SONY DCR-TRV738 Service Manual

DCR-VX2000/VX2000E

SERVICE MANUALSERVICE MANUAL

Level 2

Ver 1.0 2000. 04

Photo : DCR-VX2000

RMT-811

US Model

Canadian Model

Korea Model

DCR-VX2000

AEP Model

UK Model

Australian Model

Chinese Model

DCR-VX2000E

E Model

Hong Kong Model

Tourist Model

DCR-VX2000/VX2000E

C MECHANISM

On the VC-242 board

This service manual provides the information that is premised the

circuit board replacement service and not intended repair inside the

VC-242 board.

Therefore, schematic diagram, printed wiring board and electrical parts

list of the VC-242 board are not shown.

The following pages are not shown.

Schematic diagram .......................... Pages 4-13 to 4-50

Printed wiring board......................... Pages 4-51 to 4-54

Electrical parts list............................ Pages 6-27 to 6-36

SPECIFICATIONS

For MECHANISM ADJUSTMENTS, refer to the

“DV MECHANICAL ADJUSTMENT MANUAL

C MECHANISM ” (9-974-050-11).

DCR-VX2000 : NTSC model

DCR-VX2000E : PAL model

— Continued on next page —

DIGITAL VIDEO CAMERA RECORDER

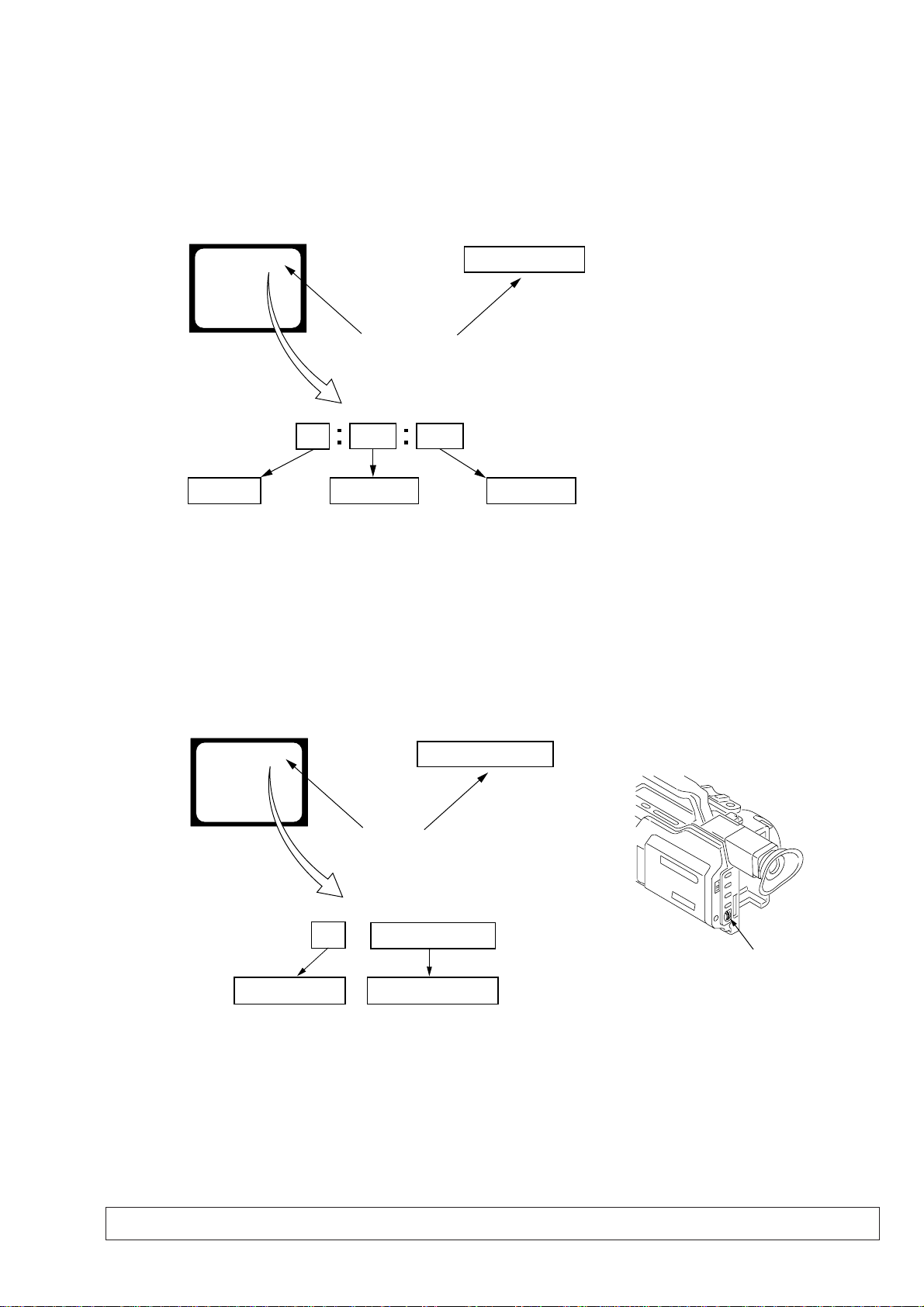

SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewf inder, LCD screen

or LCD window what to do. This function consists of two display;

self-diagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen LCD window

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

3 1

Block

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder, LCD screen or LCD window consists of an alphabet

and 4-digit numbers, which blinks at 3.2 Hz. This 5-character display

indicates the “repaired by:”, “block” in which the problem occurred,

and “detailed code” of the problem.

C : 3 1 : 11

Detailed Code

Refer to page 8.

Self-diagnosis Code Table.

3. SERVICE MODE DISPLAY

The service mode display shows up to six self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “STOP” key, set the switch from OFF to “VCR or PLAYER”, and continue pressing the “STOP” key for 5 seconds

continuously. The service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder or LCD screen

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

C : 3 1 : 1 1

Self-diagnosis Codes

3-2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

LCD window

3 C : 3 1 : 11

Control dial

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will be backed up by the coin-type lithium battery of CK-093 board BT250. When CK-093 board is removed,

the “self-diagnosis display” data will be lost by initialization.

— 7 —

4. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

Block

Function

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

61

61

62

62

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

10

00

01

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular v elocity sensor output

stopped.)

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Inspect the lens block focus reset sensor (Pin wg of LA-026 board)

when focusing is performed when the control dial is rotated in the

focus manual mode, and the focus motor drive circuit (IC140 of

LA-026 board) when the focusing is not performed.

Inspect the lens block zoom reset sensor (

when zooming is performed when the zoom lens is operated and

the zoom motor drive circuit (IC140 of LA-026 board) when

zooming is not performed.

Inspect pitch angular velocity sensor (SE601 or SE602 of SE-108

board) peripheral circuits.

Inspect yaw angular velocity sensor (SE600 or SE603 of SE-108

board) peripheral circuits.

Pin ws of LA-026 board

)

— 8 —

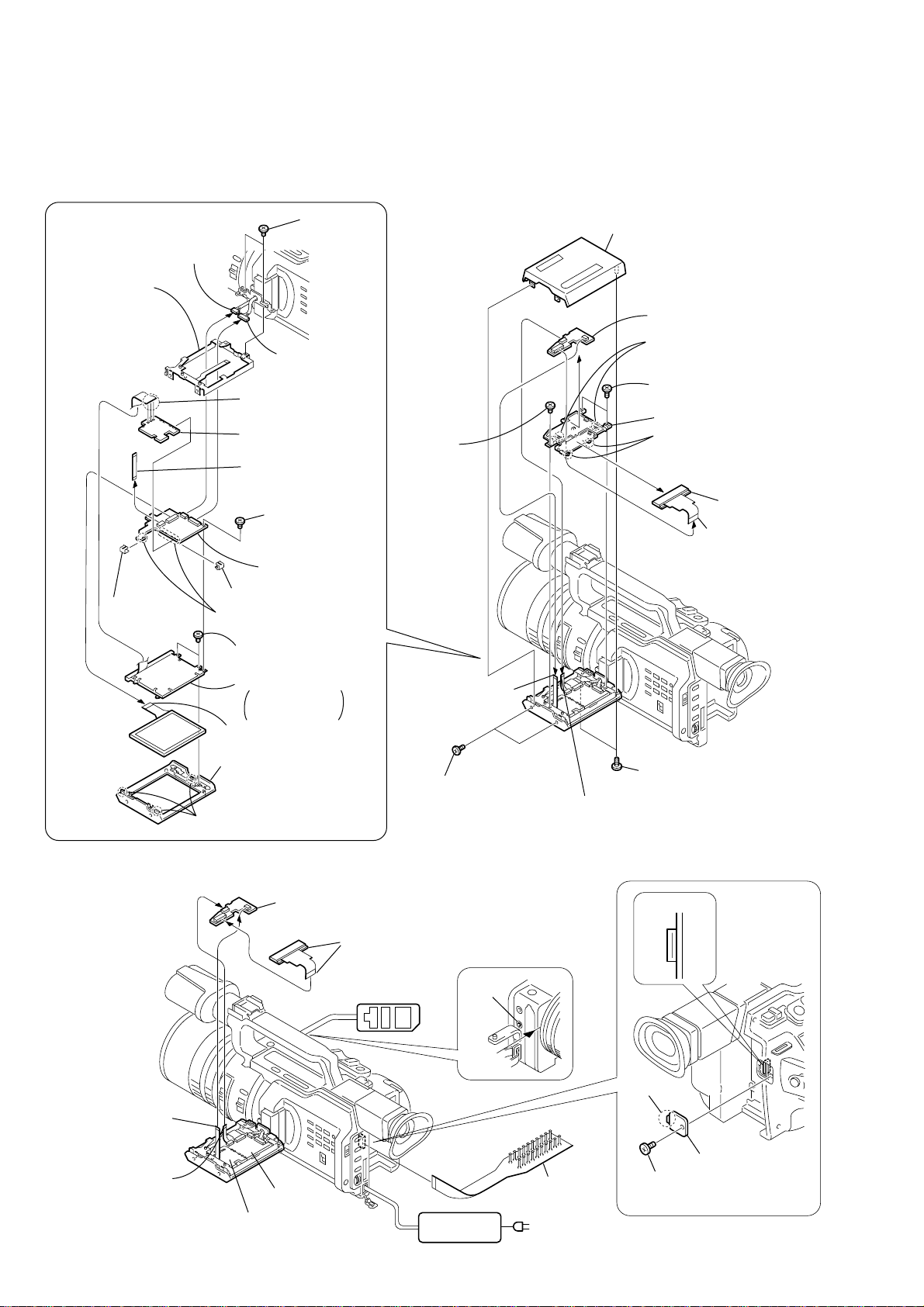

SECTION 2

DISASSEMBLY

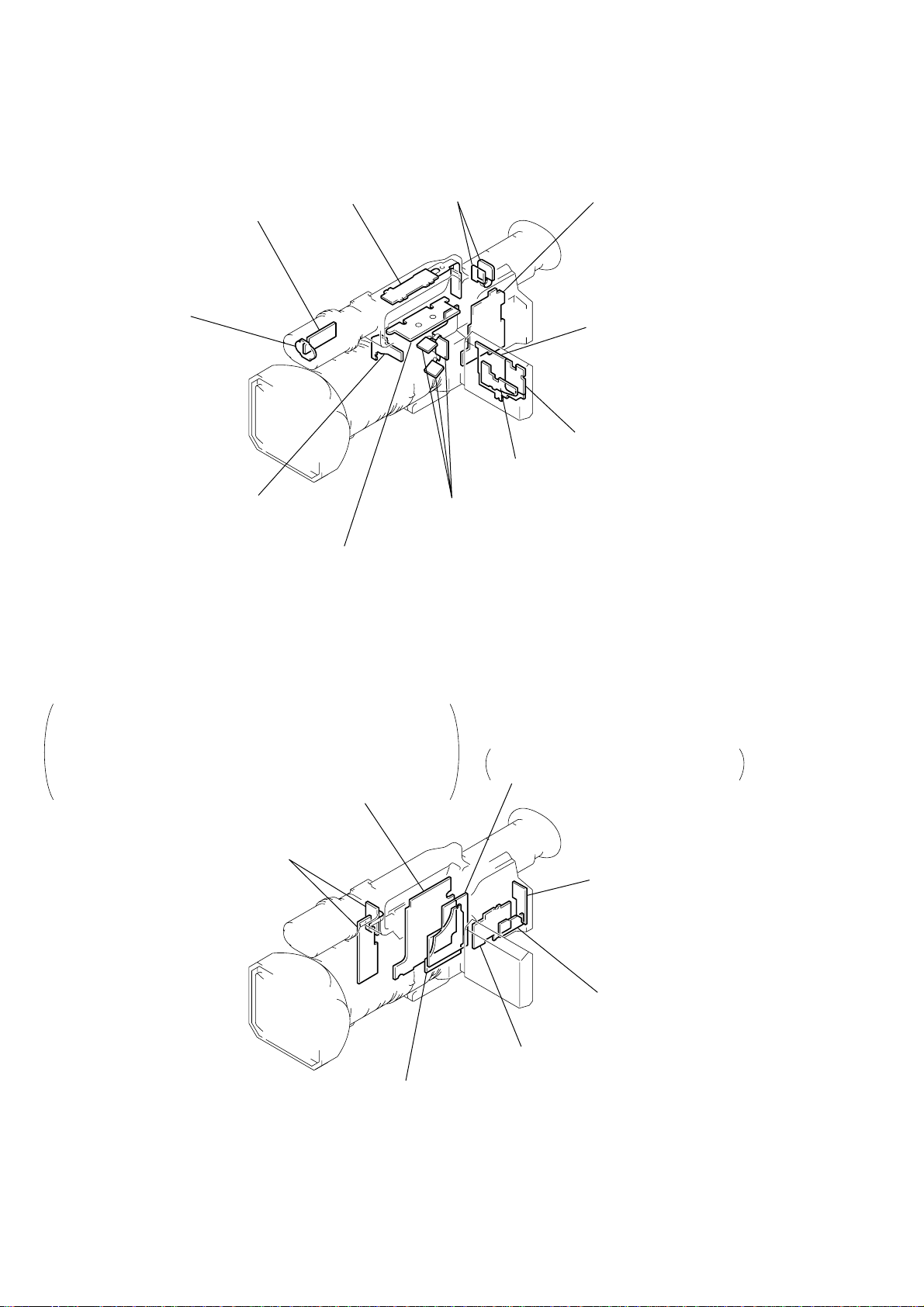

The following flow chart shows the disassembly procedure.

DCR-VX2000/VX2000E

2-1. LCD section

(HL-011, PD-126 boards, Inverter transformer unit)

2-2. EVF section (LB-065 board)

2-3. (Upper) handle block assembly

2-5. Cabinet (L) block assembly, Mechanism deck,

VC-242, DD-138, JK-190 boards

(for force eject of cassette and VTR section check)

2-13. Control switch block (PS-4980),

Control switch block (CF-4980)

2-6. Cabinet (R) block assembly

2-7. Cabinet bottom (D) assembly 2-14. CK-093 board

DCR-VX2000/VX2000E

2-8. Battery panel block assembly

(MK-014, KP-010, MS-049 boards)

HL-011, PD-126 boards service position

LB-065 board service position

2-4. FK-076, MA-386, MI-038, FT-090 boards

FK-076, MA-386, MI-038, FT-090 boards

service position

Mechanism deck service position-1

Service position to check the VTR section

CK-093 board service position

2-15. Control switch block (ED-4980),

Hinge assembly

2-9. EVF block assembly

2-10. LA-026, DD-138, VC-242, JK-190 boards,

Mechanism deck

2-11. Lens block assembly, Center frame assembly

[Connection diagram for service position (Mainly for voltage measurement and check)]

(CK-093, VC-242, JK-190, CD-254, DD-138, LA-026, KP-010, MK-014, MS-049 boards, Mechanism deck-2)

Service position to check the camera section

2-12. CD-254, SE-108 boards, Zoom lens assembly

2-1

NOTE: F ollo w the disassembly procedure in the numerical order given.

l

2-1. LCD SECTION (HL-011, PD-126 BOARDS, INVERTER TRANSFORMER UNIT)

REMOVING THE PD-126 BOARD,

INVERTER TRANSFORMER UNIT

2

4

Harness

(CP-093) (8P)

6

LCD frame,

BL retainer,

FP-196 flexible

board

qd

PCB clip

PD-126

Board

3

Three claws

T wo screws

(M2 × 3),

spring bolt

5

Harness

(CP-094) (14P)

qa

Remove the

three solderings

qh

Inverter transformer

unit

1

FP-195 flexible

board (7P)

q;

Screw

×

(M1.7

2.5),

lock ace

qj

PD-126 board

qf

PCB clip

qg

Remove the

six solderings

7

T wo screws

(M1.7 × 2.5), lock ace

qs

Back light

Cold cathode

fluorescent tube

9

Liquid crystal

indicator module (24P)

8

P cabinet (M) assembly

qa

Screw

(M2 × 3),

spring bolt

5

FP-196 flexible

board (5P)

2

T wo screws

(M2 × 5),

spring bolt

3

P cabinet (C) assembly

q;

9

B

slide the HL-011 board in

the direction of the arrow B.

qs

(M2 × 3), spring bolt

-126

D

P

oard

B

1

(M2 × 5), spring bolt

4

FP-195 flexible

board (7P)

HL-011 board

Release the two claws and

T wo screws

qd

Panel holder

7

Release the two claws and

slide the indication panel

block assembly in the

direction of the arrow A.

A

8

Indication pane

block assembly

6

FP-205 flexible

board (21P)

T wo screws

[HL-011, PD-126 BOARDS SERVICE POSITION]

HL-011 board

Indication panel

block assembly (21P)

Adjustment remote

commander (RM-95)

FP-196

flexible board (5P)

26

-1

D

P

oard

B

FP-195

flexible board (7P)

PD-126 board

Inverter transformer unit

LANC

jack

AC POWER

ADAPTOR

2-2

CPC-13 jig

(J-6082-443-A)

AC IN

CN007

20

1

2

Claw

1

Screw

(M2 × 5),

spring bolt

3

CPC cover

2-2. EVF SECTION (LB-065 BOARD)

2

EVF rear

cabinet assembly

4

EVF front cabinet (upper)

Push the lock knob

1

B

in the direction of the

arrow

EVF rear cabinet assembly

in the direction of the

A

arrow

REMOVING THE LB-065 BOARD

2

LCD (LCX033AK-J)(16P)

8

LCD (LCX033AK-J)

1

FP-193

flexible board (27P)

7

6

Illuminator (498)

5

LCD cushion (498)

4

LB-065 board

3

9

Light interception sheet

LCD cushion (498)

[LB-065 BOARD SERVICE POSITION]

Adjustment remote

commander (RM-95)

A

and remove the

B

.

3

T wo tapping

screws (M1.7 × 8)

q;

LCD holder

assembly

Two claws

LCD holder assembly

LB-065 board

6

5

EVF front cabinet

(lower) assembly

CPC-13 jig

(J-6082-443-A)

LANC

jack

2-3. (UPPER) HANDLE BLOCK ASSEMBLY

4

Tilt up the finder.

5

Screw

(M2 × 5),

spring bolt

3

Screw (M2 × 5),

spring bolt

1

T wo screws

(M2 × 5),

spring bolt

2

T wo screws

(M2 × 5),

spring bolt

(Upper) handle

9

block assembly

8

FP-200 flexible

board (36P)

AC POWER

ADAPTOR

7

AC IN

6

Tilt down the finder.

2-3

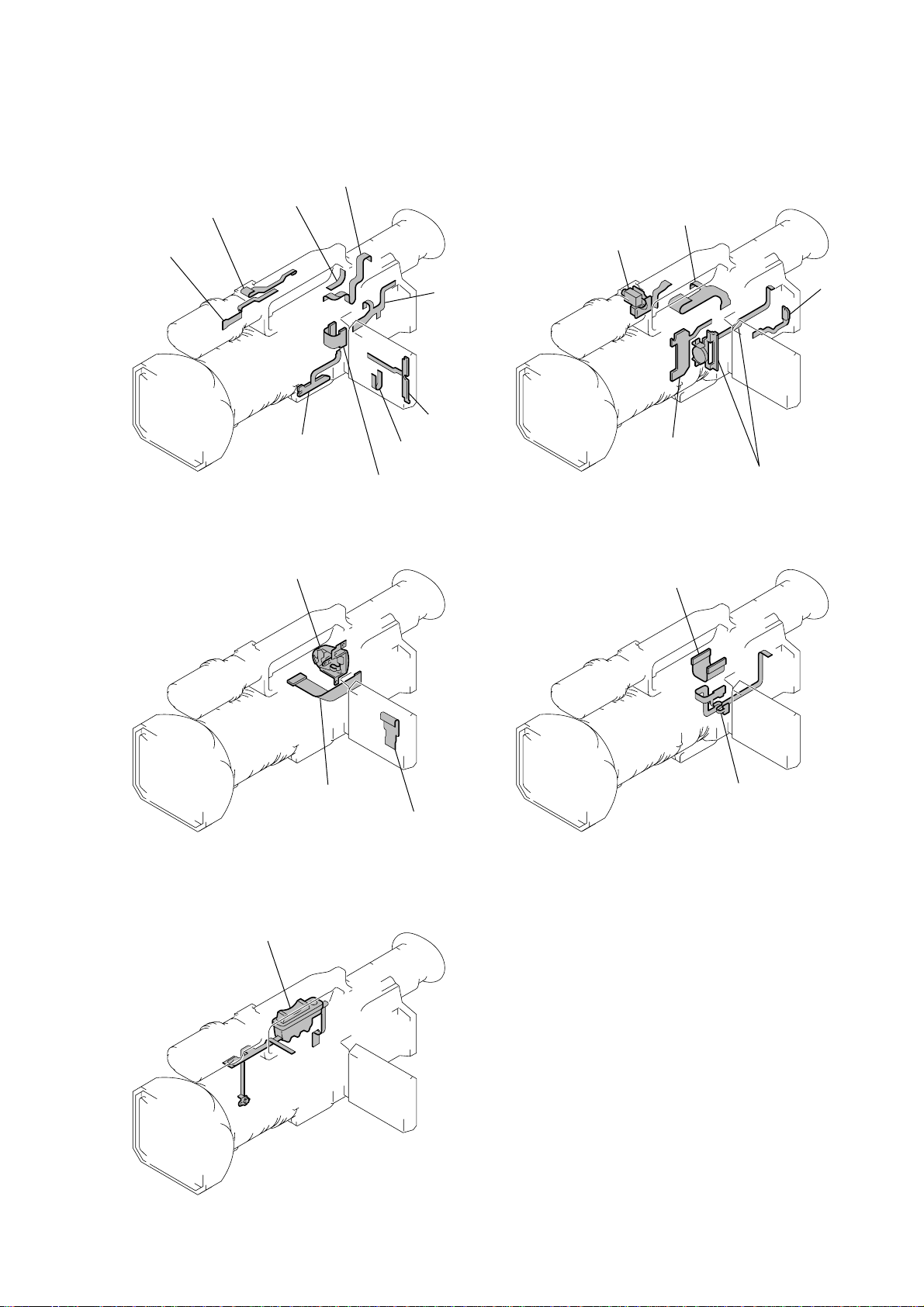

2-4. FK-076, MA-386, MI-038, FT-090 BOARDS

)

9

FP-201 flexible board (15P)

q;

Two screws (M2 × 3),

spring bolt

qa

Outer connector (hot shoe),

Strap sheet metal (F),

FP-201 flexible board

qh

Screw (M2 × 5),

spring bolt

qf

Microphon sheet

ql

Nut (M6 × 0.5)

wf

Microphone

cabinet (R) assembly

qs

FP-199 flexible

board (15P)

A

wa

qd

Remove it in the

direction of the

arrow A.

ws

M terminal

protection

qj

Screw

(M2 × 5),

spring bolt

sheet

REMOVING THE MI-038, FT-090 BOARDS

FP-198

flexible board

w;

Screw

(M2 × 3),

spring bolt

8

Microphone

cabinet (L)

5

T wo screws

(M2 × 5),

spring bolt

7

(M2 × 5),

spring bolt

Screw

6

Handle cover

assembly

qg

Screw (M2 × 3),

spring bolt

wd

board

3

FK-076 board

2

Four screws

(M2 × 3),

spring bolt

MA-386

qk

Handle assembly,

(Upper) cabinet

4

FK frame (D)

assembly

1

FP-202 flexible

board (27P)

9

Microphone case

7

1

T wo tapping

screws (B2 × 5)

2

T apping

screw (B2

×

5)

8

unit

Four claws

Microphone

6

Microphone

mask assembly

q;

Microphone

unit

[FK-076, MA-386, MI-038, FT-090 BOARDS SERVICE POSITION]

MA-386 board

FP-198

flexible board

FP-202 flexible board (27P)

FK-076 board

Microphone unit

MI-038 board

FT-090 board

Microphone unit

FP-199 flexible

board (15P)

Adjustment remote

commander (RM-95)

4

Claw

3

assembly

qa

Rubber neck

5

Microphone cover

qs

FP-199 flexible board,

MI-038 board,

FT-090 board

Microphone case

CPC-13 jig

(J-6082-443-A

LANC

jack

2-4

AC POWER

ADAPTOR

AC IN

2-5. CABINET (L) BLOCK ASSEMBLY, MECHANISM DECK,

DD138

V

C

-242

B

oard

1

Screw

(M2 × 5),

spring bolt

6

Cabinet (L)

block assembly

2

Screw

(M2 × 5),

spring bolt

3

Screw

(M2 × 5),

spring bolt

4

T wo screws

(M2 × 3),

spring bolt

9

Four screws

(M2 × 3),

spring bolt

1

T wo screws

(M2 × 5),

spring bolt

4

Screw

(M2 × 3),

spring bolt

3

Screw

(M2 × 3),

spring bolt

5

Flexible retainer

1

FP-193 flexible

board (27P)

7

FP-186 flexible

board (80P)

qa

CD-254 board

(50P)

qs

Battery terminal board (4P)

qd

DC-IN connector (3P)

qf

Mechanism deck,

VC-242, DD-138 board,

MD frame assembly

2

FP-200 flexible

board (10P)

6

FP-187 flexible

board (50P)

4

FP-191 flexible

board (60P)

8

JK-190 board (40P)

q;

Claw

5

Three screws

(M2 × 5),

spring bolt

(FOR FORCE EJECT OF CASSETTE)

(FOR VTR SECTION CHECK)

2

JK-190 board,

JK frame

3

T wo screws

(M2 × 3),

spring bolt

5

DD-138 board

6

Mechanism deck,

VC-242 board,

MD frame assembly

VC-242, DD-138, JK-190 BOARDS

(FOR FORCE EJECT OF CASSETTE AND VTR SECTION CHECK)

2-5

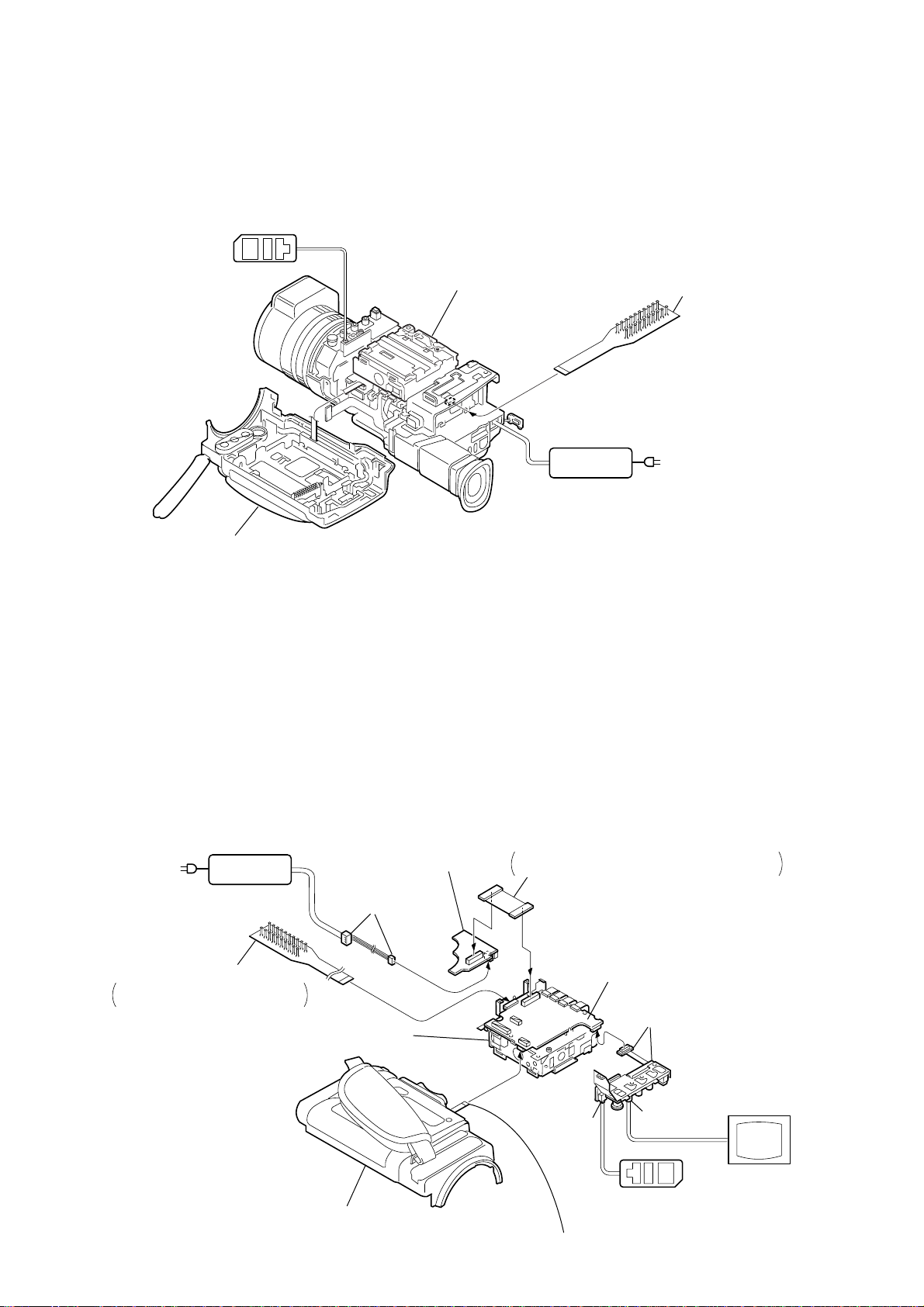

[MECHANISM DECK SERVICE POSITION-1]

Note: Use the parts only which can be removed easily from outside of the mechanism deck.

Adjustment remote

commander (RM-95)

CPC-13 jig

(J-6082-443-A)

AC IN

Cabinet (L) block assembly

Mechanism deck

AC POWER

ADAPTOR

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section

To check the VTR Section, set the VTR to the "forced VTR power ON" mode.

Operate the VTR functions using the adjustment remote commander (with the HOLD switch set in the OFF position)

(However, connect the cabinet (L) assembly when cassette is going to be ejected only.)

Setting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D , address: 10, set data: 02, and press

the PAUSE button of the adjustment remote

commander.

Exiting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D , address: 10, set data: 00, and press

the PAUSE button of the adjustment remote

commander.

3) Select page: 0, address: 01, and set data: 00.

AC IN

CPC-13 jig (J-6082-443-A)

Connect here when the tape path

check is going to be performed.

AC POWER

ADAPTOR

Cabinet (L) block assembly

DC-IN

connector (3P)

(1-794-637-11)

Mechanism deck

DD-138 board

2-6

FP-191 flexible board (60P)

Insert the FP-191 flexible board in the opposite

direction to the normal insertion direction.

VC-242 board

VC-242

Board

LANC jack

Control switch block (CF-4980) (14P)

(Connect here when cassette is going to be ejected.)

JK-190 board

VIDEO jack

Adjustment remote

commander (RM-95)

Monitor TV

2-6. CABINET (R) BLOCK ASSEMBLY

CK-093

Board

1

Screw

(M2 × 5),

spring bolt

5

Screw

(M2 × 5),

spring bolt

4

T wo screws

(M2 × 5),

spring bolt

6

T wo screws

(M2 × 5),

spring bolt

7

Cabinet (R) block assembly

Cabinet (R) block assembly

CK-093 board

3

CF ornamental plate

2

Claw

AC POWER

ADAPTOR

AC IN

Adjustment remote

commander (RM-95)

LANC

jack

[CK-093 BOARD SERVICE POSITION]

CPC-13 jig

(J-6082-443-A)

2-7. CABINET BOTTOM (D) ASSEMBLY

3

T ripod table

2

Four screws

×

(M2

spring bolt

5),

1

FP-189

flexible board (6P)

5

Cabinet bottom

(D) assembly

4

T wo screws

(M2 × 5),

spring bolt

REMOVING THE FBS COVER ASSEMBLY

2

flexible board

1

Two tapping screws

FP-189

(B2

×

5)

3

Two tapping screws

×

5)

(B2

5

FBS cover

assembly

4

Cabinet (bottom)

2-7

2-8. BATTERY PANEL BLOCK ASSEMBLY (MK-014, KP-010, MS-049 BOARDS)

8

Screw (M2 × 5),

spring bolt

7

T wo screws

(M2

spring bolt

6

T wo screws

(M2 × 5),

spring bolt

4

Screw (M2 × 3),

spring bolt

×

5),

q;

Battery panel block assembly

9

CPC cover

qa

DC jack retainer

q;

screws (B2

9

MS holder assembly

8

T wo tapping

screws (B2

7

MS-049 board

LA-026

board

qs

DC-IN connector

T wo tapping

×

×

5)

6

T wo screws

(M2

spring bolt

5)

×

MS-049

Board

3),

A

1

FP-190

flexible board (20P)

5

Screw (M2 × 5),

spring bolt

2

DC-IN connector (3P)

3

Battery terminal board (4P)

A

3

MK-014 board

2

MK retainer

1

Two tapping screws (B2 × 5)

5

KP-010 board

4

Screw (M2 × 3),

spring bolt

PRECAUTION DURING

INSTALLATION

When installing it,

align the switch position

as shown.

2-9. EVF BLOCK ASSEMBLY

1

FP-193

flexible board (27P)

6

T wo screws

×

(M2

spring bolt

LA-026

board

3),

2-8

7

4

Peel off the area

shown by shading.

3

Claw

2

Screw (M2 × 3),

spring bolt

5

Flexible clamp

EVF block assembly

2-10.LA-026, DD-138, VC-242, JK-190 BOARDS, MECHANISM DECK

LA-026

Board

LA-026

Board

LA-026

Board

VC-242

Board

DD138

A

A

B

B

D

D

C

C

1

Screw (M2 × 3),

spring bolt

8

Screw (M2 × 3),

spring bolt

9

LA joint

2

Flexible retainer

6

Three screws

(M2 × 3),

spring bolt

2

T wo screws

(M2 × 3),

spring bolt

1

T wo screws

(M2 × 3),

spring bolt

qa

T wo screws

(M2 × 3),

spring bolt

qs

T wo screws

(M2 × 3),

spring bolt

qd

Two claws

qf

JK frame

qg

JK-190 board

3

Three screws

(M2 × 3), spring bolt

5

T wo step

screws (M2)

7

MD frame assembly

q;

Mechanism deck

9

LD outer lid

6

Step

screw (M2)

8

Two screws (M2 × 2),

lock ace

2

DD-138 board

4

VC-242 board

3

T wo screws

(M2 × 3),

spring bolt

4

T wo screws

(M2

×

5),

spring bolt

5

7

LA-026 board

(LA-026 board)

3

FP-188

flexible board (6P)

4

Flexible board (39P)

(from zoom lens assembly)

1

CD-254 board (50P)

5

Flexible board (27P)

(from VAP assembly)

2-9

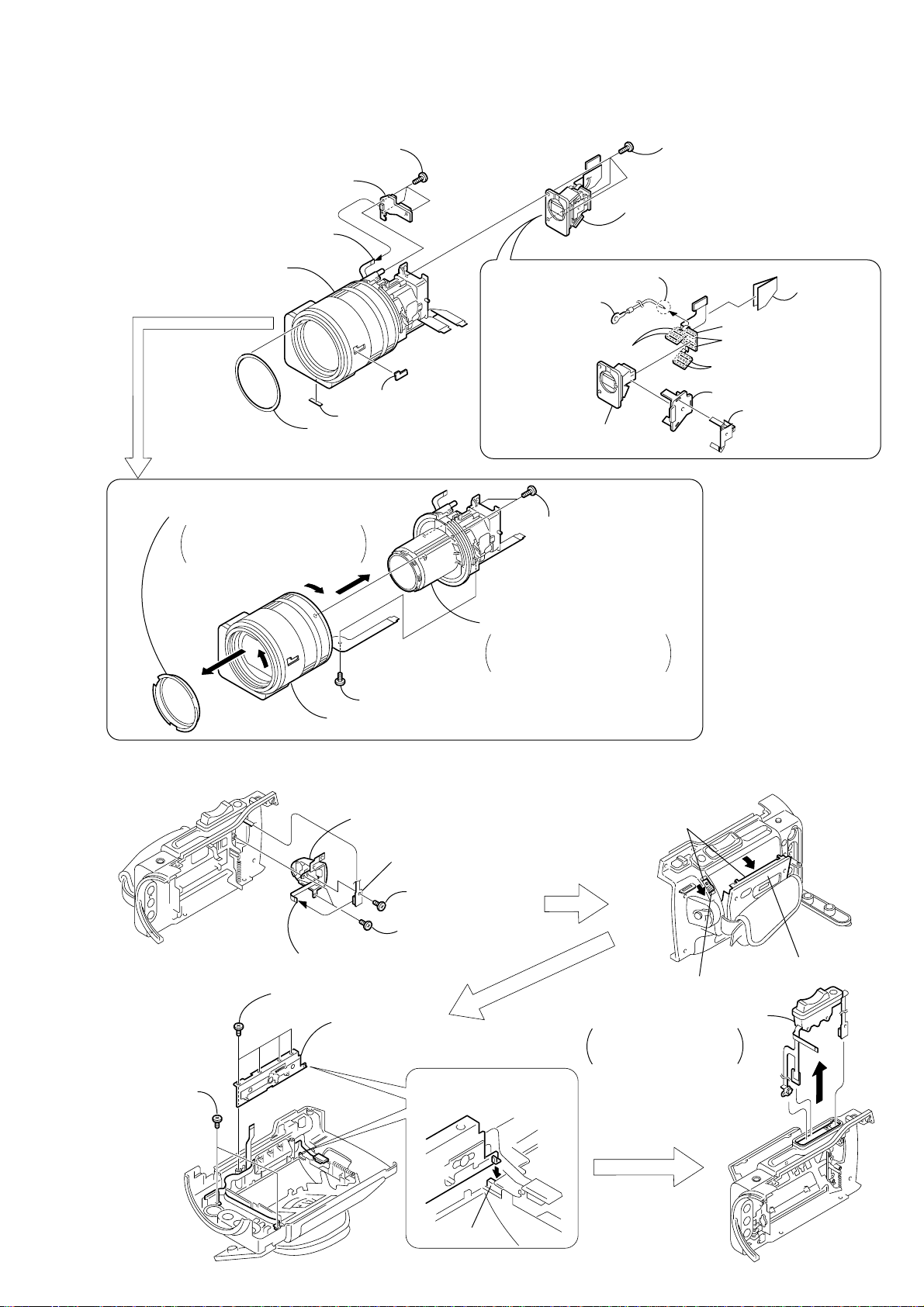

2-11.LENS BLOCK ASSEMBLY, CENTER FRAME ASSEMBLY

y

y

qs

qd

Center frame assembly

6

Screw

(M2 × 3),

spring bolt

PRECAUTION DURING INSTALLATION

When installing it.

Align the swich position.

FP-188 flexible board

Lens block assembly

Center frame assembly

FP-188 flexible board (6P)

5

q;

Two screws (M2 × 4),

lock ace

qa

Two screws (M2 × 3),

spring bolt

3

CCD cover

4

Screw (M2 × 3),

spring bolt

CJ-064 harness

9

Lens block assembl

8

T wo screws

(M2 × 5),

spring bolt

7

T wo screws

(M2 × 5),

spring bolt

2

T apping screw

(B2 × 5)

1

Screw (M2 × 3),

spring bolt

[SERVICE POSITION TO CHECK THE CAMERA SECTION]

Connection to Check the CAMERA Section

To check the CAMERA Section, set the CAMERA to the "forced CAMERA power ON" mode.

Setting the “Forced CAMERA Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D , address: 10, set data: 01, and press

the PAUSE button of the adjustment remote

commander.

FP-191 flexible board (60P)

Insert the FP-191 flexible board in the opposite

direction to the normal insertion direction.

AC IN

AC POWER

ADAPTOR

DC-IN

connector (3P)

(1-794-637-11)

DD-138 board

Extension cable

(J-6082-496-A) (50P)

Exiting the “Forced CAMERA Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D , address: 10, set data: 00, and press

the PAUSE button of the adjustment remote

commander.

3) Select page: 0, address: 01, and set data: 00.

FP-186 flexible board (80P)

Insert the FP-186 flexible board in the opposite

direction to the normal insertion direction.

LA

B

-026

oard

LA-026 board

CD-254 board (50P)

Flexible board (27P)

(from VAP assembly)

VC-242

Mechanism deck

LANC jack

Adjustment remote

commander (RM-95)

2-10

Board

VC-242 board

JK-190 board

VIDEO jack

Lens block assembl

Flexible board (39P)

(from zoom lens assembly)

Monitor TV

2-12.CD-254, SE-108 BOARDS, ZOOM LENS ASSEMBLY

1

Three tapping

screws (M1.7 × 7)

7

Sheet (CD)

1

Tapping screw (M1.7 × 4)

5

VAP assembly

4

Ornamental ring assembly

A

B

C

D

2

Two tapping

screws (B2 × 7)

3

Zoom lens assembly

3

Flexible board (6P)

(from zoom lens assembly)

9

Zoom lens

(VCL-6012WB)

2

(CCD) flexible

block assembly

5

SE-108 board

6

CCD emblem

8

Name ring

7

Rubber foot (A)

4

Three tapping screws

(B2 × 5)

1

CCD

heat sink

2

Prism cover

5

Remove the

sixteen solderings.

4

Remove the

sixteen solderings.

3

Remove the

sixteen solderings.

8

Remove the soldering.

q;

CD-254 board

6

Prism

assembly

Rotate it in the direction of

the arrow A and remove it

in the direction of the arrow B.

Rotate it in the direction of

the arrow C and remove it

in the direction of the arrow D.

REMOVING THE CD-254 BOARD

REMOVING THE ZOOM LENS ASSEMBLY

9

CJ-064 harness

2-13.CONTROL SWITCH BLOCK (PS-4980), CONTROL SWITCH BLOCK (CF-4980)

5

2

(8P)

7

Four tapping screws

(B2

9

T wo tapping

screws

(B2

×

5)

(PS-4980)

Control switch block (PS-4980)

×

5)

8

Slider assembly

Control switch block

3

Control switch block

(CF-4980)

4

(B2

1

T apping screw

×

5)

(B2

Two tapping screws

×

5)

PRECAUTION DURING

INSTALLATION

Install the slider assembly

while pushing the eject lever

fully to the left (CCW).

Eject lever

2-11

6

Push the eject knob in

the direction of the arrow,

and open the cassette lid.

q;

Control switch block (CF-4980)

Be careful not to damage

the control switch block's

(CF-4980) flexible.

Eject knob

Cassette lid

)

[CONNECTION DIAGRAM FOR SERVICE POSITION (Mainly for voltage measurement and check)]

CK-093, VC-242, JK-190, CD-254, DD-138, LA-026, KP-010, MK-014, MS-049 BOARDS,

MECHANISM DECK-2

Battery panel assembly

Battery terminal board (4P)

DD-138 board

VC-242

Board

JK-190 board

Adjustment remote

commander (RM-95)

VC-242 board

Mechanism deck

A

B

Extension cable

(J-6082-496-A) (50P)

Flexible board (27P)

(from VAP assembly)

Flexible board (39P)

from zoom lens

assembly

Lens block assembly

CD-254 board (50P)

AC IN

CPC-13 jig

(J-6082-443-A)

KP-010 board

MK-014 board

MS-049 board

Control switch block

(PS-4980) (8P)

EVF block assembly

FP-193

flexible board (27P)

AC POWER

ADAPTOR

Control switch block

(CF-4980) (14P)

DC-IN

connector (3P)

(1-794-637-11)

LA-026 board

LA-026

Board

CK-093 board

Cabinet (R) block assembly

B

A

FP-187 flexible board (50P)

2-14.CK-093 BOARD

PRECAUTION DURING

INSTALLATION

When installing it.

Align the switch position.

qf

CK-093 board

q;

Seven screws

(M2

×

3),

spring bolt

3

R flexible

protection sheet

5

T wo screws

(M2

spring bolt

9

FP-194 flexible board (5P)

×

3),

6

SP retainer

plate assembly

4

Speaker (2P)

7

Speaker

qa

Claw

qs

2

FP-197 flexible board (6P)

1

Control switch block

(ED-4980) (6P)

8

Speaker holder

qd

Harness (CP-094) (14P

Harness (CP-093) (8P)

2-12

2-15.CONTROL SWITCH BLOCK (ED-4980), HINGE ASSEMBLY

A

A

qa

FP-197

flexible board

8

Three screws

(M2 × 5),

spring bolt

1

Bright

button

9

1

Three screws

(M2 × 3),

spring bolt

6

Three screws

(M2 × 3),

spring bolt

7

2

Hinge lid

5

Harness (CP-094) (14P)

4

Harness (CP-093) (8P)

8

Harness

(CP-094)

7

Harness

(CP-093)

3

Blind door (D) assembly

2

Control switch block

(ED-4980)

1

T wo screws

(M1.7 × 2.5),

lock ace

9

Screw

(M1.7 × 2.5),

lock ace

q;

Screw

(M1.7 × 2.5),

lock ace

6

T wo harness

fixed tapes

5

Hinge cover

(front)

qs

Hinge

assembly

4

Hinge cover

(rear)

2

Screw

(M1.7 × 2.5),

lock ace

3

Three claws

Start the removal work after the LCD section has been removed referring section 2-1.

2-13

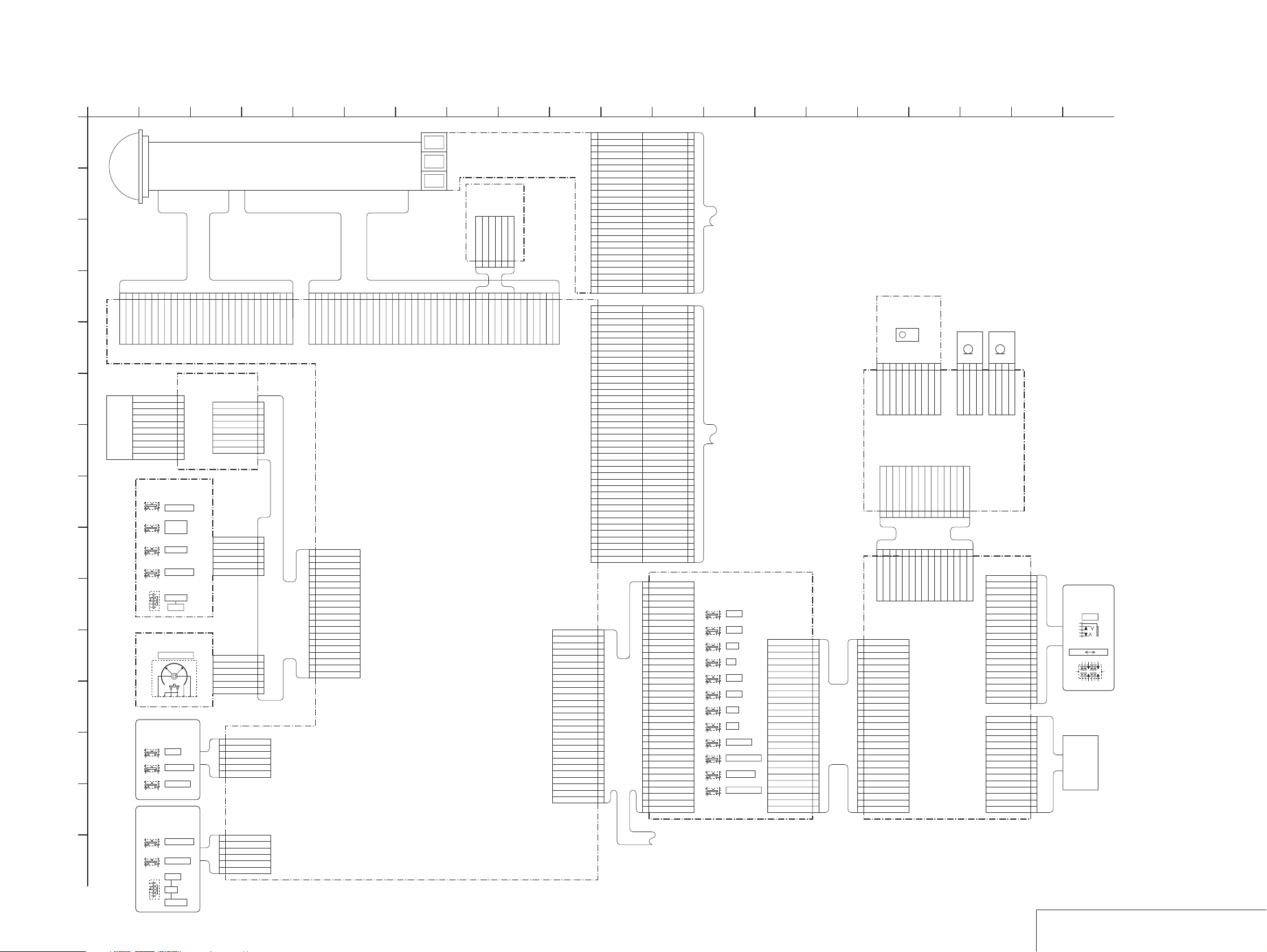

2-16.CIRCUIT BOARDS LOCATION

The circuit boards contained in the zoom lens are not shown.

FT-090

(REMOTE)

MI-038

(MIC IN)

SE-108

(VAP SENSOR)

MA-386

(AUDIO AMP)

LB-065

(BACK LIGHT)

CD-254

(CCD IMAGER)

FK-076

(CONTROL SWITCH)

CK-093

(KEY IN)

PD-126

(RGB DRIVE/TG)

INVERTER TRANSFORMER

UNIT

HL-011

(LCD DRIVE)

VC-242

S/H AGC, TG, CAMERA SIGNAL PROCESS,

MS I/F, RS232C I/F, STILL CONTROL, MS DRIVE,

DV SIGNAL PROCESS, REC/PB AMP,

LINE IN/OUT, LINE A/D, RGB DRIVE/TG,

CAMERA CONTROL, DRUM/CAPSTAN MOTOR DRIVE,

HI CONTROL, AU LINE A/D, D/A, LINE AMP

JK-190

(JACK BOARD)

DD-138

(DC/DC CONVERTER, DC REGULATOR)

LA-026

200m/FOCUS DRIVE, VAP DRIVE,

KEY IN/CONNECTOR

MK-014

(CONTROL KEY)

KP-010

(SELECT DIAL)

MS-049

(MS CONNECTOR)

2-14

2-17.FLEXIBLE BOARDS LOCATION

The flexible boards contained in the mechanism deck and that in the zoom lens are not shown.

FP-193

FP-201

FP-199

FP-202

FP-198

FP-200

FP-189

CONTROL SWITCH BLOCK

(PS-4980)

FP-195

FP-191

FP-190

FP-196

FP-194

FP-188

CONTROL SWITCH BLOCK

(ED-4980)

FP-186

FP-187

CONTROL SWITCH BLOCK

(CF-4980)

FP-197

FP-205

2-15E

SECTION 3

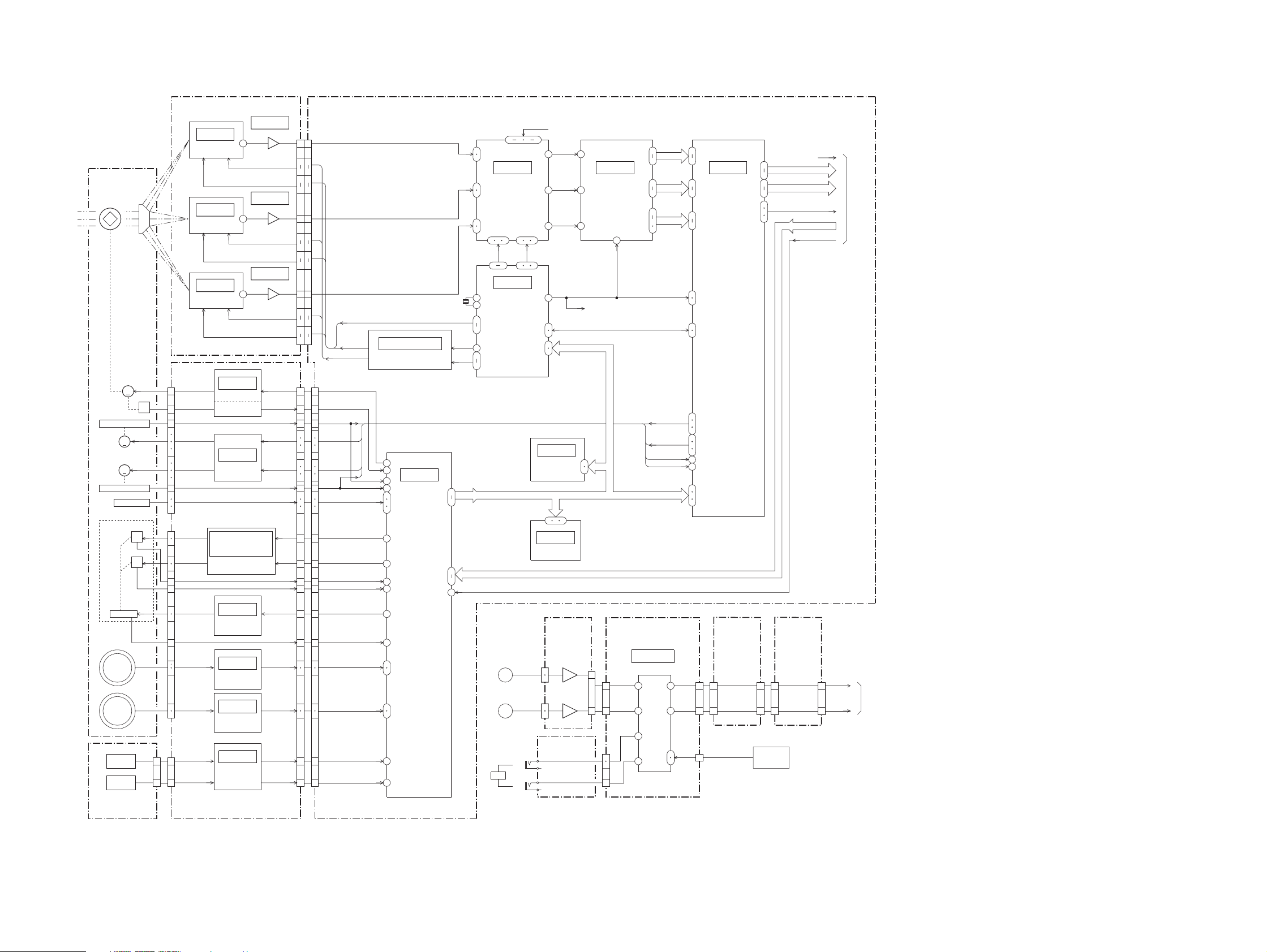

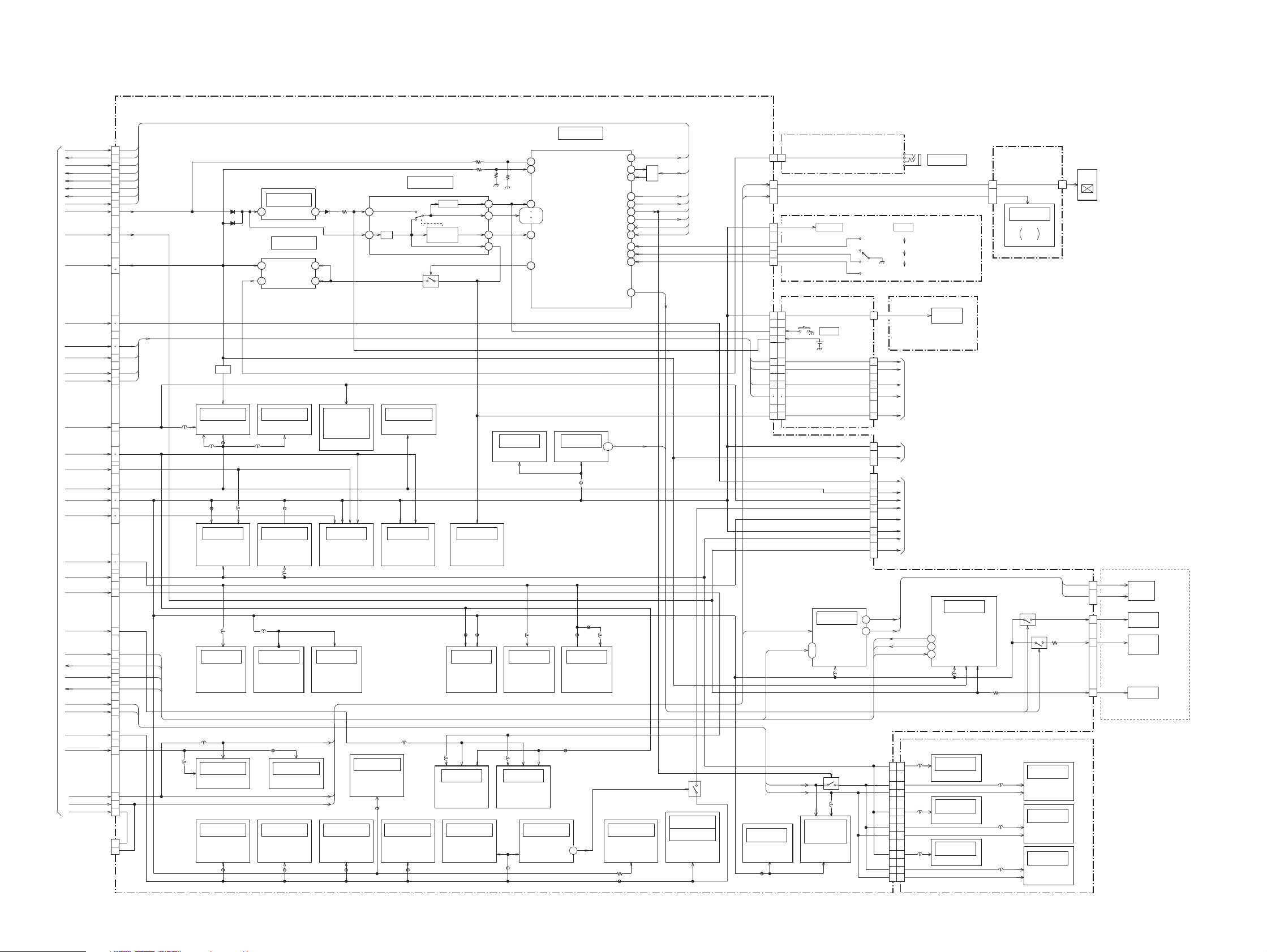

BLOCK DIAGRAMS

DCR-VX2000/VX2000E

3-1. OVERALL BLOCK DIAGRAM (1/4)

LENS BLOCK

IRIS

ZOOM RESET SENSOR

ZOOM

MOTOR

FOCUS

MOTOR

FOCUS RESET SENSOR 25

ACTIVE PRISM

ACTUATOR

ZOOM

FOCUS

SE601,602

SENSOR

SE600,603

SENSOR

SE-108

BOARD

16

(SEE PAGE 4-69)

VAP LOCK

RING

RING

PITCH

YAW

DICHROIC

IRIS

METER

M

M

M

PRISM

CD-254 BOARD

(4-9)

IC101

G-CH CCD

IMAGER

11,14-16 1-4

(4-9)

IC102

R-CH CCD

IMAGER

1-411,14-16

(4-9)

IC100

B-CH CCD

IMAGER

11,14-16 1-4

DRIVE-

20

CN600

HALL-

17

ZM RST SENS

22

1

2

ZOOM A,B

4

6

34

36

FOCUS A,B

38

39

FC RST SENS

28

ND A,B,C

27ND FILTER SW

29

CN050

P DRIV A,B

21

20

Y DRIV A,B

15

14

P OUT

12

Y OUT

22

VAP LOCK +,-

25

20

VP LOCK SENS

23

MZ F0,F1

3

5

MF F0,F1

8

9

CN052

PSD OUT

12

5

YSD OUT

10

3

CN050

H

P

Y

IC141

8

5

ZOOM MOTOR

IC140

(4-71,72)

IC070,071

073-076

ACTUATOR DRIVE

IC072

VAP LOCK DRIVE

IC144

1,2 8,13

IC143

1,2

IC200

8

SENSOR AMP

12 18

IRIS DRIVE

HALL AMP

(4-70)

DRIVE

FOCUS MOTOR

DRIVE

ACTIVE PRISM

DETECTOR

DETECTOR

PITCH/YAW

8

8

8

(4-9)

IC103

31

V1,V2A,V2B,V3

H1,H2,RG,SUB

IC104

(4-9)

31

V1,V2A,V2B,V3

H1,H2,RG,SUB

IC105

(4-9)

V1,V2A,V2B,V3

H1,H2,RG,SUB

(4-70)

10

7

(4-72)

(4-70)

(4-70)

8,13 49

(4-72)

2

LA-026 BOARD(1/4)

35

35

40

40

43

43

44

44

47

47

19

19

25

25

28

28

29

29

32

32

9

9

13

3

3

6

6

13

13

18

18

CN100

54

41

61

63

65

67

64

66

68

59

53

55

57

56

58

44

46

36

38

48

50

47

45

43

CN051

VC-242 BOARD(1/4)

CN025

53

42

62

64

66

68

63

65

67

60

54

56

58

55

57

43

45

35

37

47

49

48

50

46

44

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

AGC CONT 1,2

R,B GAIN

42 1 3

7

5

9

2111 4814

47

45

46

39

38

IC803

(4-36)

IC801

(4-35)

2

3

2

3

FP-198

(FLEXIBLE)

R,G,B OFFSET

G

R

B

EVR

243

EEPROM

MI-038

BOARD

(1/2)

Q706

CN700

Q707

CN701

CN703

19

(4-14)

IC706

A/D

CONVERTER

21

17

14

SPCK

17

16

MA-386 BOARD

(1/2)

3

5

L

12

R

10

CN1100

L

17

R

10

1

CN1101

IRIS PWM

HALL AD

EN1

DIR 1A,1B

EN0

DIR 0A,0B

P PWM

Y PWM

VP LOCK DR

MZ A,B

MF A,B

PS OUT

YS OUT

CN023

V1,V2A,V2B,V3

G CCD OUT

R CCD OUT

B CCD OUT

H1,H2,RG

SUB

IC701,702

CCD

V DRIVE

(4-13)

(4-35)

43

66

IC802

19

20

17

18

82

45

44

61

60

7

10

24

25

22

23

59

58

CAMERA

CONTROL

33

35

48

50

62

X701

27MHz

CAM SO,SI,SCK

HI SO,SI,SCK

ZOOM VR AD

31

32

29

28

35

34

31

32

17

29

10

5

9

40

(4-13)

IC704

S/H,AGC

2526 19 3837 44

XSHD

CLPDM

XSHP

PBLK

XRS

CLP OB

IC705

TIMING

GENERATOR

(4-14)

MIC

L

MIC

R

LINE

L

R

38

47

26

36

11

48

(4-101)

IC1150

MIC

AMP

35

1

33

3

1

EN1

DIR 1A,1B

EN0

DIR 0A,0B

ZM RST SENS

FC RST SENS

G

11

D0-09

R

D0-09

B

D0-09

HD,VD

22

14

CN1103

36

48

CN1102

2

83

79

99

90

47

77

70

71

62

63

64

59

60

61

58

57

14

15

66

1

2

11

(4-16)

IC771

(U-CORE)

CAMERA

SIGNAL

PROCESS

FK-076

BOARD

(1/2)

27

26

CN500 CN501

SHOE MIC L

38

45

29

36

49

50

51

36

35

INTELLIGENT

ACCESSORY

SHOE(2/2)

Y0-Y7

C0-C7

HD,VD,OE

LA-026

BOARD

(2/4)

27

26

CN053

(IC705)SPCK

HI SO,SI,SCK

ZOOM VR AD

CN051

TO

OVERALL

BLOCK

DIAGRAM

(2/4)

(SEE PAGE

3-3)

L(CH1)

2

R(CH2)

1

TO

OVERALL

BLOCK

DIAGRAM

(2/4)

(VC-242)

(SEE PAGE

3-3)

3-1 3-2

DCR-VX2000/VX2000E

3-2. OVERALL BLOCK DIAGRAM (2/4)

VC-242 BOARD(2/4)

SPCK

YO-Y7

CO-C7

HD,VD,OE

HI SO,SI,SCK

ZOOM VR AD

ZOOM VR AD

HI SO,SI,SCK

SP+,-

OSD CS,SO,SCK

PANEL R,G,B,EVF R,G,B,HD,VD

LANC SIG

232C ON

(4-19)

IC1404

RS232C

IF

Q111

12 9

14 7

JK-190

BOARD(1/2)

J301

S VIDEO

YC

G

G

J300

VIDEO

J303

LANC

TO

OVERALL

BLOCK

DIAGRAM

(1/4)

(SEE PAGE

3-2)

Y

20

20

C

22

22

17

17

V

TO

OVERALL

BLOCK

DIAGRAM

(4/4)

(SEE PAGE

3-8)

LANC SIG/232C RD

35

35

LANC GND/232C TD

37

37

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

(4-17)

37

60

51

46

38

49

48

47

82

97

106

129

111

141

142

|

|

|

•

IC1407

(HONEY)

PROCESS

140 132

DIGITAL

STILL

41

144143

X1301

13.5MHz

RXD

TXD

(4-30) (4-32)

IC1301

(TAKO)

39

LINE IN

LINE OUT

48

AGC

ACC

42

Y

18

C

14

V

22

28

30

36

34

26

46

7

910

Y

C

TAKO CK

Y

C

SPCK

Y0-Y7 |

C0-C7

HD,VD,DE

SPCK

IC903

68

(ALIGN)

A/D

CONVERTER

2

6

25

63

59

Y0-Y7

52

49

C0-C7

42

38

HD,VD,DE

37

36

34

66

(4-17)

IC1403

16Mbit DRAM

20

|

31

1

13

38

48

AFCK

A0-A8

D0-D15

VSP SO,SCK

CN300

IN/OUT

JK-190

BOARD

(2/2)

DV

(4-23)

IC301

199

77

Y0-Y7

|

70

68

C0-C3

|

64

63

HD,VD OE

62

61

96

|

Y0-Y7

87

86

C4-C7

|

83

80

HD,VD,OE

79

78

7

SYS CLK(IC1401)

AFCK(IC903)

SPCK(IC705)

8

IC302

(4-25)

CHARACTER

GENERATOR

31

OSD CS

12

JID0-JID7

|

21

OSD SO

OSD SCK

203

207

213

200

208

214

2

9

HD

20

VD

•

19

18

|

•

17

COL3

•

•

1416190

57

4

11

201

205

211

DV SIGNAL

PROCESS

215

31

17

21

23

202

206204

212

216

6

8

13 15

18

22

24

196

48

184

•

183

195COL0

•

194

•

191

•

(CAIN)

138

139

142

145

141

152

153

156

133

132

127

170

179

159

161

105

106

51

99

97

83

88

81

79

75

73

71

67

65

63

55

59

|

|

|

|

•

X301

24.576MHz

L BUS

TRCK

LCK

FRRV,TRRV,TRRT

DATA FROM SFD

6

PANEL G

PANEL R

PANEL B

HD,VD

EVF G

EVF R

EVF B

Y

C

DATA TO SFD

SFD BCK

CN006

(4-26)

45

IC361

42

(LIP)

DV INTERFACE

47

49

TPA+,-

6

TPB+,-

9

29

MC BUS

37

REC CK

REC DT

AD DT

6

TO

OVERALL

BLOCK DIAGRAM

PB CK

(3/4)

ATF ERR

(SEE PAGE

3-5)

MC BUS

FRRV,TRRV,TRRT

VSP SO,SI,SCK

CN301

626

2

J300

J302

AUDIO

(SEE PAGE

OVERALL

BLOCK

DIAGRAM

(LA-026)

3-2)

26

26

28

28

L

12

CN301

12

R

9

9

CN006

L

R

Q1008,1004

HP L

HP R

L

R

L

R

(4-48) (4-48)

IC1007

L(CH1)

R(CH2)

1

2

CN023

TO

(1/4)

VCA

2

6

IC1008

1

31

7

75

16

(4-46)

64

IC1001

2

(XYZ)

AUDIO

54

55

51

53

46

49

58

60

I/O

SP+,-

8

10

19

17

25

23

14

15

4

L

R

L

R

VSP SO,SCK

KASHAON

(4-46)

IC1002

(ADC&DAC)

D/A CONV.

A/D CONV.

15

16

3

2

DATA FROM SFD

9

DATA TO SFD

8

SFD BCK

12

IC1005

EVR

(4-48)

VSP SO, SCK

HI SO,SI SCK

XTAL OSC

2

4

20-31

(4-20)

IC1406

EEPROM

DI,CI

IC1408

16Mbit DRAM

2

4

SPCK1(IC705)

(4-19)

6

IC1412

1

SHUTTER

2

SOUND

4

(4-21)

1-13

38-48

X1411

20MHz

SCK

SYSCLK(IC1401)

28

36

(4-22)

|

38

IC1410

10

|

MEMORY

1

STICK

•

I/F

48

|

40

13

15

|

17

CN023

31

31

30

30

33

33

MS-049

BOARD

CN051

18

20

17

CN056

LA-026

BOARD(3/4)

MEMORY

STICK

CN776

SLOT

4

8

25

CN775

6

8

77

79

88

54-52

(4-19)

IC1401

DIGITAL

STILL

CONTROL

5-15 55-75

A0-A10

D0-D15

19

21

109

112

TXD

RXD

50

51

X1401

7.375MHz

SYSCLK

14

13

JID0-JID7

34

41

27

IC1409

JPEG

2,9-16

58-64

18

(4-17)

IC1411

(4-22)

3-3 3-4

DCR-VX2000/VX2000E

3-3. OVERALL BLOCK DIAGRAM (3/4)

VC-242 BOARD(3/4)

TO

OVERALL

BLOCK DIAGRAM

(2/4)

(SEE PAGE

3-4)

TO

OVERALL

BLOCK DIAGRAM

(4/4)

(SEE PAGE

3-8)

16

REC CK

REC DT

AD DT

6

PB CK

ATF ERR

MC BUS

FRRV TRRT,TRRV

VSP SO,SI,SCK

HI SO,SI,SCK

CHIME SDA,CHIME SCK,CHIME VDD

XCC DOWN

(4-38)

IC502

EEPROM

2-4

20MHz

FRRV

TRRT

TRRV

X501

95

26

|

37

106

|

108

74

|

76

1

2

83

82

81

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

CN007

FOR ADJUSTMENTS

32

SWP

RF MON

REC CK

REC DT

(4-37)

IC501

MECHA

CONTROL

60

78

|

80

CAP FG

115

CAP ON,CAP FWD

45

46

CAP PWM

69

DRUM PWM

68

47

DRUM ON,DRUM FWD,DRUM START

48

63

DRUM FG

116

DRUM PG

117

LOAD,UNLOAD

49

50

TREEL FG

114

SREEL FG

113

TAPE END

54

TAPE TOP

53

DEW DET

96

TAPE LED ON

55

REC PROOF SW

44

39

MODE SW A - MODE SW D

|

42

15

20

13

34 31

(2/2)

(4-27)

IC101

(TRF)

EQ

A/D CONV.

PLL

22 24

61

58

Q310

SWITCHING

Q311

SWITCHING

AD DT

6

PB CK

SWP

DRP SO,XDRP SCK

(4-39)

56

IC401

(RABI)

LPF

53

LPF

(2/2)

CN021 CN450

54

454746

52

48

CAP ERROR

DRUM ERROR

(4-105)

18

IC300

PWM

DRIVE

22

DD-138 BOARD(1/2)

PB Y OUT

42

SWP

CN450

393740

38

CN021

C MECHA DECK

(4-28)

IC102

40

(TRW)

42

REC/PB

AMP

27

32

2,3

(4-40)

CAP VS

18.22

DRUM VS

11

(4-39)

16,6,3

1

59

26,25

40

48

34

37

6

7

2

1

CAPSTAN

FG AMP

IC402

CAPSTAN

MOTOR

DRIVE

IC401

(RABI)

DRUM

MOTOR

DRIVE

DRUM FG AMP

DRUM PG AMP

LOADING MOTOR

DRIVE

REEL FG AMP

TAPE END DETECT

TAPE TOP DETECT

CN101

ODD

EVEN 8

(1/2)

5

6

9

14,15

21,23,19

20,22,24

64

61

28,30

42,43

45,46

35

36

(SEE PAGE 4-39)

CN024

CN020

CN022

XCC DOWN

DRUM

24

25

17

|

20

7

|

10

11

|

14

6

|

1

10

11

27

|

24

23

8

9

12

11

21

1

14

3

5

|

7

4

19

|

16

M902

CAPSTAN

M

M

DRUM FG

DRUM PG

M

DEW

SENSOR

T REEL

SENSOR

S REEL

SENSOR

Q901

TAPE END SENSOR

Q902

TAPE TOP SENSOR

D901

TAPE LED

REC PROOF

4PIN

CONNECTOR

C IN

MODE

SWITCH

S903

FG

CAPSTAN

MOTOR

M901

DRUM

MOTOR

M903

LOADING

MOTOR

S902

CN901

S901

3-5 3-6

DCR-VX2000/VX2000E

3-4. OVERALL BLOCK DIAGRAM (4/4)

CN001

CN750

1

2

4

CN255

CN256

2

4

CN254

2

ZOOM VR

START/STOP SW

EJECT SW

LID OPEN SW

CN054

2

3

5

1

6

CN055

3

10

CN056

8

8

7

7

CK-093 BOARD(1/2)

S251,253,261

DISPLAY SW

SELF TIMER SW

DATA CODE SW

S250,255,258,260,263

ZEBRA SW,TITLE SW,

DIGITAL EFECT SW,

PICTURE EFECT SW,

MEMORY MIX SW

S252,254,257,259,262

MEMORY FUNCTION SW

S256

RESET

PHOTO SW

POWER SW

START/STOP SW

(LOW ANGLE)

LA-026 BOARD(4/4)

KP-010

BOARD

INTELLIGENT

ACCESSORY

SHOE

(2/2)

MI-038

BOARD(2/2)

CN702

Q700,702,704

LED

DRIVE

CN703

14

13

BT250

LITHIUM

BATTERY

ZOOM VR AD

XPHOTO FREEZE

XPHOTO REC

XS/S SW

XVTR MODE SW

XCAM+STBY SW

PHOTO STBY SW

XEJECT SW

LID OPEN

MA-386

BOARD(2/2)

CN102

5

6

7

(4-102)

IC1102

COMMANDER

CN1100

1

2

REMOTE

RECEIVER

(REAR)

CN250

SEL/PUSH

EXEC

DIAL

S1101

CUSTUM

PRESET SW

40

40

42

42

36

36

34

34

38

38

32

32

46

46

3

4

5

6

7

8

9

10

12

13

ED-4980

BOARD

FP-197

(FLEXIBLE)

FP-194

(FLEXIBLE)

CONTROL

SWITCH BLOCK

(CF4980)

(SEE PAGE 4-86)

FP-189

(FLEXIBLE)

FP-188

(FLEXIBLE)

MK-014

BOARD

FT-090

BOARD

16

EXPOSURE

DIAL

EXPOSURE/SW

PANEL OPEN/

CLOSE SW

PANEL

REVERSE SW

MENU

FADER SW

BACK LIGHT SW

STOP LIGHT SW

INDEX SW

FOCUS SW

S001-005

REC LEVEL GAIN SW

AUTO WHITE BALANCE SW

SHUTTER SW

PROGRAM AE SW

AUTO LOCK SW

(4-89)

IC750

REMOTO

COMMANDER

RECEIVER

(FRONT)

D751

(IR EMITTER)

1

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

DIAL C

KEY AD5

20MHz OUT

20MHz IN

32KHz IN

32KHz OUT

KEY AD4

KEY AD6

XRESET

VDD

XPHOTO FREEZE

KEY AD8

XS/S SW

XVTR MODE SW14

XCAM+STBY SW

XPHOTO STBY SW

XEJECT SW

LID OPEN

KEY AD2

KEY AD3

DIAL B

MELODY

SIRCS ENV

HOT SHOE ID1

XSIRCS IN

KEY AD0

IB SI

IB SO49

LANC I/O

(4-44)

IC1104

HI CONTROL

KEY AD7

CHIME SDA

CHIME SCL

CHIME AD0

CHIME AD2

XCC DOWN

XCS OSD

XOSD SCK

BATT/EXT SW

FAST CHARGE

VTR DD ON

CAM DD ON

SHOE ON

LANC OUT

Q1104

I/F

(4-43)

10

12

VC-242 BOARD(4/4)

DIAL C,D

KEY AD5

KEY AD4

KEY AD6

HI XRESET

LI 3V

CN008

CN009

CN550

CN1103

1

1

6S550

2

22

10

8

24

21

20

VTR UNREG

BATT UNREG

1

6

2

CN056

FK-076

BOARD(2/2)

LANC SIG

6

18

20

SIRCS SIG

4

7

SIRCS PWM

8

CN500

S500-511

VTR

FUNCTION SW

CN501

3

7

EXCUTE(DIAL)

15

27

29

13

16

17

6

7

IC1102

VDD SWITCH

(4-43)

CN051

KEY AD2

KEY AD3

DIAL A,B

6

18

20

4

7

8

CN053

RESET

82

83 DIAL D

98

40

X1101

20MHz

41

52

X1102

32.768KHz

53

97

99

5

6

29

30

24

23

27

28

25

26

28

27

22

21

9

10

7

8

22

24

19

20

20

19

CN023

7

8

CN004

Q1102,1105

38

42

51

77

87

19

92

16

15

20

17

31

95

96

9798DIAL A

36

MOD

59

80

70 HOT SHOE ID2

4

93

94 KEY AD1

48

LANC

SIG

IC1103

11

HI SO

HI SI

HI SCK 35

OSD SO

BATT SIG

HSY

CN201

FP-196

(FLEXIBLE)

1

VOLUME SW

LCD BRIGHT SW

5

COM1-4

SEG1-16

LCD

5

4

2

1

4

5

3

6

7

3

2

4

1

5

CN2105

FOR

ADJUSTMENTS

INVERTER

BLOCK

1

2

3

1

3

4

INDICATOR

LCD

UNIT

ND901

J902

DC IN

J901

BATTERY

TERMINAL

BACK

LIGHT

BACK

LIGHT

DRIVE

LCD

UNIT

S

21

VG

23

15

19

22

14

ND200

BACK

LIGHT

CN301

CN300

SP901

SPEAKER

26

24

36

38

34

5

6

30

32

49

51

50

41

46

44

5

4

3

3

2

1

10

8

13

12

25

23

35

37

33

5

6

29

31

50

52

49

42

45

43

HL-011 BOARD

CN1701

6

5

4

PD-126 BOARD

3

2

1

10

8

13

12

CN2100

VR

14

VG

18

VB

13

VCO

XHD

12

CN007

EVF BL-

FOR

17

ADJUSTMENTS

EVF BL+

20

EVF BL 4.6V

R391,392

Q339

PANEL 13.5V

CAM DD ON

VTR DD ON

VTR UNREG

BATT UNREG

FAST CHARGE

BATT/EXT SW

BATT SIG

EVF 2.8V

EVF 13.5V

PANEL 2.8V

PANEL 4.6V

TRF 2.8V

CAM 12V

CAM -7V

D 1.5V

D 1.9V

A 2.8V

AU 2.8V

D 2.8V

D 3.1V

MS 3.1V

A 4.6V

AU 4.6V

RP 4.6V

MT 5.2V

48

47

46

40

39

46

45

42

48

PANEL 4.6V

1

8

7

IC2101

(4-65)

IC2103

249

CN00215

(4-105)

IC1701

RGB

DRIVE

TIMING

GENERATOR

Q2182

25

26

24

27

23

3

8

7

IC300

DC/DC

CONVERTER

(4-98)

BL ON

3

2

4

1

5

1414

25

20

21

11 2

LCD

DRIVE

30

20

VR,VG,VB

22

24

PSIG

27

COM

12

(4-65)

10

24

PWMHD OUT

LB-065 BOARD

R,G,B

COM

(4-94)

IC200

Q200

INVERTER

PWM

BACK LIGHT

DRIVE

EVF BL 4.6V

CN200

DD-138

BOARD(2/2)

CK-093

BOARD(2/2)

100

5

6

71

73

18

33

34

44

45

46

66

50

29

28

81

12LANC IN

HI SO,SI,SCK

CHIME SDA

CHIME SCK

CHIME VDD

XCC DOWN

TO

OVERALL

BLOCK

DIAGRAM

(3/4)

(SEE PAGE

3-5)

HI SO,SCK

EVF R,G,B

HI SO,SCK

XHD

XVD

22

20

16

18

29

31

35

37

9

11

41

43

CN008

48

47

46

40

39

46

45

42

1

48

PANEL R,G,B

XHD,XVD,SP+,SP-

OSD,CS,SO,SCK

HI,SO,SI,SCK

ZOOM VR AD

SHOE UNREG

P UNREG

VTR UNREG

BATT UNREG

CN250

22

20

16

18

29

31

35

37

9

11

41

43

IC1802

IC1803

EVF R,G,B

LANC SIG

(4-34)

TIMING

GENERATOR

(4-34)

RGB

DRIVE

SP+,-

OSD SO,SCK

PANEL R,G,B

CN253

91

TO

OVERALL

BLOCK

DIAGRAM

(2/4)

(SEE PAGE

3-3)

SHOE ON

KEY AD7

CN252

XHD

XVD

CN251

1

2

20

22

24

12

24

14

CN021 CN450

P UNREG

CN1702

CN1703

PSIG

COM

CN2104

Q301

3-7 3-8

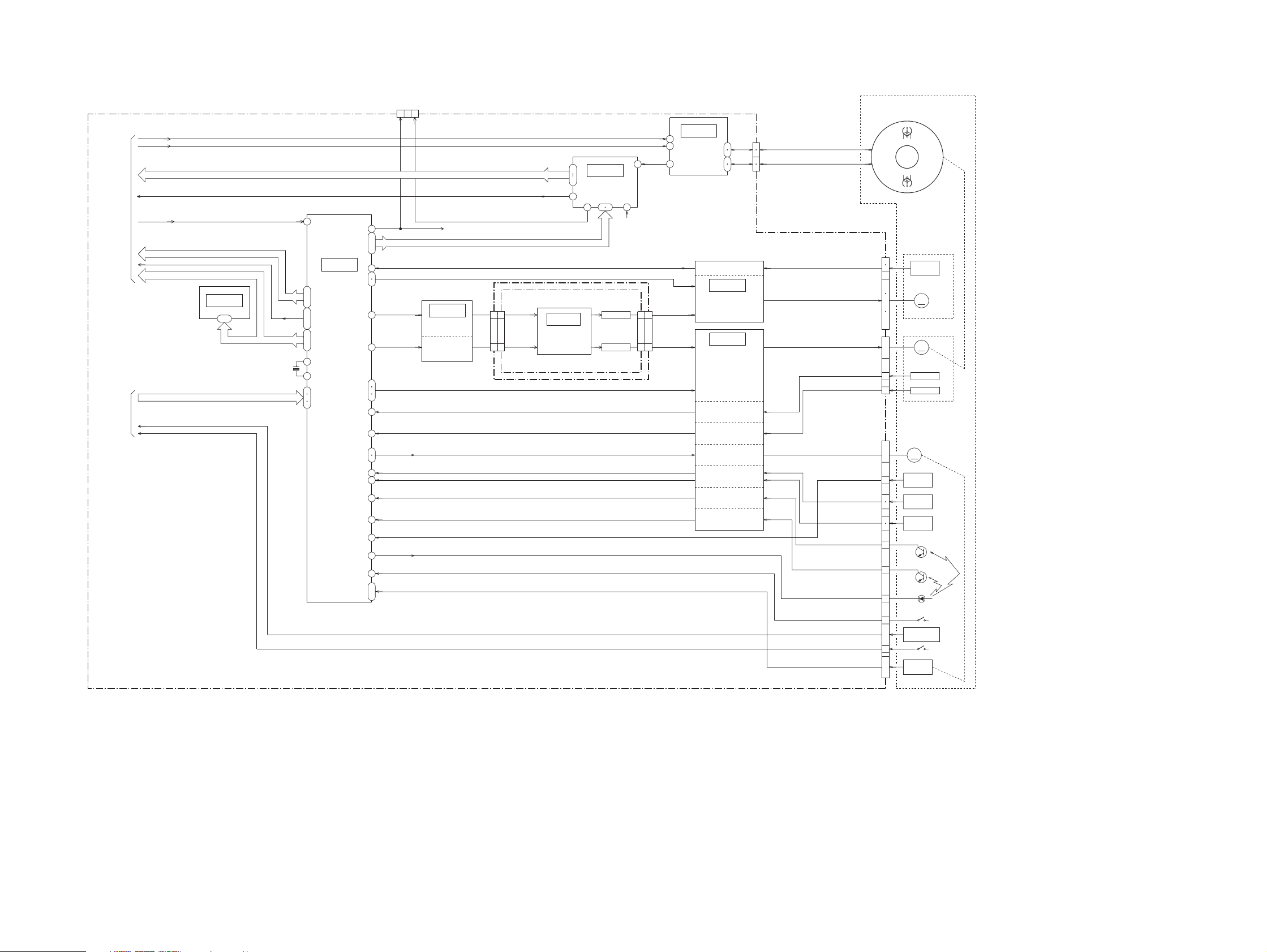

DCR-VX2000/VX2000E

3-5. POWER BLOCK DIAGRAM (1/3)

DD-138 BOARD

J901

BATTERY

TERMINAL

S

J902

DC IN

1

2

3

4

1

2

3

CN301

BATT UNREG

DCPACK SW

BATT SIG

ACV UNREG

CN300

(4-61)

BATT/XEXT

Q300,

301

BATT FET ON

SHOE ON

CHARGE

SWITCH

CHARGE INH

Q302-304

Q329,

339

INIT CHARGE ON

F300

F301

F305

F304

F303

F302

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

BATT UNREG

4

1

Q305

SWITCHING

Q306,

307

EMERGENCY

T300

5

7

8

2

3

DETECT

D306

RECT

D307

RECT

D305

RECT

VREF

VTR DD ON

D308

55

28

46

57

49

60

8

7

3

27

33

34

35

29

30

VCC(0)1234

VCC(0)5678

VCC

VSS(0)1234

VSS(0)567

VDD(0)123

VDD(0)567

+IN8

-IN8

OUT8

VREF

VB

RT

CT

CTL1-6,8

CTL7

IC300

DC/DC CONVERTER

(4-105)

OUT7-1

OUT7-2

-IN7

OUT3-1

OUT3-2

-IN3

OUT2-1

OUT2-2

-IN2

OUT4

-IN4

COMP

OUT1-1

OUT1-2

-IN1

OUT6-1

OUT6-2

+IN6

OUT5-1

OUT5-2

+IN5

Q312

SWITCHING

64

12

13

Q313

SWITCHING

53

54

40

Q314

SWITCHING

50

51

43

Q308

SWITCHING

4

56

37

11

47

48

44

61

62

18

58

59

22

Q309

SWITCHING

Q310

SWITCHING

Q311

SWITCHING

1

CHARGE INH

44

SHOE ON

33

BATT SIGSHOE UNREG

43

INIT CHARGE ON

27

VTR DD ON

31

CAM DD ON

29

FAST CHARGE

42

BATT/XEXT SW

45

BATT UNREG

R391,392

49

54

MT 5.2V

56

VTR UNREG

50

52

35

SHOE UNREG

37

P UNREG

5

6

PANEL 2.8V

17

PANEL 13.5V

20

PANEL 4.6V

19

AU 4.6V

30

D 1.9V

51

53

A 2.8V

47

AU 2.8V

28

32

D 2.8V

34

24 D 1.5V

26

39

D 3.1V

41

A 4.6V

22

RP 4.6V

55

TRF 2.8V

18

CAP VS

40

CAP ERROR

46

DRUM VS

38

DRUM ERROR

48

CAM 12V

13

CAM -7V

15

MS 3.1V

14

EVF 2.8V

21

EVF 13.5V

36

EVF BL-

23

EVF BL+

25

CN450

TO

POWER

BLOCK

DIAGRAM

(2/3)

(VC-242)

(SEE PAGE

3-11)

Q315-317,324

MT 5.2V

5.2V

REG

TRF 2.8V

L303

Q321

SWITCHING

L304

Q322

SWITCHING

L305

Q323

SWITCHING

T301

5

6

7

8

2

3

L302

Q318

SWITCHING

L300

Q319

SWITCHING

CAP ERROR

L301

Q320

SWITCHING

DRUM ERROR

D311

RECT

D312

RECT

CAP VS

DRUM VS

L312

L314

L315

L309

Q325

EMERGENCY

DETECT

D313

RECT

L316

L311

L313

L310

L319

IC301

Q327,331,332,337

Q344,348,349,351

Q333-335,338

-7V REG

L307

L306

L308

Q340,341

1.5V REG

13.5V REG

12V REG

MS 3.1V

D 3.1V

D 1.9V

D 1.5V

AMP

IC301

ERR AMP

(4-107)

D 2.8V

AU 2.8V

A 2.8V

PANEL 2.8V

EVF 2.8V

L317

EVF 13.5V

L318

PANEL 13.5V

CAM 12V

CAM -7V

PANEL 4.6V

A 4.6V

RP 4.6V

AU 4.6V

EVF BL 4.6V

16

3-9 3-10

DCR-VX2000/VX2000E

3-6. POWER BLOCK DIAGRAM (2/3)

VC-242 BOARD

SHOE ON

BATT SIG

VTR DD ON

MT 5.2V

P UNREG

AU 4.6V

AU 2.8V

RP 4.6V

TRF 2.8V

CAP VS

DRUM VS

CAM 12V

CAM -7V

MS 3.1V

EVF 2.8V

EVF 13.5V

EVF BL-

EVF BL+

D 1.9V

A 2.8V

D 2.8V

D 1.5V

D 3.1V

A 4.6V

CN021

43

34

44

28

32

30

41

46

50

53

55

49

51

36

38

5

6

18

19

20

Q1011

D1103

D1102

REG

IC1001 IC1002

29

52

54

48

27

31

33

23

25

40

42

21

56

17

37

45

39

47

14

16

13

22

L1073

L1801

(4-34)

35

24

26

2017CN007

FOR

D 2.8V

MS 3.1V

16

(XYZ)

AUDIO I/O

FB1002

L1001

A 2.8V

AU 2.8V

D 2.8V

A 4.6V

D 3.1V

RP 4.6V

MT 5.2V

D 1.9V

D 2.8V

FB901

L902

(ALIGN)

A/D CONV.

(4-32) (4-30)

L802

(4-36)

IC803 IC802 IC801 IC771 IC704 IC706

EVR CAMERA EEPROM

L1803

RGB

DRIVE

(4-19) (4-17) (4-21)(4-17) (4-20)

RS232C 16M SHUTTERDIGITALJPEG EEPROM16M DRAM

FB1401

TO

POWER

BLOCK

DIAGRAM

(1/3)

(DD-138)

(SEE PAGE

3-10)

CHARGE INH

INIT CHARGE ON

CAM DD ON

FAST CHARGE

BATT XEXT SW

BATT UNREG

VTR UNREG

SHOE UNREG

PANEL 2.8V

PANEL 13.5V

PANEL 4.6V

CAP ERROR

DRUM ERROR

ADJUSTMENTS

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

IC1104

HI CONTROL

BATT SENS

90

ACV SENS

91

REG

IC1005

EVR

IC1102

BATTER IN

DETECT

Q1106

BTT LI 3V

RESET

(4-46)

5

6

4

8

EVER 3.0V

XRESET

38

42 51

VDD

86 87

61

BATT IN

12

XLANC ON

(4-38) (4-37)

EEPROM

INIT CHARGE ON

XVTR MODE SW

XCAM+STBY SW

XPHOTO STBY SW

CHIME PWR CONT

IC501IC502

MECHA

CONTROL

FB501

14

SHOE UNREG

VTR UNREG

LANC DC

AU 4.6V

L1002

2

1

IC1101

IC1103

UNREG

LANC DC

AUDIO

ADC&DAC

FB1301

(4-46)

REG

LANC I/O

3

D1104

3

7

(4-43)

POWER

4

VCC

8

(4-43)(4-46)

(4-48) (4-48)

IC1007

IC1008

VCA,AMP

IC1301IC903 IC301 IC361 IC302

(HONEY)

DIGITAL

STILL

PROCESS

FB1404

(LIP)

DV

CHARACTER

GENERATERINTERFACESIGNAL

FB771 FB772

(U-CORE)

CAMERA

SIGNAL

PROCESS

FB706

L701

S/H

AGC

FB707

A/D

CONV.

(4-16) (4-13) (4-14)

L102

L103

L101

IC102 IC101

(TRW) (TRF)

AMP A/D CONV.

EQ,REC/PB

PLL

FB101

(4-27)(4-28)

(TAKO)

VIDEO

LINE IN/OUT

AMP

L1301,1304

L801

(4-35) (4-35)

CONTROL

FB1801

IC1803IC1802

TIMING

GENERATOR

(4-34)

EVF BL 4.6V

EVF VCC

EVF 13.5V

(CAIN)

DV

PROCESS

(4-23) (4-26) (4-25)

(4-17)

IC1407

IC1403IC1404 IC1409 IC1408 IC1406 IC1401 IC1412

(4-19)

DRAMI/F

FB1402 FB1406 FB1405

FB1403

CONTROL

118

(4-44)

SHOE ON

VTR DD ON

CAM DD ON

FAST CHARGE

CHARGE INH

BATT/XEXT

105

L702

MS VCC ON

IB SO

R1455

FB1407

IB SI

XREEL

HALL ON

RP 4.6V

D 1.9V

SOUND

81

49

48

25

29

28

50

47

66

14

15

20

7

(4-19)

Q1104

JK-190 BOARD

LANC DC

32 32

CN006

CN009

CN301

EVF VCC

11

8

EVF BL 4.6V

9

CN002

D 2.8V

2

7

8

9

ZOOM VR

POWER

VTR

OFF

CAMERA

PHOTO

BATT SIG

I/F

J303

LANC

DIGITAL I/O

CONTROL

SWITCH

BLOCK

(CF-4980)

LB-065

BOARD

CN200 CN201

17

20

21

(4-94)

IC200

INVERTER

BACK

LIGHT

DRIVE

LCD

UNIT

16

(SEE PAGE 4-86)

CN008

44

32

46

8

6

10

2

4

14

CAP_VS

D 2.8V

VTR UNREG

MT 5.2V

CK-093 BOARD

44

32

46

PANEL 4.6V

8

PANEL 2.8V

6

PANEL 13.5V

10

2

P UNREG

4

EVER 3.0V

14

CN250

EVF 13.5V

18

22

S256

RESET

BT250

LITHIUM BATTERY

D 2.8V

VTR UNREG

SHOE UNREG

AU 2.8V

AU 4.6V

VCC

D 3.1V

D 2.8V

A 4.6V

MT 5.2V

(4-40)

IC402

CAPSTAN MOTOR

DRIVE,

CAP FG AMP

L402

CN255

CN251

CN252

CN023

13

25

3

CONTROL SWITCH

BLOCK(ED-4980)

7

5

6

7

6

CN004

6

1

2

15

16

12

14

36

70

72

73

75

78

80

MR VCC

HE VCC

DRUM ERROR

D 2.8V

TO

POWER BLOCK

DIAGRAM

(3/3)

(PD-126)

(SEE PAGE

TO

POWER BLOCK

DIAGRAM

(3/3)

(FK-076)

(SEE PAGE

TO

POWER BLOCK

DIAGRAM

(3/3)

(LA-026)

(SEE PAGE

CAP ERROR

DRUM VS

EXPOSURE

(SEE PAGE 4-62)

3-13)

3-13)

3-13)

52

54

11

IRIS DIAL

IC401

(RABI)

DRUM

MOTOR DRIVE

DRUM FG,PG AMP

LOADING

MOTOR DRIVE

REEL FG AMP

TAPE TOP,END DET

DRUM,CAP ERROR AMP

L401

(4-39)

HE VCC

15

26

MR VCC

27

R024

CHIME VDD

SENSOR VCC

TAPE LED A

CN022

CN024

7

13

15

Q1109,1108

Q402

CHIME PWR CONT

R424

XREEL HALL ON

CAPSTAN

MOTOR

4PIN

CONNECTOR

T REEL,

S REEL

SENSOR

TAPE LED

C MECHA DECK

(SEE PAGE 4-39)

CD-254 BOARD

(4-9)

(4-9)

L100

(4-9)

(4-9)

L101

(4-9)

(4-9)

L107

IC101

CCD IMAGER

(G-CH)

IC102

CCD IMAGER

(R-CH)

IC100

CCD IMAGER

(B-CH)

(4-22)

IC1410

IC1411

MEMORY

STICK I/FSTILL

Q1404,1405

D 2.8V

(4-14)

IC705

TIMING

GENERATOR

FB704

A 4.6V

CAM DD ON

CAM 12V

CAM -7V

(4-13)

IC701

IC702

CCD

V DRIVE

Q701,702

L710

CN025

L106

CN100

IC103

AMP(G-CH)

L104

IC104

AMP(R-CH)

L105

IC105

AMP(B-CH)

39

39

48

48

38

38

2323

341234

24

24

14

14

88

12

3-11 3-12

DCR-VX2000/VX2000E

3-7. POWER BLOCK DIAGRAM (3/3)

PD-126 BOARD

PANEL 4.6V

7

PANEL 2.8V

5

PANEL 13.5V

MEMORY

STICK

SLOT

POWER BLOCK

(SEE PAGE

POWER BLOCK

(SEE PAGE

MK-014

BOARD

3 VCC

CN776 CN775

MS-049

BOARD

16

DIAGRAM

(CK-093)

3-12)

DIAGRAM

(VC-242)

3-12)

D003

ACCESS

LED

6

CN2100

TO

(2/3)

P UNREG

7

EVER 3.0V

6

CN2101 7

D 2.8V

UNREG VTR FUNCTION KEY

15

SHOE UNREG

16

AU 2.8V

11

TO

(2/3)

CN001

13

35

69

71

74

76

77

79

49

3

15

49

16

CN051

CN056

AU 4.6V

VCC

D 3.1V

D 2.8V

A 4.6V

MT 5.2V

D 2.8V

LA-026 BOARD

L2103

L2101

L2102

IC2101

RGB DRIVE

(4-65)

L2182

L2181

CN053

CN501

5

1

2

12

21

13

22

26

17

15

24

D 3.1V

20

11

MT 5.2V

10

1

D500-511

ILLUMINATION

LED

FK-076 BOARD

(4-70) (4-70) (4-70)

IC143

FOCUS RING

PHASE

DETECTOR

Q073,074

Q076,078

FB140

(4-70) (4-71,72) (4-72)

L140

IC140 IC070-072

ZOOM MOTOR

FOCUS MOTOR

DRIVE

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

Q2102,2104

14

P OFF

(4-65)

CN2104

VDD

18

LCD

UNIT

IC2103

TIMING

GENERATOR

4

BL ON

R186R178

IC144

ZOOM RING

PHASE

DETECTOR

ACTIVE PRISM

ACTUATOR DRIVE

VAP LOCK DRIVE

Q2181,2182

CN500

L070

INVERTER

BLOCK

BACK

LIGHT

DRIVE

CN2103

(4-101)

IC1150

MIC AMP

12

16

13

15

15

12

14

14

11

17

1

27

CN1103

L142

L1150

MA-386 BOARD

IC141

IC142

IRIS DRIVE,

V REF

L071

IC075

IC076

P PWM

Y PWM

AMP

HL-011 BOARD

(4-98)

7

CN1701

(4-43)

IC1102

REMOTE

COMMANDER

RECEIVER

(REAR)

Q200,201

L200

IC200

PITCH/YAW

SENSOR AMP

L143

L141

L072

IC073,074

ACTIVE PRISM

ACTUATOR

PRE DRIVE

L073

IC1701

LCD

INDICATOR

DRIVE

R1121R1125

(4-94)

R187

D1105

TALLY

LED

(REAR)

(4-72)

Q140,141

Q072,075

Q077

CN050

CN052

CN1102

CN1100

11

26

32

21

2

10

11

1

2

INTELLIGENT

ACCESSORY SHOE

3

4

8

7

5

10

3

12

CN703 CN750

SE VCC

4

CN600

LENS BLOCK

ZMFC SENS VCC

ND SENS VCC

DRIVE +

MZ VCC

MF VCC

VAP VCC

MI-038 BOARD

MIC AMP

MIC POWER

Q701,703,

705-707

SE-108 BOARD

PITCH/YAW

SENSOR

ZOOM RESET SENSOR

FOCUS RESET SENSOR

ND FILTER SW

IRIS METER

ZOOM RING

FOCUS RING

ACTIVE PRISM

ACTUATOR

IR LED

DRIVE

Q700,

702,

704

CN702

545

4

FT-090 BOARD

(4-89)

IC750

REMOTE

COMMANDER

RECEIVER

(FRONT)

R751

D750

R750

TALLY

LED

(FRONT)

F750

IR LED

(SIRCS OUTPUT)

D751

3-13 3-14E

SECTION 4

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/3)

DCR-VX2000/VX2000E

FLEXIBLE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

L(CH1)OUT

R(CH2)OUT

REG_GND

REG_GND

EXT_MIC_DET

EXT_MIC_MONO

ZOOM_MIC_CONT

SHOE_ID2

N.C.

SHOE_ID1

N.C.

AU_2.8V

F_TALLY_LED

AU_4.6V

SHOE_UNREG

SHOE_UNREG

D_3.1V

SIRCS_SEL1

TALLY_LED

SIRCS_PWM

XCUSTOM_PRESET

LANC_SIG

SIRCS_SEL2

SIRCS_SIG

MT_GND

MT_GND

MT_5.2V

16

FT-090

BOARD

IC750

REMOTE

COMMANDER

RECEIVER

10

MT_5.2V

MT_GND

MT_GND

SIRCS_SIG1

F_TALLY_LED

SIRCS_DRV_CL

MI-038 BOARD

MIC_GND

INT_MIC_L

MIC_GND

MIC_GND

INT_MIC_R

123456789

FP-199

FLEXIBLE

1011121314

15

N.C.

MIC_GND

MIC_GND

MIC_GND

INT_MIC_L

INT_MIC_R

MA-386 BOARD

27P

CN103

D_3.1V

MIC_GND

MIC_GND

AU_4.6V

MT_GND

MT_GND

AU_4.6V

MT_GND

MT_GND

123456789

MT_GND

MT_GND

MT_GND

4

MIC_GND

4P

10P

CN702

CN701

F_TALLY_LED

SIRCS_PWM

D_3.1V

MT_5.2V

1011121314

D_3.1V

MT_5.2V

F_TALLY_LED

MIC902 MIC901

MIC R MIC L

4

123

MIC_GND

MIC_R_GND

INT_MIC_R2

INT_MIC_R1

14P

CN703

SIRCS_SIG1

123456789

SIRCS_SIG1

SIRCS_PWM

15P

CN100

CN102 15P

SHOE_UNREG_GND

SHOE_UNREG_GND

SHOE_UNREG_GND