual noise (A-weighted):

150 µV or less

Channel separation (1 kHz/10 kHz):

(input 4.7 k ohms terminated)

60 dB/45 dB

Signal-to-noise ratio: 94 dB (A-weighted filter, 150 mV input)

Audio input

Sensitivity: 150 mV

Impedance: 50 k ohms

Audio output

Voltage: minimum 2 V without clipped

Impedance: 1 k ohms

S/N: 102 dB (A-weighted filter, 2 V output)

General

12V trigger IN: accept 10 ~ 12 V of trigger

12V trigger OUT: 300 mA max

IR input: accept up to 40 kHz IR modulation

frequency

IR output: buffered, 5 V

Power requirements: 120 VAC, 60 Hz

Power consumption: 100 W

Dimensions: 430 × 67 × 350 mm (w/h/d)

Mass: 6.5 kg

Design and specifications are subject to change without notice.

Unpacking

• TA-MR2ES amplifier

• AC power cord

• Installation Manual

• Rack-mount brackets (2)

• Screw (6)

SERVICE MANUAL

Ver. 1.0 2004.12

SPECIFICATIONS

US Model

9-879-354-01

2004L1678-1

© 2004.12

Sony Corporation

Audio Company

Published by Sony Engineering Corporation

SYSTEM INTEGRATION 2CH AMPLIFIER

TA-MR2ES

r

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

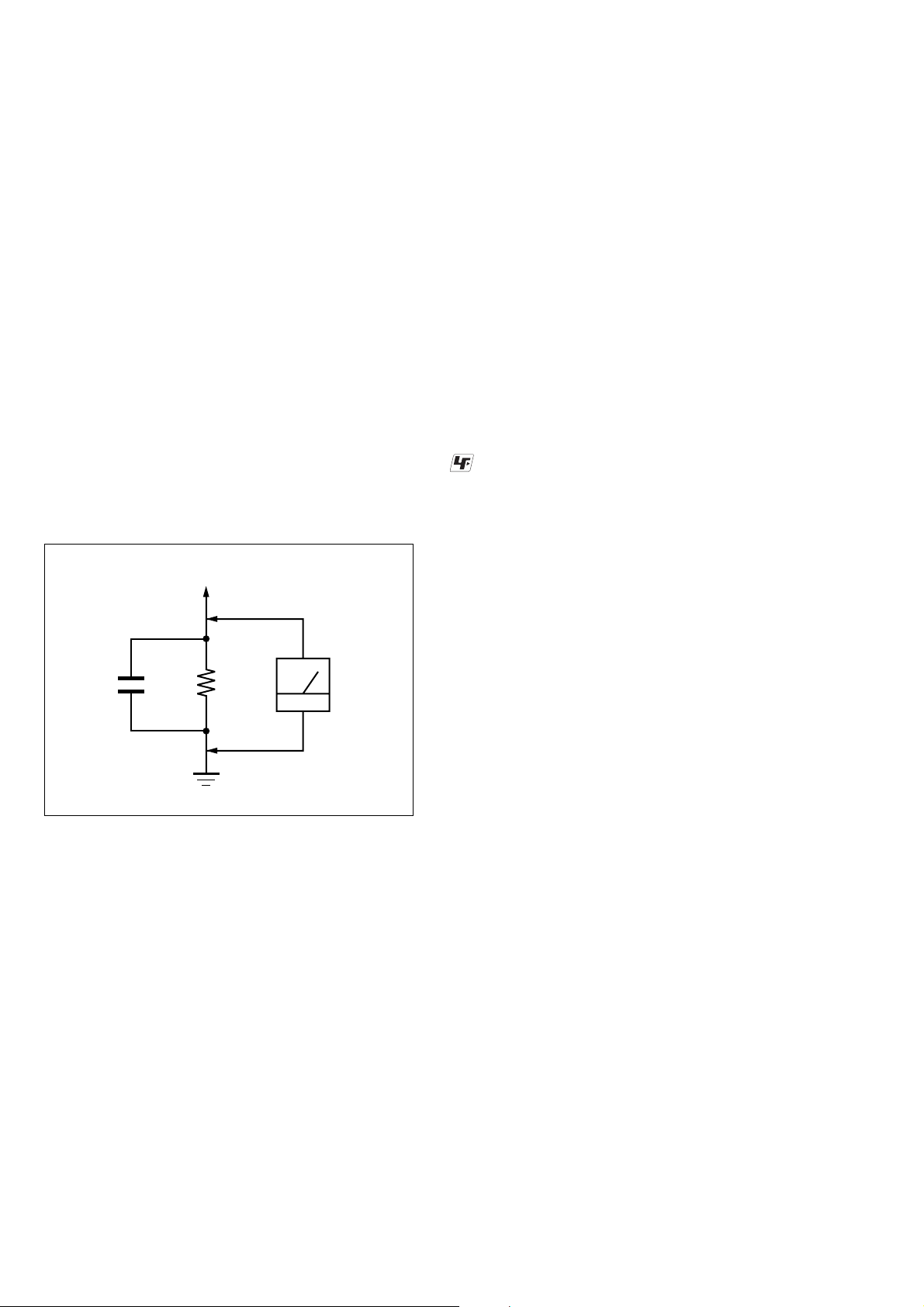

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manuf acturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate lo w-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V A C range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

voltmete

(0.75 V)

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to f low)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

TABLE OF CONTENTS

1. GENERAL ................................................................... 3

2. TEST MODE ............................................................... 4

3. DIAGRAMS

3-1. Block Diagram – AUDIO Section – ................................ 6

– MAIN/POWER Section – ............................................ 7

3-2. Printed Wiring Board

– POWER SWITCH/INLET Section – ........................... 8

3-3. Schematic Diagram – AMP Section (1/3) – ................... 9

3-4. Printed Wiring Board – AMP Section – ......................... 10

3-5. Schematic Diagram – AMP Section (2/3) – ................... 11

3-6. Printed Wiring Board – MAIN COMB Section – .......... 12

3-7. Schematic Diagram – AMP Section (3/3) – ................... 13

4. EXPLODED VIEWS

4-1. Front Panel Section ......................................................... 17

4-2. Chassis Section................................................................ 18

5. ELECTRICAL PARTS LIST .................................. 19

2

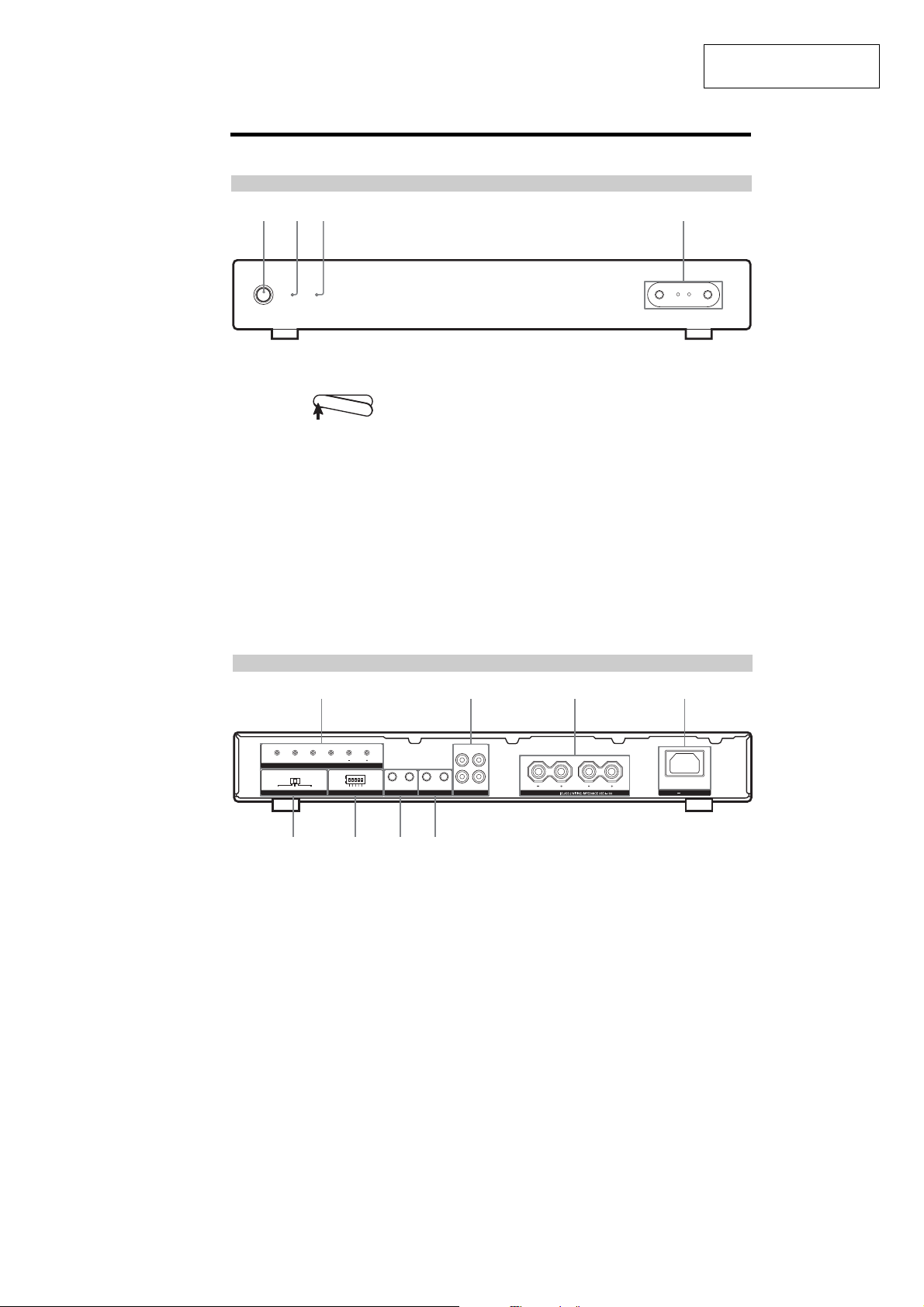

Parts and Controls

Front panel of the amplifier

SECTION 1

GENERAL

TA-MR2ES

This section is extracted

from instruction manual.

123 4

ON

POWER

*To remove the cover

IN USE

1 POWER switch

Press to turn the power on or off.

23ON indicator

The ON indicator lights up as follows:

Press either ends of the cover lid to remove the cover.

After you have finished adjusting the ATTENUATOR

L/R, place the cover lid back to its original position.

–green: the power is on.

–green (flashing three times): the amplifier’s memory

is cleared.

–off: the power is off.

IN USE indicator

The IN USE indicator lights up as follows:

–green: the amplifier is in use.

–green (flashing): the IR ID TEST switch is set to

“ON”.

–green (fast flashing): the IR TEST function is in

progress.

–red (flashing): “PROTECTION” mode is turned on.

–off: the amplifier is not in use.

4

ATTENUATOR L/R

Adjusts the maximum volume level of this amplifier to

match the room and the speakers used.

Rear panel of the amplifier

*

++

ATTENUATORL R

5

POWER

POWER

POWER

ON / OFF

OFF

ON

IR TEST

AUTO POWER SELECTOR 12V TRIGGERIR REMOTE AUDIO

MUTING

VOL

VOL

ON

OFF

4321TEST12V TRIGGER IR IN AUDIO SENSING

IR ID

IR OUT

qs qa q; 9

5 IR TEST buttons (page 12)

Press the appropriate button to output the IR codes

you want to teach through the IR OUT terminal.

6 AUDIO jacks (page 10)

a) AUDIO IN

RCA jacks for stereo line level audio input from a

multi-room system.

b) AUDIO OUT

RCA jacks for looping out to another amplifier or

component.

Note

This is a buffered audio connection, and this loop-through is

active even when the IN USE indicator is off, as long as the

AC power cord is plugged in and the POWER switch is on.

7 SPEAKERS (page 10)

Terminal which accepts speaker wire sizes up to

12AWG.

Leave the AC power cord unplugged when you hook

up speaker cables.

8 AC IN (page 10)

Removable power cord for easy serviceability of the

amplifier.

687

L

R

IN OUTINIR IN

OUT L

SPEAKERS

R

9 12V TRIGGER jacks (page 10)

a) IN

A 3.5 mm monaural mini jack to turn on the amplifier

via a 12-volt trigger input.

b) OUT

Enables the looping of amplifier control from one to

the next to trigger multiple amplifiers from a 12-volt

trigger output.

q; IR REMOTE jacks (page 10)

a) IR IN

Connects to an outboard IR repeater system so you

can operate the amplifier from a distant room.

b) IR OUT

A 3.5 mm monaural mini jack for the connection of an

IR emitter to control other components individually.

IR signals received will be routed to the IR sensor of

the other components.

Outputs IR from the IR TEST system built into the rear

of the amplifier.

qa IR ID switches (page 12)

Select from 12 discrete IR code tables to communicate

with up to 12 TA-MR2ES amplifiers (with individual

IR ID) on one IR repeater network.

qs AUTO POWER SELECTOR switch (page 11)

Selects the method for activating the amplifier.

AC IN

3

TA-MR2ES

SECTION 2

TEST MODE

1. MEMORY CLEAR

Procedure:

1 Select the TEST switch to “ON” of the IR ID at back panel.

2 Press the POWER OFF key at back panel in advance and

simultaneously press the POWER ON key at front panel.

3 See the condition of two LEDs as follows.

POWER LED IN USE LED

FIRST slow blinking 3times off while power LED

CONDITION (each 1 sec) blinking

AFTER ON

2. VERSION show

Procedure:

1 Press the VOL+ key and POWER OFF key of IR TEST in

advance, and simultaneously press the POWER ON key at

front panel.

2 If the POWER LED turn on while 250ms, the version

will show you major version.

If IN USE LED turn on while 250ms, the version will

show you minor version.

3 POWER LED goes on, IN USE LED is blinking.

slow blinking each 1

sec

4

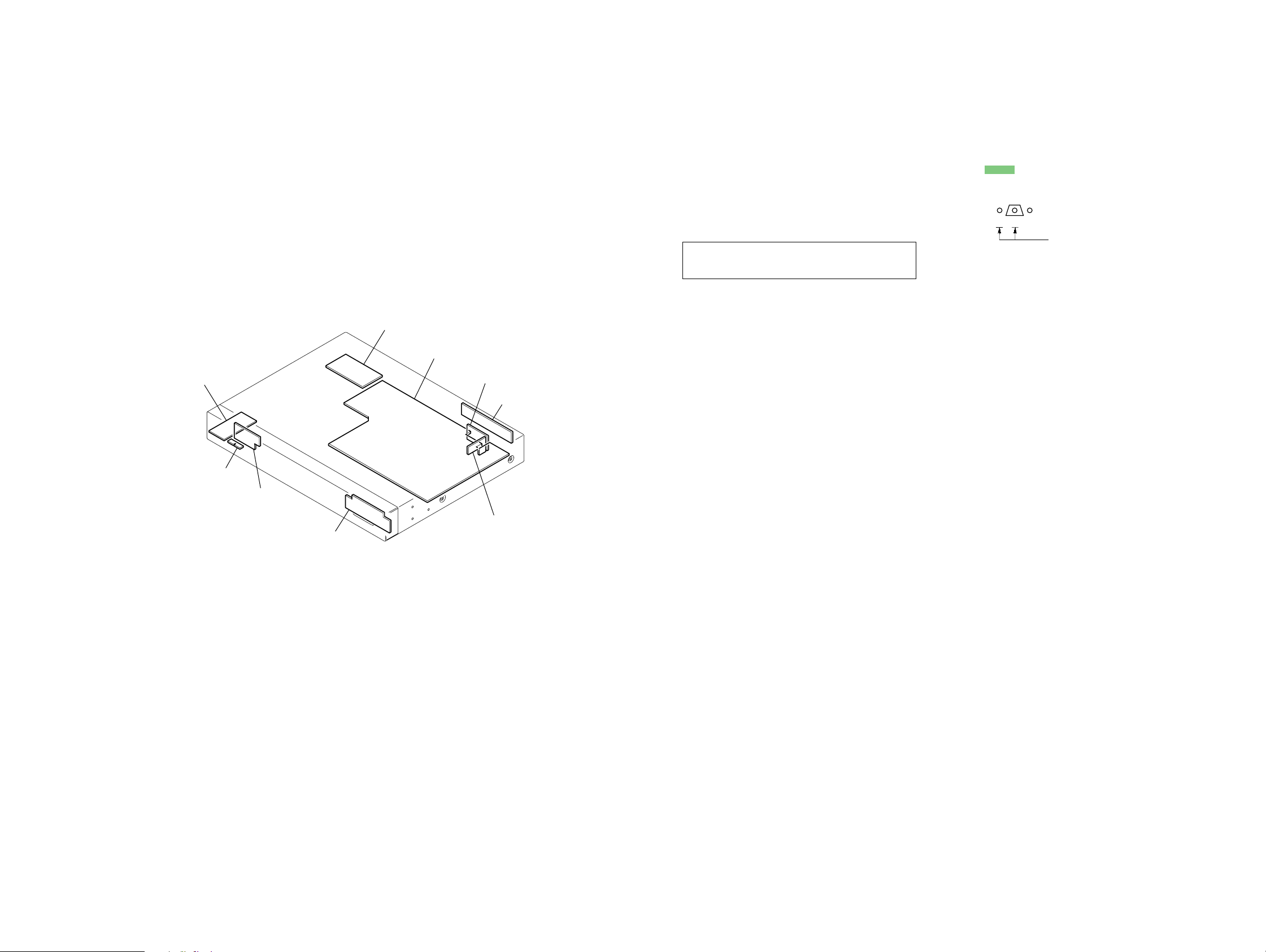

SECTION 3

DIAGRAMS

TA-MR2ES

• Circuit Boards Location

POWER SWITCH board

INLET board

AMP board

ID board

TACT SWITCH board

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Schematic Diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

• f : internal component.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• B : B– Line.

•Voltages and wavef orms are dc with respect to ground under no-signal (detuned) conditions.

No mark: POWER ON

* : Imposible to measure

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

4

W or less unless otherwise

For Printed Wiring Boards.

Note:

• X : parts extracted from the component side.

• a : Through hole.

• f : internal component.

• : Pattern from the side which enables seeing.

Q

B

CE

These are omitted.

STOPPER board

LED board

JUMPER board

VR board

TA-MR2ES

55

TA-MR2ES

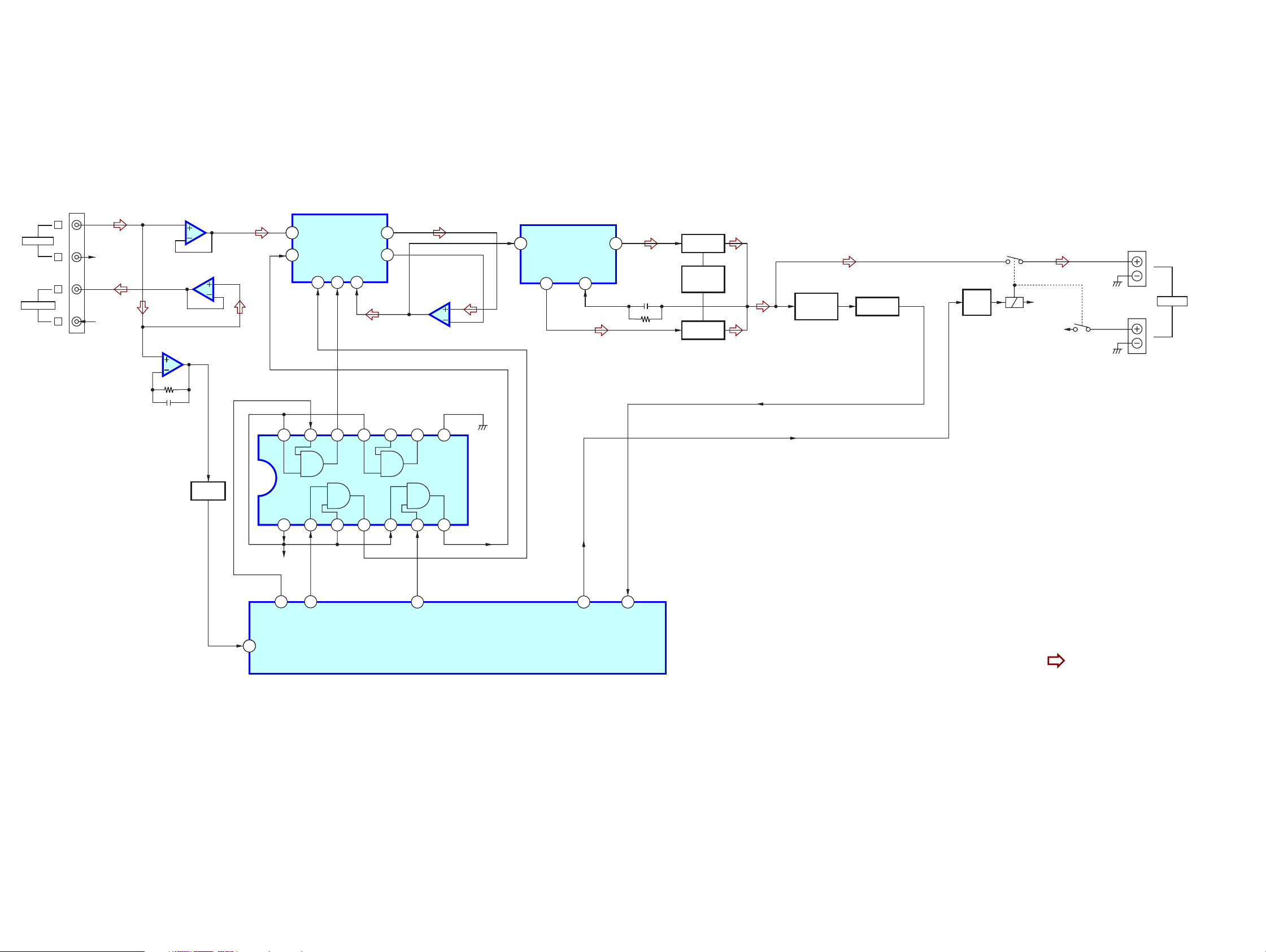

3-1. BLOCK DIAGRAM – AUDIO SECTION –

AUDIO IN

AUDIO OUT

J300

L

R

L

R

R-CH

R-CH

3

2

3

2

IC301

BUFFER

1

IC305

AUDIO SENSE

1

IC300

BUFFER

1

3

2

VRIN8

20

DATA

8

16

IC303

ELECTRIC VOLUME

LAT

CLK

13 17 25

TRIM

OUT

TRIM

IC601

POWER AMP

23

24

IC304

OP AMP

5

7

6

8

8

IN2

–VOUT2

11 9

+VOUT2

NF2

12

Q653

BOOSTER

Q651,652

LIMMITER

CONTROL

Q654

BOOSTER

Q655,656

CURRENT

DETECTOR

Q607,608,609

PROTECTOR

Q201

RELAY

DRIVE

RY202

+12V

TM650

L-CH

SPEAKER

TM600

R-CH

Q300,350

DET

AUDIO SENSE

8

15

NC

1 2 3 4

NC

VDD

14 13 12 11 10 9 8

+5V

51

31

VOL CLK

VOL STB

5

NC

6 7

52

VOL DAT

IC400(1/2)

SYSTEM CONTROLER

VSS

IC405

BUFFER

44

SPK RELAY

25

PROTECTOR

• R-CH is omitted due to same as L-CH.

• Signal Path

: AUDIO

TA-MR2ES

66

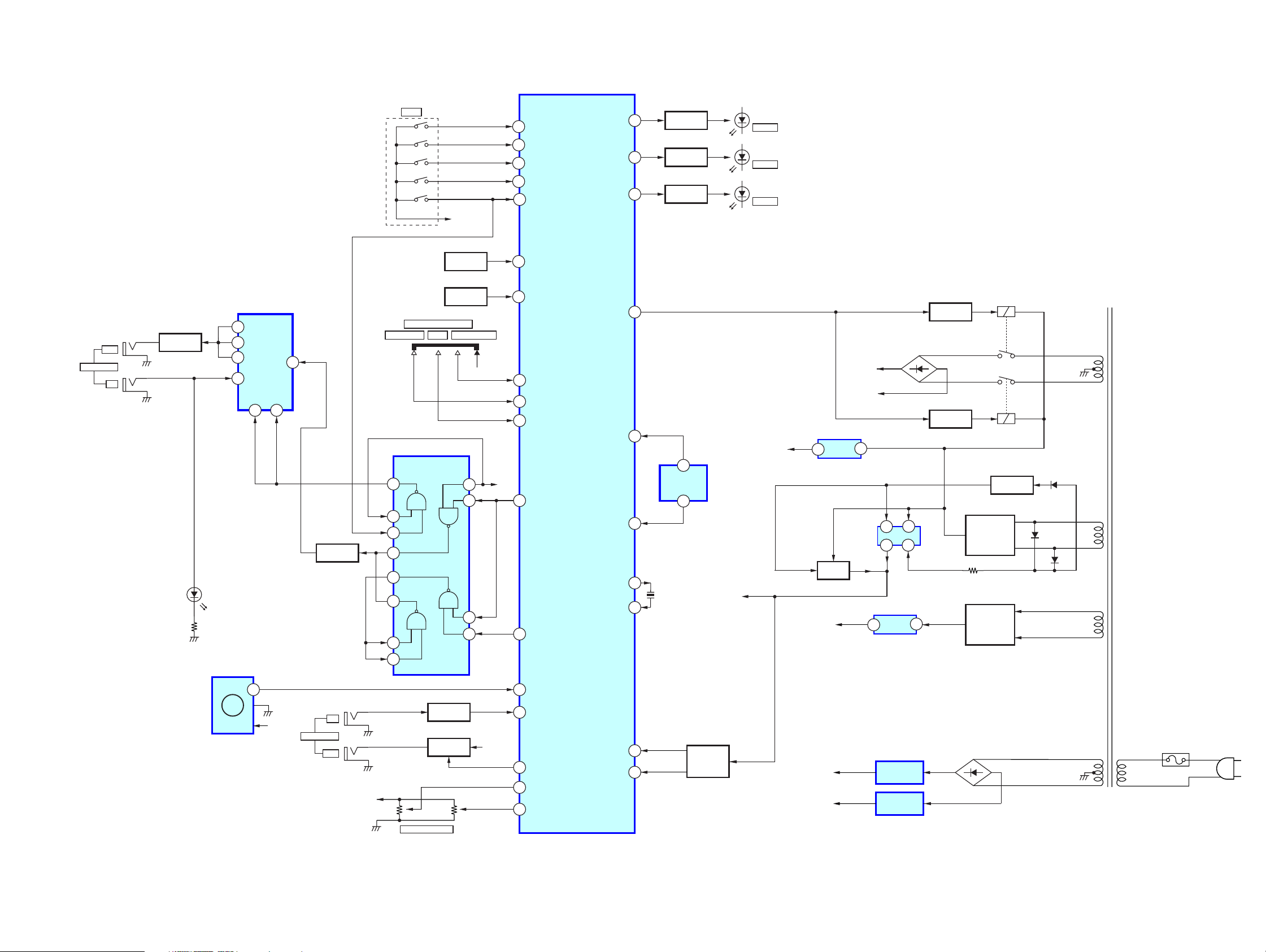

– MAIN/POWER SECTION –

TA-MR2ES

IR REMOTE

OUT

IN

J401

J400

Q400,407,410

SWITCH

D400

15

14

13

IC402

IR SIG IN

1

IC403

SELECTOR

Y

Y1

X

X1

X-X

10 11

1

+3.3V

X0

Y-Y

12

CONTROL

12VTRIGGER

OUT

Q406

IN

J402

J403

+3.3V

S400

IR ID

AUTO POWER SELECTOE

12V TRIGGER

I/O CONTROL

8

9

10

11

6

3

1

2

RV350

L ATTENUATOR R

IR IN

IC404

ID0

ID1

ID2

ID3

IR

LEARNING

S402,403,407

AUDIO SENSING

Q401

SWITCH

Q402,403

SWITCH

3.3V

S404-406

TACT

SWITCH

TACT

SWITCH

+12V

13

5

4 58

+12V

RV300

VCC

SYSTEM CONTROLLOR

50

IR LEARNING

54

ID1

57

ID2

55

ID3

59

ID4

3

A/DO

4

A/DI

34

AUDIO MODE

35

12V MODE

33

IR MODE

5312

IRSIG OUT

CARRIER FREQUENCY

14

IR SIGIN

41

12V TRIG IN

42

12V TRIG OUT

5

VOL A/D L

6

VOL A/D R

IC400(2/2)

LED2

LED1

LED0

POWER RELAY

SDA

SCL

RESET

STOP

X400

12.5MHz

Q408

LED DRIVE

Q409

LED DRIVE

Q415

LED DRIVE

5

IC401

8bit

EEPROM

6

Q404,405

Q411-413

RESET

37

38

39

43

46

47

22

X0

23

X1

19

16

+3.3V

D406

IN USE

D405

IN USE

D404

ON

+5V

3

+15V

-15V

+5V REG

Q206

REG

+12V

IC201

+32V

–32V

1

IC204

+3.3V REG

3

3

8

IC200

+12V REG

IC203

+15V REG

IC202

-15V REG

T900

POWER TRANSFORMER

F900

AC

IN

D210-213

RECT

D202-204,

D209

RECT

D214-D217

RY200

RY201

Q204,205

CONTROL

+6V

D218

D207

D208

Q202

RELAY DRIVE

D201

Q200

RELAY DRIVE

5

6

1

TA-MR2ES

77

TA-MR2ES

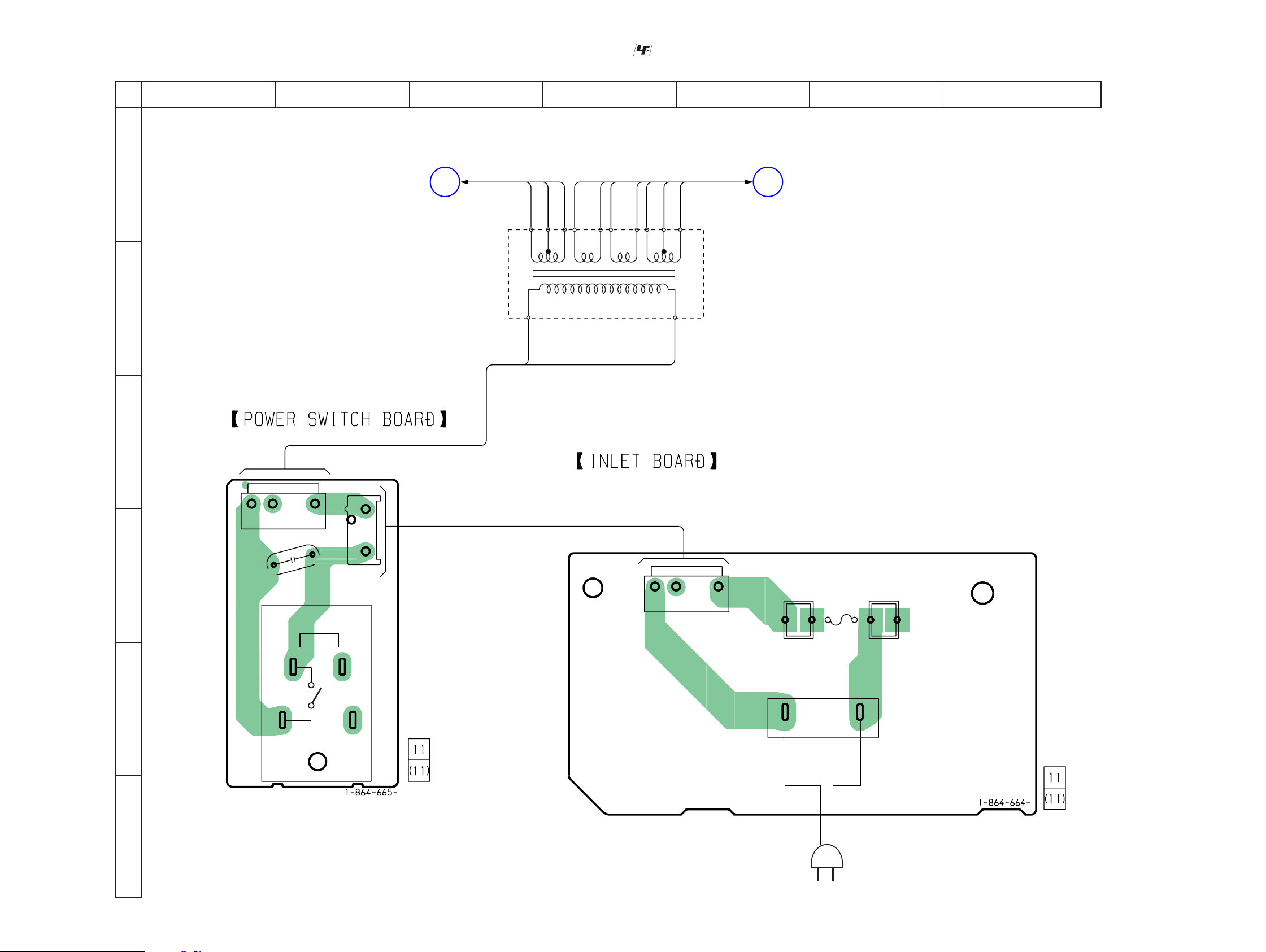

3-2. PRINTED WIRING BOARD – POWER SWITCH/INLET SECTION –

12

A

B

• See page 5 for Circuit Boards Location. • :Uses unleaded solder.

34567

B

AMP

BOARD

CN200

(Page 10)

T900

POWER TRANSFORMER

BOARD

CN202

(Page 10)

A

AMP

C

D

E

CN902

3

1

C901

S1

POWER

1

CN903

2

3

CN901

1

FH905

2

F900

FH900

CN900

1

TA-MR2ES

F

AC

IN

88

Loading...

Loading...