Page 1

HCD-WS2D

SERVICE MANUAL

Ver. 1.0 2005.04

HCD-WS2D is the amplifier, DVD/CD and

tuner section in CMT-WS2D.

This system incorporates Dolby1) and DTS2) Digital

Surround System.

1)

Manufactured under license from Dolby Laboratories.

“Dolby” and the double-D symbol are trademarks of

Dolby Laboratories.

2)

Manufactured under license from Digital Theater

Systems, Inc. “DTS” and “DTS 2.0 + Digital Out” are

trademarks of Digital Theater Systems, Inc.

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism NEW

Model Name Using Similar Mechanism HCD-DZ300

Mechanism T ype CDM85-DVBU102//M

Mechanism T ype CDM85-DVBU102

Optical Pick-up Name

Optical Pick-up Name

KHM-310CAA/C2NP

KHM-310CAA/C2NP

Main unit

Amplifier section

European and Russian models:

DIN power output (rated): 55 + 55 watts (4 ohms at

1kHz, DIN)

Continuous RMS power output (refe ren ce) :

75 + 75 watts ( 4 oh ms at

1kHz, 10% THD)

Other models:

The following measured at AC 120 V, 220 – 240 V,

50/60 Hz

DIN power output (rated) 55 + 55 watts

(4 ohms at 1 kHz, DIN)

Continuous RMS power output (refe ren ce)

75 + 75 watts

(4 ohms at 1 kHz, 10%

THD)

Inputs

VIDEO/SAT IN (phono jacks):

voltage 250/450 mV,

impedance 47 kilohms

Outputs

VIDEO/SAT OUT (phono jacks):

voltage 250 mV,

impedance 1 kilohm

VIDEO OUT (phono jack):

max. output level

1 Vp-p, unbalanced, Sync

negative, load impedance

75 ohms

SPECIFICATIONS

S VIDEO OUT (4-pin/mini-DIN jack):

COMPONENT VIDEO OUT:

DVD DIGITAL OUT (Square optical connector jack,

rear panel)

Wavelength: 660 nm

PHONES (stereo mini jack):

SPEAKER: Use only the supplied

Disc player section

System Compact disc and dig ital

Laser Semiconductor laser

Frequency response DVD (PCM 48 kHz):

Video color system format

Y: 1 Vp-p, unbalanced,

Sync negative,

C: 0.286 Vp-p, load

impedance 75 ohms

Y: 1 Vp-p, 75 ohms

B

, PR: 0.7 Vp-p, 75 ohms

P

accepts headphones of

8ohms or more

speaker SS-WS2D

audio and video system

(DVD: λ=650 nm,

CD: λ=790 nm)

Emission duration:

continuous

2 Hz – 22 kHz (±1 dB)

CD: 2 Hz – 20 kHz (±1 dB)

European and Russian

models: PAL

Other models: NTSC, PAL

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

(50 kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

European and Russian models:

531 – 1,602 kHz

(with the interval set at

9kHz)

Other models: 531 – 1,602 kHz

(with the interval set at

9kHz)

530 – 1,710 kHz

(with the interval set at

10 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

— Continued on next page —

DVD RECEIVER

9-879-665-01

2005D1678-1

© 2005.04

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

Page 2

HCD-WS2D

General

Power requirements

European and Russian models:

230 V AC, 50/60 Hz

Other models: 120 V or 220 – 240 V AC,

50/60 Hz

Adjustable with voltage

selector

Power consumption 50 watts

0.3 watts (in Power Saving

mode)

Dimensions (w/h/d) (excl. speakers)

Approx. 254.5 × 136 ×

346.5 mm

Mass Approx. 3.4 kg

Design and specifications are subject to change

without notice.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

This markng is located on the

rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

MODEL IDENTIFICATION

– Rear Panel –

Part No.

Model Part No.

AEP, UK 2-580-682-0[]

RU 2-580-682-2[]

SP6 2-580-682-5[]

E3 2-580-682-6[]

HK 2-580-682-7[]

•Abbreviation

E3 : 240 V AC Area in E model.

HK : Hong Kong model.

RU : Russian model.

SP6 : Singapore and Malaysia models.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

Page 3

TABLE OF CONTENTS

HCD-WS2D

1. SERVICING NOTE ................................................... 4

2. GENERAL ................................................................... 9

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 11

3-2. Case, Front Panel Section................................................ 12

3-3. DISPLAY Board, FUNCTION Board............................. 13

3-4. VIDEO Board, Tuner, DC Fan ........................................ 13

3-5. REGULATOR Board,

DVD Mechanism Deck (CDM85-DVBU102) ................ 14

3-6. MAIN Board, Switching Regulator,

HEADPHONE Board...................................................... 14

3-7. DMB10 Board ................................................................. 15

3-8. S-MASTER Board .......................................................... 15

3-9. Tray.................................................................................. 16

3-10. Belt, MS-203 Board ........................................................ 17

3-11. Base Unit ......................................................................... 18

3-12. Optical Pick-up (KHM-310CAA/C2NP) ........................ 18

4. TEST MODE ............................................................... 19

5. DIAGRAMS

5-1. Block Diagram – RF/SERVO Section –......................... 24

5-2. Block Diagram – VIDEO Section – ............................... 25

5-3. Block Diagram – SPEAKER Section –.......................... 26

5-4. Block Diagram – POWER Section –.............................. 27

5-5. Printed Wiring Board – DMB10 Section (Side A) – ...... 28

5-6. Printed Wiring Board – DMB10 Section (Side B) – ...... 29

5-7. Schematic Diagram – DMB10 Section (1/4) – .............. 30

5-8. Schematic Diagram – DMB10 Section (2/4) – .............. 31

5-9. Schematic Diagram – DMB10 Section (3/4) – .............. 32

5-10. Schematic Diagram – DMB10 Section (4/4) – .............. 33

5-11. Printed Wiring Board – DISPLAY Section – ................. 34

5-12. Schematic Diagram – DISPLAY Section – .................... 35

5-13. Printed Wiring Board – MAIN Section –....................... 36

5-14. Schematic Diagram – MAIN Section (1/2) – ................. 37

5-15. Schematic Diagram – MAIN Section (2/2) – ................. 38

5-16. Printed Wiring Board – REGULATOR Board – ............ 39

5-17. Schematic Diagram – REGULATOR Board –............... 40

5-18. Printed Wiring Board – S-MASTER Board – ................ 41

5-19. Schematic Diagram – S-MASTER Board – ................... 42

5-20. Printed Wiring Board – SPEAER OUT Section – ......... 43

5-21. Schematic Diagram – SPEAKER OUT Section – ......... 44

5-22. Printed Wiring Board – VIDEO Board –........................ 45

5-23. Schematic Diagram – VIDEO Board – .......................... 46

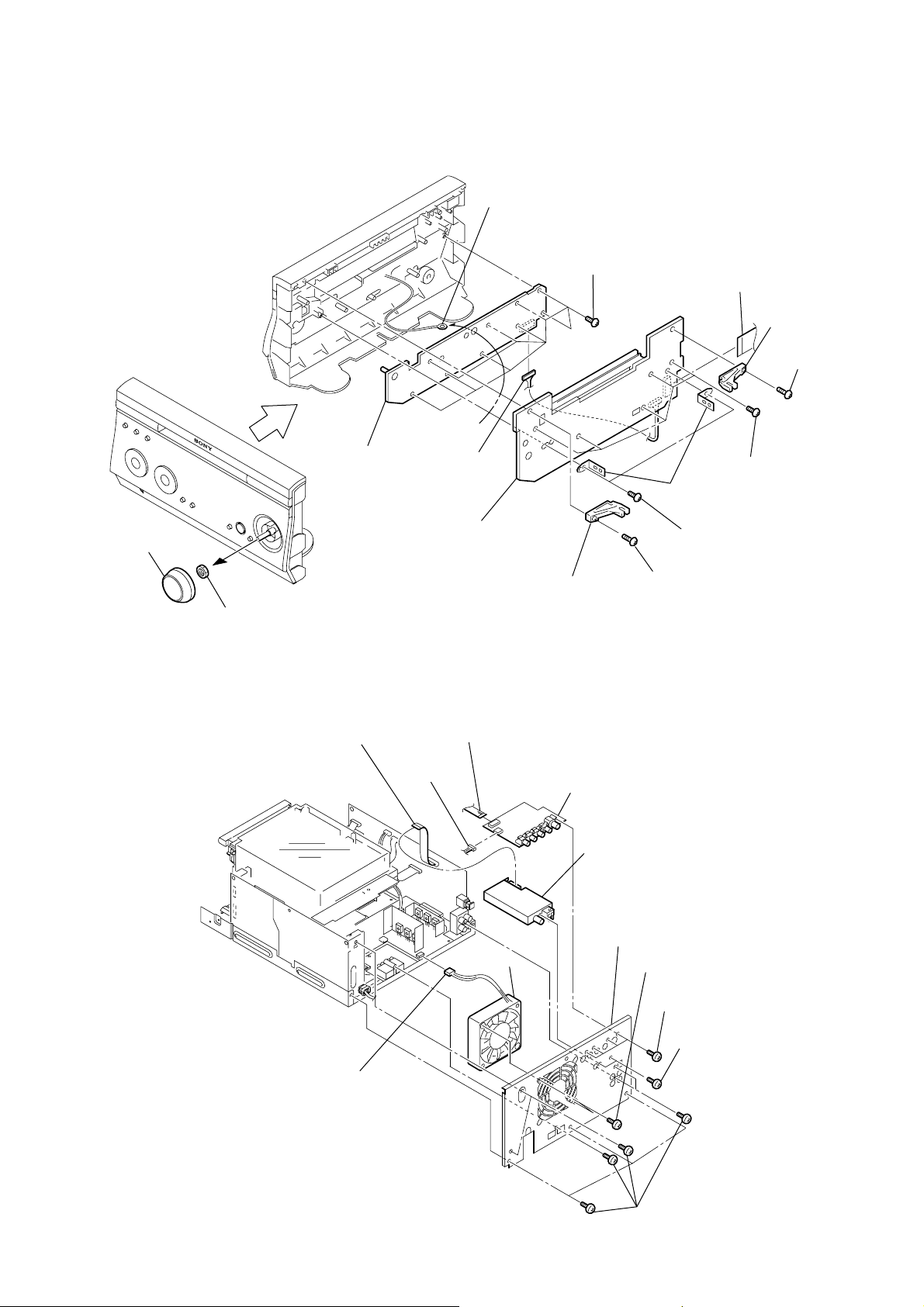

6. EXPLODED VIEWS

6-1. Overall Section ................................................................ 60

6-2. Front Panel Section ......................................................... 61

6-3. Chassis Section-1 ............................................................ 62

6-4. Chassis Section-2 ............................................................ 63

6-5.

DVD Mechanism Deck Section (CDM85-DVBU102)....

64

7. ELECTRICAL PARTS LIST .................................. 65

3

Page 4

HCD-WS2D

SECTION 1

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output several times.

Self-diagnosis Function

(When letters/numbers appear in the

display)

When the s elf -diagnosis function is activate d to

prevent the system from malfunctioning, a 5character service number (e.g., C 13 50) with a

combination of a letter and 4 digits appears on

the screen and the front pa nel display. In this

case, check the following table.

First 3

characters of

the service

number

C 13 The disc is dirty.

C 31 The disc is not inserted corr ect ly.

E XX

(xx is a number)

Cause and/or corrective action

,Clean the disc with a soft cloth .

,Restart the system, then rensert

the disc correctly.

To prevent a malfunction, the

system has performed the selfdiagnosis function.

,Contact your nearest Sony

dealer or local authorized Sony

service facility and giv e the 5character service number.

Example: E 61 10

4

Page 5

• REGULATOR board service position

HCD-WS2D

REGULATOR board

S-MASTER

BOARD

CN700

DMB10 BOARD

CN106

MAIN board

CN313

CN305

To check the soldering side of

the REGULATOR board, remove

the REGULATOR board and

MAIN boards.

It becames a resolution with

MAIN board.

CN302

MAIN BOARD

Extension cable :

J-2501-102-A

(1mm / 13pin / L300)

Extension cable :

J-2501-011-B

(1.25mm / 19pin / L300)

In such a case, the

extension cables

became necessary.

MAIN board

REGULATOR

board

5

Page 6

HCD-WS2D

• DMB10 board service position

DMB10 board

Remove the DMB10 board once.

Then create the service position.

VIDEO BOARD

Extension cable :

J-2501-102-A

(1mm / 13pin / L300)

CN100

CN313

CN302

MAIN BOARD

In such a case, the

extension cables

became necessary.

DMB10 board

Extension cable :

J-2501-244-A

(1mm / 21pin / L300)

6

Page 7

• S-MASTER board service position

HCD-WS2D

S-MASTER board

S-MASTER board

7

Page 8

HCD-WS2D

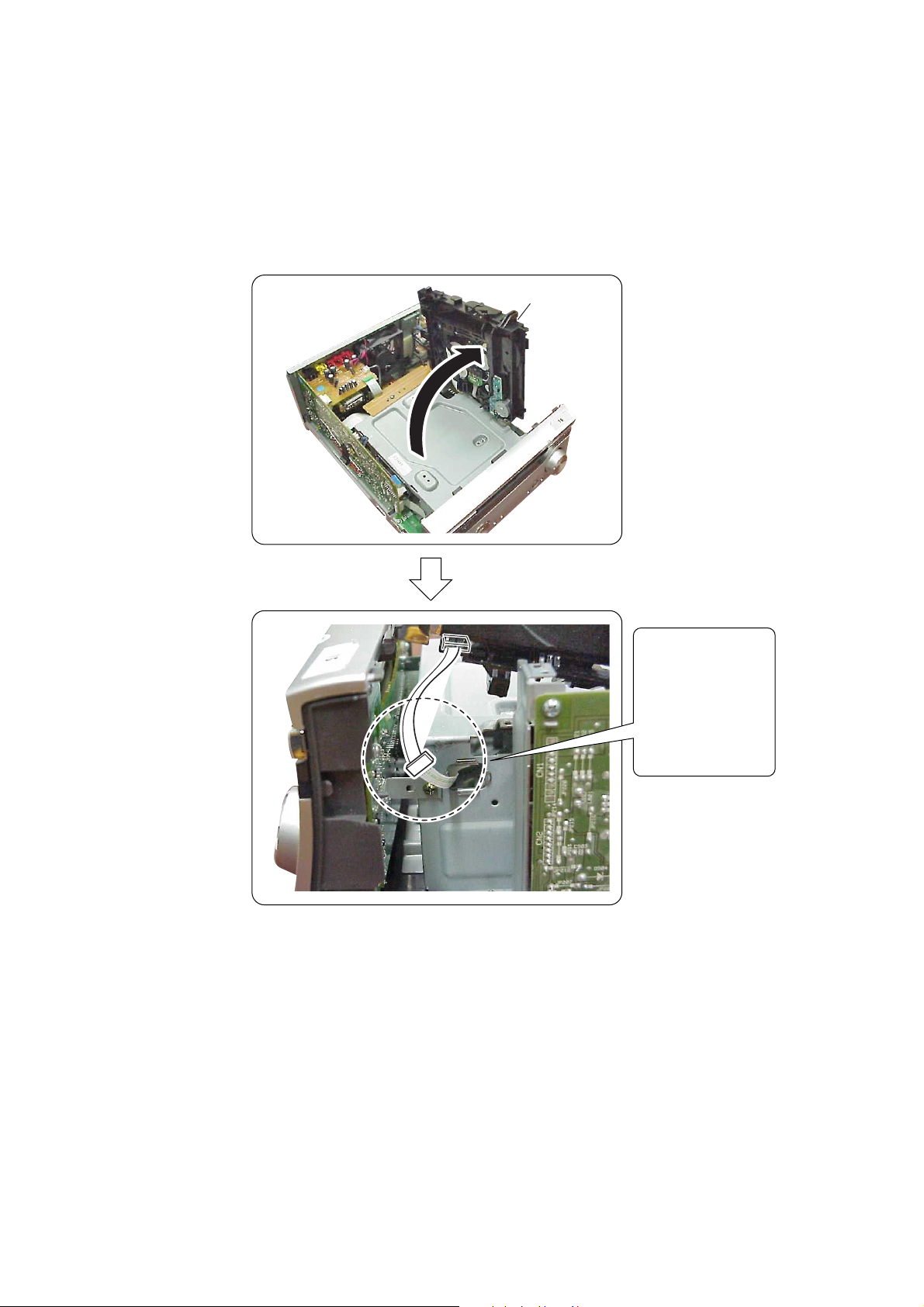

• Mechanism deck service position

Mechanism deck

In such a case, the

extension cables

became necessary.

Extension cable :

J-2501-239-A

(1mm / 5pin / L300)

8

Page 9

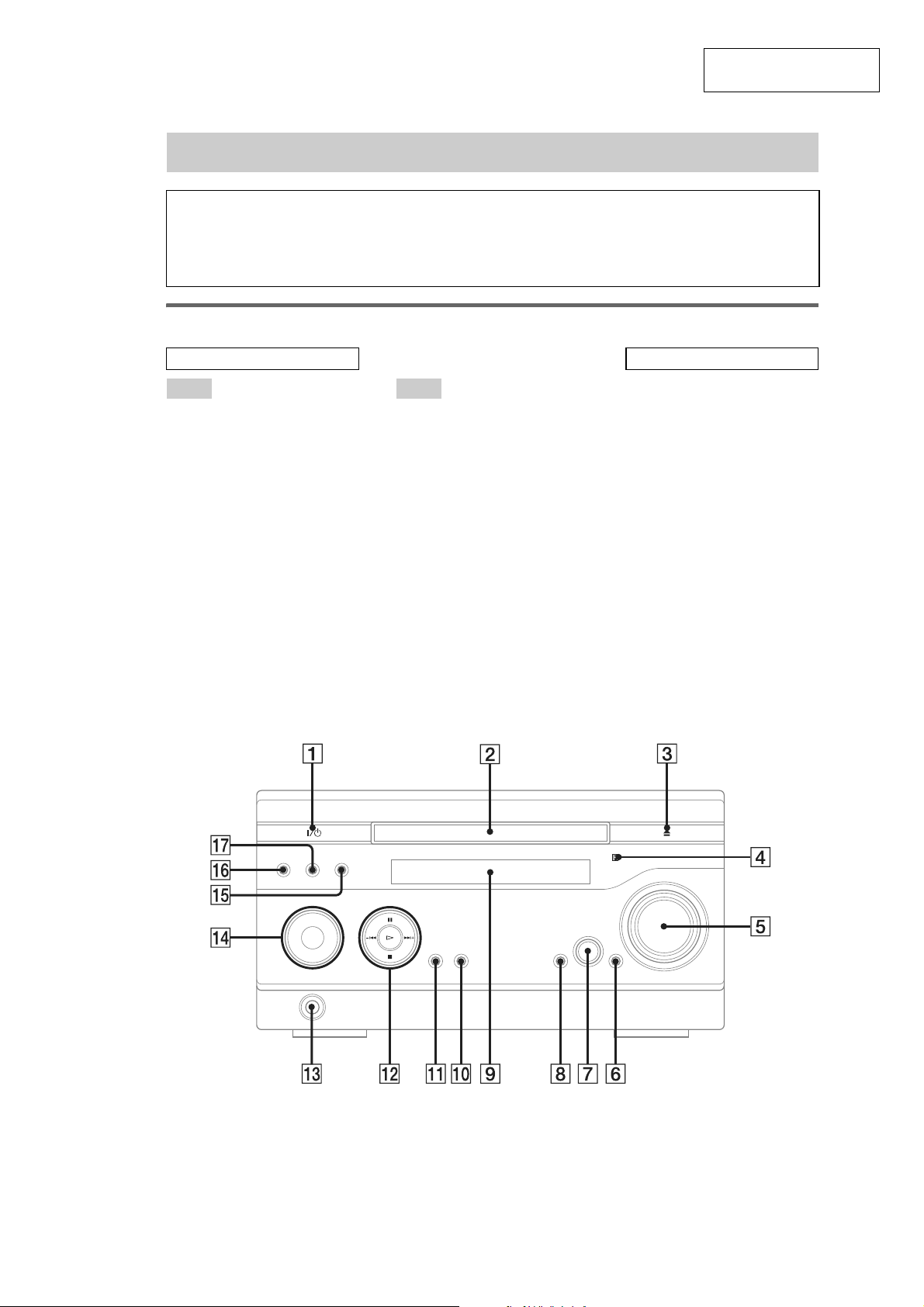

SECTION 2

GENERAL

List of button locations and reference pages

HCD-WS2D

This section is extracted

from instruction manual.

How to use this page

Use this page to find the location of buttons and other

parts of the system that are mentioned in the text.

Main unit

ALPHABETICAL ORDER

A – R S – Z

BASS/TREBLE 8 (45)

DIMMER qj (49)

Disc tray 2 (13)

DISPLAY qg (49, 53)

Display window 9

DSGX 6 (45)

DVD qf (10, 13, 35)

Headphones jack qd

PRESET +/– qs (43)

PROGRESSIVE 0 (35)

Remote sensor 4

SA-CD/CD qa (15)

SOUND FIELD 7 (45, 62)

TUNER AM qf (42, 43)

TUNER FM qf (42, 43)

TIME/TEXT qh (44, 50, 51)

VIDEO/SAT qf (56)

VOLUME control 5

Illustration number

SA-CD/CD

RR

Name of button/part Reference page

BUTTON DESCRIPTIONS

?/1 (power) 1 (9, 43, 62)

Z (open/close) 3 (13)

H (play) qs (13, 40)

X (pause) qs (10, 14)

x (stop) qs (14, 37, 62)

./> (go back/go forward)

qs (12, 14, 45)

r

qa (15)

9

Page 10

HCD-WS2D

Remote control

ALPHABETICAL ORDER

A – Q

ALBUM +/– wf (14)

ANGLE 5 (41)

AUDIO 4 (30, 46)

CLEAR es (16, 17, 19, 24, 27)

DISC SKIP

DISPLAY qj (49, 53)

ENTER qs (11, 12, 16, 17, 18, 19,

20, 23, 25, 27, 28, 31, 32, 37,

42, 43, 48)

FM MODE ws (44)

FUNCTION +/– 2 (13, 35, 42,

43)

KARAOKE MODE qg (46)

KARAOKE PON qh (47)

MENU 6 (19, 23, 25)

Number buttons

33, 37, 43, 54)

PICTURE NAVI 3 (24, 28)

PRESET + wh (43)

PRESET – e; (43)

1)

w;

2)

qf (19, 20, 27,

R – Z

REPEAT ws (18)

SLEEP qk (48)

SOUND FIELD wa (45)

SUBTITLE wd (41)

THEATRE SYNC ql (54)

TIMER MENU eg (11, 48)

TIME/TEXT ef (44, 50, 51)

TOP MENU qd (19)

TUNING + 9 (42, 44)

TUNING – qa (42, 44)

TV wk (54)

TV CH + wh (54)

TV CH – e; (54)

TV/VIDEO qk (54)

TV VOL +/–

VOLUME +/–

2)

7 (54)

2)

7 (48)

BUTTON DESCRIPTIONS

?/1 (power) 1 (9, 48)

TV ?/1 1 (54)

REPLAY/ADVANCE

8 (14)

c STEP/STEP C 8 (14)

SLOW y 9 (14)

M (fast forward) 9 (14)

X (pause) q; (14)

SLOW qa (14)

m (rewind) qa (14)

M/m/</, qs (11, 17, 31, 48)

DISPLAY wg (12, 17, 31, 46,

53)

> (go forward) wh (14, 45)

x (stop) wj (14, 37)

H (play)

. (go back) e; (12, 14, 45)

O RETURN ea (20)

-/-- es

KEY CONTROL

1)

The DISC SKIP button is not

available for this model.

2)

The H, number 5 and

VOLUME + (TV VOL +)

buttons have tactile dots. Use

the tactile dots as referenc es

when op erating the system.

2)

wl (13, 40)

#/2

ed (47)

Setting the clock

Use buttons on the remote for the operation.

1

Press ?/1 to turn on the system.

2

Press TIMER MENU.

3

Press M or m repeatedly to set the hour.

4

Press ENTER.

5

Press M or m repeatedly to set the

minute.

6

Press ENTER.

The clock starts wo rking.

To adjust the clock

1

Press TIMER MENU.

2

Press M or m to select “CLOCK SET?”, then

press ENTER.

3

Do the same procedures as step 3 to 6

above.

Notes

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

You cannot set the clock in Power Saving Mode

(page 49).

10

Page 11

3-1. DISASSEMBLY FLOW

•This set can be disassembled in the order shown below.

•The dotted square with arrow (

) are completed.

(

SET

) prompts you to move to the next job when all of the works within the dotted square

HCD-WS2D

SECTION 3

DISASSEMBLY

3-2.CASE, FRONT PANEL SECTION

3-3.DISPLAY BOARD,

FUNCTION BOARD

(Page 13)

(Page 12)

3-4.VIDEO BOARD,

TUNER,DC FAN

(Page 13)

3-5.REGULATOR BOARD,

DVD MECHANISM DECK

(CDM85-DVBU102)

(Page 14)

3-6.MAIN BOARD,

SWITCHING REGULATOR,

HEADPHONE BOARD

(Page 14)

3-9.TRAY

(Page 16)

3-8.S-MASTER BOARD

3-7.DMB10 BOARD

(Page 15)(Page 15)

3-10.BELT, MS-203 BOARD

(Page 17)

3-12.OPTICAL PICK-UP

(KHM-310CAA/C2NP)

(Page 18)

3-11.BASE UNIT

(Page 18)

11

Page 12

HCD-WS2D

)

Note: Follow the disassembly procedure in the numerical order given.

3-2. CASE, FRONT PANEL SECTION

1

Push down the F spring in the

arrow direction and release

the claw.

three claws

2

Insert your hand from the rear and

push up the front of case as shown.

qs

front panel section

9

screw

(+BVTP 3

qa

three

(+BVTP 3

×

8)

screws

Be careful not to give scar on this part.

4

screw

(case 3 TP2

6

0

screw

(+BVTP 3

8

screw

×

8)

(+BV3)(3-CR)

×

8)

7

wire (flat type)

(17 core)

(CN315)

case

3

screw

(case 3 TP2)

5

three

screws

(+BVTP 3

×

8)

12

Page 13

3-3. DISPLAY BOARD, FUNCTION BOARD

qa

DISPLAY

board

4

two

brackets (FL)

qg

FUNCTION

board

1

knob (vol)

2

nut

5

t

apping screw

(+BVTP 2.6

×

10)

7

t

apping screw

(+BVTP 2.6

×

10)

9

five t

apping screws

(+BVTP 2.6

×

8)

6

fixing CDM R

8

fixing CDM L

3

two t

apping screws

(+BVTP 2.6

×

8)

qs

nine t

apping screw

(+BVTP 2.6

×

8)

qd

earth wire

q;

wire (flat type)

(17 core)

(CN001)

qf

connector

(CN003)

HCD-WS2D

3-4. VIDEO BOARD, TUNER, DC FAN

6

wire (flat type)

(11 core) (CN311)

qa

(CN211)

3

connector

(CN101)

connector

2

wire (flat type)

(13 core) (CN100)

qs

DC fan

4

VIDEO board

7

tuner

q;

back panel

8

two screws

(+BVTP 3 × 8)

1

four screws

(+BVTP 3 × 8)

5

two screws

(+BVTP 3 × 8)

9

eight screws

(+BVTP 3 × 8)

13

Page 14

HCD-WS2D

3-5. REGULATOR BOARD, DVD MECHANISM DECK (CDM85-DVBU102)

8

loading panel

4

spring (loading panel)

5

HIMERON sheet

9

DVD mechanism deck

(CDM85-DVBU102)

6

wire (flat type)

(7 core) (CN202)

7

connector

(CN201)

2

cover

three claws

1

two

(+BVTP 3

screws

×

8)

3

three

(+BVTP 3

screws

×

8)

8

wire (flat type)

(24 core) (CN101)

qh

connector

(CN204)

qj

connector

(CN301)

qg

connector

(CN203)

qf

(CN201)

0

connector

screw

(+BV3 )

qd

three

screws

(+BV3 )

qk

REGULATOR board

3

panel comb

board

3-6. MAIN BOARD, SWITCHING REGULATOR, HEADPHONE BOARD

4

wire (flat type)

(19 core) (CN305)

6

5

screw

(+BVTP 3

MAIN board

×

8)

qk

bracket (CDM)

3

wire (flat type)

(21 core) (CN302)

qh

three

screws

(+BV3)(3-CR)

qj

clip coating

qs

bracket (SWA)

0

screw

(+BV 3)

qa

(CN215)

9

bracket (SWB)

qs

SPEAKER OUT board

connector

qf

cord bushing (2104)

qd

power cord

14

1

screw

(+BVTP 3

2

HEADPHONE

×

8)

board

qa

wire holder

7

connector

(CN1)

9

SW cover

qg

switching regulator

8

four

(+BVTP 3

screws

×

8)

Page 15

3-7. DMB10 BOARD

2

wire (flat type)

(7 core) (CN202)

1

wire (flat type)

(13 core) (CN106)

6

four

screws (3CR)

3

connector

(CN103)

4

connector

(CN401)

7

DMB10 board

5

connector

(CN101)

HCD-WS2D

3-8. S-MASTER BOARD

2

s-master

heat sink

3

four

(+BV 3)

screws

1

two

screws

(+BVTP 3

4

sheet radiation

5

×

12)

S-MASTER board

15

Page 16

HCD-WS2D

3-9. TRAY

1

Move the chuck cam

in the direction of the arrow.

bottom side

2

4

two claws

3

5

tray

16

Page 17

3-10. BELT, MS-203 BOARD

2

chuck cam

3

HCD-WS2D

belt

6

DC motor

1

two claws

7

MS-203 board

5

three claws

4

screw

(M 1.7

×

2.5)

17

Page 18

HCD-WS2D

3-11. BASE UNIT

2

chuck cam

1

two claws

3

two claws

3-12. OPTICAL PICK-UP (KHM-310CAA/C2NP)

3

four insulator screws

2

loading base

4

base unit

4

two insulators

18

bu holder

1

two claws

5

two insulators

6

optical pick-up

(KHM-310CAA/C2NP)

Page 19

SECTION 4

TEST MODE

HCD-WS2D

Note 1:Regarding the notification symbol “R”

Because the number of the operating buttons of this product

are limited, some operations require use of the operating buttons

of the remote commander.When a specific operation requires

use of the operating buttons of the remote commander, “R” is

added to the specific operating procedure in this manual.

Example MENU/NO “R” The MENU/NO button of remote

commander.

Note 2:Incorrect operations may be performed if the test mode is not

entered properly.

In this case, press the ?/1 button to turn the power off, and

retry to enter the test mode.

1. Cold Reset

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customers.

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press three buttons x , [SOUND FIELD] and ?/1 simulta-

neously.

3. When this button is operated, display as “COLD RESET” for

a while and all of the settings are reset.

2. Panel Test Mode

•This mode is used to check the software version, LCD, LED

and keyboard.

Procedure:

1. Press the ?/1 button to turn on the power.

2. Press three bottons x , [PROGRESSIVE] and [TUNER AM]

simultaneously.

3. When the panel test mode is activated, all segments are turned

on.

2-1. V ersion T est Mode

Procedure:

1. When the panal test mode is activated, press the

PRESET –

displyed, the version test mode is activated.

2. Whenever press the PRESET – . button, the version is

displayed in order of CE2, MC, SYS, UI, DVD, ST, TA, TM

and WDS2D.

3. Press the PRESET > + button and the date of the softw are

production is displayed.

4. Press the PRESET > + button again and the version is

displayed.

5. To exit from this mode, press three buttons x ,

[PROGRESSIVE] and [TUNER AM] simultaneously.

2-2. Key Test Mode

Procedure:

1. When the panel test mode is activated, press the [DSGX] button,

to select the key test mode. In the key check mode, the

fluorecent indicator displays “K 0 V0”. Each time a b utton is

pressed, “K” value increases. However, once a button is

pressed, it is no longer taken into account. When all keys are

pressed correctly, “K18 V0” is displayed.

2. To exit from this mode, press three buttons

[PROGRESSIVE] and [TUNER AM] simultaneously.

.

button and the message “WDS2D” is

x

,

3. Common Test

Procedure:

1. Press the ?/1 button to turn the power on.

2. To enter the common test mode, press three buttons x , the

[PROGRESSIVE] and [TIME/TEXT] simultaneously.

3. To exit from this mode, press the ?/1 button.

3-1. AMP Test

1. When the common test mode is activated, each time press the

[BASS/TREBLE] button, the message “EQ LVL MAX”, “EQ

LVL MIN”, “EQ LVL FLAT” is displayed in this order.

2. The message “VOLUME MAX” is displayed, when press the

[VOLUME +] button. The message “VOLUME MIN” is displayed, when press the VOLUME – button.

3. To exit from this mode, press the ?/1 button to turn off the

main power.

4. Function Change

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press the [FUNCTION] button to the function “VIDEO”.

3. Press the [VIDEO/SAT] button and the ?/1 button simulta-

neously, and the display changes to “VIDEO” or “SAT”.

4. To exit from this mode, press the ?/1 button.

5. Disc Tray Lock

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the ?/1 button to turn the set on.

2. Press the [FUNCTION] button to set DVD function.

3. Insert a disc.

4. Press the x button and the A button simultaneously for f ive

seconds.

5. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure :

1. Press the x button and the A button simultaneously for fi ve

seconds again.

2. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the ?/1 button.

6. AM Step Change

•A step of AM channels can be changed over between 9 kHz

and 10 kHz.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “TUNER”, and press the [TUNER AM]

button.

3. Press ?/1 button to turn the set OFF.

4. Press x and ?/1 buttons simultaneously , and the display of

fluorescent indicator tube changes to “ AM 9 k STEP” or “ AM

10 k STEP”, and thus the channel step is changed over.

19

Page 20

HCD-WS2D

DVD SECTION

4-1. GENERAL DESCRIPTION

The Mirror Time and IOP measurement allows you to make

diagnosis and adjustment simply by using the remote commander

and monitor TV. The instructions, diagnosis results, etc. are given

on the on screen display (OSD).

The Mirror Time and IOP measurement is required is such events

where servicing a DVD-Player includes changing the Base Unit

(BU). For each new BU to be used with a certain MV-044 board,

Mirror Time and IOP measurement need to be carried out.

4-2. STARTING TEST MODE

Press three buttons x , A and VOLUME + simultaneously

with the DVD player in standby mode.

The Test Mode starts, then the menu shown below will be

displayed on the TV screen.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History

4. Version Information

5. Video Level Adjustment

4-4. MIRROR TIME ADJUSTMENT

To enter Mirror Time Adjustment, press 5 “R” button on the remote

commander. The screen will appear as below.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold:

4. Save to EEPROM

5. Default set MIRR time

[Open] Tray open [Close] Tray close

[0] Return to previous menu

There are five main commands in the Mirr time Adjust menu as

shown in the figure above. The functions of each command are

described in the following page.

1. CD MIRR time Check

This command checks the Mirror time value for CD disc.

2. DVD MIRR time Check

This command checks the Mirror time value for DVD disc.

3. Threshold

This command displays the threshold value between CD and DVD

mirror time.

Model Name : WDS2D_XX

IF-con : V

Syscon : Ver.

er. xx.xx (xxxx)

x.xxx

The menu above is the Remocon Diagnosis Menu screen which

consists of six main function. At the bottom of the menu screen,

the model name and IF-con version. To enter Mirror Time

Adjustment menu, press button 2 “R” on the remote commander

to enter Drive Manual Operation menu. To exit from the Test Mode,

press the power button on the remote commander.

4-3. DRIVE MANUAL OPERATION

The Drive Manual Operation menu consists of five main

function. By pressing 2 “R” button on the remote commander in

the Remocon Diagnosis Menu, the screen will appear as below.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Mecha t est mode

5. MIRR time Adjust

0. Return to Top Menu

4. Save to EEPROM

This command saves an adjusted mirror time value to the EEPR OM.

5. Default set MIRR time

This command will set CD and DVD mirror time to firmware def ault

value.

[Open] / [Close]

Pressing the A button controls the tray for disc change

during mirror time adjustment.

[0] Return to previous menu

Press 0 “R” button to return to previous menu.

4-4-1. EXECUTING MIRROR TIME ADJUSTMENT

In order to execute mirror time adjustment, the following standard

procedures must be followed.

(1) In standby mode, press three buttons x , A and V OLUME

+ simultaneously.

(2) Select “2. Drive Manual Operation”.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History Check

4. Version information

5. Video Level Adjustment

20

Model : WDS2D_xx

IF-con : Ver. xx.xx (xxxx)

Syscon : Ver. x.xxx

Page 21

HCD-WS2D

(3) Select “5. MIRR time Adjust”.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Mecha test mode

5. MIRR time Adjust

0. Return to Top Menu

(4) Select “5. Default set MIRR time”.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [Close] Tray close

[0] Return to previous menu

(5) Select “3. Threshold”.

(6) Confirm the number. If it is 75, go to next step. If it is any

other value, return to step 4.

MIRR time Adjust Menu

(14) Confirm the same values are displayed. If it is not same,

return to step 7.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(15) Push A button to eject tray.

(16) Take out HLX-504 and insert Test Disc YEDS-18 into

tray.

(17) Push A button to close tray.

(18) Push “1. CD MIRR time check”.

(19) Wait for HEX number to display.

(20) Confirm the number, if YY is 5A ~ E8, proceed with next

step. If no, return to 15.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold: 75

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [Close] Tray close

[0] Return to previous menu

(7) Push A button to eject tray.

(8) Insert Test Disc HLX-504 into tray.

(9) Push A button to close tray.

(10) Push “2. DVD MIRR time Check”.

(11) Wait for HEX number to display.

(12) Confirm the number, if XX is 28 ~ 70, proceed with next

step. If no, return to 8.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check: xx xx

3. Thereshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] tray open [close] Tray close

[0] Return to previous menu

1. CD MIRR time Check: yy YY

2. DVD MIRR time Check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(21) Push “4. Save to EEPROM”.

(22) Confirm the same values are displayed. If it is not the

same, return to step 15.

MIRR time Adjust Menu

1. CD MIRR time check: YY YY

2. DVD MIRR time check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(23) Push A button to eject tray.

(24) Remove Test Disc YEDS-18 from tray.

(25) Push A button to close tray.

(26) Press 0 “R” button to the Drive Manual Operation menu.

(13) Push “4. Save to EEPROM”.

(27) Press 0 “R” button to return to the Remocon Diagnosis

Menu.

(28) Press the ?/1 button to switch OFF set.

21

Page 22

HCD-WS2D

4-5. EXECUTING IOP MEASUREMENT

In order to execute mirror time adjustment, the following standard

procedures must be followed.

(1) In standby mode, press three buttons x , A and VOLUME

+ simultaneously.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History Check

4. Version information

5. Video Level Adjustment

Model : WDS2D XX

IF-con Ver : XX.XX (XXXX)

Syscon Ver : X.XX

(2) Select “2. Drive Manual Operation” by pressing the 2 “R”

button on the remote commander. The screen will appear as

below.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Tray Aging Mode

5. MIRR time adjust

0. Return to top Menu

(5) Wait until a hexadecimal number appear.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop. ED 9E:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

Change Value

[0] Return to previous menu

(6) Convert each data from hexadecimal to decimal using

conversion table.

(7) Substract between these two values.

(8) If the remainder is smaller than 93 (decimal), then it is

OK. However if the value is higher than 93, then the BU

is defective and need to be change.

(9) Press RETURN “R” button to return back to previous menu.

(10) Press 0 “R” button to return to Top Menu and power OFF

the DVD Player.

(3) Select “3. Manual Adjustment” by pressing the 3 “R” b utton

on the remote commander. The screen will appear as below.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eg boost Adjust:

6. Iop:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

o O Change Value

[RETURN] Return to previous menu

(4) Select Iop by pressing 6 “R” button on the remote commander .

22

Page 23

SECTION 5

DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Schematic Diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note: The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• B : B– Line.

•Voltages and wavef orms are dc with respect to ground under no-signal (detuned) conditions.

•Voltages and waveforms are dc with respect to ground in

service mode.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

no mark : DVD STOP

•Voltages are taken with VOM (Input impedance 10 MΩ).

• Circled numbers refer to waveforms.

• Signal path.

J : CD PLAY

c : DVD PLAY

I : SACD PLAY

L : VIDEO

E : Y

a : CHROMA

r : COMPONENT VIDEO

q : R, G, B

f : AUDIO (TUNER)

h : AUDIO (ANALOG)

i : AUDIO (DIGITAL)

•Abbreviation

E3 : 240 V AC Area in E model.

HK : Hong Kong model.

RU : Russian model.

SP6 : Singapore and Malaysia models.

4

W or less unless otherwise

For Printed Wiring Boards.

Note:

• X : parts extracted from the component side.

• a : Through hole.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(SIDE A) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(SIDE B) the parts face are indicated.

• Indication of transistor.

C

Q

B

E

B

These are omitted.

Q

CE

These are omitted.

• Circuit Boards Location

DISPLAY board

HEADPHONE board

MS-203 board

FUNCTION board

HCD-WS2D

VIDEO board

MAIN board

DMB10 board

DROP TEST board

SPEAKER OUT board

REGULATOR board

SWITCHING REGULATOR

S-MASTER board

HCD-WS2D

2323

Page 24

HCD-WS2D

5-1. BLOCK DIAGRAM – RF/SERVO SECTION –

RFMON

RF

DETECTOR

OPTICAL PICK-UP

BLOCK

(KHM-310CAA/C2NP)

VC

LASER

DIODE

(FOR CD)

LASER

DIODE

(FOR DVD)

CD LD

PD

DVD LD

VR650

VR780

DVDRFIP

6

OSP

252 253

A

B

C

D

F

E

B

A

C

D

SW+3.3V

Q102 (1/2)

AUTOMATIC POWER

CONTROL (FOR CD)

Q102 (2/2)

AUTOMATIC POWER

CONTROL (FOR DVD)

Q101, Q103

VOLUME CONTROL

A

B

D

C

2

3

4

5

19

18

8

9

10

11

176

29

23

20

21

22

187

DVDA

DVDB

DVDC

DVDD

TPI

TNI

NA

NB

MD

MC

LI M SW

V20

LD01

MD12

MD11

LD02

MSW

OSN

IC102 (1/3)

CD/DVD RF AMP,

FOCUS/TRACKING ERROR AMP

DVD SYSTEM PROCESSOR

DIGITAL SERVO PROCESSOR

V2REF0

RXD

TXD

XTALO

XTALI

PRST

IFCK

MREQ

IFSDO

IFSDI

XIFCS

28

106

107

228

229

110

99

114

98

101

100

X101

27MH

Z

V2REF0

RXD

TXD

for TEST

34

P_ID_IO_SYSRST

PI_DVD_SCK

33

25

P_I_MREQ

32

P_I_DVD_SI

31

P_O_DVD_SO

26

P_I_DVD_XIFCS

2AXIS

DEVICE

FOCUS/

TRACKING

COIL

VCC

FCS+

FCS–

TRK+

TRK–

M2

(SLED)

M1

(SPINDLE)

M203

LOADING MOTOR

MM

MM

MM

+3.3V

SP+

SP–

FOCUS/TRACKING COIL DRIVER,

SPINDLE, SLED MOTOR DRIVER

42

41

36 48

37 1

35 3

34 4

32

31

SL–

30

SL+

29

27

28

47

46

24

25

IC201

BUFFER

FOCUS COIL

DRIVE

TRACKING COIL

DRIVE

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

BUFFER

LOADING MOTOR

DRIVER

TSD

43

10

13

40

45

19

20

22

21

15

16

17

VREF0

FOO

TRO

FMO

DMO

TROPENPWM

FWD

REV

OCSW

CKSW

VREF0

FMO

FOO

DMO

TRO

38

FMO

42

FOO

37

DND

41

TRO

V REFO

30

246

V REFO

40

IOPMON

47

SPFG

184

MUTE123

183

MUTE

181

TSDM

TROPENPWM

39

FWD

186

REV

185

OCSW

177

CKSW

179

IFBSY

KRMOD

105

207

P_VIDEO_MUTE

28

P_O_DVD_BUSY

27

P_I_KRMOD

IC401 (1/3)

SYSTEM

CONTROLLER

19

P_DVD_I_MTK_SLOT_IN

23

VMUTE

SECTION

(Page 25)

• Signal Path

A

VIDEO

: CD PLAY

: DVD PLAY

:SACD PLAY

HCD-WS2D

2424

Page 25

5-2. BLOCK DIAGRAM – VIDEO SECTION –

Y

194

YUV1

C

196

YUV2

V

198

YUV3

200

YUV4

202

YUV5

203

YUV6

171

WODE

Y/G

HCD-WS2D

IC100

VIDEO AMP, 75Ω DRIVER

6

YIN

2

CIN

4

CVBSIN

10

CYIN

Cb

Cr

12

CBIN

14

CRIN

25

SI

MUTE1

3

139

YOUT

COUT

CVBSOUT

CYOUT

CBOUT

CROUT

MUTE2

21

26

21

43

J100

S VIDEO OUT

• Signal Path

VOUT

23

J102

VIDEO OUT

: VIDEO

: Y

CYOUT

20

CBOUT

18

CROUT

16

Y,P

CB,P

C

B

R

R

J103

COMPONENT

VIDEO OUT

VMUTE

: CHROMA

: COMPONENT VIDEO

: R, G, B

RF/SERVO

A

SECTION

(Page 24)

SCL

SDA

B

SPEAKER

SECTION

(Page 26)

SCL

102

103

6 5

SCL

IC103

EEPROM

SDA

SPA

IC102(2/3)

DVD SYSTEM PROCESSOR

AD0 – AD7

81-84,86-88,91

HD0 – HD7 A0 – A21

DATA & ADDRESS BUS

DATA & ADDRESS BUS

HD0 – HD7

29,31,33,35,38,40,42,44 25-16,10-1, 48

DQ0 – DQ7

HIGHA0-7

IOA0-7, IOA18-IOA20

A16, A17

53-61, 67-72, 74-76,

78, 89, 92, 93

A0

A0 – A19DQ15/A-1

IC101

FLASH ROM

188

DSEL

A1-A21

XRD

XROMCS

2645

28OE11

CE

IOCS

77

79

XRD

XROMCS

XWR

WE

IOWR

IOUE

66

XWR

2,4,5,7,8,10,11,13,42,44,45,47,48,50,51,53

RD0 – RD15

125-123, 121, 120, 118,

117, 115, 135, 133-128, 126

RD0 – RD15

RA0 – RA11

146, 147, 149-151,

158-160, 162, 164-166

22-26,

29-35

RA0 – RA11

IC104

SDRAM

RCLK

RCS

RWE

MRAS

BA0

BA1

143

20

142

145 156 113 137 157

38

19

21

BS0

BS1

DRCLK

138

RCS

CAS

140

139

16

18

17

CAS

RAS

RWE

MDQM0

15

DQM0

MDQM1

39

DQM1

CKE

37

DRCKE

HCD-WS2D

2525

Page 26

HCD-WS2D

5-3. BLOCK DIAGRAM – SPEAKER SECTION –

IC102(3/3)

DVD SYSTEM PROCESSOR

225

VIDEO

AUDIO OUT

SPDIF

217

ASDATA0

ASDATA1

218

ASDATA2

219

ASDATA4

222

215

ACLK

214

ABCK

213

ALRCK

220

XRST

VIDEO SECTION

(Page 25)

FM/AM

TUNER UNIT

L CHFM IN

R CHAM IN

RDS CLK

RDS DATA

TUNED

DI

CLK

DO

CE

L

R

J301(1/2)

S055

CD/SACD

B

L-IN

R-IN

S044

S045

PROGRESSIVE

S056

14

15

16

13

10

9

17

8

19

20

AM

FM

DVD

PLAY

AMS+

AMS–

PAUSE

S054

DSGX

STOP

IC301

8-CH D/A CONVERTER

STDI1

STDI2

STDI3

STDI4

MCLK

BICK

LRCK

PDN

SCL

SDA

TIME/TEXT

S039

DIMMER

S052

BASS/TREBLE

S053

SOUND

FIELD

LOUT1– FL

1

LOUT1+

2

ROUT1+

48

47

ROUT1–

LOUT4+

38

LOUT4–

37

ROUT4+

33

32

ROUT4–

S043

S041

POWER

S040

DISPLAY

S042

CD OPEN

IC3711

L.P.F

2

3

5

6

3

2

5

6

IC3771

L.P.F

Q307,308

SURR/2ch STEREO

IC391

RESET

3 1

2

–

+

–

+

–

+

–

+

SELECT

1

7

1

7

Q391

FR

LT

RT

32.768KHz

X401

X402

5KHz

Q311-314

SIGNAL

SELECT

88

43

37

38

39

40

41

75

76

12

20

94

95

97

71

72

10

11

13

15

IC401(2/3)

SYSTEM CONTROLLER

P_VACS

SURR

ST TUNED

ST DIN

ST CLK

ST DOUT

ST CE

RDS CLK

RDS DATA

RESET

ACCUT

KEY_2

KEY_1

KEY_0

VOL A

VOL B

XC IN

XC OUT

X OUT

X IN

P_RECOUT_MUTING

P_SM_NSP_MUTING

AUDIO SELECTOR

SUR2 L RECA2

41

SUR1 R

42

INC2

38

INC1

5

39

INB2

4

INB1

37

IND2

IND1

6

RECB2

35

RECB1

8

CLOCK

22

DATA

21

P_AMPIC_CLK

P_AMPIC_DATA

P_HP_MUTING

P_HEADPHONE_IN

P_SM_DRV_RST

P_SM_SD

P_SM_OTW

P_ADC_RESET

SOFT_MUTE

PG_MUTE

P_SM_DATE

P_SM_CLK

P_SM_CS1

P_SM_INT

P_SM_ODF

IC301

70

69

61

42

60

54

55

56

59

57

68

67

1

2

52

58

53

RECA1

OUT2

OUT1

IC303

DIGITAL

OPTICAL OUT

36

7

25

18

A+9V

Q304

RIPPLE FILTER

2

3

5

6

Q310,368,369

MUTE

8

–

+

–

+

IC302

HP AMP

LT

1

RT

7

L-OUT

R-OUT

Q370,371

MUTE

HP SW

Q305,306

MUTE

HP R

HP L

J301(2/2)

L

R

VIDEO

AUDIO OUT

J066

i

• Signal Path

: AUDIO(TUNER)

: AUDIO(ANALOG)

: AUDIO(DIGITAL)

Q301

MUTE DRIVE

Q302

MUTE DRIVE

IC707

IC701

A/D CONVERTER

LIN

1

2

7

CLOCK GEN

2 4 1 3

49.152MHz

X702

RIN

PDWN

IC709

DOUT

BCK

LRCK

SCKI

12

11

10

15

IC703

24.576MHz GEN

CK Q

IC705

DATA CONVERTER

DATA

31

BCK

30

LRCK

29

XFSOIN

48

XFSIIN

36

NSPMUTE

18

SOFTMUTE

19

PGMUTE

20

SCDT

21

SCSHIFT

22

SCLATCH

23

INIT

27

OVF FLAGR

24

OVF FLAGL

25

OUTL1

OUTL2

OUTR1

OUTR2

/RST

/SD

/OTW

11

9

6

4

4

/RST

13

/SD

15

/OTW

2

BP

17

AP

4

13

15

2

17

POWER AMP

OUTB

OUTB

OUTA

OUTA

Q701

PROTECT

/RST

/SD

/OTW

BP

AP

IC708

POWER AMP

OUTB

OUTB

OUTA

OUTA

30

29

26

25

Q702,703

DC OFFSET

DETECT

Q752,753

DC OFFSET

DETECT

L-CH

SPEAKER

FAN CTRL

C

POWER

SECTION

(Page 27)

30

29

26

25

R-CH

SPEAKER

HCD-WS2D

2

S060

VOLUME ENCODER

1

3

2626

Page 27

5-4. BLOCK DIAGRAM – POWER SECTION –

30.5V

G+12V

A+5V

IC710

A+5V REG

HCD-WS2D

A+9V

Q011, Q012

D006

D+4V

FL001

FLOURESCENT INDICATOR

5

40

45

58

4

SEG1

39

SEG5

41

COM2

52

COM13

COM1

40

COM14

53

IC001

FL DRIVER

RESET

D+3.3V

1.8V

T001

DC/DC CONVERTER

TRANSFOTMER

D001-004

VP

Q202

OSC

–32V

63

DA

CP

62

CS

61

60

DVD M+9V

M+9V

AUDIO+9V

UNREG+10.5V

SW+5V

DVD A+5V

3.3V

3.3V

SW3.3V

1.8V REG

IC105

3.3V REG

IC107

3.3V REG

IC704

IC706

D3.3V REG

IC204

DVD M+9V REG

IC201

M9V REG

IC202

AUDIO +9V REG

IC205

SW +5V REG

IC206

SW3.3V REG

AC IN

UNREG+12V

POWER UNIT

UNREG+10.5V

EVER+4V

ON/OFF

EVER+4V

D385

IC041

REMOTE CONTROL

RECIVER

3

+3.3V

OUT

1.8V

RF1.8V

IC401(3/3)

SYSTEM CONTROLER

FAN DRIVE

47

48

49

5

DATA

7

D041

STANBY

2

CLK

6

CS

3

RESET

100

STANBY LED

4

SIRCS

P_O_DVD_POWER

STBY_RELAY

EVER+4V

D+4V

DVD_P_ON

ON/OFF

FAN DRV

IC106

1.8V REG

Q209,208

PWR CONT

SPEAKER

SECTION

(Page 26)

IC203

D+4V REG

c

FAN CTRL

Q271

Q272,273

Q274

DC FAN

HCD-WS2D

2727

Page 28

HCD-WS2D

5-5. PRINTED WIRING BOARD – DMB10 SECTION (SIDE A) –

H

VIDEO

BOARD

CN100

(Page 45)

• See page 23 for Circuit Boards Location. :Uses unleaded solder.

C3803

R3805

C3804

C3802

E

Q3801

R3804

C3805

AEP, UK, RU

E

2

1

R3803

R3788

R3787

C3784

C3783

R3785

R3786

R3782

R3784

C3781

R3782

R3781

IC103

C3777

C3773

R3775

R3782

R3778

R3777

C3774

R3776

R3774

R3772

C302

C3772

C3771

M

CN302

R3773

R3771

C306

MAIN

BOARD

CN302

(Page 36)

R3728

C3722

C3724

C3723

R3725

R3726

C3722

R3722

C3724

R3721

C3721

R3723

C305

R3653

C3701

20

21

C3718

R3718

C3711

R3712

R3776

R3718

R3717

C3774

R3716

C3712

R3713

R3711

R3651

R3802

C307

C3801

R3801

R319

IC103 (EEP ROM) can not be replaced individually.

✩

Replace it with DMB10 board assembly for service.

• Semiconductor

Location

Ref. No.

D1001 D-6

D3501 A-5

D3502 A-5

IC101 E-4

IC103 C-5

IC104 D-5

IC106 D-6

IC201 E-6

Q103 C-3

Q3801 B-5

Location

OPTICAL

PICK-UP

BLOCK

(KHM-310CAA/C2NP)

R243

CN202

C226

C225

IC101

R1545

IC102

IC104

1

5

IC106

F

R227

C223

R228

IC201

10

11

REGULATOR

BOARD

CN203

(Page 39)

for

TEST

HCD-WS2D

G

MS-203

BOARD

CN001

(Page 43)

A

MAIN

BOARD

CN313

(Page 36)

2828

Page 29

HCD-WS2D

5-6. PRINTED WIRING BOARD – DMB10 SECTION (SIDE B) –

• See page 23 for Circuit Boards Location. :Uses unleaded solder.

R3779

R3719

1

4

IC3711

C301

R314

C3702

R3729

8

5

48

1

IC301

13

IC3771

C3708

R3789

1

8

4

5

R1524

36

25

R3501

R1161

R1126

R1552

R1526

IC107

3

4

• Semiconductor

Location

R321

IC105 D-5

IC107 B-5

IC301 C-2

Ref. No.

R308

IC3711 B-2

IC3771 B-3

Q101 C-5

Q102 D-5

1

5

S

S

Location

R222

R1555

R236

R238

R2505

IC105

4

5

R239

E

E

3

1

R237

HCD-WS2D

2929

Page 30

HCD-WS2D

5-7. SCHEMATIC DIAGRAM – DMB10 SECTION (1/4) –

CN401

5P

JL4601

JL4602

JL4603 JL4604

JL4605 JL4606

JL4607 JL4608

JL4609 JL4610

40

FB402

FL401

0UH

0UH

C402

16V

47

FB404

0UH

FB403

FB401

FL403

0UH

0UH

C403

47

6.3V

FL402

EMI

0UH

FB406

0UH

FB405

0UH

31, 32, 33

31, 32, 33

33

R3781

R3783

2.2k

R3651

0

C301

ICT301

0

R3653

R3652

0

31

JL345

JL346

JL347

JL348

JL349

R314

JL344

100

JL343

0.01

IC301

AK4358VQ-L

JL3653

JL3652

JL3651

C305

0.47

C306

6.3V

100

C3771

1500p

R3803

10k

R3802

R3804

15k

C3801

6.3V

R3801

0

Q3801

2SC2712-YG

-TE85L

C3802

10

100

0

R3805

1k

C3805

47

4V

C3803

100

4V

C3804

47

6.3V

L.P.F

C3781

1500p

R3782

R3772

2.2k

R3771

2.2k

C3721

1500p

R3722

2.2k

L.P.F

R3721

2.2k

2.2k

C3701

0.1

R3784

5.6k

R3785

R3775

4.7k

R3774

5.6k

R3773

5.6k

R3724

5.6k

R3725

4.7k

5.6k

4.7k

R3723

5.6k

C3782

2200p

C3708

0.1

C3773

C3722

2200p

C3702

0.1

C3783

470p

470p

C3772

2200p

C3723

470p

R3787 R3788

1k

R3786

1k

0.1

C3707

R3776

1k

R3777

R3727

1k

R3726

1k

4.7k

C3784

470p

R3779

C3774

470p

R3778

1k 4.7k

R3728

4.7k

C3724

470p

R3789

IC3771

NJM3414AV(TE2)

1k

IC3711

NJM3414AV(TE2)

1k

R3729

CN302

R3501

1k

JL3501

0

JL3502

JL3503

JL3504

JL3505

JL3506

JL3507

JL3508

JL3509

JL3510

JL3511

JL3512

JL3513

JL3514

JL3515

JL3516

JL3517

17P

31

37

HCD-WS2D

C3714

R3719

31

R319

0

C307

100

C302

0.47

6.3V

R3712

2.2k

C3711 C3712

1500p 2200p

R3711

2.2k

4.7k

R3714

5.6k

R3713

5.6k

C3713

470p

R3716R3715

1k

R3717

1k

470p

R3718

4.7k

1k

D3501

1SS355TE-17

D3502

1SS355TE-17

3030

Page 31

HCD-WS2D

5-8. SCHEMATIC DIAGRAM – DMB10 SECTION (2/4) –

(Page 33)

R126

0

(Page 30, 32, 33)

(

KHM-

310CAA/

C2NP

(Page 33)

)

(Page 33)

(Page 32)

(Page 33)

(Page 33)

(Page 33)

TROPENPWM

CN101

FL101

0UH

24P

R101

100

CL106

C101

JL139

0.01

JL140

JL141

JL142

JL143

JL144

CL112

JL145

JL146

CL113

JL147

JL148

CL114

JL149

CL115

JL150

CL116

JL151

JL152

JL153

CL117

JL154

CL118

JL155

JL156

JL157

JL158

JL159

Q101

UM6K1N-TN

R108

ICT121

ICT123

R110

47k

R107

10k

CL107

ICT114

ICT115

ICT117

ICT118

TROPENPWM

ICT129

IC107

C192

TK11133CSCL-G

0.01

R116

1k

C117

10 16V

C115

0.1

C118

10 16V

C116

R117

0.1

47k

ICT127

R111

1M

100

R113

R112

R115

22

22

22

C105

47

6.3V

ICT124

R114

C106

R1129

100k

0.01

100k

R109

0

ICT126

RT1N241C-TP-1

22

22

22

C112

47

6.3V

121

R120

R

R118

Q102

QST8TR

• See page 55 for IC Pin Function Description. • See page 47 for Waveforms.

(Page 32)

R138

C193 C195

0.22

C114

0.1

C119

10

16V

Q103

R124

47k

R123

0

C113

0.01

C120

C121

C122

C123

C124

CL1501

ICT125

2p

100k

2

0.1

40

39

1

C

C132C130

0.10.1

ICT128

0.22

1

1

1

1

1

C125

0.1

C126

0.1

C196

0.0047

TROPENPWM

R133

3.3k

R134

3.3k

R135

3.3k

C127

0.01

C128

0.0015

CL105

JL101

JL130

JL167

JL102

JL127

JL132

JL133

CL101

JL135

CL104

CL108

CL109

CL110

JL136

k

15

C133

0.1

136

R

C1

1

.00

0.1

0

0.033

137

138

135

C

C

C

.1

0

0.1

0.1

1

141

C

JL103

C143

C146

C145

C147

0.047

.1

0

142

C

V

04

JL1

C149

0.1

C148

0.047

12p

16

150

JL105

C

JL106

10

152

C

k

0.001

750

151

141

C

R

DMB10 BOARD

(Page 30)

4

TA

A

D

AS

z

H

M

p

27

101

X

100k

142

R

T133

12

0

IC

R143

4

547

100

153

C

470

68

11

R

CXD9804R

156

14

4.7k

0.01

C

R1

R

0.1

154

C

IC102

(Page 30)

ST

XR

4.7k

7

4.7k

0

0

4

47

0

154

R

R151

47

49

53

155

47

15

160

1531

R

R1

R

R

R

1550

4.7k

R

548

.7k

1

166

4

R

JL

R

30

15

R

R1551

4.7k

C159

0.01

R1543

5

29

16

JL

10k

JL1

(3/4)

104

(Page 32)

D

O

IC

RM

M

K

4

52

1

R

0

6

52

1

0

.01

0

C161

0

2

R154

160

JL128

JL

7

C163

0.01

6

8

0

89

192

19

150

150

R

R1

1102

150

150

150

197

R1120

R195

R

R

ICT136

ICT134

JL113

CL120

JL161

JL162

0UH

150

R

R1121

0UH

R1125

0UH

R1124

0UH

R1123

0UH

R1122

0UH

R1101

2.2k

R1553

C170

0

0.01

R1161

C172

R1108

R1554

JL163

R1126

0

2.2k

C171

0.01

R1107

0.01

10k

R1109

4.7k

C173

0.01

C174

0.01

C175

0.01

C176

0.01

RB108

22

JL4701

JL4702

R4701

0

JL4703

JL4704

JL4705

JL4706

R4702

0

JL4707

JL4708

R4703

0

JL4709

JL4710

R4704

0

JL4711

JL4712

R4705

0

JL4713

R4706

0

R1103

10k

10k

R1104

10k

R1105

0

ICT1501

0

4.7k

R1555

R1111

0

RB104

0

RB103

0

RB111

0

ICT138

ICT109

ICT130

CN301

13P

R321

(Page 30, 32, 33)

0

R308

0

DMB10 BOARD

FWD

101

REV

CKSW

102

OCSW

(Page 33)

(4/4)

(Page 33)

(Page 33)

DMB10 BOARD

(4/4)

(Page 33)

H

VIDEO

BOARD

CN100

(Page 46)

HCD-WS2D

DMB10

BOARD

(1/4)

(Page 30)

100

ICT112

FL105

0UH

C129

10

16V

SCL

SDA

C131

2.2

1

C136

0.0

C144

0.01

13

T1

JL168

IC

C155

9

0.01

JL16

JL170

0

152

R

JL171

JL172

C158

0.01

C160

100

0.01

100

557

R164

1

161

100

R

R

JL164

RB113

C164

0.01

22

173

JL

0

1504

R

RB112

22

R196

C177

C162

47

0.01

6.3V

RB107

0

22

FL106

0UH

(Page 32)

(Page 32)

3131

Page 32

HCD-WS2D

5-9. SCHEMATIC DIAGRAM – DMB10 SECTION (3/4) –

IC101

*

MBM29DL32TF70-OBA4-0501GA(E3,HK,SP6)

MBM29DL32TF70-OBA4-0501CE(AEP,UK,RU)

IC101

*

(Page 31)

(Page 31)

IC103 (EEP ROM) can not be replaced individually.

✩

Replace it with DMB10 board assembly for service.

C181

0.1

RB106

47

C180

0.1

C191

0.1

A

MAIN

BOARD

CN313

(Page 38)

DMB10

BOARD

(4/4)

(Page 33)

103

OSCW1

MIC

VOICE 12

KRMOD

CN106

13

CN105

RB105

R104

0

R105

10k

R106

10k

R1546

3.3k

13P

6P

JL107

JL108

JL109

JL110

JL111

JL112

JL138

JL114

JL115

JL116

JL117

JL118

JL119

JL120

JL121

JL122

JL123

C102

0.01

R169

10k

R1133

R1134

ICT110

ICT111

0

IC106

PQ018EZ01ZP

0

FL104

0UH

R193

R191

1k

IC103

ICT104

ICT106

ICT102

R1546

3.3k

ICT107

ICT105

ICT101

R1150

R1152

3.3k

R1151

3.3k

3.3k

ICT103

0.001

C108

R1110

ICT137

FB111

0UH

FB112

0.001

C109

2.7k

R1502

FB113

FB114

FB115

0UH

0UH

0UH

0

0UH

BR24L64F-WE2

C167

0.01

1k

FL107

0UH

C178

47

4V

IC104

HY57V64162

0HGTP-HDR

ICT108

C184

0.01

C182 C188

0.22 0.22

IC105

TK11133CSCL-G

C189

0.33

R187

0

D1001

RB501V-40TE-17

C179

0.1

FL108C190

0UH47 6 . 3V

C187

47

4V

47

(Page 30, 31, 33)

(Page 31)

(Page 30, 31, 33)

HCD-WS2D

104

KRMOD

VOICE

DMB10

BOARD

(2/4)

(Page 31)

(Page 31)

3232

Page 33

5-10. SCHEMATIC DIAGRAM – DMB10 SECTION (4/4) –

(Page 31)

(Page 30, 31, 32)

(Page 31)

R212

10k

C233

0.0047

C209

0.033

R220

10k

R223

100k

R221

56k

C211

0.033

R226

R225

100k

HCD-WS2D

DMB10

102

103

BOARD

(2/4)

(Page 31)

DMB10

BOARD

(3/4)

(Page 32)

G

MS-203

BOARD

CN001

(Page 44)

CKSW

C225

0.001

R250

R236

R237

R232

18k

CL207

CL208

R234

R233

33k

10k

C215

0.01

CL209

R231

15k

R230

82k

C212

56k

0.01

0.001

C214

CL206

R238

4.7k

50

1k

1k

R239

4.7k

R246

4.7k

50V

C226

0.001

50V

R243

100

OCSW

OCSW1

OCSW1

CKSW1

GND

LDM–

LDM+

NC

7 TRG_SW

CN202

(Page 31 )

(Page 31)

TROPENPWM

R222

C205

220p

C206

220p

C208

0.01

R215

12k

R216

R214

15k

12k

CL202

CL203

CL204

CL201

R219

27k

R224

CL210

CL211

CL212

C219

0.01

C224

0.01

C218

10

16V

IC201

FAN8036L

C223

0.1

16V

C213

R228

0.01

0

ICT207

C217

16V

47

10k

C210

0.01

CL205

R227

0

C220

16V

10

C221

0.1

C222

0.1

JL201

JL202

JL203

JL204

JL205

JL206

R247

1k

R208

33k

R206

10k

R209

33k

R207 C203

2.7k 0.01

R204

1.2k

R205

10k

R210

47k

R213

6.8k

33k

CN201

6P

(Page 31)

SLED

MOTOR

SPINDLE

MOTOR

(Page 31)

(Page 30, 32, 33)

(Page 30)

HCD-WS2D

(Page 31)

(Page 31)

FWD

101

REV

DMB10

BOARD

(2/4)

(Page 31)

3333

Page 34

HCD-WS2D

5-11. PRINTED WIRING BOARD – DISPLAY SECTION –

Z

IC041

• See page 23 for Circuit Boards Location. :Uses unleaded solder.

DISPLAY

I/1

DIMMER

TIME/

TEXT

• Semiconductor

Location

Ref. No.

D001 B-1

D002 B-1

D003 B-1

D004 B-1

D005 B-1

D006 C-6

D041 A-7

IC001 C-5

IC041 B-2

Q002 C-2

Q011 C-3

Q012 C-3

Location

IC001

E

E

MAIN

BOARD

C

CN315

(Page 36)

71

X

PRESET

–

.

PRESET

N

+

>

x

TUNER

AM

DVD

TUNER

FM

VIDEO/

SAT

HCD-WS2D

VOLUME

DSGX

SOUND

FIELD

BASS/

TREBLE

PROGRESSIVE

3434

SA-CD/

CD

7

1

Page 35

5-12. SCHEMATIC DIAGRAM – DISPLAY SECTION –

FL001

14ST50GNK

HCD-WS2D

C041

47

10V

RPM7240-H9

C007

100000p

R042

C042

0.001

47

D041

SELU5223C-STP15

D005

PTZTE25-6.2A

C005

0.1

C004

R003

R005

C024

680p

100000p

C032

330

6.3V

0.1

R040

1k

IC001

ML9208

100

R018

100

R017

100

R016

R015

R014

C025

100

C026

39p

3.3k

Q012

DTC143TKA

-T146

C030

C029

C028

C027

Q011

DTC143TKA-T146

100p

100p

100p

470

C031

10

50V

R020

3.9k

R011

3.9k

2.2k

R004

C006

100

100

D006

10EDB40-TB3

220

50V

R002

10k

D001

C003

1SS355TE-17

0.01

D002

1SS355TE-17

1SS355TE-17

D004

1SS355TE-17

T001

DC TRANS

D003

Q002(1/2)

CPH5504

C002

0.022

L001

R001

3.9k

-TL-E

Q002(2/2)

CPH5504

-TL-E

C001

22

50V

CN001

C008

0.1

17P

38

PL001

MOUNT

S041

R046

1k

S043

R043

2.2k

S039

MT

S042

S040

CN003

7P

HCD-WS2D

NO002

7P

R051

1k

R047

2.2k

R048

4.7k

S044

R049

10k

MT

SMK

R052

2.2k

R053

2.2k

R054

4.7k

S045

MT

R055

10k

R056

22k

SMK

R057

1k

S052

R058

2.2k

S053

R059

2.2k

S054

R062

4.7k

S056

R060

10k

S055

S060

VOL_ENCODER

3535

Page 36

HCD-WS2D

5-13. PRINTED WIRING BOARD – MAIN SECTION –

E

E

E

DVD DIGITAL OUT

OPTICAL

IC303

• See page 23 for Circuit Boards Location. :Uses unleaded solder.

ANTENA

TUNER

PACK

E

E

E

DMB10

BOARD

M

CN302

(Page 28)

Not used

Not used

IC391

31

51

IC401

1

100

81

AEP, UK, RU,E3

HK, SP6

, RU,E3

DMB10

BOARD

A

CN106

(Page 28)

S-MASTER

BOARD

B

CN700

(Page 41)

VIDEO/

SAT

L-IN

R-IN

L-OUT

R-OUT

E

E

• Semiconductor Location

Ref. No.

D383 C-2

D384 C-2

D385 C-7

D386 D-7

D387 D-7

D389 B-6

D390 B-6

D391 A-6

D392 A-6

D393 B-7

D394 B-6

D395 B-6

D396 C-6

D398 B-6

Location

Ref. No.

D399 C-6

D400 B-6

D401 B-7

D402 B-7

D403 B-2

D404 B-2

D405 B-4

D406 B-4

IC301 C-3

IC302 C-6

IC303 C-2

IC391 A-6

IC401 B-5

Location

IC301

Ref. No.

Location

Q301 C-5

Q302 C-5

Q304 D-5

Q305 D-6

Q306 D-6

Q307 B-2

Q308 B-2

Q310 D-4

Q311 B-2

Q312 B-2

Q313 C-2

Q314 C-2

Q368 C-3

Q369 C-4

E

REGULATOR

BOARD

E

CN207

(Page 39)

Ref. No.

Q370 C-2

Q371 D-2

Q391 A-6

Q704 E-3

Q705 D-3

Q706 D-2

Q707 E-2

Q708 B-6

Q801 C-8

Q851 C-7

Q852 C-6

Q881 C-8

Q882 C-8

Q883 C-8

Location

E

E

DISPLAY

BOARD

C

CN001

(Page 34)

IC302

E

E

E

E

HEADPHONE

BOARD

D

NO004

(Page 43)

HCD-WS2D

3636

Page 37

5-14. SCHEMATIC DIAGRAM – MAIN SECTION (1/2) –

CN311

*

FB401

HCD-WS2D

CN302

17P

0

2SC3052EF 2SC3052EF

R310

100k

1k

1k

L370

R342

10k

0.047

R303R304

47k47k

Q314 Q313

100k

R312

C302

100k

10

50V

C318

22

50V

SIGNAL SELECT

Q311

2SC3052EF

R309

10k

R313

100k

C303C301R311

105010

50

C304

10

50V

R314

100k

DTC114EKA

R301

47k

R315

2.2k

0.022

50V

PET

C312 C314

0.022

50V

PET

R316

2.2k

C305

10

50V

C313C311

0.022

50V

PET

0.022

50V

PET 10k

C306

10

50V

Q307Q308

DTC114EKA

R317

10k

IC301

M61529FP-D60G

R318

0.0047

C333

100 10V

SURR/2ch STELEO

R360

1k

C315

0.0047

C309

0.068

50V

PET

C310

0.068

50V

PET

C316

50V

1 50V 2.2k

C332 R334

SELECT

10 50V

C308

50V

Q310

2SC3052EF

30

1SS355

D403

1SS355

D404

R323

C307

10

R333C331

C334

10

50V

100k

C382

1500p

10V

100

1500p

C323

C381

C371

0.1

R336

100k

R340

2SC5938

1k

Q369

2.2k1 50V

R337

4.3k

R338R339

3.3k330

Q368

2SC5938

R335

100k

R341