sony HCD-D670AV, HCD-N555AV Service Manual

HCD-D670AV/N555AV

SERVICE MANUAL

HCD-D670AV, HCD-N555AV are the tuner,

deck, CD and amplifier section in LBT-D670A V ,

LBT -N555A V.

* Manufactured under license from Dolby Laboratories

Licensing Corporation.

DOLBY, the double-D symbol a and “PRO LOGIC”

are trademarks of Dolby Laboratories Licensing

Corporation.

* Dolby noise reduction manufactured under license from

Dolby Laboratories Licensing Corporation. “DOLBY”

and the double-D symbol a are trademarks of Dolby

Laboratories Licensing Corporation.

Photo: HCD-N555AV

CD

SECTION

T APE

DECK

SECTION

US Model

Canadian Model

HCD-D670AV

AEP Model

UK Model

E Model

Australian Model

PX Model

HCD-N555AV

Model Name Using Similar Mechanism NEW

CD Mechanism type CDM37-5BD19

Base Unit Type BU-5BD19

Optical Pick-up type KSS-213BA/S-N

Model Name Using Similar Mechanism HCD-N350

T ape Transport Mechanism Type TCM-220WR2E

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS (US model)

POWER OUTPUT AND T OTAL HARMONIC DISTORTION: W ith 6 ohm

loads, both channels driven, from 70-20,000 Hz; rated 50 watts per channel

minimum RMS power, with no more than 0.9 % total harmonic distortion

from 250 milliwatts to rated output (FRONT SPEAKER).

CD player section

System compact disc

digital audio system

Laser Semiconductor laser

(λ=780nm)

Emission duration:

continuous

laser output Max 44.6 µW*

* This output is the value measured at a distance of 200 mm from the objuctive

lens surface on the Optical Pick-up Block with 7 mm aperture.

Frequency response 2 Hz-20 kHz (± 0.5 dB)

wavelength 780-790 nm

T uner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

87.5-108.0 MHz

(100 kHz step for US, Canadian models)

(50 kHz step for except US, Canadian models)

Antenna FM wire antenna

Aerial terminals 75 ohm unbalanced

Intermediate frequency

10.7 MHz

AM tuner section

Tuning range

US, Canadian models:

AM: 530-1,710 kHz (with the tuning interval set at 10 kHz)

531-1,710 kHz (with the tuning interval se at 9 kHz)

German and Italian models:

AM: 531-1,602 kHz

AEP, UK models:

MW: 531-1,602 kHz

LW: 153-279 kHz (with the tuning inteval set at 3 kHz)

Other models:

AM: 531-1,602 kHz (with the AM tuning interval set at 9 kHz)

530-1,710 kHz (with the AM tuning interv al set at 10 kHz)

Antenna AM loop Antenna

External Antenna

terminals

Intermediate frequency

450 kHz

– Continued on next page –

COMPACT DISC DECK RECEIVER

MICROFILM

— 1 —

Tape player section

Recording system

4-track 2-channel stereo

Frequency response

(DOLBY NR OFF)

40-13,000 Hz (±3 dB), using

SONY TYPE I cassette

40-14,000 Hz (±3 dB), using

SONY TYPE II cassette

Wow and flutter

± 0.15% W.Peak (IEC)

0.1% W .RMS (NAB)

± 0.2% W.Peak (DIN)

Amplifier section

US, Canadian models:

Continuous RMS power output:

FRONT SPEAKER:

60 W + 60 W (6 ohms at 1 kHz, 5% THD)

CENTER SPEAKER:

50 W (8 ohms at 1 kHz, 5% THD)

REAR SPEAKER:

25 W + 25 W (16 ohms at 1 kHz, 5% THD)

AEP, UK, German, Italian models:

DIN power output:

FRONT SPEAKER:

40 W + 40 W(6 ohms at 1 kHz)

SUPER WOOFER:

40 W + 40 W (6 ohms)

SURROUND SPEAKER CENTER:

35 W (8 ohms at 1 kHz)

SURROUND SPEAKER REAR:

17.5 W + 17.5 W (16 ohms at 1 kHz)

Continuous RMS power output:

FRONT SPEAKER:

50 W + 50 W (6 ohms at 1 kHz, 10% THD)

SUPER WOOFER:

50 W + 50 W (6 ohms, 10% THD)

SURROUND SPEAKER CENTER:

42 W (8 ohms at 1 kHz, 10% THD)

SURROUND SPEAKER REAR:

21 W + 21 W (16 ohms at 1 kHz, 10% THD)

Music power output:

FRONT SPEAKER:

80 W + 80 W (6 ohms at 1 kHz, 10% THD)

SUPER WOOFER:

80 W + 80 W (6 ohms, 10% THD)

SURROUND SPEAKER CENTER:

70 W (8 ohms at 1 kHz, 10% THD)

SURROUND SPEAKER REAR:

35 W + 35 W(16 ohms at 1 kHz, 10% THD)

Other models:

Peak music power output:

1,400 W (6 Ω at 1 kHz, 10% THD)

Continuous RMS power output:

FRONT SPEAKER

45 W + 45 W (6 ohms, at 1 kHz, 5% THD)

SUPER WOOFER

45 W + 45 W (6 ohms, 5% THD)

SURROUND CENTER SPEAKER

40 W (8 ohms, at 1kHz 5% THD)

SURROUND REAR SPEAKER

20 W + 20 W (16 ohms, at 1 kHz, 5% THD)

Inputs

PHONO (phono jack):

Sensitivity 3 mV, impedance 47 kilohms

VIDEO (AUDIO) (phono jack):

Sensitivity 250 mV, impedance 47 kilohms

MIC (phone jack): (E, Australian, Mexican, PX, Aregentine models)

Sensitivity 1 mV, impedance 10 kilohms

Outputs

PHONES (phone jack):

US, Canadian, AEP, UK, German, Italian models:

accept headphones of 8 ohms or more

Other models: accept headphones of 6 to 16 ohms

FRONT SPEAKER: accept impedance of 6 to 16 ohms

SURROUND SPEAKER REAR:

accept impedance of 16 ohms

SURROUND SPEAKER CENTER:

AEP, UK, German,Italian models:

accept impedance of 8 ohms

E, Australian, PX, Argentine, Mexican models:

accept impedance of 8 to 16 ohms

SUPER WOOFER:

AEP, UK, German, Italian models:

accept impedance of 16 ohms

E, Australian, PX, Argentine, Mexican models:

accept impedance of 6 to 16 ohms

General

Power requirements

AEP, UK, German, Italian, models:

220-230 V AC, 50/60 Hz

Australian model:

240 V AC, 50/60 Hz

US,Canadian, Mexican model:

120 V AC, 60 Hz

Other models:

110-120 V or 220-240 V AC

adjustable, 50/60 Hz

Power consumption

US model:170 W

Canadian model:190 W

AEP, UK, German, Italian models:250 W

Other models: 240W

Dimensions

Approx. 355 x 425 x 400 mm

(14 x 16 3/4 x15 3/4 inches) (w/h/d)

incl. projecting parts and controls

Mass

US, Canadian models:

Approx. 12.4 kg (27 lb 6 oz)

Except US, Canadian models:

Approx. 13 kg (28 lb11 oz)

Disegn and specifications subject to change withoutnotice.

— 2 —

MODEL IDENTIFICATION

– BACK PANEL –

Parts No.

MODEL

D670AV: US model

D670AV: Canadian model

N555AV : AEP model

N555AV: German model

N555AV: Italian model

N555AV: UK model

N555AV: E model

N555AV : Argentine model

N555AV : Australian model

N555AV: PX model

N555AV: Mexican model

NOTE: The AEP model has lndonsian and Malaysia products.

The contents of both products are completely the same.

PARTS No.

4-978-193-0π

4-978-193-1π

4-978-193-2π

4-978-193-3π

4-978-193-4π

4-978-193-5π

4-978-194-0π

4-978-194-1π

4-978-194-2π

4-978-194-3π

4-978-194-4π

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT

MARKING is located on the rear

exterior.

This caution label

is located inside

the unit.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLA CER CES COMPOSANTS

QUE P AR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

— 3 —

SAFETY CHECK-OUT

SERVICING NOTE

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

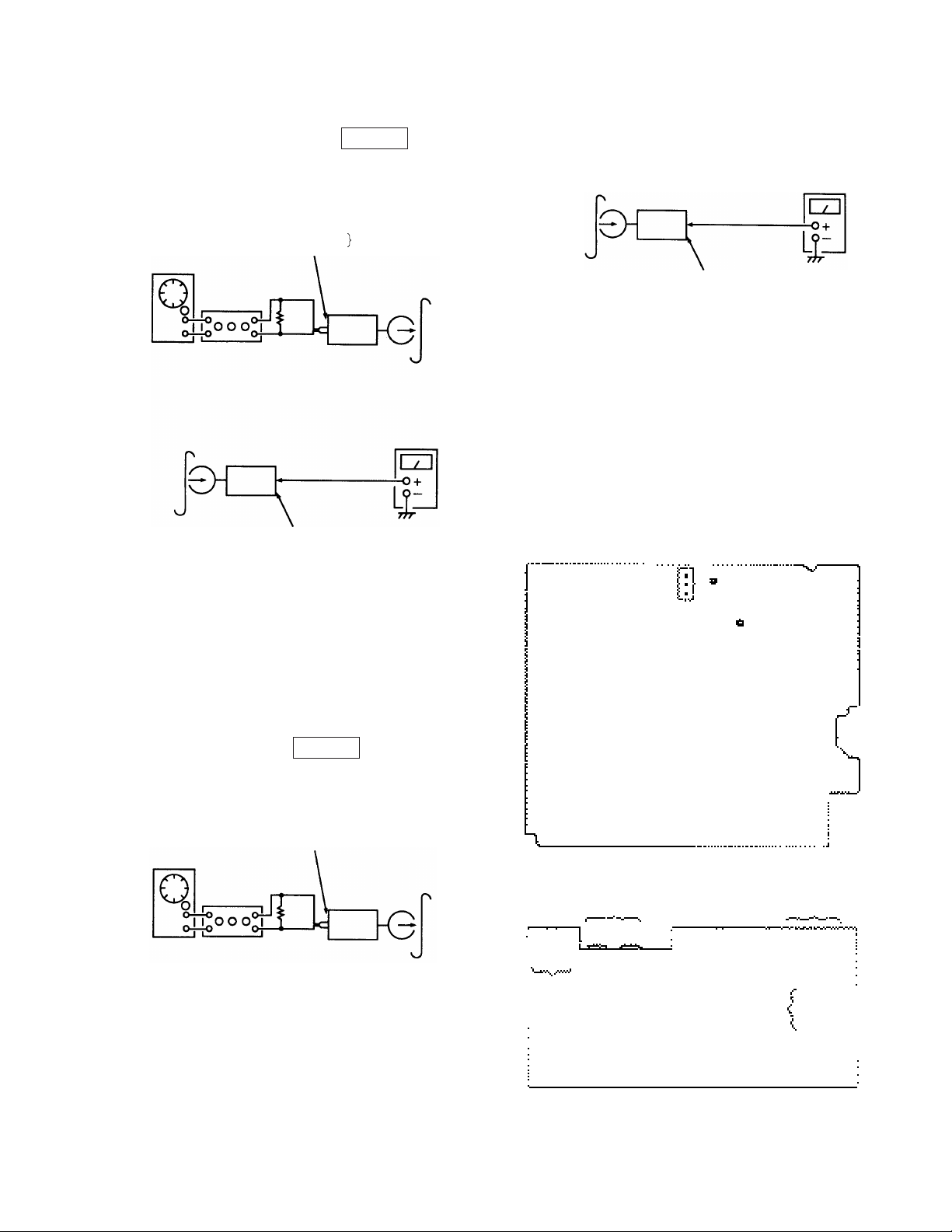

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a return

to chassis, must not exceed 0.5 mA (500 microampers). Leakage

current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passi ve

VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15µF

1.5k

Ω

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

NOTES ON HANDING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objecti ve lens in the optical pick-up

block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

[FL Display Tube, LED All Lit and Key Check mode]

When the TUNER/BAND , DISPLAY/DEMO , and FILE 2 buttons

are pressed simultaneously, the FL display tube and LEDs will all

light up. Press any button to enter the key check mode.

When the key check mode is entered, the FL display tube displays

“K 1 J0 V0”. Each time a button is pressed, the counter increases in

the following order, K 2 n K 3 n K 4.

If buttons already pressed once are pressed again, the counter will

not increase. When the VOLUME knob is rotated in the + direction,

the count increases in the following order.

V1 n V2 n V3.

When rotated in the – direction, it decreases in the following order.

V0 n V9 n V8.

When the AMS dial is rotated in the clockwise direction, the count

increases in the following order.

J1 n J2 n J3.

When rotated in the counterclockwise direction, it decreases in the

following order.

J0 n J9 n J8.

To exit form the test mode, press the TUNER/BAND , DISPLAY/

DEMO , FILE 2 buttons simultaneously again.

[Switching the channel step 9 KHz/10 KHz]

Press ENTER/NEXT button and POWER button simultaneously

to switch the AM channel step 9 kHz and 10 kHz. Be sure not to

change with carelessness.

— 4 —

TABLE OF CONTEMTS

Section Title Page

SECTION 1. GENERAL ...................................................... 6

SECTION 2. DISASSEMBLY

2-1. Front Panel Assy and Main Board ......................................... 8

2-2. TC Mechanism Deck ............................................................. 8

2-3. CD Mechanism Deck ............................................................. 9

2-4. BU Bracket Assy.................................................................... 9

2-5. Disc Table ............................................................................ 10

SECTION 3. MECHANICAL ADJUSTMENTS......... 11

SECTION 4. ELECTRICAL ADJUSTMENTS

DECK Section ............................................................................. 11

TUNER Section........................................................................... 14

CD Section................................................................................... 15

SECTION 5. DIAGRAMS

5-1. Circuit boards location ........................................................ 17

5-2. IC Pin Functions .................................................................. 18

• IC501 Graphic Control (ASD0204) .................................. 18

• IC701 Master Control (TMP87CS64YF) .......................... 19

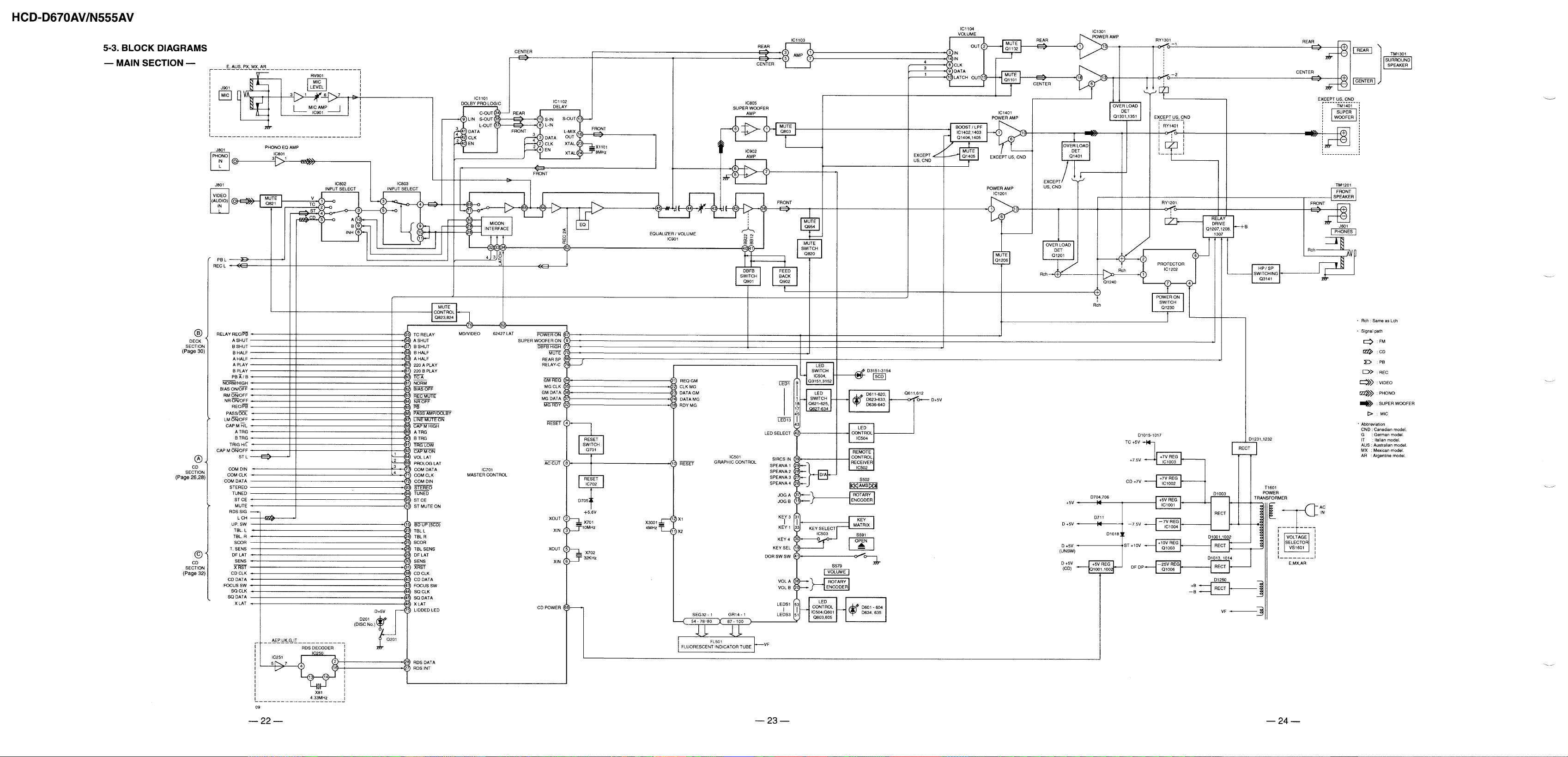

5-3. Block Diagrams

• Main Section...................................................................... 22

• Tuner Section

(US, CND, E, AUS, MX, PX, AR Model)......................... 25

• Tuner Section

(AEP, UK, G, IT Model) .................................................... 27

• DECK Section ................................................................... 29

• CD Section......................................................................... 31

5-4. Schematic Diagram — Tuner Section —

(US, CND, E, AUS, MX, PX, AR Model)........................... 34

5-5. Printed Wiring Board — Tuner Section —

(US, CND, E, AUS, MX, PX, AR Model)........................... 36

5-6. Schematic Diagram — Tuner Section —

(AEP, UK, G, IT Model) ..................................................... 38

5-7. Printed Wiring Board — Tuner Section —

(AEP, UK, G, IT Model) ..................................................... 40

5-8. Schematic Diagram — CD Panel Section — ...................... 41

5-9. Printed Wiring Board — CD Panel Section —.................... 42

5-10. Schematic Diagram — CD Section — .............................. 45

5-11. Printed Wiring Board — CD Section —............................ 47

5-12. Printed Wiring Board — Deck Section — ......................... 49

5-13. Schematic Diagram — Deck Section —............................ 51

5-14. Printed Wiring Board — Main Section —......................... 57

5-15. Schematic Diagram — Main Section —............................ 59

5-16. Schematic Diagram — Panel Section — ........................... 64

5-17. Printed Wiring Board — Panel Section — ........................ 69

5-18. Printed Wiring Board — Power Section — ....................... 73

5-19. Schematic Diagram — Power Section —.......................... 77

5-20. Schematic Diagram — CD Motor Section — ................... 80

5-21. Printed Wiring Board — CD Motor Section —................. 81

5-22. IC Block Diagrams — CD Section — ............................... 83

Section Title Page

SECTION 6. EXPLODED VIEWS

6-1. Case and Back Panel Section ............................................... 85

6-2. Panel Board Section ............................................................. 86

6-3. Front panel Section .............................................................. 87

6-4. Chassis Section .................................................................... 88

6-5. TC Mechanism Section 1 (TCM-220WR2E) ...................... 89

6-6. TC Mechanism Section 2 (TCM-220WR2E) ...................... 90

6-7. TC Mechanism Section 3 (TCM-220WR2E) ...................... 91

6-8. CD Mechanism Section(CDM37-5BD19)........................... 92

6-9. Base Unit Section (BU-5BD19)........................................... 93

SECTION 7. ELECTRICAL PARTS LIST ................... 94

• Abbreviation

G : German model

IT : Italian model

MX : Mexican model

AUS: Australian model

AR : Argentine model

— 5 —

SECTION 1

GENERAL

*3

*3

*1

FM 75Ω COAXIAL terminal

This section is extracted from

instruction manual.

*5

*1

DOLBY NR button

*6

*2

*4

Note:

*1 : AEP, UK, German, Italian models.

*2 : Except US, Canadian models.

*3 : E, Australian, Mexican, PX,

Argentine models

*4 : US, Canadian, AEP, UK,

German, Italian models.

*5 : Except AEP, UK, German,

Italian models.

*6 : E, PX, Argentine models.

KARAOKE PON/MPX button

*2

*3

— 6 —

*3

DOLBY NR B indication

*4

— 7 —

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

2-1. FRONT PANEL ASSY AND MAIN BOARD

1

Remove the connectors.

• Main board (six connectors)

• Main power amplifier board (one connector)

2

Screw (BVTP3 X 8)

3

Two earth wire

CN1301

6

Screw (BVTP 3x8)

5

Front panel assy

4

Three screws

(BVTP 3X8)

2-2. TC MECHANISM DECK

6

Button (eject-L)

Power amp board

CN402

CN401

CN701

3

Three screws

(BVTP 2.6X8)

CN203

CN201

CN250

8

Main board

5

TC mechanism deck

4

Four screws

(BVTP 2.6X8)

7

Two scrws

(BVTP 3X8)

2

Remove the two cassette lids

direction of arrow.

— 8 —

6

Button (eject-R)

1

Push the eject button.

2-3. CD MECHANISM DECK

2

Two screws

(BVTP 3X8)

1

Screw (BVTP 3X8)

3

Two screws

(BVTP 3X8)

4

CD mechanism deck

2-4. BU BRACKET ASSY

2

BU bracket assy

1

Yoke bracket

— 9 —

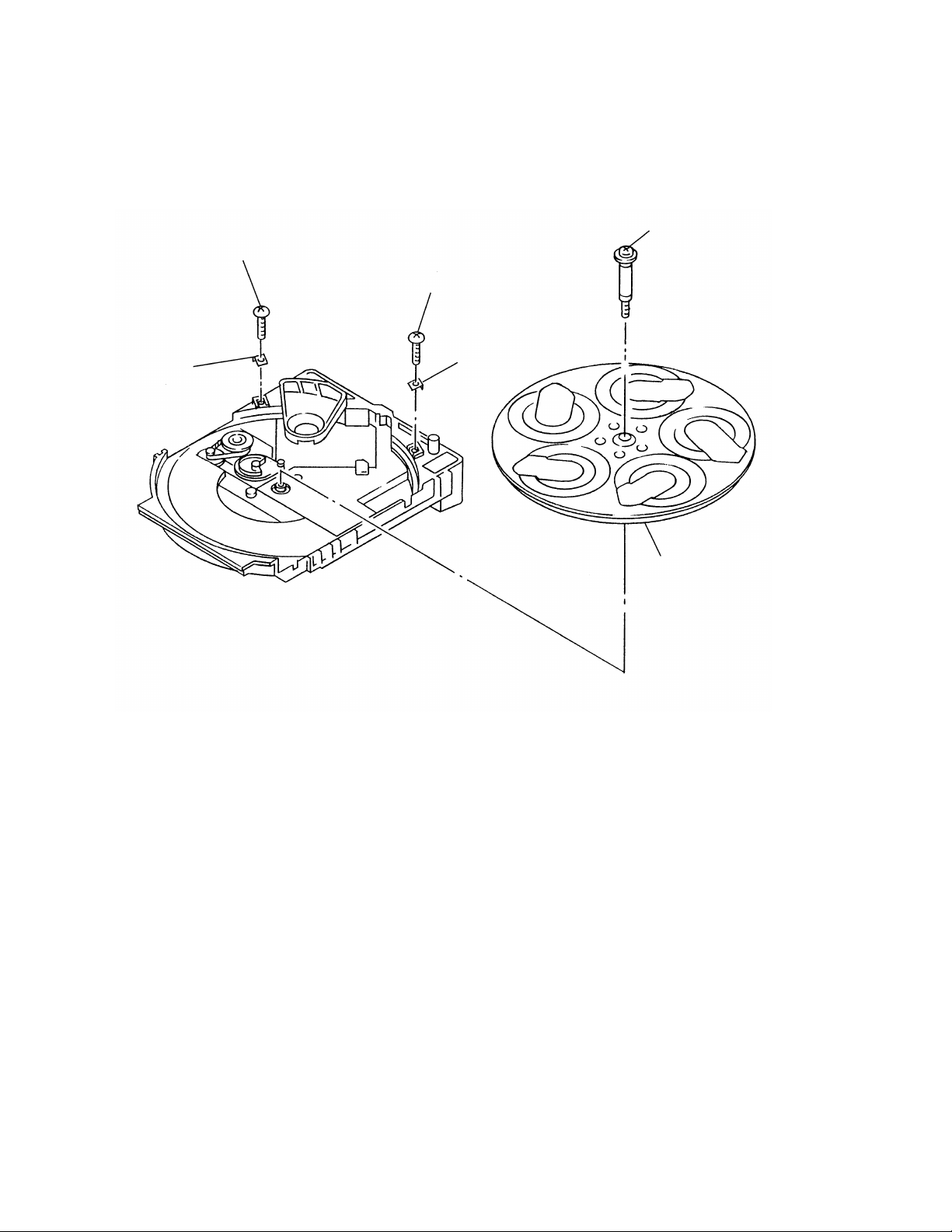

2-5. DISC TABLE

2

Bracket (BU)

1

Screw (BVTP 3X8)

3

Screw (BVTP 3X8)

4

Bracket (BU)

5

Step screw

6

Disc table

— 10 —

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured alcohol-moistened

swab :

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer .

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power supply

voltage unless otherwise noted.

Torque Measurement

Torque

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

36 to 61g • cm

(0.5–0.84 oz • inch)

2 to 6g • cm

(0.02–0.08 oz • inch)

36 to 61g • cm

(0.5–0.84 oz • inch)

2 to 6g • cm

(0.02–0.08 oz • inch)

61 to 143g • cm

(0.85–1.99 oz • inch)

100g or more

(3.53 oz or more)

100g or more

(3.53 oz or more)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head damagnetizer .

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustmetns should be performed with the rated power supply

voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and R-ch.

7. Switches and controls should be set as follows unless otherwise

specified.

DOLBY NR switch : OFF (US, CND, AEP, UK, G, IT model)

Tape

P-4-A100

WS-48B

P-4-L300

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note : Perform this adjustments for both decks.

Procedure :

1. Mode : Playback (FWD)

Signal

10 kHz, –10 dB

3 kHz, 0 dB

315 Hz, 0 dB

Used for

Azimuth Adjustment

Tape Speed Adjustment

Level Adjustment

test tape

P-4-A100

(10kHz, –10dB)

• Abbreviation

CND : Canadian model.

G : German model.

IT : Italian model.

set

main board

CN403

3

(L-CH)

Pin

Pin 1 (R-CH)

main board

CN403

Pin

2

level meter

— 11 —

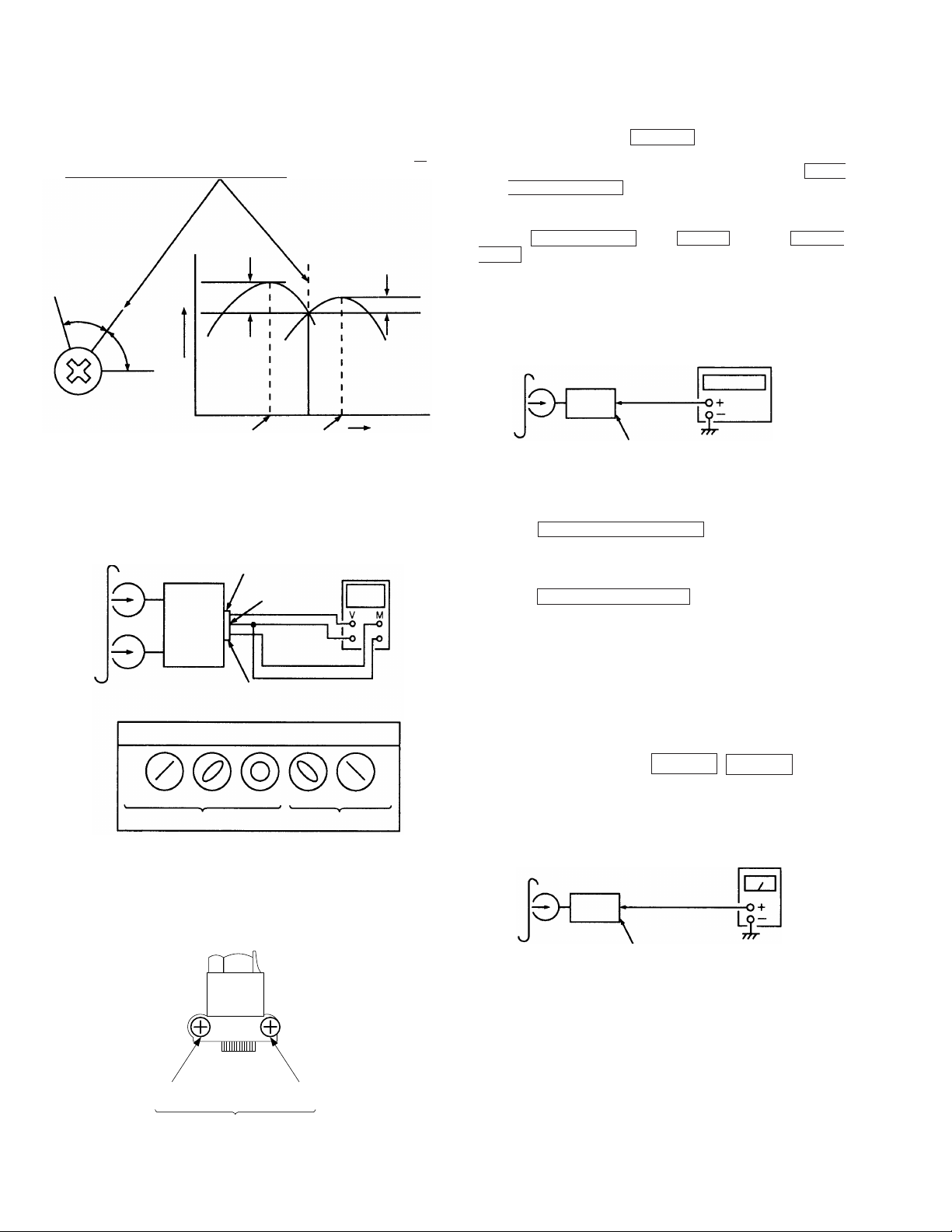

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw so

that outputs match within 1 dB of peak.

L-CH

peak

screw

position

R-CH

peak

output

level

within

1dB

L-CH

peak

R-CH

peak

within 1dB

screw

position

3. Mode : Playback (FWD)

test tape

P-4-A100

(10kHz, –10dB)

set

main board

CN403

Pin

3

Pin

L

R

oscilloscope

2

Tape Speed Adjustment DECK A

NOTE : Start the tape speed adjustment as bellow after setting the

test mode.The tape speed can be changed with the HIGH

SPEED DUBBING button during the test mode.

Method :

1. Turn the power switch on.

2. Press the DISPLAY/DEMO button, MENU 1 button and TUNER/

BAND button simulateously.

Procedure :

Mode : Playback (FWD)

test tape

WS-48B

(3kHz, 0dB)

set

main board

CN403 (Pin 3 : L-CH)

frequency counter

(Pin 1 : R-CH)

1. Insert tha WS-48B into the deck A to playback.

2. Press the HIGH SPEED DUBBING button. Then at HIGH

SPEED mode.

3. Adjust RV652 on the MD board so that the frequency counter

reading becomes 6,000 ± 30 Hz.

4. Press the HIGH SPEED DUBBING button again to be set the

NORMAL SPEED mode.

5. Set to the playback mode.

6. Adjust RV651 on the MD board so that the frequency counter

reading becomes 3,000 ± 15 Hz.

Pin

1

Waveform of oscilloscope

in phase

good

45

°

90

°

135

°

180

°

wrong

4. Repeat steps 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location : Record/Playback Head (Deck A and B)

FWD side

Adjustment screw

REV side

Frequency difference between deck A and deck B the beginning of

the tape should be within ± 1.5%.

Adjustment Location : MD board

Playback Level Adjustment DECK A DECK B

Procedure :

Mode : Playback (FWD)

test tape

P-4-L300

(315Hz, 0dB)

set

main board

CN403 (Pin

(Pin 1 : R-CH)

3

: L-CH)

level meter

Deck A is RV311 (L-CH) and RV411 (R-CH), deck B is RV301 (LCH) and RV401 (R-CH) so that adjustment within the following

adjustment level.

Adjustment level :

CN403 PB level : 301.5 to 338.3 mV (–8.2 to –7.2 dB)

level difference between the channels : within ± 0.5 dB

Adjustment Location : MD board

— 12 —

Record Bias Current Adjustment DECK B

2. Mode : Playback

Procedure :

1. Mode : record

VIDEO IN

AF OSC

attenuator

600

1) 315Hz

2) 10kHz

Ω

50mV (–23.8dB)

blank tape

CS-123

set

2. Mode : Playback

recorded

position

set

CN 403 (Pin

(Pin 1 : R-CH)

3

level meter

: L-CH)

Confirm playback the signal recorded in step 1 become adjustment

level as follows.

If these levels do not adjustment level, adjust the RV341 (L-CH) and

RV441 (R-CH) on the MD board to repeat step 1 and 2.

recorded

position

set

main board

CN403 (Pin

(Pin 1 : R-CH)

3

level meter

: L-CH)

Confirm playback the signal recorded in step 1 become adjustment

level as follows.

If these levels do not adjustment level, adjust the RV301 (L-CH) and

RV351 (R-CH) on the main board to repeat steps 1 and 2.

Adjustment level: CN 403 PB level: 47.2 to 53.0 mV

(–24.3 to –23.3 dB)

Adjustment Location : main board

Adjustment Location

[MAIN BOARD] (Component Side)

1

3

CN403

RV351 REC LEVEL (R-CH)

RV301 REC LEVEL

(L-CH)

Adjustment level : The playback output of 10 kHz level difference

against 315Hz reference should be ± 0.5 dB

Adjustment Location : MD board

Record Level Adjustment DECK B

Procedure :

1. Mode : record

VIDEO IN

315Hz, 50mV (–23.8dB)

AF OSC

attenuator

600

Ω

set

blank tape

CS-123

[MD BOARD] (Conductor Side)

RECORD

BIAS

¬

RV301

RV401¬R

PB LEVEL

– DECK B –

R

L

RV441

L

RV341

TAPE SPEED

(NORMAL)

RV651

¬

PB

LEVEL

– DECK A –

L

R

(HIGH)

RV652

¬

¬

¬

— 13 —

TUNER SECTION 0dB=1µV

Note : As a front-end (FE1) is difficult to repair if faulty, replace it

with new one.

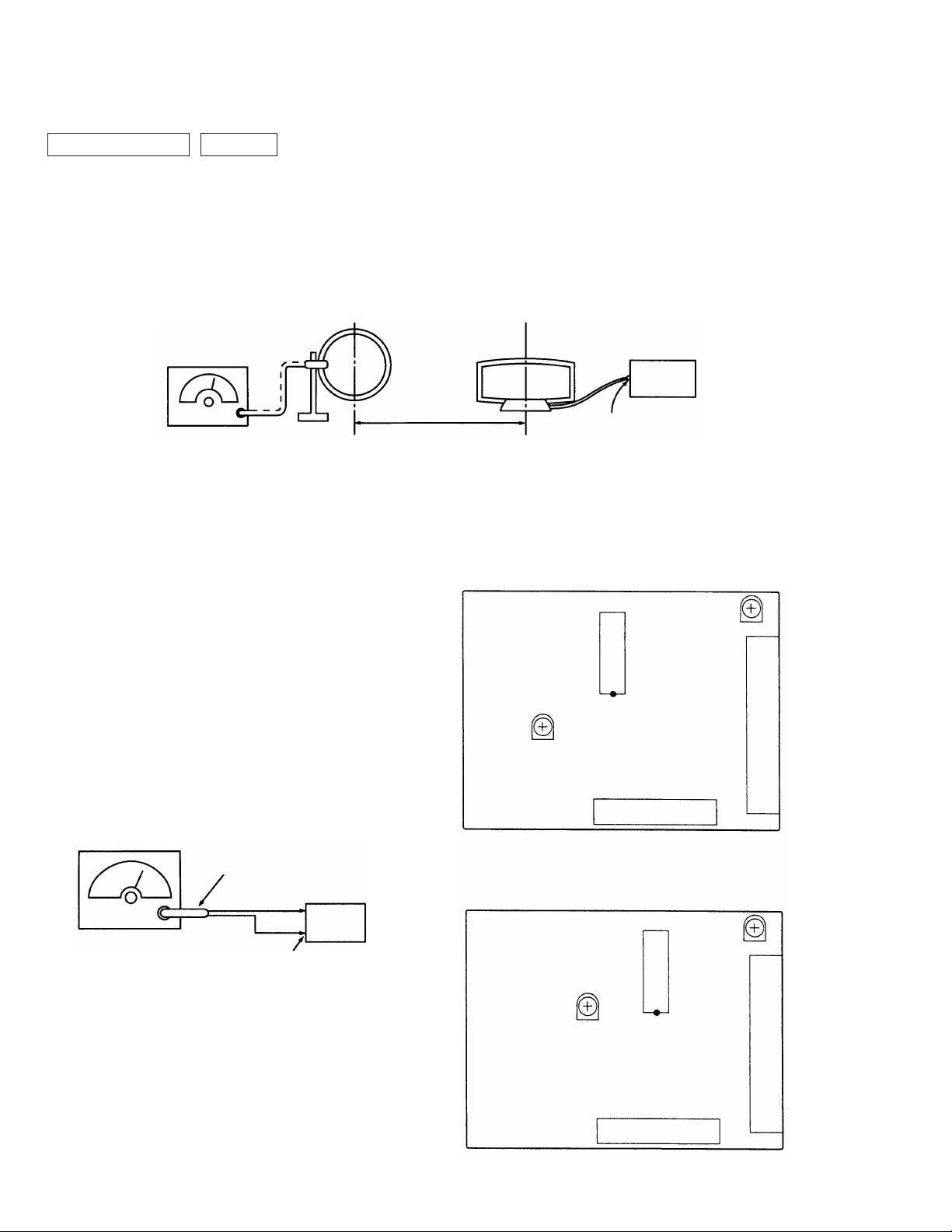

AM Tuned Level Adjustment

Note : FM Tuned Level adjustment should be performed after this

AM Tuned Level adjustment.

• Abbreviation

G : German model

IT : Italian model

Setting :

Band : AM or MW

AM RF SSG

30% amplitude

modulation by

400 Hz signal

Carrier frequency : 999kHz (at 9kHz step)

1050kHz (at 10 kHz step)

loop antenna

Procedure :

1. Set the output of SGG so that the input level of the set becomes 55

dB.

2. Tune the set to 999 kHz or 1050 kHz .

3. Adjust RV41 (AEP, UK, IT, G models), RV42 (other models) to

the point (moment) when the TUNED indicator will change from

going off to going on.

Adjustment Location : TCB board

FM Tuned Level Adjustment

Note : This adjustment should be performed after the AM Tuned

Level Adjustement.

loop antenna

(Supplied accessories)

60 cm

Field strength dB (

µ

V/m)=SGG output level dB (µV/m)–26dB.

Adjustment Location

AEP, UK, G, IT model

[TCB BOARD] (Component Side)

RV42

FM T uned Level

AM antenna

terminal (TM1)

IC41

AM T uned Level

RV41

TM1

Setting :

Band : FM

FM RF stereo signal

generator

75

Ω

coaxial

set

Carrier frequency : 98MHz

Modulation : AUDIO 1kHz, 75kHz

Output level : 25dB (at 75

deviation (100%)

Ω

open)

FM ANTENNA terminal

(TM1) (75

Ω

)

Procedure :

1. Supply a 25dB 98 MHz signal from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Adjust RV42 (AEP, UK, IT, G models), RV41 (other models) to

the point (moment) when the TUNED indicator will change from

going off to going on.

Adjustment Location : TCB board

FE1

Other model

[TCB BOARD] (Component Side)

IC2

RV41

FM T uned Lev el

FE1

RV42

AM T uned

Level

TM1

— 14 —

CD SECTION

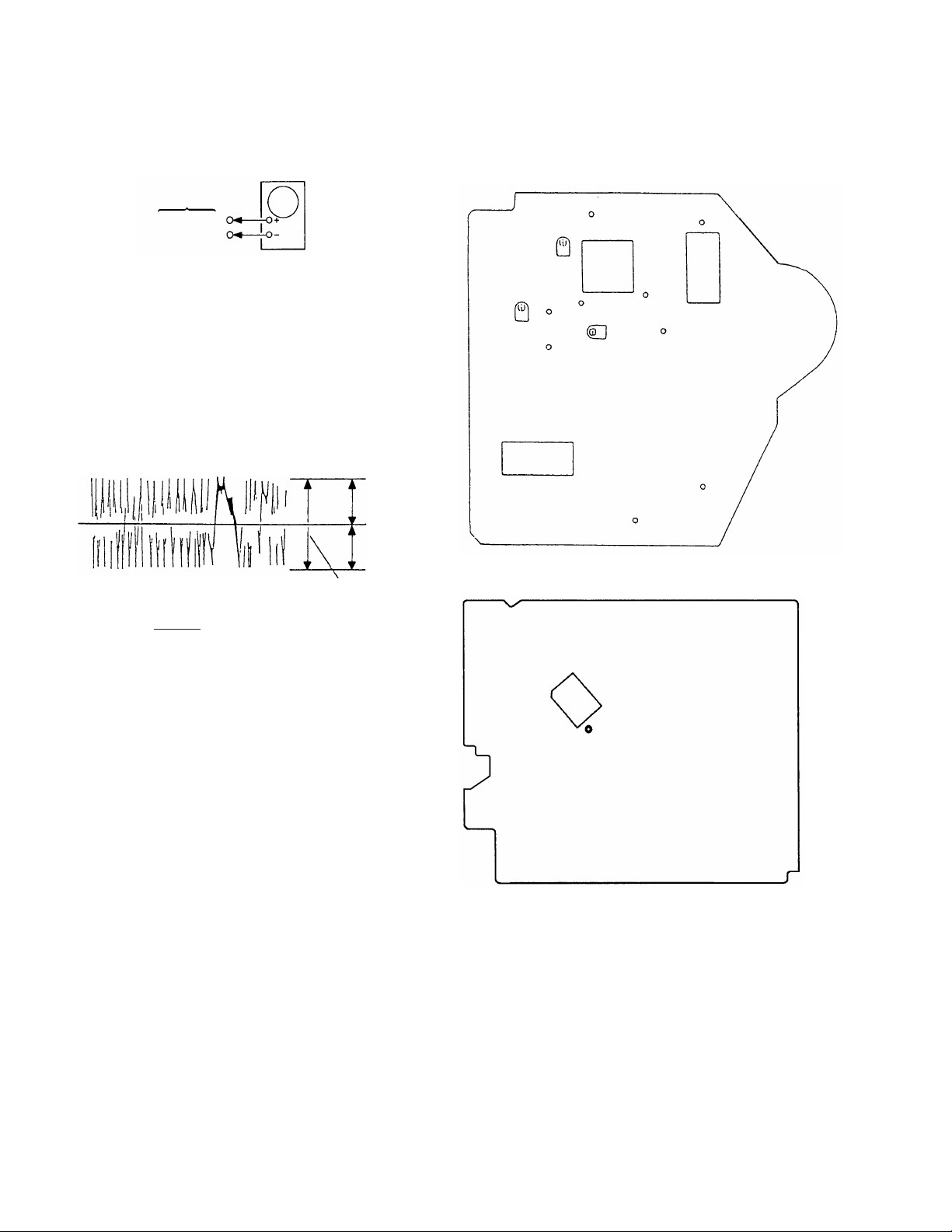

S Curve Check

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicatior with neutral detergent when

the signal level is low than specified value with the following

checks.

5. Adjust the focus bias adjustment when optical block is replaced.

Focus Bias Adjustment

oscilloscope

(DC range)

BD board

TP(RF)

TP(VC)

Procedure :

1. Connect oscilloscope to test point TP (RF).

(Ground terminal : VC)

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Adjust RV101 so that the waveform is clear.

(Clear RF signal waveform means that the shape “◊ ” can be clearly

distinguished at the center of the waveform.)

5. After adjustment, check the RF signal level.

• RF signal

VOLT/DIV : 200 mV

TIME/DIV : 500 nS

oscilloscope

BD board

TP(FE)

TP(VC)

Procedure :

1. Connect oscilloscope to test point TP (FEO).

2. Connect between test point TP (FOK) and Ground by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc table

is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And conf irm peak to peak lev el within 2.4 ± 0.7

Vp-p.

S-curve waveform

Symmetry

±

within 2.4

0.7 Vp-p

6. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio of

A : B or B :A is more than 10 :7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

level

1.3 ± 0.3 Vp-p

RF Level Check

oscilloscope

BD board

TP(RF)

TP(VC)

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that osilloscope waveform is clear and check RF signal

level is correct or not.

Note :

Clear RF signal waveform means that the shape “◊” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500nS

level : 1.3

±

0.3 Vp-p

— 15 —

E-F Balance Check

Adjustment Location :

oscilloscope

BD board

TP (TEO)

TP (VC)

Procedure :

1. Connect test point TP (ADJ) on Main board to Ground with a lead

wire.

2. Connect oscilloscope to test point TP (TEO).

3. Turned Power switch on.

4. Put disc (YEDS-18) in and playback.

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0Vdc, and check this level.

Traverse waveform

A

0V

B

level : 300 ± 100 mVp-p

[BD BOARD] (Conductor Side)

RF

RV101

IC101

RV103

IC104

TEO

VC

FEO

RV102

TEI

FEI

GND

[MAIN BOARD] (Conductor Side)

FOK

IC102

PCK

Specified level : • X 100=less than ± 7%

A-B

2(A+B)

• A+B=300 ± 100 mVp-p

6. Remove the lead wire connected in step 1.

Focus/Tracking Gain Adjustment (RV102, RV103)

This gain has a margin, so even if it is slightly off.

There is no problem.

Therfore, do not perform this adjustment.

Please note that it should be fixed to mechanical center position when

you moved and do not know original position.

IC701

TP701

(ADJ)

— 16 —

SECTION 5

DIAGRAMS

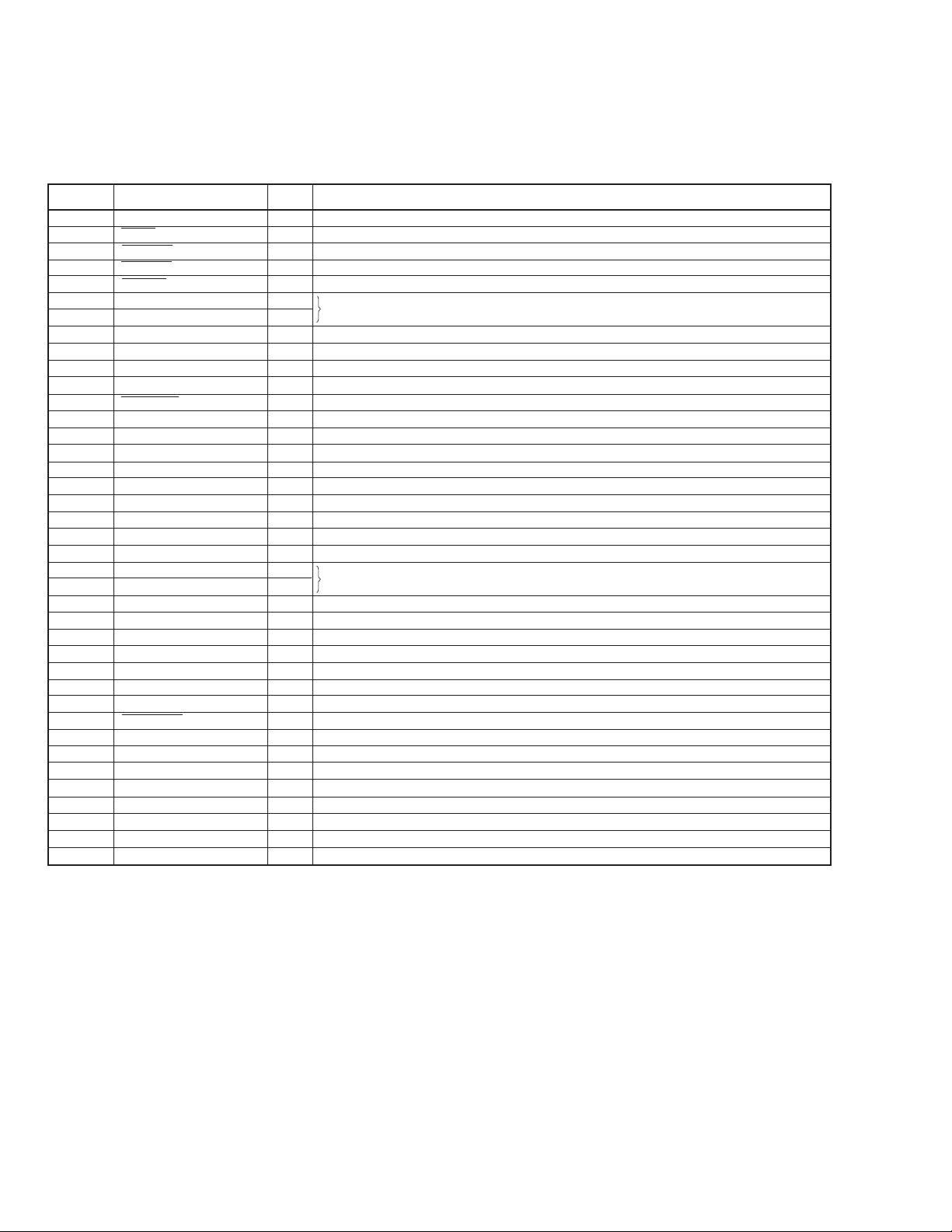

5-1. CIRCUIT BOARDS LOCATION

• Abbreviation

MX: Mexican model

AUS: Australian model

AR: Argentine model

HP board

MIC board

(E,AUS,MX,PX,AR)

CD LED board

CD (L) board

TC CONTROL board

PANEL board

TRANS board

S. WOOFER board

TCB board

POWER AMP board

MAIN board

DOOR SW board

CD (R) board

Note: rA is including in MD board.

LEAF SWITCH board

TABLE SENSOR board

r

A MOTOR board

CD JOG board

MD board (including rA)

BD board

CD MOTOR board

LED board

— 17 —

5-2. IC PIN FUNCTIONS

• IC501 GRAPHIC CONTROL (ASD0204)

Pin No.

1

2

3, 4

5-9

10

11

12

13

14

15

16

17, 18

19

20

21

22

23

24

25

26-29

30-33

34

35

36

37

38

39

40

41

42

43-45

46

47, 48

49, 50

51-53

54-78

79

80-86

87-100

VDD

LED8

LDE7, 6

LED5–1

RESET

X2

X1

IC (Vpp)

XT2

JOG B

VDD

LED10, 9

KEY SEL

VOL B

REQ. GM

CLK MG

DATA GM

DATA MG

AVSS

SPEANA 4–1

KEY 4–1

AVDD

AVREF

VOL A

JOG A

RDY MG

SIRCS

VSS

DOR SW

LED SELECT

LED13–11

VDD

LEDS7, 6

LEDS5, 4

LEDS3–1

SEG32–8

V, LOAD

SEG7–1

GR14–1

I/OPin Name

+5V

–

LED drive signal output.

O

LED drive signal output.

O

LED drive signal output.

O

Reset signal input.

I

O

X’ tal (4 MHz).

I

GND

–

Not used.

I

AMS encoder signal input.

I

+5V

–

LED drive signal output.

O

Key select control.

O

Volume encoder signal input.

I

Request signal from/to master control.

O

Serial clock input.

I

Serial data output.

O

Serial data input.

I

GND

–

Spectram analizer signal input.

I

Key matrix input.

I

–

+5V

–

Volume encoder signal input.

I

AMS encoder signal input.

I

Ready signal from master control.

I

SIRCS signal input.

I

GND

–

CD door open detection input.

I

LED select signal output.

O

LED drive signal output.

O

+5V

–

Not used.

O

Not used. (Pull down)

O

LED drive signal output.

O

FL segment signal output.

O

–25V for FL

–

FL segment signal output.

O

FL grid signal output.

O

Function

• Abbreviation

FL: Fluorescent Indicator Tube

GND: Ground

— 18 —

• IC701 MASTER CONTROL (TMP87CS64YF)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Pin Name

VSS

XOUT

XIN

RESET

XOUT

XIN

GND (test)

AC CUT

SUPER WOOFER ON

ST-MUTE ON

180-A-PLAY

180-B-PLAY

180-B-REC

V. DET

BD-UP (5CD)

TRAY CLOSE (1CD)

ENCODER-1

ENCODER-2

ENCODER-3

OUT SW OPEN

LOAD IN

LOAD OUT

TBL-L

TBL-R

SCOR

TBL-SENS

RDS INT

RDS DATA

DF LAT

SENS

XRST

MG-RDY

ADJ

GM-REQ

MG-CLK

GM-DATA

MG-DATA

CD-CLK

ADJ-2

CD-DATA

I/O

GND

–

O

X’ tal (10 MHz).

I

Reset signal input.

I

O

X’ tal for clock (32.768 kHz)

I

GND

–

Back up signal input.

I

Super woofer ON/OFF control.

O

Mute signal output for tuner.

O

I

Tape detection sigal input. (Connected to GND)

I

I

Voltage detection (Not used).

I

Disc table up detect.

I

Connected to GND

I

I

Input selector control signal output. (Pull up)

I

I

Out switch signal input. (Pull up)

I

O

Loading motor control signal output. (Not used)

O

O

Table motor control signal output.

O

Sub-code sync signal input.

I

CD Table sensor signal input.

I

RDS data start input.

I

RDS data output.

I

Latch signal for digital filter.

O

Table sence signal input.

I

Reset signal output for CD.

O

Ready signal to graphic control.

O

Test mode input.

I

Request signal from graphic control.

I

Clock signal to graphic control.

O

Data input from graphic control.

I

Data output to graphic control.

O

Clock output. Serial bus line.

O

Test mode input.

I

Data output. Serial bus line.

O

Function

• Abbreviation

FL : Fluorescent Indicator Tube

GND : Ground

— 19 —

Pin No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

AUB IN

AUB OUT

FOCUS SW

SQ-CLK

SQ-DATA

X-LAT

TEST

VAREF

SS

AV

VSS

VDD

SPEC

DESTINATION

DISC SENS

TC RELAY

A-SHUT

B-SHUT

B-HALF

A-HALF

220-A-PLAY

220-B-PLAY

62427 LAT

K-CON-LAT

VOL LAT (AV)

FRONT SP RELAY B

REAR SP RELAY C

POWER ON

CD POWER

RPOLOG LAT

MUTE

COM CLK

COM DIN

COM DATA

K CON ON

LIDDED LED

MD/VIDEO

DBFB-HIGH

PWM-OUT

PRO-LOGIC

TC A

I/OPin Name

I

Audio bus in/output. (Not used)

O

Focus switching signal output.

O

Subcode Q data read clock output.

O

Subcode Q data input.

I

Latch signal digital signal processor.

O

Test land.

I

Analog reference voltage input.

I

–

GND

–

+5V

–

I

Destination detection input.

I

Not used.

I

REC/PB select signal output.

O

I

I

I

Control signal input form deck.

I

I

I

PLL latch output.

O

Not used.

O

Latch signal for electrical volume. (Not used)

O

Not used.

O

Rear speaker relay control output.

O

Power on signal output

O

CD power control signal output.

O

Not used.

O

Mute signal for AMP.

O

PLL clock output. (PLL, Function, Graphic Equalizer)

O

PLL data input. (PLL, Function, Graphic Equalizer)

I

PLL data output. (PLL, Function, Graphic Equalizer)

O

Not used.

O

Disc No. LED drive signal output.

O

MD/VIDEO select output.

O

DBFB switching signal output.

O

Not used.

I

Dolby pro-logic control ourput.

O

Deck A, B select output.

O

Function

— 20 —

Pin No.

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

NORM

BIAS OFF

REC MUTE

NR OFF

PB

P ASS. AMP/DOLBY

LINE MUTE ON

CAP. M-HIGH

A-TRG

B-TRG

TRG LOW

CAP M ON

STEREO

TUNED

ST-CE

DELAY SEL MIC

DELAY ON

DELAY LEVEL A

DELAY LEVEL B

V

DD

I/OPin Name

NORMAL/HIGH control signal output.

O

Bias oscillation output.

O

Mute output.

O

Dolby ON/OFF signal output.

O

REC/PB control signal output.

O

Dolby switching signal output.

O

Mute signal output for deck.

O

Capstan motor control signal output.

O

O

Trigger motor control signal output.

O

Trigger motor high/low control signal output.

O

Capstan motor ON/OFF control signal output.

O

Stereo detection signal from tuner.

I

Tuned detection signal from tuner.

I

Latch signal output for tuner.

O

Not used.

O

ECHO delay ON/OFF control signal output (Not used)

O

O

ECHO delay level control signal output (Not used)

O

+5V

–

Function

— 21 —

Loading...

Loading...