Sony DEJ-2000 Service manual

D-EJ2000

SERVICE MANUAL

Ver 1.1 2002. 12

Photo : SILVER TYPE

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-3325ES2

Optical Pick-up Name DAX-25E

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Chinese Model

Tourist Model

•Abbreviation

E18 : 100 – 230 V AC area in E model

HK : Hong Kong model

JE : Tourist model

KR : Korean model

EE : East European model

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wav elength: λ = 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance

of 200 mm from the objective lens surface on

the optical pick-up block with 7 mm aperture.)

D-A conversion

1-bit quartz time-axis control

Frequency response

20 - 20 000 Hz

307)

Output (at 3 V input level)

Line output (stereo minijack)

Output level 0.7 V rms at 47 kΩ

Recommended load impedance over 10 kΩ

Headphones (stereo minijack)

Approx. 5 mW + Approx. 5 mW at 16 Ω

(Approx. 0.5 mW + Approx. 0.5 mW

at 16

*For the customers in Europe

Optical digital output (optical output connector)

Output level: –21 - –15 dBm

Wav elength: 630 - 690 nm at peak level

+1

dB (measured by JEITA CP-

–2

Ω

)*

Power requirements

For the area code of the model you

purchased, check the upper left side of the

bar code on the package.

• Sony NH-14WM (A) rechargeable battery:

1.2 V DC

• LR6 (size AA) battery: 1.5 V DC

•AC power adaptor (DC IN 3 V jack):

US, Canadian models: 120 V, 60 Hz

UK model: 230 V, 50 Hz

Australian model: 240 V, 50 Hz

AEP, JE, E18, KR and EE models:

100 - 240 V, 50/60 Hz

HK model: 230 V, 50 Hz

Chinese model: 220 V, 50 Hz

Battery life* (approx. hours)

(When you use the CD player on a flat and stable

surface.)

Playing time varies depending on how the CD

player is used.

When using G-PROTECTION

NH-14WM (A) 25 22

(charged for

about 5 hours**)

External battery case 39 34

(alkaline battery***)

NH-14WM (A) and 63 55

external battery case

(alkaline battery***)

* Measured value by the standard of JEITA (Japan

Electronics and Information Technology

Industries Association).

** Charging time varies depending on how the

rechargeable battery is used.

*** When using a Sony alkaline battery LR6 (SG)

(produced in Japan)

Operating temperature

5°C - 35°C (41°F - 95°F)

Dimensions (w/h/d) (excluding

projecting parts and controls)

Approx. 127.0 × 133.8 × 13.4 mm

3

⁄8×17⁄32 in.)

(5 × 5

Mass (excluding accessories)

Approx. 118 g (4.2 oz)

Design and specifications are subject to change

without notice.

“1” “2”

9-874-158-02

2002L1600-1

© 2002.12

PORTABLE CD PLAYER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

D-EJ2000

Ver 1.1 2002.12

TABLE OF CONTENTS

1. SERVICING NOTE ·························································· 3

2. GENERAL ·········································································· 6

3. DISASSEMBLY ································································ 7

3-1. Upper Lid Section ························································· 7

3-2. Cabinet (Middle) Section ·············································· 8

3-3. MAIN Board,

Optical Pick-Up Section (CDM-3325ES2) ··················· 8

3-4. Motor Assy Turn Table (M902),

Optical Pick-Up Assy (DAX-25E) ································ 9

4. ELECTRICAL ADJUSTMENT ·································· 10

5. DIAGRAMS ······································································ 11

5-1. Block Diagram – Main (1/2) Section – ······················· 12

5-2. Block Diagram – Main (2/2) Section – ······················· 13

5-3. Block Diagram – Power Supply Section – ·················· 14

5-4. Printed Wiring Board – MAIN Board (Side A) – ········ 15

5-5. Printed Wiring Board

– MAIN Board (Side B), SUB Board –······················· 16

5-6. Schematic Diagram – MAIN Board (1/3) – ················ 17

5-7. Schematic Diagram – MAIN Board (2/3) – ················ 18

5-8. Schematic Diagram – MAIN Board (3/3) – ················ 19

5-9. IC Block Diagram ······················································· 20

5-10.IC Pin Function Description ········································ 21

6. EXPLODED VIEWS ······················································ 23

7. ELECTRICAL PARTS LIST ······································· 26

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

On AC power adaptor

•Use only the AC power adaptor supplied or

recommended in “Accessories (supplied/

optional).” Do not use any other AC power

adaptor. It may cause a malfunction.

Polarity of the plug

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

2

SECTION 1

detection lever

detection lever

MAIN board

S804

SERVICING NOTE

D-EJ2000

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

BEFORE REPLACING THE OPTICAL PICK-UP BLOCK

Please be sure to check thoroughly the parameters as par the “Optical

Pick-Up Block Checking Procedures” (Part No.: 9-960-027-11)

issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

• FOK output: IC601 yg pin

When checking FOK, remove the lead wire to disc motor.

• RF signal P-to-P value: 0.34 to 0.74 Vp-p

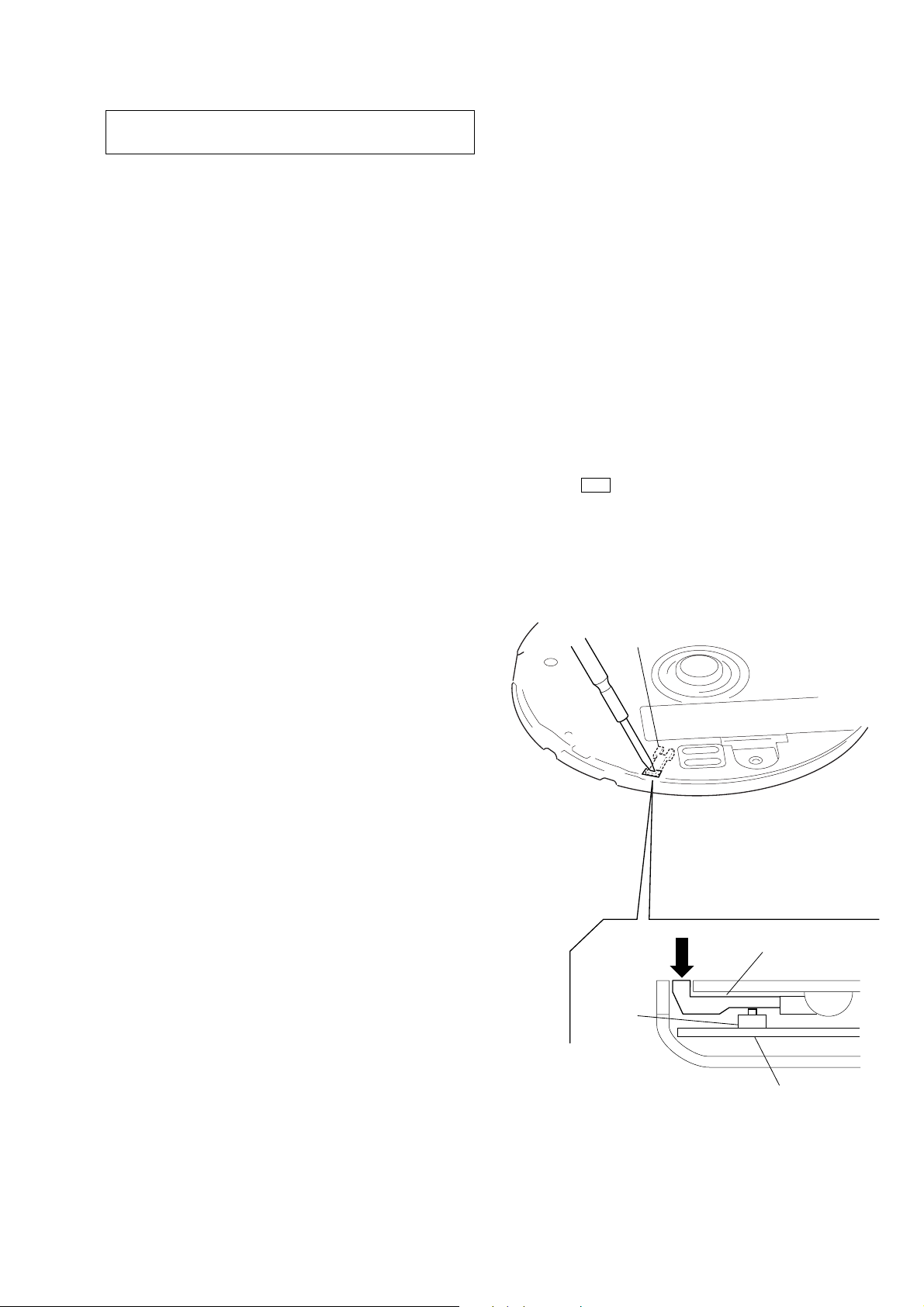

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S804. (push switch type)

The following checking method for the laser diode is operable.

• Method:

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. With a disc not set, turn on the S804 with a screwdriver having a

thin tip as shown in Fig.1.

3. Press the u button.

4. Observing the objective lens, check that the laser diode emits

light.

When the laser diode does not emit light, automatic power control

circuit or optical pickup is faulty.

In this operation, the objective lens will move up and down 4

times along with inward motion for the focus search.

Fig. 1 Method to push the S804

3

D-EJ2000

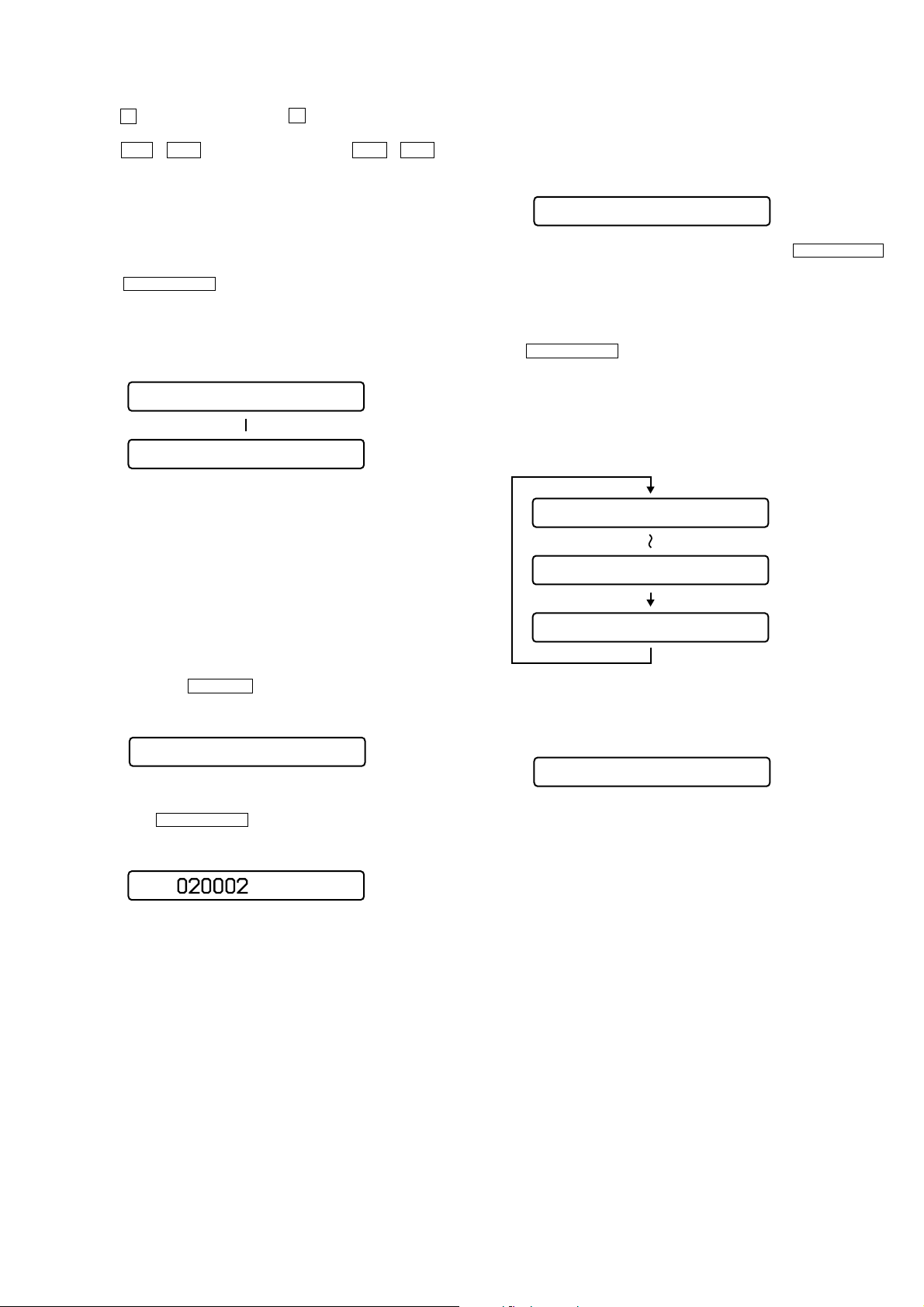

SERVICE MODE

The following confirmation can be performed when the Service

Mode is set.

1. How to set the Service Mode.

To set the Service Mode, the following method is available.

1) Confirm the set is not powered on.

2) Confirm the following settings.

OPEN/CLOSE detect switch (S804) ........ OFF

Solder Land (SL805) ................................ OPEN

[AVLS] switch (S802) ............................... NORM

[HOLD] switch (S801)............................... OFF

[G-PROTECTION] switch (S803) .............. 1

3) Short the solder land SL806 (TEST) on the MAIN board.

4) Turn on the main power.

– MAIN Board (Component side) –

SL806

(TEST)

SL805

(OPEN)

2. Operation when the Service Mode is set.

When the Service Mode becomes active, following messages are

displayed onthe remote control LCD.

Remote control LCD display

Microcomputer

version display

All lit

Service Mode

3. Operations by buttons or Rotary control

in the Service Mode.

The following confirmations can be performed by operating buttons

(on the CD player or the remote control) or Rotary control.

(Operation when a CD is not placed in the CD player)

• > / . button (the CD player) or > / . Rotary

control (the remote control)

Motion of the optical pick-up (to outside or inside)

Tracking/Sled servo off

Note : Be sure to keep your eyes apart from the direct emission

of the Laser diode.

Do not move the optical pick-up over outermost or

innermost.

VB100

888

DDDD

V-SUR

8

S804

(OPEN/CLOSE)

(Operation when a CD is placed in the CD player)

Procedure :

1) Confirm the set is not powered on.

2) Keep short the solder land SL806 (TEST) on the MAIN board.

3) After turning on the power, set a CD in the player.

Then press u /ENT button (the remote control)

Remote control LCD display

0000

PLAY mode

4

D-EJ2000

020002

040004

010001

(2 times)

(4 times)

(1 time)

Error rate : NG

• x button (the CD player) or x button (the remote control)

All servos (Focus/Tracking/Sled) off

• > / . button (the CD player) or > / . Rotary

control (the remote control)

Motion of the optical pick-up (to outside or inside)

Tracking/Sled servo off

• [VOL+/VOL-] button (the CD player) or VOL + / VOL - Rotary

control (the remote control)

Two step volume setting

• P MODE/F button (the remote control)

Every pressing the button changes CLV (the rotation velocity) 1

to 4 times.

Tracking/Sled servo on

Remote control LCD display

010001

040004

(To cancel this mode, turn off the power. Then set in the Service

Mode again.)

• [SOUND] button (the remote control)

Automatic adjustment of servo

(1 time)

(4 times)

5) C1 error rate display mode is active by pressing [DISPLAY] button

(the remote control).

The remote control LCD displays the following message.

Remote control LCD display

Er****

Note : Press [SOUND] button before pressing P MODE/F

button during playing a CD.

By pressing in a wrong order, the value of Er

becomes very big.

6) When [DISPLAY] button (the remote control) is pressed,

P MODE/ F button is effective again. Then the value of CLV

(the rotation verocity) becomes changeable.

Note : Error rate display at x1 speed is not available, therefore

skip “010001” (x1 speed) quickly.

Remote control LCD display

Value of ****

0000 – 0099 : OK

0100 – : NG

****

4. Error rate display

C1 error rate is displayed when the following operation are

performed during playing in the Service Mode.

1) Cancel the other Service Mode by turning off the power.

2) After turning on the power, set a CD in the player.

Then press u /ENT button (the remote control).

Remote control LCD display

0000

3) Set the automatic servo adjustment by pressing [SOUND] button

(the remote control).

4) Press P MODE/F button (the remote control) twice.

Remote control LCD display

7) C1 error rate is displayed on the LCD by pressing [DISPLAY]

button (the remote control).

Remote control LCD display

Er****

8) Turn off the power.

9) Open the solder land SL806 (TEST) on the MAIN board.

Note : The solder should be removed clean.

5

D-EJ2000

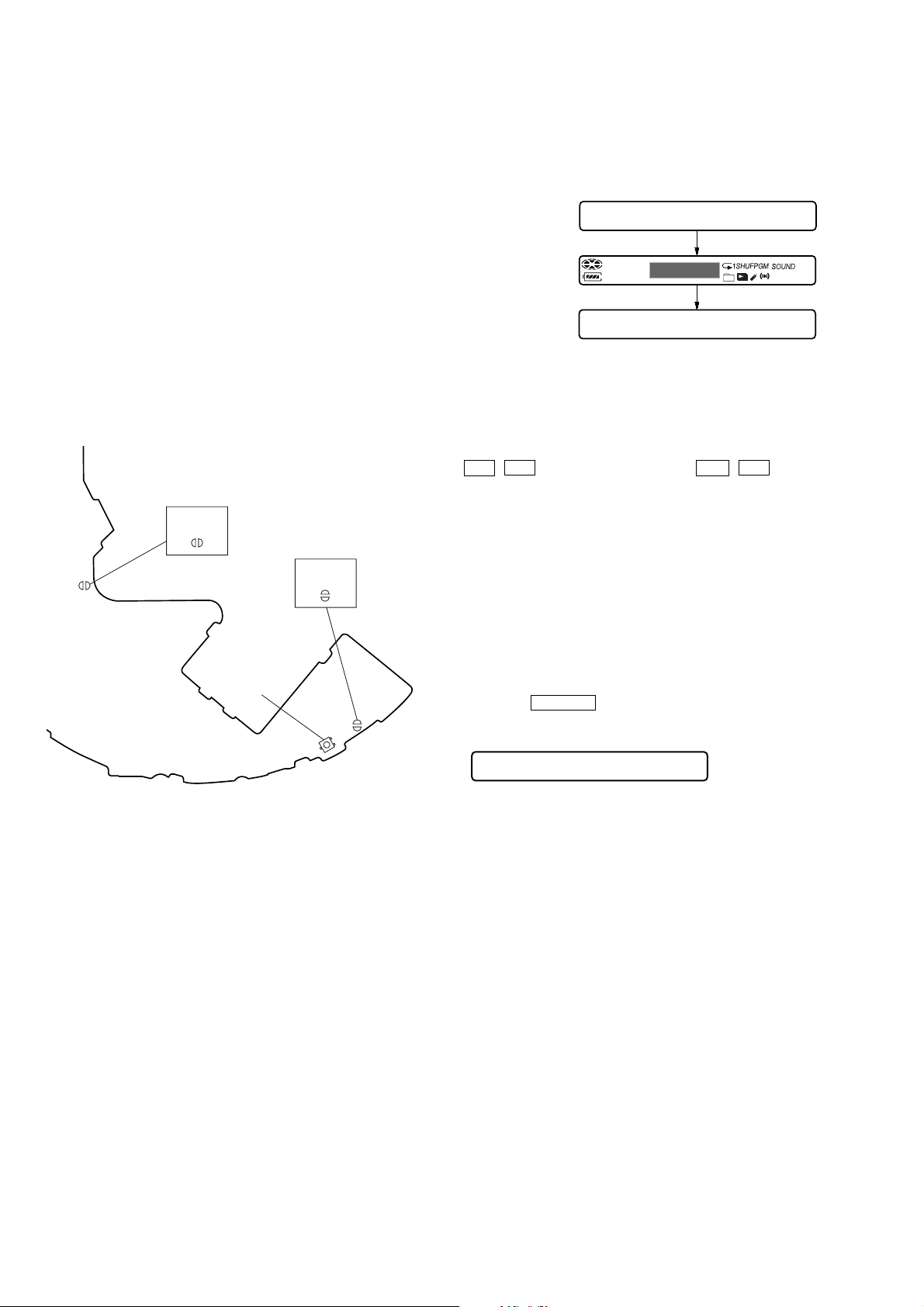

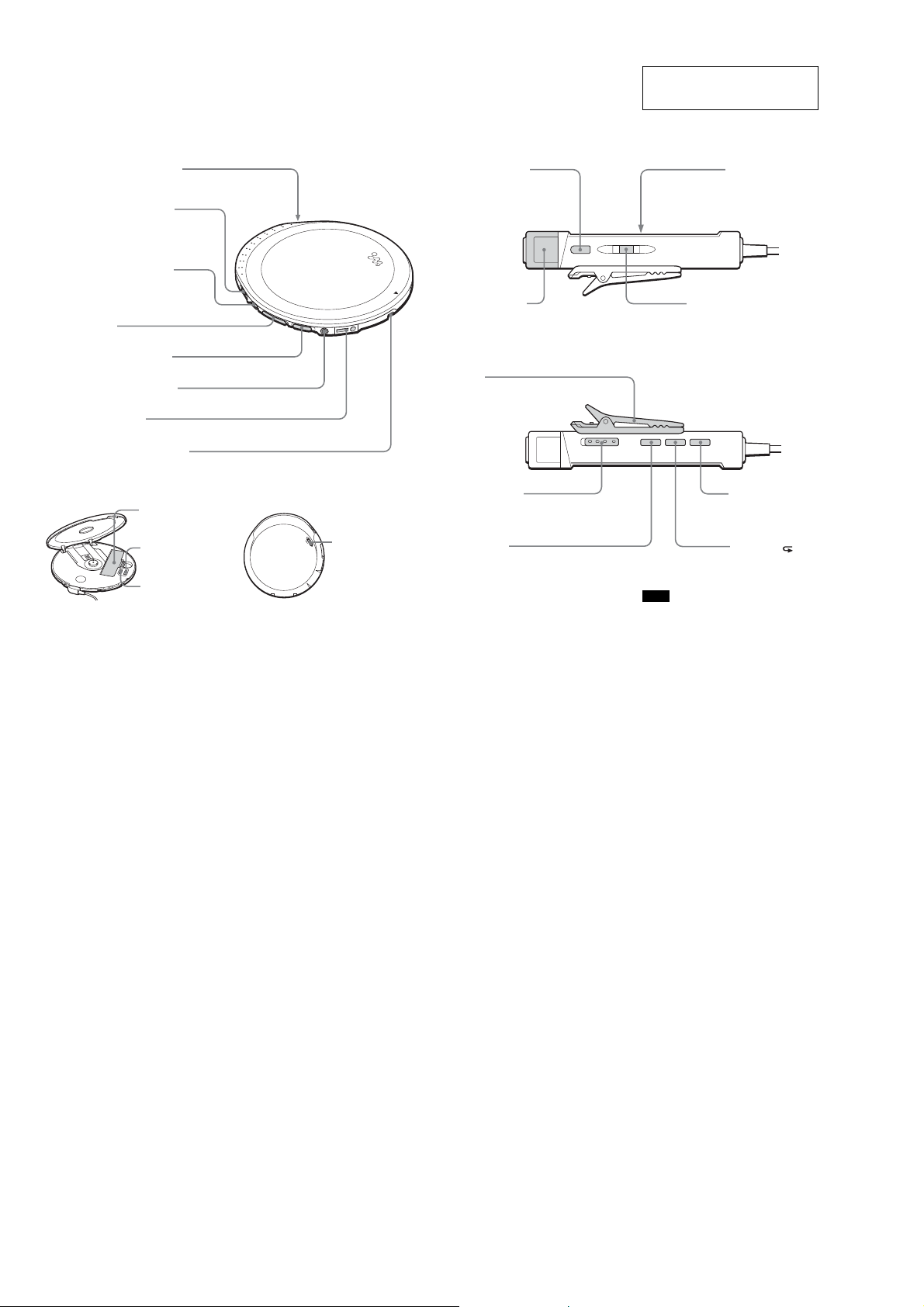

Locating the controls

SECTION 2

GENERAL

This section is extracted

from instruction manual.

CD player (front)

1 EXT BATT (external battery)/

DC IN 3 V (external power input) jack

2 Jog lever (u (play/pause)•

./> (AMS/search))

3 x (stop) /CHARGE button•

CHARGE lamp

4 OPEN switch

5 VOL (volume) +*/– control

6 LINE OUT (OPTICAL) jack

7 i (headphones) jack

8 Terminal for the charging stand

CD player (inside)

9 Battery

compartment

q; G-PROTECTION

switch

qa AVLS switch

*There is a tactile dot beside + to show the direction to turn up the volume.

CD player (rear)

qs HOLD switch

Remote control

qd x (stop) button

qf VOL (volume)

+/– control

qj Clip

ql DISPLAY

button

qg Display

qh Jog lever (u (play/pause)•

ENT (enter)•

./> (AMS/search))

w; SOUND buttonqk HOLD switch

wa P MODE/

(play mode/repeat)

button

Note

Use only the supplied remote control. You cannot

operate this CD player with the remote control

supplied with other CD players.

6

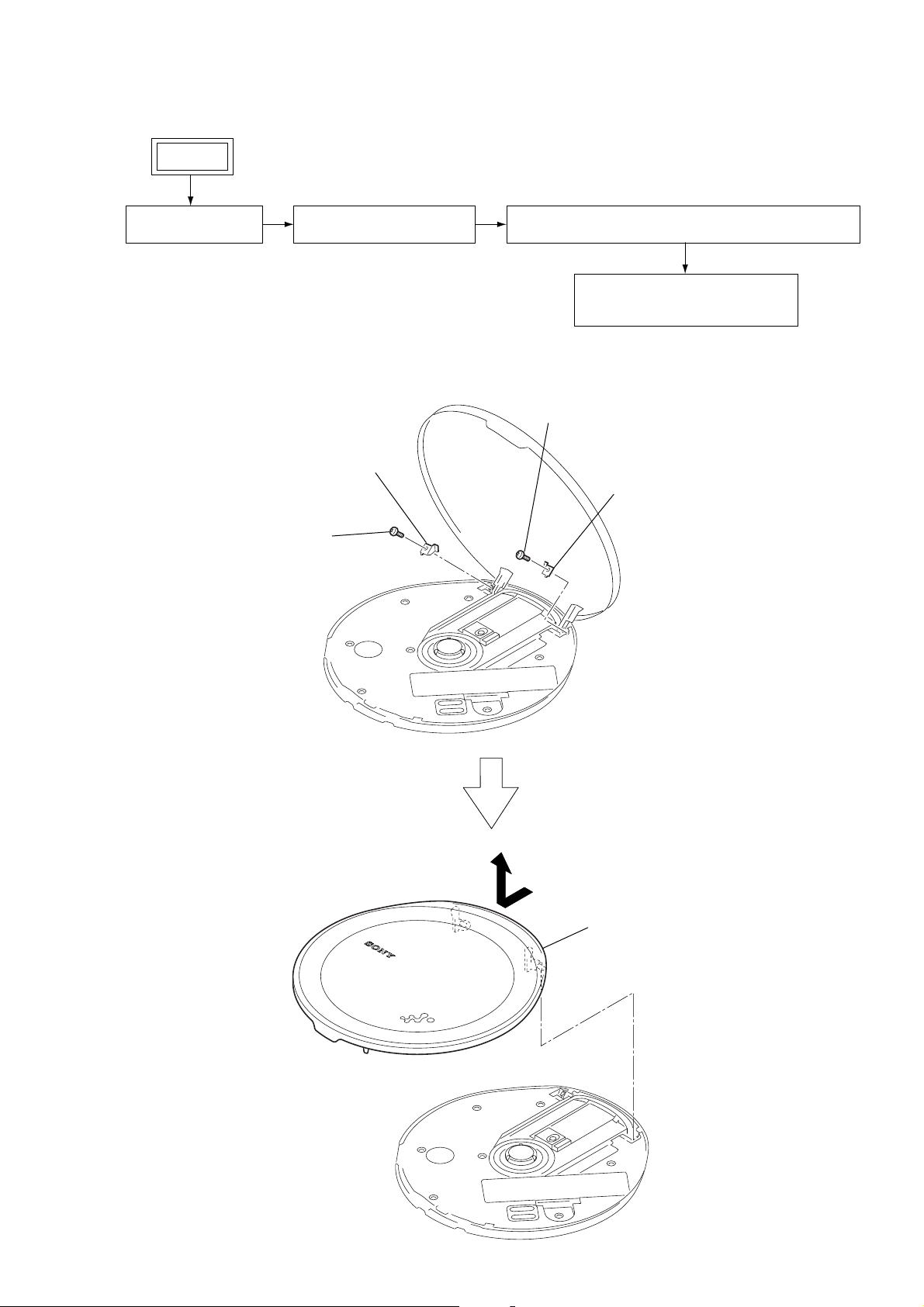

SECTION 3

SET

UPPER LID SECTION CABINET (MIDDLE) SECTION MAIN BOARD, OPTICAL PICK-UP SECTION (CDM-3325ES2)

MOTOR ASSY (TURN TABLE)(M902),

OPTICAL PICK-UP ASSY (DAX-25E)

DISASSEMBLY

Note : Disassemble the unit in the order as shown below.

Note : Follow the disassembly procedure in the numerical order given.

3-1. Upper Lid Section

2

guide plete (L)

3

screw

4

guide plete (R)

D-EJ2000

1

screw

5

upper lid assy

7

D-EJ2000

d

3-2. Cabinet (Middle) Section

1

six screws

3

two

claws

3

claw

2

screw

4

cabinet (middle) assy

5

3

claw

spring (upper lid)

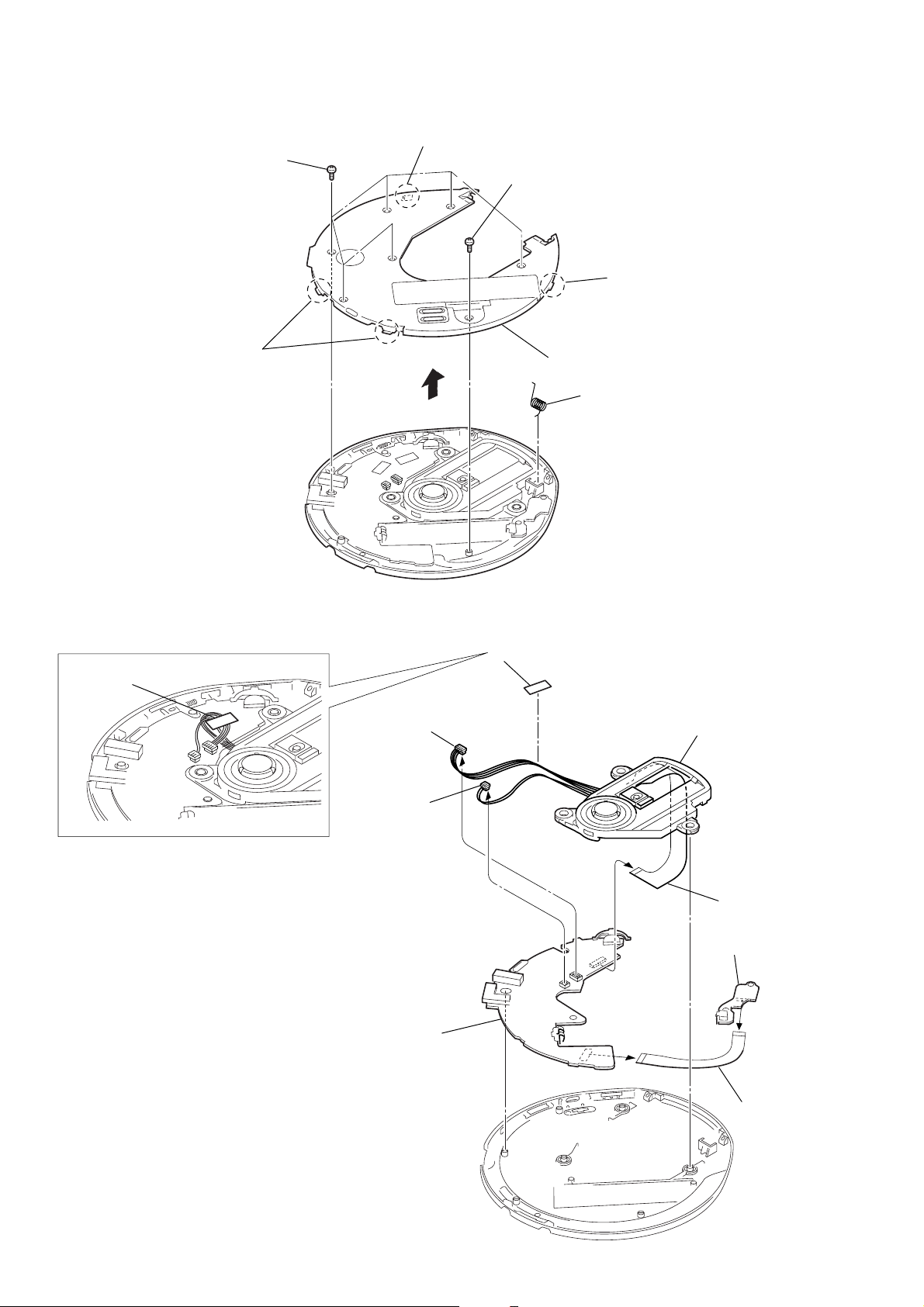

3-3. MAIN Board, Optical Pick-Up Section (CDM-3325ES2)

The cautions at the time of attachment

spacer

2

connector (4P)

(CN

601

)

3

connector (2P)

(CN

602

)

7

MAIN board

1

spacer

5

CDM-3325ES2

4

flexible boar

(CN603)

8

SUB board

6

ffc cable

8

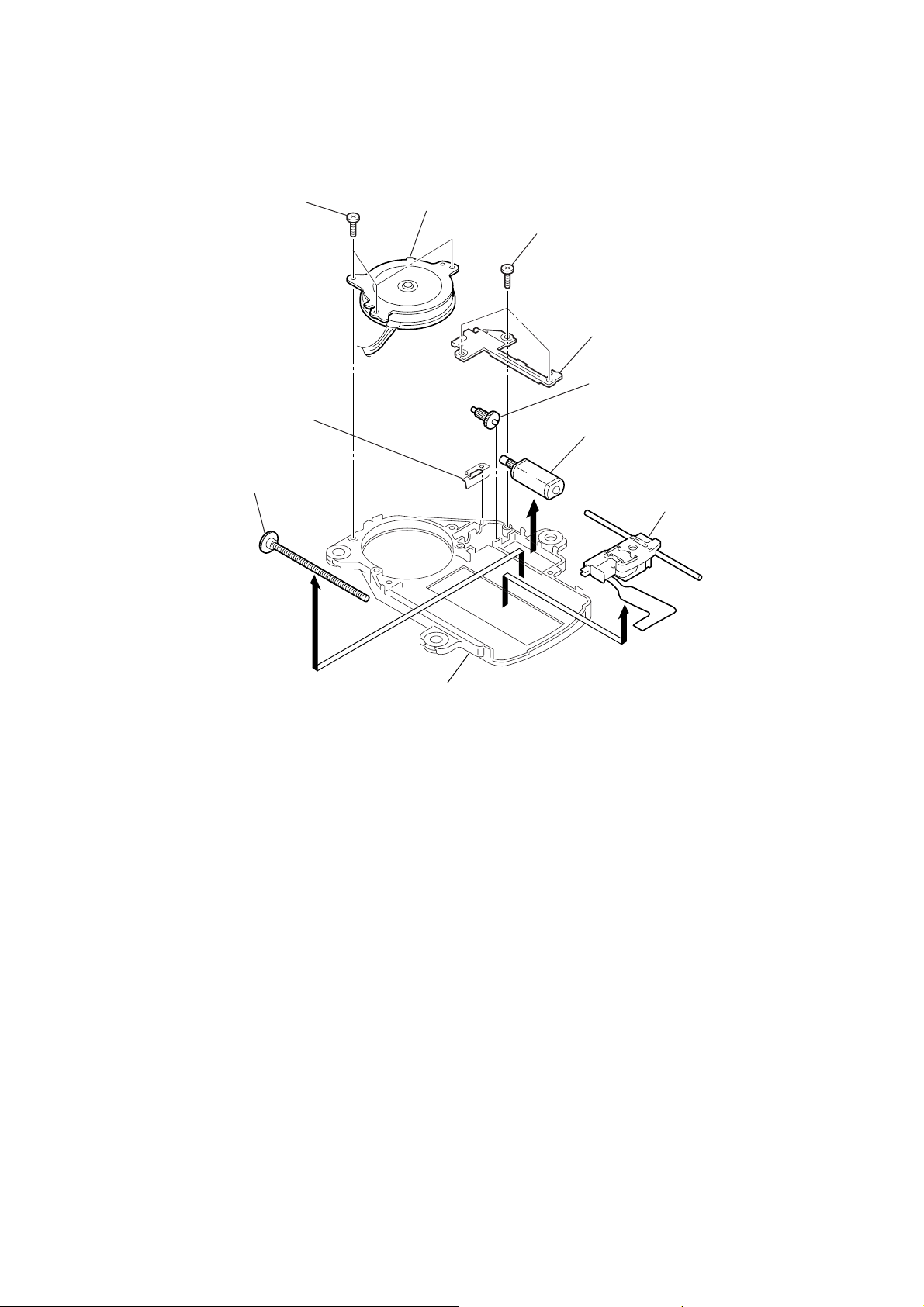

3-4. Motor Assy (Turn Table)(M902), Optical Pick-Up Assy (DAX-25E)

2

1

three screws

B 1.7 × 4

(

9

sled spring

7

screw feed assy

)

motor assy

(turn table)(

M902

)

3

three screws

B 1.7 × 4

(

4

5

6

sled motor assy

(

)

gear cover

gear (B)

M901

)

8

optical pick-up assy

(

DAX-25E

)

D-EJ2000

chassis

9

D-EJ2000

r

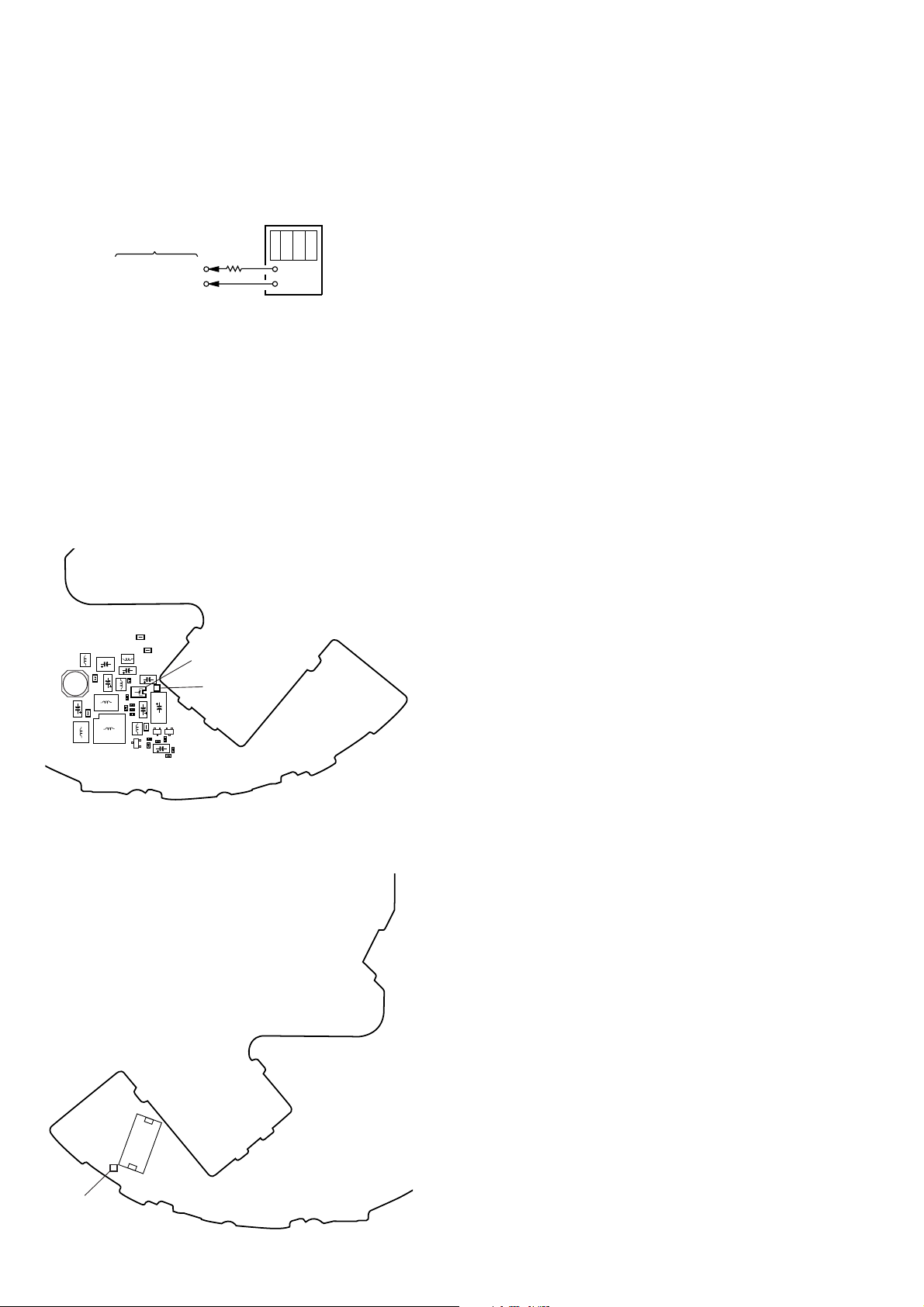

SECTION 4

ELECTRICAL ADJUSTMENT

Adjustment of VCPU

Connection :

• DC 3 V in DC IN jack (J402)

Digital Voltmete

MAIN board

TP (VCPU)

TP402 (GND)

Procedure :

1. Connect a digital voltmeter to the test points TP (VCPU) and

TP402 (GND).

2. Supply DC 3 V in DC IN jack (J402).

3. Adjust the RV401 so that the reading of the digital voltmeter

becomes 1.9V+0.05/-0.0V.

+

–

• Adjustment value : VCPU = 1.9V V (1.90V to 1.95V)

+ 0.05

– 0.0

Connecting points and adjusting point :

– MAIN board (Side A) –

R412

R411

L405

C451

L301

L409

R446

C430

L408

C417

C407

C411

C424

L407

C460

L411

C422

R421

C421

C423

R420

L401

L406

C416

L406

R405

RV401

TP (VCPU)

C406

Q403

R415

Q409

R456

C462

R407

C454

R404

– MAIN board (Side B) –

10

TP402

(GND)

CN402

Loading...

Loading...