Sony HCDW-550 Service manual

HCD-W550

SERVICE MANUAL

• HCD-W550 is the deck, CD section

in MHC-W550/W770AV.

Manufactured under license from Dolby Laboratories

Licensing Corporation.

“DOLBY” and the doub le-D symbol a are trademarks

of Dolby Laboratories Licensing Corporation.

CD

Section

Tape deck Model Name Using Similar Mechanism HCD-GR5/RX50

Section T ape Tr ansport Mechanism Type TCM-220WR2E

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Tourist Model

Model Name Using Similar Mechanism HCD-GR8/RX90

CD Mechanism Type CDM38-5BD29A

Base Unit Name BU-5BD29A

CD player section

system Compact disc and digital

audio system

Laser Semiconductor laser

(l = 780 mm)

Emission duration :

continuous

Laser output Max. 44.6 mW*

*This output is the value

measured at a distance of

200 mm from the

objective lens surface on

the Optical Pick-up Block

with 7 mm aperture.

Frequency response 2Hz - 20 kHz (± 0.5dB)

Wavelenght 780 - 790 mm

Signal to noise ratio More than 90 dB

Dynamic renge More than 90 dB

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

Wavelength 600 mm

Output Level - 18 dBm

SPECIFICATIONS

Tape player section

Recording system 4 track 2 channel stereo

Frequency response 60 - 13,000 Hz (± 3dB),

(DOLBY NR OFF) using Sony TYPE I

cassette

60 - 14,000 Hz (± 3 dB),

using Sony TYPE II

cassette

General

Dimensions (w / h / d)Approx. 280 ¥ 205 ¥ 359

mm

Mass Approx. 4.3 kg

Design and specifications are subject to change without

notice.

MICROFILM

STEREO CASSETTE DECK CD PLAYER

TABLE OF CONTENTS

1. GENERAL ······································································ 3

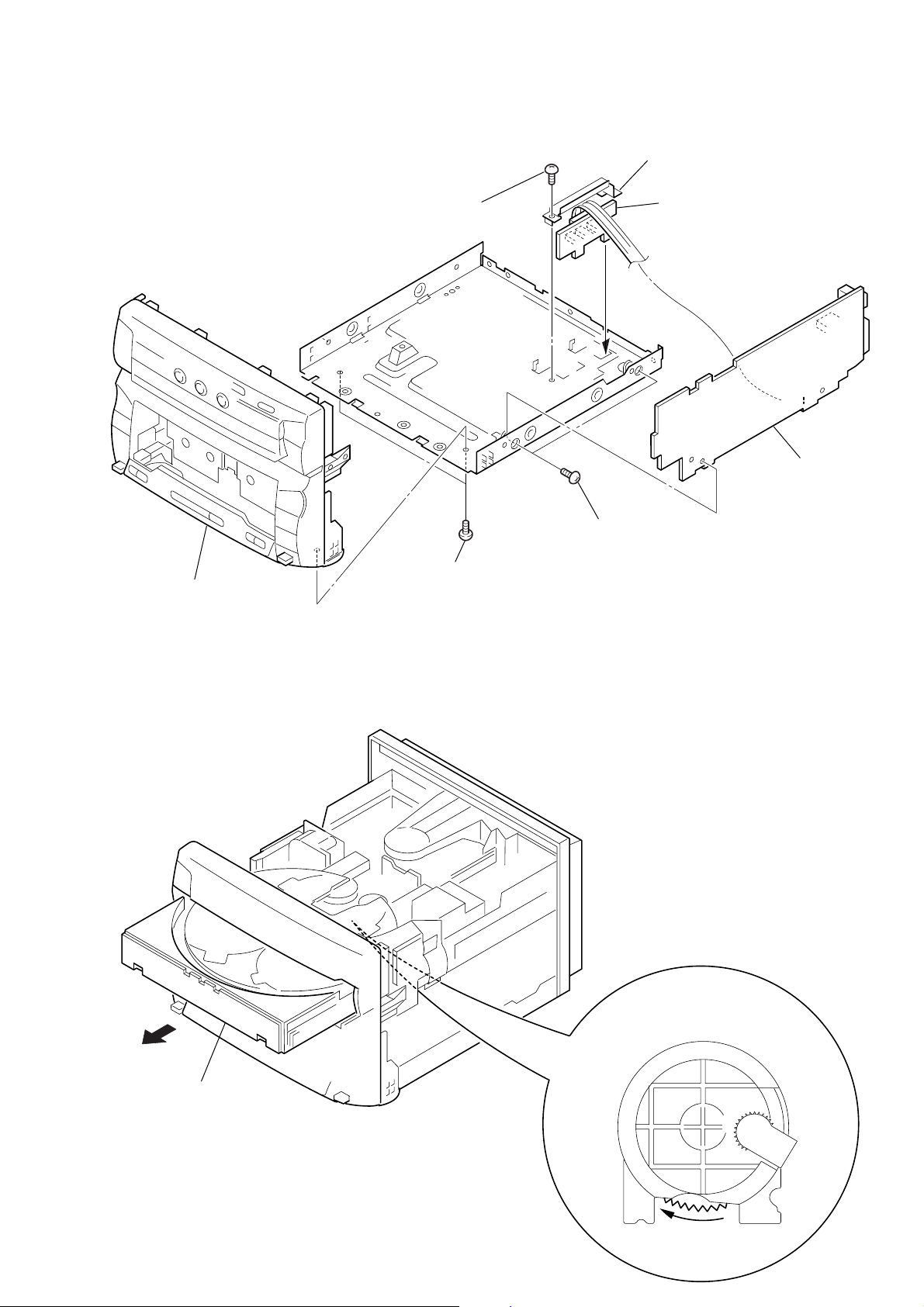

2. DISASSEMBLY

2-1. Back Panel, CD Block Removal········································· 4

2-2. Cassette Lid (A)/(B) Assy, Mechanism Deck Removal ···· 4

2-3. Main Board, Resistor Board, Front Panel Assy Removal ·· 5

3. ADJUSTMENTS

3-1. Mechanical Adjustment ······················································ 6

3-2. Electrical Adjustment ························································· 6

4. DIAGRAMS

4-1. Block Diagram ································································· 11

4-2. Circuit Boards Location ··················································· 13

4-3. Schematic Diagram — Audio Section —························· 14

4-4. Printed Wiring Board — Audio Section —······················17

4-5. Printed Wiring Board — BD Section — ·························· 19

4-6. Schematic Diagram — BD Section — ····························· 21

4-7. Printed Wiring Board — Motor Section —······················ 23

4-8. Schematic Diagram — Motor Section — ························ 25

4-9. Schematic Diagram — Panel Section — ························· 27

4-10. Printed Wiring Board — Panel Section —······················· 29

4-11. Printed Wiring Board — Main Section — ······················· 32

4-12. Schematic Diagram — Main Section — ·························· 35

4-13. IC Block Diagrams ··························································· 38

4-14. IC Pin Function ································································ 40

5. EXPLODED VIEWS

5-1. Main Section····································································· 42

5-2. Front Panel Section ·························································· 43

5-3. CD Mechanism Deck Section-1 (CDM38-5BD29A) ····· 44

5-4. CD Mechanism Deck Section-2 (CDM38-5BD29A) ····· 45

5-5. Base Unit Section (BU-5BD29A) ···································· 46

5-6. Tape Mechanism Deck Section-1 (TCM-220WR2E) ······ 47

5-7. Tape Mechanism Deck Section-2 (TCM-220WR2E) ······ 48

6. ELECTRICAL PARTS LIST ··································· 49

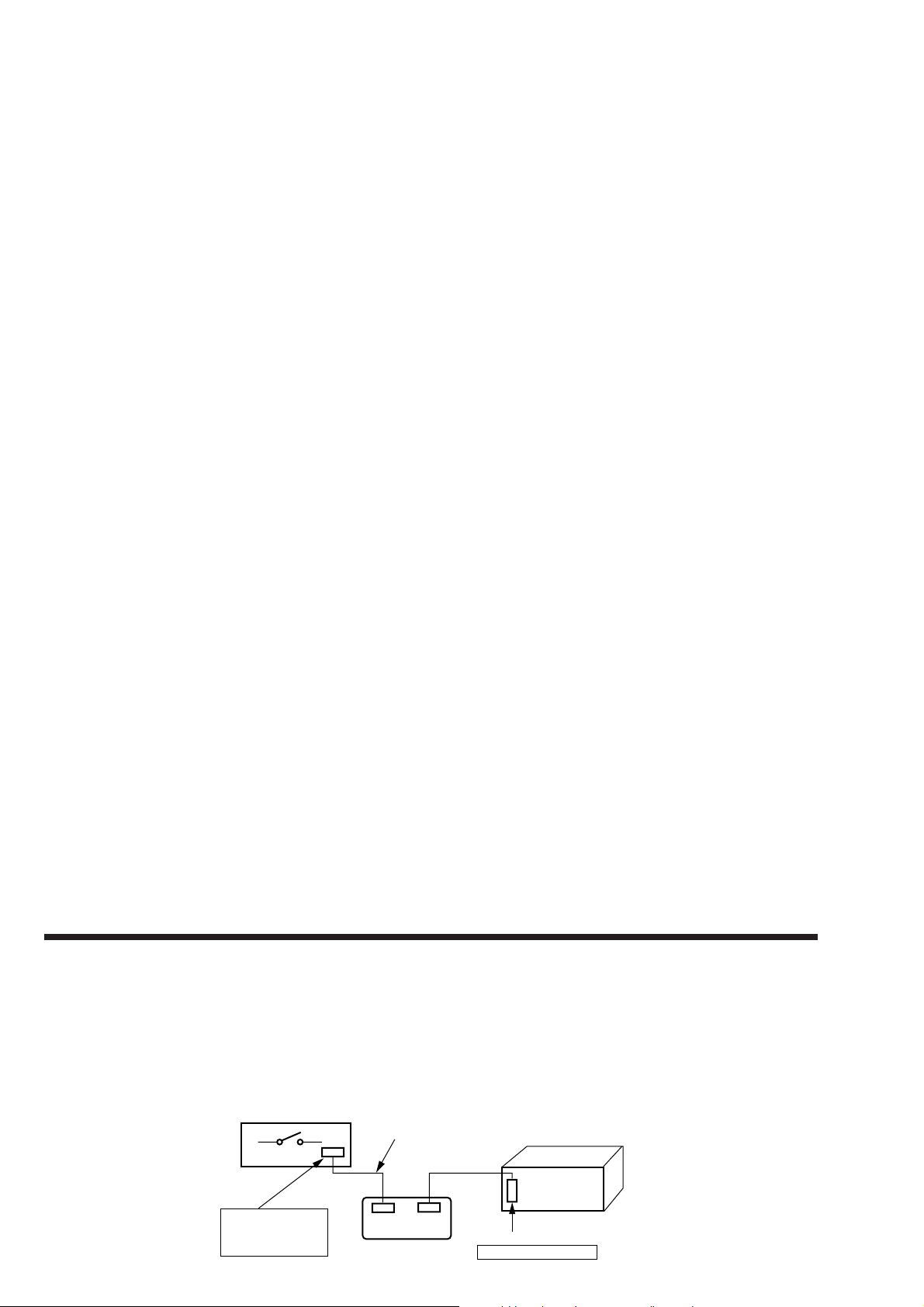

SERVICING NOTE

• Supplying power during servicing

This equipment cannot operate without using a separate power supply. Connect to the STR-W550/W770AV when performing service

work.

To apply power set the SYSTEM POWER switch on the Tuner/Amp to ON.

When other units are not available use the PFJ-1 power supply jig.

When using the PFJ-1, simultaneously press the CD STOP button and the DECK A ) (fast rightward) button to turn on the power.

[Connection Diagram]

FH-E939,838,737,

MHC-6600,5600,

CDP/TC

PFJ-1

(Power Supply Jig)

POWER SW

Connector Cable 17P

(Supplied with set)

Conversion Board

(J-2501-138-A)

Set

CNB108 17P

SYSTEM CONTROL

— 2 —

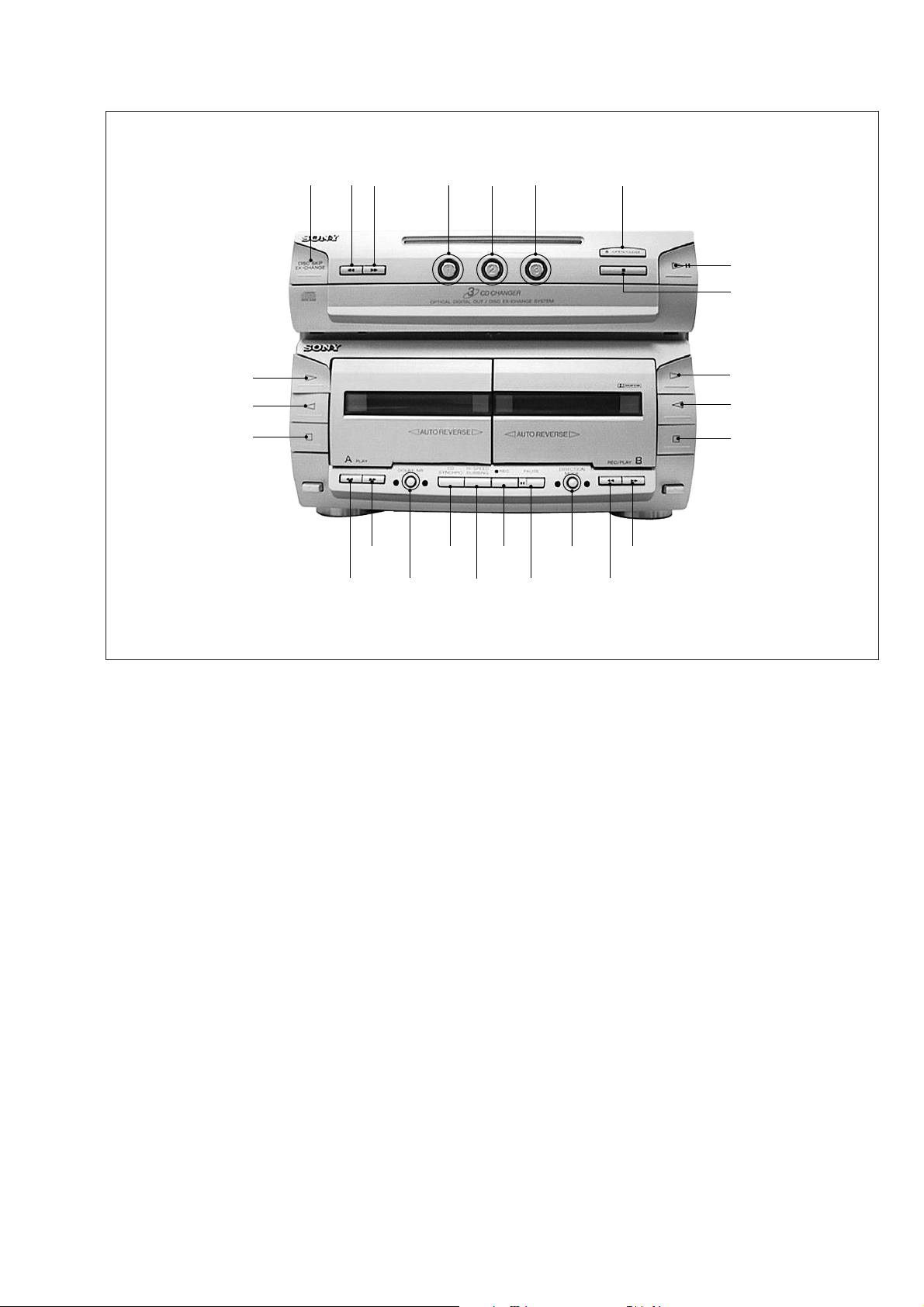

SECTION 1

GENERAL

123 456 7

8

9

@∞

@¢

@£

@¡

@™

1 DISC SKIP EX-CHANGE Button (CD)

2 0 Button (CD)

3 ) Button (CD)

4 DISC 1 Button (CD)

5 DISC 2 Button (CD)

6 DISC 3 Button (CD)

7 6 OPEN/CLOSE Button (CD)

8 ·P Button (CD)

9 p Button (CD)

!º · Button [B] (DECK)

!¡ ª Button [B] (DECK)

!™ π Button [B] (DECK)

!£ ) Button [B] (DECK)

!ª

@º

!º

!¡

!™

!¶

!•

!¢ 0 Button [B] (DECK)

!∞ DIRECTION MODE Button (DECK)

!§ PAUSE Button (DECK)

!¶ REC Button (DECK)

!• HI-SPEED DUBBING Button (DECK)

!ª CD SYNCHRO Button (DECK)

@º DOLBY NR Button (DECK)

@¡ ) Button [A] (DECK)

@™ 0 Button [A] (DECK)

@£ π Button [A] (DECK)

@¢ ª Button [A] (DECK)

@∞ · Button [A] (DECK)

!∞

!§

!£

!¢

— 3 —

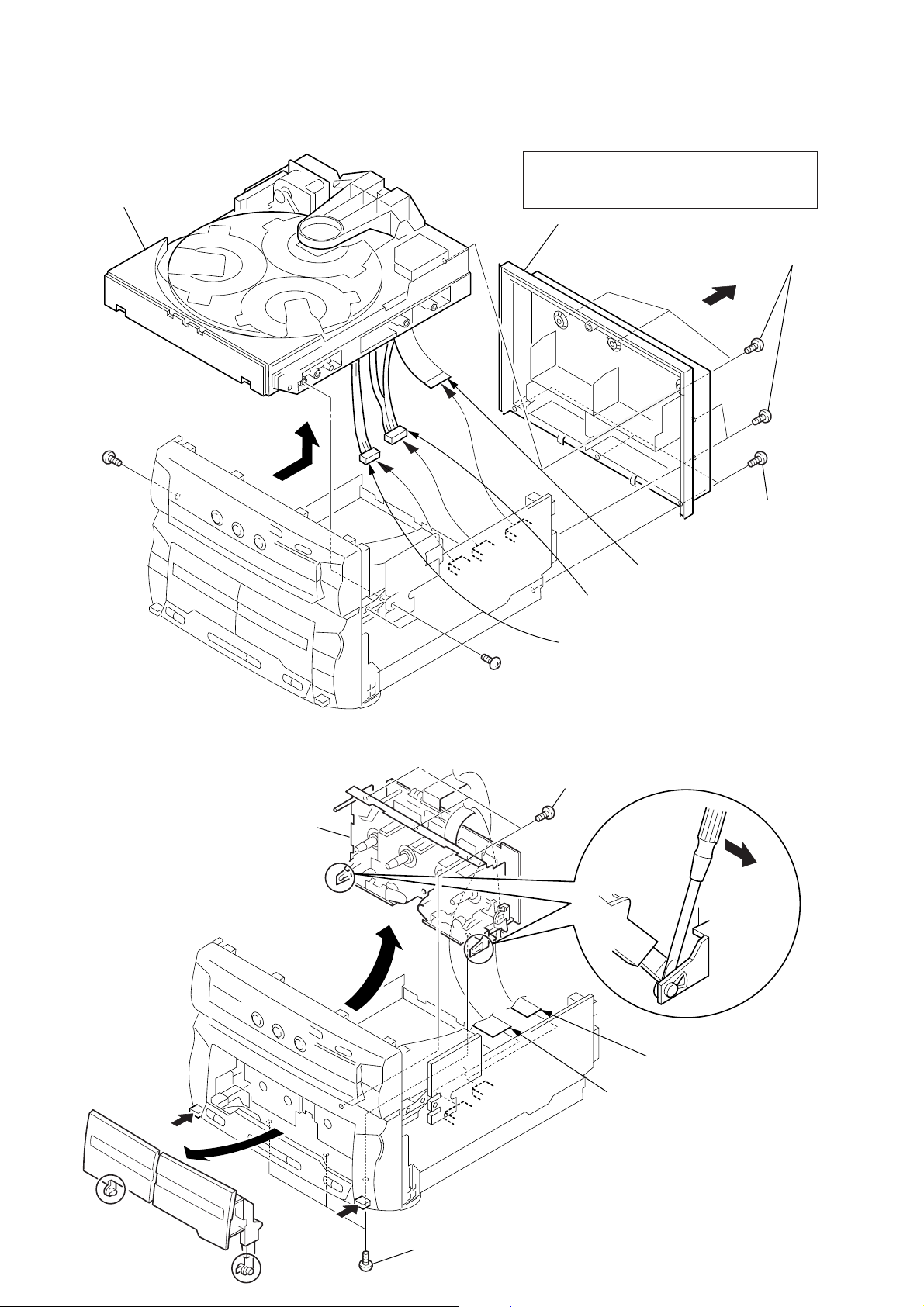

SECTION 2

0

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. BACK PANEL, CD BLOCK REMOVAL

8

CD block

7

Screw

+BVTP 3

×

10

CASE

Unscrew the fiv e case attachment in the screws (case)

(M3 × 8) × 4, (+BV 3 × 8) × 1 and remove the case.

2

Back panel

1

Screw

+BVTP 3

×

1

6

Screw

+BVTP 3

2-2. CASSETTE LID (A)/(B) ASSY, MECHANISM DECK REMOVAL

1

Press the EJECT button and open the cassette lid.

Mechanism Deck (TCM-220WR2E)

7

+BVTP 2.6

5

Screw

3

4

CN112 (9 pin)

CN111 (8 pin)

×

10

×

8

1

Screw

+BVTP 3

Flat wire (19 core)

2

×

10

1

3

1

8

6

Screw

+BVTP 3

— 4 —

4

Flat wire (11 core)

5

Flat wire (21 core)

×

8

2-3. MAIN BOARD, RESISTOR BOARD, FRONT PANEL ASSY REMOVAL

d

3

Screw

2

Front panel assy

+BVTP 3

1

+BVTP 3

Screw

×

8

6

Screw

+BVTP 3

×

8

4

Bracket (H/S)

5

Resistor board

×

8

7

Main boar

• Tray (Slide) getting out procedure on the power supply is OFF

Rotate the BU CAM assembly in the direction of the arrow and pull out the slide.

Tray (Slide)

— 5 —

1

BU CAM assy

SECTION 3

ADJUSTMENTS

3-1. MECHANICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

• T orque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension (0.028 – 0.083 oz•inch)

Reverse CQ-102RC

Reverse

Back Tension (0.028 – 0.083 oz•inch)

FF, REW CQ-201B

CQ-102C

CQ-102RC

36 to 61g•cm

(0.50 – 0.84 oz•inch)

2 to 6g•cm

36 to 61g•cm

(0.50 – 0.84 oz•inch)

2 to 6g•cm

61 to 143g•cm

(0.85 – 1.99 oz•inch)

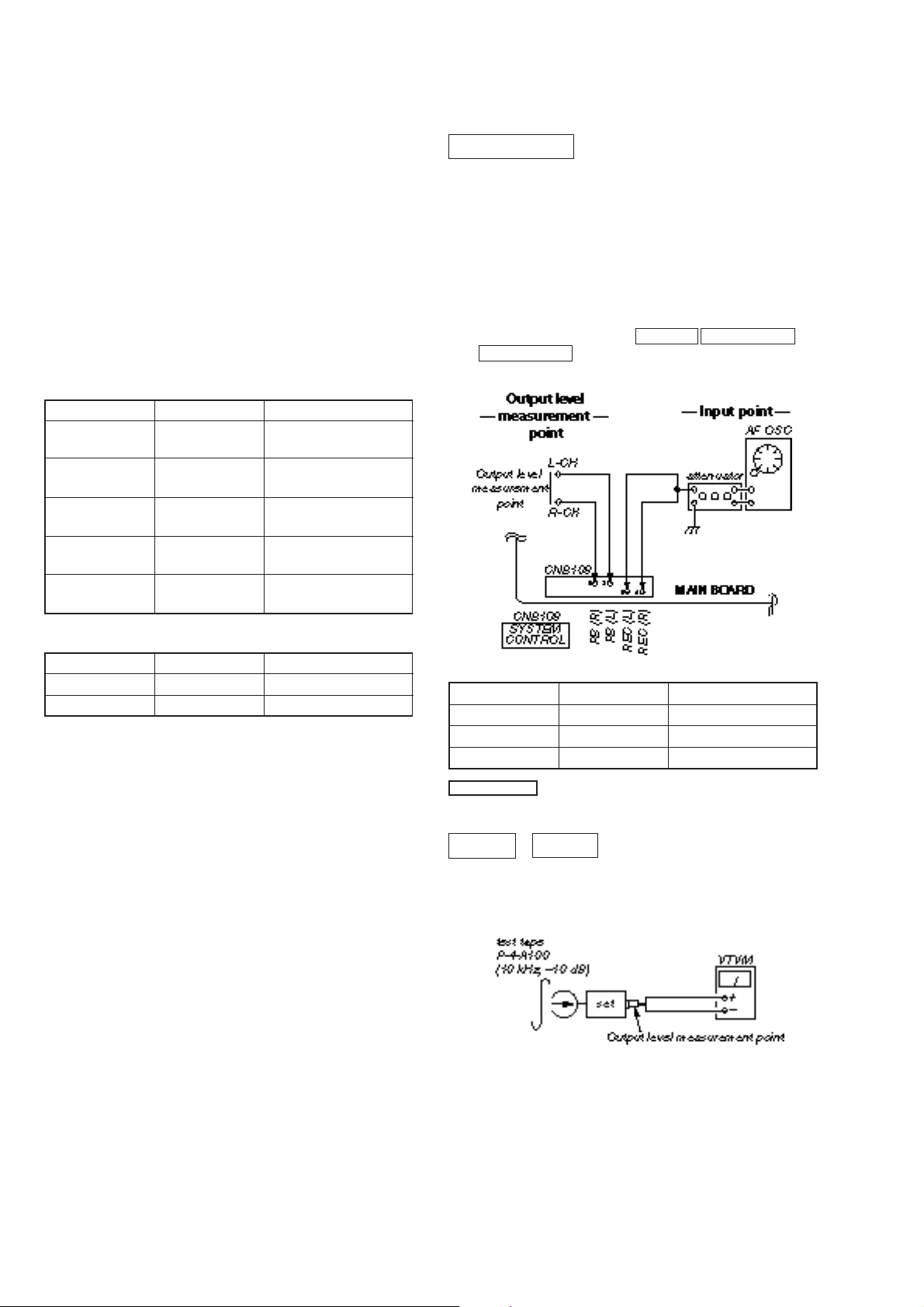

3-2. ELECTRICAL ADJUSTMENT

DECK SECTION

1. The adjustment should be performed in the publication.

(Be sure to make playback adjustment at first.)

2. The adjustment and measurement should be performed for both

L-CH and R-CH.

• Switch position

DOLBY NR switch : OFF

FUNCTION button : OFF

EFFECT switch : OFF

DBFB switch : OFF

3. Deck section electrical adjustments are made in test mode by

press key switch same time CD STOP DECK A ST OP and

DECK B STOP button.

4. Input point and output level measurement point.

• T ape Tension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A

Reverse CQ-403R

more than 100 g (3.53 oz)

more than 100 g (3.53 oz)

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB

P-4-L300 315 Hz, 0dB Level Adjustment

WS-48B 3 kHz, 0dB Tape Speed Adjustment

0 dB=0.775V

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Procedure:

1. Forward Playback mode

Reverse Playback mode

Head Azimuth Adjustment

— 6 —

2. Turn the adjustment screw for the maximum output levels. If

t

these levels do not match, turn the adjustment screw until both

of output levels match together within 1 dB.

3. Playback Mode

Tape Speed Adjustment DECK A DECK B

Note: Start the T ape Speed adjustment as belo w after setting to the

test mode.

Set to test mode. (Press key switch same time CD STOP

DECK A STOP and DECK B STOP button.)

Test mode off. (Power off.)

Procedure:

• Perform high speed adjustment before normal speed adjustment.

Mode: Playback

4. Change the playback mode and repeat the steps 1 to 3.

5. After the adjustment, lock the adjustment screw with suitable

locking compound.

Adjustment Location:

— Record/playback head (Deck A and B) —

Speed

*High

Normal

Deck

A

B

A

B

Adjustment

RV652

RV652

RV651

RV651

Frequency counter

5,910 to 6,090 Hz

2,910 to 3,090 Hz

* Continue to press HIGH SPEED DUBBING switch (S259) in

playback mode : High speed playback.

Frequency difference between the beginning and the end of the

tape should be within ± 3%.

Frequency difference between deck A and deck B the beginning

of the tape should be within 1.5 %.

Adjustment Location: AUDIO board (See page 8)

Sample Value of Wow and flutter

W.RMS (JIS) within 0.3%

(test tape: WS-48B)

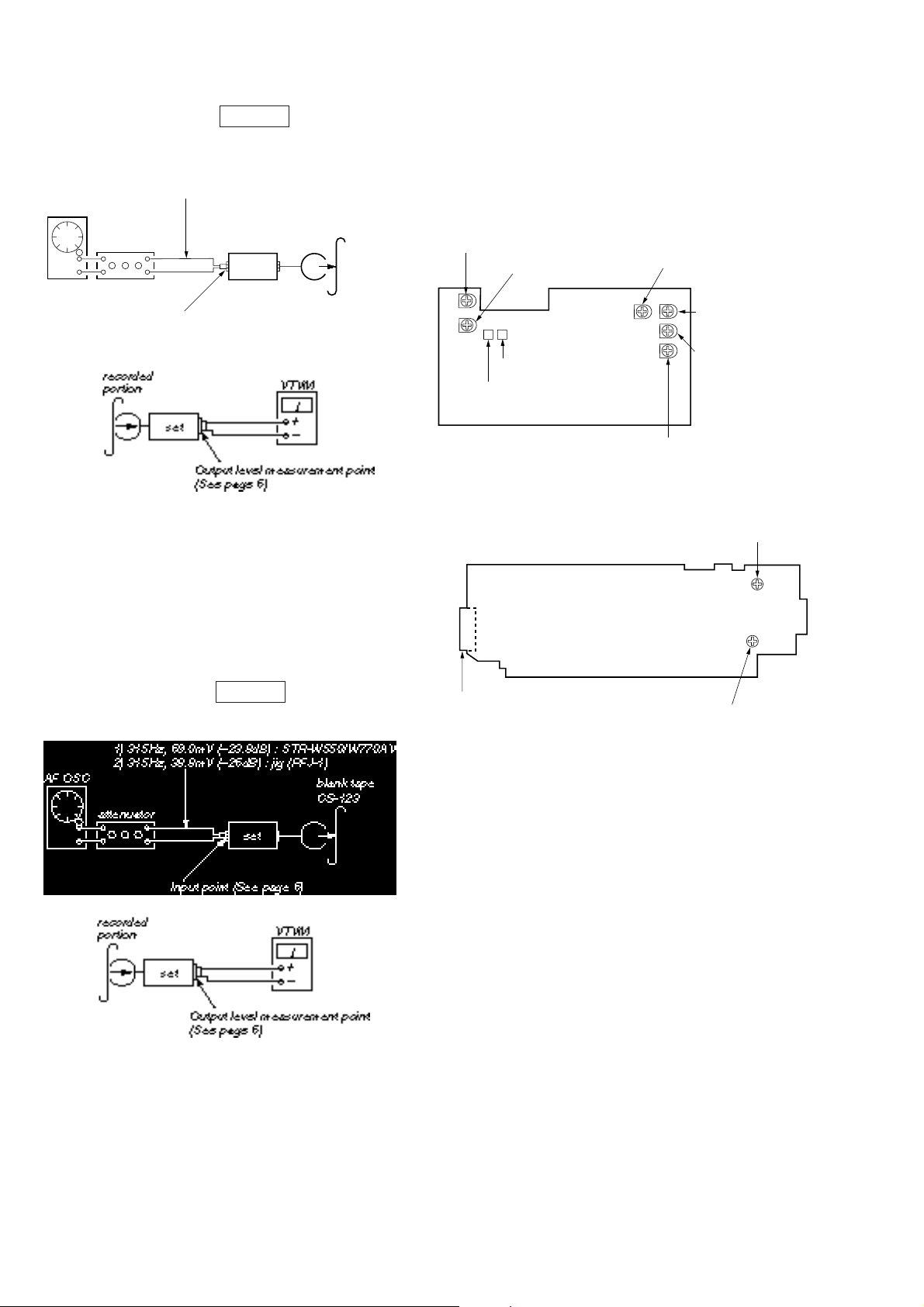

Playback level Adjustment DECK A DECK B

Procedure:

— FWD playback Mode —

test tape

P-4-L300

(315 Hz, 0 dB)

VTVM

set

Output level measurement poin

(See page 6)

+

–

Deck A is RV311 (L-CH) and RV411 (R-CH), Deck B is RV301

(L-CH) and RV401 (R-CH) so that adjustment within adjustment

level as follows.

Adjustment Level:

LINE OUT level : –8.2 to –7.2 dB (301.5 to 338.3 mV)

Level Difference between Channels : within 0.5 dB

Confirm the OUTPUT level does not change in playback mode

while changing the mode from playback to stop several times.

Adjustment Location: AUDIO board (See page 8)

— 7 —

Record Bias Adjustment DECK B

)

V

Procedure:

1. Record mode

1) 315 Hz

2) 10 kHz

AF OSC

attenuator

69.0mV (–23.8dB) : STR-W550/W770A

38.8mV (–26dB) : jig (PFJ-1)

set

blank tape

CS-123

Adjustment Level:

OUTPUT level: –23.8 dB ± 1.0 dB (56.1 to 44.6 mV)

Adjustment Location: MAIN board

Adjustment Location :

[AUDIO BOARD] — Component Side —

RV301 : Playback Level (Deck B L-CH)

RV401 : Palyback Level

(Deck B R-CH)

RV651 : Tape Speed (Normal)

Input point (See page 6)

2. Mode: Playback

3. Confirm playback the signal recorded in step 1 become

adjustment level as follows.

4. If these levels do not adjustment level, adjustment the RV341

(L-CH) and RV441 (R-CH) to repeat steps 1 and 4.

Adjustment level: Playback output of 315 Hz to playback output

of 10 kHz: 0 ± 1.0 dB (0 ± 4.5mV).

Adjustment Location: AUDIO board

Record Level Adjustment DECK B

Procedure:

1. Record mode

RV341 : Record Bias (L-CH)

RV441 : Record Bias (R-CH)

RV411 : Playback Level (Deck A R-CH)

[MAIN BOARD] — Component Side —

RV451 Record Level (R

CNB108

RV401 Record Level (L)

RV652 : Tape Speed

(Hight)

RV311 : Playback Level

(Deck A L-CH)

2. Playback mode

3. Confirm playback the signal recorded in step 1 become

adjustment level as follows.

4. If these levels do not adjustment level, adjustment the RV401

(L-CH) and RV451 (R-CH) to repeat steps 1 and 4.

— 8 —

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indica ted.

3. Use an oscilloscope with more than 10M impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

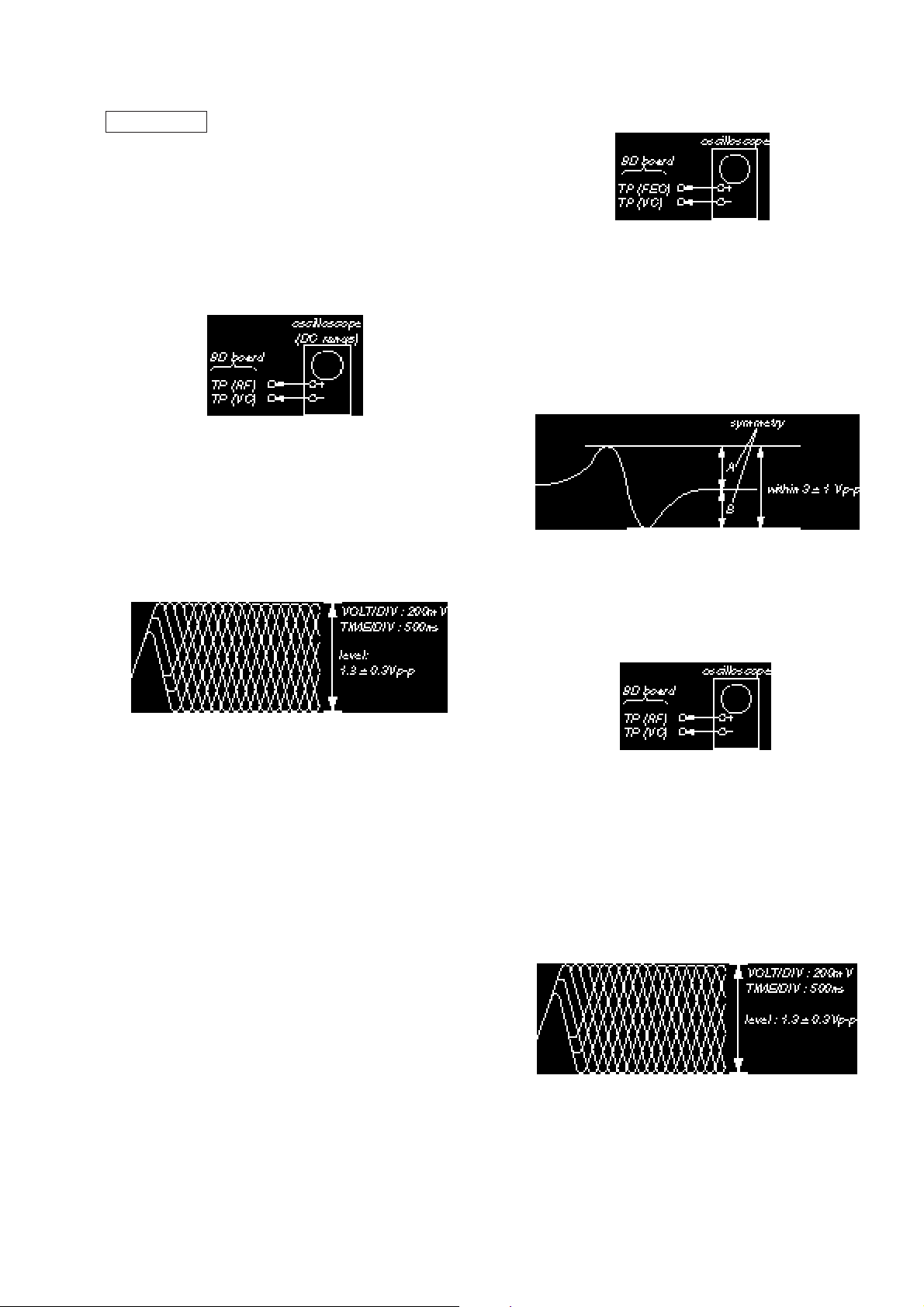

Focus Bias check

Procedure:

1. Connect oscilloscope to test point TP (RF). (GND terminal :

VC)

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that the shape “ ” can be clearly distinguished at the

center of the waveform and check the RF signal level.

• RF signal

S Curve Check

Procedure:

1. Connect oscilloscope to test point TP (FEO).

2. Connect between test point TP (FOK) and GND by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on ag ain and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak lev el within 3±1

Vp-p.

S-curve waveform

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to mak e sure than the ratio of

A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

Procedure:

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note:

Clear RF signal waveform means that the shape “ ” can be

clearly distinguished at the center of the waveform.

• RF signal

— 9 —

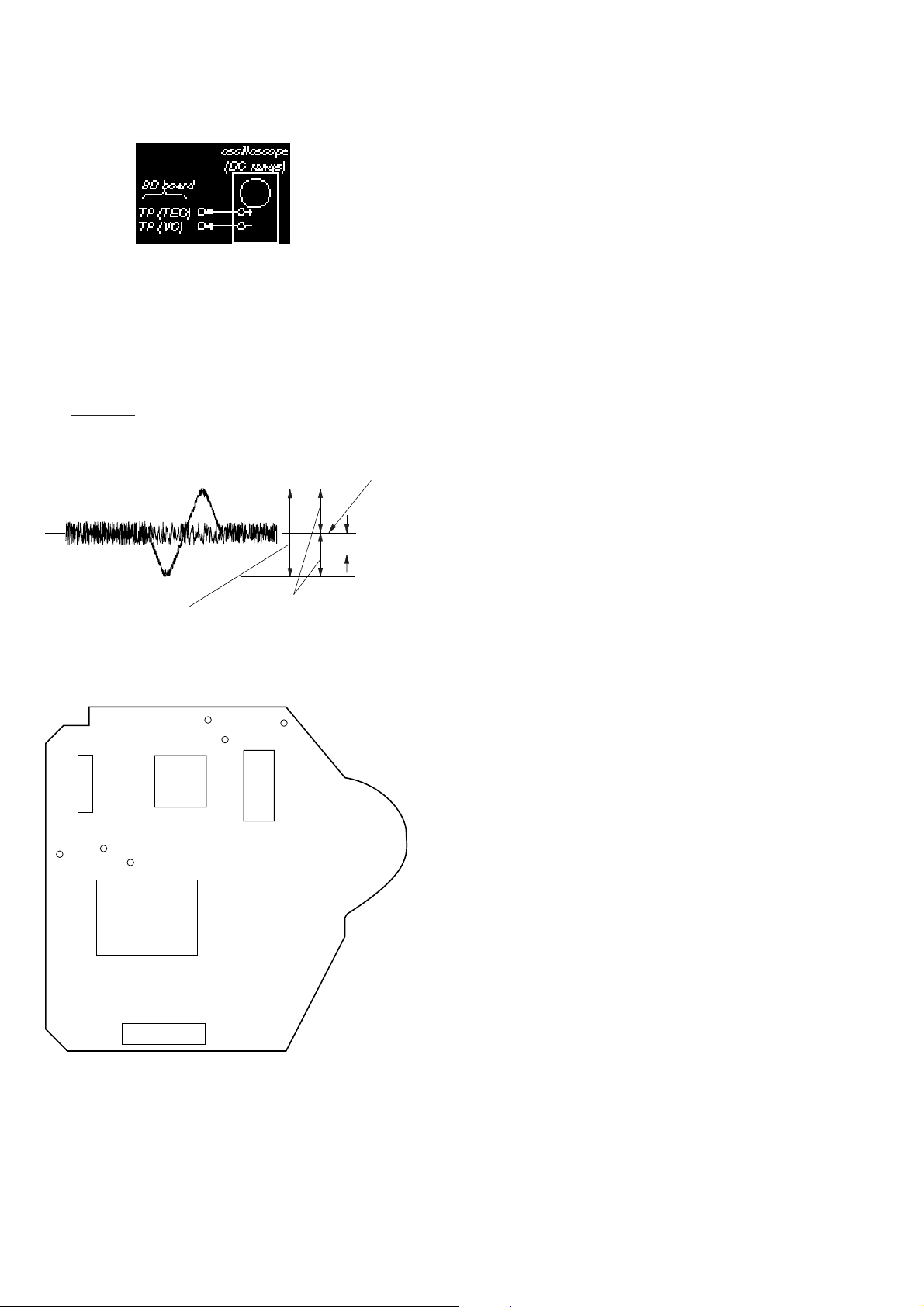

E-F Balance (1 Track Jump) check

)

(Without remote commander)

Procedure:

1. Connect oscilloscope to test point TP (TEO) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (Pause)” button. (Becomes the 1 track jump mode)

5. Check the level B of the oscilloscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following:

A – B

2 (A + B)

1 track jump waveform

× 100 = ±7 (%)

Center of the waveform

B

0V

±

level : 500 mV

100 mVp-p

Adjustment Location:

[BD BOARD] (Conductor Side)

RF

FOK

IC101

CNU101

TEO

GND

FEO

IC103

symmetry

VC

IC

I02

A (DC voltage

CNU102

— 10 —

(B)

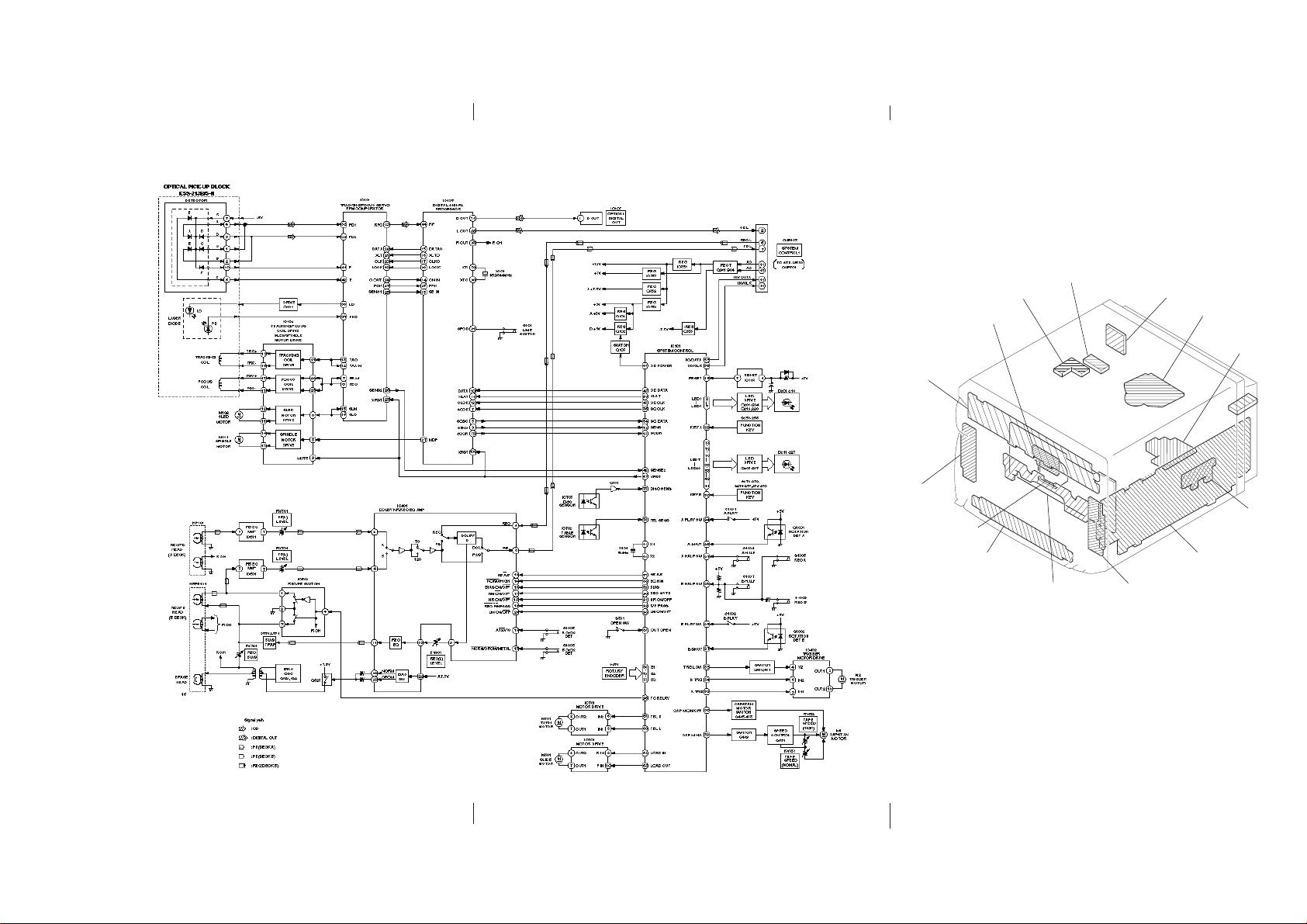

SECTION 4

DIAGRAMS

4-1. BLOCK DIAGRAM 4-2. CIRCUIT BOARDS LOCATION

CD PANEL BOARD

TC (A) BOARD

LEAF SWITCH BOARD

MOTOR BOARD

TC PANEL BOARD

CONNECTOR BOARD

SENSOR BOARD

AUDIO BOARD

MOTOR (TURN) BOARD

BD BOARD

BOARD

TC

MOTOR (SLIDE) BOARD

RESISTOR BOARD

MAIN BOARD

— 11 —

— 12 — — 13 —

Loading...

Loading...