Sony HCDGRX-3 Service manual

HCD-GRX3/RX55/R300

SERVICE MANUAL

Ver 1.1 2001. 11

HCD-GRX3/RX55/R300 are the tuner, deck,

CD and amplifier section in MHC-GRX3/

RX55/R300.

photo : HCD-GRX3

Model Name Using Similar Mechanism HCD-G101

CD

SECTION

TAPE DECK

SECTION

CD Mechanism Type CX3

Base Unit Type KSM-213BCM

Optical Pick-up Type KSS-213B/S-N

Model Name Using Similar Mechanism NEW

Tape Transpor Mechanism Type

US Model

Canadian Model

HCD-RX55

E Model

HCD-GRX3/R300

Australian Model

HCD-GRX3

CWB44RR10

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS:

(U.S.A. model only)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION:

with 6 Ω loads both channels driven, from 70 – 20,000 Hz; rated 35 W per

channel minimum RMS power, with no more than 0.9% total harmonic

distortion from 250 mW to rated output.

Amplifier section

North American model

Continuous RMS power output

50 W + 50 W (6 Ω at 1 kHz, 10% THD)

Other models

The following measured at AC 110, 220 V 60 Hz;

DIN power output (Rated) 35 W + 35 W (6 Ω at 1 kHz, DIN)

Continuous RMS power output (Reference)

45 W + 45W (6 Ω at 1 kHz, 10% THD)

The following measured at AC 120, 240 V 60 Hz;

DIN power output (Rated) 40 W + 40 W (6 Ω at 1 kHz, DIN)

Continuous RMS power output (Reference)

50 W + 50W (6 Ω at 1 kHz, 10% THD)

Peak music power output (Reference)

600 W

Inputs

MD IN (phone jacks) : voltage 450 mV, impedance 47 kΩ

Outputs

MD OUT (phone jacks) : voltage 250 mV, impedance 1 kΩ

PHONES (stereo phone jack) :

accepts headphones of 8 Ω or more

SPEAKER : accepts impedance of 6 to 16 Ω

CD player section

System Compact disc and digital audio system

Laser Semiconductor laser (λ = 780 nm)

Emission duration: continuous

Laser output Max. 44.6 µW*

*This output is the value measured at a

distance of 200 mm from the objective

lens surface on the Optical Pick-up Block

with 7 mm aperture.

Frequency response 20 Hz – 20 kHz (± 0.5 dB)

Wavelength 780 – 790 nm

DIGIT AL OUT (OPTICAL)

(Square optical connector jack, rear panel)

Wavelength 600 nm

Output Level –18 dBm

Tape deck section

Recording system 4 -track 2 -channel stereo

Frequency response 40 – 13,000 Hz (± 3dB), using Sony

TYPE Ι cassette

— Continued on next page —

MINI Hi-Fi COMPONENT SYSTEM

9-922-804-12

2001K1600-1

© 2001.11

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

SERVICING NOTE

Antenna terminals 75 Ω unbalanced

Intermediate frequency 10.7MHz

AM tuner section

Tuning range 531 – 1,602 kHz (with AM tuning interval set

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

North American model:120 V AC, 60 Hz

Mexican model: 120 V AC, 50/60 Hz

Australian and South African models:

Other models: 110 – 120 V or 220 – 240 V AC,

Power consumption 100 W

Dimensions (w/h/d) incl. projecting parts and controls

Mass Approx. 9.5 kg (20 lb 15 oz.)

Supplied accessories: AM loop antenna (1)

Design and specifications are subject to change without notice.

at 9 kHz)

530 – 1,710 kHz (with AM tuning interval set

at 10 kHz)

220 – 240 V AC, 50/60 Hz

50/60 Hz (adjustable with voltage selector)

Approx. 280 × 320 × 400 mm

1

(11

/8 × 12 5/8 × 15 3/4 in)

Remote (1)

RM-SG7 (for HCD-GRX3/RX55)

RM-SG7B (for HCD-R300)

FM lead antenna (1)

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

This caution

label is located

inside the unit.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

— 2 —

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

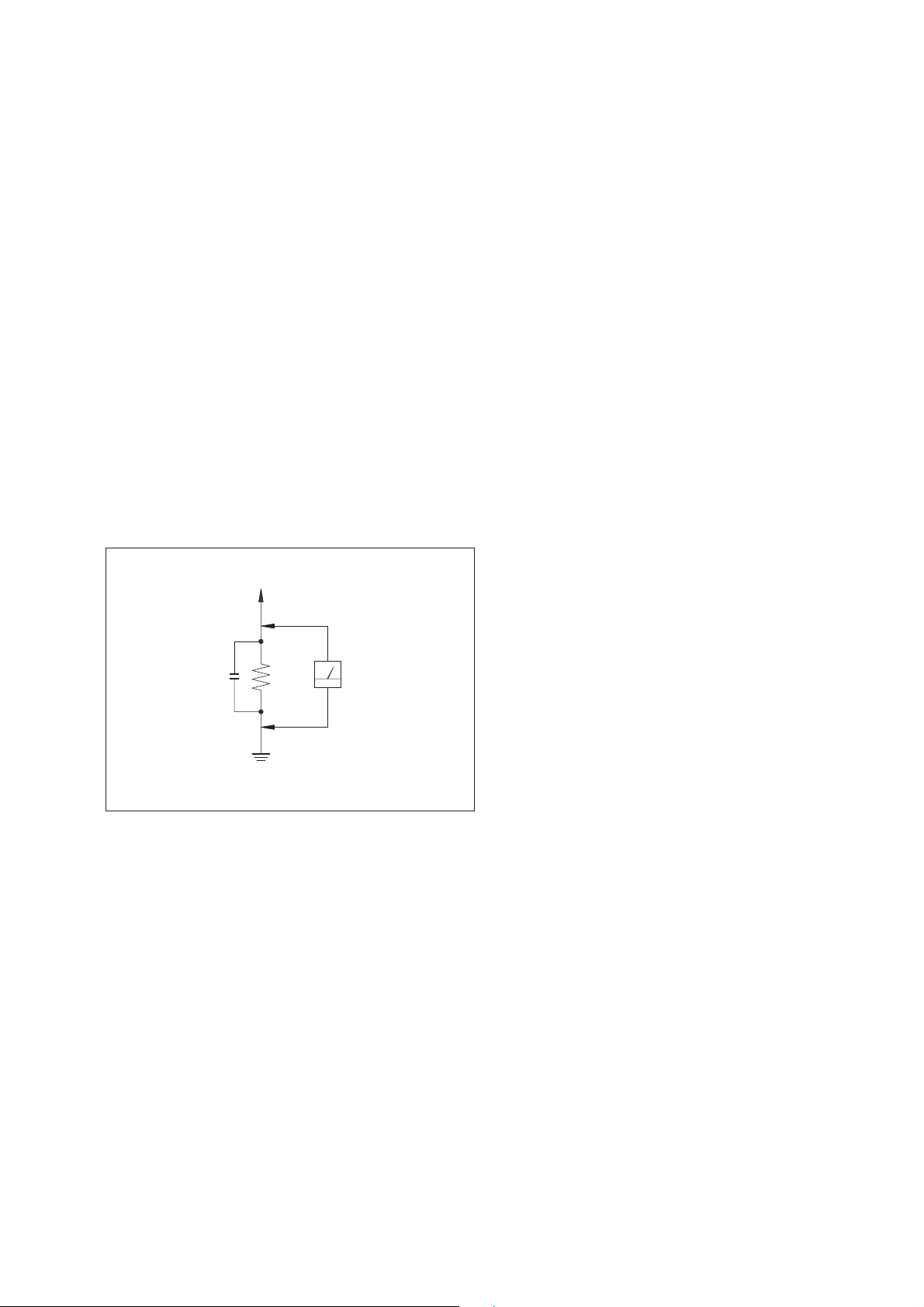

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

T o Exposed Metal

Parts on Set

AC

0.15

µ

F

1.5 k

Ω

Voltmeter

(0.75 V)

TABLE OF CONTENTS

1. GENERAL ..........................................................................4

2. DISASSEMBLY

2-1. Upper Cover and CD Door................................................. 5

2-2. Front Panel .........................................................................5

2-3. Main Board ......................................................................... 6

2-4. Amp Board ......................................................................... 6

2-5. CD Tray .............................................................................. 7

2-6. CD Decoder Board ............................................................. 7

2-7. Base Unit ............................................................................ 8

2-8. Cassette Door .....................................................................8

3. MECHANICAL ADJUSTMENTS ............................... 9

4. ELECTRICAL ADJUSTMENTS .................................9

5. DIAGRAMS

5-1. Circuit Boards Location ................................................... 14

5-2. Block Diagrams

• Deck Section ................................................................... 15

• CD Section ...................................................................... 17

5-3. IC Block Diagrams ........................................................... 19

5-4. Printed Wiring Board —CD Section — ........................... 24

5-5. Schematic Diagram — CD Section — ............................. 29

5-6. Schematic Diagram —Panel Section — .......................... 33

5-7. Printed Wiring Board —Panel Section —........................ 37

5-8. Printed Wiring Board — Deck Section — ....................... 42

5-9. Schematic Diagram —Deck Section — ........................... 47

5-10. Schematic Diagram —Main Section — ........................... 51

5-11. Printed Wiring Board —Main Section — ........................ 55

5-12. Printed Wiring Board — Amp Section — ........................ 60

5-13. IC Pin Function ................................................................ 65

Earth Ground

Fig. A. Using an A C v oltmeter to check A C leakage.

6. EXPLODED VIEWS

6-1. Cabinet Section................................................................. 67

6-2. Front Panel Section .......................................................... 68

6-3. Cassette Mechanism Deck Section................................... 69

6-4. CD Mechanism Deck Section 1 ....................................... 70

6-5. CD Mechanism Deck Section 2 ....................................... 71

6-6. Base Unit Section (KSM-213BCM)................................. 72

7. ELECTRICAL PARTS LIST ........................................ 73

— 3 —

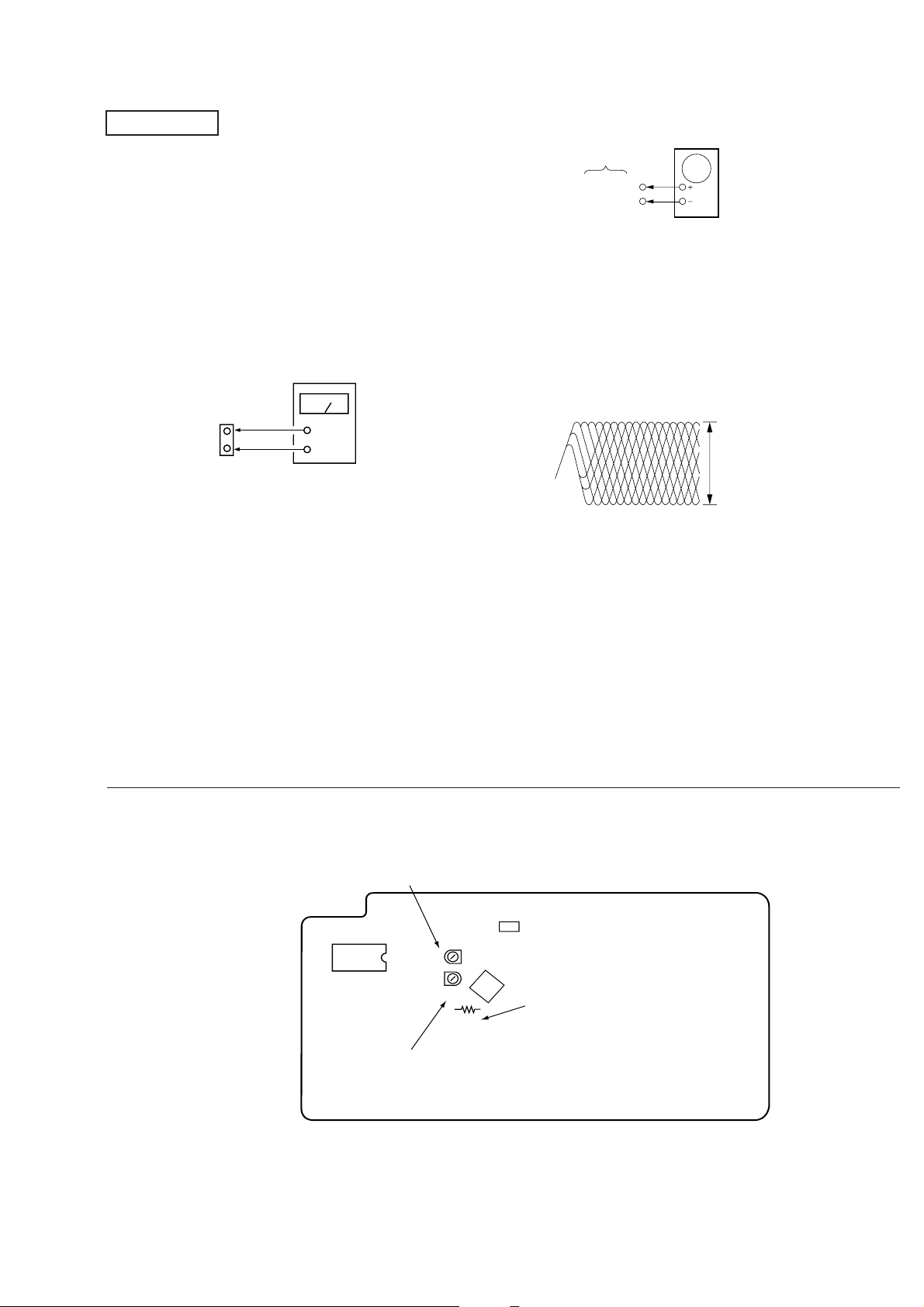

LOCATION OF PARTS AND CONTROLS

SECTION 1

GENERAL

#¡

#º

@ª

@•

@¶

@§

@∞

@¢

@£

@™

@¡

@º

1

23

4

5

6

7

8

9

0

!¡

!™

!£

!¢

!∞

!ª

1 DISC 1 button

2 DISC 2 button

3 DISC 3 button

4 DISC SKIP button

5 § OPEN/CLOSE button

6 · (TAPE B)

7 · ∏ (CD) button

8 TUNER/BAND button

9 r REC button

!º ∏ PAUSE button

!¡ CD SYNC button

!™ STEREO/MONO button

!£ VOLUME

!¢ REPEAT/MEMORY button

!∞ ‚ + button

!§ DECK B

!§

!¶!•

!¶ JOG DIAL

!• π (STOP) button

!ª DECK A

@º º – button

@¡ DBFB button

@™ SURROUND button

@£ FILE SELECT button

@¢ DISPLAY/DEMO button

@∞ EDIT/DIRECTION button

@§ PLAY MODE button

@¶ FUNCTION

@• ª (TAPE A) button

@ª I/u (POWER) button

#º · (TAPE A) button

#¡ ª (TAPE B) button

— 4 —

SECTION 2

s

e

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. UPPER COVER AND CD DOOR

6

CD door

2

Three screws

claws

4

Upper cover

3

Seven screw

1

Three srews

2-2. FRONT PANEL

5

Pull out the CD tray and remove the

CD door with releasing craws into the

directioin of arrow.

4

Flat type wire

(CN09)

5

Front panel

1

Three screws

— 5 —

2

Connector

(CN302)

3

Flat type wir

(CN09)

2-3. MAIN BOARD

5

MAIN board

4

Harness (CN08)

3

Harness (CN302)

2

Harness (CN701)

1

Five screws

2-4. AMP BOARD

5

AMP board

4

Three screws

1

Two screws

2

Three screws

— 6 —

3

Three screws

e

2-5. CD TRA Y

2

Bracket

1

Screw

6

CD tray

4

Bracket

5

(CN06)

3

Screw

Flat type wir

2-6. CD DECODER BOARD

6

CD decoder board

claws

2

Two screws

3

Flat cable

5

Connector

4

Flat cable

— 7 —

1

Two screws

2-7. BASE UNIT

5

UD-Cam

4

Screw

2

3

Screw

UD-gear

7

Spring

2-8. CASSETTE DOOR

8

Spring

9

Base unit

6

Spring

1

Two screws

— 8 —

Cassette door

(Note: Four claws are used.)

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback head pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

Torque

FWD

FWD

back tension

FF/REW

Torque meter

CQ-102C

CQ-102C

CQ-201B

Meter reading

40 to 70 g • cm

(0.56 - 0.97 oz • inch)

1 to 5 g • cm

(0.01 - 0.07 oz • inch)

55 to 140 g • cm

(0.76 - 1.94 oz • inch)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head

damagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

Tape

P-4-A100

WS-48B

Record/Playback Head Azimuth Adjustment

(Deck A, Deck B)

Note: Perform this adjustments for both decks.

Procedure:

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

Signal

10 kHz, –10 dB

3 kHz, 0 dB

SPEAKER

terminal (JK301)

Used for

Azimuth Adjustment

Tape Speed Adjustment

level meter

set

+

–

— 9 —

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 2 dB of peak.

L-CH

peak

screw

position

R-CH

peak

output

level

within

2dB

L-CH

peak

R-CH

peak

within 2dB

screw

position

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

SPEAKER

terminal (JK301)

(L-CH)

oscilloscope

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location:

Adjustment screws

REC/PB head (deck A)

or PB head (deck B)

Tape Speed Adjustment (Deck A)

Procedure:

1. Mode: Playback

test tape

WS-48B

(3kHz, 0dB)

set

frequency counter

+

–

L

set

R

SPEAKER

terminal (JK301)

(R-CH)

Waveform of oscilloscope

in phase 45˚ 90˚ 135˚ 180˚

good

wrong

SPEAKER

terminal (JK301)

2. Adjust the SFR501 so that the frequency counter reads 3,000

Hz ± 90Hz.

Adjustment Location: DECK board

Sample Value of Wow and flutter

W. RMS (JIS) within 0.3%

(test tape: WS-48B)

[DECK BOARD] — Component side —

Tape Speed

CN501

SFR501

— 10 —

TUNER SECTION 0 dB=1µV

AM T uning Voltage Adjustment

Main board

TP1

F

G

VT

DC voltmeter

+

–

Procedure:

1. Set the reception frequency of the unit to 530 kHz.

2. Adjust L105 for 1.2 ± 0.05 V reading on the DC voltmeter.

3. Set the reception frequency of the unit to 1,710 kHz.

4. Confirm that the voltage reading on the DC voltmeter is within

8.0 ± 0.5 V.

Adjustment Location: MAIN board (See page 12)

AM Trac king Adjustment

loop antenna

AM RF SSG

30% amplitude

modulation by

400 Hz signal

60 cm

Field strength dB (

µ

V/m) =SSG output level dB (µV/m) –26 dB.

loop antenna

(Supplied accessories)

set

AM ANTENNA

terminal (JK101)

Procedure:

1. Tune the set to 600 kHz.

2. Set the output of AM RF SSG so that the input level of the set

will become 60 dB (µV/m).

3. Adjust L104 so that when the waveform on the oscilloscope is

maximum, no noise appears.

4. Tune the set to 1,400 kHz.

FM T uning Voltage Adjustment

Main board

TP1

IF

G

VT

DC voltmeter

+

–

Procedure :

1. Set the reception frequency of the unit to 87.5 MHz.

2. Adjust L103 for 1.2 ± 0.05V reading on the DC voltmeter.

3. Set the reception frequency of the unit to 108 MHz.

4. Confirm that the voltage reading on the DC voltmeter is within

7.8 ± 0.5V.

5. Adjust CT102 so that when the waveform on the oscilloscope

is maximum, no noise appears.

• Repeat the procedures in each adjustment several times, and the

tracking adjustment should be finally done by the trimmer

capacitors.

Adjustment Location: MAIN board (See page 12)

Adjustment Location: MAIN board (See page 12)

— 11 —

FM Trac king Adjustment

FM Tuned Level Adjustment

Procedure:

FM RF SSG

set

SPEAKER terminal (JK301)

FM ANTENNA terminal (JK101)

Carrier frequency: 90 MHz, 106 MHz

Modulation : AUDIO 1kHz, 75kHz deviation (100%)

Output level : 20 dB (at 75

Ω

open)

oscilloscope

1. Tune the set to 90 MHz.

2. Adjust L102 so that when the waveform on the oscilloscope is

maximum, no noise appears.

3. Tune the set to 106 MHz.

4. Adjust CT101 so that when the waveform on the oscilloscope

is maximum, no noise appears.

• Repeat the procedures in each adjustment several times, and the

tracking adjustment should be finally done by the trimmer

capacitors.

Adjustment Location: MAIN board

FM RF SSG

75

Ω

coaxial

set

Carrier frequency : 98 MHz

Modulation : AUDIO 1 kHz, 75 kHz

Output level : 28 dB (at 75

deviation (100%)

Ω

open)

FM ANTENNA terminal

(JK101)

Procedure:

1. Supply a 28 dB 98 MHz signal from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Adjust SFR101 to the point (moment) when the TUNED

indicator will change from going off to going on.

Adjustment Location: MAIN board

Adjustment Location

[MAIN BOARD] — Component side —

IC103

FM Tyned Level

SFR101

TP1

IC102

AM Tuning

Voltage

L105

FM Tuning

Voltage

CT102

IC101

L103

L102

CT101

AM

Tracking

L104

JK101

FM

Tracking

JK301

— 12 —

CD SECTION

Note:

1. CD Block is basically constructed to operate without

adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

5. Adjust the focus bias adjustment when optical block is replaced.

Focus Bias Adjustment

CD DECODER

board

CN12

FEO

VC

Procedure:

1. Connect DC voltmeter to test point CN12 (FEO), (VC) on CD

DECODER board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and stop.

4. Adjust VR01 so that the DC voitmeter reading is 0 ± 20 mV.

DC voltmeter

+

–

RF Level Check

CD DECODER

board

TP (RF)

CN12 (VC)

oscilloscope

Procedure :

1. Connect oscilloscope to test point TP (RF) on CD DECODER

board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

level: 1.0 Vp-p

+0.3

–0.2

Adjustment Location: CD DECODER board

Adjustment Location: CD DECODER board

Focus Gain Adjustment (VR02)

This gain has a margin, so even if it is slightly off.

There is no problem.

Therfore, do not perform this adjusment.

Please note that it should be fixed to mechanical center position

when you moved and do not know original position.

Adjustment Location

[CD DECODER BOARD] — Component side —

Focus Gain

VR02

IC03

VR01

R07

CN12

IC01

RF Level

Focus Bias

— 13 —

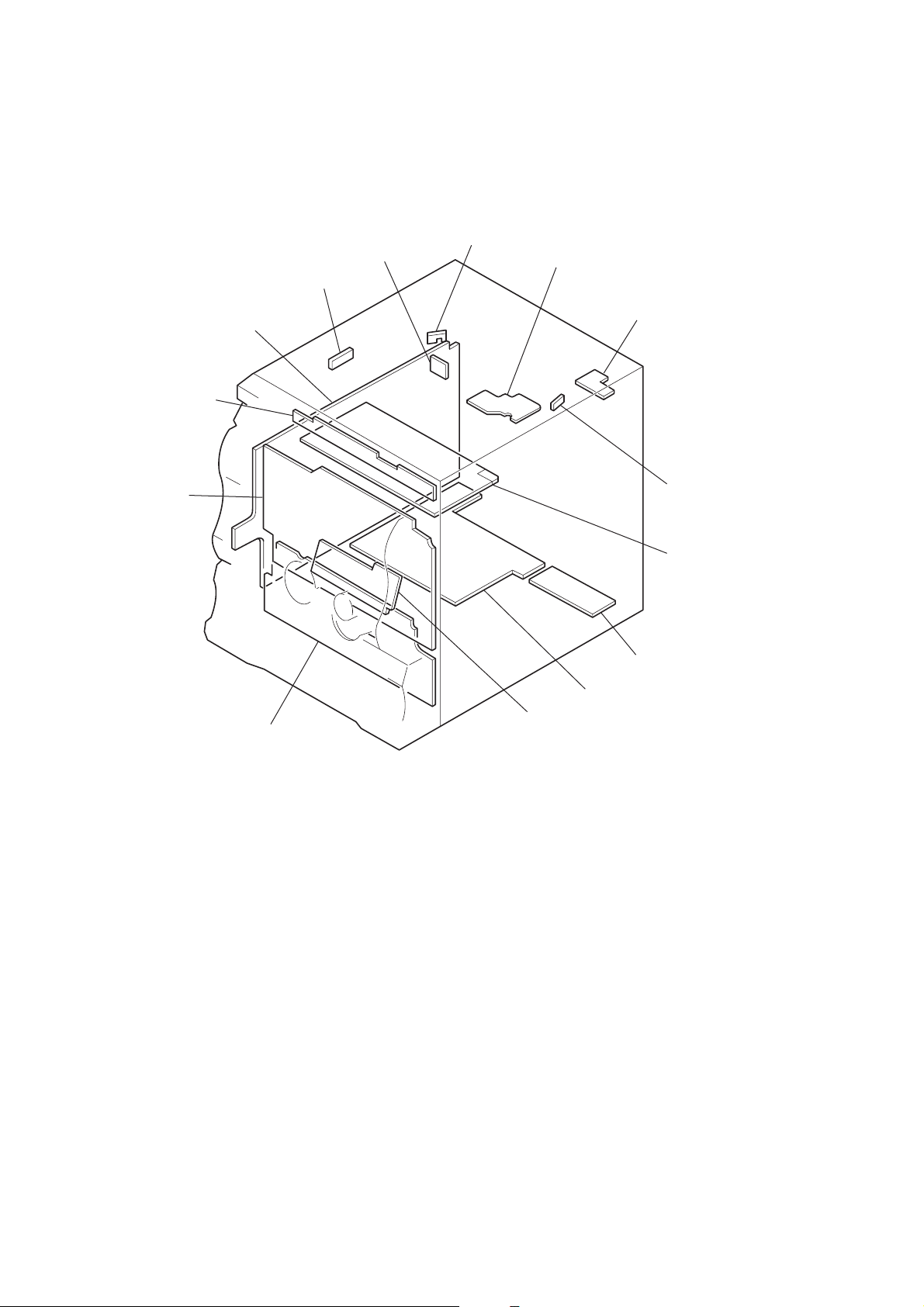

5-1. CIRCUIT BOARDS LOCATION

d

SW (C) board

SECTION 5

DIAGRAMS

SW (D) board

SW (B) board

MOTOR (6P) (S) board

CD BUTTON board

PANEL board

MAIN board

DECK board

MOTOR board

SW (A) board

CD DECODER boar

FUSE board

AMP board

VOLUME board

— 14 —

5-2. BLOCK DIAGRAMS

HCD-GRX3/RX55/R300

— DECK SECTION —

JK301

MD L

LINE

OUT L

TAPE B

HP901

PB

HEAD

R CHR CH

TAPE A

HRP901

REC/PB

HEAD

HE901

ERASE

HEAD

TU L

ST IND

A

TU MUTE

TUNER

SECTION

B

CD

SECTION

MECHA BLOCK

MTR +12V

SOL A

SOL B

SOL B

MOTOR H

MOTOR L

REC FWD

REC REV

PHOTO A

PHOTO B

MODE A

MODE B

HALF A

HALF B

16

CD L

SCOR

SENS

SQSO

XLAT

SQCK

DATA

COUNT

FOK

CLK

STB

DO

DI

CE

Q501,502

MOTOR

B+ SW

+12V

Q505,506

SOL A

DRIVE

Q503,504

SOL B

DRIVE

SFR 501

TAPE

SPEED

R CH

Q203,205

PLAY/REC

CONTROL

Q207

PLAY/REC

CONTROL

DRIVE

D202

Q208,209

BUS REGISTER

4

PLAY

5

SOL A

6

SOL B

SHIFT REGISTER

3

F REC

4

R REC

5

PHOTO A

6

PHOTO B

11

A MODE

12

B MODE

13

A HALF

14

B HALF

Q201

PLAY/REC

CONTROL

CONTROL

SWITCH

IC501

REC MUTE

IC502

D201

REC

BIAS

STB

CLK

SELECTOR

IC301

DI

CLK

36

ALATCH

Q605,615

SW

11

9

10

12

CONTROL

CLK14DI15CE

13

CLKDICE

LED DRIVE

IC603

1

12

3

17

2

LED DRIVE

IC602

13

2

11

3

12

4

10

5

SYSTEM CONTROLLER/

FLD DRIVER

PIC UP55PIC DOWN56TRAY OPEN

MODE

13

S01

CD DECK

UP/DOWN

DET

IC601

IC302 (1/2)

11 10

IC302 (2/2)

9 8

Q551,552

AMS

MUTE

24

4

DI1

SCOR

TU MUTE

VR DOWN

45

A

B

12

6

47

61

FM ST IND

JOG A49JOG B

VR612

MULTI JOG

Q417

AMS

50

62

6

TAPE REC

B

Q301

SERI MUTE

SW101

10k

5

SURROUND

+5.6V

9k

REC/PB

EQ AMP

IC201

3

1

2

9

BIAS

OSC

Q251

Q251

43

42

41

+12V

26

DECK STB

DECK DATA

DECK S/L

TAPE A/B

STB

L251

BIAS OSC

R CH

Q252,253

BIAS

SWITCH

14

12

A/B

11

13

S/I

Q'S

QH

S/L

DO

2

CLK

3

10

1

2

9

1

CE

21CE22

CLK

CLK

A/B

REC OUT

19

DO

23DO52

PB OUT

MIX OUT

FOK

12

12

4.19MHz

53

COUNT

X601

5

6

11

10

Q213

REC

MUTE

18

19

51

20

SQCK

38

XLAT

SENS

SQSO

VR UP

44

A

VR601

VOLUME

17

DATA

X211X1

LT COM

4

Q307

SURROUND

CONTROL

Q310

LED606-611

LED605

Q606,607

LED

DRIVE

Q608-613

LED

DRIVE

OPEN/CLOSE

3 2

LED601-604

TRAY CLOSE

59

60

S02

TRAY

DET

DISC COUNT

57

S03

DISC

COUNTER

DET

7

8

DBFB HIGH

DBFB NORMAL

3

SYSTEM MUTE

TURN TABLE

58

S04

TURNTABLE

OPERATION

DET

1

Q602

Q602

NORMAL

Q603

MUTE

SWITCH

RESET

SWITCH

10

Q331

HIGH

Q308

RESET

KI0 KI4

KEY

MATRIX

S601-628

LINE AMP

IC303

4

3

Q604

MUTE

Q601

Q601

2

POWER

DOWN DET

15

POWER DOWN

Q410

MUTE

DRIVE

RM601

CONTROL

RECEIVER

3

REMOTE

2

39

HP AMP

IC401

3

D602

REMOTE

64 78

1

Q408

MUTE

Q709

MUTE

+30V

-30V

-12V

-27V

+7.5V

+11.5V FILTER

+11.5V

(SWITCHED)

P1 P21

.

81 8533 29

FLD601

FLD DISPLAY

POWER AMP

IC401

1

G1 G15

100 86

10

Q401

-12V

REG

Q702

+7.5V

REG

Q409

+5.6V

REG

Q403

Q415,416

SITCHING

2

POWER

Q703

-27V

REG

Q701

+12V

REG

Q713

P MUTE

CONT

Q706

D718

D720

Q708

1

2

Q714

AC OFF

DET

D701

RECT

D731,732

VOLTAGE

DOUBLER

D705-708

RECT

+12V

IC402

SPEAKER

RELAY

DRIVE

4

Q404

AC3.4V

AC3.4V

R CH

SP

DET

RL701

6

PT001

AC

IN

JK303

PHONES

JK302

SPEAKER

• RCH is omitted

• Signal Path

: PB (DECK A)

: PB (DECK B)

: REC (DECK A)

: FM

: CD

: MD

— 15 — — 16 —

HCD-GRX3/RX55/R300

— TUNER/CD SECTION —

JK101

ANTENNA

75Ω

AM

DET

DET

AGC

FM

IF

FM

AM

SMET

20

FM/AM MPX

IC102

AM

OSCAMMIX

PL DET

PH DET11PH DET

TU LED

13

6

L

CF103

450kHz

14

R

15

R CH

Q117

MUTE

AM/FM

IF BUFF

12

MUTE

FM DET

MPX VCO

AM

IF

ST IND

AM/FM

DECODER

CF104

8

10.7MHz

CF105

17

19kHz

4

T102

AM IFT

2

7

10

TU L

ST IND

TU MUTE

DI

A

MAIN

SECTION

• R CH is omitted

• SIGNAL PATH

:FM

:AM

:CD

:DIGITAL OUT

1

3

FM FRONT END

IC101

RF MIX

OSC

D106

CF101

10.7MHz

Q102

AMP

Q108

AM RF

AMP

Q112,113

L.P.F

7.2MHz

X101

Q101

RF IF

AMP

IF

G

VT

TP1

AM/FM

TUNING

VOLTAGE

19

21

17

24

1

SFR101

FM

TUNED

LEVEL

FM

PD1

FM B+

XO

XI

CF102

10.7MHz

PLL

IC103

ST/MONO

MW OSC

B+

AM/FM

L CTR

R CTR

CLK

FM IF

1

MPX

16

AF DET

18

L105

OSC

23

AFC

22

AM RF

21

OSC/FMSD

24

AM

18

12

SD

SD

7

14

13

15

16

DI

5

DO

DO

3

DI

CLK

4

CE

2

CE

T101

6

8

FM OSC

L103

TUB+

Q114

B+

L101

FM

FM ANT

D105

L104

AM ANT

L102

FM RF

OPTICAL PICK-UP

DETECTOR

TRACKING

16

BLOCK

LD

PD

FOCUS

COIL

COIL

7

8

4

1

2

5

6

10

GND

VR

MOTOR

SPINDOL

MOTOR

MOTOR

MOTOR

VC

A

C

B

D

E

F

LD

PD

F+

F

T+

T

M102

SLED

M101

T/T

TRAY

+5V

M

M

M

M

F/T COIL

SL/SP MOTOR

T.T/TRAY MOTOR

DRIVER

IC03

4

F+

3

F

2

T+

1

T

REG OUT

18

SL+

17

SL

SP+

20

SP

19

T.T F IN

14

T.T+

T.T R IN

T.T

15

TR F IN

TR+

30

TR T IN

TR

31

MUTE IN

F IN

T IN

VCC

VCC

REG I

REG B

SL IN

SP IN

6

5

8

7

9

10

11

22

21

13

12

29

28

27

Q02

LD ON

SWITCH

Q01

APC

CN2

CN12

Q11

REG

42

1

45

48

35

36

39

38

33

34

TEO

FEO

ATSC

VC

PD1

PD2

E

F

LD

APC

PD

PD

FE BIAS EI

RV01

FOCUS

TRACKING

+7.5V

+5V

RF

AMP

COMAND

FE

AMP

SERIAL/

PARALLEL

CONVERTER

DECODER

FOCUS PHASE

COMPENSATION

FEO TAO

6

37 40

16

IC01 (2/2)

IC06

RV02

FOCUS

GAIN

14

67

CD RF/SERVO

PROSSESOR

IC01 (1/2)

IIL

TTL

TTL

IIL

TRACKING PHASE

COMPENSATION

13

RFO

FOK

C OUT

SENS

DATA

XLT

CLK

XRST

Q04

SWITCH

+5V

PH01

2

Q311

MUTE

VDD

D IN

GND

OPTICAL

DIGITAL

OUT

CD L

SCOR

SENS

SQSO

XLAT

SQCK

DATA

COUNT

FOK

DO

CLK

CE

STB

B

MAIN

SECTION

(Page)

3

1

CD DIGITAL

SIGNAL PROCESSOR

IC703

D/A

I/F

RF

DO

CLK

36

FOK

23

CN

14

SE

13

DAT

15

XLT

16

CLK

17

8

XRST

MDP

25

31

25

23

24

21

20

19

22

T.T/TRAY

MOTOR DRIVE

REG CONTROL

IC02

XRST

SPEED

T.T

TR+

TR

CONTRL

MUTE

DATA

CLOK

STB

4

2

3

1

6

11

714T.T+

13

14

5

CLV

SERVO

DIGITAL

CLV

EFM

DEMO.

SUB CODE

PROSSESOR

CPU I/F

XLON

CLOCK

DATA

SQCK

9 11 5 4 7 61

22

XLAT

10

SQSO

SENS

SCOR

SERIAL

I/F

MUTE

S05

LIMIT

SWITCH

PWM

PWM

PWM

PWM

CLOCK

GEN.

SPOA

18

D OUT

XTA1

XTA0

61

NL

NR

MIX AMP

IC05

70

2

1

3

L

69

77

R

R-CH

78

73

X701

74

— 17 — — 18 —

5-3. IC BLOCK DIAGRAMS

+

–

3

6

9

12

15

2

5

8

11

14

1

4

7

10

13

28

25

22

19

16

29

26

23

20

17

30

27

24

21

18

+

–

+–+

–

LATCH

DECODER

CONTROL

SHIFT

REGISTER

–

+

LVROUT

LVRIN

LTOUT

LTCOM

LT4

LT3

LT2

LT1

L4

L3

L2

L1

VDD

CL

DI

RVROUT

RVRIN

RTOUT

RTCOM

RT4

RT3

RT2

RT1

R4

R3

R2

R1

VREF

VSS

CE

CH2/A CH2/B NF VCC CG NF ALC

METAL

OUT

PRE

OUT

TAPE A

/TAPE B

REC

OUT

REC

IN

CH1/A CH1/B NF GND1 M/H NF

CH2

CH2

ALC

M/N

CH1

GNDGND

CH1

+

–

+

–

+

–

+

–

A/B

GNDMETAL

OUT

PRE

OUT

MIX

OUT

REC

OUT

REC

IN

IREF

VREF2

VREF1

24 23 22 21 20 19 18 17

16

15 14 13

123456789101112

HCD-GRX3/RX

IC03 (CD DECORD BOARD) BA5941FP

IN4B

IN4A

27

28

1 2

VCC

BIAS IN

IC02 (CD DECORD BOARD) TC9173P

CONTROL

T.T(M)

POSI.1

POSI.2

T.T.SW

GND

MUTE

XRST

1

2

3

4

5

6

7

8

IN3B

26

3

IN1B

DRIVER

IC01 (CD DECORD BOARD) CXA1782BQ IC101 (MAIN BOARD) LA1186

PHD2

37FE BIAS

38F

39E

40EI

41VEE

42TEO

43LPFI

44TEI

45ATSC

46TZC

47TDFCT

48VC

PHD1

36

35 34

IN3A

OP OUT

OP IN (–)

OP IN (+)

24

25

–

+

+

–

4

5

IN1A

IN2B

LATCH

23

6

IN2A

C

22

+

–

–

+

+

–

7

SERIAL I/O

CONTROL

GND

GND

NC

VCC

T

21 20

MUTE

8

GND

LATCHLATCH

NC

9

MUTE

19

Vcc

VccVcc

10

VCC

DRIVER

OUT3A

18

–

+

LEVEL SHIFT

LEVEL SHIFT

+

–

11

OUT2A

+

+

12 13

16

VDD

15

STB

14

CLOK

DATA I

13

12

DATA 0

11

LOADING

M-

10

LOADING

M+

SENSOR

9

OUT3B

–

–

OUT2B

OUT4A

1617

–

+

LEVEL SHIFT

LEVEL SHIFT

+

–

OUT1A

+

+

OUT4B

15

–

–

14

OUT1B

— 19 — — 20 — — 21 — — 22 — — 23 —

F IV AMP

BAL1

BAL2

TOG1

TOG2

• WINDOW COMP

PHD

–

+

–

+

APC

+

RF IV AMP1

RF IV AMP2

–

+

–

+

E IV AMP

BAL3

TOG3

ATSC

–

+

LD

33

–

–

+

+

–

FE AMP

+

–

TE AMP

1

FEO

RF M

32

–

+

–

+

LEVELS

+

–

FOK

TTL

IIL

FZC COMP

DFCT

3

2

FEI

FDFCT

DFCT

FS4

31

–

–

+

–

+

–

+

+

–

TZC COMP

RF O

–

+

RF I

30

–

+

+

+

–

MIRR

• IIL DATA RESISTOR • INPUT SHIFT RESISTOR

TOG1-3 FS1-4 TG1-2 TM1-7 PS1-4

BAL1-3

–

+

HPF COMP LPF COMP

• FCS PHASE

COMPENSATION

TM1

5

4

FLB

FGD

–

+

FS2

+

–

6

FE O

+

–

• ADDRESS DECODER

• OUTPUT DECODER

TG1

FS1

7

FE M

CB

29CP28

DFCT

• TRACKING

• PHASE

COMPENSATION

9

8

SRCH

TGU

–

TM7

TG2

+

TM6

TM5

TM4

TM3

CC126CC225FOK

27

–

+

24 SENS

IIL

TTL

23 C. OUT

22 XRST

TTL

21 DATA

20 XLT

IIL

19 CLK

18 VCC

• ISET

• F SET

11

10

TG2

FSET

TM2

17 ISET

–

16 SL 0

+

15 SL M

14 SL P

+

1312TA O

–

TA M

IC201 (MAIN BOARD) TA8189N

IC301 (MAIN BOARD) LC75392

1

RF IN

2

3

4

5

6

7

8

9

RF

VREF

MIX

REG

OSC BUF

BYPAS

MIX IN

GND

GND

IF

AFC

OSC

VCC

IC602 (PANEL BOARD) BU2092

CONTROL

CIRCUIT

2 3

1

VSS

DATA

CLOCK

4

LCK

12 BIT

SHIFT

REGISTER

12 BIT

STORAGE

REGISTER

VDDOEQ11

1718

Q10Q9Q8Q7Q6

OUTPUT

BUFFER

(OPEN DRAIN)

5 6 7 8 9

Q0

IC603 (PANEL BOARD) BU2114

18

VDD

17

O1

SIN

1

CK

2

3

LATCH

SOUT

4

5

EN

RST

6

GND

7

8

GND

Q5

1016 15 14 13 12 11

Q4

Q3

Q2

Q1

ENABLE

SHIFT

REGISTER

LATCH

16

O2

15

O3

14

O4

13

O5

12

O6

O7

11

10

O8

9

GND

Loading...

Loading...