MDP-V70K

RMT-M46A

SERVICE MANUAL

Model Name Using Similar Mechanism MDP-V1

Optical Pick-up Type KHS-150A

SPECIFICATIONS

E Model

Chinese Model

MICROFILM

VIDEO CD/CD/LD PLAYER

— 1 —

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

Parts No.

3-971-070-6

3-971-070-7

Model

E model

Chinese model

— 2 —

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

— 3 —

SERVICING NOTE

TABLE OF CONTENTS

SELF-DIAGNOSIS

This model has the self-diagnosis function for the video and audio

decoder sections.

Immediately after the power on, the self-diagnosis function searches

each operation of IC’s around the mode microcomputer (IC305).

The LED (D301) on the VX-97 board indicates their results.

LED (D301) INDICATION

Light

1 time blinking (Repeatedly)

[VX-97 BOARD] — SIDE B —

IC301

IC305

D301

SYMPTOM

No error

Transmission error between

IC305 and IC101.

1. GENERAL

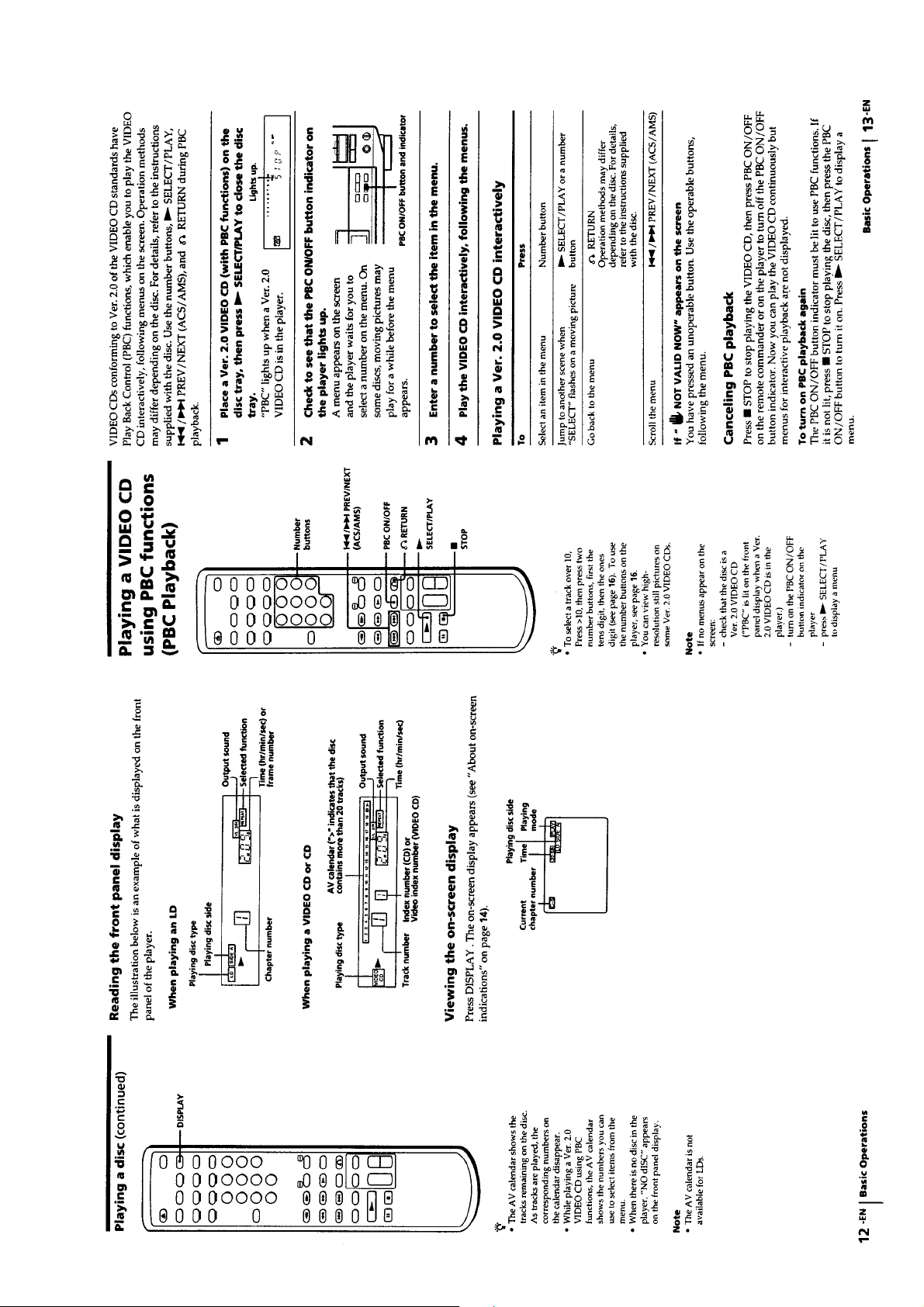

Index to parts and controls ........................................................1-1

Playing a disc ............................................................................1-2

Playing a VIDEO CD using PBC functions (PBC Playback) ...1-3

About on-screen indications ......................................................1-4

Selecting a chapter or track directly (Chapter/Track Search)....1-5

Searching by frame, time, or scene number

(Frame/ Time/Scene Search) .....................................................1-5

Searching for a particular point on a disc .................................. 1-6

Locating by observing several scenes at one time

(Digest Play) ............................................................................1-7

Viewing Frame-by-frame action................................................1-8

Resuming LD/VIDEO CD playback (Auto Resume) ...............1-8

Playing a section repeatedly (Repeat Play) ...............................1-9

Playing songs in random order (Shuffle Play).........................1-10

Playing songs in any order you like (Program Play) ............... 1-11

Playing a disc within a specified period of time

(Auto Program Play)................................................................1-11

Using the sound control functions ...........................................1-12

Reducing Distortion of the Picture

(DNR: Digital Noise Reduction) .............................................1-13

Playing Karaoke ......................................................................1-13

2. DISASSEMBLY

2-1. Opening of MB-97/VX-97 Board (Service Position) ........2-1

2-2. Front Panel Assembly .......................................................2-1

2-3. Disc Tray Assembly ...........................................................2-2

2-4. Chucking Block Assembly.................................................2-2

2-5. Frame (L, R) Assembly......................................................2-3

2-6. Mounting the Frame (R) Assembly....................................2-3

2-7. Control Gear and Loading Motor Assembly......................2-4

2-8. Mounting the Control Gear ................................................2-4

2-9. Feed Base Block Assembly................................................2-5

2-10. Mounting the Feed Base Block Assembly .......................2-6

2-11. Height Adjustment of the Turntable Assembly ................2-7

2-12. Optical Pick-up Block (KHS-150A)

Disassembly I

(Optical Pick-up Block Motor Operates) .........................2-7

Disassembly II

(Optical Pick-up Block Motor Operates) .........................2-8

Disassembly III

(Optical Pick-up Block Motor Doesn’t Operate) ............. 2-8

2-13. Mounting the Optical Pick-up Block Assembly ..............2-9

2-14. Circuit Boards Location .................................................2-10

3. BLOCK DIAGRAMS

3-1. Overall (1/3) Block Diagram .............................................3-1

3-2. Overall (2/3) Block Diagram .............................................3-3

3-3. Overall (3/3) Block Diagram .............................................3-5

3-4. Video (1/2) Block Diagram................................................3-7

3-5. Video (2/2) Block Diagram................................................3-9

3-6. Servo (1/2) Block Diagram ..............................................3-11

3-7. Servo (2/2) Block Diagram ..............................................3-13

3-8. System Control (1/2) Block Diagram .............................. 3-15

3-9. System Control (2/2) Block Diagram .............................. 3-17

3-10. Mode Control Block Diagram........................................3-19

3-11. Audio (1/2) Block Diagram............................................3-21

3-12. Audio (2/2) Block Diagram............................................3-23

3-13. Video CD (1/2) Block Diagram......................................3-25

3-14. Video CD (2/2) Block Diagram......................................3-27

3-15. Power Block Diagram ....................................................3-29

— 4 —

4. PRINTED WIRING BOARDS AND SCHEMATIC

DIAGRAMS

8. EVALUATION OF OPTICAL PICK-UP BLOCK

(KHS-150A)

4-1. Frame Schematic Diagram ................................................. 4-1

4-2. Printed Wiring Boards and Schematic Diagrams ............... 4-5

• MB-97 (Video, Servo, System Control, Audio) Board...4-7

• MB-97 (Video) Board...................................................4-11

• MB-97 (Servo, System Control) Board ........................4-16

• MB-97 (Audio) Board .................................................. 4-21

• VX-97 Board ................................................................4-25

• FP-1090 Board .............................................................. 4-33

• PW-1090, SW-1090A, SW1090B Boards ....................4-40

• YC-97 Board.................................................................4-46

• HP-97 Board .................................................................4-49

• MA-1089 Board ............................................................ 4-51

• FG-42, IB-10, MD-67, MT-59, SW-278 Boards ..........4-53

• PS-97, ST1090 Boards..................................................4-60

5. REPAIR PARTS LIST

5-1. Exploded Views ................................................................. 5-1

5-1-1. Upper Case and Front Panel Section ...........................5-1

5-1-2. Main Chassis Section (1) .............................................5-2

5-1-3. Main Chassis Section (2) .............................................5-3

5-1-4. Frame (L, R) Section ...................................................5-4

5-1-5. Mechanism Deck Section ............................................5-5

5-2. Electrical Parts List ...........................................................5-6

6. IC PIN DESCRIPTION

8-1. Preparation ........................................................................8-1

8-2. RF Level Check .................................................................8-1

8-3. Tracking Level/Tracking Balance Check...........................8-1

8-4. Crosstalk Check .................................................................8-1

9. INSTRUCTION MANUAL FOR SPECIAL

FUNCTIONS

(For the contents of section 9, refer to page 9-1.)

...................................................................9-1

6-1. Mode Control IC Pin Description

(FP-1090 Board IC102 HD6433712-C41H)......................6-1

6-2. VCD Mode Control IC Pin Description

(VX-97 Board IC305 HD6413002F10) .............................6-2

6-3. System Control IC Pin Description

(MB-97 Board IC501 MB89094PF-G-154-BND).............6-4

6-4. System Control IC Pin Description

(MB-97 Board IC502 LC21011B-X78).............................6-6

7. ADJUSTMENTS

7-1. List of Servicing Jigs .........................................................7-1

7-2. Caution on Adjustment ......................................................7-1

7-3. Power Block Check............................................................7-1

7-3-1. Power Supply Check (PS-97 board) ............................7-1

7-4. System Control System Adjustment ..................................7-1

7-4-1. Microprocessor Clock Adjustment (MB-97 board).....7-1

7-5. Adjustment After the Attachment of the Optical Pick-up

Block .................................................................................7-2

7-5-1. Jigs and Tools ..............................................................7-2

7-5-2. CD Adjustment ............................................................7-2

7-6. Servo System Adjustments ................................................7-4

7-6-1. LD Side A Adjustment .................................................7-4

7-6-2. LD Side B Adjustment.................................................7-5

7-7. Video System Adjustments ................................................7-6

7-7-1. LD Output Level Adjustment (MB-97 board) .............7-6

7-7-2. Video Clock Adjustment (VX-97 board) .....................7-6

7-7-3. Video CD Output Level Adjustment

(VX-97 board) .............................................................7-6

7-8. Arrangement Diagram For Adjustment Parts.....................7-8

— 5 —

MDP-V70K

SECTION 1

GENERAL

This section is extracted from

instruction manual.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

1-14E

SECTION 2

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

2-1. OPENING OF MB-97/VX-97 BOARD (SERVICE POSITION)

5

1

Remove the case.

Open the MB-97/VX-97 board

in the arrow direction.

MDP-V70K

2

Two screws

(Tapping screw)

3

Two screws

(BV SUMITITE (B3)

4

Two screws

(BVTP 3 x 8)

2-2. FRONT PANEL ASSEMBLY

1

Remove the case.

!¡

Remove the claws (6 portion).

2

Two screws

(+B 3 x 4)

Door assembly

6

Connector (CN301)

Two claws

!™

Front panel assembly

Two claws

4

Two screws

(Tapping screw)

9

Two screws

(Tapping screw)

!£

Flat cable

(CN101)

5

Two wires

!¢

Flat cable

(CN102)

8

Connector (CN102)

3

Door assembly

2-1

Two claws

0

Two screws

(Tapping screw)

7

Connector (CN951)

2-3. DISC TRAY ASSEMBLY

r

Tray link shaft assembly

2

Two claws

Note on installation:

Insert it with fitting to the guide

roller and fit its gear to portion

of tray link shaft assembly.

3

Disc tray assembly

Cut portion

Guide roller

2-4. CHUCKING BLOCK ASSEMBLY

1

Open the MB-97/VX-97 board in the arrow direction.

Guide roller

A

1

Turn the pulley in the

direction of arrow

A

.

8

Chucking block

assembly

2

6

Reinforcement

stay assembly

Screw (BVTP 3 x 8)

3

Screw (BVTP 3 x 8)

4

Bracket

5

Screw (BVTP 3 x 8)

7

Screw (BVTP 3 x 6)

9

Chuck plate holde

2-2

2-5. FRAME (L, R) ASSEMBLY

1

Two screws

(Tapping screw)

8

Two screws

(Tapping screw)

3

Two screws

(Tapping screw)

5

Tray link shaft

assembly

7

Flat cable

(CN301)

2

Front stay

4

Frame (L) assembly

9

Frame (R) assembly

6

Link shaft assembly

Note on installation:

Apply the grease on the area marked with

(2 portions).

(Grease: Molykote Grease EM-30LG

Part No. J-6090-014-A)

0

Tilt link shaft assembly

Note on installation:

Refer to the 2-10.

2-6. MOUNTING THE FRAME (R) ASSEMBLY

Note: Follow the assembly procedure in the numerical order given.

6

Setting the rib at the position

shown as the Fig-B.

Rib

Fig-B

*

Fig-A

2

Confirm that * screw is at the

position shown as the Fig-A.

7

Tray link shaft assembly

5

Apply the grease.

(Grease: Molykote Grease EM 30LG Part No. J-6090-014-A)

3

Two screws

(Tapping screw)

A

4

Frame (R) assembly

1

Turn the pulley in the

direction of arrow

A

.

2-3

2-7. CONTROL GEAR AND LOADING MOTOR ASSEMBLY

5

Loading motor assembly

2

Control gear

3

Belt

4

Two screws (M 3 x 2)

1

Screw (PTPWH 3 x 20)

2-8. MOUNTING THE CONTROL GEAR

Note: Follow the assembly procedure in the numerical order given.

2

Slider (R) knob

(Put aside in the direction of arrow.)

1

Tilt slider knob

(Put aside in the direction of arrow.)

3

Control gear

Note on installation:

(1) Apply the grease on the cam groove of control gear.

(Grease: Molykote Grease EM-30LG Part No. J-6090-014-A)

(2) Setting that marking at the postion shown as the figure.

4

Screw (PTPWH 3 x 20)

Marking

2-4

2-9. FEED BASE BLOCK ASSEMBLY

y

1

Remove the case.

2

Open the MB-97/VX-97 board.

3

Remove the chucking block assembly.

6

Two screws

(Tapping screw)

9

Flat cable (CN701)

!¡

Connector (CN203)

5

Two screws

(BV SUMITITE (B3))

7

Screw

(Tapping screw)

!™

Feed base block assembly

8

Flat cable (CN301)

!£

Tilt link shaft assembly

Disc tray assembly

A

0

Flat cable (CN503)

4

Rotate the pulley in the direction

of arrow

assembly.

A

, and eject the disc tra

2-5

2-10. MOUNTING THE FEED BASE BLOCK ASSEMBLY

Note: Follow the assembly procedure in the numerical order given.

2

Fix the feed base block assembly temporarily with three screws.

(BVTP 3 x 10)

9

Adjust feed base block assembly so that the Lissajous's waveform

goes to 0˚. (Tighten the screw completely.)

0

Refer to 7-5. Adjustment after the attachment of the optical pick-up block.

!¡

Two screws

(BV SUMITITE (B3))

Tilt disc

(Put aside in the

direction of arrow.)

4

Fig-B

1

Tilt link shaft assembly

Note on installation:

Setting the tilt slider and tilt disc

at the position shown as Fig-A, B.

Connector

(CN203)

8

Turn off

TRACKING and

SLED switches.

E

F

MD adjustment cable

6

Connect to the oscilloscope.

Oscilloscope

Lissajous's waveform

CH-1

CH-2

90˚ 0˚

180˚

5

Connect the connector

of MD adjustment cable

with the pattern face down.

(CN702)

7

Set the CD (YEDS-18) on the tray.

Press the PLAY (

·

) button and plays the track No. 1 PAUSE.

Tilt slider

(Put aside in the

direction of arrow.)

Fig-A

3

Three flat cable

(CN301, CN503, CN701)

2-6

2-11. HEIGHT ADJUSTMENT OF THE TURNTABLE ASSEMBLY

h

1

Remove the case.

2

Open the MB-97/VX-97 board.

3

Rotate the pulley on the right side of the set, and open the tray.

4

Remove the chucking block assembly and reinforcement stay assembly.

5

Change the turntable assembly.

Adjust the height and also the position putting in the reinforcement stay as below.

The thickness of the reinforcement is 1 mm.

6

Fix the reinforcement to fixed position.

Turntable assembly

Fixed screw

±

0.1 mm

37

FG ring

Put in the reinforcement stay between the spindle motor holder and

the FG ring, tighten the fixed screw hard after the height adjustment.

Reinforcement stay

1 mm

2-12. OPTICAL PICK-UP BLOCK (KHS-150A)

DISASSEMBLY I (OPTICAL PICK-UP BLOCK MOTOR OPERATES)

1

Set the service mode.

(1) Power is in STANDBY mode.

(2) Press the 1 button while pressing STOP (

(3) “No disc” will be appeared on the fluorescent indicator tube.

(4) Press the 10/0 button and then the 8 key of the remote control while pressing STOP (p) button

on the unit.

(5) The display will be disappeared on the display board, then enter the test mode.

Note: As for the test mode, refer to the test mode on page 9-10.

2

Move the optical pick-up block to the upper front side (full of side B) pressing the SIDE-B button

continuously.

p

) button and 10 button on the unit.

3

Pull out plug from wall socket.

5

Open the claws on

both side of housing

and remove flat cable.

Two claws

Housing

2-7

4

Pull out optical pick-up block wit

hand in the arrow direction.

DISASSEMBLY II

(OPTICAL PICK-UP BLOCK MOTOR OPERATES)

1

Remove the case.

2

Open the MB-97/VX-97 board.

3

Remove the chucking block assembly and reinforcement stay assembly.

5

Turning the power ON, the pick-up moves to the position where it

can be removed.

Two claws

8

Open the claws on

both side of housing

and remove flat cable.

4

Screen the sensor when the

power is in STANDBY mode.

Housing

6

Pull out plug from wall socket.

DISASSEMBLY III

(OPTICAL PICK-UP BLOCK MOTOR DOESN’T OPERATE)

(The pick-up block cannot be re-used by using this method)

1

Remove the case.

2

Open the MB-97/VX-97 board.

3

Remove the chucking block assembly and reinforcement stay assembly.

5

Remove a screw mounting sled motor.

6

Insert screwdriver to hole for screw removed step

and move a little sled motor in the arrow A direction.

Disengage worm gear and midway gear.

A

8

Open the claws on

both sides of housing

and remove flat cable.

Housing

9

Optical pick-up block

Worm gear

Sensor

(PH301)

B

7

Pull out optical pick-up block with hand

in the arrow direction.

4

4

Pull out plug from wall socket.

2-8

7

Pull out optical pick-up block from feed

base block assembly by moving it in the

arrow

B

direction with hand.

2-13. MOUNTING THE OPTICAL PICK-UP BLOCK ASSEMBLY

Note: Follow the assembly procedure in the numerical order given.

4

Confirm the flat cable goes through the

flexible retainer spring and over the shaft.

Flexible cable

retainer spring

6

Turn the power on.

Optical pick-up block moves

into feed base block

assembly.

Flat cable

Shaft

Shaft

5

Insert plug to wall socket.

Flat cable

Optical pick-up block

1

Insert the flat cable to housing on

optical pick-up block.

Confirm the claws on both sides

of housing are locked.

Two claws

Feed base block

Housing

Feed block assembly

Three rollers

Shaft

U guide

Rack

2

Insert the shaft and three rollers of the optical

pick-up block into their corresponding grooves

of the U guide.

3

Set so that the gear of the optical pick-up block

engages with the rack of the U guide.

Optical pick-up block

2-9

2-14. CIRCUIT BOARDS LOCATION

d

SW-1090A board

PW-1090 board

PS-97 board

FP-1090 board

MB-97 board

VX-97 board

SW-1090B board

ST-1090 board

MA-1089 board

FG-42 board

HP-97 board SW-278 board

IB-10 board

MD-67 board

MT-59 board

YC-97 boar

2-10

2-10 E

OPTICAL PICK-UP

BLOCK

(KHS-150A)

IC2

DEIC

A

BC

D

E

F

LASER

DIODE

LD

PD

RF

FE

TE

LD DN

RF AMP

IC706

BUFFER AMP

LPF

CD

LPF

Q357,359

(1/3)

IC301

AFM DEMOD,

CX NOISE

REDUCTION

IC705

IC701

BUFFER

IC706

IC401

FOCUS ERROR

AMP

(1/2)

(2/2)

(1/2)

FE

TE

DSUM

TILT IN,

TILT OUT

AMP

IC702

(1/2)

IC704

,

TIPI

FOCUS

COIL

DRIVE

IC707

TRACKING

COIL

DRIVE

FOCUS

COIL

TRACKING

COIL

M

M902

SLED

MOTOR

IC703

SLED

MOTOR

DRIVE

LOADING/

TILT

MOTOR

DRIVE

TILT

LIMIT

IC704

+

SERVO

•FOCUS SERVO

•TRACKING SERVO

•TILT SERVO

•SLED SERVO

SET DT

SET CLK

SV LT

PCMD

LRCK

BCK

DIGITAL

AUDIO

SIGNAL

PROCESSOR

SED DATA,

DSP CK

DSP LT

RF

L

R

AFM MUTE 1, AFM MUTE 2, CX

RF (V)

RF(A)

PCMD

LRCK

BCK

DIGITAL

FILTER,

D/A

CONVERTER

IC450

LPF

IC451

[MB-97 BOARD]

(Page 4 - 11, 16, 21)

TILT IN

TILT OUT

FM DEMOD,

DROP OUT

DET,

P CODE SEP,

SYNC SEP

IC101

CD

SPINDLE

ERROR

AMP

IC381

MDP

IC503

LD

LD

SPINDLE

ERROR

AMP

IC504

PC OUT 1

PC OUT 2

VCO

SYSTEM CONTROL

•FRAME NO. DECODER

•SPINDLE CONTROLLER

•REF, V, H GENERATOR

•VIDEO CONTROLLER

•DSP CLOCK CONTROLLER

•DIGITAL AUDIO CONTROLLER

MMISI

MMISO

MMICLK

IC502

P CODE

PB CS

IC151

DIGITAL

TBC, DOC,

NOISE CANCEL

IC501

SYSTEM CONTROL

(MI-COM)

•MECH. CONTROLLER

MECH SO,MECH SI,MECH CLK

FL

TCNT

ITJ

MTJ

SET DAT,

SET CLK,

XSET CK

MC SO, MC SI, MC CLK

SET DATA, SET CLK

SET DT,

SET CK

IC202

GRAY

PICTURE

INSERTION

VCD VIDEO

IC203

V SYNC

INSERTION

VIDEO

MUTING

IC204

CHARACTER

GENERATOR

CHARACTER

INSERTION

+

+

V MUTE 2

V MUTE 1

G MUTE

G VIDEO

IC453

MIXING

AMP

VIDEO

L

R

LINE OUT 1

B

MC SO,

MC SI,

MC CLK

MC CS

SP ERROR

SPDL FG1

LC SW 1–4, CD/ALD, CDV/BLD,

LD SENSE, LD DET

M

SW

TILT UP/DOWN

CONTROL

IC705

DIGITAL

OUT

OPTICAL

IC416

LD ON

LOADING LOCK

TILT UP

TILT ON

(2/2)

TIDR

(Page 4 - 58)

[MT-59 BOARD]

M401

LOADING/TILT

MOTOR

LOAD M

(Page 4 - 57)

[MD-67 BOARD]

(2/2)

09

SET DATA

SET CLK

Y LOAD

TBC REF H

L

R

CD

TILT SENSOR

FOCUS M

TRK M

SLED M

SLP1

SDR1

SDR2

(2/2)

A

(Page 3 - 3)

(Page 3 - 5)

(Page 3 - 5)

F

D

(Page 3 - 4)

E

(Page 3 - 4)

C

(Page 3 - 3)

RETURN VIDEO

EXT VCTL

CV OUT

AUDIO

VIDEO

L

R

LINE OUT 2

AUDIO

HEADPHONE

AMP

IC001

RV951

PHONES LEVEL

PHONES

[HP-97 BOARD]

(Page 4 - 49)

MIC SIG

J001 (1/2)

J001 (2/2)

J951

MIC

MUTE

Q901,902

MIC IN

MIC SIG

3-1. OVERALL (1/3) BLOCK DIAGRAM

SECTION 3

BLOCK DIAGRAMS

MDP-V70K

3-1

3-2