Sony HCD-XB33K, HCD-XB44K Service Manual

HCD-XB33K/XB44K

MICROFILM

SERVICE MANUAL

Photo: HCD-XB44K

*Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are

trademarks of the Dolby Laboratories Licensing

Corporation.

CD

Section

Tape Deck

Section

E Model

Model Name Using Similar Mechanism HCD-D290/

G3300/XB3

CD Mechanism Type CDM37L-5BD29AL

Base Unit Name BU-5BD29AL

Optical Pick-up Name KSS-213D/Q-NP

Model Name Using Similar Mechanism HCD-D290/

G3300/XB3

Tape Transport Mechanism Type TCM-220WR2

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION:

With 8 ohm loads, both channels driven, from 70-20,000 Hz; rated 100

watts per channel minimum RMS power, with no more than 0.9 % total

harmonic distortion from 250 milliwatts to rated output.

Amplifier section

(HCD-XB33K)

The following measured at AC 120/240 V, 50 Hz

DIN power output (Rated):

100 + 100 watts (6 ohms at 1 kHz, DIN)

Continuous RMS power output (Reference):

120 + 120 watts

(6 ohms at 1 kHz, 10% THD)

Peak music power potput (Reference):

1,500 watts

(HCD-XB44K)

The following measured at AC 120/240 V, 50 Hz

DIN power output (Rated):

120 + 120 watts (6 ohms at 1 kHz, DIN)

Continuous RMS power output (Reference):

140 + 140 watts

(6 ohms at 1 kHz, 10% THD)

Peak music power output (Reference):

2,000 watts

Inputs

PHONO IN (phono jacks):

sensitivity 3 mV, impedance 47 kilohms

MIX MIC (phone jack): sensitivity 1 mV, impedance 10 kilohms

VIDEO/MD (AUDIO) IN (phono jacks):

sensitivity 250 mV, impedance 47 kilohms

Outputs

PHONES (stereo phone jack):

accepts headphones of 8 ohms or more

VIDEO/MD (AUDIO) OUT (phono jacks):

voltage 250 mV, impedance 1 kilohm

SPEAKER: impedance of 6 to 16 ohms

SURROUND SPEAKER:accepts impedance of 16 ohms

(HCD-XB33K)

— Continued on next page —

COMPACT DISC DECK RECEIVER

CD player section

System Compact disc and digital audio system

Laser Semiconductor laser (λ = 780nm).

Emission

duration: continuous

Laser output Max. 44.6µW*

*This output is the value measured at a distance

of 200 mm from the objective lens surface on

the Optical Pick-up Block with 7 mm aperture.

Wavelength 780 – 790 nm

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

CD DIGITAL OUT

(square optical connector jack, rear panel)

Wave length: 600 nm

Output level: – 18 dBm

Tape player section

Recording system 4-track 2-channel stereo

Frequency response (DOLBY NR OFF)

60 – 13,000 Hz (±3 dB), using a Sony

TYPE I cassette

60 – 14,000 Hz (±3 dB), using a Sony

TYPE II cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

(2 band model)

Antenna FM wire antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 531 – 1,602 kHz

(with the tuning interval set at 9 kHz)

530 – 1,710 KHz

(with the tuning interval set at 10 kHz)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

The following caution label is located inside the unit.

Antenna AM loop antenna, External antenna terminals

Intermediate frequency 450 kHz

General

Power requirements

Other models: 110 – 120 V or 220 – 240 V

Power consumption

(HCD-XB33K): 240 watts

(HCD-XB44K): 250 watts

Dimensions (w/h/d) Approx. 355 x 425 x 435 mm (14 x 16 3/4 x 17

Mass Approx. 14.0 kg (30 lb 14 oz.)

Supplied accessories: AM loop antenna (1)

Design and specifications are subject to change without notice.

AC, 50/60 Hz Adjustable with voltage selector

1

/4 in) incl. projecting parts and controls

Remote RM-SD70S (1)

Size AA (R6) batteries (2)

FM wire antenna (1)

Speaker cords* (HCD-XB44K) (2)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

— 2 —

TABLE OF CONTENTS

1. GENERAL

– FRONT PANEL – ···························································· 5

– BACK PANEL – ······························································ 6

2. DISASSEMBLY ·····························································10

3. TEST MODE ··································································· 18

4. MECHANICAL ADJUSTMENTS ···························· 20

5. ELECTRICAL ADJUSTMENTS

DECK Section ·································································20

CD Section······································································· 23

6. DIAGRAMS

6-1. Circuit Board Location ···················································· 25

6-2. Block Diagrams

– CD/Key Control Section –············································ 26

– Main Section –······························································ 27

6-3. Printed Wiring Board – BD Section – ····························· 31

6-4 Schematic Diagram – BD Section – ································ 33

6-5. Printed Wiring Board – CD Motor Section – ················· 35

6-6. Schematic Diagram – CD Motor Section – ···················· 37

6-7. Printed Wiring Board – Deck Section – ························· 39

6-8. Schematic Diagram – Deck Section – ···························· 41

6-9. Schematic Diagram – Switch Section – ·························· 43

6-10. Printed Wiring Board – Switch Section –······················· 45

6-11. Printed Wiring Board – Headphone-Mic Section –········ 46

6-12. Schematic Diagram – Headphone-Mic Section – ··········· 47

6-13. Printed Wiring Board – Panel Section – ························· 49

6-14. Schematic Diagram – Panel Section – ····························· 51

6-15. Printed Wiring Board – Power Section –·························53

6-16. Schematic Diagram – Power Section – ··························· 55

6-17. Printed Wiring Board – Main Section – ·························57

6-18. Schematic Diagram – Main Section (1/5) – ···················· 59

6-19. Schematic Diagram – Main Section (2/5) – ···················· 61

6-20. Schematic Diagram – Main Section (3/5) – ···················· 63

6-21. Schematic Diagram – Main Section (4/5) – ···················· 65

6-22. Schematic Diagram – Main Section (5/5) – ···················· 67

6-23. Schematic Diagram – Key Control Section –·················· 69

6-24. Printed Wiring Board – Key Control Section – ··············· 69

6-25. IC Block Diagrams ·························································· 71

6-26. IC Pin Function Description ············································ 76

7. EXPLODED VIEWS ·····················································79

8. ELECTRICAL PARTS LIST ······································88

— 3 —

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

MODEL IDENTIFICATION

– BACK PANEL –

PARTS No.

MODEL PARTS No.

XB33K: SP, MY model 4-996-410-1π

XB33K: E model 4-996-410-6π

XB33K: EA model 4-996-410-7π

XB44K: SP, MY model 4-996-412-1π

XB44K: E, IA model 4-996-412-6π

XB44K: EA model 4-996-412-7π

— 4 —

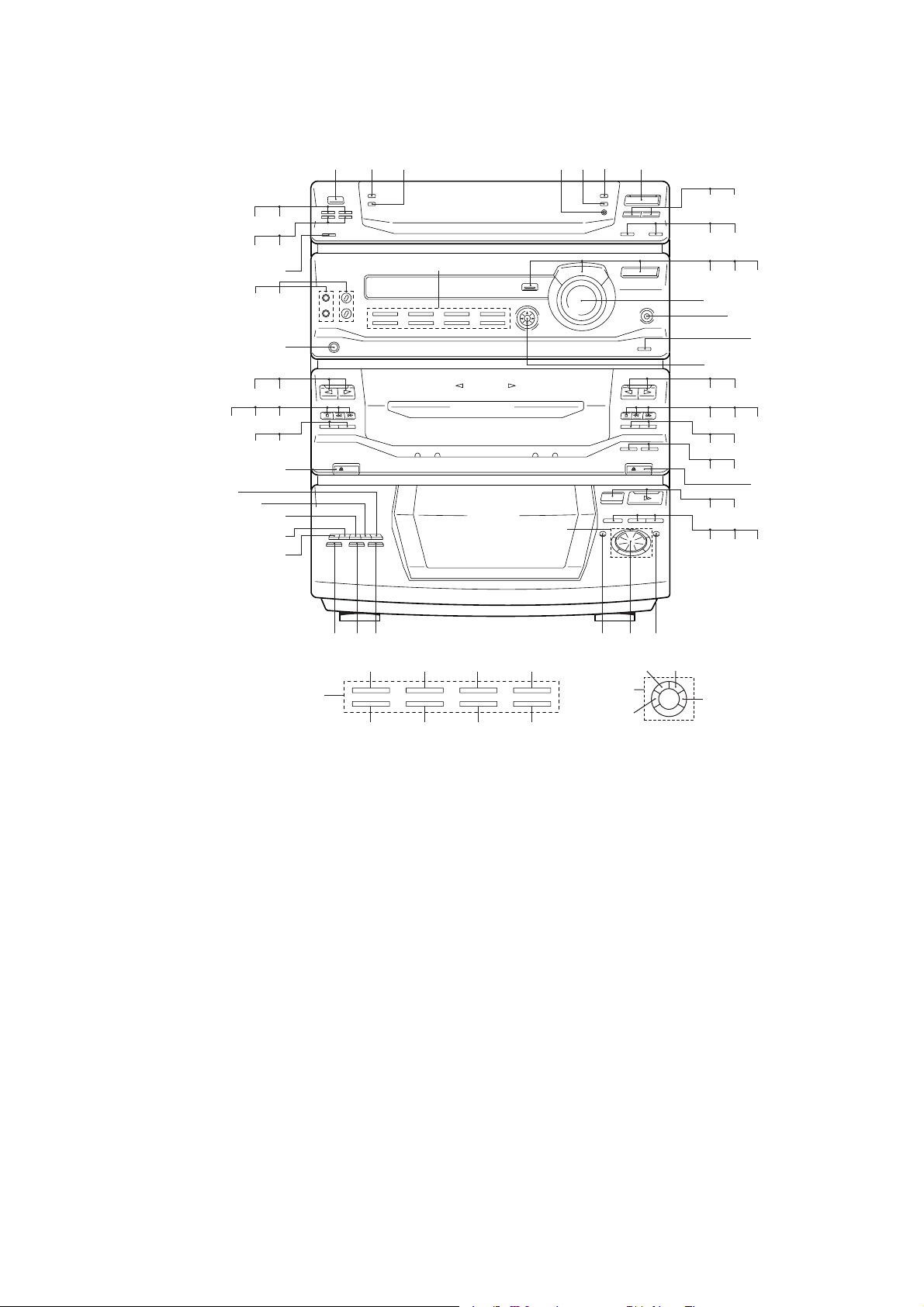

– FRONT PANEL –

SECTION 1

GENERAL

$¢

%ª ^º

%¶ %•

%§

%¢ %∞

%£

%¡ %™

$ª$• %º

$§

$¶

$∞

$£

$™

$¡

$º

123 4 6 7

A

see A

see B

5

B

89

!º !¡

!™

!£ !¢

!∞

!§

!¶

!•

!ª @º

@¡ @™ @£

@¢ @∞

@§ @¶

@ª #º

#¡ #™ #£

@•

A

1 POWER button

2 DISPLAY/DEMO button

3 SPECTRUM ANAL YZER button

4 ENTER/NEXT button

5 TUNER MEMORY button

6 TUNING MODE button

7 TUNER/BAND button

8 TUNING – button

9 TUNING + button

!º PTY button (AEP, UK model)

!¡ STEREO/MONO button

!™ EFFECT button

!£ GROOVE button

!¢ FUNCTION button

!∞ VOLUME knob

!§ SUPER WOOFER button

!¶ SUPER W MODE (XB44K model)

!• GEQ button

!ª DECK B ª (play) button

@º DECK B · (play) button

@¡ DECK B p (stop) button

@™ DECK B 0 (backward) button

@£ DECK B ) (forward) button

@¢ DECK B P (pause) button

^¡ ^™ ^£ ^¢

^• ^∞

^¶ ^§

@∞ DECK B r REC button

@§ H SPEED DUB button

@¶ CD SYNC button

@• DECK B 6 EJECT button

@ª CD 6 OPEN button

#º CD · (play) button

#¡ DISK SKIP button

#™ CD P (pause) button

#£ CD p (stop) button

#¢ CD ) (forward) button

#∞ ≠ AMS ± knob

#§ CD 0 (backward) button

#¶ FLASH button

#• LOOP button

#ª NON-STOP button

$º DISC 1 button

$¡ DISC 2 button

$™ DISC 3 button

$£ DISC 4 button

$¢ DISC 5 button

$∞ DECK A 6 EJECT button

$§ DIRECTION button

$¶ DOLBY NR button

$• DECK A p (stop) button

#¢

#∞#§#• #¶#ª

&™ ^ª

B

&¡

&º

$ª DECK A 0 (backward) button

%º DECK A ) (forward) button

%¡ DECK A ª (play) button

%™ DECK A · (play) button

%£ PHONES jack

%¢ MIC1, MIC2 jack

%∞ MIC LEVEL, ECHO LEVEL knob

%§ SLEEP button

%¶ DAILY 1 button

%• DAILY 2 button

%ª t / CLOCK SET button

^º REC button

^¡ WAVE button

^™ SURROUND button

^£ P FILE MEMORY button

^¢ GEQ CONTROL button

^∞ ENTER button

^§ KEY CONTROL ( n) button

^¶ KEY CONTROL ( ˜) button

^• KARAOKE PON/MPX button

^ª PLAY MODE button

&º REPEAT button

&¡ EDIT button

&™ 1/ALL DISCS button

— 5 —

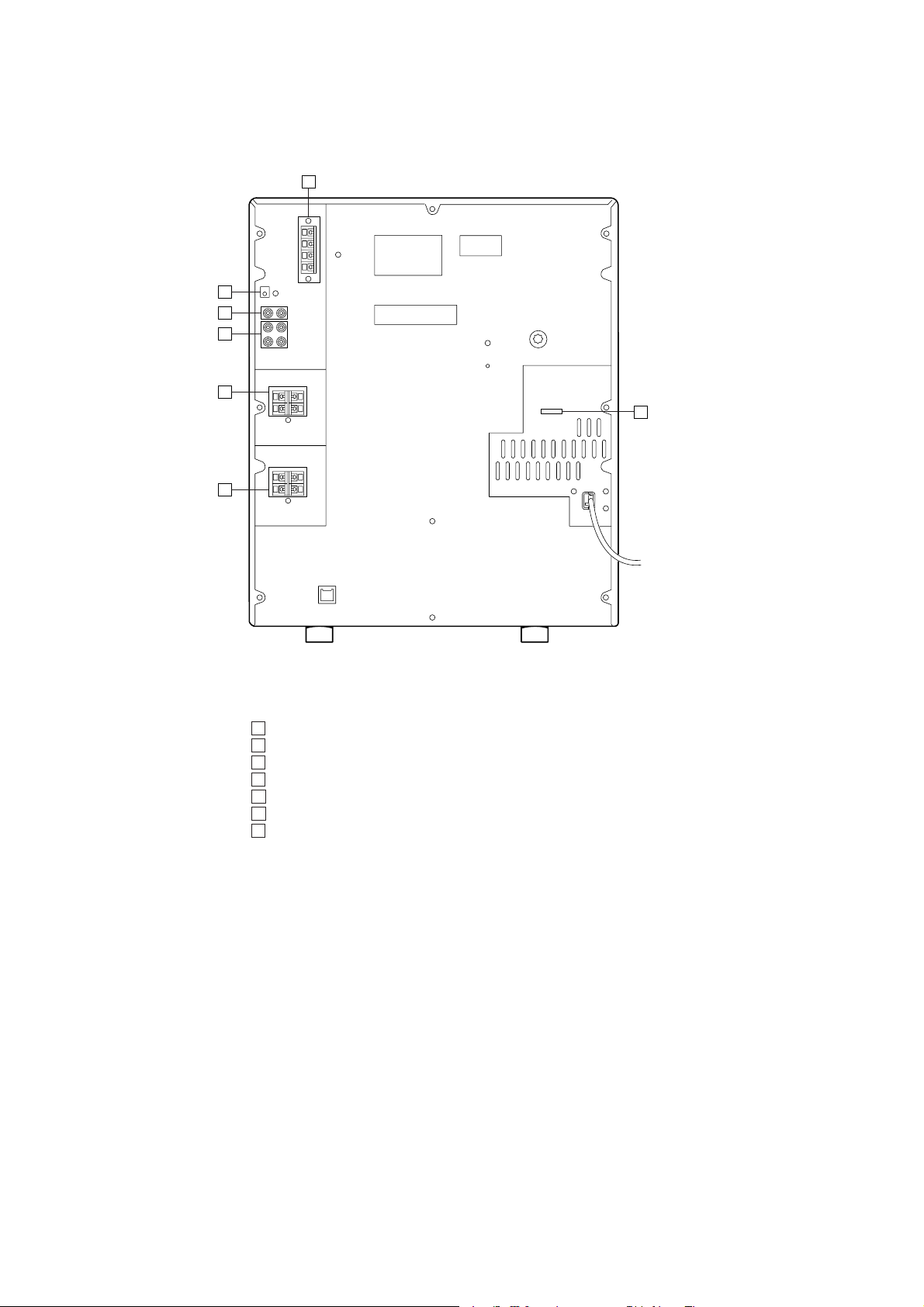

– BACK PANEL –

⁄‚⁄

⁄‚‡

⁄‚fl

⁄‚fi

⁄‚›

⁄‚‹

IN

OUT

⁄‚¤

⁄‚⁄ ANTENNA terminal

⁄‚¤ VOLTAGE SELECTOR switch (E, AR model)

⁄‚‹ SPEAKER terminal

⁄‚› SURROUND SPEAKER terminal (XB33K model)

⁄‚fi VIDEO/MD (AUDIO) jack

⁄‚fl PHONO jack

⁄‚‡ CD DIGITAL OUT connector

— 6 —

This section is extracted

from instruction manual.

— 7 —

— 8 —

— 9 —

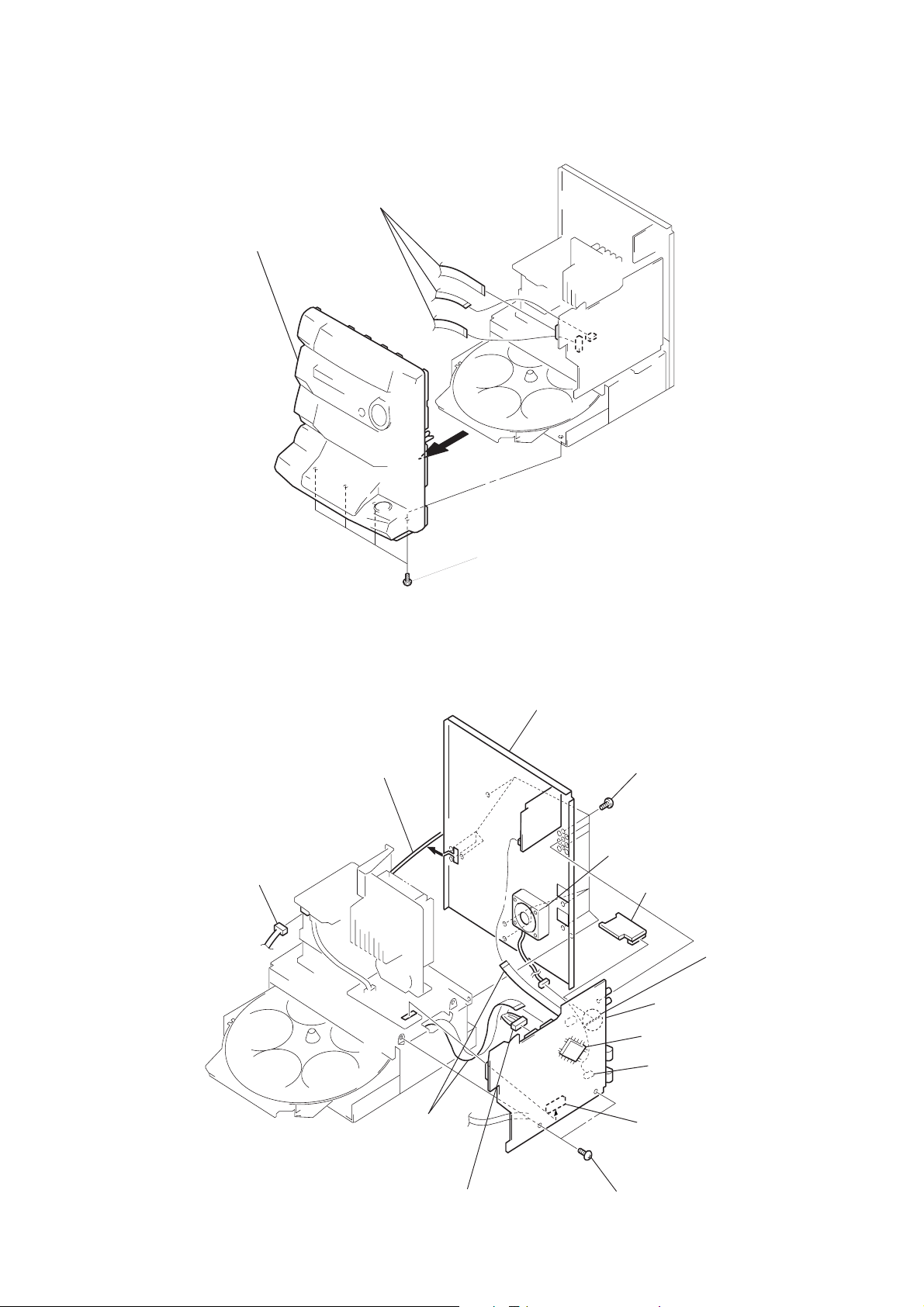

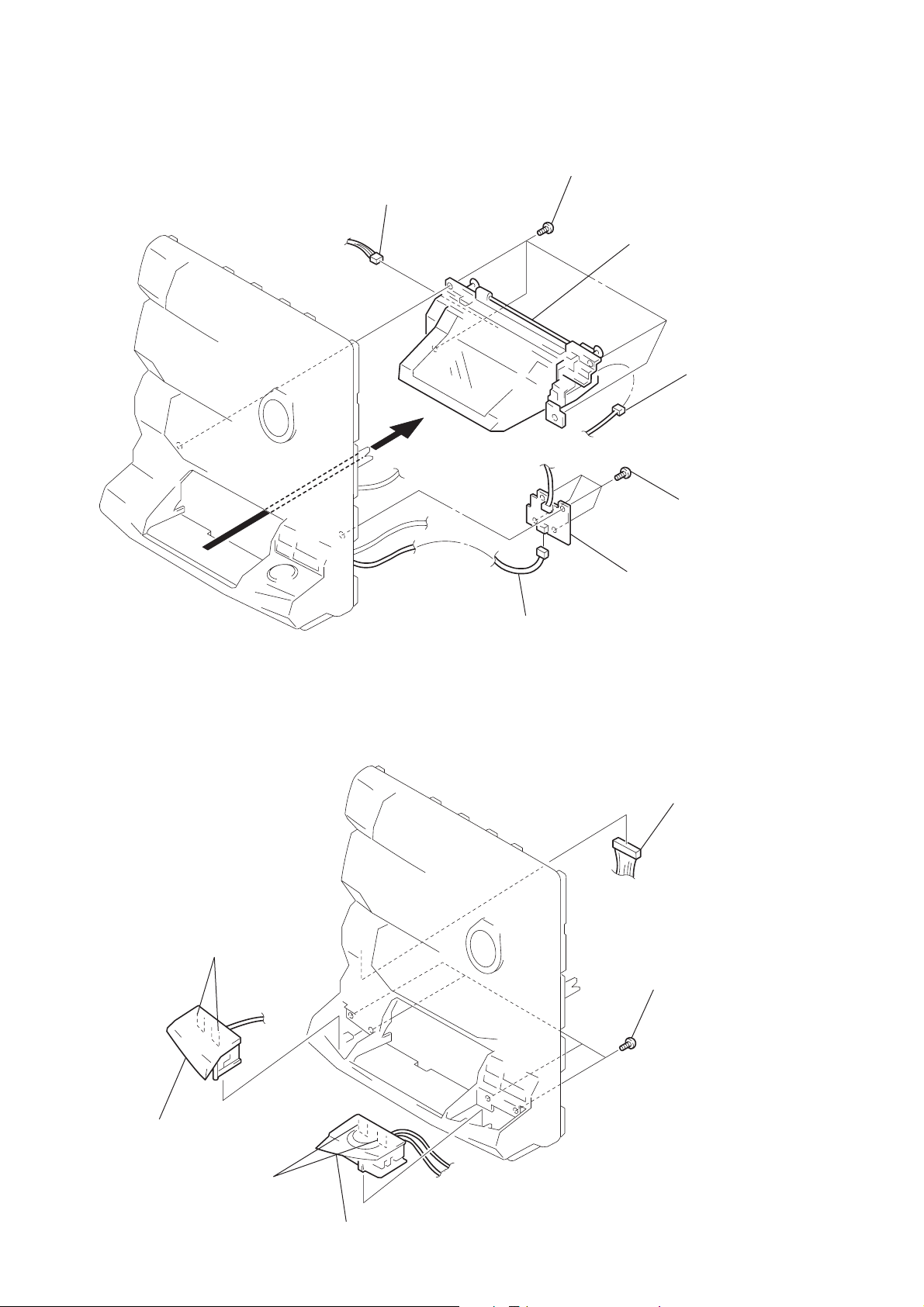

• This set can be disassembled in the order shown below.

SECTION 2

DISASSEMBLY

UPPER

CASE

(Page 10)

Note: Follow the disassembly procedure in the numerical order given.

FRONT PANEL

SECTION

(Page 11)

MAIN

SECTION

(Page 12)

TAPE MECHANISM

DECK SECTION

(Page 13)

CD LID ASSY

SECTION

(Page 14)

MAIN BOARD/KEY CON

BOARD

(Page 11)

2-1. UPPER CASE

CD MECHANISM

DECK SECTION

(Page 12)

AUDIO BOARD

(Page 17)

CASSETTE

LID ASSY

(Page 13)

PANEL (A)/(B)

SUB ASSY

(Page 14)

BASE UNIT

(Page 15)

DISC TABLE

(Page 15)

CAPSTAN MOTOR

(Page 17)

BD BOARD

(Page 16)

OPTICAL

PICK-UP

(Page 16)

SLED

MOTOR

(Page 16)

1

Three screws

(case 3 point)

3

Upper case

1

Three screws

(case 3 point)

— 10 —

2

Seven screws

(BVTT 3

×

6)

2-2. FRONT PANEL SECTION

3

Front panel section

1

Three flat wires

(CN102, 205, 206)

2

Four screws

(BVTP 3 x 8)

2-3. MAIN BOARD/KEY-CON BOARD

5

Power cord

3

Connector

(CN901)

1

(CN1,202)

Two flat wires

6

Back panel

4

Twelve screws

(BVTP 3 × 8)

Fan is for (XB44K)

!¡

KEY-CON board

0

MAIN board

IC201

9

Connector

(CN105)

(XB44K)

8

Connector

(CN101)

(Remove soldering)

2

Connector

(CN203)

— 11 —

7

Two screws

(BVTP 3 × 8)

2-4. MAIN SECTION

)

)

3

Two screws

(BVTP 3 × 8)

2

Connector

(CN203)

1

Flat wire (CN202)

4

Main section

3

(BVTP 3 × 8

3

(BVTP 3 × 8

Screw

Two screws

2-5. CD MECHANISM DECK SECTION

3

Five screws

(BVTP 3 × 8)

4

CD mechanism

deck section

2

Flat wire and

lead wire

— 12 —

1

Open the clamp.

2-6. TAPE MECHANISM DECK SECTION

)

4

Three screws

(BVTP 2.6 × 8)

3

Two flat wires

(CN601, 1001)

4

(BVTP 2.6 × 8)

A

Three screws

5

Remove the tape mechanism

deck section to direction of the arrow A.

2

Open the

cassette lid.

2-7. CASSETTE LID ASSY

1

Two springs

1

Push the

two buttons.

3

Two brackets

2

Two screws

(BVTP 2.6 × 8

4

Cassette lid assy

— 13 —

)

)

2-8. CD LID ASSY SECTION

5

Connector

(CN671)

6

Four screws

(BVTP 2.6 × 8)

7

CD lid assy

4

Connector

(CN661)

2

Four screws

(BVTP 2.6 × 8

2-9. PANEL (A) / (B) SUB ASSY

3

Two claws

1

Connector

(CN642)

3

CD-B1 SW board

1

Connector

(CN612)

2

Four screws

(BVTP 2.6 × 8

4

Panel (A) sub assy

5

Two claws

6

Panel (B) sub assy

— 14 —

e

2-10. BASE UNIT

2

Boss

3

Base unit

1

Yoke bracket

2-11. DISC T ABLE

Note:

When the disc table is installed, adjust the positions

of roller cam and mark z as shown in the figure,

then set to the groove of disc table.

A

1

Screw

(BVTP 3 × 8)

2

Bracket (BU)

1

Screw

(BVTP 3 × 8)

3

Step screw

4

Disc tabl

— 15 —

A

)

2-12. BD BOARD

s

6

the four solders.

1

(PTPWH M2.6 × 6)

3

5

Screw

(BVTP 2.6 × 8)

Removal

Two screws

Two springs

1

Two screws

(PTPWH M2.6 × 6

2

Optical pick-up

section

3

Two springs

4

Flat wire

(CN101)

7

BD board

2-13. OPTICAL PICK-UP, SLED MOTOR

3

Optical pick-up

Limit switch

4

Two screw

(P 2 × 3)

2

Sled shaft

1

Claw

— 16 —

5

Sled motor

2-14. AUDIO BOARD

o

4

Four screws

(BTP 2.6 × 4)

5

Audio board

1

Connector

(CN651)

2

Two rivets

3

Break the soldering of tw

flexible flat cables.

2-15. CAPSTAN MOTOR

1

Break the soldering of

motor lead.

4

Removal the capstan motor

to direction of the arrow.

3

Claw

2

Two screws

(BTP 2.6 × 8)

— 17 —

5

Hang the

two belts.

SECTION 3

TEST MODE

[MC Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press three buttons GROOVE , ENTER/NEXT , and

DISC 1 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

[CD Delivery Mode]

• This mode moves the pickup to the position durable to vibration.

Use this mode when returning the set to the customer after repair.

Procedure:

1. Press POWER button to turn the set ON.

2. Press PLAY MODE button and POWER button simulta-

neously.

3. A message “LOCK” is displayed on the fluorescent indicator

tube, and the CD delivery mode is set.

[MC Hot Reset]

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power cor d

is plugged in and out.

Procedure:

1. Press three buttons GROOVE , ENTER/NEXT , and

DISC 2 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

[LED and Fluorescent Indicator Tube All Lit, Key Check

Mode]

Procedure:

1. Press three b uttons GROOVE , ENTER/NEXT , and DISC 3

simultaneously .

2. LEDs and fluorescent indicator tube are all turned on.

Press DISC 2 button, and the key check mode is activated.

3. In the key check mode , the fluorescent indicator tube displays

“K 1 J0 V0”. Each time a b utton is pressed, “K”value increases.

However, once a button is pressed, it is no longer taken into

account.

“J” Value increases like 1, 2, 3 ... if rotating

≠ AMS ± knob in “+” direction, or it decreases like 0,

9, 8 ... if rotating in “–” direction.

“V” Value increases like 1, 2, 3 ... if rotating VOLUME knob

in “+” direction, or it decreases like 0, 9, 8 ... if rotating in “–”

direction.

4. To exit from this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

[Sled Servo Mode]

• This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pickup.

Procedure:

1. Select the function “CD”.

2. Press three buttons GROOVE , ENTER/NEXT , and

FLASH simultaneously.

3. The Sled Servo mode is selected, if “CD” is flashing on the

fluorescent indicator tube.

4. With the CD in stop status, press ) button in CD section to

move the pickup to outside track, or 0 button to inside track.

5. To exit from this mode, perform as follows:

1) Move the pickup to the most inside track.

2) Press three buttons in the same manner as step 2.

Note:

• Always mov e the pickup to most inside track when exiting fr om

this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessi vely, otherwise the gear can be

chipped.

[Change-over of AM T uner Step between 9kHz and 10kHz]

• A step of AM c hannels can be changed over betw een 9kHz and

10kHz.

Procedure:

1. Press POWER button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND

button to select the BAND “AM”.

3. Press POWER button to turn the set OFF.

4. Pr ess ENTER/NEXT and POWER buttons sim ultaneously,

and the display of fluorescent indicator tube changes to “AM

9k STEP” or “AM 10k STEP”, and thus the channel step is

changed over.

— 18 —

[Aging Mode]

This mode can be used for operation check of CD section and tape

deck section.

• If an error occurred:

The aging operation stops.

• If no error occurs:

The aging operation continues repeatedly.

1. Aging Mode in CD Section

1-1. Operating Method of Aging Mode

1. Set discs in DISC 1 and DISC 3 trays.

2. Select the function “CD”.

3. Press three buttons GROOVE , ENTER/NEXT , and

DISC 5 simultaneously.

4. The aging mode is activated, if a roulette mark on the

fluorescent indicator tube is flashing.

5. In the aging mode, the aging is executed in a sequence given

in “1-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

6. To e xit from the aging mode, press POWER button to tur n

the set OFF.

• If a button other than buttons in the CD section is pressed during

aging, the aging in the CD section is finished.

• To e xecute aging to the tape dec k section successively , press ·

button in the deck A.

“A GING” is displayed on the fluorescent indica tor tube. (For the

aging in tape deck, see “2. Aging Mode in Tape Deck Section”.

8. To exit from the aging mode, press POWER button to turn

the set OFF.

2-2. Operation during Aging Mode

In the aging mode, the program is executed in the following

sequence.

1. A tape on FWD side is played for one minute.

2. PAUSE STOP is made.

3. Recording is made for 3 minutes. (For the deck not having

the record function, the play is executed.)

4. FF is executed up to the end of tape.

5. A tape is reversed, and the tape on REV side is played for

one minute.

6. PAUSE STOP is made.

7. Recording is made for 3 minutes. (For the deck not having

the record function, the play is executed.)

8. FF is executed up to the end of tape.

9. Steps 1 through 8 are executed for the other deck.

10. Steps 1 through 9 are repeated unless an alarm occurred.

2-3. Deck Selection Sequence

• During the aging mode, decks are selected in the following

sequence:

Deck A (FWD) → Deck A (REV)

↑↓

Deck B (REV) ← Deck B (FWD)

1-2. Operation during aging Mode

In the aging mode, the program is executed in the following

sequence.

1. The disc tray turns to select a disc. (For a disc selection

sequence, see Section 1-3.)

2. TOC of disc is read.

3. The pickup accesses to the last track.

4. Steps 1 through 3 are repeated.

1-3. Disc Selection Sequence

• During the aging mode, discs are selected in the following

sequence:

Disc 1 → Disc 3

↑↓

Disc 3 ← Disc 1

2. Aging Mode in Tape Deck Section

2-1. Operating Method of Aging Mode

1. Load a commercially available 10-minute tape into the decks

A and B respectively.

(If a 10-minute tape is not available, another tape may be

used but a cycle time will be longer.)

2. Select the function “TAPE”.

3. Rewind tapes in advance by pressing 0 button

respectively on decks A and B.

4. Press three buttons GROOVE , ENTER/NEXT , and

DISC 5 simultaneously.

5. Press · button on deck A. (This b utton triggers the aging

mode.)

6. The aging mode is activated if “AGING A” is displayed on

the fluorescent indicator tube.

7. In the ag ing mode, the aging is executed in a sequence giv en

in “2-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

— 19 —

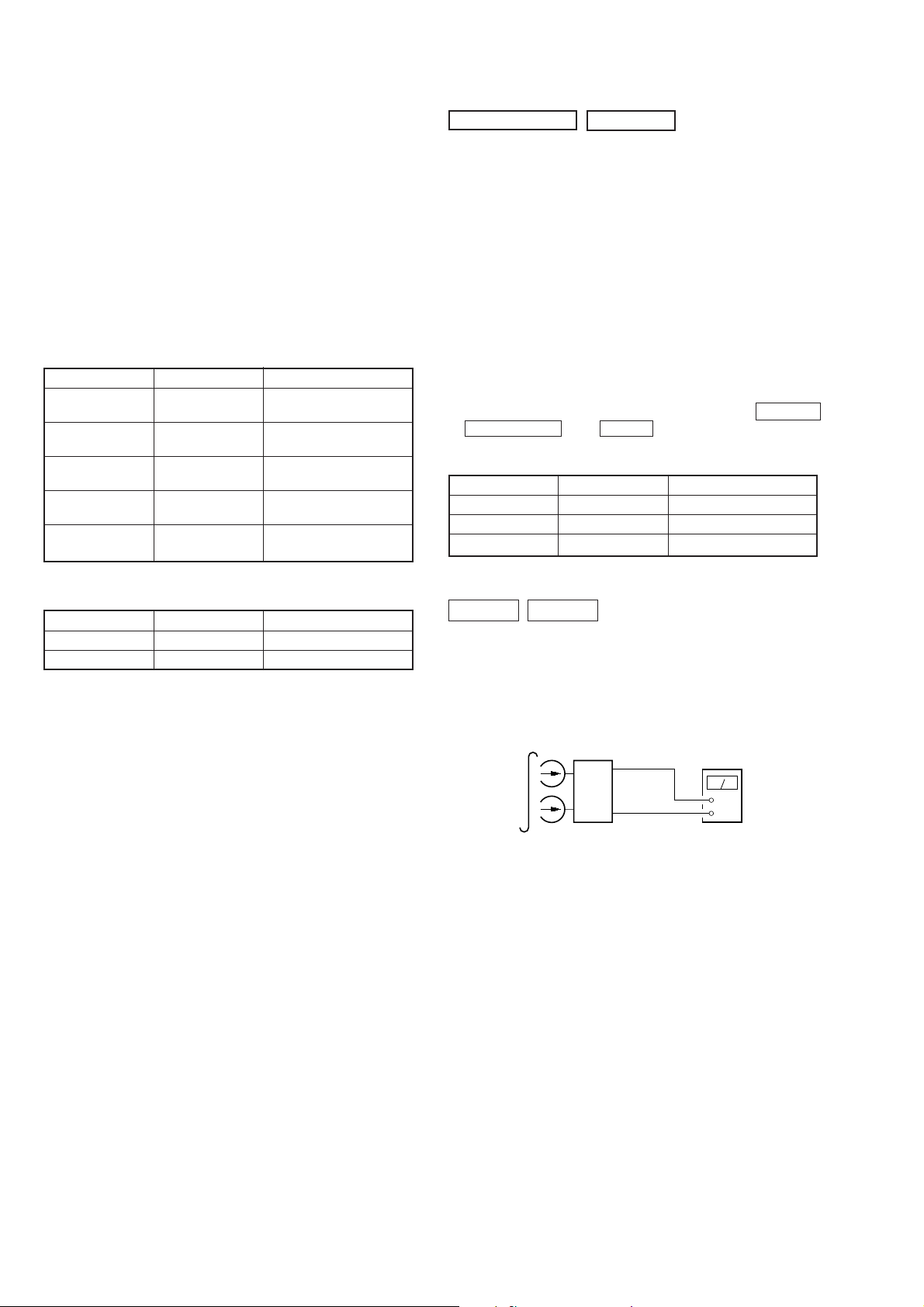

SECTION 4

set

main board

CN207

Pin

1

(L-CH)

Pin

3

(R-CH)

main board

CN207

Pin

2

+

–

level meter

test tape

P-4-A100

(10KHz, –10dB)

SECTION 5

MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

• Tor que Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension (0.026 – 0.082 oz·inch)

Reverse CQ-102RC

Reverse

Back Tension (0.026 – 0.082 oz·inch)

FF, REW CQ-201B

CQ-102C

CQ-102RC

36 to 61g·cm

(0.50 – 0.84 oz·inch)

2 to 6g·cm

36 to 61g·cm

(0.50 – 0.84 oz·inch)

2 to 6g·cm

61 to 143g·cm

(0.85 – 1.98 oz·inch)

ELECTRICAL ADJUSTMENTS

DECK SECTION

1. Demagnetize the record/playback head with a head

demagnetizer. (Do not bring the head demagnetizer close to

the erase head.)

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

8. Set to test mode. (Press key switch same time GROOVE

ENTER/NEXT and DISC 4 button.)

• Test Tape

Tape Signal Used for

P-4-A100 10kHz, –10 dB Azimuth Adjustment

WS-48B 3kHz, 0dB Tape Speed Adjustment

P-4-L300 315Hz, 0dB Level Adjustment

0dB=0.775V

• Tape T ension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A more than 100g (3.52 oz)

Reverse CQ-403R more than 100g (3.52 oz)

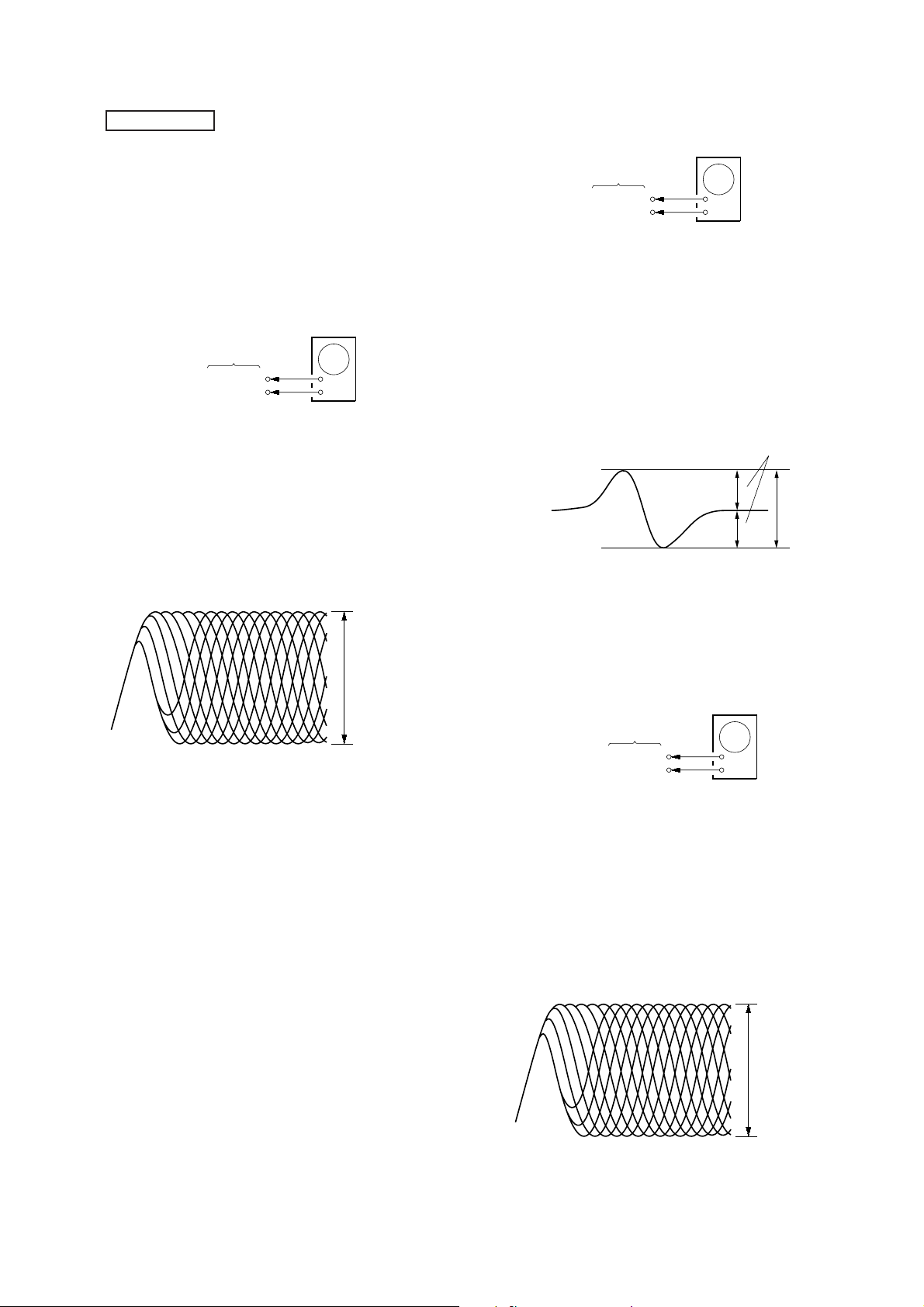

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback (FWD)

— 20 —

2. Turn the adjustment screw and check output peaks. If the peaks

e

+

–

set

test tape

WS-48B

(3 kHz, 0 dB)

main board

CN207 (Pin

1

: L-CH)

(Pin

3

:R-CH)

frequency counter

+

–

set

test tape

P-4-L300

(315 Hz, 0 dB)

main board

CN207 (Pin

1

: L-CH)

(Pin

3

: R-CH)

level meter

do not match for L-CH and R-CH, turn the adjustment screw

so

that outputs match within 1dB of peak.

output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

Screw

position

L-CH

peak

Screw

position

R-CH

peak

3. Mode: Playback (FWD)

test tape

P-4-A100

(10kHz, –10dB)

L-CH

main

board

CN207

set

R-CH

in phase 45°90°135°180

pin

1

pin

2

L

R

pin

3

waveform of oscilloscope

good

oscilloscop

V

wrong

H

°

4. Repeat steps 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

pats adjusted.

Adjustment Location: Record/Playback Head (Deck A and B)

and main board.

Tape Speed Adjustment DECK A

Notes: • Start the T a pe Speed adjustment as below after setting to the test

mode.

• In the test mode, the tape speed is high during pressing the

H. SPEED DUB button.

Procedure:

1. Turn the power switch on.

2. Press the GROOVE button, ENTER/NEXT button and

DISC 4 button simultaneously.

To exit from the test mode, press the POWER button.

Mode: Playback (FWD)

1. Insert the WS-48B into the deck A and the blank tape into the

deck B.

2. Press the REC button and · button on the deck B. Then

the deck B is at recording mode.

3. Set the deck A to playback mode.

4. Keep pressing the H. SPEED DUB button in playback mode.

Then at HIGH speed mode.

5. Adjust RV652 on the AUDIO board do that frequency counter

reads 6,000 ± 180 Hz.

6. Take off the H. SPEED DUB button.

Then at NORMAL speed mode.

7. Adjust RV651 on the AUDIO board so that frequency counter

reads 3,000 ± 90 Hz.

8. Frequency difference between deck A and deck B the be ginning

of the tape should be within ± 1.5%.

Adjustment Location: AUDIO board

Sample Value of Wow and flutter

W.RMS (JIS) within 0.3%

(test tape: WS-48B)

forward

Playback level Adjustment DECK A DECK B

Procedure:

Mode: Playback (FWD)

reverse

Deck A is RV311 (L-CH) and RV411 (R-CH), Deck B is RV301

(L-CH) and RV401 (R-CH) so tha t adjustment within adjustment

level as follows.

Adjustment Level:

CN207 PB level: 301.5 to 338.3 mV (–8.2 to –7.2 dB) level

difference between the channels: within ±0.5 dB

Adjustment Location: AUDIO and main boards

— 21 —

Record Bias Current Adjustment DECK B

r

r

Procedure:

1. Mode: record

Pin

6

(L-CH) of IC1501 on the main board.

Pin #¶ (L-CH) of IC1501 on the main board.

1) 315 Hz

2) 10 kHz

AF OSC

attenuator

Pin 2 (GND) of ICN207 on the main board.

50 mV (–23.8 dB)

600

Ω

set

2. Mode: Playback

recorded

portion

level mete

blank tape

CN-123

Adjustable limits:

CN207 PB level: 47.3 to 53.1 mV (–24.3 to –23.3 dB)

Adjustment Location: main board

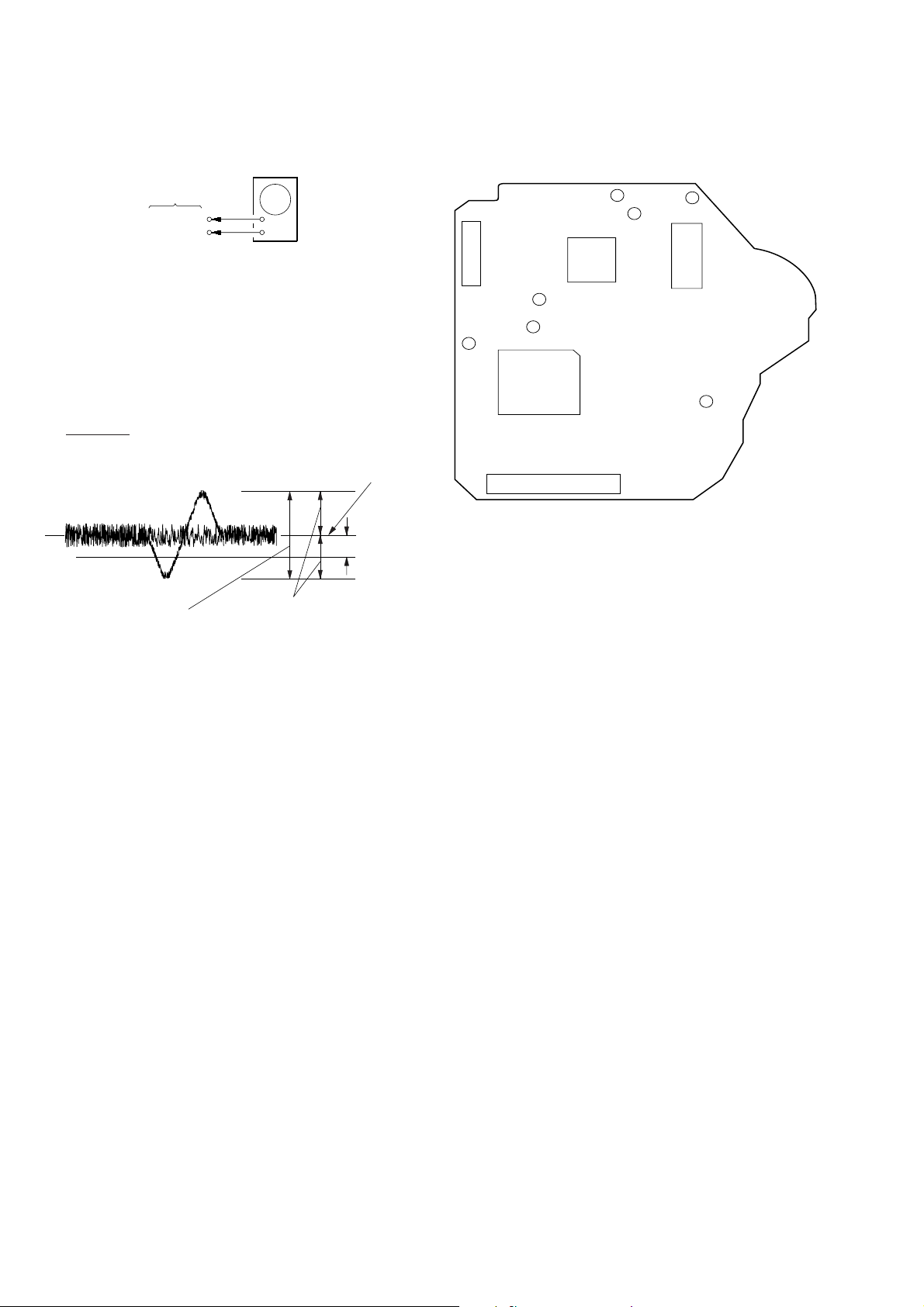

[MAIN BOARD] (Component Side)

RV1501

IC1501

RV1551

IC201

CN207

IC301

RECORD LEVEL

CN205

1

3

+

–

: L-CH)

: R-CH)

set

CN207 (Pin

(Pin

Confirm playback that the signal recorded in step 1 becomes adjustable

limits as follows.

If these levels are not adjustable limits, adjust the RV341 (L-CH) and

RV441 (R-CH) on the AUDIO board to repeat steps 1 and 2.

Adjustable limits: Playback output of 315 Hz to playback output

of 10kHz: 0±0.5 dB

Adjustment Location: AUDIO and main boards

Record Level Adjustment DECK B

Procedure:

1. Mode: record

Pin

6

(L-CH) of IC1501 on the main board.

Pin #¶ (R-CH) of IC1501 on the main board.

AF OSC

315 Hz, 50 mV (–23.8 dB)

600

attenuator

Ω

blank tape

CS-123

set

[AUDIO BOARD] (Conductor Side)

RECORD

BAIS

L

RV301

RV401®R

PB LEVEL

R

®

L

RV441RV341

– DECK B –

TAPE SPEED

(NORMAL)

RV651

®

PB

LEVEL

– DECK A –

RV311

RV411

(HIGH)

RV652

®

L

®

R

®

2

(GND) of CN207 on the main board.

Pin

2. Mode: Playback

recorded

portion

set

CN207 (Pin

(Pin

level mete

1

: L-CH)

3

: R-CH)

+

–

Confirm playback that the signal recorded in step 1 becomes

adjustable limits as follows.

If these levels are not adjustable limits, adjust the RV1501 (L-CH)

and RV1551 (R-CH) on the main board to repeat steps 1 and 2.

— 22 —

CD SECTION

V

+

–

BD board

TP (FEO)

TP (VC)

oscilloscope

+

–

BD board

TP (RF)

TP (VC)

oscilloscope

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level:

1.3

±

0.3Vp-p

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens b y an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

5. Adjust the focus bias adjustment when optical block is replaced.

Focus Bias check

oscilloscope

(DC range)

BD board

TP (RF)

VC

Procedure:

1. Connect oscilloscope to test point TP (RF). (GND terminal :

VC)

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that the shape “

≈” can be clearly distinguished at the

center of the waveform and check the RF signal level.

+

–

S Curve Check

Procedure:

1. Connect oscilloscope to test point TP (FEO).

2. Connect between test point TP (FOK) and GND by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 3±1

Vp-p.

S-curve wavef orm

symmetry

A

B

within 3

±

1 Vp-p

• RF signal

VOLT/DIV: 200 m

TIME/DIV: 500 ns

level:

±

0.3Vp-p

1.3

6. After check, remove the lead wire connected in step 2.

Notes: • Tr y to measure sever al times to mak e sure than the ratio of A : B

or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness

to obtain best waveform.

RF Level Check

Procedure:

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal

level is correct or not.

Note: Clear RF signal waveform means that the shape “≈” can be

clearly distinguished at the center of the waveform.

• RF signal

— 23 —

E-F Balance (1 Track Jump) check

)

(Without remote commander)

oscilloscope

BD board

TP (TEO)

TP (VC)

+

–

Procedure:

1. Connect oscilloscope to test point TP (TEO) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (P ause)” b utton. (Becomes the 1 track jump mode)

5. Check the level B of the oscilloscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following:

A – B

2 (A + B)

× 100 = ±7 (%)

Adjustment Location:

[BD BOARD] (Conductor Side)

TP

(RF)

TP

(FOK)

CNU101

TP

(GND)

IC103

IC101

TP (TEO)

TP (FEO)

TP

(VC)

IC

I02

1 track jump waveform

0V

level : 500 mV

±

100 mVp-p

Center of the waveform

B

A (DC voltage

symmetry

CNU102

— 24 —

Loading...

Loading...