Sony KDL-52Z5500, KDL-46Z5500 Schematic

HISTORY

Model Name: KDL-40/46/52Z5500

SERVICE MANUAL

Click on Page Number to display details of change

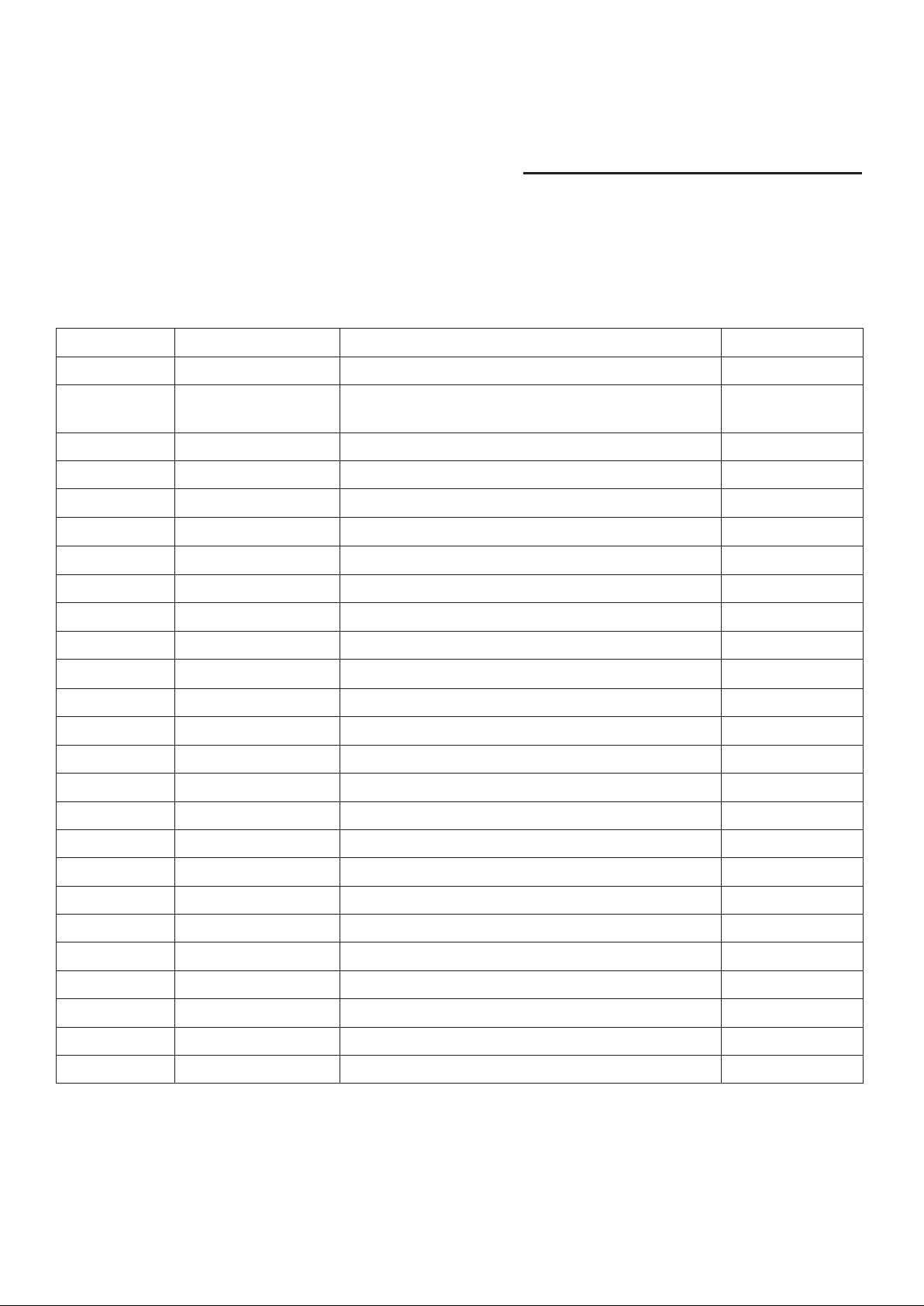

Date Part Number Description of Revisions Version

2009.02 9-883-446-01 Original Manual 1.0

2009.09 9-883-446-02

Update Self Diagnosis Table and working hours

table (P.10)

2.0

SERVICE MANUAL

MODEL DEST

KDL-40Z5500 AEP / UK

KDL-46Z5500 AEP / UK

KDL-52Z5500 AEP / UK

EX2L-Paprika

CHASSIS

- 1 -

RM-ED019

TABLE OF CONTENTS

Section Title Page Section Title Page

1. GENERAL

Caution ............................................................... 3

Specifications ...................................................... 6

Connectors .......................................................... 8

Self Diagnosis ..................................................... 9

2. DISASSEMBLY

2-1. Rear Cover Removal ............................................. 11

2-2. Rear Cover Removal (40/46 inches) ..................... 11

2-3. Rear Cover Removal (52 inches) .......................... 11

2-4. Rear Cover Installation (40/46 inches) ................. 11

2-5. Rear Cover Installation (52 inches) ...................... 12

2-6. Stand Assy Removal ............................................. 12

2-7. Stay Top Removal .................................................. 12

2-8. Stay Top Installation .............................................. 12

2-9. Switch Unit Removal ............................................ 13

2-10. Loudspeaker Removal ......................................... 13

2-11. G6NS/G7NS Board Removal .............................. 13

2-12. D1N/D3N Board Removal .................................. 13

2-13. D2N/D4N Board Removal .................................. 14

2-14. BA Board Removal ............................................. 14

2-15. HL1A Board Removal ........................................ 14

2-16. HSN Board Removal ........................................... 14

3. SERVICE MENUS

3-1. How to enter the Service Mode .......................... 15

3-2. Changing TVM Data Settings ............................ 15

3-3. Writing TVM Data ............................................. 15

3-4. Trouble Shooting ................................................ 16

4. DIAGRAMS

4-1. Block Diagram ................................................... 19

4-2. Circuit Board Location ....................................... 20

4-3. Schematic Diagrams and Printed Wiring

Boards ................................................................. 20

BA Board Schematic Diagram ........................... 21

D1N Board Schematic Diagram (40/46 inches)

D2N Board Schematic Diagram (40/46 inches) 40

D3N Board Schematic Diagram (52 inches) ..... 41

39

D4N Board Schematic Diagram (52 inches) ..... 42

G6NS Board Schematic Diagram (40 inches) ... 43

HL1A Board Schematic Diagram ...................... 45

HSN Board Schematic Diagram ........................

BA Printed Wiring Board ................................... 46

HSN Printed Wiring Board

HL1A Printed Wiring Board ............................... 47

................................. 46

45

D1N Printed Wiring Board (40/46 inches) ......... 48

D2N Printed Wiring Board (40/46 inches) ......... 49

D3N Printed Wiring Board (52 inches) .............. 50

D4N Printed Wiring Board (52 inches) .............. 51

G6NS Printed Wiring Board (40 inches) ............ 52

5. EXPLODED VIEWS

5-1. Chassis ................................................................ 54

5-2. Front Cabinet Assy & Stand Assy ...................... 56

5-3. Rear Cover & Power Supply Cords .................... 57

6. ELECTRICAL PARTS LIST

...................................... 58

WARNING !!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE WORK TO AVOID POSSIBLE SHOCK HAZARD DUE TO

LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS DIRECTLY

CONNECTED TO THE POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE EXPLODED VIEWS AND IN THE PARTS LIST ARE CRITICAL

FOR SAFE OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN

THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

£ ON

- 2 -

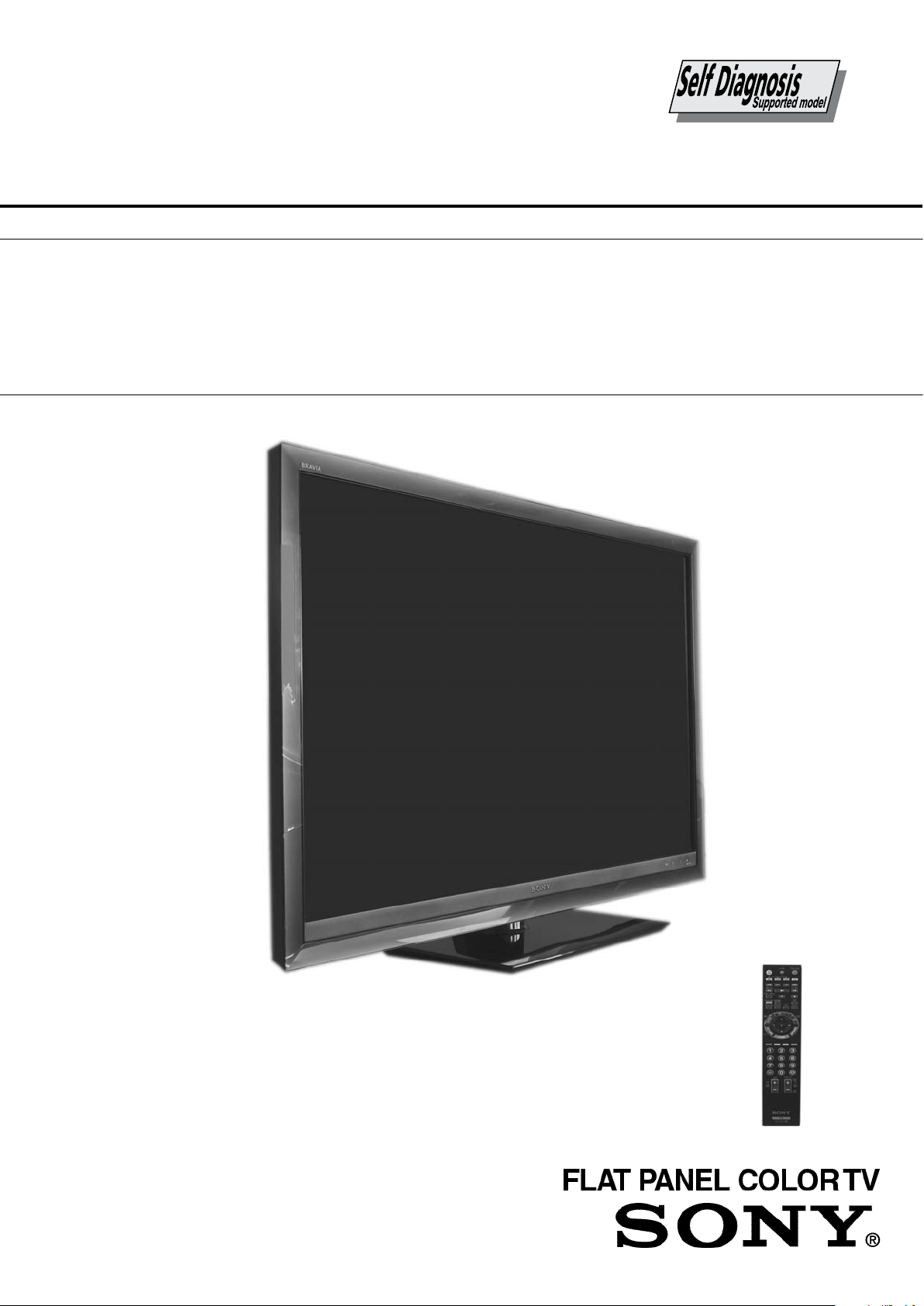

Partnumber Diameter Remarks

7-640-005-19 0.3mm 0.25Kg

7-640-005-20 0.4mm 0.50Kg

7-640-005-21 0.5mm 0.50Kg

7-640-005-22 0.6mm 0.25Kg

7-640-005-23 0.8mm 1.00Kg

7-640-005-24 1.0mm 1.00Kg

7-640-005-25 1.2mm 1.00Kg

7-640-005-26 1.6mm 1.00Kg

SECTION 1 GENERAL

How to replace the fuse.

Open the fuse compartment with

a screwdriver blade and replace

the fuse.

FUSE

ASA

T

mark.

SECTION 1 GENERAL

CAUTION

Lead Free Soldered Boards

example

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

Lead Free Solder material must be used to comply with environmental requirements of new solder joints. Lead Free Solder is available

under the following part numbers :

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade. This

requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

UK PLUG WARNING

WARNING (UK Models only)

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of the correct rating for the set. Should the fuse

need to be replaced, use a fuse of the same rating approved by ASTA

to BS 1362, ie one that carries the

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT SUITABLE

FOR THE OUTLET SOCKETS IN YOUR HOME, IT SHOULD BE CUT

OFF AND AN APPROPRIATE PLUG FITTED. THE PLUG SEVERED

FROM THE MAINS LEAD MUST BE DESTROYED AS A PLUG WITH

BARED WIRES IS DANGEROUS IF ENGAGED IN A LIVE SOCKET.

When an alternative type of plug is used, it should be fitted with the

correct rating fuse, otherwise the circuit should be protected by the

same rating fuse at the distribution board.

mark.

LCD PANEL CAUTION

Whilst working on this product, it is not recommended to lay the TV set face down when powered up, as this can result in panel problems.

If it is necessary to power up the TV set when face down, the time should be minimised as much as possible.

- 3 -

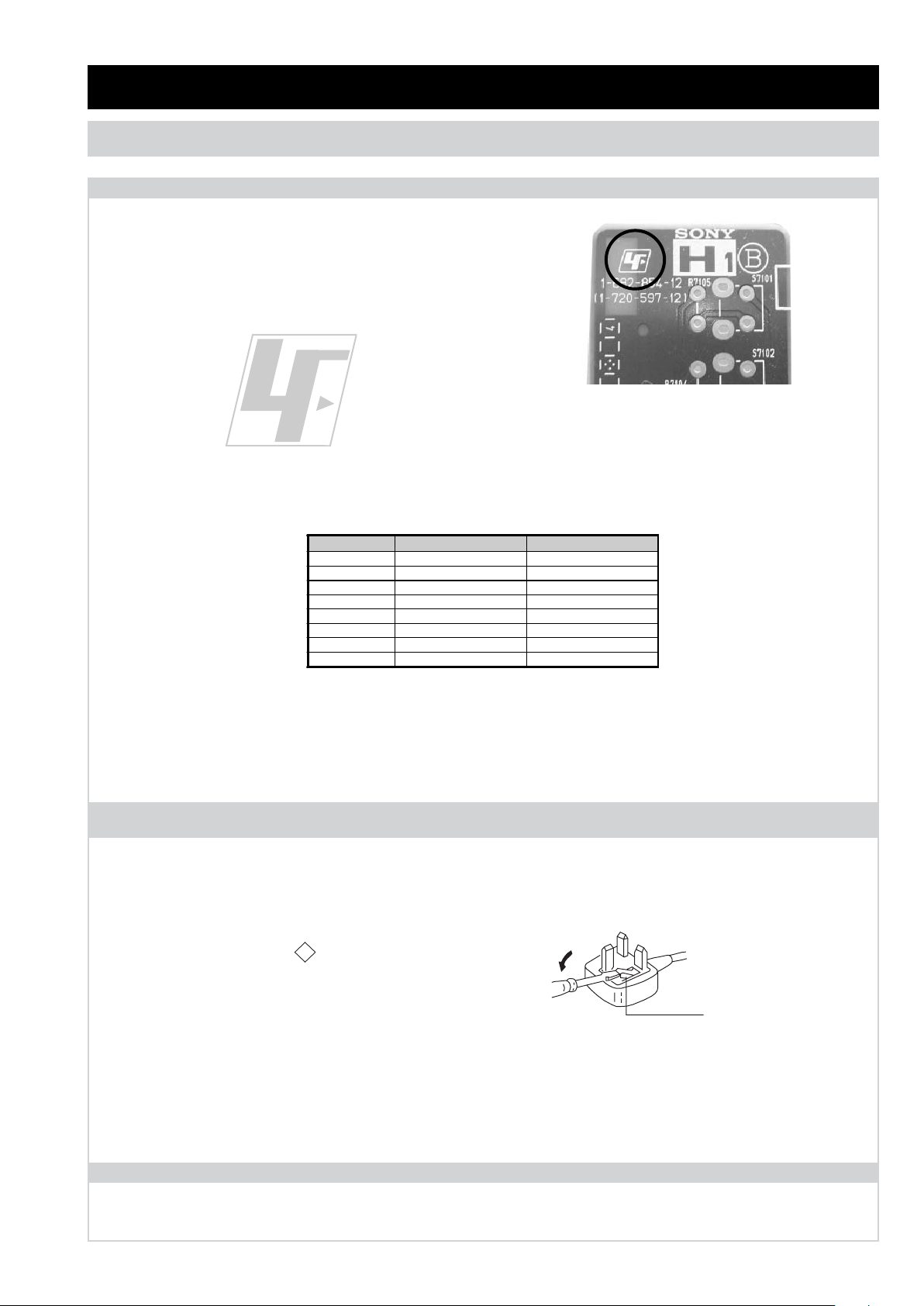

1. MDF-61 Connector (Removal)

CAUTION

Slide the slider to release slider

lock.

2. MDF-61 Connector (Refiitting)

Press the centre lock tab to

release the lock and pull the

connector up

Remove connector

Hold the centre of connector Press centre of connector to insert Slide the slider to lock connector

- 4 -

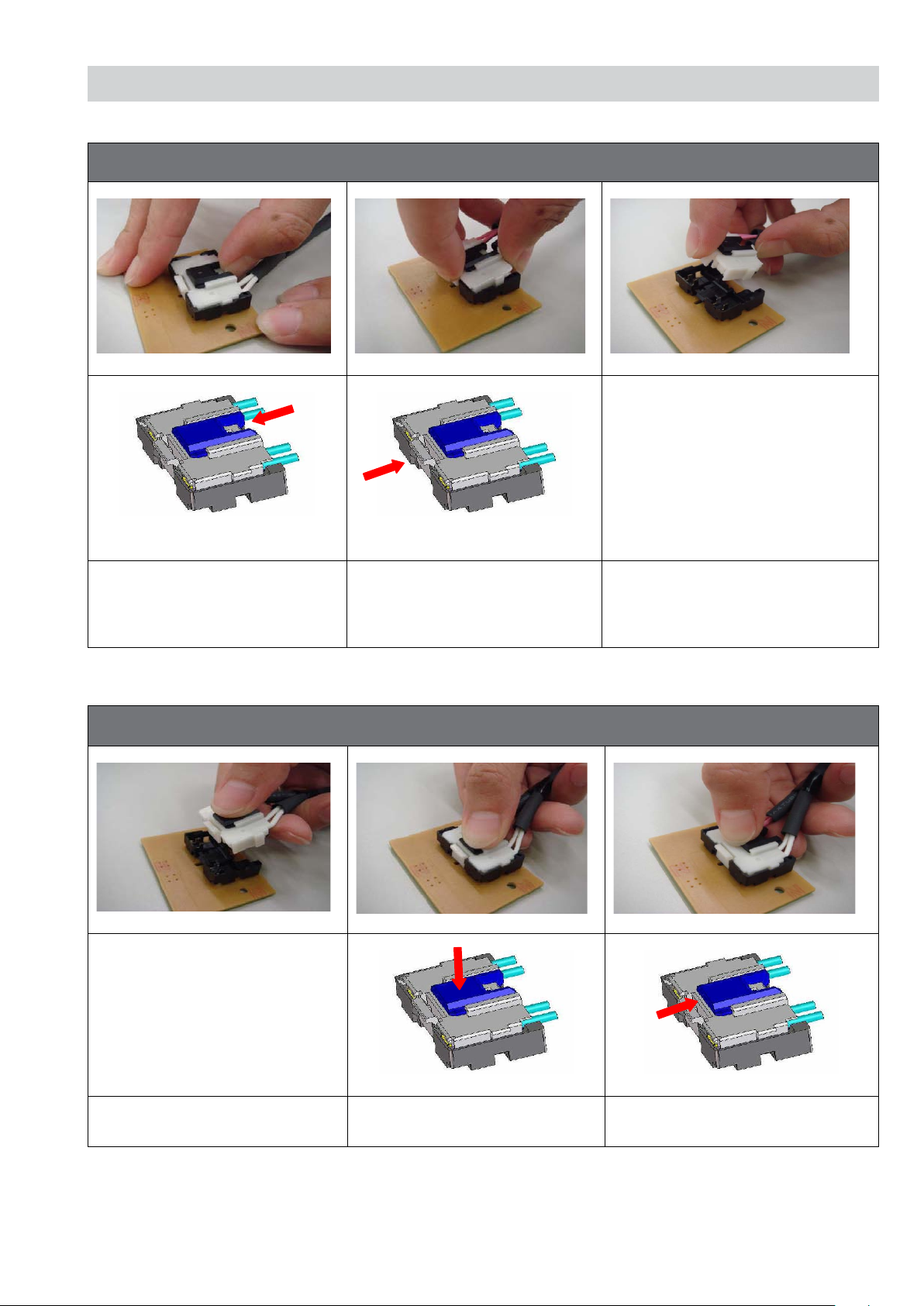

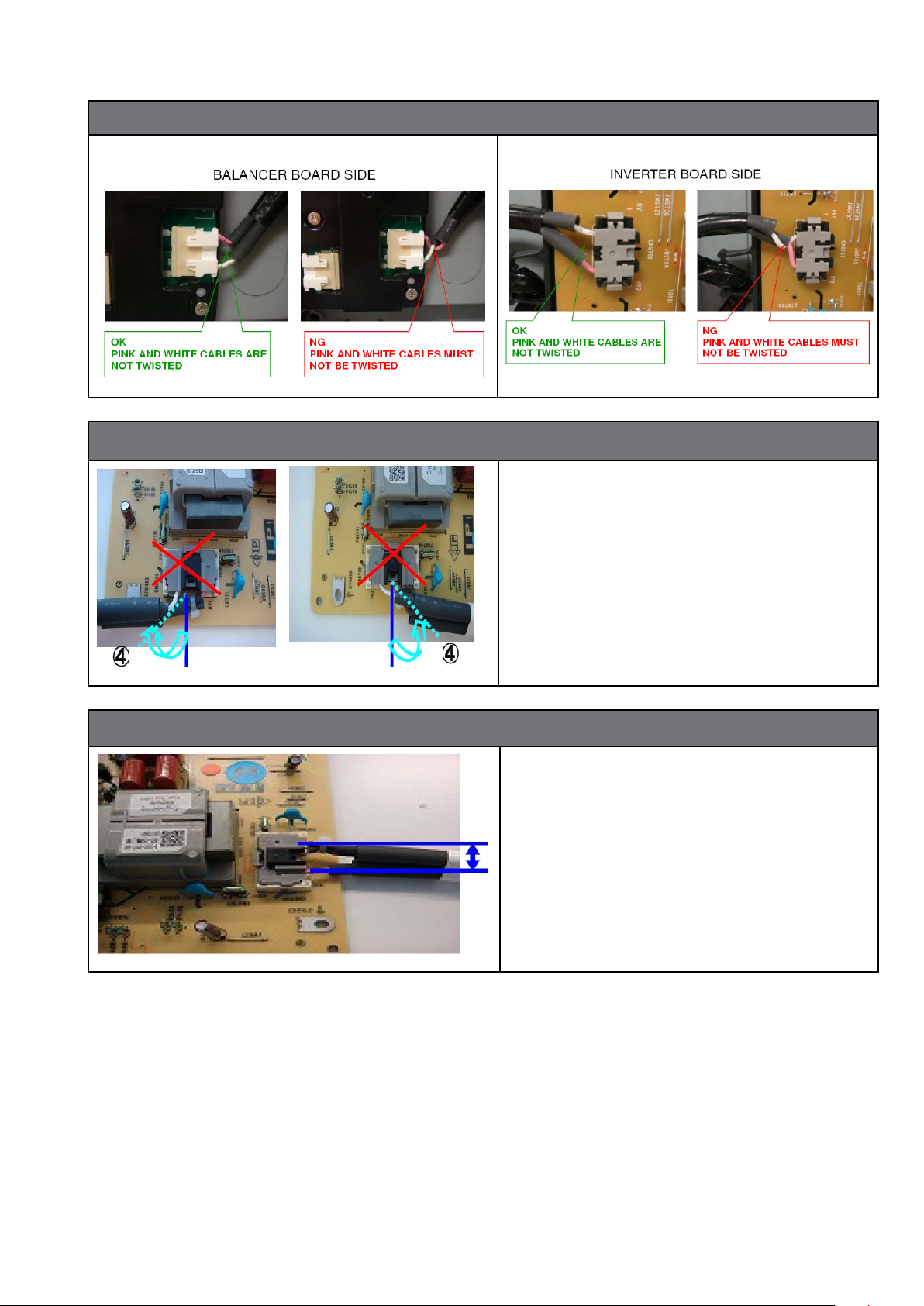

3. The harness must not be crossed or twisted

4. Wire Dressing at connector

The harness must not bend more

than 45 degrees from the direction of

the connector base to avoid crossing

or twisting.

5. Wire distance at connector

The distance between each wire must

be wider than 4mm to ensure isolation from lamp voltage.

- 5 -

System

Panel system

LCD (Liquid Crystal Display) Panel

TV system

Analogue: Depending on your country/area selection: B/G/H, D/K, L, I

Digital: DVB-T/DVB-C

Colour/video system

Analogue: PAL, PAL60 (only video input), SECAM, NTSC3.58, NTSC4.43 (only video input)

Digital: MPEG-2 MP@ML/HL, H.264/MPEG-4 AVC MP/HP@L4

Channel coverage

Analogue: VHF: E2–E12/UHF: E21–E69/CATV: S1–S20/HYPER: S21–S41

D/K: R1–R12, R21–R69/L: F2–F10, B–Q, F21–F69/I: UHF B21–B69

Digital: VHF/UHF

Sound output

10 W + 10 W

Input/Output jacks

Aerial/Antenna cable

75 ohm external terminal for VHF/UHF

/ AV1

21-pin scart connector (CENELEC standard) including audio/video input, RGB input and TV audio/video

output.

/ / AV2

21-pin scart connector (CENELEC standard) including audio/video input, RGB input and selectable

audio/video output.

COMPONENT IN

Supported formats: 1080p, 1080i, 720p, 576p, 576i, 480p, 480i

Y: 1 Vp-p, 75 ohms, 0.3V negative sync/P

B/CB

: 0.7 Vp-p, 75 ohms/

P

R/CR

: 0.7 Vp-p, 75 ohms

COMPONENT IN

Audio input (phono jacks)

HDMI IN1, 2, 3, 4

Video: 1080/24p, 1080p, 1080i, 720p, 576p, 576i, 480p, 480i

Audio: Two channel linear PCM: 32, 44.1 and 48 kHz, 16, 20 and 24 bits, Dolby Digital

Analogue audio input (minijack) (HDMI IN1 only)

PC Input (Page 7)

AV3

Video input (phono jack)

AV3

Audio input (phono jacks)

DIGITAL AUDIO

OUT (OPTICAL)

Digital optical jack (Two channel linear PCM, Dolby Digital)

Audio output (phono jacks)

PC IN

PC Input (D-sub 15-pin) (Page 7)

G: 0.7 Vp-p, 75 ohms, non Sync on Green/B: 0.7 Vp-p, 75 ohms/

R: 0.7 Vp-p, 75 ohms/HD: 1-5 Vp-p/VD: 1-5 Vp-p

PC audio input (minijack)

USB port

i

Headphones jack

CAM (Conditional Access Module) slot

LAN

10BASE-T/100BASE-TX connector (Depending on the operating environment of the network, connection

speed may differ. 10BASE-T/100BASE-TX communication rate and communication quality are not

guaranteed for this TV.)

SPECIFICATIONS

- 6 -

*Specified standby power is reached after the TV finishes necessary internal processes.

Design and specifications are subject to change without notice.

Model name KDL-52Z5500 KDL-46Z5500 KDL-40Z5500 KDL-40Z5710

Power and others

Power requirements

220 V – 240 V AC, 50 Hz

Screen size (measured

diagonally)

52 inches/

Approx. 132.2 cm

46 inches/

Approx. 116.8 cm

40 inches/Approx. 101.6 cm

Display resolution

1,920 dots (horizontal) × 1,080 lines (vertical)

Power

consumption

in “Home”/

“Standard”

mode

194 W 166 W 154 W

in “Shop”/

“Vivid”

mode

330 W 241 W 210 W

Standby power

consumption*

0.19 W (16.5 W when “Quick Start” is set to “On”)

Model

name

KDL-52Z5500 KDL-46Z5500 KDL-40Z5500 KDL-40Z5710

Dimensions (Approx.) (w × h × d)

with

TableTop

Stand

124.0 × 82.1 × 35.8 cm 109.1 × 72.5 × 33.0 cm 95.8 × 64.9 × 30.3 cm 95.8 × 64.9 × 30.2 cm

without

TableTop

Stand

124.0 × 76.7 × 8.6 cm 109.1 × 67.2 × 8.6 cm 95.8 × 59.6 × 8.6 cm

Mass (Approx.)

with

TableTop

Stand

31.3 kg 25.3 kg 20.8 kg

without

TableTop

Stand

27.2 kg 21.9 kg 17.9 kg

PC input signal reference chart for PC and HDMI IN 1, 2, 3, 4

* 1080p timing when applied to the HDMI input will be treated as a video timing and not a PC timing. This

affects the “Video Settings” menu and “Screen” menu settings.

To view PC contents, set “Screen Format” to “Wide” and “Display Area” to “Full Pixel”.

~

• This TV’s PC input does not support Sync on Green or Composite Sync.

• This TV’s PC input does not support interlaced signals.

• For the best picture quality, it is recommended to use the signals in the above chart with a 60 Hz vertical

frequency (boldfaced).

Resolution

Horizontal

frequency (kHz)

Vertical

frequency (Hz)

Standard

Signals Horizontal

(Pixel)

× Vertical

(Line)

VGA

640 × 480 31.5 60 VESA

640 × 480 37.5 75 VESA

720 × 400 31.5 70 VESA

SVGA

800 × 600 37.9 60 VESA

800 × 600 46.9 75 VESA

XGA

1024 × 768 48.4 60 VESA

1024 × 768 56.5 70 VESA

1024 × 768 60.0 75 VESA

WXGA

1280 × 720 45.0 60 EIA

1280 × 768 47.4 60 VESA

1280 × 768 47.8 60 VESA

1280 × 960 60.0 60 VESA

1360 × 768 47.7 60 VESA

SXGA

1280 × 1024 64.0 60 VESA

HDTV

1920 × 1080 66.6 60 VESA*

1920 × 1080 67.5 60 EIA*

- 7 -

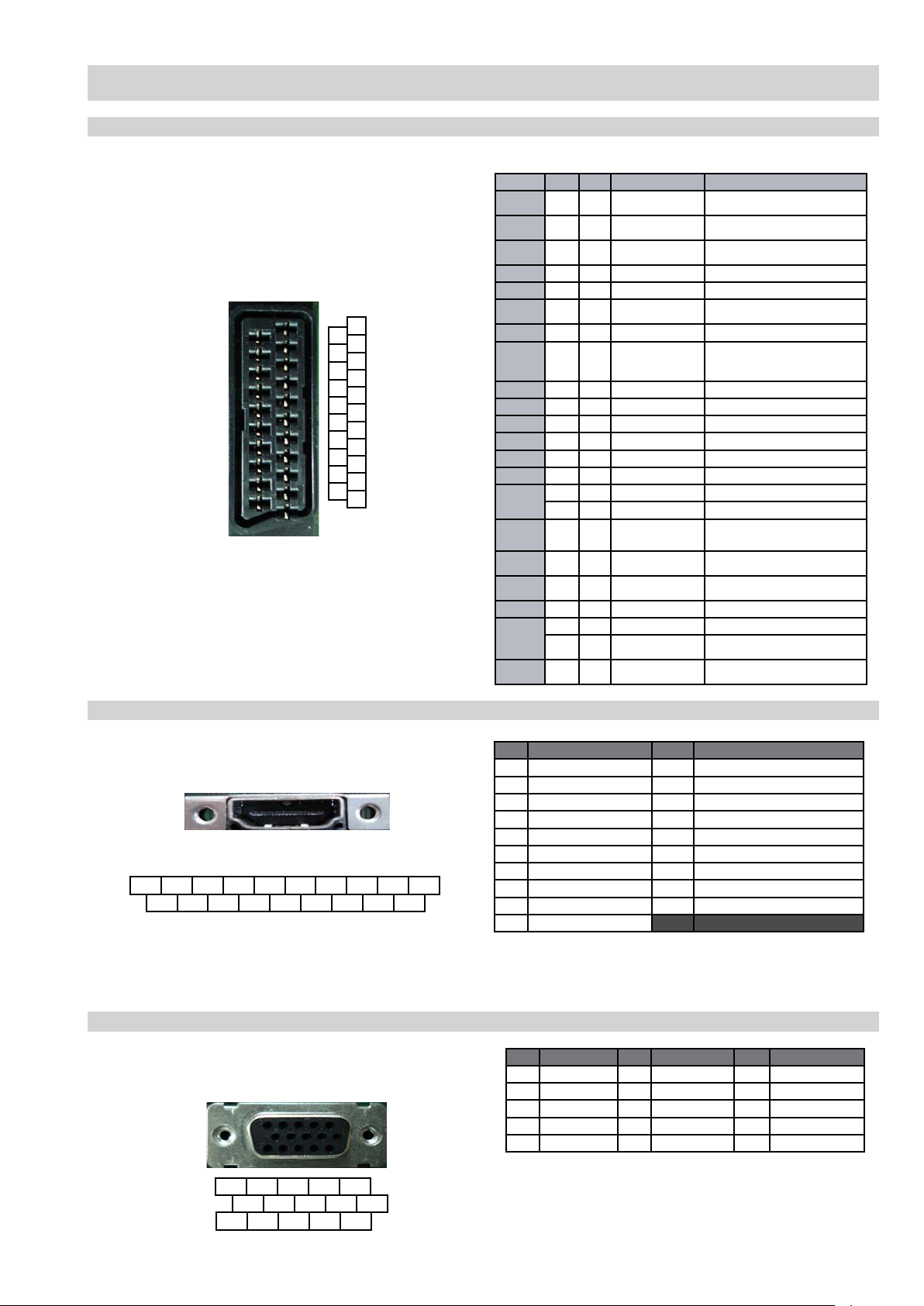

21 Pin Connector (SCART)

CONNECTORS

Pin No AV-1 AV-2 Signal Signal Level

1 • • Audio Output B

2 • • Audio Input B

3 • • Audio Output A

4 • • Ground (Audio)

5 • • Ground (Blue)

6 • • Audio Input A (Left) Standard Level: 0.5V rms

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

7 • • Blue Input 0.7V +/- 3dB, 75Ω, positive

8 • • Function Select

9 • • Ground (Green)

10 - • AV Link

11 • • Green Input 0.7V +/- 3dB, 75Ω, positive

12 - • Open

13 • • Ground (Red)

14 • • Ground (Blanking)

15

16 • • Blanking Input

17 • • Ground

18 • • Ground

19 • • Video Output 1V +/-3dB, positive sync 0.3V (-3+10dB)

20

21

• • Red Input 0.7V +/- 3dB, 75Ω, positive

• • S signal Chroma Input 0.3V +/-3dB, 75Ω, positive

• • Video Input 1V +/-3dB, positive sync 0.3V (-3+10dB)

• • Video Input Y

• • Common Ground

(Right)

(Right)

(Left)

(AV control)

(Y Signal)

(Video Output)

(Video Input)

(S Signal)

(Shield)

Standard Level: 0.5V rms

Impedance: less than 1KΩ*

Standard Level: 0.5V rms

Impedance: more than 10KΩ*

Standard Level: 0.5V rms

Impedance: less than 1KΩ*

Impedance: more than 10KΩ*

High State (9.5~12V): AV mode

Low State (0~2V): TV mode

Impedance: more than 10KΩ*

Capacitance: less than 2nF

High State (1~3V)

Low State (0~0.4V)

Impedance: 75Ω

1V +/-3dB, positive sync 0.3V (-3+10dB)

HDMI Connector

19 17 15 13 11 9 7 5 3 1

18 16 14 12 10 8 6 4 2

15 Pin D Sub Connector (PC)

Pin No Signal Assignment Pin No Signal Assignment

1 TMDS Data2+ 11 TDMS Clock Shield

2 TMDS Data2 Shield 12 TMDS Clock-

3 TMDS Data2- 13 CEC

4 TMDS Data1+ 14 Reserved (N.C. on device)

5 TMDS Data1 Shield 15 SCL

6 TMDS Data1- 16 SDA

7 TMDS Data0+ 17 DDC/CEC Ground

8 TMDS Data0 Shield 18 +5V power

9 TMDS Data0- 19 Hot Plug Detect

10 TMDS Clock+

Pin No Signal Assignment Pin No Signal Assignment Pin No Signal Assignment

1 Red Output 6 Red Return 11 Monitor IDO in display

2 Green Output 7 Green Return (Ground) 12 DCC Serial Data

3 Blue Output 8 Blue Return (Ground) 13 Horizontal Sync

4 Unused 9 +5V DC 14 Vertical Sync

5 Ground 10 Sync Return (Ground) 15 DCC Serial Clock

5 4 3 2 1

10 9 8 7 6

15 14 13 12 11

- 8 -

EX2L SELF DIAGNOSTIC SOFTWARE

erusaemretnuoCrorrEsemit gniknilB

2 DC_DET Replace either/both z Power board

(G6NS (40"), Power Unit (G7NS)

(46"/52")

z BA board

5 DC_ALERT Replace BA board.

6 BACKLIGHT Replace either/all z D1N(40"/46"), D2N(40"/46"),

D3N(52"), D4N(52")

z BA board

z

Panel

z Power Board

(G6NS (40"), Power Unit (G7NS)

(46"/52"))

7 INTERNAL TEMP Replace z BA board

A8 UDIO Replace either/all z Power board

(G6NS (40"), Power Unit (G7NS)

(46"/52")

z BA board

z Speaker

10 DIGITAL FE/DE Replace z BA board.

htob/rehtie ecalpeRHFR21 z Panel

z BA Board

13 BALANCER Replace either/all z BA board.

z Power board

G6NS (40"), Power Unit (G7NS)

(46"/52")

z D1N(40"/46"), D2N(40"/46"),

D3N(52"), D4N(52")

ecalpeRNOC-T41 z Panel.

z BA Board

The identification of errors within the EX2L chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with a continuous flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant device

number will be displayed through the LED (Series of flashes which must be counted).

LED Error Codes and Countermeasures

- 9 -

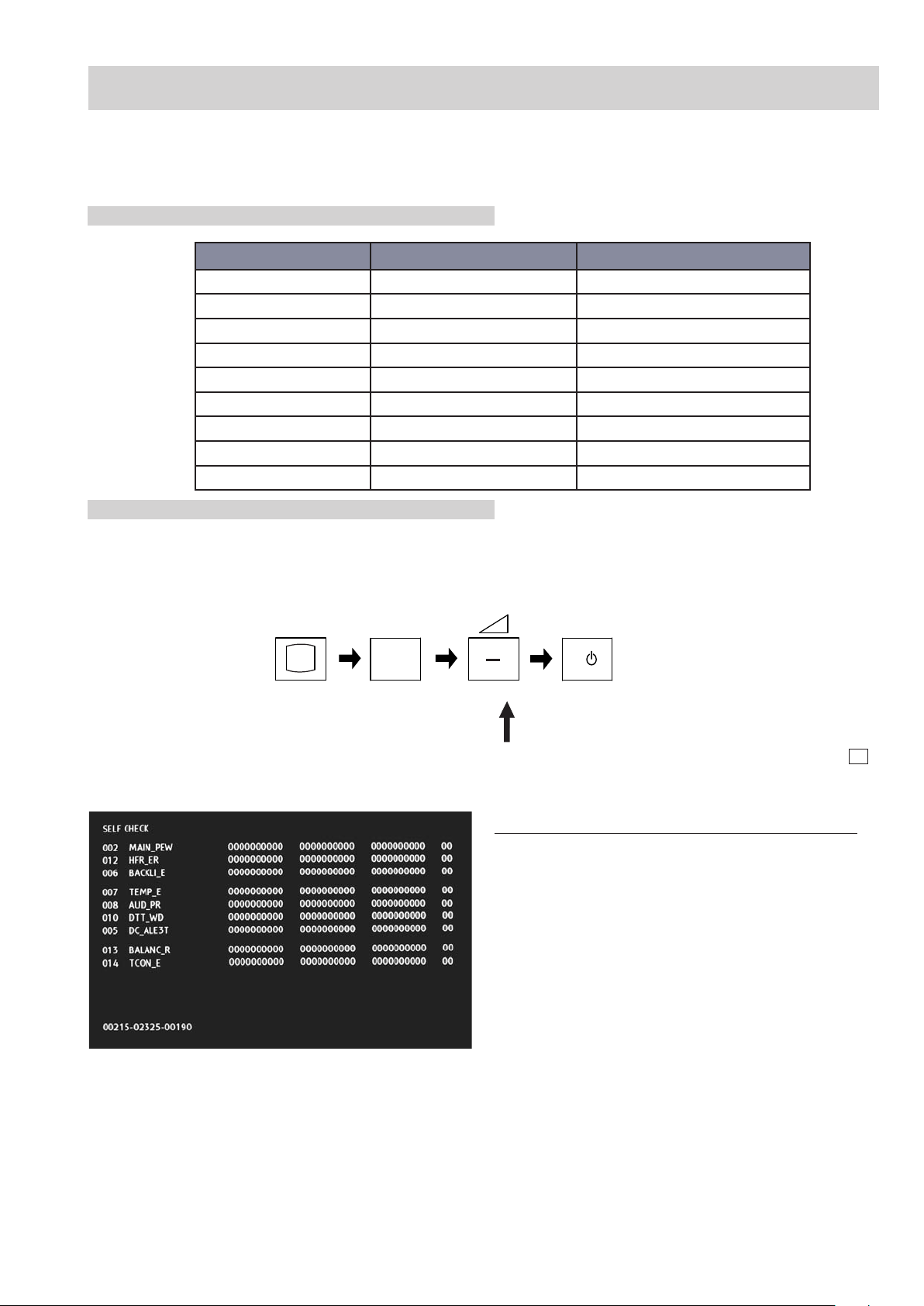

I/

TV

To bring up the self diagnostic screen display

i+

5

+

(ON SCREEN (DIGIT 5) (VOLUME +) (TV)

DISPLAY)

In standby mode, press the following buttons on the remote commander sequentially in rapid sucession as shown below:

Note that this differs from entering the service mode (Volume + )

(TV STANDBY)

(ON SCREEN

DISPLAY)

(DIGIT 5)

(VOLUME -)

The following menu appears as shown below:

Ver 2.0

EX2L SELF DIAGNOSTIC SOFTWARE

The identification of errors within the EX2L chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with a continuous flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant device

number will be displayed through the LED (Series of flashes which must be counted).

LED Error Codes and Descriptions

LED Flashes Error Description Error (Comp ref)

02 main Power Error Pwr_Err

05 DC_Alert3 DC_Alt

06 Backlight Error Bck_Lgt

07 Thermal Error Thm_Err

08 Audio Error Aud_Err

10 Digital FE/BE Error Dig_Err

12

13 Balancer Error Bal_Err

14 T-Con Error Tcn_Err

HFr Error (T-Con) Hfr_Err

Self Diagnostic Screen Display

WorkIng TImE (BoTTom LEFT CornEr)

xxxxx-yyyyy-zzzzzz(e.g. 00215-02325-00190)

1. xxxxx = Total operation time

Working time Stby+ Power on

2. yyyyy = Boot count

Power on / off / Stby operations

3. zzzzz = Working Hours (Panel)

Panel working time (backlight is on)

To exit the “Self Diagnostic Screen Display” please turn the TV set off and then on again.

- 10 -

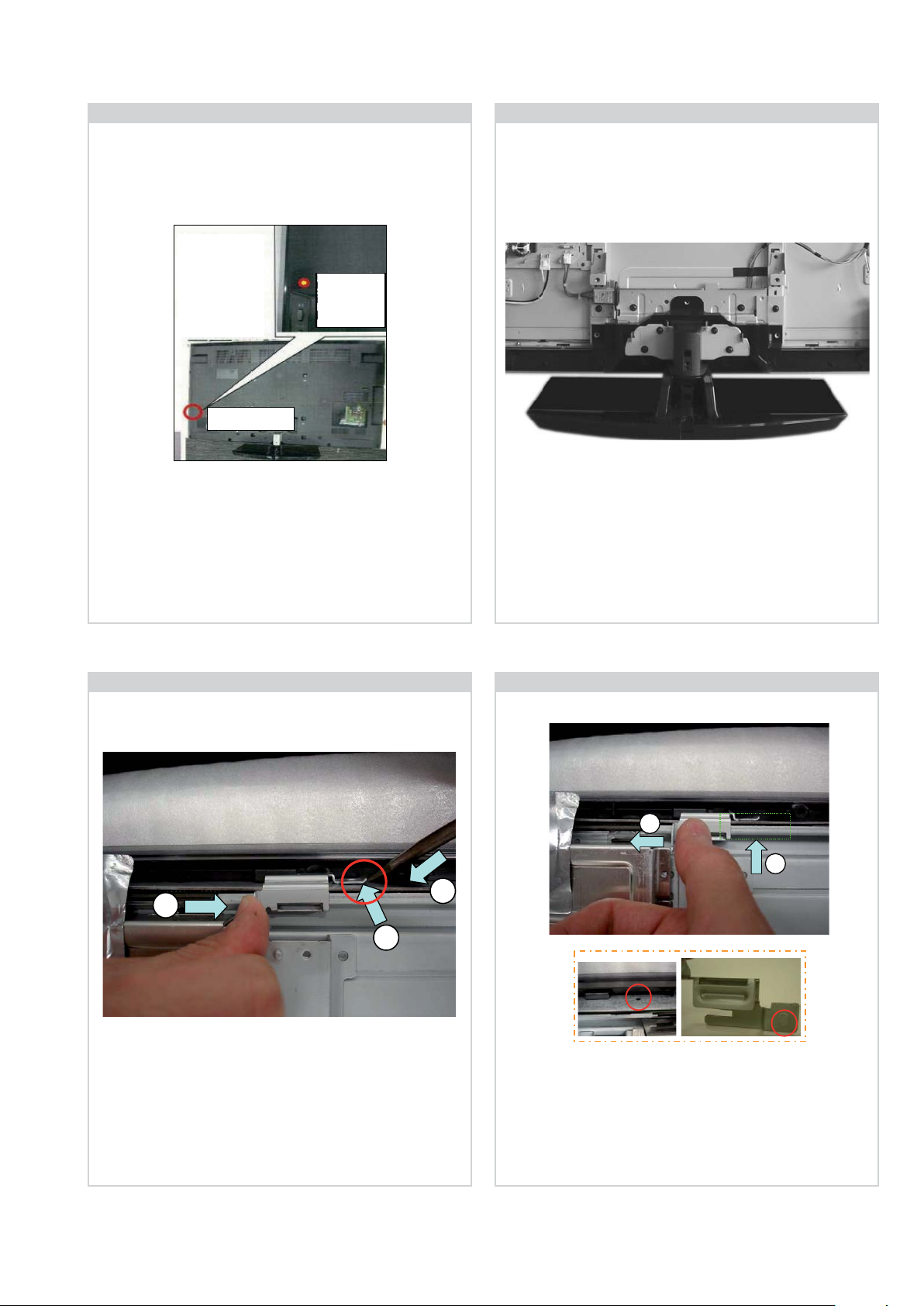

SECTION 2 DISASSEMBLY

Please pay attention

to operation trying not

to scratch stand neck.

Pay attention to

stand neck.

Scratch here

<TOP SIDE>

Clamper Point

2-1. Rear Cover Removal

=>

1

=>

3

=>

=>

=>

1

=>

3

3

=>

1

1

=>

1

=>

1

=>

1

=>

=>

3

3

=>

3

=>

1

3

=>

=>

1

Remove the rear cover fixing screws indicated and refer to

Sec 2-2-2(40/46 inches) or Sec 2-2-3(52 inches).

Screw Part number(s) and Description(s)

1) 2-580-640-01 SCREW, +BVTP2 4X16 (40/46” = 8pcs, 52” = 14pcs)

2) 7-685-648-79 SCREW, +BVTP 3X12 (40/46/52” = 2pcs)

3) 2-580-607-01 SCREW, +PSW M5X12 (40/46/52” = 7pcs)

=>

2

2-2. Rear Cover Removal (40/46 inches)

1

=>

1

=>

2

=>

1

=>

1

=>

1

=>

To remove the ‘Rear Cover’ lift the ‘Rear Cover’ from the

bottom to unlock the clamper.

2-3. Rear Cover Removal (52 inches)

To remove the ‘Rear Cover’ lift the ‘Rear Cover’ as shown

in the photo to unlock the clamper.

2-4. Rear Cover Installation (40/46 inches)

To install the ‘Rear Cover’ push the clamper points as

shown in the photo on the back surface of the ‘Rear Cover’

then replace all screws.

- 11 -

2-5. Rear Cover Installation (52 inches)

Clamper Here

Push This

Point

1

2

3

1

2

2-6. Stand Assy Removal

To install the ‘Rear Cover’ push the clamper point as shown

in the photo on the back surface of the ‘Rear Cover’ then

replace all screws.

2-7. Stay Top Removal

=>

=>

=>

=>

Remove the 4 stand fixing screws indicated and lift the TV

set up and away from the ‘Stand Assy’.

Screw Part number(s) and Description(s)

2-580-608-01 SCREW, +PSW M5X16

2-8. Stay Top Installation

To remove the ‘Stay Top’ place a flat blade screwdriver as

shown by 1 in the photo above, then lift the clamper slightly

as shown by 2 and finally slide the clamper as shown by 3.

When reusing the ‘Stay Top’ please use with the removed

set.

To install the ‘Stay Top’ slide into place as shown by 1 in the

photo above, then push the clamper as shown by 2, making

sure that the embossing on the clamper is locked in the hole

of the panel.

- 12 -

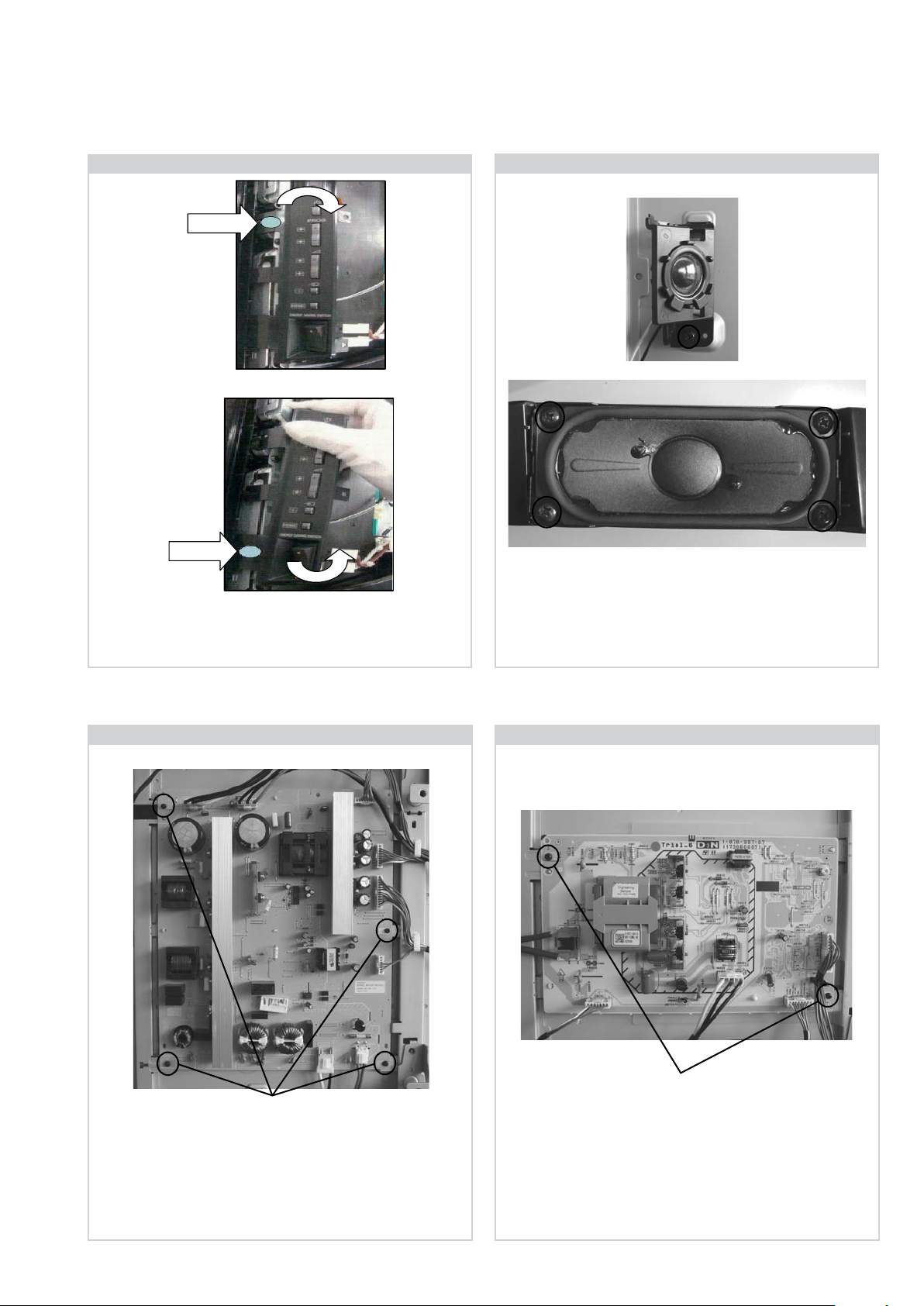

2-9. Switch Unit Removal

Push

Push

2-10. Loudspeaker Removal

a

To remove the ‘Switch Unit’ push the top of the unit in the

shaded area in the photo and rotate in the direction of the

arrow. Then repeat the procedure on the bottom of the unit.

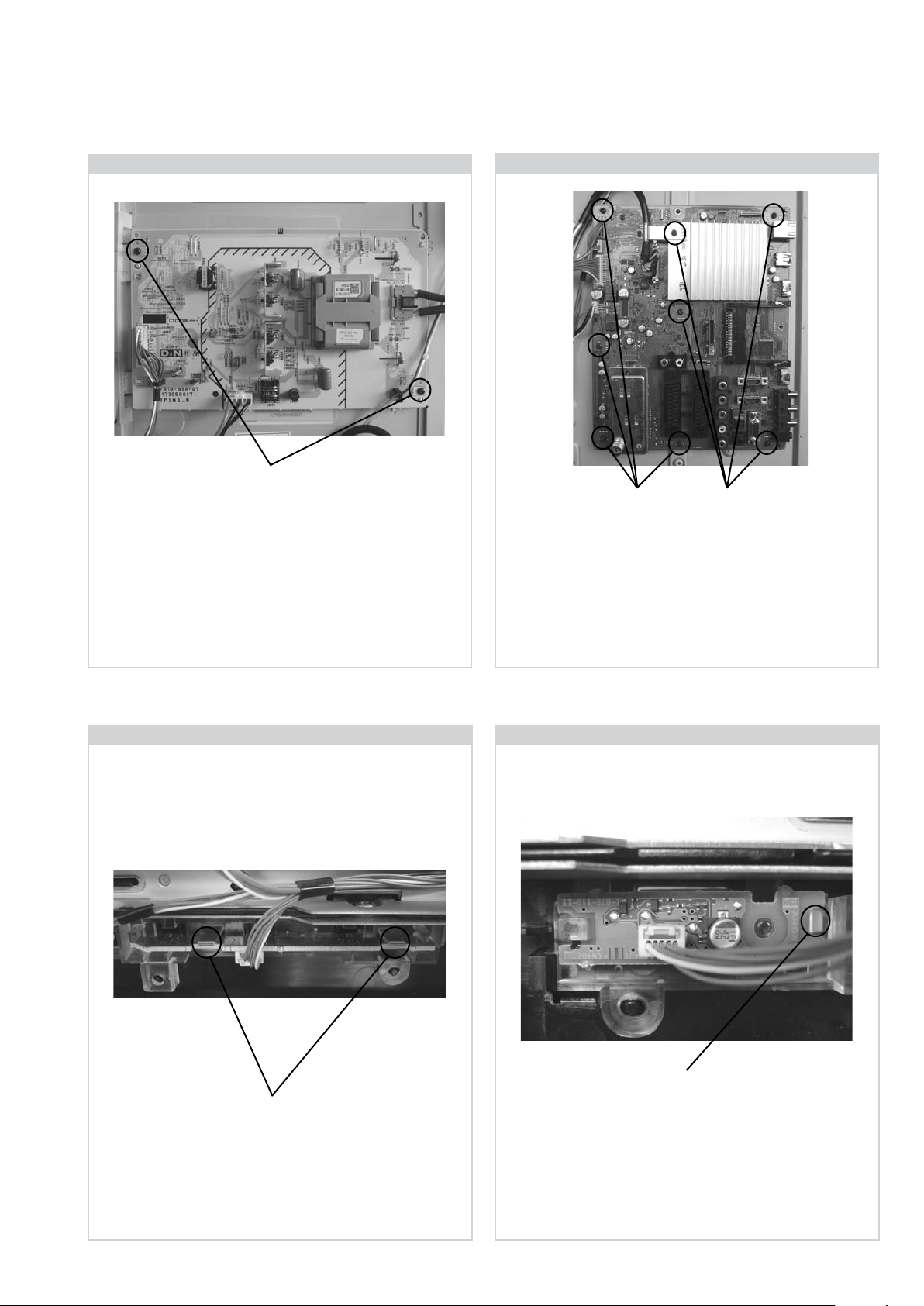

2-11. G6NS/G7NS Board Removal

b

b

b

b

To remove the ‘Loudspeakers’ first disconnect the speaker

cables and then remove the screws circled.

Screw Part number(s) and Description(s)

(a) 2-580-592-01 SCREW, +PSW M3X8

(b) 2-580-640-01 SCREW, +BVTP2 4X16

2-12. D1N/D3N Board Removal

Screws

To remove the ‘G6NS/G7NS’ board disconnect all the

connectors and then remove the 4 screws circled and ease

the board gently away from the back of the TV set.

Screw Part number(s) and Description(s)

2-580-592-01 SCREW, +PSW M3X8

- 13 -

Screws

To remove the ‘D1N/D3N’ board disconnect all the

connectors and then remove the 2 screws circled and ease the

board gently away from the back of the TV set.

Note: Refer to page 4 - Hirose MDF61 connector.

Screw Part number(s) and Description(s)

2-580-592-01 SCREW, +PSW M3X8

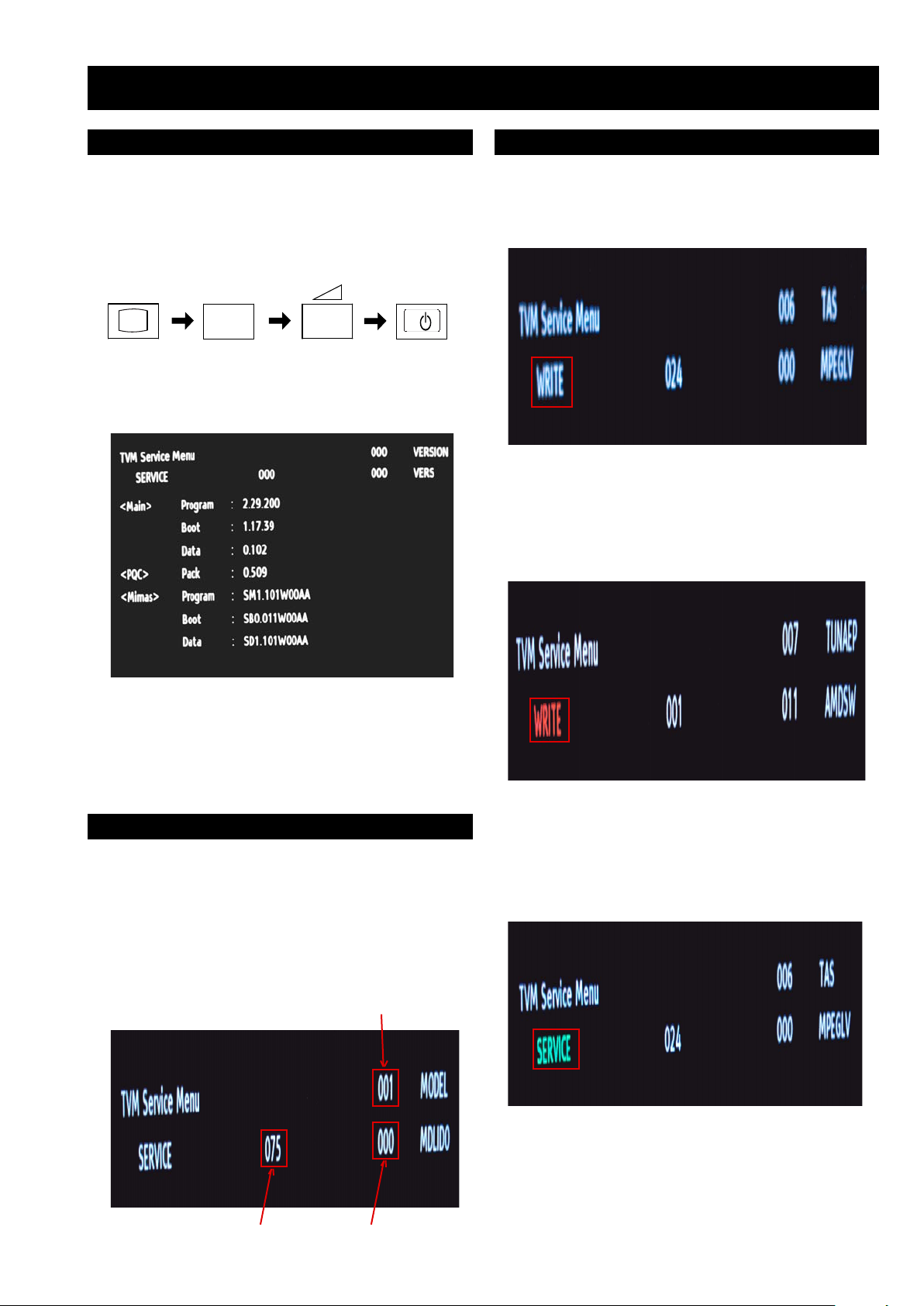

2-13. D2N/D4N Board Removal

Screws

2-14. BA Board Removal

Screws Screws

To remove the ‘D2N/D4N’ board disconnect all the

connectors and then remove the 2 screws circled and ease the

board gently away from the back of the TV set.

Note: Refer to page 4 - Hirose MDF61 connector.

Screw Part number(s) and Description(s)

2-580-592-01 SCREW, +PSW M3X8

2-15. HL1A Board Removal

To remove the ‘BA’ board disconnect all the connectors and

then remove the 8 screws circled and ease the board gently

away from the back of the TV set.

Screw Part number(s) and Description(s)

2-580-592-01 SCREW, +PSW M3X8

2-16. HSN Board Removal

Clips

To remove the ‘HL1A’ board disconnect the connector and

then release the 2 clips circled and ease the board gently

away from the back of the TV set.

Clip

To remove the ‘HSN’ board disconnect the connector and

then release the 1 clip circled and ease the board gently

away from the back of the TV set.

- 14 -

I/

TV

i+

5

+

(ON SCREEN (DIGIT 5) (VOLUME +) (TV)

DISPLAY)

(TV STANDBY)

(ON SCREEN

DISPLAY)

(DIGIT 5)

(VOLUME +)

SECTION 3 SERVICE MENUS

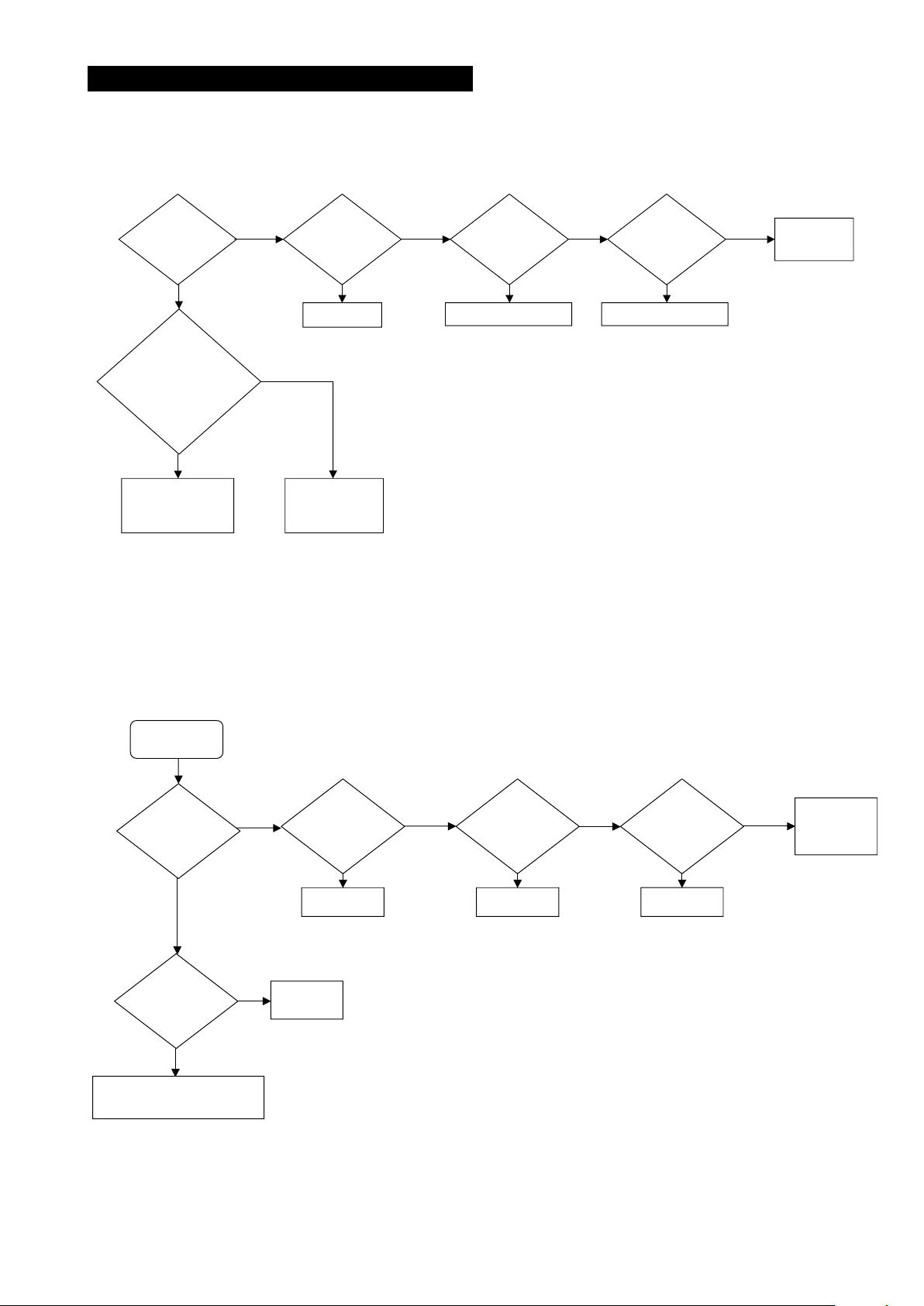

3-1. How to enter the Service Mode

Service adjustments to this model can be performed using the

supplied Remote Commander RM-ED019.

1. Turn on the power to the TV set and enter into the stand-by

mode.

2. Press the following sequence of buttons on the Remote

Commander.

3. The TVM menu appears on the screen (See Pic.1).

Pic.1

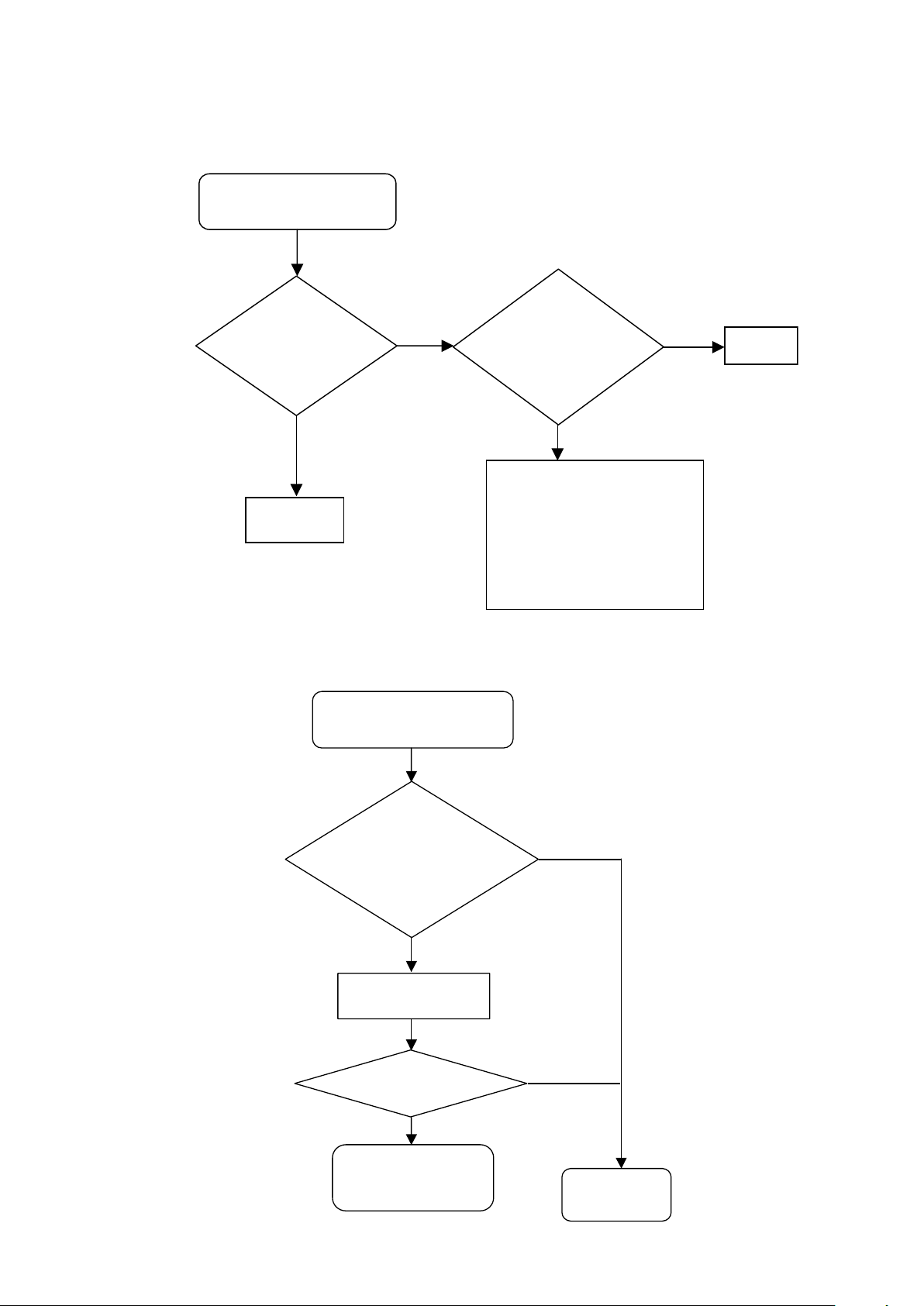

3-3. Writing TVM Data

1. Press “Mute” on the remote commander. The word “SERVICE”

changes to “WRITE” (See Pic.3).

Pic.3

2. Press “0” on the remote commander. The word “WRITE”

changes to red. This indicates writing is in progess. (See Pic.4).

Pic.4

Note :

After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set OFF

and then ON.

3-2. Changing TVM Data Settings

1. Press “2 / 5” on the remote commander to select (up / down)

category (See Pic.2).

2. Press “1 / 4” on the remote commander to select (up / down)

item (See Pic.2).

3. Press “3 / 6” on the remote commander to select (up / down)

data (See Pic.2).

Category

Pic.2

3. When red “WRITE” changes to green “SERVICE”.

This indicates writing is complete. (See Pic.5).

Pic.5

Data

Item

- 15 -

3-4. Trouble Shooting

Only?

Speaker Out

HDMI

Problem?

Analogue

Channel

Problem?

Digital

Channel

Problem?

BA Board

oNoNoNoN

Is UI of

Audio Setting

correct? Volume,

TV Speakers.

BA Board

BA Board or RF module BA Board or RF module

Confirm TV Settings,

reset using menu.

Check Speakers

or BA board.

No

Yes

Yes

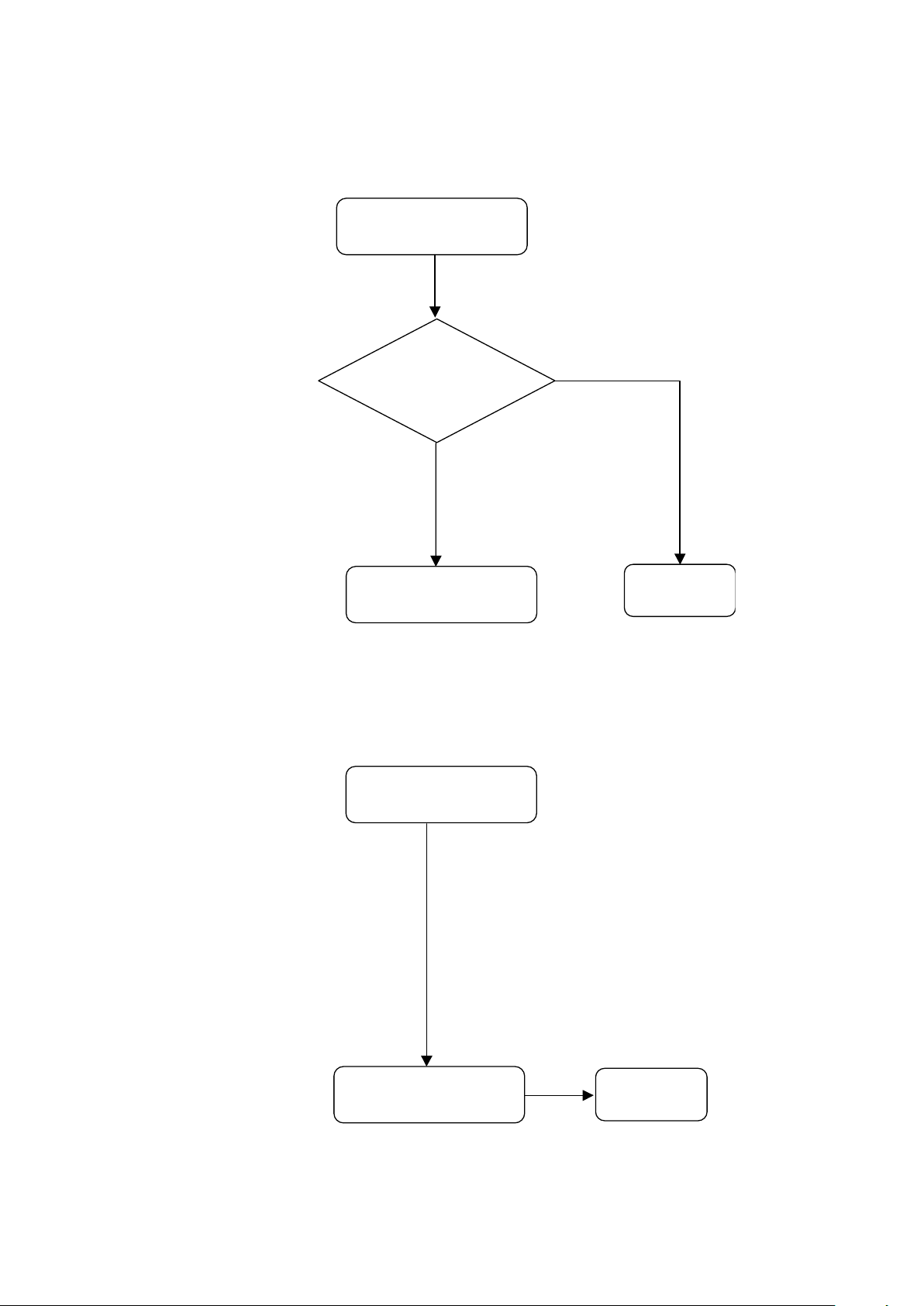

3-4-1. FLOWCHART A

3-4-2. FLOWCHART B

BA Board

Video

Problem.

Do all Inputs

have a

problem?

HDMI

Problem?

Analogue

Channel

Problem?

Digital

Channel

Problem?

oNoNoNoN

BA Board

BA Board

BA Board

Check LVDS harness connection,

BA board, or Panel.

No

Yes

Yes

Is the Backlight

turned on?

BA Board

- 16 -

3-4-3. Flowchart C

Panel Problem

6,12,13,14 LED Blinks

Backlight

turned on?

connected

correctly?

No

Panel module or

G6NS(40") /

G7NS (46" , 52") / or

D1N ( 40" , 46" ) or'

D2N ( 40", 46") or

D3N (52") or D4N (52")

Yes

BA Board

LVDS

Yes

REPLACE PANEL

Finish

6 or 13 LED Blinks

NO

Replace (OK)

Replace (OK)

NO

D1N (40",46") or

D2N ( 40", 46") or

D3N (52") or

D4N (52")

BA BOARD

12 or 14 LED Blinks

3-4-4. Flowchart D

Is the

Is the LVDS

- 17 -

NO

Replace (OK)

Finish

2 LED Blinks

G6NS(40")/

G7NS(46",52")

Replace BA Board

Finish

5, 7 or 10 LED Blinks

Replace (OK)

3-4-5. Flowchart E

3-4-6. Flowchart F

Replace BA Board

- 18 -

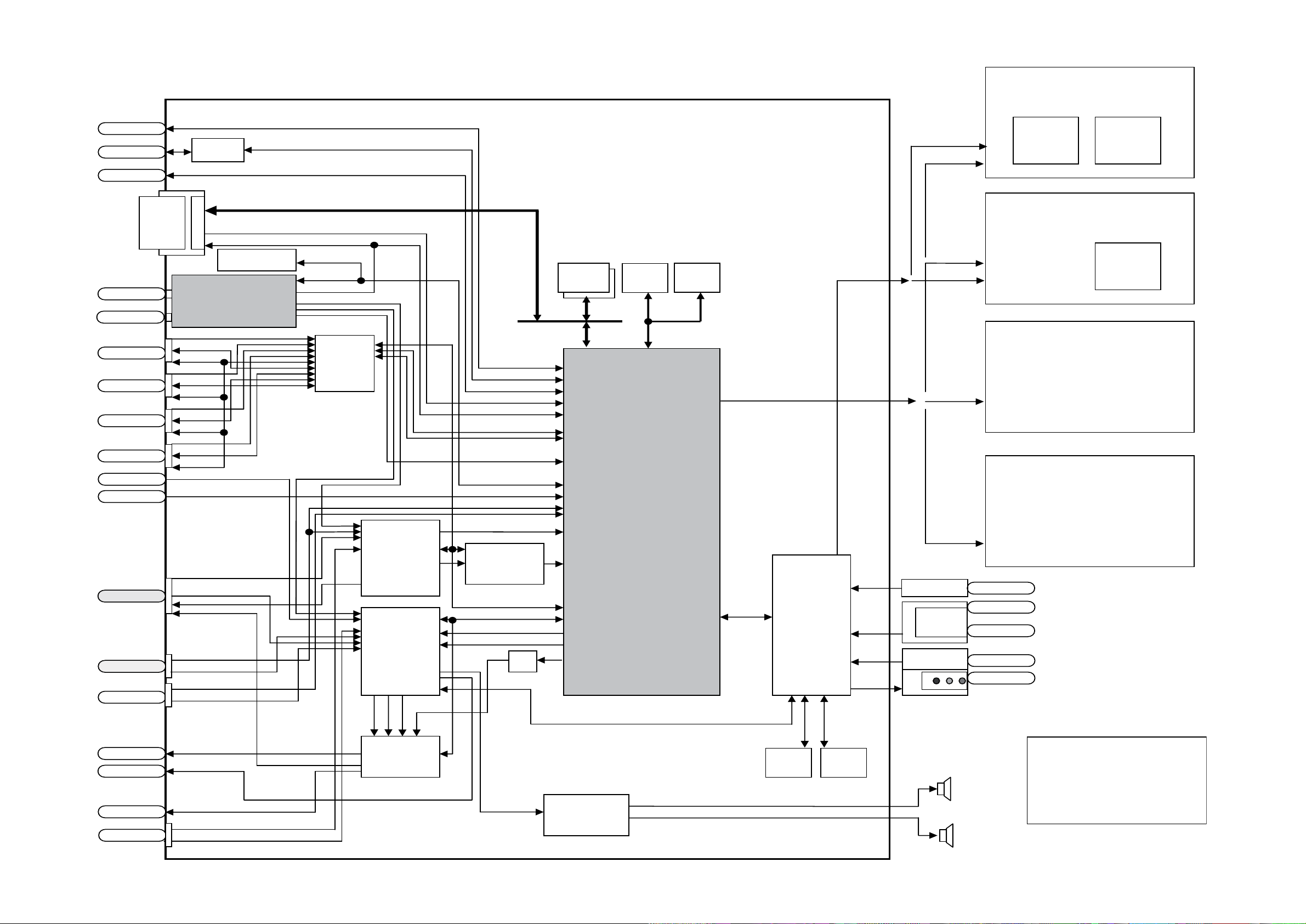

4-1. BLOCK DIAGRAM

EMMA3TL

Panel

240/200Hz

Power Supply

G6NS(40")/ G7NS

(46", 52") / D1N ( 40",

46" )/ D2N ( 40", 46")/

D3N (52") or D4N (52")

Aerial

Comp2

V1/MONout

Audio Out

Opt. Out

V2/Comp1

Tuner

USB

CI

PC In

PHY

MS (JIG)

Ether

SEIJI

CXA3785R

Audio

DSP

CXD9926

TAS

Video SW

CXA2241

DDR2

1Gb

MIMAS

Sub Chrom

SAA7115A

HDMI1

HDMI2

HDMI3

HDMI4

HDMI

EQ/SW

DDC

CEC

TMDS

DDC

CEC

TMDS

DDC

CEC

TMDS

DDC

CEC

TMDS

HP Out

CVBS/YCbCr

L/R

L/R

SPDIF

YCbCr

L/R

L/R

CVBS (SELOUT)

L/R (SELOUT)

CVBS/YC

RGB/HV

L/R

Amp

TAS5602

Side Video

YCbCr

L/R

SEL/MON

LO

HP

SPDIF

I2S 5.1ch

L/R

DAC

DDR2

512Mb

IIC1

IIC2

NVM

Temp

Sensor

UART

IIC

IIC

IIC

Power SW

Key

LOGO

IR

LED

HL1

SONY

HSN

PE-L PE-L

TS

TS

LVDS(60/50Hz)

IIC_SINK

NICAM/A2

IIC0

IIC

Panel

120/100Hz

PE-L

Panel

60/50Hz FHD

Panel

60/50Hz WXGA

NAND

512Mbx2

DVI/PC in

Cable

BA

- 19 -

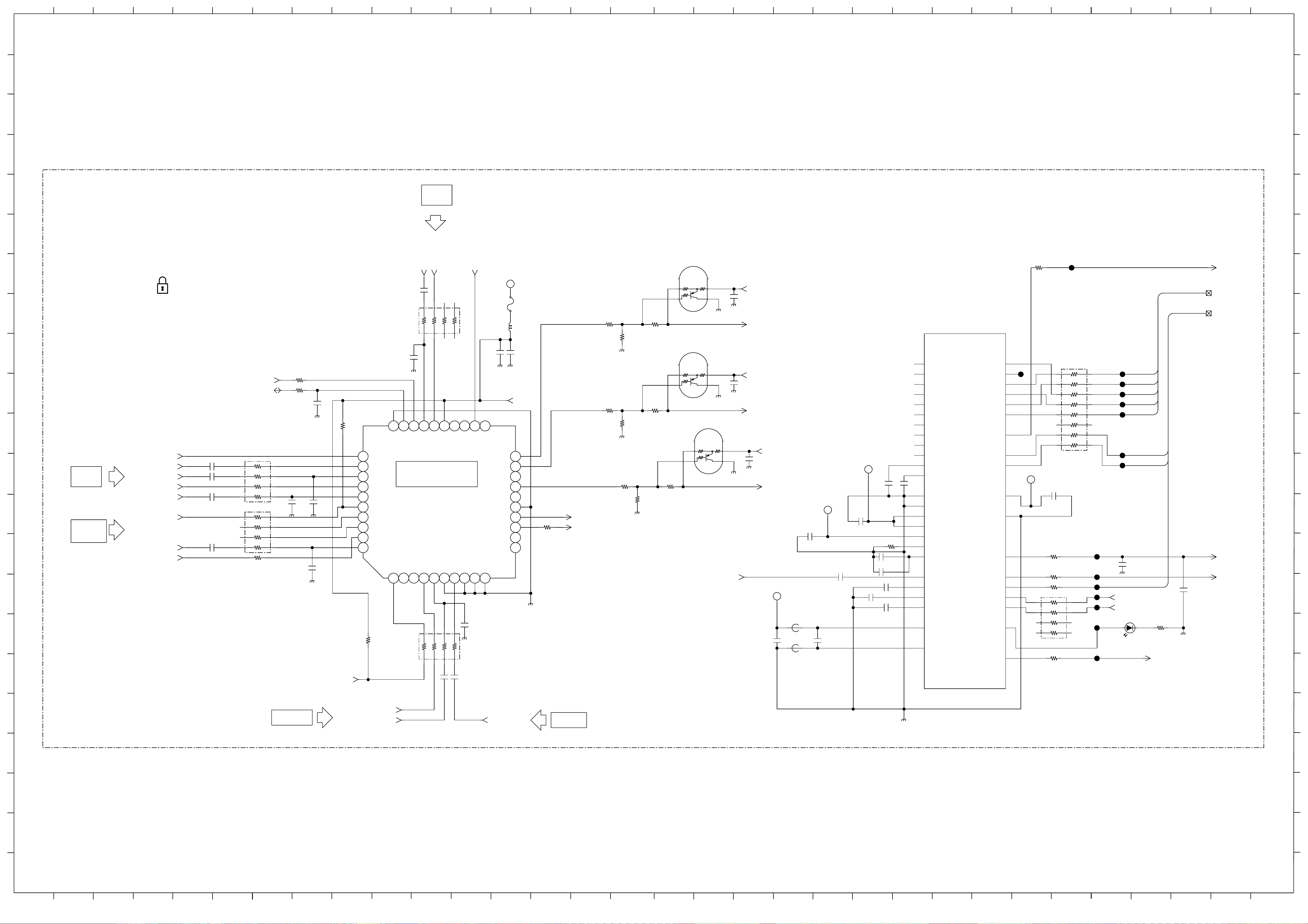

5-2. CIRCUIT BOARD LOCATION

5-3. SCHEMATIC DIAGRAMS AND

PRINTED WIRING BOARDS

Note :

• All capacitors are in µF unless otherwise noted.

• pF : µµF 50WV or less are not indicated except for

electrolytic types.

• Indication of resistance, which does not have one for

rating electrical power, is as follows.

Pitch : 5mm

Electrical power rating : 1/4W

• Chip resistors are 1/10W

• All resistors are in ohms.

k = 1000 ohms, M = 1000,000 ohms

• : nonflammable resistor.

• : fusible resistor.

• : internal component.

• : panel designation or adjustment for repair.

• All variable and adjustable resistors have

characteristic curve B, unless otherwise noted.

• All voltages are in Volts.

• Readings are taken with a 10Mohm digital mutimeter.

• Readings are taken with a color bar input signal.

• Voltage variations may be noted due to normal production

tolerences.

• : B + bus.

• : B - bus.

• : RF signal path.

• : earth - ground.

• : earth - chassis.

Reference Information

RESISTOR RN

: METAL FILM

RC

: SOLID

FPRD

: NON FLAMMABLE CARBON

FUSE

: NON FLAMMABLE FUSIBLE

RS

: NON FLAMMABLE METAL OXIDE

RB

: NON FLAMMABLE CEMENT

RW

: NON FLAMMABLE WIREWOUND

: ADJUSTMENT RESISTOR

COIL LF-8L

: MICRO INDUCTOR

CAPACITOR TA

: TANTALUM

PS

: STYROL

PP

: POLYPROPYLENE

PT

: MYLAR

MPS

: METALIZED POLYESTER

MPP

: METALIZED POLYPROPYLENE

ALB

: BIPOLAR

ALT

: HIGH TEMPERATURE

ALR

: HIGH RIPPLE

Les composants identifiés par une trame et

par une marque sont d'une importance

critique pour la sécurité. Ne les remplacer

que par des pièces de numéro spécifié.

specified.

Note :

The components identified by shading

and marked are critical for safety.

Replace only with the part numbers

specified in the parts list.

Note :

CVM Board

A Board

S1 Board

VM

C

H

D1

A

J

A2

N

D

A1

D2

C

A

4-2. CIRCUIT BOARD LOCATION

D1N/D3N

BA

HSN

D2N/D4N

G6NS/G7NS

HL1A

4-3. SCHEMATIC DIAGRAMS AND

PRINTED WIRING BOARDS

Note :

The components identified by mark

confidential information.

Strictly follow the instructions whenever the

components are repaired and/or replaced.

contain

NOTE: The G7NS board is not a Sony board so it’s schematic diagram and printed wiring

board is not shown in this Service Manual.

Schematic diagrams are for reference only. Please refer to the electrical parts

list for the correct value and part number of components.

- 20 -

DDCCBB

O

P

EE

FF

Z

10

A B C D E F G H JI K L M N

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

11

10

11

22

21

22

R

Q

O

P

EE

FF

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

A B C D E F G H JI K L M N

12

13

14

15

16

17

18

19

20

21

20

18

19

17

15

16

14

12

13

Q R S T U V W X Y AA

XX

C7609

D3.3V

1005

25V

0. 0 1

X7R

C7605

1005

25V

0. 0 1

X7R

C7602

1005

25V

0. 0 1

X7R

C7603

R0XC-P

R0XC+P

R0X0-P

R0X0+P

R0X1-P

R0X1+P

R0X2-P

R0X2+P

DSCL0P

DSDA0P

1005

25V

0. 0 1

X7R

C7608

1005

25V

0. 0 1

X7R

C7604

10

*R7600

1k

*R7603

DDC_5V_1

5V_MAIN

1/16W

CHIP

10

R7601

5V_MAIN

DDC_5V_3

1k

R7604

1/16W

RN-CP

1k

*R7605

5V_MAIN

10

*R7602

DDC_5V_4

5V_MAIN

DDC_5V_S

1k

*R7607

10

*R7606

25V

0. 0 1

X7R

C7610

HDMI_CE

25V

0. 0 1

X7R

C7607

1005

25V

0. 0 1

X7R

C7606

R0PWR5V_1

XX

R7619

1005

25V

0. 0 1

X7R

C7600

1005

25V

0. 0 1

X7R

C7601

4. 7 k

R7612

5V_MAIN

EMI

FL7600

D7603

XX

D7604

XX

D7605

XX

D7607

XX

XX

R7617

XX

R7618

5V_MAIN

XX

R7614

25V

0. 0 1

X7R

C7611

8 7 6 5

4321

M24C02-WMN6T(B)

IC7601

A1

A0

A2

E SDA

SCL

WP

VCC

16V

0.1

C7612

XX

R7623

XX

R7620

1/16W

CHIP

10k

R7621

5%

D3.3V

DDC_5V_S

DDC_5V_4

DDC_5V_3

DDC_5V_1

100

*RB7607

100

*RB7602

100

RB7601

100

*RB7600

SCL2

SDA2

CL7600

CL7601

CL7602

CL7603

XX

RB7609

10k

RB7606

EQ_MVCC

EQ_MVCC

GND_D

CEC_OUT

1/16W

CHIP

5%

27k

R7624

1005CHIP

R7622

0

CEC_IN CEC

JL7600

XX

C7613

STBY_3.3V

1 2 3

456

IC7602

XX

CEC_IN

CEC_OUT

VCC A

GND

B

CEC

D7609

MA2SD320G8S0

2. 2 k

RB7610

VD7622

XX

VD7623

XX

VD7604XXVD7607

XX

VD7601

XX

VD7620

XX

VD7621

XX

VD7603

XX

VD7606

XX

VD7600

XX

VD7624

XX

VD7625

XX

VD7605XXVD7608

XX

VD7602

XX

VD7626

XX

VD7627

XX

VD7615

XX

VD7616XXVD7617

XX

D7608

MA2SD320G8S0

100

*R7608

100

R7609

100

*R7610

100

*R7611

1k

R76271kR7628

1k

R7626

XX

R7631

XX

R7630

XX

R7632

XX

R7629

10k

R7634

16V

0.1

C7614

6.3V1

C7615

47k

*RB7605

47k

RB7604

47k

*RB7603

214

3

47k

*RB7608

1

2

3

4

8

7

6

5

0uH

*L7600

1

2

3

4

8

7

6

5

0uH

*L7601

1

2

3

4

8

7

6

5

0uH

L7602

1

2

3

4

8

7

6

5

0uH

L7603

1

2

3

4

8

7

6

5

0uH

*L7604

1

2

3

4

8

7

6

5

0uH

*L7605

1

2

3

4

8

7

6

5

0uH

*L7606

1

2

3

4

8

7

6

5

0uH

*L7607

0

*R7635

CHIP

0

R7636

0

*R7637

0

*R7638

JL7601

JL7602

JL7603

1/16W

CHIP

5%

100

R7625

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51525354555657585960616263646566676869707172737475

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

IC7600

CXB1447R-T6

SCL_D

GND

DCLKN

DCLKP

VCC

DDT0N

DDT0P

GND

DDT1N

DDT1P

VCC

DDT2N

DDT2P

GND

GPI-1

GPI-2

GPI-3

GPI-4

DDC5V_A

DDC5V_B

DDC5V_C

DDC5V_D

MVCC

DVCC

GND

EWP

SCL_E

SDA_E

SCL_M

SDA_M

ADD

REFRESH

CE

REXT

GND

ZP

ZN

VCC

YP

YN

GND

XP

XN

VCC

WP

WN

GND

SCL_SINK

SDA_SINK

DDC5V_MOUT

HPD_A

SDA_A

SCL_A

VCC

ACLKN

ACLKP

VCC

ADT0N

ADT0P

GND

ADT1N

ADT1P

VCC

ADT2N

ADT2P

GND

HPD_B

SDA_B

SCL_B

BCLKN

BCLKP

VCC

BDT0N

BDT0P

GND

GND

BDT1N

BDT1P

VCC

BDT2N

BDT2P

GND

HPD_C

SDA_C

SCL_C

GND

CCLKN

CCLKP

VCC

CDT0N

CDT0P

GND

CDT1N

CDT1P

VCC

CDT2N

CDT2P

GND

HPD_D

SDA_D

*CN7600

1D2+

2E

3D2-

4D1+

5E

6D1-

7D0+

8E

9DO-

10CLK+

11E

12CLK-

13CEC

14NC

15DDC CLK

16DDC DAT

17E

18DDC +5V

19HPD

20

20P

CN7601

1D2+

2E

3D2-

4D1+

5E

6D1-

7D0+

8E

9DO-

10CLK+

11E

12CLK-

13CEC

14NC

15DDC CLK

16DDC DAT

17E

18DDC +5V

19HPD

20

*CN7602

D2+

2E

3D2-

4D1+

5E

6D1-

7D0+

8E

9D0-

10CLK+

11E

12CLK-

13CEC

14NC

15DDC CLK

16DDC DAT

17E

18DDC +5V

19HPD

20

*CN7603

D2+

2E

3D2-

4D1+

5E

6D1-

7D0+

8E

9D0-

10CLK+

11E

12CLK-

13CEC

14NC

15DDC CLK

16DDC DAT

17E

18DDC +5V

19HPD

20

1/16W

CHIP

5%

47k

R7613

RX2_3R-

RX1_3RRX1_3R+

RX2_3R+

RXC_2R-

RX1_2R-

RX2_2R-

RXC_2R+

RX0_2R-

RX0_2R+

RX1_2R+

RX2_2R+

RXC_4R-

RXC_1R-

RXC_1R+

RX0_1R-

RX0_1R+

RX2_1R-

RX2_1R+

RX1_1R+

RX1_1R-

RXC_4R+

RX0_4RRX0_4R+

RX1_4RRX1_4R+

RXC_3R-

RXC_3R+

RX0_3R-

RX0_3R+

RX2_4R-

RX2_4R+

RX0_1R-

RX1_1R+

RX2_1R+

RXC_3R+

RX0_3R+

RX1_3R+

RX2_3R-

RXC_4R-

RX0_4R-

RX1_4R-

RX2_4R-

RXC_2R+

RX0_2R+

RX2_2R-

RX1_2R-

RXC_1R-

RXC_1R+

RX0_1R+

RX1_1R-

RX2_1R-

RXC_3R-

RX0_3R-

RX1_3R-

RX2_3R+

RXC_4R+

RX0_4R+

RX1_4R+

RX2_4R+

RXC_2R-

RX0_2R-

RX1_2R+

RX2_2R+

HDMI1

TOP

HDMI2

TOP

HDMI4

SIDE

HDMI3

SIDE

input D

input C

input B

input A

[q†«•o

00'RlN^–

CEC

TO HDMI JACK

TO MAIN MAICON

RB7609i”¯p^[–•Ø

BA-EX2L

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

BA

1/18 TUNER, MAIN MICROCONTROLLER, HDMI/AV SIDE/PC INPUT, SCARTS

- 21 -

~ BA Board Schematic Diagram [ Tuner, Main Microcontroller, HDMI/AV Input/PC Input, Scarts ] Page 1/18 ~

DDCCBB

O

P

EE

FF

Z

10

A B C D E F G H JI K L M N

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

11

10

11

22

21

22

R

Q

O

P

EE

FF

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

A B C D E F G H JI K L M N

12

13

14

15

16

17

18

19

20

21

20

18

19

17

15

16

14

12

13

Q R S T U V W X Y AA

5.6k

R4203

XX

R4211

GND_D

VSW_A5.0V

SCL2

XX

C4206

GND_D

VSW_A5.0V

CVBS_FRONT

100

RB4201

2

1

4

3

6

5

8

7

R4207

10k

5.6k

R4204

100

RB4204

CVBS_VIDEO1

XX

R4212

GND_D

1 2 3 4 5 6 7 8 9 10

11

12

13

14

15

16

17

18

19

20

21222324252627282930

31

32

33

34

35

36

37

38

39

40

CXA2241Q-T4

IC4200

S2_1

C2

Y2

S1_1

V2

GND

V1

NC

NC

OUT3

NC

COUT3

V/YOUT3

VOUT3

NC

COUT2

V/YOUT2

NC

COUT1

V/YOUT1

NC

S2_4

C5

Y5

Vcc

S1_4

V5

SCL

SDA

ADR

S2_3

C4

Y4

S1_3

V4

S2_2

C3

Y3

S1_2

V3

R4208

10k

GND_D

5V_MAIN

GND_D

GND_D

16V

0.1

C4213

22uH

L4200

1608

10V

1

X7R

C4209

RT3S02M-T111-1

Q4200

3 2 1

654

RT3S02M-T111-1

Q4201

3 2 1

654

1

C4205

1

C4210

1

C4211

R4200

0

R4202

0

GND_D

VSW_A5.0V

R4209

XX

100

R4205

RT3S02M-T111-1

Q4202

3 2 1

654

VSW_A5.0V

100

RB4200

2

1

4

3

6

5

8

7

1

C4202

1

C4201

1

C4200

RF_ANALOG_CV

Y_VIDEO1

C_SCART2

CVBS_SCART1

MODE1

MODE2

V1_DET SUB_CV/Y

BAVI00

BAVI35

A_REC/MON_OUT_CVCOMP1_DET

COMP2_DET

SIDE_V_DET/V2_DET

100

RB4203

SDA2

PC_DET

100

R4201

XX

R4213

10V

4.7

C4214

X7R

2012

RF_DIGITAL_CV

XX

C4217

XX

C4218

XX

C4219

GND_D

GND_D

GND_D

V1_S_SW

R4218

10k

R4217

10k

TV_OUT

0

*R4216

XX

C4223

GND_D

XX

C4222

GND_D

XX

C4220

GND_D

GND_D

XX

C4221

GND_D

XX

C4224

36V

1.4A

F4200

Video SW

RF

YC:Digital

CV:Analog

AV2/

VIDEO1

SIDE_CVBS

AV1/

VIDEO3

Digital_RF

BA-EX2L

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

BA

2/18

47

R5020

1/16W

CHIP 5%47

R5023

1/16W

CHIP 5%47

R5025

1/16W

CHIP 5%47

R5024

SPDIF_IN

016:2B

016:2C

016:2I

SIFIN

019:3F;022:7C

CL5011

CL5012

CL5013

CL5014

CL5015

CL5016

CL5017

CL5018

CL5019

CL5020

CL5021

CL5022

CL5023

CL5024

CL5025

FE_MCK

016:2C

SUB_MCK

016:2I

CL5027

D3.3V

D1.5V

A3.3V

0.1

C5004

0.1

C5005

GND_D

D3.3V

0.1

C5007

XX

R5050

0.1

C5009

0.1

C5010

0.1

C5011

1005

16V

0.1

C5012

XX

C5023

XX

C5024

X_HDMI_INT

016:2E

XX

C5008

XX

C5013

GND_D

SML-310MTT86

*D5000

XX

1005

1/16W

CHIP

5%

*R5026

XX

AFT_UP

022:17G

AFT_DN

022:15C;022:17G

47

RB5000

2

1

4

3

6

5

8

7

10

9

12

11

14

13

16

15

1/16W

CHIP

5%

47

R5051

XX

C5025

XX

C5026

GND_D

47

RB5001

2

1

4

3

6

5

8

7

MC-10144F1-410-LU2-A

*IC2001

AAIL0

B6

AAIR0

C6

AAIL1

A5

AAIR1

B5

AAIL2

A4

AAIR2

B4

AAIL3

C8

AAIR3

C7

AAIL4

C5

AAIR4

D7

AAILC

D6

AAIRC

D5

AAIAG33L

C4

AAIAG33R

D4

AAIAV33L

E6

AAIAV33R

E5

AAIDV15

F5

AAIIREF

E4

AAIREG

E7

SIFIN

A7

SIFVCOM

A6

SIFVRB

E8

SIFVRT

F7

SIFAVDD33

B7

SIFAGND

A8

MAAOL0

A2

MAAOR0

B1

MAAOL1

B3

MAAOR1

C3

MAAOL2

B2

MAAOR2

C1

MAO958

H5

SAAOL0

C2

SAAOR0

D2

AAO0DV33

D3

AAO0DG

A3

GPIO65/MAOMCK

M6

GPIO64/SAOMCK

M5

GPIO72/SAO0BCK

P4

GPIO67/SAO1LRCK

P5

GPIO68/SAO1D0

N4

GPIO66/SAO1BCK

N6

GPIO9/MUTE

K4

1005

16V

0.1

C5027

0uH

FB5000

0uH

FB5001

0.1

C5006

FE_LRCK

FE_BCK

FE_DATA1

SUB_DATA

SUB_BCK

SPDIF_IN

SUB_LRCK

FE_DATA3

FE_DATA2

Portion9

- 22 -

~ BA Board Schematic Diagram [ Tuner, Main Microcontroller, HDMI/AV Input/PC Input, Scarts ] Page 2/18 ~

Loading...

Loading...