Page 1

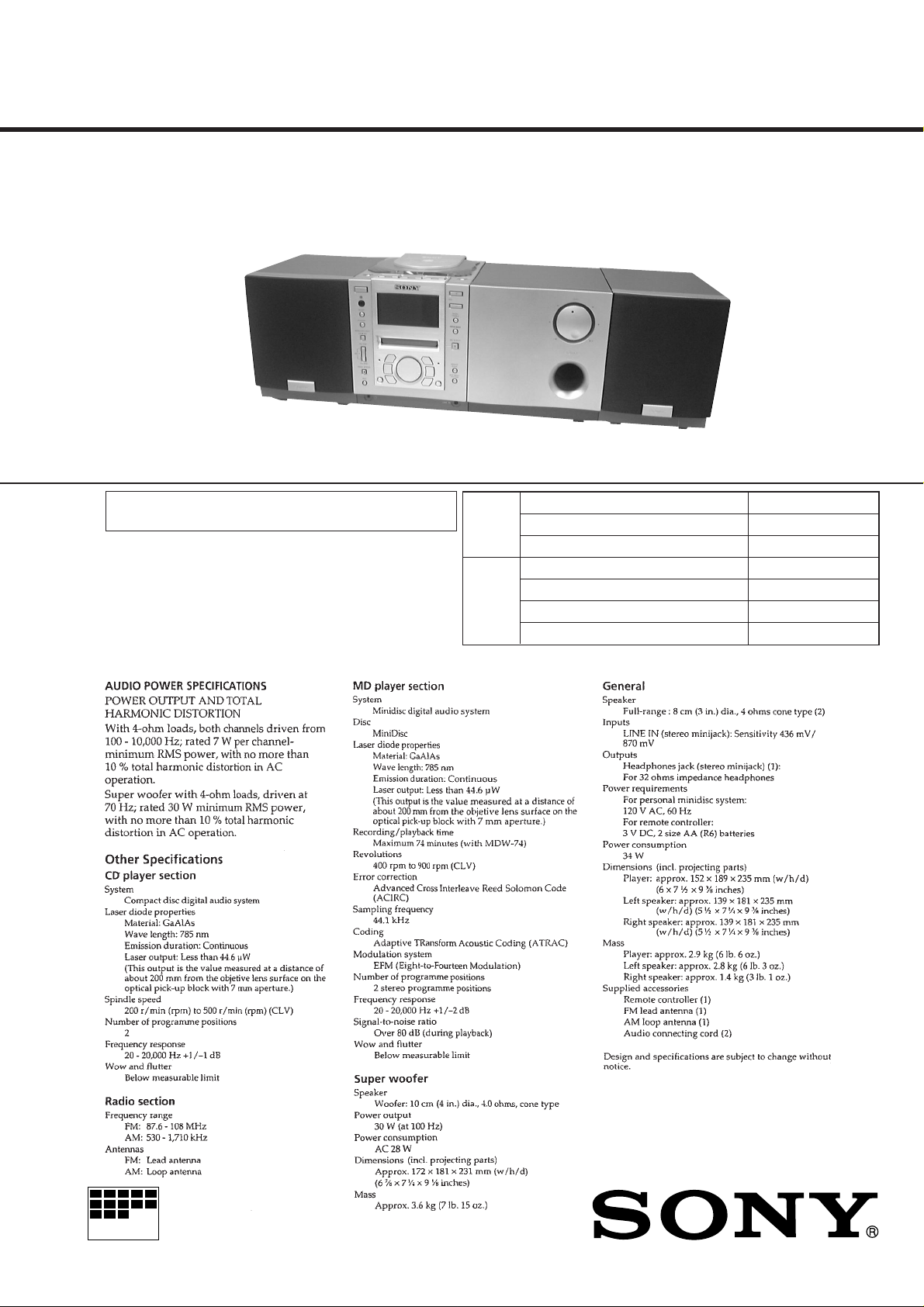

PMC-MD55

SERVICE MANUAL

Ver 1.0 1999. 06

U.S. and foreign patents licensed form Dolby Laboratories

Licensing Corporation.

CD

Section

MD

Section

US Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type KSM-213CGP

Optical Pick-up Name KSS-213C

Model Name Using Similar Mechanism MDS-JB920

MD Mechanism Type MDM-5A

Base Unit Name MBU-5A

Optical Pick-up Name KMS-260A

SPECIFICATIONS

PERSONAL

MICROFILM

MINIDISC SYSTEM

Page 2

TABLE OF CONTENTS

1. SERVICING NOTES .............................................. 3

2. GENERAL

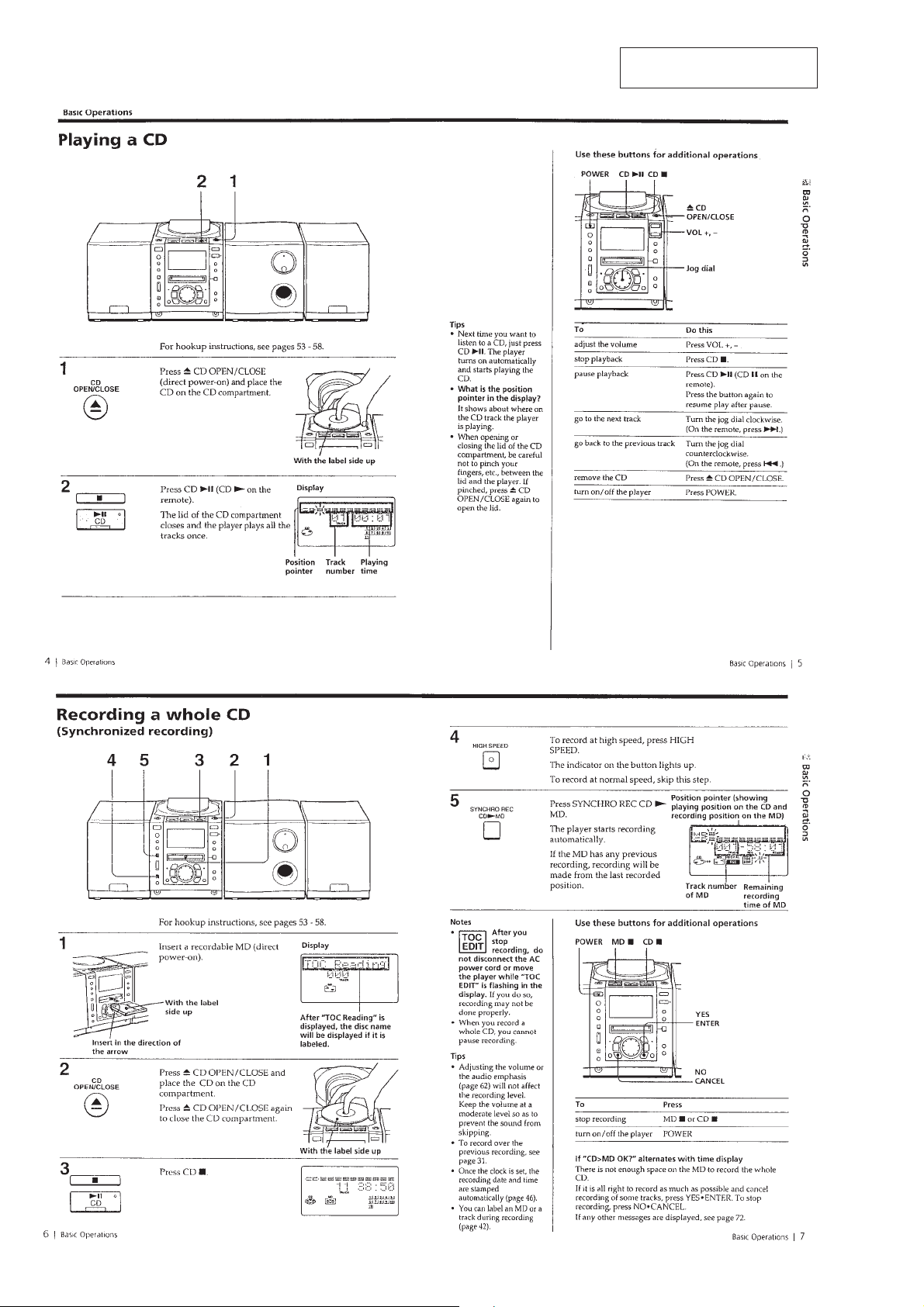

Playing a CD .................................................................. 6

Recording a Whole CD .................................................. 6

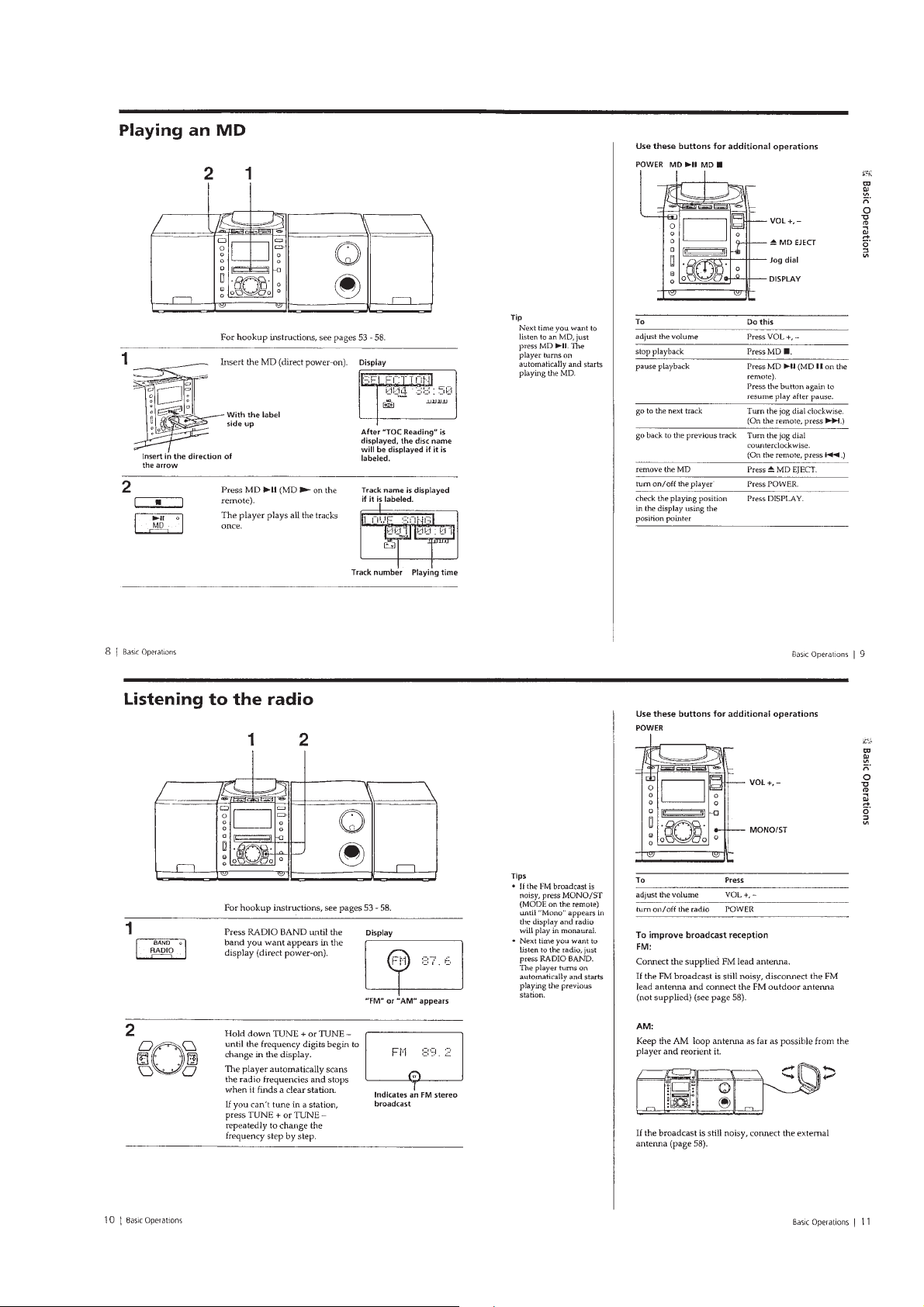

Playing an MD ............................................................... 7

Listening to the radio ..................................................... 7

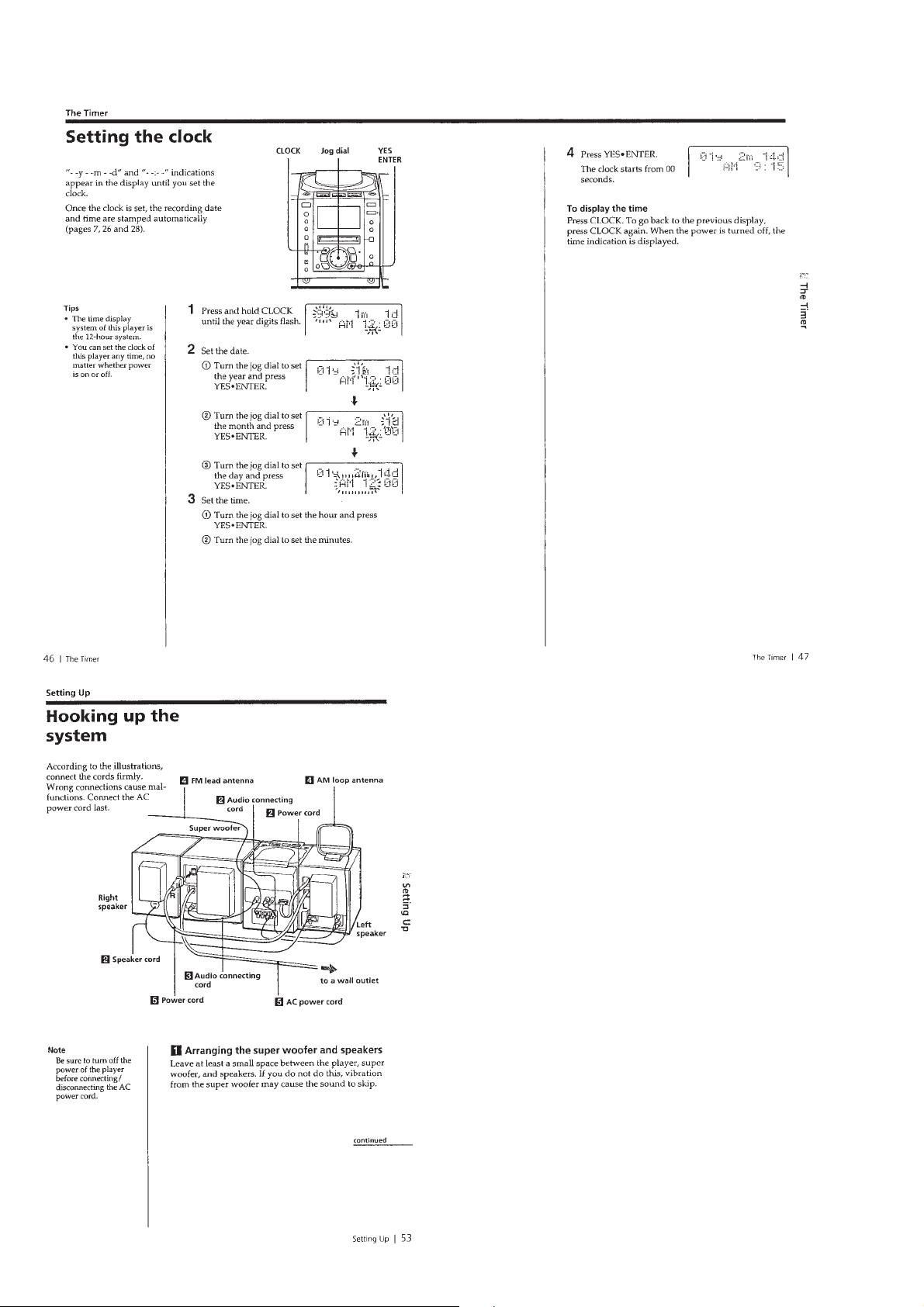

Setting the Clock ............................................................ 8

Hooking up the System.................................................. 8

3. DISASSEMBLY ........................................................ 9

4. TEST MODE............................................................. 15

5. ELECTRICAL ADJUSTMENTS

Tuner Section ................................................................. 20

MD Section .................................................................... 21

CD Section ..................................................................... 28

Display Section .............................................................. 30

6. DIAGRAMS

6-1. Block Diagram – TUNER Section – ............................ 31

6-2 Block Diagram – MD Section – ................................... 34

6-3. Block Diagram – CD Section – .................................... 37

6-4. Block Diagram

– FUNCTION SELECT/PANEL Section –................... 40

6-5. Block Diagram

– POWER AMP/POWER SUPPLY Section – .............. 43

6-6. Block Diagram – SUPER WOOFER Section – ........... 45

6-7. Printed Wiring Board – TUNER Section – .................. 49

6-8. Schematic Diagram – TUNER Section – ..................... 51

6-9. Schematic Diagram – BD Section – ............................. 53

6-10. Printed Wiring Boards – BD Section – ........................ 57

6-11. Printed Wiring Board – DG Section –.......................... 59

6-12. Schematic Diagram – DG Section –............................. 61

6-13. Printed Wiring Boards – MAIN Section – ................... 64

6-14. Schematic Diagram – MAIN (CD) Section – .............. 67

6-15. Schematic Diagram

– MAIN (SYSTEM CONTROL) Section – .................. 70

6-16. Schematic Diagram

– MAIN (FUNCTION SELECT) Section – .................. 73

6-17. Printed Wiring Board – AUDIO/JACK Section –........ 75

6-18. Schematic Diagram – AUDIO/JACK Section – .......... 77

6-19. Schematic Diagram – CD MOTOR Section – ............. 79

6-20. Printed Wiring Board – CD MOTOR Section – .......... 81

6-21. Printed Wiring Board

– CD OPEN/CLOSE Section –...................................... 82

6-22. Schematic Diagram – CD OPEN/CLOSE Section – ... 83

6-23. Printed Wiring Boards – PANEL Section – ................. 86

6-24. Schematic Diagram – PANEL Section – ...................... 89

6-25. Printed Wiring Boards

– POWER AMP/POWER Section – .............................. 91

6-26. Schematic Diagram

– POWER AMP/POWER Section – .............................. 93

6-27. Printed Wiring Boards

– SUPER WOOFER Section – ...................................... 95

6-28. Schematic Diagram

– SUPER WOOFER Section – ...................................... 97

6-29. IC Pin Function Description .......................................... 108

7. EXPLODED VIEWS ............................................... 118

8. ELECTRICAL PARTS LIST ..............................128

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMA TIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

– 2 –

Page 3

SECTION 1

SERVICING NOTES

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

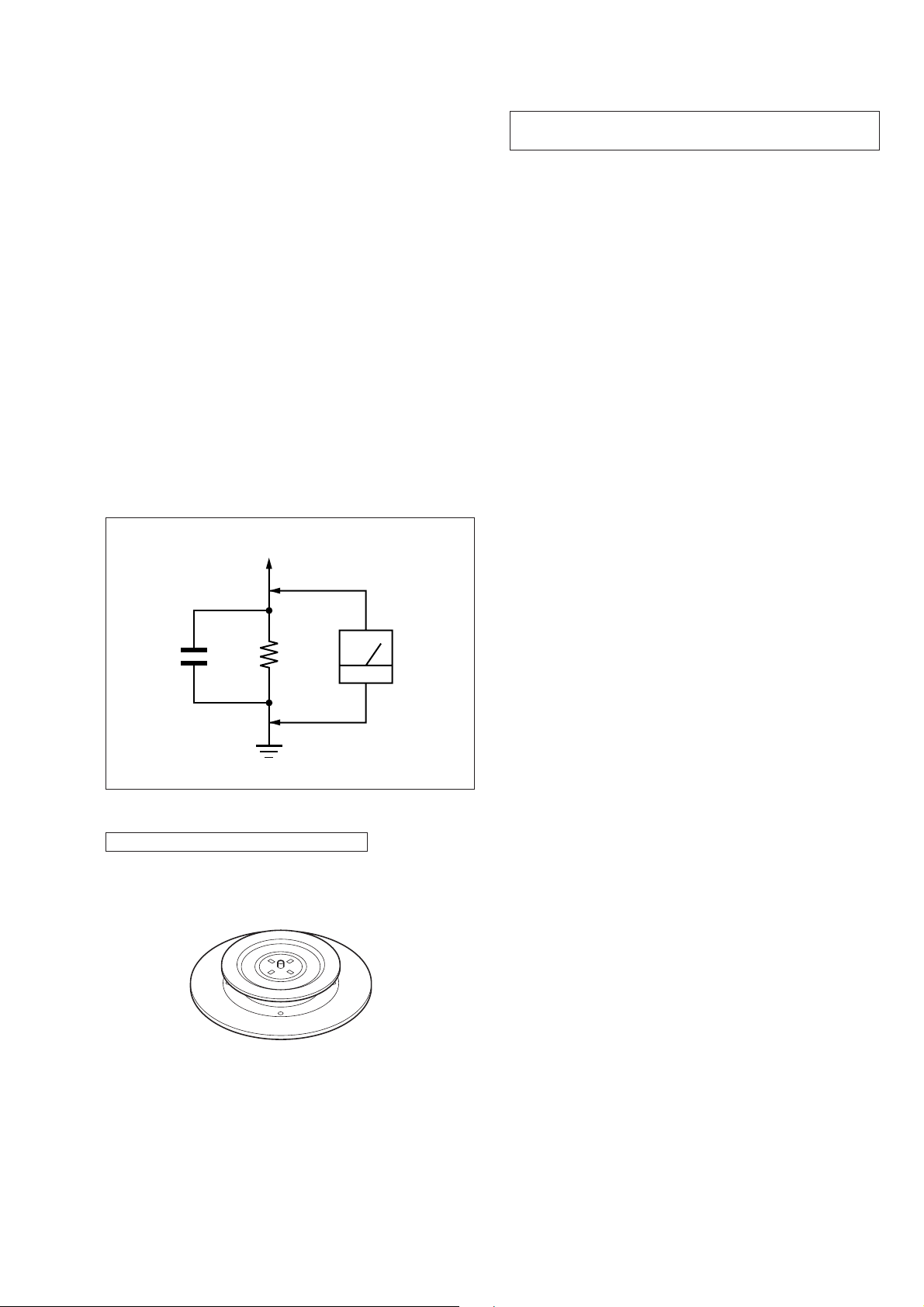

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

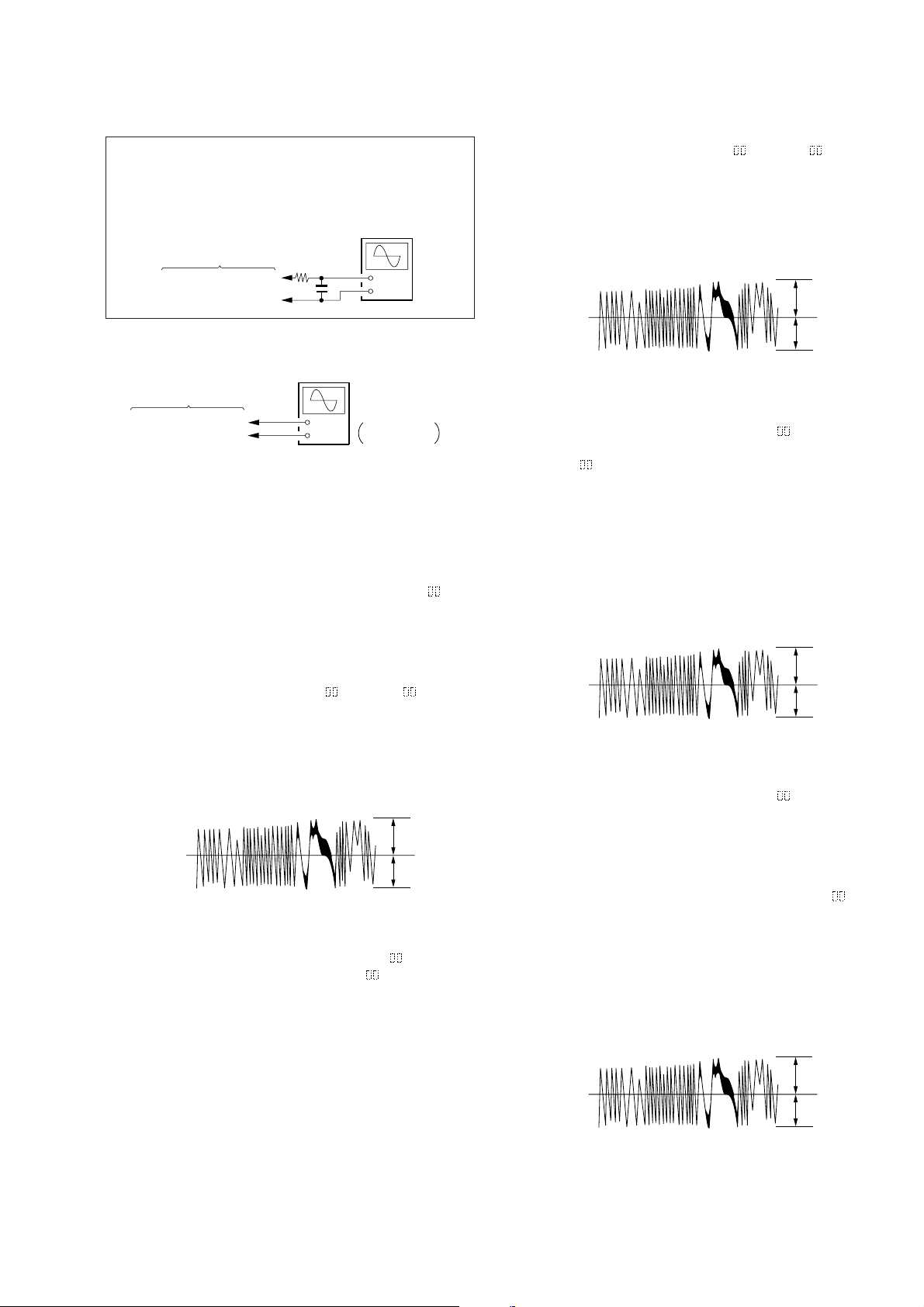

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

Ω

Earth Ground

voltmeter

(0.75 V)

– 3 –

Page 4

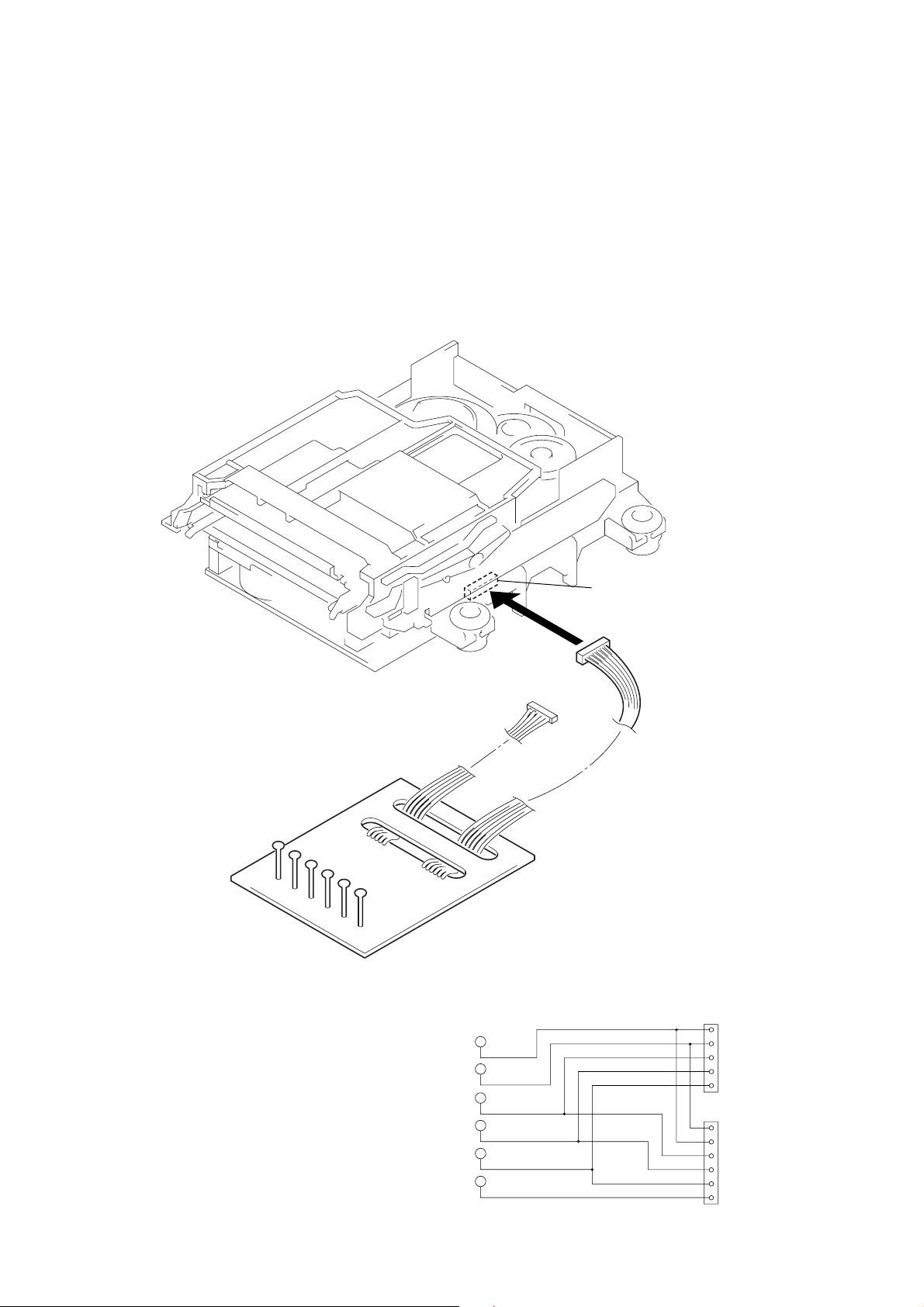

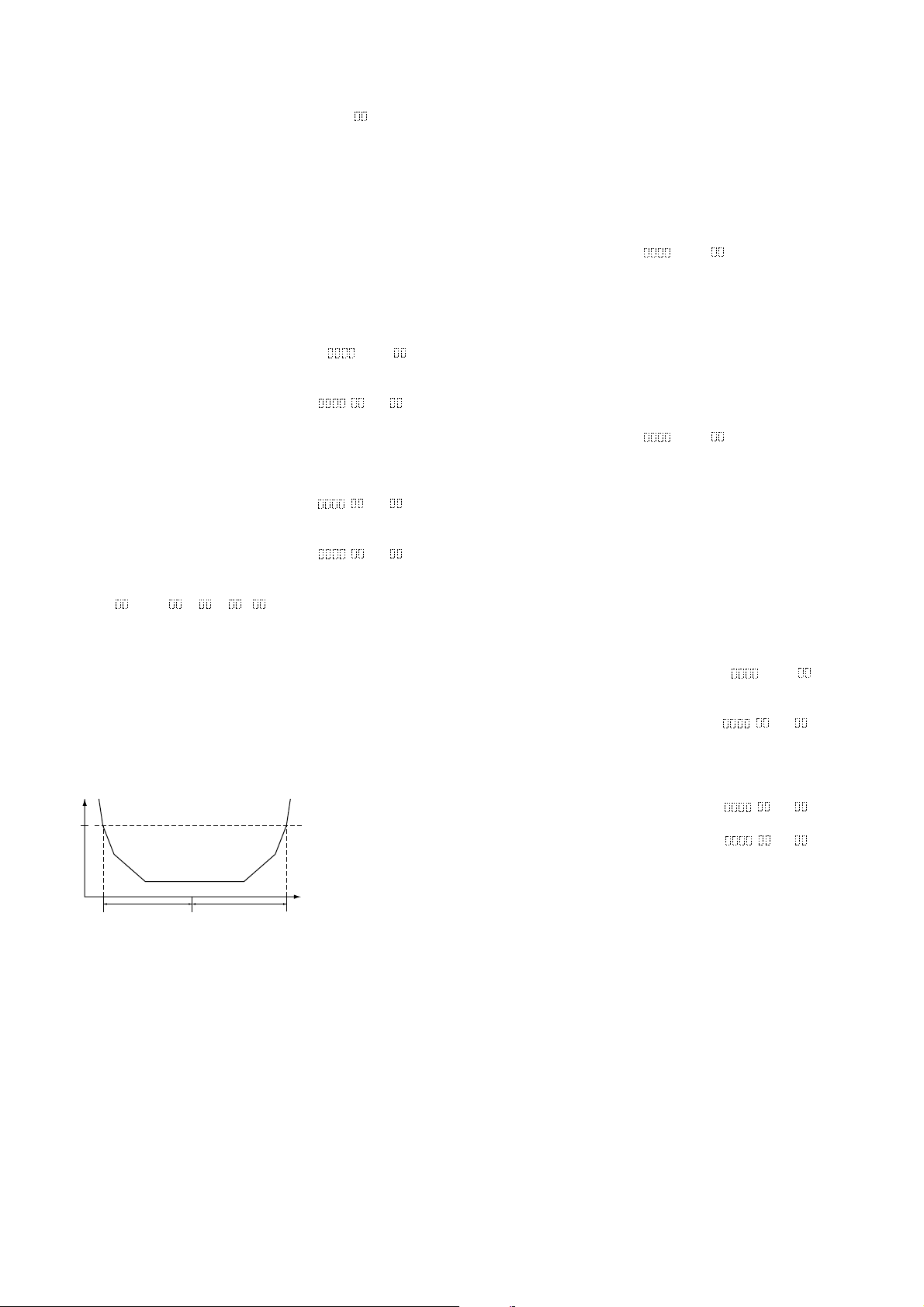

JIG FOR CHECKING BD BOARD WAVEFORM

r

The special jig (J-2501-149-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

GND: Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TEO : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

Mechanism deck

RF

VC

TEO

IOP

I+3V

GND

RF

VC

TEO

IOP

I+3V

GND

5P Connector

CN110

6P connecto

for MDM-3

1

5

for MDM-5

1

6

RF

VC

TEO

IOP

I+3V

VC

RF

TEO

IOP

I+3V

GND

– 4 –

Page 5

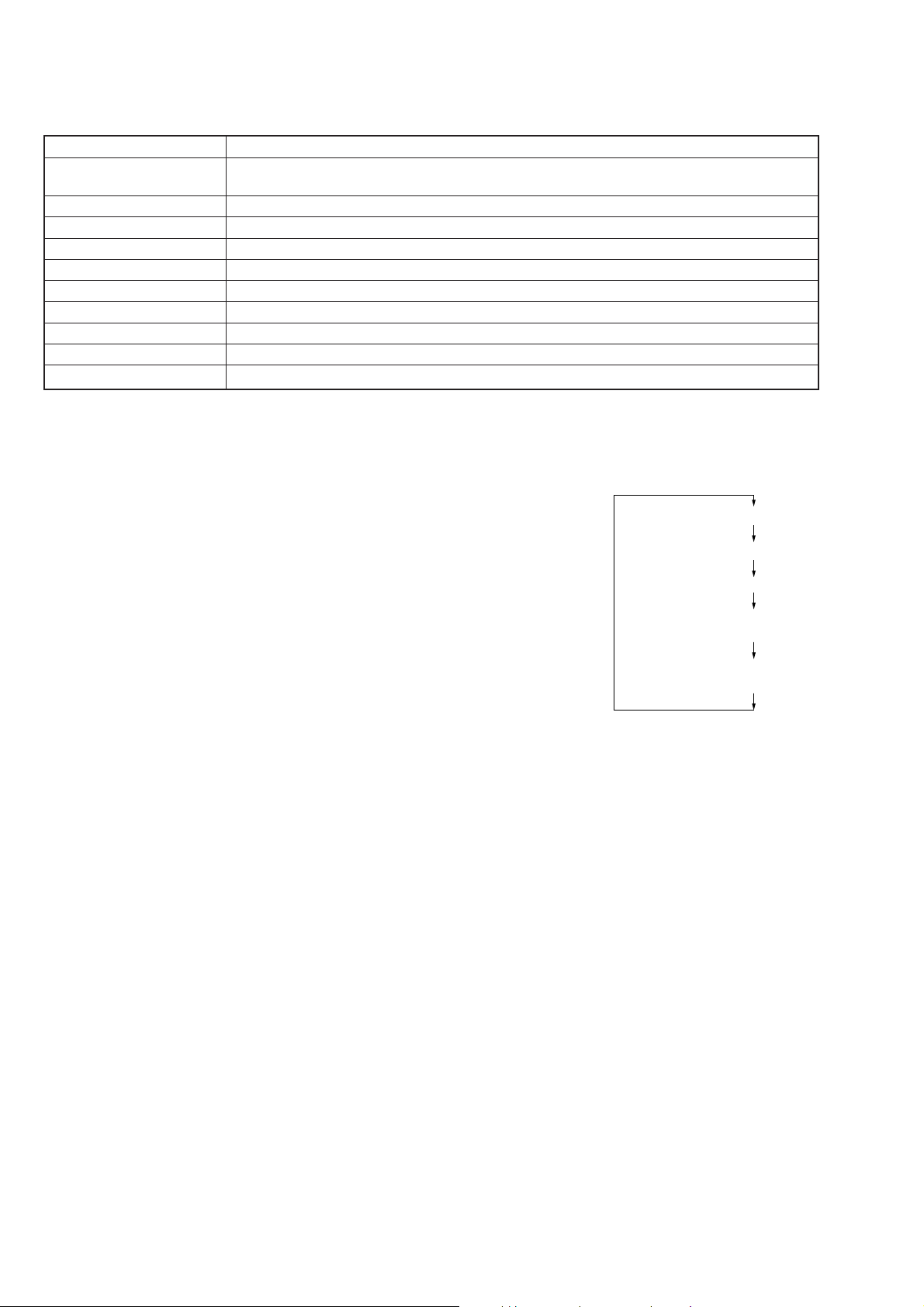

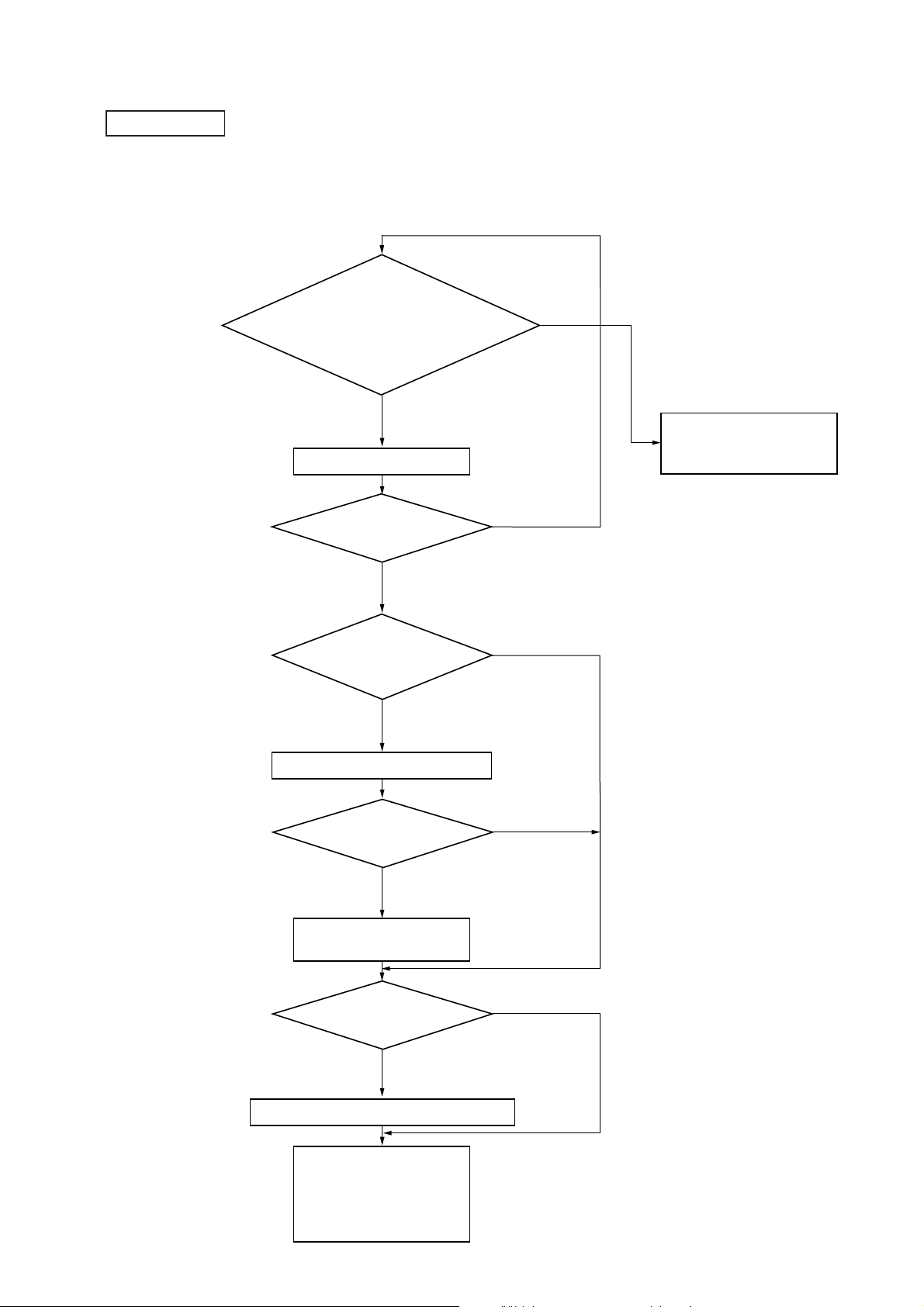

CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS (for MD Section)

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5 Electrical Adjustments”.

Laser power check

(6-1 : See page 23)

Focus bias check

(6-2 : See page 23)

C PLAY check

(6-3 : See page 23)

Self-recording/playback

check

(6-4 : See page 23)

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

• 0.9 mW power

Specified value : 0.84 to 0.92 mW

• 7.0 mW power

Specified value : 6.8 to 7.2 mW

lop (at 7mW)

• Labeled on the optical pickup

Iop value ± 10mA

• Error rate check

Specified value : For points a, b, and c

C1 error : About 200

ADER : Below 2

• Error rate check

Specified value:

a. When using test disc (MDW-74/AU-1)

C1 error : Below 80

ADER : Below 2

b. When using check disc (TDYS-1)

C1 error : Below 50

• CPLAY error rate check

Specified value:

C1 error : Below 80

ADER : Below 2

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

If always unsatisfactory:

• Replace the overwrite head

• Check for disconnection of the circuits around the

overwrite head

If occasionally unsatisfactory:

• Check if the overwrite head is distorted

• Check the mechanism around the sled

Measure if unsatisfactory:

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for

adjustments.

When performing adjustments, use the specified values for adjustments.

– 5 –

Page 6

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 6 –

Page 7

– 7 –

Page 8

– 8 –

Page 9

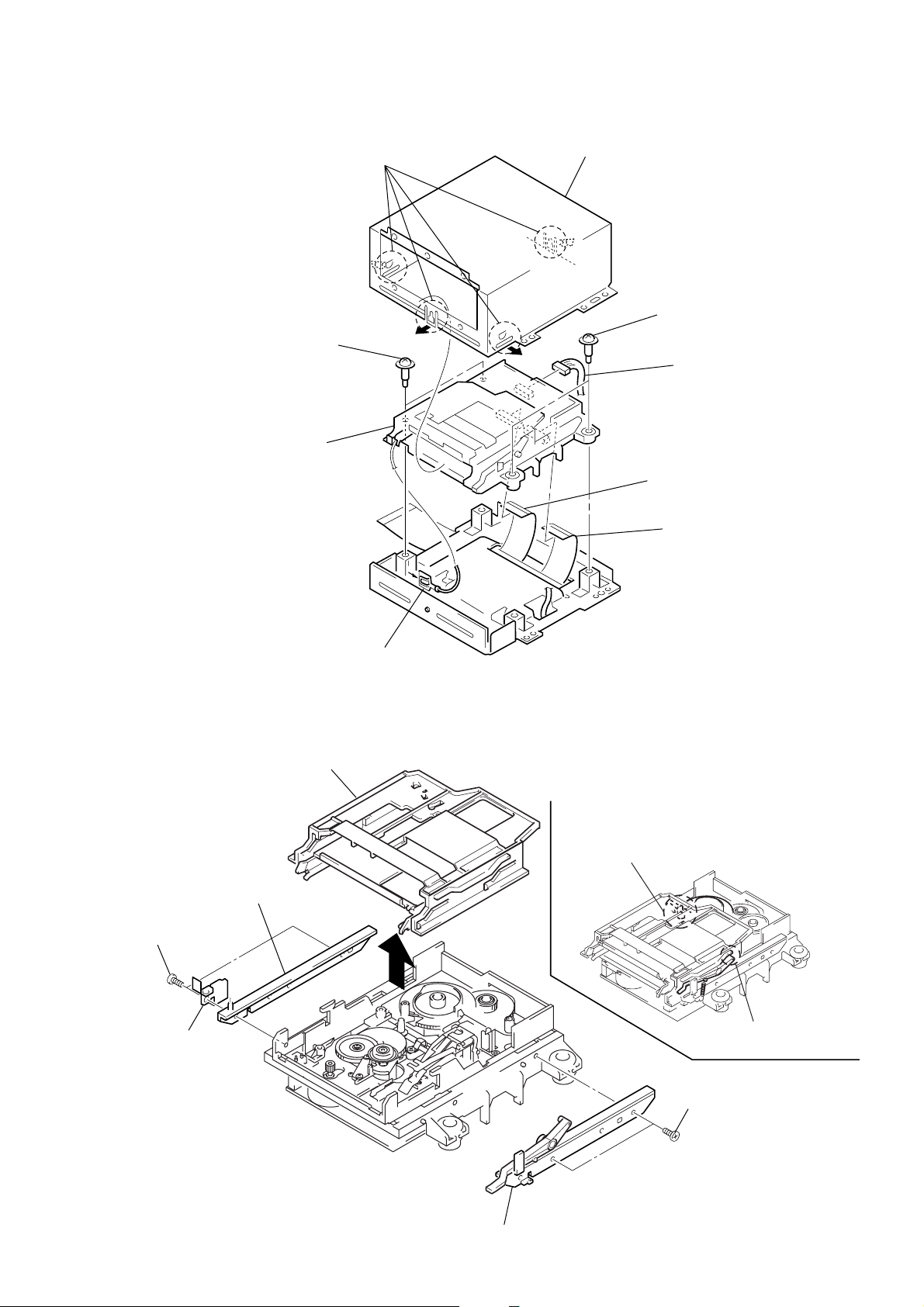

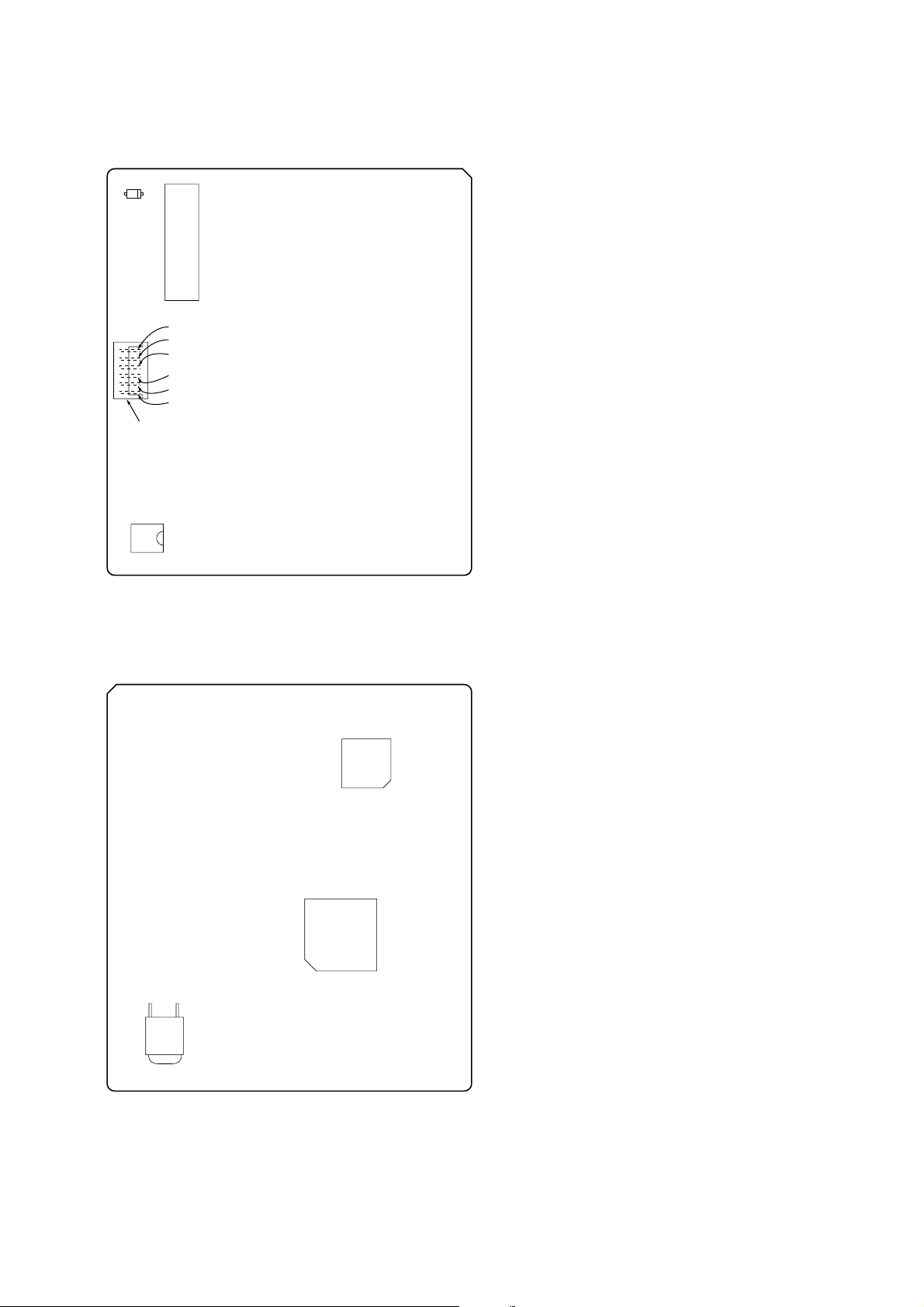

DISASSEMBLY

)

)

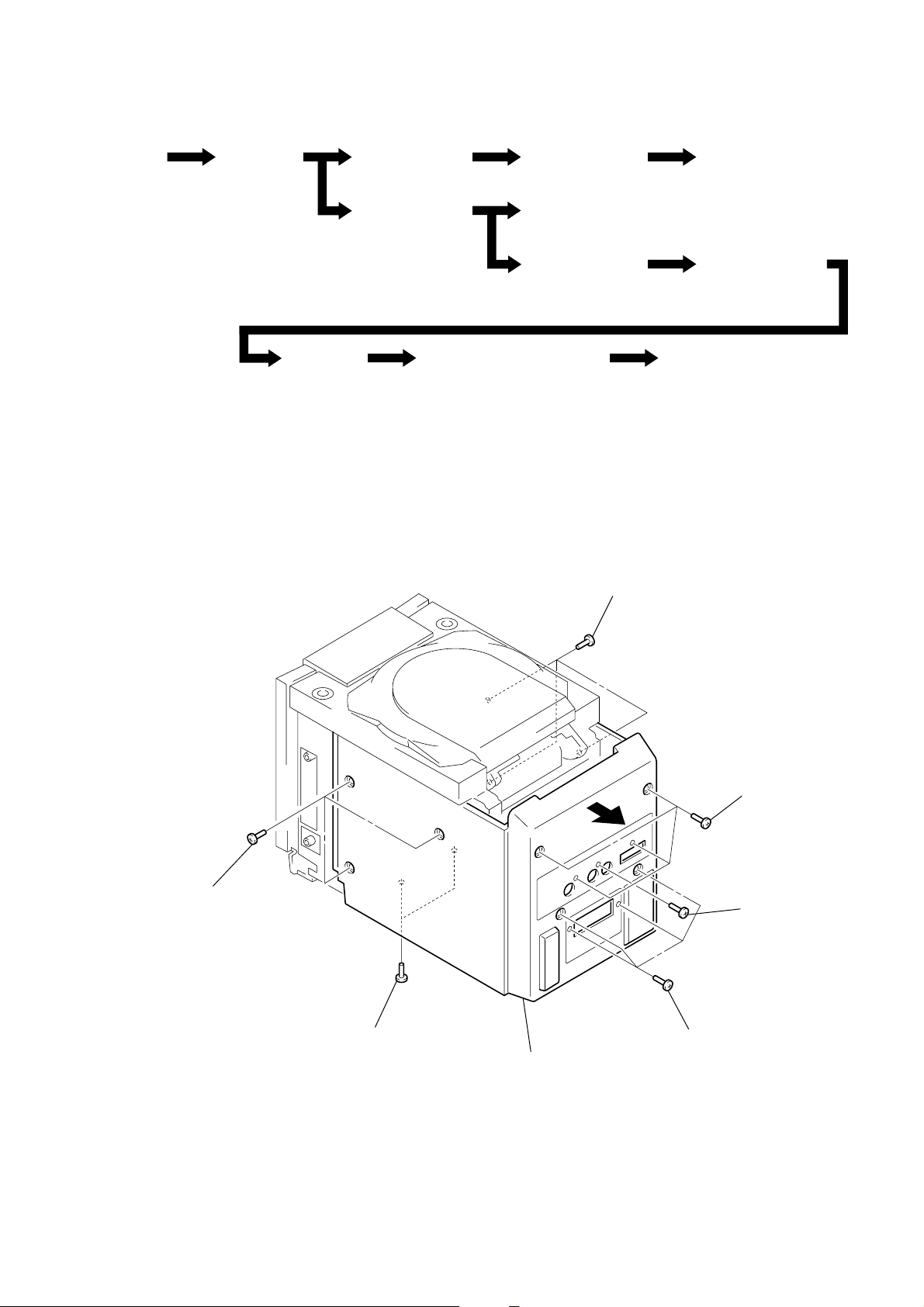

• This set can be disassembled in the order shown below.

SECTION 3

Set Rear cabinet Front cabinet block

Main board section Main board

Slider (CAM) Base unit (MBU-5A), BD board SW board, loading motor (M103)

Note: Follow the disassembly procedure in the numerical order given.

REAR CABINET

Upper cabinet block CD PICK-UP assy

TU block, MD block MD mechanism deck

1

three screws

(BTP2.6

×

8)

1

three screws

(BTP2.6

3

four screws

×

10

(BTP3

3

×

10)

screw

(BTP3

×

10

×

8)

2

two screws

×

(BVTT3

8)

4

rear cabinet

3

four screws

(BTP3

– 9 –

Page 10

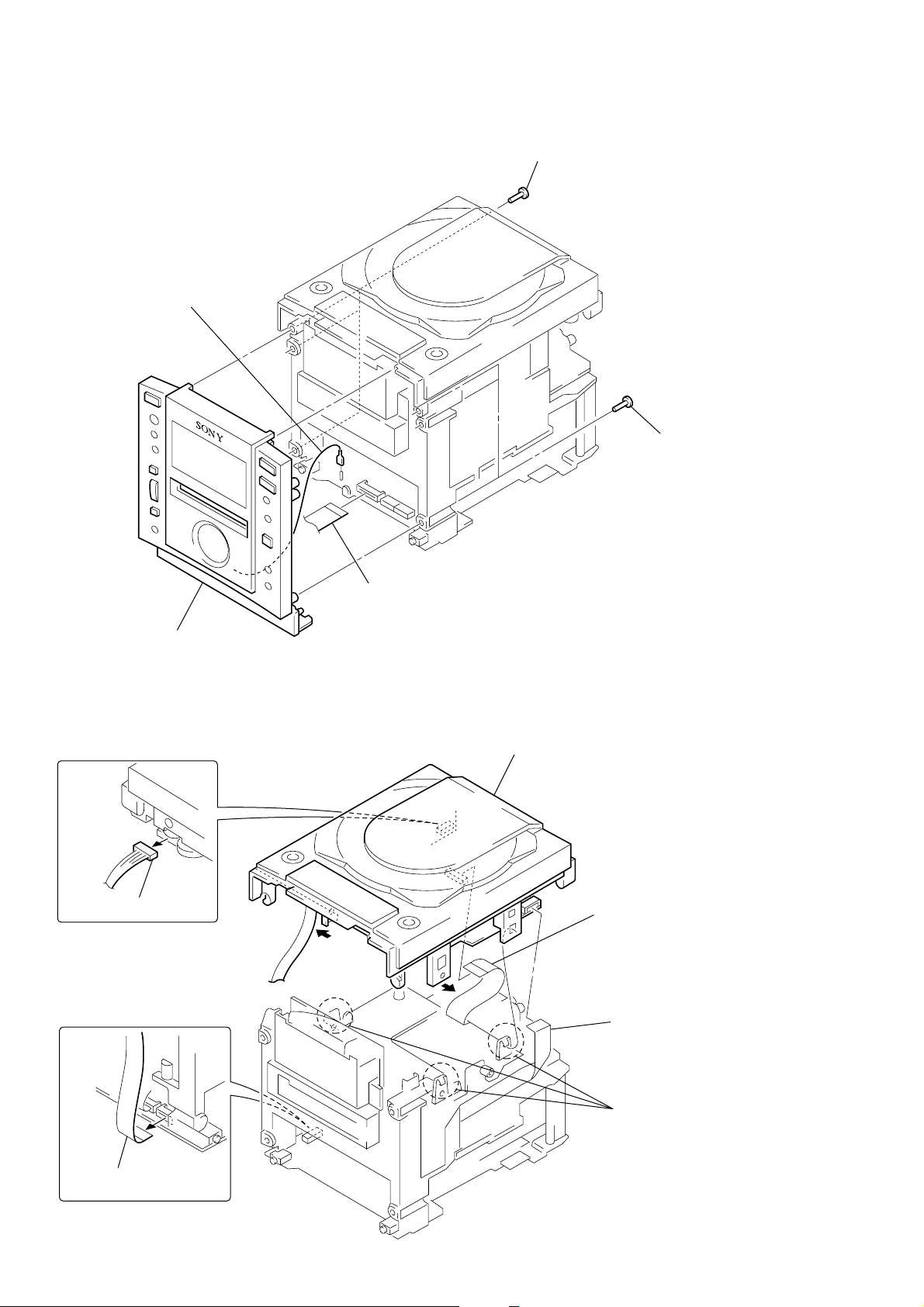

FRONT CABINET BLOCK

)

2

harness

1

three screws

(BVTP3

×

12)

1

three screws

(BVTP3

×

12

4

cabinet

(front) block

UPPER CABINET BLOCK

1

connector (CN711)

3

wire, parallel (ffc) 12P

(CN407)

3

cabinet (upper) block

1

wire, parallel (ffc) 16P

(from OPTICAL PICK-UP connector)

1

wire, parallel (ffc) 11P

(CN1001)

1

wire, parallel (ffc) 8P

(CN409)

– 10 –

2

three claws

Page 11

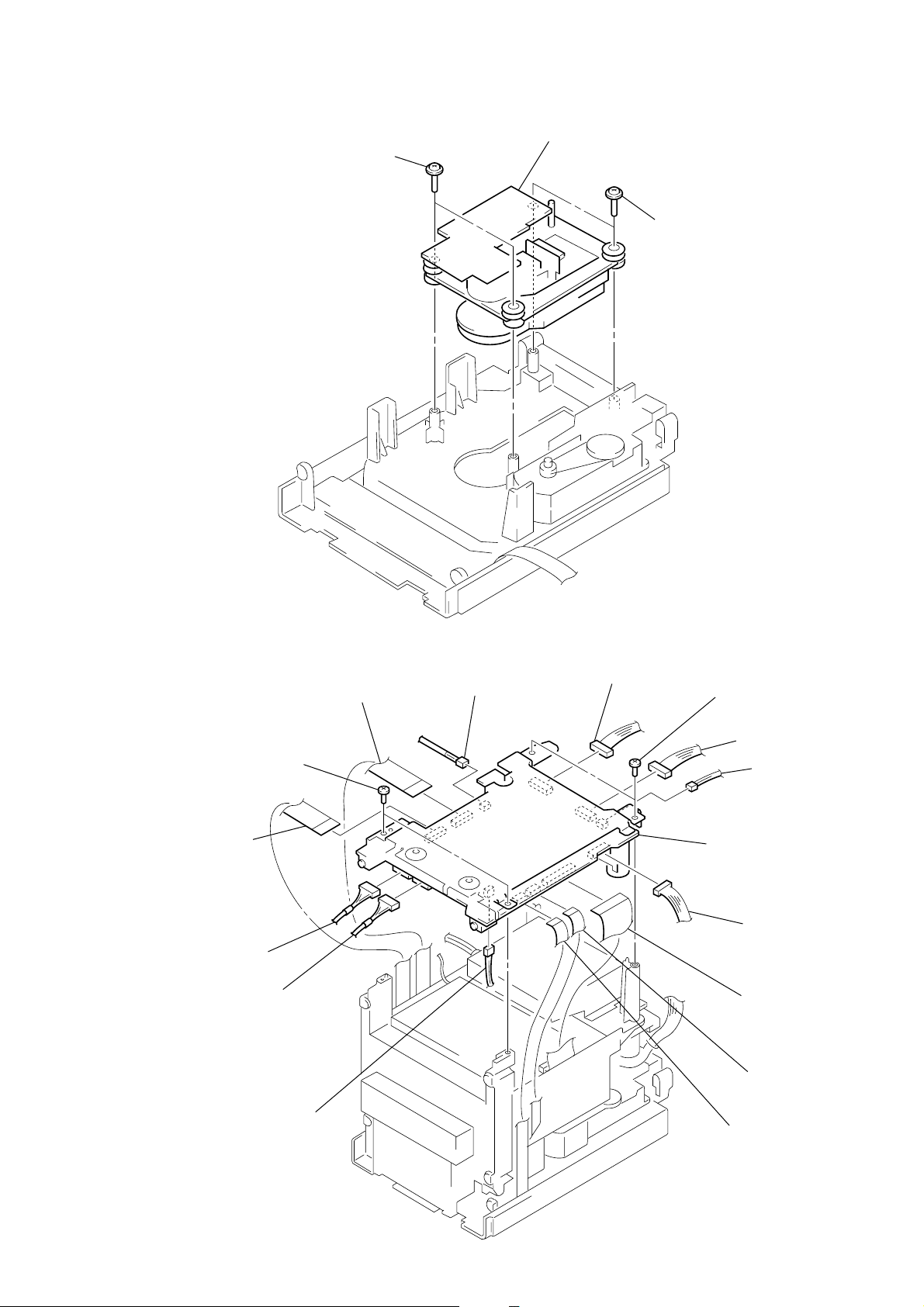

CD PICK-UP ASSY

)

P

1

two screws

(PWH2.6

×

10)

2

PICK-UP assy

1

two screws

(PWH2.6

×

10)

MAIN BOARD SECTION

3

two screws

2

wire parallel (ffc) 11P

(CN702)

1

(BVTP3

connector

(CN408)

1

connector

(CN402)

×

2

wire parallel (ffc) 16P

(CN701)

10)

1

connector

(CN704)

1

connector

(CN302)

3

two screws

(BVTP3

4

main board section

×

1

connector (CN303)

1

connector (CN401

1

connector (CN404)

2

wire parallel (ffc) 26

(CN405)

2

wire parallel (ffc) 9P

(CN406)

10)

1

connector

(CN312)

– 11 –

2

wire parallel (ffc) 8P

(CN409)

Page 12

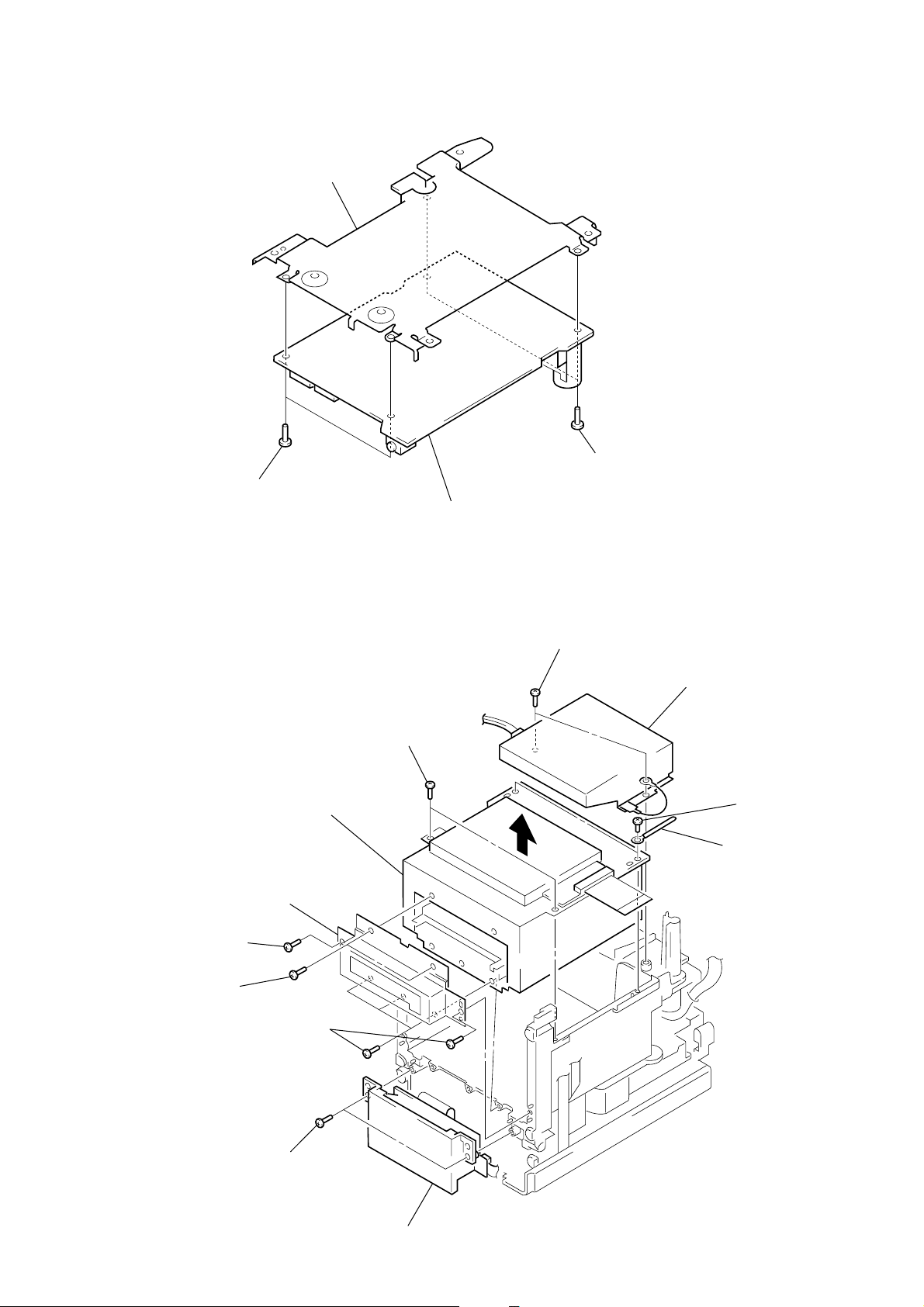

MAIN BOARD

)

shield plate (main)

1

two screws

(BVTT2.6

1

two screws

(BVTT2.6

×

6)

2

main board

×

6

TU BLOCK, MD BLOCK

3

screw

(BVTP2.6

4

two screws

(BVTT2.6

×

5

shield plate

(front)

×

8)

5)

3

four screws

(BVTP2.6

0

MD block assy

×

8)

8

two screws

(BVTP3

×

10)

6

two screws

(BVTP3

×

10)

7

TU block assy

9

8

screw

(BVTP3

harness

×

10)

1

two screws

(BVTP2.6

×

10)

2

LCD block assy

– 12 –

Page 13

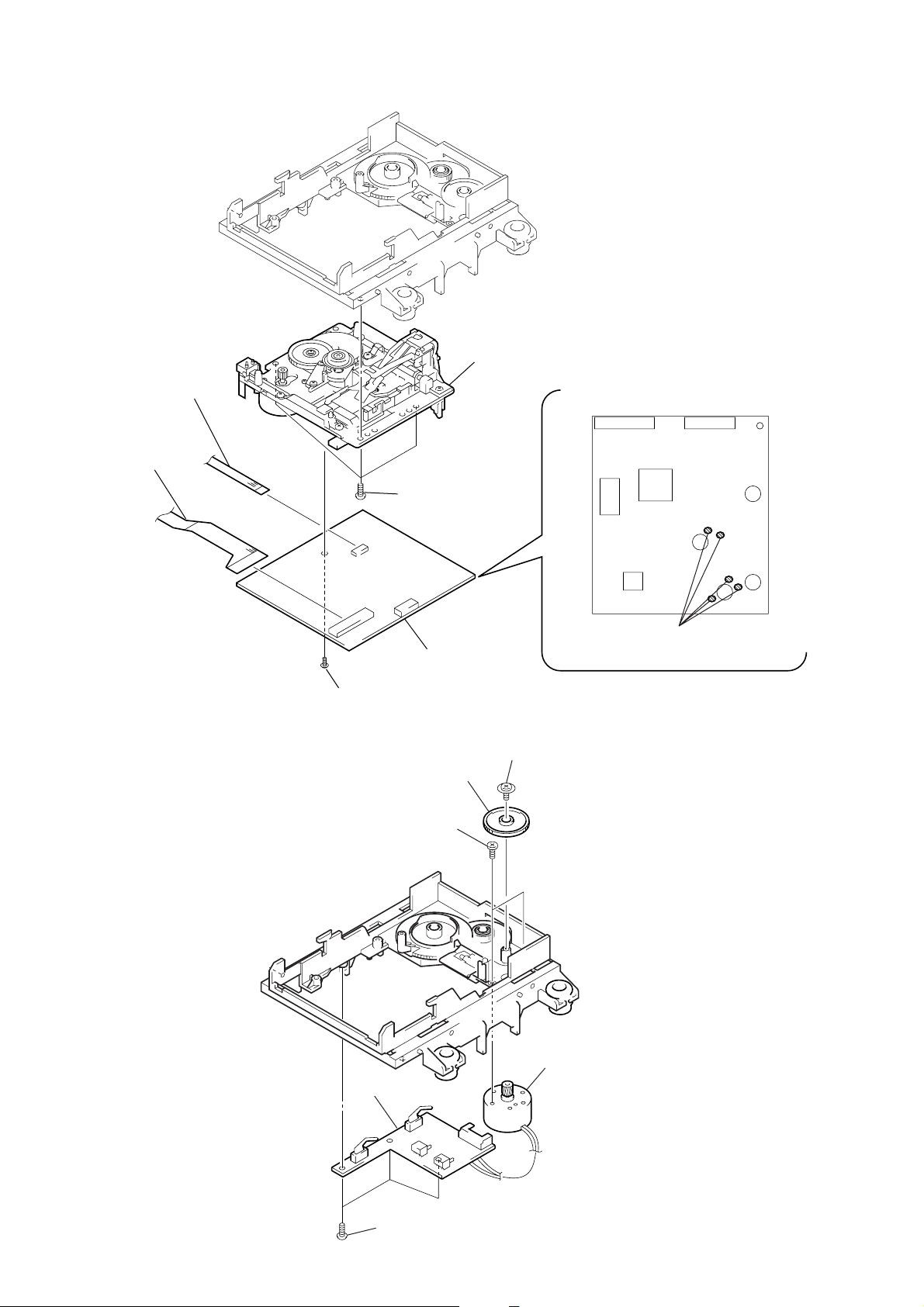

MD MECHANISM DECK

P

5

two screws

(BVTTWH M3)

7

MD mechanism deck

(MDM-5A)

1

four claws

2

shield plate (upper)

5

4

two screws

(BVTTWH M3)

3

connector

(CN601)

wire, parallel (ffc) 21P

(CN102)

4

wire, parallel (ffc) 23

(CN103)

SLIDER (CAM)

2

bracket (Guide L)

1

two screws (P2.6 × 6)

3

leaf spring

6

slider (Cam)

6

harness

• Note for Installation of Slider A (Cam)

Set the shaft of Cam gear to

be at the position in the figure.

Set the shaft of Lever (O/C) to

be at the position in the figure.

4

two screws (P2.6 × 6)

5

bracket (Guide R)

– 13 –

Page 14

BASE UNIT (MBU-5A), BD BOARD

5

flexible board

(CN104)

6

flexible board

(CN101)

2

1

three screws

(P2.6

base unit (MBU-5A)

×

6)

SW BOARD, LOADING MOTOR (M103)

4

screw (M1.7 × 4)

3

two screws

(PWH1.7

7

BD board

2

×

gear B

4)

3

Remove the solder (Five portion).

1

screw (PTPWH M2.6 × 6)

4

loading motor (M103)

6

SW board

5

three screws (BTP2.6 × 6)

– 14 –

Page 15

SECTION 4

TEST MODE

Refer to “5. ELECTRICAL ADJUSTMENT” for the test mode of CD section.

MD SECTION

1. PRECAUTIONS FOR USE OF TEST MODE

• As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc

is stopped before setting and removing it.

Even if the [MDEJECT] button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc

will not stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the [MDEJECT] button after pressing the [NO,CANCEL] button and the rotation of disc is stopped.

1-1. Recording laser emission mode and operating buttons

• Continuous recording mode (CREC MODE)

• Laser power check mode (LDPWR CHECK)

• Laser power adjustment mode (LDPWR ADJUST)

• When pressing the [REC] button.

2. SETTING THE TEST MODE

1. Set to standby state.

2. While pressing the both [BASS/TREBLE] and [EDIT] buttons, press the button [,MD] n π (MD) n [,MD] n π (MD).

3. Release the both [BASS/TREBLE] and [EDIT] buttons to enter the MD test mode.

3. RELEASING THE TEST MODE

Press the [POWER] button to turn the power OFF, or press the [RESET] (bottom of the player unit) switch.

6

6

flfl

[]

[]

4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the JOG dial, [YES,ENTER] button, and [NO,CANCEL] button.

The functions of these buttons are as follows.

Function name Function

JOG dial Changes parameters and modes

YES, ENTER button Proceeds onto the next step. Finalizes input.

NO, CANCEL button Returns to previous step. Stops operations.

– 15 –

Page 16

5. SELECTING THE TEST MODE

There are 9 types of test modes as shown below. The groups can be switched by turning the JOG dial. After selecting the g roup to be used,

press the [YES,ENTER] button. After setting a certain group, turn the JOG dial switches between these modes.

Display

TEMP ADJUST

LDPWR ADJUST

LDPWR CHECK

EFBAL ADJUST

FBIAS ADJUST

FBIAS CHECK

CPLAY MODE

CREC MODE

EEP MODE

• For details of each adjustment mode, refer to “5. Electrical Adjustments”.

• If a different mode has been selected by mistake, press the [NO,CANCEL] button to release that mode.

• EEP MODE is not used for servicing and therefore are not described in detail. If these modes are set accidentally , press the [NO,CANCEL]

button to release the mode immediately. Be especially careful this mode will overwrite the non-volatile memory and reset it, and as a

result, the unit will not operate normally.

Temperature compensation offset adjustment

Laser power adjustment

Laser power check

EF balance adjustment

Focus bias adjustment

Focus bias check

Continuous playback mode

Continuous recording mode

Non-volatile memory control

Contents

– 16 –

Page 17

5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

(1) Set the disc in the unit. (Whichever recordable discs or discs for playback only are available)

(2) Turn the JOG dial and display “CPLAY MODE”.

(3) Press the [YES,ENTER] button to change the display to “CPLAY MID”.

(4) When access completes, the display changes to “C1 = AD = ”.

Note: The numbers “ ” displayed show you error rates and ADER.

2. Changing the parts to be played back

(1) Press the [YES,ENTER] button during continuous playback to change the display as below.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

When pressed another time, the parts to be played back can be moved.

(2) When access completes, the display changes to “C1 = AD = ”.

Note: The numbers “ ” displayed show you error rates and ADER.

3. Ending the continuous playback mode

(1) Press the [NO,CANCEL] button. The display will change to “CPLAY MODE”.

(2) Press the [MDEJECT] button and take out the disc.

Note: The playback start addresses for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

5-2. Operating the Continuous Recording Mode (Use only when performing self-recording/palyback check)

1. Entering the continuous recording mode

(1) Set a recordable disc in the unit.

(2) Turn the JOG dial and display “CREC MODE”.

(3) Press the [YES,ENTER] button to change the display to “CREC MID”.

(4) When access completes, the display changes to “CREC ( )” and “[REC]” lights up.

Note: The numbers “ ” displayed shows you the recording position addresses.

2. Changing the parts to be recorded

(1) When the [YES,ENTER] button is pressed during continuous recording, the display changes as below.

“CREC MID” n “CREC OUT” n “CREC IN”

6

When pressed another time, the parts to be recorded can be changed. “

(2) When access completes, the display changes to “CREC ( )” and “[REC]” lights up.

Note: The numbers “ ” displayed shows you the recording position addresses.

3. Ending the continuous recording mode

(1) Press the [NO,CANCEL] button. The display changes to “CREC MODE” and “[REC]” goes off.

(2) Press the [MDEJECT] button and take out the disc.

Note 1: The recording start addresses for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

Note 2: The [NO,CANCEL] button can be used to stop recording anytime.

Note 3: Do not perform continuous recording for long periods of time above 5 minutes.

Note 4: During continuous recording, be careful not to apply vibration.

5-3. Non-Volatile Memory Mode (EEP MODE)

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If the unit entered this mode accidentally, press the [NO,CANCEL] button immediately to release it.

6

[REC]” goes off.

– 17 –

Page 18

6. FUNCTIONS OF OTHER BUTTONS

Function

fl, MD and EDIT

π (MD) and EDIT

)

0

REC and EDIT

SYNCHRO REC and EDIT

AUTO PRESET and EDIT

DISPLAY

MD EJECT 6

POWER or RESET

Sets continuous playback when pressed in the STOP state. When pressed during continuous playback,

the tracking servo turns ON/OFF.

Stops continuous playback and continuous recording.

The sled moves to the outer circumference only when this is pressed.

The sled moves to the inner circumference only when this is pressed.

When pressed during continuous playback, REC ON/OFF.

Switches between the pit and groove modes when pressed.

When pressed during continuous playback, switches the spindle servo mode (CLV-S ˜ CLV-A).

Switches the displayed contents each time the button is pressed

Ejects the disc

Releases the test mode

Contents

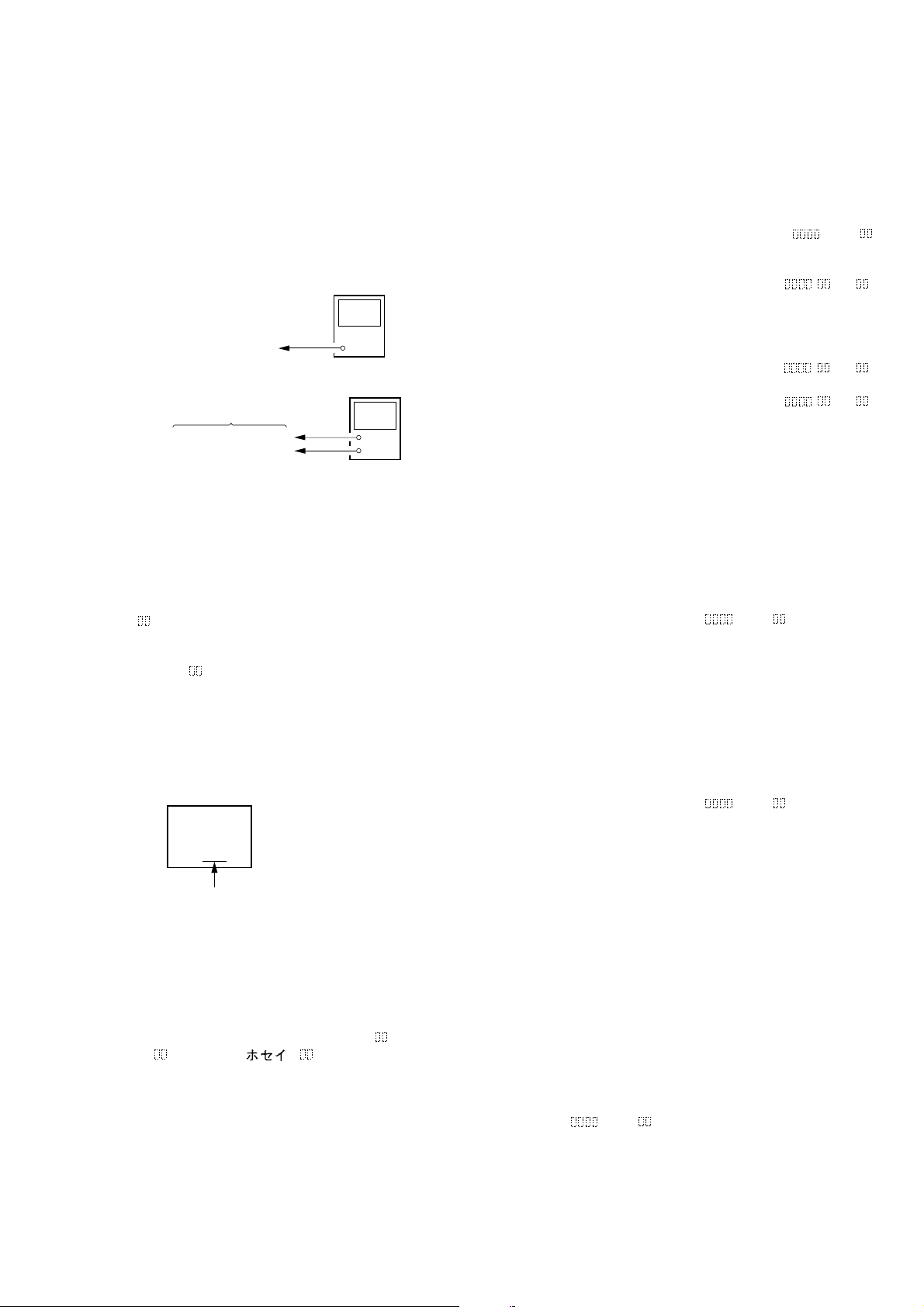

7. TEST MODE DISPLAYS

Each time the [DISPLAY] button is pressed, the display changes in the following order.

1. Mode display

Displays “TEMP ADJUST”, “CPLAYMODE”, etc.

2. Error rate display

Displays the error rate in the following way.

C1 = ππππ AD = ππ

C1 = Indicates the C1 error.

AD = Indicates ADER.

Mode display

Error rate display

Address display

3. Address display

The address is displayed as follows. (MO: recordable disc, CD: playback only disc)

Press the

h = ππππ s = ππππ (MO pit and CD)

h = ππππ a = ππππ (MO groove)

h = Indicates the header address.

s = Indicates the SUBQ address.

a = Indicates the ADIP address.

Note: “–” is displayed when servo is not imposed.

4. Auto gain display (Not used in servicing)

The auto gain is displayed as follows.

AG F = ππ T = ππ

5. IVR display (Not used in servicing)

The IVR is displayed as follows.

[ππ][ππ][ππ]

[SCROLL] button to switches between the groove display and pit display.

Auto gain display

(Not used in servicing)

IVR display

(Not used in servicing)

– 18 –

Page 19

MEANINGS OF OTHER DISPLAYS

Display

SHUF

PGM

[REC]

TOC EDIT

DIGITAL

TRACK

MD disc mark

DA TE

t

When Lit

During continuous playback (CLV: ON)

Tracking servo OFF

Recording mode ON

ABCD adjustment completed

Foucs and tracking auto gain OK

Pit

High reflection

CLV-S

CLV LOCK

Contents

When Off

STOP (CLV: OFF)

Tracking servo ON

Recording mode OFF

Blink: Focus auto gain OK,

Tracking auto gain NG

Groove

Low reflection

CLV-A

CLV UNLOCK

– 19 –

Page 20

SECTION 5

r

r

k

ELECTRICAL ADJUSTMENTS

TUNER SECTION 0 dB=1 µV

[AM]

Setting:

Function : RADIO

BAND switch: AM

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

Output level: as low as possible

[FM]

Setting:

Function : RADIO

BAND switch : FM

MONO/ST switch: stereo

FM RF signal

generator

75 kHz frequency

deviation by 1 kHz

signal

Output level: as low as possible

Put the lead-wire

antenna close to

the set.

set

TU board

µ

F

TP (FM+)

set

TU board

TP (FM–)

0.01

level mete

32 Ω

+

–

2

(headphone) jack

level mete

32 Ω

+

–

2

(headphone) jac

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter

T1 450 kHz

AM VT VOLTAGE CONFIRMATION

Adjustment Part Frequency Display Reading on Digital Voltmeter

Confirmation 530 kHz 0.7 V

Confirmation 1,710 kHz 5 ± 1 V

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L4 620 kHz

CT2 1,400 kHz

FM VT VOLTAGE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

L2 108 MHz 4.2 ± 0.2 V

Confirmation 87.5 MHz 1.9 V

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L1 87.5 MHz

CT1 108 MHz

+ 0.8

– 0.3

+ 0.2

– 0.4

digital voltmeter

TU board

TP (CV)

TP (FM–)

100 kΩ

• Repeat the procedures in each adjustment several times, and the

tracking adjustments should be finally done by the trimmer capacitors.

Adjustment Location:

– TU BOARD (Component Side) –

FM tracking

Adjustment

L2

FM VT Voltage Adjustment

T1

AM IF Adjustment

CT1

L1

L4 CT2

AM Tracking

Adjustment

– TU BOARD (Conductor Side) –

TB1

TP (FM+)

TP (CV)

TP (FM–)

IC1

– 20 –

Page 21

MD SECTION

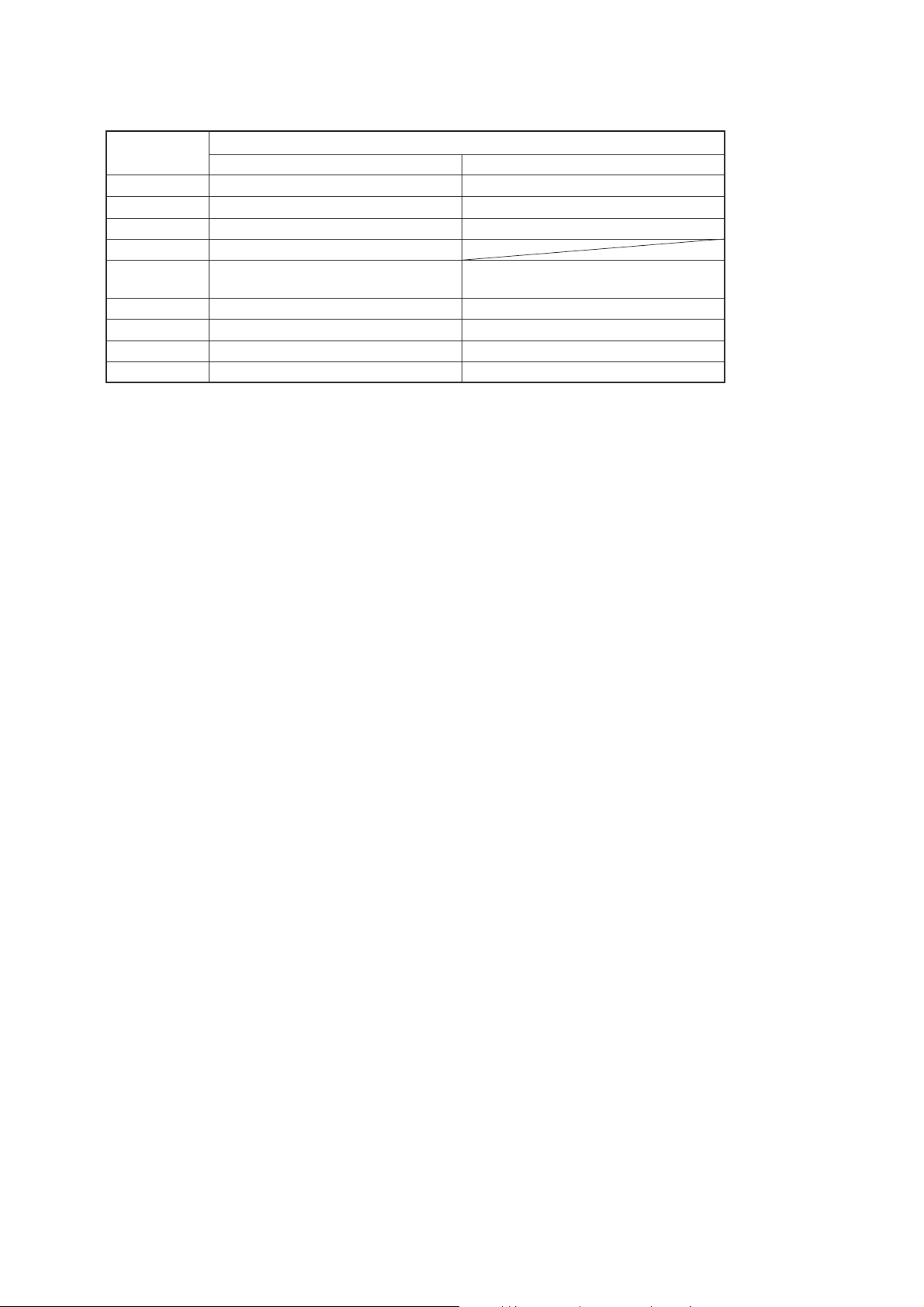

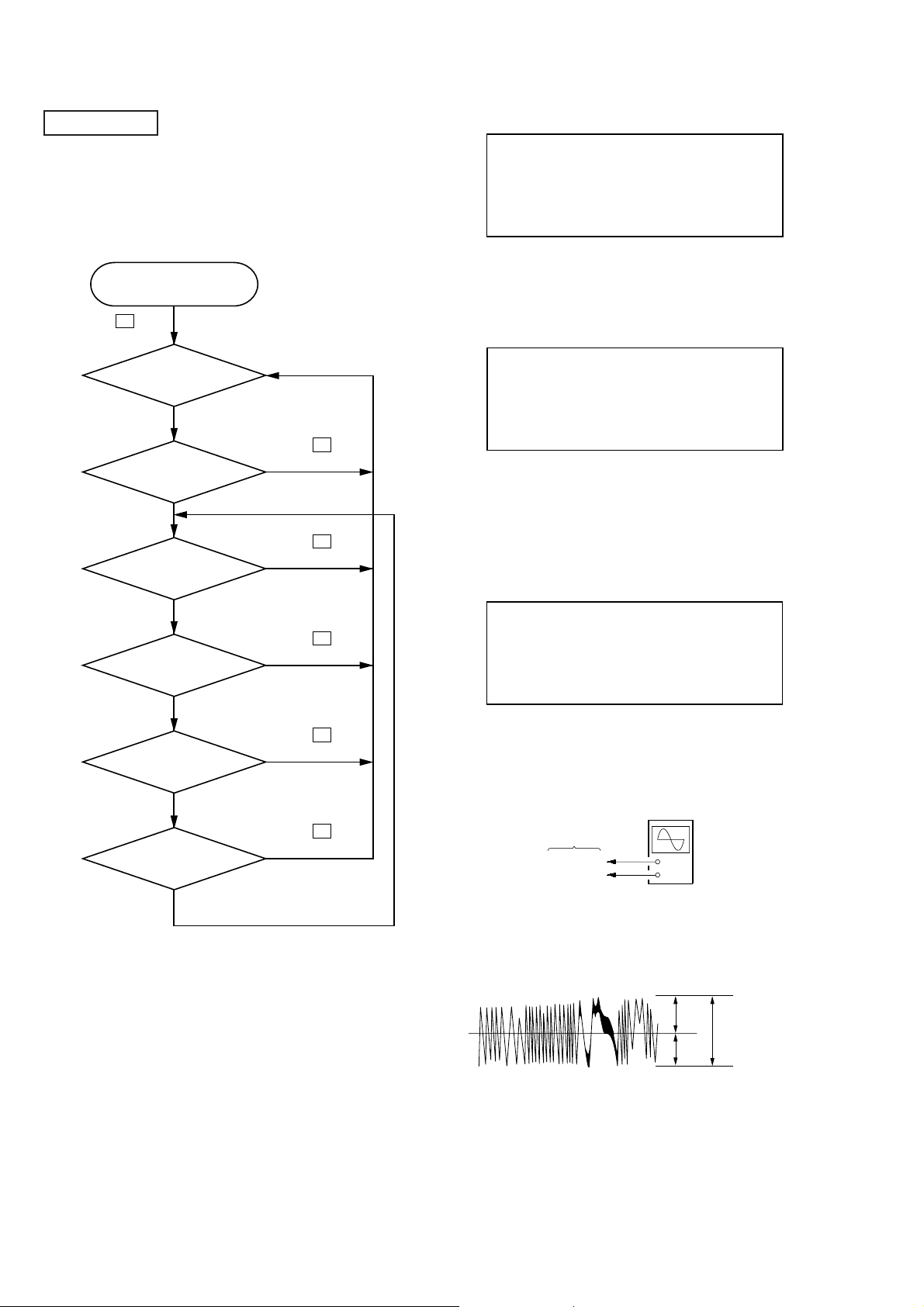

1. PARTS REPLACEMENT AND ADJUSTMENT

• Check and adjust the mechanism deck as follows.

The procedure changes according to the part replaced.

• Laser power check

• Focus bias check

• C PLAY check

• Self-recording/playback check

NG

Parts Replacement and Repair

• Abbreviation

OP : Optical pick-up

OWH :Overwrite head

OK

Check the sled and spindle

mechanisms.

Other causes can be suspected.

Has the OWH been replaced?

NO

Has OP, IC171, IC101, or

IC121 been replaced?

YES

Initial setting of the adjustment value

Has OP or IC171 been replaced?

YES

IOP information recording

(IOP value labeled on OP)

YES

NO

NO

Has IC171 or D101

been replaced?

YES

Temperature compensation offset adjustment

• Laser power adjustment

• Traverse adjustment

• Focus bias adjustment

• Error rate adjustment

• Focus bias check

• Auto gain adjustment

– 21 –

NO

Page 22

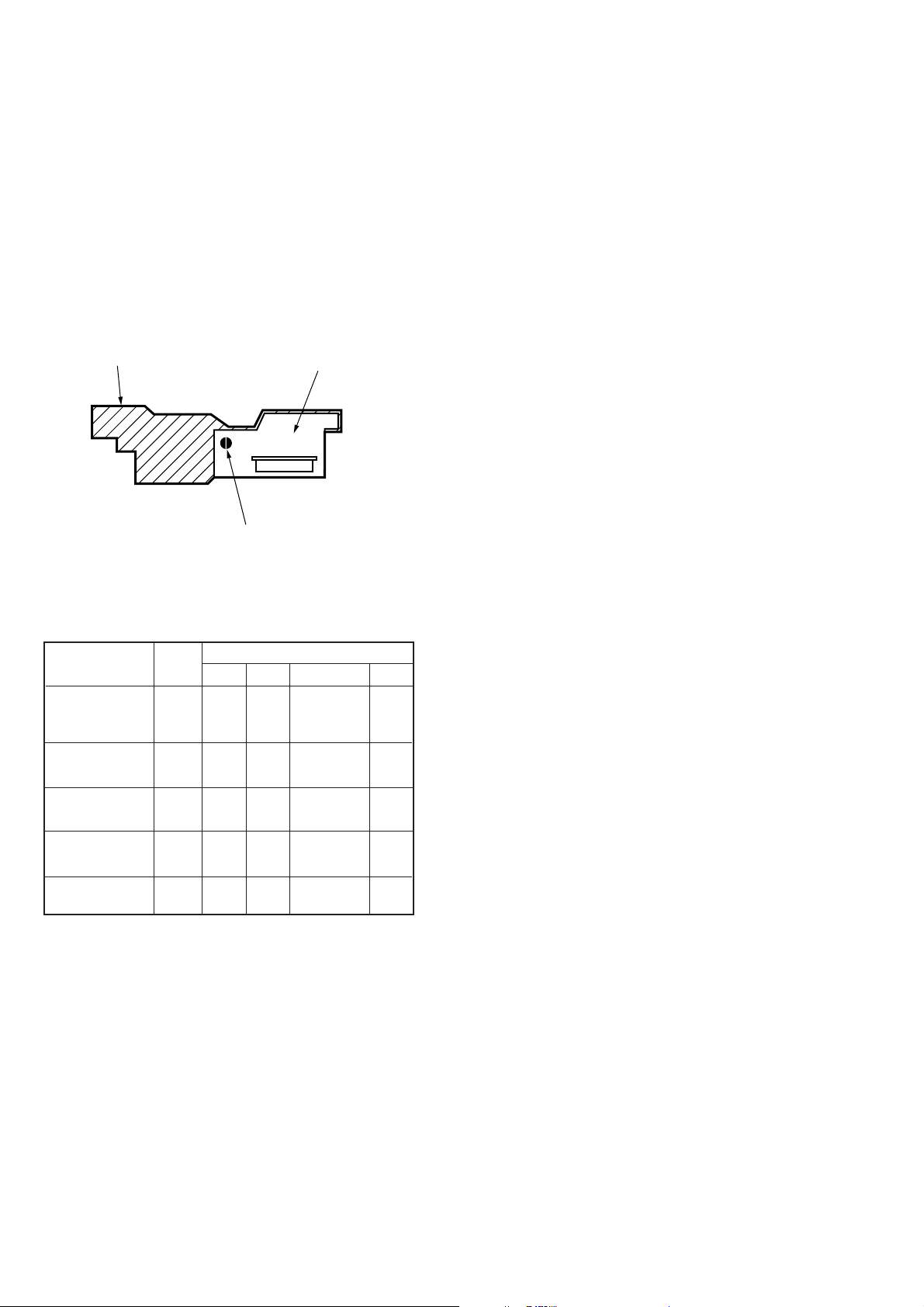

2. PRECAUTIONS FOR CHECKING LASER DIODE

EMISSION

T o check the emission of the laser diode during adjustments, nev er

view directly from the top as this may lose your eye-sight.

3. PRECAUTIONS FOR USE OF OPTICAL

PICK-UP (KMS-260A)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap of the fle xible board when using it.

Before disconnecting the connector, desolder first. Before connecting the connector, be careful not to remove the solder. Also

take adequate measures to prevent damage by static electricity.

Handle the flexible board with care as it breaks easily.

pick-up

laser tap

flexible board

Optical pick-up flexible board

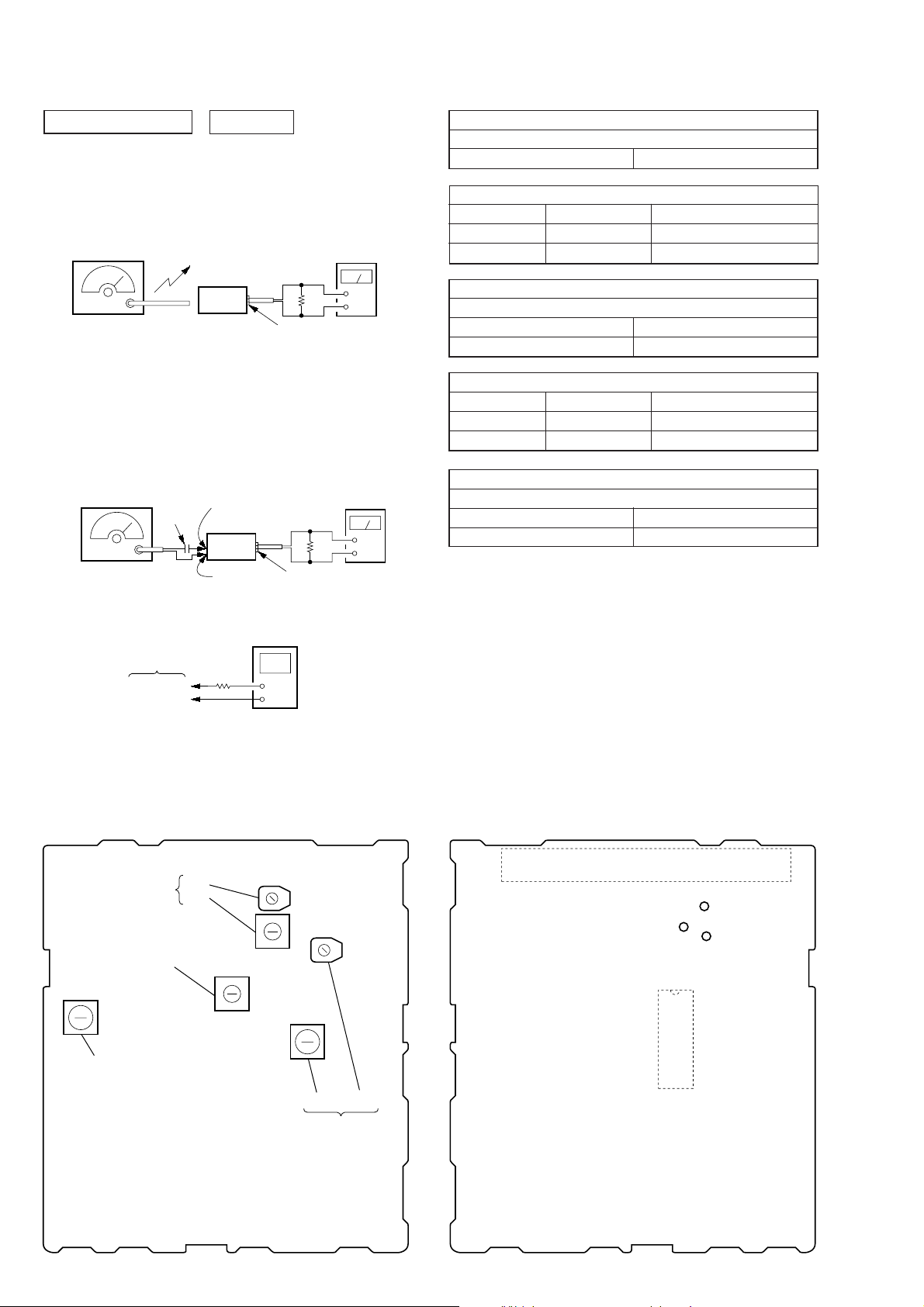

4. PRECAUTIONS FOR ADJUSTMENTS

1. When replacing the following parts, perform the adjustments

and checks with ¬ in the order shown in the following table.

D101

BD Board

IC101, IC121

¬G

IC192

1.Temperature

compensation

offset adjustment

2.Laser power

adjustment

3.EF balance

adjustment

4.Focus bias

adjustment

5.Error rate check

Optical

Pick-up

¬

IC171

¬¬GGG

¬G¬¬¬

¬G¬¬G

¬G¬¬G

¬G

4. Use the following tools and measuring devices.

• Check Disc (MD) TDYS-1

(Part No. 4-963-646-01)

• Test Disc (MDW-74/AU-1) (Part No. 8-892-341-41)

• Laser power meter LPM-8001 (Part No. J-2501-046-A)

or MD Laser power meter 8010S (Part No. J-2501-145-A)

• Oscilloscope (Measure after performing CAL of prove)

• Digital voltmeter

• Thermometer

• Jig for checking BD board waveform

(Part No. : J-2501-149-A)

5. When observing several signals on the oscilloscope, etc.,

make sure that VC and ground do not connect inside the oscilloscope.

(VC and ground will become short-circuited)

6. Using the above jig enables the waveform to be checked without the need to solder.

(Refer to Servicing Notes on page 4)

7. As the disc used will affect the adjustment results, make sure

that no dusts nor fingerprints are attached to it.

Laser power meter

When performing laser power checks and adjustment (electrical

adjustment), use of the new MD laser power meter 8010S (Part

No. J-2501-145-A) instead of the conventional laser power meter

is convenient.

It sharply reduces the time and trouble to set the laser power meter

sensor onto the objective lens of optical pick-up.

5. CREATING CONTINUOUSLY-RECORDED DISC

* This disc is used in focus bias adjustment and error rate check.

The following describes how to create a continuous recording

disc.

1. Insert a disc (blank disc) commercially available.

2. Turn the JOG dial and display “CREC MODE”.

3. Press the

Display “CREC (0300)” and start to recording.

4. Complete recording within 5 minutes.

5. Press the [NO,CANCEL] button and stop recording .

6. Press the [MDEJECT] button and remove the disc.

The above has been how to create a continuous recorded data for

the focus bias adjustment/check and MO error rate check.

Note :

• Be careful not to apply vibration during continuous recording.

[YES,ENTER] button again to display “CREC MID”.

6

2. Set the test mode when performing adjustments.

After completing the adjustments, release the test mode.

Perform the adjustments and checks in “group S” of the test

mode.

3. Perform the adjustments to be needed in the order shown.

– 22 –

Page 23

6. CHECK PRIOR TO REPAIRS

r

r

These checks are performed before replacing parts according to

“approximate specifications” to determine the faulty locations. For

details, refer to “Checks Prior to Parts Replacement and Adjustments” (See page 5).

6-1. Laser Power Check

Connection :

laser

power mete

Optical pick-up

objective lens

digital voltmete

BD board

CN110 pin 5 (I +3V)

CN110 pin

4

(IOP)

+

–

6-2. Focus Bias Check

Change the focus bias and check the focus tolerance amount.

Checking Procedure :

1. Load the test disk (MDW-74/AU-1).

2. Turn the JOG dial to display “CPLAY MODE”.

3. Press the [YES,ENTER] button twice to display “CPLAY

MID”.

4. Press the [NO,CANCEL] button when “C1 = AD = ”

is displayed.

5. Turn the JOG dial to display “FBIAS CHECK”.

6. Press the [YES,ENTER] button to display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate

the focus bias value.

Check that the C1 error is below 50 and ADER is below 2.

7. Press the [YES,ENTER] button to display “ / b = ”.

Check that the C1 error is about 200 and ADER is below 2.

8. Press the [YES,ENTER] button to display “ / a = ”.

Check that the C1 error is about 200 and ADER is below 2.

9. Press the [NO,CANCEL] button, then press the [MDEJECT]

6

button and take out the test disc.

Checking Procedure:

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press the 0 button or ) button to move the optical pick-up)

[]

[]

Connect the digital voltmeter to CN110 pin 5 (I+3V) and

CN110 pin 4 (IOP) on the BD board.

2. Then, turn the JOG dial to display “LDPWR CHECK”.

3. Press the [YES,ENTER] button once to display “LD 0.9 mW

$ ”. Check that the reading of the laser power meter become

0.84 to 0.92 mW.

4. Press the

[YES,ENTER] button once more to display “LD

7.0 mW $ ”. Check that the reading the laser power meter

and digital voltmeter satisfy the specified value.

Specified V alue:

Laser power meter reading : 7.0 ± 0.2 mW

Digital voltmeter reading : Value on the o ptical pick-up label

±10%

(Optical pick-up label)

KMS260A

27X40

B0825

lOP=82.5 mA in this case

lOP (mA) = Digital voltmeter reading (mV)/1 (

Ω

)

5. Press the [NO,CANCEL] button to display “LDPWR CHECK”

and stop the laser emission.

(The [NO,CANCEL] button is effective at all times to stop

the laser emission)

Note 1: After step 4, each time the [YES,ENTER] button is pressed,

the display will be switched “LD 0.7 mW $ ”, “LD 6.2 mW $

”, and “LD WP $ ”. Nothing needs to be performed

here.

6-3. C PLAY Check

MO Error Rate Check

Checking Procedure :

1. Load the test disk (MDW-74/AU-1).

2. Turn the JOG dial to display “CPLAY MODE”.

3. Press the [YES,ENTER] button to display “CPLAY MID”.

4. The display changes to “C1 = AD = ”.

5. If the C1 error rate is below 80, check that ADER is below 2.

6. Press the

the [MDEJECT] button and take out the test disc.

[NO,CANCEL] button to stop playback, then press

6

CD Error Rate Check

Checking Procedure :

1. Load the check disc (MD) TDYS-1.

2. Turn the JOG dial to display “CPLAY MODE”.

3. Press the [YES,ENTER] button twice to display “CPLAY

MID”.

4. The display changes to “C1 = AD = ”.

5. Check that the C1 error rate is below 50.

6. Press the [NO,CANCEL] button to stop playback, then press

the [MDEJECT] button and take out the check disc.

6

6-4. Self-Recording/playback Check

Prepare a continuous recording disc using the unit to be repaired

and check the error rate.

Checking Procedure :

1. Load a recordable disc (blank disc).

2. Turn the JOG dial to display “CREC MODE”.

3. Press the [YES,ENTER] button to display “CREC MID”.

4. When recording starts, lights up “[REC]” and display “CREC

@@@@” (@@@@ is the address).

5. About 1 minute later, press the [NO,CANCEL] button to stop

continuous recording.

6. Turn the JOG dial to display “CPLAY MODE”.

7. Press the [YES,ENTER] button to display “CPLAY MID”.

8. “C1 = AD = ” will be displayed.

9. Check that the C1 error becomes below 80 and the ADER below 2.

10. Press the [NO,CANCEL] button to stop playback, then press

the [MDEJECT] button and take out the disc.

6

– 23 –

Page 24

7. TEMPERATURE COMPENSATION OFFSET

r

r

ADJUSTMENT

Save the temperature data at that time in the non-volatile memory

as 25 ˚C reference data.

Note :

1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22 ˚C to 28 ˚C.

Perform it immediately after the power is turned on when the internal

temperature of the unit is the same as the ambient temperature of 22 ˚C

to 28 ˚C.

3. When D101 has been replaced, perform this adjustment after the temperature of this part has become the ambient temperature.

Adjusting Procedure :

1. Turn the JOG dial to display “TEMP ADJUST”.

2. Press the [YES,ENTER] button to select the “TEMP AD-

JUST” mode.

3. “TEMP = ” and the current temperature data will be dis-

played.

4. To save the data, press the [YES,ENTER] button.

When not saving the data, press the [NO,CANCEL] button.

5. When the [YES,ENTER] button is pressed, “TEMP = SAVE”

will be displayed and turned back to “TEMP ADJUST” display then. When the [NO,CANCEL] button is pressed, “TEMP

ADJUST” will be displayed immediately.

Specified Value :

The “TEMP = ” should be within “E0 - EF”, “F0 - FF”, “00 0F”, “10 - 1F” and “20 - 2F”.

8. LASER POWER ADJUSTMENT

7. Then, turn the JOG dial to display “LDPWR CHECK”.

8. Press the [YES,ENTER] button once to display “LD 0.9 mW

$ ”. Check that the reading of the laser power meter become

0.85 to 0.91 mW.

9. Press the [YES,ENTER] button once more to display “LD

7.0 mW $ ”. Check that the reading the laser power meter

and digital voltmeter satisfy the specified value.

Note down the digital voltmeter reading value.

Specified Value:

Laser power meter reading: 7.0 ± 0.2 mW

Digital voltmeter reading : Value on the op tical pick-up label

±10%

(Optical pick-up label)

KMS260A

27X40

B0825

lOP=82.5 mA in this case

lOP (mA) = Digital voltmeter reading (mV)/1 (Ω)

10. Press the

[NO,CANCEL] button to display “LDPWR CHECK”

and stop the laser emission.

(The [NO,CANCEL] button is effective at all times to stop

the laser emission)

Note 1: After step 9, each time the [YES,ENTER] button is pressed, the

display will be switched “LD 0.7 mW $ ”, “LD 6.2 mW $ ”,

and “LD WP $ ”. Nothing needs to be performed

here.

Connection :

laser

power mete

Optical pick-up

objective lens

digital voltmete

BD board

CN110 pin 5 (I +3V)

CN110 pin

4

(IOP)

+

–

Adjusting Procedure :

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press the 0 button

or ) button to move the optical pick-up)

[]

[]

Connect the digital voltmeter to CN110 pin 5 (I+3V) and

CN110 pin 4 (IOP) on the BD board.

2. Turn the JOG dial to display “LDPWR ADJUST”.

(Laser power : For adjustment)

3. Press the

[YES,ENTER] button once to display “LD 0.9 mW

$ ”.

4. Turn the JOG dial so that the reading of the laser power meter

becomes 0.85 to 0.91 mW. Press the [YES,ENTER] button

after setting the range knob of the laser power meter , and sav e

the adjustment results. (“LD SAVE $ ” will be displayed for

a moment)

5. Then “LD 7.0 mW $ ” will be displayed.

6. Turn the JOG dial so that the reading of the laser power meter

becomes 6.9 to 7.1 mW, press the [YES,ENTER] button to

save it.

Note: Do not perform the emission with 7.0 mW more than 15 seconds

continuously.

– 24 –

Page 25

9. EF BALANCE ADJUSTMENT

Note 1:Data will be erased during MO reading if a recorded disc is

used in this adjustment.

Note 2:If the traverse wa veform is not clear , connect the oscilloscope

as shown in the following figure so that it can be seen more

clearly.

BD board

CN110 pin 3 (TEO)

CN110 pin

1

330 k

(VC)

Connection :

oscilloscope

(DC range)

BD board

CN110 pin 3 (TEO)

CN110 pin

1

(VC)

Adjusting Procedure :

1. Connect an oscilloscope to CN110 pin 3 (TEO) and CN110

pin 1 (VC) on the BD board.

2. Load a disc (any available on the market). (Refer to Note 1)

3. Press the ) button to move the optical pick-up outside the

[]

pit.

4. Turn the JOG dial to display “EFBAL ADJUST”.

5. Press the [YES,ENTER] button to display “EFB = MOR”.

(Laser power READ power/Focus servo ON/tracking servo

OFF/spindle (S) servo ON)

6. Turn the JOG dial so that the waveform of the oscilloscope

becomes the specified value.

(When the JOG dial is turned, the

and the waveform changes) In this adjustment, wa veform v aries at intervals of approx. 2%. Adjust the waveform so that

the specified value is satisfied as much as possible.

(Read power traverse adjustment)

Traverse Wav ef orm

VC

Specification A = B

7. Press the [YES,ENTER] button and save the result of adjustment to the non-volatile memory . (“EFB = SAVE” will

be displayed for a moment. Then “EFB = MO-W” will be

displayed)

oscilloscope

(DC range)

Ω

10 pF

+

–

+

–

V: 0.1 V/div

H: 10 ms/div

of “EFB= ” changes

A

B

8. Turn the JOG dial so that the waveform of the oscilloscope

becomes the specified value.

(When the JOG dial is turned, the

of “EFB- ” changes

and the waveform changes) In this adjustment, wa veform v ar ies at intervals of approx. 2%. Adjust the wa veform so that the

specified value is satisfied as much as possible.

(Write power traverse adjustment)

Traverse Wav ef orm

A

VC

B

Specification A = B

9. Press the [YES,ENTER] button, and save the adjustment results in the non-volatile memory. (“EFB = SAVE” will be

displayed for a moment)

10. “EFB = MO-P” will be displayed.

The optical pick-up moves to the pit area automatically and

servo is imposed.

11. Turn the JOG dial until the waveform of the oscilloscope moves

closer to the specified value.

In this adjustment, waveform varies at intervals of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

Traverse Wav ef orm

A

VC

B

Specification A = B

12. Press the [YES,ENTER] button, and save the adjustment results in the non-volatile memory. (“EFB = SAVE” will be

displayed for a moment)

Next “EFBAL ADJUST” is displayed. The disc stops rotating

automatically.

13. Press the [MDEJECT] button and take out the disc.

6

14. Load the check disc (MD) TDYS-1.

15. Press the [YES,ENTER] button to display “EFB = CD”.

Servo is imposed automatically.

16. Turn the JOG dial so that the waveform of the oscilloscope

moves closer to the specified value.

In this adjustment, waveform varies at intervals of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

– 25 –

Traverse Wav ef orm

A

VC

B

Specification A = B

Page 26

17. Press the [YES,ENTER] button, display “EFB = SAVE”

for a moment and save the adjustment results in the non-volatile memory.

Next “EFBAL ADJUST” will be displayed.

18. Press the [MDEJECT] button and take out the disc.

6

10. FOCUS BIAS ADJUSTMENT

Adjusting Procedure :

1. Load the continuously-recorded disc. (Refer to “5. CREATING CONTINUOUSLY-RECORDED DISC”)

2. Turn the JOG dial to display “CPLAY MODE”.

3. Press the [YES,ENTER] button to display “CPLAY MID”.

4. Press the [NO,CANCEL] button when “C1 = AD = ”

is displayed.

5. Turn the JOG dial to display “FBIAS ADJUST”.

6. Press the [YES,ENTER] button to display “ / a = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [a =] indicate

the focus bias value.

7. Turn the JOG dial clockwise and find the focus bias value at

which the C1 error rate becomes about 200 (Refer to Note 2).

8. Press the [YES,ENTER] button to display “ / b = ”.

9. Turn the JOG dial counterclockwise and find the focus bias

value at which the C1 error rate becomes about 200.

10. Press the [YES,ENTER] button to display “ / c = ”.

11. Check that the C1 error rate is below 50 and ADER is 00.

Then press the [YES,ENTER] button.

12. If the “( )” in “ - - ( )” is above 20, press the

[YES,ENTER] button.

If below 20, press the [NO,CANCEL] button and repeat the

adjustment from step 2.

13. Press the

Note 1: The relation between the C1 error and focus bias is as shown in

Note 2: As the C1 error rate changes, perform the adjustment using the

C1 error

about

200

[MDEJECT] button and take out the disc.

the following figure. Find points A and B in the follo wing figure

using the above adjustment. The focal point position C is automatically calculated from points A and B.

average vale.

6

11. ERROR RATE CHECK

11-1. CD Error Rate Check

Checking Procedure :

1. Load the check disc (MD) TDYS-1.

2. Turn the JOG dial and display “CPLAY MODE”.

3. Press the [YES,ENTER] button twice and display “CPLAY

MID”.

4. The display changes to “C1 = AD = ”.

5. Check that the C1 error rate is below 20.

6. Press the [NO,CANCEL] button to stop playback, then press

the [MDEJECT] button and take out the check disc.

6

11-2. MO Error Rate Check

Checking Procedure :

1. Load the continuously-recorded disc. (Refer to “5. CREATING CONTINUOUSLY-RECORDED DISC”)

2. Turn the JOG dial to display “CPLAY MODE”.

3. Press the [YES,ENTER] button to display “CPLAY MID”.

4. The display changes to “C1 = AD = ”.

5. If the C1 error rate is below 50, check that ADER is 00.

6. Press the [NO,CANCEL] button to stop playback, then press

the [MDEJECT] button and take out the test disc.

6

12. FOCUS BIAS CHECK

Change the focus bias and check the focus tolerance amount.

Checking Procedure :

1. Load the continuously-recorded disc. (Refer to “5. CREATING CONTINUOUSLY-RECORDED DISC”)

2. Turn the JOG dial to display “CPLAY MODE”.

3. Press the [YES,ENTER] button twice to display “CPLAY

MID”.

4. Press the

is displayed.

5. Turn the JOG dial to display “FBIAS CHECK”.

6. Press the [YES,ENTER] button to display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate

the focus bias value.

Check that the C1 error is below 50 and ADER is below 2.

7. Press the [YES,ENTER] button and display “ / b = ”.

Check that the C1 error is about 200 and ADER is below 2.

8. Press the [YES,ENTER] button and display “ / a = ”.

Check that the C1 error is about 200 and ADER is below 2

9. Press the [NO,CANCEL] button, then press the [MDEJECT]

button and take out the disc.

[NO,CANCEL] button when “C1 = AD = ”

6

B

C A Focus bias value

(F. BIAS)

Note 1: If the C1 error and ADER are above other than the specified

value at points A (step 8. in the abo ve) or B (step 7. in the abov e),

the focus bias adjustment may not have been carried out properly. Adjust perform the beginning again.

– 26 –

Page 27

Adjustment Location:

– BD BOARD (Component Side) –

CN101

D101

NOTE

IC171

GND

I+3V

IOP

TEO

RF

VC

CN110

– BD BOARD (Conductor Side) –

IC101

IC121

IC192

Note: It is useful to use the jig for checking the waveform. (Refer to Ser-

vicing Notes on page 4)

– 27 –

Page 28

CD SECTION

Set the CD test mode when performing confirmations.

After completing the confirmation, release the CD test mode.

In the CD test mode, the set works as following sequence.

CD test mode sequence:

Display

88 XX XX XXX

1. Enter the CD test mode

(STOP mode 1)

π

Press the

button.

Press the

button.

Press the

button.

Press the

button.

Press the

button.

Press the

button.

Press the

button.

Note1: ALL SERVO ON mode 1 and TRACKING GAIN UP mode 1:

Note2: TRACKING GAIN UP mode 1,2 is not used in servicing.

(CD)

2. STOP mode 2

[,CD]

fl

[,CD]

fl

[,CD]

fl

[,CD]

fl

[,CD]

fl

[,CD]

fl

LPC ON (Lights up “ALL” indication)

ALL SERVO ON mode 2 and TRACKING GAIN UP mode 2:

LPC OFF (Does not lights up “ALL” indication)

*) LPC: Laser power control

3. FOCUS mode

4. ALL SERVO

ON mode 2

5. TRA CKING

GAIN UP mode 1

6. TRA CKING

GAIN UP mode 2

7. ALL SERVO

ON mode1

Press the π (CD)

button.

Press the π (CD)

button.

Press the π (CD)

button.

Press the π (CD)

button.

Press the π (CD)

button.

1. Entering the CD Test Mode

1. Press the [POWER] button to turn the power ON.

2. Press the [CDOPEN/CLOSE] button to open the disc lid,

and put a disc.

3. Press the [CDOPEN/CLOSE] button to close the disc lid.

4. Press the [POWER] button to standby state.

5. While pressing the both [BASS/TREBLE] and [EDIT] buttons,

press the button [,CD] n [] (CD) n [,CD] n

[] (CD).

π

fl

6. Release the both [BASS/TREBLE] and [EDIT] buttons.

7. After display “CD” for a few seconds, enter the CD test mode

(STOP mode 1), and display as below.

6

6

π

fl

2. STOP Mode 2

1. Press the π (CD) button to enter the STOP mode 2, and

display as below.

[]

Display

88 07 00 3A0

2. Press the + and = button to move the optical pickup to position of the track where signal is recorded.

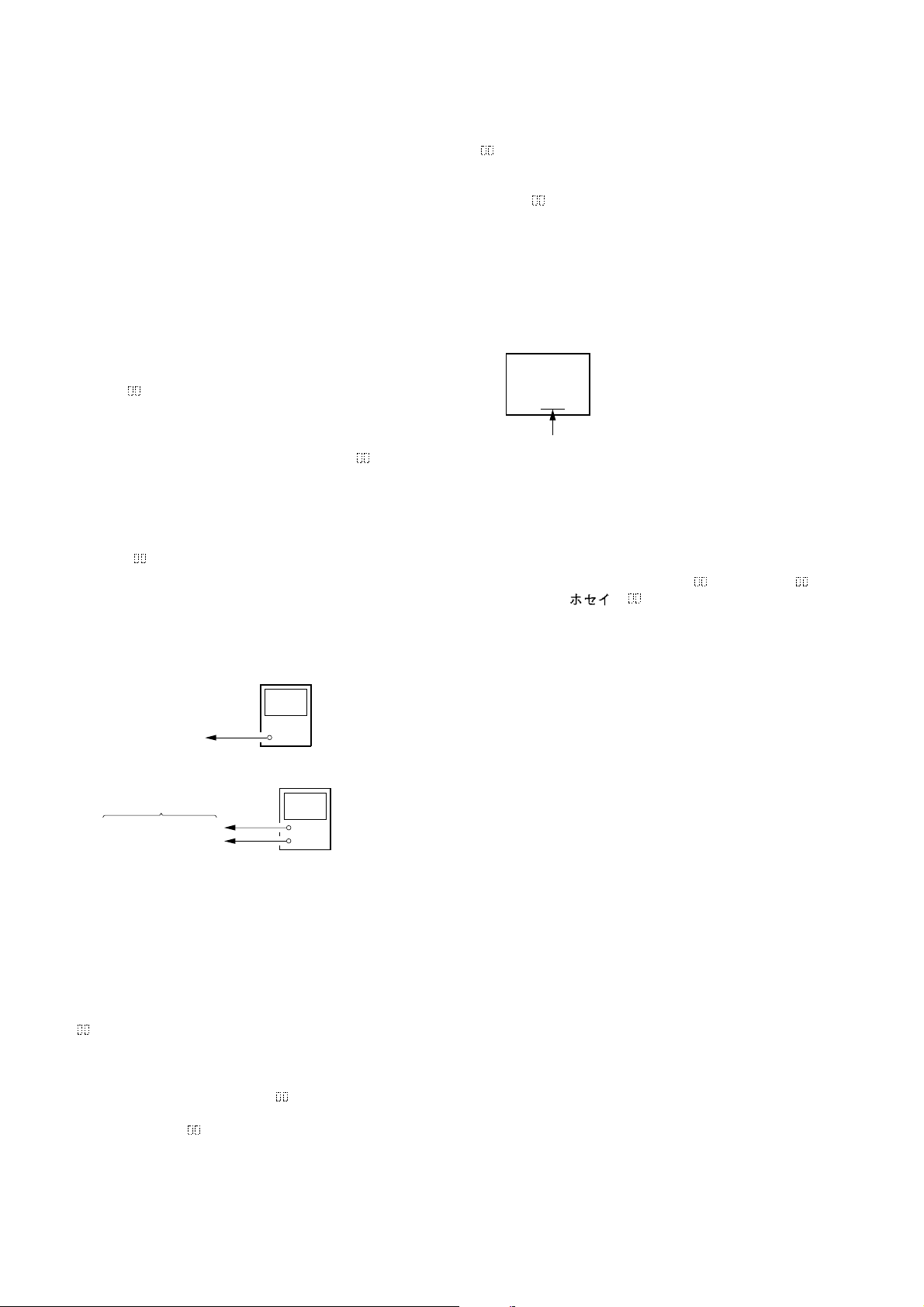

3. FOCUS Mode (Traverse Confirmation)

1. Press the fl button to enter the FOCUS mode and display

as below. (Focus servo ON. CLV-S, tacking and sled servo

OFF)

[] []

[]

Display

11 07 00 3A0

2. Connect an oscilloscope to TP (TEO) and TP (VC) on the

MAIN board.

Connection:

oscilloscope

(DC range)

MAIN board

TP (TEO)

TP (VC)

3. Confirm that the traverse level of waveform satisfy specified

value as follows.

T ra verse W a vef orm

VC

Specified Value:

traverse level: 160 to 380 mVp-p

Connecting Location: MAIN board (See page 29)

+

–

A = B

A

traverse level:

160 to 380 mVp-p

B

– 28 –

Page 29

4. ALL SERVO ON Mode 1

V

(RF Level and Jitter Confirmation 1)

1. Press the fl button four times to enter the ALL SERVO

ON mode 1 (start playback the disc) and display as below.

(All servo ON. LPC ON)

[]

Display

21 07 00 3A0

ALL

2. Connect an oscilloscope to TP (RFO) and TP (VC) on the

MAIN board.

Connection:

oscilloscope

(DC range)

MAIN board

TP (RFO)

TP (VC)

3. Confirm that the RF level and jitter of waveform satisfy specified values as follows.

+

–

6. Releasing the CD Test Mode

1. Press the π (CD) button to stop rotate the disc.

2. Press the [POWER] button or [RESET] switch (bottom of the

player unit) to release the CD test mode and turn to standby

state.

Connecting Location:

– MAIN BOARD –

(Component Side)

[]

TP (TEO)

TP (VC)

TP (RFO)

IC701

RF signal waveform

VOLT/DIV: 200 m

TIME/DIV: 500 ns

RF level:

1.0 to 1.4 Vp-p

Specified V alues:

RF level: 1.0 to 1.4 Vp-p

jitter : less than 9 nsec

Connecting Location: MAIN board

5. ALL SERVO ON Mode 2

(RF Level and Jitter Confirmation 2)

1. Press the fl button to enter the LPC OFF mode and dis-

play as below. (All servo ON. LPC OFF)

[]

Display

21 07 00 3A0

2. Confirm that the RF level and jitter of waveform satisfy speci-

fied values as follows.

Specified V alues:

RF level: 0.8 to 1.4 Vp-p

jitter : less than 9 nsec

If the RF level and jitter are out of specifide values, measure

again after clean the object lens by an applicator with lens

cleaning liquid.

– 29 –

Page 30

DISPLAY SECITON

r

Dimmer Adjustment

Connection:

digital voltmete

LCD board

TP (DIMMER)

TP (GND)

1. Connect a digital voltmeter to TP (DIMMER) and TP (GND)

on the LCD board.

2. Adjust RV550 so that the value of digital voltmeter becomes

2.83 V.

Specified Value: 2.83 to 2.93 V

Note: Connect the liquid crystal display unit (LCD500) to the LCD board

when performing adjustment.

Adjustment Location:

– LCD BOARD (Component Side) –

+

–

RV550

Dimmer Adjustment

– LCD BOARD (Conductor Side) –

CN553

TP (DIMMER)

TP (GND)

– 30 –

Page 31

6-1. BLOCK DIAGRAM – TUNER Section –

PMC-MD55

SECTION 6

DIAGRAMS

75Ω

FM

EXT ANTENNA

AM

ANTENNA

TU BOARD

TB1

CT2, L4

AM

TRACKING

L1

FM RF

L2

FM OSC

D9

FL1

B.P.F

D7

D8

CT2

CT1, L1

FM

TRACKING

L4

AM

OSC

FM VT

VOLTAGE

L3

AM ANT

CF3

10.7MHz

IF, DET, FM MPX

FM/AM FRONT-END

IC1 (1/2)

12BITS

DIVIDER

FM

IF-IN

7

AM

IF-IN

6

IF

BUFFER

ST-IND

IF-OUT

17 14 1318

FM RF-IN

2

FM RF OUT

24

CT1

FM OSC

21

L2

AM RF-IN

22

AM OSC

20

FM

MIX

FM

OSC

AM

MIX

AM

OSC

MIX-OUT

OSC-OUT

4

FM-IN

12

19

AM-IN

11

PD

16

LP-IN

17

CF1

AM IF

T1

PHASE DETECTOR

CHARGE PUMP

FM

IF AMP

Q14

MUTING

Q7

CF4

PLL, LOW-PASS FILTER

IC2

1/2

SWALLOW

COUNTER

1/16, 1/17

CF2

PROGRAMMABLE

4BIT

10

FM

DET

AM

DET

MO-ST

MONO/ST

SWITCH

Q2 (1/2)

QUAD

AM/FM

BUFFER

BAND

SWITCH

Q2 (2/2)

BAND

DET-OUT

16

IC1 (2/2)

HIGH

FREQUENCY CUT

Q1

15

MPX-IN

R-CH

DIVIDE

DECODE

VCO

MUTE

L-OUT

R-OUT

12

11

MUTING

CN1

12

RA-LCH

R-CH

Q5

A

(Page 40)

REFERENCE

DIVIDER

18

LP-OUT

X IN

19

X1

75kHz

05

X OUT

20

DATA SHIFT

REGISTER

LATCH

CCB/IF

CE

RD

1 2 3 4

ST-IND

8

MO/ST

13

IF-IN

10

MUTING

Q3

BAND

7

CK

CD

COUNT

CLK

DATA

CE

VT

MUTE

DRIVE

Q6

7

MUTE

6

COUNT

5

CLK

3

DATA

2

CE

1

VT

B

C

D

E

F

G

(Page 43)

(Page 43)

(Page 43)

(Page 43)

(Page 43)

(Page 43)

• SIGNAL PATH

: FM

: AM

R-CH : Same as L-CH.

– 31 –

– 32 –

– 33 –

Page 32

PMC-MD55

6-2. BLOCK DIAGRAM – MD Section –

BD BOARD (1/2)

CN104

1

HR901

(OVER WRITE HEAD)

OPTICAL PICK-UP BLOCK

HF MODULE

05

(KMS-260A)

F

C B

I J

D

E

LASER DIODE

2-AXIS

DEVICE

FCS+

(FOCUS)

(TRACKING)

FCS–

TRK+

TRK–

MOD

A

DETECTOR

LDPD

I

J

B

A

C

D

E

F

ILCC

PD

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

(SPINDLE)

CN101 (2/2)

4

3

2

1

8

M101

M102

(SLED)

CN101 (1/2)

16

12

13

14

18

19

20

17

9

6

IC152

MM

M

AUTOMATIC

POWER CONTROL

Q162, 163

LASER ON

SWITCH

Q101

OUT4F

6

OUT4R

8

OUT2F

27

OUT2R

25

OUT1F

21

23

OUT1R

OUT3F

12

10

OUT3R

16

PSB

IN4R

IN4F

IN2F

IN2R

IN1F

IN1R

IN3F

IN3R

CN102

DIGITAL SIGNAL PROCESSOR,

EFM/ACIRC ENCODER/DECODER,

SHOCK PROOF MEMORY CONTROLLER,

ATRAC ENCODER/DECODER

OVER WRITE

HEAD DRIVE

IC181, Q181, 182

SCTX

48 47

MORFI

MORFO

I

1

J

2

A

4

B

5

I-V

C

AMP

6

D

7

E

8

I-V

F

AMP

9

APC

11

PD

10

SPFD

3

SPRD

4

29

30

19

18

14

15

RF AMP

LD/PD

AMP

RFO

46 40

B.P.F.

3T

TEMP

WBL

AT

AMP

ABCD

AMP

APCREF

12

83 13 67 65 66 75 74 63 64

XRST

APCREF

SFDR

92

SRDR

91

FFDR

88

FRDR

89

TFDR

86

TRDR

85

ADFM

B.P.F.

COMMAND

SERIAL/PARALLEL

CONVERTER,

DECODER

SWDT

10

AUTOMATIC

POWER

CONTROL

DIGITAL SERVO

SIGNAL

PROCESS

PWM GENERATOR

DIGITAL SERVO

SIGNAL PROCESSOR

FOCUS/TRACKING ERROR AMP

FOCUS

ERROR AMP

TRACKING

ERROR AMP

SCLK

XLAT

181716

RECP

IC121 (2/2)

AGCI

WBL

PEAK &

BOTTOM

ADIN

3029

EQ

CONVERTER

AUX1

FROM CPU

INTERFACE

SEQUENCER

IC121 (1/2)

RF AMP,

IC101

RF AGC

& EQ

EQ

AUX

PEAK

BOTM

ADFG

ABCD

3T

WBL

F0CNT

V-I

FE

TE

SE

ABCD

ANALOG MUX

A/D CONVERTER

AUTO

RF

TE

SE

PEAK

FE

XLRF

CKRF

DTRF

38

33

37

36

32

35

34

26

28

20

BOTM

80

81

82

EEPROM

IC171

100

60

59

62

FILTER

61

53

54

57

78

79

XLAT

SCLK

SWDT

HF MODULE

SWITCH

IC103, Q102 – 104

EFMO

FILI

PCO

PLL

CLTV

FILO

SENS

LDOUT

RIN

VREF

OUT1

2

2

INTERFACE

SRDT

SENS

SRDT

6

CN601

(1/2)

ATRAC

CPU

ENCODER/DECODER

SWDT

SCLK

XLAT

SCLK

SWDT

VOLTAGE SWITCH

ASYO

ASYI

COMPA-

RFI

RATOR

ADFG

DEMODULATOR/

DECODER

F0CNT

CN103

(2/5)

ADIP

EFM/ACIRC

SHOCK PROOF

ENCODER/DECODER

MEMORY CONTROLLER

SUBCODE

PROCESSOR

SPINDLE

SERVO

SPFD

SPRD

DQSY

SQSY

XINT

XT

94 93

CN602

(1/4)

CN602

(2/4)

9

15

4

26

17

7

14

10

LDON

75

81

DIG-RST

80

WR-PWR

86

MOD

LOADING

MOTOR DRIVE

IC602

15

12 11 14 9 8 5 6 7 1 2 3 4

3523 7 1 15 18 10 12 20 2 8 19

16

15 12

89 32 69 67 90 77 33 41 4268

XINT

SCTX

SQSY

DQSY

LDIN

95 94

4 5

FIN

OUT2

7 1

CN605

(1/2)

1

1

M

M103

(LOADING)

SW BOARD (1/2)

CN103

(3/5)

SDA

SCL

21

22

6 53

SAMPLING

RATE

CONVERTER

DIGITAL

AUDIO

INTERFACE

CLOCK

GENERATOR

INTERNAL BUS

MONITOR

CONTROL

MNT0

FOK

42216523 9 6 14 1221 19 1 17

FOK

XLATCH

REFERENCE

Q611

IC121 (1/2)

ADDT

25

DATAI

22

XBCKI

24

LRCKI

23

DIN0

19

DIN1

20

DOUT

21

DADT

26

XBCK

28

LRCK

27

FS256

29

MNT1

MNT2

MNT3

SLOCK

XBUSY

SHOCK

CN103

(1/5)

SHOCK

MD MECHANISM CONTROLLER

MNT3 (SLOCK)

MNT2 (XBUSY)

B+

(D +5V)

32.768kHz

CN602

(3/4)

3

2

X601

12MHz

X602

IC601

39

28

27

25

24

525

MD B+

(+3.3V)

OSCI

OSCO

XOE

XWE

XRAS

XCAS

LD-LOW

XIN

XOUT

XIN-T

XOUT-T

SDA

SCL

+3.3V

3

REG

IC192

16

17

D0 – D3A00 – A09

49, 48, 50, 51

34 – 31, 36 – 40, 45

43

47

46

44

DA-RST

PACK-OUT

LIMIT-IN

REFLECT

PROTECT

SYS-RST

PDOWN

RXD (UART)

TXD (UART)

1

DIVIDER

IC123

D-RAM

IC124

1, 2, 18, 19

DQ1 – DQ4

A0 – A9

6 – 9, 11 – 15, 5

XOE

16

XWE

3

XRAS

4

XCAS

17

EMP

70

83

RECP

37

8

PBP

38

96

98

97

STB

36

20

13

57

58

RTS

59

CTS

60

CN605

(2/2)

CN602

(4/4)

13

9

8

14

10

12

1

21

3

19

5

17

7

15

15 7

3

5

7

8

13 11

11 13

CN601

3

5

7

CN103

(4/4)

16

CN601

(2/2)

DG BOARD

B+

(+5V)

12

15

11

10

S102

-1

-2

RESET

SWITCH

Q604

CONVERTER

DOUT

DIN

BCK

LRCK

SW BOARD (2/2)

(REC POSITION)

(PACK OUT)

(PLAY POSITION)

S602

S601

S604

SERIAL

INTERFACE

BD BOARD (2/2)

S101

(LIMIT IN)

S102-1

(REFLECT RATE DETECT)

S102-2

(PROTECT DETECT)

D/A, A/D

IC603

CONVERTER

CONVERTER

(+3.3V)

R-CH

R-CH

Q

CN603

2

D-IN

(Page 39)

H

CN604

(1/2)

8

DA-LCH

3

AD-LCH

12

13

5

1

2

I

J

(Page 40)

(Page 42)

LEVEL

SHIFT

IC604

VOUTL

D/A

A/D

PDADPDDADEMO

7818

VOUTR

VINL

VINR

SYSCK

MD PLAY/REC

1

CLK

7

6

512FS OSC

22.5792MHz

19

20

6

3

9

SWITCH

Q620

D FLIP–

FLOP

IC606

IC605

X603

• SIGNAL PATH

: MD PLAY

: MD REC (ANALOG)

: MD REC (DIGITAL)

R-CH : Same as L-CH.

MAIN BOARD (1/5)

REC-H

18

MD-H

17

MD-RST

19

MD-PDOWN

22

MD-STXD

70

MD-SRXD

69

MD-SCTS

20

MD-SRTS

21

SYSTEM

CONTROLLER

IC405(1/4)

CN405

(1/3)

12

13

21

26

22

23

24

25

B+

SWITCH

Q603

B+

SWITCH

Q617

B+

SWITCH

Q612

Q610

(BU +3.3V)

B+

Q616

B+

(+5V)

B+

B+

B+

(AU +3.3V)

B+

(D +5V)

CN604

(2/2)

21

26

22

23

24

25

– 34 –

– 35 –

– 36 –

Page 33

6-3. BLOCK DIAGRAM – CD Section –

PMC-MD55

OPTICAL PICK-UP

BLOCK

(KSS-213C)

+

–

–

+

–

+

+

–

+

–

–

+

LD

PD

T+

(TRACKING)

T-

F+

(FOCUS)

F-

M1001

M

(SLED)

CN1001

M1002

(SPINDLE)

S1001

(LIMIT)

M

CD MOTOR BOARD

05

SL+

SL–

(1/2)

MAIN BOARD (2/5)

DOUT

RF AMP, FOCUS/TRACKING SERVO

CN701

1

5

6

7

4

3

8

10

12

14

15

13

16

CN702(1/2)

4

4

2

2

OUT4+

15

OUT4–

16

MUTING

VC

AUTOMATIC

POWER

CONTROL

Q701

TRACKING/FOCUS COIL DRIVE,

SLED MOTOR DRIVE

T+

17

T–

18

F+

26

F–

27

SL+

11

SL–

12

MUTE DRIVE

SPINDLE MOTOR

DRIVE

IC1001

IN4

DRIVE

MUTE4

26

Q1001

IC703

LEVEL

LEVEL

LEVEL

27

46

36

37

39

38

34

35

B+

VC

PD1

PD2

E

F

LD

PD

SHIFT

SHIFT

SHIFT

APC

MUTE

MOTOR

CONTROL

Q1002-1005

TIN

FIN

SLIN

B+

SWITCH

Q1006

19

25

10

7

IC701

RF AMP

FE AMP

TRACKING PHASE

COMPENSATION

TA O

12

1 2

Q1007

ILL DATA

REGISTER

INPUT SHIFT,

REGISTER

ADRESS

DECODER

OUTPUT

DECODER

BUFFER

IC1002

IIL

TTL

TTL

IIL

FOCUS PHASE

COMPENSATION

FE O

5 15 32

CN1001

(2/2)

RFO

31

FOK

25

C.OUT

22

SENS1

23

SENS2

24

DATA

20

XLT

19

CLK

18

XRST

21

RF-H

SL O

HIGH SPEED SWITCH

Q705

CN702

(2/2)

5

5

1

1

8

8

77

3

3

99

35

18

11

10

12

13

14

79

B+

(UNREG +8V)

RF

FOK

CNIN

SEIN

DATO

XLTO

CLKO

XRST

CLV

SERVO

XLON

17

EFM

DEMO.

DIGITAL

CLV

MDP

21

D/A

I/F

SUB CODE

PROCESSOR

CPU

I/F

SPOA

15

53

BCK

43

PCMD

41

LRCK

39

EMPH

54

CD O/C BOARD

CD LID CLOSE

DETECT

Q762

(MOTOR)

BCKI

44

PCMDI

42

LRCKI

40

EMPHI

55

M703

CD LID

OPEN/CLOSE

B+

MOTOR

B+ SWITCH

Q764

Q765

DIGITAL SIGNAL PROCESSOR,

CLV SERVO, D/A CONVERTER

IC702

PWM

SERIAL

I/F

PWM

CD LID OPEN/CLOSE MOTOR

DRIVE

IC711

M–

1

M

M+

7

VREF

6

S762

CD LID CLOSE

DETECT

S761

CD LID OPEN

DETECT

B+

(+3.3V)

D704

OP

DRIVE

CL

MOTOR

CONTROL

Q763

MOTOR

CONTROL

Q766

REGULATOR CONTROL

AOUT1

AOUT2

SYSM

SCOR

SENS

SQSO

SQCK

XLAT

CLOK

DATA

XTAI

XTAO

5

4

+3.3V

REGULATOR

Q703

CD POWER

Q702

65

76

62

57

6

5

4

8

9

7

70

71

CN711

7

5

44

1

3

66

R-CH

X701

33.8688MHz

CN404

7

5

1

3

B+

(CD +6V)

B+

(CD6V)

CD-MUTE

82

CD-SCOR

78

CD-SENSE1

77

CD-SQSO

79

81

CD-SQCK

75

CD-XLAT

74

CD-CLK

76

CD-DATA

83

CD-FOK

91

CD-XRST

84

CD-SENSE2

68

HI-SPEED

10

CD-TURN

12

CD-OPEN

13

CD-CLOSE

93

SPEED-L

48

CD-DOOR

34

CD-12HISP

32

R-CH : Same as L-CH.

SYSTEM

CONTROLLER

IC405(2/4)

CD-POWER

CD-SHORT

P-CON43EXTAL42XTAL

80

100

SELECT

SELECT-GND

TU-SFT

X401

8MHz

• SIGNAL PATH

CD L-CH

TX

TEX

P-CON

B+(BU3.3V)

51

44

87

86

39

LEVEL

SHIFT

Q406

M

CN704

(Page 41)

K

(Page 41)

L

X402

32.768kHz

(Page 44)

2

D-OUT

H

(Page 36)

: CD PLAY

– 37 –

– 38 –

: MD REC (DIGITAL)

– 39 –

Page 34

PMC-MD55

6-4. BLOCK DIAGRAM – FUNCTION SELECT/PANEL Section –

(Page 33)

J303

LINE IN

RA-LCH

A

LINE IN BOARD

(Page 36)

R-CH

MAIN BOARD (3/5)

CN408

(1/2)

5

CN305

I

DA L-CH

CN301

3

2

LINE IN

MUTE

Q104

DRIVE

Q305

LINE IN LEVEL

CD L-CH

CONTROL

Q105

LINE IN LEVEL

CONTROL DRIVE

Q306

CN405(2/2)

8

(Page 38)

(Page 38 )

R-CH

LINE IN MUTE

K

L

MD

MUTE

Q102

RADIO

3

LINE

7

R-CH

IN

IN

MD MUTE

DRIVE

Q304

TUNER/LINE IN

SELECT

IC301

SW1

2

CD

MUTE

Q101

OUT

CD MUTE

DRIVE

Q303

5

BUFFER

Q103 (1/2)

R-CH R-CH

BUFFER

Q103 (2/2)

R-CH

TUNER/LINE IN

MUTE

Q106

LOW-PASS

FILTER

IC302

5 7

TUNER/LINE IN

MUTE

DRIVE

Q308

TUNER/LINE IN

MUTE SWITCH

Q307

2

RADIO/LINE

AU-CLK

AU-DATA

CN405

(1/2)

3

CN302

(1/3)

1

95

94

66

5

AD-LCH

J

(Page 36)

AU/JACK BOARD (1/4)

CN307

(1/2)

1

5

IN2

9

L-CH

R-CH

VOL

0dB/6dB

DIGITAL

CONTROL

SCK

SW (TOP) BOARD

D552

BAND

RADIO

DBC

18 2019

SI

D551

BASS TREBLE

L-CH

R-CH

CD

D550

MD

DINAMIC

BASS

ELECTRICAL

VOLUME

IC351

FILTER

PL550

CD DISC

ILLUMINATION

OUT2

N

(Page 43)

16

SW (FRONT) BOARD

HIGH SPEED

05

D555

LED

DRIVE

Q555

D554

SELECT

LED

DRIVE

Q554

D553

PRESET/AMS

LED

DRIVE

Q553

S572-580

S557-564

S565-571

MD MUTE

SWITCH

Q302

REMOTE

CONTROL

RECEIVER

IC550

S556

(JOG DIAL)

CD MUTE

SWITCH

Q301

CN551

22

111011

4

7

9

12

5

1

10

12

4

7

9

5

1

CN407

CD

99

MD

1

58

LINE-LEVEL

LINE

57

KEY1

62

KEY2

61

KEY3

60

RMC

85

JOG-A

49

JOG-B

50

LED-PRESET/AMS

55

LED-SELECT

56

HI-LED

33

SYSTEM

CONTROLLER

IC405 (3/4)

LCD-DATA

46 47 25 26

LED-RADIO

LCD-CLK

LED-CD

LED-MD

KEY4

D/LCON

LCD-RST

BL-CONT

LCD-CE

LCD-AO

CN409

(1/2)

28

29

27

59

23

24

96

CN406(2/3)

CN550 (2/2)

9

7

5

5

PILOT LAMP

DRIVE

Q405

PILOT LAMP

DRIVE

Q410

CN406

(1/3)

CN552

(3/3)

3

CN409 (2/2)

Q404

Q411

BU +3.3V

CN401

CN302

(2/3)

P

2

7

(Page 44)

LIQUID

LED

DRIVE

Q550

B/L

CONTROL

Q407

VDD

V5

VR

14

9

6

8

CN553

(2/2)

DIMMER

RV550

CN550

7

8

6

1

7

8

6

1

(1/2)

Q552

LED

DRIVE

LED

DRIVE

Q551

S550-555,

S579

LAMP BOARD

1

7

6

4

5

LCD BOARD

CN552

(2/3)

1

7

6

4

5

CN553

(1/2)

21

1

3

5

4

DATA

(LCD BACK LIGHT)

RST

AO

CE

CLK

PL553-555

CRYSTAL

DISPLY

LCD500

• SIGNAL PATH

: TUNER

: CD

: MD PLAY

: MD REC (ANALOG)

R-CH : Same as L-CH.

AU/JACK BOARD (2/4)

CN306

1

7

CN307

(2/2)

DIMMER

Q357,358

UNREG +8V

O

(Page 44)

– 40 –

– 41 –

– 42 –

Page 35

6-5. BLOCK DIAGRAM – POWER AMP/POWER SUPPLY Section –

AU/JACK BOARD (3/4)

(Page 42)

N

MEGABASS

SWITCH

R-CH

D353

MEGABASS

Q151

ON/OFF

Q360

LINE

AMP

IC352

3 1

SPEAKER

MUTE

Q152

MEGABASS

CONTROL

Q362, 363

D358

R-CH

MEGABASS

IC354,

Q352, 361

D359

HEADPHONE

AMP

IC353

6 3

HEADPHONE

MUTE

Q154

R-CH

J301

SIGNAL OUTPUT

(TO SPEAKER(L) UNIT)

L

R-CH R-CH

R

CN304

(1/2)

11

CN303

(1/2)

J391

SIGNAL INPUT

(TO PLAYER UNIT)

POWER AMP (A)

L

R

R-CH

BOARD

J301

JACK OUT

JACK IN

MAIN BOARD (4/5)

(Page 45)

Q

J302

SIGNAL OUTPUT

(WOOFER)

MUTE

DRIVE

Q351

D364

(TO SUPER WOOFER UNIT)

PMC-MD55

POWER AMP (C) BOARD

CN392

D901

RECT

1

2

J392

SPEAKER

OUTPUT

R-CH

IMPEDANCE

USE4Ω

POWER AMP (D)

SP391

L-CH

1

2

BOARD

T901

POWER

TRNSFORMER

SPEAKER(R) UNIT

SP392

(R-CH)

STANDBY

+OUT2

–OUT2

+OUT1

–OUT1

9

11

14

12

CN394

2

CN393

44

CN391

1

AUMUTE

2

PA-STBY

4

UNREG 12V

POWER

IN2

4

AMP

SIGNAL MUTE

56

STANDBY

SWITCH

Q391, 392

POWER AMP (B) BOARD

POWER BOARD

CN901

4

UNREG 12V

2

PA-STBY

1

AUMUTE

(Page 33)

(Page 33)

(Page 33)

(Page 33)

(Page 33)

(Page 33)

B+

(AU +8V)

AC

CHECK

Q412

+8V

REGULATOR

Q354

POWER

STANDBY

Q353

8

8

BU +3.3V

REGULATOR

3 2

IC402

B+

SWITCH

Q401

9

9

B+

(MD +5V)

(CD +6V)

B+

SWITCH

Q355

Q356

CN307(2/2)

10

10

(COM+5V)

RESET

SIGNAL

1 2

GENERATOR

IC404

B+

(+3.3V)

B+

RST

97

98

45

40

B+

SWITCH

Q359