SONY DVP S9 Service Manual

DVP-S9

SERVICE MANUAL

Ver 1.7 2004.09

DVP-S9 is the D VD/Video CD/CD pla yer

section in MHC-S9D.

SPECIFICATIONS

AEP Model

UK Model

E Model

Austr alian Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM63D

Optical Pick-up Name

KHM-240AAA (TYPE A)

KHM-270AAA (TYPE B)

DVD/Video CD/CD player section

Laser Semiconductor laser

Frequency response DVD (PCM 48 kHz):

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Video color system format

OPTICAL OUT

(Square optical connector jack, rear panel)

General

Power requirements

European model: 230 V AC, 50/60 Hz

Australian model: 230 – 240 V AC,

Mexican model: 120 V AC, 60 Hz

Korean model: 220 V AC, 60 Hz

Thailand model: 220 V AC, 50/60 Hz

Other models: 120 V, 220 V or

Dimensions (w/h/d)

Mass Approx. 2.9 kg

Design and specifications are subject to change

without notice.

(λ=660 nm/780 nm)

Emission duration:

continuous

2 Hz – 22 kHz = (±1 dB)

CD: 2Hz – 20 kHz =

(±1 dB)

NTSC, PAL

50/60 Hz

230 – 240 V AC,

50/60 Hz

Approx. 280 x 108 x 330 mm

9-873-280-08 Sony Corporation

2004I05-1 Audio Group

© 2004.09 Published by Sony Engineering Corporation

DVD/VIDEO CD/CD PLAYER

DVP-S9

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is

classified as a CLASS 1

LASER product. The

CLASS 1 LASER

PRODUCT MARKING

is located on the rear

exterior.

CAUTION

The use of optical instruments with this product will

increase eye hazard.

As the laser beam used in this CD/DVD Player is

harmful to eyes, do not attempt to disassemble the

cabinet. Refer servicing to qualified personnel only.

The following caution label is located inside the

apparatus.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board. (within 3 times)

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

DVP-S9

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 6

3-2. Cover ............................................................................... 7

3-3. CD Mechanism Deck (CDM63D) .................................. 7

3-4. MB Board........................................................................ 8

3-5. VIDEO Board .................................................................. 8

3-6. MAIN Board ................................................................... 9

3-7. Front Panel Section......................................................... 9

3-8. PANEL Board, SUB PANEL Board............................... 10

3-9. Lid (CD) .......................................................................... 10

4. TEST MODE.............................................................. 11

5. ELECTRICAL ADJUSTMENTS......................... 22

6. DIAGRAMS

6-1. Block Diagram – RF/SERVO Section – ........................ 23

6-2. Block Diagram – MAIN Section (1/2) –....................... 24

6-3. Block Diagram – MAIN Section (2/2) –....................... 25

6-4. Block Diagram

– INTERFACE CONTROL Section – ............................ 26

6-5. Note For Printed Wiring Boards

and Schematic Diagrams ................................................ 27

6-6. Printed W iring Board – RF Board – .............................. 28

6-7. Schematic Diagram – RF Board –................................. 29

6-8. Printed Wiring Boards – DISC SENSOR/DRIVER/

IN OUT SW/MOTOR/TRAY SENSOR Boards – ......... 30

6-9. Schematic Diagram – DISC SENSOR/DRIVER/

IN OUT SW/MOTOR/TRAY SENSOR Boards – ......... 31

6-10. Printed W iring Board

– MB Board (Component Side) –................................... 32

6-11. Printed W iring Board

– MB Board (Conductor Side) –..................................... 33

6-12. Schematic Diagram – MB Board (1/6) –....................... 34

6-13. Schematic Diagram – MB Board (2/6) –....................... 35

6-14. Schematic Diagram – MB Board (3/6) –....................... 36

6-15. Schematic Diagram – MB Board (4/6) –....................... 37

6-16. Schematic Diagram – MB Board (5/6) –....................... 38

6-17. Schematic Diagram – MB Board (6/6) –....................... 39

6-18. Printed W iring Board – MAIN Board – ........................ 40

6-19. Schematic Diagram – MAIN Board –........................... 41

6-20. Printed W iring Boards

– PANEL/SUB PANEL/VIDEO Boards – ..................... 42

6-21. Schematic Diagram

– PANEL/SUB PANEL/VIDEO Boards – ..................... 43

6-22. IC Pin Function Description ........................................... 47

SECTION 1

SERVICING NOTES

This set is a component of the MHC-S9D.

The MHC-S9D system configuration is as shown below, and therefore it does not operate normally unless all four components are

connected.

In performing the repair, connect all components with the system

cables.

Note: The precaution to the users is described on the label stuck on the

back panel (DVD/video CD/CD player) and in the troubleshooting

section in the Operation Manual.

System Configuration:

AC IN

TA

POWER SUPPLY

ST

MASTER & GRAPHIC µcon

DISPLAY

DVP

HTC & MB µcon

POWER BLOCK

TC

TC µcon

7. EXPLODED VIEWS

7-1. Case Section.................................................................... 57

7-2. Front Panel Section......................................................... 58

7-3. Chassis Section ............................................................... 59

7-4. CD Mechanism Deck Section-1 (CDM63D) ................. 60

7-5. CD Mechanism Deck Section-2 (CDM63D) ................. 61

7-6. CD Mechanism Deck Section-3 (CDM63D) ................. 62

7-7. CD Mechanism Deck Section-4 (CDM63D) ................. 63

7-8. Optical Pick-up Section .................................................. 64

8. ELECTRICAL PARTS LIST ............................... 65

3

DVP-S9

k

Ver 1.7

NOTE OF REPLACING THE MB BOARD

When replacing the MB board, since the adjustment value is not

set up correctly, “Drive Auto Adjustment” can’t be performed.

In this case, initialize Memory in the following procedures.

Procedure:

1. Set the test mode. (See page 12)

2. Press the [2] key of the remote commander , and set the “DRIVE

MANUAL OPERATION”. (See page 18)

3. Press the [6] key of the remote commander, and set the “2-6,

Memory Check”. (See page 20)

4. Press the [CLEAR] key of the remote commander, and initialize Memory.

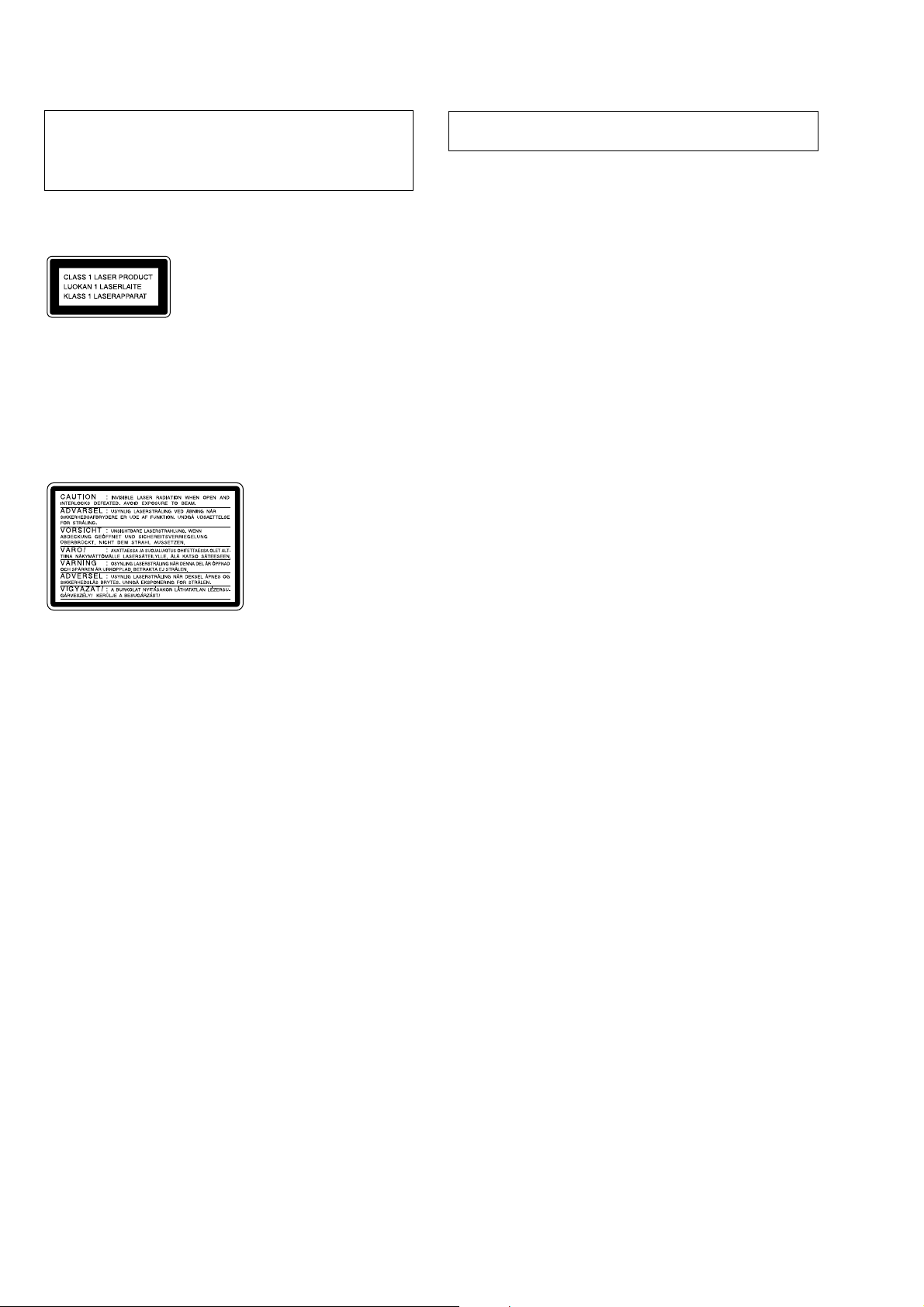

MODEL IDENTIFICATION

- Back Panel -

PART No.

Model PART No.

AEP model 4-236-808-0

UK model 4-236-808-1

Korean model 4-236-808-3

Singapore model 4-236-808-4

Saudi Arabia model 4-236-808-5

Austrarian model 4-236-808-6

Thai model 4-236-808-7

E model 4-236-808-8

Mexican model 4-236-808-9

[]

[]

[]

[]

[]

[]

[]

[]

[]

TYPE A/B DISCRIMINATION

optical device

SILVER: KHM-240AAA (TYPE A)

BLACK: KHM-270AAA (TYPE B)

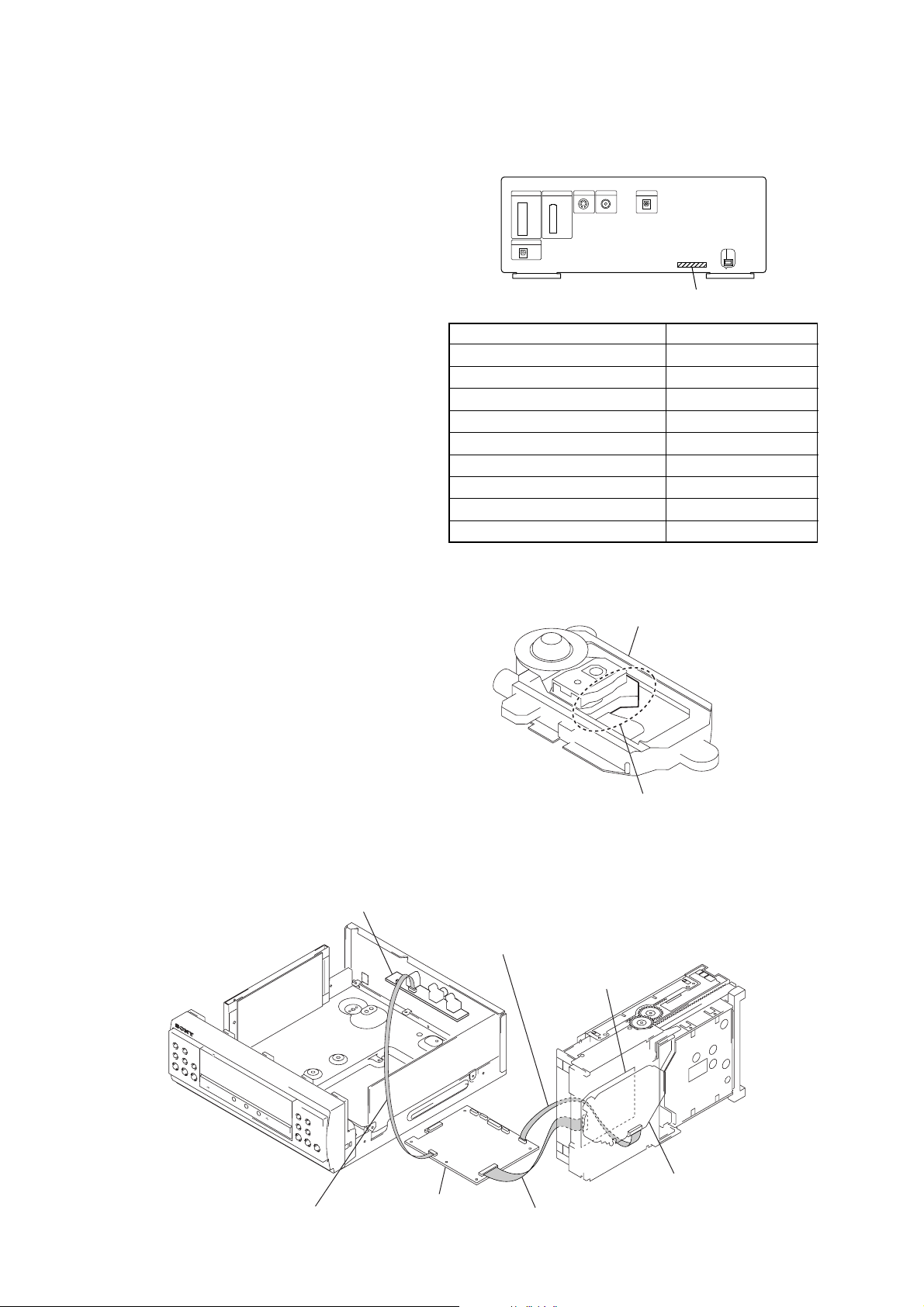

SERVICE POSITION

In checking the CD block and another board, prepare jigs (extension cable J-2501-155-A: 300 mm 9 cores, J-2501-199-A: 300 mm 25

cores, J-2501-202-A: 300 mm 8 cores).

VIDEO board

Connect jig (extension cable J-2501-155-A)

to the MB board (CN015) and optical pick-up block.

RF board

optical pick-up bloc

Connect jig (extension cable J-2501-202-A)

to the MB board (CN012) and VIDEO board (CN201).

MB board

Connect jig (extension cable J-2501-199-A)

to the MB board (CN010) and RF board (CN002).

4

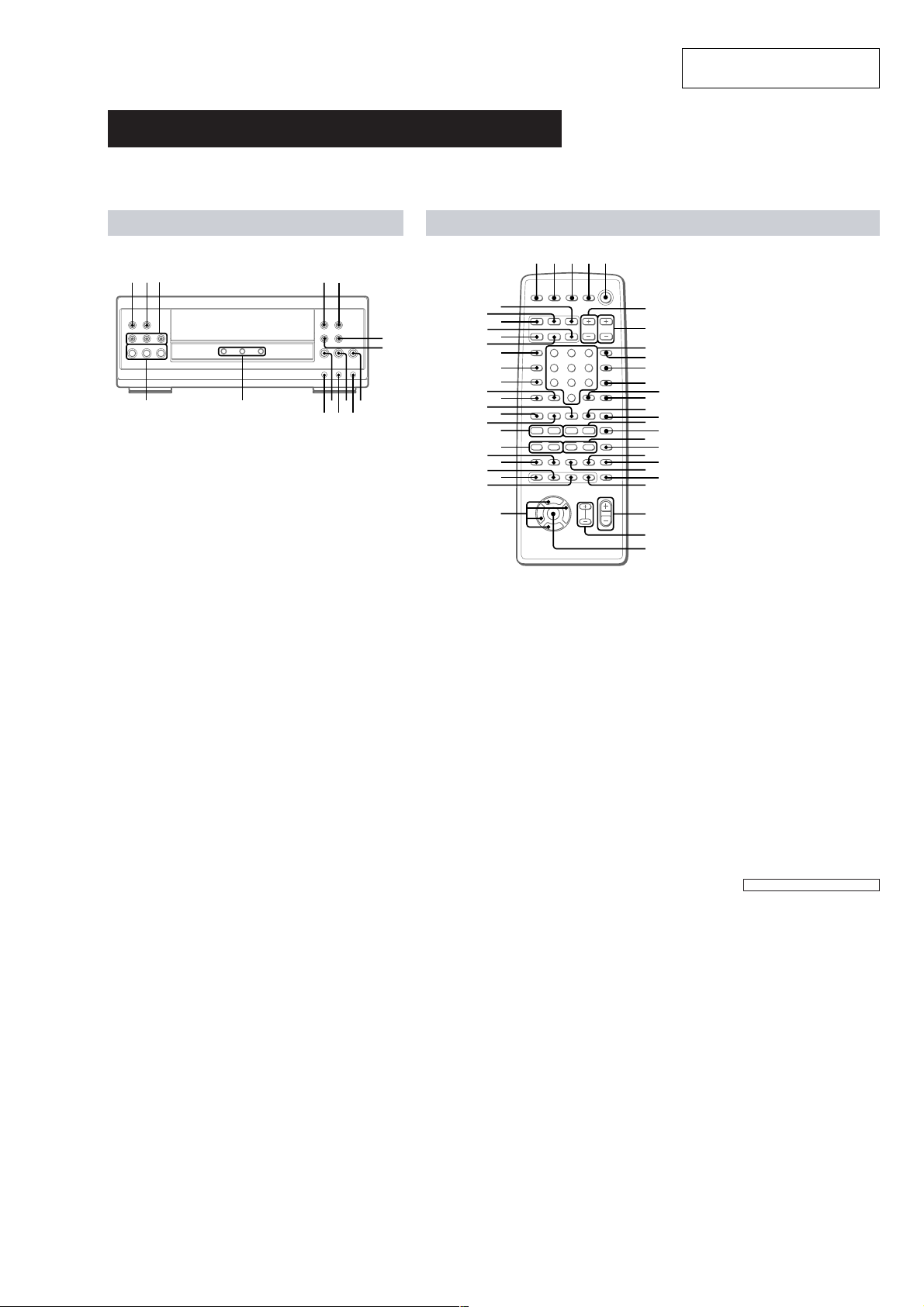

Parts Identification

The items are arranged in alphabetical order.

Refer to the pages indicated in parentheses ( ) for details.

SECTION 2

GENERAL

DVP-S9

This section is extracted from

instruction manual.

Main unit

DVD/VIDEO CD/CD player

wl e;ea es

1 2 3

rd

DISC 1–3 rd (25, 26)

DISC 1–3 indicators rs

DISC 1–3 Z (eject) ea (25, 26)

NEXT el (26, 27)

PLAY MODE wl (25, 28, 29, 46)

PREV ra (26, 27)

REPEAT e; (12, 30)

RETURN O ej (12, 27, 39, 40)

N SELECT (play) r; (25–27,

41, 55, 60)

X (pause) ek (26)

x (stop) eh (12, 26, 27, 30, 38,

45, 55, 61)

. (go back) eg (26, 28, 30)

> (go forward) ef (26, 28, 30)

m (rewind) es (26)

M (fast forward) ed (26)

ed

mM

>

.

HSx

ejelra

Remote control

1234 5

rl

rk

rj

rh

ef

eg

rf

rg

rd

rs

ra

r;

ehekr;rs

ek

eh

ed

ea

wl

el

ej

eg

ef

es

e;

wk

O

V

Bb

v

nN

Mm>.

TtCc

6

7

8

9

q;

qa

qs

qd

qf

x

X

qh

qk

w;

ws

wf

qg

qj

ql

wa

wd

wg

wh

wj

ANGLE es (37)

AUDIO ws (34)

CLEAR qs (22, 29, 30, 36)

CLOCK/TIMER SELECT 3

(47, 56)

CLOCK/TIMER SET 2 (17, 47,

56)

DBFB ra (48)

D.SKIP 9 (26)

DIGITAL rf (57)

DISPLAY rj (17, 31, 32, 43, 54)

DVD DISPLAY wd (18, 19, 30,

32–34, 36–40)

DVD MENU wa (27)

DVD SET UP ql (18, 19, 24, 39)

ENTER wj

EQ ea (52)

EQ ON/OFF wl (53)

FILE SELECT +/– wh (48, 49,

53)

FUNCTION rd (18, 25, 27, 28,

36, 45, 46, 55, 57)

GROOVE rs (48)

KARAOKE PON (Except for

North American and European

models) el (54)

MD rh (57)

Numeric buttons 8 (28, 30)

PLAY MODE qa (25, 28, 29, 46)

REPEAT q; (30)

RETURN O qd (27, 39, 40)

SELECT DVD N eh (20, 25,

27, 29, 30)

SET UP wf (14, 16, 51, 53, 54)

SLEEP 1 (55)

SLOW t/T qk (26)

SPECTRUM ANALYZER rk

(54)

STEP c/C ef (26)

SUBTITLE ed (37)

SUR e; (51)

TAPE A nN ek (44)

TAPE B nN qf (44, 45)

TITLE w; (27)

TUNER/BAND ej (42)

TV @/1 4 (13)

TV CH +/– 7 (13)

TV/VIDEO rl (13)

TV VOL +/– 6 (13)

VIDEO rg (57)

VOL +/– wg

BUTTON DESCRIPTIONS

@/1 (power) 5

X (pause) qj

x (stop) qg

m/M (rewind/fast forward),

TUNING –/+ qh

./> (go back/go forward),

PRESET –/+, PREV/NEXT eg

O/o/P/p wk

>10 r;

5

DVP-S9

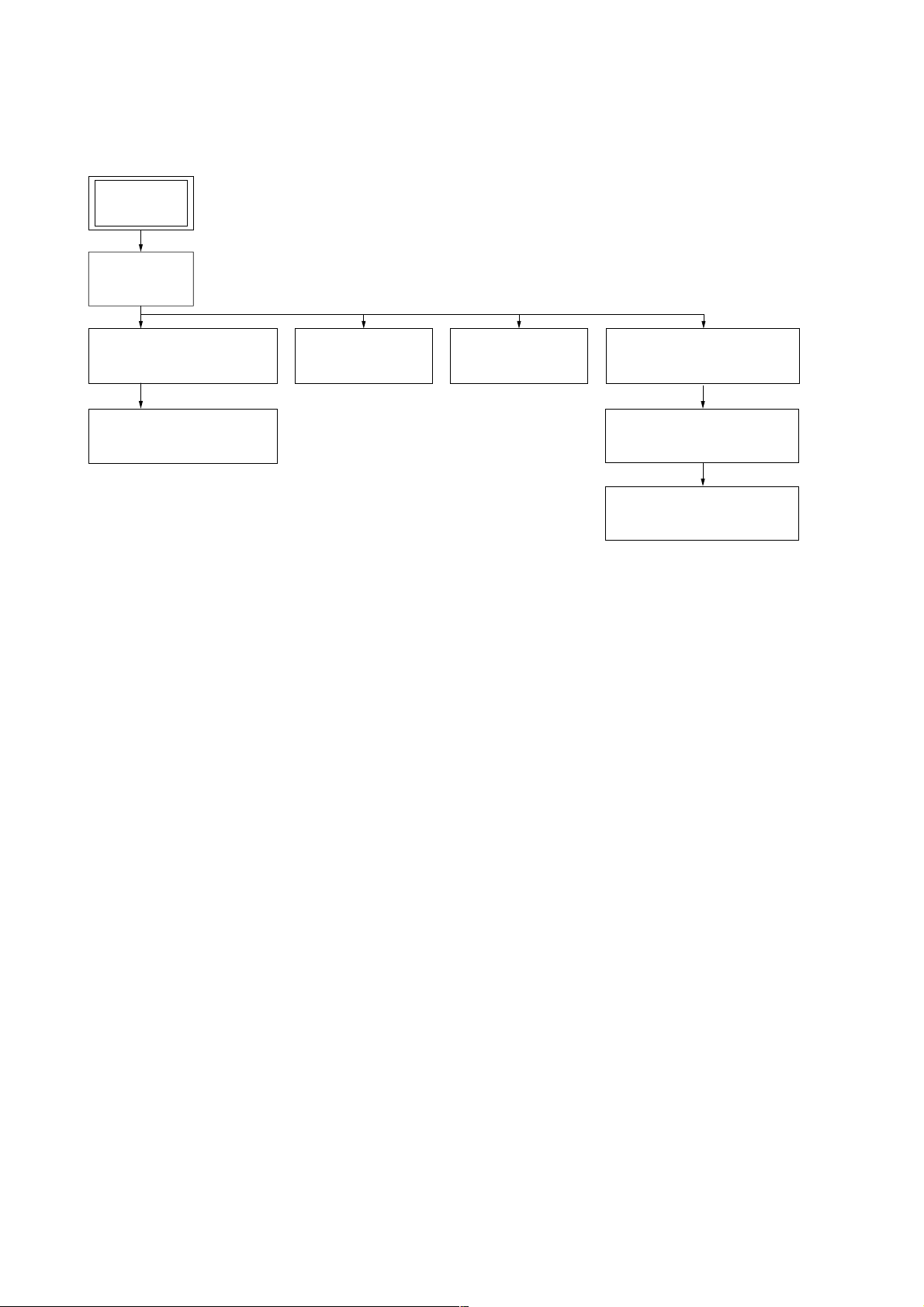

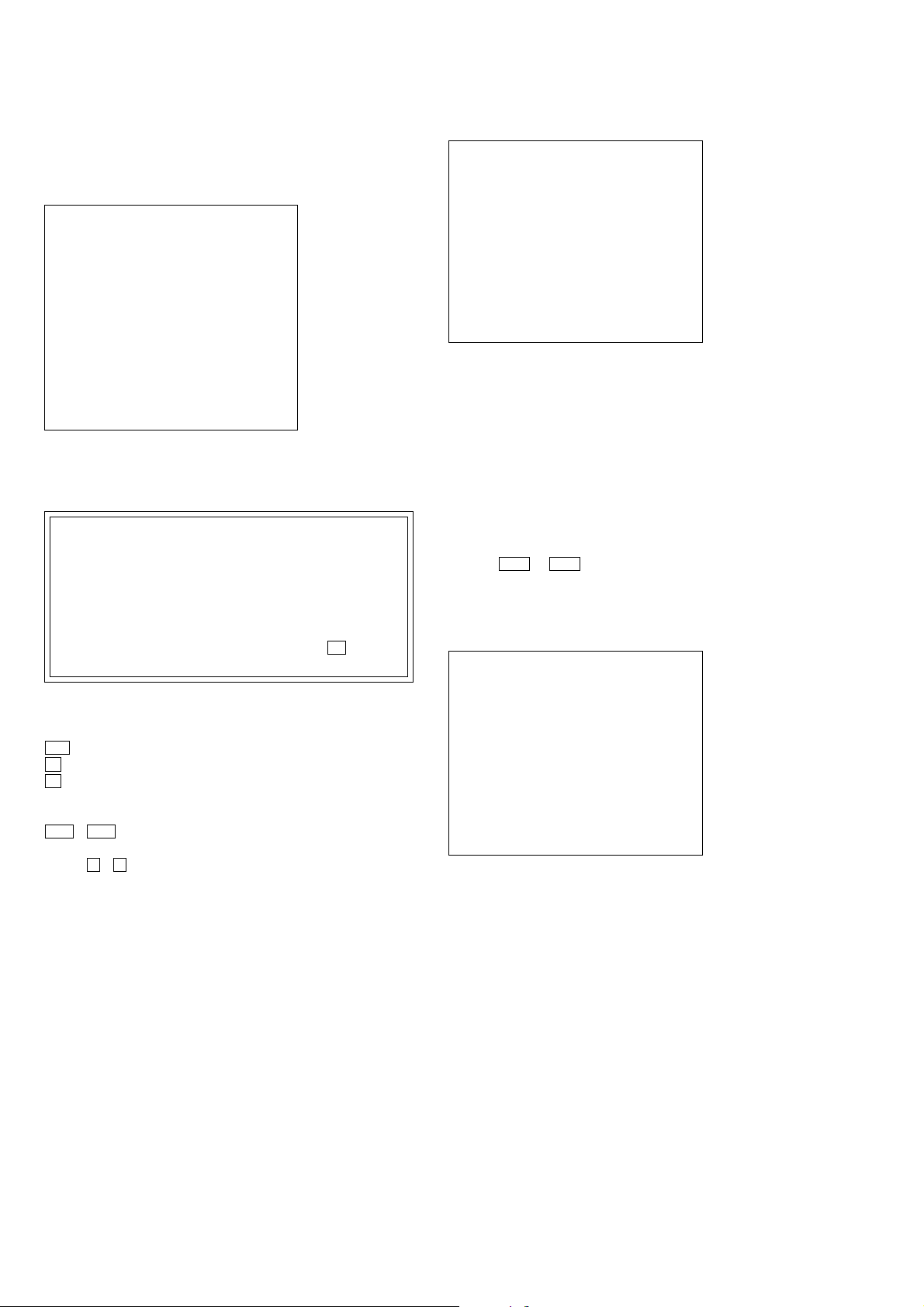

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. COVER

(Page 7)

SECTION 3

DISASSEMBLY

3-3. CD MECHANISM DECK

(CDM63D)

(Page 7)

3-4. MB BOARD

(Page 8)

3-5. VIDEO BOARD

(Page 8)

3-6. MAIN BOARD

(Page 9)

3-7. FRONT PANEL SECTION

(Page 9)

3-8. PANEL BOARD,

SUB PANEL BOARD

(Page 10)

3-9. LID (CD)

(Page 10)

6

Note: Follow the disassembly procedure in the numerical order given.

)

)

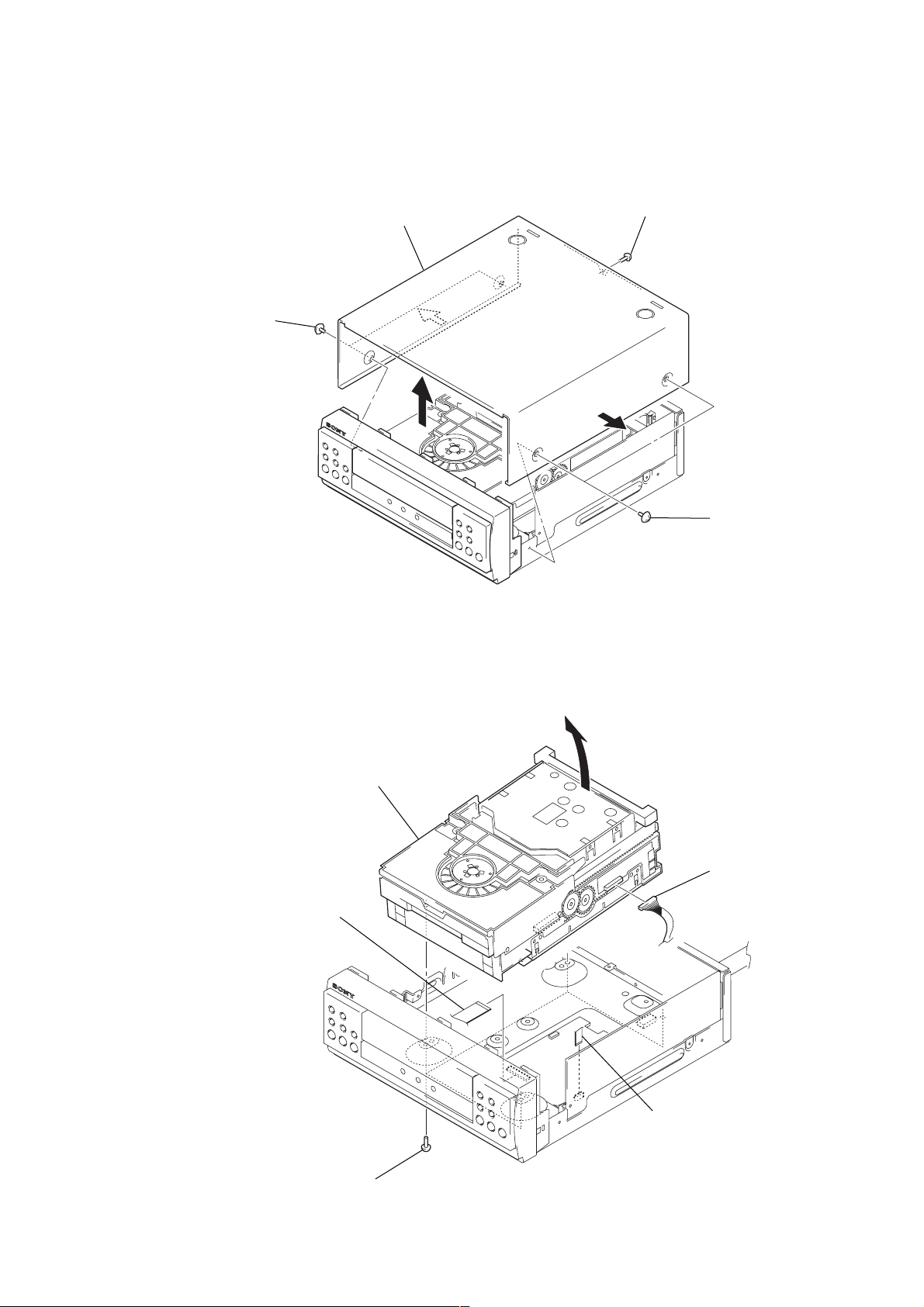

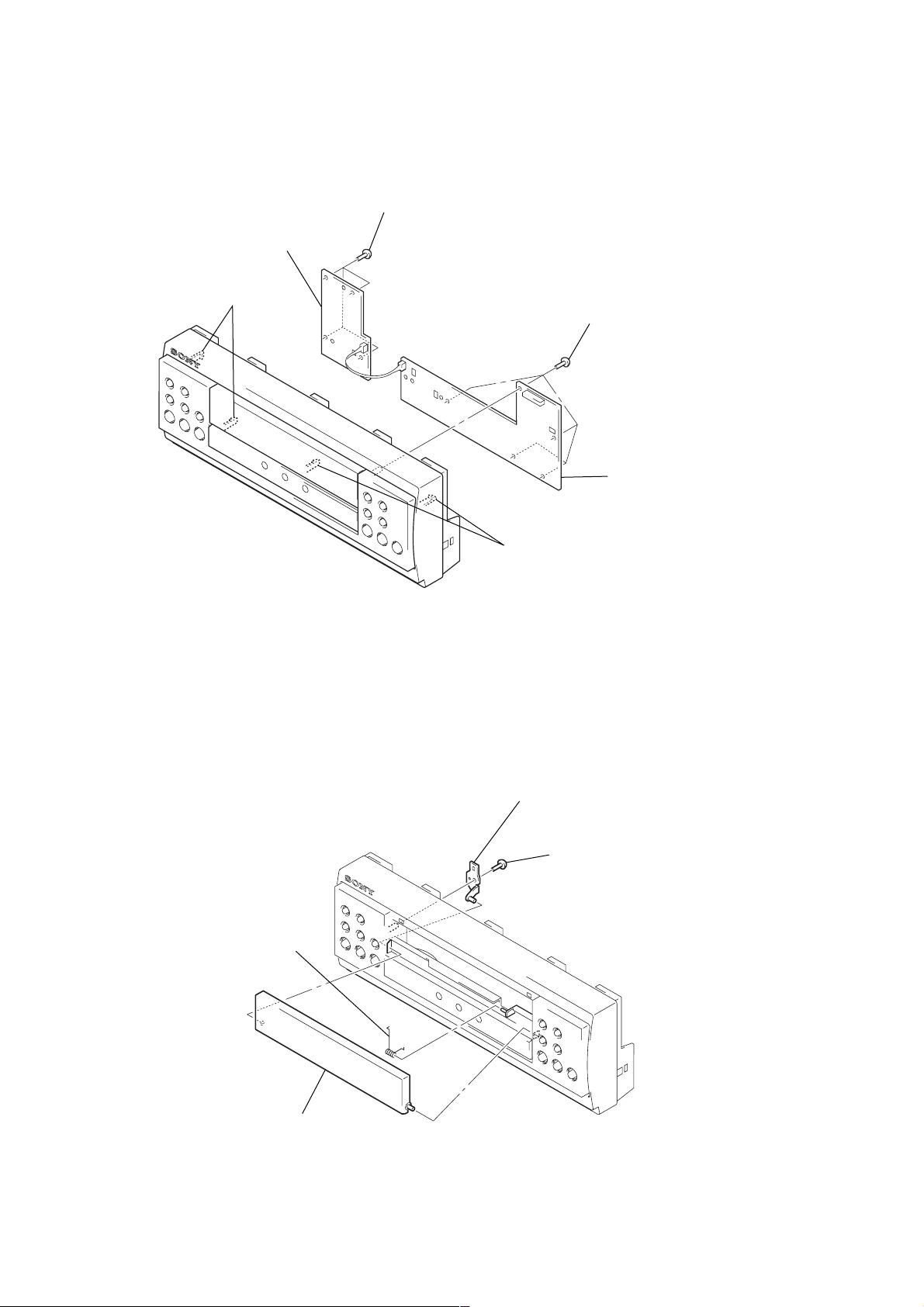

3-2. COVER

3

cover

1

two screws

(case 3 TP2)

2

screw

(BVTT3 × 6)

DVP-S9

3-3. CD MECHANISM DECK (CDM63D)

4

CD mechanism deck

(CDM63D)

5

wire (flat type) (25 core)

(CN010)

1

two screws

(case 3 TP2

2

connector

(CN701)

3

four screws

(BVTP3

1

wire (flat type) (9 core

(CN015)

×

8)

7

DVP-S9

r

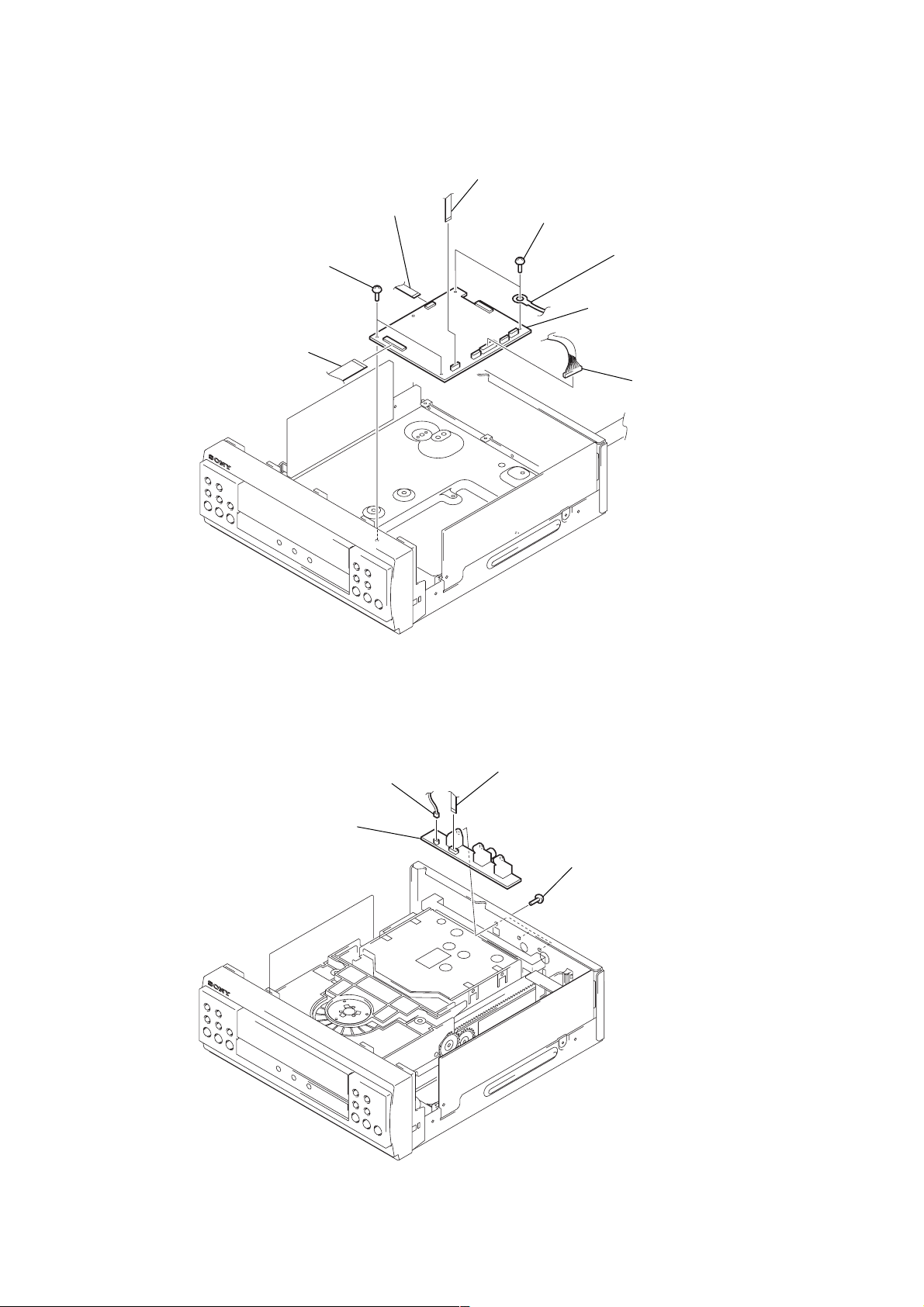

3-4. MB BOARD

2

1

4

two screws

(BV)

wire (flat type) (25 core)

(CN010)

wire (flat type) (8 core)

(CN011)

1

wire (flat type) (9 core)

(CN015)

4

two screws

(BV)

6

5

lug

MB board

3

connecto

(CN008)

3-5. VIDEO BOARD

4

VIDEO board

2

connector

(CN202)

1

wire (flat type) (8 core)

3

three screws

(BVTP3

×

8)

8

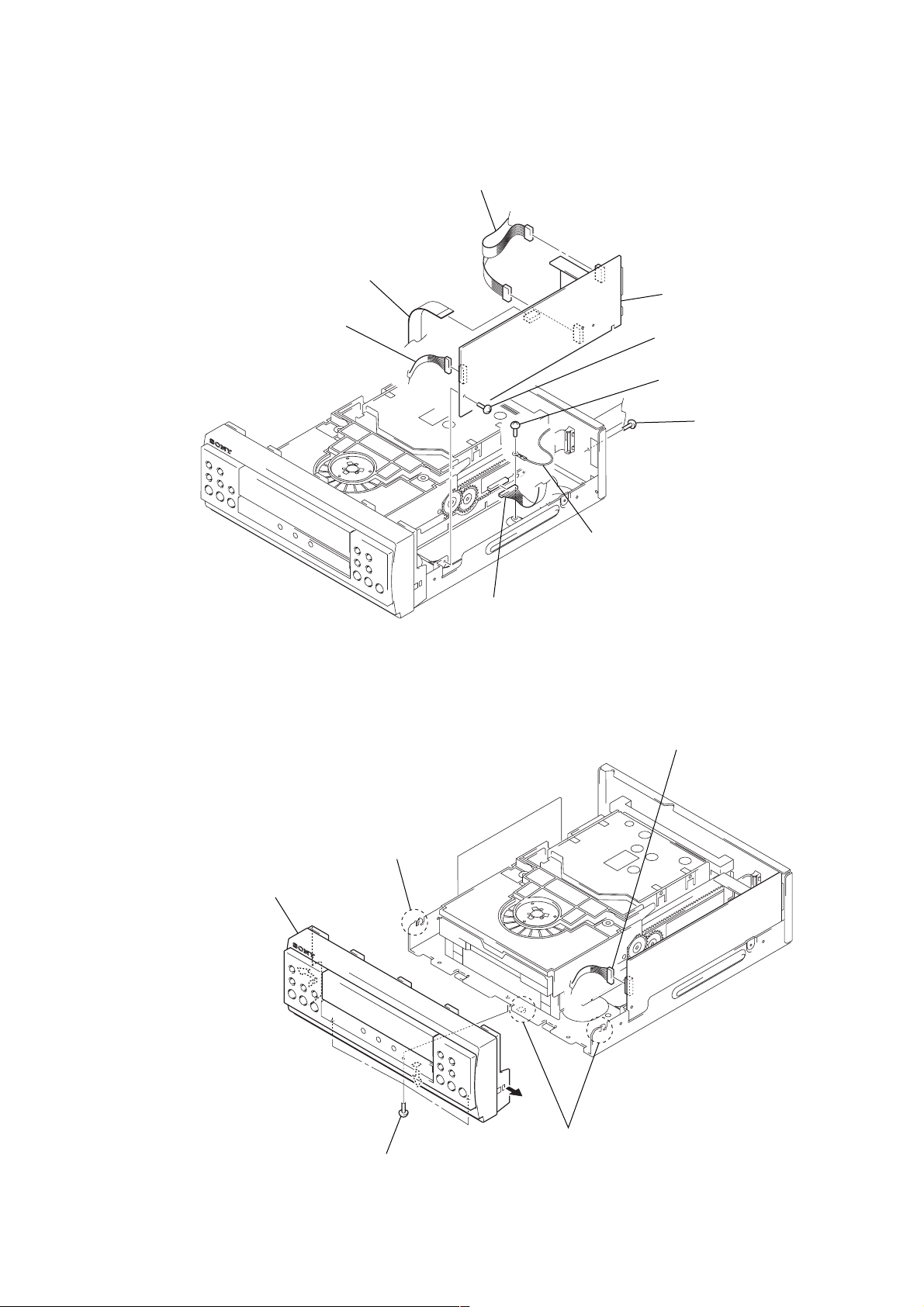

3-6. MAIN BOARD

)

1

wire (flat type) (10 core)

(CN107)

2

connector

(CN401)

3

two connectors

(CN101, 102)

9

MAIN board

7

screw

(BVTP3 × 8)

5

screw

(BVTP3 × 8)

8

screw

(BVTP3

×

8

DVP-S9

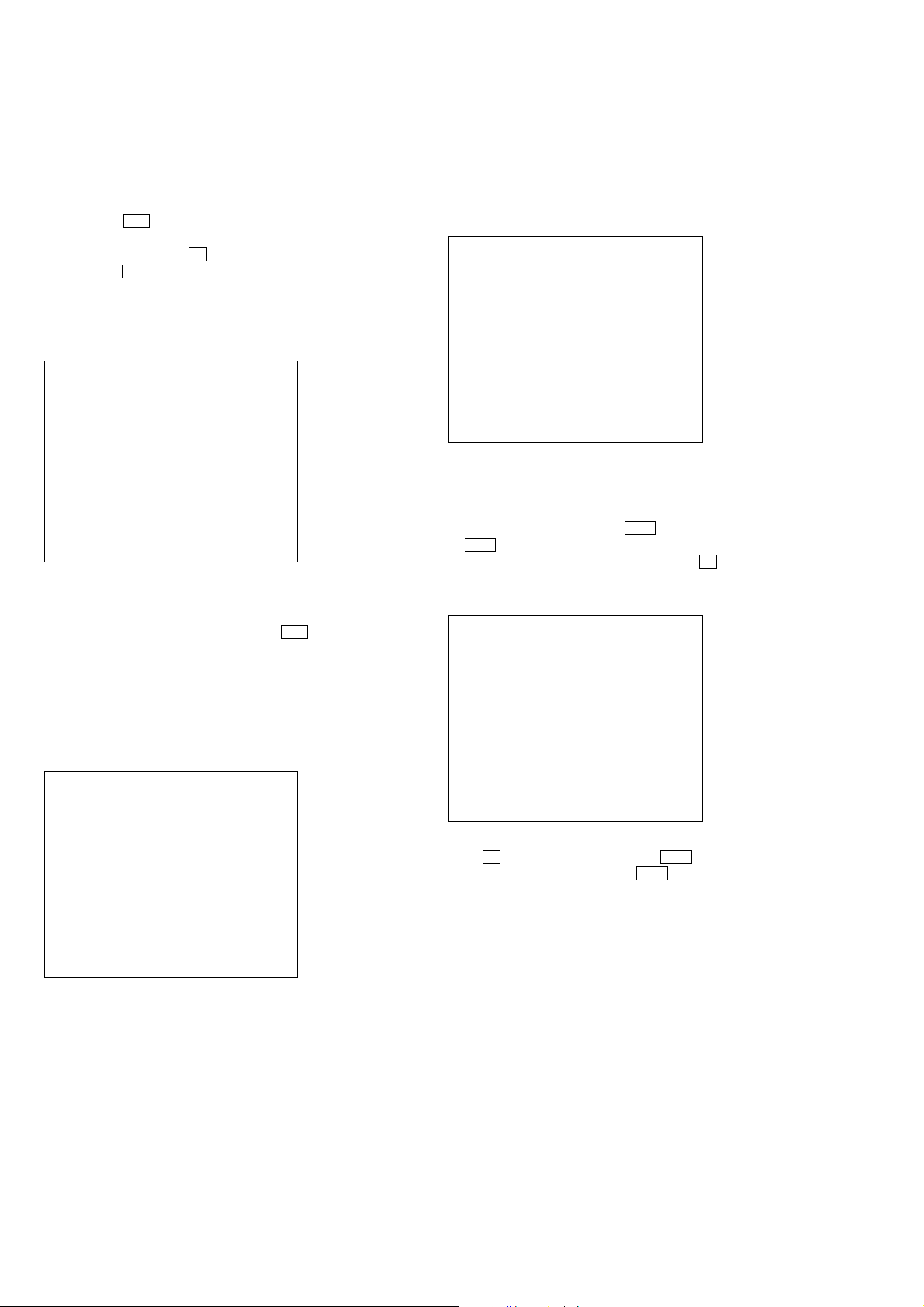

3-7. FRONT PANEL SECTION

4

front panel section

3

claw

4

connector

(CN701)

6

lug

1

connector

(CN401)

2

three screws

(BVTP3

3

two claws

×

8)

9

DVP-S9

d

)

3-8. PANEL BOARD, SUB PANEL BOARD

6

SUB PANEL board

5

two claws

4

four screws

(BVTP2.6

×

8)

1

five screws

(BVTP2.6

3

×

8)

PANEL boar

3-9. LID (CD)

4

spring (CD)

2

two claws

2

bracket (LID) assy

1

screw

(BVTP2.6 × 8

10

3

lid (CD)

SECTION 4

TEST MODE

DVP-S9

Note: Use following buttons in the test mode.

no mark: Button of DVD/video CD/CD player (DVP-S9)

*1 : Button of A/V amplifier (TA-S9D)

*2 : Button of tuner (ST-S9)

[CHANGE-OVER THE COLOR SYSTEM]

•The color system can be changed over NTSC or PAL.

Procedure:

1. Press the I/1 *1 button to turn the power on.

2. Turn the [FUNCTION]*

1

knob to select “DVD”, and press

the x button.

3. While pressing the both [RETURN] and [REPEAT] buttons,

turn the power off.

4. Press the I/1 *1 button to turn the power on. The color system is changed over.

[COLD RESET]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure 1:

1. Press the I/1 *1 button to turn the power on.

2. While pressing the both [PLAY MODE] and x buttons, press

the M button.

3. The set is reset, and becomes standby state.

Procedure 2:

1. Press the I/1 *1 button to turn the power on.

2. While pressing the [DIGITAL]*1 button, press the [DISPLAY]*

button.

3. The set is reset, and becomes standby state.

[DVD DELIVERY MODE]

•This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the I/1 *1 button to turn the power on.

2. Turn the [FUNCTION]*1 knob to select “DVD”.

3. While pressing the [EQ ON/OFF]*1 button, press the I/1 *

button.

4. The message “LOCK” is displayed on the fluorescent indicator tube of tuner unit and turn the power off automatically, and

the DVD delivery mode is set.

[GC TEST MODE]

Enter the GC Test Mode

Procedure 1:

1. Press the I/1 *1 button to turn the power on.

2. While pressing the both [PLAY MODE] and x buttons, press

the Z (DISC 1) button.

3. LEDs and fluorescent indicator tube are all turned on of all

units.

Procedure 2:

1. Press the I/1 *1 button to turn the power on.

2. While pressing the both [STEREO/MONO]*2 and

[CINEMA STUDIO C]*

button.

3. LEDs and fluorescent indicator tube are all turned on of all

units.

1

buttons, press the [CLOCK/TIMER]*

Version Display Mode

Procedure:

1. Enter the GC test mode.

2. Each time the [DISC 1] or [TUNER MEMORY]*2 button is

pressed, microcomputer or mechanism deck version is displayed of each unit.

3. Press the [DISC 3] or [TUNING +]*2 button to detail is displayed the version.

Key Check Mode

Procedure:

1. Enter the GC test mode.

2. Press the [DISC 2] or [TUNING --]*2 button to set the key check

mode, and displays “K 0 J 0 V 0” on the fluorescent indicator

tube of tuner unit.

3. All buttons are pressed of video CD unit, all LEDs are blinking of video CD unit. (not change the display of fluorescent

indicator tube)

Releasing the GC Test Mode

To release from this mode, press three buttons in the same manner

as entering this mode or disconnect the power cord.

[DVD SERVICE MODE]

•This mode can run the DVD sled motor optionally. Use this

mode, for instance, when cleaning the optical pick-up.

Procedure:

1. Press the I/1 *1 button to turn the power on.

2

2. Turn the [FUNCTION]*1 knob to select “DVD”.

3. While pressing the both [PLAY MODE] and x buttons, press

the . button.

4. Set to the DVD service mode.

5. With the DVD in stop status, press the

M button to move

the optical pick-up to outside track, or press the m button

to inside track.

6. To release from this mode, perform as follows.

1) Move the optical pick-up to the most inside track.

2) Disconnect the power cord.

Notes: • Always move the optical pick-up to most inside track when

1

releasing from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can

be chipped.

[DVD CANCELLATION MODE OF REPEAT LIMITATION]

•This mode can cancel the DVD repeat limitation (5 times).

Procedure:

1. Press the I/1 *1 button to turn the power on.

2. Turn the [FUNCTION]*1 knob to select “DVD”.

3. While pressing the both [PLAY MODE] and x buttons, press

the [REPEAT] button.

4. DVD repeat limitation is canceled.

5. To release this mode, disconnect the power cord.

[DVD DISC TRA Y LOCK MODE FOR B URGLAR Y

PREVENTION]

2

Procedure:

1. Press the I/1 *1 button to turn the power on.

2. Turn the [FUNCTION]*1 knob to select “DVD”.

3. While pressing the both [PLAY MODE] and x buttons, press

the m button, turn the power off.

11

DVP-S9

Ver 1.6

[GENERAL DESCRIPTION]

The T est Mode allo ws you to mak e diagnosis and adjustment easily using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[STARTING TEST MODE]

1. Press the I/1 *1 button to turn the power on.

2. Turn the [FUNCTION]*2 knob to select “DVD”.

3. While pressing the x and [PLAY MODE] button, press

the . button to enter the test mode.

4. It displays “TEST MODE” on the fluorescent indicator tube,

and displays the Test Mode Menu on the monitor screen as

follows. (At the bottom of the menu screen, the model name

and revision number are displayed)

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Version Information

6. Video Level Adjustment

Exit: POWER Key

_

Model : xxx-xxxx_xx

Revision: 1.xxx

5. T o e xecute each function, select the desired menu and press its

number on the remote commander (RM-SD390AV or RMSD395AV).

6. To release from test mode, press the I/1 *1 button and turn

the power off.

1. All

All items continuous check

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed for the key entry.

### Syscon Diagnosis ###

Diag All Check

No. 2 Version

2-3. ROM Check Sum

Check Sum = 2005

Press NEXT Key to Continue

Press PREV Key to Repeat

_

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press > key to go to the next item,

or . key to repeat the same check again. To quit the dia gnosis

and return to the Check Menu screen, press x or [ENTER] key.

If an error occurred, the diagnosis is suspended and the error code

is displayed as shown below.

### Syscon Diagnosis ###

[SYSCON DIAGNOSIS]

The same contents as board detail check by serial interface can be

checked from the remote commander.

On the Test Mode Menu screen, pr ess [10/0] key on the remote

commander, and the following check menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. Peripheral

4. Servo

5. Supply

6. AV Decoder

7. Video

8. Audio

_

0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

3-3. EEPROM Check

Error 03: EEPROM Write/Reed N

Address : 00000001

Write Data : 2492

Read Data : 2490

Press NEXT Key to Continue

Press PREV Key to Repeat

_

Press x key to quit the diagnosis, or > key to repeat the same

item where an error occurred, or . key to continue the check

from the item next to faulty item.

12

DVP-S9

Ver 1.6

Selecting 2 and subsequent items calls the submenu screen of each

item.

For example, if “5. Supply” is selected, the following submenu

will be displayed.

### Syscon Diagnosis ###

Check Menu

No. 5 Supply

0. Quit

1. All

2. ARP Register Check

3. ARP to RAM Data Bus

4. ARP to RAM Address Bus

5. ARP RAM Check

_

0. Quit

Quit the submenu and return to the main menu.

1. All

All submenu items continuous check

This menu checks 2 and subsequent items successively . At the item

where visual check is required for judgment or an error occurred,

the checking is suspended and the message is output for key entry .

Normally, all items are check ed successiv ely one after another automatically unless an error is found.

Selecting 2 and subsequent items executes respective menus and

outputs the results.

For the contents of each submenu, see “Check Items List”.

General Description of Checking Method

2. Version

(2-2) Revision

ROM revision number is displayed.Error: Not detected.

The revision number defined in the source file of R OM (At

the beginning of mass production, the Flash ROM of IC107

is used) is displayed with four digits.

(2-3) ROM Check Sum

Check sum is calculated.

Error: Not detected.

The 8-bit data are added at addresses 0x000F0000 ~

0x002EFFFF of ROM (IC107) and the result is displayed

with 4-digit hexadecimal number. Error is not detected.

Compare the result with the specified value.

(2-4) Model T ype

Model code is displayed.

Error: Not detected.

The model code read from EEPROM (IC101) is displayed

with 2-digit hexadecimal number.

(2-5) Region

Region code is displayed.

Error: Not detected.

The region code determined from the model code is displayed.

3. Peripheral

(3-2) EEPROM Check

Data write → read, and accord check

Error 03: EEPROM write/read discord

Data 0x9249, 0x2942, 0x4294 are written to addresses

0x00~0xFF of EEPROM (IC101), then read and checked.

Before writing, the data are saved, then after checking, they

are written to restore the contents of EEPROM.

4. Servo

(4-2) Servo DSP Check

Data write → read, and accord check

Error 12: Read data discord

Data 0x9249, 0x2942, 0x4294 are written to the address

0x602 of RAM in the Servo DSP (IC302), then read and

checked.

(4-3) DSP Driver Test

Test signal data → DSP Driver

Error: Not detected.

Caution: Do not conduct this test with a mechanical deck

connected.

The maximum voltage is applied to the Servo Driver IC

(IC401). If mechanical deck is connected, the motor and

optics could be damaged. Disconnect mechanical deck following the output message, then enter specified 4- or 5digit number from the remote commander, and press the

[ENTER]. The test is conducted only when the input data

accord. Check the output level, then press the > to finish the test.

This test is skipped if “All” is selected.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN010 and CN015

of MB board. Also, disconnect harness from the CN203.

13

DVP-S9

Ver 1.6

5. Supply

Caution: Do not conduct this check with a mechanical deck con-

nected.

An access is made to the stream supply and servo control

IC (IC302) and external RAM (IC303) using check data.

If mechanical deck is connected, the motor and optics

could be damaged. This check is also executed by the

“All” menu item.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN010 and

CN015 of MB board. Also, disconnect harness from

the CN203.

(5-2) ARP Register Check

Data write → read, and accord check

Error 08: ARP register write, and read data discord

Data 0x00 to 0xFF are written to the TMAX register (address 0xC6) in ARP (IC302), then they are read and check ed.

(5-3) ARP to RAM Data Bus

Data write → read, and accord check

Error 09: ARP ←→ RAM data bus error

Data 0x0001 to 0x8000 where one bit each is set to 1 are

written to the address 0 of RAM (IC303) connected to the

ARP (IC302) through the bus, then they are read and

checked. In case of discord, written bit pattern and read

data are displayed. If data where multiple bits are 1 are

read, the bits concerned may touch each other. Further, if

data where certain bit is always 1 or 0 regardless of written

data, the line could be disconnected or shorted.

(5-4) ARP to RAM Address Bus

Data write → other address read discord check

Error 10: ARP → RAM address bus error

Caution: Address and data display in case of an error is

different from the display of other diagnosis (de-

scribed later).

Before starting the test, all addresses of RAM (IC303) are

cleared to 0x0000.

First, 0xA55A is written to the address 0x00000, and the

address data are read and checked from addresses 0x00001

to 0x80000 while shifting 1 bit each. Next, the data at that

address is cleared, and it is written to the address 0x00001,

and read and checked in the same manner. This check is

repeated up to the address 0x80000 while shifting the address data by 1 bit each.

If data other than 0 is read at the addresses except written

address, an error is given because all addresses were already cleared to 0. In this check, the error display pattern is

different from that of other diagnosis; read data, written

address, and read address are displayed in this order. Ho wever, the message uses same template, and accordingly exchange Address and Data when reading. The following display, for example,

### Syscon Diagnosis ###

5-4. ARP to RAM Address Bus

Error 10: ARP - RAM Address B

Address : 0000A55A

Write Data : 00000000

Read Data : 00080000

Press NEXT Key to Continue

Press PREV Key to Repeat

_

shows the data 0xA55A was read from address 0x00080000

though it was written to the address 0x00000000. This implies that these addresses are in the form of shadow. Also,

if the read data is not 0xA55A, another error will be present.

(5-5) ARP RAM Check

Data write → read, and accord check

Error 11: ARP RAM read data discord

The program code data stored in ROM are copied to all

areas of RAM (IC303) connected to the ARP (IC302)

through the bus, then they are read and checked if they accord. If the detail check was selected initially, the data are

written to all areas and read, then the same test is conducted

once again with the data where all bits are inverted between

1 and 0. If discord is detected, faulty address, written data,

and read data are displayed following the error code 11,

and the test is suspended.

14

DVP-S9

Ver 1.6

6. AV Decoder

(6-2) 1930 RAM

Data write → read, and accord check

Error 13: AVD RAM read data discord

The program code data stored in ROM (IC107) are copied

to all areas oo»RAM (IC504, IC505) connected to the AVD

(IC503) through the bus, then they are read and checked if

they accord. Further, the same test is conducted once ag ain

with the data where all bits are inverted between 1 and 0. If

discord is detected, faulty address, written data, and read

data are displayed following the error code 13, and the test

is suspended.

(6-3) 1930 SP

ROM → AVD RAM → Video OUT

Error: Not detected.

The data including sub picture streams in ROM (IC107)

are transferred to the RAM (IC504, IC505) in AVD (IC503),

and output as video signals from the AVD (IC503).

They are output from all video terminals (Composite, Y/C).

7. Video

(7-2) Color Bar

AVD color bar command write → Video OUT

Error: Not detected.

The command is transferred to the AVD, and the color bar

signals are output from video terminals.

They are output from all video terminals (Composite, Y/C).

Check Items List

2) Version

(2-2) Revision

(2-3) ROM Check Sum

(2-4) Model T ype

(2-5) Region

3) Peripheral

(3-2) EEPROM Check

4) Servo

(4-2) Servo DSP Check

(4-3) DSP Driver Test

5) Supply

(5-2) ARP Register Check

(5-3) ARP to RAM Data Bus

(5-4) ARP to RAM Address Bus

(5-5) ARP RAM Check

6) AV Decoder

(6-2) 1930 RAM

(6-3) 1930 SP

7) Video

(7-2) Color Bar

(7-3) Composit Out

(7-4) Y/C Out

(7-6) Component Out

(7-3) Composit Out

(7-4) Y/C Out

(7-6) Component Out

8. Audio

(8-2) ARP → 1930

Error 14 : ARP → 1930 video NG

15 : ARP → 1930 audio NG

(8-3) Test Tone

All channels

2ch Left

2ch Right

Front Left

Front Right

Rear Left

Rear Right

Center

Sub Woof er

8) Audio

(8-2) ARP → 1930

(8-3) Test Tone

Error Codes List

00: Error not detected

01: RAM write/read data discord

02: Gate array NG

03: EEPROM NG

08: ARP register read data discord

09: ARP ←→ RAM data bus error

10: ARP ←→ RAM address bus error

11: ARP RAM read data discord

12: Servo DSP NG

13: 1930 SDRAM NG

14: ARP → 1930 video NG

15: ARP → 1930 audio NG

16: 1910 UCODE download NG

17: System call error (function not supported)

18: System call error (parameter error)

19: System call error (illegal ID number)

20: System call error (time out)

90: Error occurred

91: User verification NG

92: Diagnosis cancelled

15

DVP-S9

Ver 1.6

[DRIVE AUTO ADJUSTMENT]

On the T est Mode Menu scr een, press [1] key on the remote commander, and the drive auto adjustment menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

Exit: RETURN

Normally, [10/0] is selected to adjust DVD (single layer), CD and

DVD (dual layer). But, individual items can be adjusted for the

case where adjustment is suspended due to an error. In this mode,

the adjustment can be made easily through the operation following the message displayed on the screen.

The disc used for adjustment must be the one specified for adjustment.

0. ALL

Select [10/0] and press [ENTER] key, and the servo set data in

EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD disc

and 3. DVD-DL disc are adjusted in this order . Eac h time one disc

was adjusted, it is ejected. Replace it with the specified disc following the message. You can finish the adjustment if pressing

x button. During adjustment of each disc, the measurement

the

for disc type judgment is made. As automatic adjustment does not

judge the disc type unlike conventional models, take care not to

insert wrong type discs. Also, do not give a shock during adjustment.

1. DVD-SL (single layer)

Select

[1], insert DVD single layer disc, and press [ENTER] key,

and the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM.

DVD Single Layer Disc Adjustment Steps

1. SLED TILT Reset

2. Disc Check Memory SL

3. Wait 300 msec

4. Set Disc Type SL

5. LD ON

6. Spdl Start

7. Wait 1 sec

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. CLVA ON

11. Wait 500 msec

12. Tracking ON

13. Wait 1 sec

14. Sled ON

15. Check CLV Loc k

16. Auto LFO Adjust

17. Auto Focus Offset Adjust

18. Auto Tilt Position Adjust

19. Auto Focus Gain Adjust

20. Auto Focus Offset Adjust

21. EQ Boost Adjust

22. Auto LFO Adjust

23. Auto Track Gain Adjust, Search Check

24. 32Tj Fwd

25. 32Tj Rev

26. 500Tj Fwd

27. 500Tj Rev

28. All Servo Stop

29. Eep Copy Loop Filter Offset

16

DVP-S9

Ver 1.6

2. CD

Select [2], insert CD disc, and press [ENTER] key, and the adjustment will be made through the following steps, then adjusted values will be written to the EEPROM.

CD Adjustment Steps

1. Sled Tilt Rest

2. Disc Check Memory CD

3. Wait 500 msec

4. Set Disc Type CD

5. LD ON

6. Spdl Start

7. Wait 500 msec

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. CLVA ON

11. Wait 500 msec

12. Tracking ON

13. (TC Display Start)

14. Wait 1 sec

15. Jitter Display Start

16. Sled ON

17. Check CLV ON

18. Auto LFO Adjust

19. Auto Focus Offset Adjust

20.

21. Auto Focus Gain Adjust

22. Auto Focus Offset Adjust

23. Eq Boost Adjust

24. Auto LFO Adjust

25. Auto Track Gain Adjust, Search Check

26. 32Tj Fwd

27. 32Tj Rev

28. 500Tj Fwd

29. 500Tj Rev

30. All Servo Stop

3. DVD-DL (dual layer)

Select [3], insert DVD dual layer disc, and press [ENTER] key,

and the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM.

DVD Dual Layer Disc Adjustment Steps

1. Sled Tilt Reset

2. Disc Check Memory DL

3. Wait 500 msec

4. Set Disc Type DL

5. LD ON

6. Spdl Start

7. Wait 1 sec, Layer 1 Adjust

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. Clva ON

11. Wait 500 msec

12. Tracking ON

13. Wait 500 msec

14. Sled ON

15. Check CLV Lock

16. Auto Loop Filter Offset Auto Focus Adjust

17.

18. Auto Focus Gain Adjust

19. Auto Focus Offset Adjust

20. Eq Boost Adjust

21. Auto Loop Filter Offset

22. Auto Track Gain Adjust, Search Check

23. 32Tj Fwd

24. 32Tj Rev

25. 500Tj Fwd

26. 500Tj Rev, Layer 0 Adjust

27. Fj (L1 -> L0)

28. Auto Track Offset Adjust L0

29. Clva ON

30. Wait 500 msec

31. Tracking ON

32. Wait 500 msec

33. Sled ON

34. Check CLV Lock

35. Auto Focus Filter Offset

36. Auto Focus Adjust

37.

38. Auto Focus Gain Adjust

39. Auto Focus Offset Adjust

40. Eq Boost Adjust

41. Auto Loop Filter Offset

42. Auto Track Gain Adjust, Search Check

43. 32Tj Fwd

44. 32Tj Rev

45. 500Tj fwd

46. 500Tj Rev, Layer Jump Check

47. Lj (L0 -> L1)

48. Lj (L1 -> L0)

49. All Servo Stop

17

DVP-S9

Ver 1.6

[DRIVE MANUAL OPERATION]

On the T est Mode Men u screen, select [2], and the manual operation menu will be displayed. For the manual operation, each servo

on/off control and adjustment can be executed manually.

## Drive Manual Operation ##

1. Disc type

2. Servo Control

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

6. Memory Check

7. Sacd Water Mark

0. Disc Check Memory

_

Operation Menu

Exit: Return

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed when a disc is loaded.

1. Set correctly the disc type to be used on the Disc Type

screen.

The disc type must be set after a disc was loaded.

The set disc type is cleared when the tray is opened.

2. After power ON, if the Drive Manual Operation was selected, first perform “Reset SLED TILT” by opening 1.

Disc Type screen.

3. In case of an alarm, immediately press the x button to

stop the servo operation, and turn the power OFF.

Basic operation (controllable from front panel or remote commander)

I/1 Power OFF

x Servo stop

Z Stop+Eject/Loading

[RETURN] Return to Operation Menu or Test Mode

Menu

> , . Transition between sub modes of menu

[1] to [9], [10/0] Selection of menu items

Cursor ↑ / ↓ Increase/Decrease in manually adjusted

value

0. Disc Check Memory

Disc Check

1. SL Disc Check

2. CD Disc Check

3. DL Disc Check

0. Reset SLED TILT

_

On this screen, the mirror time is measured to judge the disc and it

is written to the EEPROM. First load D VD SL disc and press [1],

next load CD disc and press [2], and finally load DVD DL disc

and press [3].

The adjustment must be executed more than once after default

data were written. External vibration or shock to the player must

not be given. Reference value for DVD is from 10 to 20, and for

CD, from 28 to 4F.

Check that the value of CD is larger than that of DVD .

When those values are beyond a range perform this adjustment

again.

From this screen, you can go to another mode by

pressing > or . key, but you cannot enter this mode from

another mode. You can enter this mode from the Operation Menu

screen only.

1. Disc T ype

Disc Type

1. Disc Type Auto Check

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

-- SA. ------ SI. -- EMG. 00

DVD SL12cm

On this screen, select the disc type. To select the disc type, press

the number of the loaded disc. The selected disc type is displayed

at the bottom. Selecting [1] automatically selects and displays the

disc type. In case of wrong display, retry “Disc Check Memory”.

Also, opening the tray causes the set disc type to be cleared. In

this case, set the disc type again after loading.

In performing manual operation, the disc type must be set.

Once the disc type has been selected, the sector address or time

code display field will appear as shown below. These values are

displayed when PLL is locked.

18

DVP-S9

Ver 1.6

1. Disc Type Auto Check

Disc Type

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

SA. SI. EMG. 00

DVD SL 12 cm

Display when DVD SL 12cm disc was selected

Disc Type

1. Disc Type Auto Check

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

TC. : : EMG. 00

CD 12 cm

2. Servo Control

Servo Control

1. LD Off R.Sled FWD

2. SP Off L.Sled REV

3. Focus Off

4. TRK. Off

5. Sled Off

6. CLVA Off

7. FCS. Srch Off

0. Reset SLED TILT

SA. SI. EMG. 00

DVD SL 12 cm

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CL VA is turned on, the usual trace mode becomes acti ve. In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system

is faulty or RF is not present. In such a case, do not operate CL VA.

[10/0] Reset SLED TILT Reset the Sled

and Tilt to initial position.

[1] LD Turn ON/OFF the laser.

Display when CD 12cm disc was selected

[0] Reset SLED TILT Reset the Sled and Tilt to initial posi-

tion.

[1] Disk Type Check Judge automatically the loaded disc. As

the judged result is displayed at the bottom of screen, make sure that it is correct.

If Disc Check Memory menu has not

been executed after EEPROM default

setting, the disc type cannot be judged.

In this case, return to the initial menu

and make a check for three types of

discs (SL, DL, CD).

[2] to [9] Select the loaded disc. The adjusted

value is written to the address of selected disc. No further entry is necessary if [1] was selected.

[2] SP Turn ON/OFF the spindle.

[3] Focus Search the focus and turn on the focus.

[4] TRK Turn ON/OFF the tracking servo.

[5] Sled Turn ON/OFF the sled servo.

[6] CLVA Turn ON/OFF normal servo of spindle

servo.

[7] FCS. Srch Apply sam e voltage as that of focus

search to the focus drive to check the

focus drive system.

→ Sled FWD Move the sled outward. Perform this

operation with the tracking servo turned

off.

← Sled REV Move the sled inward. Perform this op-

eration with the tracking servo turned

off.

↑ Tilt UP Move the tilt upward.

↓ Tilt DOWN Move the tilt downward.

The following menus are normally not used.

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

The persons who do not know well about these menus should not

use them.

19

DVP-S9

Ver 1.6

6. Memory Check

EEPROM Data1

-– DL – CD LCD SL L0 L1

Focus Gain xx xx xx xx xx

TRK. Gain xx xx xx xx xx

FCS Balance xx xx xx xx xx

Focus Bias xx xx xx xx xx

TRV. Offset xx xx xx xx xx

L. F. Offset xx xx xx xx xx

EQ Boost xx xx xx xx xx

Mirror Time xx xx xx xx xx

_DOWN: Next Data

CLEAR: Default Set page.1/2

EEPROM Data1

-– DL – CD LCD SL L0 L1

RF Jitter xx -- xx xx xx

RF Level xx -- xx -- -FE Level xx -- xx -- -FE Balance xx -- xx -- -TRV. Level xx -- xx -- -Analog FRSW xx xx xx xx xx

PLL DacGain xx xx xx xx xx

_

UP : Prev Data

CLEAR: Default Set page.2/2

This screen displays current servo adjusted data stored in the

EEPROM. Though adjusted data can be initialized with the

[CLEAR] key, they cannot be restored after initialization.

So, before clearing, make a note of the adjusted data.

For reference, the drive has been designed so that the gain center

value is 20 and offset value is 80. Other values will be in a range

of 10 to 80. If extreme value such as 00 or FF is set, adjustment

will be faulty. In such a case, check for disc scratch or cable disconnection, then perform adjustment again.

[MECHA AGING]

### Mecha Aging ###

[EMERGENCY HISTORY]

### EMG. History ###

Laser Hours CD xxxxxxxh

DVD xxxxxxxh

1. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

2. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

Select: 1 – 9 Scroll: UP/DOWN

(1: Last EMG.) Exit: RETURN

On the Test Mode Menu screen, selecting [4] displays the information such as servo emergency history. The history information

from last 1 up to 10 can be scrolled with ↑ key or ↓ key. Also,

specific information can be displayed by directly entering that

number with ten keys.

The upper two lines display the laser ON total hours. Data below

minutes are omitted.

Clearing History Information

Clearing laser hours

Press [DVD DISPLAY] and [CLEAR] keys in this order.

Both CD and DVD data are cleared.

Clearing emergency history

Press [TITLE] and [CLEAR] keys in this order.

Initializing set up data

Press [DVD SET UP] and [CLEAR] keys in this order.

The data have been initialized when “Set Up Initialized” message is displayed. The EMG. History screen will be restored

soon.

How to see Emergency History

31.12

Press OPEN Key

Abort: STOP key

On the Test Mode Menu Screen, selecting [3] executes the aging

of the mechanism. Start aging with PLAY. During aging, the repeat cycle is displayed. Aging can be aborted at any time by pressing the x key. After the operation is stopped, press the x key

or [RETURN] key again to return to the Test Mode Menu.

SEARCH Aging is only for a CD.

20

2

1 : Emergency Code

2 : Don’t Care

These codes are used for verification of software designing.

3 : Historical order 1 to 9

DVP-S9

Ver 1.6

Emergency Codes List

10: Communication to IC001 (RF board) failed.

11: Each servo for focus, tracking, and spindle is unlocked.

12: Communication to EEPROM, IC101 (MB board) failed.

13: Writing of hours meter data to EEPROM, IC101 (MB board)

failed.

14: Communication to Servo DSP IC302 (MB board) failed, or

Servo DSP is faulty.

20: Initialization of tilt servo and sled servo failed. They are not

placed in the initial position.

21: Tilt servo operation error

22:

Syscon made a request to move the tilt servo to wrong position.

23: Sled servo operation error

24:

Syscon made a request to move the sled servo to wr ong position.

30: Tracking balance adjustment error

31: Tracking gain adjustment error

32: Focus balance adjustment error

33: Focus bias adjustment error

34: Focus gain adjustment error

35: Tilt servo adjustment error

36: RF equalizer adjustment error

37: RF group delay adjustment error

38: Jitter value after adaptive servo operation is too large.

40: Focus servo does not operate.

41: With a dual layer (DL) disc, focus jump failed.50: CLV

(spindle) servo does not operate.

51: Spindle does not stop.

60: With a DVD disc, Syscon made a request to seek nonexistent

address.

61: With a CD disc, Syscon made a request to seek nonexistent

address.

62: With a CD disc, Syscon made a request to seek nonexistent

track No. and index No.

63: With a DVD disc, seeking of target address failed.

64: With a CD disc, seeking of target address failed.

65: With a CD disc, seeking of target index failed.

70: With a D VD disc, physical information data could not be read.

71: With a CD disc, TOC data could not be read.

80: Disc type judgment failed.

81: As disc type judgment failed, retry was repeated.

82: As disc type judgment failed, a measurement error occurred.

83: Disc type could not be judged within the specified time.

84: Illegal command code was received from Syscon.

85: Illegal command was received from Syscon.

[VIDEO LEVEL ADJUSTMENT]

On the Test Mode Menu screen, selecting [6] displays color bars

for video level adjustment. During display of color bars, OSD disappears but the menu screen will be restored if pressing any key.

Measurement point :VIDEO OUT jack

(75 Ω terminating resistance)

Measuring instrument: Oscilloscope

Adjustment device : RV501 on MB board

Specified value : 1.0

+ 0.04

– 0.02

Vpp

1.0

+ 0.04

– 0.02

Vp-p

[VERSION INFORMATION]

## Version Information ##

IF con. Ver: x. xxx (xxxx)

Group 00

SYScon. Ver: x. xxx (xxxx)

Model xx

Region 0x

Servo DSP Ver:X.XXX

OPT Type:2 Laser

Exit: RETURN

On the Test Mode Menu screen, selecting [5] displays the ROM

version and region code.

The parenthesized hexadecimal number in version field is

checksum value of ROM.

21

DVP-S9

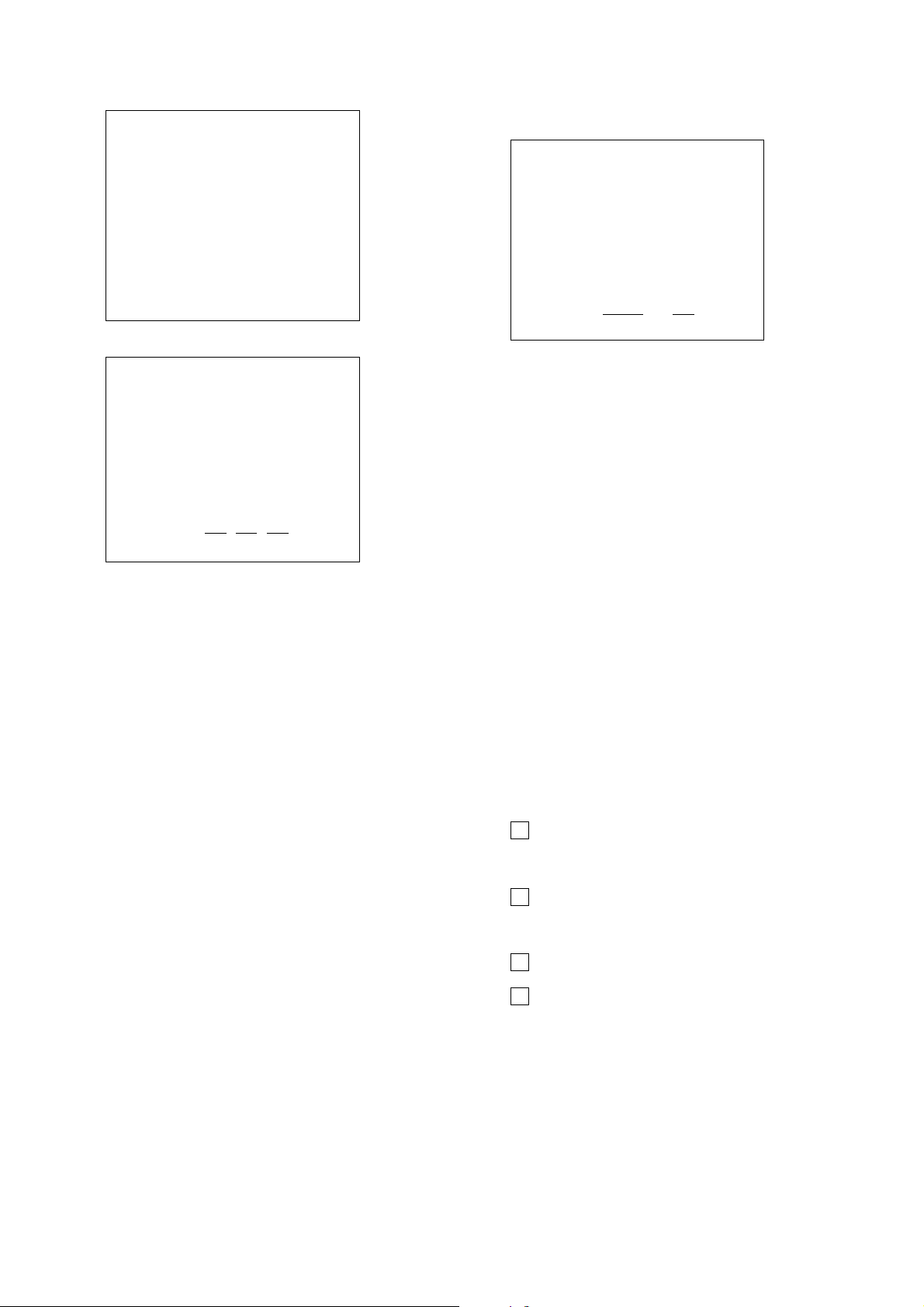

IC202

IC103

IC503

IC302

RV501

Video

Level

Adjustment

– MB Board (Component Side) –

Ver 1.6

SECTION 5

ELECTRICAL ADJUSTMENTS

Note: During diagnostic check, the characters and color bars can be seen

only with the NTSC monitor. Therefore, for diagnostic check, use

the monitor that supports both NTSC and PAL modes

Instruments required:

1) Color monitor TV

2) Oscilloscope 1 or 2 phenomena, band width over 100 MHz,

with delay mode

3) DVD reference disc

HLX-501 (J-6090-071-A) (dual layer) (NTSC)

HLX-503 (J-6090-069-A) (single layer) (NTSC)

HLX-504 (J-6090-088-A) (single layer) (NTSC)

HLX-505 (J-6090-089-A) (dual layer) (NTSC)

HLX-506 (J-6090-077-A) (single layer) (PAL)

HLX-507 (J-6090-078-A) (dual layer) (PAL)

AUTO SERVO ADJUSTMENT

After parts related to the servo circuit (RF amplifier (IC001), DSP

(IC302), motor driver (IC401), EEPROM (IC101) so on) are replaced, re-adjusting the servo circuit is necessary . Select “ALL” at

“DRIVE AUTO ADJUSTMENT” (Refer to page 16 in TEST

MODE) and adjust DVD-SL (single layer), CD and D VD-DL (dual

layer).

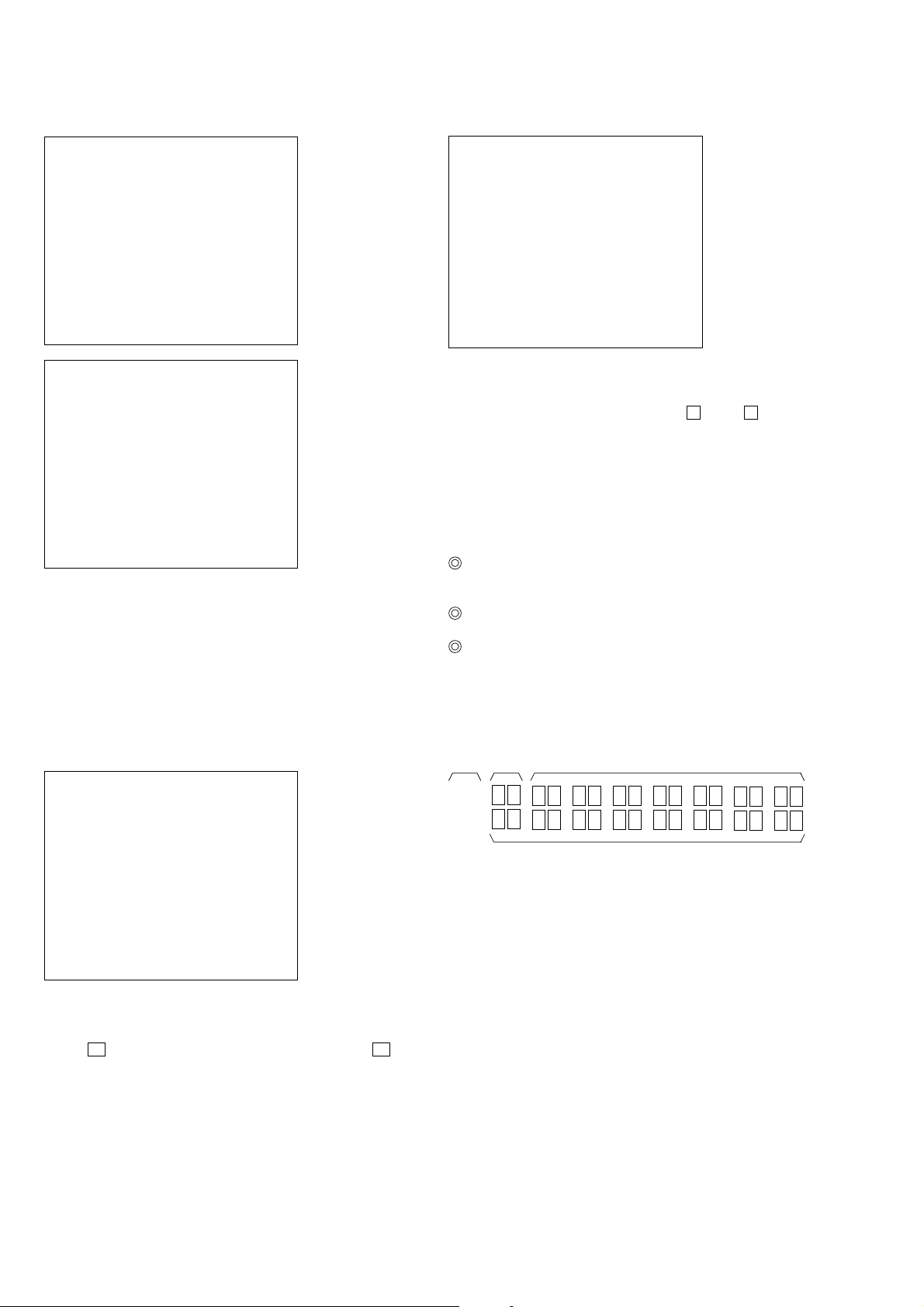

VIDEO LEVEL ADJUSTMENT

<Purpose>

This adjustment is made to satisfy the NTSC/P AL standard, and if

not adjusted correctly, the brightness will be too large or small.

Signal Color bars

Test point

VIDEO OUT jack

(75 Ω terminated)

Instrument Oscilloscope

Adjusting element RV501 (MB board)

Specified Value 1.0

+ 0.04

– 0.02

Vp-p

Procedure:

1. Press the I/1 button to turn the power on, and turn the

[FUNCTION] knob to select “DVD” of A/V amplifier (TA-

S9D).

2. Adjust the RV501 on the MB board to attain 1.0

+ 0.04

– 0.02

Vp-p.

Procedure:

1. Press the I/1 button to turn the power on, and turn the

[FUNCTION] knob to select “DVD” of A/V amplifier (TA-

S9D).

2. Confirm that the S-Y level is 1.0 ± 0.05 Vp-p.

1.0 ± 0.05 Vp-p

Figure 5-2

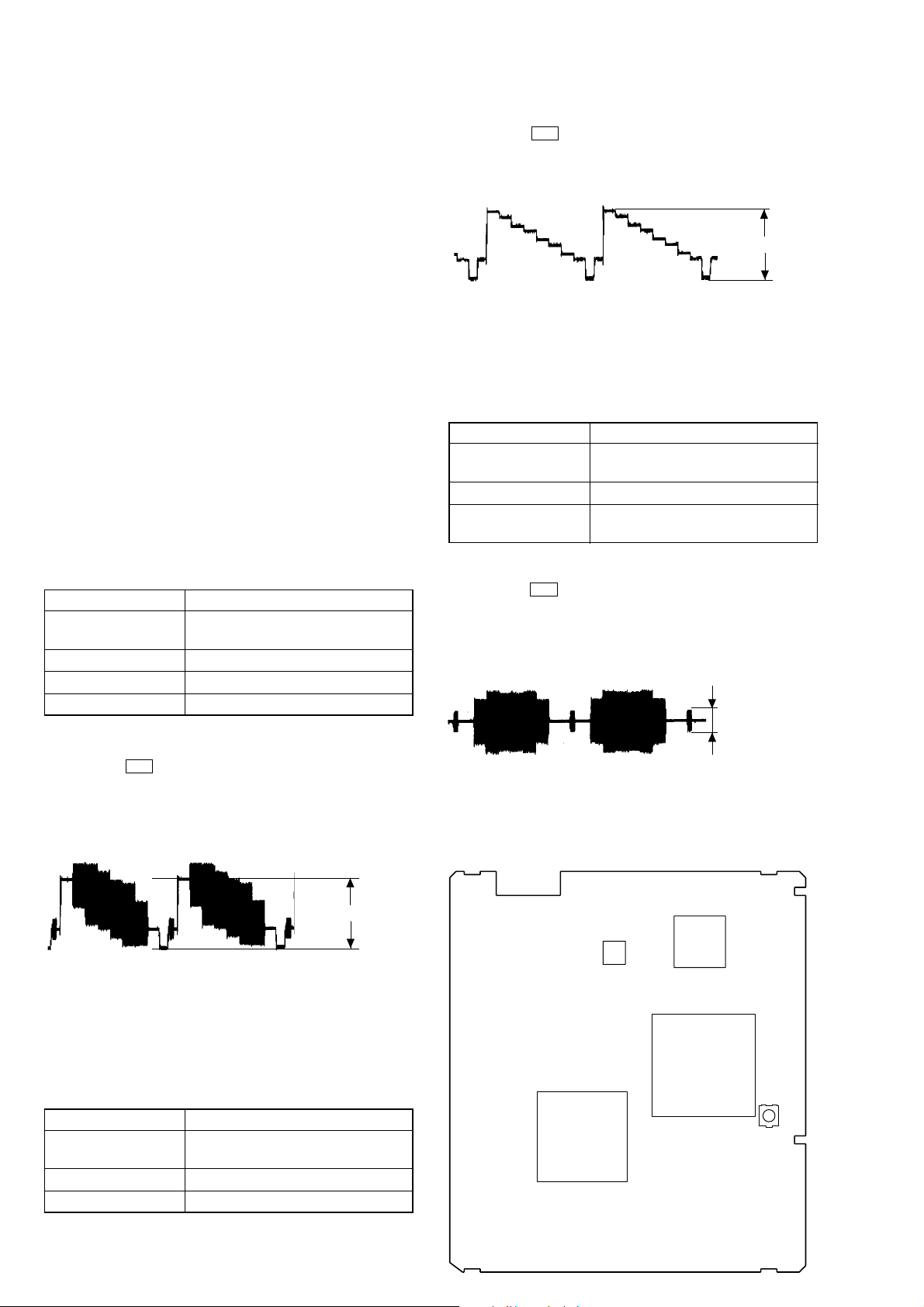

CHECKING S VIDEO OUTPUT S-C

<Purpose>

This checks whether the S-C satisfies the NTSC Standard. If it is

not correct, the colors will be too dark or light.

Signal Color bars

Test point

S VIDEO OUT (S-C) jack

(75 Ω terminated)

Instrument Oscilloscope

Specified Value

286 ± 30 mVp-p (NTSC)

300 ± 100 mVp-p (PAL)

Procedure:

1. Press the

I/1 button to turn the power on, and turn the

[FUNCTION] knob to select “DVD” of A/V amplifier (TA-

S9D).

2. Confirm that the S-C burst is 286 ± 30 mVp-p (NTSC) or 300

± 100 mVp-p (PAL).

286 ± 50 mVp-p

(NTSC)

or

300 ± 100 mVp-p

(PAL)

Figure 5-3

Adjustment Location :

+ 0.04

1.0

– 0.02

Figure 5-1

CHECKING S VIDEO OUTPUT S-Y

<Purpose>

Check S-terminal video output. If it is incorrect, pictures will not

be displayed correctly in spite of connection to the TV with a Sterminal cable.

Signal Color bars

Test point

Instrument Oscilloscope

Specified Value 1.0 ± 0.05 Vp-p

S VIDEO OUT (S-Y) jack

(75 Ω terminated)

22

Vp-p

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM – RF/SERVO Section – • Refer to servicing notes (page 4) for discrimination of TYPE A/B.

OPTICAL PICK-UP

BLOCK

(KHM-240AAA) (TYPE A)

(KHM-270AAA) (TYPE B)

ATOP

RF

RF IN

2

ATON

64

63

AIP

61

AIN

62

FNP

FNN

55

54

DIP

56

DIN

57

SIGO

59

RF+

DVP-S9

Ver 1.5

A

(Page 24)

DVD/CD

DETECTOR

DVD/CD

LASER

DIODE

MODULE

INLIMIT

SENSOR

2-AXIS

DEVICE

FOCUS

COIL

DVD LD

CD LD

INLIM

FCS+

FCS–

SW

A

B

C

D

E

F

G

H

VC

AUTOMATIC POWER

CONTROL (FOR DVD)

Q001

AUTOMATIC POWER

CONTROL (FOR CD)

PD

Q002

D+3.3V

A

14

B

13

C

12

D

11

A2

7

B2

8

C2

9

D2

10

E

15

F

16

G

17

H

18

VC

19

DVDLD

25

CDLD

26

DVDPD

21

CDPD

22

LDSELO

24

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

42

37

36

IC401

FOCUS COIL

DRIVE

DVD/CD RF AMP,

FOCUS/TRACKING ERROR AMP

IC001

40

48

1

TZIN

MIRR

TZC

SRD

SWD

SCLK

SDEN

DFT

MON

VCI

LDON

FE

42

TE

41

40

PI

36

PII

35

33

37

45

46

47

48

38

44

39

27

136

135

137

197

196

173

174

175

180

185

184

172

166

204

205

ADC1

ADC0

ADC2

MIRR

TZC

GIO6/SDI

GIO7/SDO

GIO8/SCK

GIO13

DFCTI

ADC7

GIO5/PGIN

GIO0/INT2

PDM2

PDM3

SERVO DIGITAL

SIGNAL PROCESSOR

IC302 (1/2)

• SIGNAL PATH

: DVD PLAY

: CD PLAY

XLDON

TRACKING

COIL

MM

(SPINDLE)

MM

(SLED)

TRK+

TRK–

SPM+

SPM–

SLA+

SLA–

SLB+

SLB–

35

34

46

47

27

28

32

31

30

29

TRACKING COIL

DRIVE

–

+

SPINDLE MOTOR

DRIVE

SLED MOTOR

DRIVE

TSD-M

POWER SAVE

3

4

19

5

45

13

21

7

10

20

22

39

202

203

139

140

159

161

167

198

199

7

168

PDM0

PDM1

ADC3

ADC4

MDSO

MDPO

GIO1/INT3

PWM0

PWM1

GIO2/INT4

HINT

HCS

XDSPRST

22

24

156

XSDPIT

XSDPCS

XDRVMUTE

XRST

XLDON

XSDPIT, XSDPCS,

XDRVMUTE

C

(Page 24)

B

(Page 25)

2323

Loading...

Loading...