Sony HCD-GPX5G, HCD-GPX7G, HCD-GPX8G Schematic

HCD-GPX5G/GPX7G/GPX8G

SERVICE MANUAL

Ver. 1.0 2012.03

• HCD-GPX5G is the amplifi er, USB, CD player and tuner

section in MHC-GPX5.

• HCD-GPX7G is the amplifi er, USB, CD player and tuner

section in MHC-GPX7.

• HCD-GPX8G is the amplifi er, USB, CD player and tuner

section in MHC-GPX8. Photo: HCD-GPX8G (E2 Model)

“WALKMAN” and “WALKMAN” logo are registered

trademarks of Sony Corporation.

MPEG Layer-3 audio coding technology and patents licensed

from Fraunhofer IIS and Thomson.

Windows Media is either a registered trademark or trademark

of Microsoft Corporation in the United States and/or other

countries.

This product contains technology subject to certain

intellectual property rights of Microsoft.

Use or distribution of this technology outside of this product

is prohibited without the appropriate license(s) from

Microsoft.

Amplifi er section

The following are measured at Mexican model:

AC 120 V – 240 V, 60 Hz

Other models:

AC 120 V – 240 V, 50/60 Hz

MHC-GPX8

Front/Satellite speaker

Power Output (rated):

300 W + 300 W (at 4 ohms, 1 kHz,

1% THD)

Front speaker

RMS output power (reference):

360 W + 360 W (per channel at 6 ohms,

1 kHz)

Satellite speaker

RMS output power (reference):

180 W+ 180 W (per channel at 12 ohms,

1 kHz)

Subwoofer

RMS output power (reference):

260 W + 260 W (per channel at 8 ohms,

100 Hz)

MHC-GPX7

HIGH speakers

Power Output (rated):

300 W + 300 W (at 4 ohms, 1 kHz,

1% THD)

RMS output power (reference):

495 W + 495 W (per channel at 4 ohms,

1 kHz)

LOW speakers

RMS output power (reference):

180 W + 180 W (10 ohms, 100 Hz)

MHC-GPX5

Front speaker

Power Output (rated):

240 W + 240 W (at 5 ohms, 1 kHz,

1% THD)

RMS output power (reference):

370 W + 370 W (per channel at 5 ohms,

1 kHz)

Subwoofer

RMS output power (reference):

360 W (5 ohms, 100 Hz)

Inputs

TV (AUDIO IN) L/R

Voltage 1.2 V, impedance 47 kilohms

DVD/SAT (AUDIO IN) L/R

Voltage 1.2 V, impedance 47 kilohms

PC/GAME (AUDIO IN) L/R

Voltage 1.2 V, impedance 47 kilohms

MIC (MHC-GPX8/MHC-GPX7 only)

Sensitivity 1 mV, impedance

10 kilohms

A (USB), B (USB) port: Type A

USB section

Supported bit rate

MP3 (MPEG 1 Audio Layer-3):

32 kbps – 320 kbps, VBR

WMA: 48 kbps – 192 kbps

AAC: 48 kbps – 320 kbps

Sampling frequencies

MP3 (MPEG 1 Audio Layer-3):

32 kHz/44.1 kHz/48 kHz

WMA: 44.1 kHz

AAC: 44.1 kHz

CD Section

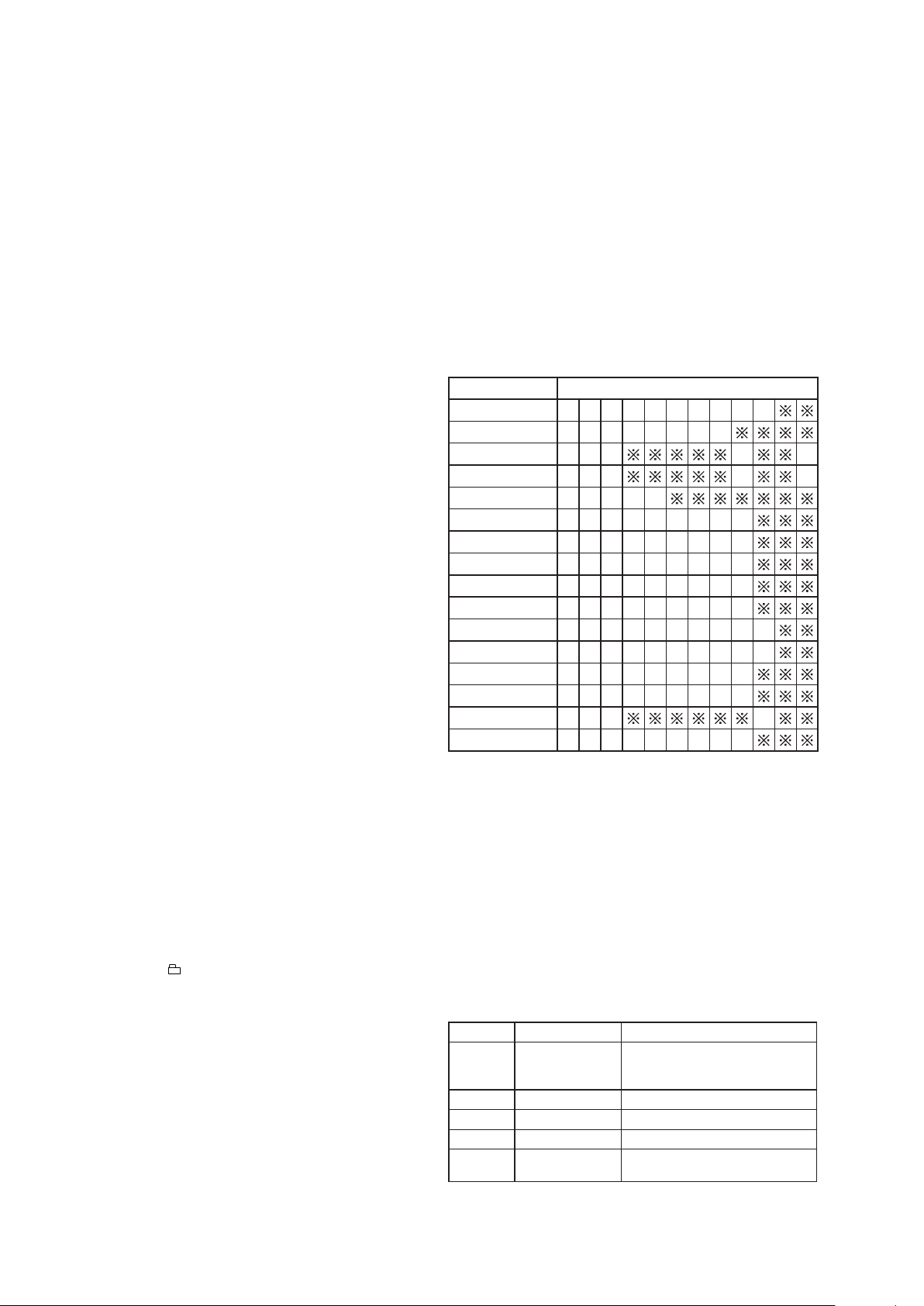

Model Name Using Similar Mechanism

CD Mechanism Type

Optical Pick-up Name

SPECIFICATIONS

Supported USB device

Mass Storage Class

Maximum current

500 mA

Disc player section

System

Compact disc and digital audio system

Laser Diode Properties

Emission Duration: Continuous

Laser Output*: Less than 44.6 μW

* This output is the value measurement

at a distance of 200 mm from the

objective lens surface on the Optical

Pick-up Block with 7 mm aperture.

Frequency response

20 Hz – 20 kHz

Signal-to-noise ratio

More than 90 dB

Dynamic range

More than 88 dB

Tuner section

FM stereo, FM/AM superheterodyne tuner

Antenna:

FM lead antenna

AM loop antenna

FM tuner section

Tuning range

87.5 MHz – 108.0 MHz (50 kHz step)

AM tuner section

Tuning range

Pan American models:

530 kHz – 1,710 kHz (10 kHz step)

531 kHz – 1,710 kHz (9 kHz step)

E Model

NEW

CDM74I-DVBU201//M

CMS-ST6RFS3

Other models:

530 kHz – 1,610 kHz (10 kHz step)

531 kHz – 1,602 kHz (9 kHz step)

General

Power requirements

Mexican model: AC 120 V – 240 V, 60 Hz

Other models: AC 120 V – 240 V, 50/60 Hz

Power consumption

MHC-GPX8: 250 W

MHC-GPX7: 230 W

MHC-GPX5: 200 W

Dimensions (w/h/d) (excl. speakers)

(Approx.)

280 mm × 355 mm × 440 mm

Mass (excl. speakers) (Approx.)

HCD-GPX8G/HCD-GPX7G/

HCD-GPX5G: 7.0 kg

Supplied accessories

Remote control (1)

R6 (Size AA) batteries (2)

FM lead/AM loop antenna (1)

Spacer A (MHC-GPX8 only) (2)

Spacer B (MHC-GPX8 only) (2)

Speaker pads (MHC-GPX7 only) (8)

Design and specifi cations are subject to change

without notice.

9-890-600-01

2012C08-1

2012.03

©

COMPACT DISC RECEIVER

Sony Corporation

Published by Sony EMCS (Malaysia) PG Tec

HCD-GPX5G/GPX7G/GPX8G

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

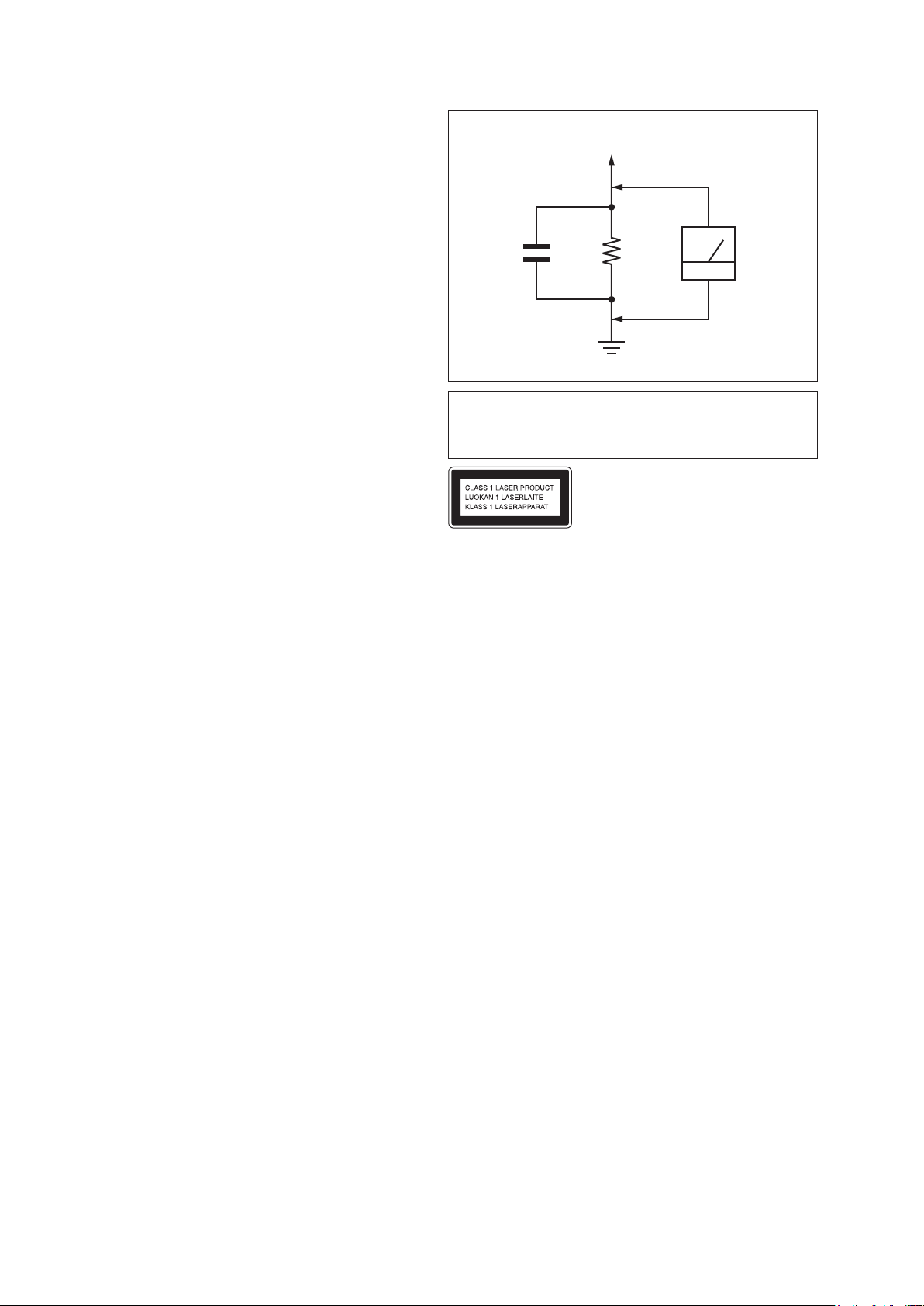

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

1.5 kΩ0.15 μF

Earth Ground

AC

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous

radiation exposure.

This appliance is classified as a CLASS 1

LASER product. This marking is located on

the rear exterior.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

TABLE OF CONTENTS

HCD-GPX5G/GPX7G/GPX8G

1. SERVICING NOTES

................................................ 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 8

2-2. Case ................................................................................. 9

2-3. Loading Panel ................................................................. 9

2-4. Front Panel Section ......................................................... 10

2-5. CD Mechanism Section (CDM741-DVBU201//M) ....... 10

2-6. TUNER1AM3R Board ................................................... 11

2-7. MAIN Board ................................................................... 11

2-8. Back Panel Section ......................................................... 12

2-9. 4CH DAMP board .......................................................... 13

2-10. Chassis Section ............................................................... 14

2-11. Cover Dust CDM ........................................................... 15

2-12. Optical Pick Up ............................................................... 15

2-13. DMB22 Board ................................................................. 16

2-14. DRIVER Board, SWITCH Board ................................... 16

2-15. SENSOR Board .............................................................. 17

2-16. MOTOR (TB) Board....................................................... 17

2-17. MOTOR (LD) Board ...................................................... 18

3. TEST MODE ............................................................. 19

4. ELECTRICAL CHECK .......................................... 22

5. DIAGRAMS

5-1. Block Diagram - CD/USB Section - ............................... 23

5-2. Block Diagram - MAIN Section - ................................... 24

5-3. Block Diagram - AMP Section - ..................................... 25

5-4. Block Diagram - PANEL/POWER SUPPLY Section - .. 26

5-5. Printed Wiring Board -

4CH DAMP Board (Component side) ............................ 28

5-6. Printed Wiring Board -

4CH DAMP Board (Conductor side) .............................. 29

5-7. Schematic Diagram - 4CH DAMP Board (1/3) - ............ 30

5-8. Schematic Diagram - 4CH DAMP Board (2/3) - ............ 31

5-9. Schematic Diagram - 4CH DAMP Board (3/3) - ............ 32

5-10. Printed Wiring Board - DISPLAY Board - ..................... 33

5-11. Schematic Diagram - DISPLAY Board - ........................ 34

5-12. Printed Wiring Board -

MAIN Board (Component side) ..................................... 35

5-13. Printed Wiring Board -

MAIN Board (Conductor side) ....................................... 36

5-14. Schematic Diagram - MAIN Board (1/4) - ..................... 37

5-15. Schematic Diagram - MAIN Board (2/4) - ..................... 38

5-16. Schematic Diagram - MAIN Board (3/4) - ..................... 39

5-17. Schematic Diagram - MAIN Board (4/4) - ..................... 40

5-18. Printed Wiring Board -

USB, VOLUME and MIC Board - ................................. 41

5-19. Schematic Diagram -

USB, VOLUME and MIC Board - ................................. 42

5-20. Printed Wiring Board - DRIVER, SENSOR, SWITCH,

MOTOR (LD) and MOTOR (TB) Board ....................... 43

5-21. Schematic Diagram - DRIVER, SENSOR, SWITCH,

MOTOR (LD) and MOTOR (TB) Board - ..................... 44

5-22. Printed Wiring Board - TUNER1AM3R Board ............. 45

5-23. Schematic Diagram - TUNER1AM3R Board - .............. 45

5-24. Printed Wiring Board - DMB22 Board - ........................ 46

5-25. Schematic Diagram - DMB22 Board (1/3) - .................. 47

5-26. Schematic Diagram - DMB22 Board (2/3) - .................. 48

5-27. Schematic Diagram - DMB22 Board (3/3) - .................. 49

6. EXPLODED VIEWS

6-1. Case Section ................................................................... 61

6-2. Front Panel Section ........................................................ 62

6-3. Back Panel Section ......................................................... 63

6-4. Chassis Section ............................................................... 64

6-5. CD Mechanism Section (1)

(CDM74I-DVBU201//M) ............................................... 65

6-6. CD Mechanism Section (2) ............................................. 66

7. ELECTRICAL PARTS LIST ............................... 67

3

HCD-GPX5G/GPX7G/GPX8G

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

MODEL IDENTIFICATION

– Back Panel –

PART No.

Model Part No.

HCD-GPX8G: E2, E51, E4

HCD-GPX7G: E2, E51

HCD-GPX5G: E2, E51

HCD-GPX8G: MX

HCD-GPX7G: MX

HCD-GPX5G: MX

4-411-595-0[]

4-411-595-1[]

4-411-595-2[]

4-411-595-3[]

4-411-595-4[]

4-411-595-5[]

NOTE OF REPLACING THE IC502 ON THE DMB22

BOARD

IC502 on the DMB22 board cannot exchange with single.

When these parts on the DMB22 board are damaged,

exchange the entire mounted board.

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure:

1. Press [I/

STANDBY] button to turn the power on.

1

2. Press the [CD/DISC SKIP] button to select CD function.

3. While pressing the [x] button, press the [ENTER] button for

more 5 seconds).

4. The message “UNLOCKED” is displayed and the disc tray is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the

[I/1 STANDBY] button.

4

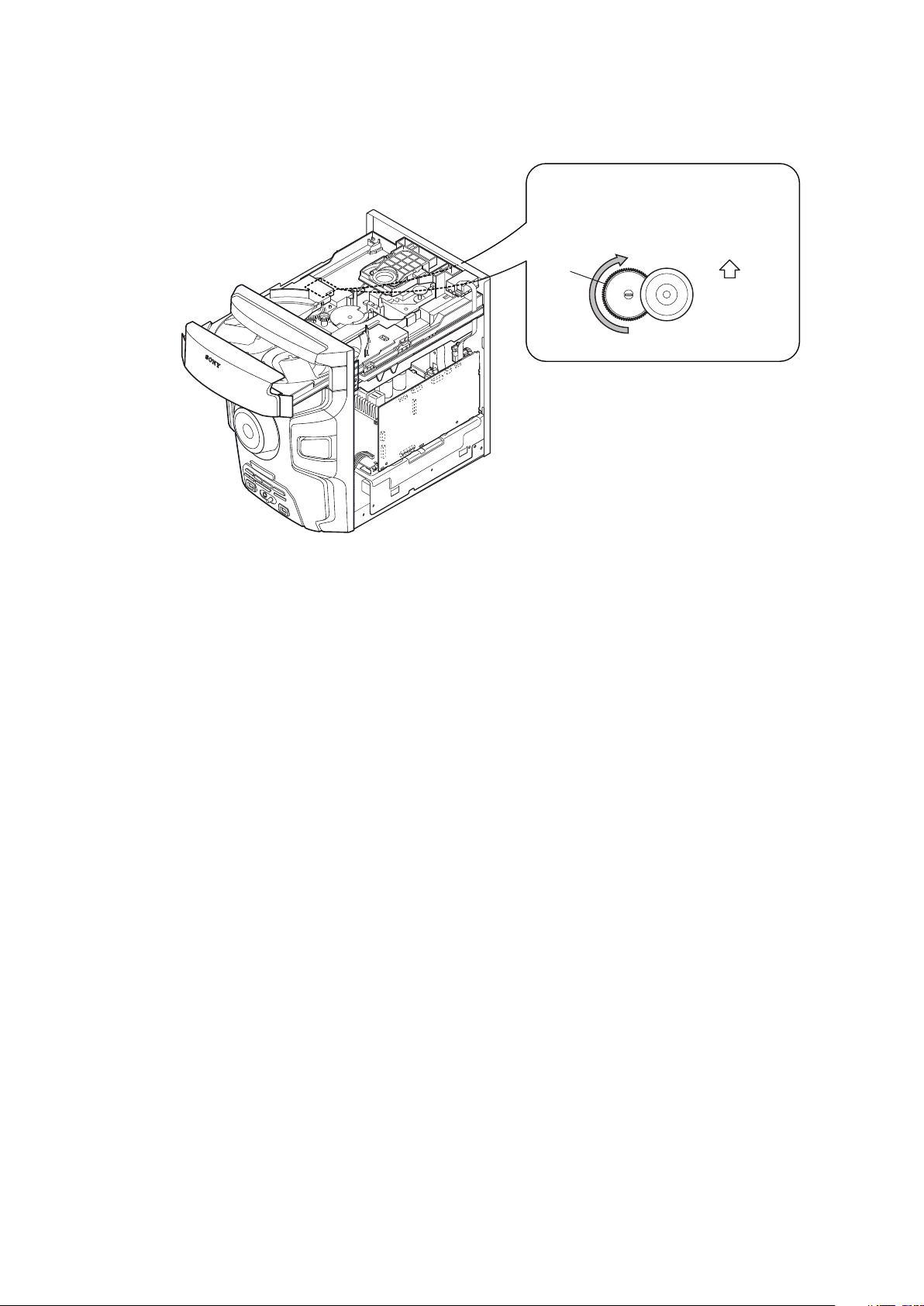

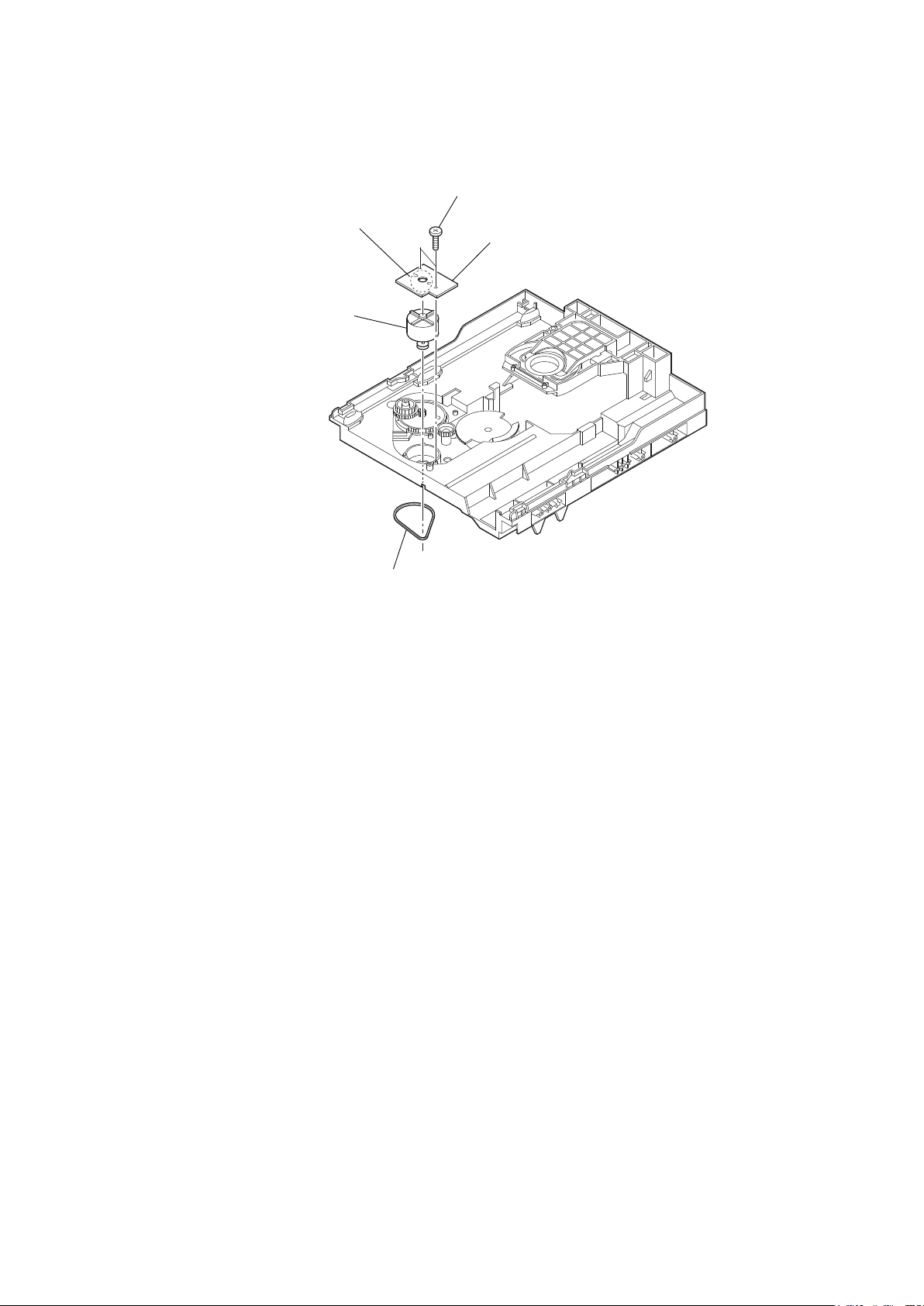

HOW TO OPEN THE TRAY WHEN POWER SWITCH TURN OFF

HCD-GPX5G/GPX7G/GPX8G

CD mechanism deck (CDM74I)

1 Turn the gear to the direction of the arrow.

(The location of this gear pulley is at the

bottom side of the CDM)

chassis side

gear

By using (-) screw driver

5

HCD-GPX5G/GPX7G/GPX8G

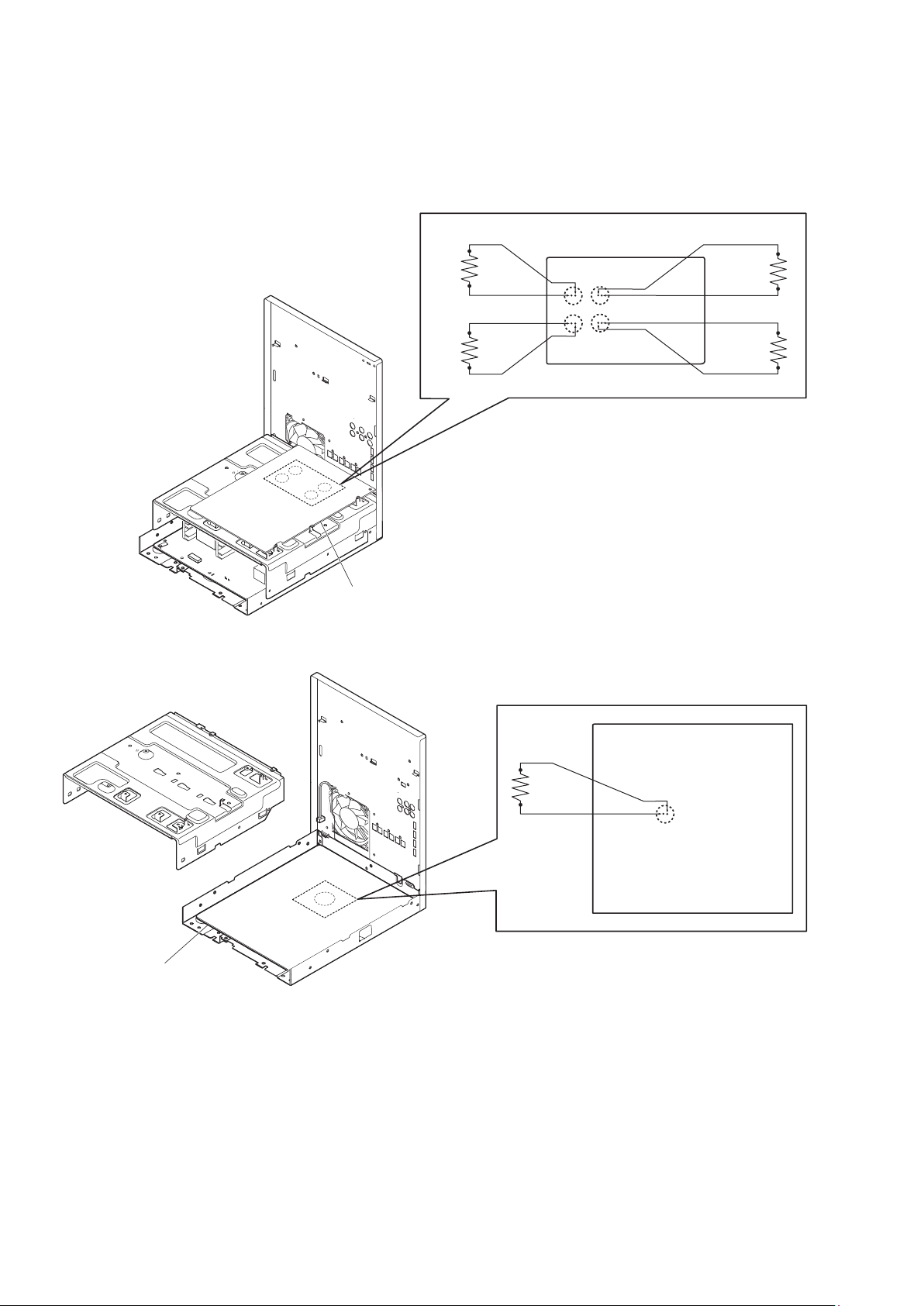

CAPACITOR DISCHARGE FOR ELECTRIC SHOCK PREVENTION

in checking the DAMP 4CH board, make a capacitor

GLVFKDUJHRI&RU&RU&DQG&

for electrical shock prevention.

4CH DAMP board

:

:

:

&

&

LQFKHFNLQJWKH5(*8/$7256:,7&+,1*ERDUGPDNH

DFDSDFLWRUGLVFKDUJHRI&IRUHOHFWULFDOVKRFNSUHYHQWLRQ

C1431

:

&

5(*8/$7256:,7&+,1* board

:

&

6

PRECAUTION WHEN INSTALLING A NEW OP UNIT/

PRECAUTION BEFORE UNSOLDERING THE STATIC

ELECTRICITY PREVENTION SOLDER BRIDGE

HCD-GPX5G/GPX7G/GPX8G

When installing a new OP unit, be sure to connect the fl exible

printed circuit board fi rst of all before removing the static electric-

ity prevention solder bridge by unsoldering.

Remove the static electricity prevention solder bridge by unsoldering after the fl exible printed circuit board has already been con-

nected.

(Do not remove nor unsolder the solder bridge as long as the OP

unit is kept standalone.)

7

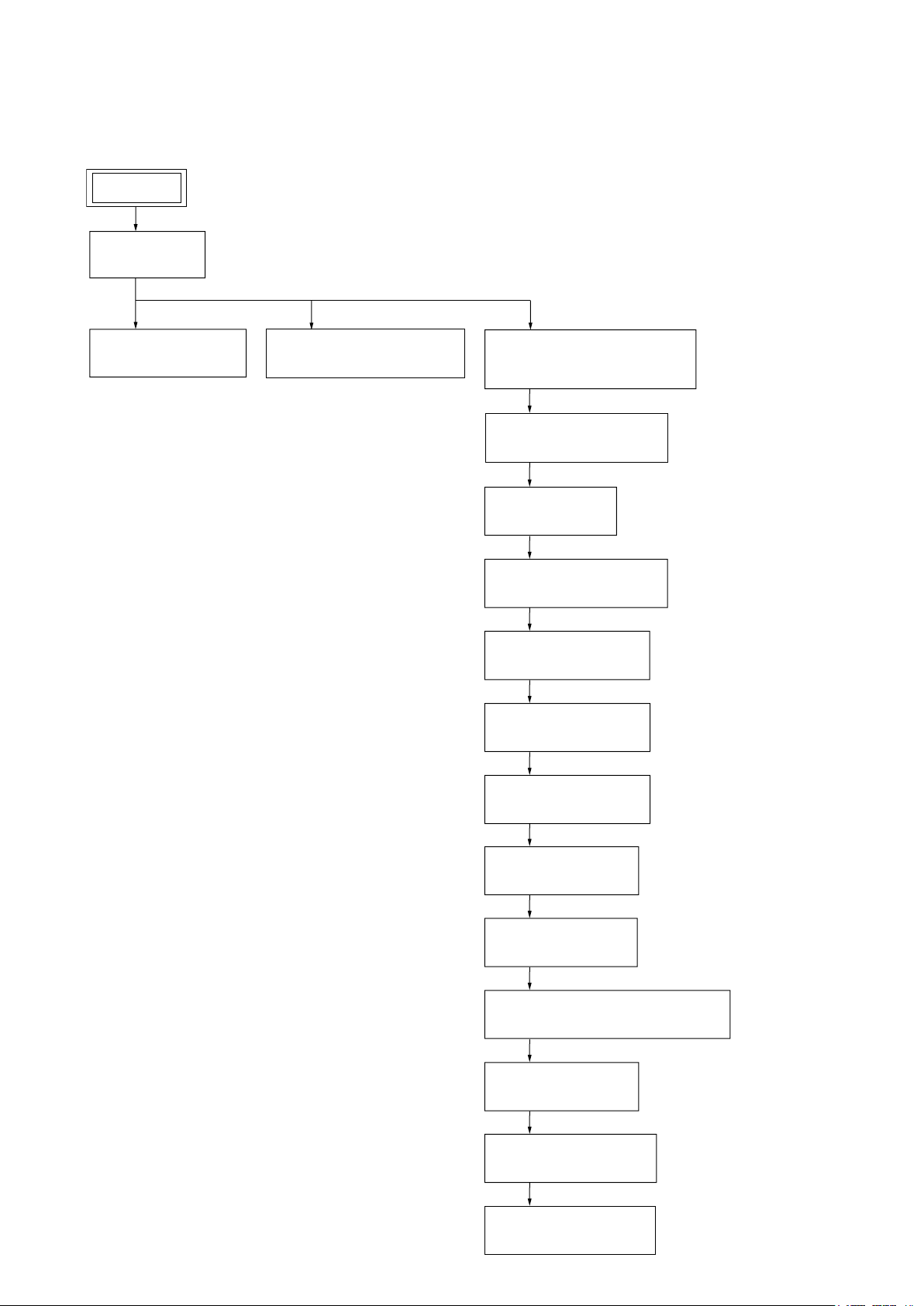

HCD-GPX5G/GPX7G/GPX8G

DISASSEMBLY

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

2-2. CASE

(Page 9)

SECTION 2

2-3. LOADING PANEL

(Page 9)

2-4. FRONT PANEL SECTION

(Page 10)

2-5. CD MECHANISM SECTION

(CDM74I-DVBU201/M)

(Page 10)

2-6. TUNER1AM3R BOARD

(Page 11)

2-7. MAIN BOARD

(Page 11)

2-8. BACK PANEL SECTION

(Page 12)

2-9. 4CH DAMP BOARD

(Page 13)

2-10. CHASSIS SECTION

(Page 14)

2-11. COVER DUST CDM

(Page 15)

2-12. OPTICAL PICK UP

(Page 15)

2-13. DMB22 BOARD

(Page 16)

2-14. DRIVER BOARD, SWITCH BOARD

(Page 16)

2-15. SENSOR BOARD

(Page 17)

2-16. MOTOR (TB) BOARD

(Page 17)

2-17. MOTOR (LD) BOARD

(Page 18)

8

Note: Follow the disassembly procedure in the numerical order given.

HCD-GPX5G/GPX7G/GPX8G

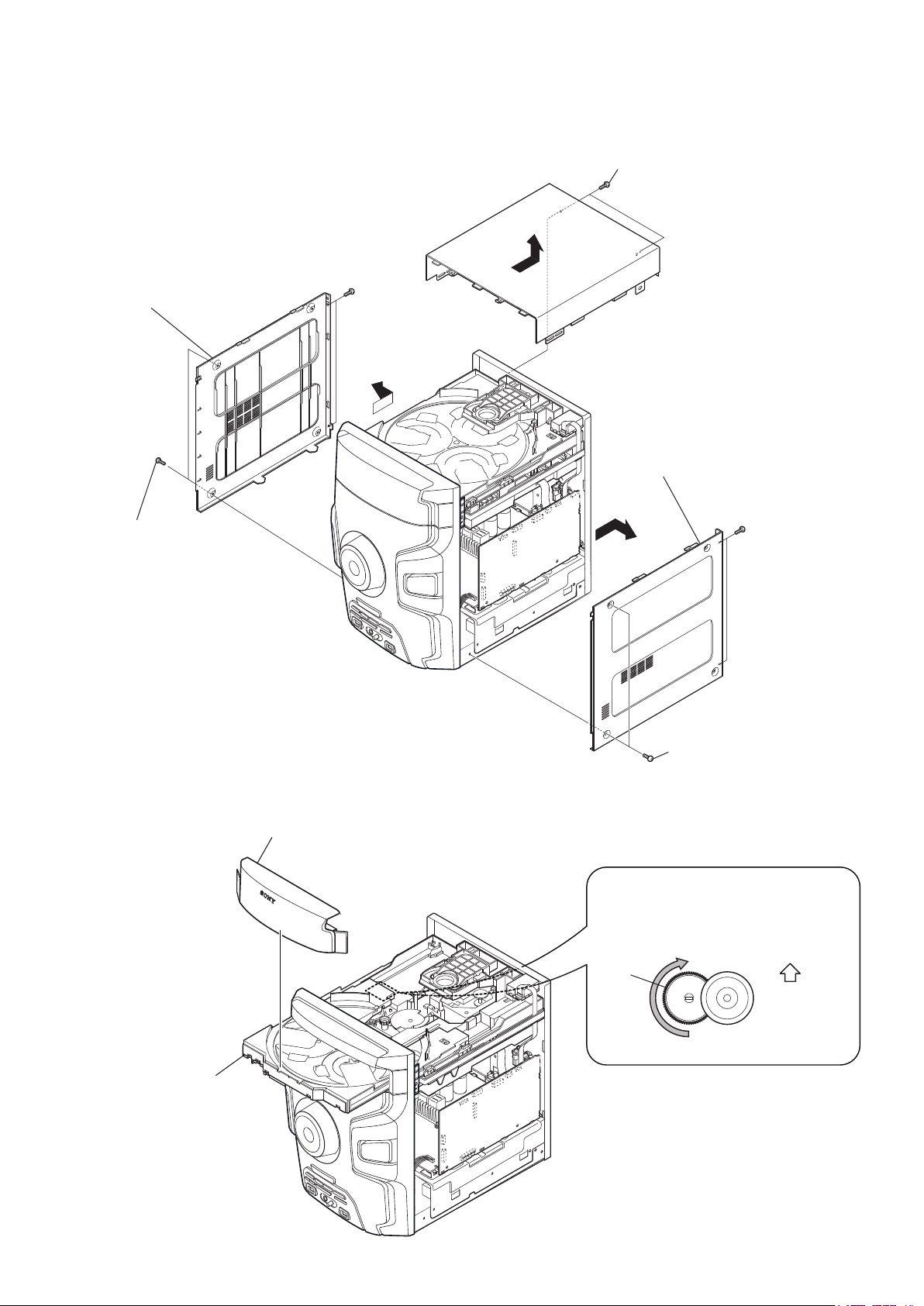

2-2. CASE

4 panel, side (L)

1 two screws

(+BVTP 3x14)

2

two screws

(+BVTP 3x14)

3

56 two screws

(+BVTP 3x14)

4 panel, side (R)

3

2 two screws

(+BVTP 3x14)

2-3. LOADING PANEL

2 Pull-out the disc tray

3

panel, loading

1

two screws

(+BVTP 3x14)

CD mechanism deck (CDM74I)

1 Turn the gear to the direction of the arrow.

(The location of this gear pulley is at the

bottom side of the CDM)

chassis side

gear

By using (-) screw driver

9

HCD-GPX5G/GPX7G/GPX8G

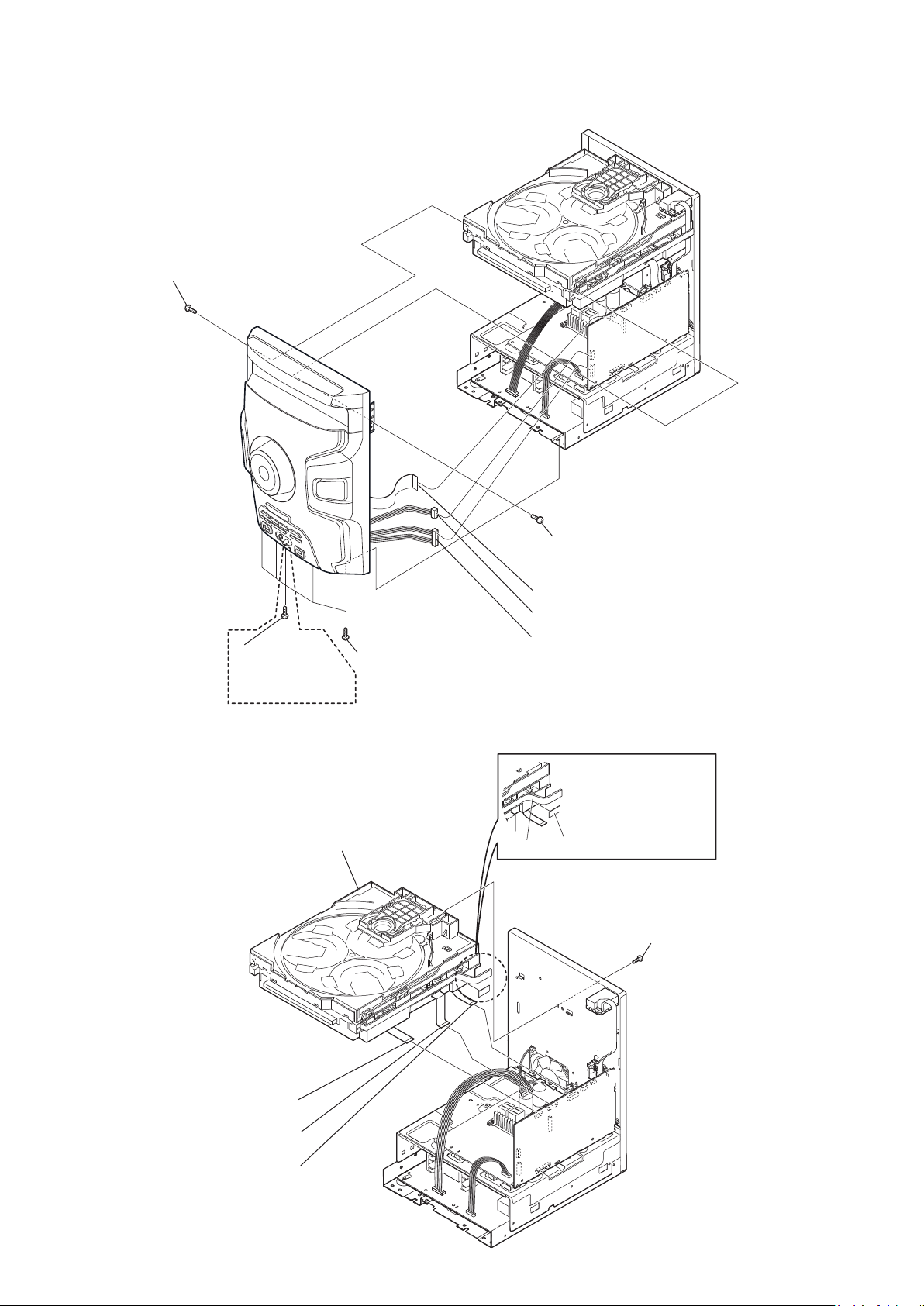

2-4. FRONT PANEL SECTION

2 one screw

(+BVTP 3x8)

1

one screws

(+BVTP 3x8)

For GPX7G/

GPX8G

1 four screws

(+BVTP 3x8)

2-5. CD MECHANISM SECTION (CDM74I-DVBU201//M)

CD mechanism section

( CDM74I-DVBU201//M)

2 one screw

(+BVTP 3x8)

3

wire (flat type) (17core) CN601

4

CN707 (4P)

5

CN705 (10P)

Peel off the cushion

and tape on the wire

(flat type) from TUNER.

cushion

tape

4 one screw

(BVTP 3x8)

10

2

wire (flat type) (19core) CN702

1

wire (flat type) (13core) CN700

3

wire (flat type) (15core) CN703

2-6. TUNER1AM3R BOARD

shield plate top

3

5

TUNER1AM3R board

4

shield plate bottom

HCD-GPX5G/GPX7G/GPX8G

1 wire (flat type) (9 core)

(CN513)

2

two screws

(BVTP 3x8)

2-7. MAIN BOARD

1 two screws

(+BVTP 3x8)

3 MAIN board

2 two screws

(+BVTP 3x8)

11

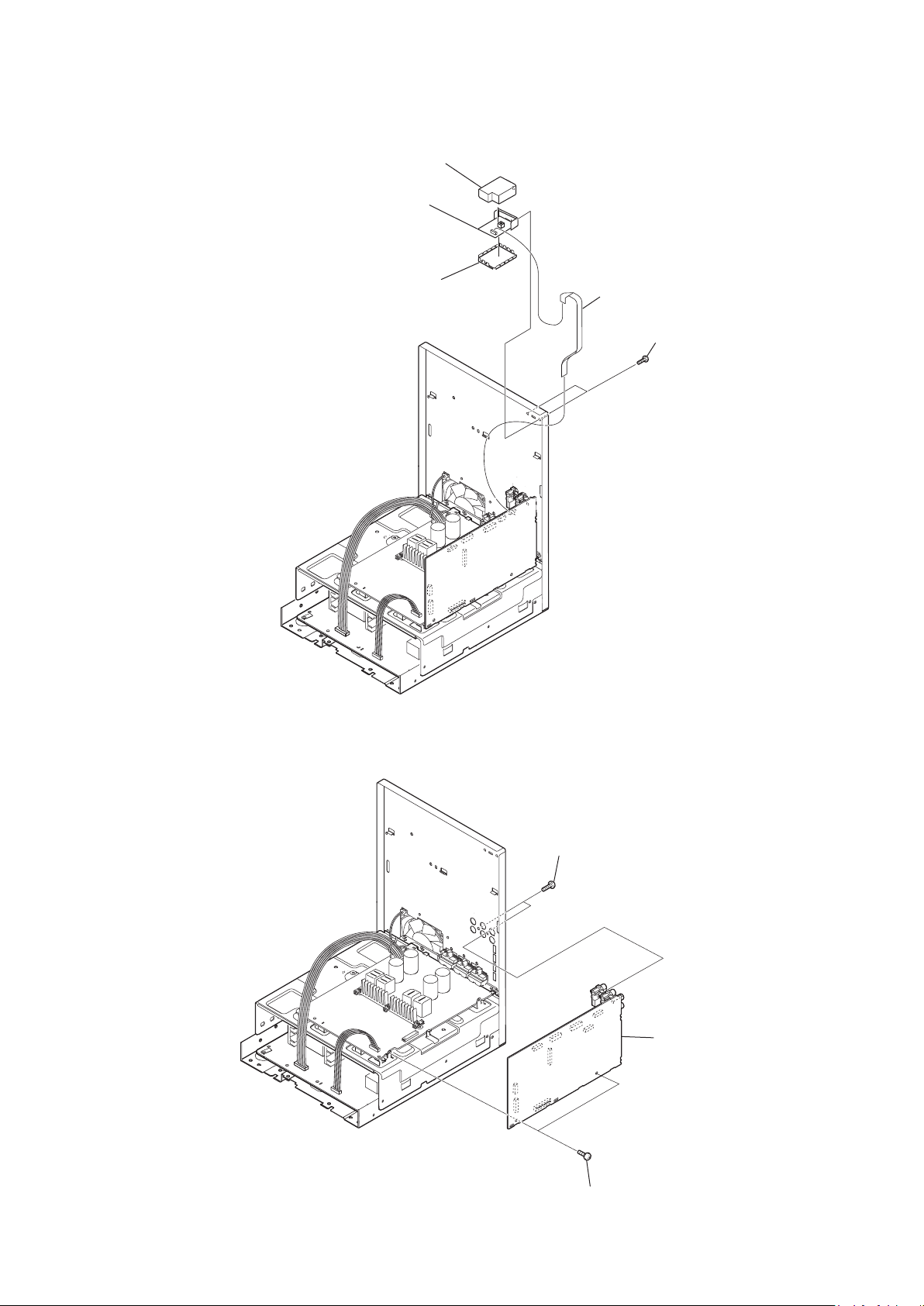

HCD-GPX5G/GPX7G/GPX8G

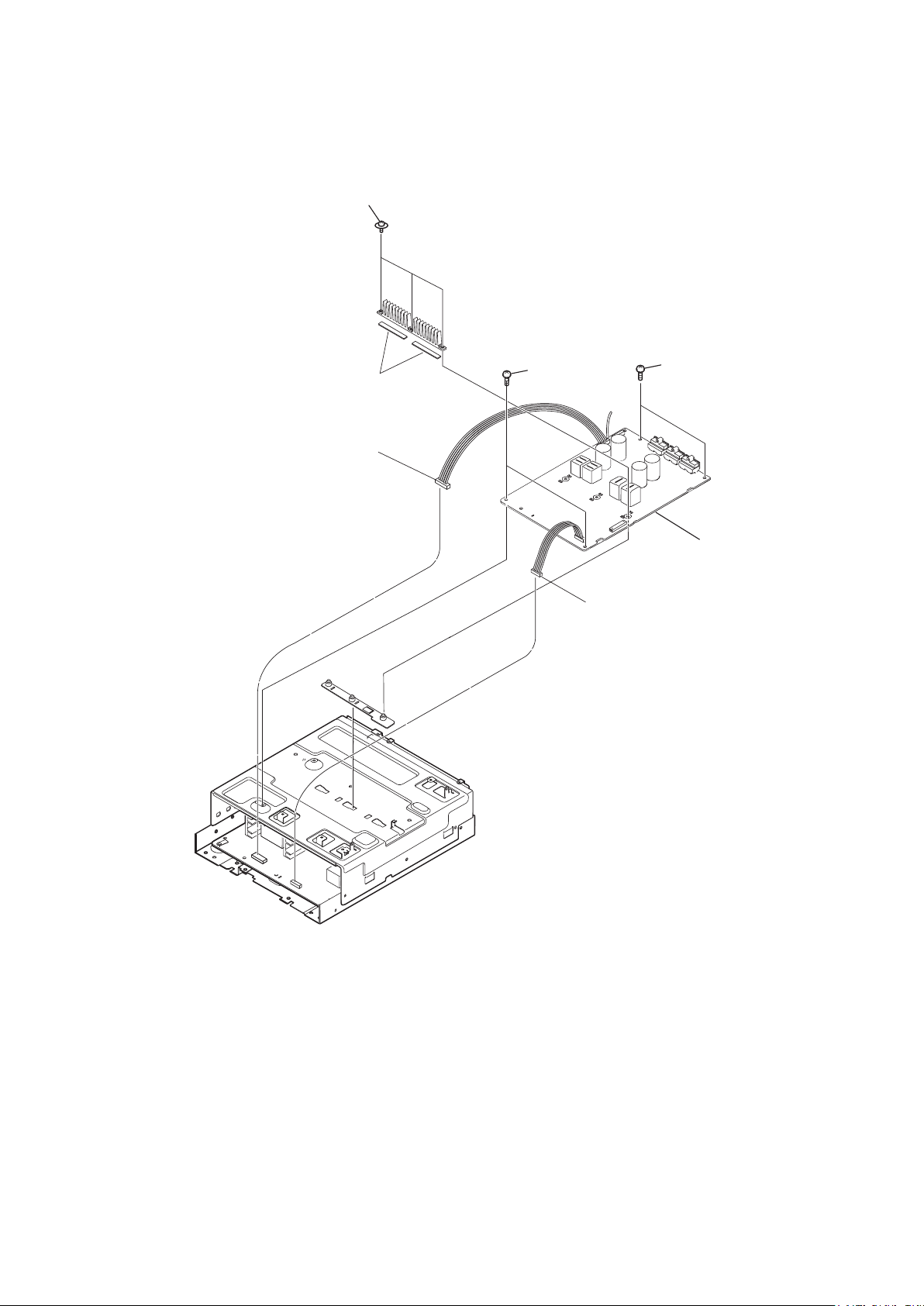

2-8. BACK PANEL SECTION

1 CN1405 (3P)

5 fan, DC

4 cover, fan

3 two screws

(BVTP 3x8)

2 two screws

(BVTP 3x8)

9 back panel section

for GPX8G

one screw

7

(+BVTP 3x8)

6 two screws

(BVTP 3x8)

8 one screws

(BVTP 3x8)

12

2-9. 4CH DAMP BOARD

HCD-GPX5G/GPX7G/GPX8G

1 three screws

(PTPWH 2.6x12)

sheet thermal

42 CN2 (9P)

3 two screws

(BVTT 3x8)

5 CN3 (5P)

3 two screws

(BVTT 3x8)

6 4CH DAMP board

13

HCD-GPX5G/GPX7G/GPX8G

2-10. CHASSIS SECTION

1 two screws

(+BVTP 3x8)

5 nine screws

(+PWH 3x8)

2 bracket, SMPS (shield)

1

(+BVTP 3x8)

two screws

6

REGULATOR,

SWITCHING

7 chassis

4

3 CN1 (2P)

E

14

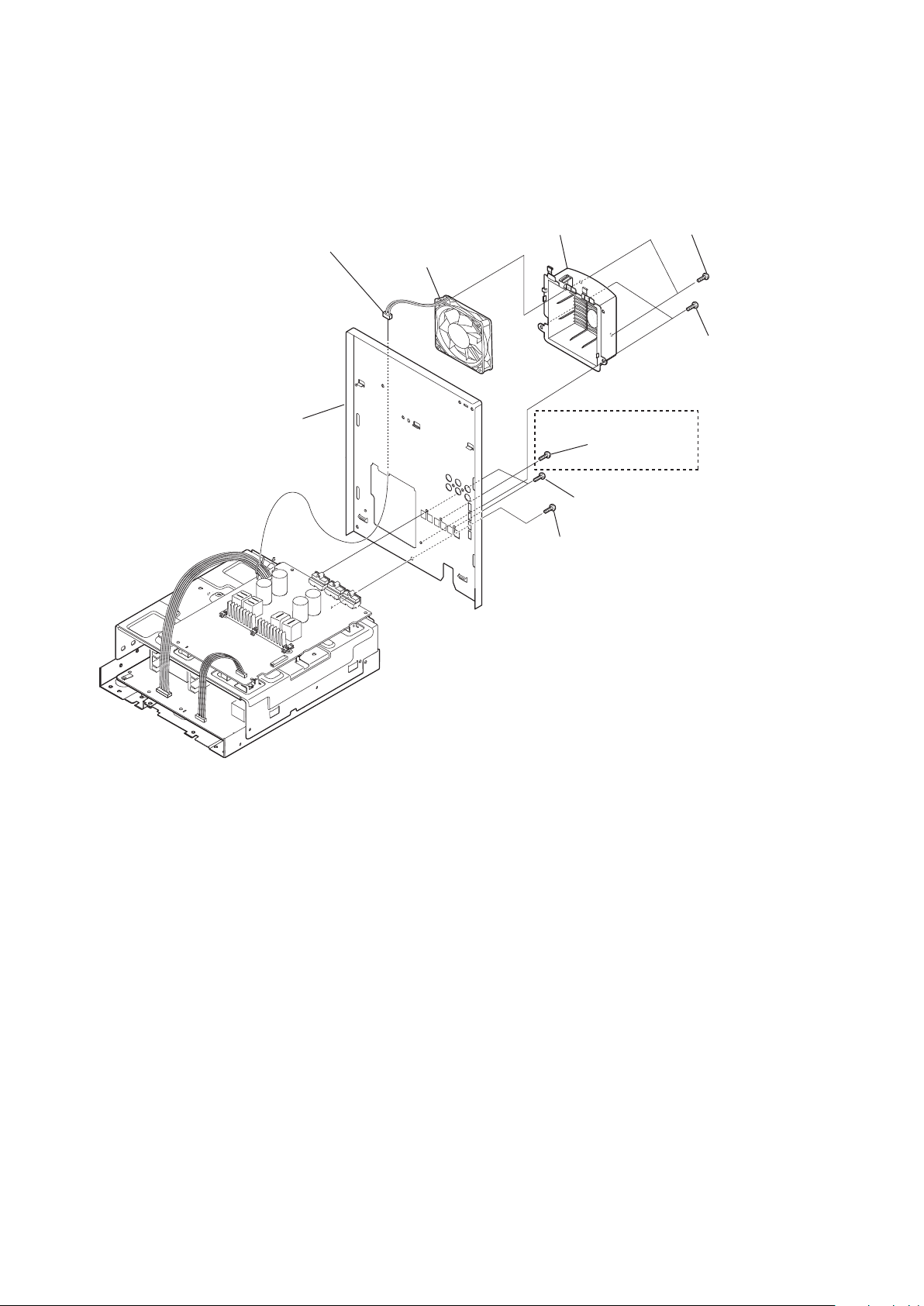

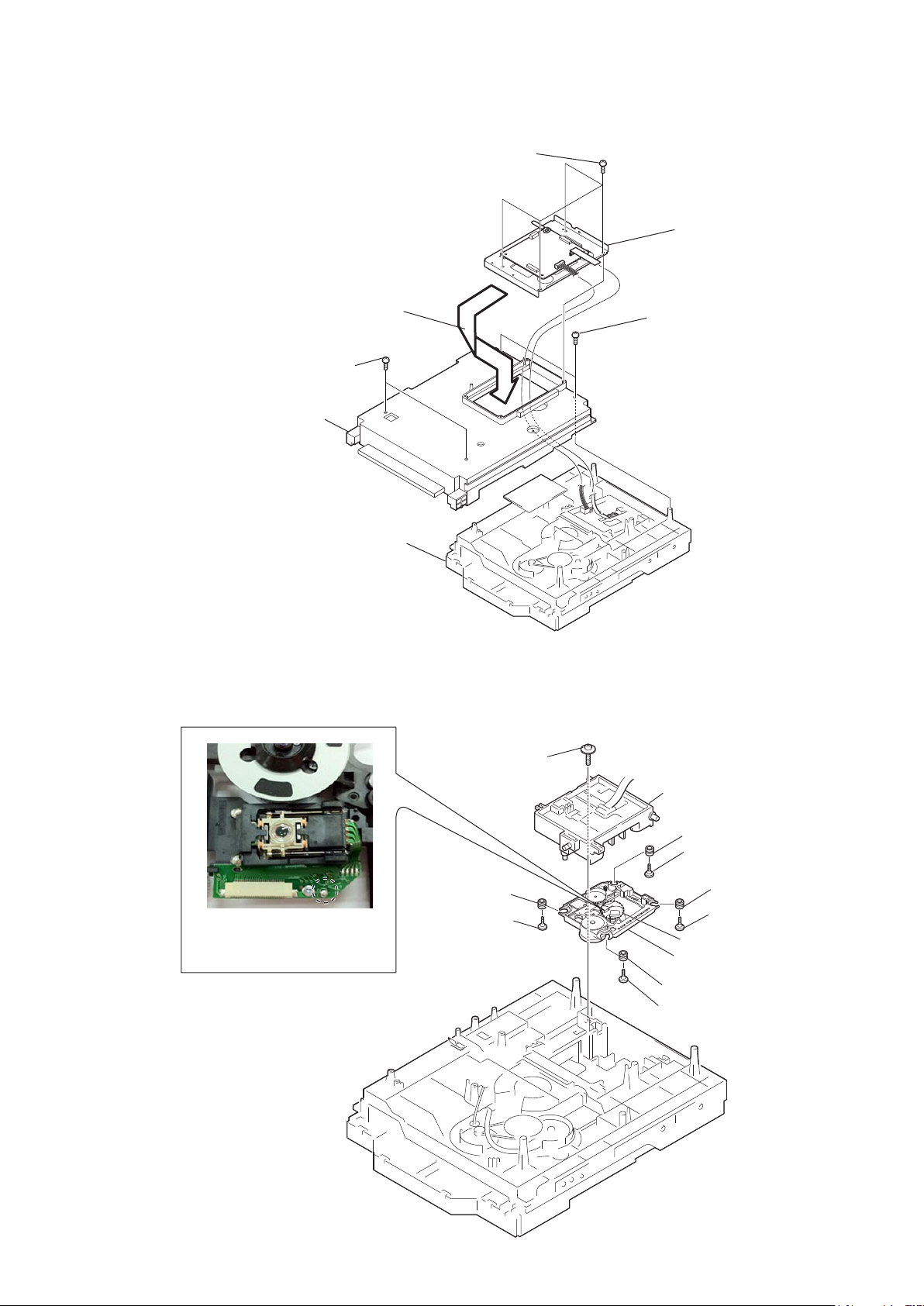

2-11. COVER DUST CDM

1 two screws

(+BVTP 3x10)

2 cover dust (CDM)

5 go through the

hole of cover dust

HCD-GPX5G/GPX7G/GPX8G

3 four screws

(+BVTP 3x10)

4 bracket, holder (DMB)

1 two screws

(+BVTP 3x10)

2-12. OPTICAL PICK UP

Solder the short-land

(Location of this point is at the bottom

side of optical device)

6 CDM74I

1 floating screw

+PTPWH M2.6)

(

4 insulator

3 insulator screw

2 CDM74I assy

4 insulator

3 insulator screw

4 insulator

3 insulator screw

solder the short land

5

device, optical

6

(CMS-ST6RFS3)

4 insulator

3 insulator screw

15

HCD-GPX5G/GPX7G/GPX8G

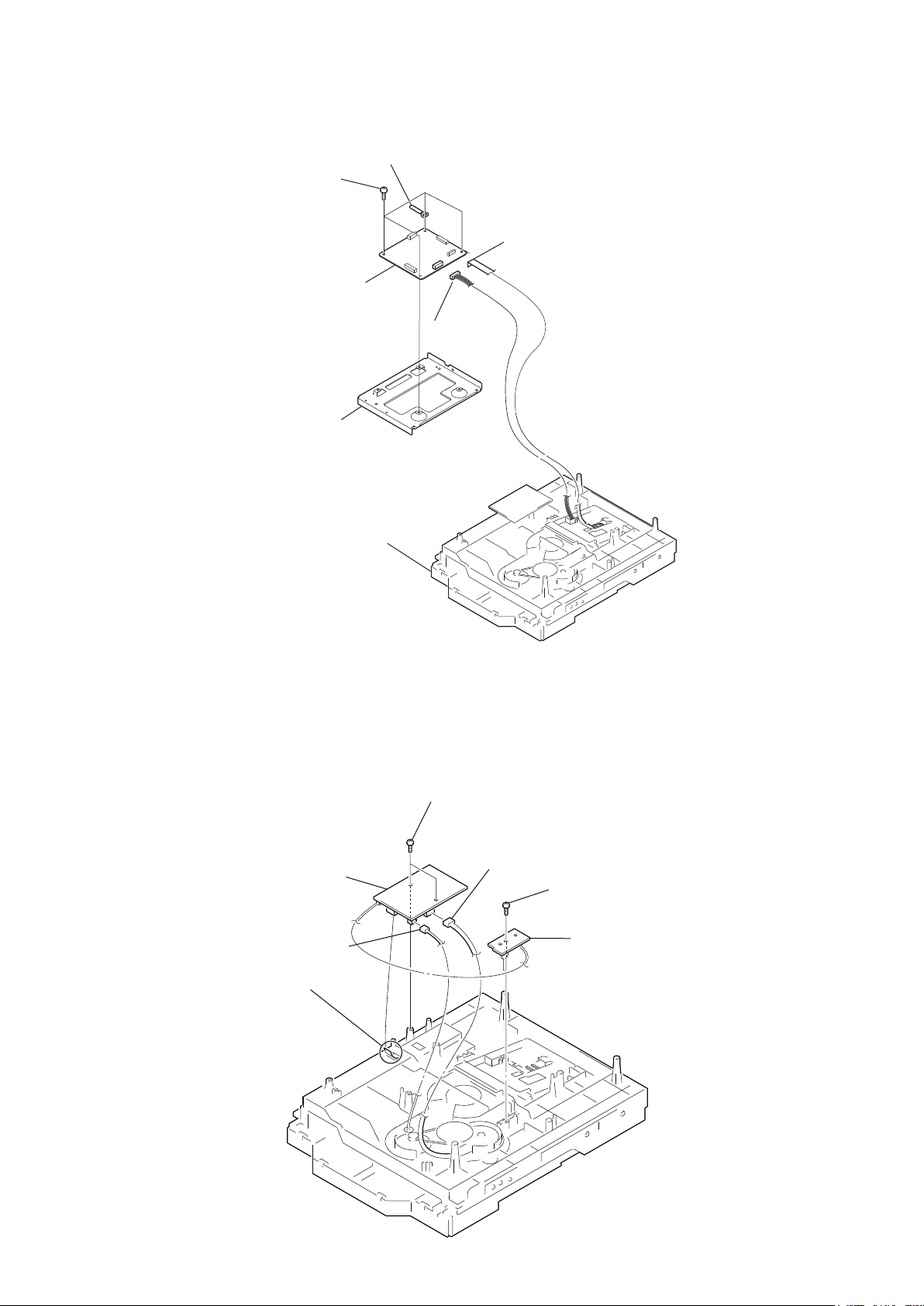

2-13. DMB22 BOARD

1 four screws

(+BVTP 3x10)

5

DMB22 board

6 bracket, holder (DMB)

7 CDM74I-DVBU201//M

2 clamp

4 wire (flat type)

(21core) (CN501)

3 CN801 (6P)

2-14. DRIVER BOARD, SWITCH BOARD

5 DRIVER board

3 CN704 (2P)

4 wire (flat type) (5 core)

(CN702)

1 two screws

(+BTTP (M2.6))

2 CN703 (4P)

6 one screw

(+BTTP (M2.6))

7 SWITCH board

16

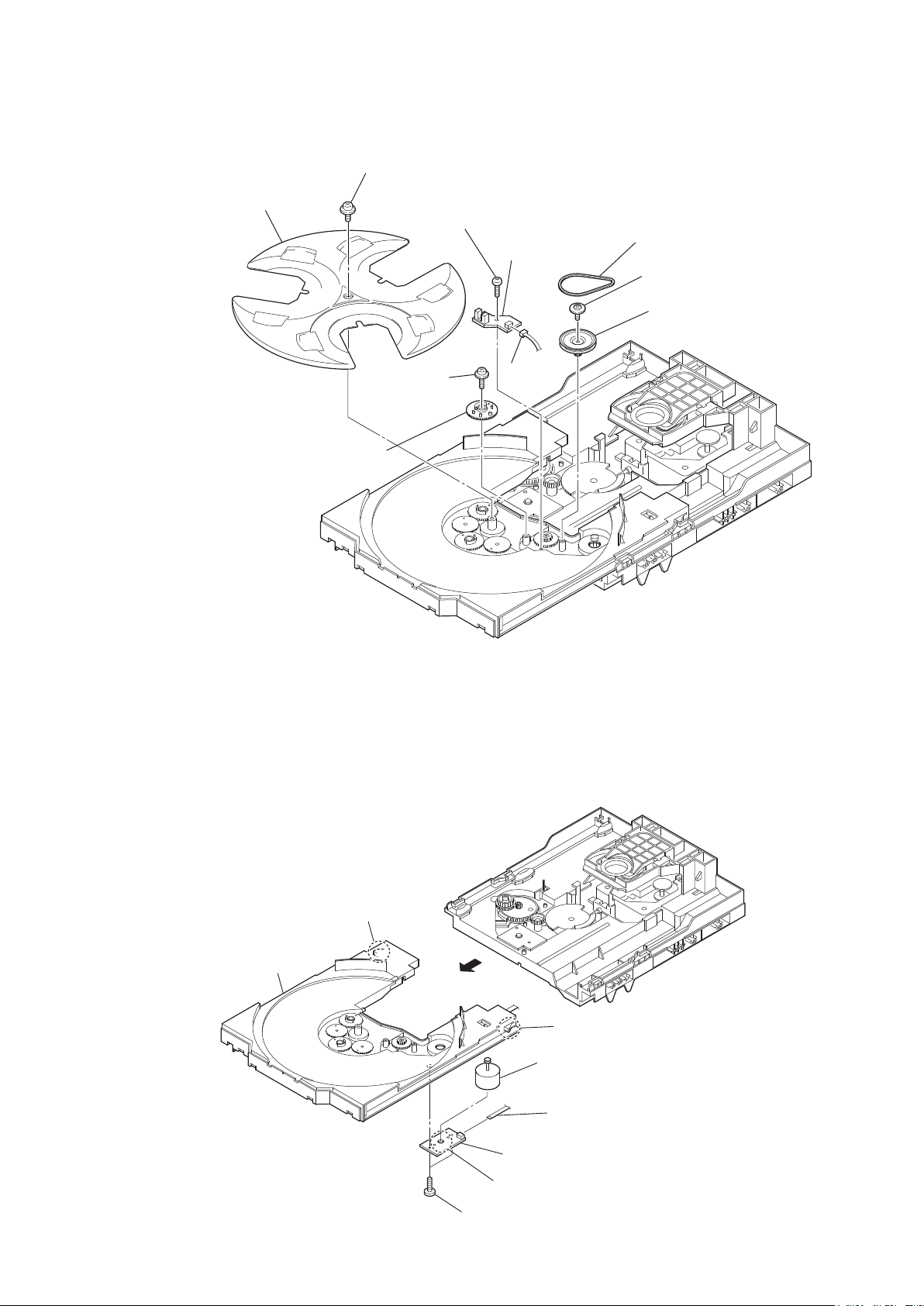

2-15. SENSOR BOARD

2 tray

HCD-GPX5G/GPX7G/GPX8G

1 floating screw

(+PTPWH M2.6)

8 one screw

(+BTTP (M2.6))

3 belt (table)

0 SENSOR board

4 floating screw

(+PTPWH M2.6)

5 pulley (table)

7 gear (geneva)

2-16. MOTOR (TB) BOARD

6 floating screw

(+PTPWH M2.6)

9 CN731

(3P)

table

1 gear (stopper)

2

1 gear (stopper)

5 motor assy, table (M741)

3 wire (flat type) (5 core)

(CN742)

7 MOTOR (TB) board

6 remove the two solderings of motor

4 two screws

(+BTTP (M2.6))

17

HCD-GPX5G/GPX7G/GPX8G

2-17. MOTOR (LD) BOARD

2 remove the two solderings of motor

4 motor assy, loading (M751)

3 two screws

(+BTTP (M2.6))

5 MOTOR (LD) board

1 belt (loading)

18

SECTION 3

TEST MODE

HCD-GPX5G/GPX7G/GPX8G

[PANEL TEST MODE]

• This mode is used to check the fl uorescent indicator tube,

LEDs, keys, [MASTER VOLUME] jog, model, destination and software version.

• Procedure:

1. Press [CD/DISC SKIP] button and [TUNER/BAND]

button simultaneously and hold 3 seconds.

2. All LEDs and segments in fl uorescent indicator tube are

lighted up.

3. When you want to enter to the software version display

mode, press [

appears on the fl uorescent indicator tube.

• “GPX 3S” is shown for MHC-GPX5.

• “GPX 4” is shown for MHC-GPX7.

• “GPX 7S” is shown for MHC-GPX8.

Press [

information.

4. During the destination information display, press [

/ ] button. Each time [

fl

software in the following sequence: SC, MTK (DMB Board

fi rmware version), UI, PF, SYS, CD, CDMA, CDMB,

ST, TA, TAS, TM and return back to model information

display.

5. When [OPTION] button is pressed while the version

numbers are being displayed except model and destination,

the date of the software creation appears. When [OPTION]

button is pressed again, the display returns to the software

version display.

6. Press [

7. In the key check mode, the fl uorescent indicator tube

displays “K 0 V0”.

Each time a button is pressed, “K” value increases.

However, once a button has been pressed, it is no longer

taken into account.

“V” value increases in the manner of 0,1, 2, 3 ... if [MAS-

TER VOLUME] knob is turned clockwise, or it decreases

in the manner of 0, 9, 8,7 ... if [MASTER VOLUME] knob

is turned counterclockwise.

8. When [ENTER] button is pressed after all LEDs and

segments in fl uorescent indicator tube light up, alternate

segments in fl uorescent indicator tube and LEDs would

light up. If you press [ENTER] button again, another half

of alternate segments in fl uorescent indicator tube and

LEDs would light up. Pressing [ENTER] button again

would cause all segments in fl uorescent indicator tube and

LEDs light up.

9. To release from this mode, press three buttons in the same

manner as step 1, or disconnect the power cord.

+

uorescent indicator tube shows the version of each category

+

/ ] button.

+

/ ] button again to view the destination

/ ↓] button, the key check mode is activated.

The model information

/ ] button is pressed, the

+

+

[COMMON TEST MODE]

• This mode is used to check operations of the Amplifi er

section.

• Procedure:

• To enter Common Test Mode

1. Press [USB/USB SELECT] button and [BASS BAZUCA]

button simultaneously and hold for 3 seconds.

2. The function is changed to TV and the volume is changed

to VOLUME MIN.

• Check of Amplifi er

1. Press [MUSIC] button repeatedly until a message “GEQ

MAX” appears on the fl uorescent indicator tube. GEQ in-

creases to its maximum.

2. Press [MUSIC] button repeatedly until a message “GEQ

MIN” appears on the fl uorescent indicator tube. GEQ

decreases to its minimum.

3. Press [MUSIC] button repeatedly until a message “GEQ

FLAT” appears on the fl uorescent indicator tube. GEQ is

set to fl at.

4. When the [MASTER VOLUME] knob is turned clockwise

even slightly, the sound volume increases to its maximum

and a message “VOLUME MAX” appears on the fl uores-

cent indicator tube.

5. When the [MASTER VOLUME] knob is turned counterclockwise even slightly, the sound volume decreases to its

minimum and a message “VOLUME MIN” appears on the

fl uorescent indicator tube.

• To release from Common Test mode

1. To release from this mode, press [

2. The cold reset is enforced at the same time.

I/1 STANDBY] button.

[USER RESET]

• The user reset clears all data including preset data stored

in the data fl ash to initial conditions exclude history mode

data

• Procedure:

1. Press [

2.

ously for 3 seconds.

3.“RESET” appears on the fl uorescent indicator tube.

After that, the fl uorescent indicator tube becomes blank

for a while, and the system is reset.

I/1 STANDBY] button to turn on the system.

Press [x] button and [

I/1 STANDBY

] button simultane

[COLD RESET]

• The cold reset clears all data including preset data stored in

the data fl ash to initial conditions. Execute this mode when

returning the set to the customer.

• Procedure:

1. Press [

2. Press [ENTER] button and [GAME] button

simultaneously for 3 seconds.

3. “COLD RESET” appears on the fl uorescent

indicator tube. After that, the fl uorescent indicator

tube becomes blank for a while, and the system is

reset.

I/1 STANDBY] button to turn on the system.

[TUNER STEP CHANGE]

• The step interval of AM channels can be toggled between

9 kHz and 10 kHz. This mode is not available for Saudi

Arabian, European and Russian models.

• Procedure:

1. Press [

2. Press [TUNER/BAND] button repeatedly to select

the “AM”.

3. Press [

4. Press [LED EFFECT] button and [

button simultaneously. The system turns on

automatically. The message “AM 9K STEP”

or “AM 10K STEP” appears on the fl uorescent

indicator tube and thus the channel step is changed.

I/1 STANDBY] button to turn on the system.

I/1 STANDBY] button to turn off the system.

I/1 STANDBY]

[CD SHIP MODE (WITH MEMORY CLEAR)]

• This mode moves the optical pick-up to the position

durable to vibration and clears all data including preset

data stored in the EEPROM to initial conditions during the

next AC-In. Use this mode when returning the set to the

customer after repair.

• Procedure:

1. Press [

2. Select CD function.

3. Press [ENTER] button and [MUSIC] button

4. A message

“MECHA LOCK” is displayed on the fl uorescent

I/1 STANDBY] button to turn on the system.

simultaneously for 3 seconds. The system turns off

automatically.

indicator tube and the CD ship mode is set.

19

HCD-GPX5G/GPX7G/GPX8G

[CD SHIP MODE (WITHOUT MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable to vibration. Use this mode when returning the set to

the customer after repair.

• Procedure:

1. Press [

I/1 STANDBY] button to turn on the system.

2. Select CD function.

3. Press [BASS BAZUCA] button and [

I/1 STANDBY]

button simultaneously. The system turns off

automatically.

4. A message

“MECHA LOCK” is displayed on the fl uorescent

indicator tube and the CD ship mode is set.

[CD TRAY LOCK MODE]

• This mode let you lock the disc tray. When this mode is activated, the disc tray will not open when [

OPEN/CLOSE]

Z

button or [EX-CHANGE] button is pressed. The message

“LOCKED” will be displayed on the fl uorescent indicator

tube. This mode only applied when there is disc(s) on the

tray.

• Procedure:

1. Press [

I/1 STANDBY] button to turn on the system.

2. Select CD function.

3. Press [

] button and [ENTER] button simultane-

x

ously and hold down until “LOCKED” or “UNLOCKED” displayed on the fl uorescent indicator

tube (around 5 seconds).

[FACTORY PRESET]

• This mode is use to load all the factory use preset frequencies into FM 1-FM 20 and AM 1-AM 10. Originally, frequency of FM 1-FM 20 and AM 1-AM10 are set to the

minimum frequency.

• Procedure:

1. Press [

I/1 STANDBY] button to turn on the system.

2. Press [CD/DISC SKIP] button and [AUDIO IN]

button simultaneously and hold for 3 seconds,

message “FACTORY” appears on the fl uorescent

indicator tube. The function is changed to TUNER

automatically.

[CDM AGING MODE]

• This mode is used to display the total count of meter

pointer touch initial switch and max switch.

• Procedure:

1. Press [

2. Select CD function and All DISC play mode.

3. Put discs on all trays and close the tray.

4. Press [

5. The fl uorescent indicator tube displays Aging

“xxxx” represents the error counter

(Maximum Value of “xxxx” = 9999)

“yyyyy” represents the cycle counter

(Maximum Value of “yyyy” = 9999)

6. Press [<<] or [>>] to search for Aging History

The fl uorescent indicator tube displays

“Mx E1E2E3E4”.

x: error history number

E1: Loading sequence JCP high

E2: Loading sequence JCP low

E3: Loading operation JCP

E4: Cam position operation JCP

I/1 STANDBY] button to turn on the system.

/ ] button and [x] button simultane-

+

ously for 3 seconds.

Display “AG xxxx/yyyy”.

Error Display.

7. Press [ENTER] to Aging Display

• To release from Meter Aging Mode.

To release from this mode, press [

I/1 STANDBY] button or

perform COLD RESET operation.

[HISTORY MODE]

• This mode is used to check important data stored in the

system when PROTECTOR happen.

• Procedure:

1. During demo mode, press [

u] button and [BASS

BAZUCA] for 5 seconds to mode in to history

mode.

2. Press the [TUNING +] or [TUNING -] button to

check history data stored

Item Display

Protector Count P R O C O U N T

Protector Type P R O T Y P E

Single Power On Time T 1 H M

Total Power On Time T 2

Input Function F U N C

Volume V O L

Actual Attenuation A T T

Low EQ Level E Q L O W

Mid EQ Level E Q M I D

High EQ Level E Q H I G H

VACS Level V A C S

AP VACS Level A P V A C S

Subwoofer Setting S W

Surround Setting S U R R

DJ Effect Setting D J

Bass Bazuca Setting B A Z U C A

H M

• To release from History Mode.

To release from this mode, press [

I/1 STANDBY] button.

[PROTECT KIND CHECK TEST MODE]

• This mode is used to check types of protect occurred during

protector on.

• Procedure:

3. During protection on, fl uorescent indicator tube

shows blinking message “PROTECT EXX”.

“EXX” – represent the error code.

4. Press [

u] button & [

5. Fluorescent indicator tube display will toggle

between “PROTECT” message & protector kind

message display.

Bellow table explains on protector kind.

Error Code Protector Message Description

E01 "AMP OCP"

E02 "MTK POWER" No power supply to DMB mount

E03 "POWER SUPPLY" Defect of power supply circuit to AMP

E04 "AMPLIFIER" Defect of AMP circuit

E06 "FAN BLOCK"

• To release from this mode.

Press [

u] button & [

x

unplug & re-plug in the power cord.

] button simultaneously.

x

The over current condition to MOSFET occurs by defect of MOSFET or

defect of PS output line.

Defect of DC FAN and DC FAN

driver circuit

] button simultaneously again or

20

1. Defect of AMP circuit

1-1. If PROTECT mode is “AMPLIFIER”,

The following defect might be possible.

Defects Possible cause

OTP (Over Tempera-

ture Protection)

DC Detection

Unusual output of

Power mount

1-2. If speaker does not have output even if the set status is not

in PROTECT mode

The following defect might be possible.

Defects Possible cause

Under Voltage IC1402 output is below 12V.

RESET defect Reset signal status from micom is not ‘H’.

2. Defect of power supply circuit to AMP

2-1. If the PROTECT mode is “POWER SUPPLY”,

There is possibility of unusual power supply of any of the

AMP IC or Pre-amplifi er.

• To release from this mode.

Press [

again or unplug and re-plug in the power cord.

Unusual heat up of MOSFET by improper assembly of heatsink, destruction

of MOSFET etc..

DC appears in SP terminal by defect of

AMP IC and MOSFET or output is shortcircuit.

The power mount has unusual output.

u] button and [

] button simultaneously

x

HCD-GPX5G/GPX7G/GPX8G

21

HCD-GPX5G/GPX7G/GPX8G

SECTION 4

ELECTRICAL CHECK

CD SECTION

Note:

1. CD Block is basically constructed to operate without adjustment.

2. Use YEDS-18 disc (Part No. 3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specifi ed value with the following checks.

5. Check the focus bias check when optical pick-up block is replaced.

FOCUS BIAS CHECK

oscilloscope

(DC range)

DMB22 board

CN507 pin 6 (RFMON)

CN507 pin 3 (GND)

+

–

Procedure :

1. Connect the oscilloscope to CN507 pin 6 (RFMON) and

CN507 pin 3 (GND) on the DMB22 board.

2. Press the [

STANDBY] button to turn the power on, and

?/1

press the [CD/DISC SKIP] button to select CD function.

3. Set disc (YEDS-18) and press the [u] button to playback.

4. Confi rm that oscilloscope waveform is as shown in the fi gure

below (eye pattern).

A good eye pattern means that the diamond shape () in the

center of the waveform can be clearly distinguished.

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level:

1.05 ± 0.45 Vp-p

TUNER SECTION

0 dB = 1 μV

FM AUTO STOP CHECK

signal

generator

set

+

75

–

Procedure:

1. Turn the power on.

2. Input the following signal from Signal Generator to FM antenna input directly.

Carrier frequency : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Please use 75 ohm “coaxial cable” to connect SG and the

set. You cannot use video cable for checking.

Please use SG whose output impedance is 75 ohm.

3. Set to FM tuner function and scan the input FM signal with

automatic scanning.

4. Confi rm that input Frequency of A, B and C detected and auto-

matic scanning stops.

The stop of automatic scanning means “The station signal is received in good condition”.

Checking Location:

-DMB22 Board (SideA)-

pin 6

(RFMON)

pin 3

(GND)

IC504

IC501

CN507

22

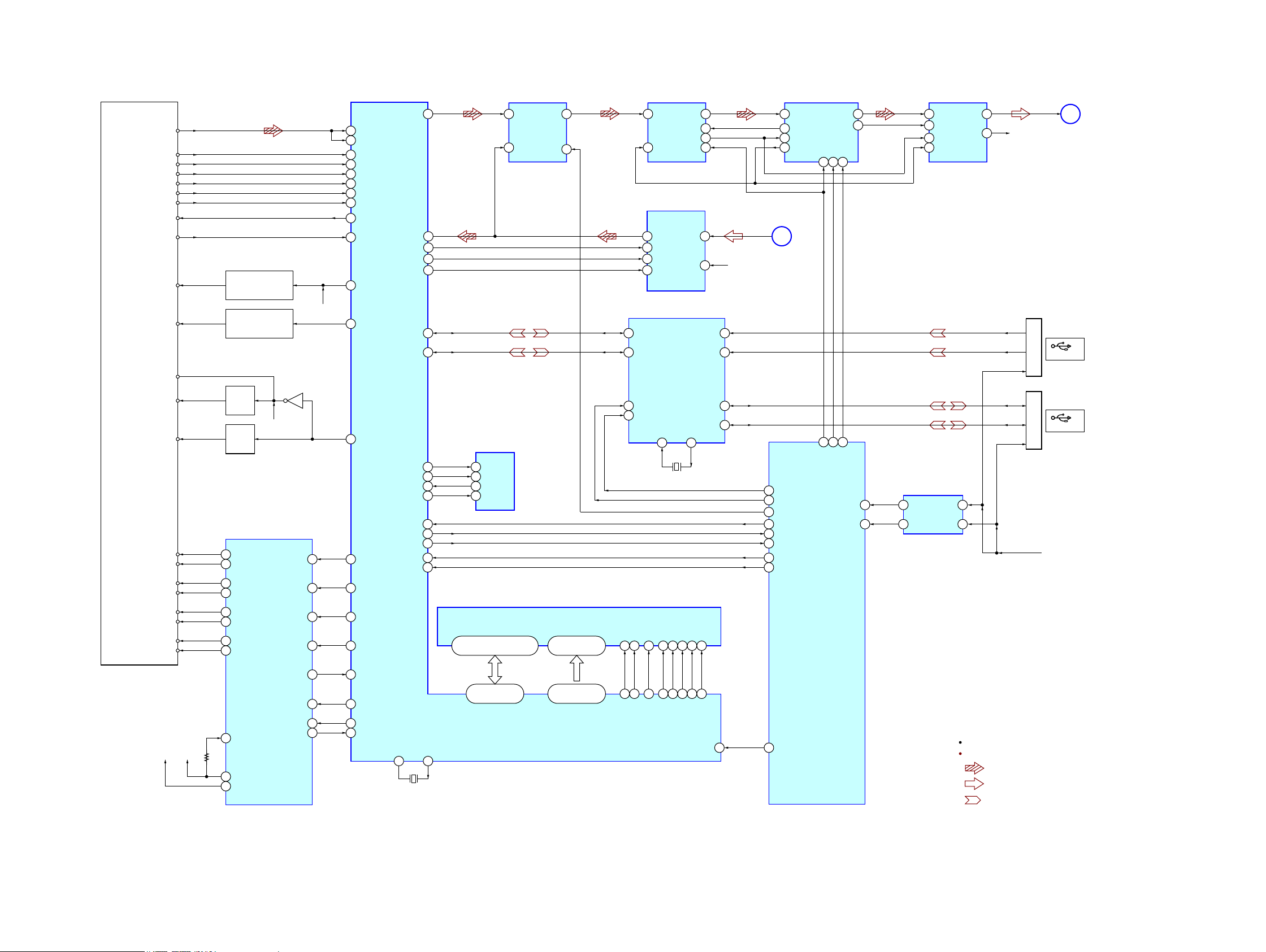

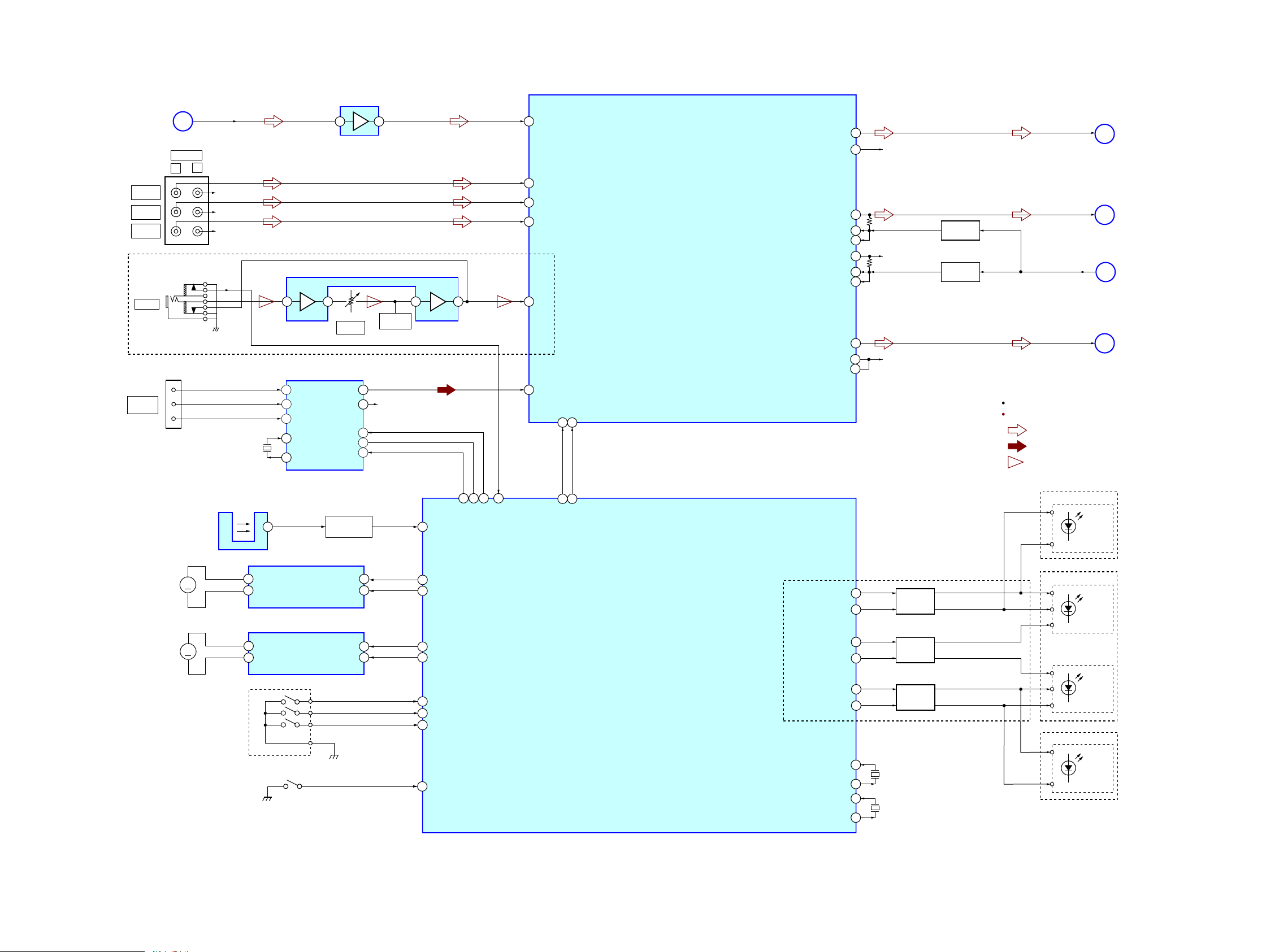

5-1. BLOCK DIAGRAM – CD/USB Section –

HCD-GPX5G/GPX7G/GPX8G

SECTION 5

DIAGRAMS

DEVICE, OPTICAL

(CMS-S76RFS3G)

VR (780)

RF

VOA/A

VOB/B

VOC/C

VOD/D

VC

MSW

FCS+

FCS–

TRK+

TRK–

SL+ 10

SL– 11

SP+ 12

SP– 13

AUTOMATIC POWER

CONTROL

Q606

AUTOMATIC POWER

CONTROL

Q605

CD ON

SWITCH

Q604-1

CD ON

SWITCH

Q604-2

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

6

VO1+

VO1-

7

9

VO2-

8

VO2+

VO3+

VO3-

VO4+

VO4-

Q603

REGO1

IC801

IN1

IN2

IN3

IN4

REGO2

24

23

22

21

RF IP123

OPOUT124

RF_C1

128

RF_B

127

RF_A

RF_D2

RF_F4VOE/E+G

RF_E3VOF/F+H

10

V2O

MDI113PD

LDO114LD (780)

LDO215LD (650)

RF AMP, SERVO DSP,

AUDIO PROCESSOR

MSW20VR (650)

FOO22

TRO21

FMO18

DMO17

IC501

ASDATA0

ADIN

ACLK

ALRCK

ABCK

USB_DP 25

USB_DM 24

SF_CK

SF_CS#

SF_DI

SF_DO

IFSDI 40

IFSDO 35

IFSCK 34

IFCS# 42

IFBSY 41

MULTIPLEXER

IC741

1C0

FLASH ROM

IC502

SCK

6

CS_

1

SI

5

SO

2

6

1C1

5

118

106

112

117

113

33

30

32

31

DG0, DQ1 – DQ15

2, 4, 5, 7, 8, 10, 11, 13, 42,

44, 45, 47, 48, 50, 51, 53

1Y

7

A

14

64M SDRAM

IC504

A0 – A11

23 – 26,

29 – 34, 22, 35

ASYNCHRONOUS SAMPLE

RATE CONVERTER

IC761

SDIN

4

2

RCKI

A/D CONVERTER

IC721

9

DOUT

6

SCKI

7

LRCK

8

BCK

USBUP_DP

31

USBUP_DM

30

USB CONTROLLER

IC700

VBUS_DET27

RESET_N26

XTAL1/

CLKIN

33

24MHz

20

21

38

15

39

X700

SDOUT

BCKO

LRCKO

/RST

VINL

VINR

XTAL2

32

18

17

23

25

24

13

13

L-IN

(Page 24)

14

R-CH

2USBDN1_DP

1USBDN1_DM

4USBDN2_DP

3USBDN2_DM

83

82

25

35

36

37

41

38

16

DSP

IC762

SDIN1

11

22

SCLKOUT1

LRCK

19

21

MCLKO

32 15 16

B

27 47 48

HUB-RESET

HUB-VBUS-DETECT

ASEL

MTK-OSD

MTK-SI

MTK-CLK

MTK-XIFCS

MTK-BUSY

SYSTEM

CONTROLLER

IC500 (1/4)

SDOUT1

SCLKOUT2

SDA1

/RESET

DSP-DATA

DSP-RESET

HUB-OC1

27

23

SCL1

DSP-CLK

84

28HUB-OC2

1

COMPARATOR

7

D/A CONVERTER

IC763

DATA

2

BCK

1

LRCK

3

SCK

16

USB

IC702

VOUT L

VOUT L

3

5

VBUS

VBUS

R-CH

D+

D–

D+

D–

CN1201

3

2

1

CN1202

3

2

1

L-OUT

VBUS +5V

A

PLAY

REC/PLAY

(Page 24)

A

B

7

8

REGO1

HCD-GPX5G/GPX7G/GPX8G

REGO2

29

39

2

OPIN-

REGVAR

REG5

VSPDL

MUTE123

MUTE4

TSDM

2335

SPFG/OPINN12627

MUTE1234533

MUTE41934

TSD_M

7

XTALI

X501

27MHz

52 – 55, 57 – 60,

69 - 62

RD0 – RD15

XTALO

8

90 - 92, 79 - 74,

88, 73

RA0 – RA11

85

86

72

61

70

83

82

80

BA0 BA0

BA1 BA1

RCLK CLK

DQM0 LDQM

DQM1 UDQM

RAS# RAS

CAS# CAS

PRST #

RWE# WE

38

MTK-RST40

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: CD PLAY

: AUDIO

: USB

2323

HCD-GPX5G/GPX7G/GPX8G

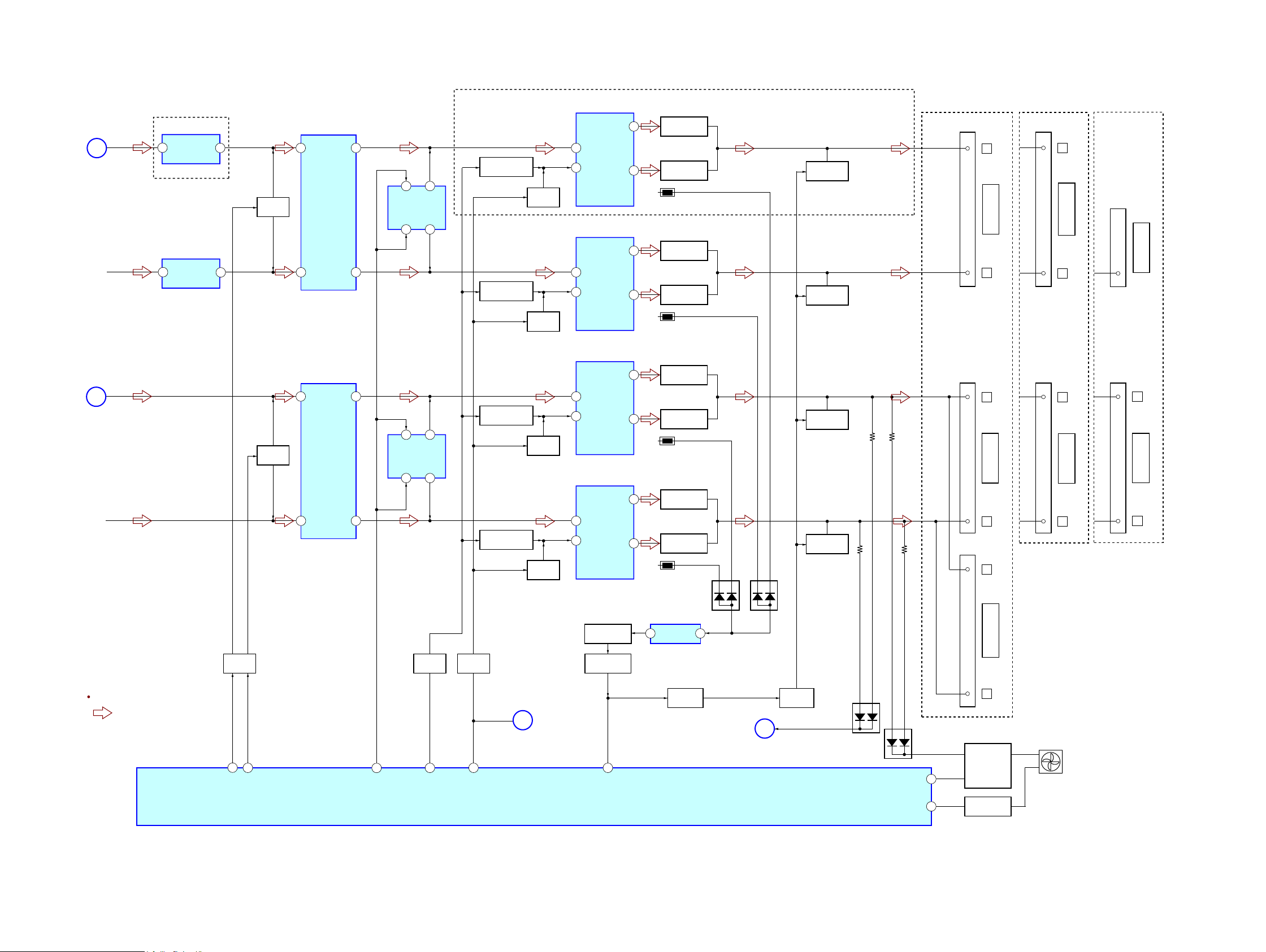

5-2. BLOCK DIAGRAM – MAIN Section –

(Page 23)

PC/

GAME

DVD/

SAT

TV

MIC IN

ANTENNA

FM/AM

J500

J1300

CN103

A

AUDIO IN

L

R

R-CH

R-CH

R-CH

L-OUT

X101

32.768kHz

4

7

6

18

19

TUNER (FM/AM)

FRF1

FRF2

ARF1

X1

X2

GPX7G/GPX8G

MIC LEVEL

MIN MAX

IC101

RV1300

LOUT

ROUT

DA

CK

RDSI

OP AMP

IC901

MIC AMP

IC1301

13

1375

MIC DRIVE

Q1302,Q1301

R-CH

14

13

10

8

39 GAME_L

43

GAME-LEFT

45

DVD LEFT

40

TV LEFT

46

MIC

42

ST-L15

21

DATA22CLK

INPUT SELECTOR,

ELECTRICAL VOLUME

IC806

INGAIN OUT L

INGAIN OUT R

OUTL

BB1L

BB2L

OUTR

BB1R

BB2R

AGCOUTL

AGCOUTR

SWOUT

OUTL

BASS AGC

SW OUT L

L-IN

B

C

E

D

(Page 23)

(Page 25)

(Page 25)

(Page 25)

38

5

R-CH

26

28

27

19

R-CH

18

17

25

20

R-CH

23

BASS AGC

Q900

BASS AGC

Q950

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: AUDIO

: TUNER (FM/AM)

: MIC

M751

(LOADING)

M

M741

M

(TABLE)

ROTARY ENCORDER

(DISK TRAY ADDRESS DETECT)

(OPEN/CLOSE DETECT)

TABLE ADDRESS SENSOR

RE701

S751

IC731

GPX7G

HIGH SPAKER (L,R)

(BLUE)

GPX8G

FRONT SPAKER (L,R)

(R,G,B)

SUBWOOFER (L,R)

(R,G,B)

GPX7G

LOW SPAKER (L,R)

(BLUE)

D1800

(RED)

D1801

D001

D001

D1800

(RED)

D1801

ST-RDS

18

77

78

ST-CLK

ST-DATA

MIC DETECT

86

AUDIO DATA

87

AUDIO CLK

SYSTEM CONTROLLER

IC500 (2/4)

FR-SPK-LED-RED

FR-SPK-LED-BLUE

FR-SPK-LED-GREEN

SW-SPK-LED-GREEN

SW-SPK-LED-RED

SW-SPK-LED-BLUE

GPX7G/GPX8G

3

4

22

24

28

30

15X-IN

13X-OUT

10XC-IN

11XC-OUT

X701

8MHz

X702

32.768kHz

LED

DRIVER

Q704

LED

DRIVER

Q707

LED

DRIVER

Q709

75

IC701

IC712

ADDRESS SENSOR

SWITCH

Q731

FIN

RIN

FIN

RIN

7

9

7

9

3

OUT2

2

4

2

4

OUT1

OUT2

OUT1

LD MOTOR DRIVER

TBL MOTOR DRIVER

52

44

43

46

45

49

50

51

53

TBL-SENS

LM-F

LM-R

TM-F

TM-R

E-1

E-2

E-3

OPEN SW

HCD-GPX5G/GPX7G/GPX8G

2424

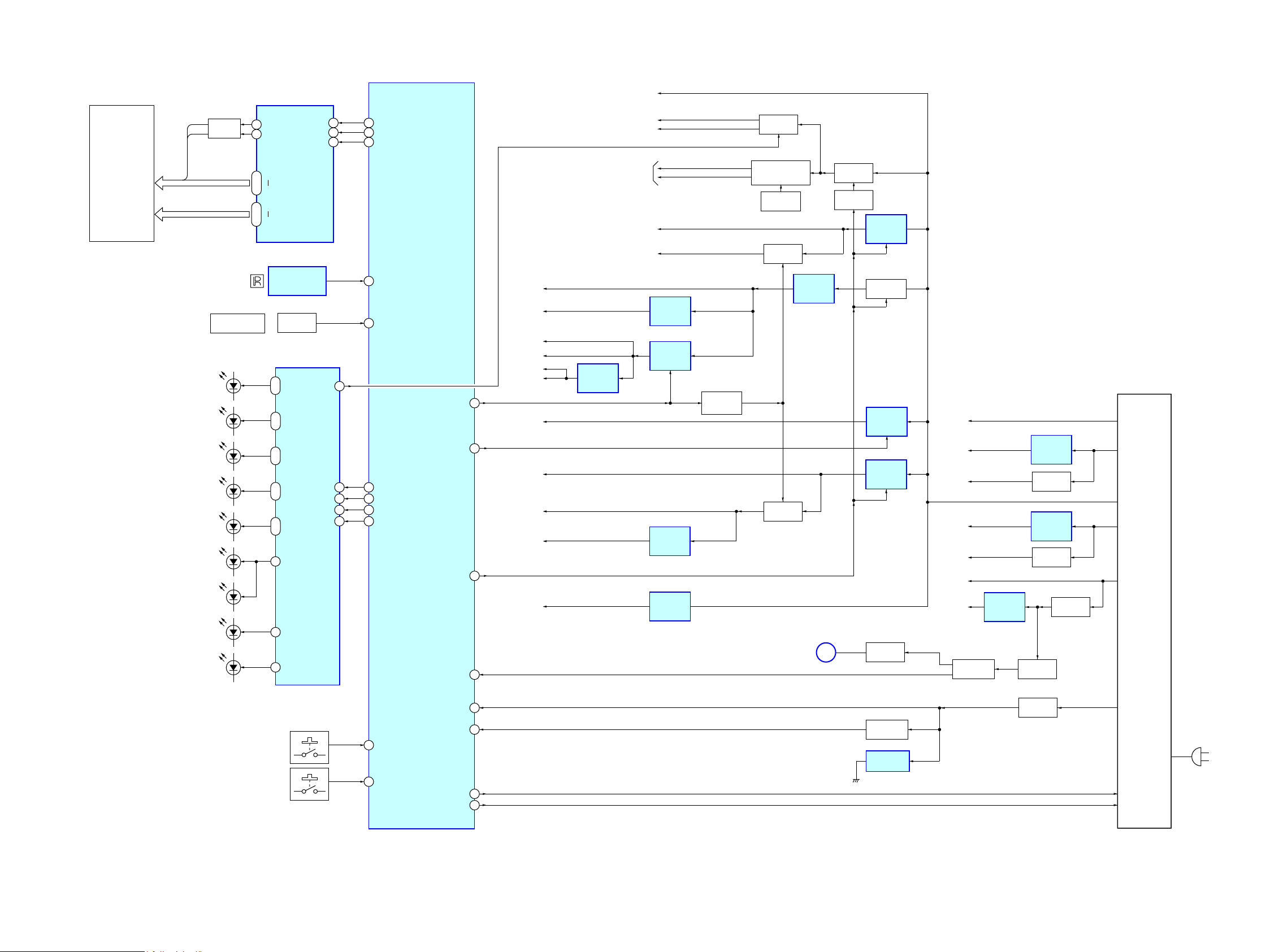

5-3. BLOCK DIAGRAM – AMP Section –

GPX8G

SW BPF-L

IC900

D

(Page 24)

C

(Page 24)

SW OUT L

R-CH

OUTL

R-CH

5

INPUT+

SW BPF-R

IC950

5

INPUT+

OUTPUT

OUTPUT

1

1

MUTE

SWITCH

Q954

MUTE

SWITCH

Q902

2

PREAMP

IC1403

5

INB+ BOUT

2

PREAMP

IC1404

5

INB+ BOUT

HCD-GPX5G/GPX7G/GPX8G

GPX8G

POWER AMP

IC1406

TH1400

TH1401

TH1402

TH1403

BOOSTER

Q1422

BOOSTER

Q1423

BOOSTER

Q1418

BOOSTER

Q1419

BOOSTER

Q1420

BOOSTER

Q1421

BOOSTER

Q1424

BOOSTER

Q1425

D1417 D1419

PROTECTION

Q1443,1454

PROTECTION

Q1444,1455

PROTECTION

Q1445,1456

PROTECTION

Q1446,1457

HO

14

1

AOUTINA-

CLOCK

IC1410

75

BOUT

AOUT

INA+ INB+

13

7

1

AOUTINA-

CLOCK

IC1411

75

BOUT

AOUT

INA+ INB+

13

7

CEC DATA SWITCH

Q1412

CEC DATA SWITCH

Q1413

CEC DATA SWITCH

Q1411

CEC DATA SWITCH

Q1410

RESET

SWITCH

Q1414

RESET

SWITCH

Q1415

RESET

SWITCH

Q1416

RESET

SWITCH

Q1417

3

5

3

5

3

5

3

5

IN

CSD

POWER AMP

IN

CSD

POWER AMP

IC1408

IN

CSD

POWER AMP

IC1409

IN

CSD

IC1407

LO

11

HO

14

LO

11

HO

14

LO

11

HO

14

LO

11

GPX8G

TB1400

TB4002

TB4001

3

2

3

2

3

L

SUBWOOFER

,03('$1&(86(ȍ

R

L

FRONT SPEAKERS

,03('$1&(86(ȍ

R

L

GPX7G

TB1400

3

2

TB4002

3

2

L

SPEAKERS LOW

,03('$1&(86(ȍ

R

L

SPEAKERS HIGH

,03('$1&(86(ȍ

R

GPX5G

TB1403

TB4002

2

3

2

SUBWOOFER

,03('$1&(86(ȍ

L

FRONT SPEAKERS

,03('$1&(86(ȍ

R

SIGNAL PATH

: AUDIO

HCD-GPX5G/GPX7G/GPX8G

80

MUTE

DRIVE

Q802

SW-MUTE

81

FRONT-MUTE

26

DAMP-CLK

SWITCH

DRIVER

Q1474

70

COMPARATOR

IC1405

OTP DRIVE

Q1469, 1470

SWITCH

DRIVER

Q1407

OTW DRIVE/

SD-SLOW DRIVE

Q1405

G

(Page 26)

7471

SYSTEM CONTROLLER

DAMP-OCP

DAMP-RESET

IC500 (3/4)

/SD-SLOW

OUT IN

PROTECTION

Q1449

21

,03('$1&(86(ȍ

SATELLITE SPEAKERS

2

R

FAN MOTOR DRIVE

Q1439, Q1441,

Q1451, Q1453,

Q1458

FAN MOTOR LOCK

Q1447

DC FAN

E

(Page 24)

PROTECTION

Q1448

BASS AGC

D1403

D1435

FAN-DRIVE

FAN-LOCK

69

61

2525

HCD-GPX5G/GPX7G/GPX8G

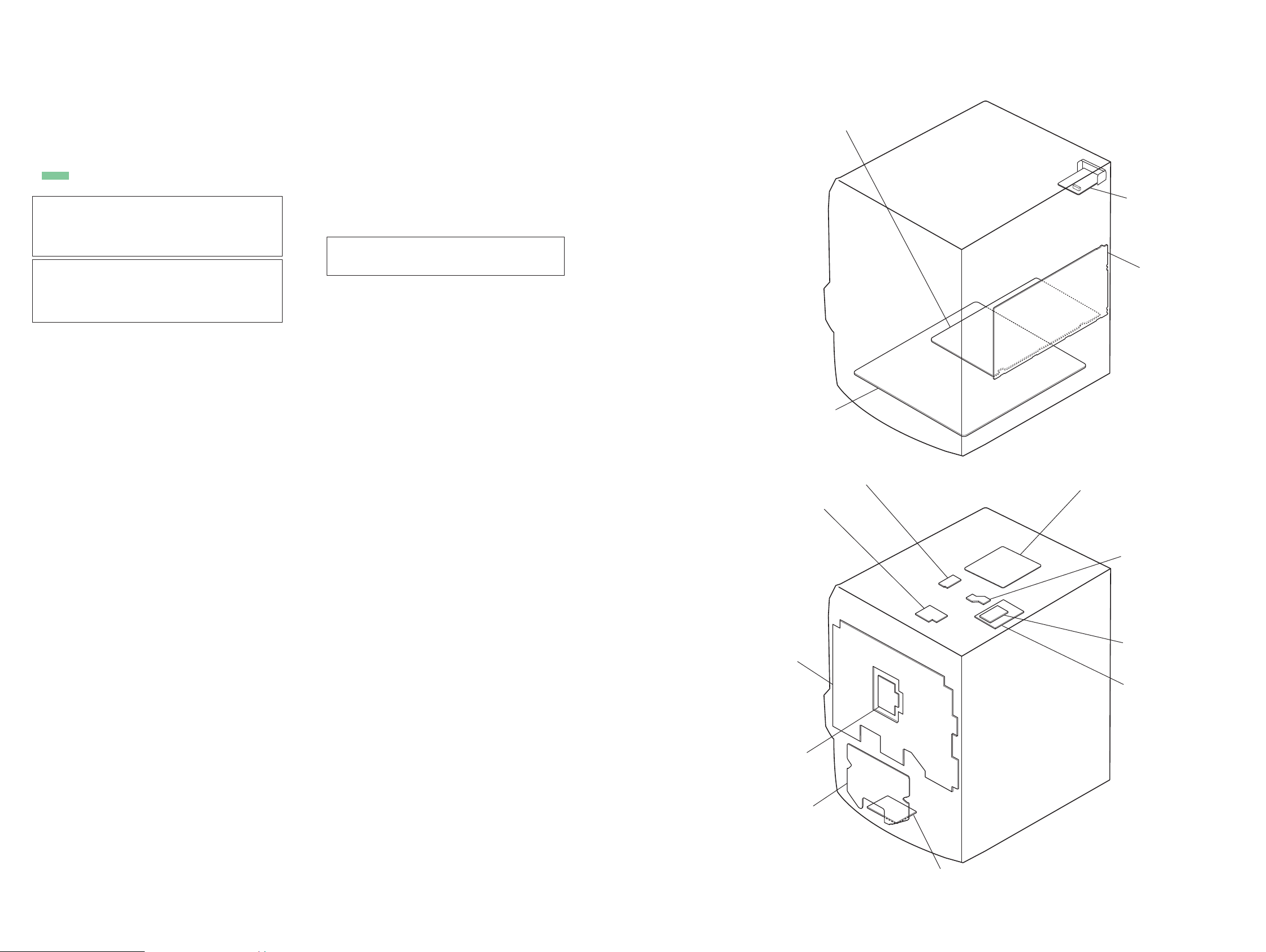

5-4. BLOCK DIAGRAM – PANEL/POWER SUPPLY Section –

VACUUM

FLUORESCENT

DISPLAY

FL1001

GRIDS 1-16

SEGMENTS 1-24

GR15

GR16

D1018 - D1021

TOP ILLUMINATION)

(LEFT

D1006 - D1009

(RIGHT TOP ILLUMINATION)

D1022 - D1024, D1026, D1027

(CENTER ILLUMINATION)

D1014 - D1017

(LEFT BOTTOM ILLUMINATION)

D1010 - D1013

(RIGHT BOTTOM ILLUMINATION)

D1223

(USB B)

D1224

(USB A)

D1221

(DJ EFFECT)

D1216, D1218

(BASS BAZOOKA)

BUFFER

Q1001

DJ CONTROL/

MASTER VOLUME

GR15

48

GR16

49

FLUORESCENT DISPLAY

DRIVER

IC1001

GR2

35 – 47

GR14

SG1/KS1

10 – 33

SG24/KS24

REMOTE CONTROL

RECEIVER

ENCODER

Q4, Q3

23,24

Q6, Q5

21, 22

Q1, Q2, Q10

1, 2, 17

Q9, Q8

18, 1911, 1 2

Q15, Q16

Q13

14

Q12

15

Q11

16

IC1003

S1250

ROTARY

LED DRIVE

CLK

DIN

STB

IC1002

Q7

DATA

/OE

LATCH

CLOCK

191

290

389

20

4

5

6

8

FL-CLK

FL-DATA

FL-CS

5 SIRCS

95

MASTER-VOLUME

LED-DATA

1

LED-DRIVER-OE

7

LED-LATCH

6

LED-CLK

2

SYSTEM CONTROLLER

IC500 (4/4)

MTK-POWER-CTL

PCONT

-PSAVE-PROTECT

(SUB ON)

VBUS-OE

/SD-FAST

+13V

LED +13.5V (SEL A)

LED +13.5V (SEL B)

VACUUM

FLUORESCENT

DISPLAY

M +9V

VM +9V

D +9V

+3.3V

TU +3.3V

AVDD +5V

DVDD +5V

AVDD +3.3V

RF +3.3V

43

VBUS +5V

25

D +3.3V

DVDD +3.3V

DVDD +1.8V

79

EVER +4V

68

+3.3V

REGULATOR

IC652

REGULATOR

IC103

+5V

REGULATOR

IC701

+1.8V

REGULATOR

IC651

+4V

REGULATOR

IC804

SWITCH

DRIVER

Q703

DINAMIC LED

DRIVING

Q1006 - Q1009

DC-DC CONVERTER

T1001

OSC

Q1004, Q1005

SWITCH

Q702

SWITCH

Q701

(Page 25)

A +9V

REGULATOR

IC803

G

SWITCH

Q716

SWITCH

Q715

M +9V

REGULATOR

IC802

SWITCH

Q806, Q807

VBUS +5V

REGULATOR

IC800

D +3.3V

REGULATOR

IC801

RESET

Q1475

SEL A :

DISPLAY BOARD

D1008, D1009, D1012, D1013, D1016, D1017,

D1018, D1019, D1022, D1023, D1027

USB BOARD

D1218, D1224

SEL B:

DISPLAY BOARD

D1006, D1007, D1010, D1011, D1014, D1015,

D1020, D1021, D1024, D1026

USB BOARD

D1216, D1221, D1223

+53V

+18V

+5.0 V

-18V

-5.0V

-53V

-40V

AMP RESET

Q1402, Q1460

-40V

REGULATOR

IC1402

REGULATOR

REGULATOR

SWITCHING

Q1401

+18V

IC1414

+5.0V REG

Q1477

-18V

IC1415

-5.0V REG

Q1478

REGURATOR

Q1400

REGULATOR,

SWITCHING

+VH

+VL

+13V

-VL

-VH

HCD-GPX5G/GPX7G/GPX8G

S1001 - S1005,

S1180 - S1184

S1006 - S1010,

S1210 - S1218

AC-CUT

19

RESET

12

67

AD-KEY0

92

AD-KEY1

PCONT-DAMP (MAIN ON)

PCONT-7V-13.5V (PCONT SUB)

65

63

μCOM RESET

Q506

μCOM RESET

IC508

BUFFER

Q507

AC-DET

(AC IN)

MAIN ON

SUB ON

2626

HCD-GPX5G/GPX7G/GPX8G

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : Parts extracted from the conductor side.

• f : Internal component.

• : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

• Abbreviation

E4 : African model

E2 : 120V AC area in E model

E51 : Chilean and Peruvian models

MX : Mexican model

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : Internal component.

• 2 : Nonfl ammable resistor.

• 5 : Fusible resistor.

• C : Panel designation.

Note: The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specifi ed.

• A : B+ Line.

• B : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM)

* : Impossible to measure

• Voltages are taken with VOM (Input impedance 10 M).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

f : TUNER (FM/AM)

N : MIC

J : CD PLAY

E : USB

• Abbreviation

E4 : African model

E2 : 120V AC area in E model

E51 : Chilean and Peruvian models

MX : Mexican model

• Circuit Boards Location

4CH DAMP board

TUNER1AM3R board

MAIN board

REGULATOR, SWITCHING board

SWITCH board

DMB22 board

MOTOR (LD) board

SENSOR board

HCD-GPX5G/GPX7G/GPX8G

DISPLAY board

MOTOR (TB) board

DRIVER board

VOLUME board

USB board

MIC board (for GPX7G/GPX8G)

2727

Loading...

Loading...