Sony PCM-R500 Service manual

PCM-R500

SERVICE MANUAL

Ver 1.1 2002.01

SPECIFICATIONS

US Model

Canadian Model

AEP Model

Model Name Using Similar Mechanism DTC-A8

Tape Transport Mechanism Type

DATM-55

9-960-833-12 Sony Corporation

2002A0500-1 Home Audio Company

C 2002.1 Published by Sony Engineering Corporation

– Continued on next page –

DIGITAL AUDIO TAPE DECK

MODEL IDENTIFICATION

– Model Number label (Printed in Back Panel) –

MODEL NO. PCM-R500

DIGITAL AUDIO TAPE DECK

US, Canadian model : AC 120 V 60 Hz 34 W

AEP Model : AC 230 V

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the

manufacturer.

Discard used batteries according to the manufacturer’s instructions.

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

⁄

50/60Hz 34 W

CAUTION

ADV ARSEL!

ADVARSEL

instruksjoner.

VARNING

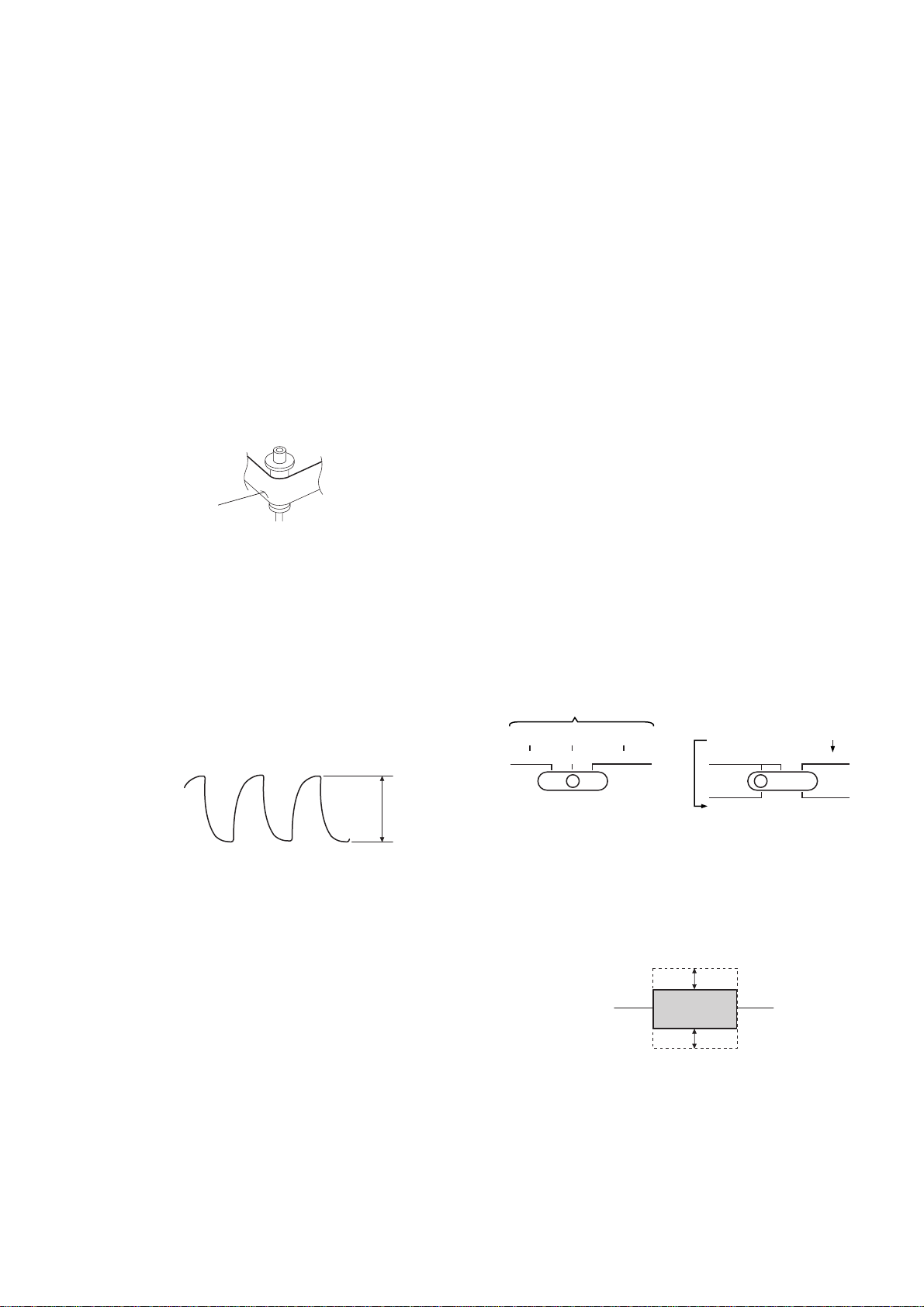

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering .

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

– 2 –

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

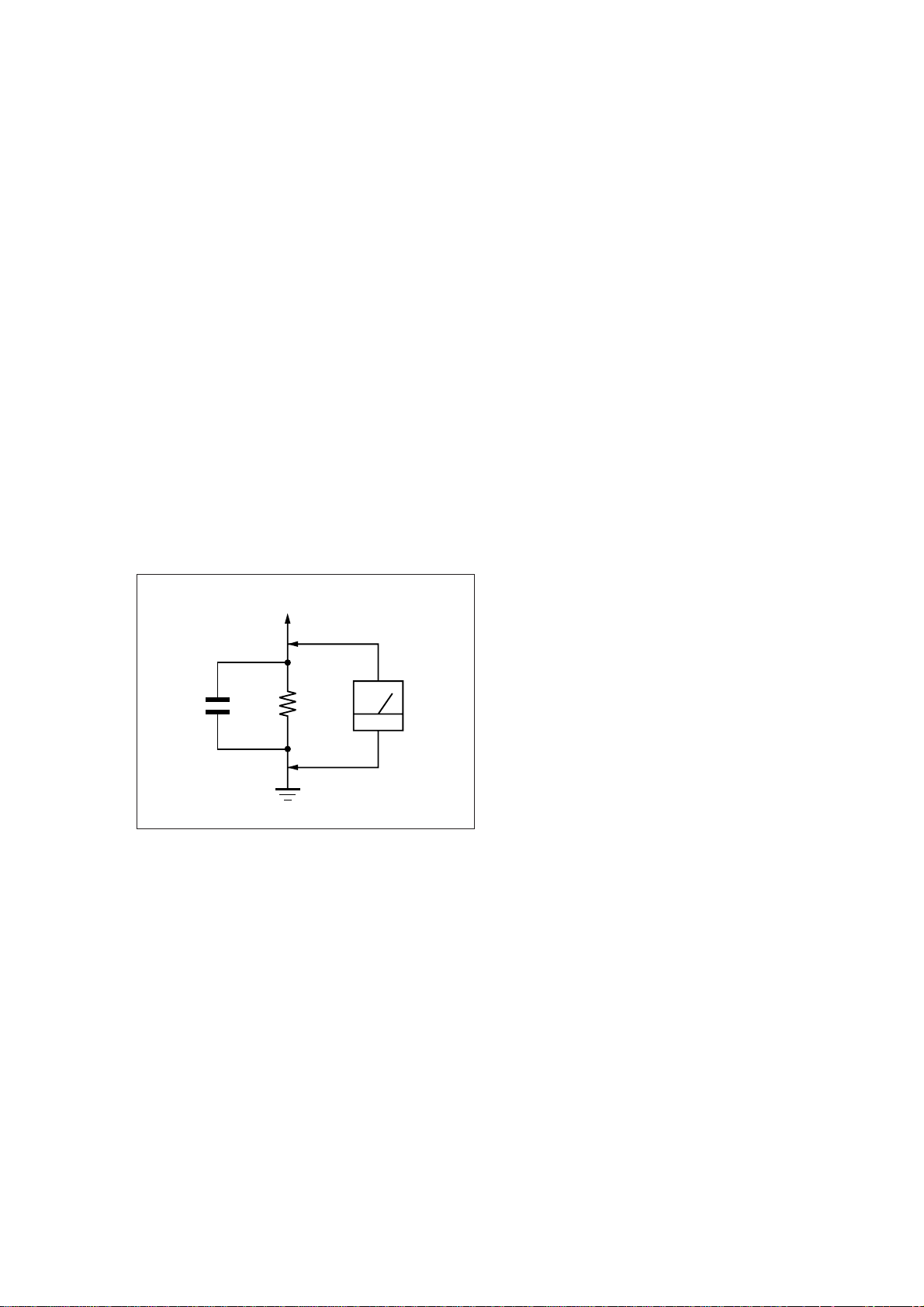

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C v oltmeter . The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V AC range are suitable. (See Fig. A)

TABLE OF CONTENTS

1. GENERAL

..................................................................... 4

2. DISASSEMBLY............................................................ 15

3. ADJUSTMENTS.......................................................... 19

4. DIAGRAMS

4-1. Block Diagrams................................................................. 26

4-2. Printed Wiring Board – RF Section –................................ 33

4-3. Schematic Diagram – RF Section –................................... 35

4-4. Printed Wiring Boards – MD Section –............................. 38

4-5. Schematic Diagram – MD Section –................................. 41

4-6. Printed Wiring Boards – DIGITAL Section – ................... 45

4-7. Schematic Diagram – DIGITAL Section – ........................ 49

4-8. Schematic Diagram – AUDIO Section –........................... 53

4-9. Printed Wiring Boards – AUDIO Section –....................... 57

4-10. Printed Wiring Boards – DISPLAY Section – ................... 61

4-11. Schematic Diagram – DISPLAY Section – ....................... 65

4-12. IC Pin Function Description .............................................. 72

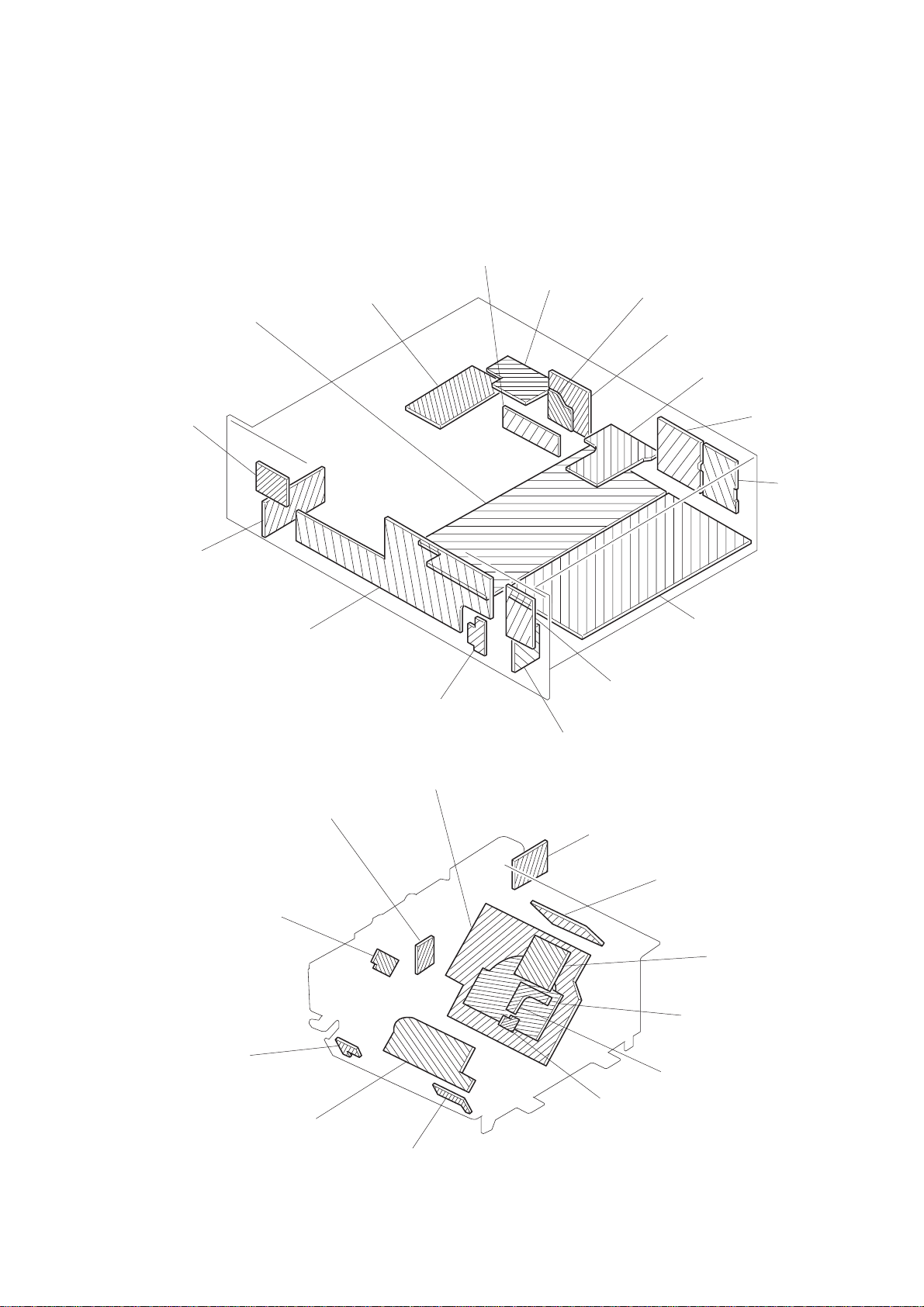

5. EXPLODED VIEWS ................................................... 83

To Exposed Metal

Parts on Set

0.15 µF

1.5 k

Ω

Earth Ground

AC

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

6. ELECTRICAL PARTS LIST .................................... 91

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMA TIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 3 –

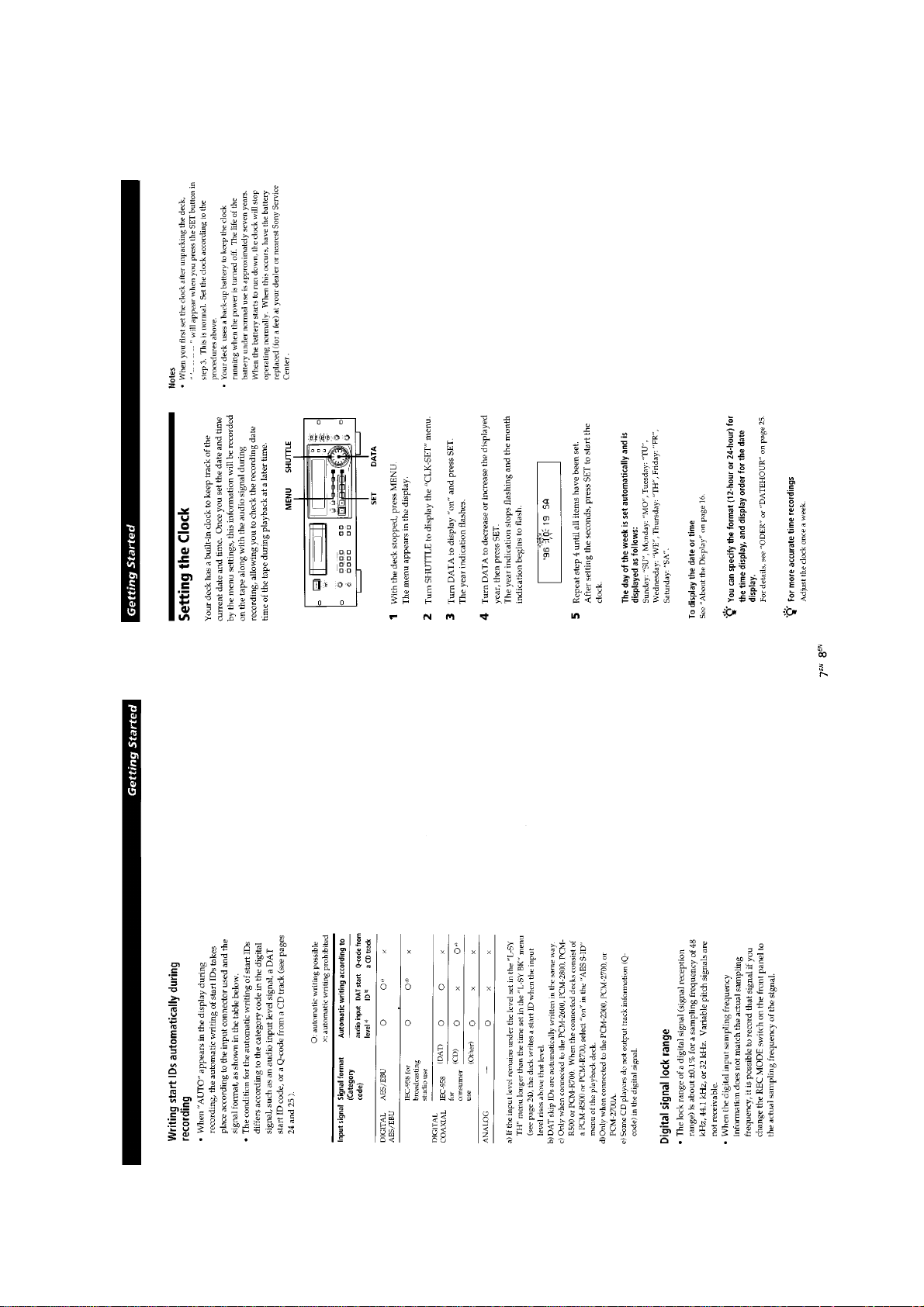

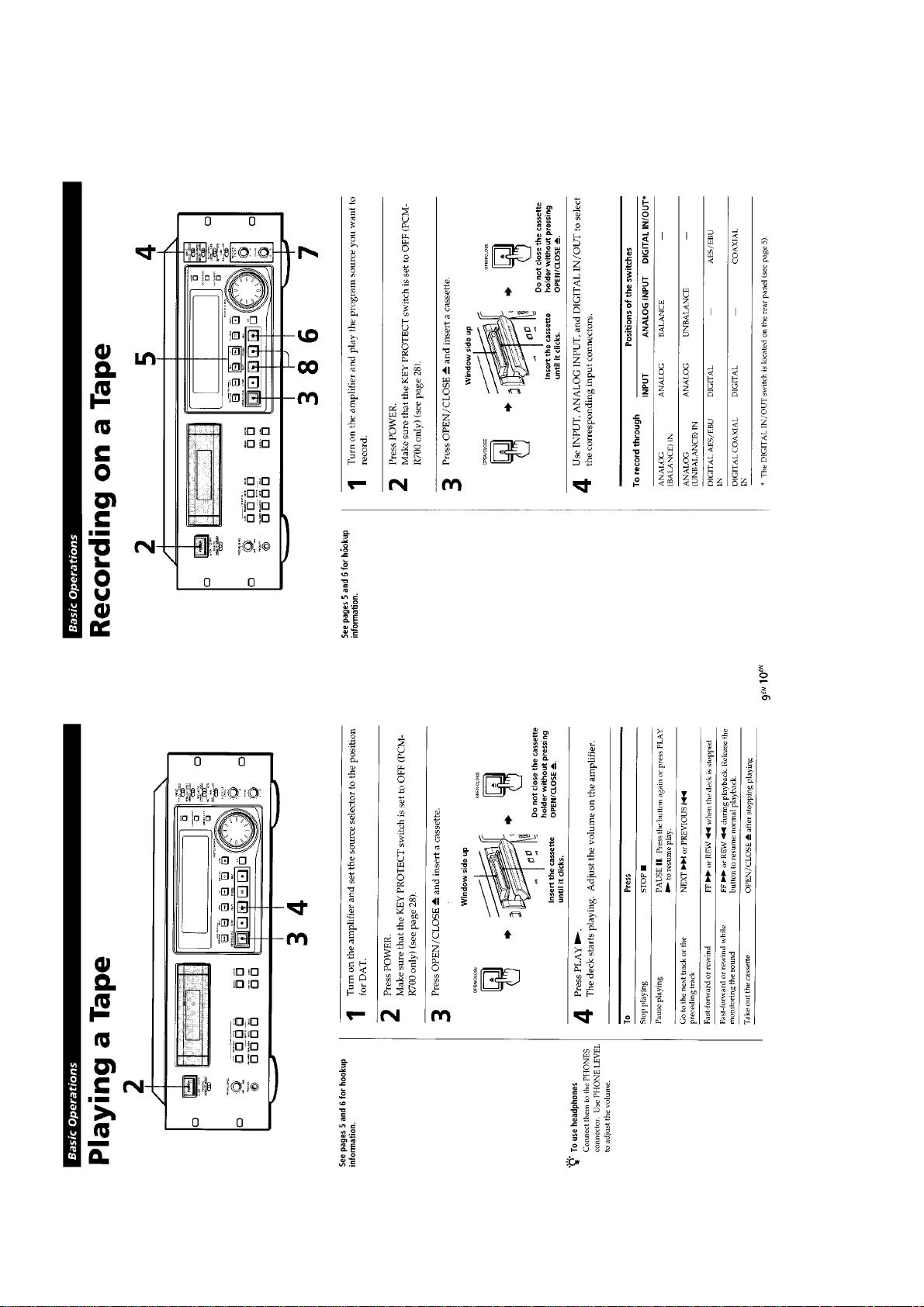

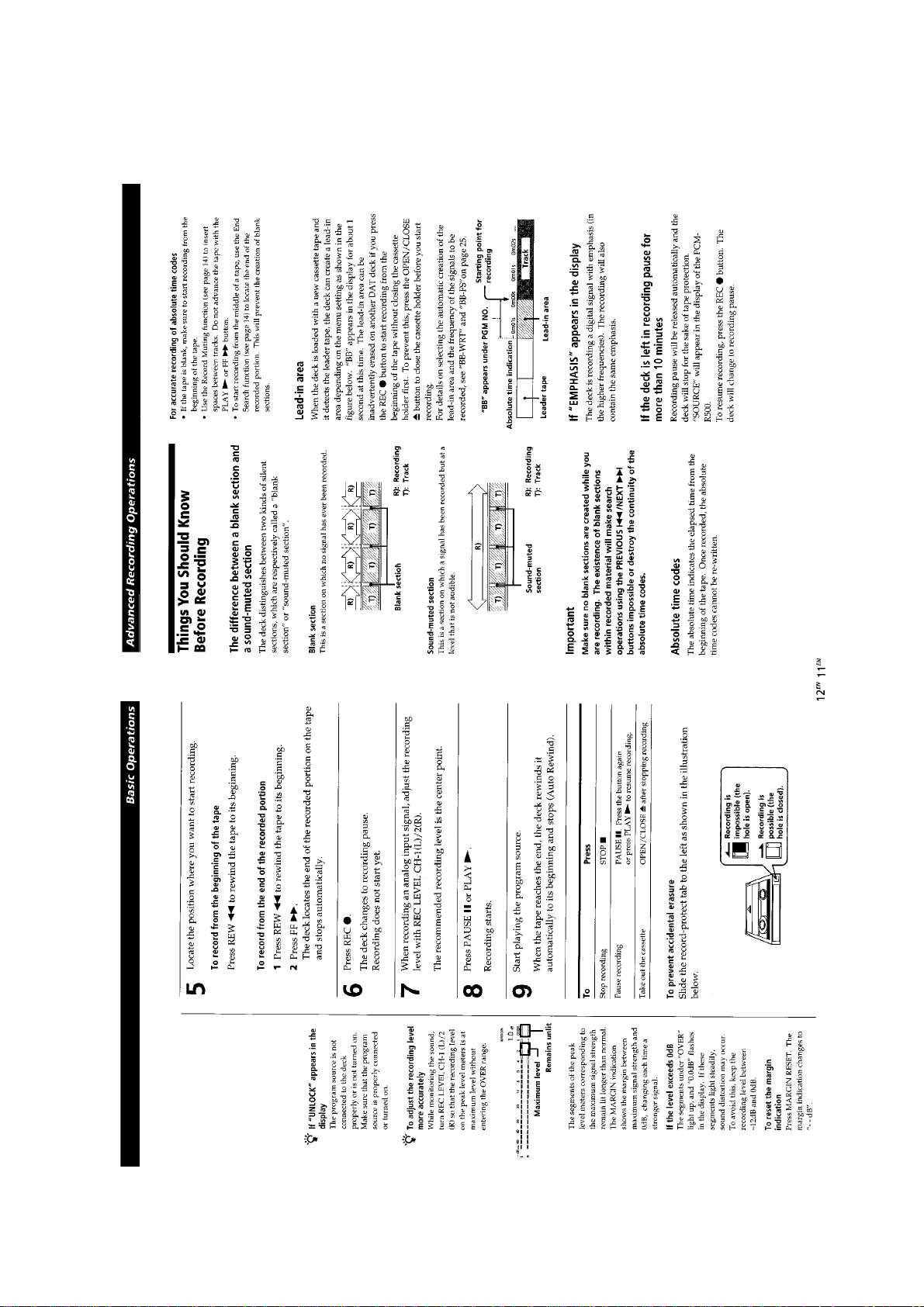

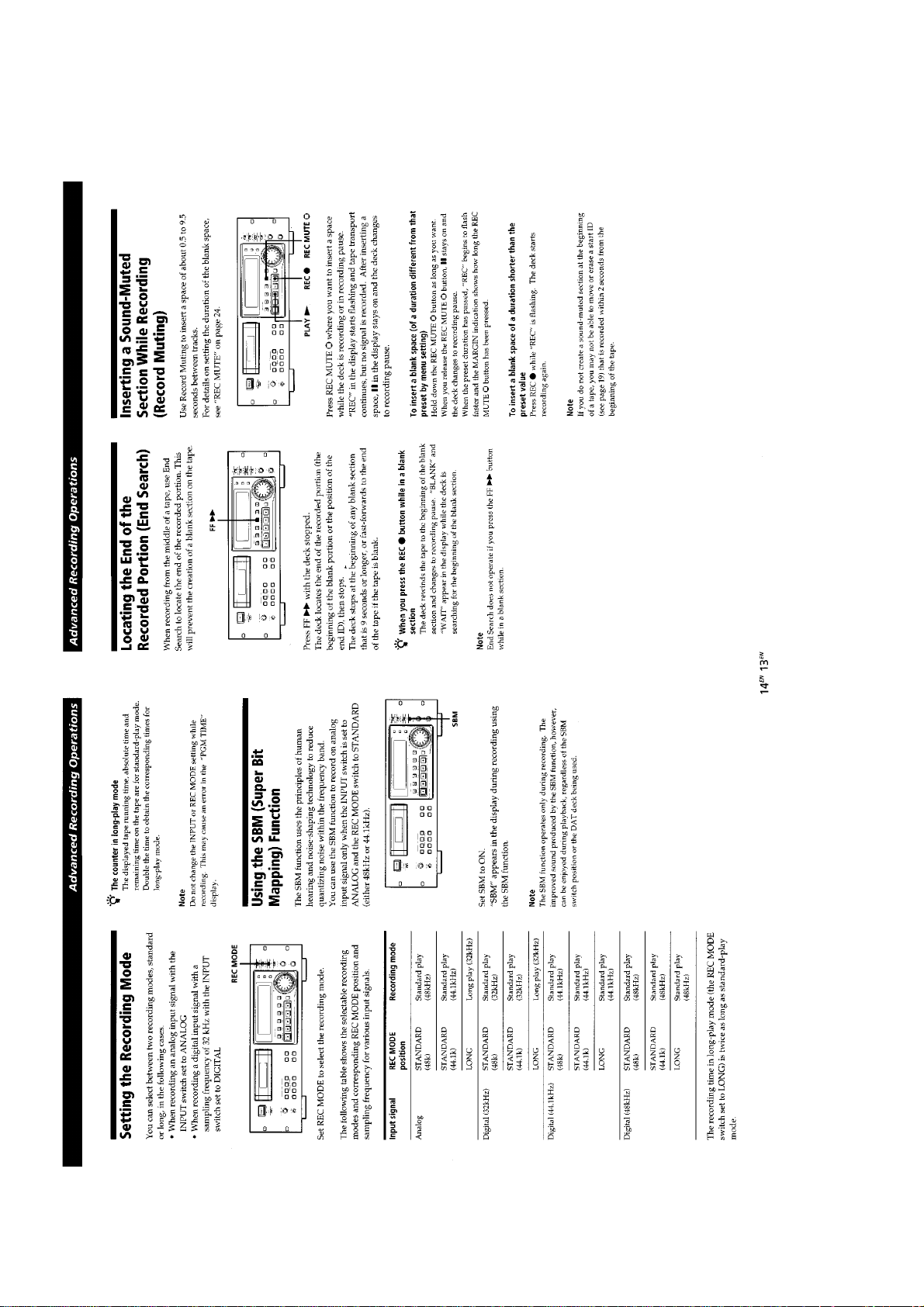

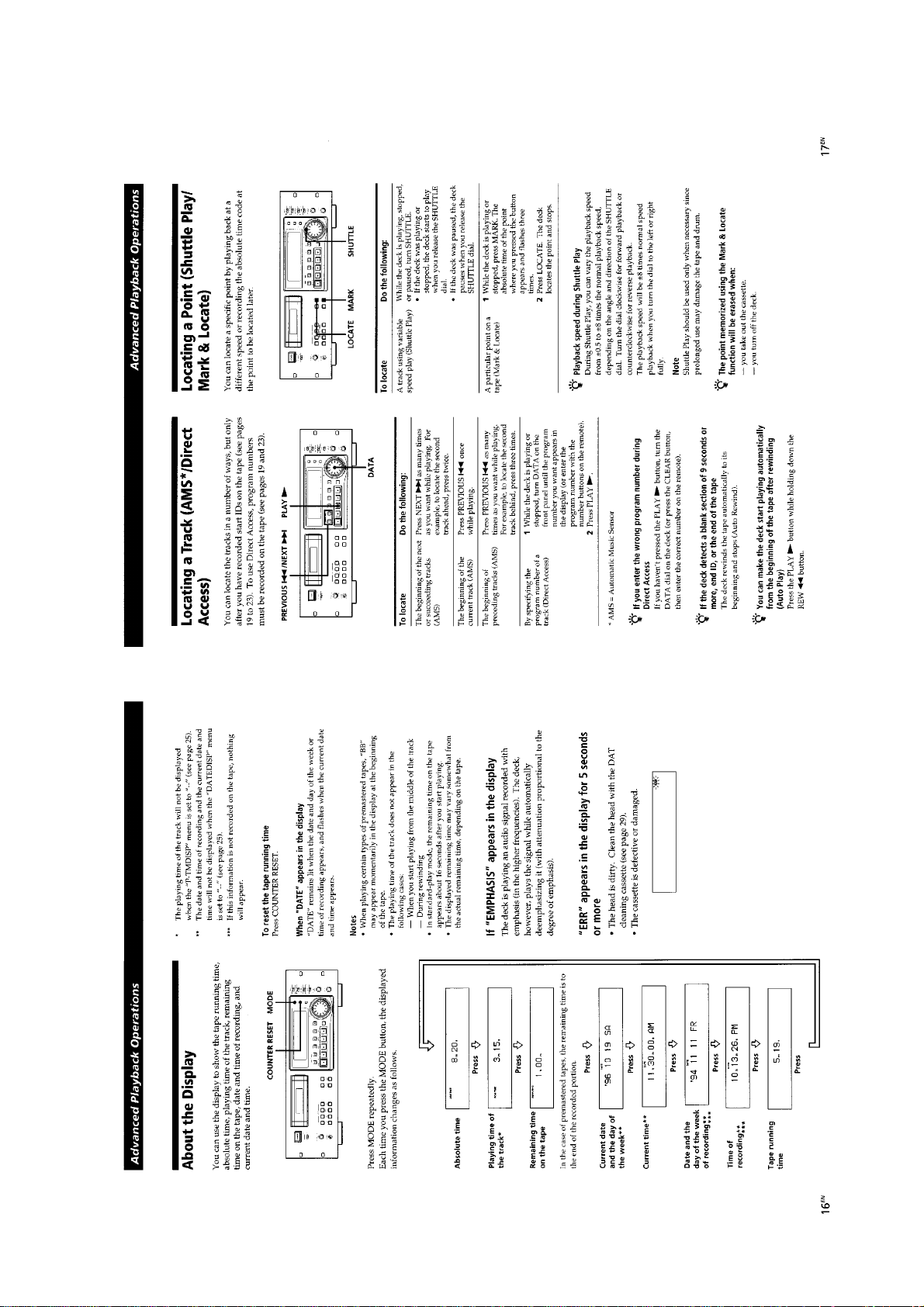

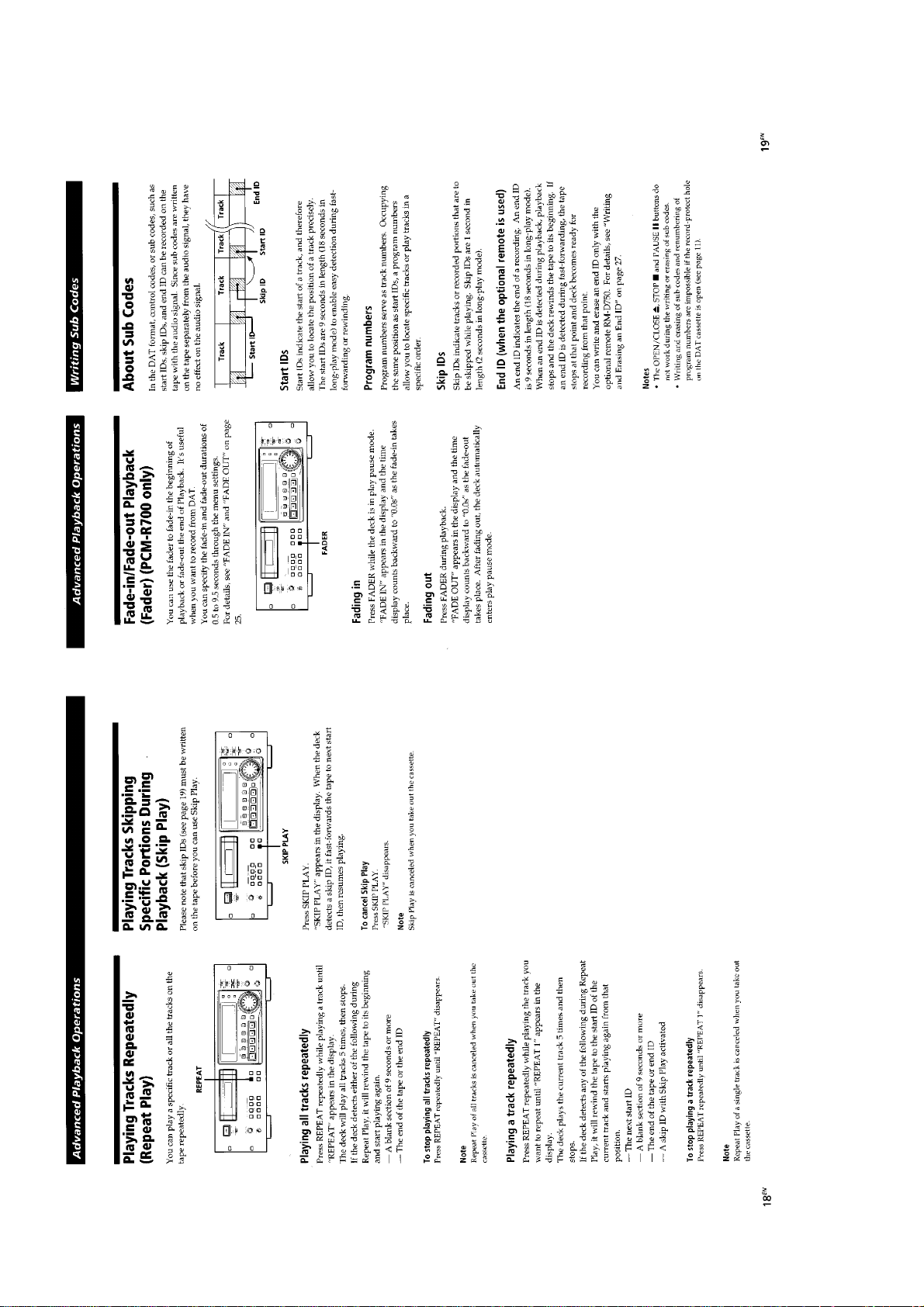

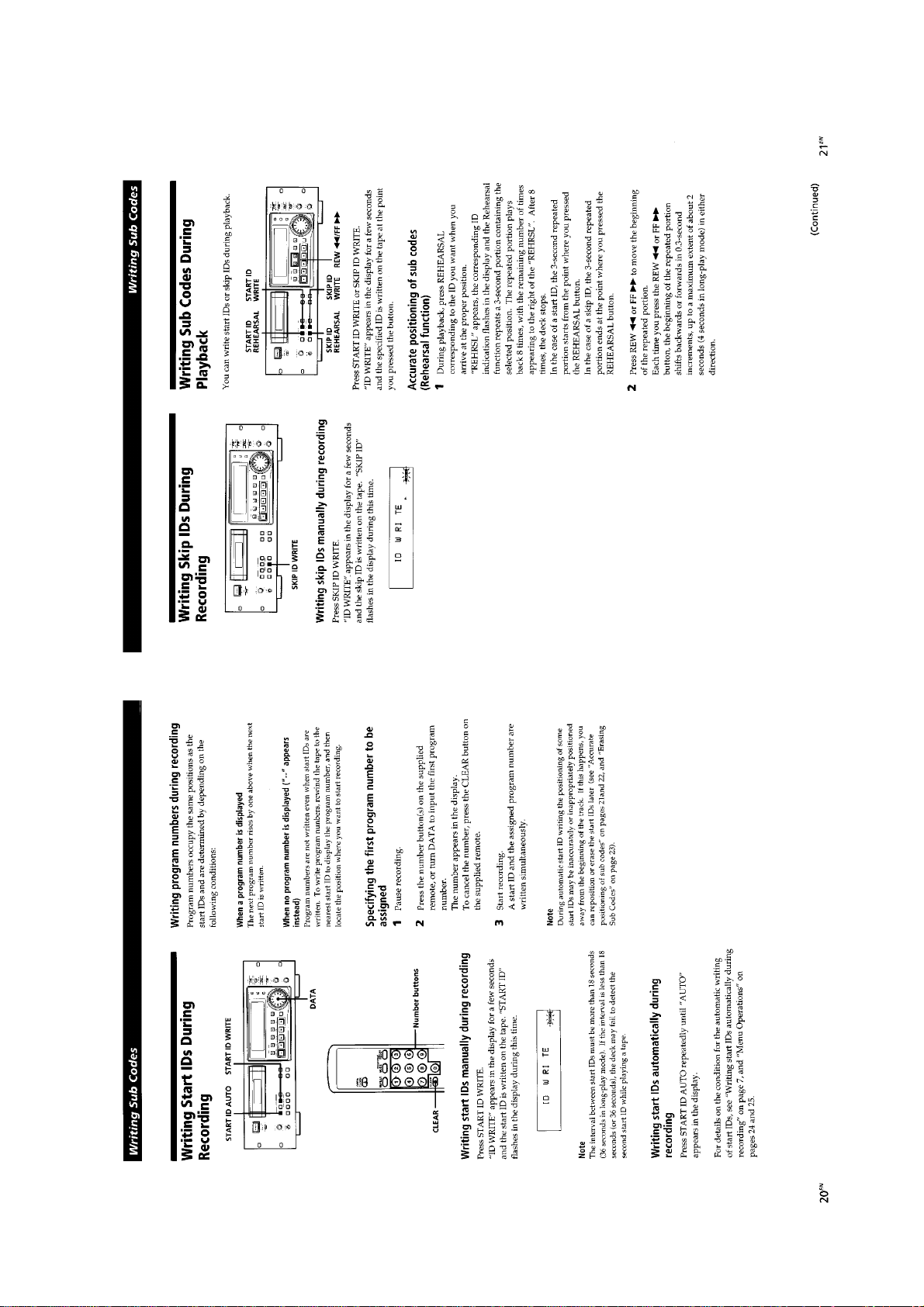

This section is extracted

from instruction manual.

SECTION 1

GENERAL

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

– 9 –

– 10 –

– 11 –

– 12 –

– 13 –

– 14 –

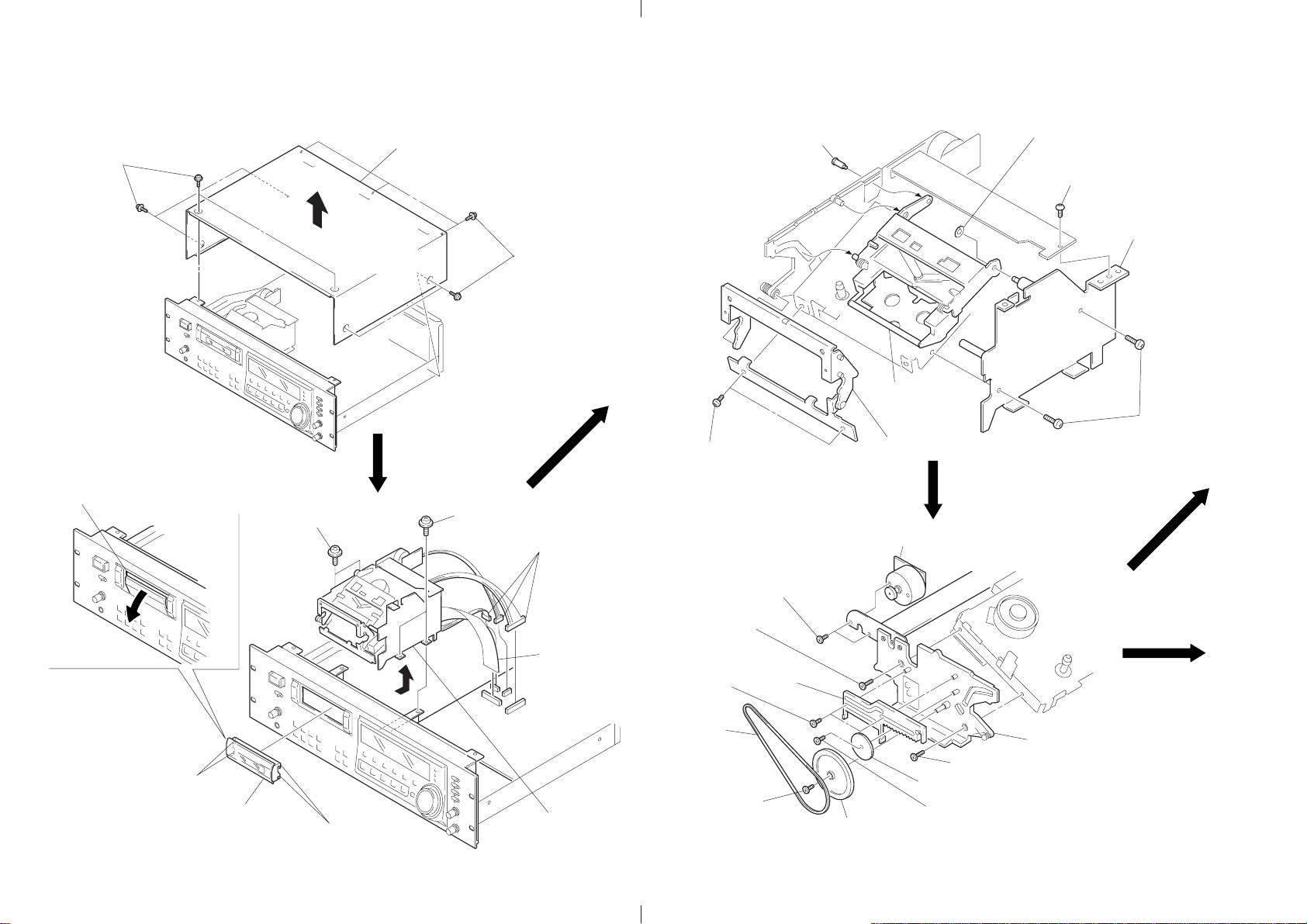

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

1

four screws

×

(case)(M3

MECHANISM DECK BLOCK

1

Open the lid.

10)

6

two screws

(PTPWH 3

HOLDER ASS’Y

3

1

two screws

(P2.6

4)

screw (step)

×

3)

8

holder ass’y

7

function plate ass’y

9

cassette compertment

motor ass’y

2

case

1

five screws

×

4

three connectors

(CN506-508)

10)

6

two screws

(B2

×

4)

CASSETTE COMPARTMENT MOTOR ASS’Y

8

0

screw

(B2.6

×

(case) (M3

6

×

6)

two screws

(PTPWH 3

×

6)

nylon washer

4

screw

(BVTT3

×

6)

5

Side plate (R) ass’y

2

two screws

(B2.6

×

4)

2

two claws

5

flat wire

(CN504)

3

lid

2

two claws

7

Remove the mechanism

deck block to direction

of the arrow.

6

1

capstan belt

2

screw

×

(B1.7

screw (B1.7 × 3)

7

slider

3)

ass’y

!¡

chassis (L)

0

screw

×

4)

(B2.6

5

driving gear

4

3

pulley

screw (B1.7 × 3)

– 15 – – 16 –

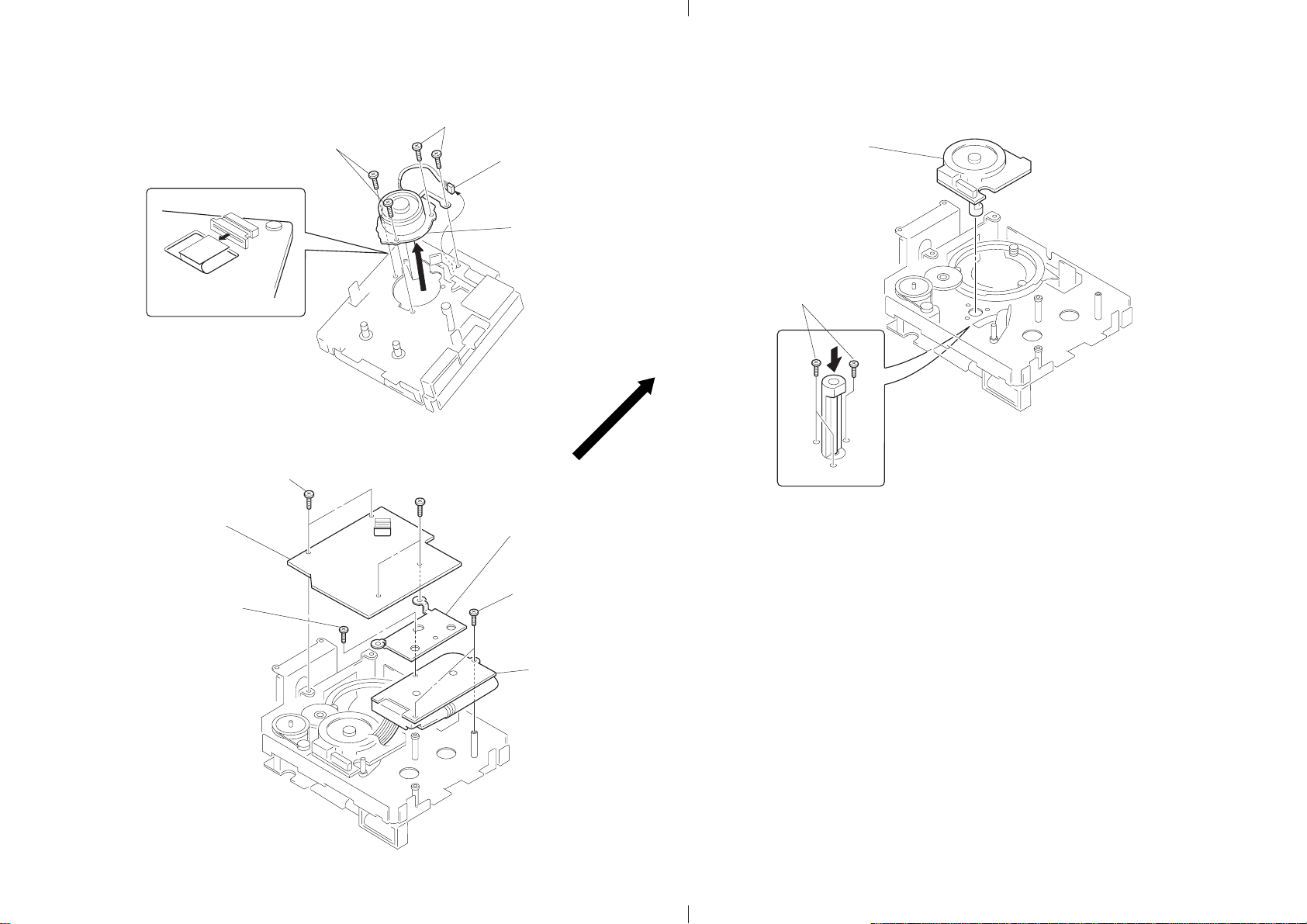

DRUM

1

flexible board (CN7)

DRUM DRIVE BOARD, REEL MOTOR

1

two screws

×

3)

(B2

2

DRUM DRIVE board

3

two screws

(B2

3

two screws

(B2

×

3)

×

3)

2

connector

(CN52)

4

drum

1

two screws

(B2

×

3)

4

bracket

CAPSTAN MOTOR

1

three screws

(P1.7

2

capstan motor

×

4)

5

3

screw

(B2

×

3)

two screws

(B2

×

3)

6

reel motor

– 17 – – 18 –

SECTION 3

ADJUSTMENTS

1. The adjustments are performed in the sequence that they are

described.

2. The required test tapes are:

TY-7111 (8-909-812-00) ................................. Level

TY-7252 (8-909-822-00)................................. Tracking

TY-7551 (8-909-814-00)................................. Function

TY-30B (8-892-358-00)................................... Blank

The required torque meter is:

TW-7131 (8-909-708-71) ................................ FWD

3. Switch and Control Settings

REMOTE switch : OFF

REC MODE switch : 48k (STANDARD)

REC LEVEL control : Minimum

PHONE LEVEL control : Minimum

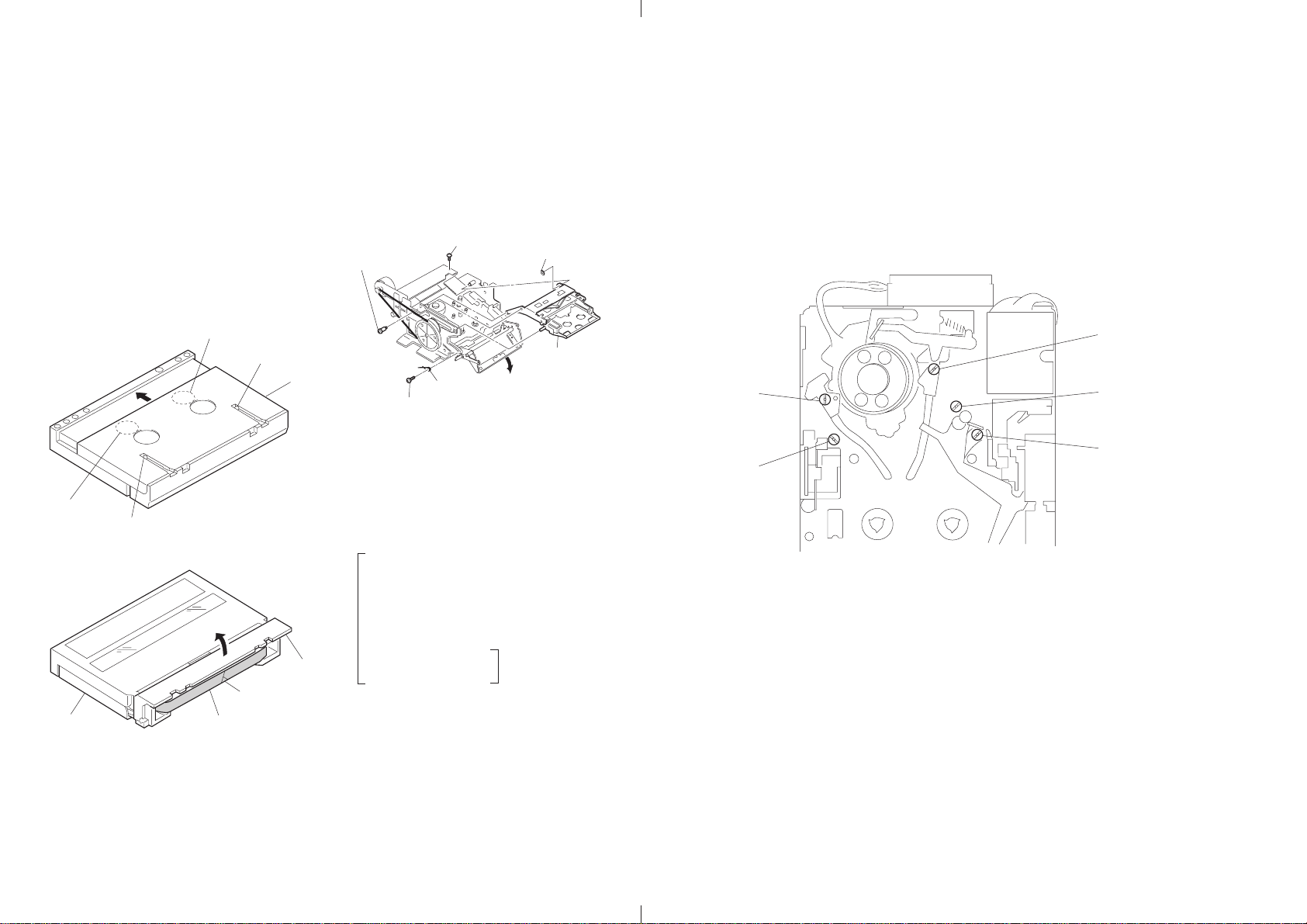

4. Preparation of End Sensor Cassette

(1) Push the slider locks of a cassette tape and slide the slider in

the direction of the arrow.

PRECAUTION

hub hole

slider lock

slider

6. When adjusting tape pass and each guide, as shown below, it is

a good practice to remove the holder assy and use the DAT cassette holder (J-8000-002-A). This facilitates adjustment work.

• When removing and installing the holder assy , turn the pulley

counterclockwise and set loading OUT condition for easy removal and installation.

• When adjusting, turn the pulley clockwise and turn on the

CASSETTE TABLE IN switch (S2) to set loading IN condition. Then, set the test tape.

1

6

Step screw

2

BVTP 3 × 6

3

BVTT 3 × 8

Cassette

spring

5

Nylon washer

7

4

Push down the holder

in the direction

Cassette

holder assy

8. After adjustment is completed, perform the following checks to

verify the tape speed.

(1) Check that with the REC MODE switch set to STAND ARD

48k, tape is normally recorded and played back. (×1)

(2) Check that with the REC MODE switch set to LONG, tape

is normally recorded and played back. (×0.5)

(3) Check that in performing the CUE (” + )) or REVIEW

(” + 0) operation, “kyur kyur” sound is heard. (×3, ×8)

Adjustment Location: mechanism deck block

S1 guide

(4) Check that after performing the FF ()) or REW (0)

operation, the time display is appropriate. (×16)

(5) Check that the AMS (+, =) operation is normal.

T1 guide

T2 guide

hub hole

slider lock

(2) Open the cassette lid and cut tape.

cassette lid

cut tape

slider

(3) Turn the hubs to take-up tape (for both T and S sides).

The end sensor cassette tape for end sensor adjustment is

now prepared.

5. Take care nev er to turn RV1 and R V2 within the RF AMP board

of the cassette compartment section.

tape

7. Test Mode

• T o enter the test mode , short between TP (MAIN-TEST) and

the GND on the DIGITAL board, then turn on the po wer. The

meter scale within the fluorescent indicator tube (FL701) will

flash.

Press the OPEN/CLOSE 6 key and set the test tape. (The

specified tape should be used for each adjustment.)

Test Mode (Short between TP (MAIN-TEST) and GND)

1 Have “DPG” display lit in the fluorescent indicator tube.

(Press the AMS + key.)

• S2, T2 and F Guide Adjustments

• End Sensor Adjustment

• Tape Pass Fine Adjustment (×1.5FWD mode)

• DPG Adjustment

2 Have “TR” display lit in the fluorescent indicator tube.

(Press the ” key.)

• FWD T orque Adjustment

• FWD Back Tension

Adjustment

• T o release the test mode, remove the short between TP (MAIN-

TEST) and GND. After necessary adjustment is completed,

be sure to release the test mode.

(Torque measurement mode)

S2 guide

– 19 – – 20 –

F guide

3-1. MECHANICAL ADJUSTMENTS

When replacing any drum related parts, after S2, T2 and F guide

adjustments have been made, tape pass fine adjustment (×1.5FWD

mode) in Electrical adjustment should be performed.

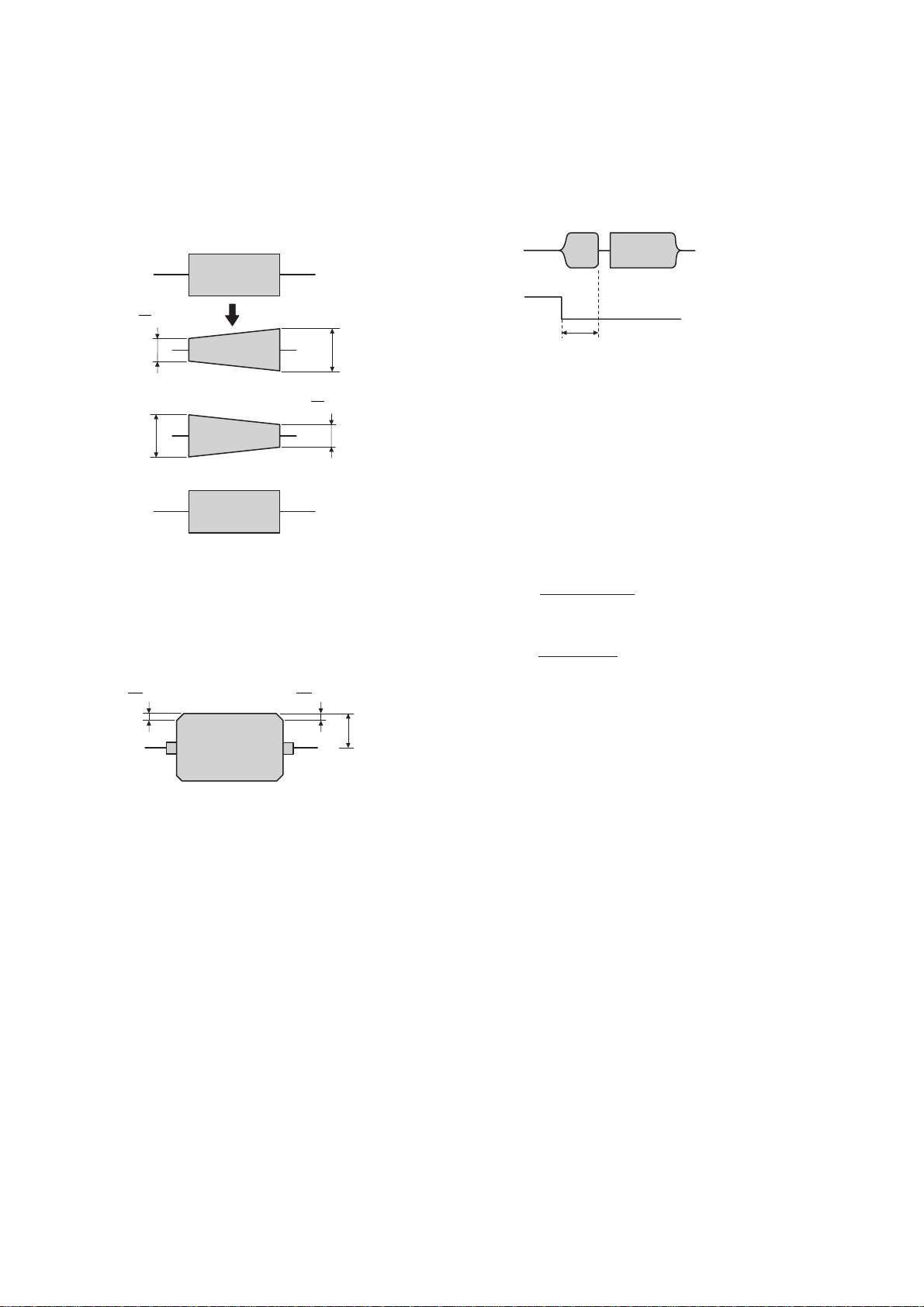

S2, T2 and F Guide Adjustments

Adjustment Method:

1. Enter the Test Mode 1 (see page 19.) and set the test tape TY7252 (8-909-822-00).

2. Set the REC MODE switch to STANDARD 48k and press the

AMS + key.

While in FWD mode, check that there is no curl on the upper

and lower flanges of the S2, T2 and F guides.

If any curl is present, put the S2, T2 and F guide of concern

back in the high position and adjust by adjusting the direction

of tightening.

*

What is curl?

Curl

Distortion that occurs on

tape during FWD operation.

3-2. ELECTRICAL ADJUSTMENTS

End Sensor Adjustment

When removing the holder assy and when replacing the mechanism

deck block, this adjustment should be performed.

Adjustment Method:

1. Connect the CH-1 terminal of an oscilloscope to TP (S-END)

and the CH-2 terminal to TP (T-END) on the DIGITAL board.

2. Enter the Test Mode 1 (see page 19.) and set the end sensor

cassette tape (see page 19.)

3. Set the STOP (p) mode.

4. Adjust RV502 (S-END) and RV501 (T-END) on the DIGITAL

board so that the respective peak to peak values of the waveforms on the oscilloscope are 1.2 Vp-p.

FWD Back Tension Adjustment

Adjustment Method:

1. Enter the T est Mode 2 (Torque Measurement Mode) (see page

19.) and set the torque meter TW-7131 (8-909-708-71).

2. Press the PLAY (”) key.

3. Press the AMS + key or = ke y and adjust so that the back

tension (S side) is within the range of 8.5 ± 0.5 g•cm.

4. When the torque meter is circulating around, check the indicated value.

5. Verify that the maximum value is less than 19.5 g•cm.

REV Torque Check and REV Back Tension Check

Check Method:

1. After FWD torque adjustment and FWD back tension adjustment are completed, press the PLA Y (”) ke y again and set REV

(“) mode.

2. Check that the REV torque value is within the range of 13.5 to

17.5 g•cm and that the REV back tension value is within the

range of 7.5 to 11.5 g•cm.

Tape Pass Fine Adjustment (×1.5FWD Mode)

When replacing any drum related parts, be sure to perform this adjustment.

Adjustment Method:

1. Connect the CH-1 terminal of an oscilloscope to TP (RF) and

the CH-2 terminal to TP (SWP) on the DIGITAL board.

2. Enter the Test Mode 1 (see page 19.) and set the test tape TY7252 (8-909-822-00).

3. Press the AMS (+) key.

Role of each switch in test mode.

OFFSET

–0 +

WIRED OFF

WIRELESS

ATF : ON

STANDARD LONG

ATF : OFF

1.2Vp-p

Adjustment Location: See page 23.

FWD Tor que Adjustment

Adjustment Method:

1. Enter the Test Mode 2 (Torque Measurement Mode) (see page

19.) and set the torque meter TW-7131 (8-909-708-71).

2. Press the PLAY (”) key.

3. Press the ) key or 0 key and adjust so that the FWD torque

value (T side take-up torque) is within the range of 11 to 13

g•cm.

4. When the torque meter is circulating around, check the indicated value.

48k 44.1k

REMOTE REC MODE

4. Put the REC MODE switch to the LONG (ATF: OFF) position

and put the REMOTE switch to either the WIRED or WIRELESS position (OFFSET: – or +), fine adjust both the S1 guide

and T1 guide so that the RF signal waveform of the oscilloscope repeatedly contracts and expands in vertical directions as

it has the same shape.

* Adjust the direction of tightening to complete this adjustment.

If there is curl on any of the upper and lower flanges of the

S2, T2 and F guides, adjust the guide of concern.

– 21 –

5. Put the REC MODE switch to the ST AND ARD 48k (ATF: ON)

s

P

position and put the REMOTE switch to either the WIRED or

WIRELESS position (OFFSET: – or +), then check the RF signal waveform.

4

A or less

5

NG

A

Check that there is a difference of 650 ± 15 µsec between the

oscilloscope’s SWP signal and the RF signal.

RF

SW

650±15 µsec

4

A’ or les

5

NG

A'

OK

6. Put the REC MODE switch to the ST AND ARD 48k (AFT : ON)

position and put the REMOTE switch to the OFF position (OFFSET: 0), then check the RF signal waveform.

(1) Verify that the peak value (B) of the RF signal w a veform is

60mV or more.

(2) Verify that the flat position of the RF signal waveform has

undershoots of 10% or less.

10

B

or less

10

B

or less

B

7. If any of the specified values are not satisfied, repeat items 3 to

6.

Adjustment Location: See page 23.

CHECK AND REPLACEMENT FOR DATE FNCTION

Clock IC Back-up Check

• When r eplacing the lithium battery (BATT501) or replacing any

of the clock IC (IC518) and peripheral parts, the clock will be

reset.

(The DATE display will be [‘-- -- --] [-[PRESENT] button is pushed.)

] even when the

h--m--s

Perform the back-up check by the following procedure.

(1) Connect a DC voltmeter between the DIGITAL board’s TP

(BATT+) as (+) side on the TP (BATT–) as (–) side.

(2) With the POWER switch of the set OFF, check that the volt-

age (1) is

less than +20 mV.

(If the measured value is more than +20 mV, inspect the IC518

and peripheral parts and replace as needed.)

(3) With the POWER switch of the set ON, check that the volt-

age (1) is

less than 0 mV (minus indication), (If plus indication, inspect the D510 and peripheral parts and replace as

needed.)

(4) When these voltages are normal, set the clock to the current

date and time according to the instruction manual.

(year/month/day/day of week/hours/minutes/seconds)*

(5) After the clock is set in item (4), turn off the POWER switch

once and in several seconds, turn on the power again and

make sure that the clock is operating.

Adjustment Location: See page 23.

Adjustment Location: See page 20.

DPG Adjustment

When replacing any drum related parts, be sure to perform this adjustment.

Adjustment Method:

1. Connect the CH-1 terminal of an oscilloscope to TP (RF) and

the CH-2 terminal to TP (SWP) on the DIGITAL board.

2. Enter the Test Mode 1 (see page 19.) and set the test tape TY7252 (8-909-822-00).

3. Put the REC MODE switch to the ST AND ARD 48k (ATF: ON)

position and put the REMOTE switch to the OFF position (OFFSET: 0).

4. Press the AMS (+) key.

5. Press the PLAY (”) key.

6. “DPG OK” is displayed in the fluorescent indicator tube.

– 22 –

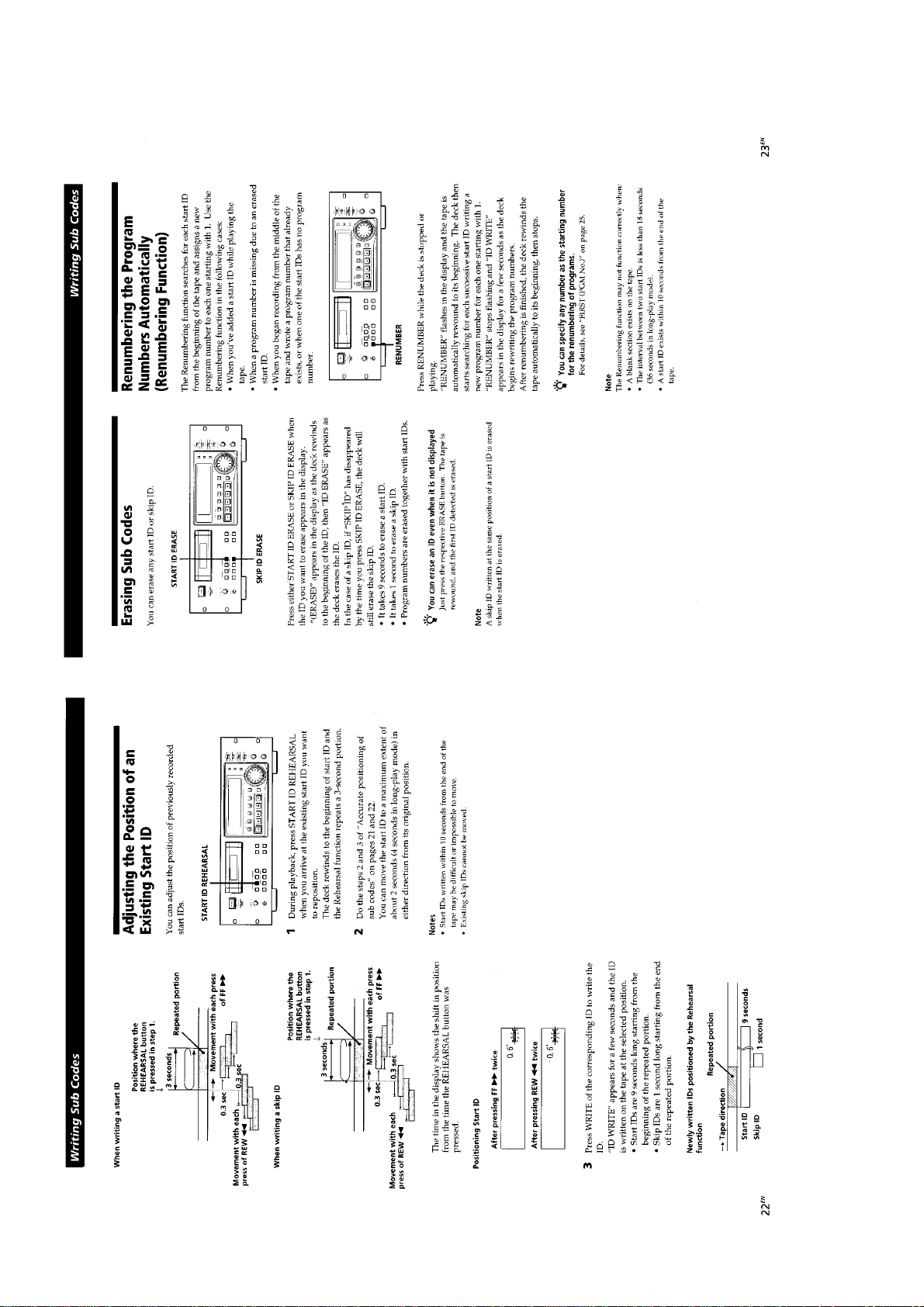

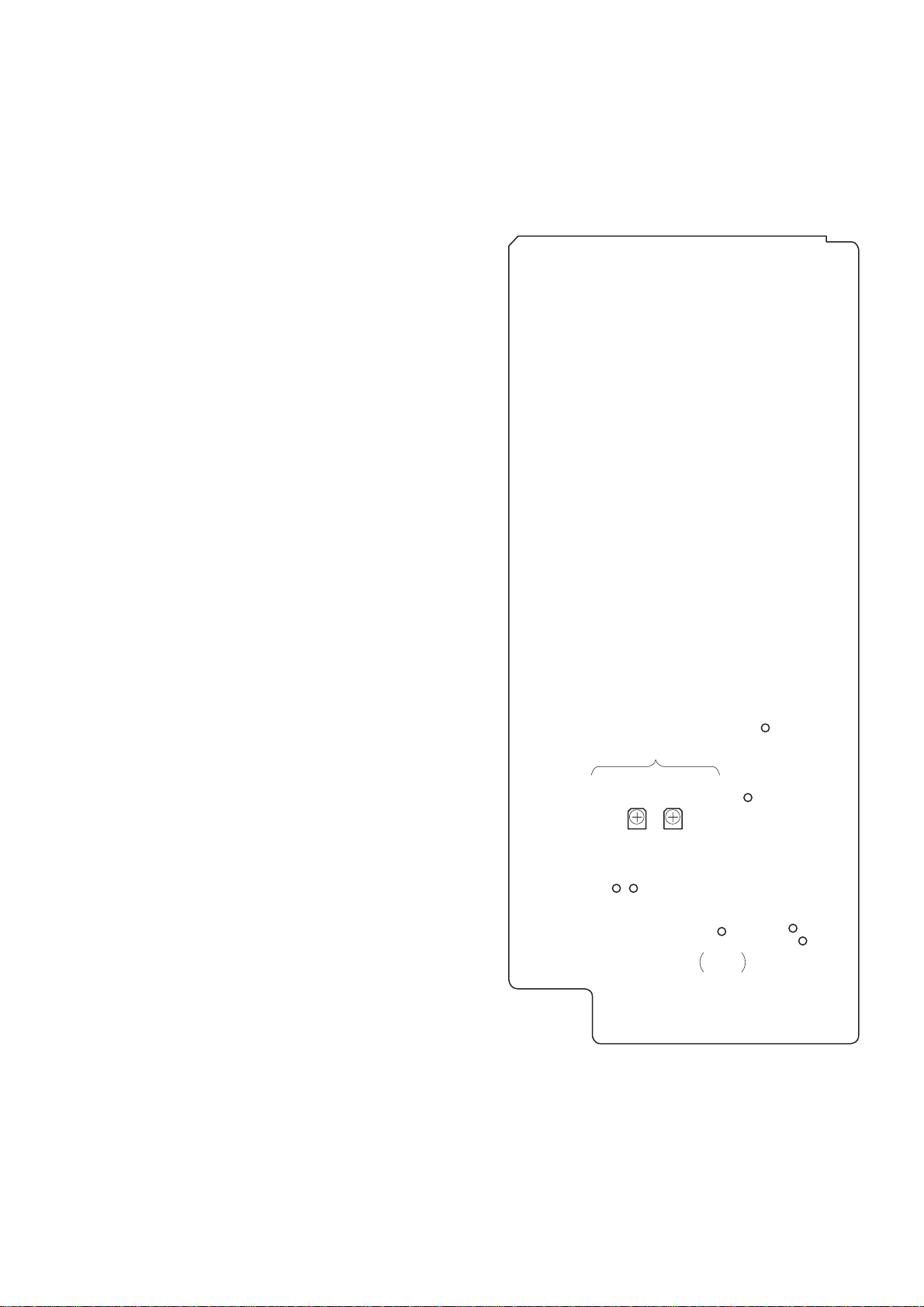

Replacement of Back-up Battery

(S-END)

RV502

(T-END)

RV501

TP

(RF)

TP

(SWP)

TP

(T-END)

TP

(S-END)

TP

(BATT+)

TP

(BATT–)

TP

MAIN–

TEST

END SENSOR ADJ

The back-up battery for clock is designed to serve for more than

seven years under normal service conditions (room temperature and

ordinary humidity).

When replacing the battery, take note of the following:

• P erform the above “Clock IC Back-up Check” and remedy the

cause of battery consumption.

• The open voltage of the battery as removed is 3.0 V or more when

it is new. If this voltage is 2.0 V or less, then battery is fully consumed and needs to be replaced.

• After the battery is replaced, perform the “Clock IC Back-up

Check” again and set the clock.

• The coin type lithium battery (CR2032) is used for replacement.

* For description of the clock setting, see page 5.

Adjustment and Check Locations :

DIGITAL board – component side –

– 23 –

– 24 –

SECTION 4

DIAGRAMS

• Circuit Boards Location

Note: A UDIO board and DIGITAL board are supplyed as MAIN board.

REG BOARD

PRIMARY BOARD

DIGITAL BOARD

REMOTE BOARD

DIGITAL OUT BOARD

DIGITAL IN BOARD

UNBAL BOARD

REM SW BOARD

HP BOARD

ANA OUT BOARD

ANA IN BOARD

AUDIO BOARD

DISPLAY BOARD

INPUT SW BOARD

SHUTTLE BOARD

REC BOARD

DRUM DRIVE BOARD

SW BOARD

MOTOR BOARD

S END BOARD

THICK BOARD

REEL MOTOR U-2A

RF BOARD

LOADING MOTOR BOARD

CAPSTAN MOTOR U-17A

(M902)

LOAD SW BOARD

T END BOARD

(M903)

REC EN BOARD

– 25 –

4-1. BLOCK DIAGRAMS

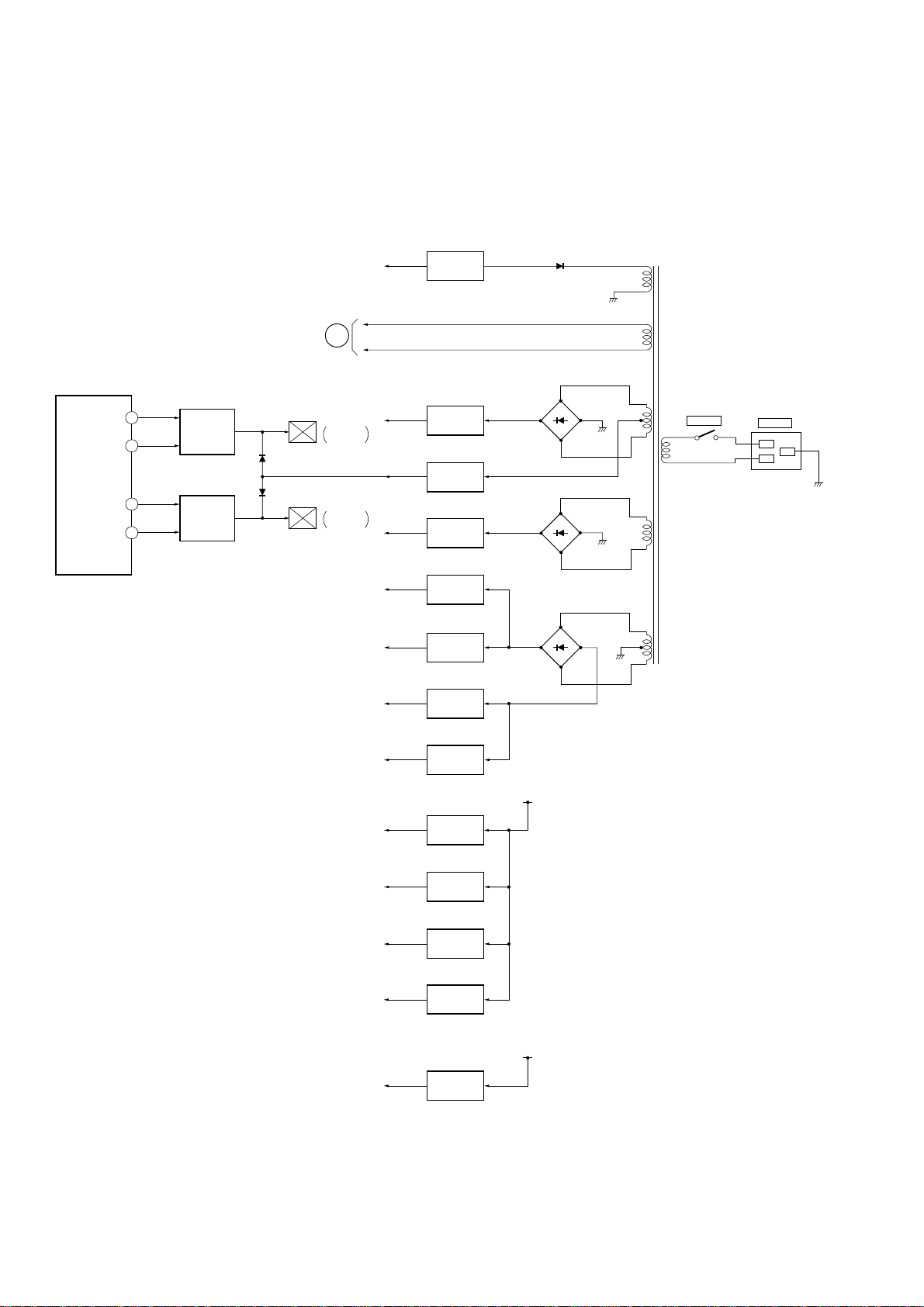

(1) Power Section

FPM KICK

FPM ON

SERVO

PROCESS

IC502 (3/3)

BPM KICK

BPM ON

-33V

FL701

E

F1, F2

1

100

4

3

FWD PM

DRIVE

Q504, 505

Q509, 511

BRAKE PM

DRIVE

Q506-508

Q510

D505

D506

PM902

FWD

PLUNGER

PM901

BRAKE

PLUNGER

+6V

+2V

+5V

+12V

+12V

-12V

-33V REG

Q502, 503

+6V REG

IC902

+2V REG

Q501, 901

+5V REG

IC901

+12V REG

IC319

+12V REG

IC301

-12V REG

IC302

D503

D502

D501

D301-304

T901

S901

POWER

IL901

~

AC IN

L

N

E

-12V

+5V (A)

+5V (B)

+5V (C)

+5V (D)

-5V

-12V REG

IC320

+5V REG

IC316

+5V REG

IC317

+5V REG

IC318

+5V REG

IC305

-5V REG

IC306

+12V

-12V

– 26 –

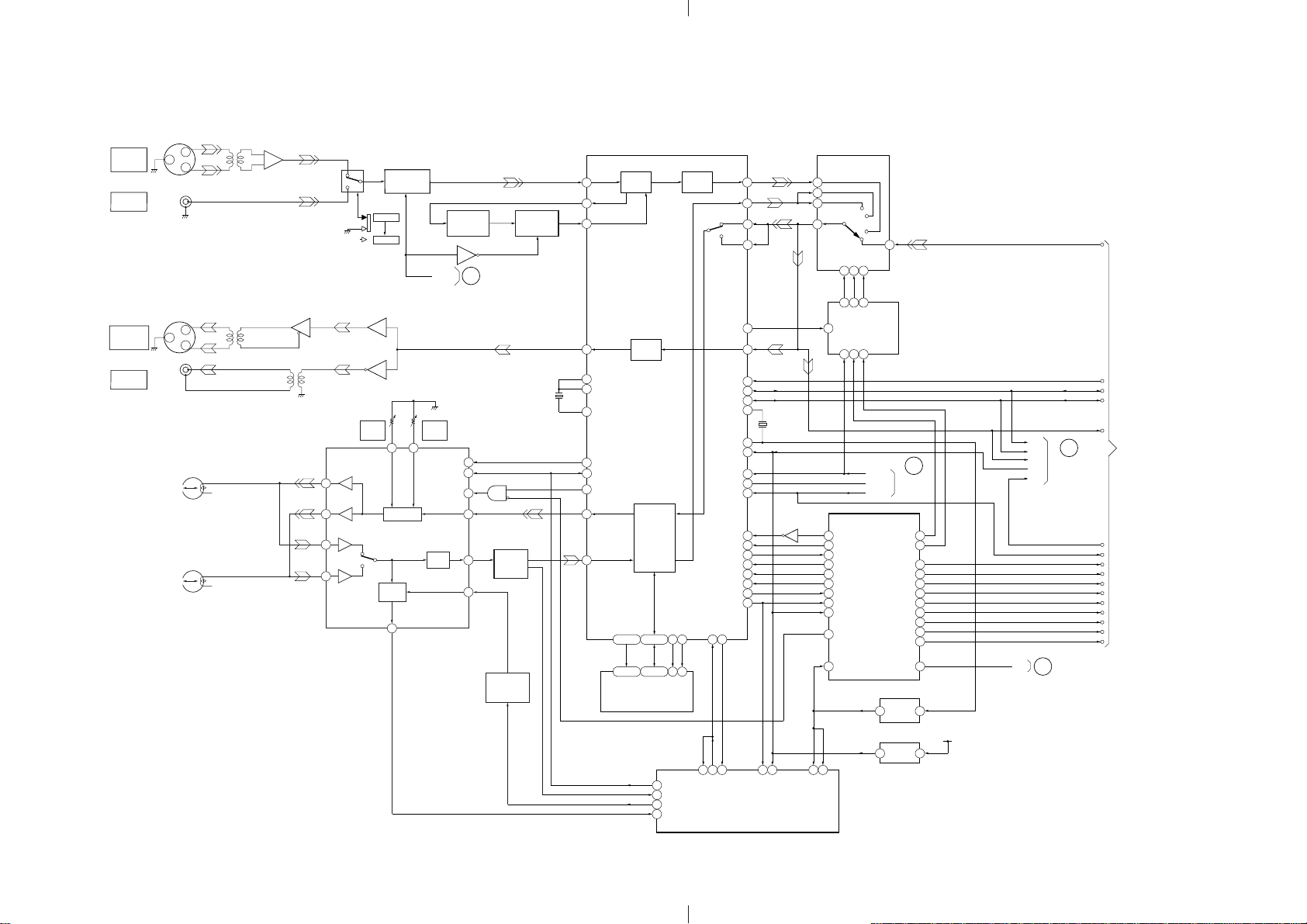

(2) Digital Audio Section

PCM-R500

DIGITAL

IN/OUT

AES/EBU IN

COAXIAL

IN

DIGITAL

IN/OUT

AES/EBU OUT

COAXIAL

OUT

J501-1

J501-2

REC/PB

REC/PB

HEAD

HEAD

J801

1

J802

1

A

B

T801

RS-422 RECEIVER

IC801 (1/2)

T802

12

+

–

11

RS-422 RECEIVER

2

IC801 (1/2)

9

10

T501

IC508

(1/4,4/4)

1

13

5

REC A

33

REC B

27

PB A

34

PB B

26

S501

AES/EBU

-COAXIAL

8

COAXIAL

AES/EBU

IC510 (1/4)

3

6

IC510 (2/4)

RV2

A REC

PCM

NORMALIZER

IC508 (2/4)

IC509 (1/2)

2

4

39 40

REC OCA

PILOT

OCA

PEV

11

VCOEN

RV1

B REC

PCM

PCM

EQ

RF AMP

IC1

PIPC

SWP

REC/PB

GCA

PHASE

CONTROL

IC513 (1/6)

IC513 (6/6)

A

46

47

45

44

1

14

IC513 (5/6, 4/6)

SYSTEM CONTROL

SECTION

Q522

PB RF

BUFFER

Q521

AGC

BUFFER

IC521 (1/2)

RX VCO

D513, Q520

X501

24.576MHz

RX

PDO

PLCO

TX

XT2I

XT3O

XT3I

PIPC

SWP

REPB

REDT

RFDT

A0-A14

1, 2, 4-8

93-100

1-10, 21

23-26

A0-A14

RX

PLL

DAT DSP

SRAM

IC504

IC503

DIGITAL

IN

DAT

DSP

84-89

91, 92

11-13

15-19

D0-D7

D0-D7

79

78

80

66

SWP

PBDT

AGC PWM

ATF

XOE

10 9 19 21

22 27

XOE

52

45

48

54

64

66

67

41

39

42

43

37

ADDI

DIGITAL

OUT

XWE

XWE

79

DADT

77

ADDN

80 9

ADDT

76 10

71 9

LRO1

DADO

78

58

F128

75

BCK

72

LRCK

14

XT1I

XT1O

XRST

MUTA

UNLK

FSEN

EXSN

MUTM

MUTE

EXCK

SDSI

SDSO

SBSY

ATSYATSY

DREF

73 91 72 48 40 43 77

DREF

ATF-S2

ATF-S2

SERVO PROCESS

13

16

47

31

68

57

38

XCS

30

29

23

24

25

26

IC502 (1/3)

X502

18.816MHz

XRST

XSBSY

Q524

SIGNAL SELECT

IC511

11

12

13

STBA

15 2 14

7 2 15

2Q2D

1Q

4Q

D F/F

CLK

IC512

1D

4D

5 4 13

MUTE A

UNLK

FSEN

96

EXSY-MUT

97

XMST-SEL

70

MUT-MONIT

98

MST-MUTE

55

SR-CK

54

SR-DTO

53

SR-DTI

52

XSBSY

XRST

40

REC-DIS

95

43 2

EXTAL

EXTAL

MSTCLK

9.4MHz

SYSTEM

CONTROL

IC501 (1/2)

XANA/DIG

9 11

6 7

XREC/PB

SBM-ON

XADLD

AUSC

AUSO

XADINT

XDAINT

XDALD

XBAL

1/2

DIVIDER

IC519

RESET

IC516

B

SYSTEM

CONTROL

SECTION

FS48

FS44

AIN

F128

BCK

LRCK

DADO

BCK

C

LRCK

DADO

SYSTEM

XRST

CONTROL

SECTION

XLM

16

15

1

11

8

7

28

29

93

94

12

ANALOG

XBAL

AUDIO

D

SECTION

18.8MHz

+5V

FSEN

SBM

ADLD

AUSC

AUSO

FS48

FS44

ADINT

DAINT

DALD

XLM

ANALOG AUDIO SECTION

2

3

2

3

– 27 – – 28 –

Loading...

Loading...