SONY DCR-VX2100 Service Manual

DCR-VX2100/VX2100E

RMT-811

SERVICE MANUAL

Ver 1.0 2003. 10

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Photo : DCR-VX2100

Link

Link

SPECIFICATIONS

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

Korea Model

DCR-VX2100

AEP Model

UK Model

Australian Model

Chinese Model

DCR-VX2100E

E Model

Hong Kong Model

Tourist Model

DCR-VX2100/VX2100E

C MECHANISM

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

• For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (987628851.pdf).

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (987628841.pdf).

• For MECHANISM ADJUSTMENTS, refer to the “DV MECHANICAL ADJUSTMENT MANUAL

C MECHANISM ” (9-974-050-11).

• Reference No. search on printed wiring boards is available.

On the VC-358 board

This service manual provides the information that is premised the circuit board replacement service and not intended repair

inside the VC-358 board.

Therefore, schematic diagram, printed wiring board, mounted parts location and electrical parts list of the

board are

The following pages are not shown.

Schematic diagram .............................Pages 4-43 to 4-78

Printed wiring board ............................Pages 4-113 to 4-118 Electrical parts list ......................... Pages 5-27 to 5-35

Waveforms ...........................................

not shown.

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

Mounted parts location ..................

Page 4-121 to 4-123

REPAIR PARTS LIST

REPAIR PARTS LIST

FP-594 and VC-358

Pages 4-127 to 4-128

DIGITAL VIDEO CAMERA RECORDER

DCR-VX2100/VX2100E

SPECIFICATIONS

Video camera

recorder

System

Video recording system

2 rotary heads

Helical scanning system

Audio recording system

Rotary heads, PCM system

Quantization: 12 bits (Fs 32 kHz,

ster

eo 1, stereo 2), 16 bits

(Fs48 kHz, stereo)

Video signal

DCR-VX2100:

NTSC color, EIA standards

DCR-VX2100E:

PAL color, CCIR standards

Usable cassette

Mini DV cassette with the

mark printed

Tape speed

SP: Approx. 18.81 mm/s

LP: Approx. 12.56 mm/s

Recording/playback time (using

cassette DVM60)

SP: 1 h

LP: 1.5 h

Fast-forward/rewind time

(using cassette DVM60)

Approx. 2 min and 30 s

Viewfinder

Electric viewfinder (color)

Image device

1/3 type CCD (3 Charge Coupled

Device)

Approx. 380 000 pixels

(Effective: Approx. 340 000 pixels)

Lens

Combined power zoom lens

Filter diameter 58 mm (2 3/8 in)

12⋅ (Optical), 48⋅ (Digital)

F1.6 - 2.4

Focal length

6 - 72 mm (1/4 - 2 7/8 in)

When converted to a 35 mm still

camera

43.2 - 518.4 mm (1 3/4 - 20 1/2 in)

Color temperature

Auto, nIndoor (3 200 K),

Outdoor (5 800 K),

Minimum illumination

1 lux (F1.6)

Input/Output connectors

S video input/output

Input/output auto switch

4-pin mini DIN

Luminance signal: 1 Vp-p,

75 ohms, unbalanced

Chrominance signal:

DCR-VX2100: 0.286Vp-p

DCR-VX2100E: 0.3Vp-p

75 ohms, unbalanced

Video input/output

Input/output auto switch

RCA pin-jack, 1 Vp-p, 75 ohms,

unbalanced

Audio input/output

Input/output auto switch

RCA pin-jack, 327 mV, (at output

impedance more than 47 kilohms)

Output impedance with less than

2.2 kilohms

Input impedance more than

47 kilohms

Headphones jack

Stereo minijack (ø 3.5 mm)

LANC control jack

Stereo mini-minijack (ø 2.5 mm)

MIC jack

Minijack, 0.388 mV low impedance with 2.5 to 3.0 V DC, output

impedance 6.8 kilohms (ø 3.5 mm)

Stereo type

DV Interface

4-pin connector

Speaker

Dynamic speaker (ø 20 mm)

LCD screen

Picture

6.2cm (2.5 type)

Total dot number

211 000 (960 ⋅ 220)

General

Power requirements

7.2 V (battery pack)

8.4 V (AC Adaptor)

Average power consumption

(when using the battery pack)

During camera recording using

LCD

4.7 W

Viewfinder

4.0 W

Operating temperature

0 °C to 40 °C (32 °F to 104 °F)

Storage temperature

–20 °C to +60 °C (–4 °F to +140 °F)

Dimensions (approx.)

120 × 159 × 393 mm (4 3/4 × 6 3/8

× 15 1/2 in) (w/h/d)

Mass (approx.)

1.5 kg (3 lb 6 oz) including the

hood with a lens cap

1.6 kg (3 lb 9 oz)

including the rechargeable battery

pack, NP-F330 and cassette

DVM60

Supplied accessories

See page 5-37.

AC Adaptor

AC-L15A/L15B

Power requirements

100 - 240 V AC, 50/60 Hz

Current consumption

0.35 - 0.18 A

Power consumption

18 W

Output voltage

DC OUT: 8.4 V, 1.5 A

Operating temperature

0 °C to 40 °C (32 °F to 104 °F)

Storage temperature

–20 °C to +60 °C (–4 °F to +140 °F)

Dimensions (approx.)

56 × 31 × 100 mm

(2 1/4 × 1 1/4 × 4 in) (w/h/d)

excluding projecting parts

Mass (approx.)

190 g (6.7 oz)

excluding power cord

Rechargeable

battery pack

NP-F330

Output voltage

DC 7.2 V

Capacity

5.0 Wh

Dimensions (approx.)

38.4 × 20.6 × 70.8 mm (1 9/16 ×

13/16 × 2 7/8 in) (w/h/d)

Mass (approx.)

70 g (2.5 oz)

Type

Lithium ion

Design and specifications are

subject to change without notice.

— 2 —

DCR-VX2100/VX2100E

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

DCR-VX2100/VX2100E

TABLE OF CONTENTS

1. SERVECE NOTE

1-1. NOTE FOR REPAIR ·······················································1-1

1-2. SERVICE NOTE ·····························································1-2

1. POWER SUPPLY DURING REPAIRS ··························1-2

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) ·····························································1-2

1-3. SELF-DIAGNOSIS FUNCTION····································1-3

1. SELF-DIAGNOSIS FUNCTION····································1-3

2. SELF-DIAGNOSIS DISPLAY ·······································1-3

3. SELF-DIAGNOSIS CODE TABLE································1-4

2. DISASSEMBLY

2-1. LCD SECTION (HL-013, PD-217 BOARDS, INVERTER

TRANSFORMER UNIT)················································2-2

2-2. EVF SECTION (LB-100 BOARD)·································2-3

2-3. (UPPER) HANDLE BLOCK ASSEMBLY ····················2-3

2-4. FK-088, MA-430, MI-050, FT-092, RM-091, ZM-030

BOARDS·········································································2-4

2-5. CABINET (L) BLOCK ASSEMBLY, MECHANISM

DECK, VC-358, DD-216, JK-267 BOARDS

(FOR FORCE EJECT OF CASSETTE AND VTR

SECTION CHECK) ························································2-6

2-6. CABINET (R) BLOCK ASSEMBLY ·····························2-8

2-7. CABINET BOTTOM ASSEMBLY ································2-8

2-8. BATTERY PANEL BLOCK ASSEMBLY

(MK-016, KP-013, MS-209 BOARDS)·························· 2-9

2-9. EVF BLOCK ASSEMBLY ·············································2-9

2-10. LA-028, DD-216, VC-358, JK-267 BOARDS,

MECHANISM DECK···················································2-10

2-11. LENS BLOCK ASSEMBLY, CENTER FRAME

ASSEMBLY ··································································2-11

2-12. CD-512, SE-147 BOARDS, ZOOM LENS ASSEMBLY···2-12

2-13. CONTROL SWITCH BLOCK (PS-4980), CONTROL

SWITCH BLOCK (CF-4980) ·······································2-12

2-14. CK-140 BOARD ···························································2-13

2-15. CONTROL SWITCH BLOCK (ED-4980), HINGE

ASSEMBLY ··································································2-14

2-16. CIRCUIT BOARDS LOCATION ·································2-15

2-17. FLEXIBLE BOARDS LOCATION ······························2-16

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/4) ···························3-1

3-2. OVERALL BLOCK DIAGRAM (2/4) ···························3-3

3-3. OVERALL BLOCK DIAGRAM (3/4) ···························3-5

3-4. OVERALL BLOCK DIAGRAM (4/4) ···························3-7

3-5. POWER BLOCK DIAGRAM (1/3) ································3-9

3-6. POWER BLOCK DIAGRAM (2/3) ······························3-11

3-7. POWER BLOCK DIAGRAM (3/3) ······························3-13

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/3)·······················4-1

FRAME SCHEMATIC DIAGRAM (2/3)·······················4-3

FRAME SCHEMATIC DIAGRAM (3/3)·······················4-5

4-2. SCHEMATIC DIAGRAMS ··········································4-11

• CD-512 (CCD IMAGER)

SCHEMATIC DIAGRAM ····························4-11

• JK-267 (JACK BOARD)

SCHEMATIC DIAGRAM ····························4-13

• CK-140 (KEY IN)

SCHEMATIC DIAGRAM ····························4-15

• CONTROL SWITCH BLOCK (ED-4980)

SCHEMATIC DIAGRAM ····························4-16

• FP-194, FP-197 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-16

• PD-217 (RGB DRIVE, TG)

SCHEMATIC DIAGRAM ····························4-17

• LA-028 (1/3) (ZOOM/FOCUS DRIVE)

SCHEMATIC DIAGRAM ····························4-19

• SE-147 (VAP SENSOR)

SCHEMATIC DIAGRAM ····························4-19

• LA-028 (2/3) (VAP DRIVE)

SCHEMATIC DIAGRAM ····························4-21

• LA-028 (3/3) (KEY IN/CONNECTOR)

SCHEMATIC DIAGRAM ····························4-23

• FP-188, FP-189 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-23

• KP-013 (SELECT DIAL),

MK-016 (CONTROL KEY),

MS-209 (MS CONNECTOR)

SCHEMATIC DIAGRAM ····························4-25

• ZM-030 (ZOOM SWITCH)

SCHEMATIC DIAGRAM ····························4-26

• FK-088 (CONTROL SWITCH)

SCHEMATIC DIAGRAM ····························4-27

• MI-050 (MIC IN), FT-092 (REMOTE)

SCHEMATIC DIAGRAM ····························4-29

• FP-893, FP-894 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-30

• LB-100 (BACK LIGHT)

SCHEMATIC DIAGRAM ····························4-31

• CONTROL SWITCH BLOCK (CF-4980, PS-4980)

SCHEMATIC DIAGRAM ····························4-32

• HL-013 (LCD DRIVE)

SCHEMATIC DIAGRAM ····························4-33

• FP-195, FP-196, FP-205 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-33

• MA-430 (AUDIO AMP)

SCHEMATIC DIAGRAM ····························4-35

• DD-216 (1/2) (DC/DC CONVERTER)

SCHEMATIC DIAGRAM ····························4-37

• DD-216 (2/2) (DC REGURATOR)

SCHEMATIC DIAGRAM ····························4-39

• RM-091 (REAR REMOCON RECEIVER)

SCHEMATIC DIAGRAM ····························4-41

Schematic diagrams of the FP-594 and VC-358

board are not shown.

Pages from 4-43 to 4-78 are not shown.

4-3. PRINTED WIRING BOARDS ·····································4-81

• CD-512 (CCD IMAGER)

PRINTED WIRING BOARD ·······················4-81

• JK-267 (JACK BOARD)

PRINTED WIRING BOARD ·······················4-83

• CK-140 (KEY IN)

PRINTED WIRING BOARD ·······················4-85

• PD-217 (RGB DRIVE, TG)

PRINTED WIRING BOARD ·······················4-87

• FP-194 FLEXIBLE

PRINTED WIRING BOARD ·······················4-88

• LA-028 (ZOOM/FOCUS DRIVE, VAP DRIVE,

KEY IN/CONNECTOR)

PRINTED WIRING BOARD ·······················4-89

• SE-147 (VAP SENSOR)

PRINTED WIRING BOARD ·······················4-91

• FP-188 FLEXIBLE

PRINTED WIRING BOARD ·······················4-91

• FP-189 FLEXIBLE

PRINTED WIRING BOARD ·······················4-92

• MS-209 (MS CONNECTOR)

PRINTED WIRING BOARD ·······················4-93

• KP-013 (SELECT DIAL)

PRINTED WIRING BOARD ·······················4-95

— 4 —

• MK-016 (CONTROL KEY)

PRINTED WIRING BOARD ·······················4-95

• FK-088 (CONTROL SWITCH)

PRINTED WIRING BOARD ·······················4-97

• MI-050 (MIC IN)

PRINTED WIRING BOARD ·······················4-99

• FT-092 (REMOTE)

PRINTED WIRING BOARD ·······················4-99

• LB-100 (BACK LIGHT)

PRINTED WIRING BOARD ·····················4-101

• HL-013 (LCD DRIVE)

PRINTED WIRING BOARD ·····················4-103

• FP-196 FLEXIBLE

PRINTED WIRING BOARD ·····················4-104

• MA-430 (AUDIO AMP)

PRINTED WIRING BOARD ·····················4-105

• DD-216 (DC/DC CONVERTER, DC REGURATOR)

PRINTED WIRING BOARD ·····················4-107

• ZM-030 (ZOOM SWITCH)

PRINTED WIRING BOARD ·····················4-109

• RM-091 (REAR REMOCON RECEIVER)

PRINTED WIRING BOARD ·····················4-111

DCR-VX2100/VX2100E

Printed wiring boards of the FP-594 and VC-358

board are not shown.

Pages from 4-113 to 4-118 are not shown.

4-4. WAVEFORMS ····························································4-119

Waveforms of the VC-358 board are not shown.

Pages 4-121 to 4-123 are not shown.

4-5. MOUNTED PARTS LOCATION ·······························4-124

Mounted parts locations of the

not shown.

Page 4-127 to 4-128 are not shown.

VC-358 board are

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································5-3

5-1-1.OVERALL SECTION-1 ·················································5-3

5-1-2.OVERALL SECTION-2 ·················································5-4

5-1-3.CABINET (L) SECTION················································ 5-5

5-1-4.CABINET (R) SECTION-1 ············································5-6

5-1-5.CABINET (R) SECTION-2 ············································5-7

5-1-6.UPPER HANDLE SECTION ·········································5-8

5-1-7.BATTERY PANEL SECTION ········································5-9

5-1-8.EVF SECTION······························································5-10

5-1-9.CENTER FRAME SECTION·······································5-11

5-1-10. LENS BLOCK SECTION ··········································5-12

5-1-11. CASSETTE COMPARTMENT, DRUM AND REEL

T ABLE ASSEMBL Y·····················································5-13

5-1-12. TAPE GUIDE, PINCH SLIDER ASSEMBLY AND

BRAKE SLIDER ASSEMBLY·····································5-14

5-1-13. EACH GEARS AND LOADING/CAPSTAN MOTOR

ASSEMBLY ··································································5-15

5-2. ELECTRICAL PARTS LIST ········································5-16

Parts list of the

Pages from 5-27 to 5-35 are not shown.

VC-358 board is not shown.

— 5 —

1-1. NOTE FOR REPAIR

DCR-VX2100/VX2100E

SECTION 1

SERVICE NOTE

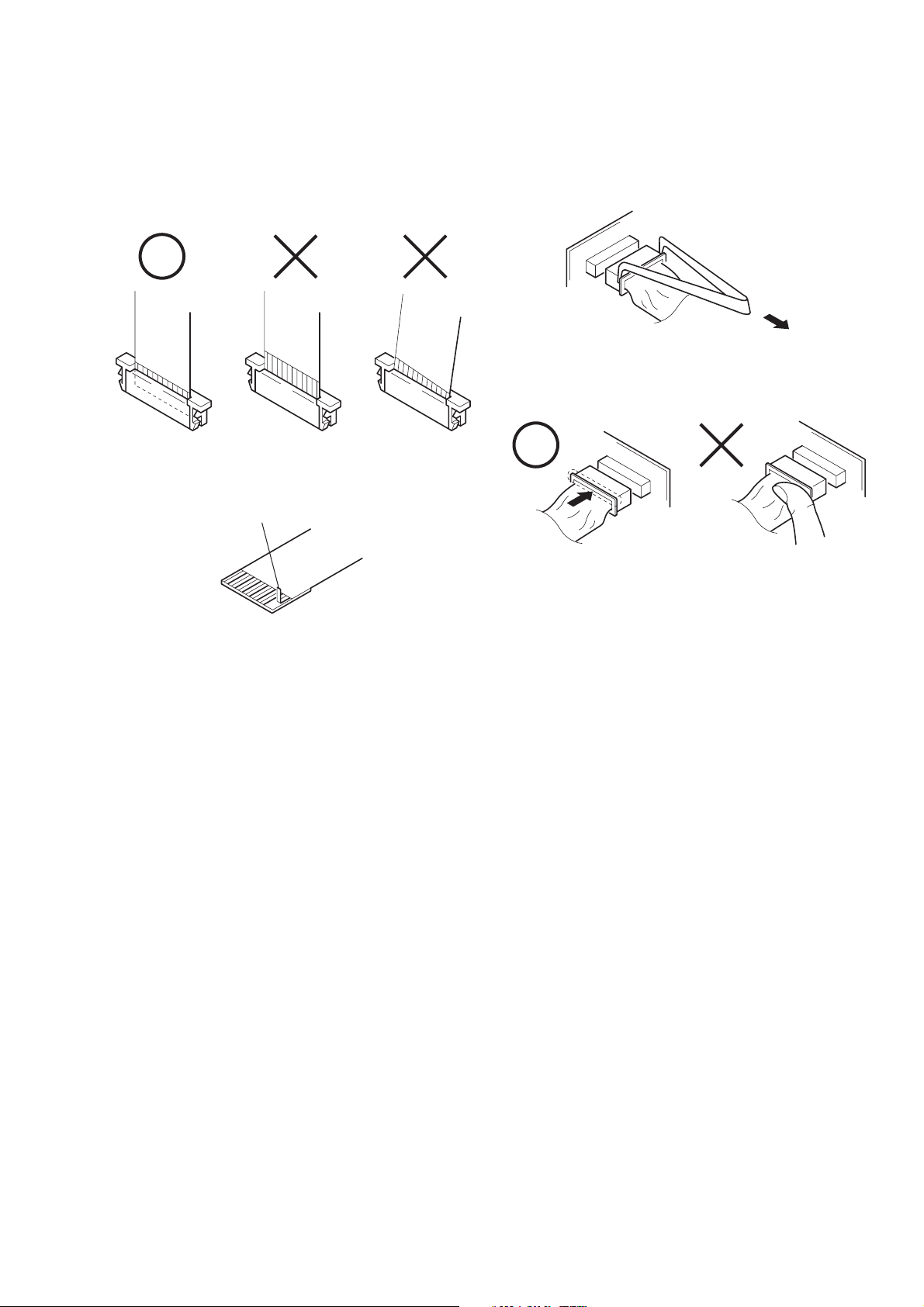

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

1-1

DCR-VX2100/VX2100E

1-2. SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated po wer supply (8.4V), the power is shut of f so

that the unit cannot operate.

These following two methods are available to prevent this. Take note of which to use during repairs.

Method 1.

Connect the servicing remote commander RM-95 (J-6082-053-B) to the LANC jack, and set the commander switch to the “ADJ” side.

Method 2.

Use the DC IN terminal. (Use the AC power adaptor. (AC-L10, AC-VQ800 etc. ))

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to page 2-3 to remove the upper handle block assembly.

2 Refer to page 2-6 to remove the cabinet (L) assembly.

3 Refer to page 2-6 to remove the mechanism deck (Including VC-358 board and DD-216 board).

4 Remove DD-216 board from the mechanism deck (Including VC-358 board).

5 Remove the CN022 (27P 0.3 mm) of VC-358 board.

6 Supply +4.5V from the DC power supply to the loading motor and unload with a pressing the cassette compartment.

DC power supply (+4.5V)

Disconnect from CN022 (27P)

of VC-358 board.

: loading

: unloading

Loading motor

1-2

DCR-VX2100/VX2100E

1-3. SELF-DIAGNOSIS FUNCTION

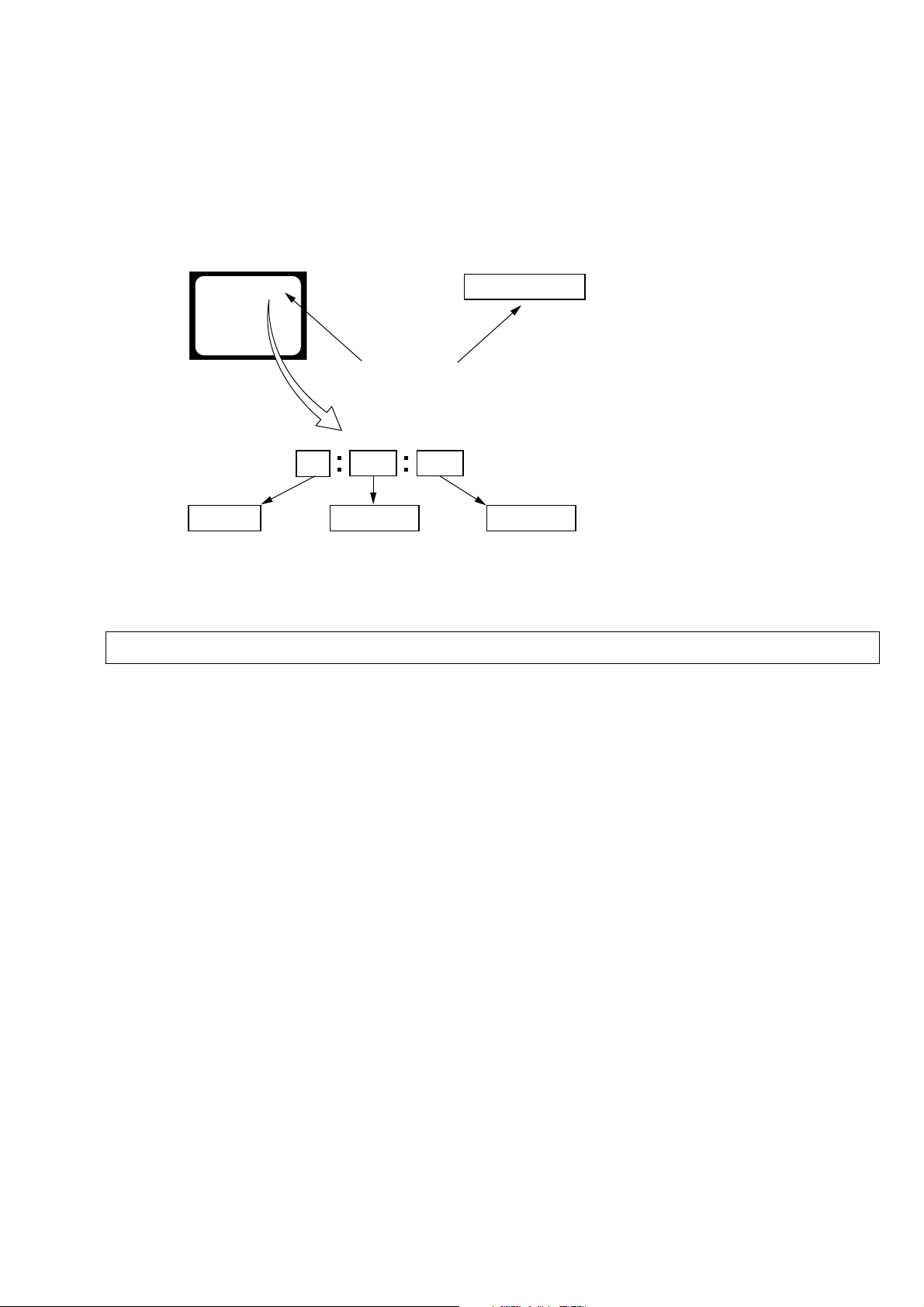

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewf inder, LCD screen

or LCD window what to do. This function consists of two display;

self-diagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen LCD window

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

3 1

Block

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder, LCD screen or LCD window consists of an alphabet

and 4-digit numbers, which blinks at 3.2 Hz. This 5-character display

indicates the “repaired by:”, “block” in which the problem occurred,

and “detailed code” of the problem.

C : 3 1 : 11

Detailed Code

Refer to

"Self-diagnosis Code Table".

Note: The “self-diagnosis display” data will be backed up by the coin-type lithium battery of ZM-030 board BT801, 802. When the (upper) handle block

is removed, the “self-diagnosis display” data will be lost by initialization.

1-3

DCR-VX2100/VX2100E

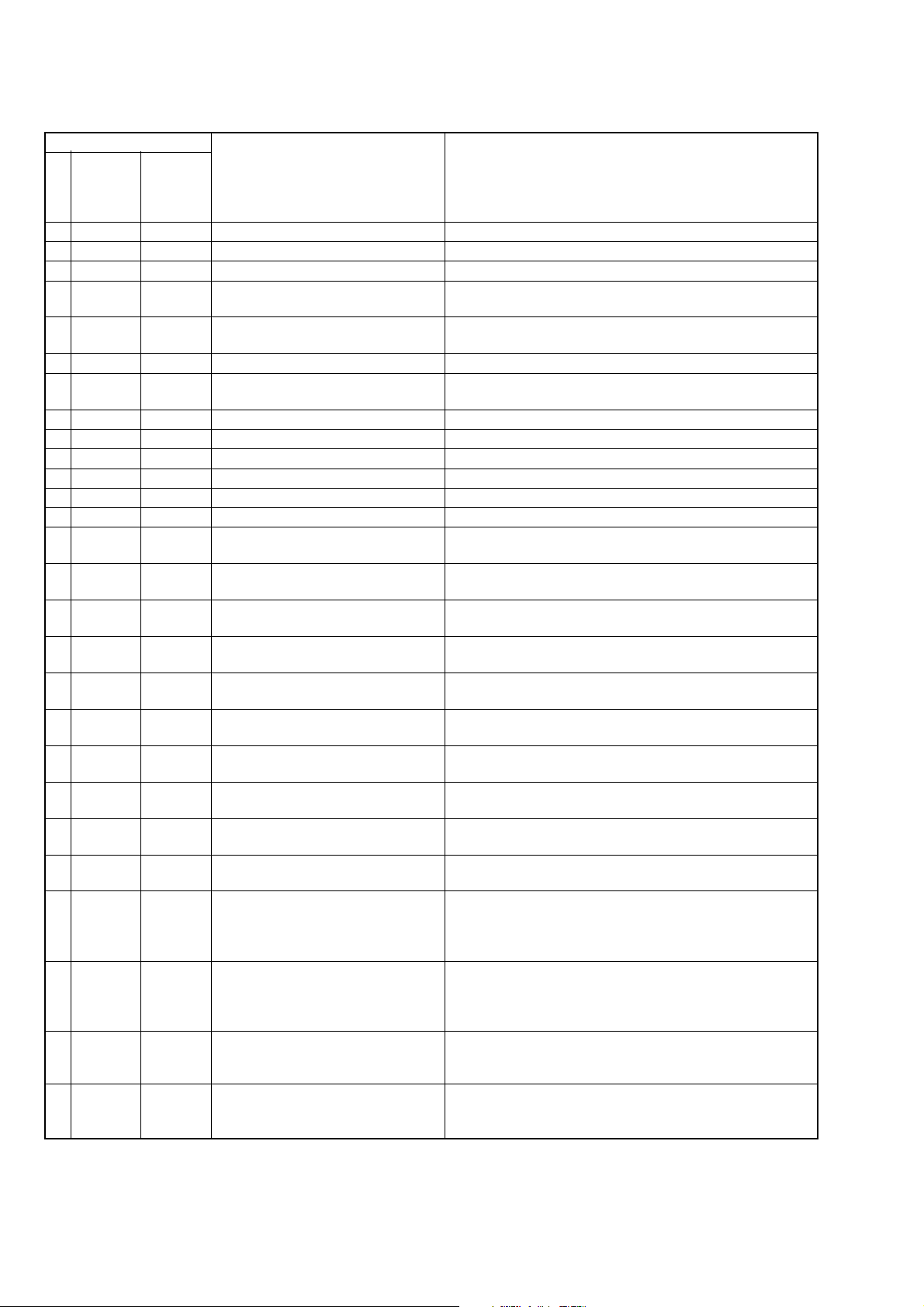

3. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

Block

Function

04

21

22

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

61

61

62

62

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

10

00

01

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular v elocity sensor output

stopped.)

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Inspect the lens block focus reset sensor (Pin wg of LA-028 board)

when focusing is performed when the focus ring is rotated in the

focus manual mode, and the focus motor drive circuit (IC140 of

LA-028 board) when the focusing is not performed.

Inspect the lens block zoom reset sensor (

when zooming is performed when the zoom lens is operated and

the zoom motor drive circuit (IC140 of LA-028 board) when

zooming is not performed.

Inspect pitch angular velocity sensor (SE601 of SE-147 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE600 of SE-147 board)

peripheral circuits.

Pin ws of LA-028 board

)

1-4E

SECTION 2

DISASSEMBLY

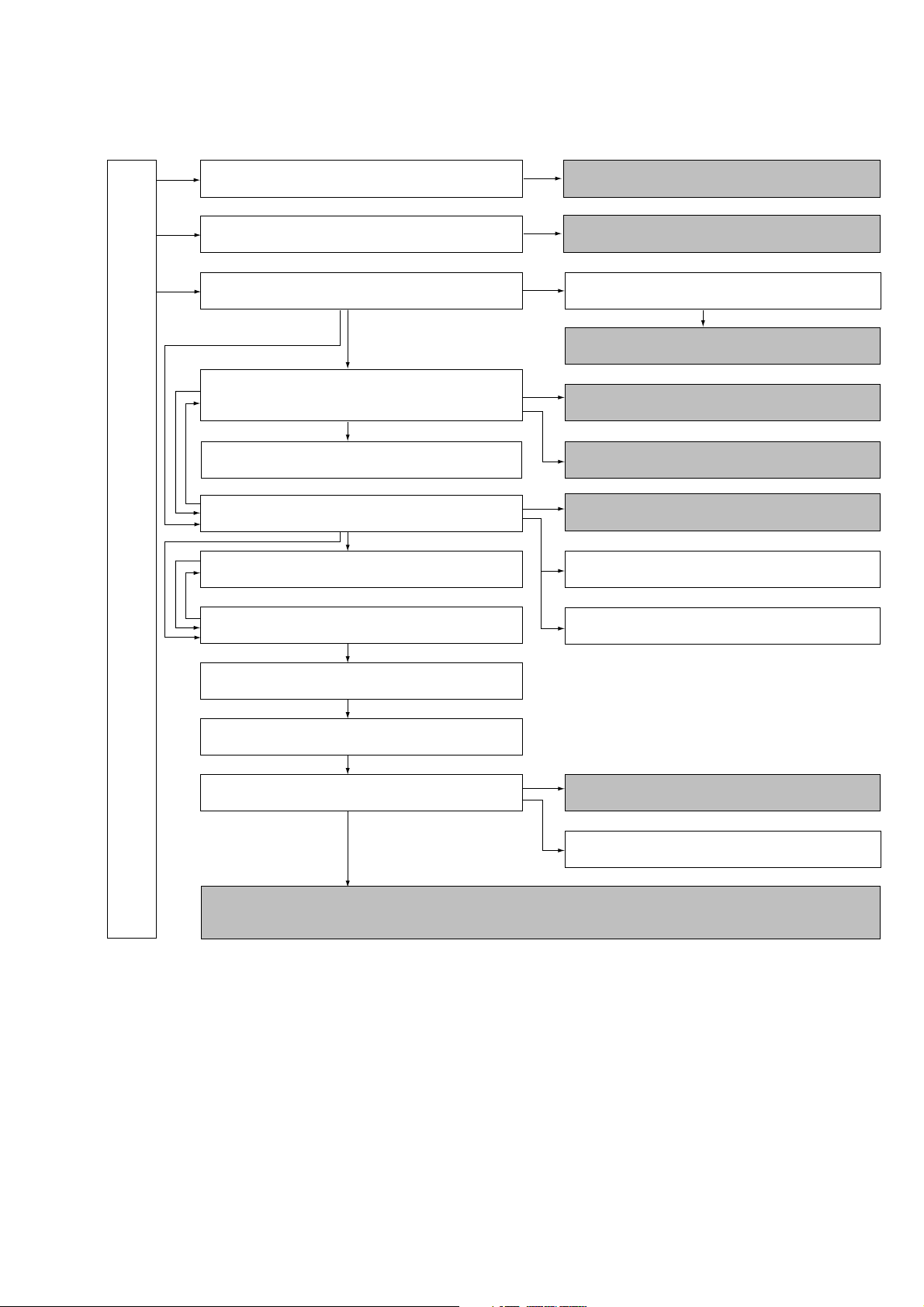

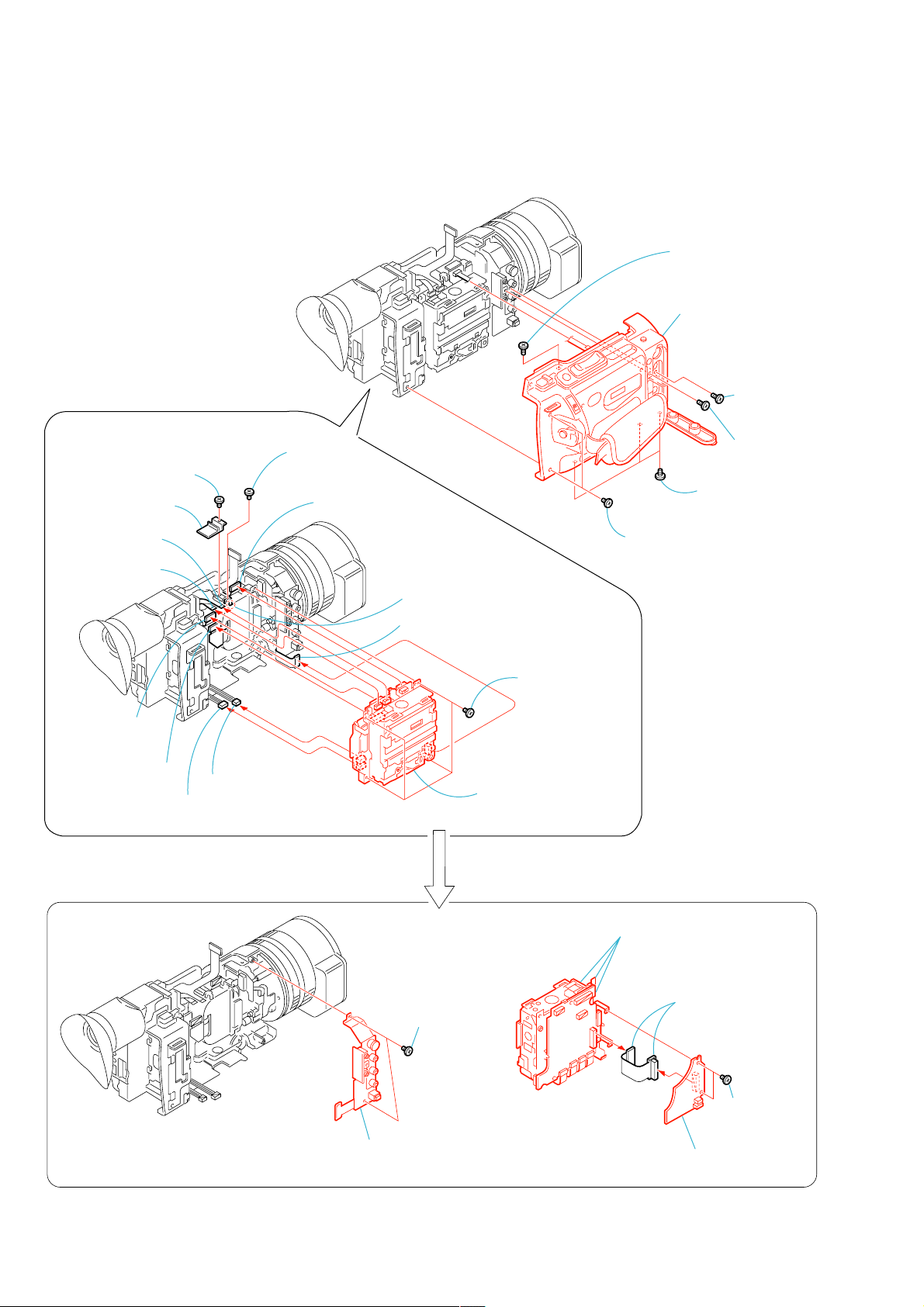

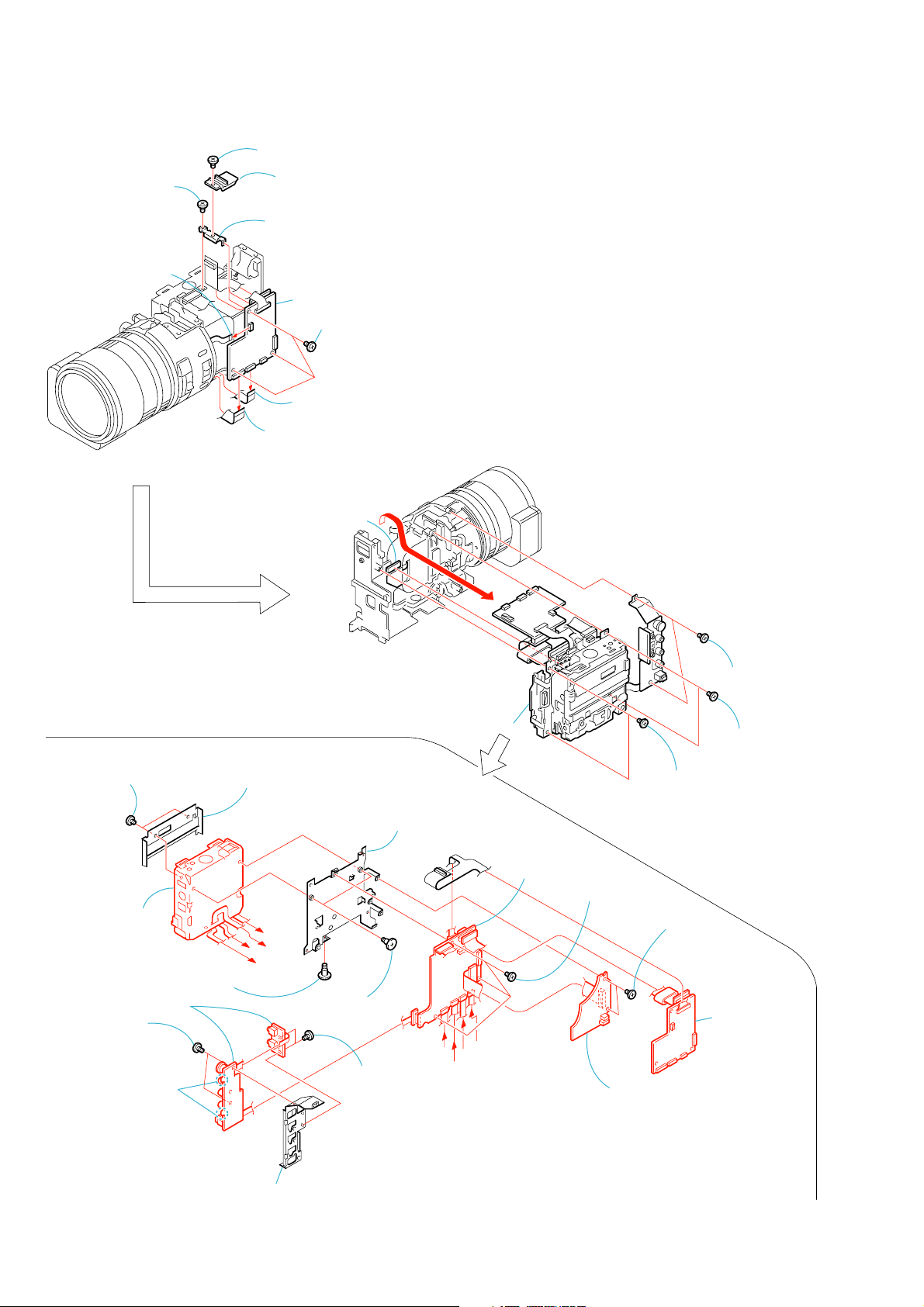

The following flow chart shows the disassembly procedure.

DCR-VX2100/VX2100E

2-1. LCD section

(HL-013, PD-217 boards, Inverter transformer unit)

2-2. EVF section (LB-100 board)

2-3. (Upper) handle block assembly

2-5. Cabinet (L) block assembly, Mechanism deck,

VC-358, DD-216, JK-267 boards

(for force eject of cassette and VTR section check)

2-13. Control switch block (PS-4980),

Control switch block (CF-4980)

2-6. Cabinet (R) block assembly

2-7. Cabinet bottom assembly 2-14. CK-140 board

DCR-VX2100/VX2100E

2-8. Battery panel block assembly

(MK-016, KP-013, MS-209 boards)

HL-013, PD-217 boards service position

LB-100 board service position

2-4. FK-080, MA-430, MI-050, FT-092, RM-091,

ZM-030 boards

FK-080, MA-430, MI-050, FT-092, RM-091 boards

service position

Mechanism deck service position-1

Service position to check the VTR section

CK-140 board service position

2-15. Control switch block (ED-4980),

Hinge assembly

2-9. EVF block assembly

2-10. LA-028, DD-216, VC-358, JK-267 boards,

Mechanism deck

2-11. Lens block assembly, Center frame assembly

[Connection diagram for service position (Mainly for voltage measurement and check)]

(CK-140, VC-358, JK-267, CD-512, DD-216, LA-028, KP-013, MK-016, MS-209 boards, Mechanism deck-2)

Service position to check the camera section

2-12. CD-512, SE-147 boards, Zoom lens assembly

2-1

DCR-VX2100/VX2100E

l

NOTE: Follow the disassembly procedure in the numerical order given.

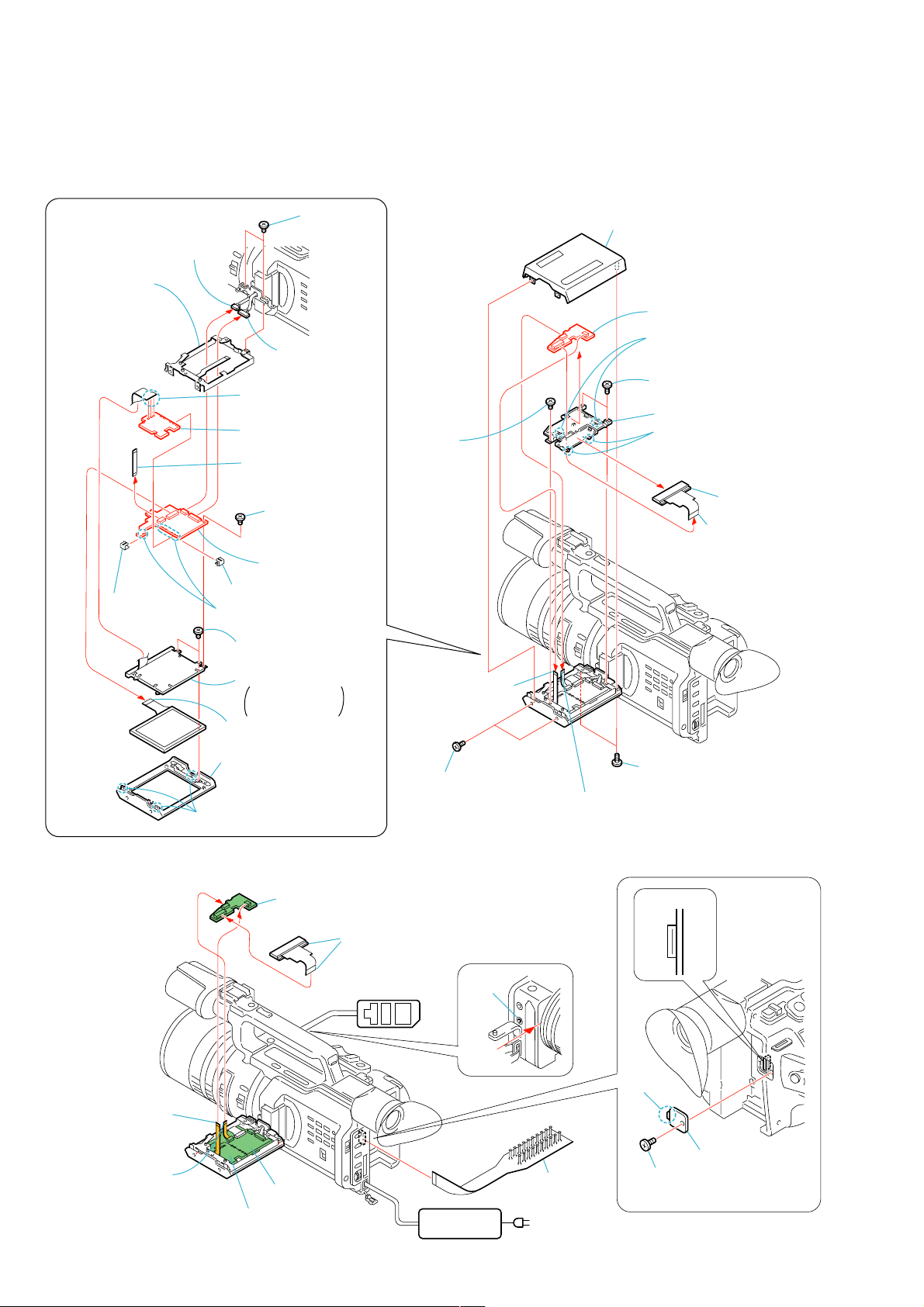

2-1. LCD SECTION (HL-013, PD-217 BOARDS, INVERTER TRANSFORMER UNIT)

REMOVING THE PD-217 BOARD,

INVERTER TRANSFORMER UNIT

2

4

Harness

(CP-093) (8P)

6

LCD frame,

BL retainer,

FP-196 flexible

board

qd

PCB clip

PD-217

Board

3

Three claws

Two screws

(M2 × 3),

lock ace

5

Harness

(CP-094) (14P)

qa

Remove the

three solderings

qh

Inverter transformer

unit

1

FP-195 flexible

board (7P)

q;

Screw

(M1.7 × 2.5),

lock ace

qj

PD-217 board

qf

PCB clip

qg

Remove the

six solderings

7

Two screws

(M1.7 × 2.5), lock ace

qs

Back light

Cold cathode

fluorescent tube

9

Liquid crystal

indicator module (24P)

8

P cabinet (M) assembly

qa

Screw

(M2 × 3),

lock ace

5

FP-196 flexible

board (5P)

2

Two screws

(M2 × 5),

lock ace

3

P cabinet (C) assembly

q;

9

B

-217

D

P

oard

B

slide the HL-013 board in

the direction of the arrow B.

1

(M2 × 5), lock ace

4

FP-195 flexible

board (7P)

HL-013 board

Release the two claws and

qs

Two screws

(M2 × 3), lock ace

qd

Panel holder

7

Release the two claws and

slide the indication panel

block assembly in the

direction of the arrow A.

A

Two screws

8

Indication pane

block assembly

6

FP-205 flexible

board (21P)

[HL-013, PD-217 BOARDS SERVICE POSITION]

HL-013 board

Indication panel

block assembly (21P)

Adjustment remote

commander (RM-95)

FP-196

flexible board (5P)

-217

D

P

oard

B

FP-195

flexible board (7P)

PD-217 board

Inverter transformer unit

LANC

jack

AC POWER

ADAPTOR

2-2

CPC-13 jig

(J-6082-443-A)

AC IN

CN007

20

1

2

Claw

1

Screw

(M2 × 5),

lock ace

3

CPC cover

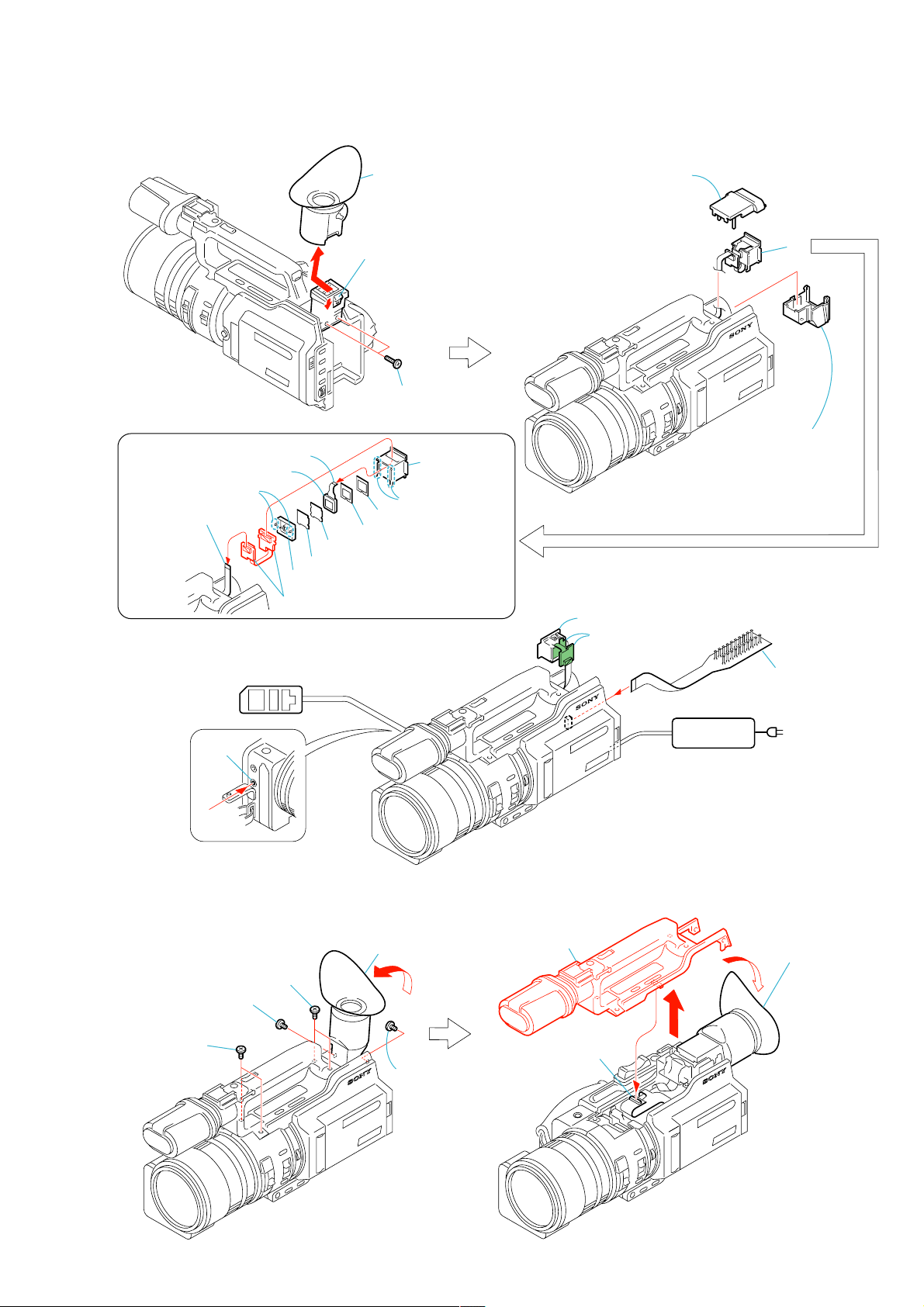

2-2. EVF SECTION (LB-100 BOARD)

A

B

1

Push the lock knob

in the direction of the

arrow

A

and remove the

EVF rear cabinet assembly

in the direction of the

arrow B.

2

EVF rear

cabinet assembly

4

EVF front cabinet (upper)

6

5

EVF front cabinet

(lower) assembly

3

Two tapping

screws (M1.7 × 8)

5

Lamp guide (20)

7

Illuminator

8

Prism sheet

q;

Light interception sheet

qa

LCD cushion

1

FP-193

flexible board (27P)

2

LCD (LCX033ANA-1)(16P)

qs

LCD holder

assembly

3

Two claws

4

Two claws

6

LB-100 board

9

LCD (LCX033ANA-1)

REMOVING THE LB-100 BOARD

LB-100 board

LCD holder assembly

Adjustment remote

commander (RM-95)

LANC

jack

AC POWER

ADAPTOR

AC IN

CPC-13 jig

(J-6082-443-A)

[LB-100 BOARD SERVICE POSITION]

DCR-VX2100/VX2100E

2-3. (UPPER) HANDLE BLOCK ASSEMBLY

2

Two screws

(M2 × 5),

lock ace

3

Screw (M2 × 5),

lock ace

1

Two screws

(M2 × 5),

lock ace

4

Tilt up the finder.

5

Screw

(M2 × 5),

lock ace

(Upper) handle

9

block assembly

8

FP-895 flexible

board (40P)

7

6

Tilt down the finder.

2-3

DCR-VX2100/VX2100E

d

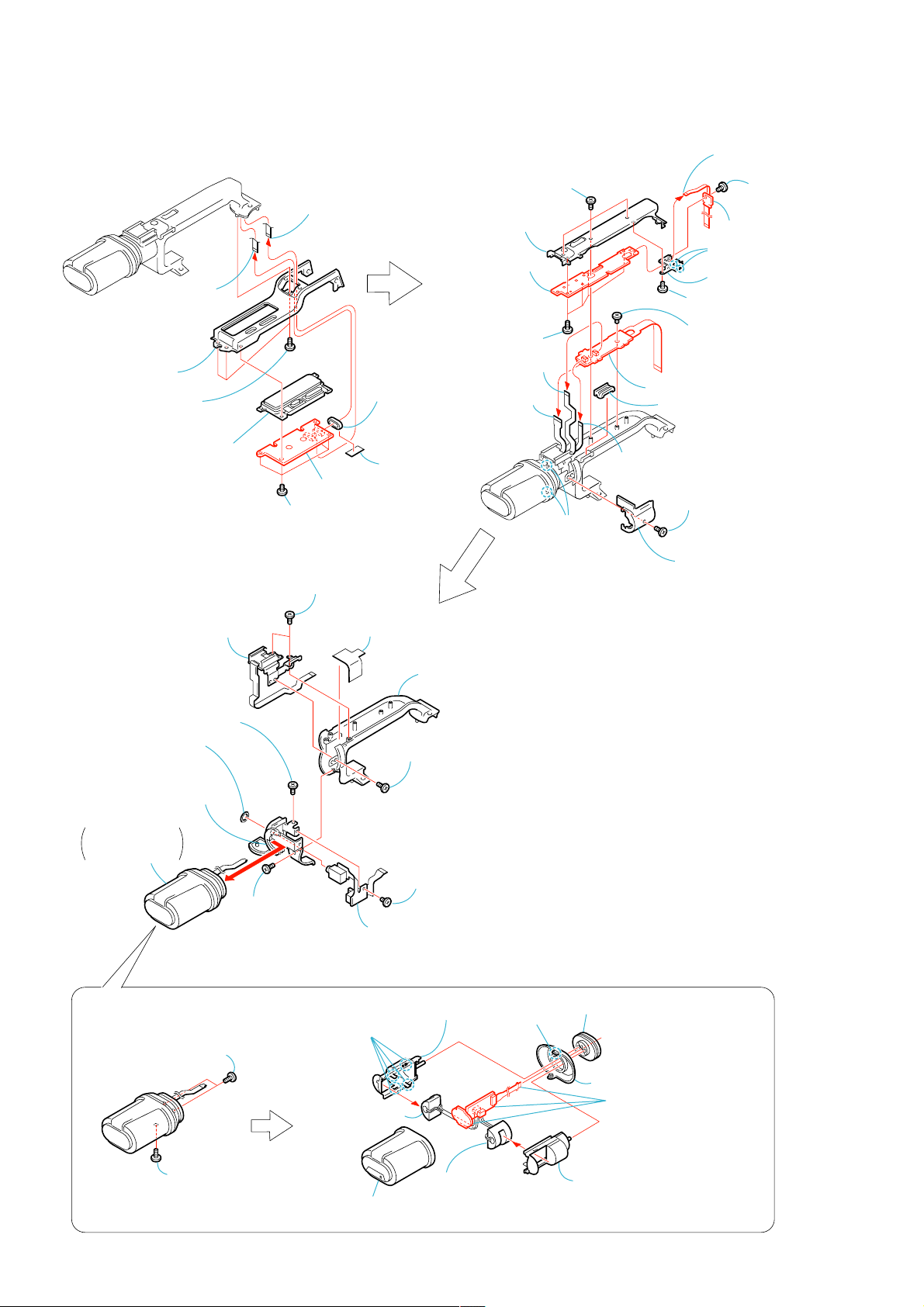

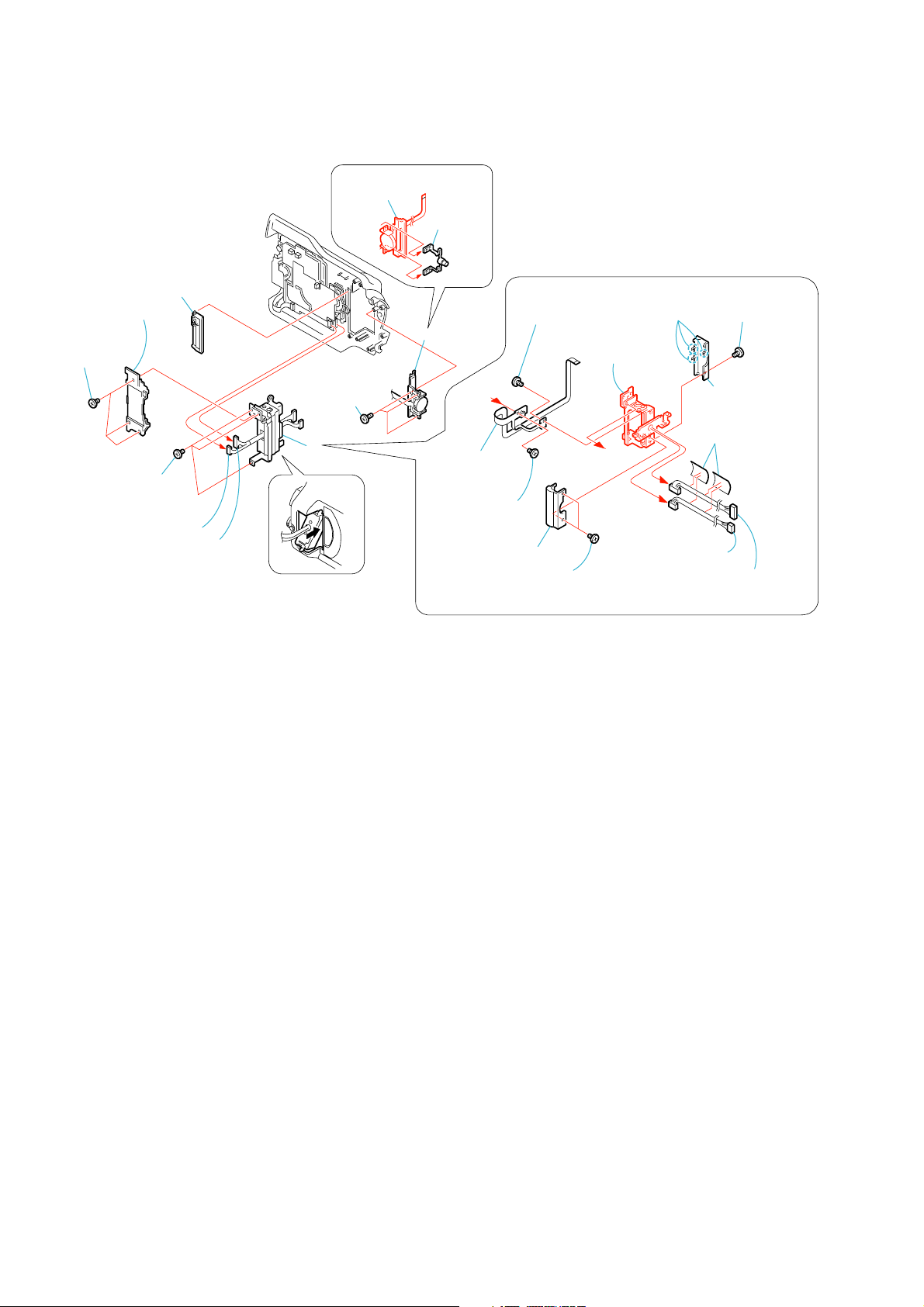

2-4. FK-088, MA-430, MI-050, FT-092, RM-091, ZM-030 BOARDS

1

Three screws

(M2 × 5),

lock ace

1

3

MA-430

board (23P)

9

Cabinet (upper)

5

Three screws

×

(M2

spring bolt

3

Strap sheet metal,

FP-896 flexible board

5),

8

FK frame

assembly

Outer connector (hot shoe),

RM-091

board (21P)

7

FK-088 board

6

Four screws

(M2 × 3),

spring bolt

1

Two screws

(M2

lock ace

4

core

×

5),

4

sheet

Ferrite

2

Sheet

Microphon

5

Handle cover

assembly

7

ZM-030 board

3

Four tapping

screws (B2 × 5)

qd

FP-896 flexible

board (15P)

qg

FP-893 flexible

board (20P)

qk

Two

claws

4

screw (B2 × 5)

qs

lock ace

qh

MA-430 board

2

Cap (ST)

qf

FP-894 flexible

board (15P)

qj

(M2

lock ace

ql

Microphone

cabinet (L)

6

RM-091

board (7P)

8

Tapping

screw

(B2 × 5)

qa

RM-091 boar

9

Two claws

q;

RM fixed

holder assembly

Tapping

Screw (M2 × 3),

Screw

×

5),

7

Screw

(M2

lock ace

q;

Nut (M6 × 0.5)

qs

Microphone

cabinet (R) assembly,

Microphone terminal bracket,

Microphone knob

5

Remove it in the

direction of the

arrow

A

.

1

Two tapping

screws (B2

8

Handle

assembly

×

5),

2

Screw

(M2 × 5),

lock ace

9

A

6

Screw

(M2 × 5),

lock ace

qa

flexible board

Screw

(M2 × 3),

lock ace

FP-893

REMOVING THE MI-050, FT-092 BOARDS

9

Microphone case

7

×

5)

8

unit (R)

Four claws

Microphone

4

Claw

3

Rubber neck

assembly

5

Microphone cover

qs

FP-894 flexible board,

MI-050 board,

FT-092 board

2

Tapping

screw (B2 × 5)

q;

Microphone

6

Microphone

mask assembly

unit (L)

2-4

qa

Microphone case

DCR-VX2100/VX2100E

FT-092 board

MI-050 board

FP-894 flexible

board (15P)

Microphone unit (L)

Microphone unit (R)

FP-893

flexible board

MA-430 board

ZM-030 board

RM-091 board

FK-088 board

Adjustment remote

commander (RM-95)

LANC

jack

AC POWER

ADAPTOR

AC IN

CPC-13 jig

(J-6082-443-A)

[FK-088, MA-430, MI-050, FT-092, RM-091 BOARDS SERVICE POSITION]

2-5

DCR-VX2100/VX2100E

2-5. CABINET (L) BLOCK ASSEMBLY, MECHANISM DECK,

VC-358, DD-216, JK-267 BOARDS

(FOR FORCE EJECT OF CASSETTE AND VTR SECTION CHECK)

(FOR FORCE EJECT OF CASSETTE)

4

(M2 × 3),

lock ace

5

Flexible retainer

2

FP-895 flexible

board (13P)

1

FP-193 flexible

board (27P)

Screw

3

Screw

(M2

×

3),

lock ace

6

FP-187 flexible

board (50P)

q;

Claw

3

Screw

(M2 × 5),

spring bolt

6

block assembly

4

Two screws

(M2 × 3),

spring bolt

Cabinet (L)

1

Screw

(M2 × 5),

lock ace

2

Screw

(M2 × 5),

spring bolt

5

Three screws

(M2

×

5),

spring bolt

7

FP-186 flexible

board (80P)

qa

CD-512 board

(50P)

qd

DC-IN connector (3P)

qs

Battery terminal board (4P)

(FOR VTR SECTION CHECK)

8

JK-267 board (40P)

qf

VC-358, DD-216 board,

MD frame assembly

1

Two screws

(M2 × 5),

spring bolt

9

Four screws

(M2 × 3),

EG grip

Mechanism deck,

-358

C

V

oard

B

6

Mechanism deck,

VC-358 board,

MD frame assembly

4

FP-191 flexible

board (60P)

2

JK-267 board,

JK frame

2-6

DD216

5

DD-216 board

3

Two screws

(M2 × 3),

lock ace

[MECHANISM DECK SERVICE POSITION-1]

Note: Use the parts only which can be removed easily from outside of the mechanism deck.

Adjustment remote

commander (RM-95)

DCR-VX2100/VX2100E

Mechanism deck

AC POWER

ADAPTOR

Cabinet (L) block assembly

CPC-13 jig

(J-6082-443-A)

AC IN

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section

To check the VTR Section, set the VTR to the "forced VTR power ON" mode.

Operate the VTR functions using the adjustment remote commander (with the HOLD switch set in the OFF position)

(However, connect the cabinet (L) assembly when cassette is going to be ejected only.)

Setting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 02, and press

the PAUSE button of the adjustment remote

commander.

Exiting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 00, and press

the PAUSE button of the adjustment remote

commander.

3) Select page: 0, address: 01, and set data: 00.

AC IN

CPC-13 jig (J-6082-443-A)

Connect here when the tape path

check is going to be performed.

AC POWER

ADAPTOR

Cabinet (L) block assembly

DC-IN

connector (3P)

(1-794-637-11)

Mechanism deck

DD-216 board

FP-191 flexible board (60P)

Insert the FP-191 flexible board in the opposite

direction to the normal insertion direction.

VC-358 board

-358

VC

oard

B

LANC jack

Control switch block (CF-4980) (14P)

(Connect here when cassette is going to be ejected.)

JK-267 board

VIDEO jack

Adjustment remote

commander (RM-95)

Monitor TV

2-7

DCR-VX2100/VX2100E

)

2-6. CABINET (R) BLOCK ASSEMBLY

4

Two screws

(M2

×

spring bolt

5),

5

Screw

×

(M2

spring bolt

5),

7

Cabinet (R) block assembly

6

Two screws

(M2 × 5),

spring bolt

1

Screw

(M2

×

spring bolt

3

2

Claw

5),

CF ornamental plate

[CK-140 BOARD SERVICE POSITION]

Adjustment remote

commander (RM-95)

LANC

jack

2-7. CABINET BOTTOM ASSEMBLY

CK-140

Cabinet (R) block assembly

REMOVING THE FBS COVER

Board

CK-140 board

AC POWER

ADAPTOR

CPC-13 jig

(J-6082-443-A

AC IN

3

Tripod table

2

Four screws

(M2 × 5),

lock ace

1

FP-189

flexible board (6P)

5

Cabinet bottom

assembly

4

Two screws

(M2 × 5),

lock ace

2-8

1

Two tapping screws

×

(B2

2

FP-189

flexible board

5)

3

Two tapping screws

(B2

4

×

5)

5

FBS cover

Cabinet (bottom)

DCR-VX2100/VX2100E

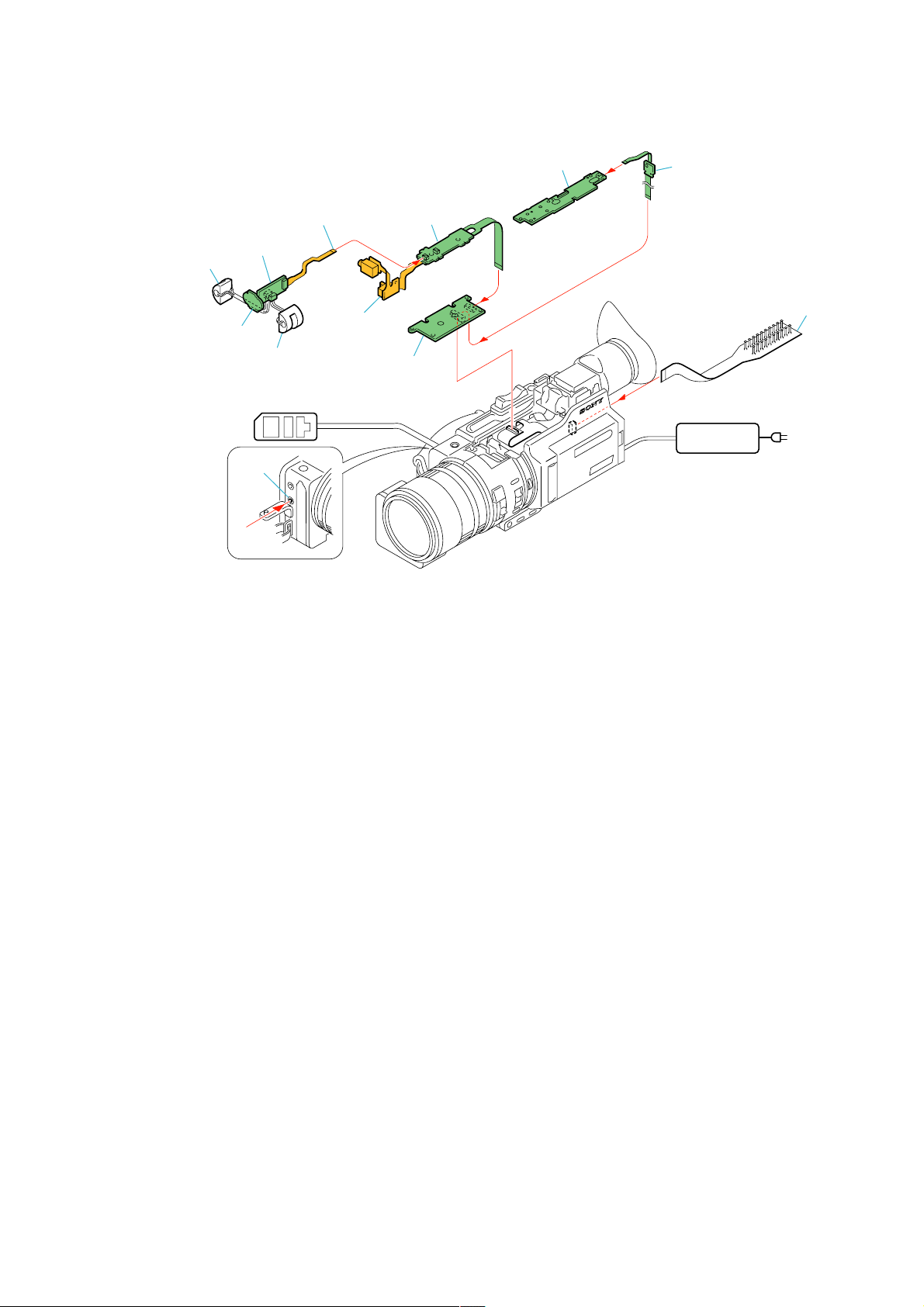

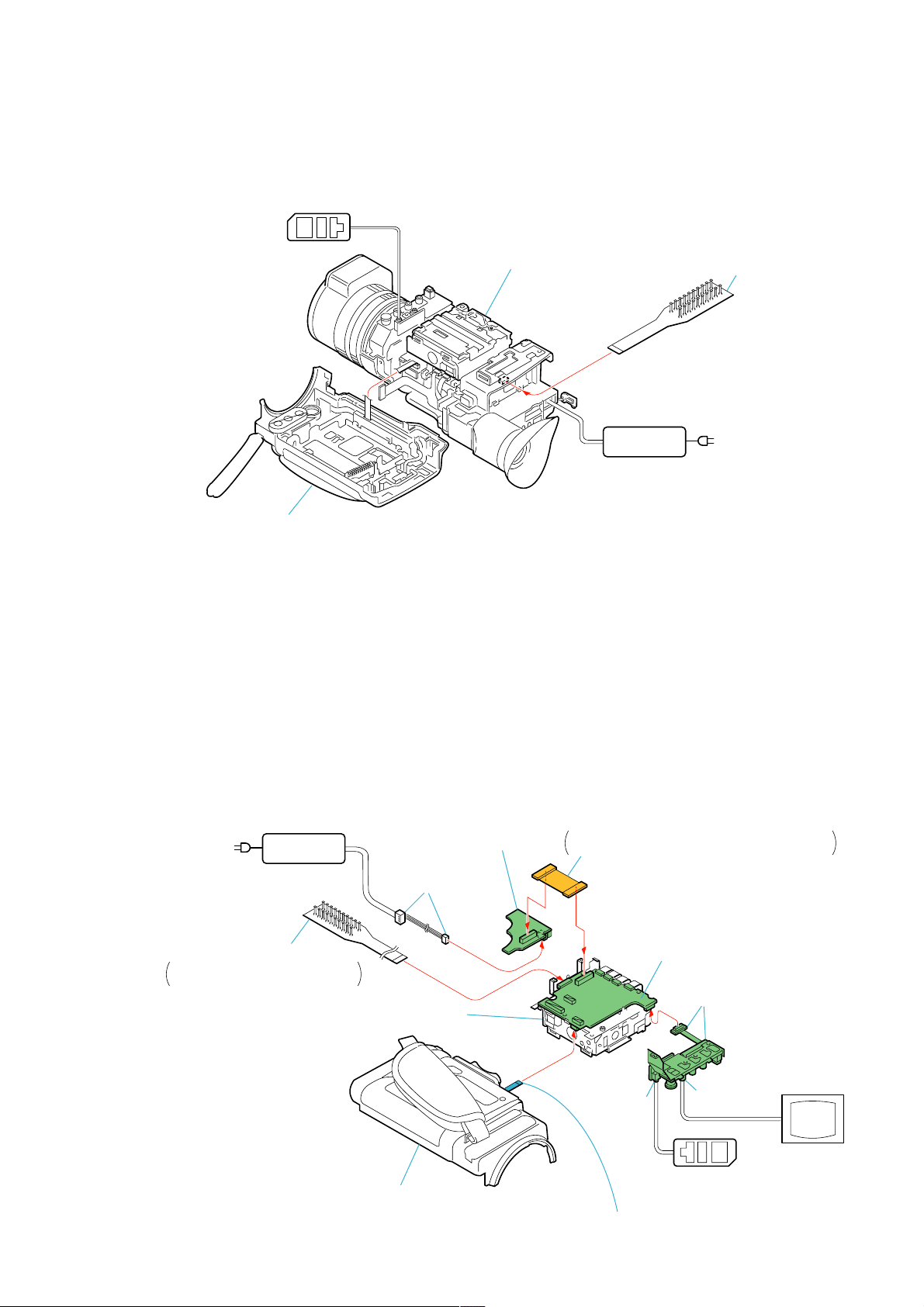

2-8. BATTERY PANEL BLOCK ASSEMBLY (MK-016, KP-013, MS-209 BOARDS)

9

CPC cover

q;

Battery panel

block assembly

8

Screw (M2 × 5),

lock ace

7

Two screws

(M2 × 5),

lock ace

6

Two screws

(M2 × 5),

lock ace

4

Screw (M2 × 3),

lock ace

qa

DC jack retainer

q;

screws (B2

9

MS holder assembly

8

Two tapping

screws (B2

7

MS-209 board

LA-028

board

qs

DC-IN connector

Two tapping

×

5)

6

Two screws

(M2 × 3),

lock ace

1

FP-190

flexible board (20P)

5

Screw (M2 × 5),

lock ace

2

DC-IN connector (3P)

3

Battery terminal board (4P)

PRECAUTION DURING

INSTALLATION

×

5)

A

When installing it,

align the switch position

as shown.

3

S-209

M

Board

A

2

1

5

4

MK-016 board

MK retainer

Two tapping screws (B2 × 5)

KP-013 board

Screw (M2 × 3),

lock ace

2-9. EVF BLOCK ASSEMBLY

1

FP-193

flexible board (27P)

6

Two screws

(M2

lock ace

8

2

-0

A

L

rd

a

o

b

×

3),

2-9

7

4

Peel off the area

shown by shading.

3

Claw

2

Screw (M2 × 3),

lock ace

5

Flexible clamp

EVF block assembly

DCR-VX2100/VX2100E

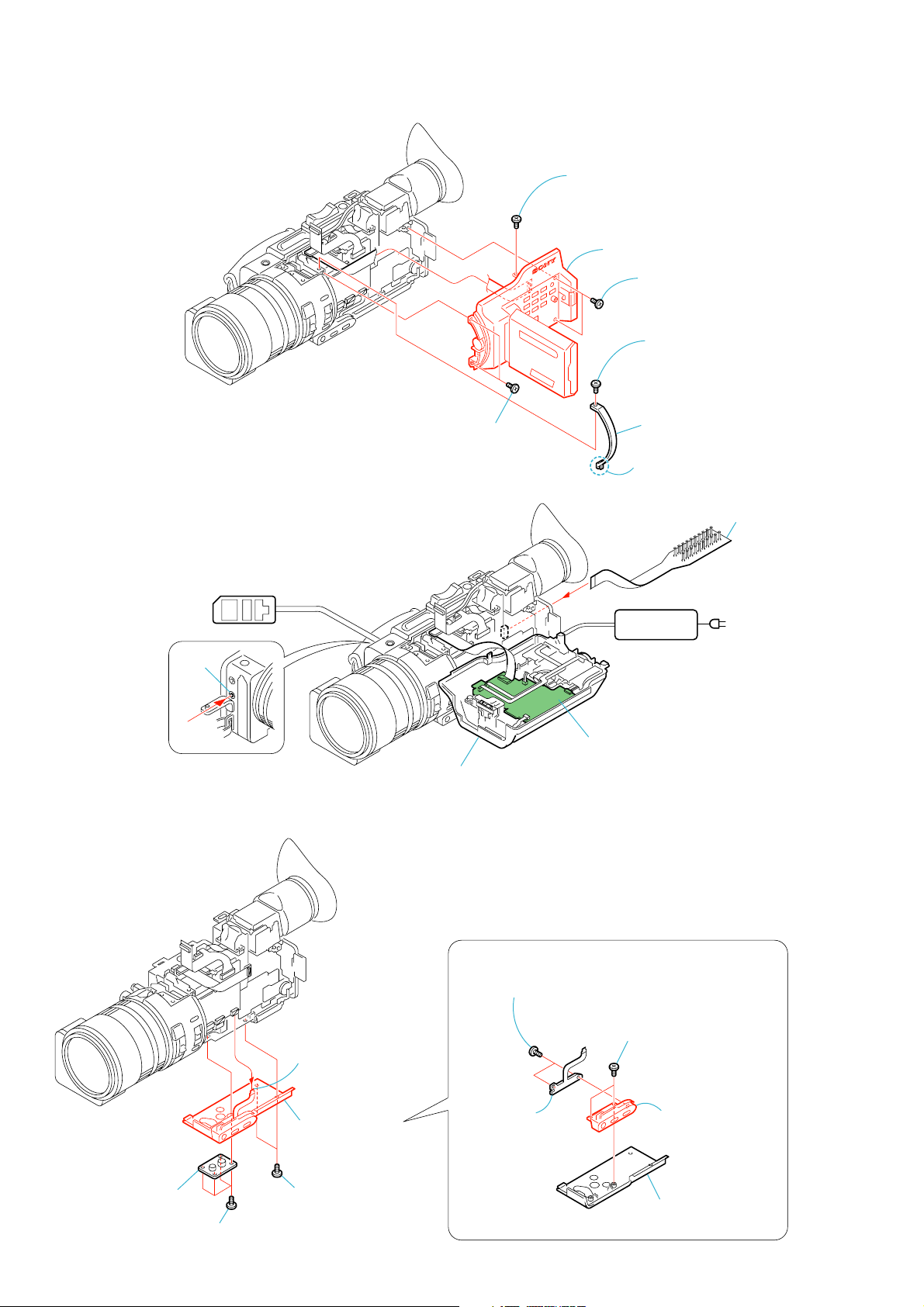

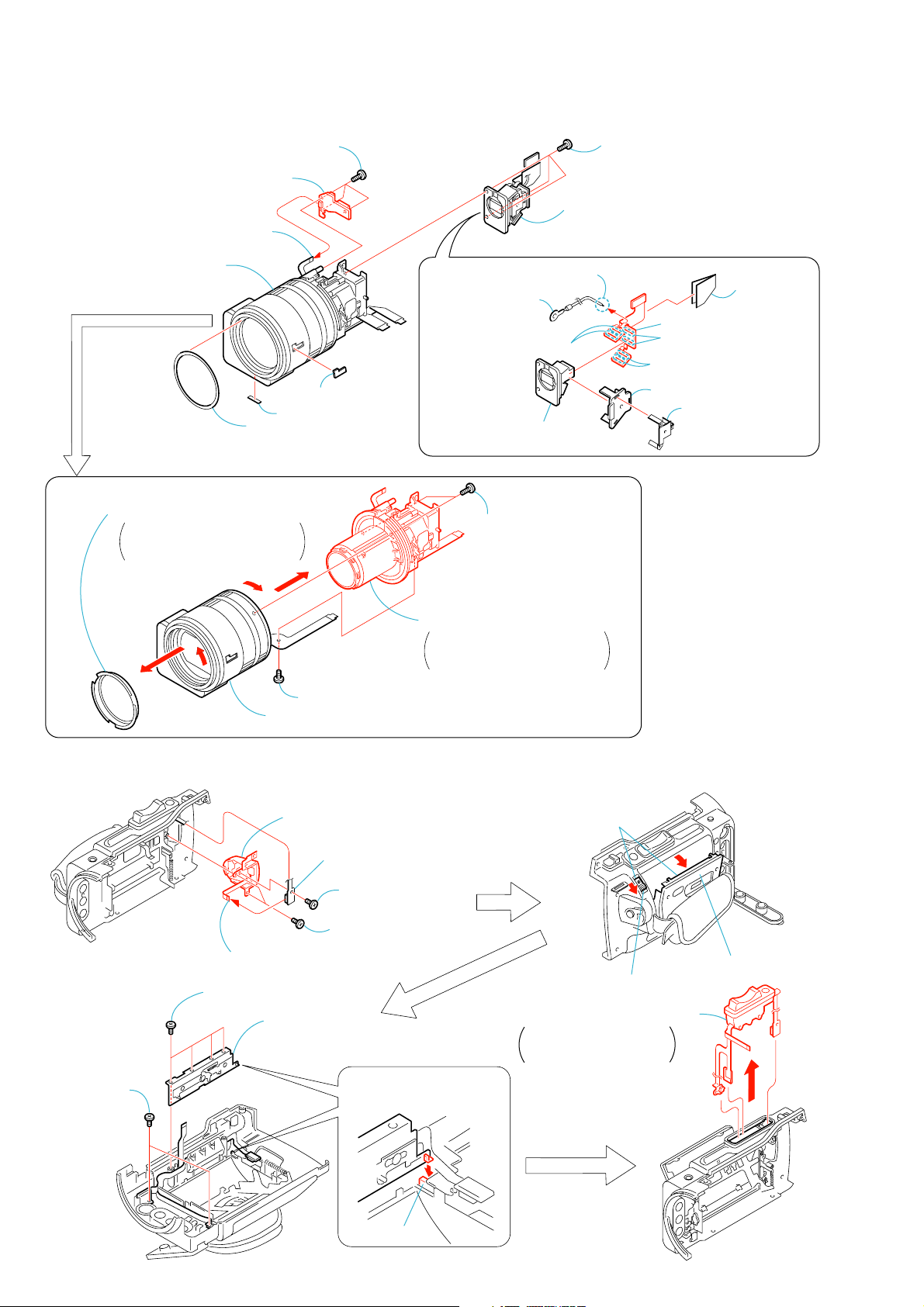

2-10.LA-028, DD-216, VC-358, JK-267 BOARDS, MECHANISM DECK

1

Screw (M2 × 3),

lock ace

2

8

Screw (M2 × 3),

lock ace

3

FP-188

flexible board (6P)

LA-028

Board

Flexible retainer

9

LA joint

LA-028 board

7

6

Three screws

(M2 × 3),

lock ace

5

Flexible board (27P)

(from VAP assembly)

4

Flexible board (39P)

(from zoom lens assembly)

8

Two screws (M2 × 2),

lock ace

q;

Mechanism deck

qg

JK-267 board

qs

Two screws

(M2 × 3),

lock ace

qd

Two claws

6

Step

screw (M2)

1

CD-512 board (50P)

9

LD outer lid

A

B

C

D

5

Two step

screws (M2)

7

MD frame assembly

qa

Two screws

(M2 × 3),

lock ace

VC-358

Board

D

C

B

A

LA-028

Board

5

4

VC-358 board

2

Two screws

(M2 × 3),

EG grip

3

Three screws

(M2 × 3), lock ace

1

Two screws

(M2 × 3),

lock ace

DD216

LA-028

Board

2

DD-216 board

4

Two screws

(M2

×

spring bolt

5),

3

Two screws

(M2 × 3),

EG grip

(LA-028 board)

qf

JK frame

2-10

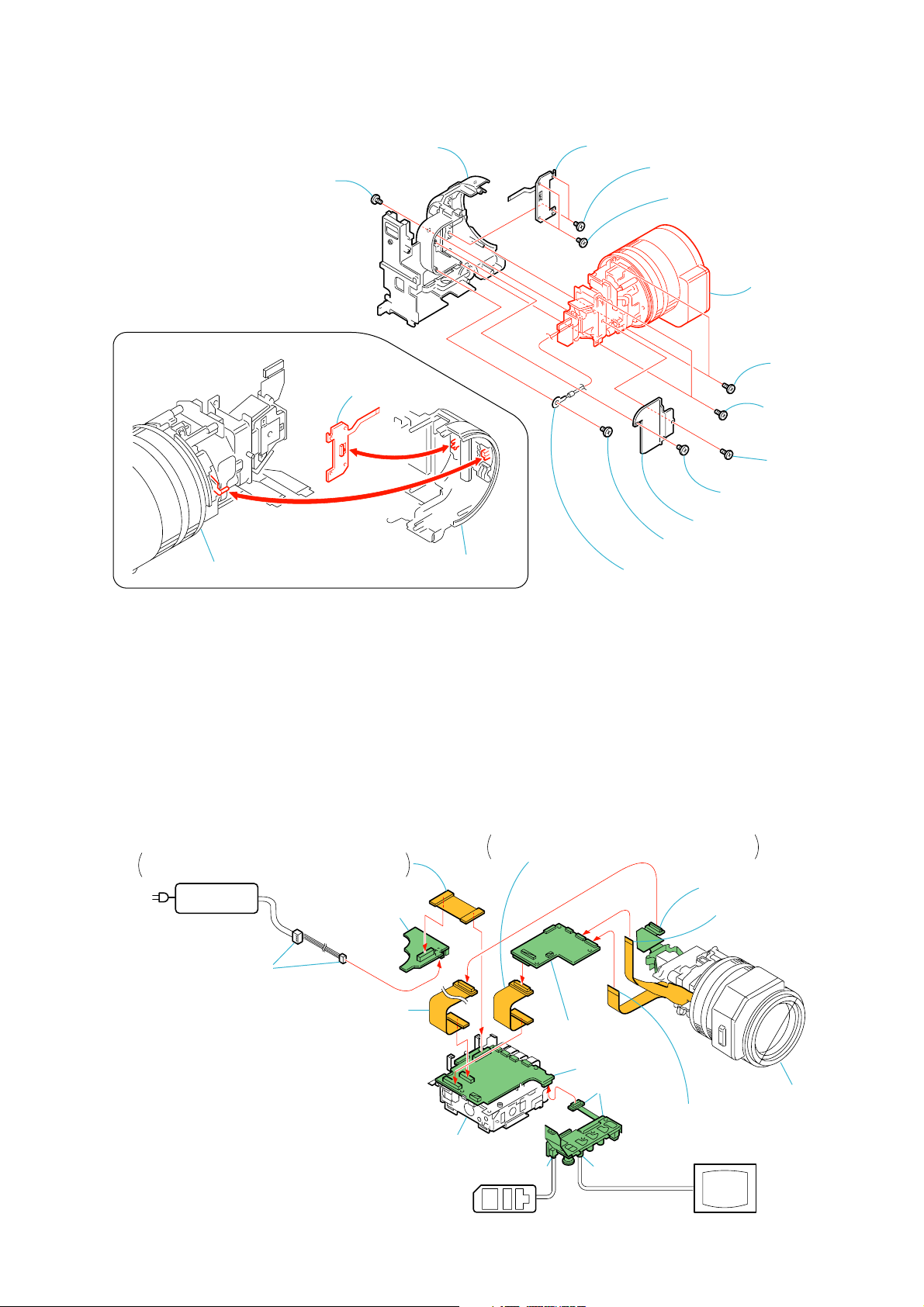

2-11.LENS BLOCK ASSEMBLY, CENTER FRAME ASSEMBLY

1

Screw (M2 × 3),

lock ace

q;

Two screws (M2 × 4),

lock ace

qa

Two screws (M2 × 3),

lock ace

qs

FP-188 flexible board (6P)

FP-188 flexible board

qd

Center frame assembly

Center frame assembly

6

Screw

(M2 × 3),

lock ace

7

Two screws

(M2 × 5),

EG grip

8

Two screws

(M2 × 5),

EG grip

4

Screw (M2 × 3),

lock ace

5

CJ-064 harness

9

Lens block assembly

Lens block assembly

2

Tapping screw

(B2

×

5)

3

CCD cover

When installing it.

Align the swich position.

PRECAUTION DURING INSTALLATION

y

DCR-VX2100/VX2100E

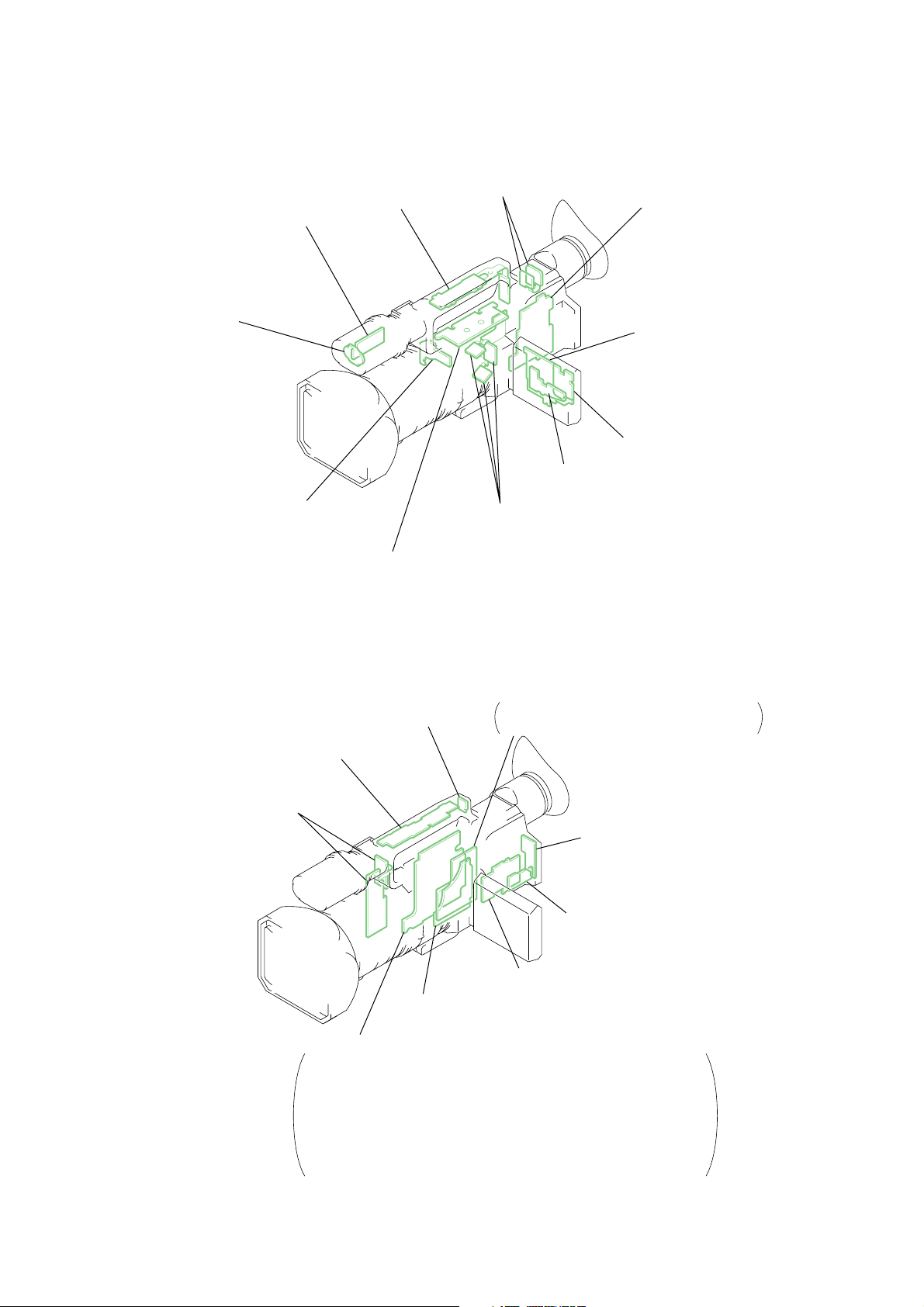

[SERVICE POSITION TO CHECK THE CAMERA SECTION]

Connection to Check the CAMERA Section

To check the CAMERA Section, set the CAMERA to the "forced CAMERA power ON" mode.

Setting the “Forced CAMERA Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 01, and press

the PAUSE button of the adjustment remote

commander.

FP-191 flexible board (60P)

Insert the FP-191 flexible board in the opposite

direction to the normal insertion direction.

AC IN

AC POWER

ADAPTOR

DC-IN

connector (3P)

(1-794-637-21)

DD-216 board

Extension cable

(J-6082-496-A) (50P)

VC-358

Mechanism deck

LANC jack

Adjustment remote

commander (RM-95)

2-11

Exiting the “Forced CAMERA Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 00, and press

the PAUSE button of the adjustment remote

commander.

3) Select page: 0, address: 01, and set data: 00.

FP-186 flexible board (80P)

Insert the FP-186 flexible board in the opposite

direction to the normal insertion direction.

B

Board

LA

-028

oard

LA-028 board

VC-358 board

JK-267 board

Flexible board (39P)

(from zoom lens assembly)

VIDEO jack

CD-512 board (50P)

Monitor TV

Flexible board (27P)

(from VAP assembly)

Lens block assembl

DCR-VX2100/VX2100E

2-12.CD-512, SE-147 BOARDS, ZOOM LENS ASSEMBLY

4

Three tapping screws

(B2 × 5)

5

SE-147 board

3

Flexible board (6P)

(from zoom lens assembly)

9

Zoom lens

(VCL-6012WB)

6

CCD emblem

7

Rubber foot (A)

8

Name ring

REMOVING THE ZOOM LENS ASSEMBLY

8

Remove the soldering.

9

CJ-064 harness

3

Remove the

sixteen solderings.

1

Three tapping

screws (M1.7 × 7)

2

(CCD) flexible

block assembly

REMOVING THE CD-512 BOARD

q;

CD-512 board

4

Remove the

sixteen solderings.

5

Remove the

sixteen solderings.

2

Prism cover

1

CCD

6

Prism

assembly

heat sink

7

Sheet (CD)

4

Ornamental ring assembly

Rotate it in the direction of

the arrow C and remove it

in the direction of the arrow D.

A

C

D

5

B

1

Tapping screw (M1.7 × 4)

VAP assembly

3

Zoom lens assembly

Rotate it in the direction of

the arrow A and remove it

in the direction of the arrow B.

Two tapping

2

screws (B2 × 7)

2-13.CONTROL SWITCH BLOCK (PS-4980), CONTROL SWITCH BLOCK (CF-4980)

6

Push the eject knob in

the direction of the arrow,

and open the cassette lid.

Eject knob

q;

Control switch block (CF-4980)

Be careful not to damage

the control switch block's

(CF-4980) flexible.

Cassette lid

9

Two tapping

screws

(B2

×

5)

5

Control switch block

(PS-4980)

3

(CF-4980)

2

Control switch block (PS-4980)

(8P)

7

Four tapping screws

(B2

×

5)

8

Slider assembly

Control switch block

1

Tapping screw

(B2

×

5)

4

Two tapping screws

×

5)

(B2

PRECAUTION DURING

INSTALLATION

Install the slider assembly

while pushing the eject lever

fully to the left (CCW).

Eject lever

2-12

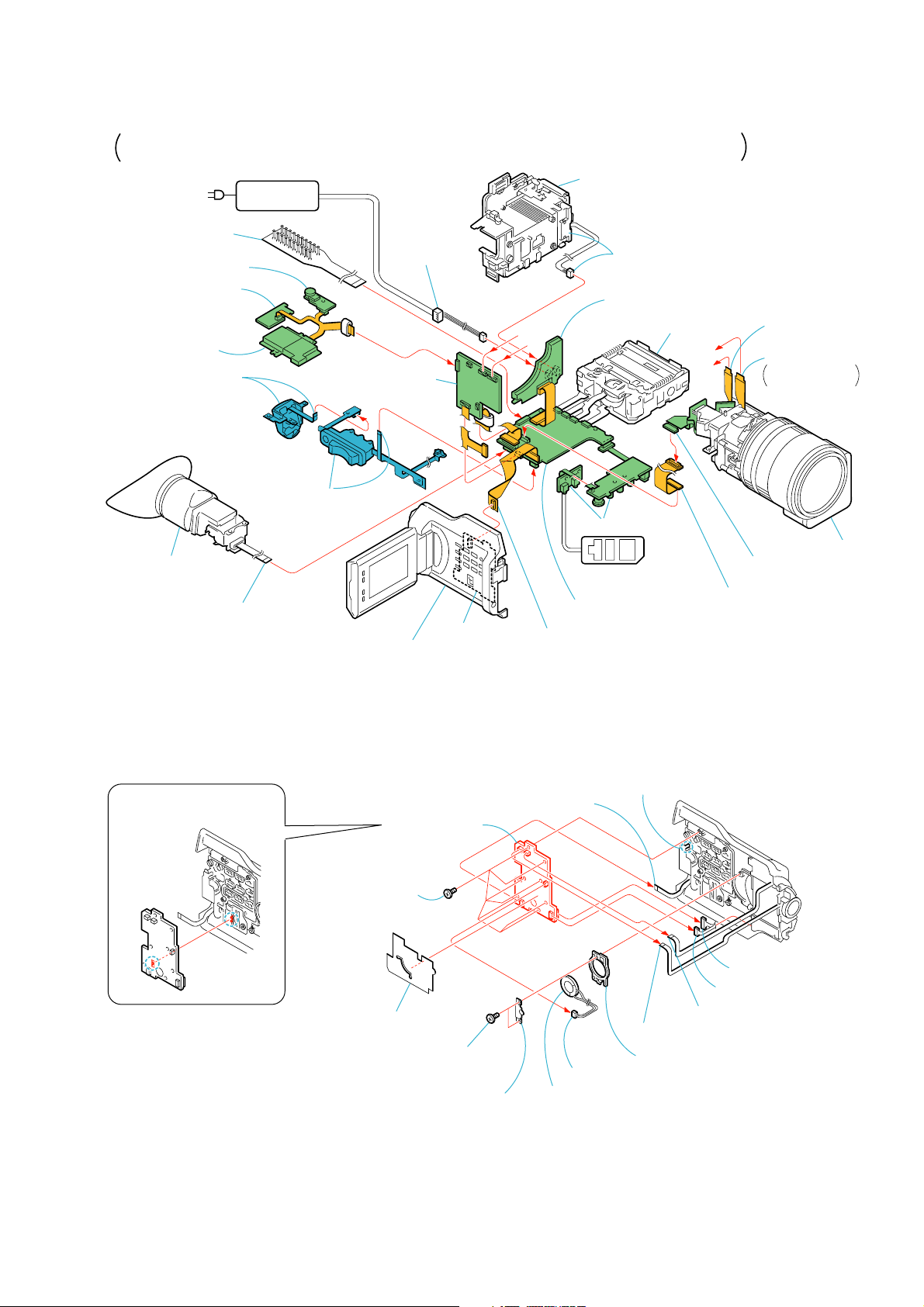

DCR-VX2100/VX2100E

)

VC-358

Board

LA-028

Board

A

A

B

B

Adjustment remote

commander (RM-95)

AC POWER

ADAPTOR

AC IN

Cabinet (R) block assembly

CK-140 board

FP-187 flexible board (50P)

DC-IN

connector (3P)

(1-794-637-21)

Battery panel assembly

Battery terminal board (4P)

KP-013 board

MS-209 board

MK-016 board

EVF block assembly

FP-193

flexible board (27P)

Mechanism deck

DD-216 board

LA-028 board

VC-358 board

JK-267 board

CD-512 board (50P)

Extension cable

(J-6082-496-A) (50P)

Flexible board (39P)

from zoom lens

assembly

Flexible board (27P)

(from VAP assembly)

Lens block assembly

Control switch block

(PS-4980) (8P)

Control switch block

(CF-4980) (14P)

[CONNECTION DIAGRAM FOR SERVICE POSITION (Mainly for voltage measurement and check)]

CK-140, VC-358, JK-267, CD-512, DD-216, LA-028, KP-013, MK-016, MS-209 BOARDS,

MECHANISM DECK-2

CPC-13 jig

(J-6082-443-A)

2-14.CK-140 BOARD

PRECAUTION DURING

INSTALLATION

When installing it.

Align the switch position.

qf

CK-140 board

q;

Seven screws

×

(M2

lock ace

3),

3

R flexible

protection sheet

5

Two screws

(M2 × 3),

lock ace

9

FP-194 flexible board (5P)

6

SP retainer

plate assembly

2-13

4

7

Speaker

qa

Claw

1

Control switch block

(ED-4980) (6P)

8

Speaker holder

Speaker (2P)

2

qd

Harness (CP-094) (14P

qs

Harness (CP-093) (8P)

FP-197 flexible board (6P)

DCR-VX2100/VX2100E

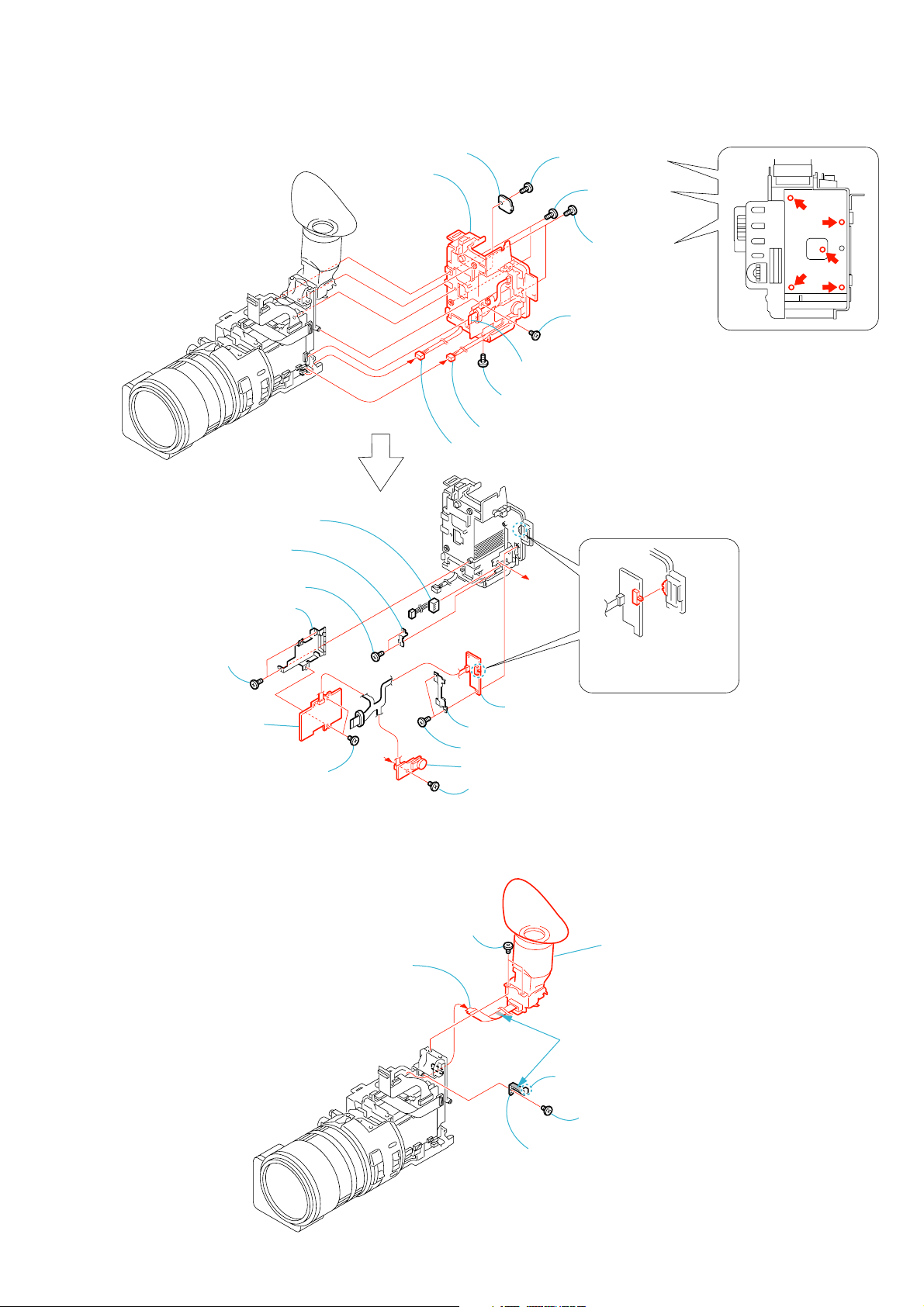

2-15.CONTROL SWITCH BLOCK (ED-4980), HINGE ASSEMBLY

Start the removal work after the LCD section has been removed referring section 2-1.

2

Control switch block

(ED-4980)

1

Bright

button

3

Blind door (D) assembly

Hinge lid

2

Three screws

1

(M2

×

lock ace

3),

6

Three screws

(M2 × 3),

spring bolt

4

Harness (CP-093) (8P)

5

Harness (CP-094) (14P)

8

Three screws

(M2 × 5),

spring bolt

7

9

A

qa

FP-197

flexible board

9

Screw

(M1.7 × 2.5),

lock ace

5

(front)

q;

(M1.7 × 2.5),

lock ace

Hinge cover

Screw

1

Two screws

(M1.7 × 2.5),

lock ace

3

Three claws

qs

Hinge

assembly

A

2

Screw

(M1.7 × 2.5),

lock ace

4

(rear)

6

fixed tapes

7

Harness

(CP-093)

Hinge cover

Two harness

8

Harness

(CP-094)

2-14

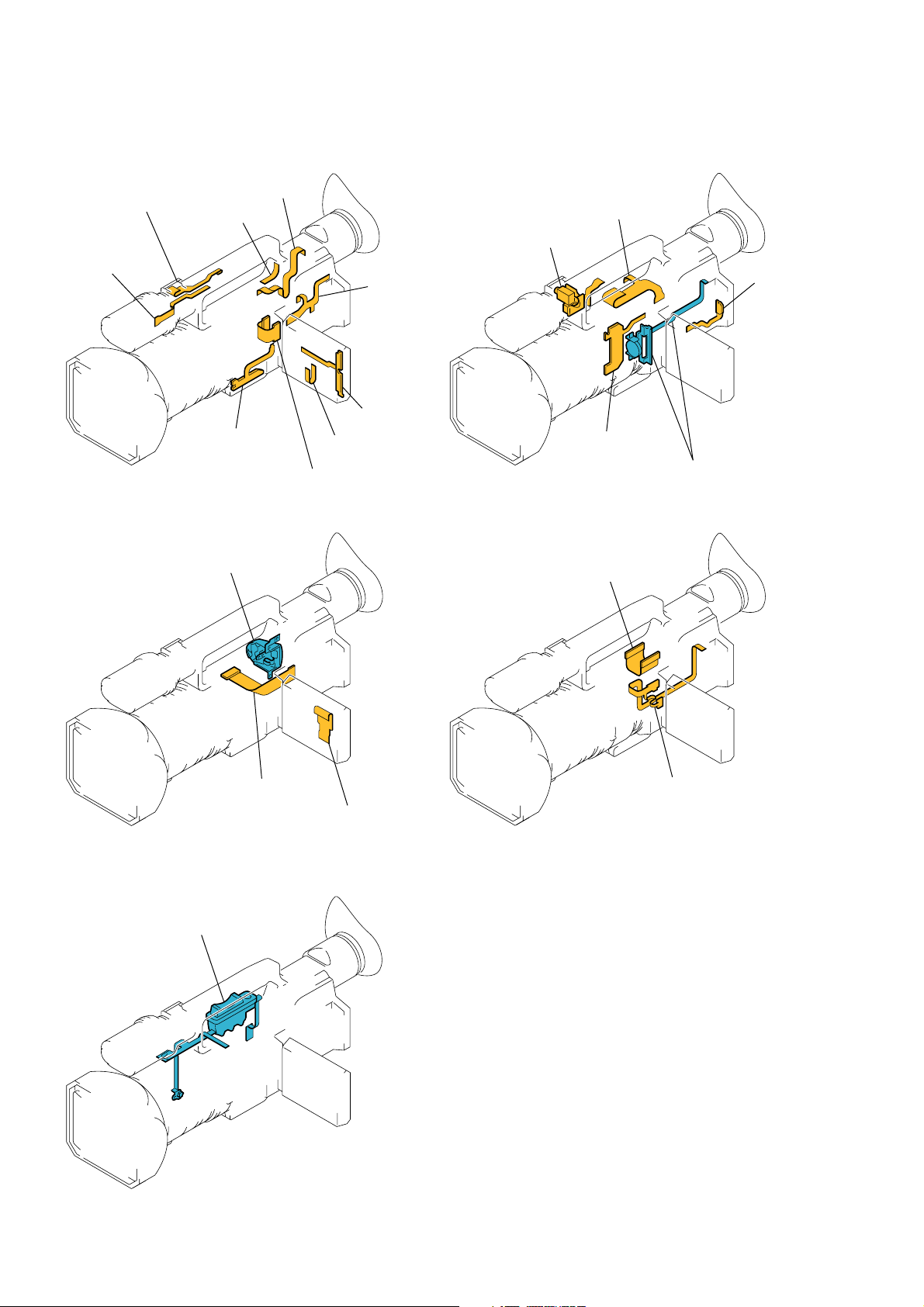

2-16.CIRCUIT BOARDS LOCATION

The circuit boards contained in the zoom lens are not shown.

DCR-VX2100/VX2100E

FT-092

(REMOTE)

MI-050

(MIC IN)

SE-147

(VAP SENSOR)

MA-430

(AUDIO AMP)

LB-100

(BACK LIGHT)

CD-512

(CCD IMAGER)

FK-088

(CONTROL SWITCH)

CK-140

(KEY IN)

PD-217

(RGB DRIVE, TG)

INVERTER TRANSFORMER

UNIT

HL-013

(LCD DRIVE)

ZM-030

(ZOOM SWITCH)

JK-267

(JACK BOARD)

VC-358

S/H AGC, TG, CAMERA SIGNAL PROCESS,

MS I/F, RS232C I/F, STILL CONTROL, MS DRIVE,

DV SIGNAL PROCESS, DV INTERFACE, REC/PB AMP,

LINE IN/OUT, LINE A/D, RGB DRIVE/TG,

CAMERA CONTROL, MECHANISM CONTROL,

DRUM/CAPSTAN MOTOR DRIVE, HI CONTROL,

AU LINE A/D, D/A, LINE AMP, CONNECTOR

RM-091

(REMOTE SENSOR)

DD-216

(DC/DC CONVERTER, DC REGULATOR)

LA-028

ZOOM, FOCUS DRIVE, VAP DRIVE,

KEY IN/CONNECTOR

MK-016

(CONTROL KEY)

KP-013

(LCD DRIVE)

MS-209

(MS CONNECTOR)

2-15

DCR-VX2100/VX2100E

2-17.FLEXIBLE BOARDS LOCATION

The flexible boards contained in the mechanism deck and that in the zoom lens are not shown.

FP-896

FP-894

CONTROL SWITCH BLOCK

(PS-4980)

FP-202

FP-189

FP-193

FP-195

FP-191

FP-190

FP-196

FP-895

FP-893

FP-194

FP-188

CONTROL SWITCH BLOCK

(ED-4980)

FP-186

FP-187

CONTROL SWITCH BLOCK

(CF-4980)

FP-197

FP-205

2-16E

Link

Link

DCR-VX2100/VX2100E

3. BLOCK DIAGRAMS

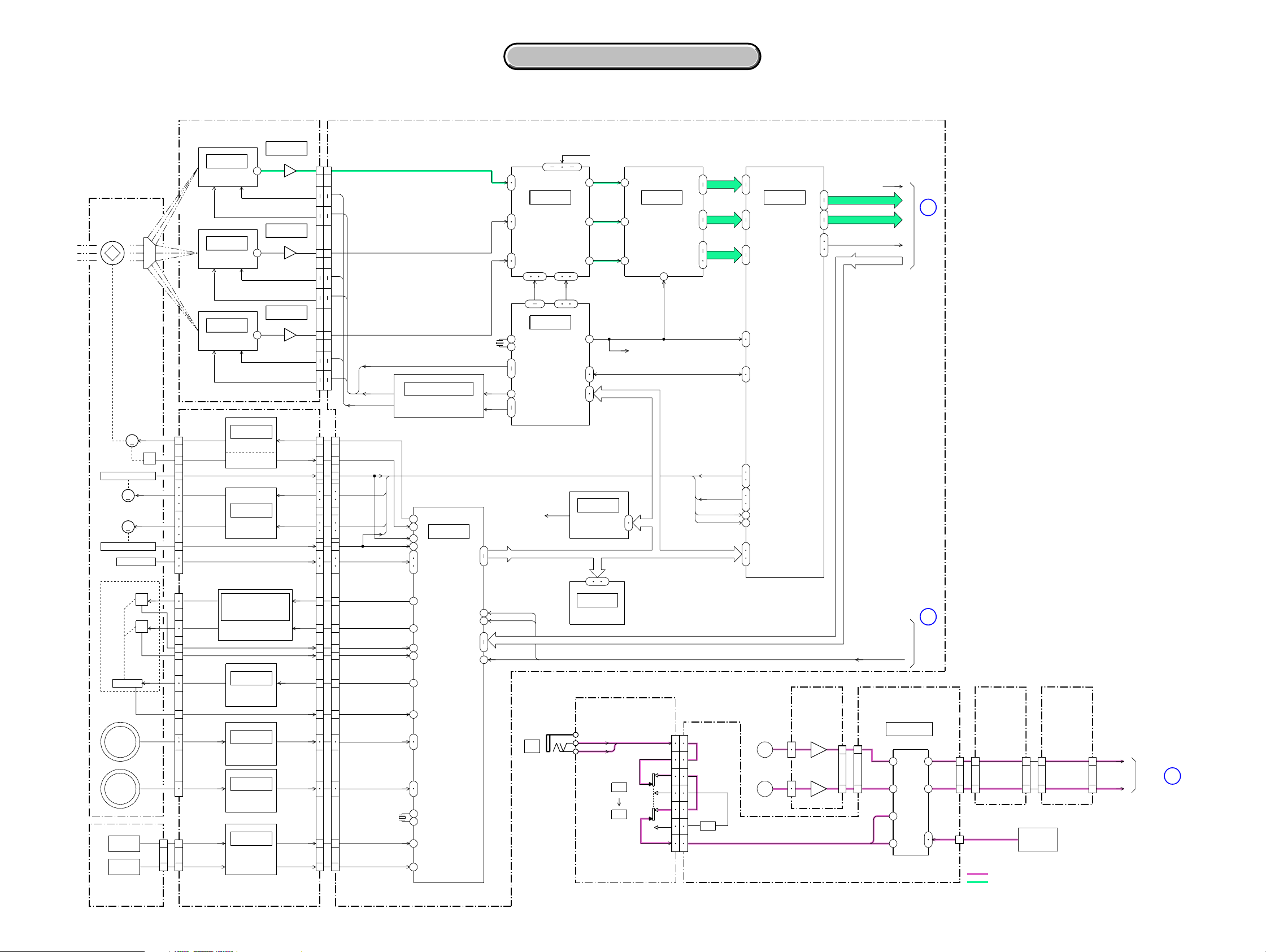

OVERALL BLOCK DIAGRAM (1/4)

OVERALL BLOCK DIAGRAM (1/4)

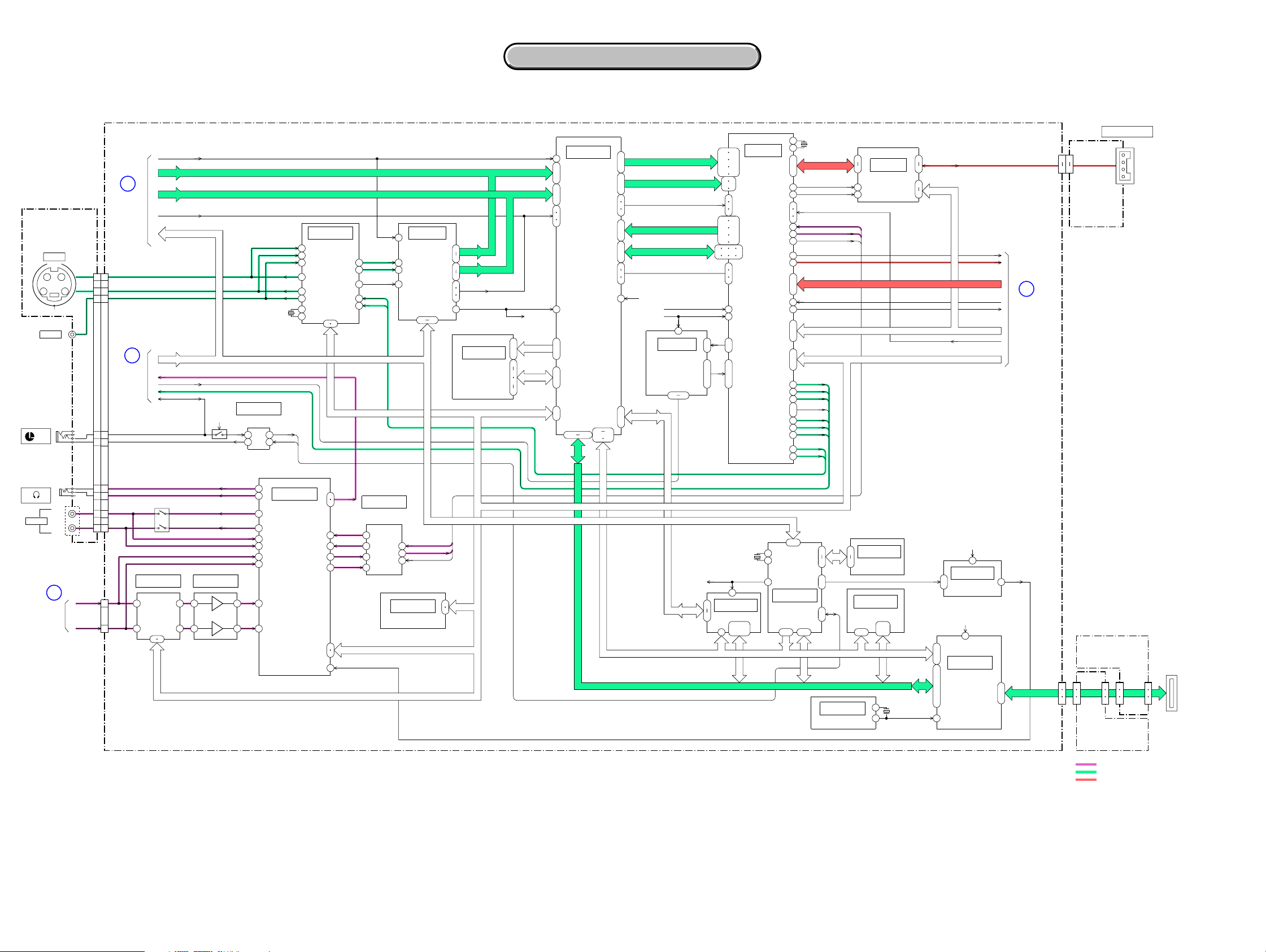

OVERALL BLOCK DIAGRAM (2/4) POWER BLOCK DIAGRAM (2/3)

OVERALL BLOCK DIAGRAM (2/4) POWER BLOCK DIAGRAM (2/3)

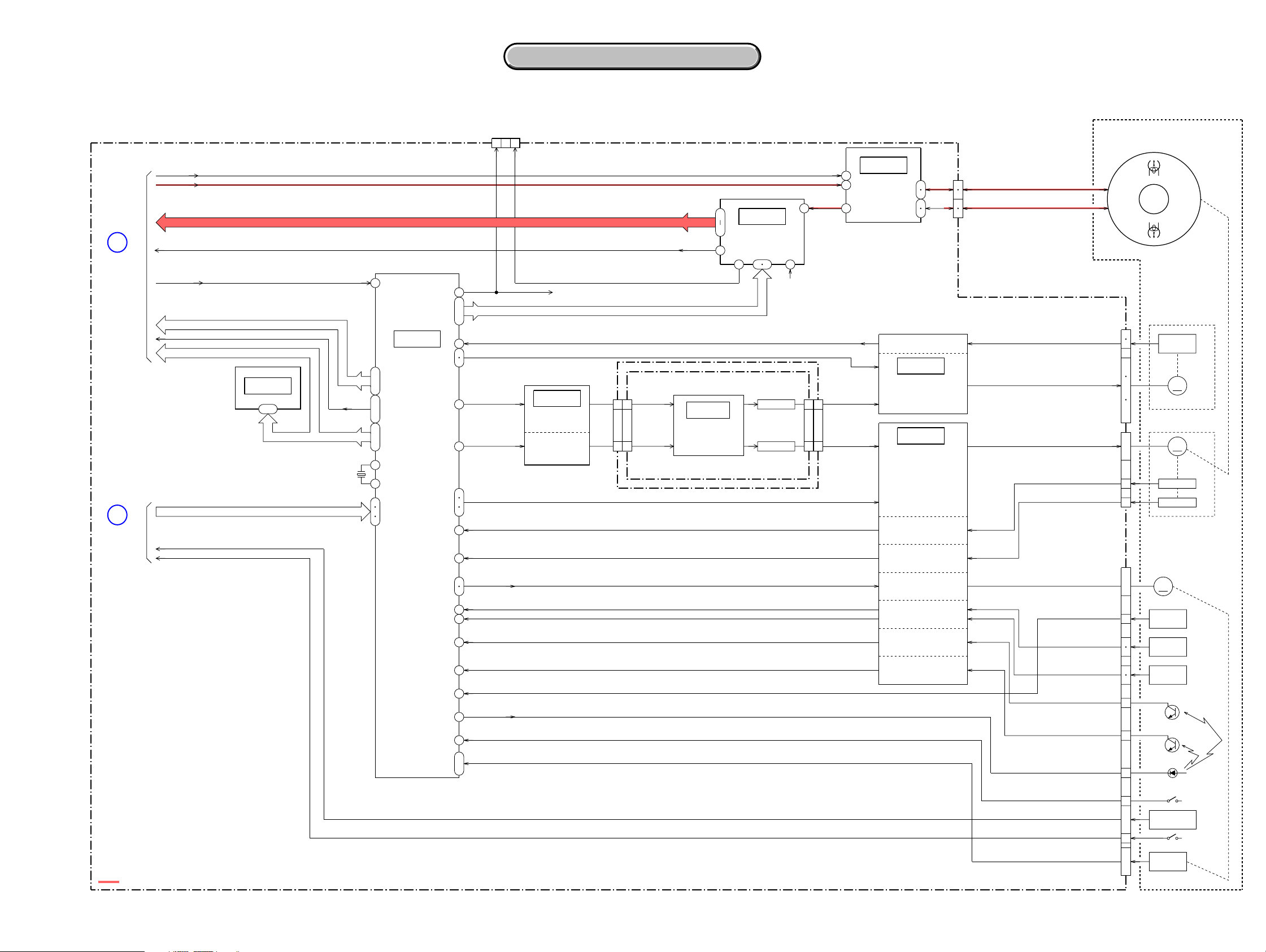

OVERALL BLOCK DIAGRAM (3/4)

OVERALL BLOCK DIAGRAM (3/4)

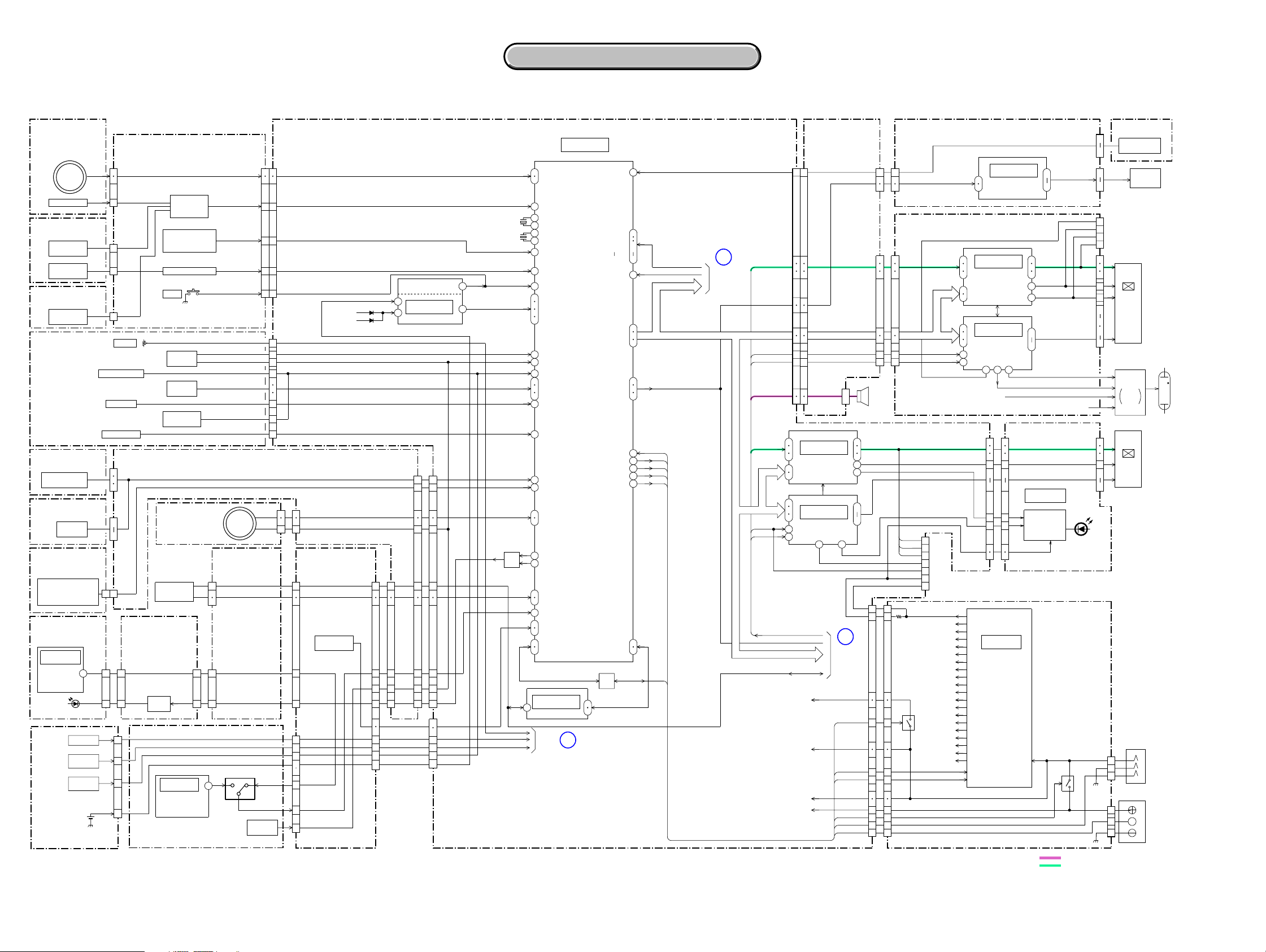

OVERALL BLOCK DIAGRAM (4/4)

OVERALL BLOCK DIAGRAM (4/4)

POWER BLOCK DIAGRAM (1/3)

POWER BLOCK DIAGRAM (1/3)

POWER BLOCK DIAGRAM (3/3)

POWER BLOCK DIAGRAM (3/3)

DCR-VX2100/VX2100E

BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/4)

CD-512 BOARD

IC103

LENS BLOCK

IRIS

ZOOM RESET SENSOR

ZOOM

MOTOR

FOCUS

MOTOR

FOCUS RESET SENSOR 25

ACTIVE PRISM

ACTUATOR

VAP LOCK

ZOOM

RING

FOCUS

RING

SENSOR

SENSOR

SE-147

BOARD

16

SE601

SE600

PITCH

YAW

DICHROIC

IRIS

METER

M

M

M

PRISM

IC101

G-CH CCD

IMAGER

11,14-16 1-4

IC102

R-CH CCD

IMAGER

IC100

B-CH CCD

IMAGER

11,14-16 1-4

DRIVE-

20

H

P

Y

CN600

HALL-

17

ZM RST SENS

22

1

ZOOM A,B

2

4

6

34

FOCUS A,B

36

38

39

FC RST SENS

28

ND A,B,C

27ND FILTER SW

29

CN050

21

P DRIV A,B

20

15

Y DRIV A,B

14

P OUT

12

Y OUT

22

VAP LOCK +,-

25

26

VP LOCK SENS

23

3

MZ F0,F1

5

MF F0,F1

8

9

CN052

PSD OUT

12

5

YSD OUT

10

3

CN050

8

5

1,2 8,13

1,2

12

82

LA-028 BOARD(1/4)

1-411,14-16

IC141

IRIS DRIVE

HALL AMP

ZOOM MOTOR

DRIVE

IC140

FOCUS MOTOR

DRIVE

IC070,071

073-076

ACTIVE PRISM

ACTUATOR DRIVE

IC072

VAP LOCK DRIVE

IC144

DETECTOR

IC143

DETECTOR

IC200

PITCH/YAW

SENSOR AMP

8

8

8

31

V1,V2A,V2B,V3

H1,H2,RG,SUB

IC104

31

V1,V2A,V2B,V3

H1,H2,RG,SUB

IC105

13

V1,V2A,V2B,V3

H1,H2,RG,SUB

CN100

10

7

8,13 49

18

CN051

SECTION 3

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-358 BOARD(1/4)

AGC CONT 1,2

R,B GAIN

2111 4814

47

45

46

39

38

IC803

(12/18)

IC801

(12/18)

FP-893

(FLEXIBLE)

L

R

R,G,B OFFSET

G

7

R

5

B

9

EVR

EEPROM

G

19

(1/18)

IC706

A/D

CONVERTER

21

17

14

SPCK

17

16

243

38

47

26

36

11

1

48

EN1

DIR 1A,1B

EN0

DIR 0A,0B

ZM RST SENS

FC RST SENS

D0-09

D0-09

D0-09

11

(2/18)

2

IC771

R

B

HD,VD

CAMERA

88

79

99

90

47

77

70

71

62

63

64

59

60

61

58

57

14

15

66

SIGNAL

PROCESS

MI-050

BOARD

(1/2)

20

20

14

14

7

7

4

4

6

CN101

6

5

5

8

8

3

3

9

9

12

12

11

11

ATT

2

2

10

10

1

1

CN1101

S001

MIC

LINE

MIC

L

MIC

R

2

3

CN700

2

3

CN701

CN025

35

35

40

40

43

43

44

44

47

47

19

19

25

25

28

28

29

29

32

32

9

9

3

3

6

6

13

13

18

18

54

53

42

41

62

61

64

63

65

66

67

68

63

64

65

66

67

68

60

59

54

53

56

55

58

57

55

56

58

57

44

43

46

45

36

35

38

37

48

47

50

49

47

48

50

43

44

45

46

CN023

IRIS PWM

HALL AD

EN1

DIR 1A,1B

EN0

DIR 0A,0B

P PWM

Y PWM

VP LOCK DR

MZ A,B

MF A,B

PS OUT

YS OUT

V1,V2A,V2B,V3

G CCD OUT

R CCD OUT

B CCD OUT

H1,H2,RG

SUB

X801

20MHz

IC701,702

CCD

V DRIVE

(1/18)

(12/18)

43

66

IC802

19

20

17

18

82

45

44

61

60

7

10

24

25

22

23

40

41

59

58

CAMERA

CONTROL

33

35

64

63

48

50

62

X701

27MHz

CAM SO,SI,SCK

ZM SPD SEL

H ZOOM AD

HI SO,SI,SCK

ZOOM VR AD

31

32

29

28

35

34

31

32

17

29

10

5

9

XSHD

XSHP

XRS

AGC CONT1,2

R,B GAIN

R,G,B OFFSET

J001

MIC/

LINE

40

42 1 3

(1/18)

IC704

S/H,AGC

2526 19 3837 44

CLPDM

PBLK

CLP OB

IC705

TIMING

GENERATOR

(1/18)

(IC705)SPCK

38

Y0-Y7

45

29

C0-C7

36

49

HD,VD,OE

50

51

HI SO,SI,SCK

1

TO

OVERALL

BLOCK

DIAGRAM

(2/4)

(SEE PAGE

3-3)

2

TO

OVERALL

BLOCK

IC1150

MIC

AMP

35

1

33

3

DIAGRAM

(4/4)

(SEE PAGE

3-7)

22

14

36

48

CN1103

CN1102

1

2

11

FK-076

BOARD

(1/2)

23

22

CN500 CN501

SHOE MIC L

AUDIO SIGNAL

VIDEO SIGNAL

36

35

INTELLIGENT

ACCESSORY

SHOE(2/2)

LA-028

BOARD

(2/4)

27

26

CN053

CN051

L(CH1)

2

R(CH2)

1

TO

OVERALL

BLOCK

DIAGRAM

(2/4)

(VC-358)

(SEE PAGE

3-3)

3

ZM SPD SEL

H ZOOM AD

ZOOM VR AD

MA-430 BOARD

(1/2)

Q706

Q707

CN703

12

3

5

L

R

10

CN1100

L

R

3-1 3-2

DCR-VX2100/VX2100E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-2. OVERALL BLOCK DIAGRAM (2/4)

VC-358 BOARD(2/4)

SPCK

YO-Y7

1

TO

OVERALL

BLOCK

DIAGRAM

JK-267

BOARD(1/2)

J301

S VIDEO

YC

G

G

J300 (1/2)

VIDEO

J303

LANC

(1/4)

(SEE PAGE

3-2)

Y

20

20

C

22

22

17

17

V

TO

OVERALL

BLOCK

DIAGRAM

(4/4)

(SEE PAGE

3-8)

LANC SIG/232C RD

35

35

LANC GND/232C TD

37

37

4

HD,VD,OE

HI SO,SI,SCK

HI SO,SI,SCK

SP+,-

OSD CS,SO,SCK

PANEL R,G,B,EVF R,G,B,HD,VD

LANC SIG

232C ON

(4/18)

IC1404

RS232C

IF

Q111

12 9

14 7

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

57

4

11

(6/18)

201

IC301

205

211

DV SIGNAL

PROCESS

215

31

17

21

23

202

206204

212

216

6

8

13 15

18

22

24

196

48

184

•

183

195COL0

•

194

•

191

•

X1301

13.5MHz

RXD

TXD

(9/18) (10/18)

IC1301

39

LINE IN

LINE OUT

48

AGC

ACC

42

Y

18

C

14

V

22

28

30

36

34

IC1301 CK

26

46

7

910

(3/18)

SPCK

Y0-Y7 |

C0-C7CO-C7

HD,VD,DE

IC903

SPCK

68

A/D

Y

C

Y

C

CONVERTER

2

6

25

63

59

Y0-Y7

52

49

C0-C7

42

38

HD,VD,DE

37

36

34

66

(3/18)

IC1403

16Mbit DRAM

20

|

31

1

13

38

48

AFCK

A0-A8

D0-D15

VSP SO,SCK

IC1407

37

60

DIGITAL

STILL

PROCESS

51

46

|

38

49

48

47

82

97

|

106

129

|

111

141

•

142

140 132

41

144143

77

Y0-Y7

|

70

68

C0-C3

|

64

63

HD,VD OE

62

61

96

|

Y0-Y7

87

86

C4-C7

|

83

80

HD,VD,OE

79

78

7

SYS CLK(IC1401)

AFCK(IC903)

SPCK(IC705)

8

IC302

(7/18)

CHARACTER

GENERATOR

31

OSD CS

12

JID0-JID7

|

21

OSD SO

OSD SCK

199

203

207

213

200

208

214

2

9

HD

20

VD

•

19

18

|

•

17

COL3

•

•

1416190

138

139

142

145

51

141

152

153

156

133

132

127

99

97

83

88

81

79

170

179

159

161

75

73

71

105

106

67

65

63

55

59

|

|

|

|

•

X301

24.576MHz

L BUS

TRCK

LCK

FRRV,TRRV,TRRT

DATA FROM SFD

6

PANEL G

PANEL R

PANEL B

HD,VD

EVF G

EVF R

EVF B

Y

C

DATA TO SFD

SFD BCK

CN300

Interface

DV

CN006

(7/18)

45

IC361

42

DV INTERFACE

47

79

TPA+,-

6

TPB+,-

9

29

MC BUS

37

REC CK

REC DT

AD DT

PB CK

ATF ERR

MC BUS

FRRV,TRRV,TRRT

VSP SO,SI,SCK

6

5

TO

OVERALL

BLOCK DIAGRAM

(3/4)

(SEE PAGE

3-5)

CN301

626

2

JK-267

BOARD

(2/2)

J300 (2/2)

J302

AUDIO

(SEE PAGE

3

OVERALL

BLOCK

DIAGRAM

(LA-028)

3-2)

26

26

28

28

L

12

CN301

12

R

9

9

CN006

L

R

Q1008,1014

HP L

HP R

L

R

L

R

(17/18) (17/18)

IC1092

L(CH1)

TO

(1/4)

R(CH2)

10

1

ATT

7

2

CN023

1312

IC1008

8

31

5

VSP SO,SCK

75

16

(16/18)

64

IC1001

2

AUDIO

54

55

51

53

46

49

58

60

I/O

8

SP+,-

10

19

17

25

23

14

15

4

L

R

L

R

VSP SO,SCK

KASHAON

(16/18)

IC1002

D/A CONV.

A/D CONV.

15

16

3

2

DATA FROM SFD

9

DATA TO SFD

8

SFD BCK

12

IC1005

EVR

(17/18)

VSP SO, SCK

HI SO,SI SCK

XTAL OSC

2

4

20-31

(4/18)

IC1406

EEPROM

DI,CI

IC1408

16Mbit DRAM

2

4

SPCK1(IC705)

(4/18)

6

IC1412

1

SHUTTER

2

SOUND

4

(5/18)

1-13

38-48

X1411

20MHz

SCK

SYSCLK(IC1401)

28

36

(5/18)

|

38

IC1410

10

|

MEMORY

1

STICK

•

I/F

48

|

40

13

DIO

CN023

SCLK

BS

15

|

17

31

31

30

30

33

33

MS-209

BOARD

CN051

18

20

17

CN056

LA-028

BOARD(3/4)

AUDIO SIGNAL

VIDEO SIGNAL

VIDEO/AUDIO SIGNAL

MEMORY

STICK

CN776

SLOT

4

8

25

CN775

6

8

77

79

88

54-52

(4/18)

IC1401

DIGITAL

STILL

CONTROL

5-15 55-75

A0-A10

D0-D15

19

21

109

112

TXD

RXD

50

51

X1401

7.375MHz

SYSCLK

14

13

JID0-JID7

34

41

27

IC1409

JPEG

18

2,9-16

58-64

(3/18)

IC1411

(5/18)

3-3 3-4

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DCR-VX2100/VX2100E

3-3. OVERALL BLOCK DIAGRAM (3/4)

VC-358 BOARD(3/4)

5

TO

OVERALL

BLOCK DIAGRAM

(2/4)

(SEE PAGE

3-4)

6

TO

OVERALL

BLOCK DIAGRAM

(4/4)

(SEE PAGE

3-8)

16

VIDEO/AUDIO SIGNAL

REC CK

REC DT

AD DT

6

PB CK

ATF ERR

MC BUS

FRRV TRRT,TRRV

VSP SO,SI,SCK

HI SO,SI,SCK

CHIME SDA,CHIME SCK,CHIME VDD

XCC DOWN

(13/18)

IC502

EEPROM

2-4

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CN007

FOR ADJUSTMENTS

32

FRRV

TRRT

TRRV

X501

20MHz

SWP

95

(13/18)

IC501

MECHA

CONTROL

26

|

37

106

|

108

74

|

76

1

2

83

82

81

60

78

|

80

CAP FG

115

CAP ON,CAP FWD

45

46

CAP PWM

69

DRUM PWM

68

47

DRUM ON,DRUM FWD,DRUM START

48

63

DRUM FG

116

DRUM PG

117

LOAD,UNLOAD

49

50

TREEL FG

114

SREEL FG

113

TAPE END

54

TAPE TOP

53

DEW DET

96

TAPE LED ON

55

REC PROOF SW

44

39

MODE SW A - MODE SW D

|

42

56

53

RF MON

SWP

(14/18)

IC401

LPF

LPF

(2/2)

DRP SO,XDRP SCK

CN021 CN450

54

454746

52

CAP ERROR

18

DRUM ERROR

48

22

DD-216 BOARD(1/2)

AD DT

6

PB CK

(1/2)

IC300

PWM

DRIVE

15

20

13

34 31

(2/2)

(8/18)

IC101

EQ

A/D CONV.

PLL

22 24

SWITCHING

61

SWITCHING

58

Q319

Q320

SWP

CN450

REC CK

40

REC DT

42

PB Y OUT

42

38

27

CN021

393740

CAP VS

DRUM VS

(8/18)

IC102

32

2,3

18.22

11

16,6,3

1

59

26,25

40

48

34

37

REC/PB

AMP

(14/18)

(14/18)

6

7

2

1

CAPSTAN

FG AMP

IC402

CAPSTAN

MOTOR

DRIVE

IC401

DRUM

MOTOR

DRIVE

DRUM FG AMP

DRUM PG AMP

LOADING MOTOR

DRIVE

REEL FG AMP

TAPE END DETECT

TAPE TOP DETECT

CN101

ODD

EVEN 8

(1/2)

C MECHA DECK

(SEE PAGE 4-39)

5

6

9

CN024

14,15

21,23,19

CN020

20,22,24

64

61

28,30

42,43

45,46

35

36

CN022

XCC DOWN

DRUM

M902

24

25

17

|

20

7

|

10

11

|

14

6

|

1

10

11

27

|

24

23

8

9

12

11

21

1

14

3

5

|

7

4

19

|

16

CAPSTAN

M

M901

M

DRUM FG

DRUM PG

M

DEW

SENSOR

T REEL

SENSOR

S REEL

SENSOR

Q901

TAPE END SENSOR

Q902

TAPE TOP SENSOR

D901

TAPE LED

REC PROOF

4PIN

CONNECTOR

C IN

MODE

SWITCH

S903

FG

CAPSTAN

MOTOR

DRUM

MOTOR

M903

LOADING

MOTOR

H902

H901

S901

CN901

S902

3-5 3-6

DCR-VX2100/VX2100E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-4. OVERALL BLOCK DIAGRAM (4/4)

CONTROL

SWITCH BLOCK

(ED-4980)

EXPOSURE/SW

FP-197

(FLEXIBLE)

PANEL OPEN/

REVERSE SW

FP-194

(FLEXIBLE)

CONTROL

SWITCH BLOCK

(CF4980)

FP-189

(FLEXIBLE)

FADER SW

BACK LIGHT SW

SPOT LIGHT SW

FP-188

(FLEXIBLE)

MK-016

BOARD

REC LEVEL GAIN SW

AUTO WHITE BALANCE SW

SHUTTER SW

PROGRAM AE SW

AUTO LOCK SW

FT-092

BOARD

IC750

REMOTO

COMMANDER

RECEIVER

(FRONT)

D751

(IR EMITTER)

16

EXPOSURE

DIAL

S002

CLOSE SW

S001

PANEL

MENU

S550-552

INDEX SW

FOCUS SW

S001-005

BT801,802

LITHIUM

BATTERY

(SECONDRY)

1

S803,804

ZOOM SW

S801

ZOOM SPEED

SW

S802

START/STOP

SW

CK-140 BOARD(1/2)

1

2

4

CN255

CN256

2

4

CN254

2

ZOOM VR

START/STOP SW

EJECT SW

LID OPEN SW

CN054

2

3

5

1

6

CN055

3

10

CN056

CN001

MI-050

BOARD(2/2)

CN750

CN702

8

8

7

7

4

2

3

5

CN801

S251,253,261

DISPLAY SW

SELF TIMER SW

DATA CODE SW

S250,255,258,260,263

ZEBRA SW,TITLE SW,

DIGITAL EFECT SW,

PICTURE EFECT SW,

MEMORY MIX SW

S252,254,257,259,262

MEMORY FUNCTION SW

S256

RESET

PHOTO SW

POWER SW

START/STOP SW

(LOW ANGLE)

LA-028 BOARD(4/4)

KP-013

BOARD

INTELLIGENT

ACCESSORY

SHOE

(2/2)

CN703

14

Q700,702,704

DRIVE

LED

13

IC1102

REMOTE

COMMANDER

RECEIVER

(REAR)

RM-091 BOARDZM-030 BOARD

ZOOM VR AD

XPHOTO FREEZE

XPHOTO REC

XS/S SW

XVTR MODE SW

XCAM+STBY SW

PHOTO STBY SW

XEJECT SW

LID OPEN

SEL/PUSH

MA-430

BOARD(2/2)

CN1102

5

6

7

CN1100

1

2

D1107-1110

1

EXEC

DIAL

H ZOOM AD

ZM SPD SEL

XS/S SW (HAND)

LI

CN250

S1106

CUSTOM

PRESET SW

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

DIAL C

KEY AD5

20MHz OUT

20MHz IN

32KHz IN

32KHz OUT

KEY AD4

KEY AD6

XRESET

VDD

XPHOTO FREEZE

KEY AD8

XS/S SW

XVTR MODE SW14

XCAM+STBY SW

XPHOTO STBY SW

XEJECT SW

LID OPEN

KEY AD2

KEY AD3

DIAL B

MELODY

SIRCS ENV

HOT SHOE ID1

XSIRCS IN

KEY AD0

IB SI

IB SO49

LANC I/O

TO

OVERALL

BLOCK

DIAGRAM

(1/4)

(SEE PAGE

3-2)

(15/18)

IC1104

HI CONTROL

2

10

12

(15/18)

KEY AD7

CHIME SDA

CHIME SCL

CHIME AD0

CHIME AD2

XCC DOWN

XCS OSD

OSD SO

XOSD SCK

BATT/EXT SW

FAST CHARGE

VTR DD ON

CAM DD ON

SHOE ON

LANC IN

LANC OUT

Q1104

I/F

HI SO

HI SI

HI SCK 35

BATT SIG

100

5

6

71

73

18

33

34

44

45

46

66

50

29

28

81

1

2

HI SO,SI,SCK

CHIME SDA

CHIME SCK

CHIME VDD

XCC DOWN

6

TO

OVERALL

BLOCK

DIAGRAM

(3/4)

(SEE PAGE

3-5)

HI SO,SCK

EVF R,G,B

HI SO,SCK

XHD

XVD

VC-358 BOARD(4/4)

40

40

DIAL C,D

42

42

KEY AD5

36

36

KEY AD4

34

34

KEY AD6

38

38

HI XRESET

32

32

CN008

CN009

3

4

5

6

7

8

9

10

12

13

1

1

6S550

6

2

2

CN550

CN056

FK-088

BOARD(2/2)

LANC SIG

5

14

16

SIRCS SIG1

1

SIRCS PWM

6

CN500

CN502

3

1

2

4

5

6

SIRCS SIG

11

13

BATT LI 3V

VTR UNREG

BATT UNREG

S500-511

VTR

FUNCTION SW

CN501

20

32

34

18

19

22

9

12

4

2

1

3

3

7

KEY AD2

KEY AD3

DIAL A,B

EXCUTE(DIAL)

6

18

20

4

7

8

CN053

IC1102

CN051

RESET

VDD SWITCH

(15/18)

29

24

27

25

28

22

9

7

22

19

20

82

83 DIAL D

98

40

X1101

20MHz

41

52

X1102

32.768KHz

5

6

30

23

28

26

27

Q1102,1105

21

10

8

24

20

19

CN023

10

11

3

1

2

4

CN004

ZOOM VR AD

H ZOOM AD

ZM SPD SEL

53

97

99

38

42

51

77

87

19

92

16

15

20

17

31

95

96

9798DIAL A

36

MOD

59

80

70 HOT SHOE ID2

4

93

94 KEY AD1

48

LANC

SIG

IC1103

11

22

20

16

18

29

31

35

37

9

11

41

43

CN008

48

47

46

40

39

46

45

42

1

48

PANEL R,G,B

EVF R,G,B

XHD,XVD,SP+,SP-

OSD,CS,SO,SCK

HI,SO,SI,SCK

SHOE UNREG

P UNREG

VTR UNREG

BATT UNREG

CK-140

BOARD(2/2)

CN250

22

20

16

18

29

31

35

37

9

11

41

SP+,-

43

(11/18)

IC1802

RGB

DRIVE

(11/18)

IC1803

TIMING

GENERATOR

LANC SIG

OSD SO,SCK

PANEL R,G,B

CN253

82

TO

OVERALL

BLOCK

DIAGRAM

(2/4)