Page 1

PMC-DR50L/DR70L

SERVICE MANUAL

REVICED

Photo : PMC-DR70L

TAPE Model Name Using Similar Mechanism NEW

Section T ape Transport Mechanism T ype MF-PMCDR50

CD

Section

AEP Model

UK Model

E Model

PMC-DR50L/DR70L

Tourist Model

PMC-DR50L

Model Name Using Similar Mechanism NEW

MD Mechanism Type KSM-213CCP

Optical Pick-up Type KSS-213C

SPECIFICATIONS

– Continued on page 2 –

PERSONAL COMPONENT SYSTEM

Page 2

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICE NOTE ........................................................... 3

2. GENERAL ...................................................................... 4

3. DISASSEMBLY

3-1. Case(bottom), “Cover ASSY, Top” .......................... 6

3-2. CD ASSY.................................................................. 7

3-3. Main Board, Jack Board ........................................... 7

3-4. Tray........................................................................... 8

3-5. ASP Board ................................................................ 8

3-6. Belt ........................................................................... 9

3-7. Motor Board, Loding Motor (M651)........................ 9

3-8. Optical Pick-up Block ............................................ 10

3-9. Mechanism Deck .................................................... 10

3-10. TC RF Board, Head Relay Board,

Capstan/Reel Motor (M160) ...................................11

3-11. Control Board ..........................................................11

3-12. Display Board ......................................................... 12

3-13. DSP Board, CPU board .......................................... 12

3-14. VOL Board ............................................................. 13

3-15. “Cabinet, Wood”, “Cabinet (R) Bottom” ............... 13

3-16. Speaker (R-CH) (SP101) ........................................ 14

3-17. Power Board ........................................................... 14

3-18. AMP Board, AMP IC Board ................................... 15

3-19. Speaker Board ........................................................ 15

3-20. “Cabinet, Wood”, “Cabinet (L) Bottom”................ 16

3-21. Speaker (L-CH) (SP201) ........................................ 16

3-22. Power Transfomer Board........................................ 17

3-23. SP Main Board, SP AMP IC Board ........................ 17

3-24. AC Outlet Board, SP Jack Board ............................ 18

3-25. Cabinet (SWF) Bottom, Connector Board ............. 18

3-26. Speaker (SP601), “Cabinet, Front”......................... 19

3-27. LED Board, Volume Board..................................... 19

4. ADJUSTMENTS

4-1. Mechanical Adjustments .......................................... 20

4-2. Electrical Adjustments.............................................. 20

5. DIAGRAMS

5-1. Explanation of IC Terminals................................... 23

5-2. Block Diagrams – Tuner Section –......................... 27

5-3. Block Diagrams – CD Section–.............................. 29

5-4. Block Diagrams – Tape Section– ........................... 31

5-5. Block Diagrams – Speaker Section– ...................... 33

5-6. Printed Wiring Boards – Main Section–................. 35

5-7. Schematic Diagram – Main Section (1/3) – ........... 37

5-8. Schematic Diagram – Main Section (2/3) – ........... 39

5-9. Schematic Diagram – Main Section (3/3) – ........... 41

5-10. Printed Wiring Boards – Jack Section – ................. 43

5-11. Schematic Diagram – Jack Section –...................... 45

5-12. Printed Wiring Boards – CD Section –................... 47

5-13. Schematic Diagram – CD • ASP Section –............. 49

5-14. Schematic Diagram – CD • DSP Section – ............ 51

5-15. Printed Wiring Boards – Control Section –............ 53

5-16. Schematic Diagram – Control Section – ................ 55

5-17. Schematic Diagram – System Control Section –.... 57

5-18. Printed Wiring Boards – AMP Section – ................ 59

5-19. Schematic Diagram – AMP Section – .................... 61

5-20. Printed Wiring Boards – Woofer Section – ............ 63

5-21. Schematic Diagram – Woofer Section –................. 65

6. EXPLODED VIEWS

6-1. Case Section ........................................................... 72

6-2. Control Section ....................................................... 73

6-3. CD Mechanism Section .......................................... 74

6-4. Mechanism Deck Section -1................................... 75

6-5. Mechanism Deck Section -2................................... 76

6-6. CD Optical Pick-up Section ................................... 77

6-7. Speaker (R-CH) Section ......................................... 78

6-8. Speaker (L-CH) Section (DR50L Only) ................. 79

6-9. Speaker (L-CH) Section (DR70L Only) ................. 80

6-10. Super Woofer Section (DR70L Only) .................... 81

7. ELECTRICAL PARTS LIST ................................... 82

– 2 –

Page 3

SECTION 1

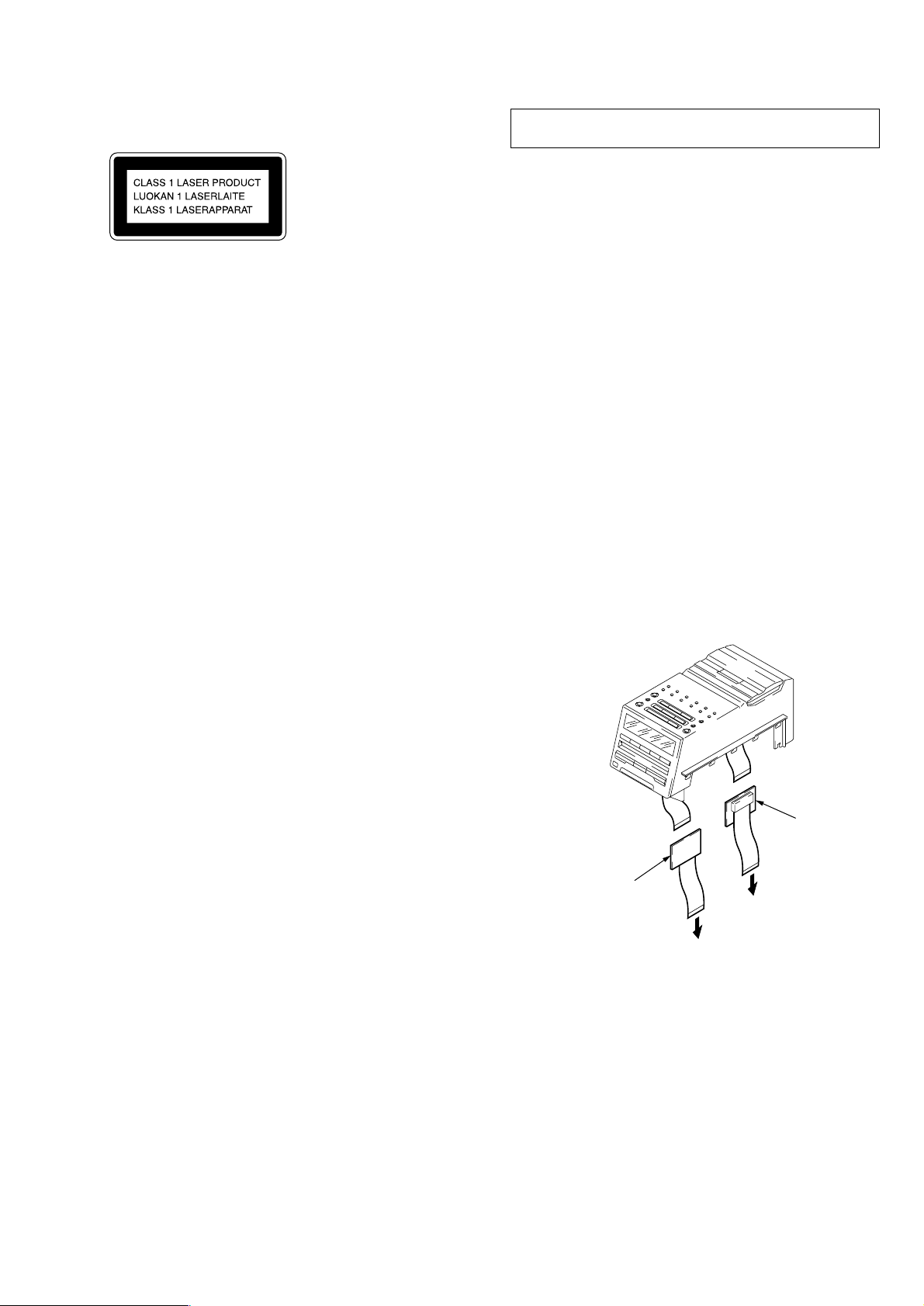

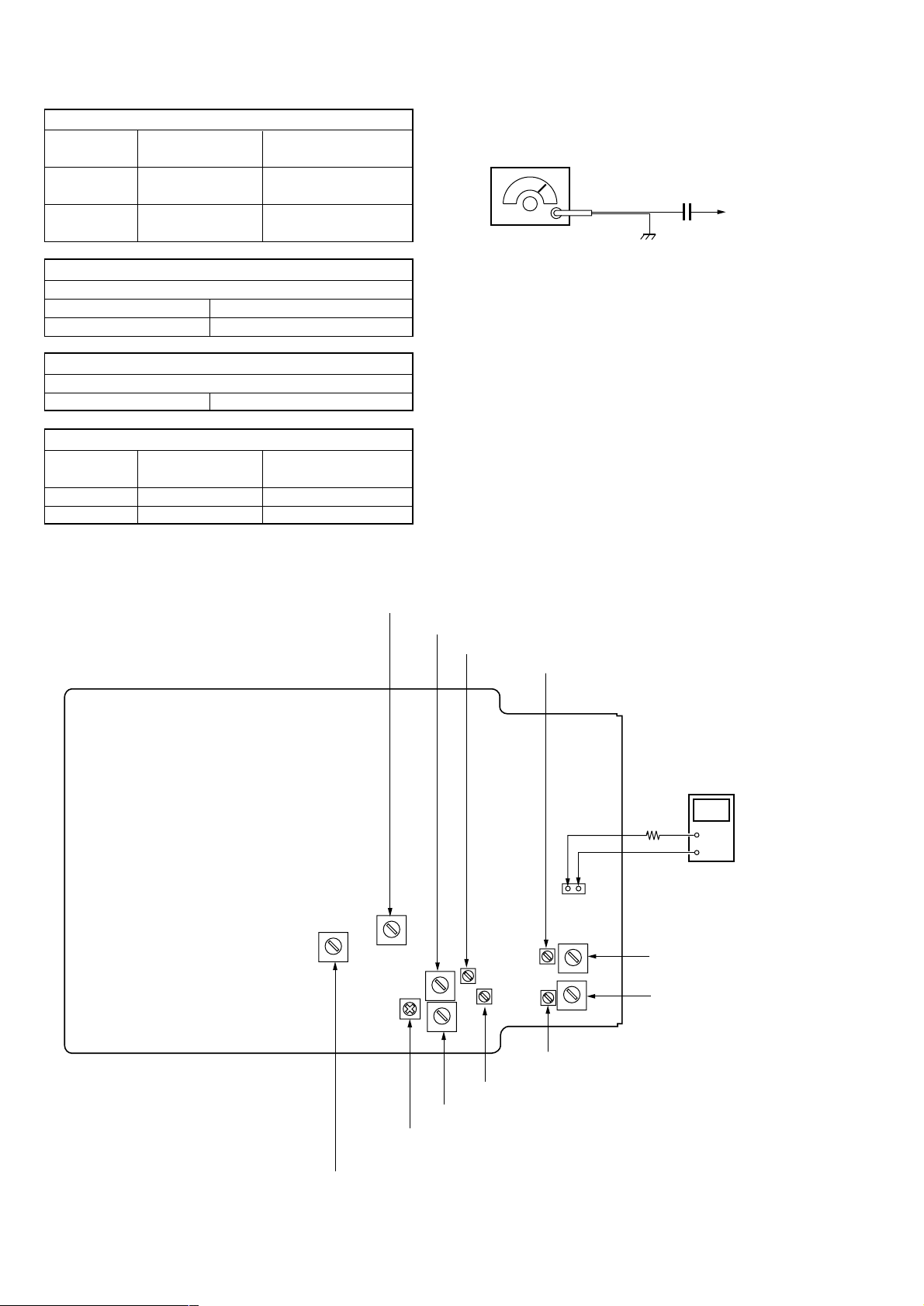

Jig (20 core)

(1-792-164-11)

Jig (19 core)

(1-792-165-11)

Main board

(CN804)

ASP board

(CN702)

SERVICE NOTE

Information

For customers in Europe

This Compact Disc player is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT label is

located at the bottom of the player.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Close the Tray for CD.

2. Press CD ^ button.

3. Confirm the laser diode emission while observing the objecting

lens. When there is no emission, Auto Power Control circuit or

Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ABOUT THE EXTENSION CABLE JIG

Extention cable jigs (1-792-164-11 and 1-792-165-11) are necessary when repair this unit.

– 3 –

Page 4

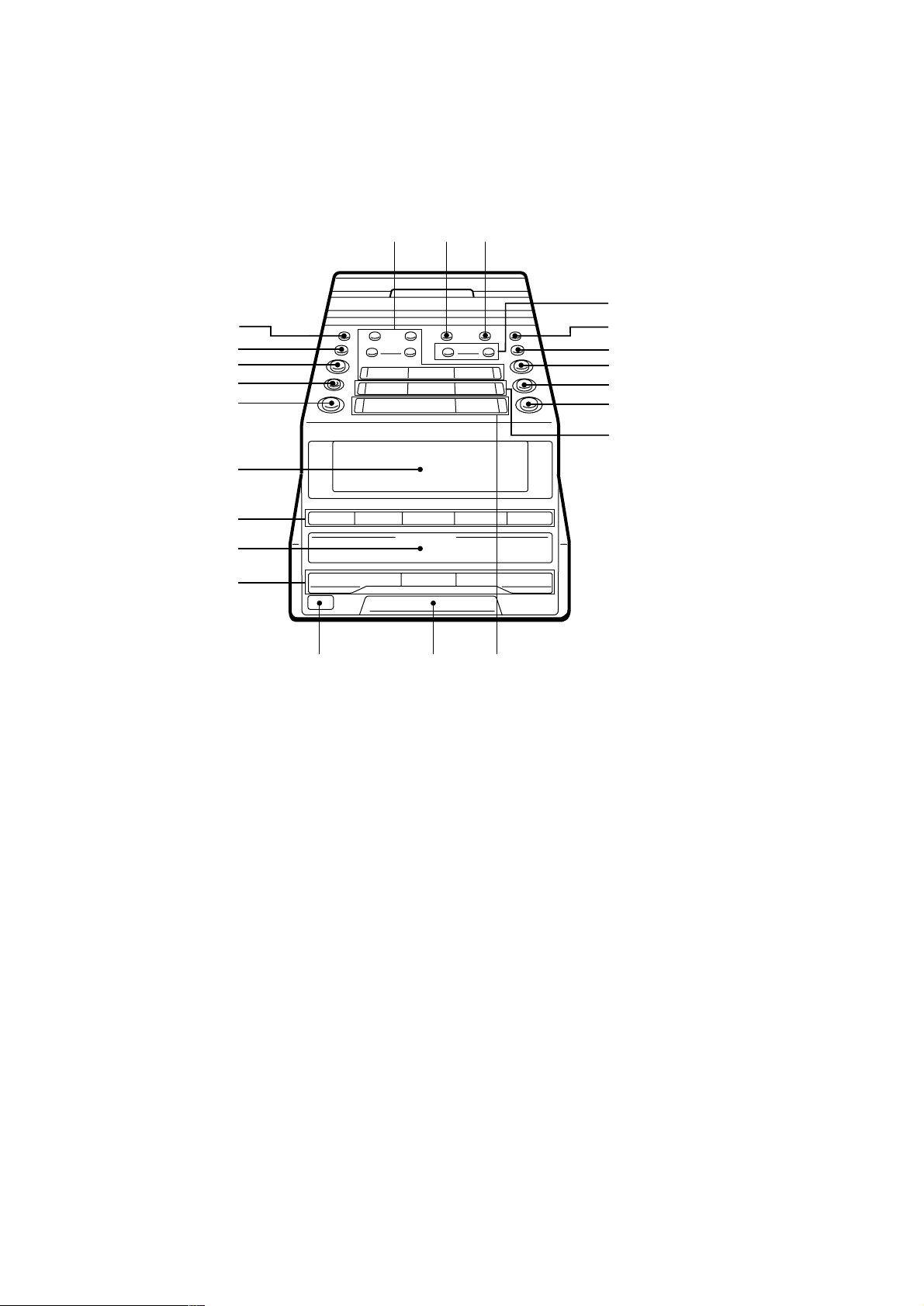

LOCATION AND FUNCTION OF CONTROLS

MAIN UNIT

9

8

7

6

5

4

SECTION 2

GENERAL

!¡!º

!™

!£

!¢

!∞

!§

!¶

!•

!ª

3

2

1

@™ @¡ @º

1 VOLUME +, – buttons

2 CD tray

3 Timer buttons

STANDBY

SLEEP

CLOCK

TIMER

DISPLAY

4 Display window

5 OPERATE button

6 RDS button

7 2 (Headphones) Jack

8 DIR MODE button

9 COUNTER RESET button

!º TAPE operation buttons

r/P (rec/pause)

DUBBING

0, ) (FF, REW)

ª, · (play)

π (stop)

!¡ PLAY MODE, MONO/ST ISS button

!™ ENTER/MEM, PGM SET button

!£ =(–) , +(+) TUNE TIME SET button

!¢ LINE IN button

!∞ SUMER TIME button

!§ MEGA BASS button

!¶ SOUND button

!• 6 CD OPEN/CLOSE button

!ª RADIO operation buttons

PRESET +

BAND

PRESET–

@º CD operation buttons

fl (play/pause)

π (stop)

@¡ SNOOZE button

@™ Remote sensor

– 4 –

Page 5

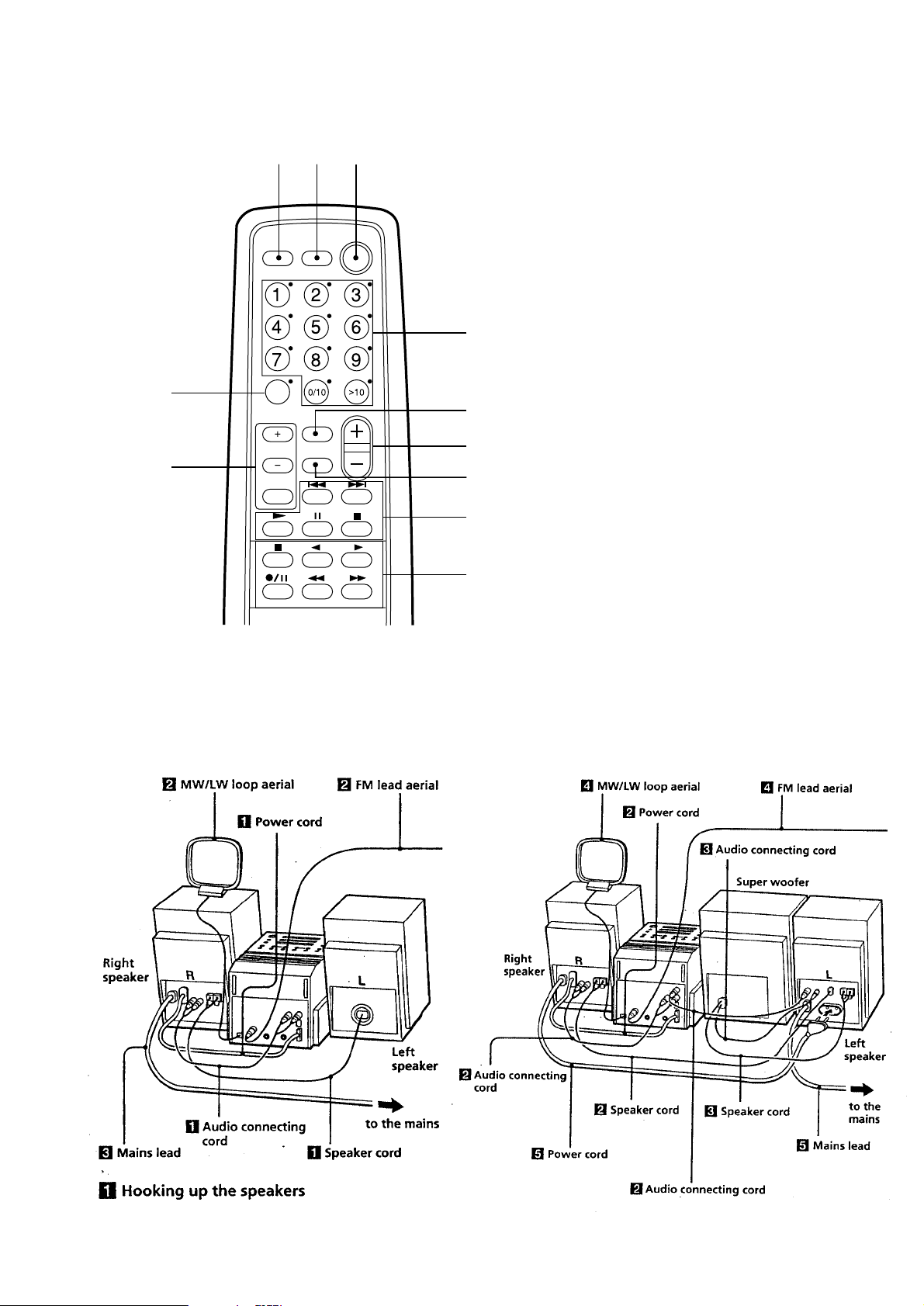

Remote commander

1 2 3

!¡

!º

DISPLAY

MODE

RADIO

TUNE

BAND

TA

SEARCH

CD/RADIO

MEGA/BASS

SOUND

TAPE

OPERATE

VOL

4

5

6

7

8

9

1 DISPLAY button

2 TA SEARCH button

3 OPERATE button

4 Number buttons

5 MEGA BASS button

6 VOLUME +, – buttons

7 SOUND button

8 CD operation buttons

=, +(AMS, search)

( (play)

P (pause)

p (stop)

9 TAPE operation buttons

p (stop)

“, ” (play)

r/P (rec/pause)

0, ) (FF, REW)

!º RADIO operation buttons

TUNE +

TUNE –

BAND

!¡ MODE button

HOOKING UP THE SYSTEM

(PMC-DR50L) (PMC-DR70L)

– 5 –

Page 6

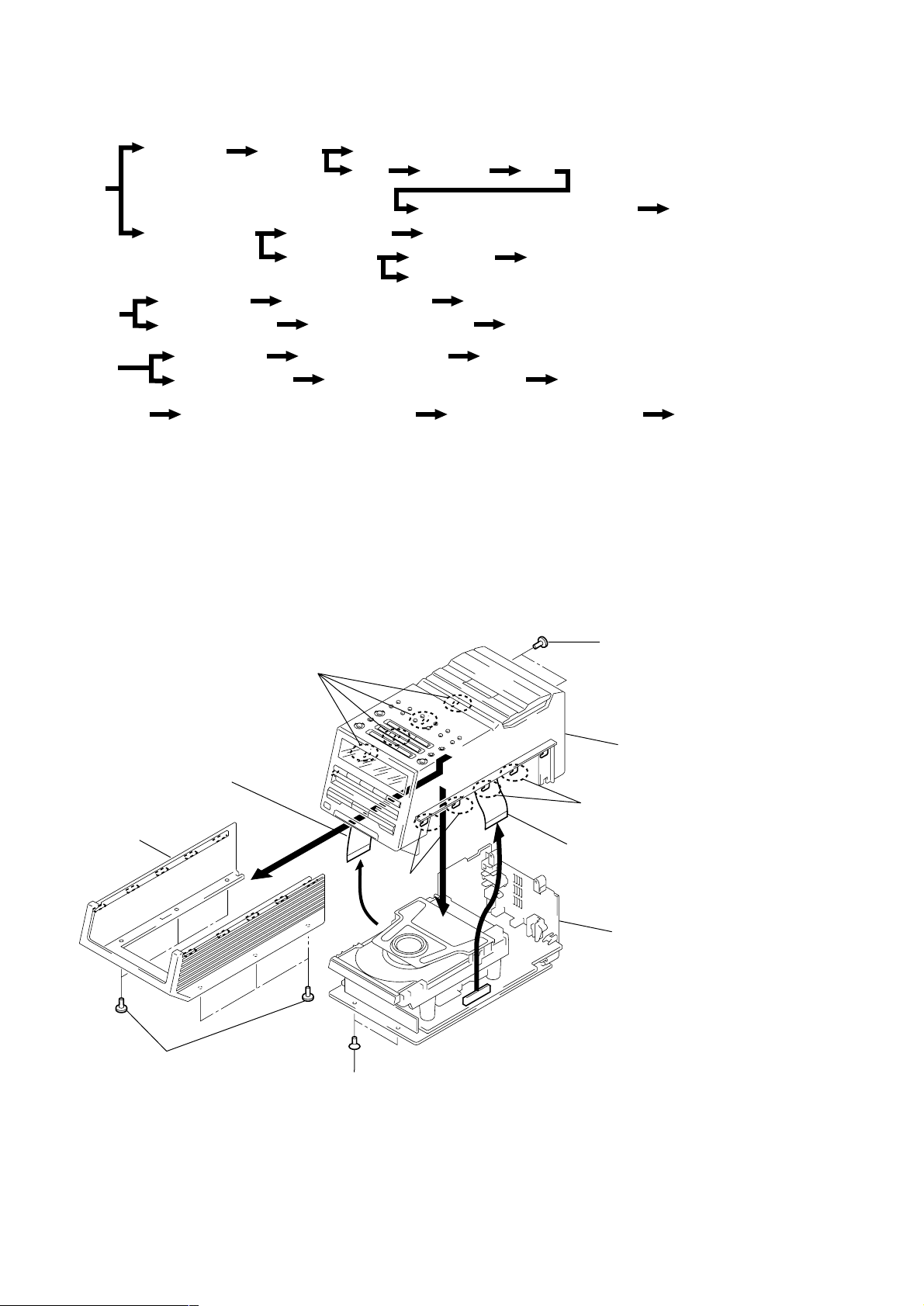

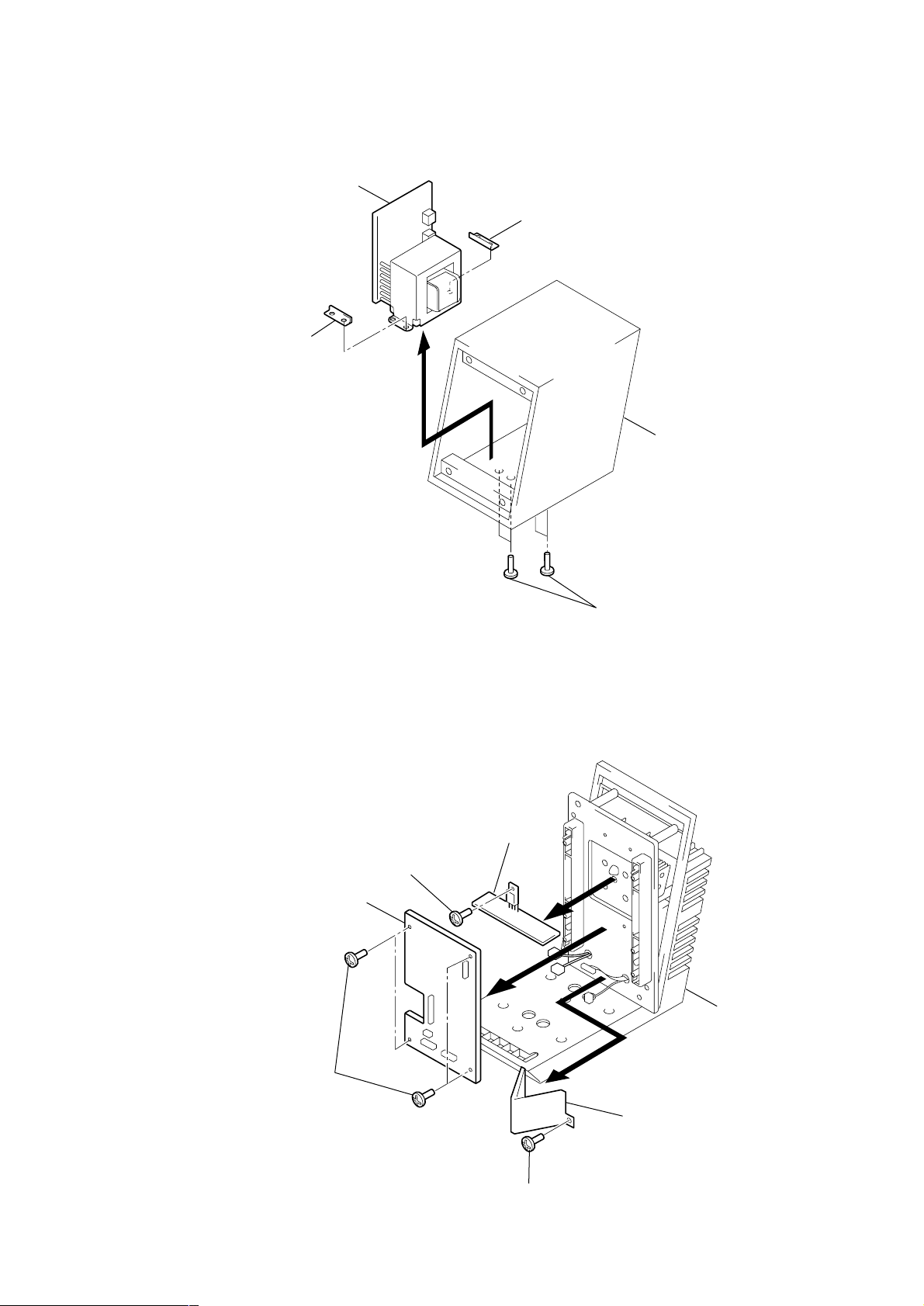

DISASSEMBLY

r

The equipment can be removed using the following procedure.

SECTION 3

Case(bottom)

CD ASSY Main board, Jack board

Tray ASP board

Main unit

Motor board, Loading motor (M651) Optical pick-up block

Cover ASSY, top

Mechanism deck TC RF board, Head relay board, Capstan/reel motor (M160)

Control board

Display board

VOL board

Speaker unit

(R-CH)

Speaker unit

(L-CH) (DR70L)

Super woofer unit

Cabinet, wood

Cabinet (R) bottom

Cabinet, wood

Cabinet (L) bottom SP main board, SP AMP IC board

Cabinet (SWF) bottom, Connector board LED board, volume board

Speaker (R-CH) (SP101) Power board

AMP board, AMP IC board

Speaker (L-CH) (SP201) Power transfomer board

(DR70L)

Note : Follow the disassembly procedure in the numerical order given.

< MAIN UNIT >

3-1. CASE (BOTTOM), “COVER ASSY, TOP”

Belt

DSP board, CPU board

Speaker board

AC outlet board, SP jack board

Speaker (SP601), “Cabinet, front”

Sub cover

2

Claws

6

Wire, parallel (20 core)

(ASP board : CN702)

3

1

Screws (+BVTT 3x10)

2

Claws

4

Screws (+KPT 3x10)

7

1

Screws (+BVTT 3x10)

Cover ASSY, top

2

Claws

5

Wire, parallel (19 core)

Case (bottom)

– 6 –

Page 7

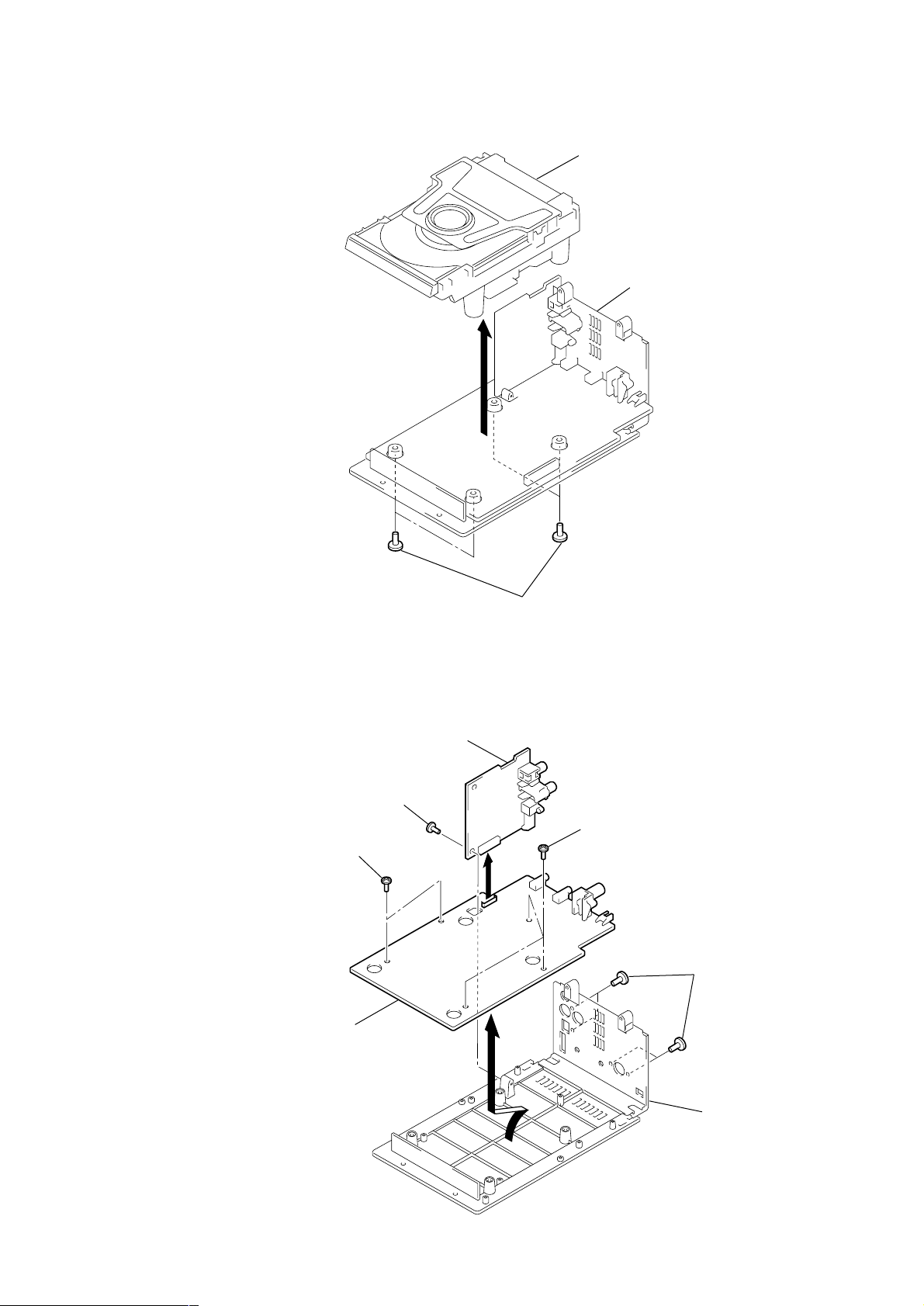

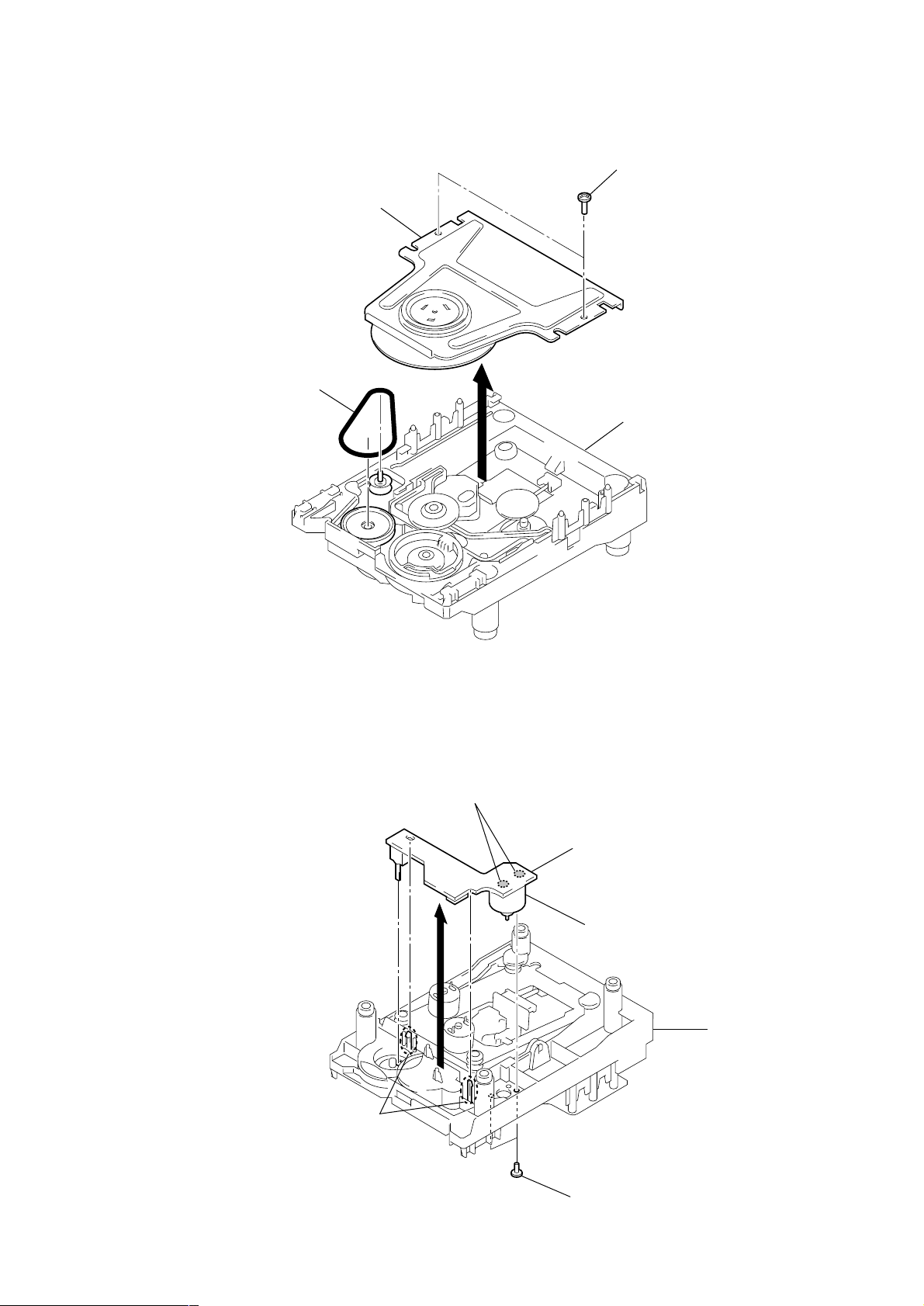

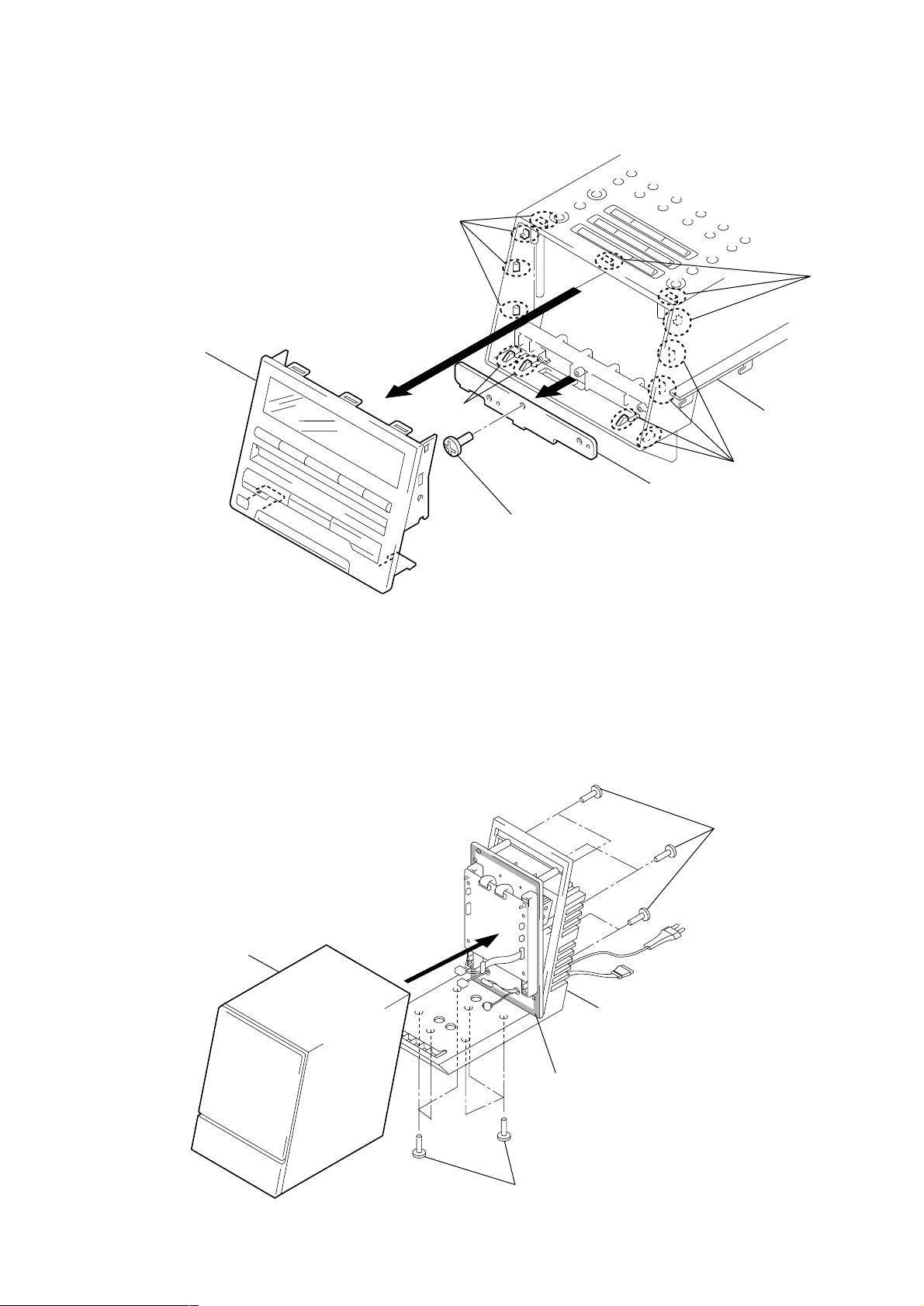

3-2. CD ASSY

)

CD ASSY

Case (bottom)

2

3-3. MAIN BOARD, JACK BOARD

4

Screws (+BVTT 2.6x8)

2

Screws (+BVTT 2.6x8)

Main board

Jack board

1

Screws (+BVTT 3x10)

5

3

2

Screws (+BVTT 2.6x8)

1

Screws (+BVTT 3x10

– 7 –

Case (bottom)

Page 8

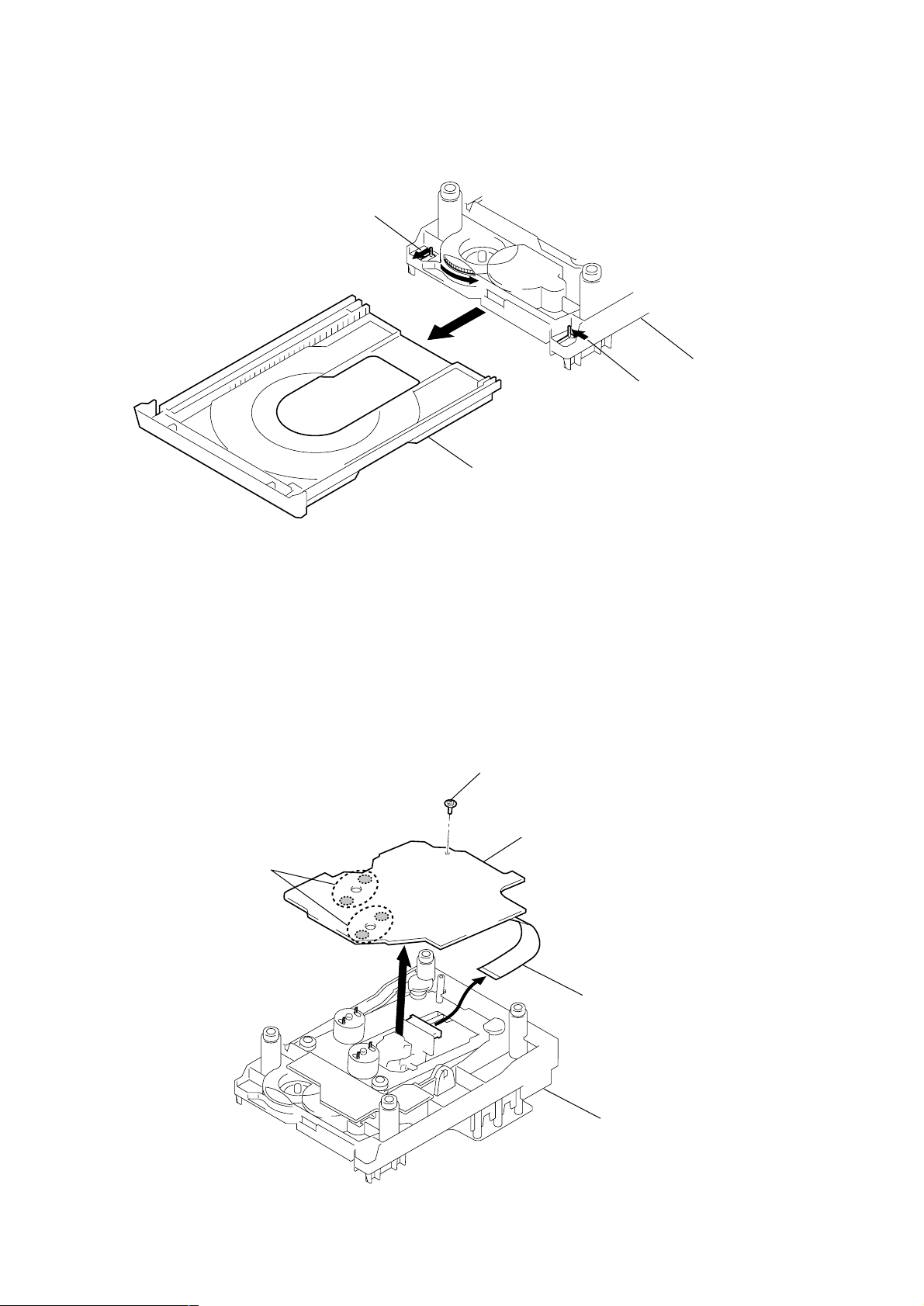

3-4. TRA Y

3

Projection

1

2

Tray

3

Projection

Chassis

3-5. ASP BOARD

2

Remove solder

4

1

Screw (+P 2x6)

ASP board

3

Wire, parallel (16 core)

Chassis

– 8 –

Page 9

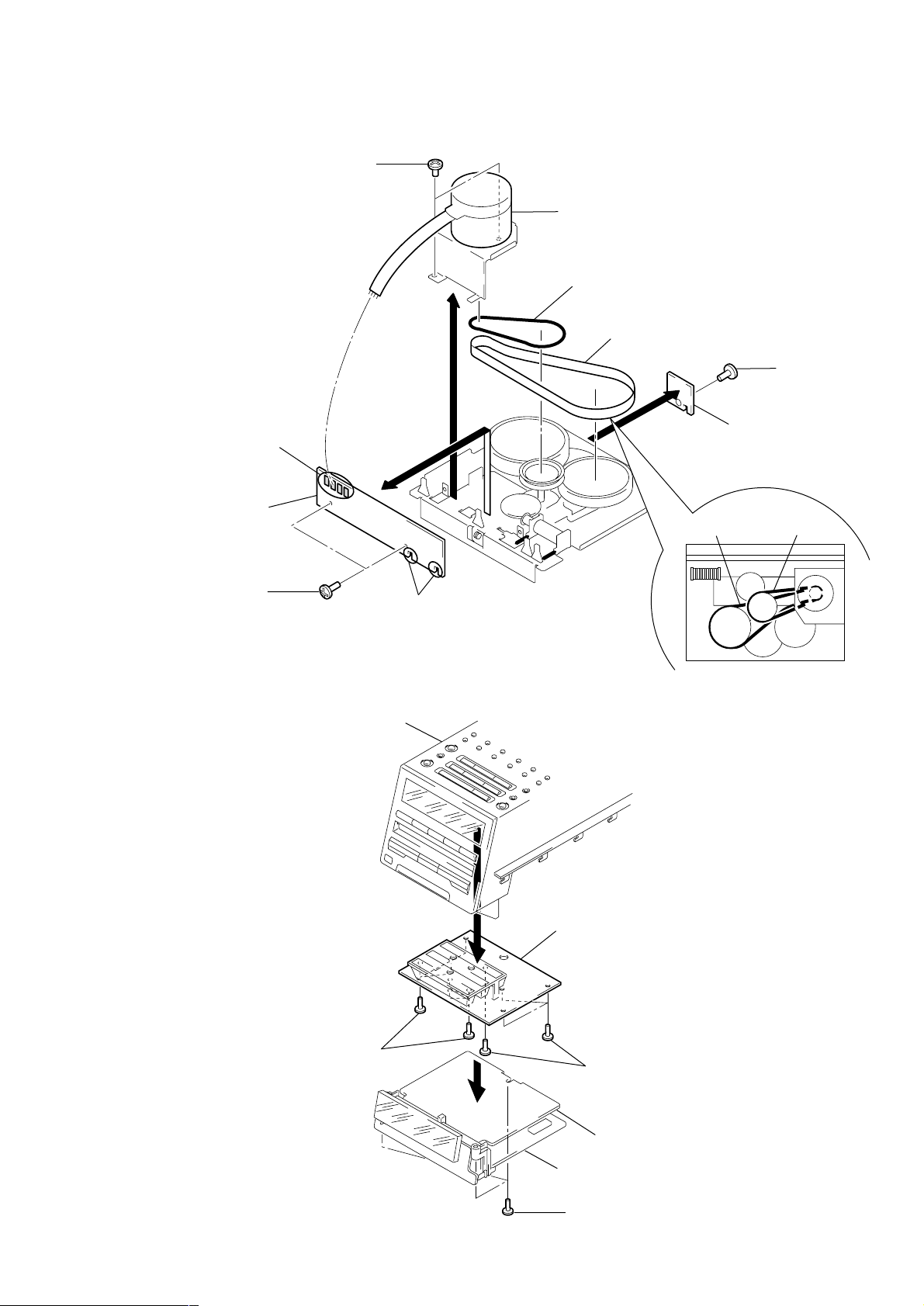

3-6. BELT

s

Chucking chassis

3

Belt

2

1

Screw (+P 2.6x8)

Chassis

3-7. MOTOR BOARD, LOADING MOTOR (M651)

3

Remove solder

2

Claws

Motor board

4

Loading motor (M651)

Chassi

– 9 –

1

Screws (+B 2x3)

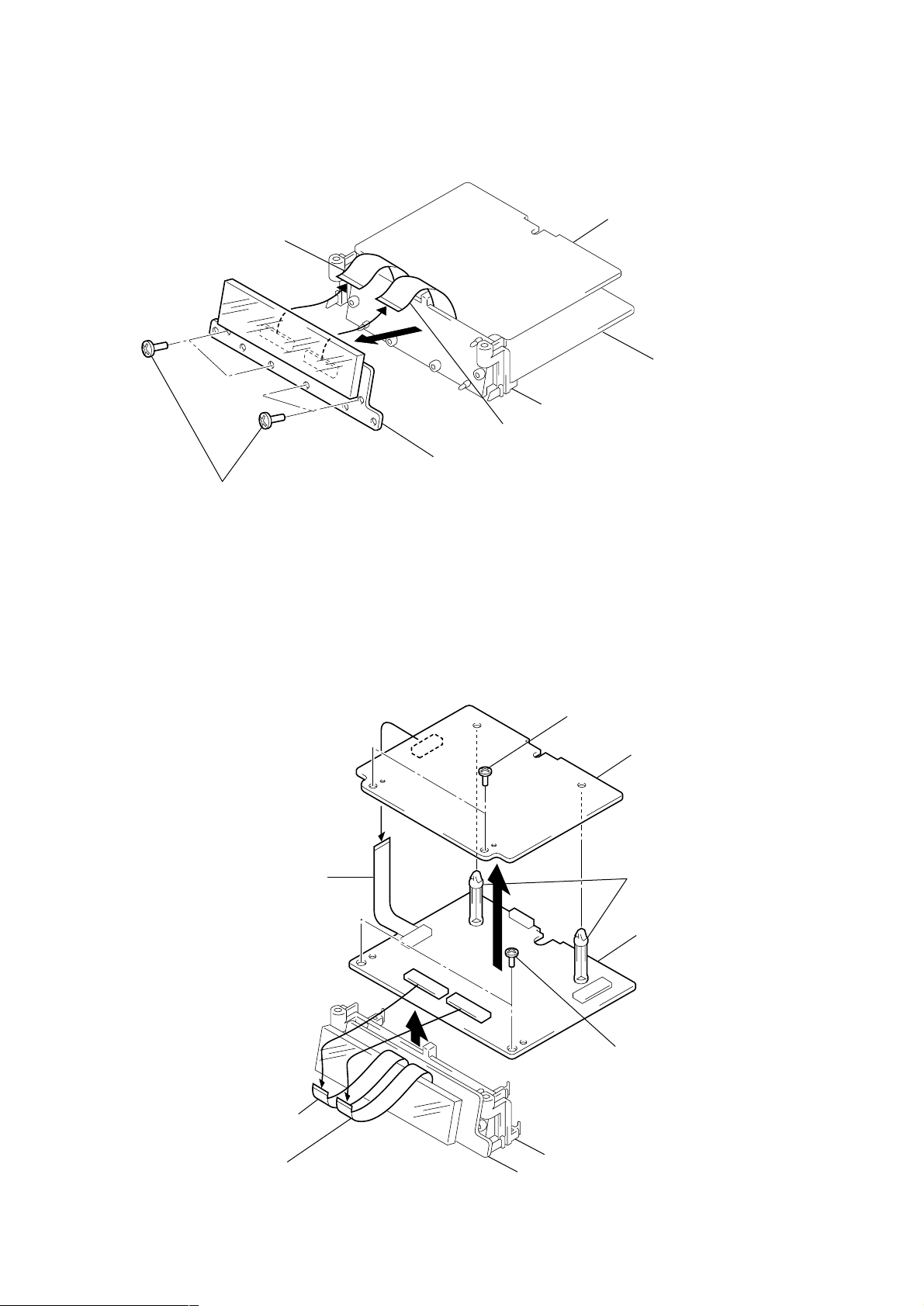

Page 10

3-8. OPTICAL PICK-UP BLOCK

)

)

1

Screws (+PWH 2.6x10)

3

4

Arm

2

Screws (+PWH 2.6x10

3

Optical pick-up block

Chassis

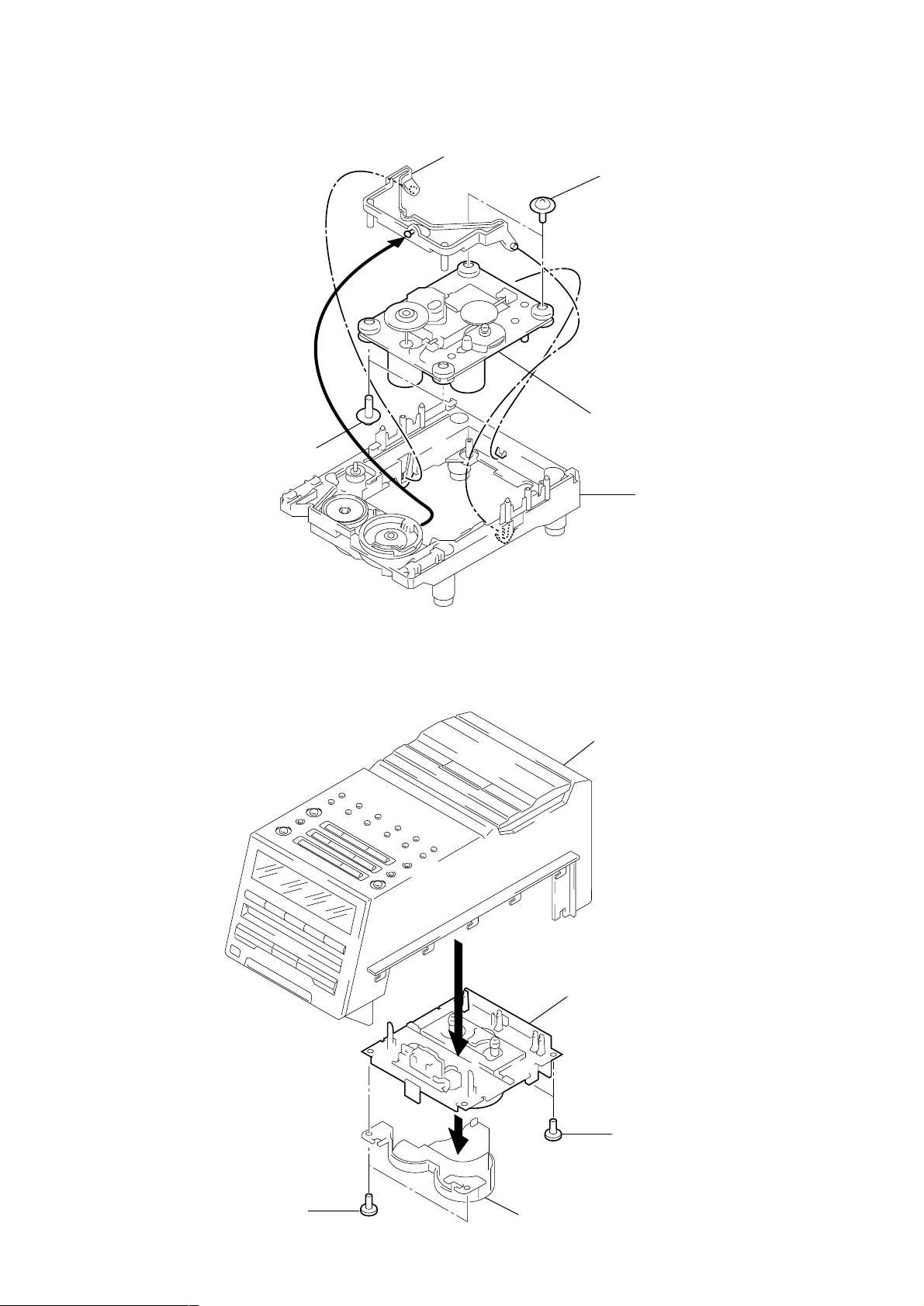

3-9. MECHANISM DECK

2

3

Cover ASSY, top

Mechanism deck

1

Screws (+BVTT 3x10

1

Screws (+BVTT 3x10)

– 10 –

Cover, deck

Page 11

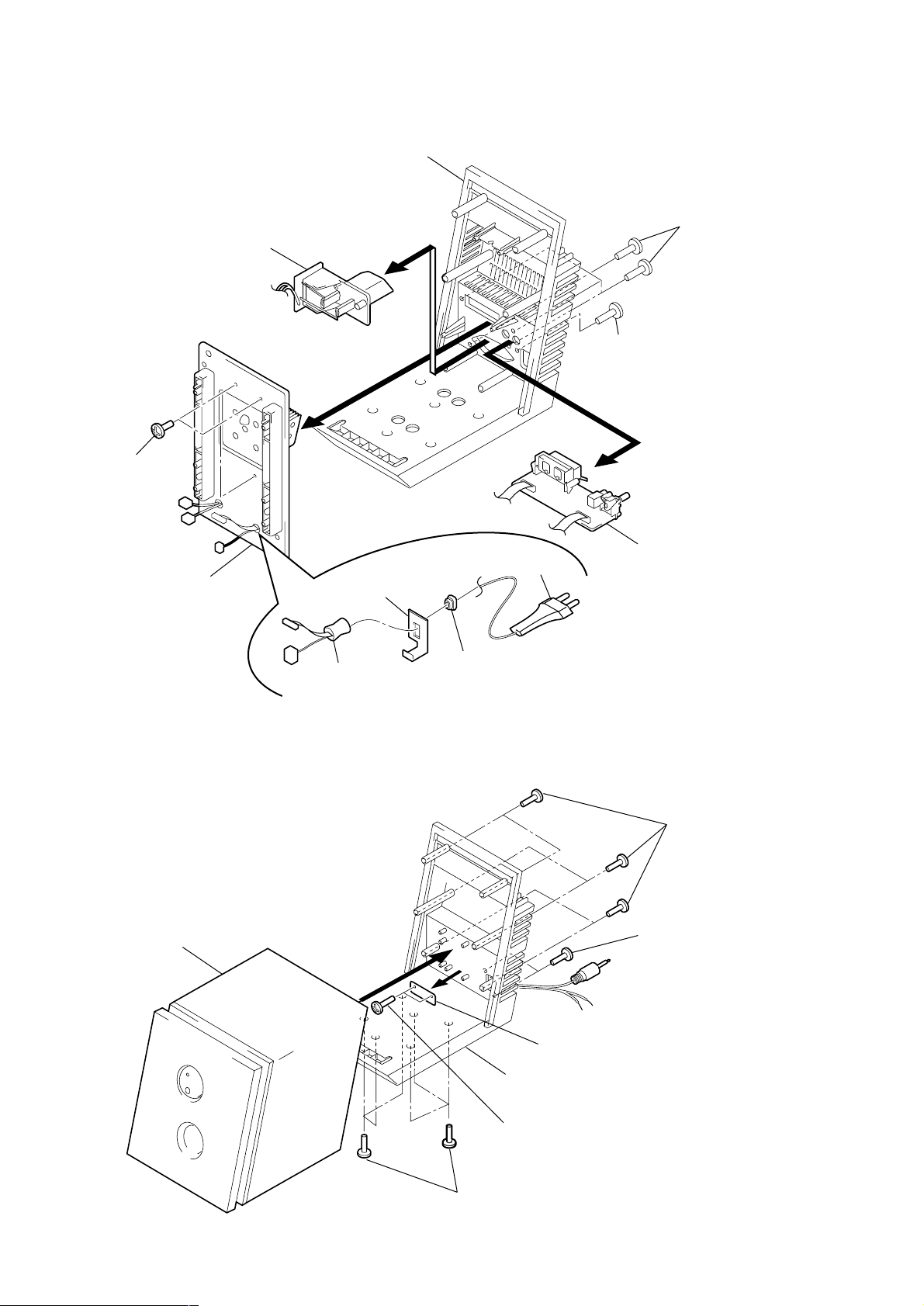

3-10. TC RF BOARD, HEAD RELAY BOARD, CAPSTAN/REEL MOTOR (M160)

6

Belt FR

Belt BR

Belt FR

7

Belt BR

1

Screws

4

Screws

9

3

5

Capstan/reel motor (M160)

Head relay board

TC RF board

8

Screws

2

Remove solder

2

Remove solder

3-11. CONTROL BOARD

3

Screws (+BVTT 2.6x8)

Cover ASSY, top

4

2

Control board

3

Screws (+BVTT 2.6x8)

– 11 –

DSP board

CPU board

1

Screws (+BVTT 2.6x8)

Page 12

3-12. DISPLAY BOARD

d

)

2

Wire, parallel (18 core)

DSP board

1

Screws (+BVTT 2.6x8)

3-13. DSP BOARD, CPU BOARD

4

Display board

Holder, Display PC board

3

Wire, parallel (19 core)

1

Screws (+BVTT 2.6x8)

CPU boar

DSP board

4

Wire, parallel (14 core)

Wire, parallel (18 core)

5

6

Wire, parallel (19 core)

8

– 12 –

3

7

Holder, Display PC board

Display board

2

Support

CPU board

Screws (+BVTT 2.6x8

Page 13

3-14. V OL BOARD

s

Panel ASSY, front

1

2

Claws

1

Claw

1

Claws

< SPEAKER UNIT (R-CH) >

3-15. “CABINET , WOOD”, “CABINET (R) BOTTOM”

4

3

Screws (+BVTT 2.6x8)

VOL board

Case (top)

1

Claws

2

Screws (+P 4x16)

Cabinet, Wood

3

– 13 –

Cabinet (R) bottom

Sponge, back board

Note : Change a “Sponge, back board”

(3-042-179-01) for a new article

when remove the cabinet (R) bottom.

1

Screws (+P 4x16)

Page 14

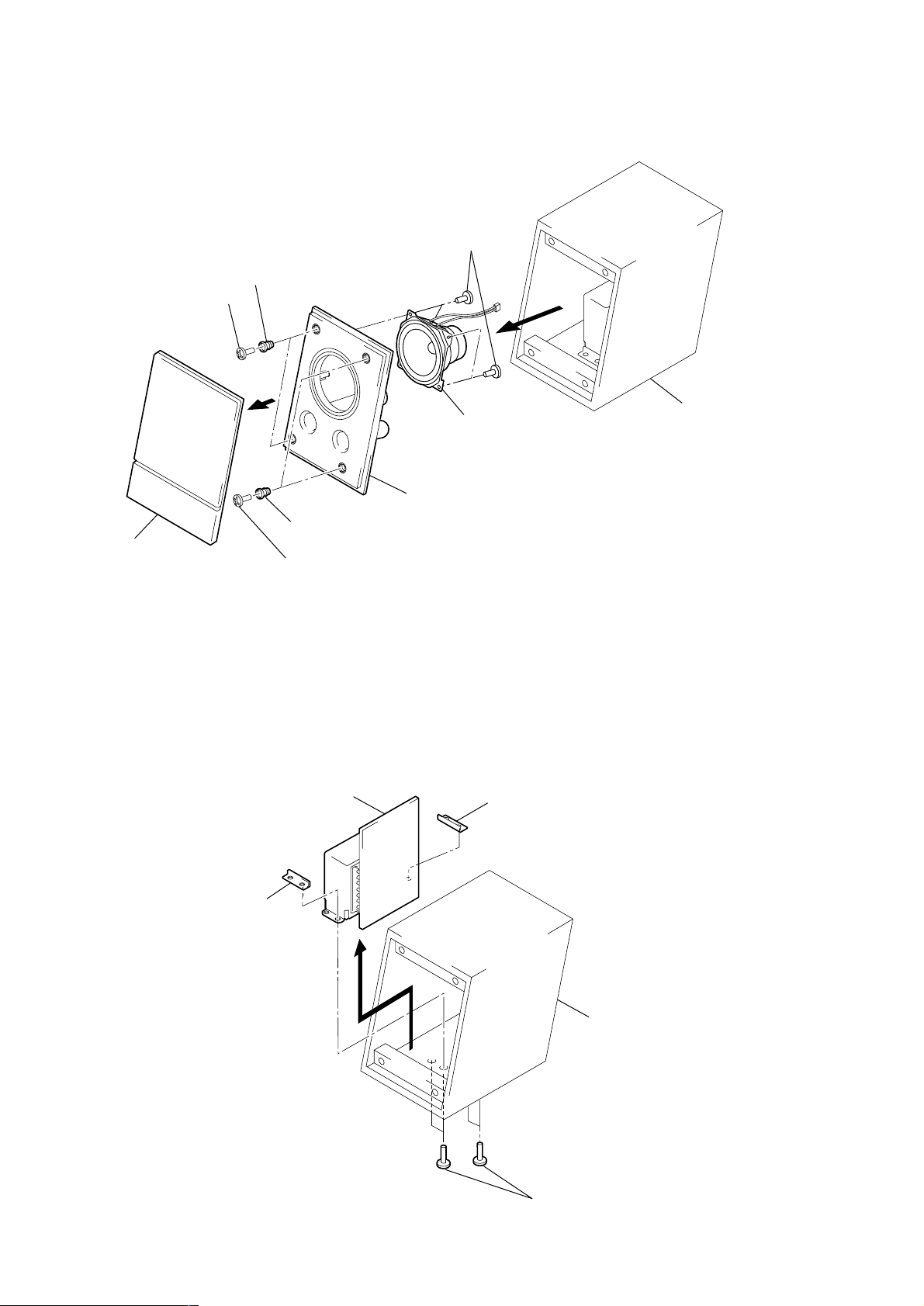

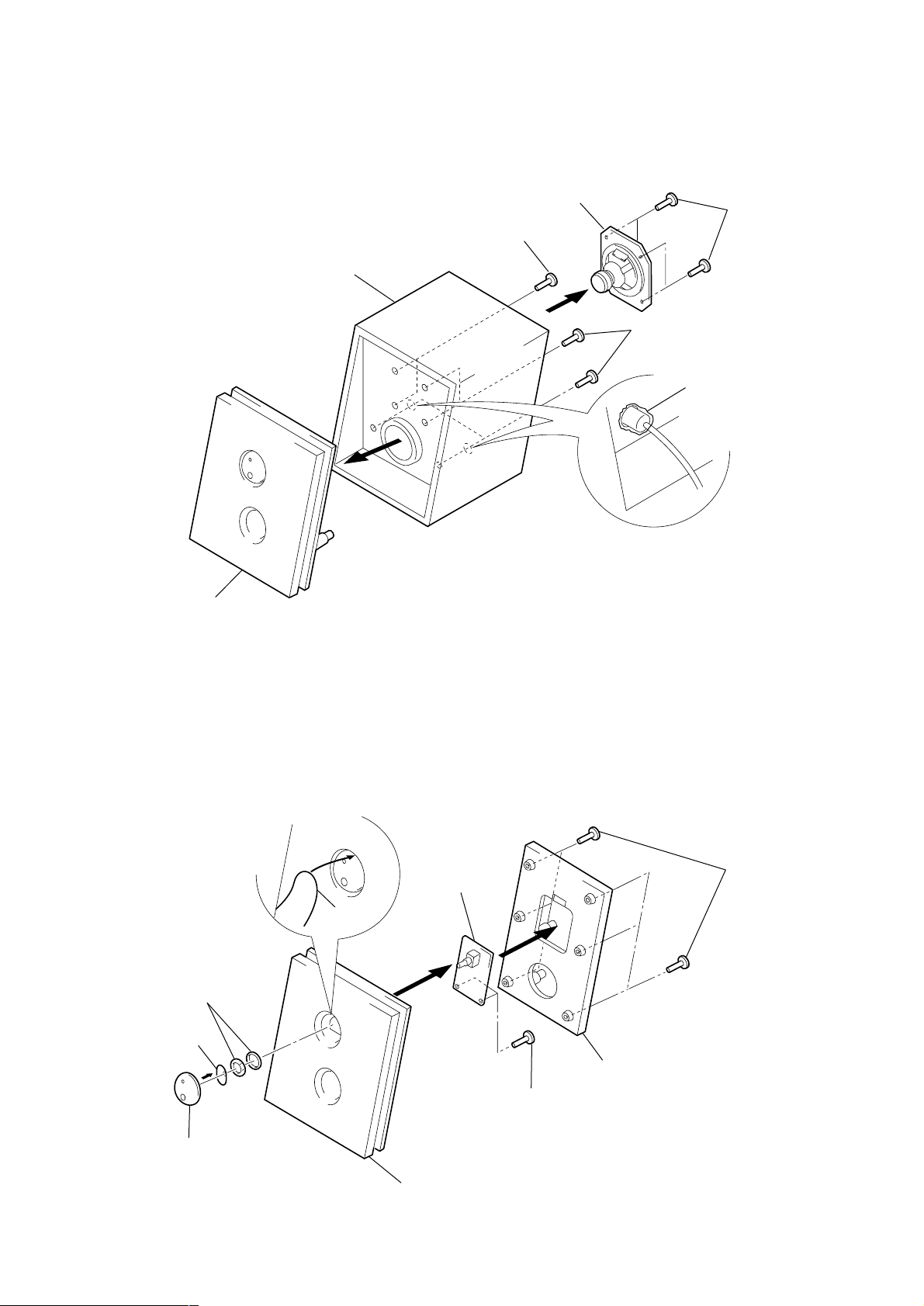

3-16. SPEAKER (R-CH) (SP101)

d

Stand, Grill

2

Screws (+BVTT 4x10)

1

Speaker grill ASSY

Stand, Grill

2

Screws (+BVTT 4x10)

4

Screws

Speaker (SP101)

Sub panel (R) ASSY

3

Cabinet, Wood

3-17. POWER BOARD

Bracket, Transfomer

Power board

Bracket, Transfomer

2

Cabinet, Woo

– 14 –

1

Screws (+P 4x10)

Page 15

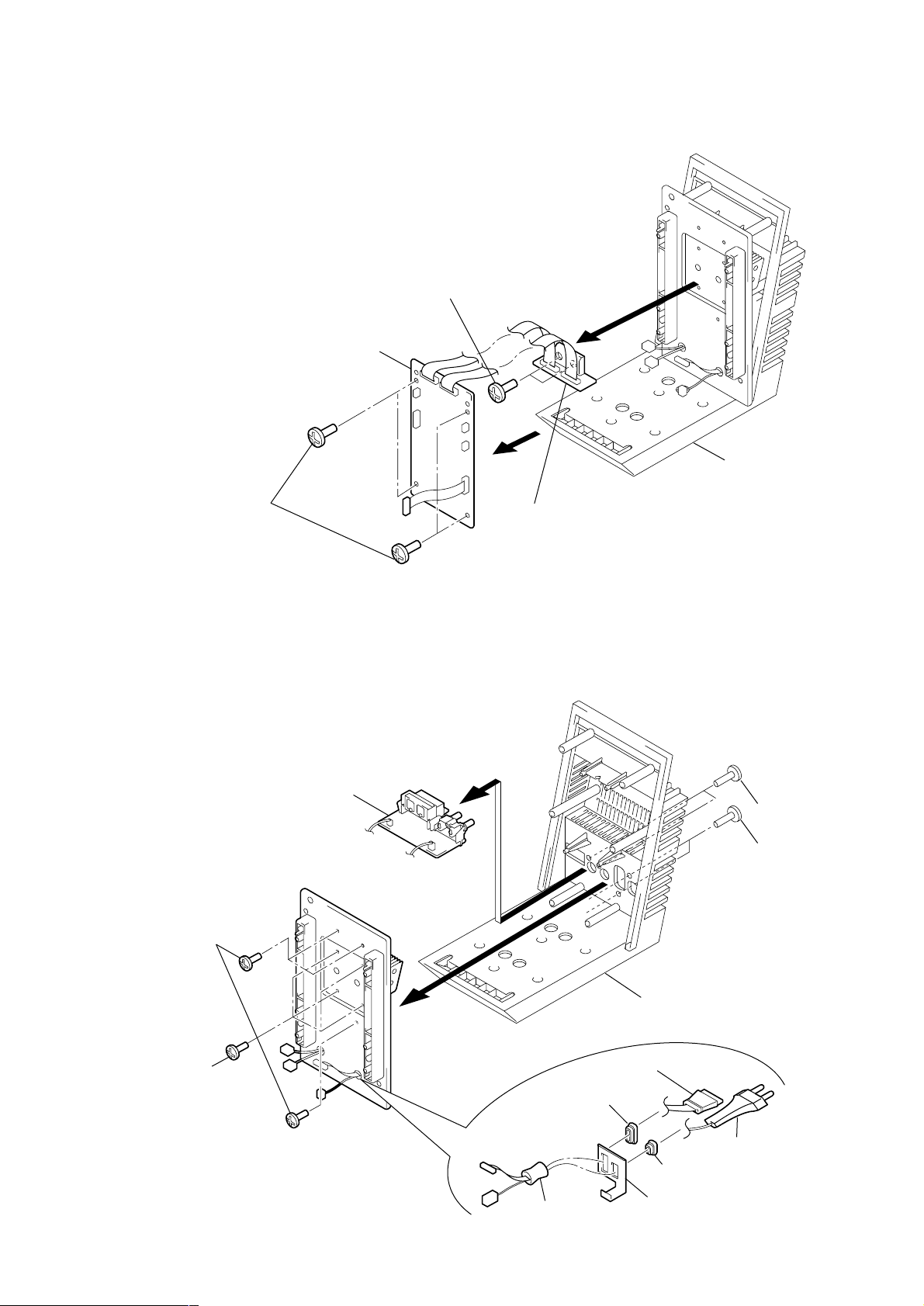

3-18. AMP BOARD, AMP IC BOARD

m

AMP board

1

Screws (+BVTT 3x12)

3

Screws (3x10)

AMP IC board

4

2

Cabinet (R) botto

3-19. SPEAKER BOARD

2

Screws

(+BVTT 3x8)

1

Screws

(+BVTT 3x10)

Speaker board

3

5

Stopper, wire

Cabinet (R) bottom

Cord with connector

4

Screws

(+BVTT 3x8)

6

Screws

(+BVTT 3x8)

– 15 –

Airtight clipper

Stopper, cord

Bracket

Cord, AC

Page 16

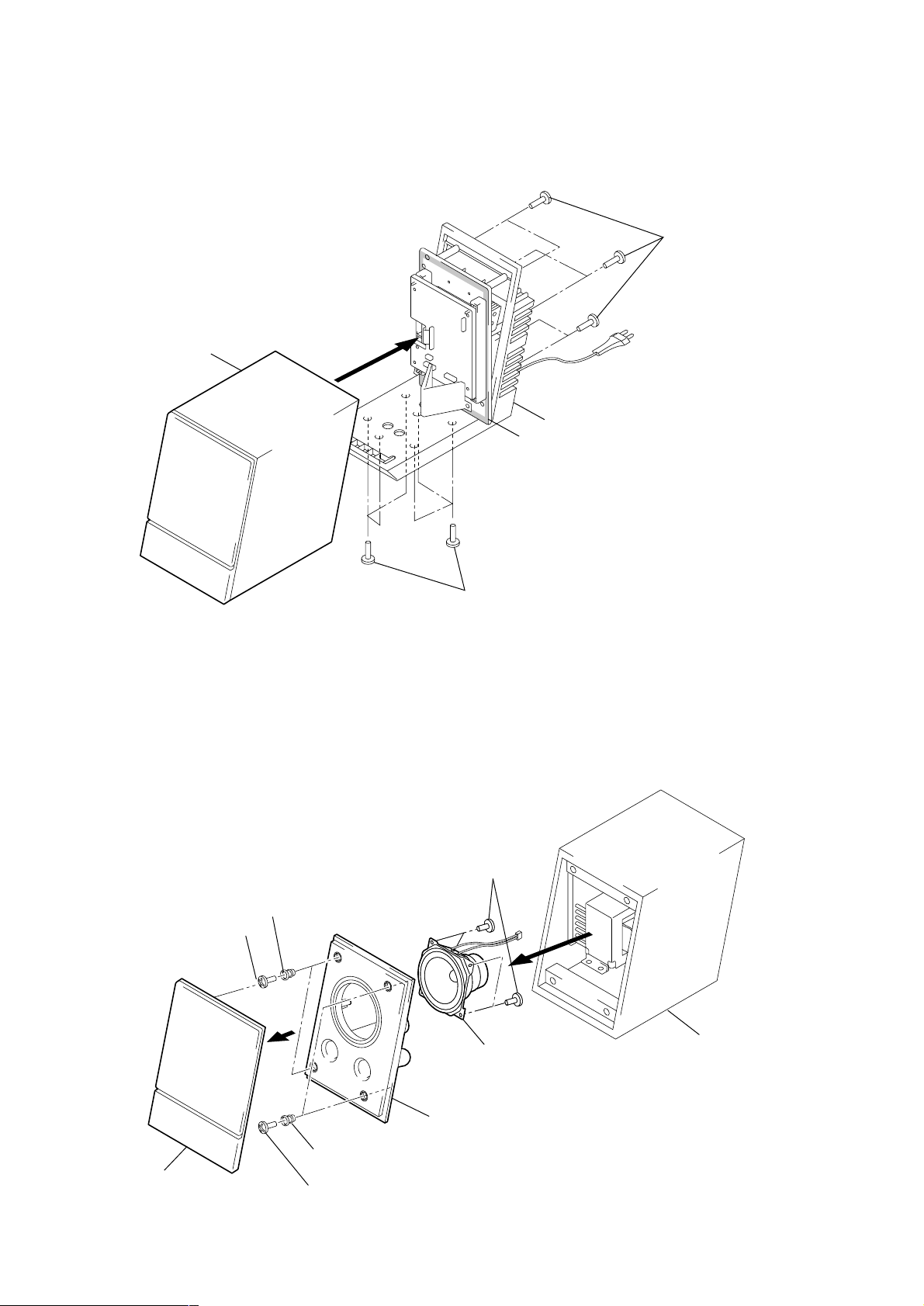

< SPEAKER UNIT (L-CH) > (DR70L)

3-20. “CABINET , WOOD”, “CABINET (L) BOTTOM”

2

Screws (+P 4x16)

Cabinet, Wood

3-21. SPEAKER (L-CH) (SP201)

3

Sponge, back board

Note : Change a “Sponge, back board”

1

Screws (+P 4x16)

Cabinet (L) bottom

(3-042-179-01) for a new article

when remove the cabinet (L) bottom.

2

Screws (+BVTT 4x10)

Speaker grill ASSY

Stand, Grill

1

Stand, Grill

2

Sub panel (L) ASSY

Screws (+BVTT 4x10)

– 16 –

4

Screws

3

Speaker (SP201)

Cabinet, Wood

Page 17

3-22. POWER TRANSFOMER BOARD

d

m

Power transformer board

Bracket, Transfomer

Bracket, Transfomer

2

Cabinet, Woo

3-23. SP MAIN BOARD, SP AMP IC BOARD

1

Screw

SP main board

SP AMP IC board

1

Screws (+P 4x10)

Cabinet (L) botto

1

Screws (+BVTT 3x12)

– 17 –

1

Screws (+BVTT 3x8)

Cover

Page 18

3-24. AC OUTLET BOARD, SP JACK BOARD

)

Cabinet (L) bottom

AC outlet board

4

3

Screws (+BVTT 3x8

6

Screw (+BVTT 3x8)

2

1

Screws

(+BVTT 3x8)

Board (L) back

Bracket

Airtight clipper

< SUPER WOOFER UNIT > (DR70L)

3-25. CABINET (SWF) BOTTOM, CONNECTOR BOARD

Stopper, cord

Cord, AC

5

SP jack board

2

Screws

(+P 4x16)

Cabinet (SWF) wood

4

– 18 –

Cabinet (SWF) bottom

5

Screws (+BVTT 3x8)

Screws (+P 4x16)

1

6

Connector board

3

Screws (+BVTT 3x8)

Page 19

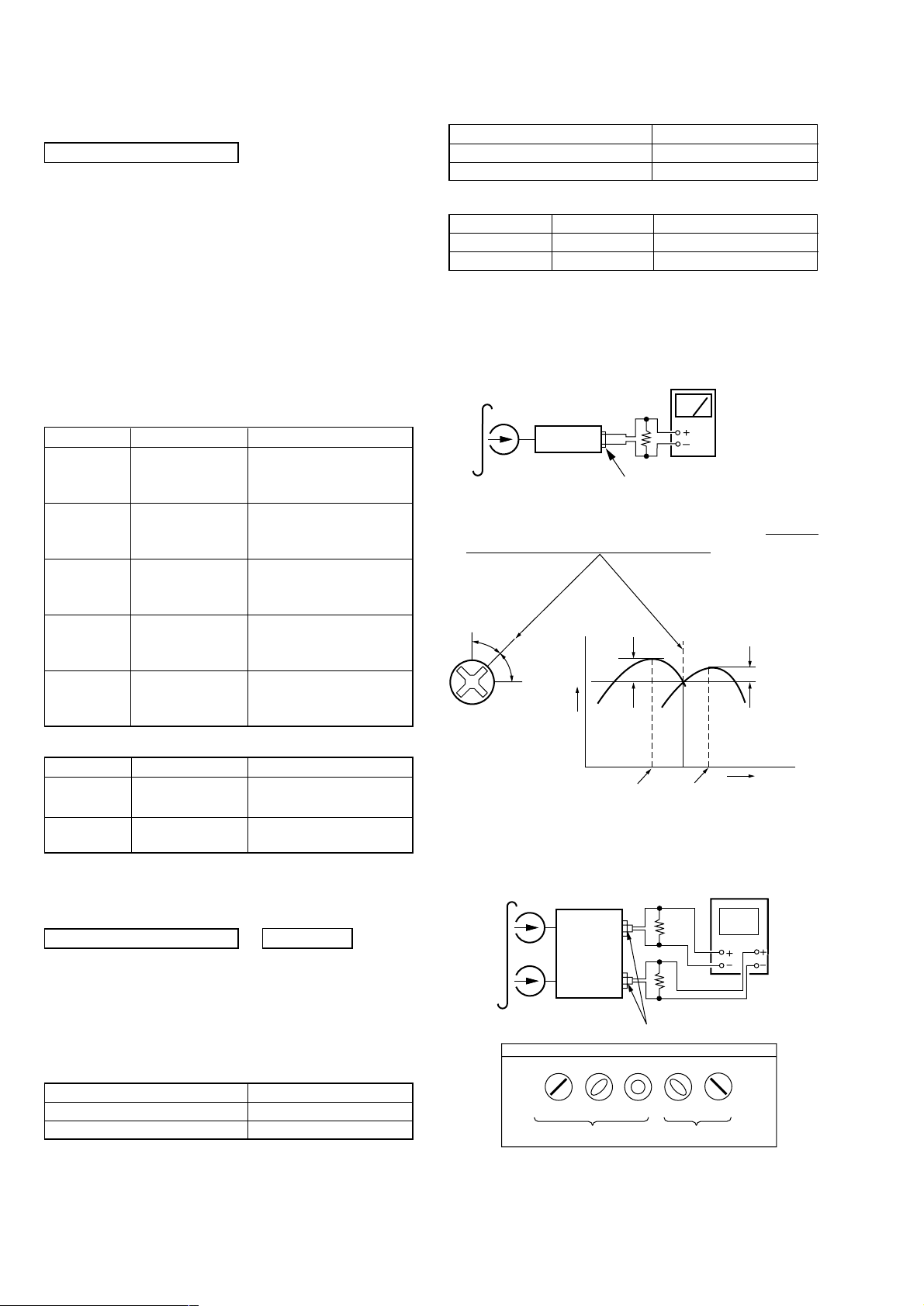

3-26. SPEAKER (SP601), “CABINET, FRONT”

2

5

Speaker (SP601)

1

Screws (+P 4x16)

4

Screws (+P 4x16)

4

Screws (+P 4x16)

3

Pull up a airtight

clipper.

Cabinet (SWF) wood

Cabinet, front

5

7

6

Screws (+BVTT 3x8)

3

Nut and waher

2

4

Screws (+PWH 3x10)

1

Hang thread in a circumuference of

“Knob ASSY, VOL”, and pull it up

LED board

Cabinet, front

Chassis (SWF) sub

Knob ASSY, VOL

Thread

Volume board

3-27. LED BOARD, VOLUME BOARD

– 19 –

Page 20

SECTION 4

)

n

ADJUSTMENTS

4-1. MECHANICAL ADJUSTMENTS

TAPE RECORDER SECTION

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback/erase head pinch roller

rubber belts capstan

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

Torque Measurement

Torque Torque Meter Meter Reading

3.54 to 5.98 mN • m

Forward CQ-102C (36 to 61 g • cm)

(0.5 to 0.84 oz • inch)

Forward

Back Tension

Reverse CQ-102RC (36 to 61 g • cm)

Reverse

Back Tension

FF/REW CQ-201B (61 to 143 g • cm)

CQ-102C (2 to 6 g • cm)

CQ-102RC (2 to 6 g • cm)

0.197 to 0.588 mN • m

(0.028 to 0.083 oz • inch)

3.54 to 5.98 mN • m

(0.5 to 0.84 oz • inch)

0.197 to 0.588 mN • m

(0.028 to 0.083 oz • inch)

5.99 to 14.02 mN • m

(0.85 to 1.98 oz • inch)

T ape Tension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A

REV CQ-403A

more than 100g

(more than 3.53 oz)

more than 100g

(more than 3.53 oz)

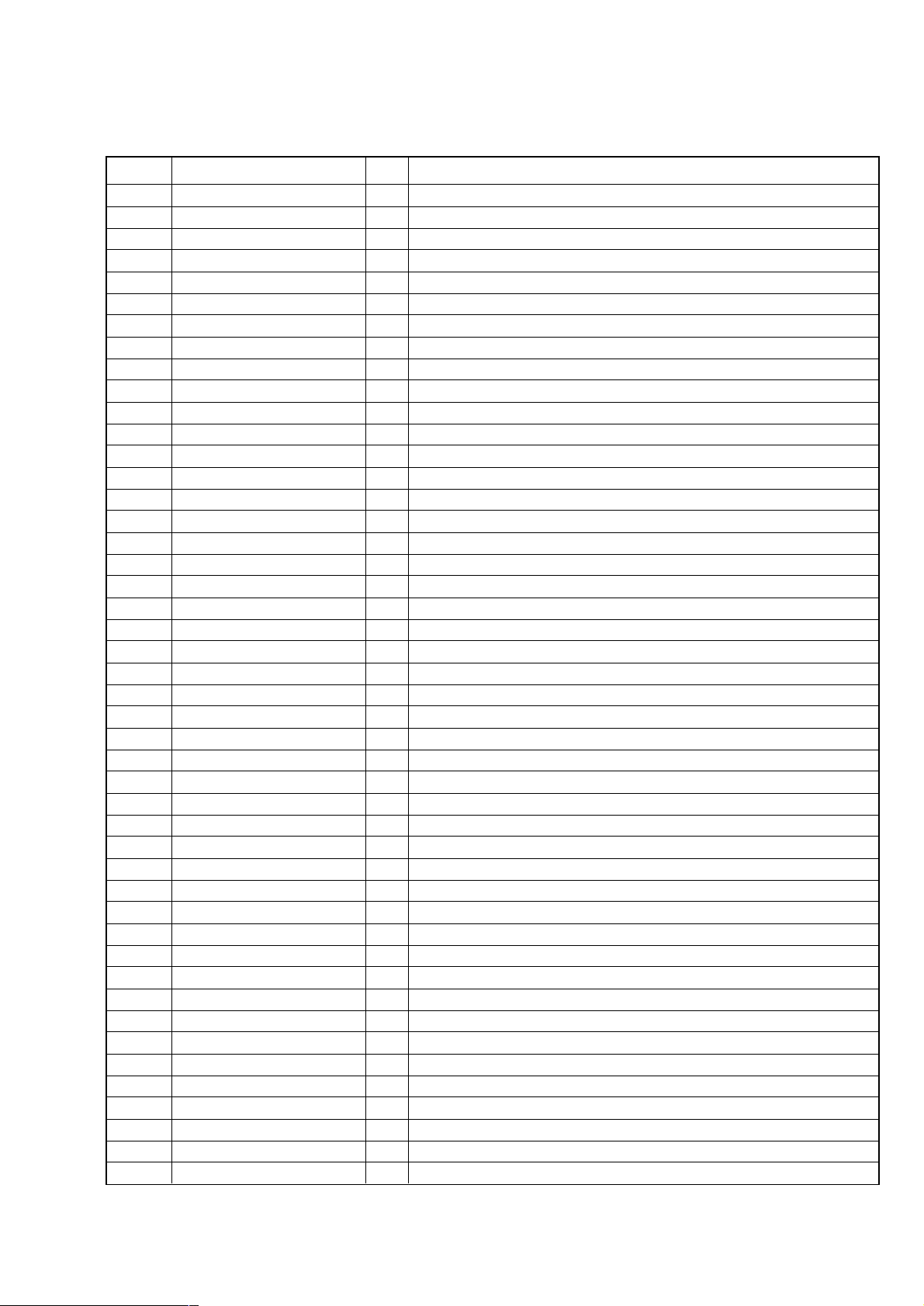

4-2. ELECTRICAL ADJUSTMENTS

Standard Output Level

Output terminal LINE OUT

load impedance 47kΩ

output signal level 0.5V (–3.8dB)

Test T ape

Type Signal Used for

P-4-A100 10kHz, –10dB Azimuth Adjustment

WS-48B 3kHz, 0dB Tape Speed Adjustment

Record/Playback/Erase Head Azimuth Adjustment

Procedure :

1. Mode : FWD playback

test tape

P-4-A100

(10kHz, –10dB)

set

level meter

47k

Ω

LINE OUT (JK301

2. Turn the adjustment screw for the maximum output levels. If

these levels do not match, turn the adjustment screw until both

of output levels match together within 1dB.

L-CH

peak

within

Screw

position

R-CH

peak

output

level

1 dB

L-CH

peak

R-CH

peak

within

1 dB

screw positio

3. Phase Check

Mode : FWD playback

test tape

P-4-A100

(10kHz, –10dB)

L-CH

47k

Ω

Osilloscope

TAPE RECORDER SECTION 0dB = 0.775V

1. The adjustnemts should be performed in the order in the service

manual. (As a general rule playback circuit adjustment should

be completed beforeming recording circuit adjustment.)

2. The adjustments should be performed for bothe L-CH and RCH unless otherwise indicated.

Standard Intput Level

Input terminal LINE IN

source impedance 10kΩ

input signal level 0.5V (–3.8dB)

– 20 –

R-CH

in phase

set

screen pattern

45

°

good

47k

Ω

LINE OUT (JK301)

135

°

wrong

180

90

°

H

V

°

Page 21

B

r

t

4. Change the reverse playback mode and repeat the step 1 to 3.

5. After the adjustment, lock the adjustment screw with suitable

locking compound.

TUNER SECTION

AM Section

0dB=1µV

Adjustment Location : – record/playback/erase head –

FWD side REV side

adjustment screw

Tape Speed Adjustment

Procedure :

– FWD Playback Mode –

test tape

WS-48B

(3kHz, 0dB)

set

frequency counter

47k

Ω

LINE OUT (JK301)

1. Set to FWD playback mode.

2. Adjust RV160 so that the frequency counter reading becomes

3,000Hz.

Standard value : 2,970 to 3,030Hz

3. Set to REV playback mode.

Confirm the frequency should be within the standard value.

4. Confirm the frequency difference between beginning and the

end of tape should be within 1.5% (45Hz).

Adjustment Location : TC RF board

Cabinet, front (Rear side)

BAND button : MW or LW

Volume : MIN

60cm

loop antenna A

AM RF signal

generator

30% amplitude modulation by 400Hz

signal

Output level : as low as possible

loop antenna

set

FM Section

BAND button : FM

Volume : MIN

FM RF signal

generator

µ

F

22.5kHz frequency deviation by

400Hz signal.

Output level : as low as possible

47k

Ω

set

LINE OUT (JK301)

0.01

level mete

FM EXT.

ANT.

terminal

+

–

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

TC RF board

RV160 : Tape speed adjustmen

– 21 –

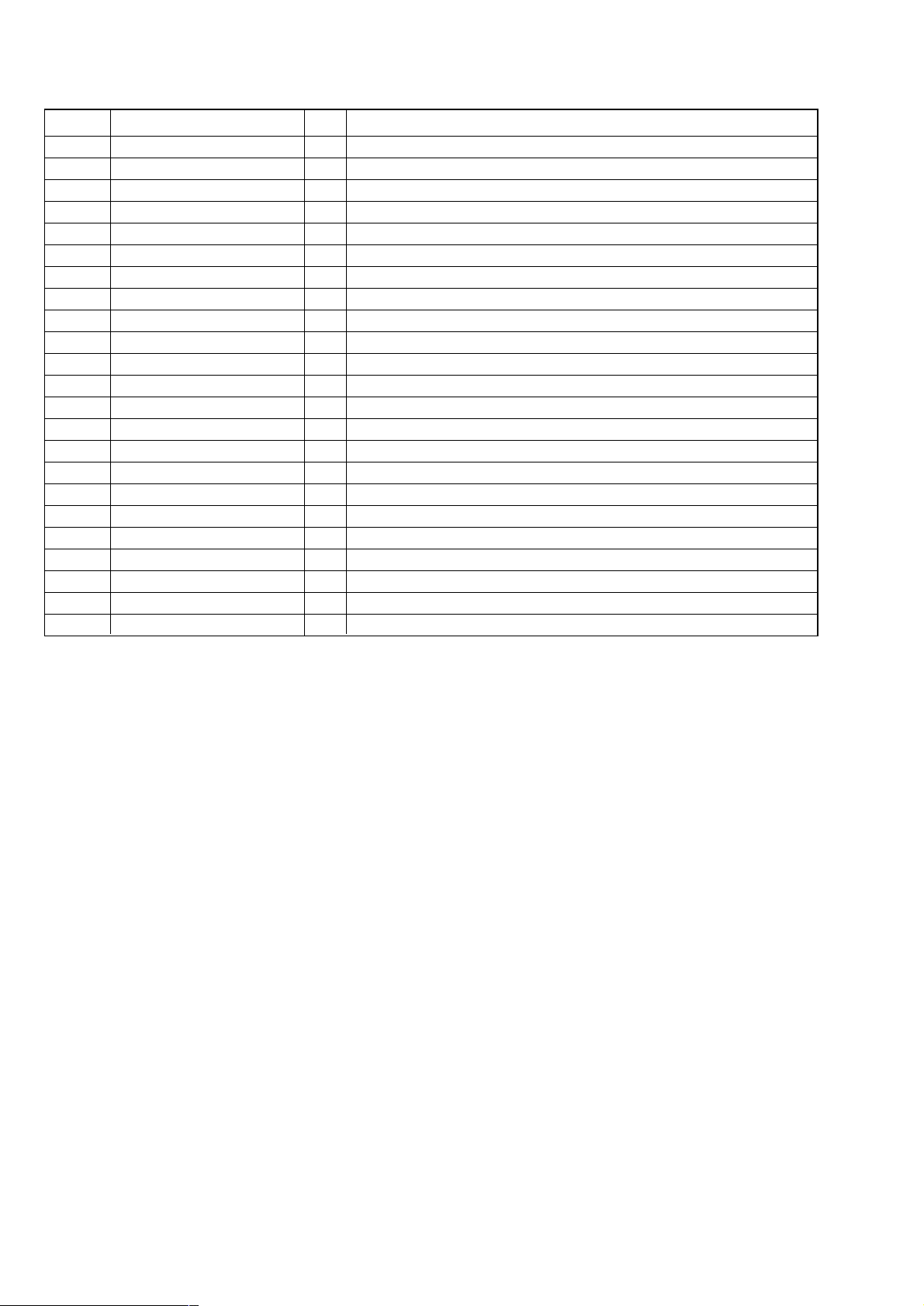

MW/LW IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T2 450kHz

MW FREQUENCY COVERAGE ADJUSTMENT

Adjust part Frequency display

L5 531kHz

CT4 1,611kHz

MW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 621kHz

TC102 1,404kHz

reading on digital

voltmeter.

Adjustment value :1.4V

Standard value : 1.2 – 1.6V

Adjustment value :7.5V

Standard value : 7.1 – 8.0V

Page 22

LW FREQUENCY COVERAGE ADJUSTMENT

t

Adjust part Frequency display

L10 153kHz

CT5 297kHz

LW TRA CKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L7 162kHz

CT3 261kHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T4 10.7MHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust part Frequency display

Confirmation 87.5MHz 1.2 – 1.8V

Confirmation 108MHz 7.7 – 7.9V

reading on digital

voltmeter

Adjustment value :1.4V

Standard value : 1.2 – 1.6V

Adjustment value :5.5V

Standard value : 5.4 – 5.6V

reading on digital

voltmeter

Connect and Adjustment Location :

Auto Stop Level Adjustment

FM RF signal

generator

µ

F

22.5kHz frequency deviation by

400Hz signal.

Output level : 30dB

µ

0.01

FM EXT.

ANT.

terminal

1. Set the frequency of FM SSG to 98MHz.

2. Press the TUNE button of the unit to start the AUTO TUNING.

3. Adjustment the SR1 to stop the auto tuning at 30dBm SSG output.

[MAIN BOARD] (Component side)

T2 : MW/LW IF Adjustment

L10 : LW Frequency coverage Adjustment

CT5 : LW Frequency coverage Adjustment

CT102 : MW Tracking Adjustment

MW/LW frequency coverage

FM frequency coverage

100 k

VT

GND

TP1

Ω

+

–

Digital voltmeter

L4 : MW Tracking Adjustmen

L7 : LW Tracking Adjustment

L5 : MW Frequency coverage Adjustment

SR1 : Auto Stop Level Adjustment

T4 : FM IF Adjustment

– 22 –

CT3 : LW Tracking Adjustment

CT4 : MW Frequency coverage Adjustment

Page 23

SECTION 5

DIAGRAMS

5-1. EXPLANATION OF IC TERMINALS

IC801 CXP82832-023Q (SYSTEM CONTROL, FL DRIVE)

Pin No. Pin name I/O Description

1 G02 O FL grid drive output.

2 G01 O FL grid drive output.

3 NC – Not used (OPEN).

4 CD SCOR I CD SCOR input.

5 T-COUNT I Tape rotation detect input.

6 P.DOWN IN (BACK UP) I Power ON detect input.

7 TAPE AMS IN I AMS signal input.

8 REMOTE IN I Remote control signal input.

9 FM STEREO IN I FM STEREO signal input.

10 RADIO SHFT CLK O Clock shift signal output.

11 LC72131 CE O Radio PLL IC chip enable output.

12 LC72131 CLK O Radio PLL IC clock output.

13 LC72131 DATA IN I Radio PLL IC data input.

14 LC72131 DATA OUT O Radio PLL IC data output.

15 CXD2589Q XRST O CD system reset output.

16 CXD2589Q XLAT O CD DSP IC command latch output.

17 CXD2589Q CLOCK O Clock output for CD DSP IC.

18 CXD2589Q DATA O CD DSP IC command data output.

19 CD OPEN SW IN I CD tray open switch input.

20 CD CLOSE SW IN I CD tray close switch input.

21 CXD2589Q SENS1 I CD SENS input.

22 BU1924F RCLK IN I Radio RDS IC clock input.

23 BU1924F RADIO DATA IN I Radio RDS IC data input.

24 BU1924F QUARTY IN I Radio RDS IC quarity input.

25 CXD2589 SQCK O Clock output for CD SUB-Q.

26 CXD2589 SQSO I CD SUB-Q input.

27 CXD2589 SENS2 I CD SENS input.

28 AVREF I Reference voltage input (for A/D converter).

29-33 KEY1-5 I Key return signal input.

34 TAPE STATUS I Tape detection input.

35 TAPE MECHA MODE SW I FWD/REV detection input.

36 VER I Destination setting terminal (fixed at “H”).

37 AVSS – Ground.

38 RESET I System reset input.

39 EXTAL O System clock output (8MHz).

40 XTAL1 I System clock input (8MHz).

41 VSS – Ground.

42 XTAL 32.768kHz I Real clock input (32.768kHz).

43 XTAL 32.768kHz O Real clock output (32.768kHz).

44 VDD – Power supply terminal.

45 VFDP – FL power supply terminal.

46 IN I I Initial setting input.

47 CD OPEN OUT O CD tray open signal output.

48 CD CLOSE OUT O CD tray close signal output.

49 P03 – Not used (OPEN).

50 P04 – Not used (OPEN).

– 23 –

Page 24

Pin No. Pin name I/O Description

51 SYS MUTE O Mute signal output.

52 TUNER MUTE O Tuner mute signal output.

53 CD MUTE O CD mute signal output.

54 LINE MUTE O Line mute signal output.

55 TAPE REC MUTE O Tape mute signal output.

56 TAPE REC O Tape REC output.

57 TAPE BIAS O Tape REC bias select output.

58 TAPE SOL O Plunger control output.

59 TAPE MECHA VCC OUT O Tape mechanism B+ ON/OFF output.

60 ISS 1 O ISS 1 ON/OFF output.

61 ISS 2 O ISS 2 ON/OFF output.

62 MEGA BASS O Mega bass ON/OFF output.

63 POWER CONT OUT O Power ON/OFF output.

64 SUMMER LED – Not used. (OPEN)

65 SOUND LED O SOUND LED ON/OFF output.

66 RDS LED O RDS LED ON/OFF output.

67 BH3854 CK O Clock output for electrical volume IC.

68 BH3854 DATA O Data output for electrical volume IC.

69 BH3854 LACH O LACH output for electrical volume IC.

70 RESERVE – Not used (OPEN).

71-88 SEG 1-18 O FL segment drive output.

89 VDD – Power supply terminal.

90-100 G03-13 O FL grid drive output.

– 24 –

Page 25

r

d

Circuit Boards Location.

MAIN UNIT-1

DISPLAY board

JACK boar

DSP board

MAIN board

MAIN UNIT-2

VOL board

CONTROL board

CPU board

TC RF board

MOTOR board

HEAD RELAY board

ASP board

– 25 –

Page 26

d

d

R-CH SPEAKER UNIT

d

AMP board

L-CH SPEAKER UNIT (DR70L only)

AMP IC board

POWER boar

SPEAKER board

POWER TRANSFORMER board

SP MAIN board

WOOFER UNIT (DR70L only)

AC OUTLET boar

SP JACK board

SP AMP IC board

LED board

– 26 –

CONNECTOR boar

VOLUME board

Page 27

PMC-DR50L/DR70L

5-2. BLOCK DIAGRAMS – TUNER SECTION –

• Signal path.

F : FM

f : MW/LW

– 27 – – 28 –

Page 28

5-3. BLOCK DIAGRAMS – CD SECTION –

PMC-DR50L/DR70L

– 29 – – 30 –

• Signal path.

J : CD

Page 29

PMC-DR50L/DR70L

5-4. BLOCK DIAGRAMS – TAPE SECTION –

– 31 – – 32 –

• Signal path.

F : FM

J : CD

E : PB

a : REC

Page 30

5-5. BLOCK DIAGRAMS – SPEAKER SECTION –

PMC-DR50L/DR70L

– 33 – – 34 –

• Signal path.

F : FM

Page 31

PMC-DR50L/DR70L

5-6. PRINTED WIRING BOARDS – MAIN SECTION – z Refer to page 25 to 26 for Circuit Boards Location.

1

2

A

3 4 5 6 7

JACK BOARD

CN303

(Page 44)

O

8

JACK BOARD

CN308

(Page 44)

N

9 10 11 12 13

C

CONTROL BOARD

CN304

(Page 54)

H

VOL BOARD

CN809

(Page 54)

L

CPU BOARD

CN811

(Page 54)

J

CPU BOARD

CN812

(Page 54)

K

DSP BOARD

CN752

(Page 48)

M M

MAIN BOARD

J164

R225

Q231

CA220

E

C

B

R111

L331

L311

R211

D3

D4

R120

R220

R214

L131

D1

D2

L111

CA51

Q131

L231

R215

J166

E

C

B

L211

Q3

B

JK301

LINE OUT

C

JK302

LINE IN

D

E

HRPE101

RECORD/PLAYBACK/ERASE

HEAD

F

L-CH

HEAD RELAY BOARD

CN301

4

3

JK1

FM75

EXT. ANT.

CN1

MW/LW

R-CH

ERASE

02

G

z

Semiconductor

1-673-339-

6

5

2

1

11

(11)

CN1

J165

Q204

E

C

B

Q232

R114

CA230

JA88

E

C

B

J101

B

C

E

CA120

E

C

B

Q104

Q132

CA50

Z

B

C

E

J169

J170

R115

X1

TP1

GND VT

L4

L7

R125

J168

CA57

CA56

CF7

R124

Q101

Q201

E

E

C

C

B

B

R224

R308

C225

C321

R223

C223

C226

J167

C94

R41

J162

R74

8765 4321

R42

1

22

CT102

Q5

E C B

CT3

R65

R61

C43

CA95

C44

R32

R15

R33

R13

C71

R43

5

IC3

R222

Q108

C73

Q351

CA96

D

S

G

CA14

R62

Q327

R384

B C E

B

C

E

R385

C125

A

R221

R321

8

IC307

5

C97

CC97

C55

11

10

121520

C59

C52

R34

C41

C42

CA13

C13

TU1

L8

CA155

RA155

CB155

RB155

D6

C16

R14

E

C

B

Q19

R60

C79

J216

R64

1

4

RC199

J198

R70

J171

J132

CA10

D8

1

R39

R31

RA31

C17

C123

R135

R17

C8

J130

C65

C78

R59

C328

C320

R123

R40

C77

R122

JC31

R30

C19

R58

D9

CT4

Q4

R121

C6

B

C

E

R5

E

C

B

Q7

J163

C212

RA70

75

P

Q368

G D S

R309

L6

C58

R8

C14

R12

CF1

R6

L10

R63

J102

J160

D20

J131

CN303

R317

J161

C126

RA24

Q6

B

C

E

D10

IC305

1

R319

R320

R349

C329

Q367

B C E

R116

R216

CN301

CC302

CA301

L14

C48

R7

J107

Z

L5

R16

QA7

S

D

G

JA7

J172

1

5

7

L13

J108

C7

RA317

D318

R227

C112

J173

R127

Q307

R110

B

C

R324

C51

Q1

B C E

CF2

R24

C20

R315

G

SFR1

Q303

J195

L9

E

B

C

E

R314

RA315

R44

J103

S

D

G

Q271

J129

J128

T2

C62

Q302

B

C

E

R204

CF4

R210

5

C324

C203

R271

J104

J213

J174

R202

C64

9

C326

D314

C325

C307

J175

R203

J106

C

R350

R212

D317

D319

R382

C208

R306

R304

J196

13 15 20

J159

IC301

12

10

C204

R201

C201

C205

C302

C202

C21

C27

CA35

C167

C18

CA204

CF3

J201

C26

R23

1 5 10 12

24

20

J214

R51

RA73

CA38

C35

CA94

R381

R240

C104

C105

IC2

R318

J215

T4

J214

R140

5

R101

C38

R21

C29

C327

J156

CA304

B

R103

C102

CA21

CA19

R73

Location

Ref. No. Location

D1 D-4

D2 D-4

D3 F-4

D4 F-4

D6 F-5

Ref. No. Location

D317 B-8

D318 B-7

D319 C-8

D361 B-12

D380 B-12

Ref. No. Location Ref. No. Location Ref. No. Location Ref. No. Location

IC302 C-11

IC304 B-12

IC305 B-7

IC307 C-6

Q102 B-10

Q104 B-5

Q108 E-5

Q131 D-4

Q132 D-5

Q304 F-11

Q305 F-11

Q306 F-11

Q307 C-7

Q308 E-11

Q328 F-11

Q329 B-11

Q330 E-12

Q333 C-9

Q351 B-5

C15

J176

C108

JA194

C103

CN811

24

1

R102

C101

J202

C23

J105

R36

C54

1315

J146

Q316

B

C

E

C22

CB304

J158

R301

R104

R374

C25

19

18

1

CN815

J147

Q171

S

D

G

J126

J127

R20

J213

C89

R307

57

3

J157

J194

J148

J149

J150

J151

J152

R112

Q333

C304

B C E

C301

D301

R171

J192

J193

J191

C24

C37

C49

C56

R28

C32

R26

C60

C30

C46

J212

CN804

15

10

I

CPU BOARD

CN804

(Page 53)

Q16

1

J135

D11

J155

E

C

B

A

J153

J154

R72

C31

56

1

DA317

J136

J134

J133

R303

R37

R57

C61

5

C98

J198

R56

J125

J113

JB210

1

2

CN812

Q202

J121

J122

C57

C33

1

J177

E

C

B

J145

CN308

CA337

B

C243

J123

J124

E

C

B

R27

J210

CA111

1

5

G

CN302

J178

Q102

Q320

E C B

CA11

Q17

RA39

E

C

B

J179

J209

56

J181

J180

C241

J212

J200

J144

CA338

C333

C

C242

R245

J188

C316

CA313

C313

Q324

B C E

J114

J112

B

C

Q306

E

J208

J111

D

JACK BOARD

(Page 44)

J211

1

CN304

P

J182

C141

DA318

R346

C142

C143

IC302

1

510 16

J110

C245

C244

J187

C314

L301

Q308

R325

J207

J206

J205

R359

R332

4

C246

B

C

E

R316

D312

R145

J211

J204

Q329

R343

R390

E

C

B

J203

Q309

C380

R38

E

C

B

C144

R347

J190

Q325

J119

B C E

E

C

B

1720253032

C312

B

C

E

Q304

Q328

R370

R337

DA316

C145

CA315

C347

E

C

B

Q326

J115

R352

C146

R371

R358

R313

C

B

J116

R335

R386

R348

R311

E

IC304

1 2 3

1

R94

C93

C311

Q305

CA64

J184

B

C

E

R388

R379

R377

C385

D380

4

R95

C91

1

5

IC4

8

C92

C336

J186

C341

J185

C335

R312

R340

C315

Q301

J118

R353

J117

R328

R389

R380

1

TC RF BOARD

CN691

(Page 44)

Q381

1

B

C

CN307

E

D361

J100

R387

CN813

R93

R91

16

12

9

R92

C337

CA342

R383

J120

R339

Q312

D316

59

X2

C339

E

C

B

JA120

D304

J140

C95

C340

R338

Q317

S D G

C334

Q330

R357

J143

J142

J141

C96

J173

J138

E C B

R344

Q311

R334

CN305

1-676-101

P

J183

E

C

B

R356

DA380

C381

C382

R378

4

11

(11)

D8 G-6

D9 D-6

D10 D-7

D11 E-10

D20 D-7

D301 D-9

D304 F-12

D312 F-11

D314 B-8

D316 F-12

DA315

DA316 C-11

DA317 B-10

DA318 B-11

DA380 F-12

IC2 F-9

IC3 D-5

IC4 C-12

IC301 C-8

– 35 – – 36 –

Q1 E-7

Q3 F-4

Q4 F-6

Q5 F-5

Q6 D-7

Q7 F-6

Q16 F-10

Q17 F-10

Q19 F-16

Q101 B-5

Q171 D-9

Q201 B-5

Q202 B-10

Q204 B-4

Q231 C-4

Q232 C-4

Q271 D-8

Q301 E-12

Q302 D-8

Q303 D-7

Q309 G-11

Q311 E-12

Q312 E-12

Q316 B-9

Q317 G-12

Q320 C-10

Q324 E-11

Q325 E-11

Q326 F-11

Q327 B-6

Q367 B-7

Q368 B-7

Q381 A-12

QA7 F-7

Note:

• X : parts extracted from the component side.

• x : parts mounted on the conductor side.

f

•

: internal component.

• b : Pattern from the side which enables seeing.

There are a few cases that the part isn’t mounted in

model is printed on diagram.

Page 32

5-7. SCHEMATIC DIAGRAM – MAIN SECTION (1/3) – z Refer to page 67 for Notes. z Refer to page 68 for Waveforms.

PMC-DR50L/DR70L

– 37 – – 38 –

Page 33

PMC-DR50L/DR70L

5-8. SCHEMATIC DIAGRAM – MAIN SECTION (2/3) – z Refer to page 67 for Notes. z Refer to page 68 for Waveforms.

– 39 – – 40 –

Page 34

5-9. SCHEMATIC DIAGRAM – MAIN SECTION (3/3) – z Refer to page 67 for Notes.

PMC-DR50L/DR70L

– 41 – – 42 –

Page 35

PMC-DR50L/DR70L

5-10. PRINTED WIRING BOARDS – JACK SECTION – z Refer to page 25 to 26 for Circuit Boards Location.

z

Semiconductor

Location

Ref. No. Location

D305 B-4

D308 D-3

D309 D-4

D310 D-4

D311 D-3

D313 D-4

D315 D-3

D320 D-3

DA399 D-2

DB399 D-2

IC303 C-4

Q103 C-4

Q203 D-4

Q314 D-3

Q315 C-2

Q318 D-3

Q319 D-4

Q323 D-2

Q334 D-4

Q335 D-2

Q398 B-2

Q399 A-2

A

DR70L

B

SIGNAL OUT

SIGNAL OUT

DSP BOARD

C

D

1

JK312

BASS

JK311

CN753

(Page 48)

PH01

OPTICAL

DIGITAL OUT(CD)

CN311

POWER IN

FROM SP-R

G

AMP BOARD

CN503

(Page 59)

A

2

3 4 5 6 7

8

TC RF BOARD

JACK BOARD

Q399

B

J14

C

Q398

C340

C399

R391

E

B

R390

C

E

C398

R344

L

J13

R

C341

CN313

R342

PH01

CN312

C313

1

C312

1

4

4

Q323

CA312

C311

CN311

7

5

1

L311

JA311

R146

JA14

C342

C

E

R398

R392

C147

CN308

C247

1

3

CA253

R379

B

J12

R399

R393

1

5

R251

Q315

B

C

E

C360

R378

E

C

B

Q335

LA312

C393

D315

R151

C397

R246

Q314

R360

C348

C153

C253

C352

C394

C391

R395

C359

J11

C

E

R376

J3

B

Q318

B

C

E

D308

RA331

R394

R253

C252

D320

R331

R252

CA352

C392

R152

R153

C152

8

5

R362

R367

J9

CA301

CN303

C355

D311

R361

R305

R330

D305

R345

IC303

J7

D309

C346

J4

R368

D310

J10

1

4

R351

R302

C155

J5

E

C

B

R369

RA15

J1

J2

C351

Q334

D313

C356

175

R255

C350

CA156

J6

C357

Q319

1-676-102-

R256

Q103

B

C

E

B

C

E

R156

C255

CN314

1

CA256

5

Q203

E C B

MAIN BOARD

N

D

MAIN BOARD

(Page 36)

F

CONTROL

BOARD

CN314

(Page 54)

11

(11)

CN308

(Page 36)

MAIN BOARD

CN305

(Page 36)

P

(FWD ERASE PROOF)

(TAPE SPEED)

S303

S305

(CrO2)

CN691

9

(HEAD POSITION)

5

1

RV160

S302

S301

(HALF DET)

PH160

R160

R158

PM160

PLUNGER

SOLENOID

M160

CAPSTAN/REEL

MOTOR

E

02

Note:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

There are a few cases that the part isn’t mounted in

model is printed on diagram.

– 43 – – 44 –

DA399

DB399

CN312

1

4

M

CPU BOARD

CN803

(Page 53)

MAIN BOARD

O

(Page 35)

CN303

S304

(REV ERASE PROOF)

1-673-338-

M

11

(11)

Page 36

5-11. SCHEMATIC DIAGRAM – JACK SECTION – z Refer to page 67 for Notes.

PMC-DR50L/DR70L

– 45 – – 46 –

Page 37

PMC-DR50L/DR70L

5-12. PRINTED WIRING BOARDS – CD SECTION – z Refer to page 25 to 26 for Circuit Boards Location.

1

2

3 4 5 6 7

8

9 10 11 12

DSP BOARD

CN752

1

6

J779

CN702

19

1

5

1

RA799

3

1

CA793

RF701

15

10

15

10

5

J752

20

2

2

CN754

CN806

C798

J753

R757

R758

R759

R760

R762

C799

J778

CA768

L754

J770

L751

J777

R763

J771

J772

J773

R752

R753

R761

J776

J775

C761

R766 R765

C768

J774

C763

J754

R756

C776

J755

R755

J769

R764

C767

R767

R754

C753

C754

C752

C756

R751

10

15

20

21

25

30

35

C764

C762

E

CPU BOARD

(Page 53)

R793

R796

C769

J768

C755

5

40

C765

C751

1

IC751

C771

C772

R768

J767

80

41

E

C

B

75

45

R769

R795

R794

Q754

R782

R784

C773

C782

XTL701

70

65

61

60

55

L752

50

13

J757

C766

J756

A

JACK BOARD

CN313

(Page 43)

E

C

B

R786

R771

C784

C779

J766

CN753

R750

J758

Q753

C781

C770

C786

C778

J765

J760

C774

C775

D751

R774

CA761

C777

R773

C785

E

C

B

Q755

J764

J763

C783

R785

R783

R781

R799

R788

CN754

R787

Q751

E

C

B

3

1

E

C

B

R789

R797

R798

1-676-104-

Q752

R790

C788

R792

C787

R791

11

(11)

A

J701(5V)

R734

J711

(VC)

C713

CA736

TP701

C720

R740

R741

R742

C730

C716

J708

C743

C737

C741

R727

R729

R733

J707

(RFO)

C729

C733

C714

C718

J710

C742C744

R743

R744

R745

R746

L701

R723

C725

C738

6

J703

J709

J706

CN651

J704

CN702

2

5

10

15

19

20

J705

1

B

CPU BOARD

CN806

(Page 54)

1

MAIN BOARD

CN302

(Page 36)

11

(11)

1-676-293-

C

L753

ASP BOARD

C724

C723

C721

R720

R701R704

R706

C706

C705

J734

C726

C711

R717

J729

(5V)

C702

C715

C703

C728

R722

C708

C739

R709

R711

C701

C710

C740

R715

B

C

C719

C712

B

C

E

J732

Q701

R719

J730

(5V)

R705

R703

R702

J731

(VC)

M701

SLED

D

R736

C734

28 25 22 21 20 15

J724

E

IC702

1 5 7 8 10 14

M

MOTOR

J723

CE736

C736

J725

J727

J726

S701

(LIMIT)

R721

R707

R712

J721

C717

C707

J733

(TEO)

C704

C709

R716

R714

M702

SPINDLE

MOTOR

R710

J728

R747

26

27

30

35

39

IC701

40

45

50

52

CN701

10

5

1

2

R726

25

J702

20

R728

15

14

C731

13

R725

10

5

C727

1

R724

C722

R732

R718

15

16

J712

J713

J714

M

R738

F

C732

C735

MOTOR BOARD

R651

OPTICAL

PICK-UP

KSS-213C

M651

LOADING

MOTOR

M

z

Semiconductor

Location

Ref. No. Location

IC651

9

J651

15

J652

C653

D751 D-10

J722

R731

IC651 F-4

R653

G

02

S651

(CD TRAY)

CLOSE OPEN

R652

L651

C652

1-676-294-

J653

C651

CN651

1

6

11

(11)

02

IC701 B-4

IC702 E-1

IC751 C-9

Q701 C-1

Q751 D-11

Q752 C-11

Q753 B-10

Q754 B-9

Q755 D-10

Note:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

– 47 – – 48 –

Page 38

5-13. SCHEMATIC DIAGRAM – CD • ASP SECTION – z Refer to page 67 for Notes. z Refer to page 68 for Waveforms.

PMC-DR50L/DR70L

– 49 – – 50 –

Page 39

PMC-DR50L/DR70L

5-14. SCHEMATIC DIAGRAM – CD • DSP SECTION – z Refer to page 67 for Notes. z Refer to page 68 for Waveforms.

– 51 – – 52 –

Page 40

5-15. PRINTED WIRING BOARDS – CONTROL SECTION – z Refer to page 25 to 26 for Circuit Boards Location.

02

2

3 4 5 6 7

8

9 10 11 12

A

1

B

C

D

E

F

G

I

MAIN BOARD

CN804

(Page 36)

CPU BOARD

DISPLAY BOARD

CONTROL BOARD

11

(11)

1-676-106-

11

(11)

1-676-105-

11

(11)

1-676-107-

C854

C853

C852

C851

C850

C849

C848

C846

C845

C825

C836

C835

C838

C839

C832

C834

C831

C833

C837

C855

C856

C883

C823

C826

C827

C824

CA824

D802

D801

E C B

Q801

E C B

Q802

3

2

1

IC802

J805

J801

J808

C890

J804

J802

J803

J807

J806

J810

L802

L859

L860

L858

L861

L862

L857

CA151

R853

R852

R851

R854

R855

R850

R849

R848

R843

R844

R841

R842

R846

R835

R862

R863

R864

R824

RA830

R839

R838

R837

R840

R856

R857

R858

R859

R860

R827

R836

R834

1

2

5

10

15

18

19

CN804

C857

C858

C859

C860

C829

J829

J828

J830

J827

J831

1

2

5

10

15

18

17

CN802

1

2

5

10

15

18

17

CN802

1

2

5

10

15

18

19

CN801

1

2

5

10

15

18

19

CN801

1

5

10

15

20

25

30

31

35

40

45

50

100

95

90

85

81

80

75

70

65

60

55

51

IC801

C847

C802

C865

C803

C811

C813

C814

CA803

C822

C815

C828

C820

C889

C888

C887

C819

C818

C810

C816

C821

C817

R801

R811

R820

RE830

RD830

RC830

R819

R818

R810

R809

R808

R807

RA815

RA816

R812

R813

R814

R803

RA801

R802

R804

R805

R806

R822

R821

R817

R815

C812

C882

RE803

J824

J823

J815

J822

J826

1

4

CN803

J821

J816

J817

J818

J819

M

JACK BOARD

CN312

(Page 43)

E

DSP BOARD

(Page 48)

1

2

5

10

14

15

CN806

B

DSP BOARD

CN806

(Page 48)

K

MAIN BOARD

CN812

(Page 36)

J

MAIN BOARD

CN811

(Page 36)

R816

R825

RA804

RB830

RA805

R823

RA803

RA817

C805

J809

J811

J812

1

1

5

7

58

CN807

1

5

6

CN811

CN812

RA895

RA894

R890

RA899

RA897

RB897

RA898

RB898

RB899

R889

R895

R888

R887

R891

R893

R892

B

C

E

Q809

B

C

E

Q810

D896

C896

J851

J855

J852

J853

S829

LINE IN

S827

PLAY MODE

MONO/ST ISS

S811

DUBBING

S812

r/P

S813

COUNTER

RESET

S814

DIR MODE

S805

DISPLAY

S804

TIMER

S821

PRESET+

S820

BAND

S819

PRESET–

S831

MEGA BASS

S830

SOUND

D809

SOUND

S833

CD OPEN/

CLOSE

6

S815

RDS

D810

RDS

S816

OPERATE

S828

ENTER/MEM

PGM SET

S832

SUMMER

TIME

1

58

CN807

R880

R881

R886

R885

R884

R882

R883

R878

R879

C251

CA820

CA251

R151

R876

R894

CA821

R251

J856

J857

JK151

2

R873

R874

R875

R877

R896

R898

R899

R897

L803

B

C

E

Q807

B

C

E

Q806

E

C

B

Q896

E

C

B

Q808

1

5

CN314

F

H

JACK BOARD

CN314

(Page 44)

1

5

CN304

MAIN BOARD

CN304

(Page 36)

R869

S803

CLOCK

R868

S802

SLEEP

S801

STANDBY

R867

R865

R866

C895

C893

C894

X801

X802

J820

C809

C881

C886

C808

C807

RA801

RA802

LCD801

RA803

C151

D831 D834 D835

D832 D833 D836

D811 D814 D815 D812 D813 D816

D821

D824

D825

D822

D823

D826

S809

)

S817

π

S818

fl

S824

ª

S822

·

S823

π

S826

=

S825

+

S810

0

TAPE

TAPE

TAPE SWITCH BACK-LIGHT

RADIO SWITCH BACK-LIGHT

CD SWITCH BACK-LIGHT

RADIO

CD

TUNE TIME SET

12

5101517

23253035404344

[VOL BOARD]

11

(11)

1-676-103-

S806

VOLUME+

S808

SNOOZE

S807

VOLUME–

R870

R872

R871

14

CN809

L

MAIN BOARD

CN307

(Page 36)

1

2

3

RM801

x

C871

x

C870

CA800

PMC-DR50L/DR70L

z

Semiconductor Location

Ref. No. Location

D801 B-3

D802 B-3

D809 D-7

D810 D-11

D811 D-8

Ref. No. Location Ref. No. Location

D821 E-8

D822 E-9

D823 E-10

D824 E-9

D825 E-9

D835 D-9

D836 D-10

D896 B-9

D936

Ref. No. Location

Q801 B-2

Q802 C-2

Q806 B-10

Q807 B-10

Q808 B-11

D812 D-9

D813 D-10

D814 D-9

D815 D-9

D816 D-10

D826 E-10

D831 D-8

D832 D-9

D833 D-10

D834 D-9

IC801 C-4

IC802 B-3

Q809 B-8

Q810 B-8

Q896 B-10

Note:

• X : parts extracted from the component side.

• p : parts mounted on the conductor side.

• b : Pattern from the side which enables seeing.

– 53 – – 54 –

Page 41

PMC-DR50L/DR70L

5-16. SCHEMATIC DIAGRAM – CONTORL SECTION – z Refer to page 67 for Notes.

– 55 – – 56 –

Page 42

5-17. SCHEMATIC DIAGRAM – SYSTEM CONTORL SECTION – z Refer to page 67 for Notes. z Refer to page 68 for Waveforms.

PMC-DR50L/DR70L

PIN

FUNCTION

– 57 – – 58 –

Page 43

PMC-DR50L/DR70L

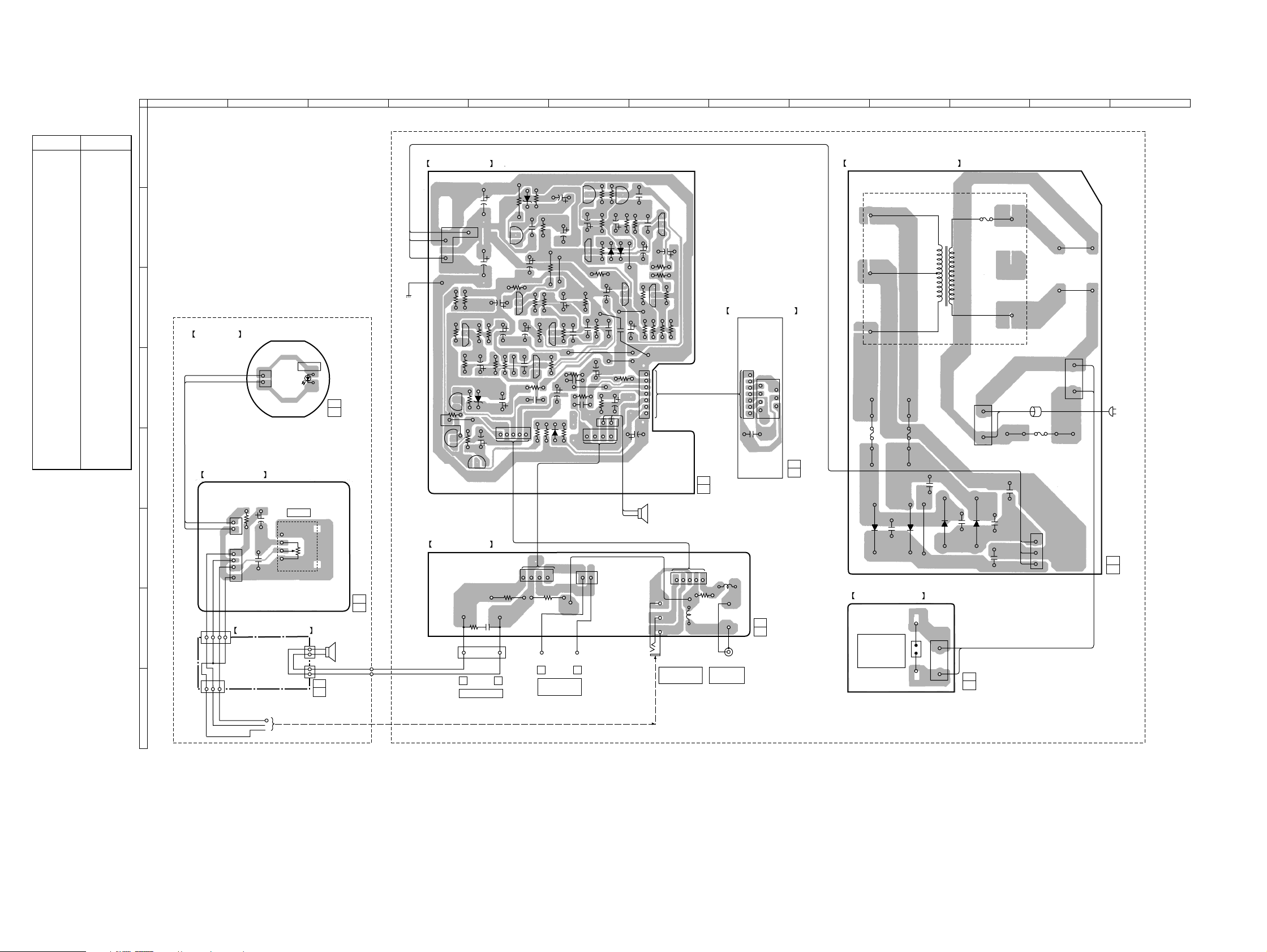

5-18. PRINTED WIRING BOARDS – AMP SECTION – z Refer to page 25 to 26 for Circuit Boards Location.

z

Semiconductor

Location

Ref. No. Location

D401 E-3

D402 E-2

D403 F-4

D404 E-2

D501 F-7

D502 E-7

D503 E-7

D504 E-7

IC309 A-3

Q401 E-4

A

B

C

D

E

F

SP101

SPEAKER

R-CH

T501

8

9

*

1

2

AMP IC BOARD

18

J510

CN514

3 4 5 6 7

POWER BOARD

IC309

1

51015

C182

175

C282

CN513

175

1-676-252-

11

(11)

POWER TRANSFORMER

AMP BOARD

C401

J512

C185

J520

J518

175

R402

J511

C381

C407

R381

C402

C386

R383

C181

C408

D401

J517

C404

CN514

R184

R284

C285

D404

C184

R183

J513

C409

C403

D402

R283

C284

CN504

+

1

–

2

CN511

1

2

CN505

R404

1

J401

5

6

R401

R405

C411

C410

J516

C382

R282

R403

J515

CN513

R182

J514

C406

Q401

E

C

B

175

C385

C281

R281

J501

C387

R181

C388

C412

C405

D403

1-676-253-

CN510

1

3

CN503

1

5

8

11

(11)

CN503

POWER OUT

TO

MAIN UNIT

G

JACK BOARD

CN311

(Page 43)

(CHASSIS)

CN505

1

5

6

J521

D504

C504

D503

C503

D502

C502

D501

C501

F501

C505

* NOT REPLACEABLE:

BUILT IN TRANSFORMER

LF501

CN501

1-676-255-

AC IN

11

(11)

Note:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

SPEAKER BOARD

CN511

1

2

G

LA503

C506

H

02

+

–

SPEAKER OUT

L-CH

JK501

3

C186

J502

R502

1-676-254-

1

CN510

L R

SIGNAL INPUT

JK502

C286

R503

11

(11)

– 59 – – 60 –

Page 44

5-19. SCHEMATIC DIAGRAM – AMP SECTION –

PMC-DR50L/DR70L

Note :

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• 2 : nonflammable resistor.

Note: The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : FM

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : FM

– 61 – – 62 –

4

W or less unless otherwise

Page 45

PMC-DR50L/DR70L

02

11

(11)

1-676-248-

11

(11)

1-676-425-

11

(11)

1-676-250-

11

(11)

1-676-249-

11

(11)

1-676-251-

11

(11)

11

(11)

1-676-295-

1-676-256-

11

(11)

1-676-257-

SP MAIN BOARD

SP JACK BOARD

POWER TRANSFORMER BOARD

SP AMP IC BOARD

AC OUTLET BOARD

VOLUME BOARD

LED BOARD

C626

C608

C699

C611

C610

CC602

C697

CA603

C698

R628

R605

R652

R653

R650

R626

R638

R623

R625

R645

R646

R651

R615

R616

R631

R621

R611

R610

R642

R612

R614

R613

R630

R633

R640

R641

R609

R608

R604

R606

R603

R632

RA607

R634

R636

R637

R647

R622

R620

R619

R617

R607

RA603

R602

C668C669

C640

C615

C613

C609

C620

C607

C621

C612

C619

C616

C641

C618

C633

C603

C606

C627

C623

C614

C617

C604

CA632

CB602

C605

D608

D609

D607

D610

D606

J602

J606

J600

J601

J603

J608

J607

J605

B

C

E

Q601

B

C

E

Q612

B

C

E

Q615

G S D

Q609

S

D

G

Q611

D

S

G

Q613

B

C

E

Q606

B

C

E

Q602

B

C

E

Q604

B

C

E

Q605

E

C

B

Q608

E

C

B

Q607

E

C

B

Q603

E

C

B

Q610

R627

R618

1

5

CN611

1

5

CN611

4

1

CN613

1

3

2

KH603

1

5

7

CN610

2

1

CN604

JK601

SIGNAL IN

BASS

JK602

VOLUME OUT

WOOFER

WOOFER OUT

SPEAKER IN

L-CH

+

+

–

–

IMPEDANCE USE 4Ω

JK604

41

CN613

CN614

SP201

SPEAKER

L-CH

–

+

+

–

1

5

7

CN610

1

2

5

6

7

IC601

SP601

SPEAKER

(WOOFER)

–

+

L-CH SPEAKER UNIT (DR70L)

WOOFER UNIT (DR70L)

R635

RA610RA610

R601

C601

*

* NOT REPLACEABLE:

BUILT IN TRANSFORMER

T601

POWER TRANSFORMER

F601

L604

F602 F603

CN606

CN607

CN607

AC IN

D601

D602

D603

D604

C661

C663

C662

C664

C665

C666

J609

JB609

JA609

1

3

KH603

JK605

AC OUTLET

MAX 50W

(UNSWITCHED)

AC230V ~50Hz

R655

CA602

C602

1

4

1

4

CN614

CN616

1

3

CN614

1

1

2

2

CN609

VR601

LEVEL

CN609

LED611

LEVEL

P601

(VOLUME IN)

2

3 4 5 6 7

8

9 10 11 12 13

A

1

B

C

D

E

F

G

H

L601

L602

CONNECTOR BOARD

(CHASSIS)

z

Semiconductor

Location

Ref. No. Location

D601 F-9

D602 F-10

D603 F-10

D604 F-11

D606 B-5

D607 B-6

D608 B-6

D609 E-6

D610 D-5

LED611 D-3

IC601 D-8

Q601 B-5

Q602 C-5

Q603 C-6

Q604 C-4

Q605 D-5

Q606 C-6

Q607 C-7

Q608 B-7

Q609 E-5

Q610 B-6

Q611 E-4

Q612 B-6

Q613 D-4

Q615 B-6

5-20. PRINTED WIRING BOARDS – WOOFER SECTION – z Refer to page 25 to 26 for Circuit Boar ds Location.

Note:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

– 63 – – 64 –

Page 46

5-21. SCHEMATIC DIAGRAM – WOOFER SECTION – z Refer to page 67 for Notes.

PMC-DR50L/DR70L

– 65 – – 66 –

Page 47

p

p

p

µ

p

p

p

p

p

Note on Schematic Diagram:

MAIN SECTION (1/3), (2/3), (3/3)

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

: internal component.

4

W or less unless otherwise

• U : B+ Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM (COMMON), REC (TAPE SECTION)

( ) : MW (RADIO SECTION),

PLAY (TAPE SECTION)

< > : LW (RADIO SECTION)

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : MW

L : LW

E : PB

a : REC

J : CD

Note on Schematic Diagram: JACK SECTION

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

• U : B+ Line.

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : FM

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : FM

c : digital out

Note on Schematic Diagram: CD •ASP SECTION

Note on Schematic Diagram: CD •DSP SECTION

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

Note: The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : CD STOP

( ) : CD PLAY

• V oltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD

c : digital out

Note on Schematic Diagram: SYSTEM CONTROL SECTION

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

• U : B+ Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : RADIO (COMMON)

( ) : CD

< > : REC

[ ] : PLAY

• V oltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

r

Waveforms

– MAIN SECTION (1/3) –

1

13.3 µsec

IC3 wa

VOLT/DIV : 0.5 V AC

TIME/DIV : 5 µsec

2

0.23 µsec

IC4 qf

r

Waveforms

VOLT/DIV : 0.2 V AC

TIME/DIV : 50 nsec

– MAIN SECTION (2/3) –

1

17.5 µsec

ATT : 1/10

L301

VOLT/DIV : 1V AC

TIME/DIV : 5 µsec

2

1.5Vp-

556mVp-

60Vp-

15Vp-

r

Waveforms

– CD SECTION –

1

(PLAY MODE)

IC701 ed

(RFO)

2

(PLAY MODE)

IC701 6

(FEO)

3

(PLAY MODE)

IC701 rg

(TO)

4

0.1162MHz

sec

8.6

IC751 wl

(PCO)

1.0 – 1.5Vp-p

VOLT/DIV : 0.5 V AC

TIME/DIV : 1 µsec

0.6Vp-p

VOLT/DIV : 1 V AC

TIME/DIV : 1 msec

0.7Vp-

VOLT/DIV : 20mV AC

TIME/DIV : 1 msec

875mVp-p

VOLT/DIV : 0.5 V AC

TIME/DIV : 5 µsec

r

Wavef orms

– SYSTEM CONTROL SECTION –

1

4.8Vp-

30.5 µsec

IC801 rs

VOLT/DIV : 1V AC

TIME/DIV : 10 µsec

2

2.5Vp-

125nsec

IC801 r;

VOLT/DIV : 0.5V AC

TIME/DIV : 50 nsec

Note on Schematic Diagram: CONTROL SECTION

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

• U : B+ Line.

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : FM

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : FM

Note on Schematic Diagram: WOOFER SECTION

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

Q301 C

17.5 µsec

VOLT/DIV : 5 V AC

TIME/DIV : 5 µsec

5

22.85 µsec

Note: The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

• U : B+ Line.

IC751 el, r;

(LRCK)

VOLT/DIV : 1 V AC

TIME/DIV : 5 µsec

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

6

no mark : FM

• V oltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : FM

IC751 ua

(XTAO)

59nsec

VOLT/DIV : 0.1V AC

TIME/DIV : 20 nsec

– 67 – – 68 –

4.7Vp-p

271mVp-

Page 48

r

R

IC Block Diagrams – MAIN SECTION (2/3) –

IC301 TA2068N

L.RAD

MIC

I/EX

L.CD

REC

23 22 21

15k

RADIO

LINE

TAPE

BUF AMP

A1

NAB

AMP1

10k

L.LO

2024

1k 1k

7dB

MUTE

B1

ALC1

REF AMP

LOGIC

ON

MONITOR

AMP

6k

10k

BUF AMP

10k

10k

10k 10k

10k

26dB

REC

AMP1

R.LO

VCC

1819 14 13

MONITOR

AMP

7dB

ON

MUTE

BUF AMP

B2

ALC2

DET

2.1

REC

AMP2

26dB

RADIO

1k

10k

10k

10k

10k

6k

BUF AMP

A2

MUTE

ON

R.CD

10k

TAPE

AMP2

RADIO

TAPETAPE

NAB

151617

LINE

TAPE

10k

R.RAD

10k

MIC

AMP1

1k

MIC

IC305 BA338

VCC

OUT

NOISE FILTER

MUTING

GND

NFB

9 8 7 6 5 4 3 2 1

IN

PRE AMP

S

B+

R

F.F.

COMPARATOR

Q

COMPARATOR

COMPARATOR

SENSE TIMING

PULSE WIDTH

L.PO

L.NF

AGC

IC302 BH3854AS

NF2

IN2

32

FILTE

AGND

31

IN1

29

30

4321

NF2

4 5 6321

L.RO

DVN2

BVN1

987 10 11 12

REF

L.IN

BIN2

BVO2

TIN2

27 26 25 24 23 20 19 18 17

28

TONE

MATRIX

SURROUND

TONE

6 7 8 9 10 11 12 13 14 15 16

5

BVO1

TIN1

BIN1

GND

TVO2

TVO1

VR

VR

R.IN

OUT2

OUT1

R.RO

VC

CONTROL

VCC

R.NF

TC

22 21

SC

R.PO

BC

PORT1

CLK

PORT2

MIC

NF

DATA

PORT3

LATCH

PORT4

VREF

DGND

– 69 –

Page 49

r

I

IC Block Diagrams – CD SECTION –

IC701 CXA1992BR

PD1

PD2

39

38 37 36 35 34 33 32 31 30 29 28 27

FOK

CP

LD

PD

VEE

RFTC

RF-

RFO

RFI

CB

CC1

CC2

F. BIAS

GND

LPFI

ATSC

TZC

TDFCT

PD2 IV

AMP

40

41

F

42

E

E IV AMP

43

EI

BAL1

BAL2

VEE

44

TOG1

TOG2

TOG3

45

TO

46

47

TI

48

49

50

ATSC

WINDOW

COMP.

TZC COMP.

F IV AMP

BAL3

BAL4

TOG4

VCC

PD1 IV

AMP

TGFL

E-F BALANCE

WINDOW COMP.

DFCT

VCC

VCC

IFB1

VEE

TM1

APC

LASER POWER CONTROL

IFB4

IFB5

IFB2

IFB3

TRK. GAIN

WINDOW COMP.

TG1

VEE

FE AMP

IFB6

RF

SUMMING

AMP

FO. BIAS

WINDOW

COMP.

FOK

FOH

FOL

TGH

TGL

BALH

BALL

ATSC

TZC

FZC

TRACKING

PHASE COMPENSATION

LDON

VEE

LEVEL S

VCC

LPCL

VEE

MIRR

LPC

TGFL

IIL DATA REGISTER,

INPUT SHIFT REGISTER,

ADDRESS DECODER,

SENS SELECTOR,

OUTPUT DECODER

DFCTO

IFB1-6

BAL1-4

TOG1-4

VCC

VCC

VEE

DFCT

IIL

↓

TTL

MIRR

DFCT1

FS1-4 TG1-2 TM1-7 PS1-4

CC1

VCC VCC

TM4 TM6

IIL

↓

TTL

TTL

IIL

ISET

26

SENS2

24

SENS1

24

C. OUT

23

XRST

22

DATA

21

↓

VCC

XLT

20

CLK

19

LOCK

VCC

18

ISET

17

16

SLO

51

VC

VCC

52

FZC

FZC COMP.

IC702 BA6898FP

GND

F-

F+

2728 26 25 24 23

D

D D

LEVEL SHIFT

LEVEL SHIFT

DD

21 3 4 5 6 7 8 9 10 11 12 13 14

SL-

SL+

SLIN

VCC

VEE

DFCT

1 2 3 4 5 6 7 8 9 10 11 12 13

FEO

FIN

T. S. D.

RST

FEI

NC

VREF

REGULATOR, BIAS,

T. S. D. MONITOR

REGD