Sony GV-D800E, GV-D800, GV-D200E, GV-D200 Service Manual

GV-D200/D200E/D800/D800E

SERVICE MANUAL

Ver 1.0 2000. 09

Photo : GV-D800E

NTSC MODEL : GV-D200/D800

PAL MODEL : GV-D200E/D800E

Function difference table

Model

Function

LCD

GV-D200/200E

—

VCR

System

Video recording system

2 rotary heads

Helical scanning system

Audio recording system

Rotary heads, PCM system

Quantization: 12 bits (Fs 32 kHz,

stereo 1, stereo 2), 16 bits (Fs 48 kHz,

stereo)

Video signal

GV-D200/D800:

NTSC color, EIA standards

GV-D200E/D800E:

PAL colour, CCIR standards

Recommended cassette

Hi8

Recording/playback time

(GV-D200/D800: using

120 min. Hi8 video cassette)

(GV-D200E/D800E: using

90 min. Hi8 (PAL) video cassette)

SP mode: 1 hour

LP mode: 1 hour and 30 minutes

Fastforward/rewind time

(GV-D200/D800: using

120 min. Hi8 video cassette)

(GV-D200E/D800E: using

90 min. Hi8 (PAL) video cassette)

Approx. 5 minutes and 15 seconds

/Digital8 video cassette

GV-D800/D800E

4.0 inches

SPECIFICATIONS

Input/output

connectors

S video input

4-pin mini DIN

Luminance signal: 1 Vp-p, 75 ohms,

unbalanced

GV-D200/D800:

Chrominance signal: 0.286 Vp-p

GV-D200E/D800E:

Chrominance signal: 0.3 Vp-p,

75 ohms, unbalanced

S video output

4-pin mini DIN

Luminance signal: 1 Vp-p, 75 ohms,

unbalanced

GV-D200/D800:

Chrominance signal: 0.286 Vp-p

GV-D200E/D800E:

Chrominance signal: 0.3 Vp-p,

75 ohms, unbalanced

Audio/Video input

AV MINIJACK

Video: 1 Vp-p, 75 ohms, unbalanced,

sync negative

Audio: 327 mV, input impedance

more than 47 kiloohms

Video output

Phono jack, 1 Vp-p, 75 ohms,

unbalanced, sync negative

Audio output

Phono jacks (2) 327 mV, output

impedance less than 1 kiloohm

RFU DC OUT

Special minijack DC 5 V

DV input/output

4-pin connector

Headphone jack

Stereo minijack (ø 3.5 mm)

LANC

Stereo mini-minijack (ø 2.5 mm)

LCD screen (GV-D800/D800E)

Picture

4.0 type

80.6 × 60.5 mm (3 1/4 × 2 1/2 in.)

Total dot number

123,200 (560 × 220)

General

Power requirements

7.2 V (battery pack)

8.4 V (AC power adaptor)

Average power consumption

(when using the battery pack)

GV-D800/D800E only

During playback using LCD

4.9 W

During playing back when you close

the LCD panel

3.0 W

Operating temperature

0 °C to 40 °C (32 °F to 104 °F)

Storage temperature

–20 °C to +60 °C (–4 °F to +140 °F)

jack

US Model

Canadian Model

GV-D200/D800

AEP Model

UK Model

E Model

GV-D200E/D800E

B MECHANISM

For MECHANISM ADJUSTMENT, refer to

the “8mm Video MECHANICAL

ADJUSTMENT MANUAL

Dimensions (Approx.)

GV-D200/D200E:

148 × 50 × 135 mm

(5 7/8 × 2 × 5 3/8 in.)

GV-D800/D800E:

148 × 65 × 135 mm

(5 7/8 × 2 5/8 × 5 3/8 in.) (w/h/d)

Mass (approx.)

GV-D200/D200E:

660 g (1 lb 7 oz)

GV-D800/D800E:

930 g (2 lb)

excluding the battery pack and

cassette

Supplied accessories

See page 2.

AC power adaptor

Power requirements

100 - 240 V AC, 50/60 Hz

Power consumption

23 W

Output voltage

DC OUT: 8.4 V, 1.5 A in the

operating mode

Operating temperature

0 °C to 40 °C (32 °F to 104 °F)

Storage temperature

–20 °C to +60 °C (–4 °F to +140 °F)

” (9-973-801-11).

— Continued on next page —

DIGITAL VIDEO CASSETTE RECORDER

Dimensions (approx.)

125 × 39 × 62 mm

(5 × 1 9/16 × 2 1/2 in.) (w/h/d)

excluding projecting parts

Mass (approx.)

280 g (9.8 oz) excluding power cord

Cord length (approx.)

Power cord: 2 m (6.6 feet)

Connecting cord: 1.6 m (5.2 feet)

Design and specifications are subject

to change without notice.

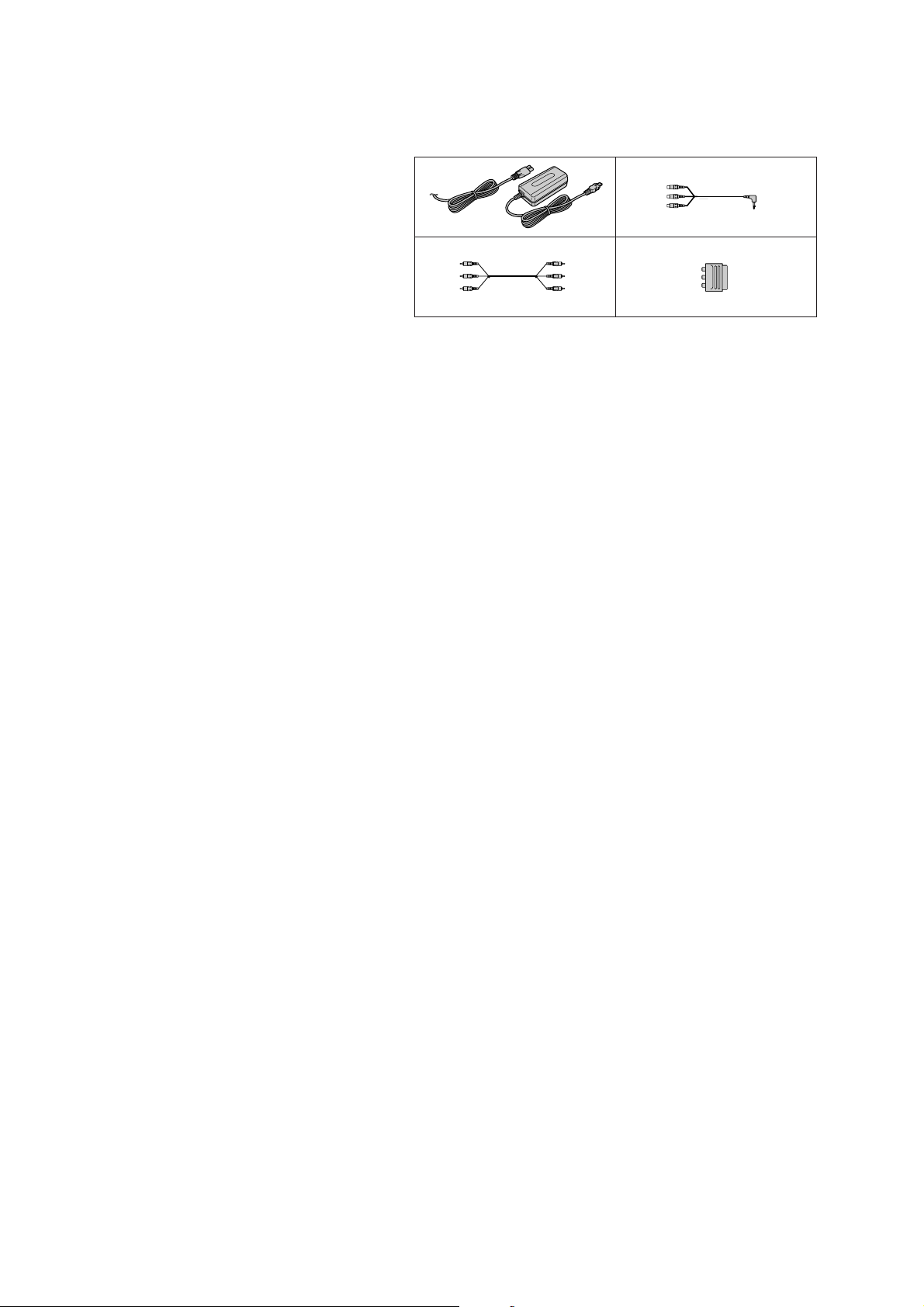

• SUPPLIED ACCESSORIES

Make sure that the following accessories are supplied with your VCR.

21

43

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

1 AC-L10A/L10B/L10C AC power adaptor (1),

Mains lead (1)

23A/V converting cable (1)

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

A/V connecting cable (1)

4 21-pin adaptor (1)

GV-D200E/D800E only

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

TABLE OF CONTENTS

SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS ····························· 6

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) (1) ·························································· 6

3. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) (2)

(TO TAKE OUT A CASSETTE WITHOUT

HURTING THE TAPE) ······················································ 7

SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION······································· 8

2. SELF-DIAGNOSIS DISPLAY ·········································· 8

3. SERVICE MODE DISPLAY ············································· 8

3-1. Display Method ·································································· 8

3-2. Switching of Backup No. ··················································· 8

3-3. End of Display····································································8

4. SELF-DIAGNOSIS CODE TABLE ···································9

2-4. PD-130, LS-56 BOARDS (D800, D800E MODEL) ······2-4

2-5. LCD WINDOW CABINET ASSEMBLY (SP-901, 902)

(D800, D800E MODEL) ·················································2-5

2-6. BATTERY PANEL ASSEMBLY, BATTERY TERMINAL

BOARD, DC-IN CONNECTOR·····································2-6

2-7. VC-250, FU-145 BOARDS·············································2-6

2-8.

CONTROL SWITCH BLOCK (FK-78), LOADING LID ··

2-9. MECHANISM DECK, MAIN FRAME ASSEMBLY ···2-7

2-10. CABINET (R) BLOCK ASSEMBLY, JACK FRAME

(IO-68, IR-38 BOARDS) ················································2-8

2-11. EX-36 BOARD, FP-570 FLEXIBLE BOARD···············2-9

2-12. UPPER CABINET ASSEMBLY,

LCD BLOCK ASSEMBLY (D800, D800E MODEL)····2-9

2-13. HINGE UNIT, FP-569 FLEXIBLE BOARD

(D800, D800E MODEL) ···············································2-10

2-14. CIRCUIT BOARDS LOCATION ·································2-12

2-15. FLEXIBLE BOARDS LOCATION ······························2-13

2-7

1. GENERAL

Getting started

Using this manual ··································································1-1

Checking supplied accessories ··············································1-1

Step 1 Preparing the power supply ········································1-1

Connecting to the mains ····················································· 1-1

Using with a battery pack (not supplied) ···························· 1-2

Step 2 Inserting a cassette····················································· 1-2

Basic operations

Playing back a tape ······························································· 1-3

Viewing the recording on TV ················································1-4

Recording from the other VCR or TV ···································1-5

Advanced operations

Enlarging playback images – PB ZOOM ······························1-6

Watching a tape with special effects – Picture effect·············1-7

Watching a tape with special performances – Digital effect··1-7

Quickly locating a scene – Zero set memory·························1-8

Searching with recording date – Date search ························1-8

Searching for a photo – Photo search/Photo scan··················1-9

Displaying recording data and screen indicators

– Data code function ······························································1-9

Superimposing a title ···························································1-10

Making your own titles ························································1-10

Editing

Dubbing a tape ·····································································1-11

Dubbing only desired scenes – Digital program editing ·····1-12

Using with an analogue video unit and a personal computer

– Signal convert function·····················································1-15

Inserting a scene from the other (playback) VCR

– Insert Editing ····································································1-15

Customizing your VCR

Changing the menu settings·················································1-16

Resetting the date and time··················································1-17

Additional information

Digital8

About i.LINK·······································································1-19

Troubleshooting ···································································1-19

Self-diagnosis display ··························································1-20

Warning indicators and messages ········································1-20

Using your VCR abroad ······················································ 1-21

Maintenance information and precautions···························1-21

Quick reference

Identifying the parts and controls ········································ 1-22

system, recording, and playback·······················1-18

2. DISASSEMBLY

2-1. CASSETTE LID ASSEMBLY ········································2-2

2-2. BOTTOM CABINET ASSEMBLY, FP-571 FLEXIBLE

BOARD (LITHIUM BATTERY) ····································2-2

2-3.

LCD CABINET ASSEMBLY (D800, D800E MODEL)··

2-3

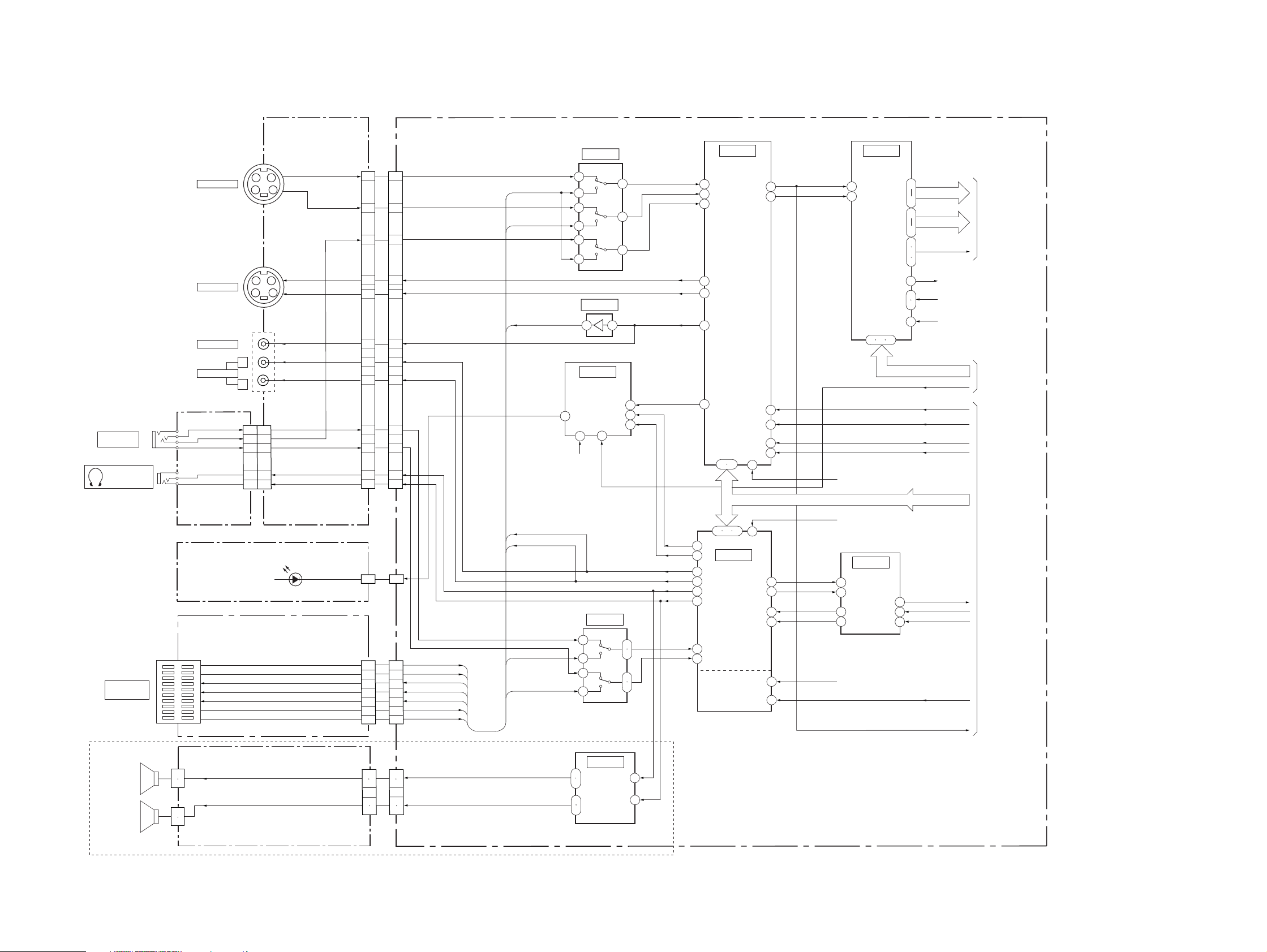

3. BLOCK DIAGRAMS

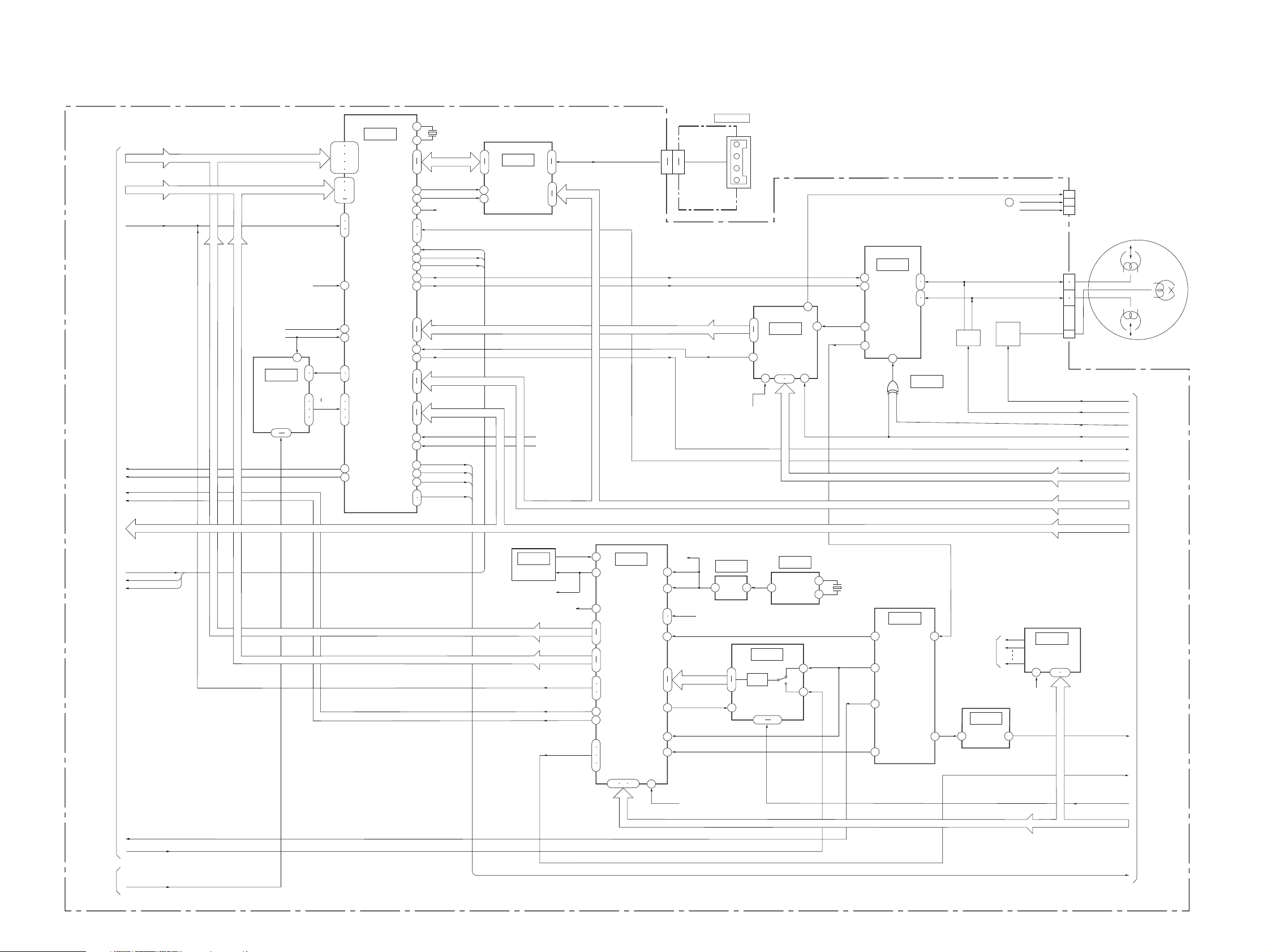

3-1. OVERALL BLOCK DIAGRAM (1/4) ···························3-1

3-2. OVERALL BLOCK DIAGRAM (2/4) ···························3-3

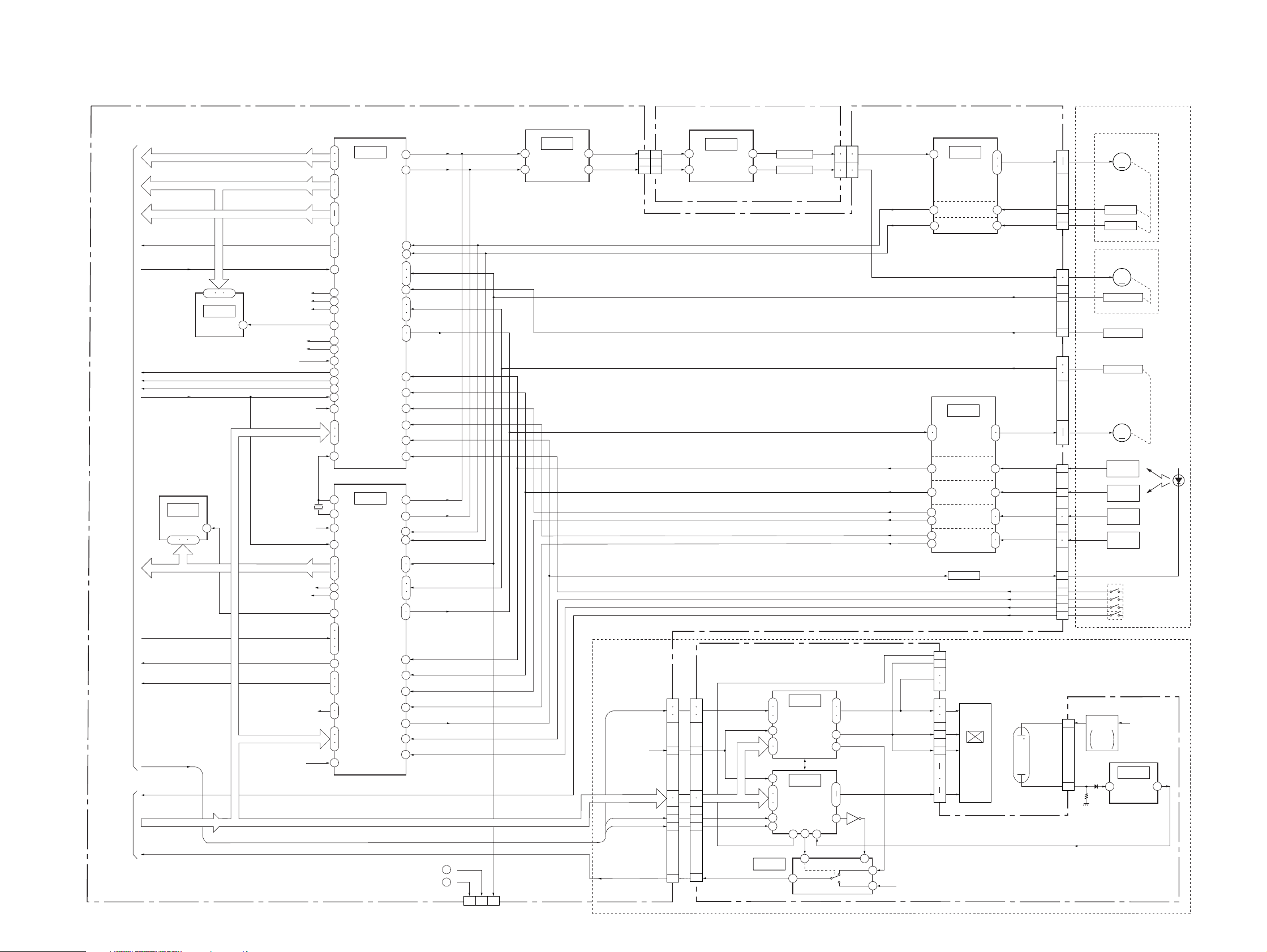

3-3. OVERALL BLOCK DIAGRAM (3/4) ···························3-5

3-4. OVERALL BLOCK DIAGRAM (4/4) ···························3-7

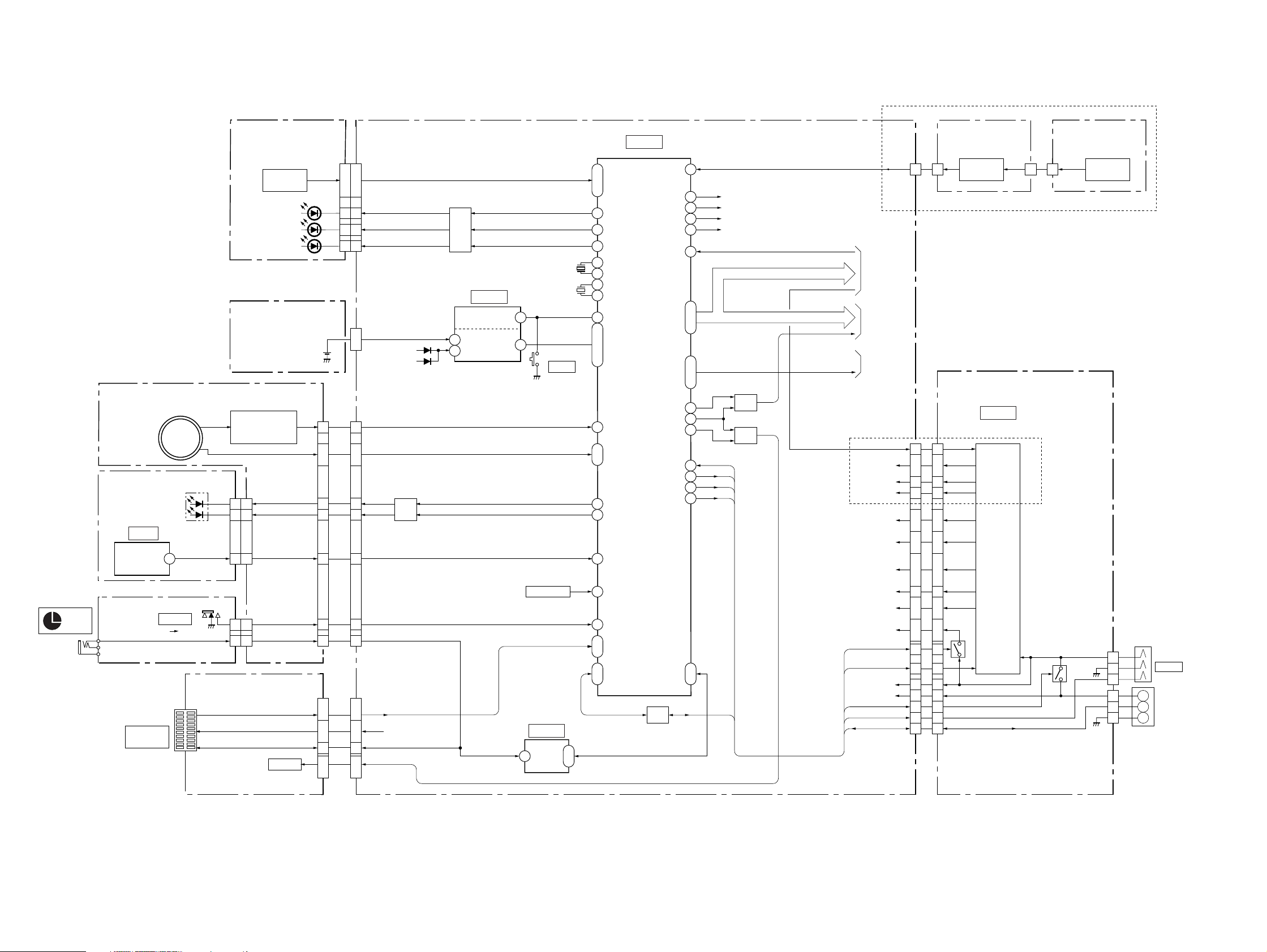

3-5. POWER BLOCK DIAGRAM (1/2)································3-9

3-6. POWER BLOCK DIAGRAM (2/2)······························3-11

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

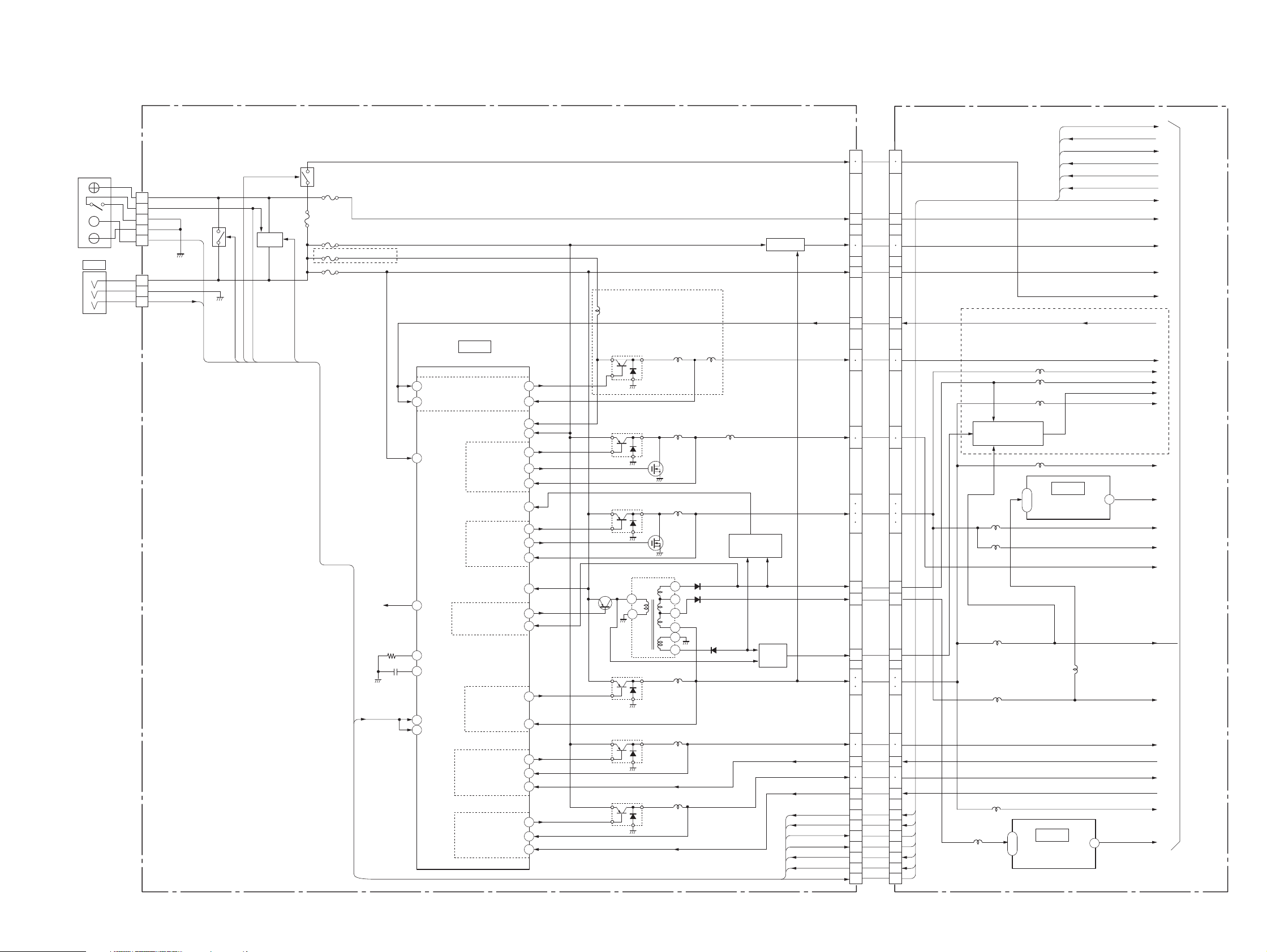

4-1. FRAME SCHEMATIC DIAGRAM (1/2)·······················4-1

FRAME SCHEMATIC DIAGRAM (2/2)·······················4-3

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS ············································4-5

• VC-250 (REC/PB AMP, DAC, DV INTERFACE,

AD CONVERTER, Y/C PROCESSOR, LINE A/D,

LINE I/O, IR, AUDIO I/O, DRUM/CAPSTAN

MOTOR DRIVE, MECHA CONTROL, HI CONTROL,

DC/DC CONVERTER, CONNECTION)

PRINTED WIRING BOARD ·························4-7

• VC-250 (REC/PB AMP)(1/16)

SCHEMATIC DIAGRAM····························4-11

• VC-250 (PB AMP, DAC)(2/16)

SCHEMATIC DIAGRAM····························4-13

• VC-250 (DV INTERFACE)(3/16)

SCHEMATIC DIAGRAM····························4-15

• VC-250 (DV INTERFACE)(4/16)

SCHEMATIC DIAGRAM····························4-17

• VC-250 (AD CONVERTER)(5/16)

SCHEMATIC DIAGRAM····························4-19

• VC-250 (Y/C PROCESSOR)(6/16)

SCHEMATIC DIAGRAM····························4-21

• VC-250 (LINE A/D)(7/16)

SCHEMATIC DIAGRAM····························4-23

• VC-250 (LINE IN/OUT)(8/16)

SCHEMATIC DIAGRAM····························4-25

• VC-250 (IR)(9/16)

SCHEMATIC DIAGRAM····························4-27

• VC-250 (MECHANISM CONTROL)(10/16)

SCHEMATIC DIAGRAM····························4-29

• VC-250 (AUDIO I/O)(11/16)

SCHEMATIC DIAGRAM····························4-31

• VC-250 (DRUM/CAPSTAN MOTOR DRIVE)(12/16)

SCHEMATIC DIAGRAM····························4-33

• VC-250 (MECHA CONTROL)(13/16)

SCHEMATIC DIAGRAM····························4-35

• VC-250 (HI CONTROL)(14/16)

SCHEMATIC DIAGRAM····························4-37

— 3 —

• VC-250 (DC/DC CONVERTER)(15/16)

SCHEMATIC DIAGRAM····························4-39

• VC-250 (CONNECTION)(16/16)

SCHEMATIC DIAGRAM····························4-41

• FP-575 (LANC), IO-68 (AV IN/OUT)

PRINTED WIRING BOARDS ·····················4-43

• IO-68 (AV IN/OUT)

SCHEMATIC DIAGRAM····························4-45

• FU-145 (DC/DC CONVERTER)

PRINTED WIRING BOARD ·······················4-47

• FU-145 (DC/DC CONVERTER)

SCHEMATIC DIAGRAM····························4-49

• PD-130 (LCD DRIVER, BACK-LIGHT)

PRINTED WIRING BOARD ·······················4-51

• LS-56 (LCD SWITCH)

PRINTED WIRING BOARD ·······················4-54

• PD-130 (LCD DRIVER, BACK-LIGHT)(1/2)

SCHEMATIC DIAGRAM····························4-55

• PD-130 (BACK-LIGHT)(2/2)

SCHEMATIC DIAGRAM····························4-57

• IR-38 (IR TRANSMITTER),

CONTROL SWITCH BLOCK (FK-78)

PRINTED WIRING BOARDS ·····················4-59

• CONTROL SWITCH BLOCK (FK-78)

SCHEMATIC DIAGRAM····························4-61

• EX-36 (MULTI CONNECTOR)

PRINTED WIRING BOARD ·······················4-63

• EX-36 (MULTI CONNECTOR)

SCHEMATIC DIAGRAM····························4-65

• FP-571 (BATTERY), FP-249 (S/T REEL)

PRINTED WIRING BOARDS ·····················4-67

4-3. WAVEFORMS ······························································4-68

4-4. MOUNTED PARTS LOCATION ·································4-70

5. ADJUSTMENTS

1. Before starting adjustment···············································5-1

1-1. Adjusting items when replacing main parts and boards.·5-2

5-1. ADJUSTMENT PREPARATIONS·································5-3

1-1. PREPARATIONS BEFORE ADJUSTMENT·················5-3

1-1-1.List of Service Tools ························································5-3

5-2. MECHANISM SECTION ADJUSTMENT····················5-4

2-1. Hi8/STANDARD8 MODE··············································5-4

2-1-1.OPERA TING WITHOUT CASSETTE ··························5-4

2-1-2.TAPE PATH ADJUSTMENT··········································5-4

1. Preparations for Adjustment············································ 5-4

2-2. DIGITAL8 MODE ··························································5-5

2-2-1.HOW TO ENTER RECORD MODE WITHOUT

CASSETTE ····································································· 5-5

2-2-2.HOW TO ENTER PLAYBACK MODE WITHOUT

CASSETTE ····································································· 5-5

2-2-3.OVERALL TAPE PATH CHECK ···································5-5

1. Recording of the tape path check signal·························· 5-5

2. Tape path check ······························································· 5-5

5-3. ELECTRICAL ADJUSTMENT······································5-6

3-1. PREPARATIONS BEFORE ADJUSTMENTS ·············· 5-6

3-1-1.Equipment to Required····················································5-6

3-1-2.Precautions on Adjusting·················································5-7

3-1-3.Adjusting Connectors ······················································5-7

3-1-4.Connecting the Equipment ·············································· 5-8

3-1-5.Alignment Tape ·······························································5-9

3-1-6.Input/output Level and Impedance ································5-10

3-2. INITIALIZATION OF C, D, E, F, 7, 8 PAGE DATA ···5-11

3-2-1.INITIALIZATION OF C, D, 8 PAGE DATA ················5-11

1. Initializing the C, D, 8 Page Data··································5-11

2. Modification of C, D, 8 Page Data ································5-11

3. C Page Table ··································································5-11

4. D Page Table··································································5-12

5. 8 Page Table···································································5-13

3-2-2.INITIALIZATION OF E, F, 7 PAGE DATA ·················5-14

1. Initializing the E, F, 7 Page Data ···································5-14

2. Modification of E, F, 7 Page Data ·································5-14

3. F Page Table ··································································5-14

4. E Page Table ··································································5-15

5. 7 Page Table···································································5-16

3-3. SYSTEM CONTROL SYSTEM ADJUSTMENT········5-17

1. Serial No. Input ·····························································5-17

1-1. Company ID Input·························································5-17

1-2. Serial No. Input ·····························································5-17

2. Battery End Adjustment ················································5-19

3-4. SERVO AND RF SYSTEM ADJUSTMENT ···············5-20

1. REEL FG Adjustment (VC-250 Board) ························5-20

2. PLL fo & LPF fo Pre-Adjustment (VC-250 Board)······5-20

3. Switching Position Adjustment (VC-250 Board)··········5-21

4. AGC Center Level and APC & AEQ Adjustment ·········5-21

4-1. Preparations before adjustments····································5-21

4-2. AGC Center Level Adjustment (VC-250 Board) ··········5-21

4-3. APC & AEQ Adjustment (VC-250 Board) ···················5-22

4-4. Processing after Completing Adjustments ···················· 5-22

5. PLL fo & LPF fo Final Adjustment (VC-250 Board) ···5-23

6. Hi8/Standard8 Switching Position Adjustment

(VC-250 Board)·····························································5-23

7. CAP FG Offset Adjustment (VC-250 board) ················5-24

3-5. VIDEO SYSTEM ADJUSTMENTS·····························5-25

1.

27MHz Origin Oscillation Adjustment (VC-250 board) ··

2. Chroma BPF fo Adjustment (VC-250 Board)···············5-25

3. S VIDEO OUT Y Level Adjustment (VC-250 Board) ··5-26

4. S VIDEO OUT Chroma Level Adjustment

(VC-250 Board)·····························································5-26

5.

VIDEO OUT Y, Chroma Level Check (VC-250 Board) ··

Hi8/Standard8 Y/C Output Level Setting (VC-250 Board)·

6.

7.

Hi8/standard 8mm AFC fo Adjustment (VC-250 board) ··

3-6. IR TRANSMITTER ADJUSTMENTS·························5-29

1.

IR Video Carrier Frequency Adjustment (VC-250 board)··

2. IR Video Deviation Adjustment (VC-250 board) ··········5-29

3. IR Audio Deviation Adjustment (VC-250 board) ·········5-30

3-7. AUDIO SYSTEM ADJUSTMENTS ····························5-31

1.

Hi8/Standard8 AFM BPF fo Adjustment (VC-250 board)··

2. Hi8/Standard8 AFM 1.5 MHz Deviation Adjustment

(VC-250 board) ·····························································5-32

3. Hi8/Standard8 AFM 1.7 MHz Deviation Adjustment

(VC-250 board) ·····························································5-32

4. Digital8 Playback Level Check ·····································5-32

5. Overall Level Characteristics Check ·····························5-32

6. Overall Distortion Check···············································5-32

7. Overall Noise Level Check············································5-33

8. Overall Separation Check·············································· 5-33

3-8. LCD SYSTEM ADJUSTMENT (GV-D800/D800E) ···5-34

1. LCD Initial Data Input (1)·············································5-34

2. LCD Initial Data Input (2)·············································5-35

3. VCO Adjustment (PD-130 board)·································5-35

4. RGB AMP Adjustment (PD-130 board)························5-36

5. Contrast Adjustment (PD-130 board)····························5-36

6. COM AMP Adjustment (PD-130 board)·······················5-37

7. V-COM Adjustment (PD-130 board) ····························5-37

8. White Balance Adjustment (PD-130 board)··················5-38

5-4. SERVICE MODE··························································5-39

4-1. ADJUSTMENT REMOTE COMMANDER ················5-39

1. Using the Adjustment Remote Commander··················5-39

2. Precautions Upon Using the Adjustment Remote

Commander ··································································· 5-39

4-2. DATA PROCESS···························································5-40

4-3. SERVICE MODE··························································5-41

1. Setting the Test Mode ····················································5-41

2. Emergence Memory Address ········································5-41

5-25

5-27

5-27

5-28

5-29

5-31

— 4 —

2-1. C Page Emergence Memory Address ····························5-41

2-2. F Page Emergence Memory Address ····························5-42

2-3. EMG Code (Emergency Code) ·····································5-42

2-4. MSW Code ····································································5-43

3. Bit V alue Discrimination ···············································5-44

4. Switch check (1) ····························································5-44

5. Switch check (2) ····························································5-44

6. Switch check (3) ····························································5-44

7. Switch check (4) ····························································5-45

8. Record of Use check······················································5-45

9. Record of Self-diagnosis check ·····································5-46

6. REPAIR PARTS LIST

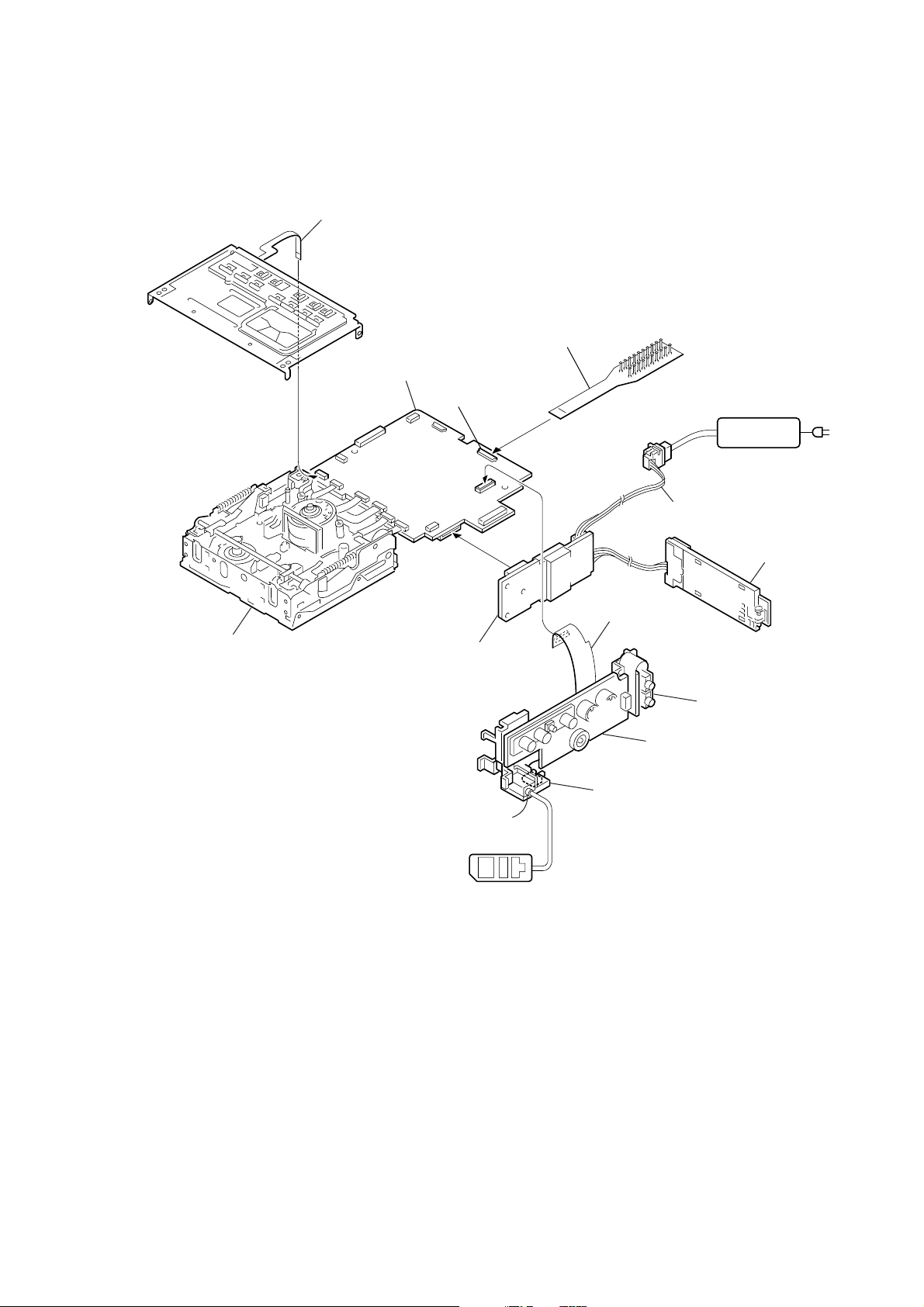

6-1. EXPLODED VIEWS ······················································6-1

6-1-1.OVERALL SECTION-1 ················································· 6-1

6-1-2.OVERALL SECTION-2 ················································· 6-2

6-1-3.LCD SECTION (D800/D800E MODEL) ·······················6-3

6-1-4.MECHANISM SECTION···············································6-4

6-1-5.CASSETTE COMPARTMENT ASSEMBLY ················6-5

6-1-6.LS CHASSIS ASSEMBLY ·············································6-6

6-1-7.MECHANISM CHASSIS ASSEMBLY ························· 6-7

6-2. ELECTRICAL PARTS LIST ··········································6-8

— 5 —

SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied (8.4V) to the battery terminal using the service power code (J-6082-223-A), the power

is shut off so that the unit cannot operate.

These following two methods are available to prevent this. Take note of which to use during repairs.

Method 1:

Connect the adjustment remote commander RM-95 (J-6082-053-B) to the LANC jack, and set the HOLD switch to the “ADJ” side.

Method 2:

Use the DC IN terminal. (Use the AC power adaptor. (AC-L10, AC-VQ800 etc.))

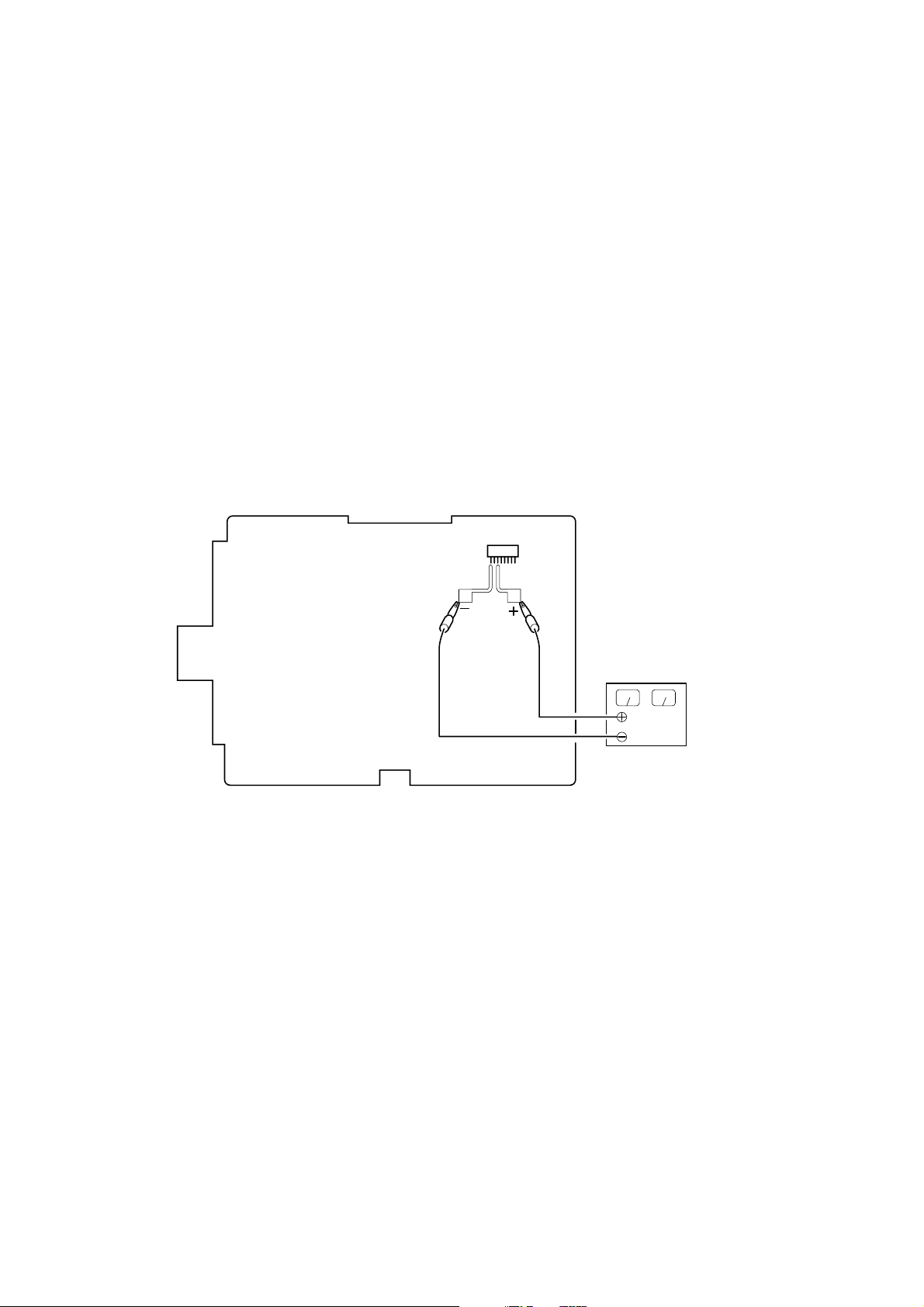

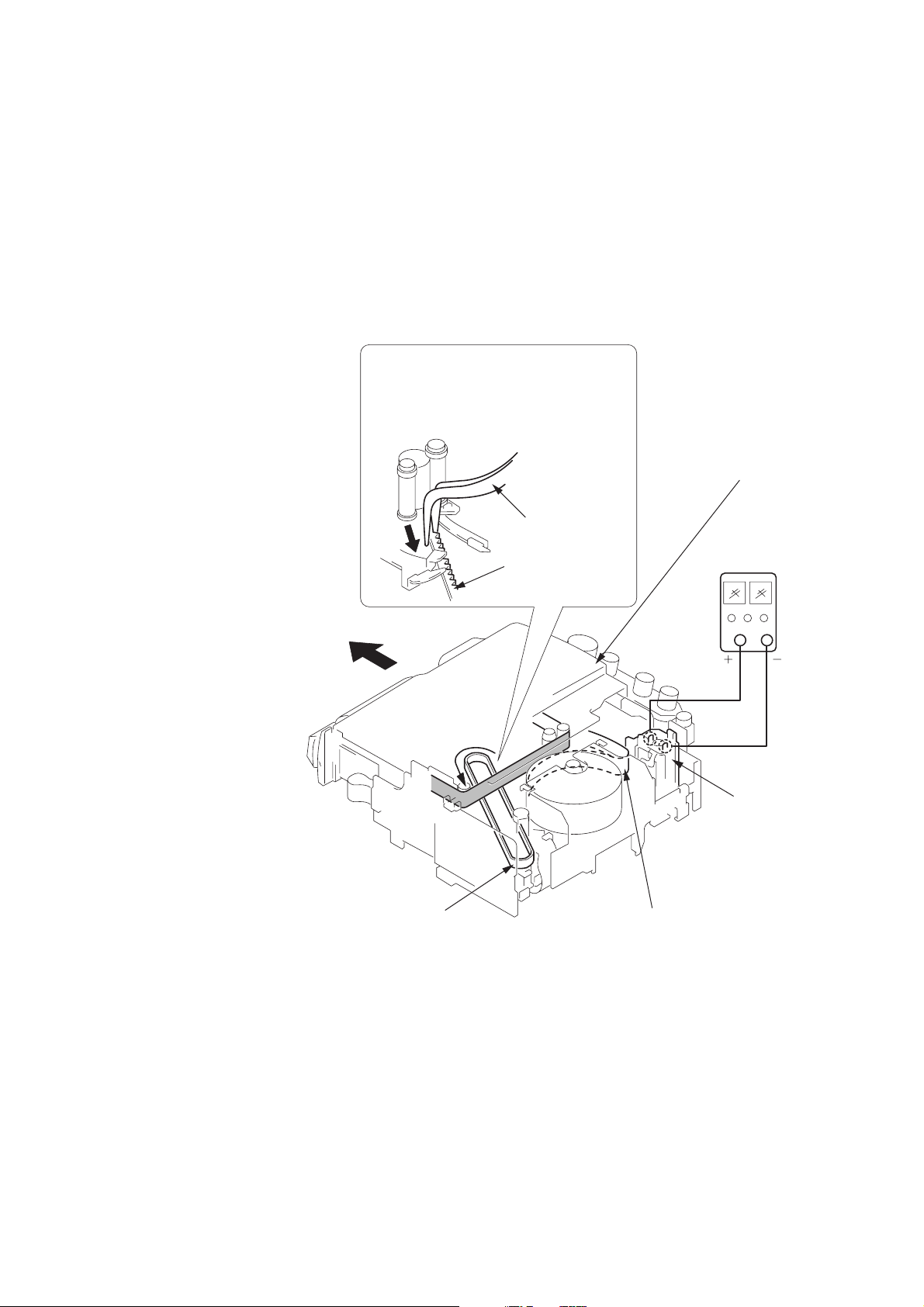

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT) (1)

1 Remove the power supply (Battery or AC power adaptor).

2 Push the EJECT switch and open the cassette lid.

3 Refer to 2-2. to remove the cabinet (lid) assembly.

4 Refer to 2-2. to remove the cabinet (bottom) assembly.

5 Add 5V from the regulated power supply between Pin 5, 6 of CN4401 (ULD5V +) and Pin 7, 8 of CN4401 (ULD5V –), and unload

the cassette.

VC-250 board

CN4401

8

ULD

5V

1

Regulated

power supply (+5V)

— 6 —

3. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT) (2)

(TO TAKE OUT A CASSETTE WITHOUT HURTING THE TAPE)

1 Disconnect the power supply (Battery or AC adaptor)

2 Refer to 2-2. to remove the cabinet (lid) assembly.

3 Refer to 2-2. to remove the cabinet (bottom) assembly.

4 Refer to 2-1. to remove the Cassette (lid) assembly.

5 Refer to 2-6 to 2-8. to remove the LCD block (GV-D800/D800E only) and the cabinet (upper) assembly.

6 Remove the FU-145 board.

7 Refer to 2-9. to remove the lid frame assembly.

8 Add +5V from the regulated power supply and unload with a pressing the cassette lid.

9

Pull the timing belt in the direction of

A

arrow

the cassette lid (take care not to damage)

to adjust the bending of a tape.

with a pincette while pressing

Press the cassette lid not to rise

the cassette compartment

0

Let go your hold the cassette

lid and rise the cassette

compartment to take out a cassette.

Timing belt

Pincette

Timing belt

Regulated

power supply

(+5V)

Loading motor

Adjust the bending of a tape

— 7 —

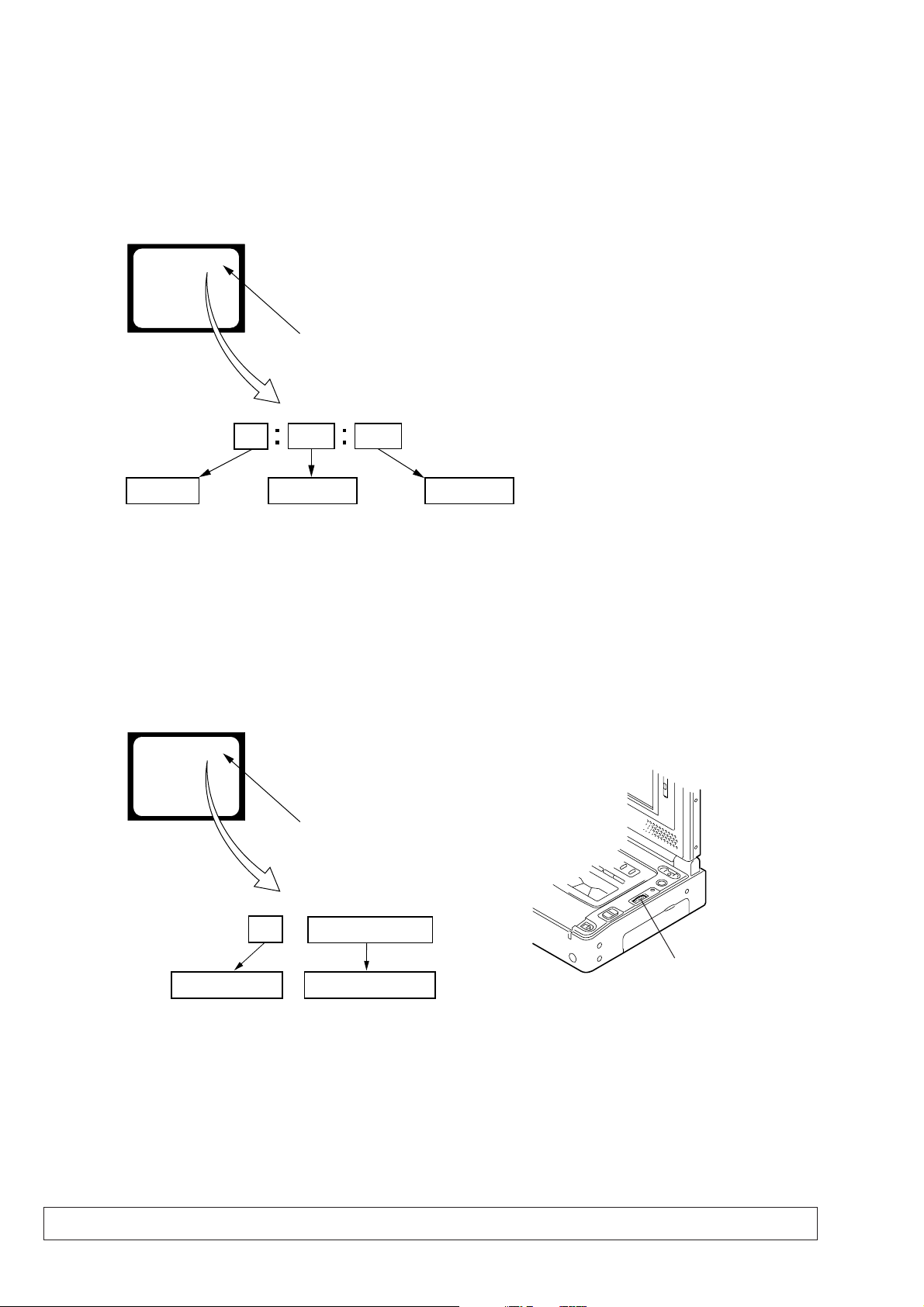

SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the LCD screen or monitor

TV (Note) what to do. This function consists of two display; selfdiagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

LCD screen or monitor TV

C : 3 1 : 1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Blinks at 3.2Hz

3 1C

Block

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn o n power again.

1 1

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder shows a 4-digit display consisting of an alphabet and

numbers, which blinks at 3.2 Hz. This 5-character display indicates

the “repaired by:”, “block” in which the problem occurred, and

“detailed code” of the problem.

Note: Set the DISPLAY in the menu system to V-OUT/LCD only for the

model with LCD screen, and press the DISPLAY button.

Detailed Code

Refer to page 9.

Self-diagnosis Code Table.

3. SER VICE MODE DISPLAY

The service mode display shows up to six self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “STOP” key , set the PO WER switch from OFF to ON, and continue pressing the “STOP” ke y for 10 seconds continuously .

The service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

LCD screen or monitor TV

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

3-2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

C : 3 1 : 1 1

Control dial

self-diagnosis codes

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis displa y” data will be backed up by the coin-type lithium battery of FP-571 flexible board. When this coin-type lithium ba ttery

is removed, the “self-diagnosis display” data will be lost by initialization.

— 8 —

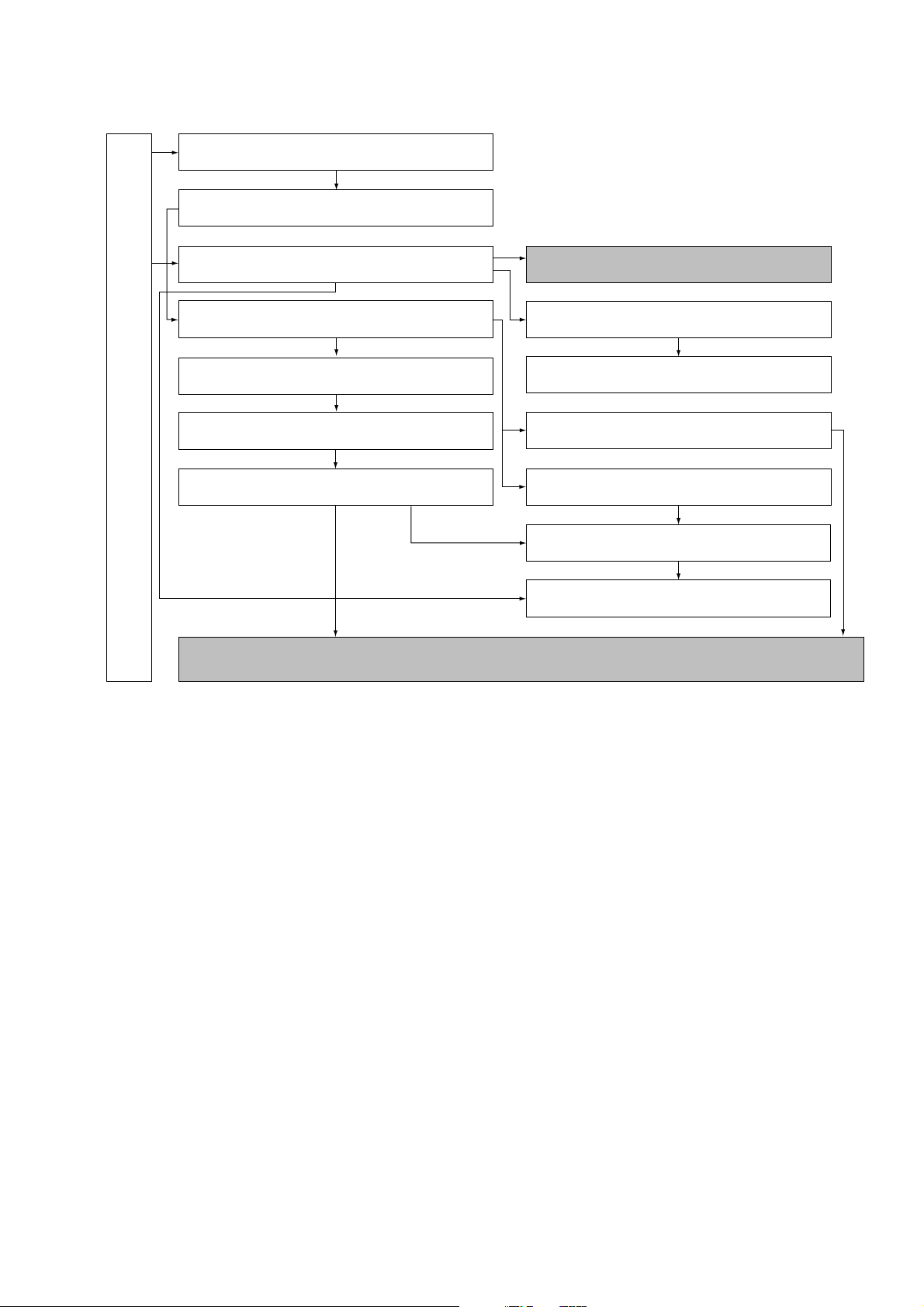

SECTION 2

DISASSEMBLY

The following flow chart shows the disassembly procedure.

2-1. Cassette Lid assembly

2-2. Bottom cabinet assembly, FP-571 flexible board

(Lithium battery)

GV-D200/D200E/D800/D800E

2-3. LCD cabinet assembly (D800, D800E model)

2-6. Battery panel assembly, Battery terminal board,

DC-IN connector

2-7. VC-250, FU-145 boards

2-9. Mechanism deck, Main frame assembly

2-10. Cabinet (R) block assembly, Jack frame

(IO-68, IR-38 boards)

GV-D200/D200E/D800/D800E

[CONNECTION DIAGRAM FOR SERVICE POSITION (Mainly for voltage measurement and check)]

(VC-250, FU-145, IO-68 boards, Mechanism deck)

PD-130 board service position

(D800, D800E model)

2-4. PD-130, LS-56 boards (D800, D800E model)

2-5. LCD window cabinet assembly (SP-901,902)

(D800, D800E model)

2-8. Control switch block (FK-78), Loading lid

2-11. EX-36 board, FP-570 flexible board

2-12. Upper cabinet assembly,

LCD block assembly (D800, D800E model)

2-13. Hinge unit , FP-569 flexible board

(D800, D800E model)

2-1

NOTE: F ollo w the disassembly procedure in the numerical order given.

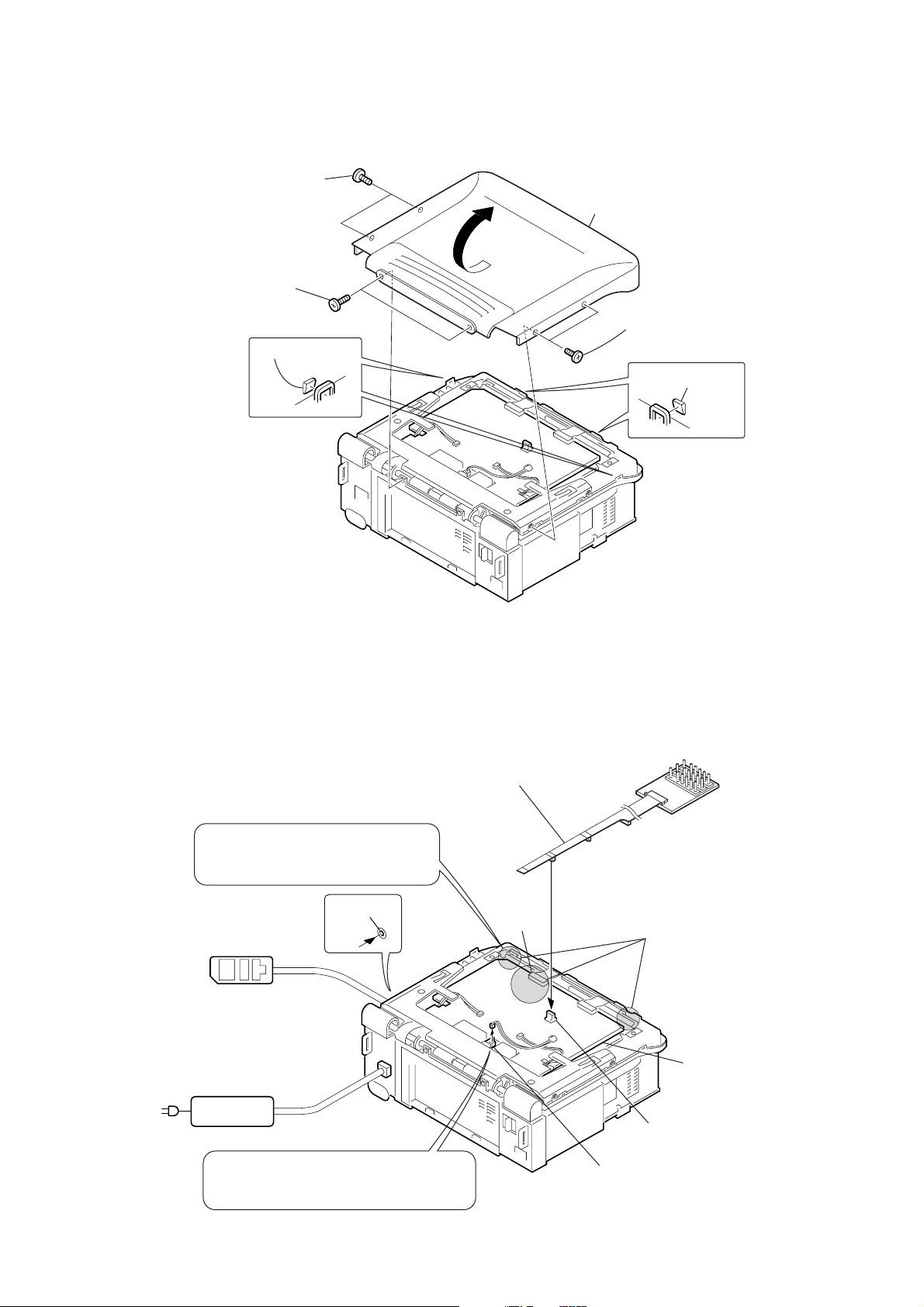

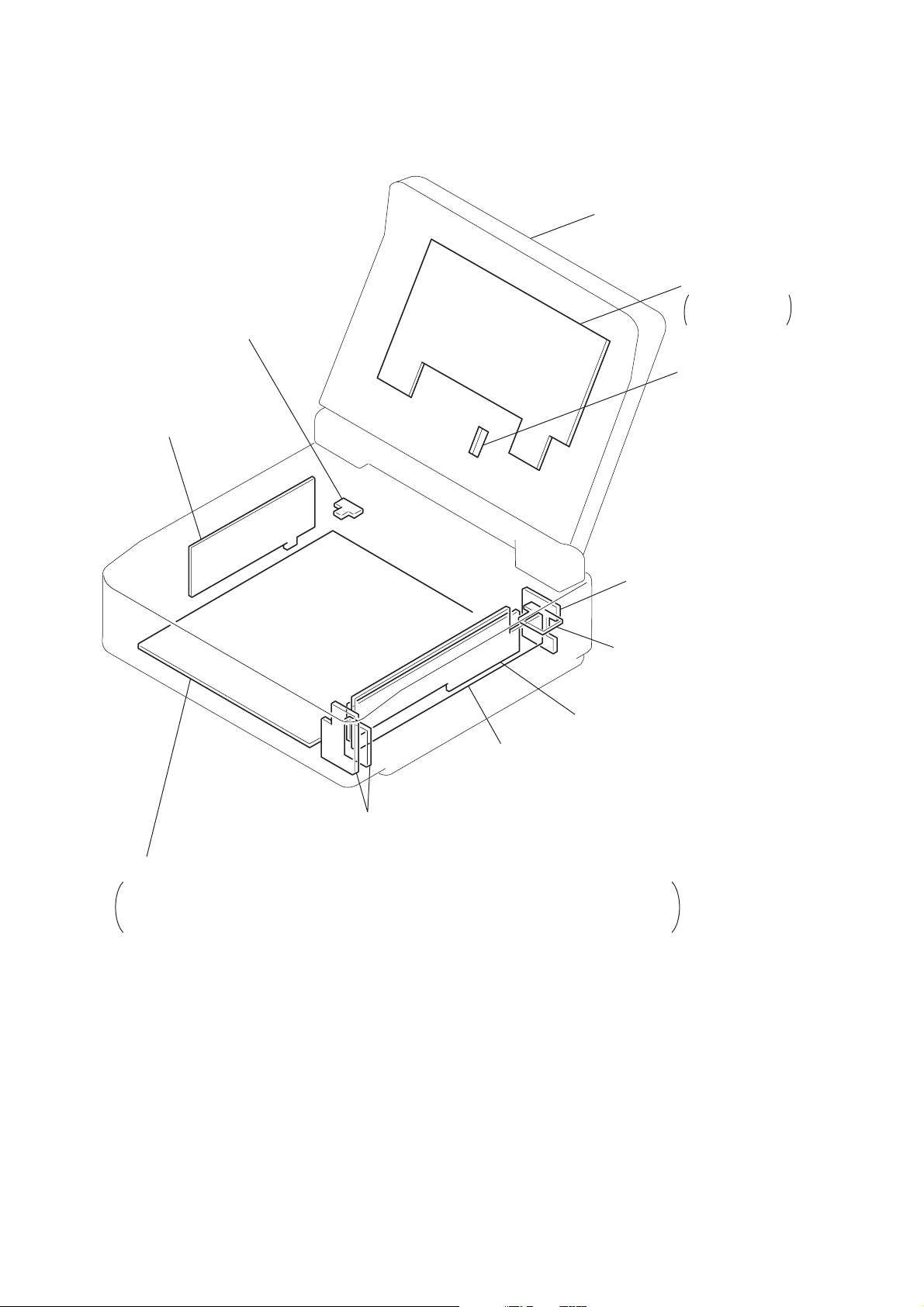

2-1. CASSETTE LID ASSEMBLY

2

Two screws (M2 × 4),

lock ace, p2

1

Open the LCD panel in the

direction of the arrow A.

(GV-D800/D800E model)

A

4

Three dowels

6

Cassette lid

assembly

Push

5

Claw

Press the cassette EJECT knob to

3

open the cassette compartment.

2-2. BOTTOM CABINET ASSEMBLY, FP-571 FLEXIBLE BOARD (LITHIUM BATTERY)

7

Bottom cabinet assembly

3

2

Press the release button to remove

the cabinet lid assembly in the

direction of the arrow

A

0

FP-571 flexible board

(4P)

Three screws (M2 × 4),

lock ace, p2

A

.

Board

VC-250

4

Two screws (M2 × 4),

lock ace, p2

6

Open the jack lid assembly

in the direction of the arrow

B

5

Screw (M2 × 4),

lock ace, p2

B

.

8

T apping screw

×

(+k 2

5)

C

9

Remove the lithium lid in the

direction of the arrow

1

Open the LCD panel little.

(GV-D800/D800E model)

C

.

2-2

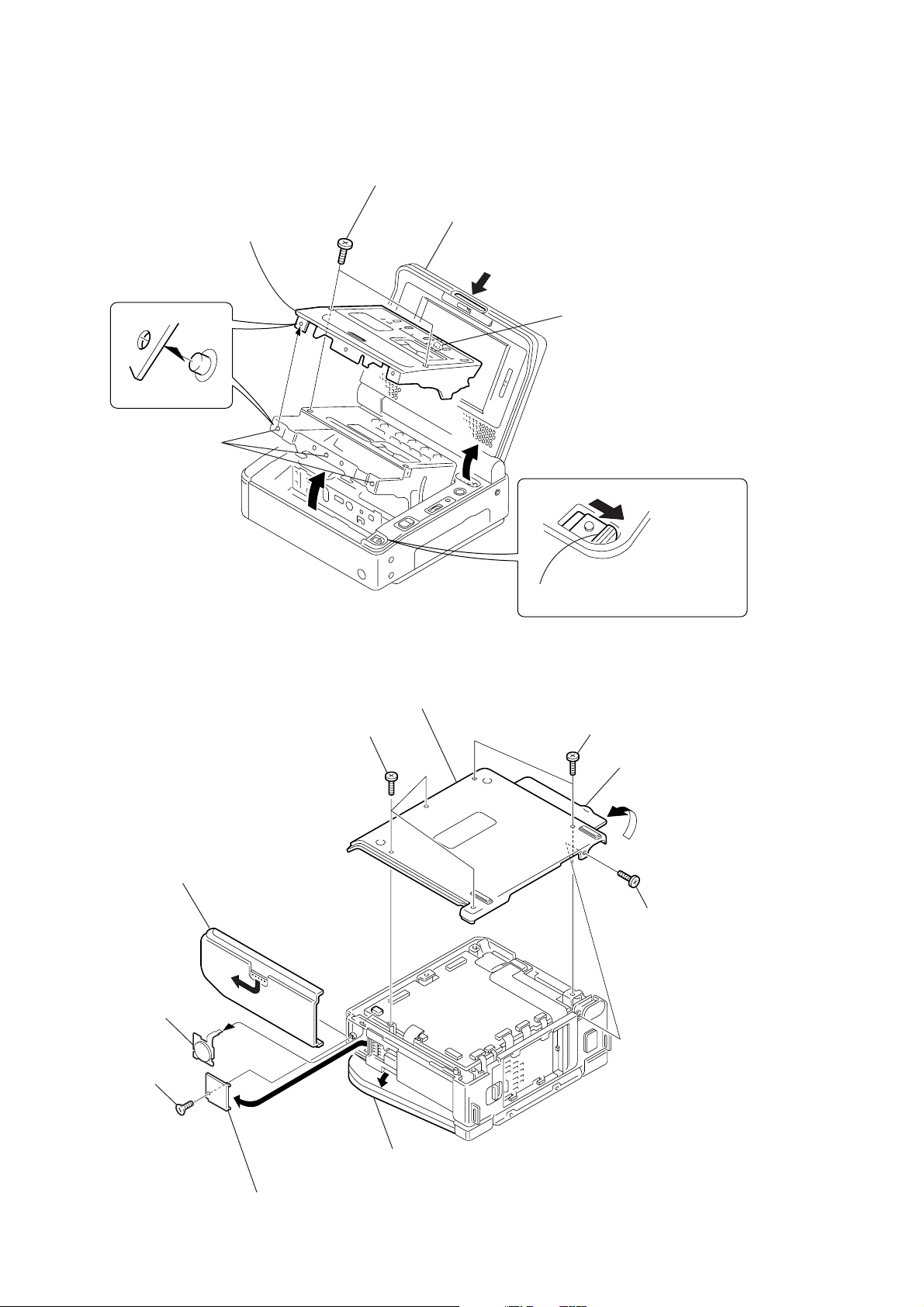

2-3. LCD CABINET ASSEMBLY (D800, D800E MODEL)

2

Two screws (M2 × 4),

lock ace, p2

3

Two screws (M2 × 3),

lock ace, p2

4

Two

claws

6

Remove the LCD cabinet assembly

in the direction of the arrow.

1

Two screws (M2 × 4),

lock ace, p2

5

Two

claws

[PD-130 BOARD SERVICE POSITION]

(D800, D800E MODEL)

Touching here is safe when the machine

is normal. However touching here can be

dangerous if defective parts exist.

LANC

jack

Adjustment remote

commander (RM-95)

AC IN

AC POWER

ADAPTOR

Multi-CPC jig

(J-6082-311-A)

CN5607

PD-130

Board

Caution

High voltage

1

2

9

10

PD-130 board

CN5502

When the hinge unit is closed to be laid down,

remove CN01 (2P) on the LS-56 board.

If not, the main power cannot be turned on.

LS-56 board

CN01 (2P)

2-3

2-4. PD-130, LS-56 BOARDS (D800, D800E MODEL)

9

Three screws (M2 × 3),

lock ace, p2

6

Two tapping screws

(B2

×

5)

PD-130

Board

7

FP-569 flexible

board (26, 32P)

0

Remove the PD-130 board

in the direction of the arrow.

3

Harness (PL-53) (2P)

8

Harness (EP-51) (2P)

qs

LS-56 board, LS bracket

qa

Screw (M2 × 3),

lock ace, p2

1

SP902 (2P)

4

ND901 (10P)

5

LCD901 (24P)

2

SP901 (2P)

2-4

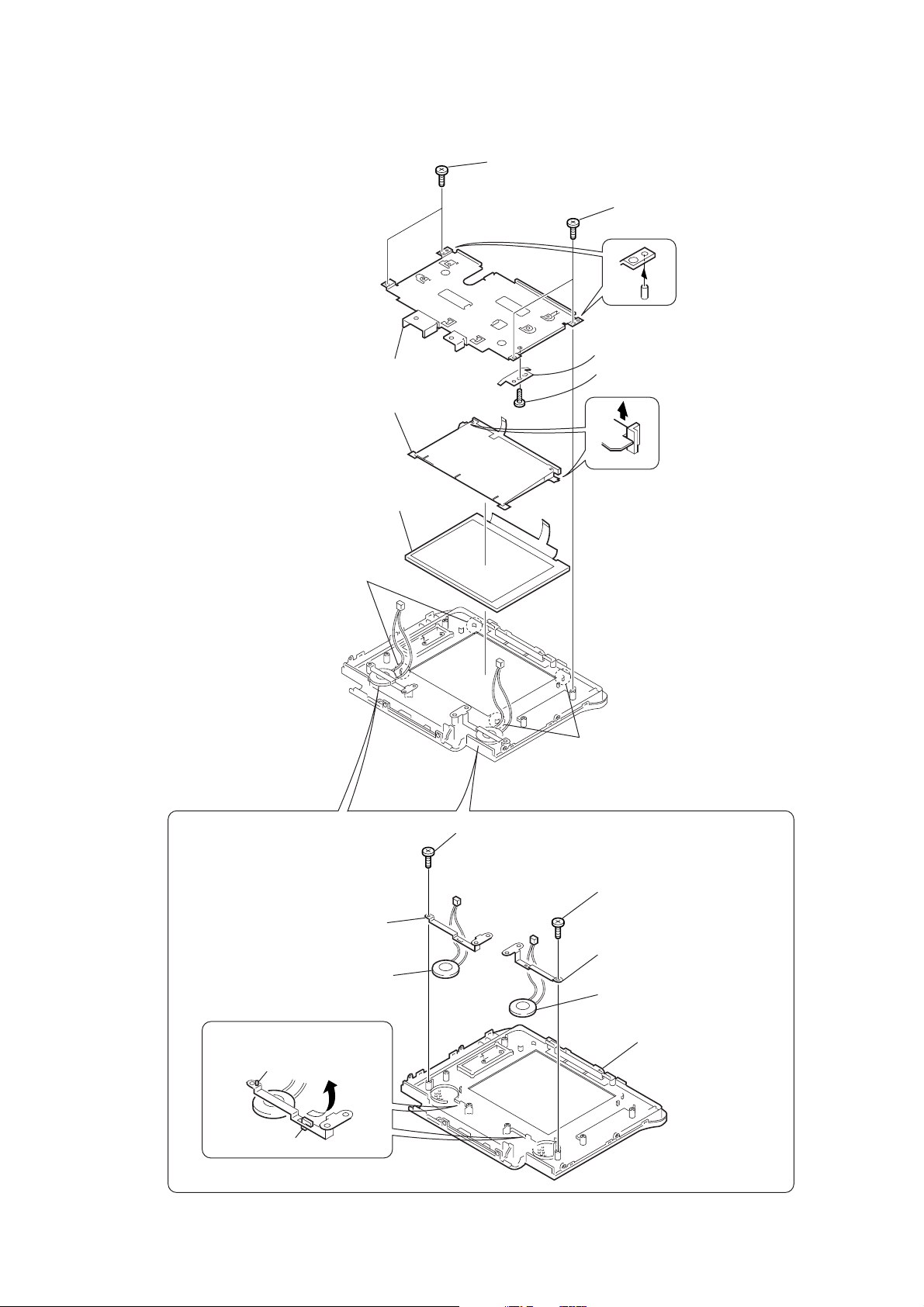

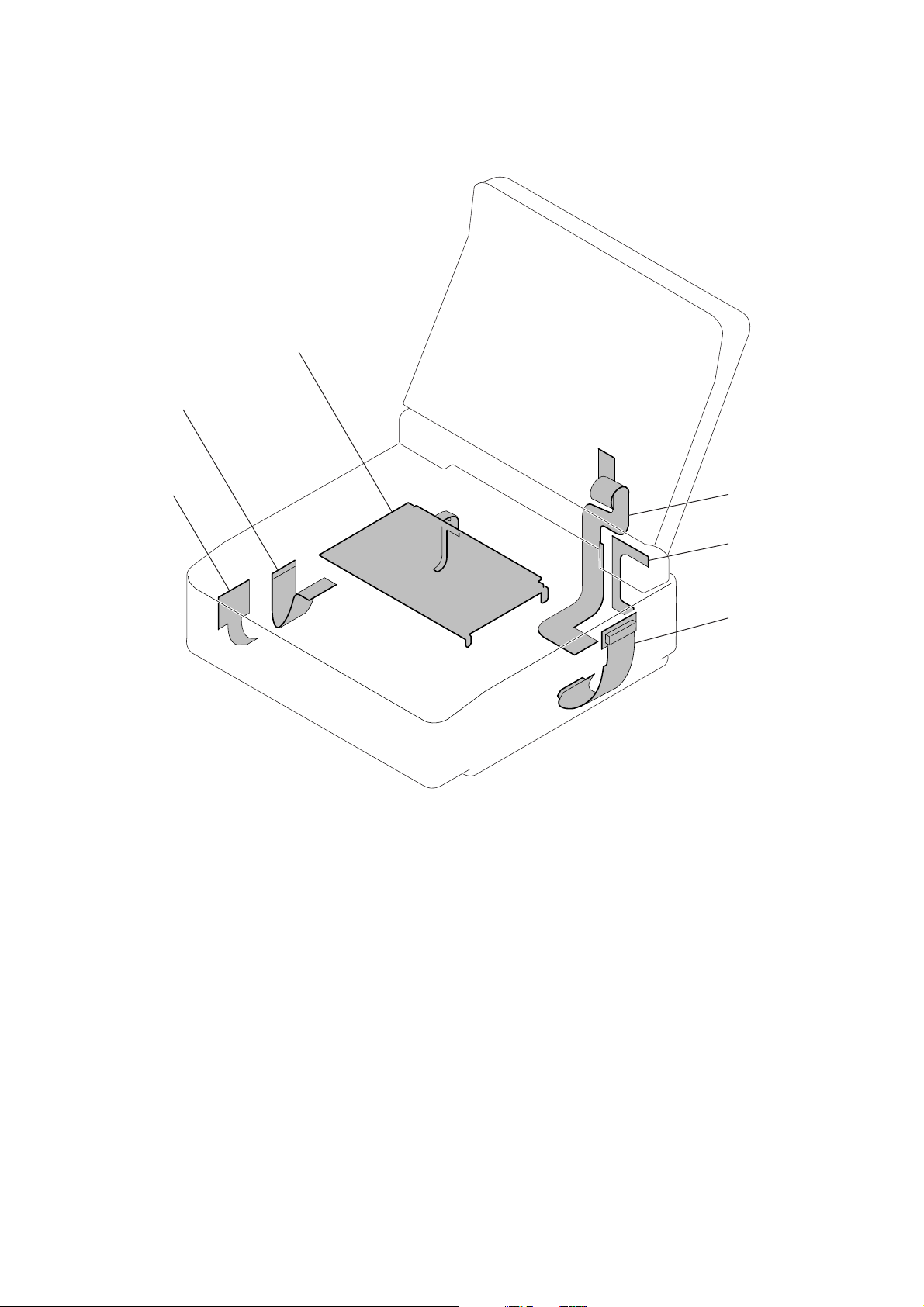

2-5. LCD WINDOW CABINET ASSEMBLY (SP-901, 902)(D800, D800E MODEL)

1

Two tapping screws

×

5)

2

Two tapping screws

(B2 × 5)

5

LCD ground plate

4

Screw (M2 × 3),

lock ace, p2

3

PD frame

6

LCD901

9

ND901

(B2

7

3

SP ground plate

4

Two claws

SP902

8

Two claws

REMOVING THE LCD WINDOW

CABINET ASSEMBLY (SP901, 902)

1

Tapping screw

×

(B2

5)

5

Tapping screw

×

(B2

6

5)

SP ground plate

7

SP901

2

Remove the SP ground plate

in the direction of the arrow.

Dowel

Claw

2-5

8

LCD window cabinet

assembly

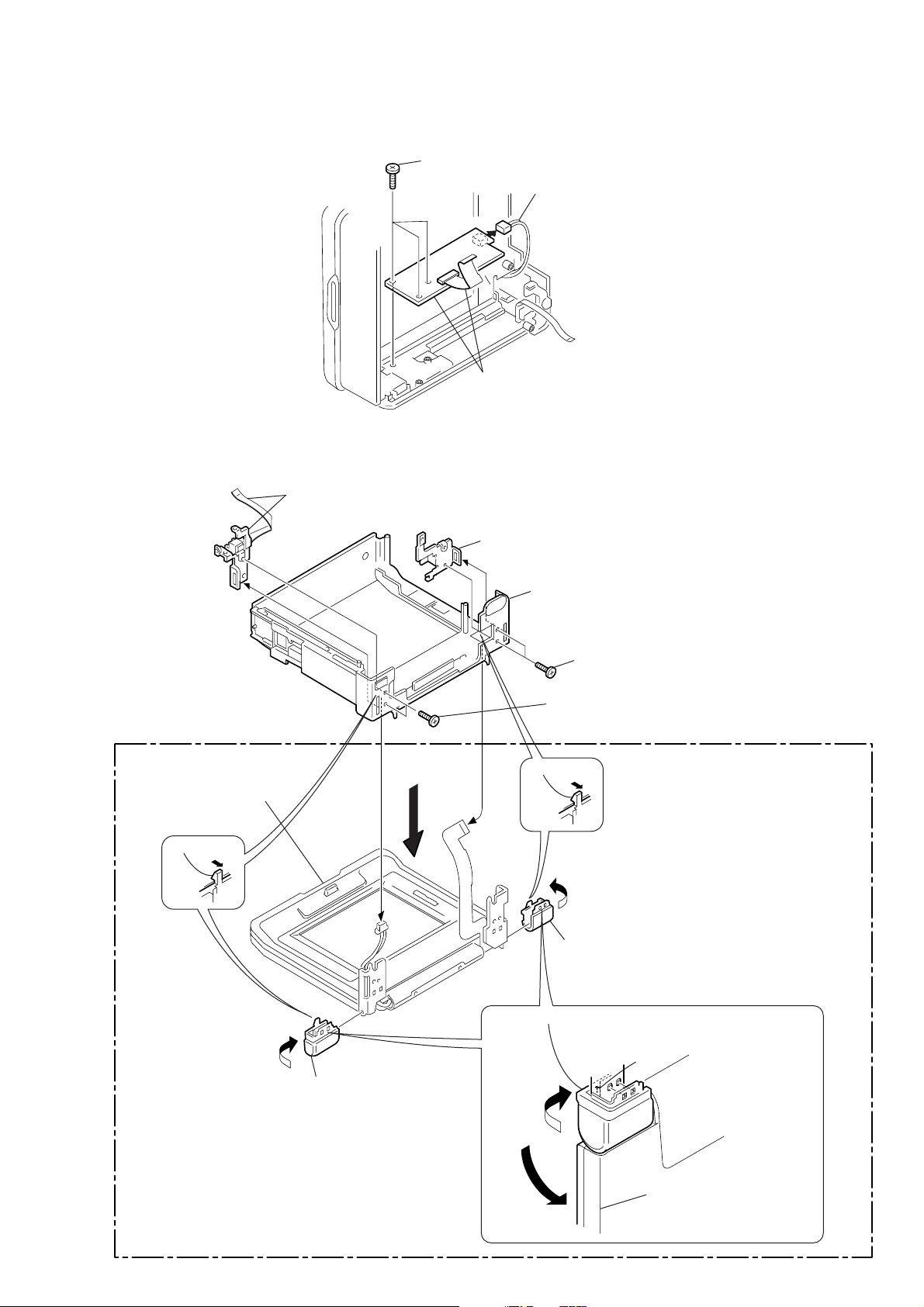

2-6. BATTERY PANEL ASSEMBLY, BATTERY TERMINAL BOARD, DC-IN CONNECTOR

7

Two tapping screws

×

5)

9

DC-IN connector (3P),

DC jack assembly

6

Battery panel assembly,

Battery terminal board

5

FP-247 flexible board

(50P)

3

FP-569 flexible board

(26, 32P)

0

Mechanism section

1

FP-570 flexible board

(40P)

(B2

Board

VC-250

8

Two screws (M2 × 4),

lock ace, p2

2-7. VC-250, FU-145 BOARDS

3

Three screws (M2 × 3),

lock ace, p2

VC-250

5

Mechanism deck

A

B

B

oard

C

D

E

4

VC-250 board

F

4

FP-572 flexible board

(6, 10P)

2

FP-602 flexible board

(5P)

A

Control switch block (FK-78) (10P)

B

Flexible board

(from loading motor, mode switch) (8P)

C

Flexible board (from video head) (16P)

D

Flexible board (from drum motor) (10P)

E

Flexible board (from capstan motor) (12P)

F

Flexible board (from S reel/T reel) (15P)

1

Two screws (M2 × 3),

lock ace, p2

2

FU-145 board

A

B

C

D

E

F

Battery panel assembly,

Battery terminal board

2-6

2-8. CONTROL SWITCH BLOCK (FK-78), LOADING LID

2

Screw (M1.4 × 1.6)

7

Two screws (M2 × 4),

lock ace, p2

4

Dowel

1

Remove the control switch block

(FK-78) (10P) in the direction of the arrow.

6

Control switch block

(FK-78) (10P)

3

Screw (M1.4 × 1.6)

5

Dowel

8

Loading lid

9

Mechanism deck

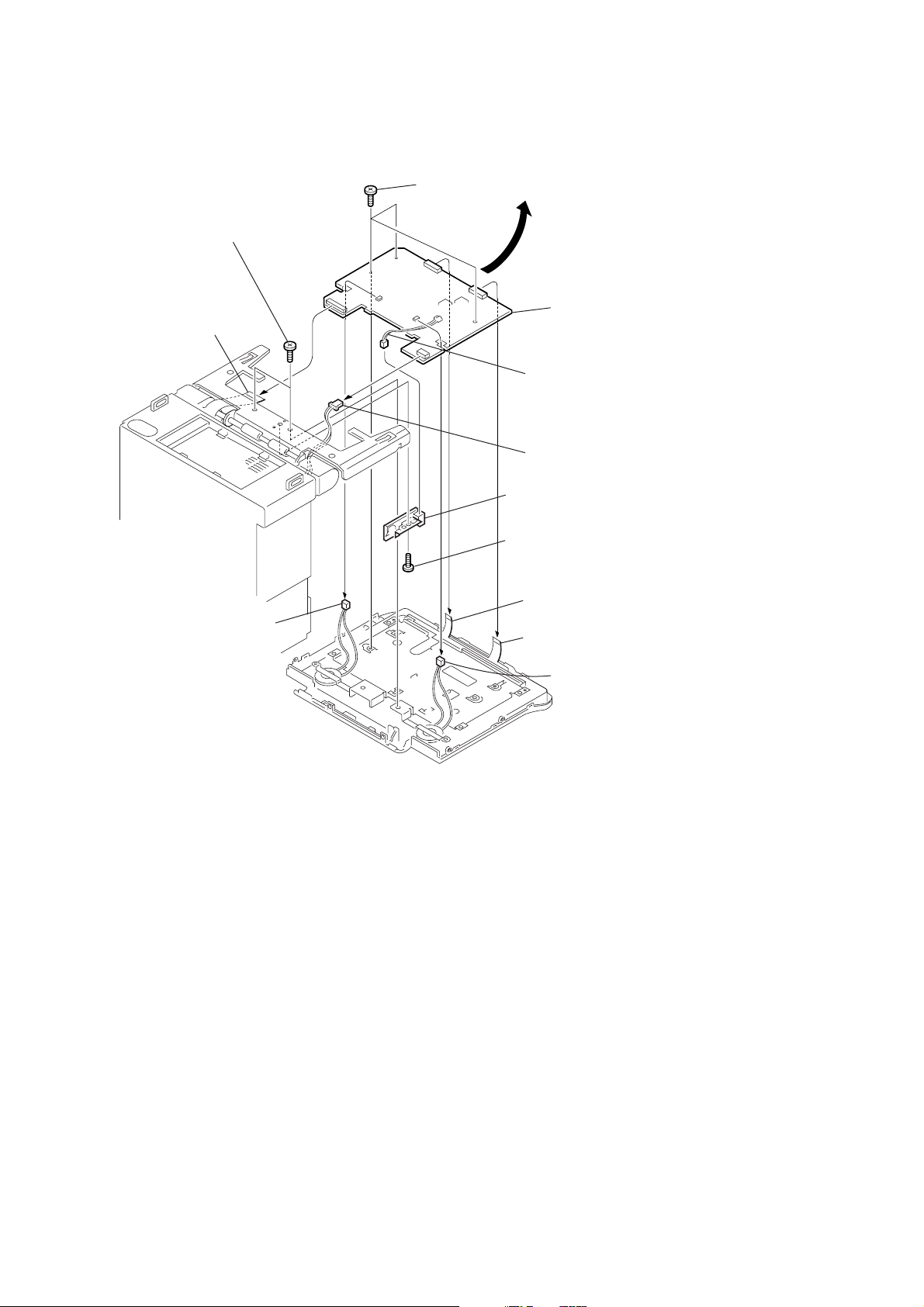

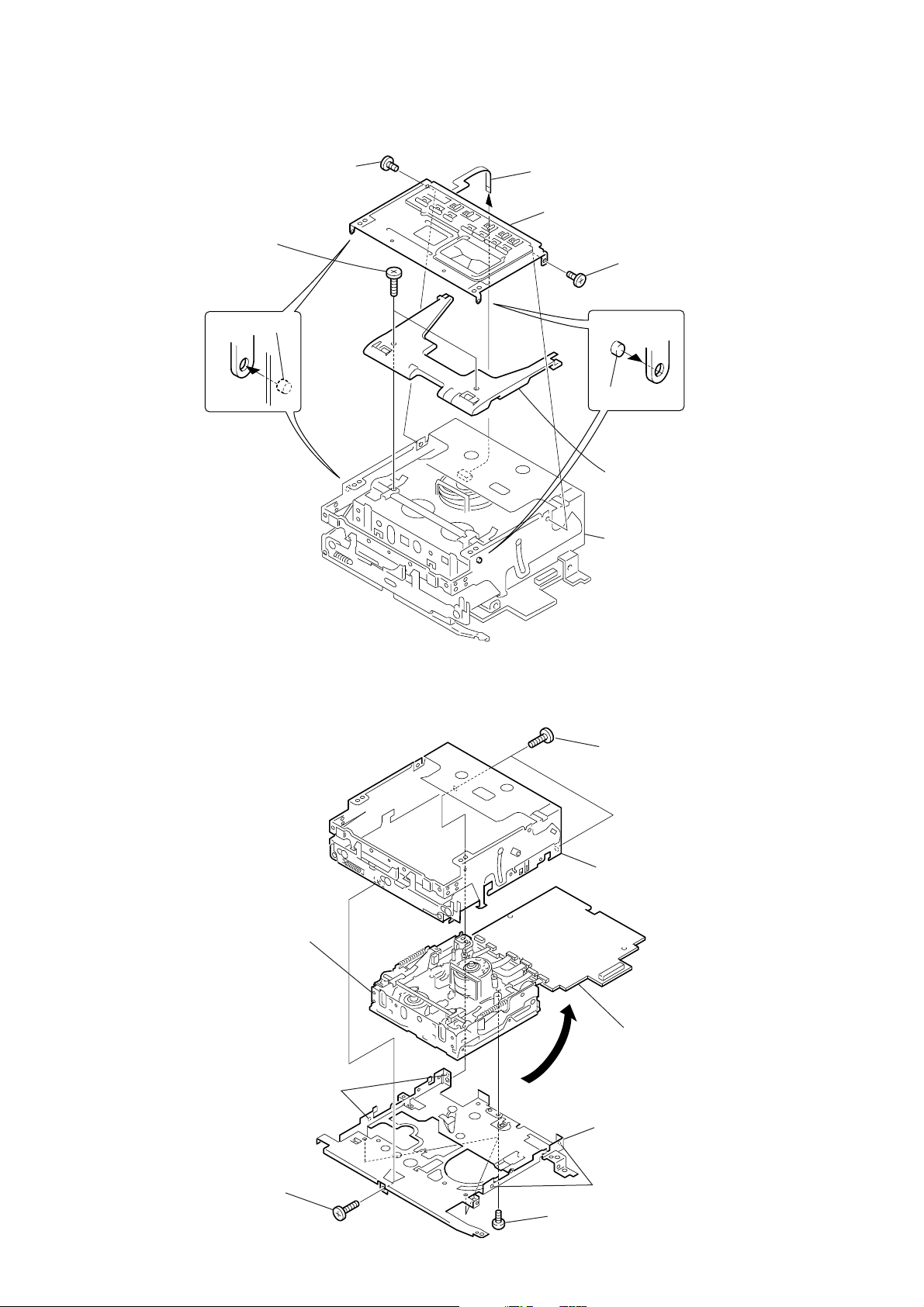

2-9. MECHANISM DECK, MAIN FRAME ASSEMBLY

9

Mechanism deck

3

Two dowels

Board

VC-250

1

Two screws (M2 × 3),

lock ace, p2

5

Lid frame assembly

6

Open the VC-250 board in the

direction of the arrow .

8

Main frame assembly

2

Screw (M2 × 3),

lock ace, p2

2-7

4

Two dowels

7

Three screws (M2 × 3),

lock ace, p2

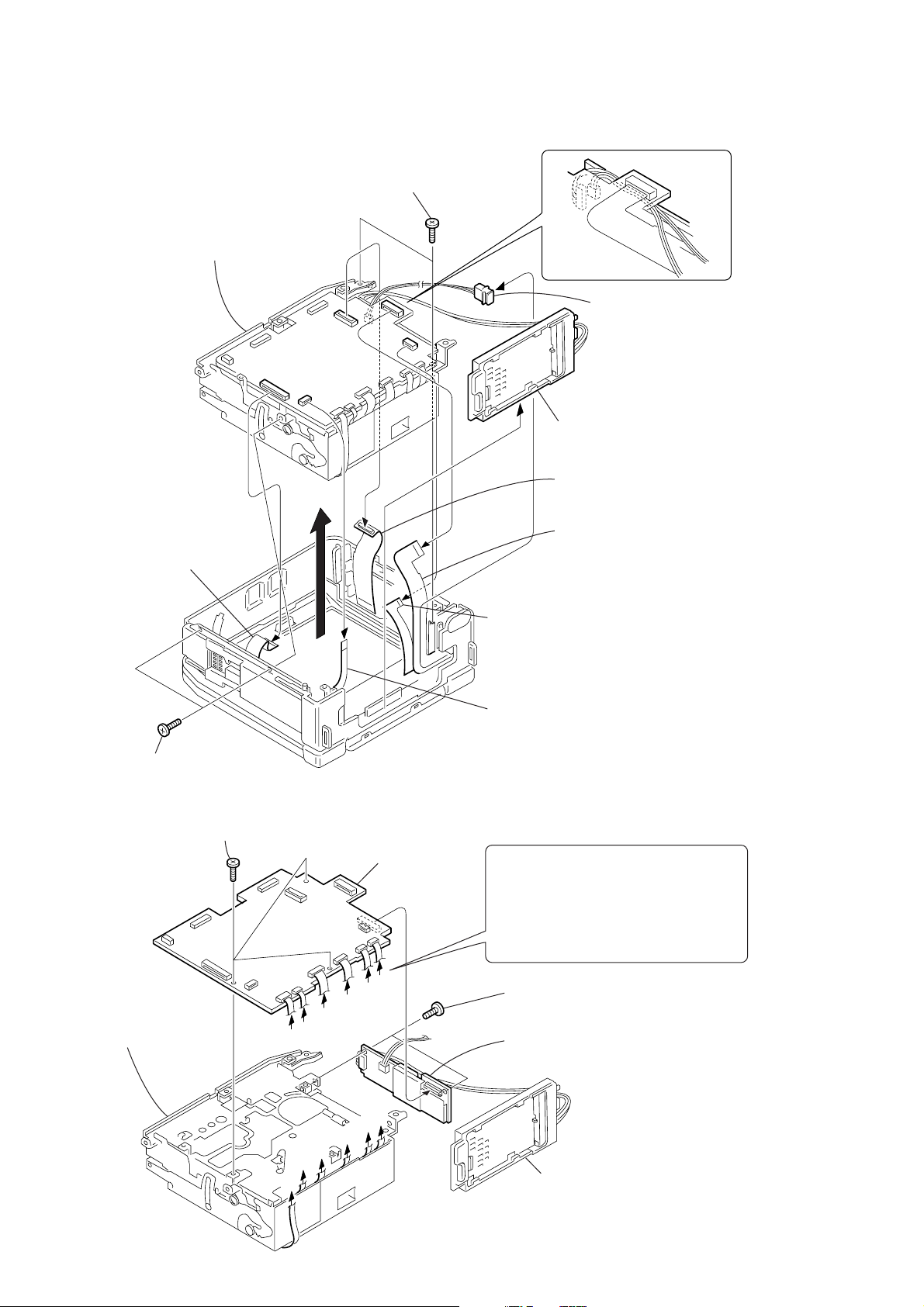

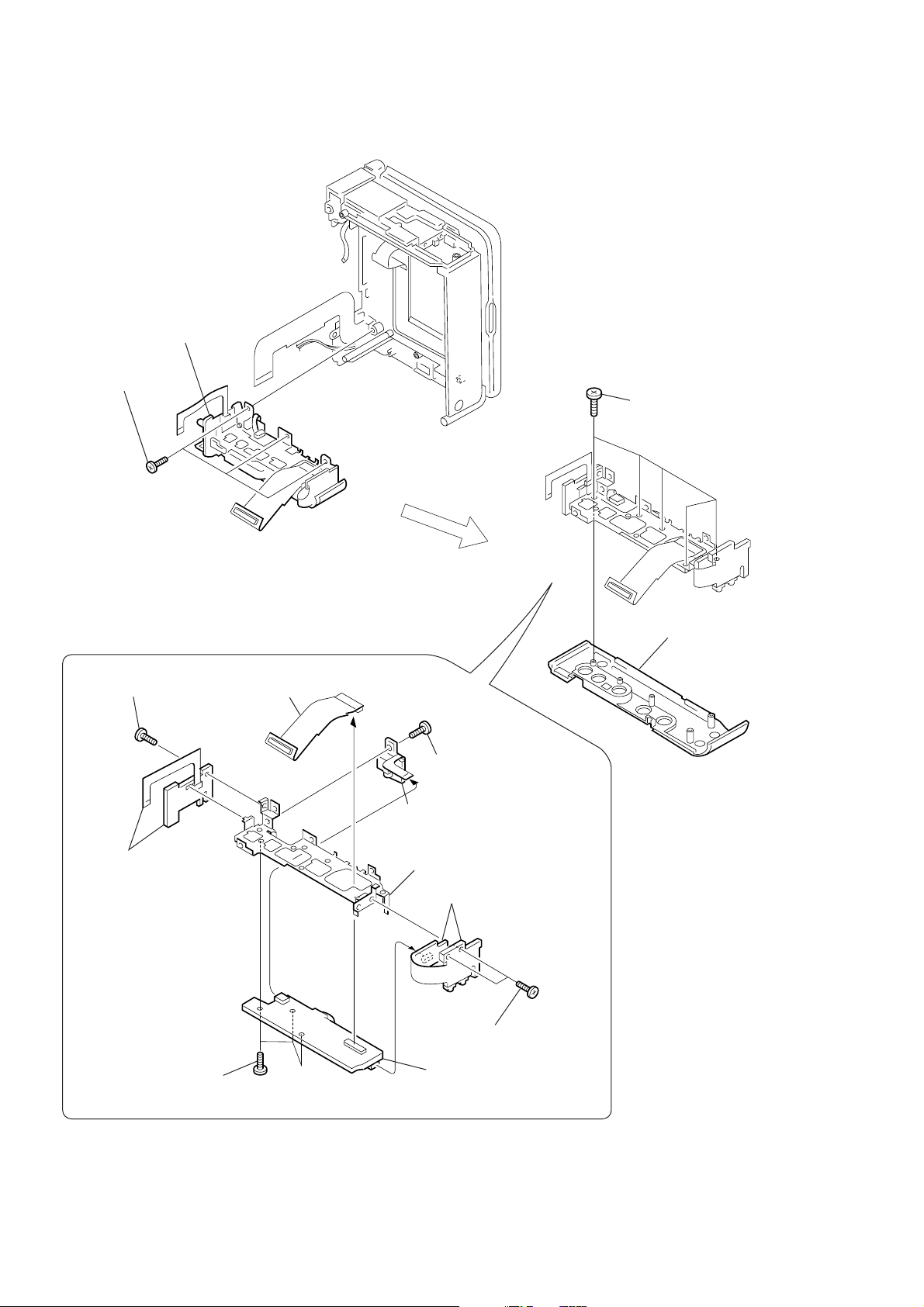

2-10.CABINET (R) BLOCK ASSEMBLY, JACK FRAME (IO-68, IR-38 BOARDS)

2

Cabinet (R)

block assembly

1

Three tapping

screws (B2

×

5)

3

Five tapping screws (B2 × 6)

REMOVING THE JACK FRAME

8

Screw (M2 × 3),

lock ace, p2

9

IR-38 board,

FP-572 flexible board

(6, 10P)

6

Three screws

(M2 × 4), lock ace, p2

5

board (50P)

IR-38

FP-247 flexible

IO-68

Board

3

Screw (M2 × 3),

lock ace, p2

4

FP-575 flexible board (6P)

0

Jack frame

2

FP-246 flexible

board (16P)

FP-246

1

Two screws (M2 × 3),

lock ace, p2

7

IO-68 board

4

Cabinet (R)

2-8

2-11.EX-36 BOARD, FP-570 FLEXIBLE BOARD

)

1

Three tapping screws (B2 × 5)

EX-36 board

3

EX-36 board,

FP-570 flexible board (40P)

2-12.UPPER CABINET ASSEMBLY,

LCD BLOCK ASSEMBLY (D800, D800E MODEL)

2

FP-602 flexible board (5P),

Strap sheet metal (L)

4

Strap sheet metal (R)

2

Harness (EP-51) (2P

(GV-D800/D800E model)

8

Remove the LCD block

assembly in the direction

of the arrow

6

A

Claw

5

Upper cabinet assembly

3

Two screws (M2 × 4),

lock ace, p2

1

Two screws (M2 × 4),

lock ace, p2

7

A

.

C

qa

Shaft cover (L)

Claw

D

qs

Shaft cover (R)

0

Remove the shaft cover (R), shaft cover

(L) in the direction of the arrow

Claw

CD

.

2-9

B

9

Open the LCD block

assembly in the direction

of the arrow

B

.

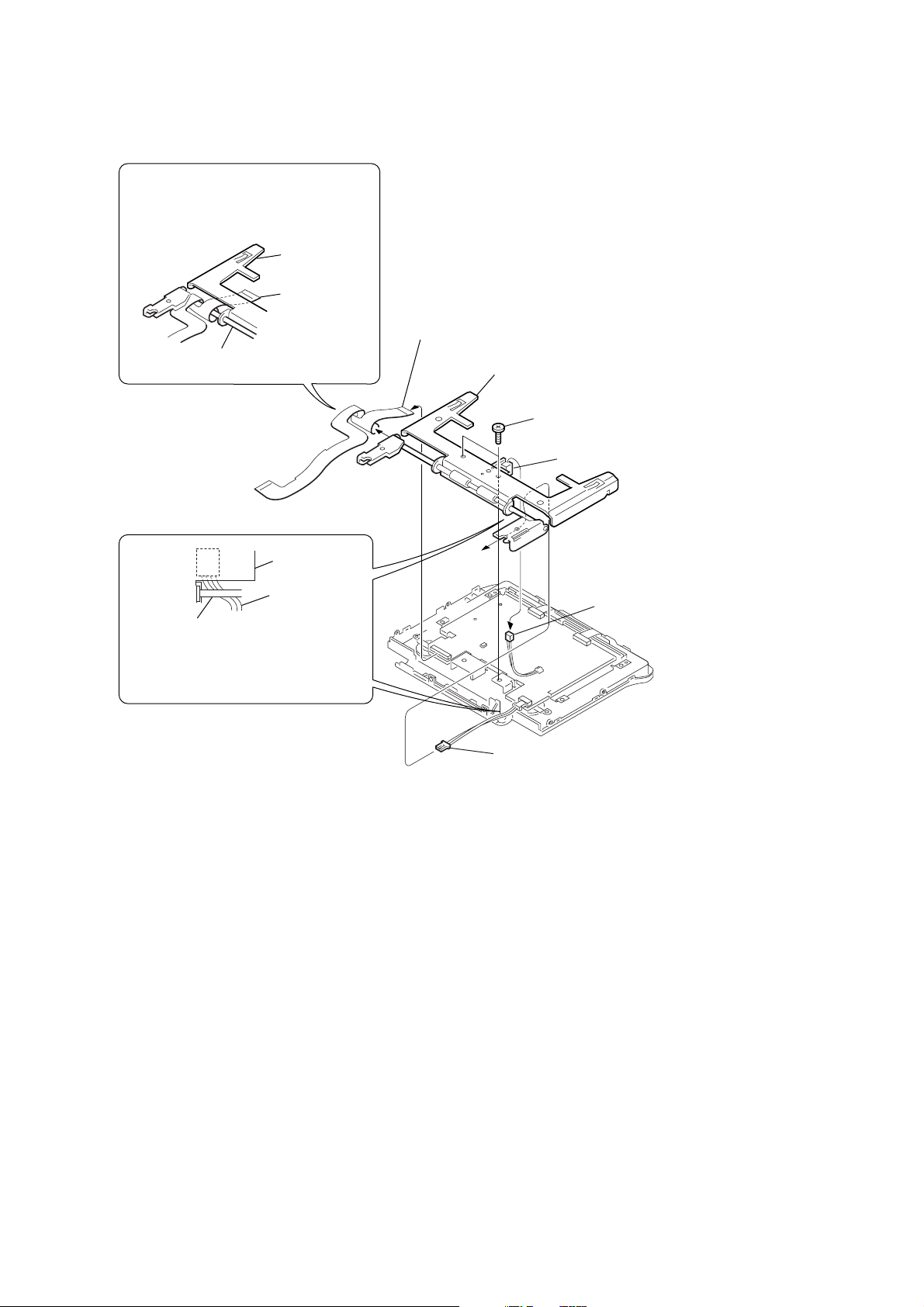

2-13.HINGE UNIT, FP-569 FLEXIBLE BOARD (D800, D800E MODEL)

When attaching the hinge unit, wrap the

FP-569 flexible board hinge shaft as shown

while taking care so that the flexible board

must not be caught or pinched.

Hinge unit

FP-569 flexible

board (26, 32P)

3

FP-569 flexible

Hinge shaft

Hinge unit

board (26, 32P)

4

Hinge unit

1

Two tapping screws

×

(B2

5)

LS-56 board

Harness

(EP-51) (2P)

Hinge shaft

When attaching the hinge unit, route the

harness through the notch as shown while

taking care so that the harness must not

be caught or pinched.

2

PD-130

Board

Harness (EP-51) (2P)

Harness (PL-53) (2P)

2-10

[CONNECTION DIAGRAM FOR SERVICE POSITION (Mainly for voltage measurement and check)]

(VC-250, FU-145, IO-68 BOARDS, MECHANISM DECK)

Control switch block

(FK-78) (10P)

CPC-13 jig

(J-6082-443-A)

VC-250 board

CN933

AC POWER

Mechanism deck

VC-250

Board

20

FU-145 board

ADAPTOR

1

DC-IN connector (3P),

DC jack assembly

Battery panel assembly,

Battery terminal board

FU-145

Board

FP-247 flexible

board (50P)

AC IN

LANC

jack

Adjustment remote

commander (RM-95)

IO-68

Board

FP-575 flexible

board (6P)

IO-68 board

FP-246 flexible

board (16P)

2-11

)

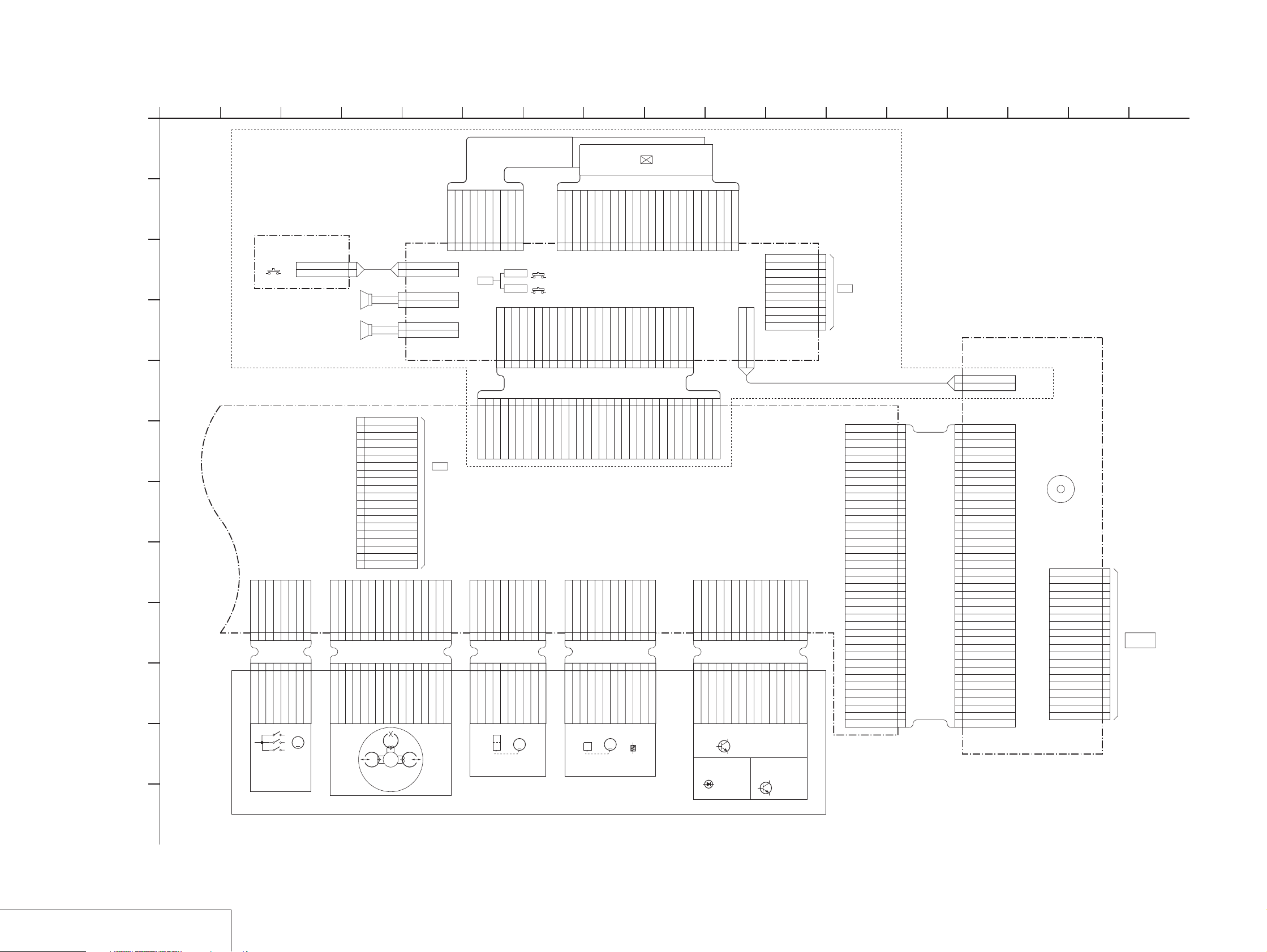

2-14.CIRCUIT BOARDS LOCATION

FP-602

(DV IN/OUT)

EX-36

(MULTI CONNECTOR)

LCD DISPLAY

MODULE

(D800/D800E ONLY)

PD-130

LCD DRIVER,

BACK LIGHT

LS-56

(LCD SWITCH

IR-38

(IR TRANSMITTER)

FP-575

(LANC)

FU-145

(DC/DC CONVERTER)

IO-68

(AV IN/OUT)

FP-246

(REMOTE COMMANDER RECEIVER)

VC-250

REC/PB AMP, DAC, DV INTERFACE, AD CONVERTER, Y/C PROCESSOR,

LINE A/D, LINE IN/OUT, IR, AUDIO IN/OUT, DRUM/CAPSTAN MOTOR DRIVE,

MECHA CONTROL, HI CONTROL, DC/DC CONVERTER

2-12

9

2

7

2-15.FLEXIBLE BOARDS LOCATION

The flexible boards contained in the mechanism deck are not shown.

CONTROL SWITCH BLOCK

(FK-78)

FP-570

FP-571

FP-56

FP-57

FP-24

2-13E

SECTION 3

BLOCK DIAGRAMS

GV-D200/D200E/D800/D800E

3-1. OVERALL BLOCK DIAGRAM (1/4)

(SEE PAGE 4-45)

IO-68 BOARD VC-250 BOARD(1/4)

(1/2)

13

1

2

5

7

CN104

L

V

R

HP L

HP R

Y

C

Y

C

V

L

R

J001

AUDIO/VIDEO

IN

J002

(HEADPHONES)

J101

S VIDEO IN

J103

S VIDEO OUT

VIDEO OUT

AUDIO OUT

J102

CN001

L

R

1

2

13

5

7

FP-246(1/2)

(FLEXIBLE)

(SEE PAGE 4-45)

IR-38 BOARD

(SEE PAGE 4-27)

D362,363

(SUPER LASER LINK)

EX-36 BOARD(1/2)

(SEE PAGE 4-63)

3

1

2

1

2

CN5505

20

1

15

14

6

5

PD-130 BOARD(1/3)

(SEE PAGE 4-55)

(GV-D800/D800E)

SPEAKER(L)

SPEAKER(R)

16

CN204

MULTI

CONNECTOR

SP901

SP902

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

(4-25)

IC3702

CN924

29

31

35

19

17

15

11

9

37

39

43

41

43

CN922

EX Y/V IN

EX C IN

EX VIDEO OUT

EX AUDIO L OUT

EX AUDIO R OUT

22

IR FSC

(IC3301)

11

14

16

1

8

9

IC3703

1

(4-27)

IC3901

IR

TRANSMITTER

18

7

(4-31)

3

5

3

6

(4-25)

41

46

48

Y

C

V

Y

C

V

IR V

IR L

IR R

IR L

IR R

L

R

HP L

HP R

CN103

30

32

36

20

18

16

12

10

38

40

44

42

CN361

IC5703

CN203

CN5503CN5506

1

2

19

13

17

15

6

4

EX Y/V IN

2

EX C IN

19

EX VIDEO OUT

13

EX AUDIO L OUT

17

EX AUDIO R OUT

15

EX AUDIO L IN

6

EX AUDIO R IN

4

CN931

EX AUDIO L IN

EX AUDIO R IN

4

8

11

IC5704

25

26

1

2

SP L+,L-

SP R+,R-

CN923

2

1

26

25

13

16

7

4

SPEAKER

AMP

(4-31)

2

3

9

10

11

9

L

R

L

R

(4-26)

IC3701

(TAKO)

LINE IN

LINE OUT

39

AGC

48

ACC

42

18

14

22

24

910

20 21 22

55

56

IC5701

AUDIO

57

58

52

54

64

3

I/O

8mm

PB AUDIO

PROCESS

Y

36

C

34

46

7

44

5

11

23

4

5

7

8

14

26

L

R

L

R

(4-31)

(4-23)

IC3603

(ALIGN)

A/D

CONVERTER

2

6

66 64 63

XCS TAKO (IC4501)

XCS AU (IC4501)

(4-32)

IC5702

AUDIO

A/D CONV.

3

D/A CONV.

2

15

16

AFM FSC (IC2201)

59

Y0-Y7

52

49

C0-C7

42

38

HD,VD,DE

37

36

34

AFCK

68

SPCK

31

(IC1505)

XCS ALIGN

65

(IC4803)

HI SO,HI SI,XHI SCK

SIRCS PWM

CAIN Y

CAIN C

KINUTA Y

KINUTA C

VSP SO,VSP SI,XVSP,SCK

DATA TO SFD

8

DATA FROM SFD

9

12

SFD BCK

PB RF

TO

OVERALL

BLOCK(2/4)

(SEE PAGE 3-3)

TO

OVERALL

BLOCK(4/4)

(SEE PAGE 3-8)

TO

OVERALL

BLOCK(2/4)

(SEE PAGE 3-3)

Y

3-1 3-2

GV-D200/D200E/D800/D800E

3-2. OVERALL BLOCK DIAGRAM (2/4)

VC-250 BOARD(2/4)

TO

OVERALL

BLOCK(1/4)

(SEE PAGE

3-2)

Y0-Y7

C0-C7

HD, VD, OE

CAIN Y

CAIN C

KINUTA Y

KINUTA C

Y0-Y7

C0-C7

HD,VD,OE

AFCK (IC2603)

SPCK (IC1505)

IC3302

CHARACTER

GENERATOR

(4-15)

13

XCS OSD

OSD SO

XOSD SCK

IR FCS

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

(4-15)

IC3301

199 201

203 205

207 211

213 215

13

57

916

8

HD

VD

20

19

COL0

18

COL3

17

16

14

(CAIN)

DV SIGNAL

PROCESS

17

21

23

182

196

48

184

183

195

194

191

190

55

59

138

X3301

24.576MHz

139

142

L BUS

145

TRCK

51

LCK

141

VREF

151

152

PRRV,TRRV,TRRT

153

156

DATA TO SFD

133

DATA FROM SFD

132

127

99

97

83

88

81

79

170

179

159

161

163

162

75

73

71

105

106

SFD BCK

6 6

MC BUS

VSP SO, SI, SCK

PANEL G

PANEL R

PANEL B

PANEL HD,VD

45

42

47

79

(4-17)

IC3303

(LIP)

DV INTERFACE

TPA+,-

6

TPB+,-

9

29

MC BUS

37

XCS SFD (IC4501)

XCS VFD (IC4501)

CN929

REC CK

REC DT

AD DT

6

PB CK

ATF ERR

CN1104

2

4

5

1

FP-602

(FLEXIBLE)

(SEE PAGE 4-17)

CN1105

DV IN/OUT

AD DT

PB CK

15

20

13

XCS TRF

(IC4501)

(4-11)

IC3101

(TRF)

EQ

A/D CONV.

PLL

25 31

22 24

RF MON

16

CN933(1/2)

PB RF (IC3202 )

AFC FO (IC2201)

14

(4-12)

IC3103

40

42

27

29

(TRW)

REC/PB

AMP

35

4

12

6

7

2

1

Q3107

Q3109,3110

Q3112-3115

IC3102

(4-11)

ODD

EVEN 12

Q3104,3108

Q3111,3116

FLYING

FILTER

SW

ERASE

OSC

REC CK

REC DT

34

PB Y OUT

42

DV PB RF

CN3101

FOR

5

ADJUSTMENTS

2

10

9

13

16

ERRV,TRRV,TRRT

DRP SO,XDRP SCK

(SEE PAGE 4-11)

XFE ON

DRUM 8PB

VC RF SWP

DV RF SWP

ATF ERR

MC BUS

DRUM

ODD

EVEN

FLYING

ERASE

TO

OVERALL

BLOCK(4/4)

(SEE PAGE 3-8)

16

DATA TO SFD

DATA FROM SFD

SFD BCK

PB RF

Y

XCS OSD

OSD SO

XOSD SCK

(4-21)

OSCI

IC2202

VCO (KINUTA)

AFC FO

AFM FSC

Y0-Y7

C0-C3

HD,VD,OE

Y

C

MECHA HD

MECHA VD

MECHA FLD

TBC VD

AMPO

67

53

79

139

122

112

199

146

144

142

4

213

93

94

89

168

(4-21)

IC2201

HI8/STD8

PB Y/C

PROCESS

9695 97

VSP SO,VSP SI,XVSP SCKVSP SO,VSP SI,XVSP SCK

9

7

DV PB RF

(4-13)

IC3201

HI8/STD8

PB RF

AMP

TO

OVERALL

BLOCK(3/4)

(4-13)

18

ADJUSTMENT

VOLTAGE

(4-13)

IC2291

3

DA STB

(IC4902)

D/A CONV.

(EVR)

12

(SEE PAGE

3-5)

IC3202

RF ENV

DET

3

5

4

RF ENV DET

MECHA HD

MECHA VD

MECHA FLD

TBC VD

XCS CH

CH SO

XCH SCK

VC SO,VC SI,XVC SCK

PANEL R

PANEL G

PANEL B

PANEL HD,VD

4

IC1502

A/D

REC

(4-19)

46 48

(4-19)

IC1504

27MHz

PB

XTAL

OSC

X1501

27MHz

4

2

PB C RF

36

34

PB RF

DOP

11

14

SPCK

SPCK

81

VCK

198

101

100

RF AGC OUT

51

196

187

AD CK

185

PB C RF

49

77

98

XCS KINUTA(IC4902)

(4-19)

IC1505

5 1

CK CONT 1,2(IC4902)

AD1-AD10

1/2

2

11

16

3-3 3-4

GV-D200/D200E/D800/D800E

3-3. OVERALL BLOCK DIAGRAM (3/4)

VC-250 BOARD(3/4)

DRP SO,DRP SI,XDRP SCK

VSP SO,VSP SI,XVSP SCK

MC BUS

FRRV,TRRT,TRRV

ATF ERR

XCS VFD (IC3301)

XCS SFD (IC3301)

XCS TAKO (IC3701)

XCS EEP

1

XCS AU (IC5701)

XCS TRF (IC3101)

VREF (IC3301)

XCS MECHA (IC4803)

HI SO,HI SI,XHI SCX

LINE OUT V (IC3301)

XCS KINUTA (IC2201)

DA STRB (IC2291)

CK CONT 1,2 (IC2201)

HI SO,HI SI,XHI SCX

XCS VC (IC4803)

X4901

20MHz

XCS EEPROM

16

TO

OVERALL

BLOCK(2/4)

(SEE PAGE

3-4)

TO

OVERALL

BLOCK(4/4)

(SEE PAGE

3-8)

32 4

IC4502

EEPROM

(4-36)

DV RF SWP

XFE ON

DRUM 8 PB

RF ENV DET

(4-29)

IC4901

EEPROM

1

32 4

VC SO,VC SI,XVC SCX VC SO,VC SI,XVC SCX

MECHA FLD

MECHA HD

MECHA VD

TBC VD

VC RF SWP

XCS CH,CH SO,XCH SCK

PANEL R

PANEL G

PANEL B

PANEL HD,VD

XCC DOWN

HI SO,HI SI,XHI SCK

BL CONT

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

(4-35)

78

IC4501

79

80

DIGITAL8

MECHA

74

CONTROL

SIGNAL

75

PROCESS

76

CONTROL

26

38

106

107

108

95

17

28

18

88

21

23

112

62

59

111

99

72

81

82

83

1

DRUM PWM DRUM PWM

68

CAP PWM

69

DRUM FG

116

DRUM PG

117

115

CAP FG

110

109

DEW DET

96

39

MODE SW A-C

40

41

LOAD

UNLOAD

49

50

TAPE END

54

TAPE TOP

53

T REEL FG

114

S REEL FG

113

TAPE LED ON

55

REC PROOF

44

CAP PWM

(4-33)

IC4401

28

25

(3/3)

LPF

DRUM ERROR

29

CAP ERROR

27

(4-29)

2

IC4902

HI8/STD8

1

MECHA

CONTROL

114

39

78

79

80

19

21

27

111

112

113

118

47

83

82

81

104

110

74

75

76

78

DRUM PWM

69

CAP PWM

68

DRUM FG

116

DRUM PG

117

CAP FG

115

109

35

MODE SW A-C

36

37

LOAD

UNLOAD

32

33

TAPE END

42

TAPE TOP

41

T REEL AFG

96

S REEL AFG

95

TAPE LED ON

31

ME SW

38

HI8 MP SW

40

DV RF SWP (IC4501 )

VC RF SWP (IC4902 )

62

47

8 13 15

CN933(2/2)

FOR ADJUSTMENTS

PANEL R

PANEL G

PANEL B

XCS LCD

(IC4803)

HI SO,XHI SCK

PANEL HD

PANEL VD

BL CONT

FU-145 BOARD(1/2)

IC1301

15

9109

10

11

CN1301CN921

PD-130 BOARD(2/3)

5

22

6

21

7

20

14

13

13

14

15

12

10

17

11

16

23

4

CN923

CN5503

PWM

DRIVE

(4-49)

HD OUT

(1/2)

(4-57)

58

64

IC5601

48

47

46

41

40

39

44

46

45

42

1

48

Q1306

SWITCHING

SWITCHING

Q1305

GENERATOR

CN1301

RGB

20

22

24

27

35

10

24

IC5501

DRIVE

(4-55)

IC5502

TIMING

(4-55)

8

2 5

5 2

1

3

4

1

2

9

CN921

3

4

1

2

VR,VG,VB

COM

DA

Q5601

DRUM YS

DRUM FG

DRUM PG

LOAD

UNLOAD

TAPE END

TAPE TOP

T REEL FG

T REEL AFG

S REEL FG

S REEL AFG

TAPE LED ON

HD OUT

PANEL COM

VR,VG,VB

VCOM

VGLAC

CN5501

7

6

PANEL 2.8V

3-5 3-6

(4-33)

IC4401

6

(1/3)

DRUM

MOTOR

DRIVE

FG AMP

16

PG AMP

22

(4-33)

IC4401

LED DRIVE

8

4

CN5502

FOR

5

ADJUSTMENTS

3

1

19

20

21

11

4

5

10

12

18

(2/3)

LOADING

MOTOR

DRIVE

TAPE END

DETECT

TAPE TOP

DETECT

T REEL

FG AMP

S REEL

FG AMP

Q4401

LCD

UNIT

55

56

47 46

44

41

39

33

34

61

59

57

17

20

53

51

45

38

39

36

35

MODE SW A-C

LM(+),LM(-)

TAPE END(C)

TAPE TOP(C)

T REEL(+),(-)

S REEL(+),(-)

REC PROOF

HI8 MP SW

XCC DOWN

ND901

BACKLIGHT

CN4402

U, V, W

CN4403

CAP VS

CAP FG

DEW DET

CN4401

ME SW

CN4404

BL HIGH

BL LOW

CN5604

B710-MECHA DECK

(SEE PAGE 4-56)

M901

10

5

3

1

8

7

1

12

2

3

4

5

8

8

2

12

11

5

4

14

7

6

3

15

10

DRUM MOTOR

DRUM FG

DRUM PG

CAPSTAN MOTOR

CAPSTAN FG

DEW SENSOR

MODE SWITCH

LOADING MOTOR

Q002

TAPE END

Q001

TAPE TOP

S001

S002

T5601

Q5602

INVERTER

BACK

LIGHT

DRIVE

M

M902

M

S901

M903

M

SENSOR

SENSOR

T REEL

SENSOR

S REEL

SENSOR

IC5602

CURRENT

3

3

BL DET

REC PROOF

ME/MP

HI8 MP

CC DOWN

BL REG

(4-57)

DET

D001

TAPE

H001

H002

(GV-D800/D800E)

4

LED

GV-D200/D200E/D800/D800E

3-4. OVERALL BLOCK DIAGRAM (4/4)

FK-78 BOARD VC-250 BOARD (4/4)

(SEE PAGE 4-61)

S001–016

FUNCTION

SWITCH

D001 (REC)

D002 (PAUSE)

D003 (CAUTION)

(SEE PAGE 4-37)

FP-571

(FLEXIBLE)

VANADIUM

LITHIUM

BATTERY

IO-68 BOARD (2/2)

S101, 102, 104, 105

EXEC

S. LASER LINK SW

CN001

8

10

14

121

VOLUME SW

MENU SW

CN104

X POWER LED

8

X CHARGE LED

10

SIRCS SIG

14

LANC SIG

2

CN105

J001

(LANC)

(SEE PAGE 4-45)

S103

FP-246 (2/2)

(FLEXIBLE)

COMMANDER

(SEE PAGE 4-45)

(POWER)

(CHARGE)

IC001

REMOTE

RECEIVER

FP-575

(FLEXIBLE)

OFF ON

(SEE PAGE 4-45)

SEL/PUSH

EXEC

DIAL

1

S001

POWER

D001

EX-36 BOARD(2/2)

CN204

MULTI

CONNECTOR

11, 17

18, 19

8

(SEE PAGE 4-65)

16

BZ201

BUZZER

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

CN001

6

BT001 1

CN103 CN922

23

26

•

25

46

43

45

2

1

10

•

11

23

|

CN203

26

8

39

•

40

LANC SIG

6

•

•

5

5

•

•

7

7

2

2

4

4

3

3

CN926

•

2

24

25

•

26

45

44

46

1

2

10

•

11

23

|

26

8

39

•

40

X REC LED

X PAUSE LED

X CAUTION LED

BATT LI 3V

VTR UNREG

BATT UNREG

Q4808–4810

DRIVE

EX UNREG

BEEP

CN931

LED

Q906–908

LED

DRIVE

3

7

(4-37)

IC4801

RESET

VDD SWITCH

LANC SIG

5

6

IC4802

X4801

20MHz

X4802

32.768kHz

S4801

RESET

S4802

EJECT SW

(4-37)

LANC I/O11

93

•

94

•

95

6

8

55

40

41

52

53

38

42

•

51

•

77

•

87

98

67

•

68

5

57

4

17

14

72

•

73

48

•

49

10

•

12

(4-37)

IC4803

HI CONTROL

KEY AD0

KEY AD1

KEY AD2

X REC LED

X PAUSE LED

X CAUTION LED

20MHz OUT

20MHz IN

32kHz IN

32kHz OUT

XRESET

VDD

KEY AD5

DIAL A

DIAL B

X POWER LED

X CHARGE LED

SIRCS SIG

X EJECT SW

X VTR MODE SW

ID1

ID2

IB SI

IB SO

XCS MECHA

XCS ALIGN

XOSD SCK

SIRCS ENV

MELODY ENV

BATT/EXT SW

FAST CHARGE

VTR DO ON

LANC OUT

Q4804

XCS VC

XCS LCD

HI SO

HI SI

HI SCK

XCS OSD

OSD SO

MELODY

SHOE ON

LANC IN

IF

99KEY AD6

80

3

58

27

18XCC DOWN

33

•

34

•

35

44

•

45

•

46

59

36

56

66

50

29

81

1

•

2

BATT SIG

XCS MECHA (IC4501)

XCS VC (IC4902)

XCS ALIGN (IC3603)

XCS LCD (IC5501, 5502)

HI SO, HI SI, XHI SCK

HI SO, HI SI, XHI SCK

Q4802, 4805

MOD

Q4803

MOD

XCC DOWN

BL CONT

SIRCS, PWM

XCS OSD

OSD SO

XOSD SCK

(GV-D800/D800E)

CN923

TO

OVERALL

BLOCK(3/4)

(SEE PAGE

3-5)

TO

OVERALL

BLOCK(1/4)

(SEE PAGE

3-2)

TO

OVERALL

BLOCK(2/4)

(SEE PAGE

3-3)

(GV-D800/D800E)

BL CONT

BL REG

PANEL –15V

PANEL 13V

1.5V

2.8V

4.75V

RP UNREG

MT 5V

EX UNREG

SHOE ON

VTR DO ON

VTR UNREG

BATT UNREG

PD-130

LS-56 BOARD

BOARD (3/3)

S5601, 5602

23 4 11

LCD BRIGHT

CN5503

(SEE PAGE 4-57)

AD6

SW

CN001CN5608

(SEE PAGE 4-56)

FU-145 BOARD (2/2)

(4-49)

IC1301

DC-DC CONVERTER

(2/2)

42

42

46

46

•

•

45

45

44

44

43

43

26

26

•

•

25

25

22

22

|

|

19

19

16

16

•

•

15

15

•

•

14

14

13

13

8

8

•

•

7

7

32

•

31

30

29

35

36

39

38

37

Q507

VTR UNREG

BATT UNREG

FAST CHARGE

BATT/EXT SW

BATT SIG

CN1301CN921

32

•

31

30

29

35

36

39

38

37

Q502

S001

LCD ON/OFF

SW

CN502

CN501

+

S

–

J902

DC IN

J901

BATTERY

TERMINAL

1

2

3

1

5

4

3-7 3-8

GV-D200/D200E/D800/D800E

S

7

31

28

2

6

5

1

57

54

18

41

45

42

40

49

50

34

27

6

7

2

3

46

37

21

22

29

30

64

10

11

58

14

15

1

4

5

8

4

3

1

2

3

4

5

1

2

3

1

5

IC1301

IC1303

IC1302

J901

BATTERY

TERMINAL

J902

DC IN

CN501

BATT (+)

BATT SW(+)

BATT SW(–)

BATT(–)

BATT SIG

Q501,

502

Q506,

507

ACV UNREG

BATT/XEXT SW

CN502

FAST CHARGE

SHOE ON

DC PACK SW

F501

F502

F504

F505

F503

Q503–505

CHARGE

SWITCH

INIT CHARGE ON

(GV–D800/D800E)

C/D VS D1.5V

BL UNREG

VTR UNREG

BL CONT

VC–250 BOARD(1/2)FU–145 BOARD

DC/DC CONVERTER

(4–39)

(4–39)

(4–49)

NONINV

INPUT–7

STANDBY–7

OUTPUT–7

MONITOR-7

OUTPUT

OUTPUT VCC–7

OUTPUT VCC–4,5,6

OUTPUT–4

MOS GATE–4

OUTPUT

MONITOR–4

OUTPUT–1

MOS GATE–1

OUTPUT

MONITOR–1

VCC

COMP

VREF

VTR DD ON

16

VREF

OUTPUT VCC–1,2,3

OUTPUT–3

OUTPUT MONITOR–3

RT

CT

OUTPUT–2

OUTPUT

MONITOR–2

OUTPUT–6

OUTPUT MONITOR–6

NONINV INPUT–6

OUTPUT–5

OUTPUT MONITOR–5

NONINV INPUT–5

STANDBY–3

STANDBY

VTR DD ON

SHOE ON

BATT SIG

BATT/XEXT SW

FAST CHARGE

INIT CHARGE ON

DC PACK SW

29

30

37

38

39

40

41

29

30

37

38

39

40

41

1

2

10

3

4

9

1

2

10

3

4

9

44 44

14

15

16

43

13

43

13

19

20

21

22

19

20

21

22

2.8V

PANEL 13V

RP UNREG

25

26

25

26

1.5V

BL CONT

BL REG

BATT UNREG

MT 5V

VTR UNREG

42

45

46

42

45

46

31

32

36

7

8

35

31

32

36

7

8

35

CAP VS

CAP ERROR

DRUM VS

DRUM ERROR

PANEL –15V

4.75V

5.9V

REG

2

5

BL REG

PANEL 2.8V

PANEL 13.3V

PANEL –15.3V

PANEL 4.75V

A 4.75V

A 2.8V

AU 2.8V

D 1.5V

D 1.9V

1.9V REG

TO

POWER

BLOCK(2/2)

L1313

AV 4.75V

(GV–D800/D800E)

–15.3V

REG

L1309

L1320

L1315

Q1322,1324,1326

L1311

L1316

CAP VS

CAP ERROR

DRUM VS

DRUM ERROR

RP 4.75V

RP 6.0V

L1314

L1306

L1321

D 2.8V

L1307

L1308

Q1303

SWITCHING

Q1308

SWITCHING

Q1307

SWITCHING

Q1304

SWITCHING

Q1301

SWITCHING

Q1302

SWITCHING

Q1305

SWITCHING

Q1306

SWITCHING

L1305 L1310

L302

T1301

Q1314

D1302 (1/2)

RECT

D1306

RECT

D1302

RECT

EMERGENCY

DETECT

RECT

D1301,305

L1301

L1303

L1304

CAP VS

CAP ERROR

DRUM VS

DRUM ERROR

BATT UNREG

(GV–D800/D800E)

L501

L1317

L1318

Q1309

SWITCHING

EX UNREG

DC PACK SW

SHOE ON

BATT SIG

INIT CHARGE ON

VTR DD ON

FAST CHARGE

BATT/XEXT SW

BATT UNREG

MT 5V

VTR UNREG

EX UNREG

BL CONT

CN921

CN1301

5V REG

Q1310–1313

EX UNREG

14

15

16

(SEE PAGE

3-11)

3-5. POWER BLOCK DIAGRAM (1/2)

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

3-9 3-10

GV-D200/D200E/D800/D800E

3-6. POWER BLOCK DIAGRAM (2/2)

VC-250 BOARD(2/2)

DC PACK SW

SHOE ON

BATT SIG

INIT CHARGE ON

VTR DD ON

FAST CHARGE

16

TO

POWER BLOCK

(1/2)

(SEE PAGE

3-10)

BATT XEXT SW

BATT UNREG

MT 5V

VTR UNREG

EX UNREG

BL CONT

BL REG

PANEL 2.8V

PANEL 13.3V

PANEL -15.3V

PANEL 4.75V

AU 4.75V

D 1.9V

A 2.8V A 2.8V

AU 2.8V

D 1.5V

A 4.75V A 4.75V

D 2.8V D 2.8V

CAP VS

CAP ERROR

DRUM VS

DRUM ERROR

RP 4.75V

RP 6.0V

D4802

D4801

VTR UNREG

MT 5V

AU 4.75V

AU 2.8V

D 2.8V

FB3601

L3602

IC3603

(ALIGN)

A/D CONV.

A 2.8V

MT 5V

D 1.5V

L3707

IC3703

VIDEO OUT

AMP

RP 4.75V

A 2.8V

D 2.8V

FB1501

IC1504

XTAL

OSC

(4-19) (4-19)

LANC DC

IC5701

AUDIO I/O

(4-23)

(4-25)

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

(4-37)

IC4803

HI CONTROL

INIT CHARGE ON

XVTR MODE SE

XCHARGE LED

FB4501

L2201-2203,

L2208

SHOE ON

IB SO

IB SI

VTR DD ON

FAST CHARGE

CHARGE INH

BATT/XEXT

XPOWER LED

FB1504

(4-37)

IC901

REG

1

14

(4-31)

FB3701

L3701,

3705

L3706

IC4802

LANC I/O

UNREG

LANC DC

L5701

IC3701

(TAXO)

VIDEO

LINE IN/OUT

AMP

(4-26)

IC3702

VIDEO

INPUT

SELECT

(4-25)

IC1505

FREQUENCY

DIVIDER

IC4801

D901

3 32

Q4806

IC5704

SPEAKER

(GV-D800/D800E)

REG 1.5V

(LIP)

DV

(4-17)

IR DRV

RF ENV

DET

(4-14)

AMP

L2209

L3102

BATTER IN

DETECT

(4-31)

L2204

REG

DV

7

(4-31)

IC5703

AUDIO

INPUT

SELECT

IC3303

INTERFACE

POWER

VCC

IC5702

AUDIO

ADC&DAC

(4-37)

(4-31)

FB3303

FB3370

4

8

IC3301

(CAIN)

SIGNAL

PROCESS

(4-15)

L3901

(4-27)

IC3901

TRANSMITTER

L3201 L3104 L3103

IC3201

IR

HI8/STD8

PB RF

AMP

24

Q3903

IC3202

(4-13)

(4-37)

RESET

CHARACTER

IC3103

(TRW)

REC/PB

5

6

4

8

EVER 3.0V

IC3302

GENERATER

(4-15)

FB2202

IC2201

RF 1.9V

AMP

42 51

86 87

S4801

RESET

(4-36) (4-35)

IC4502

EEPROM

IC2291

D/A CONV.

L2291

FB2204

HI8/STD8

PB Y/C

PROCESS

IC3101

(TRF)

EQ.

A/D CONV.

PLL

90

91

38

61

12

(EVR)

FB2203,

FB2205

(4-11)(4-12)

BATT SENS

ACV SENS

XRESET

VDD

BATT IN

XLANC ON

IC4501

DIGITAL8

MECHA

CONTROL

FB2291

(4-13)

(4-21)

81

49

48

25

29

50

47

66

14

5

57

Q904,905

CURRENT

LIMITER

IC1502

AGC,

A/D CONV.

(4-19)

Q4804

I/F

DC PACK SW

Q4809,4810

LED DRIVE

Q4808

LED DRIVE

L1501

BATT LI3V

BATT SIG

CN926

PANEL 4.75V

PANEL -15.3V

PANEL 13.3V

PANEL 2.8V

BL CONT

D 2.8V

CN927

BL REG

EX UNREG

CN931

(4-29) (4-29)

IC4901

EEPROM

D 2.8V

VTR UNREG

MT 5V

IR DRV

1

2

1

5

22

45

44

47

12

9

5

6

10

4

CN923

1 1

34

36

23

26

FB4901

2

6

21

46

43

48

11

34

36

23

26

IC4902

HI8/STD8

CONTROL

Q901-903

BT001

VANADIUM

LITHIUM

BATTERY

(SEE PAGE 4-45)

IO-68

BOARD

XVTR MODE SW

LANC SW

CN105

LED

EVER 3.0V

XPOWER LED

XCHARGE LED

A 4.75V

CN104

RFU DC OUT

CN103

(SEE PAGE 4-61)

FK-78 BOARD

CN001

LED

EX-36

BOARD

18

19

CN203

MECHA

1

IR 5V

2

FP-571

(SEE PAGE 4-37)

1

6

6

8

10

12

1

CN205

CAP VS

DRUM ERROR

CAP ERROR

DRUM VS

1

2

CN361CN924

(FLEXIBLE)

S001

POWER

CN001

6

8

10

12

RFU DC OUT

J102

(CHARGE)

PD-130 BOARD

PANEL 4.75V

18

PANEL -15.3V

22

PANEL 13.3V

6

PANEL 2.8V

17

BL CONT

23

CN5503

BL REG

2

CN5607

CN204

MULTI

CONNECTOR

(SEE PAGE 4-65)

(4-33)

IC4401

(RABI)

DRUM

MOTOR DRIVE

29

DRUM FG,PG AMP

27

LOADING

MOTOR DRIVE

6

REEL FG AMP

TAPE TOP,END DET

DRUM,CAP ERROR AMP

D362,363

F361

OFFON

D001

(POWER)

L5501

IR LED

SUPER

LASER

LINK

FP-575

IC001

REMOTE

COMMANDER

RECEIVER

L5504

L5503

IC5501

RGB DRIVE

(4-55)

IC5601,5602

INVERTER

BACKLIGHT

R4407

R4411

IR-38 BOARD

(SEE PAGE 4-27)

(FLEXIBLE)

(SEE PAGE 4-45)

(4-45)

FP-246

(SEE PAGE 4-45)

L5502

(4-55)

IC5502

TIMING

GENERATOR

DRIVE

CN4403

SENSOR VCC

TAPE LED(A)

CN4404

(FLEXIBLE)

Q5502-5506

28

IC5503

(4-57)

7

8

9

10

13

9

B710 MECHA

DECK

(SEE PAGE 4-33)

5

(4-56)

BL HIGH

CAPSTAN

TAPE LED

CN5501

4

2

CN5604

MOTOR

T REEL,

S REEL

SENSOR

J001

24

3

18

23

10

(LANC)

(GV-D800/D800E)

LCD

UNIT

ND901

BACKLIGHT

3-11 3-12E

SECTION 4

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/2)

GV-D200/D200E/D800/D800E

10

CN922

1 XVTR_MODE_SW

1XVTR_MODE_SW

2 LANC_SIG

2LANC_SIG

3 XLANC_JACK_IN

3XLANC_JACK_IN

4 REG_GND

4REG_GND

5 LANC_DC

5LANC_DC

6 REG_GND

6REG_GND

7RCH_DET

7 RCH_OUT_DET

8LCH_DET

8 LCH_OUT_DET

9AUDIO_R_OUT

9 AUDIO_R_OUT

10AUDIO_GND

10 REG_GND

11AUDIO_L_OUT

11 AUDIO_L_OUT

12RF_DC_OUT

12 RF_DC_OUT

13 V_JACK_OUT_DET

13V_JACK_DET

14 VIDEO_OUT_GND

14VIDEO_OUT_GND

15 VIDEO_OUT

15VIDEO_OUT

16 S_C_GND

16S_C_GND

17 S_C_OUT

17S_C_OUT

18 S_Y_GND

18S_Y_GND

19 S_Y_OUT

19S_Y_OUT

20 REG_GND

20REG_GND

21 XS_JACK_OUT_DET

21XS_JACK_OUT_DET

22 EVER_3.0V

22EVER_3.0V

23 XIR_LED_ON

23XIR_LED_ON

24 KEY_AD5

24KEY_AD5

25 DIAL_A

25DIAL_A

26 DIAL_B

26DIAL_B

27 XS_JACK_IN_DET

27XS_JACK_IN

28 S_Y_GND

28S_Y_GND

29 S_Y_IN

29S_Y_IN

30 S_C_GND

30S_C_GND

31 S_C_IN

31S_C_IN

32 REG_GND

32REG_GND

33 AV_JACK_IN_DET

33AV_JACK_IN

34 VIDEO_GND

34VIDEO_GND

35 VIDEO_IN

35VIDEO_IN

36 REG_GND

36REG_GND

37 AUDIO_L_IN

37AUDIO_L_IN

38 AUDIO_GND

38AUDIO_GND

39 AUDIO_R_IN

39AUDIO_R_IN

40 XHP_SENS

40XHP_SENS

41 HP_R

41HP_R

42 HP_GND

42HP_GND

43 HP_L

43HP_L

44 XCHARGE_LED

44XCHARGE_LED

45 XPOWER_LED

45XPOWER_LED

46 XSIRCS_SIG

46XSIRCS_SIG

47 A_4.75V

47A_4.75V

48 REG_GND

48REG_GND

49 REG_GND

49REG_GND

50 REG_GND

50REG_GND

50P

CN001

924 7

50P

1

38

5 13

A

J102

VIDEO

OUT

RFU

DC OUT

L

(MONO)

AUDIO

B

C

D

0UT

J103

S VIDEO

J101

S VIDEO

R

C

Y

S

OUT

G

S

IN

G

S

G

C

Y

S

G

IO-68 BOARD

D109

(SUPER LASER LINK)

S103

SEL/PUSH

EXEC

S101

E

S102

S104

S105

F

J001

G

LANC

H

FP-575

FLEXIBLE

POWER

OFF-ON

S001

1 XVTR_MODE_SW

2 LANC_SIG

3 REG_GND

4 REG_GND

5 REG_GND

6 LANC_DC

6PCN105

16PCN104

6

SUPER LASER LINK

MENU

VOLUME+

VOLUME-

50PCN5713

AV_JACK_IN_DET

FP-247

FLEXIBLE

1LANC_SIG

1 LANC_SIG

2XVTR_MODE_SW

2 XVTR_MODE_SW

3REG_GND

3 REG_GND

4XLANC_JACK_IN

4 XLANC_JACK_IN

5REG_GND

5 REG_GND

6LANC_DC

6 LANC_DC

7LCH_OUT_DET

7 LCH_DET

8RCH_OUT_DET

8 RCH_DET

9REG_GND

9 AUDIO_GND

10AUDIO_R_OUT

10 AUDIO_R_OUT

11RF_DC_OUT

11 RF_DC_OUT

12AUDIO_L_OUT

12 AUDIO_L_OUT

13VIDEO_OUT_GND

13 VIDEO_OUT_GND

14V_JACK_OUT_DET

14 V_JACK_OUT_DET

15S_C_GND

15 S_C_GND

16VIDEO_OUT

16 VIDEO_OUT

17S_Y_GND

17 S_Y_GND

18 S_C_OUT

18S_C_OUT

19 REG_GND

19REG_GND

20 S_Y_OUT

20S_Y_OUT

21 EVER_3.0V

21EVER_3.0V

22 XS_JACK_OUT

22XS_JACK_OUT_DET

23 KEY_AD5

23KEY_AD5

24 XIR_LED_ON

24XIR_LED_ON

25 DIAL_B

25DIAL_B

26 DIAL_A

26DIAL_A

27 S_Y_GND

27S_Y_GND

28 XS_JACK_IN

28XS_JACK_IN_DET

29 S_C_GND

29S_C_GND

30 S_Y_IN

30S_Y_IN

31 REG_GND

31REG_GND

32 S_C_IN

32S_C_IN

33 VIDEO_GND

33VIDEO_GND

AV_JACK_IN

34

34

35 REG_GND

35REG_GND

36 VIDEO_IN

36VIDEO_IN

37 AUDIO_GND