Sony T 300h Service Manual

Pressures to 20,000 PSI

T-300H

Flows to 10.3 GPM S Power 100 HP

Features

S Inline fluid end design.

S Pressure range of 15,000 PSI to

20,000 PSI.

S Flow rates from 2.6 GPM to

10.3 GPM.

S High volumetric efficiency for

maximum horsepower

utilization.

S Maximum frame load of

7,000 Lbs. / 3178 Kg.

S Field proven design.

S Extremely reliable -

thousands in service.

S Easy field maintenance.

S Autofrettaged fluid clyinders and valve

assemblies.

S Manufactured on state-of-the-art machinery.

S Rigorously subjected to full load testing.

Applications

S Water Blasting

S Chemical Injection

S Hydrostatic Testing

S Surface Preparation

Performance Specifications

T-300H

Note: All flows are

based on 100%

volumetric efficiency.

Stroke: 3” / 76 mm • Max. Speed: 600 RPM • Weight: 810 Lbs. / 368 Kg

PLUNGER DIA. PSI BAR GPM LPM GPM LPM GPM LPM

0.650” - 17mm 20K 1379 2.6 9.8 5.1 19.5 7.7 29.3

0.750” - 19mm 15K 1034 3.4 12.9 6.8 25.9 10.3 39.0

FLOW

MAX. PRESSURE 200 RPM 400 RPM 600 RPM

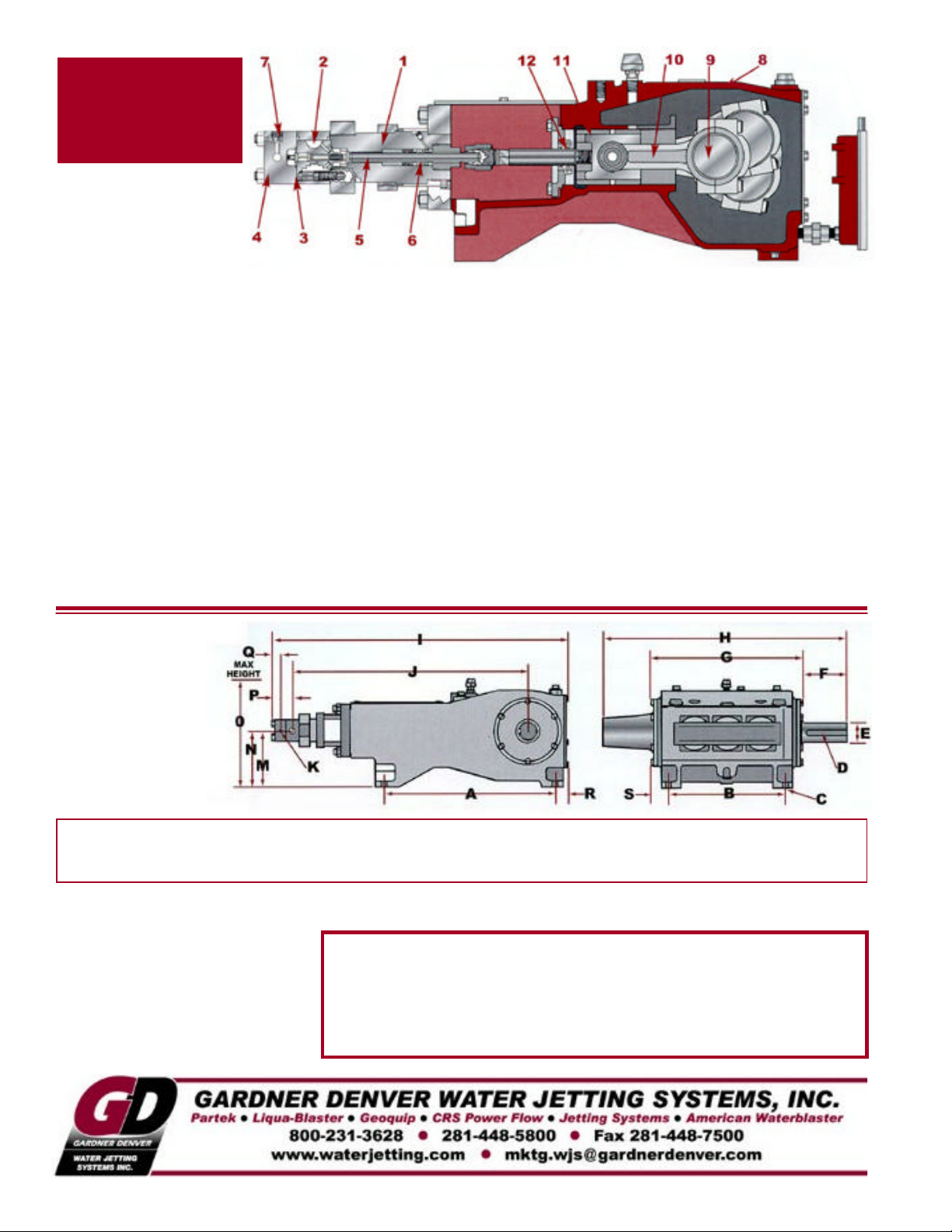

1

T-300H

PUMP

Fluid End

1. Fluid Cylinder Body: Three cylinders machined from

hardened stainless steeland autofrettaged for extended

life.

2. Suction Manifold: Hard, anodized aluminum. Also

available in stainless for salt water applications.

3. Valve Assembly: Hardned stainless steel and

autofrettaged for extended life. Valves are spring loaded

for positive closing with a common seat used for both

suction and discharge valves.

4. Discharge Manifold: Manufactured from

precipitation hardened stainless steel.

5. Plungers: Collet style and made of tungsten carbide.

6. Plunger Packing: Carbon filled TeflonTMand

polyethylene base, spring loaded, self-adjusting and

easily replaceable from the rear of the stuffing box.

Force-fed water provides lubrication and cooling.

7. Pressure Relief: Pressure safety head assembly

(two rupture discs), mounted to the discharge manifold.

Dimensions

T-300H

Power End

8. Power Frame: Manufactured from a single piece

casting of high strength gray cast iron.

9. Crankshaft: Double extended alloy steel with tapered

roller bearings to minimize side thrust load.

10. Connecting Rods: Ductile iron with automotive type

split insert bearings.

11. Crossheads: Large, piston-type constructed of gray

iron.

12. Diaphragm Seals: Installed with o-rings or gaskets

and neoprene oil seals.

Bearings and crossheads are oil lubricated with a combined

splash gravity system that insures adequate circulation at

speeds as low as 200 RPM.

A

B

C

D

E

F

G

H

I

J

K

in.

241/4

151/2

0.8125

0.625

21/2

43/8

21

301/2

42

343/4

1MPL11/2NPTM77/8

mm

616

394

21

16

64

111

533

775

1067

883

Gardner Denver Water Jetting Systems reserves the right to change specifications without notice.

GARDNER DENVER

Your local distributor/representative is:

200

N

77/8

200

O

151/4

387

P

41/2

114

WATER JETTING

SYSTEMS, INC.

12300 North Houston-Rosslyn Road

Houston, TX 77086 USA

Q

13/4

44

R

15/8

41

S

25/8

67

Loading...

Loading...