Sony HCD-GT22, HCD-GT55, HCD-GT44 User Manual

HCD-GT22/GT44/GT55

SERVICE MANUAL

Ver. 1.2 2008.05

• HCD-GT22 is the amplifier, USB, CD pla yer , tape

deck and tuner section in MHC-GT22/GT22BP.

• HCD-GT44 is the amplifier, USB, CD pla yer , tape

deck and tuner section in MHC-GT44/GT44BP.

• HCD-GT55 is the amplifier, USB, CD pla yer , tape

deck and tuner section in MHC-GT55/GT55BP.

CD

Section

TAPE Model Name Using Similar Mechanism NEW

Section Tape Transport Mechanism Type CWN42FF609

Photo: HCD-GT55

Model Name Using Similar Mechanism NEW

CD Mechanism Type

Base Unit Name BU-K6BD91UR-WOD74

Optical Pick-up Block Name KSM-213DCP

E Model

HCD-GT22/GT44/GT55

Australian Model

HCD-GT22/GT44

CDM74KF-K6BD91UR-WOD or

CDM74KFV-K6BD91UR-WOD

Amplier section

HCD-GT55

The following are measured at AC 120, 127,

220, 240V 50/60Hz

Front speaker

Power output (rated): 110 W + 110 W

(at 6 Ω, 1 kHz, 1% THD)

RMS output power (reference):

200 W + 200 W (per channel at 6 Ω,

1 kHz, 10% THD)

Subwoofer

RMS output power (reference): 190 W

(at 6 Ω, 80 Hz, 10% THD)

HCD-GT44

The following are measured at AC 120, 127,

220, 240V 50/60Hz

Front speaker

Power output (rated): 90 W + 90 W

(at 6 Ω, 1 kHz, 1% THD)

RMS output power (reference):

150 W + 150 W (per channel at 6 Ω,

1 kHz, 10% THD)

Subwoofer

RMS output power (reference): 150 W

(at 6 Ω, 80 Hz, 10% THD)

SPECIFICATIONS

HCD-GT22

The following are measured at AC 120, 127,

220, 240V 50/60Hz

Power output (rated): 110 W + 110 W

(at 6 Ω, 1 kHz, 1% THD)

RMS output power (reference):

200 W + 200 W (per channel at 6 Ω,

1 kHz, 10% THD)

Inputs

AUDIO (phono jack): voltage 250 mV,

impedance 47 kilohms

MIC (phone jack): sensitivity 1 mV,

impedance 10 kilohms

(USB) port: Type A

Outputs

PHONES (stereo mini jack): accepts

headphones of 8 Ω or more

SPEAKER: accepts impedance of 6 to 16 Ω

SUB WOOFER OUT (HCD-GT55/GT44

only): accepts impedance of 6 to 16 Ω

USB section

Supported bit rate

MP3 (MPEG 1 Audio Layer-3):

32 – 320 kbps, VBR

Sampling frequencies

MP3 (MPEG 1 Audio Layer-3):

32/44.1/48 kHz

Transfer speed

Full-Speed

Supported USB device

Mass Storage Class

Maximum current

500 mA

CD player section

System: Compact disc and digital audio

system

Laser: Semiconductor laser (λ=770 –

810 nm)

Emission duration: continuous

Frequency response: 20 Hz – 20 kHz

Signal-to-noise ratio: More than 90 dB

Dynamic range: More than 88 dB

– Continued on next page –

9-887-722-03

2008E05-1

© 2008.05

COMPACT DISC DECK RECEIVER

Sony Corporation

Audio Business Group

Published by Sony Techno Create Corporation

HCD-GT22/GT44/GT55

Tape deck section

Recording system: 4-track 2-channel, stereo

Frequency response: 50 – 13,000 Hz (±3

dB), using Sony TYPE I cassettes

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section:

Tuning range:

87.5 – 108.0 MHz (50 kHz step)

Antenna: FM lead antenna

Antenna terminals: 75 ohms unbalanced

Intermediate frequency: 10.7 MHz

AM tuner section:

Tuning range

Latin American and Oceanian

models:

530 – 1,710 kHz (with 10 kHz tuning

interval)

531 – 1,710 kHz (with 9 kHz tuning

interval)

Other models:

530 – 1,610 kHz (with 10 kHz tuning

interval)

531 – 1,602 kHz (with 9 kHz tuning

interval)

Antenna: AM loop antenna, external

antenna terminal

Intermediate frequency: 450 kHz

General

Power requirements

Oceanian model: AC 230 – 240 V,

50/60 Hz

Mexican model: AC 127 V, 60 Hz

Argentine model: AC 220 V, 50/60 Hz

Other models: AC 120, 220 or

230 – 240 V, 50/60 Hz, Adjustable

with voltage selector

Power consumption

HCD-GT55: 225 W

HCD-GT44: 250 W

HCD-GT22: 150 W

Dimensions (w/h/d) (excl. speakers)

HCD-GT55:

Approx. 280 × 365 × 425 mm

HCD-GT44/GT22:

Approx. 280 × 325 × 425 mm

Mass (excl. speakers)

HCD-GT55: 10.5 kg

HCD-GT44/GT22: 10.0 kg

Design and specifications are subject to

change without notice.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance

is classified

as a CLASS 1

LASER product.

This marking is

located on the rear

exterior.

2

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

TABLE OF CONTENTS

HCD-GT22/GT44/GT55

Ver. 1.1

1. SERVICING NOTES ............................................... 4

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Case (Side-L), Case (Side-R) .......................................... 8

3-3. Case (Top) ....................................................................... 8

3-4. Lid (CD) .......................................................................... 9

3-5. CD Mechanism Deck, USB board .................................. 9

3-6. Front Panel Block............................................................ 10

3-7. Mecha Deck (CWN42FF609) ......................................... 10

3-8. Back Panel Block ............................................................ 11

3-9. MAIN Board.................................................................... 11

3-10. CD Board......................................................................... 12

3-11. DRIVER Board, SW Board............................................. 12

3-12. Optical Pick-up Block (KSM-213D)............................... 13

3-13. SENSOR Board ............................................................... 13

3-14. MOTOR (TB) Board ....................................................... 14

3-15. MOTOR (LD) Board....................................................... 14

4. TEST MODE.............................................................. 15

5. MECHANICAL ADJUSTMENTS ....................... 19

6. ELECTRICAL ADJUSTMENTS ......................... 20

7. DIAGRAMS

7-1. Block Diagram – CD SERVO, USB Section – ............... 23

7-2. Block Diagram – MAIN Section –.................................. 24

7-3. Block Diagram – AMP Section – .................................... 25

7-4. Block Diagram – PANEL, POWER AMP Section –....... 26

7-5. Printed Wiring Board – CD Board – ............................... 28

7-6. Schematic Diagram – CD Board – .................................. 29

7-7. Printed Wiring Boards – CHANGER Section –.............. 30

7-8. Schematic Diagram – CHANGER Section – .................. 31

7-9. Printed Wiring Board – USB Board – ............................. 32

7-10. Schematic Diagram – USB Board –................................ 33

7-11. Printed Wiring Board – TC Board –................................ 34

7-12. Schematic Diagram – TC Board – .................................. 35

7-13. Printed Wiring Boards – MAIN Section – ...................... 37

7-14. Schematic Diagram – MAIN Section (1/4) – .................. 38

7-15. Schematic Diagram – MAIN Section (2/4) – .................. 39

7-16. Schematic Diagram – MAIN Section (3/4) – .................. 40

7-17. Schematic Diagram – MAIN Section (4/4) – .................. 41

7-18. Printed Wiring Board – MIC Board – ............................. 42

7-19. Schematic Diagram – MIC Board – ................................ 43

7-20. Printed Wiring Board

– AMP Board (GT22/GT55) – ........................................ 44

7-21. Schematic Diagram – AMP Board (GT22/GT55) –........ 45

7-22. Printed Wiring Board – AMP Board (GT44) – ............... 46

7-23. Schematic Diagram – AMP Board (GT44) – .................. 47

7-24. Printed Wiring Boards

– SUB WOOFER Section (GT44/GT55) – ..................... 48

7-25. Schematic Diagram

– SUB WOOFER Section (GT44/GT55) – ..................... 49

7-26. Printed Wiring Boards – PANEL Section –..................... 50

7-27. Schematic Diagram – PANEL Section – ......................... 51

7-28. Printed Wiring Boards – KEY Section – ......................... 52

7-29. Schematic Diagram – KEY Section – ............................. 53

7-30. Printed Wiring Board

– TRANS Board (GT22/GT55) –.................................... 54

7-31. Schematic Diagram

– TRANS Board (GT22/GT55) –.................................... 55

7-32. Printed Wiring Board – TRANS Board (GT44) – ........... 56

7-34. Schematic Diagram – TRANS Board (GT44) – ............. 57

8. EXPLODED VIEWS

8-1. Case Section .................................................................... 69

8-2. KEY TOP Board Section................................................. 70

8-3. TC Mecha Deck Section.................................................. 71

8-4. PANEL Board Section..................................................... 72

8-5. Front Panel Section ......................................................... 73

8-6. MAIN Board Section....................................................... 74

8-7. POWER Board, SUB WOOFER Board Section ............. 75

8-8. Chassis Section................................................................ 76

8-9. CD Mechanism Deck Section-1

(CDM74KF-K6BD91UR-WOD or

CDM74KFV-K6BD91UR-WOD)................................... 77

8-10. CD Mechanism Deck Section-2

(CDM74KF-K6BD91UR-WOD or

CDM74KFV-K6BD91UR-WOD)................................... 78

9. ELECTRICAL PARTS LIST................................ 79

3

HCD-GT22/GT44/GT55

Ver. 1.2

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

RELEASING THE ANTITHEFT LOCK

The disc table lock function for the antitheft of an demonstration

disc in the store is equipped.

MODEL IDENTIFICATION

– Model Number Label –

Power Voltage

Indication

Model Power voltage indication

GT22: E2, E3, E51 AC: 120V/220V/230-240V - 50/60Hz 150W

GT22: E13, AUS AC: 230-240V - 50/60Hz 150W

GT22: MX ca-127V 60Hz 150W

GT22: AR ca 220V - 50/60Hz 150W

GT44: E13, AUS AC: 230-240V - 50/60Hz 250W

GT44: E2, E3, E51 AC: 120V/220V/230-240V - 50/60Hz 250W

GT44: MX ca-127V 60Hz 250W

GT44: AR ca 220V - 50/60Hz 250W

GT55: E2, E3, E51 AC: 120V/220V/230-240V - 50/60Hz 225W

GT55: MX ca-127V 60Hz 225W

GT55: AR ca 220V - 50/60Hz 225W

• Abbreviation

AR : Argentina model

AUS: Australian model

E2 : 120V AC Area in E model

E3 : 240V AC Area in E model

E13 : 220V - 230V AC Area in E model

E51 : Chilean and Peruvian models

MX : Mexican model

HOW TO OPEN THE TRAY WHEN POWER SWITCH

TURN OFF

Releasing Procedure :

1. Press the

I/1 button to turn the power on.

2. Press the CD button to select “CD”.

3. While pressing the x button, press the Z button until

“UNLOCKED” displayed on the fluorescent indicator tube

(around 5 seconds).

Note: When “LOCKED” is displayed, the antitheft lock is not released by

turning power on/off with the I/1 button.

4

1

Turn the gear (loading A)

to the direction of the arrow.

2

HCD-GT22/GT44/GT55

)

Ver. 1.1

SERVICE POSITION

In checking the CD mechanism deck, prepare jig (extension cable J-2501-248-A (27 core/300 mm))/J-2501-077-A (13 core/300 mm)

MAIN board

Connect jig (extension cable J-2501-248-A

to the flexible flat cable (27 core) and

CD board (CN202).

CD mechanism deck

Connect jig (extension cable J-2501-077-A)

to the flexible flat cable (13 core) and

DRIVER board (CN701).

NOTE OF REPLACING CD MECHANISM DECK

As for except Mexican model, CD mechanism deck has been changed from CDM74KF-K6BD91UR-WOD to CDM74KFV-K6BD91URWOD on the way of production.

Please repair after confirming which type repaired CD mechanism deck is without fail according to ho w to distinguish the figure below when

you repairing exchange each part of CD mechanism deck.

DISCRIMINATION

for CDM74KF-K6BD91UR-WOD

CD mechanism deck

for CDM74KFV-K6BD91UR-WOD

– lifter (KSM) –

– lever (lifter) –

5

HCD-GT22/GT44/GT55

• Location of Controls

SECTION 2

GENERAL

This section is extracted from

instruction manual.

Unit

HCD-GT55

HCD-GT44/GT22

* HCD-GT44 only

Remote

1

4/1 (on/standby)

Press to turn on the system.

Unit: STANDBY indicator

Lights up when the system is off.

2

Remote sensor

3

DISPLAY

Press to change the information on the

display.

Unit: ILLUMINATION

Press to change the illumination pattern

around MASTER VOLUME

qg

4

CD

Press to select the CD function.

TUNER/BAND

Press to select the TUNER function.

Press to select FM or AM reception

mode.

Unit: T APE A/B

Press to select the TAPE function. Press

to select TAPE A or TAPE B.

Unit: AUDIO

Press to select the AUDIO function.

USB

Press to select the USB function.

Remote: FUNCTION

Press to select the function.

5

(HCD-GT55/GT44 only)

SUBWOOFER

Press to turn on and off the subwoofer.

SUBWOOFER indicator

Lights up when the subwoofer is on.

6

Z PUSH

Press to insert or eject a tape.

7

ERASE

Press to erase MP3 files and folders

from the connected optional USB device

(Digital music player or USB storage

media).

.

8

Unit: PRESET EQ,

GROOVE, SURROUND

Remote: EQ

Press to select the sound effect.

9

PLAY MODE/TUNING MODE

(HCD-GT55 only)

Press to select the play mode of a CD,

MP3 disc or an optional USB device

(Digital music player or USB storage

media).

Press to select the tuning mode.

EQ BAND (HCD-GT44/GT22 only)

Press to select the frequency band.

q;

PHONES jack

Connect the headphones.

qa

AUDIO INPUT L/R jacks

Connect to an audio component

(Portable audio player, etc.).

qs

(USB) port

Connect an optional USB device (Digital

music player or USB storage media).

qd

REC/ERASE indicator

Lights up when recording to the

connected optional USB device (Digital

music player or USB storage media), or

when erasing MP3 files or folders.

qf

MIC jack

Connect an optional microphone.

MIC LEVEL

Turn to adjust the microphone volume.

qg

Unit: MASTER VOLUME

Turn to adjust the volume.

Remote: VOLUME +/–

Press to adjust the volume.

qh

OPERATION DIAL

Turn to select a track, file or folder.

qj

Unit: NX (play/pause)

Remote: N (play)

X (pause)

Press to start or pause playback.

x (stop)

Press to stop playback.

./> (go back/go forward)

Press to select a track or file.

Unit: TUNING +/–

Remote: +/– (tuning)

Press to tune in the desired station.

+/– (select folder)

Press to select a folder.

m/M (rewind/fast forward)

Press to find a point in a track or file.

qk

CD-USB SYNC/REC1

Press to record from a disc onto the

connected optional USB device (Digital

music player or USB storage media).

CD-TAPE SYNC

TAPE REC PAUSE/START

Press to record onto a tape.

ql

Z OPEN/CLOSE

Press to insert and eject a disc.

w;

Unit: DISC 1 – 3

Press to select a disc. Press to switch to

the CD function from other function.

Unit: DISC SKIP/EX-CHANGE

Press to select a disc. Press to exchange a

disc while playing.

Remote: DISC SKIP

Press to select a disc.

wa

RETURN

Press to return to the parent folder.

Press to exit search mode.

ws

ENTER

Press to enter the settings.

wd

(HCD-GT55 only)

ENTER

Press to enter the settings.

+/– (equalizer level)

Press to adjust the equalizer level.

wf

(HCD-GT55 only)

BASS

Press to select low frequency. The

indicator lights up when the button is

pressed.

VOCAL

Press to select mid frequency. The

indicator lights up when the button is

pressed.

GUITAR

Press to select high frequency. The

indicator lights up when the button is

pressed.

FOCUS

Press to emphasize equalizer level of the

selected band.

wg

CLOCK/TIMER SELECT

CLOCK/TIMER SET

Press to set the clock and the timers.

wh

REPEAT/FM MODE

Press to listen to a disc, an USB device, a

single track or file repeatedly.

Press to select the FM reception mode

(monaural or stereo).

wj

Battery compartment lid

wk

CLEAR

Press to delete a pre-programmed track

or file.

wl

TUNER MEMORY

Press to preset the radio station.

e;

PLAY MODE/TUNING MODE

Press to select the play mode of a CD,

MP3 disc or an optional USB device

(Digital music player or USB storage

media).

Press to select the tuning mode.

ea

SLEEP

Press to set the Sleep Timer.

6

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. CASE (SIDE-L), CASE (SIDE-R)

(Page 8)

3-3. CASE (TOP)

(Page 8)

SECTION 3

DISASSEMBLY

HCD-GT22/GT44/GT55

Ver. 1.1

3-4. LID (CD)

(Page 9)

3-5. CD MECHANISM DECK, USB BOARD

(Page 9)

3-6. FRONT PANEL BLOCK

(Page 10)

3-7. MECHANICAL DECK

(CWM42FF609)

(Page 10)

3-8. BACK PANEL BLOCK

(Page 11)

3-9. MAIN BOARD

(Page 11)

3-10. CD BOARD

(Page 12)

3-12. OPTICAL PICK-UP BLOCK

3-11. DRIVER BOARD,

SW BOARD

(Page 12)

(KSM-213D)

(Page 13)

3-13. SENSOR BOARD

(Page 13)

3-14. MOTOR (TB) BOARD

(Page 14)

3-15. MOTOR (LD) BOARD

(Page 14)

7

HCD-GT22/GT44/GT55

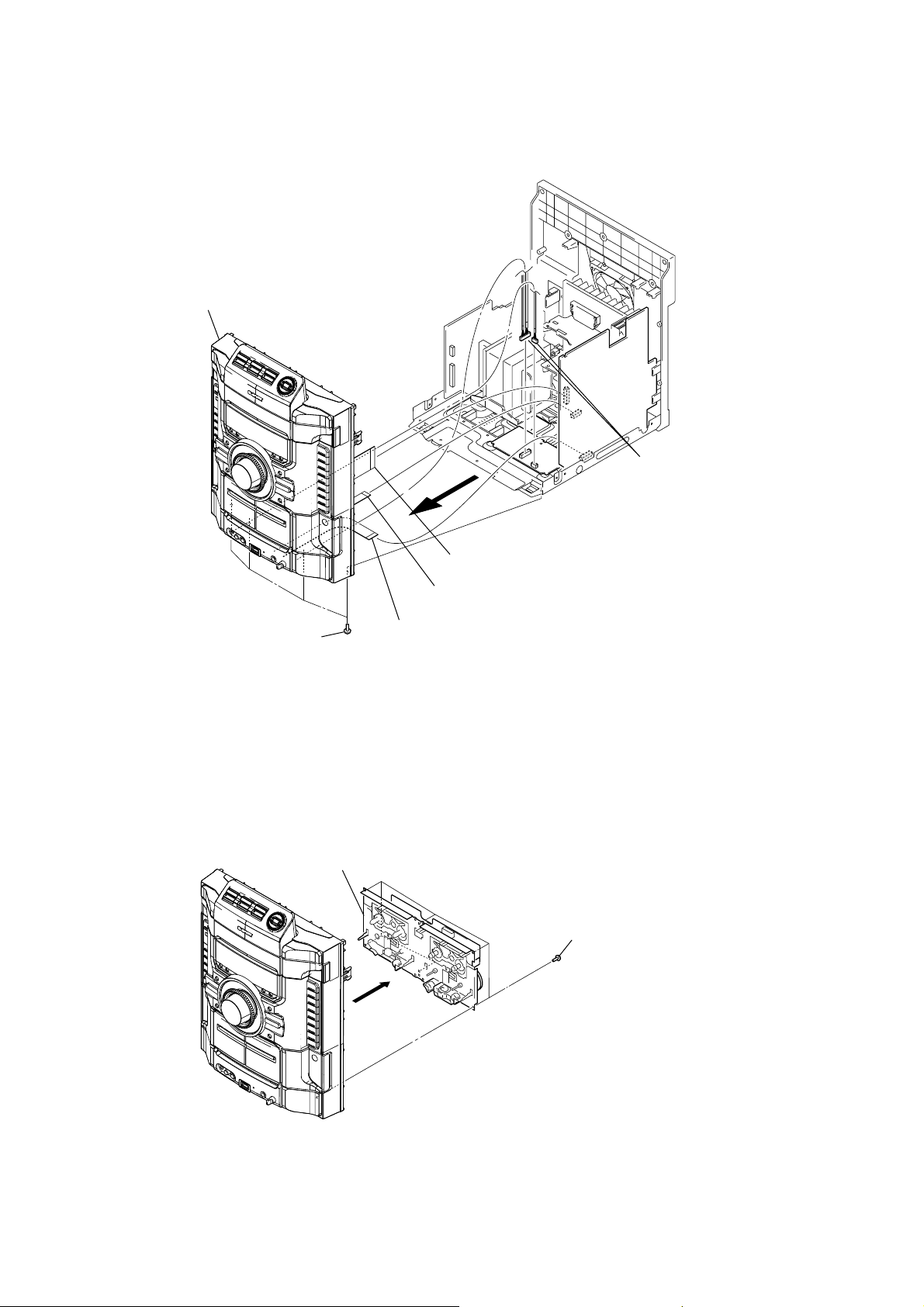

Note: Follow the disassembly procedure in the numerical order given.

3-2. CASE (SIDE-L), CASE (SIDE-R)

3

case (side-L)

2

two screws

1

three screws

(case 3 TP2)

(BVTP3

×

10)

6

case (side-R)

3-3. CASE (TOP)

2

Open the case (top).

4

four claws

2

Open the case (top).

3

4

three screws

(case 3 TP2)

1

5

two screws

(BVTP3

×

case (top)

5

two screws

(BVTP3

10)

×

10)

2

Open the case (top).

8

HCD-GT22/GT44/GT55

)

Ver. 1.1

3-4. LID (CD)

1

Turn the gear (loading A)

to the direction of the arrow.

3

four claws

2

4

lid (CD

3-5. CD MECHANISM DECK, USB BOARD

8

CD mechanism deck

(CDM74KF-K6BD91UR-WOD or

CDM74KFV-K6BD91UR-WOD)

4

connector (CN901)

0

USB board

9

two screws (M2.6)

5

connector (CN903)

6

screw

(BVTP3

×

8)

1

flexible flat (13 core) cable

(CN701)

2

flexible flat (27 core) cable

(CN302)

7

three screws

(BVTP3

×

8)

3

flexible flat (21 core) cable

(MAIN board: CN301/USB board: CN907)

6

screw (BVTP3 × 8)

9

HCD-GT22/GT44/GT55

3-6. FRONT PANEL BLOCK

6

front panel block

4

two connectors

(CN301, CN302)

5

four screws

(BVTP3

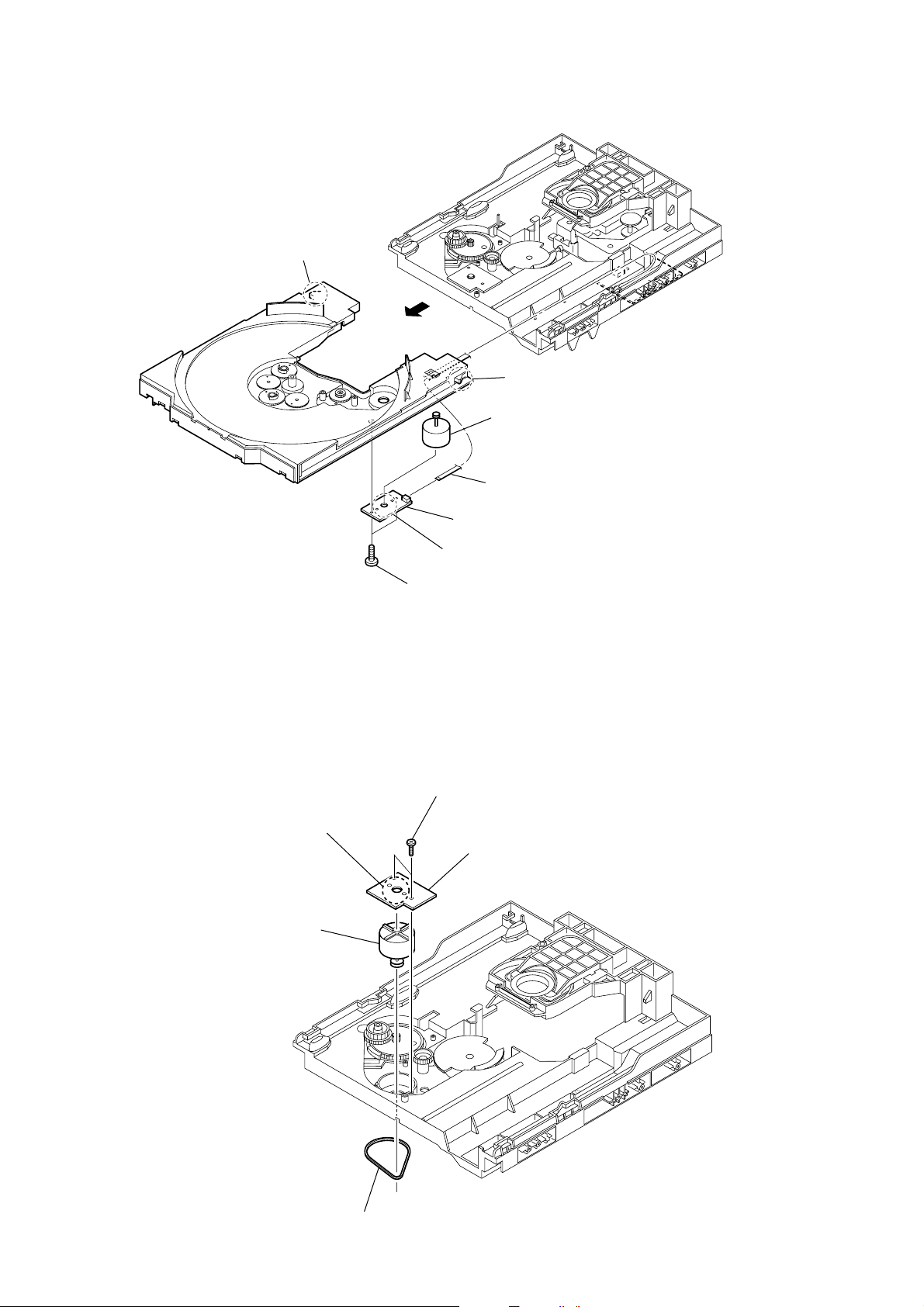

3-7. MECHA DECK (CWN42FF609)

mecha deck

3

(CWN42FF609)

1

flexible flat cable (27 core)

(CN901)

2

flexible flat cable (11 core)

(CN201)

3

flexible flat cable (13 core)

2

(CN061)

1

six screws

(BVTP2.6

×

8)

×

8)

10

3-8. BACK PANEL BLOCK

d

3

connector

(CN701)

(except Australian model)

2

connector

(CN041)

5

back panel block

HCD-GT22/GT44/GT55

1

flexible flat cable (9 core)

(tuner (FM/AM))

4

two screws

(BVTP3 × 10)

(GT44/GT55)

4

two screws

(BVTP3 × 10)

3-9. MAIN BOARD

3

connector

(CN907)

2

connector

(CN903)

8

two screws

(BVTT4

4

two screws

(BVTP3 × 10)

×

8)

qs

POWER board

7

screw

(BV3)

4

connector

(CN271)

qa

0

MAIN boar

connector

(CN031)

1

flexible flat cable (11 core)

(CN008)

9

5

screw

(BVTP3

6

screw

(BVTP3

×

8)

×

8)

11

HCD-GT22/GT44/GT55

e

3-10. CD BOARD

5

Remove soldering from the four points.

1

3

cover (OP)

screw

(BVTP3

2

6

CD

board

screw

(BVTP2.6)

4

flexible flat (16 core) cabl

(CN301)

×

8)

3-11. DRIVER BOARD, SW BOARD

1

two

(BTTP (M2.6))

5

DRIVER

2

wire (flat type) (5 core)

(CN702)

board

screws

4

connector

(CN704)

CD machanism deck

(bottom side)

3

connector

(CN703)

6

screw

(BTTP (M2.6))

7

SW board

12

CD machanism deck

(bottom side)

3-12. OPTICAL PICK-UP BLOCK (KSM-213D)

qd

optical pick-up block

(KSM-213D)

8

two

7

two

coil springs

(insulator)

6

two floating

(PTPWH M2.6)

insulators

screws

9

qs

HCD-GT22/GT44/GT55

2

h

older (213) assy or holder (KSM) assy

1

floating

screw

(PTPWH M2.6)

5

two

insulators

4

two

coil springs

(insulator)

3

qa

C

D board

two floating

(PTPWH M2.6)

flexible flat

(CN301)

screws

cable (16 core)

Ver. 1.1

3-13. SENSOR BOARD

2

t

ray

0

1

floating

(PTPWH M2.6)

6

floating

(PTPWH M2.6)

7

g

ear (geneva)

Remove the four solders of motor.

screw

8

s

crew

(BTTP (M2.6))

0

SENSOR board

9

screw

connector

(

CN731)

3

b

elt (table)

4

floating

(PTPWH M2.6)

5

p

screw

ulley (table)

13

HCD-GT22/GT44/GT55

3-14. MOTOR (TB) BOARD

2

stopper

4

1

stopper

7

t

able motor assy (M741)

3

wire (flat type) (5 core) (CN742)

3-15. MOTOR (LD) BOARD

3

Remove the two solderings of motor.

4

l

oading motor assy (M751)

8

6

5

two

screws

(BTTP (M2.6))

2

two

(BTTP (M2.6))

MOTOR (TB) board

Remove the two solderings of motor.

screws

5

MOTOR (LD) board

14

1

b

elt (loading)

SECTION 4

TEST MODE

HCD-GT22/GT44/GT55

COLD RESET

The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press three buttons of x , u and [GROOVE] simultaneously.

2. The message “COLD RESET” is displayed on the fluorescent

indicator tube momentarily, then becomes standby states.

TUNING STEP CHANGE-OVER

A step of AM tuning interval can be changed over between 9 kHz

and 10 kHz.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [TUNER/BAND] button to select “AM”.

3. Press the I/1 button to turn the power off.

4. Press two buttons of [TUNING +] and I/1 simultaneously.

5. The message “AM 9K STEP” or “ AM 10K STEP” is displayed

on the fluorescent indicator tube, and thus the tuning interval

is changed over.

CD SHIP (LOCK) MODE

This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Press two buttons of u and I/1 simultaneously.

4. The message “LOCK” is displayed on the fluorescent indicator

tube, and the CD ship mode is set.

CD SHIP (LOCK) MODE & COLD RESET

This mode is used to perform CD ship (lock) mode and cold reset

simultaneously.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Press three buttons of x , [ILLUMINATION] and I/1

simultaneously.

4. The message “COLD RESET” is displayed on the fluorescent

indicator tube momentarily, then becomes standby states.

ANTITHEFT LOCK MODE

This mode is used to unable to take sample disc out of disc table in

the shop.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Insert a disc.

4. Press two buttons of x and Z for 5 seconds.

5. The message “LOCKED” is displayed on the fluorescent

indicator tube and the disc table is locked. (Even if pressing

the Z button, the message “LOCKED” is displayed on the

fluorescent indicator tube and the disc table is locked)

6. To release this mode, press two buttons of x and Z for 5

seconds.

7. The message “UNLOCKED” is displayed on the fluorescent

indicator tube and the disc table is unlocked.

AMP TEST MODE

This mode is used to display the parameter of amplifier IC and

display the VACS status.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press three buttons of x , u and [USB] simultaneously.

3. When the AMP test mode is activated, the message “AMP

TEST IN” is displayed on the fluorescent indicator tube

momentarily, then amplif ier adjustment mode is displayed on

the fluorescent indicator tube.

4. Press the [TAPE REC PAUSE/START] button to changed over

between VACS status display mode and the amplifier IC

parameter display mode.

5. In this mode, press the [GROOVE] button to changed over

DBFB on/off, and “DBFB ON” or “DBFB OFF” is displayed

on the fluorescent indicator tube.

6. In this mode, press the [SURROUND] button to changed over

surround on/off, and “SURROUND ON” or “SURROUND

OFF” is displayed on the fluorescent indicator tube.

− For GT22/GT44 −

7. In this mode, press the [EQ BAND] button to enter the equalizer

adjustment mode.

In the equalizer adjustment mode, press the [EQ BAND] button

to change over the adjustment band as LOW/MID/HIGH. And

turn the [OPERATION DIAL] knob to adjust the equalizer lev el

of each bands.

− For GT55 −

7. In this mode, press the [BASS], [VOCAL] or [GUITAR] button

to enter the parametric equalizer adjustment mode.

In the parametric equalizer adjustment mode, press the [BASS],

[VOCAL] and [GUITAR] button to change over the adjustment

band. And press the [BASS], [VOCAL] or [GUITAR] button to

change over the equalizer frequency of each bands, or press

the [+] and [--] buttons to adjust the equalizer level of each

bands.

8. To release the amplifier IC parameter display mode or equalizer

adjustment mode, press the

I/1 button to the power off.

MC TEST MODE

This mode is used to check operations of microprocessor.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press three buttons of x , u and [AUDIO] simultaneously.

3. When the MC test mode is activated, VACS lev el is displayed

on the fluorescent indicator tube momentarily.

4. Press the [TUNING +] button, the message “ALL EQ MAX”

is displayed on the fluorescent indicator tube momentarily

and press the [TUNING --] button, the message “ ALL EQ MIN”

is displayed on the fluorescent indicator tube momentarily.

5. Press the [ENTER] button, the message “ALL EQ FLAT” is

displayed on the fluorescent indicator tube momentarily.

6. Turn the [VOLUME] knob cloc kwise, the message “VOLUME

MAX” is displayed on the fluorescent indicator tube

momentarily and turn the [VOLUME] knob counterclockwise,

the message “VOLUME MIN” is displayed on the fluorescent

indicator tube momentarily.

7. Press the [TAPE REC PAUSE/START] button to changed over

VACS on/off.

8. Press the I/1 button to release from this mode, then cold reset

is performed.

15

HCD-GT22/GT44/GT55

VERSION DISPLAY MODE

This mode is used to check the model, destination and software

version.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press three buttons of x , u and [ILLUMINATION] simultaneously.

3. When this mode is activated, model type and destination (*1)

are displayed on the fluorescent indicator tube.

*1) GRL2H : HCD-GT22

GRL2HS : HCD-GT44

GRL3HS : HCD-GT55

Example: GRL3HS_LATIN: Latin American models of HCD-GT55

4. Press the [TAPE REC PAUSE/START] button to display the software version (*2) and year, month, day of the software creation.

*2) G**.*** : The version of system controller (IC901 on the MAIN

board).

M**.*** : The version of USB control module in the sysytem

controller.

U**.*** : The version of USB controller (IC901 on the USB

board).

5. To release this mode, press three buttons of x , u and

[ILLUMINATIOM] simultaneously.

CD ERROR CODE DISPLAY MODE

This mode can be used for error code display of CD section.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Press three buttons of x , [CD] and [SURROUND] simultaneously.

4. When this mode is activated, mechanism deck error code is

displayed on the fluorescent indicator tube.

5. Press the [ENTER] button to changed over between optical

pick-up error code display mode and mechanism deck error

code mode.

Note: There are two [ENTER] buttons on the HCD-GT55, but it works in

the same way whichever button is pressed.

6. Press the [TUNING +]/[TUNING ---] button to change over dis-

play of error history number.

7. To release this mode, press the I/1 button to turn the power

off.

1. Mechanism Deck Error Code Mode

When this mode is entered, mechanism deck error code is displayed

with the 10-character format on the fluorescent indicator tube.

The first digit from the left indicates:

The first digit from the left indicates which mode the error history

is. In the mechanism deck error code mode, “M” is displayed on

the fluorescent indicator tube.

The second digit from the left indicates:

(Error history number display)

The second digit from the left indicates which order the error history

is. “0” indicates the latest error history, and each time the number

increases by one, the error history goes back to one-previous error.

The third and 4th digit from the left indicates:

(Error status display)

The third and 4th digit from the left indicates which error status is

indicated.

Display Status

00 No error

08 Table operation time-out (Table does not move to the tar get

position within the specified time)

16 In the chucking down operation, the operation was retried

by the maximum number of times but the operation could

not be completed

17 In the chucking up and down operation, the reverse

recovery processing was attempted but it could not be

recovered

18 In the chucking up operation, the operation was retried by

the maximum number of times but the operation could not

be completed

20 Loading operation time-out (Table does not move to the

target position within the specified time)

22 As the chuck was in the ex-open status at the initialization,

the closing was attempted but could not be completed

The 5th and 6th digit from the left indicates:

(Present status display)

The 5th and 6th digit from the left indicates which operating status

when an error occurred is indicated.

Display Status

01 Open completion status

02 From open status, the movement to chucking down position

is under way

03 From chucking down position, the open operation is under

way

04 Chucking down completion status

10 The chucking down operation is under way

11 The chucking up operation is under way

12 Close completion status

13 From close status, the ex-open operation is under way

14 From ex-open status, the close operation is under way

18 Ex-pen completion status

The 7th and 8th digit from the left indicates:

(Motor status display)

The 7th and 8th digit from the left indicates which motor output

status when an error occurred is indicated.

Display Status

× 0 No table motor output

× 1Table motor forward output

× 2Table motor backward output

× 3Table motor break output

0 × No loading motor output

1 × Loading motor forward output

2 × Loading motor backward output

3 × Loading motor break output

16

HCD-GT22/GT44/GT55

The 9th and 10 th digit from the left indicates:

(Tray status display)

The 9th and 10th digit from the left indicates which target processing

when an error occurred is indicated.

Display Status

01 Open operation

12 Close operation

18 Ex-open operation

2. Optical Pick-up Error Code Mode

When this mode is entered, optical pick-up error code is displayed

with the 8-character format on the fluorescent indicator tube.

The first digit from the left indicates:

The first digit from the left indicates which mode the error history

is. In the optical pick-up error code mode, “D” is displayed on the

fluorescent indicator tube.

The second digit from the left indicates:

(Error history No. display)

The second digit from the left indicates which order the error history

is. “0” indicates the latest error history, and each time the number

increases by one, the error history goes back to one-previous error.

The third and 4th digit from the left indicates:

(Error status display)

The third and 4th digit from the left indicates which error status is

indicated.

Display Status

01 Not focused (TOC read without a disc)

02 GFS NG (TOC read with a disc chucked)

03 Start operation time-over

04 Defocused continuously (Defocused during TOC reading)

05 Q code not entered for specified time

06 Tracking not turned ON

07 Blank disc (Blank disc TOC read)

The 5th and 6th digit from the left indicates:

(Error step display)

The 5th and 6th digit from the left indicates which processing when

a trouble occurred

Display Contents

01 Power OFF in progress

02 Initialize in progress

03 Oscillation stopping

04 From oscillation stop, oscillation starting

05 Stopping

06 Stop operation is under way

07 Start operation in progress

08 TOC read in progress

09 Search operation is under way

0A Playback operation is under way

0B Pause operation is under way

0C Playback manual search operation is under way

0D Pause manual search operation is under way

0E —

The 7th and 8th digit from the left indicates:

The 7th and 8th digit from the left indicates which operation in

progress when a trouble occurred. (Step of each processing of the

5th and 6th digits is indicated)

5 REPEAT LIMIT CANCEL MODE

Number of repeat for CD playback is 5 times when the repeat mode

is “REPEAT”. This mode is used to enables CD to repeat playback

for limitless times.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Press three buttons of x , [CD] and u simultaneously.

4. The message “LIMIT OFF” is displayed on the fluorescent

indicator tube momentarily, CD repeat 5 limit is cancelled.

CD/USB POWER MANAGE

This mode is used to changed over CD and USB power on/off for

decreasing of reception noise in the tuner mode.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Press the I/1 button to turn the power off.

4. Press two buttons of x and I/1 simultaneously.

5. The message “CD POWER ON” or “CD POWER OFF” is

displayed on the fluorescent indicator tube, and CD and USB

power on/off changed over in the tuner mode.

BOOSTER ON/OFF

This mode is used to changed over MP3 booster on/off.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [USB] button to select “USB”.

3. Press three buttons of x , [SURROUND] and [USB] simulta-

neously.

4. The message “BOOSTER ON” or “BOOSTER OFF” is

displayed on the fluorescent indicator tube, and MP3 booster

on/off changed over.

EXCITER ON/OFF

This mode is used to changed over the exciter on/off.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Insert a MP3 disc.

4. Press three buttons of x ,[SURROUND] and [AUDIO] simul-

taneously.

5. The message “EXCITER ON” or “EXCITER OFF” is

displayed on the fluorescent indicator tube, and the exciter

on/off changed over.

CD SERVICE MODE

This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the optical pick-up.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Press three buttons of x , [FOLDER ---] and [SURROUND]

simultaneously, the message “SERVICE” is displayed on the

fluorescent indicator tube.

4. Press the [TUNING ---] button to move the optical pick-up to

inside track and the message “SLED IN” is displayed on the

fluorescent indicator tude, or press the [TUNING +] button to

outside track and the message “SLED OUT” is displayed on

the fluorescent indicator tude.

5. Press the [DISPLAY] button, “LD ON” or “LD OFF” is displayed on the fluorescent indicator tude. Each time [DISPLAY]

button is pressed, laser diode on/off is changed over.

6. To release this mode, press three buttons of x , [FOLDER ---]

and [SURROUND].

17

HCD-GT22/GT44/GT55

PANEL TEST MODE

This mode is used to check the fluorescent indicator tube, LEDs, phones jack, keys and control knobs.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press three buttons of x , [SURROUND] and [TUNER] simultaneously.

3. All segments on the fluorescent indicator tube and all LEDs light up.

4. Press two buttons of [ILLUMINATUION] and [ENTER] simultaneously to enter the key routes check mode.

5. In this mode, each time any button is pressed, it displays key route and key number of the button. (Refer to following table)

KeyKey Routes

No. KEY0 KEY1 KEY2 KEY3 KEY4 (GT55 only)

1 DISPLAY ILLUMINATION ENTER DISC 1 +

2 POWER ERASE RETURN DISC 2 ENTER(PEQ)

3 CD PRESET EQ FOLDER + DISC 3 –

4 TUNER/BAND GROOVE TUNING +

5 TAPE A/B SURROUND PLA Y/PAUSE STOP FOCUS (GUITAR)

6 AUDIO

7 USB FOLDER – CD-TAPE SYNC VOCAL

SUBWOOFER

8

(GT44/GT55) PAUSE/START

9 FOCUS (BASS)

EQ BAND (GT22/GT44)

PLAY MODE (GT55)

TUNING – CD-USB SYNC/REC1 FOCUS (VOCAL)

OPEN/CLOSE

Example: [DISPLAY] button : “KEY 10000”

[TUNER/BAND] button : “KEY 40000”

[ILLUMINATION] button : “KEY 01000”

[CD-TAPE SYNC] button : “KEY 00070”

EX-CHANGE/

DISC SKIP

TAPE REC

GUITAR

BASS

6. Press two buttons of [ILLUMINATUION] and [ENTER] simultaneously to enter the key check mode.

7. In this mode, each time any button is pressed, “KEYCONT” value increases. Howev er, once a button is pressed, it is no longer

taken into account. (Maximum numbers are GT22: 29, GT44: 30, GT55: 39)

8. Press two buttons of [ILLUMINATUION] and [ENTER] simultaneously to enter the phones jack check mode.

9. In this mode, “H_P ON” is displayed when phones jack is inserted, and “H_P OFF” is displayed when phones jack is pulled out.

10. Press two buttons of [ILLUMINATUION] and [ENTER] simultaneously to enter the volume check mode and display “VOLUME

FLAT”.

11. In this mode, “VOLUME UP” is displayed when [VOLUME] knob is turned clockwise, and “VOLUME DOWN” is displayed

when [VOLUME] knob is turned counterclockwise.

12. Press two buttons of [ILLUMINATUION] and [ENTER] simultaneously to enter the jog check mode and display “JOG FLAT”.

13. In this mode, “JOG UP” is displayed when [OPERATION DIAL] knob is turned clockwise, and “JOG DOWN” is displayed when

[OPERATION DIAL] knob is turned counterclockwise.

14. Press two buttons of [ILLUMINATUION] and [ENTER] simultaneously to release the Panel Test mode.

18

SECTION 5

MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer. (Do not bring the head magnetizer close to the

erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, appiy suitable locking compound to

the parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

TORQUE MEASUREMENT

Mode Torque Meter Meter Reading

2.6 – 6.9 mN⋅m

FWD CQ-102C (30 – 70 g⋅cm)

(0.41 – 0.97 oz⋅inch)

FWD

Back Tension

FF/REW CQ-201B 55 – 170 g⋅cm)

CQ-102C (1.5 – 6.0 g⋅cm)

0.15 – 0.59 mN⋅m

(0.021 – 0.083 oz⋅inch)

5.4 – 16.7 mN⋅m

0.76 – 2.35 oz⋅inch)

HCD-GT22/GT44/GT55

TAPE TENSION MEASUREMENT

Mode Tension Meter Meter Reading

FWD CQ-403A

more than 100 g

(more than 3.53 oz)

19

HCD-GT22/GT44/GT55

r

SECTION 6

ELECTRICAL ADJUSTMENTS

0 dB=0.775 VDECK SECTION

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

TEST TAPE

Tape Signal Used for

P-4-A063 6.3 kHz, -10 dB Azimuth Adjustment

RECORD/PLA YBA CK HEAD AZIMUTH ADJUSTMENT

Note: Perform this adjustment for both decks.

Procedure:

1. Mode: Playback

test tape

P-4-A063

(6.3 kHz, –10 dB)

MIC board

PHONES jack

(J803)

set

level mete

+

–

4. After the adjustments, apply suitable locking compound to

the pats adjusted.

Adjustment Location: Playback Head (DECK-A)

Record/Playback/Erase Head (DECK-B)

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

Screw

position

L-CH

peak

Screw

position

R-CH

peak

3. Mode: Playback

test tape

P-4-A063

(6.3 kHz, –10 dB)

set

MIC board

PHONES jack

(J803)

oscilloscope

H

V

20

waveform of oscilloscope

–45

°

0°+45

good

°

+90

°

+135°+180

wrong

°

HCD-GT22/GT44/GT55

+

–

CD board

TP121 (RFI)

TP124 (VC)

oscilloscope

(DC range)

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level:

1.2

±

0.3 Vp-p

TUNER SECTION

FM TUNE LEVEL CHECK

signal

generator

set

Procedure:

1. Turn on the set.

2. Input the following signal from signal generator to FM antenna

input directly.

Carrier frequency: A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Use 75 ohm coaxial cable to connect signal generator and the set.

You cannot use video cable for checking.

Use signal generator whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Confirm “TUNED” is lit on the display for A, B and C signals.

When the selected station signal is received in good condition,

“TUNED” is displayed.

CD SECTION

Note:

1. CD Block is basically constructed to operate without adjustment.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

5. Check the focus bias check when optical pick-up block is replaced.

FOCUS BIAS CHECK

Procedure :

1. Connect oscilloscope to TP121 (RFI) and TP124 (VC) on the

CD board.

2. Press the I/1 button to turn the power ON.

3. Set disc (YEDS-18) on the tray and press the u button to

playback.

4. Confirm that oscilloscope waveform is as shown in the f igure

below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

Checking Location:

– CD Board (Conductor Side) –

TP124

(VC)

TP121

(RFI)

IC101

21

HCD-GT22/GT44/GT55

MEMO

22

SECTION 7

DIAGRAMS

7-1. BLOCK DIAGRAM – CD SERVO, USB Section –

HCD-GT22/GT44/GT55

DETECTOR

A

B

C

D

I-V AMP

E

F

LASER DIODE

PD

LD

OPTICAL PICK-UP

BLOCK

(KSM-213DCP)

M401

(SPINDLE)

M402

(SLED)

2-AXIS

DEVICE

(TRACKING)(FOCUS)

M

M

VCC

SP+

SP–

SL+

SL–

BD+3.3V

A

B

C

D

E

F

AUTOMATIC

LD

PD

VC

T+

T–

F+

F–

POWER

CONTROL

Q301

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: CD PLAY

: USB

95

FNi1 (A)

97 FPi1 (B)

94 FNi2 (C)

96 FPi2 (D)

100 TNi (E)

98 TPi (F)

91 LDo 92MDi

FOCUS/TRACKING COIL DRIVE,

SLED/SPINDLE MOTOR DRIVE

2 VO1+

1 VO1–

12 VO2–

11 VO2+

18 VO3+

17 VO3–

26 VO4+

27

VO4–

IC401

MUTE

7

RFo

89

3RFRP RFZi

23

BIAS

3

IN1

9

IN2’

20

IN3’

24

IN4’

S201

(LIMIT)

X102

16.9344MHz

BD+3.3V

88

AGCi

2

76TEi TEZi

84 VRo

13 DMo

12 FMo

10 TRo

9 FOo

20 IO0 (/HSO)

23 XI

24 XO

83RFEQo 81 RFi

82 RFRPi

CD-MP3 PROCESSOR

IC101

30LO

27RO

R-CH

47AOUT2 (PO5)

63

BCK (PO8)

65AIN (PI4)

66BCKi (PI5)

67LRCKi (PI6)

51PIO3

46AoUT3 (PO4)

38BUS0

39BUS1 3 4 16 CD-BUS1 (I/O)

40BUS2 (SO) 9 8 15 CD-BUS2 (I/O)

41BUS3 (SI) 11 10 14 CD-BUS3 (I/O)

42BUCK (CLK) 4

43XCCE

48PIO0

54SBSY

37XRST

DATA

CLK

A-IN

BCK

LRCK

GATE

ST-REQ

BUS SWITCH

IC301

1 2 17 CD-BUS0 (I/O)

1 2

3 4

9 8

11 10

DATA SELECTOR

7

14

13

10

11

BUS SWITCH

IC302

IC303

SELECT

1

13

5

6

BUS0-U

13

BUS1-U

5

BUS2-U

6

BUS3-U

12

2

BUCK-U

3

5

6

12

9

CCE-U

REQ-U

SYSTEM CONTROLLER

19 CD-SEL112

12 CD-BUCK

13 CD-CCE

18 MP3 IREQ

21 CD-SEL2

29 I-SBSY

6 CD XRST

7

CD-M-MUTE

IC901 (1/4)

CD-L

O-USB-LED

O-LM-F

O-LM-R

O-TM-F

O-TM-R

I-CD-SENS

I-ENCD

I-OPEN-SW

(Page 24)

A

43O-USB-TXD (SO)

42I-USB-RXD (SI)

10O-USB-RST (DO)

9I-USB-CTS (DI)

11O-USB-RESET

37

LOADING MOTOR DRIVE

23

7

9

22

TABLE MOTOR DRIVE

25

7

9

24

26

55

27

LED DRIVE

Q931

IC701

OUT1

FIN

OUT2

RIN

IC712

OUT1

FIN

RIN

OUT2

LEVEL SHIFT

Q731

ROTARY

ENCODER

S711

DATA

CLK

A-IN

BCK

LRCK

GATE

ST-REQ

BUS0-U

BUS1-U

BUS2-U

BUS3-U

BUCK-U

CCE-U

REQ-U

4

2

4

2

OPEN

CLOSE

85 DATA

86 CLOCK

93 DATA

92 BCK

71 LRCK

94 GATE

97 ST-REQ

55 BUS0

56 BUS1

57 BUS2

58 BUS3

59 /BUCK

60 /CCE

96 REQ

88 RXD1

87 TXD1

2DI

84 DO

1 /RESET

M751

M

(LOADING)

M741

M

(TABLE)

DISC TABLE

IC731

DISC TABLE

S751

DISC TABLE

OPEN/CLOSE

DETECT

75 X1

73 X2

D801

REC

(USB)

X901

9MHz

ADDRESS SENSOR

ADDRESS DETECT

USB CONTROLLER

IC901

USBOC

D0 – D15

A1 – A16

RD

79D+

80D–

VBUS

+5V

78USBPON

77

18 – 25, 28 – 35

37 – 43, 46 – 54

70CS2

64

65WR

66SRLLB

67SRLUB

VBUS POWER

ON/OFF SWITCH

IC915

4 OUT

IN

EN

FLG

1

S-RAM

7 – 10, 13 – 16,

29 – 32, 35 – 38

21 – 18, 5 – 1

44 – 42, 27 – 24,

CE6

OE41

WE17

LB

39

UB40

5

3

IC921

I/O0 – I/O15

A0 – A15

VBUS

CN803

(USB)

3

D+

2

D–

1

HCD-GT22/GT44/GT55

2323

HCD-GT22/GT44/GT55

Ver. 1.2

7-2. BLOCK DIAGRAM – MAIN Section –

HP1

(PB)

(DECK-A)

HRPE1

(REC/PB/ERASE)

(DECK-B)

ERASE

FM75Ω

(COAXIAL)

AM

L-CH

R-CH

L-CH

R-CH

ANTENNA

(Page 25)

(Page 23)

R-CH

R-CH

J801

MIC

TUNER (FM/AM)

FM ANT

AM ANT

B

A

MUTING

MUTING

MUTING

Q401, 403

T001

BIAS OSC

HP IN

J802

AUDIO

CD-L

Q305

Q307

BIAS OSC

Q453

TUNER-L

TUNER-R

PLL DO

PLL DI

PLL CLK

PLL CE

TUNED

AUDIO+9V

R-CH

R-CH

R-CH

REC BIAS

SWITCH

Q454, 455

PB SWITCH

PB SWITCH

MUTING CONTROL

CONTROL SWITCH

R-CH

MIC AMP

IC801 (1/2)

MUTING

Q801

(DECK-A)

Q301

R-CH

(DECK-B)

Q303

R-CH

MUTING

SWITCH

Q305, 306

Q407

AUDIO

+9V

SELECT SWITCH,

SELECT SWITCH

49

O-BIAS

31 I-LV23004T-DI

33 O-LV23004T-DO

32 O-LV23004T-CLK

28 O-LC72121-CE

34 I-TUNED

DECK-A/B

REC/PB

Q408

46

O-REC/PB

RV801

MIC LEVEL

+

REC SWITCH

REC CONTROL

Q409, 410

Q405

SWITCH

48

MIC AMP

IC801 (2/2)

R-CH

58

O-REC-MUTE

I-HP/MIC

PB AMP

IC301

REC AMP

IC401

R-CH

37 MIX2

210AUX-L

40 CD-L

39 TAPE-L

1 TUNER-L

DATA15CLK

16

41

45

O-F-DATA

O-AUDIO-CLK

3REC OUT-L

SYSTEM CONTROLLER

IC901 (2/4)

INPUT SELECTOR, TONE CONTROL,

ELECTRICAL VOLUME

IC103

(GT22/GT44)

(GT55)

PARAMETRIC EQUALIZER

IC102

2

LIN

44

9LOUT

DATA6CLK

5

O-P-DATA

11 VOL IN-LTONE OUT-L 14OUT-L

SAOUT

4

BAND-PASS

FILTER

Q111, 112

D213 D211

67

59

I-VACS

I-STREAM

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: TUNER (FM/AM)

: CD PLAY

: TAPE PLAY (DECK-A)

: TAPE PLAY (DECK-B)

• Abbreviation

AR : Argentina model

E2 : 120V AC Area in E model

E3 : 240V AC Area in E model

E13 : 220V - 230V AC Area in E model

E51 : Chilean and Peruvian models

MX : Mexican model

: TAPE REC

: AUDIO IN

: MIC

OUT

(GT44/GT55)

J701

D-LIGHT

SYNC OUT

Q911, 914

Q913, 916

Q912, 915

BASS AGC

3

4

SW OUT

L+R SIGNAL

D-LIGHT B+

12BB12

13BB22

BASS AGC

+

R-CH

R-CH

D031

Q113

BUFFER

Q702

O-A-SOL

O-B-SOL

I-RELL-A

I-RELL-B

+4.1V

REGULATOR

Q701

85

88

87

78

79

60

CAPSTAN/REEL

MOTOR DRIVE

TRIGGER PLUNGER

DRIVE (DECK-A)

TRIGGER PLUNGER

DRIVE (DECK-B)

M+9V

(GT22: E2, E3, E13, E51, MX, AR/GT44: E2, E3, E13, E51, MX, AR/GT55)

O-MOTOR

I-TAPE-STAT

C

D

(Page 25)

E

(Page 25)

(Page 25)

TAPE MECHANISM

DECK BLOCK

CAMP+

M

A-SOL

B-SOL

A-PHOTO

B-PHOTO

B-REC-F

B-HALF

A-HALF

HCD-GT22/GT44/GT55

2424

7-3. BLOCK DIAGRAM – AMP Section –

HCD-GT22/GT44/GT55

E

(Page 24)

C

(Page 24)

BASS AGC

OUT

BUFFER

IC251

MUTING

Q251

R-CH

IC441 (GT22/GT55)

IC441 (GT44)

POWER AMP

STANDBY SWITCH

Q489

OVER LOAD

R-CH

TEMPERATURE

DETECT

Q441

+

DETECT

Q503, 507

DC DETECT

Q481, 482

+

OVER LOAD

DETECT

Q501

+

TH441

TEMPERATURE

DETECT

Q483, 484

+

++

DC DETECT

Q505, 506

R-CH

PROTECTOR

Q485

R-CH

D037

RELAY DRIVE

Q486, 488 (GT22)

Q480, 486, 488 (GT44/GT55)

PROTECT

DETECT

Q487

R-CH

HP IN

AUDIO+9V

R-CH

–1

JK441

+

–

–2

–

+

RY441

FAN MOTOR

DRIVE

Q043 – 045

M

FAN MOTOR

DETECT

Q046

+

M001

(FAN)

J803

PHONES

L

SPEAKER

R

PROTECT

B

F

(Page 24)

(Page 26)

SW OUT

D

(Page 24)

(GT44/GT55)

BUFFER

Q121

CONTROL SWITCH

MUTING

Q261

1

LINE AMP

IC252

O-SYS-MUTE

36

O-STK-MUTE

MUTING

Q272

POWER AMP

IC501

SYSTEM CONTROLLER

IC901 (3/4)

RY501

RELAY DRIVE

Q502

SUB WOOFER

SWITCH

Q274

2

O-SWR

JK501

+

SUB WOOFER OUT

–

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: TUNER (FM/AM)

HCD-GT22/GT44/GT55

2525

HCD-GT22/GT44/GT55

Ver. 1.2

7-4. BLOCK DIAGRAM – PANEL, POWER AMP Section –

FLUORESCENT INDICATOR

FL701

FLUORESCENT

INDICATOR

TUBE

GRID DRIVE

Q701 – 714

DR35 [S0] –

DR16 [S19]

38 – 19

DR0 [T0] –

DR13 [T13]

15, 16

2 – 13,

TUBE DRIVER

IC701

SCK

CSb

RSTb

XTb

XT

SI

46

OSC

45

SYSTEM CONTROLLER

IC901 (4/4)

O-NJM3427A-DATA49 84

O-NJM3427A2-CLK48 86

O-NJM3427FA2-CS51 68

O-NJM3427FA2-RESET52 69

FOR

FLUORESCENT

INDICATOR

TUBE

AMP

SECTION

B+

(GT22/GT55)

(GT44)

AMP

SECTION

B+

–VFL

+VH

–VH

+VL

–VL

+VCC

–VCC

PT901

MAIN POWER

TRANSFORMER

VF

VF

–27V

REGULATOR

Q902

RECT

D401

RECT

D402

RECT

D401

D908

F908

F909

F904

F905

F909

F904

D607

GUITAR

S601 – 608 (KEY0),

S611 – 616 (KEY1),

S621 – 628 (KEY2),

S631 – 638 (KEY3),

S641 – 649 (KEY4)

S608 (GT44/GT55),

S641 – 649 (GT55)

D601 – 606

(STREAM)

D608

VOCAL

(GT44/GT55)

SUBWOOFER

D609

BASS

D612

D611

STANDBY

KEY0 – KEY4 KEY0 – KEY3

S651

MASTER

VOLUME

S652

OPERATION

DIAL

REMOTE CONTROL

LED DRIVE

Q601 – 606

LED DRIVE

Q921 – 923

LED DRIVE

Q607

(GT55)

ROTARY

ENCODER

ROTARY

ENCODER

RECEIVER

IC601

KEY0

KEY4

O-S-LED1 –

O-S-LED6

70 – 75 61 – 64

O-G-LED,

O-V-LED,

38 – 40

O-B-LED

76 O-SWR-LED

77 O-STBY-LED

83 I-WAKEUPKEY

I-KEY0 –I-KEY3

56 I-KEY4

66 I-VOL

65 I-JOG

81 I-SIRCS-IN

RELAY B+

3O-FRONT-SP-RELAY

M+9V

M+7V

D301, 302

AUDIO+9V

UNREG +16V

B+ SWITCH

Q041, 042

D009

+9V

REGULATOR

IC021

+9V

REGULATOR

IC011

RECT

D021 – 024

RECT

D011 – 014

F907

• Abbreviation

AR : Argentina model

AUS : Australian model

E2 : 120V AC Area in E model

BD+3.3V

D+1.5V

4O-CD-POWER

USB+3.3V

8O-USB-POWER

52I-USB-MONI

+3.3V

VBUS+5V

EVER +10V

VDD+3.3V

D+3.3V,

VREF+3.3V

+1.5V

REGULATOR

IC201

D902

B+ SWITCH

Q301, 302

B+ SWITCH

Q303, 304

+4V

REGULATOR

Q901, 902

D008

+3.3V

REGULATOR

IC006

+5V

REGULATOR

IC007

D006

D902 – 905

RECT

D001

RECT

F906

PT902

SUB POWER

TRANSFORMER

E3 : 240V AC Area in E model

E13 : 220V - 230V AC Area in E model

E51 : Chilean and Peruvian models

MX : Mexican model

GT22: MX, AR, AUS/

GT44: MX, AR, AUS/

GT55: MX, AR

GT22: E2, E3, E13, E51/

GT44: E2, E3, E13, E51/

GT55: E2, E3, E51

VOLTAGE

SELECTOR

S901

GT22: MX, AR, AUS/

GT44: MX, AR, AUS/

GT55: MX, AR

RY901

POWER ON/OFF

RELAY DRIVE

Q903

(AC IN)

HCD-GT22/GT44/GT55

X902

20MHz

X901

32.768kHz

95 X1

94 X2

92 XT1

91 XT2

90RESET

35I-AC-CUT

57I-PROTECTOR

5O-POWER-RELAY

RESET SWITCH

Q903 – 905

RESET SIGNAL

GENERATOR

IC902

D007

PROTECT

DETECT

Q011

LEVEL SHIFT

Q908

RECT

D910

PROTECT

F

(Page 25)

2626

HCD-GT22/GT44/GT55

)

• Note For Printed Wiring Boards and Schematic Diagrams

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

• f : internal component.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• Indication of transistor

C

Q

B

E

B

These are omitted.

Q

CE

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• B : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

– CD Board –

no mark : CD PLAY

[]: USB

– USB Board –

no mark : USB

– TC Board –

no mark : TAPE PLAY

(): T APE REC

〈〈 〉〉 : TAPE A

{ }: TAPE B

– Other Board –

no mark : TUNER (FM/AM)

(): CD PLAY

[]: TAPE PLAY

∗ : Impossible to measure

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER (FM/AM)

J : CD PLAY

: USB

E : TAPE PLAY (DECK-A)

d : TAPE PLAY (DECK-B)

G : TAPE REC

f : AUDIO IN

N : MIC

• Abbreviation

AR : Argentina model

AUS: Australian model

E2 : 120V AC Area in E model

E3 : 240V AC Area in E model

E13 : 220V – 230V AC Area in E model

E51 : Chilean and Peruvian models

MX : Mexican model

4

W or less unless otherwise

• Circuit Boards Location

KEY TOP board

(GT55)

KEY LEFT board

PANEL board

VOLUME board

MIC board

TRANS board

SW board

MOTOR (LD) board

D-LIGHT SYNC board (except Australian model)

CD board

SENSOR board

DRIVER board

TUNER (FM/AM

MOTOR (TB) board

USB board

KEY RIGHT board

SUB WOOFER board (GT44/GT55)

5V REG board

SW-SP board

(GT44/GT55)

MAIN board

HCD-GT22/GT44/GT55

AMP board

TC board

2727

HCD-GT22/GT44/GT55

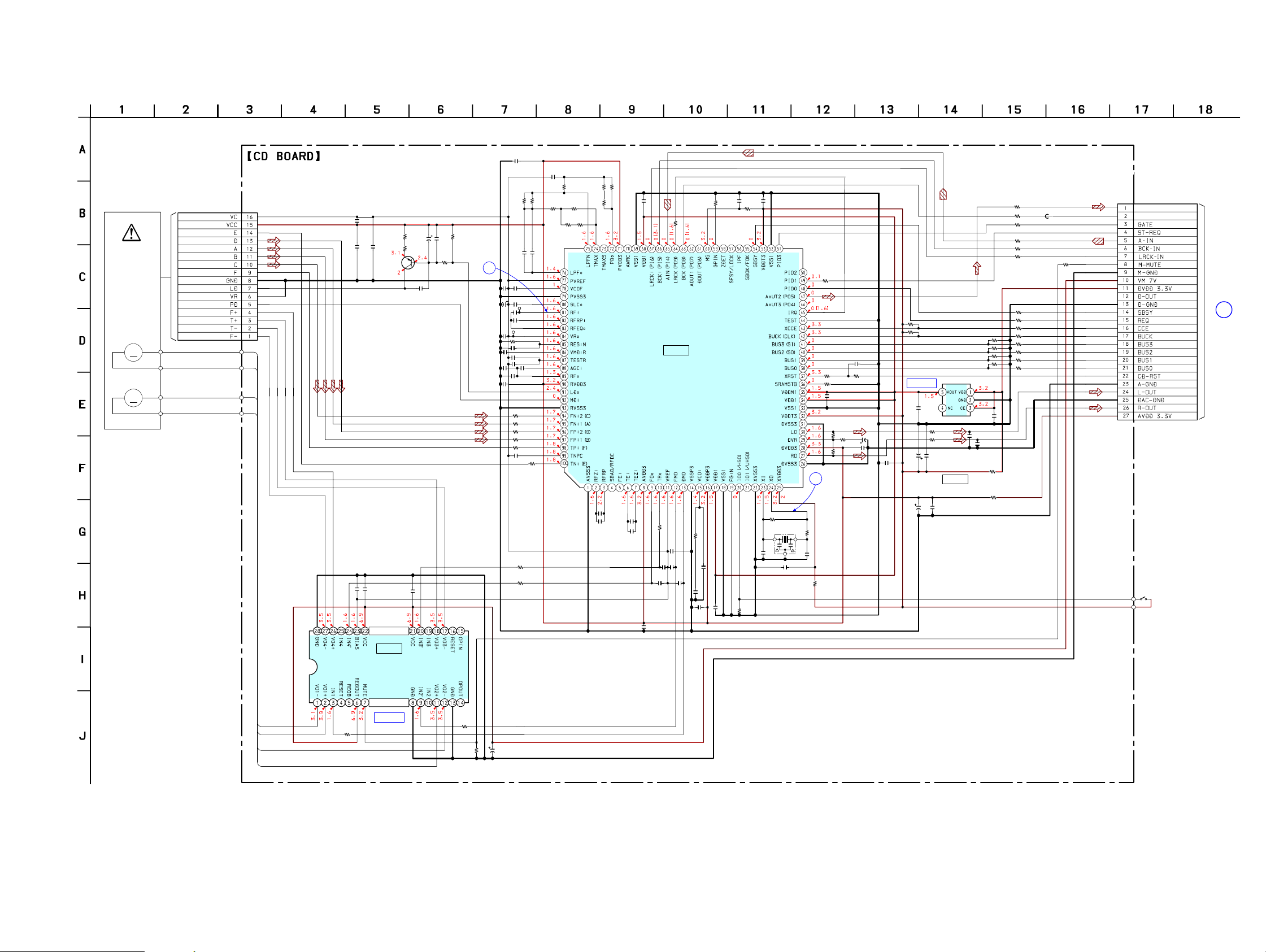

7-5. PRINTED WIRING BOARD – CD Board –

1 2 3 4 5 6 7 8 9 10

A

CD BOARD

(COMPONENT SIDE)

C401

B

C405

C

R213

C201

R216

R121

C115

D

R211

C207

IC201

135

E

C206

R201

4

C205

C202

C204

F

• See page 27 for Circuit Boards Location.

R415

R118

C153

R112

R111

X102

R212

R214

C108

R119

C133

R155

C130

C128

C112

R114

C309

Q301

R302

E

C307

R303

R304

R301

1-872-620-

: Uses unleaded solder.

C106

C306

11

(11)

CD BOARD

TP124(VC)

C122

R140

C123

R142

R143

R151

C138

C140

TP121

(RFI)

C141

R144

C143

C144

C148

C149

(CONDUCTOR SIDE)

M401

(SLED)

C125

C124

R139

C137

C146

C139

C142

R148

C150

C147

R136

R135

C145

R146

R134

C118

C104

R145

R147

R149

R150

R129

R128

R130

C100

C105

C117

CN301

C136

C135

C120

C107

C119

M

IC101

C102

C101

C113

C103

R101

C126

C127

R109

R108

C303

R106

R102

C301

R402

R105

C302

R414

C109

(LIMIT)

C110

R154

R104

C132

S201

C116

R153

C404

IC401

R110

R220

R221

R222

R223

R210

R209

R218

R219

R408

R157

R156

C403

R224

R208

R207

R206

R205

R204

R203

R202

R405

C151

C152

CN202

M

M402

(SPINDLE)

A

MAIN BOARD

CN302

(Page 37)

HCD-GT22/GT44/GT55

X102

OPTICAL PICK-UP

BLOCK

(KSM-213DCP)

1-872-620-

11

(11)

2828

HCD-GT22/GT44/GT55

7-6. SCHEMATIC DIAGRAM – CD Board –

CN301

16P

OPTICAL

PICK-UP

BLOCK

(KSM-213DCP)

M401

(SPINDLE)

M

M402

(SLED)

M

SP-

SP+

SL+

SL-

• See page 36 for Waveforms. • See page 58 for IC Block Diagrams. • See page 61 for IC Pin Function Description.

C107

0.1

Q301

2SA2119K

AUTOMATIC POWER

C301

0.1

C405

0.1

CONTROL

R303

C306

2.2

100

C303C302

1010

C404

0.1

10V

R304

2.2

C309

0.001

C403

0.1

R301

C307

100k

1

R302

0

R143

47k

C137

0.01

1

C100

0.1

C139

C106

100

10V

C105

0.1

C144

0.1

C148

47p

C104

0.1

C140

C141

C142

TP124 (VC)

R144

C143

C146

C145

C149

R405

10k

R402

2.2k

0.01

TP121 (RFI)

R145

R146

R147

R148

R149

C150

R142 R139

22k 47k

470p

C138

0.01

0.0022

0.1

22k

0.01

470p

0.01

0.1

C147

22p

0

0

0

0

0

0.001

R150

0

C136

47p

R129

1k

470k

R134

R140

1M

0

R136 R135

22k 470k

C112 C108

R130

4.7k

0.1 0.1

R128

0

R119

IC101

CD-MP3 PROCESSOR

IC101

TC94A70FG-008 (S, D)

C153

R118

100k

R114

0.1

10k

R121

100

0.1

C133

R112

100

100

R111

R110

10k

0.1

C110

R153

1M

R154

C115

47

R155

22

6.3V

0.1

C116

1M

2

C117

0.022

C119

0.022

C118

0.01

C120

0.01

0

R151

C123

470p

C122

470p

C101

0.1

220

R101

0.1

C102

0.0022

C127

0.0047

0.1

C124

C126

0.1

0.0047

C113

C125

C103

0.1

R105

16.9344MHz

5p

C128

R102

10k

1k

1M

R106

X102

5p

C130

C132

0.1

R104

0

CN202

R224 100

R109 100

R108

R216

100

R214 100

R213 100

R211

R212

100

R210

100

R209

100

R218

100k

R219

100k

R220

100k

R221

100k

R222

100k

R223

100k

R208

100

R207

100

R206

100

R205

100

R204

100

R203

100

100

27P

DATA

CLK

+

+

A

MAIN

BOARD

(3/4)

CN302

(Page 40)

IC B/D

C207

1

R157

100

R156

100

C205

C201

0.1

100

10V

C109

0.1

TK63115SCL-G@GT

IC201

+1.5V REGULATOR

C202

C204

100

0.1

10V

IC201

C206

1

C151

470p

470p

C152

R201

0

R202

0

S201

(LIMIT)

+

HCD-GT22/GT44/GT55

IC401

FOCUS/TRACKING COIL DRIVE,

SLED/SPINDLE MOTOR DRIVE

IC401

BA5826SFP-E2

SP-

SP+

R414

4.7k

IC B/D

SL+

SL-

R408

2.2k

C401

R415

220

47k

10V

2929

HCD-GT22/GT44/GT55

• Semiconductor

Location

Ref. No. Location

D701 E-7

D711 E-7

IC701 F-7

IC712 F-8

IC731 F-5

Q731 C-9

7-7. PRINTED WIRING BOARDS – CHANGE Section –

1 2 3 4 5 6 7 8 9 10

A

B

C

12

CN721

SENSOR BOARD

D

MOTOR (TB) BOARD

741

CN

1

731

3

CN

E

741

M

(TABLE)

M

F

• See page 27 for Circuit Boards Location.

MOTOR (LD) BOARD

M751

(LOADING)

M

1-687-133-

E

C

IC731

A

K

SW BOARD

12

(12)

S711

ROTARY ENCODER

DISC TABLE

ADDRESS DETECT

12

(12)

1-687-132-

: Uses unleaded solder.

DRIVER BOARD

2

N704

C

CN703

C751

1

737

C

C736

C735

723

4

1

R

R722

721

R

701

702

701

R

R

D

IC701

1

713

JW

714

JW

D711

705

N

N702

C

R733

734

R

R732

710

JW

C741

708

709

JW

JW

713

R

711

R

R

IC712

712

1

JW

736

R

704

JW

703

JW

702

JW

731

R

C

12

731

Q

E

711

707

JW

706

JW

705

JW

R751

752

C

712

JW

C715

B

701

CN

MAIN

BOARD

(Page 37)

HCD-GT22/GT44/GT55

9

S751

DISC TABLE

OPEN/CLOSE

DETECT

OPEN

G

742

CN

12

1-687-134-

(12)

CN751

CLOSE

2

1

JW

9

701

C731

1-866-201-

12

(12)

H

12

1-687-669-

(12)

3030

Loading...

Loading...