Page 1

REVISION HISTORY

EG1L(GA)

CHASSIS

MODEL

PA RT NO.: 9-872-994-10

KLV-32V400A

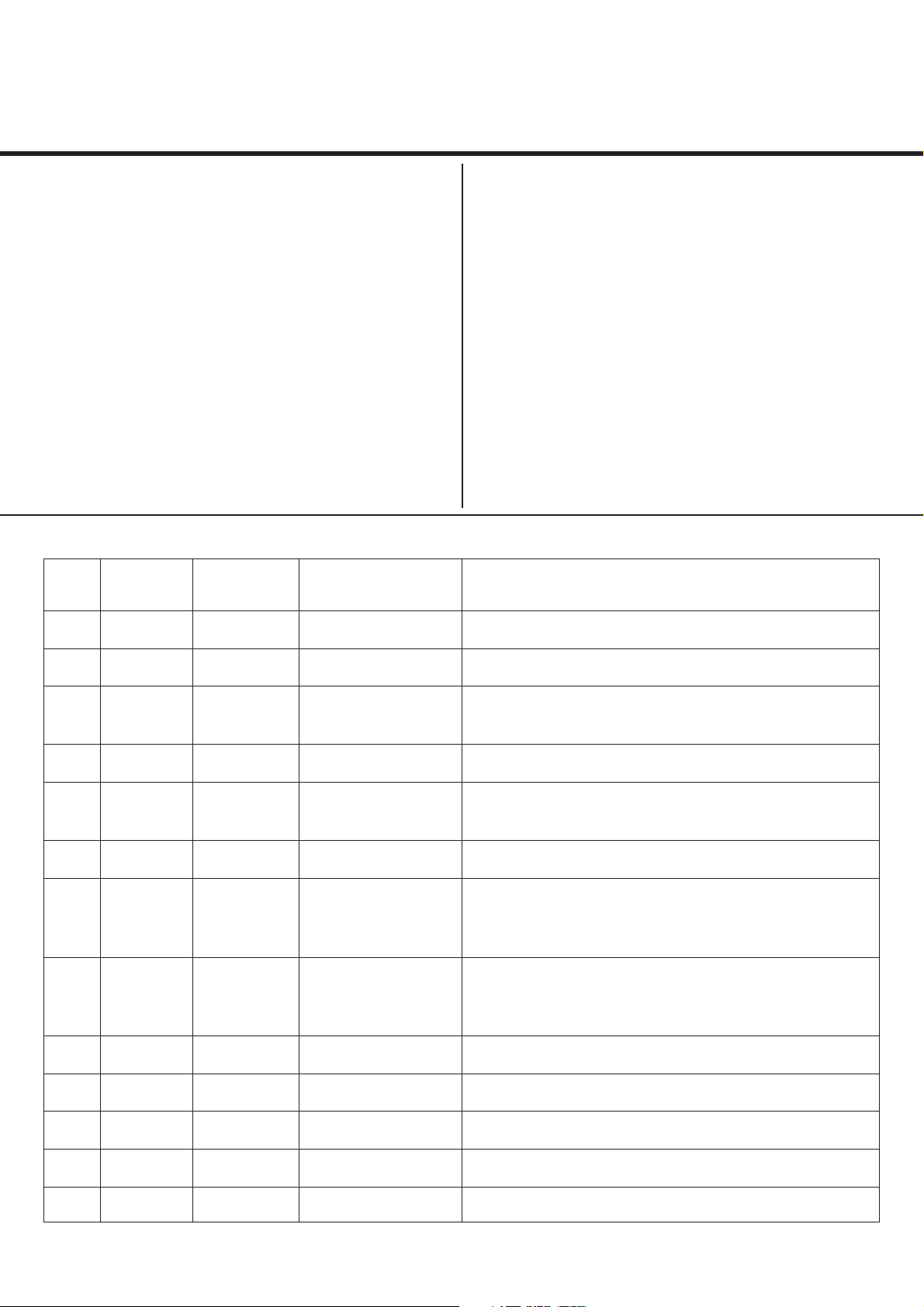

NO. SUFFIX DATE SUPP / CORR DESCRIPTION

1 -01 2008/4 _ _ 1st Issue

2 -02 2008/7 SUPP-1 New model addition (Page 31)

3 -03 2008/7 CORR-1 Service Adjustment changes

(Page 18)(Page 19)(Page20)

4 -04 2008/8 SUPP-2 Part number change (Page 40)

5 -05 2008/8 SUPP-3 Part Information Change:

REAR COVER PART NUMBER (Page 41)

6 -06 2008/8 SUPP-4 Supplement (Wall Mount) Addition (Page 42)

7 -07 2008/9 SUPP-5 Part Information Change:

1. H4 Change to H4K (Page 44)

2. H3E Part number Change (Page 44)

8 -08 2008/10 CORR-2 1. Exploded View Changes (Page 23)(Page 24)

(Page 25)(Page 27) (Page 28)

2. Electrical Parts List Changes (Page 29)(Page 30)

9 -09 2008/11 CORR-3 Changes in Standby LED Error Display (Page 6)

10 -10 2008/12 SUPP-6 New model addition (Page 45)

Page 2

SERVICE MANUAL

EG1L(GA)

CHASSIS

MODEL COMMANDER DEST.

KLV-32V400A

KLV-32V400A/R

(Metal Red) Philippines,

KLV-32V400A/T

(Mat Brown) Philippines,

RM-GA011 E, EA, India, Iran,

ME, Philippines,

Saudi Arabia,

South Africa,

Thailand, Vietnam

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa

MODEL COMMANDER DEST.

KLV-32V400A/W

(Pearl White) Philippines,

KLV-32V400B

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

RM-GA011 Saudi Arabia,

Thailand

RM-GA011

LCD COLOR TV

Page 3

KLV-32V400A, V400B

RM-GA011

TABLE OF CONTENTS

Section Title Page

1. SAFETY NOTES

1-1. Caution Handling of LCD Panel ..................................... 3

1-2. Safety Check Out ............................................................. 3

1-3. Leakage Test .................................................................... 3

1-4. WARNING ! .................................................................... 3

1-5. LED Free Information ..................................................... 4

2. SELF DIAGNOSTIC FUNCTION

2-1. Overview of Control Buttons .......................................... 5

2-2. LED Display Specification.............................................. 5

2-3. LED Display Control ....................................................... 5

2-4. LED Pattern ..................................................................... 5

2-5. Standby LED Error Displays .......................................... 6

3. DISASSEMBLY

3-1. Rear Cover Removal........................................................ 7

3-2. Stand Assy Removal ........................................................ 7

3-3. Switch Unit Removal ...................................................... 8

3-4. GP Board and G1 Bracket Removal ............................... 9

3-5. BG1 Board & Bracket Removal.................................... 10

3-6. Vesa Frame Removal ..................................................... 11

3-7. H4, H3E Board and Speaker Bracket Removal ............ 12

3-8. LCD Panel and Bezel Assy Removal ............................ 13

4. WIRE DRESSING

4-1-1. Wire dressing overview for Non-CISPR model ........ 14

4-1-2. Wire dressing overview for CISPR model ................ 14

4-1-3. Dress LVDS cable with Sheet Core C (2X)

as shown ..................................................................... 14

4-1-4. i) Dress LVDS cable with Sheet Core C &

Shield Tape as shown

ii) Screw LVDS cable's clamp on main bracket

as shown ................................................................ 14

4-1-5. Dress Connector Assy 13P at G1 bracket's hook ...... 15

4-1-6. Dress Connector Assy 14P + 20P at G1

bracket's hook(5X) ..................................................... 15

4-1-7. Dress Connector Assy 14P + 20P with slide

clamp(2X) .................................................................. 15

4-1-8. Dress Connector Assy 14P + 20P on top of

Connector Assy 13P ................................................... 15

Section Title Page

4-1-9. Dress Connector Assy 14P + 20P & Speaker wire

with sheet core C(2X) ................................................ 15

4-1-10.i) Dress Speaker wire and Connector assy 14P + 20P

with Sheet Core C & Slide clamp

ii) Dress Speaker Wire with LCD tape ...................... 15

4-1-11.Dress Speaker Wire(L) with LCD tape(2X) ............. 16

4-1-12.Dress Connector Assy 14P + 20P with LCD tape .... 16

4-1-13.Install AC Cord Holder on AC Power Cord .............. 16

4-1-14.Install AC Cord Holder on AC Power Cord .............. 16

4-1-15.i) Screw Connector Assy 1P on BG1 Main Bracket

ii) Put Connector Assy 1P underneath

Speaker Wire ......................................................... 17

5. SERVICE ADJUSTMENTS

5-1. Accessing Diagnostic Menu .......................................... 18

5-2. Aging ............................................................................ 18

5-3. Accessing Service Menu ............................................... 18

5-4. Resetting the User Menu- Factory Reset ...................... 19

5-5. White Balance Adjustment............................................ 19

5-6. Board and Panel Replacement ...................................... 20

6. DIAGRAMS

6-1. Block Diagram ............................................................... 21

6-2. Circuit Board Location .................................................. 21

6-3. Schematic Diagram ....................................................... 22

6-4. Printed Wiring Boards ................................................... 22

6-5. Semiconductor ............................................................... 22

7. EXPLODED VIEWS

7-1. Rear Cabinet and Stand Assy ........................................ 23

7-2. Frame and Cover ...........................................................24

7-3. Chassis-1 ........................................................................ 25

7-4. Chassis-2 ........................................................................ 26

7-5. H3E & H4 Boards and Speaker .................................... 27

7-6. Bezel Assy and LCD Panel ........................................... 28

8. ELECTRICAL PARTS LIST .............................................. 29

OPERATING INSTRUCTIONS

– 2 –

Page 4

SECTION 1

SAFETY NOTES

KLV-32V400A, V400B

RM-GA011

1-1. Caution Handling of LCD Panel

When installing the LCD Panel, make sure you are grounded

with a wrist band.

When installing the LCD Panel on the wall, the panel must be

secured using the 4 mounting holes on the rear cover.

1) Do not press the panel or frame edge to avoid the risk of

electric shock.

2) Do not scratch or press on the panel with any sharp

objects.

3) Do not leave the module in high temperature or in areas of

high humidity for an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause short circuit within

the module.

6) Disconnect the AC adapter when replacing the backlight

(CCFL) or inverter circuit. (High voltage occurs at the inverter

circuit at 650Vrms)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the

inverter circuit. Damaging the wires may cause a short circuit.

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

1-2. Safety Check-Out

After correcting the original service problem, perform the

following safety checks before releasing the set to the

customer:-

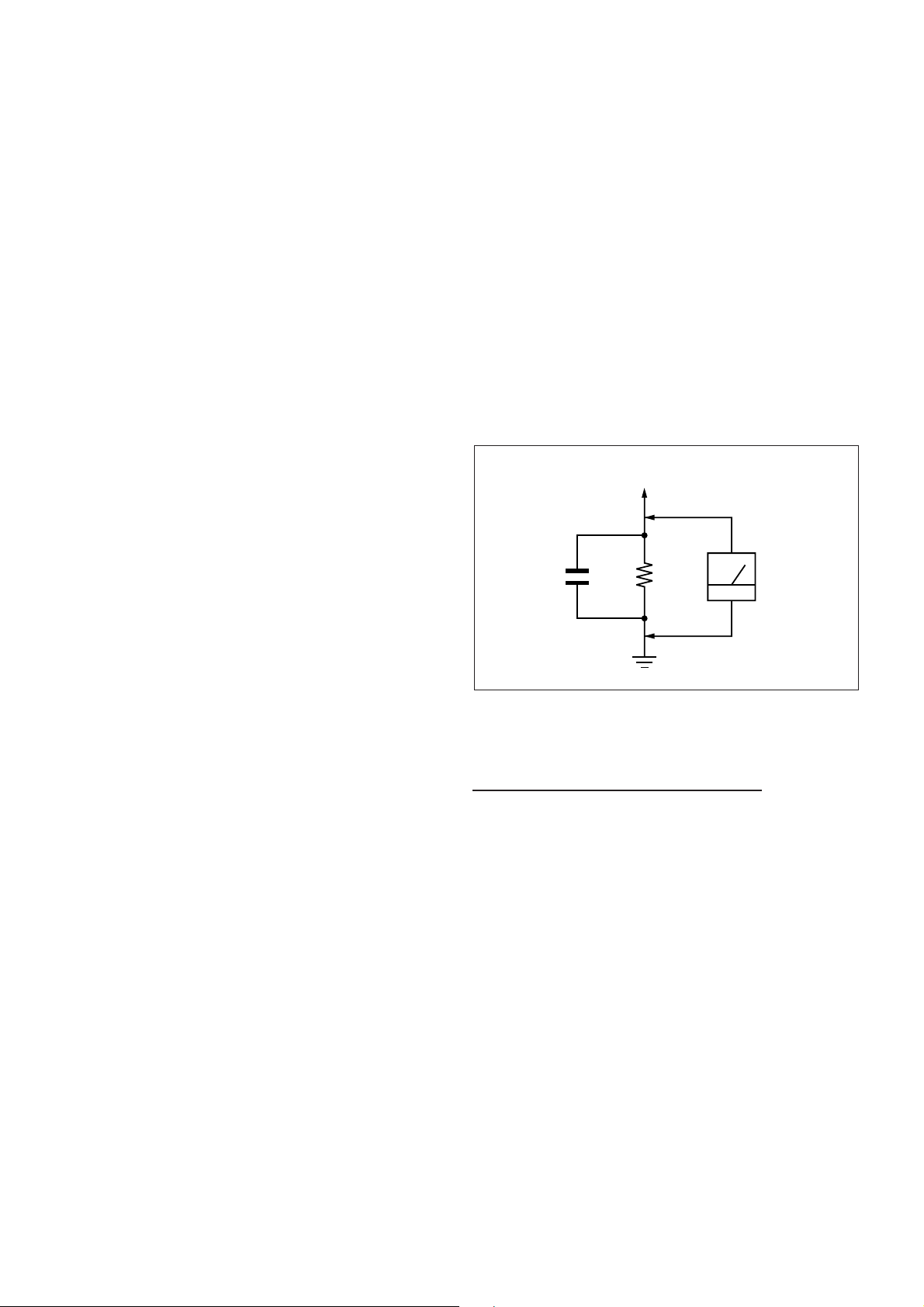

1-3. Leakage Test

The AC leakage from any exposed metal part to earth

ground and from all exposed metal parts to any exposed

metal part having a return to chassis must not exceed 0.5mA

(500 microamperes). Leakage current can be measured by

any one of the three methods:-

1. A commercial leakage tester such as the SIMPSON 229

or RCA WT-540A. Follow the manufacturers instructions to

use those instructions.

2. A battery-operated AC milliampmeter. The DATA

PRECISION 245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means

of a VOM or battery operated AC voltmeter. The 'limit' indication is 0.75V so analog meters must have an accurate low

voltage scale. The SIMPSON'S 250 and SANWA SH-63TRD

are examples of passive VOMs that are suitable. Nearly all

battery operated digital multimeters that have a 2 VAC range

are suitable. (see FIGURE 1)

To Exposed Metal

Parts on Set

0.15 µF

1.5 k

Ω

AC

Voltmeter

(0.75 V)

1) Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface for

solder splashes and bridges.

2) Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3)Check all control knobs, shields, covers, ground straps and

mounting hardware have been replaced. Be absolutely certain

you have replaced all the insulators.

4) Look for unauthorized replacement parts, particularly

transistors that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

5) Look for parts which, though functioning show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

6) Check the line cords for cracks and abrasion.

Recommend the replacement of any such line cord to the

customer.

7) Check the antenna terminals, metal trim, "metallized"

knobs, screws and all other exposed metal parts for AC

leakage. Check leakage test as described next.

Earth Ground

Figure 1. AC voltmeter to check AC leakage

1-4. WARNING !

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY SHADING AND MARK

!

ON THE EXPLODED VIEWS ARE CRITICAL FOR SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE

CRITICAL FOR SAFE OPERATION ARE IDENTIFIED IN

THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED

OR IMPROPER OPERATION IS SUSPECTED.

– 3 –

Page 5

KLV-32V400A, V400B

RM-GA011

1-5. LED Free Information

The circuit boards used in these models have been processed

using Lead Free Solder. The boards are identified by the LF

logo located close to the board designation.

Figure 2: LF logo

Figure 3: LF logo on circuit board

The servicing of these boards requires special precautions. It

is strongly recommended to use Lead Free Solder material in

order to guarantee optimal quality of new solder joints. Lead

Free Solder is available under the following part numbers:-

rebmuntraP retemaiD skrameR

7

91-500-046-mm

02-500-046-7m4.0Kg05.0

12-500-046-7m5.0Kg05.0

22-500-046-7m6.0Kg52.0

32-500-046-7m8.0Kg00.1

42-500-046-7m0.1Kg00.1

52-500-046-7m2.1Kg00.1

62-500-046-7m6.1Kg00.1

3.0Kg52.0

m

m

m

m

m

m

m

Due to high melting point of Lead Free Solder, the soldering

iron tip temperature needs to be set to 370 degrees

centigrade. This requires soldering equipment capable of

accurate temperature control coupled with a good heat

recovery characteristics.

For more information on the use of Lead Free Solder,

please refer to http://www.sony-training.com

– 4 –

Page 6

SECTION 2

SELF DIAGNOSTIC FUNCTION

KLV-32V400A, V400B

RM-GA011

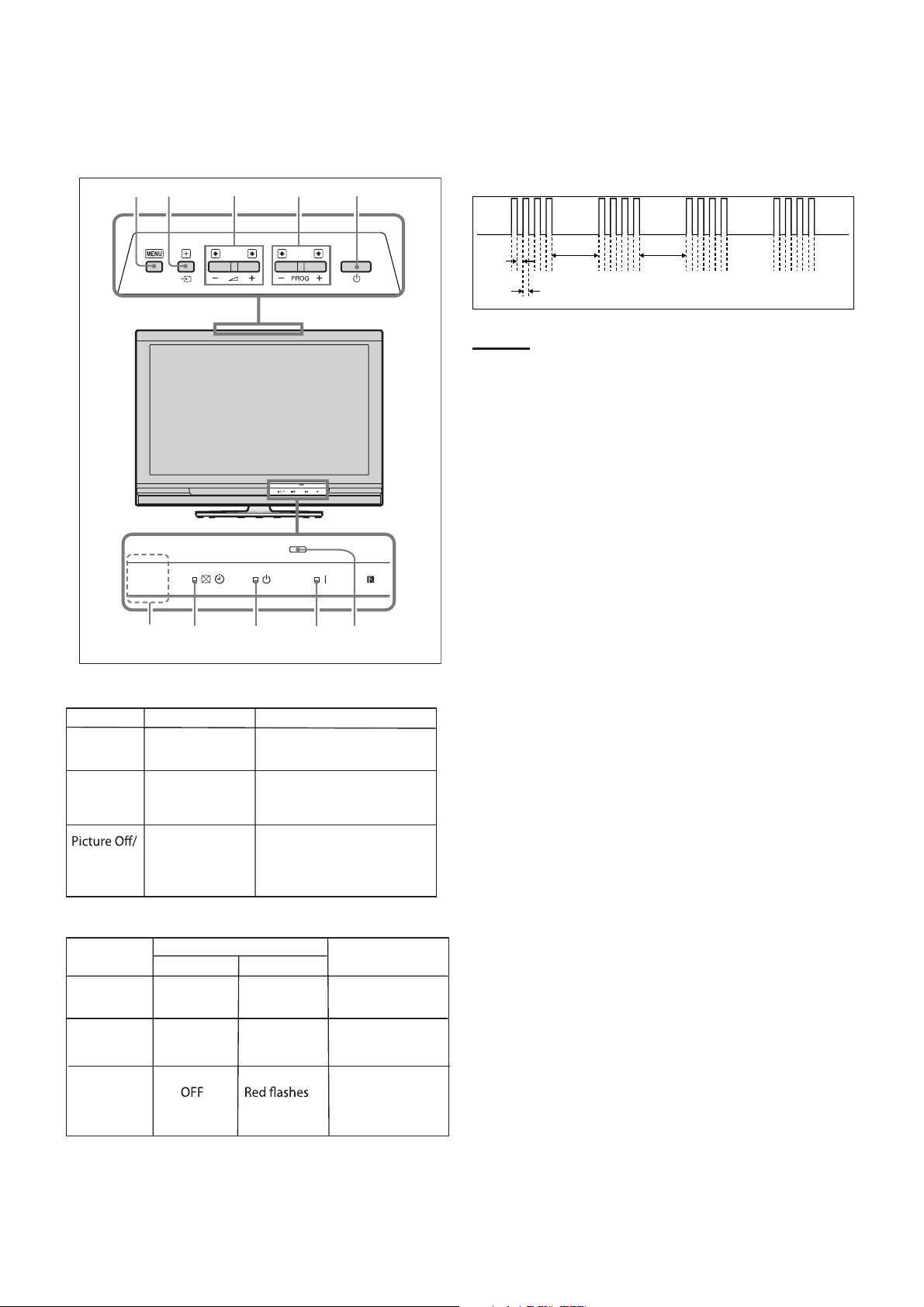

2-1. Overview of Control Buttons

MENU TV/VIDEO VOLUME CHANNEL POWER

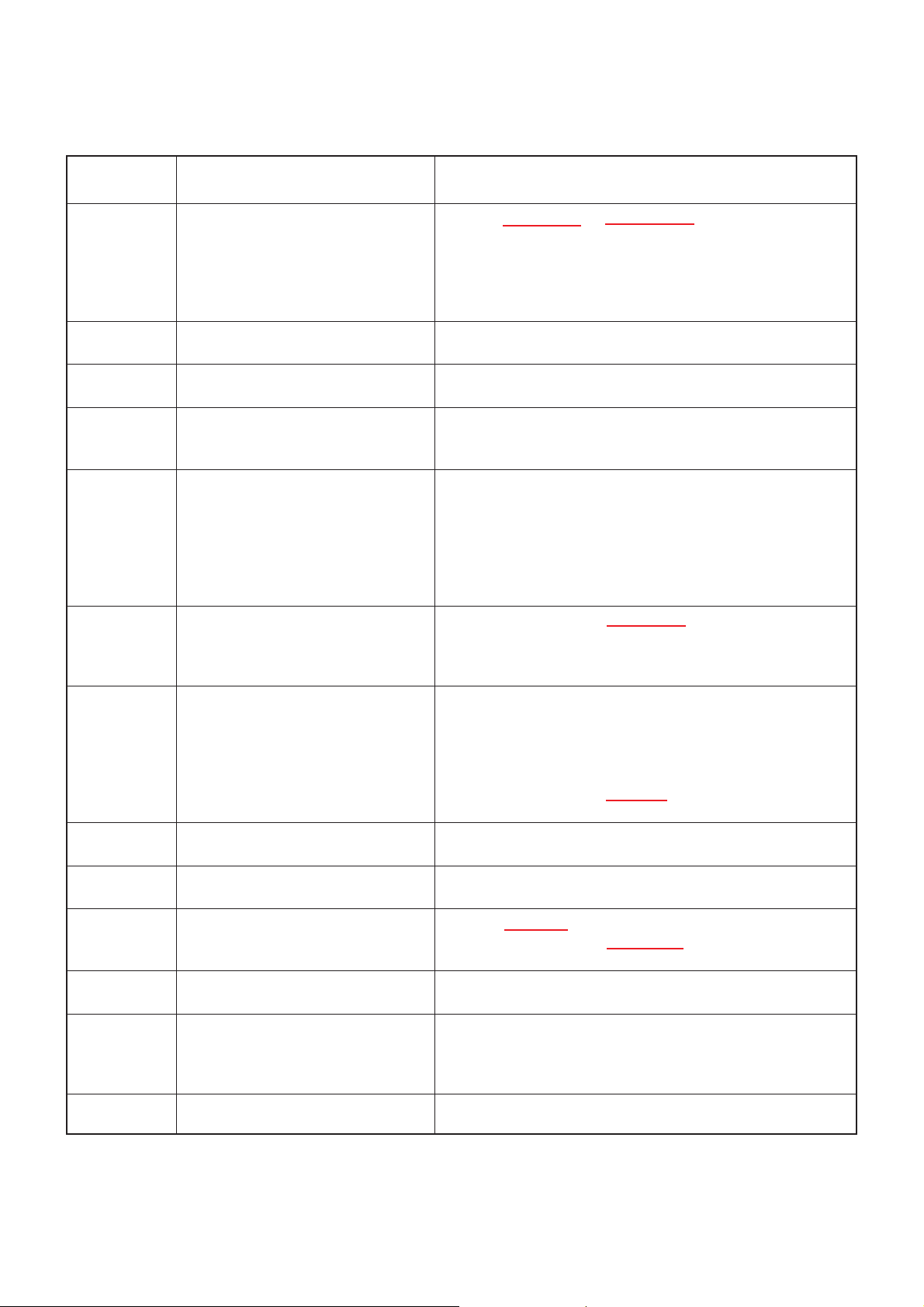

2-4. LED Pattern

When safety shutdown occurs, Standby LED display reports the

cause by using the lightning patterns as indicated below.

0.3 sec

0.3 sec

2.0 sec 2.0 sec

Example:

The figure above shows LED display when

SHUTDOWN is caused by DC_ALERT 2. It repeats

flashing for a specified number of times in 0.3sec/

cycle and has a 2 seconds interval of lighting off.

Please note that a 2 seconds interval of lighting off

is fixed regardless of abnormal state types.

LIGHT

SENSOR

PICTURE

OFF/

TIMER

STANDBY POWER

REMOTE

SENSOR

2-2. LED Display Specification

LED Typ e Description

POWER Green: LED

Remark

Green lights at power ON.

STANDBY Red: One LED Red lights during standby.

Green lights during Picture

OFF and amber lights

Timer

Green/Amber

: Two LEDs

during Timer activation.

2-3. LED Display Control

Status

Power LED

Display

Standby LED

POWER ON Green lights OFF

STANDBY

OFF Red lights

Remark

Microcomputer is

in a normal state.

Microcomputer is

in a sleep state.

Failure

Classify the

trouble causes by

the no. of red.

– 5 –

Page 7

KLV-32V400A, V400B

RM-GA011

2-5. Standby LED Error Display

Perform below countermeasures according to Standby LED blinking times.

Blinking times Error Countermeasure

2 DC_DET (12V Main Voltage) Replace either/both z BG1 Board

3 DC_ALERT 1 Replace BG1 board.

4 DC_ALERT 2 Replace BG1 board.

5 DC_ALERT 3 Replace either/both z BG1 board

z GD Board (20”)

z GP Board (26" and 32")

z G2 Board (37”)

z IP5 Board (40”, 46”)

z Panel

6BACKLIGHT/ Replace either/all z GD Board (20”)

INVERTER ERROR z GP Board (26” and 32”)

z G2 Board (37”)

z IP5 Board (40”, 46”)

z BG1 Board

z Panel

7 INTERNAL TEMP Replace either/both z GP board

ERROR z BG1 board

z Panel

8AUDIO ERROR Replace either/all z GD Board (20”)

z GP Board (26” and 32”)

z G2 Board (37”)

z IP5 Board (40”, 46”)

z BG1 Board

z Speaker

9 Not used for GA —

10 Not used for GA —

11 NVM ERROR Replace either/all z BG1 Board

z GP board

12 IIC ERROR Replace BG1 board.

13 BALANCER ERROR Replace either/all z IP5 Board (40”,46”)

z BG1 Board

z Panel

14 HDMI ERROR Replace BG1 board

Note: Each of the above blinking repeats every 2 seconds.

– 6 –

Page 8

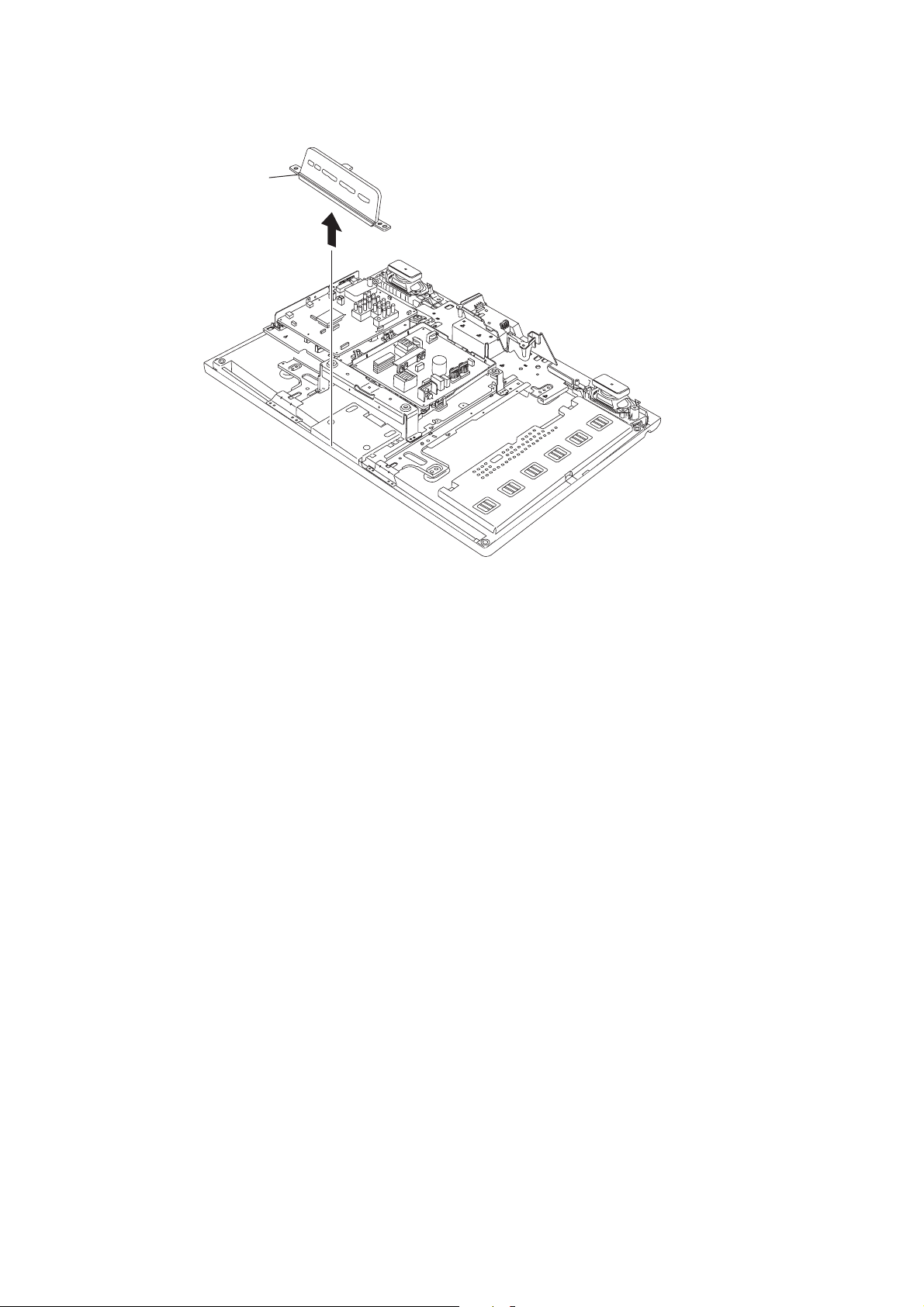

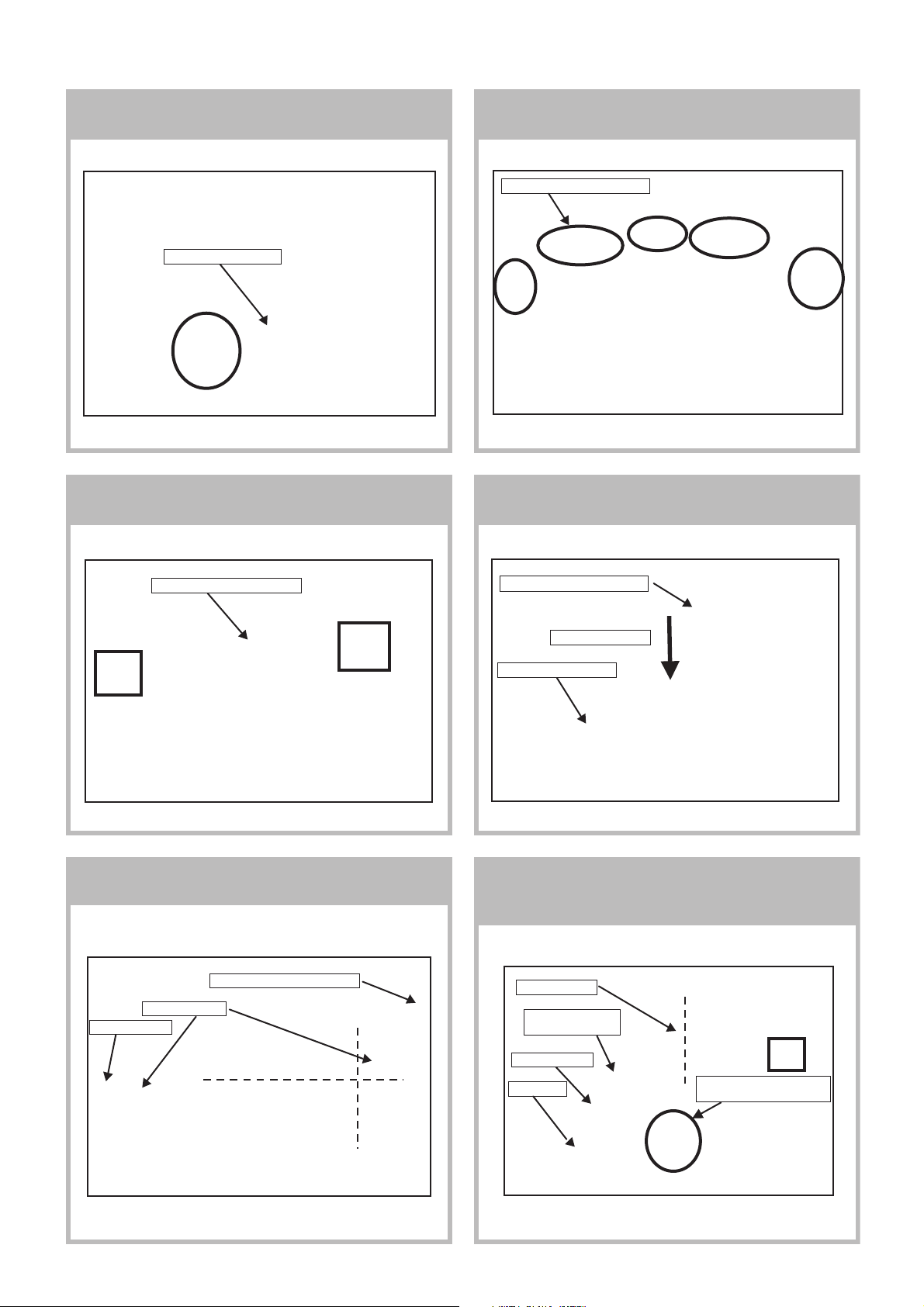

1-1. Rear Cover Removal

2 Two screws

(+BVTP 3 X 12)

3 Two screws

(+PSW M3 X 5)

1 Eighteen screws

(BVTP2 4 X 16)

KLV-32V400A, V400B

RM-GA011

SECTION 3

DISASSEMBLY

4 One screw

(PSW 5 X 8)

5 Lift to remove Rear Cover

3-2. Stand Assy Removal

1 Three screws

(+PSW 5 X 16)

2 Stand assy

3 One screw

(BVTP2 4 X 16)

4 Under Bar (M) Assy

– 7 –

Page 9

KLV-32V400A, V400B

RM-GA011

3-3. Switch Unit Removal

3

Switch unit

1

2

Lift tabs to

remove board

– 8 –

Page 10

3-4. GP Board and G1 Bracket Removal

1 Four screws

(+PSW 3SG)

KLV-32V400A, V400B

RM-GA011

2 Two connectors

CN6201 and CN6202

6 Three holder

PC board

3 One connector

CN6102

4 GP board

5 G1 bracket

– 9 –

Page 11

KLV-32V400A, V400B

RM-GA011

3-5. BG1 Board and Bracket Removal

1 One screw

(+PSW 3 X 5)

3 Eight connectors

CN2000, CN2004, CN3000,

CN3003, CN7000, CN9003,

CN9200, CN9512

6 One screw

(BVTP2 4 X 16)

5 Side Jack Bracket Assy

2 Nine screws

(+BVST 3 X 8)

4 BG1 board

7 Two screws

(+BVST 3 X 8)

8 Main Bracket

– 10 –

Page 12

3-6. Vesa Frame Removal

KLV-32V400A, V400B

RM-GA011

3 Vesa Frame (Bottom) (32L)

qh Two screws

(+PSW M4 X 8)

2 One screw

(+PSW M4 X 8)

1 One screw

(BVTP2 4 X 16)

5 Frame, spine (32L)

qg One screw

(BVTP2 4 X 16)

6 Two screws

(+PSW M4 X 8)

4 One screw

(+PSW M4 X 8)

qj Vesa top

7 Two screws

(+BVTP 3 X 12)

8 Under Cover (M)

qh One screw

(+PSW M4 X 8)

9 One screw

(+PSW M4 X 8)

q; Two screws

(+PSW M4 X 8)

qf Vesa Frame (Bottom) (32R)

qs Frame Spine (32R)

qa Two screws

(BVTP2 4 X 16)

qd Frame Bottom (32)

– 11 –

Page 13

KLV-32V400A, V400B

RM-GA011

3-7. H4, H3E Board and Speaker Bracket Removal

1 Four screws

(+BVTP 4 X 12)

0 Two screws

(+BVTP2 4 X 16)

3 Loudspeaker (5.5 X 12cm)

2 Four screws

(+BVTP 3 X 12)

5 H3E board

4 H4 board

6 One screw

(+BVTP 3 X 12)

7 Guide Light

8 Bezel assy

9 Clear panel

– 12 –

Page 14

3-8. LCD Panel and Bezel Assy Removal

KLV-32V400A, V400B

RM-GA011

2 Harness

with connector

1 Two screws

(BVTP2 4 X 16)

3 LCD panel

4 Bezel assy

– 13 –

Page 15

KLV-32V400A, V400B

RM-GA011

Legend

HookSlide Clamp

SECTION 4

WIRE DRESSING

CAUTION :

1. Do not overpull the wires during dressing

--> avoid disconnection of wires.

2. Make sure wires are kept away from

sharp edges, heatsinks & other

high-temperature parts.

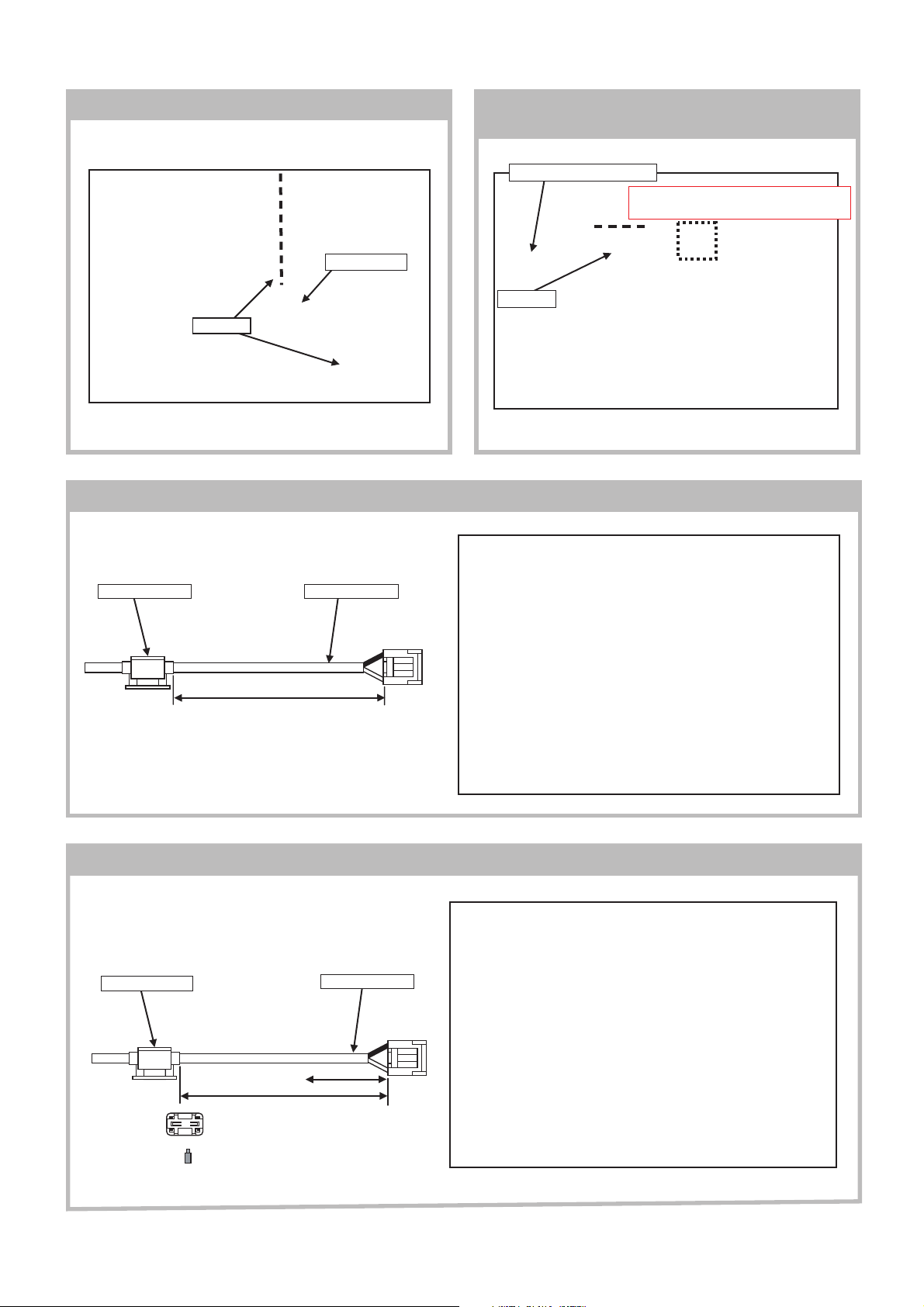

4-1-1. Wire dressing overview for

Non-CISPR model

For Non-CISPR model only

4-1-3. Dress LVDS cable with Sheet Core C (2X) as shown

Make sure LVDS connector fully inserted

with correct direction as shown.

LVDS cable

4-1-2. Wire dressing overview for CISPR model

Datum

Datum

Sheet Core C

Use UL tape

location as

guide line

UL Tape

Datum

For CISPR model only

4-1-4. i) Dress LVDS cable with Sheet Core C & Shield Tape as shown

ii) Screw LVDS cable's clamp on main bracket as shown

Apply tape at

the middle of

Shield Tape

Sheet Core C

this area.

Datum

Datum

LVDS cable

Screw

LVDS cable's clamp

– 14 –

Page 16

KLV-32V400A, V400B

RM-GA011

4-1-5. Dress Connector Assy 13P at

G1 bracket's hook

Connector assy 13P

4-1-7. Dress Connector Assy 14P+20P with

slide clamp(2X)

4-1-6. Dress Connector Assy 14P+20P at G1

bracket's hook(5X)

Connector assy 14P+20P

4-1-8. Dress Connector Assy 14P+20P on top of

Con

nector Assy 13P

Connector assy 14P+20P

4-1-9. Dress Connector Assy 14P+20P &

Speaker wire with sheet core C(2X)

Connector assy 14P+20P

Sheet Core C

Speaker Wire

Connector assy 14P+20P

Pull wire straight

Connector assy 13P

4-1-10. i) Dress Speaker wire and Connector assy

14P+20P with Sheet Core C & Slide clamp

ii) Dress Speaker Wire with LCD tape

Sheet Core C

Connector assy

14P+20P

Datum

Datum

Datum

– 15 –

Speaker Wire

LCD tape

Insert wire into speaker

bracket's hook

Page 17

KLV-32V400A, V400B

RM-GA011

4-1-11. Dress Speaker Wire(L) with LCD tape(2X). 4-1-12. Dress Connector Assy 14P+20P with

LCD tape.

Datum

Speaker Wire

LCD tape

For Non-CISPR model only

4-1-13. Install AC Cord Holder on AC Power Cord.

AC Cord holder

AC Power Cord

Connector assy 14P+20P

Datum

LCD tape

Caution : Pull wire until cannot reach

Caution : Pull wire until cannot reach

sharp edge area when apply LCD tape.

sharp edge area when apply LCD tape.

170mm

For CISPR model only

4-1-14. Install AC Cord Holder on AC Power Cord.

AC Cord holder

170mm

Ferrite Core

AC Power Cord

70mm

Cable tie

Note : Make sure tighten cable tie and cut excess part.

– 16 –

Page 18

4-1-15. i) Screw Connector Assy 1P on BG1 & Main Bracket.

ii) Put Connector Assy 1P underneath Speaker Wire.

Speaker Wire

Connector Assy 1P

KLV-32V400A, V400B

RM-GA011

~90

– 17 –

Page 19

KLV-32V400A, V400B

ERROR

DC_DET

DC_ALERT1

DC_ALERT2

DC_ALERT3

BACKLIGHT

INTERNAL TEMP ERROR

AUDIO ERROR

NVM ERROR

IIC ERROR

BALANCER ERROR

HDMI ERROR

0

0

0

0

0

0

0

0

0

0

0

RESET

0

RM-GA011

SECTION 5

SERVICE ADJUSTMENTS

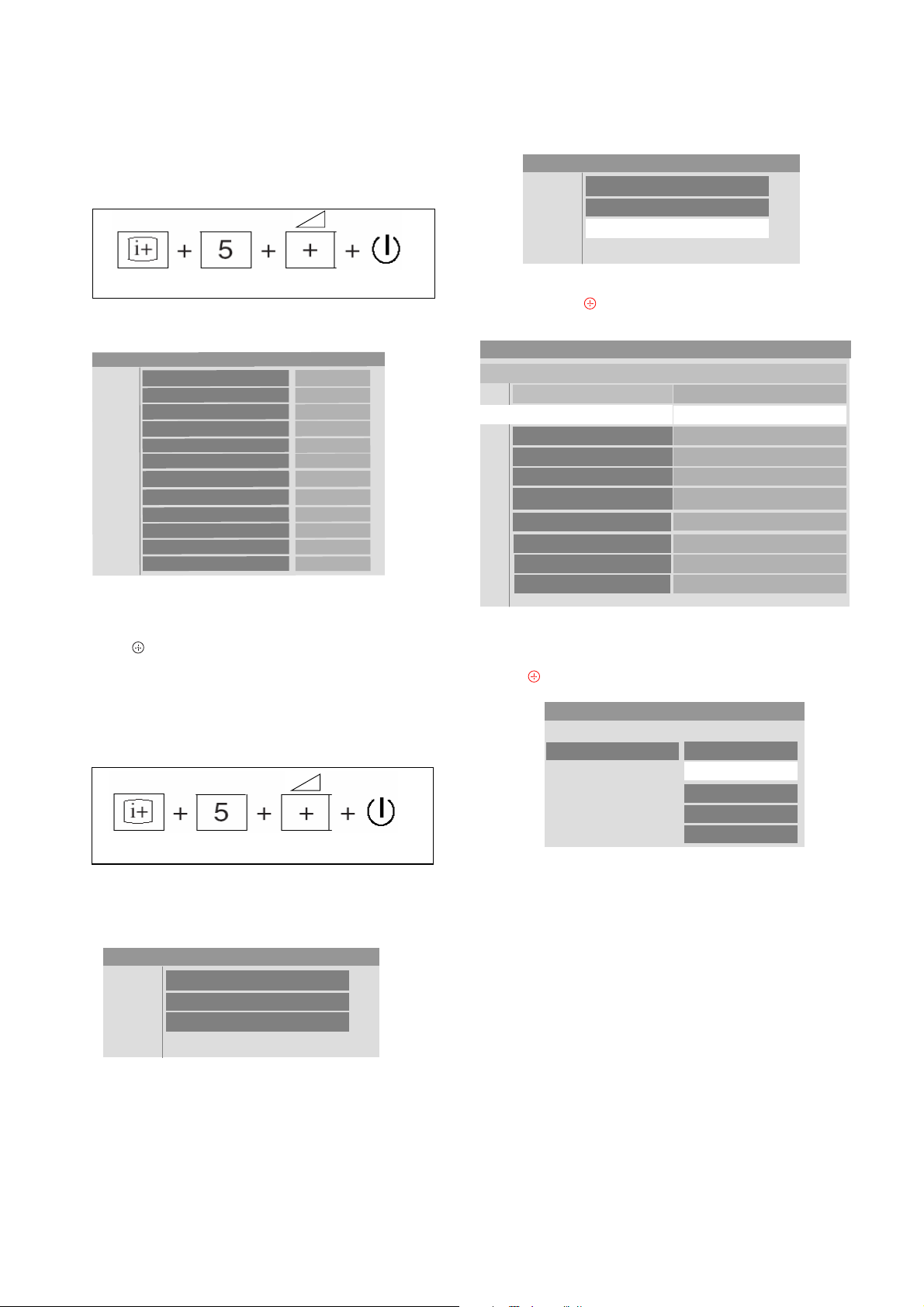

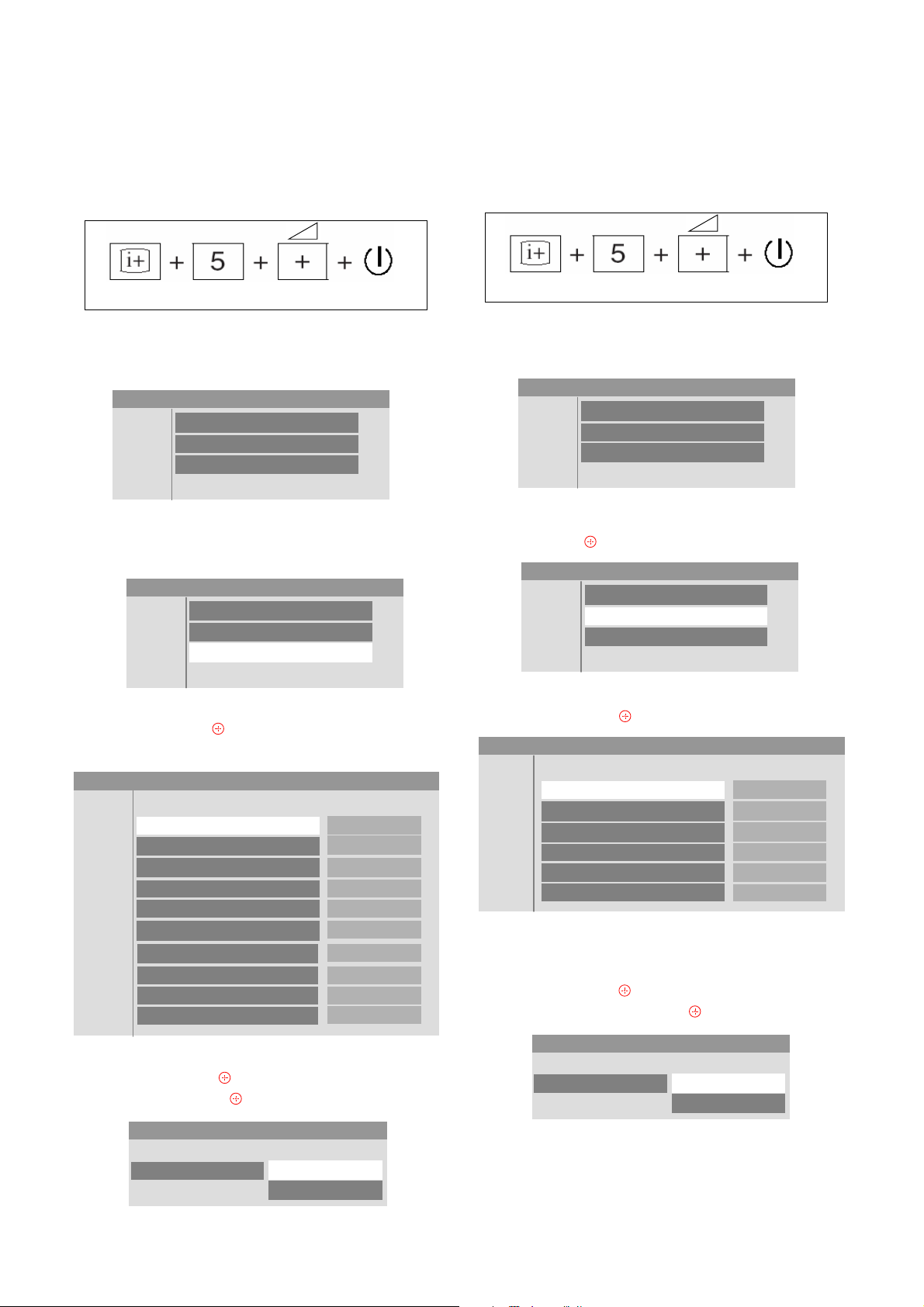

5-1. Accessing Diagnostic Menu

1. While TV set on standby, press the following sequence on

the remote commander (RM-GA011).

On screen

display

Channel 5

Volume (-)

POWER

2. The following menu will appear on the screen:

Figure 1

3. Press V/v to select ‘Service’.

Service Menu

Status

W/B

Service

Figure 4

4. Press B/b or

to view ‘Service’ category items.

Press V/v to selec /‘P ATTERN’.

Service Menu

Service

TEST RESET

PATTERN

PRODUCTION

APC

OVER MODULATION

OPTIONS

AUTOSET FACTORY

SERIAL NUMBER EDIT

ETI1 CLEAR

No Signal Mute

Cancel

WHITE PATTERN

11111111

Normal

Off

OPT 1

DEFAULT

Cancel

Off

3. To reset, select ‘RESET’ using remote commander and

press

to execute RESET.

4. To quit the diagnostic menu, turn off and on the TV set.

5-2. Aging

1. While TV set on standby, press the following sequence on

the remote commander (RM-GA011).

On screen

display

Channel 5 Volume (+)

POWER

Figure 2

2. The following menu will appear on the screen.

Service Menu

Status

W/B

Service

Figure 5

5. Then press B/b then V/v to select ‘WHITE PATTERN’

and .

Service Menu

Service

PATTERN

Off

WHITE PATTERN

RED PATTERN

GREEN PATTERN

BLUE PATTERN

Figure 6

6. The aging Condition is as the following:

a) Supply voltage : Rating

b) Time : 20 minutes or over

c) Ambient Temp : 22~28 degrees

Figure 3

– 18 –

Page 20

KLV-32V400A, V400B

RM-GA011

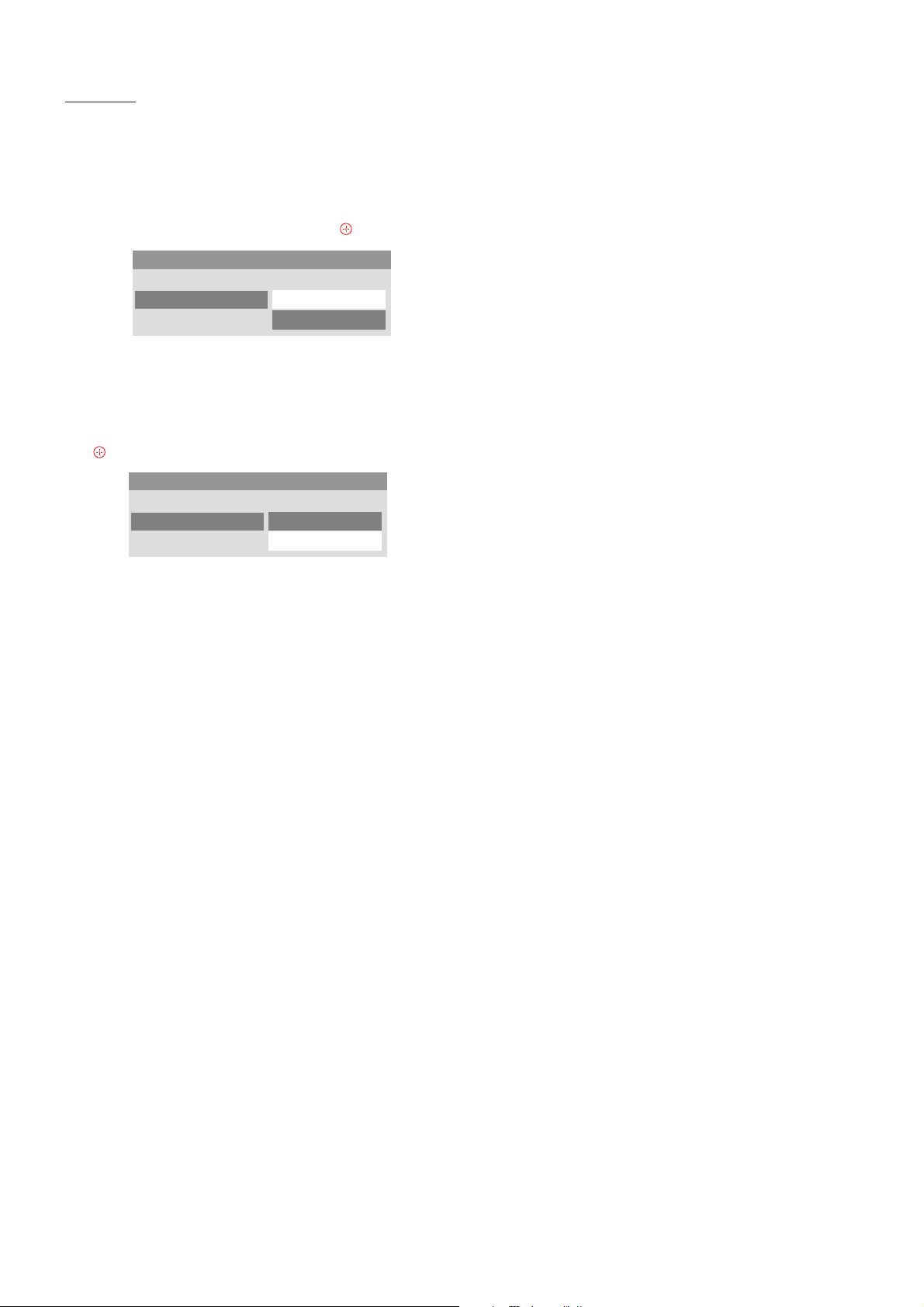

5-3. Resetting the User Menu - Factory Reset

Note: THE TEST RESET option resets all the customer

adjustable data back to factory defaults.

1. While TV set on standby, press the following sequence on

the remote commander (RM-GA011).

On screen

display

Channel 5

Volume (-)

POWER

Figure 7

2. The following menu will appear on the screen:

Service Menu

Status

W/B

Service

Figure 8

3. Press V/v to select ‘Service’.

Service Menu

Status

W/B

Service

5-4. White Balance Adjustment

Note: The white balance need to be adjusted when BG1 board

and Panel is replaced.

1. While TV set on standby, press the following sequence on

the remote commander (RM-GA011).

On screen

display

Channel 5

Volume (-)

POWER

Figure 12

2. The following menu will appear on the screen:

Service Menu

Status

W/B

Service

Figure 13

3. Press B/b or

to view ‘W/B’.

Service Menu

Status

W/B

Service

Figure 9

4. Then press B/b or

to view ‘Service’ category items.

Next select ‘TEST RESET’ by pressing V/v .

Service Menu

Service

TEST RESET

PATTERN

PRODUCTION

APC

OVER MODULATION

OPTIONS

AUTOSET FACTORY

SERIAL NUMBER EDIT

ETI1 CLEAR

No Signal Mute

Cancel

Off

11111111

Normal

Off

OPT1

DEFAULT

Cancel

Off

Figure 10

5. Finally press B/b or then V/v to select ‘OK’ and confirm

selection by pressing .

Service Menu

Service

TEST RESET

OK

Cancel

Figure 14

4. Then press B/b or to view ‘W/B’ category items.

Service Menu

W/B

INITIALIZE

LEVEL

R_DRIVE

G_DRIVE

B_DRIVE 0

COLOR_SAVE

INIT START

0

0

0

Cancel

Figure 15

5. Press V/v to select ‘INITIALIZE’.

6 Then press B/b or then V/v to select ‘INIT START’ and

execute selection by pressing .

Service Menu

W/B

INITIALIZE

INIT START

INIT END

Figure 16

7. W/B need to be adjusted for all LEVEL (0~4).

Figure 11

– 19 –

Page 21

KLV-32V400A, V400B

RM-GA011

For Level 0

8. Select 'LEVEL' using V/v and choose ‘0’.Then do

adjustment for R_Drive, G_Drive and B_Drive. To increase/

decrease data value, press V/v .

9. Once adjustment has completed for R_Drive, G_Drive and

B_Drive, press V/v to select ‘COLOR SAVE’. Next press

B/b then V/v to choose ‘OK’ and press

Service Menu

W/B

COLOR_SAVE

10. Repeat step 8 and 9 for level 1~4.

11. Once W/B adjustment has been completed for all levels

(0~4), select ‘INITIALIZE’, choose ‘INT END’ and press

.

OK

Cancel

Figure 17

.

Service Menu

W/B

INITIALIZE

INIT START

INIT END

Figure 18

5-5. Board & Panel Replacement

When replacing the BG1 board and Panel, make sure to readjust

the W/B.

– 20 –

Page 22

6-1. BLOCK DIAGRAM

KLV-32V400A, V400B

RM-GA011

SECTION 6

DIAGRAMS

Due to complexity of the board, performing

component level field repairs are not recommended.

Complete board replacement is required if service is

necessary.

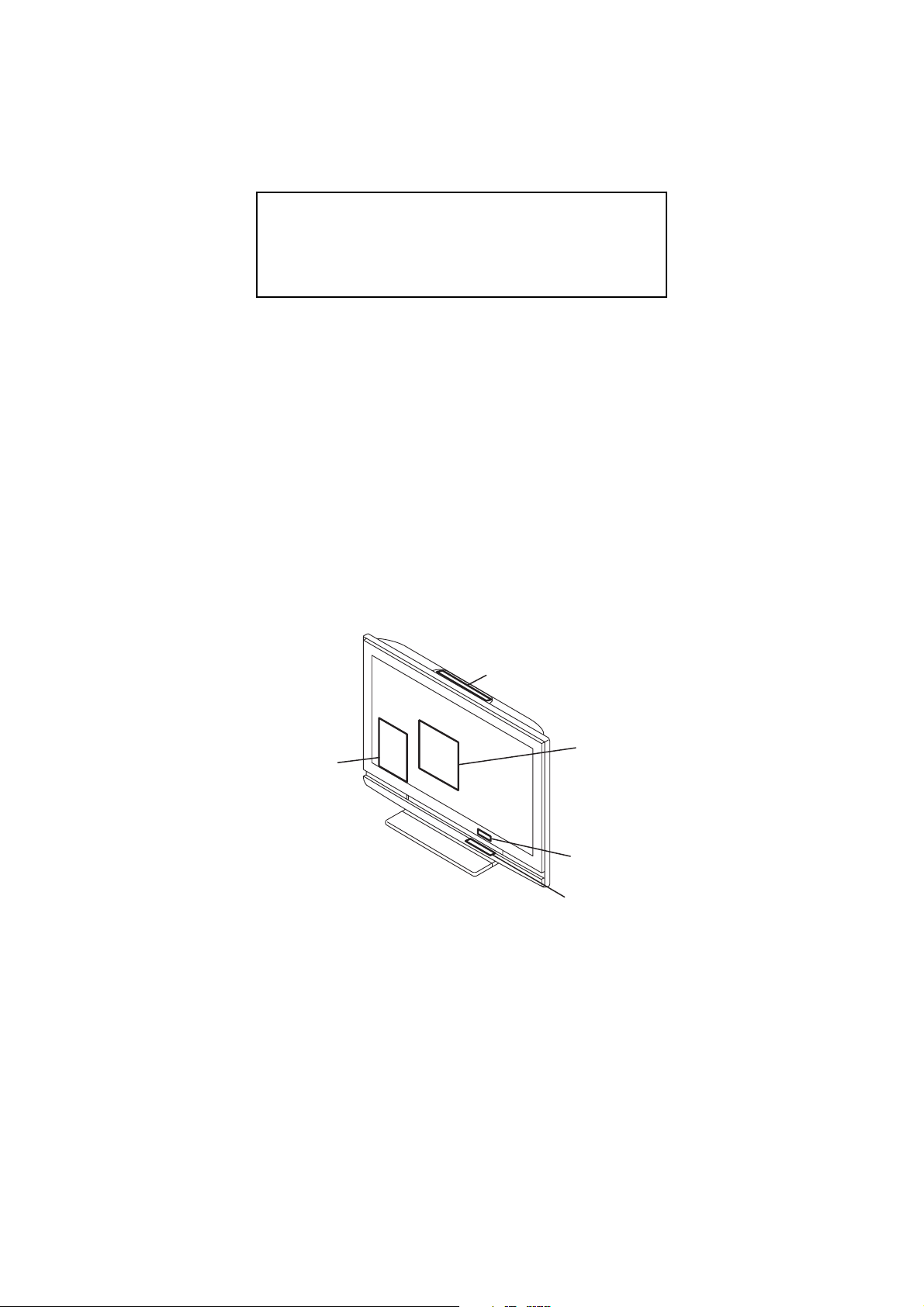

6-2. CIRCUIT BOARD LOCATION

BG1 Board

Switch Unit

GP Board

H4 Board

H3E Board

– 21 –

Page 23

KLV-32V400A, V400B

RM-GA011

6-3. SCHEMATIC DIAGRAM 6-4. PRINTED WIRING BOARDS

Board Function Note

BG1 I/O/Audio/VCTP/DDR/HDMI/ Due to complexity of the board, performing

GP Power Supply necessary.

H4 SIRCS printed wiring boards are not included.

H3E LED/Optical Sensor Exploded View or Electrical Parts List

6-5. SEMICONDUCTOR

DC-DC Converter/Tuner/Sub component level field repairs are not

Croma/STBY Micro recommended. Complete board

replacement is required if service is

Therefore schematic diagrams and

For part number information, refer to

section in this manual.

Due to complexity of the board, performing

component level field repairs are not recommended.

Complete board replacement is required if service is

necessary.

– 22 –

Page 24

SECTION 7

EXPLODED VIEWS

KLV-32V400A, V400B

RM-GA011

• Components not identified by a part

number or description are not stocked

because they are not required for routine

service.

NOTE: The components identified by shading and ! mark are

critical for safety. Replace only with part number specified.

Note: The components identified by mark contain

confidential information. Strictly follow the instructions

whenever the components are repaired and /or replaced.

• The component parts of an assembly

are indicated by the reference numbers

in the far right column of the part list and

within the dotted lines of the diagram.

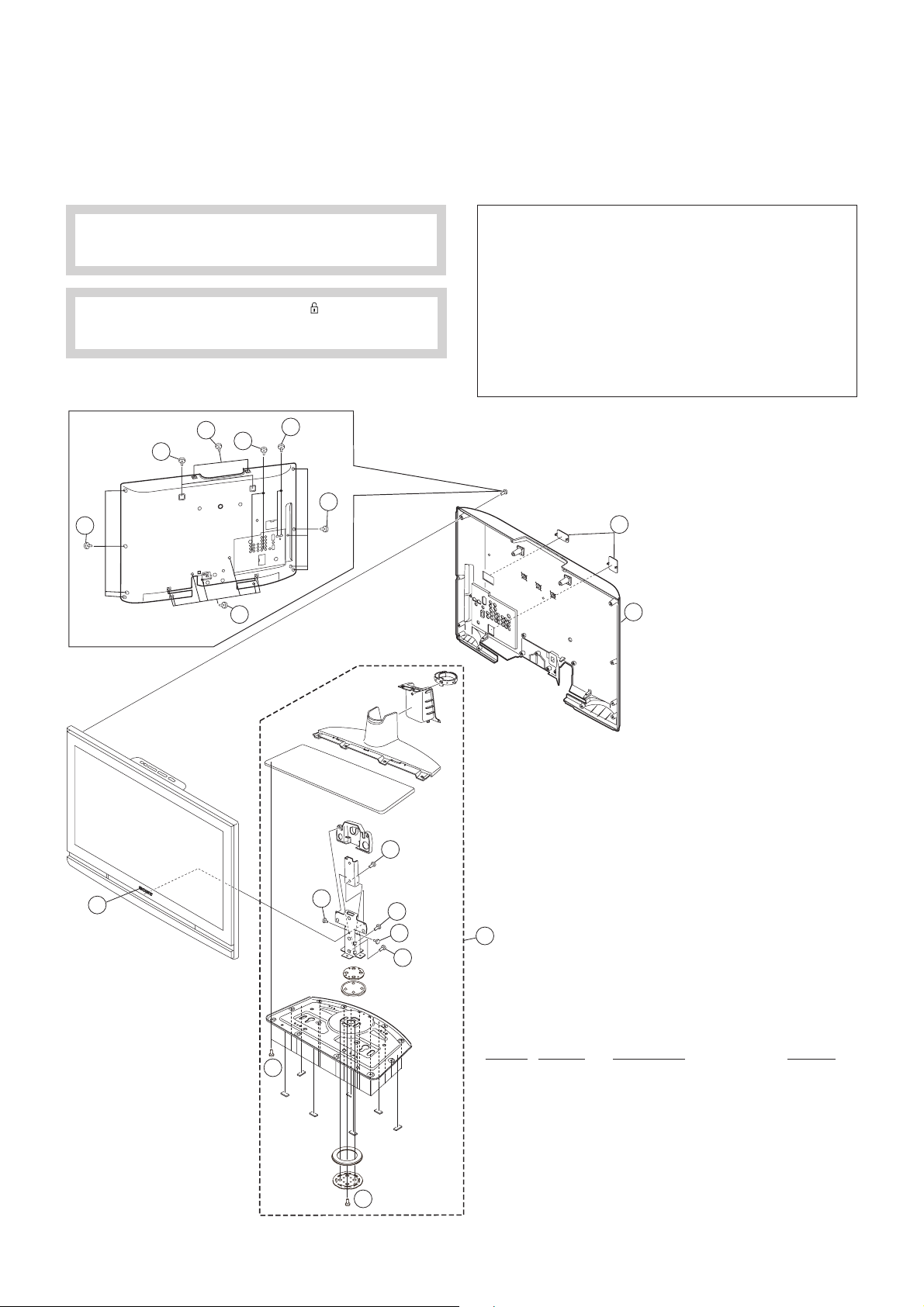

7-1. REAR CABINET AND STAND ASSY

f

f

f

a

k

f

• Item marked with an asterisk (*) are not

stocked since they are seldom required

for routine service. Some delay should

be anticipated when ordering these

components.

a 2-580-591-01 SCREW, +PSW M3X5

b 2-580-600-01 SCREW, +PSW M4X8

c 2-580-606-01 SCREW, +PSW M5X8

d 2-580-626-01 SCREW, SP 4-4O UNC

e 2-580-629-01 SCREW, +BVST 3X8

f 2-580-640-01 SCREW, +BVTP2 4X16

g 2-580-644-01 SCREW, +KTP2 3X8

h 2-674-965-31 SCREW, +PSW 3SG

i 3-873-012-01 SCREW, +PWH M5X16

j 3-873-013-01 SCREW, +PWH M5X10

k 7-685-648-79 SCREW, +BVTP 3X12 TYPE2 IT-3

l 2-580-608-01 SCREW +PSW M5 X 16

2

1#

f

1

j

4

j

j

j

3

j

g

i

REF. NO. PART NO. DESCRIPTION REMARK

1COVER, REAR

2*3-106-086-02 COVER, ECS (Except 32V400A/R/T/W(EA))

* 3-106-086-01 COVER, ECS (32V400A/R/T/W(EA))

3 X-2189-409-1 STAND(M)ASSY

(Except 32V400A/R/T/W(E,EA,ME,Philippines,

Saudi Arabia,South Africa),32V400A/R/W(Thailand))

X-2318-611-1 STAND (M)(W), ASSY

(32V400A/R/T/W(E,EA,ME,Philippines,

Saudi Arabia,South Africa),32V400A/R/W(Thailand))

4 4-103-642-21 EMBLEM, SONY NO.8

(Except 32V400A/W(E,EA,ME,Philippines,

Saudi Arabia,South Africa,Thailand))

– 23 –

Page 25

KLV-32V400A, V400B

RM-GA011

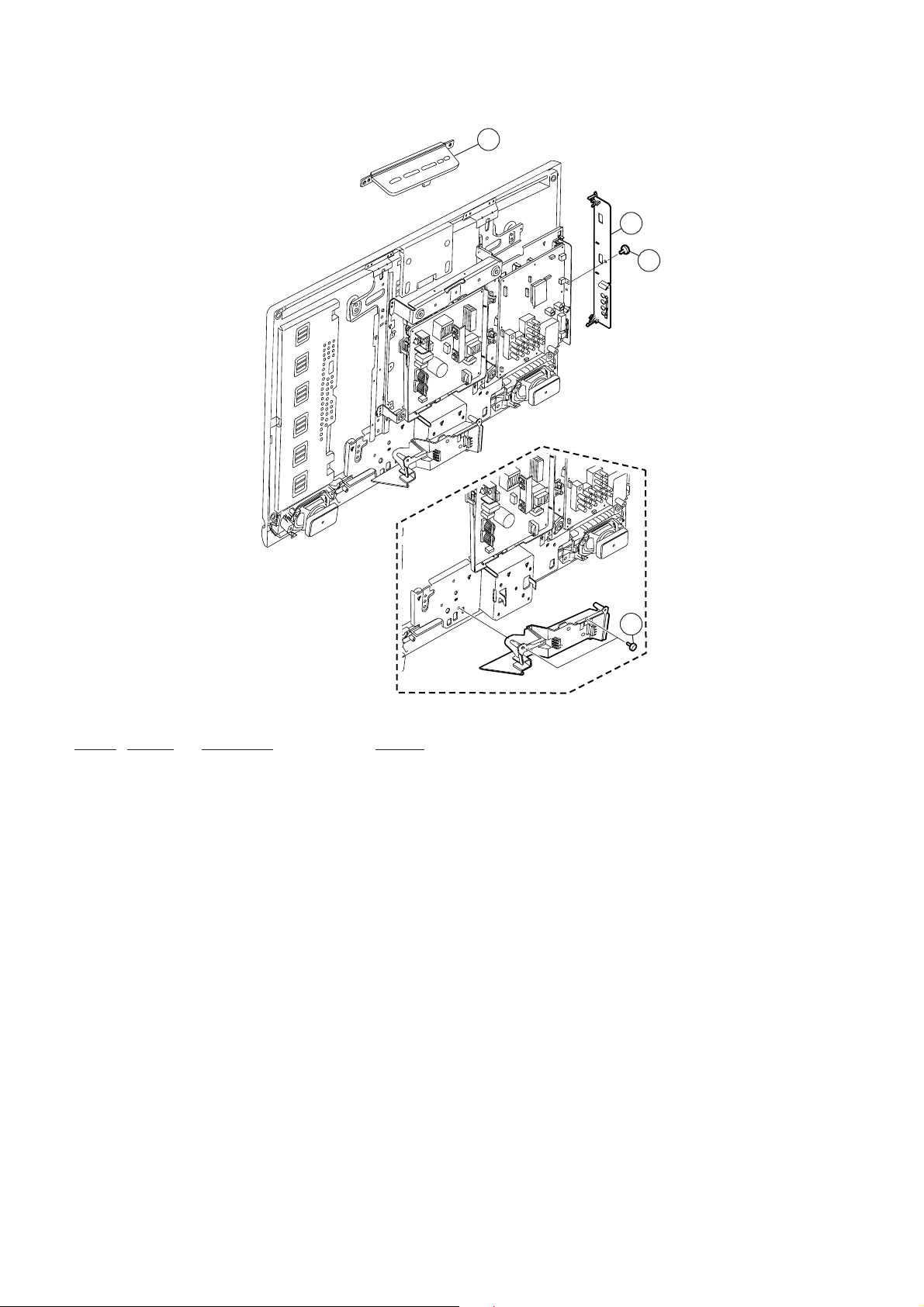

7-2. FRAME AND COVER

51

52

a

REF. NO. PART NO. DESCRIPTION REMARK

51 1-480-709-11 SWITCH UNIT

52 X-2318-678-1 BRACKET, SIDE JACK ASSY (PF1)

(32V400A/R/T/W(EA),

32V400A/T(ME,Philippines,South Africa))

k

– 24 –

Page 26

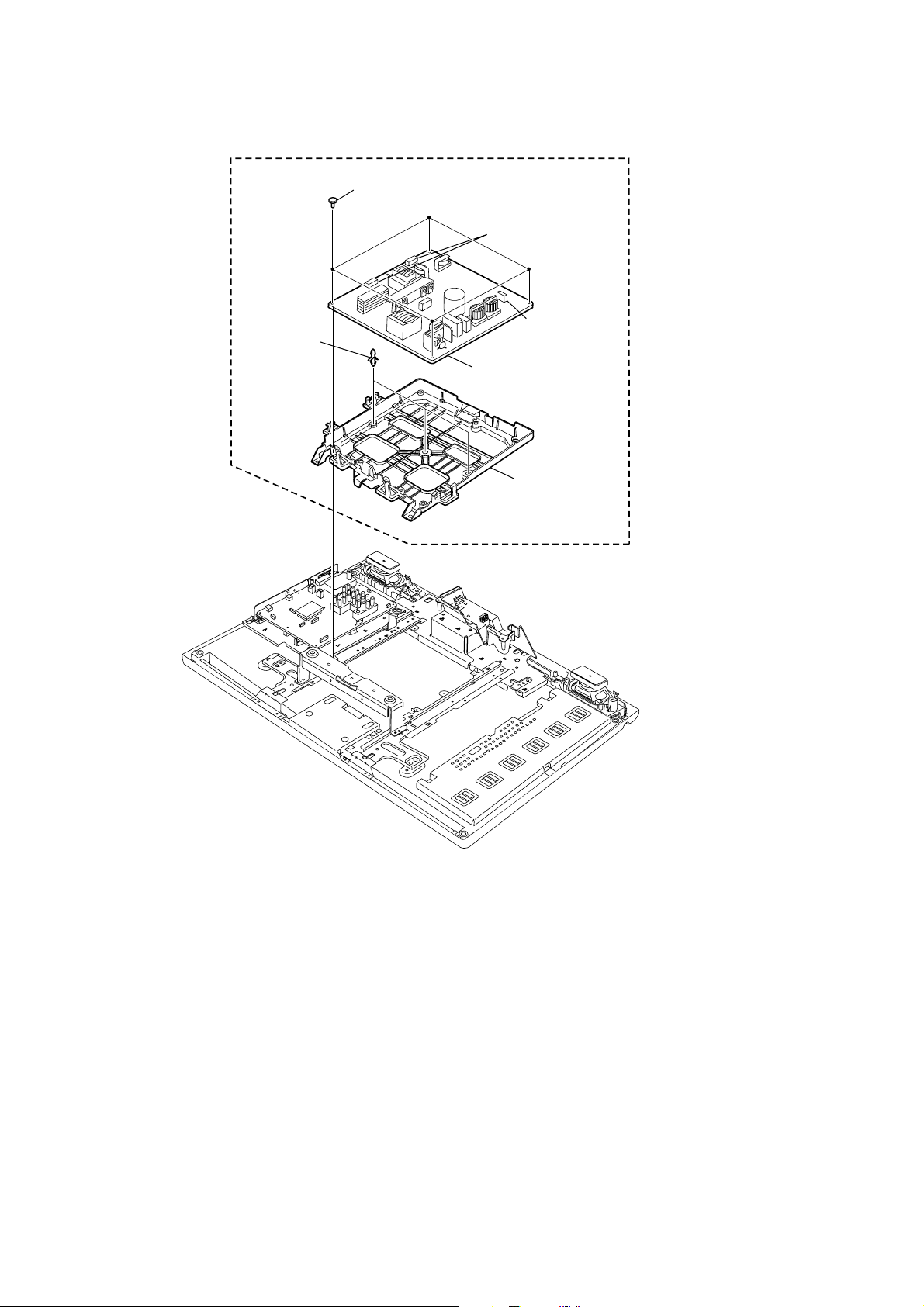

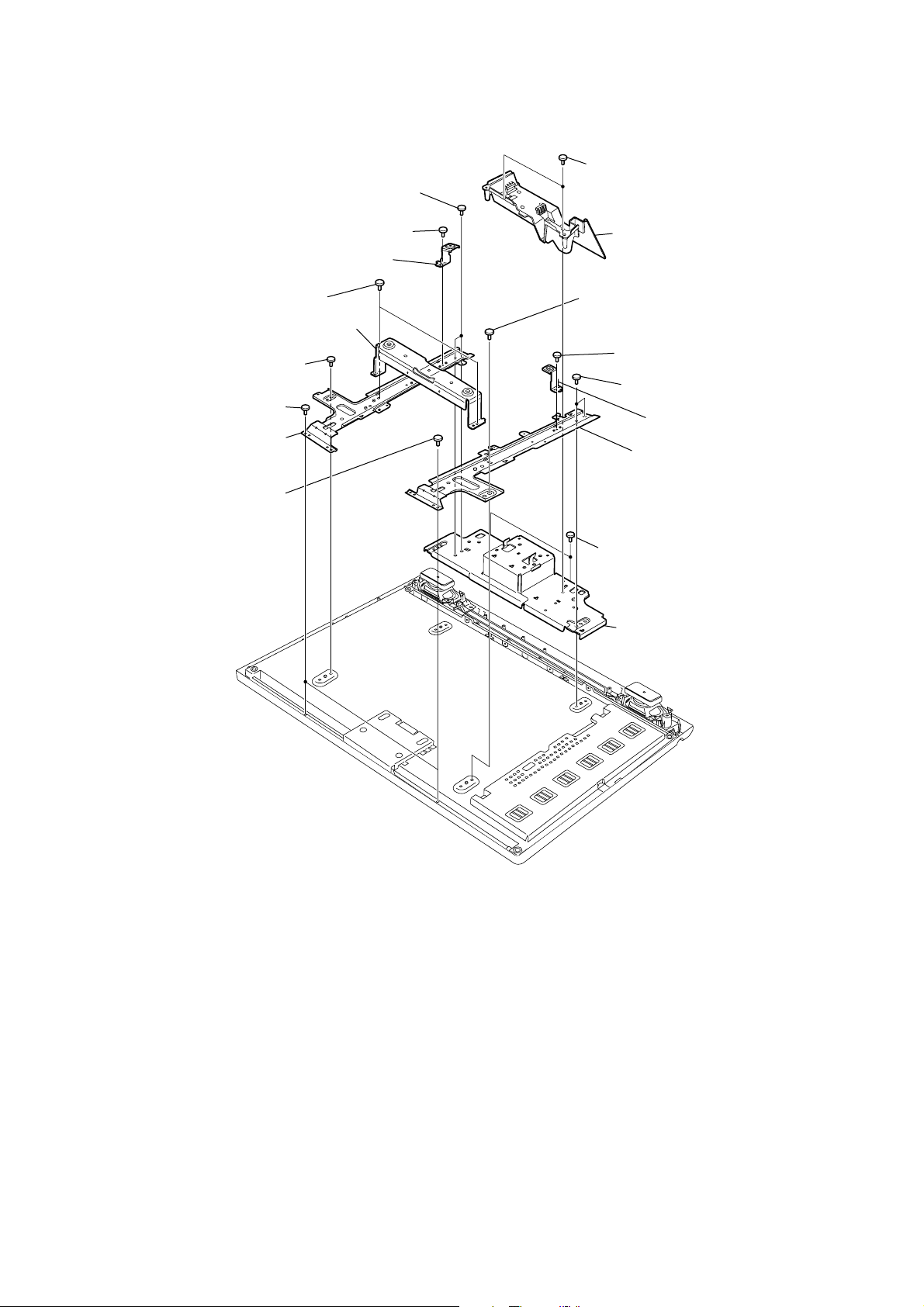

7-3. CHASSIS-1

KLV-32V400A, V400B

RM-GA011

f

b

f

f

102

101

REF. NO. PART NO. DESCRIPTION REMARK

101 ! 1-835-136-11 POWERSUPPLYCORD(WITHCONNECTER)

(Except 32V400A(India,Thailand),

32V400A/W(Thailand)/32V400B(Thailand))

! 1-835-280-11 POWERSUPPLYCORD(WITHCONNECTOR)

(32V400A(India))

! 1-835-127-11 POWERSUPPLYCORD(WITHCONNECTER)

(32V400A(Thailand),32V400A/W(Thailand)/

32V400B(Thailand))

102 4-022-115-00 HOLDER, AC CORD (Except 32V400A(Vietnam))

4-022-115-21 HOLDER, AC CORD (32V400A(Vietnam))

b

b

b

b

b

b

b

k

– 25 –

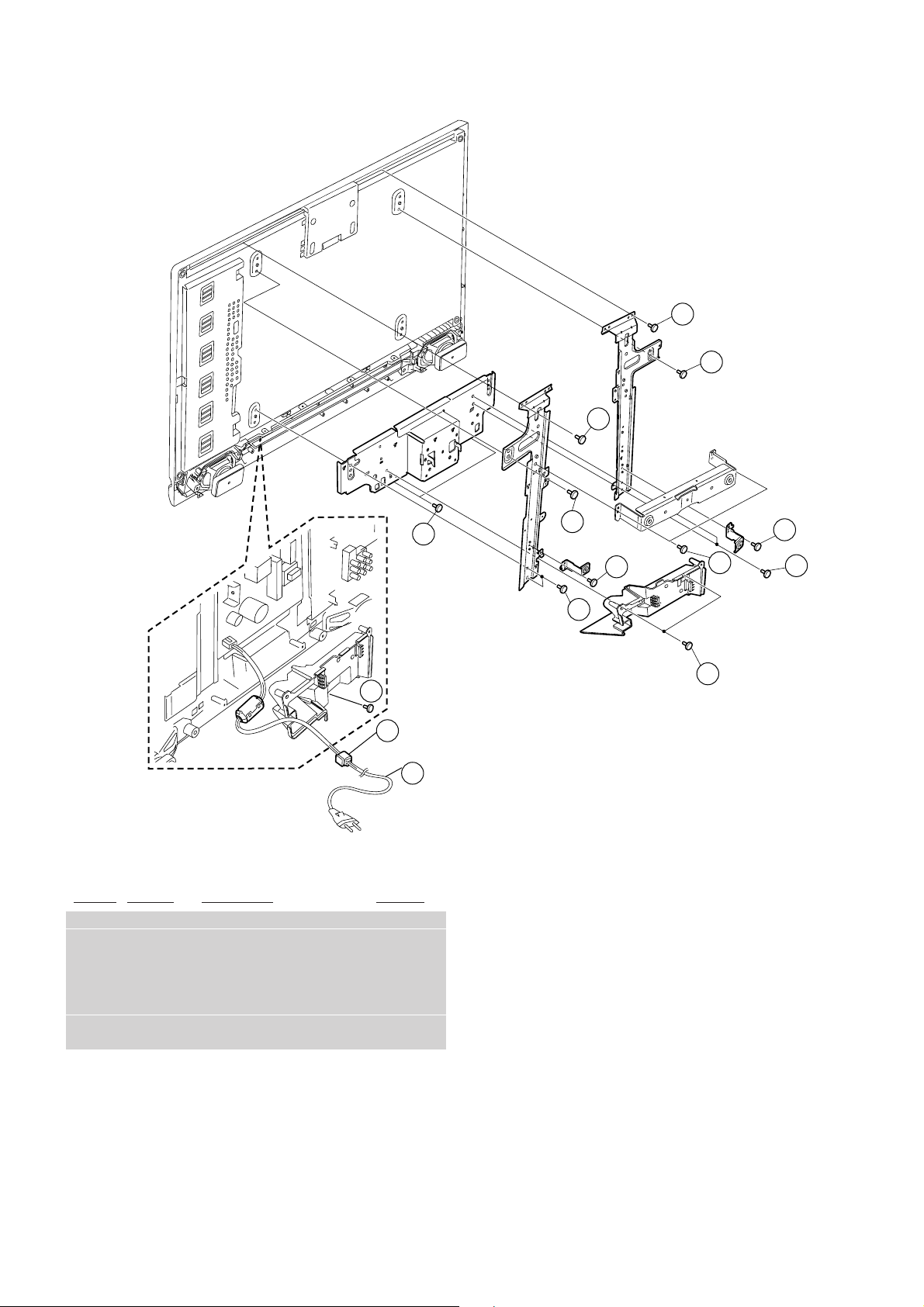

Page 27

KLV-32V400A, V400B

RM-GA011

7-4. CHASSIS-2

f

b

152

f

a

b

b

b

b

b

b

k

b

e

e

h

151

REF. NO. PART NO. DESCRIPTION REMARK

151 A-1540-080-A GP COMPLETE KIT (32)

152 A-1530-495-A BG1 MOUNT SERVICE (Except KLV-32V400B)

A-1527-549-A BG1 MOUNT SERVICE (KLV-32V400B)

– 26 –

Page 28

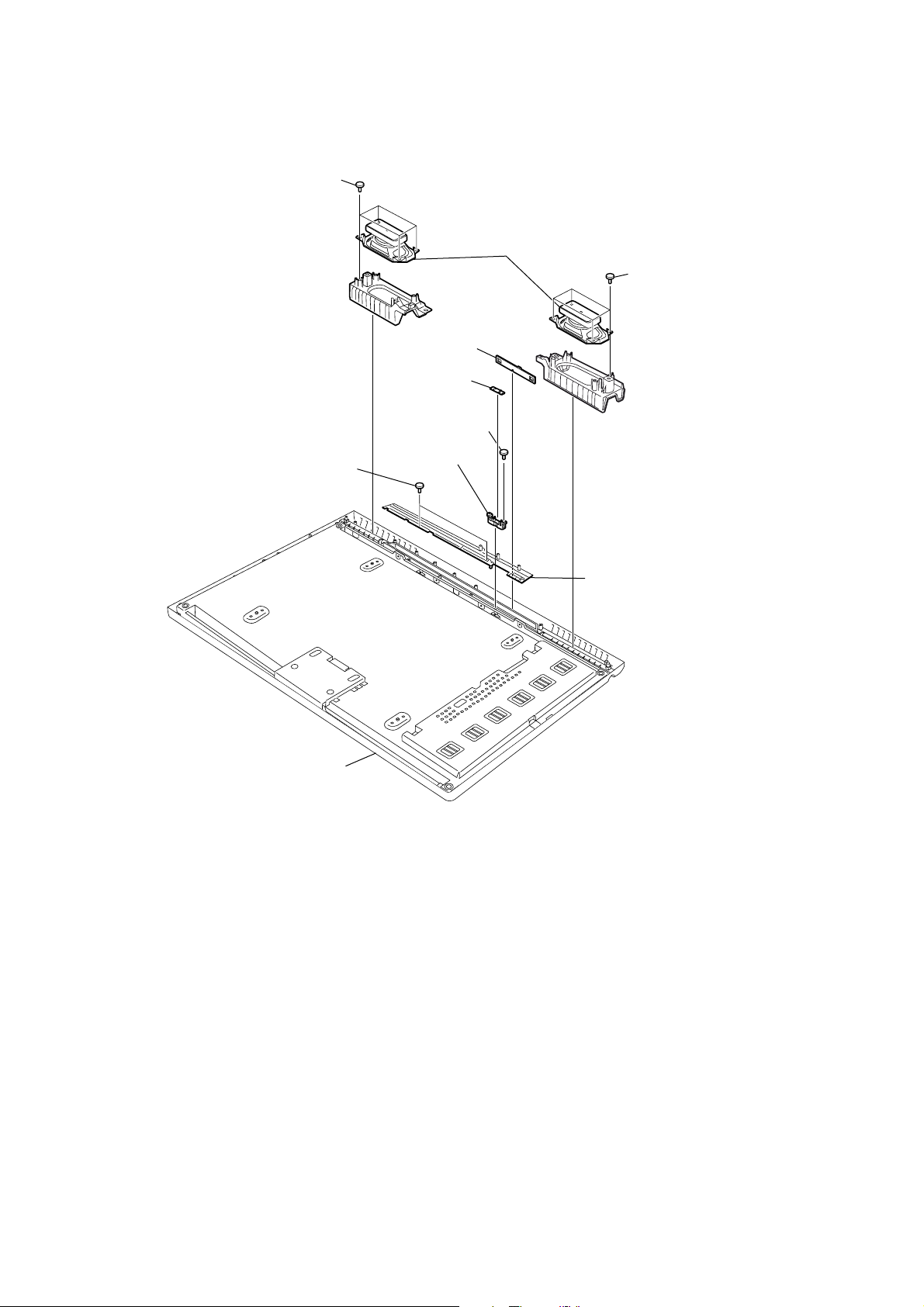

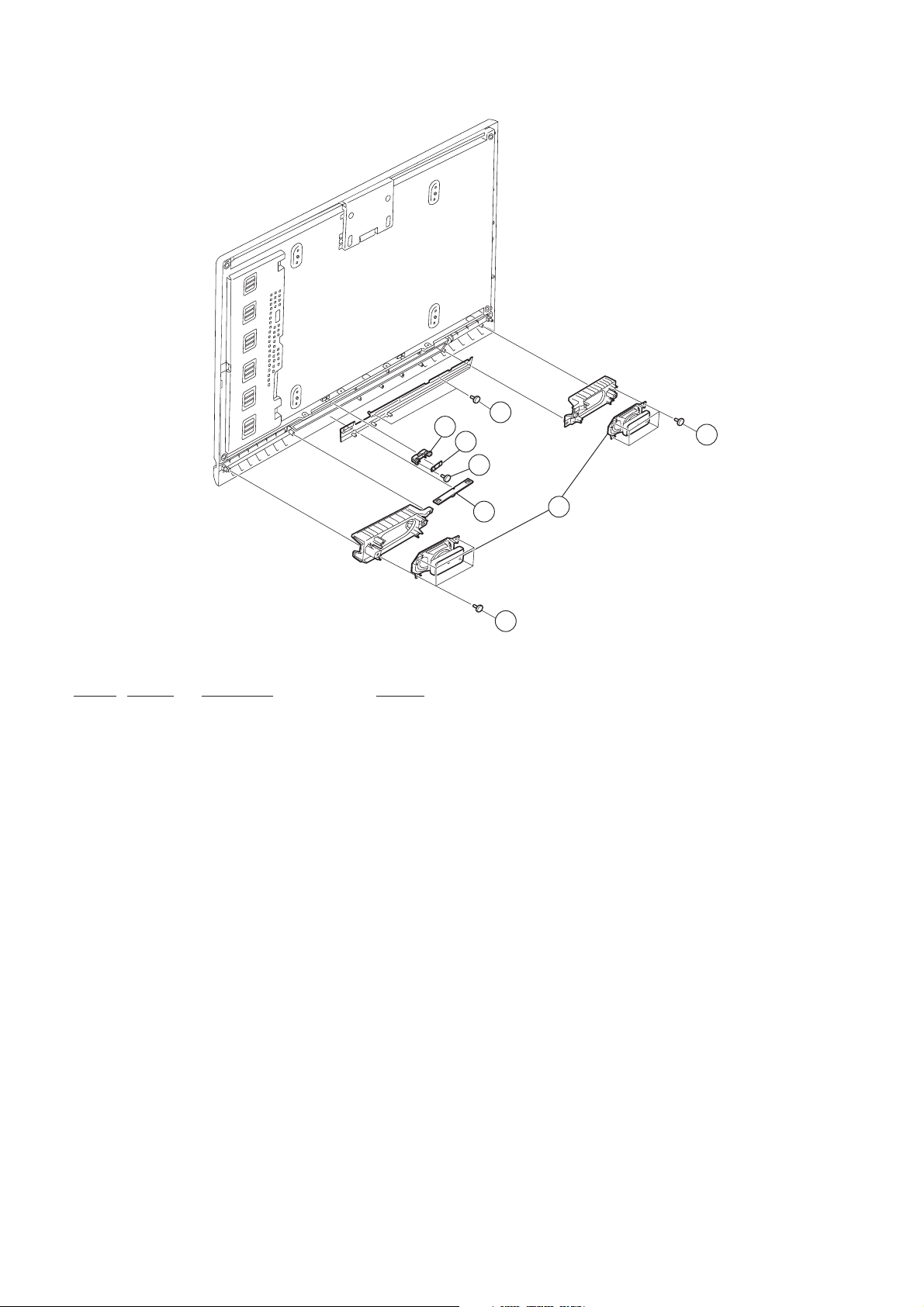

7-5. H3E & H4 BOARDS AND SPEAKER

KLV-32V400A, V400B

RM-GA011

REF. NO. PART NO. DESCRIPTION REMARK

201 * A-1530-492-A H4 MOUNT

202 * A-1535-202-A H3E MOUNT

203 1-826-892-11 LOUDSPEAKER (5.5X12CM)

203 1-826-892-21 LOUDSPEAKER (5.5X12CM)

204 * 3-290-361-01 GUIDE, LIGHT (Except 32V400A/W(EA))

* 3-290-361-11 GUIDE, LIGHT (32V400A/W(EA))

204

201

k

202

f

k

203

k

– 27 –

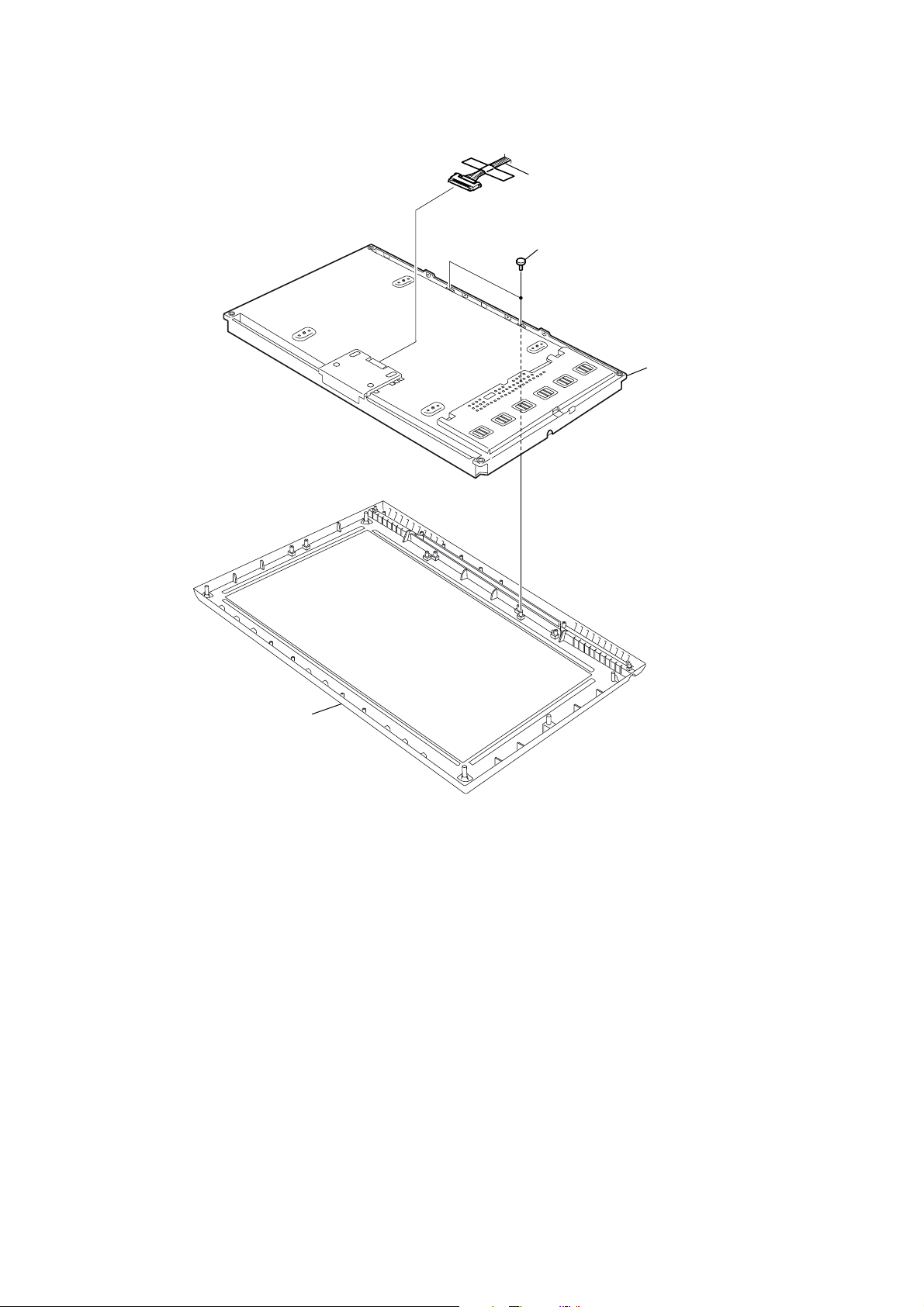

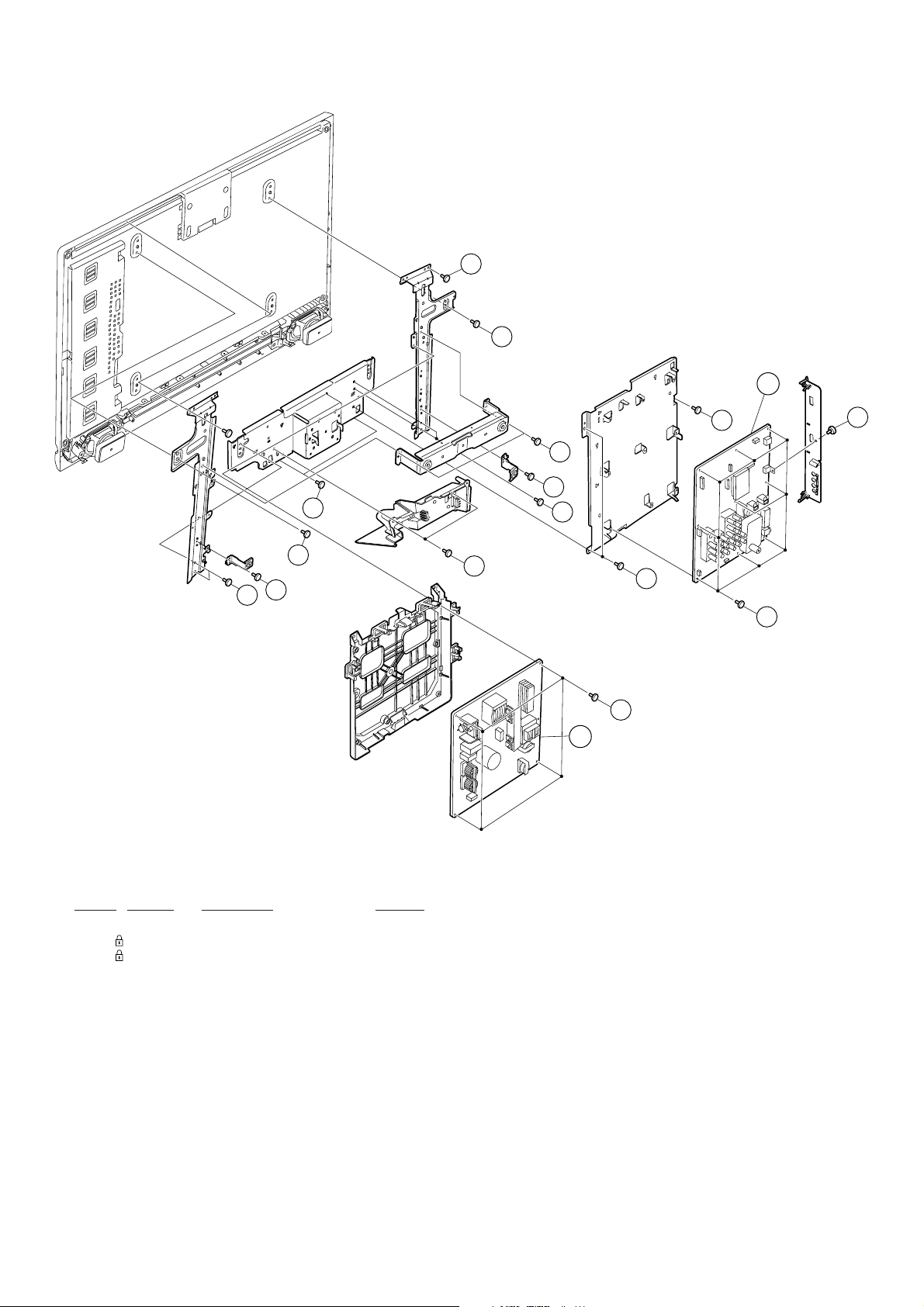

Page 29

KLV-32V400A, V400B

RM-GA011

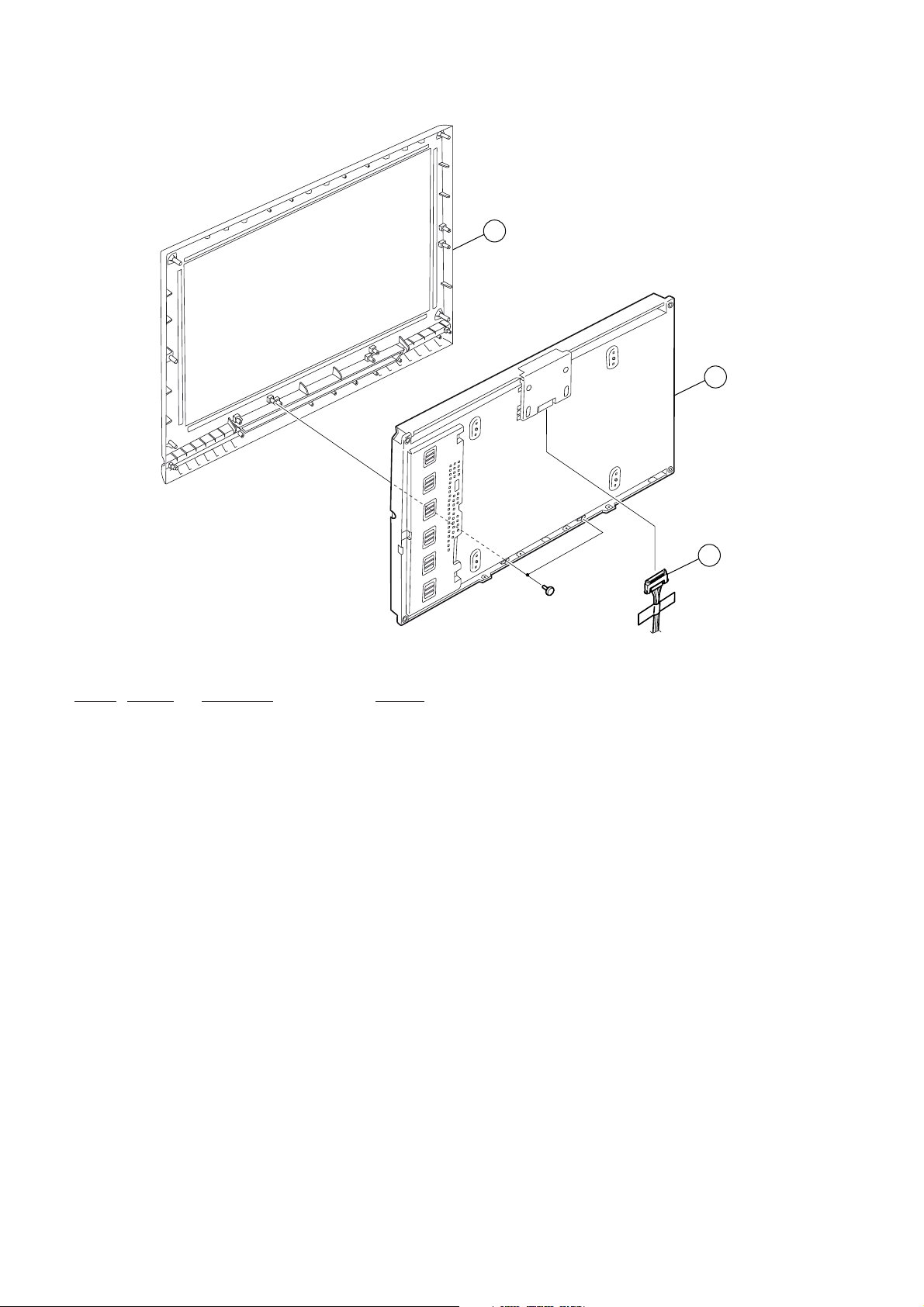

7-6. BEZEL ASSY and LCD Panel

251

252

REF. NO. PART NO. DESCRIPTION REMARK

251 X-2190-023-1 BEZEL ASSY (32AM) (32V400A,32V400B)

X-2318-766-1 BEZEL ASSY (32AM) (R)

(32V400A/R(E,EA,ME,Philippines,Saudi Arabia,

South Africa,Thailand))

X-2318-765-1 BEZEL ASSY (32AM)(T)

(32V400A/T(E,EA,ME,Philippines,Saudi Arabia,

South Africa))

X-2190-035-1 BEZEL ASSY (32AM)(W)

(32V400A/W(E,EA,ME,Philippines,

Saudi Arabia,South Africa,Thailand))

252 1-802-653-12 LCD PANEL (32 WXGA TFT)

253 1-966-101-21 HARNESS WITH CONNECTOR (LVDS)

(Except 32V400A(Iran,Vietnam))

1-966-101-31 HARNESS WITH CONNECTOR (LVDS)

(32V400A(Iran,Vietnam))

253

– 28 –

Page 30

KLV-32V400A, V400B

The components identified by shading

and mark ! are critical for safety.

Replace only with part number specified.

The components identified by mark contain

confidential information. Strictly follow the

instructions whenever the components are

repaired and /or replaced.

SECTION 8

ELECTRICAL PARTS LIST

NOTE:

REF NO. PART NO. DESCRIPTION REMARK REF NO. PART NO. DESCRIPTION REMARK

The components identified by shading

and mark ! are critical for safety.

Replace only with part number specified.

The components identified by mark contain

confidential information. Strictly follow the

instructions whenever the components are

repaired and /or replaced.

REF NO. PART NO. DESCRIPTION REMARK REF NO. PART NO. DESCRIPTION REMARK

A-1530-495-A BG1 MOUNT SERVICE (Except 32V400B)

A-1527-549-A BG1 MOUNT SERVICE (32V400B)

**********************************

A-1540-080-A GP COMPLETE KIT (32)

*********************

* A-1535-202-A H3E MOUNT

************

* A-1530-492-A H4 MOUNT

***********

Due to complexity of the board, performing component level field

repairs is not recommended.

If service is required, complete board replacement is required.

Part number information refer to the Exploded View or Electrical

Par ts Lists section of this Service Manual.

*********************************************************************

• Items marked " ∗ " are not stocked since

they are seldom required for routine

service. Some delay should be anticipated when ordering these items.

• All variable and adjustable resistors have

characteristic curve B, unless otherwise

noted.

* 3-874-911-01 CUSHION LOWER

* 3-300-886-01 INDIVIDUAL CARTON

* 3-879-145-01 INDIVIDUAL CARTON (32V400A(Iran))

* 3-874-909-01 INDIVIDUAL CARTON

* 3-878-302-01 INDIVIDUAL CARTON (32V400A(Vietnam)

* 3-879-649-01 INDIVIDUAL CARTON (32V400B(Saudi Arabia)

* 4-000-461-01 INDIVIDUAL CARTON (32V400B(Thailand))

1-821-947-11 ADAPTOR CONVERSION (EURO 3P)

• All resistors are in ohms

• F : nonflammable

CAPACITORS

• MF : µF, PF : µµF

COILS

• MMH : mH, UH : µH

(32V400A(ME,Philippines,

South Africa,Thailand),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W

(Thailand),32V400B(Thailand))

(Except 32V400A(Iran,ME,Philippines,

South Africa,Thailand,Vietnam),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W

(Thailand),32V400B)

(32V400A(ME,Philippines,

South Africa,Thailand),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W(Thailand))

(32V400A(E),32V400A/R/T/W(E))

RM-GA011

CONNECTORS

***************

1-910-043-78 CONNECTOR ASSY 14P+20P

1-966-101-21 HARNESS WITH CONNECTOR (LVDS)

(Except 32V400A(Iran,Vietnam))

1-966-101-31 HARNESS WITH CONNECTOR (LVDS)

(32V400A(Iran,Vietnam))

*********************************************************************

ACCESSORIES AND PACKING

*****************************

* 3-289-963-01 PANEL, CLEAR (32)

* 3-295-215-01 CUSHION (UPPER)

(Except 32V400A(ME,Philippines,

South Africa,Thailand),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W

(Thailand),32V400B(Thailand))

* 3-874-910-01 CUSHION UPPER

(32V400A(ME,Philippines,

South Africa,Thailand),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W

(Thailand),32V400B(Thailand))

* 3-295-216-01 CUSHION (LOWER)

(Except 32V400A(ME,Philippines,

South Africa,Thailand),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W

(Thailand),32V400B(Thailand))

1-569-008-22 ADAPTOR, CONVERSION 2P

(32V400A(Philippines),32V400A/R/T/W(Philippines))

1-821-926-11 PLUG CONVERSION ADAPTOR

(32V400A(South Africa),32V400A/R/T/W(South Africa))

3-214-128-13 INSTRUCTION (WALL MOUNT)

(32V400A(E,EA,India,Saudi Arabia,

South Africa),32V400A/R/T/W(E,EA,

Saudi Arabia),32V400B(Saudi Arabia))

3-214-128-32 INSTRUCTION (WALL MOUNT) (32V400A(Iran))

3-214-128-23 INSTRUCTION (WALL MOUNT)

(32V400A(ME,Philippines,

South Africa,Thailand),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W

(Thailand),32V400B(Thailand))

3-219-725-13 INSTRUCTION (WALL MOUNT) (32V400A(Vietnam))

4-108-226-11 MANUAL,INSTRUCTION(WALL MOUNT)

(32V400A/R/T/W(EA))

3-300-887-11 MANUAL, INSTRUCTION

(32V400A(E,EA,India,Saudi Arabia),32V400A/R/T/W

(E,EA,Saudi Arabia))

3-300-887-21 MANUAL, INSTRUCTION

(32V400A(E),32V400A/R/T/W(E))

3-300-887-31 MANUAL, INSTRUCTION

(32V400A(EA,Saudi Arabia),

32V400A/R/T/W(EA,Saudi Arabia))

3-300-887-41 MANUAL, INSTRUCTION

(32V400A(EA),32V400A/R/T/W(EA))

3-879-152-11 MANUAL, INSTRUCTION (32V400A(Iran))

3-874-917-11 MANUAL, INSTRUCTION

(32V400A(ME,Philippines,

South Africa,Thailand),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W(Thailand))

– 29 –

Page 31

KLV-32V400A, V400B

RM-GA011

The components identified by mark contain

confidential information. Strictly follow the

instructions whenever the components are

repaired and /or replaced.

The components identified by shading

and mark ! are critical for safety.

Replace only with part number specified.

REF NO. PART NO. DESCRIPTION REMARK

3-874-917-21 MANUAL, INSTRUCTION

(32V400A(Thailand),32V400A/W(Thailand))

3-874-917-31 MANUAL, INSTRUCTION (32V400A(ME),

32V400A/R/T/W(ME),32V400A/R(Thailand))

3-878-303-11 MANUAL, INSTRUCTION (32V400A(Vietnam))

3-879-650-11 MANUAL, INSTRUCTION (32V400B(Saudi Arabia))

3-879-650-21 MANUAL, INSTRUCTION (32V400B(Saudi Arabia))

3-879-650-31 MANUAL, INSTRUCTION (32V400B(Saudi Arabia))

4-000-347-11 MANUAL, INSTRUCTION (32V400B(Thailand))

4-000-347-21 MANUAL, INSTRUCTION (32V400B(Thailand))

X-2190-783-1 BAG ASSY, RUDDER LOCK

(Except 32V400A(ME,Philippines,

South Africa,Thailand),32V400A/R/T/W

(ME,Philippines,South Africa),32V400A/R/W

(Thailand),32V400B(Thailand))

*********************************************************************

REMOTE COMMANDER

************************

1-480-705-11 REMOTE COMMANDER (RM-GA011)

9-885-117-43 BATTERY COVER, REMOTE COMMANDER

REF NO. PART NO. DESCRIPTION REMARK

– 30 –

Page 32

SUPPLEMENT-1

r

EG1L (GA)

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

MODEL COMMANDER DEST. CHASSIS NO.

KLV-32V400A RM-GA011 Egypt

KLV-32V400A/1 RM-GA011 EA

KLV-32V400A/2 RM-GA011 EA

KLV-32V400A/T RM-GA011 India

(Mat Brown)

SUBJECT : New model addition

This supplement shows only variant information for the new model(s).

Other information remains the same as in the original issue.

SECTION 3. DISASSEMBLY

3-1. Rear Cover and R2 Board Removal (refer page 7)

(For KLV-32V400A/1, /2 only)

1 Eighteen screws

(BVTP2 4 X 16)

2 Two screws

(+BVTP 3 X 12)

3 Two screws

(+PSW M3 X 5)

4 One screw

(PSW 5 X 8)

1 Remove

R Bracket (Top)

2 Disconnect

CN001

3 Two screws

(+BVTP 3 X 14)

4 R2 Board

5 Lift to remove Rear Cove

– 31 –

Page 33

SECTION 5 SERVICE ADJUSTMENT (refer page 18)

(For KLV-32V400A/1, /2 only)

Preset "Test" button on remote commander

1. Press the following buttons simultaneously on the

remote commander RM-GA011 for a few seconds.

5

+

+

Channel 5

2. Once completed, the below button operates as a TEST

button.

Entering Hotel Menu Mode

1. While TV set is on standby, press the following sequence

on the remote commander(RM-GA011).

6. The following menu appears on the screen.

Function Settings

Off

Both Controls

Use

Use

Unspecify

Use

7. Press

Hotel Mode

TV / Remote Controls

Freeze

Display Key

AC Power On Setting

Wide Mode Key

Initialize Hotel Settings

B/b to select 'Hotel Mode'.

8. Now press B/b then V/v to select 'ON' and press .

Function settings

Hotel Mode

On

Off

9. The TV set resets and restarts.

10. Now press 'Menu' on the remote commander.

11. The following menu confirms the hotel mode is ON.

On screen

display

TEST

Volume (+)

POWER

2. When the TV turns on, the indication "Hotel Mode

Settings in Progress" appears on the bottom center of

the screen.

Hotel Mode Settings in Progress

3. Press 'Menu' on the remote commander.

4. The following menu appears on the screen:

Menu

Favourites

Programme List

External Inputs

Settings

Hotel Mode Settings

Language

Sleep Timer

Exiting Hotel Menu Mode

1. While TV set is ON, press the following sequence on the

remote commander(RM-GA011).

MUTE MENU

On screen

display

2. The TV set restarts and show "Hotel Mode Settings in

Progress" on the bottom center of the screen.

Hotel Mode Settings in Progress

3. Now press 'Menu' on the remote commander.

4. The following menu confirms the hotel mode is OFF.

Volume (+)

5. Press V/v to select 'Hotel Mode Settings' and press .

Menu

Favourites

Programme List

External Inputs

Settings

Hotel Mode Settings

– 32 –

Page 34

Disable Hotel Menu Mode

1. While TV set is on standby, press the following sequence

on the remote commander(RM-GA011).

TEST

On screen

display

2. Press 'Menu' on the remote commander.

3. The below menu appears on the screen.

TEST

Volume (-)

Menu

Favourites

Programme List

External Inputs

Settings

4. This menu confirms the hotel menu mode is disabled.

POWER

SECTION 6. DIAGRAMS

6-2. Circut Board Location (refer page 21)

R2 Board

(KLV-32V400A/1, /2)

H4K Board

6-3. SCHEMATIC DIAGRAM & PRINTED WIRING BOARDS (refer page 25)

H4K & R2 Boards

Board Function Note

R2 Hotel Mode Due to complexity of the board, performing component

(KLV-32V400A/1, /2)

level field repairs are not recommended. Complete board

replacement is required if service is necessary.

Therefore schematic diagrams and printed wiring boards

are not included. For part number information, refer to

Exploded View or Electrical Parts List section in this

manual.

H4K SIRCS

– 33 –

Page 35

m 7-685-649-79 SCREW +BVTP 3X14

SECTION 7. EXPLODED VIEWS

7-1. Rear Cabinet and Stand Assy (refer page 23)

☛

☛

m

1

5

4

☛

☛

j

3

g

j

j

j

j

i

2

☛

REF. NO. PART NO. DESCRIPTION REMARK

1*3-106-086-03 COVER, ECS

2 X-2189-409-3 STAND (M) ASSY (Except 32/T)

X-2318-611-1 STAND (M) (W), ASSY (32/T)

3 4-103-642-21 EMBLEM, SONY NO 8

4 A-1565-554-A R2, MOUNT (32/1, /2)

5*4-111-643-01 R BRACKET(TOP) (32/1, /2)

– 34 –

Page 36

7-2. Frame and Cover (refer page 24)

REF. NO. PART NO. DESCRIPTION REMARK

52 X-2318-678-1 BRACKET, SIDE JACK ASSY (PF1)

7-3. CHASSIS-1 (refer page 25)

52

☛

a

f

102

101

REF. NO. PART NO. DESCRIPTION REMARK

101 !* 1-835-136-11 POWER SUPPLY CORD (WITH CONNECTOR)

(Except 32/T)

! 1-835-280-11 POWER SUPPLY CORD (WITH CONNECTOR)

(32/T)

102 4-022-115-12 HOLDER, AC CORD

b

☛

☛

– 35 –

Page 37

7-4. CHASSIS-2 (refer pager 26)

f

b

f

b

b

b

b

b

b

k

b

e

h

151

☛

152

a

e

☛

REF. NO. PART NO. DESCRIPTION REMARK

151 A-1568-990-A GP COMPLETE KIT

152 A-1530-495-B BG1 MOUNT (SERVICE) (Except 32/1, /2)

A-1565-592-A BG1 MOUNT (SERVICE) (32/1)

A-1568-769-A BG1 MOUNT (SERVICE) (32/2)

– 36 –

Page 38

7-5. H3E & H4K BOARDS AND SPEAKER (refer page 27)

☛

204

201

f

☛

k

k

REF. NO. PART NO. DESCRIPTION REMARK

201 A-1556-724-A H4K MOUNT 37

202 A-1556-723-A H3E MOUNT 37

204 3-879-107-01 GUIDE, LIGHT

202

203

k

– 37 –

Page 39

7-6. BEZEL ASSY and LCD Panel (refer page 28)

251

☛

252

253

REF. NO. PART NO. DESCRIPTION REMARK

251 X-2190-023-1 BEZEL ASSY (32AM) (Except 32/T)

X-2318-765-1 BEZEL ASSY (32AM)(T) (32/T)

– 38 –

Page 40

SECTION 8 ELECTRICAL PARTS LIST (refer page 29)

REF NO. PART NO. DESCRIPTION REMARK

A-1530-495-B BG1 MOUNT (SERVICE) (Except 32/1, /2)

A-1565-592-A BG1 MOUNT (SERVICE) (32/1)

A-1568-769-A BG1 MOUNT (SERVICE) (32/2)

A-1568-990-A GP COMPLETE KIT (32)

A-1556-723-A H3E MOUNT 37

A-1556-724-A H4K MOUNT 37

Due to complexity of the board, performing component level field

repairs are not recommended.

Complete board replacement is required if service is necessary.

For part number information refer to the Exploded View or

Electrical Parts List section of this Service Manual.

**********************************************************************

***********************************

***************************

***************************

*********************

**************

**************

ACCESSORIES AND PACKING

***************************

3-295-215-01 CUSHION (UPPER)

3-295-216-02 CUSHION (LOWER)

4-113-870-01 INDIVIDUAL CARTON

3-300-886-01 INDIVIDUAL CARTON

4-108-226-51 SUPPLEMENT (WALL MOUNT)

3-214-128-14 SUPPLEMENT (WALL MOUNT)

4-108-226-11 SUPPLEMENT (WALL MOUNT)

4-113-871-11 MANUAL, INSTRUCTION

3-300-887-12 MANUAL, INSTRUCTION

3-300-887-32 MANUAL, INSTRUCTION

3-300-887-42 MANUAL, INSTRUCTION

(Except 32/1, /2, /T)

(32/1, /2, /T)

(Except 32/1, /2, /T)

(32/1, /2, /T)

(32/1, /2, /T)

(Except 32/1, /2, /T)

(32/1, /2, /T)

(32/1, /2)

(32/1, /2)

– 39 –

Page 41

SUPPLEMENT-2

EG1L (GA)

CHASSIS

MODEL COMMANDER DEST.

KLV-32V400A

KLV-32V400A/1

KLV-32V400A/2

KLV-32V400A/R

(Metal Red) Philippines,

This Supplement applies only to the models listed above.

Other information remains the sama as in the original issue and previous supplements.

RM-GA011 E, EA, Egypt, India,

Iran, ME,

Philippines,

Saudi Arabia,

South Africa,

Thailand, Vietnam

RM-GA011 EA

RM-GA011 EA

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

SUBJECT : Part number Change

MODEL COMMANDER DEST.

KLV-32V400A/T

(Mat Brown) ME,

KLV-32V400A/W

(Pearl White) Philippines,

KLV-32V400B

SECTION 7. EXPLODED VIEW

7-4. CHASSIS-2 (refer page 26)

RM-GA011 E, EA, India,

Philippines,

Saudi Arabia,

South Africa

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

RM-GA011 Saudi Arabia,

Thailand

REF. NO. PART NO. DESCRIPTION REMARK

151 A-1527-466-A GP COMPL(32)

SECTION 8. ELECTRICAL PARTS LIST

REF NO. PART NO. DESCRIPTION REMARK

A-1527-466-A GP COMPL(32)

h

151

☛

– 40 –

Page 42

SUPPLEMENT-3

EG1L (GA)

CHASSIS

MODEL COMMANDER DEST.

KLV-32V400A

KLV-32V400A/1

KLV-32V400A/2

KLV-32V400A/R

(Metal Red) Philippines,

This Supplement applies only to the models listed above.

Other information remains the sama as in the original issue and previous supplements.

RM-GA011 E, EA, Egypt, India,

Iran, ME,

Philippines,

Saudi Arabia,

South Africa,

Thailand, Vietnam

RM-GA011 EA

RM-GA011 EA

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

SUBJECT : Part Information Change: REAR COVER PART NUMBER

MODEL COMMANDER DEST.

KLV-32V400A/T

(Mat Brown) ME,

KLV-32V400A/W

(Pearl White) Philippines,

KLV-32V400B

SECTION 7. EXPLODED VIEW

7-1. REAR CABINET AND STAND ASSY

RM-GA011 E, EA, India,

Philippines,

Saudi Arabia,

South Africa

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

RM-GA011 Saudi Arabia,

Thailand

REF. NO. PART NO. DESCRIPTION REMARK

1 3-289-960-11 COVER, REAR

(Except 32/R(EA, Philippines, South Africa, Thailand),

32/T(Philippines), 32/W(ME, Philippines, South Africa, Thailand))

3-877-315-11 COVER, REAR

(32/R(EA, Philippines, South Africa, Thailand),

32/T(Philippines), 32/W(ME, Philippines, South Africa, Thailand))

2

☛

1

– 41 –

Page 43

SUPPLEMENT-4

EG1L (GA)

CHASSIS

MODEL COMMANDER DEST.

KLV-32V400A

KLV-32V400A/1

KLV-32V400A/2

KLV-32V400A/R

(Metal Red) Philippines,

This Supplement applies only to the models listed above.

Other information remains the sama as in the original issue and previous supplements.

Note:

Supplement is necessary to add Supplement (Wall Mount) Instruction Manual.

Please refer to next page for the Supplement (Wall Mount).

RM-GA011 E, EA, Egypt, India,

Iran, ME,

Philippines,

Saudi Arabia,

South Africa,

Thailand, Vietnam

RM-GA011 EA

RM-GA011 EA

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

SUBJECT : Supplement (Wall Mount) addition

MODEL COMMANDER DEST.

KLV-32V400A/T

(Mat Brown) ME,

KLV-32V400A/W

(Pearl White) Philippines,

KLV-32V400B

RM-GA011 E, EA, India,

Philippines,

Saudi Arabia,

South Africa

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

RM-GA011 Saudi Arabia,

Thailand

– 42 –

Page 44

SUPPLEMENT-5

EG1L (GA)

CHASSIS

MODEL COMMANDER DEST.

KLV-32V400A

KLV-32V400A/R

(Metal Red) Philippines,

KLV-32V400A/T

(Mat Brown) Philippines,

This supplement applies only to the models listed above.

Other information remains the same as in the original issue and previous supplements.

RM-GA011 E, EA, India, Iran,

ME, Philippines,

Saudi Arabia,

South Africa,

Thailand, Vietnam

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa

SUBJECT : Part Information Change:

1. H4 Change to H4K

2. H3E Part Number Change

MODEL COMMANDER DEST.

KLV-32V400A/W

(Pearl White) Philippines,

KLV-32V400B

RM-GA011 E, EA, ME,

Saudi Arabia,

South Africa,

Thailand

RM-GA011 Saudi Arabia,

Thailand

– 43 –

Page 45

SECTION 7. EXPLODED VIEW

7-5. H3E & H4 BOARDS AND SPEAKER

201

REF. NO. PART NO. DESCRIPTION REMARK

201 * A-1556-724-A H4K MOUNT 37

202 * A-1556-723-A H3E MOUNT 37

SECTION 8 ELECTRICAL PARTS LIST

REF NO. PART NO. DESCRIPTION REMARK

* A-1556-723-A H3E MOUNT 37

* A-1556-724-A H4K MOUNT 37

202

– 44 –

Page 46

SUPPLEMENT-6

r

EG1L (GA)

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

MODEL COMMANDER DEST. CHASSIS NO.

KLV-32V400A/3 RM-GA011 EA

SUBJECT : New model addition

This supplement shows only variant information for the new model(s).

Other information remains the same as in the original issue.

SECTION 3. DISASSEMBLY

3-1. Rear Cover and R2 Board Removal (refer page 7)

1 Eighteen screws

(BVTP2 4 X 16)

2 Two screws

(+BVTP 3 X 12)

3 Two screws

(+PSW M3 X 5)

4 One screw

(PSW 5 X 8)

1 Remove

R Bracket (Top)

2 Disconnect

CN001

3 Two screws

(+BVTP 3 X 14)

4 R2 Board

5 Lift to remove Rear Cove

– 45 –

Page 47

SECTION 5 SERVICE ADJUSTMENT (refer page 18)

Preset "Test" button on remote commander

1. Press the following buttons simultaneously on the

remote commander RM-GA011 for a few seconds.

5

+

+

Channel 5

2. Once completed, the below button operates as a TEST

button.

Entering Hotel Menu Mode

1. While TV set is on standby, press the following sequence

on the remote commander(RM-GA011).

6. The following menu appears on the screen.

Function Settings

Off

Both Controls

Use

Use

Unspecify

Use

7. Press

Hotel Mode

TV / Remote Controls

Freeze

Display Key

AC Power On Setting

Wide Mode Key

Initialize Hotel Settings

B/b to select 'Hotel Mode'.

8. Now press B/b then V/v to select 'ON' and press .

Function settings

Hotel Mode

On

Off

9. The TV set resets and restarts.

10. Now press 'Menu' on the remote commander.

11. The following menu confirms the hotel mode is ON.

On screen

display

TEST

Volume (+)

POWER

2. When the TV turns on, the indication "Hotel Mode

Settings in Progress" appears on the bottom center of

the screen.

Hotel Mode Settings in Progress

3. Press 'Menu' on the remote commander.

4. The following menu appears on the screen:

Menu

Favourites

Programme List

External Inputs

Settings

Hotel Mode Settings

Language

Sleep Timer

Exiting Hotel Menu Mode

1. While TV set is ON, press the following sequence on the

remote commander(RM-GA011).

MUTE MENU

On screen

display

2. The TV set restarts and show "Hotel Mode Settings in

Progress" on the bottom center of the screen.

Hotel Mode Settings in Progress

3. Now press 'Menu' on the remote commander.

4. The following menu confirms the hotel mode is OFF.

Volume (+)

5. Press V/v to select 'Hotel Mode Settings' and press .

Menu

Favourites

Programme List

External Inputs

Settings

Hotel Mode Settings

– 46 –

Page 48

Disable Hotel Menu Mode

1. While TV set is on standby, press the following sequence

on the remote commander(RM-GA011).

TEST

On screen

display

2. Press 'Menu' on the remote commander.

3. The below menu appears on the screen.

TEST

Volume (-)

Menu

Favourites

Programme List

External Inputs

Settings

4. This menu confirms the hotel menu mode is disabled.

POWER

SECTION 6. DIAGRAMS

6-2. Circut Board Location (refer page 21)

R2 Board

H4K Board

6-3. SCHEMATIC DIAGRAM & PRINTED WIRING BOARDS (refer page 25)

H4K & R2 Boards

Board Function Note

R2 Hotel Mode Due to complexity of the board, performing component

level field repairs are not recommended. Complete board

replacement is required if service is necessary.

Therefore schematic diagrams and printed wiring boards

are not included. For part number information, refer to

Exploded View or Electrical Parts List section in this

manual.

H4K SIRCS

– 47 –

Page 49

m 7-685-649-79 SCREW +BVTP 3X14

SECTION 7. EXPLODED VIEWS

7-1. Rear Cabinet and Stand Assy (refer page 23)

m

2

6

5

1

4

REF. NO. PART NO. DESCRIPTION REMARK

1 3-289-960-11 COVER, REAR (32)

2*3-106-086-01 COVER, ECS

* 4-115-101-01 COVES, ECS

3 X-2189-409-3 STAND (M) ASSY

4 4-103-642-21 EMBLEM, SONY NO 8

5*A-1565-554-A R2, MOUNT

6*4-111-643-01 R BRACKET(TOP)

3

– 48 –

Page 50

7-2. Frame and Cover (refer page 24)

52

REF. NO. PART NO. DESCRIPTION REMARK

52 X-2318-678-2 BRACKET, SIDE JACK ASSY (PF1)

– 49 –

Page 51

7-3. CHASSIS-1 (refer page 25)

REF. NO. PART NO. DESCRIPTION REMARK

101 ! 1-835-136-11 POWER SUPPLY CORD (WITH CONNECTOR)

102 4-022-115-00 HOLDER, AC CORD

102

101

– 50 –

Page 52

7-4. CHASSIS-2 (refer pager 26)

153

152

REF. NO. PART NO. DESCRIPTION REMARK

151 A-1527-466-A GP COMPL (32)

152 A-1706-939-A BG1 MOUNT (SERVICE)

153 * 3-292-896-01 COVER, MS/USB

151

– 51 –

Page 53

7-5. H3E & H4K BOARDS AND SPEAKER (refer page 27)

204

201

202

REF. NO. PART NO. DESCRIPTION REMARK

201 * A-1556-724-A H4K MOUNT 37

202 * A-1556-723-A H3E MOUNT 37

204 3-879-107-01 GUIDE, LIGHT

7-6. BEZEL ASSY and LCD Panel (refer page 28)

251

252

REF. NO. PART NO. DESCRIPTION REMARK

251 X-2190-023-2 BEZEL ASSY (32AM)

252 1-802-653-21 LCD PANEL (32 WXGA TFT)

– 52 –

Page 54

SECTION 8 ELECTRICAL PARTS LIST (refer page 29)

REF NO. PART NO. DESCRIPTION REMARK

A-1706-939-A BG1 MOUNT (SERVICE)

A-1527-466-A GP COMPL (32)

* A-1556-723-A H3E MOUNT 37

* A-1556-724-A H4K MOUNT 37

Due to complexity of the board, performing component level field

repairs are not recommended.

Complete board replacement is required if service is necessary.

For part number information refer to the Exploded View or

Electrical Parts List section of this Service Manual.

**********************************************************************

* 1-910-049-38 CONNECTOR ASSY 6P

1-966-101-21 HARNESS WITH CONNECTOR (LVDS)

*********************************************************************

**********************

*********************

**************

**************

CONNECTORS

*************

ACCESSORIES AND PACKING

***************************

* 3-295-215-01 CUSHION (UPPER)

* 3-295-216-02 CUSHION (LOWER)

* 3-300-886-02 INDIVIDUAL CARTON

3-214-128-15 SUPPLEMENT (WALL MOUNT)

3-300-887-12 MANUAL, INSTRUCTION

3-300-887-32 MANUAL, INSTRUCTION

3-300-887-42 MANUAL, INSTRUCTION

*********************************************************************

MISCELLANEOUS

****************

* 3-290-353-01 BAR UNDER (M)

* 3-452-793-12 LABEL, REAR TERMINAL (PF1)

Sony Corporation

Sony EMCS (Malaysia) Sdn. Bhd.

9-872-994-10

FTVG

2008.11

– 53 –

English

Page 55

LCD Colour TV

Operating Instructions

KLV-46V400A

KLV-40V400A

KLV-32V400A

© 2008 Sony Corporation 3-300-887-11(2)

Page 56

Introduction Trademark information

Thank you for choosing this Sony product.

Before operating the TV, please read this manual

thoroughly and retain it for future reference.

The illustrations used in this manual are of the

KLV-32V400A unless otherwise stated.

• HDMI, the HDMI logo and High-Definition Multimedia

Interface are trademarks or registered trademarks of

HDMI Licensing LLC.

• “BRAVIA” and are trademarks of Sony

Corporation.

GB

2

Page 57

Table of Contents

Start-up Guide 4

Checking the accessories ...........................4

Inserting batteries into the remote...............4

1: Attaching the stand .................................4

2: Connecting an antenna/cable/VCR .........5

3: Preventing the TV from toppling over......6

4: Bundling the cables .................................6

5: Connecting the AC power cord ...............6

6: Performing the initial set-up ....................7

Selecting the language............................. 7

Auto-tuning the TV .................................... 7

Watching TV .............................................. 8

Adjusting the viewing angle of the TV .........8

Adjust the angle left and right (swivel) ..... 8

Detaching the Table-Top Stand from

the TV..........................................................9

Safety information .....................................10

Precautions ...............................................11

Overview of the remote ..........................12

Using the Tools menu ............................. 15

Overview of the TV buttons and

indicators .................................................16

17

Using Optional Equipment

22

Using MENU Functions

Navigating through menus........................ 22

Using the Favourite List ............................ 23

Settings adjustment .................................. 24

Picture menu ...........................................26

Sound menu ............................................ 27

Screen menu ........................................... 28

Set-up menu............................................ 29

PC Settings menu.................................... 32

Channel Set-up menu .............................33

35

Additional Information

Specifications ........................................... 35

Troubleshooting ........................................ 36

Connecting optional equipment.................17

Viewing pictures from the connected

equipment .................................................18

Viewing Twin Picture .................................20

Viewing PIP (Picture in Picture) ................20

Using BRAVIA Sync (Control for HDMI) ...21

To connect the equipment that is

compatible with control for HDMI ........... 21

To make the control for HDMI settings ... 21

Control for HDMI ..................................... 21

GB

3

Page 58

Start-up Guide

Checking the

accessories

AC power cord* (KLV-46/40V400A only)

Stand (1) and screws (3) (KLV-32V400A)

Stand (1) and screws (4) (KLV-46/40V400A)

Remote RM-GA011 (1)

Size AA batteries (R6 type) (2)

* For models with ferrite cores, do not remove these cores.

Inserting batteries into

the remote

Push and lift the cover to open.

1: Attaching the stand

B For KLV-46V400A/KLV-40V400A

• Observe the correct polarity when inserting

batteries.

• Do not use different types of batteries together or

mix old and new batteries.

• Dispose of batteries in an environmentally

friendly way. Certain regions may regulate the

disposal of batteries. Please consult your local

authority.

• Handle the remote with care. Do not drop or step

on it, or spill liquid of any kind onto it.

• Do not place the remote in a location near a heat

source, a place subject to direct sunlight, or a

damp room.

GB

4

Page 59

B For KLV-32V400A

2: Connecting an

antenna/cable/VCR

Connecting an antenna/cable

Antenna cable

(not supplied)

8

Connecting an antenna/cable and VCR

Start-up Guide

8

1 Place the TV onto the stand by aligning the

screw hole alignment lines over the stand

as shown.

2 Fix the TV to the stand according to the

arrow marks that guide the screw holes

using the supplied screws.

• This TV is very heavy, so two or more people

should place the TV on the stand.

• If using an electric screwdriver, set the tightening

torque at approximately 1.5N·m (15kgf·cm).

• When installing the TV onto the wall, follow step

1 to prevent the TV panel from falling over.

• Ensure the AC power cord is away from screw

holes during stand installation to avoid damage to

the AC power cord (KLV-32V400A only).

Audio/Video

cable (not

supplied)

VCR

8

8

Antenna cable

(not supplied)

S video

cable

(not

supplied)

Antenna cable

(not supplied)

GB

5

Page 60

3: Preventing the TV

from toppling over

4: Bundling the cables

5: Connecting the AC

power cord

1 Install a wood screw (4 mm in diameter, not

supplied) in the TV stand.

2 Install a machine screw (M5 x 12, not

supplied) into the screw hole of the TV.

3 Tie the wood screw and the machine screw

with a strong cord.

KLV-46/40V400A KLV-32V400A

* Type of AC power cord supplied (with or without ferrite

core) varies depending on the countries.

GB

6

Page 61

6: Performing the initial

set-up

,

1

3

Press F/f to select the language displayed

on the menu screens, then press .

English

4 Press F/f to select the country/region,

then press .

Select country

Start-up Guide

3, 4, 5, 6, 9,

10, 11

8

Selecting the language

1 Connect the TV to your AC power outlet

(110-240 V AC, 50/60 Hz).

2 Press 1 on the top edge of the TV.

When the TV is in standby mode (the 1 (standby)

indicator on the TV front panel is red), press "/1

on the remote to turn on the TV.

When you turn on the TV for the first time, the

“Language” menu appears on the screen.

• Area 1: Asia (except Philippines), Middle

East, Africa and Oceania.

• Area 2: Philippines.

5 Press F/f to select “Home”, then press .

Auto-tuning the TV

6 Press G/g to select “OK”, then press .

The TV starts searching for all available channels.

This may take some time, please be patient and do

not press any buttons on the TV or remote.

If a message appears for you to confirm the

antenna connection

No programmes found. Please connect antenna

(aerial) and select “Confirm” to start auto-tuning

again. If 100 channels are found, auto-tuning is

stopped.

Continued

GB

7

Page 62

7 When the “Programme Sorting” menu

appears on the screen, follow the steps of

“Programme Sorting” (page 33).

If you do not change the order in which the channels

are stored on the TV, go to step 8.

8 Press MENU to exit.

The TV has now tuned in all the available

channels.

9 Select day and time.

10 Select “Yes” to link the operations of the

TV and the connected equipment that is

compatible with control for HDMI

automatically.

Do you want to enable control for compatible

HDMI devices?

Watching TV

1 Press 1 on the top edge of the TV to turn

on the TV.

2 Press the number buttons or PROG +/– to

select a TV channel.

3 Press 2 +/– to adjust the volume.

Adjusting the viewing

angle of the TV

This TV can be adjusted within the angles shown

below.

Adjust the angle left and right (swivel)

Top view

11 Press G/g to select the desired setting in

“Display this menu next time?” dialogue,

then press

z •If “Yes” is selected and the TV is turned off

by pressing 1 on the TV, or is disconnected

from the AC power outlet, the initial set-up

procedure restarts the next time the TV is

turned on.

to exit.

Front

GB

8

Page 63

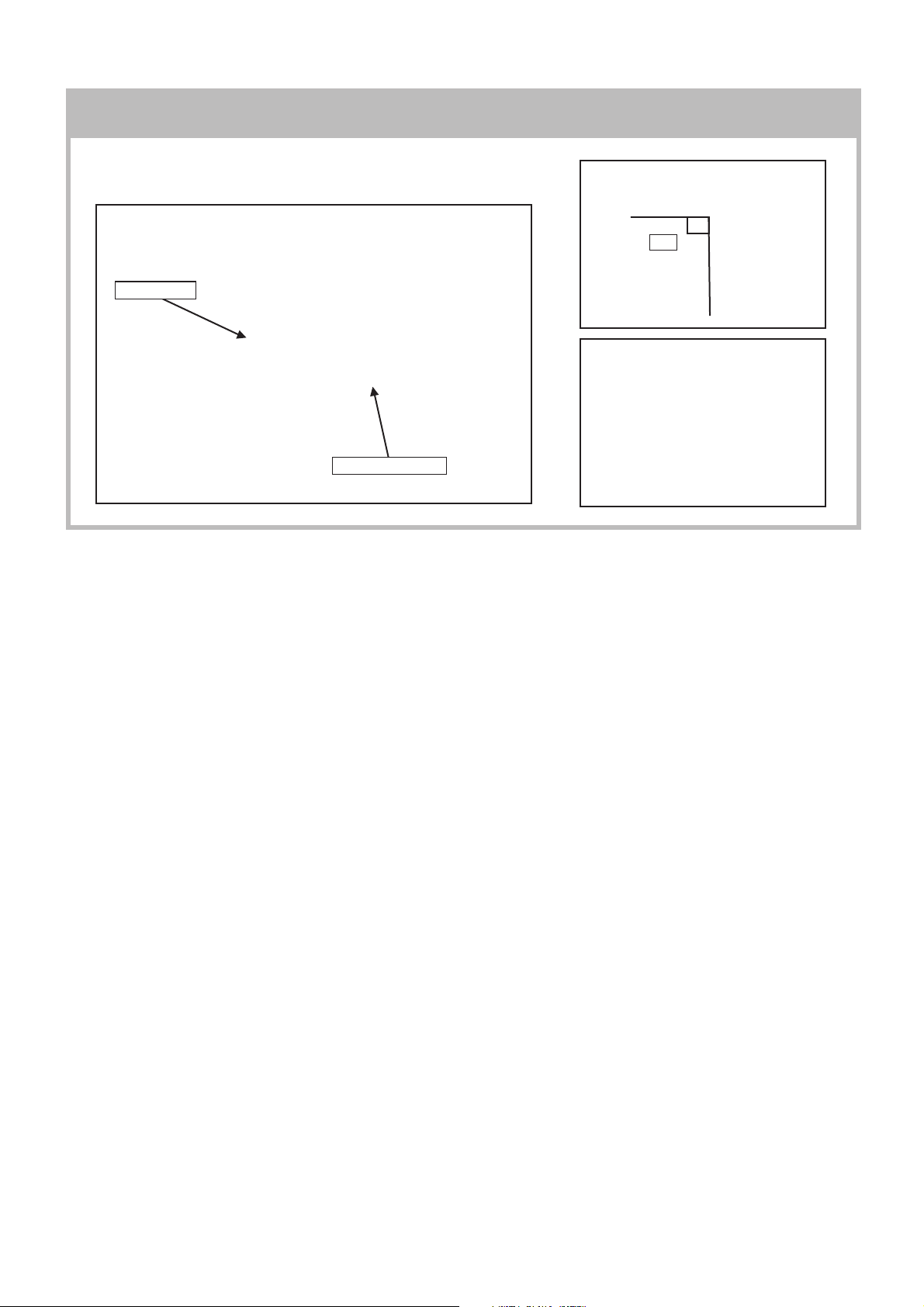

Detaching the TableTop Stand from the TV

Remove the screws guided by the arrow marks of

the TV.

Do not remove the Table-Top Stand for any reason

other than to wall-mount the TV.

B For KLV-46V400A/KLV-40V400A

B For KLV-32V400A

Start-up Guide

• For bracket installation, refer to the instruction

guide provided by the Wall-Mount Bracket model

for your TV. Sufficient expertise is required in

installing this TV, especially to determine the

strength of the wall for withstanding the TV’s

weight. For product protection and safety

reasons, Sony strongly recommends that you

use the Wall-Mount Bracket model designed

for your TV and the wall-mounting of your TV

should be performed by Sony dealers or

licensed contractors.

GB

9

Page 64

Safety information

Installation/Set-up

Install and use the TV set in accordance with the

instructions below in order to avoid any risk of fire,

electrical shock or damage and/or injuries.

Installation

• The TV set should be installed near an easily accessible

AC power outlet.

• Place the TV set on a stable, level surface to avoid it from

falling down and cause personal injury or damage to the

TV.

• Only qualified service personnel should carry out wall

installations.

• For safety reasons, it is strongly recommended that you

use Sony accessories, including:

Wall-mount bracket SU-WL500 and SU-WL50B

TV stand SU-FL300M

• Be sure to use the screws supplied with the Wall-mount

bracket when attaching the mounting hooks to the TV set.

The supplied screws are designed so that they are 8 mm to

12 mm in length when measured from the attaching

surface of the mounting hook.

The diameter and length of the screws differ depending on

the Wall-mount bracket model.

Use of screws other than those supplied may result in

internal damage to the TV set or cause it to fall, etc.

Installed on the wall

30 cm

10 cm 10 cm

10 cm

Leave at least this space around the set.

Installed with stand

30 cm

10 cm 10 cm 6 cm

Leave at least this space around the set.

• To ensure proper ventilation and prevent the collection of

dirt or dust:

– Do not lay the TV set flat, install upside down,

backwards, or sideways.

– Do not place the TV set on a shelf, rug, bed or in a closet.

– Do not cover the TV set with a cloth, such as curtains,

or items such as newspapers, etc.

– Do not install the TV set as shown below.

Air circulation

Air circulation is blocked.

is blocked.

8mm - 12mm

Screw (supplied with the Wall-mount

bracket)

Mounting Hook

Hook attachment on rear of TV set

Transporting

• Before transporting the TV set,

disconnect all cables.

• Two or more people are needed to

transport a large TV set.

• When transporting the TV set by

hand, hold it as shown on the right.

Do not put stress on the LCD panel.

• When lifting or moving the TV set,

hold it firmly from the bottom.

• When transporting the TV set, do

not subject it to jolts or excessive

vibration.

• When transporting the TV set for

repairs or when moving, pack it

using the original carton and

packing material.

Ventilation

• Never cover the ventilation holes or

insert anything in the cabinet.

• Leave space around the TV set as

shown below.

• It is strongly recommended that you

use a Sony wall-mount bracket in

order to provide adequate aircirculation.

GB

10

Be sure to hold

the bottom of the

panel, not the

front part.

Do not handle

with dent area.

Do not handle

with the

transparent

bottom part.

Wall

Wall

AC power cord

Handle the AC power cord and outlet as follows in

order to avoid any risk of fire, electrical shock or

damage and/or injuries:

– Use only Sony supplied AC power cords, not those of

other brands.

– Insert the plug fully into the AC power outlet.

– Operate the TV set on a 110-240 V AC supply only.

– When wiring cables, be sure to unplug the AC power

cord for your safety and take care not to catch your feet

on the cables.

– Disconnect the AC power cord from the AC power

outlet before working on or moving the TV set.

– Keep the AC power cord away from heat sources.

– Unplug the AC power plug and clean it regularly. If the

plug is covered with dust and it picks up moisture, its

insulation may deteriorate, which could result in a fire.

Notes

• Do not use the supplied AC power cord on any other

equipment.

• Do not pinch, bend, or twist the AC power cord

excessively. The core conductors may be exposed or

broken.

• Do not modify the AC power cord.

• Do not put anything heavy on the AC power cord.

• Do not pull on the AC power cord itself when

disconnecting the AC power cord.

• Do not connect too many appliances to the same AC

power outlet.

• Do not use a poor fitting AC power outlet.

Page 65

Prohibited Usage

Do not install/use the TV set in locations,

environments or situations such as those listed below,

or the TV set may malfunction and cause a fire,

electrical shock, damage and/or injuries.

Location:

Outdoors (in direct sunlight), at the seashore, on a ship or

other vessel, inside a vehicle, in medical institutions,

unstable locations, near water, rain, moisture or smoke.

Environment:

Places that are hot, humid, or excessively dusty; where

insects may enter; where it might be exposed to mechanical

vibration, near flammable objects (candles, etc). The TV

shall not be exposed to dripping or splashing and no objects

filled with liquids, such as vases, shall be placed on the TV.

Situation:

Do not use when your hands are wet, with the cabinet

removed, or with attachments not recommended by the

manufacturer. Disconnect the TV set from AC power outlet

and antenna during lightning storms.

Broken pieces:

• Do not throw anything at the TV set. The screen glass may

break by the impact and cause serious injury.

• If the surface of the TV set cracks, do not touch it until you

have unplugged the AC power cord. Otherwise electric

shock may result.

When not in use

• If you will not be using the TV set for several days, the TV

set should be disconnected from the AC power for

environmental and safety reasons.

• As the TV set is not disconnected from the AC power

when the TV set is just turned off, pull the plug from the

AC power outlet to disconnect the TV set completely.

• However, some TV sets may have features that require the

TV set to be left in standby to work correctly.

For children

• Do not allow children to climb on the TV set.

• Keep small accessories out of the reach of children, so that

they are not mistakenly swallowed.

If the following problems occur...

Turn off the TV set and unplug the AC power cord

immediately if any of the following problems occur.

Ask your dealer or Sony service centre to have it

checked by qualified service personnel.

When:

– AC power cord is damaged.

– Poor fitting of AC power outlet.

– TV set is damaged by being dropped, hit or having

something thrown at it.

– Any liquid or solid object falls through openings in the

cabinet.

Precautions

Viewing the TV

• View the TV in moderate light, as viewing the TV in poor

light or during long period of time, strains your eyes.

• When using headphones, adjust the volume so as to avoid

excessive levels, as hearing damage may result.

LCD Screen

• Although the LCD screen is made with high-precision

technology and 99.99% or more of the pixels are effective,

black dots may appear or bright points of light (red, blue,

or green) may appear constantly on the LCD screen. This

is a structural property of the LCD screen and is not a

malfunction.

• Do not push or scratch the front filter, or place objects on

top of this TV set. The image may be uneven or the LCD

screen may be damaged.

• If this TV set is used in a cold place, a smear may occur in

the picture or the picture may become dark. This does not

indicate a failure. These phenomena disappear as the

temperature rises.

• Ghosting may occur when still pictures are displayed

continuously. It may disappear after a few moments.

• The screen and cabinet get warm when this TV set is in

use. This is not a malfunction.