Sony HVRDR-60 Service manual

HVR-DR60

SERVICE MANUAL

Ver 1.2 2008.02

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Revised-1

Replace the previously issued

SERVICE MANUAL 9-852-146-11

with this Manual.

US Model

Canadian Model

AEP Model

Chinese Model

Japanese Model

Link

Link

SPECIFICATIONS

SERVICE NOTE

DISASSEMBLY

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety .

Replace only with part number specified.

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAM

SCHEMATIC DIAGRAMS

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

PRINTED WIRING BOARDS

REPAIR PARTS LIST

ADJUSTMENT

HVR-DR60

Sony EMCS Co.

HARD DISK RECORDING UNIT

2008B0800-1

© 2008.02

Published by Kohda TEC9-852-146-12

SPECIFICATIONS

System

File system FAT32

Hard disk 60 GB

The capacity is the value when 1 GB equals 1 billion bytes.

The actual usable capacity may be slightly less because administrative files etc. are included.

File format HDV recording MPEG-2TS (.m2t)

DVCAM/DV recording AVI-Type1 (.AVI)

RAW DV (.DV)

Input signal HDV recording/playback Video: MPEG-2TS

Audio: MPEG1 Audio Layer2 Stereo

DVCAM/DV recording/playback Video: DV embedded

Audio: PCM digital (12/16 bit, 32k, 48k)

Recording/playback time Approx. 270 minutes

General

Power requirement DC 7.2 V (battery pack)

DC 8.4 V (AC adaptor)

Power consumption 2.7 W

Operating temperature 0 °C to 40 °C (32 °F to 104 °F)

Storage temperature –20 °C to +60 °C (–4 °F to +140 °F)

Operating humidity 20 % (20 °C) to 90 % (35 °C) (no condensation)

Operating altitude Maximum 3,000 m (9,843 feet)

Dimensions Approx. 81 × 45 × 100 mm (w × h × d) (3 1/4 × 1 3/4 × 4 in.)

Mass Approx. 230 g (8 oz.)

Input/output jack i.LINK (IEEE1394 6-pin connector S400)

Included items i.LINK cable (6-pin – 4-pin) 70 cm (1)

Operating instructions (1)

Guide to supported models and their functions (1)

CD-ROM manual (1)

Shoe adaptor (1)

Optional accessories AC adaptor/charger AC-VQ1050B

Battery pack NP-F570/F770/F970

ENGLISH JAPANESE

ENGLISH JAPANESE

Design and specifications are subject to change without notice.

HVR-DR60

— 2 —

概略仕様

システム

ファイルシステム FAT32

ハードディスク 60GB

ファイルフォーマット

対応入力信号 HDV記録再生時 ビデオ: MPEG-2TS

録画/再生時間 約 270分

電源部、その他

電源電圧 バッテリー端子入力7.2V

消費電力 2.7 W

動作温度 0 °C~40 °C

保存温度

動作湿度

動作高度 海抜 3,000 m以下

外形寸法 約

本体質量 約 230 g

入力端子 i.LINK (IEEE1394 6 ピンコネクター s400)

付属品 i.LINKケーブル (6ピン –4ピン ) 約 70 cm (1)

別売アクセサリー ACアダプター /チャージャー AC-VQ1050B

本機の仕様および外観は、改良のため予告なく変更することがありますが、ご了承ください。

容量は、 1GBを 10億バイトで計算した場合の数値です。

また管理用ファイルなどを含むため、実際使用できる容量は若干減少する場合があります。

HDV記録時 MPEG-2TS (.m2 t)

DVCAM/DV記録時 AVI-Type1 (.AVI)

RAW DV (.DV)

オーディオ: MPEG1 Audio Layer2 Stereo

DVCAM/DV記録再生時 ビデオ: DV embedded

オーディオ: PCMデジタル (12/16 bit,32k,48k)

DC端子入力 8.4V

–20 °C~+60 °C

20 % (20 °C) ~90 (35 °C) % (結露がないこと )

81 × 45 × 100 mm (幅/高さ/奥行き )

保証書 (1)

取扱説明書 (1)

対応機種機能ガイド (1)

CD-ROMマニュアル (1)

シューアダプター (1)

バッテリーパック NP-F570/F770/F970

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-DR60

— 3 —

ENGLISH JAPANESE

ENGLISH JAPANESE

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DO TTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, sho w obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

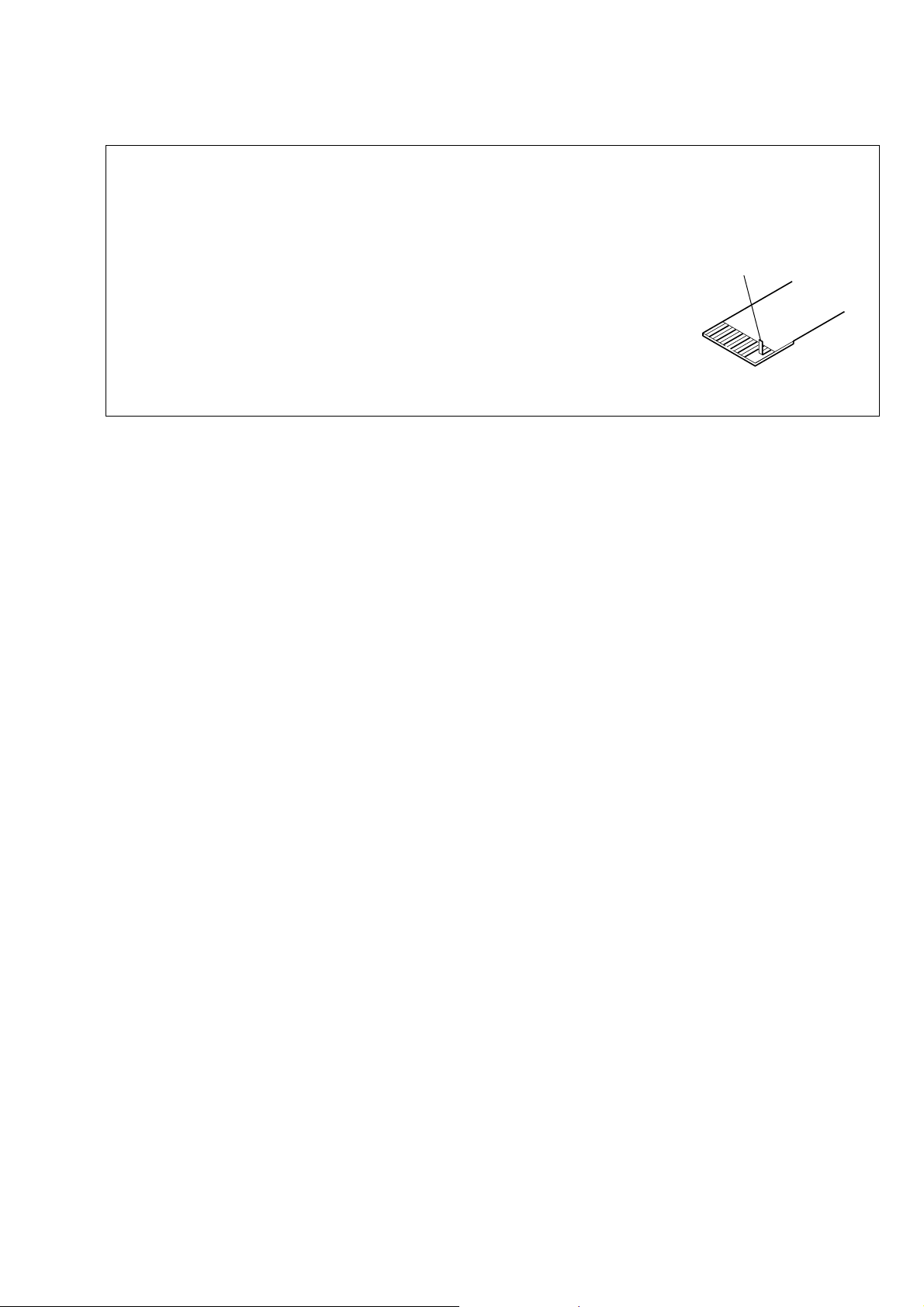

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQ UE 0 SUR LES

DIAGRAMMES SCHÉMA TIQ UES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

•Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

HVR-DR60

— 4 —

ENGLISH JAPANESE

ENGLISH JAPANESE

電池の交換は,正しく行わないと破裂する恐れがあり

注意

ます。電池を交換する場合には必ず同じ型名の電池

又は同等品と交換してください。

サービス,点検時には次のことにご注意下さい。

1. 注意事項をお守りください。

サービスのとき特に注意を要する個所については,

キャビネット,シャーシ,部品などにラベルや捺印で

注意事項を表示しています。これらの注意書き及び取

扱説明書等の注意事項を必ずお守り下さい。

2. 指定部品のご使用を

セットの部品は難燃性や耐電圧など安全上の特性を

持ったものとなっています。従って交換部品は,使用

されていたものと同じ特性の部品を使用して下さい。

特に回路図,部品表に0印で指定されている安全上重要

な部品は必ず指定のものをご使用下さい。

3. 部品の取付けや配線の引きまわしはもとどおりに

安全上,チューブやテープなどの絶縁材料を使用した

り,プリント基板から浮かして取付けた部品がありま

す。また内部配線は引きまわしやクランパによって発

熱部品や高圧部品に接近しないよう配慮されています

ので,これらは必ずもとどおりにして下さい。

4. サービス後は安全点検を

サービスのために取外したネジ,部品,配線がもとど

おりになっているか,またサービスした個所の周辺を

劣化させてしまったところがないかなどを点検し,安

全性が確保されていることを確認して下さい。

5. チップ部品交換時の注意

• 取外した部品は再使用しないで下さい。

• タンタルコンデンサのマイナス側は熱に弱いため交

換時は注意して下さい。

6. フレキシブルプリント基板の取扱いについて

• コテ先温度を270℃前後にして行って下さい。

• 同一パターンに何度もコテ先を当てないで下さい。

(3回以内)

• パターンに力が加わらないよう注意して下さい。

7. 無鉛半田について

無鉛半田を使用している基板には,無鉛(LeadFree)を

意味するレッドフリーマークがプリントされています。

(注意:基板サイズによっては,無鉛半田を使用して

いてもレッドフリーマークがプリントされて

いないものがあります)

:レッドフリーマーク

無鉛半田には,以下の特性があります。

• 融点が従来の半田よりも約40℃高い。

従来の半田こてをそのまま使用することは可能です

が,少し長めにこてを当てる必要があります。

温度調節機能のついた半田こてを使用する場合,約

350℃に設定して下さい。

注意: 半田こてを長く当てすぎると,基板のパター

ン(銅箔)がはがれてしまうことがあります

ので,注意して下さい。

• 粘性が強い

従来の半田よりも粘性が強いため,IC端子などが半田

ブリッジしないように注意して下さい。

• 従来の半田と混ぜて使用可能

無鉛半田には無鉛半田を追加するのが最適ですが,

従来の半田を追加しても構いません。

HVR-DR60

— 5 —

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-1. Service Note ···································································1-1

1-2. Description on Self-diagnosis Display ···························1-2

2. DISASSEMBLY

2-1. Disassembly ···································································2-2

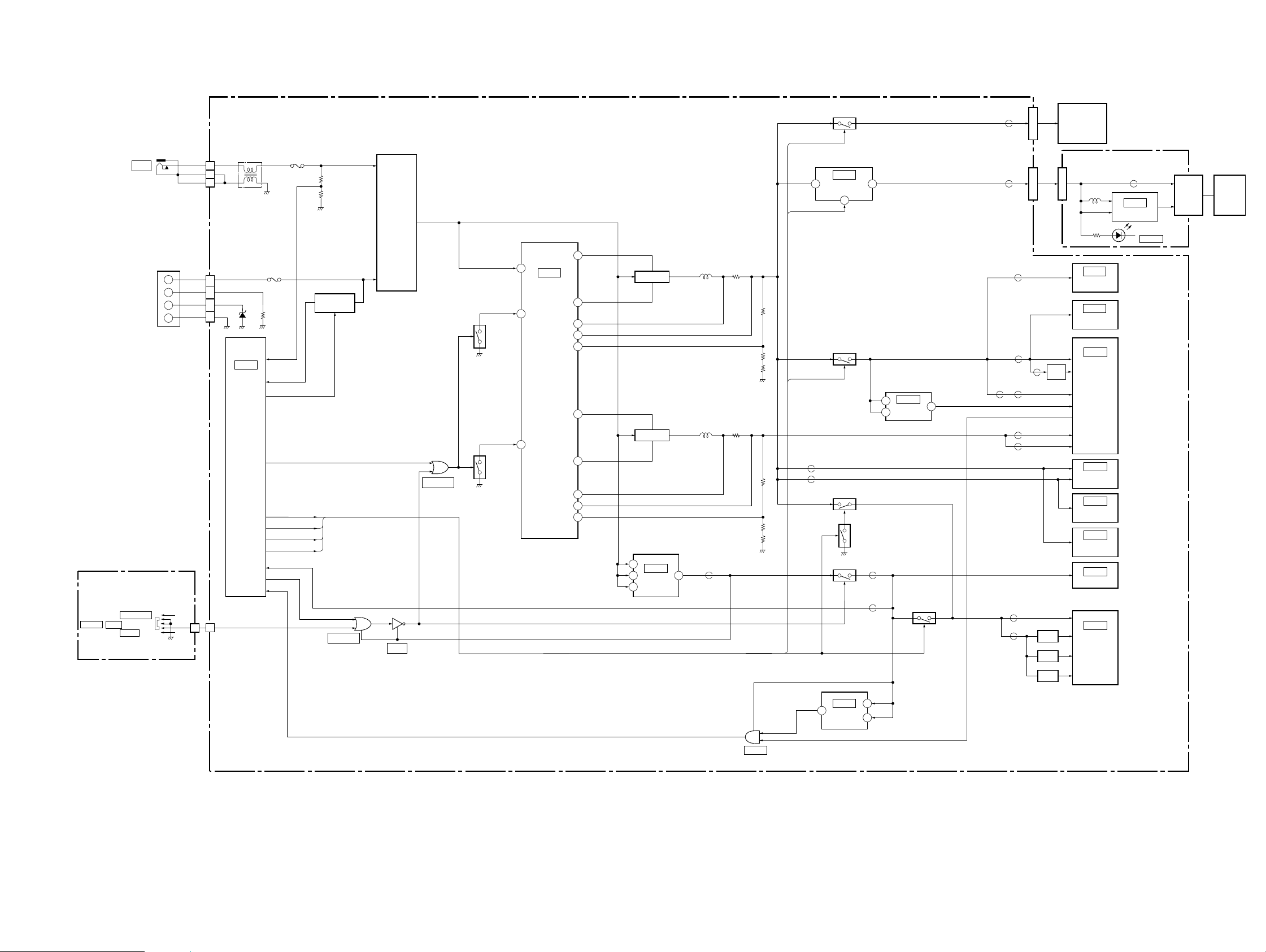

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/2) ·········································3-1

3-2. Overall Block Diagram (2/2) ·········································3-2

3-3. Power Block Diagram ····················································3-3

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram ·············································4-1

4-2. Schematic Diagrams·······················································4-3

4-3. Printed Wiring Boards ··················································4-13

4-4. Mounted Parts Location ···············································4-20

5. REPAIR PARTS LIST

5-1. Exploded Views······························································5-2

5-2. Electrical Parts List ························································5-6

6. ADJUSTMENT

6-1. Adjustment Items Required at Replacement

of Main Parts and Boards ···············································6-1

6-2. List of Service Tools ······················································6-2

6-3. Installation of Driver ······················································6-3

6-4. HDD Check ····································································6-7

6-5. HDD AVC Mode Recording Check ·····························6-10

6-6. Confirmation of HDV AVC Mode Playback ················6-10

6-7. Confirmation of DV SBP Mode Playback ···················6-10

6-8. Key Check ····································································6-11

6-9. LCD Indication Check ·················································6-11

6-10. Battery Check·······························································6-11

6-11. G-sensor Check ····························································6-12

6-12. HDD Format (File Erasure) ·········································6-12

6-13. History Clear ································································6-13

HVR-DR60

— 6 —

1. SERVICE NOTE

1-1. SERVICE NOTE

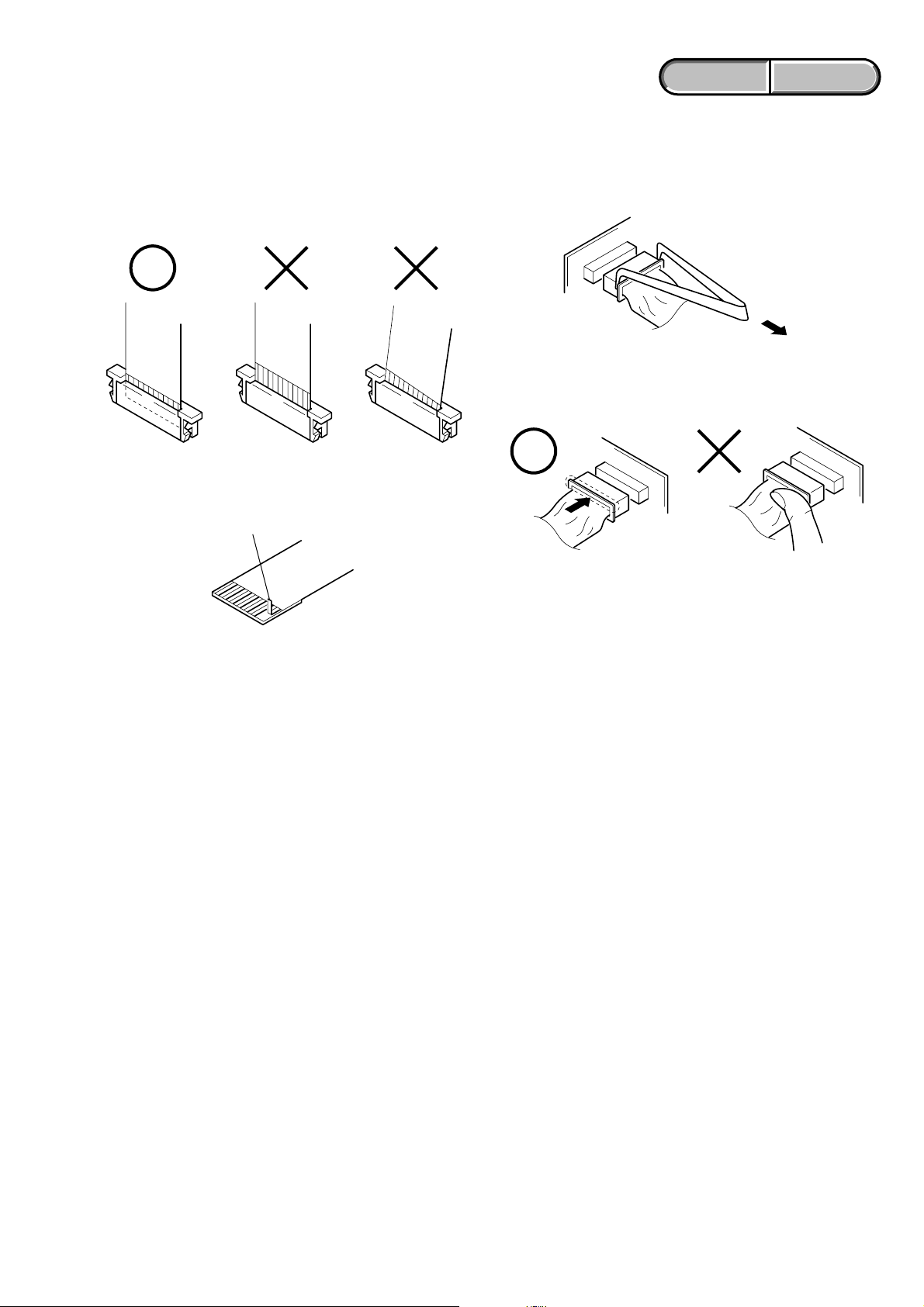

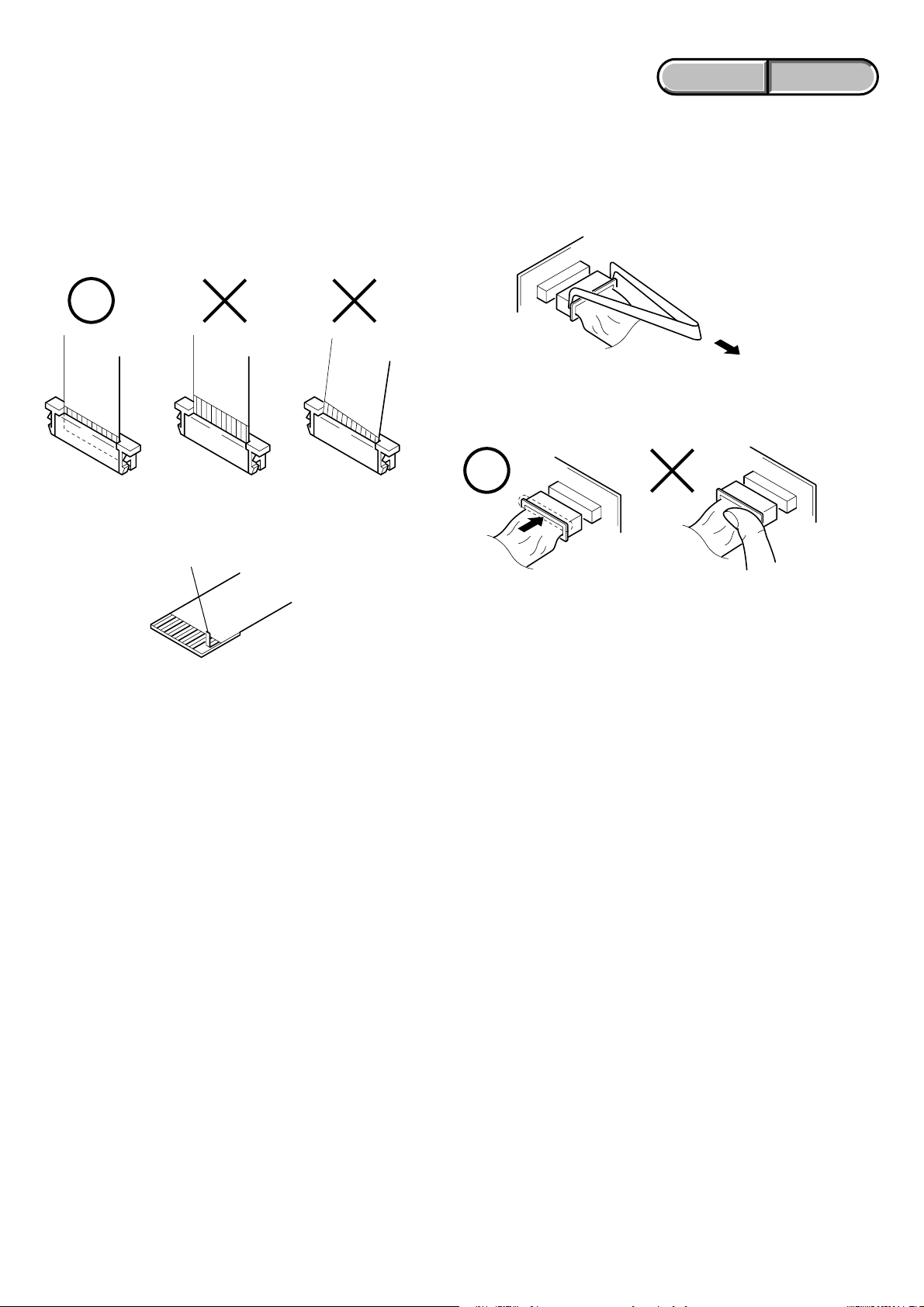

1. NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

ENGLISH JAPANESE

ENGLISH JAPANESE

When remove a connector, don’t pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don’t press do wn at wire of connector .

Be in danger of the snapping of a wire.

2. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V),

the power is shut off so that the unit cannot operate.

This following method are available to prevent this.Take note of which to use during repairs.

Method 1.

Use the AC power adaptor.

HVR-DR60

1-1

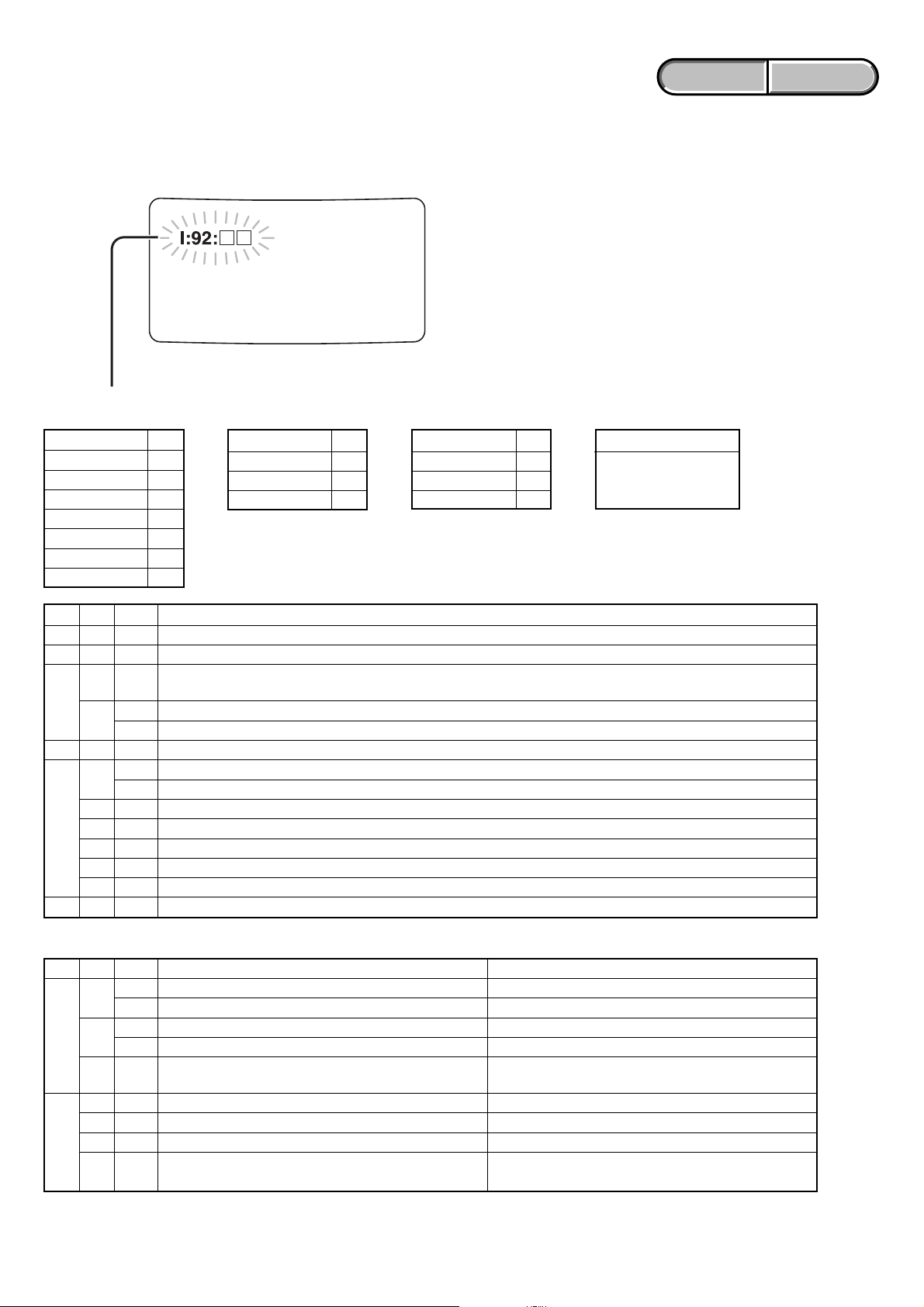

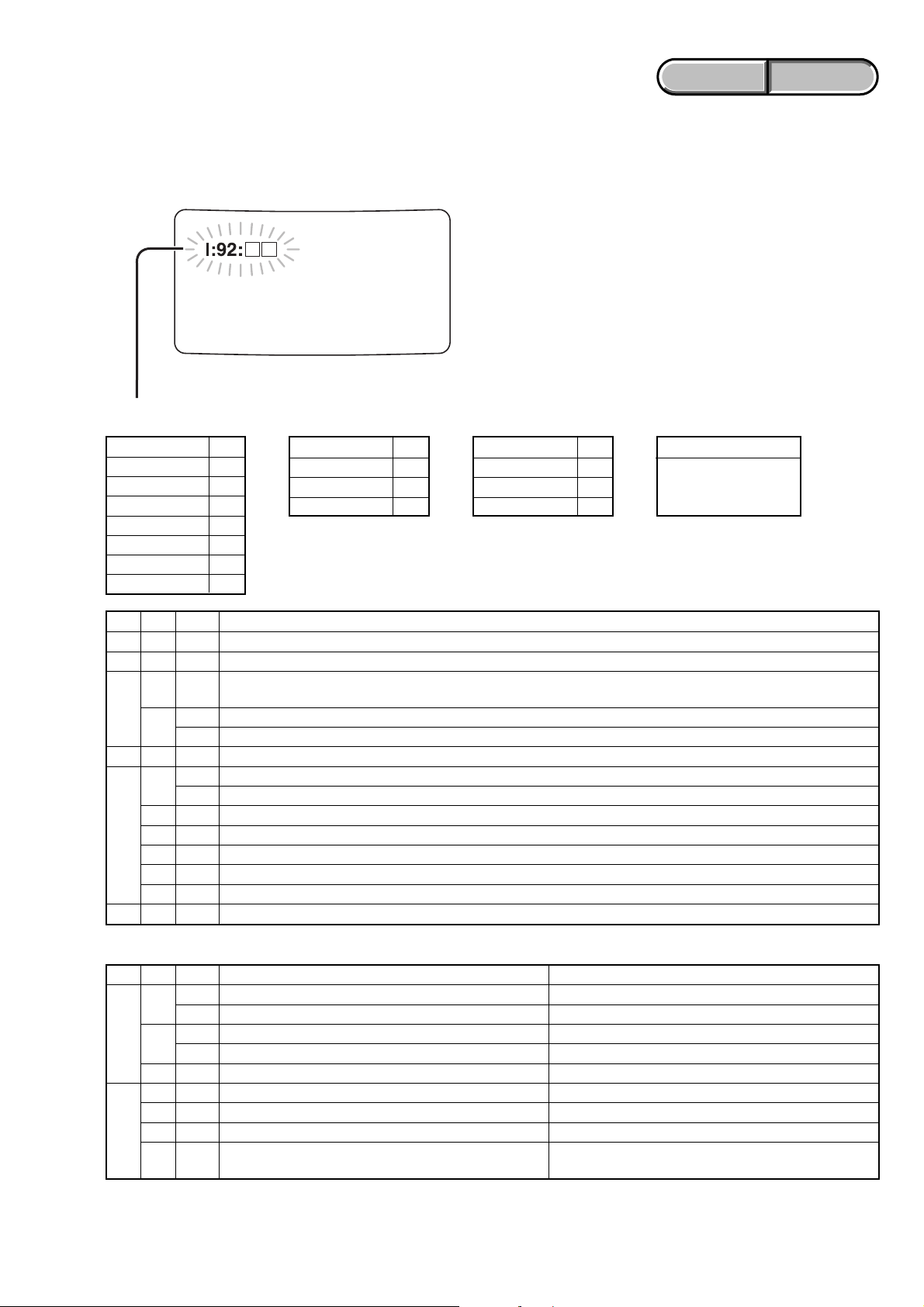

1-2. DESCRIPTION ON SELF-DIAGNOSIS DISPLAY

When an error occurs the following warning indicators may appear on the LCD screen.

And this unit is sent error code to camera.

Self-diagnosis display : X:Yy:ZZ

ENGLISH JAPANESE

ENGLISH JAPANESE

X

i.LINK I:

ATA A:

Power Supply P:

Button K:

MPEG/AVI M:

Other X:

Fatal Error F:

XYyZZDescription

I12ZZReturnable i.LINK-related error (The code that is corresponded to ZZ, is representative for status of i.LINK..)

A12ZZReturnable HDD-related error (The code that is corresponded to ZZ, is representative for error of ATA..)

12 ZZ

P

21

M12ZZStream processor abnormally (ZZ is given value. Such as, when AVI format is differed, ZZ becomes 01 etc.)

11

12 ZZ In case that error has been detected into file system etc.

F21ZZIn case that cannot communicates to Sub controller

22 ZZ In case that cannot controls the others device from Sub controller

91 ZZ Others, fatal error related with hardware

92 ZZ Others, fatal error related with software

X99ZZIn case that for DV SIGNAL PROCESSOR (IC501), error code etc. of firmware is to displaying.

Error is occurred when the power supply -related command is sent from Main controller to Sub controller. (ZZ is

given value)

01 In case that error has been occurred with power supply controller of each device using by Sub controller.

02 Cannot enter into sleep mode

01 HDD failure

02 i.LINK error

Y

Main 1y

Sub 2y

Other 9y

y

Physical Y1

Logical Y2

Other Y9

ZZ

When error is defined

in the devise, the error

code of it is displayed.

Principal Eroor Code

XYyZZ Countermeasure Description

01 Turn the unit back on again. Overflow of receiving buffer.

12

02 Turn the unit back on again. FAT error.

A90

F2001Turn the unit back on again. Unit failed PHY (Physical Layer) reset.

01 Store the unit at room temperature for a little Caution the unit to low temperature.

11 Store the unit at room temperature for a little Caution the unit to high temperature.

91 01

11 01 Turn the unit back on again. HDD has failed, or communication error between HDD.

12 01 Format the HDD HDD format error.

29 00

Turn the unit back on again. Detect the communication error with selecting the

There is partucularly no solution. (In this case, No writing into the sub controller firmware.

perform the firmware updates automatically.)

HVR-DR60

1-2

computer mode.

ENGLISH JAPANESE

ENGLISH JAPANESE

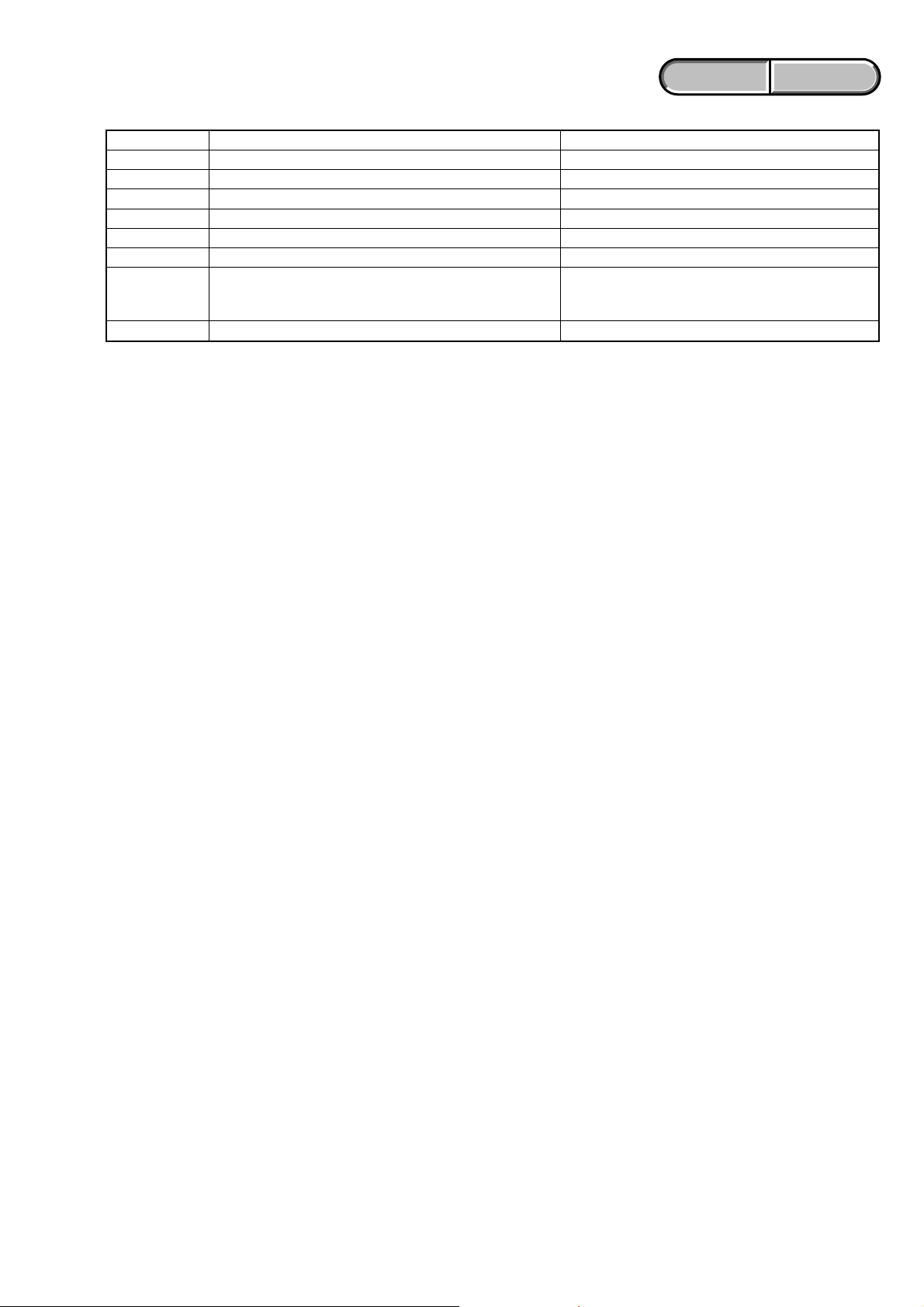

Following is error code that has been described to instructoin manual.

Display Code Countermeasure Cause

A:11:ss Turn this unit off and then back on. Cannot read or write to the HDD.

A:19:ss Turn this unit off and then back on. Internal error has occurred.

I:11:ss Turn this unit off and then back on. i.LINK communication error has occurred.

I:92:ss Turn this unit off and then back on. Internal error has occurred.

M:11:ss Turn this unit off and then back on. The recorded image cannot be manipulated.

X:ss:ss Turn this unit off and then back on. Internal error has occurred.

F:12:ss Format this unit by selecting DELETE and then FORMAT. There is a conflict in the HDD logic structure.

If you still cannot operate the unit, contact Sony Customer

Service.

F:29:ss Contact Sony Customer Service. There is an internal malfunction.

HVR-DR60

1-3

1. SERVICE NOTE

1-1. サービスノート

1. 修理時の注意

本フラットケーブルおよびフレキシブル基板の端子面に欠

け,折れ等がないことを確認する。

また,コネクタへの接続は,差し込み不足や斜め差しになら

ないように注意する。

ENGLISH JAPANESE

ENGLISH JAPANESE

コネクタを取り外す時に,線材部(極細)を持って引っ張る

と断線する恐れがありますので,絶対に線材部(極細)を

持って引っ張れないで下さい。

線材部(極細)を押さえながらコネクタを差し込むと,線材

部(極細)が断線する恐れがありますので,絶対に線材部

(極細)には負担をかけないで下さい。

先端の剥がれたメッキ部はカットして除去する。

(メッキ破片がコネクタ内に残っている場合もあるので注意)

2. 修理/調整時の電源供給について

本機では,安定化電源(8.4Vdc)からバッテリー端子に電源を供給した場合,約1 0 秒後にシャットオフし,動作しなくなりま

す。

これを避けるため,下記のいずれかの方法を用いてください。

方法1:

ACアダプタを使用する。

HVR-DR60

1-4

ENGLISH JAPANESE

ENGLISH JAPANESE

1-2. 自己診断表示について

エラーが発生した場合は,エラー内容に合わせて液晶表示画面にエラーコードが表示されます。

また,カメラ側にエラーコードが送信されます。

自己診断表示:X:Yy:ZZ

X

i.LINK I:

ATA A:

電源 P:

ボタン K:

MPEG/AVI M:

Other X:

致命的なエラー

XYyZZ エラー内容

I12ZZ復帰可能なi.LINK関連のエラー(ZZにあたる部分のコードは、i.LINKのステータスを返す)。

A12ZZ復帰可能なHDD関連エラー(ZZにあたる部分のコードは、ATAのエラーを返す)。

12 ZZ

21

M12ZZ

11

12 ZZ ファイルシステム等のエラー。

F21ZZSubコントローラーと通信できないとき。

22 ZZ Subコントローラーから他のデバイスを制御できないとき。

91 ZZ その他ハード関連の致命的なエラー。

92 ZZ その他ソフト関連の致命的エラー。

X99ZZDVSIGNALPROCESSOR(IC501)のファームウェアのエラーコード等を表示させたいとき。

F:

MainコントローラーからSubコントローラーに電源関連の命令を送信時に発生したエラー(ZZは任意

の値)。

01 Subコントローラーから各デバイスの電源制御時に発生したエラー。

02 スリープモードに入れなかったとき。

ストリームプロセッサ-のエラー(ZZは任意の値。例えば、AVIのフォーマットが違うときは01等。)。

01 HDD故障。HDD故障。

02 i.LINKエラー。

Y

Main 1y

Sub 2y

Other 9y

y

Physical Y1

Logical Y2

Other Y9

ZZ

デバイスにエラーの

規定があれば,その

コードを表示する。

主なエラーコード

XYyZZ 対処方法 原因

01 電源を再投入する。 受信バッファのオーバーフロー。

12

02 電源を再投入する。 FATの異常。

A

F2001電源を再投入する。 PHYのリセット失敗。

01 しばらく常温で保管する。 低温警告。

90

11 しばらく常温で保管する。 高温警告。

91 01 電源を再投入する。 コンピューターとの通信モード時にダウン検出。

11 01 電源を再投入する。 HDD故障,HDD間通信異常。

12 01 HDDのフォーマットを行う。 HDDフォーマットエラー。

29 00

特になし(ファームウェアの自動アップデートが Subコントローラーのファームウェアが書きこま

行われる)。 れていない。

HVR-DR60

1-5

ENGLISH JAPANESE

ENGLISH JAPANESE

下記は取扱説明書に記載されているエラーコードです。

表示コード 対処方法 原因

A:11:ss 本機の電源を切り,再度電源を入れなおしてください。HDDへの読み込み,または書き込みができません

でした。

A:19:ss 本機の電源を切り,再度電源を入れなおしてください。内部エラーです。

I:11:ss 本機の電源を切り,再度電源を入れなおしてください。i.LINKの通信エラーです。

I:92:ss 本機の電源を切り,再度電源を入れなおしてください。内部エラーです。

M:11:ss 本機の電源を切り,再度電源を入れなおしてください。記録動画を正しく処理できませんでした。

X:ss:ss 本機の電源を切り,再度電源を入れなおしてください。内部エラーです。

F:12:ss

F:29:ss コールセンターにお問い合わせください。 内部装置に異常があります。

メニュー設定画面で「DELETE」を選び,「FORMAT」

を選んで本機の初期化を行ってください。

初期化を行ってもだめな場合,コールセンターにお問

い合わせください。

HDD内の論理構造に矛盾を見つけました。

HVR-DR60

1-6E

NOTE FOR REPAIR

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, dont’ pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, dont’ press down at wire of connector.

It is possible that a wire is snapped.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

HVR-DR60

2-1

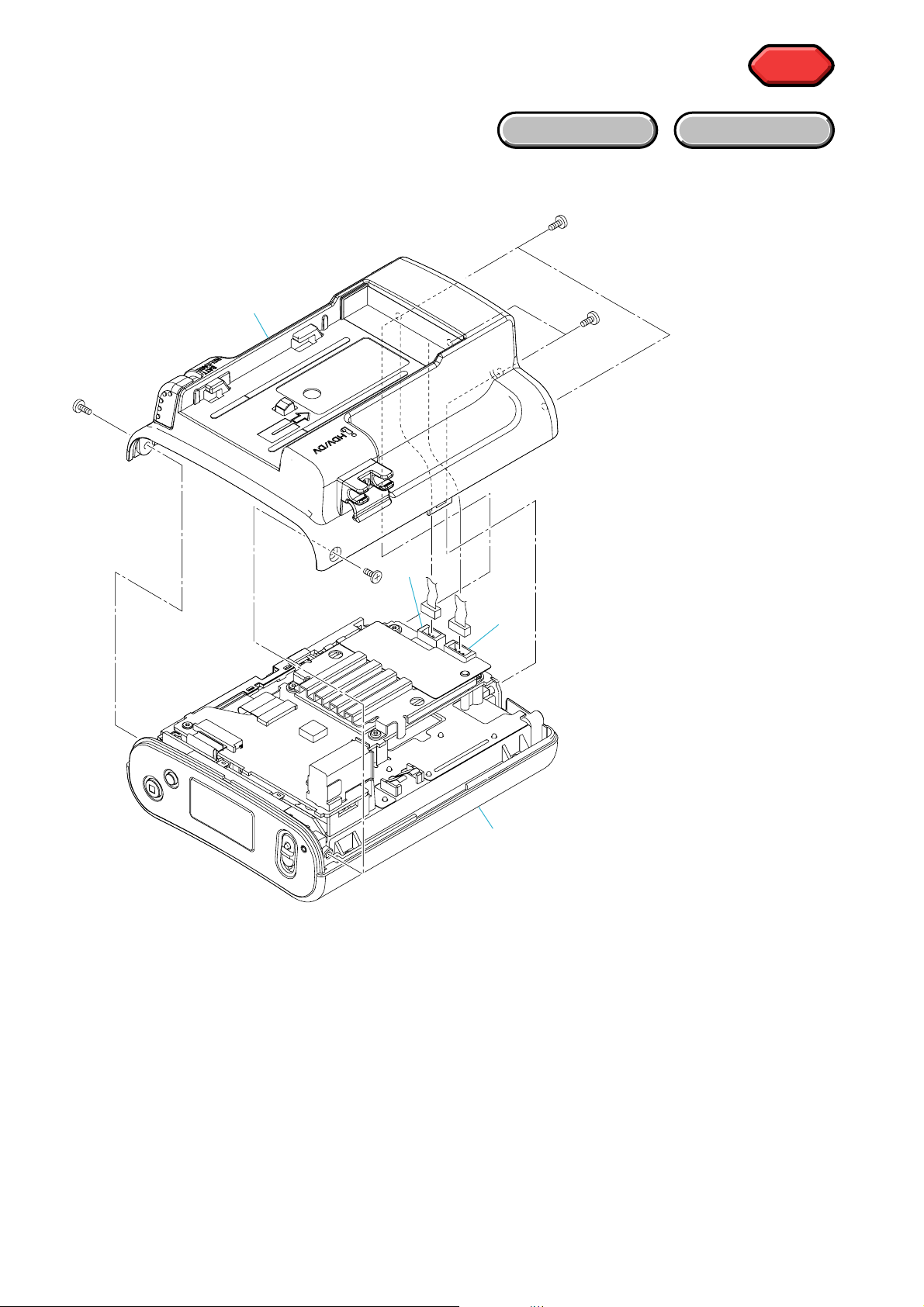

EXPLODED VIEW

HELP

HELP

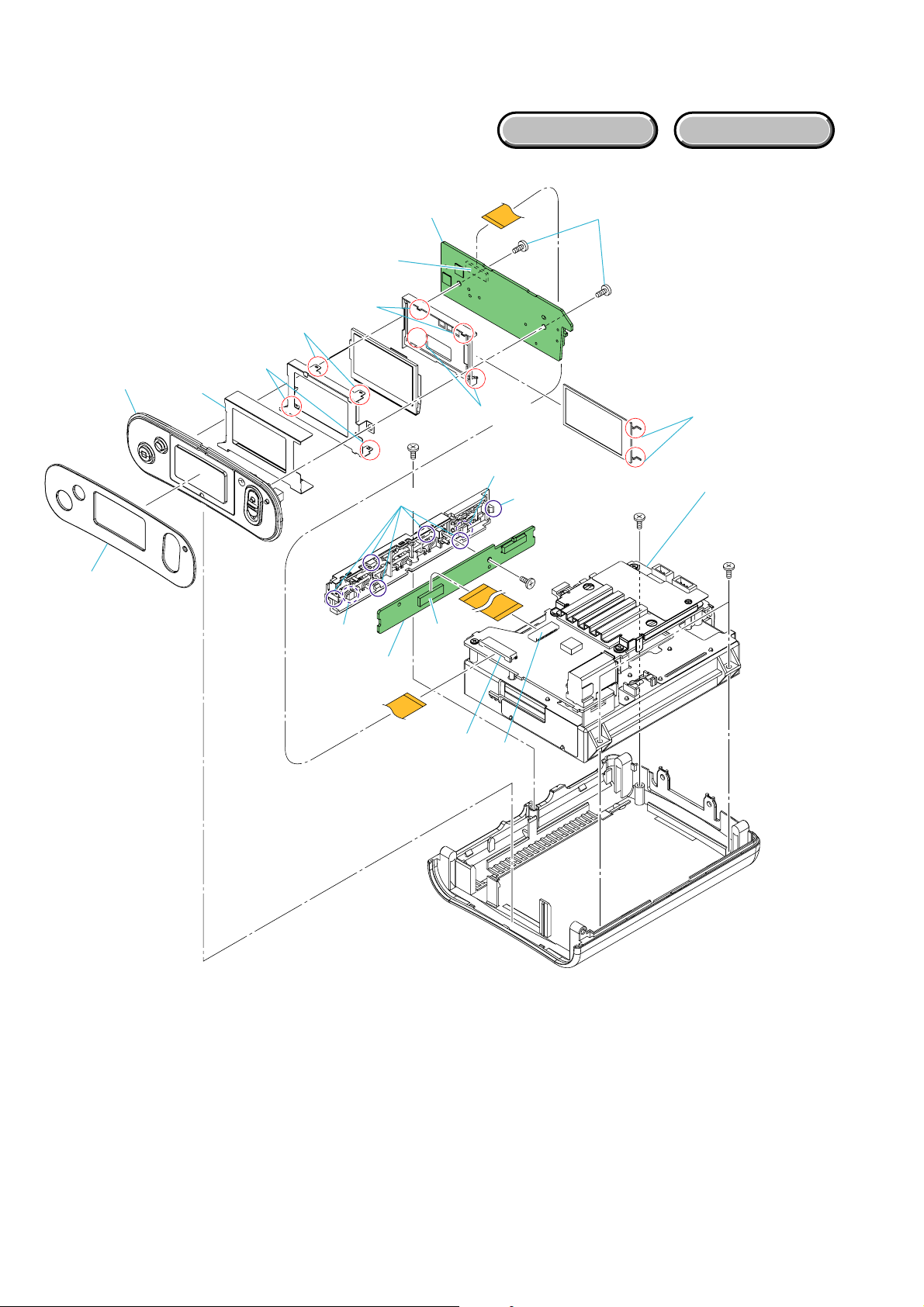

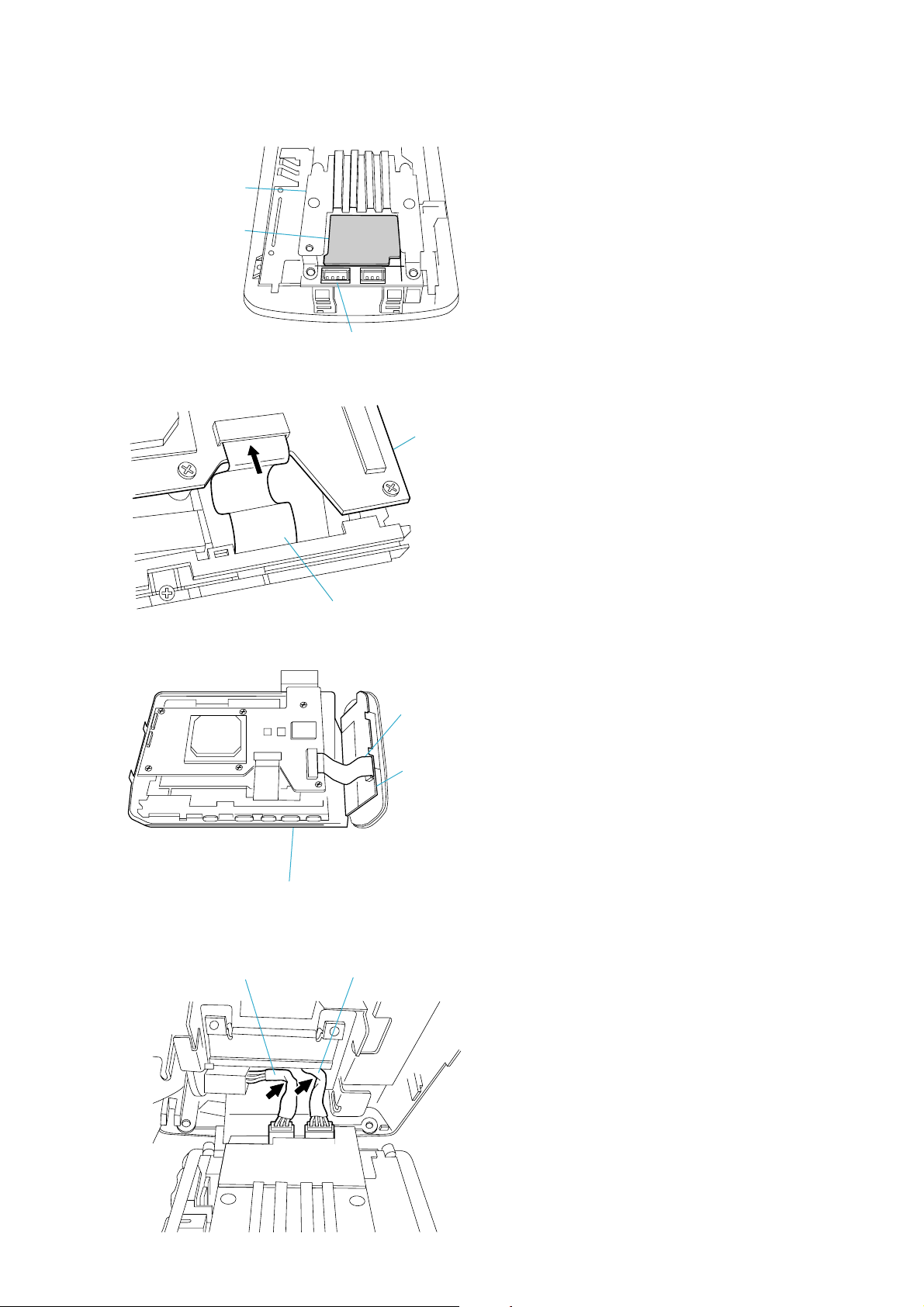

2-1. DISASSEMBLY

2-1-1. OVERALL ASSEMBLY

1

Bottom Case Block

1-1(#53)

HARDWARE LIST

1-4(#53)

1-3(#49)

1-6

1-2(#53)

1-5

HVR-DR60

2-2

2

Main Block

2-1-2. BOTTOM CASE ASSEMBLY

r

1

Bottom Case Block

1-1

EXPLODED VIEW

3-1(#49)

HARDWARE LIST

2

DC-IN Connecto

1-4(Clow)

1-6(Clow)

1-7

1-5

(#23)

1-3

(Boss)

4-1

1-2

(#53)

3-4

4

Board

3

Heatsink A

2-2

2-3

2-1(#23)

4-2

Battery Terminal

3-2(#23)

3-2(#23)

3-5

HVR-DR60

3-6

2-3

3-3

3-7

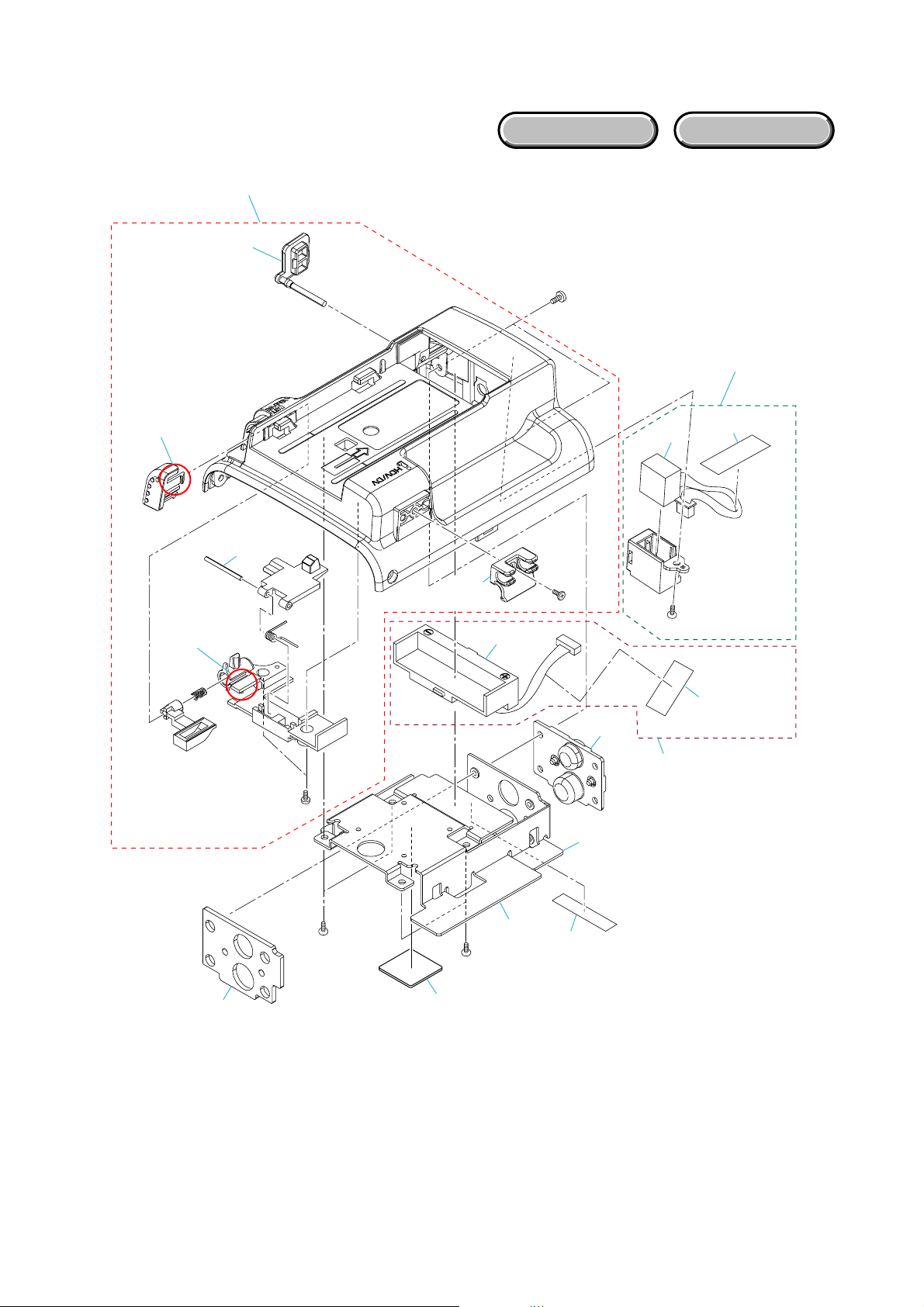

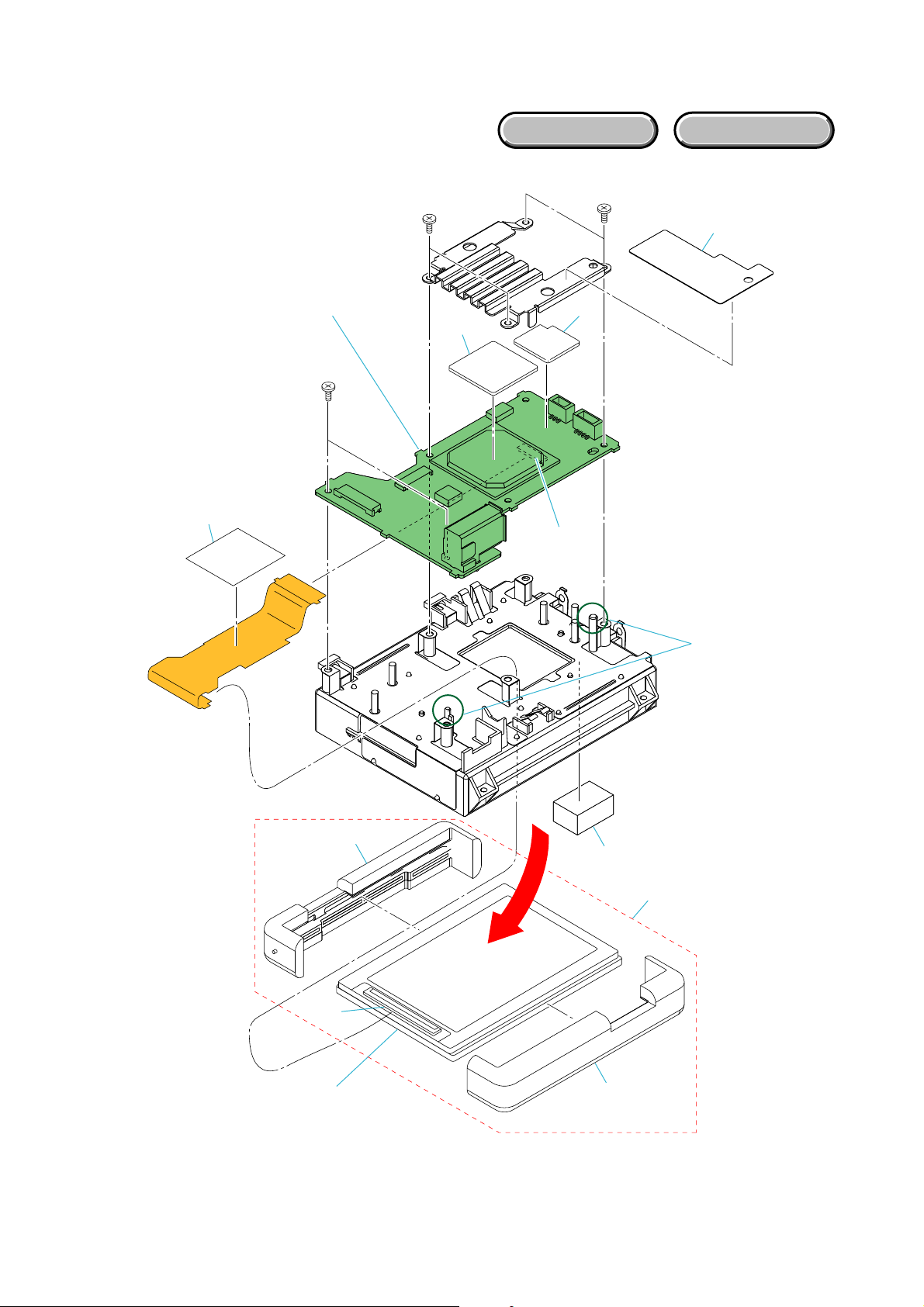

2-1-3. MAIN BLOCK

EXPLODED VIEW

k

HARDWARE LIST

1-10

1-1

1-6(Solder)

1-6(Solder)

1-5

1

LC-093 Board

1-7(Clow)

3-2(Clow)

1-3

3-1(#23)

3-4(Clow)

3-5

LC-093

1-9(Boss)

3-2(Clow)

SW-492

3-4(Clow)

3-3(#23)

1-4(#23)

2-2(#23)

1-8(Solder)

2

HDD Case Bloc

2-2 (#23)

3

SW-492

Board

1-2

2-1

HVR-DR60

2-4

2-1-4. HDD CASE BLOCK

EXPLODED VIEW

HARDWARE LIST

2-7

2

HD-035 Board

2-4(#64)

2-2(#64)

2-2(#64)

2-1

2-9

2-3

HD-035

2-6

2-5(Boss)

1-3

1-2

1

HDD

HVR-DR60

2-5E

2-8

1-1

1-4

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

1. Attach the sheet (FP-431) to the FP-431 flexible cable of PWB by referring to the figure below.

Sheet (FP-431)

Tolerance: 0 to 2 mm

Reference

Attach the sheet starting from the

portion shown by the arrows.

Wind the sheet around the FP-431

mount.

FP-431 Mount.

2. Attach the sheet (heatsink A) to the heatsink A by referring to the figure below.

Attach the slit portion of the

Heatsink A

Attach the sheet

(Heatsink A) to

standard portion.

sheet to the bent portion.

Fold back

Sheet (Heatsink A)

3. Attach the harness sheet to the battery terminal board and DC-IN connector by referring to the figure below.

Cut the harness sheet into 40 x 40 mm square to use.

Battery Terminal Board

Harness Sheet Harness Sheet

1 to 3 mm

DC-IN Connector

HVR-DR60

1 to 3 mm

HELP

4. Attach the heat conduction sheet to the heatsink A by using four holes as a guide.

Holes

Heatsink A

Holes

Heat Conduction Sheet

5. Tighten two screws fixing the HDD board to the HDD case assembly in the order of numbers shown in the figure below.

HD-035 Board

2

1

HDD Case Assy

6. Insert the tip of FP-431 Flexible Board to the connector on HDD straight and firmly.

HDD

FP-431 Flexible Board

HVR-DR60

HELP

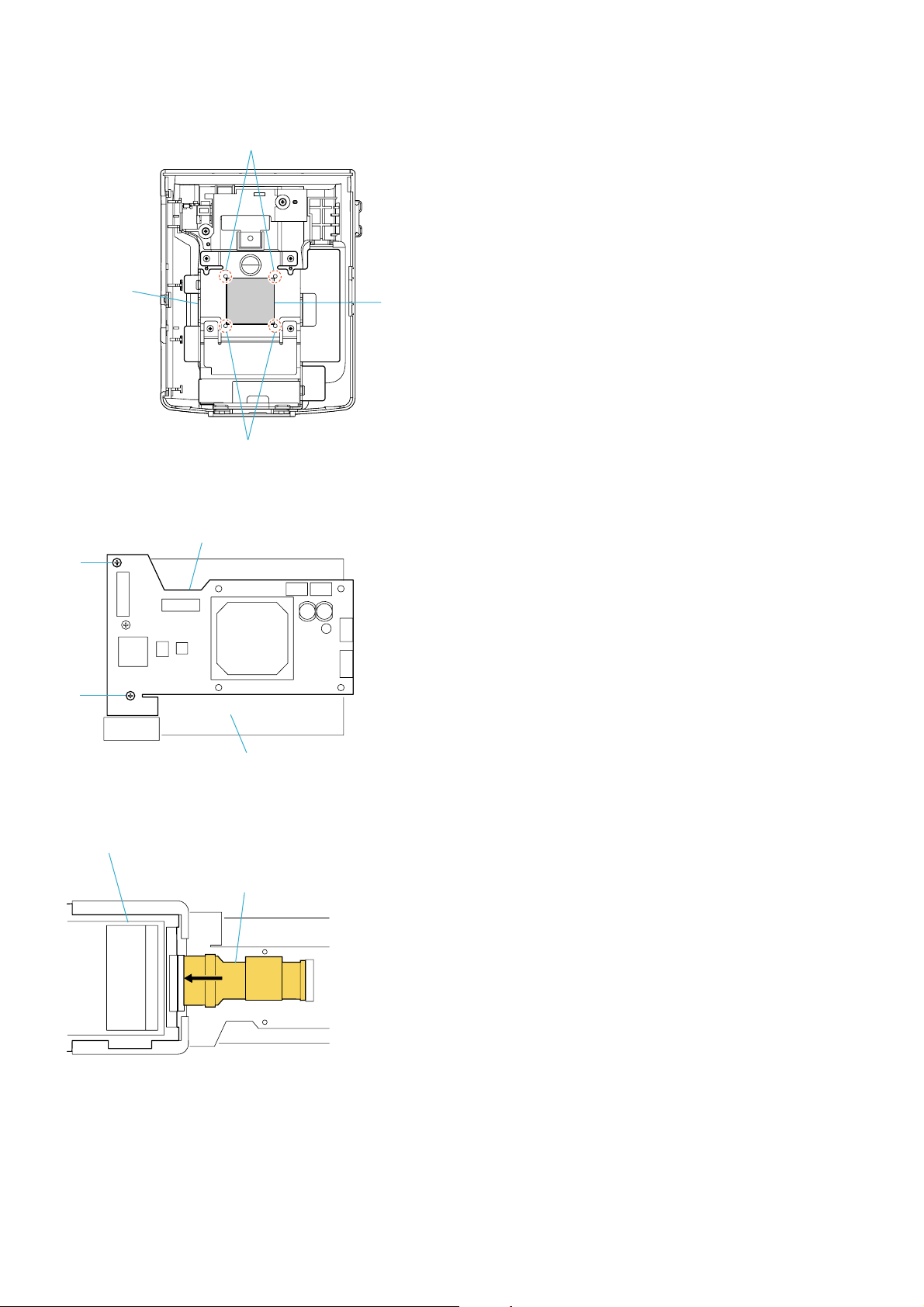

7. Attach the sheet (HD-035) sheet to the heatsink B fitting to the corner of connector.

Heatsink B

Sheet Bus (HD-035)

Connector

8. Insert the other end of FBH-002 connected to the SW-492 board to the connector on HD-035 board.

HD-035 Board

FBH-002

9. Place the FBH-002 cable connected to the LCD PWB board between the TOP CASE BLOCK ASSEMBLY and LCD PWB board.

Flexible Flat Cable (FBH-002)

LC-093 Board

Top Case Block Assy

10. Place the harnesses from the battery terminal board and DC-IN connector as shown in the figure below.

Harness of DC-IN Connector

Harness of Battery terminal board

HVR-DR60

HELP

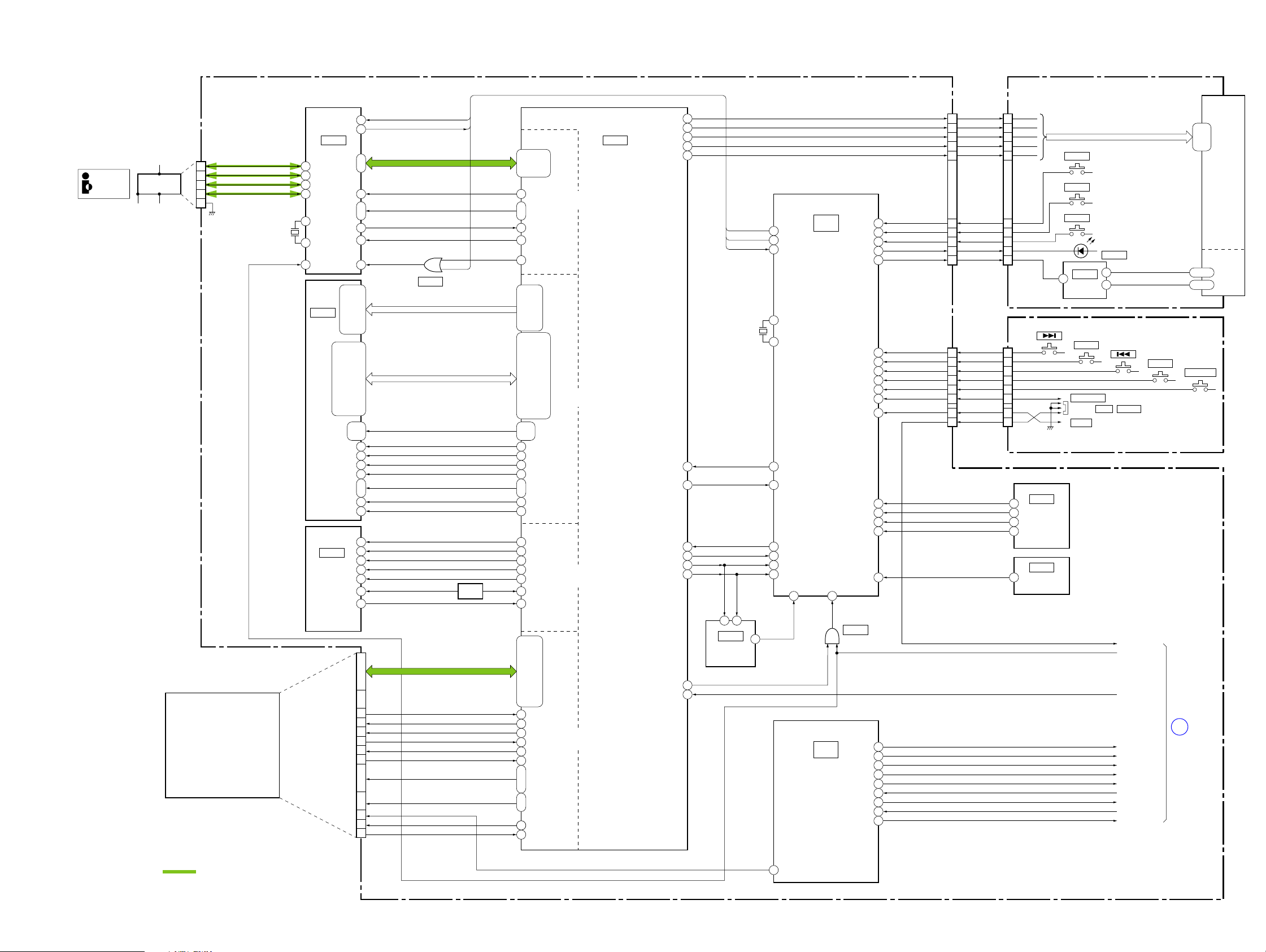

3. BLOCK DIAGRAMS

Link

Link

OVERALL BLOCK DIAGRAM (1/2) POWER BLOCK DIAGRAM

OVERALL BLOCK DIAGRAM (2/2)

HVR-DR60

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2)

HD-035 BOARD (1/2) LC-093 BOARD

34

35

36

37

59

60

53

PHY LINK

IC301

SDRAM

64M

(3/5)

MEMORY

HDV/DV

CN402

8

12

79

56

CN402

3

4

5

6

2

1.8 INCH HDD

(60GB)

TPBTPB+

TPATPA+

POR-

X401

24.576MHz

FP-431

FLEXIBLE BOARD

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

14

3

IC401

(4/5)

IC503

FLASH

(5/5)

6 - 134, 5

1

2

19

15

G7, H9, H3

G8, G9, F7, F3, G1

G2, G3, H1, H2, J3

A1, B1, R1, P1, E2, D2, C2, A2

C7, D7, M7, N7, A8, C8, D8, E8

L8, M8, N8, R8, A9, B9, P9, R9

R2, N2, M2, L2, D3, C3, N3, M3

F8, F2

K9, K1

J8 D1

J9

K7 F2

K8 G4

J7, H8

J2

J1

1

2

3

4

5

6

8

CN401

34 - 49

31

29

27

25

23

21

17, 19, 1614, 15

13

51

18

PD

CNA

LREQ

CTL0, CTL1

PCLK

LKON

LPS

4

LD0 - LD7

(IEEE 1394)

2

1

SUSPEND

IC402

(4/5)

DA0 - DA12

DDQ0 - DDQ31

DQM0 - DQM3

#CS

RAS

CAS

#WE

BA0, BA1

CLKE

CLKD

SI

SCLK

SRESET-

SCSSWE-

SD

DD0 - DD15

DMARQ

#DIOW-

#DIOR-

IORDY

#DMACK-

INTRQ

DA0 - DA2

#CS0-, #CS1-

HDD_NDASP

#RESET

#PDTAG

X503

27MHz

LPS

CLK

DV SIGNAL PROCESS

C7, A6

B7, A7

A10, A11

C11, B11

D7

C6

B12

A12

W2, W1, V2, U3, P4

D5, A3, B4, C5, A4, C8, B8, A8, D9, C10

H1, H3

E2

D2, E4 A5, B6

A17

C9

F18

E20

C19

E17

D19

L1

D20

W16, V16, T17, U20, T19

W15

V14

Y15

W14

W11

Y11

W9, Y10, V9U9, Y8

V10

M19

PHY LINK

INTERFACE

K1, J3, T2

R2, R1, P2, N2, M4

SDRAM

INTERFACE

J18, K19, R20, R19, U18, U19

A18, D16, C17, B17, A19, B19, B20, D18

C20, E18, E19, G17, G18, G19, H18, H20

G3, F1

FLASH ROM

INTERFACE

T18, V20, W17, Y17, V15

P19, N18, M18, N19, P20, T20

HDD

INTERFACE

IC501

(5/5)

E1

E3

F3

C2

B1

G1

C1

A20

C18

Y5

Y4

D3

V3

SUB_S_CNVSS

I2C_SDA

I2C_SCL

G_ALERT

SUB_TXD

SUB_RXD

56

IC202

LCD

EEPROM

(2/5)

PD

SUSPEND

CNA

X201

8MHz

7

SUB_S_RESET

LCD_RESET

LCD_CS1

LCD_A0

LCD_SDA

LCD_SCL

55

20

21

22

23

45

18

14

15

54

53

61 19

WP

IC203

(1/2)

SUB-CON

(2/5)

12

IC203

(2/2)

SUB-CON

(2/5)

CN203

15

13

11

9

7

EL_OFF

39

STOP

35

REC_ON

34

LED_ON

32

ENA

26

36

33

37

38

40

16

17

FF

PLAY

REW

REPEAT

CAM LINK

AVC_ON

SBP_ON

SW_OFF

5

4

3

2

17

CN201

22

33

44

5

6

8

9

7

CN601

#RES

15

#CS

13

A0

11 ND001

SDA

9

SCL

7

5

4

3

2

17

CN701

5

6

8

9

7

S706

S602

MENU

S601

STOP

S603

REC

3

LCD DRIVE

COMPUTER

VIDEO

IC601

S702

PLAY

D601

5

6

REC

S703

POWEROFF

S701

OUT1

OUT2

S704

REPEAT

26, 27

LND050

LND051

S705

CAM LINK

38, 39, 42

EL

SW-492 BOARD

1

2

3

62

58

4

IC212

(2/5)

AOZ

AOY

AOX

STBYB

VREF

3

4

5

10

6

SE201

G-SENSOR

(2/5)

IC213

2.5V REG

(2/5)

SW_OFF

POR-

MRESET

A

30

28

27

25

42

44

46

60

41

PWR_SUB_33

PWR_MAIN_33

PWR_HDD

PWR_LCD

PWR_P33

DCIN_AD

IB_ENABLE

BATT_AD

SLEEP

HD-035

BOARD (2/2)

(PAGE 3-2)

: VIDEO/AUDIO SIGNAL

08

HVR-DR60

31

3-1

3-2. O VERALL BLOCK DIAGRAM (2/2) ( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

HD-035 BOARD (2/2)

Q115, Q118

Q108, Q109

DC POWER

SELECT

SPWR

Q103

TG2

14

23

IC101

DC_DC

CONV.

(1/5)

13

BG2

18

12

11

9

SWTCHING

Q105

SENSE2+

SENSE2-

VOSENSE2

L101

1DC IN

1BATT IN

CN101

CN102

PLUS

BATT (+)

F101

F102

DCIN_AD

Q106, Q107

BATT

DATA

PWR_MAIN_33

PWR_HDD

Q111

Q110

MAIN M3.3V

IC110

2

RESET

4

1

GEN

(1/5)

HDD H3.3V

A

HD-035

BOARD (1/2)

(PAGE 3-1)

BATT_AD

IB_ENABLE

SLEEP

1SW_OFF

2PWR_SUB_33

IC116(2/2)

(1/5)

IC106

5

LCD POWER REG

(1/5)

TG1

26

L102

2

IC114

3.3V

5

6

REG.

(1/5)

3

Q102

28

BG1

22

30

31

1

IC116(1/2)

6SLEEP

(1/5)

5

3

IC115

(1/5)

42

7

SWTCHING

Q114

SENSE1+

SENSE1-

VOSENSE1

PWR_LCD

Q101

Q104

4

1

Q116

LCD 3.0V

Q117

1.8V

A1.8V

S3.3V

P3.3V

PWR_MAIN_33

PWR_HDD

PWR_P33

PWR_LCD

POR-

MRESET

08

HVR-DR60

3-2

PWR_P33

IC105

2

RESET

1

GEN

4

(1/5)

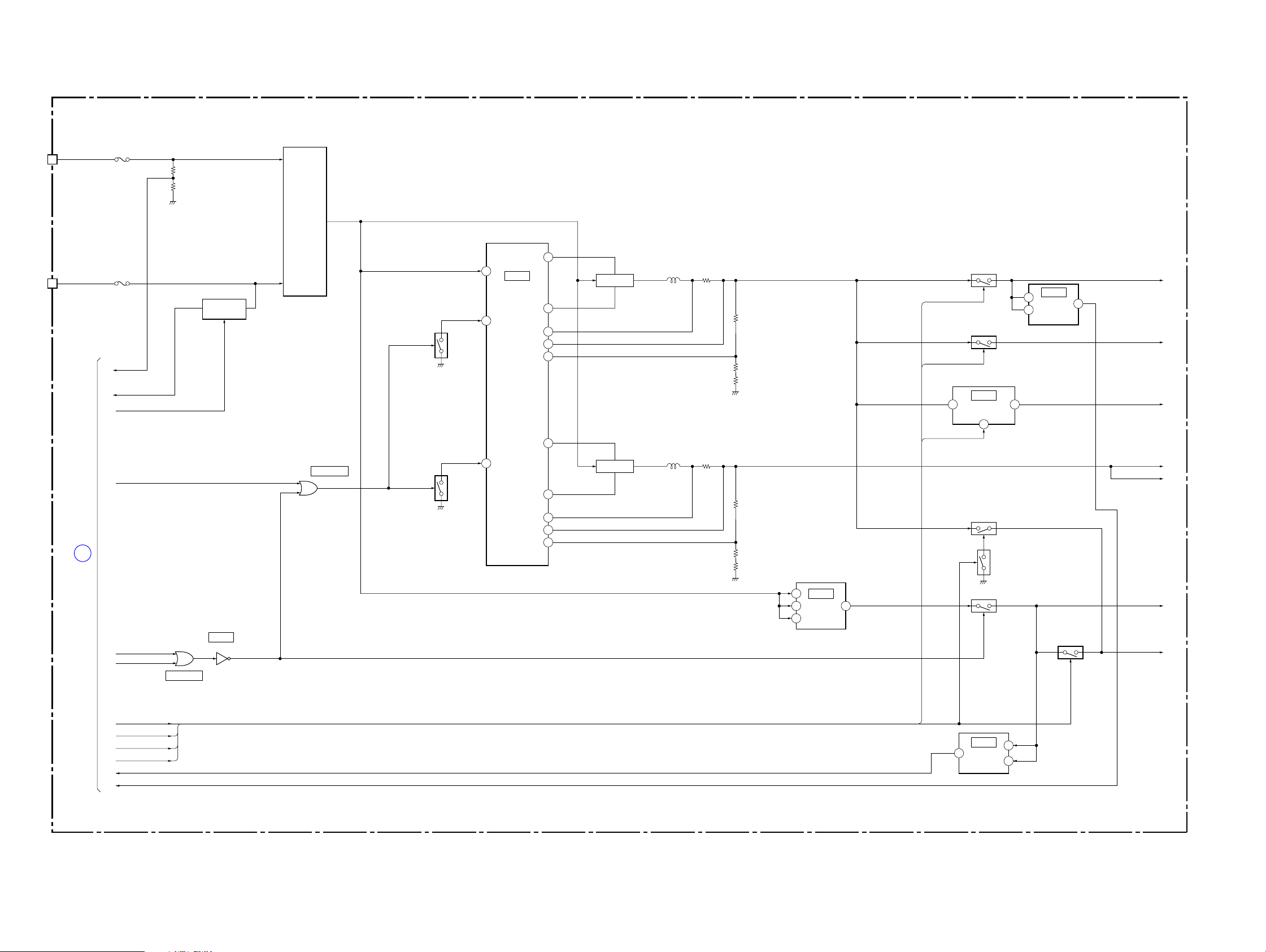

3-3. POWER BLOCK DIAGRAM

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SW-492 BOARD

OFF

COMPUTER

VIDEO

S701

POWER

J001

DC IN

BH001

BATTERY

TERMINAL

3.3V

FB403

FB108

FB401

FB402

CN401

CN203

FB301

FB502

FB504FB106

FB102

FB501

5 - 1019,20

M3.3V

M3.3V

X503

27MHz

FB505

M3.3VA

MRESET

SUB_S_RESET

A1.8V

1.8V

FL401

FL402

FL403

1.8 INCH HDD

LC-093 BOARD

CN601

19,20

L601

IC301

SDRAM 64M

(3/5)

IC503

FLASH MEMORY

(5/5)

IC501

DV SIGNAL

PROCESS

(5/5)

SE201

G-SENSOR

(2/5)

IC202

LCD EEPROM

(2/5)

IC213

2.5V REG

(2/5)

IC402

AND GATE

IC401

PHY LINK

(4/5)

L602

IC601

LCD DRIVE

D601

REC

ND001

LCD901

LCD

MONITOR

IC106

LCD POWER REG

5

Q110

(1/5)

Q111

Q101

Q104

H3.3V

4

1

IC110

2

RESET GEN.

4

(1/5)

Q116

FB201

3.0V

MAIN M3.3V

1

A3.3V

S3.3V

Q117

P3.3V

HD-035 BOARD

Q115, Q118

CN101

1

2

3

1

2

3

4

7

CN102

CN201

BATT (+)

SUB-CON

LF101

IC203

(2/5)

D123

F101

F102

DCIN_AD

BATT_AD

IB_ENABLE

SLEEP

PWR_MAIN_33

PWR_HDD

PWR_P33

PWR_LCD

S3.3V

Q106, Q107

BATT

DATA

PWR_SUB_33

SW_OFF

IC116 (2/2)

(1/5)

2

1

PLUS

MINUS-A

MINUS-B

BATT(+)

+

SW

SIG

BATT(-)

−

CN701

7

Q108, Q109

DC POWER

SELECT

TG2

14

23

IC101

DC_DC

CONV.

(1/5)

13

Q103

28

6

5

3

IC116 (1/2)

(1/5)

452

7

8

IC115

(1/5)

Q102

BG2

18

12

11

9

TG1

26

BG1

22

30

31

1

SWTCHING

SENSE2+

SENSE2-

VOSENSE2

SWTCHING

SENSE1+

SENSE1-

VOSENSE1

2

5

6

Q105

Q114

IC114

3.3V REG.

(1/5)

L101

L102

FB109 FB112

3

PWR_HDD

PWR_LCD

PWR_MAIN_33

FB104

FB103

PWR_P33

HVR-DR60

3-3E

RESET GEN.

5

2

POR-

4

1

SUB_S_RESET

IC212

(2/5)

(1/5)

4

2

IC105

1

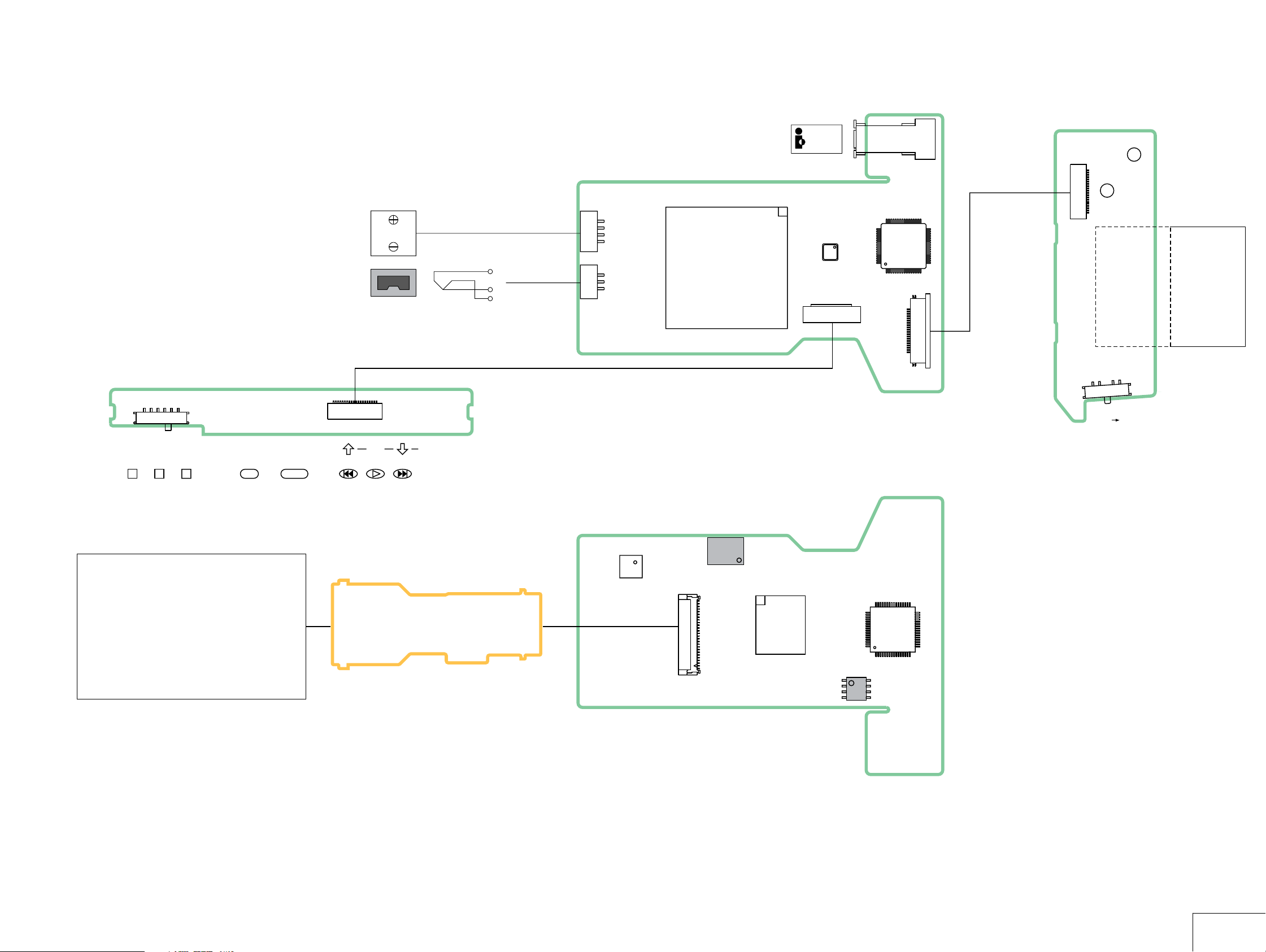

4-1. FRAME SCHEMATIC DIAGRAM

BATTERY

TERMINAL

DC IN

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

HDV/DV

HD-035 BOARD (SIDE A)

4131

CN101 CN102

IC501

DV SIGNAL

PROCESS

SE201

G-SENSOR

SE201

120

CN201

CN402

49 32

IC401

64 17

LC-093 BOARD

(SIDE B)

12756

3

4

1 20

CN601

3348

65

161

201

CN203

S601

S602

ND001

S601

STOP

S602

MENU

LCD901

LCD MONITOR

SW-492 BOARD (SIDE B)

S701

POWER

OFF

S701

HDD

(1.8 INCH 60GB)

CAM LINK

S705

S603

1

REPEATCOMPUTER VIDEO

20

CN701

EXEC (MENU)

PLAY

S703 S702

S603

REC

S706S704

HD-035 BOARD (SIDE B)

5

4

IC503

FLASH MEMORY

FP-431

FLEXIBLE BOARD

8171

91632

IC101

24

25

CN401

IC503

8

1

(Not supplied)

51

IC301

64

1

IC202

LCD EEPROM

8

IC202

5

41

IC203

(Not supplied)

3348

3249

17

61

HVR-DR60

4-1

FRAME

Loading...

Loading...