Sony MHCGTX-888 Service manual

HCD-GTX777/GTX787/GTX888

HCD-GTX777/GTX787/GTX888

SERVICE MANUAL

Ver. 1.1 2008. 05

• HCD-GTX777/GTX787/GTX888

are the tuner, deck, CD and

amplifi er section in

MHC-GTX777/GTX787/GTX888.

Photo : HCD-GTX888 (E Model)

Model Name Using Similar Mechanism HCD-GTX66/GTX77/GTX88

CD CD Mechanism Type CDM74KF-K6BD93-WOD//M

Section

Tape Deck Model Name Using Similar Mechanism NEW

Section Tape Mechanism Type CFP42608

Optical Pick-up Name KSM-213DCP/C2NP

AEP Model

HCD-GTX777

E Model

HCD-GTX777/GTX787/GTX888

Australian Model

HCD-GTX888

AUDIO POWER SPECIFICATION

Amplifi er section

MHC-GTX888 (HCD-GTX888)

The following are measured at

Mexican model: AC 127 V, 60 Hz

Other models: AC 120, 220, 230 – 240 V, 50/60 Hz

Front/Surround speaker

Power Output (rated): 190 W + 190 W (at 8 : and 24 :,

1 kHz, 1% THD, at LINK MODE)

RMS output power (reference):

295 W + 295 W (per channel at 8 : and

24 :, 1 kHz, 10% THD, at LINK MODE)

Subwoofer

RMS output power (reference):

160 W + 160 W (per channel at 6 :,

100 Hz, 10% THD)

SPECIFICATIONS

MHC-GTX787 (HCD-GTX787)

The following are measured at

Mexican model: AC 127 V, 60 Hz

Other models: AC 120, 220, 230 – 240 V, 50/60 Hz

Front speaker

Power Output (rated): 230 W + 230 W (at 4 :, 1 kHz, 1% THD)

RMS output power (reference):

380 W + 380 W (per channel at 4 :, 1 kHz, 10% THD)

MHC-GTX777 (HCD-GTX777)

European model only

The following are measured at

AC 230 V, 50/60 Hz

Front/Surround speaker

Power Output (rated): 235 W + 235 W (at 8 : and 8 :, 1 kHz,

1% THD, at LINK MODE)

RMS output power (reference):

380 W + 380 W (per channel at 8 : and

8 :, 1 kHz, 10% THD, at LINK MODE)

– Continued on next page –

CD DECK RECEIVER

9-890-504-02

2008E08-1

© 2008. 05

Sony Corporation

Audio Business Group

Published by Sony EMCS (Malaysia) PG Tec

1

HCD-GTX777/GTX787/GTX888

Other models

The following are measured at

AC 120, 220, 230 – 240 V, 50/60 Hz

Front/Surround speaker

Power Output (rated): 235 W + 235 W (at 8

1% THD, at LINK MODE)

RMS output power (reference):

380 W + 380 W (per channel at 8

8

Inputs

VIDEO (AUDIO IN) L/R:

Voltage 250 mV, impedance 47 kilohms

AUDIO INPUT L/R: Voltage 450 mV, impedance 47 kilohms

MIC: Sensitivity 1 mV, impedance 10 kilohms

(USB) port:

Outputs

PHONES: accepts headphones of 8

:

, 1 kHz, 10% THD, at LINK MODE)

Type A

:

and 8 :, 1 kHz,

:

or more

:

and

Disc player section

System Compact disc and digital audio system

Laser Semiconductor laser

(

Emission duration: continuous

Laser Output Max. 44.6 µW*

* This output is the value measured at

a distance of 200 mm from the

objective lens surface on the Optical

Pick-up Block with 7 mm aperture.

Frequency response 20 Hz – 20 kHz

Wave length 770 – 810 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 88 dB

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I tape

Wow and fl utter ±0.35% W.Peak (IEC)

0.3% W.RMS (NAB)

±0.4% W.Peak (DIN)

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

Brazil model: 87.5 – 108.0 MHz (100 kHz step)

Other models: 87.5 – 108.0 MHz (50 kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range Pan-American and Oceanian models:

530 – 1,710 kHz (with the interval set at 10 kHz)

531 – 1,710 kHz (with the interval set at 9 kHz)

European model: 531 – 1,602 kHz (with the interval set at 9 kHz)

Other models: 531 – 1,602 kHz (with the interval set at 9 kHz)

530 – 1,610 kHz (with the interval set at 10 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

O

= 770 – 810 nm)

USB section

Supported bit rate MP3 (MPEG 1 Audio Layer 3): 32 – 320 kbps, VBR

WMA: 32 – 192 kbps, VBR AAC: 48 – 320 kbps

Sampling frequencies MP3 (MPEG 1 Audio Layer 3): 32/44.1/48 kHz

WMA: 44.1 kHz, AAC: 44.1 kHz

Transfer speed Full-Speed

Supported USB device Mass Storage Class

Maximum current 500 mA

General

Power requirements

European model: 230 V AC, 50/60 Hz

Mexican model: 127 V AC, 60 Hz

Oceanian model: 230 – 240 V AC, 50/60 Hz

Argentina models: 220 V AC, 50/60 Hz

Other models: 120 V, 220 V or 230 – 240 V AC, 50/60 Hz,

adjustable with voltage selector

Power consumption MHC-GTX888: 430 W

MHC-GTX787/MHC-GTX777: 300 W

Dimensions (w/h/d) (Approx.)

HCD-GTX888/HCD-GTX787/

HCD-GTX777: 281 × 365 × 454 mm

(11 1/8 × 14 3/8 × 17 7/8 inches)

Mass (Approx.) HCD-GTX888: 14.0 kg (30 lb 14 oz)

HCD-GTX787/HCD-GTX777:

12.0 kg (26 lb 8 oz)

Supplied accessories Remote Commander (1)

R6 (size AA) batteries (2)

AM loop antenna (1)

FM lead antenna (1)

Front speaker pads (8)

Surround speaker pads

(MHC-GTX888/MHC-GTX777 only) (8)

Subwoofer pads (MHC-GTX888 only) (Black) (8)

Speaker cords (MHC-GTX787 only) (2)

Spacer A (MHC-GTX888 only) (2)

Spacer B (MHC-GTX888 only) (2)

Spacer C (MHC-GTX777 only) (2)

Audio cable (1) (Mexico only)

Design and specifi cations are subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMA TIC DIA GRAMS AND IN THE

P ARTS LIST ARE CRITICAL T O SAFE OPERA TION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

2

HCD-GTX777/GTX787/GTX888

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to fl ow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may also

be added to ordinary solder.

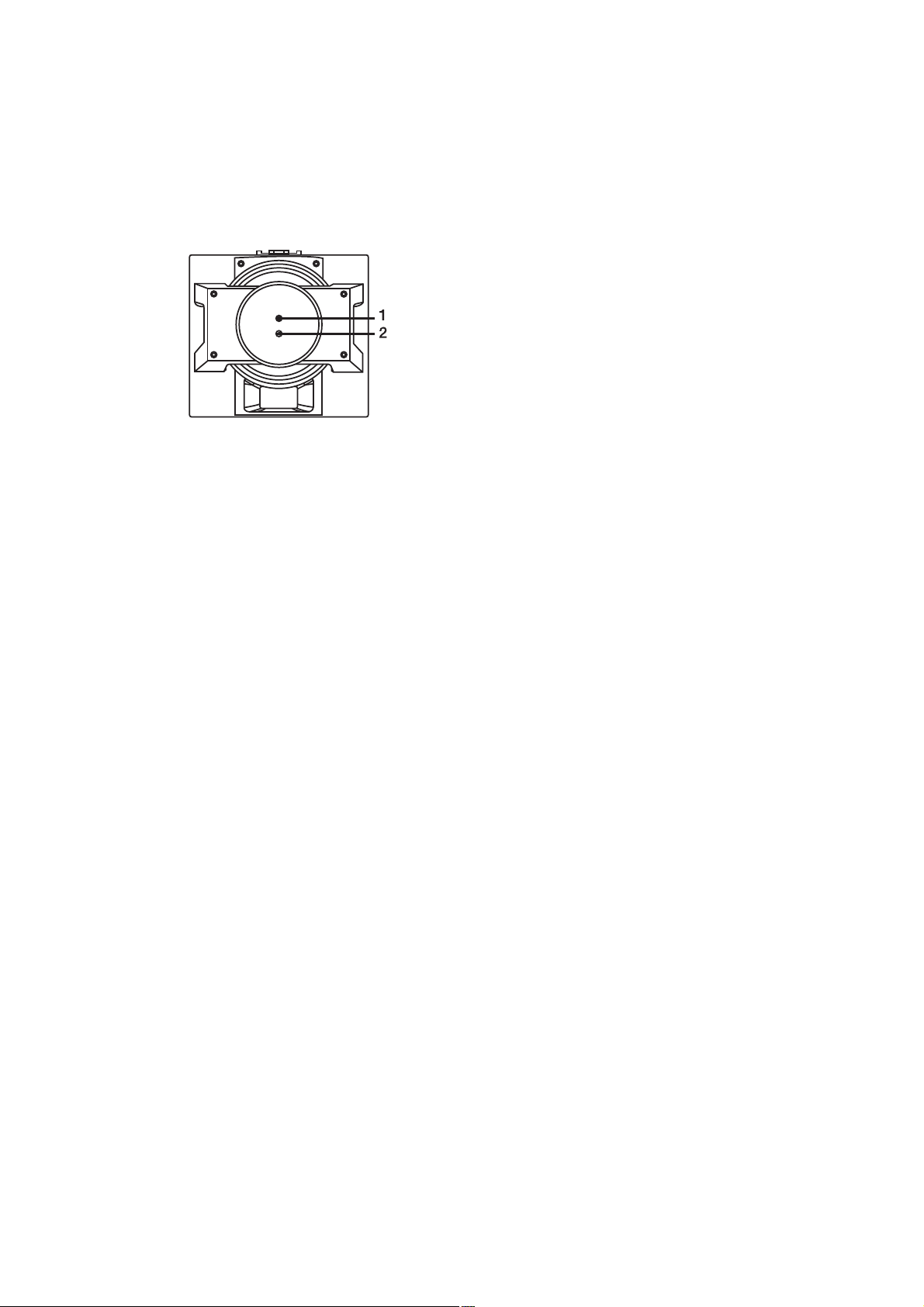

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc refl ective surface by the objective lens in the optical pick-up

block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is

claassifi ed as a CLASS 1

LASER product. This

label is located on the

rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous

radiation exposure.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

3

HCD-GTX777/GTX787/GTX888

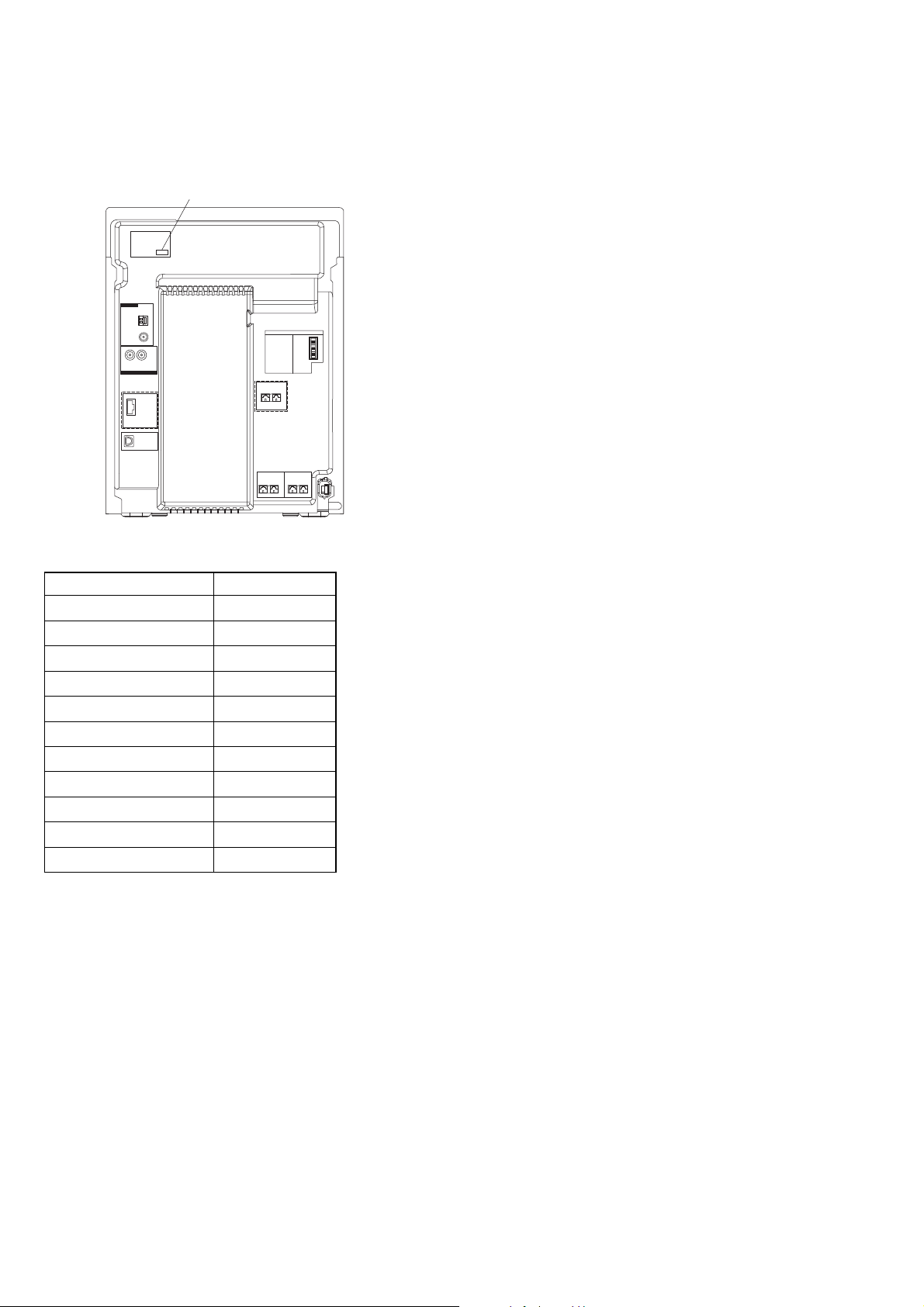

MODEL IDENTIFICATION

– MODEL NUMBER LABEL –

PART NO

(GTX888 ONLY)

• Abbreviation

E2 : 120V AC area in E model

E3 : Middle Easten, African and Indian model

E51 : Chilean and Peruvian model

AR : Argentina model

AUS : Australian model

MX : Mexican model

(GTX888 ONLY)

MODEL Parts No

GTX888: E2, E51

GTX777: E2, E51

GTX787: E2

GTX777: AEP

GTX888: AR

GTX777: AR

GTX888: AUS

GTX888: E3

GTX777: E3

GTX888: MX

GTX777: MX

3-290-078-0s

3-290-078-1s

3-290-078-2s

3-290-079-1s

3-873-456-0s

3-873-456-1s

3-873-457-0s

3-873-458-0s

3-873-458-1s

3-873-459-0s

3-873-459-1s

4

TABLE OF CONTENTS

HCD-GTX777/GTX787/GTX888

1. GENERAL

Guide to parts and controls ...................................................... 6

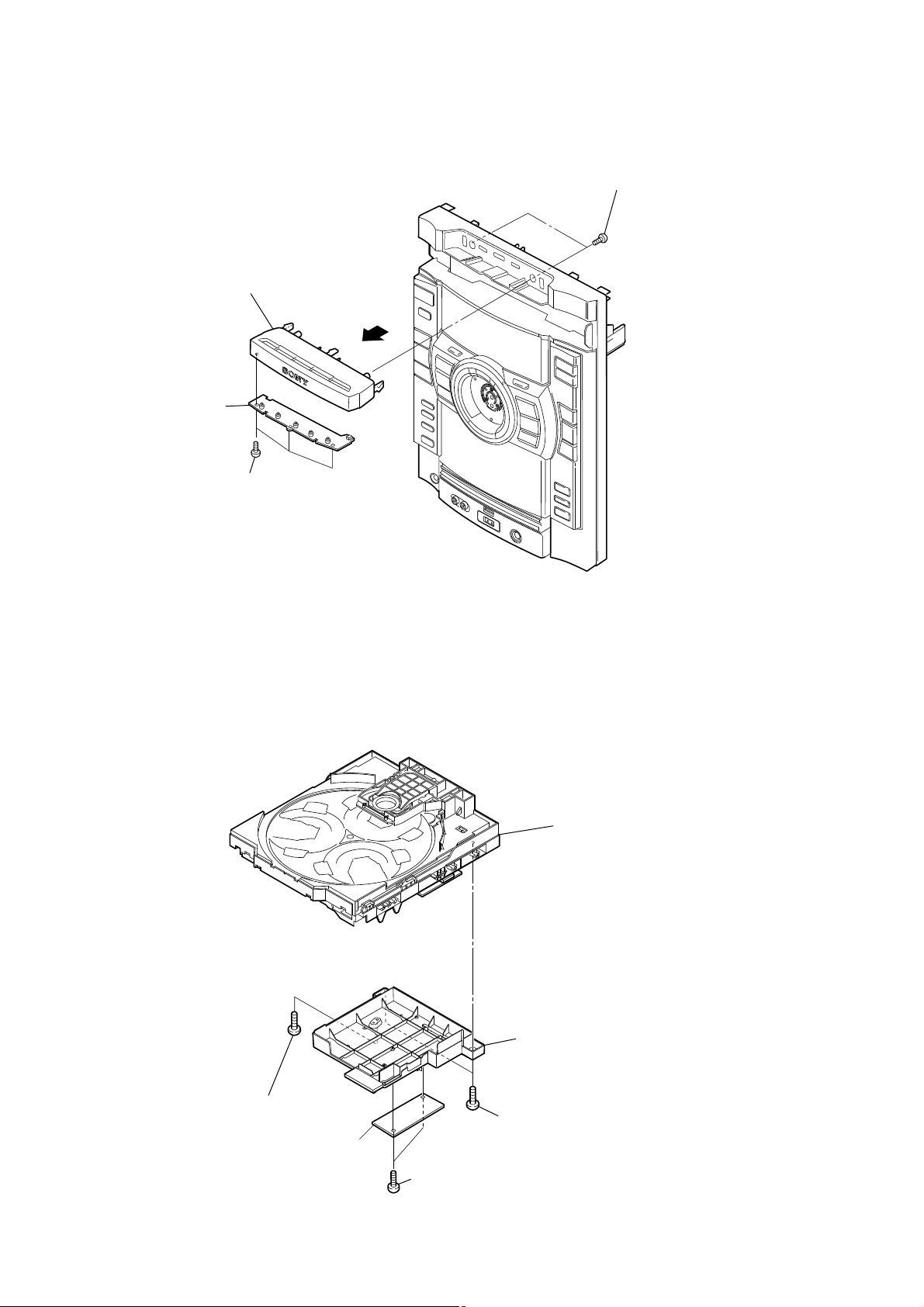

2. DISASSEMBLY

2-1. Case (Top) .......................................................................... 13

2-2. Loading Panel .................................................................... 13

2-3. CD Block Section .............................................................. 14

2-4.

Front Panel Section

Tape Mechanism Deck, Mic Board,

2-5.

USB Connector Board .......................................................15

2-6.

Panel Board, Function Board, Jog Board

CD-SW Board

2-7.

2-8.

Cover (CDM)

2-9. Tuner Pack .........................................................................17

2-10. Back Panel Section

Main Board

2-11.

2-12.

Power Board Section

2-13. Subwoofer Board, Power Board ........................................19

2-14. Power Transformer (T1200) .............................................. 19

2-15. BD93 Board ....................................................................... 20

2-16. Driver Board, SW Board, USB Board ............................... 20

2-17. Optical Pick-up .................................................................. 21

2-18. Sensor Board ...................................................................... 21

2-19. Motor (TB) Board .............................................................. 22

2-20. Motor (LD) Board ............................................................. 22

3. TEST MODE

4. MECHANICAL ADJUSTMENTS .........................

5. ELECTRICAL ADJUSTMENTS ..........................

............................................................ 14

.......................... 15

.................................................................... 16

..................................................................... 16

, Sub Trans Board

....................................................................... 18

......................................................... 18

..............................................................

............................... 17

23

27

28

6. DIAGRAMS

6-1. Block Diagram — RF/Servo Section — ........................... 31

6-2. Block Diagram — Tape/Tuner Section — ......................... 32

6-3. Block Diagram — Main Section — .................................. 33

6-4. Block Diagram — USB Section — ................................... 34

6-5. Block Diagram — AMP/Subwoofer Section — ................35

6-6. Block Diagram — Display/Power Section — ................... 36

6-7. Circuit Boards Location ..................................................... 37

6-8. Printed Wiring Board — BD93 Board — .........................40

6-9. Schematic Diagram — BD93

6-10. Printed Wiring Boards — Driver

6-11. Schematic Diagram — Driver

6-12. Printed Wiring Board — Main Board — ........................... 44

6-13. Schematic Diagram — Main

6-14. Schematic Diagram — Main

6-15. Schematic Diagram — Main

6-16. Schematic Diagram — Main

6-17. Printed Wiring Board — USB

6-18. Schematic Diagram — USB

6-19. Printed Wiring Board — Panel Function

6-20. Schematic Diagram —

6-21. Printed Wiring Board — Power

6-22. Schematic Diagram — Power

6-23. Printed Wiring Board — Sub Woofer

6-24. Schematic Diagram — Sub Woofer

6-25. Printed Wiring Boards — Trans

6-26. Schematic Diagram — Trans

6-27. Printed Wiring Board —

6-28. Schematic Diagram —

6-29. Printed Wiring Board — MIC

6-30. Schematic Diagram — MIC

6-31. Printed Wiring Boards — TC

6-32. Schematic Diagram — TC

6-33. Printed Wiring Boards — Meter Display Board — .......... 65

6-34. Schematic Diagram — Meter Display Board — ............... 66

Board

— ............................ 41

Board

— ....................... 42

Board

— ........................... 43

Board

(1/4) — ..................... 45

Board

(2/4) — ..................... 46

Board

(3/4) — ..................... 47

Board

(4/4) — ..................... 48

Board

— ...........................49

Board

— .............................. 50

Board

Panel Function Board

Board

— ......................... 53

Board

— ............................ 54

Board

Board

— ................... 56

Board

— ......................... 57

Board

— ............................. 58

Illumination Board

Illumination Board

Board

Board

Board

Board

— ................................. 64

— .................. 60

— ........................... 61

— .............................. 62

— ............................ 63

— ........... 51

— .............. 52

— ................ 55

— ...............59

7. EXPLODED VIEWS

7-1. Main Section ...................................................................... 80

7-2. Back Panel Section ............................................................ 81

7-3. Front Panel Section (1) ...................................................... 82

7-4. Front Panel Section (2) ...................................................... 83

7-5. Meter Display Assy ........................................................... 84

7-6. Chassis Section .................................................................. 85

7-7. CD Mechanism Section (1) ...............................................86

7-8. CD Mechanism Section (2) ...............................................87

8. ELECTRICAL PARTS LIST .................................

88

5

HCD-GTX777/GTX787/GTX888

XLX

X

X

SECTION 1

GENERAL

Note:

This section is extracted

from instruction manual.

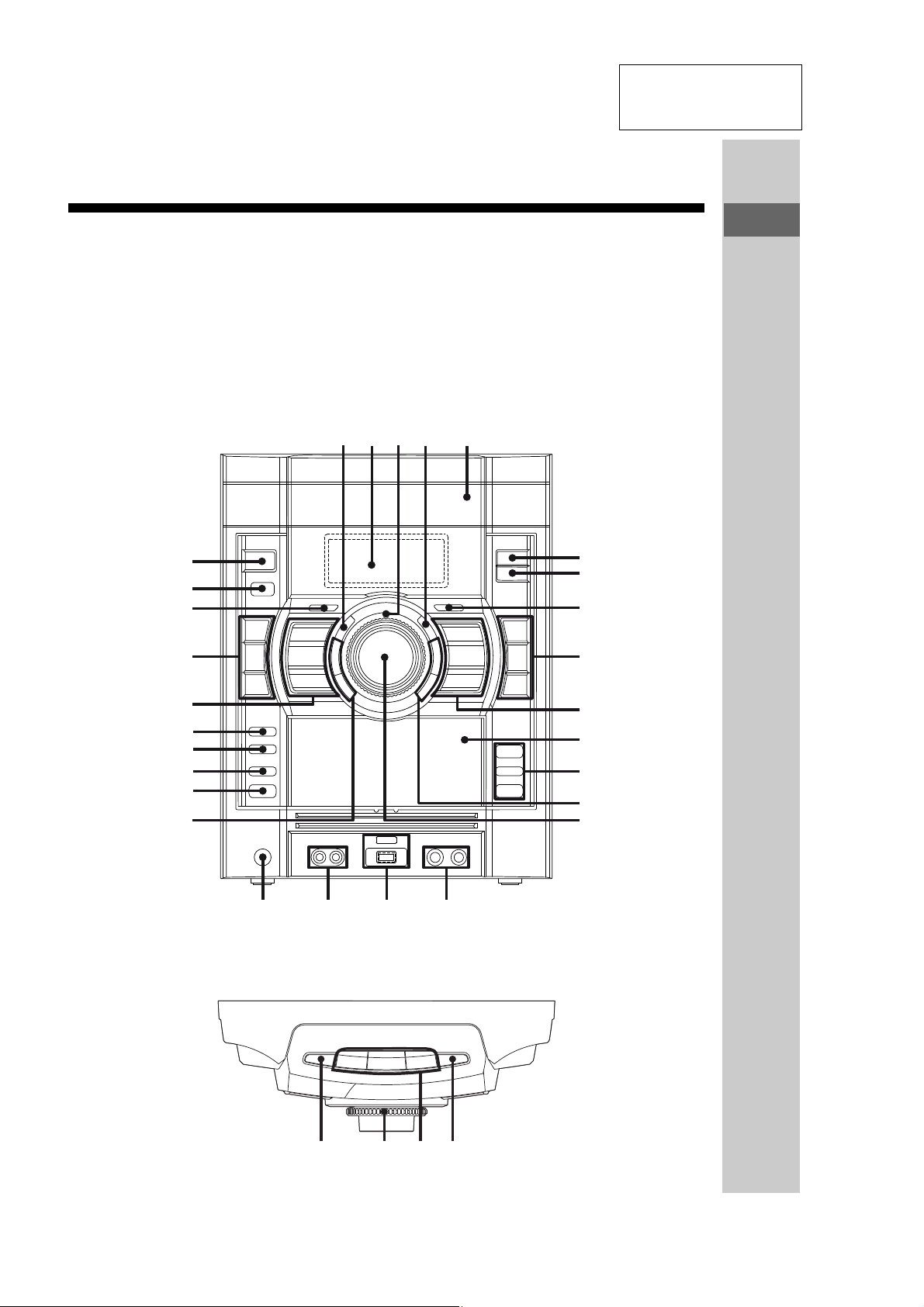

Guide to parts and controls

This manual mainly explains operations using the buttons on the unit, but the same

operations can also be performed using the buttons on the remote having the same or

similar names.

Unit

– Front view

Guide to parts and controls

– Top view

XH

XG

XE

R

XT

XB

X

RM

RE

RKRL RI

R

RB

RT

RE

RG

RH

M

6

K

I

Continued

M

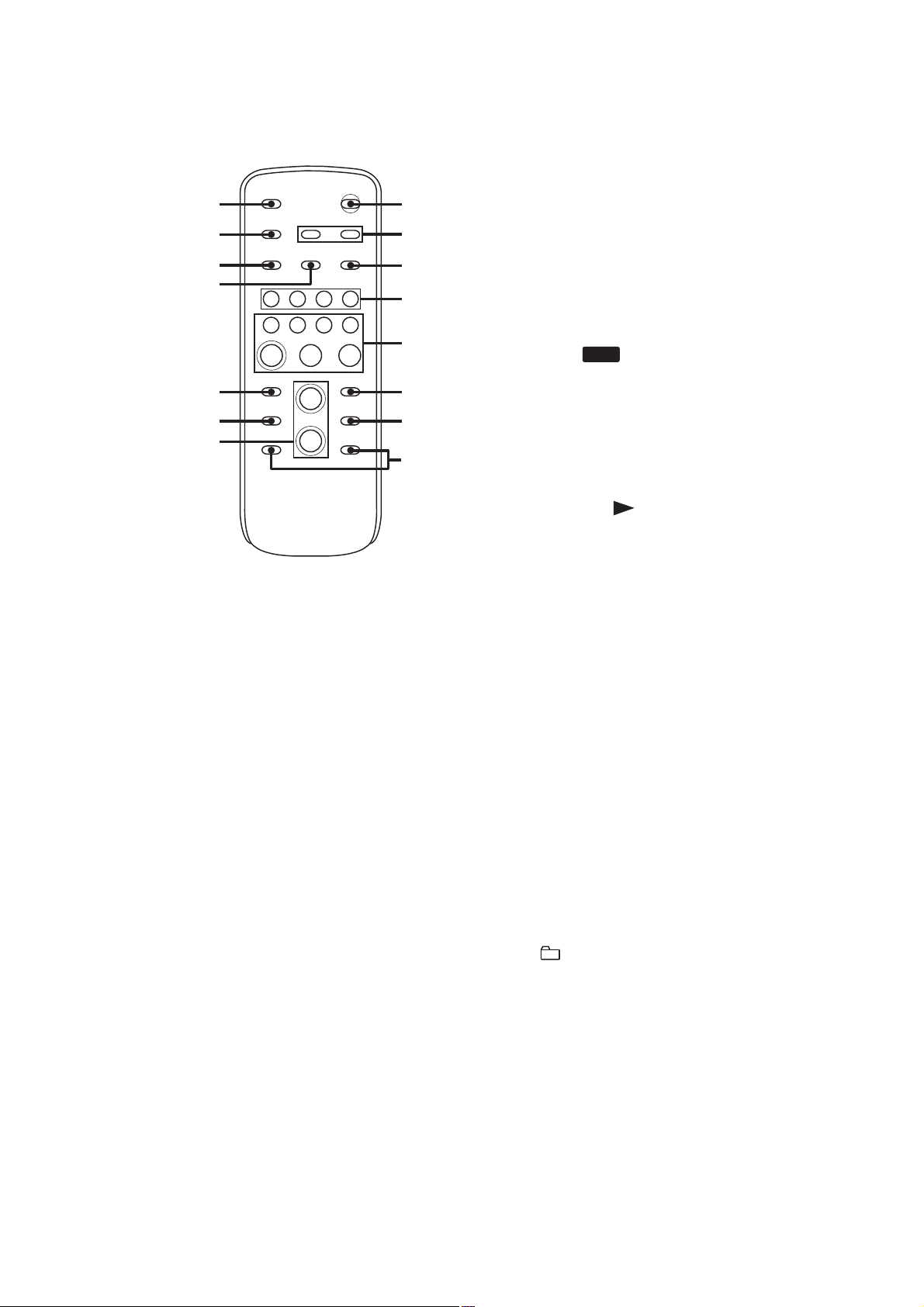

HCD-GTX777/GTX787/GTX888

Remote

FI

XE

FH

FG

FE

FT

RG

" EQ BAND/MEMORY (page 38)

Press to select a frequency band.

# Display (pages 11, 31, 32, 48)

Meter display (page 32)

$ Power illuminator (pages 31, 32)

XH

F

FB

R

RM

XM

R

) METER MODE (page 32)

Press to select a preset display

pattern.

* Function buttons:

CD (pages 15, 20, 24, 32, 33, 36)

TUNER/BAND (pages 22, 32)

Unit: TAPE (pages 29, 32)

Unit: AUDIO (pages 29, 32)

Unit: VIDEO (pages 29, 32)

Unit:

USB

(

pages 25, 27, 32, 33

Remote: USB (pages 25, 27, 33)

Remote: FUNCTION (page 29)

Press to select a function.

+ Unit: /9 (play/pause)

(pages 20, 24, 27, 29, 44)

Remote: (play) (pages 20,

27, 29, 44)

Remote: 9 (pause) (pages 20,

29)

Press to start or pause playback.

Y (stop) (pages 20, 22, 27, 29,

37, 43)

Press to stop playback, recording or

transferring.

)

% PRESET EQ (pages 30, 38)

Press to select a preset sound effect.

& Disc tray (pages 11, 20, 43, 48)

' SURROUND SPEAKER MODE

(MHC-GTX888 only) (page 30)

Press to select the sound system.

SURROUND

(MHC-GTX787/MHC-GTX777

only) (page 30)

Press to select the surround effect.

( GROOVE (page 30)

Press to reinforce the bass.

(go backward/go

forward) (pages 20, 27, 34)

Press to select a track or file.

Unit: TUNING +/– (page 22)

Remote: +/– (tuning) (pages 22,

35)

Press to tune in a radio station.

+/– (pages 20, 27, 33, 36)

Press to select a folder.

N.(rewind/fast forward)

(pages 20, 28, 29)

Unit: Press to fast forward or rewind.

Remote: Press to find a point in a

track or file.

7

HCD-GTX777/GTX787/GTX888

, PUSH ;OPEN/CLOSE

(page 29)

Press to insert or eject a tape.

Tape deck (pages 29, 36, 40, 47)

- REC TO TAPE (page 37)

Press to record onto a tape.

REC TIMER (page 40)

Press to set the Recording Timer.

REC TO (page 24)

Press to transfer onto the connected

optional USB device.

. FLANGER (pages 31, 43, 47)

DELAY (pages 31, 43, 47)

CHORUS (pages 31, 43, 47)

SOUND FLASH (page 31)

Press to create a party atmosphere.

/ Unit: MASTER VOLUME

(pages 20, 27, 29, 31, 42)

Turn to adjust the volume.

Remote: VOLUME +/–

(pages 20, 27, 29, 31, 42)

Press to adjust the volume.

USB

*

0 MIC (jack) (pages 39, 42, 53)

Connect an optional microphone.

MIC LEVEL (pages 37, 39, 42)

Turn to adjust the microphone

volume.

1 (indicator)

Lights up when transferring to the

connected optional USB device, or

when erasing audio files or folders.

(USB) port (pages 23, 25,

27, 46, 53)

Connect an optional USB device.

2 AUDIO INPUT L/R (jacks)

(page 29)

Connect to an audio component

(Portable audio player, etc.).

3 PHONES (jack) (pages 42, 53)

Connect the headphones.

4 ENTER (pages 20, 27, 30, 31,

34, 35, 38)

Press to enter the selection.

5 RETURN (page 20)

Press to return to the parent folder.

Press to exit search mode.

Guide to parts and controls

* The VOLUME+button has atactile dot.

Use the tactile dot as a reference when

operating the system.

6 ERASE (page 25)

Press to erase audio files or folders

on the connected optional USB

device.

Continued

M

8

HCD-GTX777/GTX787/GTX888

7 OPTIONS (pages 30, 31)

Press to select the display pattern,

MP3 BOOSTER+ function and USB

SELECT.

8 DISPLAY (pages 19, 32, 32, 36)

Press to change the information in

the display.

9 IR Receptor (page 42)

: (on/standby) (pages 14, 15,

42, 48)

Press to turn the system on or off.

; OPEN/CLOSE ; (pages 15, 20,

43)

Press to load or eject a disc.

XK DISC 1 ~ 3 (pages 21, 33)

Press to select a disc.

Press to switch to CD functi on from

other function.

XL OPERATION DIAL (pages 20,

27, 31, 38)

Turn to select a track, file or folder.

Turn to select a setting.

XM Unit: DISC SKIP/EX-CHANGE

(pages 15, 20, 21, 33)

Press to select a disc.

Press to exchange other discs during

playback.

F CLOCK/TIMER SELECT

(page 40)

CLOCK/TIMER SET (pages 19,

40)

Press to set the clock and the timers.

F[ REPEAT/FM MODE (pages 20,

23, 28, 47)

Press to change the Repeat Play

setting.

Press to select the FM monaural or

stereo reception.

FT EQ (pages 30, 38)

Press to select a preset sound effect.

FE CLEAR (page 34)

Press to delete a pre-programmed

track.

FG PLAY MODE/TUNING MODE

(pages 21, 22, 28, 33, 35, 37, 44,

48)

Press to select the play mode of CD

or USB function.

Press to select the tuning mode.

FH TUNER MEMORY (page 35)

Press to preset a radio station.

FI SLEEP (page 39)

Press to activate the Sleep Timer.

Remote: DISC SKIP (pages 21,

33)

Press to select a disc.

9

HCD-GTX777/GTX787/GTX888

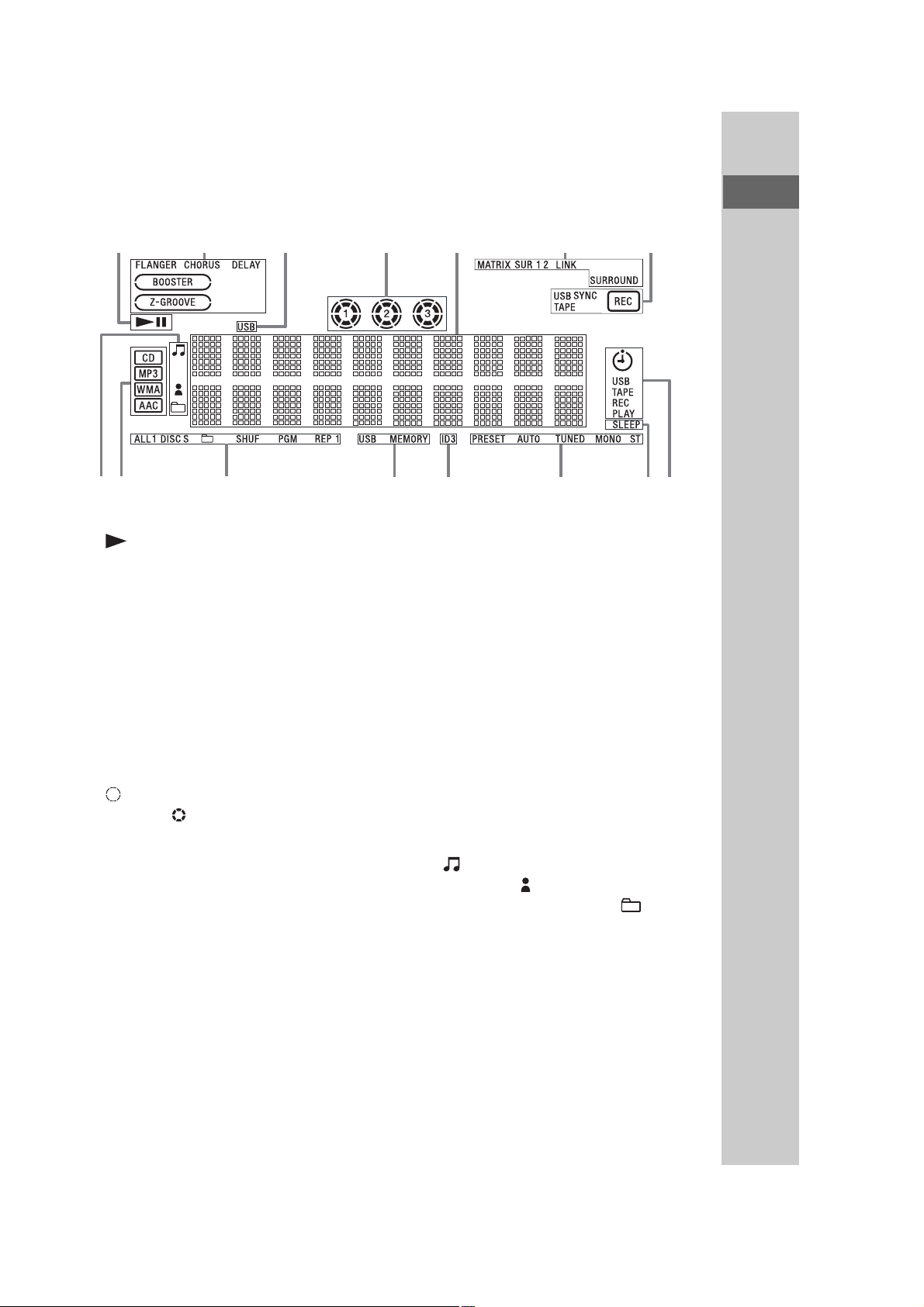

– Display

Guide to parts and controls

RERG

"

“ ” lights up during playback.

“

/9

” lights up when playback is

paused.

#

Indicates the activated sound effect

(pages 30, 31, 38).

Note

“LINK”, “MATRIX SUR 1” and

“MATRIX S UR 2” light up for

MHC-GTX888 only.

$

Lights up when the USB func tion is

selected (page 27).

%

Indicators for the disc tray (page 20).

“ ” lights up w hen the disc is

selected. “ ” lights up when there is

a disc on the disc tray. “1”, “2” and

“3” light up when the syste m is turned

on.

&

Displays the current status and

information (page 32).

'

Lights up during transferring onto an

USB device or recording onto a tape

(pages 23, 36).

RBRT

R

(

Lights up when the timer is set

(page 39).

)

Lights up when the Sleep Timer is

activated (page 39).

*

Indicators for the TUNER function

(pages 22, 35).

+

Lights up when the MP3 file contains

ID3 tag information.

,

Lights up when an optional U S B

device is recognized (page 23).

-

Indicates the selected play mode

(pages 21, 28).

.

Indicates the type of disc or file that

the system recognized.

/

Indicates the type of audio file

information that displayed (page 32).

“ ” lights up when a file name is

displayed. “ ” lights up when an

artist name is displayed. “ ” lights

up when a folder name is displayed.

10

Using the subwoofers

(MHC-GTX888 only)

You can use the subwoofers to enhance

the bass.

Subwoofer A (SS-WG888A)

1 Press SUBWOOFER ON/OFF on

the subwoofer A to light up the

indicator.

HCD-GTX777/GTX787/GTX888

The subwoofers are turned on.

2 Turn SUBWOOFER LEVEL on the

subwoofer A to adjust the level.

11

HCD-GTX777/GTX787/GTX888

SECTION 2

DISASSEMBLY

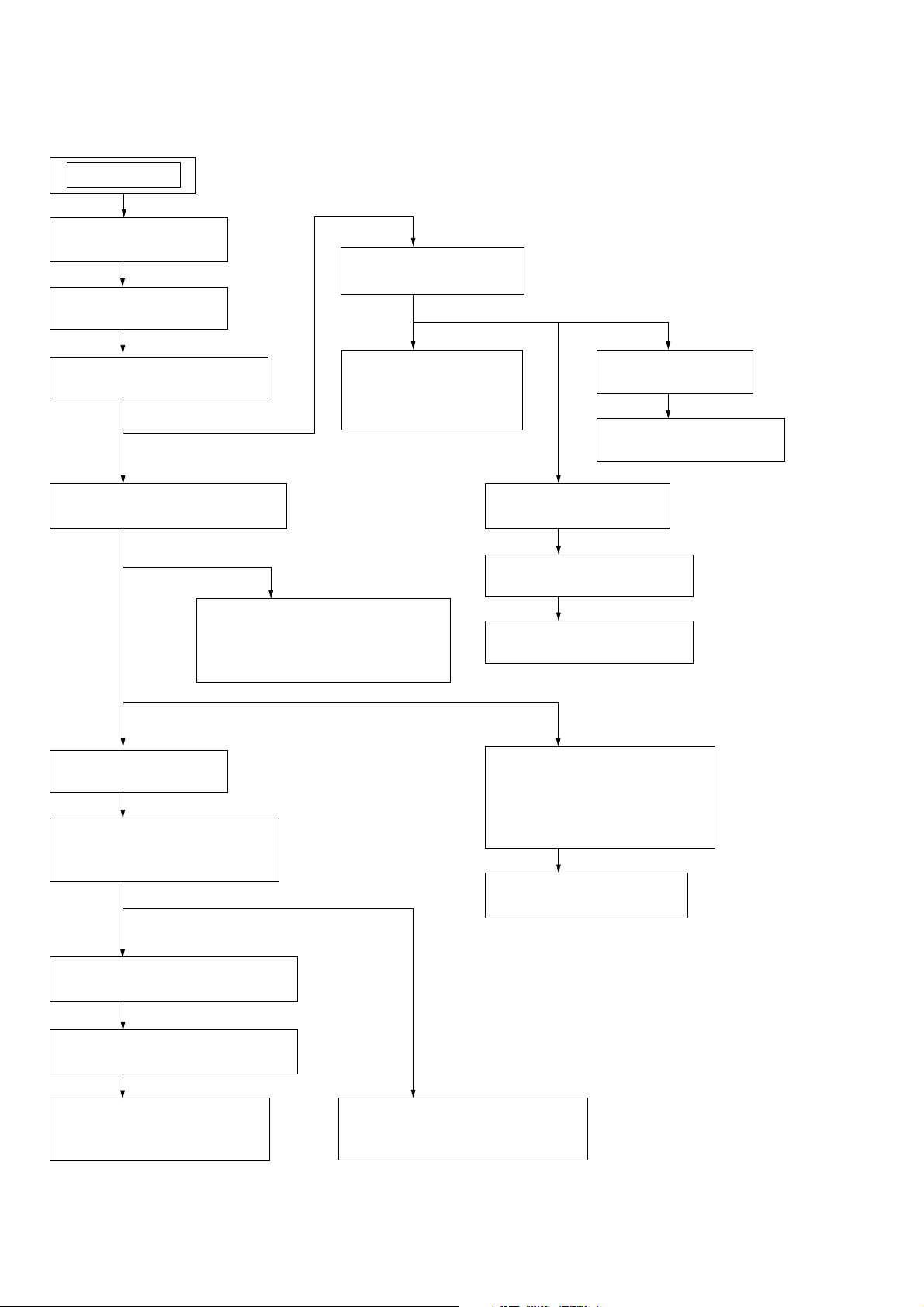

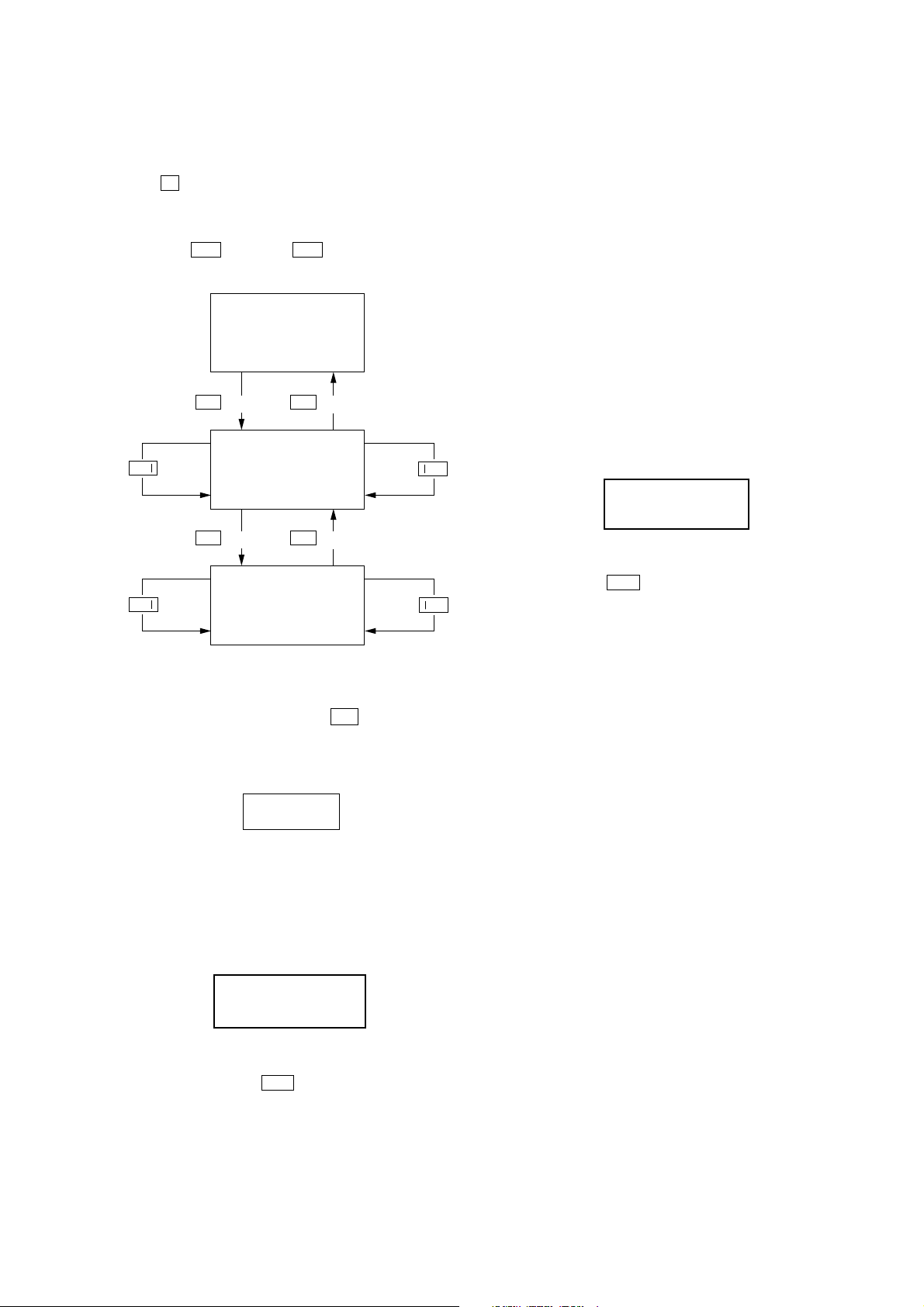

Note : This set can be disassembled in the order shown below.

SET

2-1. CASE (TOP)

(Page 13)

2-2. LOADING PANEL

(Page 13)

2-8. COVER (CDM)

(Page 16)

2-3. CD BLOCK SECTION

(Page 14)

2-4. FRONT PANEL SECTION

(Page 14)

2-5. TAPE MECHANISM DECK,

MIC BOARD,

USB CONNECTOR BOARD

(Page 15)

2-9. TUNER PACK

(Page 17)

2-10. BACK PANEL SECTION,

SUB TRANS BOARD

(Page 17)

2-16. DRIVER BOARD,

SW BOARD,

USB BOARD

(Page 20)

2-18. SENSOR BOARD

(Page 21)

2-19. MOTOR (TB) BOARD

(Page 22)

2-20. MOTOR (LD) BOARD

(Page 22)

2-6. METER DISPLAY ASSY

PANEL BOARD,

FUNCTION BOARD,

JOG BOARD

(Page 15)

2-7. CD-SW BOARD

(Page 16)

2-15. BD93 BOARD

(Page 20)

2-17. OPTICAL PICK-UP

(Page 21)

2-11. MAIN BOARD

(Page 18)

2-12. POWER BOARD SECTION

(Page 18)

2-13. SUBWOOFER BOARD,

POWER BOARD

(Page 19)

12

2-14. POWER TRANSFORMER

(T1200)

(Page 19)

Note : Follow the disassembly procedure in the numerical order given.

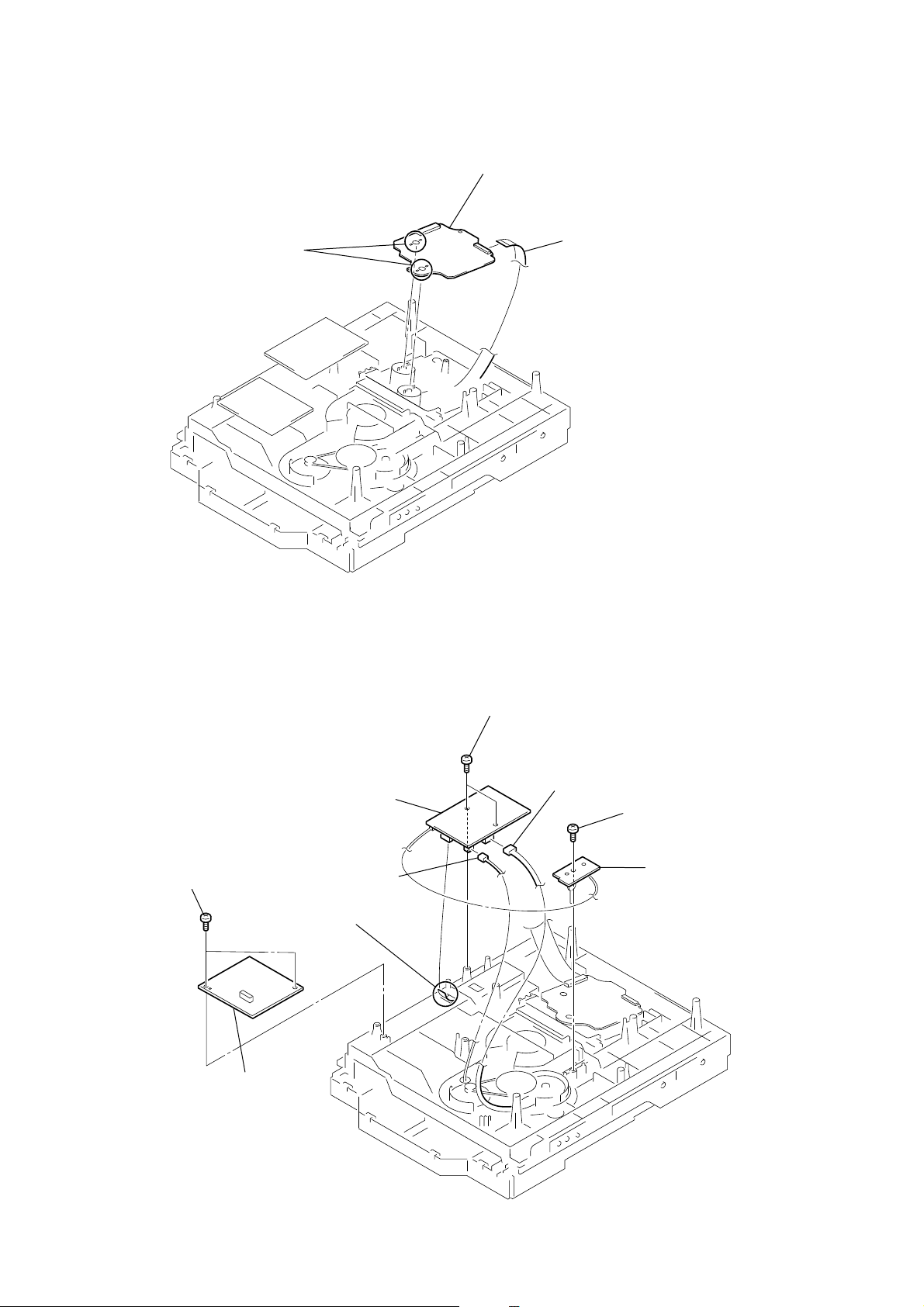

2-1. CASE (TOP)

two screws

(+BVTP 3 x 10)

panel (side-L)

two

screws

(case 3 TP2)

screw

(case 3 TP2)

RT

HCD-GTX777/GTX787/GTX888

RB

two screws

(+BVTP 3 x 10)

RE

case (top)

panel (side-R)

two

screws

(case 3 TP2)

2-2. LOADING PANEL

CD mechanism deck (CDM74KF)

Turn the pulley to the direction of the arrow.

pulley

Front panel side

loading panel

two screws

(+BVTP 3 x 10)

screw

(case 3 TP2)

Pull-out the disc tray.

13

HCD-GTX777/GTX787/GTX888

Ver. 1.1

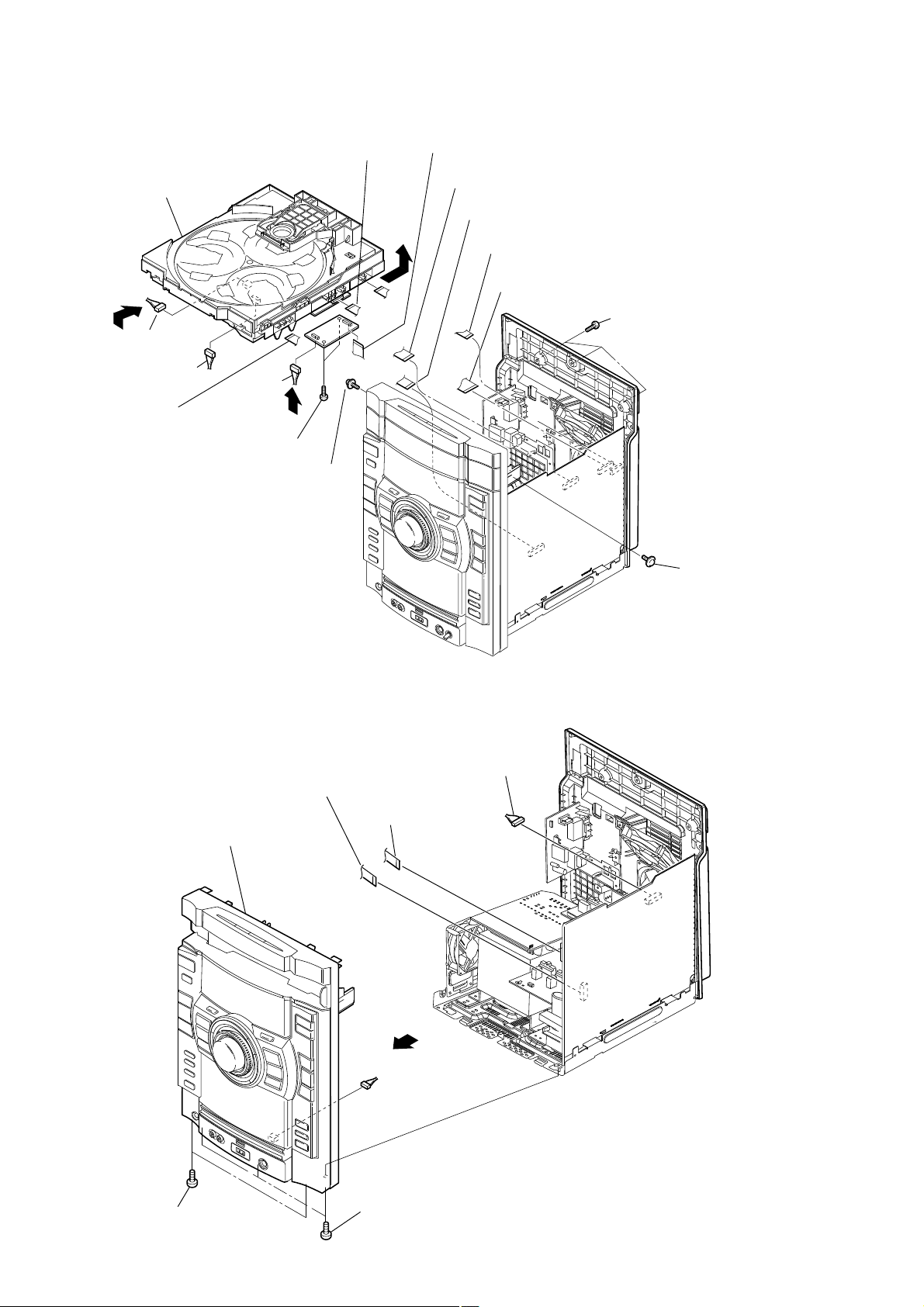

2-3. CD BLOCK SECTION

wire (flat type) (13 core)

(CN701)

RB

CD block section

CN901 (2P)

CN903 (5P)

RT

Wire (flat type) (21 core)

(CN907)

RE

CN400

(8p)

RG

two screws

(+BVTP 3

a

x 10)

tapping screw

wire (flat type) (11 core)

(CN410 )

wire (flat type) (13 core)

(CN110)

RH

wire (flat type) (11 core)

(CN102)

wire (flat type) (31 core)

(CN430)

wire (flat type) (21 core)

c

b

b

d

d

(CN204)

c

a

b

screw s

three

(+BVTP 3

c

a

x 12)

2-4. FRONT PANEL SECTION

front panel section

d

wire (flat type) (7 core)

CN101 (7P)

(CN115)

wire (flat type) (25 core)

(CN114)

tapping screw

14

screw s

two screw s

(+BVTP 3 x 10)

three

(+BVTP 3 x 10)

HCD-GTX777/GTX787/GTX888

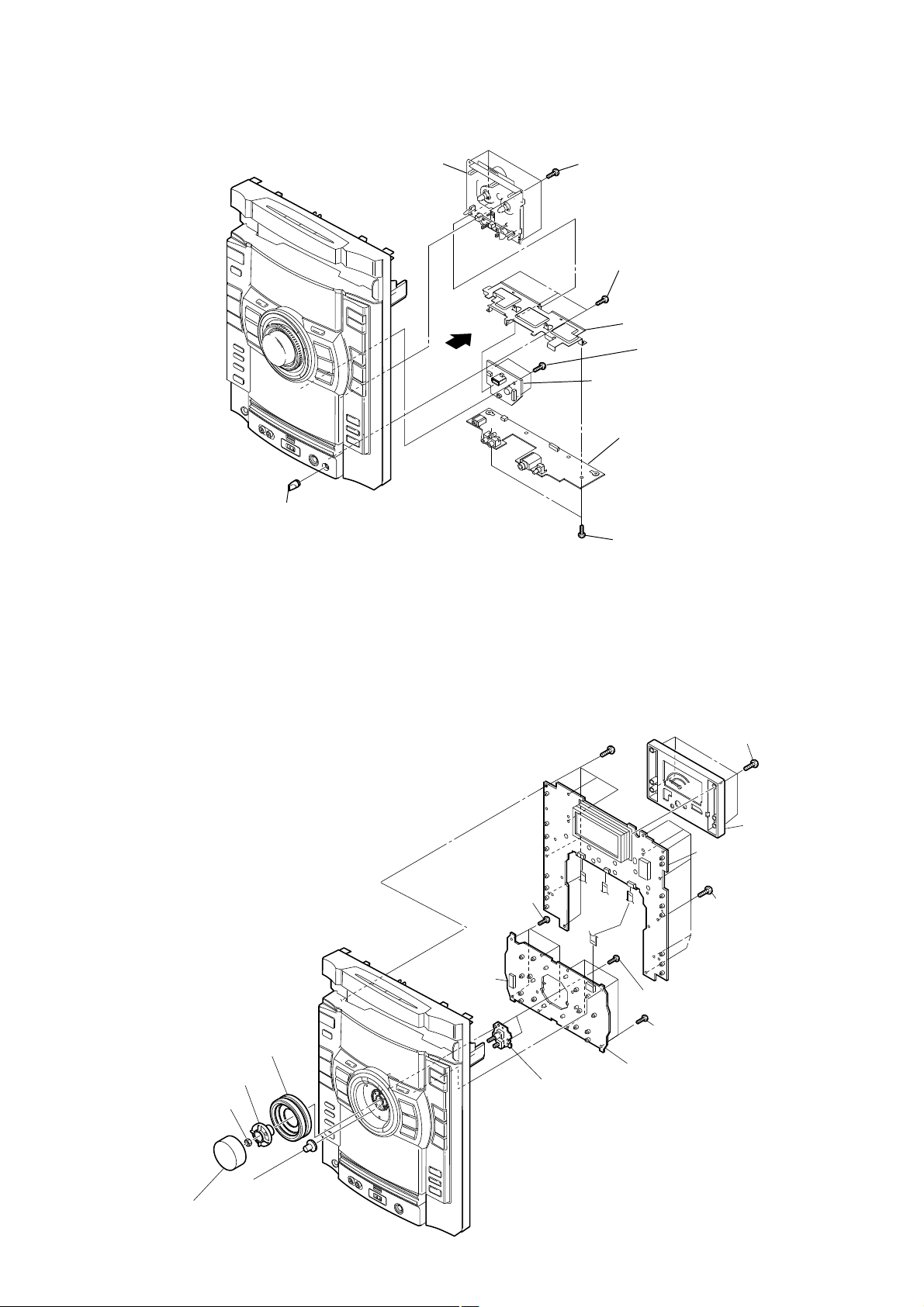

2-5. TAPE MECHANISM DECK, MIC BOARD, USB CONNECTOR BOARD

tape mechanism deck

four screws

(+BVTP 2.6 (3CR))

three screws

(+BVTP 2.6 (3CR))

knob (MIC)

2-6. PANEL BOARD, FUNCTION BOARD, JOG BOARD

bracket (MIC shield)

(+BVTP 2.6 (3CR))

USB CONNECTOR board

MIC board

two

(+BVTP 2.6 (3CR))

six screws

(+BVTP 2.6 (3CR))

three screws

screws

four

(+BVTP 2.6 (3CR))

screws

RE

RT

holder (jog)

RB

nut

knob (volume)

knob jog assy

RG

gear (encoder)

four screws

(+BVTP 2.6 (3CR))

b

RH

JOG board

meter display assy

panel board

b

a

two screws

(+BVTP 2.6 (3CR))

four screws

(+BVTP 2.6 (3CR))

illumination board

six screws

(+BVTP 2.6 (3CR))

15

HCD-GTX777/GTX787/GTX888

Ver. 1.1

2-7. CD-SW BOARD

escucheon (CD)

CD-SW board

three

(+BVTP 2.6 (3CR))

screws

screws

two

(+BVTP 2.6 (3CR))

2-8. COVER (CDM), TC BOARD

one screw

(+BVTP 3

TC board

CD mechanism deck

cover (CDM)

s

10)

two screws

(+BVTP 3

s

10)

16

two screw

(+BVTP 2.6 (3CR))

2-9. TUNER PA CK

tuner pack

HCD-GTX777/GTX787/GTX888

Ver. 1.1

wire (flat type) (9 core)

(CN1)

two

screw s

(+BVTP 3 x 8)

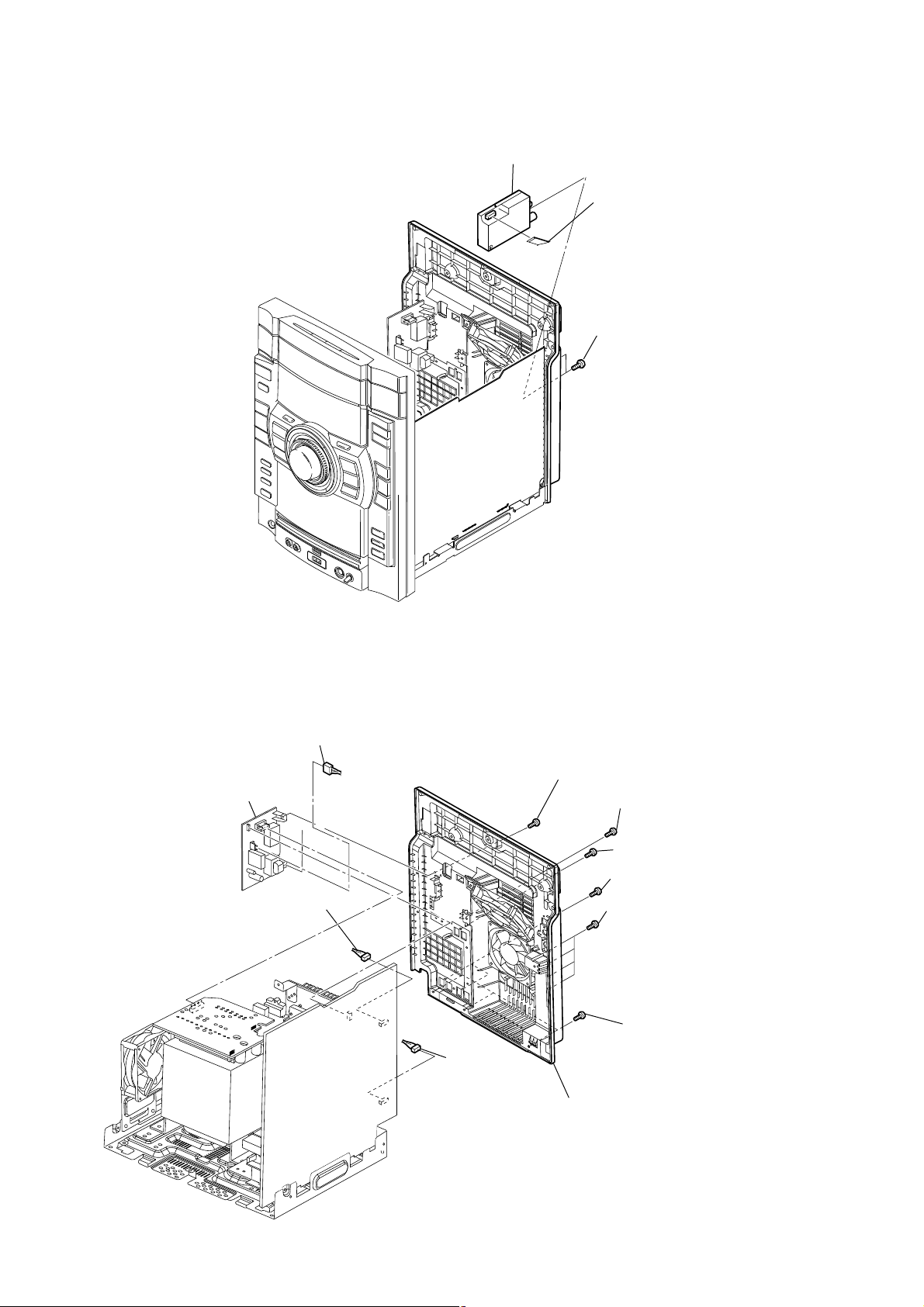

2-10. BACK PANEL SECTION, SUB TRANS BOARD

CN1203 (4P)

sub tran s b oa rd

CN206 (3P)

CN202 (3P)

two screw s

(+BVTP 3

RB

back panel section

s

10)

one

screw (GTX888 only)

(+BVTP 3

one

(+BVTP 3

one screw

two screw s

two screws

three screw s

three screw s

(+BVTP 3

s

10)

screw (GTX888 only)

s

10)

(+BVTP 3

(+BVTP 3

(+BVTP 3

(+BVTP 3

s

s

s

s

10)

10)

(GTX787)

10)

(GTX777/GTX888)

10)

(GTX777/GTX787)

s

10)

(GTX888)

17

HCD-GTX777/GTX787/GTX888

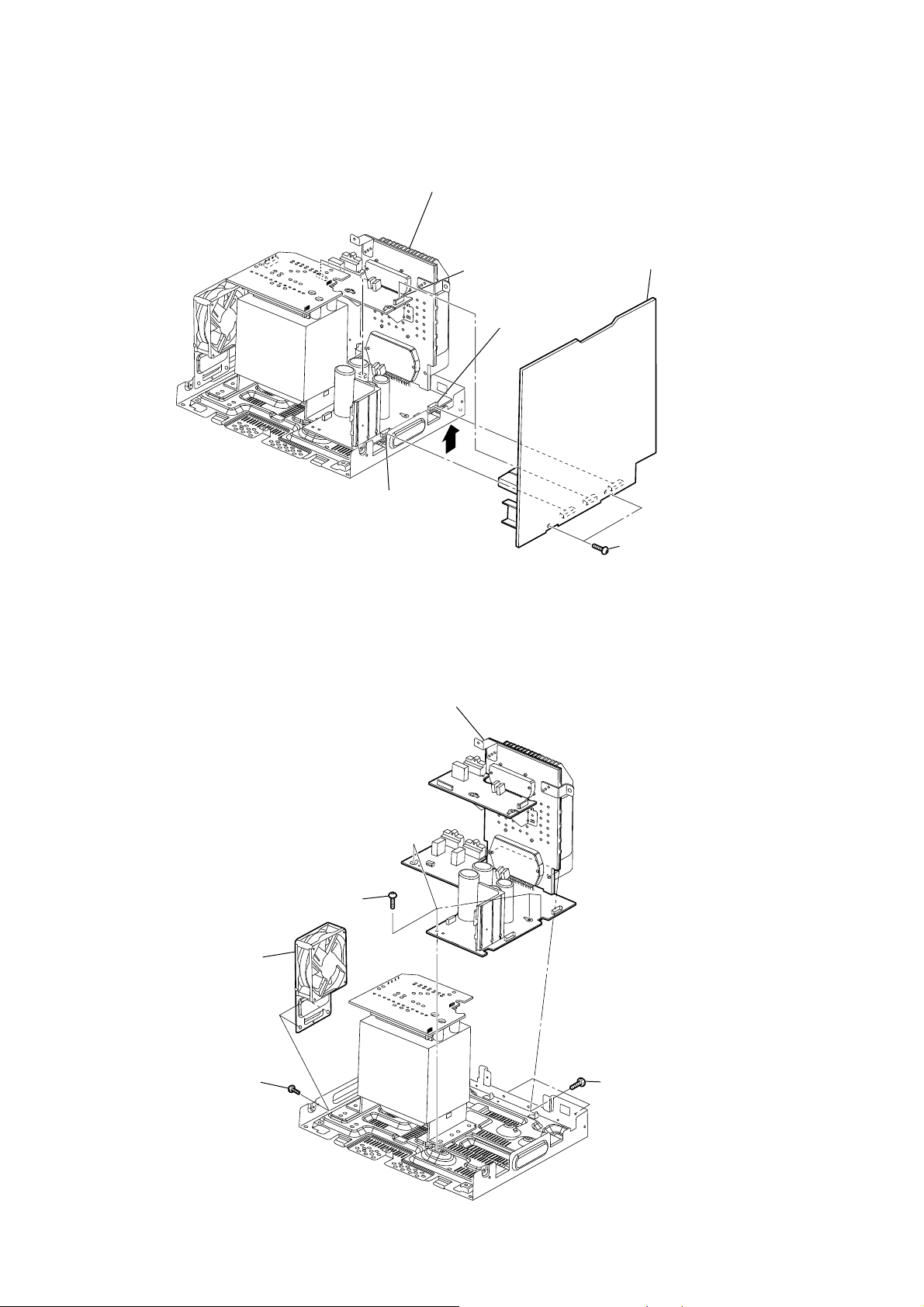

2-11. MAIN BOARD

P O WER board assy

MAIN board

CN809 (9 pin)

CN610

(8 pin)

CN611

(8 pin)

2-12. POWER BOARD SECTION, DC FAN (FOR GTX888)

P O WER board section

four screw s

(+BV3 (3-CR))

two screw s

(+BV3 (3-CR))

18

DC fan (M893)

TX

(Fo r G

two screw s

(+BVTP 3

888 Only)

×

10)

three screw s

(+BVTP 3

×

10)

2-13. SUBWOOFER BOARD, POWER BOARD

SUBWOOFER board

two screws

(transistor)

(+BV3 (3-CR))

heat sink assy

HCD-GTX777/GTX787/GTX888

two screws

POWER board

(transistor)

2-14. POWER TRANSFORMER (T1200)

TRANS board

three

(+BVTT 4 x 8)

screws

two screws

power transfomer (T1200)

three

(+BVTT 4 x 8)

screws

19

HCD-GTX777/GTX787/GTX888

Ver. 1.1

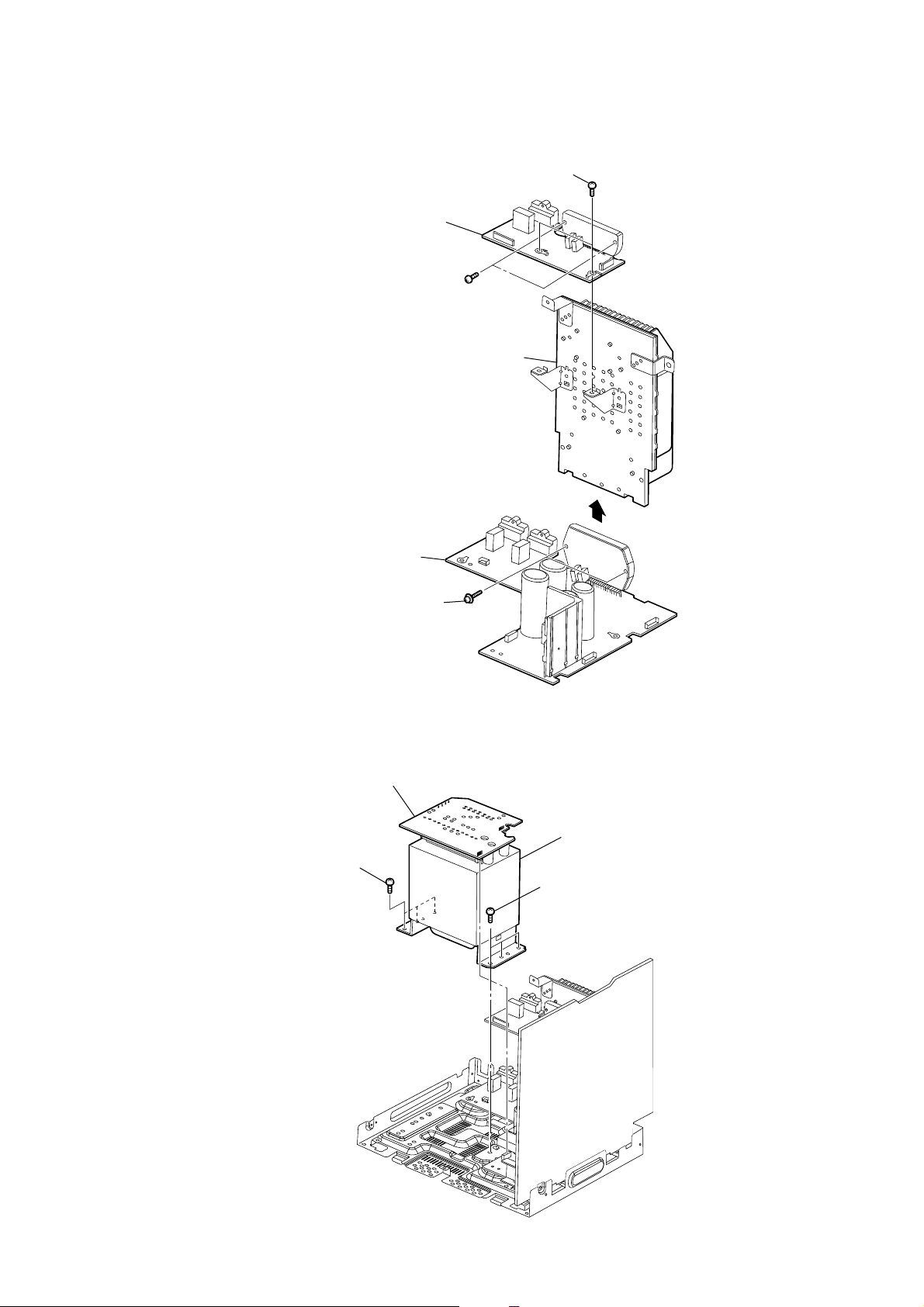

2-15. BD93 BOARD

Remove the four solders.

BD93

board

wire (flat type) (16 core)

(CN301)

2-16. DRIVER BOARD, SW BOARD, USB R BOARD

DRIVER board

two screws

(+BVTP2.6 (3CR))

USB board

CN704 (2P)

wire (flat type) (5 core)

(CN702)

two screws

(+BVTT (M2.6))

CN703 (4P)

screw

(+BVTT (M2.6))

SW board

20

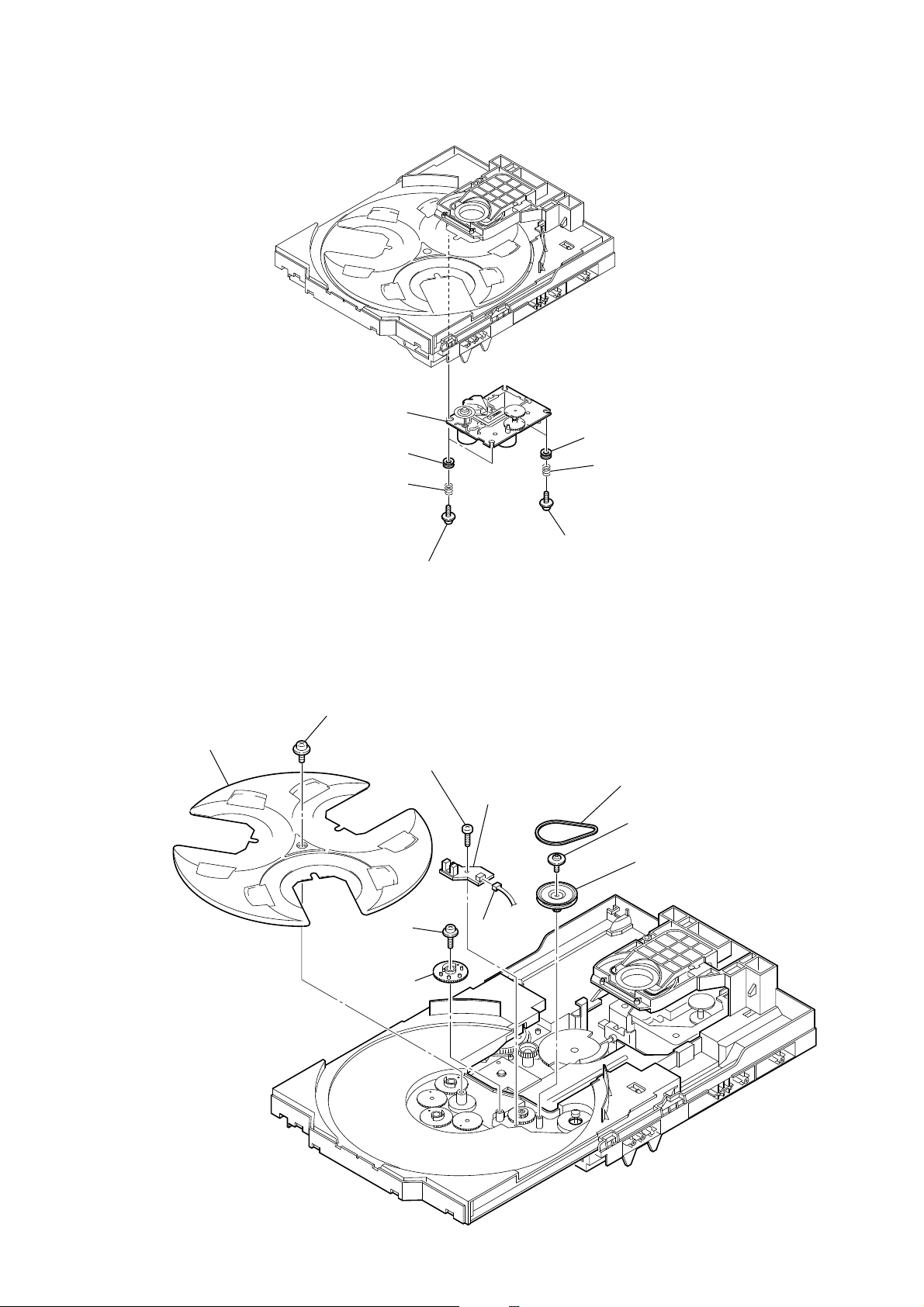

2-17. OPTICAL PICK-UP

optical pick-up

(BU-K6BD93UR)

two insulators

two coil springs

(insulator)

HCD-GTX777/GTX787/GTX888

two insulators

two coil springs

(insulator)

2-18. SENSOR BOARD

t

ray

floating

(+PTPWH M2.6)

floating

(+PTPWH M2.6)

g

screw

(+BTTP (M2.6))

screw

ear (geneva)

one screw

two floating screws

(+PTPWH M2.6)

SENSOR board

CN731

(3P)

two floating screws

(+PTPWH M2.6)

b

elt (table)

floating

(+PTPWH M2.6)

p

ulley (table)

screw

21

HCD-GTX777/GTX787/GTX888

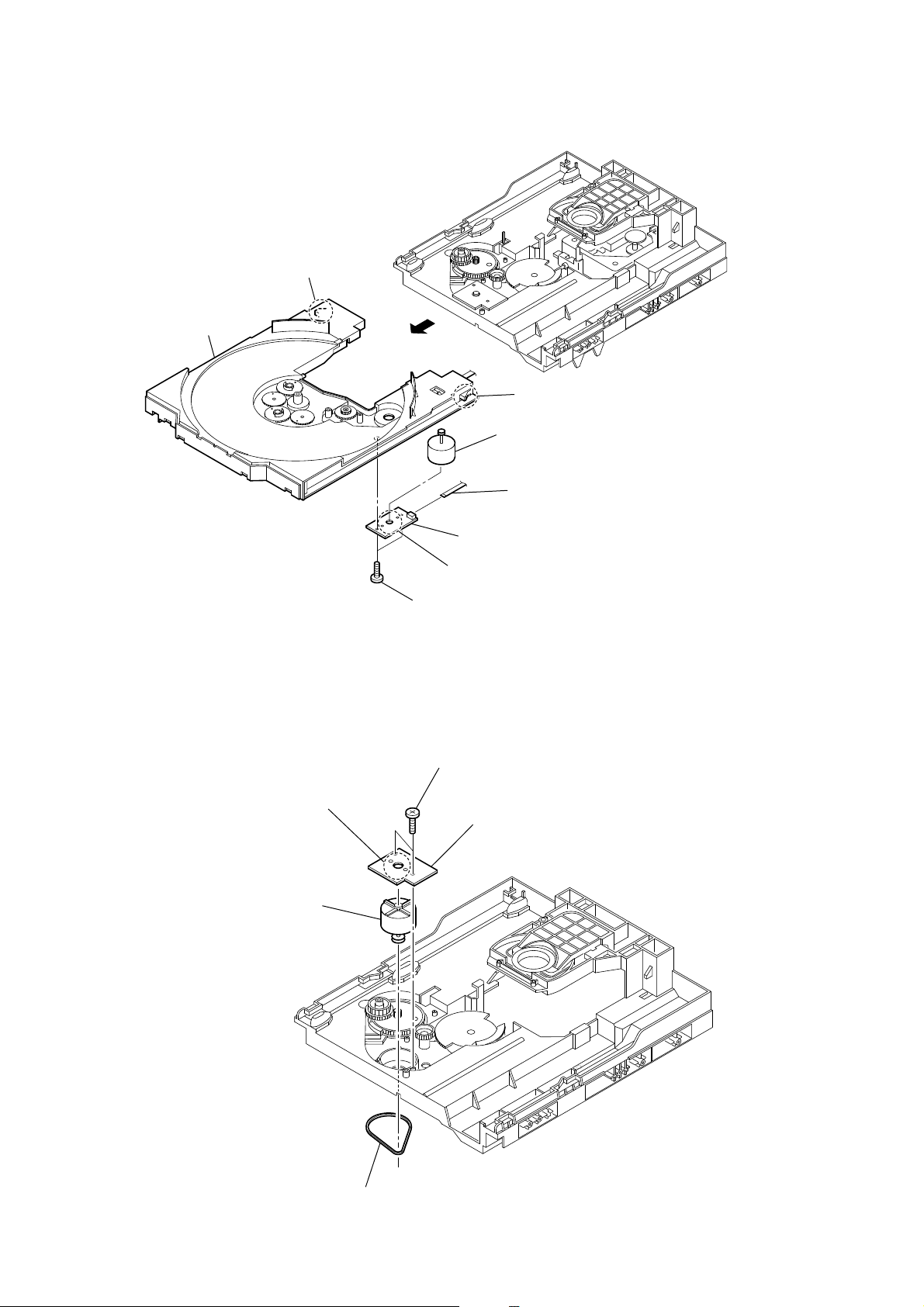

2-19. MOTOR (TB) BOARD

stopper

table

2-20. MOTOR (LD) BOARD

Remove the two solderings of motor.

Remove the two solderings of motor.

two screws

(+BTTP (M2.6))

two screws

(+BTTP (M2.6))

stopper

t

able motor assy (M741)

wire (flat type) (5 core)

(CN742)

MOTOR (TB) board

MOTOR (LD) board

22

l

oading motor assy (M751)

b

elt (loading)

SECTION 3

TEST MODE

HCD-GTX777/GTX787/GTX888

[GC TEST MODE]

• This mode is used to check the fl uorescent indicator tube, LEDs,

buttons, MASTER VOLUME knob, OPERATION DIAL knob,

model, destination, software version.

Procedure:

1. Press x button,

simultaneously.

2. All LEDs and segments in fl uorescent indicator tube are lighted

up.

All LEDs are lighted up in red color except for

the LED is lighted up in red and blue color.

3. When you want to enter to the model version and destination

display mode, press

appears on the fl uorescent indicator tube.

4. Each time

display software version and date of the software creation. The

sequence is SC version, GC version, SYS version, CD version,

CDDM version, CDMA version, CDMB version, BD A version,

BDB version, ST version, TC version, TA version, TM version,

MM1 version, MM2 version and MTR version in this order , and

returns to the model version display.

5. Press

6. In the key check mode, the fl uorescent indicator tube displays

Turn the

“V” value increases in the manner of 0, 1, 2, 3 ... if

counterclockwise.

7. When

8. T o release from this mode, press three b uttons in the same man-

[DISC 2]

“K 0 J0 V0”.

[OPERATIONAL DIAL]

by one. Turn the

value decreases by one. Each time a button is pressed, “K” value

increases. Press other keys on main unit to check whether the

key is detected. However, once a button has been pressed, it is

no longer taken into account.

VOLUME]

of 0, 9, 8, 7 ... if

[DISC SKIP/EX-CHANGE]

and segments in fl uorescent indicator tube light up, alternate

segments in fl uorescent indicator tube and LED would light up.

If you press

of alternate segments in fl uorescent indicator tube and LEDs

would light up. Press

cause all segments in

off. Pressing

all LED and segments lights up.

ner as step 1, or disconnect the power cord.

[DELAY]

[DISC 1]

button, the key check mode is activated.

[OPERATIONAL DIAL]

knob is turned clockwise, or it decreases in the manner

[MASTER VOLUME]

[DISC SKIP/EX-CHANGE]

[DISC SKIP/EX-CHANGE]

button and

[DISC 1]

button is pressed, the display changes to

[DISC SKIP/EX-CHANGE]

fl

uorescent indicator tube and LED turns

[DISC 2]

button. The model information

clockwise; “J” value increases

knob is turned

button is pressed after all LEDs

button again, another half

button again would cause

button

LED where

counterclockwise; “J”

[MASTER

button would

[MC TEST MODE]

• This mode is used to check operations of the respective sections

of Amplifi er, Tuner and Tape.

Procedure:

• To enter MC Test Mode

x

1. Press

simultaneously.

2. The CD ring indicators fl ash on the fl uorescent indicator tube.

The function is changed to VIDEO.

* Check of Amplifi er

1. Press

“GEQ MAX” appears on the fl uorescent indicator tube. GEQ

increases to its maximum.

2. Press

“GEQ MIN” appears on the fl uorescent indicator tube. GEQ

decreases to its minimum.

button,

[EQ BAND/MEMORY]

[EQ BAND/MEMORY]

[DELAY]

button and

button repeatedly until a message

button repeatedly until a message

[DISC 3]

button

3. Press

4. When the

5. When the

* Tape function

1. Insert a tape in deck. The function is changed to VIDEO au-

2. During recording, press

* To release from MC Test mode

1. To release from this mode, press

2. The cold reset is enforced at the same time.

[EQ BAND/MEMORY]

“GEQ FLAT” appears on the fl uorescent indicator tube. GEQ

is set to fl at.

[MASTER VOLUME]

slightly, the sound v olume increases to its maximum and a message “VOLUME MAX” appears on the fl uorescent indicator

tube.

[MASTER VOLUME]

even slightly , the sound volume decreases to its minimum and a

message “VOLUME MIN” appears on the fl uorescent indicator

tube.

tomatically when the recording is started by pressing

then press

TAPE]

the function is changed to TAPE and rewind the tape in Deck

until the recording start position and playback of the tape in

Deck is started.

[ENTER]

button repeatedly until a message

knob is turned clockwise even

knob is turned counter-clockwise

[REC TO

button.

m

button will stop the recording and

?/1

button.

[COLD RESET]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press x button,

simultaneously.

2. The fl uorescent indicator tube becomes blank for while, and the

set is reset.

[DELAY]

button and ?/1 button

[VACS ON/OFF]

• This mode is used to switch ON and OFF the VACS (Variable

Attenuation Control System).

Procedure:

1. Press ?/1 button to turn on the system.

2. Press

x

button and

message “V A CS OFF” or “VACS ON” appears on the fl uorescent

indicator tube.

[OPTIONS]

button simultaneously. The

[TUNER STEP CHANGE]

• The step interval of AM channels can be toggled between 9 kHz

and 10 kHz.

Procedure:

1. Press ?/1 button to turn on the system.

2. Press

3. Press

4. Press

[TUNER/BAND]

?/1

button to turn off the system.

[ENTER]

system will turn on automatically. The message “ AM 9K STEP”

or “AM 10K STEP” appears on the fl uorescent indicator tube

and thus the channel step is changed.

button to select the “AM”.

button and ?/1 button simultaneously. The

23

HCD-GTX777/GTX787/GTX888

[CD SERVICE MODE]

• This mode let you move the CD sled motor freely. Use this mode

when you want to clean the optical pick-up.

Procedure:

1. Press ?/1 button to turn on the system.

2. Select CD function.

3. Press

x

button,

[DELAY]

button and

[OPEN/CLOSE]

button

simultaneously.

4. The CD service mode is activated. The message “SERVICE

MODE” appears on the fl uorescent indicator tube.

5. With the CD in stop status, press

up to outside track, or turn

M

to move the optical pick-

m

to move to inside track. The

message “SLED OUT” or “SLED IN” appears on the fl uorescent

indicator tube.

6. To turn on or off the laser , press

>

button. The message “LD

ON” or “LD OFF” appears on the fl uorescent indicator tube.

?/1

7. To release from this mode, press

button to turn off the

system.

[CD AGING MODE]

• This mode can be used for operation check of CD section. If

an error occurs, the aging operation would stops and the status

is displayed. If there were no error occurs, the aging operation

would continue repeatedly.

Procedure:

1. Press ?/1 button to turn on the system.

2. Select CD function.

3. Load three discs on disc tray.

4. Press

5. Press

6. Aging operation is started.

7. To release from this mode, press

[PLAY MODE/TUNING MODE]

button on the remote con-

trol repeatedly to select the “ ALL DISCS” mode, and press the

[REPEAT/FM MODE]

button on the remode control repeatedly

to select repeat mode off.

x

button,

[DELAY]

button and

[DISC SKIP/EX-CHANGE]

button simultaneously.

?/1

button or disconnect the

power cord to turn the power OFF.

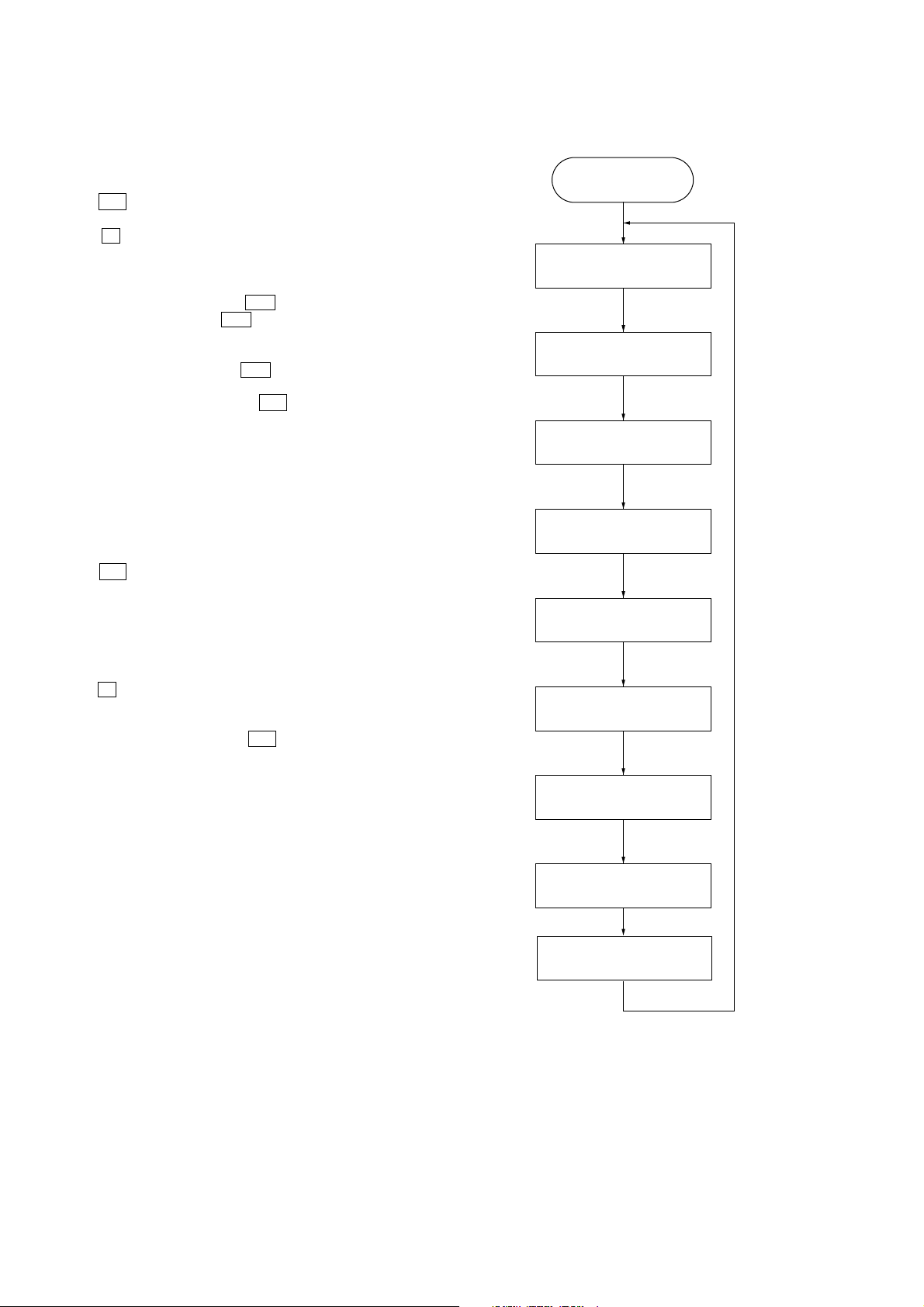

• Aging mode sequence:

START

DISC CHUCKING

TOC READING

PLAY FIRST TRACK FOR 2

SECONDS

PLAY LAST TRACK FOR 2

SECONDS

EX-CHANGE OPEN/CLOSE

OPEN THE DISC TRAY

DISC SKIP

CLOSE THE DISC TRAY

CHANGE THE NEXT DISC

24

HCD-GTX777/GTX787/GTX888

[CD ERROR CODE MODE]

• Display the CD error code when an error occurred.

Procedure:

1. Press x button,

[DELAY]

button and

[DISC 1]

button

simultaneously to enter the error code display mode.

2. The fl uorescent indicator tube display the number of total error.

3. Each time

m

button and M button are turned, display

change as below.

DISPLAY OF

TOTAL ERROR

.N

.

.

BUTTON

DISPLAY OF

MECHANICAL

ERRORS

.N

BUTTON

DISPLAY OF

NO DISC

ERRORS

BUTTON

.

BUTTON

.

4. To clear the error record, operate the cold reset. (Refer to the

“MC COLD RESET”.)

5. To release from this mode, press the

?/1

button or disconnect

the power plug to turn the power OFF.

• Display of total error

Em**Ed**

Em** : The number of times for CDM (mechanical) errors.

Ed** : The number of times for BD error (after chucking the

disc.).

• Display of CDM (mechanical) error. It is show with “M” and

11 digit number.

M*$$%%&&0–

000

M* : The number of history error for mechanical. (“0” is

latest one) (Turn

$$ : Mechanical errors occur in the operation.

FF : Mechanical error during normal operation.

Other : Mechanical error during initializing operation.

>

button to display next error.)

%% : The process when trouble occurs

01 : Process ejecting DISC

02 : Process waiting for inserting DISC

03 : Process sending request to insert a disc to upper

layer.

04 : Process sending request to eject a disc to upper

layer.

05 : Process pulling a DISC in.

06 : Chucking process

07 : Re-chucking process

08 : Process cancelling chucking

&& : The operation when trouble occurs

00 : Waiting for operation.

10/11/12/13: During eject operation

20 : While pulling a disc in

30 : While cancelling chucking

40/41/42/43: During eject operation due to error.

0000 : Not used (Value is fi xed to 0000).

• Display of BD error. It is shown with “D” and 11 digits

number.

D*$$%%&&#–

#00

D* : The number of error history (“0” is latest one)

>

(Press

button to display next error.)

$$ : The detail of trouble

01 : Can not focus

02 : GFS error

03 : Start-up time over

04 : Continuously out of focus

05 : Q code is not input for certain time

06 : Tracking on is impossible

07 : Blank disc

%% : The process when trouble occurs

01 : While SHIP process is performed

02 : While POWER OFF is processed

03 : While INITIALIZE (POWER ON) is processed.

04 : While oscillation stops

05 : From stopping oscillation to start oscillation

06 : During stop

07 : During STOP operation

08 : While start-up is processed

09 : While TOC reading is processed

0a : During search operation

0b : During PLAY operation

0c : During pause operation

0d : During PLAY manual search operation

0e : During PAUSE manual search operation

&& : Processing operation when trouble occurs

Show each STEP mentioned in %% digits.

## : Disc speed when trouble occurs.

01 : x1 speed

02 : x2 speed (for models which support x2 speed)

04 : x4 speed

00 : Not used (value is fi xed to 00).

25

HCD-GTX777/GTX787/GTX888

[CD REPEAT 5 LIMIT OFF MODE]

• The number of repeat for CD playback is 5 times when the repeat mode is “REPEAT ALL”. This mode enables CD to repeat

playback for limitless times.

Procedure:

1. Press ?/1 button to turn on the system.

2. Select CD function.

3. Press

• To release from this mode, operate the cold reset.

(Refer to the “MC COLD RESET”.)

[EQ BAND/MEMORY]

button simultaneously to enter the CD repeat 5 limit off mode

and the fl uorescent indicator tube displays “LIMIT OFF”.

button,

[CD]

button and

[DISC 1]

[CD SHIP MODE (WITH MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable to

vibration and clears all data including preset data stored in the

RAM to initial conditions. Use this mode when returning the set

to the customer after repair.

Procedure:

1. Press ?/1 button to turn on the system.

2. Select CD function.

x

3. Press

simultaneously. The system will turn off automatically.

4. After the “STANDBY” blinking display fi nishes, a message

“MECHA LOCK” is displayed on the fl uorescent indicator tube

and the CD ship mode is set.

5. The Memory is clear after AC Power OFF.

button,

[SOUND FLASH]

button and ?/1 button

[CD SHIP MODE (WITHOUT MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press ?/1 button to turn on the system.

2. Select CD function.

[CD]

3. Press

will turn off automatically.

4. After the “STANDBY” blinking display fi nishes, a message

“MECHA LOCK” is displayed on the fl uorescent indicator tube

and the CD ship mode is set.

button and ?/1 button simultaneously . The system

[CD TRAY LOCK MODE]

• This mode let you lock the disc tray . When this mode is acti vated,

the disc tray will not open when

SKIP/EX-CHANGE]

will be displayed on the fl uorescent indicator tube.

Procedure:

1. Press ?/1 button to turn on the system.

2. Select CD function.

3. Press

x

hold down until “LOCKED” or “UNLOCKED” displayed on

the fl uorescent indicator tube (around 5 seconds).

button is pressed. The message “LOCKED”

button,

[OPEN/CLOSE]

[OPEN/CLOSE]

button simultaneously and

button or

[TCM OFFLINE MODE]

• This mode is used to prevent the system from turning off automatically when TCM is not connected. Therefore, measurements can

be done even when TCM is not connected during production.

Procedure:

1. When the system is turned off, press

button,

2. The message “TCM OFFLINE” will be displayed on the fl uo-

[TAPE]

button and ?/1 button simultaneously. The

system will turn on automatically.

rescent indicator tube.

[EQ BAND/MEMORY]

[VACS DISPLAY]

• This mode is used to check the VACS level.

Procedure:

1. Press ?/1 button to turn on the system.

2. Press

3. The VACS Le vel Display , the fl uorescent indicator tube displays

x

button,

CHANGE]

“VATB F APC”. “V” represent VACS, A represent VACS lev el

which is triggered by signal level, “T” represent Thermal VACS

NEO, B represent VACS le vel which is triggered by temperature,

“F” represent FAN is triggered by software to turn in to high

speed, “AP” represent APVACS (Abuse Protection VACS) and

“C” represent APVACS level which is triggered.

[CHORUS]

button simultaneously.

button and

[DISC SKIP/EX-

[DISC

26

HCD-GTX777/GTX787/GTX888

[METER SWITCH TOUCH COUNT DISPLAY]

• This mode is used to display the total count of meter pointer

touch initial switch and max switch.

Procedure:

1. Press

2. Press

button to turn on the system.

x

button,

[ENTER]

button and

[DISPLAY]

button

simultaneously.

3. The fl uorescent indicator tube displays “IxxxxxMyyyyy”.

“I” represents the Initial Switch touch.

“xxxxx” represents the total count of Initial Switch touch.

(Maximum Value of “xxxxx” = 65535)

“M” represents the Max Switch touch.

“yyyyy” represents the total count of Max Switch touch.

(Maximum Value of “yyyyy” = 65535)

4 To release from this mode, do step (2) again.

The fl uorescent indicator tube displays “MODE OUT”.

[METER TEST MODE]

• This mode is used to check the meter device.

Procedure:

1. Press

2. Press

button to turn on the system.

x

button,

[ENTER]

button and

[METER MODE]

button

simultaneously.

3. Meter Backlight LEDs, Meter Pointer LEDs, Power Illuminator

LEDs and fl uorescent indicator tube are lighted up.

4. When you want to perform count total step from Initial Switch

to Max Switch operation mode, press

[>>]

button. The meter

pointer will move from Initial Switch to Max Switch and fi nally

move back to the middle position. The total step count information appears on the fl uorescent indicator tube. “xxx STP yy” is

shown.

“xxx” represents the total step.

(Value of “xxx” should between 430 steps to 470 steps)

“yy” represents the status of total step count.

(If total step between 430 steps to 470 steps, “yy” is OK,

else “yy” is NG)

5. When you want to perform count total step from Max Switch

[<<]

to Initial Switch operation mode, press

button. The meter

pointer will move from Max Switch to Initial Switch and fi nally

move back to the middle position. The total step count information appears on the fl uorescent indicator tube. “xxx STP yy” is

shown.

“xxx” represents the total step.

(Value of “xxx” should between 430 steps to 470 steps)

“yy” represents the status of total step count.

(If total step between 430 steps to 470 steps, “yy” is OK,

else “yy” is NG)

6 To release from this mode, do step (2) again.

The fl uorescent indicator tube displays “TST MODE OUT”.

SECTION 4

MECHANICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

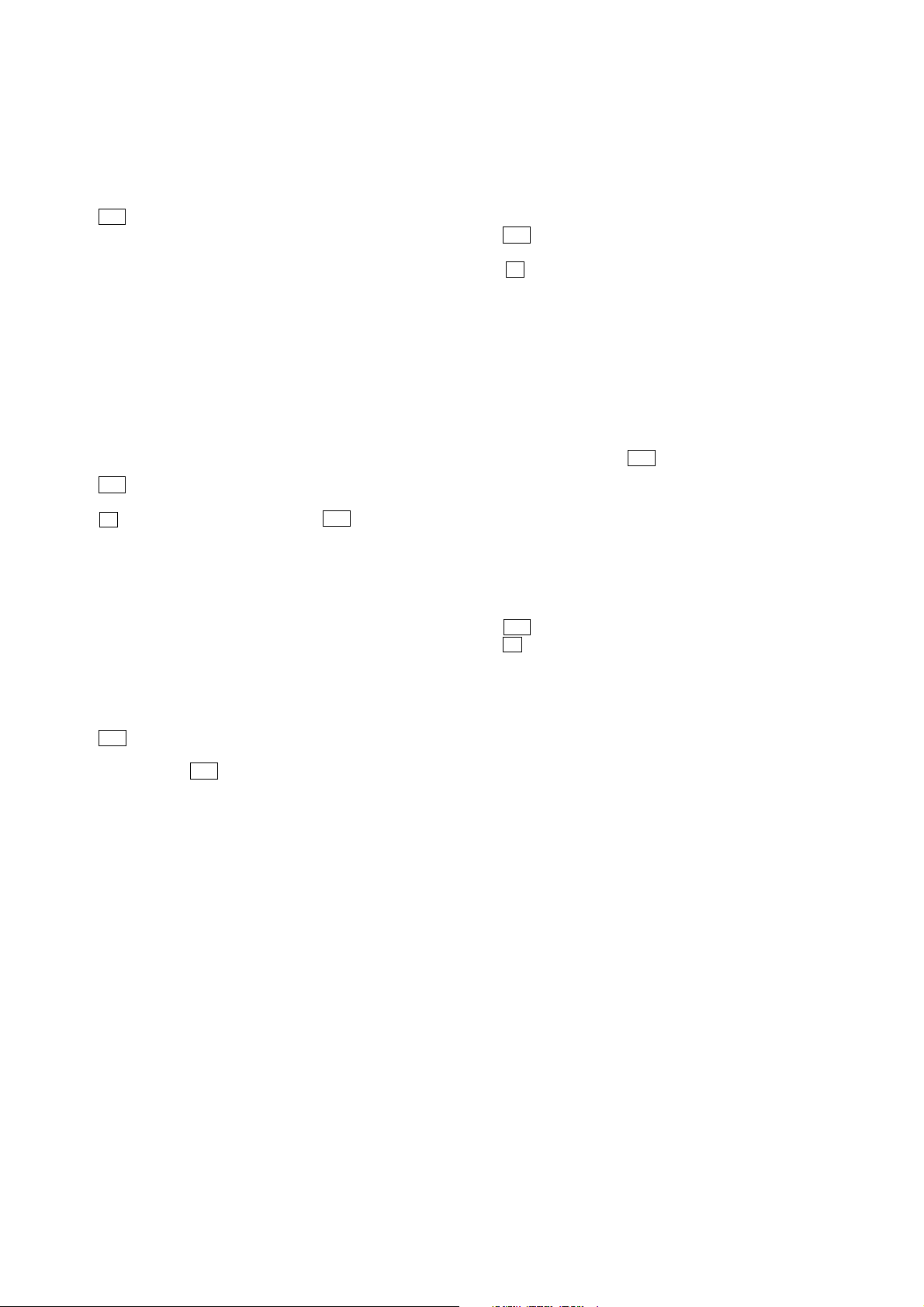

Mode Torque meter Meter reading

2.9m N • m to 6.9m N • m

FWD CQ-102C 30 to 70 g • cm

(0.42 – 0.97 oz • inch)

FWD 0.15m N • m to 0.59m N • m

back tension CQ-102C 2 to 6 g • cm

(0.03 – 0.08 oz • inch)

2.9m N • m to 6.9m N • m

REV CQ-102RC 30 to 70 g • cm

(0.42 – 0.97 oz • inch)

0.15m N • m to 0.59m N • m

REV

CQ-102RC 2 to 6 g • cm

back tension

4.8m N • m to 16.7m N • m

FF/REW CQ-201B 49 to 170 g • cm

(0.68 – 2.36 oz • inch)

(0.03 – 0.08 oz • inch)

27

HCD-GTX777/GTX787/GTX888

ELECTRICAL ADJUSTMENTS

SECTION 5

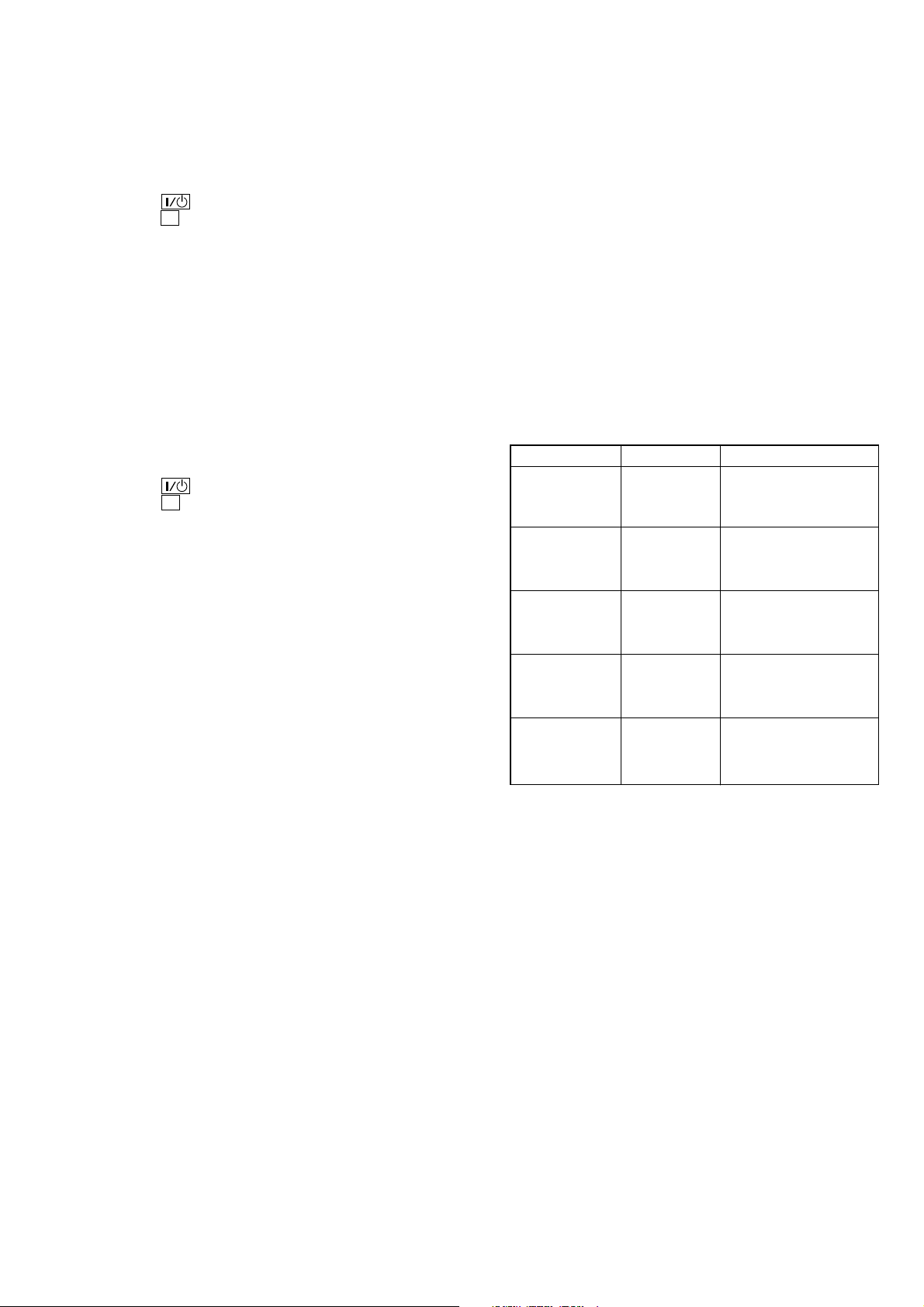

TUNER SECTION 0 dB = 1 µV

[FM Tune Level Check]

FM signal generator

SET

Procedure:

1. Turn the power on.

2. Input the following signal from Signal Generator to FM antenna input directly.

* Carrier Freq : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note:

Please use 75 ohm “coaxial cable” to connect SG and the set. You

cannot use video cable for checking.

Please use SG whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Confi rm “TUNED” is lit on the display for A, B and C signals.

The mark of “TUNED” means “The selected station signal is received in good condition.”

OUT (75 7)

DECK SECTION 0 dB = 0.775 V

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specifi ed.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

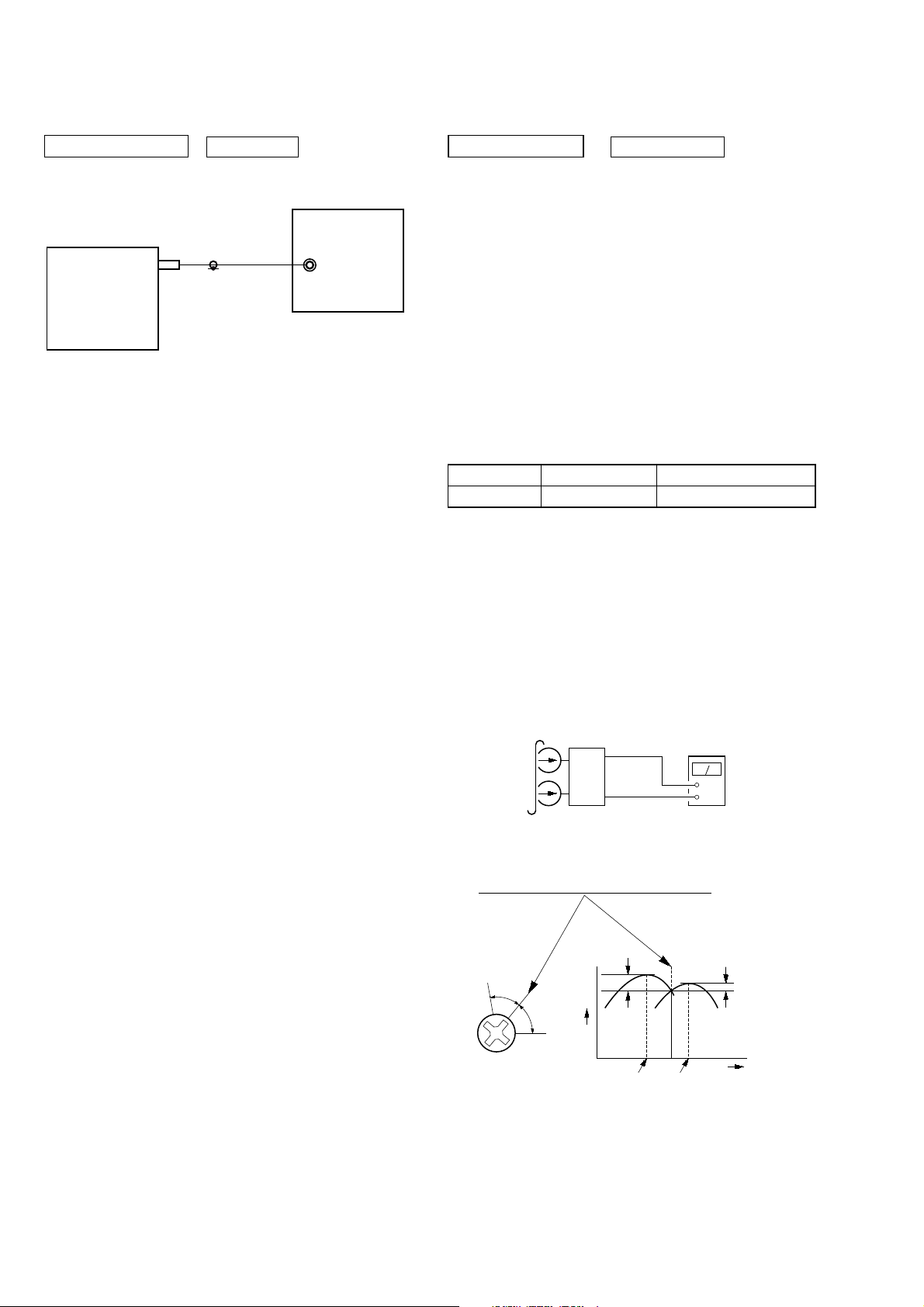

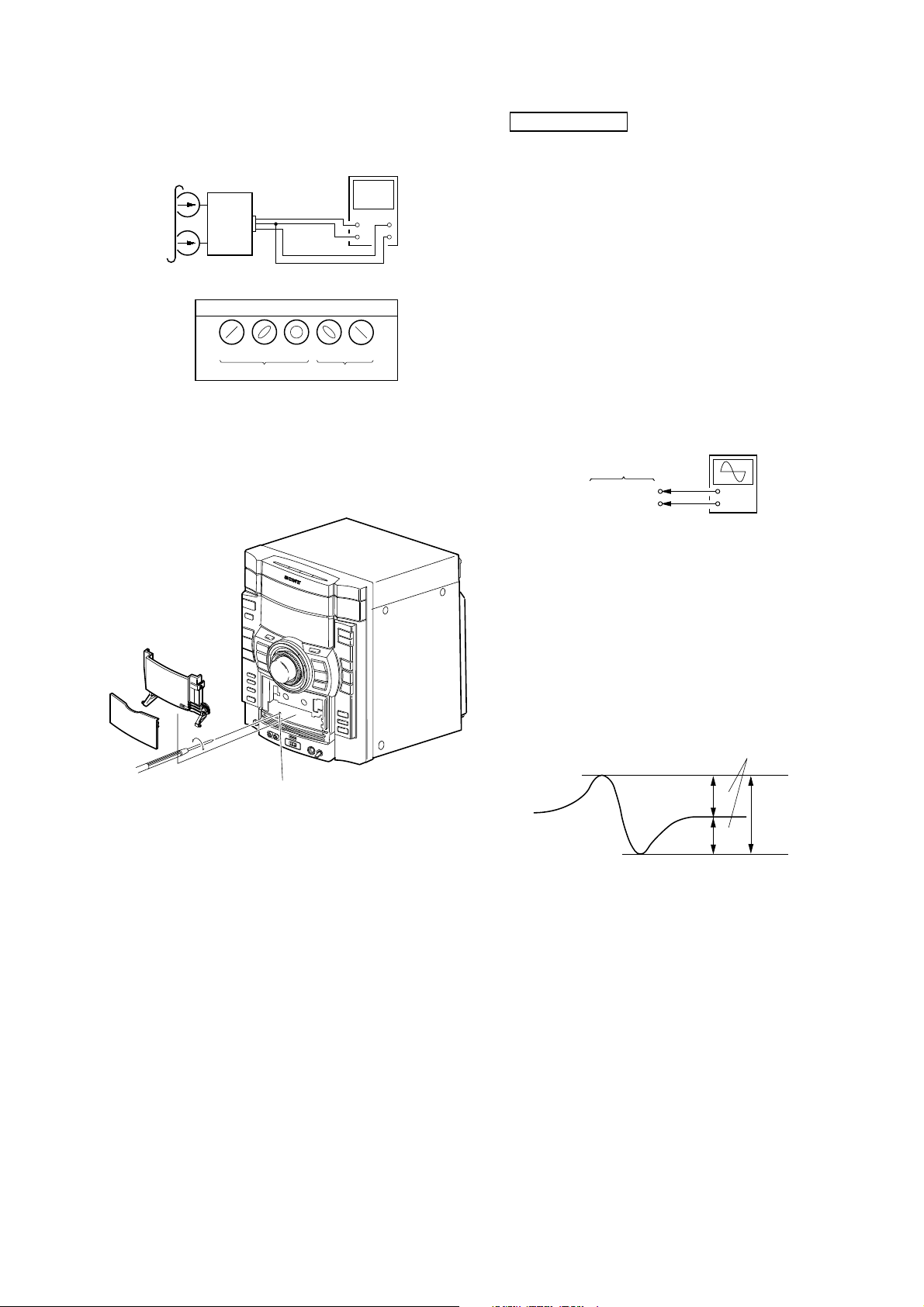

[RECORD/PLAYBACK HEAD AZIMUTH

ADJUST-MENT]

Note:

Perform this adjustments for Single deck

Procedure:

1. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

(L-CH & R-CH)

set

level meter

+

–

2. T urn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

screw

position

L-CH

peak

screw

position

R-CH

peak

28

HCD-GTX777/GTX787/GTX888

3. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

R-CH

waveform of oscilloscope

in phase

L

R

45o 90 o 135o 180 o

good

oscilloscope

V

wrong

H

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

Adjustment Location:

Playback Head (Deck).

CD SECTION

[TEST DISC LIST]

Use the following test disc on test mode.

• CD: YEDS-18 (PART No. 3-702-101-01)

or

PATD-012 (PART No. 4-225-203-01)

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MW impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specifi ed value with the

following checks.

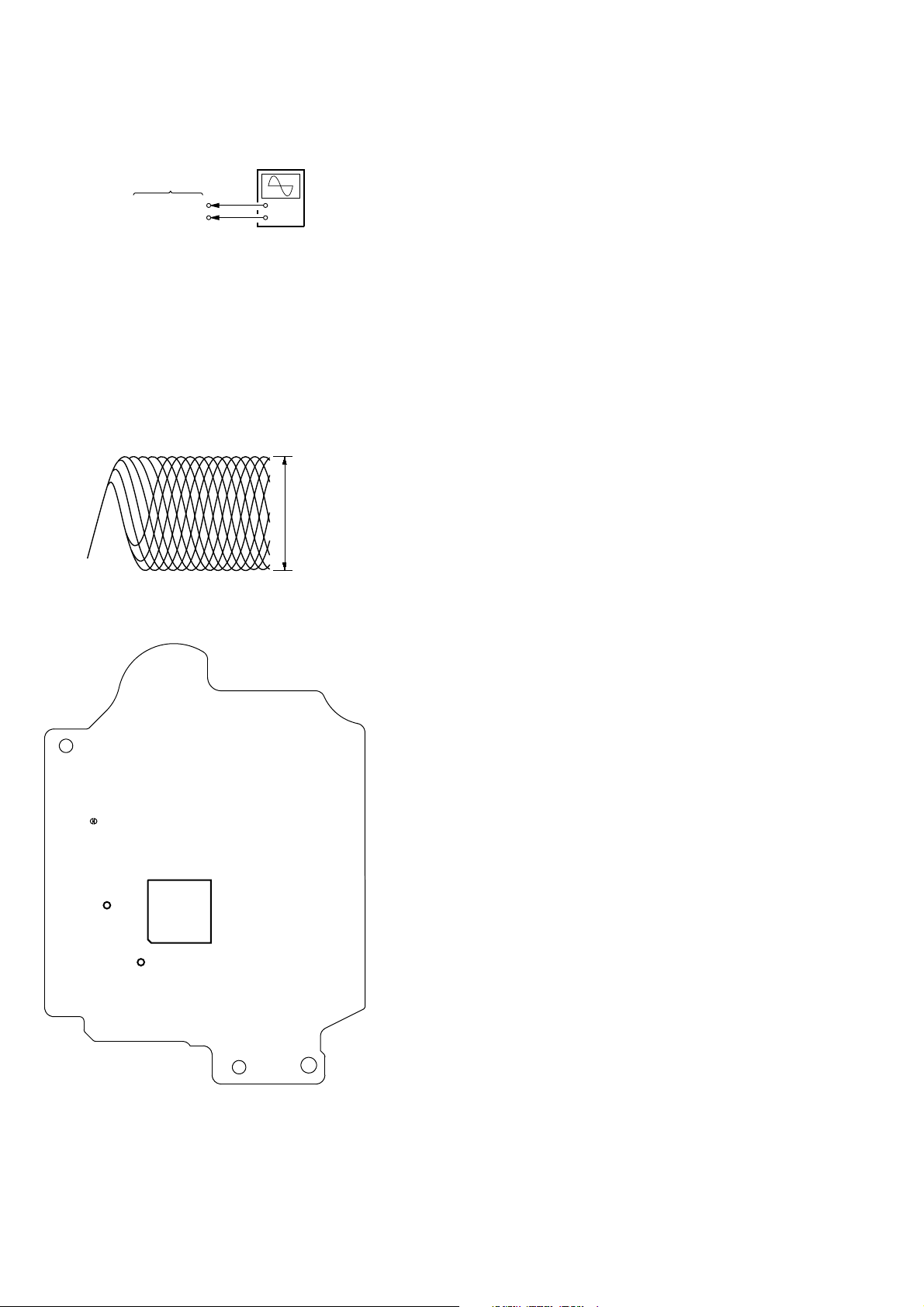

[S-CURVE CHECK]

oscilloscope

BD93 board

TP106(FE)

TP124(VC)

Procedure :

1. Connect an oscilloscope to TP106 (FE) and TP124 (VC).

2. Turn the power on.

3. Load a disc (YEDS-18) and actuate the focus search. (In

consequence of open and close the disc tray, actuate the focus

search)

4. Confi rm that the oscilloscope waveform (S-curve) is symmetrical

between A and B and confi rm peak to peak level within 3 ± 0.5

Vp-p.

+

–

forward

Note:

S-curve waveform

symmetry

A

within 3

±

0.5Vp-p

B

• Try to measure several times to make sure that the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

29

HCD-GTX777/GTX787/GTX888

[RF LEVEL CHECK]

oscilloscope

BD93 board

TP123(RFO)

TP124(VC)

Procedure :

1. Connect an oscilloscope to TP123 (RFO) and TP124 (VC).

2. Turn the power on.

3. Load a disc (YEDS-18) and playback.

4. Confi rm that oscilloscope waveform is clear and check if RF

signal level is correct or not.

Note:

Clear RF signal waveform means that the shape “ ¡ ” can

be clearly distinguished at the center of the waveform.

+

–

RF signal waveform

Connecting Location:

– BD93 Board (SIDE B) –

TP124

(VC)

76

100

75

IC101

1

TP106

(FE)

TP123

(RFO)

CD board

51

50

26

25

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 1.3

±

0.3 Vp-p

30

Loading...

Loading...