Sony KDL-40R485A, KDL-32R435A, KDL-46R485A, KLV-40R472A, KLV- 32R422A Service Manual

...

HISTORY INFORMAT ION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL (COMMON)

Version Date Subject

1 6/2013 1stIssue.

ITC2CHASSIS

Segment: BA

LCD TV

9-888-144-01

For SM - Unique , please refer :

9-888-144-P1 ( Pan Asia )

9-888-144-A1 ( America )

9-888-144-E1 ( Europe)

SERVICE MANUAL (COMMON)

ITC2CHASSIS

LCD TV

Segment: BA

MODEL LIST

N

KLV

24R402A

KLV

32R402A

KLV

40R452A

KLV

46R452A

KLV

32R422A

KLV

40R472A

KDL

46R485A

THIS SERVICE MANUAL CONTAINS COMMON INFORMATION FOR BELOW REGIONS AND MODELS:

REGIO

ASIA AMERICA EUROPE

MODEL

-

-

-

-

KLV-24R422A KLV-32R407A KLV-40R457A KLV-46R472A

-

-

-

KDL-32R435A KDL-40R485A

3

TABLE OF CONTENTS

A

A

4

3. Accessing Self Diagnostic History…………………………………..…….

57

A

A

A

5. DIAGRAMS

3-2. No P

11

g

g

3

12.

RTC

Troubleshooting Flow

………………………………………………….

55

Circuit Board Location

Section Title Page

1. SAFETY NOTES

1-1. Warnings and Caution………………………………………………………. 5

1-2. Caution Handling of LCD Panel ......…………….................................... 5

1-3. Safety Check Out ........................……………......................................... 6

1-4. Leakage Test .......................................................................................... 6

1-5. How to Find a Good Earth Ground………………………………………… 7

1-6. Lead Free Information….…………………………………………………… 7

1-7. Handling the Flexible Flat Cable (FFC)……………………………………. 7

2. SELF DIAGNOSTIC FUNCTION

2-1. Overview of Control Buttons ................................................................... 8

2-2. LED Display Control ………..................................................................... 8

2-3. LED Pattern………………........................................................................ 8

2-4. Standby LED Error Display…………………………………………………. 8

2-5. Triage Chart ............................................................................................ 9

3. TROUBLE SHOOTING

3-1. Troubleshooting Flow…….…………………………………………………… 10

ower……………….………………………………………......................

3-3. Standby Led Blinking……………………………........................................ 14

3-4. No Picture............................................................................................. ... 25

3-5. Audio Problem.......................................................................................... 27

3-6. Troubleshooting Video Problem…………………………………………… 35

3-7. HDMI Troubleshootin

3-8. MHL No Picture…………………………………………………………….. 47

3-9. Tuner Troubleshooting Flow………………………………………………… 50

3-10. IR Troubleshooting Flow…………………………………………………….. 53

3-11. Switch Unit Troubleshooting Flow………………………………………… 54

-

Flow……………………………………………… 43

Section Title Page

4. SERVICE ADJUSTMENTS

4-1.

4-2.

4-4.

4-5.

4-6.

4-7. Updating the Software…………………………………………………….. 61

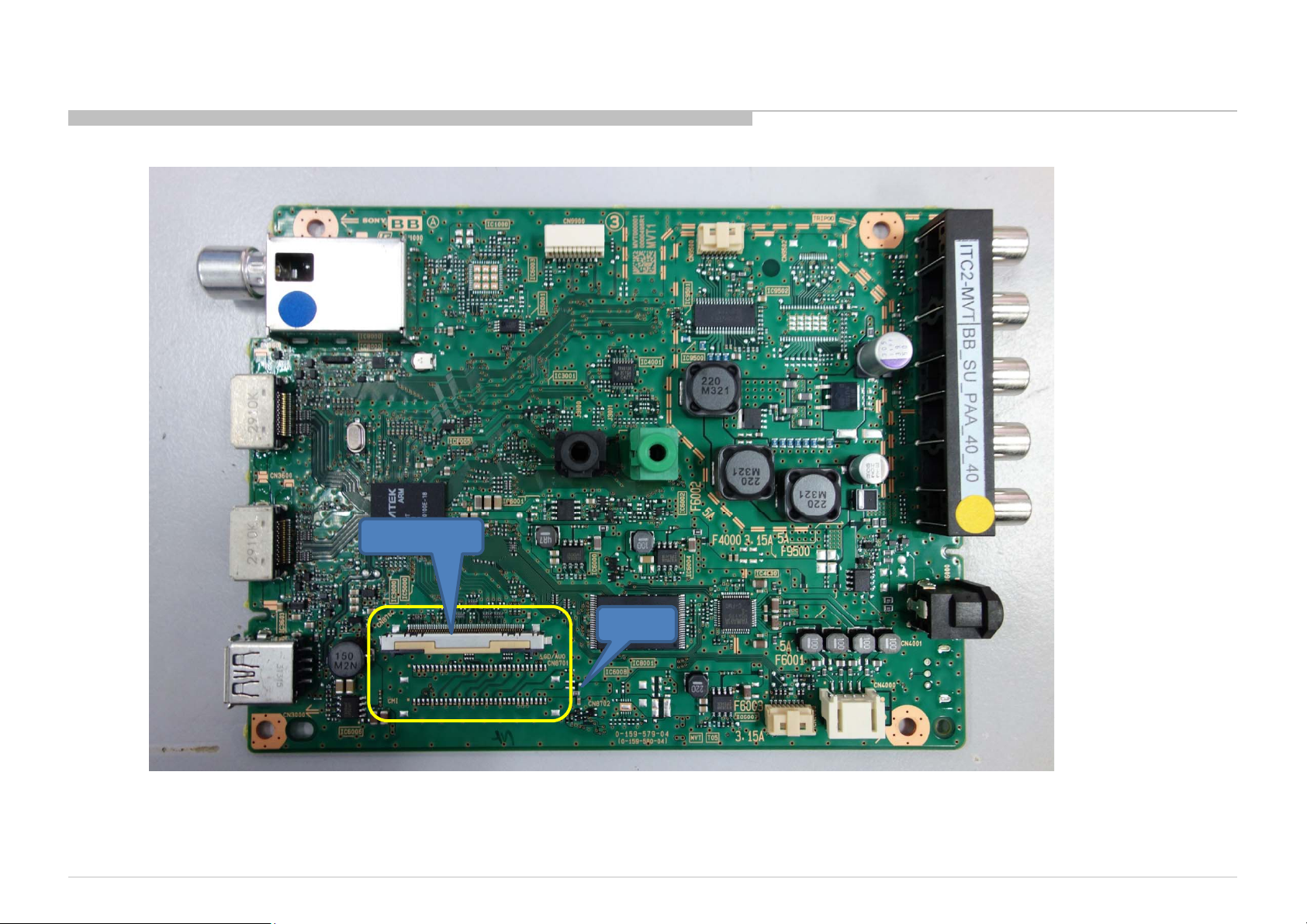

5-1. Circuit Board Location ......................................................................... 62

5-2. Block Diagram...................................................................................... 63

5-3. Connector Diagram ………………………………………...................... 65

ccessing Service Mode ..................................................................... 56

ccessing Software Version……….…………………………………….. 56

ccessing Self Diagnostic Menu…………………………………………… 57

ccessing Serial Number Edit……………………………………….. 58

ccessing Model Name Edit……………………………………………… 59

Please refer Service Manual – Unique for below information :

-Safety Warnings

-Wire Dressing

-

-Disassembly and Exploded View.

4

SECTION 1

3) Do not leave the module in high temperature or in areas of high humidity for

r

t

handpl

hil

TV

i

t

for

8) Use care when handling the wires or connectors of the inverter circuit

components

with

Sony

parts

whose

part

numbers

appear

as

shown

in

this

operation

is

suspected

.

SAFETY NOTES

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

1-1. Warnings and Caution

1) These servicing instructions are for use by qualified service personnel only.

2) To reduce the risk of electric shock, do not perform any servicing other than

that contained in the operating instructions unless you are qualified to do so.

3) An isolation transformer should be used during any service to avoid

Possible shock hazard, because of live chassis. The chassis of this receiver is

directly connected to the ac power line.

4) Be sure to follow these guidelines to protect you

avoid causing serious injury :

• Carry the TV with an adequate number of people; larger size TVs require

two or more people.

•Correc

safety and to avoid damages.

5) Components identified by shading and mark on the exploded views,

and in the parts list are critical for safe operation. Replace these

manual or in supplements published by Sony. Circuit adjustments that are

critical for safe operation are identified in this manual. Follow these

procedures whenever critical components are replaced or improper

acementw

e carryingthe

!

property and

sveryimportan

1-2. Caution Handling of LCD Panel

When repairing the LCD Panel, make sure you are grounded with a wrist band.

When repairing the LCD Panel on the wall, the panel must be secured using the

4 mounting holes on the rear cover.

1) Do not press the panel or frame edge to avoid the risk of electric shock.

2) Do not scratch or press on the panel with any sharp objects.

an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause short circuit within the module.

6) Disconnect the AC power when replacing the backlight (CCFL) or

inverter circuit. (High voltage occurs at the inverter circuit at 650Vrms)

7) Always clean the LCD panel with a soft cloth material.

.

Damaging the wires may cause a short circuit.

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

10) During the repair, DO NOT leave the Power On or Burn-in period for more

than 1 hour while the TV is face down on a cloth.

Do not leave Power ON > 1 hour

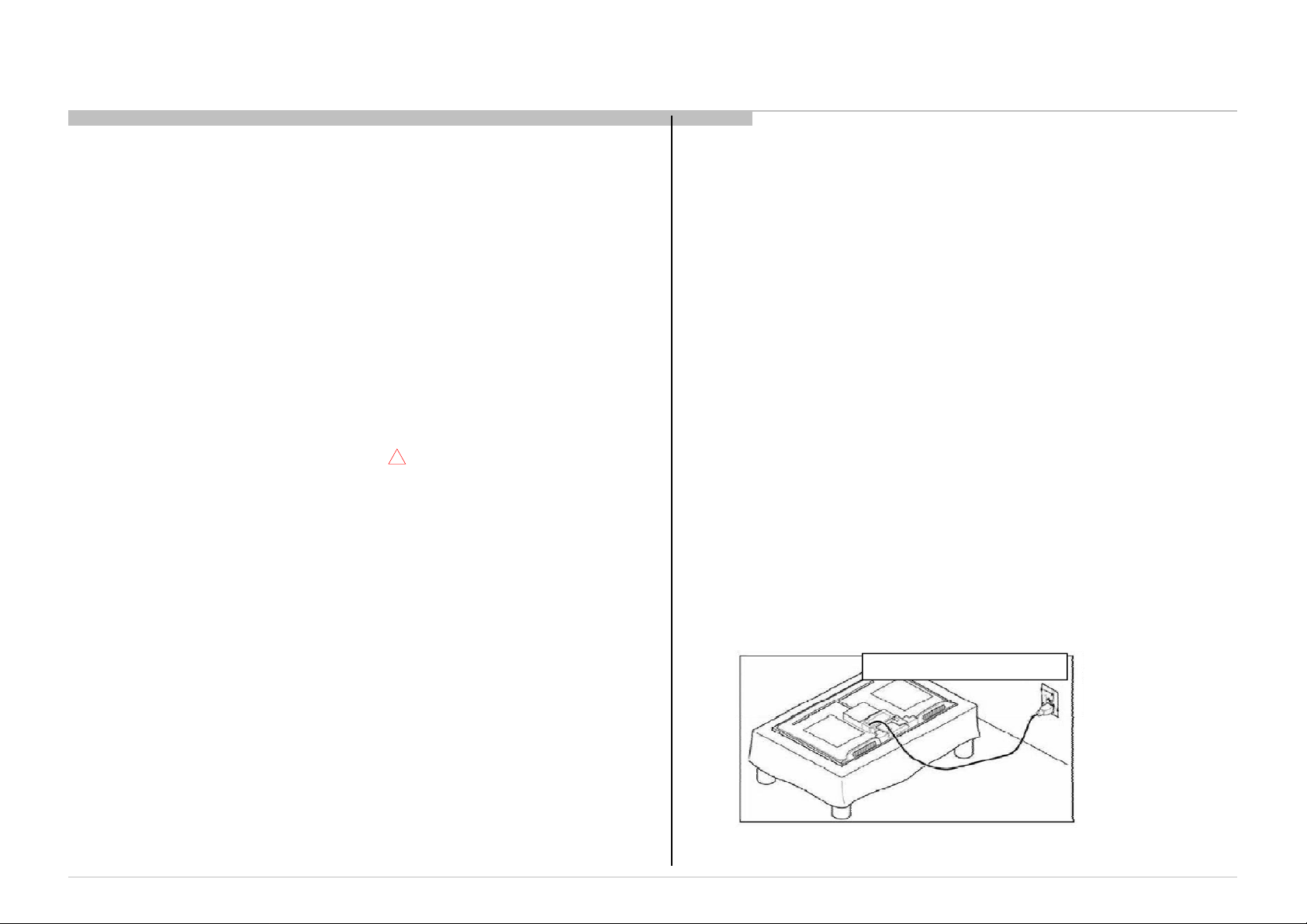

Figure 1. TV is faced down on a cloth during repair.

5

Safety Notes

not exceed 0.5mA (500 microamperes)

multimeter

is suitable for this job

3

)Check

l

knob

operated digital multimeter that have a 2 VAC range are suitable

d

their

h

li

d

toth

hibited

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

1-3 Safety Check-Out

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:-

1) Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and bridges.

2) Check the inter board wiring to ensure that no wires are pinched or

contact high-wattage resistors.

allcontro

hardware have been replaced. Be absolutely certain you have replaced all

the insulators.

4) Look for unauthorized replacement parts, particularly transistors that

were installed during a previous repair. Point them out to the customer and

recommen

replacement.

5) Look for parts which, though functioning show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6) Check the line cords for cracks and abrasion. Recommend the

replacementofany suc

7) Check the antenna terminals, metal trim, metalized knobs, screws and all

other exposed metal parts for AC leakage. Check leakage test as described

next.

8. For safety reasons, repairing the Power board and/or Inverter board is

pro

.

s, shields, covers, groundstraps andmounting

ne cor

ecustomer.

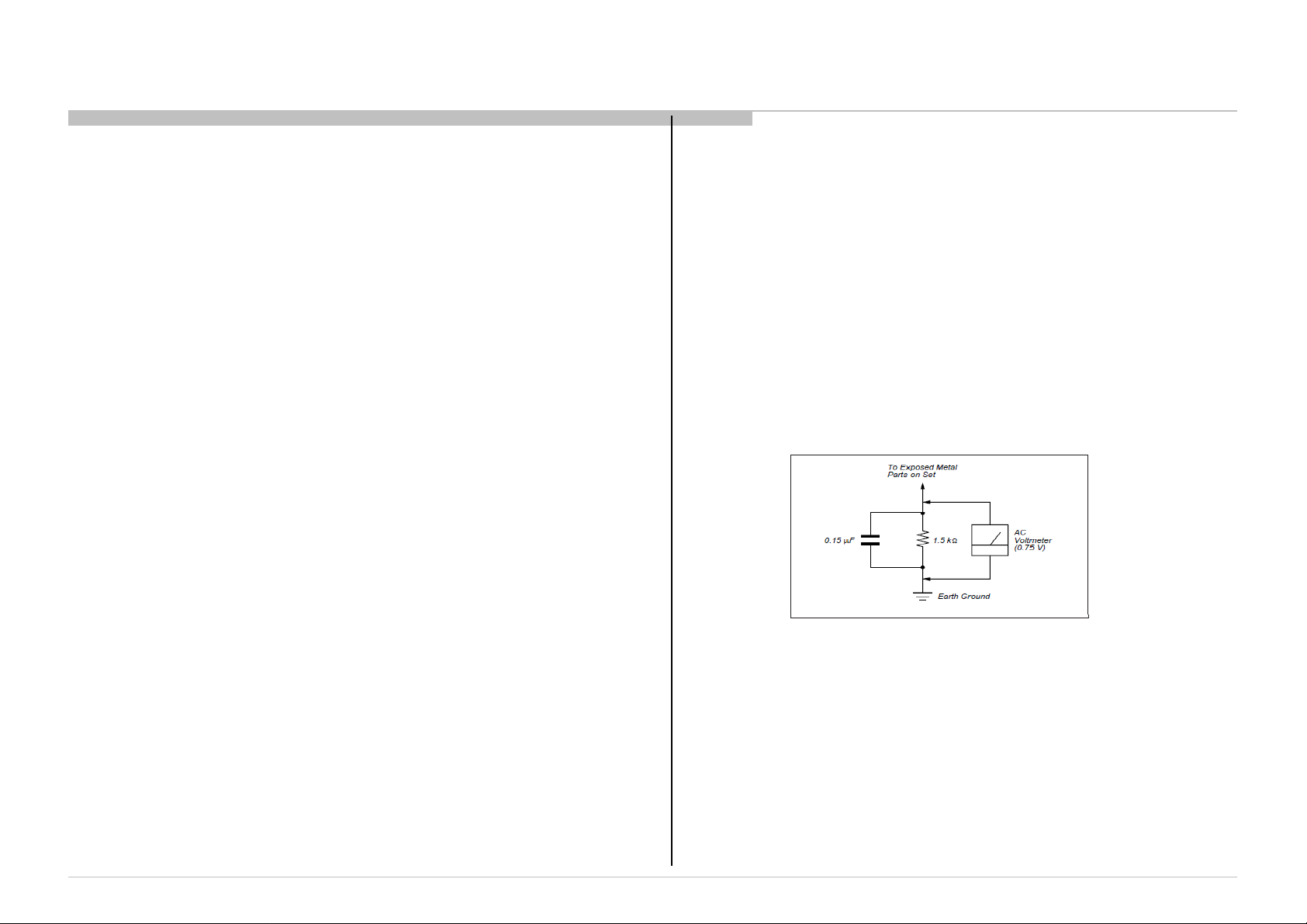

1-4.Leakage Test

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis must

.

Leakage current can be measured by any one of the three methods:-

1) A commercial leakage tester such as the SIMPSON 229 or RCA WT540A.

Follow the manufacturers instructions to use those instructions.

2) A battery-operated AC milliampmeter The DATA PRECISION 245 digital

.

3) Measuring the voltage drop across a resistor by means of a VOM or battery

operated AC voltmeter. The 'limit' indication is 0.75V so analog meters must

have an accurate low voltage scale. The SIMPSON'S 250 and SANWA SH63TRD are examples of passive VOMs that are suitable. Nearly all battery

.

(see Figure 2.)

Figure 2. AC voltmeter to check AC leakage

6

Safety Notes

2) If the retaining screw is to be used as your earth ground, verify that it is at

retaining screw. Try both slots, if necessary, to locate the hot side on the line;

Th

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

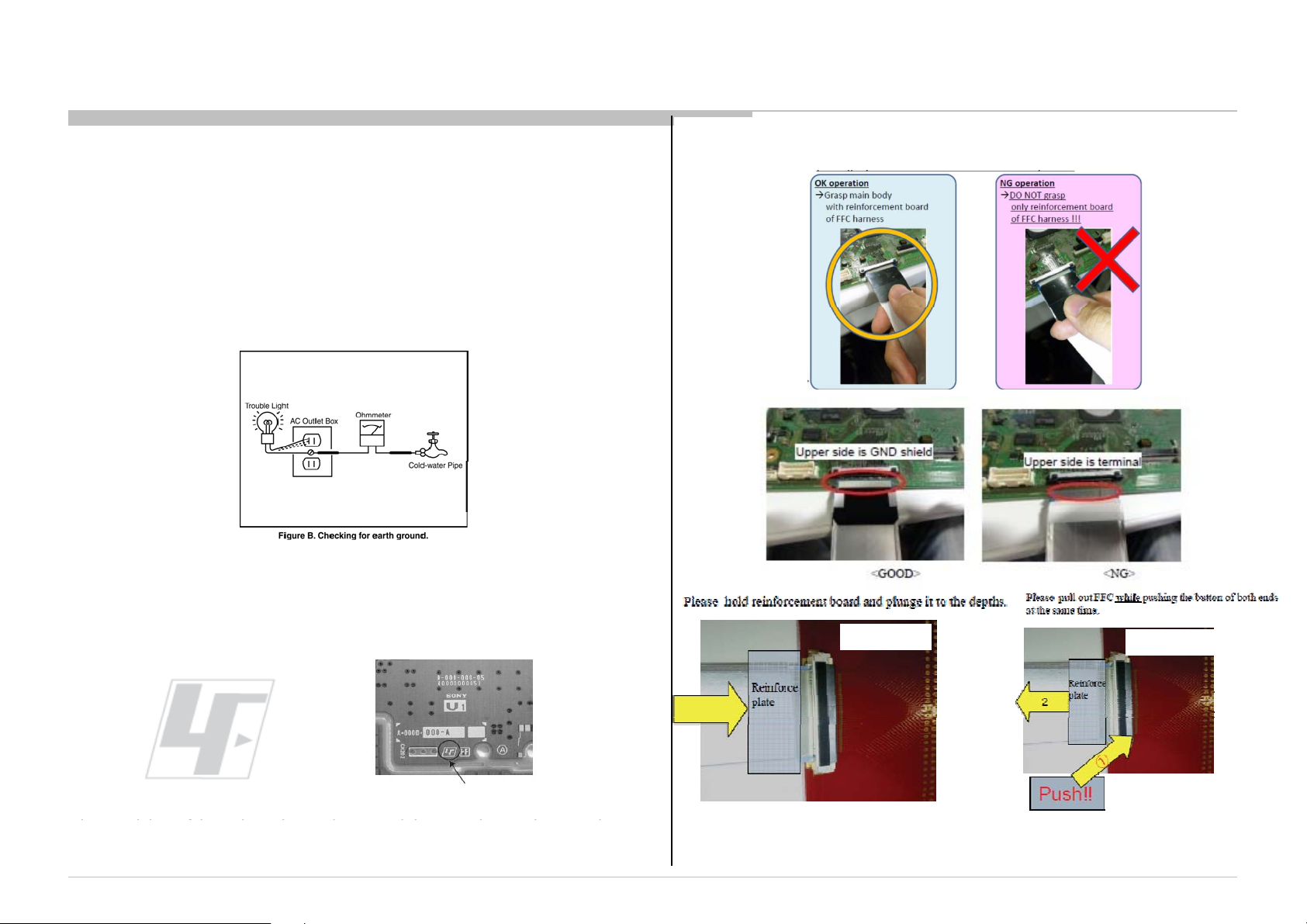

1-5. How to Find a Good Earth Ground

1) A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground.

ground by measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

3) If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

the lamp should light at normal brilliance if the screw is at ground potential

(see Figure 3).

Figure 3. Checking for earth ground.

1-7. Handling the FLEXIBLE FLAT CABLE (FFC)

When you insert / pull out FFC, please grasp a reinforcement board and main body of

FFC.

1-6. Lead Free Information

The circuit boards used in these models have been processed using Lead

Free Solder. The boards are identified by the LF logo located close to the

board designation.

Figure 4: LF Logo

e servicing of these boards requires special precautions. It is strongly

recommended to use Lead Free Solder material in order to guarantee optimal

quality of new solder joints.

Figure 5: LF logo on circuit board

< Insertion>

Main Board

Main Board

<Pull out>

7

Self Diagnostic Function

2-1. Overview of Control Buttons

2

3. LED Pattern

Standby LED

(

)

(y)

Blinking

0.5sec Green

SECTION 2

SELF DIAGNOSTIC FUNCTION

-

When safety shutdown occurs, Standby LED display reports the cause by using the lightning

patterns as indicated below

.

2-2. LED Display Control

Status LED Colour Remarks

Power Off

( AC Off and *1)

Power On Green

Standby

( by remote control off only )

Picture Off Green

Set "Sleep Timer" Amber

Set "On Timer"

( Power On )

Set "On Timer"

Standby

Picture Frame Amber

Failure Red Blinking

Error of panel ID

OFF

Red

Amber

Amber

Amber/Green

*1 power switch off (by

touch button)

The number of LED blinking

indicates cause of failure.

Blinking:0.5sec Amber/

Amber = Red + Green

0.5sec

Example: The figure above shows LED display when SHUTDOWN is caused by Audio

Error. It repeats flashing for a specified number of times in 0.5sec/cycle and has a 3 seconds

interval of lighting off. Please note that a 3 seconds interval of lighting off is fixed regardless of abnormal state types.

0.5sec

3.0sec 3.0sec

2-4. Standby LED Error Display

The Number of

(RED blinking)

2 Main Power Error AC adapter Error

3 Audio Error BB board Error

4 Panel Power Error BB board Error

5 Panel I2C COMM Error BB or Source board Error

6 Backlight Error BB board Error

Detection Items Board Error Item

Software Updating Amber Blinking Blinking: 1sec On / 1sec Off

8

Self Diagnostic Function

Ref

A

r

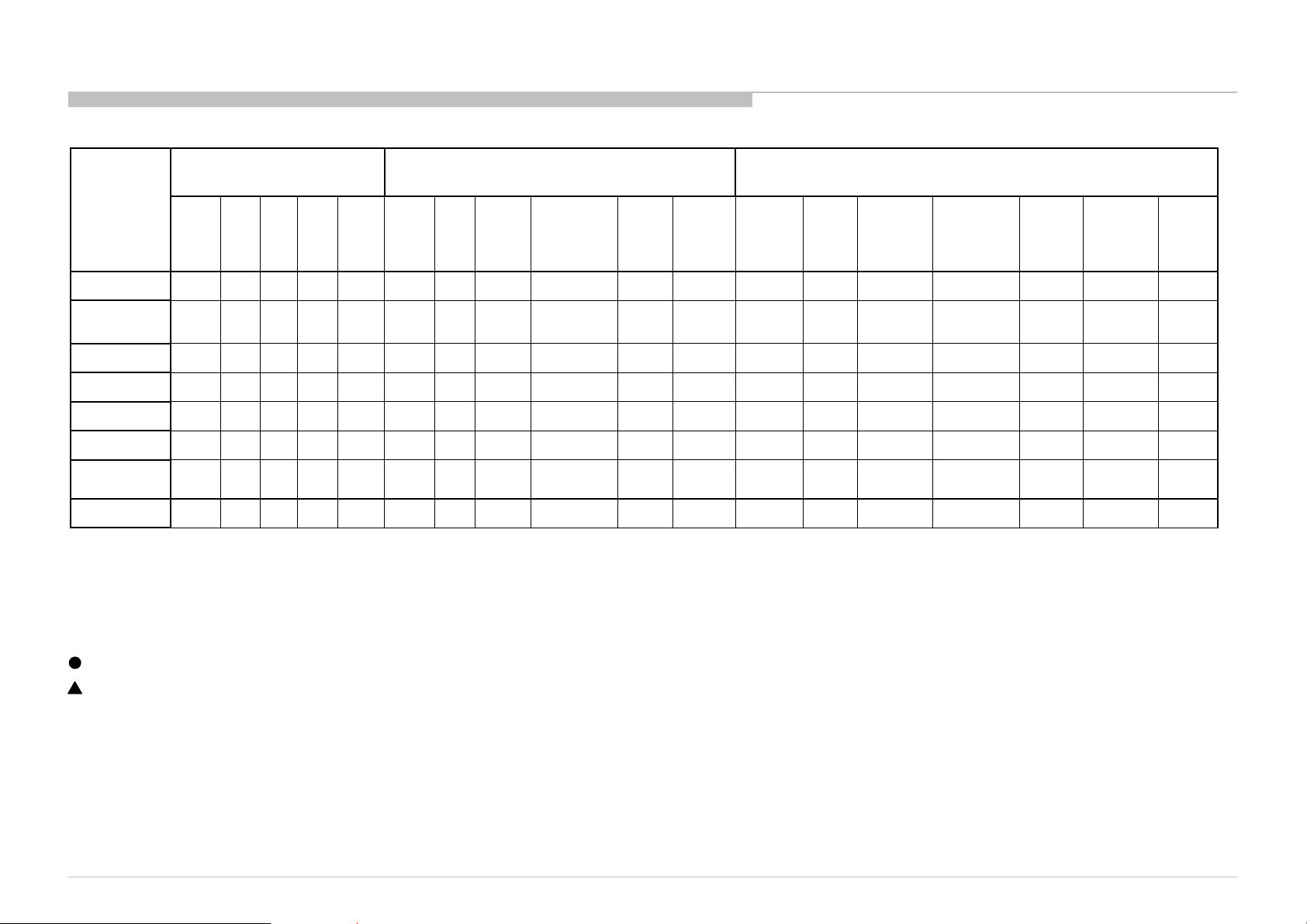

2-5. Triage Chart

erence

23456Tuner USB Video Component HDMI MHL

Blinking

No Picture No Sound

Main

Speaker

HP Video Component Tuner HDMI USB

BB Board

Light Source

Board

Open Cell

C Adapto

Speaker Unit

LS Harness

Main

Harness

FFC Cable

Most likely defective part

Secondary possible defective part

Note: Details refer to Troubleshooting Section.

9

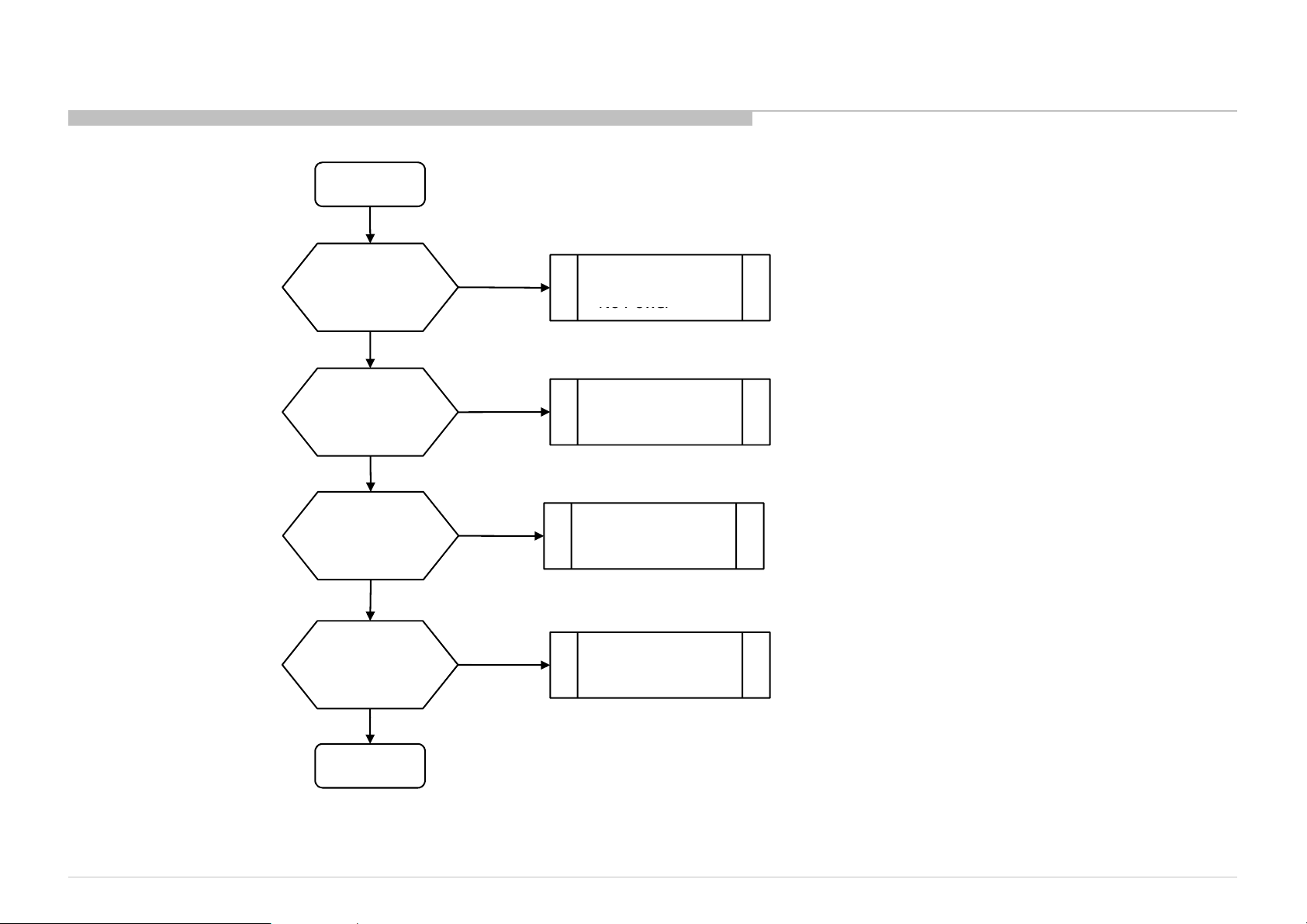

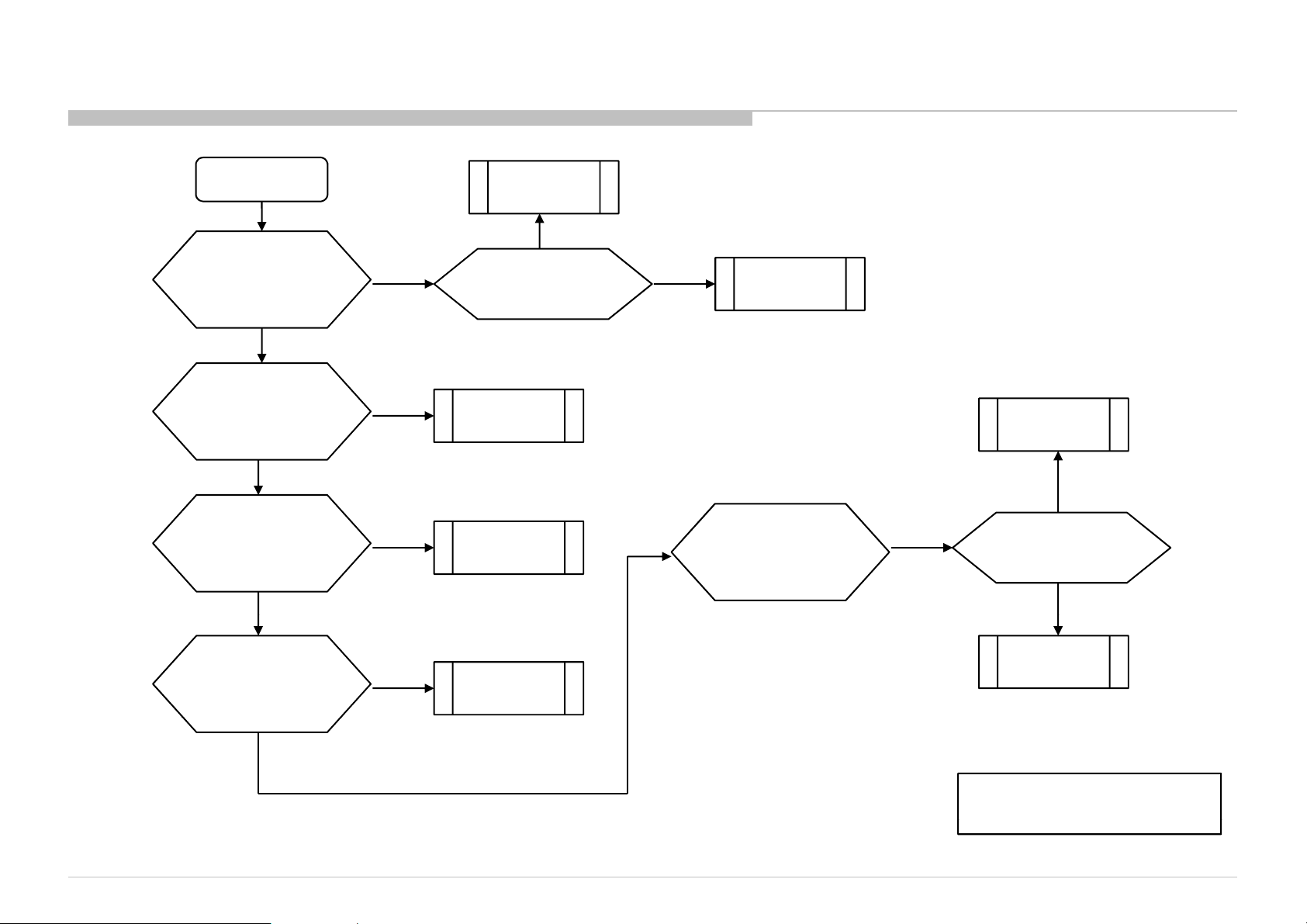

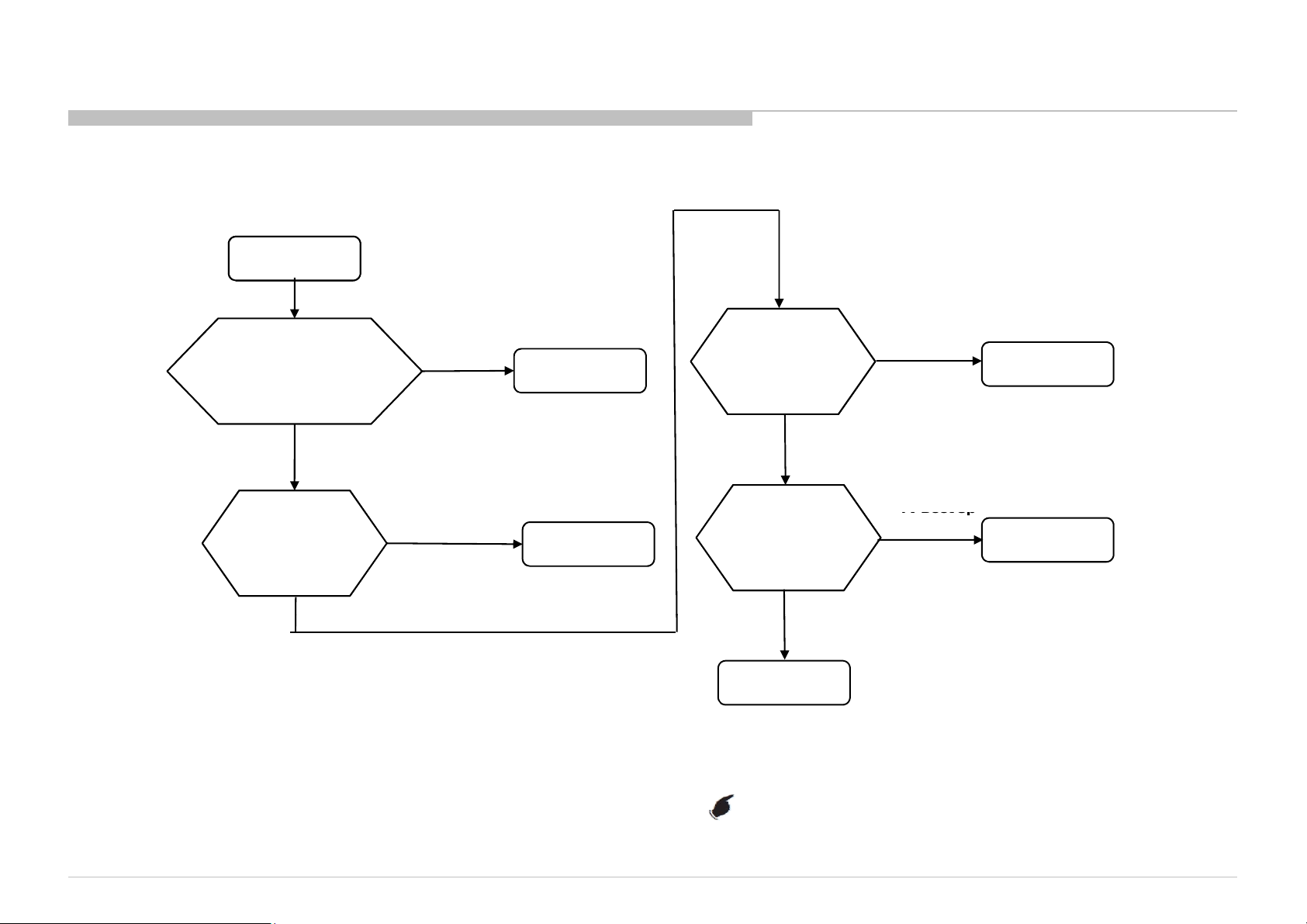

3-1. Troubleshooting Flow

No Power

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

SECTION 3

TROUBLESHOOTING

START

Does the Power Led

stay on when the

TV is switched on ?

Is the Standby Led

blink ?

Green & Amber

blink?

Is the Picture and

Sound OK ?

Open Detail

-

Open Detail

- Standby LED Blink

- Panel ID Error

- Panel Not Supported

Open Detail

- Picture/Audio/Video

END

10

Troubleshooting

Sheet

Tak

NG

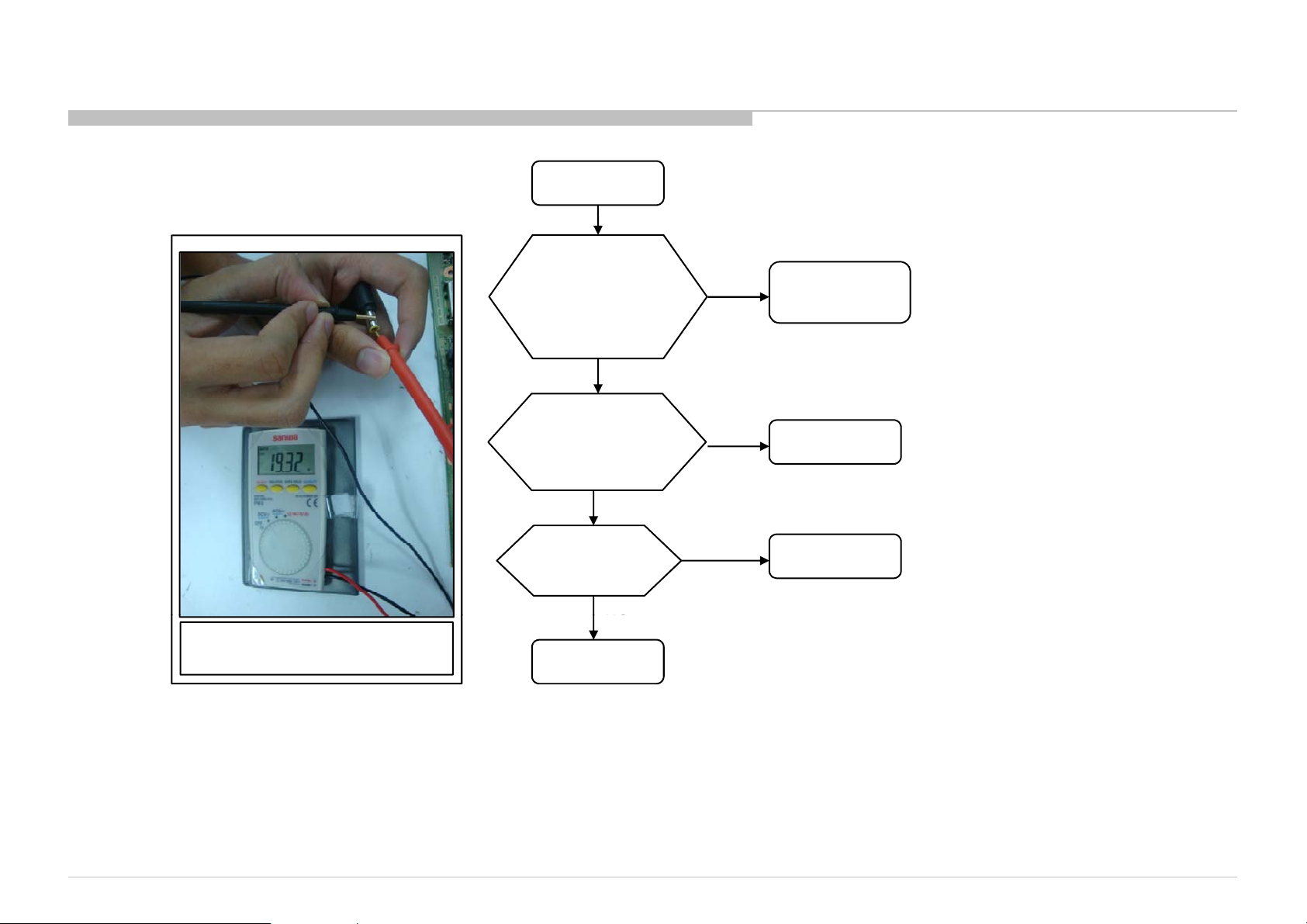

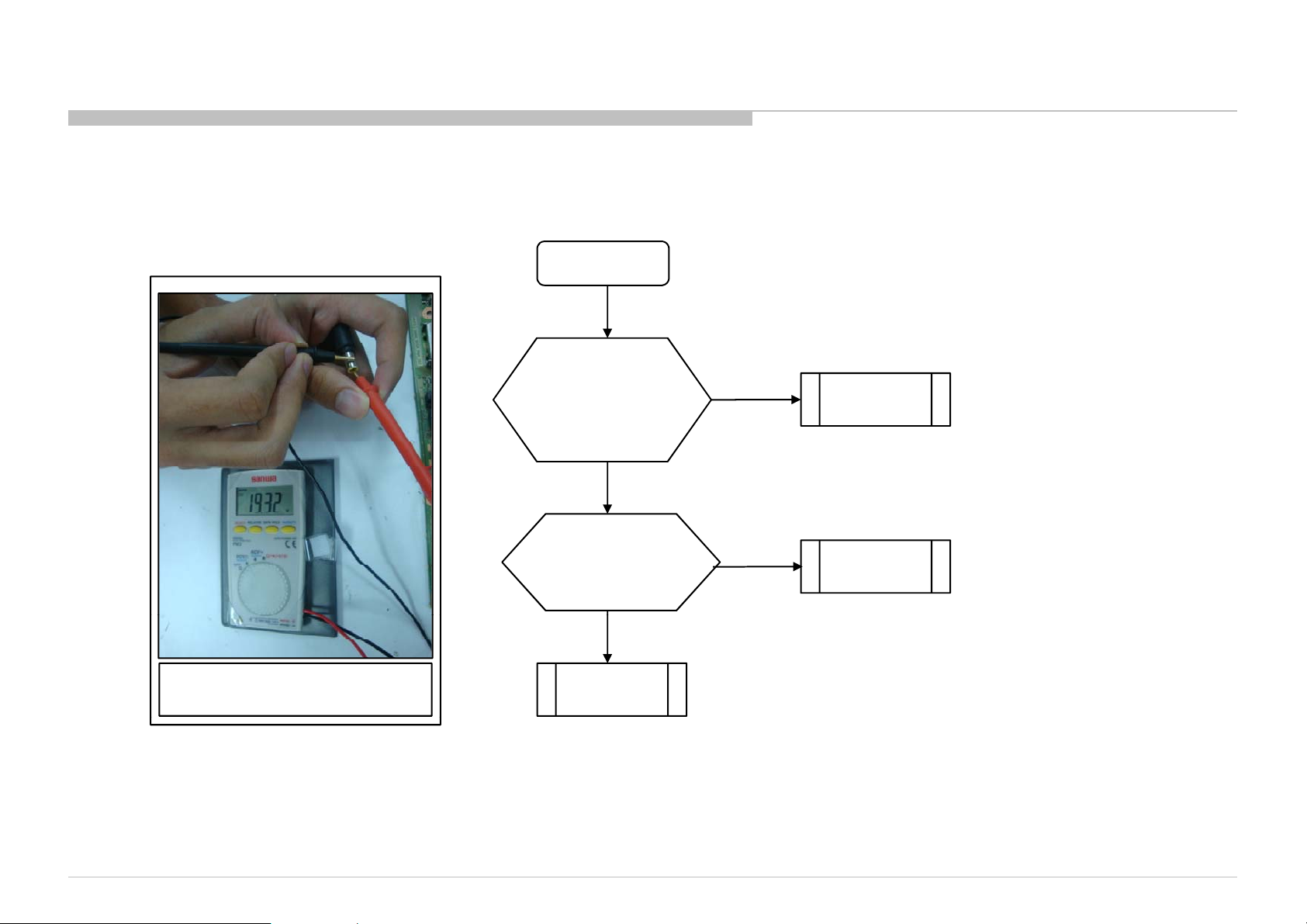

3-2. No Power

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

No Power

Figure 1: How to test DC voltage

at adaptor output

Check DC voltage at

JL6001

Is it 19.5V?

No

e out adaptor

and test at adaptor

output is it 19V – 19.5V?

(Refer Figure 1)

No

Change adaptor

and test again

AC source

Yes

Yes

OK

•See DDCON

BB board

Adaptor

11

Troubleshooting

Change BB

Yes

NG

NG condition & change

board

3-2-1. DD Con

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

Start

Check voltage at JL6003

is it 3.3V?

Yes

Check voltage at JL6000

is it 1.2V?

Yes

Check voltage at JL6002

Is it 1.5V?

No

No

DDCON

OK

Check F6001

& F6002

board

Change BB

board

NGNo

Fuse

DDCON

OK

Check voltage at JL6012.

Is it 12V?

No

Check F6003.

Is it ok.

Check voltage at JL6005

is it 5V?

No

Yes

Fuse

Change BB

board

After checking, take note of

BB

12

Troubleshooting

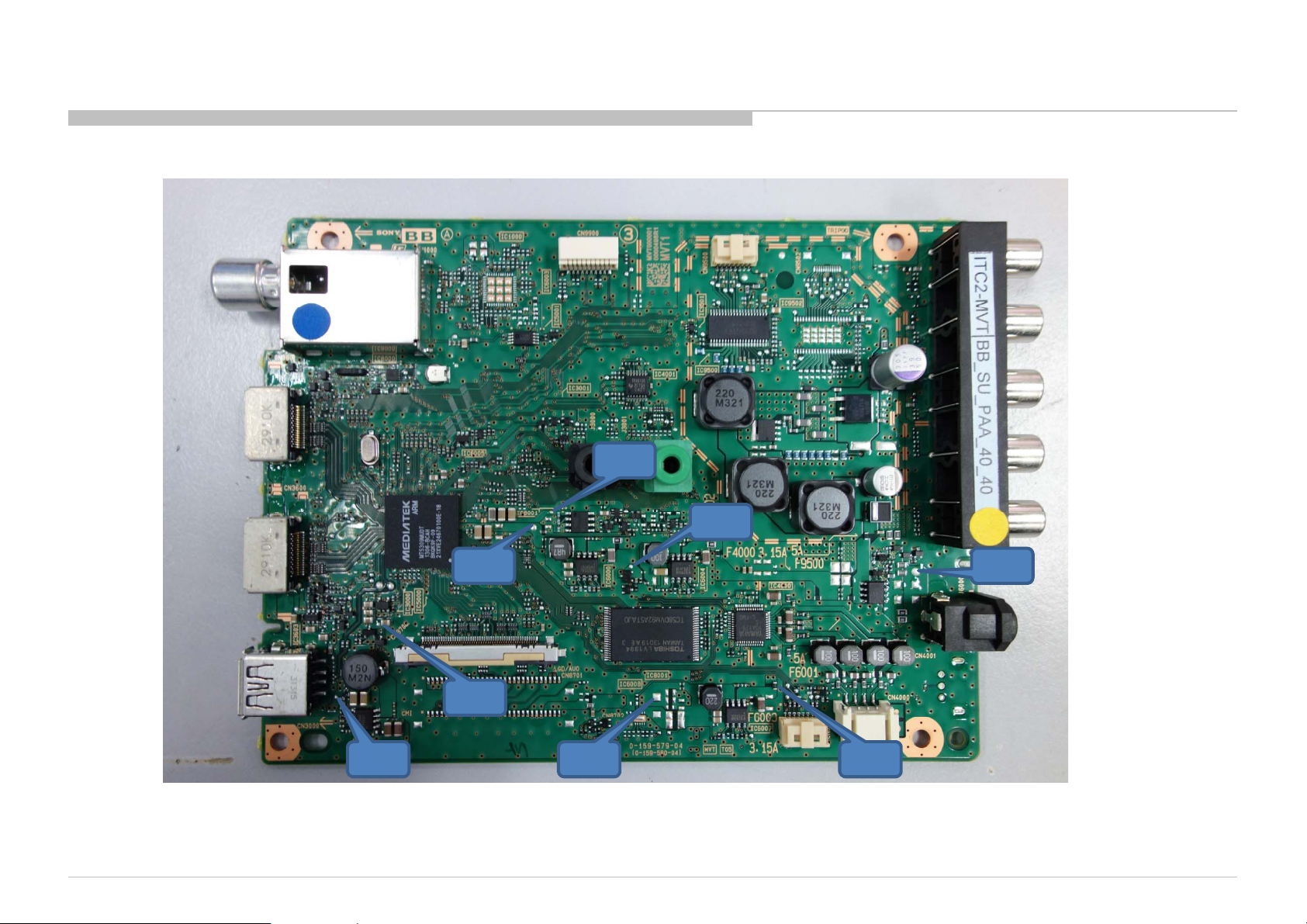

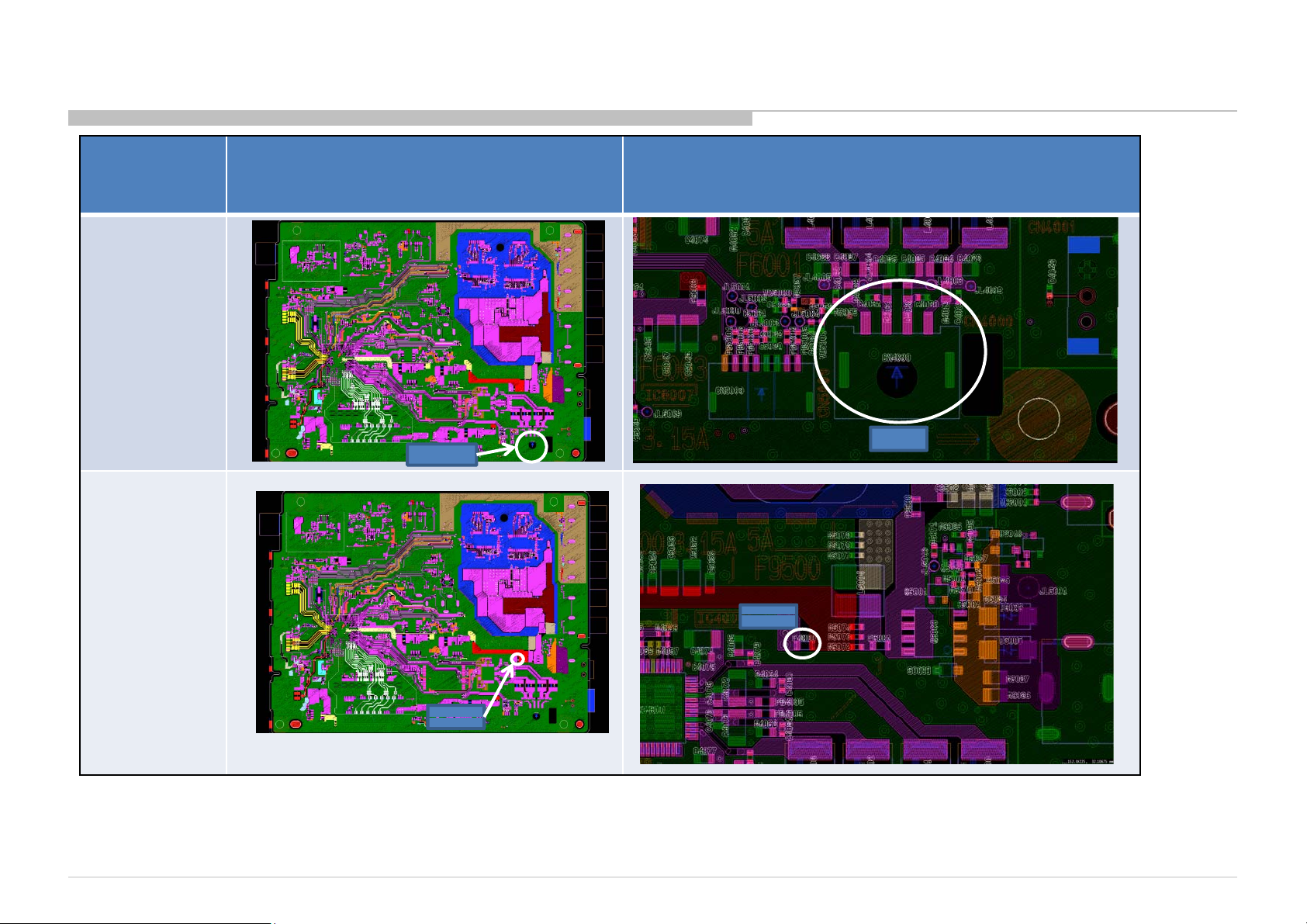

Troubleshooting References (BB Board)

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

JL6002

JL6003

JL6000

JL6006

JL6005 JL6006 F6003

JL6001

13

Troubleshooting

3-3

Standby LED Blinking

board

.

3-3-1. 2-times Blinking

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

2 times Blinking

Figure 1: How to test DC voltage

at adaptor output

Check DC voltage at

JL6001

Is it 18V - 19.5V?

No

Take out adaptor

and test at adaptor

output is it 18V – 19.5V?

(Refer Figure 1)

No

Change

adaptor

Yes

Yes

Change BB

Change BB

board

14

Troubleshooting

3-3

Standby LED Blinking

S

Change

.

3-3-2. 3-times Blinking

3x blinking

at CN4000 & perform

3x blinking

START

Remove

peaker Connector

AC OFF - ON

No

3x blinking

Check Speaker harness

and Speaker impedance

No connectivity for

speaker harness

Speaker

Harness

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

Speaker impedance

≠ 6~8 Ω

Change

Speaker

F4000 broken

No connectivity

of F4000

Check connectivity

3x blinking

& F4000 OK

Audio IC problem,

IC4000 damage

Change BB

3x blinking

of F4000.

board

DONE

Connect back

Speaker Connector to CN4000

& perform AC OFF - ON

No 3x blinking

15

Troubleshooting

Troubleshooting References (BB Board)

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

JL6012

F4000

IC4000

CN4000

16

Troubleshooting

F4000

F4000

F4000

Troubleshooting References

BoardName Board PWB(Aside) Detail

BB

CN4000

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

CN4000

CN4000

17

Troubleshooting

3-3

Standby LED Blinking

N

.

3-3-3. 4-times Blinking

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

No 12V

Check F6003.

Is it ok?

Yes

Check JL6009.

Is it 3.3V?

Yes

Check JL6012.

Is it 12V?

Yes

LVDS

No

Fuse

No

BB board

o

DDCON

18

Troubleshooting

JL6009

Troubleshooting References (BB Board)

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

LVDS FFC

CONNECTOR

JL6012

F6003

19

Troubleshooting

3-3

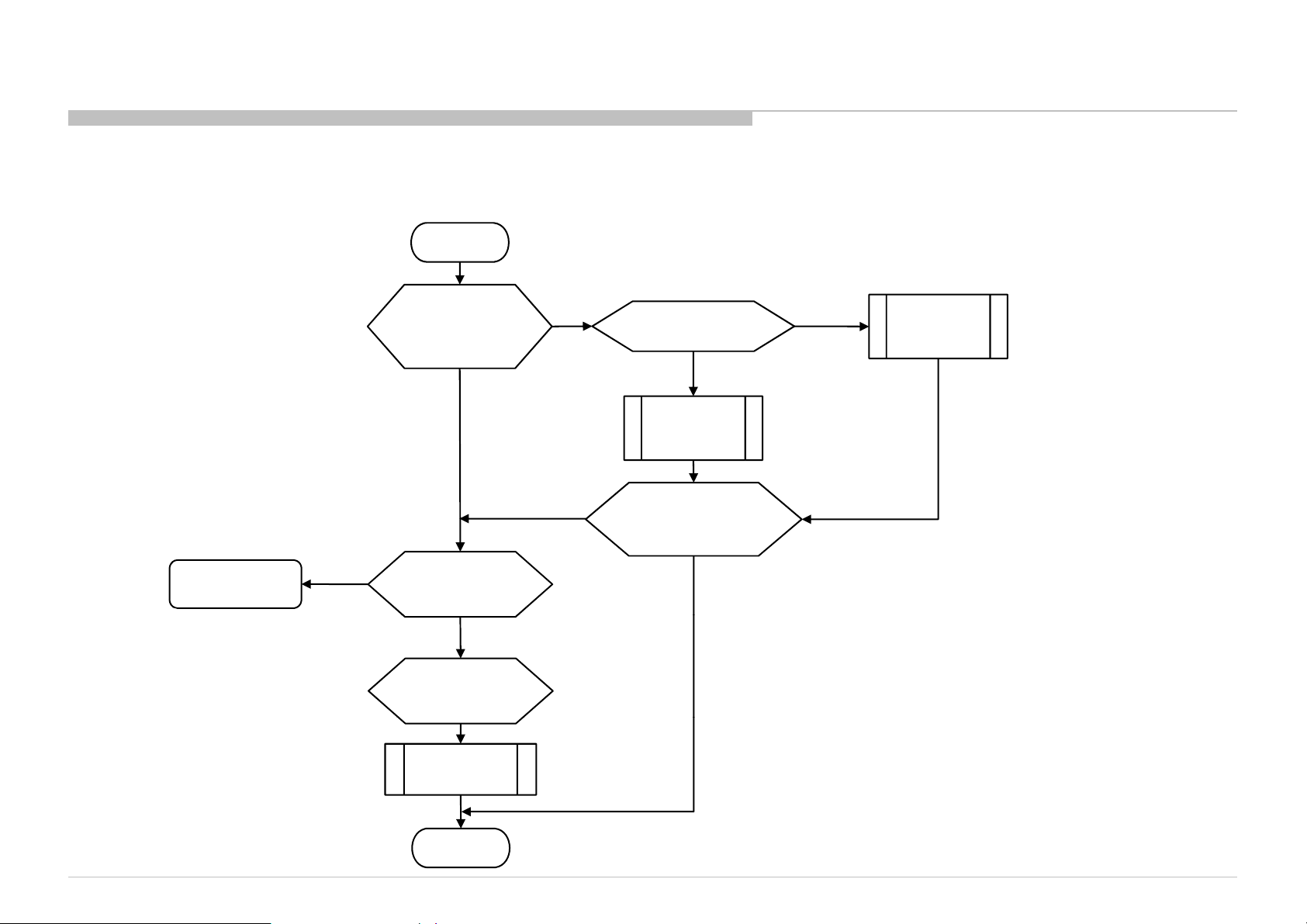

Standby LED Blinking

Remove and reinsert LVDS Flat

TV Boot Up

TV Boot Up

.

3-3-4. 5-times Blinking

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

START

Remove and reinsert LVDS Flat

Flexible Cable (FFC) at

BB Board and

Panel

5x Blinking is Still

Observed

Replace LVDS Flat

Flexible Cable (FFC)

5x Blinking is Still Observed

TV Boot Up

Normally

Normally

Incorrect FFC

Insertion

LVDS

Cable Issue

Replace B-Board

5x Blinking is Still Observed

** Replace

O-Cell or Panel Module

END

TV Boot Up

Normally

Normally

BB Board Issue

O-Cell Issue

** Not recommended at Service Side.

20

Troubleshooting

Troubleshooting References (BB Board)

ITC2 CHASSIS

R402/ R407/ R422/ R435/ R452/ R457/ R472/ R488

LVDS FFC

CONNECTOR

JL6007

21

Loading...

Loading...