Sony STR-DA9000ES Service manual

STR-DA9000ES

SERVICE MANUAL

Ver 1.2 2004.09

This receiver incorporates Dolby* Digital and Pro

Logic Surround and the DTS** Digital Surround

System.

*Manufactured under license from Dolby

Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are

trademarks of Dolby Laboratories.

** “DTS”, “DTS-ES Extended Surround”, and

“Neo:6” are trademarks of Digital Theater Systems,

Inc.

US Model

Canadian Model

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

(Models of area code US only)

With 8 ohm loads, both channels driven, from 20

– 20,000 Hz; rated 170 watts per channel

minimum RMS power, with no more than

0.09% total harmonic distortion from 250

milliwatts to rated output.

Amplifier section

POWER OUTPUT

Rated Power Output at Stereo Mode

(8 ohms, 20 Hz – 20 kHz, THD 0.15%)

(4 ohms, 20 Hz – 20 kHz, THD 0.15%)

Reference Power Output

(8 ohms, 1 kHz, THD 0.09%)

(4 ohms, 1 kHz, THD 0.09%)

200 W + 200 W

220 W + 220 W

1)

: 200 W + 200 W

FRONT

1)

CENTER

SURR

SURR BACK

FRONT

CENTER

SURR

SURR BACK

: 200 W

1)

: 200 W + 200 W

1)

: 220 W + 220 W

1)

: 220 W

1)

: 220 W + 220 W

1)

: 200 W + 200 W

1)

: 220 W + 220 W

SPECIFICATIONS

Frequency response

PHONO RIAA equalization curve

Power Amp Block 10 Hz – 50 kHz

Inputs (Analog)

PHONO Sensitivity: 3.5 mV

CD/SACD, TAPE,

MD/DAT, DVD, LD,

TV/SAT, VIDEO 1, 2,

3, 4, 5

2) Input shorted and sealed at VOL MAX.

3) Weighted network + 20 kHz LPF, input level.

±0.5 dB

± 3 dB (8 ohms)

Impedance: 50 kilohms

S/N2): 90 dB (A, 40 mV3))

Sensitivity: 170 mV

Impedance: 50 kilohms

2)

: 100 dB (A, 2 V3))

S/N

Inputs (Digital)

CD/SACD, DVD, LD,

VIDEO 1, TV/SAT

(Coaxial)

CD/SACD, DVD, LD,

TV/SAT, MD/DAT,

VIDEO1, 3 (Optical)

Outputs

TAPE, MD/DAT

(REC OUT), VIDEO

1, 2, 3 (AUDIO OUT)

FRONT L/R,

CENTER,

SURROUND L/R,

SURROUND BACK

L/R, SUB WOOFER

EQUALIZER

Gain levels ±10 dB, 1 dB step

Impedance: 75 ohms

S/N: 100 dB

(A Network, 20 kHz LPF)

S/N: 100 dB

(A Network, 20 kHz LPF)

Voltage: 170 mV

Impedance: 2.2 kilohms

Voltage: 2 V

Impedance: 220 ohms

– Continued on next page –

1) Depending on the sound field settings and the

source, there may be no sound output.

9-961-292-03 Sony Corporation

2004I05-1 Audio Group

© 2004.09 Published by Sony Engineering Corporation

FM STEREO FM/AM RECEIVER

STR-DA9000ES

FM tuner section

Tuning range 87.5 - 108.0 MHz

Antenna FM wire antenna

Antenna terminals 75 ohms, unbalanced

Sensitivity

Mono: 18.3 dBf, 2.2 µV/75 ohms

Stereo: 38.3 dBf, 22.5 µV/75 ohms

Useable sensitivity 11

S/N

Mono:

Stereo:

Harmonic distortion at 1 kHz

Mono: 0.3%

Stereo: 0.5%

Separation 45 dB at 1 kHz

Frequency response 30 Hz – 15 kHz,

Selectivity 60 dB at 400 kHz

.2 dBf, 1 µV/75 ohms

76 dB

70 dB

+0.5/–2 dB

AM tuner section

Tuning range 530 – 1,710 kHz

(With 10-kHz tuning scale)

531 – 1,710 kHz

(With 9-kHz tuning scale)

Antenna Loop antenna

Usable sensitivity 50 dB/m (at 1,000 kHz or 999

kHz)

S/N 54 dB (at 50 mV/m)

Harmonic distortion 0.5% (50 mV/m, 400 Hz)

Selectivity

At 9 kHz: 35 dB

At 10 kHz: 40 dB

4) You can change the AM tuning scale to 9 kHz or 10

kHz. After tuning in any AM station, turn off the

receiver. While holding down PRESET TUNING +

or TUNING +, press ?/1. All preset stations will be

erased when you change the tuning scale. To reset

the scale to 10 kHz (or 9 kHz), repeat the procedure.

4)

4)

Video section

Inputs/Outputs

Video: 1 Vp-p, 75 ohms

S-video: Y: 1 Vp-p, 75 ohms

COMPONENT VIDEO:Y: 1 Vp-p, 75 ohms

C: 0.286 Vp-p, 75 ohms

/B-Y: 0.7 Vp-p, 75

P

B/CB

ohms

/R-Y: 0.7 Vp-p, 75

P

R/CR

ohms

i.LINK section

Pin 4 pins

Transmission speed S200 (Maximum data

Transmission protocol A/M transmission protocol

Format (input) Super Audio CD* (DSD

*Conforms to the copy protection technology of

DTLA (Revision 1.2).

transmission speed 200

Mbps)

PLAIN)

2 channel linear PCM (IEC60958-3)

Sampling frequency: 44.1

kHz

General

Power requirements 120 V AC, 60 Hz

Power consumption 600 W

Power consumption (during standby mode)

AC outlets 1 switched, 120 W/1A MAX

Dimensions 430 × 238 × 480 mm

Mass (Approx.) 28.5 kg

1 W

including projecting parts and

controls

Supplied accessories

AC power coad (1)

Easy Setup Guide (1)

FM wire antenna (1)

AM loop antenna (1)

Remote commander RM-TP2 (1)

Operating Instructions for RM-TP2 (1)

AC adapter AC-96NP (1 for RM-TP2)

RMB-TP1 (1 for RM-TP2)

Remote commander RM-US106 (1)

Operating Instructions for RM-US106 (1)

R6 (size-AA) batteries (2)

Design and specifications are subject to change

without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

STR-DA9000ES

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

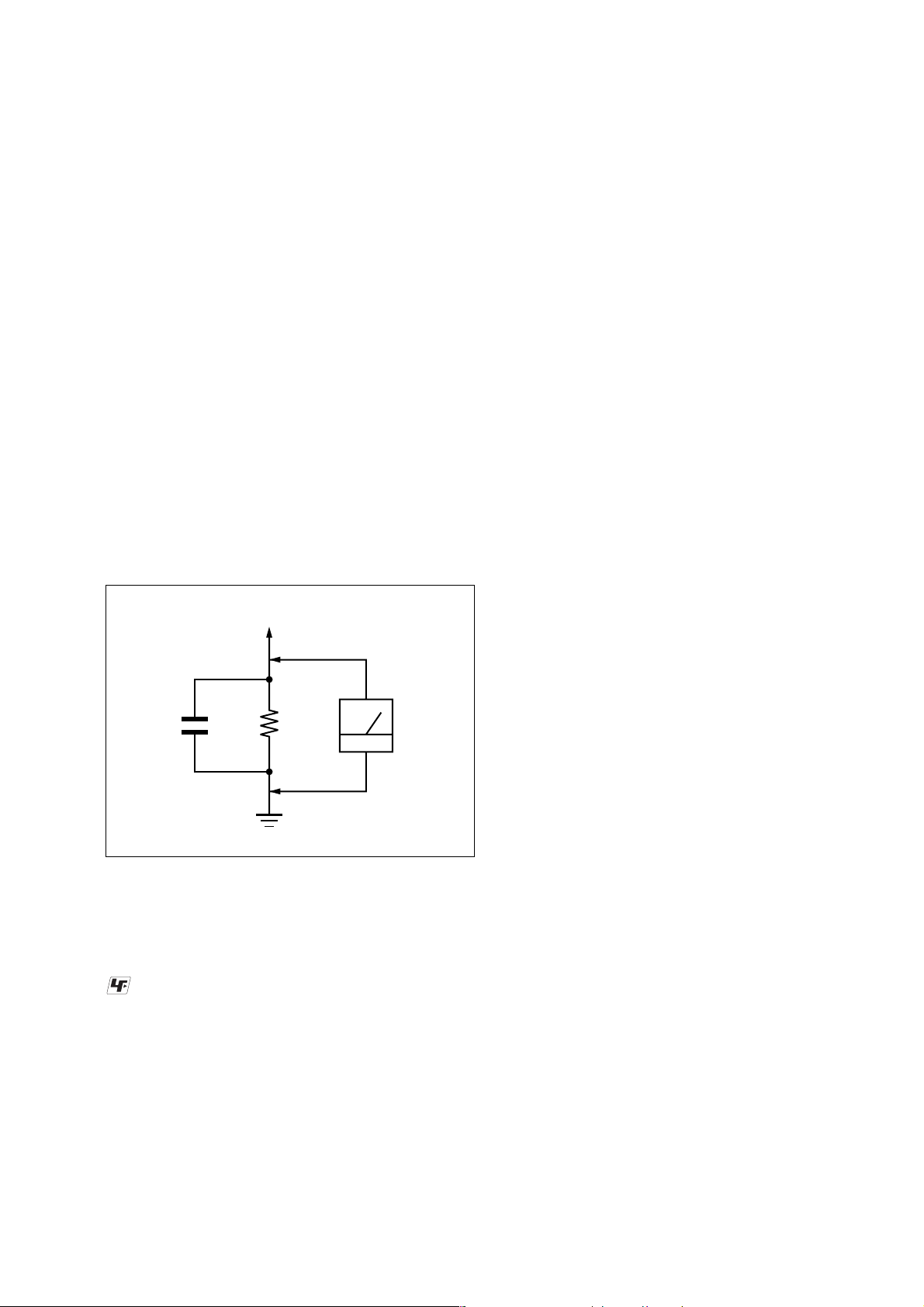

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the v oltage drop across a resistor by means of a V OM

or battery-operated A C voltmeter . The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Ω

Earth Ground

AC

voltmeter

(0.75 V)

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 5

2. GENERAL

Location of Controls ....................................................... 9

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 12

3-2. Case (Top)/(Side-L)/(Side-R) ......................................... 13

3-3. Bracket (J)/(P-B) ............................................................. 13

3-4. AMP Board Block........................................................... 14

3-5. Tuner, COMPONENT/TRIGGER/DVI Board Block .... 14

3-6. S-VIDEO/VIDEO Board Block ..................................... 15

3-7. SUB Board, PREOUT Board, MAIN Board.................. 15

3-8. I. LINK Board, DIGITAL Board .................................... 16

3-9. MOTHER Board Section ................................................ 16

3-10. MOTHER Board ............................................................. 17

4. TEST MODE.............................................................. 18

5. ELECTRICAL ADJUSTMENTS......................... 21

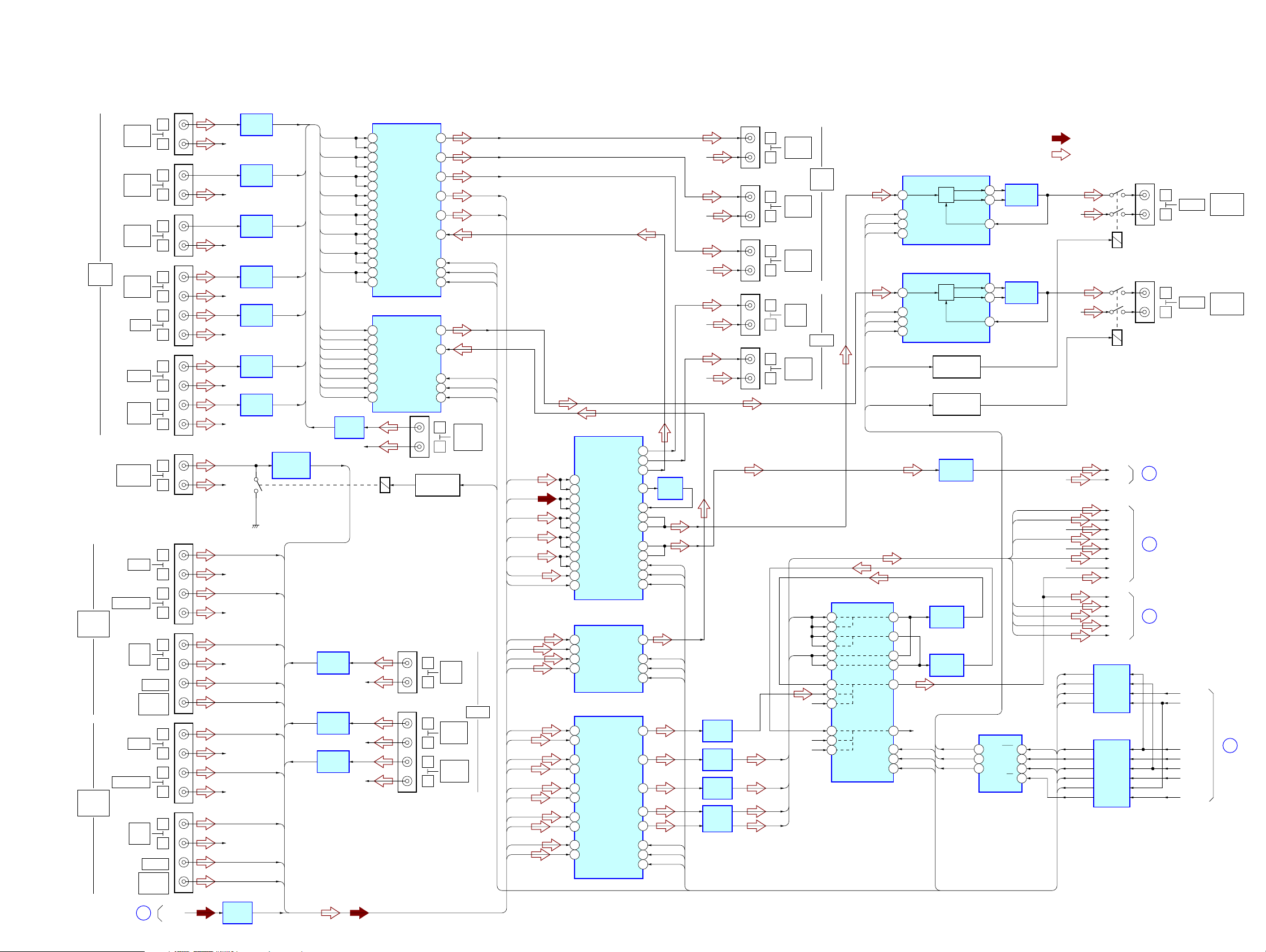

6. DIAGRAMS

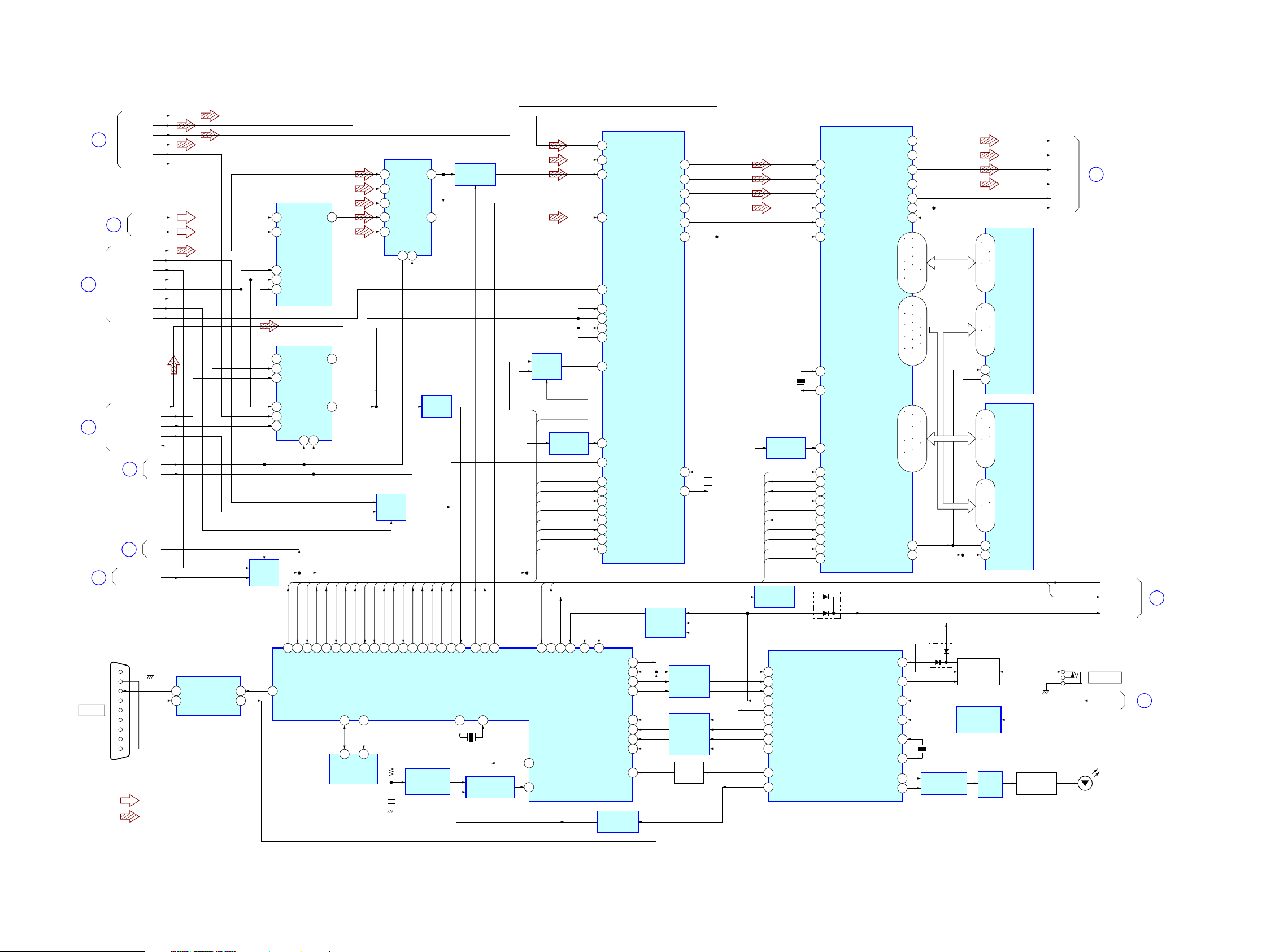

6-1. Block Diagram – AUDIO INPUT Section – ................. 23

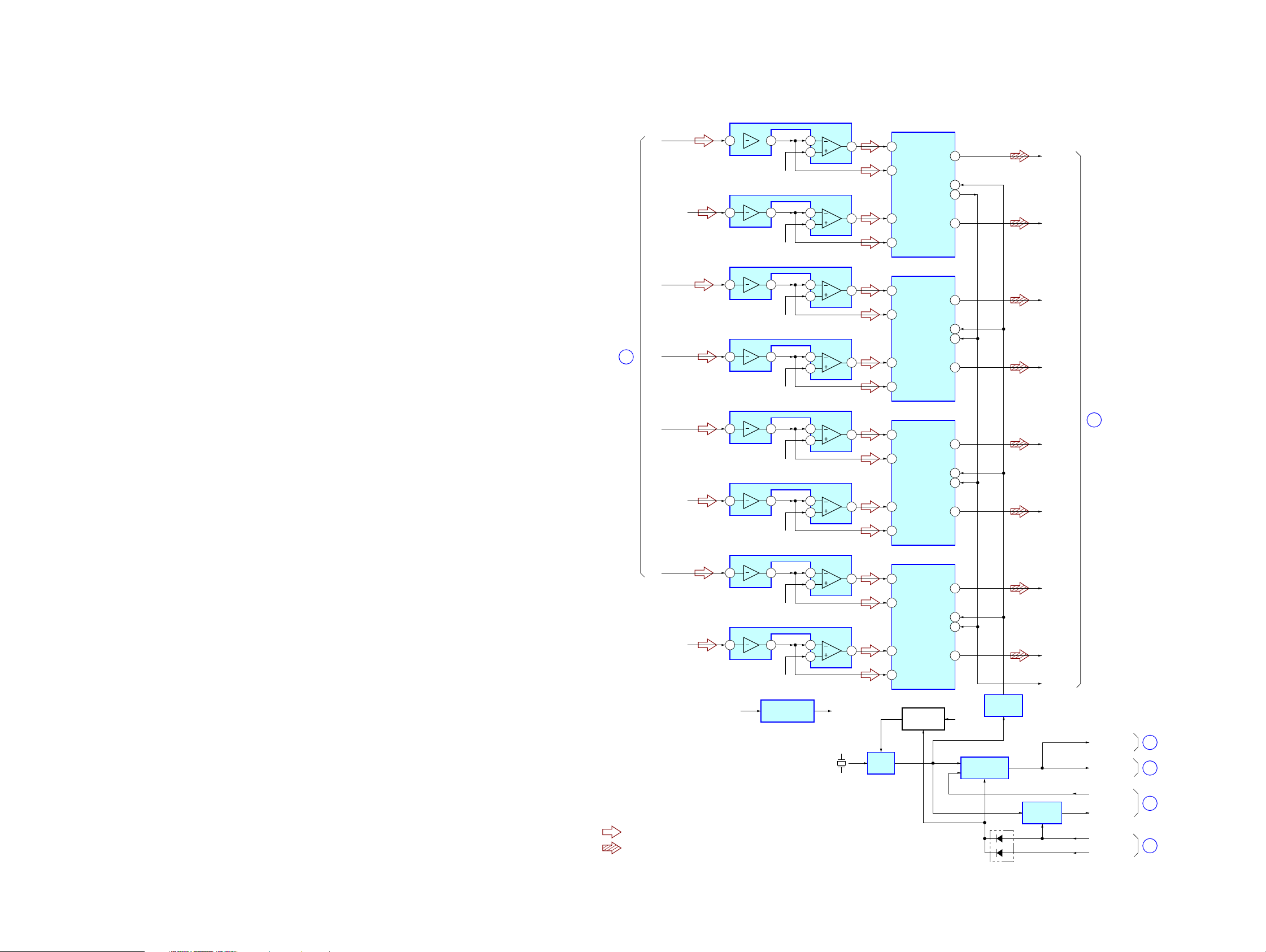

6-2. Block Diagram – A/D CONVERTER Section – ........... 24

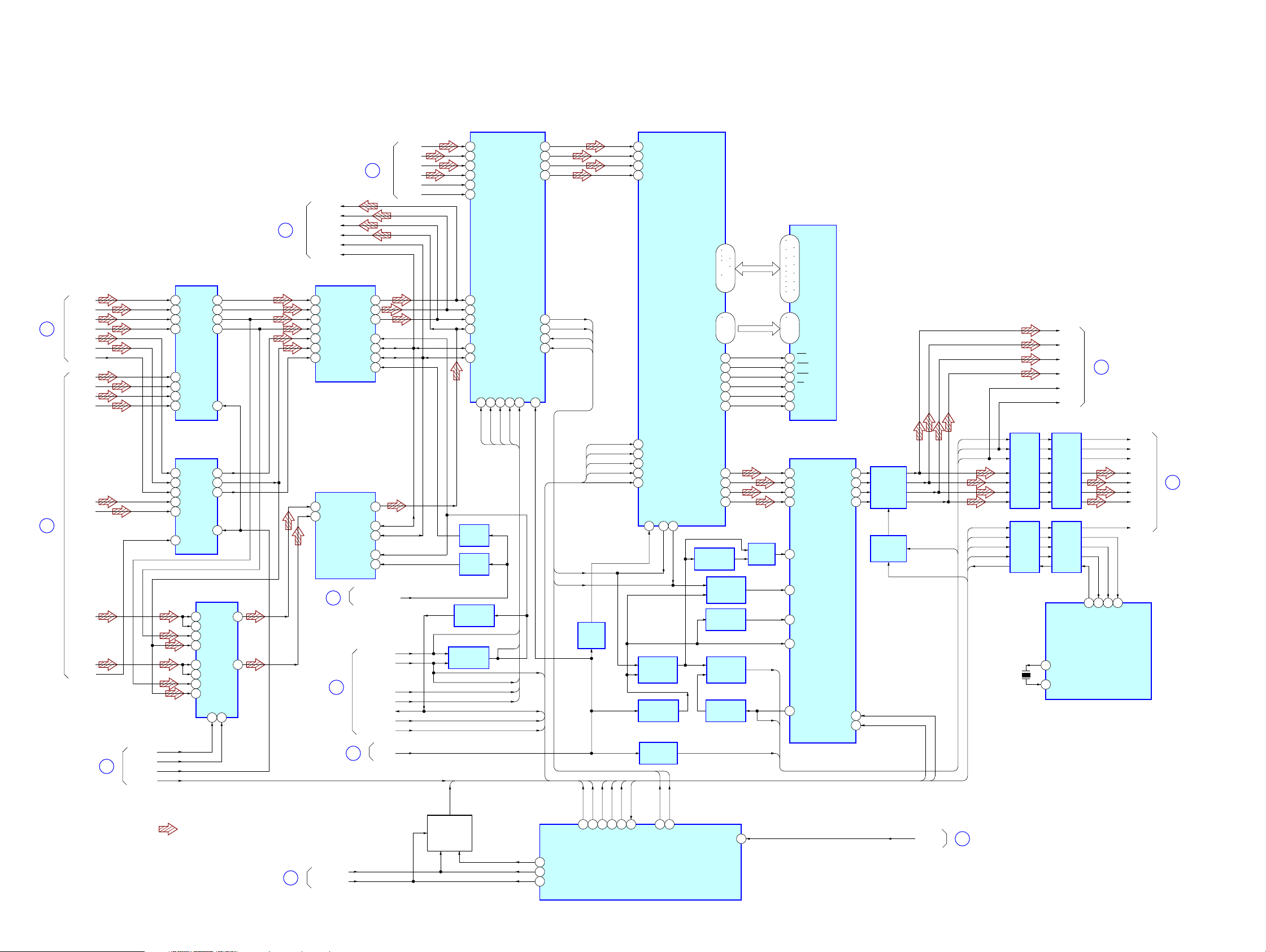

6-3. Block Diagram

– DIGITAL INPUT, TUNER Section –.......................... 25

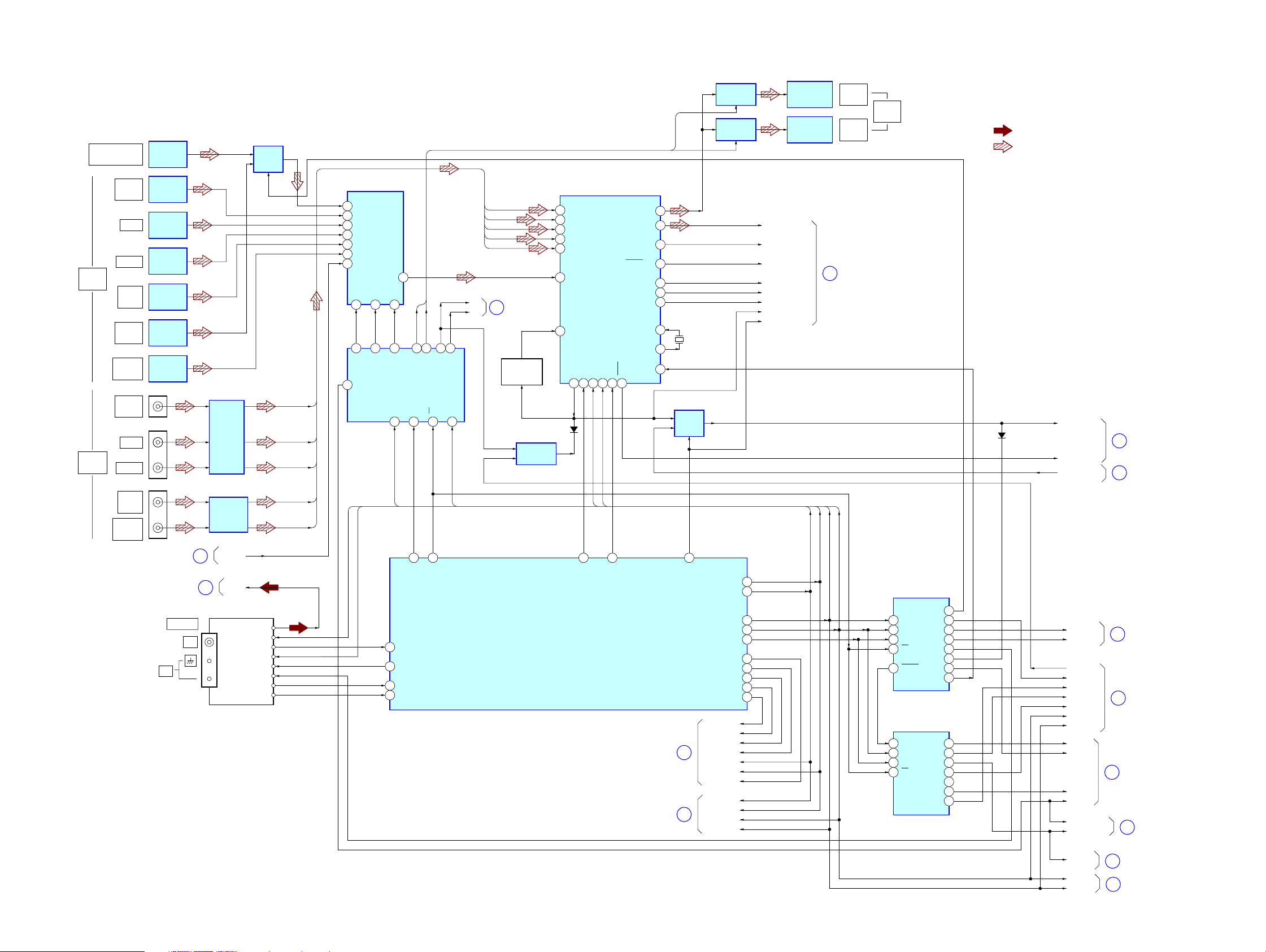

6-4. Block Diagram – I. LINK Section –.............................. 26

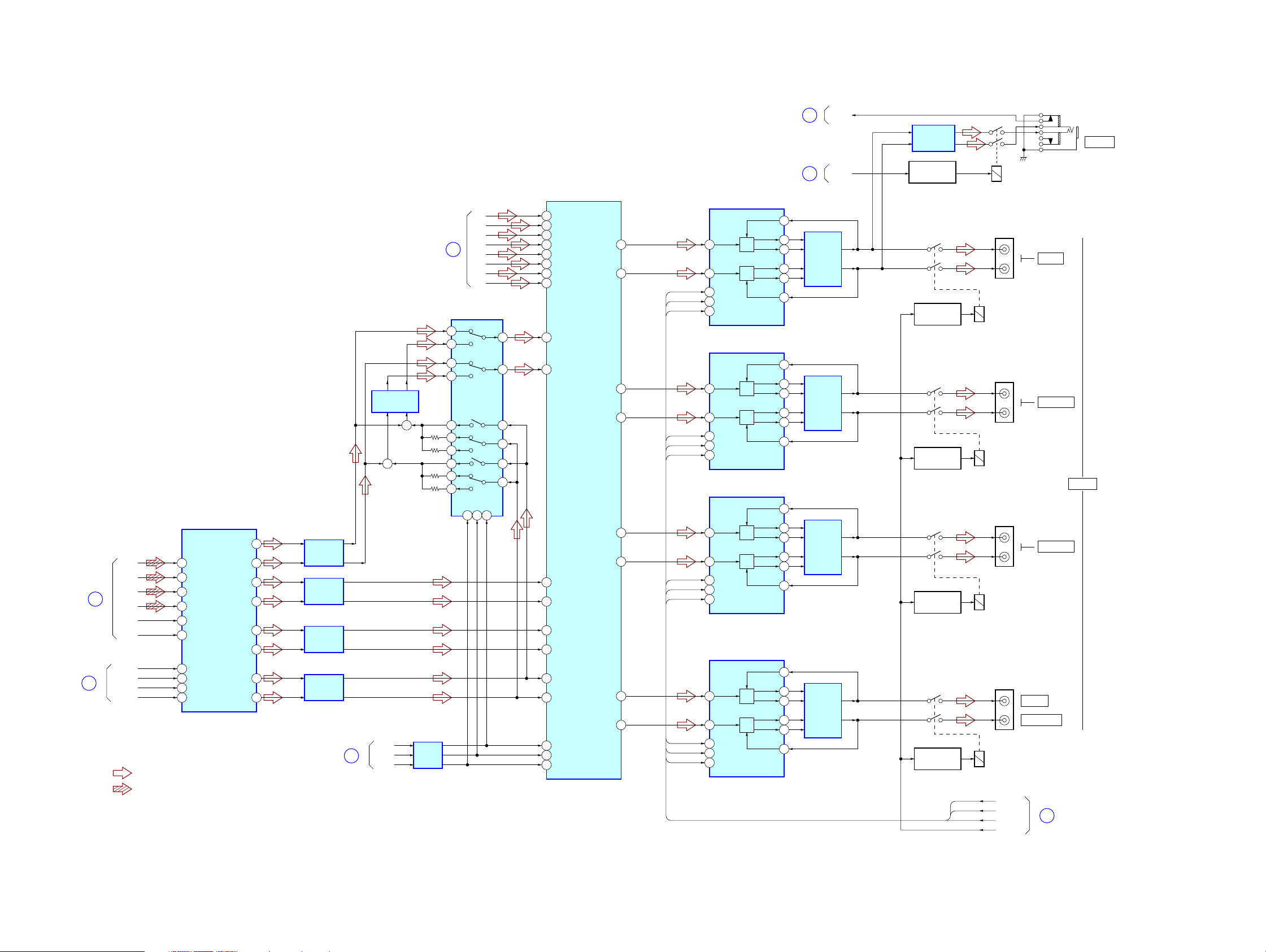

6-5. Block Diagram – DSP Section – ................................... 27

6-6. Block Diagram – DIGIT AL A UDIO Section – ............. 28

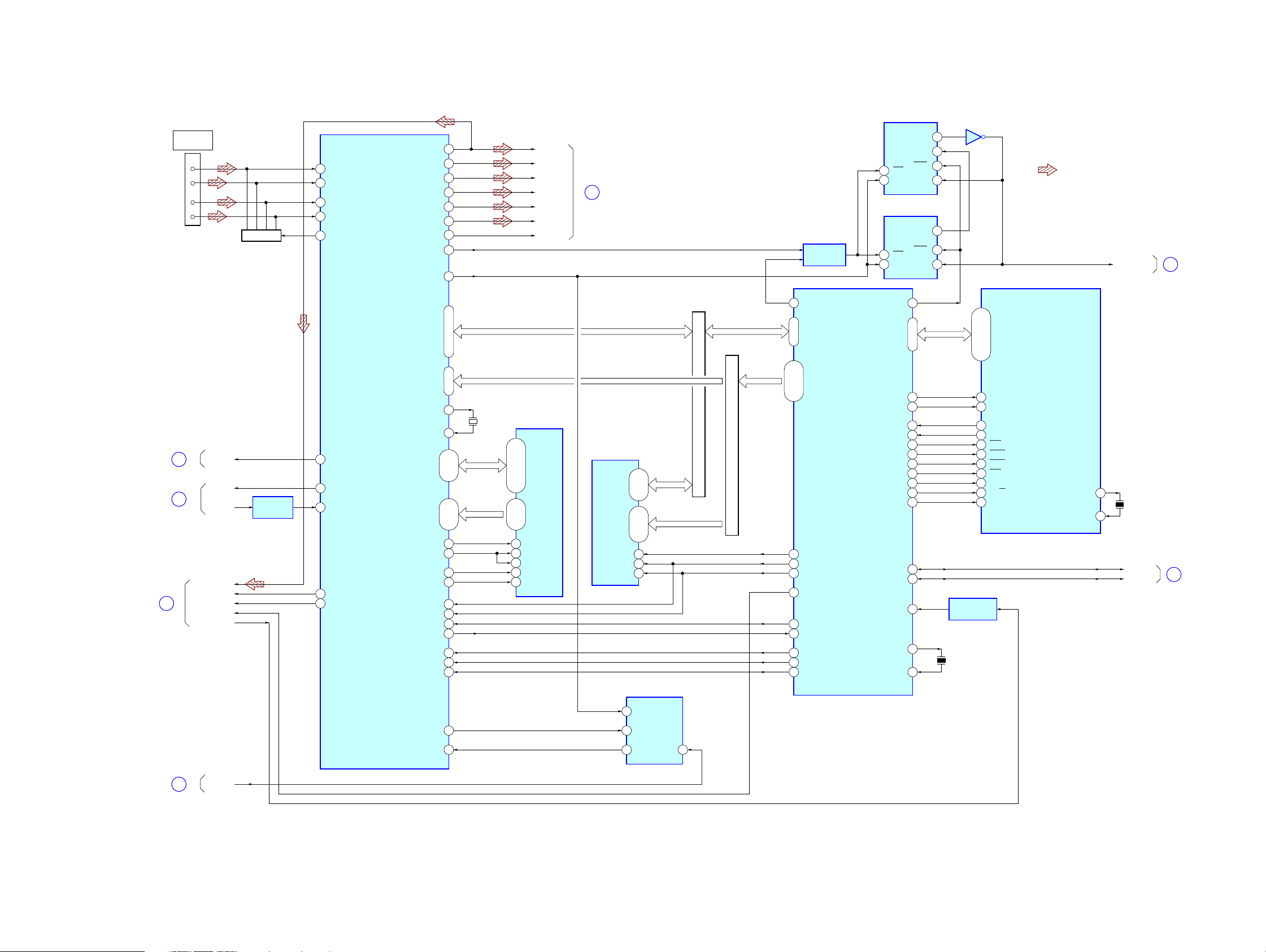

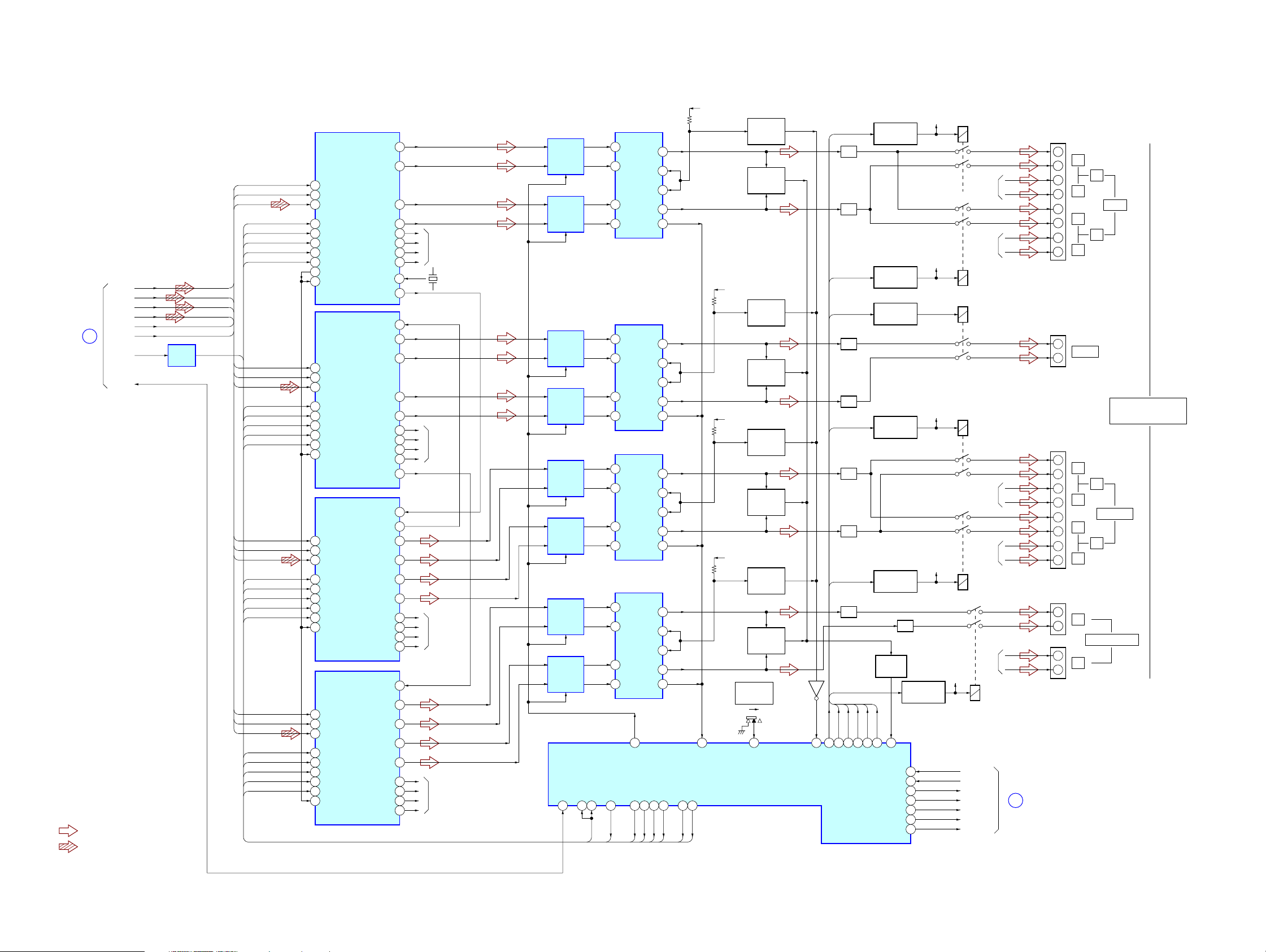

6-7. Block Diagram – AUDIO OUTPUT Section – ............. 29

6-8. Block Diagram – POWER AMP Section – ................... 30

6-9. Block Diagram – VIDEO INPUT/OUT Section –........ 31

6-10. Block Diagram – COMPONENT VIDEO Section – .... 32

6-11. Block Diagram

– DVI, DISPLAY/CONTROL Section – ........................ 33

6-12. Block Diagram – POWER SUPPLY Section – ............. 34

6-13. Note for Printed Wiring Boards

and Schematic Diagrams ................................................ 35

6-14. Printed Wiring Board

– DIGITAL Board (Component Side) – ......................... 36

6-15. Printed Wiring Board

– DIGITAL Board (Conductor Side) –........................... 37

6-16. Schematic Diagram – DIGITAL Board (1/11) –........... 38

6-17. Schematic Diagram – DIGITAL Board (2/11) –........... 39

6-18. Schematic Diagram – DIGITAL Board (3/11) –........... 40

6-19. Schematic Diagram – DIGITAL Board (4/11) –........... 41

6-20. Schematic Diagram – DIGITAL Board (5/11) –........... 42

6-21. Schematic Diagram – DIGITAL Board (6/11) –........... 43

6-22. Schematic Diagram – DIGITAL Board (7/11) –........... 44

6-23. Schematic Diagram – DIGITAL Board (8/11) –........... 45

6-24. Schematic Diagram – DIGITAL Board (9/11) –........... 46

6-25. Schematic Diagram – DIGITAL Board (10/11) – ......... 47

6-26. Schematic Diagram – DIGITAL Board (11/11) – ......... 48

6-27. Schematic Diagram – MAIN Board (1/3) – .................. 49

6-28. Schematic Diagram – MAIN Board (2/3) – .................. 50

6-29. Schematic Diagram – MAIN Board (3/3) – .................. 51

6-30. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 52

6-31. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 53

6-32. Printed Wiring Board

– SUB Board (Component Side) – ................................. 54

6-33. Printed Wiring Board

– SUB Board (Conductor Side) – ................................... 55

3

STR-DA9000ES

6-34. Schematic Diagram – SUB Board (1/2) – ..................... 56

6-35. Schematic Diagram – SUB Board (2/2) – ..................... 57

6-36. Printed Wiring Board – PREOUT Board – ................... 58

6-37. Schematic Diagram – PREOUT Board – ...................... 59

6-38. Printed Wiring Board – VIDEO Board –....................... 60

6-39. Schematic Diagram – VIDEO Board – ......................... 61

6-40. Printed Wiring Board – S-VIDEO Board – ................... 62

6-41. Schematic Diagram – S-VIDEO Board –...................... 63

6-42. Printed Wiring Board

– COMPONENT Section (Component Side) –.............. 64

6-43. Printed Wiring Boards

– COMPONENT Section (Conductor Side) – ............... 65

6-44. Schematic Diagram

– COMPONENT Section (1/4) –.................................... 66

6-45. Schematic Diagram

– COMPONENT Section (2/4) –.................................... 67

6-46. Schematic Diagram

– COMPONENT Section (3/4) –.................................... 68

6-47. Schematic Diagram

– COMPONENT Section (4/4) –.................................... 69

6-48. Printed Wiring Board – TRIGGER Board – ................. 70

6-49. Schematic Diagram – TRIGGER Board – .................... 71

6-50. Schematic Diagram – DVI Board (1/2) –...................... 72

6-51. Schematic Diagram – DVI Board (2/2) –...................... 73

6-52. Printed Wiring Board – DVI Board – ............................ 74

6-53. Schematic Diagram – AMP Board (1/5) – .................... 75

6-54. Schematic Diagram – AMP Board (2/5) – .................... 76

6-55. Schematic Diagram – AMP Board (3/5) – .................... 77

6-56. Schematic Diagram – AMP Board (4/5) – .................... 78

6-57. Schematic Diagram – AMP Board (5/5) – .................... 79

6-58. Printed Wiring Board

– AMP Board (Component Side) –................................. 80

6-59. Printed Wiring Board

– AMP Board (Conductor Side) – .................................. 81

6-60. Printed Wiring Board – FCOIL Board – ....................... 82

6-61. Schematic Diagram – FCOIL Board – .......................... 83

6-62. Printed Wiring Board – RCOIL Board – ....................... 84

6-63. Schematic Diagram – RCOIL Board –.......................... 85

6-64. Printed Wiring Boards – SP Section –........................... 86

6-65. Schematic Diagram – SP Section – ............................... 87

6-66. Printed Wiring Board

– I. LINK Board (Component Side) – ............................ 88

6-67. Printed Wiring Board

– I. LINK Board (Conductor Side) –.............................. 89

6-68. Schematic Diagram – I. LINK Board (1/4) –................ 90

6-69. Schematic Diagram – I. LINK Board (2/4) –................ 91

6-70. Schematic Diagram – I. LINK Board (3/4) –................ 92

6-71. Schematic Diagram – I. LINK Board (4/4) –................ 93

6-72. Printed Wiring Board – DISPLAY Section –................ 94

6-73. Schematic Diagram – DISPLAY Section – ................... 95

6-74. Printed Wiring Boards – PANEL Section – .................. 96

6-75. Schematic Diagram – PANEL Section –....................... 97

6-76. Printed Wiring Board

– MOTHER Board (Component Side) – ........................ 98

6-77. Printed Wiring Board

– MOTHER Board (Conductor Side) –.......................... 99

6-78. Schematic Diagram – MOTHER Board (1/3) – ........... 100

6-79. Schematic Diagram – MOTHER Board (2/3) – ........... 101

6-80. Schematic Diagram – MOTHER Board (3/3) – ........... 102

6-81. Schematic Diagram – DC Board – ............................... 103

6-82. Printed Wiring Board

– DC Board (Component Side) – ..................................104

6-83. Printed Wiring Board

– DC Board (Conductor Side) – .................................... 105

6-84. Printed Wiring Board – A C Board –............................. 106

6-85. Schematic Diagram – AC Board –................................ 107

6-86. IC Pin Function Description .......................................... 124

7. EXPLODED VIEWS

7-1. Case Section ................................................................... 146

7-2. Disp Board Section ........................................................ 147

7-3. Volume Section .............................................................. 148

7-4. Panel (Door) Section...................................................... 149

7-5. Front Panel Section ........................................................ 150

7-6. Base Panel Section ......................................................... 151

7-7. AMP Board Section ....................................................... 152

7-8. Tuner Section ................................................................. 153

7-9. Main Board Section .......................................................154

7-10. Digital/I. link Board Section.......................................... 155

7-11. Back Panel Section......................................................... 156

7-12. Transformer Section....................................................... 157

7-13. MOTHER Board Section ............................................... 158

8. ELECTRICAL PARTS LIST .............................. 159

4

STR-DA9000ES

SECTION 1

SER VICING NOTES

NOTES ON REPLACEMENT OF I. LINK BOARD

New part of microcomputer (IC3002) and EEPROM (IC3001) on the I. LINK board cannot be used. Therefore, if the mounted I. LINK

board (A-4733-759-A) is replaced, exchange new microcomputer and new EEPROM with that used before the replacement.

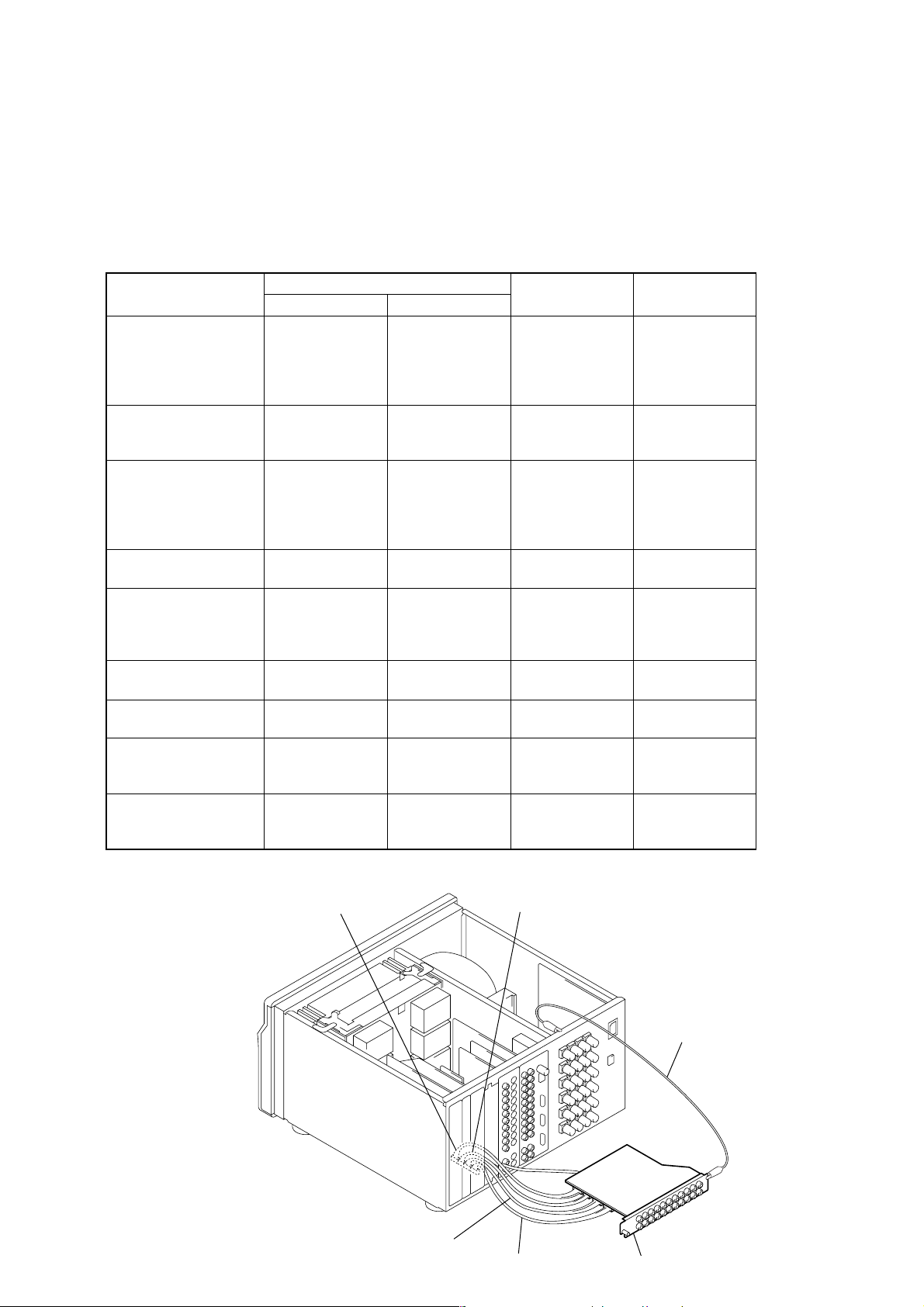

OPERATION CHECK OF STANDING BOARDS ON THE MOTHER BOARD

The standing boards connected to the MOTHER board via the connectors can be operated using the jig with the standing boards disconnected from the MOTHER board.

In such a case, for the board with the bracket (back panel), remove the board together with the bracket from the MOTHER board, and

connect the bracket to the chassis using a cable attached with alligator clips for GND connection.

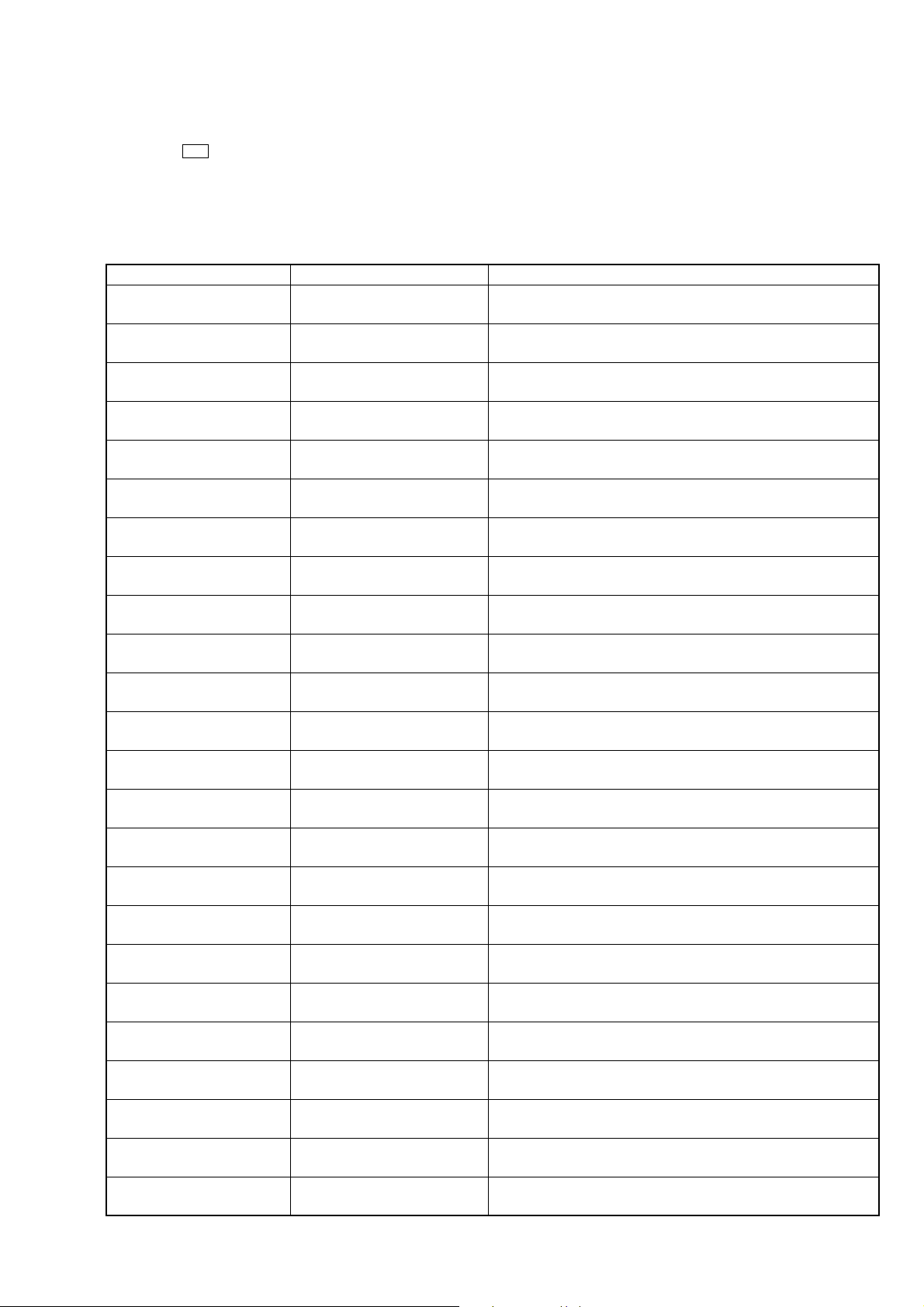

Board

DIGITAL board CN2001 CNS801 1.25mm/20 pin J-2501-260-A

I. LINK board CN3501 CNS806 1.25mm/16 pin J-2501-258-A

MAIN board CN101 CNS810 1.25mm/14 pin J-2501-257-A

PREOUT board CN1201 CNS822 1.25mm/16 pin J-2501-258-A

SUB board CN1003 CNS812 1.25mm/14 pin J-2501-257-A

VIDEO board CN302 CNS816 1.25mm/18 pin J-2501-259-A

S-VIDEO board CN402 CNS817 1.25mm/20 pin J-2501-260-A

COMPONENT board CN1303 CNS819 1.25mm/20 pin J-2501-260-A

AMP board CN1501 CN824 2.5mm/20 pin J-2501-262-A

Ref. No. of connector

Each board MOTHER board

CN2002 CNS802 1.25mm/20 pin J-2501-260-A

CN2003 CNS803 1.25mm/16 pin J-2501-258-A

CN2004 CNS804 1.25mm/18 pin J-2501-259-A

CN2005 CNS805 1.25mm/20 pin J-2501-260-A

CN3502 CNS807 1.25mm/18 pin J-2501-259-A

CN3503 CNS808 1.25mm/6 pin J-2501-253-A

CN102 CNS811 1.25mm/14 pin J-2501-257-A

CN103 CNS809 1.25mm/8 pin J-2501-254-A

CN104 CNS825 1.25mm/20 pin J-2501-260-A

CN105 CNS824 1.25mm/10 pin J-2501-255-A

CN1203 CNS823 1.25mm/10 pin J-2501-255-A

CN1002 CNS813 1.25mm/14 pin J-2501-257-A

CN1001 CNS814 1.25mm/8 pin J-2501-254-A

CN1006 CNS826 1.25mm/12 pin J-2501-256-A

CN301 CNS815 1.25mm/8 pin J-2501-254-A

CN401 CNS818 1.25mm/6 pin J-2501-253-A

CN1302 CNS820 1.25mm/16 pin J-2501-258-A

CN1301 CNS821 1.25mm/20 pin J-2501-260-A

CN1507 CN816 2.5mm/6 pin J-2501-261-A

CN1508 CN815 2.5mm/6 pin J-2501-261-A

Pitch/Pin Part No. of jig

Example of Connection

connecting jig connecting jig

connecting jig

connecting jig

aligator clip

board

5

STR-DA9000ES

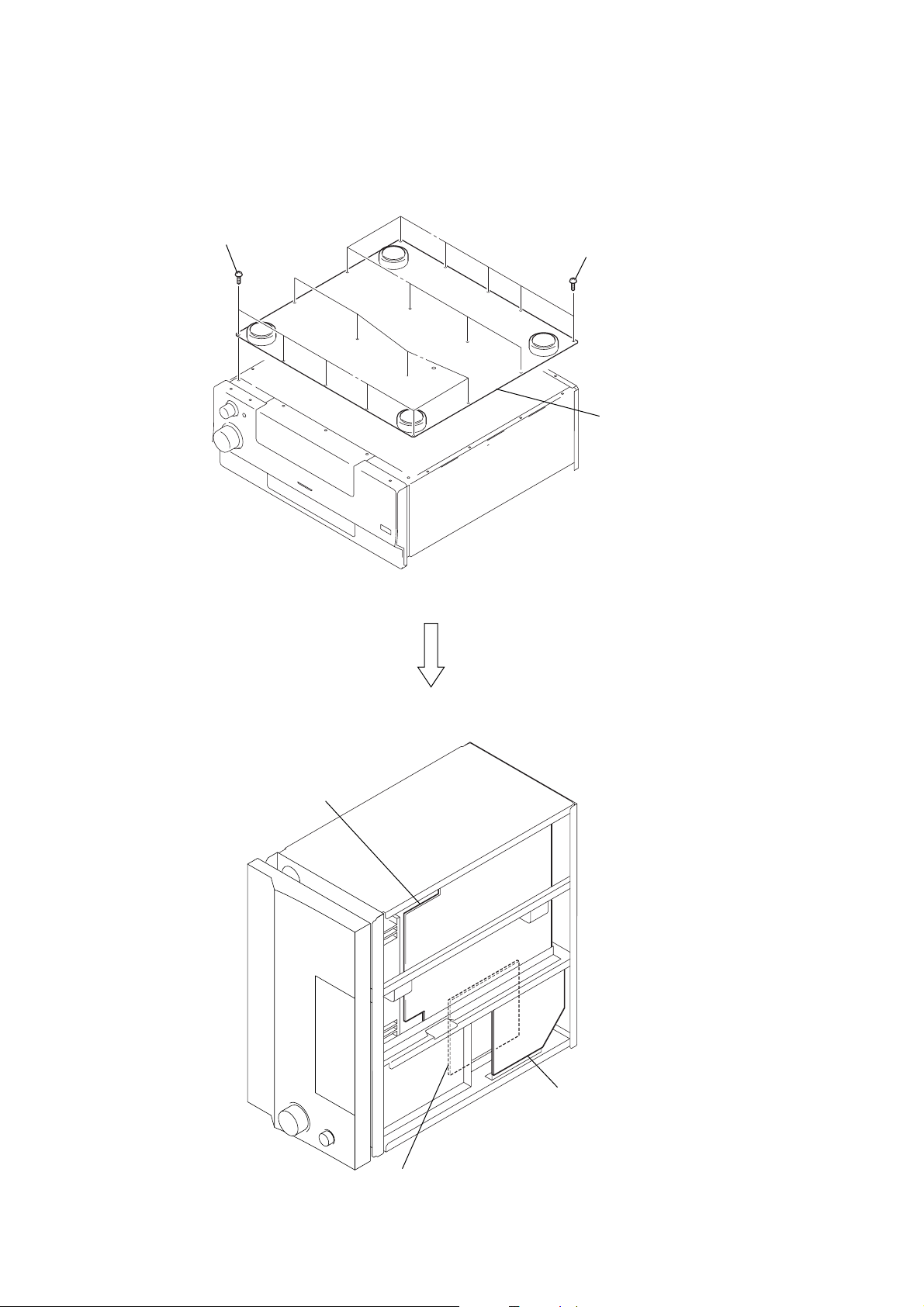

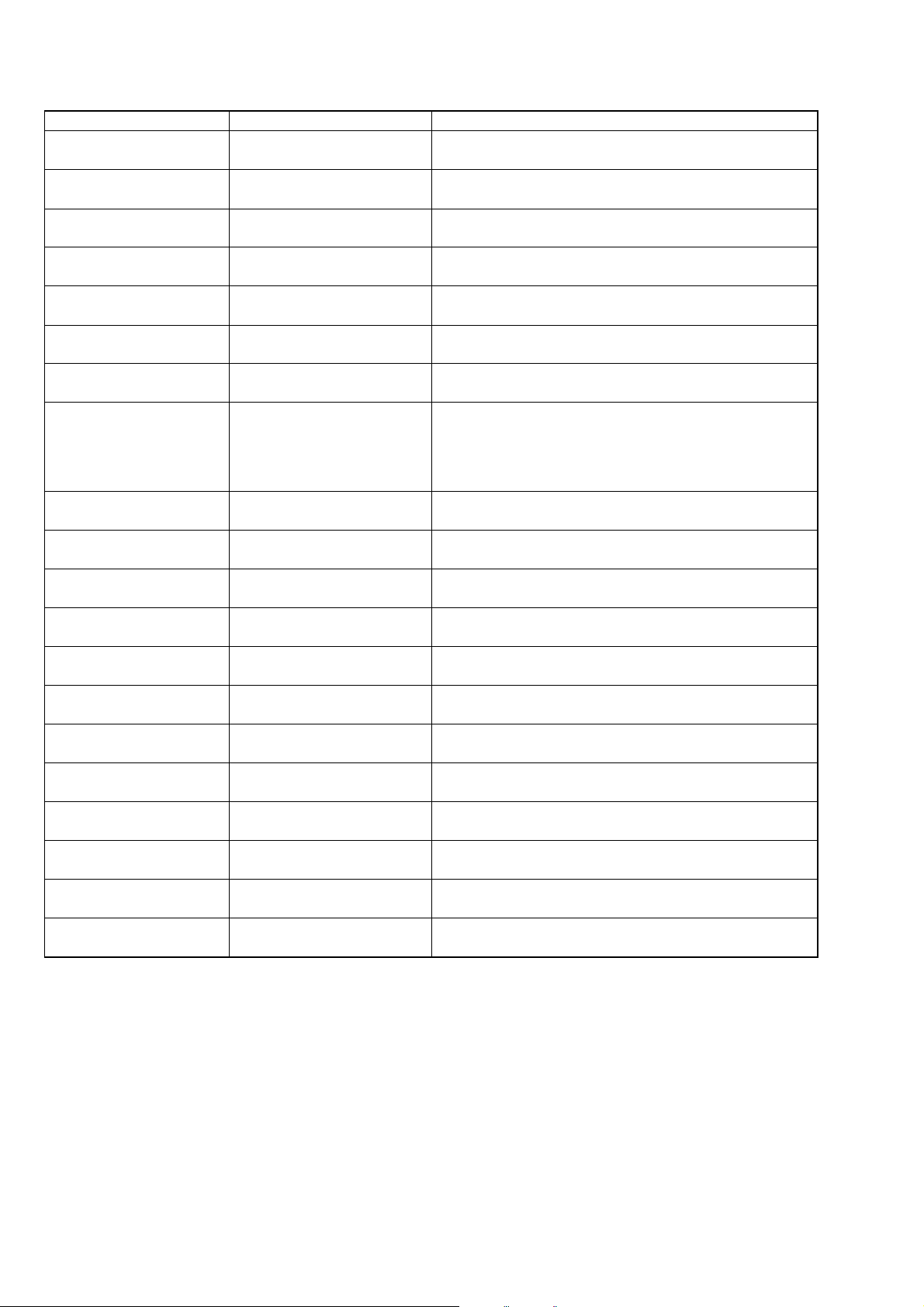

Note: Follow the disassembly procedure in the numerical order given.

– BOTTOM VIEW –

1

nine screws

(BV3

×

8)

2

nine screws

(BV3

3

×

8)

bottom plate

mother board

DC board

FSP board

NOTE:

•

FSP board can be removed in this state.

•

In the same state after removing a FSP board,

the check of DC board can be performed.

6

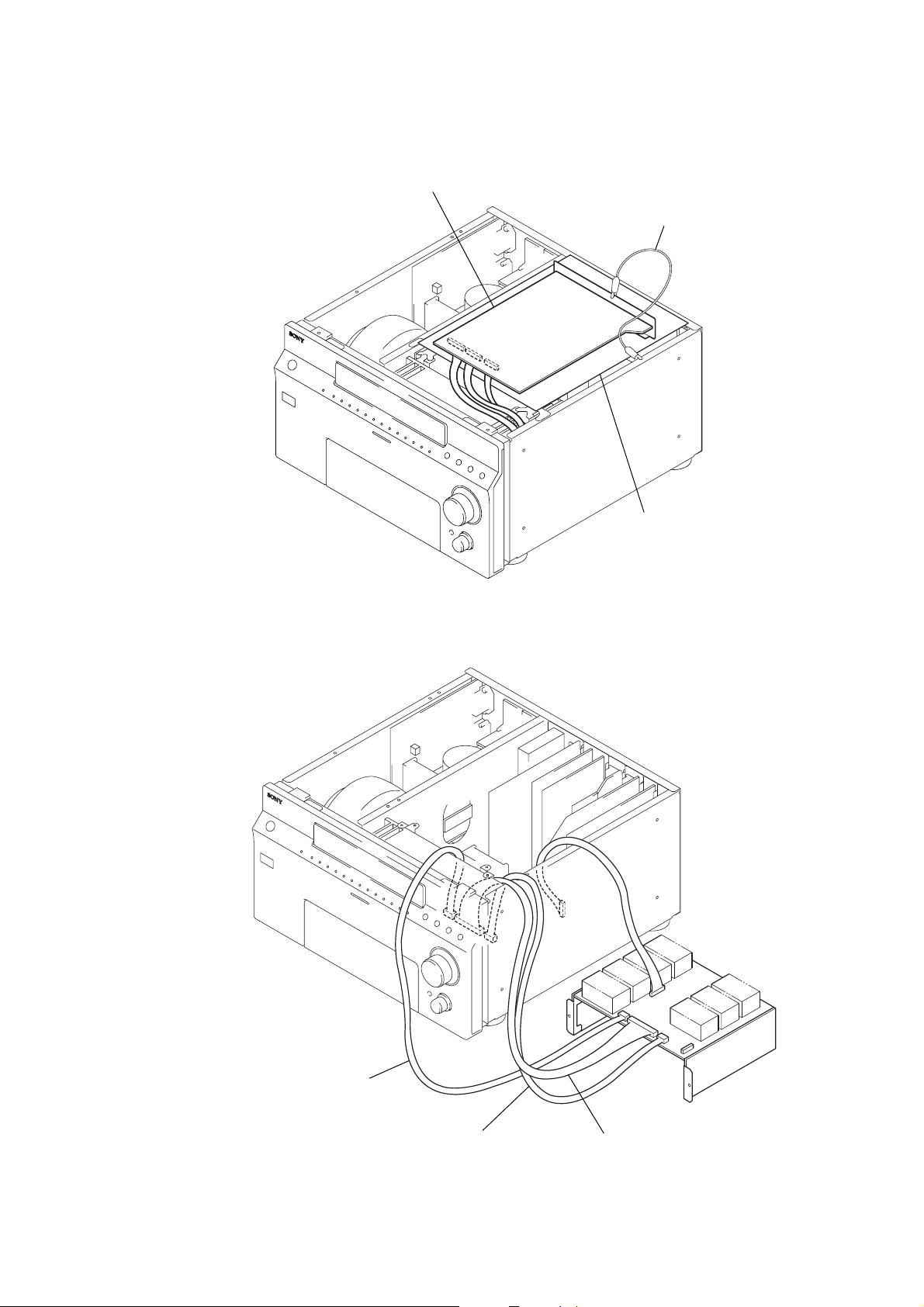

DIGITAL BOARD SERVICE POSITION

Note: Case (top) and Case (side-L)/(side-R) are removed.

STR-DA9000ES

digital board

aligator clip

AMP BOARD SERVICE POSITION

Please place a sheet

for insulation.

Connect jig (J-2501-253-A)

to the AMP board (CN1508)

and mother board (CN815).

Connect jig (J-2501-253-A)

to the AMP board (CN1507)

and mother board (CN816).

Connect jig (J-2501-260-A)

to the AMP board (CN1501)

and mother board (CN824).

7

STR-DA9000ES

Ver 1.2

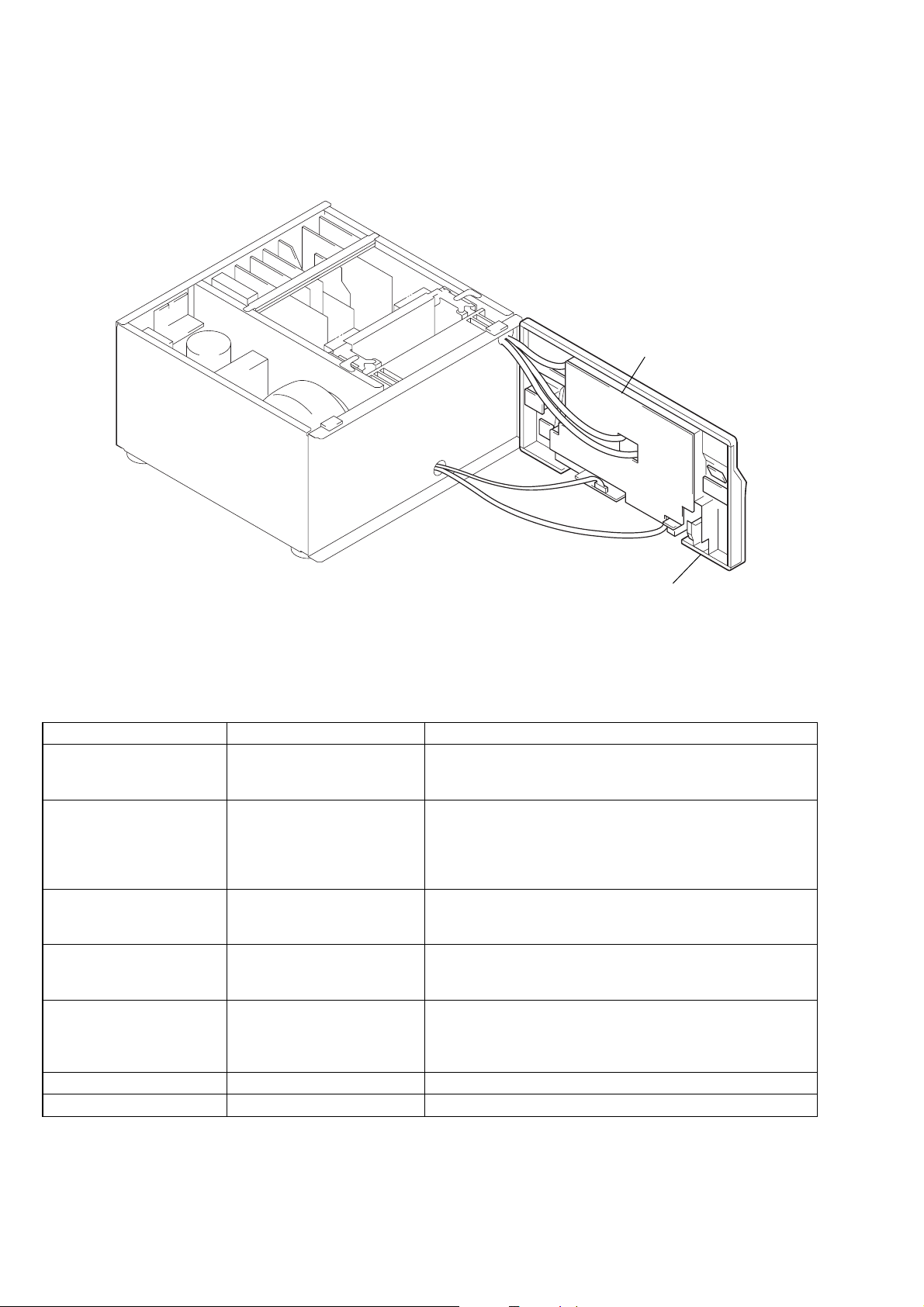

DISP BOARD SERVICE POSITION

Note: Please open a front panel on the right hand side of the set front.

DISP board

front panel section

ERROR MESSAGES

If there is a malfunction, the display shows a code of two numbers and a message. You can check the condition of the system by message.

Refer to the following table to solve the problem.

messages check code cause and response

DECODE ERROR 01 Appears when the signal which the receiver can not decode

(example DSD-CD) is input when “DEC. PRI.” in the CUSTOM

IZE menu is set to “PCM”. Set to “AUTO”.

PROTECTOR 11 Irregular current output to the speakers. Turn off the receiver and

check the speaker connection. Then turn on the power again. Be

comes this display, When short current flowed with breakage of

the power MOS, or when detection resistor becomes open in

connection with it.

PROTECTOR 12 The amplifier section is overheated. Turn off the receiver and

check that the ventilation hole is not covered. Leave the receiver

for a while and turn on the power again.

PROTECTOR 13 The power supply section is overheated. Turn off the receiver and

check that the ventilation hole is not covered. leave the receiver

for a while and turn on the power again.

PROTECTOR 21 DC between speaker terminal is detected (abnomalities such as

DSD 0DATA and signal clip can be considered). Turn off the

receiver and check the speaker connection. Then turn on the power

again.

PROHIBITED 71 The receiver can't output the sound due to the copyright protection.

UNKNOWN SIGNAL 72 The receiver isn't compatible with the format of the input signal.

8

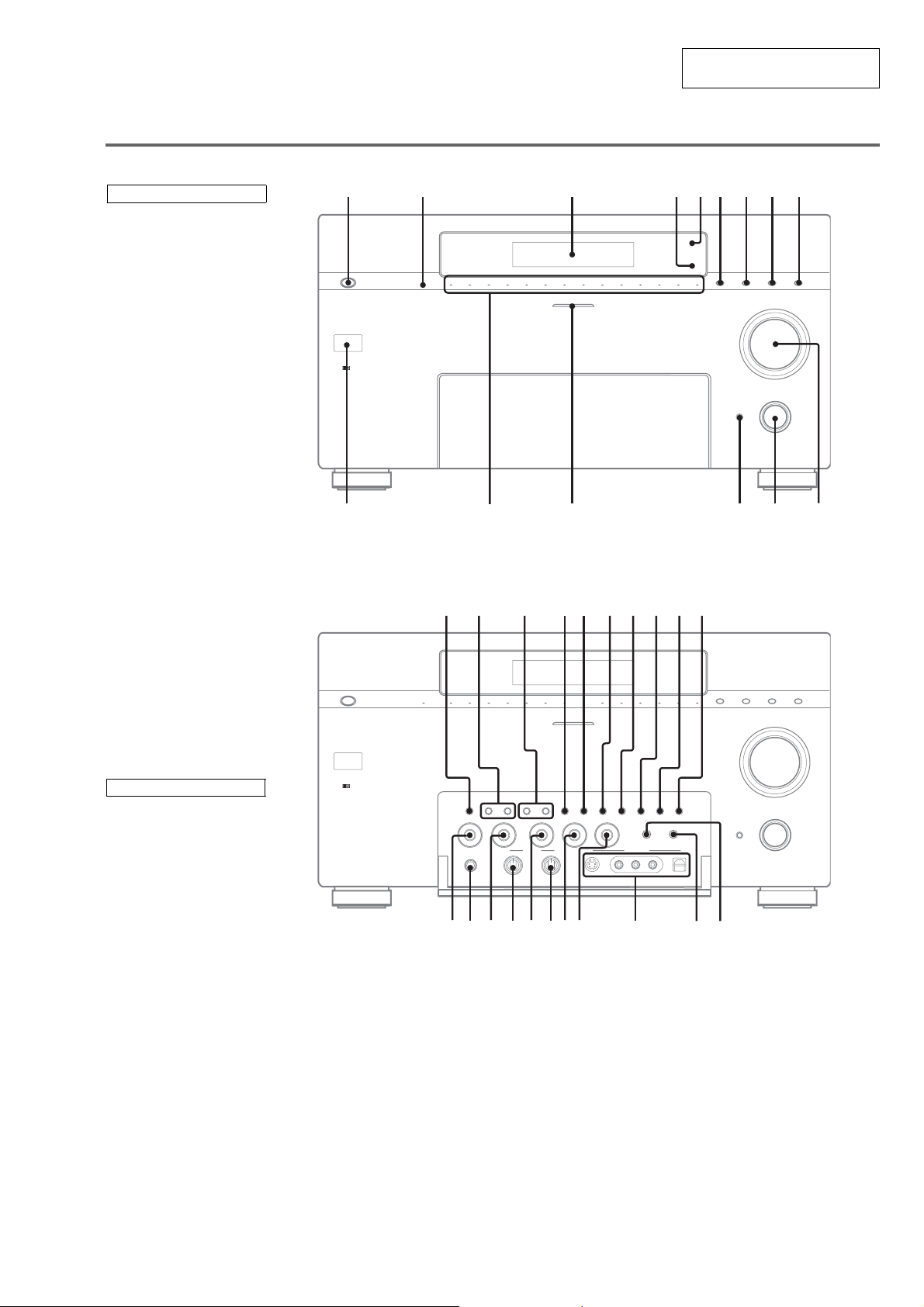

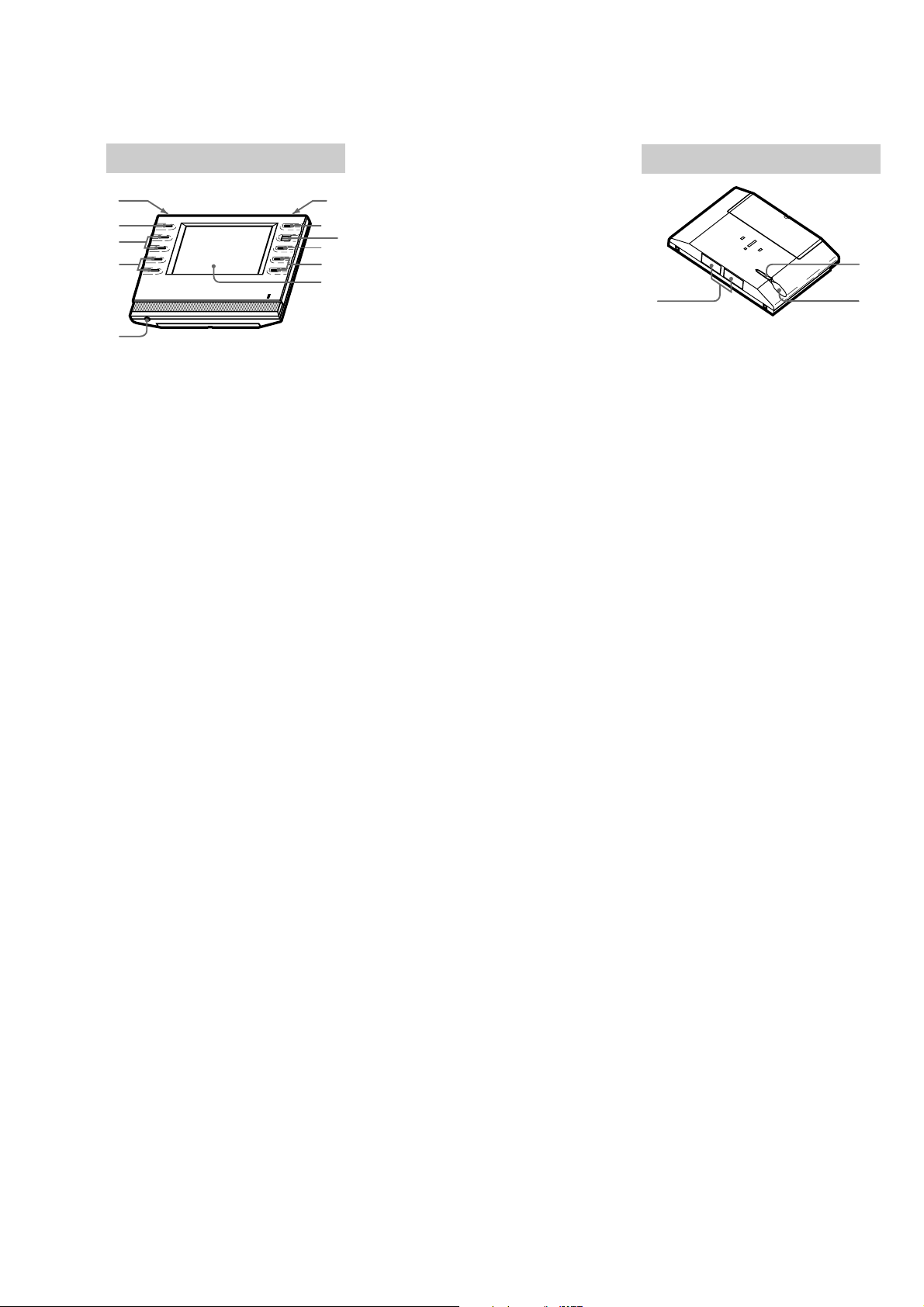

SECTION 2

1 2 3654 7 8 9

GENERAL

LOCATION OF CONTROLS

Main unit

ALPHABETICAL ORDER

A.F.D. 7

BASS eh

DECODE PRIORITY ws

Digital Cinema Sound indicator

5

DIRECT wd

DIRECT indicator 2

DISPLAY wa

Display 3

FM/AM qh

Input indicators qf

INPUT MODE qs

INPUT SELECTOR qa

IR receptor qg

MAIN MENU es

MASTER VOLUME q;

MEMORY/ENTER ql

MENU e;

MOVIE 8

MULTI CH IN 1/2 wf

MULTI CHANNEL DECODING

indicator qd

MUSIC 9

PHONES jack eg

PRESET TUNING –/+ qj

SB DEC indicator 4

SPEAKERS FRONT switch ed

SPEAKERS SURROUND switch

ea

SURR BACK DECODING wg

TREBLE ef

TUNING –/+ qk

USER PRESET w;

VIDEO 5 INPUT jacks wk

ZONE 2ND wh

ZONE 3RD wj

qf

This section is extracted from

instruction manual.

qdqg qaqs

v

wgqkqjqh ql w; wa ws

wd wf

STR-DA9000ES

0

NUMBERS AND SYMBOLS

2CH 6

?/1 (power) 1

–/+ wl

eg edef eseh ea wke;wl wj wh

9

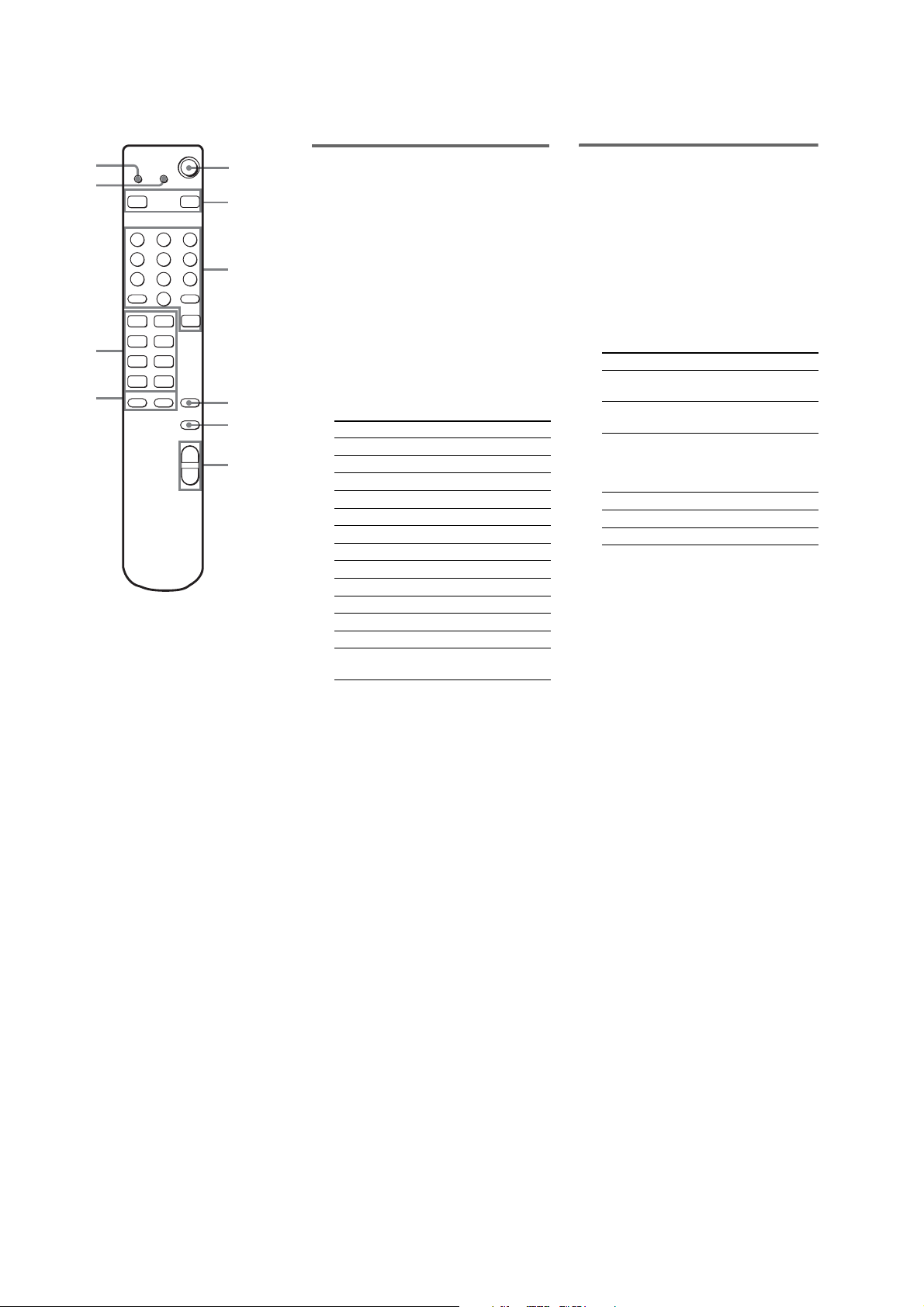

STR-DA9000ES

– Remote Commander –

0

9

8

7

?/1

USE MODE

2ND ZONE 3RD ZONE

VIDEO 1 VIDEO 2

VIDEO 4 VIDEO 5 LD

DVD TV/SAT TAPE

MD/DAT

n

CH/PRESET/D.SKIP

CD/SACD

N

xX

>.

Mm

+–

VIDEO 3

TUNER

SOURCE

SHIFT

MUTING

MASTER

VOL

+

–

1

2

3

4

5

6

Operating the main receiver

from the 2nd (or 3rd) zone

?/1

1

Press to turn the receiver in the 2nd (or 3rd)

zone on or off.

Command mode buttons

Press to select the command mode of the

remote (2ND ZONE or 3RD ZONE).

Input buttons

3

Press one of the buttons to select the

component you want to use. When you

press any of the input buttons, the receiver

turns on. The buttons are factory assigned to

control Sony components as follows. You

can change the button assignments

Button Assigned Sony component

VIDEO1 VCR (VTR mode 3)

VIDEO2 VCR (VTR mode 1)

VIDEO3 VCR (VTR mode 2)

VIDEO4 VCR (VTR mode 4)

VIDEO5 VCR (VTR mode 5)

LD LD player

DVD DVD player

TV/SAT TV tuner

TAPE Tape deck B

MD/DAT MD deck

CD/SACD CD/Super Audio CD player

b)

TUNER

SOURCE The current input selected for the

Built-in tuner

main receiver

2

Operating the components

connected to the main

receiver from the 2nd (or 3rd)

zone

CH/PRESET/D.SKIP +/–

Press repeatedly to select a preset station or

channel. When using a multi-disc changer,

press to skip a disc.

Operation buttons

The following table describes the function

of the buttons.

Button(s) Function

N Starts play. (Starts play on the

n Starts play on the reverse side of

X Pauses play or recording, and

x Stops play.

./> Skips tracks.

m/M Fast forwards or rewinds.

*The function of these buttons switches automatically

each time you press the input buttons (3). The

above explanation is intended to serve as an example

only. Therefore, depending on the component, the

above operation may not be possible or may operate

differently than described.

*

7

*

8

front side of the cassette.)

the cassette.

starts recording when the

component is in recording

standby.

b)

The setting cannot be changed.

MASTER VOL +/– 6

Press to adjust the volume level for 2ND

ZONE or 3RD ZONE output.

MUTING 5

Press to mute the sound.

SHIFT

4

When the tuner is selected, press repeatedly

to select a memory page for presetting radio

stations or tuning to preset stations.

USE MODE

9

Press to change the category of the buttons.

USE MODE indicator

q;

10

– Interactive Remote Commander –

STR-DA9000ES

Front panel

qa

0

9

8

7

1 BACK LIGHT button

Press to turn the backlight on or off. Hold

down for about 2 seconds to turn the LCD

off. When the LCD is off, press to turn on

the LCD and backlight.

¥ To prolong use of the battery, the LCD

automatically turns off if there is no command

entered in the touch panel for 60 seconds.

¥ To view the LCD display without turning on the

backlight, touch the touch panel when both the

backlight and LCD are off.

2 ?/1/SYSTEM STANDBY button*

Normally used to turn the amplifier/receiver

on or off. When the amplifier/receiver in the

2nd or 3rd zone is on use, only the main

receiver turns on or off.

When pressed for more than 2 seconds, it

turns off all Sony components (SYSTEM

STANDBY) by executing the Macro Play

function SYSTEM OFF program,

even when the amplifier/receiver in the 2nd

or 3rd zone is on use.

2

4

5

6

1

3 Jog dial

Rotate to scroll through items in a list (etc.).

Push to select the highlighted item.

4 MUTING button*

3

Use to mute the sound of the amplifier/

receiver.

5 MASTER VOL +/— buttons*

Use to adjust the volume of the amplifier/

receiver.

6 Touch panel

Touch to operate. The commander turns on

automatically.

7 Stereo mini jack

Use to upgrade the firmware in the future.

8 TV VOL +/— buttons*

Use to adjust the volume of the TV.

9 TV CH +/— buttons*

Use to select the channel of the TV.

0 TV INPUT button*

Use to select the input of the TV.

qa SLEEP button*

Use to operate the amplifier/receivers sleep

timer function. The sleep timer settings

appear in the amplifier/receivers display,

not the commanders LCD.

* The commander emits the remote code for

operating the AMP (amplifier/receiver) or TV that

is registered to this commander using the IR

SETUP function.

If you register two or more AMPs or TVs, the

commander emits the remote code for the

component (icon) that appears first (on the left top

side) in the RM SELECT screen.

Rear panel

1

23

1 Touch pen

2 Touch pen holder

Keep the touch pen here w hen not in use.

3 Transmitter/receiver section

Remote code receiver section

Transmits and receives infrared signals to

and from t he component.

When using the L earni ng f uncti on, t hi s

secti on recei ves the remot e codes from

other remot e control s.

11

STR-DA9000ES

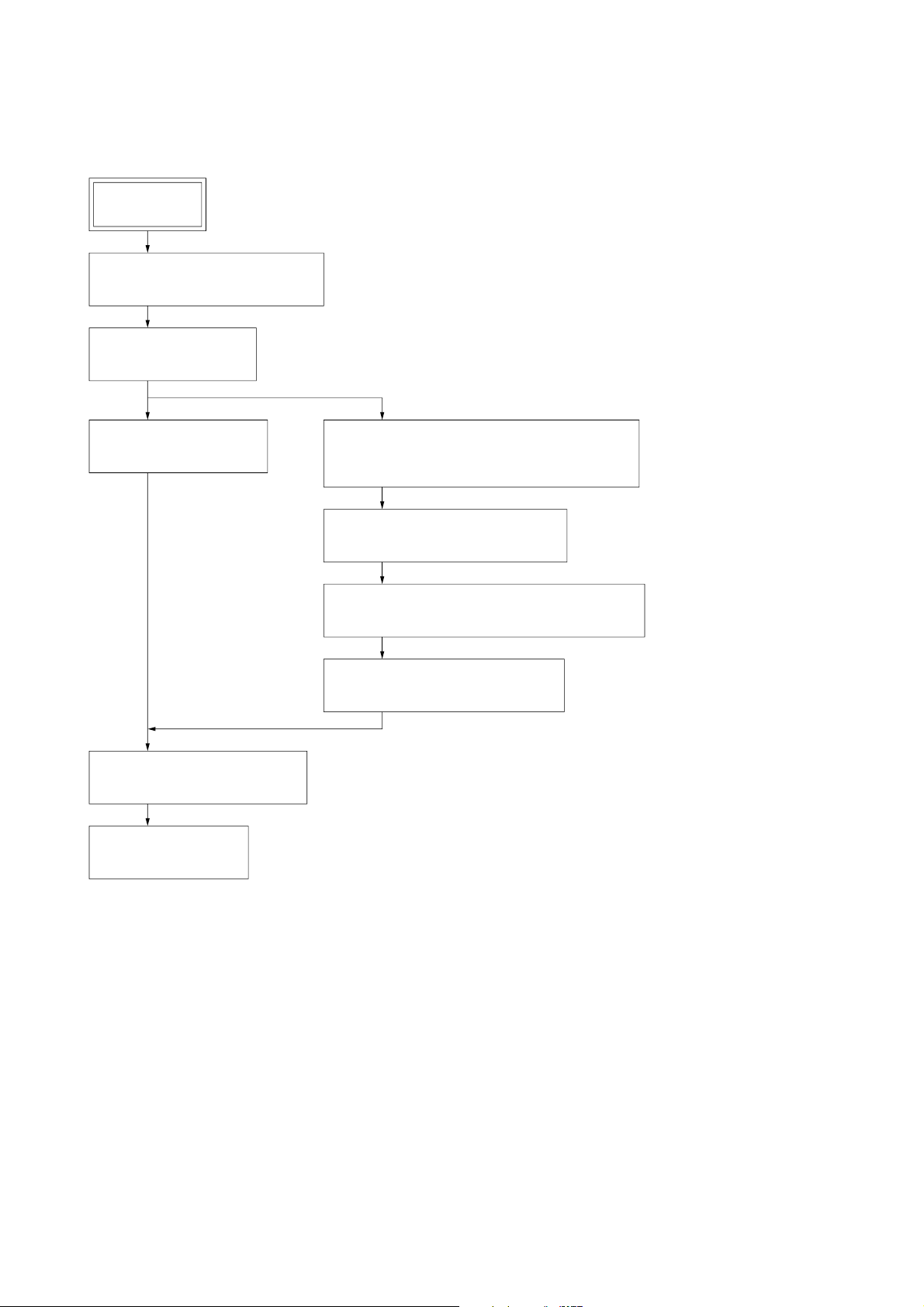

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. CASE (TOP)/(SIDE-L)/(SIDE-R)

(Page 13)

3-3. BRACKET (J)/(P-B)

(Page 13)

SECTION 3

DISASSEMBLY

3-4. AMP BOARD BLOCK

(Page 14)

3-9. MOTHER BOARD SECTION

(Page 16)

3-10. MOTHER BOARD

(Page 17)

3-5. TUNER,

COMPONENT/TRIGGER/DVI BOARD BLOCK

(Page 14)

3-6. S-VIDEO/VIDEO BOARD BLOCK

(Page 15)

3-7. SUB BOARD, PREOUT BOARD, MAIN BOARD

(Page 15)

3-8. I. LINK BOARD, DIGITAL BOARD

(Page 16)

12

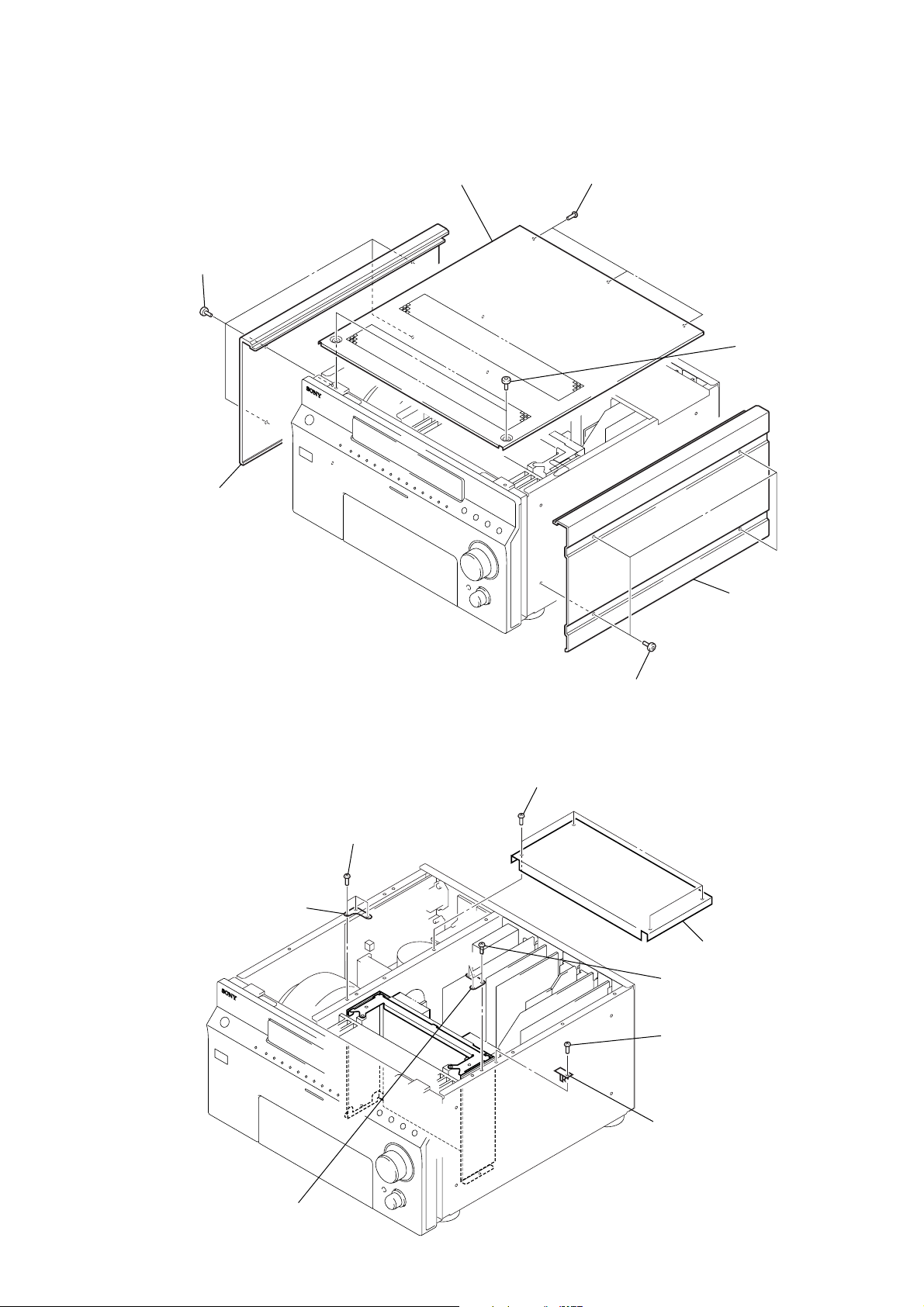

Note: Follow the disassembly procedure in the numerical order given.

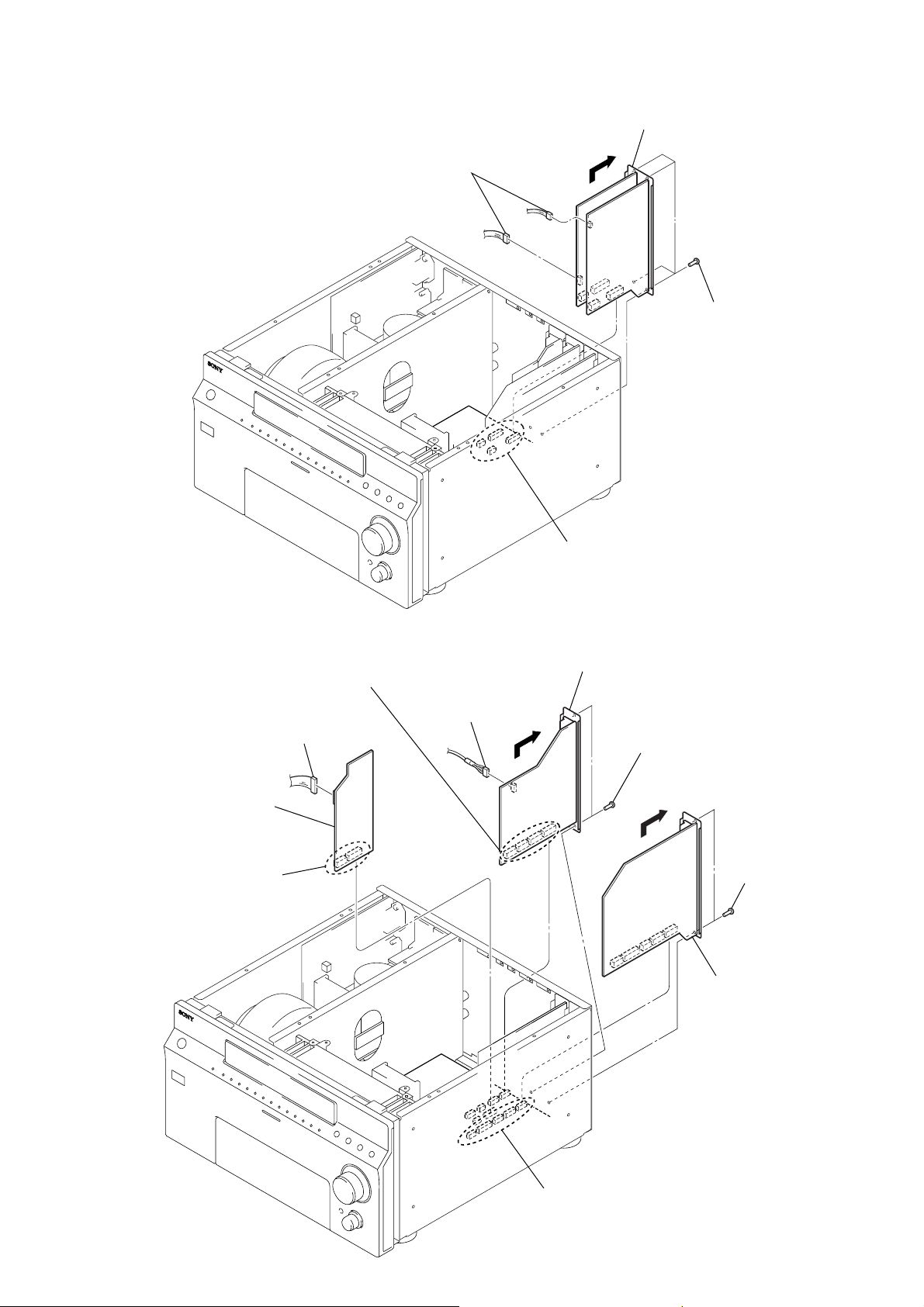

3-2. CASE (TOP)/(SIDE-L)/(SIDE-R)

3

case (top)

4

four screws

1

three screws

(BV/ring)

STR-DA9000ES

2

two screws

5

case (side-L)

3-3. BRACKET (J)/(P-B)

8

bracket (P-B)

7

three screws

(BV3

7

case (side-R)

6

four screws

1

four screws

×

8)

(BV3

×

8)

6

bracket (P-B)

5

three screws

(BV3

3

screw

(BV3

4

bracket (D-H)

2

bracket (J)

×

8)

×

8)

13

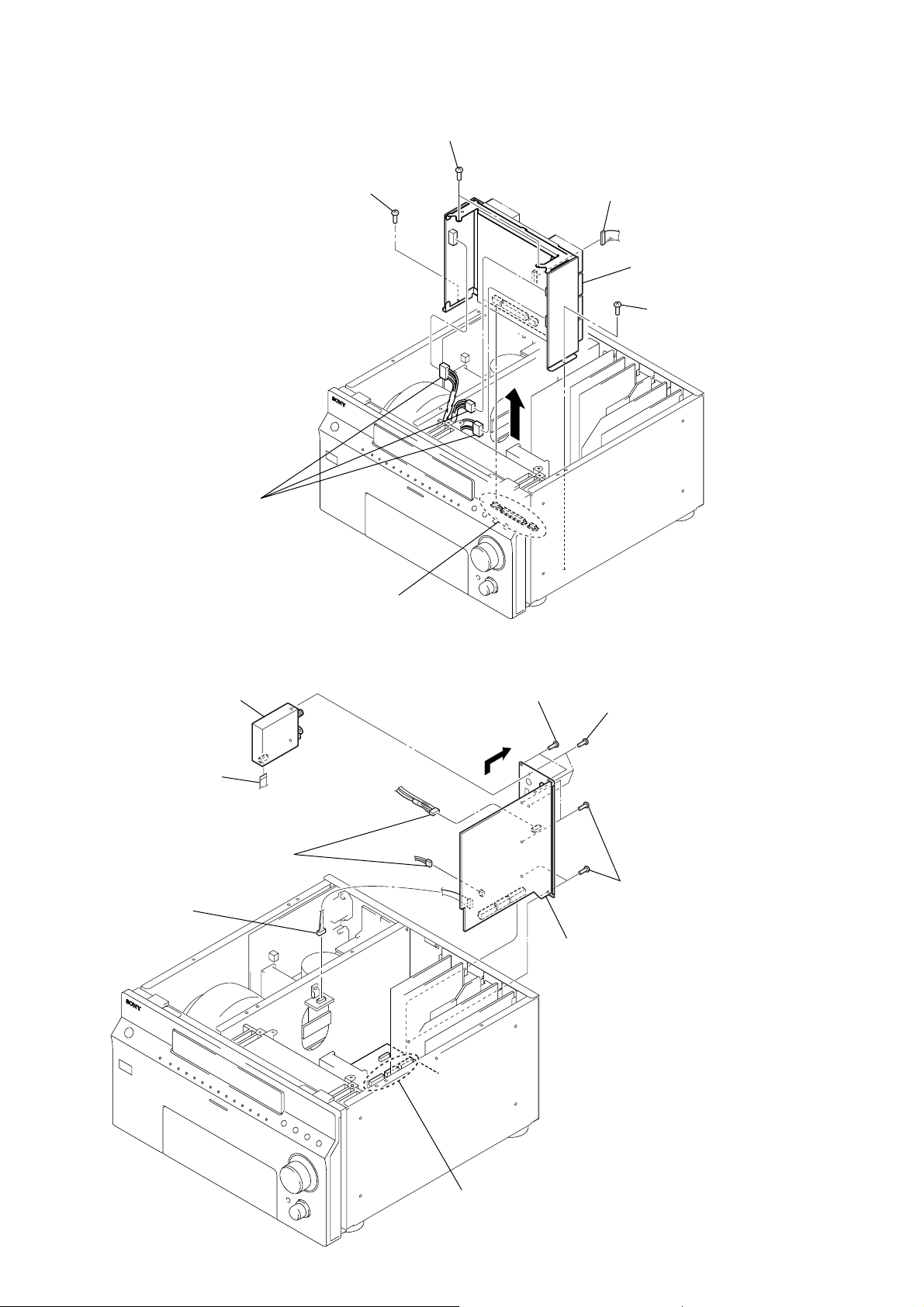

STR-DA9000ES

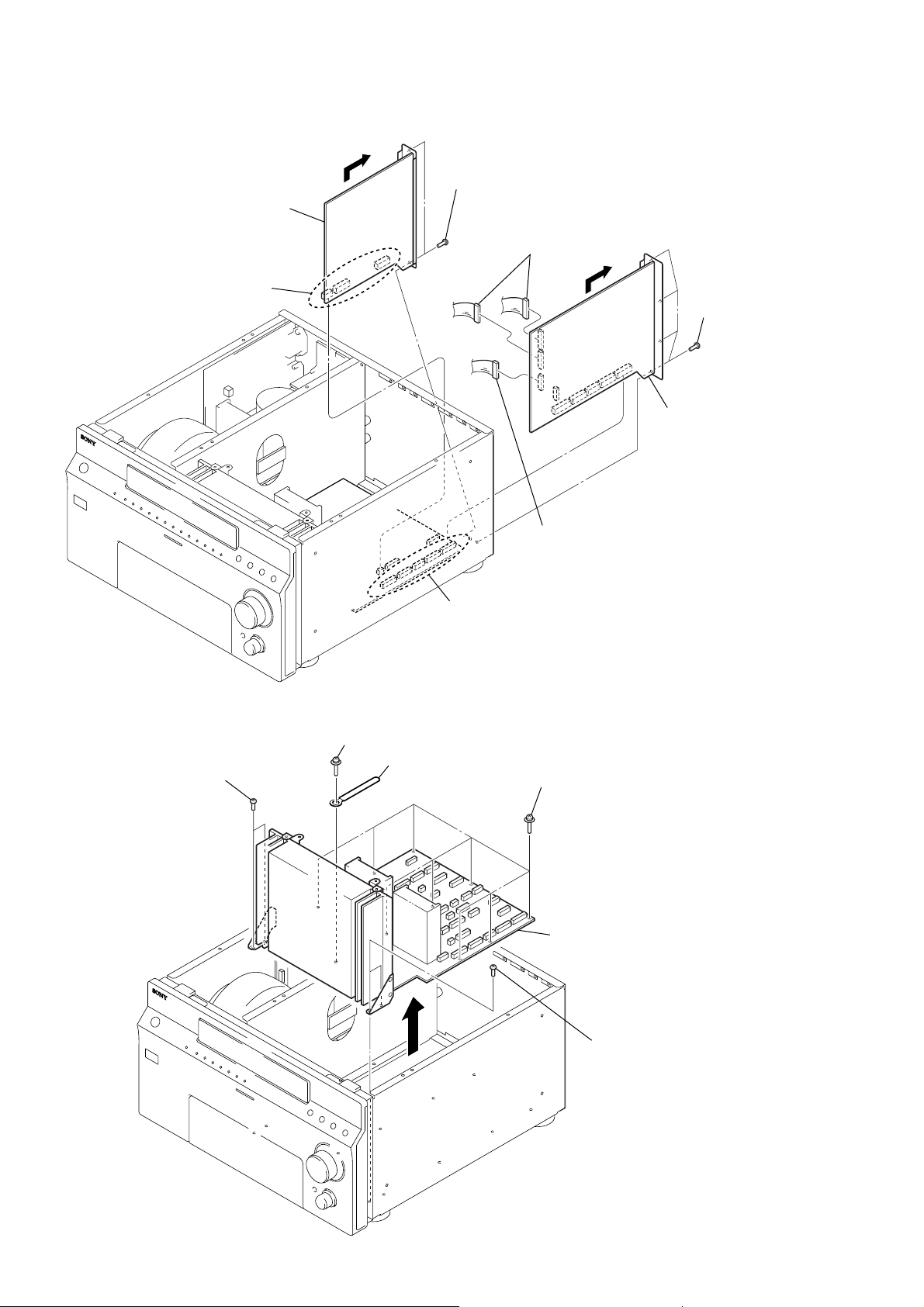

3-4. AMP BOARD BLOCK

2

screw

(BV3 × 8)

3

two screws

(BV3 × 8)

5

6

connector (CN1503)

8

AMP board

1

screw

(BV3 × 8)

7

three connectors

(CN1506, 1512, 1516)

4

three connectors

(CN815, 816, 824)

3-5. TUNER, COMPONENT/TRIGGER/DVI BOARD BLOCK

4

3

tuner

2

connector

(CN2)

8

two connectors

(CN1305, 1306)

9

connector

(CN1301)

two screws

(BV/ring)

7

1

three screws

(BV3

5

four screws

(BV/ring)

×

8)

14

6

three connectors

(CN819, 820, 821)

0

component/trigger/DVI board block

STR-DA9000ES

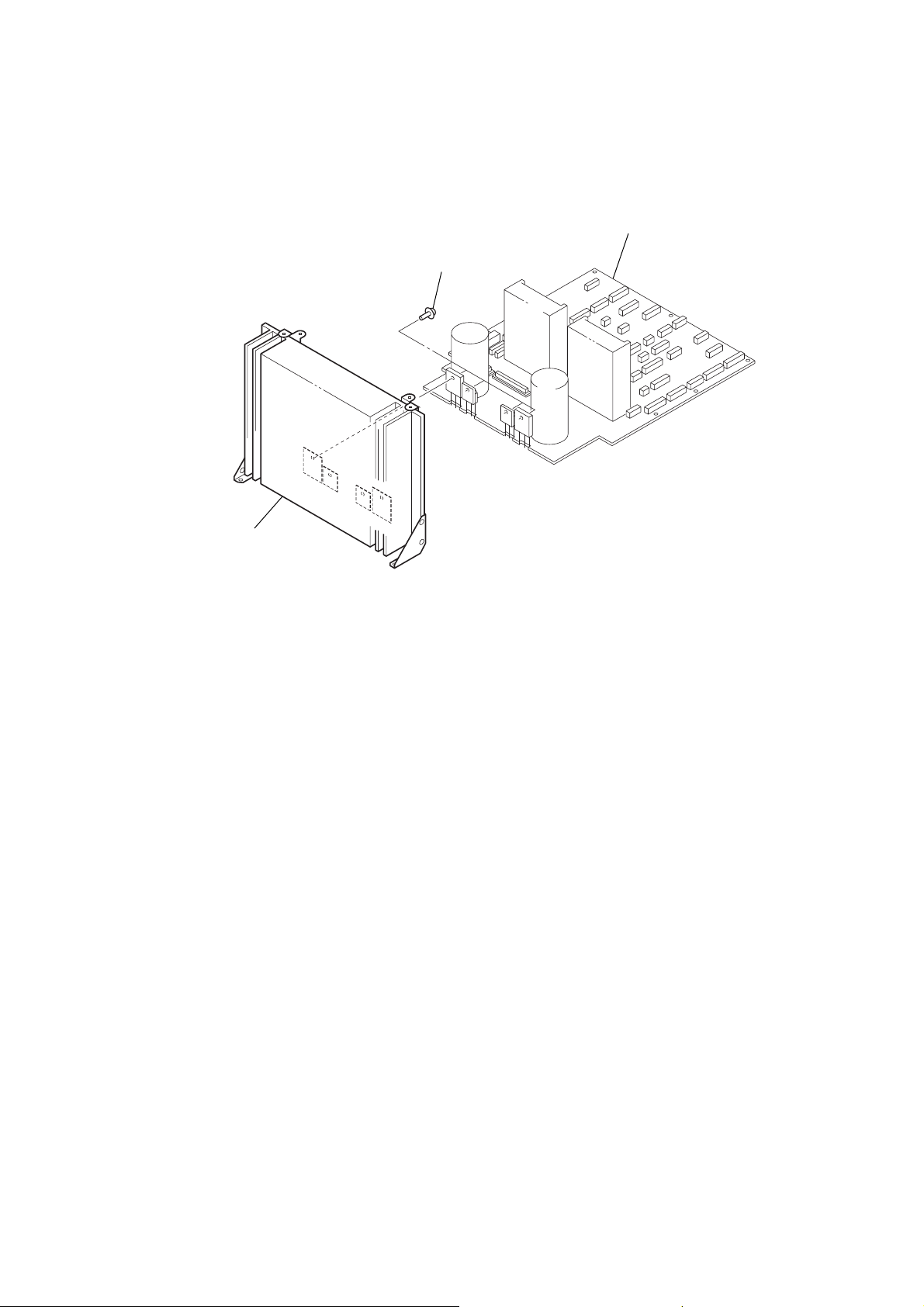

3-6. S-VIDEO/VIDEO BOARD BLOCK

3

two connectors

(CN303, 403)

4

S-video/video board block

2

four connectors

(CN815, 816, 817, 818)

1

four screws

(BV/ring)

3-7. SUB BOARD, PREOUT BOARD, MAIN BOARD

2

four connectors

(CN1001, 1002, 1003, 1006)

4

connector

(CN1005)

8

preout board

6

two connectors

(CN1201, 1203)

7

connector

(CN1202)

3

5

SUB board

1

two screws

(BV/ring)

9

qa

main board

two screws

(BV/ring)

0

five connectors

(CN101, 102, 103, 104, 105)

15

STR-DA9000ES

3-8. I. LINK BOARD, DIGITAL BOARD

3

I. link board

2

three connectors

(CN3501, 3502, 3503)

1

two screws

(BV/ring)

6

two connectors

(CN2007, 2008)

4

four screws

(BV3

8

digital board section

×

8)

3-9. MOTHER BOARD SECTION

2

two screws

×

8)

(BV3

4

screws (transistor)

5

coaching clip

7

connector (CN2006)

5

five connectors

(CN2001, 2002, 2003, 2004, 2005)

3

nine screws

(transistor)

6

mother board section

16

1

two screws

(BV3

×

8)

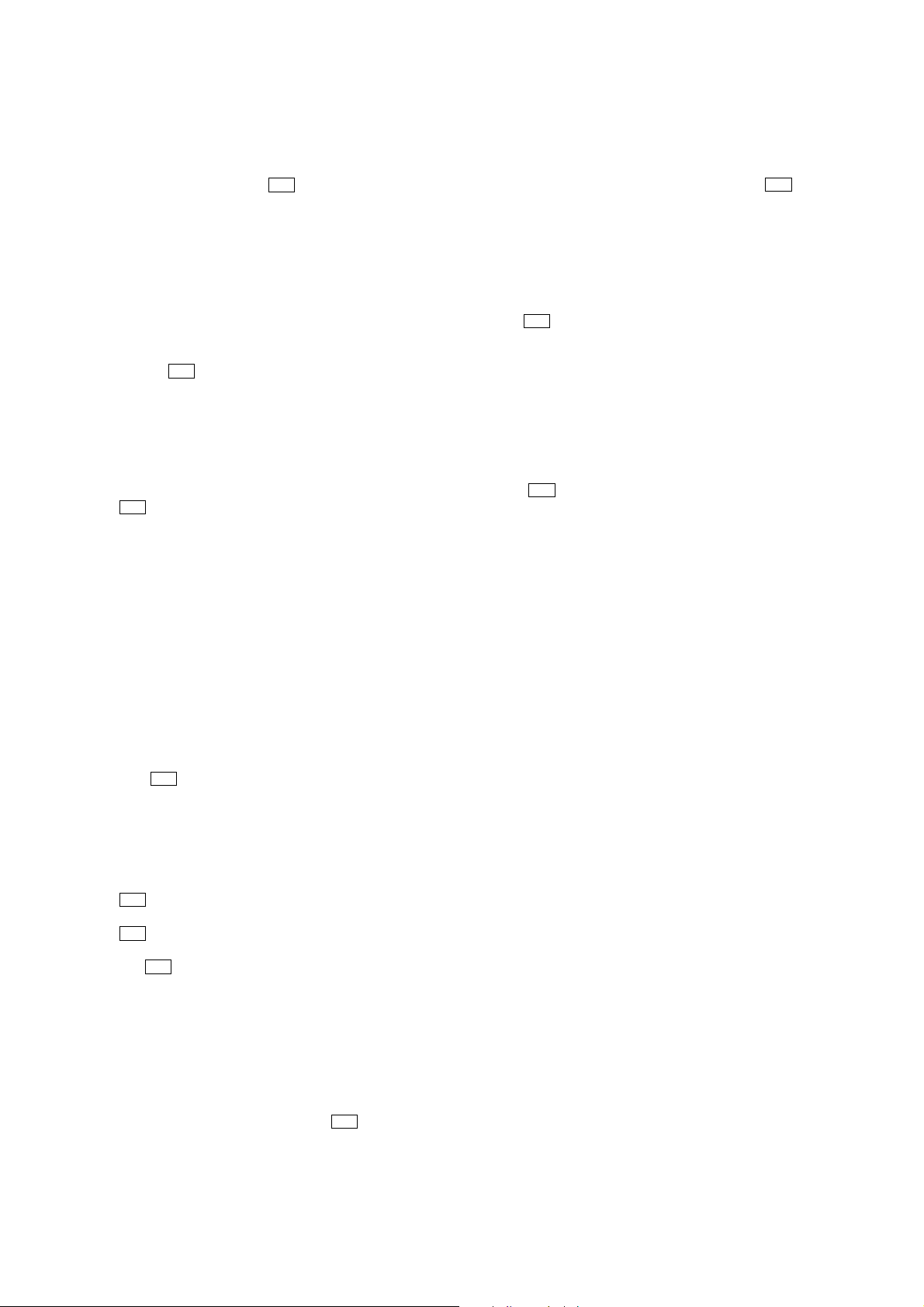

3-10. MOTHER BOARD

1

four screws

(transistor)

3

mother board

STR-DA9000ES

2

heat sink

17

STR-DA9000ES

Ver 1.1

SECTION 4

TEST MODE

TUNER FACTORY PRESET MODE

All preset contents are reset to the default setting.

Procedure:

1. While pressing the [SURR BACK DECODING] and [PRE-

SET TUNING --] buttons, press the I/1 button to turn on the

main power.

2. The message “FACTORY PRESET” appears and the present

contents are reset to the default values.

MEMORY CLEARING MODE

All preset contents are cleared when this mode is activated. Use

this mode before returning the product to clients upon completion

of repair.

Procedure:

1. While pressing the [INPUT MODE] and [MEMORY/ENTER]

buttons, press the I/1 button to turn on the main power.

2. The message “MEMORY CLEARING...” appears and the

memories are reset to the default values.

3. When done, the message “MEMORY CLEARED !” appears.

SWAP MODE

Procedure:

1. While pressing the [2CH] and [MEMORY/ENTER] buttons,

press the I/1 button to turn on the main power.

2. The message “SWAP MODE !” appears.

3. Press the [DISPLAY] button.

4. The message “–35.5dB” appears. (Volume level is “MID”)

5. Press the [DISPLAY] button once again.

6. The message “+22.0dB” appears. (Volume level is “MAX”)

7. Press the [DISPLAY] button once again.

8. The message “–oodB” appears. (Volume level is “MIN”)

FLUORESCENT INDICATOR TUBE PATTERN

CHECK MODE

All fluorescent segments are tested. When this test is acti vated, all

segments turn on at the same time, then each segment turns on one

after another.

Procedure:

1. While pressing the [DISPLAY] and [MEMORY/ENTER] buttons, press the I/1 button to turn on the main power.

2. All segments and all LEDs turn on.

TUNER AM STEP CHANGE (9 kHz/10 kHz) MODE

Either the 9 kHz step or 10 kHz step can be selected for the AM

channel step.

Procedure:

1. Press the I/1 button to turn on the main power.

2. Turn the [INPUT SELECTOR] dial to select the “AM”

3. Press the I/1 button to turn off the main power.

4. While pressing the [PRESET TUNING +] or [TUNING +] but-

ton, press the I/1 button to turn on the main power.

5. Either the message “AM 9K STEP” or “AM 10K STEP”

appears. Select the desired step.

COMMAND MODE CHANGE MODE

The command mode of the remote-commander which this set receives can be changed.

Procedure:

1. While pressing the [INPUT MODE] button, press the I/1 button to turn on the main power.

2. Either the message “COMMAND MODE [AV1]” or “COMMAND MODE [AV2]” appears. Select the desired mode.

SF LOCK ON/OFF CHANGE MODE

Procedure:

1. While pressing the [MUSIC] and [MEMORY/ENTER] buttons,

press the I/1 button to turn on the main power.

2. Either the message “SF LOCK [OFF]” or “SF LOCK [ON]”

appears.

OPERATION CHECK OF i. LINK TERMINAL

Connect the set to a unit equipped with the i. LINK terminal to

check if the communication can be made correctly . By this operation check, a loose connection of the connector or a disconnection

of the i. LINK cable can be confirmed.

Procedure:

1. Press the I/1 button to turn on the power, and rotate the

[INPUT SELECTOR] knob to set the function to the “i. LINK”

so that the “No LINC” is displayed.

2. Turn on the power of the unit equipped with the i. LINK terminal.

3. Connect the set to the unit equipped with the i. LINK terminal

using the i. LINK cable.

At this time, check that “i. LINK CONNECTING” is displayed

on the set.

4. After the display of “i. LINK CONNECTING”, check that the

equipment information is displayed.

5. Moving the i. LINK cable with the i. LINK connection maintained, check that the “i. LINK CONNECTING” is not displayed.

If nothing is displayed in step 3 and 4, or if “i. LINK CONNECT ING” is displayed continuously, the i. LINK cable will be disconnected or the connector connection will be loose.

If “i. LINK CONNECTING” is displayed in step 5 though the

cable is not removed, the i. LINK cable will be disconnected or

the connector connection will be loose.

SOUND FIELD INITIALIZE MODE

The preset sound field is cleared when this mode is activated. Use

this mode before returning the product to clients upon completion

of repair.

Procedure:

1. While pressing the [MUSIC] button, press the I/1 button to

turn on the main power.

2. The message “S. F. Initialize” appears and initialization is per formed.

18

STR-DA9000ES

SPECIAL MENU MODE

Procedure:

1. Press the I/1 button to turn on the main power, then while pressing the [MEMORY/ENTER] button, press the [MUSIC], [DIRECT],

[MOVIE] button in order.

2. The message “MENU SPECIALIZED !” appears.

3. Each time the [MENU] dial is turned clockwise, the item is switched in order as follows.

4. To release from this mode, while pressing the [MEMORY/ENTER] button, press the [MUSIC], [DIRECT], [MOVIE] button in order

again.

5. The message “MENU SPECIALIZED OFF” appears.

Items Display Remark

Version display SPECIAL

A9ES U_CA v*.** XXXX XXXX: Sum value of flash memory in the main microprocessor

Distinatin change SPECIAL

MODEL [

FL display fonts test SPECIAL Not used for the servicing

FL FONT 0x** = [X

FL display test ALL ON Each time

Audio swap SPECIAL Switching with [--/+] dial

SWAP [XXXXXXXXXXX

DSP reset SPECIAL XXX: ON or OFF (switching with [--/+] dial)

DSP RESET [XXX

DSP 1 IRAM DSP 1 IRAM Not used for the servicing

[

I

DSP 1 ARAM DSP 1 ARAM Not used for the servicing

D

DSP 2 IRAM DSP 2 IRAM Not used for the servicing

[

I

DSP 2 ARAM DSP 2 ARAM Not used for the servicing

D

DSP 2 ARAM DSP 2 ARAM Not used for the servicing

D

1st bass gain SPECIAL Not used for the servicing

1st BASS GAIN X.XdB

1st bass frequency SPECIAL Not used for the servicing

1st BASS FREQ XXXHz

2nd bass gain SPECIAL Not used for the servicing

2nd BASS GAIN X.XdB

2nd bass frequency SPECIAL Not used for the servicing

2nd BASS FREQ XXHz

Bass select SPECIAL Not used for the servicing

BASS SELECT [1st or 2nd]

Bass management SPECIAL Not used for the servicing

BASS MAN. [

DSP boot error SPECIAL Not used for the servicing

DSP BOOT ERROR:XXX

DSP write 1 error SPECIAL Not used for the servicing

DSP WRT1 ERR OR:XXX

DSP write 2 error SPECIAL Not used for the servicing

DSP WRT2 ERR OR:XXX

DSP write 3 error SPECIAL Not used for the servicing

DSP WRT3 ERR OR:XXX

DSP read 1 error SPECIAL Not used for the servicing

DSP RAD1 ERROR:XXX

DSP read 2 error SPECIAL Not used for the servicing

DSP RAD2 ERROR:XXX

DSP read 3 error SPECIAL Not used for the servicing

DSP RAD3 ERROR:XXX

*****

[

*****

*****

[

*****

[

*****

AE9S

]=

XXXX

]=

XXXXXXXX

]=

XXXX

]=

XXXXXXXX

]=

XXXXXXXX

****

****

]

]

XX

]

] XX

]

: main microprocessor software version

*.**

: destination, XX: at or fx (switching with [--/+] dial)

****

[DISPLAY] button to change as follows.

all on t test pattern 1 t test pattern 2 t all off t all on

19

STR-DA9000ES

Ver 1.2

Items Display Remark

DSP HALT SPECIAL XXX: ON or OFF (switching with

DSP HALT [XXX

DSP Version display SPECIAL XXX: DSP version

DSP Ver 1:vXXX,2:vXXX

Volume value display SPECIAL

(FL/FR) FL

Volume value display SPECIAL

(SL/SR) SL

Volume value display SPECIAL

(CT/SW) CT

Volume value display SPECIAL

(SBL/SBR) SBL

EEPROM debug SPECIAL Not used for the servicing

Super reset SPECIAL Not used for the servicing

2nd volume value display SPECIAL XX: 2nd zone volume value (oo to

3rd volume value display SPECIAL XX: 3rd zone volume value (oo to

FL display duty change SPECIAL XXX: Duty value of FL display (0% to 100%)

SDRAM check SPECIAL Check the operation of LIP SYNC

Error count display SPECIAL Not used for the servicing

Version displa y SPECIAL XXX: sub microprocessor software version

958 hats off SPECIAL Not used for the servicing

I.link test mode SPECIAL Not used for the servicing

YUV Y DRIVE SPECIAL Not used for the servicing

YUV U DRIVE SPECIAL Not used for the servicing

YUV V DRIVE SPECIAL Not used for the servicing

Analog direct SPECIAL Not used for the servicing

****

****

****

****

EEPROM

SUPER RESET [XXX

2nd VOLUME –XX (switching with [--/+] dial)

3RD VOLUME –XX (switching with [--/+] dial)

DARK OUT DUTY [XXX%

SDRAM CHECK [XXXXX

SCOM ERROR COUNT XXX

Sub Micom Ver. X.XX

958 HATS OFF [SPDIF or PCM]

i.LINK TEST MODE IN?

YUV Y DRIVE [XX]

YUV U DRIVE [XX]

YUV V DRIVE [XX]

ANALOG DIRECT [2Fs or 4FS]

]

: Front L-ch volume value,

FR XXXX XXXX: Front R-ch volume value

SR XXXX XXXX: Surround R-ch volume value

SW XXXX XXXX: Volume value display

SBR XXXX XXXX: Surround back R-ch volume value

[

****

]

XX

]

****

: Surround L-ch volume value,

****

: Center volume value,

****

: Surround back L-ch volume value,

****

If super reset is performed, “up convert signal level adjustment”

will also be initialized

When EEPROM initialization is required, perform the “memory

clearing mode” (see page 18)

]

(switching with [--/+] dial)

]

XXXXX: PASS (OK) or ERROR (NG)

[--/+] dial)

)

∞

)

∞

20

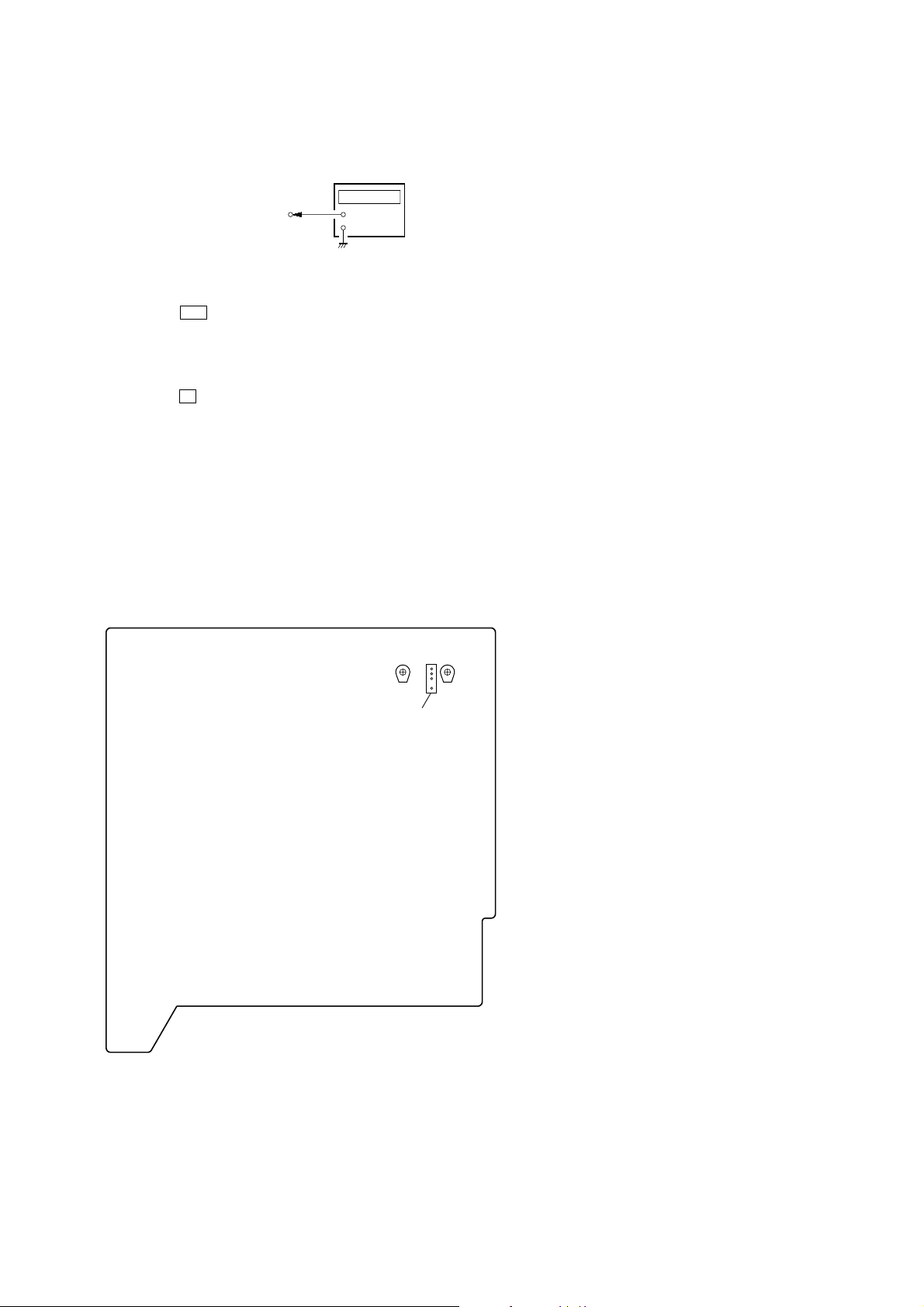

OSD ADJUSTMENT

r

Connection

STR-DA9000ES

SECTION 5

ELECTRICAL ADJUSTMENTS

frequency counte

COMPONENT board

CN1309 pin

1. Connect a frequency counter to the CN1309 pin 1 on the

COMPONENT board.

2. Press the I/1 button to turn on the main power.

3. Perform the MEMORY CREARING MODE. (See page 18)

4. Press the [RM SELECT] button on the remote commander (RMTP2).

5. Press the [AMP] button on the remote commander (RM-TP2).

6. Press the b button three times on the remote commander (RMTP2).

7. Press the [ON SCREEN] button on the remote commander to

display “ON SCREEN [ON]”.

8. Adjust the CT1304 so that the frequency counter reading is 7.20

MHz.

9. Connect a frequency counter to the CN1309 pin 2 on the

COMPONENT board.

10. Adjust the CT1301 so that the frequency counter reading is

3.579545 MHz ± 50 Hz.

Adjustment and Connection Location:

1

or pin

2

+

–

– COMPONENT BOARD (Component Side) –

CT1304

4

1

CN1309

CT1301

21

STR-DA9000ES

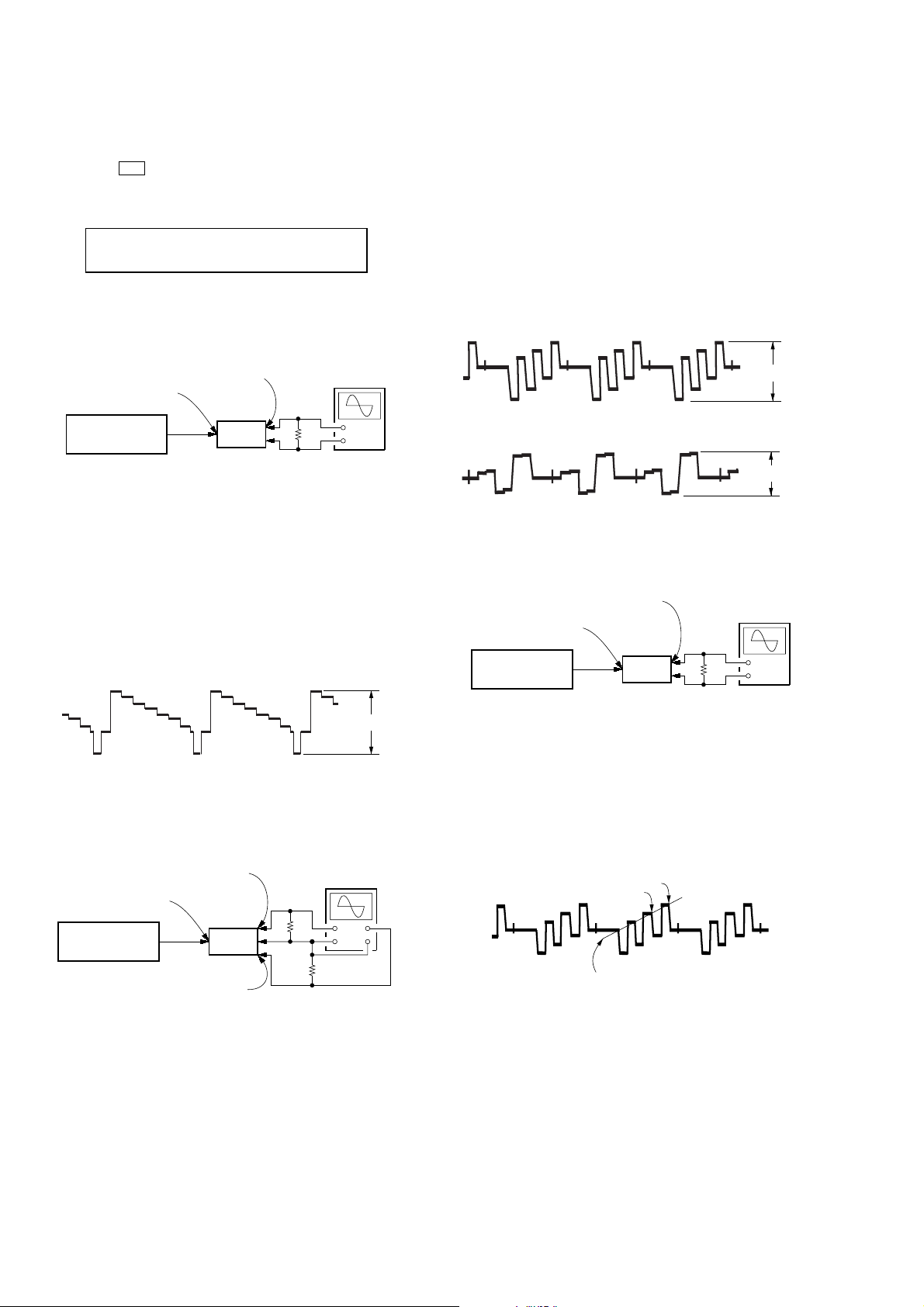

p

UP CONVERT SIGNAL LEVEL ADJUSTMENT

Enter the test mode

1. While pressing the [INPUT MODE] and [DISPLAY] buttons,

press the I/1 button to turn on the main power.

2. It enters the test mode, and display as below figure.

Display

HUE

[7]

1. Y LEVEL ADJUSTMENT

Setting:

S-VIDEO board

VIDEO 1

S2 VIDEO IN jack

(J406)

color pattern

generator

color bars 100%

Procedure:

1. Connect a color pattern generator to the VIDEO 1 S2 VIDEO

IN jack (J406) on the S-VIDEO board, and connect an

oscilloscope to the COMPONENT VIDEO MONITOR OUT

Y jack (J1305) on the COMPONENT board. (75Ω terminated)

2. Enter the test mode.

3. Input color bars signal from the color pattern generator.

4. Adjust the [MENU] dial so that the Vp-p value of waveform

becomes 1 Vp-p.

Y waveform:

2. COLOR LEVEL ADJUSTMENT

Setting:

S-VIDEO board

VIDEO 1

S2 VIDEO IN jack

(J406)

color pattern

generator

color bars 100%

COMPONENT board

COMPONENT VIDEO

MONITOR OUT

P

R/CR

(J1305)

CONTRAST

[7]

COMPONENT board

COMPONENT

MONITOR OUT

VIDEO Y jack

(J1305)

set

COMPONENT board

COMPONENT VIDEO

MONITOR OUT

B/CB

/B-Y jack

P

(J1305)

set

/R-Y jack

COLOR

[7]

75

75

Ω

oscilloscope

(AC range)

Ω

oscilloscope

(AC range)

+

–

75

Ω

+

–

1 Vp-p

Procedure:

1. Connect a color pattern generator to the VIDEO 1 S2 VIDEO

IN jack (J406) on the S-VIDEO board, and connect an

oscilloscope to the COMPONENT VIDEO PB/CB/B-Y jack and

COMPONENT VIDEO PR/CR/R-Y jack (J1305) on the

COMPONENT board. (75Ω terminated)

2. Enter the test mode.

3. Input color bars signal from the color pattern generator.

4. Display two waveforms of CB and CR simultaneously.

5. Adjust the [--/+] dial so that the Vp-p v alue of wav eforms of C

and CR both may be most set to 0.7V closely.

CB waveform:

0.7 Vp-

CR waveform:

0.7 Vp-p

3. HUE LEVEL ADJUSTMENT

Setting:

COMPONENT board

COMPONENT VIDEO

MONITOR OUT

P

B/CB

S-VIDEO board

VIDEO 1

S2 VIDEO IN jack

(J406)

color pattern

generator

color bars 100%

(J1305)

/B-Y jack

set

75

Ω

oscilloscope

(AC range)

+

–

Procedure:

1. Connect a color pattern generator to the VIDEO 1 S2 VIDEO

IN jack (J406) on the S-VIDEO board, and connect an

oscilloscope to the COMPONENT VIDEO P

/B-Y jack on

B/CB

the COMPONENT board. (75Ω terminated)

2. Enter the test mode.

3. Input color bars signal from the color pattern generator.

4. Adjust the [MAIN MENU] dial so that the waveform as bellow.

CB waveform:

Adjust so that the height of

A and B may be located in a line

on this line.

B

A

B

22

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM – AUDIO INPUT Section –

STR-DA9000ES

VIDEO

AUDIO

MULTI

CHANNEL

IN 1

MULTI

CHANNEL

IN 2

VIDEO 1

IN

VIDEO 2

IN

VIDEO 3

IN

VIDEO 4

IN

LD IN

DVD IN

TV/SAT

IN

AUDIO

PHONO IN

FRONT

SURROUND

SURR

BACK

FRONT

SURROUND

SURR

BACK

CENTER

SUB

WOOFER

CENTER

SUB

WOOFER

J1006 (1/2)

L

R

J1005 (1/2)

L

R

J1004 (1/2)

L

R

J1003 (1/2)

L

R

L

R

J1002 (1/2)

L

R

L

R

L

R

L

R

L

R

L

R

L

R

L

R

L

R

J1001

J103

J104

J105

J106

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

R-CH

LINE AMP

IC1017

LINE AMP

IC1016

LINE AMP

IC1014

LINE AMP

IC1013

LINE AMP

IC1012

LINE AMP

IC1011

LINE AMP

IC1009

1SB-L

2SB-L

1F-L

1S-L

1C

1SW

2F-L

2S-L

2C

2SW

V1-L

V2-L

V3-L

V4-L

LD-L

DVD-L

TV/SAT-L

EQUALIZER

AMP

IC1002

TAPE-L

MD-L

CD-L

V1-L

V2-L

V3-L

V4-L

V5-L

LC-L

DVD-L

TV/SAT-L

V1-L

V2-L

V3-L

V4-L

V5-L

LD-L

DVD-L

TV/SAT-L

V5-L

PHONO-L

LINE AMP

IC126

LINE AMP

IC125

LINE AMP

IC124

BUFFER

IC1018

R-CH

R-CH

R-CH

R-CH

INPUT SELECT

2

VIDEO 1

41 VIDEO 1

5 VIDEO 2

38 VIDEO 2

6 VIDEO 3

37 VIDEO 3

7 VIDEO 4

36 VIDEO 4

4 VIDEO 5

39 VIDEO 5

11 CD

32 CD

13 DVD

30 DVD

9 TV/SAT

34 TV/SAT

INPUT SELECT

27 VIDEO 1

25 VIDEO 2

24 VIDEO 3

23 VIDEO 4

26 VIDEO 5

21 LD

20 DVD

22

TV/SAT

RY1003

J101 (1/3)

J102 (1/2)

IC1015

IC1019

J702 (1/2)

V1 26

V2 25

V3 24

MAIN 15

2ND 28

REC IN

LAT

DATA

CLK

LOUT

AUDIO

LCK

DATA

CLK

RELAY DRIVE

Q1005, 1006

L

R

L

R

L

R

27

23

22

21

17

19

16

15

14

L

R

TAPE

IN

MD/DAT

CD/SACD

VIDEO 5

IN

IN

AUDIO

INPUT

MAIN AV L

2ND AV L

LAT927

DATA2

CLK2

LAT927

DATA2

CLK2

RY3

AUDIO

PHONO-L

TUNER-L

CD-L

MD-L

TAPE-L

MAIN AV L

2ND AV L

TUNER-L

CD-L

MD-L

TAPE-L

1S-L

2S-L

1S-BL

2S-BL

1C

2C

1F-L

2F-L

1SW

2SW

INPUT SELECT

IC105

2 PHONO

41 PHONO

4 TUNER

39 TUNER

6 CD/SACD

37 CD/SACD

8 MD/DAT

35 MD/DAT

10 TAPE/CD-R

33 TAPE/CD-R

12 AV IN

31 AV IN

INPUT SELECT

IC104

25 TUNER

23

CD/SACD

21 MD/DAT

19 TAPE/CD-R

INPUT SELECT

IC102

41 CH1 SL

39 CH2 SL

35 CH1 SBL

34 CH2 SBL

31 CH1 C

30 CH2 C

28 CH1 L

26 CH2 L

12 W

13 W

TAPE

MD

AV OUT

REC OUT 16

REC OUT

2ND 29

2ND 17

DSD 15

MAIN

LAT 23

DATA

CLK

LOUT

LAT 16

DATA

CLK

COM L

COM SL

COM SBL 33

COM C 29

COM W

LAT 23

DATA

CLK

J1006 (2/2)

L

VIDEO 1

OUT

J1005 (2/2)

J1004 (2/2)

J101 (2/2)

J102 (2/2)

R

VIDEO

AUDIO

L

VIDEO 2

OUT

R

L

VIDEO 3

OUT

R

L

TAPE

OUT

R

AUDIO

L

MD/DAT

OUT

R

W

34

35

9

8

31

8

39

41

4

2

SBL

C

R-CH

R-CH

SL

C

W

AUDIO MIX

IC101

CLK2

DATA

LATVOL

CLK2

DATA

LATVOL

RY1

RY2

LAT 23

DATA

CLK

33

10

29

14

3738

65

22

21

M-IN

20

13 CLK

16 DATA

17 LAT

M-IN

20

13 CLK

16 DATA

17 LAT

LAT1

DATA1

CLK1

ELECTRICAL VOLUME

IC1007

M-OUT

T-OUT

ELECTRICAL VOLUME

IC1003

M-OUT

T-OUT

RELAY DRIVE

Q1001, 1002

RELAY DRIVE

Q1003, 1004

AMP

IC112, 123

MIX AMP

IC107

MIX AMP

IC108

R-CH

RY1

RY2

RY3

23

24

T-IN

25

23

24

T-IN

25

15 QA

1QB

2QC

RELAY CONTROL

IC1005

LINE AMP

IC1008

LINE AMP

IC1004

S-IN

LAT

CLK

OE

R-CH

R-CH

R-CH

R-CH

R-CH

26

25

24

AMP

IC106

27

19

LAT1

DATA1

22

CLK1

21

17

LAT1

DATA1

15

CLK1

14

24

37

14

LAT3

DATA1

22

CLK1

21

BUFFER

IC111

BUFFER

IC109

BUFFER

IC127

BUFFER

IC110

• SIGNAL PATH

R-CH D/A-R

W

C

SBR-CH

SBL

SR-CH

SL

R-CH R

SL

SBL

C

W

DATA2

14

LAT

12

CLK2

11

13

: TUNER

: AUDIO (ANALOG)

R-CH

R-CH

DATA1

CLK1

LAT1

LAT3

DATA2

CLK2

LATVOL

LAT927

LEVEL

SHIFT

LEVEL

SHIFT

IC1001

RY1002

RY1001

D/A-L

W

C

SBR

SBL

SR

SL

L

L

SL

SBL

C

W

IC122

J1302 (1/2)

J1301

2

(Page 27)

3

(Page 29)

4

(Page 24)

L

R

L

R

AUDIO

AUDIO

LAT-DM

LAT-927X

DATA

LAT-595

CLK

LAT-VOL

OE

ZONE OUT

2ND

ZONE OUT

3RD

5

(Page 25)

• R-CH is omitted due to same as L-CH.

(Page 25)

TUNER-L

TU-L

1

BUFFER

IC826

2323

STR-DA9000ES

6-2. BLOCK DIAGRAM – A/D CONVERTER Section –

AMP

IC115

6 7 2

3

VREF

6 7 2

VREF

6 7 2

VREF

6 7 2

VREF

6 7 2

VREF

6 7 2

VREF

6 7 2

VREF

6 7 2

VREF

+15V VREF

+5V REGULATOR

IC113

AMP

IC114

3

AMP

IC119

3

AMP

IC118

3

AMP

IC117

3

AMP

IC116

3

AMP

IC121

3

AMP

IC120

3

X2301

22.5792MHz

1

1

1

1

1

1

1

1

IC2304

(Page 23)

L

R-CH

C

W

4

SL

SR-CH

SBL

SBR-CH

OSC

A/D CONVERTER

4 VINL+

5 VINL–

17 VINR+

16 VINR–

A/D CONVERTER

4 VINL+

5 VINL–

17 VINR+

16 VINR–

A/D CONVERTER

4 VINL+

5 VINL–

17 VINR+

16 VINR–

A/D CONVERTER

4 VINL+

5 VINL–

17 VINR+

16 VINR–

B+ SWITCH

Q2302, 2303

IC2011

IC2031

IC2021

IC2041

DSDR

DSDR

11DSDL

9SCKI

10BCK

12DSDR

11DSDL

9DSDL

10BCK

12DSDR

11DSDL

9DSDL

10BCK

12

11DSDL

9DSDL

10BCK

12

D3.3V

CLOCK SELECT

1/2 DIVIDER

IC2306

IC2051

AD-L

AD-R

AD-C

AD-W

AD-SL

AD-SR

AD-SBL

AD-SBR

AD-BCK

(Page 28)

6

I LINK/AD512

I LINK/AD512

7

8

(Page 27)

(Page 28)

• R-CH is omitted due to same as L-CH.

• SIGNAL PATH

: AUDIO (ANALOG)

: AUDIO (DIGITAL)

2424

D2301

SWITCHING

IC2308

I512

22.5792

HATS ON/OFF

595C

10

9

(Page 26)

(Page 25)

STR-DA9000ES

6-3. BLOCK DIAGRAM – DIGITAL INPUT, TUNER Section –

INPUT SELECT

VIDEO 5 INPUT

DIGITAL OPTICAL

DIGITAL

OPTICAL

DIGITAL

COAXIAL

VIDEO 1

IN

LD IN

DVD IN

TV/SAT

IN

MD/DAT

IN

CD/SACD

IN

VIDEO 1

IN

LD IN

DVD IN

TV/SAT

IN

CD/SACD

IN

OPTICAL

RECEIVER

IC707

OPTICAL

RECEIVER

IC2082

OPTICAL

RECEIVER

IC2084

OPTICAL

RECEIVER

IC2085

OPTICAL

RECEIVER

IC2086

OPTICAL

RECEIVER

IC2087

OPTICAL

RECEIVER

IC2088

J2080

J2081

J2082

(Page 26)

11

WAVE

SHAPER

IC2091

WAVE

SHAPER

IC2092

958OUT

IC2095

B

A

Y

CD/SACD

VIDEO1

DVD

TV/SAT

INPUT SELECT

IC2093

14 D5

15 D4

1D3

2D2

3D1

4D0

12 D7

A1

A0

10

11

5

QF

2QR

LD

COM2-CLK

COM2-DAT

9

6

7

QG

INPUT/OUTPUT

CONTROL

11

COM1-CLK

5Y

A2

QE

QD

3QD4

QE

QH

DIGITAL

IC2451

CLK12LAT13OE

D-SEL-LAT

D-595OE

34

33

15

QA

1

QB

S-IN

14

COM1-DAT

A

B

VIDEO1

LD

DVD

TV/SAT

CD/SACD

12

PLL CLOCK

Q2122, 2123

(Page 27)

SELECT

SWITCHING

IC2211

4 RX2

5 RX3

8 RX4

9 RX5/VI

10 RX6/UI

2 RX0

13 LPF

D2201

DIGITAL AUDIO

INTERFACE RECEIVER

IC2121

RERR

21

39CE40CL38DI37DO36

COM1-DAT

COM1-CLK

20

CKST

34

XIN 29

XOUT 28

XMODE 41

1RXOUT

21RDATA

16RMCK

33AUDIO/V0

17RBCK

20RLRCK

27XMCK

QE

QD

X2121

24.576MHz

SWITCHING

IC2602

A

B

104

Y

SWITCHING

IC2089

SWITCHING

IC2090

TRANSCEIVER

TRANSCEIVER

D. SD

DIR-RMCK

DIR-AUDIO

DIR-BCK

DIR-LRCK

DIR-MCK

DIR-RERR

ERR/AUD SEL

OPTICAL

IC2081

OPTICAL

IC2083

COM2-CLK

13

COM1-CLK

COM2-DAT

COM1-DAT

VIDEO 1

OUT

MD/DAT

OUT

(Page 27)

DIGITAL

OPTICAL

• R-CH is omitted due to same as L-CH.

• SIGNAL PATH

: TUNER

: AUDIO (DIGITAL)

DIR ERR

D2602

DIR CKST

ERROR-3210

14

15

(Page 28)

(Page 26)

(Page 23)

ANTENNA

AM

DATA DECODER

IC2461

14 S-IN

11 CLK

12 LAT

13 OE

9S-OUT

14 S-IN

11 CLK

12 LAT

13 OE

DATA DECODER

IC2462

QA

QB

QC 2

QD

QE

QF

QG

QH

QB 1

QC

QD

QE

QF

QG

QH

15

1

3

4

5

6

7

2

3

4

5

6

7

V POWER

I POWER

CLKSEL

SELFS1

SELFS2

SELCF1

SELCF2

COM1-CLK

COM1-DAT

TA-RST

SWAP1

SWAP2

595C

595C

HATS ON/OFF

I512 OFF

CLK

DATA

18

19

20

16

17

(Page 34)

(Page 28)

(Page 28)

(Page 24)

10

(Page 26)

(Page 32)

ERR/AUD-SEL

5

44

COM2-DAT

COM2-CLK 39

COM1 DAT 37

D595-LAT2 35

RY595-LAT

D. MIX LAT 47

COM2-CLK

COM2-DAT

COM1-CLK

COM1-DAT

DIR-CE

TU-L

1

TU2051

TUNER UNIT

TUN-LCH

FM

COM2 CLK

COM2 DATA

LAT

MUTE

TUNED

STEREO

DO

82 TUN-DO

79 TUN-LAT

80 TUN-TUNED

81 TUN-STEREO

D595-OE

D595-LAT1

MAIN SYSTEM

CONTROLLER

IC2601 (1/4)

DIR-DO

(Page 23)

(Page 33)

COM2 CLK 36

FUN LAT

RY595-OEOE40

SVOL LAT 48

LAT-VOL

LAT-DM

LAT-927X

CLK

DATA

LAT-595

38

42

46

2525

STR-DA9000ES

6-4. BLOCK DIAGRAM – I. LINK Section –

J3002

i. LINK S200

AUDIO IN

TAIP

TAIN

TBIP

TBIN

4

3

2

1

BIAS

14

TRA1P

143

TRA1N

142

TRB1P

141

TRB1N

145

DI1O

DI2O

DI5O

DI6O

DI3O

DI4O

VALIB OUT

ERR_OUT

SYTOUT

DIVIDER

IC3009

QC

15

16

19

20

17

18

3

174

24

DSD-L

DSD-R

DSD-SL

DSD-SR

DSD-C

DSD-W

64FS

22

(Page 28)

SWITCHING

IC3007 (1/2)

1 CLR

2CK

1 CLR

2CK

LOAD

DIVIDER

IC3006

LOAD

ENT

ENP

C0

ENP

12

10

15

9

7

9

7

IC3007 (2/2)

• SIGNAL PATH

ERROR-3210

: AUDIO (DIGITAL)

ERROR-3210

15

(Page 25)

(Page 25)

(Page 24)

21

(Page 27)

11

9

I512

DATA

MILES AUDIO

MILES RESET

LEVEL SHIFT

IC3013

164

27

167

171

172

DOUT958OUT

FSS12 OUT

FSS1222.5792

SACKOBCK

LRCKOLRCK

I. LINK INTERFACE

IC3003

XRAS

XCAS

XWE

XOE

XRD

XWR

XCS

XRDY

PWD

XRESETO

XRESETL

47 – 40, 38 – 31

DATA0 – DATA15

55 – 62

ADDRESS8

ADDRESS1 –

129

XO

XI

130

90 – 83

99 – 92,

DT0 – DT15

69 – 66

A0 – A9

76 – 71,

78

79

81

80

52

51

50

53

119

122

165

X3001

24.576MHz

SD-RAM

IC3008

D0 – D15

2 – 5, 7 – 10,

41 – 44, 46 – 49

27 – 32

A0 – A9

21 – 24,

18

XRAS

34

UCAS

35

LCAS

17

XWE

33

XOE

D0 – D15 D0 – D15

A1 – A8

EEPROM

IC3001

D0 – D7

15 – 19

D0 – D7

11 – 13,

25 – 23

A0 – A12

10 – 2, 21,

20 48CE EEP_CS

OE RD

22 44

27

WE

VCO

IC3005

DATA BUS

A1 – A13

A1 – A13

ADDRESS BUS

35 ERR CLR

88 – 73

D0 – D15

61 – 57

A1 – A13

71 – 65, 63,

46 WR

18 MIES AUDIO

49

CXD3270_XCS

39

RDY

89

PHY_BIAS

90

PHY_RST

92

LINK_RST

I. LINK SYSTEM

CONTROLLER

IC3002

UN-MUTE

XOUT

XIN

10

7 – 1, 100

HD0 – HD7

51HCNTL0

52HCNTL1

19AKE_XF

21HRDY

22XHAS

23XHDS1

24XHDS2

25XHCS

26XRS

54HRW

53HBIL

30IIC DATA

29IIC CLK

12RESET

13

15

58, 69, 81, 95,

39 HCNTL0

46 HCNTL1

27 XF

55 HRDY

13 HAS

127 H D S 1

129 H D S 2

17 HCS

98 RS

18 HR/W

62 HBIL

RESET SWITCH

IC3011

X3002

10MHz

HD0 – HD7

120, 124, 135, 6

I. LINK DSP

IC3012

X2/CLKIN

96

X1

X3003

20MHz

97

I2C-DATA

I2C-CLK

23

(Page 33)

19

(Page 25)

I512 OFF

REFOUT

PLLCKI

4 FINA

23

25

5 FINB

3VCOO

10VCOX

2626

6-5. BLOCK DIAGRAM – DSP Section –

STR-DA9000ES

(Page 28)

13

(Page 25)

21

(Page 26)

(Page 24)

RS232C

24

2

(Page 23)

ERR/AUD SEL

(Page 25)

(Page 28)

7

J3501

1

2

3

4

5

6

7

8

9

• SIGNAL PATH

F2 SBLR

F2 FLFR

F2 CSW

F2 SLSR

F2 LRCK

F2 BCK

D/A-R

D. SD

DIR-AUDIO

DIR-RMCK

DIR-LRCK

DIR-BCK

DIR-MCK

DIR-RERR

DATA

LRCK

MILES AUDIO

MILES RESET

12

25

I LINK/AD512

BCK

A

B

MCK

RS-232C DRIVER

IC3501

TXD

T1OUT

17

DTR

16 R1IN

: AUDIO (ANALOG)

: AUDIO (DIGITAL)

DSP1

IC2201

DIGITAL AUDIO SELECT

IC2208

6 1C0

2XRST

12

2XRST

114

1HACN

11

1HACN

SCL

6

SCL

5 1C1

3 1C3

10

11 2C1

SWITCHING

IC2204

A

B

S

1HCS

1HDOUT

10

8

1HCS

1HDOUT

2C0

A

Y

1BST

1GP9

7

6

1BST

1GP9

RESET SIGNAL

B

214

1PM

5

1PM

1XRST

4

1XRST

BUFFER

IC2604

A/D CONVERTER

IC2001

IC2205

2HACN

17

2HACN

A

B

214

2HCS

2HDOUT

16

2HCS

2HDOUT

2BST

15

12DOUTD/A-L

71Y

92Y

2BST

2GP3

14

2GP3

2PM

13

2PM

SDA

113

5

SDA

EEPROM

IC2603

1

2 VINR

11 BCK

10 LRCK

15 SCKI

CLOCK SELECT

6 1C0

5 1C1

3 1C3

2C0

10

11 2C1

13 2C3

S

A

Y

B

CLOCK

SELECT

IC2307

2EXLOCK

19

18

2EXLOCK

109 SOUT1

13T1IN

15R1OUT

71Y

92Y

BUFFER

IC2210

1BST SEL

3

1BST SEL

DSP CLK

DSP HDIN

2

1

89

DSP CLK

DSP HDIN

57

SWITCHING

IC2209

125

72

FSRATE

PCM-SEL

X1

58

X2601

16.5MHz

RESET SWITCH

IC2605

SWITCHING

IC2207

A

B

IBST

IBST SEL

1HACN

1HDOUT

1GP9

1PM

1XRST

DSP HDIN

DSP CLK

1HCS

STOP

23

ILINK RST

DIR-DTAAO

MAIN SYSTEM CONTROLLER

X0

78

STOP

IC2601 (2/4)

69 RST TRG

55 RSTX

Y

S

LEVEL SHIFT

IC2203

POW RY2

75

76

POW RY

POW RY2

115 S D I 4

114 SDI3

30 SDI2

18 SDI1VINL

59 EXLOCK

17 BCKI1

29 BCKI2

28 LRCKI2

15 LRCKI1

56 BST

22 KFSIO

69 GP8

32 HACN

35 HDOUT

68 GP9

112 P M

2 XRST

33 HDIN

34 HCLK

36 HCS

52

60

54

MD2

A1IN

51A1 OUT

MD0

110SIN1

70END-FLAG

71A1-LAT

50MBUS-STS0

64MBUS-STS1

65MBUS-STS2

66MBUS-STS3 42 STAT3

67MBUS-STS4 41 STAT4

BUFFER

IC2703 (2/3)

BUFFER

IC2703 (1/3)

IC2704 (2/2)

23SDO1

24SDO2

25SDO3

26SDO4

20BCKO

19LRCKO

9MCLK1

12MCLK2

BUFFER

BUFFER

IC2702

BUFFER

Q2703

X2201

13.5MHz

LEVEL SHIFT

IC2254

2EXLOCK

2HACN

2HDOUT

2HCS

2BST

2GP3

2PM

2XRST

DSP HDIN

DSP CLK

BUFFER

IC2704 (1/2)

26 URTIN

25 ENDFLG

5 CTRL-LATCH

23 OUTHI2

24 OUTLO2

1 STAT0

44 STAT1

43 STAT2

19 RESETC

X2251

13.5MHz

27 SDI1

28 SDI2

35 SDI3

39 SDI4

38 BCKI1

29 LRCKI1

144 MCLK1

139 MCLK2

62 KFSIO

136 EXLOCK

83 HACN

82 HDOUT

76 HCS

141 B S T

120 G P 3

140 P M

8XRST

74 HDIN

75 HCLK

D2603

SUB SYSTEM

CONTROLLER

IC2701

DSP2

IC2251

D16 – 31

A0 – 15

D0 – 15

SDO1

60

61

SDO2

SDO3

25

BCKO

64

LRCKO

111

GP7

79 68 67 58 – 56

122 114 113 106 105

129 128 125 – 123

85WEO

84CSO

12A1-IN

11A1-OUT

10SIRCS_INPUT

14RESET

15XIN

16XOUT

2CARRIER-OUT

33SIRCS-OUT

31 22 – 20

53 – 51 44 43 32

59 50 42 41 34

95 86 78 77 70 69

116 115 104 103

94 – 92 89 – 87 80

D2701

X2701

7.28MHz

SIRCS SWITCH

IC2705

7 – 10 13 – 16

44 – 42 27 – 24

17 WE

6CE

7 – 10 13 – 16

44 – 42 27 – 24

17 WE

6CE

CONTROL A1

INTERFACE

Q2701, 2702

RESET SIGNAL

GENERATOR

IC2706

LEVEL

SHIFT

IC704

D0 – 15

29 – 32 35 36

A0 – 15

21 – 18 5 – 1

D0 – 15

29 – 32 35 36

A0 – 15

21 – 18 5 – 1

S-RAM

IC2252

S-RAM

IC2253

D+5V

LED DRIVE

Q701 – 703

SD01

SD02

SD03

SD0426SDO4

BCK

LRCK63

STOP

ROW-RY2

26

(Page 28)

J3533

CTRL A1

STOP

ROW-RY2

POW-RY1

II

SIRCS

(Page 33)

D710 – 713,

D716, 717

(IR RECEPTER)

27

(Page 34)

28

2727

STR-DA9000ES

6-6. BLOCK DIAGRAM – DIGITAL AUDIO Section –

22

(Page 26)

6

(Page 24)

DSD-L

DSD-R

DSD-SL

DSD-SR

DSD-C

DSD-W

64FS

AD-L

AD-R

AD-SL

AD-SR

AD-C

AD-W

AD-SBL

AD-SBR

AD-BCK

18

(Page 25)

SWAP1

SWAP2

595C

TA-RST

DSD SELECT

IC2063

2A0

5A1

11 A2

14 A3

3B0

6B1

10 B2

13 B3

DSD SELECT

IC2064

2A0

5A1

11 A2

3B0

6B1

10 B2

DSD SELECT

IC2052

10 1C0

11 1C1

12 1C2

13 1C3

6 2C0

5 2C1

4 2C2

3 2C3

DC CUT

DIGITAL FILTER

IC2401

SDO1

SDO2

26

(Page 27)

F2 FLFR

F2 CSW

F2 SLSR

24

(Page 27)

4Y0

7Y1

9Y2

12Y3

1S

4Y0

7Y1

9Y2

1S

91Y

72Y

F2 SBLR

F2 BCK

F2 LRCK

DSD/PCM CONVERTER

IC2161

39 DSIFL

40 DSIFR

41 DSICT

42 DSISW

43 DSISL

44 DSISR

38 DSBCK

DSD/PCM CONVERTER

IC2163

39 DSIFL

40 DSIFR

I LINK/AD512

8

(Page 24)

17

AB

142

(Page 25)

COM1-CLK

COM1-DAT

25

(Page 27)

SDO3

SDO4

BCK

LRCK

23POFLR

22POCSW

21POSLR

3SEL4FS

19PBCK

20PLRCK

27MCK

23POFLR

19PBCK

20PLRCK

3SEL4FS

27MCK

SELFS1

SELFS2

SELCF1

SELCF2

CLKSEL

MCK

TA-XRST

32 PIA12

33 PIA34

34 PIA56

35 PIA78

29 PA BCK

30 PA WCK

41 PIB12

42 PIB34

43 PIB56

44 PIB78

38 PBBCK

39 PBMCK

BUFFER

IC2162

BUFFER

IC2164

BUFFER

IC2428 (3/5)

SWITCHING

IC2402

45

PID

SELCF2

SELPID

5

SCF2

SELCF1

4

SCF1

SFS1

PID

SFS2

SCF1

SCF2

3

SFS2

FS

CLKSEL

SELFS1

SELFS2

2

SFS1

CLK

DAT

20PIO12

21PIO34

22PIO56

23PIO78

P0BCK

17P0BCK

P0WCK

18P0WCK

INIT

47INIT

BBSEL

11BBSEL

MCK

27

CLK

DAT

TA-SO

TA-XCS

TA-XRST

P0WCK

P0BCK

LEVEL

SHIFT

IC2303

LIP SYNC ADJUST

66 FLFRI

65 SLSRI

64 CSWI

63 DLDRI

72 SCLK

74 SI

75 SO

73 XCS

70 XRST

CK51259LRCKI60BCKI

68

SHIFT

REGISTER

IC2429 (1/2)

BUFFER

IC2428 (1/5)

1/2 DIVIDER

IC2305

IC2301

D0 – 15

A0 – 11

BUFFER

IC2428 (5/5)

IC2429 (2/2)

IC2428 (2/5)

IC2428 (4/5)

100 1 – 5 7 8

17 – 22

10WE

11CAS

12RAS

13CS

14CLK

15CKE

47FLFRO

46SLSRO

45CSWO

44BL_BRD

SHIFT

REGISTER

BUFFER

SHIFT

REGISTER

IC2430

BUFFER

90 – 95 97 98

24 – 29

DELAY

IC2427

LRCKO

BCKO

MCK1

DQ0 – 15

2 3 5 6 8 9 11 12 39

40 42 43 45 46 48 49

A0 – 11

19 – 24

27 – 32

15 WE

16 CAS

17 RAS

18 CS

35 CLK

34 CKE

35 DATA_1

36 DATA_2

37 DATA_3

38 DATA_4

PROGRAMMABLE

LOGIC DEVICE

IC2426

1 EDGE

2 BCKIN

3 BCK2IN

5 MCK

12 MCKOUT

SD-RAM

IC2302

22DIOUT_1

21DIOUT_2

20DIOUT_3

19DIOUT_4

32CLKSEL

33FS

MUTING

IC2511

MUTING

CONTROL

IC2512

FS

LRCKO

MUTE

CLKSEL

MCK1

BCKO

LRCKO

RESET

MUTE

U-MAIN

U-SUB1

U-SUB2

X1501

8MHz

BUFFER

IC2501

BUFFER

IC2503

D01

D02

D03

D04

LRCK

BCK

BUFFER

IC2504

BUFFER

IC2506

OUTPUT CONTROLLER

23 X1

22 X0

29

(Page 29)

60

U-SUB242U-SUB114U-MAIN

IC1800 (1/2)

64

MUTE

MCK1

BCKO

LRCKO

DATA1

DATA2

DATA3

DATA4

RESET

30

(Page 30)

• SIGNAL PATH

: AUDIO (DIGITAL)

14

(Page 25)

DIR ERR

DIR CKST

MUTE

SYSTEM

MUTING

SWICTH

Q2601 – 2603

84 S-MUTE

22 DIR-ERROR

24 DIR-CKST

TA-XCS

29

TA-XCS

TA-SO

30

RESET

83

TA-SO

U-MAIN

U-SUB1

85

87

SUB-RST

MAIN CLK

U-SUB2

86

SUB DATA

MAIN DATA

2828

INIT

BBSEL

25

88

9776-INIT

BBSEL

MAIN SYSTEM

CONTROLLER

IC2601 (3/4)

115HP IN

HP SW

31

(Page 29)

6-7. BLOCK DIAGRAM – AUDIO OUTPUT Section –

31

(Page 28)

HP SW

HEADPHONE

AMP

IC1315

STR-DA9000ES

J701

PHONES

29

(Page 28)

32

(Page 33)

• SIGNAL PATH

: AUDIO (ANALOG)

: AUDIO (DIGITAL)

DATA145D01

DATA246D02

DATA347D03

DATA431D04

BCK40BCK

LRCK41LRCK

MDI34DA-DAT

MC35DA-CLK

MDO33DA-OUT

ML36DA-LAT

D/A CONVERTER

IC2901

VOUT1

VOUT2

VOUT3

VOUT4

VOUT7

VOUT8

VOUT5

VOUT6

HP RY

23

24

25

23

24

25

23