Sony PCM-7040 Maintenance Manual

微电子时空 基准带 好音乐的休闲时光

fzmcu.taobao.com

DIGITAL AUDIO RECORDER

PCM-7040

SUPPLEMENT-1

FOR MAINTENANCE MANUAL

Please replace and add this SUPPLEMENT-1 with your own manual.

Applicable Manual (Manual Code)

1st Edition (9-976-828-01)

Contents

Changed information for SSP-11 board, CP-268 board and CP-269 board.

Table of Contents

Section 1 Installation

Section 5 Electrical Alignment

Section 6 Spare Parts

Section 9 Board Layouts

Section 10 Schematic Diagrams

PCM-7040 (J)

PCM-7040 (UC)

PCM-7040 (CE) J, E

9-976-828-81

Printed in Japan

Sony Corporation 1998. 6 08

Broadcasting & Professional Systems Company © 1998

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 5 (E)

Contents ............................................................................................................... 5 (E)

Related manuals................................................................................................... 6 (E)

1. Installation

1-1. Installation Environment.......................................................................1-1 (E)

1-2. Power Requirements .............................................................................1-1 (E)

1-2-1. AC Power Supply.................................................................1-1 (E)

1-2-2. Power cord ...........................................................................1-1 (E)

1-3. Dimensions............................................................................................1-2 (E)

1-4. Rack Mounting......................................................................................1-3 (E)

1-5. Connection Connectors/Cables .............................................................1-4 (E)

1-6. Switch setting and LED function ..........................................................1-5 (E)

1-7. ISR (Interactive Status Reporting) ........................................................1-8 (E)

1-7-1. Connection ...........................................................................1-9 (E)

1-7-2. Commands............................................................................1-9 (E)

2. Service Overview

2-1. Boards Location ....................................................................................2-1 (E)

2-2. Cabinet Removal...................................................................................2-2 (E)

2-3. Main Part Replacement .........................................................................2-2 (E)

2-3-1. Lythium Battery Replacement .............................................2-2 (E)

2-3-2. Fuse Replacement ................................................................2-3 (E)

2-3-3. SSP-11 Board Replacement .................................................2-3 (E)

2-4. Removing the Cassette in Emergency...................................................2-4 (E)

2-5. Errors/Caution Codes ............................................................................2-5 (E)

2-6. Service Menu ........................................................................................2-7 (E)

2-6-1. Print Menu............................................................................2-9 (E)

2-6-2. Display Menu .....................................................................2-10 (E)

2-6-3. Test Menu...........................................................................2-17 (E)

2-6-4. Preset menu ........................................................................2-27 (E)

3. Periodical Inspection and Maintenance

3-1. Cleaning ................................................................................................3-1 (E)

3-2. Periodic check (maintenance) schedule ................................................3-2 (E)

3-3. Maintenance after repaires ....................................................................3-2 (E)

PCM-7040

1(E)

4. Replacement and Adjustment of Mechanism Deck

4-1. Replacement of Mechanical Deck Assy and Parts................................4-1 (E)

4-2. Adjustments and Checks .......................................................................4-5 (E)

4-2-1. Preparations..........................................................................4-7 (E)

4-2-2. Adjustments and checks in the service menu.......................4-9 (E)

4-2-3. Checking after SV-147A board replacement .....................4-31 (E)

5. Electrical Alignment

5-1. Preparation ............................................................................................5-1 (E)

5-1-1. Equipment ............................................................................5-1 (E)

5-1-2. Switch and Control Initial Setting........................................5-2 (E)

5-2. Signal Processing Block Adjustment ....................................................5-2 (E)

5-2-1. Master Clock Adjustment ....................................................5-2 (E)

5-2-2. Timer Clock Adjustment......................................................5-3 (E)

5-2-3. RF PLL Adjustment .............................................................5-4 (E)

5-3. AD/DA Block Adjustment....................................................................5-8 (E)

5-3-1. AD Conversion Level Adjustment.......................................5-9 (E)

5-3-2. DA Conversion Level Adjustment.......................................5-9 (E)

5-3-3. C. M. R. R. Adjustment......................................................5-11 (E)

5-3-4. Output Balance Adjustment ...............................................5-12 (E)

5-4. Time Code Output Level Adjustment .................................................5-13 (E)

6. Spare Parts

6-1. Notes on Repair Parts.................................................................................. 6-1

6-2. Exploded Views .......................................................................................... 6-2

6-3. Electrical Parts Lists..................................................................................6-10

6-4. Accessories Supplied ................................................................................6-27

7. Semiconductor Pin Assignments

8. Block Diagrams

OVERALL ..................................................................................................8-1

MECHA DECK BLOCK ............................................................................8-2

SSP-11 BOARD ..........................................................................................8-4

KY-192 BOARD....................................................................................... 8-17

2(E)

PCM-7040

9. Board Layouts

SSP-11 (Suffix -11)..................................................................................... 9-2

KY-192........................................................................................................9-6

CP-268 (Suffix -11).....................................................................................9-8

VR-109........................................................................................................9-9

SW-420 .......................................................................................................9-9

LED-104......................................................................................................9-9

HP-48 ..........................................................................................................9-9

PS-451 .........................................................................................................9-9

PS-452 .........................................................................................................9-9

CN-1487......................................................................................................9-9

CP-269 (Suffix -11)...................................................................................9-10

RF-53.........................................................................................................9-10

Capstan Flexible........................................................................................ 9-10

Reel FG. Dew Flexible..............................................................................9-10

Reel FG .....................................................................................................9-10

Recogni End Flexible................................................................................ 9-10

SV-147A ...................................................................................................9-11

Goma .........................................................................................................9-11

Tenregi Motor Encoder Flexible...............................................................9-11

Tenregi ......................................................................................................9-11

SSP-11 (Suffix -12, -13) ...........................................................................9-14

CP-268 (Suffix -12)...................................................................................9-18

CP-269 (Suffix -12)...................................................................................9-19

PCM-7040

10. Schematic Diagrams

SSP-11 (Suffix -11)

AD Block ................................................................................................ 10-2

DA Block ................................................................................................ 10-3

PS Block ................................................................................................. 10-4

SY Block .................................................................................................10-6

RM Block................................................................................................ 10-8

SP Block ............................................................................................... 10-10

MEM Block ..........................................................................................10-12

TC Block ...............................................................................................10-14

DIO Block .............................................................................................10-16

KY-192....................................................................................................10-18

CP-268A (Suffix -11) (UC,CE) ..............................................................10-20

CP-268B (Suffix -11) (J).........................................................................10-21

RF-53.......................................................................................................10-23

SV-147A .................................................................................................10-24

3(E)

FRAME WIRING (1/2) ..........................................................................10-26

CN-1487 ..................................................................................................10-26

PS-451 ..................................................................................................... 10-26

PS-452 ..................................................................................................... 10-26

FRAME WIRING (2/2) ..........................................................................10-27

CP-269 (Suffix -11).................................................................................10-27

HP-48 ......................................................................................................10-27

LED-104.................................................................................................. 10-27

SW-420 ................................................................................................... 10-27

VR-109 ....................................................................................................10-27

SSP-11 (Suffix -12, -13)

AD Block .............................................................................................. 10-30

DA Block .............................................................................................. 10-31

PS Block ............................................................................................... 10-32

SY Block ...............................................................................................10-34

RM Block.............................................................................................. 10-36

SP Block ............................................................................................... 10-38

MEM Block ..........................................................................................10-40

TC Block ...............................................................................................10-42

DIO Block .............................................................................................10-44

CP-268A (Suffix -12) (UC,CE) .............................................................. 10-45

CP-268B (Suffix -12) (J)......................................................................... 10-46

FRAME WIRING (1/2) ..........................................................................10-48

CN-1487 ..................................................................................................10-48

PS-451 ..................................................................................................... 10-48

PS-452 ..................................................................................................... 10-48

FRAME WIRING (2/2) ..........................................................................10-49

CP-269 (Suffix -12).................................................................................10-49

HP-48 ......................................................................................................10-49

LED-104.................................................................................................. 10-49

SW-420 ................................................................................................... 10-49

VR-109 ....................................................................................................10-49

4(E)

PCM-7040

1-6. Switch setting and LED function

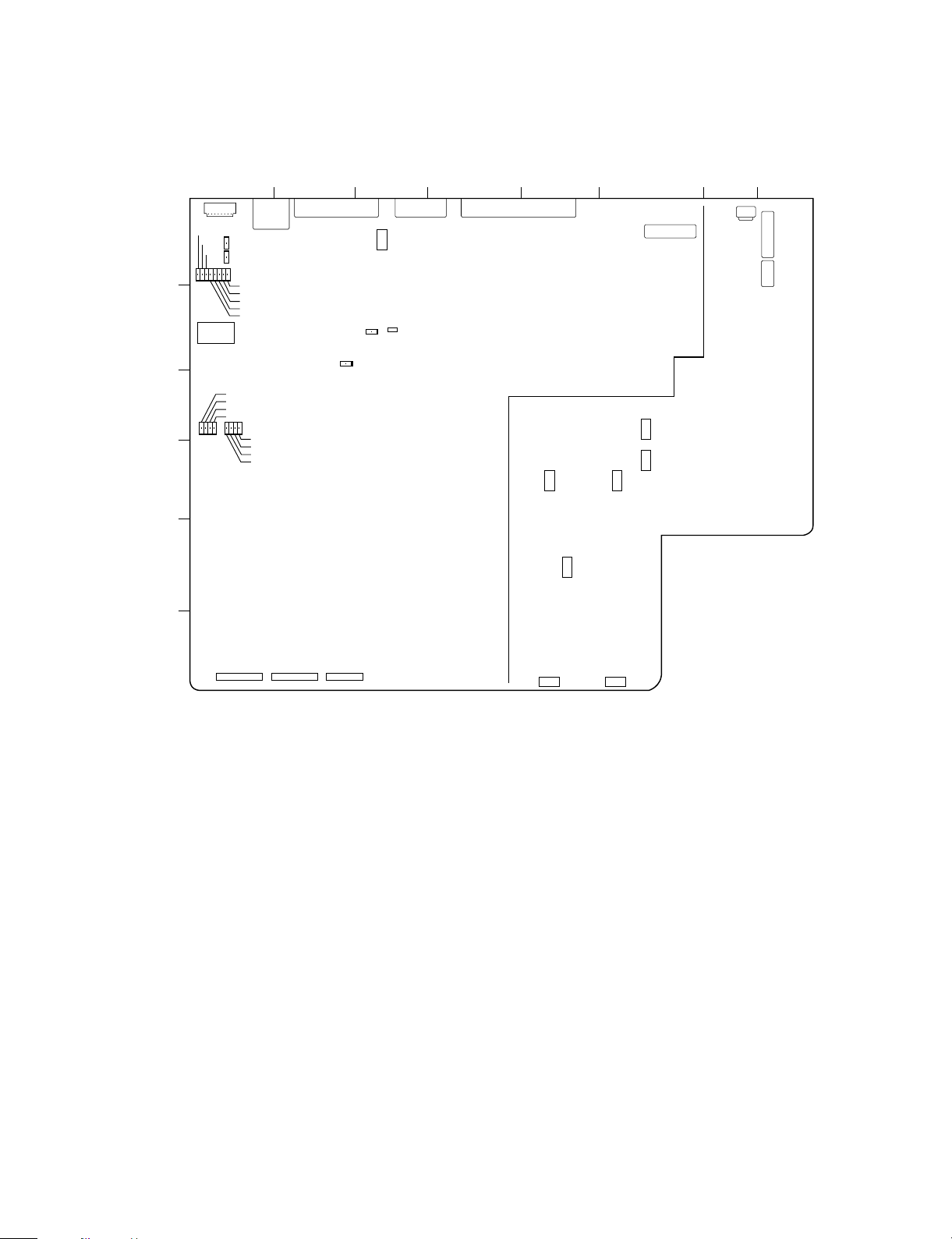

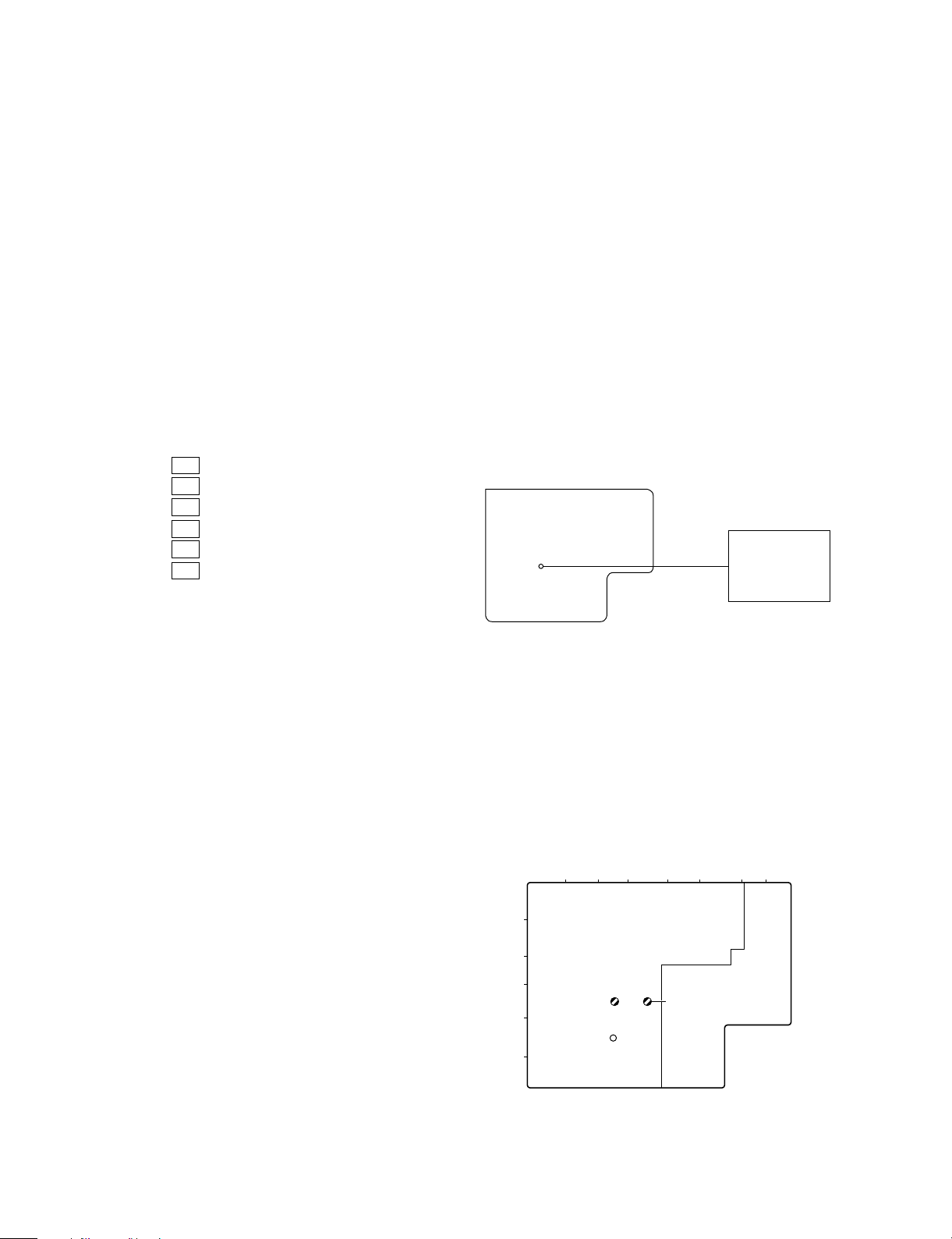

SSP-11 board (A side)

ABCDE FG

H

CN702

D303

D304

1

2

3

4

5

6

D316

D305

D317

D310

D309

D308

D307

D306

S302

D608

D607

D606

D605

D601

D602

D603

D604

CN405 CN406 CN309

CN308

CN305

D302

D301

CN306 CN307

S801*1

S301

RV203

1

S202

S51

RV202

1

RV201*1

1

S201 S101

S102

RV206*1

1

RV102

RV103

1

RV106*1

1

1

RV101*1

1

CN51

S203*1

S103*1

CN1

CN3

CN2

*1 :Applicable board number suffix ; -12 and higher

LED indicators

D301 (C2) (red) : CPU initialization indicator

Turns on when reset, and turns off

when initialization process is completed.

D302 (B2) (yellow) : EEPROM access indicator

Turns on during data read/write of

EEPROM (IC308).

D303 (A1) (red) : Backup memory data initialization

indicator

Turns on when backup memory

(IC309, IC310) is initilized (cleared).

D304 (A1) (green) : Normal operation indicator

Turns on when when the main CPU

(IC304) operates normally.

D305 (A1) (yellow) : Mute indicator

Turns on when the playback audio

signal is muted (in such mode as STOP).

D306 (A1) (yellow) : DSP output indicator

Turns on when the monitor sound is

(any of the following) DSP (IC604)

outputs.

. The SYNC REC lamp on the front

panel turns on. (sync record mode)

. Memory jog, memory rehearsal

and memory start play

D307 (A1) (yellow): RMW mode indicator

Turns on when the leading head is

playing back and the trailing head is

recording (any of the followings).

. The SYNC REC lamp on the front

panel turns on. (sync record mode)

. When playing back the wide track

pitch tape.

. When the leading head playback

mode is selected by the error rate

selection (service menu “rAtE

SEL”).

D308 (A1) (green) : 9-pin CPU interface normal operation

indicator

Turns on when communication

between the 9-pin CPU (IC318) and

the main CPU (IC304) is established.

PCM-7040

1-5(E)

D309 (A1) (red) : 9-pin data reception (9-pin CPU →

main CPU) indicator

Turns on while the main CPU is

receiving data from the 9-pin CPU.

D310 (A1) (green) : 9-pin data send (9-pin CPU ← main

CPU) indicator

Turns on while the main CPU is

sending data to the 9-pin CPU.

D316 (A1) (red) : 9-pin data reception (SCU → 9-pin

CPU) indicator

Turns on while the 9-pin CPU is

receiving data from the SCU (Serial

Control Unit, IC306).

D317 (A1) (green) : 9-pin data send (SCU ← 9-pin CPU)

indicator

Turns on while the 9-pin CPU is

sending data to the SCU.

D601 (A3) (red) : Recorder (playback sound) sound

memory write indicator

Turns on while writing data into the

recorder sound memory.

D602 (A3) (yellow) : Recorder (playback sound) sound

memory read indicator

Turns on while reading data from

the recorder sound memory.

D603 (A3) (green) : Recorder (playback sound) sound

memory IN-point trigger indicator

Turns on when cross-fade is applied

to the recorder sound memory data

at IN-point.

D604 (A3) (green) : Recorder (playback sound) sound

memory OUT-point trigger indicator

Turns on when cross-fade is applied

to the recorder sound memory data

at OUT-point.

D605 (A3) (red) : Player (input sound) sound memory

write indicator

Turns on while writing data into the

player sound memory.

D606 (A3) (yellow) : Player (input sound) sound memory

read indicator

Turns on while reading data from

the player sound memory.

D607 (A3) (green) : Player (input sound) sound memory

IN-point trigger indicator

Turns on when cross-fade is applied

to the player sound memory data at

IN-point.

D608 (A3) (green) : Player (input sound) sound memory

OUT-point trigger indicator

1-6(E)

Switches

S301 (C2) : RESET switch

CPU (IC304) reset switch

S302 (A2) : Mode setting

S302-1, 2: Destination setting

S302-1 S302-2 Destination setting

OFF OFF For UC

ON OFF For J

OFF ON For CE

ON ON For UC

S302-3, 4: Device type setting for 9 PIN

S302-3 S302-4 Device type setting

for 9PIN

OFF OFF PCM-7030

(Factory setting)

ON OFF PCM-7050

OFF ON PCM-7040

ON ON PCM-7040

S302-5 to -7 : Reserved

S302-8 : Backup memory initialization

setting

S302-8: Backup memory initialization setting

OFF Not initialized when the main power is

turned on.(Factory setting)

ON Initialized when the main power is turned

on. “-ALL cLEAr-” appears on the display.

In the cases as described below, set the

destination using S302-1 and -2, then

perform initialization.

1. When the SSP-11 board is replaced.

2. When IC309 or IC310 (RAM) on the

SSP-11 board is replaced.

When any switch of S302-5 to -7 is set to on, the

ALARM indicator on the front panel flashes, and

“cAution 1-50” is triggered.

Factory setting

S302-1, -2 ; Items 1 and 2 are set in accordance

with destination.

S302-3 to -8; off

PCM-7040

S801(C1):Used during designing

Factory setting ; LO side position

S51 (E5) : AD/DA signal path switch

Switch for AD/DA digital audio signal changing over

S51 Signal path setting

NORMAL Normal signal path(Factory setting)

TEST AD converter output is input to the DA converter

S101 (F6) : Input reference signal level (CH-1) switch

S201 (E6) : Input reference signal level (CH-2) switch

S102 (F4) : Output reference signal level (CH-1) switch

S202 (E4) : Output reference signal level (CH-2) switch

Reference signal level (+4 dBs/_20 dBs)

changing switches

S101, S102, Reference signal level setting

S201, S202

+4 dBs The +4 dBs input/output signal will be

displayed as _20 dB on the level meter

(FL display).(factory setting)

_20 dBs The _20 dBs input/output signal will be

displayed as _20 dB on the level meter

(FL display).

(0 dBs = 0.775 Vrms)

S103 (F4) : MONITOR output reference level (CH-1) switch

S203 (F4) : MONITOR output reference level (CH-2) switch

Reference output level changing switches for

MONITOR output connectors (CH-1, CH-2)

S103, S203 Reference output level setting of

MONITOR output connectors (CH-1, CH-2)

+10 _10 dBs(factory setting)

0 _20 dBs

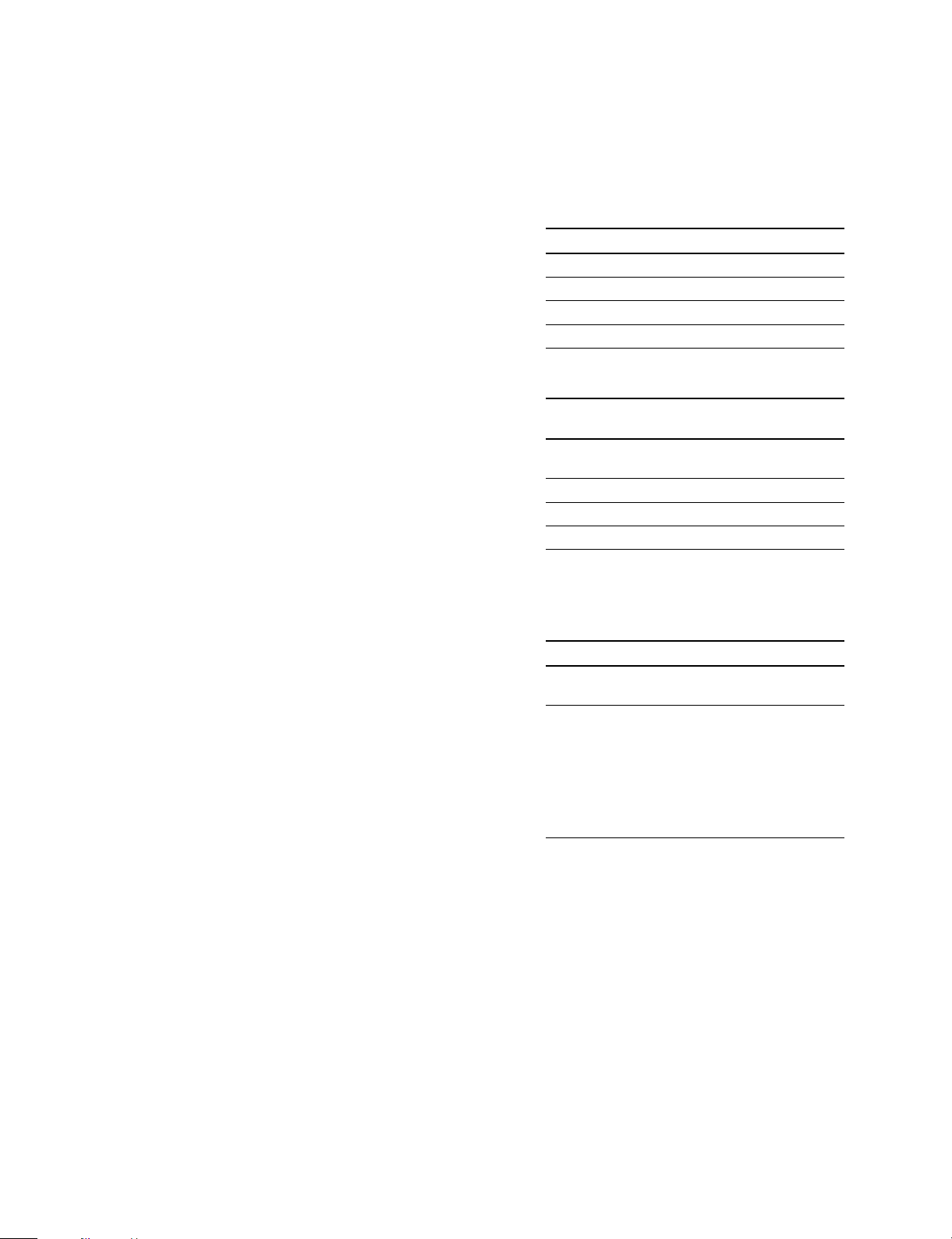

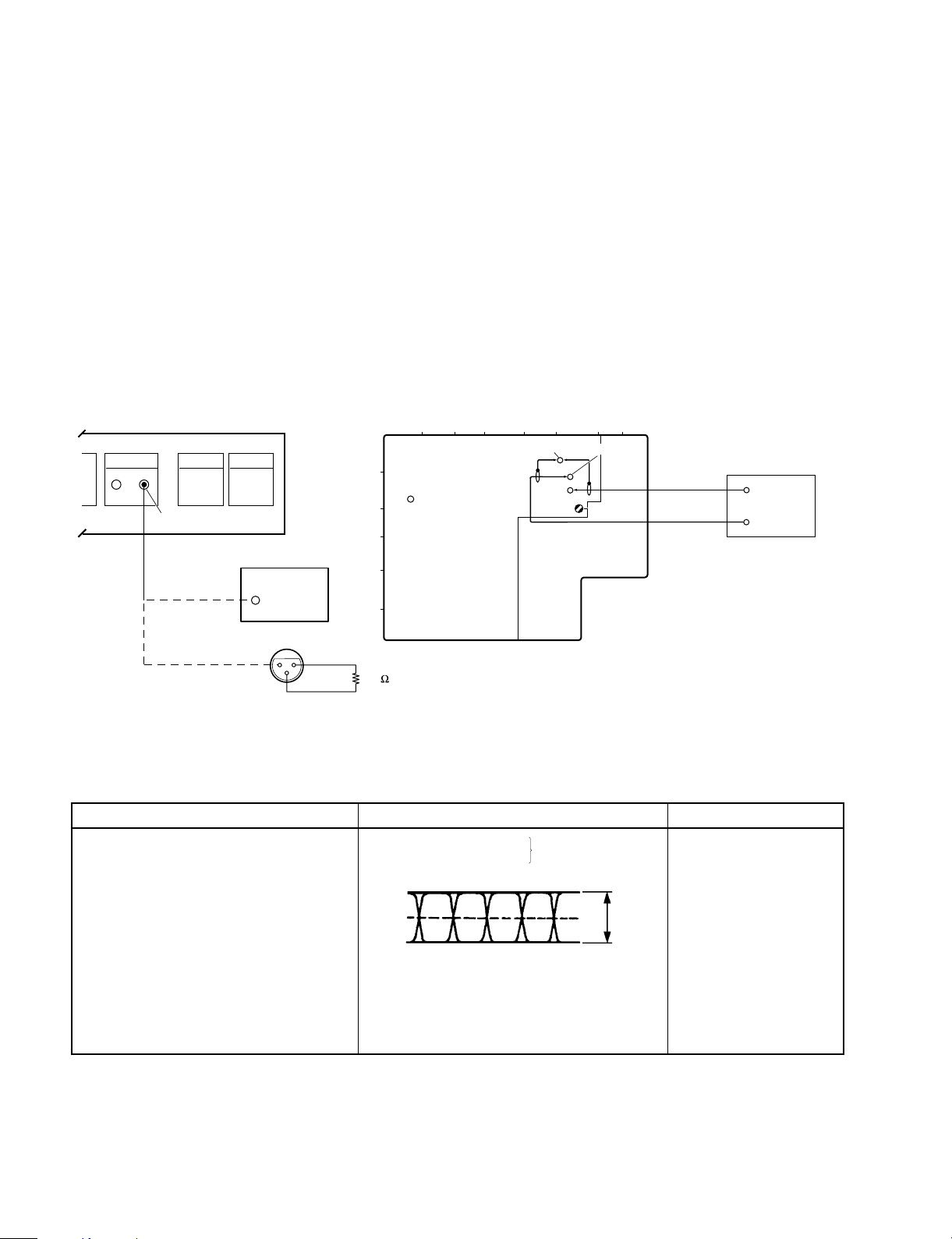

CP-268 board (A-side)

Switches

ABCD

S11 S21

CN52 CN501

S11 (A1) :

Analog audio (CH-1) input impedance setting switch

Set the CH-1 input impedance.

S21 (A1) :

Analog audio (CH-2) input impedance setting switch

Set the CH-2 input impedance.

S11, 21 Input impedance setting

OFF 10 kZ

ON 600 Z (Factory setting)

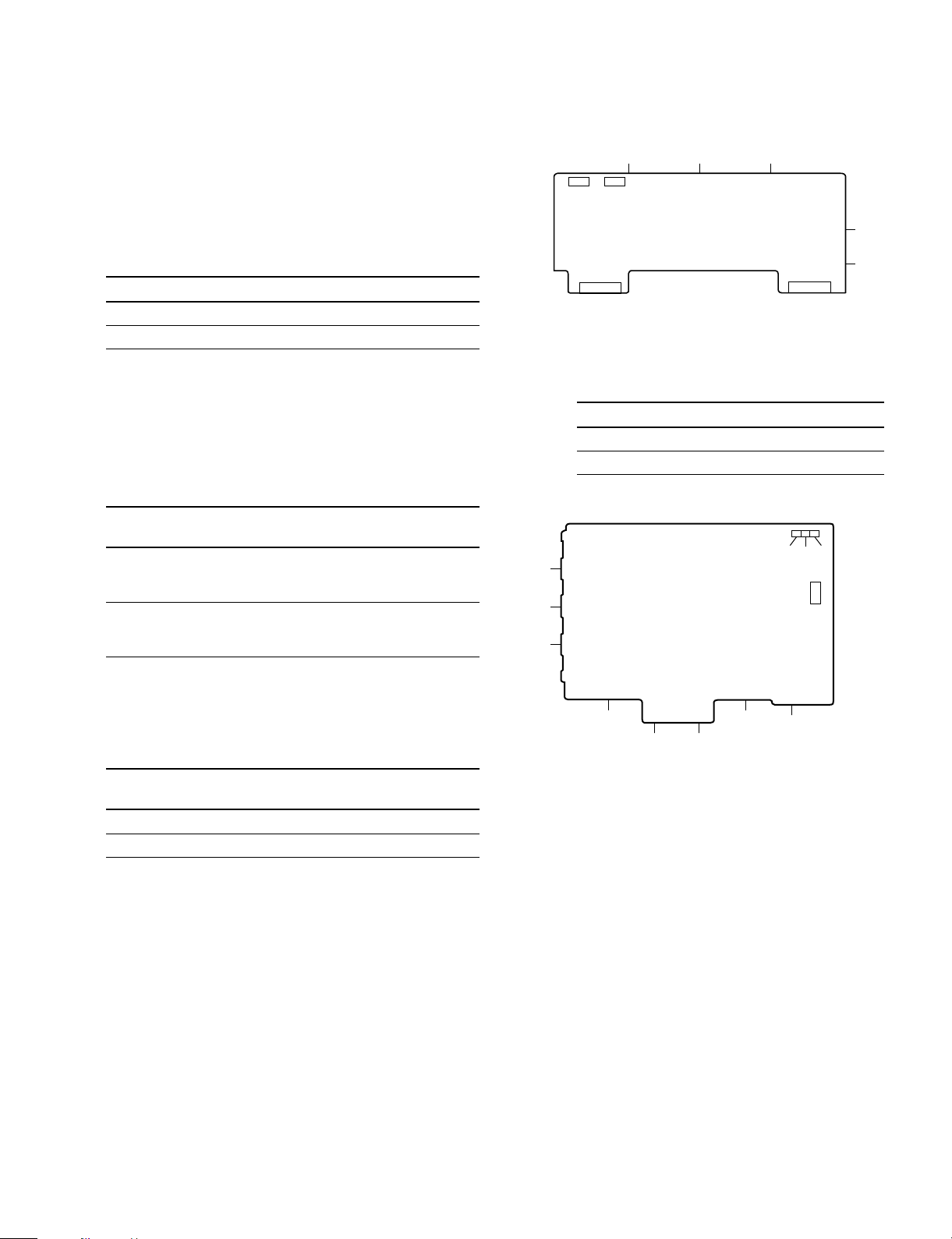

SV-147A board (B-side)

A

B

C

D

21

3

4

D3S1D2

D1

56

Switch

S1 (S1-1 to S1-4) ; Adjustment Mode Setting Switch

(For details, refer to “Section 4.

Replacement and Adjustment of

Mechanism Deck”)

1

2

3

When reference level has been changed, adjust the following volumes.

RV102 (F6) : Adjustment for input level (CH1)

RV202 (E6) : Adjustment for input level (CH2)

RV103 (F4) : Adjustment for output level (CH1)

RV203 (E4) : Adjustment for output level (CH2)

RV106(F4) : Adjustment for output linearity (CH-1)

RV206(F4) : Adjustment for output linearity (CH-2)

PCM-7040

Factory setting

S1-1 to S1-4 ; All OFF

(Setting for normal operations)

LED indicators

D1 ; CPU Operation Indicator

Blinking (Approx.every 1 sec.)

: When operating normally.

Blinking quickly (Approx.every 0.5 sec.)

: When an error is detected.

Lit or off : When not operating

D2 ; Adjusting Mode Indicator

Lit : When adjustment mode is ON.

Off : When adjustment mode is OFF.

D3 ; Servo Lock Indicator

Lit : Locked

Off : Unlocked

1-7(E)

1-7. ISR (Interactive Status Reporting)

The PCM-7040 corresponds to a ISR (Interactive Status Reporing) function.

Using this function, the status of the PCM-7040 or the contents of a generated error can be intensively monitored and

managed on the monitor screen of a personal computer. The data displayed on the monitor screen can be stored or printed as

a file.

The major functions of the PCM-7040 are as follows.

Management functions

. Identification information

Manufacture : SONY

Model : PCM-7040

Device ID : Identification number or identification name within 50 alphanumeric characters.

Serial number : Serial number which is set from the PCM-7040 (service menu).

VM type : 02 (VTR)

Destination : Destination UC, J, CE

ROM : ROM information for main CPU, servo CPU and display CPU (Board name, ROM name, version, board

address)

. Hour meter information

Integrating meter for Operation, Drum Running, Tape Running, Threading Counter

. Upload and download of setup menu data (global setting)

Monitor function

. Error/caution message

Indication of the error or caution (warning) number and its meaning. Or indication of error history.

. Signal processing error (Channel Condition) message

Indication of signal processing error. Or indication of error history.

Level:

0: Good

1: Correction of certain amount of error or more

2: Interpolation

4: Mute

. Operation statas

Indication for tape path mode

TAPE UNTHREAD, STOP, STANDBY OFF, PLAY, PLAY LOCK, REC, REC LOCK, EDIT, EDIT LOCK, F.FWD,

REW, SHUTTLE STILL, SHUTTLE FWD, SHUTTLE REV, JOG STILL, JOG FWD, JOG REV, VAR STILL,

VAR FWD, VAR REV, PREROLL, PREVIEW, AUTO EDIT, CHASE

. Test

Main CPU test, sound memory test

Control function

. Remote control

EJECT, STANDBY ON/OFF, STOP, PLAY, REC, F.FWD, REW, CUEUP(TC LOCATE)

1-8(E)

PCM-7040

Section 5

Electrical Alignment

This section describes the following electrical adjustment

when SSP-11 board is repaired or maintained.

SSP-11 board adjustment items

5-2. Signal processing block adjustment

5-2-1. Master clock adjustment

5-2-2. Timer clock adjustment

5-2-3. RF PLL adjustment

5-3. AD/DA block adjustment

5-3-1. AD conversion level adjustment

5-3-2. DA conversion level adjustment

5-3-3. C.M.R.R adjustment

5-3-4. Output balance adjustment

5-4. Time code output level adjustment

5-1. Preparation

5-1-1. Equipment

Equipment

Oscilloscope

Audio analyzer

Frequency counter

Specification

Frequency:DC to 150 MHz

Dual trace or more (Add mode)

. AF Oscillator

Range:10 to 100 kHz

Level:_70 to +24 dBm

. Level meter

Effective digits:8 digits or more

Model name

TEKTRONIX 2445A

or equivalent

TEKTRONIX SG505 (OP2),

AA501

or equivalent

ADVAN TEST TR5822,

HEWLETT PACKARD 5315A

or equivalent

PCM-7040

5-1(E)

5-1-2. Switch and Control Initial Setting

5-2. Signal Processing Block Adjustment

Front panel

Switches

REMOTE (9P)/LOCAL ; LOCAL

SYNC EXT/INT/VIDEO ; INT

AUDIO INPUT ANALOG/DIGITAL ; ANALOG

SAMPLING FREQ 44.1 kHz/48 kHz ; 48 kHz

Controls

ANALOG CH-1 input level; Center click position

ANALOG CH-2 input level; Center click position

SSP-11 board

AD/DA block

S51 switch; NORMAL

S101 switch; +4

S201 switch; +4

S102 switch; +4

S202 switch; +4

S103* switch; +0

S203* switch; +0

CPU-268 board

S11 switch; ON (600Z)

S21 switch; ON (600Z)

* Applicable board No. suffix ; -12 and higher

To perform the adjustments, first remove the top panel.

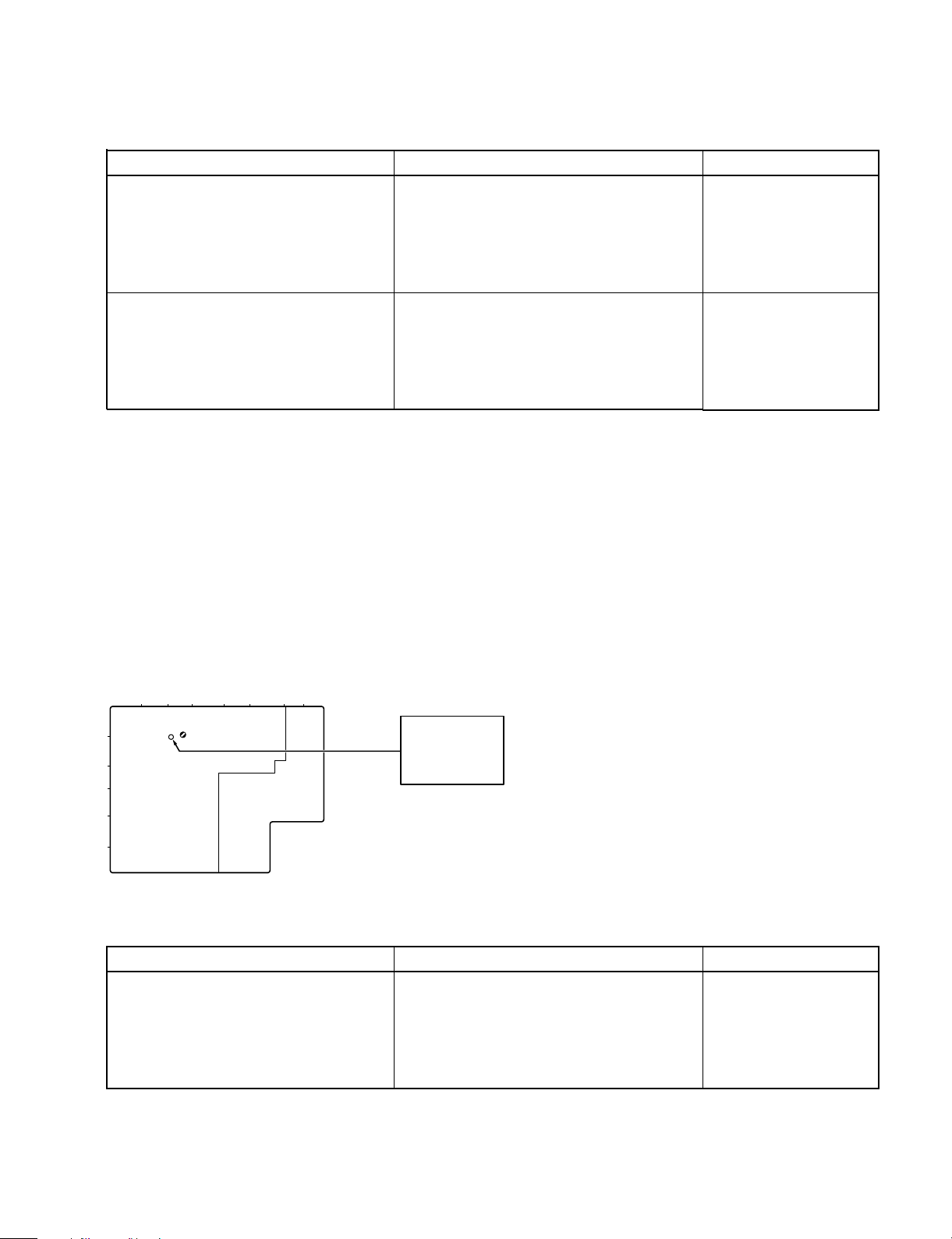

5-2-1. Master Clock Adjustment

This section describes the oscillation frequency adjustments of X’tal which generates the Fs system clock of

master clock block.

Perform the adjustment/checking when SSP-11 board and

master clock block components are replaced.

Equipment required

Frequency counter

Connection

Frequency counter

TP50

SSP-11 board (A side)

Switch and control setting

Same as “5-1-2. Switch and Control Initial Setting” except

the followings:

Front panel

REMOTE (9P)/LOCAL switch ; LOCAL

SYNC EXT/INT/VIDEO switch ; INT

SAMPLING FREQ 44.1 kHz/48 kHz switch ; 48 kHz

5-2(E)

Adjustment Location

A2BC D E F GH

1

3

4

5

6

*1 Applicable board No. suffix ; -11

*2 Applicable board No. suffix ; -12 and higher

*1

CT401 (C4)

*2

or X403 (C4)

TP50 (C5)

*1

CT402 (D4)

*2

or X404 (D4)

SSP-11 board (A-side)

PCM-7040

Adjustment procedure

Adjustment condition

Step 1

. Disconnect the connecting cables of rear panel.

. Connect the frequency counter to the TP50

(C5)/SSP-11 board.

. Check that the frequency at TP50 (C5) satisfies the

following specification (47999.76 to 48000.24 Hz).

If the specification are not satisfied, adjust the

*1

CT401

(C4)/X403*2 (C4).

. SAMPLING FREQ. switch(Front panel)

: 48 kHz

Specification (frequency at TP50)

Fs (48 kHz) = 48000.00 ±0.24 Hz

Step 2

The settings remain in the same as step 1

except the following.

. SAMPLING FREQ. switch(front panel)

. Check that the frequency at TP50 (C5) satisfies the

following specification (44099.78 to 44100.22 Hz).

If the specifications are not satisfied, adjust the

CT402*1 (D4)/X404*2 (D4).

: 44.1 kHz

Specification (frequency at TP50)

Fs (44.1 kHz) = 44100.00 ±0.22 Hz

5-2-2. Timer Clock Adjustment

Perform the adjustment/checking when SSP-11 board and

time clock block components (X304, CT301 and peripheral components) are replaced.

Equipment required

Frequency counter

Specification

Adjustment (SSP-11 board)

*1 Board No. suffix: -11

1CT401 (C4)

*2 Board No. suffix:

-12 and higher

1X401 (C4)

*1 Board No. suffix: -11

1CT402(D4)

*2 Board No. suffix:

-12 and higher

1X404 (D4)

Switch and control setting

This has no switches and controls that need to be set during

adjustment.

Connection/Adjustment Location

A2BC D E FGH

1

TP36 (C2)

3

4

5

6

CT301 (C2)

SSP-11 board (A-side)

Adjustment procedure

Adjustment condition

. Connect the frequency counter to the TP36

(C2) SSP-11 board.

Frequency counter

Specification

. Check that the frequency at TP36 (C2) satisfies the

following specification (2047.99 to 2048.01 Hz).

If the specifications are not satisfied, adjust the

CT301 (C2).

Specification

Frequency at TP36 = 2048.00 ±0.01 Hz

Adjustment (SSP-1 board)

1CT301 (C2)

PCM-7040

5-3(E)

5-2-3. RF PLL Adjustment

The RF PLL block generates the clock for extracking the

playback data from the head. In correspondence to the

head/RF amplifier characteristics, adjust the RF PLL block

to obtain the best error rate.

Perform this adjustment when replacing SSP-11 board and

RF PLL block components, and replacing the mechanism

assembly, drum assembly and RF assembly.

Preparation

. Disconnect the connection plugs (COP401 and COP402)

from the connection pins (COR401 and COR402) (D6)

on the SSP-11 board. (See “Adjustment Location”.)

The connection plugs (COP401 and COP402) are to be

reinserted after the RF PLL adjustment.

Equipment required

Oscilloscope

Pre-recorded music DAT tape (Fs = 48 kHz)

Connection

TP512 (A3)

TP53 (D6)

TP55 (D6)

SSP-11 board (A side)

Oscilloscope

CH 1

CH 2

CH 1; 1 V/div

CH 2; 5 V/div

10 ms/div

Switch and Control setting

Same as “5-1-2. Switch and Control Initial Setting” except

the followings:

Front panel

REMOTE (9P)/LOCAL switch ; LOCAL

SYNC EXT/INT/VIDEO switch ; INT

SAMPLING FREQ 44.1 kHz/48 kHz switch ; 48 kHz

Adjustment Location

A

1

2

3

4

5

6

BC D E FGH

TP512 (A3)

RV401 (C6)

COR402 (D6)

LV402 (C6)

RV403 (C6)

COR401 (D6)

LV403 (C6)

LV401

(D5)

RV402 (D6)

TP54 (D6)

TP53 (D6)

TP56 (D6)

TP55 (D6)

SSP-11 board (A-side)

5-4(E)

PCM-7040

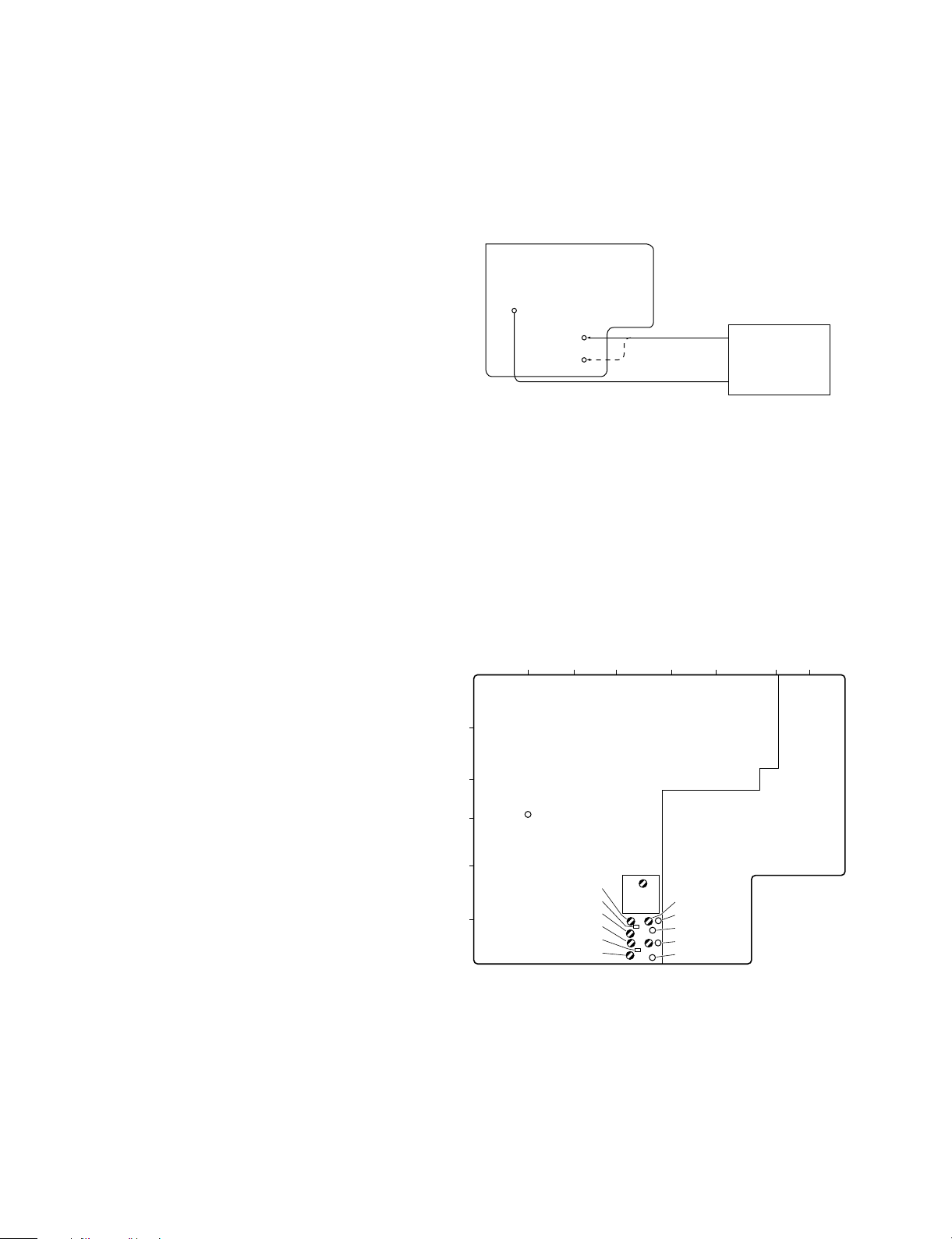

1. Leading head RF PLL Adjustment

Adjustment Condition

Step 1

. Connect the oscilloscope as follows:

Oscilloscope SSP-11 board

CH1 → TP53 (D6)

CH2 → TP512 (A3)

(TRIGGER)

. Insert the pre-recorded music cassette tape

(Fs = 48 kHz) and playback the tape. (PLAY

mode)

Step 2

Same as step 1.

Step 3

Same as step 1.

Step 4

. Insert the pre-recorded music cassette tape

(Fs = 48 kHz) and set CUE FWD (X16 speed).

. The connectings remain the same as step 1.

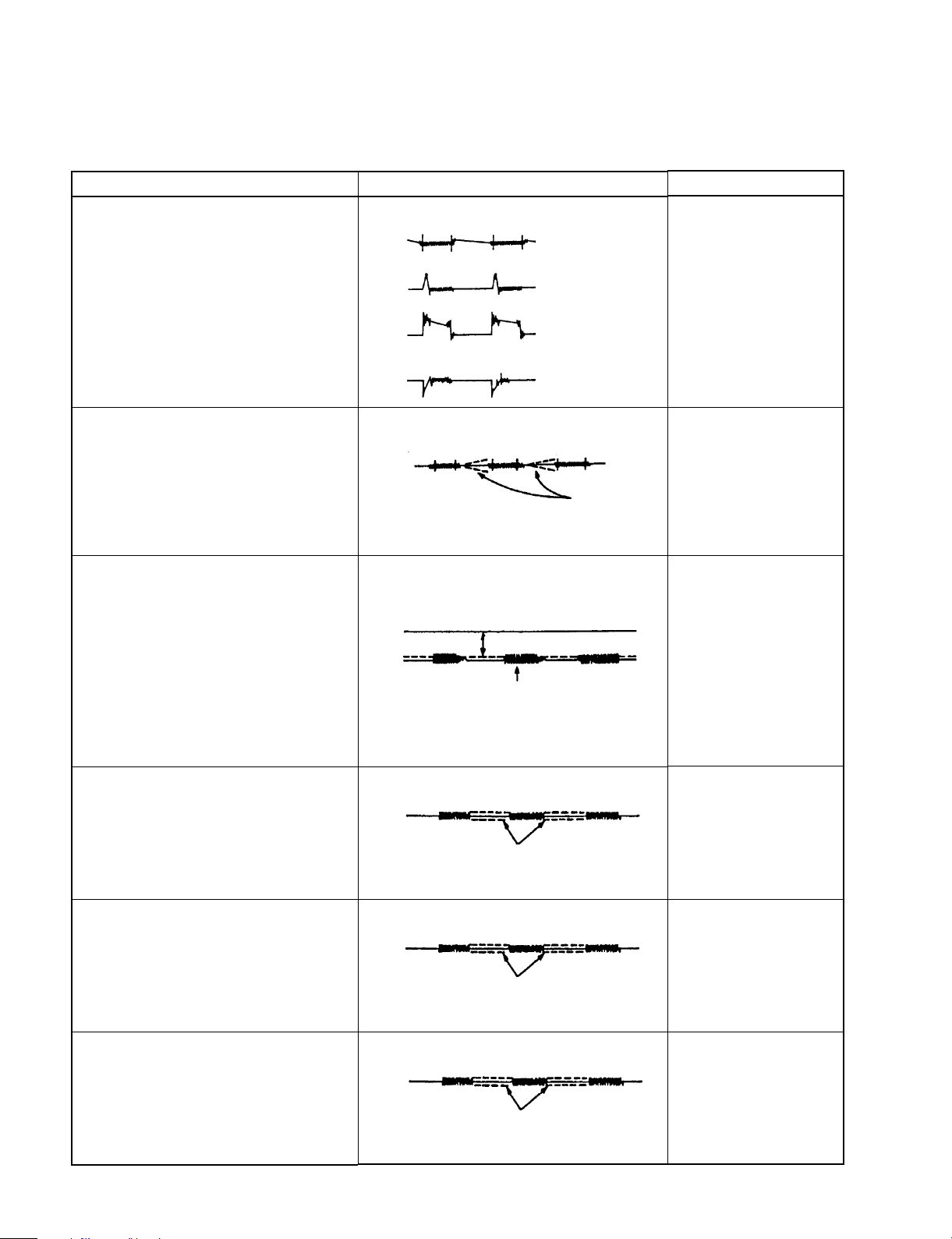

Specification

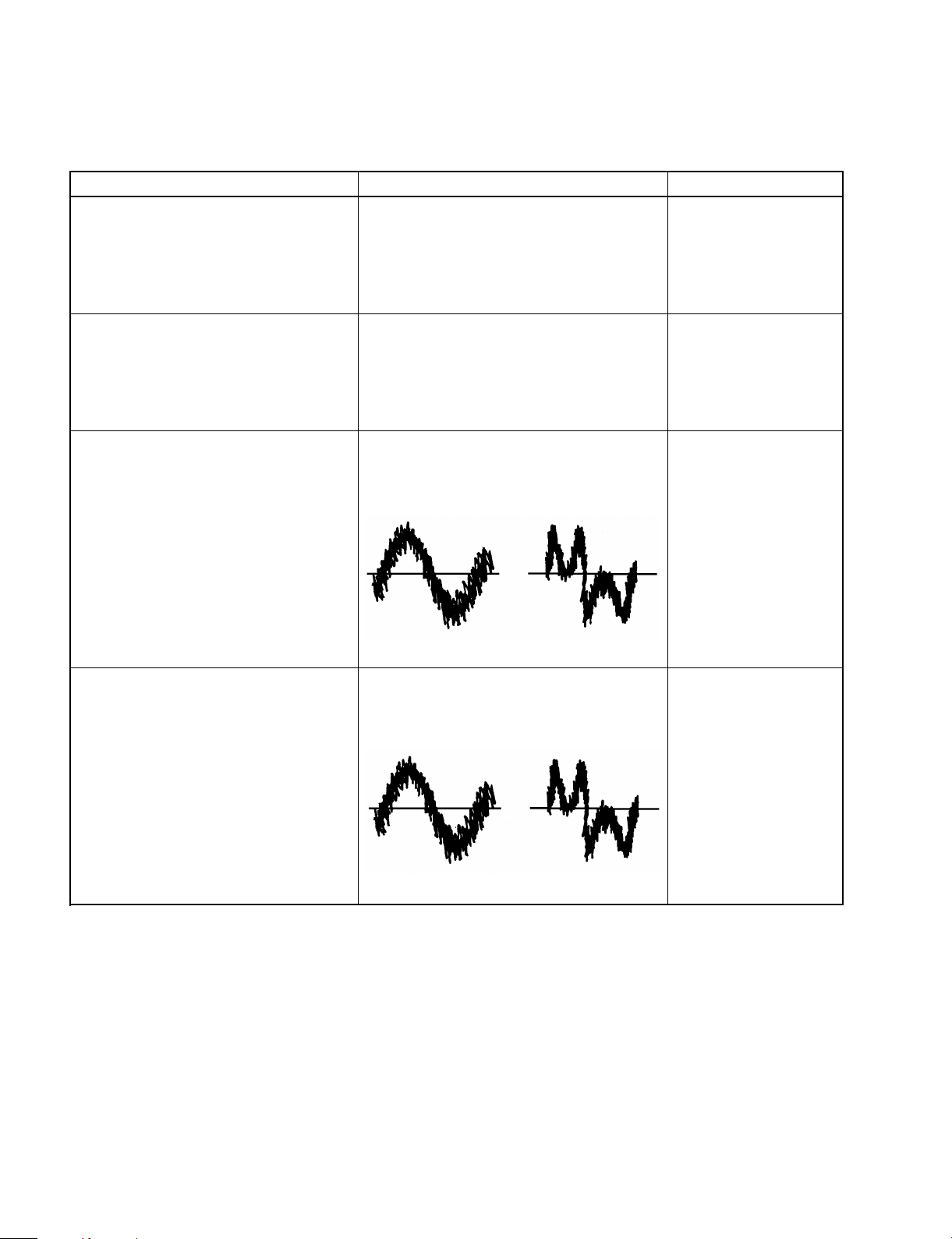

TP53 (D6) output waveform

OK

NG

NG

NG

TP53 (D6) output waveform

TP53 (D6) output waveform

Amplitude’s center voltage where is RF.

TP53 (D6) output waveform

TRIG: TP512 (A3)

This portion

is to be flat.

TRIG: TP512 (A3)

TRIG: TP512 (A3)

Adjustment (SSP-11 board)

1RV402 (D6)

If the waveform is no good,

turn 1RV401 slightly and then

readjust 1RV402.

1RV401 (C6)

1LV402 (C6)

Note: After being turned

clockwise all the way,

adjust 1LV402 so that

it can be loosened

within one full turn. If it

is too tight, the core

may be damaged. And

if it is too loose, the

core may come off.

1RV402 (D6)

Step 5

. Insert the pre-recorded music cassette tape

(Fs = 48 kHz) and set CUE REV (X16 speed).

. The connectings remain the same as step 1.

Step 6

. Insert the pre-recorded music cassette tape

(Fs = 48 kHz) and set CUE FWD and CUE

REV (X3 speed). Repeatedly two or three

times.

. The connectings remain the same as step 1.

PCM-7040

This portion is to be flat.

TRIG: TP512 (A3)

TP53 (D6) output waveform

This portion is to be flat.

TRIG: TP512 (A3)

TP53 (D6) output waveform

This portion is to be flat while the tape is running.

TRIG: TP512 (A3)

1RV402 (D6)

5-5(E)

2. Trailing head RF PLL Adjustment

Adjustment Condition

Step 1

. Connect the oscilloscope as follows:

Oscilloscope SSP-11 board

CH1 → TP55 (D6)

CH2 → TP512 (A3)

(TRIGGER)

. Insert the pre-recorded music cassette tape

(Fs = 48 kHz) and playback the tape. (PLAY

mode)

Step 2

Same as step 1.

Step 3

Same as step 1.

Step 4

. Insert the pre-recorded music cassette tape

(Fs = 48 kHz) and set CUE FWD (X16 speed).

. The connectings remain the same as step 1.

Specification

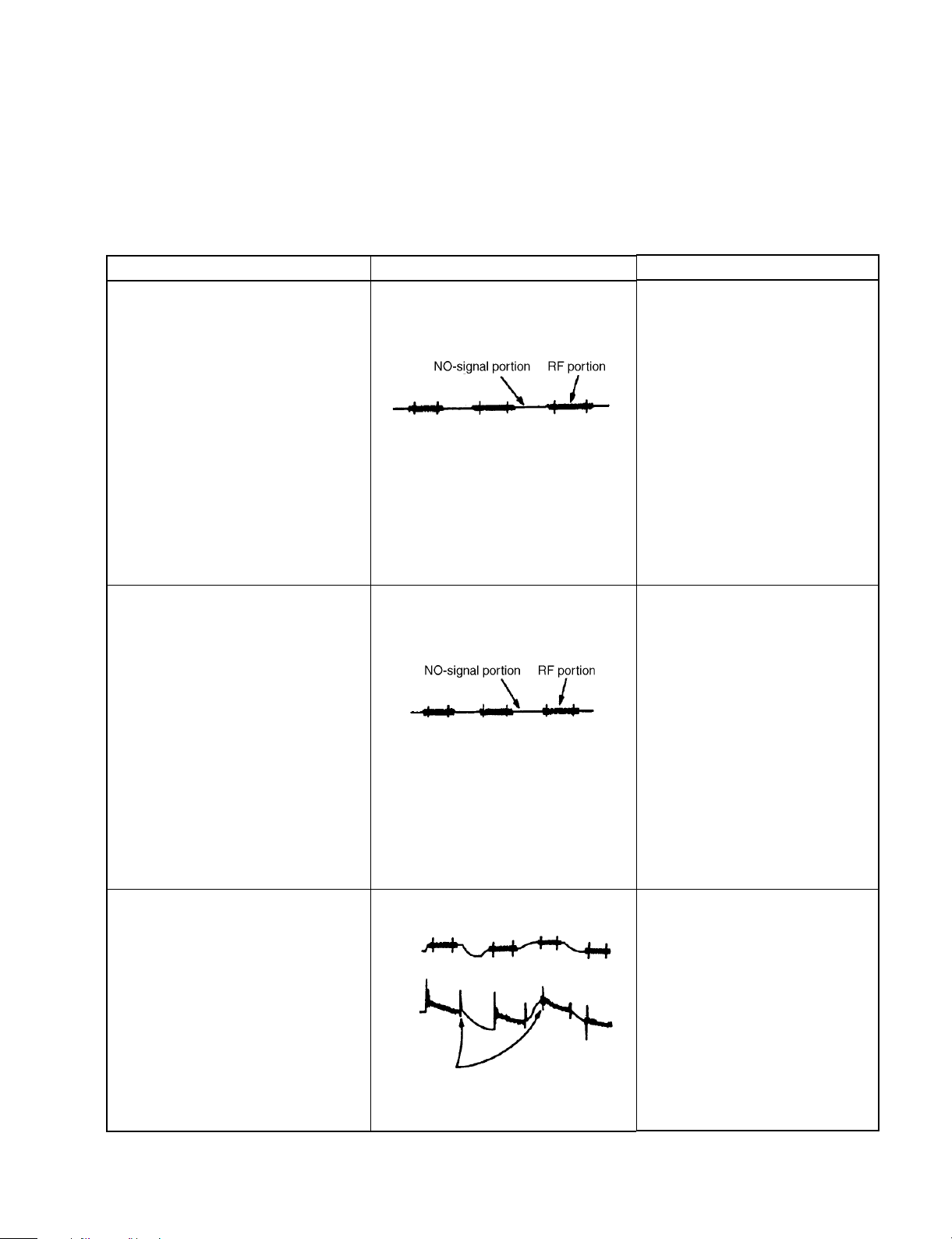

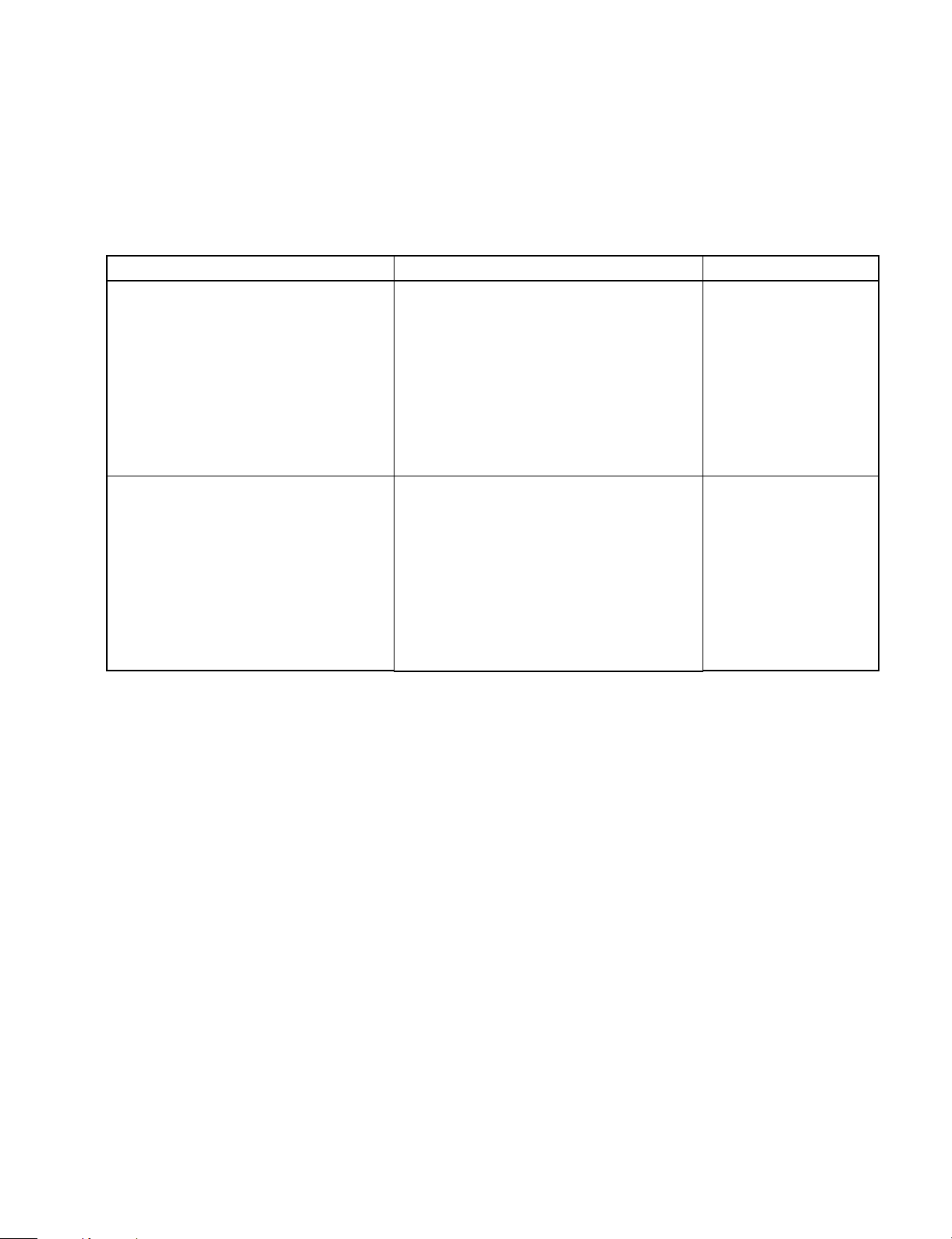

TP55 (D6) output waveform

OK

NG

NG

NG

TP55 (D6) output waveform

TP55 (D6) output waveform

_2.6 ± 0.5V

Amplitude’s center voltage where is RF.

TP55 (D6) output waveform

TRIG: TP512 (A3)

This portion

is to be flat.

TRIG: TP512 (A3)

TRIG: TP512 (A3)

Adjustment (SSP-11 board)

1RV404 (D6)

If the waveform is no good,

turn 1RV403 slightly and

then readjust 1RV404.

1RV403 (C6)

1LV403 (C6)

Note: After being turned

clockwise all the way,

adjust 1LV403 so that

it can be loosened

within one full turn. If it

is too tight, the core

may be damaged. And

if it is too loose, the

core may come off.

1RV404 (D6)

Step 5

. Insert the pre-recorded music cassette tape

(Fs = 48 kHz) and set CUE REV (X16 speed).

. The connectings remain the same as step 1.

Step 6

. Insert the pre-recorded music cassette tape

(Fs = 48 kHz) and set CUE FWD and CUE

REV (X3 speed). Repeatedly two or three

times.

. The connectings remain the same as step 1.

5-6(E)

This portion is to be flat.

TRIG: TP512 (A3)

TP55 (D6) output waveform

This portion is to be flat.

TRIG: TP512 (A3)

TP55 (D6) output waveform

This portion is to be flat while the tape is running.

TRIG: TP512 (A3)

1RV404 (D6)

PCM-7040

3. RF PLL Fine Adjustment

Preparation:

Before performing the adjustment, turn off the POWER switch and reinsert the connection plugs (COP401 and COP402)

into the connection pins (COR401 and COR402) on the SSP-11 board.

Then turn on the POWER switch and perform the adjustment.

Adjustment Condition

Step 1

. Connect the oscilloscope as follows:

Oscilloscope SSP-11 board

CH1 → TP55(D6)

CH2 → TP512(A3)

(TRIGGER)

. Insert the pre-recorded music cassette

tape (Fs = 48 kHz) and playback the tape.

(PLAY mode)

Step 2

. Connect the oscilloscope as follows:

Oscilloscope SSP-11 board

CH1 → TP53(D6)

CH2 → TP512(A3)

(TRIGGER)

. Insert the pre-recorded music cassette

tape (Fs = 48 kHz) and playback the tape.

(PLAY mode)

Specification

TP55 (D6) output waveform

TP53 (D6) output waveform

TRIG: TP512 (A3)

Adjustment (SSP-11 board)

1LV401 (D5)

Adjust 1LV401 so that the center of the

RF portion and no signal portion

becomes flat. If the center cannot be

flattened, redo the adjustments from

steps 3 to 6 for “2. Trailing head RF PLL

adjustment”.

Before making the re-adjustment, shift

the center voltage within the adjustment

standard range stated in step 3 of “2.

Trailing head RF PLL adjustment”.

Note: After being turned clockwise all

the way, adjust 1LV401 so that it

can be loosened within one full

turn. If it is too tight, the core may

be damaged. And if it too loose,

the core may come off.

1LV402 (C6)

Adjust 1LV402 so that the center of the

RF portion and no signal portion

becomes flat. If the center cannot be

flattened, redo the adjustments from

steps 3 to 6 for “1. Leading head RF PLL

adjustment”.

Before making the re-adjustment, shift

the center voltage within the adjustment

standard range stated in step 3 of “1.

Leading head RF PLL adjustment”.

Step 3

. Connect the oscilloscope as follows:

Oscilloscope SSP-11 board

CH1 → TP53(D6), TP55(D6)

CH2 → TP512(A3)

(TRIGGER)

. Insert the pre-recorded music cassette

tape (Fs = 48 kHz) and set the FF and

REW modes.

PCM-7040

TRIG: TP512 (A3)

TP53 (D6) and TP55 (D6) output waveform

OK

NG

As the voltage is high, the waveform swings

to plus.

TRIG: TP512 (A3)

Note: After being turned clockwise all

the way, adjust 1LV402 so that it

can be loosened within one full

turn. If it is too tight, the core may

be damaged. And if it too loose,

the core may come off.

5-7(E)

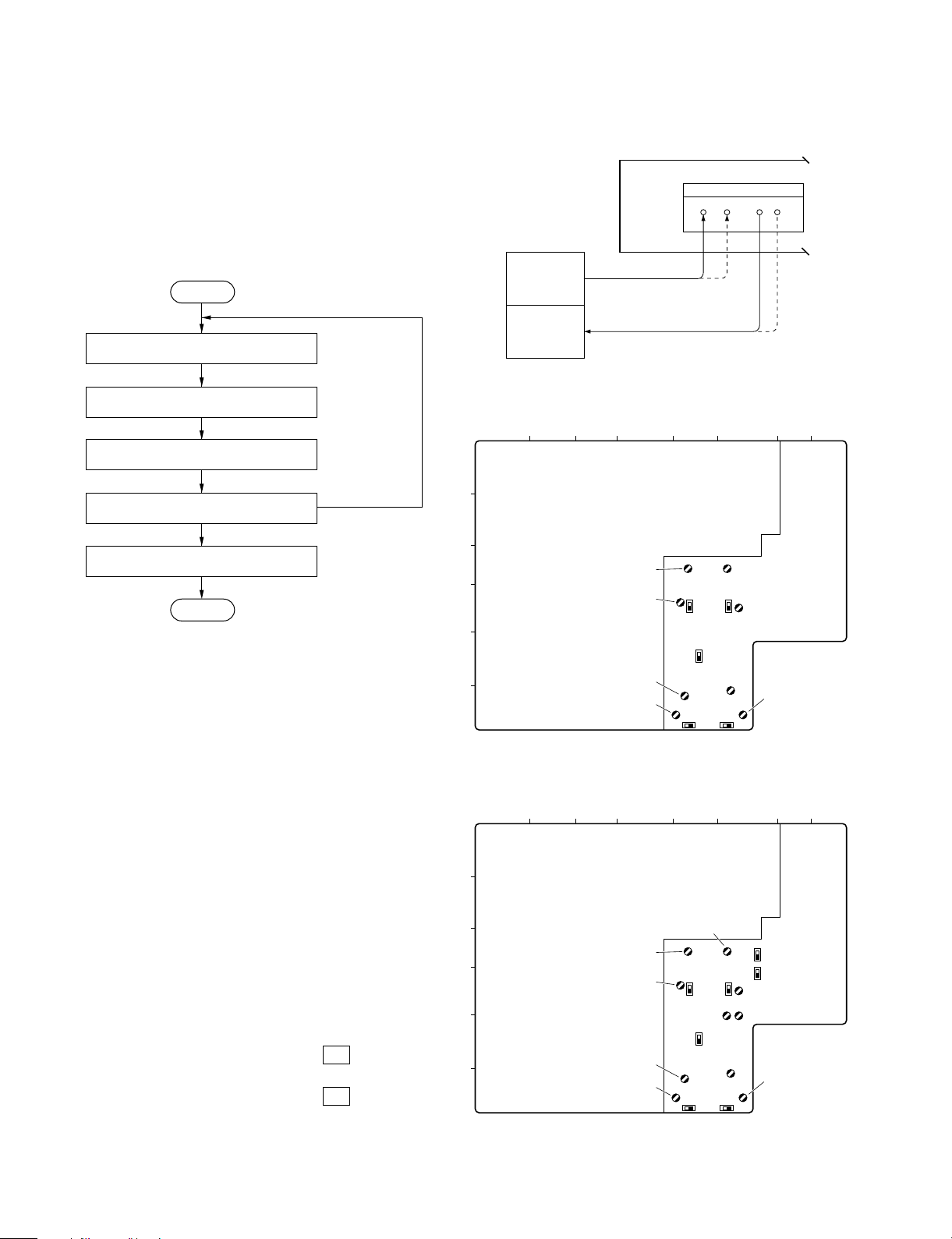

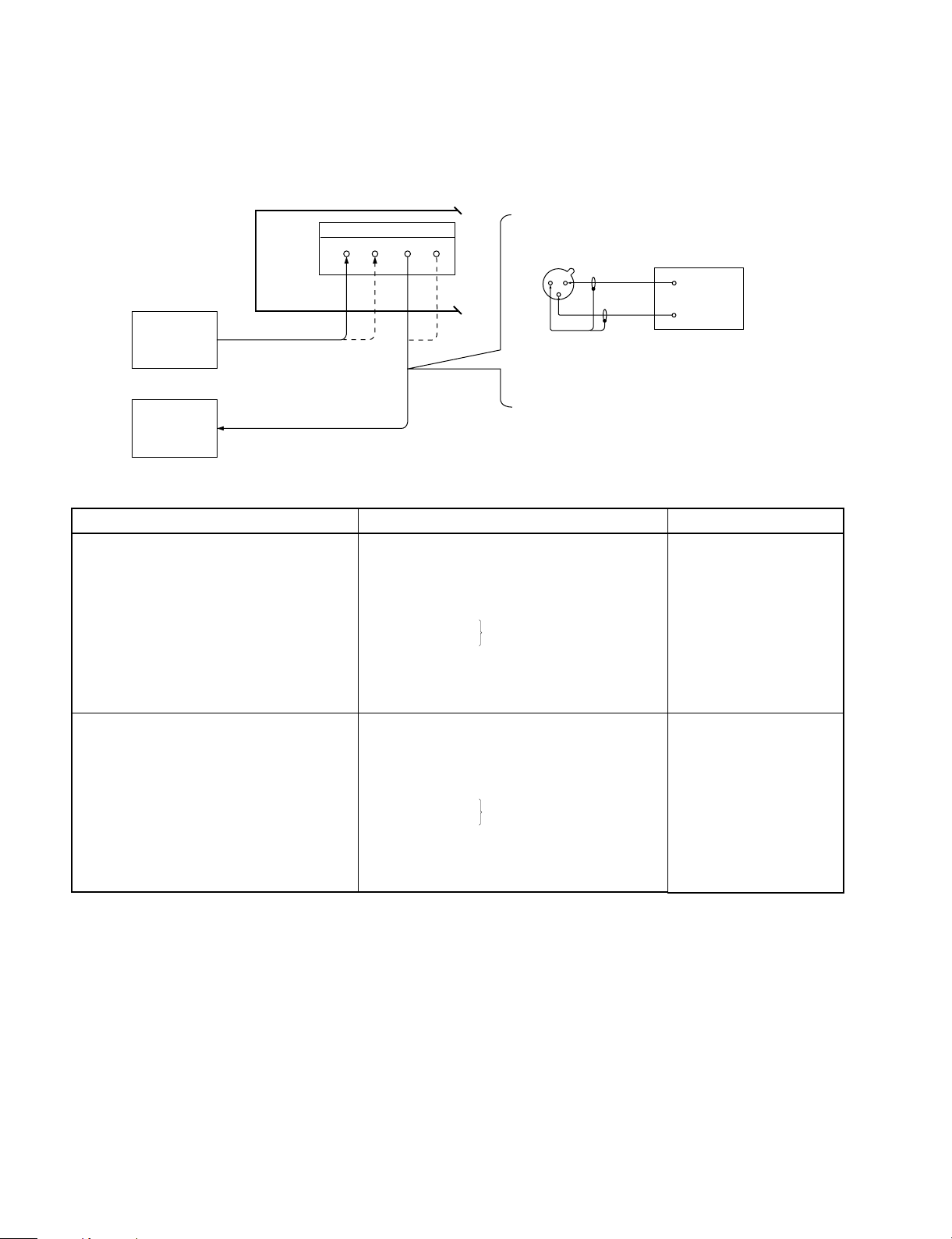

5-3. AD/DA Block Adjustment

To perform the adjustments, first remove the top panel.

Perform the adjustments according to the following

adjustment procedure.

AD/DA Block adjustment procedure

START

5-3-1. AD conversion level adjustment

Connection

Audio analyzer

Oscillator

Level meter

Rear panel

ANALOG

INPUT

CH1CH2 CH1 CH2

OUTPUT

5-3-2. DA conversion level adjustment

5-3-3. C.M.R.R Adjustment

AD conversion level checking : OK

YES

5-3-4. Output balance adjustment

END

NO

Equipment required

Audio analyzer

Oscilloscope

Switch and control setting

Same as “5-1-2. Switch and Control Initial Setting” except

the followings:

Front panel

SAMPLING FREQ 44.1 kHz/48 kHz switch ; 48 kHz

AUDIO INPUT ANALOG/DIGITAL switch ; ANALOG

ANALOG CH-1 input level control

; click center position

ANALOG CH-2 input level control

; click center position

INPUT MONITOR key

; ON (LED lighting)

SSP-11 board (AD/DA block)

S101, S102, S201, S202 switches ; +4

S151 switch ; NORMAL

S103*, S203* switches ; +0

* Applicable board No. suffix ; -12 and higher

CP-268 board

S11, S21 switch ; ON (600Z)

5-8(E)

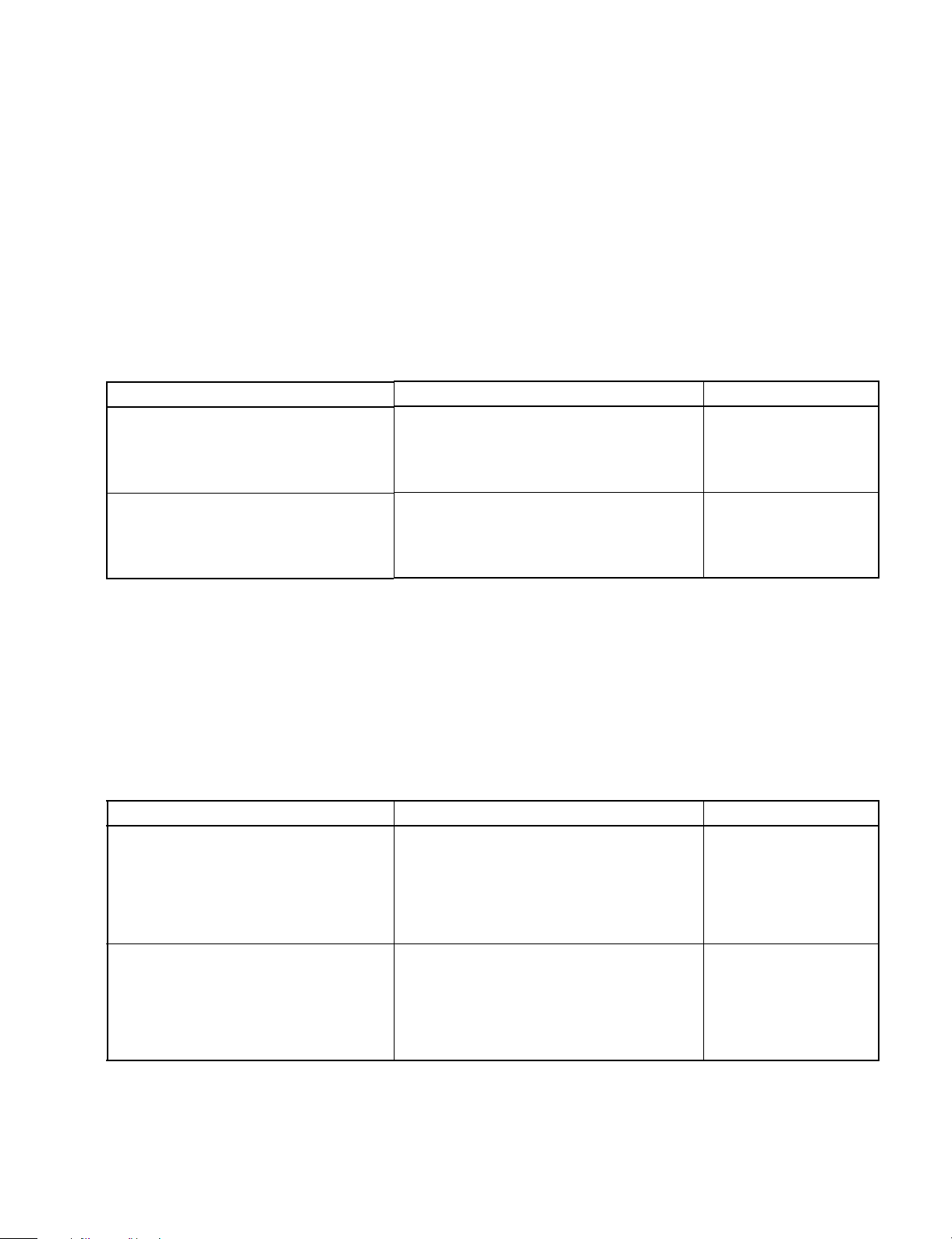

Adjustment Location

A

1

2

3

4

5

6

A

1

2

3

4

5

6

BC D E F GH

RV205 (E3)

RV203 (E4)

RV202 (E6)

RV201 (E6)

BC D E F GH

RV205 (E3)

RV203 (E4)

RV202 (E6)

RV201 (E6)

RV105 (F3)

S202 S102

S151

RV105 (F3)

S202 S102

S151

SSP-11 board (A-side)

Board No. 1-633-709-12 and higher

RV103 (F4)

RV102

(F5)

RV101 (F6)

S101S201

SSP-11 board (A-side)

Board No. 1-633-709-11

S203

S103

RV103 (F4)

RV106 (F4)RV206 (F4)

RV102

(F5)

RV101 (F6)

S101S201

PCM-7040

5-3-1. AD Conversion Level Adjustment

Perform the AD block adjustments on the SSP-11 board,

perform the adjustment first.

Preparation

Before performing the adjustment, set the FL tube display

on the front panel as follows. For setting, refer to the

operation manual.

FL tube display (front panel)

Au-rEF (input signal level’s digital indication mode)

EMPH OFF (emphasis OFF mode)

Adjustment condition

Step 1

. Input a 1 kHz, +4 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG IN CH-1 connector from

the audio analyzer (AF oscillator).

Step 2

. Input a 1 kHz, +4 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG IN CH-2 connector from

the audio analyzer (AF oscillator).

Value of the Au-rEF CH1 (left side) on the FL tube

display

Value of the Au-rEF CH2 (right side) on the FL tube

display

5-3-2. DA Conversion Level Adjustment

Perform the DA block adjustments on the SSP-11 board,

perform this adjustment after completing “5-3-1. AD

conversion level adjustment”.

1. Adjustment for board No. suffix -11

Adjustment condition

Step 1

ANALOG OUTPUT CH-1 output level:

_20.0 dB

_20.0 dB

Specification

Specification

Adjustment (SSP-11 board)

1RV102 (F5)

1RV202 (E6)

Adjustment (SSP-11 board)

1RV103 (F4)

. Input a 1 kHz, +4 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG IN CH-1 connector from

the audio analyzer (AF oscillator).

. Connect the audio analyzer (level meter) to the

ANALOG OUTPUT CH-1 connctor.

Step 2

. Input a 1 kHz, +4 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG IN CH-2 connector from

the audio analyzer (AF oscillator).

. Connect the audio analyzer (level meter) to the

ANALOG OUTPUT CH-2 connctor.

PCM-7040

+4.0 dBs ±0.1 dB

ANALOG OUTPUT CH-2 output level:

+4.0 dBs ±0.1 dB

1RV203 (E4)

5-9(E)

2. Adjustment for board No. suffix -12 and higher

Adjustment condition

Step 1

. Input a 1 kHz, +4 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG IN CH-1 connector from

the audio analyzer (AF oscillator).

. Connect the audio analyzer (level meter) to the

ANALOG OUTPUT CH-1 connctor.

Step 2

. Input a 1 kHz, +4 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG IN CH-2 connector from

the audio analyzer (AF oscillator).

. Connect the audio analyzer (level meter) to the

ANALOG OUTPUT CH-2 connctor.

Step 3

. Input a 1 kHz, _60 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG IN CH-1 connector from

the audio analyzer (AF oscillator).

. Connect the audio analyzer (level meter) to the

ANALOG OUTPUT CH-1 connctor.

. Connect the oscilloscope to the monitor output

of audio analyzer.

Specification

ANALOG OUTPUT CH-1 output level:

+4.0 dBs ±0.1 dB

ANALOG OUTPUT CH-2 output level:

+4.0 dBs ±0.1 dB

Satisfy 1, 2 below both at the same time.

1 Output level of CH-1:

Between _60.0 to _60.5 dBs

2 Oscilloscope waveform : sine wave

Adjustment (SSP-11 board)

1RV103 (F4)

1RV203 (E4)

1RV106 (F4)

Step 4

. Input a 1 kHz, _60 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG IN CH-2 connector from

the audio analyzer (AF oscillator).

. Connect the audio analyzer (level meter) to the

ANALOG OUTPUT CH-2 connctor.

. Connect the oscilloscope to the monitor output

of audio analyzer.

OK (sine wave) NG

Satisfy 1, 2 below both at the same time.

1 Output level of CH-2:

Between _60.0 to _60.5 dBs

2 Oscilloscope waveform : sine wave

OK (sine wave) NG

1RV206 (F4)

5-10(E)

PCM-7040

5-3-3. C. M. R. R. Adjustment

FL tube display (front panel) setting

Au-rEF (Input signal level's digital indication)

Adjustment procedure

Adjustment condition

Step 1

. Input the in-phase signal of 1 kHz, +4 dBs (0

dBs = 0.775 Vrms) to the ANALOG IN CH-1

connector, from an audio analyzer (AF

oscillator).

Connection of the input signal must be made

between hot (pin-2) and GND (pin-1), and

between cold (pin-3) and GND (pin-1) of the

CH-1 connector, in parallel.

. Connect an audio analyzer (level meter) to the

ANALOG OUTPUT CH-1 connector.

Step 2

. Input the in-phase signal of 1 kHz, +4 dBs (0

dBs = 0.775 Vrms) to the ANALOG IN CH-2

connector, from an audio analyzer (AF

oscillator).

Connection of the input signal must be made

between hot (pin-2) and GND (pin-1), and

between cold (pin-3) and GND (pin-1) of the

CH-2 connector, in parallel.

. Connect an audio analyzer (level meter) to the

ANALOG OUTPUT CH-2 connector.

Specification

ANALOG OUTPUT CH-1 output level:

_56 dBs or less

. Confirm at this time that the numeric value

appearing on Au-rEF (left side) of the FL tube

display satisfies the specification indicated in

section “5-3-1. AD Conversion Level Adjustment”.

When the specification is not satisfied, perform

step 1 of section “5-3-1. AD Conversion Level

Adjustment” again until the specification is

satisfied.

ANALOG OUTPUT CH-2 output level:

_56 dBs or less

. Confirm at this time that the numeric value

appearing on Au-rEF (left side) of the FL tube

display satisfies the specification indicated in

section “5-3-1. AD Conversion Level Adjustment”.

When the specification is not satisfied, perform

step 2 of section “5-3-1. AD Conversion Level

Adjustment” again until the specification is

satisfied.

Adjustment (SSP-11 board)

1RV101 (F6)

1RV201 (E6)

PCM-7040

5-11(E)

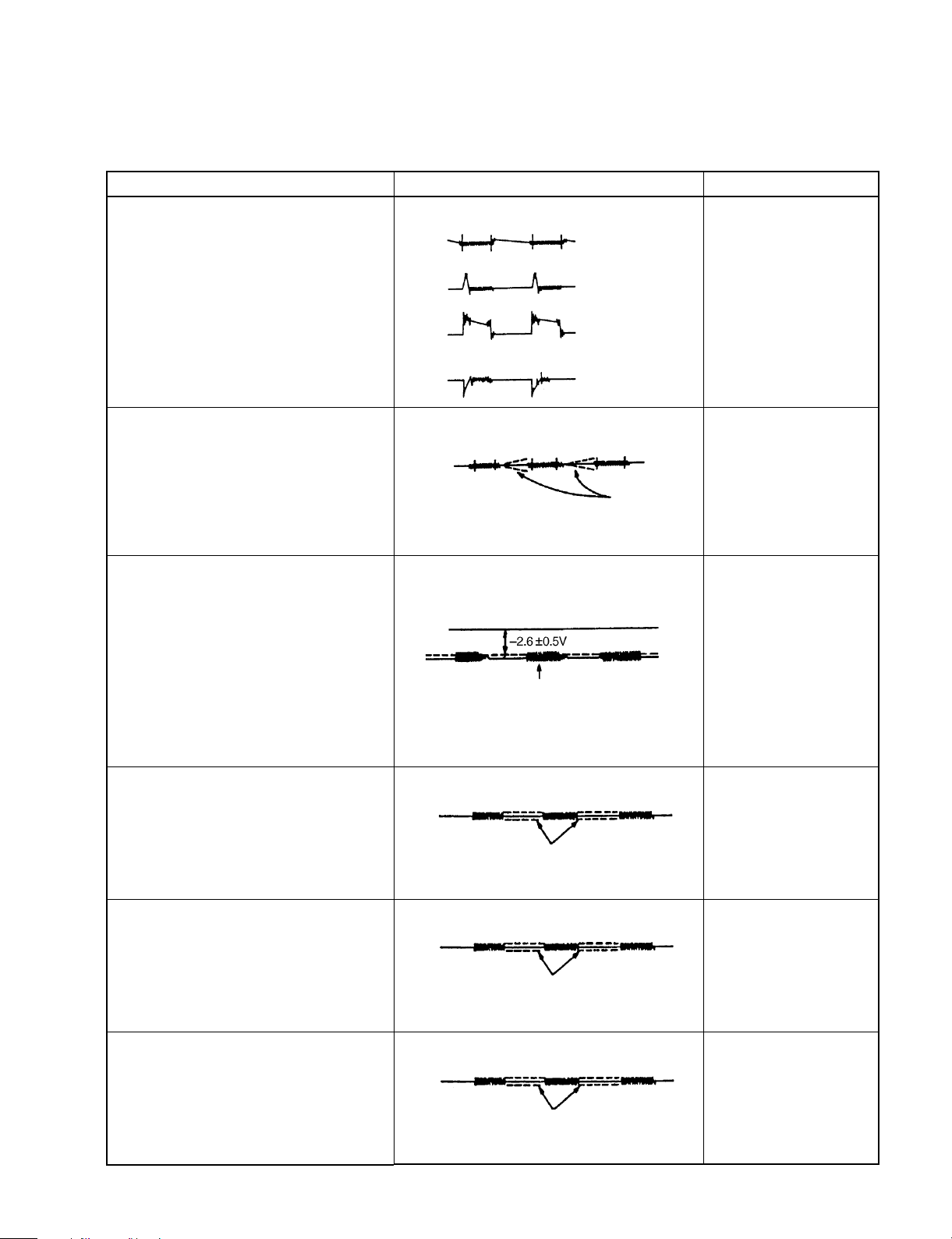

5-3-4. Output Balance Adjustment

Connection

Rear panel

CH1CH2

Audio analyzer

AF oscillator

Oscilloscope

Adjustment procedure

ANALOG

INPUT

OUTPUT

CH1

CH2

ANALOG

OUTPUT CH-1, CH-2

1

2

3

Oscilloscope

CH 1

CH 2

CH 1; 1 V/div

CH 2; 1 V/div

ADD mode; ON

1 ms/div

Adjustment condition

Step 1

. Input the 1 kHz, +4 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG INPUT CH-1 connector.

. Connect an oscilloscope to the ANALOG

OUTPUT CH-1 connector as follows:

Oscilloscope ANALOG OUTPUT

CH-1 connector

CH-1 → Across pin-2 and pin-1 (GND)

CH-2 → Across pin-3 and pin-1 (GND)

Step 2

. Input the 1 kHz, +4 dBs (0 dBs = 0.775 Vrms)

signal to the ANALOG INPUT CH-2 connector.

. Connect an oscilloscope to the ANALOG

OUTPUT CH-2 connector as follows:

Oscilloscope ANALOG OUTPUT

CH-2 connector

CH-1 → Across pin-2 and pin-1 (GND)

CH-2 → Across pin-3 and pin-1 (GND)

Output balance between + (pin-2) and _ (pin-3) of

the ANALOG OUTPUT CH-1 :

Adjustment procedure

Oscilloscope CH-1

Oscilloscope CH-2

Adjust 1RV105 until amplitude of the ADDed

waveform is 34.6 mVp-p or less.

Output balance between + (pin-2) and _ (pin-3) of

the ANALOG OUTPUT CH-2 :

Adjustment procedure

Oscilloscope CH-1

Oscilloscope CH-2

Adjust 1RV205 until amplitude of the ADDed

waveform is 34.6 mVp-p or less.

Specification

1% or less *

ADD mode ON

1% or less *

ADD mode ON

Adjustment (SSP-11 board)

1RV105 (F3)

1RV205 (E3)

* : Output balance between + (pin-2) and _ (pin-3) of the ANALOG OUTPUT must be 1%, means that the amplitude of

the ADDed waveform must be 34.6 mVp-p or less when the amplitude before ADDition is 3.46 Vp-p (+4 dBs).

5-12(E)

PCM-7040

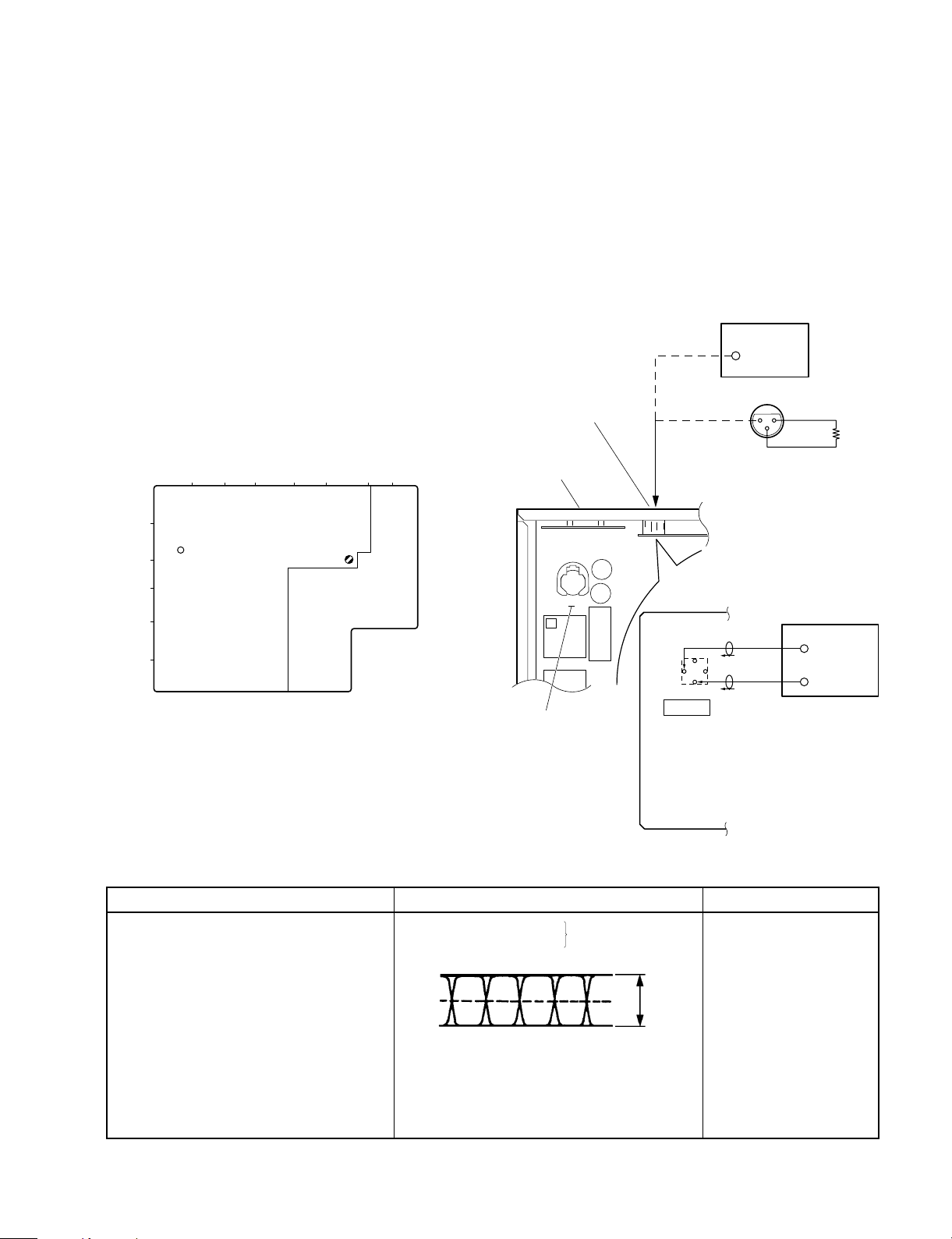

5-4. Time Code Output Level Adjustment

To perform the adjustment, first remove the top plate.

Perform the adjustment when SSP-11 board and TC block

components are replaced, or if time code output level is to

be changed.

1. Adjustment for board No. suffix -11

Equipment and Tools

Oscilloscope

Pre-recorded time code DAT tape

XLR 3PIN (female) connector

10 kZ 1/4 W resistor

Adjustment Location

A2BC D E F GH

1

E3 (A2)

3

4

5

6

RV701 (F3)

SSP-11 board (A-side)

Board No. 1-663-709-11

Switch and control setting

Same as “5-1-2. Switch and Control Initial Setting”.

Connection

TC OUTPUT

Rear panel

E3(A2),SSP-11 board

Equipment used

TC INPUT

or

12

XLR 3PIN (female)

connector

-WIRING SIDE-

CP-268 board (B-side)

CN57

4

E3/SSP-11

1

2

3

TC OUT

E3/SSP-11

OUT(+)

3

OUT(

-

)

Oscilloscope

CH1

CH2

CH1,2 : 0.5V/div

100us/div

INVERT : ON

ADD : ON

10kZ

Adjustment Procedure

Adjustment Condition

. Connect a 10 kZ dummy load (See “Connec-

tion”.) or equipment (for using time code) to the

TIME CODE OUTPUT (rear panel) connector.

. Connect the oscilloscope as follows:

Oscilloscope Connect to

CH1 → 2pin, TC OUT connector

(CPU-268 board)

E3 (A2), GND

CH2 → 3pin, TC OUT connector

(CPU-268 board)

E3 (A2), GND

. Insert the pre-recorded time code DAT tape

and playback tape (PLAY mode).

PCM-7040

Specification

Oscilloscope CH-1

Oscilloscope CH-2; INVERT

Both channels:

ADD mode

A

A = 2.4 Vp-p

. If the time code output level is to be changed,

adjust 1RV701 so that voltage A above becomes

the desired voltage.

Adjustment (SSP-11 board)

1RV701 (F3)

5-13(E)

2. Adjustment for board No. suffix -12 and higher

Equipment and Tools

Oscilloscope

Pre-recorded time code DAT tape

XLR 3PIN (female) connector

10 kZ 1/4 W resistor

Switch and control setting

Same as “5-1-2. Switch and Control Initial Setting”.

Connection/Adjustment Location

Rear panel

TIME CODE

OUTPUT

Equipment used

TC INPUT

or

3

12

XLR3 pin(female)

connector

-WIRING SIDE-

Adjustment Procedure

Adjustment Condition

. Connect a 10 kZ dummy load (See “Connec-

tion”.) or equipment (for using time code) to the

TIME CODE OUTPUT (rear panel) connector.

OUT(+)

OUT(

A2BC D E F GH

1

E3 (A2)

3

4

5

6

10k

-

)

Oscilloscope CH-1

Oscilloscope CH-2; INVERT

E1 (F1)

TP73

(F2)

TP74 (F2)

RV701 (F3)

SSP-11board (A-side)

Board No.1-663-709-12 and higher

Specification

Both channels:

ADD mode

Oscilloscope

CH 1

CH 2

CH 1, 2 ; 0.5 V/div

INVERT; ON

ADD

100 µs/div

; ON

Adjustment (SSP-11 board)

1RV701 (F3)

. Connect the oscilloscope as follows:

Oscilloscope Connect to

CH1 → TP73 (F2)

E1 (F1), GND

CH2 → TP74 (F2)

E1 (F1), GND

. Insert the pre-recorded time code DAT tape

and playback tape (PLAY mode).

5-14(E)

A

A = 2.4 Vp-p

. If the time code output level is to be changed,

adjust 1RV701 so that voltage A above becomes

the desired voltage.

PCM-7040

6-1. Notes on Repair Parts

1. Safety Related Components Warning

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts

commonality and improvement.

Parts list has the present standardized repair parts.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may be not stocked. Therefore, the

delivery date will be delayed.

Section 6

Spare Parts

4. Units Representation

The following represented units are changed or omitted

in writing.

Units Representation

Capacitance uFuF

Inductance uHuH

Resistance Z Abbreviation

Temperature dC XXX-DEG-C

PCM-7040

6-1

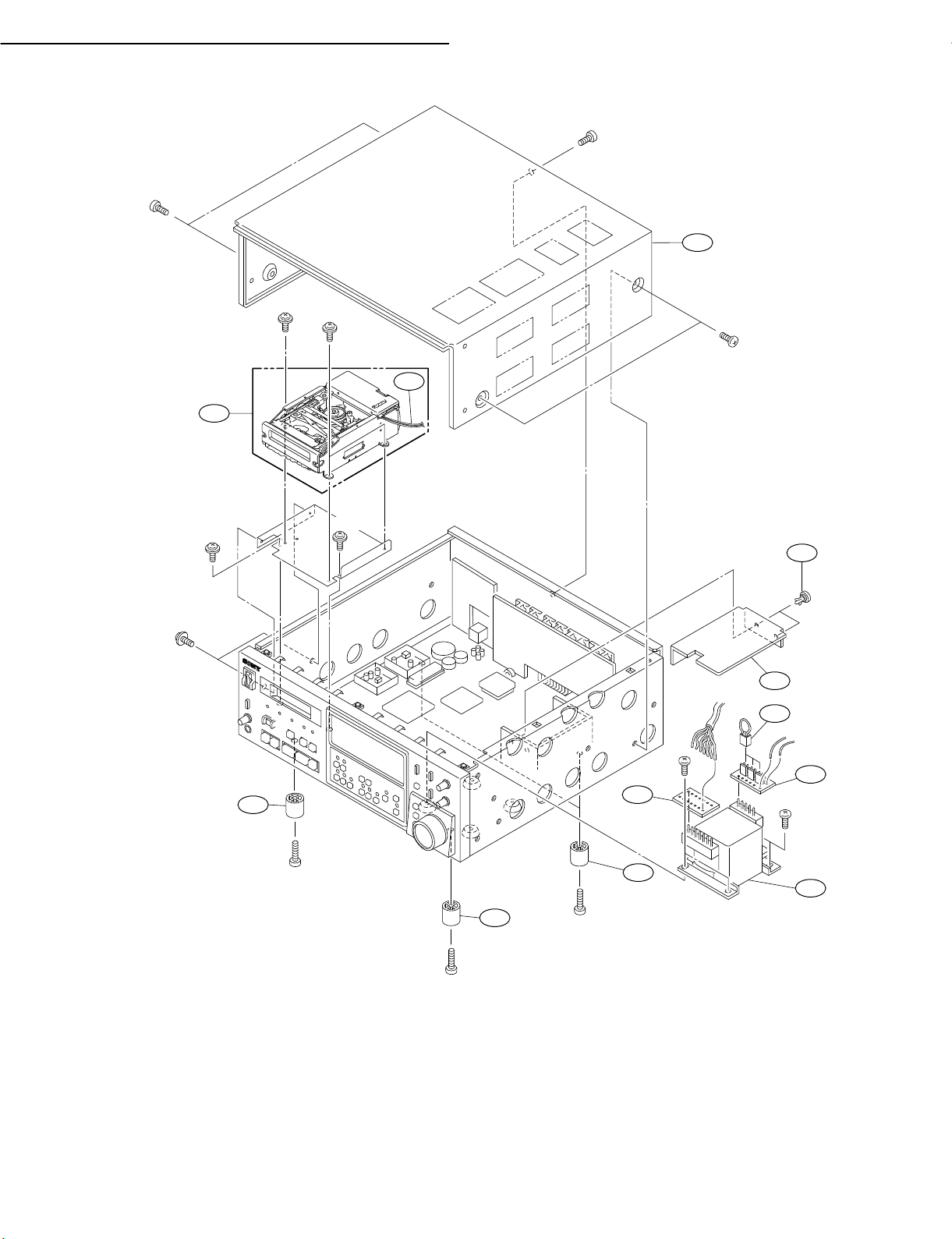

MD ASSY/POWER TRANSFORMER/ TOP PLATE

6-2. Exploded Views

B4 x 6

B3 x 6

8

PWH3 x 6

PWH3 x 6

1

PWH3 x 6

9

PWH3 x 6

B4 x 6

5

PWH3 x 6

10

7

6

B4 x 6

3

4

B4 x 6

B4 x 20

9

No. Part No. SP Description

B4 x 20

1 A-8311-799-A s MD ASSY

2 ! 1-429-937-11 s TRANSFORMER, POWER

3 1-663-710-11 o PRINTED WIRING BOARD, PS-451

4 1-663-711-11 o PRINTED WIRING BOARD, PS-452

5 1-956-633-11 o HARNESS, SUB (RF2)

6 1-956-640-11 o HARNESS, SUB (CN)

7 3-191-386-01 o INSULATING SHEET

8 3-191-392-01 o PLATE, TOP

9 3-642-656-01 s FOOT

10 4-818-403-00 s RIVET, NYLON

6-2

9

2

B4 x 20

PCM-7040

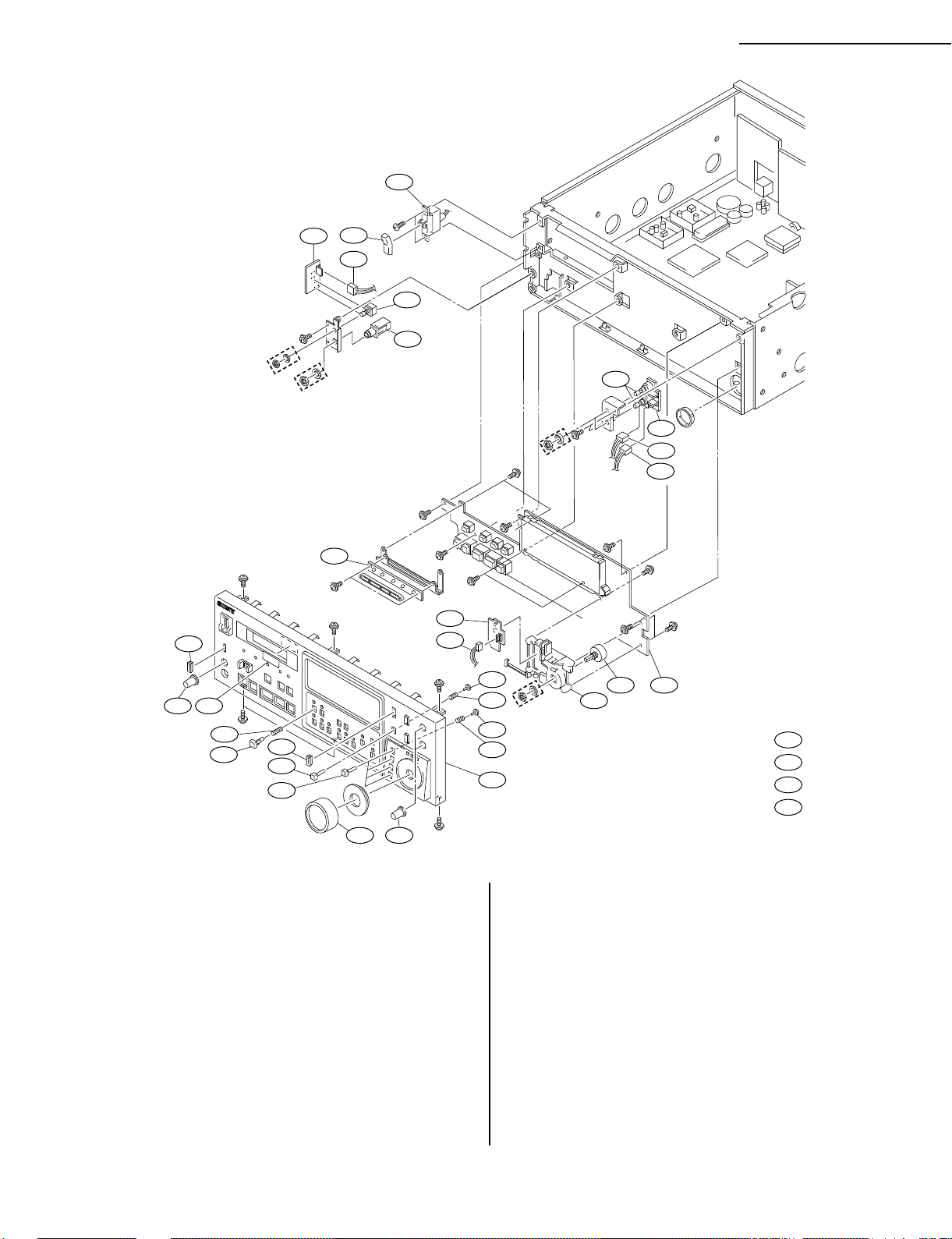

112

FRONT PANEL ASSY

109

B3 x 6

125

117

105

103

118

122

PWH3 x 6

126

119

PWH3 x 6

*1

PWH3 x 6

118

120

120

*2

PWH3 x 5

110

PWH3 x 6

PWH3 x 6

PWH3 x 6

102 103

108

111

114

PWH3 x 6

PWH

3 x 6

PWH3 x 6

PWH

3 x 5

124

123

124

123

104

PWH

3 x 6

106

PWH

3 x 6

*3

PWH

3 x 6

PWH3 x 6

*4

121

113

115

116

PWH3 x 6

107 101

PWH3 x 6

*1: Supplied with 105

*2: Supplied with 108

*3: Supplied with 106

*4: Supplied with 107

No. Part No. SP Description No. Part No. SP Description

101 A-8311-410-A o KY-192A MOUNTED CIRCUIT BOARD 116 1-956-644-11 o HARNESS, SUB (REC VR2)

102 X-3165-315-3 s DIAL ASSY 117 1-956-645-11 o HARNESS, SUB (HP)

103 X-3167-823-1 s KNOB ASSY (P), VOL 118 3-166-928-02 o ESCUTCHEON, SW

104 X-3167-892-2 s PANEL ASSY, FRONT 119 3-166-929-11 o KEY TOP (LARGE)

105 1-241-331-11 s RES, VAR, CARBON 10K/10K 120 3-166-930-01 o KEY TOP (SMALL)

106 1-241-332-11 s RES, VAR, CARBON 20K 121 3-167-806-03 o TABLE, ENCORDER

107 1-466-955-11 s ENCODER, ROTARY 122 3-184-994-01 o ISR STICKER (S)

108 1-507-863-51 s JACK, LARGE TYPE 123 3-567-099-01 o SPRING, COMPRESSION

109 ! 1-762-953-11 s SWITCH, POWER 124 3-668-009-02 o PIN, PUSH BUTTON

110 1-637-269-11 o PRINTED WIRING BOARD, LED-104 125 3-688-814-01 s CAP, SWITCH

111 1-637-270-11 o PRINTED WIRING BOARD, SW-420 126 4-862-354-00 s SPRING, COMPRESSION

112 1-637-283-14 o PRINTED WIRING BOARD, HP-48

113 1-637-284-13 o PRINTED WIRING BOARD, VR-109

114 1-946-966-11 o HARNESS (SW)

115 1-956-643-11 o HARNESS, SUB (REC VR1)

PCM-7040

6-3

Loading...

Loading...