Page 1

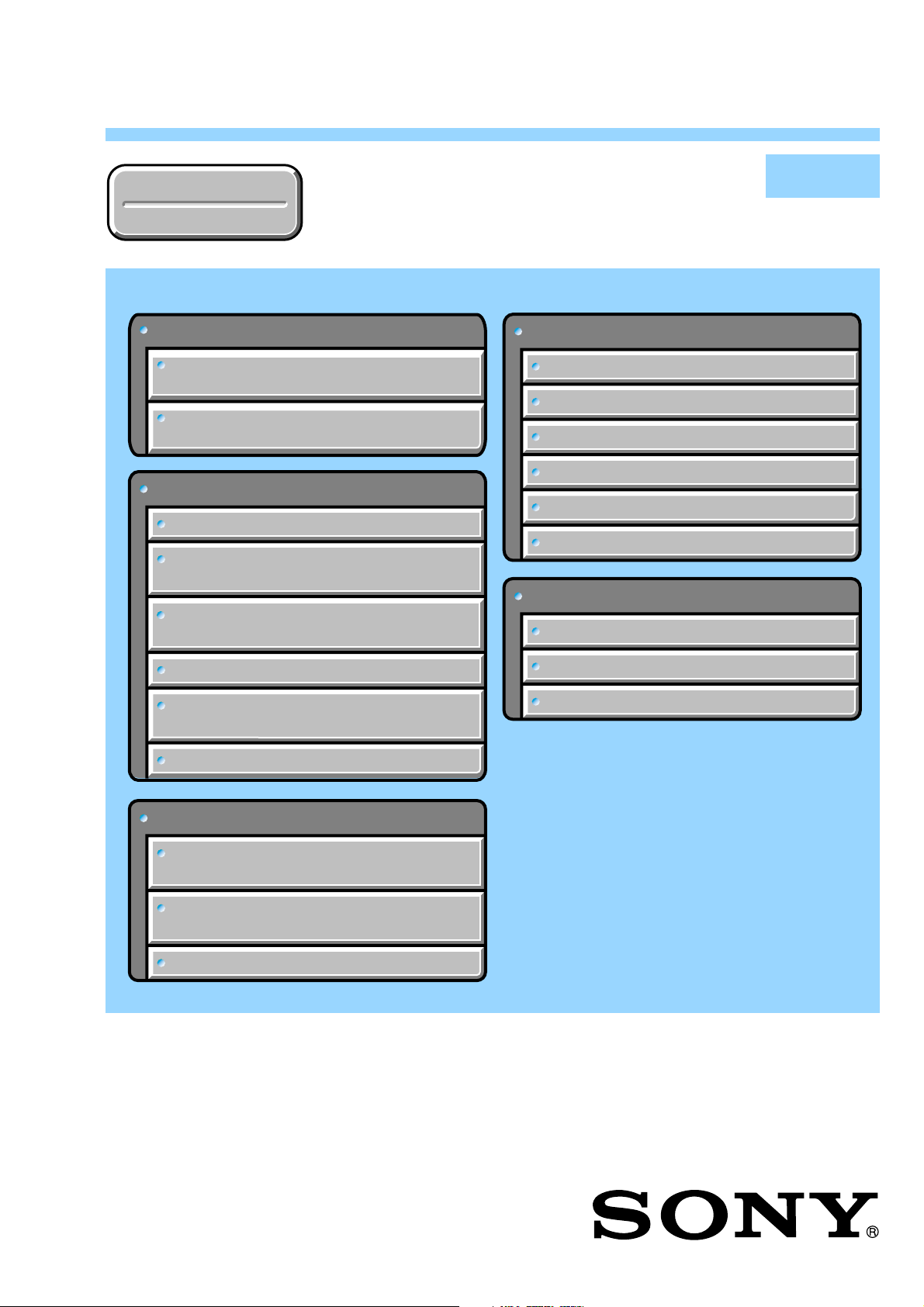

DCR-HC17E/HC19E/HC21/HC21E/HC22E/

HC32/HC32E/HC33/HC33E

RMT-830/831

Ver 1.0 2005.01

Revision History

Revision History

Link

Link

Before starting adjustments

Before starting adjustments

Adjusting items when replacing main parts and boards

Adjusting items when replacing main parts and boards

(Non MS model)

(Non MS model)

Adjusting items when replacing main parts and boards

Adjusting items when replacing main parts and boards

(MS model)

(MS model)

CAMERA SECTION ADJUSTMENTS

CAMERA SECTION ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

INITIALIZATION OF 8, A, C, D, E, F, 1C, 1F

INITIALIZATION OF 8, A, C, D, E, F, 1C, 1F

PAGE DATA (Non MS model)

PAGE DATA (Non MS model)

INITIALIZATION OF 8, A, B, C, D, E, F, 18, 1A,

INITIALIZATION OF 8, A, B, C, D, E, F, 18, 1A,

1B, 1C, 1E, 1F PAGE DATA (MS model)

1B, 1C, 1E, 1F PAGE DATA (MS model)

SECTION 6

ADJUSTMENTS

ADJ

VIDEO SECTION ADJUSTMENTS

VIDEO SECTION ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

SYSTEM CONTROL SYSTEM ADJUSTMENTS

SYSTEM CONTROL SYSTEM ADJUSTMENTS

SERVO AND RF SYSTEM ADJUSTMENTS

SERVO AND RF SYSTEM ADJUSTMENTS

VIDEO SYSTEM ADJUSTMENTS

VIDEO SYSTEM ADJUSTMENTS

AUDIO SYSTEM ADJUSTMENTS (Non MS model)

AUDIO SYSTEM ADJUSTMENTS (Non MS model)

AUDIO SYSTEM ADJUSTMENTS (MS model)

AUDIO SYSTEM ADJUSTMENTS (MS model)

SERVICE MODE

SERVICE MODE

ADJUSTMENT REMOTE COMMANDER

ADJUSTMENT REMOTE COMMANDER

CAMERA SYSTEM ADJUSTMENTS

CAMERA SYSTEM ADJUSTMENTS

ELECTRONIC VIEWFINDER SYSTEM

ELECTRONIC VIEWFINDER SYSTEM

ADJUSTMENTS

ADJUSTMENTS

LCD SYSTEM ADJUSTMENTS

LCD SYSTEM ADJUSTMENTS

MECHANISM SECTION ADJUSTMENTS

MECHANISM SECTION ADJUSTMENTS

HOW TO ENTER RECORD MODE WITHOUT

HOW TO ENTER RECORD MODE WITHOUT

CASSETE

CASSETE

HOW TO ENTER PLAYBACK MODE WITHOUT

HOW TO ENTER PLAYBACK MODE WITHOUT

CASSETE

CASSETE

TAPE PATH ADJUSTMENT

TAPE PATH ADJUSTMENT

NON MS model: DCR-HC17E/HC19E/HC21/HC21E/HC22E

MS model: DCR-HC32/HC32E/HC33/HC33E

DATA PROCESS

DATA PROCESS

SERVICE MODE

SERVICE MODE

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

9-876-782-51

Sony EMCS Co.

2004L0500-1

© 2004.12

Published by DI Technical Support Section

Page 2

TABLE OF CONTENTS

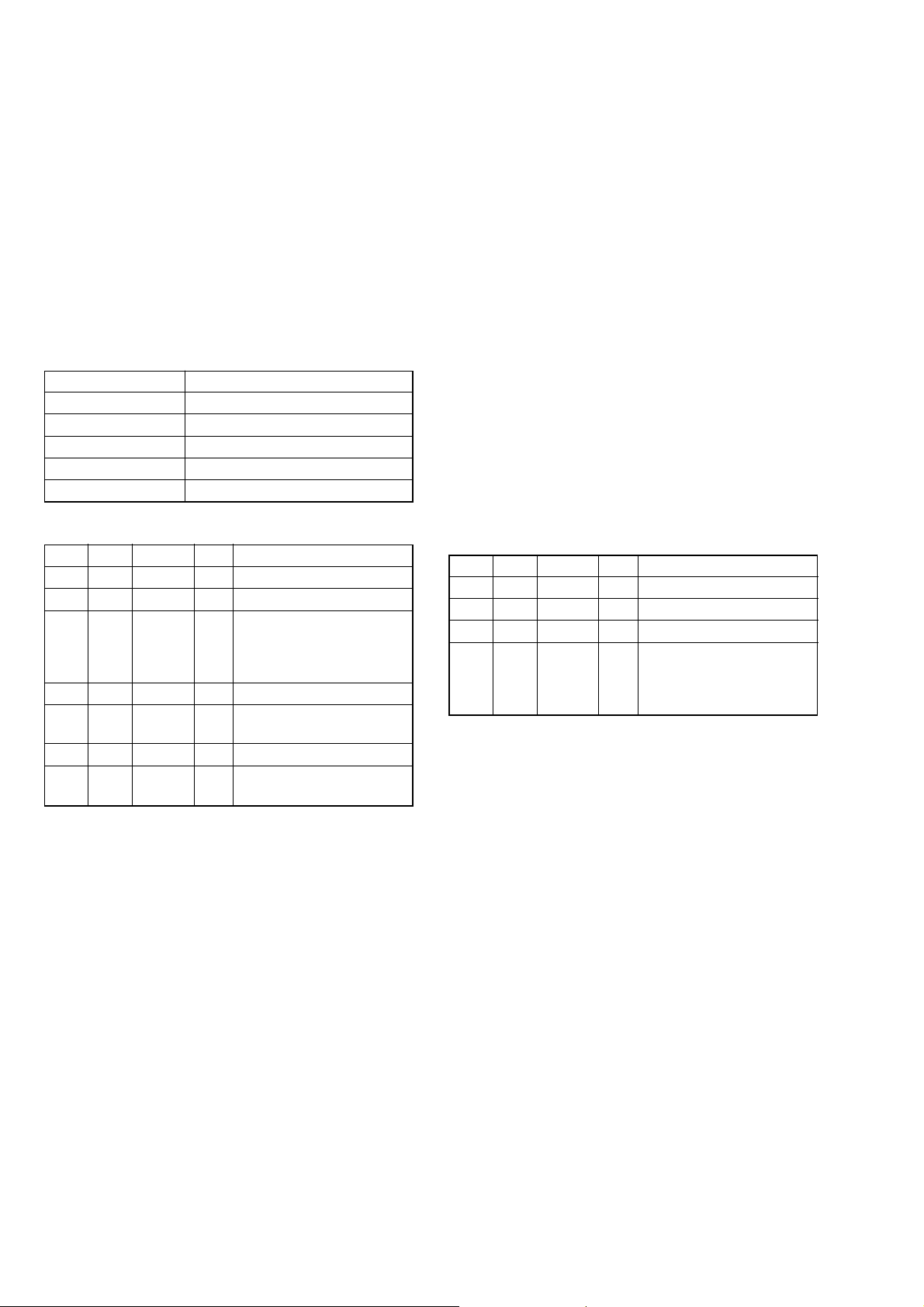

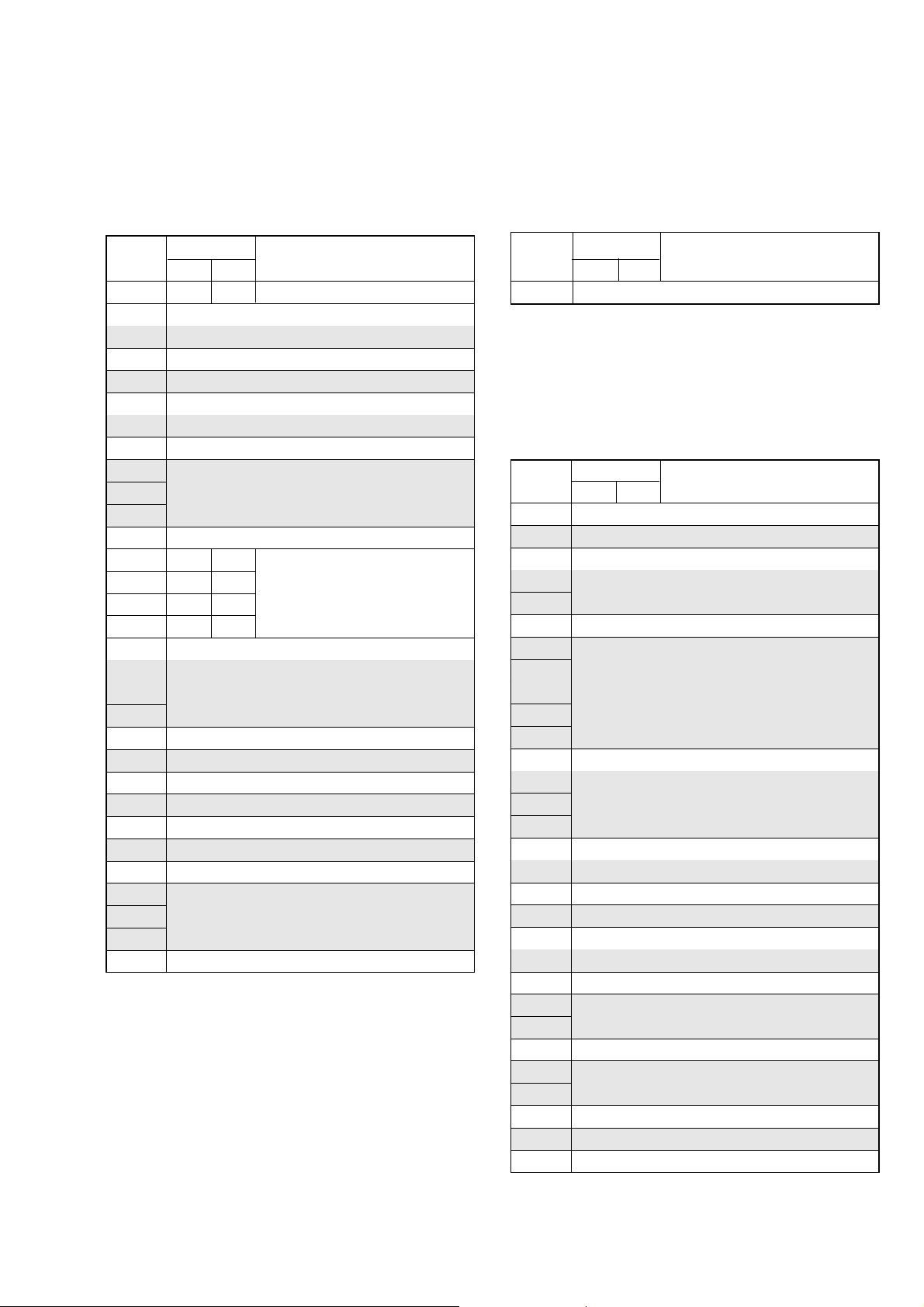

Section Title Page Section Title Page

6. ADJUSTMENTS

1. Before Starting Adjustments ···········································6-1

1-1. Adjusting Items when Replacing Main Parts and

Boards (Non MS model) ·················································6-2

1-2. Adjusting Items when Replacing Main Parts and

Boards (MS model) ·························································6-4

6-1. Camera Section Adjustments···········································6-6

1-1. Preparations before Adjustments (CAMERA Section)···6-6

1-1-1.List of Service Tools ························································6-6

1-1-2.Preparations ····································································· 6-7

1-1-3.Precaution········································································6-8

1. Setting the Switch····························································6-8

2. Order of Adjustments ······················································6-8

3. Subjects ··········································································· 6-9

4. Preparing the Flash Adjustment Box·····························6-10

1-2. Initialization of 8, A, C, D, E, F, 1C, 1F Page Data

(Non MS model)····························································6-11

1-2-1.Initialization of A, D Page Data ····································6-11

1. Initializing of A, D Page Data ·······································6-11

2. Modification of A, D Page Data ····································6-11

3. A Page Table ··································································6-12

4. D Page Table ··································································6-12

1-2-2.Initialization of 8, C, 1C Page Data·······························6-13

1. Initializing of 8, C, 1C Page Data ·································6-13

2. Modification of 8, C, 1C Page Data ······························6-13

3. 8 Page Table ···································································6-14

4. C Page Table ··································································6-14

5. 1C Page Table ································································6-15

1-2-3.Initialization of E, F, 1F Page Data································6-16

1. Initializing of E, F, 1F Page Data ··································6-16

2. Modification of E, F, 1F Page Data ······························· 6-16

3. E Page Table ··································································6-17

4. F Page Table ··································································6-17

5. 1F Page Table ································································6-19

1-3. Initialization of 8, A, B, C, D, E, F, 18, 19,

1A, 1B, 1C, 1E, 1F Page Data (MS model) ··················6-20

1-3-1.Initialization of A, B, D, 1A, 1B Page Data ··················6-20

1. Initializing of A, B, D, 1A, 1B Page Data ·····················6-20

2. Modification of A, B, D, 1A, 1B Page Data··················6-20

3. A Page Table ··································································6-21

4. B Page Table ··································································6-21

5. D Page Table ··································································6-21

6. 1A Page Table ································································6-22

7. 1B Page Table ································································6-22

1-3-2.Initialization of 8, C, 18, 1C Page Data·························6-23

1. Initializing of 8, C, 18, 1C Page Data ···························6-23

2. Modification of 8, C, 18, 1C Page Data ························6-23

3. 8 Page Table ···································································6-24

4. C Page Table ··································································6-25

5. 18 Page Table ·································································6-26

6. 1C Page Table ································································6-27

1-3-3.Initialization of E, F, 19, 1E, 1F Page Data ···················6-28

1. Initializing of E, F, 19, 1E, 1F Page Data······················6-28

2. Modification of E, F, 19, 1E, 1F Page Data···················6-28

3. E Page Table ··································································6-29

4. F Page Table ··································································6-29

5. 19 Page Table ·································································6-31

6. 1E Page Table ································································6-31

7. 1F Page Table ································································6-32

1-4. Camera System Adjustments·········································6-33

1. 36MHz Origin Oscillation Adjustment

(VC-376 board (Non MS model))

(VC-377 board (MS model)) ········································ 6-33

2. Hall Adjustment·····························································6-34

3. Flange Back Adjustment

(Using the minipattern box or

flange back adjustment jig) ···········································6-35

4. Flange Back Adjustment

(Using the flange back adjustment chart and

subject more than 500 m away)·····································6-36

4-1. Flange Back Adjustment (1)··········································6-36

4-2. Flange Back Adjustment (2)··········································6-37

5. Flange Back Check························································6-37

6. Optical Axis Adjustment ··············································· 6-38

7. Picture Frame Setting

(Color reproduction adjustment frame) ·························6-39

8. Picture Frame Setting (Center frame) ···························6-40

9. F No. standard data input ··············································6-40

10. Mechanical Shutter Adjustment

(DCR-HC32/HC32E/HC33/HC33E) ····························6-41

11. Color Reproduction Adjustment····································6-42

12. Auto White Balance Standard Data Input ·····················6-43

13. LV Standard Data Input·················································6-43

14. Auto White Balance Adjustment ···································6-44

15. Auto White Balance Check ···········································6-45

16. MAX GAIN Adjustment ···············································6-46

17. Steadyshot Check ··························································6-47

1-5. Electronic Vie wfinder System Adjustments ··················6-48

1. EVF Automatic Adjustment (LB-109 board) ················6-48

1-6. LCD System Adjustments ·············································6-49

1. LCD Automatic Adjustment (PD-237 board)················6-49

2. V-COM Adjustment (PD-237 board) ····························6-50

3. Transmissive Mode White Balance Adjustment

(PD-237 board)······························································6-50

6-2. Mechanism Section Adjustments ··································6-51

2-1. How To Enter Record Mode Without Cassette··············6-51

2-2. How To Enter Playback Mode Without Cassette ··········6-51

2-3. Tape Path Adjustment····················································6-51

1. Preparation for Adjustment ···········································6-51

2. Procedure After Operations ···········································6-51

6-3. Video Section Adjustments ···········································6-52

3-1. Preparations Before Adjustments ·································· 6-52

3-1-1.Equipment Required······················································6-52

3-1-2.Precautions on Adjusting···············································6-52

3-1-3.Adjusting Connectors ···················································· 6-52

3-1-4.Connecting the Equipment ············································6-53

3-1-5.Alignment Tapes····························································6-54

3-1-6.Input/Output Level and Impedance·······························6-54

3-2. System Control System Adjustments ····························6-55

1. Initialization of 8, A, C, D, E, F,

1C,1F Page Data (Non MS model) ·······························6-55

2. Touch Panel Adjustment (Non MS model) ···················6-55

3. Initialization of 8, A, B, C, D, E, F, 18, 19,

1A, 1B, 1C, 1E, 1F Page Data (MS model) ··················6-56

4. Touch Panel Adjustment (MS model) ···························6-56

5. Node Unique ID No. Input ············································6-57

3-3. Servo and RF System Adjustments ·······························6-59

1. CAP FG Duty Adjustment

(VC-376 board (Non MS model))

(VC-377 board (MS model)) ·········································6-59

2. Switching Position Adjustment

(VC-376 board (Non MS model))

(VC-377 board (MS model)) ········································ 6-60

3. Error Rate Check

(VC-376 board (Non MS model))

(VC-377 board (MS model)) ·········································6-61

3-1. Preparations Before Adjustments ·································· 6-61

3-2. Error Rate Check ···························································6-61

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

— 2 —

Page 3

Section Title Page

3-4. Video System Adjustments ············································6-62

1. S VIDEO OUT Y Level Adjustment

(VC-376 board (Non MS model))

(VC-377 board (MS model)) ·········································6-62

2. S VIDEO OUT Chroma Level Adjustment

(VC-376 board (Non MS model))

(VC-377 board (MS model)) ·········································6-63

3. VIDEO OUT Level Check

(VC-376 board (Non MS model))

(VC-377 board (MS model)) ·········································6-64

3-5. Audio System Adjustments (Non MS model)···············6-65

1. Playback Level Check ···················································6-65

2. Overall Level Characteristics Check ·····························6-65

3. Overall Distortion Check···············································6-66

4. Overall Noise Level Check············································6-66

5. Overall Separation Check··············································6-66

3-6. Audio System Adjustments (MS model)·······················6-67

1. Playback Level Check ···················································6-67

2. Overall Level Characteristics Check ·····························6-67

3. Overall Distortion Check···············································6-68

4. Overall Noise Level Check············································6-68

5. Overall Separation Check··············································6-68

6-4. Service Mode·································································6-69

4-1. Adjustment Remote Commander ··································6-69

1. Using the Adjustment Remote Commander··················6-69

2. Precautions Upon Using the Adjustment

Remote Commander······················································6-69

4-2. Data Process ··································································6-70

4-3. Service Mode·································································6-71

1. Setting the Test Mode ···················································· 6-71

1-1. Setting the Test Mode (Non MS model)························6-71

1-2. Setting the Test Mode (MS model) ······························· 6-71

2. Emergence Memory Address (Non MS model) ············6-71

2-1. Emergency Memory Address (Camera section)············6-71

2-2. EMG Code (Emergency Code) ·····································6-71

3. Emergence Memory Address (MS model) ····················6-72

3-1. Emergency Memory Address (Camera section)············6-72

3-2. EMG Code (Emergency Code) ·····································6-72

4. Emergence Memory Address (Mechanism section)······6-72

4-1. EMG Code (Emergency Code) ·····································6-73

4-2. MSW Code ····································································6-74

5. Bit V alue Discrimination ···············································6-75

6. Jack Check (Non MS model) ········································6-75

6-1. Jack Check (1) (Handycam station) (DCR-HC22E) ·····6-75

6-2. Jack Check (2) ·······························································6-75

7. Jack Check (MS model) ················································6-76

7-1. Jack Check (1) (Handycam station) ······························6-76

7-2. Jack Check (2) ·······························································6-76

8. Switch Check (Non MS model) ····································6-76

8-1. Switch Check (1) ···························································6-76

8-2. Switch Check (2) ···························································6-76

8-3. Switch Check (3) ···························································6-77

8-4. Switch Check (4) ···························································6-77

9. Switch Check (MS model) ············································6-78

9-1. Switch Check (1) ···························································6-78

9-2. Switch Check (2) ···························································6-78

9-3. Switch Check (3) ···························································6-78

9-4. Switch Check (4) ···························································6-79

10. LED, IR Light Check (Non MS model) ························6-80

11. LED, IR Light Check (MS model) ································6-80

12. Record of Use Check (1) ···············································6-80

13. Record of Use Check (2) (Non MS model)···················6-81

14. Record of Use Check (3) (MS model)···························6-82

15. Record of Use Check (4) ···············································6-82

16. Record of Self-diagnosis Check ····································6-83

* The camera optical axis frame is shown on page 6-84.

The camera color reproduction frame is shown on page

6-85.

Note : Non MS model: DCR-HC17E/HC19E/HC21/HC21E/

HC22E

MS model: DCR-HC32/HC32E/HC33/HC33E

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

— 3 —

Page 4

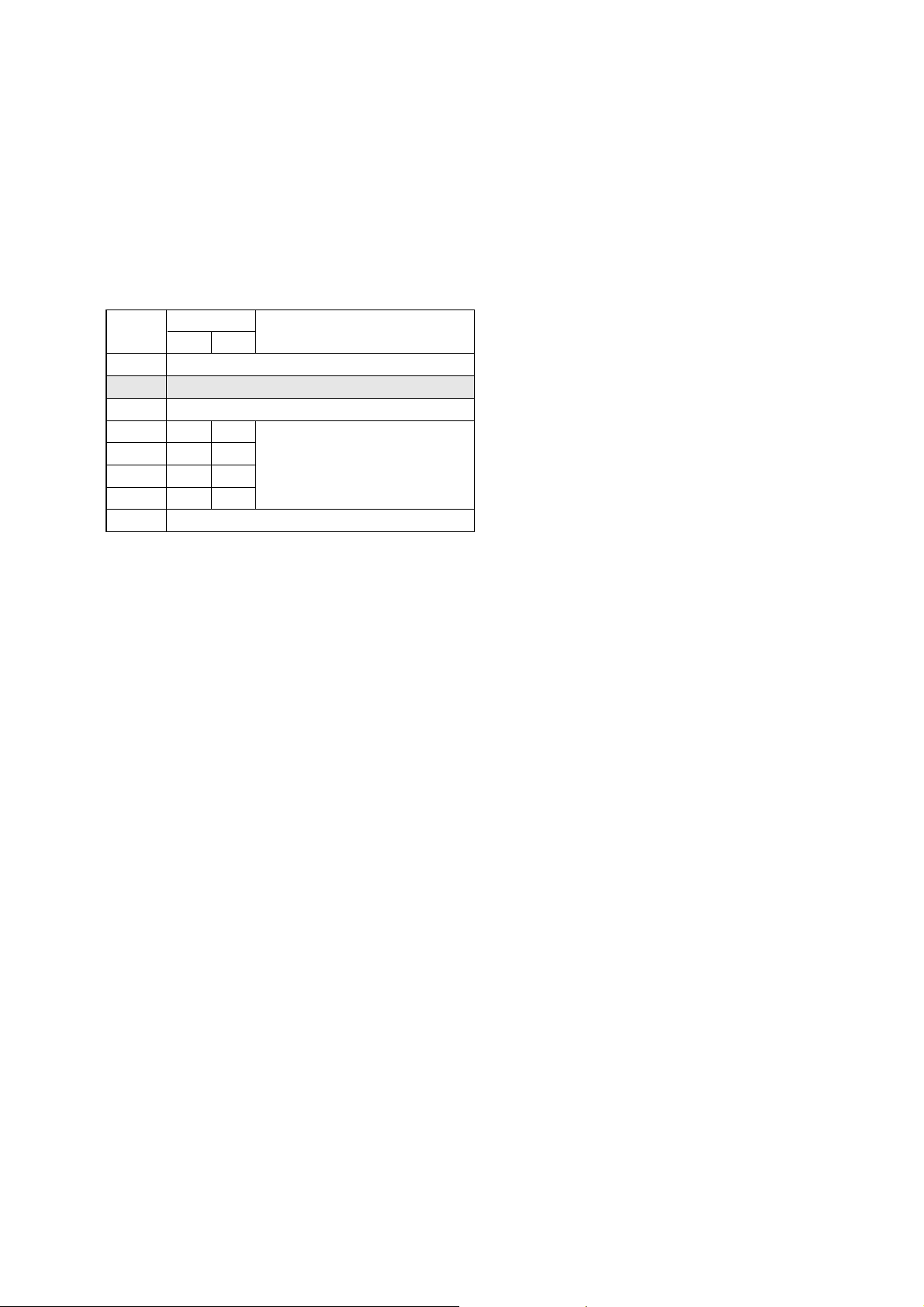

1. Before starting adjustments

(Machine before starting repair)

(Machine after a board is replaced)

PC PC

Save the EVR data

to a personal computer.

Download the saved

data to a machine.

EVR Data Re-writing Procedure When Replacing Board

The data that is stored in the repair board, is not necessarily correct.

Perform either procedure 1 or procedure 2 or procedure 3 when replacing board.

Procedure 1

Save the EVR data of the machine in which a board is going to be replaced. Download the saved data after a

board is replaced.

SECTION 6

ADJUSTMENTS

Procedure 2

Remove the EEPROM from the board of the machine that is going to be repaired. Install the removed

EEPROM to the replaced board.

Remove the EEPROM and install it.

(Former board)

(New board)

Procedure 3

When the data cannot be saved due to defective EEPROM, or when the EEPROM cannot be removed or

installed, save the data from the same model of the same destination, and download it.

(Machine to be repaired) (Machine to be repaired)

PC

Download the data.

(The same model of the same destination)

After the EVR data is saved and downloaded, chec k the

respective items of the EVR data.

(Refer to page 6-3 or 6-5 for the items to be checked)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

Save the data.

6-1

Page 5

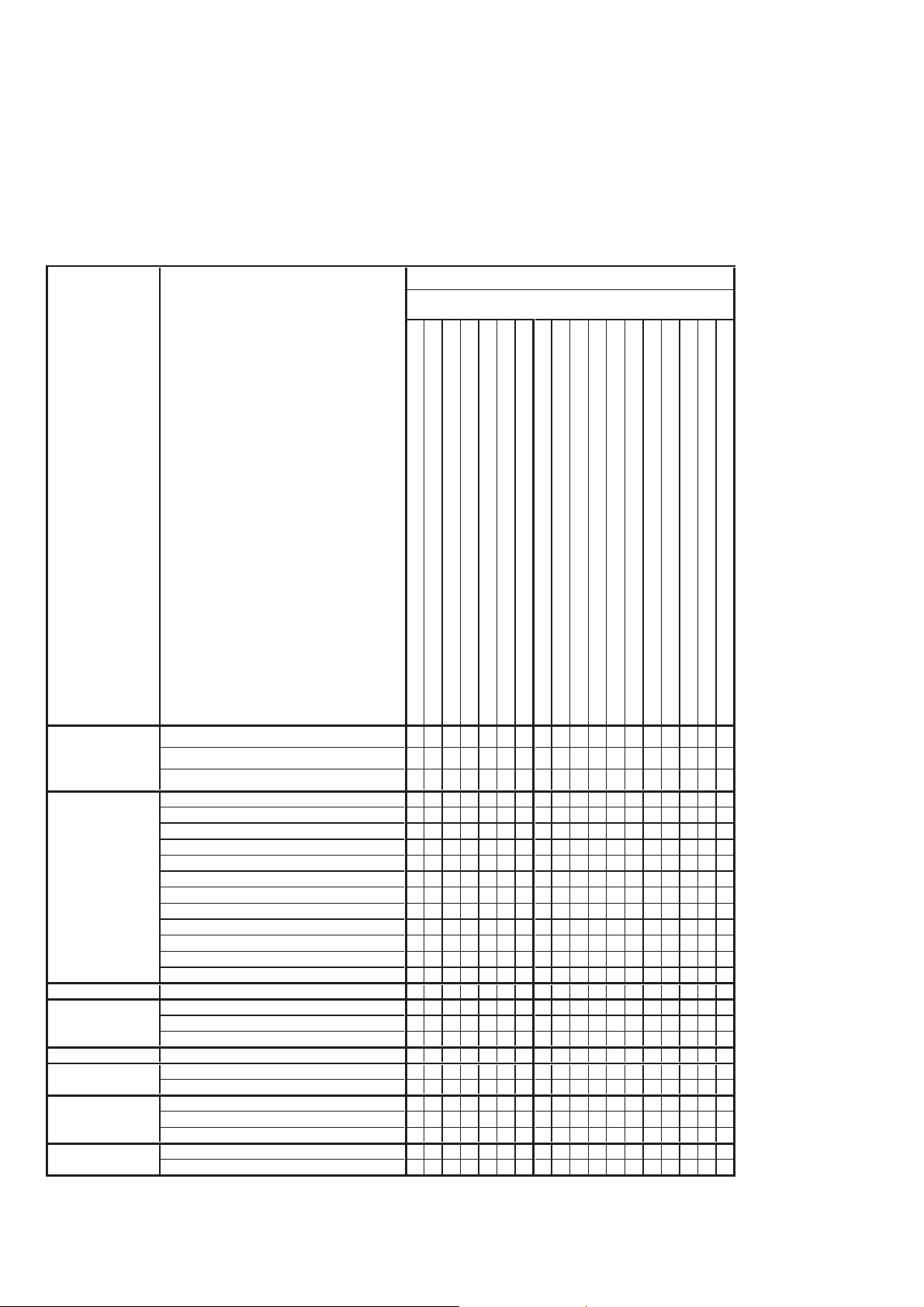

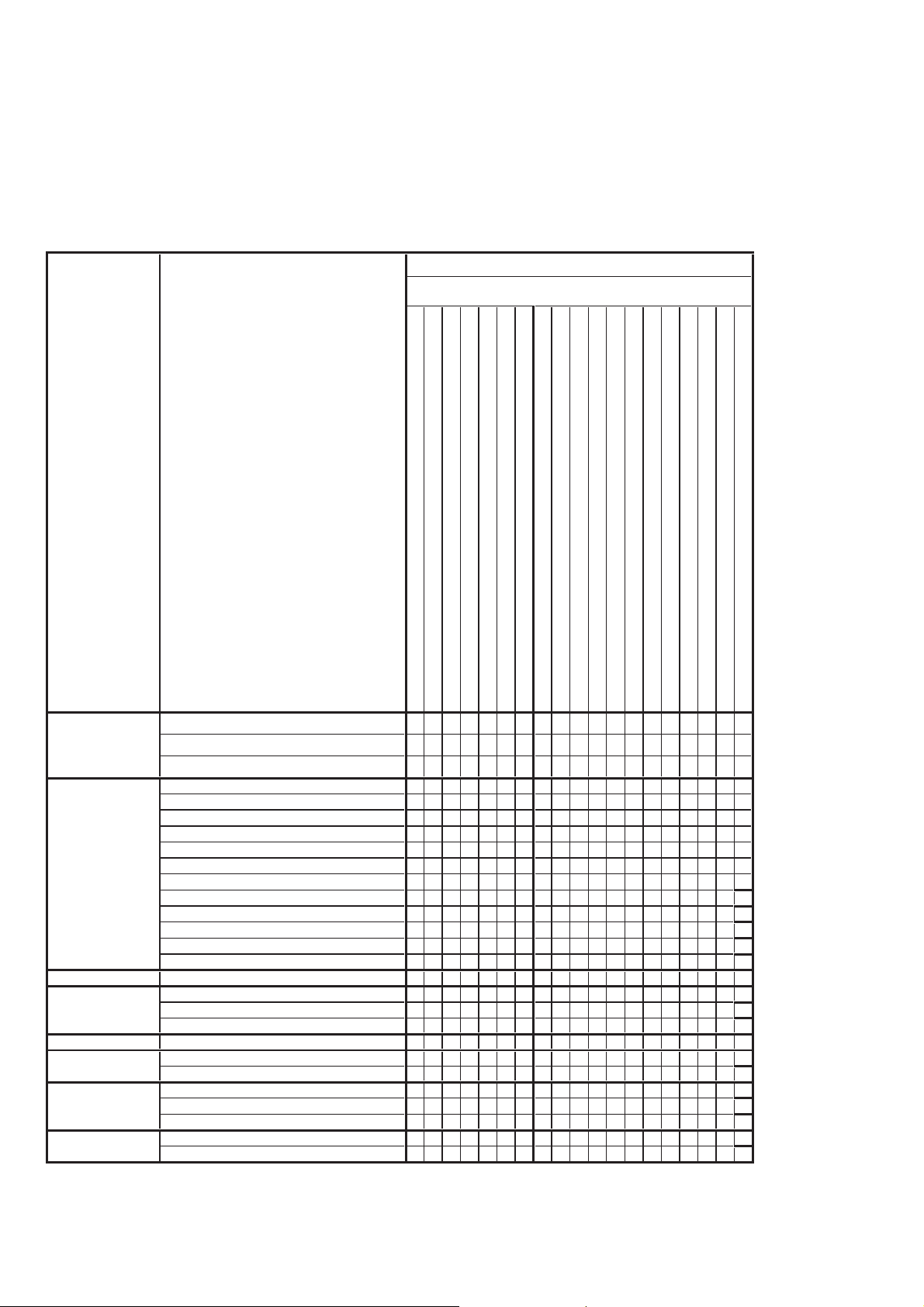

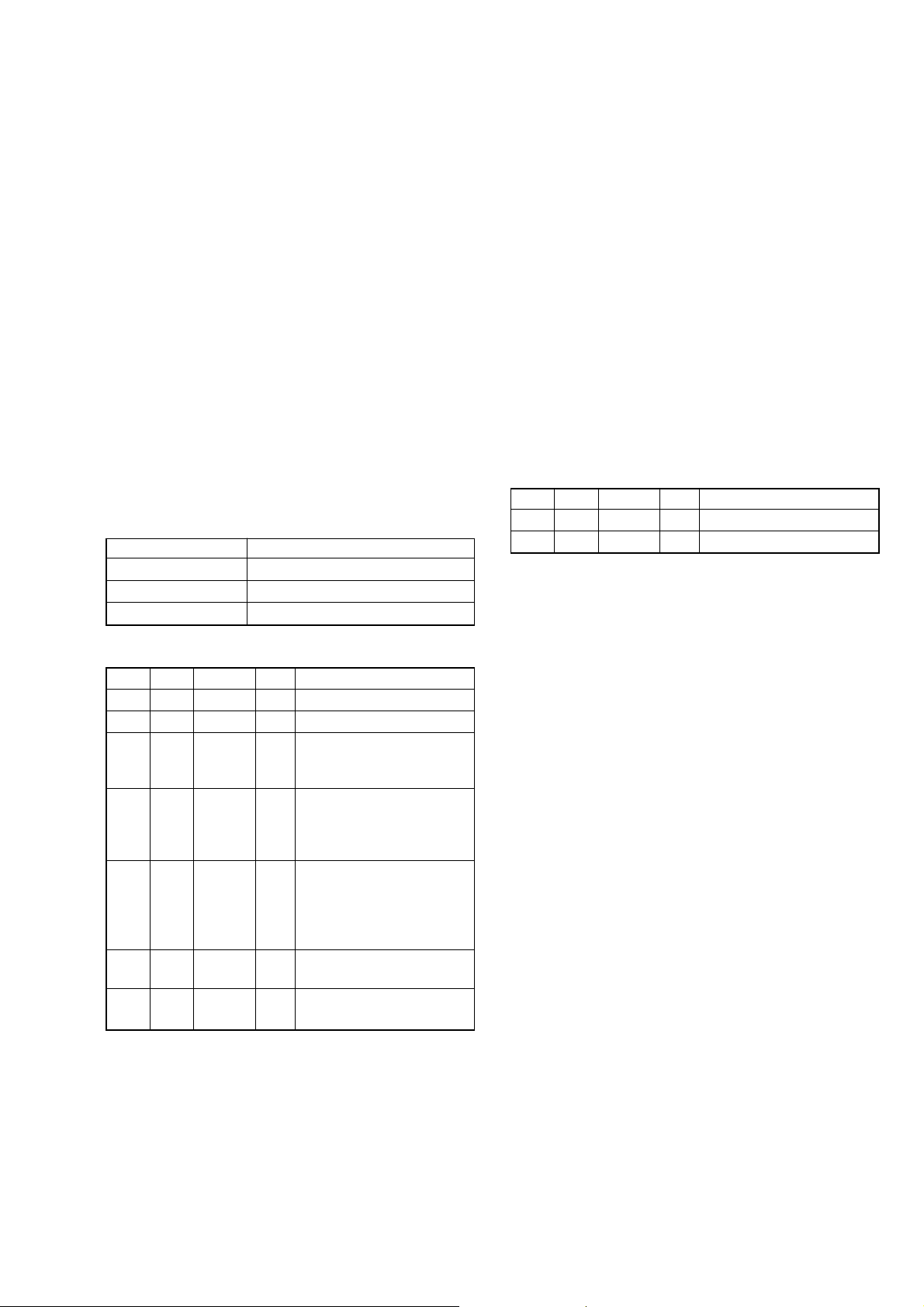

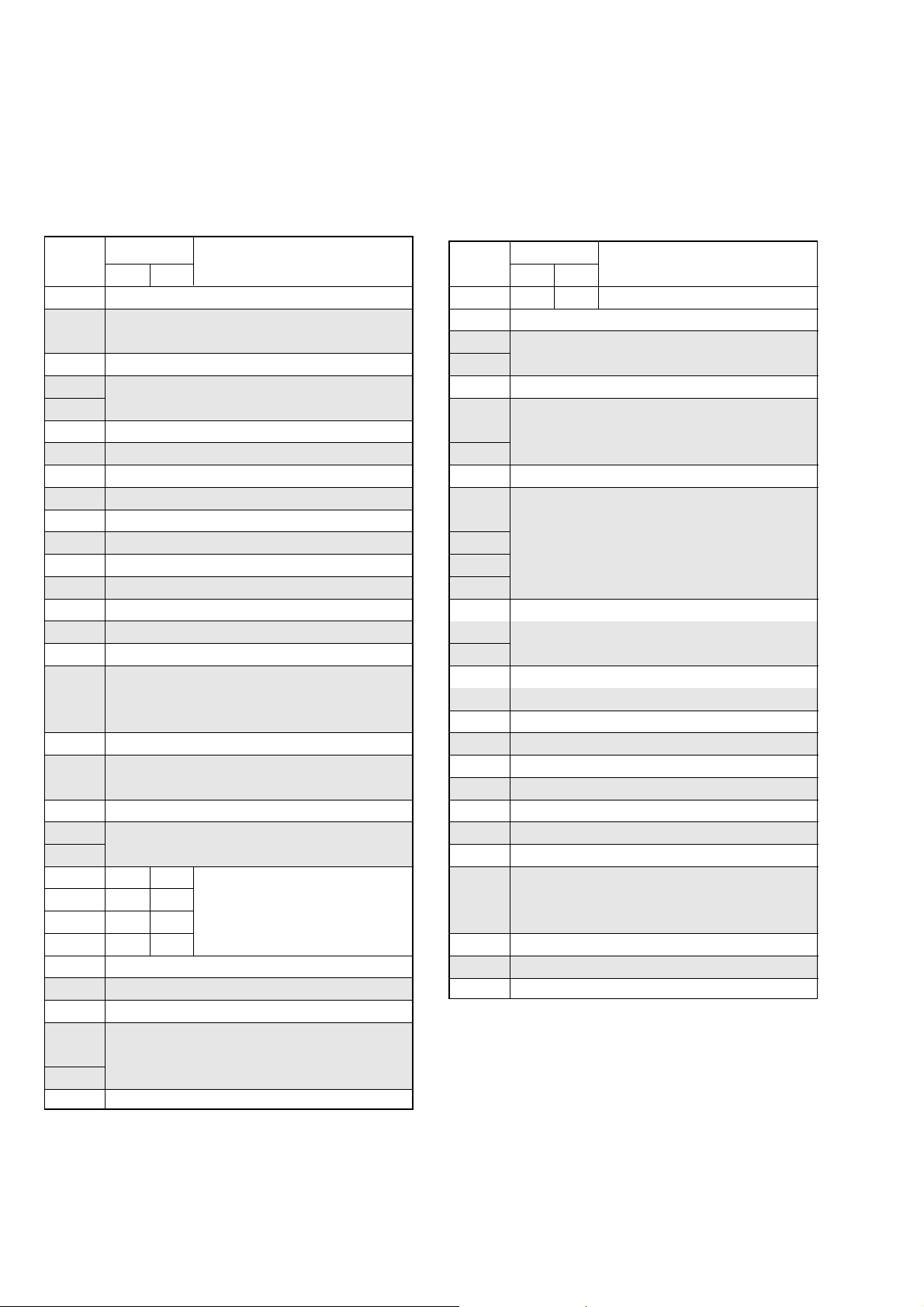

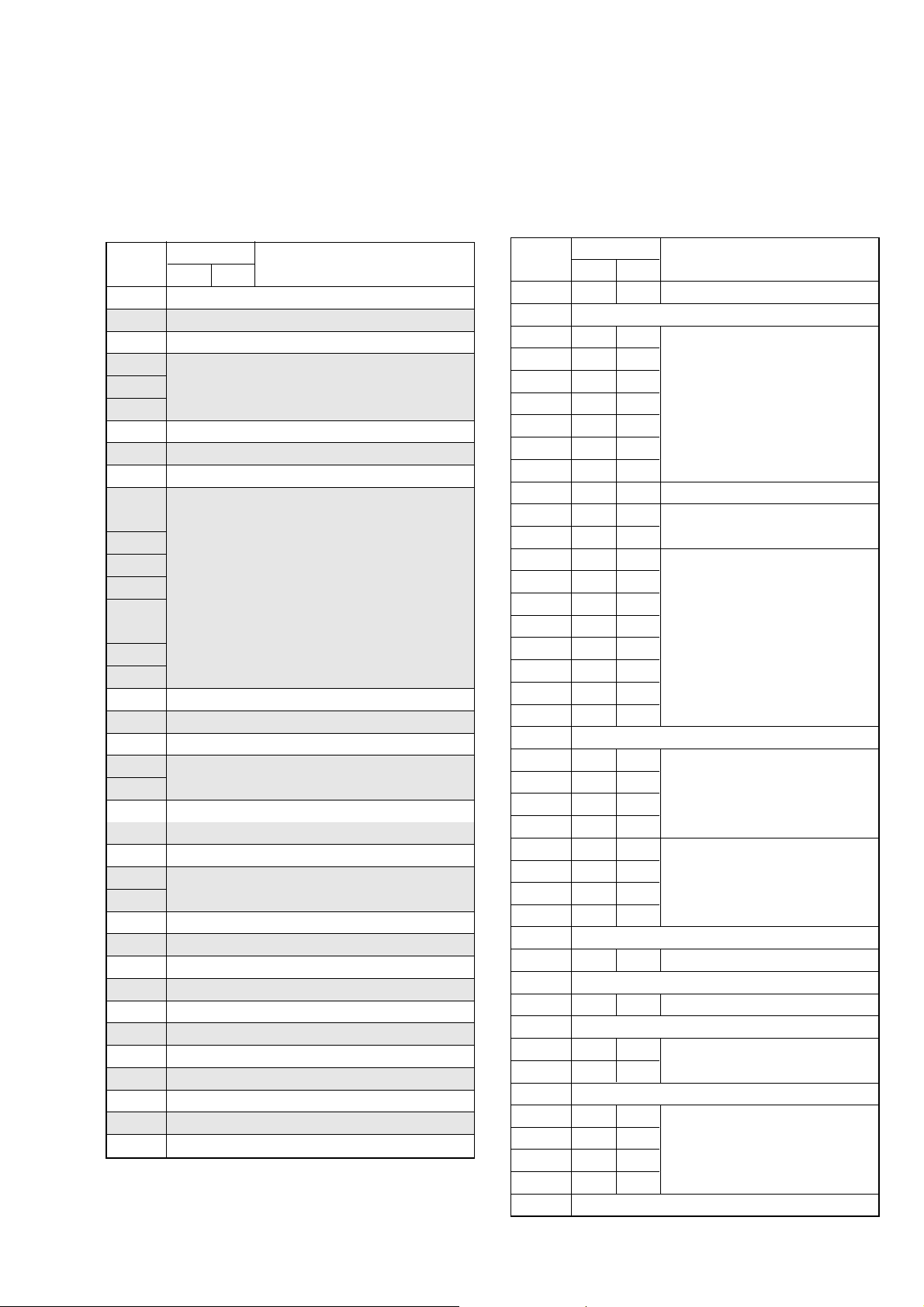

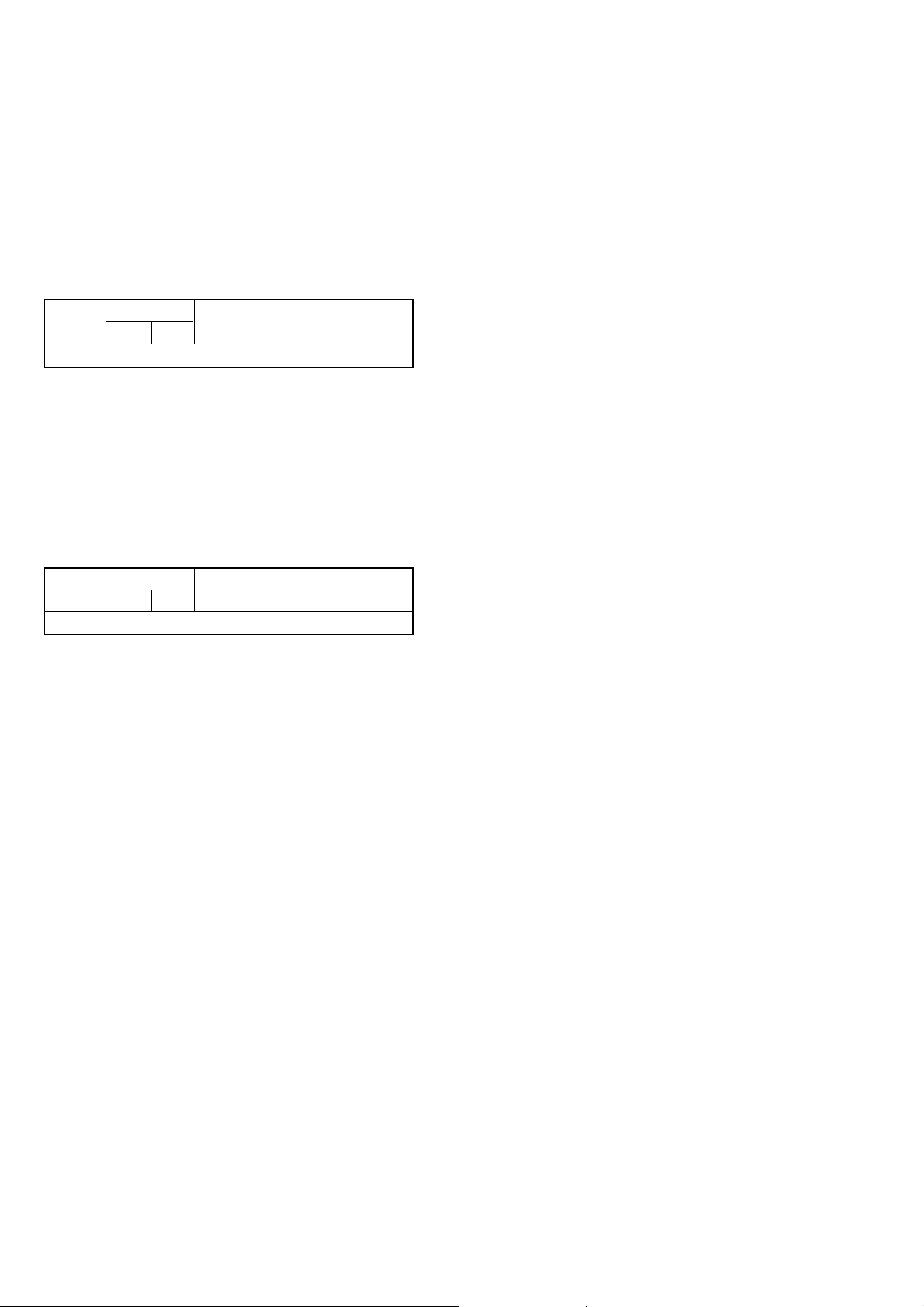

1-1. Adjusting items when replacing main parts and boards (Non MS model)

• Adjusting items when replacing main parts

When replacing main parts, adjust the items indicated by z in the following table.

Note 1: When replacing the drum assy or the mechanism deck, reset the data of page: 7, address: A8 to AB to “00”. (Refer to “Record of

Use check” of “6-4. SERVICE MODE”)

Note 2: Non MS model: DCR-HC17E/HC19E/HC21/HC21E/HC22E

Note 3: DCR-HC32/HC32E/HC33/HC33E model only.

Replaced part

Adjustment Section Adjustment

Block replacement Mounted part replacement

(LCD panel, Touch panel)

(Back light LED)

(LCD panel)

(Drum assembly) (Note 1)

(CCD imager)

(Back light (EVF))

(LCD drive)

(PITCH, YAW sensor)

(Timing generator)

(S/H, AGC, A/D converter)

(DV signal process)

Initialization of 8,

A, C, D, E, F, 1C,

1F page data

Initialization of A, D page data

Initialization of 8, C, 1C page data

Initialization of E, F, 1F page data

Camera 36MHz origin oscillation adj.

HALL adj.

Flange back adj.

Optical axis adj.

F No. standard data input

Mechanical shutter adj. (Note 3)

Color reproduction adj.

Auto white balance standard data input

LV standard data input

Auto white balance adj.

MAX GAIN adj.

Steadyshot check

EVF EVF automatic adj.

LCD LCD automatic adj.

V-COM adj.

Transmissive mode white balance adj.

Mechanism Tape path adj.

System control Touch panel adj.

Node uniqe ID No. input

Servo, RF CAP FG duty adj.

Switching position adj.

Error rate check

Video S VIDEO OUT Y level adj.

S VIDEO OUT chroma level adj.

Lens device

LCD block LCD901

LCD block D901

EVF block LCD902

Mechanism deck (Note 1)

Mechanism deck M901

Mechanism deck MD block

CD-533 board IC101

LB-109 board D303

PD-237 board IC602

SI-042 board SE601, 602

VC-376 board IC3001, X3001

VC-376 board IC3002

VC-376 board IC6001

z

z

zz

zz

zz

z

zz

zz

zz

zz

zz

z

zzz

zz

zz

zz z

zzz

z

zz

zzz

zzz z

z

z

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

Table 6-1-1 (1)

6-2

Page 6

• Adjusting items when replacing a board or EEPROM

When replacing a board or EEPROM, adjust the items indicated by z in the following table.

Replaced part

Adjustment Section Adjustment

Initialization of 8,

A, C, D, E, F, 1C,

1F page data

Initialization of A, D page data

Initialization of 8, C, 1C page data

Initialization of E, F, 1F page data

Camera 36MHz origin oscillation adj.

HALL adj.

Flange back adj.

Optical axis adj.

F No.standard data input

Mechanical shutter adj. (Note 3)

Color reproduction adj.

Auto white balance standard data input

LV standard data input

Auto white balance adj.

MAX GAIN adj.

Steadyshot check

EVF EVF automatic adj.

LCD LCD automatic adj.

V-COM adj.

Transmissive mode white balance adj.

Mechanism Tape path adj.

System control Touch panel adj.

Node uniqe ID No. input

Servo, RF CAP FG duty adj.

Switching position adj.

Error rate check

Video S VIDEO OUT Y level adj.

S VIDEO OUT chroma level adj.

(COMPLETE)

(COMPLETE)

(COMPLETE)

(COMPLETE)

(COMPLETE)

(EEP ROM)

RadarWRadarWRadarW

CD-533 board

LB-109 board

PD-237 board

SI-042 board

VC-376 board

VC-376 board IC8602

Supporting

zz

zz

zz

zz

zz z

zzzz

zzz

zzzz

zz z

zzz

zzzz

zzzz

zzzz

zzzz

zzz z

zz z

zzzz

zzz

zzz

zz

zz

zz z

zz z

zz z

zz

zz

Table 6-1-1 (2)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-3

Page 7

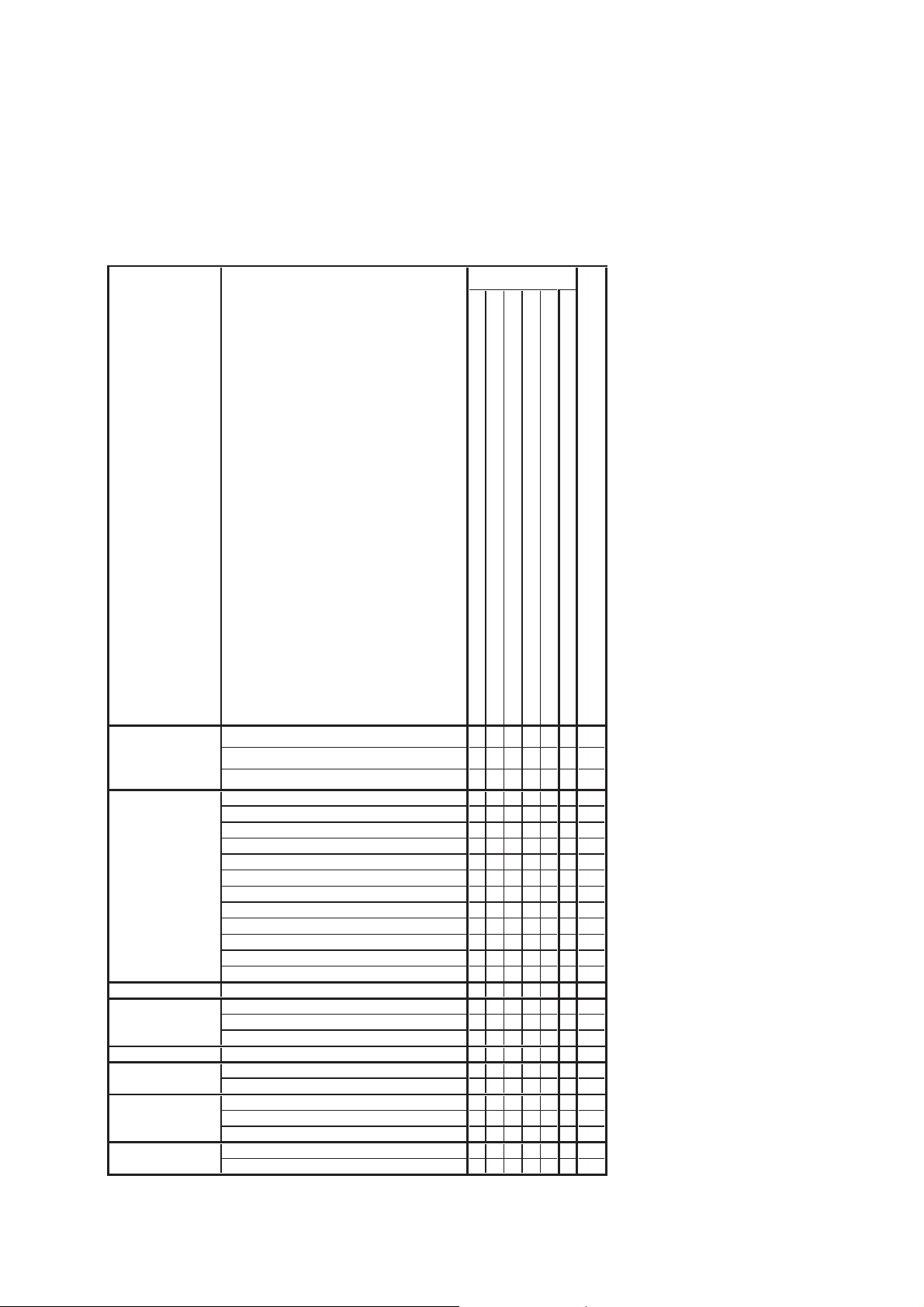

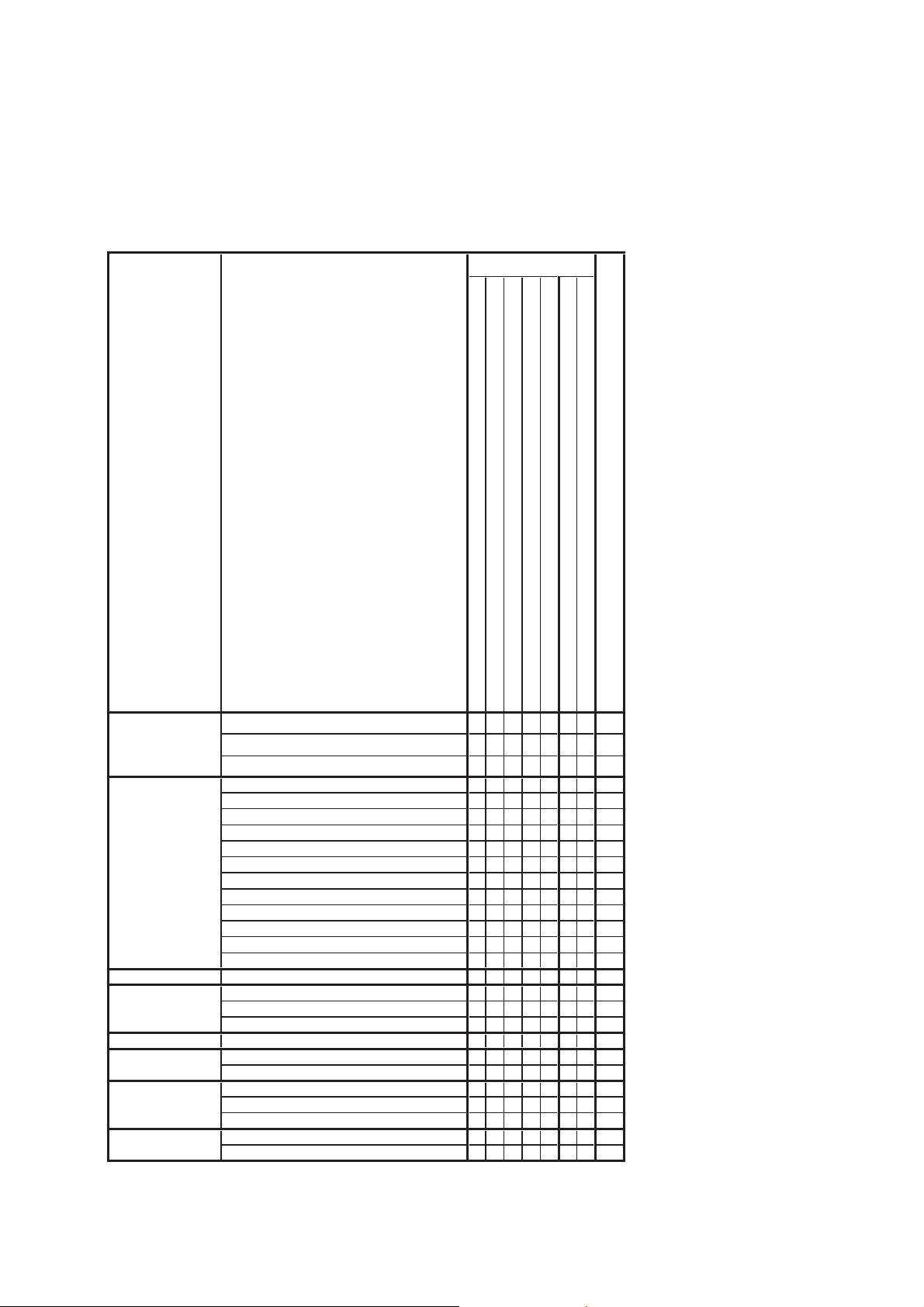

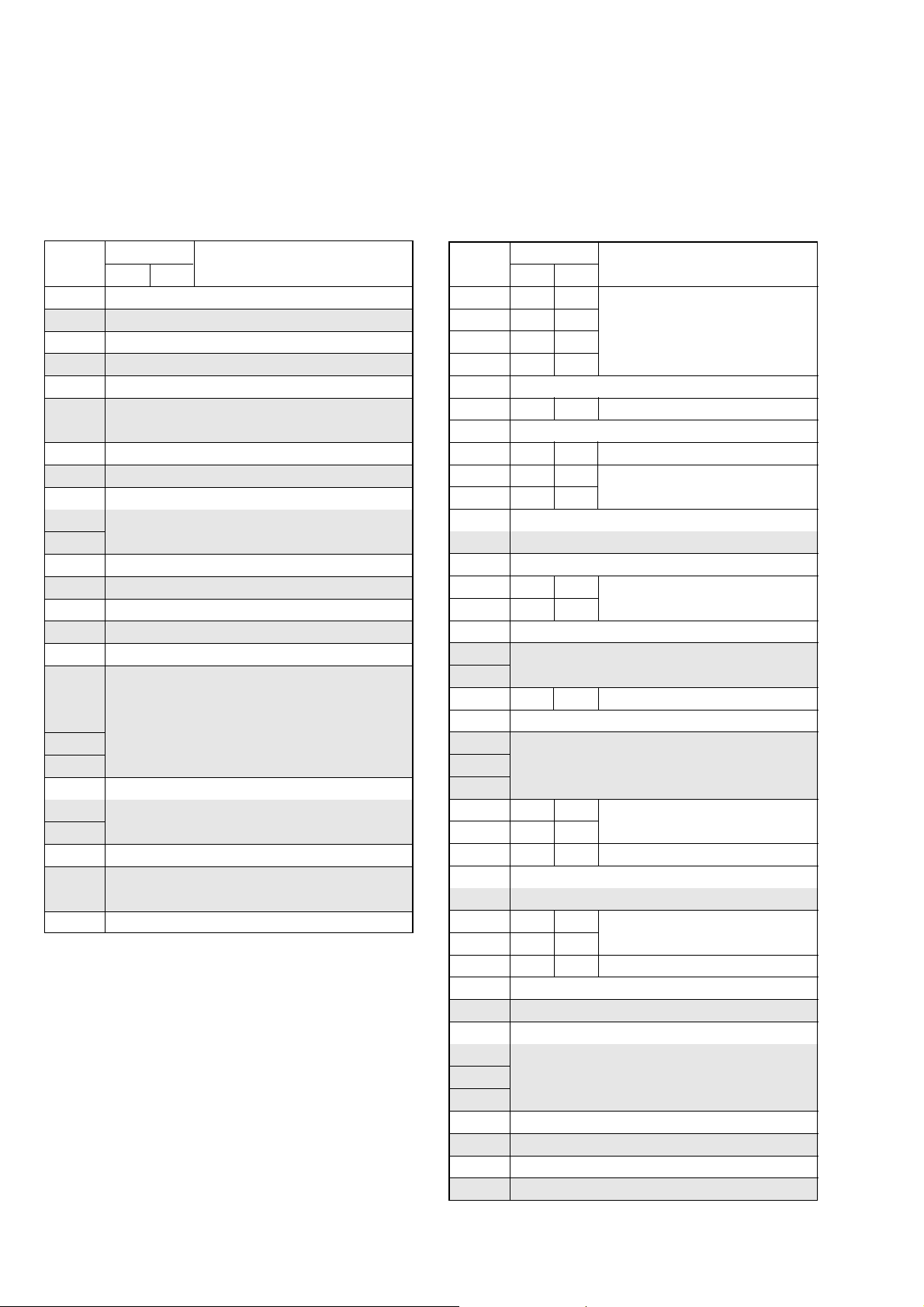

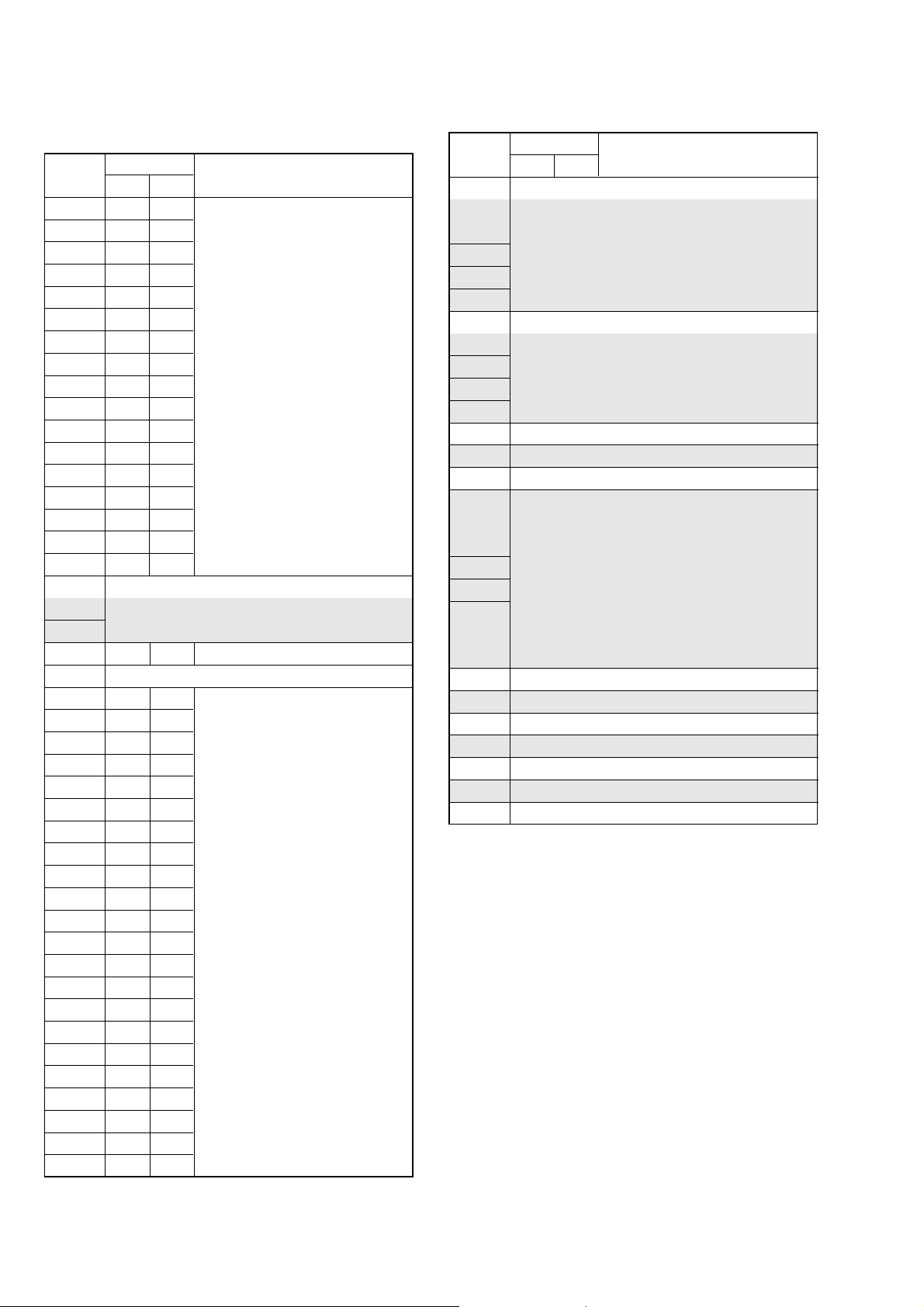

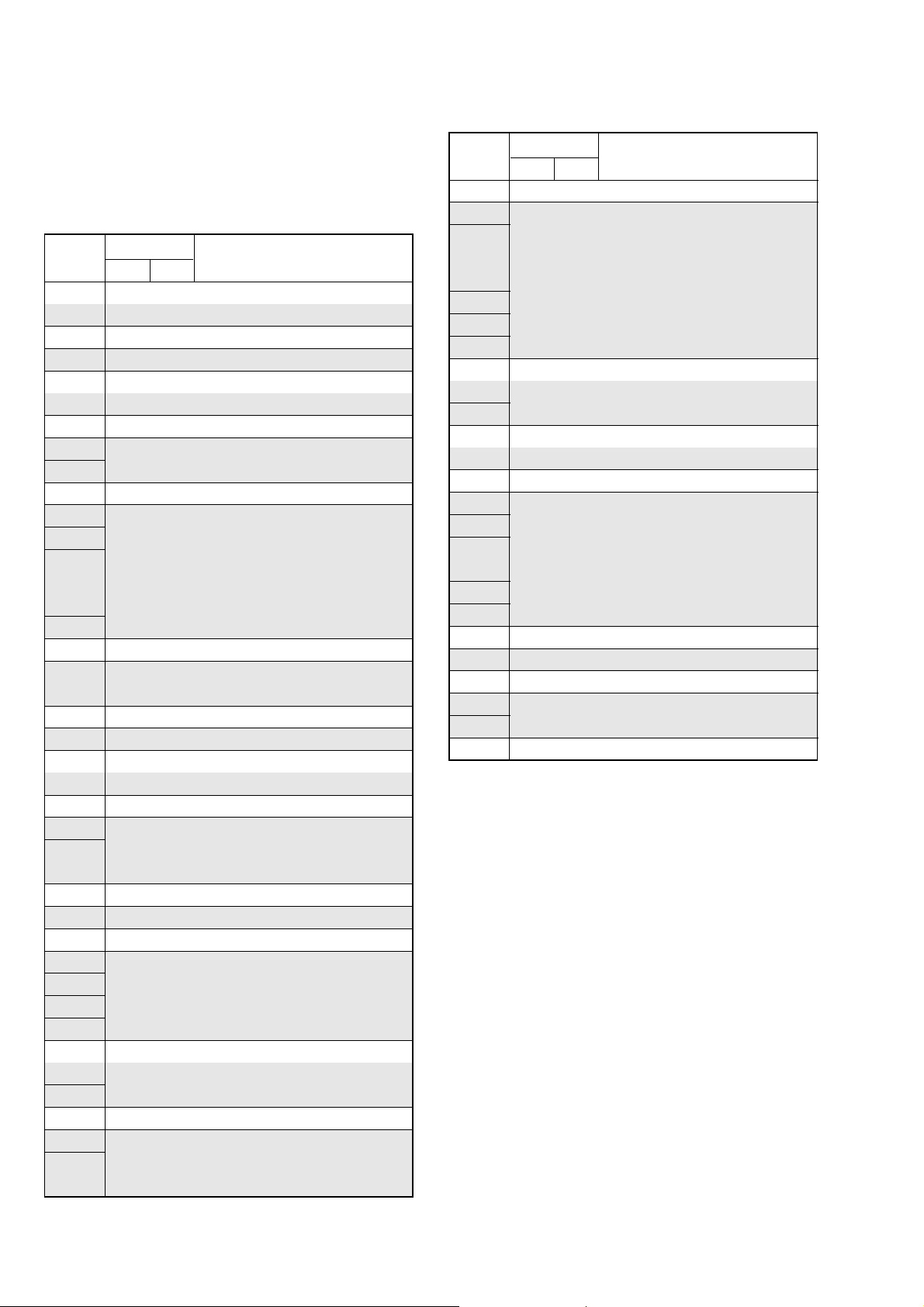

1-2. Adjusting items when replacing main parts and boards (MS model)

• Adjusting items when replacing main parts

When replacing main parts, adjust the items indicated by z in the following table.

Note 1: When replacing the drum assy or the mechanism deck, reset the data of page: 7, address: A8 to AB to “00”. (Refer to “Record of

Use check” of “6-4. SERVICE MODE”)

Note 2: MS model: DCR-HC32/HC32E/HC33/HC33E

Replaced part

Block replacement Mounted part replacement

Adjustment Section Adjustment

(LCD panel, Touch panel)

(Back light LED)

(LCD panel)

(Drum assembly) (Note 1)

(CCD imager)

(Back light (EVF))

(LCD drive)

(PITCH, YAW sensor)

(Timing generator)

(S/H, AGC, A/D converter)

(Video/Audio DSP, D/A converter etc)

(DV signal process)

(REC/PB AMP)

(Video IN/OUT)

(HI/DS control)

(EVF drive)

Initialization of 8,

A, B, C, D, E, F, 18,

19, 1A, 1B, 1C, 1E,

1F page data

Initialization of A, B, D, 1A, 1B page data

Initialization of 8, C, 18, 1C page data

Initialization of E, F, 19, 1E, 1F page data

Camera 36MHz origin oscillation adj.

HALL adj.

Flange back adj.

Optical axis adj.

F No. standard data input

Mechanical shutter adj.

Color reproduction adj.

Auto white balance standard data input

LV standard data input

Auto white balance adj.

MAX GAIN adj.

Steadyshot check

EVF EVF automatic adj.

LCD LCD automatic adj.

V-COM adj.

Transmissive mode white balance adj.

Mechanism Tape path adj.

System control Touch panel adj.

Node uniqe ID No. input

Servo, RF CAP FG duty adj.

Switching position adj.

Error rate check

Video S VIDEO OUT Y level adj.

S VIDEO OUT chroma level adj.

Lens device

LCD block LCD901

LCD block D901

EVF block LCD902

Mechanism deck (Note 1)

Mechanism deck M901

Mechanism deck MD block

CD-533 board IC101

LB-109 board D303

PD-237 board IC602

SI-042 board SE601, 602

VC-377 board IC3101, X3101

VC-377 board IC3102

VC-377 board IC4001

zz

z

zz

zz

zz

z

zz

zz

zz

zz

zz

z

zzz

zz

zz

zz z

zzz

z

zz

zzz

zzz zz

zz

zz

VC-377 board IC4201

VC-377 board IC4301

VC-377 board IC4401

VC-377 board IC5102

VC-377 board IC7001

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

Table 6-1-2 (1)

6-4

Page 8

• Adjusting items when replacing a board or EEPROM

When replacing a board or EEPROM, adjust the items indicated by z in the following table.

Adjustment Section Adjustment

Initialization of 8,

A, B, C, D, E, F, 18,

19, 1A, 1B, 1C, 1E,

1F page data

Initialization of A, B, D, 1A, 1B page data

Initialization of 8, C, 18, 1C page data

Initialization of E, F, 19, 1E, 1F page data

Camera 36MHz origin oscillation adj.

HALL adj.

Flange back adj.

Optical axis adj.

F No.standard data input

Mechanical shutter adj.

Color reproduction adj.

Auto white balance standard data input

LV standard data input

Auto white balance adj.

MAX GAIN adj.

Steadyshot check

EVF EVF automatic adj.

LCD LCD automatic adj.

V-COM adj.

Transmissive mode white balance adj.

Mechanism Tape path adj.

System control Touch panel adj.

Node uniqe ID No. input

Servo, RF CAP FG duty adj.

Switching position adj.

Error rate check

Video S VIDEO OUT Y level adj.

S VIDEO OUT chroma level adj.

Replaced part

(COMPLETE)

(COMPLETE)

(COMPLETE)

(COMPLETE)

(COMPLETE)

(EEP ROM)

(EEP ROM)

Note 3: IC5202 (Flash memory) on

RadarWRadarWRadarW

CD-533 board

LB-109 board

PD-237 board

SI-042 board

VC-377 board

VC-377 board IC5302

VC-377 board IC5101

Supporting

zz

zz

zz

zz

zz z

zzzz

zzz

zzzz

zz z

zzzz

zzzz

zzzz

zzzz

zzzz

zzz z

zzzz

zzz z

zzz

zzz

zz

zz

zz z

zz z

zz z

zz

zz

the VC-377 board cannot be

replaced.

Table 6-1-2 (2)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-5

Page 9

6-1. CAMERA SECTION A DJUSTMENTS

1-1. PREPARATIONS BEFORE ADJUSTMENTS (CAMERA SECTION)

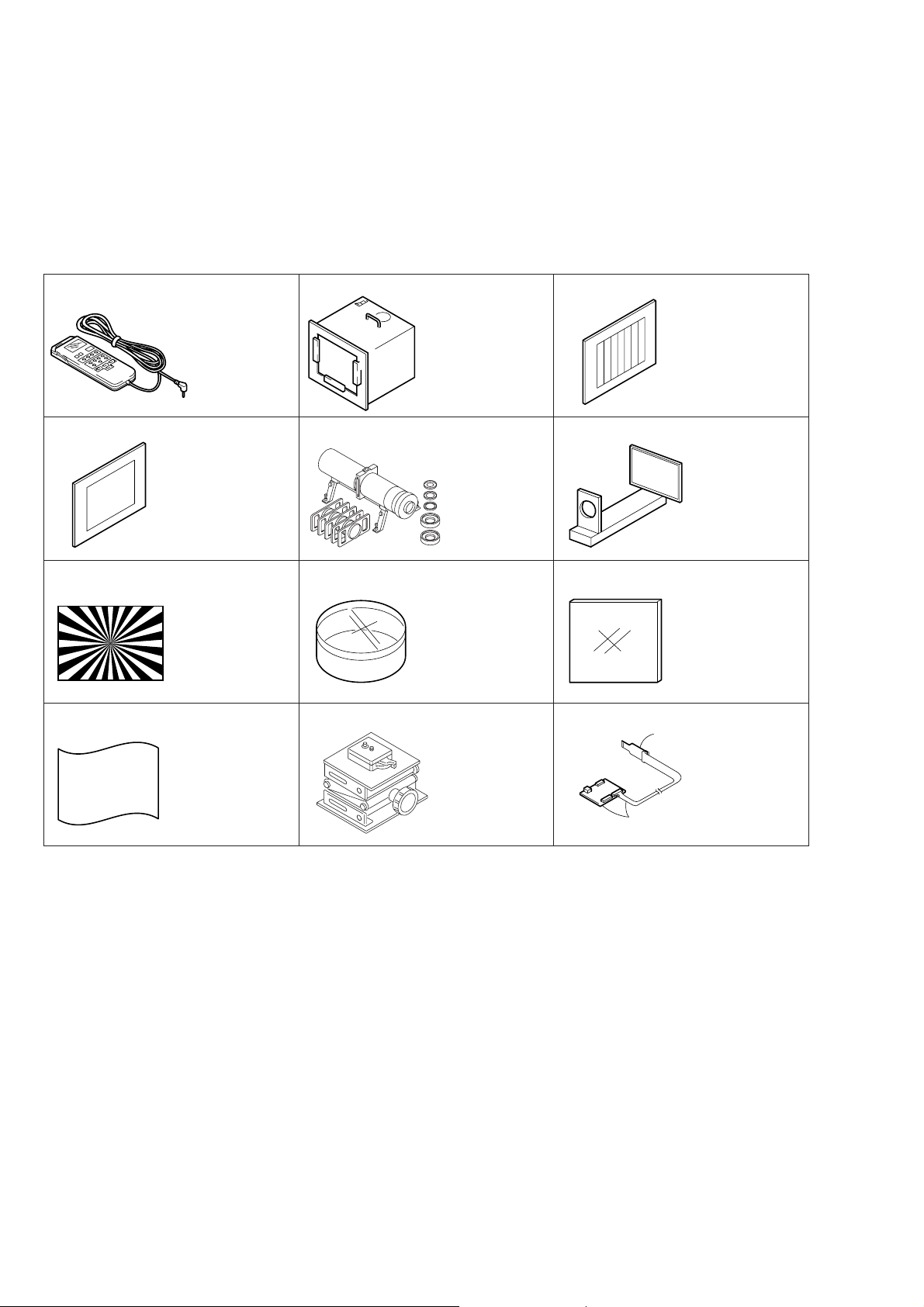

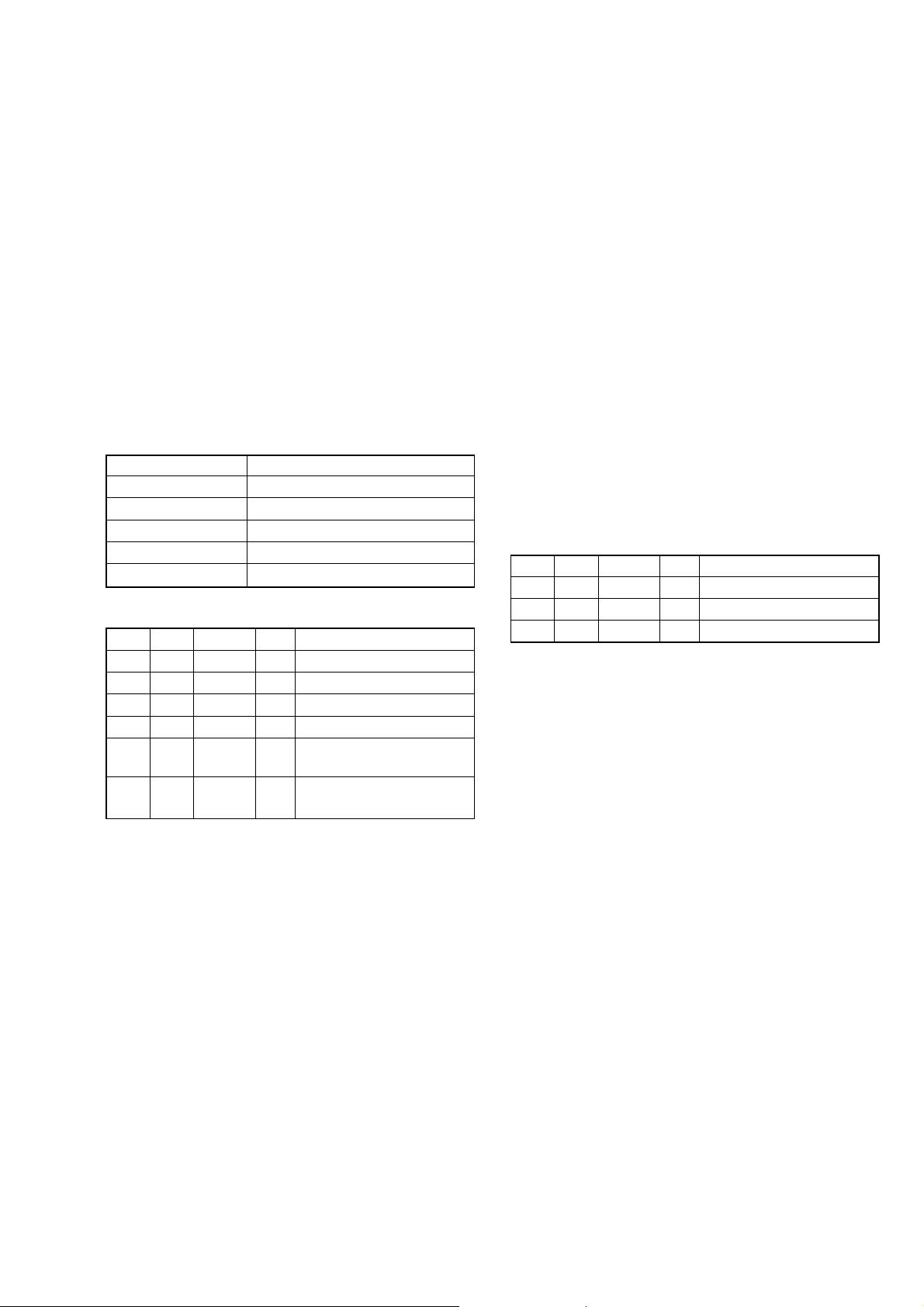

1-1-1. List of Service Tools

• Oscilloscope • Color monitor • Vectorscope

• AC power adapter • Frequency counter

J-1

J-4

J-7

J-10

Adjustment remote

commander

J-6082-053-B

Clear chart

For PTB-450:

J-6080-621-A

For PTB-1450:

J-6082-560-A

Siemens star chart

J-6080-875-A

Back ground paper

J-2501-130-A

J-2

J-3

Pattern box PTB-450

J-6082-200-A

or

Small pattern box

PTB-1450

J-6082-557-A

J-5

J-6

Minipattern box

J-6082-353-B

J-8

J-9

Filter for color

temperature correction

(C14)

J-6080-058-A

J-11 J-12

Camera table

J-6082-384-A

Color bar chart

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6082-559-A

Flange back

adjustment jig

J-6082-563-A

ND filter 1.0

J-6080-808-A

ND filter 0.4

J-6080-806-A

ND filter 0.1

J-6080-807-A

A

A: CPC-15

J-6082-564-A

B: I/F unit for

LANC control

B

J-6082-521-A

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

Fig. 6-1-1

6-6

Page 10

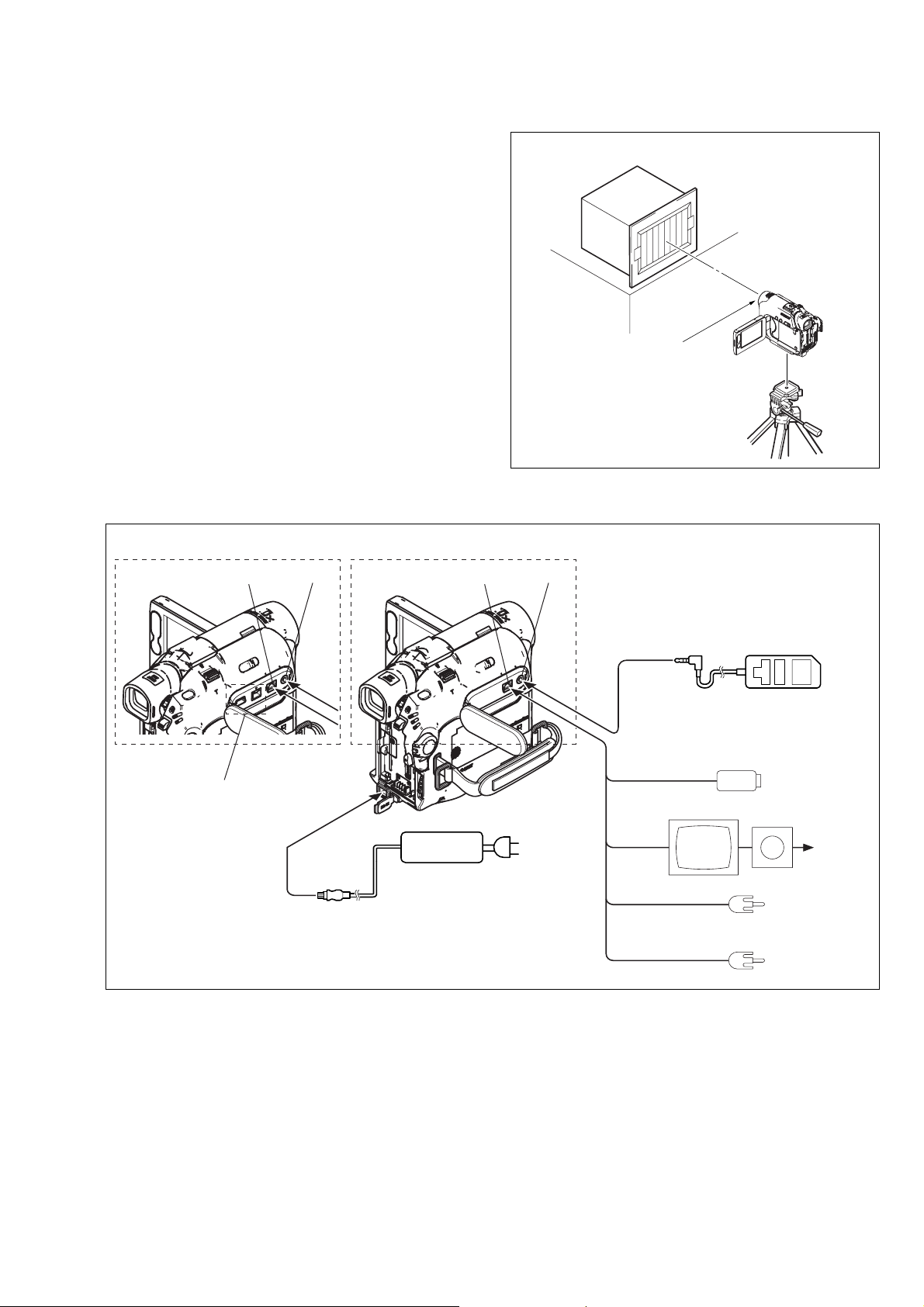

1-1-2. Preparations

Note: Before perform the adjustment, check that the data of page:

0, address: 10 is “00”.

If not, select page: 0, address: 10, and set data “00”.

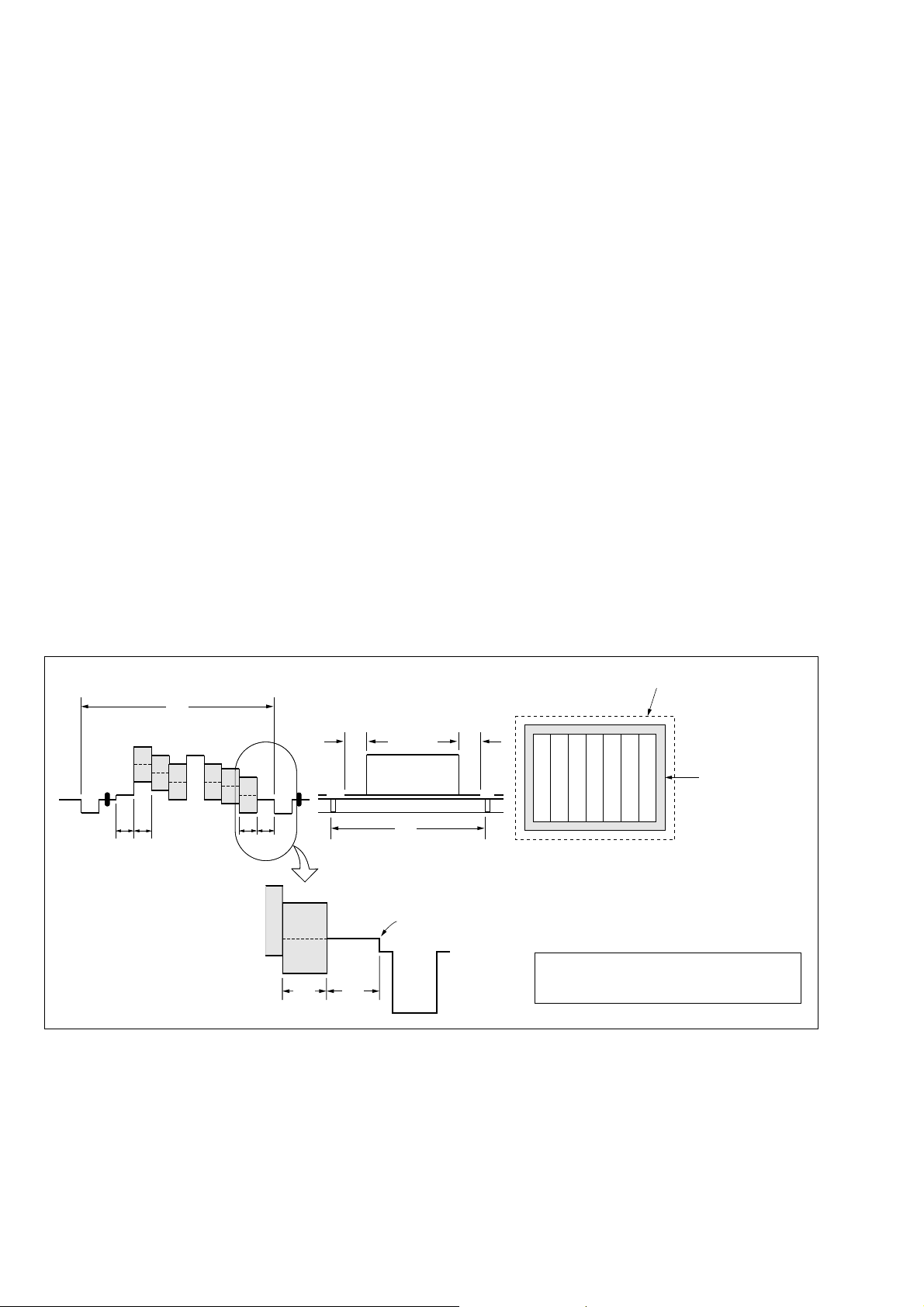

1) Connect the equipment for adjustments according to Fig. 6-1-3.

Pattern box

Front of the lens

L = 1m (PTB-450)

L = 40cm (PTB-1450)

Fig. 6-1-2

L

(Non MS model)

A/V OUT jack

Except DCR-HC22E

Note: Non MS model: DCR-HC17E/HC19E/HC21/HC21E/HC22E

MS model: DCR-HC32/HC32E/HC33/HC33E

LANC jack

To DC IN jack

(MS model)

AC adaptor

A/V jack

LANC jack

AC IN

S Video

(Black)

Video

(yellow)

Audio L

(White)

Audio R

(Red)

Adjustment remote commander

Color monitor

(RM-95)

Vectorscope

Terminated

75 Ω

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

Fig. 6-1-3

6-7

Page 11

1-1-3. Precaution

1. Setting the Switch

Unless otherwise specified, set the switches as follows and perform adjustments without loading cassette.

Note : Non MS model: DCR-HC17E/HC19E/HC21/HC21E/HC22E

MS model: DCR-HC32/HC32E/HC33/HC33E

(Non MS model)

1. POWER switch (SS10300 block) .........................CAMERA

2. LENS COVER switch (Lens block) ........................... OPEN

3. NIGHTSHOT PLUS switch (Lens block) ..................... OFF

4. BACK LIGHT (FP-187 flexible) ................................... OFF

5. PROGRAM AE (MENU setting)................................ AUTO

9. D ZOOM (MENU setting) ............................................. OFF

10. WIDE SEL (MENU setting) .............................................4:3

11. STEADY SHOT (MENU setting).................................. OFF

12. P EFFECT (MENU setting) ........................................... OFF

13. DEMO MODE (MENU setting) .................................... OFF

6. EXPOSURE (MENU setting) ..................................... AUTO

7. WHITE BAL (MENU setting).................................... AUTO

8. FOCUS (MENU setting) ...................................... MANUAL

(MS model)

1. POWER switch (SS10300 block) ..............CAMERA-TAPE

2. LENS COVER switch (Lens block) ........................... OPEN

3. NIGHTSHOT PLUS switch (Lens block) ..................... OFF

4. BACK LIGHT (FP-187 flexible) ................................... OFF

5. PROGRAM AE (MENU setting)................................ AUTO

6. EXPOSURE (MENU setting) ..................................... AUTO

7. WHITE BAL. (MENU setting)................................... AUTO

9. COLOR SLOW S (MENU setting)................................ OFF

10. DIGITAL ZOOM (MENU setting) ................................ OFF

11. WIDE SELECT (MENU setting) .....................................4:3

12. STEADY SHOT (MENU setting).................................. OFF

13. D EFFECT (MENU setting) .......................................... OFF

14. PICT EFFECT (MENU setting) .................................... OFF

15. DEMO MODE (MENU setting) .................................... OFF

8. FOCUS (MENU setting) ...................................... MANUAL

2. Order of Adjustments

Basically carry out adjustments in the order given.

Color bar chart (Color reproduction adjustment frame)

H

Yellow

Cyan

Green

AB B

Fig. a

(VIDEO terminal of A/V jack

output waveform)

A=B

White

Magenta

Red

Blue

A

B

CD

Enlargement

A

C=D

V

Difference in level

Fig. 6-1-4

Electronic beam scanning frame

Red

Cyan

White

Green

Yellow

Fig. b (monitor TV picture)

Adjust the camera zoom and direction to

obtain the output wavef orm shown in Fig. a and

the monitor TV display shown in Fig. b.

Blue

Magenta

CRT picture frame

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-8

Page 12

3. Subjects

1) Color bar chart (Color reproduction adjustment frame)

When performing adjustments using the color bar chart, adjust

the picture frame as shown in Fig. 6-1-4. (Color reproduction

adjustment frame)

2) Mixed color compensation chart (Color reproduction

adjustment frame)

Remove the color bar chart from the pattern box and insert a

mixed color compensation chart in its place. (Do not perform

zoom operations during this time)

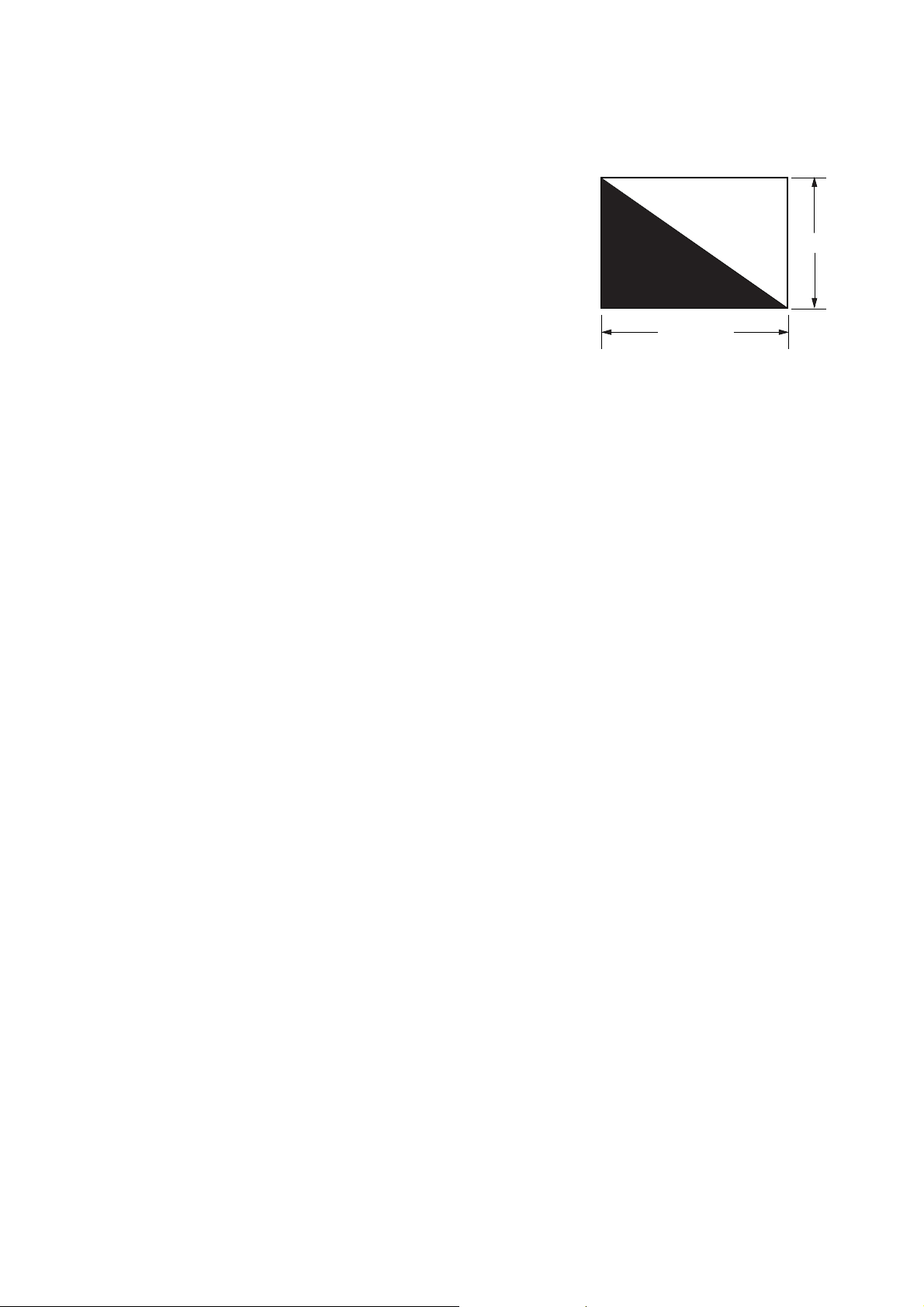

3) Chart for flange back adjustment

Join together a piece of white A0 size paper (1189mm × 841

mm) and a piece of black paper to make the chart shown in

Fig. 6-1-5.

Note: Use a non-reflecting and non-glazing vellum paper. The

size must be A0 or larger and the joint between the white

and black paper must not have any undulations.

White

841 mm

Black

1189 mm

Fig. 6-1-5

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-9

Page 13

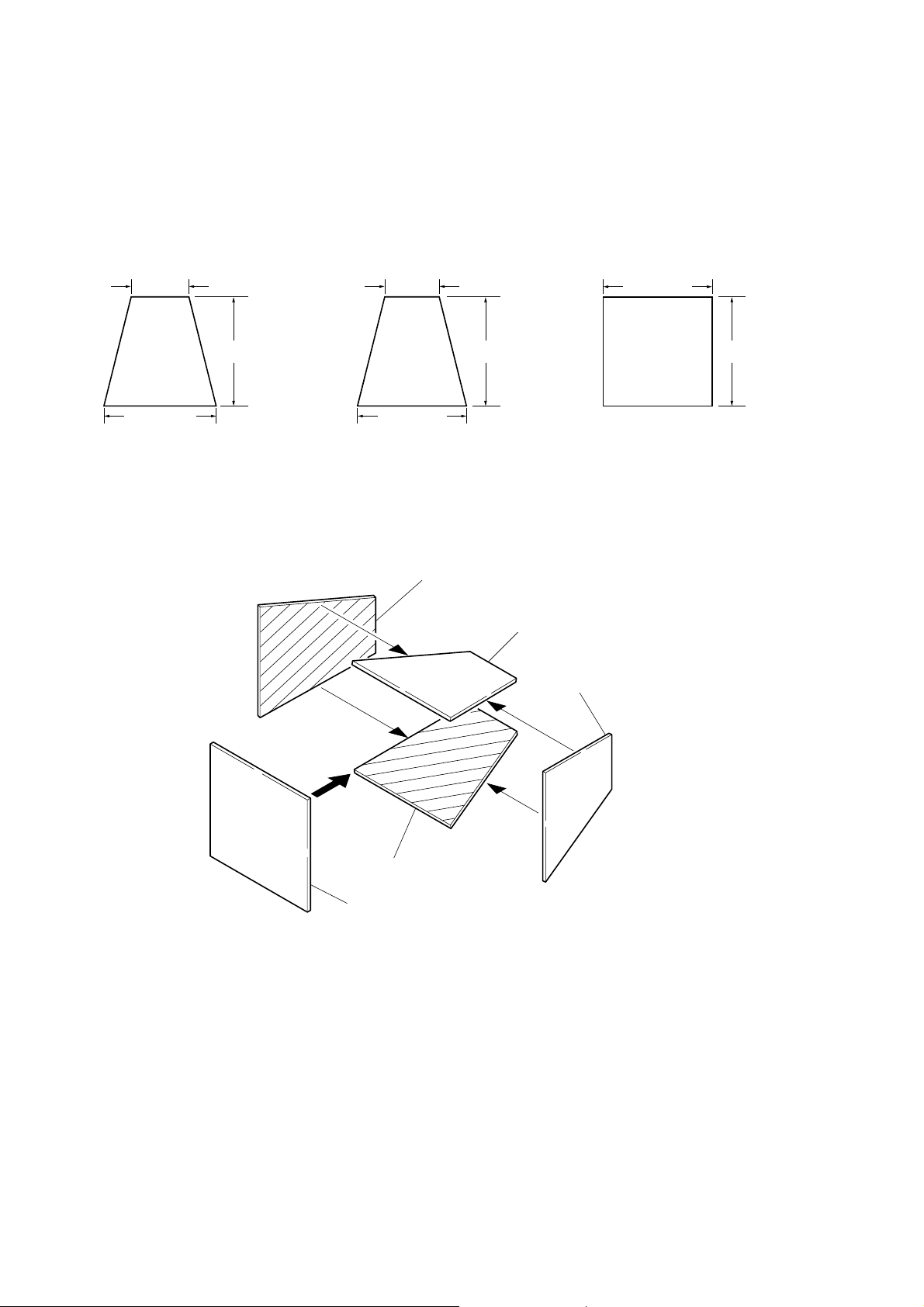

4. Preparing the Flash Adjustment Box

A dark room is required to provide an accurate flash adjustment.

If it is not available, prepare the flash adjustment box as given

below;

1) Provide woody board A, B and C of 15 mm thickness.

woody board A (2)

400 mm

513 mm 513 mm 700 mm

woody board B (2)

370 mm

700 mm730 mm

Fig. 6-1-6

2) Apply black mat paint to one side of woody board A and B.

3) Attach background paper (J-2501-130-A) to woody board C.

4) Assemble so that the black sides and the background paper

side of woody board A, B and C are internal. (Fig. 6-1-7)

woody board C (1)

700 mm

woody board A

woody board B

woody board A

woody board C

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

woody board B

Fig. 6-1-7

6-10

Page 14

1-2. INITIALIZATION OF 8, A, C, D, E, F, 1C, 1F

PAGE DATA (Non MS model)

Note 1: If reading/writing data on pages 1C, 1F, set data: 01 to

page: 0, address: 10, and then select pages C, F. By this

data setting, the pages 1C, 1F can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to “00”.

Note 2: Non MS model: DCR-HC17E/HC19E/HC21/HC21E/

HC22E

1-2-1. Initialization of A, D Page Data

Note: Check that the data of page: 0, address: 10 is “00”.

1. Initializing of A, D Page Data

Note 1: If “Initialization of Pages A, D” is executed, all data on

pages A, D are initialized.

Note 2: If the A, D page data has been initialized, the following

adjustments need to be performed again.

1) Modification of A, D page data

2) Touch panel adjustment

Note 3: NTSC model: DCR-HC21/HC32/HC33

PAL model: DCR-HC17E/HC19E/HC21E/HC22E/

HC32E/HC33E

Adjustment Page A

Adjustment Address 10 to FF

Adjustment Page D

Adjustment Address 10 to 7F

Initializing method:

Order Page Address Data Procedure

10 0101

20 1000

Set the following data.

37 03

47 00

57 01

67 02

7

01: NTSC model

81: PAL model

Set the following data.

20: Initializing A page

22: Initializing D page

28: Initializing A and D pages

Set the following data, and

press PAUSE button.

20: Initializing A page

22: Initializing D page

28: Initializing A and D pages

Check the data changes to

“01”.

Perform “Modification of A,

D Page Data”

2. Modification of A, D Page Data

If the A, D page data has been initialized, change the data of

the“Fixed data-2” address shown in the following table b y manual

input.

Modifying method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) New data for changing are not shown in the tables because

they are different in destination. When changing the data, cop y

the data built in the same model.

Note 1: If copy the data built in the different model, the

camcorder may not operate.

3) When changing the data, press the PAUSE button of the adjustment remote commander each time when setting new data

to write the data in the non-volatile memory.

4) Check that the data of adjustment addresses is the initial value.

If not, change the data to the initial value.

Processing after completing modification A, D page data:

Order Page Address Data Procedure

12 0029

22 01 29 Press PAUSE button.

Note 2: If the following symptoms occur after completing of

the“Modification A, D page data”, check that the data of

the “Fixed data-2” addresses of A, D page are same as

those of the same model of the same destination.

1) The power is shut off so that unit cannot operate.

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-11

Page 15

3. A Page Table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the A, D Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of A, D Page Data”)

4. D Page Table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the A, D Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of A, D Page Data”)

Address

Initial value

NTSC PAL

Remark

10 to 19 Fixed data-1 (Initialized data)

1A

1B

Fixed data-2

1C to 30 Fixed data-1 (Initialized data)

31

32

Fixed data-2

33 to 38 Fixed data-1 (Initialized data)

39 Fixed data-2

3A to 43 Fixed data-1 (Initialized data)

44 Fixed data-2

45 to 4A Fixed data-1 (Initialized data)

4B Fixed data-2

4C Fixed data-1 (Initialized data)

4D Fixed data-2

4E Fixed data-1 (Initialized data)

4F Fixed data-2

50 to 52 Fixed data-1 (Initialized data)

53

54

Fixed data-2

55

56 to 79 Fixed data-1 (Initialized data)

7A

7B

Fixed data-2

7C to 7F Fixed data-1 (Initialized data)

80

81

Fixed data-2

82 CB CC

83 20 1D

Touch panel adj

84 CF C4

85 1C 28

86 to 8F Fixed data-1 (Initialized data)

90 Fixed data-2

91 to F0 Fixed data-1 (Initialized data)

F1

F2

Fixed data-2

F3

F4 to FF Fixed data-1 (Initialized data)

Address

Initial value

NTSC PAL

Remark

10 00 00 Test mode

11 Fixed data-1 (Initialized data)

12

13

Fixed data-2

14 to 16 Fixed data-1 (Initialized data)

17

18

Fixed data-2

19

1A to 21 Fixed data-1 (Initialized data)

22

23

24 Fixed data-2

25

26

27 to 29 Fixed data-1 (Initialized data)

2A

2B

Fixed data-2

2C to 36 Fixed data-1 (Initialized data)

37 Fixed data-2

38, 39 Fixed data-1 (Initialized data)

3A Fixed data-2

3B, 3C Fixed data-1 (Initialized data)

3D Fixed data-2

3E, 3F Fixed data-1 (Initialized data)

40 Fixed data-2

41 to 54 Fixed data-1 (Initialized data)

55

56 Fixed data-2

57

58 to 6E Fixed data-1 (Initialized data)

6F Fixed data-2

70 to 7F Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-12

Page 16

1-2-2. Initialization of 8, C, 1C Page Data

Note: If reading/writing data on pages 1C, set data: 01 to page:

0, address: 10, and then select pages C. By this data setting, the pages 1C can be selected.

After the data reading/writing finished, return the data on

page: 0, address: 10 to “00”.

1. Initializing of 8, C, 1C Page Data

Note 1: If “Initialization of Pages 8, C, 1C” is executed, all data

on pages 8, C, 1C are initialized. (Only an individual

page cannot be initialized)

Note 2: If the 8, C, 1C page data has been initialized, the follow-

ing adjustments need to be performed again.

1) Modification of 8, C, 1C page data

2) Electronic viewfinder system adjustments

3) LCD system adjustments

4) Node unique ID No. input

5) Servo, RF system adjustments

6) Video system adjustments.

Adjustment Page 8

Adjustment Address 00 to FF

Adjustment Page C

Adjustment Address 10 to FF

Adjustment Page 1C

Adjustment Address 00 to FF

Initializing method:

Order Page Address Data Procedure

10 0101

20 1000

33 81 Check that the data is “00”.

43 80 0C Press PAUSE button.

53 80

6

Check the data changes to

“1C”.

Perform “Modification of 8,

C, 1C Page Data”

2. Modification of 8, C, 1C Page Data

If the 8, C, 1C page data has been initialized, change the data of

the “Fixed data-2” address shown in the following table by manual

input.

Modifying method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) If modification of data on pages 8, C, set data: 00 to page: 0,

address: 10, and then select pages 8, C.

3) If modification of data on pages 1C, set data: 01 to page: 0,

address: 10, and then select pages C. After the modif ication of

data finished, return the data on page: 0, address: 10 to “00”.

4) New data for changing are not shown in the tables because

they are different in destination. When changing the data, cop y

the data built in the same model.

Note: If copy the data built in the different model, the

camcorder may not operate.

5) When changing the data, press the PAUSE button of the adjustment remote commander each time when setting new data

to write the data in the non-volatile memory.

6) Check that the data of adjustment addresses is the initial value.

If not, change the data to the initial value.

Processing after completing modification 8, C, 1C page data:

Order Page Address Data Procedure

10 1000

22 0029

32 01 29 Press PAUSE button.

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-13

Page 17

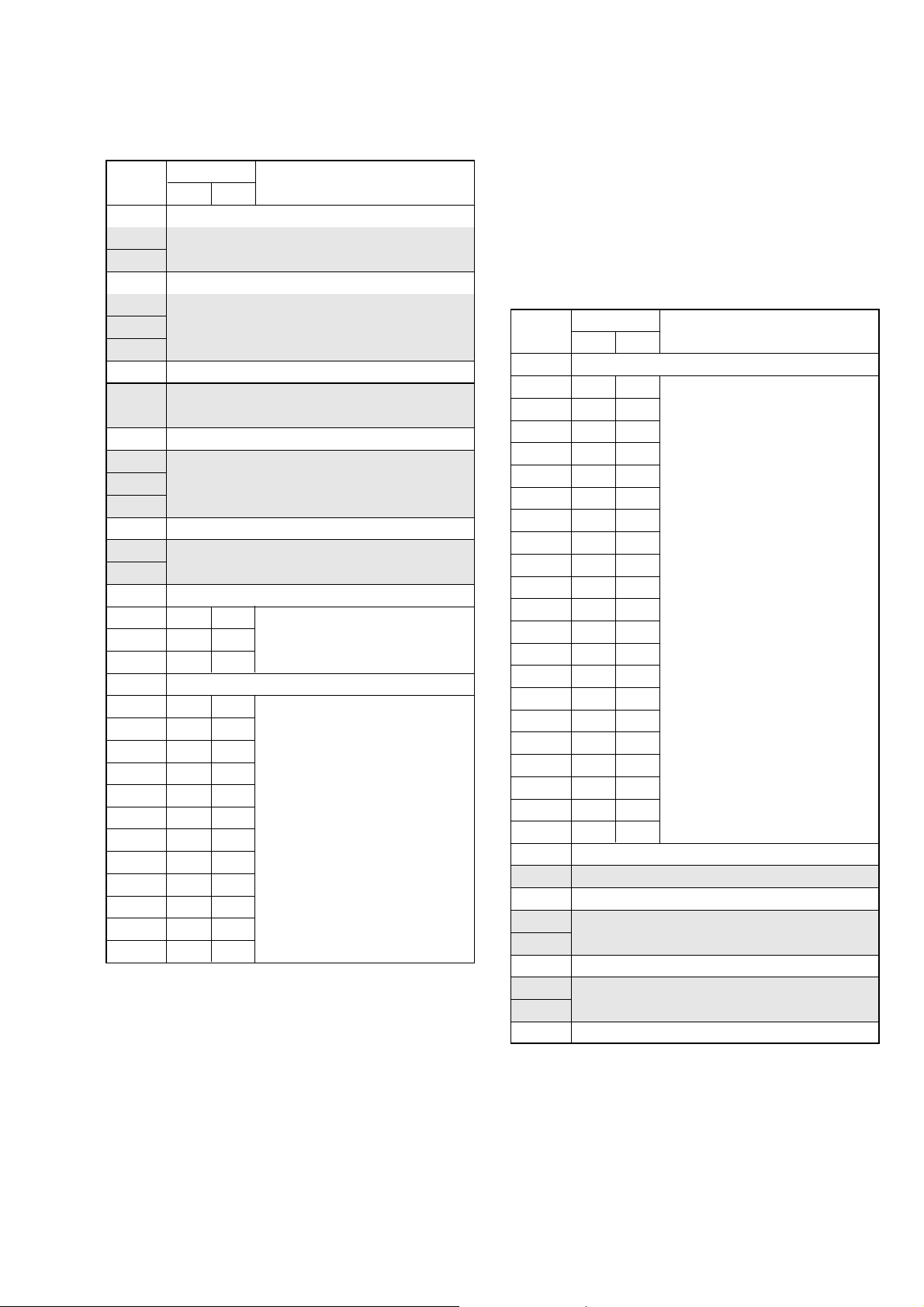

3. 8 Page Table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the 8, C, 1C Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of 8, C, 1C Page Data”)

4. C Page Table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the 8, C, 1C Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of 8, C, 1C Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to 3F Fixed data-1 (Initialized data)

40 Fixed data-2

41 to 4C Fixed data-1 (Initialized data)

4D Fixed data-2

4E to 79 Fixed data-1 (Initialized data)

7A

7B

Fixed data-2

7C to 89 Fixed data-1 (Initialized data)

8A Fixed data-2

8B to 8D Fixed data-1 (Initialized data)

8E

8F

Fixed data-2

90 to B2 Fixed data-1 (Initialized data)

B3 Fixed data-2

B4 to BE Fixed data-1 (Initialized data)

BF Fixed data-2

C0 to C3 Fixed data-1 (Initialized data)

C4

C5

C6 Fixed data-2

C7

C8

C9 Fixed data-1 (Initialized data)

CA

CB

Fixed data-2

CC to D5 Fixed data-1 (Initialized data)

D6

D7

Fixed data-2

D8 to FF Fixed data-1 (Initialized data)

Address

Initial value

NTSC PAL

Remark

10 EE EE

11 00 00

12 00 00

Switching position adj.

13 00 00

14, 15 Fixed data-1 (Initialized data)

16 E0 E0 CAP FG duty adj.

17 to 24 Fixed data-1 (Initialized data)

25 80 80 S VIDEO OUT Y level adj.

26 90 90

27 65 65

S VIDEO OUT chroma level adj.

28 to 3B Fixed data-1 (Initialized data)

3C Fixed data-2

3D, 3E Fixed data-1 (Initialized data)

3F 6C 6C

40 90 90

EVF automatic adj. (VCO adj.)

41 to 44 Fixed data-1 (Initialized data)

45

46

Fixed data-2

47 28 28 EVF automatic adj. (Contrast adj.)

48 to 4C Fixed data-1 (Initialized data)

4D

4E

Fixed data-2

4F

50 6C 6C

51 90 90

LCD automatic adj. (VCO adj.)

52 BC BC V-COM adj. (LCD)

53, 54 Fixed data-1 (Initialized data)

55 Fixed data-2

56 7D 7D Transmissive mode white balans

57 73 73 adj. (LCD)

58 52 52 LCD automatic adj. (Contrast adj.)

59 to 5E Fixed data-1 (Initialized data)

5F Fixed data-2

60 to 65 Fixed data-1 (Initialized data)

66

67

Fixed data-2

68

69 to 74 Fixed data-1 (Initialized data)

75 Fixed data-2

76 to A8 Fixed data-1 (Initialized data)

A9 Fixed data-2

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-14

Page 18

C Page Table

Address

Initial value

NTSC PAL

Remark

AA Fixed data-1 (Initialized data)

AB

AC

Fixed data-2

AD to AF Fixed data-1 (Initialized data)

B0

B1 Fixed data-2

B2

B3 Fixed data-1 (Initialized data)

B4

B5

Fixed data-2

B6 to D1 Fixed data-1 (Initialized data)

D2

D3 Fixed data-2

D4

D5 to DD Fixed data-1 (Initialized data)

DE

DF

Fixed data-2

E0 to E4 Fixed data-1 (Initialized data)

E5 00 00

E6 00 00 Node unique ID No. Input

E7 00 00

E8 to F3 Fixed data-1 (Initialized data)

F4 00 00

F5 00 00

F6 00 00

F7 00 00

F8 00 00

F9 00 00

FA 00 00

Emergency memory address

(Mechanism section)

FB 00 00

FC 00 00

FD 00 00

FE 00 00

FF 00 00

5. 1C Page Table

Note 1: If reading/writing data on pages 1C, set data: 01 to page:

0, address: 10, and then select pages C. By this data setting, the pages 1C can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the 8, C, 1C Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of 8, C, 1C Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to B2 Fixed data-1 (Initialized data)

B3 00 00

B4 00 00

B5 00 00

B6 00 00

B7 00 00

B8 80 80

B9 00 00

BA 00 00

BC 00 00

BD 00 00

BE 00 00

SD error rate check (LP)

BF 00 00

C0 00 00

C1 00 00

C2 00 00

C3 80 80

C4 00 00

C5 00 00

C6 00 00

C7 00 00

C8 00 00

C9 to E5 Fixed data-1 (Initialized data)

E6 Fixed data-2

E7 to E9 Fixed data-1 (Initialized data)

EA

EB

Fixed data-2

EC to EE Fixed data-1 (Initialized data)

EF

F0

Fixed data-2

F1 to FF Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-15

Page 19

1-2-3. Initialization of E, F, 1F Page Data

Note: Check that the data of page: 0, address: 10 is “00”.

1. Initializing of E, F, 1F Page Data

Note 1: If “Initialization of Pages E, F, 1F” is executed, all data

on pages E, F , 1F are initialized. (Only an individual page

cannot be initialized)

Note 2: If the E, F , 1F page da ta has been initialized, the follow-

ing adjustments need to be performed again.

1) Modification of E, F, 1F page data

2) Camera system adjustments

Note 3: NTSC model: DCR-HC21/HC32/HC33

PAL model: DCR-HC17E/HC19E/HC21E/HC22E/

HC32E/HC33E

Adjustment Page E

Adjustment Address 00 to FF

Adjustment Page F

Adjustment Address 10 to FF

Adjustment Page 1F

Adjustment Address 00 to FF

Initializing method:

Order Page Address Data Procedure

10 0101

20 1000

Set the following data, and

36 01

press PAUSE button.

2D: NTSC model

2F: PAL model

46 03 FF Press PAUSE button.

56 02

Check the data changes to

“01”.

66 01 00 Press PAUSE button.

7

Perform “Modification of E,

F, 1F Page Data”

2. Modification of E, F, 1F Page Data

If the E, F, 1F page data has been initialized, change the data of

the “Fixed data-2” address shown in the following table by manual

input.

Modifying method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) If modification of data on pages E, F, set data: 00 to page: 0,

address: 10, and then select pages E, F.

3) If modification of data on pages 1F, set data: 01 to page: 0,

address: 10, and then select pages F. After the modification of

data finished, return the data on page: 0, address: 10 to “00”.

4) New data for changing are not shown in the tables because

they are different in destination. When changing the data, cop y

the data built in the same model.

Note: If copy the data built in the different model, the

camcorder may not operate.

5) When changing the data, press the PAUSE button of the adjustment remote commander each time when setting new data

to write the data in the non-volatile memory.

6) Check that the data of adjustment addresses is the initial value.

If not, change the data to the initial value.

Processing after completing modification E, F, 1F page data:

Order Page Address Data Procedure

10 1000

22 0029

32 01 29 Press PAUSE button.

Perform “36MHz Origin

4

Oscillation Adjustment” of

CAMERA SYSTEM

ADJUSTMENTS.

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-16

Page 20

3. E Page Table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the E, F, 1F Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of E, F, 1F Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to 11 Fixed data-1 (Initialized data)

12 F i xed data-2

13, 14 Fixed data-1 (Initialized data)

15

16 F i xed data-2

17

18 to 34 Fixed data-1 (Initialized data)

35 F i xed data-2

36 to 41 Fixed data-1 (Initialized data)

42

43

44

45

46 F i xed data-2

47

48

49

4A

4B Fixed data-1 (Initialized data)

4C Fixed data-2

4D to 55 Fixed data-1 (Initialized data)

56

57

Fixed data-2

58 to 68 Fixed data-1 (Initialized data)

69 F i xed data-2

6A to 8D Fixed data-1 (Initialized data)

8E

8F

Fixed data-2

90 Fixed data-1 (Initialized data)

91 F i xed data-2

92 to A3 Fixed data-1 (Initialized data)

A4 Fixed data-2

A5 to BD F ixed data-1 (Initialized data)

BE Fixed data-2

BF to DA Fixed data-1 (Initialized data)

DB Fixed data-2

DC to E4 Fixed data-1 (Initialized data)

E5 Fixed data-2

E6 to FF Fixed data-1 (Initialized data)

4. F Page Table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the E, F, 1F Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of E, F, 1F Page Data”)

Address

Initial value

NTSC PAL

Remark

10 80 80 36MHz origin osillation adj.

11 Fixed data-1 (Initialized data)

12 50 50

13 50 50

14 89 89

15 00 00

Hall adj.

16 17 17

17 00 00

18 00 00

19 A8 A8 MAX GAIN adj.

1A 36 36

LV standard data input

1B 00 00

1C 00 00

1D 00 00

1E 00 00

1F 00 00

20 00 00

F No. standard data input

21 00 00

22 00 00

23 00 00

24 to 29 Fixed data-1 (Initialized data)

2A 27 27

2B 00 00

2C 08 08

Auto white balance standard data

input

2D 00 00

2E 18 18

2F 00 00

30 0E 0E

Auto white balance adj.

31 00 00

32 Fixed data-1 (Initialized data)

33 48 47 Color reproduction adj.

34 Fixed data-1 (Initialized data)

35 2A 2B Color reproduction adj.

36 to 39 Fixed data-1 (Initialized data)

3A 00 FF

3B EF ED

Color reproduction adj.

3C, 3D Fixed data-1 (Initialized data)

3E 2A 2A

3F 00 C0

Auto white balance adj.

40 5D 5C

41 00 00

42, 43 Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-17

Page 21

F Page Table

Address

Initial value

NTSC PAL

Remark

44 3A 3A

45 74 74

46 3F 3F

47 2C 2C

48 17 17

49 4A 4A

4A 00 00

4B 00 00

4C 00 00

Flange back adj.

4D 00 00

4E 4F 4F

4F 19 19

50 00 00

51 30 30

52 04 04

53 00 00

54 00 00

55 to 57 Fixed data-1 (Initialized data)

58

59

Fixed data-2

5A FF FF Optical axis adj.

5B to 67 Fixed data-1 (Initialized data)

68 00 00

69 00 00

6A 00 00

6B 00 00

6C 00 00

6D 00 00

6E 00 00

6F 00 00

70 00 00

71 00 00

72 00 00

73 00 00

Mechanical shutter adj.

74 00 00

75 00 00

76 00 00

77 00 00

78 00 00

79 00 00

7A 00 00

7B 00 00

7C 00 00

7D 00 00

Address

Initial value

NTSC PAL

Remark

7E to 8B Fixed data-1 (Initialized data)

8C

8D

8E

Fixed data-2

8F

90

91, 92 Fixed data-1 (Initialized data)

93

94

Fixed data-2

95

96

97, 98 Fixed data-1 (Initialized data)

99 Fixed data-2

9A to A8 Fixed data-1 (Initialized data)

A9

AA

AB

AC

AD

Fixed data-2

AE

AF

B0

B1 to EA Fixed data-1 (Initialized data)

EB Fixed data-2

EC, ED Fixed data-1 (Initialized data)

EE Fixed data-2

EF to FA Fixed data-1 (Initialized data)

FB Fixed data-2

FC to FF Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-18

Page 22

5. 1F Page Table

Note 1: If reading/writing data on pages 1F , set data: 01 to page:

0, address: 10, and then select pages F. By this data setting, the pages 1F can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the E, F, 1F Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of E, F, 1F Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to 07 Fixed data-1 (Initialized data)

08 F i xed data-2

09 to 59 Fixed data-1 (Initialized data)

5A 00 00 Emergency memory address

5B 00 00 (Camera section)

5C 00 00

5D 00 00

5E to FF Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-19

Page 23

1-3. INITIALIZATION OF 8, A, B, C, D, E, F, 18, 19,

1A, 1B, 1C, 1E, 1F PAGE DATA (MS model)

Note 1: If reading/writing data on pages 18, 19, 1A, 1B, 1C, 1E,

1F, set data: 01 to page: 0, address: 10, and then select

pages: 8, 9, A, B, C, E, F.

By this data setting, the pages 18, 19, 1A, 1B, 1C, 1E,

1F, can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to “00”.

Note 2: MS model: DCR-HC32/HC32E/HC33/HC33E

1-3-1. Initialization of A, B, D, 1A, 1B Page Data

Note: Check that the data of page: 0, address: 10 is “00”.

1. Initializing of A, B, D, 1A, 1B Page Data

Note 1: If the A, B, D, 1A, 1B page data has been initialized, the

following adjustments need to be performed again.

1) Modification of A, B, D, 1A, 1B page data

2) Touch panel adjustment

Note 2: NTSC model: DCR-HC32/HC33

PAL model: DCR-HC32E/HC33E

Adjustment Page A

Adjustment Address 10 to FF

Adjustment Page B

Adjustment Address 00 to FF

Adjustment Page D

Adjustment Address 10 to 70

Adjustment Page 1A

Adjustment Address 00 to FF

Adjustment Page 1B

Adjustment Address 00 to FF

Initializing method:

Order Page Address Data Procedure

10 0101

20 1000

37 04

47 01

57 00 01 Press PAUSE button.

67 02

7

Set the following data

20: NTSC model

21: PAL model

Set the following data

20: Initializing A page

21: Initializing B page

22: Initializing D page

23: Initializing 1A page

24: Initializing 1B page

25: Initializing A and 1A

page

26: Initializing B and 1B

page

28: Initializing A, B, D, 1A

and 1B page

Check the data changes to

“01”.

Perform “Modification of A,

B, D, 1A, 1B Page Data”

2. Modification of A, B, D, 1A, 1B Page Data

If the A, B, D, 1A, 1B page data has been initialized, change the

data of the “Fixed data-2” address shown in the follo wing table by

manual input.

Modifying Method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) If modification of data on pages A, B, D, set data: 00 to page:

0, address: 10, and then select pages A, B, D.

3) If modification of data on pages 1A, 1B, set data: 01 to page:

0, address: 10, and then select pages A, B.

After the modification of data finished, return the data on page:

0, address: 10 to “00”.

4) New data for changing are not shown in the tables because

they are different in destination. When changing the data, cop y

the data built in the same model.

Note 1: If copy the data built in the different model, the

camcorder may not operate.

5) When changing the data, press the PAUSE button of the adjustment remote commander each time when setting new data

to write the data in the non-volatile memory.

6) Check that the data of adjustment addresses is the initial value.

If not, change the data to the initial value.

Processing after Completing Modification A, B, D, 1A, 1B

page data:

Order Page Address Data Procedure

10 1000

22 0029

32 01 29 Press PAUSE button.

Note 2: If following symptoms occur after completing of the

“Modification A, B, D, 1A, 1B page data”, check that

the data of the “Fixed data-2” address of A, B, D, 1A, 1B

page are same as those of same model of same destination.

1) The power is shut off so that unit cannot operate.

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-20

Page 24

3. A Page table

Note 1: Check that the data of page: 0, address: 10 is“00”.

Note 2: Fixed data-1: Initialized data. (Refer to“1. Initializing the

A, B, D, 1A, 1B Page Data”)

Fixed data-2: Modified data. (Refer to“2. Modification

of A, B, D, 1A, 1B Page Data”)

Address

Initial value

NTSC PAL

Remark

10 00 00 Test mode

11 to 17 Fixed data-1 (Initialized data)

18 F i xed data-2

19 to 2E Fixed data-1 (Initialized data)

2F Fixed data-2

30 Fixed data-1 (Initialized data)

31 F i xed data-2

32 to 60 Fixed data-1 (Initialized data)

61

62 F i xed data-2

63

64 to 8F Fixed data-1 (Initialized data)

90 E0 DD

91 1D 1C

92 D4 C7

Touch panel adj

93 24 2A

94 to CF Fixed data-1 (Initialized data)

D0

D1 Fixed data-2

D2

D3, D4 Fixed data-1 (Initialized data)

D5 Fixed data-2

D6 Fixed data-1 (Initialized data)

D7 Fixed data-2

D8 Fixed data-1 (Initialized data)

D9 Fixed data-2

DA to F0 Fixed data-1 (Initialized data)

F1

F2 Fixed data-2

F3

F4 to FF Fixed data-1 (Initialized data)

4. B Page table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the A, B, D, 1A, 1B Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of A, B, D, 1A, 1B Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to FF Fixed data-1 (Initialized data)

5. D Page table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the A, B, D, 1A, 1B Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of A, B, D, 1A, 1B Page Data”)

Address

Initial value

NTSC PAL

Remark

10 to 13 Fixed data-1 (Initialized data)

14 Fixed data-2

15 Fixed data-1 (Initialized data)

16

17

Fixed data-2

18 to 27 Fixed data-1 (Initialized data)

28

29

2A Fixed data-2

2B

2C

2D Fixed data-1 (Initialized data)

2E

2F Fixed data-2

30

31, 32 Fixed data-1 (Initialized data)

33 Fixed data-2

34 to 44 Fixed data-1 (Initialized data)

45 Fixed data-2

46, 47 Fixed data-1 (Initialized data)

48 Fixed data-2

49 Fixed data-1 (Initialized data)

4A

4B

Fixed data-2

4C Fixed data-1 (Initialized data)

4D

4E

Fixed data-2

4F to 56 Fixed data-1 (Initialized data)

57 Fixed data-2

58 to 70 Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-21

Page 25

6. 1A Page table

Note 1: If reading/writing data on pages 1A, set data: 01 to page:

0, address: 10, and then select pages: A. By this data setting, the pages 1A can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the A, B, D, 1A, 1B Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of A, B, D, 1A, 1B Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to FF Fixed data-1 (Initialized data)

7. 1B Page table

Note 1: If reading/writing data on pages 1B, set data: 01 to page:

0, address: 10, and then select pages: B. By this data setting, the pages 1B can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the A, B, D, 1A, 1B Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of A, B, D, 1A, 1B Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to FF Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-22

Page 26

1-3-2. Initialization of 8, C, 18, 1C Page Data

1. Initializing of 8, C, 18, 1C Page Data

Note1: If “Initialization of Pages 8, C, 18, 1C” is executed, all

data on pages 8, C, 18, 1C are initialized. (Only an individual page cannot be initialized)

Note2 : If the 8, C, 18, 1C page data has been initialized, the

following adjustments need to be performed again.

1) Modification of 8, C, 18, 1C page data

2) Electronic viewfinder system adjustments (if all areas

were initialized)

3) LCD system adjustments (if all areas were initialized)

4) Node unique ID No. input (if all areas were initialized)

5) Servo, RF system adjustments (if all areas were initialized)

6) Video system adjustments (if all areas were initialized)

Adjustment Page 8

Adjustment Address 00 to FF

Adjustment Page C

Adjustment Address 10 to FF

Adjustment Page 18

Adjustment Address 00 to FF

Adjustment Page 1C

Adjustment Address 00 to FF

Initializing method:

Order Page Address Data Procedure

10 0101

20 1000

33 81 Check the data is “00”.

43 80 0C Press PAUSE button.

53 80

6

Check the data changes to

“1C”.

Perform “Modification of 8,

C, 18, 1C Page Data”

Note 3: If other than adjustment address was initialized, the ad-

justed data is not initialized.

2. Modification of 8, C, 18, 1C Page Data

If the 8, C, 18, 1C page data has been initialized, change the data

of the “Fixed data-2” address shown in the following table by

manual input.

Modifying Method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) If modification of data on pages 8, C, set data: 00 to page: 0,

address: 10, and then select pages 8, C.

3) If modification of data on pages 18, 1C, set data: 01 to page:

0, address: 10, and then select pages 8, C.

After the modification of data finished, return the data on page:

0, address: 10 to “00”.

4) New data for changing are not shown in the tables because

they are different in destination. When changing the data, cop y

the data built in the same model.

Note: If copy the data built in the different model, the

camcorder may not operate.

5) When changing the data, press the PAUSE button of the adjustment remote commander each time when setting new data

to write the data in the non-volatile memory.

6) If all areas were initialized, check that the data at the addresses

for adjustment are initial values (adjustment initial values)

listed in the table.

If different, change them to the adjustment initial values.

Processing after Completing Modification 8, C, 18, 1C page

data:

Order Page Address Data Procedure

10 1000

22 0029

32 01 29 Press PAUSE button.

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-23

Page 27

3. 8 Page table

Note 1: Check that the data of page: 0, address: 10 is“00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the 8, C, 18, 1C Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of 8, C, 18, 1C Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to 29 Fixed data-1 (Initialized data)

2A Fixed data-2

2B to 3F Fixed data-1 (Initialized data)

40 Fixed data-2

41 to 4C Fixed data-1 (Initialized data)

4D Fixed data-2

4E to 79 Fixed data-1 (Initialized data)

7A

7B

Fixed data-2

7C to 83 Fixed data-1 (Initialized data)

84

85

86

87

Fixed data-2

88

89

8A to 8D Fixed data-1 (Initialized data)

8E

8F

Fixed data-2

90 to A8 Fixed data-1 (Initialized data)

A9 Fixed data-2

AA, AB Fixed data-1 (Initialized data)

AC Fixed data-2

AD to B1 Fixed data-1 (Initialized data)

B2

B3 Fixed data-2

B4

B5 Fixed data-1 (Initialized data)

B6 Fixed data-2

B7 Fixed data-1 (Initialized data)

B8

B9

BA

Fixed data-2

BB

BC, BD Fixed data-1 (Initialized data)

BE

BF

Fixed data-2

C0 to C2 Fixed data-1 (Initialized data)

C3

C4 Fixed data-2

C5

Address

Initial value

NTSC PAL

Remark

C6 Fixed data-1 (Initialized data)

C7

C8

C9

CA Fixed data-2

CB

CC

CD

CE to D5 Fixed data-1 (Initialized data)

D6

D7

Fixed data-2

D8 to DF Fixed data-1 (Initialized data)

E0 Fixed data-2

E1 Fixed data-1 (Initialized data)

E2

E3

E4

E5

Fixed data-2

E6

E7

E8 to EF Fixed data-1 (Initialized data)

F0 Fixed data-2

F1 to F9 Fixed data-1 (Initialized data)

FA

FB

Fixed data-2

FC to FF Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-24

Page 28

4. C Page table

Note 1: Check that the data of page: 0, address: 10 is “00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the 8, C, 18, 1C Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of 8, C, 18, 1C Page Data”)

Address

Initial value

NTSC PAL

Remark

10 EE EE

11 00 00

Switching position adj.

12 00 00

13 00 00

14, 15 Fixed data-1 (Initialized data)

16 E0 E0 CAP FG duty adj.

17 to 24 Fixed data-1 (Initialized data)

25 80 80 S VIDEO OUT Y level adj.

26 54 54

27 3D 3D

S VIDEO OUT chroma level adj.

28 to 3B Fixed data-1 (Initialized data)

3C

3D Fixed data-2

3E

3F A0 A0

40 B0 B0

EVF automatic adj. (VCO adj.)

41 Fixed data-1 (Initialized data)

42 F i xed data-2

43 Fixed data-1 (Initialized data)

44

45 F i xed data-2

46

47 28 28 EVF automatic adj. (Contrast adj.)

48

49

Fixed data-2

4A, 4B Fixed data-1 (Initialized data)

4C

4D

4E

Fixed data-2

4F

50 A0 A0

51 B0 B0

LCD automatic adj. (VCO adj.)

52 BC BC V-COM adj. (LCD)

53, 54 Fixed data-1 (Initialized data)

55 F i xed data-2

56 88 88

Transmissive mode white balans

57 71 71 adj. (LCD)

58 50 50 LCD automatic adj. (Contrast adj.)

59 F i xed data-2

5A to 5E Fixed data-1 (Initialized data)

5F Fixed data-2

Address

Initial value

NTSC PAL

Remark

60, 61 Fixed data-1 (Initialized data)

62

63

Fixed data-2

64, 65 Fixed data-1 (Initialized data)

66

67 Fixed data-2

68

69, 6A Fixed data-1 (Initialized data)

6B Fixed data-2

6C to 74 Fixed data-1 (Initialized data)

75 Fixed data-2

76 to 78 Fixed data-1 (Initialized data)

79

7A

7B

Fixed data-2

7C

7D Fixed data-1 (Initialized data)

7E Fixed data-2

7F to A0 Fixed data-1 (Initialized data)

A1

A2

A3

Fixed data-2

A4

A5 to A8 Fixed data-1 (Initialized data)

A9

AA

AB

Fixed data-2

AC

AD to B1 Fixed data-1 (Initialized data)

B2

B3

B4

Fixed data-2

B5

B6 to CB Fixed data-1 (Initialized data)

CC

CD

CE

CF

D0 Fixed data-2

D1

D2

D3

D4

D5 to DD Fixed data-1 (Initialized data)

DE

DF

Fixed data-2

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-25

Page 29

C Page table

Address

Initial value

NTSC PAL

Remark

E0 to E4 Fixed data-1 (Initialized data)

E5 00 00

E6 00 00 Node unique ID No. Inputs

E7 00 00

E8 to F3 Fixed data-1 (Initialized data)

F4 00 00

F5 00 00

F6 00 00

F7 00 00

F8 00 00

F9 00 00

FA 00 00

Emergency memory address

(Mechanism section)

FB 00 00

FC 00 00

FD 00 00

FE 00 00

FF 00 00

5. 18 Page table

Note 1: If reading/writing data on pages 18, set data: 01 to page:

0, address: 10, and then select pages: 8. By this data setting, the pages 18 can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to“00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the 8, C, 18, 1C Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of 8, C, 18, 1C Page Data”)

Address

Initial value

NTSC PAL

Remark

00 Fixed data-1 (Initialized data)

01 Fixed data-2

02 to FF Fixed data-1 (Initialized data)

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-26

Page 30

6. 1C Page table

Note 1: If reading/writing data on pages 1C, set data: 01 to page:

0, address: 10, and then select pages: C. By this data setting, the pages 1C can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to“00”.

Note 2: Fixed data-1: Initialized data. (Refer to “1. Initializing

the 8, C, 18, 1C Page Data”)

Fixed data-2: Modified data. (Refer to “2. Modification

of 8, C, 18, 1C Page Data”)

Address

Initial value

NTSC PAL

Remark

00 to B2 Fixed data-1 (Initialized data)

B3 00 00

B4 00 00

B5 00 00

B6 00 00

B7 00 00

B8 80 80

B9 00 00

BA 00 00

BB 00 00

BC 00 00

BD 00 00

BE 00 00

SD error rate check (LP)

BF 00 00

C0 00 00

C1 00 00

C2 00 00

C3 80 80

C4 00 00

C5 00 00

C6 00 00

C7 00 00

C8 00 00

C9 to E5 Fixed data-1 (Initialized data)

E6 Fixed data-2

E7 Fixed data-1 (Initialized data)

E8

When IC5301 is Type A.

(This data vary according to the

00 00

type of the IC5301 of VC-37

board.) (Note 3)

When IC5301 is Type B.

(This data vary according to the

1E 1E

type of the IC5301 of VC-377

board.) (Note 3)

E9 Fixed data-1 (Initialized data)

EA

EB

Fixed data-2

EC to EE Fixed data-1 (Initialized data)

Address

EF

F0

Initial value

NTSC PAL

Remark

Fixed data-2

F1 to F7 Fixed data-1 (Initialized data)

When IC5301 is Type A.

(This data vary according to the

00 00

F8

type of the IC5301 of VC-377

board.) (Note 3)

When IC5301 is Type B.

(This data vary according to the

60 60

type of the IC5301 of VC-377

board.) (Note 3)

F9 to FF Fixed data-1 (Initialized data)

Note 3: By checking the data of page: 6, address: FF, the type of

IC5301 of VC-377 board can be discriminated.

Order Page Address Data Procedure

10 1000

Check the data.

26 FF

01: Type A

02 or more: Type B

DCR-HC17E/HC19E/HC21/HC21E/HC22E/HC32/HC32E/HC33/HC33E

6-27

Page 31

1-3-3. Initialization of E, F, 19, 1E, 1F Page Data

1. Initializing of E, F, 19, 1E, 1F Page Data

Note 1: If “Initialization of Pages E, F, 19, 1E, 1F” is executed,

all data on pages E, F , 19, 1E, 1F are initialized. (Only an

individual page cannot be initialized)

Note 2: If the E, F, 19, 1E, 1F page data has been initialized, the

following adjustments need to be performed again.

1) Modification of E, F, 19, 1E, 1F page da ta

2) Camera system adjustment (if all areas were initialized)

Note 3: NTSC model: DCR-HC32/HC33

PAL model: DCR-HC32E/HC33E

Adjustment Page E

Adjustment Address 00 to FF

Adjustment Page F

Adjustment Address 10 to FF

Adjustment Page 19

Adjustment Address 00 to 33

Adjustment Page 1E

Adjustment Address 00 to FF

Adjustment Page 1F

Adjustment Address 00 to FF

Initializing method:

Order Page Address Data Procedure

10 0101

20 1000

Set the following data

36 01 2D: NTSC model

2F: PAL model

46 03 FF Press PAUSE button.

56 02

Check the data changes to

“01”.

66 01 00 Press PAUSE button.

7