Sony RM-PJ25, VPL-HW40ES Service Manual

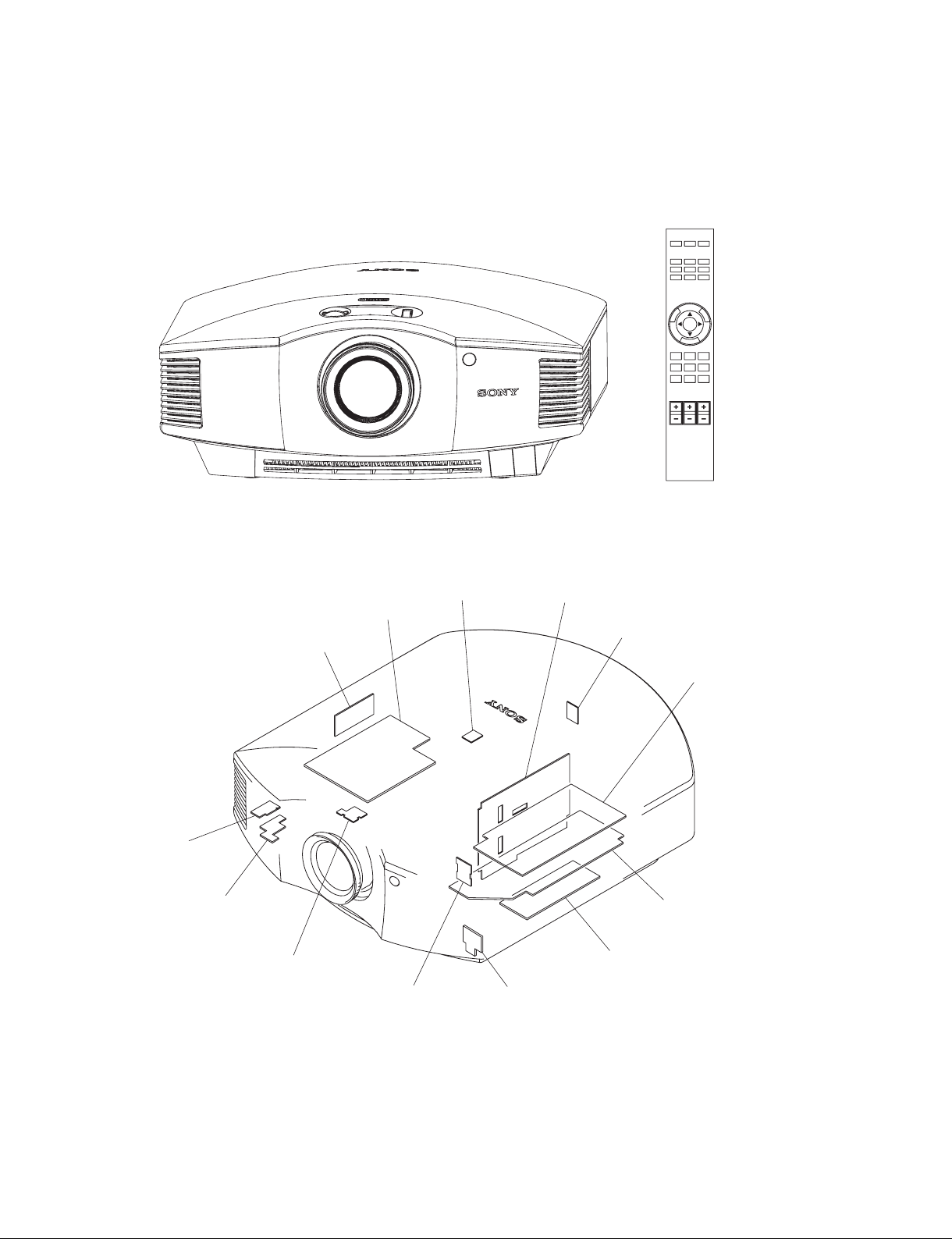

VIDEO PROJECTOR

VPL-HW40ES

REMOTE COMMANDER

RM-PJ25

SERVICE MANUAL

1st Edition

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

警告

万一,異常が起きた際に,お客様が電源を切ることが

できるように,設置の際には,機器近くの固定配線内

に専用遮断装置を設けるか,機器使用中に,容易に抜

き差しできるコンセントに電源プラグを接続してくだ

さい。

WARNING

When installing the unit, incorporate a readily accessible

disconnect device in the fi xed wiring, or connect the

power cord to a socket-outlet which must be provided

near the unit and easily accessible, so that the user can

turn off the power in case a fault should occur.

WARNUNG

Beim Einbau des Geräts ist daher im Festkabel

ein leicht zugänglicher Unterbrecher einzufügen,

oder das Netzkabel muß mit einer in der Nähe

des Geräts befi ndlichen, leicht zugänglichen

Wandsteckdose verbunden werden, damit sich bei

einer Funktionsstörung die Stromversorgung zum Gerät

jederzeit unterbrechen läßt.

For kundene i Norge

Dette utstyret kan kobles til et IT-strømfordelingssystem.

VPL-HW40ES

注意

注意

FÖRSIKTIGHET!

指定以外の電池に交換すると,破裂する危険があります。

必ず指定の電池に交換してください。

使用済みの電池は,国または地域の法令に従って

処理してください。

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

When you dispose of the battery, you must obey the

law in the relative area or country.

ATTENTION

Il y a danger d’explosion s’il y a remplacement incor-

rect de la batterie. Remplacer uniquement avec

une batterie du même type ou d’un type équivalent

recommandé par le constructeur.

Lorsque vous mettez la batterie au rebut, vous devez

respecter la législation en vigueur dans le pays ou la

région où vous vous trouvez.

Fara för explosion vid felaktigt placerat batteri.

Byt endast mot samma eller likvärdig typ av batteri,

enligt tillverkarens rekommendationer.

När du kasserar batteriet ska du följa rådande lagar

för regionen eller landet.

PAS PÅ

Fare for eksplosion, hvis batteriet ikke udskiftes

korrekt.

Udskift kun med et batteri af samme eller tilsvarende

type, som er anbefalet af fabrikanten.

Når du bortskaffer batteriet, skal du følge

lovgivningen i det pågældende område eller land.

HUOMIO

Räjähdysvaara, jos akku vaihdetaan virheellisesti.

Vaihda vain samanlaiseen tai vastaavantyyppiseen,

valmistajan suosittelemaan akkuun.

Noudata akun hävittämisessä oman maasi tai

alueesi lakeja.

VORSICHT

Explosionsgefahr bei Verwendung falscher Batterien.

Batterien nur durch den vom Hersteller empfohlenen

oder einen gleichwertigen Typ ersetzen.

Wenn Sie die Batterie entsorgen, müssen Sie die

Gesetze der jeweiligen Region und des jeweiligen

Landes befolgen.

FORSIKTIG

Eksplosjonsfare hvis feil type batteri settes i.

Bytt ut kun med samme type eller tilsvarende

anbefalt av produsenten.

Kasser batteriet i henhold til gjeldende avfallsregler.

注意

如果更换的电池不正确,就会有爆炸的危险。

只更换同一类型或制造商推荐的电池型号。

处理电池时,必须遵守相关地区或国家的法律。

VPL-HW40ES

1 (P)

Table of Contents

Manual Structure

Purpose of this manual ............................................................ 3 (E)

Related manuals ...................................................................... 3 (E)

1. Service Overview

1-1. Appearance Figure/Board Location ..........................1-1 (E)

1-2. Tighten Torque ..........................................................1-2 (E)

1-3. Disassembly ..............................................................1-3 (E)

1-3-1. Top Cover Assembly and HA Board ................ 1-5 (E)

1-3-2. HB Board and TL Board .................................. 1-6 (E)

1-3-3. Front Cover Assembly ..................................... 1-6 (E)

1-3-4. NF Board .........................................................1-7 (E)

1-3-5. DC Fan (EX) ....................................................1-7 (E)

1-3-6. C Board-1 ......................................................... 1-8 (E)

1-3-7. C Board-2 and U Board ...................................1-9 (E)

1-3-8. C Board-3 ....................................................... 1-10 (E)

1-3-9. Optical Unit Assembly ...................................1-10 (E)

1-3-10. DC Fan ........................................................... 1-11 (E)

1-3-11. GA Board .......................................................1-12 (E)

1-3-12. GB Board ....................................................... 1-13 (E)

1-3-13. Power Supply Unit ......................................... 1-14 (E)

1-3-14. QB Board ....................................................... 1-15 (E)

1-3-15. DC Fan and V Board-1 .................................. 1-16 (E)

1-3-16. DC Fan and V Board-2 .................................. 1-17 (E)

1-3-17. QA Board .......................................................1-18 (E)

1-3-18. EM Board ....................................................... 1-19 (E)

1-4. Optional Fixtures ..................................................... 1-20 (E)

1-4-1. Extension Boards and Extension Cables .......1-20 (E)

1-4-2. Connection .....................................................1-21 (E)

1-5. Indicator ..................................................................1-23 (E)

1-6. Circuit Description .................................................. 1-24 (E)

1-7. Disconnecting/

Connecting the Flexible Card Wires ....................... 1-25 (E)

1-8. Lead-free Solder ......................................................1-26 (E)

2. Electrical Adjustments

2-1. Preparations ...............................................................2-1 (E)

2-1-1. Required Equipment ........................................2-1 (E)

2-1-2. How to Enter the Service Mode ....................... 2-1 (E)

2-1-3. How to Enter the Model Name Display

(Shop Demonstration) Mode ...........................2-2 (E)

2-1-4. How to Enter the Motionflow

(Shop Demonstration) Mode ...........................2-2 (E)

2-2. Notes on Servicing ....................................................2-3 (E)

2-2-1. When the Optical Unit Assembly is

Replaced...........................................................2-3 (E)

2-2-2. When Replacing the QA Board .......................2-3 (E)

2-2-3. When Replacing the C Board ..........................2-3 (E)

2-2-4. When the GA, GB, HA, HB, NF, QB, TL, U, or

V Board is Replaced ........................................2-3 (E)

2-3. White Balance Adjustment ........................................ 2-4 (E)

2-3-1. D93 Mode of Video .........................................2-4 (E)

2-3-2. D75 Mode of Video .........................................2-4 (E)

2-3-3. D65 Mode of Video .........................................2-5 (E)

2-3-4. D55 Mode of Video .........................................2-5 (E)

2-3-5. Custom Setting ................................................. 2-5 (E)

2-4. Adjust Value Writing .................................................2-6 (E)

2-4-1. Panel Driver Gain B Data Copy ......................2-6 (E)

2-4-2. Panel Alignment Data Copy ............................2-6 (E)

2-5. Panel Driver Gain B Adjustment ...............................2-6 (E)

2-6. Software Upgrade Method ........................................2-7 (E)

2-6-1. Preparation .......................................................2-7 (E)

2-6-2. SUB CPU Upgrade ..........................................2-8 (E)

2-6-3. Scan Converter Upgrade ..................................2-9 (E)

2-6-4. Data Write Method of 3DGamma/LookUpTable/

DDC/NVM/ABGamma/LCK/OGMData/

CSMatrixTable ...............................................2-10 (E)

2-6-5. Data Obtain Method of 3DGamma/LookUpTable/

DDC/NVM/ABGamma/LCK/OGMData/

CSMatrixTable from the Board ..................... 2-12 (E)

2-7. Memory ................................................................... 2-13 (E)

2-8. Adjustment Item Initialize Data .............................. 2-16 (E)

VPL-HW40ES

1 (E)

3. Spare Parts

6. Board Layouts

3-1. Notes on Repair Parts ...................................................... 3-1

3-2. Exploded Views ............................................................... 3-2

3-3. Electrical Parts List .........................................................3-9

3-4. Packing Materials & Supplied Accessories ................... 3-36

4. Block Diagrams

Overall ............................................................................. 4-1

QA ................................................................................... 4-2

HA ................................................................................... 4-3

HB ................................................................................... 4-3

NF ....................................................................................4-3

QB ................................................................................... 4-3

TL .................................................................................... 4-3

U ...................................................................................... 4-3

V ...................................................................................... 4-3

C ...................................................................................... 4-5

GA ................................................................................... 4-7

GB ................................................................................... 4-7

C ...................................................................................... 6-2

GA ...................................................................................6-4

GB ................................................................................... 6-6

QA ...................................................................................6-8

EM ................................................................................. 6-10

HA ................................................................................. 6-10

HB ................................................................................. 6-10

NF .................................................................................. 6-11

QB ................................................................................. 6-11

TL .................................................................................. 6-11

U .................................................................................... 6-11

V .................................................................................... 6-11

5. Schematic Diagrams

HA ................................................................................... 5-2

HB ................................................................................... 5-2

C ...................................................................................... 5-3

EM ................................................................................. 5-13

GA ................................................................................. 5-14

GB ................................................................................. 5-15

QA ................................................................................. 5-17

NF ..................................................................................5-28

QB ................................................................................. 5-28

TL .................................................................................. 5-28

U .................................................................................... 5-28

V .................................................................................... 5-28

Frame Wiring.................................................................5-29

2 (E)

VPL-HW40ES

Purpose of this manual

Related manuals

Manual Structure

This manual is the Service Manual of the Video Projector VPL-HW40ES.

This manual contains the service overview, adjustments, spare parts, block diagrams,

schematic diagrams, and board layouts.

In addition to this Service Manual, the following manuals are provided.

. “Operating Instruction” CD-ROM (Supplied with unit)

This manual is necessary for application and operation of this unit.

. Protocol Manual (Available on request)

This manual describes the protocol for controlling this unit.

VPL-HW40ES

3 (E)

Section 1

Service Overview

1-1. Appearance Figure/Board Location

Appearance figure

RM-PJ25

Board location

QB

U

QA

HA

V

HB

NF

EM

C

TL

GA

GB

Power supply unit

VPL-HW40ES

1-1 (E)

1-2. Tighten Torque

Tighten the each screw with the torque below.

n

When using the torque driver with the notation of cN.m, interpret it as follows.

Example: 0.8 N.m = 80 cN.m

. BVTP3 x 8: 0.80 ?0.12 N.m (8.16 ?1.22 kgf.cm)

. BVTP3 x 12: 0.80 ?0.12 N.m (8.16 ?1.22 kgf.cm)

. BVWHTP3 x 12: 0.80 ?0.12 N.m (8.16 ?1.22 kgf.cm)

. PSW3 x 8: 0.80 ?0.12 N.m (8.16 ?1.22 kgf.cm)

. PSW4 x 8: 1.40 ?0.2 N.m (14.3 ?2.0 kgf.cm)

. PSW4 x 16: 1.40 ?0.2 N.m (14.3 ?2.0 kgf.cm)

. SP4-40 UNC screw: 0.53 ?0.07 N.m (5.40 ?0.71 kgf.cm)

. Tapping screw1.7 x 4: 0.15 ?0.01 N.m (1.53 ?0.10 kgf.cm)

. Hexagon screw (for connector): 0.53 ?0.07 N.m (5.40 ?0.71 kgf.cm)

1-2 (E)

VPL-HW40ES

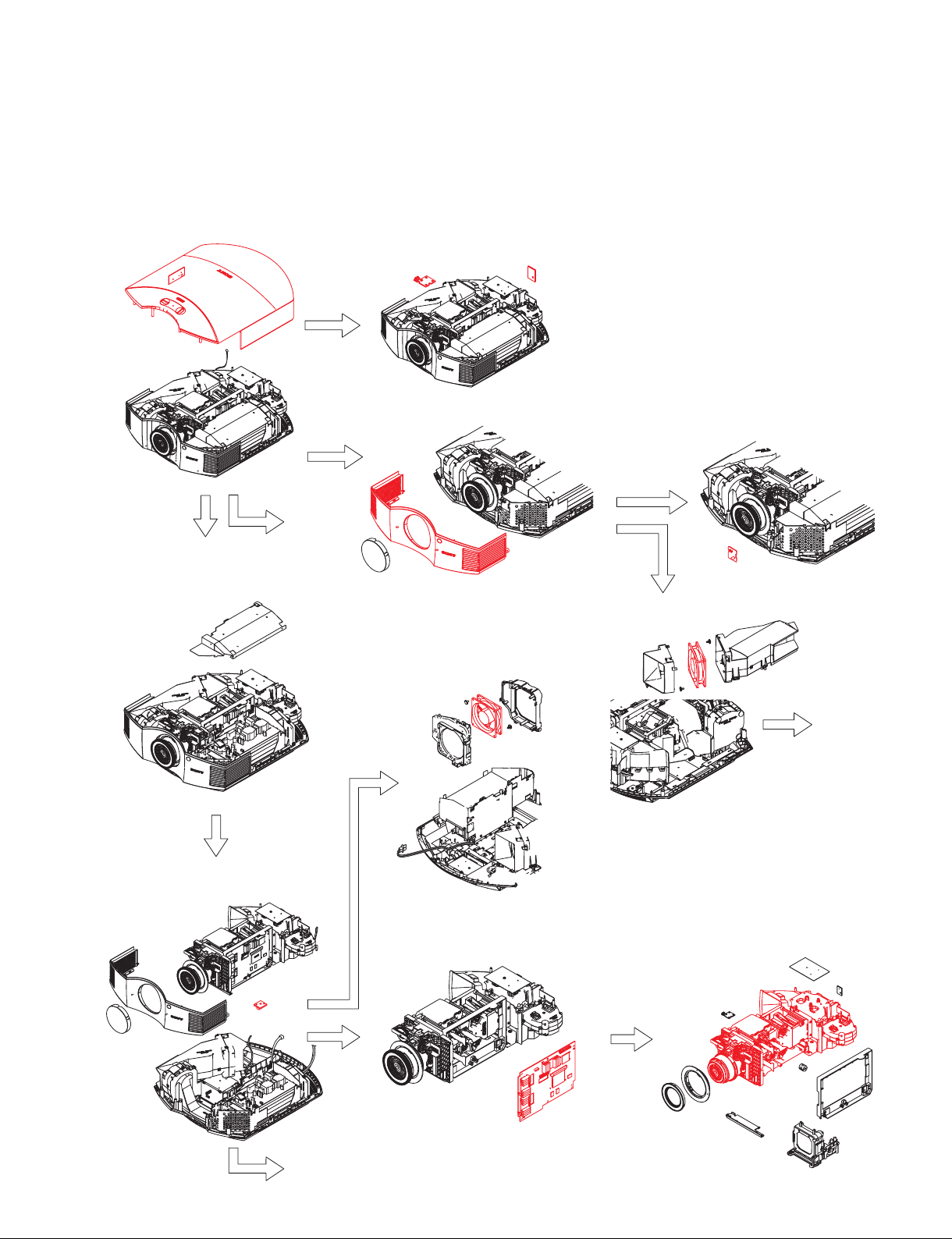

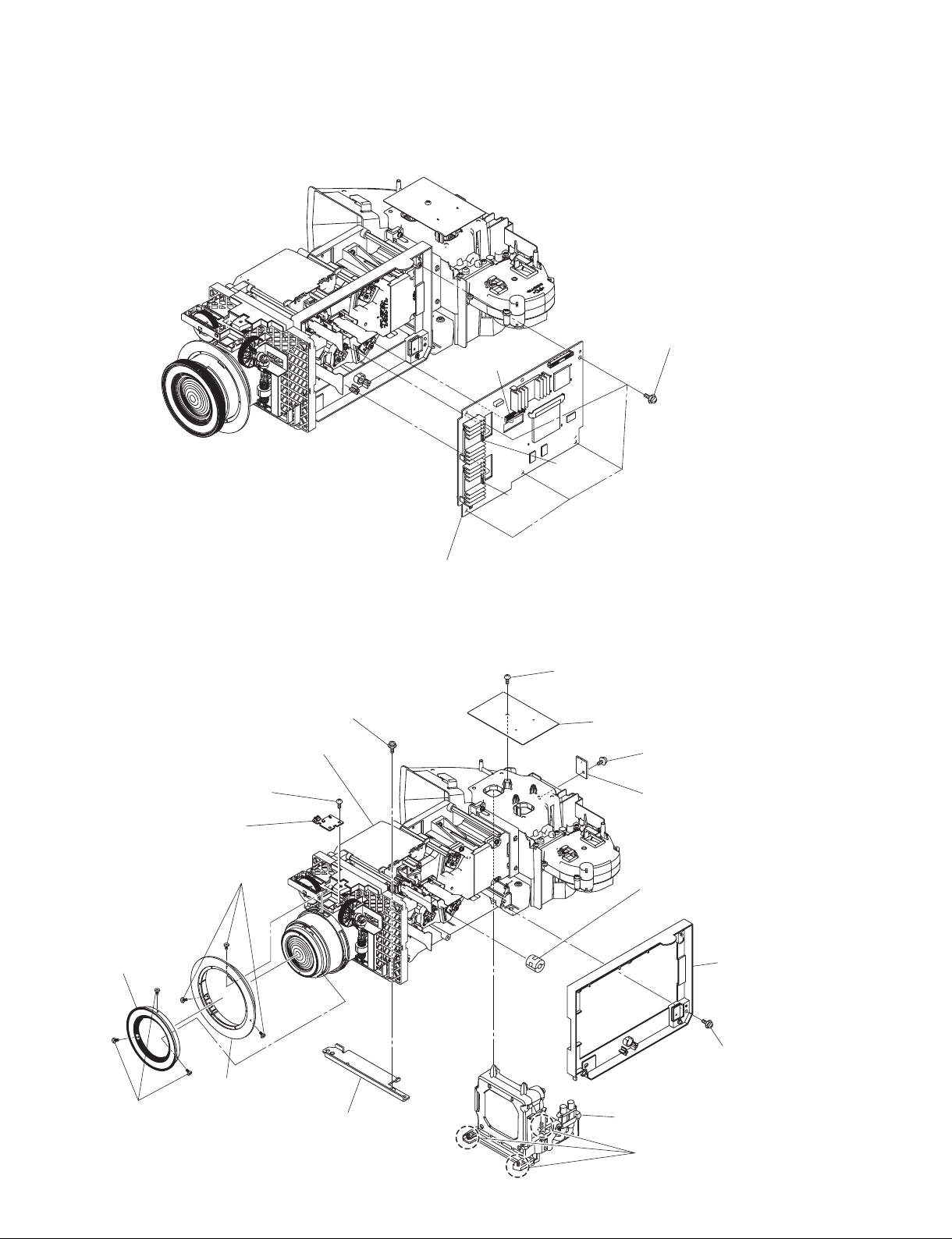

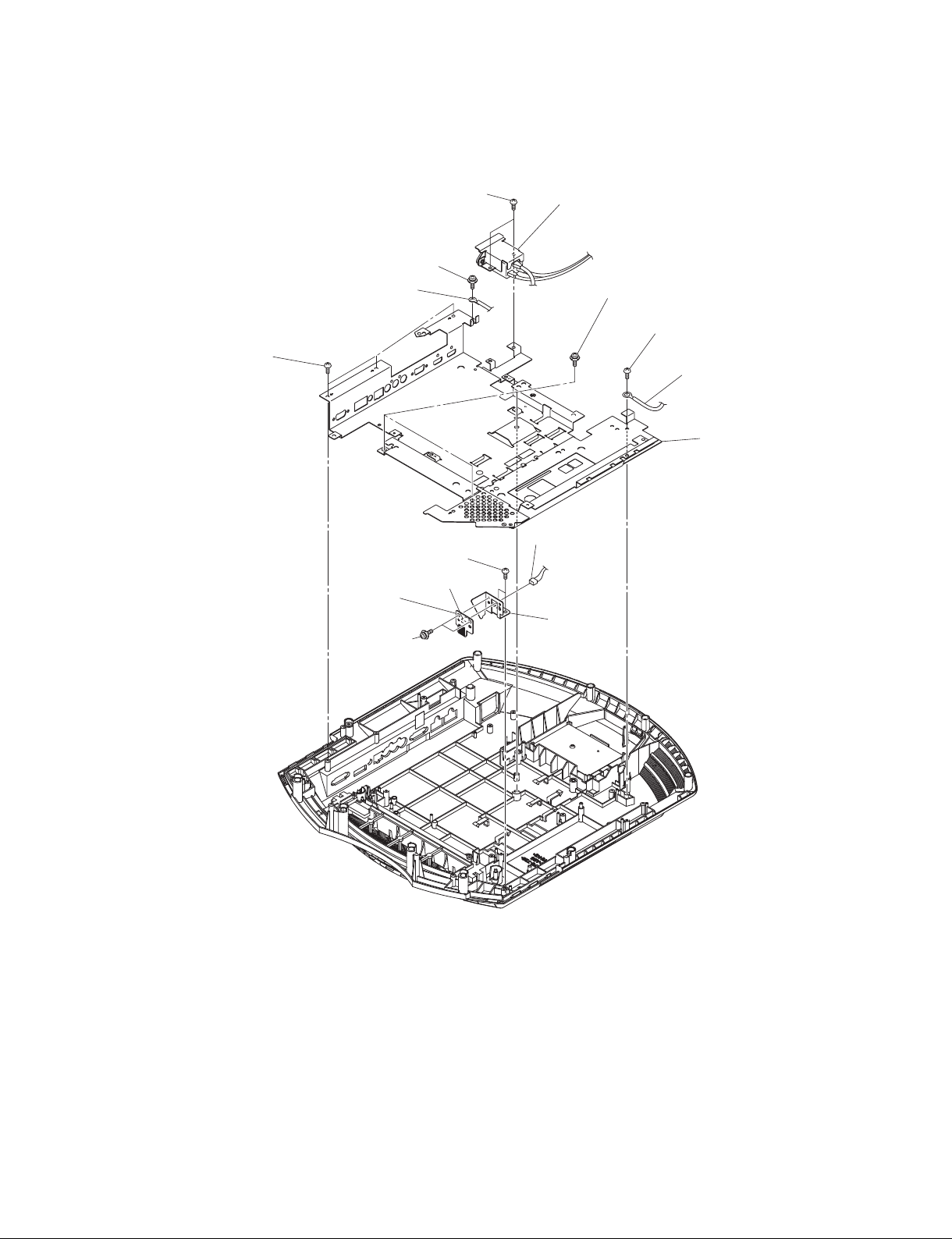

1-3. Disassembly

n

Remove parts in the order of numbers shown in the figure, in this section.

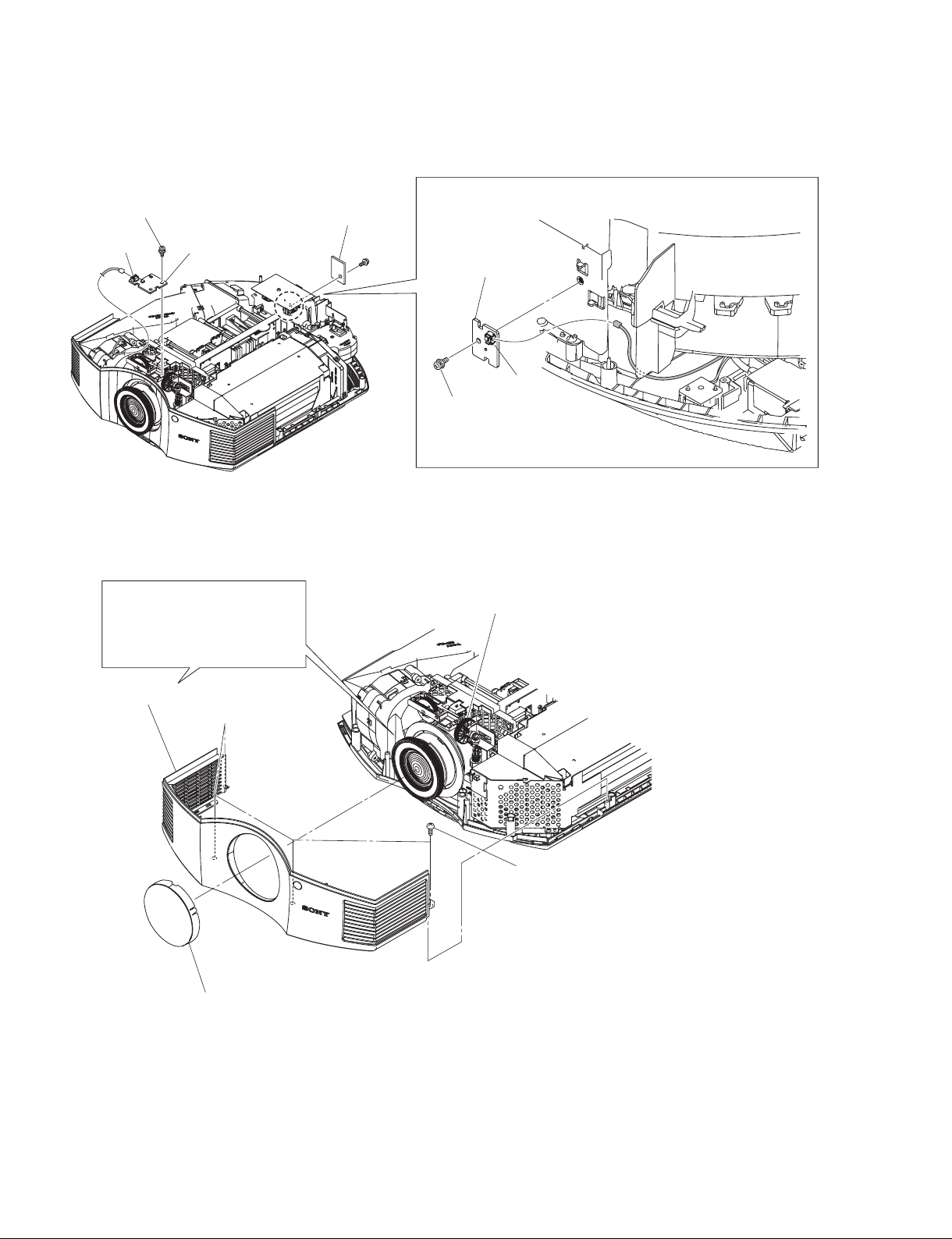

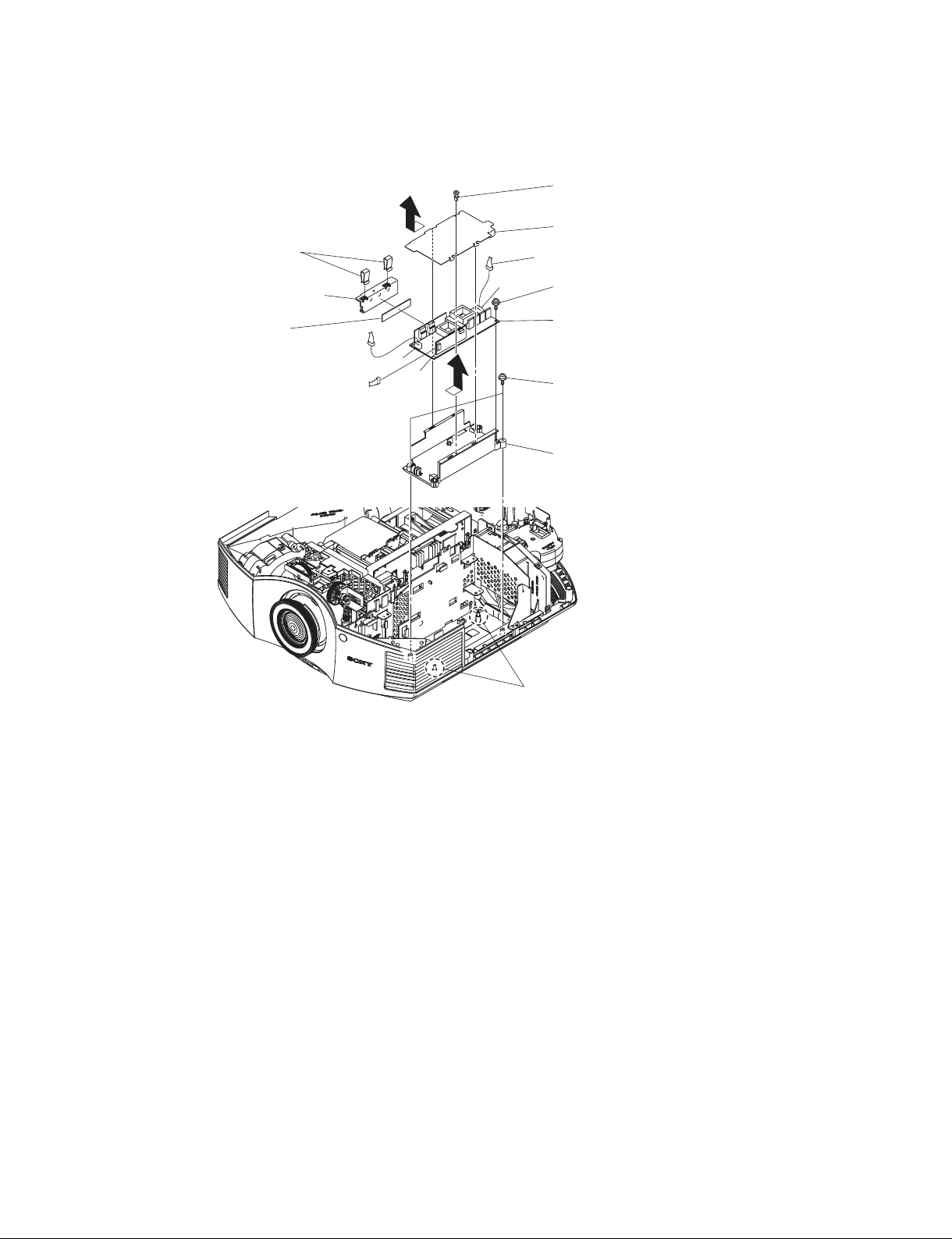

1-3-1. Top Cover Assembly and HA Board

1-3-2. HB Board and TL Board

1-3-6. C Board-1

A

1-3-3. Front Cover Assembly

1-3-10. DC fan

1-3-4. NF Board

1-3-5. DC Fan (EX)

C

VPL-HW40ES

1-3-7. C Board-2 and U Board

B

1-3-8. C Board-3

1-3-9. Optical Unit Assembly

1-3 (E)

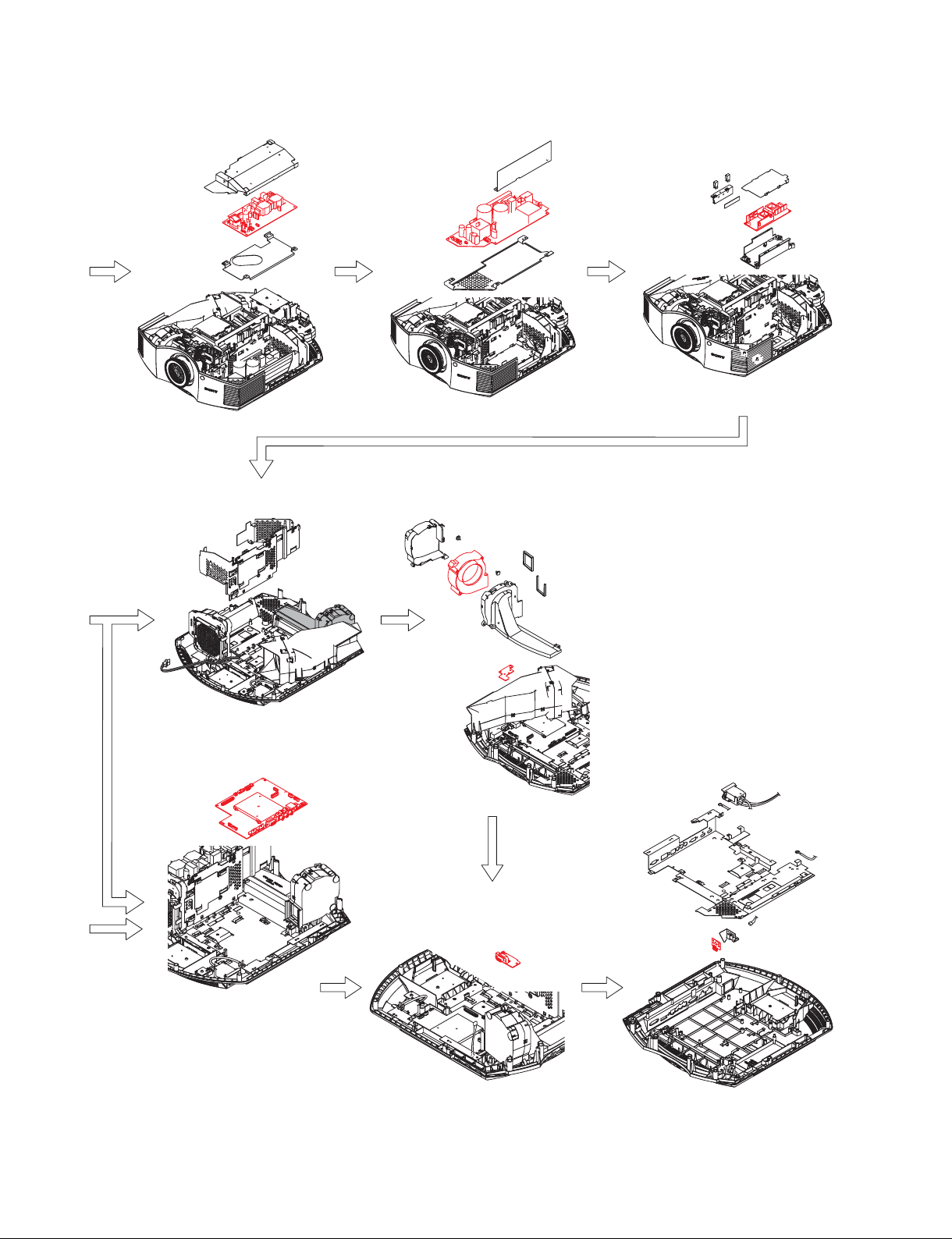

A

1-3-11. GA Board 1-3-12. GB Board 1-3-13. Lamp Power Supply

1-3-15. DC Fan and V Board-1 1-3-16. DC Fan and V Board-2

B

C

1-3-17. QA Board 1-3-18. EM Board

1-3-14. QB Board

C

1-4 (E)

VPL-HW40ES

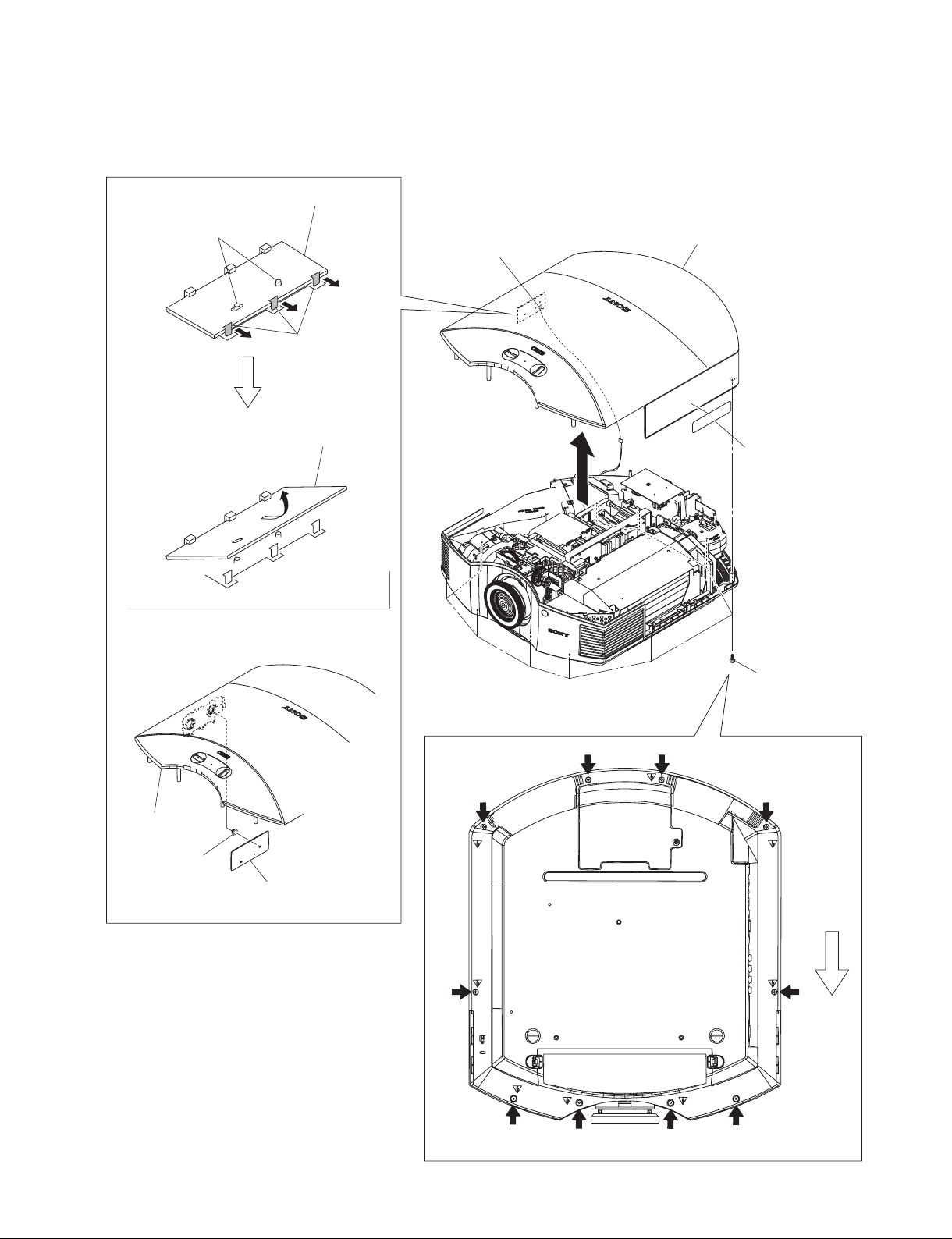

1-3-1. Top Cover Assembly and HA Board

HA board

4 Two dowels

5 Remove the HA board in the

direction of the arrow A.

A

3 Three hooks

2 HA board

CN11

9 Top cover assembly

8 Lens caution label

1 Ten screws

(BVTP3 x 12)

Top cover assembly

6 Button (P)

VPL-HW40ES

7 HA board

Front side

1-5 (E)

1-3-2. HB Board and TL Board

1 Screw

(BVTP3 x 8)

TL board

CN20

2 HB board

1-3-3. Front Cover Assembly

When removing the front cover

assembly, shift the lens so as to

remove the front cover assembly

smoothly by rotating the dial

indicated in the figure.

3 Front panel assembly

4 TL board

CN60

3 Screw

(BVTP3 x 8)

Dial

1-6 (E)

2 Four screws

(BVTP3 x 12)

1 Lens cap

VPL-HW40ES

1-3-4. NF Board

1 Hook

NF board

2 NF board

CN30

1-3-5. DC Fan (EX)

2 Three screws

4 Remove the DC fan (EX) block

in the direction of the arrow.

(BVTP3 x 12)

7 Fan duct

(EX)

3 Two dowels

0 DC fan (EX)

Label side

5 Two screws

(BVTP3 x 12)

8 Top duct (EX),

bottom duct (EX)

6 Two hooks

9 Eight fan dampers

VPL-HW40ES

1 Fan connector

Front

1-7 (E)

1-3-6. C Board-1

t When removing the C board, perform the procedure in Sections

1-3-6 to 1-3-8.

1 Ta p e

3 Shield (PW)

2 Four screws

(PSW3 x 8)

The lug terminal should not

protrude exceeding the chassis.

Optical unit

7 Two fan connectors

HB board

CN20

Harness

Fuse connector assembly

6 Six hooks

4 Two screws

(BVWHTP3 x 12)

5 Lamp power

connector assembly

0 Loosen screw.

Front side

Bottom cover

assembly

When installing the GND wire harness,

insert the GND wire harness in between

the optical unit and the bottom cover

assembly.

Chassis

Pull the GND harness front to

give tension.

8 Screw

(PSW3 x 8)

9 GND wire

harness

TL board

CN60

1-8 (E)

!= Three harnesses

C board

CN1000

!- Remove the fuse connector

assembly in the direction of the

arrow.

Fuse connector assembly

!\ Harness

To the chassis.

!] Lead with connector

(LVDS)

1-3-7. C Board-2 and U Board

3 Front cover assembly

1 Lens cap

Note in operation:

Do not damage the harnesses.

4 Four screws

(PSW4 x 16)

2 Four screws

(BVTP3 x 12)

CN70

6 Optical unit block (C board)

7 Screw

(BVTP3 x 12)

8 U board

5 Two dowels

Place the harness at a right

angle as shown in the figure.

Harness

GA board

CN301

Marking is printed on the top.

Lead with connector (LVDS)

CN600

CN602

CN400

CN1001

QA board

When installing the harness,

the harness should not protrude

exceeding the shaded area.

G board holder block

Front side

Hooks of plate clamp

Hooks of bottom cover

assembly

Harness of the lead with connector

(LVDS) should not override on top

of the chassis screw.

Lead with connector

(LVDS)

Chassis screw

CN301

Chassis

Tape

VPL-HW40ES

1-9 (E)

1-3-8. C Board-3

CN9000

2 C board

1 Five screws

(PSW3 x 8)

CN9500

CN8000

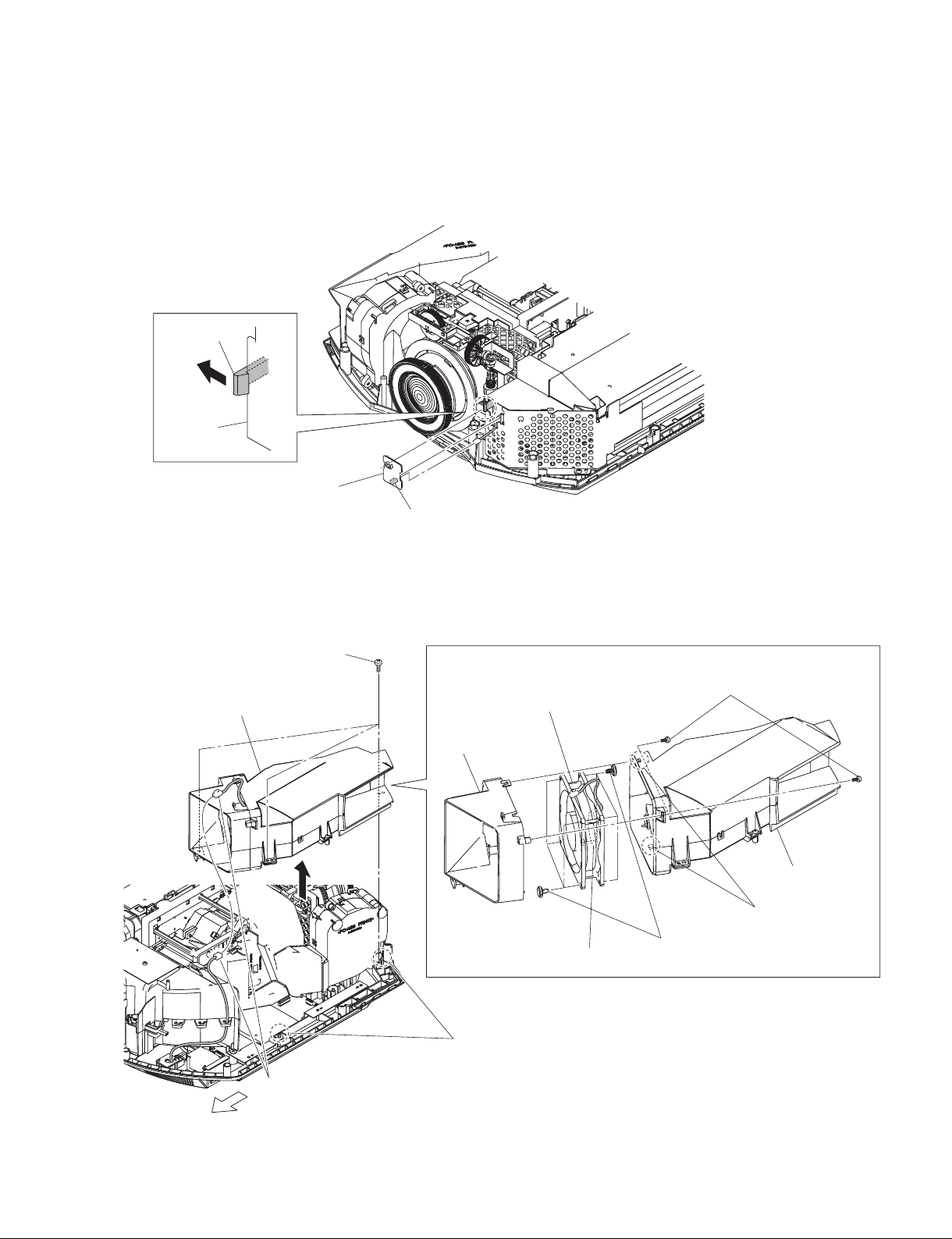

1-3-9. Optical Unit Assembly

!= Screw

(PSW4 x 16)

!, Optical unit assembly

5 Screw

(BVTP3 x 8)

6 HB board

!] Three tapping screws

(1.7 x 4)

!; Focus ring

assembly

!' Zoom ring assembly

!\ Three tapping screws

(1.7 x 4)

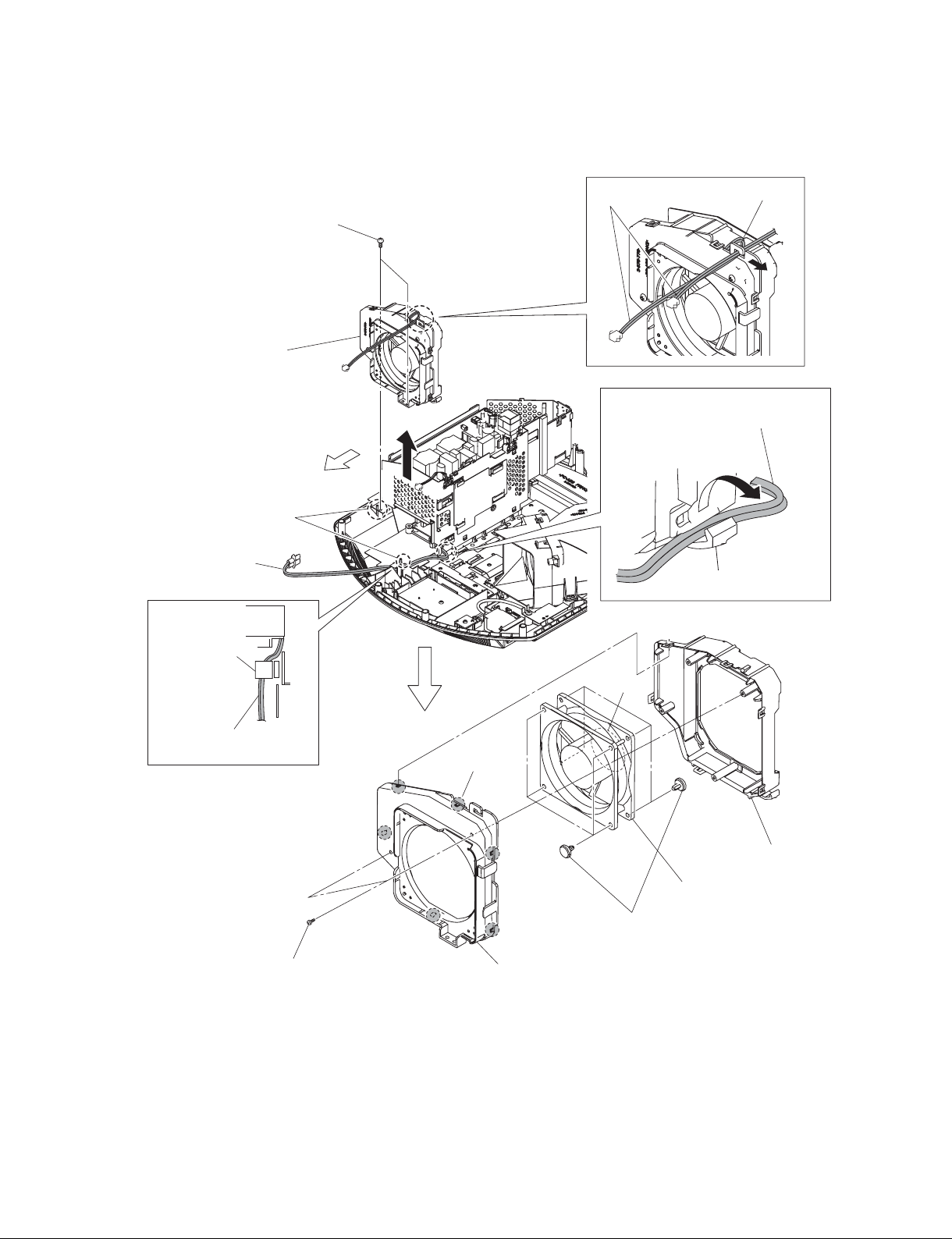

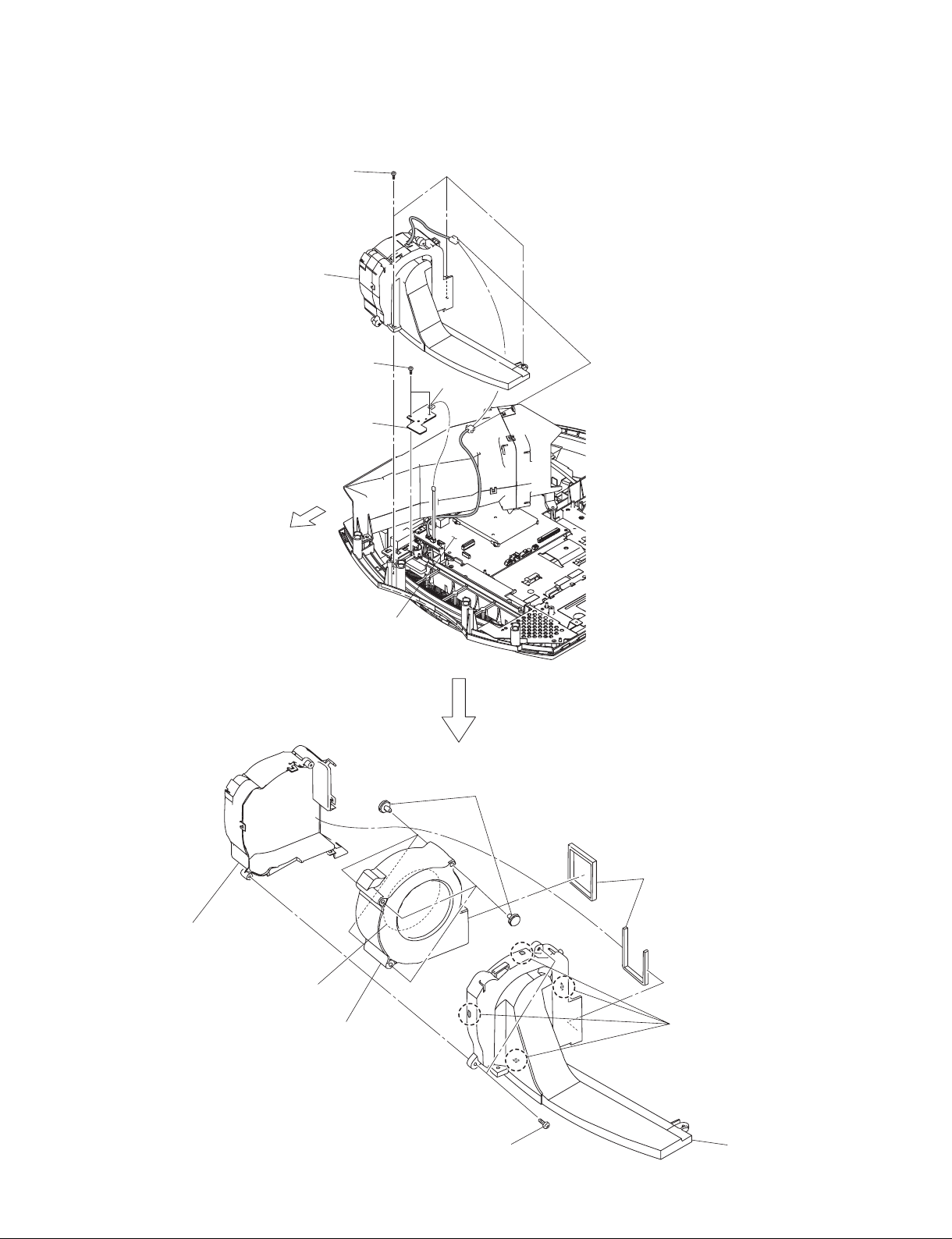

1-3-10. DC Fan

3 Two screws

(BVTP3 x 12)

5 Remove the DC fan block

in the direction of the

arrow B.

Front side

4 Two dowels

Lamp power connector

assembly

B

Two fan harnesses

1 Remove the lamp power connector

assembly in the direction of the

arrow A.

2 Hook

A

Hook

Chassis

Lamp power connector

assembly

6 Two screws

(BVTP3 x 12)

Label side

7 Six hooks

8 Fan bracket

(F) (CH)

!- DC fan

0 Eight fan dampers

9 Fan bracket (R) (CH)

VPL-HW40ES

1-11 (E)

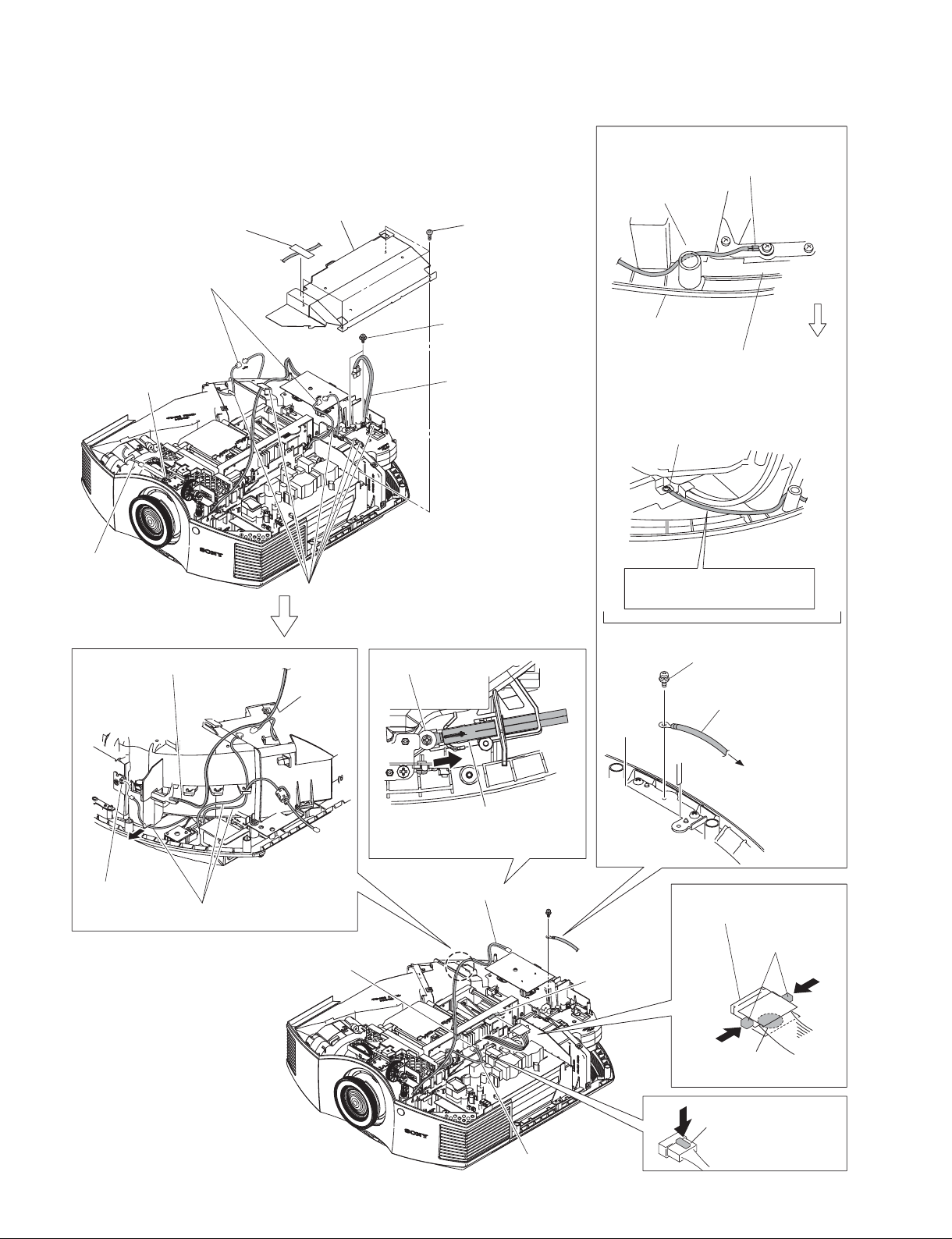

1-3-11. GA Board

1 Ta p e

Fuse connector assembly

CN102

CN103

2 Four screws

(PSW3 x 8)

3 Shield (PW)

CN101

4 GA board

CN104

CN105

5 Shield (PWG)

1-12 (E)

VPL-HW40ES

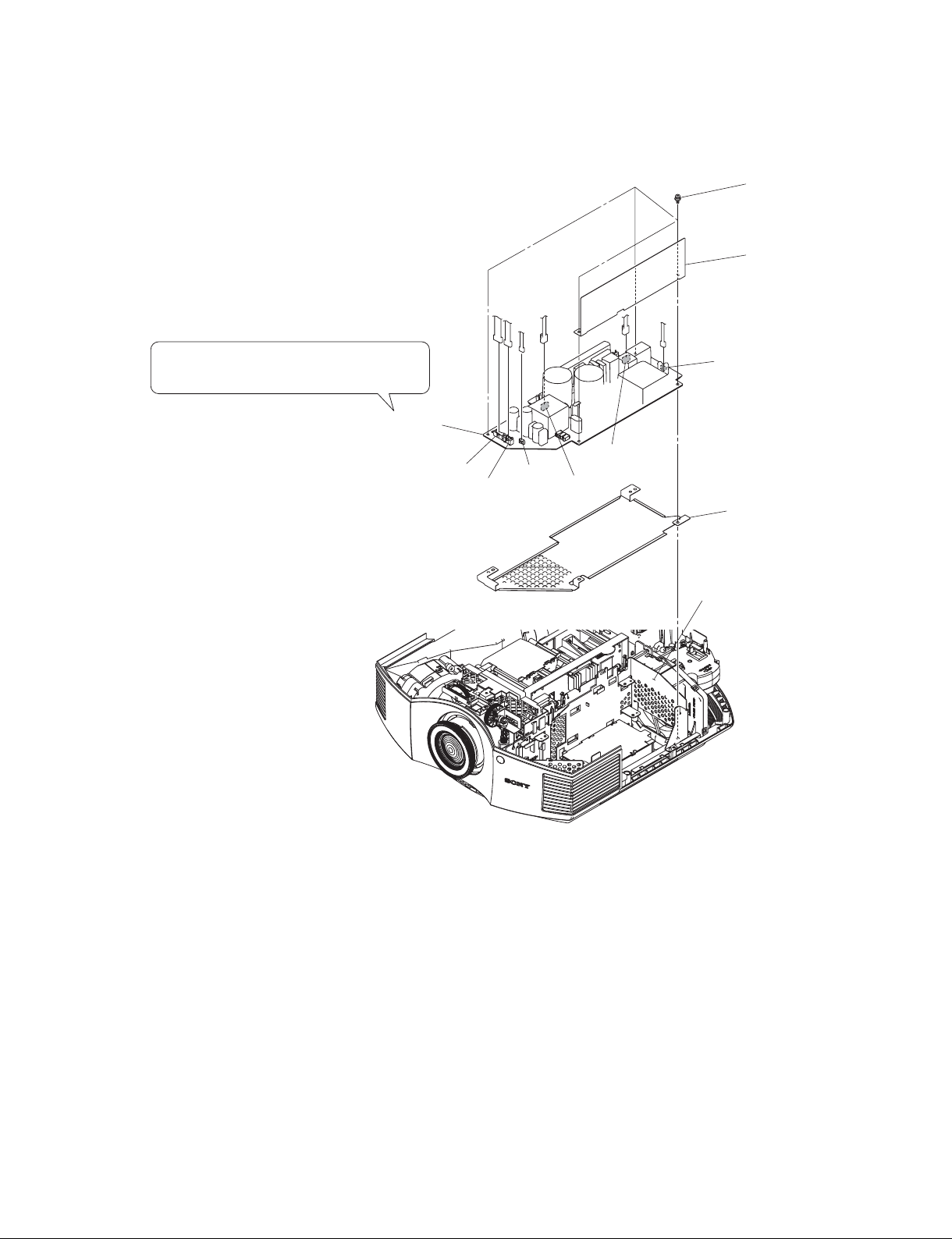

1-3-12. GB Board

1 Four screws

(PSW3 x 8)

2 Shield (GB)

When removing the GB board, remove it in the

way that the GB board should not contact with

the metal plate of the G board holder.

3 GB board

CN301

CN302

CN303

CN201

CN202

CN203

4 Shield (BLT)

G board holder block

VPL-HW40ES

1-13 (E)

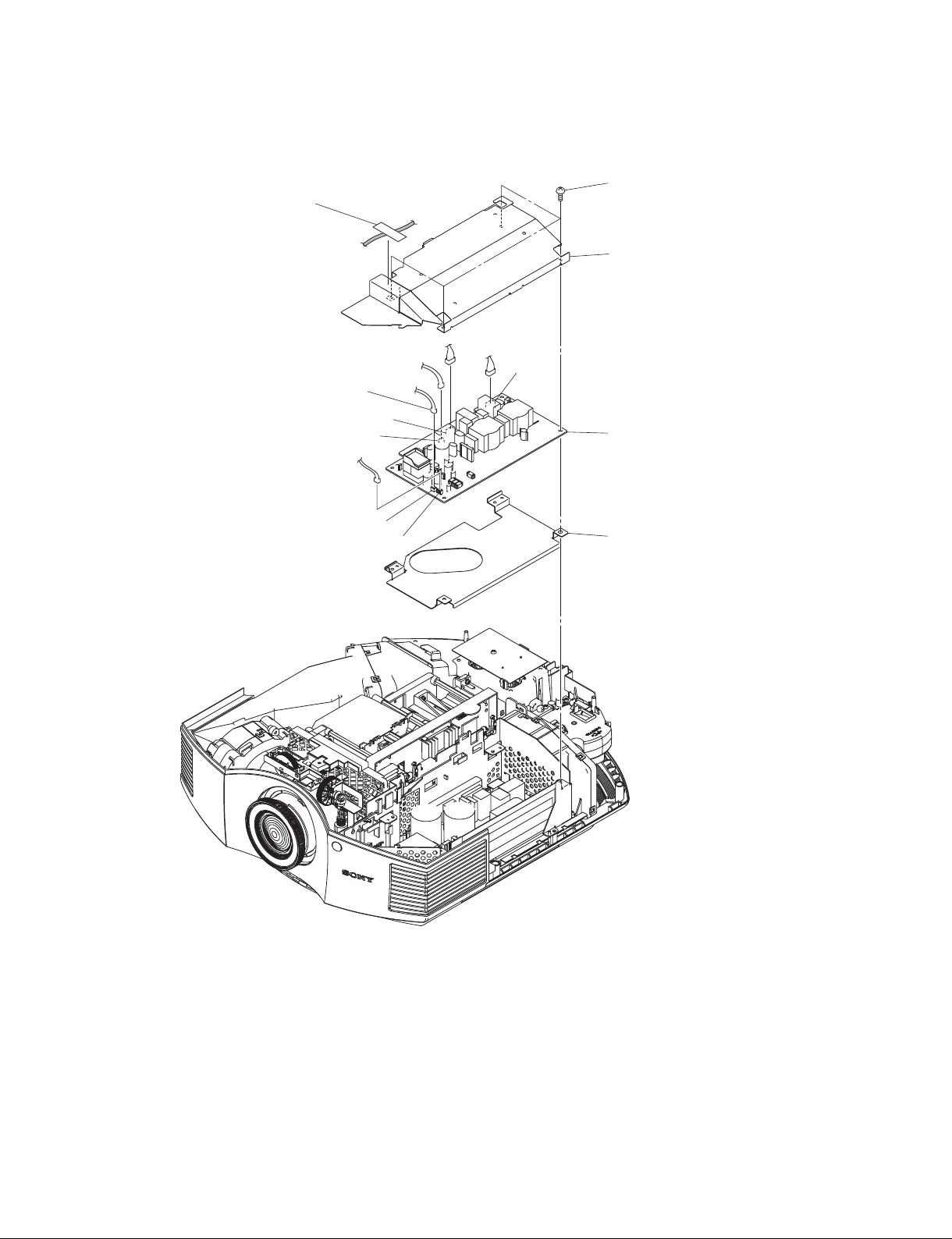

1-3-13. Power Supply Unit

8 Two clips (BA)

9 Heat sink (BA)

0 Sheet (BA)

X1

X2

1 Rivet

2 Sheet (BLT)

Lamp power connector assembly

X3

6 Screws

(PSW3 x 8)

7 Power supply unit

3 Two screws

(BVWHTP3 x 12)

4 Holder (BLT)

5 Two dowels

1-14 (E)

VPL-HW40ES

1-3-14. QB Board

CN91

2 QB board

QA board

1 Two hexagon screws

(There is a height difference.)

QA board QB board

VPL-HW40ES

1-15 (E)

1-3-15. DC Fan and V Board-1

n

When removing the V board, perform the procedure in Sections 1-3-15 and 1-3-16.

5 Remove the lamp power connector

assembly from the hook of fan (CH)

bracket and hole of the plate clamp.

Hole of plate clamp

Hook of fan (CH) bracket

Place the harness at a right

angle as shown in the figure.

Harness

4 Four screws

(BVTP3 x 12)

GA board

A

Lead with connector

(LVDS)

A

A

Front side

7 G board holder block

DC fan block

Front side

1 Open the two edge clamps

When installing the harness,

the harness should not protrude

exceeding the shaded area.

G board holder block

Hook of plate clamp

3 Pull out the harness from the hole.

2 Remove the harness from the eight

hooks.

Harness of the lead with connector

(LVDS) should not override on top

of the chassis screw.

A

A

6 Four

dowels

Front side

Hook of bottom cover assembly

1-16 (E)

CN301

CN600

Marking is printed on the top.

Ta pe

CN602

CN400

CN1001

QA board

Lead with connector

(LVDS)

Chassis screw

CN301

Ta pe

Chassis

VPL-HW40ES

1-3-16. DC Fan and V Board-2

2 Three screws

(BVTP3 x 12)

3 DC fan block

4 Two screws

(BVTP3 x 12)

5 V board

Front side

1 Two fan connectors

CN80

9 Fan cover

(84C)

Label side

!= DC fan

QA board

!- Six fan dampers

7 Two sirocco cushions

8 Four hooks

VPL-HW40ES

6 Two screws

(BVTP3 x 12)

0 Fan cover

(84I)

1-17 (E)

1-3-17. QA Board

Place the harness at a right

angle as shown in the figure.

Harness

GA board

Lead wire with connector

(LVDS)

When installing the harness,

the harness should not protrude

exceeding the shaded area.

Marking is printed on the top.

Lead wire with connector

(LVDS)

CN600

CN301

Marking is printed on the top.

CN600

CN301

CN602

Ta pe

CN400

CN602

CN400

CN1001

CN1001

CN702

CN800

G board holder block

Hooks of plate clamp

Hooks of bottom cover assembly

Harness of the lead with connector

(LVDS) should not override on top

of the chassis screw.

Lead with connector

(LVDS)

Chassis screw

QA board

CN301

1 Four screws

(PSW3 x 8)

CN701

Front side

Ta pe

Chassis

QA board

1-18 (E)

6 Remove the QA board

in the direction of the

arrow D.

432

Two SP4-40 UNC screws (No height difference)

CN703

CN801

QB board

D

Front side

5 Two dowels

2 Two screws

(BVTP3 x 12)

3 Two SP4-40 UNC screws

(No height difference)

4 Two screws

(PSW3 x 8)

VPL-HW40ES

1-3-18. EM Board

3 Two screws

1 Screw

(PSW4 x 8)

(BVTP3 x 12)

4 AC inlet

8 Three screws

(BVTP3 x 12)

2 Ground wire

!- Two screws

(BVTP3 x 12)

!] EM board

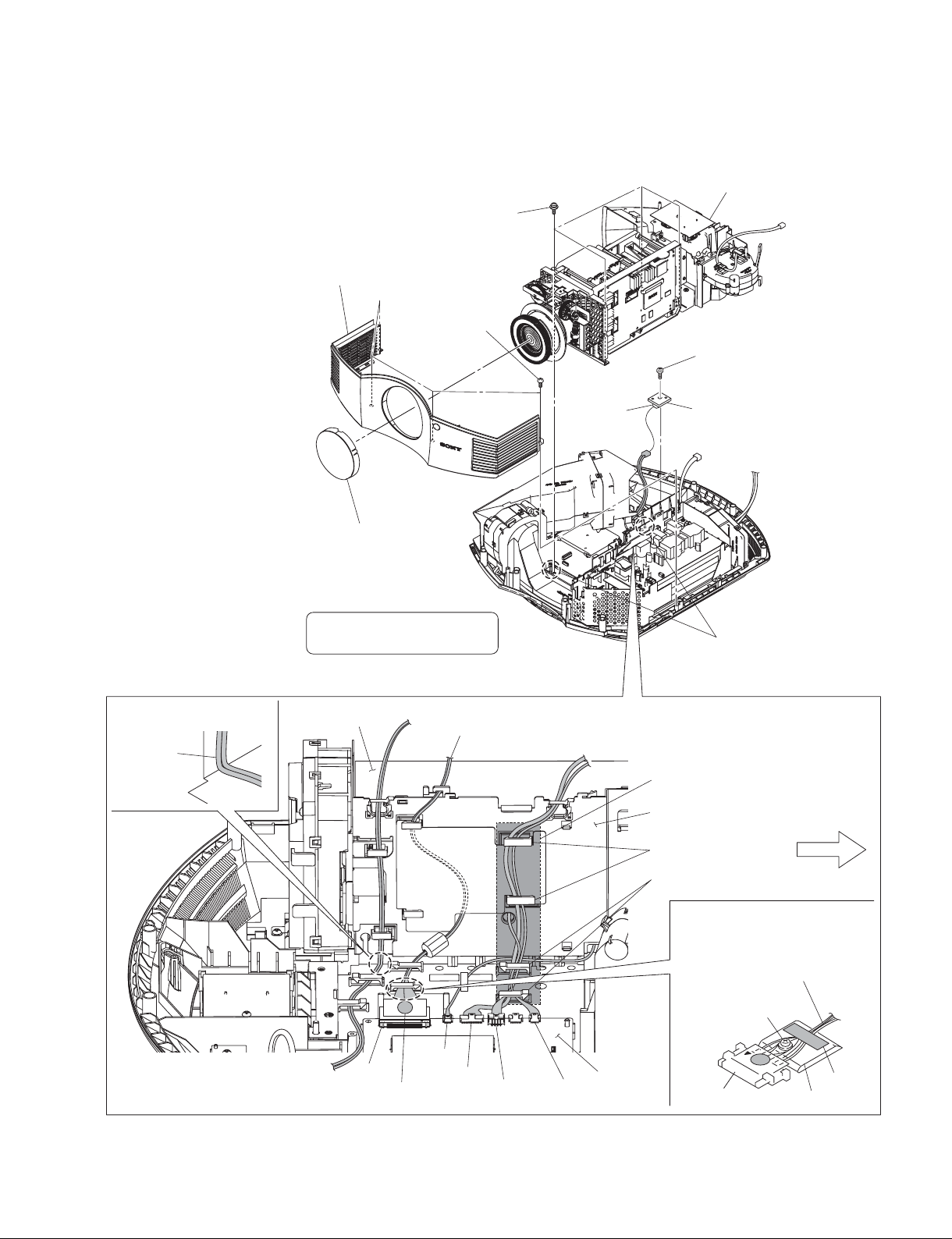

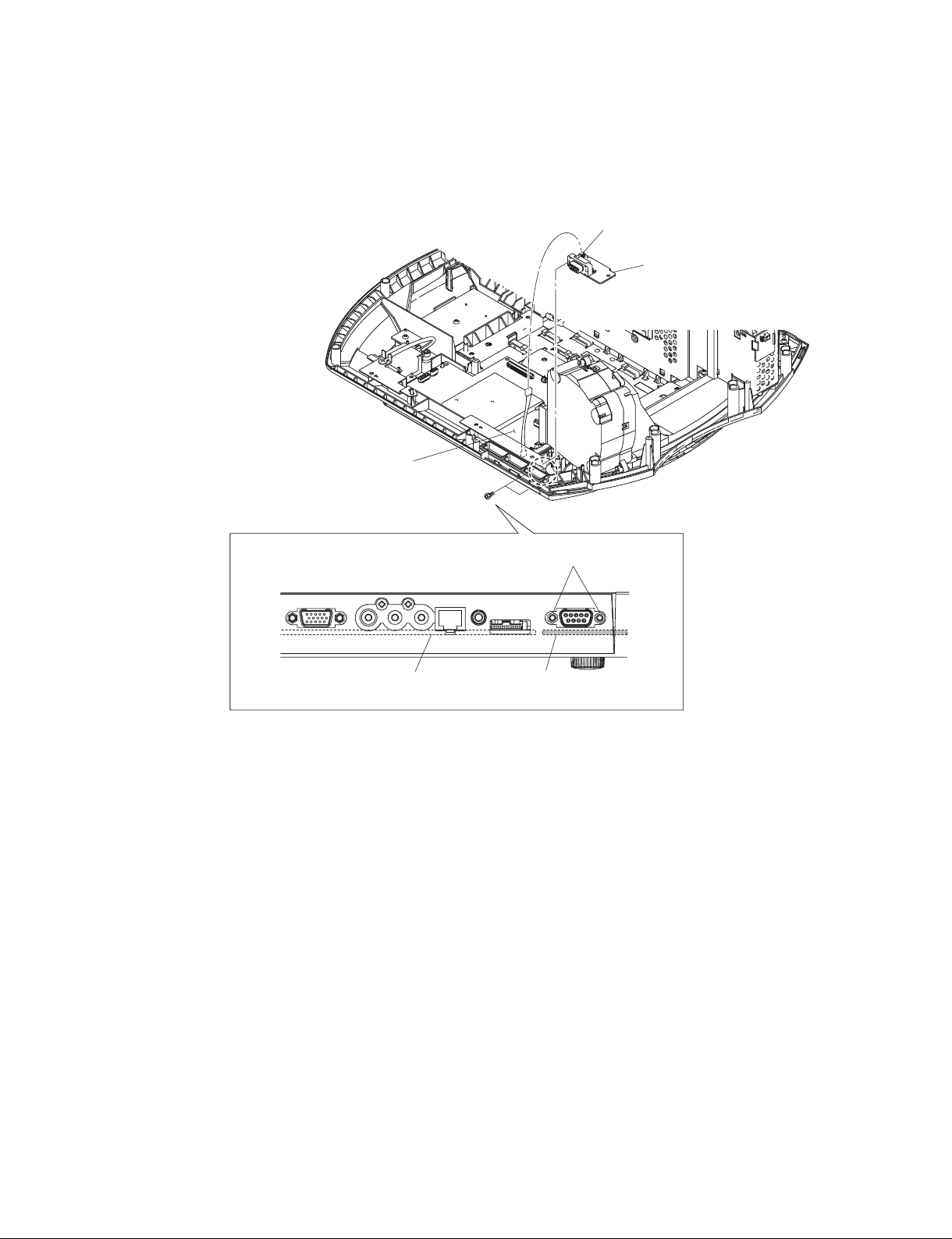

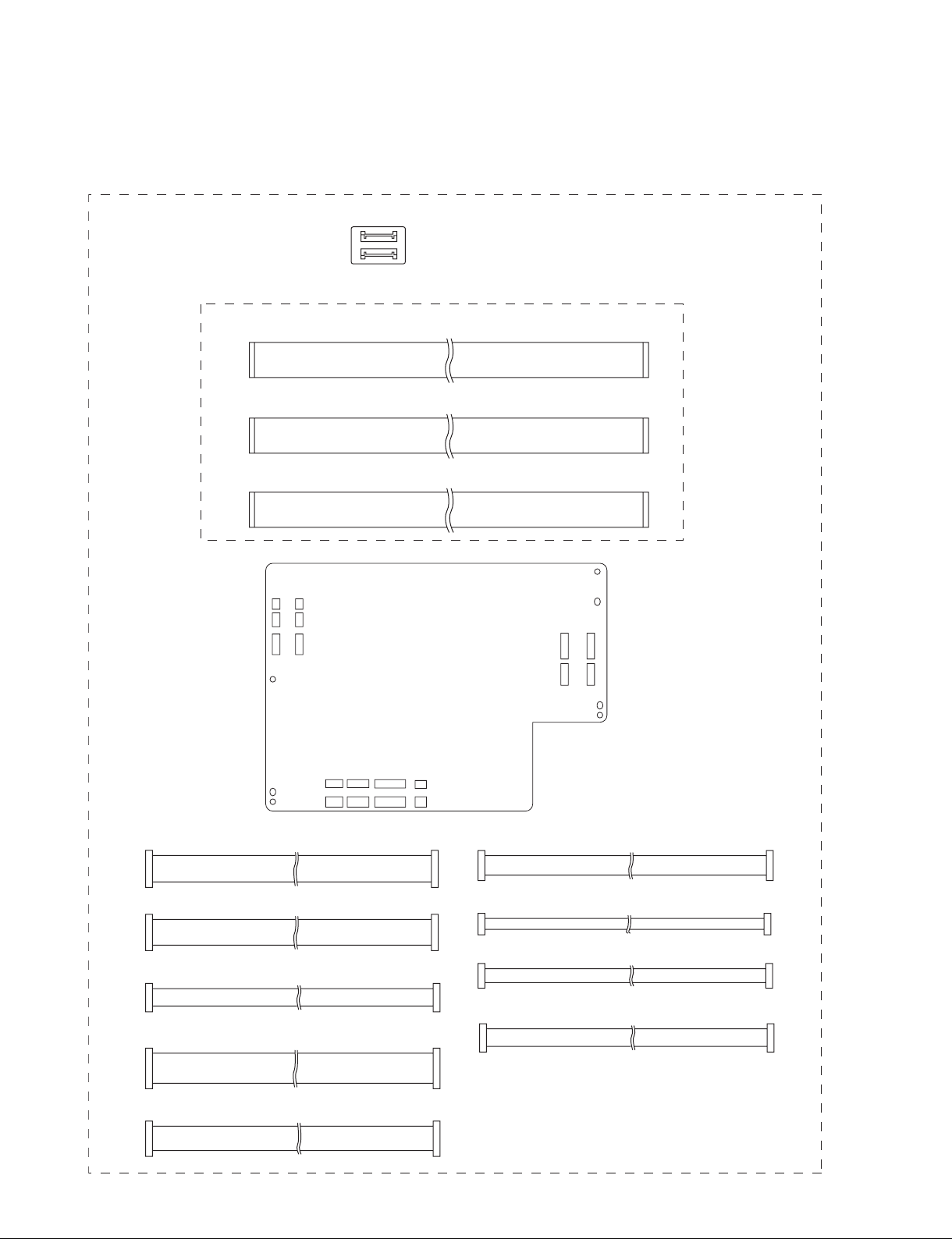

1-4. Optional Fixtures

1-4-1. Extension Boards and Extension Cables

X kit assembly (Part No. A-1848-223-A)

The panel extension cable for R, G and B are common.

I-1 PANEL EXTENSION CABLE (80P)

I-2 PANEL EXTENSION CABLE (80P)

I-3 PANEL EXTENSION CABLE (80P)

CJ board x 3

A CONNECTOR ASSY, JST SVC 9P

B CONNECTOR ASSY, MOLEX SVC 10P

C CONNECTOR ASSY, MOLEX SVC 5P

D CONNECTOR ASSY, MOLEX SVC 15P

E CONNECTOR ASSY, JST SVC 4P

XQA board

F CONNECTOR ASSY, MOLEX SVC 9P

G CONNECTOR ASSY, JST SVC 3P

H CONNECTOR ASSY, MOLEX SVC 4P

J CONNECTOR ASSY, JST SVC 6P

1-20 (E)

VPL-HW40ES

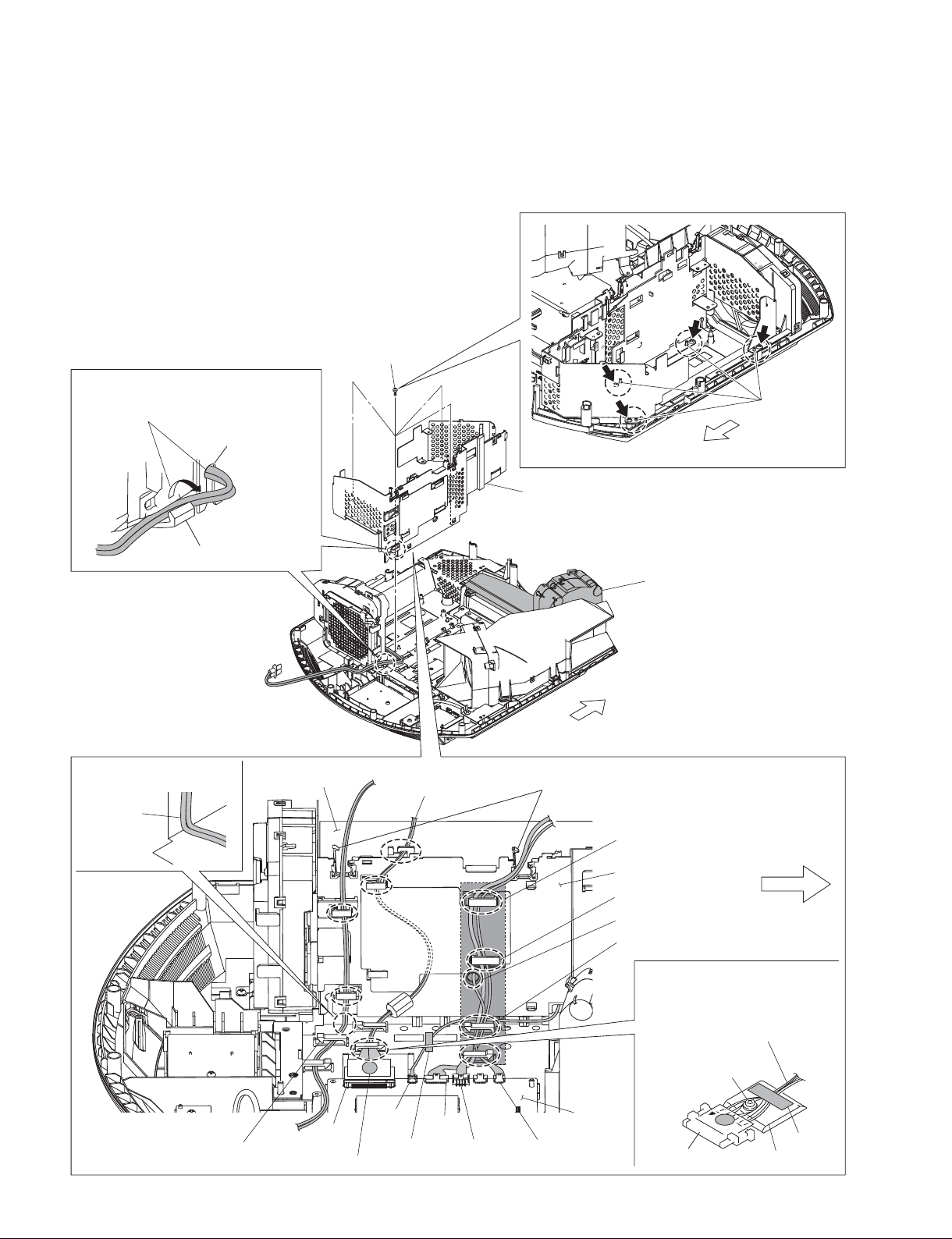

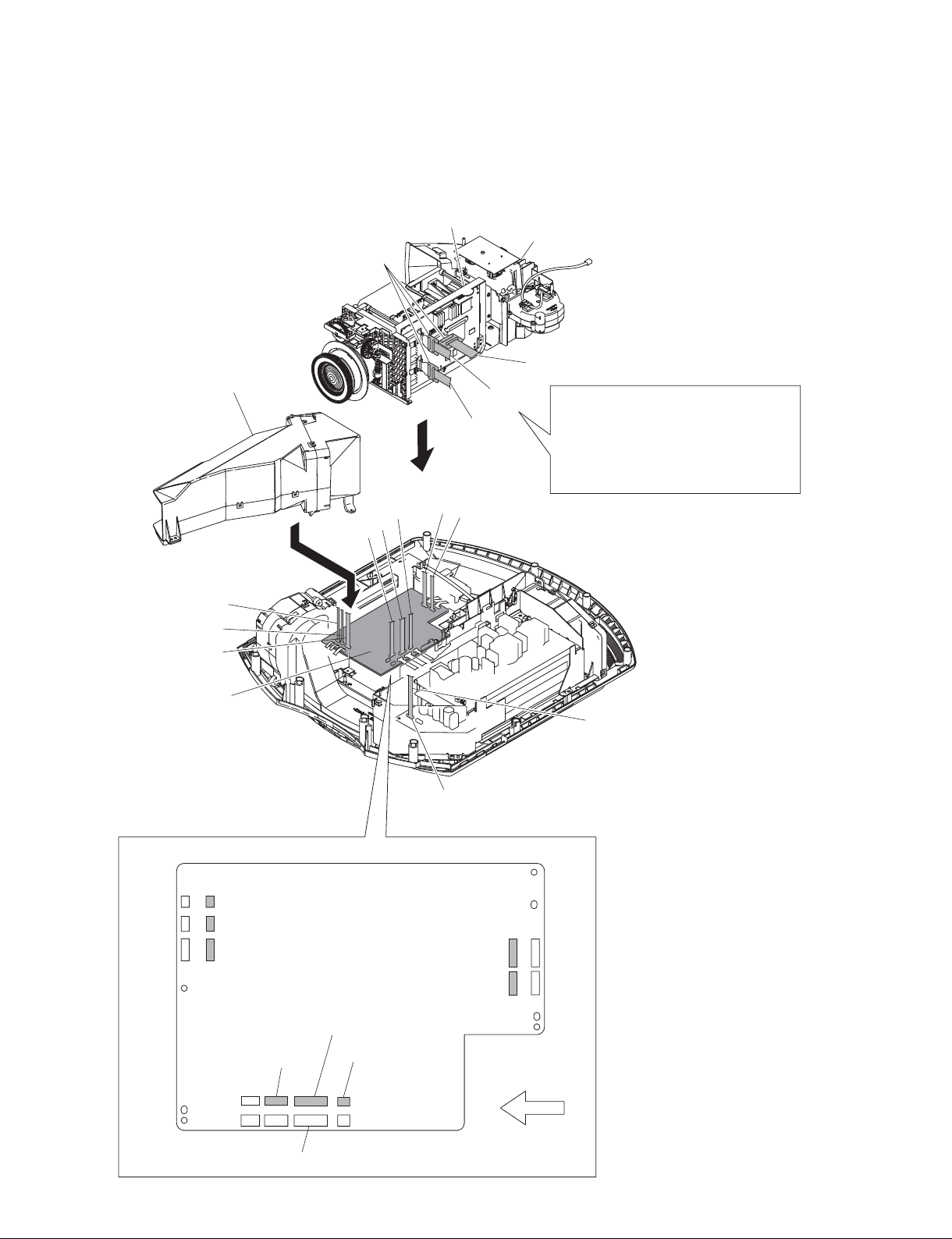

1-4-2. Connection

n

Secure the XQA board to the main unit with the two screws.

C board holder

CJ board x 3

DC fan (EX) block

I-1

A

B

E

D

C

Optical unit block

I-2

I-3

n

Do not pull or stress the 80P flexible card

wire coming from the panel on the optical

unit block.

Doing so may displace the panel and

deteriorate image quality.

CN800

CN703

H

G

F

XQA board

CN1705 HCN705

CN1800 G

CN1703 F

CN1401 E

XQA board

CN1602 D

CN1605 C

GB board

CN301

CN1801 A

CN1704 B

CN801

CN704

Front side

J

A JST service connector assembly (9P)

B MOLEX service connector assembly (10P)

C MOLEX service connector assembly (5P)

D MOLEX service connector assembly (15P)

E JST service connector assembly (4P)

F MOLEX service connector assembly (9P)

G JST service connector assembly (3P)

H MOLEX service connector assembly (4P)

I-1 Panel extension cable (80P)

I-2 Panel extension cable (80P)

I-3 Panel extension cable (80P)

J JST service connector assembly (6P)

VPL-HW40ES

CN401

CN602

CN605

1-21 (E)

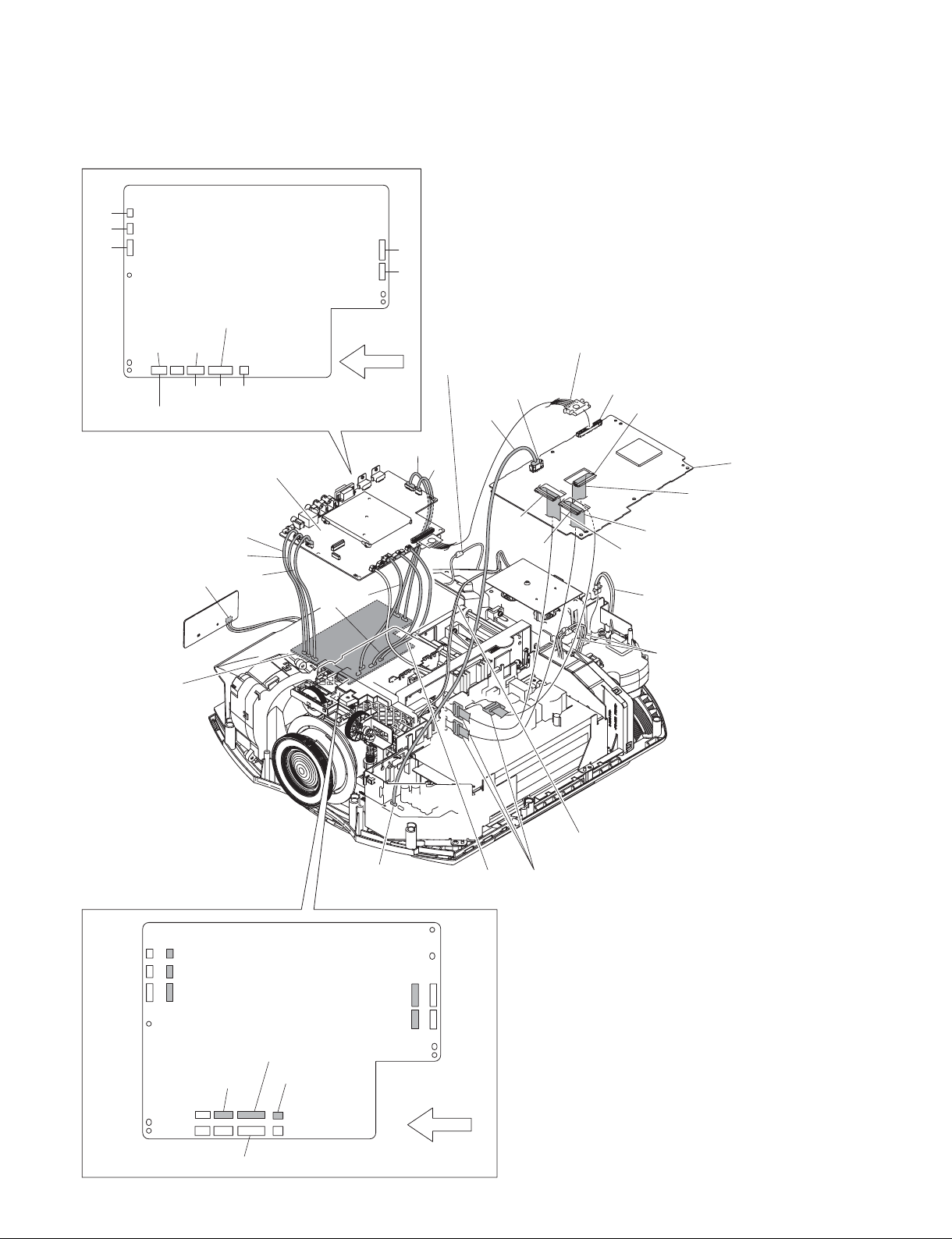

n After the connecting with the C board, QA board, and XQA board, place the C board and QA

board on the insulator and then operate.

CN701

H

CN800

G

CN702

F

QA board

CN801

CN703

A

B

CN602

CN400CN1001

Harness from the EM-11 board

HA board

CN11

XQA board

CN600

E D C

QA board

H

G

F

D

Front side

E

Fan connector

A

B

Lead wire with connector (LVDS)

CN1000

J

CN9500

CN8000

CN2000

I-3

CN9000

C board

I-2

I-1

Lamp power connector assembly

Two fan connectors

CN800

CN703

1-22 (E)

CN1705 HCN705

CN1800 G

CN1703 F

CN1401 E

CN401

CN602

XQA board

CN1602 D

CN1605 C

CN605

GB board

CN301

CN1801 A

CN1704 B

CN801

CN704

Front side

C

Fuse connector assembly

CJ board x 3

A JST service connector assembly (9P)

B MOLEX service connector assembly (10P)

C MOLEX service connector assembly (5P)

D MOLEX service connector assembly (15P)

E JST service connector assembly (4P)

F MOLEX service connector assembly (9P)

G JST service connector assembly (3P)

H MOLEX service connector assembly (4P)

I-1 Panel extension cable (80P)

I-2 Panel extension cable (80P)

I-3 Panel extension cable (80P)

J JST service connector assembly (6P)

VPL-HW40ES

Loading...

Loading...