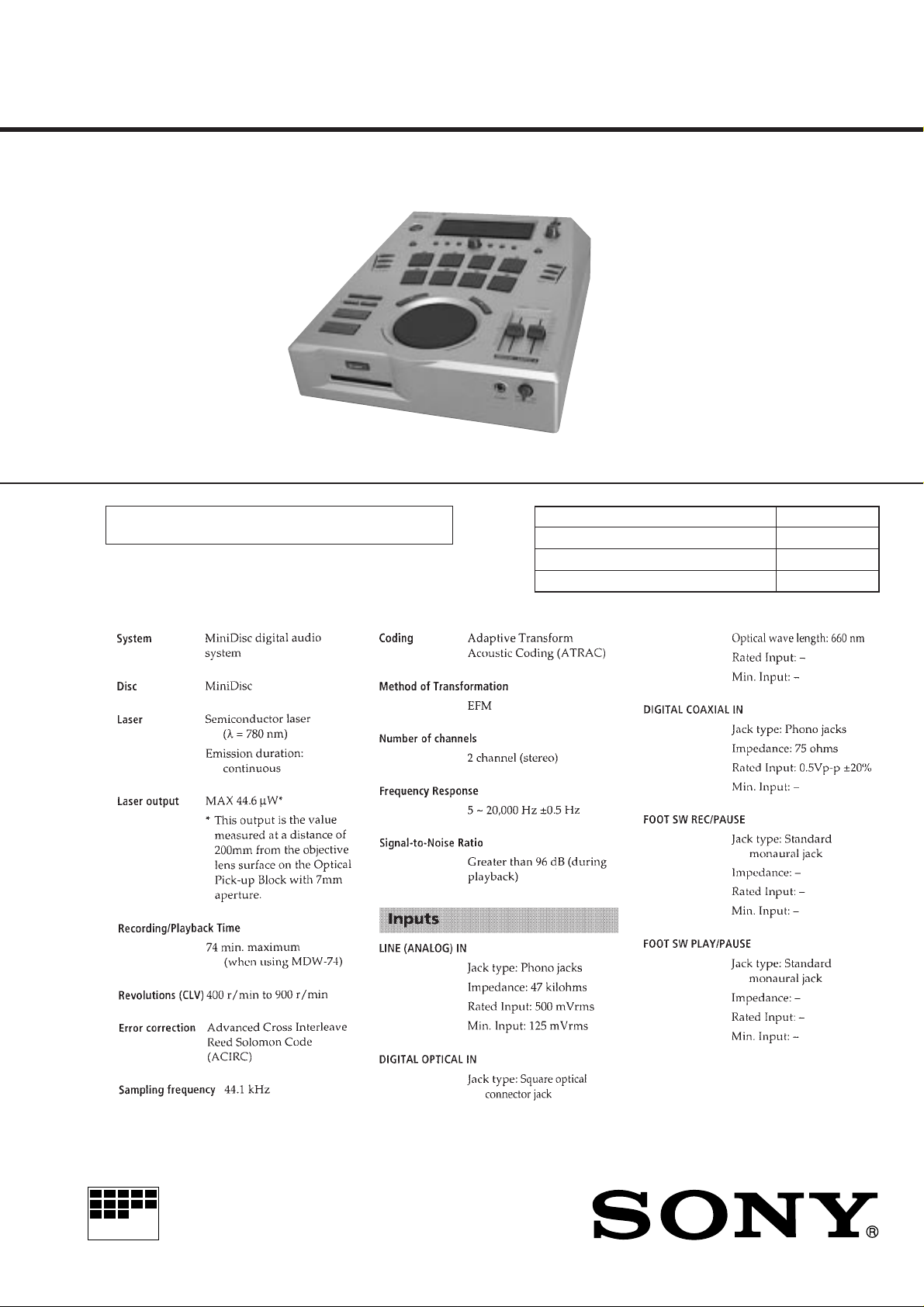

Sony MDSDRE-1 Service manual

MDS-DRE1

SERVICE MANUAL

U.S. and foreign patents licensed form Dolby Laboratories

Licensing Corporation.

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

Model Name Using Similar Mechanism MDS-JA3ES

MD Mechanism Type MDM-2CR

Base Unit Name MBU-2B

Optical Pick-up Name KMS-210A/J-N

MICROFILM

– Continued on next page –

MINIDISC RECORDER/PLAYER

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 7

3. DISASSEMBLY ......................................................... 9

4. TEST MODE.............................................................. 12

5. ELECTRICAL ADJUSTMENTS......................... 15

6. DIAGRAMS

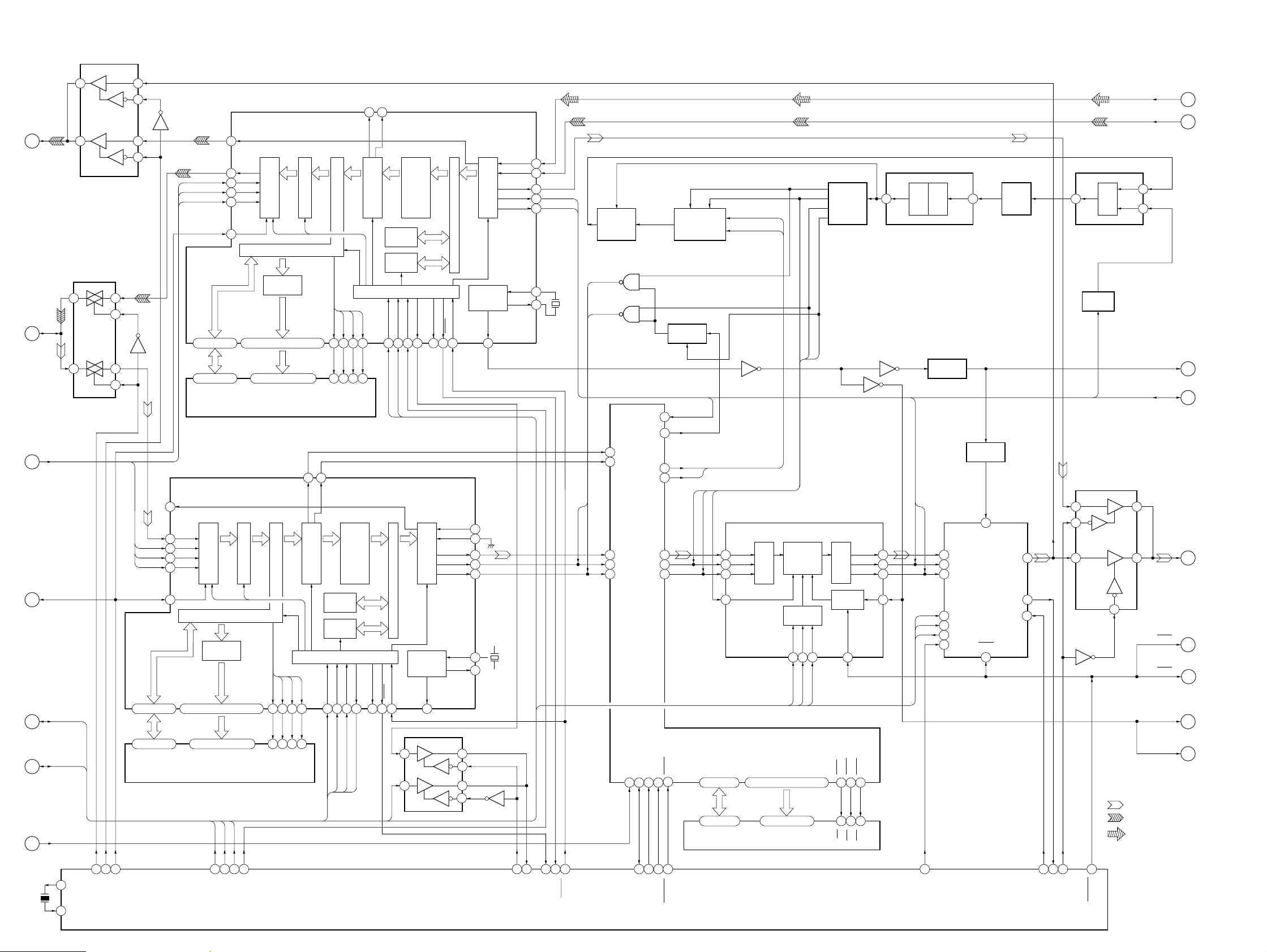

6-1. Block Diagram – SERVO Section – .............................. 21

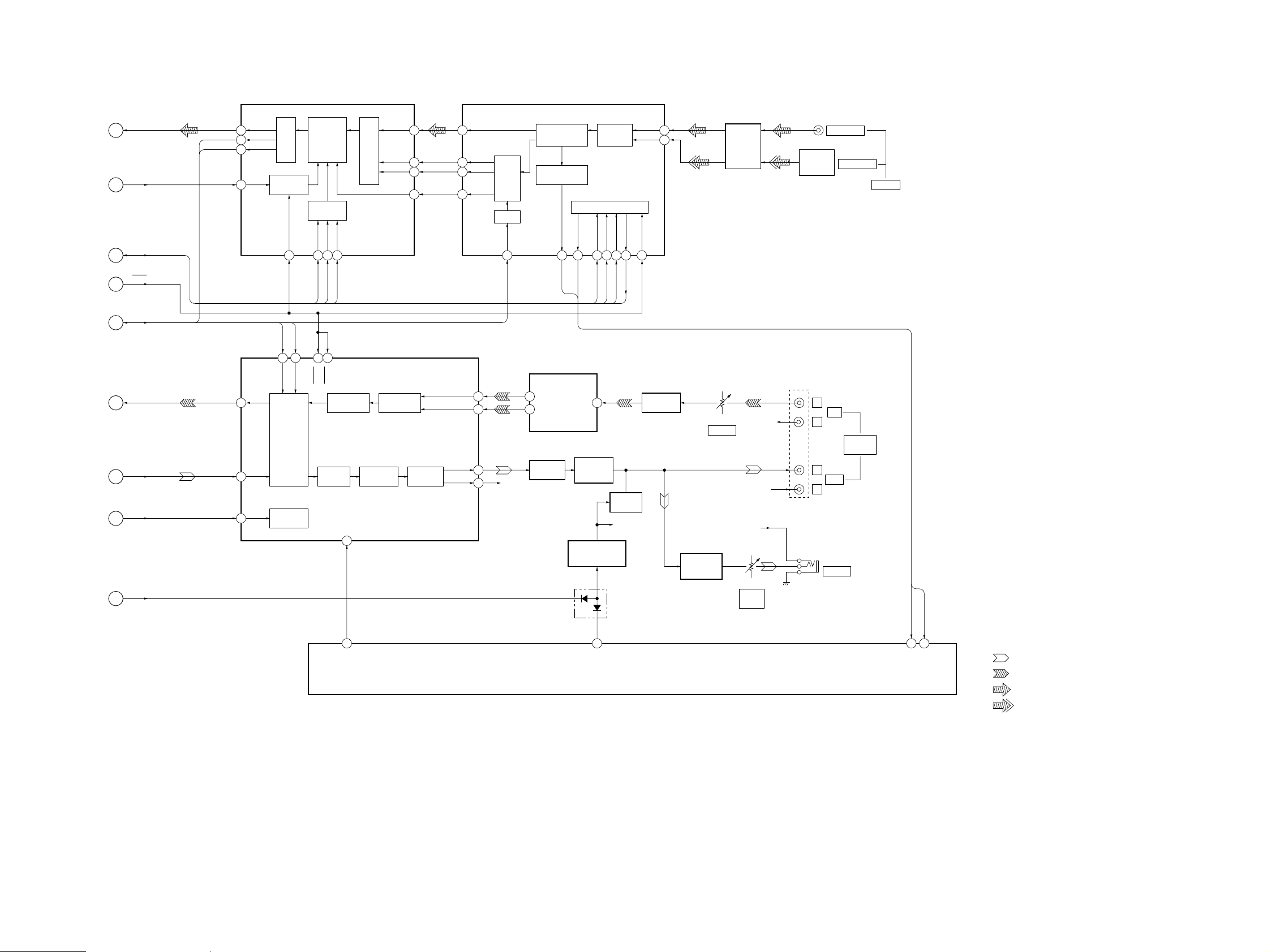

6-2. Block Diagram – MAIN Section (1/2) – ....................... 23

6-3. Block Diagram – MAIN Section (2/2) – ....................... 25

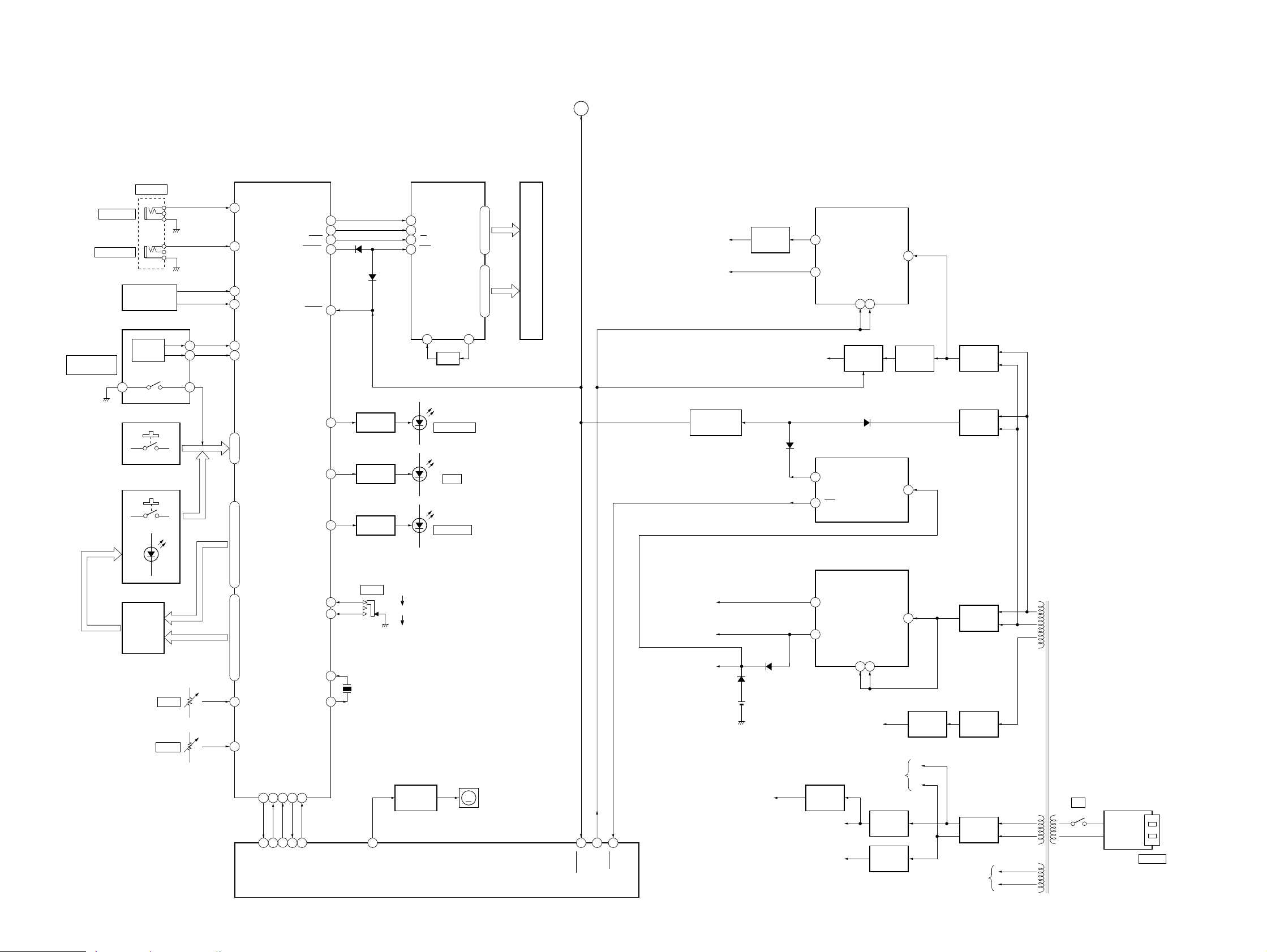

6-4. Block Diagram

– DISPLAY/KEY/POWER SUPPLY Section –............. 27

6-5. Notes for Printed Wiring Board

and Schematic Diagram .................................................. 30

6-6. Printed Wiring Board – BD Board (SIDE A) – ............. 31

6-7. Printed Wiring Board – BD Board (SIDE B) –............. 33

6-8. Schematic Diagram – BD Section (1/2) – ..................... 35

6-9. Schematic Diagram – BD Section (2/2)– ...................... 37

6-10. Printed Wiring Boards

– DETECTION SW Board, MOTOR Board –............... 39

6-11. Schematic Diagram

– DETECTION SW/MOTOR Section – ........................ 41

6-12. Printed Wiring Board – DIGITAL Board (SIDE A) – ... 43

6-13. Printed Wiring Board – DIGITAL Board (SIDE B) – ... 45

6-14. Schematic Diagram – DIGITAL Section (1/4) – .......... 47

6-15. Schematic Diagram – DIGITAL Section (2/4) – .......... 49

6-16. Schematic Diagram – DIGITAL Section (3/4) – .......... 51

6-17. Schematic Diagram – DIGITAL Section (4/4) – .......... 53

6-18. Pr inted Wiring Board – PANEL Section (1) – .............. 56

6-19. Schematic Diagram – PANEL Section (1) – ................. 57

6-20. Pr inted Wiring Boards – PANEL Section (2) – ............. 59

6-21. Schematic Diagram – PANEL Section (2) – ................. 61

6-22. Pr inted Wiring Boards – POWER Section – ................. 63

6-23. Schematic Diagram – POWER Section – ..................... 65

6-24. IC Pin Function Description ........................................... 77

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMA TIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

7. EXPLODED VIEWS................................................ 88

8. ELECTRICAL PARTS LIST ............................... 93

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

SECTION 1

SERVICING NOTES

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

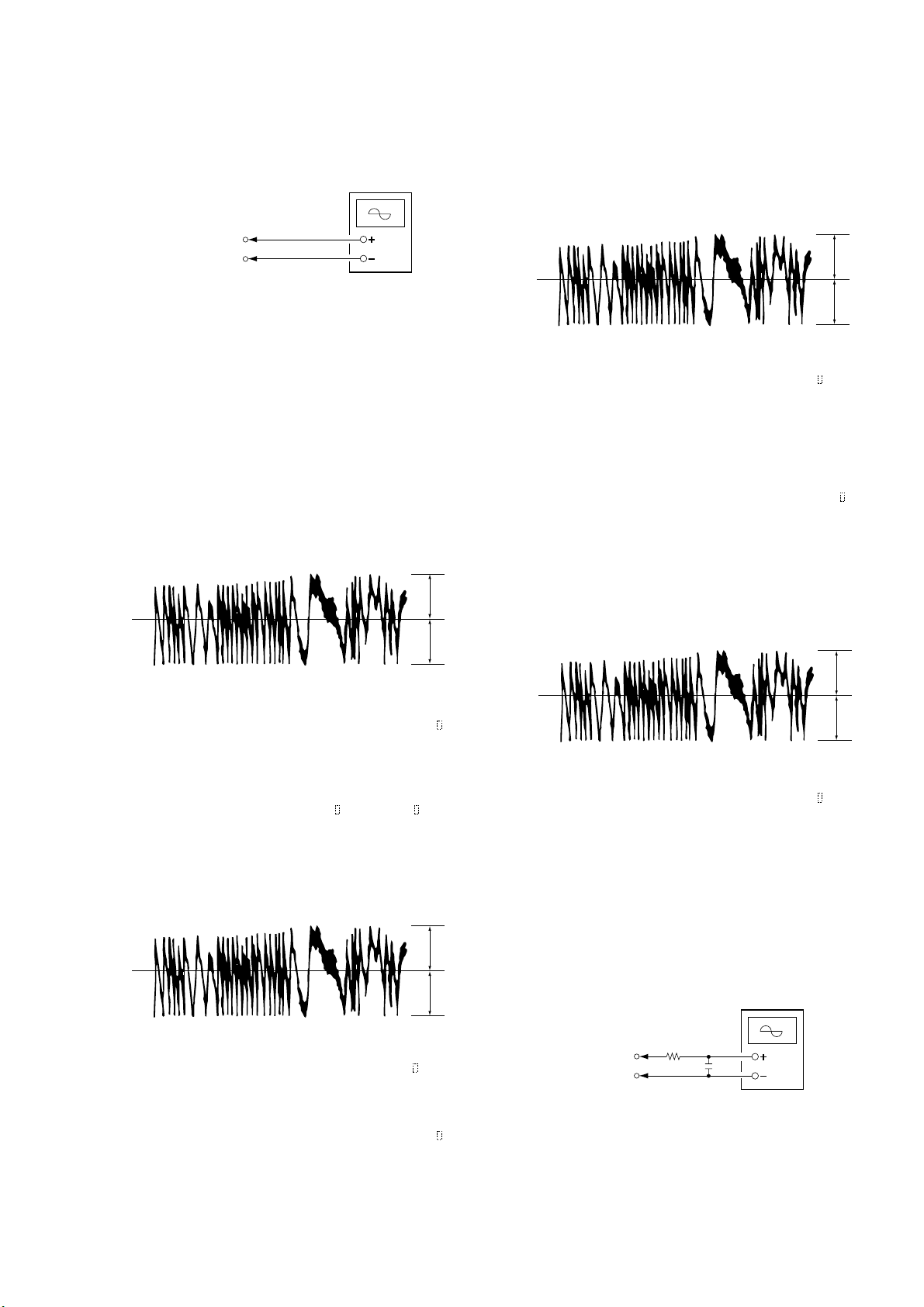

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

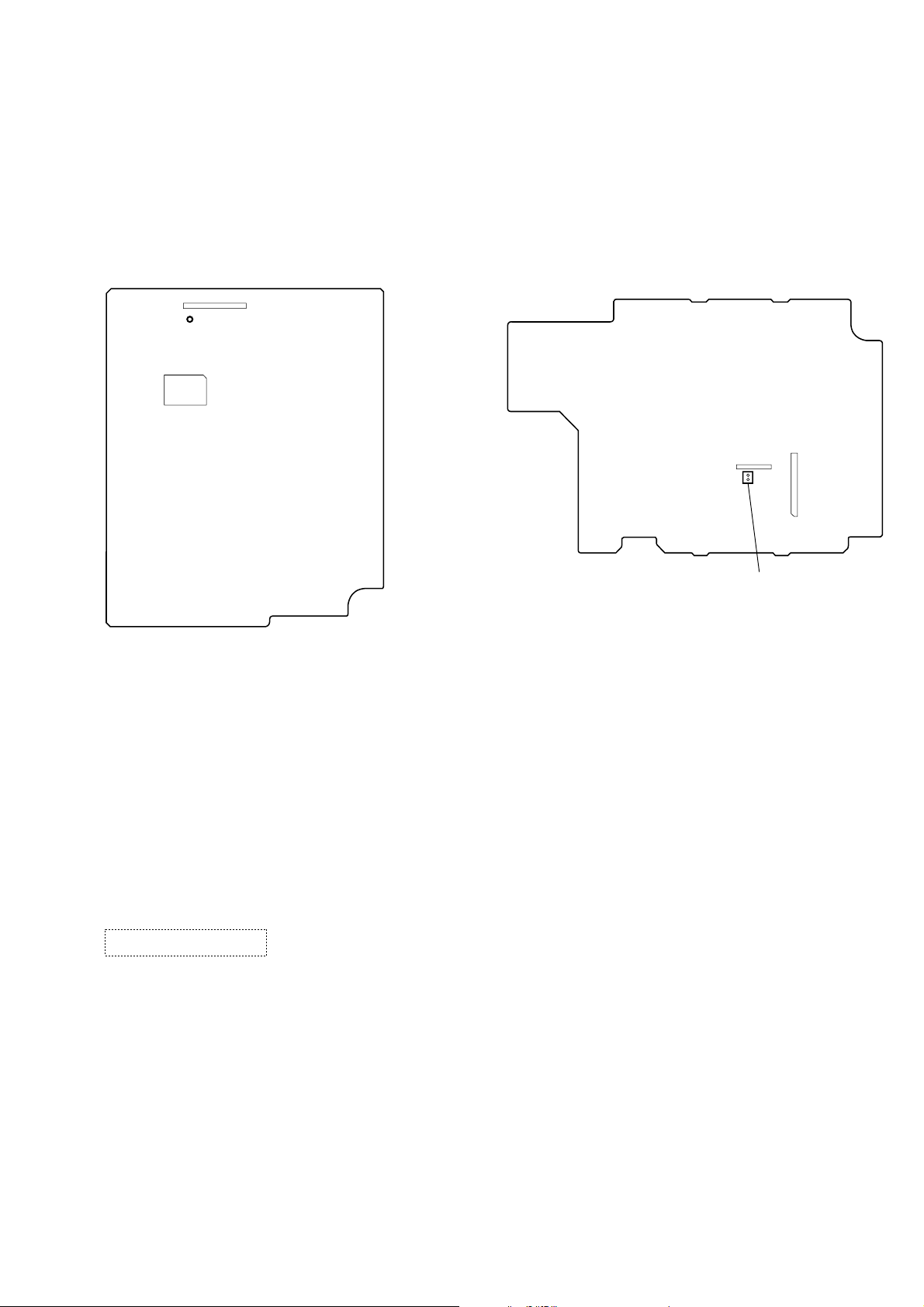

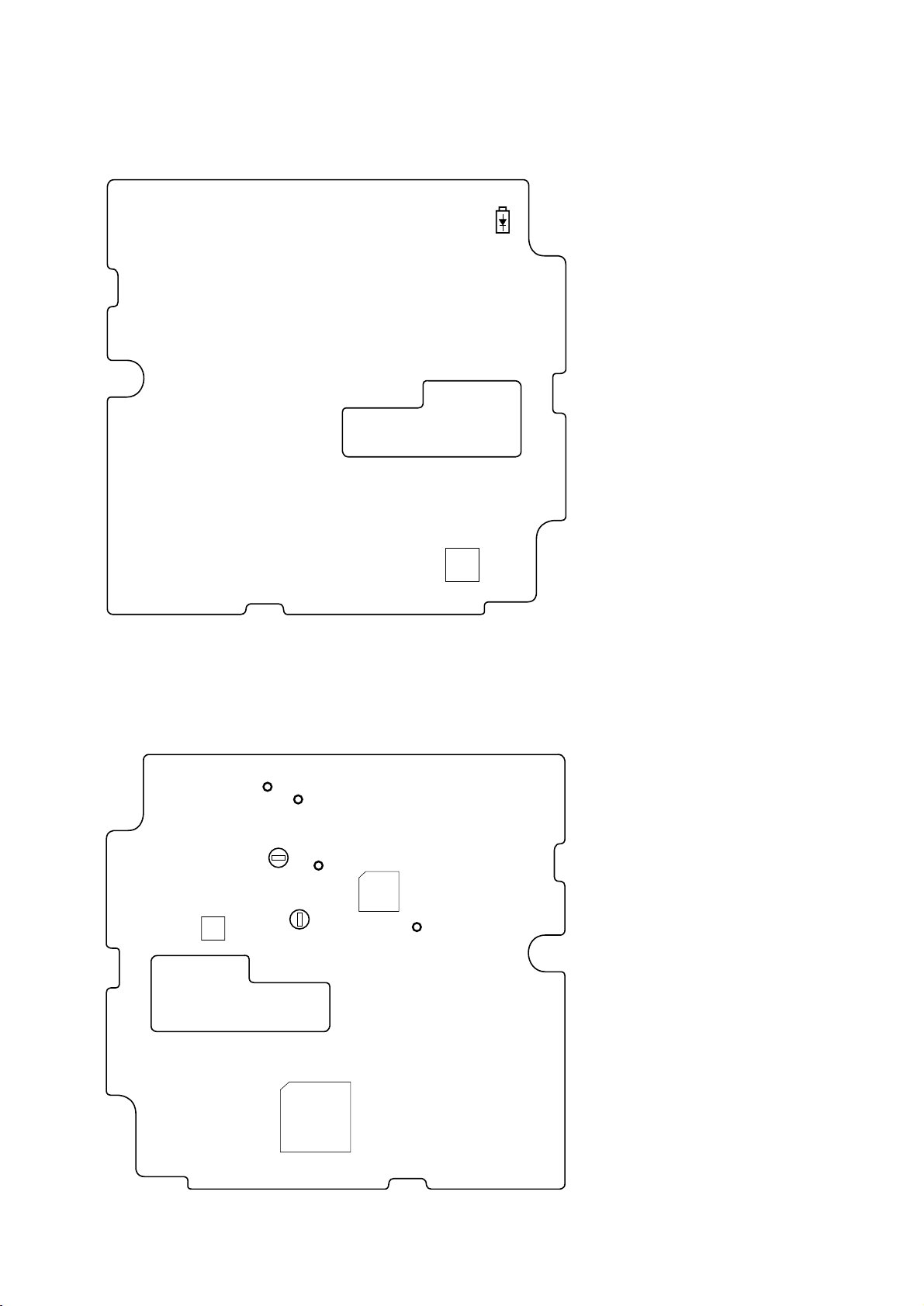

MODEL IDENTIFICATION

— LOWER SIDE CABINET (BOTTOM VIEW) —

Front Side

Part No.

4-210-100-1

4-210-100-2

π

: AEP and UK models

π

: US and

AC

voltmeter

(0.75 V)

Canadian models

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laitev almistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

– 3 –

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 4 –

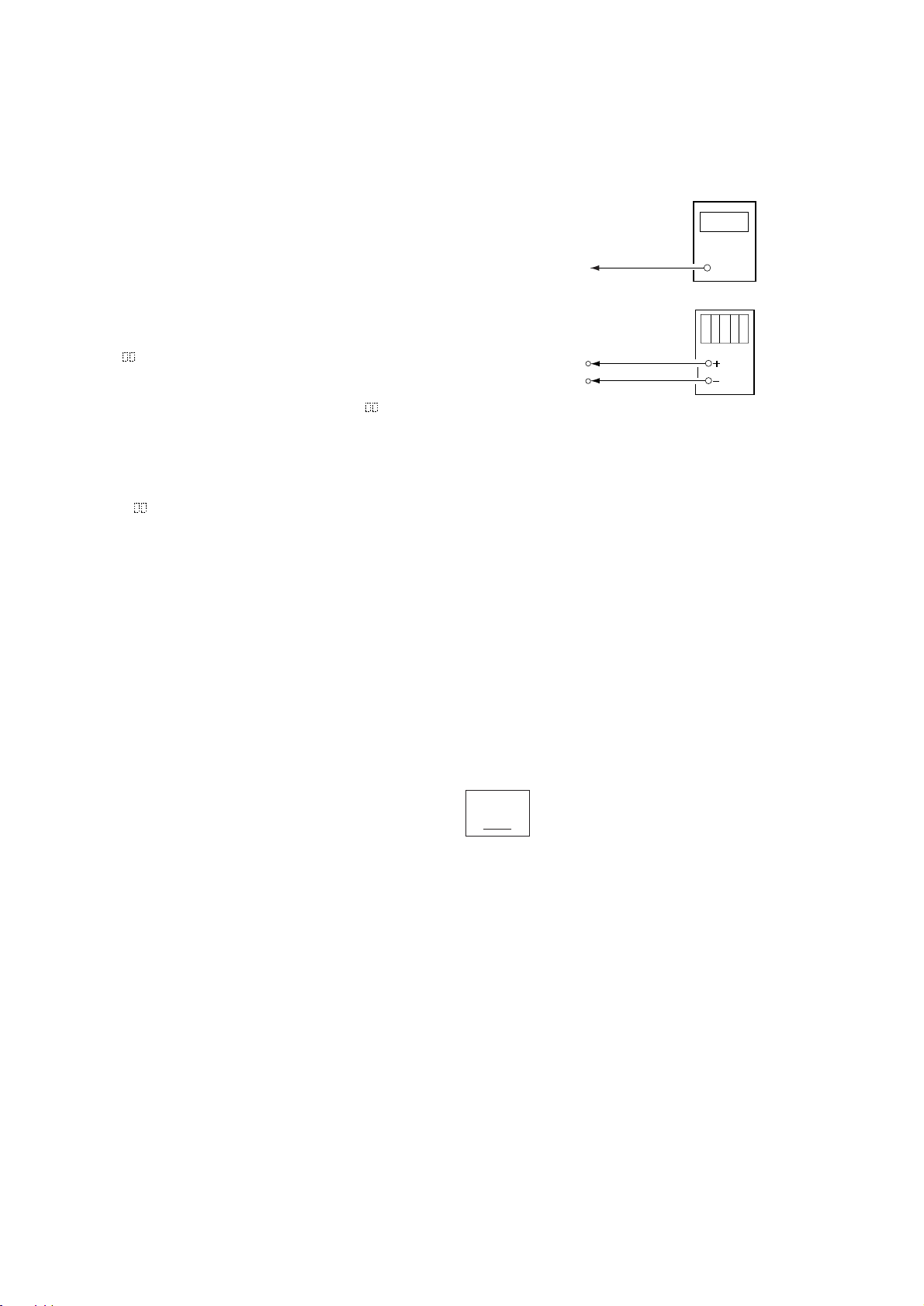

FORCED RESET

CN901

BT451

1

2

CN451

(RESET)

The system microprocessor can be reset in the following way.

Use these methods when the unit cannot be operated normally due to the overrunning of the microprocessor, etc.

Method 1:

Set TP (RESET) of the DIGITAL board to ground momentarily.

[DIGITAL board] (Side A)

CN1

TP

(RESET)

IC101

Method 2:

Disconnect the power plug, and short-circuit CN451 of the POWER

board with a pair of tweezers, etc.

[POWER board] (Component Side)

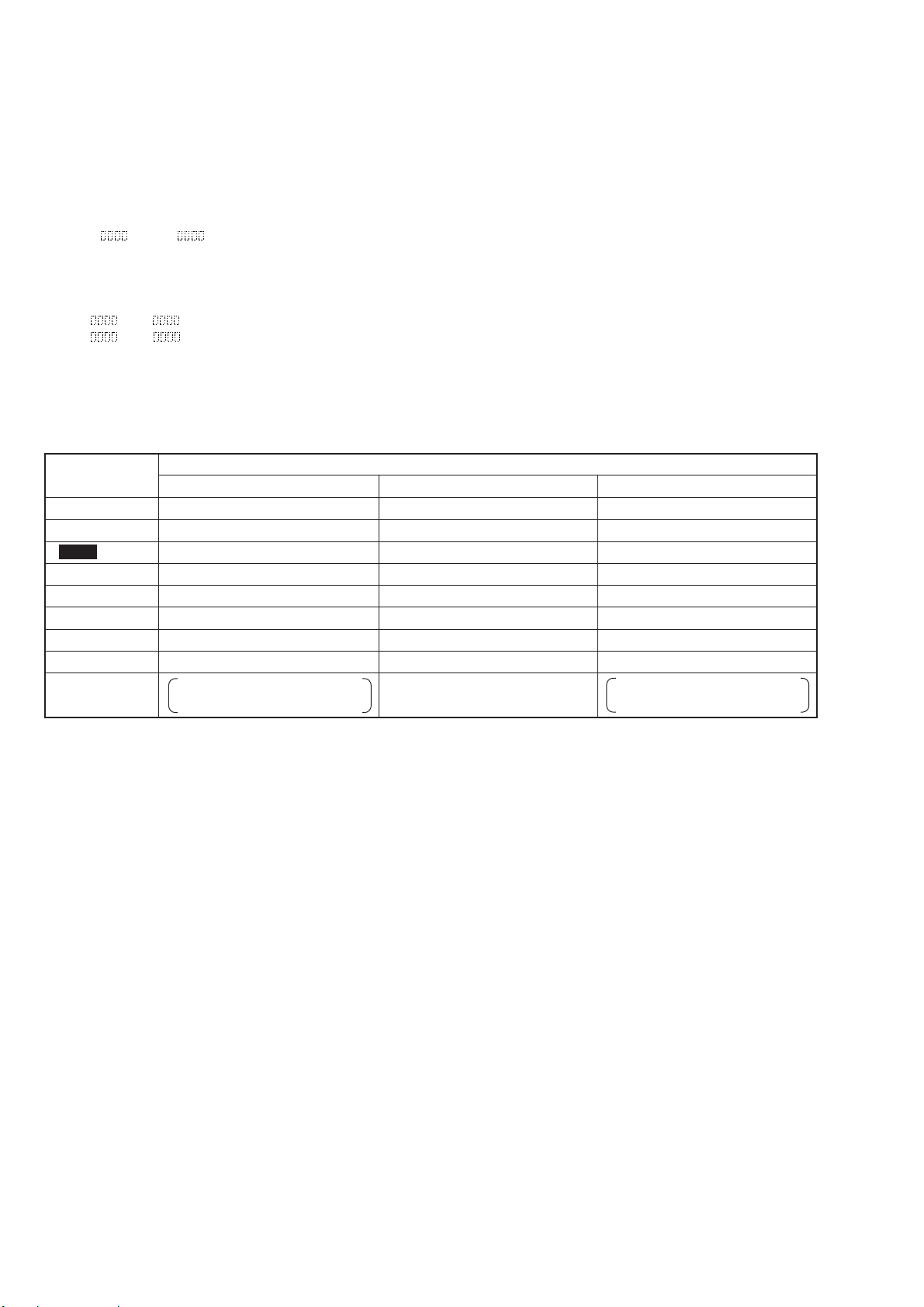

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent display tube.

This is useful for locating the faulty part of the unit.

• The retry cause, number of retries, and number of retry errors are displayed. Each is displayed in hexadecimal number.

Method:

1. Load a recordable disc whose contents can be erased into the unit.

2. Press the [STOP] button, [EJECT] button, [PAD1] button simultaneously.

3. Press the [REC] button, and start recording.

r

§

4. The ## value increases with each retry. If an error occurs after a retry, the @@ count will also increase.

5. To exit the test mode, press the [] (POWER) button.

U

Fig. 1 Reading the Test Mode Display

R.T s ∗ ∗ c # # e @@

Fluorescent Display Tube Signs

∗ ∗ : Cause of retry

# # : Number of retries

@@: Number of retry errors

All three displays above are in hexadecimal numbers.

– 5 –

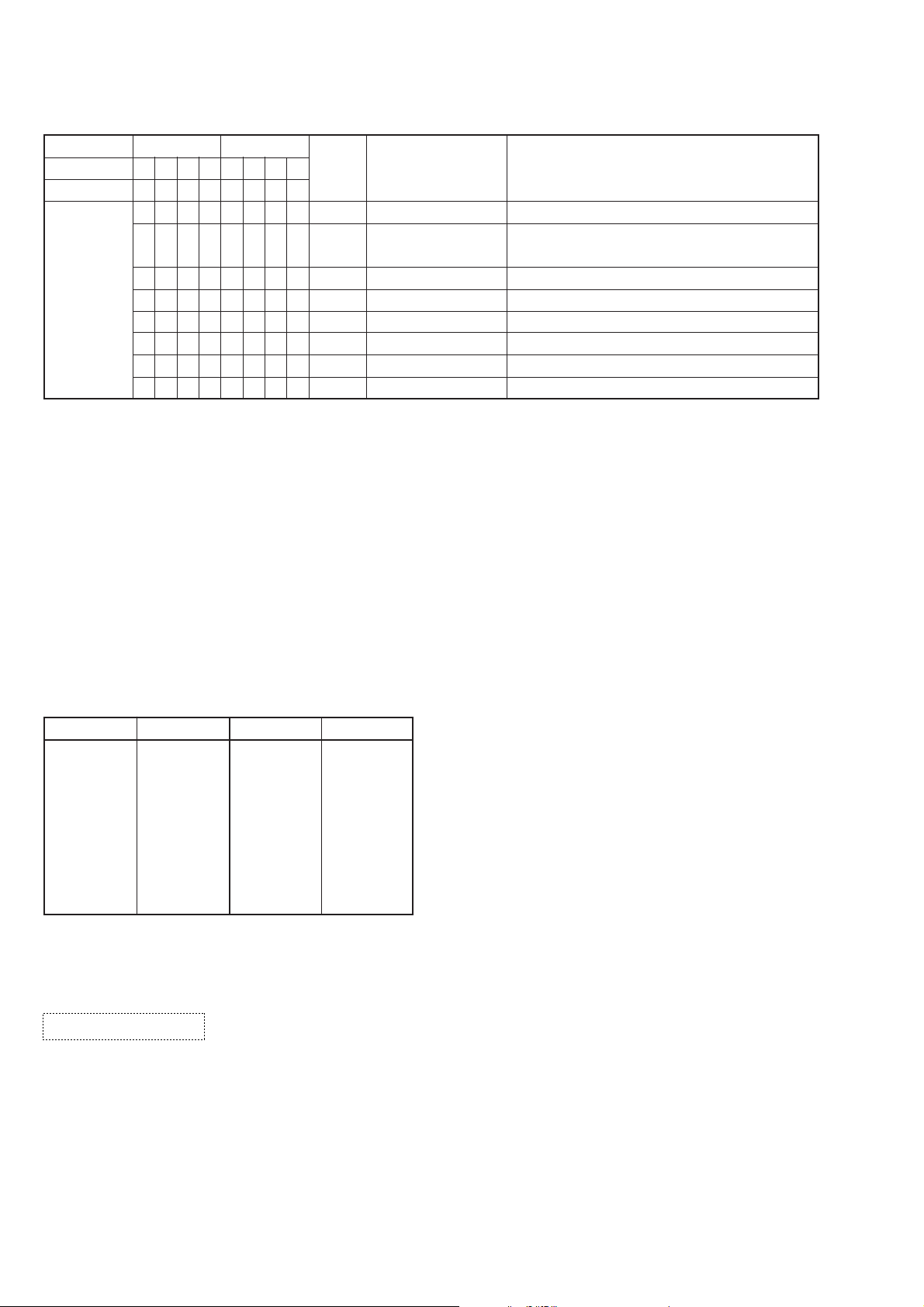

Reading the Retry Cause Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

*1 Some displays are not used depending on the microprocessor version.

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 n b6

Lower bit : 2 = 0010 n b1

In this case, the retry cause is combined of “spindle is slow” and “ader5”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

Cause of Retry Occurring conditions

shock *1

ader5

Discontinuous address

(Not used)

FCS incorrect

IVR rec error

Spindle is slow

Access fault

When more than 3.5 shocks are detected

When ADER was counted more than

five times continuously

When ADIP address is not continuous

(Not used)

When not in focus

When ABCD signal le vel exceeds the specified r ange

When spindle rotation is detected as slow

When access operation is not performed normally

When A2 is displayed:

Higher bit : A = 1010 n b7+b5

Lower bit : 2 = 0010 n b1

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

Hexadecimal n Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

Reference:

In this test mode, when the [PLAY/PAUSE] button is pressed, and the disc is played back, the “PLAYBACK MODE” is set.

The display becomes as shown in Fig. 2. The playback mode is not used in particular during servicing.

44 ¢¢¢¢¢¢ p

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

Fig. 2 Display during Playback Mode

4 : Parts No. (Name of area named on TOC)

¢¢¢¢¢¢ : Address (Physical address on disc)

p : Track mode (Copyright information of each part, information on copyright, etc.)

– 6 –

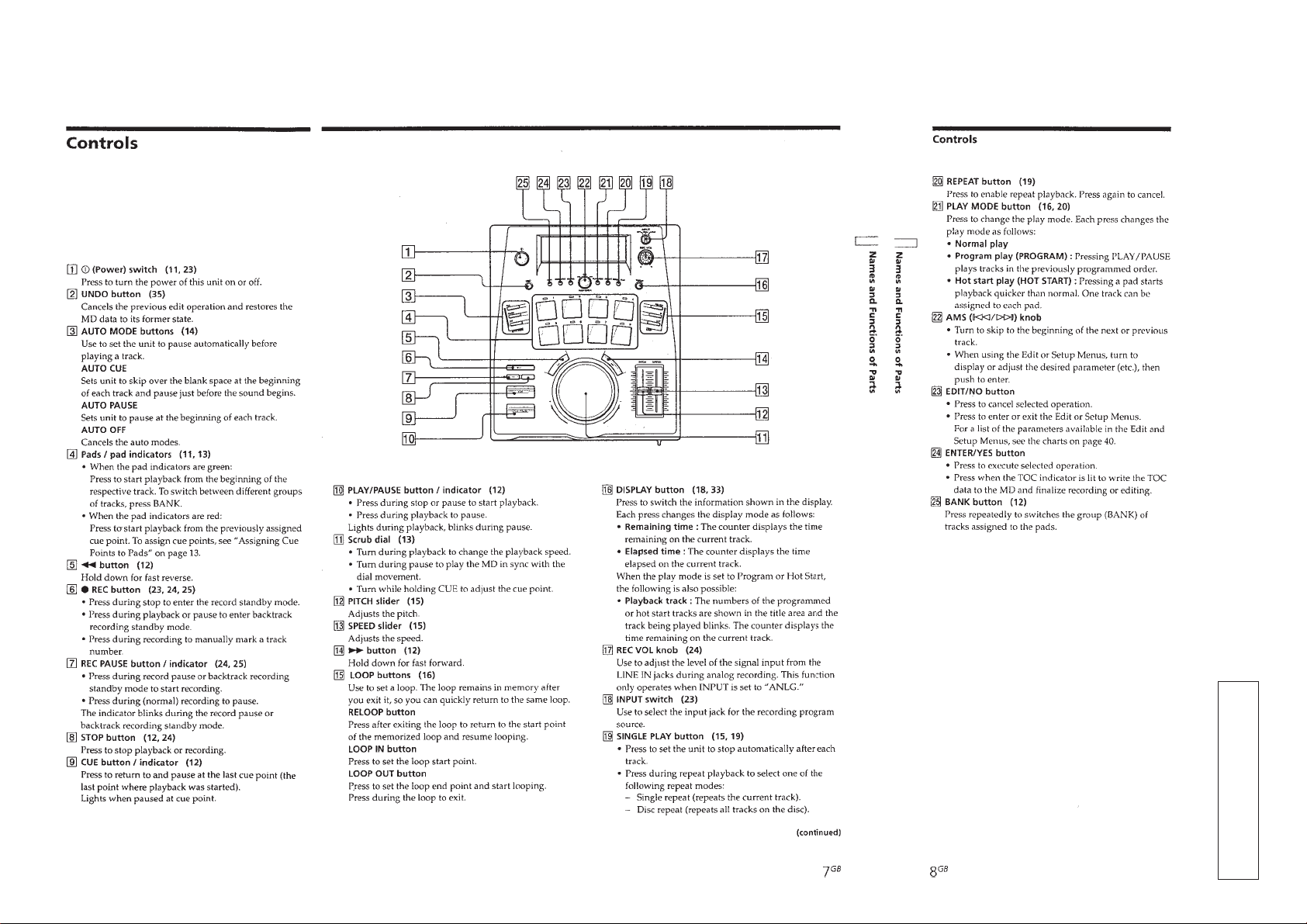

NAMES AND FUNCTIONS OF PARTS

– 7 –

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 8 –

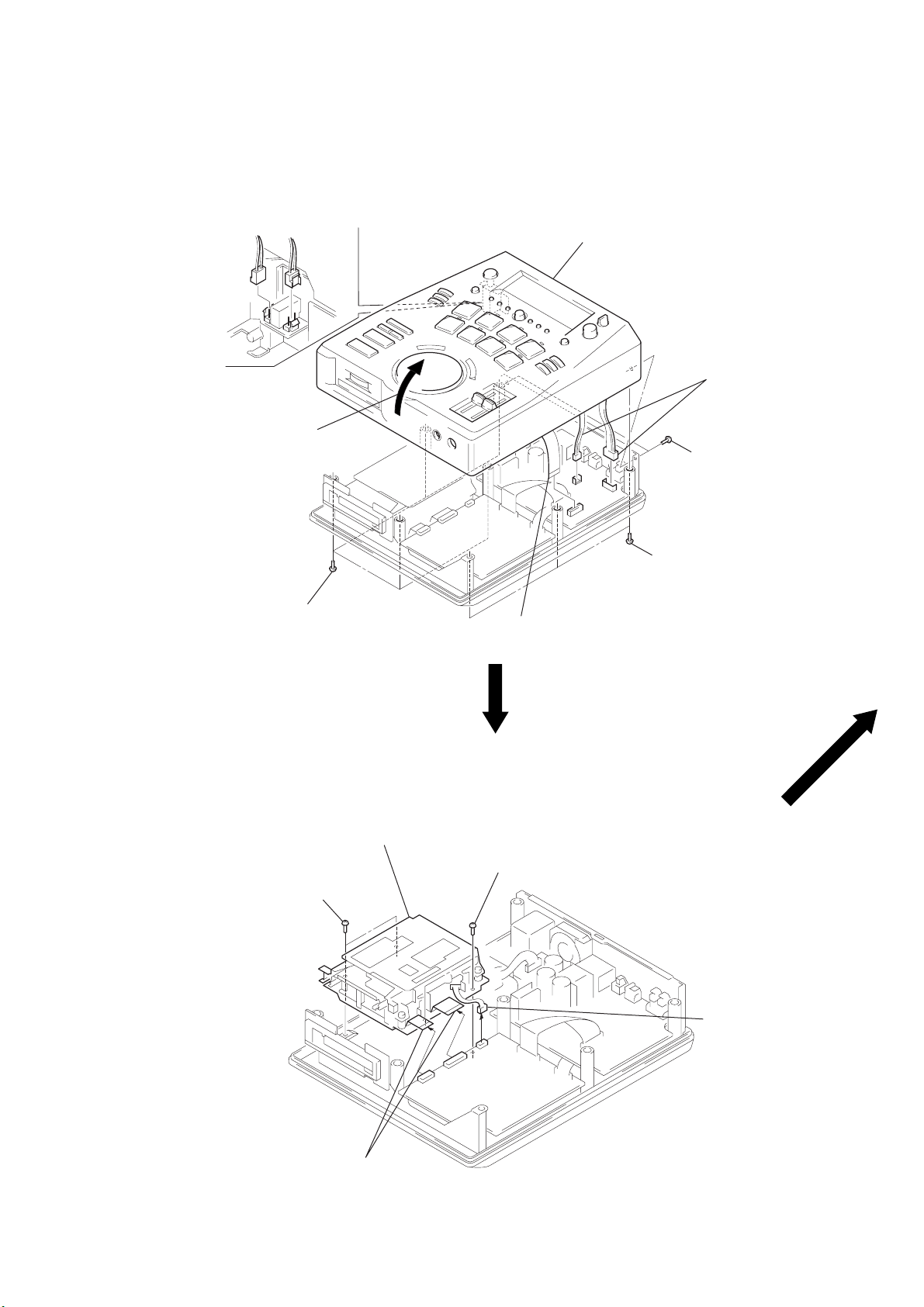

SECTION 3

s

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

UPPER CABINET SECTION

4

two connectors

(CN801, 802)

3

Open the upper cabinet

section in arrow direction.

6

upper cabinet section

4

2

two screws

(BV3

two connector

(CN701, 751)

×

8)

MD ASSEMBLY

1

3

two screws

(BVTP3

five screws

(BV3

×

10)

×

8)

4

MD assembly

5

3

two screws

(BVTP3

flat wire

(CN902)

×

8)

1

three screws

(BV3

×

10)

2

two flat wires

(CN4, 5)

– 9 –

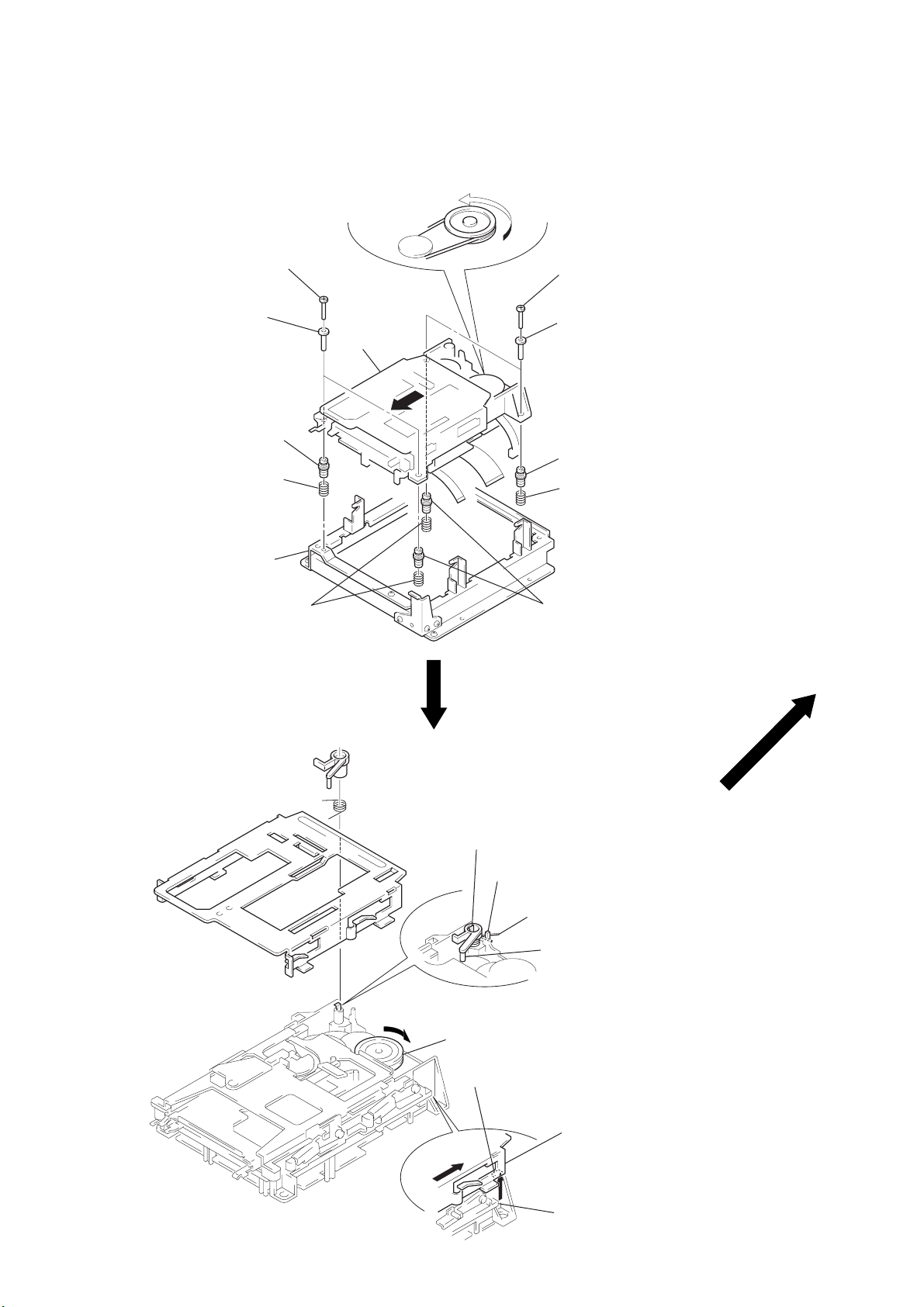

1

connector

(CN3)

BRACKET (MD)

3

two collars

4

insulator (MD)

5

compression spring

6

bracket (MD)

2

two screws

(B2.6

×

18)

1

Rotate the pully (BD) in arrow

direction

assembly in arrow direction

slider

assembly

A

and move the slider

B

B

A

.

2

two screws

(B2.6

×

18)

3

two collars

4

insulator (MD)

5

compression spring

SLIDER (M) ASSEMBLY

5

two compression

springs

C

4

two insulators (MD)

claw

B

A

claw

1

Disengage a coil spring

from the claw

2

Disengaging the claw B,

raise the lever (SLM)

upwards to remove.

3

Rotate the pully (BD) in arrow direction C.

A

.

A

– 10 –

claw

C

B

Move the claw C on the slider

4

up to the base groove in arrow

direction

direction

Base groove

A

, and raise it in arrow

B

to remove.

BASE UNIT AND LOADING MOTOR ASSEMBLY

r

1

screw

(BV3

×

6)

3

belt

4

two screws

(B2.6

×

5)

6

loading moto

assembly

2

base unit

SLIDER ASSEMBLY MOUNTING

B

1

two screws

(BV3

×

6)

3

Move the slider assembly in

arrow direction

to the lever (SLM).

A

B

, and lock it

1

Rotate fully the lever (SLM)

in arrow direction

A

5

.

connector

(CN192)

C

– 11 –

2

Rotate the pully (BD)

in arrow

C

direction.

SECTION 4

TEST MODE

4-1. Setting the Test Mode

U

Press [] (POWER) switch while pressing the [AMS] knob to turn POWER ON.

4-2. Exiting the Test Mode

Press the [REPEAT] button. Unplug the power plug from an outlet.

4-3. Basic Operations of the Test Mode

All operations are performed using the [AMS] knob, [ENTER/YES] button, and [EDIT/NO] button.

The functions of these buttons are as follows.

Function

[AMS] knob

[ENTER/YES] button

[EDIT/NO] button

Changes parameters and modes

Proceeds onto the next step. Finalizes input.

Returns to previous step. Stops operations.

Contents

4-4. Selecting the Test Mode

Eight test modes are selected by turning the [AMS] knob.

Display

TEMP ADJUS

LDPWR ADJUS

EFBAL ADJUS

FBIAS ADJUS

FBIAS CHECK

CPLAY MODE

CREC MODE

EEP MODE

For detailed description of each adjustment mode, refer to 5. Electrical Adjustments.

If a different adjustment mode has been selected by mistake, press the

* The EEP MODE is not used in servicing. If set accidentally, press the [EDIT/NO] button immediately to exit it.

4-4-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

1 Set the disc in the unit (either MO or CD).(MO: Recordable disc, CD: Disc for playback only)

2 Rotate the [AMS] knob and display “CPLAY MODE”.

3 Press the [ENTER/YES] button to change the display to “CPLAY IN”.

4 When access completes, the display changes to “C1 = AD = ”.

Note: The “ ” displayed are arbitrary numbers.

2. Changing the parts to be played back

1 Press the [ENTER/YES] button during continuous playback to change the display to “CPLAY MID”, “CPLAY OUT”.

When pressed another time, the parts to be played back can be changed.

2 When access completes, the display changes to “C1 = AD = ”.

Note: The “ ” displayed are arbitrary numbers.

3. Ending the continuous playback mode

1 Press the [EDIT/NO] button. The display will change to “CPLAY MODE”.

2 Press the [EJECT] button and remove the disc.

Note 1: The playback start addresses for IN, MID, and OUT are as follows.

§

IN 40h cluster

MID 300h cluster

OUT 700h cluster

Temperature compensation offset adjustment

Laser power adjustment

Traverse adjustment

Focus bias adjustment

Focus bias check

Continuous playback mode

Continuous recording mode

Non-volatile memory mode *

Contents

[EDIT/NO] button to exit from it.

– 12 –

4-4-2. Operating the Continuous Recording Mode

1. Entering the continuous recording mode

1 Set the MO disc in the unit.

2 Rotate the [AMS] knob and display “CREC MODE”.

3 Press the [ENTER/YES] button to change the display to “CREC IN”.

4 When access completes, the display changes to “CREC ( ” and REC lights up.

Note : The “ ” displayed are arbitrary numbers.

2. Changing the parts to be recorded

1 When the [ENTER/YES] button is pressed during continuous recording, the display changes to “CREC MID”, “CREC OUT” and

REC goes off.

When pressed another time, the parts to be recorded can be changed.

2 When access completes, the display changes to “CREC ( ” and REC lights up.

Note : The “ ” displayed are arbitrary numbers.

3. Ending the continuous recording mode

1 Press the [EDIT/NO] button. The display changes to “CREC MODE” and REC goes off.

2 Press the [EJECT] button and remove the disc.

Note 1: The recording start addresses for IN, MID, and OUT are as follows.

§

IN 40h cluster

MID 300h cluster

OUT 700h cluster

Note 2: The [EDIT/NO] button can be used to stop recording anytime.

Note 3: During the test mode, the erasing-protection tab will not be detected. Therefore be careful not to set the continuous recording mode when a

Note 4: Do not perform continuous recording for long periods of time above 5 minutes.

Note 5: During continuous recording, be careful not to apply vibration.

disc not to be erased is set in the unit.

4-4-3. Non-Volatile Memory Mode (EEP MODE)

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If set accidentally, press the [EDIT/NO] button immediately to exit it.

4-5. Functions of Other buttons

Function

PLAY/PAUSE

STOP

)

0

r REC

BANK

PLAY MODE

DISPLAY

Note: The erasing-protection tab is not detected during the test mode. Recording will start regardless of the position of the erasing-protection tab when the

r

[REC] button is pressed.

Sets continuous playback when pressed in the STOP state. When pressed during continuous playback, the tracking serv o

turns ON/OFF.

Stops continuous playback and continuous recording.

The sled moves to the outer circumference only when this is pressed.

The sled moves to the inner circumference only when this is pressed.

Turns recording ON/OFF when pressed during continuous playback.

Switches between the pit and groove modes when pressed.

Switches the spindle servo mode (CLVS and A).

Switches the display when pressed.Returns to previous step. Stops operations.

Contents

– 13 –

4-6. Test Mode Displays

Each time the [DISPLAY] button is pressed, the display changes in the following order.

MODE display n Error rate display n Address display

1. MODE display

Displays “TEMP ADJUS”, “CPLAY MODE”, etc.

2. Error rate display

Error rates are displayed as follows.

C1 = AD =

C1 = : Indicates C1 error

AD = : Indicates ADER

3. Address display

Addresses are displayed as follows.

“h = s = ” (MO pit and CD)

“h = a = ” (MO groove)

h = : Header address

s = : SUBQ address

a = :ADIP address

Note: “—” is displayed when the address cannot be read.

4-7. Meanings of Other Displays

Display

·

P

REC

CLOCK

TRACK

DISC

DA TE

A. PAUSE

A – B

Light

During continuous playback

Tracking servo OFF

Recording mode ON

CLV LOCK

Pit

High reflection

CLV-S

ABCD adjustment completed

Focus auto gain successful

Tracking auto gain successful

STOP

Tracking servo ON

Recording mode OFF

CLV UNLOCK

Groove

Low reflection

CLV-A

Contents

Off

Blinking

Focus auto gain successful

Tracking auto gain failed

4-8. Precautions for Use of Test Mode

1 As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc is

stopped before setting and removing it.

Even if the [EJECT] button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not

stop rotating.

Therefore, it will be ejected while rotating.

Always press the [EDIT/NO] button first before pressing the [EJECT] button.

2 The erasing-protection tab is not detected in the test mode. Therefore, when modes which output the recording laser power such as

continuous recording mode and traverse adjustment mode, etc. are set, the recorded contents will be erased regardless of the position of

the tab. When using a disc that is not to be erased in the test mode, be careful not to enter the continuous recording mode and traverse

adjustment mode.

§

§

– 14 –

SECTION 5

ELECTRICAL ADJUSTMENTS

Precautions for Checking Laser Diode Emission

T o check the emission of the laser diode during adjustments, never

view directly from the top as this may lose your eye-sight.

Precautions for Use of optical pick-up (KMS-210A)

As the laser diode in the optical pick-up is easily damaged by

static electricity, solder the laser tap of the flexible board when

using it.Before disconnecting the connector, desolder first. Before connecting the connector, be careful not to remove the solder.

Also take adequate measures to prevent damage by static electricity. Handle the flexible board with care as it breaks easil y.

laser tap

Optical pick-up flexible board

• Abbreviation

MO: Recordable disc

CD: Disc for playback only

Precautions for Adjustments

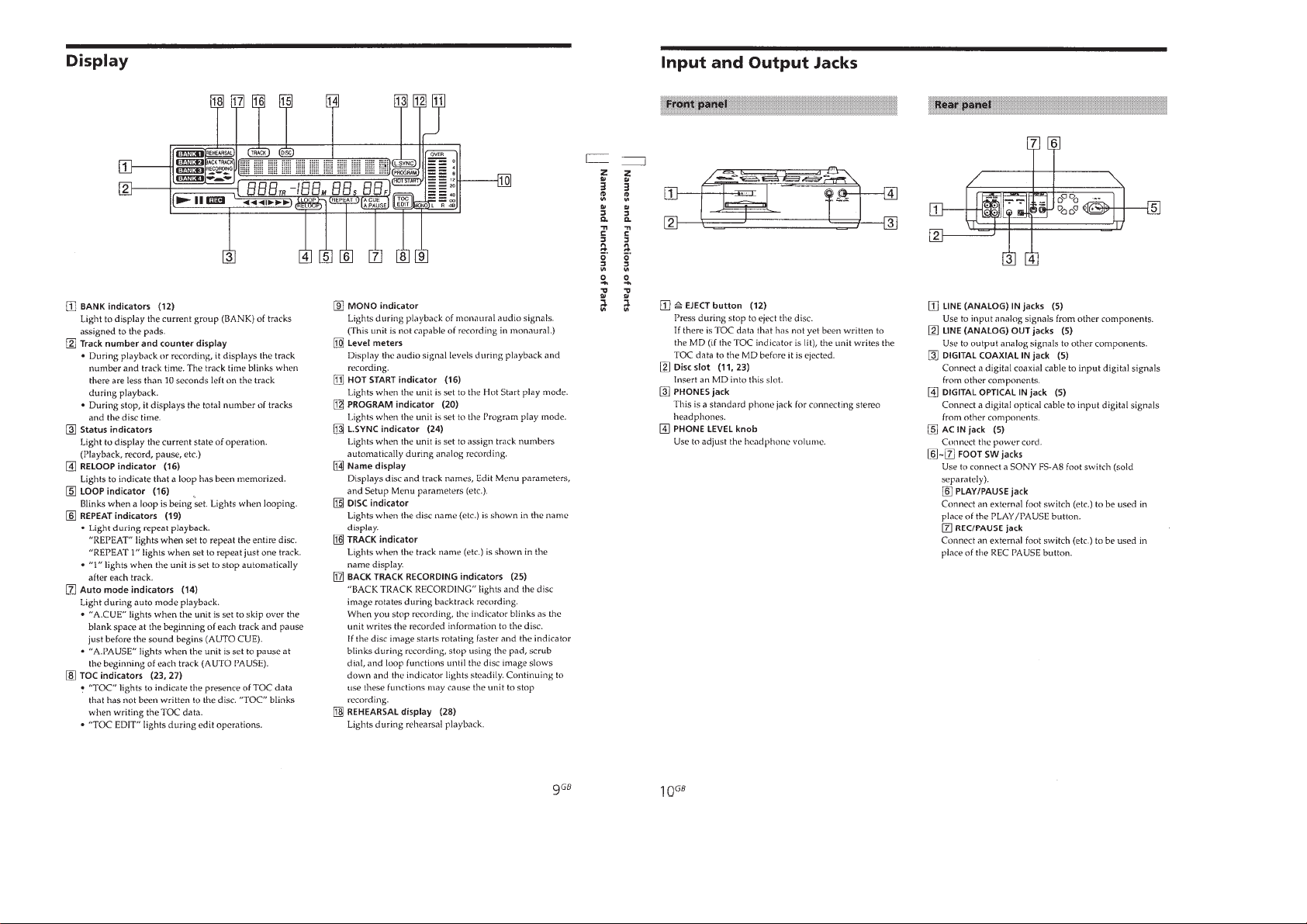

1) When replacing the following parts, perform the adjustments

and checks with ® in the order shown in the following table.

Optical

Pick-up

1. Temperature

compensation

offset adjustment

2. Laser power

adjustment

3. Trav erse

adjustment

4. Focus bias

adjustment

5. Error rate check

IC171

G

¬

¬¬

¬¬ ¬

¬

¬

GG

¬¬

2) Set the test mode when performing adjustments.

After completing the adjustments, exit the test mode.

3) Perform the adjustments in the order shown.

4) Use the following tools and measuring devices.

• Check Disc (MD) TDYS-1 (Parts No. 4-963-646-01)

• Laser power meter LPM-8001 (Parts No. J-2501-046-A) or

MD Laser power meter 8010S (Parts No. J-2501-145-A)

• Oscilloscope

• Digital voltmeter

• Thermometer

5) When observing several signals on the oscilloscope, etc.,

make sure that VC and ground do not connect inside the oscilloscope.

(VC and ground will become short-circuited.)

BD Board

IC101, IC121, IC191

D101

¬¬

¬

G

G

G

¬

Laser power meter

When performing laser power checks and adjustment (electrical

adjustment), use of the new MD laser power meter 8010S (J-2501145-A) instead of the conventional laser power meter is convenient.

It sharply reduces the time and trouble to set the laser power meter

sensor onto the objective lens of the pick-up.

Creating Continuously Recorded Disc

* This disc is used in focus bias adjustment and error rate check.

The following describes how to create a continuous recording

disc.

1. Insert a MO disc (blank disc) commercially available.

2. Rotate the

[AMS] knob and display “CREC MODE”.

3. Press the [ENTER/YES] button and display “CREC IN”.

4. Press the [ENTER/YES] button again to display “CREC MID”.

“CREC (0300” is displayed for a moment and recording starts.

5. Complete recording within 5 minutes.

6. Press the [EDIT/NO] button and stop recording .

7. Press the [EJECT] button and remove the MO disc.

§

The above has been how to create a continuous recording data for

the focus bias adjustment and error rate check.

Note:

• Be careful not to apply vibration during continuous recording.

– 15 –

Temperature Compensation Offset Adjustment

r

Laser Power Adjustment

Save the temperature data at that time in the non-volatile memory

as 25 ˚C reference data.

Note:

1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22 ˚C to 28 ˚C.

Perform it immediately after the power is turned on when the internal

temperature of the unit is the same as the ambient temperature.

3. When D101 has been replaced, perform this adjustment after the temperature of this part has become the ambient temperature.

Adjusting Method:

1. Rotate the [AMS] knob and display “TEMP ADJUS”.

2. Press the [ENTER/YES] button and select the “TEMP ADJUS”

mode.

3. “TEMP = ” and the current temperature data will be displayed.

4. To save the data, press the [ENTER/YES] button.

When not saving the data, press the [EDIT/NO] button.

5. When the [ENTER/YES] button is pressed, “TEMP = SAV”

will be displayed for some time, followed by “TEMP ADJUS”.

When the [EDIT/NO] button is pressed, “TEMP ADJUS” will

be displayed.

Specifications:

The “TEMP = ” should be within “E0 - EF”, “F0 - FF”, “00 0F”, “10 - 1F” and “20 - 2F”.

Connection:

Laser power

meter

Optical pick-up

objective lens

Digital voltmete

BD board

TP57 (I + 5V)

TP58 (IOP)

Adjusting Method:

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly , press the [] but-

)

ton or [] button and move the optical pick-up.)

0

Connect the digital volt meter to TP58 (IOP) and TP57 (I+5V).

2. Rotate the [AMS] knob and display “LDPWR ADJUS”.

(Laser power : For adjustment)

3. Press the [ENTER/YES] button twice and display “LD $ 4B =

3.5 mW”.

4. Adjust RV102 of the BD board so that the reading of the laser

power meter becomes 3.4 mW.

+ 0.1

– 0

5. Press the [ENTER/YES] button and display “LD $ 96 = 7.0

mW”.

(Laser power: MO writing)

6. Check that the laser power meter and digital voltmeter readings satisfy the specified value.

Specification:

Laser power meter reading: 7.0 ± 0.3 mW

Digital voltmeter reading: Optical pickup displayed value ± 10%

(Optical pickup label)

KMS

210A

27X40

B0825

n

lop = 82.5 mA in this case

lop (mA) = Digital voltmeter reading (mV)/ 1 (Ω)

7. Press the [ENTER/YES] button and display “LD $ 0F = 0.7

mW”.

(Laser power: MO reading)

8. Check that the laser power meter at this time satisfies the specified value.

Specification:

Laser power meter reading: 0.70 mW

9. Press the [EDIT/NO] button and display “LDPWR ADJUS”,

and stop laser emission.

(The [EDIT/NO] button is effective at all times to stop the laser emission.)

+ 0.05

– 0.1

– 16 –

Traverse Adjustment

A

B

A

B

VC

A

B

Specification A = B

VC

A

B

Specification A = B

e

Connection:

Oscilloscope

11. Rotate the

[AMS] knob until the waveform of the oscilloscope

moves closer to the specified value.

In this adjustment, waveform varies at interv als of approx. 3%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

BD board

TP75 (TEO)

TP31 (VC)

Adjusting method:

1. Connect an oscilloscope to TP75 (TEO) and TP31 (VC) of the

BD board.

2. Load a MO disc (any available on the market). (Refer to Note

1)

3. Press the [] button or [] button and move the optical

0

)

pick-up outside the pit.

4. Rotate the [AMS] knob and display “EFBAL ADJUS”.

5. Press the [ENTER/YES] button and display “EFBAL MO-W”.

(Laser power WRITE power/Focus servo ON/tracking servo

OFF/spindle (S) servo ON)

6. Adjust RV101 of the BD board so that the waveform of the

oscilloscope becomes the specified value.

(MO groove write power traverse adjustment)

(T r averse W av eform)

VC

(Traverse Wav ef orm)

12. Press the

[ENTER/YES] button, display “EFB = $ SAV” for

a moment and save the adjustment results in the non-volatile

memory.

Next “EFBAL CD” is displayed. T he disc stops rotating automatically.

13. Press the [EJECT] button and remove the MO disc.

§

14. Load the check disc (MD) TDYS-1.

15. Press the

[ENTER/YES] button and display “EFB = $ CD”.

Servo is imposed automatically.

16. Rotate the [AMS] knob so that the waveform of the oscilloscope moves closer to the specified value.

In this adjustment, waveform varies at interv als of approx. 3%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

(Traverse Wav ef orm)

7. Press the

R”.

(Laser power: MO reading)

8. Rotate the [AMS] knob so that the waveform of the oscilloscope becomes the specified value.

(When the

and the waveform changes.) In this adjustment, wa veform var ies at intervals of approx. 3%. Adjust the waveform so that

the specified value is satisfied as much as possible.

(MO groove read power traverse adjustment)

(T r averse W av eform)

VC

9. Press the [ENTER/YES] button, display “EFB = $ SAV” for

a moment and save the adjustment results in the non-volatile

memory.

Next “EFBAL MO-P” is displayed.

10. Press the

P”.

The optical pick-up moves to the pit area automatically and

servo is imposed.

Specification A = B

[ENTER/YES] button and display “EFB = $ MO-

[AMS] knob is rotated, the of “EFB = $ ” changes

Specification A = B

[ENTER/YES] button and display “EFB = $ MO-

17. Press the [ENTER/YES] button, display “EFB = $ SAV” for

a moment and save the adjustment results in the non-volatile

memory.

Next “EFBAL ADJUS” is displayed.

18. Press the [EJECT] button and remove the test disc TD YS-1.

Note 1: Data will be erased during MO reading if a recorded disc is used

Note 2: If the traverse waveform is not clear , connect the oscilloscope as

§

in this adjustment.

shown in the following figure so that it can be seen more clearly.

Oscilloscop

BD board

TP75 (TEO)

TP31 (VC)

330 k

Ω

10 pF

– 17 –

Focus Bias Adjustment

Adjusting Method:

1. Load a continuously recorded disc (Refer to “Page 15 Creating Continuously Recorded Disc”).

2. Rotate the [AMS] knob and display “CPLAY MODE”.

3. Press the [ENTER/YES] button twice and display “CPLAY

MID”.

4. Press the [EDIT/NO] button when “C1 = AD = ” is

displayed.

5. Rotate the [AMS] knob and display “FBIAS ADJUS”.

6. Press the [ENTER/YES] button and display “ / a = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [a =] indicate

the focus bias value.

7. Rotate the [AMS] knob in the clockwise direction and find the

focus bias value at which the C1 error rate becomes about 200

(Refer to Note 2) .

8. Press the [ENTER/YES] button and display “ / b = ”.

9. Rotate the [AMS] knob in the counterclockwise direction and

find the focus bias value at which the C1 error rate becomes

about 200.

The C1 error rate at this time should be almost same as the

value set in step 7.

10. Press the [ENTER/YES] button and display “ / c = ”.

11. Check that the C1 error rate is below 50 and ADER is 00.

Then press the [ENTER/YES] button.

12. If the “( ” in “ - - ( ” is above 20, press the

[ENTER/YES] button.

If below 20, press the [EDIT/NO] button and repeat the adjustment from step 2 again.

13. Press the [EDIT/NO] button and press the [EJECT] button

to remove the continuously recorded disc.

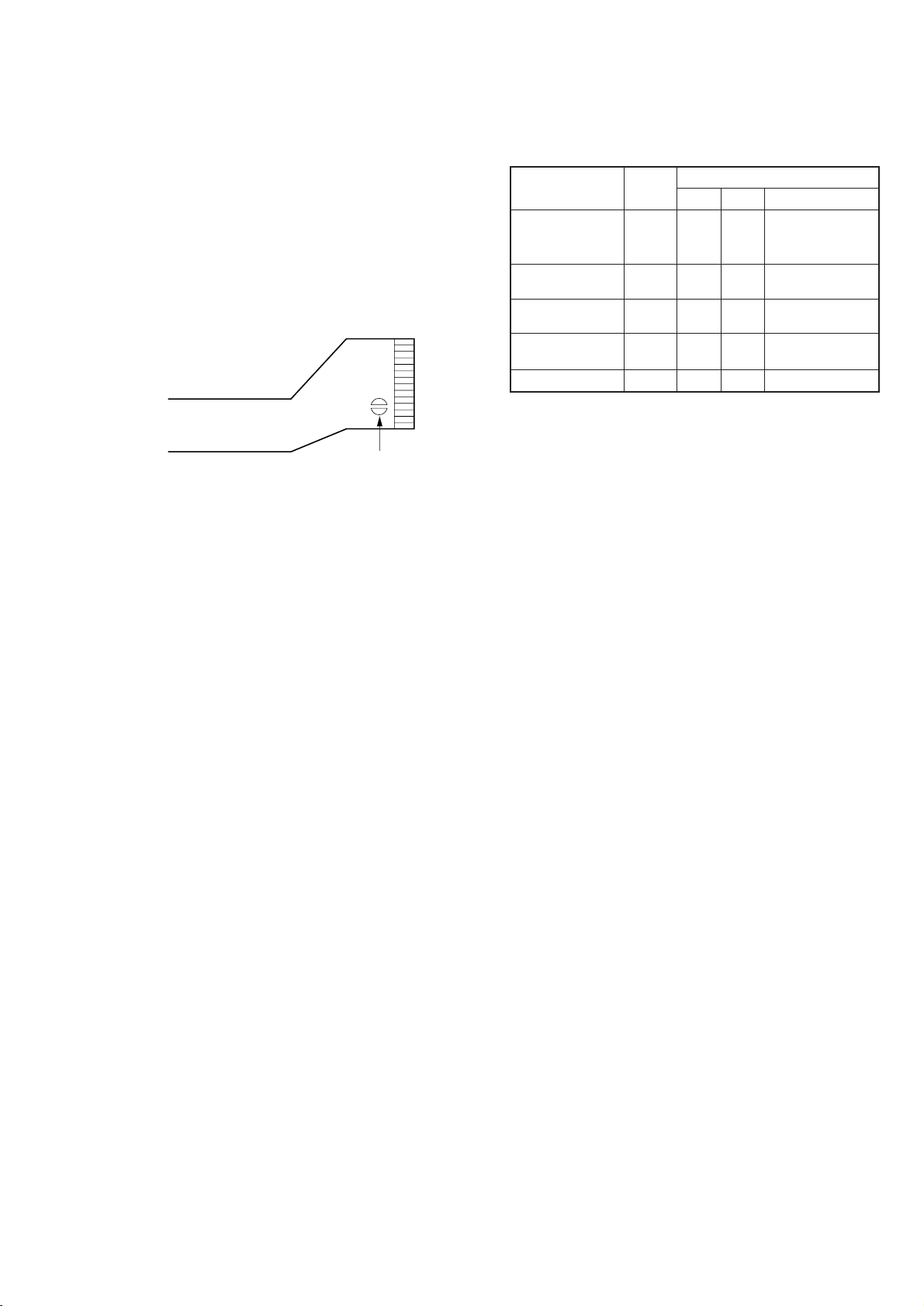

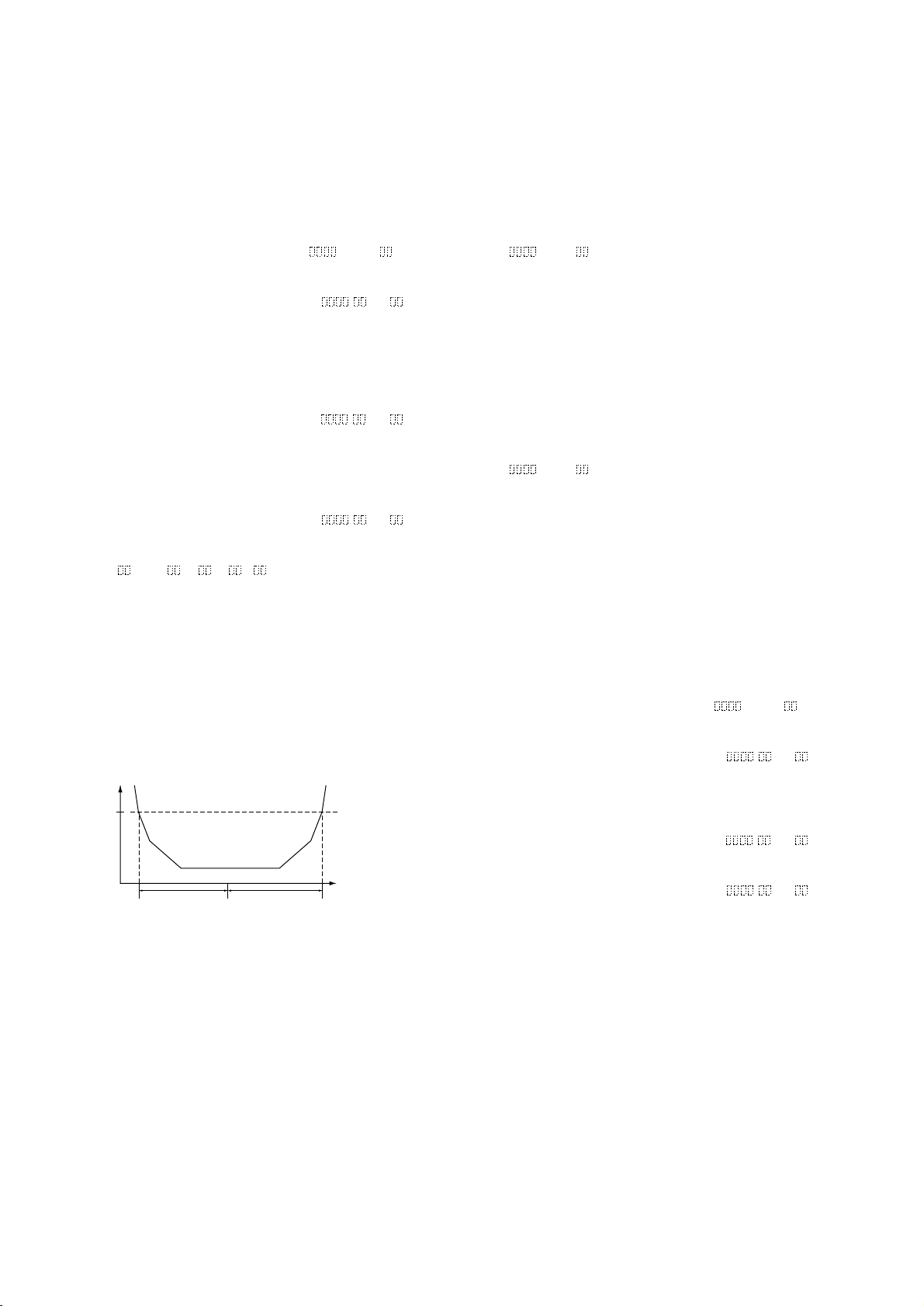

Note 1: The relation between the C1 error and focus bias is as shown in

Note 2: As the C1 error rate changes, perform the adjustment using the

the following figure. Find points a and b in the following figure

using the above adjustment. The focal point position C is

auto

matically calculated from points a and b.

average value.

C1 error

about 200

bc a

§

Focus bias

value

(F. BIAS)

Error Rate Check

CD Error Rate Check

Checking Method:

1. Load a check disc (MD) TDYS-1.

2. Rotate the [AMS] knob and display “CPLAY MODE”.

3. Press the [ENTER/YES] button twice and display “CPLAY

MID”.

4. “C1 = AD = ” is displayed.

5. Check that the C1 error rate is below 20.

6. Press the [EDIT/NO] button, stop playback, press the [EJECT]

§

button, and remove the check disc.

MO Error Rate Check

Checking Method:

1. Load a continuously recorded disc (Refer to “Page 15 Creating Continuously Recorded Disc”).

2. Rotate the [AMS] knob and display “CPLAY MODE”.

3. Press the [ENTER/YES] button twice and display “CPLAY

MID”.

4. “C1 = AD = ” is displayed.

5. If the C1 error rate is below 50, check that ADER is 00.

6. Press the [EDIT/NO] button, stop playback, press the [EJECT]

§

button, and remove the continuously recorded disc.

Focus Bias Check

Change the focus bias and check the focus tolerance amount.

Checking Method:

1. Load a continuously recorded disc (Refer to “Page 15 Creating Continuously Recorded Disc”).

2. Rotate the

3. Press the [ENTER/YES] button twice and display “CPLAY

MID”.

4. Press the [EDIT/NO] button when “C1 = AD = ” is

displayed.

5. Rotate the [AMS] knob and display “FBIAS CHECK”.

6. Press the [ENTER/YES] button and display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate

the focus bias value.

Check that the C1 error is below 50 and ADER is 00.

7. Press the [ENTER/YES] button and display “ / b = ”.

Check that the C1 error is not below about 200 and ADER is

not above 00 every time.

8. Press the [ENTER/YES] button and display “ / a = ”.

Check that the C1 error is not below about 200 and ADER is

not above 00 every time.

9. Press the [EDIT/NO] button, next press the [EJECT] button,

and remove the continuously recorded disc.

[AMS] knob and display “CPLAY MODE”.

§

Note 1: If the C1 error and ADER are above 00 at points a or b, the focus

bias adjustment may not have been carried out properly. Adjust

perform the beginning again.

– 18 –

Adjusting Points and Connecting Points

[BD Board] (Side A)

D101

[BD Board] (Side B)

IC171

TP58

(IOP)

RV101

TP57

(I + 5V)

TP31

(VC)

RV102

IC191

IC101

TP75

(TEO)

IC121

– 19 –

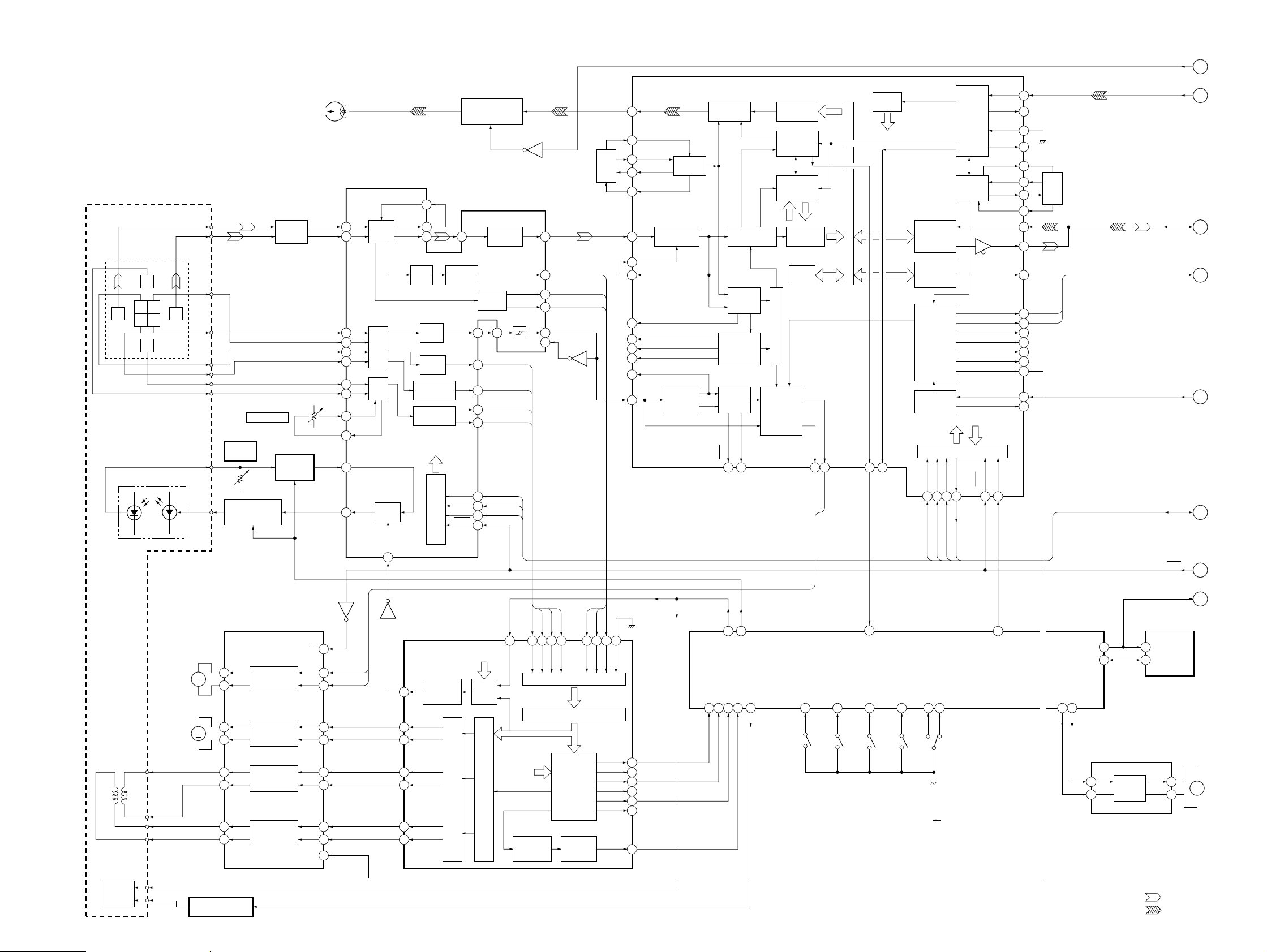

6-1. BLOCK DIAGRAM – SERVO Section –

F

C

I

DA

E

OPTICAL PICK-UP

(KMS-210A/J-N)

LASER DIODE

PD

B

DETECTOR

I

J

B

J

A

C

D

E

F

RV102

LASER

POWER

PD

ILCC

LD

AUTOMATIC

POWER CONTROL

Q162, 163

RV101

E-F BALANCE

I-V AMP

IC172

LASER ON

SWITCH

Q101

SECTION 6

DIAGRAMS

HR901

OVER WRITE HEAD

RF AMP, FOCUS/TRACKING

ERROR AMP

I

47

J

48

A

2 30

B

C

AMP

4

D

5

E

6

F

AMP

7

FI

8

FO

9

PD

10

AAPC

14

IC101

RF

AMP

I-V

I-V

APC

APCREF

11

OVER WRITE

HEAD DRIVE

IC181, Q181, 182

4

2

IC182

MORFI

45

MORFO

46

RFO

44 41 58

B.P.F.

AT

AMP

ABCD

AMP

FOCUS

ERROR AMP

TRACKING

ERROR AMP

SERIAL TO PARALLEL

43

AUX

SWITCH

ADFM

ABCD

SWDT

SCLK

XLAT

DECODER

XRST

AGCI

37

FE

35

TE

26

SE

29

18

19

20

17

RF

AGC & EQ

PEAK &

BOTTOM

ADIN

31 33

AUX

PEAK

BOTM

TLB

RF

34

39

38

ADFG

273

4

IC102

MDS-DRE1

SCTX

DIGITAL SIGNAL PROCESSOR,

EFM/ACIRC ENCODER/DECODER

IC121 (1/2)

EFMO

45

FILI

62

CLTV

60

PCO

61

FILTER

FILO

63

RFI

ASYI

56

ASYO

55

XPLCK

44

WFCK

41

GTOP

42

GFS

2

43

FMCK

22

ADFG

82

34MHz

PLL

COMPARATOR

ADIP

DEMODU-

LATOR

EFM

MODULATOR

EFM

DEMODULATOR

EFM

DIGITAL

PLL

EFM-SYNC

DETECTOR/

PROTECTOR

ADIP

DECODER

ADSY

ATER

23 13 93 94 14 15

REGISTER

SUBCODE

P TO W

PROCESSOR

SUBCODE Q

READER/

GENERATOR

REGISTER

32K

RAM

TIMING GENERATOR

DIGITAL

CLV

PROCESSOR

SPRD

SPFD

PEAK

DETECT

INTERNAL BUS

SQSY

DQSY

DIGITAL

AUDIO

IN/OUT

DIN PLL

(22MHz)

AUDIO

DATA

CONTROL

ECC

ENCODER/

DECODER

TIMING

GENERATOR

CLOCK

GENERATOR

CPU INTERFACE

SWDT

SCLK

XLAT

SRDT

8 9 10 11 16 24

XRST

DODT

DIDT

DOUT

DIFO

DICV

DIPD

C2PO

LRCK

MCLK

XBCK

WDCK

RFCK

XTAI

XTAO

REC

DIN

DIFI

DTI

DTO

BCK

FS4

27

28

21

20

53

51

49

52

29

30

31

33

32

36

37

39

40

90

35

34

FILTER

SWDT, SCLK, XLAT, SRDT

DODT

DATA

BCK, LRCK, C2PO

512FS

XRST

A

B

C

D

E

F

G

(Page 23)

(Page 23)

(Page 23)

(Page 23)

(Page 24)

(Page 23)

(Page 24)

4

SPINDLE/SLED MOTOR DRIVE,

FOCUS/TRACKING COIL DRIVE

IC151

FO4

M102

(SPINDLE)

M101

(SLED)

2-AXIS

DEVICE

(FOCUS)

HF

MODULE

05

TRK+

(TRACKING)

TRK–

FCS+

FCS–

WRPWR

MOD

22

M

M

HF MODULE SWITCH

Q164

RO4

24

FO2

15

RO2

13

FO3

29

RO3

26

FO1

8

RO1

11

SPINDLE

MOTOR DRIVE

SLED

MOTOR DRIVE

TRACKING

COIL DRIVE

FOCUS

COIL DRIVE

RI4

F/R4

RI2

RI3

RI1

CLK

Q151

33

OE

SPFD

19

SPRD

20

FI2

17

18

FI3

31

32

FI1

6

5

3

IC122

2

DIGITAL SERVO SIGNAL

LDDR

APC PWM

84

GENERATOR

SFDR

92

SRDR

91

TFDR

86

TRDR

85

FFDR

87

FRDR

89

PROCESSOR

IC121 (2/2)

PWM GENERATOR

APC

COMP./

FILTER

SERVO

SIGNAL PROCESSOR

676 7677 66 64 65 68 78

FE

TE

SE

WRPWR

SERVO

SEQUENCER

AUTO

ABCD

ANALOG MUX

A/D CONVERTER

OFTRK/

DFCT/FOK/

COUT/SHCK/

FS256

PROCESSOR

CONTROL

SENS

PEAK

BOTM

AUX1

OFTRK

DFCT

FOK

COUT

SHCK

FS256

SENS

AUX2

PLAY SW

S192

S192

(PACK OUT)

5

SYSTEM CONTROLLER

SQSY

OUT SW

57

LOW REFELECT RATE/

IC101 (1/4)

REC SW

59

S193

S193

(REC POSITION)

(REFLECT/PROTECT DETECT)

UN-PROTECT

PROTECT

REFLECT

77 78

S102

S102

HIGH REFELECT RATE/

WRITE PROTECT

71

79

LD-ON

WPOWER

FG

FOK

SENSE

SHOCK

68 69 70 76 66

MOD

98

3

2

99

4

1

12

LIMIT-IN

80 58

S101

(LIMIT)

S191

(PLAY POSITION)

S191

65

REC/PB

LOAD OUT

61 60

75

SCL

SDA

74

LOAD IN

LOADING MOTOR DRIVE

IN1

9

IN2

10

IC901

MOTOR

DRIVE

SCL

SCL

6

SDA

5

EEPROM

IC171

OUT1

4

OUT2

2

• SIGNAL PATH

: PLAY

: REC

H

M

(Page 23)

M191

(LOADING)

– 21 – – 22 –

MDS-DRE1

6-2. BLOCK DIAGRAM – MAIN Section (1/2) –

B

(Page 22)

C

(Page 22)

D

(Page 22)

A

(Page 22)

F

(Page 22)

I

(Page 25)

H

(Page 22)

X101

10MHz

DODT

DATA

BCK, LRCK,

C2PO

SCTX

SWDT, SCLK,

XLAT, SRDT

SWDT, SCLK,

XLAT, SRDT

SCL

13

15

6 5

3

DODT SELECTOR

IC153 (1/2)

SERIAL DATA

SELECTOR

IC154

3 4

2 1

53

52

XOUT

DSEL

XIN

DODT-SEL

4

2

IC151

(1/4)

1

2

1

5

IC151

8

(2/4)

9

13

95

93

BCK

91

LRCK

90

C2PO

92

12

D0 – D3

69, 68, 70, 71

2, 3, 22, 23

DQ1 – DQ4 A0 – A11

67

SCTX

DODT

95

DATA

93

BCK

LRCK

C2PO

69, 68, 70, 71

2, 3, 22, 23

DQ1 – DQ4 A0 – A11

DODT

DATA

BCK

LRCK

C2PO

TX

GENERATOR

55 – 52, 56 – 60, 65, 49, 48

8 – 11, 14 – 19, 7, 6

D-RAM

IC602

91

90

92

12

D0 – D3

INTERFACE

EFM DECODER

ADDRESS

A00 – A11

XLAT

SCLK

SWDT

39

33

31

SCLK

SWDT

XLAT-DEC

BCK

LRCK

C2PO

TX

40

INTERFACE

EFM ENCODER

ADDRESS

GENERATOR

55 – 52, 56 – 60, 65, 49, 48

8 – 11, 14 – 19, 7, 6

D-RAM

IC502

CD-ROM DECODER

XWE

67 66 62 61 2 3 4 9 17

4 5 21 20

XLAT-ENC

CD-ROM ENCODER

A00 – A11

40

34

F86

EXE

INTERFACE

ATRAC DECODER

RAM R/W CONTROLLER

MEMORY

DECODER

CPU INTERFACE

XRAS

XCAS

XOE

SWDT

SWDT

XOE

XWE

XCAS

XRAS

XWE

67 66 62 61 2 3 4 9 175 6

4 5 21 20

XWE

DATA

ATRAC

SCK

SCLK

40

34

F86

EXE

INTERFACE

ATRAC ENCODER

RAM R/W CONTROLLER

XRAS

XCAS

XOE

XOE

XCAS

XRAS

SHOCK PROOF MEMORY CONTROLLER,

MEMORY

INTERFACE

CONTROLLER

SENSE

XLAT

XLAT

XINT

SRDT

5 6

SRDT

SYSTEM CONTROLLER

SHOCK PROOF MEMORY CONTROLLER,

MEMORY

CONTROLLER

DATA

MEMORY

ATRAC

ENCODER

CPU INTERFACE

SWDT

SCK

XLAT

SRDT

SCLK

SWDT

ATRAC DECODER

IC601

CLOCK

GENERATOR

XRST

2

5 6

SRDT

IC101 (2/4)

INTERFACE

SENSE

XINT

AUDIO

INTERFACE

SPO

87

IC152

ATRAC ENCODER

IC501

CLOCK

GENERATOR

SPO

XRST

87

DIDT

94

DIN

42

DOUT

41

ABCK

43

ALRCK

44

OSCI

37

OSCO

36

90.3168MHz

SRDT SELECTOR

3

1

4

6

IC151 (3/4)

AUDIO

INTERFACE

X601

IC152

DIDT

DOUT

ABCK

ALRCK

OSCO

5

85

DIN

OSCI

32

SRDT

SRDT-SEL

94

42

41

43

LRCK

44

37

36

X501

45.1584MHz

23 24 47

XINT-DEC

BCK

XINT-ENC

BCK

RST-37

LRCK

COUNTER

IC253 – 255

LRCK

8

BCK

11

73

75

57

51

55

CLK

GPIO3

GPIO1

SDI0

SCKR

WSR

IC271

(1/2)

IC271

(2/2)

DSP

IC701

SCL

72 81 56 41

PARALLEL

DATA

10

9

13

12

EXTAL

GPIO2

SDO1

SDO2

SDO0

SCKT

WST

SDA

GPIO0

RVS

SDA-CDSP

SHIFT REGISTER

9

FLIP-FLOP

IC202 (1/2)

27

74

46

45

47

49

50

SDI1

RESET

36

RPD0

RST-DSP

& LATCH

IC256, 257

11

BCK

BCK

LRCK

MD0 – MD3

71, 69 – 67

1, 2, 18, 19

DQ1 – DQ4

LATCH

BCK

SDO1 (DATA)

SDO2 (ENABLE)

12

IC201

(1/4)

34

SAMPLING RATE CONVERTER

FS128

1

3

2

7

IC751

DATAI

BCKI

INPUT

LRCKI

FSI28

INTERFACE

MA00 – MA09

25 – 22, 20 – 18, 16, 14, 13

6 – 9, 11 – 15, 5

D-RAM

IC702

SAMPLING

CONVERTER

ATT/MODE

CONTROL

SWDT

42 41

SWDT

A0 – A9

BCK

RATE

SCK

SCLK

FS128

XLAT

40

XLAT

LRCK

COUNTER

IC259, 260

OUTPUT

INTERFACE

FRAME

COUNTER

INIT

10

MWR

7826 35 76 56

79 80

3 4 17

WE

VCO

OUT

3

IC201

(2/4)

563 5

2

1

IC201

(3/4)

DATAO

30

BCKO

31

LRCKO

32

XI

13

MRAS

MCAS

CAS

RAS

VCO

1/2

DIVIDER

VCO

IC251 (1/2)

DIVIDER

IC202 (1/2)

BCK

LRCK

86

87

88

SWDT

3

SCLK

4

SRDT

7

5

43 44 45

LAT-KEY

VCO

SI

BCK

LRCK

RVDT

SCK

TRDT

XLAT

IN

CONTROL

13

OSC

IC201 (4/4)

8

33

XTLI

KEY

IC801

XRST

10

WAVE

SHAPER

IC252

SO

REDY

XWO

(Page 25)

DIDT

J

SDTO

K

(Page 25)

PFD

PLL

IC251 (2/2)

LATCH

IC258

LRCK

LINE OUT

SELECTOR

IC153 (2/2)

4

FINB

5

FINA

4

(Page 25)

MCLK

L

BCK, LRCK

8

M

(Page 25)

SDTI

N

(Page 25)

13

XRST

G

(Page 22)

XRST

O

(Page 25)

512FS

E

(Page 22)

512FS

P

(Page 25)

PFD

OUT

612

9

10

12

6

8

12 11

IC151

(4/4)

3

• SIGNAL PATH

: PLAY

: REC (ANALOG IN)

: REC (DIGITAL IN)

54

48

AOUT-SEL

RST-DIG

XWO-KEY

READY-KEY

05

6-3. BLOCK DIAGRAM – MAIN Section (2/2) –

MDS-DRE1

(Page 24)

(Page 24)

(Page 23)

(Page 24)

(Page 24)

(Page 24)

(Page 24)

(Page 24)

(Page 27)

J

P

I

O

M

K

N

L

Q

DIDT

512FS

SWDT, SCLK,

XLAT, SRDT

XRST

BCK, LRCK

SDTO

SDTI

MCLK

POWER DOWN

SAMPLING RATE CONVERTER

DATAO

30

BCK

LRCK

BCKO

31

LRCKO

32

XI

13

SDTO

14

SDTI

13

MCLK

15

IC451

OUTPUT

INTERFACE

FRAME

COUNTER

INIT

10

BCK

LRCK

11

12

SCLK

LRCK

SERIAL I/O

INTERFACE

CLOCK

DIVIDER

SAMPLING

RATE

CONVERTER

ATT/MODE

CONTROL

SWDT

SCK

42 41 40

SCLK

SWDT

24

23

PWAD

PWDA

DECIMATION

INTER-

POLATOR

XLAT

XLAT

FILTER

DEM0

16

DATAI

BCKI

INPUT

INTERFACE

LRCKI

FI128

A/D, D/A CONVERTER

IC301

Σ∆

MODULATOR

Σ∆

MODULATOR

1

3

2

7

LOW-PASS

FILTER

INTERFACE RECEIVER

DATA OUT

23

BCKO

21

LRCKO

22

FS128

20

AINL+

5

AINL–

6

AOUTL

26

AOUTR

27

DIGITAL AUDIO

IC401

TIMING

PLL

AVOCKLRCK

11

R-CH

DEMODULATOR

LOCK ERROR

AOUTL+

10

9

AOUTL–

BUFFER

IC342 (1/2)

DATA

DETECT

ERROR

24

BUFFER

IC311

INPUT

INTERFACE

CPU INTERFACE

DQSY

SCK

SWDT

18

16

14

15

SCLK

SWDT

INL–

4

LOW-PASS

FILTER

IC342 (2/2)

MUTING

CONTROL SWITCH

Q101

D101

XLAT

SRDT

17

XLAT

SRDT

MUTING

Q352

R-CH

DIN1

DIN2

XMODE

10

LINE AMP

IC701

1

2

HEADPHONE

AMP

IC751

RV701

REC VOL

WAVE

SHAPER

IC602

R-CH

RV751

PHONE

LEVEL

R-CH

R-CH

J701

OPTICAL

RECEIVER

IC601

L

R

L

R

J601

COAXIAL IN

OPTICAL IN

IN

OUT

J751

PHONES

IC601

LINE

(ANALOG)

DIGITAL

42

05

DEEMP-ADA

49

AMUTE

SYSTEM CONTROLLER

IC101 (3/4)

50

19

ERROR

DQSY

• SIGNAL PATH

: PLAY

: REC (ANALOG IN)

: REC (COAXIAL DIGITAL IN)

: REC (OPTICAL DIGITAL IN)

– 25 –

– 26 –

MDS-DRE1

6-4. BLOCK DIAGRAM – DISPLAY/KEY/POWER SUPPLY Section –

FL DRIVER CONTROL,

KEY CONTROL, LED DRIVE

REC/PAUSE

PLAY/PAUSE

S305

≠ AMS ±

PUSH ENTER

J851

FOOT SW

JOG DIAL

DETECT SENSOR

PH381, 382

ROTARY

ENCODER

2

1

24

23

A

1

B

3

54

25

26

FSW1

FSW0

JOG0

JOG1

JOGA

JOGB

IC201

SWDT

SCLK

FLCS

FL-RES

RESET

31

33

34

46

D102

12

16

15

14

13

D101

FL DRIVER

IC101

SDATA

SCK

CS

RST

XIN

21 20

OSC

C107, R101

D1 – D16S1 – S36

12 – 1, 64 – 6159 – 33, 31 – 23

XOUT

FLUORESCENT

INDICATOR TUBE

FL101

(Page 25)

Q

POWER DOWN

+5V

MD SERVO SECTION B+

HEAD/PWM +5V

+5V

REGULATOR

IC191

10

6

DIG +5V

+5V/+7V REGULATOR

IC411

OUT 7V

OUT 5V

5V ON/OFF

+5V

REGULATOR

IC421

7V ON/OFF

21

VCC

REGULATOR

7

+10V

IC422

RECT

D205, 206

S301 – 304, 306,

S311 – 316, 361 – 365,

S371 – 376

PAD UNIT

LED DRIVE

IC421, 431

RV392

PITCH

RV391

SPEED

89 – 9465, 67, 69, 71, 73, 75, 77, 79

KEY6, KEY7

KEY0 – KEY3,

LED-R.PAUSE

LED1-O – LED8-O

66, 68, 70, 72, 74, 76, 78, 80

INPUT-SEL0

INPUT-SEL1

LED1-G – LED8-G

KEY-CONT

97

SPEED-CONT

95

DTCK

DTIN

DTOUT

DTIN

DTCK

DTOUT

RTS

PMCU-REF

35 36 37 38 20

36 353738 34

LED-PP

LED-CUE

XIN

XOUT

DTCS

DTCS

POWER DOWN

LDDRV +7V

LOADING MOTOR

DRIVE (IC901) B+

SYS +5V

MCU +5V

(IC101) B+

DETECT

IC431

+5V

A/D, D/A CONVERTER

(IC301) B+

D451

D453

BT451

LITHIUM

BATTERY

D431

INI

2

3

RST

OUT 7V

10

OUT 5V

6

FL DRIVER (IC101) B–

+5V

REGULATOR

IC302

DRIVE

D364 – 366

PLAY/PAUSE

D361 – 363

CUE

D371

REC PAUSE

M801

M

(FAN)

SYSTEM CONTROLLER

IC101 (4/4)

7

PDOWN

SYSTEM CONTROLLER

12

51

STB

RESET

LED DRIVE

30

29

28

88

87

15

13

Q363, 364

LED DRIVE

Q361, 362

LED DRIVE

S601

INPUT

X201

10MHz

Q371

ANLG

COAX

OPT

FAN MOTOR

Q801, 802

87

FAN CONT

D432

RESET SIGNAL

GENERATOR

IC451

+5V/+7V REGULATOR

IC401

5V ON/OFF

7V ON/OFF

1

2

–32V

HEADPHONE

AMP (IC751)

A+6V

A–6V

REGULATOR

REGULATOR

+6V

IC301

–6V

IC302

VCC

VCC

5

7

–32V

REGULATOR

IC501

B+

B–

RECT

D207, 208

RECT

D210, 211

RECT

D209

RECT

D201 – 204

TO FL101

T901

POWER

TRANSFORMER

S801

U

(POWER)

NOISE

FILTER

AC

AC

~ AC IN

05

– 27 –

– 28 –

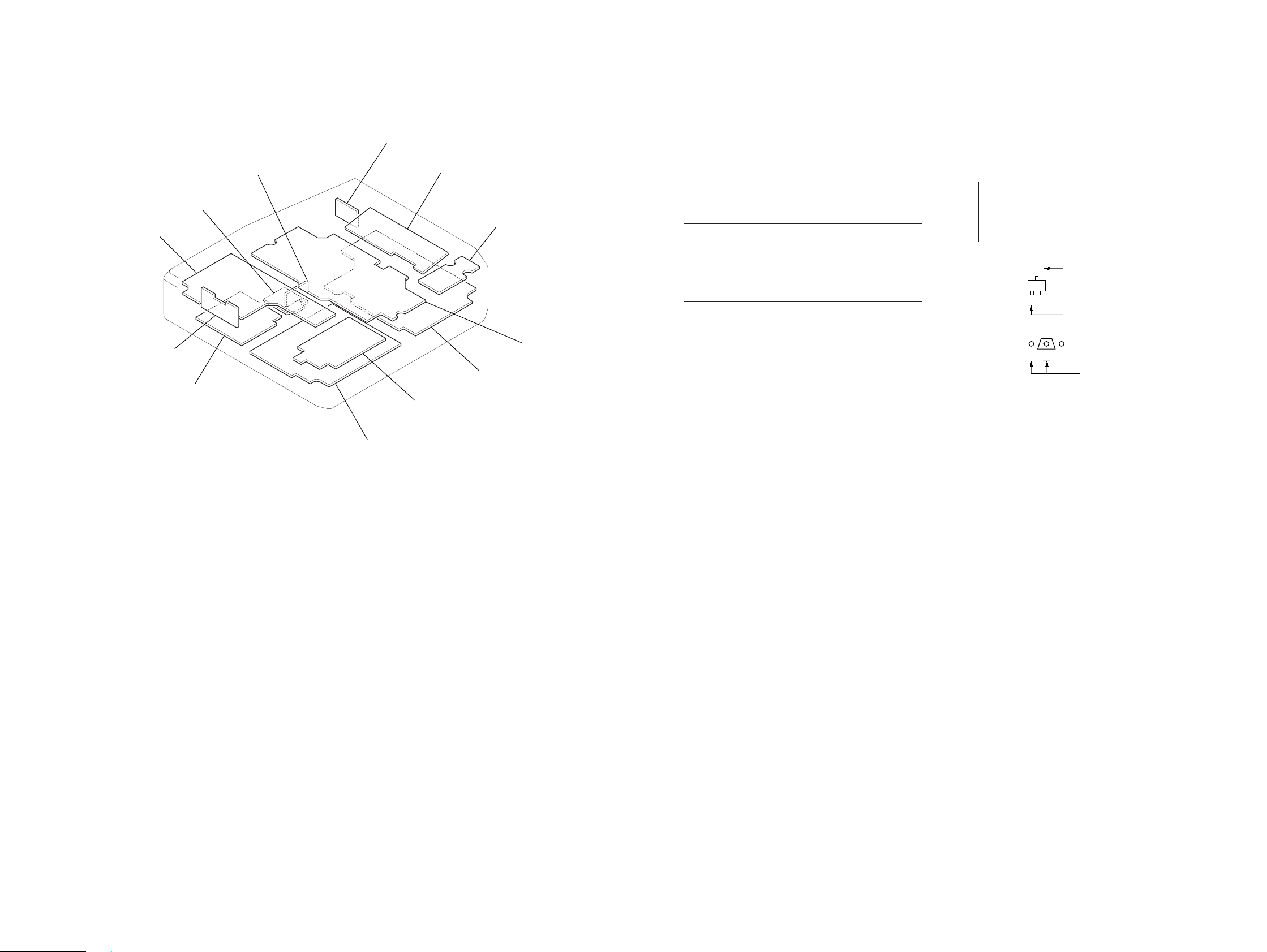

MDS-DRE1

• Circuit Boards Location

MOTOR board

JOG board

EJECT board

BD board

DETECTION SW board

PSW board

FADER board

DIGITAL board

DISPLAY board

POWER board

REC board

CENTER board

6-5. NOTES FOR PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

(In addition to this, the necessary note is printed in each block)

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

¢

•

• 2 : nonflammable resistor.

• C : panel designation.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a V OM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

under no-signal conditions.

no mark : STOP

( ) : PLAY

〈〈 〉〉 : REC

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

E : PLAY

j : REC (ANALOG IN)

k : REC (DIGITAL IN)

f : REC (COAXIAL DIGITAL IN)

h : REC (OPTICAL DIGITAL IN)

: Impossible to measure

∗

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

®

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Side A) the parts face are indicated.

• Indication of transistor.

: Through hole.

C

Q

B

E

Q

B

CE

These are omitted.

These are omitted.

– 29 –

– 30 –

Loading...

Loading...