Page 1

D-EJ785

SERVICE MANUAL

Ver 1.0 2002.12

SPECIFICATIONS

Canadian Model

AEP Model

UK Model

E Model

Austr alian Model

Chinese Model

Tourist Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-3325ER

Optical Pick-up Name DAX-25E

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW (This output is the value

measured at a distance of 200 mm from the objective lens

surface on the optical pick-up block with 7 mm aperture.)

Power requirements

For the area code of the model you purchased, check the

upper left side of the bar code on the package.

•Sony NH-WM2AA rechargeable batteries: 2.4 V DC

•Two LR6 (size AA) batteries: 3 V DC

•AC power adaptor (DC IN 4.5 V jack):

Canadian and Taiwan models: 120 V, 60 Hz

UK model: 230 V, 50 Hz

Australian model: 240 V, 50 Hz

AEP, East European, E, Korean and Tourist models:

100 - 240 V, 50/60 Hz

Hong Kong model: 230 V, 50/60 Hz

Chinese model: 220 V, 50 Hz

Battery life* (approx. hours)

(When the CD player is used on a flat and stable place.)

Playing time varies depending on how the CD player is

used.

G-PROTECTION

on off

Two NH-7WMAA 15 10

(charged for

about 2 hours**)

NH-WM2AA 32 24

(charged for

about 4 hours**)

Two Sony alkaline 50 35

batteries LR6 (SG)

(produced in Japan)

*Measured value by the standard of JEITA (Japan

Electronics and Information Technology Industries

Association).

** Charging time varies depending on how the

rechargeable battery is used.

Dimensions (w/h/d) (without projecting

parts and controls)

Approx. 136.0 × 19.6 × 136.0 mm (5 3⁄

Mass (excluding accessories)

Approx. 155 g (5.5 oz)

Operating temperature

5°C - 35°C (41°F - 95°F)

Supplied accessories

AC power adaptor (1)

Headphones/earphones with remote control (1)

Rechargeable batteries (2)

Battery carrying case (1)

Design and specifications are subject to change without

notice.

× 25⁄32 × 5 3⁄8 in.)

8

9-874-272-01 Sony Corporation

2002L0500-1 Personal Audio Company

C 2002.12 Published by Sony Engineering Corporation

PORTABLE CD PLAYER

Page 2

D-EJ785

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 3

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Disassembly Flow........................................................... 7

3-2. Spring (A)/(B) ................................................................. 7

3-3. Lid (Upper) Sub Assy ..................................................... 8

3-4. Cabinet (Front) Block ..................................................... 8

3-5. Optical Pick-up Section (CDM-3325ER),

MAIN Board ................................................................... 9

4. ELECTRICAL CHECK .......................................... 10

5. DIAGRAMS

5-1. Block Diagram – MAIN Section –................................ 11

5-2. Block Diagram

– AUDIO/PO WER SUPPLY Section – .......................... 12

5-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 13

5-4. Printed W iring Board

– MAIN Board (Component Side) – .............................. 14

5-5. Printed W iring Board

– MAIN Board (Conductor Side) – ................................ 15

5-6. Schematic Diagram – MAIN Board (1/3) –.................. 16

5-7. Schematic Diagram – MAIN Board (2/3) –.................. 17

5-8. Schematic Diagram – MAIN Board (3/3) –.................. 18

5-9. IC Pin Function Description ........................................... 21

On AC power adaptor

• Use only the AC power adaptor supplied. Do not use

any other AC power adaptor. It may cause a

malfunction.

Polarity of the plug

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

6. EXPLODED VIEWS

6-1. Front Cabinet Section ..................................................... 26

6-2. Rear Cabinet Section ...................................................... 27

6-3. Optical Pick-up Section (CDM-3325ER)....................... 28

7. ELECTRICAL PARTS LIST ............................... 29

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

2

Page 3

SECTION 1

SERVICING NOTES

D-EJ785

ABOUT CD-Rs/CD-RWs

• This CD player can play CD-Rs/CD-RWs recorded in the Compact Disc Digital Audio (Audio CD) format, b ut playback capability may vary depending on the quality of the disc and the

condition of the recording device.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

BEFORE REPLACING THE OPTICAL PICK-UP BLOCK

Please be sure to check thoroughly the parameters as par the “Optical Pick-Up Block Checking Procedures” (Part No.: 9-960-027-

11) issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

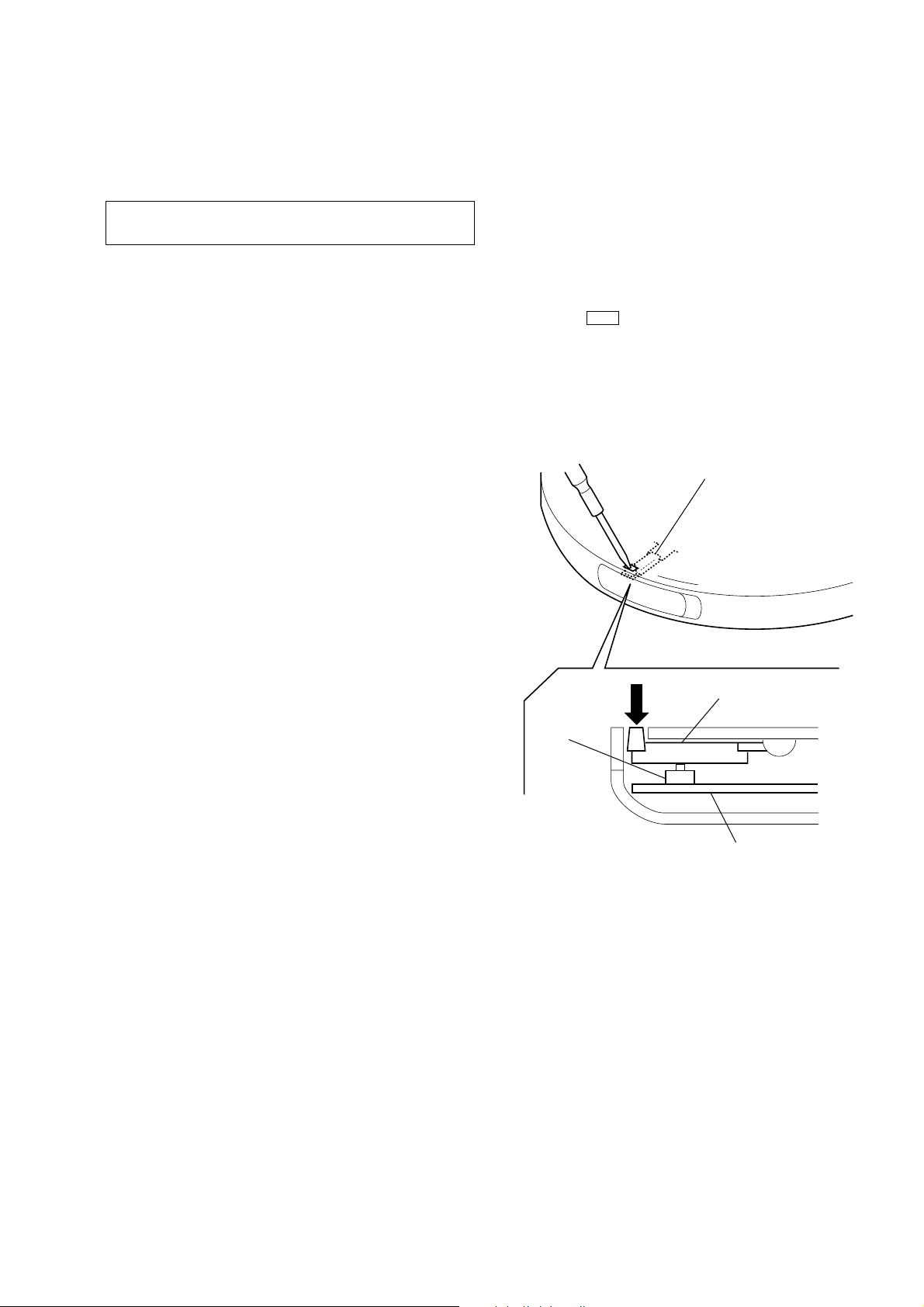

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S801. (push switch type)

The following checking method for the laser diode is operable.

• Method:

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. With a disc not set, turn on the S801 with a screwdri ver having

a thin tip as shown in Fig.1.

3. Press the

4. Observing the objective lens, check that the laser diode emits

light.

When the laser diode does not emit light, automatic power

control circuit or optical pickup is faulty.

In this operation, the objective lens will move up and down 5

times along with inward motion for the focus search.

B X key.

detection lever

• FOK output: IC601 yg pin

When checking FOK, remove the lead wire to disc motor.

• RF signal P-to-P value: 0.45 to 0.65 Vp-p

detection lever

S801

MAIN board

Fig. 1 Method to push the S801

3

Page 4

D-EJ785

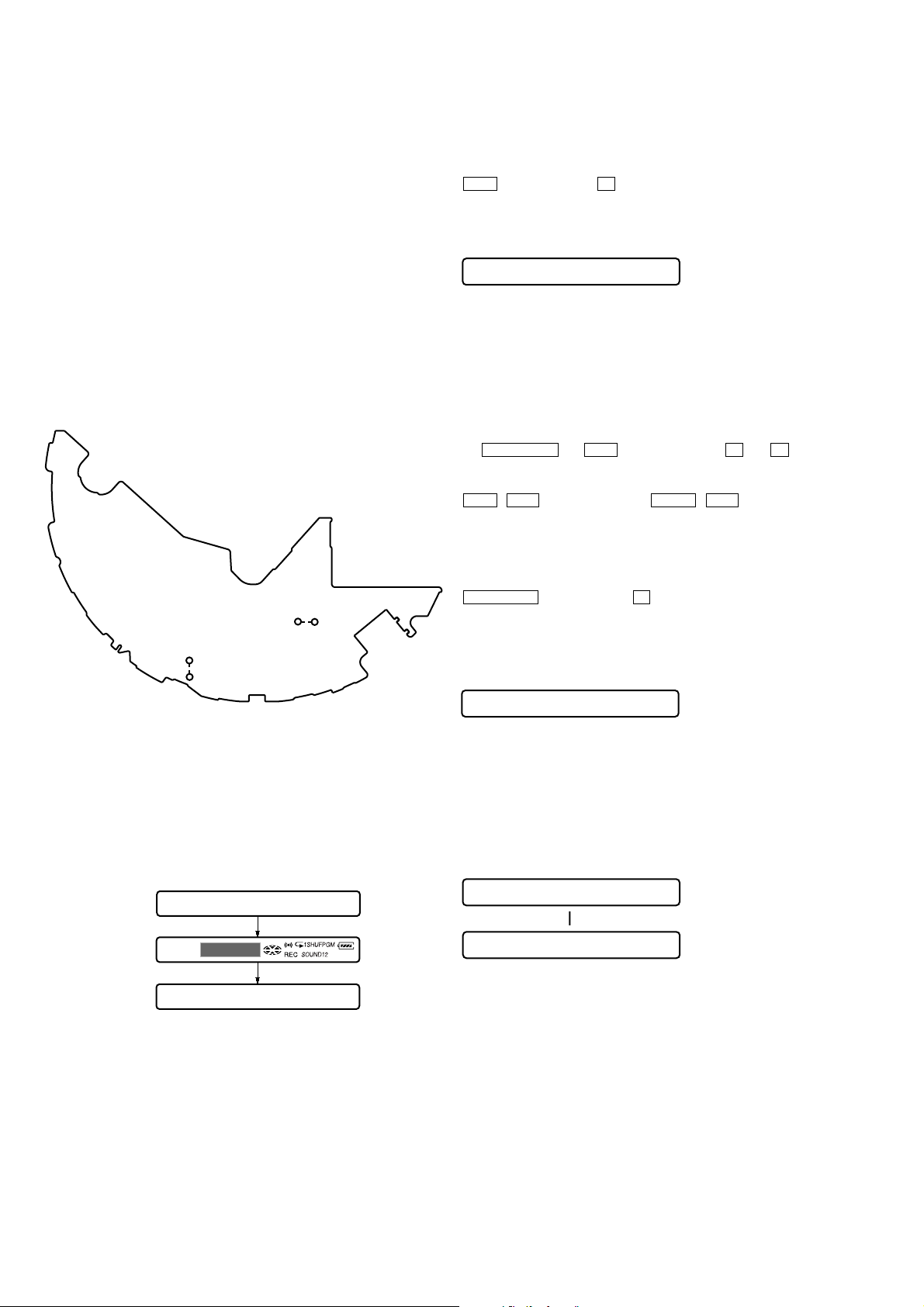

SERVICE MODE

In the Service mode, this set can check the following.

Note: Use RM-MC10L (Part No. 1-476-211-

mode. (Use dot matrix Remote Commander)

1. Service Mode Setting Method

To set the service mode, perform as follows.

1) Make sure that the power is not turned on.

2) Check for the following states:

CD lid open detection switch (S801) .... OFF

Solder bridge at TAP802 (OPEN) ......... OPEN

[][]

), when you operate service

[HOLD] switch (S803) .......................... OFF

[AVLS] switch (S808) ........................... OFF

[G-PROTECTION] switch (S802) ........ ON

3) Short the solder bridge at the TAP801 (TEST) on the MAIN

board (see Fig. 2).

4) Turn the power on, and then set a CD.

– MAIN Board (Component Side) –

TAP801

(TEST)

TAP802

(OPEN)

3. Operation of Keys and Knobs in Service Mode

The following operation can be checked by operating the buttons

on the set and remote commander.

• B X key on the set or X key on the remote commander

Focus and tracking/sled servo off

Spindle servo on

Remote Commander LCD display

0000

Note: Do not look directly at the laser beam from the optical pick-up.

(play mode)

[HOLD] switch is on:

Auto adjustment value a becomes as follows each time the key is

pressed.

1) [TRK:MIN:SEC] = RF:FE:TE DC offset adjustment value

2) [TRK:MIN:SEC] = EF: :EF balance adjusted value

3) [TRK:MIN:SEC] = Ga:FG:TG gain adjusted value

[AVLS] switch is on:

Press CHARGE x and B X keys on the set or x and X keys

on the remote commander simultaneously, and RF gain changes

to 0 dB (for normal CD) and +12 dB (for CD-RW).

• . / > keys on the set or B > / . knobs on the

remote commander

Tracking servo off

Optical pick-up movement (outward or inward)

Note: Do not move forcibly the optical pick-up exceeding the most-out-

side or most-inside track.

• CHARGE x key on the set or x key on the remote commander

All servos (focus/tracking/sled) off

• [RPT/ENT] key on the remote commander

Tracking gain up mode

Fig. 2

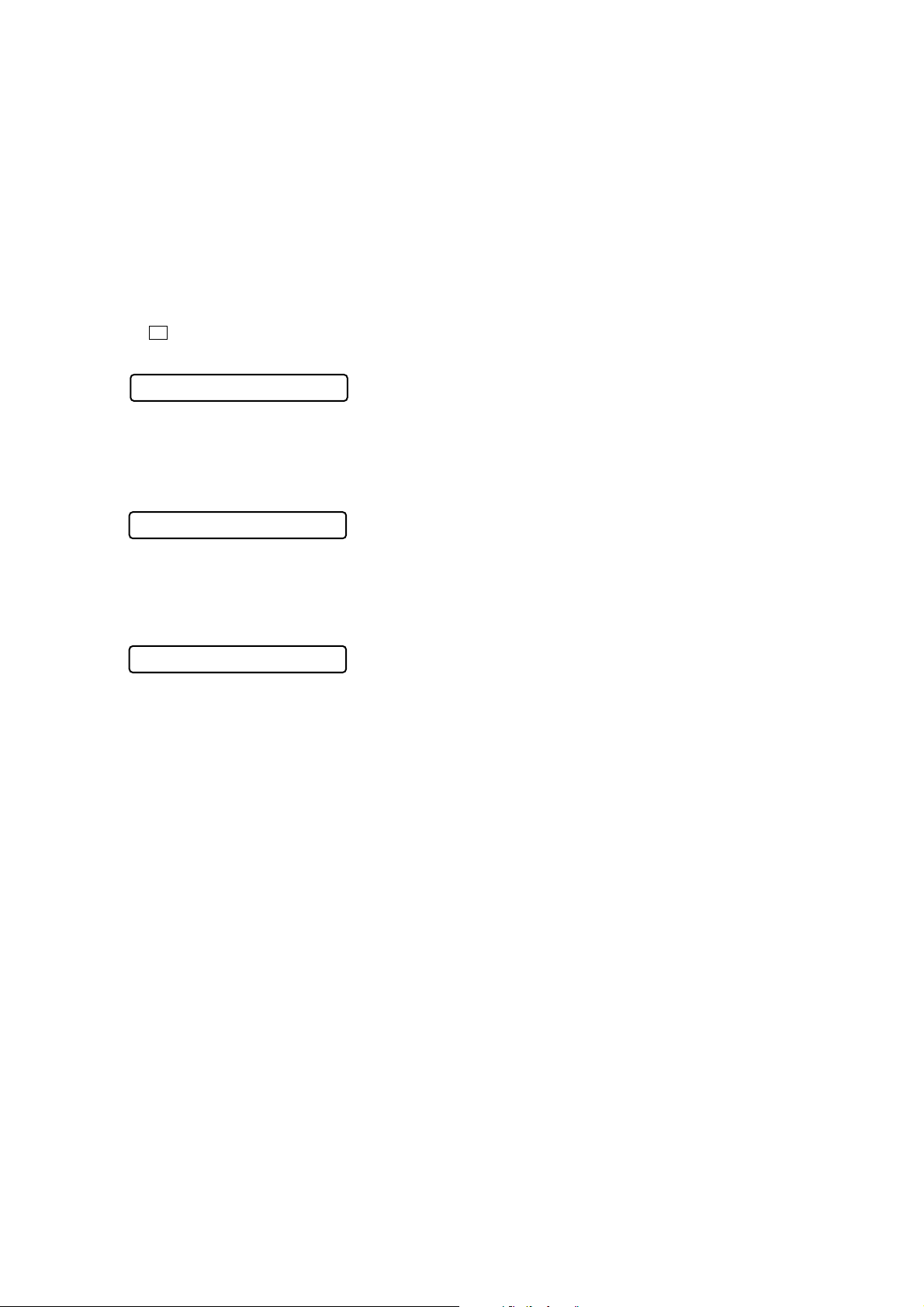

2. Operation in Service Mode

When the Service mode is set, the LCD on the remote commander

displays the microcomputer version display.

Remote commander LCD display

Microcomputer

version display

All lit

Service mode

VA020

888

DDDD

BASS12

Remote Commander LCD display

Up0000

(For the rest, turn the power off and then turn it on again)

[PLAYMODE] key on the remote commander

•

[HOLD] switch is off:

Spindle speed becomes 1.65/2.0/2.65/3.5 times each time the

key is pressed

Tracking/spindle servo on

Remote Commander LCD display

010001

040004

(For the rest, turn the power off and then turn it on again)

• [SOUND] key on the remote commander

Servo gain adjustment

Tracking servo off

• [DISPLAY] key on the remote commander

On/off switching of the DOUT LED (AEP, UK and East European models) and error rate display

• [VOL +] / [VOL --] keys on the set or remote commander

2-step volume setting

(1.65 times)

(3.5 times)

4

Page 5

4. Service Mode Releasing Method

To release the service mode, perform as follows.

1) Turn the power off.

2) Open the solder bridge at the TAP801 (TEST) on the MAIN

board.

Note: Remove the solder completely.

5.Error Rate Check Display

The C1 error rate check display mode becomes active if the following operation is performed during the operation in the service

mode.

1) Turn the power off, and cancel other service operations.

2) Turn the power on, and then set a CD and play it with

the X key on the remote commander.

Remote Commander LCD display

0000

3) Press the [SOUND] button on the remote commander to make

automatic adjustment.

4) Press the [PLAYMODE] button on the remote commander.

D-EJ785

Remote Commander LCD display

010001

5) Press the [DISPLAY] key on the remote commander, and the

C1 error rate display will be activated and the LCD on the

remote commander will display as follows.

Remote Commander LCD display

Er****

Note: In the play state, press the [SOUND] key on the remote commander

before pressing the [PLAYMODE] key. Wrong order of button operations will result in very large Er**** value.

6) Turn the power off.

7) Open the solder bridges at the TAP801 (TEST) on the MAIN

board.

Note: Remove the solder completely.

**** value

0000 to 0099 : OK

more than 0100 : NG

5

Page 6

D-EJ785

CD player (front)

12 Jog lever (u (play/

pause)•./> (AMS/

search))

3 CHARGE/x •

CHARGE lamp

4 VOL +*/–

SECTION 2

GENERAL

This section is extracted from

instruction manual.

Strap holes

OPEN

A

i (headphones) jack

5 HOLD

*The button has a tactile dot.

**AEP, UK and East European models only

CD player (inside)

6 AVLS

7 G-PROTECTION

Remote control

Display

3x

4 VOL +/–

12 Jog lever (u

B

Open the battery

compartment lid.

(play/pause)•ENT

(enter) • ./>

(AMS/search))

DC IN 4.5 V (external power

input) jack

LINE OUT/LINE OUT (OPTICAL)**

jack

Insert the # end first (for both

batteries).

Display on the remote control

AV LS

Playing time

Track number

Play mode

Clip

5 HOLD

8 DISPLAY

Note

Use only the supplied remote control. You cannot operate

this CD player with the remote control supplied with other

CD players.

9 SOUND

q; P MODE/

Remaining battery power

Sound mode

6

Page 7

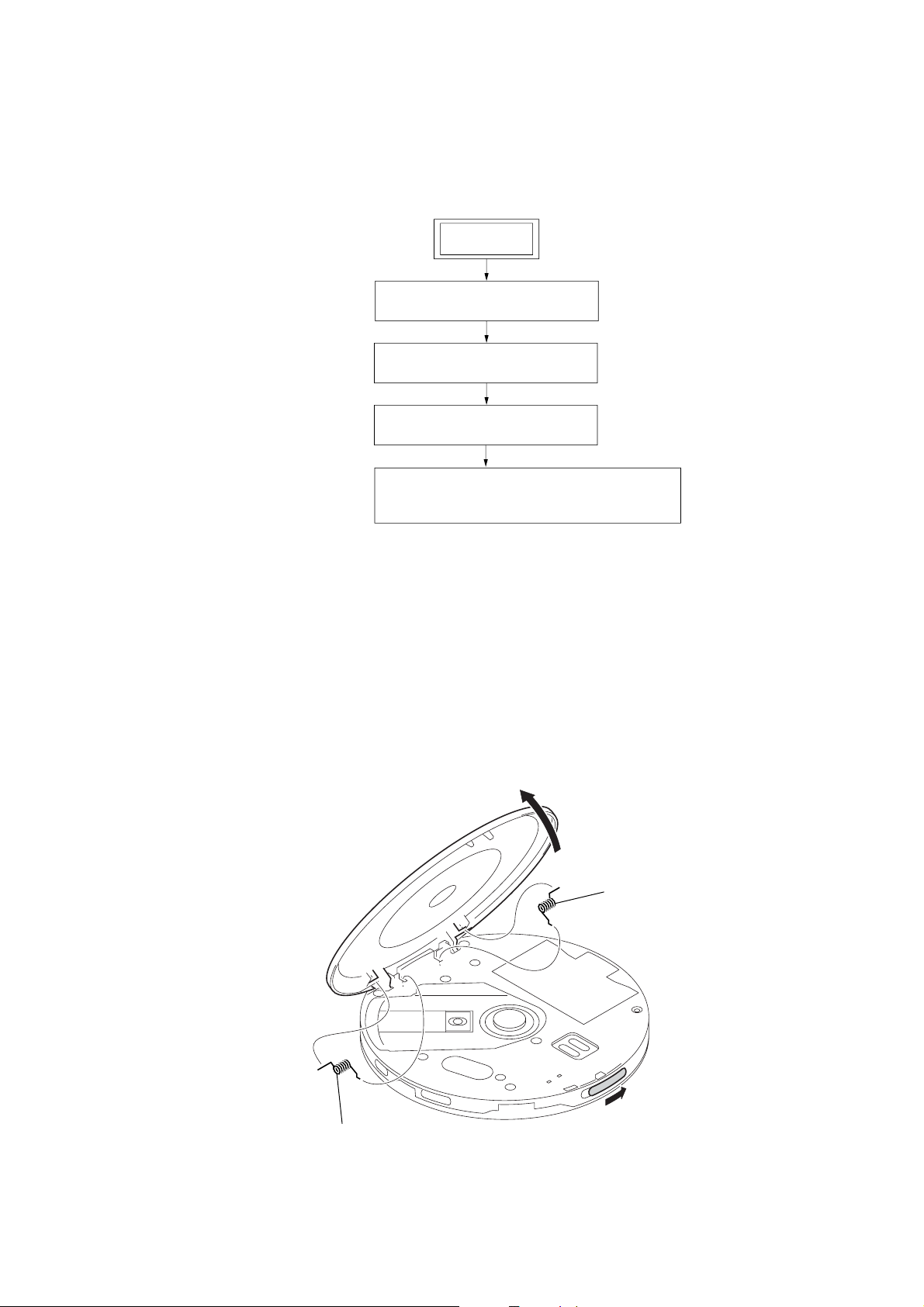

• This set can be disassembled in the order shown below.

)

3-1. DISASSEMBLY FLOW

D-EJ785

SECTION 3

DISASSEMBLY

SET

3-2. SPRING (A)/(B)

(Page 7)

3-3. LID (UPPER) SUB ASSY

(Page 8)

3-4. CABINET (FRONT) BLOCK

(Page 8)

3-5. OPTICAL PICK-UP SECTION (CDM-3325ER),

MAIN BOARD

(Page 9)

Note: Follow the disassembly procedure in the numerical order given.

3-2. SPRING (A)/(B)

2

4

spring (B

3

spring (A)

1

7

Page 8

D-EJ785

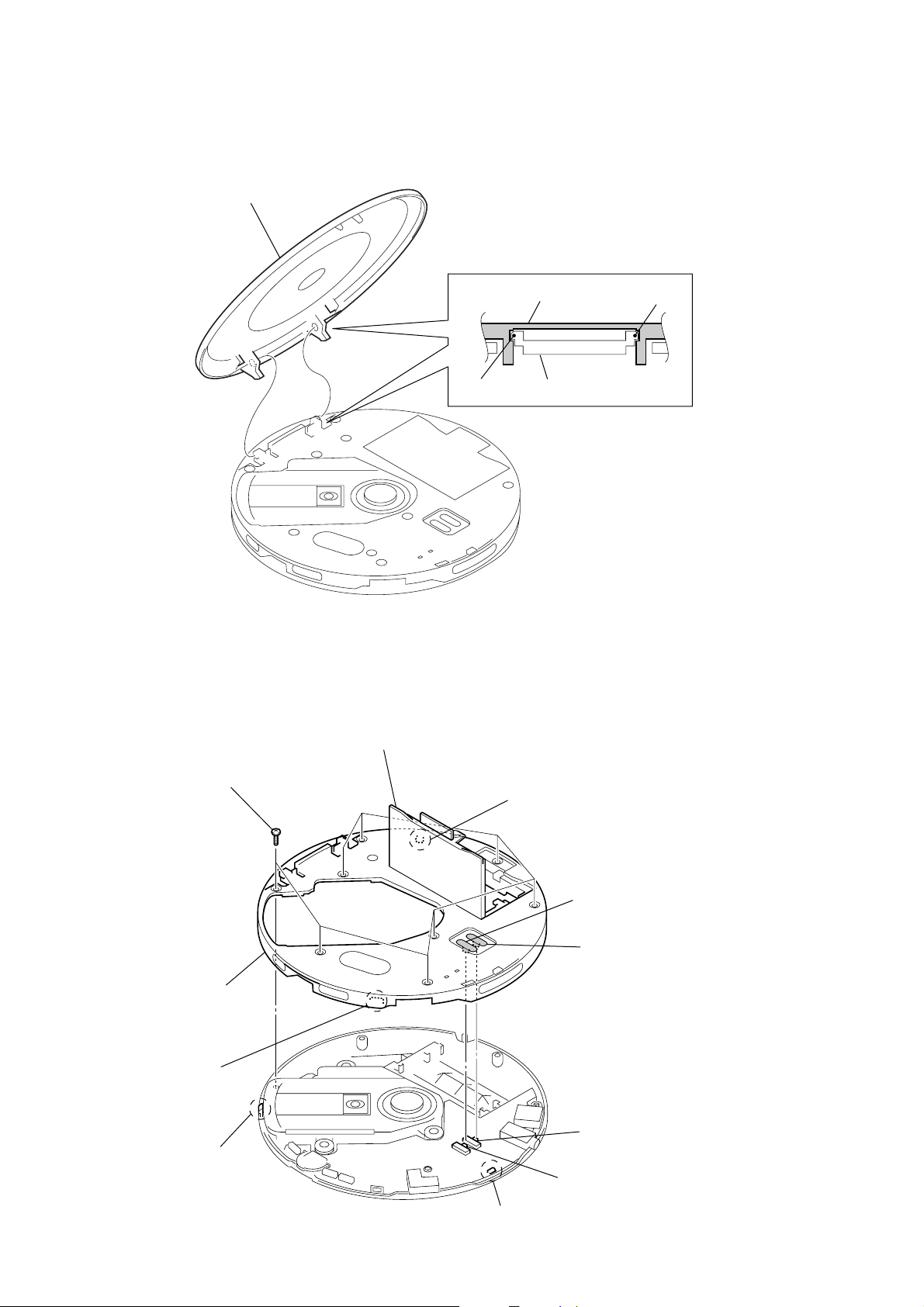

3-3. LID (UPPER) SUB ASSY

3

lid upper sub assy

3-4. CABINET (FRONT) BLOCK

1

Open the lid battery case.

lid upper sub assy

1

boss

2

cabinet front sub assy

boss

2

eight screws (B2)

7

cabinet (front) section

5

claw

4

claw

6

3

claw

knob (AVLS)

knob (G-PRO)

Note : On installation of cabinet (front) assy,

adjust the position of switch (S802)

and knob (G-PRO),

switch (S808) and knob (AVLS).

S802

S808

claw

8

Page 9

3-5. OPTICAL PICK-UP SECTION (CDM-3325ER), MAIN BOARD

qa

main board

4

spacer

6

flexible board

(CN501)

9

insulator

0

optical pick-up section

(CDM-3325ER)

1

screw (B) (1.4)

2

Hold up both the main board and the optical

pick-up section at once, and remove them

form the cabinet (lower) sub assy.

Note : Handle the flexible board with care when

you hold up the optical pick-up section.

Note : On installation of main board,

adjust the position of switch

(S803) and knob (hold).

7

insulator

8

insulator

5

two connectors

(CN502, 503)

3

terminal board

(relay), battery

knob (hold)

S803

D-EJ785

9

Page 10

D-EJ785

p

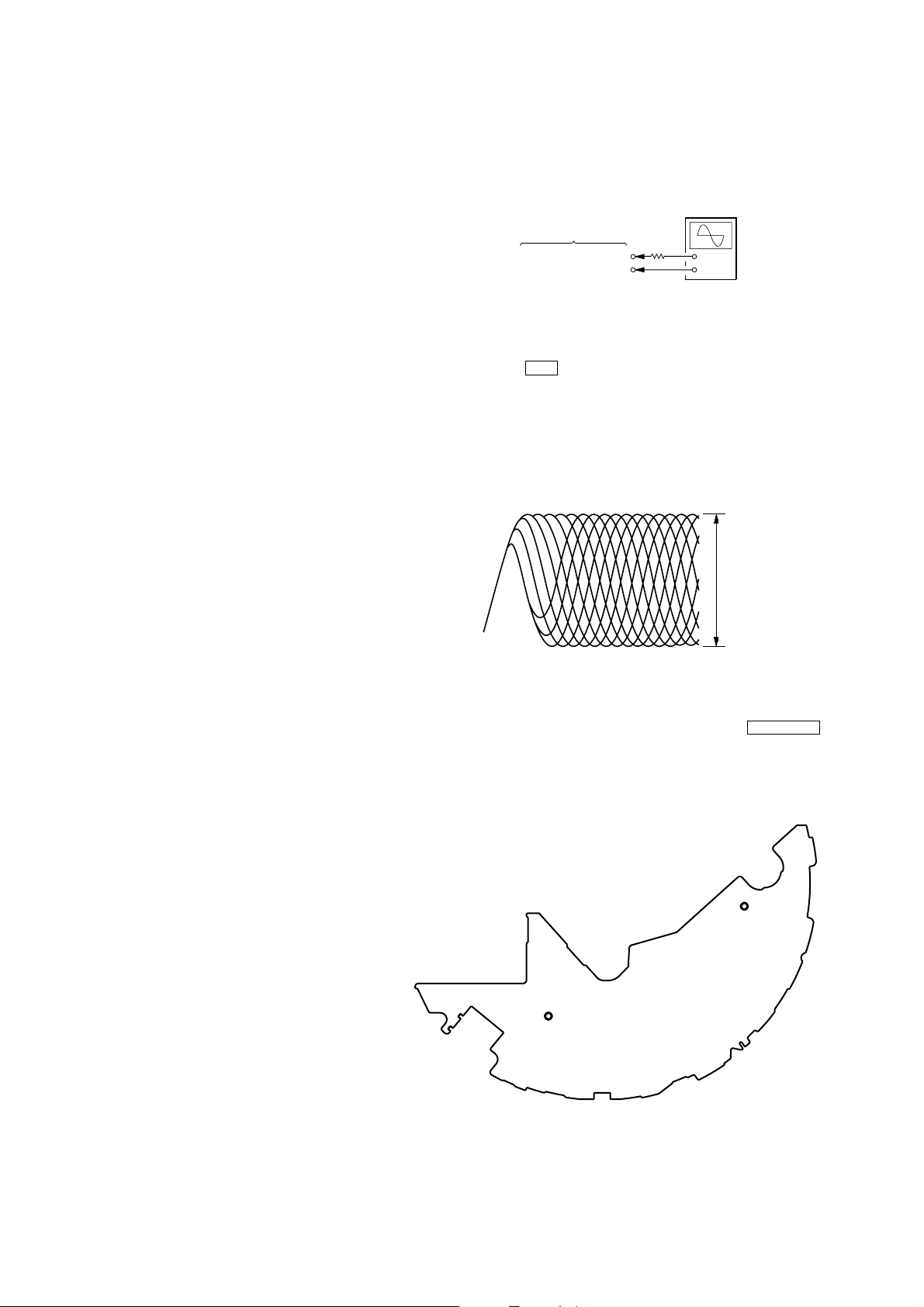

SECTION 4

ELECTRICAL CHECK

The CD section adjustments are done automatically in this set.

In case of operation check, confirm that focus bias.

PRECAUTIONS FOR CHECK

1. Perform adjustment in the order given.

2. Use YEDS-18 disc (P art No.: 3-702-101-01) unless otherwise

indicated.

3. Power supply voltage requirement: DC4.5 V in DC IN jack.

(J401)

VOLUME : Minimum

[AVLS] switch : NORM

[HOLD] switch : OFF

[G-PROTECTION] switch : ON

FOCUS BIAS CHECK

Condition:

• Hold the set in horizontal state.

Connection:

MAIN board

TP630 (RF)

TP421 (MAINGND)

2 k

Ω

oscilloscope

(AC range)

+

–

Procedure:

1. Connect the oscilloscope to the test points TP630 (RF) and

TP421 (MAINGND) on the MAIN board.

2. Set a disc. (YEDS-18)

3. Press the B X key on the set.

4. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

RF Signal reference Waveform (Eye Pattern)

VOLT/DIV : 100 mV (With the 10:1 probe in use)

TIME/DIV : 500 ns

RF level

0.45 to 0.65 Vp-

To watch the eye pattern, set the oscilloscope to AC range and

increase the vertical sensitivity of the oscilloscope for easy watching.

5. Stop revolving of the disc motor by pressing the CHARGE x

key on the set.

Connecting and Checking Location:

– MAIN Board (Conducter Side) –

TP630

(RF)

10

TP421

(MAINGND)

Page 11

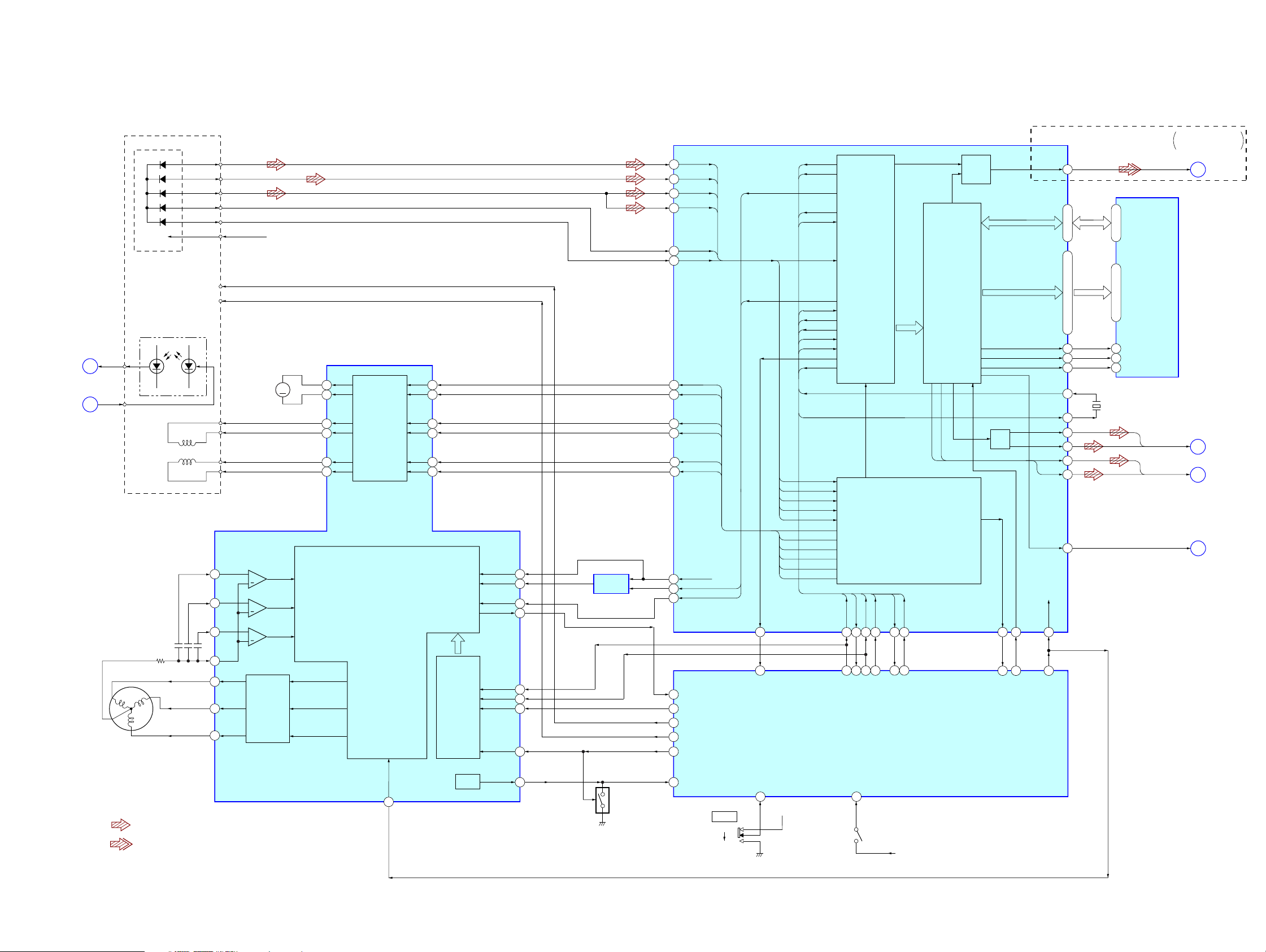

5-1. BLOCK DIAGRAM – MAIN Section –

DETECTOR

A

(Page 12)

B

(Page 12)

OPTICAL PICK-UP BLOCK

LASER DIODE

PD

LD

(FOCUS)

2-AXIS

DEVICE

(TRACKING)

M902

(SPINDLE)

V

U

W

A

B

RF

E

F

VCC

DAX-25E

PD

OPSTB

OPGSW

LD

A

B

RF

E

F

VCC2

M901

M

(SLED)

U1

79

78

77

80

2

4

6

V1

W1

COM

U OUT

V OUT

W OUT

+

+

+

PREDRIVER

SECTION 5

DIAGRAMS

FOCUS/TRACKING COIL DRIVER

SLED/SPINDLE MOTOR DRIVER

IC401 (1/2)

FO1

52

RO1

50

FO2

48

46

44

42

RO2

H BRIDGE DRIVER

FO3

RO3

CONTROLLER,

CONTROL

CIRCUIT

RI1

RI2

RI3

D-EJ785

RF AMP,

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR,

D-RAM CONTROLLER

IC601

A

92

B

91

RFDC

88

RFAC

84

E

89

F

90

FI1

56

55

FI2

58

57

FI3

60

59

SYNC

34

CPU

INTERFACE

PWM

BRK

DATA

CLOCK

LATCH

WAKEUP

72

70

FG

74

39

38

40

37

BUFFER

IC403

100

99

96

95

98

97

104

103

102

72

75

77

78

66

SFDR

SRDR

FFDR

FRDR

TFDR

TRDR

C176

MDP

MDS

FG/FGSEL

XPOWLT

HG XSTB

HG GUP

XWAKE

SCOR

27

SCOR

WDCK

WFCK

MDS

XTAO

XTAI

RFAC

XSOE

SENS

R4M

XLAT

CLOK

SCOR

SDTO

RFDC

SFDR

SRDR

FFDR

FRDR

TFDR

TRDR

SIGNAL

PROCESSOR

MDP

E

F

B

A

SDTD

SENS

161415181711

MSDTO

SYSTEM CONTROLLER

IC801 (1/2)

BLOCK

CLOCK

MSDTI

XLAT

MSCK

SYSM

25

13

AMUTE

DOUT

62

D0-D3

4, 3, 6, 5

A0-A9

116 – 113, 17 – 15, 13 – 11

XRAS

1

XWE

2

XCAS

9

XTAI

47

XTAO

48

AOUT1

51

AOUT2

56

HPL

43

HPR

44

LRMU

61

XRST

28

79

XRST

1, 2, 24, 25

9 – 12, 14 – 18, 5

4

XRAS

3

XWE

23

XCAS

X601

16.9344MHz

D1 – D4A0 – A9

D-RAM

IC603

DIGITAL

OUT

MEMORY

CONTROLLER,

BUS BOOST

BLOCK

LPF

SERVO

BLOCK

XSOE

R4M

242232232021

2

XIN

XLAT

XSOE

FOK

FOK

65

9

FOK

AEP, UK,

Eeast European models

DOUT

C

AOUTL,

AOUTR

D

(Page 12)

HPL,

HPR

E

(Page 12)

LRMU

F

(Page 12)

(Page 12)

• SIGNAL PATH

: CD PLAY (ANALOG OUT)

: CD PLAY (OPTICAL OUT)

XRST

36

RESET

RSTOUT

RESET

35

WAKEUP

SWITCH

Q402

8

S803

HOLD

HOLD

OFF

40

HOLD

VCPU B+

CLOSE

28

S801

CD LID OPEN

()

DETECT

VCPU B+

1111

Page 12

D-EJ785

5-2. BLOCK DIAGRAM – AUDIO/POWER SUPPLY Section –

(Page 11)

(Page 11)

(Page 11)

(Page 11)

DOUT

C

AEP, UK,

Eeast European models

D

E

LRMU

F

HPL

HPR

AOUTL

AOUTR

MUTING

LINE MUTING

CONTROL SWITCH

AEP, UK,

Eeast European models

Q303

Q302

13

14

11

8

9

LIN

RIN

MUTE

PWRSW

BEEP

HEADPHONE AMP

IC301

MUTE SW

STANDBY

SW

BEEP

LOUT

ROUT

J301

AEP, UK,

VCC3 B+

6

4

B+ SWITCH

Q601

VCPU B+

OPTICAL

TRANSCEIVER

(LINE OUT JACK)

J302

i

VCPU 2V

6

4

TSB

3

RMKEY

REMO TU

2

GND

1

Eeast European models

LINE OUT

(OPTICAL)

LINE OUT

EXCEPT AEP, UK,

Eeast European models

• SIGNAL PATH

: CD PLAY (ANALOG OUT)

: CD PLAY (OPTICAL OUT)

S808

AVLS

LIMIT

NORM

73 24 74 30 26

DOUTON

AVLS

39

VCPU B+

SYSTEM CONTROLLER

IC801(2/2)

S802

G-PROTECTION

ON

OFF

38

AD SEL

ESP

VCPU B+

BEEP

PWRSW

AD KEY

25

S804, 805 S806, 807

AD KEY2

23

LEDDISP

80

D803

CHARGE

AD DCINMNT

AD BATMNT21AD CHGMNT70AGCPWM

27

22

31

TSB

12

REMO TU

AD RMKEY

VCC1 B+

VCC2 B+

VCC3 B+

VCPU B+

POWER CONTROL

IC401 (2/2)

L401

10

17

18

11

19

24

67

66

22 23

ssw

VCC1

VCC2

VCC3

VCPU

SEP

CHGMNT

VMMNT

SEO

POWER CONTROL

VCC0_O

SEM

VCC0_I

AUTOMATIC

Q420

16

20

25

STG

8

LG

12

VIN

68

BTM1

69

BTM2

63

DET

67

CHGB

62

REGB

61

DCIN

L420

B+ SWITCH

Q404

L403

CHARGE ON

SWITCH

Q403

CHARGE

CONTROL

Q405

VIN B+

CHARGE

B+ SWITCH

Q401

D400

B+ SWITCH

Q412

LD

(Page 11)

B

PD

(Page 11)

A

RECHARGEABLE

BATTERY

NH-7WMAA

2PCS. 2.4V

OR

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION LR6)

2PCS. 3V

J401

L412D401

L411

DC IN 4.5V

–

+

1212

Page 13

D-EJ785

5-3. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Component Side) the parts face are indicated.

• MAIN board is multi-layer printed board. Howe ver , the patterns

of intermediate-layer have not been included in the diagram.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

•%: indicates tolerance.

• C : panel designation.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

• A : B+ Line.

•Total current is measured with CD installed.

•Power voltage is dc 4.5 V and f ed with regulated dc power

supply from DC IN 4.5V jack (J401).

•Voltages and wavef orms are dc with respect to ground in

CD play mode.

no mark : CD PLAY

•Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD PLAY (ANALOG OUT)

c : CD PLAY (DIGITAL OUT)

•Abbreviation

EE : East European model

4

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro

spécifié.

W or less unless otherwise

•Waveforms

1 IC601 w; (CLOCK)

950 ns

2 IC601 es (R4M)

236 ns

3 IC601 rk (XTAO)

2.1 Vp-p

2.3 Vp-p

6 IC401 ek (CLOCK)

2.1 Vp-p

950 ns

7 IC801 2 (XIN)

2.2 Vp-p

236 ns

8 IC801 qk (MSCK)

59.1 ns

4 IC601 if (RFAC) (CD play mode)

5 IC601 ik (RFDC) (CD play mode)

2.1 Vp-p

450 to 650

mVp-p

400 to 600

mVp-p

2.1 Vp-p

950 ns

1313

Page 14

D-EJ785

• Semiconductor

Location

Ref. No. Location

D302 G-8

D401 F-8

D501 D-8

D502 D-8

D803 H-1

D805 E-6

IC601 D-3

IC801 E-5

Q401 E-8

Q403 D-8

Q404 G-5

Q405 F-8

Q420 E-6

VDR303 F-3

5-4. PRINTED WIRING BOARD – MAIN Board (Component Side) – :Uses unleaded solder.

1 2 3 4 5 6 7 8 9 10

(COMPONENT SIDE)

A

S805

CHARGE

D803

CHARGE

MAIN BOARD

S805

D803

R837

B

S804

S804

C

D

E

F

G

S807

−

VOL

S807

S806

C628

R626

C609

IC601

S806

C605

+

R612

C607

C606

L603

R613

C111

C610

R614

R313

C604

L604

R111

L110

L310

KK

VDR303

A

GND

J302

L606

R625

C354

VDR102

R627

L

C630

C621

R624

C615

L605

C601

C620

X601

R

R623

R622

R618

R619

TAP904

C211

VDR202

R353

C602

R601

R620

C616

R832

R315

C312

C619

C618

R621

C617

C818

R211

L210

R316

VDR304

C827

R825

IC801

L401

R830

C822

R817

C402

C812

C811

C301

L319

C815

R818

L801

R401

TAP802

(OPEN)

R819

R836

C820

L402

Q404

S801

CD LID

OPEN

DETECT

M902

(SPINDLE)

U

N

VW

14

C409

TAP902

R422

Q420

R420

R402

R421

C819

TAP402

D805

C424

L420

R835

S808

AVLS

C410

R411

NORM

LIMIT

L430

R839

C430

G-PROTECTION

C401

C413

C408

M901

(SLED)

M

−+

12

14

CN502

S802

OFF

ON

C101

CN503

R106

R101

12

TAP801

(TEST)

C202

L301

Q403

L101

C102

BT401

D501

R447

R448

Q401

D401

D302

C453

L201

D502

Q405

BT400 BT402

R410

RECHARGEABLE

BATTERY

NH-7WMAA

2PCS. 2.4V

OR

DRY BATTERY

SIZE"AA"

(IEC DESIGNATION)

2PCS. 3V

1-686-249-

J401

DC IN 4.5V

−

+

11

(11)

1414

Page 15

5-5. PRINTED WIRING BOARD – MAIN Board (Conductor Side) – :Uses unleaded solder.

D-EJ785

A

B

C

D

E

F

G

1 2 3 4 5 6 7 8 9 10

R826

R816

R827

R814

R828

R829

MAIN BOARD

LINE OUT

(OPTICAL)

(AEP, UK, EE)

LINE OUT

EXCEPT AEP,

(CONDUCTOR SIDE)

D403

D408

J301

UK, EE

D404

L412

D400

VDR409

C451

L411

R430

EXCEPT AEP,

R809

VDR201

R434

R433

Q412

TP421

(MAIN GND)

UK, EE

R823

VDR101

C816

D305

1C

Q301

1E 1B 2C

R446

C445

54

C444

R888

R824

2B

1C

1E 1B 2C

2B

2E

D407

R429

R441

C447

13

L320

C201

R206

R201

2E

Q302

R105

R205

C454

D406

R403

TAP461

IC403

R436

S803

HOLD

ON OFF

R451

R452

C433

C431

L601

C432

C435

R455

C434

L602

C436

C411

R457

R437

TAP401

(AEP, UK, EE)

L403

C403

Q601

R630

L410

C406

C808

C807

L409

IC401

C421

C407

R821

R813

C813

OPTICAL

PICK-UP

BLOCK

DAX-25E

TAP905

TAP903

C817

C814

R822

C810

R406

Q402

C419

C405

C404

C805

C809

R408

C416

C804

C417

R1

R615

C418

C414

TAP901

R820

D410

R414

R2

C627

C626

C353

D303

1-686-249-

C357

C612

C352

D301

D306

R635

C633

TAP302

C355

R354

CN501

R636

C611

C361

11

(11)

C502

R361

C631

C629

C632

R633

R634

C613

IC301

C358

C351

C360

R360

R632

R637

R210

C210

R224

TAP301

R631

TP630

(RF)

C635

R639

C634

C110

C224

R212

R110

R223

R604

R225

R112

C625

IC603

R125

C123

R124

C222

C124

C223

VDR800

C122

R123

R833

VDR801

R834

R811

• Semiconductor

Location

Ref. No. Location

D301 F-8

D303 G-8

D305 G-4

D306 F-8

D400 E-3

D403 E-2

D404 F-3

D406 E-5

D407 E-5

D408 E-2

D410 F-8

R810

IC301 E-9

IC401 F-7

IC403 F-5

IC603 D-10

Q301 G-4

Q302 G-4

Q402 E-7

Q412 E-4

Q601 E-6

1515

Page 16

D-EJ785

5-6. SCHEMATIC DIAGRAM – MAIN Board (1/3) – • See page 13 for Waveforms. • See page 19 for IC Block Diagram.

M902

(SPINDLE)

U

N

WV

M901

(SLED)

PDLD

(FOCUS)

+

-

(TRACKING)

+

-

2-AX1S

DEVICE

(1/3)

CN502

4P

D501

MM3Z5V1T1

DETECTOR

CN503

2P

CN501

A

B

RF

VCC

E

F

15P

+

-

D502

MM3Z5V1T1

OPGSW

OPSTB

COM

W

V

U

S+

S-

C615

0.1

A

B

RF

LD

PD

E

F

F+

T-

T+

F-

C617

4700p

C618

0.47

R621

1M

C619

0.47

C502

4.7

TP630

R631

(RF)

22k

RF

C631

22p

47k

R632

R633

22k

E

R635

22k

F

R637

22k

B

R639

22k

A

C620

100p

C629

2200p

R634

100k

C632

C633 R636

470p 100k

R1 R2

DOUT

FOK

R620

10k

R622

R623

R624

4V

C602

470p

00

MU0

R619R618C616

2.2k2.2k0.1

220k

10k

470k

C630R627

2200p0

R601C601

47k47

0.1

C634

470p

C635

470p

L601

0

C612

C611

22

0.1

6.3V

1

S

S

V

LRMU

DOUT

ATSK XRST_I

RFDC

E

F

B

FFDR

TRDR

FRDR

L606

10µH

C613

R615

0.1

22

L605

0

X601

C621

16.9344MHz

22p

R625

C626

2.2

C627

2.2

ST

TE

TES1

C

V

A

SFDR

SRDR

TFDR

0

RF AMP,

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR,

D-RAM CONTROLLER

IC601

CXD3039AR

DS

DP

SYNC

M

M

C604

10

4V

R604

C603

0.1

4.7

C201

4.7

C101

C110

2.2

C210

2.2

∗

∗

22k

22k

R210

R110

R112

R212

470p

C224

LIN

RIN

BEEP

PWRSW

TAP302

C351

0.22

MU1

MU0

C352

22

6.3V

BIAS0

BIAS1

C355

470p

C353

22

6.3V

DOUTON

DOUT

D-RAM

10µH

C606

0.1

R613

R223

R224

4.7k

R123

4.7k

470p

C222

C123 C223

470p 470p

C605

0.47

0

L320

0

L602

2.2k

R124

2.2k

470p

C124

XRST

R612

100k

SCOR

AMUTE

XSOE

XLAT

MSDTI

MSDTO

MSCK

C609

100p

L603

470p

C122

R4M

A4

A5

A6

A7

A8

A9

XCAS

D2

D3

D0

D1

XWE

XRAS

C625

C628

10

2.2

4V

L604

0

R614 C607

C610

220 47p 2.2k

47

4V

R225

10k

R125

10k

R4M

VSS0A11

XWRE

XQOK

PWMI

D1

XWE

XRAS

A12

A13

R626

0

0

A0

A1

A2

A3

BIAS0

LIN

RIN

HEADPHONE AMP

R630

0

(AEP,UK,EE)

VCC

A4

A4

MU0

∗

4.7k (AEP,UK,EE)

100k

TAP301

A1

A2

A3

A3

A2

A1

A7

A6

A5

A7

A6

A5

R106

100k

R110,220

(EXCEPT AEP,UK,EE)

AN17881F-E1

GND

BEEP

MUTE_

MUTE

PWRSW

BIAS

BIAS_IN

A0

A0

IC603

41SV4105

A8

A8

IC301

τ

R206

100k

LINE MUTING

CONTROL SWITCH

LINRIN

PGND

LOUT

VREF

ROUT

VCC

OCLSW

RFIN

DTA143EUA

B+ SWITCH

A9

A9

XOE

-1 -2

Q302

XP4312

R809

∗

(EXCEPT AEP,UK,EE)

0

(AEP,UK,EE)

47k

C358

2200p

R360

R361

0

0

C361

C360

2200p

R354

0

C354

100 6.3V

Q601

E

D0

D1

XW

XRAS

D1

D0

XWE

XRAS

XCAS

D3

VSS

D2

2

D3

D

XCAS

2200p

220 4V

C357

22

6.3V

R205

1k

-1 -2

R201

220

R101

C202

220

1000p

L301

4.7µH

D302

R313

0

C111

C211

220

4V

R353

4.7

MM3Z5V1T1

R824

470k

(EXCEPT AEP,UK,EE)

R111

470

R211

470

D305

MM3Z5V1T1

100k

4.7µH

4.7µH 4.7µH

D306

MM3Z5V1T1

R823

47k

L310

L110

Q301

XP4501

MUTING

C102

1000p

∗

(AEP,UK,EE)

(EXCEPT AEP,UK,EE)

C312

1000p

R315

10k

C301

10

4V

R316

1k

∗

L210

D301

MM3Z5V1T1

R823

L201

4.7µH

L101

4.7µH

R105

1k

R809

∗

C816

100p

VDR202VDR102

VDR303

UMZ-8.2T-T106

D303

MM3Z5V1T1

L319

0

VDR304

VDR201

VDR101

J301

LINE OUT

EXCEPT

AEP,UK,EE

LINE OUT

(OPTICAL)

(AEP,UK,EE)

J302

A1

A2

A3

A4

A5

1

(Page 17) (Page 18)

A6

A7

A8

A9

B1

B2

2

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

B3

B4

B5

B6

1616

Page 17

5-7. SCHEMATIC DIAGRAM – MAIN Board (2/3) – • See page 13 for Waveform. • See page 19 for IC Block Diagram.

D-EJ785

A4

5

A

(Page 16)

7

A6

A

9

A8

A

1

2

A1

A

3

A

(2/3)

FFDR

R429

D406

47k

MA111-TX

R441

R410

470

2SC4116GL

CHARGE CONTROL

Q405

470k

C444

4.7

1SS355

D401

Q403

2SD1781K

CHARGE ON

SWITCH

BUFFER

IC403

TC75S57F

TAP461

MDP1

C447

0.1

Q401

2SB16990

B+ SWITCH

D400

MA2YD2300L

R446

100

R433

R434

C445

R403

0

MDP

22k

22k

47p

MA2ZD1400

D407

SYNC

CHGMNT

R437

0.022

0.022

0

C431

10000p

C432

10000p

C433

10000p

MDS

C434

1

FG

C435

C436

COM

R436

47k

TFDR

TRDR

FRDR

SFDR

S+

SRDR

FOCUS/TRACKING COIL DRIVER,

SLED/SPINDLE MOTOR DRIVER,

POWER CONTROL

IC401

BH6580KVT

F-

F+

S-

T-

T+

C417

C416

C414 R414

2200p 10k

C413

220

6.3V

C820

0.1

1000p

0.047

AGCPWM

XPOWLT

MSDTO

XWAKE

RESET

RESET

MSCK

XRST

SYNC

XWAKE

LD

PD

L409L410

10µH10µH

R422

2.2k

R411

0

R406

100k

C418

D410

0.22

1SS355

C419

1

Q402

DTC143TUA

WAKEUP SWITCH

R408

470k

TAP402

LD

R421R402

100k4.7

C409

10

4V

C1

3

RECHARGEABLE

BATTERY

NC-7WMAA

2PCS. 2.4V

OR

DRY BATTERY

SIZE"AA"

(IEC DESIGNATION LR6)

2PCS. 3V

DC IN 4.5V

(Page 18)

Q420

2SB16790

L420R420

10µH

TAP901

R820

0

C2

C3

100µH

R447

R448

2.2

1

U

BT400

B+

BT401

BCENTER

BT402

B-

R430

Q412

470

2SB169300LSO

B+ SWITCH

C451

4700p

VDR409

J401

L412

4.7µH

4.7µH

TP421

MAINGND

L411

1

C453

1T1

2300L

04

4

D

2YD

A

M

1T1

Z5V

403

408

3

3Z5V

D

D

M

M

M

M

R457

0

R451

220k

R452

C424

0.1

C454

0.022

47k

R455

L430

10µH

6.3V

220

01

C4

C410

0.1

22k

V

220µH

L403

L401

W

C430

220

6.3V

6V

1

V

4

4.7

2.2

47

3

11

40

406

C

C4

C

DCINMNT

BATTMNT

L402

47µH

P401

A

T

Q404

2SB16790

B+ SWITCH

6.3V

4V

4V

4V

00

0.1

1

8

402

C40

C

0.1

47

47

47

7

5

421

404

40

40

C

C

C

C

R401

100k

2.2

AUTOMATIC

POWER CONTROL

1717

Page 18

D-EJ785

5-8. SCHEMATIC DIAGRAM – MAIN Board (3/3) – • See page 13 for Waveforms.

3

(Page 17)

9

EG

S

AD_KEY2

E_O

O

S

X

XSOE

XLAT

11

10

G

EG

E

S

S

TI_I

T_O

D

A

S

L

M

X

TI

SD

M

(Page 16)

2

3

1

1

G

EG

E

S

S

XSTAND_ON_I

TEXTSKIP_I

AD_DCINMNT

O

_

_O

TO

K

D

C

S

S

M

M

SCK

SDTO

M

M

SEG15

14

EG

S

RCHG2/1_I

DIG_TU_I

XEXBATT_I

TSB_I/O

BEEP_O

AD_RMKEY

AD_KEY

AD_SEL

D

_A

U

P

C

V

HOLD_I

AVLS_I

ESP_I

CLOSE

D

A

F_

E

R

V

B3

R839

R835

B4

B5

B6

22k (EXCEPT AEP, UK, EE)

220k (AEP, UK, EE)

∗

R821

∗

R822

100k

S803

S804

HOLD

HOLD

OFF

S808

AVLS

LIMIT

NORM

G-PROTECTION

S801

CD LID OPEN

DETECT

S802

ON

OFF

C822

1000p

C810

C815 R818

4700p 220k

VDR800

S805

C809

4700p

4700p

R837

S807

R811R810

10k4.7k

R827

R828 R814

2.2k 4.7k

R829

0

2.2k

VOL -

R834

22k

S806

VOL +

VDR801

1k

10k

10k

TAP801

DCINMNT

TEST

BATTMNT

CHGMNT

HOLD

AVLS

G-PRO

R817

R830

R836

R819

BEEP

10k

10k

10k

1M

C813

4700p

LED

C812

4700p

R833

22k

R826

10k

SML-310LTT

R816

100

C811

D803

CHARGE

CHARGE

4700p

HOLD

AVLS

G-PRO

TAP802

OPEN

B2

R888 R821

0

C817

4700p

C819

1000p

PPG

R813

100k

C807C808

C814

100p

L801

0

0.10.1

2

B1

(3/3)

C1

C2

4

7

6

5

G

E

S

IC801

T5AJ4

_I

K

FO

8

EG

EG

EG

EG

S

S

S

S

AD_BATMNT

AD_CHGMNT

_I

O

O

_

_TU

W

_I

S

TE_

O

R

R

U

O

EM

C

M

W

A

S

P

R

TE

U

SCOR

AM

XWAKE

AGCPWM

FG

DOUTON

PWRSW

XPOWLT

OPSTB

OPGSW

LED

XRST

R4M

C827

0

1

M

M

O

O

C

C

TAP905

10

4V

R825

22k

TAP904

V3

V2

V1

C1

C0

XWAKE_O

PGMSO_0

PGMSI_I

PGMSCK_O VDD2

AGCPWM_O

IR_RMC_I

FG_I/FGSEL_I

DOUTON_O

PWRSW

XPOWLT_O

CHGGND_SL_I

HG_XSTB_O

HG_GUP_O

XRST_O

LEDDISP_O

D

N

IN

X

G

TAP902

D805

MA2ZD1400

1

3

2

0

3

2

G

G

G

M

M

E

EG

E

E

O

O

S

S

S

S

C

C

SYSTEM CONTROLLER

_I

EL

S

_

T

1

M

T

U

O

ES

T

X

RESET

ET

A

D

S

C

R

E

D

N

R

V

D

10k

0.1

R832

C805

FOK

C804

2.2

C3

C818

0.1

1818

Page 19

• IC Block Diagrams

IC301 AN17881F-E1

D-EJ785

LIN

1RFIN

C-AMP

2OCL SW

SWITCH

3VCC

4ROUT

5VREF

6LOUT

7PGND

8

+

−

+

−

+

−

BIAS

ALC

STANDBY

SWITCH

MUTING

SWITCH

BEEP

16 BIAS IN

15 BIAS

14 PWRSW

13 BIAS IN

12 BIAS

11 BEEP

10 GND

9 RIN

19

Page 20

D-EJ785

IC401 BH6580KV-F

FIN3

55

56

57

58

59

60

DGND

54

FO151PGND1

VM1

53

RIN1

FIN1

RIN2

FIN2

RIN3

VM12

RO1

45

49

5052

4648

VM23

RO2

FO247PGND2

VM3

4244

41

RO3

FO343PGND3

VCC

VCC

CH3

H BRIDGE

−

+

−

+

VG

INTERFACE

RESET

10m SEC

DELAY

−

+

40 LATCH

39 DATA

38 CLOCK

37 WAKEUP

36 XRST

35 RSTOUT

34 SYNC

33 PREGND

32 SOFT

31 SLOW

30 EI

29 EO

28 VCC2NF

27 VCPUNF

−

+

26 PMG

25 STNG

VCC2

24

SEP

61DCIN

HV PROT

VGVCC

CONTROLLER

62REGB

63DET

64DCIN S

65CHGB

66VMMNT

67CHGMNT

68BATM1

69BATM2

70BRK

71PREGND

72PWM

73SOFTPWM

74FG

75CSL2

76CSL1

CHARGE

INPUT

SELECT

SLOPE

SIGNAL

MONITOR

AMP

LEVEL

SHIFT

H BRIDGE

VM

CH1

CH2

H BRIDGE

CLK

SAWGEN

20

COM

+

WI

77

78

VI

79UI

80

−

+

−

+

−

SPVCC

21

U_OUT

LOGIC

VG

PRE DRIVE VG

3

4

5

6

7

V_OUT

SPGND

SPVCC

W_OUT

SPGND

VG

VCC3

VIN

1312

14

DSW

POWGND

1110

9

8

LG

VG

SSW

VCC3

15

USW

VCC4

16

VCC017VCC118VCC2

19

VCPU

VCC

20

VCC

23

SEM

22 SEO

21 GSW

Page 21

5-9. IC PIN FUNCTION DESCRIPTION

•

IC601 CXD3039AR

(RF AMP, DIGITAL SIGNAL PROCESSOR, DIGITAL SERVO PROCESSOR, D-RAM CONTROLLER)

Pin No. Pin Name I/O Description

1 XRAS

2

3 to 6

7 DCLK O

8 DCKE O

9 XCAS O

10

11 to 13 A9 to A7 O

14 DVSS —

15 to 17 A6 to A4 O

18 XRDE I

19

20 CLOCK

21 SDTO

22 SENS

23

24

25 SYSM

26

27

28 XRST I

29 PWMI

30 XQOK

31 XWRE I

32 R4M O System clock output to the system controller

33 VSS0 —

34 SQCK I SQSO readout clock signal input terminal Not used

35 SCLK I SENS serial data read clock signal input terminal Not used

36

37

38

39

40 EXCK O SQSO readout clock signal output terminal Not used

41 XSTL I

42 HVSS —

43 HPL O PDM signal output for L-ch headphone to the headphone amplifier

44 HPR O PDM signal output for R-ch headphone to the headphone amplifier

45

46

47 XTAI I

48 XTAO O

49 XVSS —

50

XWE

D1, D0, D3, D2

WFCK O WFCK signal output terminal Not used

VDD0 — Power supply terminal (digital system) (+2V)

XLAT I Serial data latch pulse signal input from the system controller

XSOE I Serial data output enable signal input from the system controller

WDCK O GRSCOR signal output to the system controller Not used

SCOR O Subcode sync (S0+S1) detection signal output to the system controller

SQSO O CD text data output terminal Not used

XEMP O D-RAM read prohibition signal output terminal Not used

XWIH O D-RAM write prohibition signal output terminal Not used

SBSO O Subcode P to W serial data output terminal Not used

HPVDD — Power supply terminal (for headphone) (+2V)

XVDD — Power supply terminal (for master clock) (+2V)

AVDD1 — Power supply terminal (analog system) (+2.6V)

O Row address strobe signal output to the D-RAM

OData input enable signal output to the D-RAM

I/O

Two-way data bus with the D-RAM

Not used

Not used

Column address strobe signal output to the D-RAM

Address signal output to the D-RAM

Ground terminal (for D-RAM interface)

Address signal output to the D-RAM

D-RAM read enable signal input terminal Not used

I Serial data transfer clock signal input from the system controller

I Serial data input from the system controller

O Serial data output to the system controller

IAnalog muting on/off control signal input from the system controller “H”: muting on

Reset signal input from the system controller “L”: reset

I Spindle motor external control signal input terminal Not used

I Subcode Q OK signal input terminal Not used

D-RAM write enable signal input terminal Not used

Ground terminal (digital system)

Input terminal for the system clock frequency setting

“L”: 16.9344 MHz, “H”: 33.8688MHz (fixed at “L” in this set)

Ground terminal (for headphone)

System clock input terminal (16.9344 MHz)

System clock output terminal (16.9344 MHz)

Ground terminal (for master clock)

D-EJ785

21

Page 22

D-EJ785

Pin No. Pin Name I/O Description

51 AOUT1 O L-ch analog audio signal output

52 VREFL O

53, 54 AVSS1, AVSS2 —

55 VREFR O

56 AOUT2 O R-ch analog audio signal output

57

58 TES1 I Input terminal for the test (normally: fixed at “L”)

59 TEST I Input terminal for the test (normally: fixed at “L”)

60 VSS1 —

61 LRMU

62 DOUT O Digital audio signal output

63 ATSK I/O Input/output terminal for anti-shock Not used

64 DFCT I/O Defect signal input/output terminal Not used

65 FOK O

66 MIRR I/O Defect signal input/output terminal Not used

67 COUT I/O

68

69

70

71

72

73 PCO O

74 FILI I

75 FILO O

76 CLTV I

77 VCTL I

78 VPCO O

79 AVSS3 —

80 ASYO O

81 ASYI I

82 BIAS I

83

84 RFAC I

85

86 IGEN I

87 AVSS0 —

88 RFDC I

89 E I

90 F I

91 B I

92 A I

93 VC I

94 VSS2 —

95 FRDR O

96 FFDR O

AVDD2 — Power supply terminal (analog system) (+2.6V)

C2PO O C2PO signal output terminal Not used

GFS O GFS signal output terminal Not used

XUGF O XUGF signal output terminal Not used

XPCK O XPCK signal output terminal Not used

VDD1 — Power supply terminal (digital system) (+2V)

AVDD3 — Power supply terminal (analog system) (+2V)

AVDD0 — Power supply terminal (analog system) (+2V)

L-ch reference voltage output terminal

Ground terminal (analog system)

R-ch reference voltage output terminal

Ground terminal (digital system)

Muting on/off control signal output to the audio line and the headphone amplifier

O

“H”: muting on

Focus OK signal output to the system controller “L”: NG, “H”: OK

Numbers of track counted signal input/output terminal Not used

Charge pump output for master PLL

Filter input for master PLL

Filter output for master PLL

VCO1 control voltage input terminal for multiplier

VCO2 control voltage input terminal for broad-band EFM PLL

Charge pump output terminal for broad-band EFM PLL

Ground terminal (analog system)

EFM full-swing output terminal

Asymmetry comparator voltage input terminal

Asymmetry circuit constant current input terminal

EFM signal input from the optical pick-up

Stabilized current input for operational amplifiers

Ground terminal (analog system)

RF signal input from the optical pick-up

E signal input from the optical pick-up

F signal input from the optical pick-up

B signal input from the optical pick-up

A signal input from the optical pick-up

Middle point voltage input terminal Not used

Ground terminal (digital system)

Focus servo drive signal (–) output to the power control

Focus servo drive signal (+) output to the power control

22

Page 23

Pin No. Pin Name I/O Description

6

0

97 TRDR O

98 TFDR O

99 SRDR O

100 SFDR O

101 SSTP I

102 MDS O

103 MDP O

104 C176 O

105

106 LRCKO O

107 LRCKI I

108 PCMDO O

109 PCMDI I

110 BCKO O

111 BLKI I

112

113 to 11

117 to 12

VDD2 — Power supply terminal (digital system) (+2V)

DVDD — Power supply terminal (for D-ARM interface) (+2V)

A3 to A0 O

A10 to A13 O

Tracking servo drive signal (–) output to the power control

Tracking servo drive signal (+) output to the power control

Sled servo drive signal (–) output to the power control

Sled servo drive signal (+) output to the power control

Disc inner position detection signal input terminal Not used

Spindle motor drive signal output to the power control

Spindle motor servo control signal output to the power control

176.4 kHz clock signal output to the power control and power control

L/R sampling clock signal (44.1 kHz) output terminal

L/R sampling clock signal (44.1 kHz) input terminal

Serial data output terminal

Serial data input terminal

Bit clock signal (2.8224 MHz) output terminal

Bit clock signal (2.8224 MHz) input terminal

Address signal output to the D-RAM

Address signal output terminal to the D-RAM Not used

D-EJ785

23

Page 24

D-EJ785

• IC801 T5AJ4-SZX1-M0 (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Description

1 GND

2 XIN I System clock input from the CXD3039AR

3

4

5

6

7NC

8 RESET I

9 FOK I

10 PWRSW

11

12

13 AMUTE

14

15

16 MSDTI

17 MSDTO

18 MSCK

19

20

21 AD CHGMNT I

XOUT O High frequency oscillator output terminal Not used

TEST I Test terminal for IC Not used

VDD1 — Power supply terminal (+2V)

DRAM SEL I 4M/64M D-RAM selection signal input terminal

SCOR I Subcode sync (S0+S1) detection signal input from the CXD3039AR

REMO TU I Radio on/off switch signal input from the remote commander (A/D input)

XSOE O Serial data output enable signal output to the CXD3039AR

XLAT O Serial data latch pulse signal output to the CXD3039AR

VCPU — Power supply terminal (+2V)

VREF — Reference voltage (+2V) input terminal

— Ground terminal (digital system)

O Not used

System reset signal input from the power control “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Focus OK signal input from the CXD3039AR “L”: NG, “H”: OK

O Not used

O Analog muting on/off control signal output to the CXD3039AR “H”: muting on

I Serial data input from the CXD3039AR

O Serial data output to the power control and CXD3039AR

O Serial data transfer clock signal output to the power control and CXD3039AR

Battery charge voltage detection signal input from the power control

22 AD BATMNT

23 AD KEY2

24 AD SEL

25

26 AD RMKEY I Key input from the headphone with remote commander (A/D input)

27 AD DCINMNT I

28 CLOSE I

29

30 BEEP O Beep sound output to the headphone amplifier

31 TSB I/O Communication two-way data bus with the headphone with remote commander

32 VDD2 — Power supply terminal (+2V)

33 XEXTBATT I External battery detection signal input terminal Not used

34 TEXTSKIP I Not used “L”: CD-TEXT ENABLED, “H”: CD-TEXT DISABLED

35 DIG TU I Not used

36 RCHG2/1 I Not used

37 XSTAND ON I Charge stand detection signal input terminal Not used

38 ESP I G-PROTECTION switch input terminal “L”: OFF “H”: ON

39 AVLS I AVLS (Automatic Volume Limiter System) switch input terminal “L”: normal, “H”: limit

40 HOLD I HOLD switch input terminal “L”: hold off, “H”: hold on

AD KEY I Key input terminal (A/D input)

PPG

I Battery voltage detection signal input and rechargeable battery use/no use detection signal input

I Key input terminal (A/D input)

I Plug-in detection signal input of LINE OUT (OPTICAL)

DC input voltage detection signal input (A/D input) and DC input jack use/no use detection signal

input

CD lid open/close detection switch input terminal “L”: CD lid open, “H”: CD lid close

The stop status is reset with the falling edge of input signal

O Not used

24

Page 25

Pin No. Pin Name I/O Description

41 to 56 SEG15 to SEG0 O Segment drive signal output terminal for the liquid crystal display Not used

57 to 60 COM3 to COM0 O Common drive signal output terminal for the liquid crystal display Not used

61 to 63 V3 to V1 O Liquid crystal display drive bias control signal output terminal Not used

64, 65 C1, C0 O

66 XWAKE O

67 PGMSO O Not used

68 PGMSI I Not used

69 PGMSCK O Not used

70 AGCPWM O

71 IR RMC I Not used

72 FG/FGSEL O

73 DOUTON O Digital output LED control signal output “L”: ON

74 PWRSW O

75 XPOWLT O

76 CHGGND SL I Ground select signal input terminal Not used

77 HG XCTB O

78 HG GUP O

79 XRST O

80 LEDDISP O

Terminal for doubler circuit capacitor connection to develop liquid crystal display drive voltage

Not used

Wakeup control signal output to the power control (for system standby reset)

“L”: wakeup The stop status is reset with the falling edge of input signal

AGC control pulse signal output to the power control

FG pulse signal input from the spindle motor driver

Power on/off switching signal output to the headphone amplifier

Serial data latch pulse signal output to the power control

Hologram control signal output to the optical pick-up “L”: stop

CD-RW gain control signal output to the optical pick-up “H”: gain up

Reset signal output to the headphone amplifier power control and CXD3039AR

“L”: reset

CHARGE LED drive signal output “L”: LED on

D-EJ785

25

Page 26

D-EJ785

SECTION 6

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

• Abbreviation

EE : East European model

6-1. FRONT CABINET SECTION

6

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Accessories are given in the last of the electrical parts list.

7

The components identified by mark

0 or dotted line with mark 0 are

critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

3

8

2

9

1

10

rear cabinet section

Ref. No. Part No. Description Remark

1 X-3382-629-1 CABINET FRONT SUB ASSY (SILVER)

1 X-3382-630-1 CABINET (FRONT) SUB ASSY (BLUE)

1 X-3382-631-1 CABINET (FRONT) SUB ASSY (ORANGE)

2 3-245-862-31 SCREW (B2), TAPPING

3 3-245-246-01 SPRING (A)

6 3-245-247-01 SPRING (B)

7 X-3383-013-1 LID (UPPER) SUB ASSY (SILVER)

26

Ref. No. Part No. Description Remark

7 X-3383-015-1 LID (UPPER) SUB ASSY (BLUE)

7 X-3383-016-1 LID (UPPER) SUB ASSY (ORANGE)

8 3-245-861-01 LID, BATTERY CASE (SILVER)

8 3-245-861-11 LID BATTERY CASE (BLUE)

8 3-245-861-21 LID BATTERY CASE (ORANGE)

9 3-245-550-21 KNOB, OPEN

10 3-233-998-01 SPRING, TENSION

Page 27

6-2. REAR CABINET SECTION

53

BT400

BT402

D-EJ785

54

CDM-3325ER

56

52

BT401

52

55

57

52

51

Ref. No. Part No. Description Remark

51 X-3382-632-1 CABINET (REAR) SUB ASSY (SILVER)

51 X-3382-633-1 CABINET (REAR) SUB ASSY (BLUE)

51 X-3382-634-1 CABINET (REAR) SUB ASSY (ORANGE)

52 3-245-331-01 INSULATOR

* 53 A-3180-790-A MAIN BOARD, COMPLETE (AEP, UK, EE)

* 53 A-3180-796-A MAIN BOARD, COMPLETE

(EXCEPT AEP, UK, EE)

Ref. No. Part No. Description Remark

54 3-318-201-01 SCREW (B) (1.4X3), TAPPING

55 3-831-441-99 SPACER

56 3-252-725-01 SPACER, CDM

57 3-251-873-01 PSA, FLEXIBLE CABLE

BT400 3-245-555-01 TERMINAL (+), BATTERY

BT401 3-245-557-01 TERMINAL BOARD (RELAY), BATTERY

BT402 3-245-556-01 TERMINAL (-), BATTERY

27

Page 28

D-EJ785

6-3. OPTICAL PICK-UP SECTION

(CDM-3325ER)

104

M902

101

108

102

110

111

103

106

109

107

105

M901

101

Ref. No. Part No. Description Remark

101 3-318-203-61 SCREW (B1.7X4), TAPPING

0102 X-3380-950-1 OPTICAL PICK-UP (DAX-25E)

103 3-221-473-01 COVER, GEAR

104 3-221-472-02 CHASSIS

105 3-221-474-01 SPRING, SLED

106 A-3331-663-A SCREW (FEED) ASSY

107 3-221-268-01 GEAR (B)

28

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark

108 3-221-475-01 SHAFT, STANDARD

109 3-222-298-01 RACK

110 3-222-299-01 SPRING, RACK RETAINER

111 3-348-998-31 SCREW (M1.4X2.5), TAPPING, PAN

M901 A-3174-850-A MOTOR ASSY, SLED

M902 A-3174-848-A MOTOR ASSY, TURN TABLE (SPINDLE)

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

Page 29

D-EJ785

SECTION 7

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

•Abbreviation

AUS: Australian model

CH : Chinese model

CND: Canadian model

EE : East European model

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* A-3180-790-A MAIN BOARD, COMPLETE (AEP, UK, EE)

* A-3180-796-A MAIN BOARD, COMPLETE

*********************

< BATTERY >

BT400 3-245-555-01 TERMINAL (+), BATTERY

BT401 3-245-557-01 TERMINAL (RELAY), BATTERY

BT402 3-245-556-01 TERMINAL (–), BATTERY

< CAPACITOR >

C101 1-117-720-11 CERAMIC CHIP 4.7uF 10V

C102 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C110 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C111 1-125-899-11 TANTALUM CHIP 220uF 20% 4V

C122 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C123 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C124 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C201 1-117-720-11 CERAMIC CHIP 4.7uF 10V

C202 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C210 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C211 1-125-899-11 TANTALUM CHIP 220uF 20% 4V

C222 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C223 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C224 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C301 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C312 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C351 1-115-467-11 CERAMIC CHIP 0.22uF 10% 10V

C352 1-104-852-11 TANTALUM CHIP 22uF 20% 6.3V

C353 1-104-852-11 TANTALUM CHIP 22uF 20% 6.3V

C354 1-128-964-11 TANTALUM CHIP 100uF 20% 6.3V

C355 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C357 1-104-852-11 TANTALUM CHIP 22uF 20% 6.3V

C358 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C360 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C361 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C401 1-128-829-11 TANTALUM CHIP 220uF 20% 6.3V

C402 1-128-964-11 TANTALUM CHIP 100uF 20% 6.3V

C403 1-107-686-11 TANTALUM CHIP 4.7uF 20% 16V

C404 1-110-569-21 TANTALUM CHIP 47uF 20% 4V

C405 1-110-569-21 TANTALUM CHIP 47uF 20% 4V

C406 1-110-569-21 TANTALUM CHIP 47uF 20% 4V

C407 1-110-569-21 TANTALUM CHIP 47uF 20% 4V

C408 1-164-156-11 CERAMIC CHIP 0.1uF 25V

HK : Hong Kong model

JE : Tourist model

KR : Korean model

TW : Taiwan model

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

C409 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C410 1-164-156-11 CERAMIC CHIP 0.1uF 25V

(EXCEPT AEP, UK, EE)

C411 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C413 1-128-829-11 TANTALUM CHIP 220uF 20% 6.3V

C414 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C416 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C417 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C418 1-115-467-11 CERAMIC CHIP 0.22uF 10% 10V

C419 1-115-156-11 CERAMIC CHIP 1uF 10V

C421 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C424 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C430 1-128-829-11 TANTALUM CHIP 220uF 20% 6.3V

C431 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C432 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C433 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C434 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C435 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C436 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C444 1-117-720-11 CERAMIC CHIP 4.7uF 10V

C445 1-162-923-11 CERAMIC CHIP 47PF 5% 50V

C447 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C451 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C453 1-115-156-11 CERAMIC CHIP 1uF 10V

C454 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C502 1-117-720-11 CERAMIC CHIP 4.7uF 10V

C601 1-110-569-21 TANTALUM CHIP 47uF 20% 4V

C602 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C603 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C604 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C605 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C606 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C607 1-162-923-11 CERAMIC CHIP 47PF 5% 50V

C609 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C610 1-110-569-21 TANTALUM CHIP 47uF 20% 4V

C611 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C612 1-104-852-11 TANTALUM CHIP 22uF 20% 6.3V

C613 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C615 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C616 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C617 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C618 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C619 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C620 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

ELECTRICAL PARTS LIST

MAIN

29

Page 30

D-EJ785

MAIN

Ref. No. Part No. Description Remark

C621 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C625 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C626 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C627 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C628 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C629 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C630 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C631 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C632 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C633 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C634 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C635 1-164-315-11 CERAMIC CHIP 470PF 5% 50V

C804 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C805 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C807 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C808 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C809 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C810 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C811 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C812 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C813 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C814 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C815 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C816 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

Ref. No. Part No. Description Remark

IC401 6-703-034-01 IC BH6580KV-F

IC403 8-759-594-55 IC TC75S57F (TE85R)

IC601 8-752-420-71 IC CXD3039AR

IC603 6-703-608-01 IC 41SV4105-100TG

IC801 6-802-362-01 IC T5AJ4-SZX1-M0

< JACK >

J301 1-816-884-11 JACK, OPTICAL OUT (AEP, UK, EE)

(LINE OUT (OPTICAL))

J301 1-816-931-11 JACK (EXCEPT AEP, UK, EE) (LINE OUT)

J302 1-816-954-21 JACK (i)

J401 1-793-156-31 JACK, DC (DC IN 4.5V)

< COIL >

L101 1-400-202-21 INDUCTOR 4.7uH

L110 1-400-202-21 INDUCTOR 4.7uH

L201 1-400-202-21 INDUCTOR 4.7uH

L210 1-400-202-21 INDUCTOR 4.7uH

L301 1-400-202-21 INDUCTOR 4.7uH

L310 1-400-202-21 INDUCTOR 4.7uH

L319 1-216-295-00 SHORT CHIP 0

L320 1-216-295-00 SHORT CHIP 0

L401 1-414-404-41 INDUCTOR 100uH

L402 1-419-403-41 INDUCTOR 47uH

C817 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C818 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C819 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C820 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C822 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C827 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

< CONNECTOR >

* CN501 1-815-832-21 CONNECTOR, FFC/FPC (ZIF) 15P

* CN502 1-785-877-21 HOUSING, CONNECTOR 4P

CN503 1-784-342-21 HOUSING, CONNECTOR 2P

< DIODE >

D301 8-719-084-06 DIODE MM3Z5VT1

D302 8-719-084-06 DIODE MM3Z5VT1

D303 8-719-084-06 DIODE MM3Z5VT1

D305 8-719-084-06 DIODE MM3Z5VT1

D306 8-719-084-06 DIODE MM3Z5VT1

D400 8-719-085-43 DIODE MA2YD2300LS0

D401 8-719-988-61 DIODE 1SS355TE-17

D403 8-719-084-06 DIODE MM3Z5VT1

D404 8-719-085-43 DIODE MA2YD2300LS0

D406 8-719-404-50 DIODE MA111-TX

D407 8-719-072-70 DIODE MA2ZD14001S0

D408 8-719-084-06 DIODE MM3Z5VT1

D410 8-719-988-61 DIODE 1SS355TE-17

D501 8-719-084-06 DIODE MM3Z5VT1

D502 8-719-084-06 DIODE MM3Z5VT1

L403 1-414-406-11 INDUCTOR 220uH

L409 1-469-967-21 INDUCTOR 10uH

L410 1-469-967-21 INDUCTOR 10uH

L411 1-412-056-11 INDUCTOR 4.7uH

L412 1-412-056-11 INDUCTOR 4.7uH

L420 1-469-967-21 INDUCTOR 10uH

L430 1-469-967-21 INDUCTOR 10uH

L601 1-216-295-00 SHORT CHIP 0

L602 1-216-295-00 SHORT CHIP 0

L603 1-414-754-11 INDUCTOR 10uH

L604 1-216-295-00 SHORT CHIP 0

L605 1-216-295-00 SHORT CHIP 0

L606 1-469-967-21 INDUCTOR 10uH

L801 1-216-864-11 METAL CHIP 0 5% 1/10W

< TRANSISTOR >

Q301 8-729-427-72 TRANSISTOR XP4501-TXE

Q302 8-729-429-50 TRANSISTOR XP4312-TXE

Q401 6-550-396-01 TRANSISTOR 2SB16990LSO

Q402 8-729-029-10 TRANSISTOR DTC143TUA-T106

Q403 8-729-921-73 TRANSISTOR 2SD1781K-T146-QR

Q404 8-729-054-79 TRANSISTOR 2SB167900LSO

Q405 8-729-231-74 TRANSISTOR 2SC4116GL-TE85L

Q412 6-550-071-01 TRANSISTOR 2SB169300LSO

Q420 8-729-054-79 TRANSISTOR 2SB167900LSO

Q601 8-729-028-86 TRANSISTOR DTA143EUA-T106

(AEP, UK, EE)

< RESISTOR >

D803 8-719-064-07 LED SML-310LTT86 (CHARGE)

D805 8-719-072-70 DIODE MA2ZD14001S0

< IC >

IC301 6-703-556-01 IC AN17881F-E1

30

R1 1-216-295-00 SHORT CHIP 0

R2 1-216-295-00 SHORT CHIP 0

R101 1-216-813-11 METAL CHIP 220 5% 1/10W

R105 1-216-821-11 METAL CHIP 1K 5% 1/10W

R106 1-216-845-11 METAL CHIP 100K 5% 1/10W

Page 31

D-EJ785

MAIN

Ref. No. Part No. Description Remark

R110 1-216-845-11 METAL CHIP 100K 5% 1/10W

(EXCEPT AEP, UK, EE)

R110 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

(AEP, UK, EE)

R111 1-216-817-11 METAL CHIP 470 5% 1/10W

R112 1-216-837-11 METAL CHIP 22K 5% 1/10W

R123 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R124 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R125 1-216-833-11 METAL CHIP 10K 5% 1/10W

R201 1-216-813-11 METAL CHIP 220 5% 1/10W

R205 1-216-821-11 METAL CHIP 1K 5% 1/10W

R206 1-216-845-11 METAL CHIP 100K 5% 1/10W

R210 1-216-845-11 METAL CHIP 100K 5% 1/10W

(EXCEPT AEP, UK, EE)

R210 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

(AEP, UK, EE)

R211 1-216-817-11 METAL CHIP 470 5% 1/10W

R212 1-216-837-11 METAL CHIP 22K 5% 1/10W

R223 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R224 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R225 1-216-833-11 METAL CHIP 10K 5% 1/10W

R313 1-216-864-11 METAL CHIP 0 5% 1/10W