Sony FVP-1E Service Manual

FVP-1E

SERVICE MANUAL

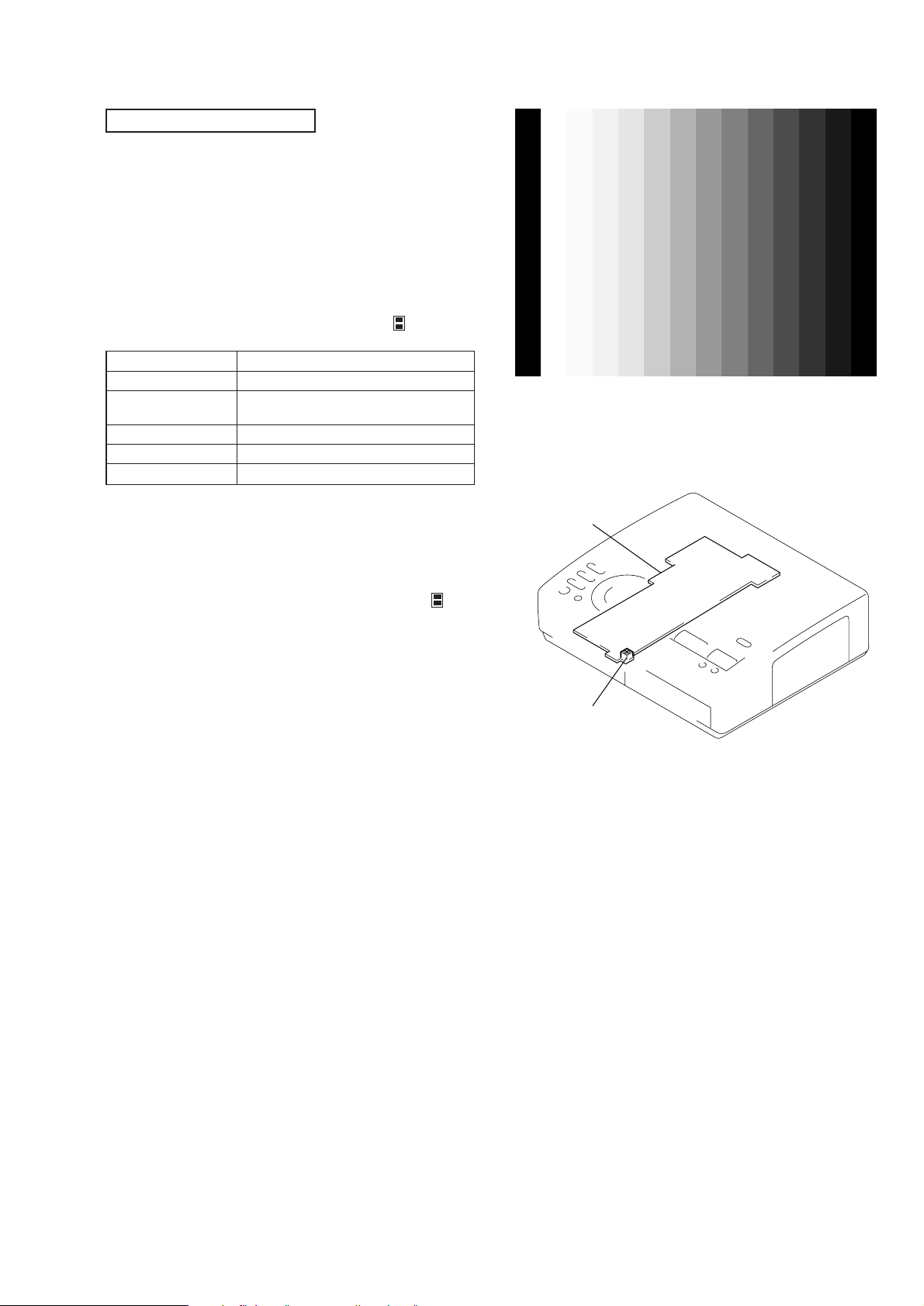

SPECIFICATIONS

Printing system Sublimation dye transfer printing

(Yellow/Magenta/Cyan 3 pass)

Effective pixels 1,376 (H) × 1,024 (V) dot

Printing size 114 (H) × 85 (V) mm (maximum)

(41/2 × 33/8 inches)

Gradations 256 levels (8 bits), per color (24 bits)

Approx. 16,770,000 colors

Printing time (excluding data transmission time)

Approx. 100 seconds per sheet

Input/output connectors VIDEO INPUT connector (phono jack

× 1)

1 Vp-p, 75 ohms (unbalanced),

sync nagative

S VIDEO INPUT connector

(4-pin mini-DIN × 1)

Y: 1 Vp-p, 75 ohms (unbalanced),

sync negative

C: 0.286 Vp-p (color burst),

75-ohms (unbalanced)

VIDEO OUTPUT connector

(phono jack × 1)

1 Vp-p, 75 ohms (unbalanced),

sync negative

3.5" Floppy disk drive

AEP Model

UK Model

Print cartridge and Print paper (100 × 140 mm (4 × 55/8inches))

VPM-P50STB (Standard papers)

VPM-P200STB (Standard papers)

VPM-P50WTB (Adhesive-label sheets

for sticker)

VPM-P50S04B (4-cut adhesive-label

sheets for sticker)

VPM-P50S16B (16-cut adhesive-label

sheets for sticker)

Power requirements 220 – 240 V AC

Power consumption 72 W (printing)

13 W (stand by mode)

Operating temperature 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity 20% to 80%

Dimensions Approx. 301 × 83 × 246 mm

(w/h/d, excluding protruding parts)

(12 × 33/8 × 97/8 inches)

Mass Approx. 3 kg (6 lb 10 oz)

Supplied accessories AC power cord (1)

Video connecting cable (1)

CD-ROM (for Microsoft Windows

95/98/NT4.0) (1)

Instruction Manual (1)

User’s guide for the printer utility (1)

Warranty (1)

Design and specifications are subject to change without notice.

9-928-114-31

DIGITAL COLOR PRINTER

TABLE OF CONTENTS

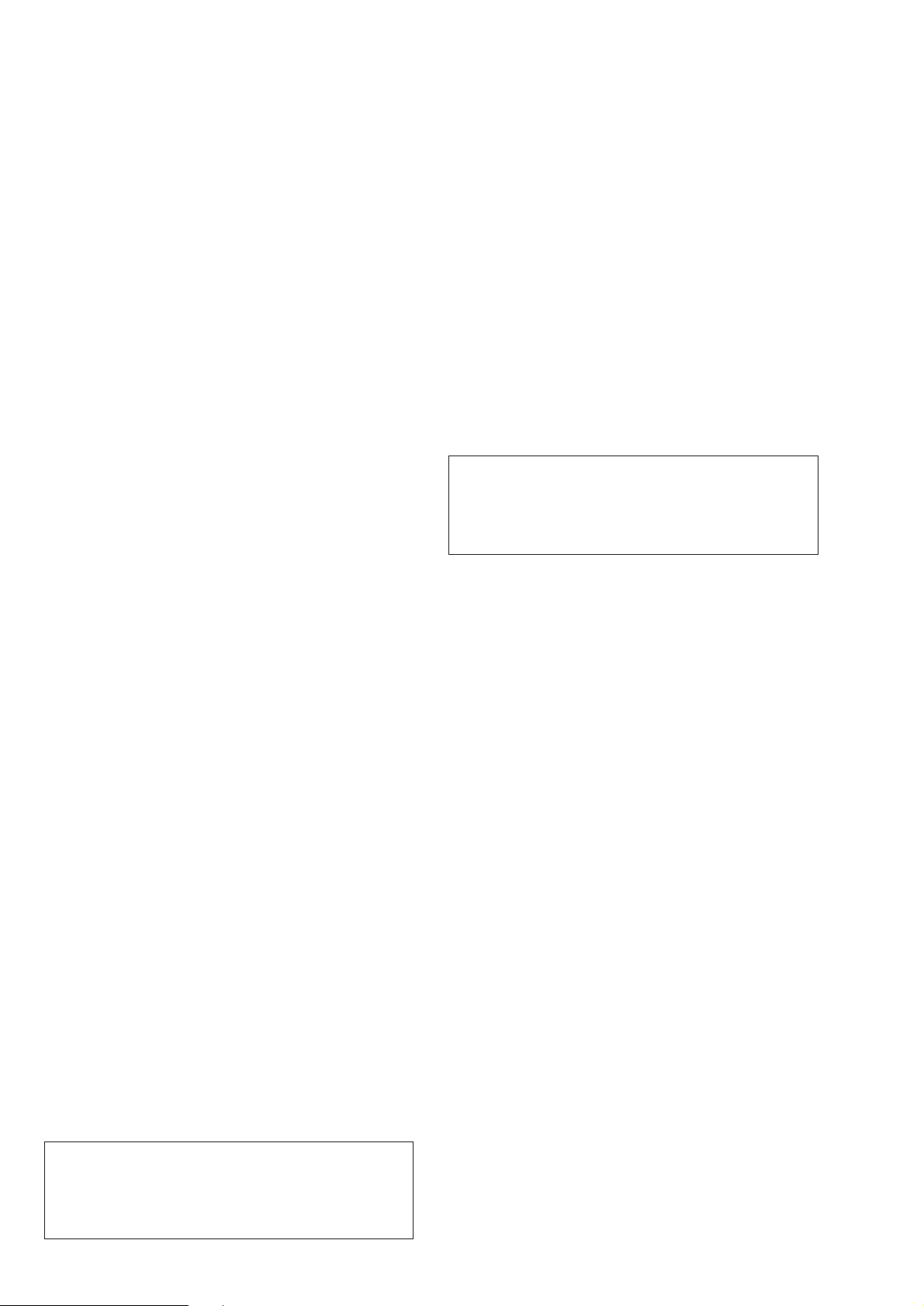

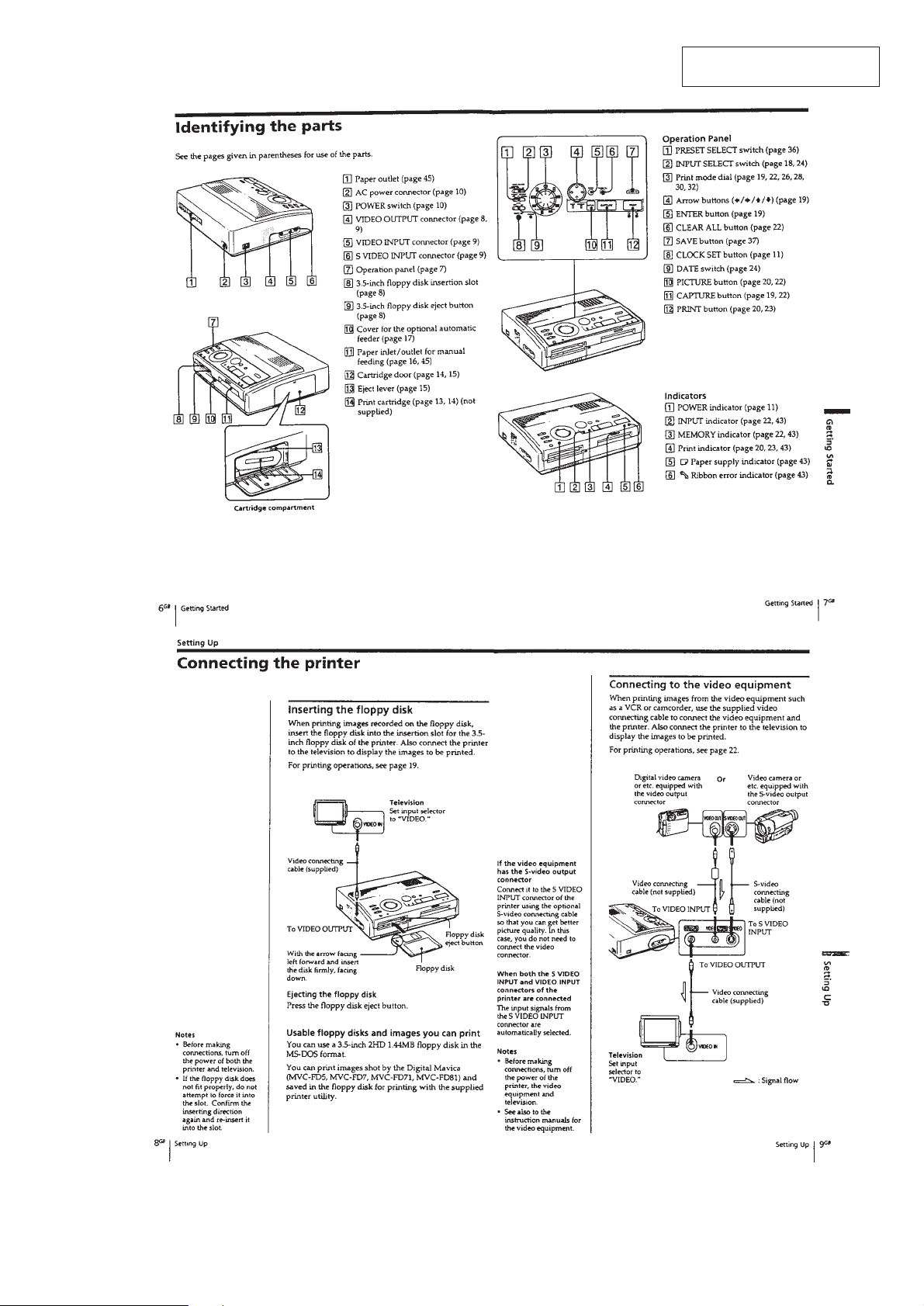

1. GENERAL

Identifying the parts ..................................................... 1-1

Setting Up .................................................................... 1-1

Printing ......................................................................... 1-4

Making V arious Prints.................................................. 1-5

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

2. DISASSEMBLY ...................................................... 2-1

3. MECHANICAL ADJUSTMENTS.................... 3-1

4. ELECTRICAL ADJUSTMENTS...................... 4-1

5. DIAGRAMS

5-1. Block Diagram – VIDEO Section – ........................... 5-1

5-2. Block Diagram – MAIN Section – .............................. 5-5

5-3. Frame Schematic Diagram .......................................... 5-9

5-4. Notes for Printed Wiring Board and

Schematic Diagram...................................................... 5-12

5-5. Printed Wiring Board – VS-39 Board – ..................... 5-13

5-6. Schematic Diagram – VS-39 Board – ......................... 5-13

5-7. Printed Wiring Board – FE-39 Board –....................... 5-14

5-8. Schematic Diagram – FE-39 Board –.......................... 5-14

5-9. Printed Wiring Board – VI-39 Board – ...................... 5-15

5-10. Schematic Diagram – VI-39 Board – .......................... 5-17

5-11. Printed Wiring Board – DK-39 Board –..................... 5-23

5-12. Schematic Diagram – DK-39 Board (1/3) – ............... 5-25

5-13. Schematic Diagram – DK-39 Board (2/3) – ............... 5-30

5-14. Schematic Diagram – DK-39 Board (3/3) – ............... 5-35

5-15. Printed Wiring Board – SW-39 Board –..................... 5-37

5-16. Schematic Diagram – SW-39 Board – ........................ 5-39

5-17. Printed Wiring Boards

– MD-39/JD-39/RD-39/HP-39 Boards – .................... 5-41

5-18. Schematic Diagram

– MD-39/JD-39/RD-39/HP-39 Boards – .................... 5-43

5-19. IC Pin Function Description ........................................ 5-51

6. EXPLODED VIEWS ............................................. 6-1

7. ELECTRICAL PARTS LIST ............................ 7-1

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’ s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laite valmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

•Microsoft, MS, MS-DOS and Windows

are registered

trademarks of Microsoft Corporation in the United States

and other countries.

•IBM PC/AT is a registered trademarks of IBM Corpor ation

of the U.S.A.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMA TIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

SECTION 1

GENERAL

This section is extracted from

instruction manual.

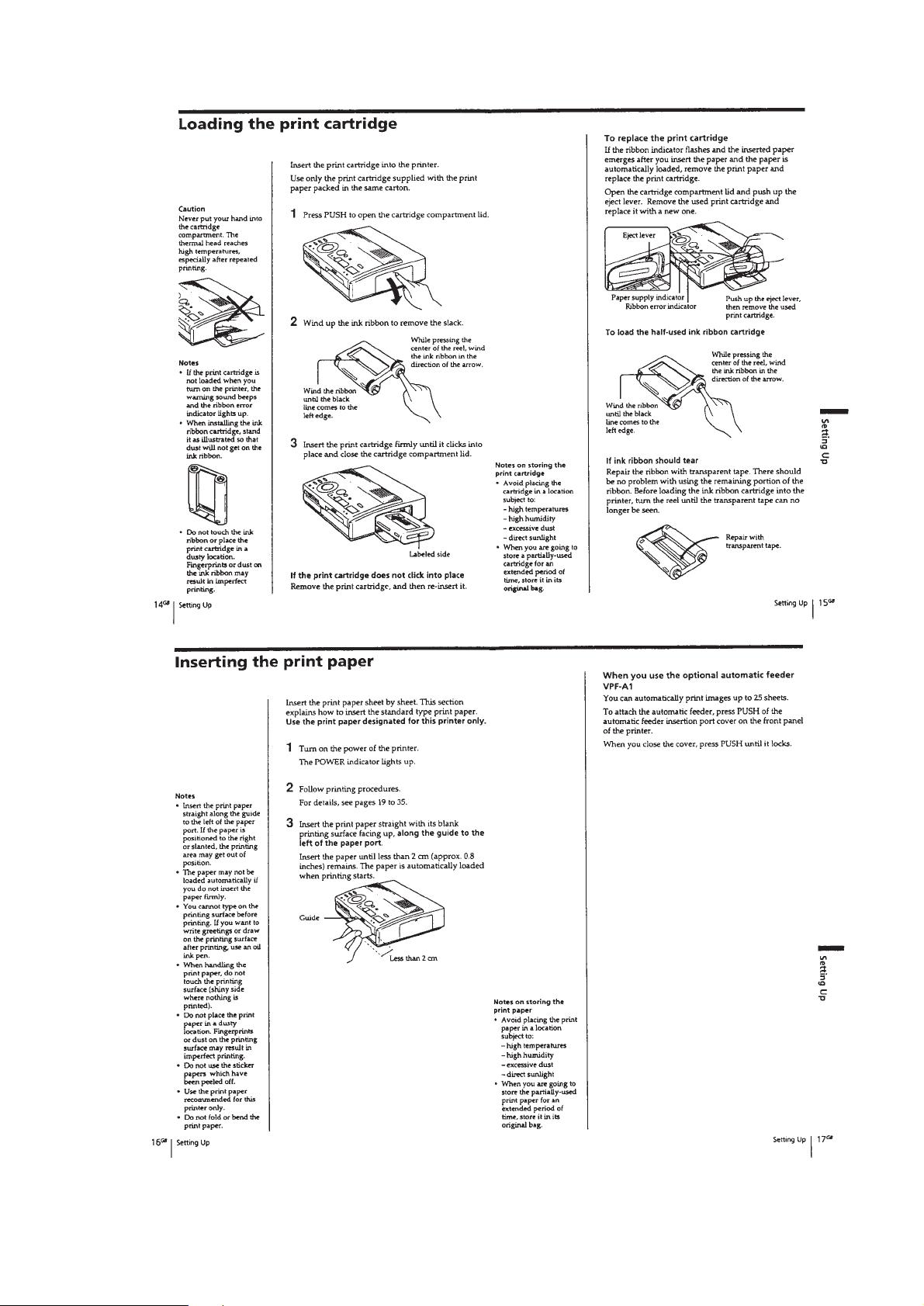

1-1

1-2

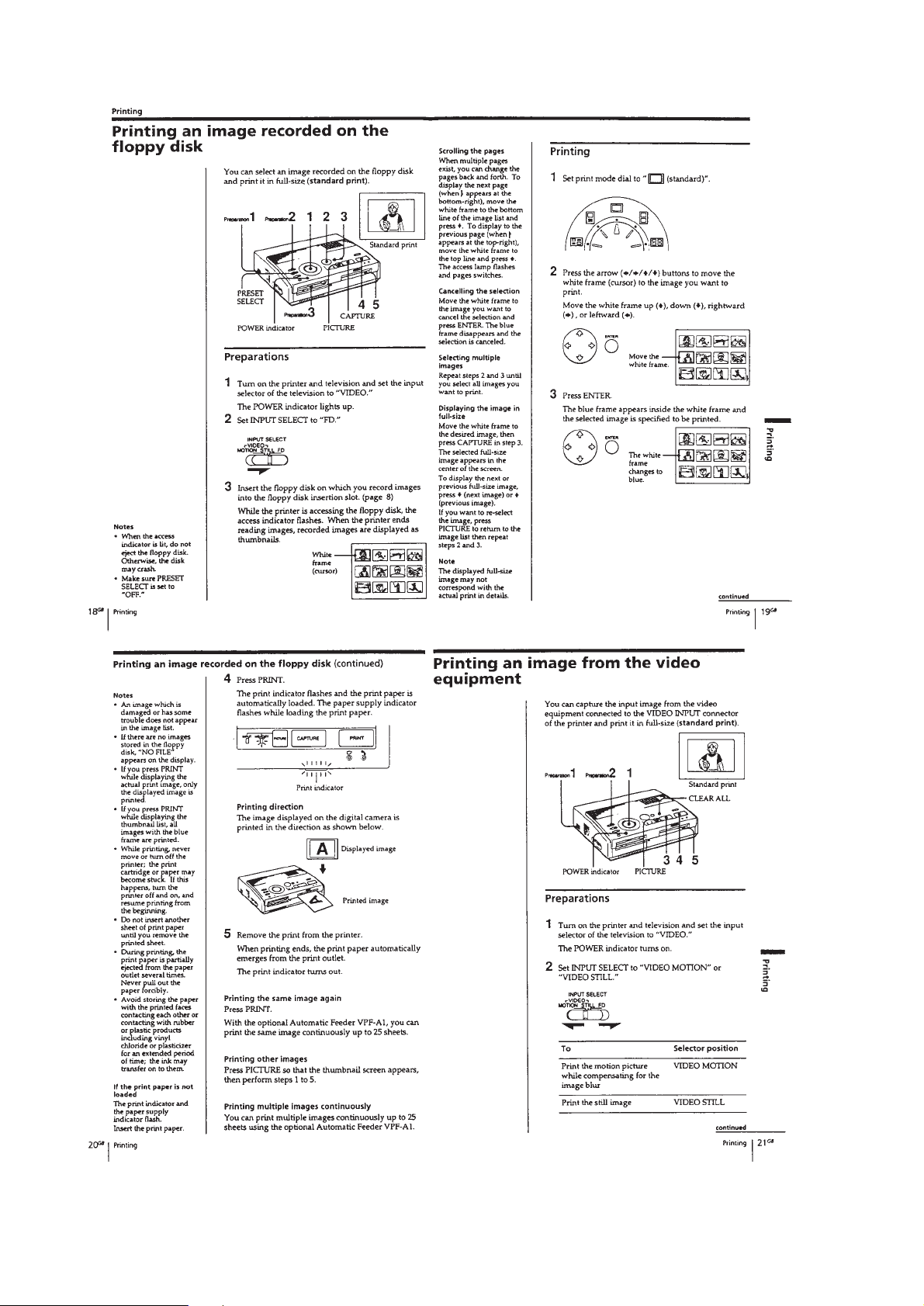

1-3

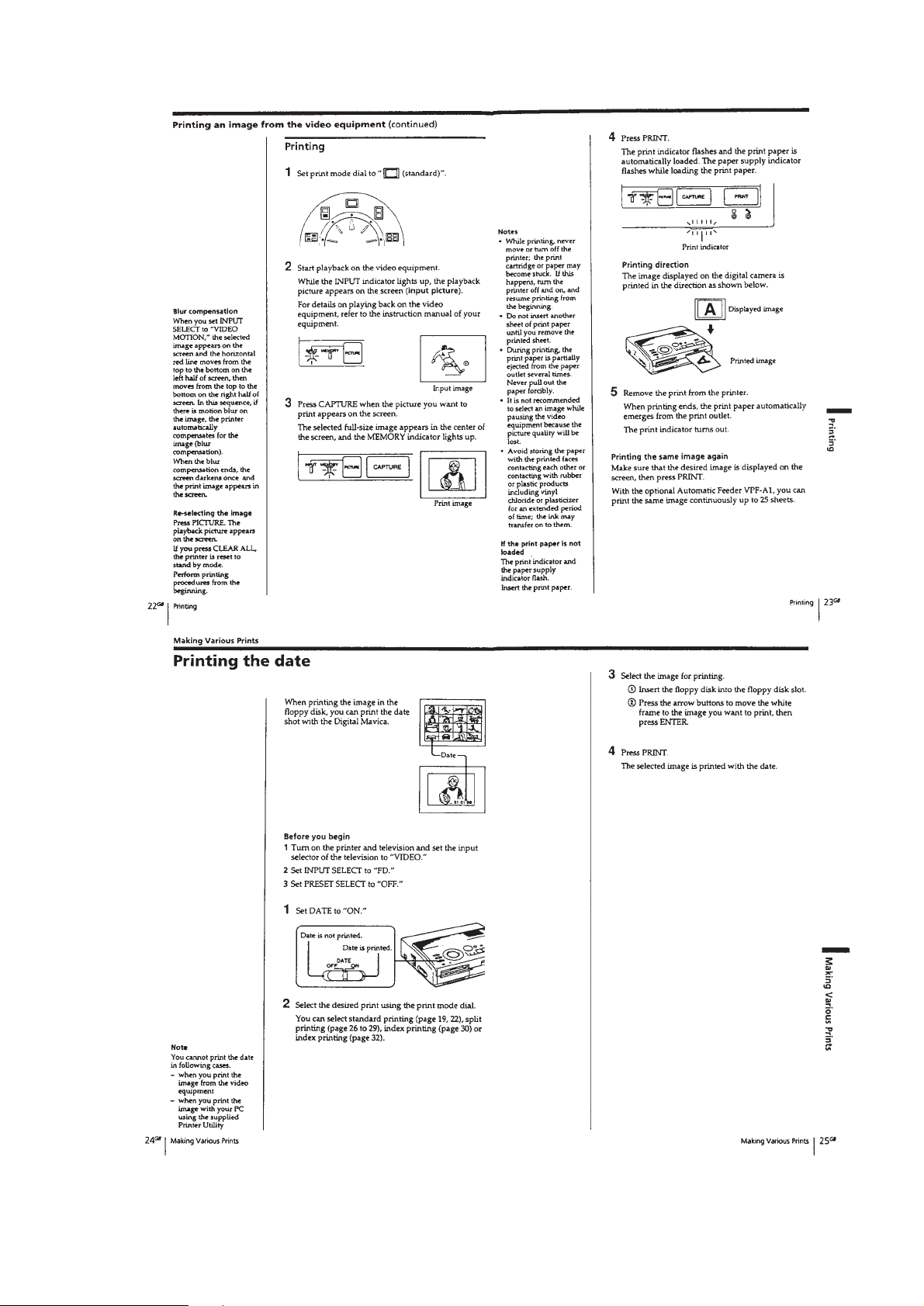

1-4

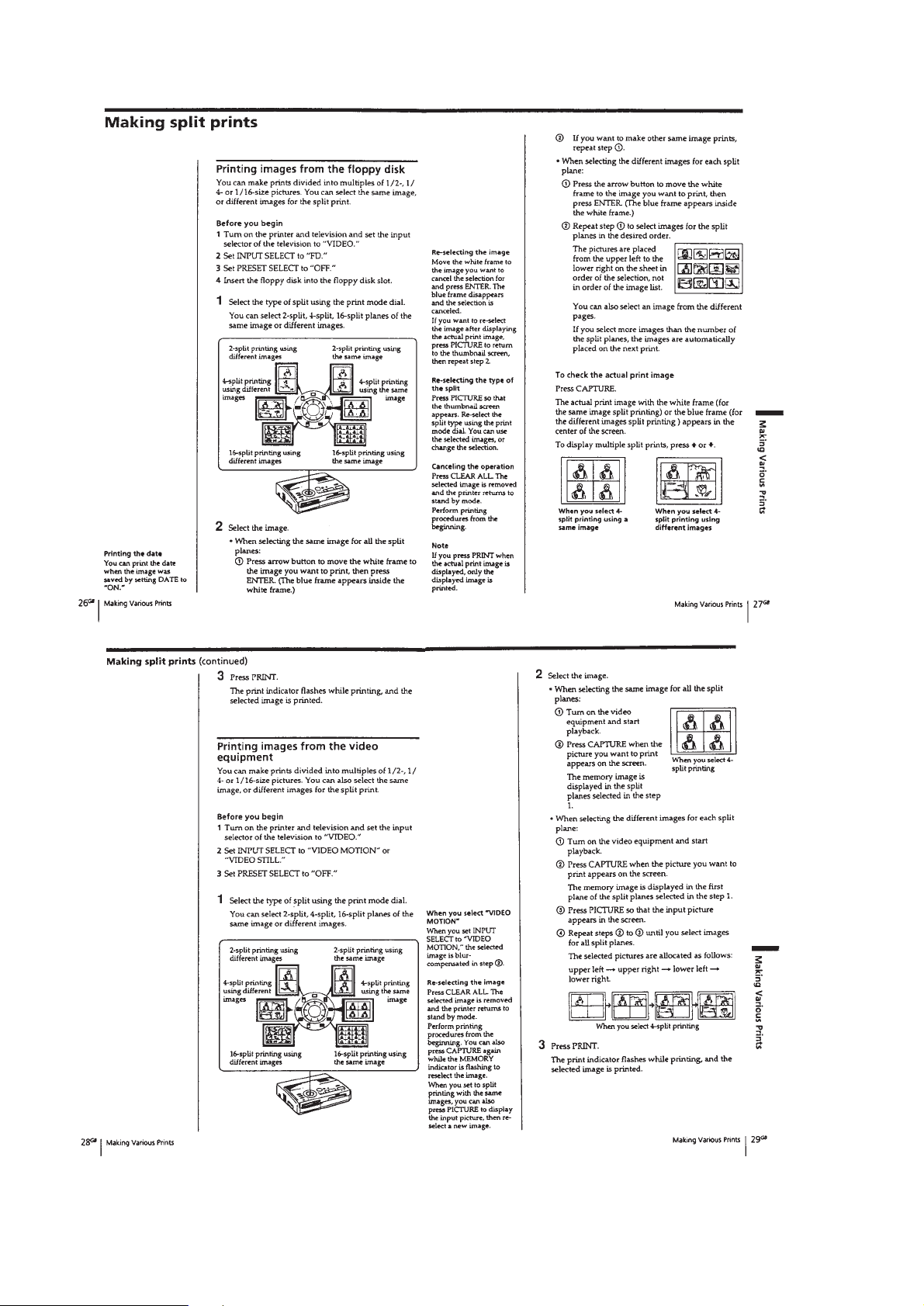

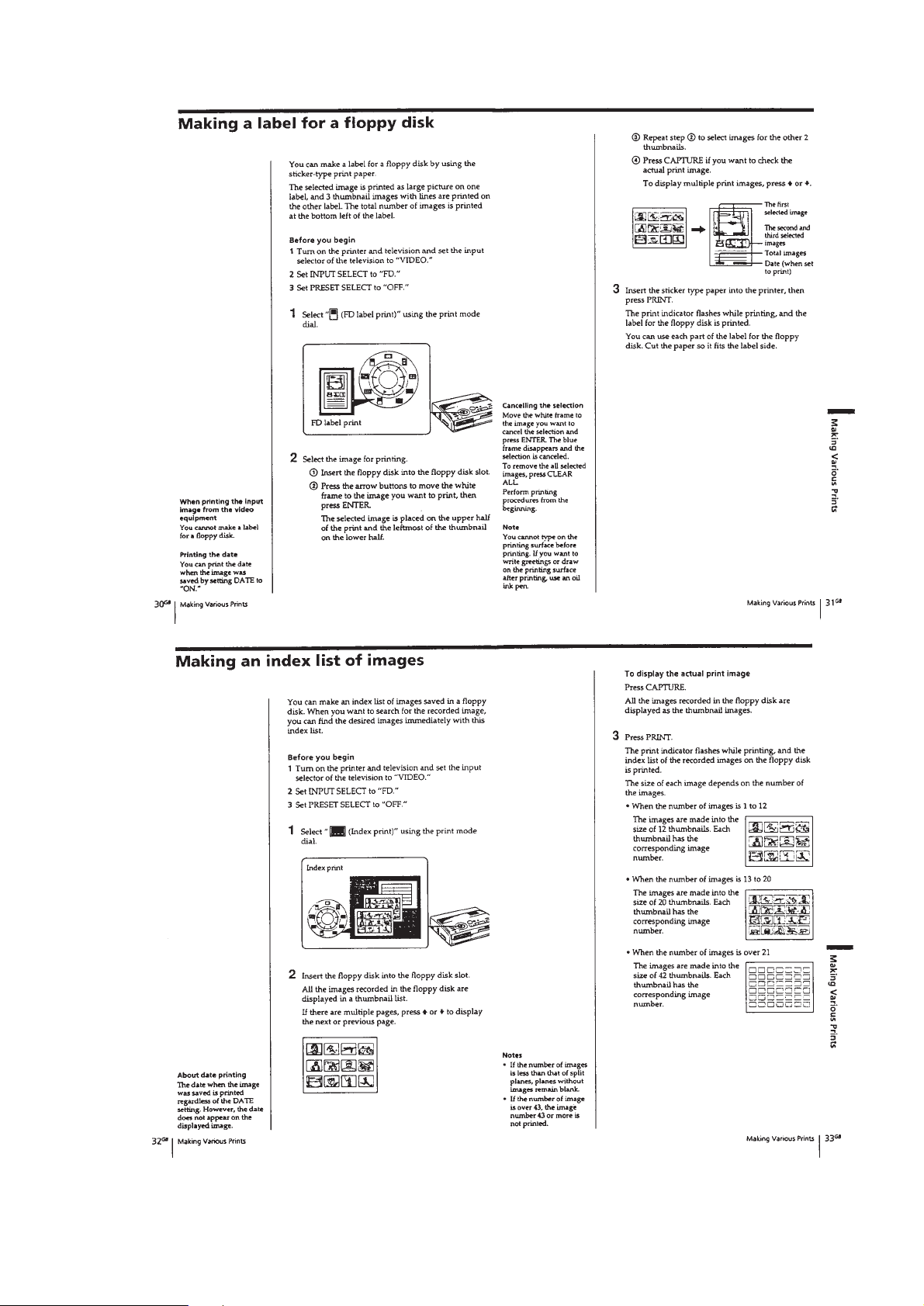

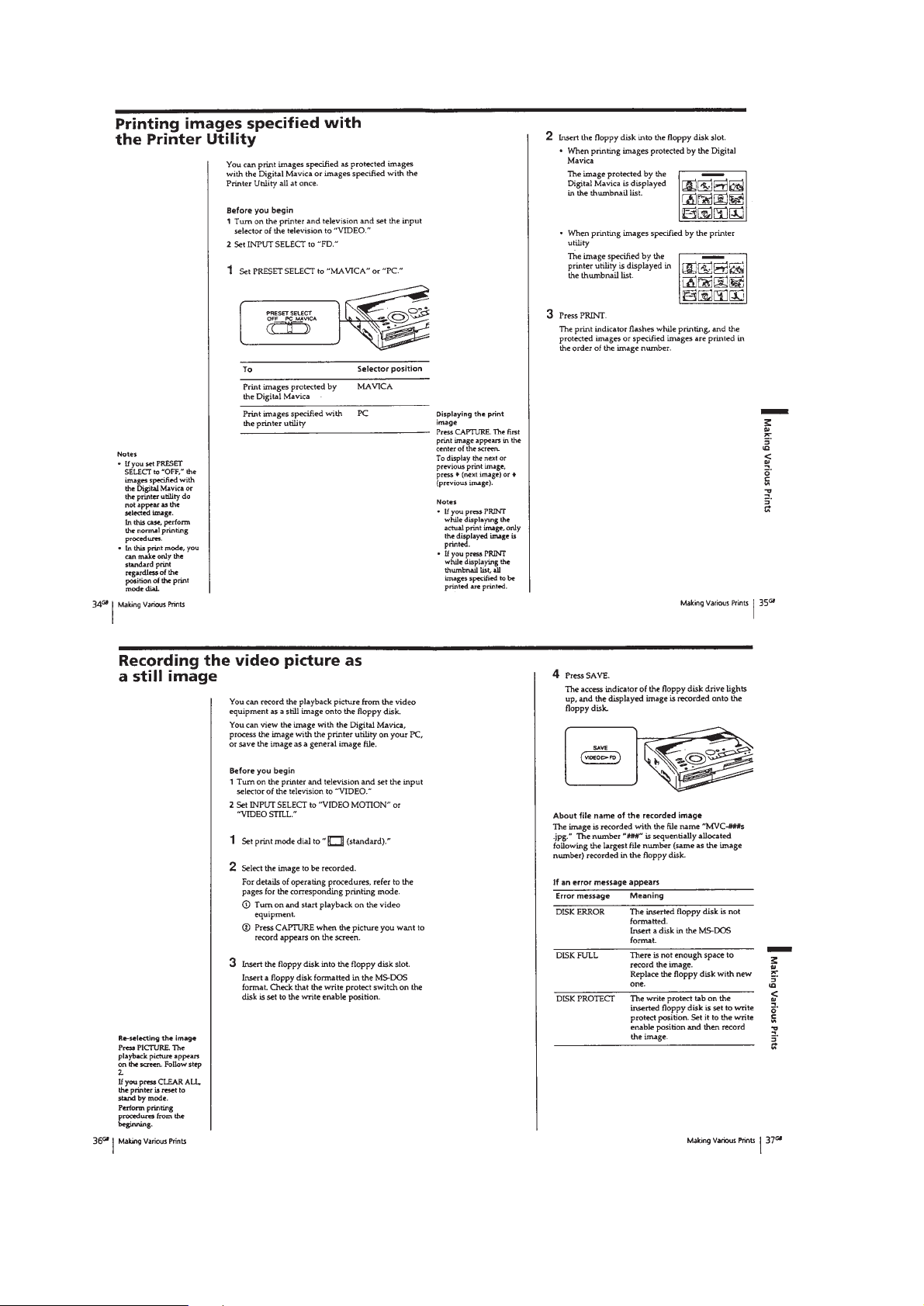

1-5

1-6

1-7

1-8 E

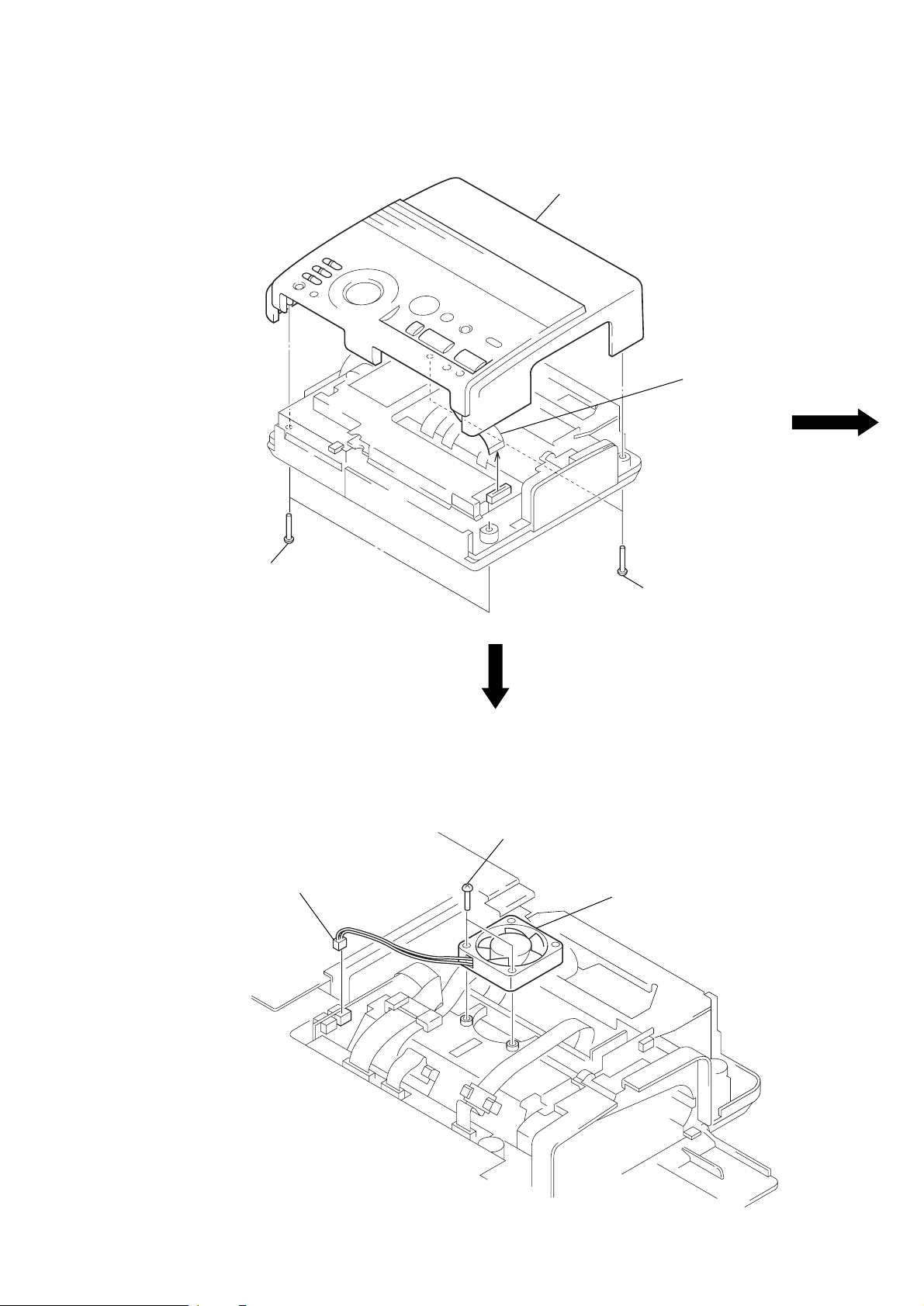

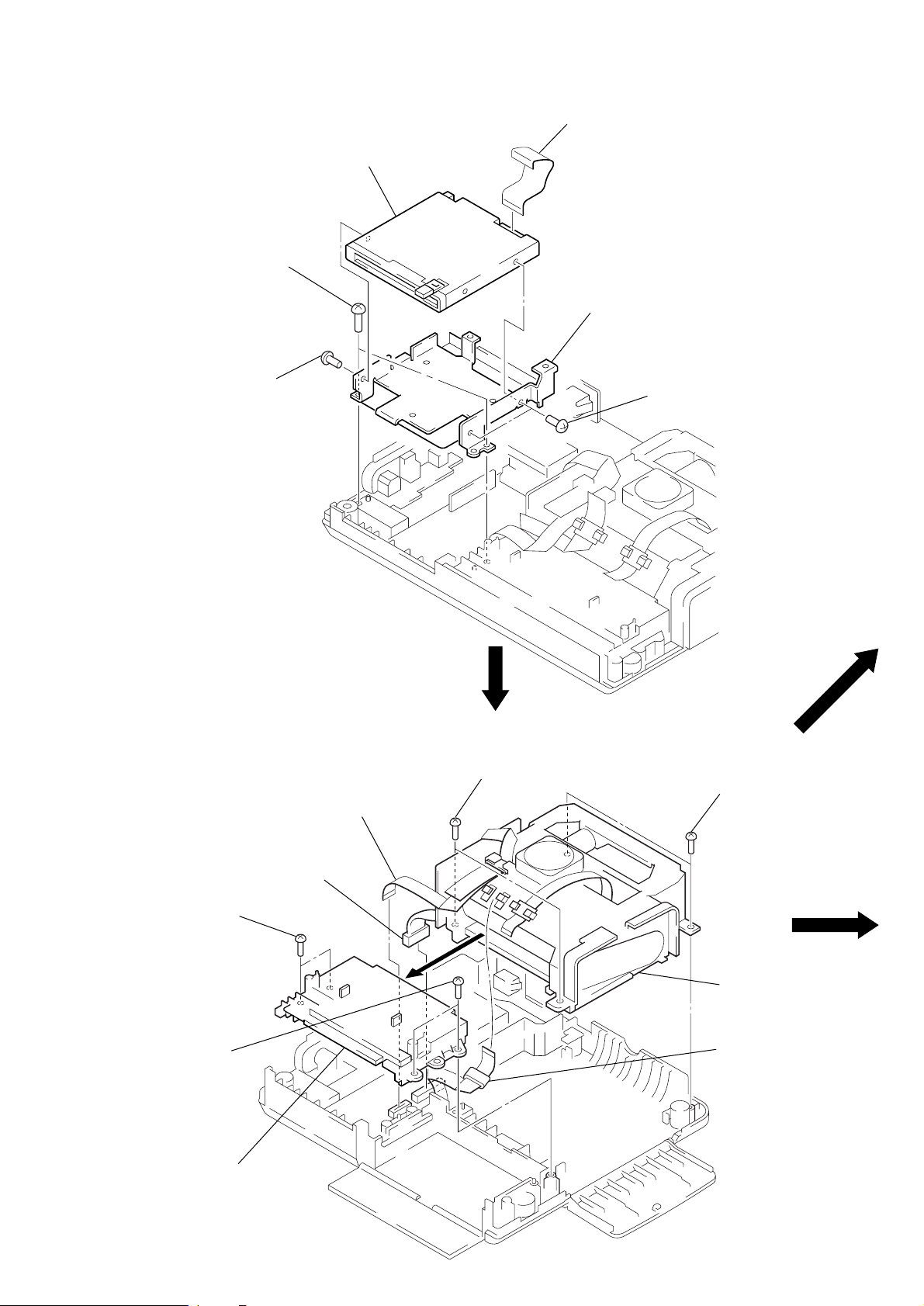

SECTION 2

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

UPPER CABINET ASS’Y

2

upper cabinet ass’y

3

flat cable (DKSW39

(CN504)

1

two screws

(BVTP3

×

DC FAN (HEAD FAN) (M901)

1

connector

(CN1938)

20)

2

two screws

(BTP2.6

×

12)

1

two screws

(BVTP3

3

DC fan (head fan) (M901)

×

20)

2-1

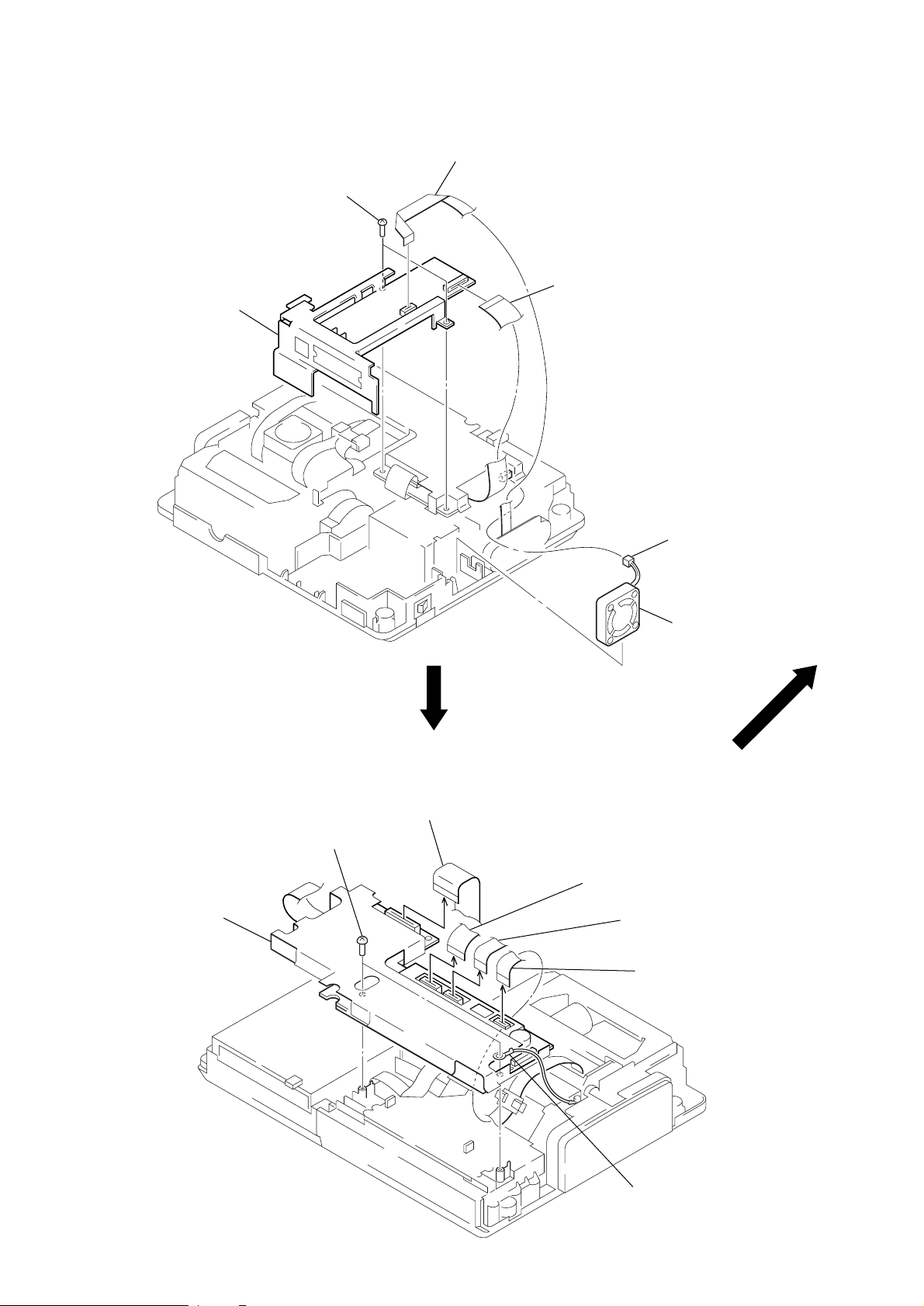

VI-39 BOARD SECTION, DC FAN (POWER FAN) (M905)

)

3

flat cable (VIVS39)

(CN101)

4

two screws

(BV2.6

×

8)

5

VI-39 board section

3

flat cable (VIDK20)

(CN102)

1

connector

(CN402)

DK-39 BOARD SECTION

4

DK-39 board section

2

two screws

(BV2.6

2

DC fan (power fan)

(M905)

1

flat cable (DKFD39)

(CN2100)

×

8)

1

FP-700 flexible board

(CN501)

1

flat cable (ADFE13)

(CN503)

1

flat cable (ADHE13

(CN502)

2-2

3

harness

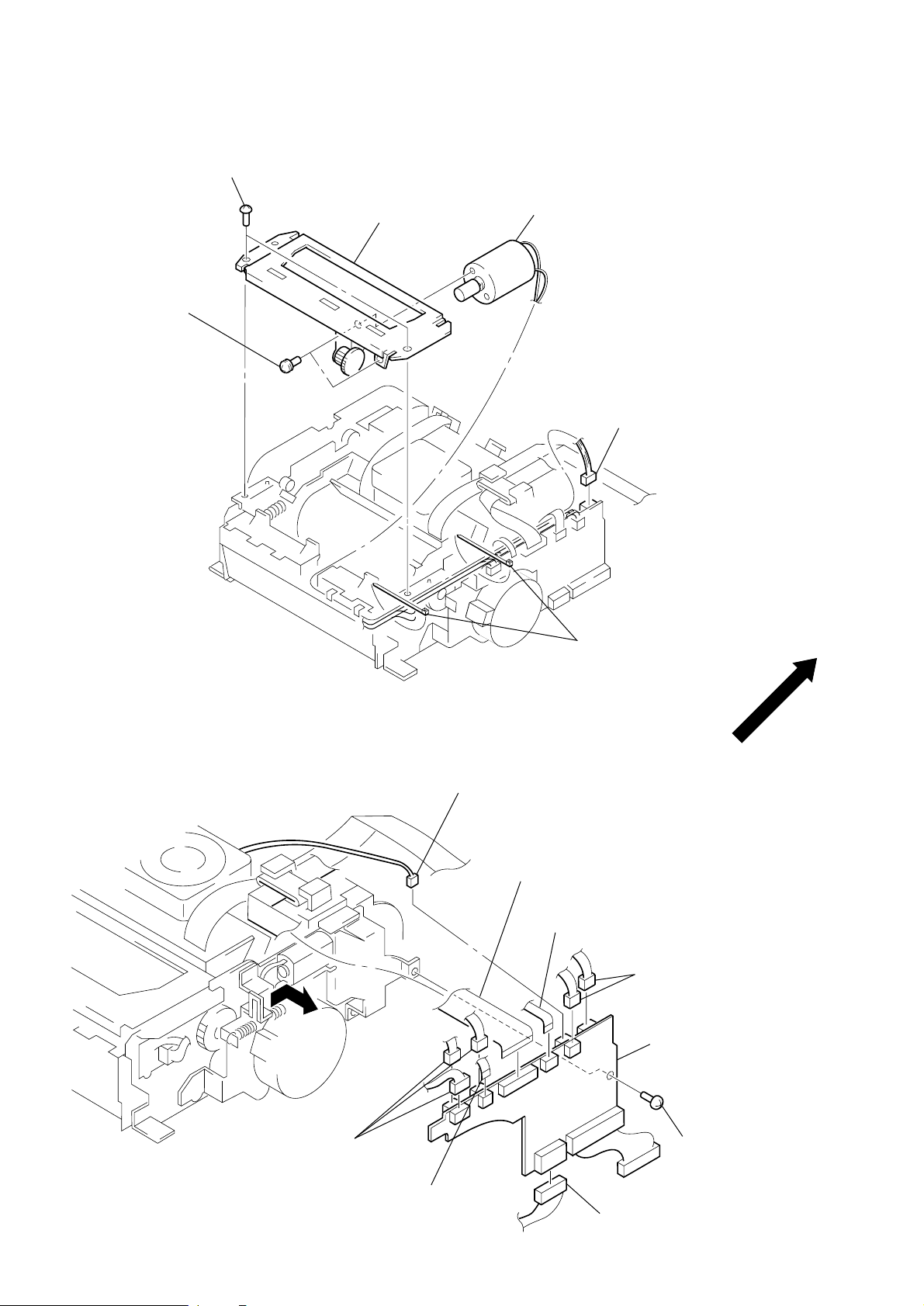

FLOPPY DISK DRIVE (3.5 inch)

s

5

floppy disk drive (3.5 inch)

2

two screws

(BV2.6

×

8)

4

screw

(M2

×

3)

1

flat cable (DKFD39)

3

FD bracket

4

two screw

(M2 × 3)

ESCUTCHEON (60) BLOCK ASS’Y, MECHANISM DECK SECTION

6

two screws

(BV2.6

×

8)

4

flat cable (POHE13)

(CN202)

3

connector

(CN201)

1

two screws

(BV2.6

×

8)

1

two screws

×

(BV2.6

2

escutcheon (60) block ass’y

8)

6

two screws

×

(BV2.6

7

machanism deck section

5

core (FPC)

8)

2-3

HEAD MOTOR BLOCK ASS’Y (HEAD UP/DOWN) (M902)

d

3

5

two screws

(PS3

×

4)

two screws

(BVTT2.6

×

6)

4

HM bracket ass’y

6

head motor block ass’y (head up/down)

(M902)

2

connector

(CN1940)

MD-39 BOARD

2

connector

(CN1938)

1

FP-700 flexible board

(CN1936)

1

FP-703 flexible board

(CN1934)

1

two clamps (LOW TYPE)

2

two connectors

(CN1940, 1941)

4

Removal the MD-39 boar

to direction of the arrow.

2

three connectors

(CN1931, 1932, 1935)

1

FP-702 flexible board

(CN1933)

2-4

2

connector

(CN1942)

3

screw

(BVTT2.6

×

6)

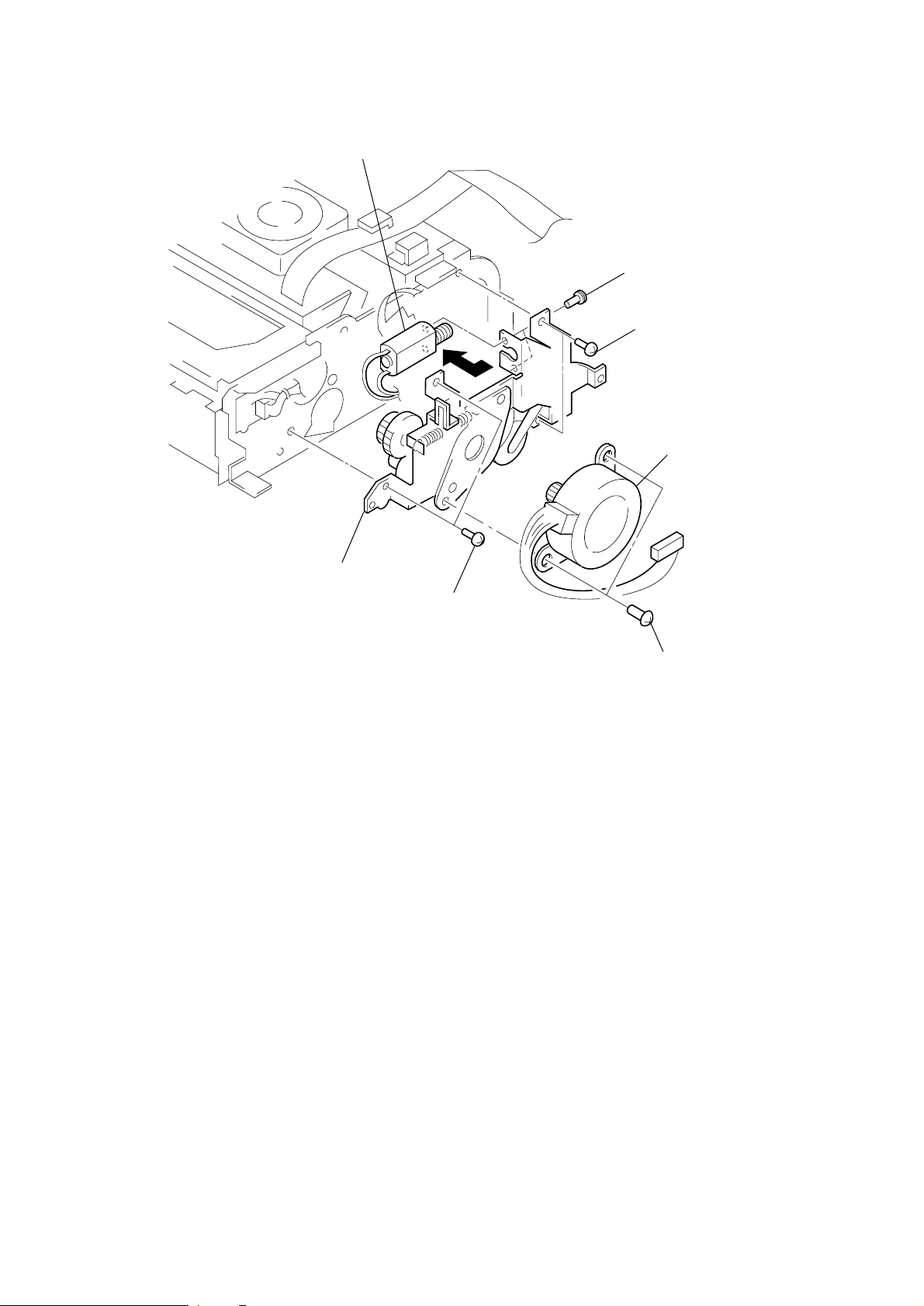

DC MOTOR (STEPPING MOTOR) (PLATEN) (M904), REEL MOTOR BLOCK ASS’Y (RIBBON) (M903)

6

reel motor block ass’y (ribbon) (M903)

5

two screws

(PS2

×

4)

3

two screws

(BVTT2.6

×

6)

2

DC motor (stepping motor)

(platen) (M904)

4

motor bracket ass’y section

3

two screws

(BVTT2.6

×

6)

1

two screws

(BVTT2.6

×

6)

2-5 E

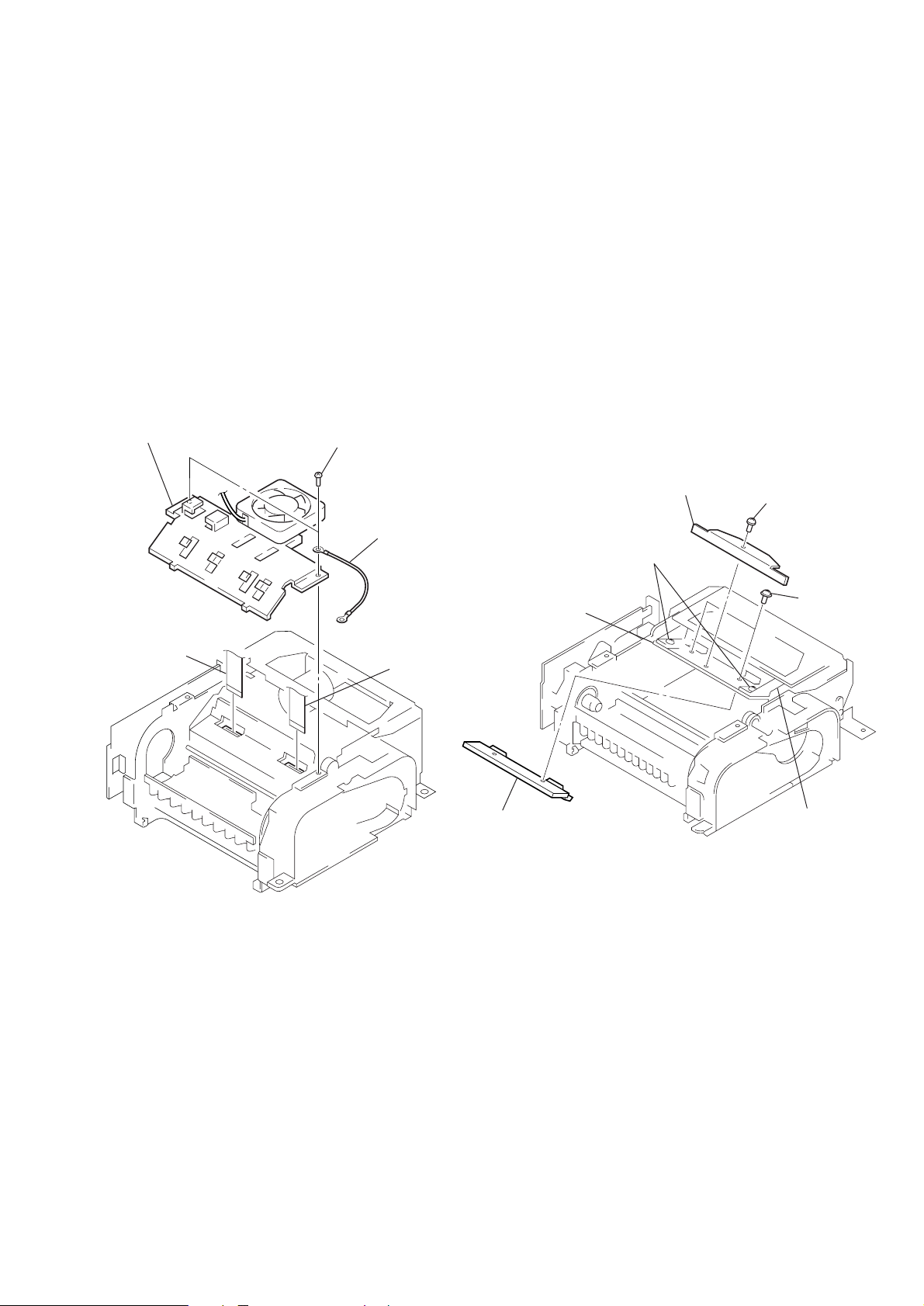

SECTION 3

)

MECHANICAL ADJUSTMENTS

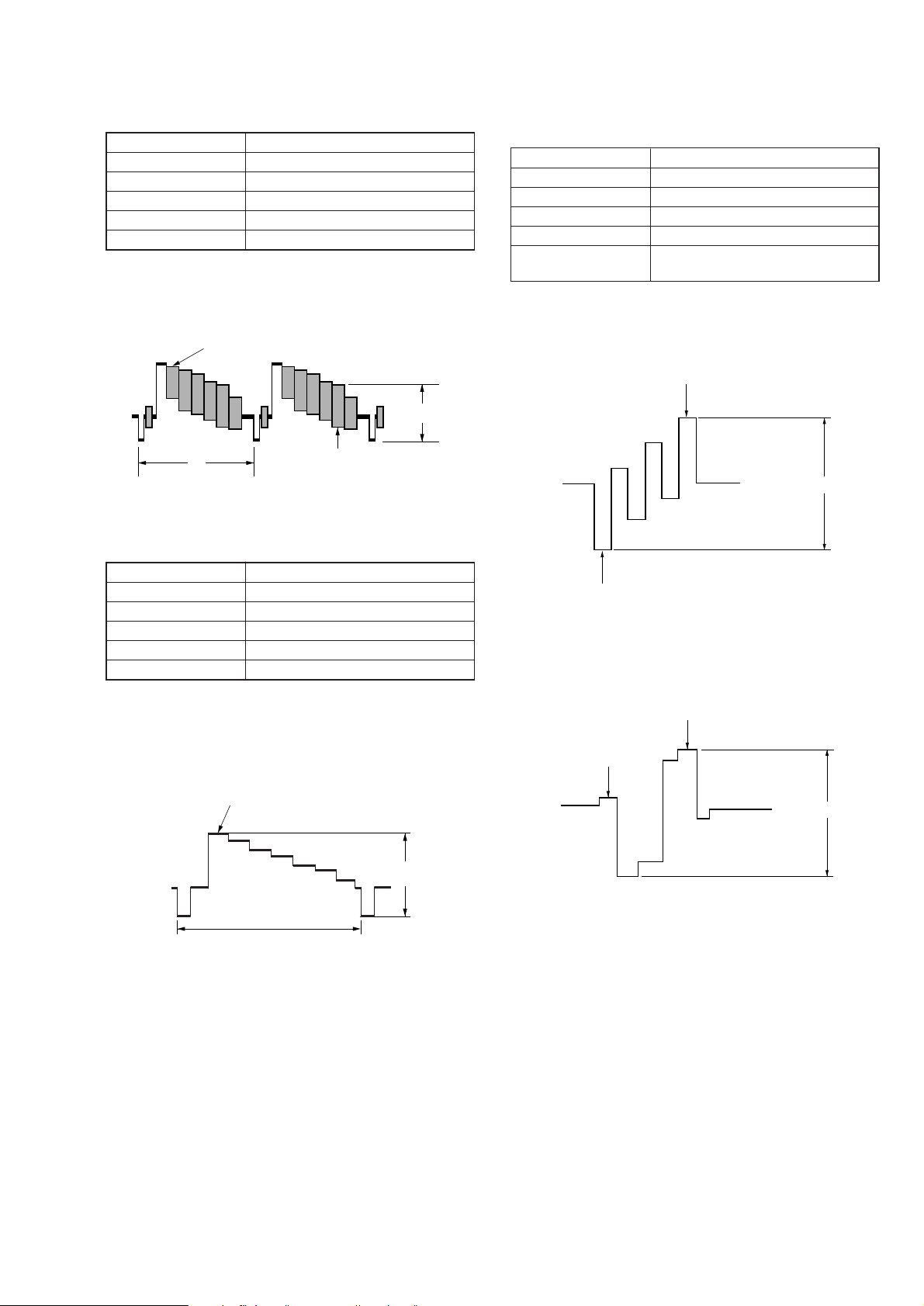

Replacing the Thermal Head

1) Before replacing the head, print the stair-step pattern with the

old head (faulty head).

Note 1: Only when the head is not entirely damaged with black or

white lines.

Note 2: To reproduce the stair-step pattern, refer to “Adjusting

Method 1” in “4. Electrical Adjustments”.

2) Remove the upper cabinet. (Refer to “2. Disassembly”.)

3) Remove the flat cables 1 (POHE13) and 2 (ADHE13) from

the thermal head. (Refer to Fig. 1)

4) Remove the two screws 3 (BVTT2.6 × 6) and remove the

harnesses 4 and fan holder 5. (Refer to Fig. 1)

5) Remove screw 6, (PS2.6 × 4) and remove the ribbon guide

7. (Refer to Fig. 2)

5

fan holder

3

two screws

(BVTT2.6

4

×

6)

harness

6) Remove the two scre ws 8 (PSW2.6 × 8) and remove the ther -

mal head 9 from the heat sink 0. (Refer to Fig. 2)

Note: Do not remove the screw !™ fixing the heat sink 0 and head

arm !¡.

7) Replace the thermal head 9.

Note: Make sure that the silicon grease (white) does not stick onto

the printing screen of the thermal head. If it does, remove with

alcohol.

8) Assemble in the reverse order of steps 2) to 6).

9) Perform “Head Voltage Adjustment” of “4. Electrical Adjustments” (Page 4-3).

7

!™

two screws

Note: Do not remove

the screw.

ribbon guide

6

screw

(PS2.6

×

4)

1

flat cable

(POHE13)

Fig. 1

2

flat cable

(ADHE13)

0

heat sink

9

thermal head

Fig. 2

8

two screws

(PSW2.6

!¡

head arm

×

8

3-1 E

SECTION 4

ELECTRICAL ADJUSTMENTS

During the adjustment, see the Adjustment and Adjustment Pats on page 4-7.

Pre-Adjustment Preparations

1. Equipment required

Electrical adjustment requires the following measuring equipment.

(1) Monitor TV

(2) Oscilloscope: 2 phenomena, bend 30 MHz or more, with de-

lay mode (use 10 : 1 probe unless otherwise specified)

(3) Frequency counter

(4) Pattern generator

(5) Digital voltmeter

(6) Video print paper

(7) Video print cartridge

(8) Vector scope

If S-VIDEO is designated

•

If pattern generator does not provide Y/C separate

output terminals

Pattern Generator

VIDEO OUT

(75

Ω

VTR with S-VIDEO terminal (E-E mode)

VIDEO IN

)

S-VIDEO OUT

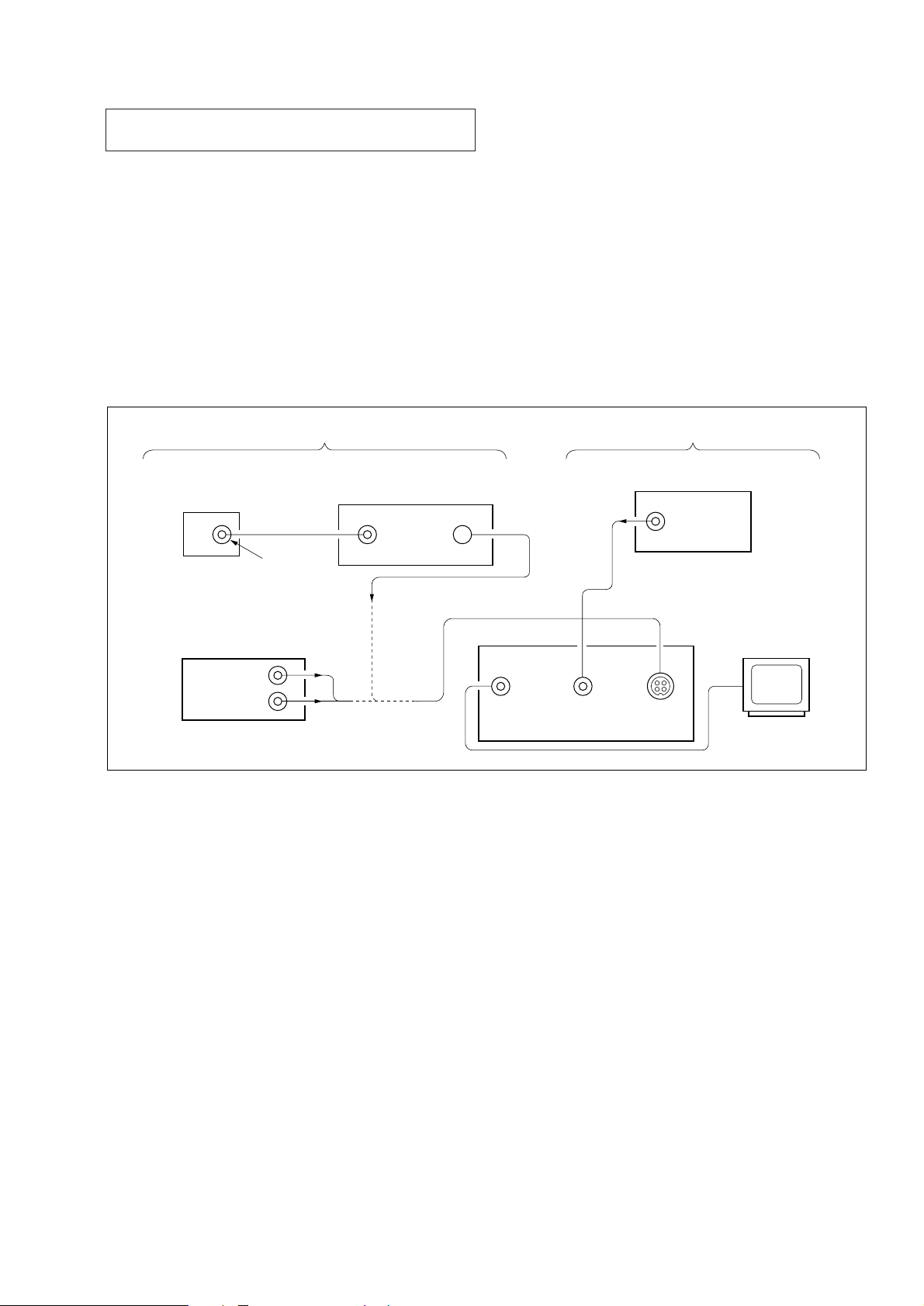

2. Connection of Equipment

Following the designation of input terminal (S-VIDEO or VIDEO),

connect measuring units as shown in Fig. 4-1 and make adjustment.

The input terminal is designated with ( ) in the signal column.

Unless otherwise designated, either input terminal may be used.

Note: In the adjustment where the S-VIDEO input is designated, if ad-

justment was made with the VIDEO input. The specification of

this set will not be satisfied. Always follow the designation.

If adjustment was made using the VTR with S-VIDEO OUT terminal as a signal source, the performance of this set depends on that

VTR. Therefore, use the pattern generator with the Y/C separate

output terminals, if possible.

If VIDEO is designated

Pattern Generator

VIDEO OUT

Ω

)

(75

•

If pattern generator provide

Y/C separate output terminals

Pattern Generator

Y OUT (75

Chroma OUT

(75

Ω

)

Ω

)

VIDEO

OUT

Fig. 4-1

VIDEO IN

Set

Monitor TV

S-VIDEO

IN

4-1

3. Input Signal Check

V

V

The video circuit adjustment uses as adjustment signals the video

signals obtained from the pattern generator, and therefore these

video output signals must be within the specification.

(1) When S-VIDEO is input

Connect an oscilloscope to the Y signal pin of the S-VIDEO IN

connector, and check that the sync signal of Y signal is 300 mV,

video amplitude is 700 mV, and the setup level is 0 mV. (If using

the VTR with S-VIDEO OUT terminal, check further that the

chroma signal and burst signal do not remain.)

Also, connect an oscilloscope to the chroma signal pin of the SVIDEO IN connector, and check that the burst signal amplitude of

chroma signal is 300 mV and it is flat, and moreover, the amplitude ratio of burst signal to chroma signal is 0.30 : 0.66. The Y

signal and chroma signal used for adjustment are shown in

Fig. 4-2.

Setup level: Potential difference between black and pedestal

(2) When VIDEO is input

Connect an oscilloscope to the VIDEO IN terminal, and check

that the sync signal amplitude of VIDEO signal is 300 mV, video

amplitude is 700 mV, the setup level is 0 mV, and the burst signal

amplitude is 300 mV and it is flat. Also, check that the level ratio

of burst signal to red signal is 0.3 : 0.66.

The VIDEO signal (color bars) used for adjustment is shown in

Fig. 4-3.

White (Approx. 100%)

Burst signal

Approx.

Approx.

0.3 V

0.7 V

Red

Horizontal sync signal

(To be flat)

Approx.

0.3 V

Y signal

White (100%)

Black

Approx. 700 mV

Pedestal

Horizontal

sync signal

Chroma signal

300

Chroma

amplitude

Burstsignal

to be flat

Burst amplitude : chroma amplitude = 0.30 : 0.66

Fig. 4-2 Color bar signals of pattern generator

(at terminating resistance 75 Ω)

Approx.

300 m

±

10 m

Fig. 4-3 Color bar signal of pattern generator

(at terminating resistance 75 Ω)

4-2

POWER SUPPLY BLOCK

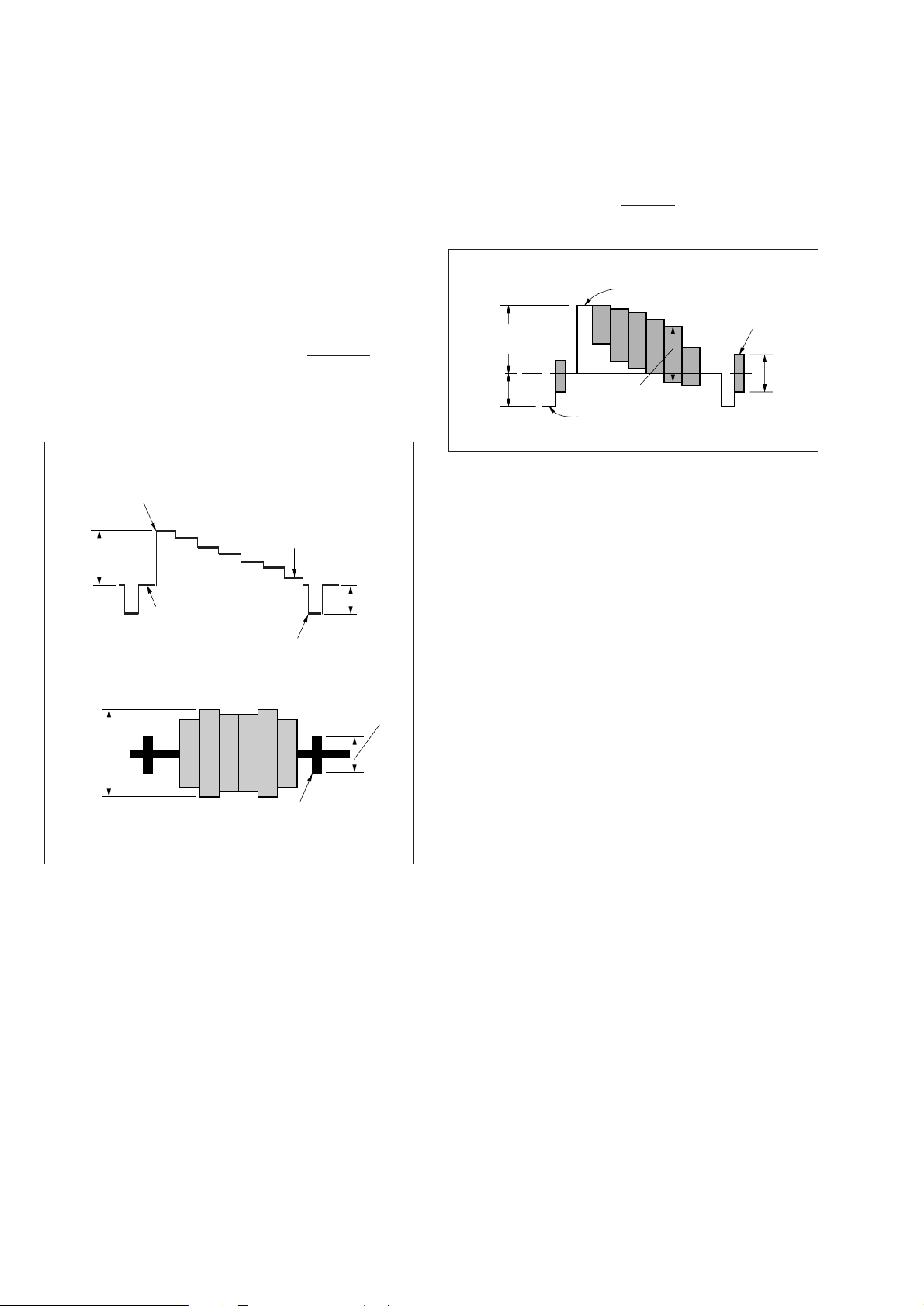

[Head V oltage Adjustment]

Before performing this adjustment, print the stair-step pattern

(Note 2) two times continuously with the old head (Note 1) or

normal unit. The second print will be used as a sample of the print

density.

Note 1: Only when the old head (faulty head) is not entirely damaged

with black or white lines.

Note 2: To print the stair -step test pattern, turn on the power switch while

pressing the S1707 (CAPTURE) and S1717 (ENTER) on the SW39 board.

(Press the S1707 (CAPTURE) and S1717 (ENTER) until a peep

is heard.) Set the S1701 (Rotaly switch) to the position, and

press the S1706 (print), then the print will start.

Mode Test mode (Note 2)

Signal Test pattern (Stair-step)

Measuring points

Measuring instrument Digital Voltmerter

Adjustment part VR201

Specification Print density should be the same as the sample

+: CN1943 2 pin (MD-39 board)

–: CN1943 3 pin

Fig. 4-4 Stair-step pattern

* VR201 is in the power block (1-468-364-11).

Adjustment Location:

Adjustment Procedure:

(1) To print the stair-step test pattern, turn on the power switch

while pressing the S1707 (CAPTURE) and S1717 (ENTER)

on the SW-39 board.

(Press the S1707 (CAPTURE) and S1717 (ENTER) until a

peep is heard.) Set the S1701 (Rotaly switch) to the posi-

tion, and press the S1706 (print), then the print will start.

(2) After printing, repeat (1) immediately.

(3) Compare the second printed pattern density with that of the

sample, and if the density differs, perform the following ad-

justment.

(4) Adjust VR201 according to the print density.

If darker than the sample: Decrease the head voltage.

If lighter than the sample: Increase the head voltage.

(5) Print the stair-step pattern two times continuously.

(6) Compare the second printed pattern density with that of the

simple, and if the density differs, repeat steps (3) to (6).

Note: Only one print is required after the second time.

(7) Turn off the power switch.

power block

VR201

4-3

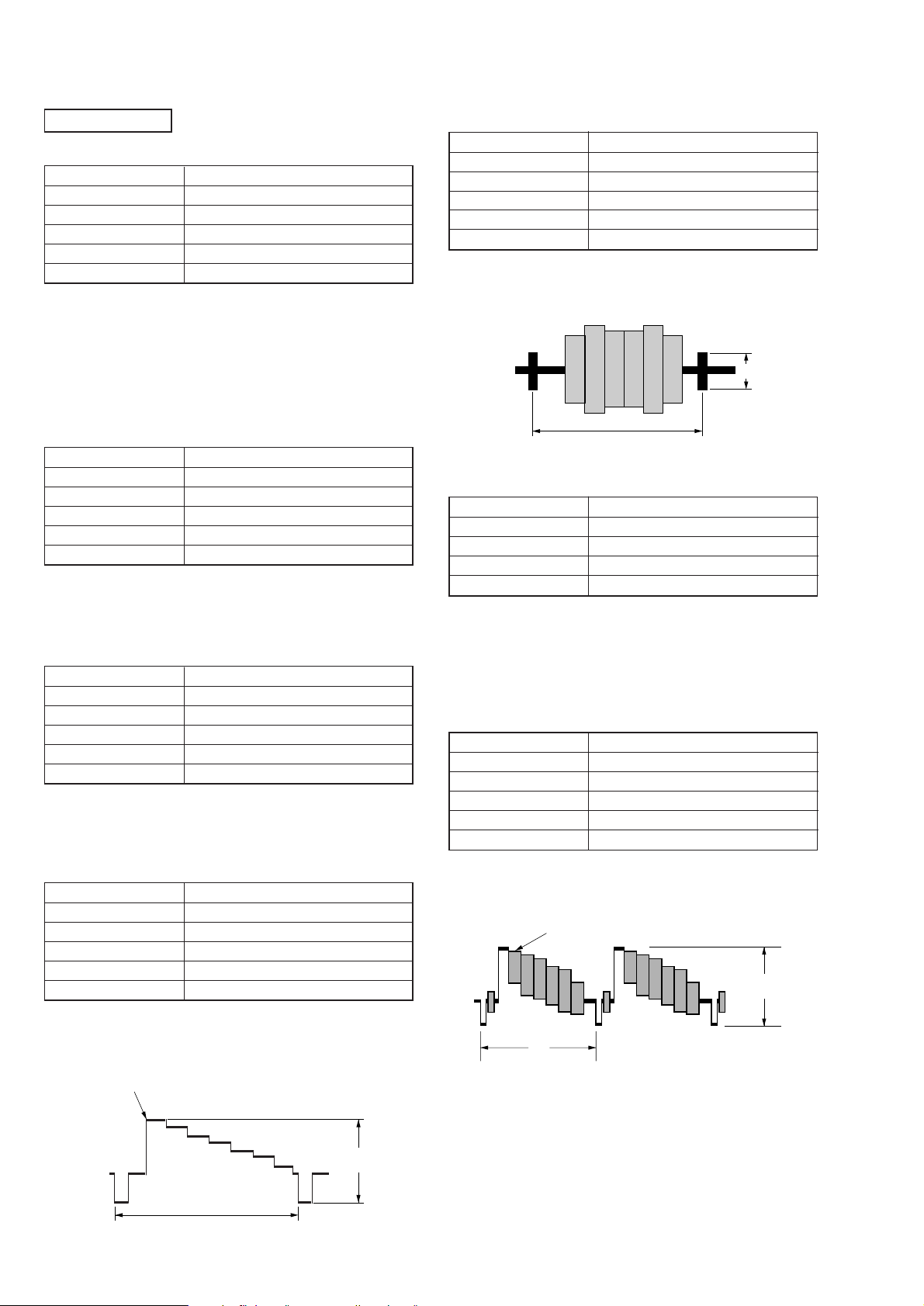

VIDEO BLOCK

[Free-Run Frequency Adjustment (1)] (VI-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN) (Note 1)

Measuring point IC108 !• pin

Measuring equipment Frequency Counter

Adjustment part CT102

Specification value 4.433619 MHz ± 30 Hz

Note 1: Connect IC108 5 pin to the GND via 0.1µF capacitor (chroma

signal grounded.)

Adjustment Procedure:

(1) Connect IC108 7 pin to the GND via 1 MΩ resisitor.

(2) Adjust CT102 so that the frequency counter reading satisfies

the specification value.

[Free-Run Frequency Adjustment (2)] (DK-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point IC407 `⁄⁄‹ pin

Measuring equipment Frequency Counter

Adjustment part CT500

Specification value 14.21875 MHz ± 100 Hz

Adjustment Procedure:

(1) Adjust CT500 so that the frequency counter reading satisfies

the specification value.

[910fh Adjustment] (DK-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point IC401 !¡ pin (or CL427)

Measuring equipment Digital Voltmeter

Adjustment part CT401

Specification value 2.5 ± 0.1 Vdc

Adjustment Procedure:

(1) Adjust CT401 so that the digital voltmeter reading satisfies

the specification value.

[Y/C Separation CHROMA Level] (VI-39 board)

Mode VIDEO Input

Signal Color bar (VIDEO IN)

Measuring point CL129

Measuring equipment Oscilloscope

Adjustment part RV102

Specification value 300 ± 5 mVp-p

Adjustment Procedure:

(1) Adjust RV102 so that the A level (white) of waveform on

the oscilloscope satisfies the specification value.

A

H

Fig. 4-6

[1H Delay Adjustment] (VI-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point FL106 3 pin

Measuring equipment Oscilloscope

Adjustment part RV105, 250, CT250

Adjustment Procedure:

(1) Set RV105 so that the luminescent spot of center.

(2) Set R V250 and CT250 so that the luminescent spots of phase

and gain.

[D/A Output Y Level Adjustment] (DK-39 board)

Note: Turn of the power switch once, then turn it on again.

Mode VIDEO Input

Signal Color bar (VIDEO IN)

Measuring point J1802 (OUTPUT)

Measuring equipment Oscilloscope

Adjustment part RV401

Specification value 700 ± 5 mVp-p

[Y/C Separation Y Level Adjustment] (VI-39 board)

Mode VIDEO Input

Signal Color bar (VIDEO IN)

Measuring point CL138

Measuring equipment Oscilloscope

Adjustment part RV103

Specification value 700 ± 10 mVp-p

Adjustment Procedure:

(1) Adjust RV103 so that the A level (white) of waveform on

the oscilloscope satisfies the specification value.

White (100%)

A

H

Fig. 4-5

Adjustment Procedure:

(1) Adjust RV401 so that the A level (white) of waveform on

the oscilloscope satisfies the specification value.

White (100%)

A

H

Fig. 4-7

4-4

[D/A Output CHROMA Level Adjustment] (DK-39 board)

Mode VIDEO Input

Signal Color bar (VIDEO IN)

Measuring point J1802 (OUTPUT)

Measuring equipment Oscilloscope

Adjustment part RV402

Specification value 681 ± 5 mVp-p

Adjustment Procedure:

(1) Adjust RV402 so tha t the A lev el (Red) of wa v eform on the

oscilloscope satisfies the specification value.

(2) Turn off the power switch.

White (100%)

A

[A/D Input R-Y/B-Y Level Adjustment]

(VI-39, DK-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point CL407, 408

Measuring equipment Oscilloscope

Adjustment parts RV106, 405

Specification value

CL407 (R-Y) 1.05 ± 0.01 Vp-p

CL408 (B-Y) 1.20 ± 0.01 Vp-p

Adjustment Procedure:

(1) Connect on oscilloscope to the CL408.

(2) Adjust R V106 so that the A lev el (B-Y) of wav eform on the

oscilloscope satisfies the specification value.

Blue

H

Red

Fig. 4-8

[A/D Input Y Level Adjustment] (DK-39 board)

Note: Turn off the power switch once, then turn it on again.

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point CL409

Measuring equipment Oscilloscope

Adjustment part RV404

Specification value 1.30 ± 0.01 Vp-p

Adjustment Procedure:

(1) Connect on oscilloscope to the CL409 (from IC407 ^¢ pin

to the point via R478).

(2) Adjust RV404 so that the A level (white) of waveform on

the oscilloscope satisfies the specification value.

White (100%)

A

H

A

Yellow

Fig. 4-10

(3) Connect on oscilloscope to the CL407.

(4) Adjust R V405 so that the A lev el (R-Y) of wav eform on the

oscilloscope satisfies the specification value.

Red

Yellow

A

Fig. 4-11

Fig. 4-9

4-5

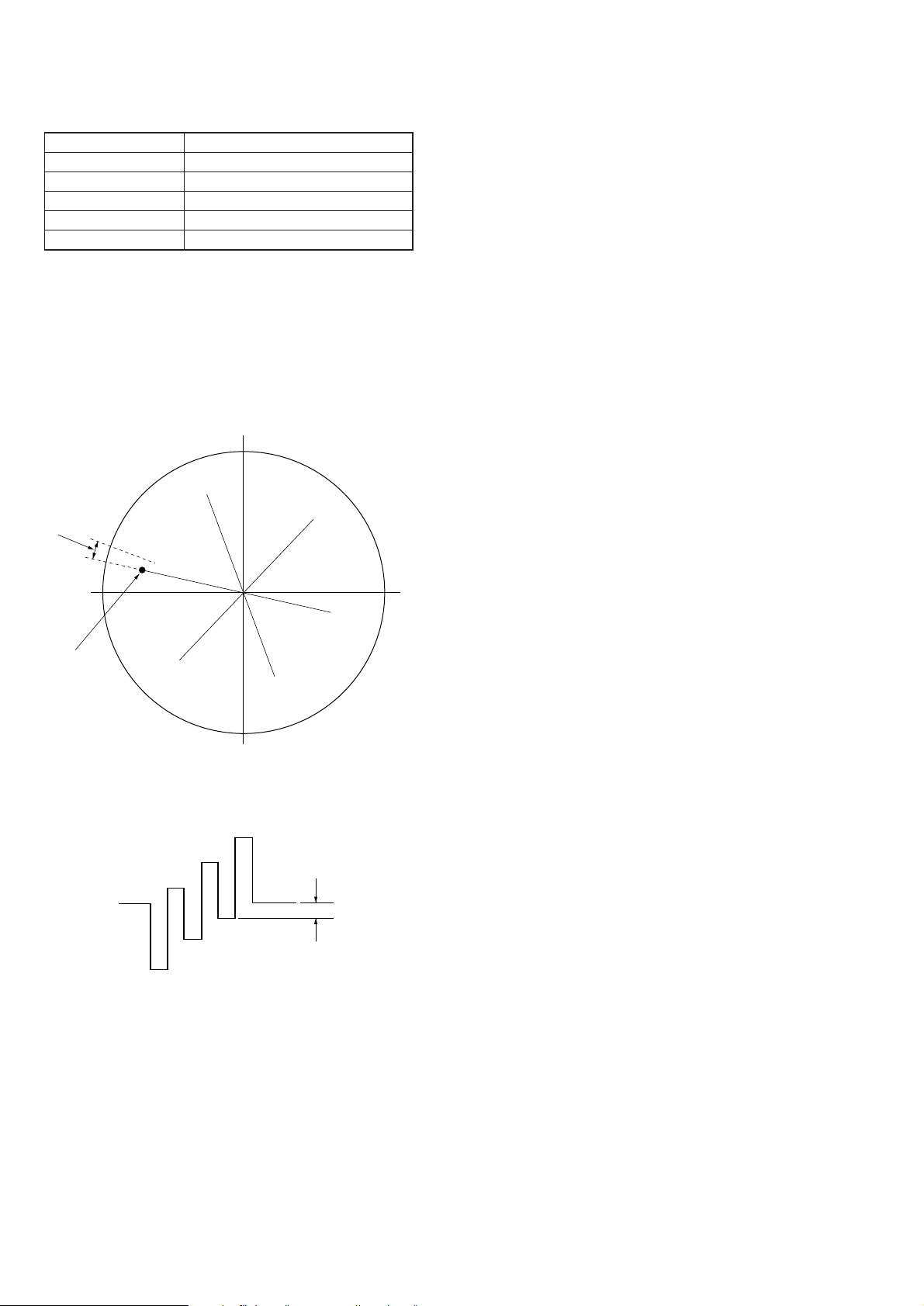

[HUE Level Adjustment] (VI-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point J1802 (OUTPUT)

Measuring equipment Vector scope

Adjustment part RV105

Specification value Yellow phase 167 ± 4 deg

Adjustment Procedure:

(1) Connect on vector scope to the J1802.

(2) Press the S1707 (CAPTURE).

(3) Check yellow phase satisfies the specification value.

(4) If NG, press the S1708 (PICTURE) and lights on the D1733

(INPUT)

(5) A little adjust the RV105 and press the S1707.

(6) Repeat steps (2) to (5) until yellow phase satisfies the speci-

fication value.

90

°

167 ± 4

°

180

°

Yellow

Fig. 4-12

Reference : B-Y Waveform (CL408)

•

•

Fig. 4-13

A

If yellow phase is under 163 °,

extend the A level.

If yellow phase is over 171°,

shorten the A level.

0

°

4-6

Loading...

Loading...