Page 1

MODEL INFORMATION TABLE

PRINTED WIRING BOARDS

SCHEMATIC DIAGRAMS

REPAIR PARTS LIST

DCR-HC23E/HC24E/HC26/HC26E/HC35E

RMT-830

SERVICE MANUAL

Ver 1.0 2006.01

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

N MECHANISM (MDX-N110)

Link

Link

Photo: DCR-HC35E

LEVEL 3

US Model

Canadian Model

AEP Model

UK Model

East European Model

North European Model

E Model

Argentine Model

Australian Model

Brazilian model

Chinese Model

Hong Kong Model

Korea Model

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

DIGITAL VIDEO CAMERA RECORDER

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

Sony EMCS Co.

2006A0500-1

© 2006.1

Published by DI Technical Support Department9-876-927-11

Page 2

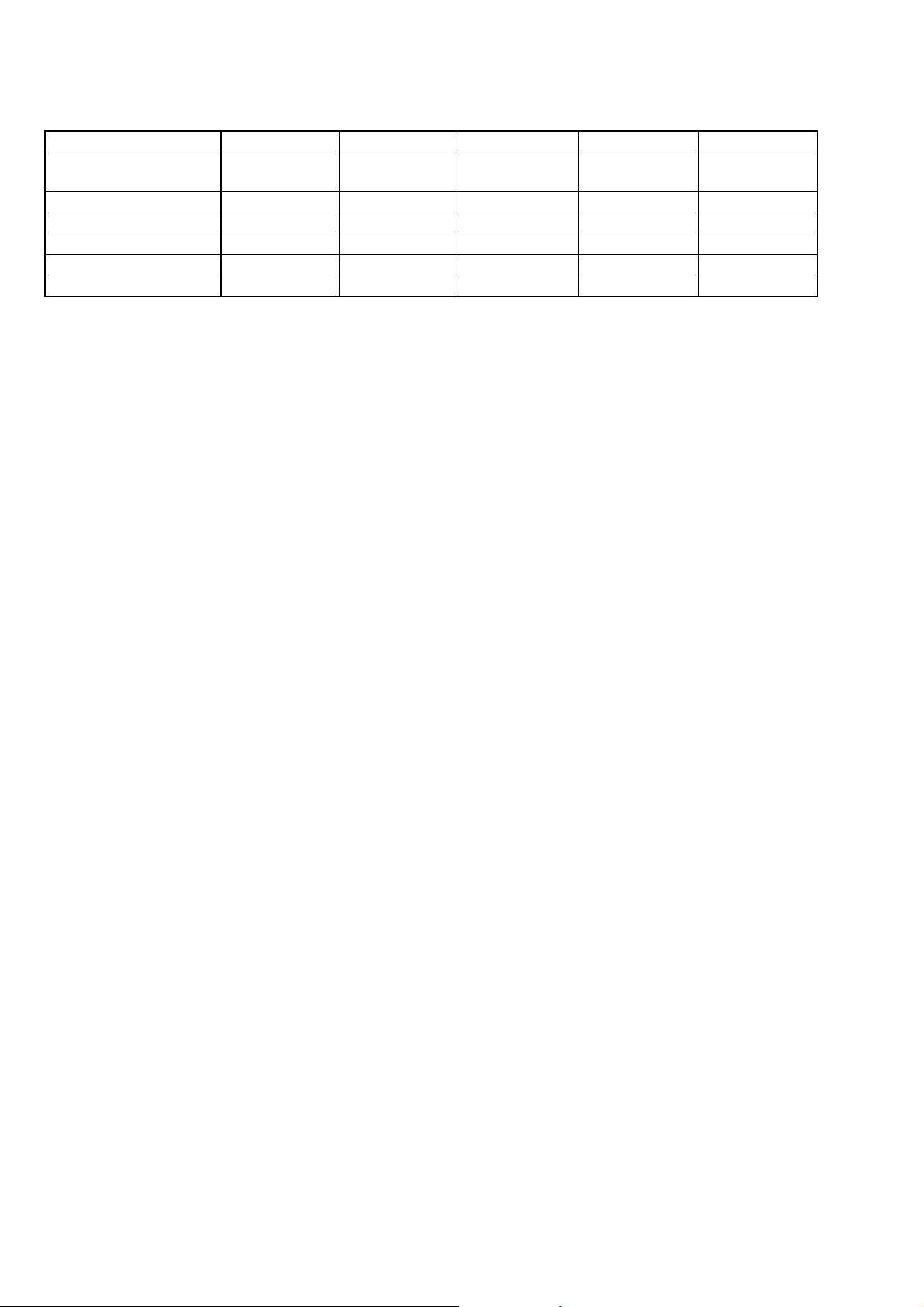

Model information table

Model DCR-HC23E DCR-HC24E DCR-HC26 DCR-HC26E DCR-HC35E

Destination AEP, EE, NE AEP, UK, EE, NE

Color system PAL PAL NTSC PAL PAL

DV Interface OUT OUT IN/OUT IN/OUT IN/OUT (Note)

Remote commander × a ××a

Cradle (Handycam Station) ××××a

CR board ××××CR-061

Note: DV Interface on the Cradle (Handycam Station)

•Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND: Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

NE : North European model

US, CND, E, AR NE, E, AUS, CH,

BR, KR HK

AEP, UK, EE, NE

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

— 2 —

Page 3

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

CAUTION

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT A YANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

— 3 —

Page 4

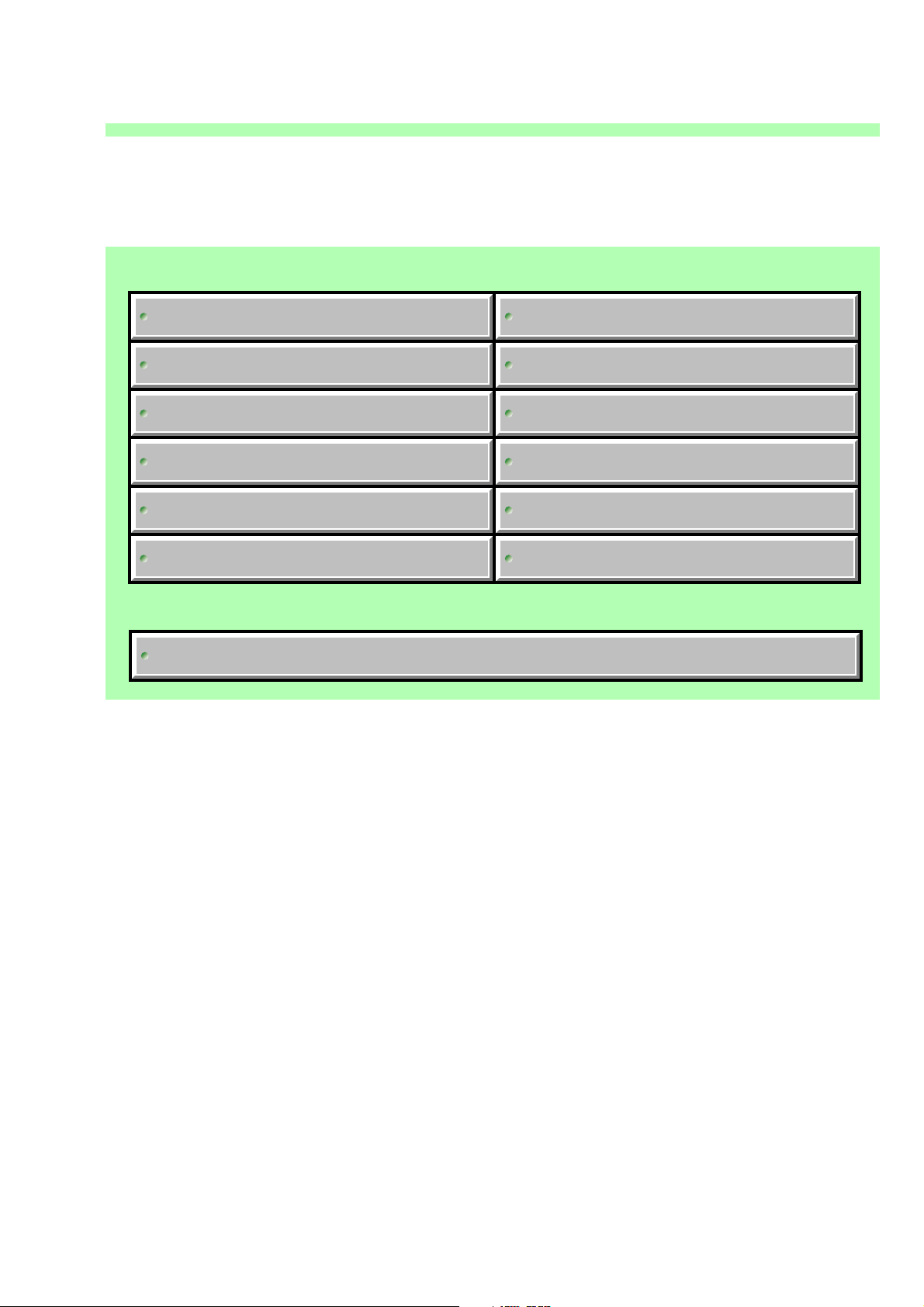

TABLE OF CONTENTS

Section Title Page

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-2. Schematic Diagrams························································4-3

4-3. Printed Wiring Boards ···················································4-25

4-5. Mounted Parts Location ················································4-35

5. REPAIR PARTS LIST

5-2. Electrical Parts List ·······················································5-14

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

— 4 —

Page 5

Link

Link

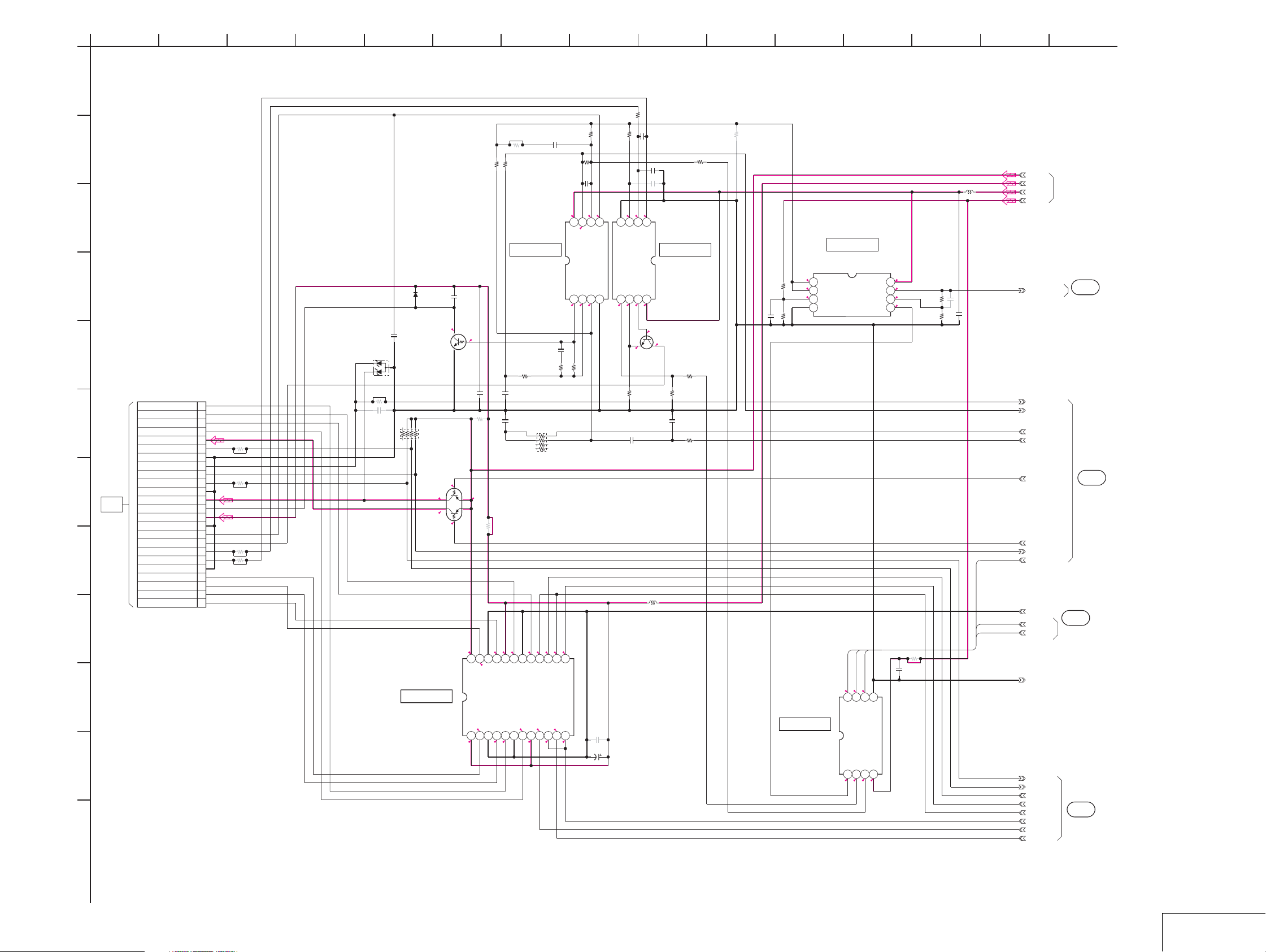

4-2. SCHEMATIC DIAGRAMS

VC-416 BOARD (1/12)

(A/D CONVERTER, TIMING GENERATOR)

VC-416 BOARD (2/12) (LENS DRIVE, EVR)

VC-416 BOARD (3/12)

(DV SIGNAL PROCESS, DV INTERFACE)

VC-416 BOARD (4/12) (REC/PB AMP)

VC-416 BOARD (5/12)

(VIDEO OUT, AUDIO I/O)

VC-416 BOARD (6/12) (LCD/EVF DRIVE)

COMMON NOTE FOR SCHEMATIC DIAGRAMS

VC-416 BOARD (7/12)

(CAMERA/MECHA CONTROL)

VC-416 BOARD (8/12) (SERVO)

VC-416 BOARD (9/12) (HI CONTROL)

VC-416 BOARD (10/12) (DC IN)

VC-416 BOARD (11/12)

(DC/DC CONVERTER)

VC-416 BOARD (12/12) (CONNECTOR)

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

Page 6

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

µF. 50 V or less are not indicated except f or electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

External dimensions (mm)

Case size

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

•Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors hav e characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: not use circuit

(Measuring conditions voltage and waveform)

•Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

•Voltage values change depending upon input

impedance of VOM used.)

1. Connection

Pattern box

Pattern box PTB-450

J-6082-200-A

or

Small pattern box

PTB-1450

J-6082-557-A

L = 1 m (PTB-450)

L = 40 cm (PTB-1450)

Pattern box

Color bar chart

L

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6082-559-A

Front of the lens

Camera

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

Red

Blue

Electronic beam

scanning frame

CRT picture frame

Precautions for Replacement of Imager

• If the imager has been replaced, carry out all the adjustments

for the camera section.

• As the imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with

dusts nor exposed to strong light.

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

When indicating parts by reference number, please

include the board name.

The components identified by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifie.

4-3

Page 7

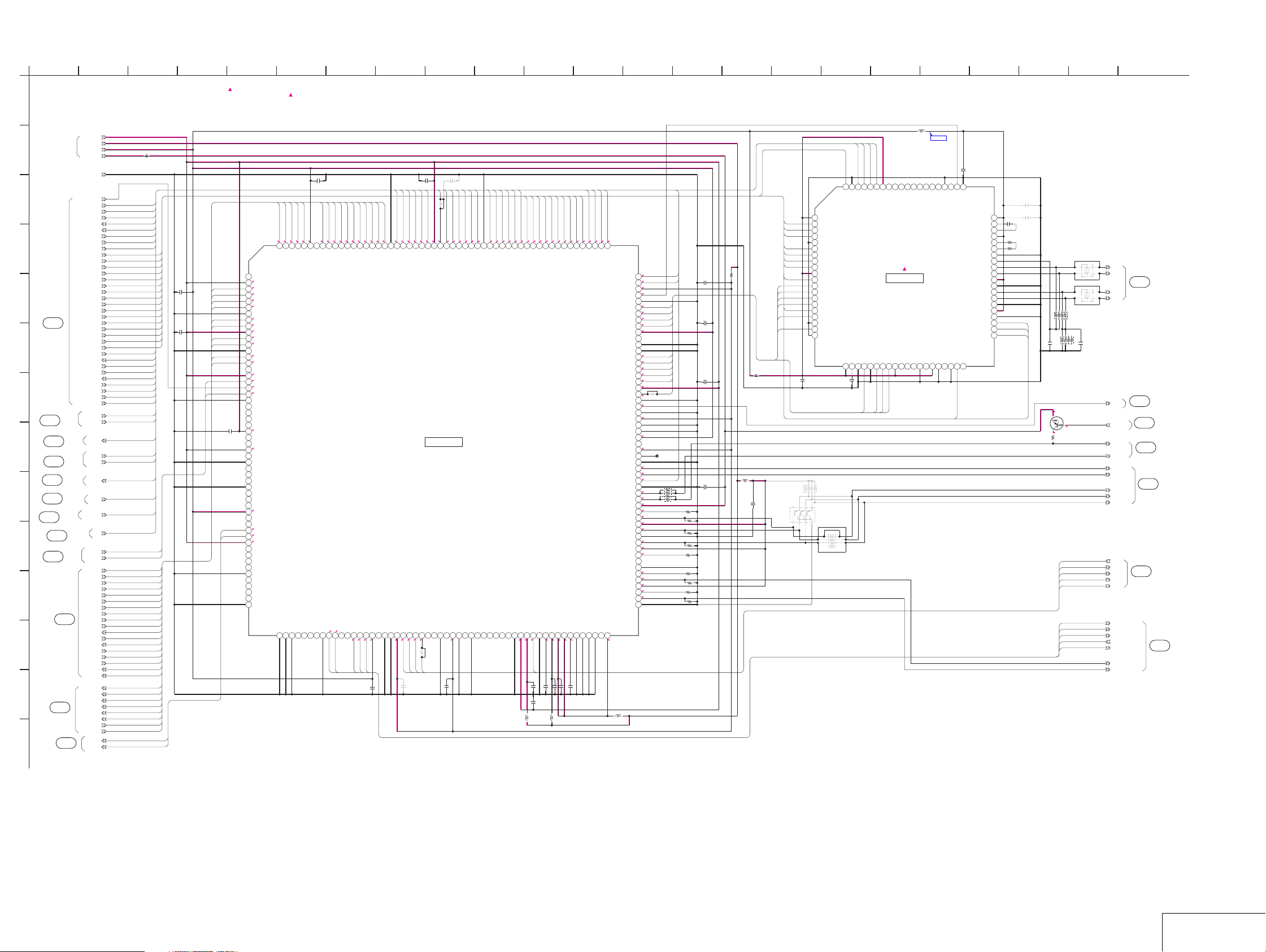

1

VC-416 BOARD (1/12)

A

A/D CONVERTER, TIMING GENERATOR

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

B

C

CD-631

CN101

THROUGH THE

FLEXIBLE FLAT CABLE

D

E

F

(FFC-063)

PAGE 4-5

of LEVEL2

CCD_OUT

VSHT

4 123

14PCN3001

14

GND

13

V4

12

V3

11

10

V2

9

V1

8

GND

7

H2

6

H1

5

RG

4

3

VH

2

VL

1

GND

VSHT

V4

V3

V2

V1

XSHP

XSHD

C3001

0.01u

R3013

R3014

C3003

XX

68p

C3004

68p

XX

R3001

100k

C3002

0.33u

C3006

4.7u

C3028

C3027

65

C3011

R3012

XX

FB3003

R1.6/P0

R1.4/P0

C3005

2.7

R0.4

/P0

2.7

2.7

1u

XX

XX

R3004

XX

1.6

12

VDD2

13

VSS3

14

R1.7/P0

XSHP

15

R1.7/P0

XSHD

16

XRS

17

RG

18

VDD3

19

VDD4

20

H1

21

H2

22

VSS4

23

NC

24

25

R-0.3/P0

R-0.3/P0

V2

1.1

11

VICK(CL)

V226V1

V1

CL3001

2.8

10

SYSCK

27VH28

VDD1

XX

C3029

9

TEST

CHCK

IC3001

TIMING GENERATOR

CXD2444AR-T4

V329VL

R-7/P0

R14.7/P0

V3

XX

X3001

36MHz

0.01u

C3009

1.2

1.5

5

6

7CK8

VSS2

IC3001

30VM31V432NC33

R-7/P0

R-7.4/P0.3

V4

8

1.2

4

OSCI

OSCO

XSHT34XSG135SSO36VGAT

0.1u

R-7.4/P0.3

C3013

VSHT

C3014

0.01u

R2.2/P0

2

R2.7/P0

PBLK3VSS1

R2.7/P0

1

CLPDM

2.5

0

91327

D3001

1SV329(TPL3)

R3007

470k

R1.3/P0

ID

48

CKCONT1

47

VDD5

2.7

46

R2.7/P0

AVD

45

2.9

AHD

44

2.8

43

R2.8/P0

42

0

XV1

41

2.8

RST

40

R0.2/P2.7

SEN

39

0

SSI

38

2.6

SSK

37

CKCONT2

DSGAT

10 11

R3016

XX

XRST_VTR

XCS_TG

CAM_SO

CAM_SCK

CAM_SI

CAM_SCK

CAM_SO

CAM_SI

XCS_TG

CH_SO

CH_SCK

CS_CH

XRST_VTR

CAM_DD_ON

CAM_15V

CAM_-7.5V

A_2.8V

D_2.8V

REG_GND

FREQ_AMPOUT

@002

CAM_SCK

CAM_SO

CAM_SI

XCS_TG

CH_SO

CH_SCK

CS_CH

XRST_VTR

TG_ID

TG_VGAT

TG_ZV1

TG_ZSG1

VCK

TG_AVD

TG_AHD

FE_CLPOB

(11/12)

@001

@003

@004

@005

(7/12)

@006

(2/12)

(7/12)

(11/12)

14

(3/12)

(7/12)

(2/12)

(3/12)

(7/12)

(3/12)

(7/12)

(8/12)

@007

G

AD9

0

0

FB3004

H

C3007

1u

0.1uC3026

XX

I

XSHP

XSHD

R3015

R2.2/P0

R1.7/P0

R1.7/P0

R2.7/P0

2.8

DRVDD

13

DRVSS

14

DVSS

15

1.6

ADCLK

16

2.8

DVDD

17

2.8

18

DVDD

19

PBLK

2.7

CLPOB

20

21

XSHP

XSHD

22

CLPDM

23

2.8

24

AVDD

J

C3008

XX

DVSS

R0.8/P0

AVSS26AVSS27AVDD28L1+29L2+

25

2.8

R1/P0

C3016

0.33u

R1/P0

R1/P0

R1.1/P0

IC3002

S/H. AGC, A/D

CONVERTER

IC3002

VSP995PTR

R1.5/P0

CCD_IN

30

31

XX

C3030

CCD_GND

C3019

0.1u

AD1

R1/P0

R1.1/P0

R1.1/P0

AVDD34LINE35AVSS36CHROMA

32L33

2.8

XX

R0.9/P0

R3017

AD0

2D03D14D25D36D47D58D69D710D811D912

R1.1/P0

C3020

1

DVSS

1u

LATCHSELECT

CMLEVEL

XSCK

SYSV

RSTB

AVSS

AVSS

AVDD

REFN

REFP

C3024

10u

2.8

48

0

SI

47

2.7

XCE

46

45

44

2.8

43

42

41

2.8

40

1.3

39

1.8

38

1.5

37

C3021

0.1u

C3022

0.1u

C3023

0.1u

CH_SCK

CH_SO

CS_CH

XRST_VTR

AD2

AD3

AD4

AD5

AD6

AD7

AD8

L3001

10uH

AD9

AD8

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

AD9

AD8

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

(3/12)

K

FB3005

R3005

C3012

0.1u

05

47

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

4-6

VC-416 (1/12)

Page 8

1

VC-416 BOARD (2/12)

A

LENS DRIVE, EVR

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

B

C

D

E

24PCN3101

ZM_A

F

G

LENS

BLOCK

H

LENS BLOCK is replaced as block,

I

so that there PRINTED WIRING BOARD

and SCHEMATIC DIAGRAM are omitted.

J

K

L

ZM_XA

ZM_XB

FC_SENS_Vcc

FC_SENS_OUT

NightShot_Vcc

THERMO_OUT

ZM_SENS_OUT

ZM_SENS_Vcc

I_DRIVE(-)

I_DRIVE(+)

I_HALL(-)

I_BIAS(-)

I_HALL(+)

I_BIAS(+)

ZM_B

FC_XA

FC_XB

GND

GND

GND

GND

FC_A

FC_B

R3113

15k

4.6

0.9

6

7

8

Vcc

B_OUT

R1.4/P0.2

A_OUT2A_IN-3A_IN+4GND

1

R0.6/P0

R1.4/P0

R1.4/P0.2

470k

R3111

B_IN-

8

R3127

1k

R3128

1k

0.9

0.8

B_IN+

0.8

3

4

GND

A_IN+

B_IN+6B_IN-7B_OUT8Vcc

5

0.200.6

0

R3115

C3113

0.01u

5

914117

C3111

0.001u

R3114

C3114

470k

0.022u

C3115

XX

1.1

1

2

A_IN-

A_OUT

HALL

CONTROL

IC3105

NJM12904V(TE2)

4.6

0.6

Q3103

2SC584600LS0

HALL GAIN

0.6

CONTROL

R3117

10k

R3116

C3116

2200p

1k

R3118

47k

330

R3135

10

XX

IC3103

HALL REG, XTAL AMP

IC3103

NJM12904V(TE2)

C3120

R3120

±0.5%

0.1u

0.8

1

A_OUT

0.8

22k

R3121

±0.5%

2

A_IN-

0.8

3

A_IN+

4

GND

10k

B_OUT

B_IN-

B_IN+

4.6

8

Vcc

1.9

7

1

6

1.1

5

R3122

R3123

470k

13

D_2.8V

10uH

L3102

C3121

XX

330k

C3118

4.7u

MT_5V

A_4.6V

A_2.8V

FREQ_AMPOUT

XNS_SW

HALL_AD

IRIS_PWM

IRIS_COM

ZM_RST_LED

15

(11/12)

@001

(1/12)

@008

(7/12)

FC_RST_LED

LENS_TEMP_AD

DA_STRB

(MT_GND)

REG_GND

CAM_SCK

CAM_SO

REG_GND

ZM_RST

FC_RST

LD_DIR1B

LD_DIR1A

LD_EN1

LD_EN0

LD_DIR0A

LD_DIR0B

@003

(1/12)

(3/12)

(7/12)

@009

(3/12)

C3108

C3123

DA_STRB

L3101

4.7uH

CAM_SCK

CAM_SO

R9201

C9201

4.7u

XX

CAM_SO

DA_STRB

CAM_SCK

0

2.6

0

5

6DI7

8

LD

CLK

GND

IC9201

EVR

XX

33u

10V

(D/A CONVERTER)

IC9201

NJW5210RB1

AO12AO23AO34VCC

1

1.110.8

2.8

3

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R3102

R3101

R3136

XXR3137

XX

XX

XX

4

D3101

DF3A3.3FV(TL3SONY)

0.022u

2

3

C3101

R3141

C3122

XX

XX

5

1SS387-TPL3

RN1119FV(TL3SONY)

1

1234567

UPD16877MA-6A5-E2

D3102

Q3101

IRIS DRIVE

8

RB3101

47k

SENSOR SWITCH

R0.8

/P-1.6

R0.6

/P-1.5

IC3101

FOCUS/ZOOM

MOTOR DRIVE

IC3101

R1.8/P2.8

UP04116008S0

6122

R3106

1M

C3103

4700p

R0.6

/P0

C3104

4.7u

XXR3105

Q3102

2.8

2

2.8

1

6

4

3

5

2.8

R3138

2.8

R1/P0.5

21

22

23

24

VDD

PGND

OUT1B

R1.1/P0.6

R1.2/P0.6

VM12OUT 1A3PGND4OUT2A5OUT3A6PGND7OUT4A8VM49IN110EN111IN212EN2

1

4.8

1.3

XX

OUT2B

R3112

XX

R3107

2200

C3105

C3112

0.47u

4.8

R1.1/P0.5

19

20

VM23

1.3

C3109

0.047u

R3110

470k

C3107

470p

IC3104 IC3105

IRIS DRIVE,

HALL AMP BIAS/GAIN

IC3104

NJM12904V(TE2)

C3106

0.1u

R3109

R3108

220k

10k

0.1u

2

1

4

3

6

5

8

7

RB3102

22k

0

0

R0.9/P0.5

R2.4/P0

R2.4/P0

13

14

15

16

17

18

IN3

IN4

EN3

EN4

PGND

OUT4B

OUT3B

R1/P1.4

R0.5/P0

R0.3/P0

0

0

4.8

05

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

4-7

VC-416 (2/12)

Page 9

1

VC-416 BOARD (3/12)

A

DV SIGNAL PROCESS, DV INTERFACE

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

D_1.5V

A_2.8V

(11/12)

(5/12)

(7/12)

(8/12)

(1/12)

(7/12)

(8/12)

@007

(1/12)

@016

(7/12)

(7/12)

(6/12)

(7/12)

(1/12)

(2/12)

(7/12)

(1/12)

(7/12)

(7/12)

(9/12)

(12/12)

(4/12)

(7/12)

USB_3.1V

REG_GND

XCS_IC_6001

XCS_IC_6002

IC_6002_SLEEP

XRST_LINK

XRST_PHY

XCS_SFD

XCS_VFD

LINE_OUT_VD

XCS_IC_6001-2

XIRQ_IC_6001

ATF_LATCH

XUSB_EN

XVSP_SCK

CAM_SCK

CAM_SO

XRST_VTR

FE_CLPOB

TG_VGAT

TG_ZSG1

TG_AHD

LD_DIR0A

LD_DIR0B

LD_DIR1A

LD_DIR1B

ZM_RST

D_2.8V

XCS_VD

D24A00

D25A01

D26A02

D27A03

D28A04

D29A05

D30A06

D31A07

DXXA08

DXXA09

XDVCN

VSP_SO

VSP_SI

CAM_SI

OSD_V

VD_SO

VD_SCK

TG_ZV1

TG_AVD

LD_EN0

LD_EN1

FC_RST

VFO_VD

VFO_OE

WRX

RDX

FRRV

TRRT

DRP

ALE

LPS

OFR

VREF

TRRV

SWP

AD9

AD8

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

TG_ID

VCK

B

C

D

E

@010

(7/12)

F

G

@011

@012

H

@003

@004

I

@013

@006

@014

J

@015

K

L

M

@009

(2/12)

N

05

3 20

FB6001

XCS_IC_6001

WRX

RDX

FRRV

TRRT

DRP

ALE

XCS_IC_6002

D24A00

D25A01

D26A02

D27A03

D28A04

D29A05

D30A06

D31A07

DXXA08

DXXA09

XDVCN

IC_6002_SLEEP

LPS

OFR

XRST_LINK

XRST_PHY

VREF

TRRV

XCS_SFD

XCS_VFD

LINE_OUT_VD

XCS_IC_6001-2

XIRQ_IC_6001

ATF_LATCH

XUSB_EN

XVSP_SCK

VSP_SO

VSP_SI

CAM_SCK

CAM_SO

CAM_SI

OSD_V

XRST_VTR

SWP

VD_SO

VD_SCK

AD9

AD8

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

FE_CLPOB

TG_ID

TG_VGAT

TG_ZSG1

TG_ZV1

VCK

TG_AVD

TG_AHD

LD_DIR0A

LD_DIR0B

LD_DIR1A

LD_DIR1B

LD_EN0

LD_EN1

FC_RST

ZM_RST

VFO_VD

VFO_OE

4

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

1

TG TGCKO

1.5

2

VFO_VD

VFO_OE

RAM VDD0

R2.7/P0

3

TG AVD

R2.5/P2.8

TG AHD

4

R2.4/P0

LD DIR0A

5

R0.4/P0

LD DIR0B

6

RAM VSS0

7

R0.4/P0

LD DIR1A

8

R2.4/P0

LD DIR1B

9

1.5

RAM VDD1

10

0

LD EN0

11

0

LD EN1

12

RAM VSS1

13

2.8

LD SENSE0

14

2.8

LD SENSE1

15

LD IRIS

16

1.5

RAM VDD2

17

0.1

OSD SI OSD0

18

2.4

OSD XSC OSD1

19

2.6

OSD XSCK OSD2

20

RAM VSS2

21

BMOSD0(CPY)

22

BMOSD1(OSDCB)

23

BMOSD2(OSDCR)

24

BMOSD3(OSDY)

25

1.5

26

DVDD0

C6004

BMOSD4(CPTONE)

27

0.01u

BMOSD5(PILOT)

28

1.5

RAM VDD3

29

OSDHD

30

DVss0

31

YI0

32

YI1

33

CI

34

RAM VSS3

35

SYNCI0

36

37

SYNCI1

CKI54

38

2.8

IOVDD0

39

CKI135

40

SYNCO0(HDO)

41

R1.4/P0

SYNCO1(VDO)

42

R1.5/P2.8

43

SYNCO2(OEO)

1.5

44

RAM VDD4

45

YO0

YO1

46

YO2

47

YO3

48

RAM VSS4

49

YO4

50

YO5

51

YO6

52

YO7

53

IOVSS0

54

TG_AVD

C6002

0.01u

C6003

1u

TG_AHD

LD_DIR0A

LD_DIR0B

LD_DIR1A

LD_DIR1B

LD_EN0

LD_EN1

FC_RST

ZM_RST

VD_SO

VD_SCK

6122 18

C6005

0.01u

AD0

AD1

AD6

AD5

AD4

AD3

IOVDD3

CO2

FE_CLPOB

2.7

FE CLPDM

CO3

R1.1/P0

FE CLPOB

IOVSS1

DATA_TO_SFD

AD2

R1.1/P0

R1.1/P0

FE ADIN1

FE ADIN0

ADAI1

ADAO1

0.7

0.6

DATA_FROM_SFD

R1.1/P0

FE ADIN2

ADAI2

R1.1/P0

FE ADIN3

ADAO2

1.4

FE ADIN4

LRCKO

SFD_LRCK

R1.1/P0

1.4

SFD_BCK

C6006

R1/P0

FE ADIN5

BCKO

0.9

SFD_FCK

4.7u

VCK

TG_ID

TG_ZV1

TG_ZSG1

TG_VGAT

1.6

0.102.8

R2.7/P0

R1.3/P0

TG ID

TG ZV1

TG ZSG1

TG VGAT

TG CHCK

IC TEST

TP TEST

CO1

CO0

SCAN EN

55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

8 23

C6008

C6009

0.01u

XX

XX

OSD_V

CAM_SI

CAM_SO

AD9

AD8

AD7

R0.8/P0

FE ADIN6

FCKO

2.8

FE ADIN7

IOVDD1

R0.2/P0

FE ADIN8

PCO

CAM_SCK

XIRQ_IC_6001

0

2.8

2.6

0.1

2.6

CAM SI

IODSS3

CAM SO

FE ADIN9

CAM SCK

IC_6001 IRQ

PLL VDD2

RECDT

RECA1

POI

RECA2

PLLVSS2

2.8

R2.7/P0

R2.7/P0

R1.2/P0

RECA1

RECA2

RECDT

C6007

XX

XCS_IC_6001-2

2.5

2.6

CAM XCE

CAM SYSV

IC6001

DV SIGNAL PROCESS

RECCK

PLLSW

R1.3/P0

R6002

RECCK

XX

1.4

R6003

XRST_VTR

2.8

DVDD3

IC6001

CXD3164R

PLLMSK

XCS_IC_6001

XRST

DVSS1

C6010

4.7u

XCS_SFD

2.7

CS IC_6001

PCOR

2.8

2.7

MSCSS

PLL VDD3

XCS_VFD

MSCSV

TRXOSCIN

VSP_SI

VSP_SO

XVSP_SCK

2.8

2.802.5

MSSCK

MSI TO UCON(VSP SI)

MSO FROM UCON(VSP SO)

TRXOSCOUT

PLLVSS3

ADDT0

LINE_OUT_VD

DVSS3

ADDT1

10

VREF

2.800.5

MCVD

ADDT2

MCVREF

ADDT3

ALE

FRRV

TRRT

TRRV

D31A07

D30A06

D29A05

DXXA08

DXXA09

XCS_IC_6002

1.4

1.4

2.8

2.7

2.2

2.2

R2.2/P2.5

FRRV

TRRT

TRRV

MCCE

MCHA0

MCDA7

MCDA6

MCHA1

ADAVSS

DVDD1

ADDT5

RFIN

ADDT4

L6002

VRT

ADAVDD

PBCK

1.4

2.8

R2.6/P1.5

R2.8/P0.9

RFIN

C6011

4.7u

0.1u

C6013

0.01u

C6012

L6003

10uH

10uH

RDX

MCDA4

ICOVDD

WRX

D27A03

D26A02

D25A01

D24A00

2.8

2.2

2.2

2.2

2.2

2.2

RDX

WRX

MCDA1

MCDA2

MCDA0

MCDA3

ICOVSS

DACVSS

VRB

ADDVSS

DACVDD

REFVSS

2.8

2.8

R2.8/P0.9

C6016

0.1u

4.7u

C6015

D28A04

2.2

MCDA5

ADDVDD

100 101 102 103 104 105 106 107 108

2.8

4.7u

C6014

ATF_LATCH

2.7

0

163164165166167168169170171172173174175176177178179180181182183184185186187188189190191192193194195196197198199200201202203204205206207208209210211212213214215216

ALE

CRCK(20.25MHz)

IOUT

13 21

0.7

ATF LATCH

PLLTHROUGH

PLL MODE0

PLL MODE1

REFVDD

2.8

L6004

10uH

PLLVDD4

PLLVSS4

IOVDD2

IODSS2

PLLVDD1

PLLVSS1

PLLVDD0

PLLVSS0

USB XEN

USBVSS

USBVDD

REX PNL

DACVDD_2

DACVSS_2

DACVDD1

REX EVF

EVFOUT

DACVSS_1

DACVDD_0

DACVSS0

SWP

DRP

LCKO

LBUS0

LBUS1

LBUS2

LBUS3

XOO

XOI

FRL

FCLR

DIR

XENA

XACC

DVDD2

TRCKO

DVSS2

SPCKO

CKO

PHD

PVD

DM

DP

PNL G

PNL R

PNL B

REX C

COUT

REX Y

YOUT

SWP

1.4

162

1.4

161

2.8

160

1.3

159

158

LBUS0

2.8

157

LBUS1

2.8

156

LBUS2

2.8

155

LBUS3

2.8

154

2.8

153

152

151

150

FRL

0

149

FCLR

2.7

148

DIR

0

147

XENA

2.8

146

XACC

2.8

145

1.5

144

TRCKO

143

R6005

1.3

142

1.2

141

140

2.8

139

138

137

2.8

136

135

2.8

134

CL6001

133

132

2.6

131

2.8

130

XUSB_EN

2.8

129

128

1

0

3

127

5

0

7

126

3.1

RB6001 56

125

1

124

0.1

123

2.8

470

122

0.1

121

470

120

0.1

119

2.8

470

118

0

117

116

115

1

114

0.4

113

2.8

112

1

111

0.3

110

109

C6017

4.7u

DRP

C6018

0.01u

C6019

0.01u

XX

2

C6020

4

0.1u

6

8

R6004

10k

±0.5%

R6013

±0.5%

R6014

±0.5%

R6015

±0.5%

R6008

10k

R6009

10k

R6010

680

R6011

4700

R6012

270

15

R6024

4.7

FB6002

L6006

10uH

C6021

4.7u

165

D24A00

D25A01

D26A02

D27A03

D28A04

D29A05

D30A06

D31A07

XACC

XENA

FCLR

FRL

OFR

DIR

TRCKO

C6022

0.01u

1234567

7

8

6

Q6001

XX

324

1

17

ALE

RDX

WRX

XCS_IC_6002

XRST_LINK

74

75

76

77

78

80

ALE

XCS79VSS

VDD

XRD

XRW

XRESETL

1

VDD

2

DA0

3

DA1

4

DA2

VSS

5

6

DA3

7

DA4

DA5

8

DA6

9

VDD

10

DA7

11

XACC

12

XPEN

13

FCLR

14

FR

15

0FR

16

IDIR

17

VSS

18

PCLK

19

PMODE

20

VDD22REGOUT23REGENZ24PD025VSS26PD127PD228PD329VDD30N.C.31N.C.32N.C.33VSS34N.C.35VDD36TM037N.C.38MSP10039PWD40CNC

21

C6024

0.001u

8

RB6002

XX

5

2

1

4

3

6

5

8

7

RB6005

XX

IC6002

DV INTERFACE

IC6002

SN0306037AZVWR

LBUS0

LBUS1

LBUS2

LBUS3

19

L6009

10uH

D_2.8V

65

N.C.66N.C.67N.C.68N.C.69N.C.70N.C.71N.C.72N.C.73N.C.

22914117

C6025

4.7u

61

62XI63

64

N.C.

VSS

VSSPLL

VDDPLL

FILTER1

FILTER0

VDDA

R1

R0

VSSA

TPBIAS

TPAP

TPAN

VDDA

VSSA

TPBP

TPBN

VSSA

VDDA

VSS

XRESETP

LPS

CNA

IC_6002_SLEEP

C6031

XX

C6030

XX

60

C6026

59

0.1u

58

R6020

57

130

±0.5%

56

R6021

6200

55

±0.5%

54

53

52

51

50

49

48

47

46

45

44

XRST_PHY

43

LPS

42

XDVCN

41

C6027

1u

R6023

1500

8

3.1

0

RB6004

56

1234567

8

1234567

RB6006

10k

Q6003

UNR31A300LS0

USB PULL UP

2.8

RFIN

RECA2

RECA1

RECCK

RECDT

SFD_LRCK

SFD_BCK

SFD_FCK

DATA_TO_SFD

DATA_FROM_SFD

LF6001

XX

2

4

1

3

42

3

1

LF6002

XX

C6028

220p

TPA+

TPA-

TPB+

TPB-

SPCK

XUSB_ON

USB_D+

USB_D-

PANEL_HD

PANEL_VD

PANEL_G

PANEL_R

PANEL_B

RFIN

RECA2

RECA1

RECCK

RECDT

SFD_LRCK

SFD_BCK

SFD_FCK

DATA_TO_SFD

DATA_FROM_SFD

IC_6001_C_OUT

IC_6001_Y_OUT

@017

(12/12)

@018

(8/12)

@019

(7/12)

@020

(12/12)

@021

@022

(4/12)

(6/12)

@023

(5/12)

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

4-8

VC-416 (3/12)

Page 10

1

48

53

62

9117

10

VC-416 BOARD (4/12)

A

REC/PB AMP

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

B

C

D

E

F

(11/12)

@024

(12/12)

@014

@022

(3/12)

(3/12)

(7/12)

(12/12)

RP_4.6V

RP_2.8V

REG_GND

RF_MON

SWP

RFIN

RECA1

RECA2

RECCK

RECDT

RECA1

RECA2

RECCK

RECDT

L6501

C6501

4.7u

10uH

R6502

22k

10uHL6502

C6503

4.7u

R6505

C6508

0.47u

C6505

0.47u

R6501

C6502

0.01u

10k

1

3

C6506

0.01u

16V

C6504

XX

10k

R3.9/P2.6

C6509

0.01u

R2.1/P0.7

R3.1/P2

R3.1/P2

R1/P2.2

2

4

C6510

0.01u

25

26

27

2.6

28

4.5

29

30

31

32

33

0.9

34

35

1.3

36

R6506

C6511

PB_X_OUT

GND

PB_Y_OUT

PB_RF_IN

VCC_PB_4.6V

TEST_OUT

GND

AGCTC_Ech

AGCTC_Och

PB_RF_OUT

LPF_f0

10k

0.1u

0.1u

R6507

±0.5%

C6512

2.3

2.3

1.3

4.5

CE

CO

PB_IR

R0/P1.7

PB_FBDP

VCC_REC_4.6V

R6508

±0.5%

R2.3/P0

REC_IR_ME

10k

R6510

R2.3/P0

REC_IR_MP

REC_PEAK_I_ME

10k

22k

IC6501

REC/PB AMP

IC6501

CXA3619R-T4

CTRL0

SW_PS

37 38 39 40 41 42 43 44 45 46 47 48

1.4

R2.8/P0

2.8

CTRL1

REC_A1

R2.7/P0

2.8

VCC_2.8V

REC_A2

R2.7/P0

2.8

MODE1

REC_CLK

22k

±0.5%

±0.5%

R6512

4.5

R1.2/P0

REC_PEAK_T

REC_PEAK_I_MP

REC_DATA

MODE2

R1.2/P0

R1.2/P0

0

2.8

XX

C6513

131415161718192021222324

XME/MP

VCC_HEAD

VCC_D2.8V

TEST

GND

D1O

D2O

GND

GND

D2E

D1E

GND

N MECHANISM

10P

CN1008

10

R6513

220

12

R2.9/P1.7

11

R2.9/P1.7

XO

10

R2.9/P1.7

YO

9

R2.9/P1.7

8

7

6

R2.9/P1.7

5

R2.9/P1.7

YE

4

R2.9/P1.7

XEAGC_EVR

3

R2.9/P1.7

2

1

±0.5%

R6514

220

±0.5%

R6515

220

±0.5%

R6516

220

±0.5%

9

8

7

6

5

4

3

2

1

GND

YSDL(N.C.)

XSDL(N.C.)

GND

XODD

YODD

GND

YEVEN

XEVEN

GND

VIDEO HEAD

DECK

(MDX-N110)

(1/2)

ODD

EVEN

SW_PS

CONT1

ALL_PS

G

@025

(7/12)

05

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

RECA1

RECA2

C6514

XX

4-9

RECCK

RECDT

VC-416 (4/12)

Page 11

1

48

53

VC-416 BOARD (5/12)

A

B

C

D

E

F

VIDEO OUT, AUDIO I/O

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

A_4.6V

D_2.8V

(11/12)

@026

(7/12)

AU_2.8V

VTR_UNREG

AU_4.6V

REG_GND

BEEP

INT_MIC_L

INT_MIC_R

AUDIO_L_I/O

AUDIO_R_I/O

@027

(12/12)

R6726

100k

R6727

6800

Q6701

2SD1834-T100

3.4V REG

R6728

4700

RB6702

2200

8

8.3

R6729

L6701

10uH

C6705

4.7u

RB6703

2

4

6

8

C6709

4.7u

4.7u

2200

RB6704

100k

1

3

5

7

1234567

C6707

0.01u

C6708

0.01u

4.7u

C6704

4.7u

XX

C6701

C6710

C6727

0.1u

XX

C6702

C6713

R6722

XX

R6723

XX

L6702

10uH

0.1u

C6714

3.2

4.1

47k

C6703

1u

8

1234567

INTMIC_L

37

1.4

INTMIC_R

38

1.4

OFFSET_L

39

1.4

VREFH

40

2.3

LINEOUT_L

41

2.4

PMUTE_L

42

0

GND

43

PMUTE_R

44

0

LINEOUT_R

45

2.4

VCCH

46

4.6

BEEP_IN

47

1.6

VCCSP

48

3.2

C6719

4.7u

C6718

XX

1.4

34

35

36

VREF

INTLPF_L

SPOUT_+2SPGND3SPOUT_-4OFFSET_SP5VREFSP6Y_INV7Y_OUT8DRIVEGND9V_OUT10V_INV11VCCHDRIVE12C_OUT

1

1.6

1.6

6 122 9117

C6712

C6724

1u

XX

1u

1u

C6747

C6748

R2.5/P0

1.4

1.4

2.8

29

30

31

32

33

VCC

MICVCC

AGCLINK

EXTMIC_L

EXTMIC_R

INTLPF_R

IC6701

VIDEO OUT, AUDIO I/O

IC6701

AN12920AAVB

1.9

1.4

1.9

1.6

10

XCS_AU1

XPWDA

@028

(7/12)

@023

(3/12)

XPWAD

SFD_BCK

SFD_FCK

SFD_LRCK

DATA_FROM_SFD

DATA_TO_SFD

IC_6001_C_OUT

IC_6001_Y_OUT

DEM1

DEM0

1.4

0.9

1.4

2.8

2.8

1.4

1.4

9

10

11

12

13

15

16

SDTI

LRCK

MCLK

SCLK

XPWAD14XPWDA

AOUTL

AOUTR

IC6702

A/D, D/A

1u

C6744

CONVERTER

IC6702

PCM3008TG/2K

C6745

4.7u

R6810

XX

C6732

C6730

28

GND

1.8

4.7u

27

1.8

R6776

100k

0.3

26

AGC_TC

4.6

1u

1.3

25

RECOUT_L

RECOUT_R

2.3

1.3

PBIN_L

PBIN_R

VCCD

DATA

CLOCK

OFFSET_R

VGND

C_IN

VCCH_V

SDC_OUT

DEM1

SDTO

7

8

0.6 0.6

1u

C6741

1uC6742

XX

0.01u

4.7u

R6813

XX

C6749

0.1u

0.1uC6738

L6704

10uH

VSP_SO

C6740

XX

XX

XVSP_SCK

24

1.4

23

1.4

22

2.8

21

0

20

2.6

CS

19

2.7

18

1.4

YIN

17

2.2

16

15

2.3

14

4.6

13

C6750

C6735

C6751

C6736

VSS5VDD6DEM0

1

2

3

4

0

2.8

2.8

1.4

C6743

1.4

1.4

1u

@011

(3/12)

(7/12)

(8/12)

VCOM

AINR

AINL

G

4V

4V

6.3V

C6726

C6716

XX

XX

H

S_Y_I/O

VIDEO_I/O

S_C_I/O

05

C6720

0.1u

C6722

4.7u

C6725

C6731

C6728

100u

22u

100u

1234567

C6733

22u

6.3V

8

RB6701

75

C6734

0.01u

R6779

XX

D1021

XX

1

2

3

CONTROL

2PCN1001

2

SP-

1

SP+

KEY

BLOCK

(CF17000)

PAGE 4-23

of LEVEL2

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

4-10

VC-416 (5/12)

Page 12

1

VC-416 BOARD (6/12)

A

LCD/EVF DRIVE

XX MARK:NO MOUNT

NO MARK:LCD/EVF MODE

L:LCD MODE

E:EVF MODE

3

4

6122

8

914117

10

13

15

165

17

@030

(7/12)

D_2.8V

EP_8.5V

A_4.6V

(EP_4.6V)

A_2.8V

(EP_2.8V)

REG_GND

PANEL_R

PANEL_G

PANEL_B

PANEL_VD

PANEL_HD

XCS_EVF

VD_SCK

VD_SO

XSYS_RST

EVF_BL_ON

PANEL_BL_ON

VD_SI

PANEL_VD

PANEL_HD

XCS_EVF

VD_SCK

VD_SO

VD_SI

XSYS_RST

RB9302

1234567

47k

R9329

C9304

XX

1u

C9302

C9303

C9301

VD_SI

XCS_EVF

VD_SO

PANEL_HD

PANEL_VD

XSYS_RST

8

C9307

4.7u

C9305

R9302

L9303

10uH

L9302

10uH

L9301

C9308

10uH

0.01u

0.01u

0.01u

0.1u

68k

/E4.6

C9306

R9307

L3.3

L3.9/E0

C9309

XX

10u

4V

R9309

560p

XX

1.3

1.4

2.8

2.8

470

2.6

2.8

2.6

R9308

XX

R9310

4700

R9311

L3.3

2200

L0.6

/E0

1

4

/E4.6

2

6

L0.1/E4.6

3

4.6

5

UP04501008S0

R9303

33k

±0.5%

C9312

C9311

XX

4.7u

R9313

100k

±0.5%

TRST

373839404142434445464748

GND1

OPOUT

OPIN

TEST

SO

XCS

XSCK

L0.2/E0.9

SI

VDD

SCAN

XHD

R9312

22

±0.5%

R9305

1k

L4

/E4.6

Q9302

R9301

220k

±0.5%

/E4.6

L3.2/E0 L3.2/E0

2SA1576A-T106-QR

Q9301

C9313

2.2u

1.3

2.8

1.7

1.7

1.7

RIN

GIN

Filter

VCC1

IC9301

L2.8/E0

XVD

VSS

XCLR

POFF

123456789101112

2.8

2.8

2.8

RGT_P

C9310

XX

R9314

22

±0.5%

L4

/E4.6

L3.3

Q9303

2SA1576A-T106-QR

Q9301-Q9304

LCD BACKLIGHT DRIVE

/E4.6

C9314

XX

1.4

L1.1/E0.8

BIN

EXTDA

LCD/EVF DRIVE

IC9301

CXM3018R-T4

HCK1

RGT

1.4

1.400.2

EVF_HCK1

EVF_HCK2

R9315

22

±0.5%

L3.3

L3.2/E0

2SA1576A-T106-QR

EVF_REF

10k

REF

HCK2

C9315

COM_P

R9318

1.9

COMDA_PANEL

HST

EVF_HST

EVF_PCG

L4

/E4.6

Q9304

XX

10u

10uC9318

C9317

3.8

1.9

COMREF

COM_PANEL

L0/E2.8

L2.8/E0

XSTBY_E

PCG

DWN_P

EVF_STBY

C9316

4.7u

252627282930313233343536

COM_EVFDWN

2.5

R9317

L2.5/E2.3

COMDA_EVF

EN

EVF_EN

EVF_VP

EVF_VR

EVF_VG

EVF_VB

8.5 8.5

2.8

D9301

XX

8

0

5

EVF_EN

EVF_VST

EVF_REF

EVF_PCG

EVF_VCK

EVF_STBY

WIDE

EVF_HCK2

EVF_HCK1

EVF_HST

0

TP_X

TP_SEL1

TP_SEL2

TP_Y

KEY_AD1

C9321

0.01u

RB9303

6

3

1

4

8

XX

1234567

R9328

R9327

XX

XX

2

Q9305

XX

@040

(9/12)

C9319

XX

10k

CL9302

R9321

L7.3/E0.3

B_OUT

B_IN-

B_IN+

R9322

EVF_VP

EVF_VB

EVF_VG

EVF_VR

XSTBY_P

WIDEVD_SCK

EVF_VST

EVF_VCK

1800

/E0.3

XX

8

Vcc

7

L0/E0.3

6

5

L0.4

/E0.3

L0

/E0.9

L7.3

5

C9320

0.1u

R9325

XX

R9326

XX

R9306

XX

R9304

XX

L3.3

/E1.4

6

4

2

L0/E0.9

1

3

L0/E0.3

UP04601008S0

EVF BACKLIGHT

R9323

39

±0.5%

Q9306

DRIVE

XSTBY_P

DWN_P

RGT_P

COM_P

R9324

KEY_AD1

TP_X

TP_SEL1

TP_Y

TP_SEL2

TP_X

TP_SEL1

TP_SEL2

TP_Y

KEY_AD1

Q9308

NDS356AP

100k

B+ SWITCH

Q9307

UNR32A300LS0

SWITCH

RB9304

XX

1234567

2.5

VP

4.6

XSTBY_P

1

3

5

7

RB9305

100k

VCC2

GND2

WIDE

VB

VG

VR

19 20 21 22 23 24

VST

VDD

VCK

VSS

13 14 15 16 17 18

2

4

6

8

R9320

XX

±0.5%

RB9301

2.5

8

2.5

6

4

2.5

2

L2.8/E0

0

0

2.8

1.4

R9319

XX

±0.5%

L3.9/E0 8.5

1

A_OUT

L4/E4.6

2

A_IN-

4

3

A_IN+

4

GND

CL9301

10

7

5

3

CL9303

1

IC9302

LCD/EVF BACKLIGHT

CONTROL

IC9302

NJM12904V(TE2)

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

LED_K

EP_4.6V

REG_GND

EVF_COM_CS

EVF_PSIG

EVF_VR

EVF_VG

EVF_VB

EVF_EN

EVF_VST

EVF_REF

EVF_PCG

EVF_VCK

EVF_STB

EVF_BLK

EVF_HCK2

EVF_HCK1

EVF_HST

REG_GND

EVF_VDD

PANEL_VR

PANEL_VG

PANEL_VB

REG_GND

REG_GND

VDD_P

EP_2.8V(N.C.)

D_2.8V

BL_H3

BL_H2

BL_H1

REG_GND

KEY_AD1

TP_X

TP_SEL1

TP_Y

REF

WIDE

HCK1

HCK2

HST

PCG

EN

PSIG

XSTBY

DWN

RGT

VST

VCK

COM

20PCN9301

LB-121

CN301

THROUGH THE

FP-379 FLEXIBLE

PAGE 4-21

of LEVEL2

30PCN9302

FP-380

FLEXIBLE

LND001-LND030

PAGE 4-18

of LEVEL2

B

(11/12)

C

@021

D

(3/12)

@029

(7/12)

@015

(3/12)

@031

(7/12)

(7/12)

(9/12)

(12/12)

E

F

G

H

@049

I

(7/12)

J

K

05

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

4-11

VC-416 (6/12)

Page 13

1

2

3

6 20 211715

7

8

91254 14131110 18 19

16

VC-416 BOARD (7/12)

A

CAMERA/MECHA CONTROL

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

B

XNS_SW

ZM_RST_LED

FC_RST_LED

@025

(4/12)

@030

@002

(1/12)

(11/12)

@029

(6/12)

@035

(12/12)

(6/12)

(9/12)

(12/12)

LENS_TEMP_AD

SIRCS_SIG

SYSTEM_AD

XCS_MC_FLASH

XREEL_HALL_ON

(6/12)

(3/12)

(6/12)

(3/12)

(9/12)

@026

(5/12)

IRIS_PWM

IRIS_COM

HALL_AD

DA_STRB

VST_C_RESET

PITCH_AD

YAW_AD

XCS_EEP

EEP_SO

EEP_SCK

UNLOAD

XCS_IC_9001

DRUM_PWM

CAP_PWM

LM_LIM_DET

TREEL_FG

SREEL_FG

TAPE_TOP

TAPE_END

DRUM_FG

DRUM_PG

MODE_SW_A

MODE_SW_B

MODE_SW_C

TAPE_LED_ON

CAP_FWD

CAP_FG

CAP_ON

DEW_AD

XFFREW_UP

ALL_PS

VD_SCK

CAM_DD_ON

XCS_EVF

USB_DET

ZOOM_VR_AD

IC_8001_SCK

XCS_IC_8001

IC_8001_SI

IC_8001_SO

XSYS_RST

PANEL_BL_ON

EVF_BL_ON

IR_ON

EEP_SI

MD2

LOAD

CONT1

SW_PS

VD_SI

VD_SO

OSD_V

SYS_V

BEEP

@008

(2/12)

C

@032

(12/12)

D

@033

(12/12)

E

F

@034

(8/12)

G

H

I

@015

@013

J

K

@036

(9/12)

L

@031

@049

M

(6/12)

N

XNS_SW

ZM_RST_LED

FC_RST_LED

IRIS_PWM

IRIS_COM

LENS_TEMP_AD

HALL_AD

DA_STRB

VST_C_RESET

PITCH_AD

YAW_AD

SIRCS_SIG

SYSTEM_AD

XCS_EEP

EEP_SCK

XCS_MC_FLASH

UNLOAD

XCS_IC_9001

DRUM_PWM

CAP_PWM

LM_LIM_DET

TREEL_FG

SREEL_FG

TAPE_TOP

TAPE_END

DRUM_FG

DRUM_PG

MODE_SW_A

MODE_SW_B

MODE_SW_C

XREEL_HALL_ON

TAPE_LED_ON

CAP_FWD

DEW_AD

XFFREW_UP

CAM_DD_ON

XCS_EVF

USB_DET

ZOOM_VR_AD

IC_8001_SCK

XCS_IC_8001

IC_8001_SI

IC_8001_SO

XSYS_RST

PANEL_BL_ON

EVF_BL_ON

EEP_SI

EEP_SO

CAP_FG

CAP_ON

CONT1

ALL_PS

SW_PS

VD_SCK

VD_SO

OSD_V

SYS_V

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

VFO_VD

LINE_OUT_VD

MELODY_CARR

VREF

MELODY_CARR

CAM_VD(MEGA_CAM_VD)

XVSP_SCK

OOE/FLD

VSP_SO

VFO_OE

VSP_SO

VSP_SI

OFR

C8610

XX

VSS

LINE_OUT_VD

VSP_SI

GCAM_XSCK

CH_SCK

PANEL_BL_ON

DRUM_PG

FP

PANEL_ON

CH_SO

DRUM_FG

DRUM_PG

GCAM_SO

CHIME_SDA

CL8605

DRUM_FG

XWE_EEP

CAM_SCK

CHIME_SCK

CHIME_SCL

TCHIME_SDA

CAM_SCK

DEMO

DEM0

SIRCS_SIG

CAM_SO

CAP_FG

TREEL_FG

SREEL_FG

R8656 XX

VDD

TREEL_FG

SREEL_FG

SIRCS_SIG

(D_1.5V)

IC8601

CAMERA/MECHA CONTROL

IC8601

MB91195ABGL-G-180-ERE1

(D_1.5V)

CAM_SO

CAM_SI

VDD

VD_SCK

0.1u

C8611

CAM_SI

VD_SCK

CL8614

CAP_FG

XCRADLE_IN

REC_CRRTO

VD_SO

CL8607

VD_SO

XNS_SW

0.1u

C8612

XS_JACK_IN

XNS_ON_SW

AV_JACK_IN_CRADLE

VD_SI

EEP_SCK

XFFREW_UP

EEP_SCK

VD_SI

XFFREW_UP

MIC_IN

AV_JACK_IN

EEP_SI(MC_FLASH_SI)

EEP_SO

EEP_SO

EEP_SI

MIC_MONO

DRUM_PWM

1234567

DRUM_PWM

CAP_PWM

SYS_V

VSS

CAP_PWM

8

TAPE_LED_ON

SYSV

TAPE_LED_ON

ATF_DEBUG

V_LIGHT_PWM

CL8602

RB8607

10k

TRRT

TRRV

CL8610

TRRT

TRRV

VSS

PB4

IRIS_PWM

CL8606

PK2

REC_CRRT1

IRIS_PWM

IRIS_COM_PWM

IRIS_COM

XCS_MC_FLASH

EXT_STROBO

XCS_MC_FLASH

PB7

XCS_IC_6001

XCS_IC_6001

MELODY_ENV

CAM_DD_ON

CAM_DD_ON

MELODY_ENV

1234567

CONT1

PJ1

CONT1/RF_SWP

N.C.

XRST_VTR

8

XRST_VTR

RB8604

100k

XFE_ON

EASY_MODE_LED

VSS

OSC1

C8613

0.1u

VREF

8

1234567

MF_A

MF_B

XRST_LINK

DA_STRB(XCS_DAC)

P22

XCS_OSD

XX

R8610

CS_CH

XCS_VD

XIRQ_IC_6001

SDC_ON

XINT_IC_6001

XCS_GCAM

IC_8001_XSCK

IC_8001_SCK

IR_ON

IC_6002_SLEEP

IR_ON(PM2)

IC_6002_SLEEP

XCS_IC_8001

IC_8001_SI

XCS_IC_8001

IC_8001_SI

SHUTTER_OPEN

IC_8001_SO

IC_8001_SO

XVSP_SCK

OSD_V

XCS_SFD

XRST_LINK

C8608

0.1u

100k

RB8611

PO4

VDD

IR_ON

C8604

MD2

MD2

LOAD

VD_SI

XSYS_RST

XCS_EEP

UNLOAD

LOAD

XCS_IC_9001

XCS_IC_6002

XCS_TG

ALE

FRRV

WRX

RDX

XDVCN

ALL_PS

SW_PS

TAPE_TOP

TAPE_END

DXXA09

DXXA08

XCS_EVF

VST_C_RESET

XCS_AU1

D31A07

D30A06

D29A05

D28A04

D27A03

D26A02

D25A01

D24A00

MELODY_ENV

MELODY_CARR

Q8601

UNR32A300LS0

Q8601, Q8602

MODULATOR

R8616

47k

6

4

2

0

R8657

C8606

C8605

2SC584600LS0

RB8610

1k

X8601

20MHz

C8603

10p

10p

10k

R8601

100

C8625

0.01u

0.1u

CL8608

XX

C8607

0.1u

Q8602

C8609

1u

0

2.80

78

5

3

1

0

A1A2

C1C2D1D2E4E2E1F4F2F1G1G2G4H1H2H4J1J2J4K1K2K4L2L1L4M1M2M4N1N2N4P1P2R1P4T1AA1AB2

X1

VSS

X0

XIN

MD2

MD1

MD0

XINIT(XRST)

PO7

XCS_EEP

XCS_GANDHI

XCS_TRF

LM-

VDD

LM+

XCS_IC_9001

XCS_IC_6001_BUS

XCS_IC_6002

XAUDIO_IN

XCS_TG

VSS

ALE

FRRV

WR01

RDX

VOUT_ON

XDVCN

ALL_PS

SW_PS

TAPE_TOP

TAPE_END

DXXA09

DXXA08

VSS

C1

VDD

XME/MP

XCS_LCD

XCS_EVF

VST_C_CHARGE

P43

N.C.

XCS_AU1

U4AA2 U2Y2 V1W4 T4W2 T2Y1 U1V4 R4V2 R2W1

LENS_DETE

D31A07

D30A06

D29A05

D28A04

D27A03

D26A02

D25A01

D24A00

VDD

ZM_RST_SENS

B1D4

(D_2.8V)

(D_1.9V)

(D_2.8V)

CL8619

CL8620

CL8621

CL8622

CL8623

OSD_V

XCS_SFD

(D_2.8V)

ZM_RST_LED

FC_RST_SENS

FC_RST_LED

VSS

AC3 AB3 AB4 AC4 Y5 AB5 AC5 Y6 AB6 AC6 Y7 AB7 AC7 Y8 AB8 AC8 Y9 AB9 AC9 Y10 AB10 AC10 Y11 AB11 AC11 Y12 AB12 AC12 Y13 AB13AC13 AC14AB14 Y14 AC15AB15 Y15 AC16AB16 Y16 AC17 AB17 Y17 AC18AB18 Y18 AC19AB19 AC20 Y19 AC21 AB20AB21 AB22

A22 A23 B23 D20

ZM_RST_LED

FC_RST_LED

DA_STRB

VDD

XEVF_TALLY

(D_2.8V)

(D_2.8V)

VDD

OSC0

CAP_ON

CAP_FWD

CL8613

CAP_FWD

PANEL_VG_AD

CL8615

MODE_SW_A

SWP

CL8611

CL8612

A21B21B20D19A20B19A19D18B18A18D17B17A17D16B16A16D15B15D14A15B14A14D13B13A13D12B12D11A12B11A11A10B10D10A9B9D9A8B8D8A7B7D7A6B6D6A5B5D5A4B4B3B2A3

SWP

CAP_ON

MODE_SW_A

MODE_SW_B

CL8616

CL8617

MODE_SW_B

DRP

DRP

(D_2.8V)

(D_2.8V)

CHIME_PWR_CONT

(D_2.8V)

(D_2.8V)

(D_2.8V)

(D_2.8V)

MODE_SW_C

CL8618

MODE_SW_C

CHIME_PWR_CONT

Y20AB23AC22AC23

ATF_LATCH

XCS_IC_6001-2

(D_1.9V)

HP_JACK_IN

XRST_PHY

XREEL_HALL_ON

HOLD_EEP

(D_2.8V)

GENERAL_AD

SYSTEM_AD

LM_LIM_DET

ZOOM_SW_AD

PITCH_AD

IRIS_HALL_AD

LENS_TEMP_AD

HI8_MP_SW

CHIME_AD2

CHIME_AD1

CHIME_AD0

XVIDEO_IN

PANEL_COM_AD

REC_PROOF

Q8606

XX

XCS_VFD

AVDD_U

AVRH_U

AVSS_U

MF_LED

XPWDA

XPWAD

XUSB_EN

XUSB_ON

YAW_AD

AVSS_1

AVRH_1

AVDD1

AVDD_0

AVRH_0

AVSS_0

DEW_DET

SDC_IN

EVF_ON

USB_DET

ME_SW

C8626

XX

C8614

1u

VDD

LPS

PH4

PH2

VDD

C2

VSS

TUL

ANIN1

ANIN0

DEM1

PG1

R8651

2200

Q8603

C8616

XX

J23 H20 H22 G20 H23 G22 G23 F20 F22 F23 E23 E22 E20 D23 D22 C23 C22 B22

C8602

XX

R8630

XX

C8615

1u

R8634

68k

R8633

220k

R8636

47k

AA23AA22 Y22 Y23 W20 W22 W23 V20 V22 U23 V23 U22 U20 T20 T22 T23 R20 R23 R22 P20 P22 P23 N20 N22 N23 M20 M22 M23 L20 L22 L23 K20 K22 K23 J20 J22

Y4 AB1 AC1 AC2

R8626

XX

XX

R8625

R8627

XX

2

XX

CHIME_SCK

CHIME_SDA

CHIME_VDD

R8629

XX

Q8604

6

3

XX

5

1

4

R8628

0

2.8

2

1

3

4

6

5

8

7

RB8612

3300

C8617

0.1u

1

3

5

7

RB8606

100k

1

3

56

7

RB8609

1M

R8653

100k

2.7

2.8

2

4

6

8

2

4

8

R8603

R8604

Q8605

2SA2030T2L

CHIME VDD

SWITCH

XX

47k

R8652

100k

RB8605

7

5

3

1

D_1.5V

FB8602

R8650

D_2.8V

XX

R8643

100k

XCS_EEP

R8605

XX

R8606

0

ATF_LATCH

XCS_IC_6001-2

LPS

XRST_PHY

XCS_VFD

XREEL_HALL_ON

SYSTEM_AD

DEM1

LM_LIM_DET

XPWDA

ZOOM_VR_AD

XPWAD

CHIME_PWR_CONT

XUSB_EN

XUSB_ON

2

1

RB8608

YAW_AD

4

XX

3

6

5

7

R8641

XX

PITCH_AD

8

HALL_AD

1k

LENS_TEMP_AD

DEW_AD

EVF_BL_ON

USB_DET

REC_PROOF

8

6

4

2

EEP_SI

SWP

XCS_VD

XCS_IC_6001

XDVCN

XRST_PHY

LPS

OFR

IC_6002_SLEEP

XRST_LINK

XCS_IC_6002

ALE

WRX

RDX

DXXA09

DXXA08

D31A07

D30A06

D29A05

D28A04

D27A03

D26A02

D25A01

D24A00

ATF_LATCH

XIRQ_IC_6001

FRRV

DRP

TRRT

TRRV

LINE_OUT_VD

VREF

XCS_IC_6001-2

XCS_VFD

XCS_SFD

XUSB_EN

XVSP_SCK

VSP_SO

VSP_SI

XRST_VTR

CAM_SCK

CAM_SO

CAM_SI

XCS_TG

CS_CH

CH_SCK

CH_SO

XCS_AU1

DEM0

XPWAD

XPWDA

DEM1

XUSB_ON

VFO_OE

VFO_VD

REC_PROOF

CHIME_VDD

CHIME_SCK

CHIME_SDA

2.8

1

CS

2.7

2

RXD3

2.8

3

XRDY

4

GND

IC8602

64K EEPROM

IC8602

M95640-WDW6TG

SWP

XCS_VD

XCS_IC_6001

XDVCN

XRST_PHY

LPS

OFR

IC_6002_SLEEP

XRST_LINK

XCS_IC_6002

ALE

WRX

RDX

DXXA09

DXXA08

D31A07

D30A06

D29A05

D28A04

D27A03

D26A02

D25A01

D24A00

ATF_LATCH

XIRQ_IC_6001

FRRV

DRP

TRRT

TRRV

LINE_OUT_VD

VREF

XCS_IC_6001-2

XCS_VFD

XCS_SFD

XUSB_EN

XVSP_SCK

VSP_SO

VSP_SI

XRST_VTR

CAM_SCK

CAM_SO

CAM_SI

XCS_TG

CS_CH

CH_SCK

CH_SO

XCS_AU1

DEM0

XPWAD

XPWDA

DEM1

XUSB_ON

VFO_OE

VFO_VD

REC_PROOF

CHIME_VDD

CHIME_SCK

CHIME_SDA

D_1.5V

D_2.8V

VDD

HOLD

SCK3

TXD3

@014

(11/12)

8

7

6

5

@011

@012

(3/12)

@006

@003

@004

@005

(1/12)

@028

(5/12)

@019

(3/12)

@016

(3/12)

@037

2.8

2.8

2.8

0

(8/12)

(3/12)

(4/12)

(12/12)

@010

(3/12)

(1/12)

(2/12)

(3/12)

(1/12)

(3/12)

C8622

0.01u

(3/12)

(5/12)

(8/12)

(1/12)

(3/12)

(8/12)

EEP_SCK

EEP_SO

REG_GND

05

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

4-12

VC-416 (7/12)

Page 14

1

2

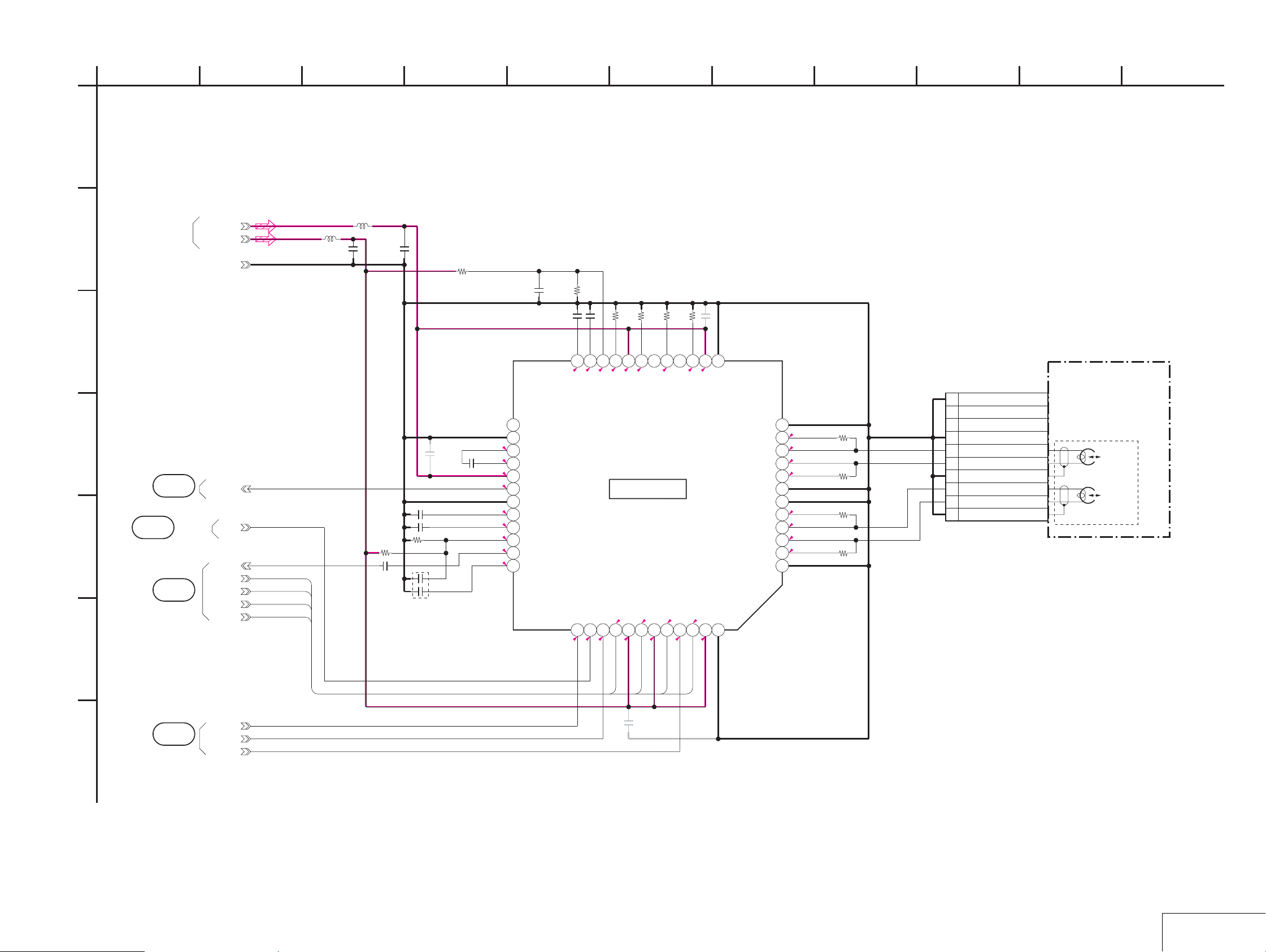

VC-416 BOARD (8/12)

A

SERVO

(11/12)

B

@048

(11/12)

N MECHANISM

DECK

(MDX-N110)

C

D

E

F

G

H

I

J

K

L

05

DCR-HC23E/HC24E/HC26/HC26E/HC35E_L3

(2/2)

M901

DRUM MOTOR

MECHANISM

BLOCK

(LOADING MOTOR)

PAGE 4-22

of LEVEL2

HALL

M903

CAPSTAN

MOTOR

FG

@037

(7/12)

PG/FG

MIC/REC_SW_GND

REC_PROOF

CHIME_VDD

CHIME_SCK

CHIME_SDA

CN1009

FG/PG_COM

M_COM

DRUM_U

DRUM_U

DRUM_W

DRUM_W

DRUM_V

DRUM_V

CN1007

LM_LOAD

LM_LOAD

LM_UNLOAD

LM_UNLOAD

XMODE_SW_A

XMODE_SW_B

XMODE_SW_C

SW_COM

XREC_PROOF

CHIME_VDD

CHIME_SDA

CHIME_SCK

TAPE_TOP

Cin_GND

XCCDOWN_SW

TREEL-

TREEL+

HALL_VCC

SREEL+

SREEL-

HALL_GND

TAPE_LED_K

TAPE_LED_A

TOP/END_GND

TAPE_END

CN1010

HE_GND

HE_VCC

CAP_W

CAP_W

CAP_W

CAP_W

FG_GND

FG_GND

FG_VCC

FG_VCC

DEW-

DEW+

UHE+

VHE+

WHE+

WHE-

CAP_V

CAP_V

CAP_V

CAP_V

CAP_U

CAP_U

CAP_U

CAP_U

10P

FG

PG

29P

NC

27P

UHE-

VHE-

N.C

FG2

FG1

3

MT_GND

REG_GND

VTR_UNREG

DRUM_VS

REG_GND

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

REC_PROOF

CHIME_VDD

CHIME_SCK

CHIME_SDA

MT_5V

D_2.8V

CAP_VS

DRUM_FG_SENS

DRUM_PG_SENS

FG_PG_COM

DRUM_COM

DRUM_U

DRUM_W

DRUM_V

R1001

33

C1004

0.1u

MODE_SW_A

MODE_SW_B

MODE_SW_C

R1023

XX

4

DEW_AD

R1002

XCC_DOWN

R1007

1 C_FRC

2 TEST

3 VMR

4 CFGOUT

5 C_PGND

6 GND

7 CFGIN+

8 CFGIN-

9 CAGC

10 U+

11 U-

12 V+

13 V-

14 W+

15 W-

16 VCC1

17 VH

18 TOPIN

19 TOPOUT

20 ENDIN

0.01u

0.01u

UNLOAD

XCS_IC_9001

DRUM_PWM

CAP_PWM

LM_LIM_DET

TREEL_FG

SREEL_FG

TAPE_TOP

TAPE_END

DRUM_FG

DRUM_PG

MODE_SW_A

MODE_SW_B

MODE_SW_C

TAPE_LED_ON

CAP_FWD

CAP_FG

CAP_ON

DEW_AD

XFFREW_UP

8

C9011

C9013

0.1u

0.1u

10V

10V

R9009

2.2

2.8

78

79NC80

CAPON

2.8

2.7

ENDOUT22RLP123RLM124RLO125RLDO126RLP227RLM228RLO229RLDO230VCC231LIMOUT32DEC133DEC234XRESET35MCK36SCK37XCS38SI39DGND40CSR

21

2.8

0.2

16V

16V

C9016

UNLOAD

LOAD

XCS_IC_9001

DRUM_PWM

CAP_PWM

LM_LIM_DET

TREEL_FG

SREEL_FG

TAPE_TOP

TAPE_END

DRUM_FG

DRUM_PG

MODE_SW_A

MODE_SW_B

MODE_SW_C

XREEL_HALL_ON

TAPE_LED_ON

CAP_FWD

CAP_FG

CAP_ON

DEW_AD

XFFREW_UP

C9015

0.1u

10V

2.2

R9010

0.4

0.9

76

77

C_W

C_VS

0.2*0.2

XX

LOAD

914117

C9018

0.1u

10V

2.2

R9011

0.5

0.9

74

75

C_V

C_U

C_VS

DRUM/CAPSTAN/LOADING

C9020

XX

LM_-

1u

C9022

0.4

0.1

71NC72

73

L_OUT2

L_PGND

IC9001

MOTOR DRIVE

IC9001

BD6639AKV-E2

0.2*8.3

C9021

0.1u

10V

6.3V

69

70

L_VM

LM_LIM_DET

LM_+

4.8

2.8

C9023

R9012

0.1

68

L_OUT1

0

XX

XX

10

1.2

D_W

D_VS

0

C9024

0.1u

10V

2.3

1.2

64

65

66NC67

D_V

D_VS

2.802.8

1.2

2.6

XCS_IC_9001

C9031

C9029

0.1u

0.1u

10V

10V

C9034

0.1u

10V

DRUM_W

DRUM_V

DRUM_U

R9014

270

1.2

61

63

NC62NC

D_U

D_PGND

COM

WIN

VIN

UIN

DFILTER

DFC

DFGOUT

DFGIN

VREF

PGOUT

PGIN

PGC

VG

ISNF

DBOUT

DBIN

CBLOUT

CBOUT

CBIN

0.5

Q9004

UNR32A100LS0

SWITCH

C9025

R9028

0.01u

C9032

C9035

470p

470p

C9030

470p

60

1.3

59

1.2

58

1.3

57

1.3

56

0.9

55

2

54

1.4

53

1.2

52

1.2

51

0.1

50

1.2

49

1.1

48

13.2

47

46

0

45

0.8

44

0.8

43

0.3

42

41

0.3

R9034

47k

0

XX

C9026

1u

0.022uC9027

C9036

DRUM_COM

C9028

0.047u

2.8

1u

C9002

XX

4-13

C9038

R9021

0.1u

XXR9016

XX

C9040

0.1u

R9023

C9039

470p

R9018 XX

15k

13

TAPE_LED_ON

XREEL_HALL_ON

R9025

4700

R9027

R9022

R9038

XX

100k

C9041

6800p

R9026

16V

22k

10k

VSP_SO

XVSP_SCK

SPCK

XRST_VTR

2.8

2.6

0.5

0

DRUM_FG_SENS

FG_PG_COM

DRUM_PG_SENS

IC_9001_13.5V

DRUM_ERROR

CAP_ERROR

R9024

2200

4

2SC584600LS0

@011

@018

(3/12)

@006

2SA2030T2L

B+ SWITCH

Q9002

LED DRIVE

C9042

6800p

Q9003

SENSOR_VCC

TAPE_LED_A

TAPE_LED_K

@039

(11/12)

XFFREW_UP

DRUM_PWM

(3/12)

(5/12)

(7/12)

DRUM_FG

DRUM_PG

(11/12)

UNLOAD

CAP_PWM

(1/12)

(3/12)

(7/12)

LOAD

VC-416 (8/12)

5

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

*:IMPOSSIBLE TO MEASURE THE

VOLTAGE AT THE MARKED POINTS.

R9037

XX

R9036

XX

CAP_W

CAP_V

CAP_U

LM_+

LM_-

MR_VCC

XX

REC_PROOF

CHIME_VDD

CHIME_SDA

CHIME_SCK

TAPE_TOP_C

T_REEL_-

T_REEL_+

33

SENSOR_VCC

S_REEL_+

S_REEL_-

TAPE_LED_K

TAPE_LED_A

TAPE_END_C

UHE+

UHE-

VHE+

VHE-

WHE+

WHE-

HE_VCC

CAP_V

CAP_W

CAP_U

FG2

MR_VCC

FG1

FG1

FG2

UHE+

UHE-

VHE+

VHE-

WHE+

WHE-

HE_VCC

@038

612

XX

R9032

R9035

XX

CAP_ON

CAP_FWD

CAP_FG

TAPE_TOP

TAPE_TOP_C

TAPE_END_C

TAPE_END

S_REEL_+

S_REEL_-

SREEL_FG

T_REEL_+

T_REEL_-

TREEL_FG

C9004

C9044

0.01u

16V

XX

R9033

8

1234567

RB9001

10k

12

4

3

C9045

0.047u

10V

1.4

1.3

1.3

0.3

0.1

0.1

0.3

0.3

0.5

0.5

2.8

0.6

1.2

2.8

1.2

C9009

C9010

C9043

0.001u

50V

4

3

2

1

1u

2

1

4

3

@034

(7/12)

XREEL_HALL_ON

XCC_DOWN

XCC_DOWN

(9/12)

Page 15

1

3 15

5428

7

9

10

13 141211

166

17

VC-416 BOARD (9/12)

A

HI CONTROL

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

BATT_UNREG

B

C

D

E

F

CONTROL

BLOCK

(CF17000)

LND001-LND008

PAGE 4-23

G

of LEVEL2

CONTROL

H

BLOCK

(SS17000)

LND001-LND014

PAGE 4-23

of LEVEL2

I

J

KEY

KEY

(11/12)

@040

(6/12)

XCHARGE_LED

CHARGE_LED_VDD

KEY_AD5(SS)

XEJECT_SW

XVTR_LED(XMEM_LED)

N.C(XVTR_LED)

MODE_LED_VDD

XPOWER_SW

XMODE_SW

KEY_AD2(PHOTO)

VTR_UNREG

EVER_3.0V

REG_GND

TP_SEL1

TP_SEL2

KEY_AD1

CN1017

XRESET

REG_GND

BATT_INFO

D_2.8V

KEY_AD3

CN1012

REG_GND

XCAM_LED

REG_GND

D_2.8V

ZOOM_VR

REG_GND

REG_GND

D_2.8V

VOUT

N.C

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

NON CRADLE model:DCR-HC23E/HC24E/HC26/HC26E

CRADLE model:DCR-HC35E

R8006

XX

12

34567

RB8008

R8046

10k

100k

R8001

R8002

100k

1M

TP_Y

TP_X

654

8P

1

2

3

4

5

6

7

8

14P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

D1008

12

3

R1022

47

150R1017

3

XX

D1006

XX

2.8

D1022

UNR31AF00LS0

TOUCH PANEL

SELECT SWITCH

3

0

XX

12

654

TP_SEL1

TP_SEL2

KEY_AD1

XBATT_INFO_SW

KEY_AD3

XCHARGE_LED

KEY_AD5

XEJECT_SW

XCAM_LED

XVTR_LED

XPOWER_SW

XMODE_SW

KEY_AD2

12

3

654

D1007

XX

TP_Y

TP_X

KEY_AD1

KEY_AD2

KEY_AD3

KEY_AD5

MULTI_JACK_IN

XRESET

XPOWER_SW

TP_SEL2

Q8002

C8006

R8015

±0.5%

C8009

C8007

470k

0.1u

0.01u

22u

6.3V

CL8005

47kR8007

R8012

R8011

100k

±0.5%

8

R8016

±0.5%

C8001

XX

2

1

4

3

6

5

8

7

RB8002

XX

2

1

4

3

6

5

8

7

RB8009

1k

1M

±0.5%

C8018

0.01u

47k

XX

C8002

C8015

0.01u

C8019

XX

C8003

CL8008

CL8009

XX

XX

C8024

1234567

RB8013

1k

8

BATT/XEXT

TP_X

TP_Y

C8025

0

NON

CRADLE

model

H6G6J7H7J8J9H8H9G9G8F8F9F7D7J1H2

MULTI_JACK_IN_CRADLE

R8031

CRADLE

100k

model

R8047

1k

TP_X

TP_Y

BATT_SENSE

ACV_SENSE

KEY_AD0

KEY_AD1

KEY_AD2

AVCC

AVSS

KEY_AD3

KEY_AD4

KEY_AD5

MULTI_JACK_AD

XRSTX

DD CON

TP_SEL2

C8008

0.01u

R8014

CL8007

10M

RB8004

C8013

C8010

9p

10p

X8001

32.768kHz

R8017

0

N.C.

VSS

VDD

32MHz_IN

32MHz_OUT

MULTI_JACK_CRA_AD

IC8001

MB89F083LGA-G-122-ERE1

XBATTINFO_SW

DIAL_B/TP_SEL1

XEJECT_SW

XCCDOWN_SW

XMODE_SW

XPOWER_SW

B8 A8 B7 A7 B6 A6 C6 B5 B4 C4 A3 B3 A4 A5 A2 A1

8

1k

XMODE_SW

XBATT_INFO_SW

1234567

XEJECT_SW

XCC_DOWN

R8013

TP_SEL1

4700

IB_SI

IB_SO

HI CONTROL

IC8001

BATT/EXT

XLANC_POWER_ON

XLANC_PWR_ON

LANC_OUT

CL8001

TEST_OUT

XPLAY_LED

XVTR_LED

LANC_IN

INIT_CHARGE_ON

LANC_IN

LANC_OUT

XCAM_LED

XFTALLY_LED

CL8003

XCHARGE_LED

XCAM_LED

XLANC_ON

FAST_CHARGE

INIT_CHARGE

FAST_CHARGE

GND

XCHARGE_LED

CL8004

VTR_DD_ON

XLANC_ON

VTR_DD_ON

XMEM_LED

VDD

CL8006

VOUT

SSM6L16FE(TPLR3)

BATTERY CHARGE

C9D8D9E8E9F3F2F1G1G2H1H5J5J4H4J6

XLANC_JACK_IN

XTO_HI_CS

TO_HI_SCK

TO_HI_SO

FR_EVER_SCK

FR_EVER_SO

TO_HIDVOUT

XSYS_REST

N.C.

DETECTOR

XHI_MAD

SYS_V

BATT_IN

FM_HI_SI

XCS_DD

Q8001

TEST

TEST

CP0

VCI

0.2

BATT_SIG

2.8 0.2