Sony HCD-VP700 Service manual

HCD-VP700

SERVICE MANUAL

Ver 1.0 2001.06

• HCD-VP700 is the tuner, deck, CD

and amplifier section in MHCVP700.

Model Name Using Similar Mechanism HCD-VX555/VX555J

CD CD Mechanism Type CDM58E-30BD61A

Section Base Unit Name BU-30BD61A

Optical Pick-up Name A-MAX.3

Tape deck Model Name Using Similar Mechanism HCD-DP800AV

Section Tape Transport Mechanism Type TCM-230MWR41/AWR41

E Model

SPECIFICATIONS

Amplifier section

The following measured at AC 120, 220, 240 V,

50/60 Hz

DIN power output (rated) 130 + 130 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

180 + 180 watts

(6 ohms at 1 kHz, 10%

THD)

Inputs

GAME IN: voltage 250 mV,

(phono jacks) impedance 47 kilohms

MD/VIDEO IN: voltage 450 mV/250 mV,

(phono jacks) impedance 47 kilohms

OPTICAL IN:

(Square optical connector jacks, front and rear panels)

wavelength ——

MIC 1/2: sensitivity 1 mV,

(phone jack) impedance 10 kilohms

Outputs

MD (VIDEO) OUT: voltage 250 mV

(phono jacks) impedance 1 kilohms

VIDEO OUT: max. output level

(phono jack) 1 Vp-p, unbalanced,Sync

S-VIDEO OUT: Y: 1 Vp-p, unbalanced,

(4-pin/mini-DIN jack) Sync negative,

PHONES: accepts headphones of

(stereo mini jack) 8 ohms or more

SPEAKER:

SUB WOOFER: Voltage 1 V,

negative, load impedance

75 ohms

C: 0.286Vp-p,

load impedance 75 ohms

accepts impedance of 8 to

16 ohms

impedance 1 kilohms

— Continued on next page —

9-873-175-01

2001F0200-1

© 2001. 6

MINI HI-FI COMPONENT SYSTEM

Sony Corporation

Home Audio Company

Shinagawa Tec Service Manual Production Group

HCD-VP700

VIDEO CD/CD player section

System Compact disc and digital

Laser Semiconductor laser

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Video color system format

DIGITAL OUT OPTICAL

(Square optical connector jack, rear panel)

wavelength 660 nm

audio system

(λ=660 nm)

NTSC, PAL

Tape player section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz (±3 dB),

(DOLBY NR OFF) using Sony TYPE I

cassette,

40 – 14,000 Hz (±3 dB),

using Sony TYPE II

cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

Tourist model: 76.0 – 108.0 MHz

Other models: 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

531 – 1,602 kHz

(with the interval set at

9 kHz)

530 – 1,710 kHz

(with the interval set at

10 kHz)

General

Power requirements

Thailand model: 220 V AC, 50/60 Hz

Other models: 120 V, 220 V or

Power consumption

Dimensions (w/h/d)

Mass

Supplied accessories: AM loop antenna (1)

Design and specifications are subject to change

without notice.

230 – 240 V AC,

50/60 Hz

Adjustable with voltage

selector

195 watts

Approx. 280 x 360 x 365 mm

Approx. 11.0 kg

FM lead antenna (1)

Remote commander (1)

Batteries (2)

Video cable (1)

Front speaker pads (8)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

2

TABLE OF CONTENTS

1. GENERAL ·········································································· 4

2. DISASSEMBY ··································································· 6

3. TEST MODE ···································································· 13

4. MECHANICAL ADJUSTMENTS ····························· 17

5. ELECTRICAL ADJUSTMENTS ······························· 17

6. DIAGRAMS

6-1. Circuit Board Location ················································· 24

6-2. Block Diagrams ···························································· 25

6-3. Schematic Diagram BD Section ······························· 28

6-4. Printed Wiring Board BD Section ···························· 29

6-5. Printed Wiring Board Main Section ························· 30

6-6. Schematic Diagram Main Section (1/3) ··················· 31

6-7. Schematic Diagram Main Section (2/3) ··················· 32

6-8. Schematic Diagram Main Section (3/3) ··················· 33

6-9. Printed Wiring Board DSP Section··························· 34

6-10. Schematic Diagram DSP Section (1/2) ··················· 35

6-11. Schematic Diagram DSP Section (2/2) ··················· 36

6-12. Printed Wiring Board OPT Section························· 37

6-13. Schematic Diagram OPT Section ··························· 37

6-14. Printed Wiring Board Front Amp Section ··············· 38

6-15. Schematic Diagram Front Amp Section ················· 39

6-16. Printed Wiring Board Surround Amp Section ········ 40

6-17. Schematic Diagram Surround Amp Section ··········· 41

6-18. Printed Wiring Board Panel Section ······················· 42

6-19. Schematic Diagram Panel Section (1/2) ················· 43

6-20. Schematic Diagram Panel Section (2/2) ················· 44

6-21. Printed Wiring Board Leaf SW Section ·················· 45

6-22. Schematic Diagram Leaf SW Section ····················· 45

6-23. Printed Wiring Board Driver Section······················ 46

6-24. Schematic Diagram Driver Section ························ 46

6-25. Printed Wiring Board Video Section······················· 47

6-26. Schematic Diagram Video Section (1/3) ················· 48

6-27. Schematic Diagram Video Section (2/3) ················· 49

6-28. Schematic Diagram Video Section (3/3) ················· 50

6-29. Printed Wiring Board Trans Section ······················· 51

6-30. Schematic Diagram Trans Section ·························· 52

6-31. IC Pin Function Description ······································· 54

6-32. IC Block Diagrams ····················································· 63

HCD-VP700

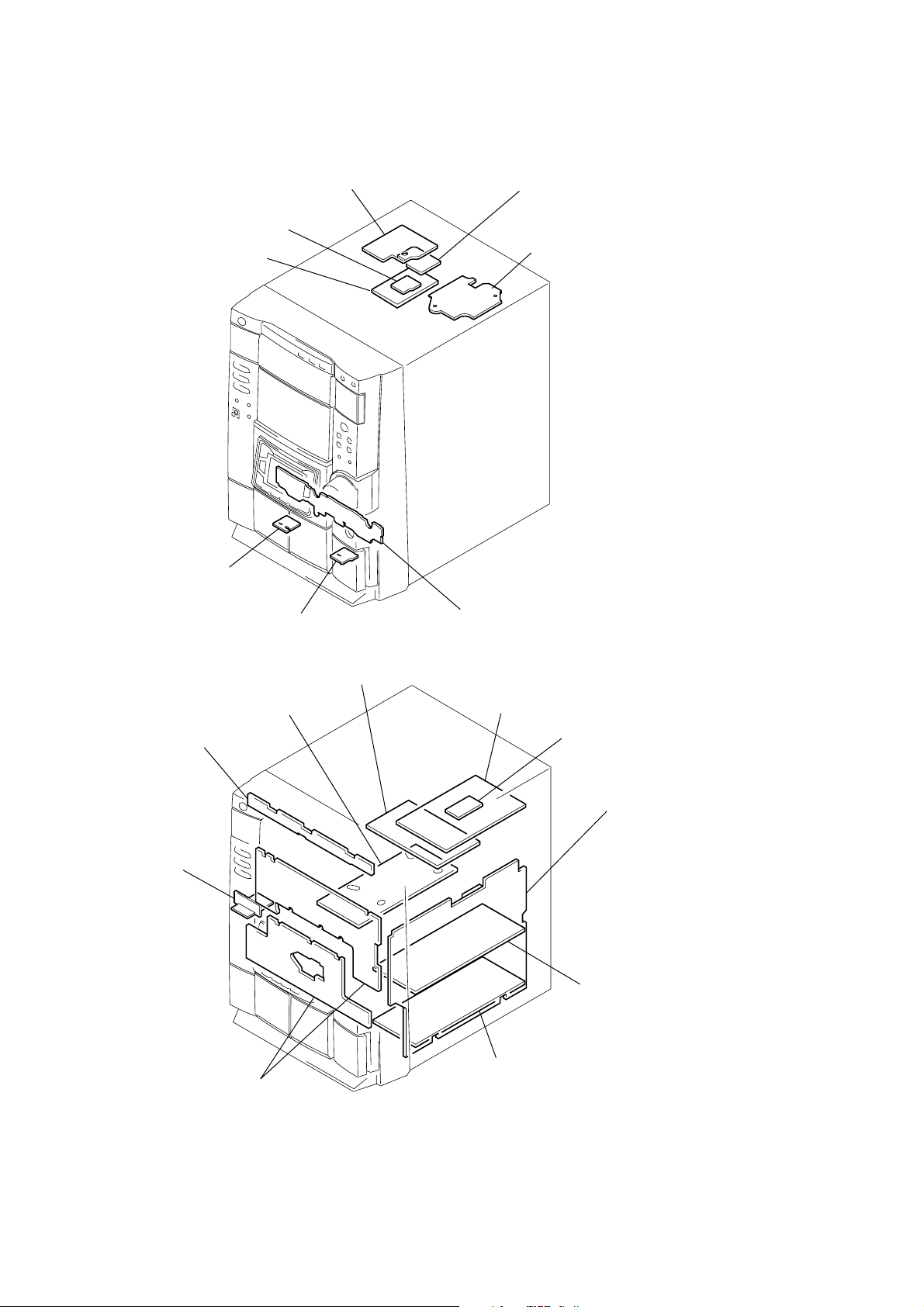

7. EXPLODED VIEWS

7-1. Main Section ································································· 67

7-2. Front Panel Section ······················································· 68

7-3. Chassis Section ····························································· 69

7-4. Tape Mechanism Deck Section-1 (TCM-230MWR41) 70

7-5. Tape Mechanism Deck Section-2 (TCM-230AWR41) 71

7-6. CD Mechanism Deck Section (CDM58E-30BD61A) ·· 72

7-7. Base Unit Section (BU-30BD61A) ······························ 73

8. ELECTRICAL PARTS LIST ······································· 74

3

HCD-VP700

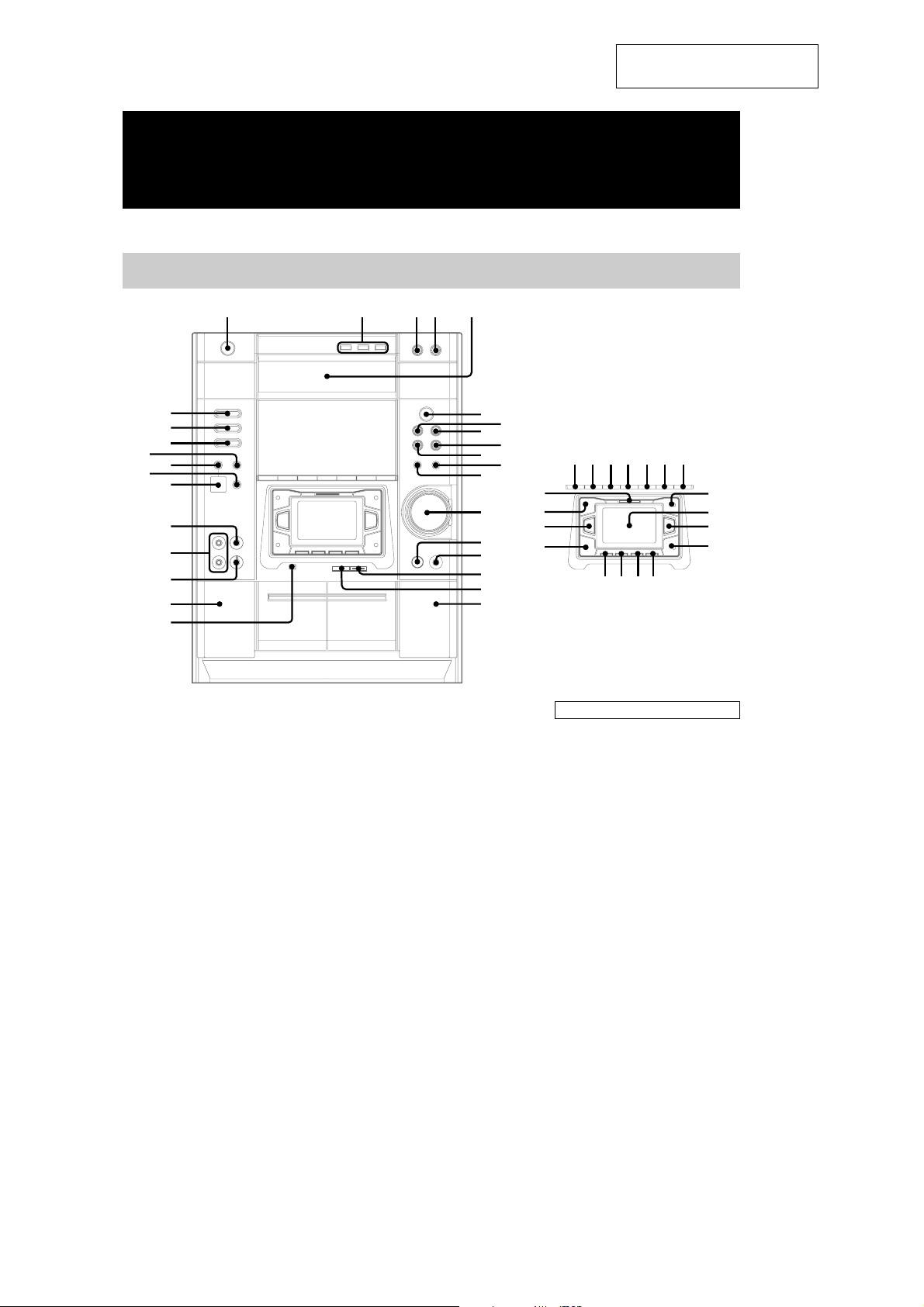

Parts Identification

The items are arranged in alphabetical order.

Main unit

SECTION 1

GENERAL

12345

This section is extracted from

instruction manual.

e;

wl

wk

wj

wh

wg

wf

wd

ws

wa

w;

ql

2CH/MULTI rs (27)

CD e; (9, 12–15, 22, 23)

CD SYNC HI-DUB qj (22, 23)

CLOCK/TIMER SET ed (11, 23,

29)

DECK A Z w; (21)

DECK B Z qk (21)

digipad el (6, 10, 11, 13, 15,

19–21, 24, 26, 30)

DIGITAL wh (31)

DIGITAL IN 2 (OPTICAL) jack

wf (31)

DIRECTION eg (21–23, 28)

DISC 1–3 2 (12–15, 23)

DISC SKIP EX-CHANGE 3

(12–14)

Disc tray 5 (12)

DISPLAY ea (11, 16)

DOLBY NR eh (21–23)

DSP EDIT rj (25)

ECHO LEVEL control wd (28)

EDIT eg (23)

EFFECT rd (25, 26)

ENTER r; (11, 14, 15, 19, 20,

23, 24, 26, 29, 30)

6

7

8

9

q;

qa

qs

qd

qf

qg

qh

qj

qk

FM MODE eh (20)

GAME wg (31)

GAME MODE rh (25)

GROOVE rf (25)

IR receptor qf

KARAOKE PON es (27, 28)

MD (VIDEO) wj (31)

MIC 1/2 jack ws (27, 28)

MIC LEVEL control wa (27, 28)

MOVIE MODE ek (25)

MULTI CHANNEL DECODING

indicator rl (29)

MUSIC MODE rk (25)

P FILE rg (26)

PICTURE EFFECT ql (19)

PHONES jack qg

PLAY MODE ej (12, 14, 15, 23)

REC/PAUSE START qh (22, 23,

28)

REPEAT eh (13, 15)

TAPE A/B wk (21, 22)

TIMER SELECT ef (24, 30)

TOOL MODE ra (25)

TUNER/BAND wl (20)

TUNER MEMORY ej (20)

VOLUME control qd

eaesedefegeh

rl

rk

rj

rh

rfrdrs

rg

BUTTON DESCRIPTIONS

@/1 (power) 1

Z OPEN/CLOSE (disc tray) 4

nN (play) 6

X (pause) 7

x (stop) 8

. (go back) q;

> (go forward) 9

m/– (rewind) qs

M/+ (fast forward) qa

ej

ek

el

r;

ra

4

Setting the time

1 Turn on the system.

2 Press CLOCK/TIMER SET.

When you set the time for the first time,

proceed to step 5.

3 Press . or > repeatedly to select

“CLOCK SET”.

4 Press ENTER.

5 Press . or > repeatedly to set the

hour.

6 Press ENTER.

7 Press . or > repeatedly to set the

minutes.

8 Press ENTER.

Tips

• If you have made a mistake or want to change the

time, start over from step 2.

• You can use the digipad instead of ./>.

Note

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

HCD-VP700

5

HCD-VP700

)

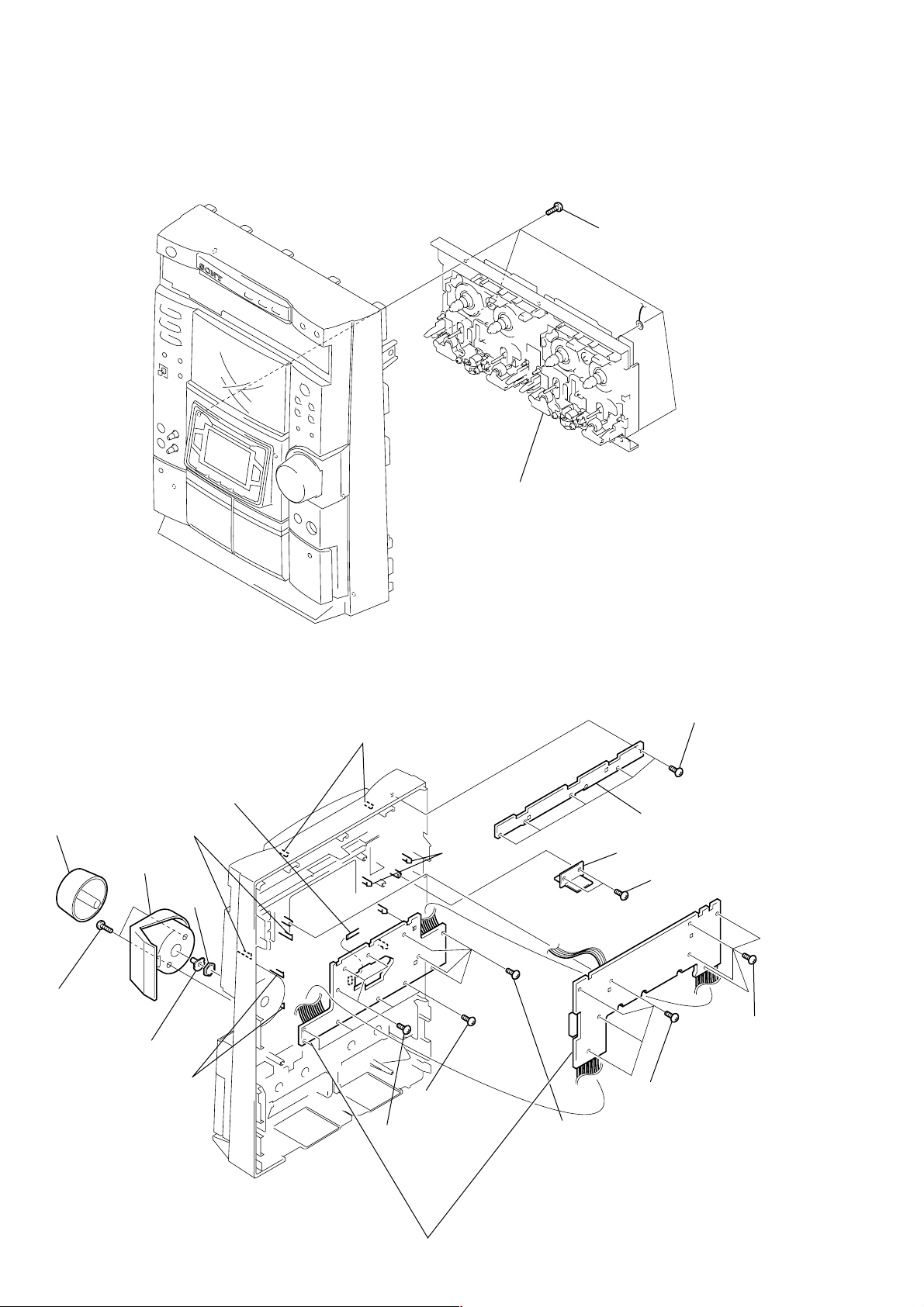

SECTION 2

DISASSEMBLY

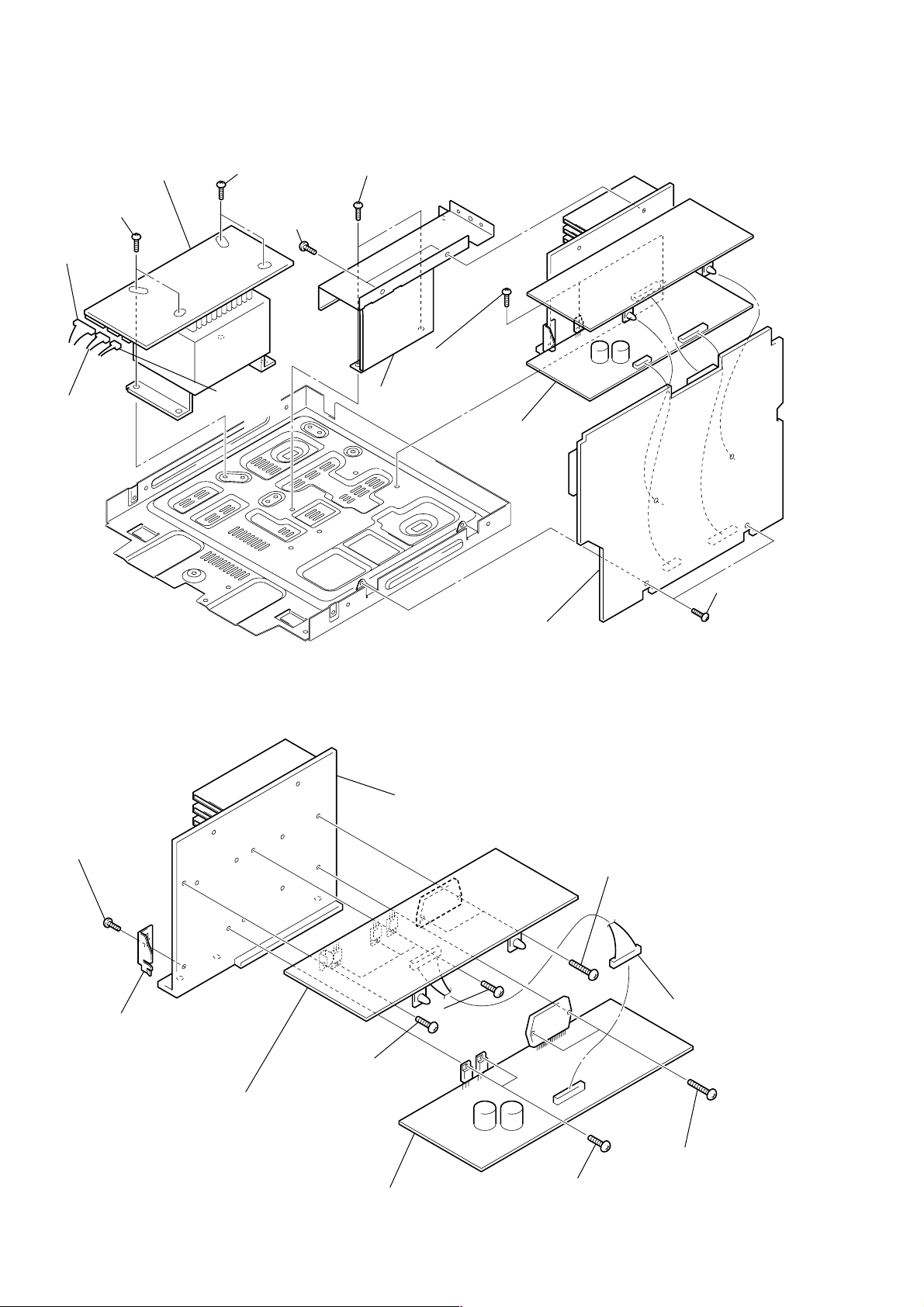

• The equipment can be removed using the following procedure.

Set Case (Top) Loading Panel Front Panel Section

Tape Mechanism Deck

(TCM-230AWR41/MWR41)

CD Panel board, Panel board, OPT IN Board

Chassis section

DSP board, SUB Trans board, Back panel, Fan, OPT IN rear board

Tnans board, Main board

CD mechanism deck

(CDM58)

Base unit, BD board

(BU-30BD61A)

Video board, Driver board, Motor board, CD sensor board

Note : Follow the disassembly procedure in the numerical order given.

2-1. CASE (TOP)

• Abbreviation

SP : Singapre model

MY : Malaysia model

TH : Thai model

LEAF SW board, Head (A) board,

Head (B) board

Escutcheon pad

(With touch pad)

Front AMP board, Surround AMP board

4

screw (case 3 TP2)

3

two screws (case 3 TP2)

8

5

two screws (+BVTT 3

case

×

6

8)

three screws (+BVTT 3

7

two screws

(+BVTT 3

2

screw (case 3 TP2)

1

two screws (case 3 TP2)

×

8)

×

8

6

2-2. LOADING PANEL

CD mechanism deck (CDM58)

1

turn the pulley to the direction of arrow.

front panel side

4

pull-out the disc tray.

loading panel

HCD-VP700

pulley

2

pull-out the disc tray.

2-3. FRONT PANEL SECTION, CD MECHANISM DECK (CDM58)

3

qd

3

screw (+BVTP 3

5

front panel section

4

three screws (+BVTT 3

CD mechanism deck (CDM58)

×

10)

1

connector (CN601)

2

screw

(+BVTP 3

7

connector (CN1)

×

8)

×

10)

qs

connector (CN701)

6

flat type wire (CN1001)

8

connector (CN2)

0

two screws (+BVTP 3

9

flat type wire (CN201)

× 10

)

qa

two screws

(+BVTP 3

chassis section

× 10

)

7

HCD-VP700

)

)

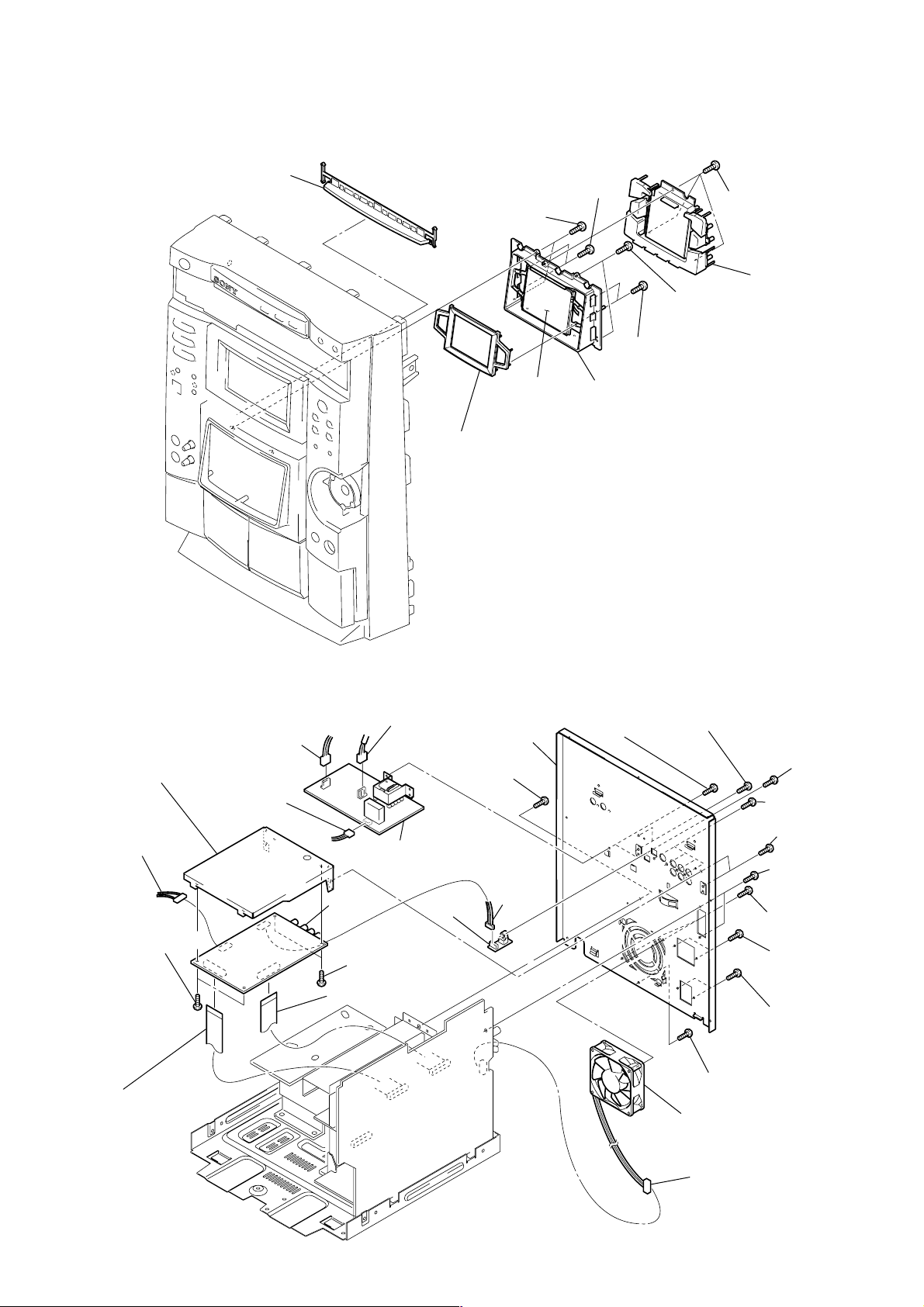

2-4. TAPE MECHANISM DECK (TCM-230AWR41/MWR41)

1

four screws (+BVTP 2.6

2

tape mechanism deck

(TCM-230AWR41/MWR41)

×

8

2-5. CD PANEL BOARD, PANEL BOARD, OPT IN BOARD

two claws

qf

flat type wire (CN108)

5

ring (vol)

×

8)

6

cover(vol)

two claws

two claws

7

nut

qa

five screws

(+BVTP 2.6

0

three

screws

(+BVTP 2.6

3

knob (vol)

4

two screws

(+BVTP 2.6

two claws

×

8)

×

1

five screws

(+BVTP 2.6

2

CD panel board

qh

OPT IN board

qg

two screws

(+BVTP 2.6

8

four screws

(+BVTP 2.6

9

five screws

8)

qs

four screws

(+BVTP 2.6

(+BVTP 2.6

×

8)

×

×

×

8)

8)

×

8

8)

qd

PANEL board

8

2-6. ESCUTCHEON PAD (WITH TOUCH PAD)

)

1

button (edit)

3

two screws

(+BVTP 2.6

touch pad

7

holder (pad)

6

two screws

(TPG +P 2

×

8)

×

8)

5

two screws

(TPG +P 2

4

escutcheon (pad)

8

three screws

(+BVTP 2.6

2

two screws

(+BVTP 2.6

×

8)

HCD-VP700

×

8)

9

button (DSP

×

8)

2-7. DSP BOARD, SUB TRANS BOARD, BACK PANEL, FAN, OPT IN REAR BOARD

1

two screws

(+BVTP 3

×

8)

wg

qf

connector (CN902)

0

bracket (DSP)

7

connector

(CN601)

9

two screws

(+BVTP 3

5

flat type wire (CN602)

×

8)

qg

connector

(CN903)

qd

connector (CN901)

qh

SUB trans board

qa

DSP

board

8

two screws

(+BVTP 3

4

flat type wire (CN603)

×

ws

wa

screw

(+BVTP 3

OPT IN

rear board

8)

back panel

×

6

connector

(CN801)

8)

qs

two screws

(+BVTP 3

×

w;

rew (+BVTP 3

fan

8)

wh

(+BVTP 3

3

(+BVTP 3

qj

(+BVTP 3

wf

(+BVTP 3

qk

(+BVTP 3

ql

(+BVTP 3

screw

four screws

2

(+BVTP 3

two screws

×

two screws

two screws

two screws

two screws

×

8)

×

8)

8)

×

8)

×

8)

×

10

)

×

8)

×

8)

wd

connector

(CN104)

9

HCD-VP700

)

2-8. TRANS BOARD, MAIN BOARD

4

6

5

two screws

(+BVTT 4

1

connector

(CN914)

2

connector

(CN915)

TRANS board

×

8)

two screws

(+BVTT 4

7

two screws

(+BVTT 3

3

connector

(CN913)

×

8

two screws

×

8)

(+BVTP 3

9

8)

×

8)

0

two

screws

(+BVTP 3

cover (heat sink)

qa

SURROUND and

FRONT AMP

board ASSY

×

8)

2-9. FRONT AMP BOARD, SURROUND AMP BOARD

heat sink assy

1

screw

(+BVTT 3

2

bracket

×

8)

qd

8

t

hree screws

(+BVTT 3

MAIN board

×

8)

9

two

screws

(+BVTP 3

qs

two

(+BVTP 3

×

16)

3

connector (CN803

screws

×

8)

10

0

SURROUND AMP board

7

screw

(+BVTT 3

6

FRONT AMP board

×

8)

5

two

screws

(+BVTP 3

4

two

screws

(+BVTT 3

×

8)

×

16)

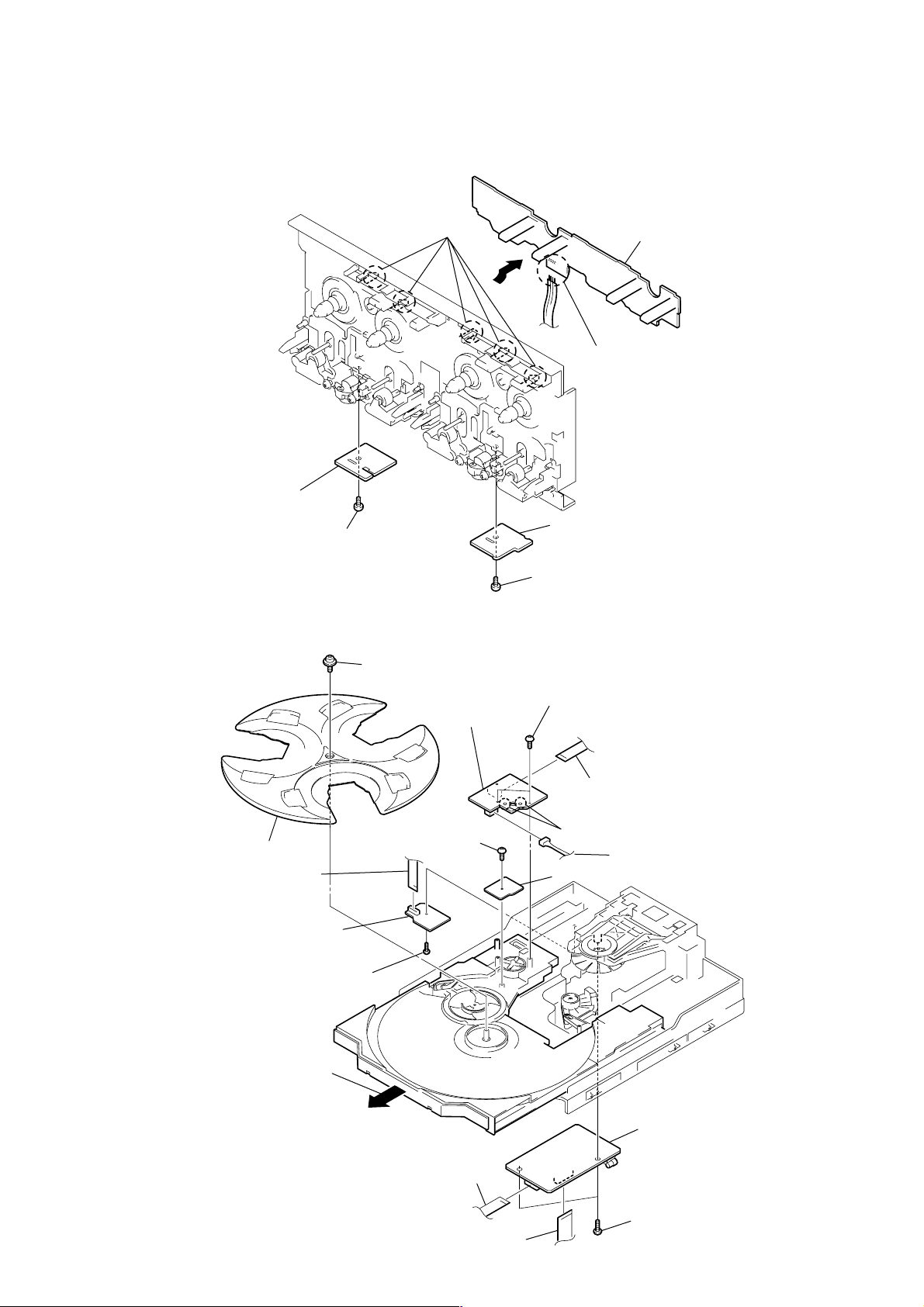

2-10. LEAF SW BOARD, HEAD (A) BOARD, HEAD (B) BOARD (TCM-230AWR41/MWR41)

Note: This illustration is for TCM-230MWR, but in case of TCM-230AWR, you can remove them in the same way.

1

five claws

2

LEAF SW board

3

remove the four solderings.

HCD-VP700

5

HEAD (A) board

6

4

screw (+PTT 2

ground point

×

4),

HEAD (B) board

4

screw (+PTT 2

ground point

×

4),

2-11. VIDEO BOARD, DRIVER BOARD, MOTOR BOARD, CD SENSOR BOARD

q;

qa

Tray

3

Flat type wire

(CN702)

2

DRIVER board

Screw (+PTPWH 2.6

qs

Screw (+BVTP 2.6

8

×

8)

4

MOTOR board

×

8)

Two screws (+BVTP 2.6

6

Flat type wire (CN721)

5

Remove the two solderings of motor.

7

Connector (CN722)

qd

CD SENSOR board

×

8)

1

Screw (+BVTP 2.6

9

Pull-out the Table.

×

8)

qf

Flat type wire (CN502)

qg

Flat type wire (CN501)

qj

VIDEO board

qh

Tw o

Screws

(+BVTP 2.6

×

8)

11

HCD-VP700

)

2-12. BASE UNIT, BD BOARD

1

Pulley(B)(BU-30), chucking

2

Tw o

Screws (+PTPWH M2.6)

3

Lever (lifter)

5

Screw (+PTPWH M2.6)

4

Turn the pulley to the direction of arrow.

pulley

9

Remove the solder

(four portions).

6

Spring (insulator),

coil

qh

Two insulators

qs

Two stoppers

qa

Two screws (+BVTP 2.6

Holder assy

Base unit

×

8)

q;

BD board

qg

qf

Spring

(insulator),

coil

8

Flat type wire (CN102)

7

Spring (insulator), coil

qh

Two insulators

Screw (DIA. 12)

qd

Tw o

screws (+PTPWH M2.6

Flat type wire (CN101)

12

SECTION 3

TEST MODE

HCD-VP700

[Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press three buttons x , DISPLAY , and DISC 1

simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

[Tuner Step Change] (Except for European and Middle Eastern

models)

• A step of AM channels can be changed over between 9 kHz and

10 kHz.

Procedure:

1. Press `/1 button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND button

to select the BAND “AM”.

3. Press `/1 button to turn the set OFF.

4. Press ENTER and `/1 buttons simultaneously, and the

display of fluorescent indicator tube changes to “AM 9 k ST”

or “AM 10 k ST”, and thus the channel step is changed over.

[GC Test Mode]

• This mode is used to check the software version, FL tube, LED,

keyboard and VACS.

Procedure:

1. Press three buttons x , DISPLAY , and DISC 2

simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

3. When you want to enter the software version display mode,

press DISC 1 .The model number and destination are displayed.

4. Each time DISC 1 is pressed, the display changes stating from

MC version, GC version, CD version, CDD, CDM version BD,

ST version, TA version, TM version, TC version, in this order,

and returns to the model number and destination display.

5. When DISC 3 is pressed while the version numbers are being

displayed except model number and destination, year, month

and day of the software creation appear. When DISC 3 is pressed

again, the display returns to the software version display. When

DISC 1 is pressed while year, month and day of the software

creation are being displayed, the year, month and day of creation

of the software versions are displayed in the same order of

version display.

6. Press DISC 2 button, and the key check mode is activated.

7. In the key check mode, the fluorescent indicator tube displays

“KOJOVO”. Each time a button is pressed, “KEY” value

increases.

However, once a button is pressed, _it is no longer taken into

account.

“VOL” value increases like 1, 2, 3...if rotating VOLUME knob

in “+” direction, or it decreases like 0, 9, 8...if rotating in

“_”direction.

8. Also when DISC 3 is pressed after lighting of all LEDs and FL

tubes, value of VACS appears.

9. To exit from this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

[MC Test Mode]

• This mode is used to check operations of the respective sections

of Amplifier, Tuner, and Tape.

Procedure:

• To enter MC Test Mode

1. Press the `/1 button to turn on the set.

2. Press the three buttons of x , DISPLAY and DISC 3

simultaneously.

3. Cursor segment flash on the FL display tube. The input

FUNCTION is changed to GAME.

* Check of Amplifier

Initial settings: Input , GAME

EQ , FLAT

Mode , MUSIC

VA C S , OFF

Output channel switching:

MUSIC key: L , LR , R through

MOVIE key: L , SL R , SR through

GAME key:L , L, SL, C R , R, SR, SW through

TOOL MODE key: L , CR , SW through

1. When the VOLUME control knob is turned clockwise even

slightly, the sound volume increases to is maximum and a

message “VOLUME MAX” appears for two seconds, then the

display returns to the original display.

2. When the VOLUME control knob is tuned counter-clockwise

even slightly, the sound volume decreases to its minimum and a

message “VOLUME MIN” appears for two seconds, then the

display returns to the original display.

* Tuner function

1. In the test mode, the default-preset channel is called even when

the TUNER is selected and an attempt is made to call the preset

channel that has been stored in memory. (It means that the

memory is cleared.)

2. The minimum, center and maximum frequency of each band is

set then.

* Tape recording test

1. To enter the MC Test Mode.

2. Load tapes in both tape decks A and B.

3. Press the REC button to start recording.

4. Pressing the M , m buttons during recording returns the

tape to the recording start position and stops it at this position.

5. Pressing the “High Speed Dubbing” key while playing back the

tape of deck B switches the playback speed between “Normal

Speed” and “High Speed”.

Note:

When the playback direction of the tape is set to other than “ONY

WAY”, the restriction on the number of times playback which can

be repeated will be cleared.

* AMS Test Mode

1. Set TAPE function

2. Select the desired loop by pressing the PLAY MODE button.

Insert a test tape AMS-110A or AMS-120 to Deck A.

3. Press the SPECTRUM or KARAOKE PON button to enter

the AMS test mode.

4. After a tape is rewound first, the FF AMS is checked, and the

mechanism is shut off after detecting the AMS signal the AMS

signal twice.

5. Then the REW AMS is checked and the mechanism is shut off

after detecting the AMS signal twice.

6. When the check is complete, a message of either OK or NG

appears.

* To return to normal mode again.

1. When you want to exit this mode, press the `/1 button.

2. The cold reset is enforced at the same time.

13

HCD-VP700

[CD Ship Mode (No Memory Clear)]

• This mode moves the position to the position durable to vibration Use this mode when returning the set to the customer after

repair.

Procedure:

1. Press `/1 button to turn the set ON.

2. Press three ENTER , DISK 1 button and CD button

simultaneously.

3. After the “STANBY” display blinks six times, a message

“LOCK” is displayed on the fluorescent indicator rube, and the

CD ship mode is set.

[CD Ship Mode (Memory Clear)]

• This mode moves the pickup to the position durable to vibration. Use this mode when returning the set to the customer after

repair.

Procedure:

1. Press

2. Press three buttons CD and

3. After the “STANDBY” display blinks six times, a message

“LOCK” is displayed on the fluorescent indicator tube, and the

CD ship mode is set.

button to turn the set ON.

`/1

button simultaneously.

`/1

[CD Service Mode]

• This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pickup.

Procedure:

1. Press

2. Select the function “CD”.

3. Press three buttons ENTER , DISC 1 , and x simultaneously.

4. The CD service mode is selected.

5. With the CD in stop status, press M button to move the

pickup to outside track, or press m button to inside track.

6. To exit from this mode, perform as follows:

1) Move the pickup to the most inside track.

2) Press

Note:

• Always move the pickup to most inside track when exiting from

this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can

be chipped.

button to turn the set ON.

`/1

button to turn the set OFF.

`/1

14

HCD-VP700

[VCD COLOR SYSTEM MODE]

• This mode is used for changing the COLOR SYSTEM of the

VCD.

Procedure:

1. Set the standby mode.

2-1.Press the two buttons

`/1

and

simultaneously to set the

>

COLOR SYSTEM of the VCD to AUTO.

2-2.Press the two buttons

`/1

and

simultaneously to fix the

.

COLOR SYSTEM of the VCD to PAL.

2-3.Press the two buttons

and X simultaneously to fix the

`/1

COLOR SYSTEM of the VCD to NTSC.

3. The power tune ON automatically and the function sets to“CD’’.

4. The FL tube shows the COLOR SYSTEM mode see .

5. The COLOR SYSTEM mode set is maintained (memorized)

until COLD RESET is executed.

[VIDEO CD Color-bars Mode]

On this mode, the data of the color-bars signal as a picture signal

and the 1 kHz sine wave signal as a sound signal are output by the

mechanism controller (IC502) for the video CD signal check. When

measurement of the voltage and waveform on the VIDEO board,

perform it in this mode.

For reference, the color-bars signal can be observed at J302 using

an oscilloscope.

Procedure:

1. Short the both ends of the land of SL503 of the VIDEO board.

2. Turn the power on. Press the CD button to select CD.

3. The color-bars appears when the CD is in stop status, and it

disappears when the CD goes in play status.

4. After measuring, remove the lead wire connected.VIDEO board

(SIDE B)

[VIDEO BOARD] (SIDE A)

J301

CN501

SL503

SL502

SL501

CHECK LED

CN502

1 2 3

J302

CN503

[CD Servo ON/OFF Mode]

Procedure:

1. Short SL502 on the VIDEO board by soldering.

2. Turn on the main power. Set a disc on the DISC1 tray. Select

CD.

3. Press the hH button to play back CD.

4. When the > button is pressed, 100 track jump is executed.

5. Also, every pressing of the PLAY MODE button triggers

between ON and OFF of TRACKING SERVO and SLED

SERVO.

How to quit the CD servo ON/OFF mode:

1. Press the ?/1 button to turn off the main power.

2. Remove soldering from SL502.

[REPEAT 5 LIMIT OFF MODE]

• This mode is used to enable infinite repetitions.

Normally, the number of repetitions allowed is 5.

Procedure:

1. Press the

button to turn ON the power supply.

`/1

2. Set the function “CD”.

3. Press the three burtons ENTER , DISC 3 , and x is

simultaneously.

4. Infinite repetitions is enabled.

5. This state is maintained ( memorized ) until COLD RESET is

executed.

15

HCD-VP700

MEMO

16

SECTION 4

r

MECHANICAL ADJUSTMENTS

HCD-VP700

SECTION 5

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

3.06 N • m to 6.96 N • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.19 N • m to 0.58 N • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

3.06 N • m to 6.96 N • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.19 N • m to 0.58 N • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

6.96 N • m to 14.02 N • m

71 to 143 g • cm

(0.98 – 1.99 oz • inch)

9.80 N • m

100 g or more

(3.53 oz or more)

9.80 N • m

100 g or more

(3.53 oz or more)

DECK SECTION

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Level Adjustment

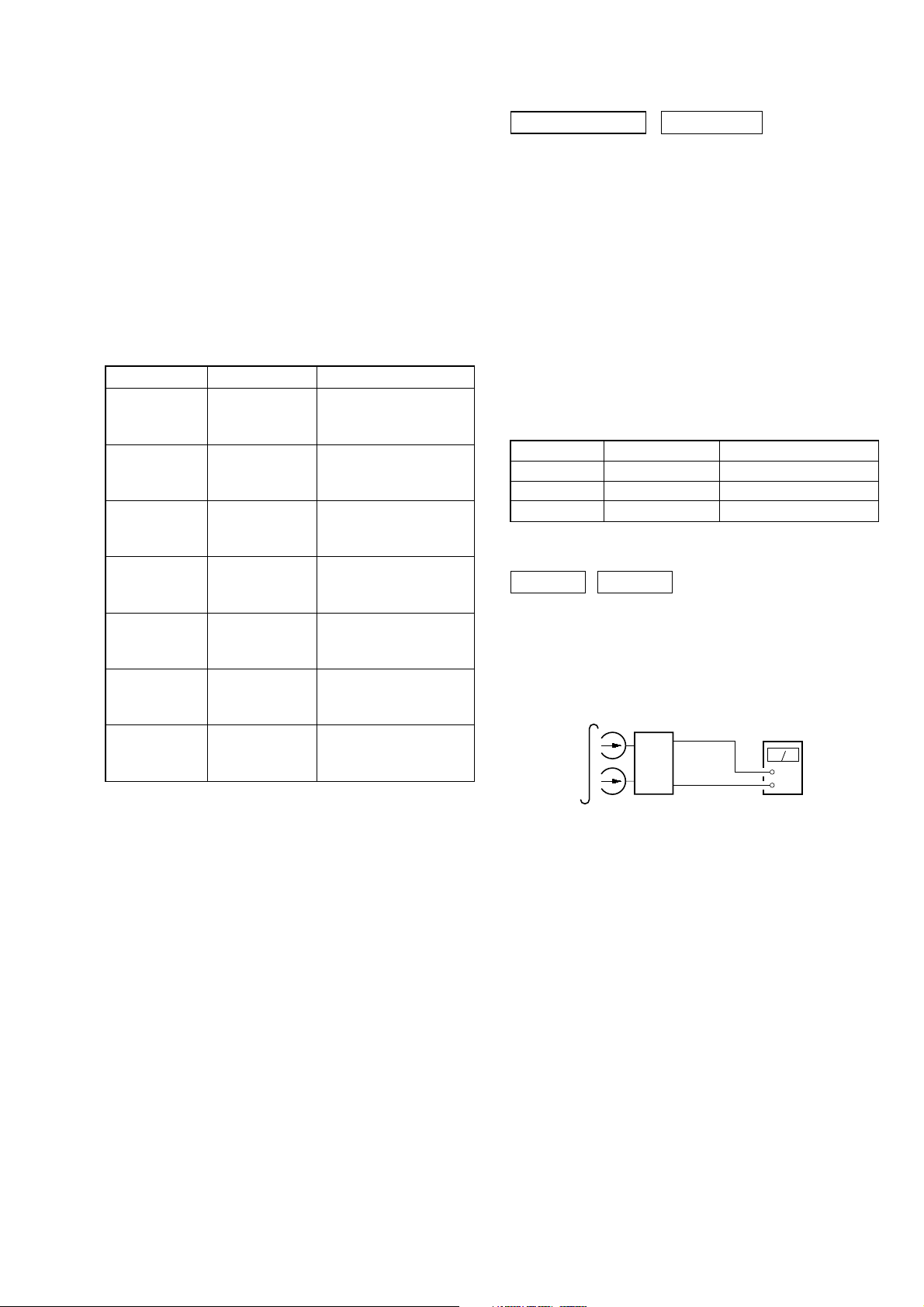

Record/Playback Head Azimuth Adjustment

0 dB=0.775 V

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

main board

CN301

Pin 3 (L-CH)

Pin 1 (R-CH)

set

main board

CN301

Pin 2 (GND)

level mete

+

–

17

HCD-VP700

e

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

Screw

position

L-CH

peak

Screw

position

R-CH

peak

3. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

MAIN

board

CN301

set

R-CH

waveform of oscilloscope

in phase 45 ° 90° 135° 180°

pin 3

pin 2

L

R

pin 1

good

oscilloscop

V

wrong

H

4. After the adjustments, apply suitable locking compound to the

pats adjusted.

Adjustment Location: Playback Head (Deck A).

Record/Playback/Erase Head (Deck B).

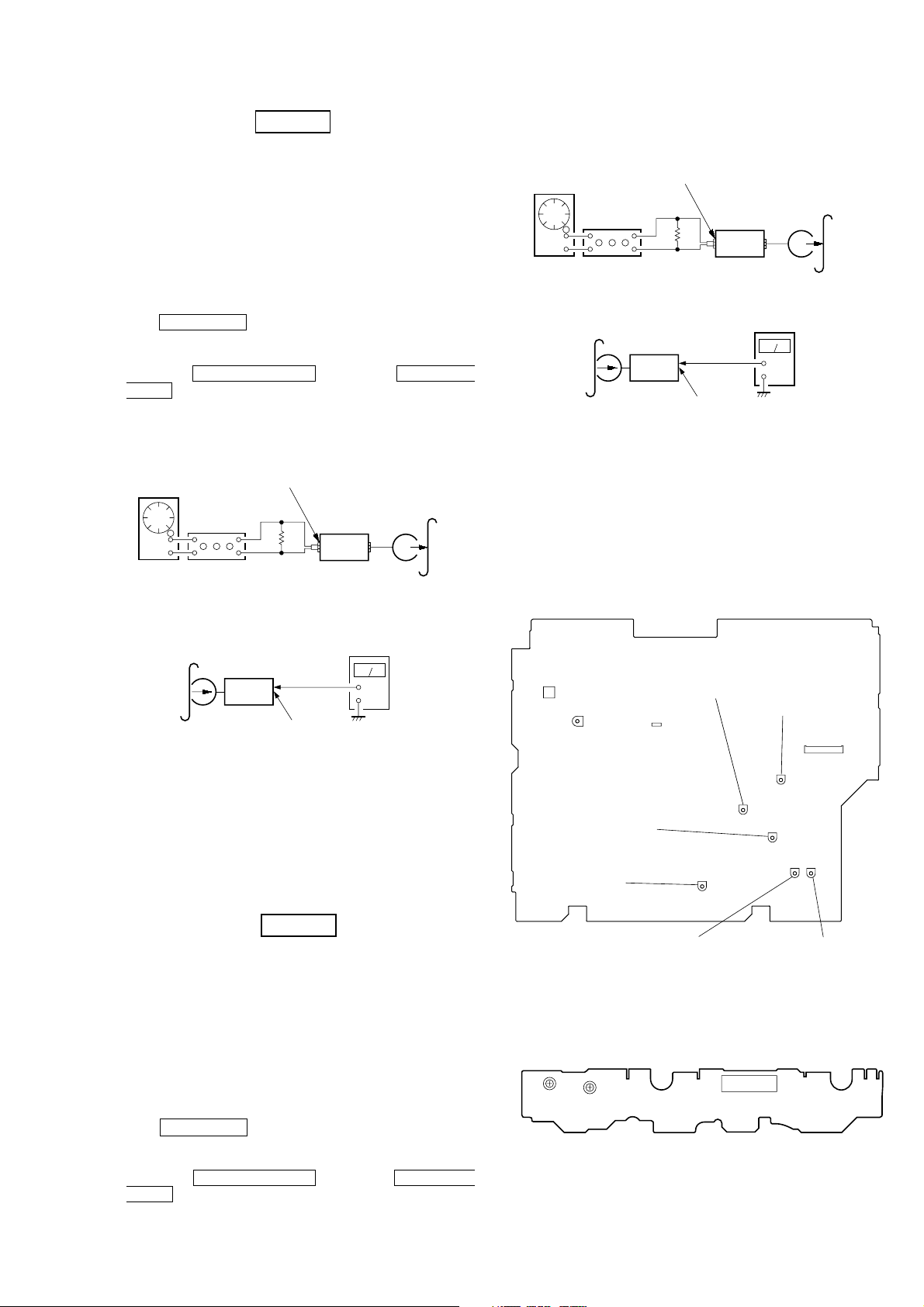

Tape Speed Adjustment DECK B

Note: Start the Tape Speed adjustment as below after setting to the test

mode.

In the test mode, the tape speed is high during pressing the

CD SYNC HI-DUB button.

Procedure:

1. Turn the power switch on.

2. Press the x button, DISPLAY button and DISC 3 button

simultaneously.

(Cursor segment flash on the FL display tube.)

To exit from the test mode, press the ?/1 button.

Mode: Playback

test tape

WS-48B

(3 kHz, 0 dB)

set

main board

CN301 (Pin 3 : L-CH)

frequency counter

+

–

(Pin 1 : R-CH)

1. Insert the WS-48B into the deck B.

2. Press the Y button on the deck B.

3. Press the CD SYNC HI-DUB button in playback mode.

Then at HIGH speed mode.

4. Adjust RV1001 on the LEAF SW board do that frequency

counter reads 6,000 ± 30 Hz.

5. Press the CD SYNC HI-DUB button.

Then back to NORMAL speed mode.

6. Adjust RV1002 on the LEAF SW board so that frequency

counter reads 3,000 ± 15 Hz.

Adjustment Location: LEAF SW board

Playback level Adjustment DECK A DECK B

Procedure:

Mode: Playback

test tape

P-4-L300

(315 Hz, 0 dB)

level meter

forward

reverse

set

main board

CN301 (Pin 3 : L-CH)

(Pin 1 : R-CH)

+

–

Deck A is RV302 (L-CH), Deck B is RV303 (L-CH) so that

adjustment within adjustment level as follows.

Adjustment Level:

CN301 PB level: 334 to 375 mV (–6.8 dB ± 0.5 dB) level

difference between the channels: within ±0.5 dB

Adjustment Location: MAIN board

Sample Volue of Wow and Flutter: 0.3% or less W. RMS

(WS-48B)

18

HCD-VP700

r

set

MD/VIDEO (AUDIO) IN

315 Hz, 50 mV (–23.8 dB)

blank tape

CS-123

600 Ω

attenuator

AF OSC

+

–

set

recorded

portion

CN301 (Pin 3 : L-CH)

(Pin 1 : R-CH)

level meter

REC Bias Adjustment DECK B

Procedure:

INTRODUCTION

When set to the test mode performed in Tape Speed Adjustment,

when the tape is rewound after recording, the “REC memory mode”

which rewinds only the recorded portion and playback is set.

This “REC memory mode” is convenient for performing this

adjustment. During recording, the input signal FUNCTION will

automatically switch to VIDEO.

(If do not operation of stopped from recording complete, and rotette

of shuttle knob then rewind to recording start position.)

1. Press MD (VIDEO) button to select VIDEO. (This step is not

necessary if the above test mode has already been set.)

2. Insert a tape into deck B.

3. After press REC PAUSE/START button, press REC PAUSE/

START button, then recording start.

4. Mode: Record

MD/VIDEO (AUDIO) IN

1) 315 Hz

2) 10 kHz

AF OSC

attenuator

50 mV (–23.8 dB)

600 Ω

blank tape

CN-123

set

4. Mode: Record

5. Mode: Playback

6. Confirm playback the signal recorded in step 3 become

adjustable level as follows.

If these levels do not adjustable level, adjustment the RV301

(L-CH) and RV351 (R-CH) on the MAIN board to repeat steps

4 and 5.

Adjustable level:

CN301 PB level: 33.4 to 37.5 mV (–27.3 to –26.3 dB)

Adjustment Location: MAIN board

5. Mode: Playback

6. Confirm playback the signal recorded in step 3 become

adjustable level as follows.

If these levels do not adjustable level, adjustment the RV304

(L-CH) and RV354 (R-CH) on the AUDIO board to repeat steps

4 and 5.

Adjustable level: Playback output of 315 Hz to playback output

Adjustment Location: MAIN board

REC Level Adjustment DECK B

Procedure:

INTRODUCTION

When set to the test mode performed in Tape Speed Adjustment,

when the tape is rewound after recording, the “REC memory mode”

which rewinds only the recorded portion and playback is set.

This “REC memory mode” is convenient for performing this

adjustment. During recording, the input signal FUNCTION will

automatically switch to VIDEO.

(If do not operation of stopped from recording complete, and rotate

of shuttle knob then rewind to recording start position.)

1. Press MD (VIDEO) button to select VIDEO. (This step is not

necessary if the above test mode has already been set.)

2. Insert a tape into deck B.

3. After press REC PAUSE/START button, press REC PAUSE/

START button, then recording start.

recorded

portion

set

of 10 kHz: ±1.0 dB

level mete

+

–

CN301 (Pin 3 : L-CH)

(Pin 1 : R-CH)

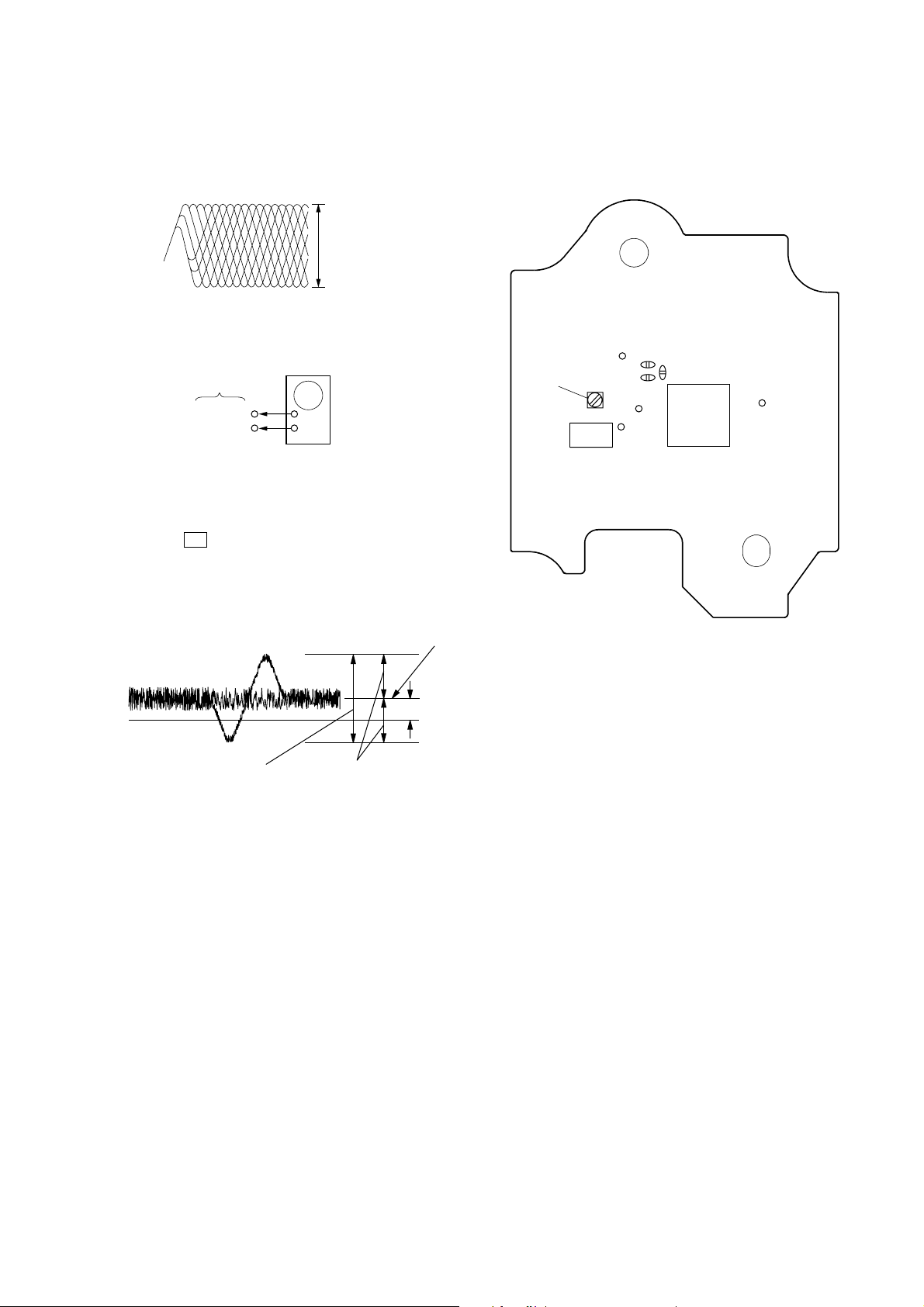

[MAIN BOARD] (Component Side)

T11

RV11

REC LEVEL (R)

(B)

[LEAF SW BOARD] (Component Side)

TAPE SPEED

(NORMAL) (HIGH)

RV1002

CN301

PB LEVEL (L)

(B)

RV1001

REC LEVEL (L)

(B)

RV301

RV351

REC BIAS (L)

(B)

PB LEVEL (L)

(A)

RV304

REC BIAS (R)

CN1001

CN304

RV302

RV303

RV354

(B)

19

HCD-VP700

TP(RFAC)

TP(DVC)

BD board

oscilloscope

BD board

Oscilloscope

TP(FE)

TP(DVC)

FM Tuned Level Adjustment

FM RF SSG

75

Ω

coaxial

set

Carrier frequency : 98 MHz

Modulation : AUDIO 1 kHz, 75 kHz

deviation (100%)

Output level : 28 dB (at 75

Ω

open)

FM ANTENNA terminal

(TM1)

Procedure:

1. Supply a 28 dB 98 MHz signal from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Adjust RV11 to the point (moment) when the TUNED indicator

will change from going off to going on.

Adjustment Location: MAIN board

Null Adjustment

FM RF SSG

75 Ω coaxial

set

Carrier frequency : 98 MHz

Modulation : AUDIO 1 kHz, 75 kHz

deviation (100%)

Output level : 25 dB (at 75 Ω open)

FM ANTENNA terminal

(TM1)

Procedure:

1. Supply a 25 dB 98 MHz signal from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Measure voltage between pin 22 and pin 3 of IC 11. Adjust

T11 ubtil the voltage becomes 0 V.

Adjustment Location: MAIN board

Adjustment Location

[MAIN BOARD] Component side

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

S-Curve Check

Procedure :

1. Connect oscilloscope to TP (FEO).

2. Connect between TP (FE) and TP (DVC) by lead wire.

3. Turn Power switch on.

4. Load a disc (YEDS-18) and actuate the focus search. (In

consequence of open and close the disc tray, actuate the focus

search)

5. Confirm that the oscilloscope waveform (S-curve) is

symmetrical between A and B. And confirm peak to peak level

within 4 ±1 Vp-p.

S-curve waveform

symmetry

A

±

within 4

B

7. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

1Vp-p

T11

12

13

20

1

IC11

RV11

24

FM TUNED LEVEL

CN301

NULL

RV351

RV301

RV303

RV304

RV302

RV354

CN304

Procedure :

1. Connect oscilloscope to TP (RFAC).

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal

level is correct or not.

5. Measure the RFDC in the same way.

HCD-VP700

)

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.1 ± 0.3Vp-p

E-F Balance (1 Track jump) Adjustment

oscilloscope

BD board

TP (TE)

TP (DVC)

+

–

Procedure:

1. Connect oscilloscope to TP (TE) and TP (DVC) board.

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the X button. (Becomes the 1track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope

waveform.

Adjustment Location :

[ BD (CD) BOARD ] — SIDE B —

TP (DVC)

RV101

IC103

TP(TE)

TP(RFDC)

TP

(RFAC)

TP(SE)

TP(FE)

IC101

TP

(XPCK)

1 track jump waveform

Center of

waveform

B

0V

level=1.3 ±0.6Vp-p

Symmetry

A (DC voltage

Specification level: x 100=less than ±22%

6. Adjust RV101 so that (DC voltage) becomes 0.

7. After check, remove the lead wire connected in step 1.

21

HCD-VP700

r

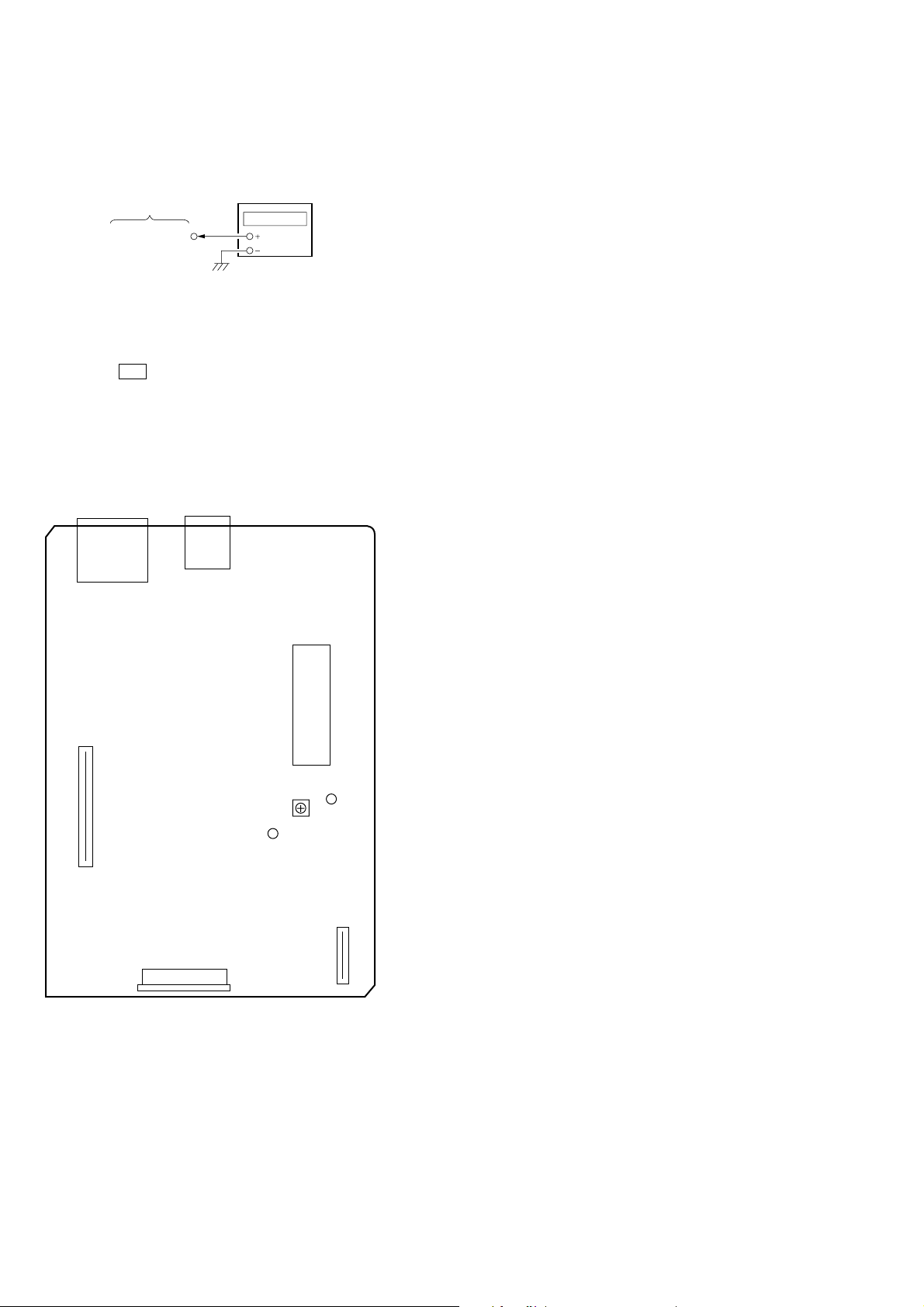

VIDEO SECTION

Frequency Adjustment

Connection:

VIDEO board

(27 MHz)

Procedure:

1. Connect the frequency counter to check point of the VIDEO

board.

2. Turned power switch on.

3. Press the CD button to select the CD.

4. Adjust CT503 on the VIDEO board so that the frequency counter

reading 27.0 MHz ± 80 Hz at stop status.

Adjustment Location:

[VIDEO BOARD] (SIDE A)

frequency counte

CN501

J301

CN502

J302

(27MHz)

IC507

(GND)

CT503

VIDEO

Frequency

Adjustment

CN503

22

SECTION 6

C

B

These are omitted.

E

Q

DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• Abbreviation

: internal component.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

under no-signal (detuned) conditions.

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM

E : PB (DECK A)

d : PB (DECK B)

G : REC (DECK B)

J : CD

c : digital out

g : MD (VIDEO)

SP : Singapare model

MY : Malaysia model

TH : Thai model

4

W or less unless otherwise

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

• Indication of transistor.

Q

B

CE

These are omitted.

HCD-VP700

23

HCD-VP700

d

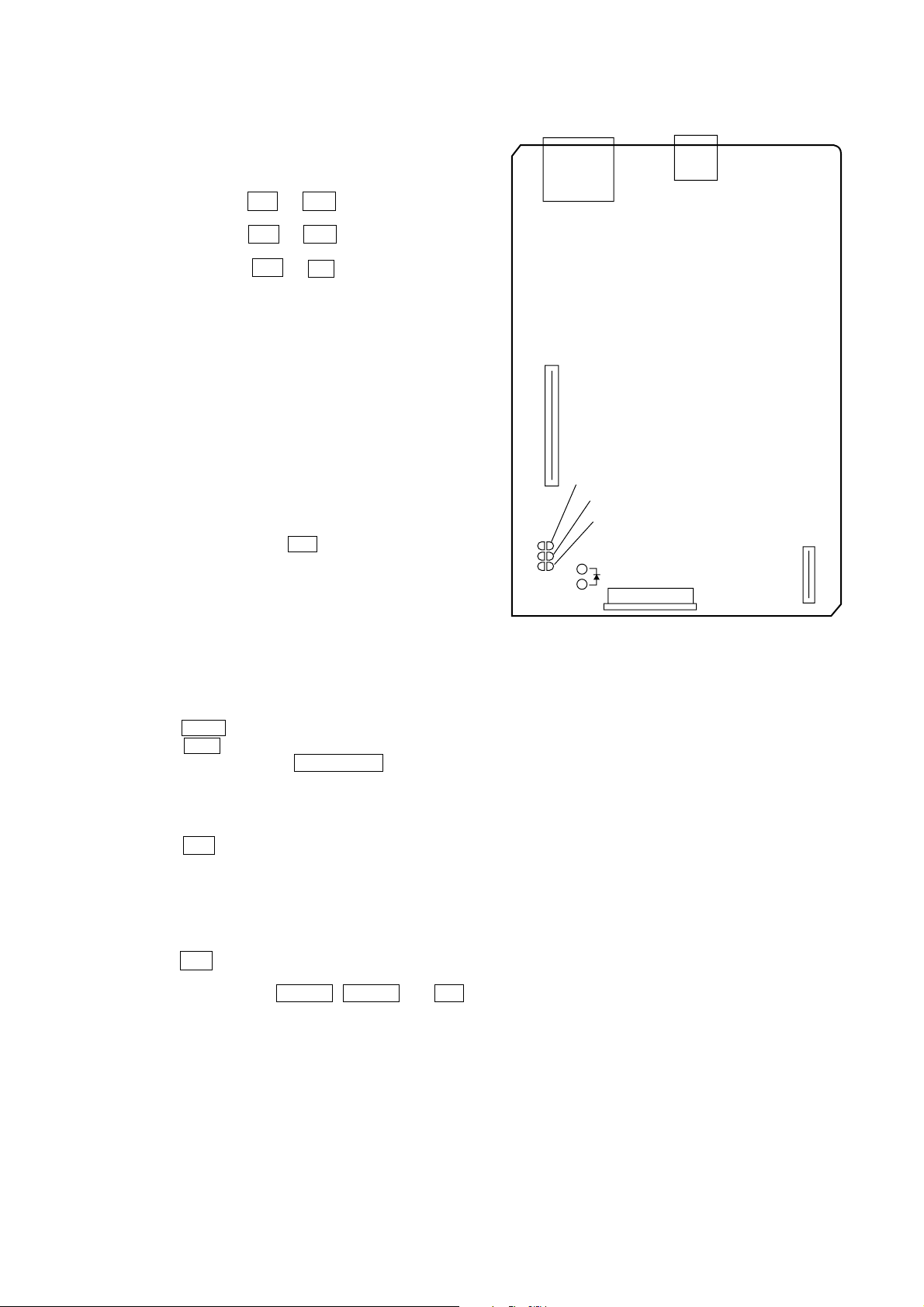

6-1. CIRCUIT BOARD LOCATION

CD SENSOR board

VIDEO board

HEAD (A) board

MOTOR board

HEAD (B) board

DRIVER board

BD board

LEAF SW board

CD PANEL board

OPT IN board

TRANS board

PANEL board

SUB TRANS board

DSP board

OPT IN REAR board

MAIN board

SURROUND AMP boar

FRONT AMP board

24

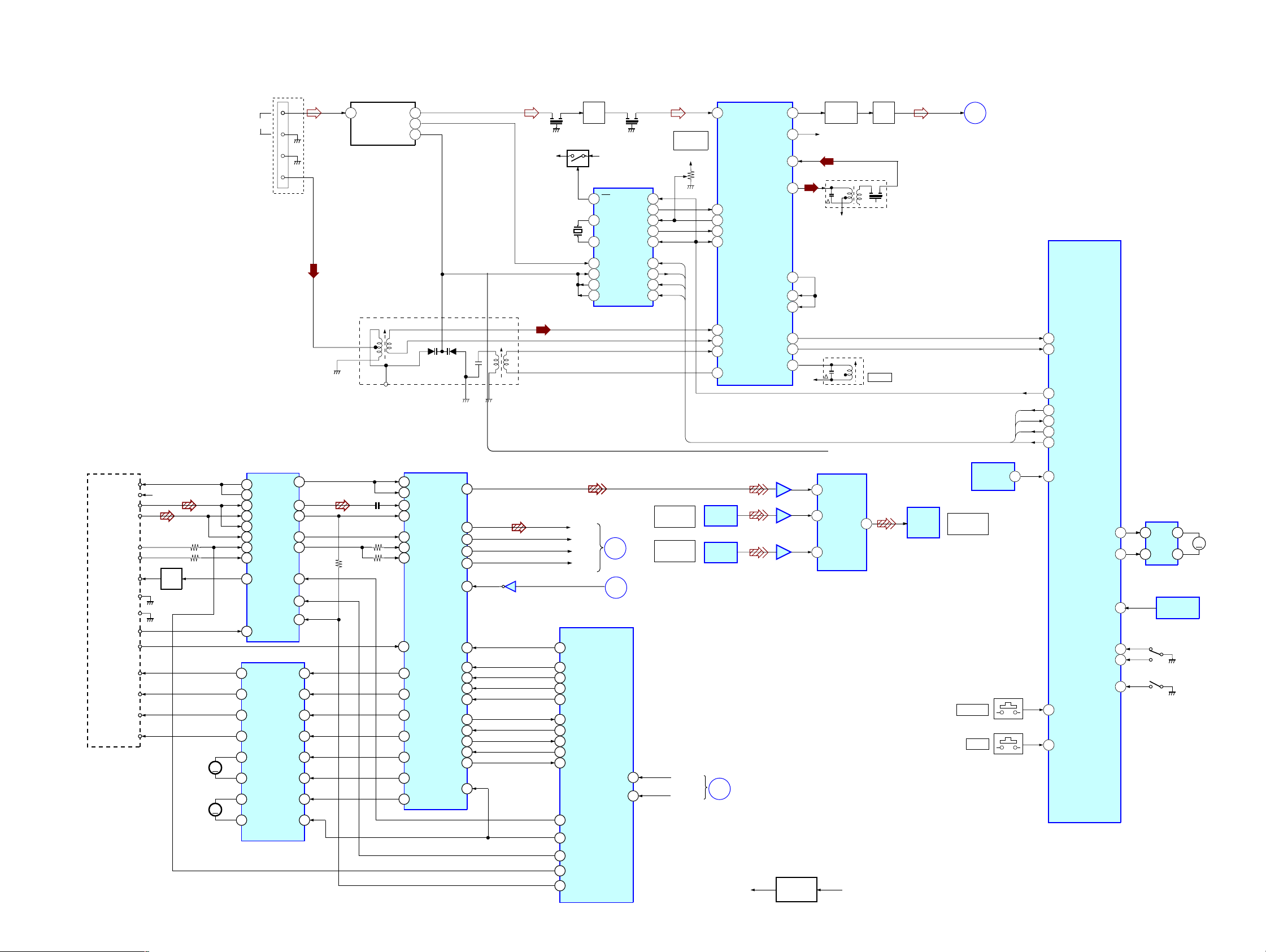

6-2. BLOCK DIAGRAMS

– TUNER/CD SECTION –

OPTICAL PICK-UP

BLOCK

(A-MAX.3)

VC

+5V

VCC

PD1

PD2

I5-10

I1-6

LD

LD GND

GND

PD

SW

F+

F-

T+

T-

Q101

LD

DRIVE

M102

SLED

MOTOR

M101

SPINDLE

MOTOR

IC102

M

M

TM1

FM 75Ω

G

AM

IC103

RF AMP

27

VC

25

VFC

6

A

7

B

8

C

9

D

10

E

11

F

1

LD

RFDCI

2

PD

MOTOR/COIL DRIVE

52

VO1(-)

47

VO1(+)

56

VO2(-)

55

VO2(+)

1

VO3(+)

2

VO3(-)

5

VO4(+)

10

VO4(-)

1

ANT IN

2

11

14

DVC

RFAC

15

RFDC

28

16FE

18TE

SW

12

FEI

17

29

IN1+

35

IN1-

34

IN2+

32

31

IN2-

27

IN3+

IN3-

26

IN4R

24 MDP

STBY

8

FE1

IF OUT

7

OSC OUT

8

VT

5

10

49

RB41

IC101

DIGITAL SERVO

DIGITAL SIGNAL PROC.

38

VC

CE

RFAC

RFDC

FE

TE

SE

D OUT

PCMD

BCLK

LRCK

C2PO

XTAI

42

50

43

39

41

40

6

64

66

67

65

14

71

1

3

8

7

4

2

IC106

26 SSTP

33

FFDR

34

FRDR

31

TFDR

32

TRDR

29

SFDR

30

SRDR

25

XTSL

DATA

CLOK

XLAT

MUTING

SQSO

SQCK

SENS

SCLK

SCOR

XRST

CTRL1(1-2)

69

4

6

5

3

76

77

7

8

15

2

DATA

CLK

XLT

MUTING

SQSO

SQCK

SENS

SCLK

SCOR

LDON

XRST

PWM1

PWM2

PWM3

Q2

ADATA

BCLK

LRCK

C2PO

IC502(1/2)

CTRL1

DSP DATA

5

DSP CLK

DSP LATCH

DSP MUTING

SUBQ DATA

SUBQ CLK

1

SENSE

2

SENSE CLK

SCOR

LD ON

DEVICE RESET

PWM1 (BD)

PWM2 (BD)

PWM3 (BD)

Q1

RF IF

AMP

10

1

22

16

20

19

18

MCLK

CF1 CF2

+B

(FE1-3)

X51

4.5MHz

CD DATA

CD BCK

CD LRCK

CD MECHANISM CONTROLLER

11

95

97

10

84

83

18

82

77

28

26

24

FM TUNED

A+12V

PLL

LEVEL

A+12V

IC51

IF IN

FM

XIN

XOUT

FM OSC

AOUT

AIN

PD

VIDEO

SECTION

(Page 27)

D

C

I2C.DATA I2C-DATA

I2C.CLK I2C-CLK

FM

AM OSC

CL

CE

VIDEO

SECTION

(Page 27)

30

29

12

7

15

9VCO STOP

8IF REQ

6DO

4DI

5

3

DIGITAL IN

DIGITAL IN

DO

DI

DI

CL

CE

OPTICAL

OPTICAL

RV11

IC1195

DIGITAL

IC801

DIGITAL

1

FM IF

11

AM/FM

24

OSC FM

12

VCO STOP

10

IF REQ MUTE

21

AM RF IN

22

AFC

23

AM OSC

VCC

9

IN

IN

E

AM/FM IF MPX

IC11

AM IF IN

AM MIX OUT

DECORDER

PLL IN OUT

DECORDER

MAIN

SECTION

(Page 26)

+3.3V

L OUT

R OUT

IN

TUNED

STEREO

FM-DET

IC608

3

5

IC608

1

IC608

13

14

4

2

18

17

16

6

7

8

A+12V

10

8

12

Q103,D101

+3.3V

REG.

BUFFER

Q11

R-CH

A+12V

AEP

DIGITAL AUDIO

INTERFACE

IC604(2/2)

DIN0

3

DIN1

4

SPDIF

5

DIN2

+5V

IFT11

2

T11

LPF11

NULL

LPF

IC609

OPTICAL

DIGITAL

OUT

OUT

L-CH

(Page 26)

DIGITAL OUT

OPTICAL

A

MAIN

SECTION

DISPLAY

_/1

IC1102

REMOTE

SENSOR

S1135

S1115

HCD-VP700

• RCH is omitted

• Signal Path

: FM

F

: AM

f

: CD

J

: DIGITAL OUT

c

MASTER CONTROL

IC401(1/2)

TUNED

88

STEREO

87

21

ST MUTE

DO

23

DI

CL

CE

1

ST-DOUT

25

ST-DIN

27

ST-CLK

CE

22

SIRCS

4

BU UP/DOWN SW

73

DISPLAY KEY

74

POWER KEY

LOAD IN

T SENS

IC701

9

44

45LOAD OUT

7

MOTOR

DRIVE

4

2

M721

M

TURN

MOTOR

IC711

49

46OPEN SW

47CLOSE SW

48

TBL ADDRESS

SENSOR

OPEN/CLOSE

S711

BU UP/

DOWN

S701

2525

HCD-VP700

– MAIN SECTION –

TUNER/CD

SECTION

(Page 25)

VIDEO

SECTION

(Page 27)

MD/VIDEO

(AUDIO)

HEAD

REC/PB

HEAD

ERASE

HEAD

L

R

PB

TC BLOCK

A

B

J101

DECK-A

DECK-B

A120/70

B120/70

B SHUT

A SHUT

B PLAY

A PLAY

B HALF

A HALF

A TRG M+

B TRG M+

CAP M H/L

CAP M+

CN304

L-CH

L-CH

L-CH

R-CH

IC303

R-CH

R-CH

R-CH

E+6V

g

g

PB EQ

AMP

PB EQ

AMP

IC304

RV304

REC

BIAS(L)

E+6V

Q393,394

A TRIG

DRIVE

Q391,392

B TRIG

DRIVE

Q395

CAP MOTOR

SPEED CONT

Q396,397

CAP MOTOR

DRIVE

• RCH is omitted

• Signal Path

C332,L301

BIAS

TRAP

T301

: PB (DECK A)

: PB (DECK B)

: REC (DECK B)

: FM

: CD

: MD(VIDEO)

: AM

: DIGITAL OUT

RV302

RV303

REC/PB SWITCH

IC302

1

2

3

BIAS

OSC

Q302,303

+6V

VIDEO

SECTION

(Page 27)

Q301

J1201

MIC1

R CH

TC A+12V

Q141

DC

BIAS

IC1220

ECHO

9

1

RV1201

MIC-VOL

DOLBY

B

DOL

PAS

BIAS ON/OFF

ALC ON/OFF15RM ON/OFF22NR ON/OFF23REC /PB/PASS24LM ON/OFF25MS OUT

PB A/B16NORM/HIGH

20

18

67

66

68

65

61

ALC

BIAS

PB A/B

EQ H/N

CODEC-SMUTE

CD/DVDPOWER

AMP

2

REC

60

59

58

R/PB PAS

REC MUTE

NR ON/OFF

SP PROTECT

FRONT RELAY

AMP-DATA

AMP-CLK

AMP-LAT

STK-MUTE

LINE-MUTE

DSP-CS

DIG-TX

DIG-CLK

DIR-STATE

DIR-RX

DIR-CS

IICDATA

IICCLK

M-RESET

DSP-RX

DSP-ACK

DSP-DECODE

DIR-UNLOCK

ACOUT

RESET

STBY RELAY

70

120

38

RV301

REC(L)

LEVEL

IC1201(1/2)

MIC

3

AMP

DECK PROC.

IC301

REC

PB

39

B NORM/CROM/METAL

A120/70

17

19

MASTER CONTROL

IC401(2/2)

J1202

MIC2

48

A

B

46

SWITCH

4

Q304,305

EQ OUT(L)

REC

36

EQ

NORM

33

BIAS

CROM

SW

32

TC A+12V

B SHUT

90

A SHUT

89

57

B PLAY

A PLAY

56

B HALF

91

70

A HALF

TC RELAY

69

A TRIG

50

B TRIG

52

CAP M H/L

54

55

CAP M CONT

XC IN

10

X401

32.768kHz

X402

16MHz

F

XC OUT

11

X OUT

13

X IN

15

X RST

43

PB

26

53

TC MUTE

FAN

43

40

AMS IN

86

84

1

2

3

72

71

79

81

5

7

77

78

76

94

30

29

41

6

80

82

15

98

100

12

83

RV1202

ECHO

LEVEV

MIC

7

6

AMP

IC1201(2/2)

Q502

LINE

MUTE

Q504-506

POWER

MUTE

Q501

RESET

SWITCH

MUTE

SWITCH

Q612

1

67

71

69

64

70

15

16

17

IC607(1/2)

SOUND PROCESSOR

MAC IN

LIN2

LIN6

LIN4

LREC OUT1

FLOUT

LREC OUT

LIN5

SWOUT

FRBB2

FRBB1

FLBB2

FLBB1

IC607(2/2)

SOUND PROCESSOR

ADL+OUT

ADL-OUT

L-REC IN

B PLAY

PORT3

B PLAY

B PLAY

PORT1

PORT4

PORT5

IC603(2/2)

BUFFER

6

2

IC604(1/2)

DIGITAL IN

REFER TO

IC604(2/2)

IC801

46 10

63

66

LIN1

69

LIN4

28

Q611

MUTE

52

51

45

44

MULTI-CHANEL AUDIO DECODE

6

30

7

9

2

20

18

21

22

X601

13.5MHz

5

1

29

27

25

17

3

17

35

37

36

38

3

4

5

21

22

DSP-RX

DSP-DATA

DSP-DECODE

DIR-UNLOCK

FLIN

Q607

MUTE

Q604

DBFB

CONT

Q605

DBFB

CONT

IC605

LIN+

LINLOUT1

LOUT2

PDN

SMUTE

Q613

RESET

SWITCH

IC604(1/2)

DIGITALAUDIO

INTERFACE

XSTATE

DO

CE

DI

CL

DIN0

DIN1

DIN2

XOUT

XIN

IC603(1/2)

BUFFER

12

10

8

4

18

MCLK

BCK

DATA0

DATA1

DATA2

DATA3

LRCK

DATA

LRCK

CKOUT

XMCK

AUDIO

ERROR

Q823

Q821,822

BCK

13

11

39

16

14

15

13

20

24

34

9

3

POWER

AMP

MUTE

MUTE

SWITCH

4

9

6

7

8

5

R-CH

R-CH

TM801

L

M961

R CH

1

FAN

58

64

64

65

66

56

57

60

61

77

F916

F917

D830,831

F918

F919

D961,962

D911

FRONT

SPEAKER

R

DISPLAY CONTROL

IC1101

HEADPHONE

KEY0

KEY0

PB7/SO1 LED11

PA3/AN3 LED10

PB4/AN2 LED9

KEY1

RLED5 FIP/LED0

LED4 FIP/LED1

KEY2

VOL 1A

VOL 1B

LED1 FIP/LED2

LED1 FIP/LED3

PB0/IC1 LED15

PB1/C11 LED14

IIC DATA

IICCLOCK

RSTX

IC901

+5.7V

3

REG

RELAY

DRIVER

Q901

J1101

PHONES

2-10

FIP17

12-22

I

24-41

FIP59

43-47

FIP/LED5

90

I

100

FIP/LED16

PLAY1

55

59

67

76

85

86

PB6/AN13

78

PB6/AN14

79

PB7/AN15

80

87

88

89LED1 FIP/LED4

52

53

54PB8/S10 LED13

XIN

83

XOUT

82

T911

POWER TRANSFORMER

1

11

12

+B

14

20

18

23

20

25

19

67

56

2

113

36

33

34

30

29

28

22

12

9

69

OVER LOAD

Q816,817

TEMPERATURE

DETECTOR

AUDIO DECODER

SCKOUT

BCK

SDI1

SDO1

SDO4

SDO3

LRCKO

GP10

BST

XRST

PM

HCS

HD IN

HCLK

SDI2

BCKI2

LRCKI2

KFSI2

MCLK2

MCLK1

GP8(AUDIO)

DETECTOR

IC601

HACN

323568

Q801

HDOUT

GP9(DECODE)

Q835-837

D891

Q831,832

FEED BACK

72

I

80

•

98

•

99

•

102

I

108

64

I

66

•

83

I

85

•

92

I

97

•

109

•

110

•

112

CSO

45

WEO

EXLOCK(ERROR)

59

PROTECT

DETECTOR

PROTECT

CONT

IC602

16

D15

I

13

•

10

I

7

•

38

I

35

•

32

I

29

20

I

18

•

A15

2

I

4

•

1

•

5

•

21

•

24

•

42

I

44

•

27

I

25

61744

CS

WE

S-RAM

D0

A0

D606

Q833,834

PROTECT

I2C-DATA

I2C-CLK

TC+9V

RELAY

DRIVE

Q881,882

D111

Q507

MUTE

TUNER/CD

SECTION

E

(Page 25)

IC922

3

REG

MUTE

MUTE

SWITCHT

Q121

Q503

1

IC923

A+12V

3

1

REG

IC932

3

1

IC610

3

2.6V

1

REG

D+5V

D+3.3V

IC931

3

SWD+5V

5VREG

REG

IC934

3

1

REG

Q931,932

B+SWITCH

1

Q111-113

FAN

DRIVER

Q114

FAN

SWITCH

S1136-1138,1140-1147

S1110-1114

S1129-1134,1139

S1116-1128

+VH

-VH

+VL

-VL

(UNREG+16V)

VP

(-30V)

(UNREG+9V)

R-CH

S1135

DISPLAY

SW

FUCTION

KEY

FUCTION

KEY

FUCTION

KEY

S1101

VOLUME

D871

D1071

D950

D959

Q971

AC1

AC1

AC2

AC2

AC3

AC3

REG

AC4

AC4

IC501

3

RESET

EVER5.7V

L REC OUT

SWOUT

MULTI

CHANNEL

DECODING

EFFECT

GROOVE

LED CTL

REC /

GAME

DIGITAL

MD(VIDEO)

TAPE A/B

TUNER/BAND

TUNER

CD

DISC1

DISC2

DISC3

MY, SP

F911

F912

F913

JW905

TH

D902-905

TRANSFORMER

L IN1

L IN4

F1

ENTER

X1101

4.0MHz

JW906

MY, SP

J601

J602

FLOURESCENT

INDICATOR TUBE

Q1107,1111

Q1108-1110,

Q1101-1106

Q1114-1116

RY901

JW901

MY, SP

T901

SUB

FL1101

97 99

1112

LED

DRIVER

1113

LED

DRIVER

LED

DRIVER

LED

DRIVER

L

OUT

R

L

IN

R

L

IN

R

SUB WOOFER

OUT

Q1123,1124

GRID

DRIVER

D1107,1111

D1108,1113

D1101-1106

D1114-1116

MY, SP

S901(1/2)

230-240

220

120

TH

JW907

JW902

MY, SP

S901(2/2)

230-240

120

F2

1112

JW903

MD VIDEO

GAME

S901

VOLTAGE

SELECTOR

CN901

2

AC

IN

1

2626

– VIDEO SECTION –

TUNER/CD

SECTION

(Page 25)

CN503

(TO FLASH WRITER)

TXD

SCLK

BUSY

RXD

RST

PGM

XWR

HOLD

MAIN

SECTION

(Page 26)

D

XRST

F

ADATA

BCLK

LRCK

C2PO

DATA1I

32

CLK1

33

RTS1

34

DATA1O

31

XRESET

12

CNVSS

9

BUS XWRL

46

BUS XHOLD

41

CROMA LEVEL

DAC RESET

IC502(2/2)

CD MECHANISM

CONTROLLER

DF LATCH

CL680 INTERRUPT

CL680 HSEL

CL680 HRDY

680 RESET

BGP

DATAI

DATAO

CLK1

XIN

XOUT

1

22

65V.MUTING

66

36

35

88

37

21H SYNC IN

45V SYNC

20

87

85

86

15

13

+5V

HCD-VP700

IC501

BUFFER

324

13

4

3RESOLUTION

1112 10

968

5

IC505 (1/2)

MPEG VIDEO/AUDIO DEC

VIDEO SIGNAL PROC

4

CD-DATA

Y OUT

3

CD-BCK

5

CD-LRCK

6

CD-C2PO

Q301

C OUT

69

75

IC509

DIGITAL FILTER

D/A CONV

10

RSTB

9

MD

8

MC

7

ML

V OUT R

V OUT L

IC303

Y AMP

L.P.F

L.P.F

14

11

R-CH

10

VIN

5

CCT

IC302

1

VIN

5

BGP

8

TINT

IC101

C AMP

VOUT

L.P.F

1VOUT

6

75

IC304

VIDEO MIX BUFFER

2

Y IN

7

C IN

1

MUTE A

8

MUTE B

C OUT

15Y OUT1

14Y OUT2

9

12MIX OUT1

11MIX OUT2

Y

2

4

3

1

C

V

S VIDEO

LOUT

J301

OUT

J302

VIDEO

OUT

MAIN

SECTION

B

(Page 26)

IC505 (2/2)

MPEG VIDEO/AUDIO DEC

X501

10MHz

Q531

+3.3V REG

Q501

Q502

+3.3V

(IC505 VDD)

VIDEO SIGNAL PROC

112

HD OUT

119

HD IN

117

HCK

101

H SYNC

93

V SYNC

114

HINT

121

HSEL

113

HRDY

60

RESET

DA DATA

DA BCK

DA LRCK

DA XCLK

VCK IN

MD0

MD15

MA0

MA10

RAS0

CAS

MWE

MCE

111

110

108

106

44

18

17

IC504

86

IC504

27MHz

10

15

.

17

.

19

.

21

.

23

29

58

56

.

54

.

52

50

.

48

.

46

42

40

38

37

19

111098

20

3456

4

DATA

BCK

LRCK

384FSO

MCKO

IC507

DRAM

16

A0

19

.

A8

22

26

14

RAS

28

UCAS

29

LCAS

13

WE

IC510

FLASH ROM

12

5

.

A0

27

.

A10

26

.

23

CE

22

XT1

XT2

DQ1

DQ16

O0

O7

A11

ı

A17

1

X503

27MHz

24

MCLK

2

5

.

7

10

.

31

34

.

36

39

13

15

.

17

21

.

25

.

4

.

28

.

29

.

3

.

2

.

30

• R-ch is omitted due to same as L-ch.

• Signal Path

: CD

: VIDEO

CD

SECTION

C

(Page 25)

2727

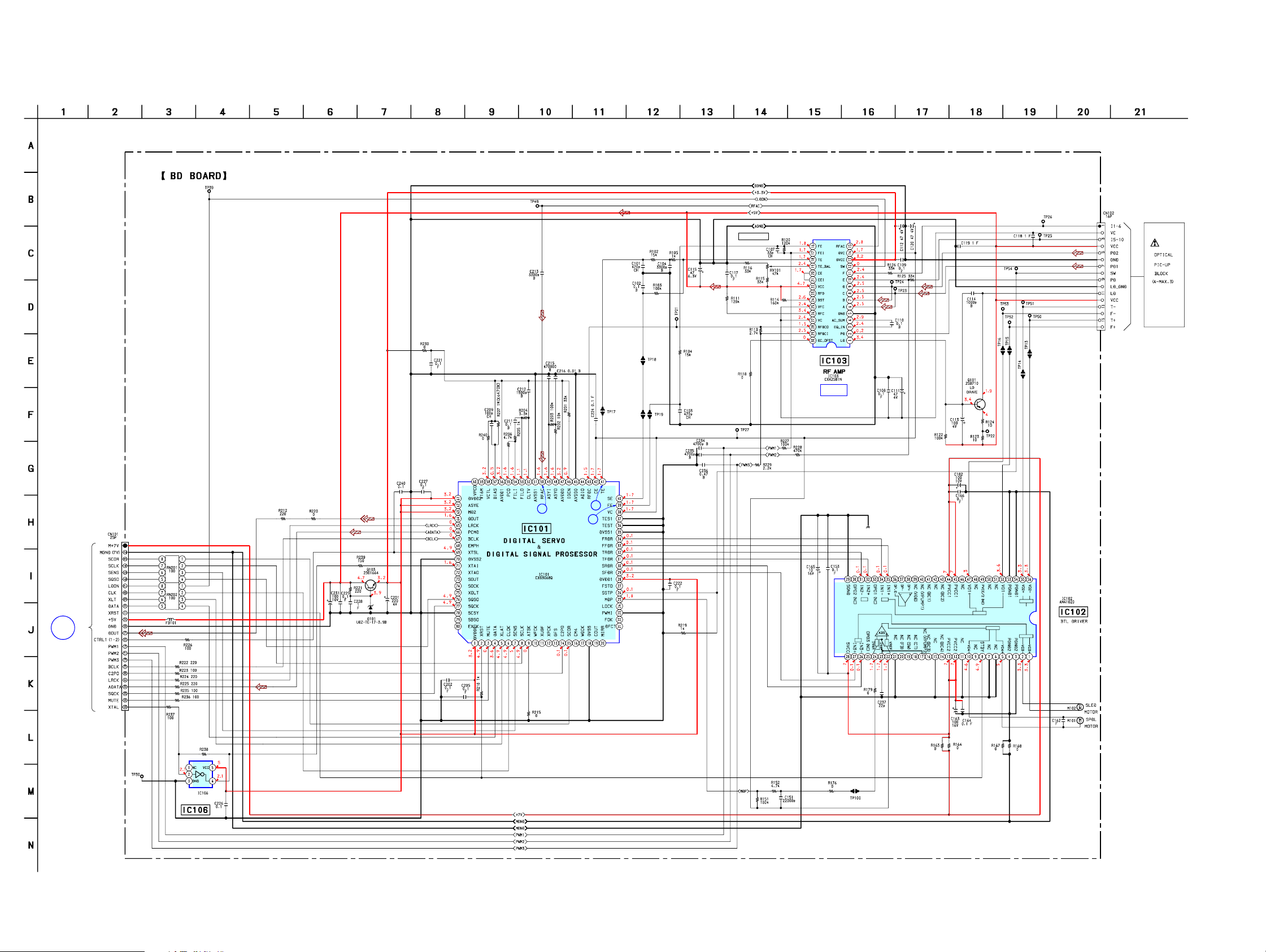

HCD-VP700

6-3. SCHEMATIC DIAGRAM – BD SECTION – • See page 53 for Waveforms. • See page 54 for IC Pin Function. • See page 63 for IC Block Diagrams.

(RFAC)

E-F BALANCE

(RFDC)

P

VIDEO BOARD(1/3)

(Page 47)

IC B/D

(TE)

TP18

(SE) (FE)

(DVC)

1

2

3

INVERTER

2828

Loading...

Loading...