Page 1

DSR-PDX10/PDX10P

SERVICE MANUAL

RMT-811

US Model

Canadian Model

DSR-PDX10

Ver 1.8 2005. 11

Revision History

Revision History

Link

Link

SPECIFICATIONS

SPECIFICATIONS

SERVICE NOTE

SERVICE NOTE

BLOCK DIAGRAMS

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

AEP Model

UK Model

E Model

DSR-PDX10P

J MECHANISM

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

REPAIR PARTS LIST

REPAIR PARTS LIST

DISASSEMBLY

DISASSEMBLY

• INSTRUCTION MANUAL is shown at the end of this document.

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

ADJUSTMENTS

ADJUSTMENTS

DIGITAL CAMCORDER

Page 2

DSR-PDX10/PDX10P

COVER

COVER

Video camera

recorder

System

Video recording system

2 rotary heads

Helical scanning system

Audio recording system

Rotary heads, PCM system

Quantization: Fs 32 kHz (12 bits,

channels 1/2, channels 3/4), Fs 48

kHz (16 bits, channels 1/2)

Video signal

DSR-PDX10:

NTSC color, EIA standards

DSR-PDX10P:

PAL colour, CCIR standards

Usable cassette

Mini DVCAM cassette with the

mark printed

Mini DV cassette with the

mark printed

Tape speed

DVCAM format:

Approx. 28.218 mm/s

DV format SP mode:

Approx. 18.812 mm/s

Recording/playback time (using

cassette PDVM-40ME)

DVCAM format: 40 min.

DV format SP mode: 1 hour

Fastforward/rewind time (using

cassette PDVM-40ME)

When using the battery pack:

Approx. 2 min. and 30 seconds

When using the AC power

adaptor:

Approx. 1 min. and 45 seconds

Viewfinder

Electric viewfinder (B&W)

Image device

3.8 mm (1/4.7 type) 3 CCD

(Charge Coupled Device)

Gross: Approx. 1 070 000 pixels

Effective (still):

Approx. 1 000 000 pixels

Effective (moving):

Approx. 690 000 pixels

SPECIFICATIONS

Lens

Combined power zoom lens

Filter diameter: 37 mm

(1 1/2 in)

12× (Optical), 48× (Digital)

F 1.6 – 2.8

Focal length

3.6 – 43.2 mm (5/32 – 1 3/4 in.)

When converted to a 35 mm still

camera

In CAMERA

4:3 mode :

49 – 588 mm (1 15/16 – 23 1/4 in.)

16:9 mode :

41 – 492 mm (1 5/8 – 19 3/8 in.)

In MEMORY

41 – 492 mm (1 5/8 – 19 3/8 in.)

Colour temperature

Auto, nIndoor (3 200 K),

Outdoor (5 800 K),

Minimum illumination

7 lx (lux) (F 1.6)

Input/Output connectors

S video input/output

4-pin mini DIN

Luminance signal: 1 Vp-p,

75 Ω (ohms), unbalanced

DSR-PDX10:

Chrominance signal: 0.286 Vp-p

75 Ω (ohms), unbalanced

DSR-PDX10P:

Chrominance signal: 0.3 Vp-p,

75 Ω (ohms), unbalanced

Audio/Video input/output

AV MINI JACK, 1 Vp-p,

75 Ω (ohms), unbalanced, sync

negative

327 mV, (at output impedance

more than 47 kΩ (kilohms))

Output impedance with less than

2.2 kΩ (kilohms)/Stereo minijack

(ø 3.5 mm)

Input impedance more than

47 kΩ (kilohms)

DV input/output

4-pin connector

Headphone jack

Stereo minijack (ø 3.5 mm)

LANC jack

Stereo mini-minijack (ø 2.5 mm)

USB jack

mini-B

MIC jack

Minijack, 0.388 mV low impedance

with 2.5 to 3.0 V DC, output

impedance 6.8 kΩ (kilohms) (ø 3.5

mm)

Stereo type

INPUT1/INPUT2 connectors

XLR 3-pin, female, –60 dBu:

3 kilohms, +4 dBu: 10 kilohms

(0 dBu = 0.775 Vrms)

LCD screen

Picture

8.8 cm (3.5 type)

72.2 × 50.4 mm (2 7/8 × 2 in.)

Total dot number

246 400 (1 120 × 220)

General

Peak inrush current

Hot switching inrush current,

measured in accordance with

European standard EN55103-1:

6.3 A (230 V)

Power requirements

7.2 V (battery pack)

8.4 V (AC power adaptor)

Average power consumption

(when using the battery pack)

During camera recording using

LCD

6.3 W

Viewfinder

5.0 W

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

–20°C to + 60°C

(–4°F to + 140°F)

Dimensions (Approx.)

93 × 99 × 202 mm

(3 3/4 × 4 × 8 in.) (w/h/d)

Mass (Approx.)

950 g (2 lb 1 oz)

main unit only

1.4 kg (3 lb)

including the battery pack

NP-FM50, the XLR adaptor, the

Microphone, cassette PDVM40ME, the lens cap and shoulder

strap

Supplied accessories

See page 3.

AC power adaptor

Power requirements

100 – 240 V AC, 50/60 Hz

Power consumption

23 W

Output voltage

DC OUT: 8.4 V, 1.5 A in the

operating mode

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

–20°C to + 60°C

(–4°F to + 140°F)

Dimensions (approx.)

125 ⋅ 39 ⋅ 62 mm

(5 × 1 9/16 × 2 1/2 in.) (w/h/d)

excluding projecting parts

Mass (approx.)

280 g (9.8 oz)

excluding mains lead

Battery pack

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Capacity

8.5 Wh (1 180 mAh)

Dimensions (approx.)

38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 in.)

(w/h/d)

Mass (approx.)

76 g (2.7 oz)

Type

Lithium ion

“Memory Stick”

Memory

Flash memory

8MB: MSA-8A

Operating voltage

2.7 – 3.6 V

Power consumption

Approx. 45 mA in the operating

mode

Approx. 130 µA in the standby

mode

Dimensions (approx.)

50 × 2.8 × 21.5 mm

(2 × 1/8 × 7/8 in.) (w/h/d)

Mass (approx.)

4 g (0.14 oz)

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

Design and specifications are

subject to change without notice.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

— 2 —

Page 3

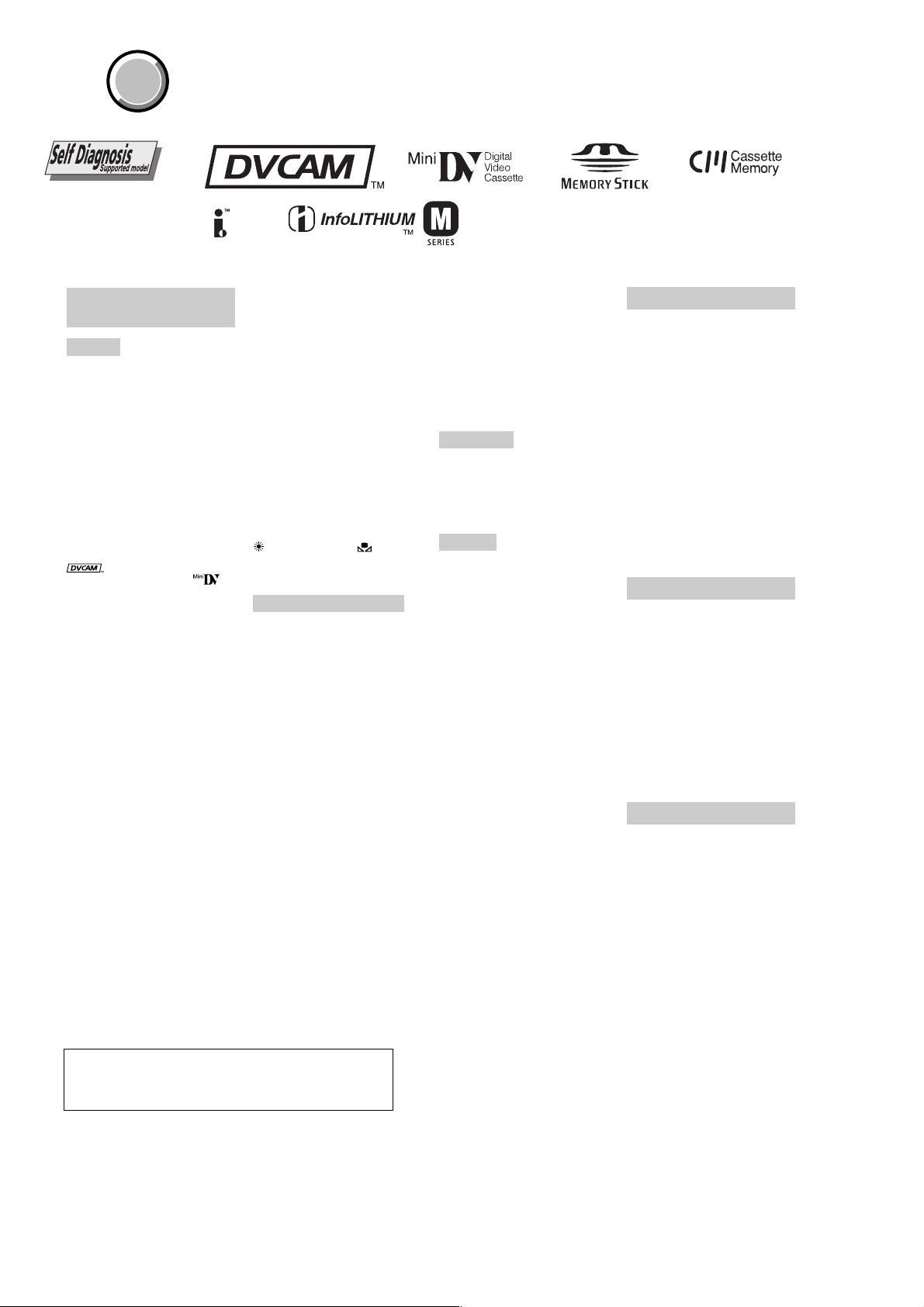

• SUPPLIED ACCESSORIES

Make sure that the following accessories are supplied with your camcorder .

DSR-PDX10/PDX10P

1

4

9

qf

1 AC-L10A/L10B/L10C AC power

adaptor (1), mains lead (1)

2 NP-FM50 battery pack (1)

3 A/V connecting cable (1)

4 Wireless Remote Commander (RMT-811)(1)

5 R6 (Size AA) battery for Remote Commander (2)

6 Shoulder strap (1)

7 Lens cap (1)

8 “Memory Stick” (1)

5

q;

6

qa

qg

2

7

qs

9 USB cable (1)

0 CD-ROM (SPVD-008 USB Driver) (1)(DSR-PDX10P)

CD-ROM (SPVD-008 (I) USB Driver) (1)(DSR-PDX10)

qa Cleaning cloth (1)

qs Wide lens hood (1)

qd XLR adaptor (with a Microphone holder) (1)

qf Microphone (1), Wind screen (1)

qg Clamp filter (1)

3

8

qd

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

Page 4

DSR-PDX10/PDX10P

TABLE OF CONTENTS

1. SERVICE NOTE

1-1. NOTE FOR REPAIR·····················································1-1

1-2. POWER SUPPLY DURING REPAIRS ·······················1-2

1-3. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) ····························································1-2

1-4. NOTES ON HANDLING THE LASER DIODE······· 1-3

1-4-1.Soldering Conditions of Laser Unit (D501) ····················1-3

1-5. SELF-DIAGNOSIS FUNCTION···································1-4

1-5-1.Self-diagnosis Function···················································1-4

1-5-2.Self-diagnosis Display·····················································1-4

1-5-3.Service Mode Display ·····················································1-4

1-5-4.Self-diagnosis Code Table ···············································1-5

2. DISASSEMBLY

2-1. CABINET (R) BLOCK···················································2-2

2-2. P CABINET (C) ······························································2-2

2-3. LCD MODULE ·······························································2-3

2-4. LCD BLOCK ··································································2-4

2-5. FP-495 FLEXIBLE BOARD ·········································· 2-4

2-6. CK-134 BOARD ·····························································2-5

2-7. F PANEL BLOCK···························································2-5

2-8. AF LASER BRACKET ASSEMBLY ·····························2-6

2-9. MA-425 BOARD ····························································2-7

2-10. FP-504 FLEXIBLE BOARD ··········································2-7

2-11. BATTERY PANEL BLOCK ···········································2-8

2-12. DB-016 BOARD ·····························································2-8

2-13. MD BLOCK ····································································2-9

2-14. LENS BLOCK ······························································2-10

2-15. VC-318 BOARD ···························································2-10

2-16. MECHANISM DECK (J210) ·······································2-11

2-17. EVF BLOCK·································································2-11

2-18. FP-497 FLEXIBLE BOARD ········································2-12

2-19. JK-222 BOARD ····························································2-12

2-20. CONTROL SWITCH BLOCK (PS-1870)····················2-15

2-21. SE-132 BOARD ···························································· 2-15

2-22. GRIP CABINET BLOCK ············································· 2-16

2-23. CONTROL SWITCH BLOCK (CF-1870) ···················2-17

2-24. MS ASSEMBL Y ···························································2-17

2-25. VF LENS ASSEMBLY ················································· 2-18

2-26. XLR BLOCK ································································2-19

2-27. XK-001 BOARD ···························································2-19

XM-002 BOARD, XD-002 BOARD, XS-002 BOARD··

2-28.

2-29. CIRCUIT BOARDS LOCATION·································2-21

2-30. FLEXIBLE BOARDS LOCATION ······························2-22

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/5) ··························· 3-1

3-2. OVERALL BLOCK DIAGRAM (2/5) ··························· 3-3

3-3. OVERALL BLOCK DIAGRAM (3/5) ··························· 3-5

3-4. OVERALL BLOCK DIAGRAM (4/5) ··························· 3-7

3-5. OVERALL BLOCK DIAGRAM (5/5) ··························· 3-9

3-6. POWER BLOCK DIAGRAM (1/3) ······························3-11

3-7. POWER BLOCK DIAGRAM (2/3) ······························3-13

3-8. POWER BLOCK DIAGRAM (3/3) ······························3-15

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/4)·······················4-1

FRAME SCHEMATIC DIAGRAM (2/4)······················ 4-3

FRAME SCHEMATIC DIAGRAM (3/4)·······················4-5

FRAME SCHEMATIC DIAGRAM (4/4)·······················4-7

4-2. SCHEMATIC DIAGRAMS

• CD-389 (CCD IMAGER)

SCHEMATIC DIAGRAM ··························· 4-11

• SE-132 (PITCH/YAW SENSOR)

SCHEMATIC DIAGRAM ····························4-13

2-20

• MA-425 (MIC AMP, AF LASER CONTROL)

SCHEMATIC DIAGRAM ····························4-15

• CK-134 (CONTROL SWITCH)

SCHEMATIC DIAGRAM ····························4-17

• JK-222 (AV IN/OUT, DV/USB CONNECTOR)

SCHEMATIC DIAGRAM ····························4-19

• PD-191 (1/2) (LCD DRIVER, TIMING GENERATOR)

SCHEMATIC DIAGRAM ···························4-21

• PD-191 (2/2) (LCD DRIVER, BACKLIGHT)

SCHEMATIC DIAGRAM ····························4-23

• LB-089 (EVF, EVF BACKLIGHT)

SCHEMATIC DIAGRAM ····························4-25

• FP-504 FLEXIBLE SCHEMATIC DIAGRAM·········4-27

• FP-100, FP-102, FP-228 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-29

• VC-318 (1/17) (A/D CONVERTER, TIMING GENERA-

TOR)

SCHEMATIC DIAGRAM ····························4-31

• VC-318 (2/17) (CAMERA RGB PROCESSOR)

SCHEMATIC DIAGRAM ····························4-33

• VC-318 (3/17) (CAMERA PROCESSOR)

SCHEMATIC DIAGRAM ····························4-35

• VC-318 (4/17) (MPEG MOVIE/DIGITAL STILL

PROCESS)

SCHEMATIC DIAGRAM ····························4-37

• VC-318 (5/17) (HI CONTROL, DIGITAL STILL

CONTROL)

SCHEMATIC DIAGRAM ····························4-39

• VC-318 (6/17) (FLASH MEMORY, SDRAM)

SCHEMATIC DIAGRAM ····························4-41

• VC-318 (7/17) (DV SIGNAL PROCESS)

SCHEMATIC DIAGRAM ····························4-43

• VC-318 (8/17) (DV INTERFACE)

SCHEMATIC DIAGRAM ····························4-45

• VC-318 (9/17) (REC/PB AMP)

SCHEMATIC DIAGRAM ····························4-47

• VC-318 (10/17) (USB INTERFACE)

SCHEMATIC DIAGRAM ····························4-49

• VC-318 (11/17) (VIDEO A/D CONVERTER)

SCHEMATIC DIAGRAM ····························4-51

• VC-318 (12/17)(DRUM/CAPSTAN/LOADING DRIVE)

SCHEMATIC DIAGRAM ····························4-53

• VC-318 (13/17) (CAMERA/MECHA CONTROL)

SCHEMATIC DIAGRAM ····························4-55

• VC-318 (14/17) (HI CONTROL)

SCHEMATIC DIAGRAM ····························4-57

• VC-318 (15/17) (LANC, RESET, BEEP, AFLD)

SCHEMATIC DIAGRAM ····························4-59

• VC-318 (16/17) (CONNECTOR)

SCHEMATIC DIAGRAM ····························4-61

• VC-318 (17/17) (CONNECTOR, EVR)

SCHEMATIC DIAGRAM ····························4-63

• DB-016 (1/9) (LENS MOTOR DRIVE)

SCHEMATIC DIAGRAM ····························4-65

• DB-016 (2/9) (VAP DRIVER)

SCHEMATIC DIAGRAM ····························4-67

• DB-016 (3/9) (MIC VOL)

SCHEMATIC DIAGRAM ····························4-69

• DB-016 (4/9) (AUDIO PROCESSOR 1)

SCHEMATIC DIAGRAM ····························4-71

• DB-016 (5/9) (AUDIO PROCESSOR 2)

SCHEMATIC DIAGRAM ····························4-73

• DB-016 (6/9) (VIDEO IN/OUT)

SCHEMATIC DIAGRAM ····························4-75

• DB-016 (7/9) (EVF DRIVE, TIMING GENERATOR)

SCHEMATIC DIAGRAM ····························4-77

— 4 —

Page 5

DSR-PDX10/PDX10P

• DB-016 (8/9) (CONNECTOR)

SCHEMATIC DIAGRAM ···························· 4-79

• DB-016 (9/9) (DC/DC CONTROL)

SCHEMATIC DIAGRAM ···························· 4-81

• XD-002/XS-002 (DC/DC CONVERTER,

MIC SELECT)

SCHEMATIC DIAGRAM ···························· 4-83

• XM-002 (MIC AMP) SCHEMATIC DIAGRAM ·····4-85

4-3. PRINTED WIRING BOARDS

• SE-132 (PITCH/YAW SENSOR)

PRINTED WIRING BOARD ·······················4-89

• CD-389 (CCD IMAGER)

PRINTED WIRING BOARD ·······················4-91

• MA-425 (MIC AMP, AF LASER CONTROL)

PRINTED WIRING BOARD ·······················4-95

• PD-191(LCD DRIVER, TIMING GENERATOR,

BACKLIGHT)

PRINTED WIRING BOARD ·······················4-97

• JK-222 (AV IN/OUT, DV/USB CONNECTOR)

PRINTED WIRING BOARD ·························4-9

• CK-134 (CONTROL SWITCH)

PRINTED WIRING BOARD ·····················4-103

• LB-089 (EVF, EVF BACKLIGHT)

PRINTED WIRING BOARD ·····················4-107

• FP-504 FLEXIBLE BOARD ···································4-109

• FP-495, FP-497 FLEXIBLE BOARD······················4-111

• FP-100, FP-102, FP-228 FLEXIBLE BOARD ······· 4-113

•

XD-002 (DC/DC CONVERTER), XS-002 (MIC SELECT)

PRINTED WIRING BOARD ···················· 4-115

• XM-002 (MIC AMP), XK-001 (LOW CUT SW)

PRINTED WIRING BOARD ···················· 4-117

• VC-318 (A/D CONVERTER, TIMING GENERATOR,

CAMERA RGB PROCESSOR, CAMERA PROCESSOR, MPEG MOVIE/DIGITAL STILL PROCESS,

HI CONTROL, DIGITAL STILL CONTROL, FLASH

MEMORY, SDRAM, DV SIGNAL PROCESS, DV

INTERFACE, REC/PB AMP, USB INTERFACE,

VIDEO A/D CONVERTER, DRUM/CAPSTAN/

LOADING DRIVE, CAMERA/MECHA CONTROL,

HI CONTROL, LANC, RESET, BEEP, AFLD,

CONNECTOR, EVR)

PRINTED WIRING BOARD ·····················4-119

• DB-016 (LENS MOTOR DRIVE, VAP DRIVER, MIC

VOL, AUDIO PROCESSOR 1, AUDIO PROCESSOR 2,

VIDEO IN/OUT, EVF DRIVE, TIMING GENERATOR,

CONNECTOR, DC/DC CONTROL)

PRINTED WIRING BOARD ·····················4-123

4-4. WAVEFORMS ···························································· 4-127

4-5. MOUNTED PARTS LOCATION ·······························4-132

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································5-1

5-1-1.MAIN SECTION ····························································5-1

5-1-2.F PANEL BLOCK ···························································5-2

5-1-3.CABINET (R) BLOCK···················································5-3

5-1-4.LCD BLOCK ··································································5-4

5-1-5.CABINET (L) BLOCK ···················································5-5

5-1-6.GRIP CABINET BLOCK ···············································5-6

5-1-7.XLR BLOCK ··································································5-7

5-1-8.EVF BLOCK···································································5-8

5-1-9.BATTERY PANEL BLOCK ···········································5-9

5-1-10. MD BLOCK ·······························································5-10

5-1-11. LENS BLOCK ····························································5-11

5-1-12.

OVERALL MECHANISM DECK SECTION (J210) ·

5-1-13. LS CHASSIS BLOCK ASSEMBLY ··························5-13

5-1-14. MECHANISM CHASSIS BLOCK ASSEMBLY ······5-14

5-2. ELECTRICAL PARTS LIST ········································5-15

5-12

6. ADJUSTMENT

1. Before starting adjustment ············································6-1

1-1. Adjusting items when replacing main parts and boards ··6-2

6-1. CAMERA SECTION ADJUSTMENT ························6-4

1-1. PREPARATIONS BEFORE ADJUSTMENT

(CAMERA SECTION) ·················································6-4

1-1-1. List of Service Tools ·····················································6-4

1-1-2. Preparations ··································································6-6

1-1-3. Precaution ·····································································6-8

1-2. INITIALIZATION OF 8, A, B, C, D, E, F, 1B, 1E,

1F PAGE DAT A ··························································6-10

1-2-1. INITIALIZATION OF A, D PAGE DATA ·················6-11

1. Initializing the A, D Page Data ···································6-11

2. Modification of A, D Page Data ·································6-11

3. A Page Table ······························································· 6-12

4. D Page Table ······························································· 6-12

1-2-2. INITIALIZATION OF 8, C PAGE DATA ·················· 6-13

1. Initializing the 8, C Page Data ····································6-13

2. Modification of 8, C Page Data ··································6-13

3. 8 Page Table ································································6-13

4. C Page Table ·······························································6-14

1-2-3. INITIALIZATION OF E, F, 1E, 1F PAGE DATA······6-15

1. Initializing the E, F, 1E, 1FA Page Data ····················· 6-15

2. Modification of E, F, 1E, 1F Page Data ······················6-15

3. E Page Table································································6-16

4. F Page Table ································································6-17

5. 1E Page Table······························································ 6-18

6. 1F Page Table······························································6-19

1-2-4. INITIALIZATION OF B, 1B PAGE DATA················6-20

1. Initializing the B, 1B Page Data ································· 6-20

2. Modification of B, 1B Page Data································6-20

3. B Page Table ·······························································6-20

4. 1B Page Table ·····························································6-20

1-3. CAMERA SYSTEM ADJUSTMENTS ·····················6-21

1. 66MHz/54MHz Origin Oscillation Adjustment ·········6-21

(VC-318 board) ···························································6-21

2. HALL Adjustment ······················································6-22

3. MR Adjustment ···························································6-23

4. Flange Back Adjustment (Using Minipattern Box) ···· 6-24

5. Flange Back Adjustment (Using Flange Back Adjustment

Chart and Subject More Than 500m Away) ················6-25

5-1. Flange Back Adjustment (1) ·······································6-25

5-2. Flange Back Adjustment (2) ·······································6-25

6. Flange Back Check ·····················································6-26

7. Picture Frame Setting··················································6-26

8. Auto White Balance Standard Data Input···················6-27

9. MAX GAIN Adjustment·············································6-27

10. F No. & ND Light Quantity Standard Data Input·······6-28

11. LV Standard Data Input ·············································· 6-28

12. Auto White Balance Adjustment ································6-29

13. Color Reproduction Adjustment ································· 6-30

14. White Balance Check··················································6-31

15. PSD Sensor Gain Adjustment·····································6-32

15-1. PSD Sensor Gain Adjustment (1) ·······························6-32

15-2. PSD Sensor Gain Adjustment (2) ·······························6-33

16. Angular Velocity Sensor Sensitivity Adjustment········6-34

17. Mechanical Shutter Adjustment··································6-34

18. AF Laser Output Adjustment······································6-35

19. AF Laser Axis Check··················································6-36

1-4. ELECTRONIC VIEWFINDER SYSTEM

ADJUSTMENT ··························································6-37

1. VCO Adjustment (DB-016 board)······························6-37

2. RGB AMP Adjustment (DB-016 board)·····················6-38

3. Contrast Adjustment (DB-016 board)·························6-38

4. Backlight Adjustment (DB-016 board)·······················6-39

1-5. LCD SYSTEM ADJUSTMENT ·································6-40

1. VCO Adjustment (PD-191 board) ······························6-40

— 5 —

Page 6

DSR-PDX10/PDX10P

2. RGB AMP Adjustment (PD-191 board) ·····················6-41

3. Contrast Adjustment (PD-191 board) ·························6-41

4. COM AMP Adjustment (PD-191 board) ····················6-42

5. V COM Adjustment (PD-191 board)··························6-42

6. White Balance Adjustment (PD-191 board) ··············· 6-43

6-2. MECHANICAL SECTION ADJUSTMENT ·············6-44

2-1. Preparations for Check, Adjustment and

Replacement of Mechanism Block ·····························6-44

2-1-1. Cassette Compartment Assy, Damper Assy ················6-44

2-2. Periodic Inspection and Maintenance ························· 6-45

2-2-1. Rotary Drum Cleaning················································6-45

2-2-2. Tape Path System Cleaning (Refer to Fig. 6-2-2.) ······6-45

2-2-3. Periodic Inspection List ··············································6-46

2-2-4. Mode Selector II Operating Procedure ·······················6-47

2-4-1. Introduction·································································6-47

2-4-2. Mechanism Status (Position) Transition Table

Using Mode Selector II ···············································6-48

2-3. Check, Adjustment and Replacement of

Mechanical Parts ·························································6-49

2-3-1. Drum ···········································································6-49

2-3-2. 6-L. Motor Holder Block Assy (Loading) and

FP-228 Flexible Wiring Board (DEW Sensor) ···········6-50

2-3-3. Retainer Plate Assy, LED Retainer ·····························6-51

2-3-4. Brake-T Block Assy, T-reel Table Assy,

Gooseneck Gear Assy ·················································6-52

2-3-5. TG1 Assy, Tension Coil Spring (Tension Regulator)··6-53

2-3-6. TG1 FWD Position Adjustment··································6-54

2-3-7. FWD Back-tension Adjustment··································6-55

2-3-8. Reel Torque Check ······················································6-55

2-3-9. TG3 Guide Zenith Adjustment ···································6-55

2-3-10. TG6 Guide Zenith Adjustment ···································6-56

2-3-11. LS Cam Plate Position Adjustment·····························6-56

2-3-12. LS Chassis Block Assy, LS Guide Retainer ···············6-57

2-3-13. LS Cam Plate, Tension Coil Spring (Brake-S), Brake-S,

Torsion Coil Spring (Brake Arm), Cassette Position

Set-S, Brake-S Driving Arm Assy·······························6-58

2-3-14. TG7 Block Assy, Torsion Coil Spring

(TG7 Return, Pinch Return), Pinch Arm Assy············6-59

2-3-15. Layout Diagram of FP-102 Flexible Wiring Board ····6-60

2-3-16. TG1 Cam Slider, LS Arm, LS Roller, Mode Gear Assy,

LS Guide Roller ··························································6-61

2-3-17. Guide Rail ···································································6-62

2-3-18. Gear Cover B, GL Driving Gear ·································6-63

2-3-19. Drum Base Block Assy, Coaster-S Block Assy,

Coaster-T Block Assy ·················································6-64

2-3-20. DC Motor (Capstan), Conversion Gear, Relay Gear ··6-65

2-3-21. Gear Cover C, Pinch Driving Arm Assy, Cam Gear B ······ 6-66

2-3-22. Gear Cover A, FP-100 Flexible Wiring Board ············6-67

2-3-23. Deceleration Gear, Mode Gear Assy,

FP-100 Flexible Wiring Board, Cam Gear A··············6-68

2-4. Tape Path Adjustment ·················································6-69

2-4-1. Adjustment Preparation ·············································· 6-69

2-4-2. Tracking Adjustment···················································6-70

2-4-3. TG3 Guide Adjustment···············································6-70

2-4-4. TG7 Guide Adjustment···············································6-71

2-4-5. Check upon Completion of Adjustment······················6-71

6-3. VIDEO SECTION ADJUSTMENT ···························6-73

3-1. PREPARATIONS BEFORE ADJUSTMENTS ··········6-73

3-1-1. Equipment to Required ···············································6-73

3-1-2. Precautions on Adjustment ·········································6-74

3-1-3. HOW TO ENTER RECORD MODE WITHOUT

CASSETTE·································································6-74

3-1-4. HOW TO ENTER PLAYBACK MODE WITHOUT

CASSETTE·································································6-74

3-1-5. Adjustment Connectors···············································6-75

3-1-6. Connecting the Equipment··········································6-75

3-1-7. Alignment T a pes ·························································6-76

3-1-8. Input/Output Level and Impedance·····························6-76

3-2. SYSTEM CONTROL SYSTEM ADJUSTMENT ·····6-77

1. 6-Initialization of 8, A, B, C, D, E, F, 1B, 1E, 1F Page

Data ·············································································6-77

2. Touch Panel Adjustment ·············································6-77

3. Serial No. Input···························································6-78

3-1. Company ID Input ······················································6-78

3-2. Serial No. Input···························································6-78

3-3. SERVO AND RF SYSTEM ADJUSTMENT·············6-80

1. Cap FG Duty Adjustment (VC-318 Board) ················ 6-80

2. PLL f0 & LPF f0 Pre-Adjustment (VC-318 Board) ····6-80

3. Switching Position Adjustment (VC-318 Board) ·······6-81

4. AGC Center Level and APC & AEQ Adjustment·······6-81

4-1. Preparations before adjustments ·································6-81

4-2. AGC Center Level Adjustment (VC-318 Board)········6-81

4-3. APC & AEQ Adjustment (VC-318 Board)·················6-82

4-4. Processing after Completing Adjustments ··················6-82

5. PLL f0 & LPF f0 Fine Adjustment (VC-318 Board) ···6-83

3-4. VIDEO SYSTEM ADJUSTMENTS ··························6-84

1. Chroma BPF f0 Adjustment (DB-016 Board)·············6-84

2. S VIDEO OUT Y Level Adjustment

(VC-318 Board) ··························································6-84

3. S VIDEO OUT Chroma Level Adjustment

(VC-318 Board) ··························································6-85

4. VIDEO OUT Y, Chroma Level Check

(VC-318 Board) ··························································6-85

3-5. AUDIO SYSTEM ADJUSTMENTS··························6-86

1. Playback Level Check·················································6-86

2. Overall Level Characteristics Check···························6-86

3. Overall Distortion Check ············································6-86

4. Overall Noise Level Check·········································6-87

5. Overall Separation Check ···········································6-87

3-6. XLR ADAPTER ADJUSTMENT ······························6-88

1. Audio Level Check ·····················································6-88

6-4. SERVICE MODE ·······················································6-89

4-1. ADJUSTMENT REMOTE COMMANDER··············6-89

1. Using the adjustment remote commander ··················6-89

2. Precautions upon using the adjustment remote

commander··································································6-89

4-2. DATA PROCESS ························································6-90

4-3. SERVICE MODE ·······················································6-91

1. Setting the Test Mode ·················································6-91

2. Emergence Memory Address ······································6-91

2-1. EMG Code (Emergency Code)···································6-91

2-2. MSW Code ·································································6-92

3. Bit value discrimination··············································6-93

4. Switch check (1) ·························································6-93

5. Switch check (2) ·························································6-93

6. Switch check (3) ·························································6-94

7. LED, LCD (display window) check ···························6-94

8. Record of Use check (1) ·············································6-94

9. Record of Use check (2) ·············································6-95

10. Record of Self-diagnosis check ·································· 6-95

* Color reproduction frame is shown on page 323.

— 6 —

Page 7

DSR-PDX10/PDX10P

When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

COVER

COVER

SECTION 1

SERVICE NOTE

1-1. NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

When remove a connector, don’t pull at wire of connector.

It is possible that a wire is snapped.

1-1

Page 8

DSR-PDX10/PDX10P

1-2. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated po wer supply (8.4V), the power is shut of f so

that the unit cannot operate.

These following two methods are available to prevent this. Take note of which to use during repairs.

Method 1.

Use the AC power adaptor (AC-L10, AC-VQ800 etc.).

Method 2.

Connect the servicing remote commander RM-95 (J-6082-053-B) to the LANC jack, and set the commander switch to the “ADJ” side.

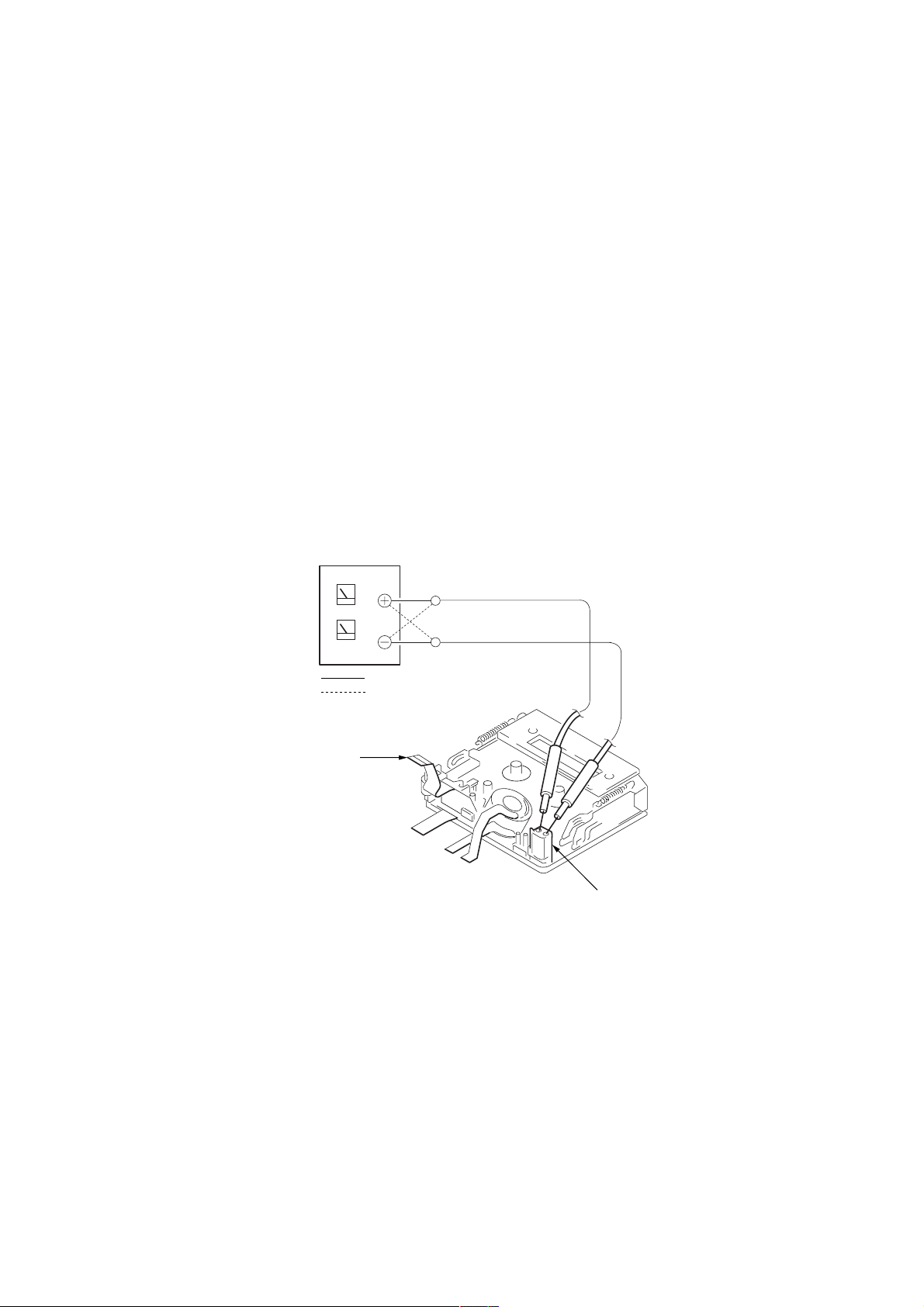

1-3. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to 2-2. to remove the cabinet (R) block assembly.

2 Refer to 2-7. to remove the F panel block.

3 Refer to 2-11. to remove the battery panel block.

4 Refer to 2-21. to remove the CS frame block.

5 Refer to 2-12. to remove the DB-016 board.

6 Refer to 2-13. to remove the MD block.

7 Supply +4.5V from the DC power supply to the loading motor and unload with a pressing the cassette compartment.

DC power supply

(+4.5Vdc)

Disconnect from CN1006 (27P)

of VC-318 board

: Unloading

: Loading

Loading motor

1-2

Page 9

1-4. NOTES ON HANDLING THE LASER DIODE

[LASER UNIT (D501)]

The laser diode may suffer electrostatic breakdown because of the

potential difference generated by the charged electrostatic load, etc.

on clothing and the human body.

During repair, pay attention to electrostatic breakdo wn and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

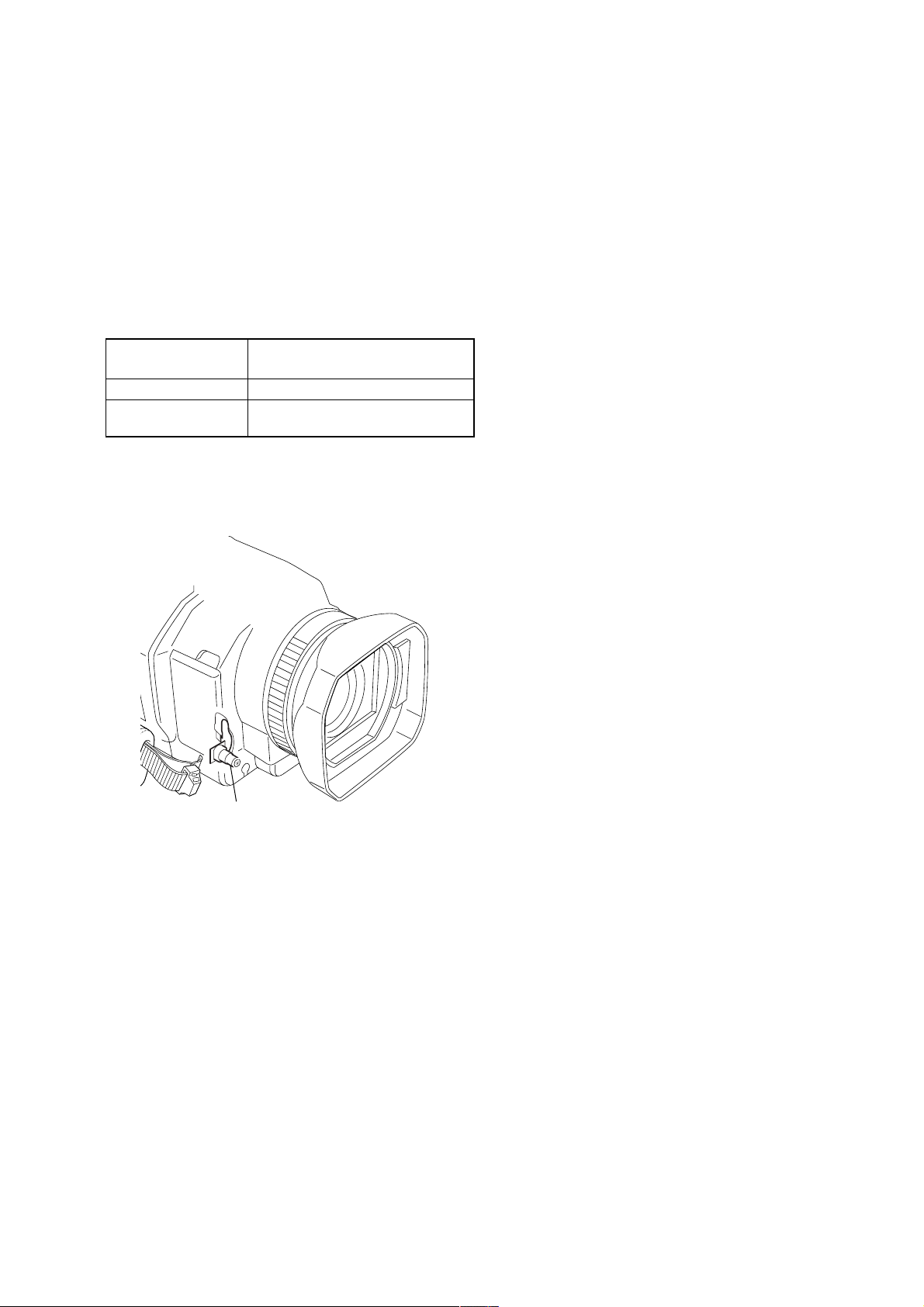

1-4-1. Soldering Conditions of Laser Unit (D501)

Temperature of

the Soldering Iron

Time to Solder Within 3 seconds

Interval to Solder

Note: Adjustment is needed when laser unit (D501) is replaced.

Refer to “18. AF Laser Output Adjustment” and “19. AF

Laser Axis Check” of “6-1. CAMERA SECTION

ADJUSTMENT”.

Less than 350 °C

Next terminal is soldered after

waiting for 1 second

DSR-PDX10/PDX10P

Laser unit

(D501)

1-3

Page 10

DSR-PDX10/PDX10P

w

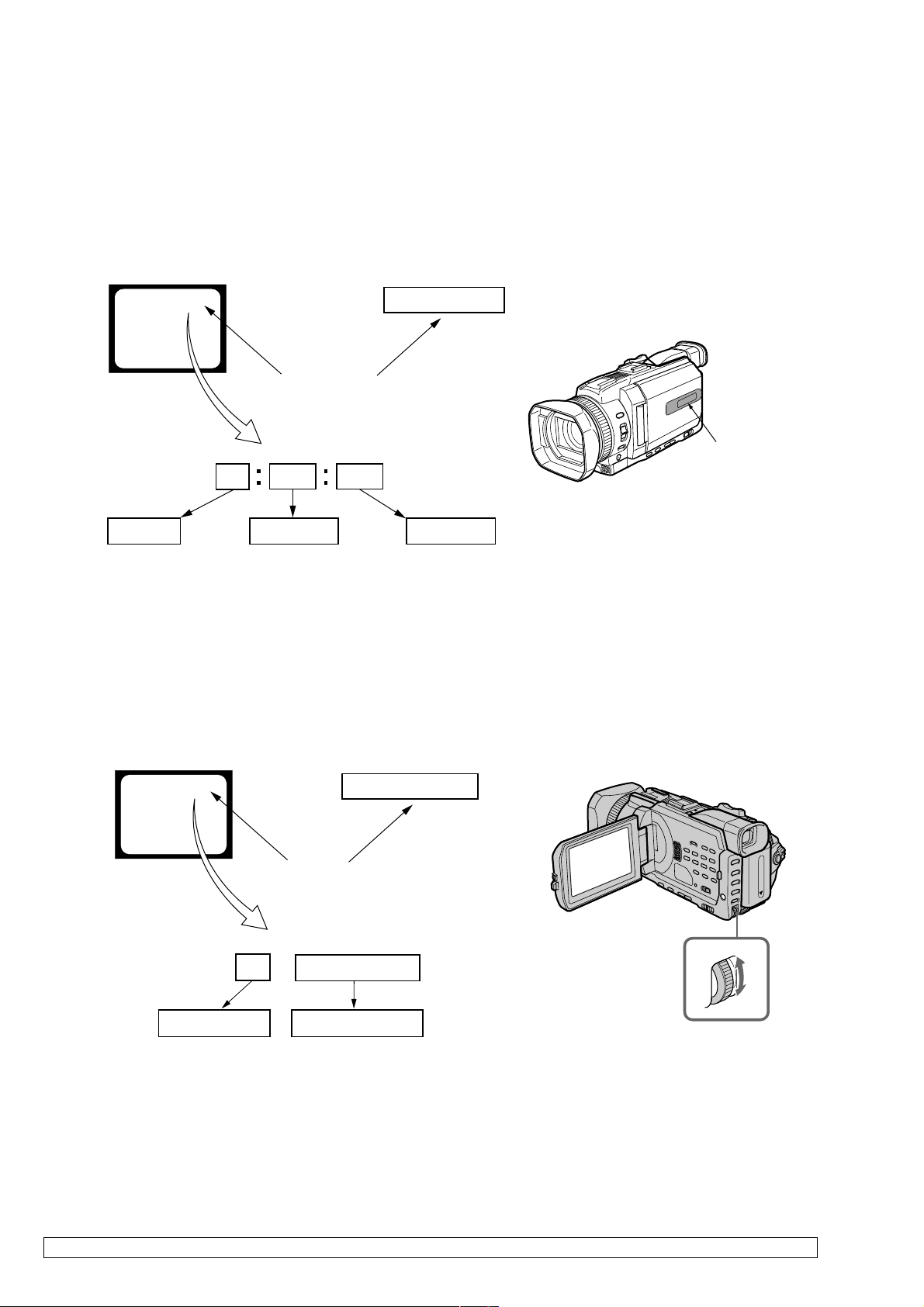

1-5. SELF-DIAGNOSIS FUNCTION

1-5-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or Display

window what to do. This function consists of two display; selfdiagnosis display and service mode display .

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder Display window

C : 3 1 : 1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Blinks at 3.2Hz

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

3 1

Block

1 1

C : 3 1 : 11

Refer to “1-5-4. Self-diagnosis Code Table”.

1-5-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or Display window shows a 4-digit display consisting

of an alphabet and numbers, which blinks at 3.2 Hz. This 5-character

display indicates the “repaired by:”, “block” in which the problem

occurred, and “detailed code” of the problem.

Display windo

Detailed Code

1-5-3. Service Mode Display

The service mode display shows up to six self-diagnosis codes shown in the past.

1. Display Method

While pressing the “STOP” key, set the switch from OFF to “VCR”, and continue pressing the “STOP” key for 5 seconds continuously. The

service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder

[3] C : 3 1 : 1 1

[3]

Backup No.

Order of previous errors

Lights up

C : 3 1 : 1 1

Self-diagnosis Codes

Display window

3 C : 3 1 : 11

Control dial

2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will not be erased (reset) when the lithium 3 V supply (CK-134 board BT5201) is removed.

1-4

Page 11

Ver 1.5 2004. 07

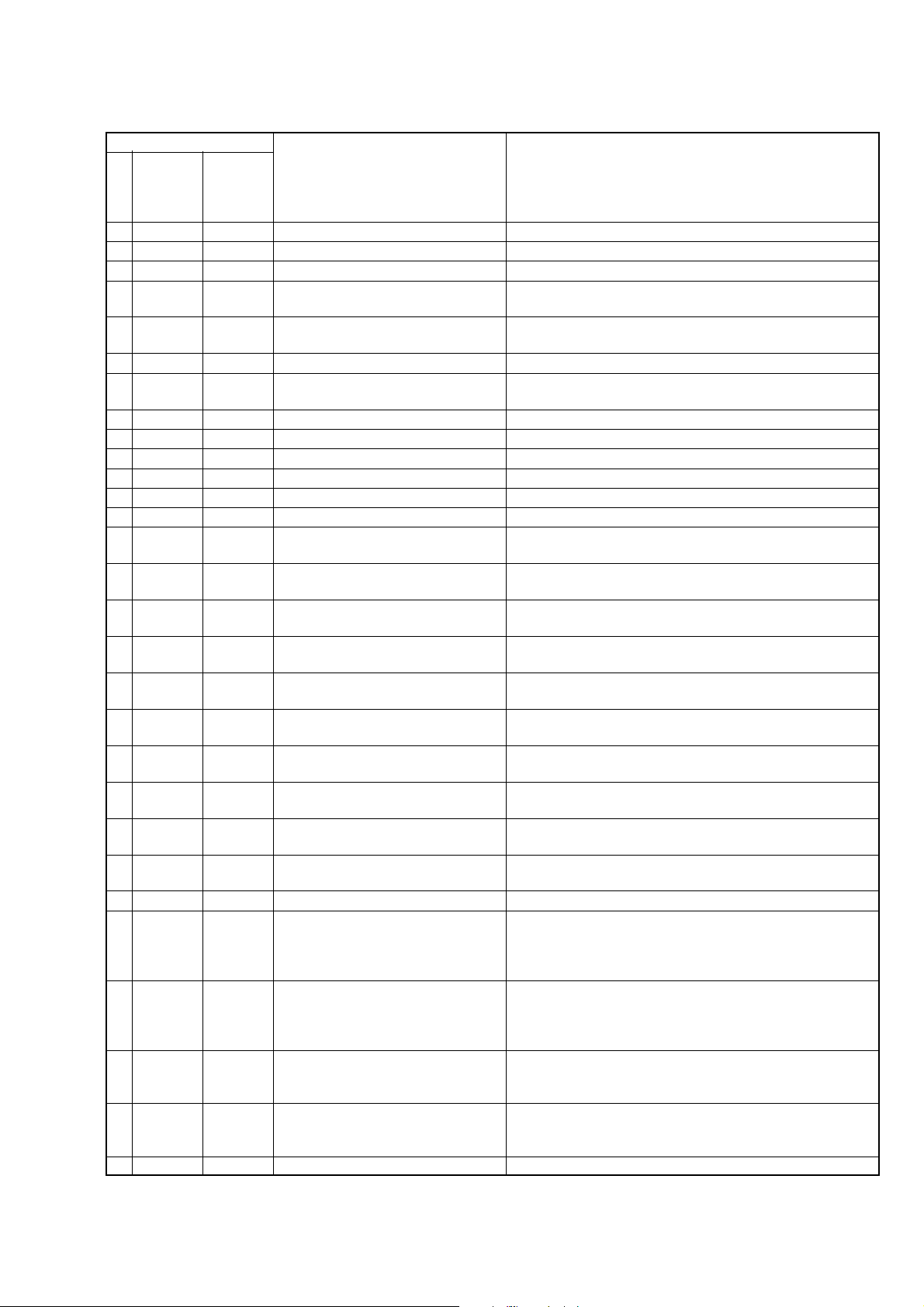

1-5-4. Self-diagnosis Code Table

Self-diagnosis Code

DSR-PDX10/PDX10P

Function

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

E

E

Block

04

21

22

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

20

61

61

62

62

91

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

00

10

00

01

01

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

EEPROM data error

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular v elocity sensor output

stopped.)

Abnormality when flash is being charged.

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Initialize A, D page data (EEPROM data).

Inspect the lens block focus MR (Pin qf, qg of DB-016 board

CN1004) when focusing is performed when the focus ring is rotated

in the focus manual mode, and the focus motor drive circuit (IC3402

of DB-016 board) when the focusing is not performed.

Inspect the lens block zoom MR (

CN1004

operated and the zoom motor drive circuit (IC3402 of DB-016

board) when zooming is not performed.

Inspect pitch angular velocity sensor (SE4001 of SE-132 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE4002 of SE-132 board)

peripheral circuits.

Checking of flash unit or replacement of flash unit.

) when zooming is performed when the zoom lens is

Pin 0, qs of DB-016 board

1-5E

Page 12

DSR-PDX10/PDX10P

COVER

COVER

SECTION 2

DISASSEMBLY

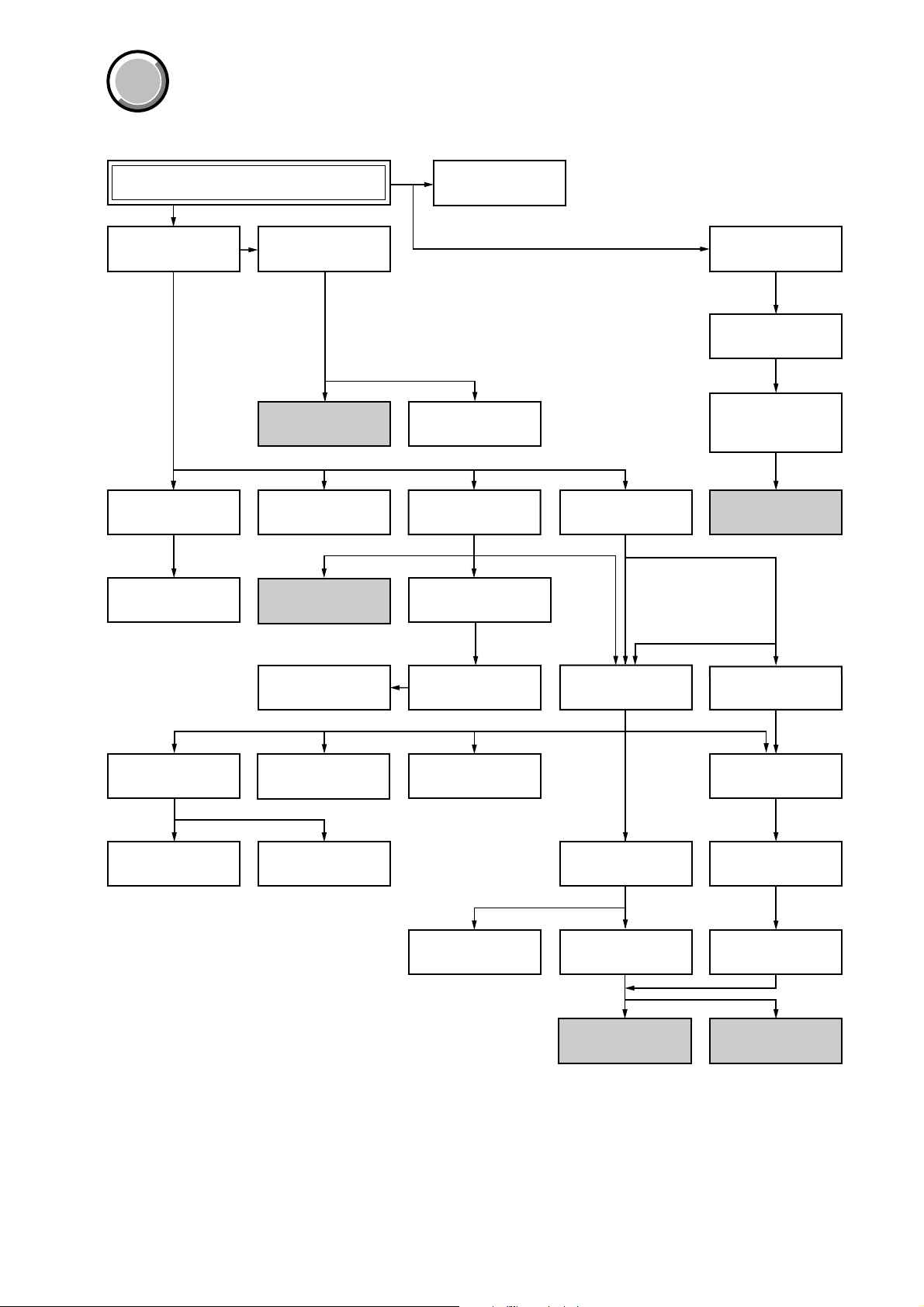

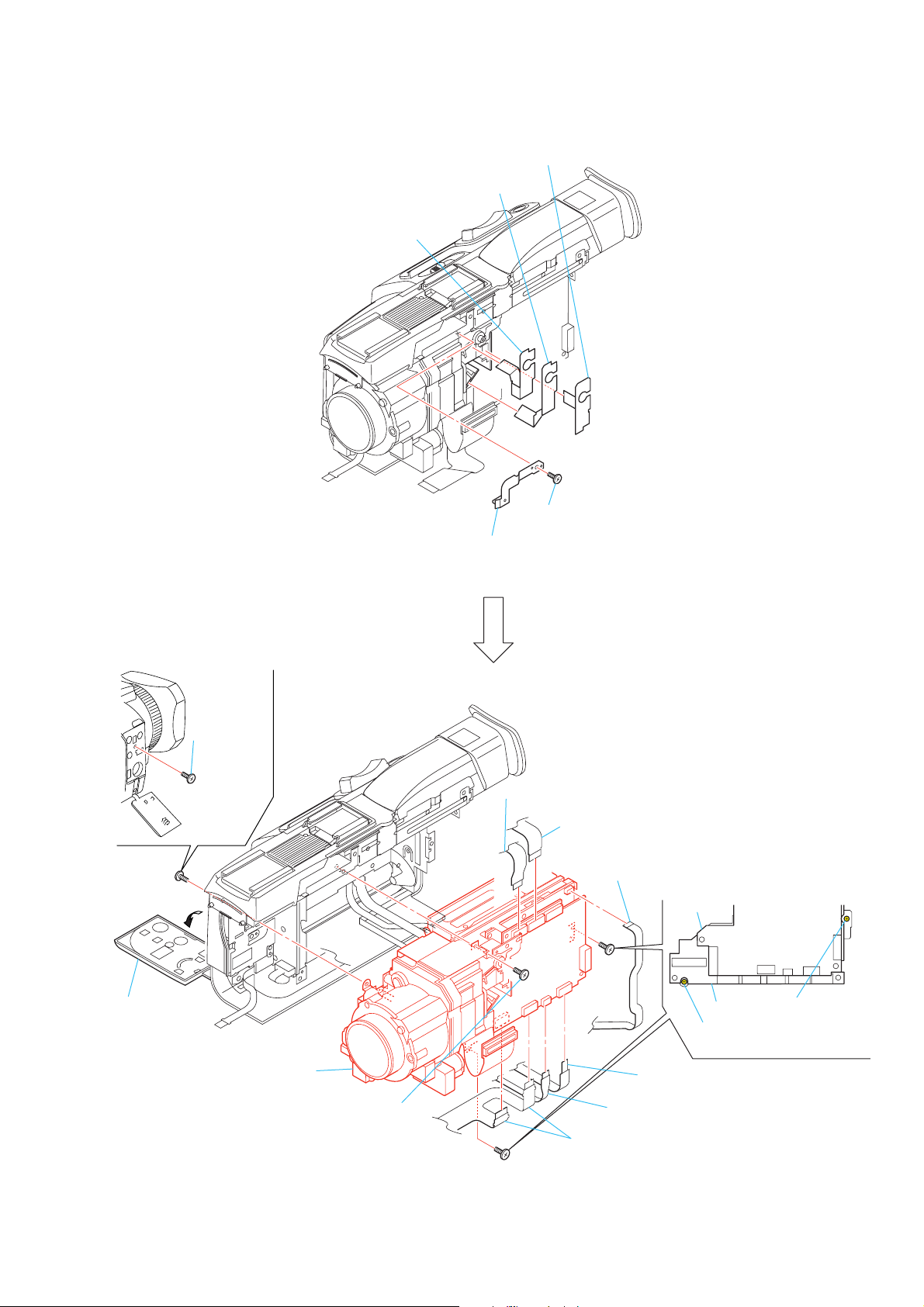

The following flow chart shows the disassembly procedure.

2-25.

2-3. LCD MODULE

(Page 2-3)

2-7. F PANEL BLOCK

(Page 2-5)

2-1.

CABINET (R) BLOCK

(Page 2-2)

2-4. LCD BLOCK

(Page 2-4)

DSR-PDX10/PDX10P

2-2. P CABINET (C)

(Page 2-2)

SERVICE POSITION TO

CHECK PD-191 BOARD

(Page 2-3)

2-6. CK-134 BOARD

(Page 2-5)

VF LENS ASSEMBLY

(Page 2-18)

2-11.BATTERY PANEL

BLOCK (Page 2-8)

2-26.XLR BLOCK

(Page 2-19)

2-27.XK-001 BOARD

(Page 2-19)

2-28.XM-002 BOARD,

XD-002 BOARD,

XS-002 BOARD

(Page 2-20)

SERVICE POSITION TO

CHECK THE XLR

SECTION (Page 2-20)

2-5. FP-495

FLEXIBLE BOARD

(Page 2-4)

2-22.GRIP CABINET

BLOCK

(Page 2-16)

2-23.CONTROL SWITCH

BLOCK (CF-1870)

(Page 2-17)

SERVICE POSITION

(MA-425 BOARD)

(Page 2-6)

2-10.FP-504

FLEXIBLE BOARD

(Page 2-7)

2-20.CONTROL SWITCH

BLOCK (PS-1870)

(Page 2-15)

2-24.MS ASSEMBLY

(Page 2-17)

2-8. AF LASER BRACKET

ASSEMBLY

(Page 2-6)

2-9. MA-425 BOARD

(Page 2-7)

2-21.SE-132 BOARD

(Page 2-15)

2-18.FP-497

FLEXIBLE BOARD

(Page 2-12)

2-13.MD BLOCK

(Page 2-9)

2-17.EVF BLOCK

(Page 2-11)

2-19.JK-222 BOARD

(Page 2-12)

SERVICE POSITION TO

CHECK THE CAMERA

SECTION (Page 2-13)

2-12.DB-016 BOARD

(Page 2-8)

2-14.LENS BLOCK

(Page 2-10)

2-15.VC-318 BOARD

(Page 2-10)

MECHANISM DECK

2-16.

(J210) (Page 2-11)

SERVICE POSITION TO

CHECK THE VTR

SECTION (Page 2-14)

2-1

Page 13

DSR-PDX10/PDX10P

)

s

NOTE: F ollo w the disassembly procedure in the numerical order given.

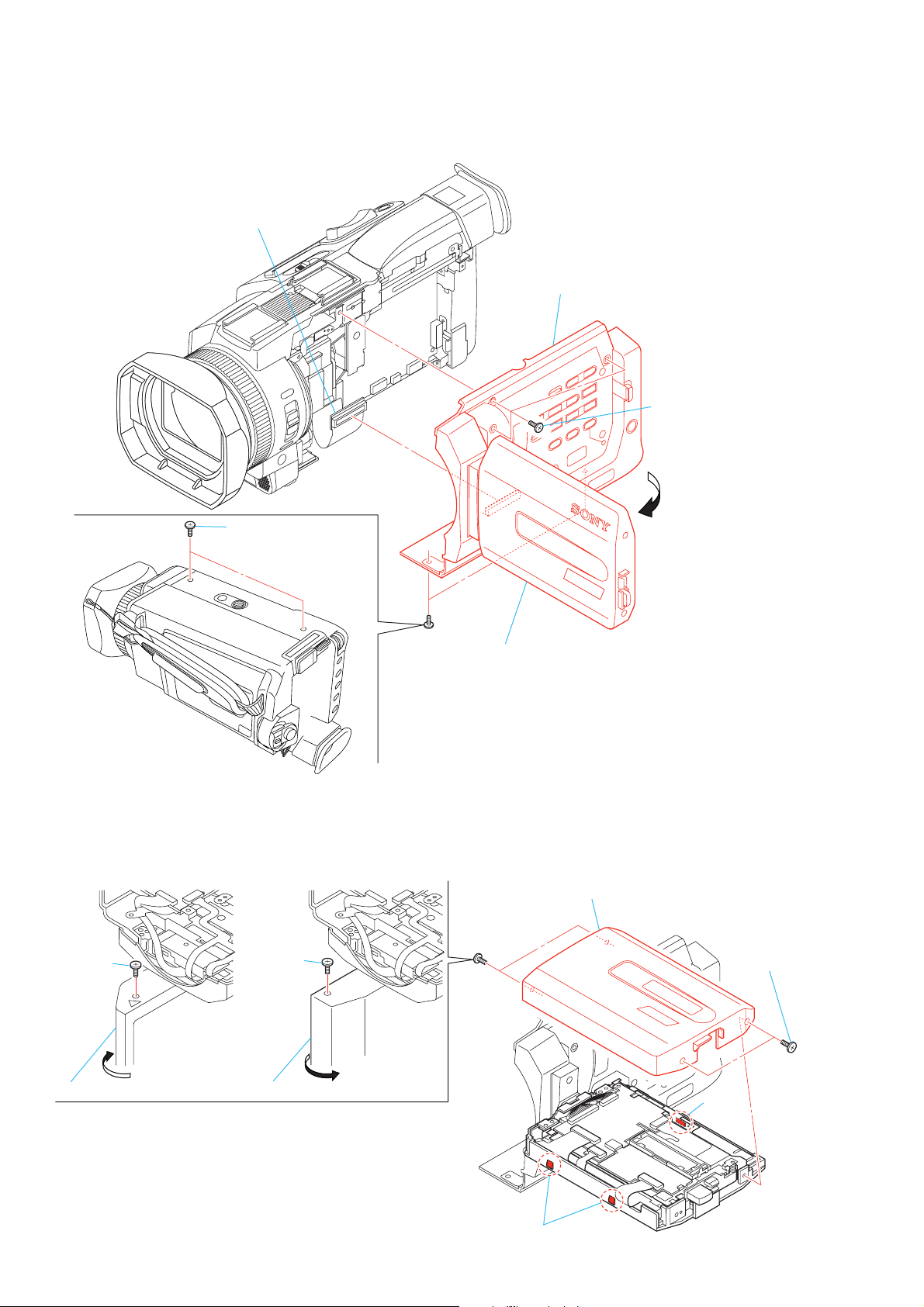

2-1. CABINET (R) BLOCK

5

FP-496 flexible board

(CN5203)

4

Cabinet (R) block

3

Three screws (M1.7

2-2. P CABINET (C)

2

Screw

(M1.7)

1

Two screws (M1.7)

4

Screw

(M1.7)

2

Open the LCD panel.

8

P cabinet (C)

5

Two screw

(M1.7)

1

Turn the LCD panel.

3

Turn the LCD panel.

2-2

6

Two claws

7

Claw

Page 14

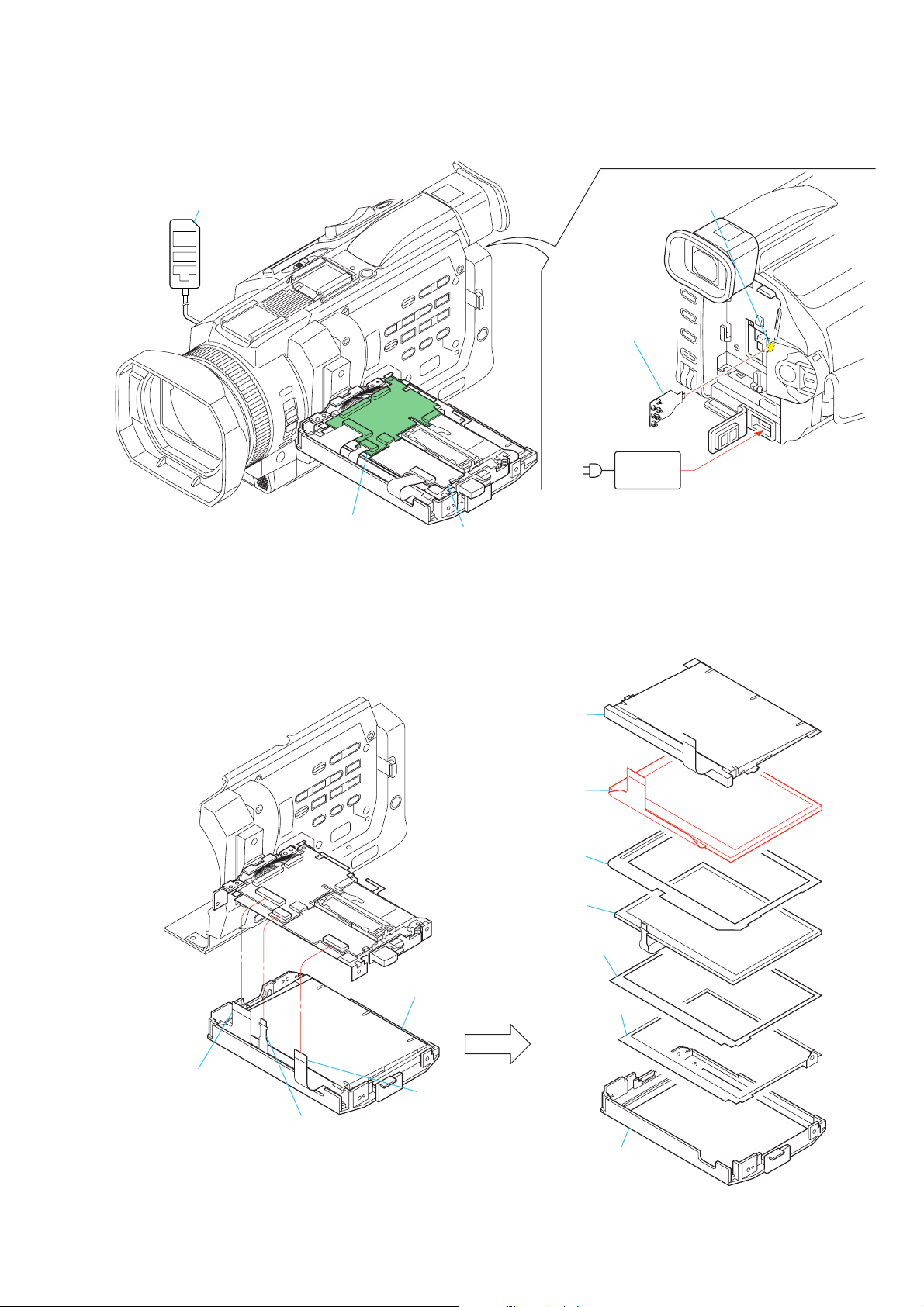

DSR-PDX10/PDX10P

PD-191

PD-191 board

Inverter transformer unit

CPC jig for LCD panel

(J-6082-529-A)

CN1024

1

6

DC-IN

AC power

adaptor

Adjustment remote

commander (RM-95)

[SERVICE POSITION TO CHECK PD-191 BOARD]

2-3. LCD MODULE

1

Flexible board

(LCD module)

(CN5701)

2

Flexible board

(touch panel)

(CN5803)

4

P cabinet (M) block

3

Flexible board

(back light unit)

(CN5805)

5

Back light unit

6

LCD module

7

Cushion (L)

8

Touch panel

9

0

Ground plate (P)

Cushion (C)

P cabinet (M)

2-3

Page 15

DSR-PDX10/PDX10P

k

2-4. LCD BLOCK

2

Two screws

(M1.7)

5

Harness guide

4

Screw (M1.7)

6

Two harness (PC-087, 088)

(CN5201, 5202)

3

Hinge blind lid assemby

Hinge blind lid assembly

1

FP-495 flexible board

(CN5206)

9

LCD bloc

Harness guide

Harness (PC-087) Harness (PC-088)

Note:

When installing Hinge blind lid assembly,

please attach, as shown in a figure.

2-5. FP-495 FLEXIBLE BOARD

Note:

When installing FP-495 flexible board,

please attach, as shown in a figure.

1

Screw

×

2.5)

(M1.7

S001

SW lever

7

Hinge cover (rear)

2

S001

7

Five screws

(M1.7)

8

Cabinet (hinge)

Note:

When installing FP-495 flexible board

and harness, please attach, as shown

in a figure.

FP-495 flexible board

harness

8

4

Screw

(M1.7

Screw

(M1.7

×

2.5)

3

Two screws

(M1.7)

×

2.5)

S002

9

5

Two claws

FP-495 flexible board

6

Hinge cover (front)

2-4

Page 16

2-6. CK-134 BOARD

7

Three screws (M1.7)

1

Harness (PC-087)

(CN5201)

2

Harness (PC-088)

(CN5202)

3

FP-495 flexible board

(CN5206)

K

C

Knob (auto lock)

-134

S5201

8

S5202

CK-134 board

6

Three screws (M1.7)

4

Harness (speaker)

(CN5204)

5

Flexible board (KP1870)

(CN5205)

DSR-PDX10/PDX10P

Knob (zebra)

2-7. F PANEL BLOCK

4

Screw (M1.7)

6

Screw (M1.7)

5

Open the

jack cover.

Note:

When installing CK-134 board, connect knob (auto lock)

with S5201 and knob (zebra) with S5202.

7

F panel block

3

Screw (M1.7)

2

Screw (M1.7)

8

Flexible board (JK-222)

(CN5904)

Note:

Remove it while taking care as

the flexible board is connected.

2-5

1

FP-494 flexible board

(CN5906)

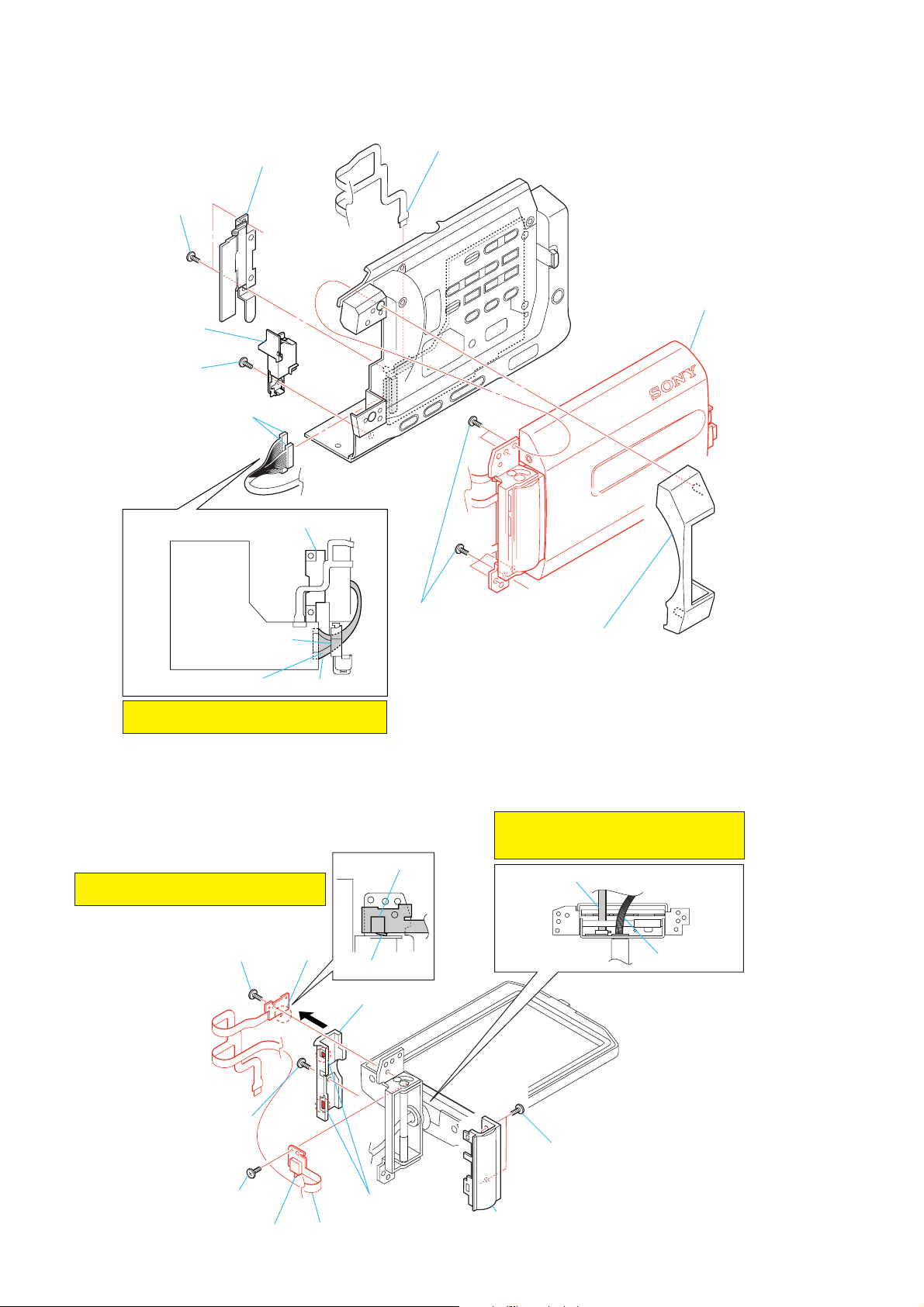

Page 17

DSR-PDX10/PDX10P

d

[SERVICE POSITION TO CHECK MA-425 BOARD]

Monitor

MA-425

Adjustment remote

commander (RM-95)

AC power

adaptor

MA-425 board

AC IN

2-8. AF LASER BRACKET ASSEMBLY

3

AF laser bracket assembly

1

FP-500 flexible boar

(CN5903)

2

Two screws

(M1.7 × 4)

2-6

Page 18

2-9. MA-425 BOARD

e

1

Open microphone jack cover.

2

FP-500 flexible board

(CN5903)

6

Two connectors

(CN5901, 5902)

5

MA-425

DSR-PDX10/PDX10P

7

Two screws

(M1.7

×

2.5)

3

FP-504 flexible board

(CN5905)

8

MA-425 board

4

Two screws

(M1.7

×

2.5)

2-10.FP-504 FLEXIBLE BOARD

5

Screw

(M1.7 × 4)

6

Screw

(M1.7 × 2.5)

3

7

8

Screw (M1.7 × 4)

Two screws

(M1.7 × 4)

Screw (M1.7 × 4)

9

1

Screw

(M1.7 × 4)

qf

FP-504 flexible board

FP-504

S601

qs

MF knob retainer

Note:

When installing FP-504 flexible board,

connect MF knob with S601.

qd

Three screws

(M1.7 × 2.5)

0

Ornamental plat

qa

MF knob

4

Microphone grille assembly

2

Bracket

2-7

Page 19

DSR-PDX10/PDX10P

k

)

2-11.BATTERY PANEL BLOCK

4

Three screws (M1.7)

3

Screw (M1.7)

5

Lift the view finder.

6

7

Battery panel bloc

2-12.DB-016 BOARD

2

Screw (M1.7)

4

DB-016 board

1

Harness (BT terminal)

(CN7202)

1

Flexible board (lens block)

(CN1004)

3

Two screws

(M1.7

2-8

×

2.5)

DB-016

2

Flexible board (lens block

(CN1501)

Page 20

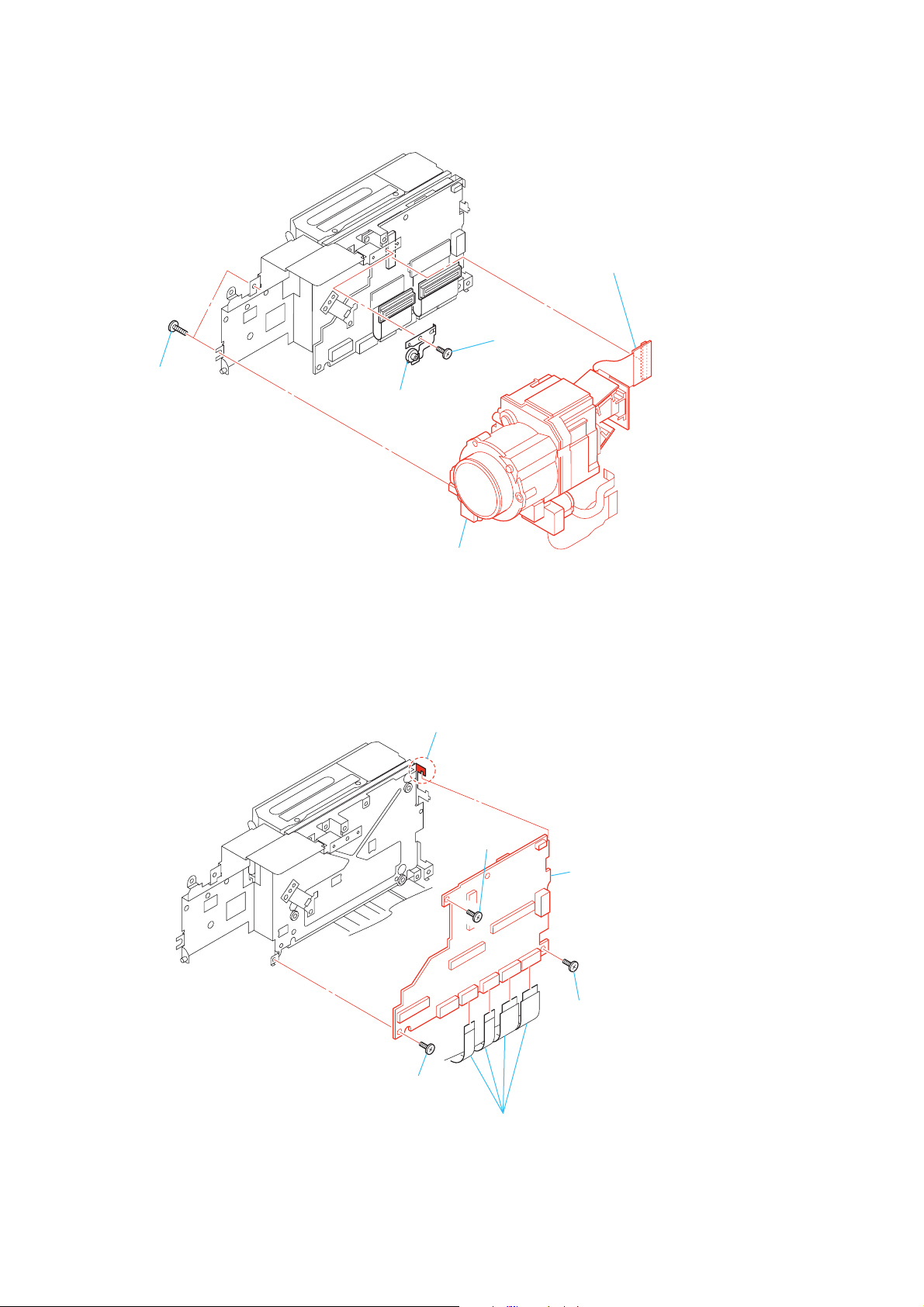

2-13.MD BLOCK

5

CCD heat sink (B)

4

CCD heat sink (G)

3

CCD heat sink (R)

DSR-PDX10/PDX10P

qh

Screw

(M1.7 × 2.5)

2

MF knob retainer plate

1

Screw

×

2.5)

(M1.7

6

FP-547 flexible board

(CN7211)

7

FP-497 flexible board

(CN7205)

8

FP-503 flexible board

(CN1009)

DB-016

qg

Open the

jack cover.

qj

MD block

qs

Screw

(M1.7

qf

VC-318

qd

Screw

(M1.7 × 2.5)

9

Flexible board (CF1870)

(CN7200)

0

×

2.5)

qa

Flexible board (PS1870)

(CN7201)

Two flexible boards (JK-222)

(CN1005, 7204)

Screw

(M1.7 × 2.5)

2-9

Page 21

DSR-PDX10/PDX10P

d

2-14.LENS BLOCK

4

Two screws

2

Heat sink bracket

3

Flexible board (CD-389)

(CN1201)

1

Screw

(M1.7 × 2.5)

2-15.VC-318 BOARD

5

Lens block

5

Claw

4

Screw

(M1.7 × 2.5)

VC-318

6

VC-318 boar

3

Screw

(M1.7 × 2.5)

2

Screw

(M1.7 × 2.5)

1

Four flexible boards (Mechanism deck)

(CN1006, 1007, 1022, 1901)

2-10

Page 22

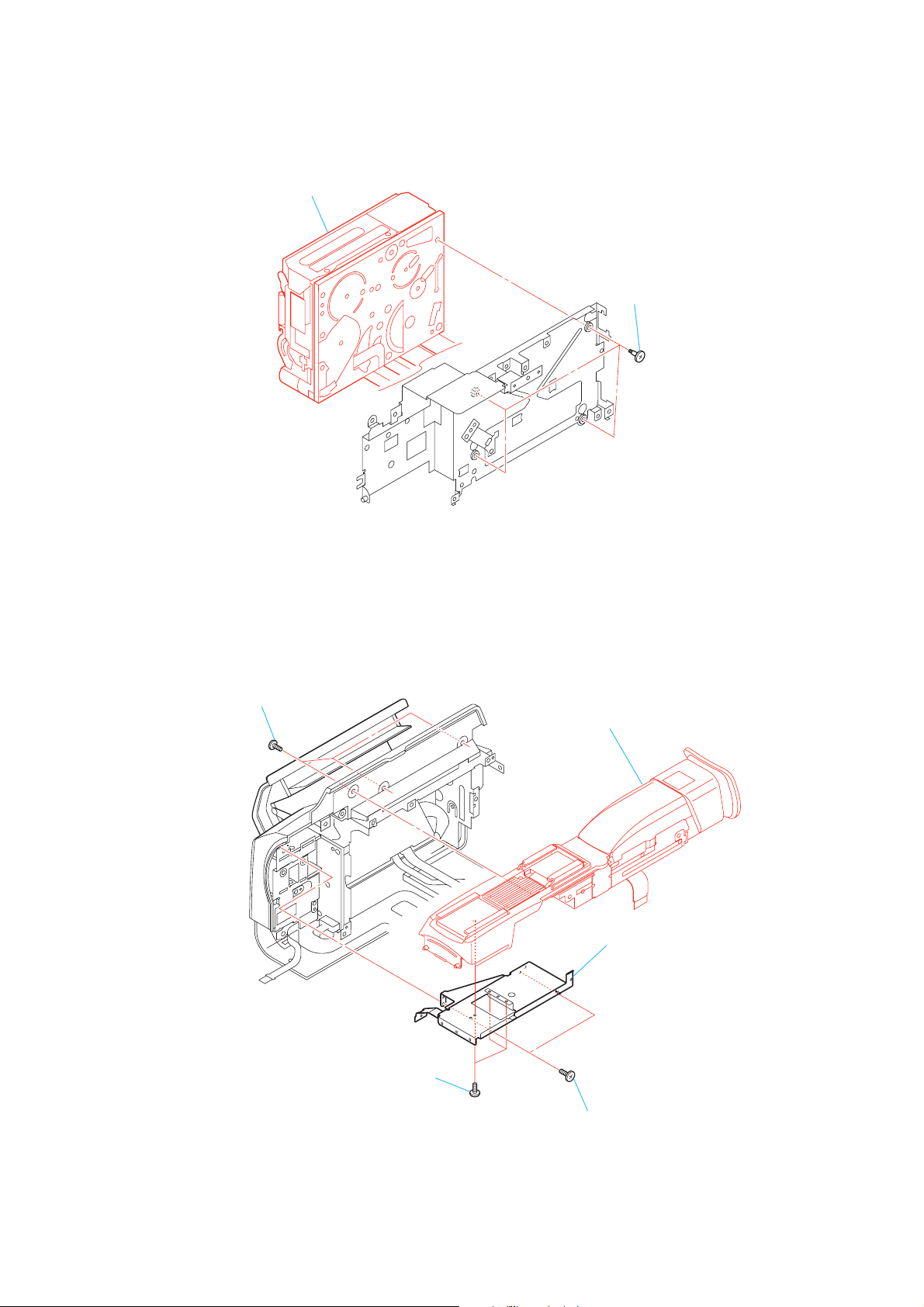

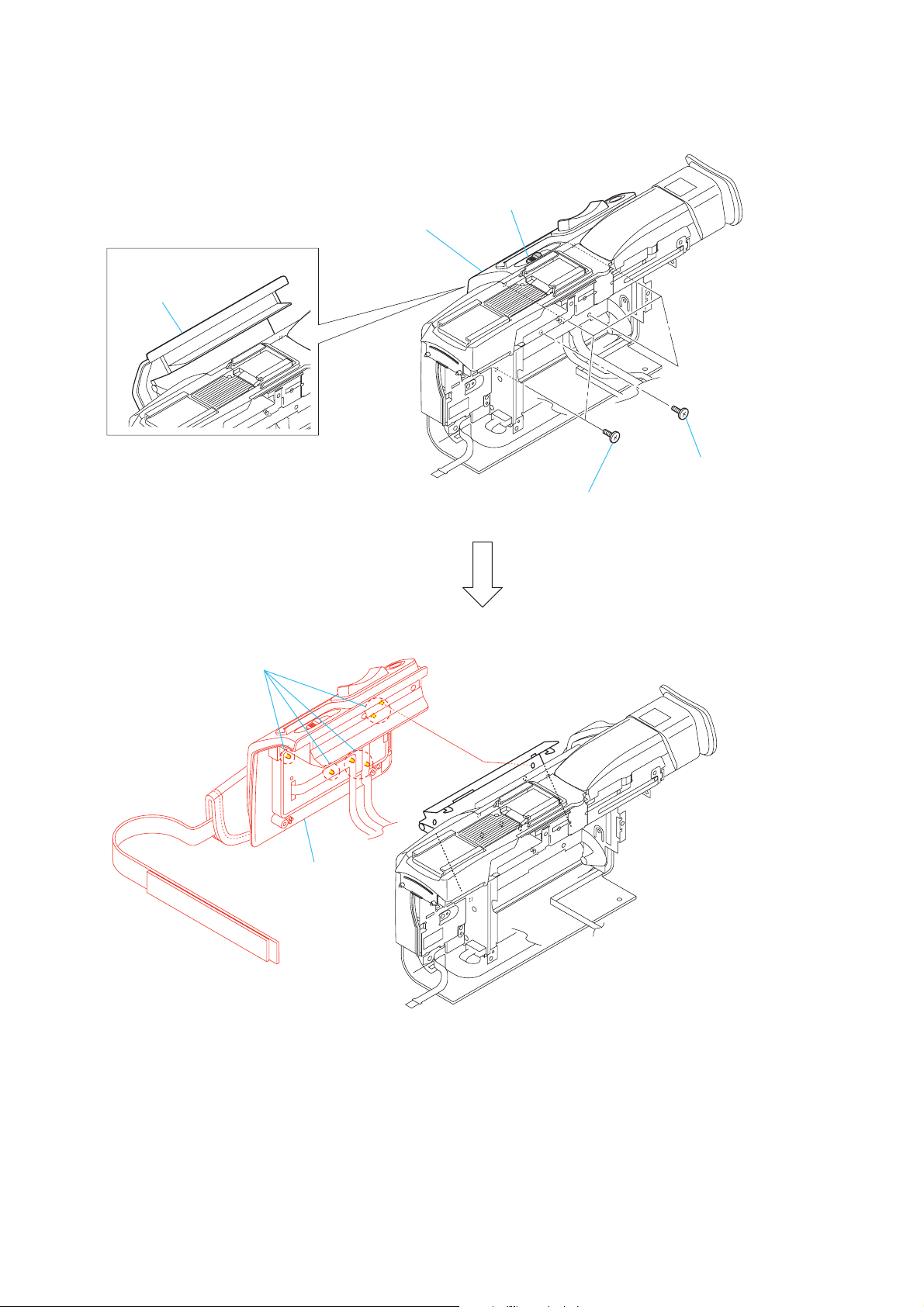

2-16.MECHANISM DECK (J210)

y

2

Mechanism deck

(J210)

1

Four screws

(M1.4

×

DSR-PDX10/PDX10P

1.5)

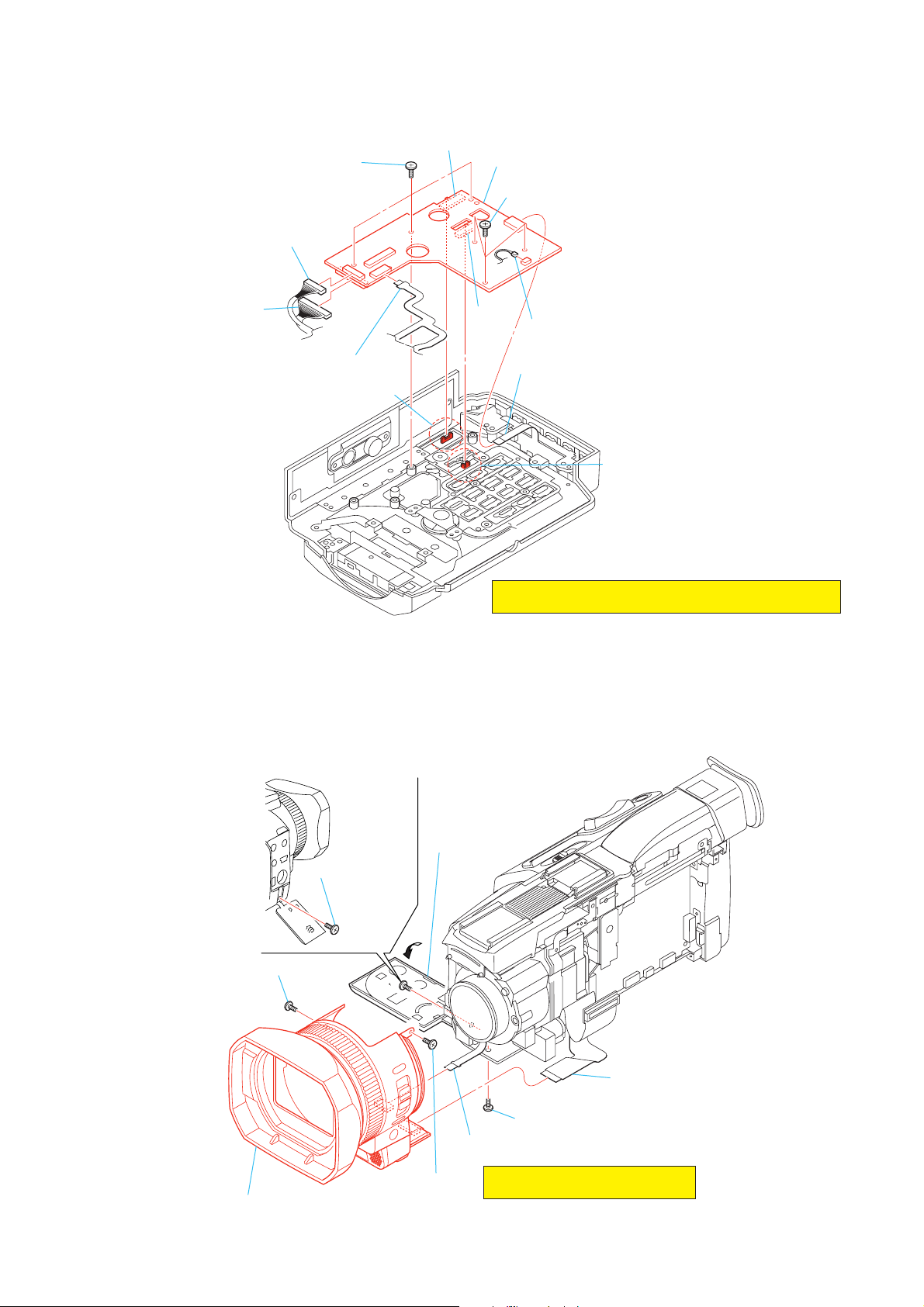

2-17.EVF BLOCK

1

Three screws

(M1.7)

3

Three screws

(M1.7)

5

EVF block

4

TOP chassis assemb

2

Two screws

(M1.7

×

6)

2-11

Page 23

DSR-PDX10/PDX10P

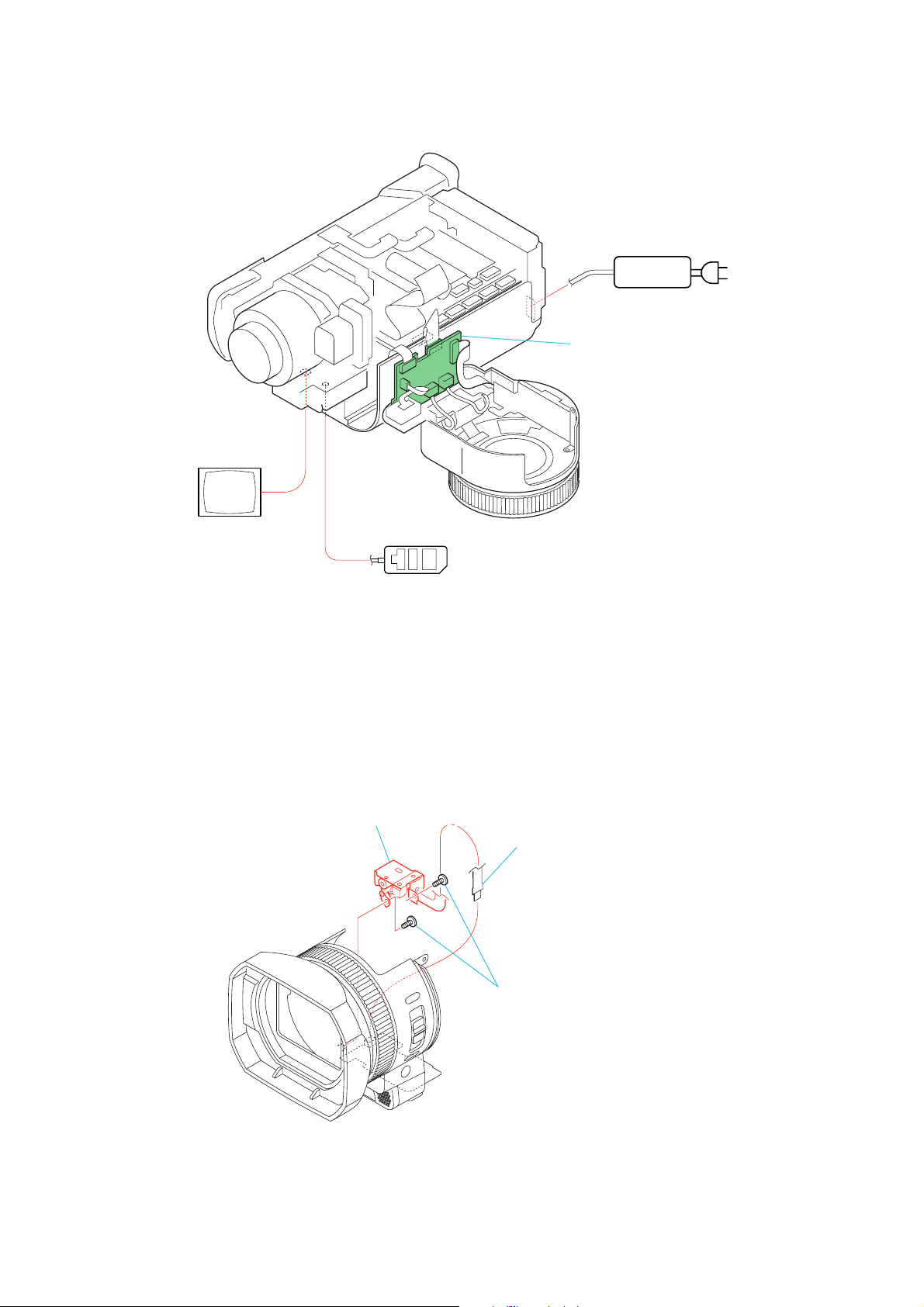

2-18.FP-497 FLEXIBLE BOARD

2

Two screws

(M1.7)

6

External connector

3

5

Top cabinet assy

7

FP-497

Screw

(M1.7 × 2.5)

8

FP-497 flexible board

1

2-19.JK-222 BOARD

2

Open the jack cover.

4

Two screws

(M1.7 × 2.5)

FP-547 flexible board

FP-497 flexible board

Note:

When installing FP-497 flexible board

and FP-547 flexible board,

please attach, as shown in a figure.

1

Flexible board

(CN4005)

5

Screw

(M1.7

×

4)

2-12

6

JK-222 board

3

Two screws

(M1.7

-222

JK

4

Screw

(M1.7 × 4)

×

4)

Page 24

DSR-PDX10/PDX10P

[SERVICE POSITION TO CHECK THE CAMERA SECTION]

Connection to Check the Camera Section

To check the camera section, set the camera to the “Forced camera power ON” mode.

Operate the camera functions of the zoom and focus using the adjustment remote commander (with the HOLD switch set in

the OFF position).

Setting the “Forced Camera Power ON” mode

1) Select page: O, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 01 and

press the PAUSE button of the adjustment remote

commander.

Exiting the “Forced Camera Power ON” mode

1) Select page: O, address: 01, and set data: 01.

2) Select page: D, address: 10, data: 00, and press the PAUSE

button of the adjustment remote commander.

3) Select page : 0, address: 01, and set data: 00.

AC IN

AC power

adaptor

Battery panel block

DB-016 board

FP-498 flexible board

VC-318 board

VC-318

Mechanism deck

Extention cable

(J-6082-466-A)

Lens block

DB-016

FP-499 flexible board

JK-222

CD-389 board

JK-222 board

Adjustment remote

commander (RM-95)

Monitor

2-13

Page 25

DSR-PDX10/PDX10P

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section

To check the VTR section, set the VTR to the “Forced VTR power ON” mode. (Or, connect the control switch block (PS-1870)

to the CN7201 of DB-016board and set the power switch to the “VIDEO” position.)

Operate the VTR function using the adjustment remote commander (with the HOLD switch set in the OFF position).

Setting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 02 and

press the PAUSE button of the adjustment remote

commander.

AC IN

AC power

adaptor

Battery panel block

DB-016 board

Exiting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, data: 00, and press the PAUSE

button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

When exiting the “Forced VTR Power ON” mode, connect the control

switch block (PS-1870) to the CN7201 of DB-016 board. Or,

when ejecting the cassette, connect the control switch block (PS-1870)

to the CN402 of JK-222 board. and press the EJECT switch.

Eject switch

DB-016

Control switch block

(PS-1870)

CPC-8 jig

(J-6082-388-A)

FP-498 flexible board

VC-318

VC-318 board

FP-499 flexible board

Monitor

Mechanism deck

JK-222 board

JK-222

Adjustment remote

commander (RM-95)

2-14

Page 26

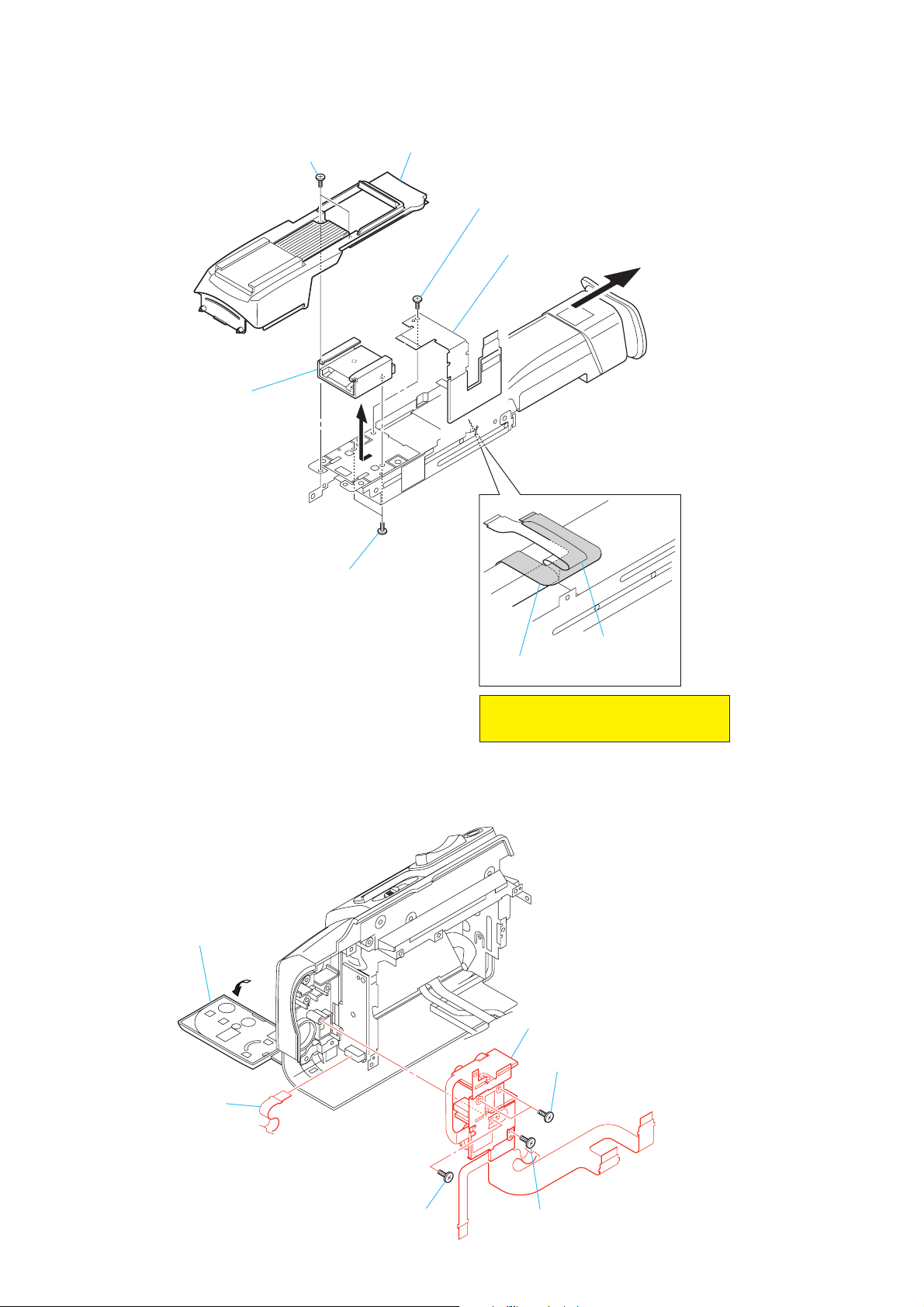

2-20.CONTROL SWITCH BLOCK (PS-1870)

k

1

screw

(M1.7

×

2.5)

DSR-PDX10/PDX10P

3

Control switch bloc

(PS-1870)

2

Two screws

×

4)

(M1.7

2-21.SE-132 BOARD

SE-132

4

CS frame

2

Two screws

(M1.7

3

Two screws

(M1.7

×

4)

×

4)

5

Three screws

(M1.7

×

2.5)

6

SE-132 board

1

Flexible board (JK-222)

(CN4005)

2-15

Page 27

DSR-PDX10/PDX10P

2-22.GRIP CABINET BLOCK

Grip cabinet block

4

Open grip cabinet block.

3

Slide open knob.

1

Four screws

(M1.7

2

Screw

(M1.7)

×

4)

5

Six bosses

6

Grip cabinet block

2-16

Page 28

2-23.CONTROL SWITCH BLOCK (CF-1870)

2

Control switch block

(CF-1870)

1

Two screws

(M1.7

DSR-PDX10/PDX10P

×

4)

2-24.MS ASSEMBLY

4

MS assembly

3

Claw

2

Two screws

(M1.7 × 2.5)

1

Screw

(M1.7 × 4)

2-17

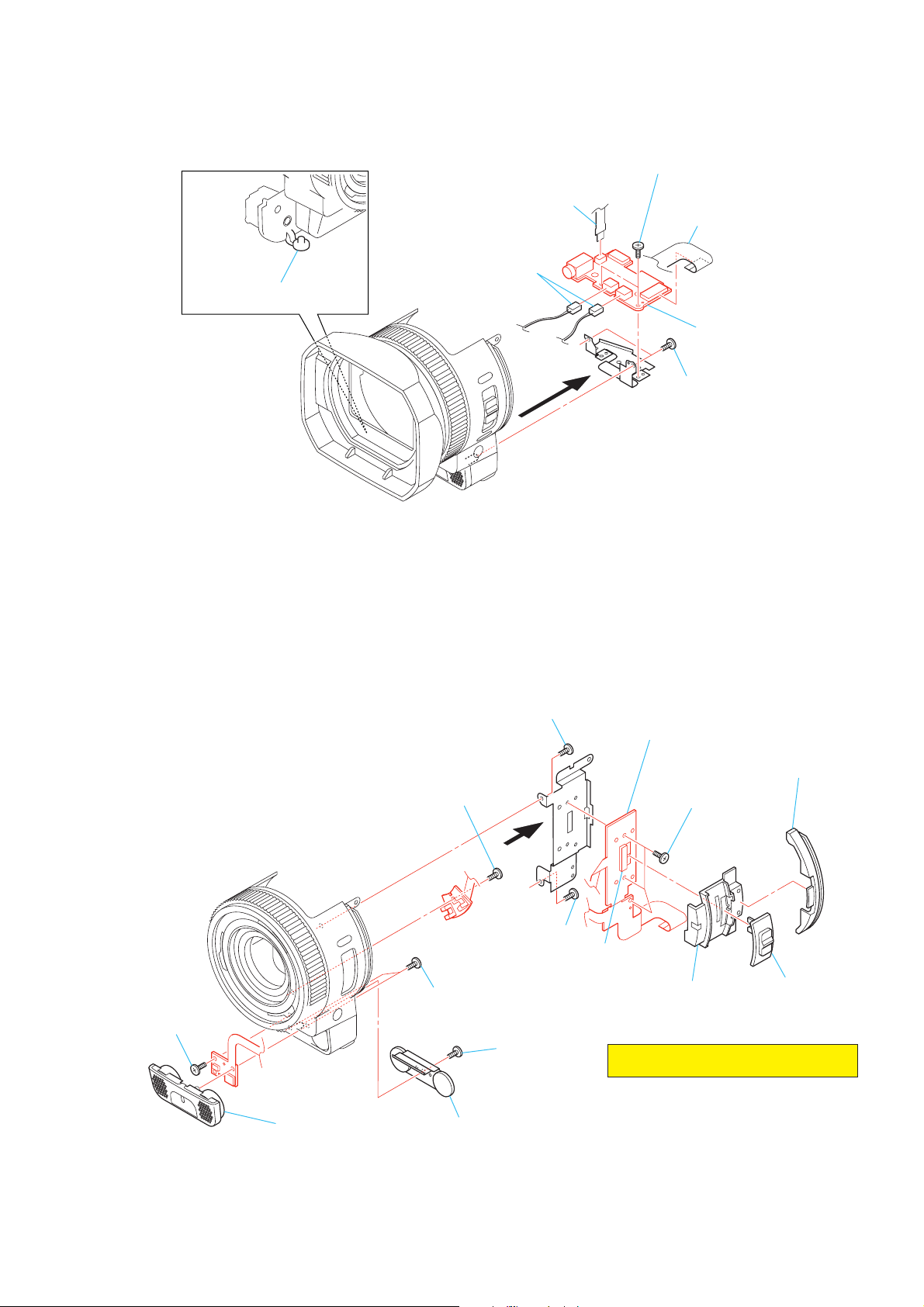

Page 29

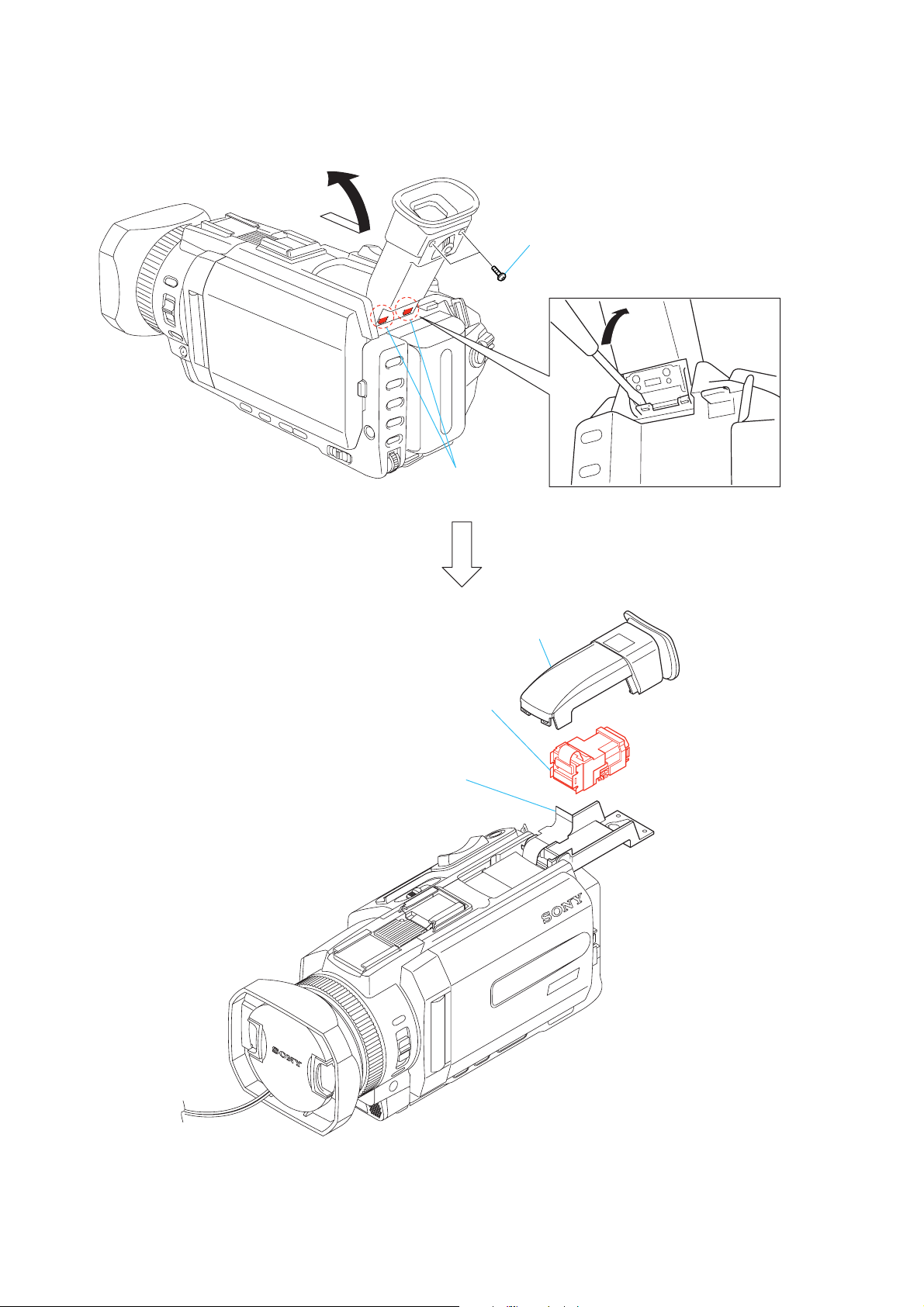

DSR-PDX10/PDX10P

2-25.VF LENS ASSEMBLY

1

3

Two claws

2

Two screws

(M1.7

×

6)

4

VF cabinet (upper)

6

VF lens assembly

5

FP-547 flexible board

(CN6101)

2-18

Page 30

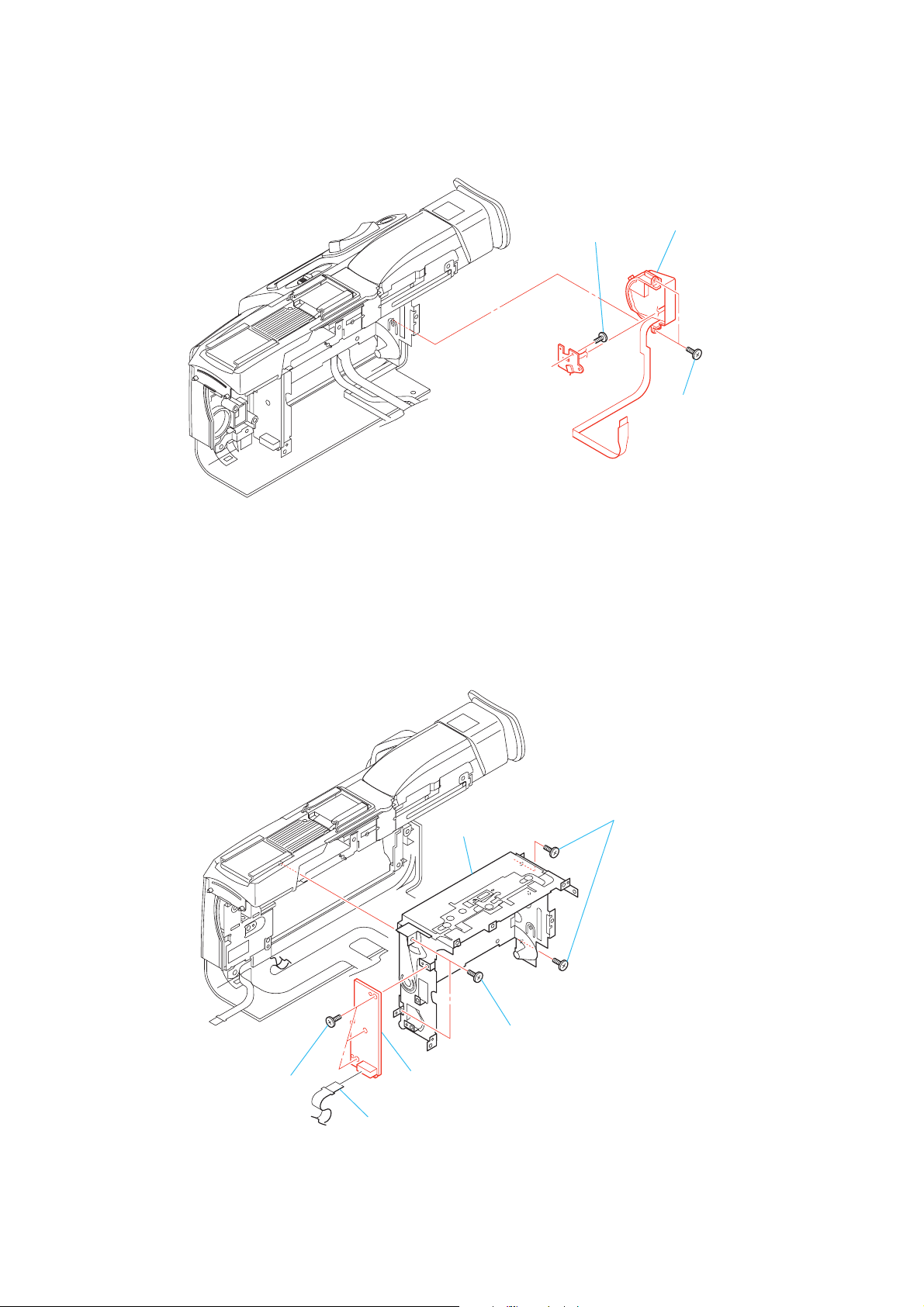

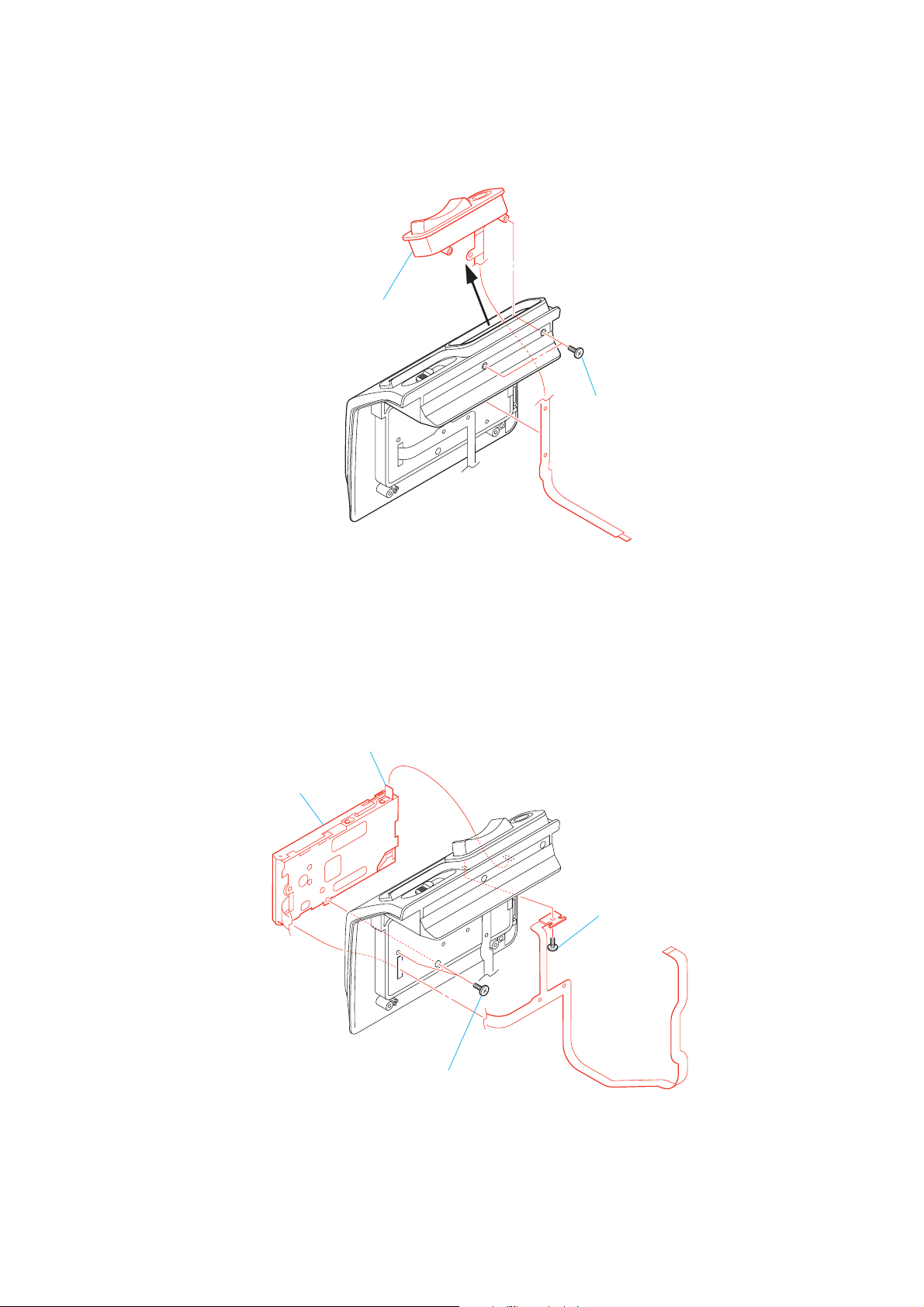

2-26.XLR BLOCK

)

1

XLR block

DSR-PDX10/PDX10P

2-27.XK-001 BOARD

2

Micro phone holder

assembly

1

T wo screws

(+B3 × 10)

7

Two tapping screws

(B2 × 5)

8

XK-001 board

3

T wo screws

(M2 × 5)

6

XL cabinet rear

sub assembly

4

Two tapping screws

(P2 M1.7 × 4)

5

Harness (XK-050

(CN001)

2-19

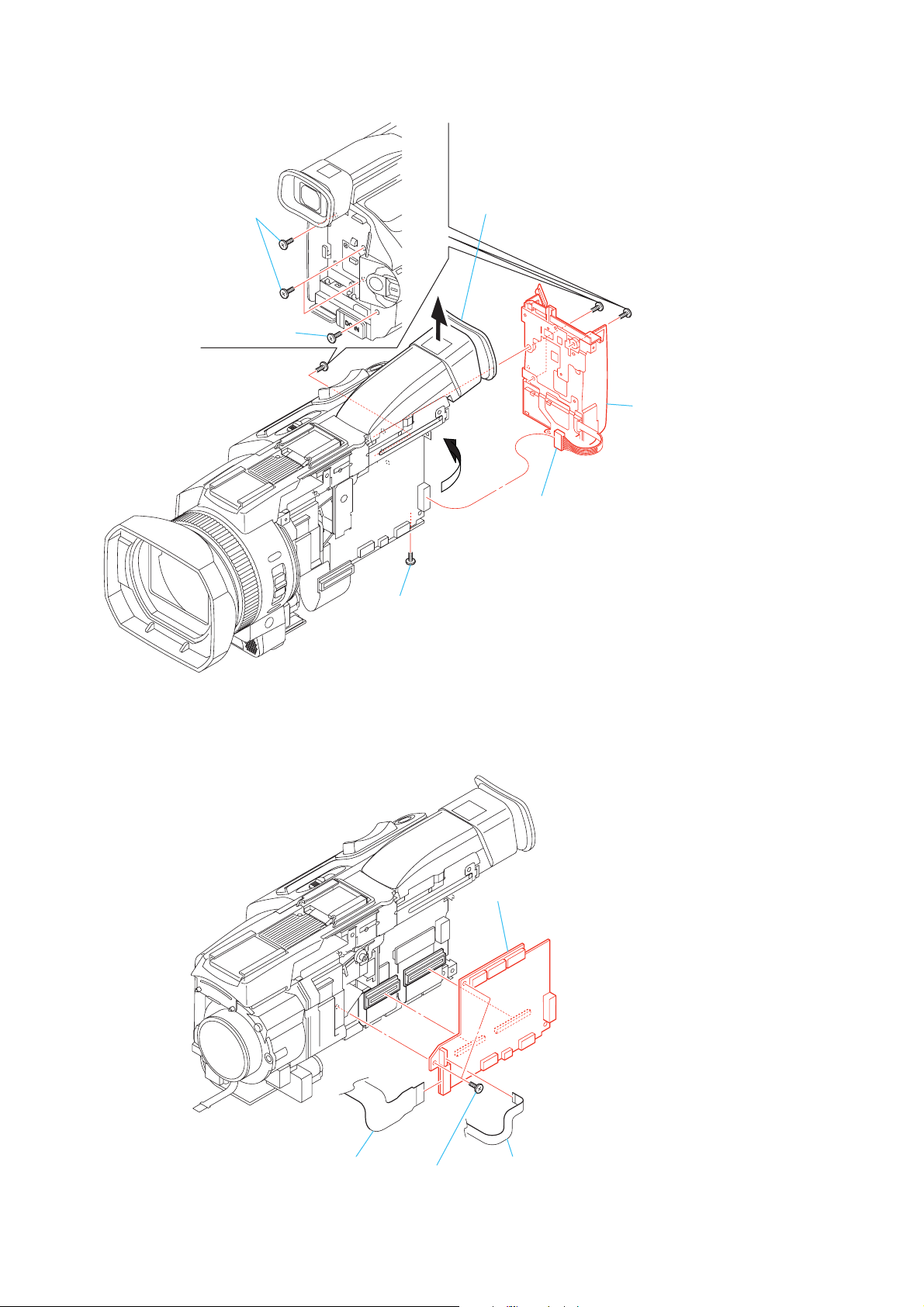

Page 31

DSR-PDX10/PDX10P

2-28.XM-002 BOARD, XD-002 BOARD, XS-002 BOARD

Remove the XM-002 board

and XLR sheet metal in the

direction of the arrow.

5

Screw (M2.6)

6

4

Four screws

(M2.6)

1

Three screws

(M2 × 3)

9

8

XM-002 board,

XLR sheet metal

qd

board

Handle cabinet (R)

0

T apping screw

(B2 × 5)

FP-218 flexible

(CN401)

qa

Screw (M2 × 3)

Cable holder

qs

DD bracket

qf

XD-002 board

ws

XL cabinet center assembly

3

Two FP-217 flexible

boards

(CN201,301)

qg

Three tapping screws

(B2 × 5)

2

T wo screws

(M2 × 3)

ql

When installing it, align the five switch

positions as arrow.

XS-002 board

7

qh

Harness (XH-050)

(CN103)

qj

Two tapping screws (B2 × 5)

qk

SW insulated plate

w;

Handle cabinet (L)

assembly

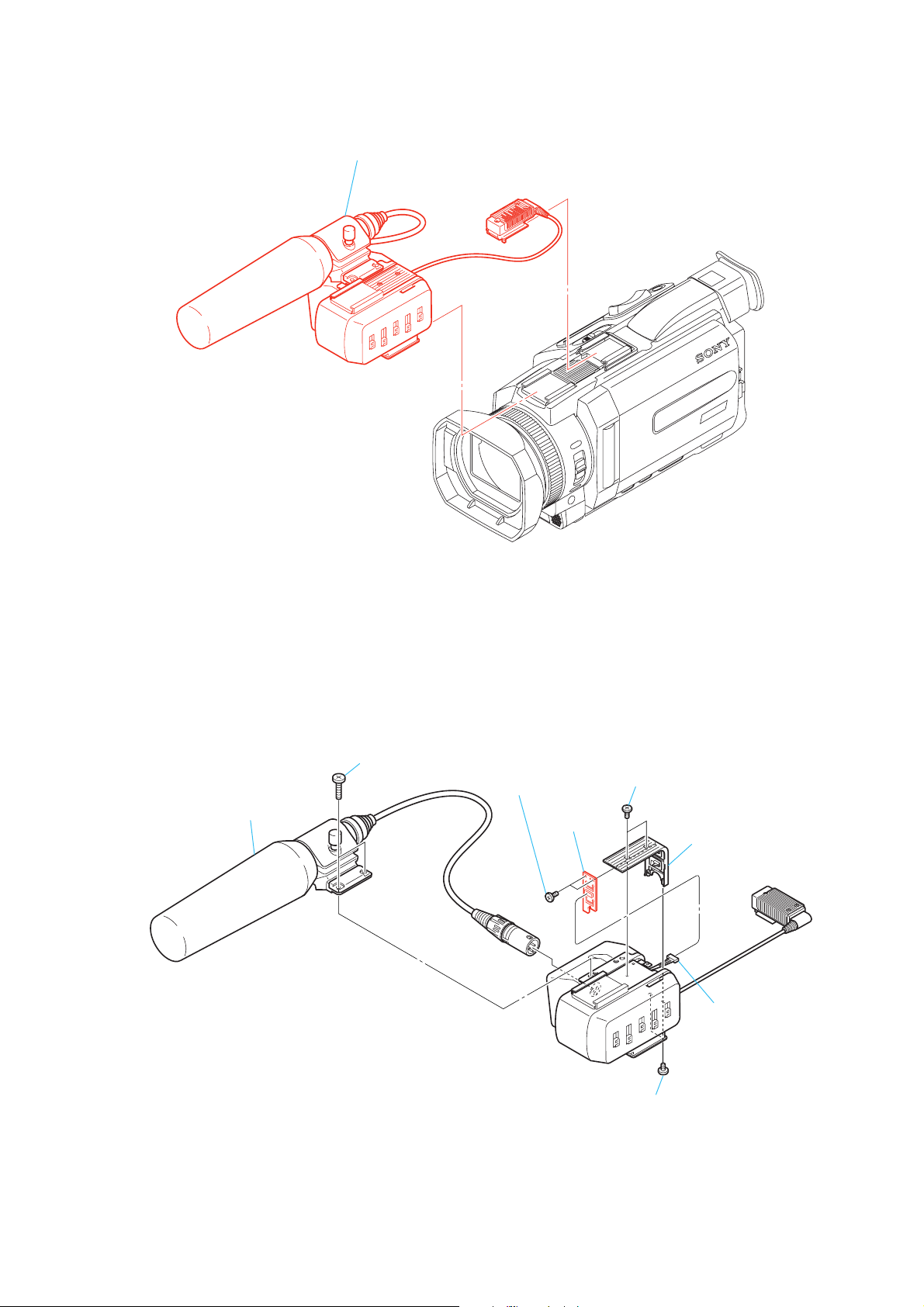

[SERVICE POSITION TO CHECK XLR SECTION]

XK-001 board

Harness (XK-050)

(CN001)

XM-002 board

FP-218 flexible

board (CN401)

XD-002 board

Adjustment remote

commander (RM-95)

LANC

jack

Two FP-217 flexible

boards (CN201, 301)

Harness (XH-050)

(CN103)

XS-002 board

CPC jig for LCD panel

(J-6082-529-A)

AC POWER

ADAPTOR

AC IN

2-20

Page 32

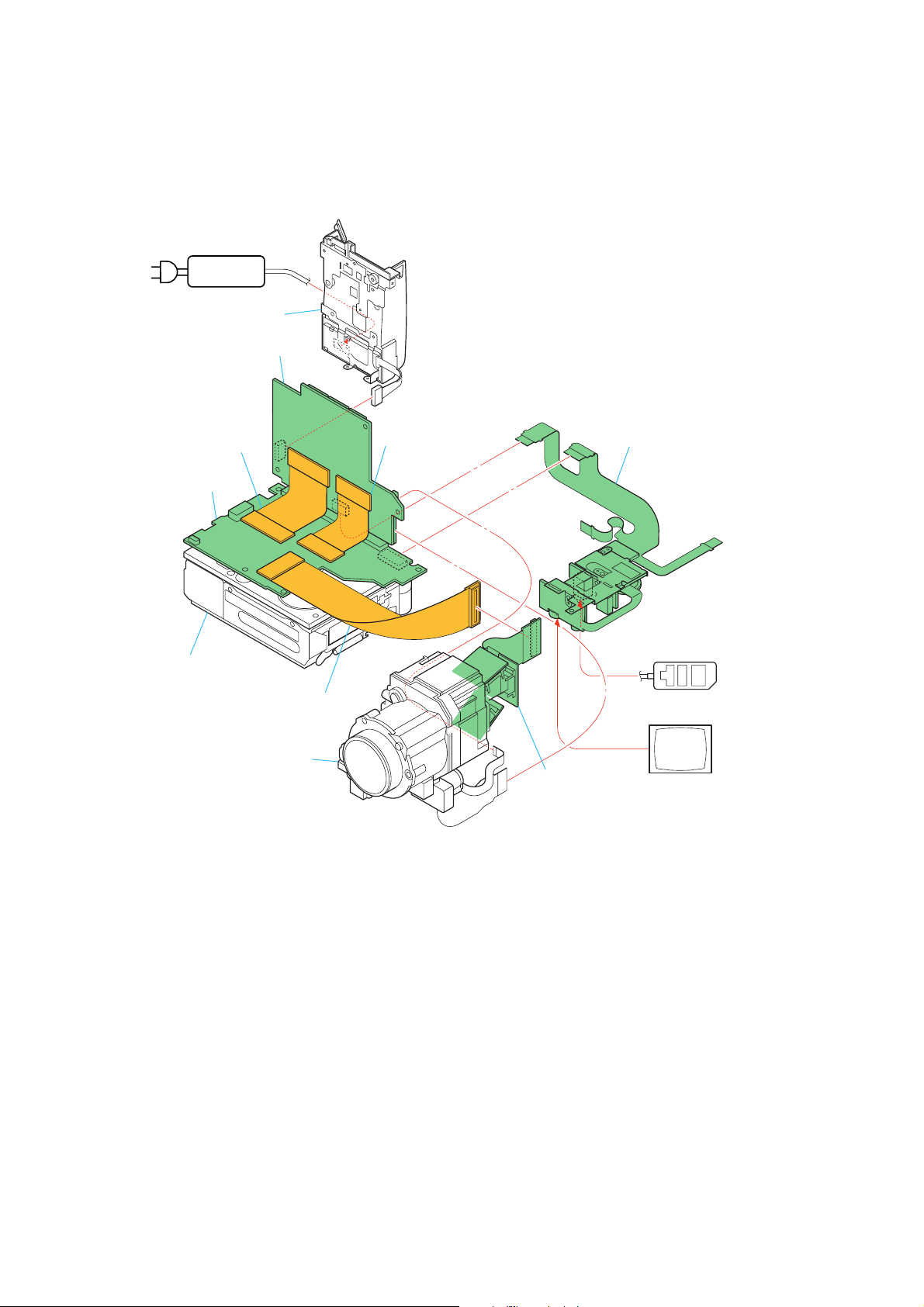

2-29.CIRCUIT BOARDS LOCATION

XS-002

XM-002

XD-002

JK-222

XK-001

CD-389

VC-318

DSR-PDX10/PDX10P

LB-080

CK-134

PD-191

DB-016

SE-132

MA-425

Board Name Function

CD-389 CCD IMAGER

CK-134 CONTROL SWITCH

DB-016 LENS MOTOR DRIVE, VAP DRIVER, MIC VOL, AUDIO PROCESS,

VIDEO IN/OUT, EVF DRIVE, TIMING GENERATOR, CONNECTOR,

DC/DC CONTROL

JK-222 AV IN/OUT, DV/USB CONNECTOR

LB-080 EVF, EVF BACK LIGHT

MA-425 MIC AMP, AF LASER CONTROL

PD-191 LCD DRIVER TIMING GENERATOR, BACK LIGHT

SE-132 PITCH/YAW SENSOR

VC-318 A/D CONVERTER, TIMING GENERATOR, CAMERA RGB PROCESS,

CAMERA PROCESS, MPEG MOVIE/DIGITAL STILL PROCESS,

HI CONTROL, DIGITAL STILL CONTROL, FLASH MEMORY,

SDRAM, DV SIGNAL PROCESS, DV INTERFACE, REC/PB AMP,

USB INTERFACE, VIDEO A/D CONVERTER,

DRUM/CAPSTAN/LOADING DRIVE, CAMERA/MECHA CONTROL,

HI CONTROL, LANC, RESET, BEEP, AFLD, CONNECTOR, EVR

XD-002 DC/DC CONVERTER SIRCS

XK-001 LOW CUT SW

XM-002 MIC AMP

XS-002 MIC SELECT

2-21

Page 33

DSR-PDX10/PDX10P

k

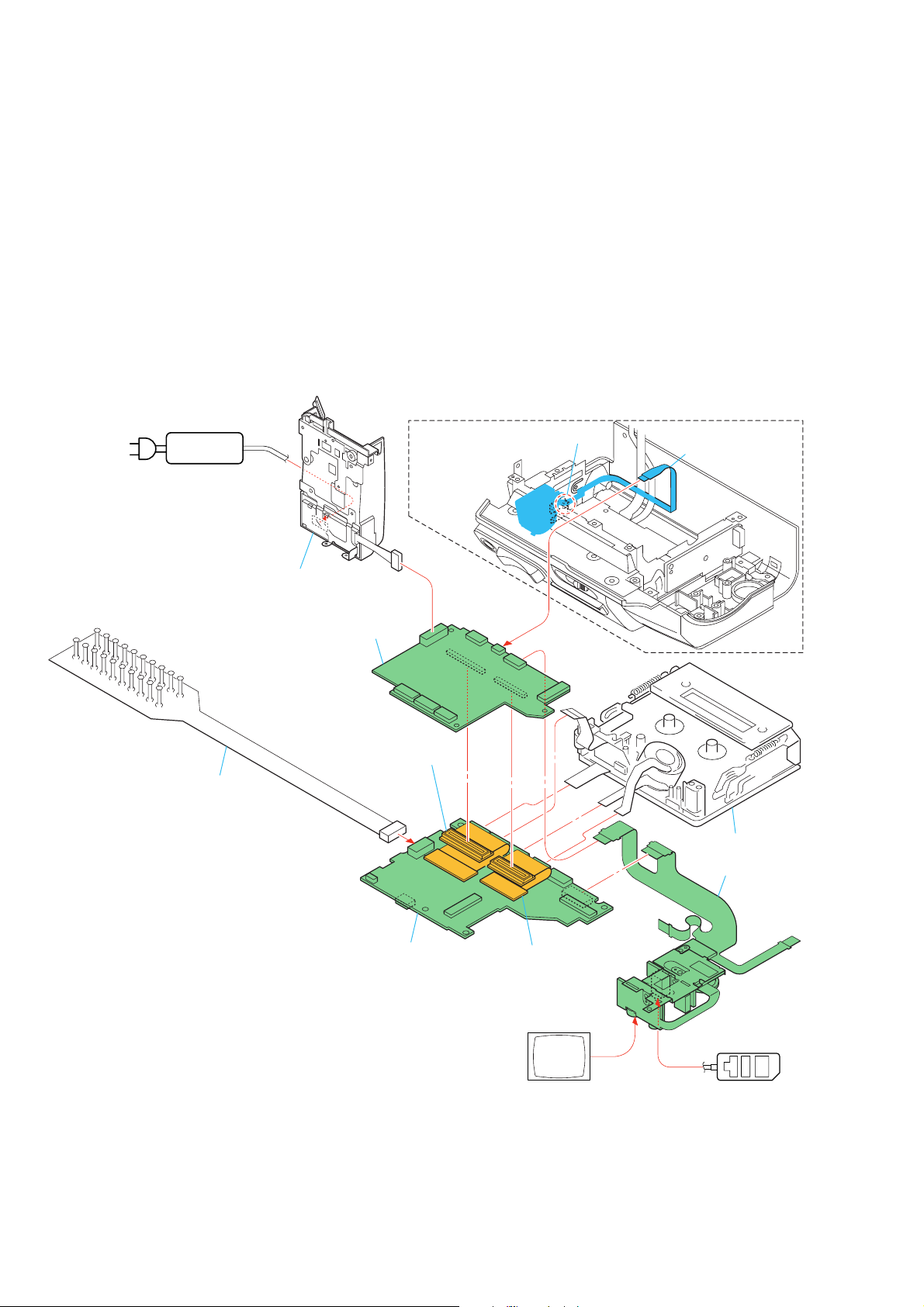

2-30.FLEXIBLE BOARDS LOCATION

FP-495

FP-503

FP-218

FP-500

FP-217

FP-504

Control switch block

(CF-1870)

FP-497

FP-498

FP-496

FP-494

FP-499

FP-547

Control switch bloc

(PS-1870)

Control switch block

(KP-1870)

2-22E

Page 34

COVER

COVER

Link

Link

DSR-PDX10/PDX10P

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/5)

OVERALL BLOCK DIAGRAM (1/5)

OVERALL BLOCK DIAGRAM (2/5)

OVERALL BLOCK DIAGRAM (2/5)

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (4/5)

OVERALL BLOCK DIAGRAM (4/5)

OVERALL BLOCK DIAGRAM (5/5)

OVERALL BLOCK DIAGRAM (5/5)

POWER BLOCK DIAGRAM (1/3)

POWER BLOCK DIAGRAM (1/3)

POWER BLOCK DIAGRAM (2/3)

POWER BLOCK DIAGRAM (2/3)

POWER BLOCK DIAGRAM (3/3)

POWER BLOCK DIAGRAM (3/3)

Page 35

DSR-PDX10/PDX10P

COVER

COVER

BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/5)

CD-389 BOARD

(1/9)

IC3401

IRIS

DRIVE

11

IC102

B-CH

S/H

11

IC103

R-CH

S/H

11

IC104

G-CH

S/H

14

2

PRE DRIVE

10

.

HALL AMP

6

LENS BLOCK

DICHROIC

PRISM

IRIS

IRIS

METER

M

H

IC105

B-CH CCD

IMAGER

IC100

R-CH CCD

IMAGER

IC101

G-CH CCD

IMAGER

DB-016 BOARD (1/4)

CN1004

28

IG DRIVE+,-

.

19

22

IG HALL+,-

.

25

8

1

4

.

10

14

8

1

4

.

10

14

8

1

4

.

10

14

1

SECTION 3

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

(1/9)

IC3403

IRIS

IRIS

VC-318 BOARD (1/5)

CCD+B

CCD-B

XHDSDB

XSHPB

CLPDM

CCD+R

CCD-R

XHDSDR

XSHPR

CLPDM

CCD+G

CCD-G

XHDSDG

XSHPG

CLPDM

V1B-V4B

SHTB

H1B,H2B

RGB

V1R-V4R

SHTR

H1R,H2R

RGR

V1G-V4G

SHTG

H1G,H2G

RGG

CN100

51,50

47,46,39

21,22

29,32,39

11,14,39

42,41,44,45

58,55,57,54

38,35,36,31

30,26,28,25

13,16,18,17

12,8,10,7

CN7207

IRIS PWM

I HALL AD

3,4

5

.

4

13

.

14

.

1

5

.

4

13

.

14

.

1

5

.

4

13

.

14

.

1

12

8

80

72

51,50

47,46,39

21,22

29,32,39

3,4

11,14,39

42,41,44,45

58,55,57,54

38,35,36,31

30,26,28,25

13,16,18,17

12,8,10,7

1

9

CN1201

CN1002

XSHD

XSHP

CLPDM

42

.

40

.

1

63

58

.

37

.

38

.

28

23

18

.

30

.

31

.

25

55

50

.

34

.

35

.

26

(1/17)

IC1202

TIMING

GENERATOR

46

47

2

5

10

.

9

.

8

12

14

.

13

.

15

X1201

66MHz (PDX10)

54MHz (PDX10P)

PBLK

CAM DD ON

30

.

31

19

16

30

.

31

19

16

30

.

31

19

16

(1/17)

IC1203

B-CH

AGC

A/D CONV.

(1/17)

IC1204

R-CH

AGC

A/D CONV.

(1/17)

IC1205

G-CH

AGC

A/D CONV.

47

.

48

.

1

13

44

.

45

20

47

.

48

.

1

13

44

.

45

20

47

.

48

.

1

13

44

.

45

20

SO GCAM

SCK GCAM

SO GCAM

SCK GCAM

SO GCAM

SCK GCAM

BIL0-BIL13

RIL0-RIL13

GIL0-GIL13

CLPOB

CHCK

HD,VD,FLD

SHTTER ON

DIRA1

DIRB1

EN1

ANALOG VIDEO SIGNAL

ANALOG AUDIO SIGNAL

DIGITAL VIDEO SIGNAL

(2/17)

IC1301

141

124

103

95

.

68

62

41

42

310

306

314

.

315

.

316

181

189

.

190

.

188

CAMERA

RGB

PROCESS

151

142

168

154

175

.

174

.

173

192

169

242

DQ0-31

285

(2/17)

SDRAM

3

14

.

32

59

.

77

88

DQ0-DQ31

IC1351

AD0-13

22

28

.

63

69

209

229

300

.

303

.

301

177

85

Y02-Y09

C02-C09

HD,VD,FLD

SPCK

SRCK0

IRIS PWM

I HALL AD

ND HALL AD

ND PWM

ZM RST

PITCH PWM

YAW PWM

PITCH POS AD

YAW POS AD

CAM SO,SI,SCK

SO GCAM

SCK GCAM

EXT STROBE ON

STROBE A IN

CAM DD ON

1

TO

OVERALL

BLOCK DIAGRAM

(2/5)

(PAGE 3-3)

TO

OVERALL

BLOCK DIAGRAM

(3/5)

(PAGE 3-5)

TO

OVERALL

BLOCK DIAGRAM

(5/5)

(PAGE 3-10)

2

3

ND FILTER

METER

PITCH

ACTIVE

ACTUATOR

FOCUS

MOTOR

ZOOM

MOTOR

ZOOM

RESET

SENSOR

LENS

YAW

(1/9)

6

5

7

8

.

4

2

IC1503

PITCH/YAW

PRE AMP

IC3405

9

.

12

HALL AMP

ND FILTER

1 3

PRE DRIVE

(1/9)

FC PWM

FC EN

(2/9)

ND

67

98

33

.

34

46

.

1

12

.

15

14

(1/9)

IC3404

FOCUS/

ZOOM

CONTROL

IC1504

(2/9)

LPF

28

.

CAM SO,SI SCK

27

.

26

23

37

128

PITCH POS ADPITCH POS AD

ND HALL AD

ND PWM

SHUTTER ON

CAM DD ON

CN7206

CN7207

SPCK

DIRA1

DIRB1

EN1

CN7206

ZM RST

PITCH PAW

YAW PAW

CN7207

YAW POS AD

74

7

78

3

49

76

5

28

CN1001

40

61

.

.

38

63

.

.

42

59

CN1002

11

90

65

16

.

.

34

47

.

.

36

45

CN1001

31

70

48

53

CN200

INPUT1

CN300

INPUT2

XM-002 BOARD

IC200

IC201

CH1

MIC/LINE

AMP

IC300

IC301

CH2

MIC/LINE

AMP

IC205

(1/2)

LOW

5

CUT

AMP

IC205

(2/2)

LOW

3

CUT

AMP

IC204

(1/2)

11

14

7

IC204

(2/2)

9

8

1

1

12

7

2

CN202

CN201

5

CN301

6

CN102

14

3

11

6

1

16

CN101

14

3

11

6

1

16

XS-002 BOARD

S103

INPUT1

INPUT

LEVEL

SELECT

S104

INPUT2

INPUT

LEVEL

SELECT

S102

INPUT1

REC CH

SELECT

CH1

CH1 + CH2

S100

INPUT1

+48V

OFF ON

S105

INPUT2

+48V

OFF ON

CN103 CN402

L (CH1) OUT

7

R (CH1) OUT

5

SHOE UNREG

2

CN100

6

.

7

CH1 MIC 48V

CH2 MIC 48V

5

10

4

7

ACCESSORY

5

1

XD-002 BOARD

CN401

8

.

7

9

CONVERTER

SHOE

PLUG

IC401

DC/DC

TO

OVERALL

BLOCK DIAGRAM

(3/5)

(PAGE 3-5)

4

XK-001 BOARD

S001

INPUT1

46

55

CN1002

70

11

68

13

LOW CUT

S002

INPUT2

LOW CUT

CN001

1

2

XLR ADAPTOR

36

ND HALL+,-

H

M

M

MR

M

MR

.

34

39

.

30

18

.

19

15

.

14

4

.

1

.

3

.

2

12

.

10

8

.

8

.

9

8

.

9

6

1

CN1501

ND DRIVE+,-

FOCUS+,-

FMR A,B

ZOOM A+,ZOOM B+,-

ZMR A,B

ZOOM RST

P DRIVE A,B

Y DRIVE A,B

P OUT

Y OUT

1

.

7

1

.

7

23

.

24

22

.

21

15

.

14

38

.

34

.

42

.

41

(2/9)

IC1502

VAP

PITCH

DRIVE

(2/9)

IC1501

VAP

YAW

DRIVE

ND FILTER

DRIVE

SHUTTER

DRIVE

FOCUS

MOTOR

DRIVE

(1/9)

IC3402

ZOOM

MOTOR

DRIVE

6

6

12

11

3-1 3-2

Page 36

DSR-PDX10/PDX10P

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-2. OVERALL BLOCK DIAGRAM (2/5)

VC-318 BOARD (2/5)

Y02-Y09

C02-C09

HD,VD,FLD

SPCK

SRCK0

1

TO

OVERALL

BLOCK DIAGRAM

(1/5)

(PAGE 3-2)

IRIS PWM

I HALL AD

ND HALL AD

ND PWM

ZM RST

PITCH PWM

YAW PWM

PITCH POS AD

SE-132 BOARD

SE4001

PITCH

SENSOR

SE4002

YAW

12

SENSOR

FP-504 BOARD (1/2)

PH601

PH602

8

IC4001

PITCH/YAW

SENSOR

AMP

MANUAL

FOCUS

PHOTE

SENSOR

18

2

CN4005

JK-222

BOARD

(1/5)

2

4

MA-425

BOARD

(1/3)

CN5905

8

.

7

CN5906

3

.

4

CN1005

PITCH AD

26

YAW AD

25

CN1021

3

MF A,B

.

4

OVERALL

BLOCK DIAGRAM

(PAGE 3-10)

(5/5)

YAW POS AD

SO GCAM

SCK GCAM

5

TO

ZOOM VR AD

HS TXD,RXD,SCK

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

(3/17)

97

IC1601

50

57

40

49

39

.

36

.

35

95

15

CAM SO,SI,SCKCAM SO,SI,SCK

94

128

136

93

54

95

96

131

132

73

.

71

129

130

210

.

211

135

(13/17)

IC2501

(1/2)

CAMERA

CONTROL

77

.

78

.

75

1

3

X2501

20MHz

(1/17)

17

.

IC1801

16

EVR

.

16

.

18

CAMERA

PROCESS

3

1

.

Y0-7

175

169

7

C0-7

4

8

HD,VD,OE

10

VCK

98

154

D0-15

133

(4/17)

2

IC1701

A0-13

Y

C

IC7001 CK

SPCK

20

35

31

.

68

2

6

25

64Mbit

SDRAM

(11/17)

IC2001

A/D CONV.

VIDEO

13

.

42

53

59

Y0-7

52

49

C0-7

42

AFCK

34

38

HD,VD,OE

36

121

102

(4/17)

IC1704

83

76

MPEG

MOVIE

PROCESS

72

65

84

86

177

CHARACTER

GENERATOR

CHARACTER

GENERATOR

170

153

DIGITAL

STILL

PROCESS

144

137

.

133

128

44

74

115

99

97

91

117

119

87

88

123

120

61

62

59

34

27

.

22

11

9

2

48

47

25

.

.

Y0-7

C0-3

HD,VD,OE

HD,VD

COL0-3

ADAI2

ADAO2

SFD BCK

D0-7

A16-23

SPCK

(6/17)

20

IC3001

26

.

16Mbit

29

SDRAM

35

(6/17)

1

IC3002

10

.

16Mbit

16

FLASH

MEMORY

25

.

48

2

13

.

42

53

30

36

.

38

45

X2101

24.576MHz

X2901

48MHz

2

.

3

.

5

.

6

(10/17)

IC2302

AUDIO

A/D CONV.

JK-222

BOARD (2/5)

FRRV/TRRV,TRRT

VSP SO,SI,SCK

PANEL R,G,B

DATA TO SFD

DATA FROM SFD

3

2

CN1005

18

19

CN1009

7

5

3

MC BUS

AD DT

REC DT

REC CK

PB CK

ATFERR

HD,VD

BW Y

SFD BCK

IC7001 CK