SONY D EJ360 Service Manual

D-EJ360/EJ368CK

SERVICE MANUAL

Ver 1.0 2003.01

Photo : D-EJ360 (YELLOW)

US Model

Model Name Using Similar Mechanism New

CD Mechanism Type CDM-3325ER

Optical Pick-up Type DAX-25E

SPECIFICATIONS

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW (This output is the valuemeasured at a

distance of 200 mm from the objective lens surface on the optical pick-up

block with 7 mm aperture.)

Power requirements

For the area code of the model you purchased, check the upper left side of

the bar code on the package.

• Two LR6 (size AA) batteries: 3 V DC

• AC power adaptor (DC IN 4.5 V jack): 120 V, 60 Hz

Dimensions (w/h/d) (without projecting parts and controls)

Approx. 136 x 26 x 150 mm (5 3⁄8 x 1 1⁄16 x 6 in.)

Mass (excluding accessories)

Approx. 185 g (6.6 oz)

Operating temperature

5°C - 35°C (41°F - 95°F)

Design and specifications are subject to change without notice.

Supplied Accessories

D-EJ360: Headphones/earphones (1)

D-EJ368CK*:

AC power adaptor (1)

Headphones/earphones (1)

Car connecting pack (1)

Car battery cord (1)

Rotary commander (1)

Velcro tape for the CD player (2)

Velcro tape for the rotary commander (1)

* “Operating Instructions for the car kit” is enclosed.

9-877-027-01

2003A0200-1

© 2003.01

PORTABLE CD PLAYER

Sony Corporation

Personal Audio Company

Pubulished by Sony Engineering Corporation

D-EJ360/EJ368CK

TABLE OF CONTENTS

DANGER

Invisible laser radiation when open and interlock failed or defeated.

Avoid direct exposure to beam.

CAUTION

Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation

exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

z

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the

lead-free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed

with the lead free mark due to their particular size.)

Specifications ............................................................................ 1

1. SERVICING NOTES ................................................... 3

2. GENERAL

Locating the Controls ......................................................... 3

3. DISASSEMBLY

3-1. Upper Lid ASSY, Cabinet (Upper) Sub ASSY ........... 4

3-2. MD ASSY, Main Board .............................................. 5

3-3. “Motor ASSY (Sled) (M902)”,

Optical Pick-up (DAX-25E),

“Motor ASSY, Turn Table (Spindle) (M901)” ............ 5

4. ELECTRICAL ADJUSTMENS ............................... 6

5. DIAGRAMS

5-1. Block Diagram ............................................................ 7

5-2. Printed Wiring Boards ................................................ 8

5-3. Schematic Diagram –MAIN SECTION (1/3)– ......... 9

5-4. Schematic Diagram –MAIN SECTION (2/3)– ....... 10

5-5. Schematic Diagram –MAIN SECTION (3/3)– ........ 11

5-6. IC Pin Function Description ..................................... 14

6. EXPLODED VIEWS

6-1. Cabinet Section ......................................................... 16

6-2. Optical pick-up Section (CDM-3325ER) ................. 17

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to

be applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set

to about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to

flow) than ordinary solder so use caution not to let solder

bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder

may also be added to ordinary solder.

7. ELECTRICAL PARTS LIST ................................... 18

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE

PA RTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PA RT NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

2

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK OR

BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the charged

electrostatic load, etc. on clothing and the human body. During repair,

pay attention to electrostatic breakdown and also use the procedure in

the printed matter which is included in the repair parts.

The flexible board is easily damaged and should be handled with care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on the

disc reflective surface by the objective lens in the optical pick-up block.

Therefore, when checking the laser diode emission, observe from more

than 30cm away from the objective lens.

Before Replacing the Optical pick-up Block

Please be sure to check thoroughly the parameters as per the “Optical

pick-up Block Checking Procedure” (Part No. : 9-960-027-11) issued

separately before replacing the optical Pick-up block.

Note and specifications required to check are given below.

• FOK output : IC601 yg pin

When checking FOK, remove the lead wire to disc motor.

• RF signal P-to-P value : 0.4 to 0.8Vp-p

D-EJ360/EJ368CK

Laser Diode Checking Methods

During normal operation of the equipment, emission of the laser diode

is prohibited unless the upper panel is closed while turning ON the S809

(push switch type).

The following two checking methods for the laser diode are operable.

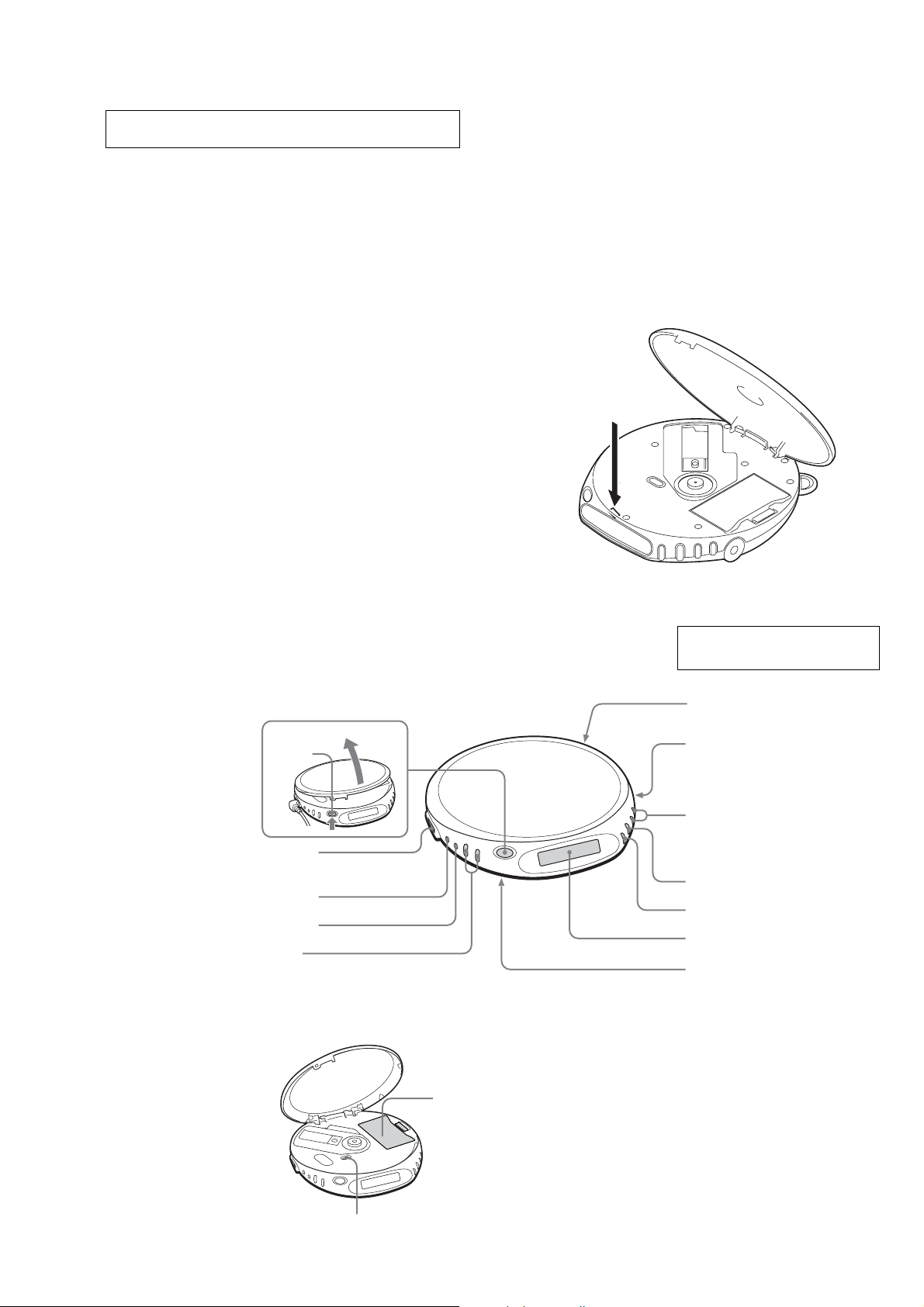

Method :

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. Push the S809 as shown in Fig. 1 .

3. Check the object lens for confirming normal emission of the laser

diode. If not emitting, there is a trouble in the automatic power

control circuit or the optical pick-up. During normal operation, the

laser diode is turned ON about 2.5 seconds for focus searching.

S809

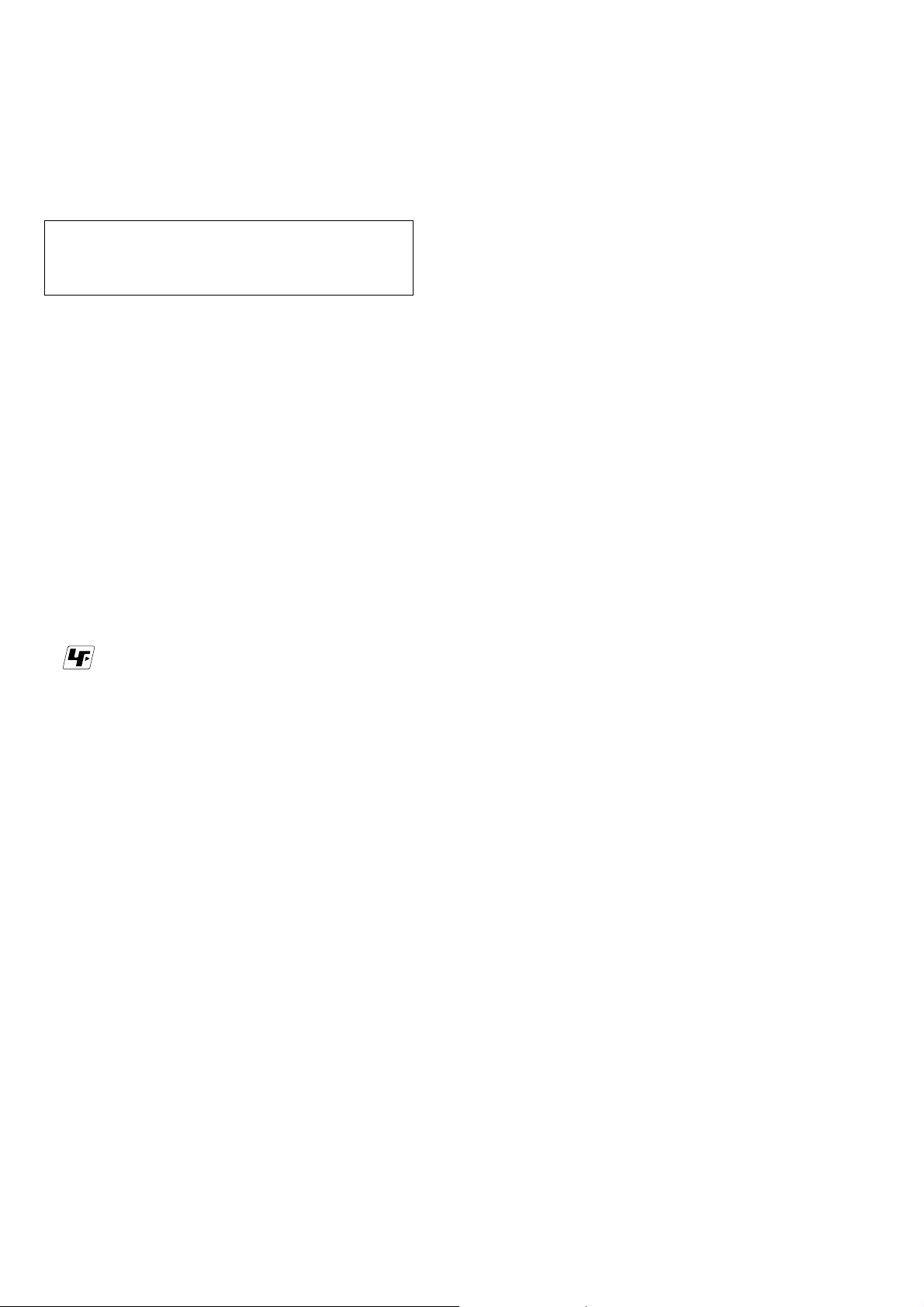

LOCATING THE CONTROLS

CD player (front)

OPEN

i (headphones) jack

SOUN/AVLS

P MODE/ F

VOL +*/–

*The button has a tactile dot.

SECTION 2

GENERAL

Fig.1 Method to push S809

This section is extracted from

instruction manual.

Strap holes

DC IN 4.5 V

(external power

input) jack

.>

u*

x

Display

HOLD

CD player (inside)

Battery Compartment

G-PROTECTION

3

D-EJ360/EJ3688CK

z

The equipment can be removed using the following procedure.

SECTION 3

DISASSEMBLY

MD ASSY “Motor ASSY (Sled) (M902)”, Optical pick-up (DAX-25E),

Set

Upper lid ASSY,

Cabinet (upper) sub ASSY

Main board

Note : Follow the disassembly procedure in the numerical order given.

3-1. UPPER LID ASSY, CABINET (UPPER) SUB ASSY

5

Upper lid Assy

7

Ten screws (B2)

4

2

1

Open

3

“Motor ASSY, turn table (spindle) (M901)”

• CAUTION DURING ASSEMBLY

1

Spring (L)

2

Spring (R)

6

0

Cabinet

(upper) sub ASSY

9

8

Three craws

5

6

Spring (L)

4

1

3

Spring (R)

2

4

3-2. MD ASSY, MAIN BOARD

)

7

MAIN board

1

CN601

5

MD ASSY

4

2

Connector (CN401

3

Connector (CN402)

D-EJ360/EJ3688CK

6

Cabinet (lower) sub ASSY

3-3. “MOTOR ASSY (SLED) (M902)”, OPTICAL PICK-UP (DAX-25E), “MOTOR ASSY, TURN TABLE (SPINDLE) (M901)”

1 Three screws

(B1.7x4)

2

3 Cover, Gear

8 Three screws

(B1.7x4)

6

0 Motor ASSY, Turn table

(Spindle) (M901)

5 Motor ASSY

(Sled) (M902)

9

7 Optical pick-up

(DAX-25E)

4

Chassis

5

D-EJ360/EJ368CK

)

C202

C

Q601

SECTION 4

ELECTRICAL ADJUSTMENTS

The CD section adjustments are done automatically in this set.

Precautions for Check

1. Perform check in the order given.

2. Use YEDS-18 disc (Part No.: 3-702-101-01) unless otherwise

indicated.

3. Power supply voltage requirement : DC4.5 V in DC IN jack.

(J401)

VOLUME button : Minimum

HOLD switch : OFF

Focus bias Check

Condition:

• Hold the set in horizontal state.

Connection:

oscilloscope

(AC range)

TJ601(RF)

[MAIN BOARD] (SIDE B)

C610

R6

BCE

L601

R610

TJ601(RF)

R601

R603

R611

R602

C412

C60

R409

14 13

IC603

Procedure:

1. Connect the oscilloscope to the test point TJ601(RF) on the

MAIN board.

2. Set a disc. (YEDS-18)

3. Press the u button.

4. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape (◊) in the center of the waveform can be clearly distinguished.

RF Signal reference Waveform (Eye Pattern)

VOLT/DIV : 100 mV (With the 10 : 1 probe in use

TIME/DIV : 500ns

RF level

0.4 to 0.8 Vp-p

6

To watch the eye pattern, set the oscilloscope to AC range and

increase the vertical sensitivity of the oscilloscope for easy

watch-ing.

5. Stop revolving of the disc motor by pressing the x button.

5-1. BLOCK DIAGRAM

SECTION 5

DIAGRAMS

IC603

D-RAM(16M)

D-EJ360/EJ368CK

OPTICAL

PICK-UP

BLOCK

(DAX-25E)

OP IC

OPGSW

VCC

OPSTB

RF

A

A

E

F

LD

PD

VCC1_2.2V

LD

DRIVER

Q601

VCC1_2.2V

D0-3 A0-9

2,3,24,25 9-12,15-19,21,8

16 17

DETI

RFGO

RFI

13

A

9

B

8

E

6

F

7

RFDC

88

LD

2

APC

RF

AMP

A/D

PD

3

DEMODULATOR

87,88,84,85 97-100,96-91,82

D0-D3

EFM

SERVO

PWM

FDOP

FDON

TDOP

TDON

75 74 77 76 79 78 72 73 71 504947533738

FIN-

TIN-

FIN+

TIN+

SDOP

SIN+

SDON

SIN-

CLVON

CPOL

PROCESSOR

A0-A10

SUB CODE

CLVOP

CLKDRV

SYNC

CLVOP

XRAS

XCAS

5 23 4

90 83 89

XCAS

XRAS

CLOCK

OSC

XOUT

X601

16.934MHz

XWE

XIN

XWE

IC601

RF AMP,SERVO

DIGITAL SIGNAL PROCESSOR

D-RAM CONTROLLER

D/A CONVERTER

LDACO LOUT

31

DAC

RDACO

36

DVDDIO

VCHK

80

86

34

40

51

5

SIO

AVDD2 2.25V

DVDDV 1.5V

XRST

44

CLK4M

SCLK

SDIN

SDOUT

48

SRWI

POFF

SCOR

XBUSY_O

DEFDCT_O

GFS

657064524345

FOK O

14

15

VCC2_2.0V

VCC1_2.2V

VCPU_1.5V

IC301

HEADPHONE AMP

LIN

RIN

MUTE

BEEP20PWRSW5VCC

1719

ROUT

+V BAT

8

629

EJ368CK

VCC2_2.0V

VCPU_2.0V

J301

i

IC403 (2/2)

POWER CONTROL

VCC2

18

SEM

SEO

VCPU_1.5V

23

22

L410

FOCUS

COIL

TRACKING

COIL

M902

SLED

MOTOR

M901

SPINDLE

MOTOR

21

D405

D402

GSW

VCC

VCC0

STNG

VIN

BATM1

BATM2

DCIN_S

LG

VCC1_2.2V

VCPU_2.0V

3074 12

BEEP_O

AMUTE_O

HOLD_I

S810

.

HOLD

OFF ON

26

HPSW_O

AD_CHGMNT

WP/AD_RMKEY

AD_BATMNT

WP/AD_DCINMNT

GPROSW

38

19

S811

G.PROTECTION

OFF ON

22

24 66

Q401

CHARGE

SWITCH

27

AVCPU

ADVREF

20

VCPU_2.0V

• SIGNAL PATH

: CD PLAY

DEFECT_I

COM0

I

COM3

6711371177

GFS_I

FOK_I

IC801

SYSTEM

CONTROL

MICON

WP/AD_KEY_1

AD_KEY_2

2523 28 40

KEY MATRIX

S801 S805

| |

S804 S808

WP/XOPEN

S809

(OPEN)

15

SRW O

SCOR_I

POFF_O

XIN

2

OPGSW O

79

XOPSTBY_O

FIN3

FIN+

F+

F-

T+

T-

S+

M

S-

W

M

V

U

+VBAT

L403

44

42

48

46

52

50

80

53

49

45

41

6

4

2

1

FO3

RO3

FO2

RO2

FO1

RO1

W

U

V

COMCOM

VM1

VM12

VM23

VM3

SPVCC

CH3

H

BRIDGE

CH2

H

BRIDGE

CH1

H

BRIDGE

CH4

H

BRIDGE

IC403 (1/2)

FOCUS/TRACKING COIL DRIVE

SLED/SPINDLE MOTOR DRIVE

LEVEL

SHIFTER

LEVEL

SHIFTER

I/F

RIN3

FIN1

RIN1

FIN2

RIN2

BRK

PWM

SYNC

LATCH

DATA

CLOCK

WAKEUP

RESETO

XRST

60

FIN-

59

SIN+

56

SIN-

55

TIN+

58

TIN-

57

CPOL

70

SLVOP

72

SYNC

34

74

FG

40

39

38

37

35

36

DEFFERENTIAL

Q407

D802

78

FG I

72

XPOWLT_O

14

SDTI_I

16

SDTO_O

17

SCK_O

18

XWAKEUP_O

66

8

XREST_I

XRST_O

76

XBUSY_I

SEG0

I

SEG15

56-41 60-57

LCD801

LIQUID

CRYSTAL

DISPLAY

17

VCC1

19

VCPU 2.0V

CHGMNT

67

VMMNT_O

DCIN

61

REGB

62

DET

63

CHGB

65

+VBAT

SWITCH

Q402, 403

Q406

20

16

Q404

25

L404

8

12

68

69

64

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION LR6)

2PCS, 3V

L401

L402

J401

DC IN 4.5V

!

77

Loading...

Loading...