Page 1

HCD-EX5

Amplifier section

For the U.S. model

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

With 4 ohms loads, both channels driven, from

120 - 10,000 Hz; rated 12 watts per channel

minimum RMS power, with no more than 10%

total harmonic distortion from 250 milli watts

to rated output.

North American model:

Continuous RMS power output (Reference):

15 + 15 W

(4 ohms at 1 kHz, 10%

THD)

European model:

DIN power output (Rated):12 + 12 W

(4 ohms at 1 kHz, DIN)

Continuous RMS power output (Reference):

15 + 15 W

(4 ohms at 1 kHz, 10%

THD)

Music power output (Reference):

15 + 15 W

Other models:

The following measured at 220 V AC, 60 Hz

DIN power output (Rated):

12 + 12 W

(4 ohms at 1 kHz, DIN,

110 V – 240 V AC)

Continuous RMS power output (Reference):

15 + 15 W

(4 ohms at 1 kHz, 10%

THD, 110 V – 240 V AC)

Inputs

PC/TAPE/MD IN (stereo mini jack):

voltage 450 mV (MD)/

250 mV (PC/TAPE),

impedance 47 kilohms

AM tuner section

Tuning range

Pan-American model: 530 – 1,710 kHz

(with the interval set at

10 kHz)

531 – 1,710 kHz

(with the interval set at

9kHz)

European model: 531 – 1,602 kHz

(with the interval set at

9kHz)

Other models: 530 – 1,710 kHz

(with the interval set at

10 kHz)

531 – 1,602 kHz

(with the interval set at

9kHz)

Antenna AM loop antenna, external

antenna terminal

Intermediate frequency 450 kHz

Outputs

PC/TAPE/MD OUT (stereo mini jack):

voltage 250 mV,

impedance 1 kilohm

PHONES (stereo mini jack):

accepts headphones with

an impedance of 8 ohms

or more

OPTICAL CD DIGITAL OUT (Supported sampling

frequency: 44.1 kHz)

CD player section

System Compact disc and digital

audio system

Laser Semiconductor laser

(λ = 795 nm)

Emission duration:

continuous

Frequency response 2 Hz – 20 kHz

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

North American model: 87.5 – 108.0 MHz

(100-kHz step)

Other models:

87.5

– 108.0 MHz

(50-kHz step)

Antenna FM wire antenna

Antenna terminals

75 ohms unbalanced

Intermediate frequency 10.7 MHz

SERVICE MANUAL

Ver 1.1 2003. 12

This set is the tuner, CD and amplifier

section in CMT-EX5

CD

SECTION

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Chinese Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM71C-31BD63A

Base Unit Type BU-31BD63A

9-874-036-02

2003L16-1

© 2003.12

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

MICRO Hi-Fi COMPONENT SYSTEM

— Continued on next page —

Page 2

HCD-EX5

General

Power requirements

North American model: 120 V AC, 60 Hz

European model: 230 V AC, 50/60 Hz

Mexican model: 120 V AC, 60 Hz

Australian model: 220 – 240 V AC,

Korean model: 220 V AC, 60 Hz

Chinese model: 220 V AC, 50/60 Hz

Other models: 110 – 240 V AC,

Power consumption

European model: See the nameplate

Other models: See the nameplate

Dimensions (w/h/d) Approx. 186 × 235 ×

Mass Approx. 3.0 kg

Design and specifications are subject to change

without notice.

50/60 Hz

50/60 Hz

0.25 W (at the Power

Saving Mode)

157 mm incl. projecting

parts and controls

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The A C leakage from any e xposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

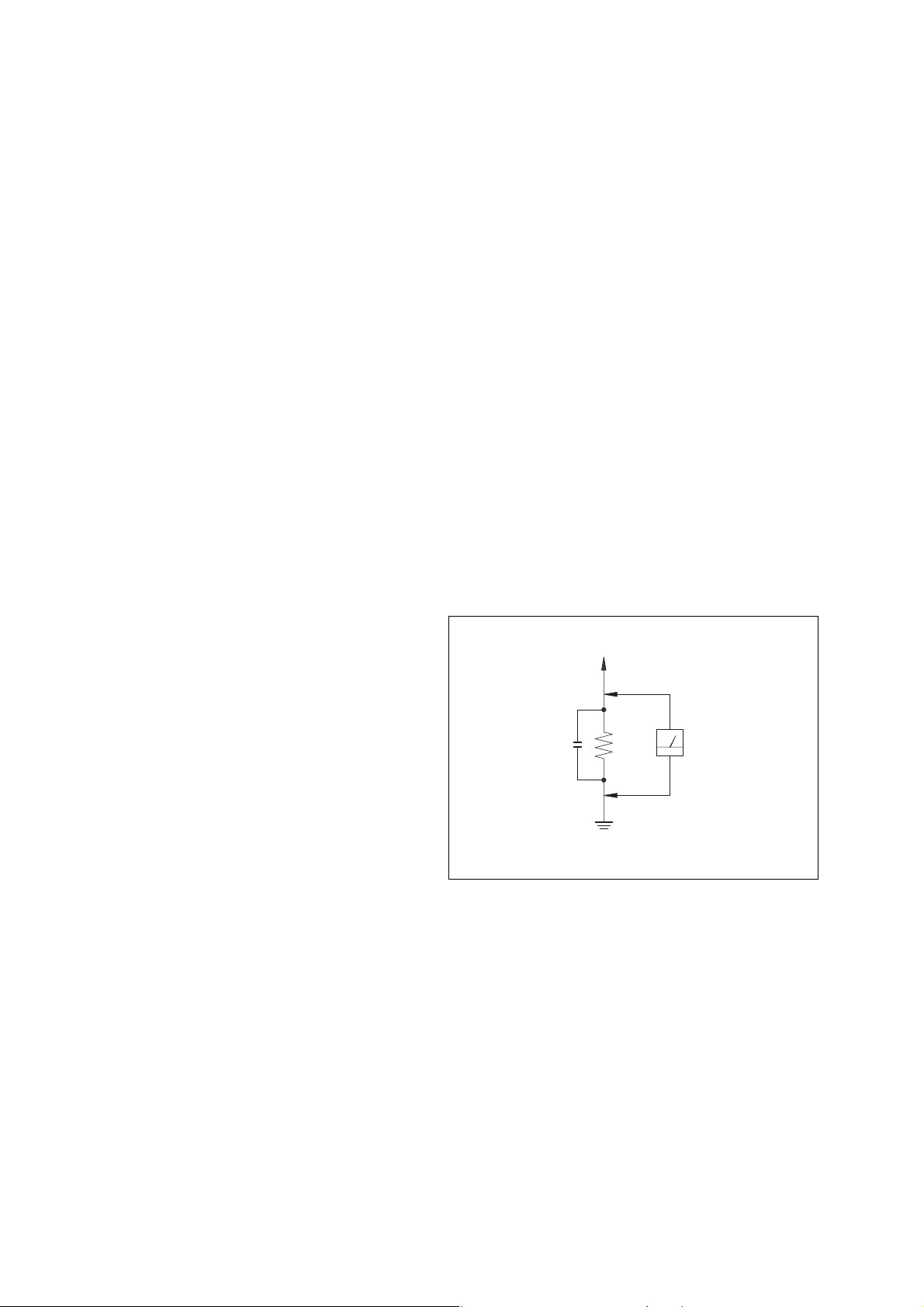

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated A C voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-v olta ge

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 µF

Fig. A. Using an A C v oltmeter to check A C leakage.

1.5 kΩ

Earth Ground

Voltmeter

(0.75 V)

2

Page 3

TABLE OF CONTENTS

1. SERVICING NOTES ······················································· 4

2. GENERAL ·········································································· 5

3. DISASSEMBLY ································································ 8

3-1. Case ··············································································· 9

3-2. OC Boad,OS Boad ························································ 9

3-3. Glass Windo w Assy (U) ·············································· 10

3-4. POWER Board ···························································· 10

3-5. BD Board····································································· 11

3-6. MAIN Board, Tunner ·················································· 11

3-7. CD Mechanism (CDM71C-31BD63A)·······················12

3-8. Base Unit(BU-31BD63A) ··········································· 12

3-9. Holder Assy, Sled Motor Assy (M102) ······················· 13

3-10.Case Button Assy, LID Board ····································· 13

3-11.LID (CD) ····································································· 14

3-12.Ornament (Mecha Panel)············································· 14

3-13.L.MOTOR Board························································· 15

3-14.C MOTOR Board, L.SENSOR Board························· 15

3-15.ENCODER Board, D.SENSOR Board ·······················16

3-16.RTR Pulley Assy, RTL Pulley Assy,

Belt (CDM71), Belt (Roller) (L) ································· 17

3-17.SPT Pulley Assy, Gear (RT) Assy, Gear (KT),

Belt (CDM71) ····························································· 19

4. TEST MODE····································································21

HCD-EX5

6. DIAGRAMS······································································ 25

6-1. Block Diagrams··························································· 25

6-2. Circuit Boards Location ·············································· 28

6-3. Schematic Diagram – BD Board – ······························29

6-4. Printed Wiring Board – BD Board (Side A) – ············· 30

6-5. Printed Wiring Board – BD Board (Side B) – ············· 31

6-6. Schematic Diagram – MAIN Section (1/2) – ·············· 32

6-7. Schematic Diagram – MAIN Section (2/2) – ·············· 33

6-8. Printed Wiring Board – MAIN Board (Side A) –········ 34

6-9. Printed Wiring Board – MAIN Board (Side B) – ········ 35

6-10.Printed Wiring Board – PANEL Section (Side A) –····36

6-11.Printed Wiring Board – PANEL Section (Side B) –···· 37

6-12.Schematic Diagram – MOTOR Section – ···················38

6-13.Printed Wiring Board – MOTOR Section – ················ 39

6-14.Printed Wiring Board – POWER Board (Side A) – ···· 40

6-15.Printed Wiring Board – POWER Board (Side B) – ···· 41

6-16.Schematic Diagram – POWER Section – ···················42

6-17.IC Pin Function Description········································ 43

7. EXPLODED VIEWS ······················································ 47

7-1. Case Section ································································ 47

7-2. Chassis Section-1 ························································48

7-3. Chassis Section-2 ························································49

7-4. Mechanism Section(CDM71C-31BD63A)-1·············· 50

7-5. Mechanism Section(CDM71C-31BD63A)-2·············· 51

7-6. Base Unit (BU-31BD63A) ·········································· 52

5. ELECTRICAL ADJUSTMENTS ······························· 24

8. ELECTRICAL PARTS LIST ······································· 53

3

Page 4

HCD-EX5

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

This caution

label is

located inside

the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

4

Page 5

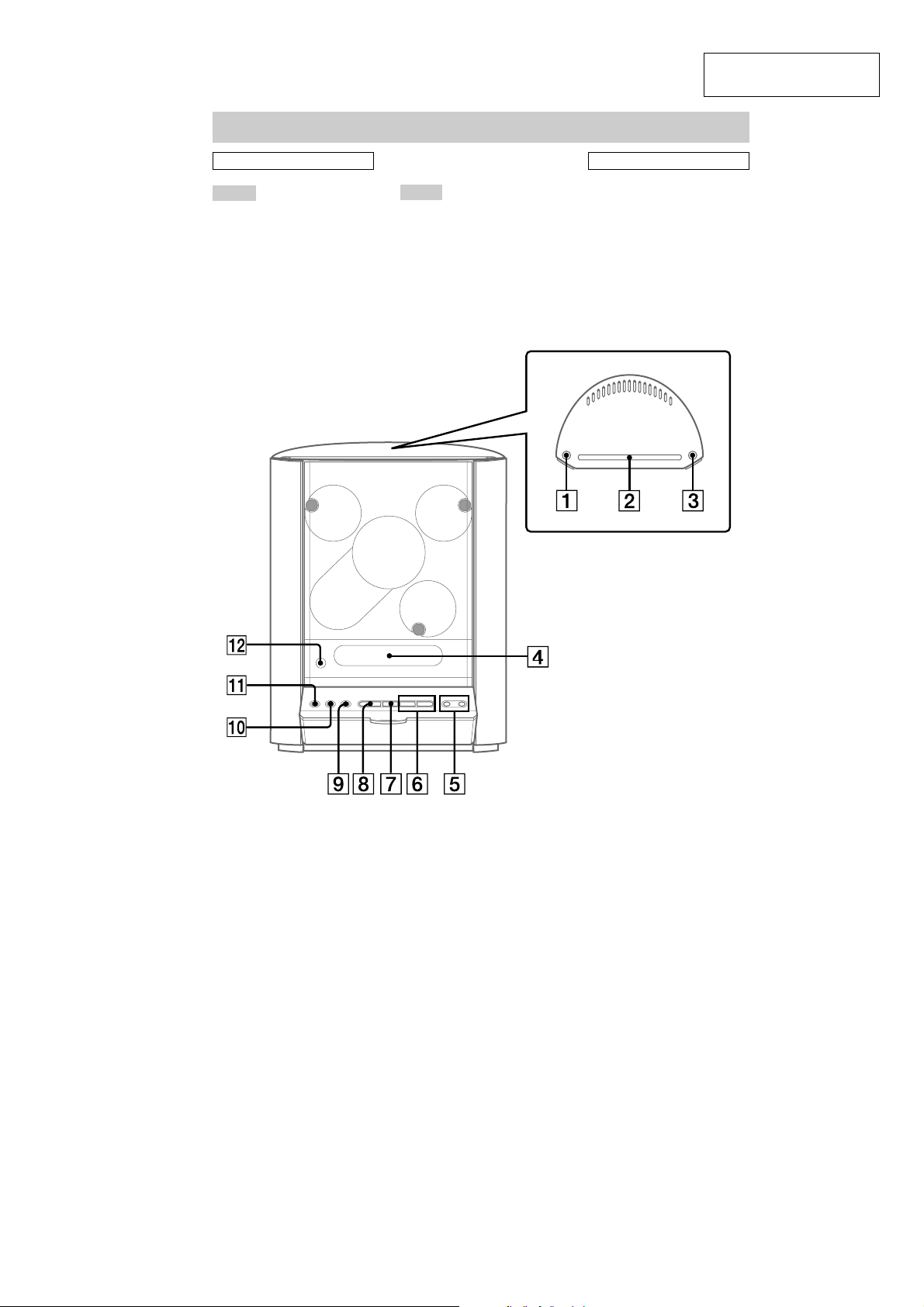

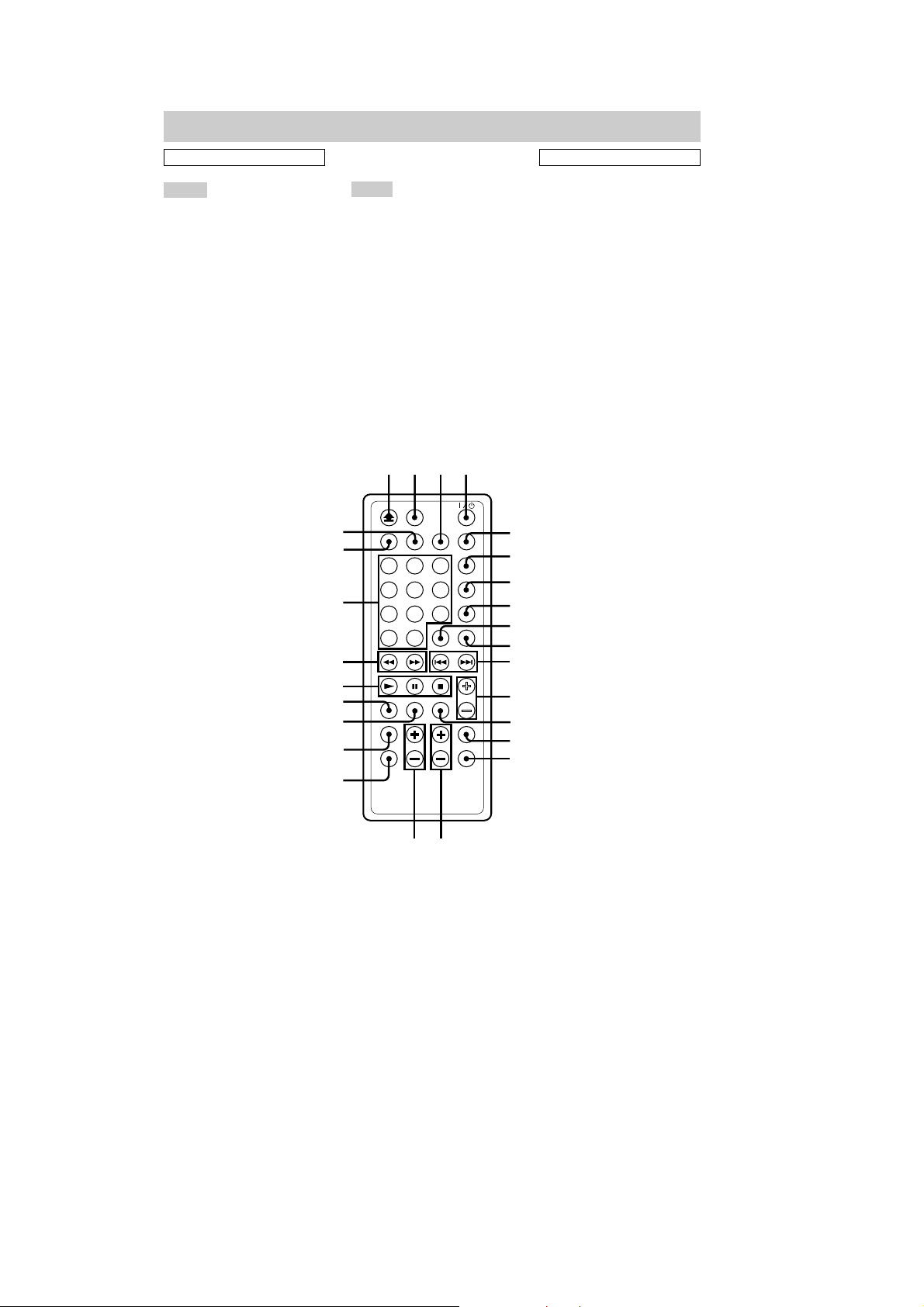

Main unit

SECTION 2

GENERAL

HCD-EX5

This section is extracted

from instruction manual.

ALPHABETICAL ORDER

A – Q

Disc slot 2 (23)

Display window 4

DISPLAY qa (16, 19, 20)

FUNCTION 0 (9 - 13, 15, 22,

24)

R – Z

Remote sensor qs

TUNER/BAND 9 (13 - 15, 24)

TUNING +/– 6 (13 -15)

VOLUME +/– 5 (18)

BUTTON DESCRIPTIONS

@/1 (power) 1

Z 3

./> 6

m/M 6

x 7

NX 8

To open the front cover, push

down on the knob under the

display window.

5

Page 6

HCD-EX5

Remote control

ALPHABETICAL ORDER

A – K

BASS +/– qj (17)

CD N ws (9 - 11, 23)

CLEAR 9 (10 - 12, 16)

CLOCK/TIMER SELECT 6

(19)

CLOCK/TIMER SET 7 (8, 18)

CURSOR T/t wd (8, 12)

DIMMER qk (19)

DISPLAY wg (16, 19, 20)

DSG qf (17)

ENTER/YES 8 (8, 10, 12 - 14,

16, 18, 19, 22)

FM MODE qd (15, 24)

FUNCTION ql (9 - 13, 15, 22,

24)

L – Z

Letter/Number buttons wf (10,

12, 15)

MENU/NO q; (12 - 14, 16, 22)

NAME EDIT/SELECT 3 (11,

16)

PLAY MODE w; (9 - 11, 13, 23,

25)

REPEAT qd (10)

SCROLL 5 (12, 20)

SLEEP 2 (17)

SURROUND qg (17)

TIME wh (11, 20)

TREBLE +/– qh (17)

TUNER BAND wa (13 -15)

TUNING MODE w; (13 - 15)

VOL +/– qs (18)

1 234

wh

wg

wf

wd

ws

wa

w;

ql

qk

BUTTON DESCRIPTIONS

Z 1

@/1 (power) 4

./> qa

+/– qa

X ws

x ws

m/M wd

5

6

7

8

9

0

qa

qs

qd

qf

qg

qhqj

6

Page 7

HCD-EX5

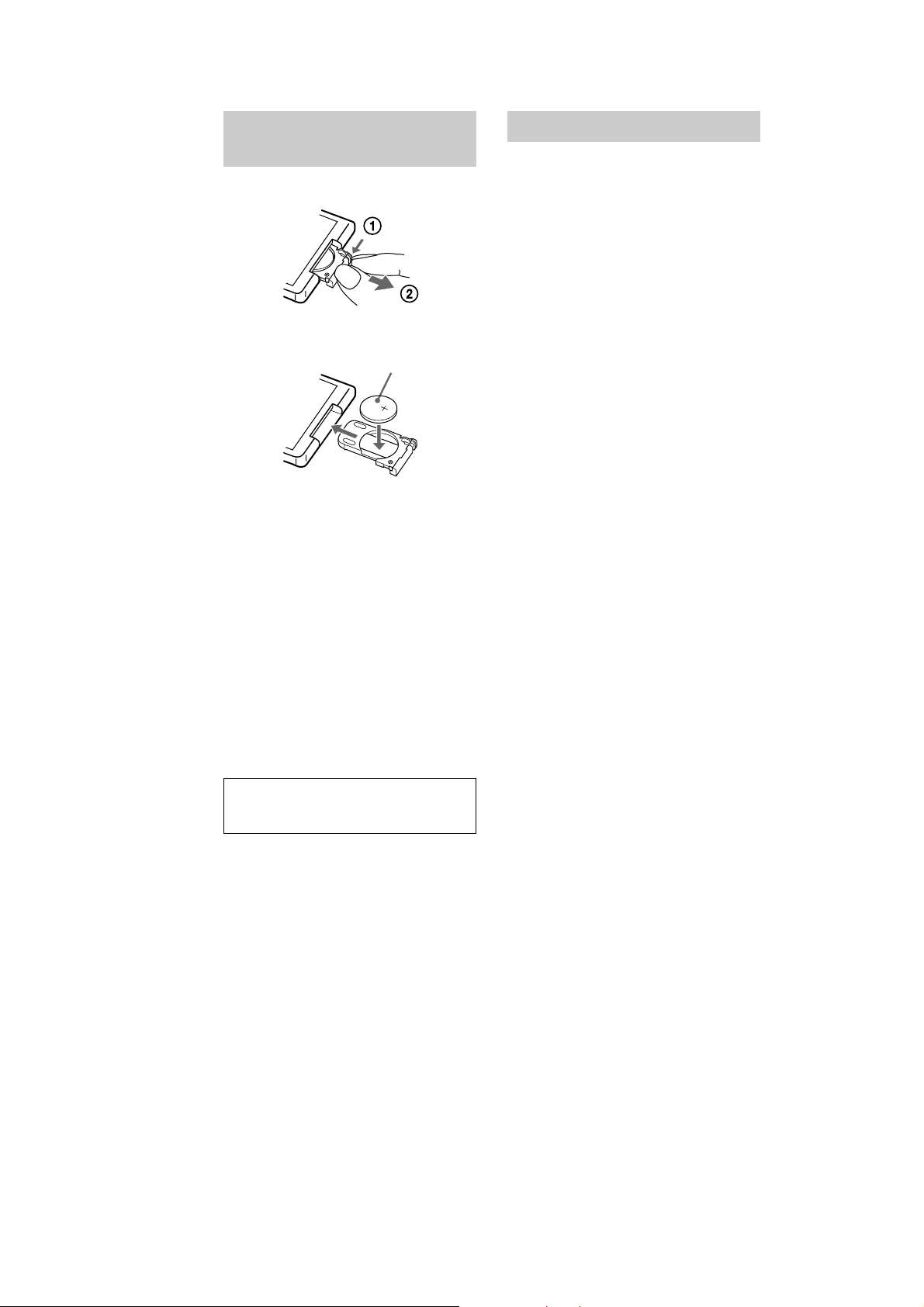

Replacing the battery in

the remote

1

Slide out and remove the battery case.

2

Insert a new lithium battery CR2025

with the + side facing up.

A lithium battery CR2025

3

Slide the battery case back in.

Tip

When the remote no longer operates the system,

replace the battery with a new one.

Note

If you do not use the remote for a long period of time,

remove the battery to avoid possible damage from

battery leakage and corrosion.

Notes on lithium battery

• Keep the lithium battery out of the reach of

children. Should the battery be swallowed,

immediately consult a doctor.

• Wipe the battery with a dry cloth to assure a good

contact.

• Be sure to observe the correct polarity when

installing the battery.

• Do not hold the battery with metallic tweezers,

otherwise a short-circuit may occur.

Setting the clock

1

Turn on the system.

2

Press CLOCK/TIMER SET on the

remote.

The day indication flashes.

3

Press . or > on the remote

repeatedly to set the day, then press

ENTER/YES on the remote.

The hour indication flashes.

4

Press . or > on the remote

repeatedly to set the hour, then press

ENTER/YES on the remote.

The minute indication flashes.

5

Press . or > on the remote

repeatedly to set the minuite, then

press ENTER/YES on the remote.

If you made a mistake

Press TCURSOR or CURSORt on the remote

repeatedly until the indication you want to change

(day, hour, minuite) flashes, and then change the

setting.

To adjust the clock

1

Press CLOCK/TIMER SET on the remote.

2

Press . or > on the remote

repeatedly to select “CLOCK SET?”, then

press ENTER/YES on the remote.

3

Do the same procedures as steps 3 to 5

above.

WARNING

Battery may explode if you mistreated.

Do not recharge, disassemble or dispose of in fire.

7

Page 8

HCD-EX5

SECTION 3

DISASSEMBLY

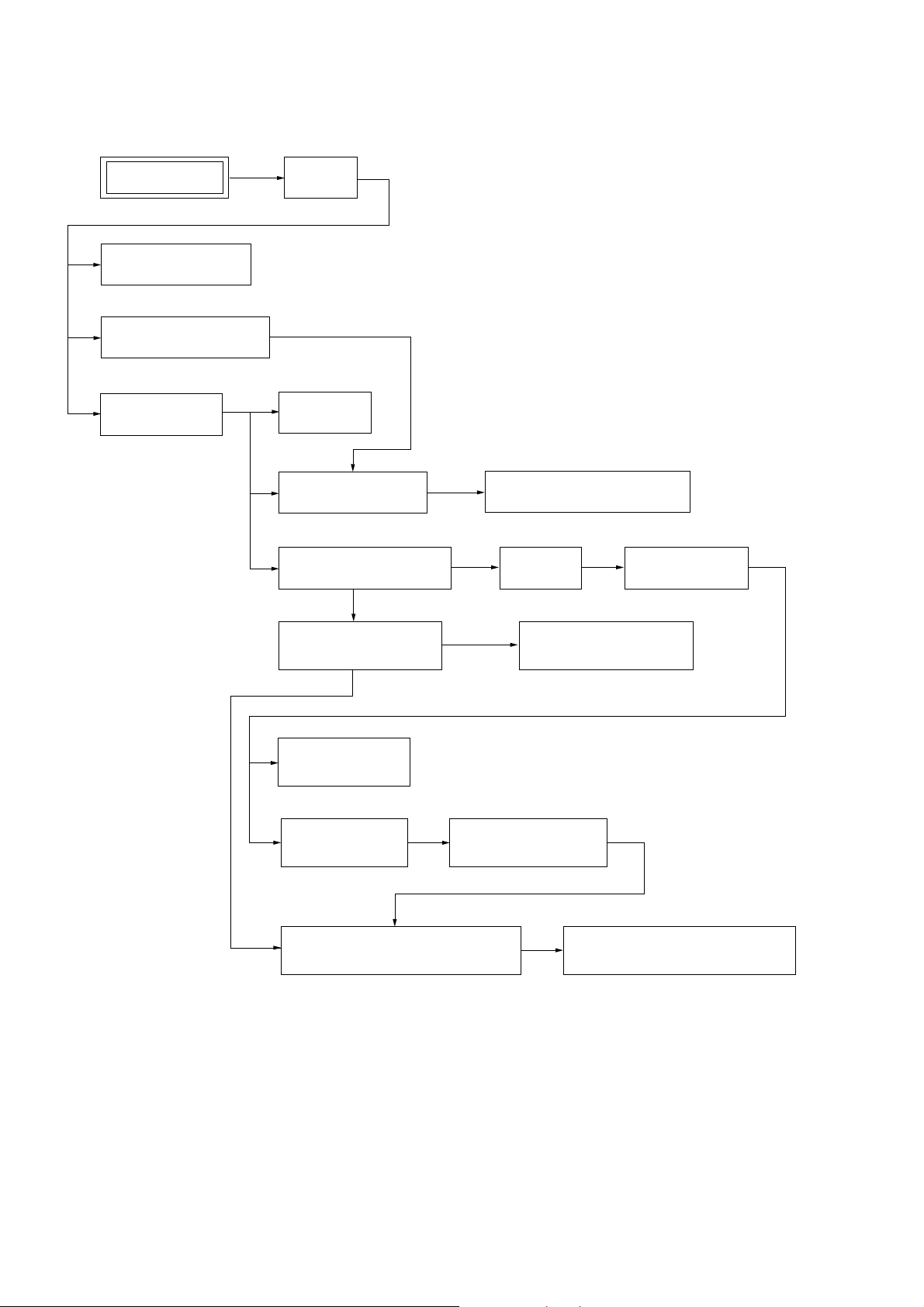

• The equipment can be removed using the following procedure.

SET (HCD-EX5) CASE

OC BOARD,OS BOARD

GLASS WINDOW ASSY (U)

POWER BOARD

BD BOARD

MAIN BOARD,TUNNER

CD MECHANISM

(CDM71C-31BD63A)

BASE UNIT (BU-31BD63A)

C MOTOR BOARD,

L.SENSOR BOARD

L.MOTOR BOARD

CASE BUTTON ASSY,LID BOARD

LID(CD)

HOLDER ASSY ,

SLED MOTOR ASSY (M102)

ENCODER BOARD,

D.SENSOR BOARD

(MECHA PANEL)

ORNAMENT

RTR PULLEY ASSY,RTL PULLEY ASSY,

BELT (CDM71), BELT (ROLLER) (L)

SPT PULLEY ASSY,GEAR (RT)ASSY,

GEAR (KT), BELT (CDM71)

8

Page 9

Note : Follow the disassembly procedure in the numerical order given.

e

3-1. Case

7

HCD-EX5

case

2

six screws (+BVTP 3

3-2. OC Boad,OS Boad

× 8

6

c

onnector

(CN621)

4

four

screws (+BVTP 3

3

cover (bottom)

)

× 8

)

5

1

cover (back)

6

OS board

1

5

two claws

two

screws (+BTP 2.6

× 8

4

guide disc assy

cas

7

two claws

8

OC board

3

bracket

)

2

screw (+BTP 2.6

× 8

)

9

Page 10

HCD-EX5

)

3-3. Glass Window Assy (U)

4

retainer plate

3

t

hree screws (+BVTP 3

(L)

× 8

)

1

t

hree screws (+BVTP 3

× 8

)

3-4. POWER Board

5

6

four bushings (bracket)

four

step

screws (slider)

qf

shield (lower)

7

glass

window assy (U)

qg

insulator (power 1)

qh

2

retainer plate

POWER board

qd

five

screws (+BVTP 3

6

(R)

c

onnector

7

two

screws (+BVTP 3

× 8

)

qs

shield (upper)

qa

four

(+BVTP 3

× 8

screws

)

× 8

)

10

1

two

screws

(+BVTP 3

× 8

5

(15 core)

)

f

lat type wire

q;

(+BVTP 3

four

screws

× 8

)

8

(+BVTP 3

two

screws

× 8

3

clamp

2

three

screws

screws

)

× 8

× 8

)

(+BVTP 3

9

two

(+BVTP 3

4

three

(+BVTP 3

)

screws

× 8

Page 11

3-5. BD Board

)

1

f

lat type wire (23 core)

2

(BLK)

(RED)

Remove solder (two portions ).

7

BD board

4

screw (+B 2

HCD-EX5

× 4

)

3-6. MAIN Board, Tunner

1

two

screws

(+BVTP 3

× 8

2

)

5

h

ook

f

ront panel assy

6

flxible

board

6

3

Remove solder (two portions ).

tunner

5

f

lat type wire

(11 core or 15 core)

3

seven

screws (+BVTP 3

× 8

7

connector

(CN601)

9

MAIN board

8

f

lat type wire

(23 core)

4

back panel

11

Page 12

HCD-EX5

)

3-7. CD Mechanism (CDM71C-31BD63A)

7

CD mechanism (CDM71C-31BD63A)

3

f

lat type wire

(23 core)

4

connector (CN302)

6

four

screws (+BVTP 3

× 8

)

5

connector (CN303)

1

two

screws (+BVTP 3

× 8

)

3-8. Base Unit(BU-31BD63A)

Rotate the SPT pulley assy in the direction of to move the Base unit shaft

forward.

1

1

cam (A)

2

f

ront panel assy

2

screw

(+PTPWH M2.6)

5

base unit

(BU-31BD63A

12

SPT pulley assy

shaft

4

3

shaft

Page 13

HCD-EX5

3-9. Holder Assy, Sled Motor Assy (M102)

9

two screws

(+PTPWH M2.6)

holder assy

7

coil spring (C) (holder)

5

BD board

q;

qs

screw

(+P 2

h

×

ook

8

screw

(+PTPWH M2.6)

qa

base unit

4

flxible

board

qd

sled motor assy (M102)

3)

6

coil spring (B) (holder)

1

Remove solder

(two portions ).

(RED)

(BLK)

3-10. Case Button Assy, LID Board

7

four

screws (+BVTP 3

qd

two

screws

(+KTP 2.6

× 6

)

8

3

screw

(+BTP 2

6

4

two

(+BVTP 3

× 8

)

× 8

)

frame (L)

screws

8

× 8

2

Remove solder

(two portions ).

)

5

two

hooks

3

frame (R)

2

two

hooks

qf

glass window assy (L)

q;

three

screws (+BTP 2.6

9

case button assy

qa

LID board

× 8

)

qs

two

screws (+KTP 2.6

× 6

1

)

screw (+BVTP 3

× 8

)

13

Page 14

HCD-EX5

)

)

3-11. LID (CD)

4

three

(+BVTT 2.6

5

screws

× 4

)

retainer plate (L)

6

LID (CD)

2

three

(+BVTT 2.6

screws

×

4

)

3-12. Ornament (Mecha Panel)

2

ornament (mecha panel)

3

retainer plate (R)

1

tension coil spring (CD door

14

1

four

screws

(+BVTP 2.6

×

8

Page 15

3-13. L.MOTOR Board

)

)

1

Remove solder (two portions ).

4

L.MOTOR board

2

two

screws

(+BVTP 2.6

×

HCD-EX5

8

3

(CN711)

3-14. C MOTOR Board, L.SENSOR Board

3

connector

(CN711)

5

(CN753)

connector

c

onnector

4

c

onnector

(CN754)

1

Remove solder

(two portions ).

6

c

onnector

(CN755)

9

L.SENSOR board (R)

8

screw

(+BTP M 2.6

×

7

6)

2

two screws

(+BTP M 2.6

C MOTOR board

×

6

15

Page 16

HCD-EX5

Ver 1.1 2003.12

3-15. ENCODER Board, D.SENSOR Board

7

D.SENSOR board

4

6

(+BTP 2.6

screw (+PWH 2

5

ENCODER

screw

×

6)

×

6)

3

cover (encoder)

board

2

screw (+BTP 2.6

1

(+BTP 2.6

screw

× 8

)

×

6)

PRECAUTION DURING ENCODER board INSTALLATION

Rotate the pulley (LDG2) until the mark of the cam (A) becomes visible.

Install the ENCODER board in the way that it is sandwiched by

the cut-outs of the ENCODER board.

pulley (LDG2)

ENCODER board

cam (A)

16

Page 17

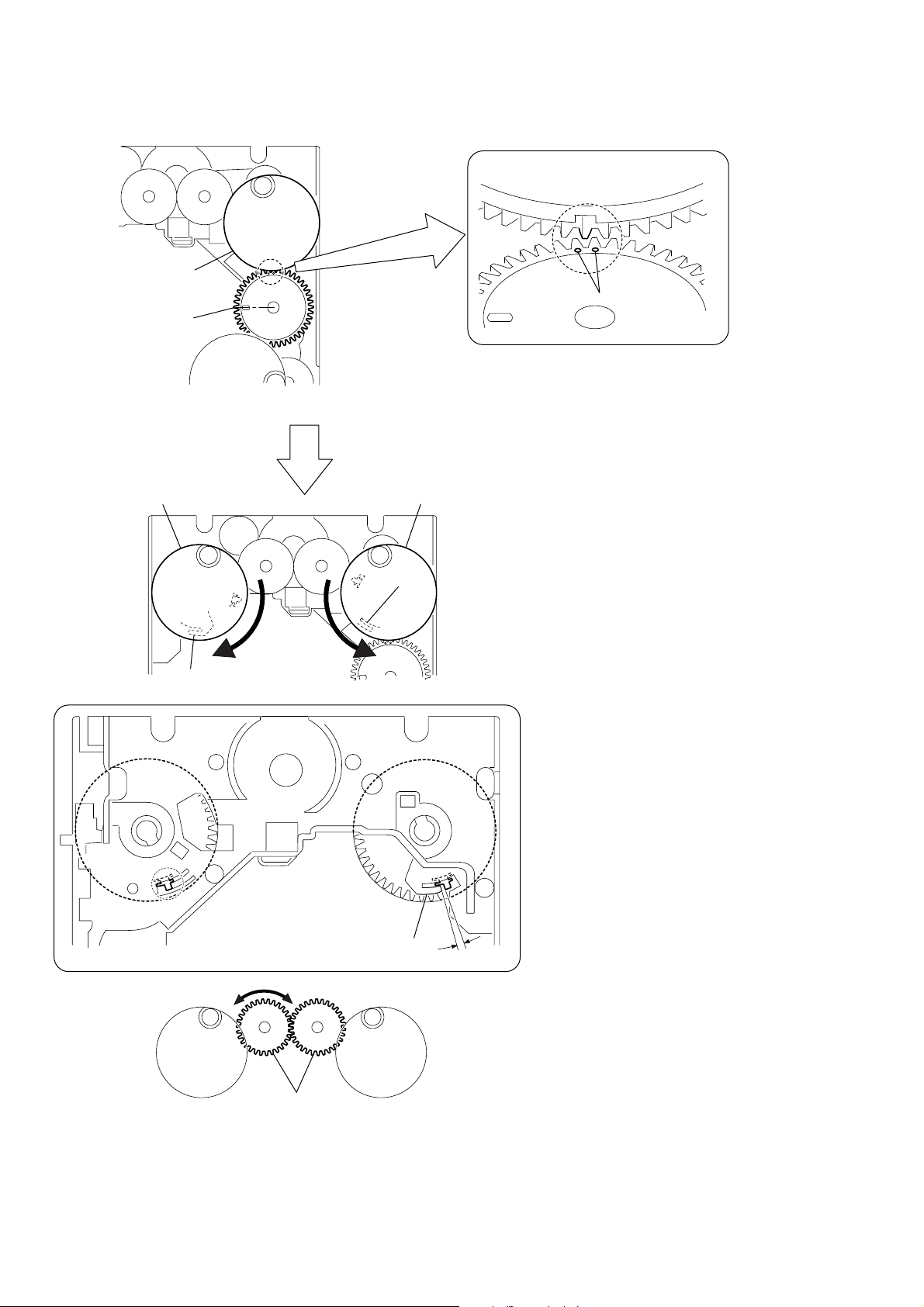

3-16. RTR Pulley Assy, RTL Pulley Assy, Belt (CDM71), Belt (Roller) (L)

6

screw

7

D.SENSOR board

(+BTP 2.6

5

ENCODER

(When installing it, see the ENCODER board item.)

×

6)

3

cover (encoder)

4

screw (+PWH 2

board

2

screw (+BTP 2.6

×

1

screw

(+BTP 2.6

6)

× 8

×

HCD-EX5

)

6)

qf

RTL pulley assy

9

qg

gear (S1)

c

law

qh

belt (CDM71)

q;

8

pulley (RTR) assypulley (RTL) assy

c

law

q;

RTL pulley assy

qd

RTR pulley assy

qs

RTR pulley assy

qj

belt (ROLLER) (L)

qa

17

Page 18

HCD-EX5

PRECAUTION DURING PULLEY (RTR) ASSY, PULLEY (RTL) ASSY INSTALLATION

pulley (RTR) assy

pulley (RTR) assy

gear (S2)

(9 o'clock position)

pulley (RTL) assy

claw

marks of the gear (S2)

Place the holes of the gear (S2) at the 9 o'clock position and install

the pulley (RTR) assy.

Install it in the way that the gear of the cut-out portion as shown is located in

between the marks of the gear (S2).

pulley (RTR) assy

claw

Then install the pulley (RTL) assy in the way that it can perform

the symmetrical movement with the pulley (RTR) assy.

Then lock both claws.

pulley (RTR) assy

pulley (RTL) assy

Confirm that the pulley (RTR) contacts the claws.

Opposite to it, the pulley (RTL) assy must

have clearance of 1 to 2 mm with the claw.

It should contact with claw.

If clearance is too large or it contacts with claw,

adjustment is necessary.

claw

1 to 2 mm

Method of adjustment is as follows.

Raise the right gear (S1) a little and perform adjustment

by moving the left gear (S1).

gear(S1)

18

Page 19

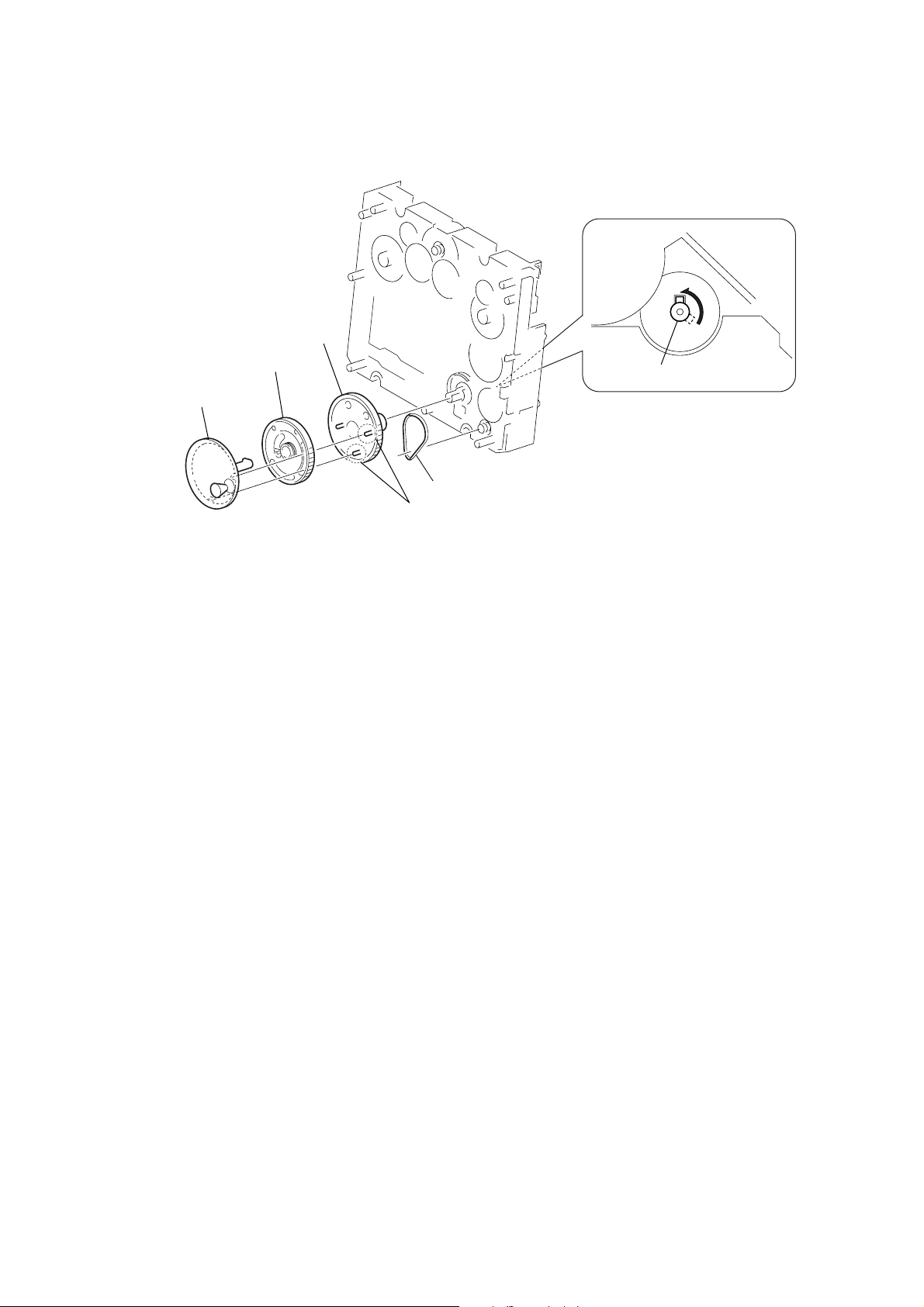

3-17. SPT Pulley Assy, Gear (RT) Assy, Gear (KT), Belt (CDM71)

HCD-EX5

3

2

SPT pulley assy

4

gear (KT)

gear (RT) assy

Rotate the SPT pulley assy in the direction of , and remove your hands

at the position where the shaft agrees with the hole shape on the chassis.

SPT pulley assy

5

belt (CDM71 )

When installing, align the protruded portion of the KT gear with groove of the SPT

pulley assy.

1

1

19

Page 20

HCD-EX5

)

PRECAUTION DURING gear (RT) assy, gear (KT) INSTALLATION

lever (ST)

cam (A)

pulley (LDG2)

Rotate the pulley (LDG2) until it reaches the position

where the cam (A) contacts with the lever (ST).

gear (S2)

torsion spring (M)

The boss that is closest to the inside

gear (KT

Install the gear (KT) and position it so that the boss

that is closest to the inside is located at the 9 o'clock position.

gear (S2)

gear (RT) assy

Install the gear (RT) assy so that the two bosses are aligned

in between the torsion spring (M).

Install the gear (S2) so that its hole is located at the 9 o'clock position.

gear (RT) assy

Confirm that the gear (S2) mark is located

in between the gear (RT) assy marks.

20

Page 21

SECTION 4

TEST MODE

HCD-EX5

[Key Check Mode]

* Keyboard check.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. To enter the test mode, press three buttons Z , DISPLAY ,

and > simultaneously.

3. In the key check mode, the message “KEY00” is displayed.

Each time a button is pressed, “KEY00” value increases.

However, once a button is pressed, it is no longer taken into

account.

4. To e xit from this mode, press three b uttons Z , DISPLAY ,

and > simultaneously.

[Version Display Mode]

* The version or destination is displayed.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. To enter the test mode, press three buttons Z , DISPLAY ,

and x simultaneously.

3. The model name and destination are displayed.

4. Press the DISPLAY button. The STR version is displayed.

5. Press the DISPLA Y button again. The CD v ersion is displayed.

6. Press the DISPLAY button. The model name and destination

are displayed again.

7. To exit from this mode, press the ?/1 button to turn off the set.

[LCD Test Mode]

* All LCD segments are tested.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. To enter the test mode, press three buttons Z , DISPLAY ,

and . simultaneously.

3. The following segments are turned on.

PROGRAM REPEAT SURR

SHUFFLE SLEEPPLAY

DISCID3

MP3

ALBUM

TRACK TUNED MONO MANUAL

ALBUM

1

DSG

STEREO AUTO PRESET

c

These segments remain when entering into the LCD test mode.

4. Press the DISPLAY button. All segments are turned off.

5. Press the DISPLA Y b utton. Confirm the pa ttern of segments.

TEXT SLEEPPLAY

PROGRAM SURR

DISCID3 PRESET

1

TUNED MANUAL

[Amp Test Mode]

* Volume level is changed for the amplifier test.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. To enter the test mode, press three buttons Z , DISPLAY ,

and NX simultaneously.

3. V olume lev el is changeable at three steps as “VOLUME MIN”,

“VOLUME 21”, “V OLUME MAX” by pressing V OLUME +

or VOLUME – button.

4. In this test mode, the tuning mode is set to the preset mode.

5. To exit from this mode, press the ?/1 button to turn off the set.

[Forced Reset]

* All micro-processors are forced to reset at the same time.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press three buttons Z , FUNCTION , and TUNER/BAND

simultaneously.

3. The message “COLD RESET” is displayed and the set is reset.

Then the set is turned off.

[CD Ship Position]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press the FUNCTION button for the setting CD.

3. Press three buttons Z , VOLUME – , and > simulta-

neously.

4. The message “COLD RESET” is displayed and CD is set to

the shipment position. Then the set is turned off.

[Loading Mechanism Lock]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press two buttons of x and Z simultaneously for fiv e seconds.

3. The message “LOCKED” is displayed and the loading

mechanism is locked. (Even if exiting from this mode, the

loading mechanism is still locked.)

4. Press two buttons of x and Z simultaneously for five seconds

again.

5. The message “UNLOCKED” is displayed and the loading

mechanism is unlocked.

6. To exit from this mode, press the ?/1 button to turn the set

off.

6. Press the DISPLA Y b utton. Confirm the pa ttern of segments.

MP3

SHUFFLE

ALBUM

TRACK MONO

ALBUM

REPEAT

STEREO AUTO

DSG

c

7. Every pressing of the DISPLA Y button turns on each se gment

one after another in the same order.

8. To e xit from this mode, press the ?/1 button to turn off the set.

[Aging In1 Mode]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Insert the disc.

3. Select the FUNCTION to CD.

4. To enter the test mode, press three b uttons VOLUME – , NX

and Z simultaneously.

5. Aging operation starts automatically.

6. The CD is out, drawn in and the first track is played. Then the

last track is played.

7. The CD is out again, and the message “AGIN00000001” is

displayed. This value is cycle times of aging operation and

displays hexadecimal data.

8. The CD is drawn in and aging operation is continued.

9. To exit from this mode, press the ?/1 button to turn off the set.

21

Page 22

HCD-EX5

[Aging In Mode]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Select the FUNCTION to CD.

3. To enter the test mode, press three buttons VOLUME + ,

> and Z simultaneously.

4. Confirm that “dvt AGING” is displayed.

5. Press the Z button.

6. Confirm that “dvt AGING SL” is displayed.

Releasing Method of Test Mode

1. Press the x button to display “dvt AGING”.

2. Press the x button again.

Menu Selection of Aging Selection Mode

1. Select the operation in the menu by pressing the . or

> button.

2. Press the Z button. The menu is selected.

3. Press the x button to return to the menu again.

SELECTION OF AGING AND START “dvt AGING SL”

Y

DISPLAY OF TIMES OF A GING “dvt AGING DP”

Selection of Aging and Start

1. Confirm that “AGING SEL=00” is displayed.

2. Select the aging operation in the menu by pressiing the .

or > button. Normally “00” is suitable.

3. Press the Z button.

4. Aging operation starts automatically.

DISPLAY : “AGING SEL = ##”

## : type of aging

00 : OPEN c CHUCK c the first track playback c the last

track playback c OPEN c CHUCK c

…

01 to 03 : not for service

04 : the first track playback c the last track playback c the

first track playback c

…

05 to o6 : not for service

Display of Times of Aging

1. Confirm that “dvt AGING DP” is diplayed.

2. Press the Z button.

DISPLAY : “AGING********”

******** : 0 to FFFFFFFF (hexadecimal) times of aging cycle executed

Releasing Method of Aging Operation

Press the ?/1 button to turn off the set.

[Error History Display Mode]

Procedure:

Setting Method of Test Mode

1. Press the ?/1 button to turn the set ON.

2. Select the FUNCTION to CD.

3. T o enter the test mode, press three buttons Z , V OLUME + ,

and NX simultaneously.

4. Confirm to display “dvt ERR CODE”.

5. Press the Z button.

Releasing Method of Test Mode

1. Press the x button to display “dvt ERR CODE”.

2. Press the x button.

Menu Selection of Error History Display Mode

1. Select the operation in the menu by pressing the . or >

button.

2. Press the Z button. The menu is selected. If returning to the

menu again, press the x button.

DISPLAY OF TIMES OF ERROR

DISPLAY OF MECHANISM ERROR HISTORY

RESET OF MECHANISM ERROR HISTORY

RESET OF ERROR HISTORY

RESET OF NO DISC ERROR HISTORY

DISPLAY OF NO DISC ERROR HISTORY

" Emc=**Edc=## "

" dvt ECODE MEC "

" dvt ECNT0 MEC "

" dvt ECNT0 ALL "

" dvt ECNT0 BU "

" dvt ECODE BU "

Display of Times of Error

* Number of times of mechanism error and no disc error is displayed

in hexadecimal.

DISPLAY : “ Emc=**Edc=## “

** : number of times of mechanism error (hexadecimal)

## : number of times of no disc error (hexadecimal)

Display of Mechanism Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECODE MEC”.

2. Press the Z button.

3. Select the mechanism error code by pressing the . or >

button.

22

Page 23

HCD-EX5

DISPLAY : “ E**M##%%0000 “

** : order of mechanism error happens (hexadecimal)

00 : the newest error

09 : the error ten times before

## : completion of an initialization (hexadecimal)

ff : completion

others : not completed

%% : condition of CDM operation when the trouble happened

(hexadecimal)

00 : during an initialization

1x : during opening (x : not fixed)

16 to 19 : during a kick by falure of opening

2x : completion of opening

28 : completion of opening under the condition of no disc

3x : during close request

4x : during open request

5x : during closing

6x : during chucking

80 : during releasing

9x : during operation of BU down

ax : during operation of shutter opening or closing

b0 : during BU up request

c0 : during BU down request

dx : during operation of BU up

0000: fixed

Reset of Mechanism Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECONT0 MEC”.

2. Press the NX button. Mechanism error history is reset.

Display of No Disc Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECODE BU”.

2. Press the Z button.

3. Select the no disc code by pressing the . or > button.

DISPLAY : “ E**D##%%@@&& “

** : order of no disc happens (hexadecimal)

00 : the newest

09 : ten times before

## : description of the trouble (hexadecimal)

01 : focus NG

02 : GFS NG

03 : time-over of starting

04 : continuous unlock of focus

05 : no input of Q-codes in fixed time

%% : condition when the trouble happened (hexadecimal)

01 : during shipment position processing

02 : during power off processing

03 : during processing of initialization

04 : during stop condition

05 : during stop processing

06 : during process of starting

07 : during process of TOC reading

08 : during search operation

09 : during playback

0a : during pause

0b : during playback manual searching

0c : during pause manual searching

@@ : do not care

&& : rotating speed of a disc when the trouble happened

(hexadecimal)

01 : x1

02 : x2 (double speed)

03 : x4

Reset of No Disc Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECONT0 BU”.

2. Press the NX button. No disc error history is reset.

Reset of Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECONT0 ALL”.

2. Press the NX button. Error history is reset.

[Servo Test Mode]

*Error Rate Display

Procedure:

Setting Method of Test Mode

1. Press the ?/1 button to turn the set ON.

2. Insert the disc.

3. Select the FUNCTION to CD.

4. Press the NX button to play the CD.

5. To enter the test mode, press three buttons VOLUME + , x

and Z simultaneously. Confirm that the message “bdt STEST”

is displayed.

6. Press the . or > button to display “dvt ERR RATE”.

7. Press the Z button.

Description of Error Rate

" ****####%%@@&& "

C1 C2 TNO MIN SEC

Releasing Method of Test Mode

1. Press the x button to display “dvt ERR RATE”.

2. Press three buttons V OLUME + , x and Z simultaneously.

[CD Repeat 5 Times Limit Release Mode]

Procedure:

Setting Method of Test Mode

1. Press the ?/1 button to turn the set ON.

2. Select the FUNCTION to CD.

3. Press three buttons Z , VOLUME – and . simulta-

neously.

4. The message “dvt REP LMT” is displayed.

5. Press the Z button.

Releasing Method of Test Mode

1. Press the x button to display “dvt REP LMT”

2. Press the x button.

Selection of Repeat 5 Times Limit ON/OFF

1. Press the . or > button to display “REP LMT ON” or

“REP LMT OFF”.

2. Press the x button to select ON or OFF and “dvt REP LMT”

is displayed.

23

Page 24

HCD-EX5

)

SECTION 5

ELECTRICAL ADJUSTMENTS

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

RF Level Check

oscilloscope

BD board

TP(RFAC)

TP(DVC)

Procedure :

1. Connect oscilloscope to TP (RFAC).

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Confirm that oscilloscope waveform is clear and check RF signal

level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

Adjustment Location :

[ BD BOARD ] — SIDE A —

IC103

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.1 ± 0.3Vp-p

E-F Balance (1 Track jump) Check

oscilloscope

BD board

TP (TE)

TP (DVC)

+

–

Procedure:

1. Connect oscilloscope to TP (TE) and TP (DVC) board.

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the u button. (Becomes the 1track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope

waveform.

1 track jump waveform

Center of

waveform

IC101

TP(DVC)

TP(TE)

TP

(RFAC)

B

0V

level=1.3 ±0.6Vp-p

Specification level: x 100=less than ±22%

A

B

Symmetry

24

A (DC voltage

Page 25

HCD-EX5

6-1. Block Diagrams

– CD Section –

OPTICAL PICK-UP

BLOCK

5

VCC

9

PD1

4

PD2

10

I5-10

8

I1-6

6

LD+

11

GND

7

2

VCC

LIMIT IN

SWITCH

FOCUS

COIL

TRACKING

COIL

TR+

SW

TR-

SECTION 6

DIAGRAMS

IC381

OSCILLATOR

23 5

6

• R-CH is omitted due to same as L-CH.

• Signal Path

X381

16.934MHz

IC101

DIGITAL SERVO,

DIGITAL SIGNAL PROCESSOR

IC103

RF AMP

VC

CD+5V

Q101

LD

DRIVE

RV101

PD

F-

F+

M102

SLED

MOTOR

M101

SPINDLE

MOTOR

CD+5V

M

M

27

VC

25

VFC

6

RFAC

A

7

RFDCO

B

8

C

RFDCI

9

D

10

E

11

F

1

LD

SW

19 TE_BAL

2

PD

IC102

MOTOR/COIL DRIVER

47

VO1+

52

VO1-

55

VO2+

56

VO2-

1

VO3+

VO3-

2

VO4-

10

VO4+

5

IN1+

IN2+

IN3+

IN4R

STBY

IN2-

IN3-

71

XTAI

67

50

15

28

29

16FE

17FEI

18TE

12

35

34IN1-

32

31

27

26

24

8

43

39

41

40

26 SSTP

33

34

32

30

25

IC721

L SENSOR

RFAC

RFDC

FE

TE

SE

FFDR

FRDR

TFDR31

TRDR

SFDR29

SRDR

MDP

BCLK

PCMD

LRCK

D OUT

SQSO

SENS

SCLK

SQCK

SCOR

S731

L MOTOR

C MOTOR

66

65

64

4DATA

6CLOK

5XLAT

76

7

8

77

15

2XRST

IC106

42

S741

ROTARY

ENCODER

XRST

IC301

DAC

16

MCLK

1

BCK R-CH

2

DATA

3

LRCK

13

DATA

14

CLK

15

LAT

IC701 (1/2)

MASTER CONTROLLER

54

DACDAT

55

DACCLK

4

DACLAT

CXD-DATA

7

CXD-CLK

8

CXD-XLT

11

15

SUBQ

14

SENSE

17

SQCLK

95

SCOR

BDRST

23

12

PWM1

PWM2

PWM3

LDON

ENC1

ENC2

ENC3

ENC4

L.MTR SW2

C.MTR SW1

OPT SNS2 (L)813

(LO-MTR F)

LOD1POS

(LO-MTR R)

LOD1NEG

(CK-MTR F)

LOD2POS

(CK-MTR R)

LOD2NEG

19

20

13

82

83

84

89

73

72

7

LOUT CD-L

8

ROUT

10

VCOM

22

BDPWR

67

68

69

70

+3.3V

IC301

IC371

IC381

+3.3V

CD+5V

IC302

LPF

6

–

+

5

Q391

RIPPLE

FILTER

Q103,D101

+3.3V

REG

: CD DIGITAL OUT

: CD

7

IC711

LO MOTOR DRIVER

FIN

7

OUT1

OUT2

RIN

9

IC701

CK MOTOR DRIVER

FIN

7

OUT1

OUT2

RIN

9

D OUT

Q781, 782

B+

SWITCH

4

2

4

2

3

CD+5V

M

M

IC371

OPTICAL

OUT

M701

(LO)

M702

(CK)

A

SECTION

CD DIGITAL OUT

OPTICAL

MAIN

CD+5V

Q701

B+

SWITCH

IC731

D SENSOR

80

3

OPT SNS1 (D)

71

DSNSOUT

2525

Page 26

– MAIN Section –

PC/MD/TAPE

FM75Ω

ı

ANTENNA

AM

ı

J101

IN

CD

SECTION

CD-L

A

TUNER PACK

L OUT

R OUT

ST DOUT

ST DIN

ST CLK

ST CE

TUNED

STEREO

ST MUTE

RDS DATA

RDS INT

RDS +5V

• R-CH is omitted due to same as L-CH.

• Signal Path

: FM

: CD

: PC/MD/TAPE(PB)

: PC/MD/TAPE(REC)

R-CH

R-CH

Q401,402

+5V

REG

4

5

6

AEP, UK

+10V

INB1

INC1

IND1

IC121

PRE AMP

CLOCK

22 21

IC631

REMOTE

CONTROL

RECEIVER

S621,622

FUNCTION

KEY

S601,602,615,616

FUNCTION

KEY

S603,611-614

FUNCTION

KEY

DATA

1

INEX1

OUT1

BB A1

BB B1

7

18

16

17

SIRCS

DETECT

X701

32.768kHz

X702

20MHz

D703

Q121

DBFB

SWITCH

IC701 (2/2)

MASTER CONTROLLER

29

GEQ-DATA

GEQ-CLK

30

DIG-AMP-SLEEP

44

PLL-DI(ST UCOM)

45

PLL-DO(UCOM ST)

43

PLL-CLK

46

PLL-CE

49

TUNED

48

STEREO

47

ST-MUTING

50

RDS-DATA

96

RDS-CLK

51

AM

94

SIRCS

(WAKE UP)RM_INIT

93

KEY1

77

(WAKE UP)KEY_INIT

90

78

KEY2

79

KEY3

XT1

35

36

XT2

39

X1

X2

38

D501

HP-MUTE

LINE-MUTING

SPK-RELAY

HP IN

DISP-DATA

DISP-CLK

DISP-CS

DISP-RS

POWER SAVE

DIM0

DIM1

STANDBY LED

AC_CUT

RESET

HCD-EX5

R-CH

Q111

MUTING

Q122

MUTING

Q124

27

28

33

26

24

1

2

57

56

64

31

32

66

91

34

MUTING

SWITCH

Q123

MUTING

SWITCH

Q791

RESET

SWITCH

Q801

LCD601

LIQUID CRYSTAL

DISPLAY

4

SDA

SCL

5

6

CS

RS

7

VDD

Q672,674

DIM

CONTROL

IC501

(HP AMP)

R-CH

2

ST+10V

IC121

Q591

RIPPLE

FILTER

D621

(STANDBY)

`/1

IC791

4 5

RESET

Q691,692

B+

SWITCH

D681 - 684

(BACK LIGHT)

Q792,793

VOLTAGE

DETECT

SYS+5V

A+10V

CD+5V

SYS+5V

3 1

3 1CD+7V

3

D792

D791

IC911

+5V

REG

IC921

+7V

REG

IC931

+10V

REG

IC101

DIGITAL POWER AMP

10

IN1 L-IN

18

FAULT

11

MUTE

17

SLEEP

IC501

HEADPHONE AMP

3

+13.5V

(IC101)

1

IC951

+5.5V

3 1BACKUP+5V

REG

OUTM1

(-)L-

OUTP1

(+)L+

Q952,953

ECO

1

24

26

DELAY

1

D902

IC102

DC CANCEL

R-CH

IC941

ERROR

1

AMP

Q951

SWITCH

3

2

D901

2

D951

MUTING

Q841,842

DETECT

T1

PC1

T51

PC51

DC

Q501

R-CH

LPF

LPF

RY891

RELAY

DRIVE

D10

Q1

B+

SWITCH

Q52

B+

SWITCH

Q51

B+

SWITCH

R-CH

R-CH

Q843

R-CH

Q53

J111

OUT

L

CN801

SPEAKER

R

J501

PHONES

AC IN

IC1

MAIN CONVERTER

D

3

OCP/INH

1

VCC

4

GND

2

FB/OCP

5

R51

BOOT

D53

RESISTOR

IC51

STANDBY

CONVERTER

D

7

D

8

VIN

3

GND

2

S

1

FB/OCP

4

PC/MD/TAPE

2626

Page 27

HCD-EX5

B

These are omitted.

CE

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

f

•

• 2 : nonflammable resistor.

• 1 : fusible resistor.

• C : panel designation.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground

•Voltages are taken with a VOM (Input impedance 10 MΩ).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

•Abbreviation

: internal component.

Note:

The components identified by mark 0 or dotted

line with mark 0 are criti-

cal for safety.

Replace only with part

number specified.

under no-signal (detuned) conditions.

Voltage variations may be noted due to normal produc-

tion tolerances.

Voltage variations may be noted due to normal produc-

tion tolerances.

F : FM

E : PB

a : REC

J : CD (Analog)

c : CD (Digital)

MX : Mexican model.

AUS: Australian model.

SP : Singapore model.

HK : Hong Kong model.

TW : Taiwan model.

KR : Korean model

CND : Canadian model.

1

4

/

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

For printed wiring boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

a

•

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

: Through hole.

• Indication of transistor

B

CE

These are omitted.

C

Q

B

E

These are omitted.

27

Page 28

HCD-EX5

d

6-2. Circuit Boards Location

OS board

POWER board

OC board

LED board

BD board

D.SENSOR board

SPK board

MAIN board

LID board

L.MOTOR board

ENCODER boar

28

C MOTOR board

tuner

L.SENSOR board

Page 29

HCD-EX5

6-3. Schematic Diagram – BD Board –

• See page 45 for IC Block Diagrams. • See page 46 for Wavefoms.

IC B/D

TO

MAIN

BOARD

(2/2)

CN301

(Page 33)

IC B/D

2929

Page 30

HCD-EX5

6-4. Printed Wiring Board – BD Board (Side A) –

IC101

• See page 28 for Circuit Boards Location.

TO

MAIN BOARD

CN301

(Page 34)

23

IC106

(BLK)

TP(DVC)

TP(TE)

TP(RFAC)

IC103

IC102

(RED)

12

(12)

• Semiconductor

Location

Ref. No. Location

IC101 A-1

IC102 B-4

IC103 B-3

IC106 A-2

Q101 C-3

3030

Page 31

HCD-EX5

6-5. Printed Wiring Board – BD Board (Side B) –

• See page 28 for Circuit Boards Location.

• Semiconductor

Location

12

(12)

Ref. No. Location

D201 B-5

Q103 A-2

3131

Page 32

HCD-EX5

6-6. Schematic Diagram – MAIN Section (1/2) –

• See page 46 for IC Block Diagrams. • See page 46 for Wavefoms.

IC B/D

R384

470

C381

1

C100

470P

C799

C798

0.1

0.1

3232

Page 33

HCD-EX5

6-7. Schematic Diagram – MAIN Section (2/2) –

(Page 29)

C398

0.1

• See page 43 for IC Pin Function Description. • See page 46 for Wavefoms.

(Page 38) (Page 38)

(Page 42)

C399

Q691

DTA114EKA

SWITCH

55

5

Q692

DTC114EKA

DETECT

0.1

3333

Page 34

HCD-EX5

6-8. Printed Wiring Board – MAIN Board (Side A) –

(Page 39)

AEP,UK

(Page 39)

(Page 36)

• See page 28 for Circuit Boards Location.

IC121

AEP,UK

*

IC501

IC302

IC701

IC301

CD DIGITAL

OUT

OPTICAL

IC371

IC381

AEP,UK

IC631

IC791

(Page 40)

(Page 36)

(Page 30)

(Page 36)

• Semiconductor

Location

Ref. No. Location

D101 A-2

D102 A-3

D191 C-1

D401 D-2

D501 A-4

D621

D701 D-6

D702 D-6

D703 D-5

D791 C-6

D792 C-6

D793 C-6

D794 D-6

D795 D-7

IC121 B-2

IC301 B-5

IC302 B-4

IC371 A-5

IC381 B-5

IC501 B-4

IC631 D-6

IC701 C-4

IC791 C-6

Q111 A-2

Q121 B-2

Q122 B-2

Q123 C-3

Q124 C-3

Q161 A-3

Q171 C-2

Q172 B-2

Q391 B-6

Q401 C-2

Q402 D-2

Q501 A-5

Q551 A-4

Q591 A-4

Q672 D-2

Q674 D-2

Q691 D-4

Q692 D-4

Q701 C-5

Q781 B-6

Q782 B-6

Q791 D-6

Q792 D-7

Q793 C-6

*

3434

Page 35

HCD-EX5

6-9. Printed Wiring Board – MAIN Board (Side B) –

• See page 28 for Circuit Boards Location.

3535

Page 36

HCD-EX5

6-10. Printed Wiring Board – PANEL Section (Side A) –

• See page 28 for Circuit Boards Location.

R872 C876

C875

C874

C825

C826

R822

C824

(Page 34)

(Page 40)

TUNER

BAND

(Page 34)

(Page 34)

(BACK LIGHT)

3636

Page 37

HCD-EX5

6-11. Printed Wiring Board – PANEL Section (Side B) –

• See page 28 for Circuit Boards Location.

3737

Page 38

HCD-EX5

6-12. Schematic Diagram – MOTOR Section –

• See page 45 for IC Block Diagrams.

TO

MAIN

BOARD

(2/2)

CN302

(Page 33)

M701

IC B/D

M702

IC B/D

TO

MAIN

BOARD

(2/2)

CN303

(Page 33)

3838

Page 39

HCD-EX5

6-13. Printed Wiring Board – MOTOR Section –

A

IC721

B

• See page 28 for Circuit Boards Location.

M702

(CK)

IC701

C

D

E

IC731

M701

(LO)

TO

MAIN

BOARD

CN303

(Page 34) (Page 34)

TO

MAIN

BOARD

CN302

F

12

IC711

345678

3939

Page 40

HCD-EX5

6-14. Printed Wiring Board – POWER Board (Side A) –

• See page 28 for Circuit Boards Location.

IC941

AUS,SP,MX,

HK,TW,KR

PC1

PC51

IC1

IC51

IC931

IC102

IC921

IC101

IC911

(Page 36)

• Semiconductor

Location

Ref. No. Location

D1 B-1

D2 C-3

D3 C-3

D4 C-3

D5 C-3

D6 C-6

D10 E-2

D21 C-3

D22 C-3

D53 D-2

D54 D-3

D55 D-3

D56 D-2

D57 D-3

D58 C-3

D801 B-5

D802 B-5

D803 B-4

D805 C-5

D821 B-5

D822 A-6

D823 A-6

D824 B-6

D871 C-6

D872 C-6

D873 C-5

D874 C-5

D901 A-2

D902 C-4

D951 D-4

D952 C-4

IC951

AEP,UK

(Page 34)

IC1 C-3

IC51 D-3

IC101 B-5

IC102 C-4

IC911 A-6

IC921 A-5

IC931 A-4

IC941 B-3

IC951 D-4

Q1 C-3

Q51 D-1

Q52 D-2

Q53 D-2

Q801 D-6

Q841 D-6

Q842 D-6

Q843 A-6

Q844 A-5

Q891 D-6

Q892 D-6

Q951 C-4

Q952 C-4

Q953 C-4

4040

Page 41

HCD-EX5

6-15. Printed Wiring Board – POWER Board (Side B) –

• See page 28 for Circuit Boards Location.

4141

Page 42

6-16. Schematic Diagram – POWER Section –

HCD-EX5

C824 2200p

C825 2200p

C874 2200p

C875 2200p

C826

0.1

R822

10

C876

0.1

EPT801

AUS,SP,MX,HK,TW,KR

PC1

PC51

FB801

R872

10

(Page 33)

4242

Page 43

6-17. IC Pin Function Description

• IC701 µPD703030BYGF-M02-3BA Master Controller (Main Board)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31, 32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Pin Name

DISP_DATA

DISP_CLK

IIC DATA

DACLAT

IIC CLK

CD_ADJ

CXD-DATA

CXD-CLK

EVDD

EVSS

CXD-XLT

PWM1

LDON

SENSE

SUBQ

SOFT_CHEK_1

SQCLK

SOFT_CHECK_2

PWM2

PWM3

VPP

BDPWR

BDRST

HP_IN

HP_MUTING

SPK-RELAY

HP MUTE

DIG-AMP-SLEEP

GEQ-DATA

GEQ-CLK

DIM0, DIM1

LINE-MUTING

RESET

XT1

XT2

REGC

X2

X1

VSS

VDD

CLKOUT

PLL-CLK

PLL-DI(STpUCOM)

PLL-DO(UCOMpST)

PLL-CE

ST-MUTING

STEREO

TUNED

RDS-DATA

AM

I/O

O

Data output to the LCD601

O

Clock output to the LCD601

I/O

IIC data input/output (fixed at “H”)

O

Latch signal output to the DAC (IC301)

I/O

IIC clock input/output (fixed at “H”)

I

CD adjustment mode input (fixed at “H”)

O

Data output to the CXD3068Q (IC101)

O

Clock output to the CXD3068Q (IC101)

—

Power supply (+5V)

—

Ground

O

Latch signal output to the CXD3068Q (IC101)

O

PWM1 signal output

O

Laser power control signal output

I

SENSE signal input from the CXD3068Q (IC101)

I

SUBQ data input from the CXD3068Q (IC101)

O

Check terminal (open)

O

SUBQ clock output to the CXD3068Q (IC101)

O

Check terminal (open)

O

PWM2 signal output

O

PWM3 signal output

—

Internal connection/power for writing to the flash ROM

O

BD power control signal output

O

BD reset signal output

I

Headphone detection signal input

O

Not used (open)

O

Speaker relay control signal output

O

PC/TAPE/MD output muting signal output

O

Sleep signal output to the digital power amplifier (IC101)

O

Data output to the pre-amplifier (IC121)

O

Clock output to the pre-amplifier (IC121)

O

Back light control signal output

O

Line muting signal output

I

System reset signal input

I

Sub clock input

O

Sub clock output

—

Capacitor terminal for stabilizing the regulator output

O

Main clock output

I

Main clock input

—

Ground

—

Power supply (+5V)

O

Clock output terminal (open)

O

Clock output for the PLL for the tuner

I

Data input from the PLL for the tuner

O

Data output to the PLL for the tuner

O

Chip enable signal output the PLL for the tuner

O

Muting signal output for the tuner

I

Stereo detection signal input

I

Tuner tuning signal input

I

RDS data input

O

AM signal output for the RDS noise reduction

HCD-EX5

Description

43

Page 44

HCD-EX5

Pin No.

52

53

54

55

56

57

58

59

60 to 63

64

65

66

67

68

69

70

71

72

73

74

75

76

77 to 79

80

81

82 to 84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Pin Name

DEVICE RESET

DEVICE ACCUT

DACDATA

DACCLK

DISP_RS

DISP_CS

BVDD

BVSS

DEST1 to DEST4

POWER SAVE

DEVICE VDD

STANDBY LED

(LO-MTR F)

LOD1POS

(LO-MTR R)

LOD1NEG

(CK-MTR F)

LOD2POS

(CK-MTR R)

LOC2NEG

DSNSOUT

C.MTR SW1

L.MTR SW2

AVDD

AVSS

AVREF

KEY1 to KEY3

OPTSNS1(D)

OPTSNS2(L)

ENC1 to ENC3

MODEL1

DEVICE1

DEVICE2

DEVICE3

ENC4

(WAKE UP) KEY INT

AC_CUT

SOFT_CHECK_3

(WAKE UP)

RM_INT

SIRCS

SCOR

RDS-CLK

IO-DI

IO-DO

IO-CLK

IIC HELP

I/O

O

Device reset signal output (open)

O

Device AC cut signal output (open)

O

Data output to the DAC (IC301)

O

Clock output to the DAC (IC301)

O

Reset signal output to the LCD601

O

Chip select signal output to the LCD601

—

Power supply (+5v)

—

Ground

I

Destination setting terminal 1 to 4 (refer to destination, model and device sheet)

O

Power save control signal output (“H” : clock display, “L” : eco mode)

O

Device power control signal output

O

Standby LED control signal output

O

Loading motor control signal output (+)

O

Loading motor control signal output (–)

O

Chucking motor control signal output (+)

O

Chucking motor control signal output (–)

O

D. sensor output enable signal output

I

Chucking motor switch signal input

I

Loading motor switch signal input

—

Power supply (+5V)

—

Ground

I

Analog reference voltage input

I

Key signal input 1 to 3

I

D. sensor signal input

I

L. sensor signal input

I

Encoder 1 to 3 signal input

I

Model setting input teminal

I

Device setting input teminal (DISPLAY)

I

Device setting input teminal (IO)

I

Device setting input teminal (CD)

I

Encoder 4 signal input

I

Key interrupt signal input

I

AC off detection signal input

O

Check terminal (open)

I

Remote control interrupt signal input

I

Data input from the remote control receiver

I

Subcode Q sync detection signal input from the CXD3068Q (IC101)

I

RDS clock input

I

Flash ROM data input

O

Flash ROM data output

I

Flash ROM clock input (open)

O

IIC-HELP signal output (open)

Description

44

Page 45

• IC Block Diagrams

– BD BOARD –

IC101 CXD3068Q

VCTL

VPCO

V16M

XTSL

XTAO

XTAI

FSTO

CAM

RFAC

ASYI

ASYO

ASYE

BIAS

XPCK

FILO

PCO

CLTV

MDP

LOCK

PWMI

SENS

DATA

XLAT

CLOK

SCOR

SBSO

EXCK

SCSY

SQSO

SQCK

RFDC

IGEN

FILI

CE

TE

SE

FE

VC

CLOCK

GENERATOR

ASYMMETRY

CORRECTOR

DIGITAL

PLL

DIGITAL

CLV

CPU

INTERFACE

OPAMP

ANALOG SW

DEMODURATOR

A/D

CONVERTER

ADIO

EMPH

GFS

XUGF

EFM

SERVO

AUTO

INTERFACE

FCK

W

SUB CODE

PROCESSOR

TRACKING

ERROR

CORRECTOR

SERVO

INTERFACE

MIRR

DFCT

FOK

SERVO DSP

FOCUS

SERVO

SERVO

SLED

SERVO

32K

RAM

C2PO

LRCK

WDCK

D/A

INTERFACE

DIGITAL

SERVO BLOCK

PWM GENERATOR

FOCUS PWM

GENERATOR

TRACKING PWM

GENERATOR

SLED PWM

GENERATOR

PCMD

OUT

BCK

MUTE

IC103 CXA2581N-T4

TES1

TEST

XRST

DVC

EQ IN

AC SUM

GND

DVCC

DVC

RFAC

VC

LD

1

PD

2

APC AMP

3

4

5

6

A

7

B

8

C

9

D

10

E

11

F

12

SW

13

DVC

14

15

MD2

DOUT

SOUT

SOCK

XOLT

SCLK

COUT

SSTP

ATSK

MIRR

DFCT

FOK

FFDR

FRDR

TFDR

TRDR

SFDR

SRDR

VC

A

B

C

D

APC-OFF

(Hi-Z)

RW/ROM

(H/L)

–

+

SUMMING

BCD

A

GM

GM

RFAC

AMP

HCD-EX5

RW/ROM

DC OFST

30

RFDCI

A

–

+

B

C

DVC

D

VOFST

B

D

A

C

RW/ROM

EQ ON/OFF

RW/ROM

B

C

A

D

RW/ROM

RW/ROM

RW/ROM

RW/ROM

RW/ROM

VOFST

–

+

–

+

VOFST

–

+

DVC

VCC

DVC

VC

VC

DVC

VC

–

+

RFAC

VCA

VCC

–

+

–

+

29

RFDCO

28

VC

VC

27

RFC

26

EQ

VFC

25

BST

24

23

RFG

22

VCC

21

CEI

20

CE

19

TE BAL

18

TE

17

FEI

16

FE

– C MOTOR BOARD –

IC701 BA6956AN

– L.MOTOR BOARD –

IC711 BA6956AN

TSD

CONTROL LOGIC

1 2 3 4 5 6 7 8 9

VREF

OUT2

RNF

OUT1

VM

VCC

FIN

GND

RIN

45

Page 46

HCD-EX5

– MAIN BOARD –

IC301 PCM1748E/2K

BCK

DATA

LRCK

DGND

VDD

VCC

LOUT

ROUT

1

Serial

Input

2

3

4

5

6

7

8

I/F

Power

Supply

8x Oversampling Digital Filter

with Function Controller

Enhanced Multi-Level

Deita-Sigma Modurator

Output Amp and

Low-Pass Filter

System Clock

DACDAC

Output Amp and

Low-Pass Filter

System Clock

Manager

Function

Control

I/F

Zero Detect

16

MCLK

LAT

15

14

CLK

13

DATA

DZFL

12

11

DZFR

VCOM

10

AGND

9

• Waveforms

1 IC101 us (XTAO)

59 ns

1V/DIV,20ns/DIV

5.8 Vp-p

2 IC381 2 FUNCTION:CD

59 ns

1V/DIV,20ns/DIV

4.2 Vp-p

3 IC701 eh (XT2)

31 µs

1V/DIV,10µs/DIV

4 IC701 ek (X2)

50 ns

1V/DIV,20ns/DIV

3.3 Vp-p

3.2 Vp-p

46

Page 47

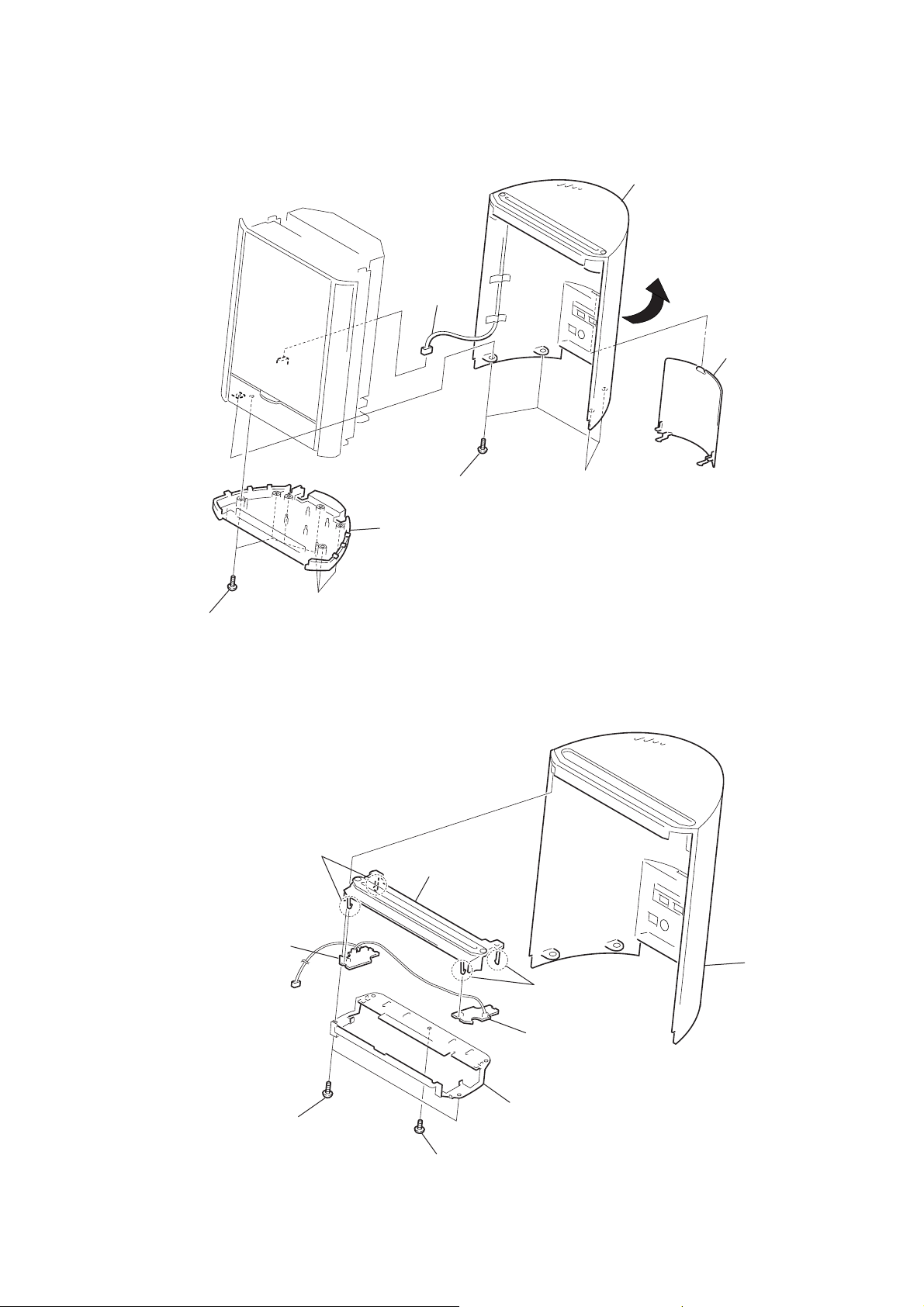

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• The mechanical parts with no reference number

in the exploded views are not supplied.

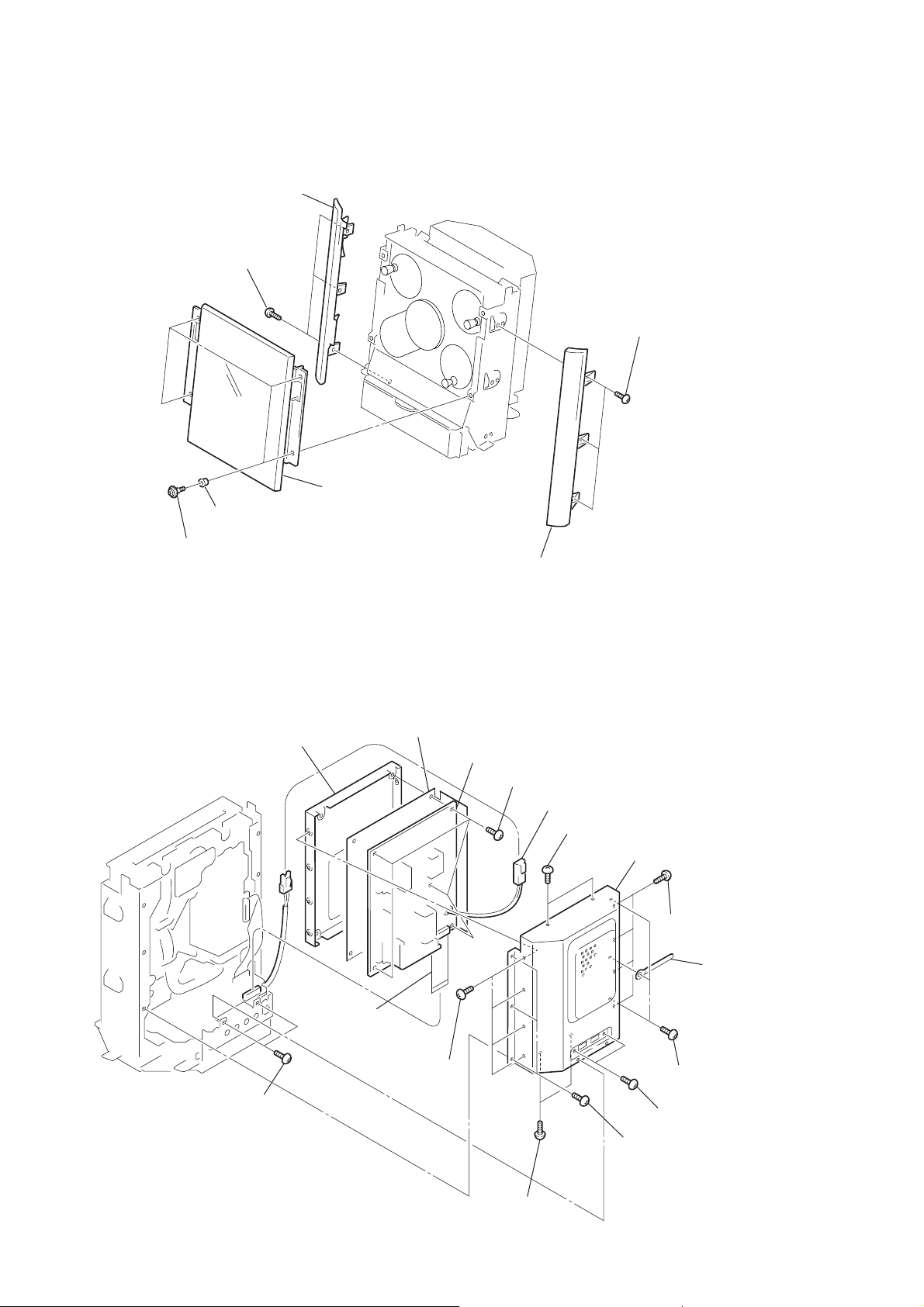

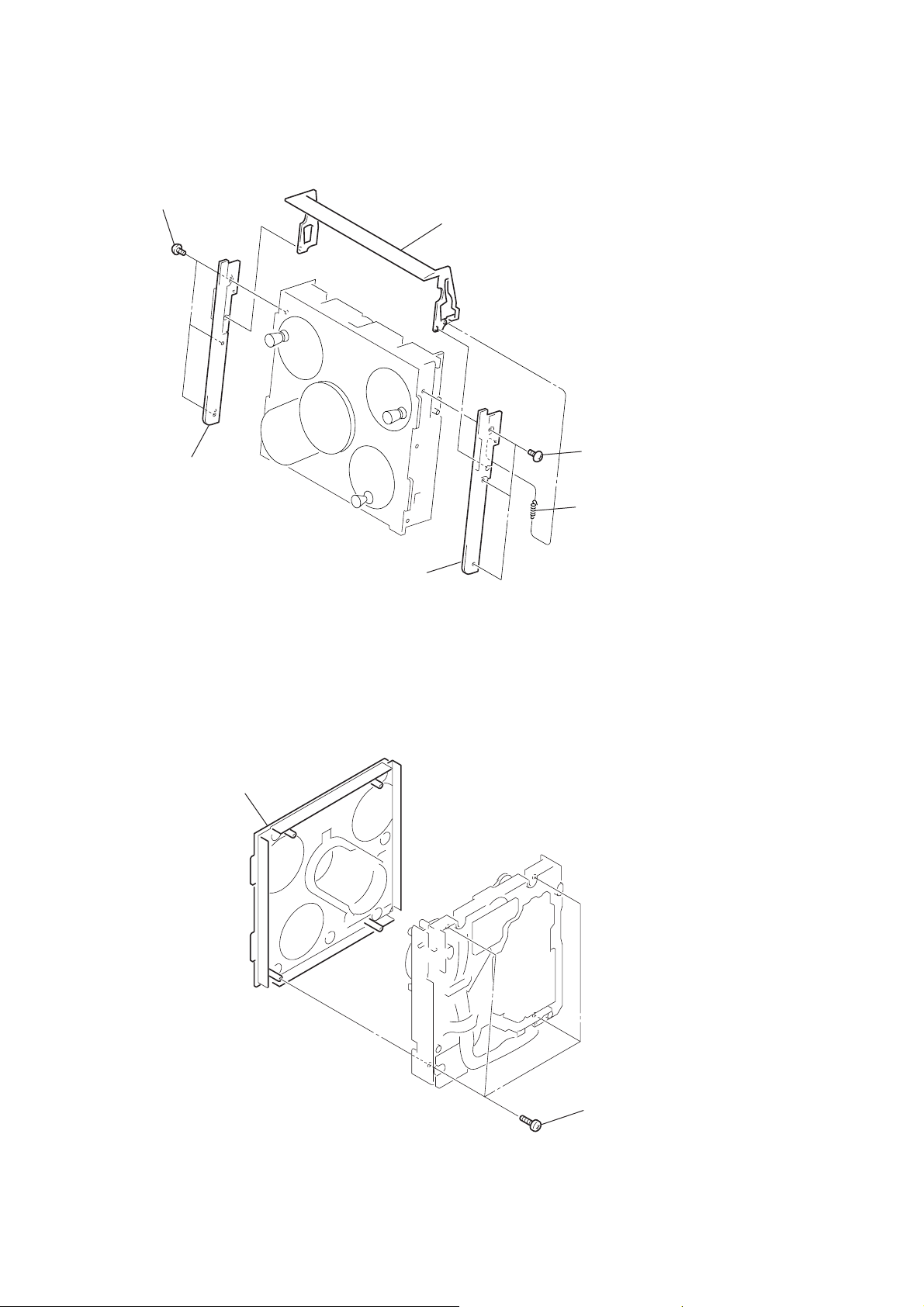

7-1. Case Section

SECTION 7

EXPLODED VIEWS

•Abbreviation

MX : Mexican model.

AUS: Australian model.

SP : Singapore model.

HK : Hong Kong model.

TW : Taiwan model.

KR : Korean model

CND : Canadian model.

HCD-EX5

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

8

#1

4

chassis section-1

not

supplied

5

6

3

2

9

#2

7

#1

1

13

11

#1

10

12

#1

12

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 X-4954-715-1 WINDOW ASSY (U), GLASS

2 4-989-494-12 SCREW (SLIDER), STEP

3 4-240-304-01 BUSHING (BRACKET)

4 4-240-308-01 PLATE (L), SIDE

5 X-4954-719-1 DISC ASSY, GUIDE

6 1-684-938-11 OS BOARD

7 1-684-939-11 OC BOARD

8 4-240-323-01 CASE (US,CND)

8 4-240-323-11 CASE (AEP,UK)

8 4-240-323-21 CASE (AUS,SP,MX,HK,TW,KR)

9 4-218-253-21 SCREW (M2.6), +BTTP

10 4-240-302-01 COVER (BACK)

11 4-240-309-01 PLATE (R), SIDE

12 4-240-321-01 FOOT

13 4-240-301-01 COVER (BOTTOM)

#1 7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

#2 7-685-534-14 SCREW +BTP 2.6X8 TYPE2 N-S

47

Page 48

HCD-EX5

d

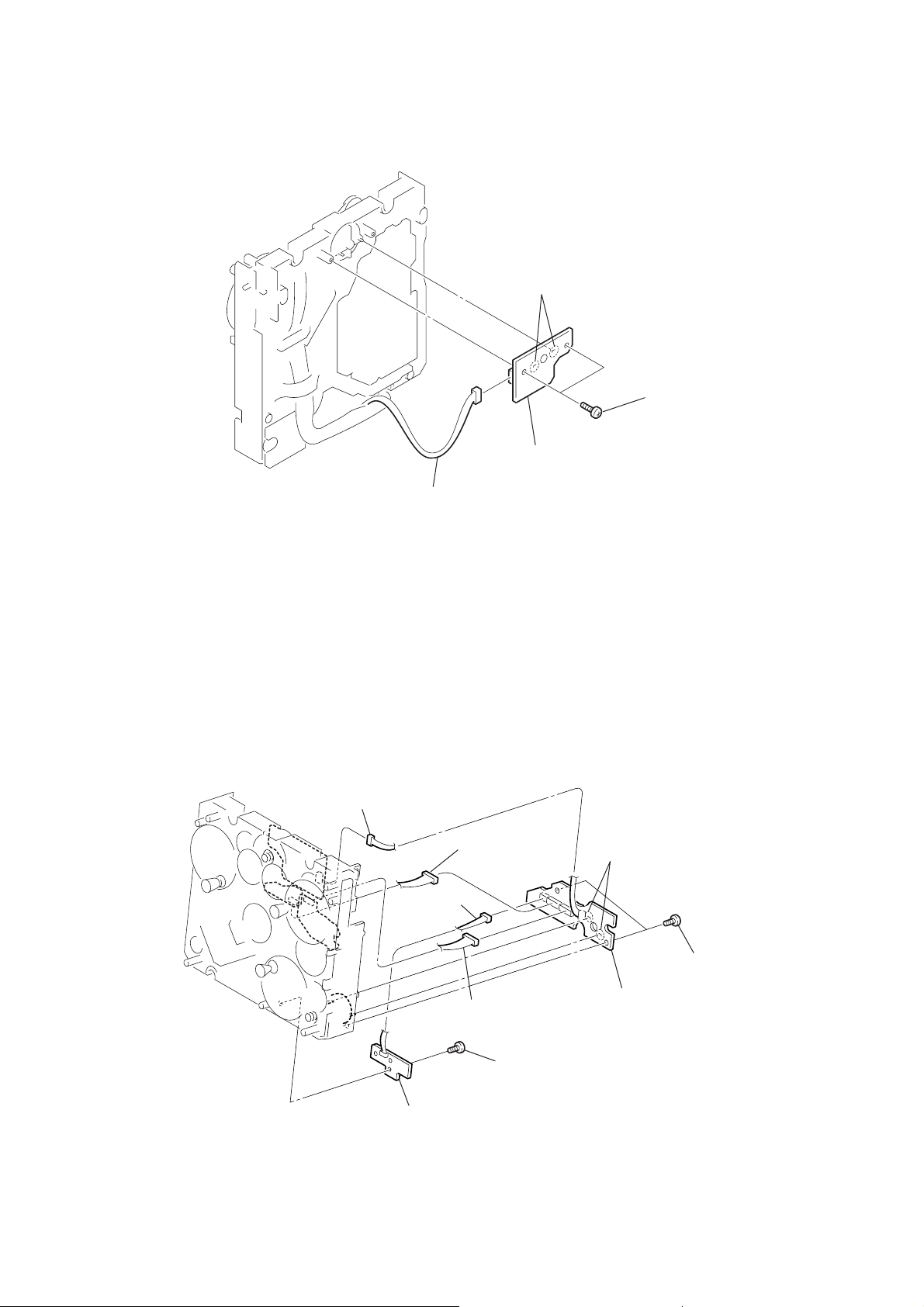

7-2. Chassis Section-1

not

supplied

not

supplied

F1

53

52

F801

55

#1#1

#1

54

not

supplied

#1

#1

#1

#1

not

supplie

#1

#1

CD mechanism section

(CDM71C-31BD63A)

#1

chassis section-2

51

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 X-4954-720-1 PANEL ASSY, FRONT

52 1-773-001-11 WIRE (FLAT TYPE) (15 CORE)

53 A-4676-617-A POWER BOARD, COMPLETE (US,CND)

53 A-4676-644-A POWER BOARD, COMPLETE (AEP,UK)

53 A-4676-650-A POWER BOARD, COMPLETE

(AUS,SP,MX,HK,TW,KR)

54 1-684-940-11 SPK BOARD

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

* 55 3-703-150-11 CLAMP

0 F1 1-533-451-11 FUSE, GLASS TUBE (DIA. 5) 3.15A/125V(US,CND)

0 F1 1-533-470-11

0 F801 1-533-453-11 FUSE, GLASS TUBE (DIA. 5) 5A/125V

#1 7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

FUSE, GLASS TUBE (DIA. 5) 3.15A/250V(TIME-LAG)

(AEP,UK,AUS,SP,MX,HK,TW,KR)

48

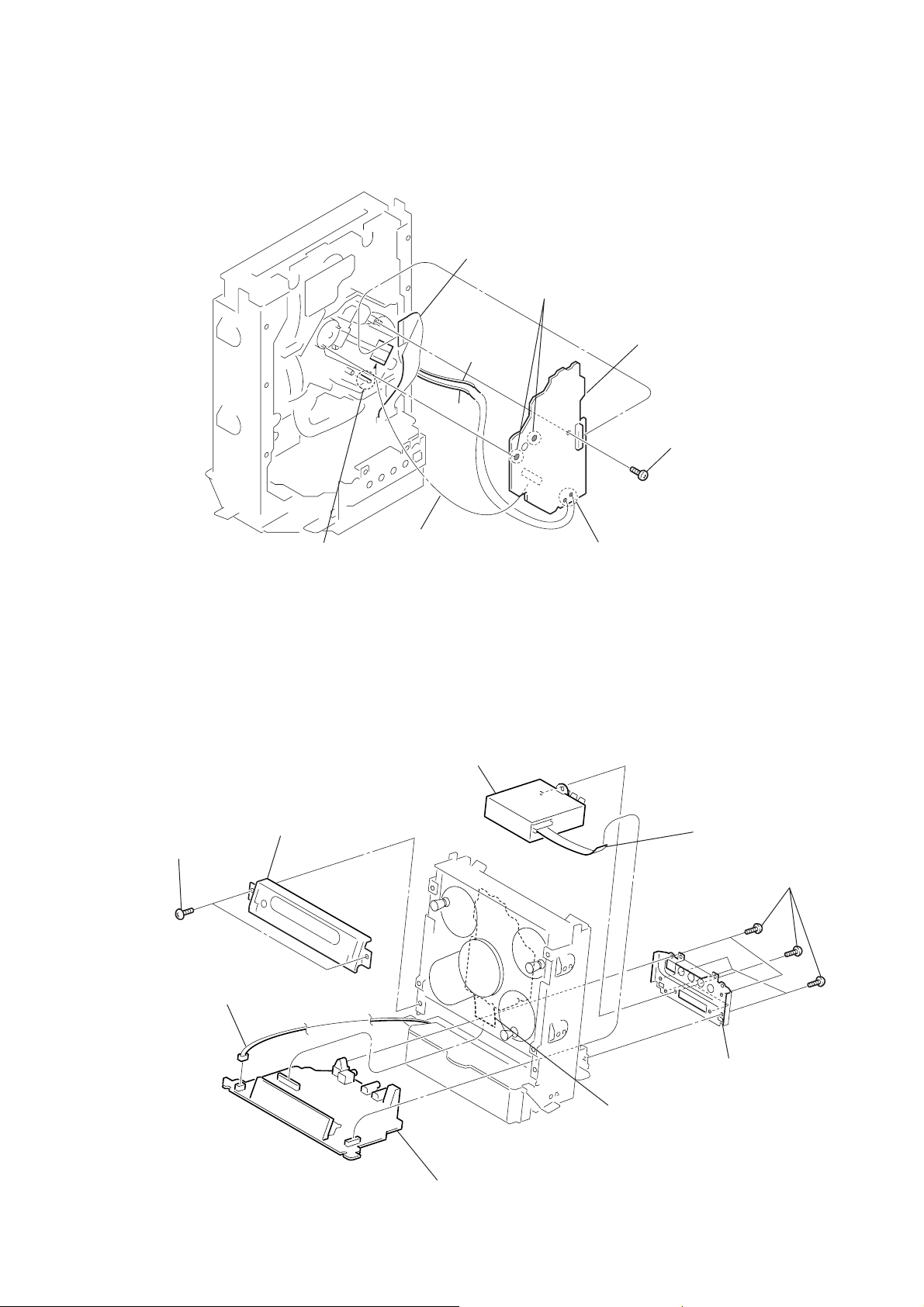

Page 49

7-3. Chassis Section-2

HCD-EX5

101

not

supplied

#1

#3

104

#4

not

supplied

103

106

LCD601

102

#1

107

not

supplied

104

#4

#3

105

111

108

not

supplied

109

#1

#1

#1

110

#1

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 X-4954-716-1 WINDOW ASSY (L), GLASS

102 1-684-937-11 LID BOARD

103 X-4954-718-1 BUTTON ASSY, CASE

104 3-239-275-01 DAMPER (S), SMALL

105 A-4676-614-A MAIN BOARD, COMPLETE (US,CND)

105 A-4676-642-A MAIN BOARD, COMPLETE (AEP,UK)

105 A-4676-648-A MAIN BOARD, COMPLETE (AUS,SP,HK,TW,KR)

105 A-4729-141-A MAIN BOARD, COMPLETE (MX)

106 4-240-311-01 ILLUMINATOR

107 4-240-310-01 HOLDER, LCD

108 1-684-936-11 LED BOARD

109 1-693-529-11 TUNER (FM/AM) (AEP,UK)

109 1-693-531-71 TUNER (FM/AM) (AUS,SP,MX,HK,TW)

109 1-693-534-11 TUNER (FM/AM) (US,CND)

109 1-693-538-11 TUNER (FM/AM) (KR)

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

110 1-769-940-11 WIRE (FLAT TYPE) (11 CORE) (EXCEPT AEP,UK)

110 1-773-004-11 WIRE (FLAT TYPE) (15 CORE) (AEP,UK)

111 4-966-266-01 BUSHING (S) (FBS002), CORD (MX)

111 4-966-267-04 BUSHING (FBS001), CORD (EXCEPT MX)

0 112 1-769-079-11 CORD, POWER (KR)

0 112 1-775-790-51 CORD, POWER (AUS)

0 112 1-777-071-62 CORD, POWER (AEP,UK,SP,HK,TW)

0 112 1-783-531-31 CORD, POWER (US,CND)

0 112 1-792-382-21 CORD, POWER (MX)

LCD601 1-804-713-11 DISPLAY PANEL, LIQUID CRYSTAL

#1 7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

#3 7-685-852-04 SCREW +BVTT 2X5 (S)

#4 7-685-233-19 SCREW +KTP 2.6X6 TYPE2 SLIT

112

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

not

supplied

#1

49

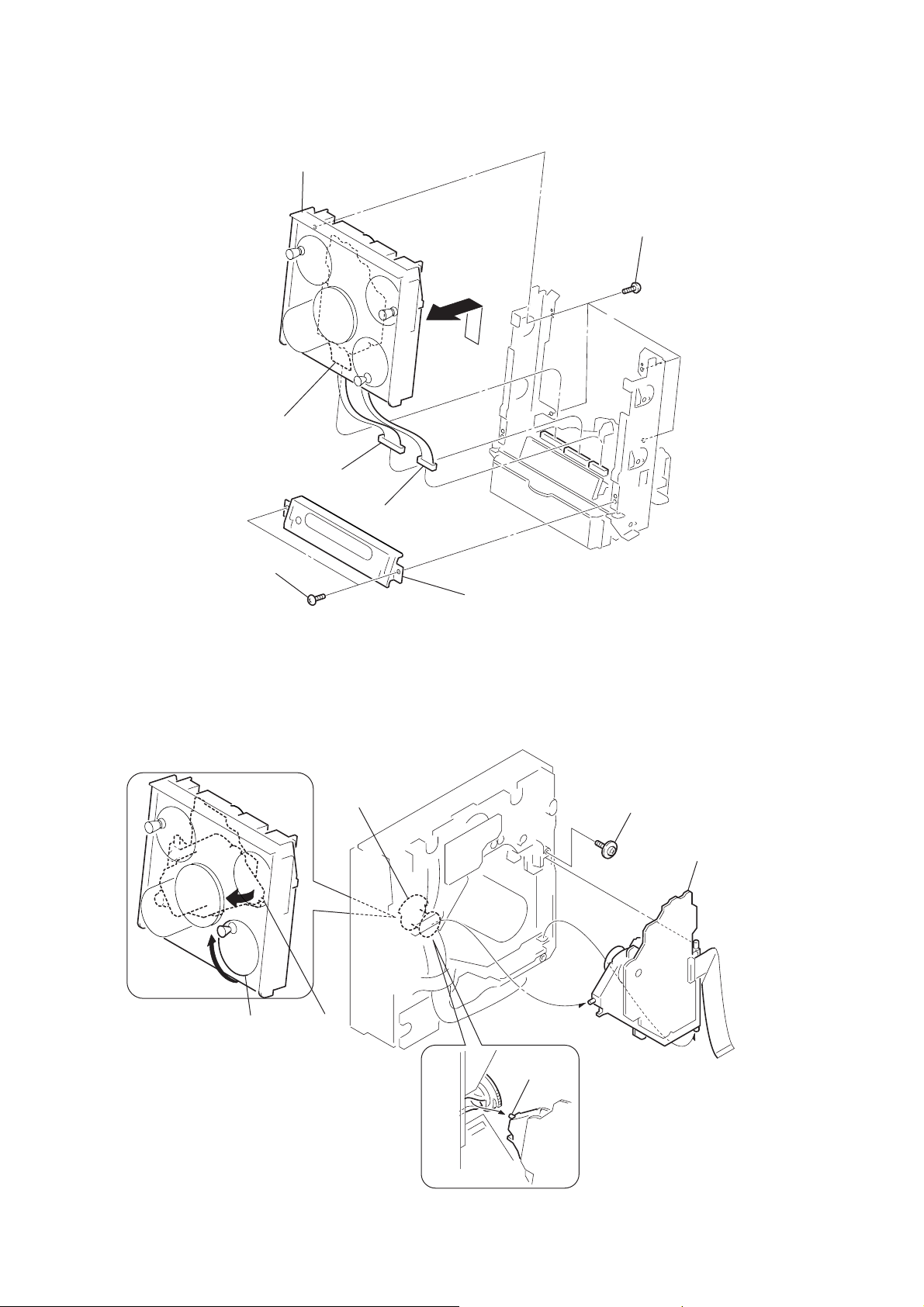

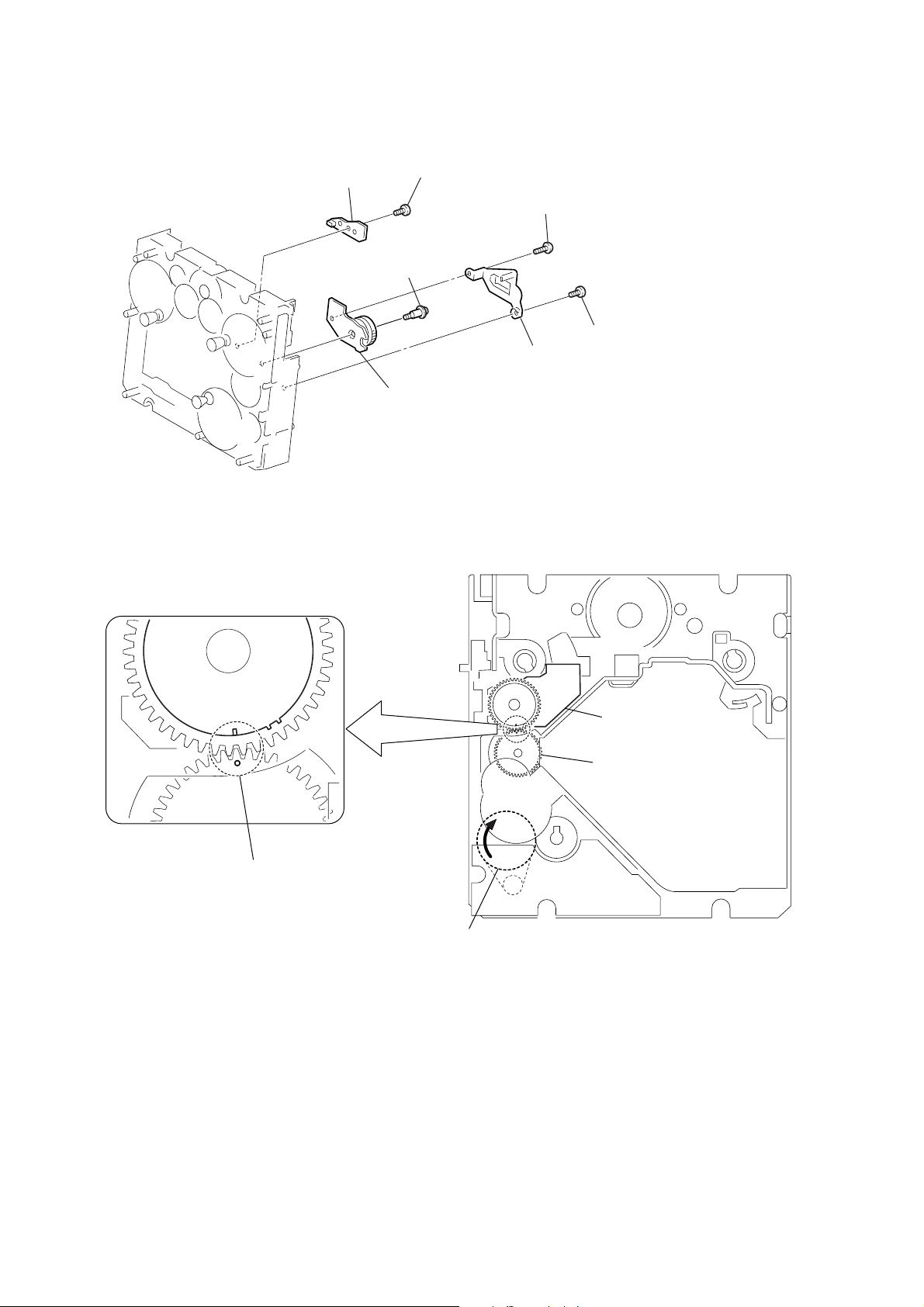

Page 50

HCD-EX5

7-4. Mechanism Section(CDM71C-31BD63A)-1

#6

412

not

supplied

mechanism section

(CDM71C-31BD63A)-2

406

412

403

not

supplied

#8

413

M701

404

#8

#5

419

409

415

#5

411

#5

408

405

#5

417

418

M702

#9

not supplied

414

#5

416

#6

402

401

407

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

401 4-240-317-01 SPRING (CD DOOR), TENSION COIL

402 4-240-313-01 LID (CD)

403 A-4735-610-A MOTOR (LD) ASSY

404 1-683-912-12 D.SENSOR BOARD

405 1-683-914-11 ENCODER BOARD

406 4-237-947-01 BELT (ROLLER) (L)

407 X-4954-812-1 CAP (CHUCK) ASSY

408 1-683-913-12 L.SENSOR BOARD

409 4-359-697-01 CUSHION (F)

410 4-240-533-01 ORNAMENT (MECHA PANEL)

410

not

supplied

414 A-4728-283-A C MOTOR BOARD, COMPLETE

415 4-237-426-02 COVER (AT)

416 4-237-425-02 PULLEY (AT)

417 4-237-416-02 HOLDER (AT)

418 4-239-618-01 SCREW (+PWH,2X6), STEP TAPPING

419 4-239-574-01 COVER (ENCODER)

M701 1-763-790-11 MOTOR, DC (LO)

M702 A-4735-611-A MOTOR (CK) ASSY (CK)

#5 7-685-133-19 SCREW +BTP 2.6X6 TYPE2 N-S

#6 7-685-860-04 SCREW +BVTT 2.6X4 (S)

411 4-237-428-01 SHEET (MG)

412 4-237-427-01 BELT (CDM71)

413 1-683-915-12 L.MOTOR BOARD

50

#8 7-685-534-19 SCREW +BTP 2.6X8 TYPE2 N-S

#9 7-685-860-04 SCREW +BVTT 2.6X4 (S)

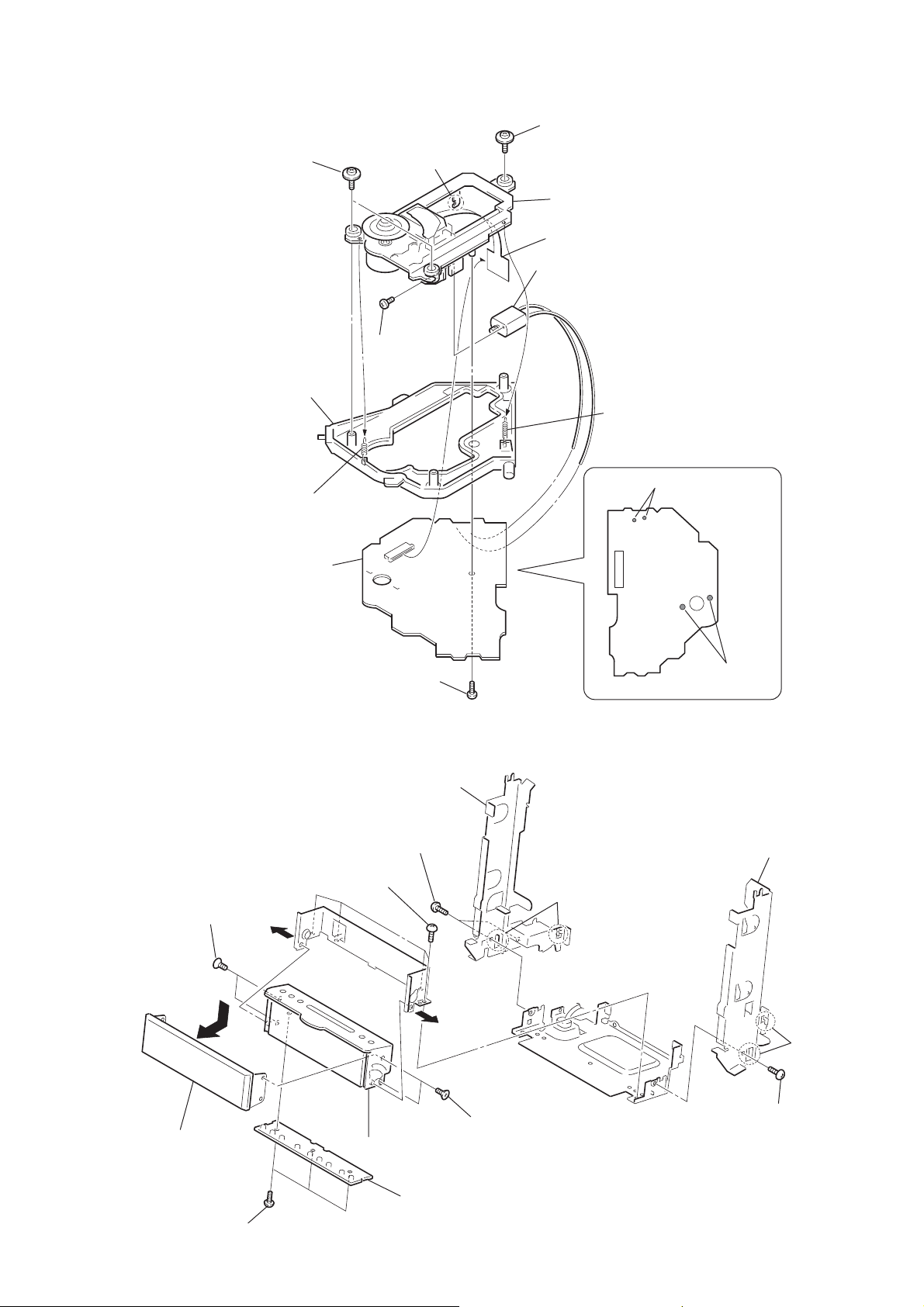

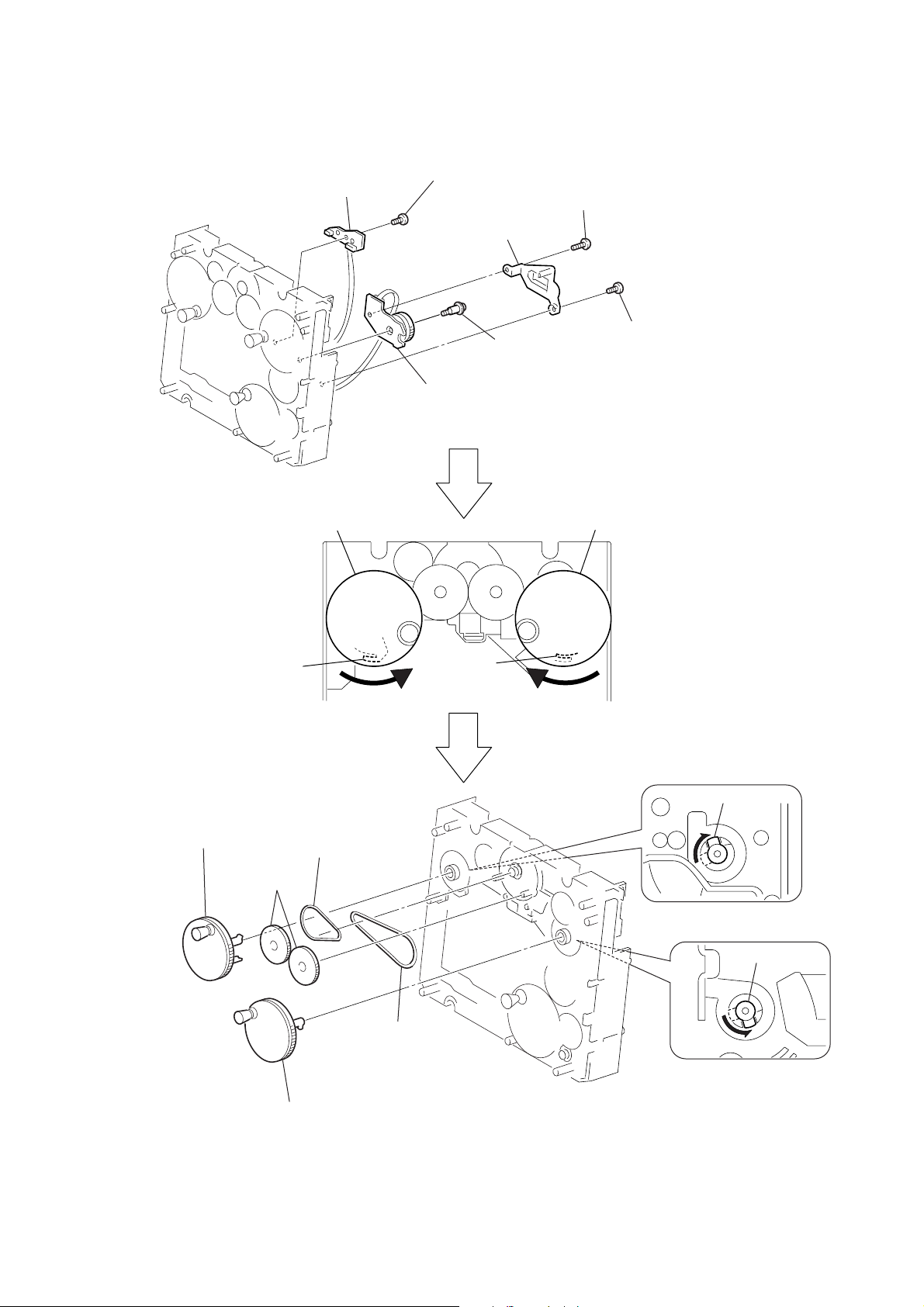

Page 51

7-5. Mechanism Section(CDM71C-31BD63A)-2

459

453

HCD-EX5

466

459

453

463

458

457

451

467

455

455

462

456

452

453

464

454

470

not

supplied

#5

465

not

supplied

473

460

#7

471

469

468

base unit (BU-31BD63A)

461

453

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

451 X-4954-292-1 PULLEY (SPT) ASSY

452 4-237-417-02 CAM (A)

453 4-238-841-01 BUSHING (GEAR)

454 4-237-430-01 SPRING (S), TORSION

455 4-237-414-01 GEAR (L1)

456 4-237-413-01 GEAR (S1)

457 X-4954-291-1 PULLEY (RTR) ASSY

458 X-4954-290-1 PULLEY (RTL) ASSY

459 4-237-411-01 PULLEY (LDG)

460 4-237-420-03 CHASSIS

461 4-237-460-01 PULLEY (LDG2)

462 4-237-429-02 SPRING (M), TORSION

463 4-218-252-51 SCREW (+PTPWH M2.6), FLOATING

464 X-4954-644-1 GEAR (RT) ASSY

465 4-238-552-01 REFLECTOR (CDM71)

466 4-237-459-01 GEAR (LA)

467 4-237-415-01 GEAR (S2)

468 4-237-424-01 GEAR (KT)

469 4-237-423-01 GEAR (C2)

470 4-237-421-01 GEAR (C1)

471 4-237-952-03 LEVER (ST)

473 4-238-835-02 SPRING (71L), TENSION

#5 7-685-133-19 SCREW +BTP 2.6X6 TYPE2 N-S

#7 7-685-134-19 SCREW +P 2.6X8 TYPE2 NON-SLIT

51

Page 52

HCD-EX5

2

7-6. Base Unit (BU-31BD63A)

516

506

not supplied

505

513

512

501

502

510

M101

(including

Ref. No. 516)

517

508

504

not supplied

506

502

501

503

509

501

502

not supplied

#9

#10

511

M10

514

515