Sony DEJ-011 Service manual

This file was downloaded and provided FREE OF CHARGE

from the ManualDirectory community.

You can find many free to download Service Manuals & Schematics at

http://www.manualdirectory.co.uk

D-EJ011

SERVICE MANUAL

Ver. 1.0 2006.12

SPECIFICATIONS

E Model

Model Name Using Similar Mechanism D-EJ010

CD Mechanism Type CDM-3525A

Optical Pick-up Name DAX-25E

System: Compact disc digital audio system

Laser diode properties

Emission duration: Continuous

Laser output: Less than 44.6 µW (This output is the

value measured at a distance of 200 mm from the

objective lens surface on the optical pick-up block

with 7 mm aperture.)

Power requirements

• Two LR6 (size AA) batteries: 1.5 V DC × 2

Dimensions (w/h/d) (without projecting parts and controls)

Approx. 139.8 × 27.9 × 139.8 mm

Mass (excluding accessories)

Approx.188 g

Operating temperature 5°C - 35°C (41°F - 95°F)

Battery life* (approx. hours)

(When the CD player is used on a flat and stable

place.)

Playing time varies depending on how the CD player

is used.

G-PROTECTION G-on G-off

Two Sony alkaline batteries LR6 (SG)

(produced in Japan)

* Measured value by the standard of JEITA (Japan

Electronics and Information Technology Industries

Association).

• The indicator sections of roughly show the

remaining battery power. One section does not

always indicate one-fourth of the battery power.

Design and specifications are subject to change

without notice.

Supplied accessories

Headphones (1)

16 11

9-887-511-01

2006L02-1

© 2006.12

PORTABLE CD PLAYER

Sony Corporation

Personal Audio Division

Published by Sony Techno Create Corporation

D-EJ011

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL ................................................................... 3

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 4

3-2. Cabinet (Inner) Assy,

Cabinet (Lower) Assy...................................................... 4

3-3. Optical Pick-up (CDM-3525A),

MAIN Board.................................................................... 5

4. ELECTRICAL ADJUSTMENT ............................. 6

5. DIAGRAMS

5-1. Block Diagram ................................................................ 8

5-2. Printed Wiring Board

– Main Board (Side A) – ................................................. 9

5-3. Printed Wiring Board

– Main Board (Side B), Jack Board – ............................. 10

5-4. Schematic Diagram – Main Board (1/2) – ..................... 11

5-5. Schematic Diagram – Main Board (2/2), Jack Board – . 12

5-6. IC Pin Function Description............................................ 15

6. EXPLODED VIEWS ................................................. 17

7. ELECTRICAL PARTS LIST .................................. 18

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHO WN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

SECTION 1

.

SERVICING NOTES

D-EJ011

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

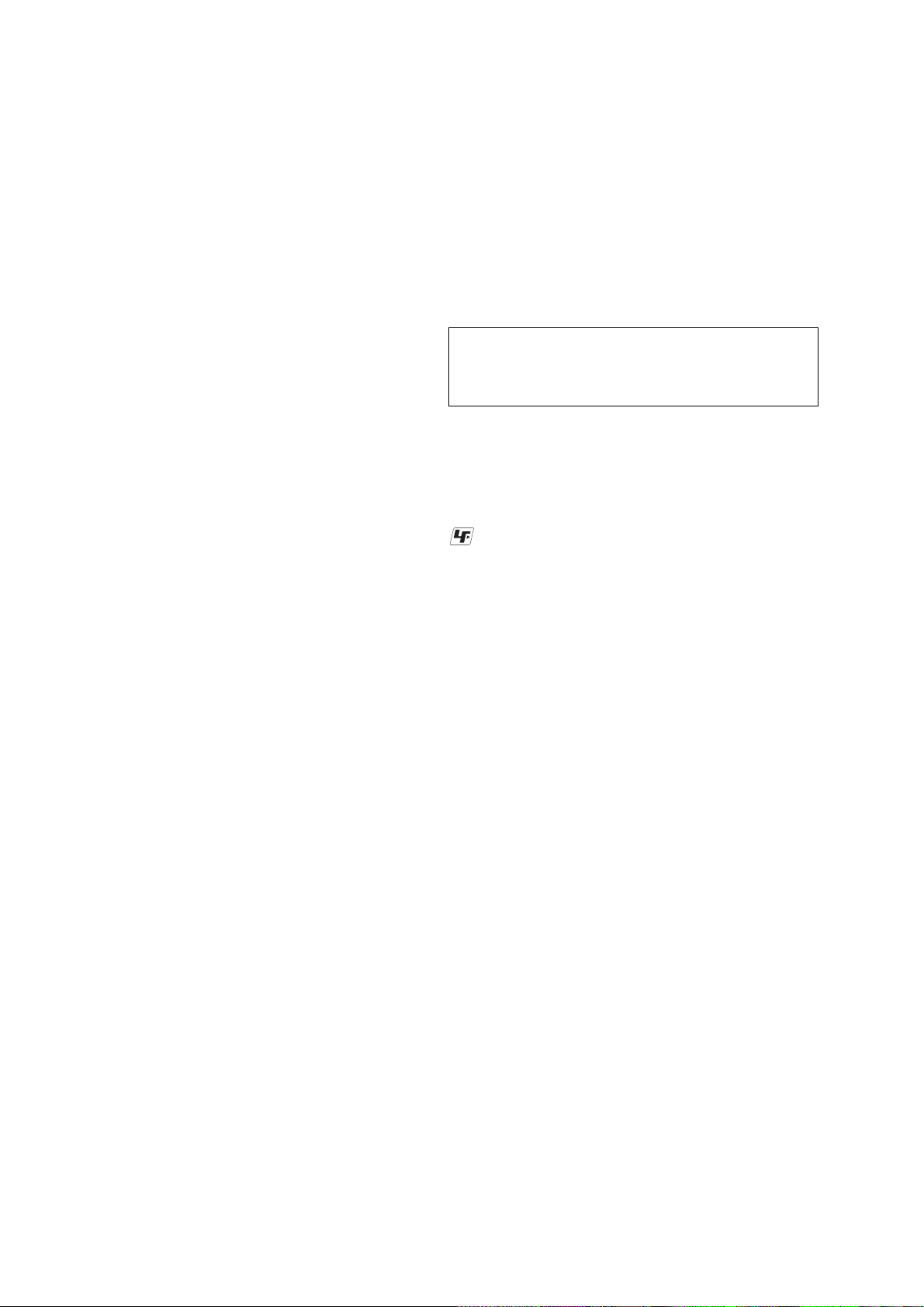

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S811. (push switch type)

The following checking method for the laser diode is operable.

• Method:

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. With a disc not set, turn on the S811 with a screwdriver having

a thin tip as shown in Fig.1.

3. Press the u button.

4. Observing the objective lens, check that the laser diode emits

light.

When the laser diode does not emit light, automatic power

control circuit or optical pick-up is faulty.

In this operation, the objective lens will move up and down 2

times along with inward motion for the focus search.

S811

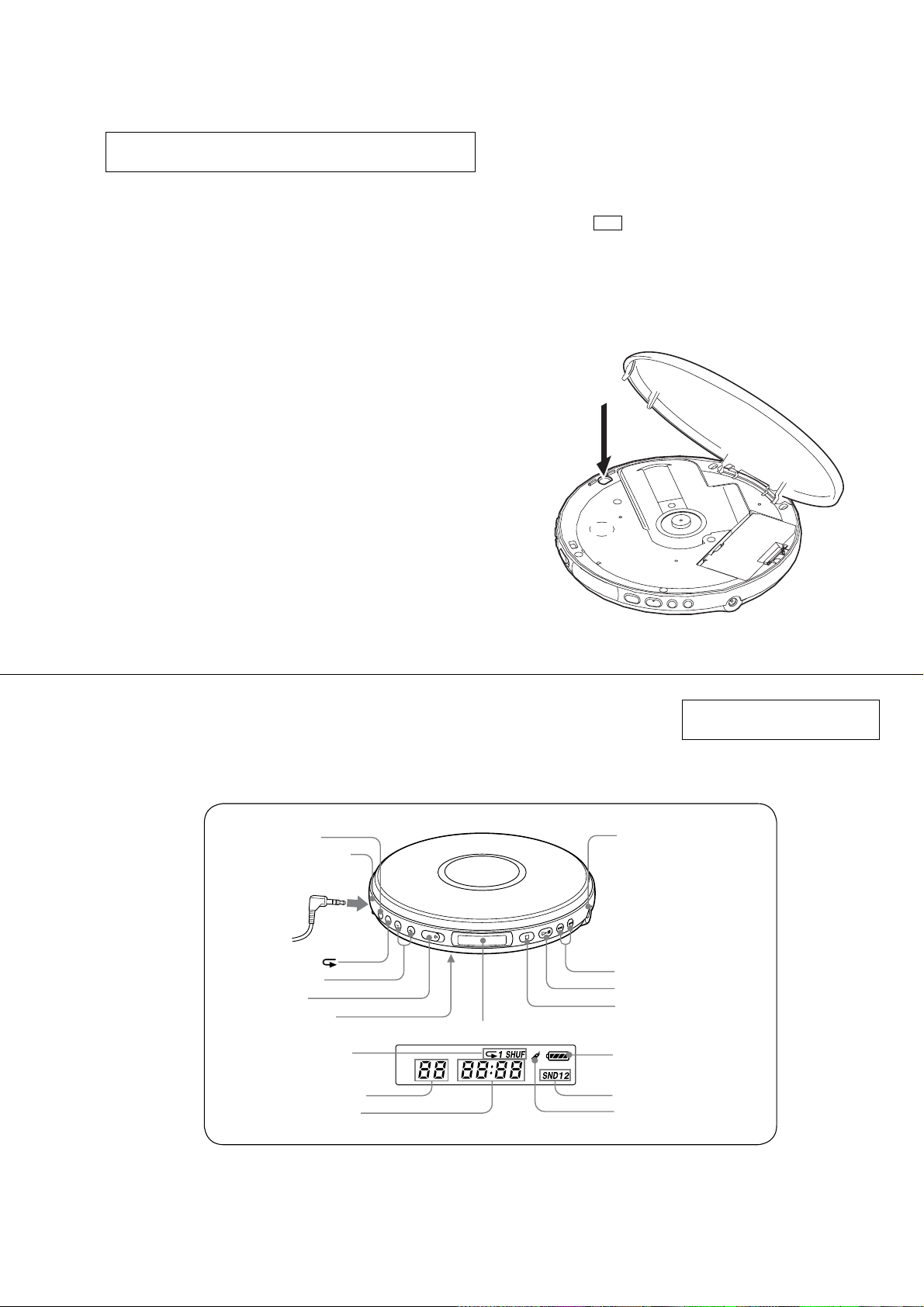

LOCA TING THE CONTROLS

SOUND/AVLS

2 (headphones) jack

Headphones

P MODE/

VOL –/+*

OPEN

HOLD (rear)

Play mode

SECTION 2

GENERAL

Display

Fig. 1 Method to push the S811

This section is extracted from

instruction manual.

DC IN 4.5 V

=+/

^*(play/pause)

p(stop)

Remaining battery power

Track number

Playing time

Sound mode

Bookmark

* The button has a tactile dot

3

D-EJ011

y

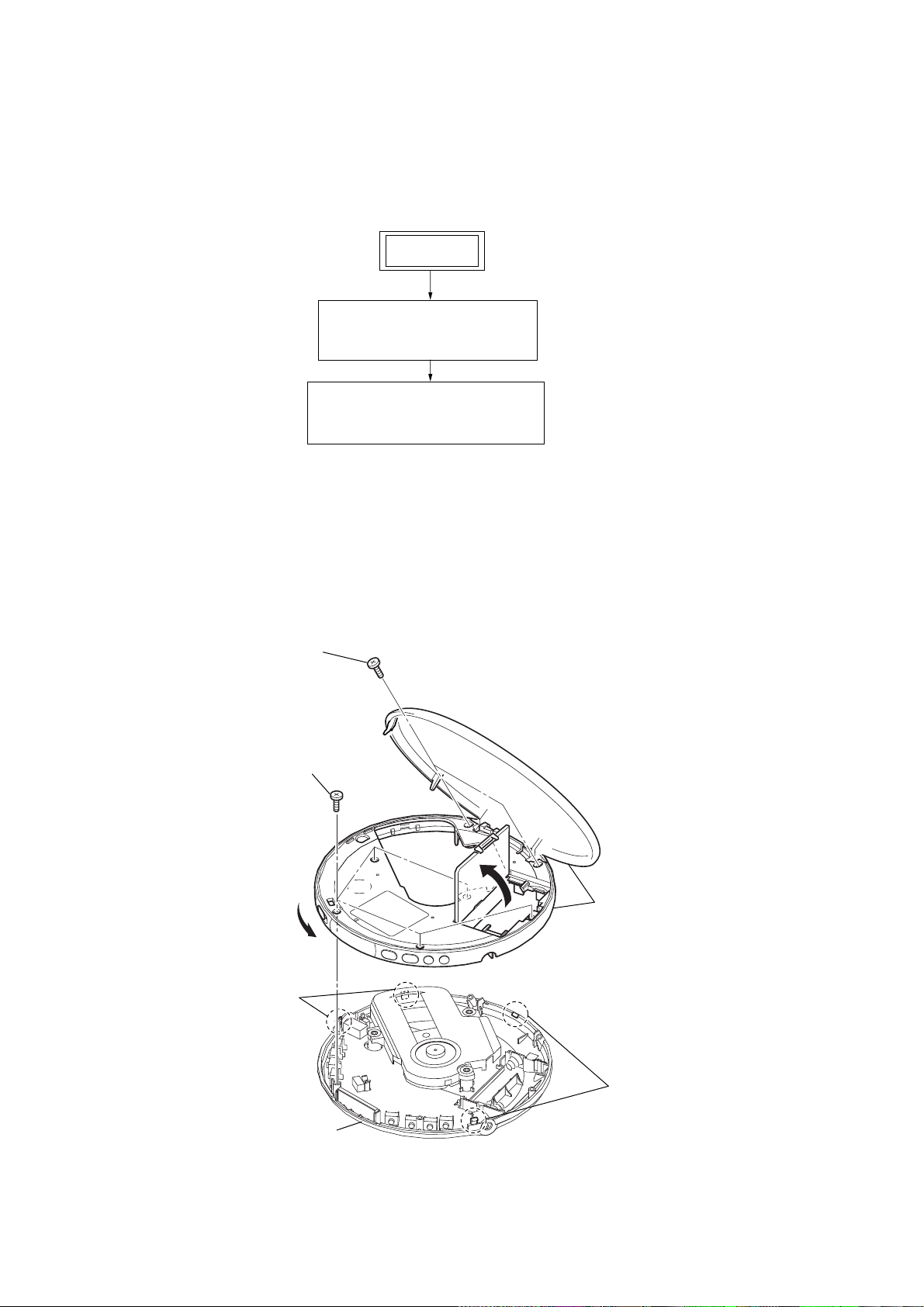

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

3-2. CABINET (INNER) ASSY,

CABINET (LOWER) ASSY

3-3. OPTICAL PICK-UP (CDM-3525A),

MAIN BOARD

(Page 5)

SECTION 3

DISASSEMBLY

SET

(Page 4)

Note: Follow the disassembly procedure in the numerical order given.

3-2. CABINET (INNER) ASSY, CABINET (LOWER) ASSY

4

two screws

3

five screws

1

2

cabinet (inner) ass

5

two claws

6

two claws

cabinet (lower) assy

4

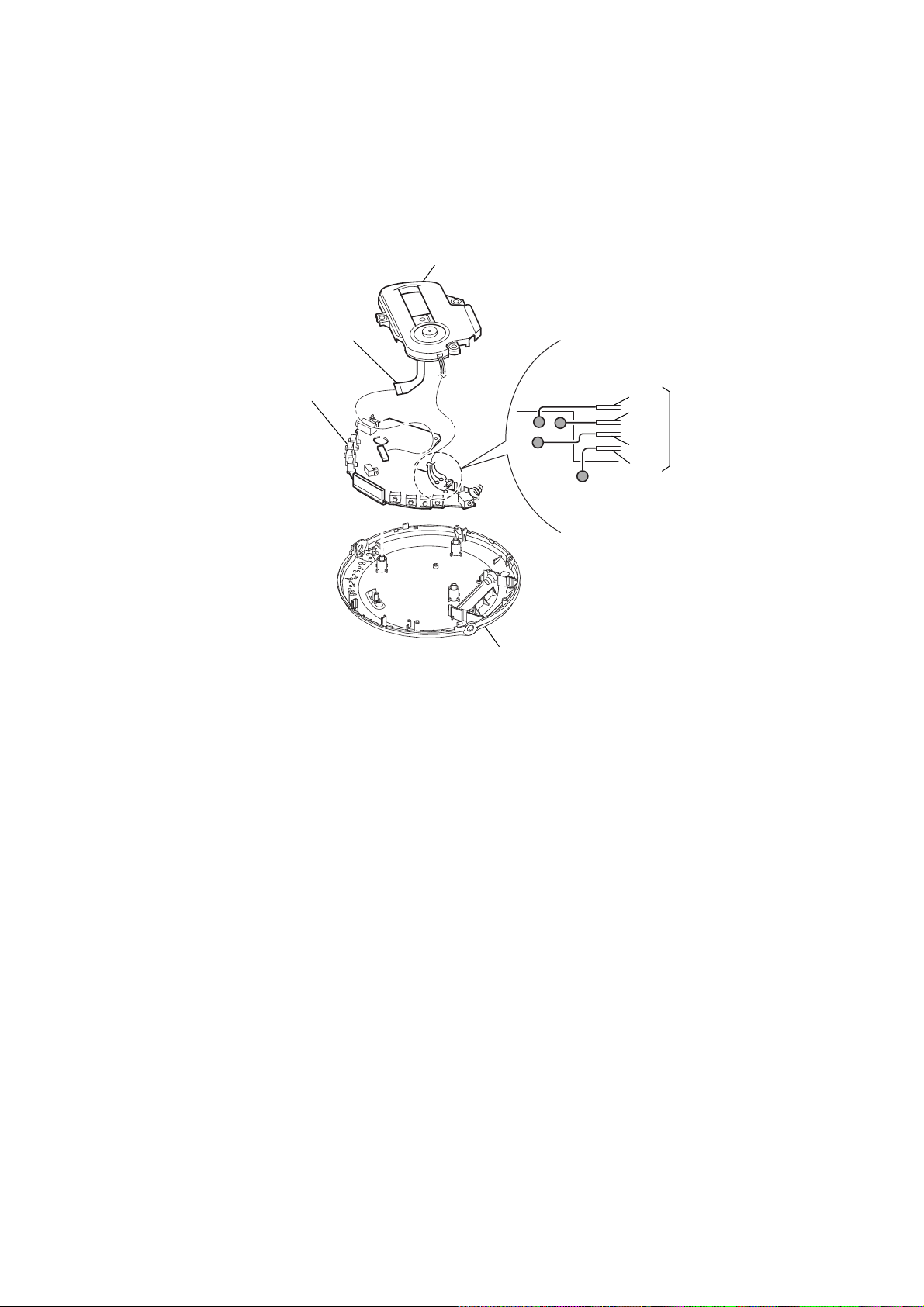

3-3. OPTICAL PICK-UP (CDM-3525A), MAIN BOARD

e

3

optical pick-up CDM-3525A

1

CN501

4

MAIN board

2

Unsolder four lead wires

BLK

RED

ORG

GRY

D-EJ011

To/From

Optical devic

CDM-3525A

MAIN Board (side A)

cabinet (lower) assy

5

D-EJ011

)

SECTION 4

ELECTRICAL ADJUSTMENTS

The CD section adjustments are done automatically in this set.

Adjusting Procedure:

1. Perform check in the order given.

2. Use YEDS-18 disc (Part No: 3-702-101-01) unless otherwise

indicated.

3. Power supply voltage requirement :DC4.5 V in DC IN jack.

(J401)

VOLUME button : Minimum

HOLD switch :OFF

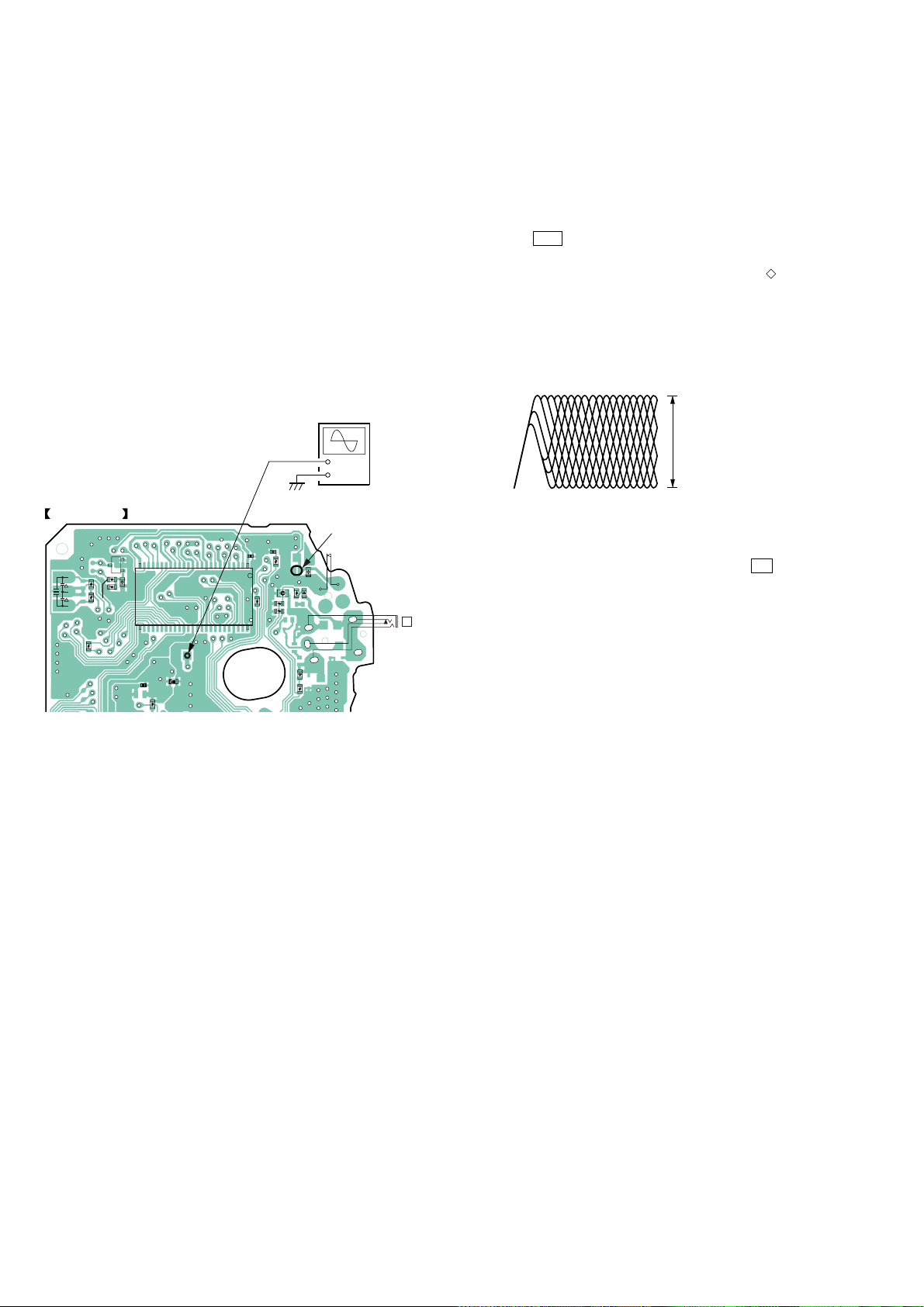

Focus bias Check

Condition:

• Hold the set in horizontal state.

Connection:

MAIN BOARD

X601

R618

R625

R622

(SIDE B)

E

Q602

25

C625

R626

26 50

IC602

(EQOUT)

C627

1

R107

R207

R305

TP604

C110

R101

L301

oscilloscope

(AC range)

SL801

(OPEN)

SL801

(OPEN)

C803

L101

R111

+

–

S811

(OPEN)

Procedure:

1. Make a solder bridge to short SL801 (OPEN) on the MAIN

board side B.

2. Connect the oscilloscope to the test point TP604 (EQOUT)

and TP406 (M-GND) on the MAIN board side B.

3. Set a disc. (YEDS-18)

4. Press the u button.

5. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape ( ) in the

center of the waveform can be clearly distinguished.

RF Signal reference Waveform (Eye Pattern)

VOLT/DIV : 500 mV (With the 10 : 1 probe in use

TIME/DIV : 500ns

RF level

±

0.2 Vp-p

1.3

To watch the eye pattern, set the oscilloscope to AC range and

increase the vertical sensitivity of the oscilloscope for easy

watch-ing.

6. Stop revolving of the disc motor by pressing the x button.

7. SL801 is opened by taking the solder bridge.

1

J30

i

R617

C612

R602

C629

TP604

EQ OUT

L201R211

6