Sony MDXF-5800 Service manual

MDX-F5800

SERVICE MANUAL

Ver 1.1 2004.09

US and foreign patents licensed from Dolby

Laboratories.

SPECIFICATIONS

US Model

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MG-165A-138

Optical Pick-up Name KMS-242E

AUDIO POWER SPECIFICATIONSAUDIO POWER SPECIFICATIONS (US model)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION 23.2 watts per channel minimum

continuous average power into 4 ohms, 4 channels driven from 20 Hz to 20 kHz with no more than 5%

total harmonic distortion.

MD Player section

Signal-to-noise ratio 90 dB

Frequency response 10 − 20,000 Hz

Wow and flutter Below measurable limit

Tuner section

FM

Tuning range 87.5 − 107.9 MHz

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 9 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 67 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

Frequency response 30 − 15,000 Hz

AM (US model)

Tuning range 530 − 1,710 kHz

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

MW/LW (AEP, UK models)

Tuning range MW: 531 − 1,602 kHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity MW: 30 µV

69 dB (mono)

0.5 % (stereo),

0.3 % (mono)

LW: 153 − 279 kHz

LW: 40 µV

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 − 8 ohms

Maximum power output 52 W × 4 (at 4 ohms)

General

Outputs Audio output terminals

Inputs Telephone ATT control

Tone controls Low:

(sure seal connectors)

(front, rear/sub switchable)

Power antenna relay control

terminal

Power amplifier control

terminal

terminal

Remote controller input

terminal

BUS control input terminal

BUS audio input terminal

Antenna input terminal

±10 dB at 60 Hz (XPLOD)

Mid:

±10 dB at 1 kHz (XPLOD)

High:

±10 dB at 10 kHz (XPLOD)

Power requirements 12 V DC car battery

Dimensions Approx. 178 × 50 × 181 mm

Mounting dimensions Approx. 182 × 53 × 161 mm

Mass Approx. 1.2 kg

Supplied accessories Parts for installation and

Note

This unit cannot be connected to a digital preamplifier

or an equalizer which is Sony BUS system compatible.

Design and specifications are subject to change

without notice.

(negative ground)

1

(7

/8× 2 × 7 1/4 in)

(w/h/d)

1

/4× 2 1/8× 6 3/8 in)

(7

(w/h/d)

(2 lb 10 oz)

connections (1 set)

Front panel case (1)

FM/AM (MW/LW) MINIDISC PLAYER

9-877-611-02 Sony Corporation

2004I05-1 e Vehicle Company

© 2004.09 Published by Sony Engineering Corporation

MDX-F5800

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 3

2. GENERAL

Location of Controls ....................................................... 4

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 11

3-2. Sub Panel Assy................................................................ 12

3-3. Mechanism Deck (MG-165A-138) ................................ 12

3-4. MAIN Board ................................................................... 13

3-5. SERVO Board ................................................................. 13

3-6. MD Cover Assy............................................................... 14

3-7. Float Block ...................................................................... 14

3-8. Lever (LE23) Assy .......................................................... 15

3-9. Holder Assy ..................................................................... 15

3-10. Chucking Arm Assy ........................................................ 16

3-11. Optical Pick-up (KMS-242E) ......................................... 16

3-12. SL Motor Assy (Sled) (M902),

SP Motor Assy (Spindle) (M901)................................... 17

4. ELECTRICAL ADJUSTMENTS

Test Mode........................................................................ 17

MD Section ..................................................................... 17

Tuner Section .................................................................. 17

5. DIAGRAMS

5-1. Block Diagram – SERVO Section – ............................... 18

5-2. Block Diagram – MAIN Section – ................................. 19

5-3. Block Diagram – PANEL/BUS CONTROL/

POWER SUPPLY Section – ........................................... 20

5-4. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 21

5-5. Schematic Diagram – SERVO Section (1/2) –............... 22

5-6. Schematic Diagram – SERVO Section (2/2) –............... 23

5-7. Printed Wiring Boards – SERVO Section – ................... 24

5-8. Printed Wiring Boards – MAIN Section – ..................... 25

5-9. Schematic Diagram – MAIN Section (1/3) –................. 26

5-10. Schematic Diagram – MAIN Section (2/3) –................. 27

5-11. Schematic Diagram – MAIN Section (3/3) –................. 28

5-12. Printed Wiring Board – SUB Board – ............................ 29

5-13. Schematic Diagram – SUB Board – ............................... 29

5-14. Printed Wiring Board – KEY Board –............................ 30

5-15. Schematic Diagram – KEY Board – .............................. 31

6. EXPLODED VIEWS

6-1. Chassis Section ............................................................... 45

6-2. Front Panel Section ......................................................... 46

6-3. Mechanism Deck Section-1 (MG-165A-138) ................ 47

6-4. Mechanism Deck Section-2 (MG-165A-138) ................ 48

6-5. Mechanism Deck Section-3 (MG-165A-138) ................ 49

7. ELECTRICAL PARTS LIST ............................... 50

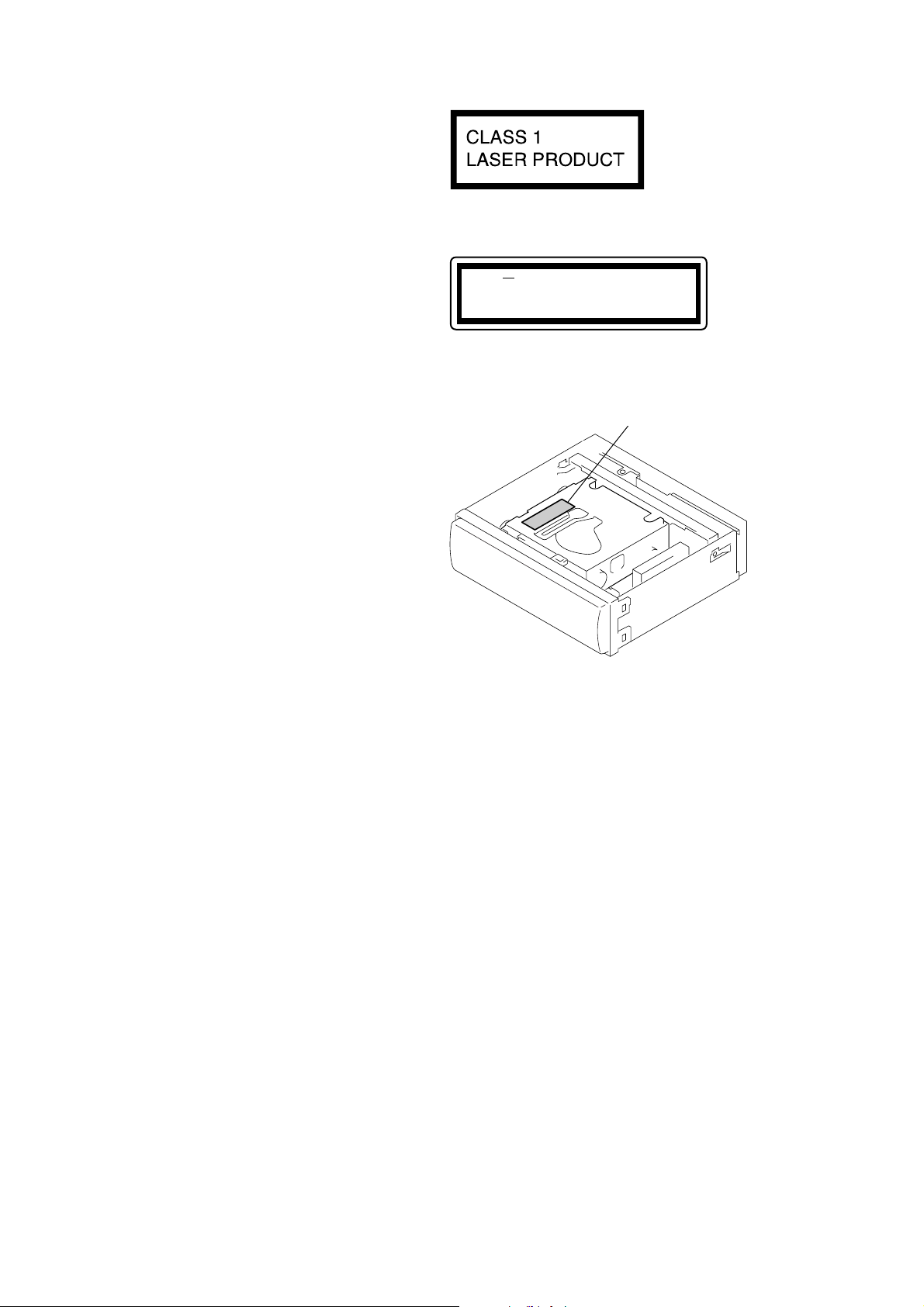

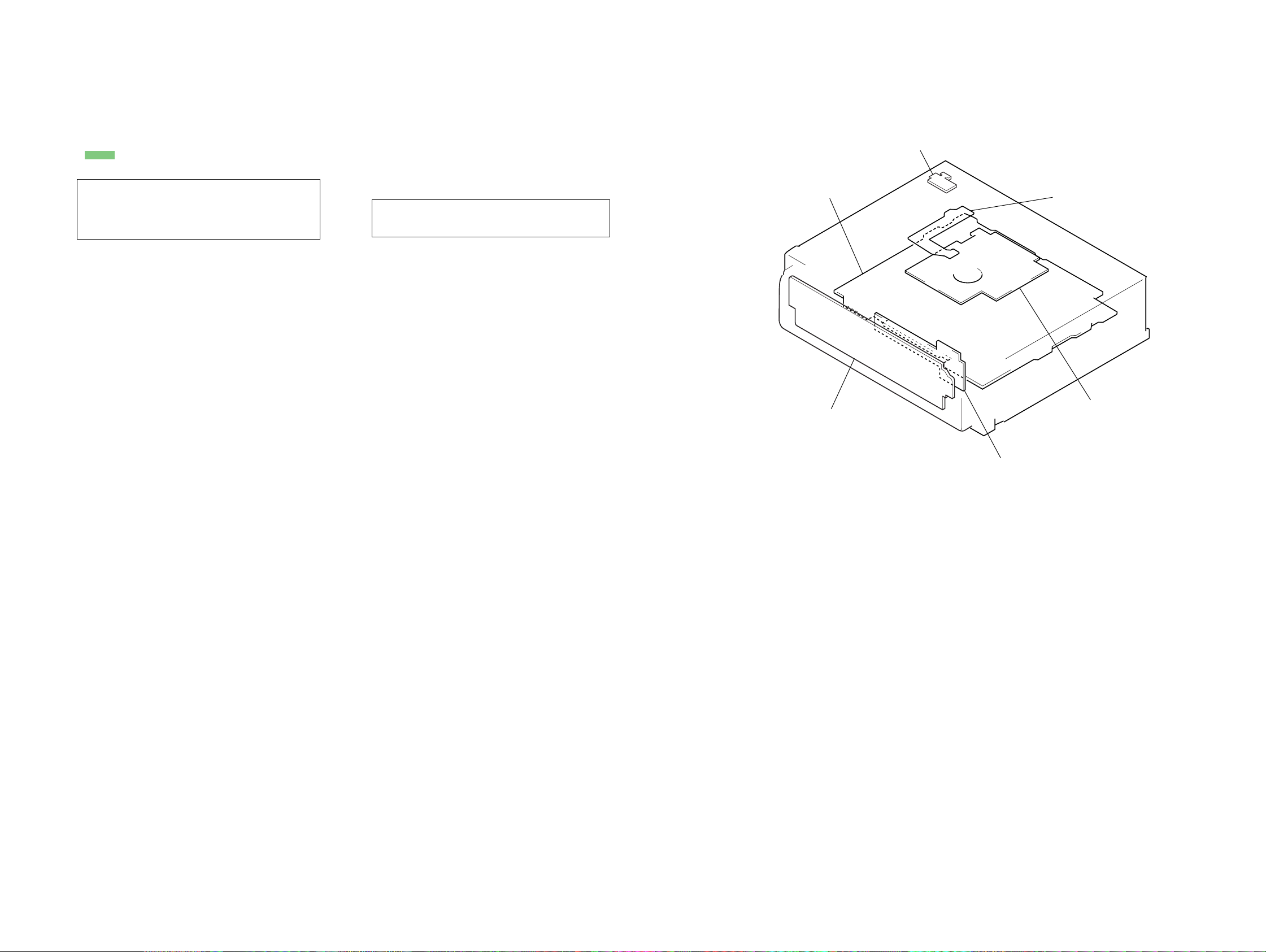

This product is classified as a

CLASS 1 LASER PRODUCT.

This label is located on the bottom of the

chassis.

CAUTION INVISIBLE

VIEW DIRECTLY

This label is located on the drive unit’s internal

chassis. (Refer to below figure)

LASER RADIATION WHEN OPEN

DO NOT STARE INTO BEAM OR

WITH OPTICAL INSTRUMENTS

– Upper view –

Caution label

During service do not take the Optical Pick-up Block apart and do

not adjust the APC circuit. If there is a breakdown in the APC

circuit (including laser diode), replace the entire Optical Pick-up

Block (including SERVO board).

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

p

SECTION 1

– MAIN Board (Conductor Side) –

IC600

C606

C607

MN101E01KDJ : TYPE1

MN101E01JRD1 : TYPE2

SERVICING NOTES

MDX-F5800

Ver 1.1

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right avove when

checking it for adustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(KMS-242E).

The laser diode in the optical pick-up block may suffer electrostatic break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform measures against electrostatic break-down sufficiently before the operation. The flexible board is easily damaged and should be handled

with care.

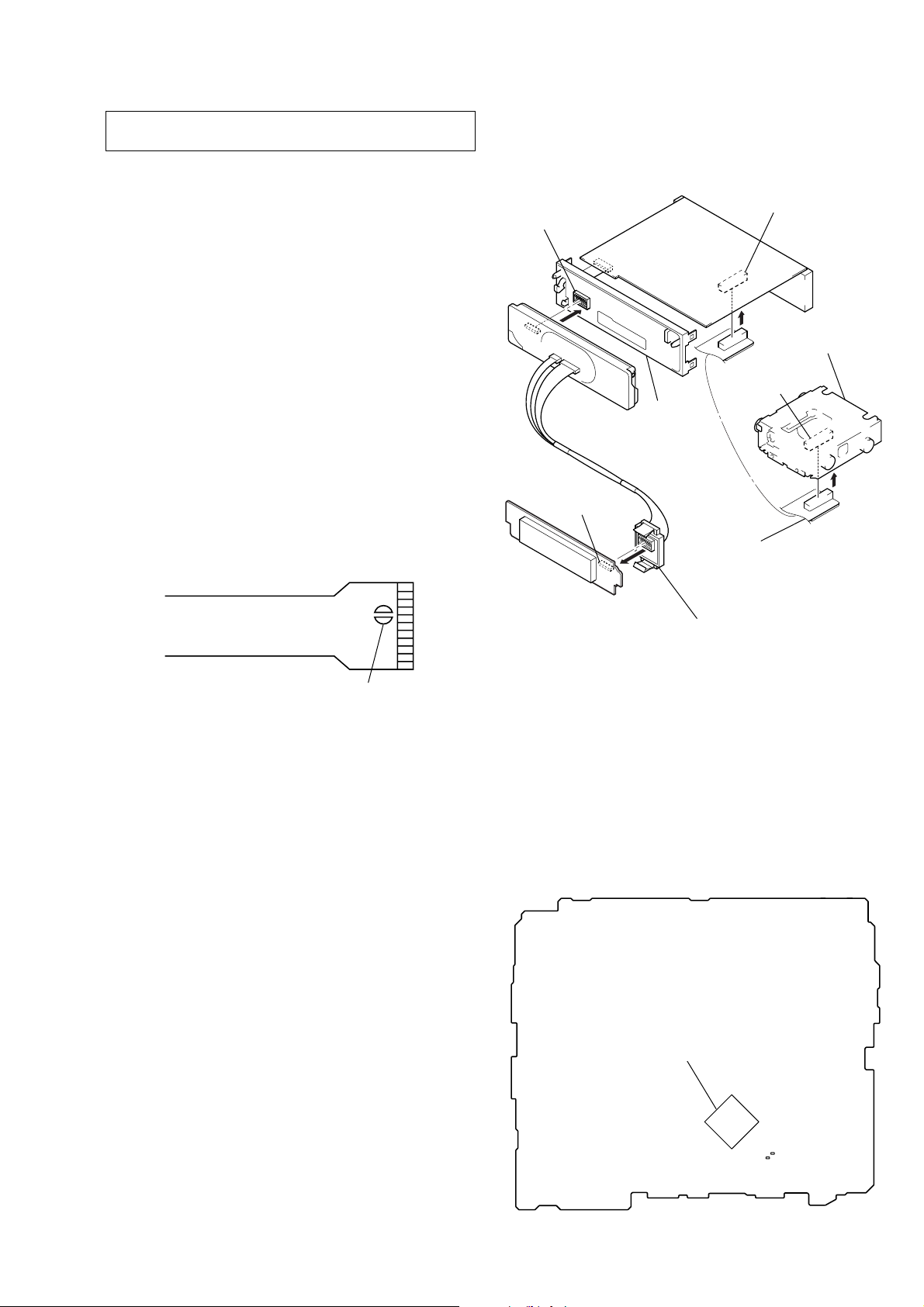

SERVICE POSITION

In checking the key board and main board, prepare two jigs (connection cable J-2502-011-1 and

connection cable for F/P to main J-2502-071-1).

sub board

(CN801)

key board

(CN901)

sub panel

assy

connect jig

(connection cable J-2502-011-1)

to the main board (CNP500) and

servo board (CN5).

main board (CNP500)

mechanism deck

servo board

(CN5)

OPTICAL PICK-UP FLEXIBLE BOARD

NOTE FOR REPLACING THE IC600

There are two types of IC600 on the MAIN board. In case IC600

is replaced, after surely checking which type of IC600 is mounted

on the set, it exchanges according to the following procedure.

In case of type1:

After surely checking the type of IC600 newly mounted on the

MAIN board, it replaces in the procedure according to each type.

Replacing procedur to type1

1. IC600 is replaced for MN101E01KDJ (PART No. 6-804-093-

01).

Replacing procedur to type2

1. IC600 is replaced for MN101E01JRD1 (PART No. 6-804-511-

02).

2. C606 is replaced for ceramic chip 15PF (PART No. 1-162917-11).

3. C607 is replaced for ceramic chip 12PF (PART No. 1-162916-11).

In case of type2:

Replacing procedure

1. IC600 is replaced for MN101E01JRD1 (PART No. 6-804-511-

02).

connect jig

(connection cable

for F/P to main J-2502-071-1)

to the key board (CN900) and

laser-ta

sub board (CN801).

3

MDX-F5800

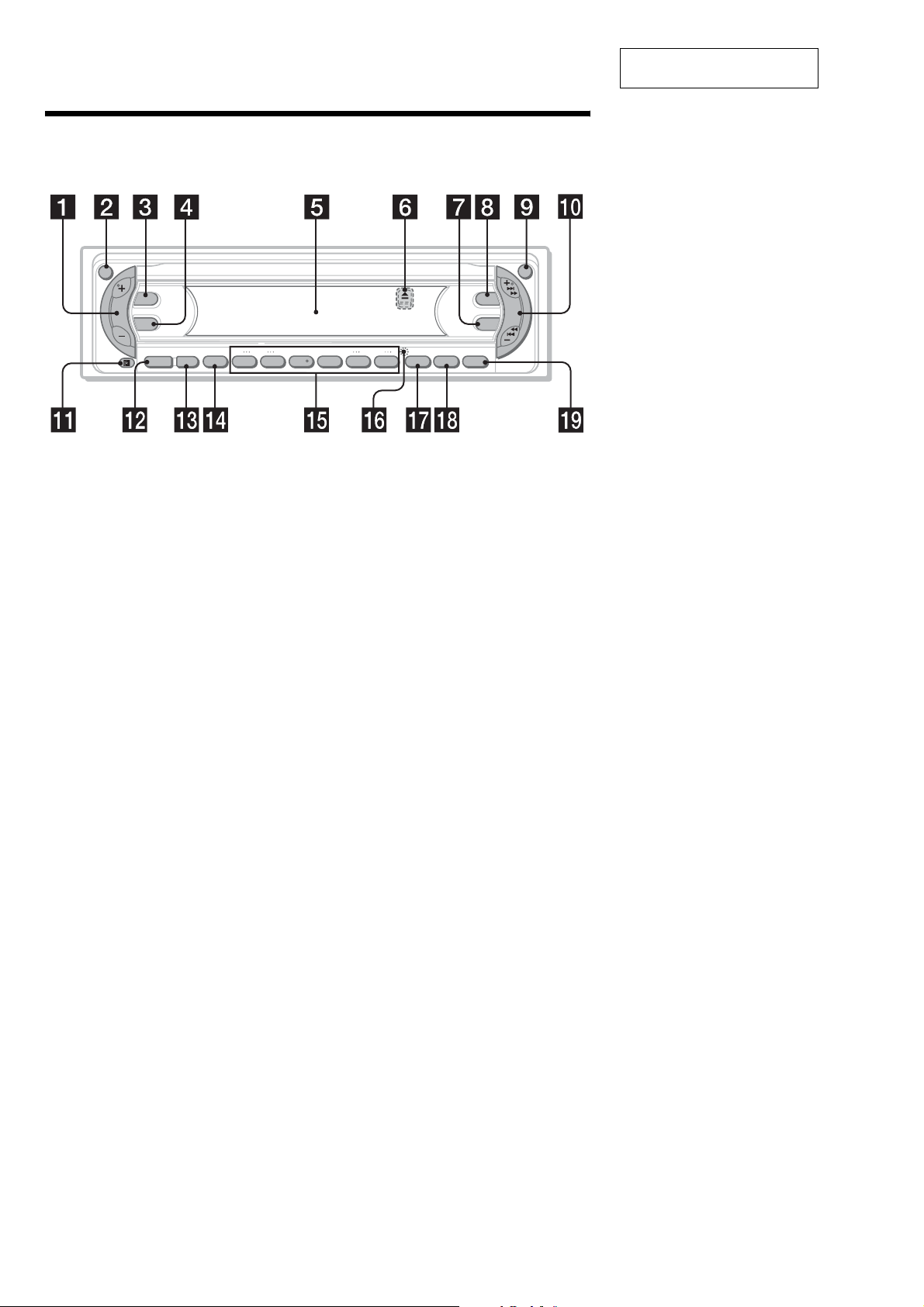

Location of controls

Refer to the pages listed for details.

SECTION 2

GENERAL

This section is extracted from

instruction manual.

AT T

DSPL

SEL

–+

DISC REP SHUF BTM LIST

SOURCE MODE

OFF

1 2 3 4 5 6

a Volume +/– button

b ATT (attenuate) button

c DSPL (display mode change) button

d SEL (select) button

To select items.

e Display window

f Z (eject) button (located on the front side

of the unit, behind the front panel)

g EQ3 button

h DSO button

i OPEN button

j SEEK +/– button

Radio:

To tune in stations automatically/find a

station manually.

MD/CD (MP3 files*

1

):

To skip tracks/fast-forward, reverse a track.

k Receptor for the card remote

commander

l SOURCE (Power on/Radio/MD/CD*

2

)

button

To select the source.

m MODE button

To change operation.

n OFF (Stop/Power off) button*

3

DSO

EQ3

–+

GP/ALBM

BTM SENS LIST

CAT

o Number buttons

Radio:

To store the desired station on each number

button.

MD/CD (MP3 files*

1

):

(1): DISC –

(2): DISC +

(3): REP

(4): SHUF

(5): GP*

(6): GP*

11

12

4

/ALBM*1 –

4

/ALBM*1 +

p RESET button (located on the front side of

the unit, behind the front panel )

q B

TM button (US model)

AF/TA button (AEP, UK models)

r S

ENS button (US model)

SENS/BTM button (AEP, UK models)

T/CAT*

5

button (US model)

s LIS

PTY (programme type)/LIST button

(AEP, UK models)

*1

Available only when an optional CD unit with the

MP3 file control function is connected, and MP3 file

is played.

*2

When an optional CD unit is connected.

*3

Warning when installing in a car without

an ACC (accessory) position on the

ignition switch

After turning off the ignition, be sure to press

and hold

(OFF)

on the unit until the display

disappears.

Otherwise, the display does not tu rn off and thi s

causes battery drain.

*4

Available only when an MD containing groups is

inserted in this unit and played.

*5

The CAT button is available only when the XM

tuner is connected.

OPEN

SEEK

4

(US model)

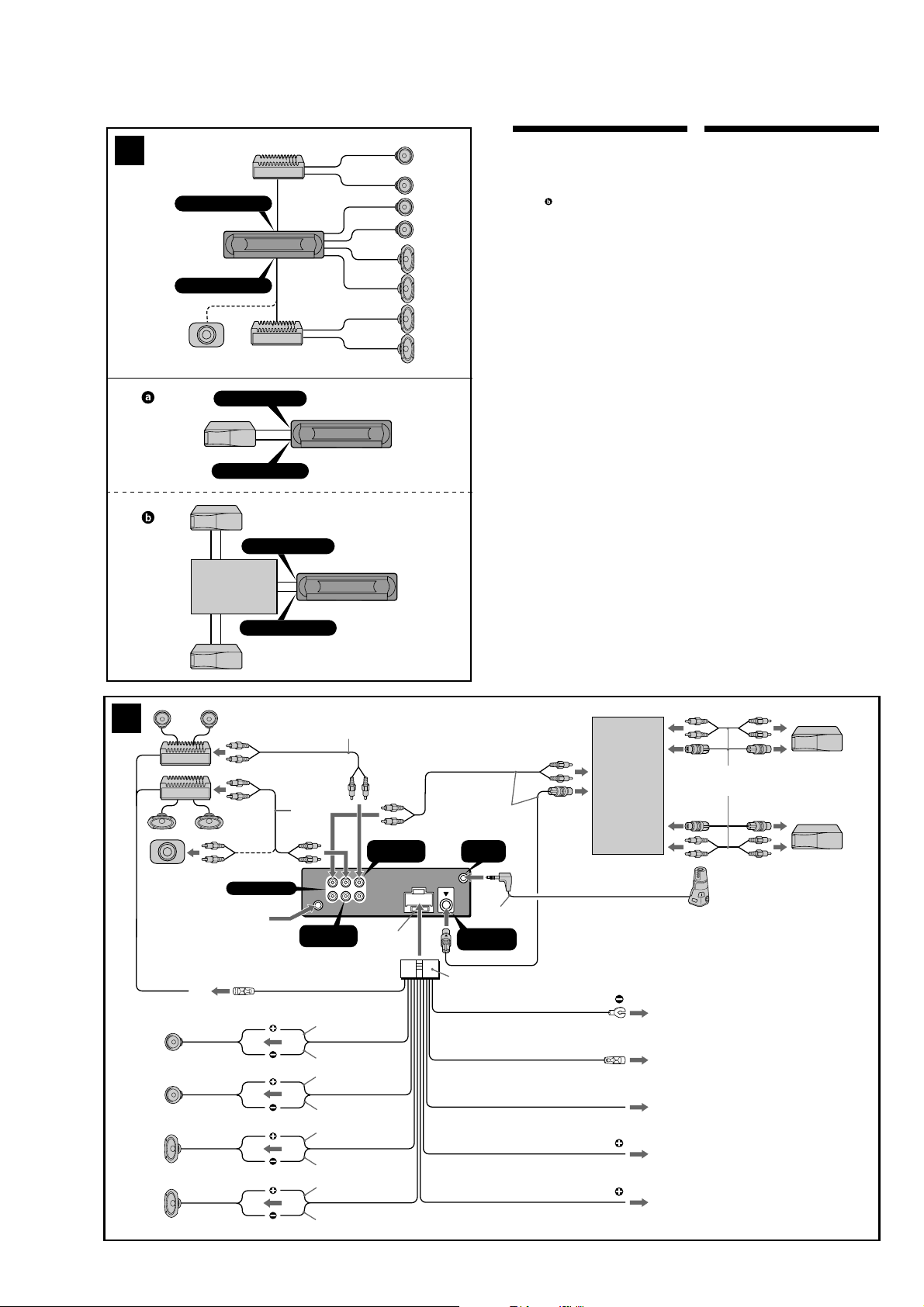

Connection example (2)

Notes (2-A)

• Be sure to connect the ground lead before connecting

the amplifier.

• If you connect an optional power amplifier and do not

use the built-in amplifier, the beep sound will be

deactivated.

Tip (2-B-

)

For connecting two or more MD/CD changers, the source

selector XA-C30 (optional) is necessary.

Connection diagram (3)

1

To a metal surface of the car

First connect the black ground lead, then connect

the yellow and red power input leads.

2

To the power antenna control lead or power

supply lead of antenna booster amplifier

Notes

• It is not necessary to connect this lead if there is no

power antenna or antenna booster, or with a

manually-operated telescopic antenna.

•When your car has a built-in FM/AM antenna in

the rear/side glass, see “Notes on the control and

power supply leads.”

3

To AMP REMOTE IN of an optional power

amplifier

This connection is only for amplifiers. Connecting

any other system may damage the unit.

4

To the interface cable of a car telephone

5

To the +12 V power terminal which is energized

in the accessory position of the ignition key

switch

Notes

• If there is no accessory position, connect to the +12

V power (battery) terminal which is energized at

all times.

Be sure to connect the black ground lead to a

metal surface of the car first.

•When your car has a built-in FM/AM antenna in

the rear/side glass, see “Notes on the control and

power supply leads.”

6

To the +12 V power terminal which is energized

at all times

Be sure to connect the black ground lead to a metal

surface of the car first.

Notes on the control and power supply leads

• The power antenna control lead (blue) supplies +12 V

DC when you turn on the tuner.

•When your car has built-in FM/AM antenna in the rear/

side glass, connect the power antenna control lead

(blue) or the accessory power input lead (red) to the

power terminal of the existing antenna booster. For

details, consult your dealer.

•A power antenna without a relay box cannot be used

with this unit.

Memory hold connection

When the yellow power input lead is connected, power

will always be supplied to the memory circuit even when

the ignition switch is turned off.

Notes on speaker connection

• Before connecting the speakers, turn the unit off.

• Use speakers with an impedance of 4 to 8 ohms, and

with adequate power handling capacities to avoid its

damage.

• Do not connect the speaker terminals to the car

chassis, or connect the terminals of the right speakers

with those of the left speaker.

• Do not connect the ground lead of this unit to the

negative (–) terminal of the speaker.

• Do not attempt to connect the speakers in parallel.

• Connect only passive speakers. Connecting active

speakers (with built-in amplifiers) to the speaker

terminals may damage the unit.

•To avoid a malfunction, do not use the built-in speaker

leads installed in your car if the unit shares a common

negative (–) lead for the right and left speakers.

• Do not connect the unit’s speaker leads to each other.

Note on connection

If speaker and amplifier are not connected correctly,

“FAILURE” appears in the display. In this case, make sure

the speaker and amplifier are connected correctly.

2

A

MDX-F5800

AUDIO OUT FRONT

AUDIO OUT REAR

B

3

Left

Right

Left

Right

BUS AUDIO IN

BUS CONTROL IN

BUS AUDIO IN

Source selector*

Sélecteur de source*

Selector de fuente*

XA-C30

BUS CONTROL IN

1

*

BUS AUDIO IN

from car antenna

AMP REM

3

1

*

AUDIO OUT

REAR

Blue/white striped

Max. supply current 0.3 A

White

White/black striped

Gray

Gray/black striped

Green

Green/black striped

Purple

Purple/black striped

2

*

AUDIO OUT

FRONT

L

R

Fuse (10 A)

* not supplied

Supplied with XA-C30

REMOTE

IN

3

*

BUS

CONTROL IN

4

Black

Blue

Light blue

Red

Yellow

Source selector

(not supplied)

ANT REM

Max. supply current 0.1 A

ATT

XA-C30

Supplied with the MD/CD changer

1

2

4

5

6

*1RCA pin cord (not supplied)

2

*

AUDIO OUT can be switched to REAR

or SUB.

For details, see the supplied operating

instructions.

3

*

Insert with the cord downwards.

5

MDX-F5800

4

1

Orient the release key

correctly.

5

3

c

1 23

5

182 m

m

53 m

m

1

2

5

Face the hook inwards.

c

1

Dashboard

1

3

Claws

c

6 A

2

max. size

5 × 8 mm

7

(

/32 × 11/32 in)

Dimensions

7 A

TOYOTA

Bracket

1

2

to dashboard/center console

Existing parts supplied with your car

Bracket

B

2

max. size

5 × 8 mm

7

/32 × 11/32 in)

(

Dimensions

B

max. size

5 × 8 mm

7

(

/32 × 11/32 in)

Dimensions

NISSAN

2

Bracket

Existing parts supplied with your car

A

B

to dashboard/center console

Bracket

c

2

max. size

5 × 8 mm

7

/32 × 11/32 in)

(

Dimensions

6

MDX-F5800

Precautions

•Choose the installation location carefully so

that the unit will not interfere with normal

driving operations.

•Avoid installing the unit in areas subject to

dust, dirt, excessive vibration, or high

temperatures, such as in direct sunlight or

near heater ducts.

•Use only the supplied mounting hardware for

a safe and secure installation.

Mounting angle adjustment

Adjust the mounting angle to less than 45°.

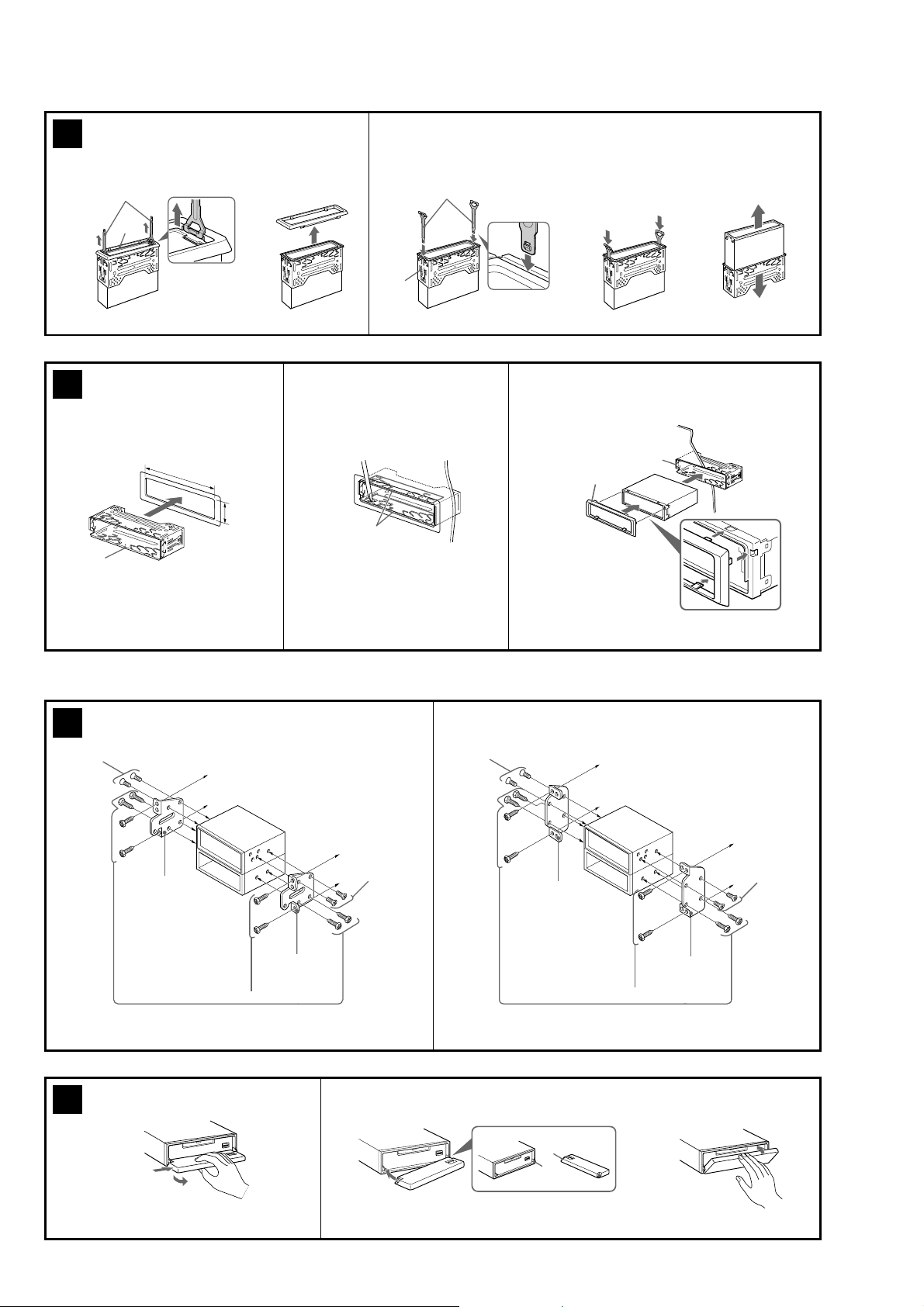

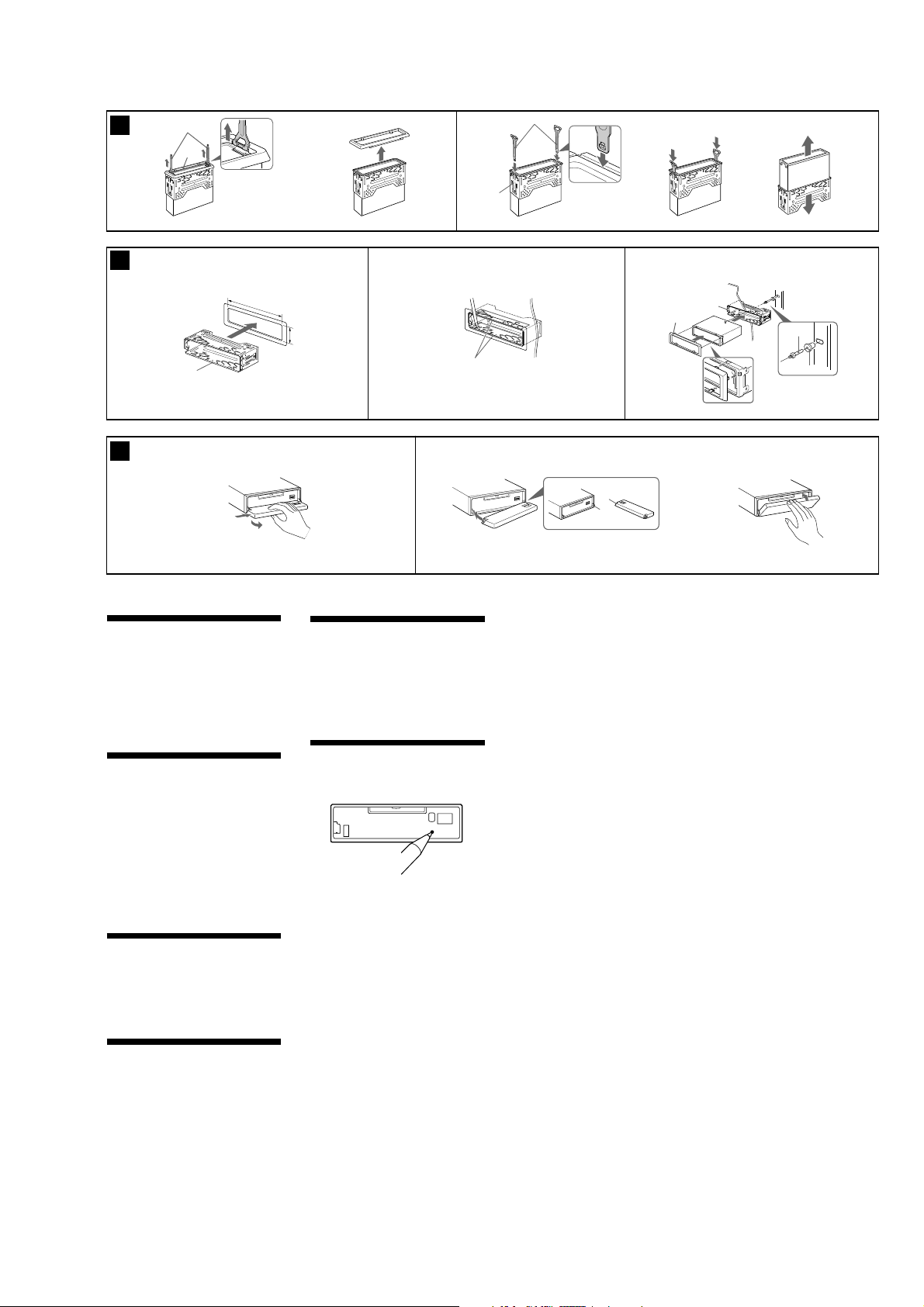

Removing the protection collar

and the bracket (4)

Before installing the unit, remove the

protection collar 3 and the bracket 1 from

the unit.

1

Remove the protection collar 3.

1 Engage the release keys 5 together with

the protection collar 3.

2 Pull out the release keys 5 to remove the

protection collar 3.

2

Remove the bracket 1.

1 Insert both release keys 5 together

between the unit and the bracket 1 until

they click.

2 Pull down the bracket 1, then pull up

the unit to separate.

Mounting example (5)

Installation in the dashboard

Notes

• Bend these claws outward for a tight fit, if

necessary (5-2).

•Make sure that the 4 catches on the protection

collar 3 are properly engaged in the slots of the

unit (5-3).

How to detach and attach the

front panel (7)

Before installing the unit, detach the front

panel.

7-A To detach

Before detaching the front panel, be sure to

press (OFF). Press (OPEN), then slide the front

panel to the right side, and pull out the left side.

7-B To attach

Place the hole A in the front panel onto the

spindle B on the unit as illustrated, then push

the left side in.

Warning when installing in a car

without ACC (accessory)

position on the ignition key

switch

After turning off the ignition, be sure to

press and hold (OFF) on the unit until the

display disappears.

Otherwise, the display does not turn off and this

causes battery drain.

RESET button

When the installation and connections are

completed, be sure to press the RESET button

with a ball-point pen, etc., after detaching the

front panel.

Mounting the unit in a

Japanese car (6)

You may not be able to install this unit in some

makes of Japanese cars. In such a case, consult

your Sony dealer.

Note

To prevent malfunction, install only with the

supplied screws 2.

7

MDX-F5800

(AEP, UK models)

2

A

AUDIO OUT FRONT

AUDIO OUT REAR

B

BUS AUDIO IN

BUS CONTROL IN

BUS AUDIO IN

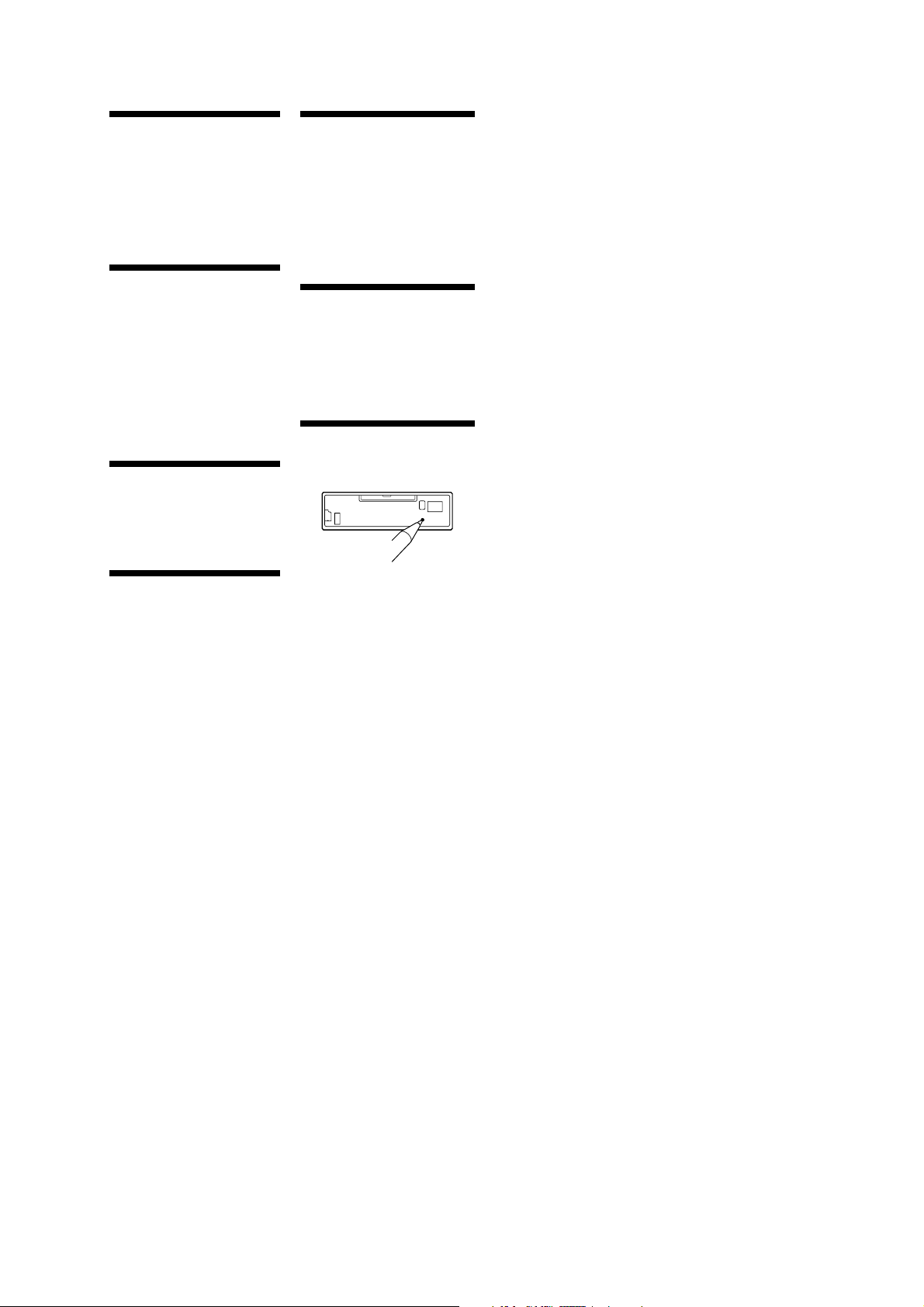

Connection example (2)

Notes (2-A)

• Be sure to connect the earth lead before connecting the amplifier.

• If you connect an optional power amplifier and do not use the

built-in amplifier, the beep sound will be deactivated.

Tip (2-B-

)

For connecting two or more MD/CD changers, the source selector XAC30 (optional) is necessary.

Connection diagram (3)

A

To AMP REMOTE IN of an optional power amplifier

This connection is only for amplifiers. Connecting any other

system may damage the unit.

B

To the interface cable of a car telephone

Warning

If you have a power aerial without a relay box, connecting this unit

with the supplied power connecting lead 7 may damage the aerial.

Notes on the control leads

• The power aerial control lead (blue) supplies +12 V DC when you

turn on the tuner, or when you activate the AF (Alternative

Frequency) or TA (Traffic Announcement) function.

• When your car has built-in FM/MW/LW aerial in the rear/side glass,

connect the power aerial control lead (blue) or the accessory power

input lead (red) to the power terminal of the existing aerial

booster. For details, consult your dealer.

•A power aerial without a relay box cannot be used with this unit.

Memory hold connection

When the yellow power input lead is connected, power will always

be supplied to the memory circuit even when the ignition switch is

turned off.

Notes on speaker connection

• Before connecting the speakers, turn the unit off.

• Use speakers with an impedance of 4 to 8 ohms, and with

adequate power handling capacities to avoid its damage.

• Do not connect the speaker terminals to the car chassis, or connect

the terminals of the right speakers with those of the left speaker.

• Do not connect the earth lead of this unit to the negative (–)

terminal of the speaker.

• Do not attempt to connect the speakers in parallel.

• Connect only passive speakers. Connecting active speakers (with

built-in amplifiers) to the speaker terminals may damage the unit.

•To avoid a malfunction, do not use the built-in speaker leads

installed in your car if the unit shares a common negative (–) lead

for the right and left speakers.

• Do not connect the unit’s speaker leads to each other.

Note on connection

If speaker and amplifier are not connected correctly, “FAILURE”

appears in the display. In this case, make sure the speaker and

amplifier are connected correctly.

3

Max. supply current 0.3 A

Source selector

XA-C30

2

*

BUS AUDIO IN

5

1

from car aerial

*

AUDIO OUT

AMP REM

A

AT T

B

See “Power connection diagram” on the reverse side for details.

*

BUS CONTROL IN

2

*

Fuse (10 A)

3

REAR

*

Blue/white striped

Light blue

AUDIO OUT

FRONT

L

R

* not supplied

Supplied with XA-C30

REMOTE

IN

4

*

BUS

CONTROL IN

7

4

Yellow

5

Positions 1, 2, 3 and 6 do not have pins.

Blue

Source selector

(not supplied)

continuous power supply

power aerial control

Supplied with the MD/CD changer

XA-C30

from the car’s power connector

7

Red

8

Black

48

switched power supply

earth

*1Note for the aerial connecting

If your car aerial is an ISO (International

Organisation for Standardisation) type, use the

supplied adaptor 5 to connect it.

First connect the car aerial to the supplied

adaptor, then connect it to the aerial jack of the

master unit.

2

RCA pin cord (not supplied)

*

3

AUDIO OUT can be switched REAR or SUB.

*

For details, see the Operating Instructions

manual.

4

*

Insert with the cord downwards

57

1

Purple

2

3

Grey

4

Negative polarity positions 2, 4, 6, and 8 have striped leads.

+

–

+

–

Speaker, Rear, Right

Speaker, Rear, Right

Speaker, Front, Right

Speaker, Front, Right

from the car’s speaker connector

5

White

6

7

Green

8

+

–

+

–

13 57

24 6

Speaker, Front, Left

Speaker, Front, Left

Speaker, Rear, Left

Speaker, Rear, Left

8

8

MDX-F5800

4

1

1

5 23

6

4

1

Orient the release key correctly.

182 m

m

c

53 mm

2

Claws

6

c

1

Face the hook inwards.

Dashboard

1

4

6 AB

A

1

2

B

c

c

Fire wall

2

3

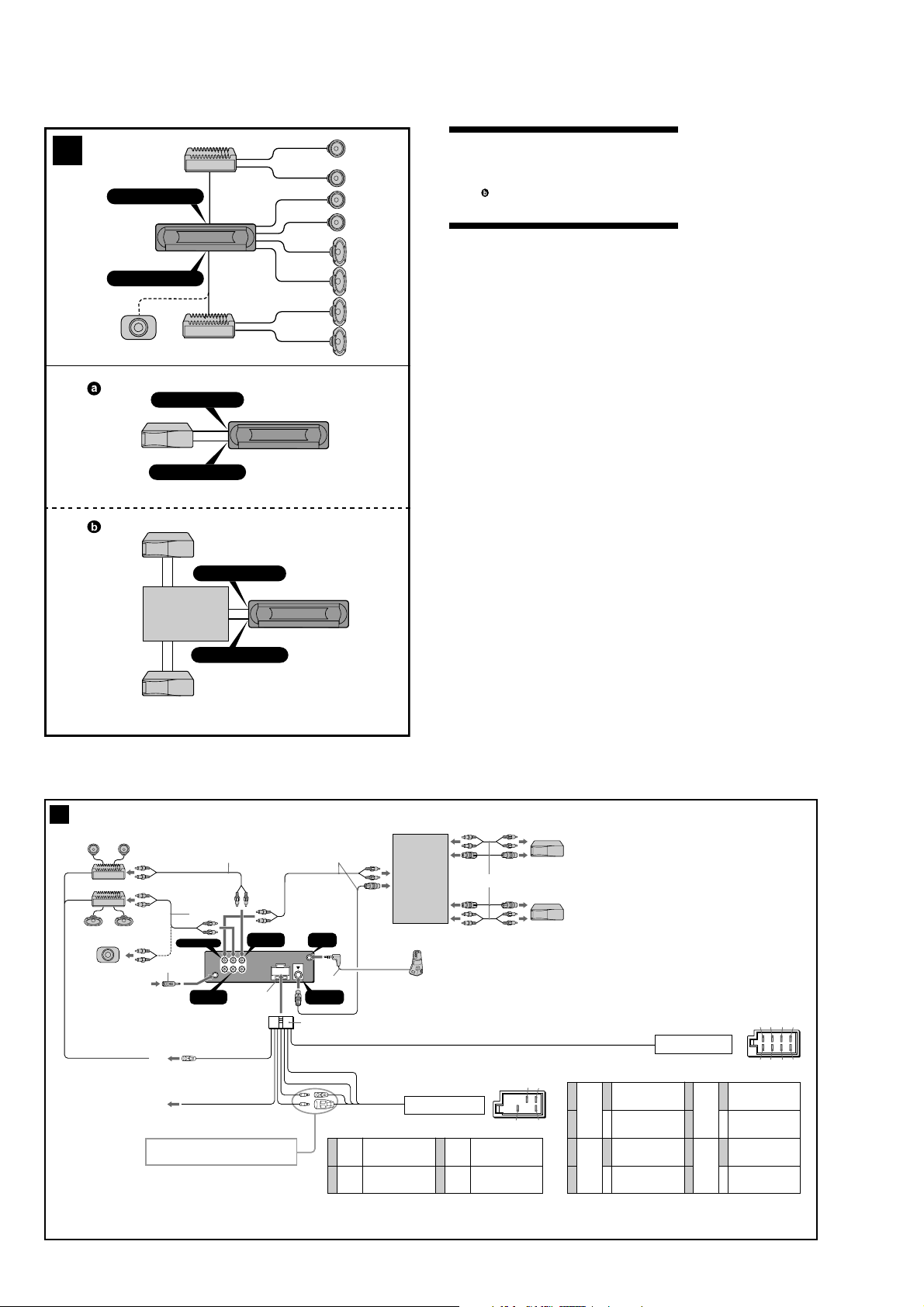

Precautions

•Choose the installation location carefully so that

the unit will not interfere with normal driving

operations.

•Avoid installing the unit in areas subject to dust,

dirt, excessive vibration, or high temperature,

such as in direct sunlight or near heater ducts.

•Use only the supplied mounting hardware for a

safe and secure installation.

Mounting angle adjustment

Adjust the mounting angle to less than 45°.

Removing the protection collar

and the bracket (4)

Before installing the unit, remove the protection

collar 4 and the bracket 1 from the unit.

1

Remove the protection collar 4.

1 Engage the release keys 6 together with the

protection collar 4.

2 Pull out the release keys 6 to remove the

protection collar 4.

2

Remove the bracket 1.

1 Insert both release keys 6 together between

the unit and the bracket 1 until they click.

2 Pull down the bracket 1, then pull up the

unit to separate.

Mounting example (5)

Installation in the dashboard

Notes

• Bend these claws outward for a tight fit, if

necessary (5-2).

• Make sure that the 4 catches on the protection

collar 4 are properly engaged in the slots of the

unit (5-3).

How to detach and attach the

front panel (6)

Before installing the unit, detach the front

panel.

6-A To detach

Before detaching the front panel, be sure to press

(OFF). Press (OPEN), then slide the front panel to

the right side, and pull out the left side.

6-B To attach

Place the hole A in the front panel onto the spindle

B on the unit as illustrated, then push the left side

in.

Warning when installing in a car

without ACC (accessory)

position on the ignition key

switch

After turning off the ignition, be sure to press

and hold (OFF) on the unit until the display

disappears.

Otherwise, the display does not turn off and this

causes battery drain.

RESET button

When the installation and connections are

completed, be sure to press the RESET button with

a ballpoint pen, etc., after detaching the front panel.

9

MDX-F5800

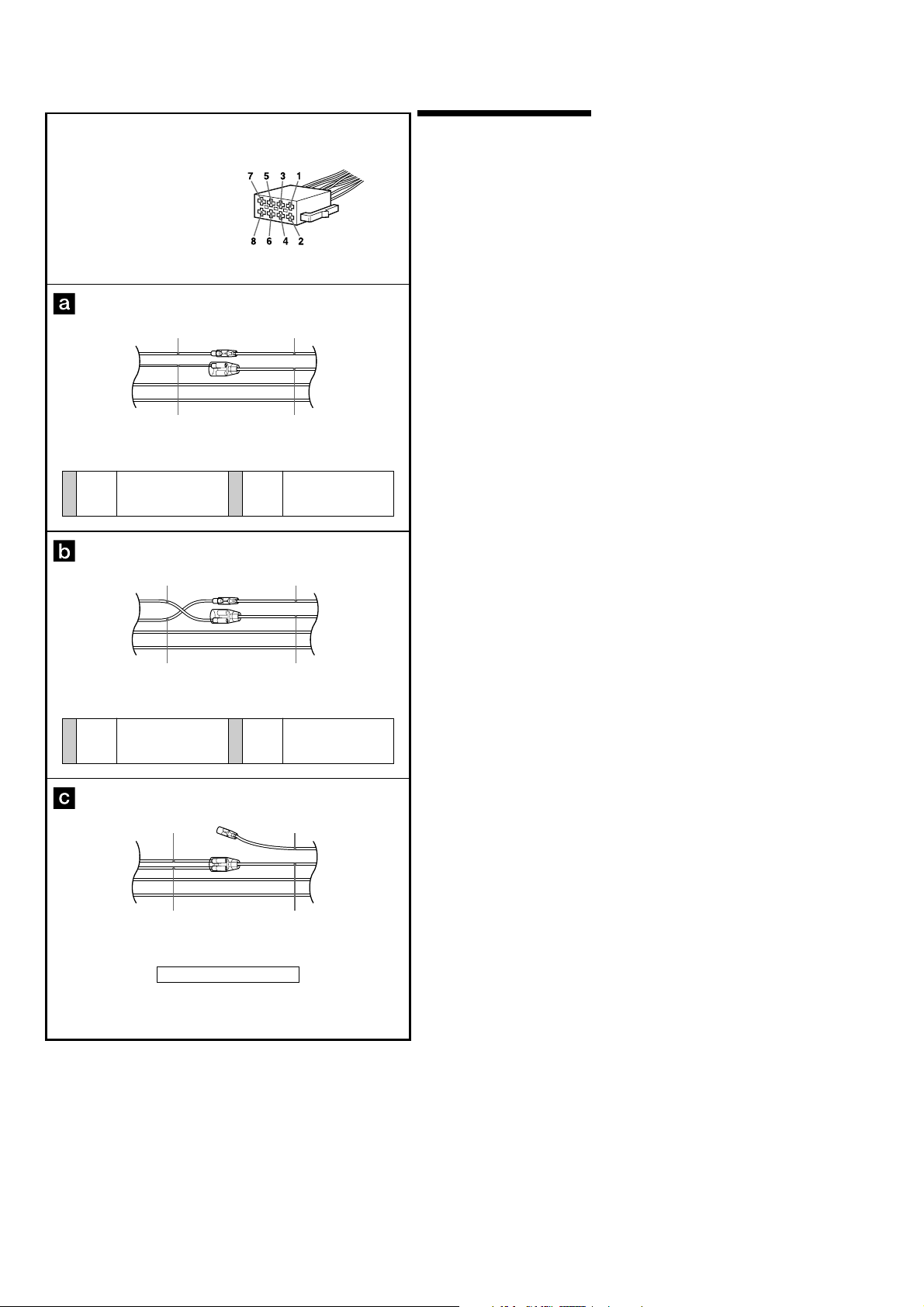

Auxiliary power connector

Power connection diagram

Auxiliary power connector may vary depending on

the car. Check your car’s auxiliary power connector

diagram to make sure the connections match

correctly. There are three basic types (illustrated

below). You may need to switch the positions of the

red and yellow leads in the car stereo’s power

connecting lead.

After matching the connections and switched

power supply leads correctly, connect the unit to

the car’s power supply. If you have any questions

and problems connecting your unit that are not

covered in this manual, please consult the car

dealer.

4

Yellow

continuous power supply

Yellow Yellow

4

Yellow switched power supply

Red

Yellow

Red

Yellow

7

Red

switched power supply

RedRed

7

Red continuous power supply

10

Red

Yellow Yellow

the car without ACC position

Red

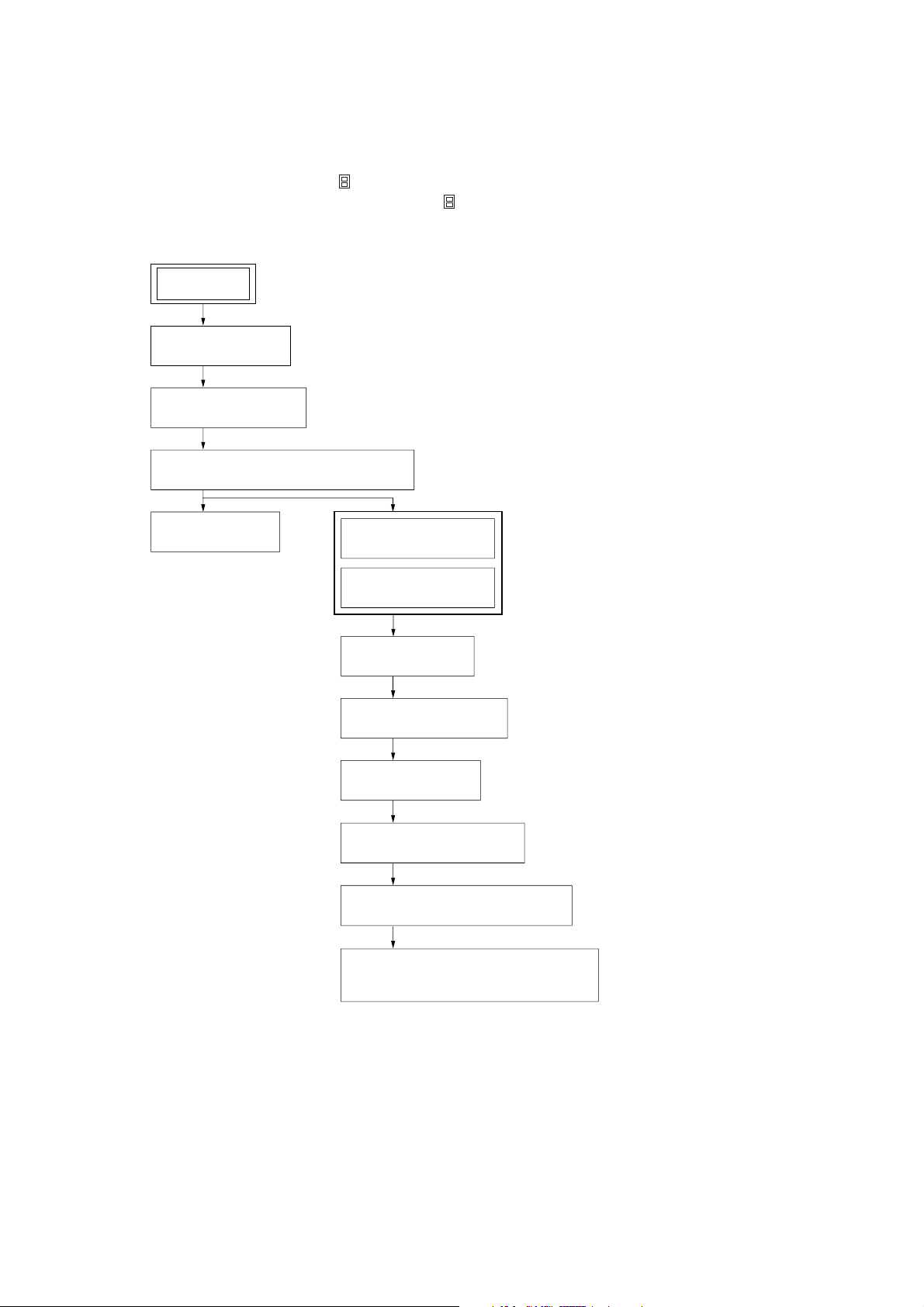

SECTION 3

DISASSEMBLY

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

Note 3: Illustration of disassembly is omitted.

SET

FRONT PANEL ASSY

(Note 3)

3-2. SUB PANEL ASSY

(Page 12)

3-3. MECHANISM DECK (MG-165A-138)

(Page 12)

MDX-F5800

3-4. MAIN BOARD

(Page 13)

3-5. SERVO BOARD

(Page 13)

3-6. MD COVER ASSY

(Page 14)

3-7. FLOAT BLOCK

(Page 14)

3-8. LEVER (LE23) ASSY

(Page 15)

3-9. HOLDER ASSY

(Page 15)

3-10. CHUCKING ARM ASSY

(Page 16)

3-11. OPTICAL PICK-UP (KMS-242E)

(Page 16)

3-12. SL MOTOR ASSY (SLED) (M902),

SP MOTOR ASSY (SPINDLE) (M901)

(Page 17)

11

MDX-F5800

r

)

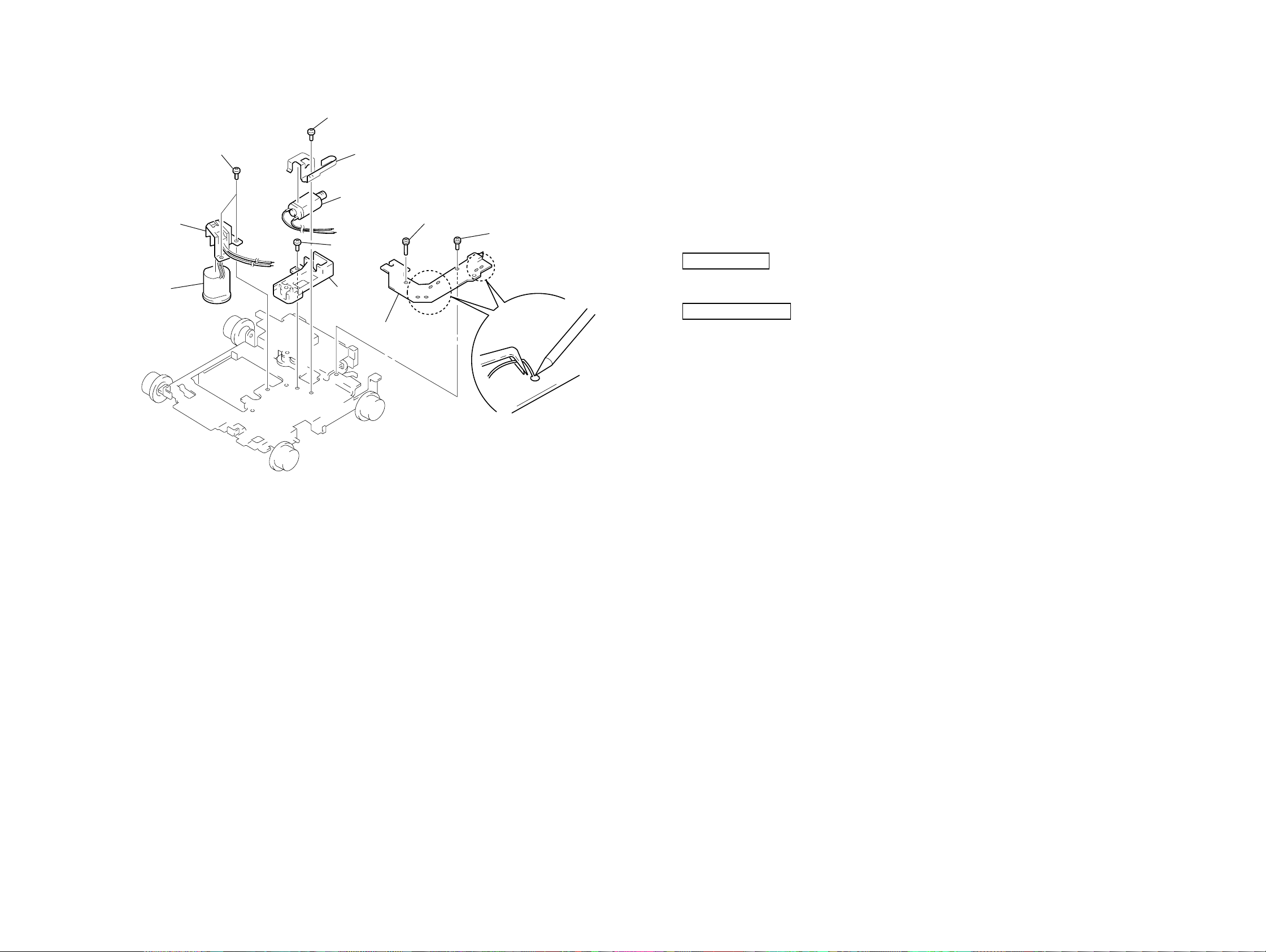

Note: Follow the disassembly procedure in the numerical order given.

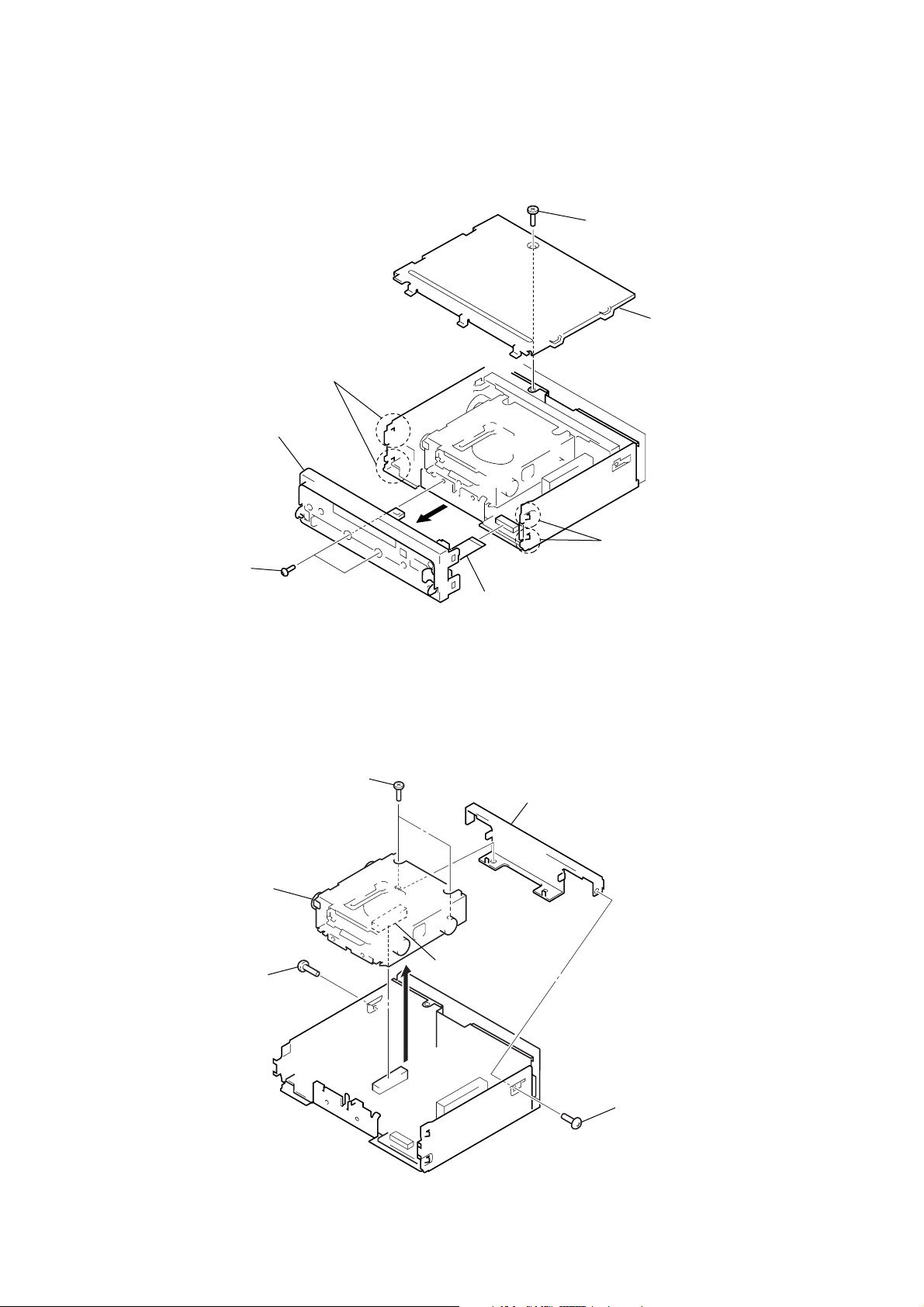

3-2. SUB PANEL ASSY

4

two claws

7

sub panel assy

1

screw

(PTT2.6 × 6)

2

cove

3

two screws

(PTT2.6 × 6)

3-3. MECHANISM DECK (MG-165A-138)

3

two screws

(PTT2.6

5

mechanism deck

(MG-165A-138)

1

screw

(PTT2.6

×

6)

5

4

two claws

6

flexible flat (14 core) cable

(CN370)

×

6)

4

bracket (MD)

2

connector

(CNP500)

12

1

screw

(PTT2.6

×

6

3-4. MAIN BOARD

e

1

3

three screws

(BTT2.6

main board

MDX-F5800

×

5)

2

four screws

(PTT2.6

×

6)

3-5. SERVO BOARD

2

four screws

×

(BVTT2

3

servo board

1

parallel (FFC) (10core) wir

(CN3)

4)

1

optical pick-up flexible board

(CN2)

13

MDX-F5800

)

y

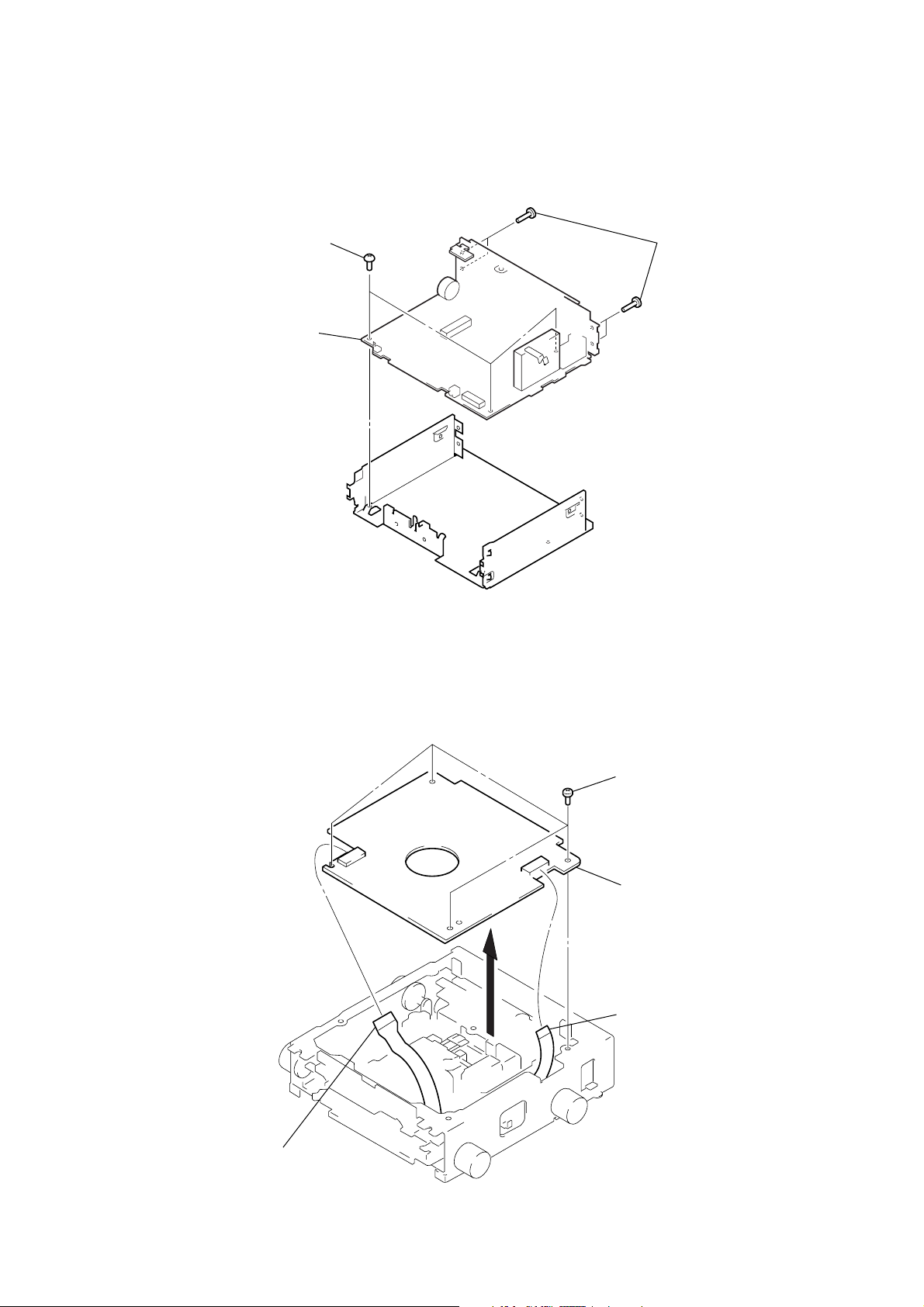

3-6. MD COVER ASSY

3

MD cover assy

shaft (MD cover guide)

cassette holder

1

four screws

(BVTT2 × 4

3-7. FLOAT BLOCK

float block

A

2

Pushing the cassette holder in the direction of the arrow A with a

screwdriver, etc., disengage the shaft (MD cover guide) from

the slot in the MD cover assy.

Note: Take care not to scratch the optiocal pick-up when pushing

the cassette holder with a screwdriver. etc.

3

Pushing an arrow A part, raise the float block

up ward at the front to release a lock.

1

tension spring (FL2)

A

5

two dampers assy

6

float block

5

two dampers ass

14

lever (lock R)

lever (lock L)

2

two tension springs (float F)

4

1

tension spring (FL2)

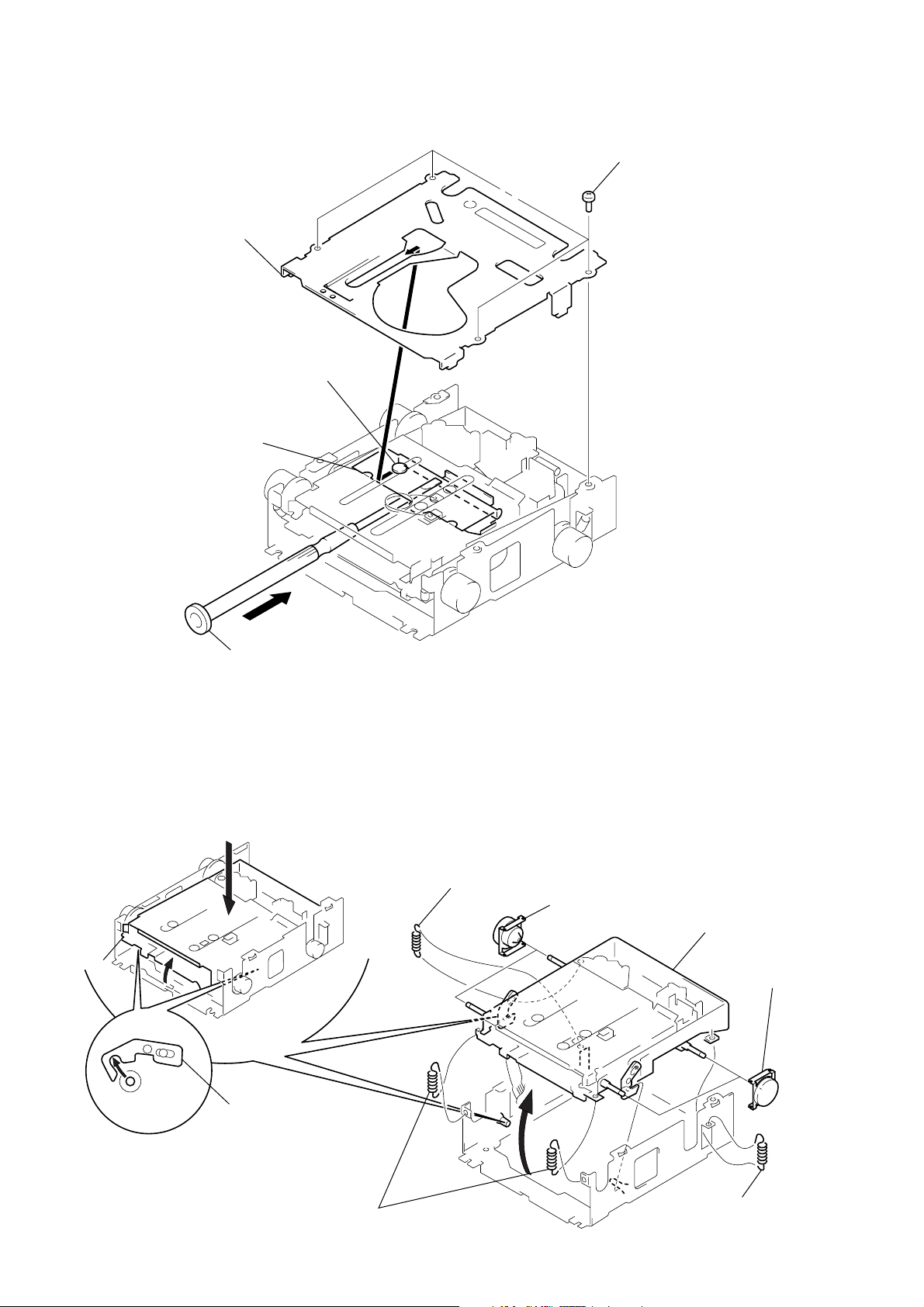

3-8. LEVER (LE23) ASSY

y

2

stopper washer

1

4

roller (GLE)

3

lever (LE23) ass

MDX-F5800

3-9. HOLDER ASSY

2

1

spring (CHKG)

2

type-E stop ring 1.5

3

lever (lock R)

type-E stop ring 1.5

4

Remove the holder assy in the

direction of the arrow.

2

type-E stop ring 1.5

3

lever (lock L)

2

type-E stop ring 1.5

1

spring (CHKG)

15

MDX-F5800

y

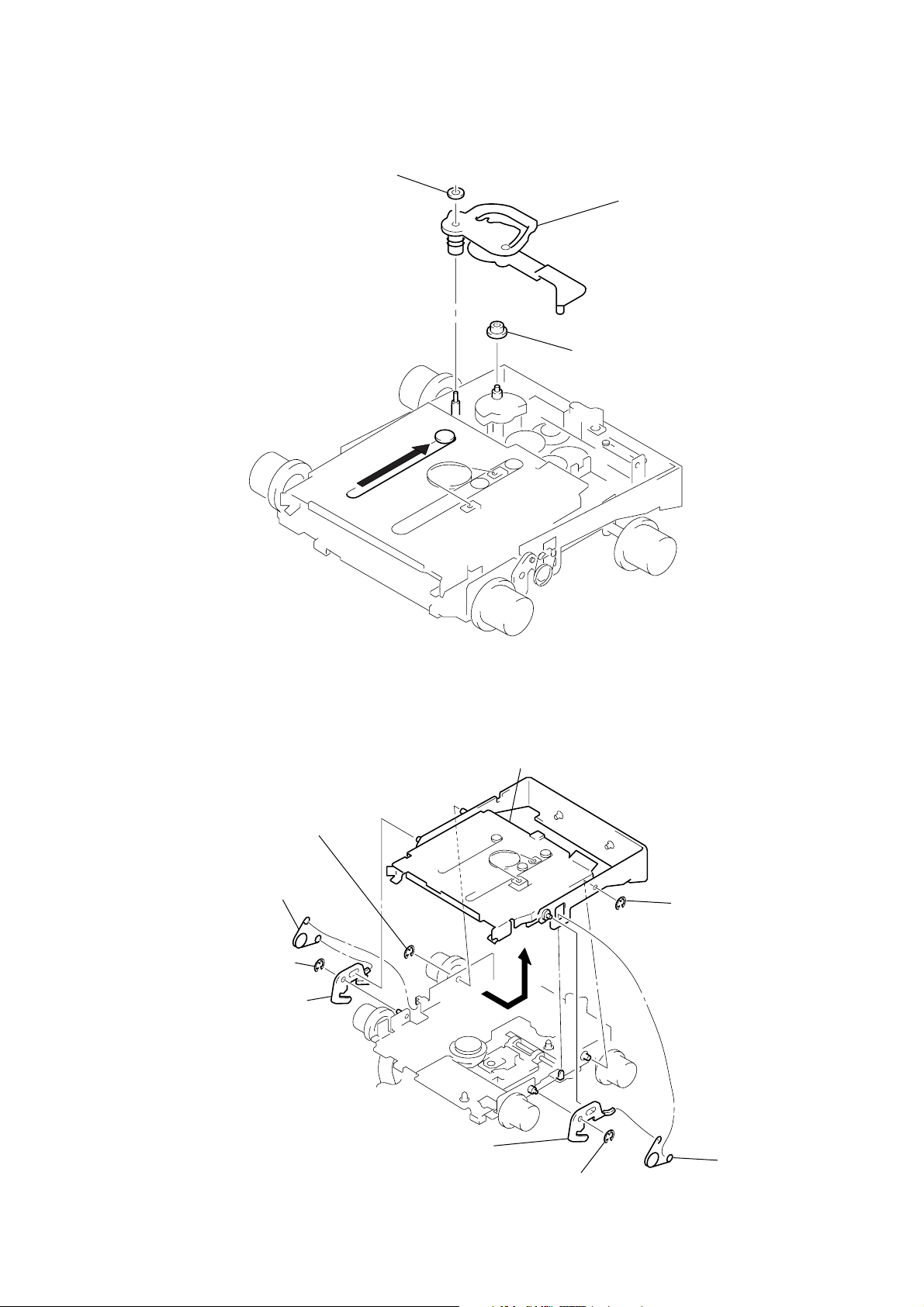

3-10. CHUCKING ARM ASSY

holder assy

1

Remove the chucking arm ass

in the direction of the arrow.

3-11. OPTICAL PICK-UP (KMS-242E)

7

optical pick-up

(KMS-242E)

1

two screws

(K2

×

3)

2

shaft (SL2)

4

screw

(B2

×

3)

6

bearing (SL)

5

feed screw assy

3

screw

(K2

×

3)

16

SECTION 4

ELECTRICAL ADJUSTMENTS

MDX-F5800

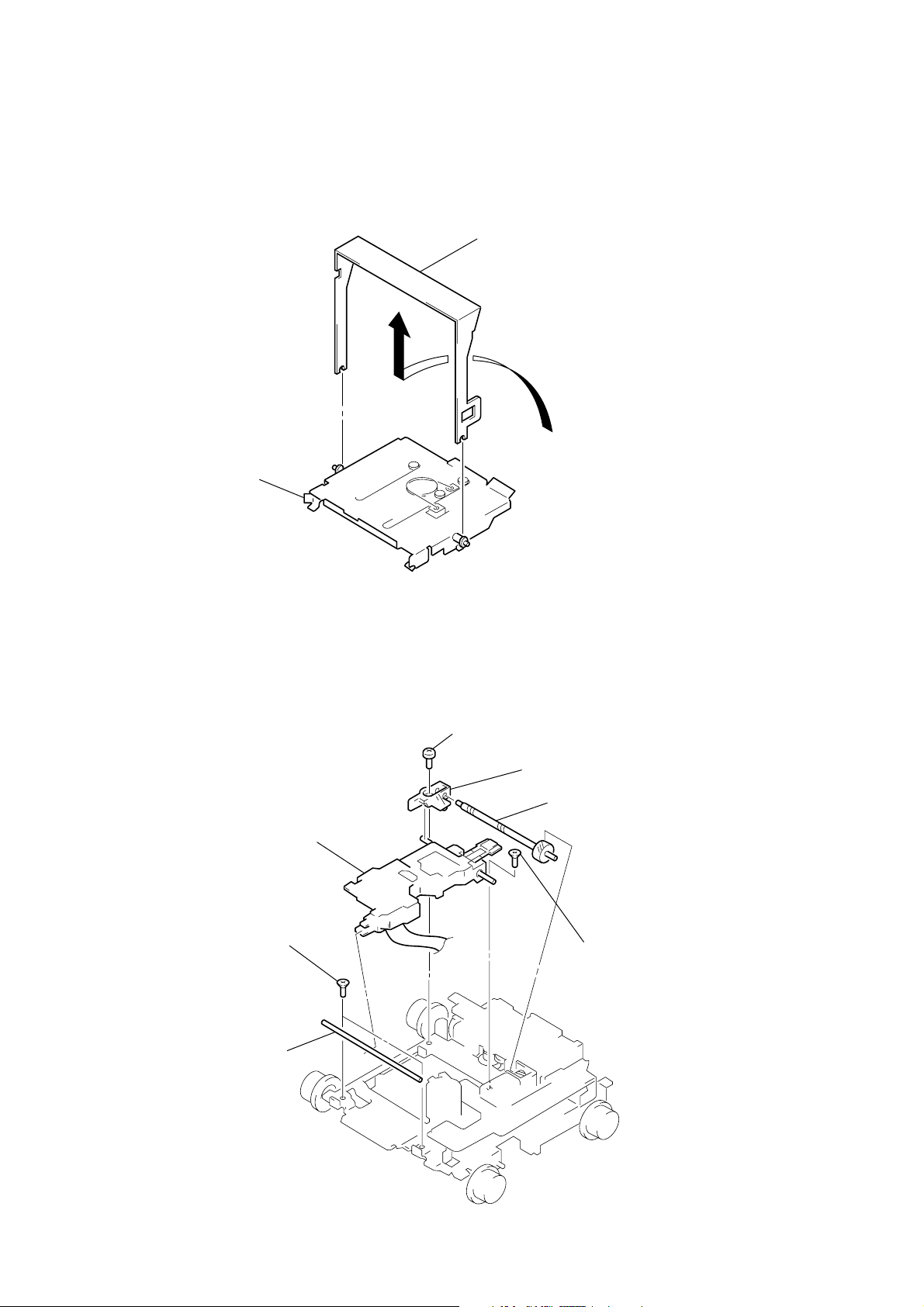

3-12. SL MOTOR ASSY (SLED) (M902), SP MOTOR ASSY (SPINDLE) (M901)

5

screw

×

1.8)

(P1.7

0

two screws

(P1.7

×

qa

retainer (SP)

qs

SP motor assy

(spindle) (M901)

1.8)

9

6

7

SL motor assy

(sled) (M902)

8

screw

×

(B2

base (SL)

bracket (SL)

3)

4

sensor board

3

screw (PS2 × 8)

2

screw (PS2 × 4)

TEST MODE

This set have the test mode function.

<Set the Test Mode>

1. Turn ON the regulated pow er supply. (The clock is displayed)

Note: Press the [OFF] button, if the clock is not displayed.

2. Push the preset [4] button.

3. Push the preset [5] button.

4. Press the preset [1] button for more than two seconds.

5. Then the display indicates all lights, the test mode is set.

<Release the Test mode>

1. Push the [OFF] button.

MD SECTION

MD section adjustments are done automatically in this set.

TUNER SECTION

Tuner section adjustments are done automatically in this set.

1

Remove solders of motors

(M901, M902, M903).

1717

MDX-F5800

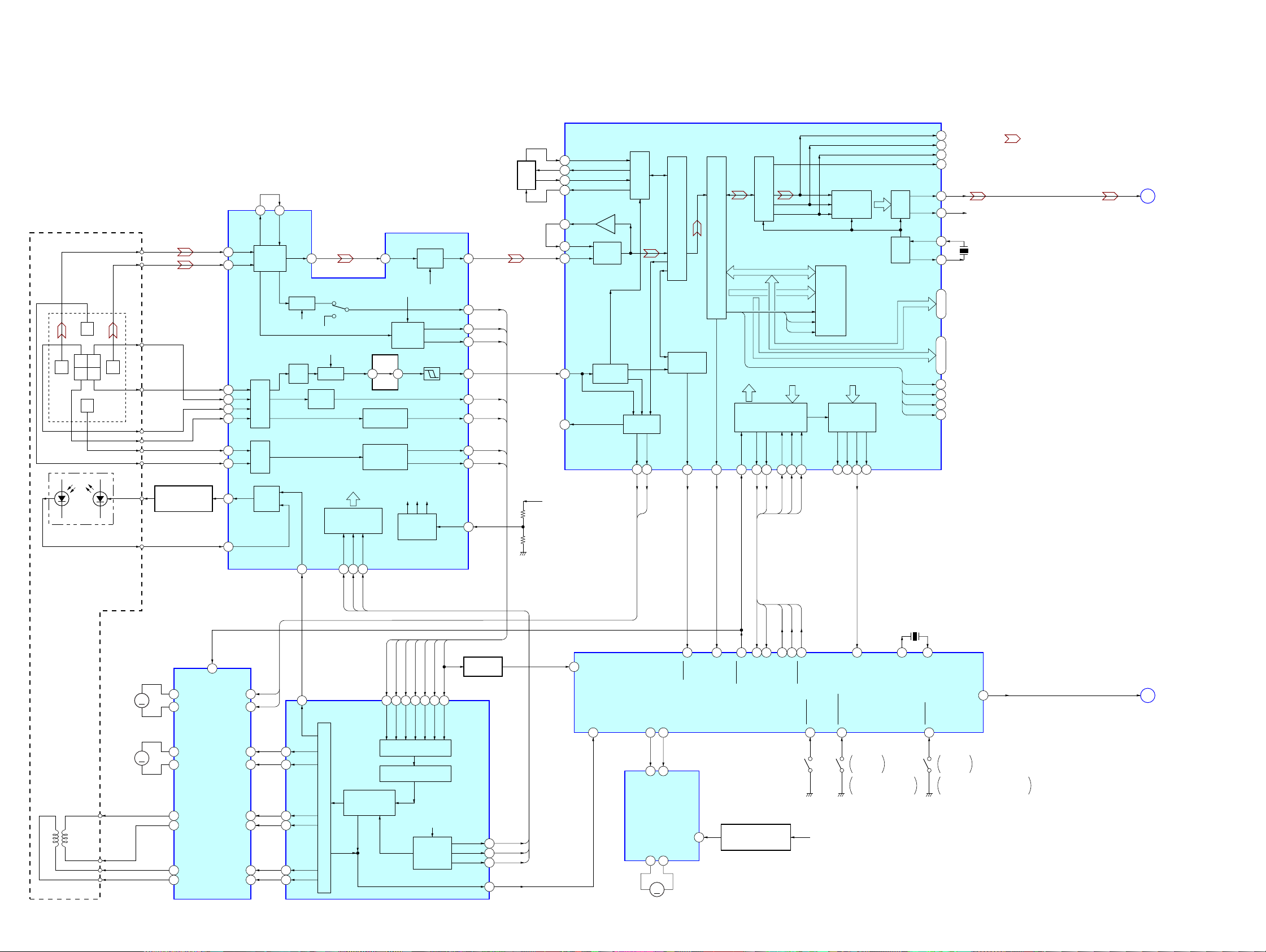

5-1. BLOCK DIAGRAM − SERVO Section −

SECTION 5

DIAGRAMS

OPTICAL PICK-UP BLOCK

(KMS-242E)

F

C B

I J

A

D

E

DETECTOR

LDPD

LASER DIODE

ILCC

MON

I

J

B

A

C

D

E

F

AUTOMATIC

POWER CONTROL

Q1

MD DSP

IC4 (1/2)

DADT

36

XBCK

38

LRCK

FILI

105

PCO

104

CLTV

107

FILTER

48 47

MORFI

MORFO

I

1

J

2

A

4

B

5

I-V

C

AMP

6

D

7

E

8

I-V

F

AMP

9

APC

11

PD

10

RF AMP

LD/PD

AMP

RFO

46 40

B.P.F.

3T

TEMP

WBL

AT

B.P.F.

AMP

ABCD

AMP

COMMAND

SERIAL/PARALLEL

CONVERTER,

DECODER

APCREF

12

SWDT

ADFM

SCLK

FOCUS

ERROR AMP

TRACKING

ERROR AMP

XLAT

181716

RF AMP,

FOCUS/TRACKING ERROR AMP

AGCI

WBL

PEAK &

BOTTOM

ADIN

3029

EQ

V-I

CONVERTER

IC1

RF AGC

& EQ

EQ

3T

WBL

RF

AUX AUX

PEAK

BOTM

ADFG

ABCD

FE

TE

SE

F0CNT

38

33

PEAK

37

BOTM

36

32

ABCD

35

FE

34

TE

26

SE

28

20

SERVO

3.3V

106

98

99

102

67

70

FILO

ASYO

ASYI

RFI

ADFG

F0CNT

COMPA-

RATOR

DECODER

ADIP

PLL

SPINDLE

SERVO

SPFD

SPRD

114 113

SPFD

SPRD

EFM/ACIRC DECODER

SUBCODE

PROCESSOR

SQSY35XINT

16

ATRAC

SHOCK RESISTANT

MEMORY CONTROLLER

INTERFACE

XRST

SENS13SRDT

15 14 9 10 11

SENS

ENCODER/DECODER

XWE

XRAS

XCAS

CPU

SWDT

SCLK

XLAT

SRDT

SWDT

SCLK

XLAT

4Mbit

D-RAM

D/A

CONVERTER

MONITOR

CONTROL

MNT0

MNT1

MNT2

5 6 7 8

LPF

OSC

MNT3

37

FS256

39

AOUTL L-CH

25

AOUTR

28

OSCI

20

OSCO

21

D0 – D3A00 – A11

60 – 63

41 – 51, 55

XOE

53

XWE

57

XRAS

56

XCAS

54

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: MD PLAY

R-CH

X1

22.57MHz

A

(Page 19)

2-AXIS

DEVICE

(TRACKING)

FCS+

(FOCUS)

FCS–

TRK+

TRK–

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

M901

(SPINDLE)

M902

(SLED)

IC2

MM

M

DTRF

CKRF

XLRF

SRDT

SENS

SRDT

SWDT

SWDT

(LIMIT)

SCLK

SCLK

MD-LAT

LIMIT_IN

LO_6V

MNT2

LOAD_END

CHUCKING

DETECT

ON : When completion

of a disc loading

SENS

FE

TE

SE

AUX

PEAK

ABCD

16

PSB

OUT4F

6

OUT4R

8

OUT2F

27

OUT2R

25

OUT1F

21

23

OUT1R

OUT3F

12

10

OUT3R

IN4R

IN4F

IN2F

IN2R

IN1F

IN1R

IN3F

IN3R

SPFD

3

SPRD

4

SFDR

29

30

19

18

14

15

112

SRDR

111

FFDR

64

FRDR

65

TFDR

77

TRDR

76

MD DSP

IC4 (2/2)

74 83 92 91 80 81 84 82

FE

APCREF

DIGITAL SERVO

SIGNAL

PROCESS

PWM GENERATOR

BOTM

TE

SE

PEAK

BOTM

ANALOG MUX

A/D CONVERTER

FROM CPU

INTERFACE

AUTO

SEQUENCER

AUX

ABCD

PEAK HOLD

XLRF

CKRF

DTRF

FOK/FCS

Q2

XLRF

71

CKRF

72

DTRF

73

120

REF_

41

LEVEL

FOK

100 85

84

5 4

LOADING

MOTOR DRIVE

1 7

M903

(LOADING)

52 46 1695 18

SQ_SY

CC-XINT

MD MECHANISM CONTROLLER

EJECT

LOAD

FIN

RIN

IC6

6

VREF

OUT1

OUT2

M

MD-RST

IC7 (1/2)

REFERENCE VOLTAGE

REGULATOR

Q3

XLAT

X2

18.43MHz

8194

X1

8019 9817

X0

ATT

DISC-IN

538887

LOADING

DETECT

ON : When a disc loading start

and a disc eject completion

7

MECH_ATT

B

(Page 19)

1818

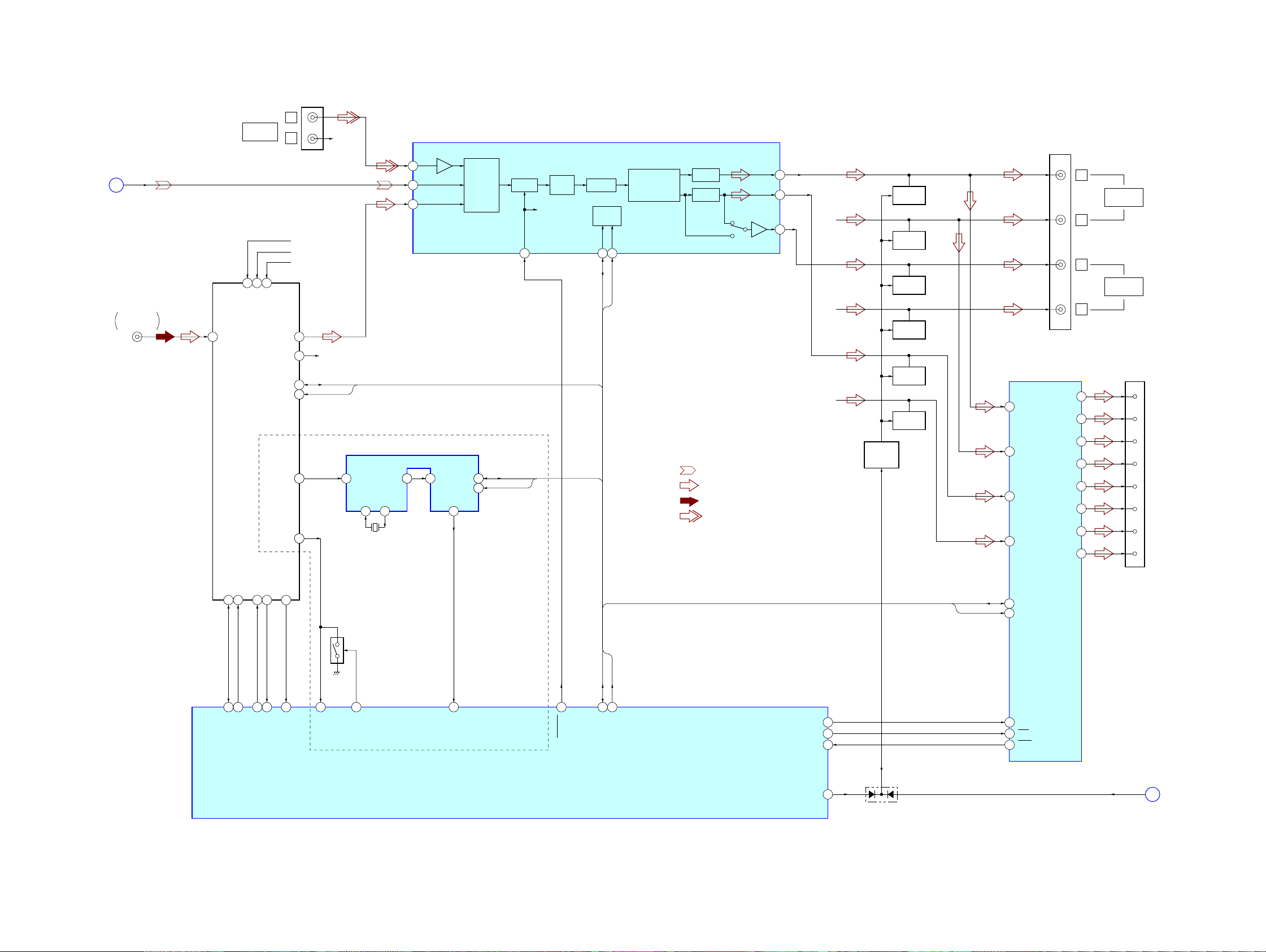

5-2. BLOCK DIAGRAM − MAIN Section −

MDX-F5800

(Page 18)

L-CH

A

J10

FM/AM

ANTENNA IN

ANT

PJ210 (1/2)

BUS

AUDIO IN

15

10 11

E2PVDD

VCC8.3V

FM/AM

TUNER PACK

TU10

VDD5V

SDA

SCL

L

R

L

R

BU5.0V

AU 8.3V

TU5V

41

14

11313

119RDS_OUT

115QUALITY

R-CH

R-CH

I2C_SDA

I2C_SCL

RDS DECODER

16 MPX 19 CIN

OSCI

OSCO

5 4

X90

4.332MHz

BUS-LCH

5

MD-LCH

11

TU-LCH

7

IC90

1118SCOUT 119SDA

DAVN

8

INPUT

SELECTOR

1110SCL

INPUT SELECT,

ELECTRICAL VOLUME

MUTE

R-CH

INPUT

GAIN

MUTE VOLUME

(AEP, UK)

I2C_SDA

I2C_SCL

IC120

IIC BUS

LOGIC

SDA

31

I2C_SDA

SCL

3029

I2C_SCL

TONE CONTROL/

EFFECT

CIRCUIT

OUT-FL

OUT-RL

23

22

17

FADER

FADER

SUBOUT-RL

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: MD PLAY

: FM

: AM

: BUS AUDIO IN

R-CH

R-CH

R-CH

MUTING

CONTROL

Q350, 351

MUTING

Q210

MUTING

Q240

MUTING

Q220

MUTING

Q230

MUTING

Q260

MUTING

Q250

12

14

11

15

POWER AMP

IC300 (1/2)

IN-FL

IN-FR

IN-RL

IN-RR

PJ210 (2/2)

OUT-FL+

OUT-FL–

OUT-FR+

OUT-FR–

OUT-RL+

OUT-RL–

OUT-RR+

OUT-RR–

L

AUDIO OUT

FRONT

R

L

AUDIO OUT

REAR

R

CN300 (1/2)

5

3

21

23

9

7

17

19

1

9

4

12

2

10

3

11

FRONT L+

FRONT L–

FRONT R+

FRONT R–

REAR L+

REAR L–

REAR R+

REAR R–

E2PSDA

17 16

68

E2P_SIO

E2PSCL

67

E2P_CKO

TUN_MUTE

MUTE_CON

7 8

64

28

TUATT

TUATTIN

6

93

VSM S-METER

92

QUALITY

Q71

NOISE DET

DISCHARGE

SWITCH

66

NS_MASK

82

DAVN

SYSTEM CONTROLLER

IC600 (1/2)

I2C_SDA

57 79 81

VOLATT

I2C_SIO

I2C_SCL

I2C_CKO

BEEP

AMPSTB

DIAG

ATT

I2C_SDA

I2C_SCL

85

70

56

24

D350

2

SDA

4

SCL

16

BEEP

22

STB

25

DIAG

MECH_ATT

B

(Page 18)

1919

MDX-F5800

5-3. BLOCK DIAGRAM − PANEL/BUS CONTROL/POWER SUPPLY Section −

CNJ400

BUS CONTROL IN

RESET

DATA

CLK

BUS ON

BATT

SONY BUS INTERFACE

IC400

2

5

4

6

TH400

7

BUS ON SWITCH

BAT B+

Q401

D404

RST

DATA I/O

CLK

BUS

ON

BATT

RESET

SWITCH

BUS ON

SWITCH

BATTERY

SWITCH

2 13

6 9

4 11

1 12

3 10

RST

DATA IN

DATA OUT

8

CLK-IN

BUS ON

B/U_C BU_IN

UNISO

UNISI

UNICKO

BUS-ON

CN901

FRONT PANEL

SIDE

1

CN370

MAIN UNIT SIDE

5

UNISO

UNISI

UNICKO

BUS-ON

BU_IN

UNISO

UNISI

UNICKO

BUS-ON

BUS-ON

MD MECHANISM CONTROLLER

D405

(1/2)

57

UNISO

56

UNISI

UNICLK

58

50

BUS_ON

51 BU_IN

14

EJECT_OK

2

LINKOFF

D405

(2/2)

33

UNISO

UNISI

34

UNICKO

35

BUSON

40

31 BU_IN

DOORSW

55

IC7 (2/2)

MDMON

1 15

30 39

MDMON

RSTX

OPEN_REQ

OPENREQ

S601

RESET

D500

LO_6V

SERVO3.3V

RESET SIGNAL

GENERATOR

IC601

BU3.3V

+3.3V

REGULATOR

IC700

BU5.0V

REGULATOR

IC300 (2/2)

27 ANT-REM

29 AMP-REM

37 REG2

CN300 (2/2)

5

6

AMP-R

ANT-R

69MDMON_CHECK

70MDON_CHECK

93MD_ON

75

42SYSRST

19RESET

J370

(REMOTE IN)

S901 – 907,

S910 – 923

96 20 95

RCIN0

RCIN1

LSW801,

KEYIN0

94

KEYIN1

D600

78

DI

77

CL

76

LIQUID CRYSTAL

DISPLAY

LCD901

LED DRIVE

Q961

LED961, 962

(LCD BACK LIGHT)

KEY ACTIVE

SWITCH

Q600

27 25 12 13

ADON

KEYACK

BU3.3V

LCD DRIVER

65 – 68 7 – 14, 16 – 31, 33 – 64

COM1 – COM4 SEG1 – SEG56

1 LED

REMOTE CONTROL

RECEIVER

SIRCS AMP

Q371, 372

SYSTEM CONTROLLER

IC901

IC971

83

IC600 (2/2)

SIRCS

OSC

CE

74

OSC

C985, R989

X601

27.648MHz

OSCOUT

(NOSE DETECT)

16 15

OSCIN

S600

X602

32.768kHz

XOUT

XIN

59

76

78

77

NOSESW

LCDSO

LCDCKO

LCDCE

DOORIND

+5V

LED801,

LED802

REGULATOR

Q504

+2.5V

REGULATOR

IC3

+5V

REGULATOR

Q60

AU8.3V

ACCESSORY

CHECK

Q361

LEVEL SHIFT

Q360

LED DRIVE

Q370

VOLTAGE

CHECK

Q402

33 REG4

31 REG3

30 REG1

34 REG5

D406

D407

35VP

BAT B+

19

+B

7

ACC

13

TEL-ATT

15

TEST

DRIVER5V

29MDON

69

21ACCIN

23TELATT

22TESTIN

REGULATOR

CONTROL

Q505

SERVO3.3V

+3.3V

LCD3.3V

(DISC SLOL ILLUMINATION)

REGULATOR

LED801

LED802

Z

IC981

LO_6V

L2.5V

TU5V

ILL 10V

LED901 – 907,

LED910 – 923

2020

MDX-F5800

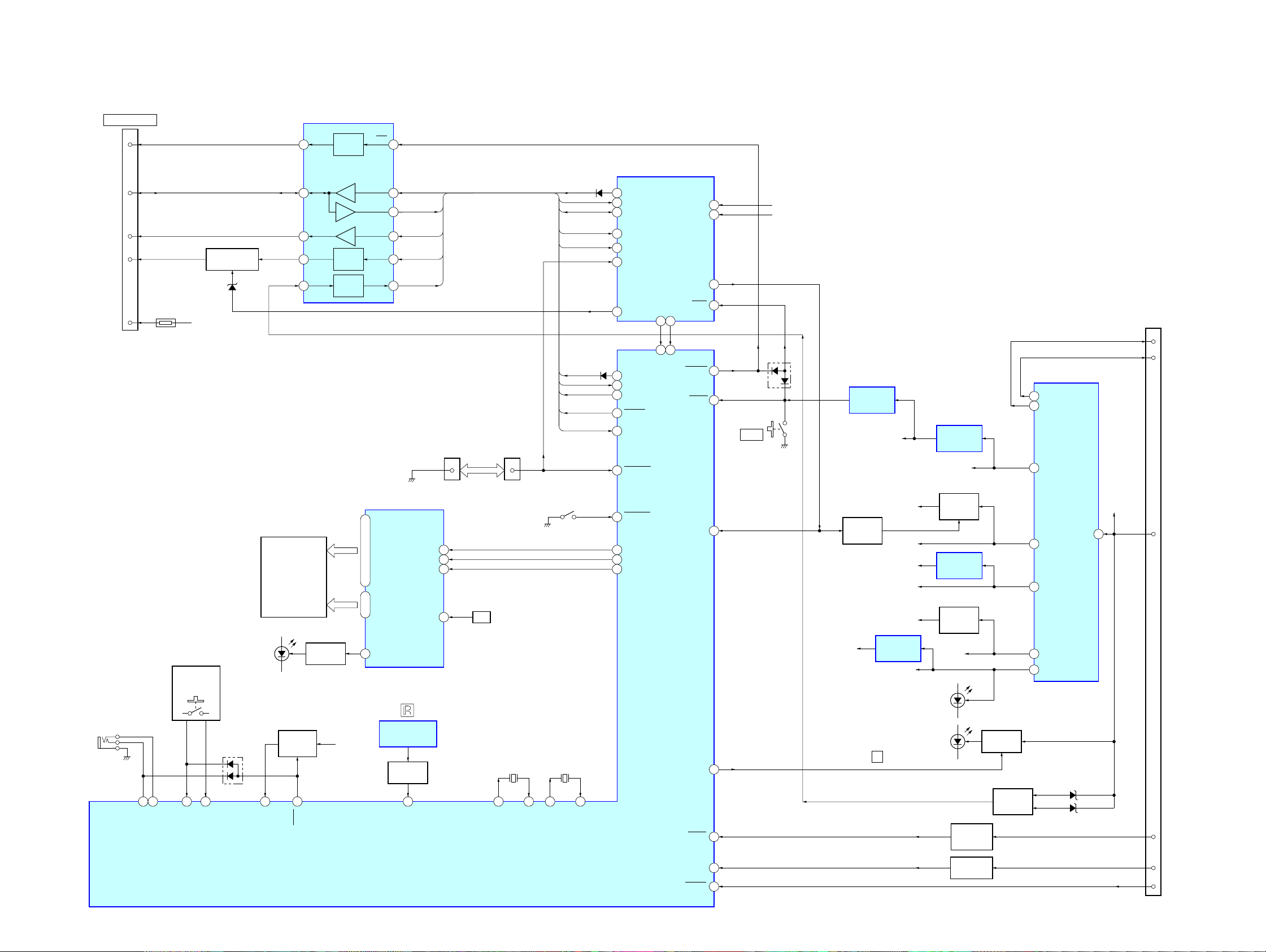

5-4. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

f

•

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

: internal component.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

• Power voltage is dc 14.4V and fed with regulated dc power

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

supply from ACC and BATT cords.

under no-signal (detuned) conditions.

− SERVO Section −

no mark : MD PLAY

− MAIN/KEY Section −

no mark : FM

〈〈 〉〉 : AM (MW/LW)

(): MD PLAY

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

E : MD PLAY

F : FM

f : AM (MW/LW)

L : BUS AUDIO IN

4

W or less unless otherwise

• Circuit Boards Location

MAIN board

KEY board

MINIATURE JACK board

SENSOR board

SERVO board

SUB board

2121

Loading...

Loading...