Page 1

CDX-CA650X/CA660X/CA690X

SERVICE MANUAL

Ver 1.1 2001. 07

Photo: CDX-CA660X

• The tuner and CD sections have no adjustments.

AUDIO POWER SPECIFICATIONS (US Model)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

23 watts per channel minimum continuous average power into

4 ohms, 4 channels driven from 20 Hz to 20 kHz with no more

than 5% total harmonic distortion.

CD player section

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Laser Diode Properties (US, Canadian Model)

Material GaAlAs

Wavelength 780 nm

Emission Duration Continuous

Laser output power Less than 44.6 µW*

* This output is the value measured at a distance

of 200 mm from the objective lens surface on the

Optical Pick-up Block.

Tuner section

FM

Tuning range 87.5 – 107.9 MHz (US, Canadian model)

FM tuning interval (E Model):

50 kHz/200 kHz switchable

87.5 – 108 MHz (at 50 kHz step)

87.5 – 107.9 MHz (at 200 kHz step)

Antenna terminal External Antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

72 dB (mono)

Harmonic distortion at 1 kHz

0.6% (stereo),

0.3% (mono)

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

AM

Tuning range 530 – 1,710 kHz (US, Canadian model)

AM tuning interval (E model):

9 kHz/10 kHz switchable

531 – 1,602 kHz (at 9 kHz step)

530 – 1,710 kHz (at 10 kHz step)

Antenna terminal External Antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

SPECIFICATIONS

US Model

Canadian Model

CDX-CA650X/CA660X

E Model

CDX-CA690X

Model Name Using Similar Mechanism NEW

CD Drive Mechanism Type MG-393X-121//K

Optical Pick-up Name KSS-720A

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4 – 8 ohms

Maximum power output 50 W × 4 (at 4 ohms)

General

Outputs Audio outputs

Power Antenna relay control lead

Power amplifier control lead

Inputs Telephone ATT control lead

Tone controls Bass ±10 dB at 62 Hz (US, Canadian model)

Bass ±8 dB at 100 Hz (E model)

Treble ±10 dB at 16 kHz (US, Canadian model)

Treble ±8 dB at 10 kHz (E model)

Loudness (E model) +8 dB at 100 Hz

+2 dB at 10 kHz

Power requirements 12 V DC car battery

(negative ground)

Dimensions Approx. 178 × 50 × 176 mm

(7 1/8 × 2 × 7 in.) (w/h/d)

Mounting dimensions Approx. 182 × 53 × 161 mm

(7 1/4 × 2 1/8 × 6 3/8 in.) (w/h/d)

Mass Approx. 1.2 kg

(2 lb. 10 oz.)

Supplied accessories Parts for installation and connections (1 set)

Front panel case (1)

Card remote commander

RM-X114

Note

This unit cannot be connected to a digital preamplifier or an equalizer.

Design and specifications are subject to change without

notice.

FM/AM COMPACT DISC PLAYER

9-870-259-12

2001G0400-1

© 2001. 7

Sony Corporation

e Vehicle Company

Shinagawa Tec Service Manual Production Group

1

Page 2

CDX-CA650X/CA660X/CA690X

k

SERVICE NOTES

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

If the optical pick-up block is defective, please replace the whole

optical pick-up block.

Never turn the semi-fixed resistor located at the side of optical

pick-up block.

optical pick-up bloc

semi-fixed resistor

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

TABLE OF CONTENTS

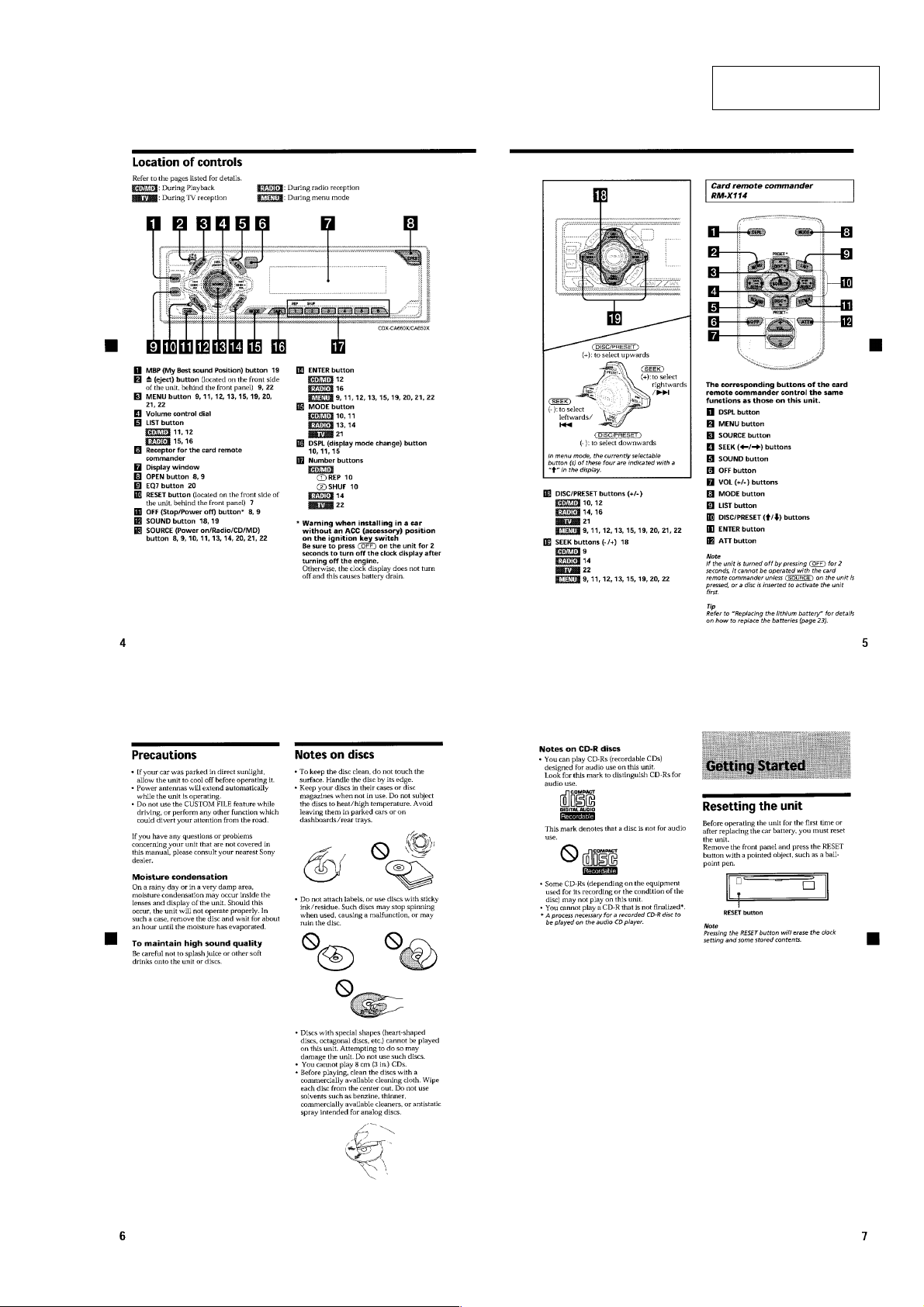

1. GENERAL

Location of controls................................................................. 3

Getting Started......................................................................... 3

CD Player ................................................................................ 4

Radio ....................................................................................... 5

Other Functions ....................................................................... 6

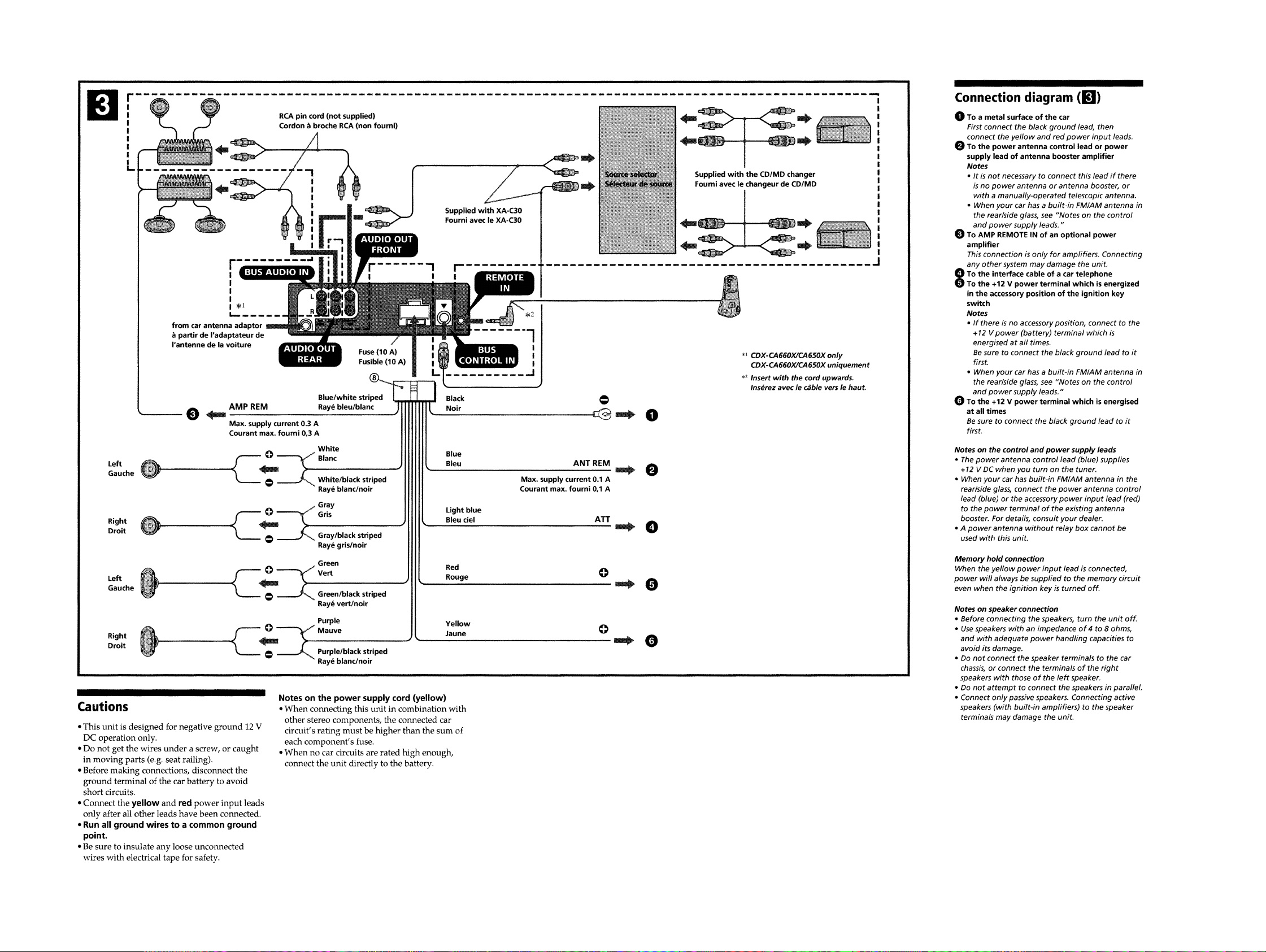

Connection Diagram................................................................ 7

2. DISASSEMBLY

2-1. Sub Panel (CD) Assy...........................................................8

2-2. CD Mechanism Block .........................................................8

2-3. Main Board ......................................................................... 8

2-4. Heat Sink (Main)................................................................. 9

2-5. Chassis (T) Sub Assy .......................................................... 9

2-6. Lever Section .................................................................... 10

2-7. Servo Board....................................................................... 10

2-8. Arm Roller Assy ................................................................ 11

2-9. Floating Block ................................................................... 11

2-10. Optical Pick-up Block ....................................................... 12

3. DIAGRAMS

3-1. IC Pin Descriptions ........................................................... 13

3-2. Block Diagram –CD Section–........................................... 15

3-3. Block Diagram –Tuner Section–....................................... 16

3-4. Block Diagram –Display Section–.................................... 17

3-5. Circuit Boards Location .................................................... 17

3-6. Printed Wiring Boards –CD Mechanism Section–............ 18

3-7. Schematic Diagram –CD Mechanism Section– ................ 20

3-8. Printed Wiring Boards –Main Section– ............................ 21

3-9. Schematic Diagram –Main Section (1/2)– ........................ 22

3-10. Schematic Diagram –Main Section (2/2)– ........................ 23

3-11. Printed Wiring Board –Relay Section– ............................. 24

3-12. Schematic Diagram –Relay Section–................................ 25

3-13. Schematic Diagram –Display Section–............................. 26

3-14. Printed Wiring Board –Display Section–.......................... 27

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

4. EXPLODED VIEWS

4-1. Chassis Section ................................................................. 30

4-2. Front panel Section ........................................................... 31

4-3. CD Mechanism Section (1) ............................................... 32

4-4. CD Mechanism Section (2) ............................................... 33

4-5. CD Mechanism Section (3) ............................................... 34

5. ELECTRICAL PARTS LIST ........................................ 35

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

2

Page 3

SECTION 1

GENERAL

CDX-CA650X/CA660X/CA690X

This section is extracted

from instruction manual.

3

Page 4

CDX-CA650X/CA660X/CA690X

4

Page 5

CDX-CA650X/CA660X/CA690X

5

Page 6

CDX-CA650X/CA660X/CA690X

6

Page 7

CDX-CA650X/CA660X/CA690X

77

Page 8

CDX-CA650X/CA660X/CA690X

8

6

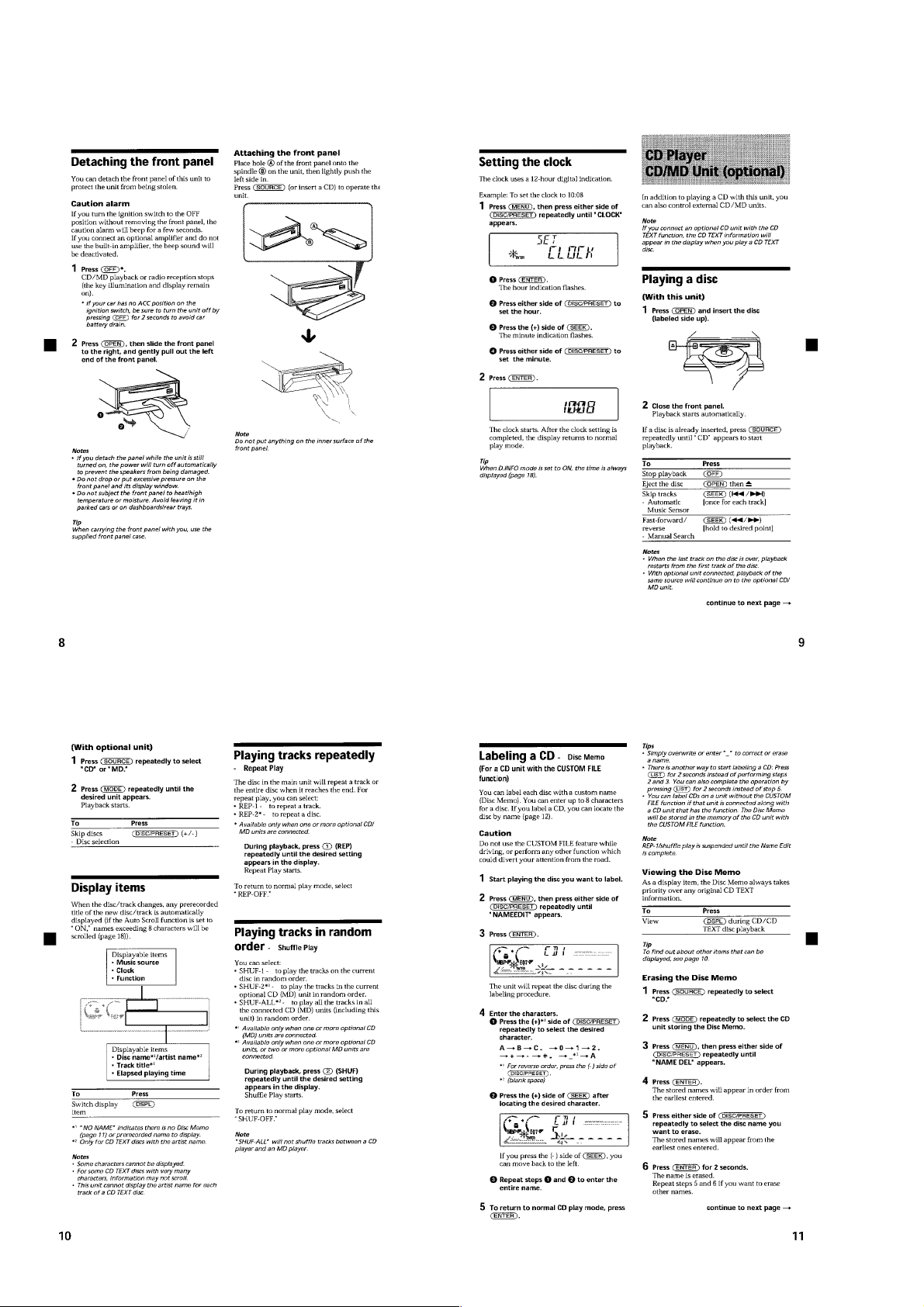

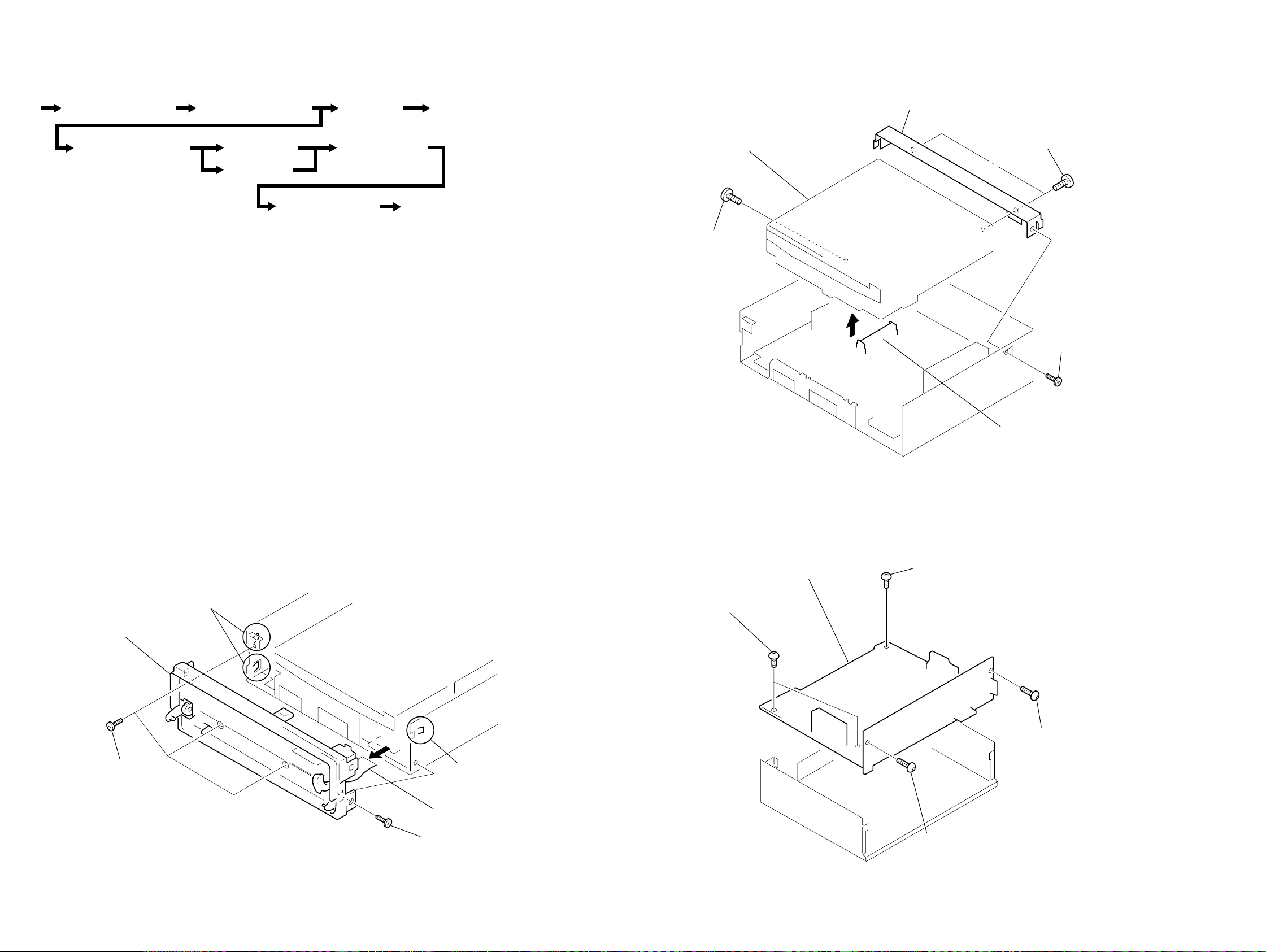

SECTION 2

DISASSEMBLY

Note : This equipiment can be removed usiing the following procedure.

Set Sub Panel (CD) Assy CD Mechanism Block

Chassis (T) Sub Assy Lever Section

Servo Board

Floating Block Assy Optical Pick-up Block

Main Board Heat Sink (Main)

Arm Roller Assy

2-2. CD MECHANISM BLOCK

5 CD mechanism block

2 PTT 2.6x6

7 bracket (CD)

6 PTT 2.6x6

3

1 PTT 2.6x

Note : Follow the disassembly procedure in the numerical order given.

2-1. SUB PANEL (CD) ASSY

4 two claws

6 sub panel (CD) assy

2-3. MAIN BOARD

4 screws (+BTT)

5 MAIN board

4 CNP701

3 screw (+BTT)

2 PTT 2.6x

2 PTT 2.6x6

3 claw

1 PTT 2.6x6

5 CNP802

1 PTT 2.6x8

88

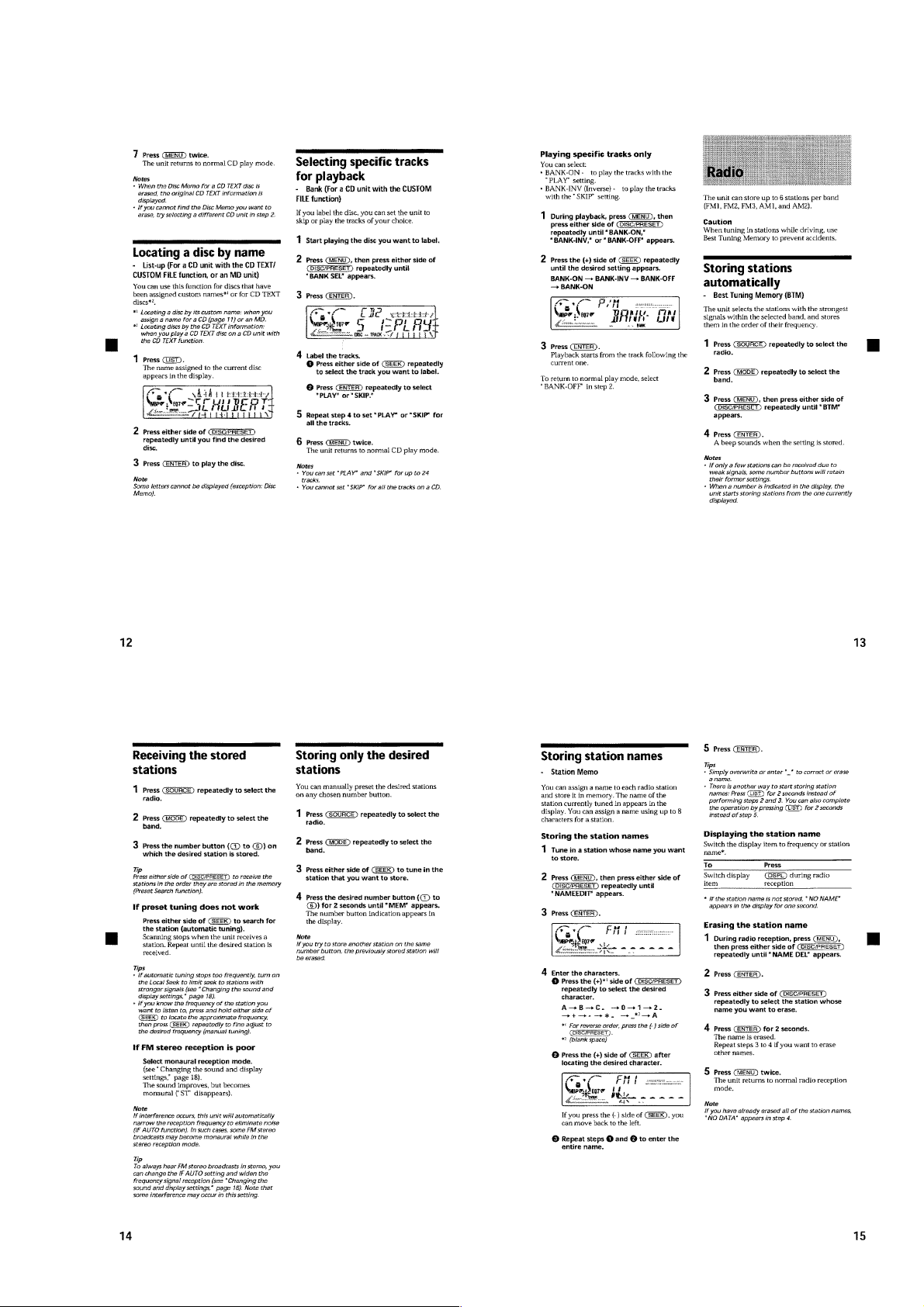

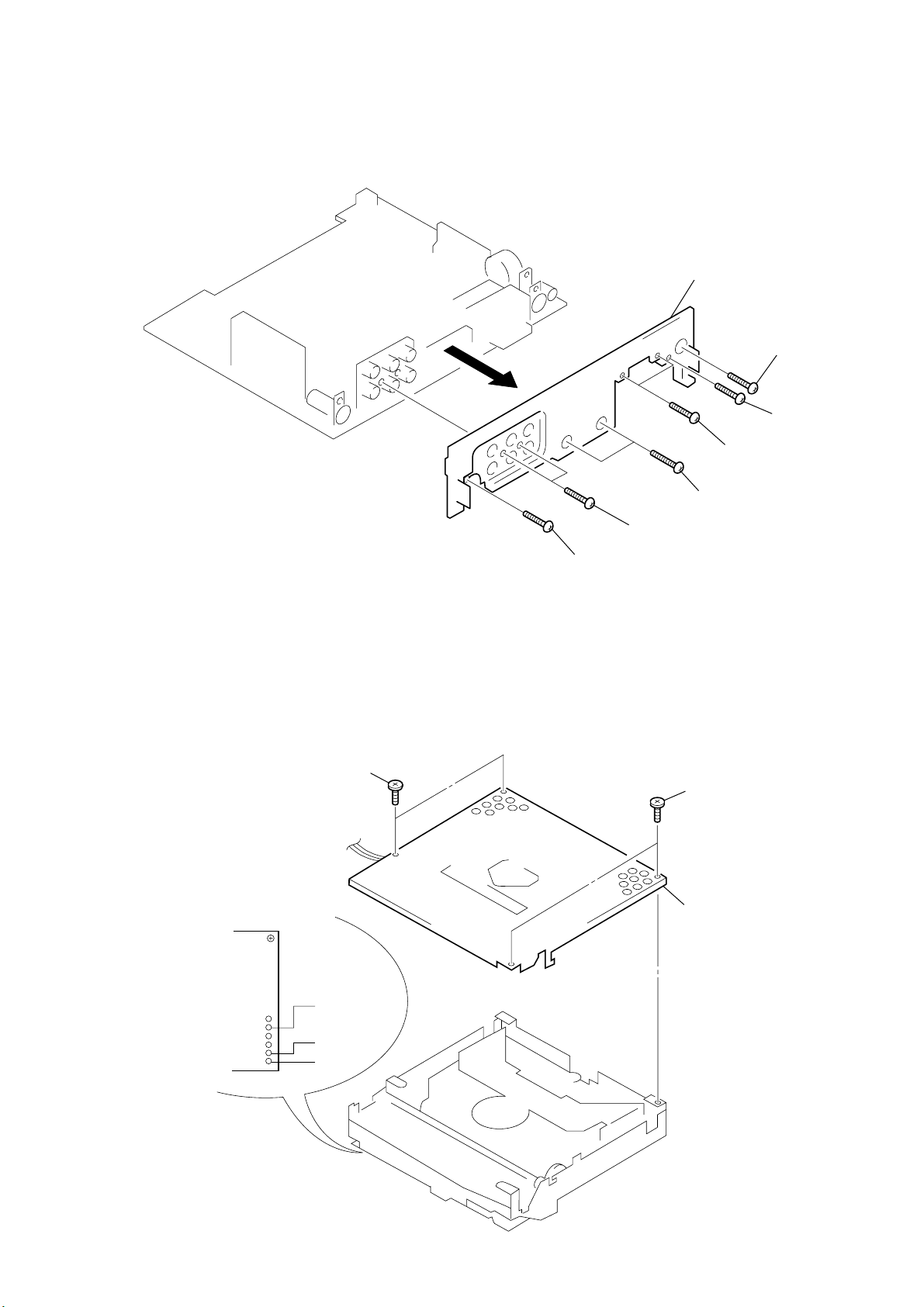

Page 9

7 heat sink (main)

1 PTT 2.6x8

2 PTT 2.6x8

4 PTT 2.6x8

5 PTT 2.6x8

3 PTT 2.6x12

6 PTT 2.6x8

2-4. HEAT SINK (MAIN)

CDX-CA650X/CA660X/CA690X

2-5. CHASSIS (T) SUB ASSY

1 Unsolder the

lead wires.

2 P 2x3

black

red

white

3 P 2x3

4 chassis (T) sub assy

9

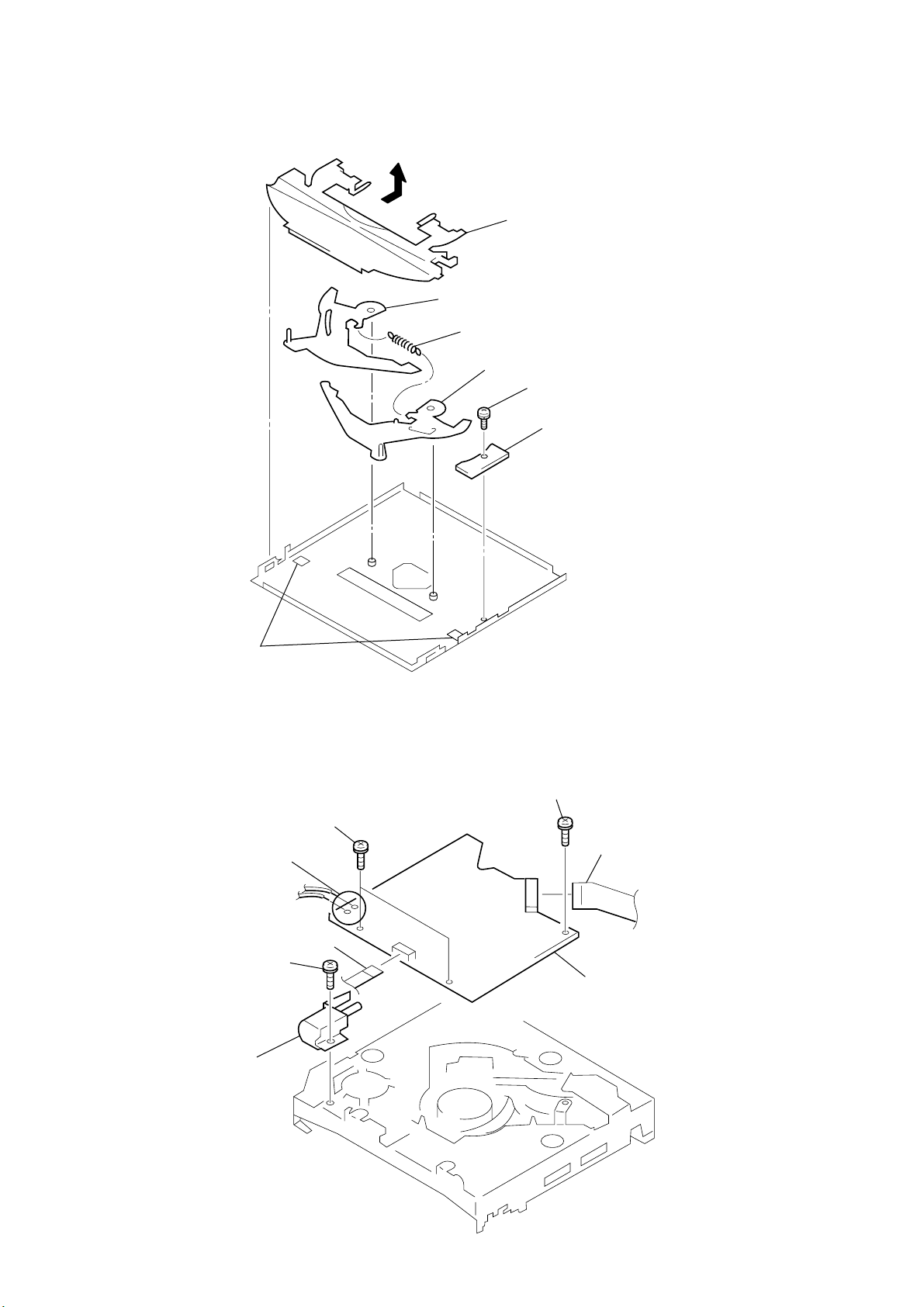

Page 10

CDX-CA650X/CA660X/CA690X

2-6. LEVER SECTION

5 guide (disc)

6 lever (R)

3 tension spring (LR)

7 lever (L)

1 special screw

2 IN SELF SW board

2-7. SERVO BOARD

4 claws

6 special screw

3 Removal the solders.

1 CN3

4 P 2x3

5 loading motor assy

7 special screw

2 CN2

8 SERVO board

10

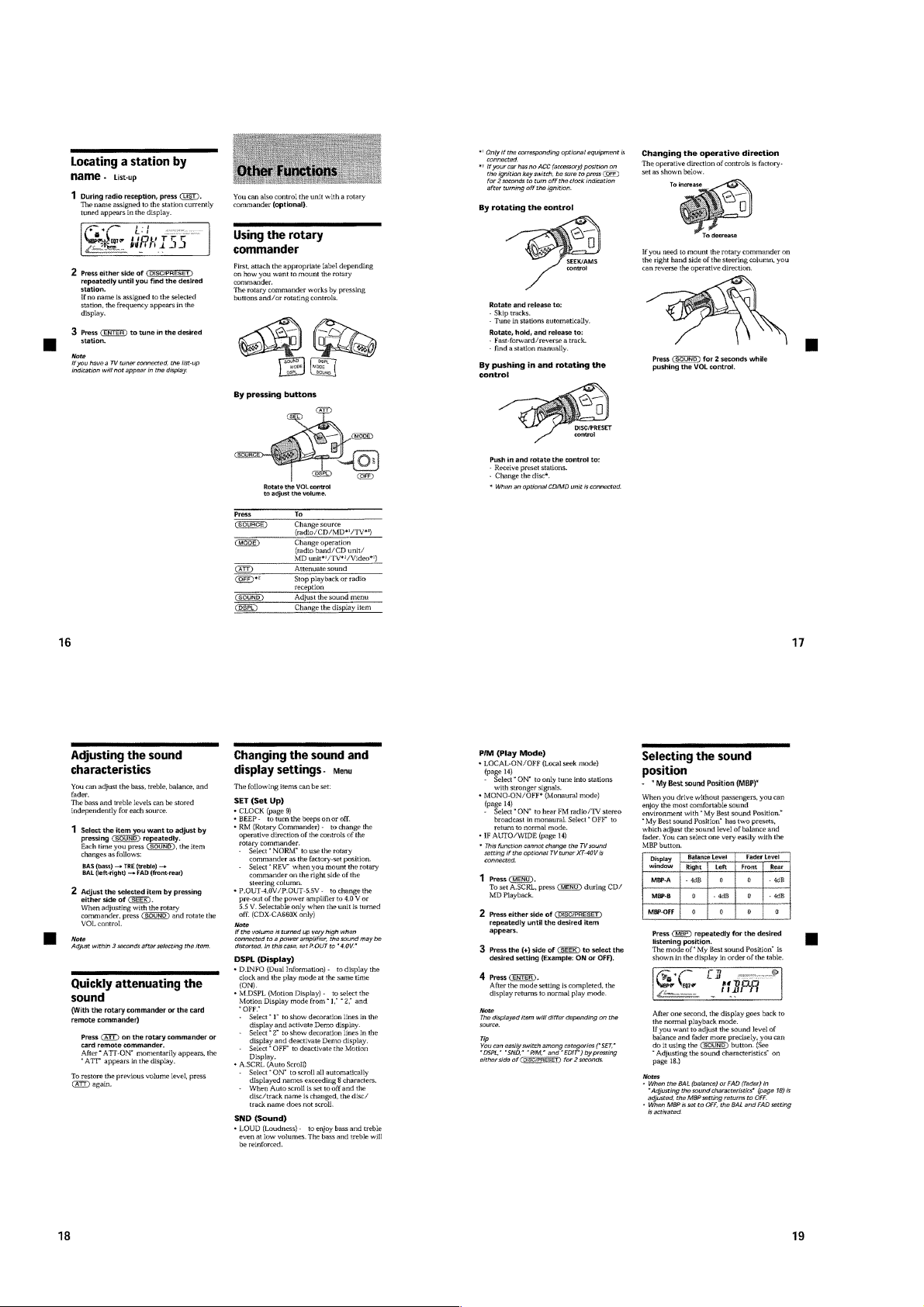

Page 11

)

2-8. ARM ROLLER ASSY

• When installing, take note of the positions

arm (roller) and washers. (Fig. 1)

CDX-CA650X/CA660X/CA690X

3 retaing ring (RA)

4 shaft retainer

(roller)

shaft retainer (roller)

retaing ring (RA)

arm

washer

Fig. 1

5 shaft roller assy

2 arm (roller)

washer

arm

shaft retainer (roller

2-9. FLOATING BLOCK ASSY

7 compression spring (FL)

1 tension spring (KF1)

1 tension spring (RA)

6 floating block assy

8 compression spring (FL)

4 Fit lever (D) in the

direction of the arrow.

5 Turn loading ring in the

direction of the arrow.

3 damper (T)

2 damper (T)

11

Page 12

CDX-CA650X/CA660X/CA690X

2-10. OPTICAL PICK-UP BLOCK

1 P 2x3

2 sled motor assy

3 optical pick-up block

12

Page 13

CDX-CA650X/CA660X/CA690X

SECTION 3

DIAGRAMS

3-1. IC PIN DESCRIPTION

• IC801 MN101C49KTG1 (SYSTEM CONTROL)

Pin No. Pin Name I/O Pin Description

1 VREF– — Ground for A/D converter power supply

2 VSM I S-meter voltage detection signal input from tuner unit (TU601)

3 NIL I Connect to ground.

4 KEYIN1 I Key signal input

5 KEYIN0 I Key signal input

6 RC IN0 I Rotary commander key signal input from remote in jack (CNP801)

7, 8 NIL I Not used. (Connect to ground.)

9 DSTSEL I

10 VREF+ — A/D converter power supply

11 VDD — Power supply (+5 V) input pin

12 OSCOUT O High speed clock signal output (18.432 MHz)

13 OSCIN I High speed clock signal input (18.432 MHz)

14 VSS — Ground for power supply

15 XIN I Low speed clock signal input (32.768 kHz)

16 XOUT O Low speed clock signal output (32.768 kHz)

17 MMOD I

18 LCDSO O LCD serial data signal output to LCD driver (IC501)

19 LCDCE O LCD chip enable signal output to LCD driver (IC501)

20 LCDCKO O LDC serial clock signal output to LCD driver (IC501)

21 CD SO/TSO O CD servo IC serial data signal output

22 CD SI/TSI I CD servo IC serial data signal input

23 CD CKO/TCKO O CD servo IC serial clock signal output

24 SYSRST O System reset signal output to bus interface (IC803)

25 BUS ON O Bus on signal output to bus interface (IC803)

26 KEYACK I Key acknowledge detection signal input

27 NIL I Not used. (Connect to ground.)

28 BU IN I Back up current detection signal input

29 SIRCS I Remote signal input from remote control receiver (IC502)

30 CD SELFSW I CD mechanism self load position detection switch signal input from self switch (SW2)

31 CD PACK I CD text pack sync signal input from CD servo (IC1)

32 NIH I Connect to power supply.

33 RESET I microcomputer reset signal input from reset IC (IC802) “L”: reset

34 NOSE SW I Front panel attachment detection signal input from nose detect switch (S902) “L”: ON

35 BEEP O Beep signal output to power amp (IC404)

36 NCO O Not used. (Open)

37 TESTIN I Test mode detection signal input

38 ACCIN I Accessory power supply detection signal input

39 NCO O Not used. (Open)

40 TELATT I Telephone ATT detection signal input

41 NIH I Connect to power supply.

42 BUSSO O Sony-Bus serial data signal output to bus interface (IC803)

43 BUSSI I Sony-Bus serial data signal input from bus interface (IC803)

44 BUSCKO O Sony-Bus serial clock signal output to bus interface (IC803)

45 I2CSIO I/O I2C bus serial data signal input/output

46 NCO O Not used. (Open)

47 I2CCKO O I2C bus serial clock signal output

48 NCO O Not used. (Open)

49 TUNON O Tuner power supply control signal output to power supply (IC901)

50 PW ON O System power supply control signal output to power supply (IC901)

Destination set up detection signal input (“L”: CDX-CA650X/CA660X,

“H”: CDX-CA690X)

Memory mode select signal input (Input to “Low” (single chip mode).)

(Connect to ground.)

13

Page 14

CDX-CA650X/CA660X/CA690X

Pin No. Pin Name I/O Pin Description

51 CD TSTB O CD text parameter strob signal output to servo IC (IC1)

52 CD RFOK I RF OK signal input from servo IC (IC1)

53 CD XRST O Reset signal output to servo IC (IC1)

54 CD A0 O

55 CD STB O Data strob signal output to servo IC (IC1)

56 CD XTALEN O Crystal oscillation control signal output to servo IC (IC1)

57 CD LIMIT I CD Mechanism in-limit switch signal input from limit switch (SW3)

58 CD PH1 I CD Mechanism PH1 detection signal input Not used in this set.

59 CD DSW I CD Mechanism down switch signal input from down switch (SW4)

60 CD INSW/PH2 I CD Mechanism disc-in switch detection signal input from disc-in switch (SW1)

61 CD PH3 I CD Mechanism PH3 detection signal input Not used in this set.

62 CD LM LO O CD Mechanism loading motor control signal output to loading motor drive (IC2)

63 CD LM EJ O CD Mechanism eject motor control signal output to loading motor drive (IC2)

64, 65 NCO O Not used. (Open)

66 AMPATT O Power amp ATT control signal output to power amp (IC404)

67 AMPON O Power amp standby control signal output to power amp (IC404)

68 CDM ON O CD mechanism deck power supply control signal output

69 ATT O System ATT control signal output

70 VOLATT O Electrical volume ATT control signal output to electrical volume (IC401)

71 – 75 NCO O Not used. (Open)

76 4VPRE I Pre-out menu selection set up signal input CA650X/CA690X: “H”, CA660X: “L”

77, 78 NCO O Not used. (Open)

79 CD ON O CD on signal output “H”: Play, “L”: Loading or standby

80 – 85 NCO O Not used. (Open)

86 EE SIO I/O EEPROM serial data signal input/output

87 EE CKO O EEPROM serial clock signal output

88 NCO O Not used. (Open)

89 FLASH W I Flash microcomputer write detection signal input “L”: Write mode

90 NCO O Not used. (Open)

91 XKEYON O Key power supply control signal output

92 DOORIND O Sub panel power supply control signal output

93 ILLON O Illumination power supply control signal output

94 DOOR SW I Front panel open/close detection signal input “L”: Close, “H”: Open

95 DAVSS — Ground pin

96 RE IN1 I Rotary encoder signal input from rotary encoder (RE501)

97 RE IN0 I Rotary encoder signal input from rotary encoder (RE501)

98 RC IN I

99 NCO O Not used. (Open)

100 DAVDD — Power supply pin

Command/parameter identification signal output to servo IC (IC1)

“L”: Command, “H”: Parameter

Rotary commander shift key signal input from remote in jack (CNP801)

“L”: Shift key on

14

Page 15

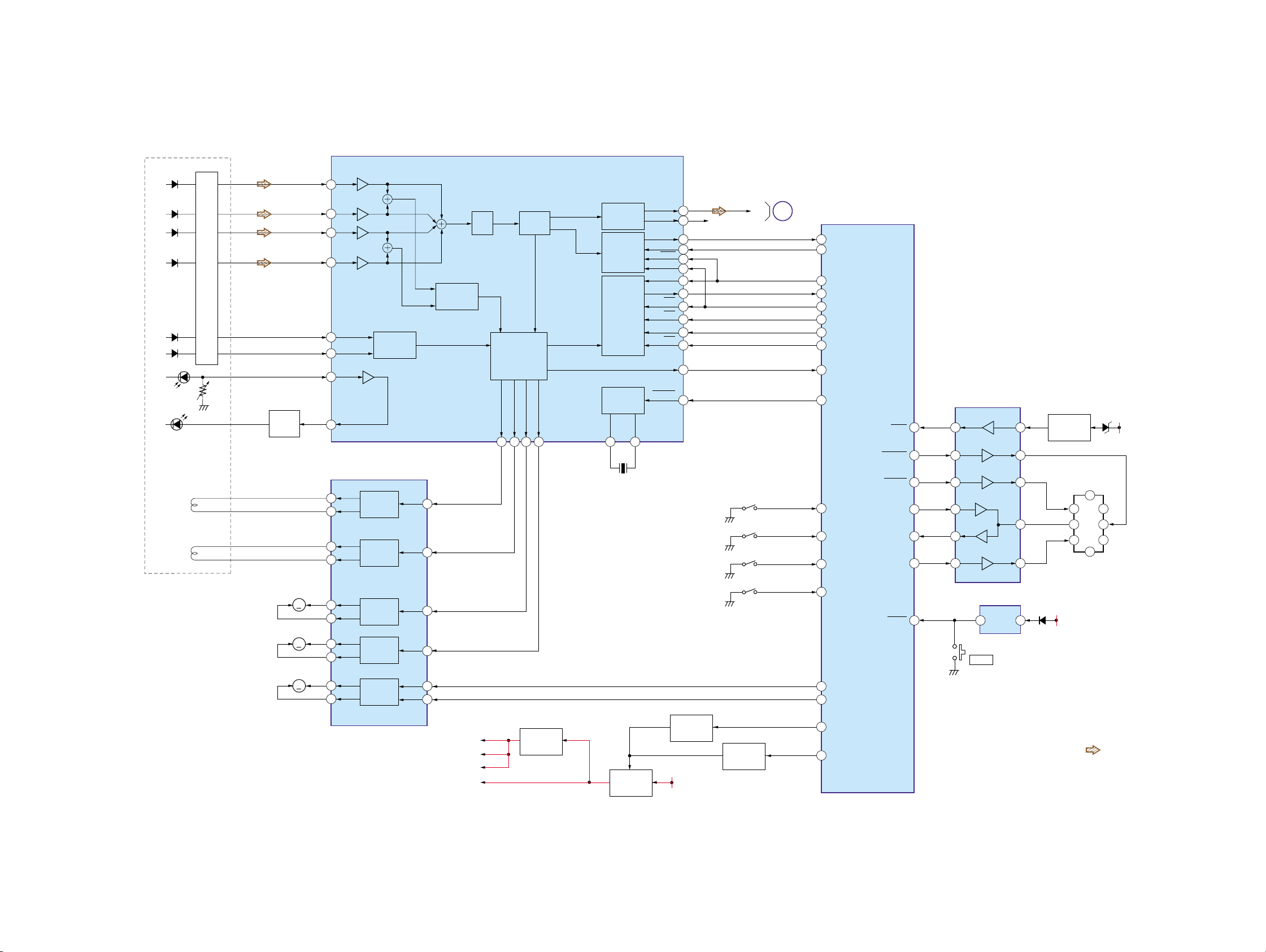

3-2. BLOCK DIAGRAM — CD SECTION —

OPTICAL PICK-UP

KSS-720A

RF AMP,DIGITAL SERVO

DIGITAL SIGNAL PROCESSOR

IC1

CDX-CA650X/CA660X/CA690X

A

C

B

D

E

F

PD

LD

FOCUS

COIL

TRACKING

COIL

I-V

CONV.

M902

(SLED)

LD

DRIVE

Q1

A

82

C

83

B

84

D

85

E

87

F

86

PD

97

LD

98

FOCUS/TRACKING COIL DRIVE

SLED/SPINDLE/LOADING MOTOR DRIVE

FCS-

15

FCS+

16

TRK+

17

TRK-

18

SL-

M

13

SL+

14

FOCUS

DRIVE

TRACKING

DRIVE

SLED

MOTOR

DRIVE

TRACKING

ERROR

APC

IC2

COIL

COIL

(Page 16)

TUNER

LOUT

RF

EQ

FORCUS

ERROR

FD

26

TD

23

SD

5

EFM

DEMOD

SERVO

CTL

FDTDSD

62 63 64 65

MD

D/A

CONV

DSUB CODE

PROCESS

I/F

OSC

23 24

X1

16.9344MHz

ROUT

PACK

TSTB

TSCK

TSI

SCK

STB

RST

RFOK

XTALEN

16

12

R-CH

52

56

55

54

SI

8

SO

7

6

5

AO

4

3

2

9

SW1

(DISC IN)

SW2

(SELF)

SW3

(LIMIT)

SW4

(DOWN)

CDL

SECTION

A

SYSTEM CONTROL

CD PACK

31

TSTB

51

21

CD_SO/TSO

22

CD_SI/TSI

23

CD_CKO/TCKO

55

CD_TSTB

54

CD_AO

53

CD_XRST

52

CD_RFOK

CD_XTALEN

56

60

CD_INSW/PH2

30

CD_SELF SW

CD_LIMIT

57

59

CD_DSW

IC801(1/3)

28

BU IN

24 13 2

SYS RST

25

BUS ON

42

BUS SO

43 8

BUS SI

44

BUS CKO

33

RESET

10 3

12 1

9

11 4

BUS BUFFER

IC803

IC802

1

RESET

6

5

4

CNJ801

D804

BATT

8

3

2

1

7

BATT DET

Q803

6

(BUS CONTROL IN)

D901

2

BU 5V

M901

(SPINDLE)

M903

(LOADING)

SP+

M

11

SP-

12

LD-

M

9

LD+

10

SPINDLE

MOTOR

DRIVE

LOADING

MOTOR

DRIVE

MD

6

LOAD

1

EJECT

2

POWER

CONTROL

A5V

AU5V

D5V

DR6V

REG

Q911

REG

Q910

Q908, 909

BATT

POWER

CONTROL

Q907

62

63

68

79

CD_LM LO

CD_LM EJ

CDM ON

CD ON

S901

RESET

• Signal path

:CD

15 15

Page 16

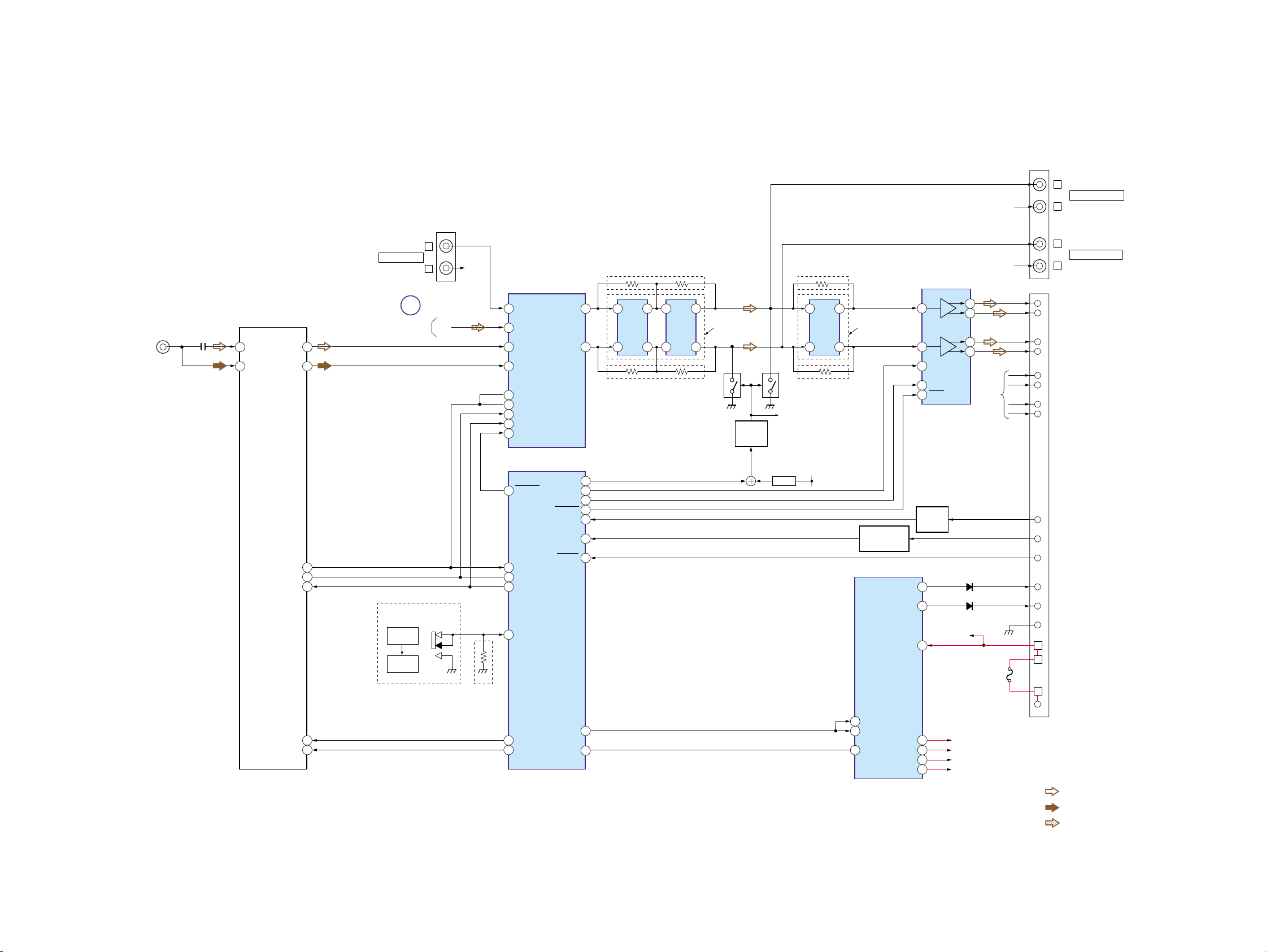

CDX-CA650X/CA660X/CA690X

3-3. BLOCK DIAGRAM — TUNER SECTION —

PJ601

(ANTENNA)

TUNER UNIT

TU601

ANTFM MPX

2 10

ANTAM

1

AM DET

S-METER

I2C SDA

I2C SCL

E2PROM SDA

E2PROM SCL

PJ401 (2/2)

L

AUDIO OUT FRONT

R-CH

PJ401 (1/2)

L

BUS AUDIO IN

R

(Page 15)

A

CD

SECTION

8

14

12

13

FREQUENCY

()

SELECT

FM 50K

AM 9K

FM 200K

AM 10K

17

18

SW802

CA690X

CDL

R-CH

CA650X/

CA660X

ELECTRONIC VOLUME

IC401

AUX LCH OUT FL

4 28

MD LCH

43

MPXI

12

AM

9

LEVEL

13

MPIN

14

SDA

19

SCL

20

EXA ATT

17

SYSTEM CONTROL

VOL ATT

70

VSM

2

I2C SIO

45

I2C CKO

47

DSTSEL

9

EE SIO

86

EE CKO

87

OUT RL

IC801 (2/3)

ATT

BEEP

AMP ON

AMP ATT

TEL ATT

ACC IN

TEST IN

TUN ON

PW ON

CA650X/CA690X

3

1

2

13

L-CH

AMP

IC301

27

5

CA650X/CA690X

69

35

67

66

40

38

37

49

50

L-CH

AMP

IC431

7

7

CA660X

12

Q102

MUTE

MUTE

CONT

Q912,913

CA650X/CA690X

3

5

Q101

MUTE

CA650X/CA690X

R-CH

D908

DELAY BATT

L-CH

AMP

IC405

1

7

CA660X

ACC

CHECK

Q902, D934, 935

POWER SUPPLY

IC901

2

8.7V ON

3

5.6V ON

4

STB

POWER AMP

IC404

12

11

AUX

16

STBY

4

MUTE

22

TEL

ATT

Q901

6

AMP +B

8

ANT +B

7

VCC

5

BU+B BU 5V

9

COM 8V

10

TU 5.6V

11

TU 8.7V

D919

D907

BATT

COM 8V

TU 5.6V

TU 8.7V

R-CH

5

3

9

7

R-CH

F901

10A

R

L

R

CNP902

1

FL+

9

FL-

2

RL+

10

RL-

4

FR+

12

FR-

3

RR+

11

RR-

13

ATT

7

ACC

15

TEST

5

AMP R

6

ANT R

8

GND

19

17

18

+B (BATT)

16

• Signal path

AUDIO OUT REAR

:FM

:AM

:CD

1616

Page 17

CDX-CA650X/CA660X/CA690X

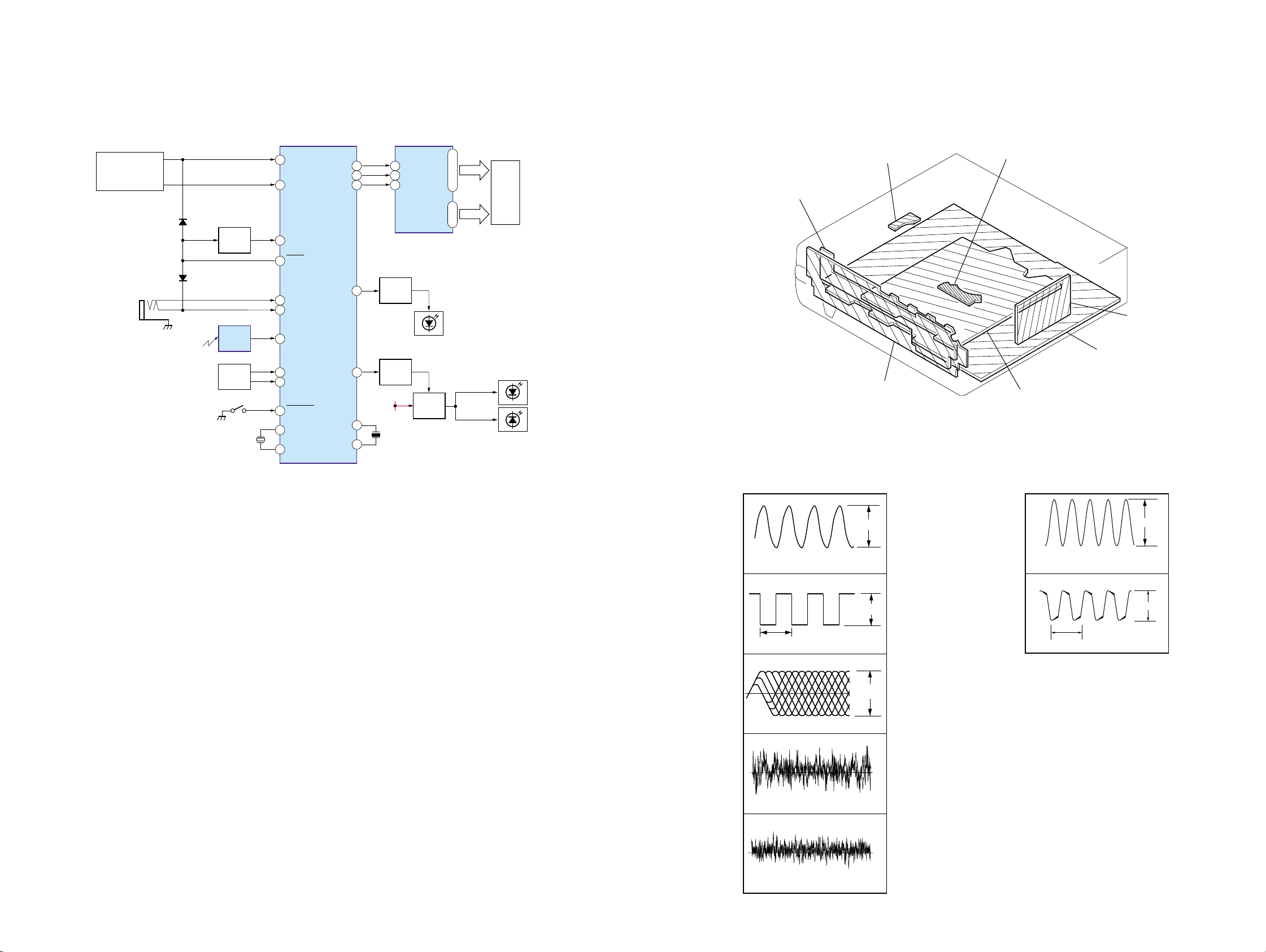

3-4. BLOCK DIAGRAM — DISPLAY SECTION —

SYSTEM CONTROL

IC801 (3/3)

KEY IN0

KEY MATRIX

LSW501-510,

LSW513-522

CNP801

(REMOTE IN)

D801

D802

S902

(NOSE DET)

KEY

ACTIVE

Q801

IC502

IR

RECEIVE

ROTARY

ENCODER

RE501

X802

32.768kHz

5

26

91

98

6

29

97

96

34

15

16

KEY IN1

KEY ACK

AD ON

RC IN1

RC IN0

SIRCS

RE IN0

RE IN1

NOSE SW

XIN

XOUT

LCD SO

LCD CKO

LCD CE

DOOR IND

ILL ON

OSC OUT

OSC IN

3-5. CIRCUIT BOARDS LOCATION

LCD DRIVE

IC501

80

SEG2

SEG66

COM1

COM4

•

|

1

|

64

65

|

|

68

LCD

LCD500

RELAY board

18

20

194

92

78

77

76

DOOR IND

DRIVE

Q914, 915

DATA

CLK

CE

IN SELF SW board

SL SW board

tuner unit

(TU601)

LED905,LSW916

MAIN board

POWER

93

12

13

CONT

Q906

BATT

X801

18.43MHz

SWITCH

Q905

LSW501-510

LSW513-522

LED510-513

KEY

()

ILLUMINATION

LCD BACK

()

LIGHT

DISPLAY board

SERVO board

• Waveforms

— Servo Board —

(MODE: CD PLAY)

— Main Board —

1

2

3

4

5

16.9344MHz

IC1

wd

34msec

IC1

ts

IC1

uj

Approx. 1Vp-p

IC1

oa

(XTAL)

(PACK)

(RFO)

(FEO)

4.4Vp-p

4.8Vp-p

1.2Vp-p

0V

1

2

IC801

IC801

18.43MHz

(OSCOUT)

qs

30.5µsec

(XOUT)

qh

3.8Vp-p

5Vp-p

17 17

Approx. 400mVp-p

od

(TEO)

IC1

0V

Page 18

CDX-CA650X/CA660X/CA690X

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

for schematic diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

f

•

• C : panel designation.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

• A : B+ Line.

• Power voltage is dc 14.4V and fed with regulated dc power

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

supply from ACC and BATT cords.

Voltage variations may be noted due to normal produc-

tion tolerances.

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM

J : CD

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

3-6. PRINTED WIRING BOARDS — CD MECHANISM SECTION —

for printed wiring boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• x : parts mounted on the conductor side.

a

•

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

: Through hole.

(The other layer’s patterns are not indicated.)

1818

Page 19

(Page 21)

CDX-CA650X/CA660X/CA690X

• Semiconductor

Location

Ref. No. Location

IC1 D-2

IC2 G-2

Q1 B-3

19 19

Page 20

CDX-CA650X/CA660X/CA690X

• Refer to page 17 for Waveforms.

3-7. SCHEMATIC DIAGRAM — CD MECHANISM SECTION — • Refer to page 28 for IC Block Diagrams.

IC B/D

IC B/D

(Page 22)

Note:

• Voltage is dc with respect to

ground under no-signal conditions.

no mark : CD PLAY

2020

Page 21

3-8. PRINTED WIRING BOARD — MAIN SECTION —

CDX-CA650X/CA660X/CA690X

• Semiconductor Location

Ref. No. Location

D601 J-1

D801 J-6

D802 K-7

D803 I-12

D804 I-12

D805 D-12

D806 D-12

D807 D-12

D809 K-4

D811 K-4

D812 K-3

D813 K-3

D814 K-3

D815 J-2

D816 K-3

D817 K-2

D818 K-4

D901 H-12

D902 D-11

D906 D-11

D907 F-11

D908 D-9

D909 D-9

D911 A-9

D912 A-9

D913 C-10

D914 C-10

D915 A-9

D916 A-9

D917 B-10

D918 A-10

D919 F-11

D920 C-11

D931 B-14

D932 E-12

(D933) D-7

D934 D-10

D935 D-10

( ): CDX-CA660X only

Ref. No. Location

D941 G-10

(IC301) H-5

(IC302) I-5

IC401 I-3

IC404 A-7

(IC405) D-5

(IC406) D-5

(IC431) G-4

(IC441) E-4

IC801 I-9

IC802 J-12

IC803 H-11

IC901 G-13

Q101 C-4

Q102 B-3

Q201 B-5

Q202 B-4

Q801 K-11

Q803 I-11

Q901 E-10

Q902 D-11

Q905 J-13

Q906 K-13

Q907 H-12

Q908 D-13

Q909 E-13

Q910 B-13

Q911 F-10

Q912 D-8

Q913 D-8

Q914 H-13

Q915 H-13

(Q922) D-7

(Q923) D-7

(Q924) D-7

(Page 24)

(Page 19)

21 21

Page 22

CDX-CA650X/CA660X/CA690X

• Refer to page 17 for Waveforms.

3-9. SCHEMATIC DIAGRAM — MAIN SECTION (1/2) — • Refer to page 28 for IC Block Diagrams.

IC B/D

IC B/D

IC B/D

(Page 20)

(Page 23)

Note:

• Voltage is dc with respect to ground under

no-signal (detuned) condition.

no mark : FM

( ) : AM

< > : CD PLAY

2222

Page 23

3-10. SCHEMATIC DIAGRAM — MAIN SECTION (2/2) — • Refer to page 29 for IC Block Diagrams.

CDX-CA650X/CA660X/CA690X

(Page

22)

IC B/D

IC B/D

(Page 25)

23 23

Note:

• Voltage is dc with respect to

ground under no-signal

(detuned) condition.

no mark : FM

Page 24

CDX-CA650X/CA660X/CA690X

3-11. PRINTED WIRING BOARD — RELAY SECTION —

(Page 21)

(Page 27)

2424

Page 25

3-12. SCHEMATIC DIAGRAM — RELAY SECTION —

CDX-CA650X/CA660X/CA690X

(Page 26)

(Page 23)

25 25

Page 26

CDX-CA650X/CA660X/CA690X

3-13. SCHEMATIC DIAGRAM — DISPLAY SECTION —

(Page 25)

Note:

• Voltage is dc with respect to ground under no-signal

(detuned) condition.

no mark : FM

2626

Page 27

3-14. PRINTED WIRING BOARD — DISPLAY SECTION —

CDX-CA650X/CA660X/CA690X

• Semiconductor

Location

Ref. No. Location

(D501) A-11

(D502) A-10

(D503) B-10

(D504) B-6

(IC501) B-9

IC502 A-5

LED510 B-12

LED511 A-12

LED512 B-5

LED513 B-5

( ) : SIDE B

(Page 24)

27 27

Page 28

CDX-CA650X/CA660X/CA690X

+

–

+

–

+

–

+

–

OVER VOLTAGE

PROTECT

REGULATOR

1

2 3

4

5 6 7 8 9

10

12

11

NC

STB

VDD

AMP

VCC

ANT

COM

AM

FM

GND

• IC BLOCK DIAGRAMS

AGCI

RFO

EQ2

EQ1

RF-

AGND

AVDD

REFOUT

FEO

TE-

TEO

TE2

TEC

AGND

AVDD

VCC1

IN1

SVR1

INM1

INM2

SVR2

IN2

VCC2

IC431, 441 NJM2160AM-TE2IC1 µPD63711GC-8EU

1

2

BUFFER

3

BUFFER

REFERENCE

4

5

REFERENCE

BUFFER

6

7

BUFFER

8

VCCL

VCCL

VCCR

VCCR

LIFT

AMP

SIGNAL

AMP

SIGNAL

AMP

LIFT

AMP

C1+

16

C1–

15

GND1

14

OUT1

13

12

OUT2

GND2

11

C2-

10

9

C2+

IC2 BA5810FP

BIAS

FWD

REV

LDCONT

IN1

IN2

PREVCC

POWVCC

VOL–

VOL+

VO2–

VO2+

VO1–

VO1+

PS

1

2

3

4

5

6

7

8

9

10

10k

11

12

10k

10k

13

14

10k

X3

POWER

PREVCC

(PRE.LOADING)

POWVCC12

(CH1.CH2)

–

+

+

–

–

+

+

–

SAVE

10k

10k

10k

10k

LOADING PRE

FWD REV

7.5k

–

16k

LEVEL

SHIFT

16k

+

7.5k

–

LEVEL

SHIFT

+

–

+

7.5k

+

–

+

–

16k

7.5k

CH1-4

–

LEVEL

SHIFT

+

LEVEL

SHIFT

MUTE

16k

POWVCC34

(CH3,CH4)

10k

10k

10k

10k

AGCO74RFI73C3T72ASY71EFM70AVDD697E DAC3687D DAC2677C DAC1667F DAC065MD64SD63TD62FD

75

76

77

78

EFM

COMPARATOR

EFM

D/A

79

80

AUTO GAIN

CONTROLLER

FD/TD/SD/MD

CONTROLLER

81

PROCESSOR

DEFECT

COMPARATOR

RFENV

TRACKING

REGISTER

FOCUS

REGISTER

ADDER

MULTIPLIER

SVROM

CLV

SVCRAM

ROM

DECODER

A

82

C

83

B

84

D

85

F

86

E

87

RF

AMP BLOCK

FEOFS

TEOFS

EFM

SVDRAM

88

89

FE-

90

91

92

93

94

95

96

PD

97

LD

98

99

PN

100

SWITCH

DEFECT

FOK

A3T

MIRR

FEO

TEO

COMPARATOR

MICROCOMPUTER INTERFACE

MIRENV

A/D CONVERTER

ATEST59TEST158TEST057DGND56TSTB55TSCK54TSI53TSO52PACK51DVDD

AGND

60

61

MICROCOMPUTER INTERFACE

CD-TEXT DECODER

MEMORY

PROCESSOR

16K

SRAM

SUB-CODE PROCESSOR

EFM DEMODULATOR

TIMING GENERATOR

D/A

INTERFACE

CIRCUIT

DE-EMPHASIS CIRCUIT

OCTUPLED

OVERSAMPLING DIGITAL FILTER

NOISE SHAVER

OUTPUT BUFFER

SCF

NOISE SHAVER

OUTPUT BUFFER

OSC

DIGITAL PLL

DIGITAL

AUDIO

INTERFACE

OUTPUT PROCESSOR

ERROR

PROCESSOR

CORRECTION

C2D3

50

C2D2

49

C2D1

48

C1D2

47

C1D1

46

DGND

45

PLCK

44

MIRR/WFCK

43

RFCK

42

LOCK

41

DVDD

40

TSOI

39

C16M

38

DGND

37

TX

36

HOLD/WDCK

35

LRCK

34

LRCKIN

33

SCKO

32

SCKIN

31

DOUT

30

DIN

29

FLAG

28

EMPH

27

DVDD

26

28

OPIN4+

27

OPIN4–

26

OPOUT4

25

OPIN3+

24

OPIN3–

23

OPOUT3

22

MUTE

21

POWVCC

20

GND

19

10k

–

+

+

–

–

+

+

–

10k

10k

10k

VO3–

18

VO3+

17

VO4–

16

VO4+

15

1

2

3

4A05

6

7SO8SI9

STB

RST

RFOK

DGND

SCK

10

11

12

13

DVDD

XTALEN

ROUT

DAVDD

DAGND

REGC

1514

DAGND

16

17

18R+19R–20L+21L–22

LOUT

DAVDD

23

XVDD

XTAL24XTAL

25

XGND

IC901 BA4908-V3

2828

IC803 BA8270F-E2

BUS ON

1

2

RST

BATT

3

4

CLK

5

VREF

6

DATA

GND

7 8

BUS ON

SWITCH

RESET

SWITCH

BATTERY

SWITCH

14

13

12

11

10

9

VCC

RST

BUS ON

CLK IN

BU IN

DATA IN

DATA OUT

Page 29

IC401 TDA7406T

CDX-CA650X/CA660X/CA690X

SWIN

ACINR

ACOUTR

SWACOUT

AC OUTL

CREF

MIXINFL

MIXINRL

MIXINFR

MIXINRR

OUTFL

OUTRL

28 2730 2932 31

MIXER

SOFT STEP

FADER

OUTPUT SELECTOR

HIGH PASS

7BAND

EQUALIZER

SOFT STEP

VOLUME

SOFT MUTE

LOUDNESS

IN GAIN

+ AUTO

ZERO

OUTFR

OUTRR

26 25 24 23

SOFT STEP

FADER

SPECTRUM

ANALIZER

OUTSW

SOFT STEP

FADER

SUB

WOOFER

FILTER

MONO

FADER

BEEP

PAUSE

II

C-BUS

DIGITAL

CONTROL

HIGH OUT

S & H

25kHz

LP

DEMODULATOR

+STEREO ADJUST

+STEREO BLEND

PILOT

CANCELLATION

SAOUT

QUAL.

PIL, DET

PLL

CREF

MULTI

PATH

DETECTOR

SUPPLY

PULSE

FORMER

AM/FM

NOISE

BLANKER

A/D

22

21

20

19

18

17

16

15

14

13

VDD

SACLK

SCL

SDA

GND

ATT

QUAL

MP OUT

MP IN

LEVEL

ACINL

33

34

35

36

37

38

39

CDR

CDL

MDR

MDL

TAPEL

MAIN SOURCE

40

41

42

43

44

SELECTOR

INPUT MULTIPLEXER

1 2 3 4 5 6 7 8 9 10 11

FDL–

FDR+

TAPE R

FDL+

PAUSE

MIXING

SELECTOR

TIM

PHONE

NAVI

86kHz

LP

STD

IN GAIN

AM/MPX2

AMIF

CMPX

12

AUX1

29

Page 30

CDX-CA650X/CA660X/CA690X

SECTION 4

EXPLODED VIEWS

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

4-1. CHASSIS SECTION

9

8

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

RR

Parts Color Cabinet’s Color

• Accessories and packing materials and

hardware (# mark) list are given in

the last of this parts list.

11

MG-393X-121//K

10

12

17

13

14

16

15

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiques pour

la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

#2

#1

#1

#1

#1

#3

#1

#1

#1

4

3

1

2

20

7

5

6

#2

#5

#2

#5

#5

19

Ref. No. Part No. Description Remark

1 X-3380-007-1 PANEL ASSY (CD), SUB

2 3-041-039-01 BUTTON (EJECT)

* 3 1-679-988-11 RELAY BOARD

4 X-3376-686-1 GEAR ASSY

5 3-030-909-01 DAMPER, OIL

#2

TU601

#6

12

#2

#2

F901

18

Ref. No. Part No. Description Remark

* 13 A-3283-087-A MAIN BOARD, COMPLETE (CA660X)

* 13 A-3283-091-A MAIN BOARD, COMPLETE (CA690X)

13 A-3283-156-A MAIN BOARD, COMPLETE (CA650X)

14 3-226-766-01 HEAT SINK (MAIN)

* 15 3-019-565-01 BRACKET (IC)

6 3-713-786-51 SCREW +P 2X3

7 X-3376-687-1 LOCK ASSY

* 8 3-224-309-01 COVER

9 1-776-207-82 CORD (WITH CONNECTOR) (POWER)

* 10 3-024-285-01 CUSHION (RUBBER)

* 11 3-041-173-01 BRACKET (CD)

12 3-922-535-11 SCREW (+BTT)

30

* 16 3-041-261-01 BRACKET (TR)

* 17 3-224-313-01 HEAT SINK (REG)

* 18 3-224-308-01 CHASSIS

19 3-035-250-01 SCREW (LOCK)

* 20 X-3376-689-1 BRACKET (GEAR) ASSY

F901 1-532-877-11 FUSE (BLADE TYPE) (AUTO FUSE) 10A

TU601 A-3220-738-A TUNER UNIT (TUX-020)

Page 31

4

4-2. FRONT PANEL SECTION

CDX-CA650X/CA660X/CA690X

66

#4

#4

63

64

59

LCD500

60

58

61

56

65

#

not supplied

(DISPLAY board)

62

57

55

51

51 3-224-293-11 BUTTON (CROSS)

52 3-224-300-11 BUTTON (OPEN)

53 3-038-318-01 SPRING (RELEASE)

54 X-3379-986-1 PANEL (S) ASSY, FRONT (CA650X)

54 X-3379-993-1 PANEL (S) ASSY, FRONT (CA660X)

54 X-3380-014-1 PANEL (S) ASSY, FRONT (CA690X)

55 3-224-299-01 BUTTON (1-6)

56 3-224-298-01 BUTTON (OFF)

57 3-224-297-01 BUTTON (MANU)

58 3-224-296-01 BUTTON (EQ)

52

54

53

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

* 59 3-224-306-01 PLATE (LCD), GROUND

60 1-694-787-11 CONDUCTIVE BOARD, CONNECTION

* 61 3-224-307-01 SHEET (DIFFUSION)

* 62 X-3379-981-1 HOLDER (LCD) ASSY

63 3-224-292-11 KNOB (VOL)

64 3-224-295-01 BUTTON (SOURCE)

65 X-3379-982-1 PANEL ASSY, FRONT BACK

66 3-231-599-01 CUSHION (1-6)

LCD500 1-804-294-11 DISPLAY PANEL, LIQUID CRYSTAL

31

Page 32

CDX-CA650X/CA660X/CA690X

4-3. CD MECHANISM SECTION (1)

(MG-393X-121//K)

101

115

104

114

109

116

103

#8

102

#8

107

106

105

111

114

113

108

C

M903

#7

#7

110 3-040-040-01 ARM (ROLLER)

* 111 A-3283-048-A SERVO BOARD, COMPLETE

112 3-221-779-01 BRACKET (MOTOR)

113 3-040-034-01 SPRING (RA), TENSION

114 3-040-042-01 WASHER

#8

#9

112

105

C

110

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 101 1-676-709-11 IN SELF SW BOARD

102 3-040-039-01 CHASSIS (T)

103 3-040-038-01 SPRING (LR), TENSION

104 3-040-050-01 LEVER (L)

105 3-040-022-01 RETAINER (ROLLER), SHAFT

106 3-040-044-01 ROLLER (S)

107 3-040-067-01 LEVER (R)

108 A-3301-980-A SHAFT ROLLER ASSY

109 3-040-037-01 GUIDE (DISC)

32

115 3-043-880-01 RING (RA), RETAINING

116 3-044-206-11 SCREW, SPECIAL

M903 A-3315-039-A MOTOR SUB ASSY, LO (LOADING)

Page 33

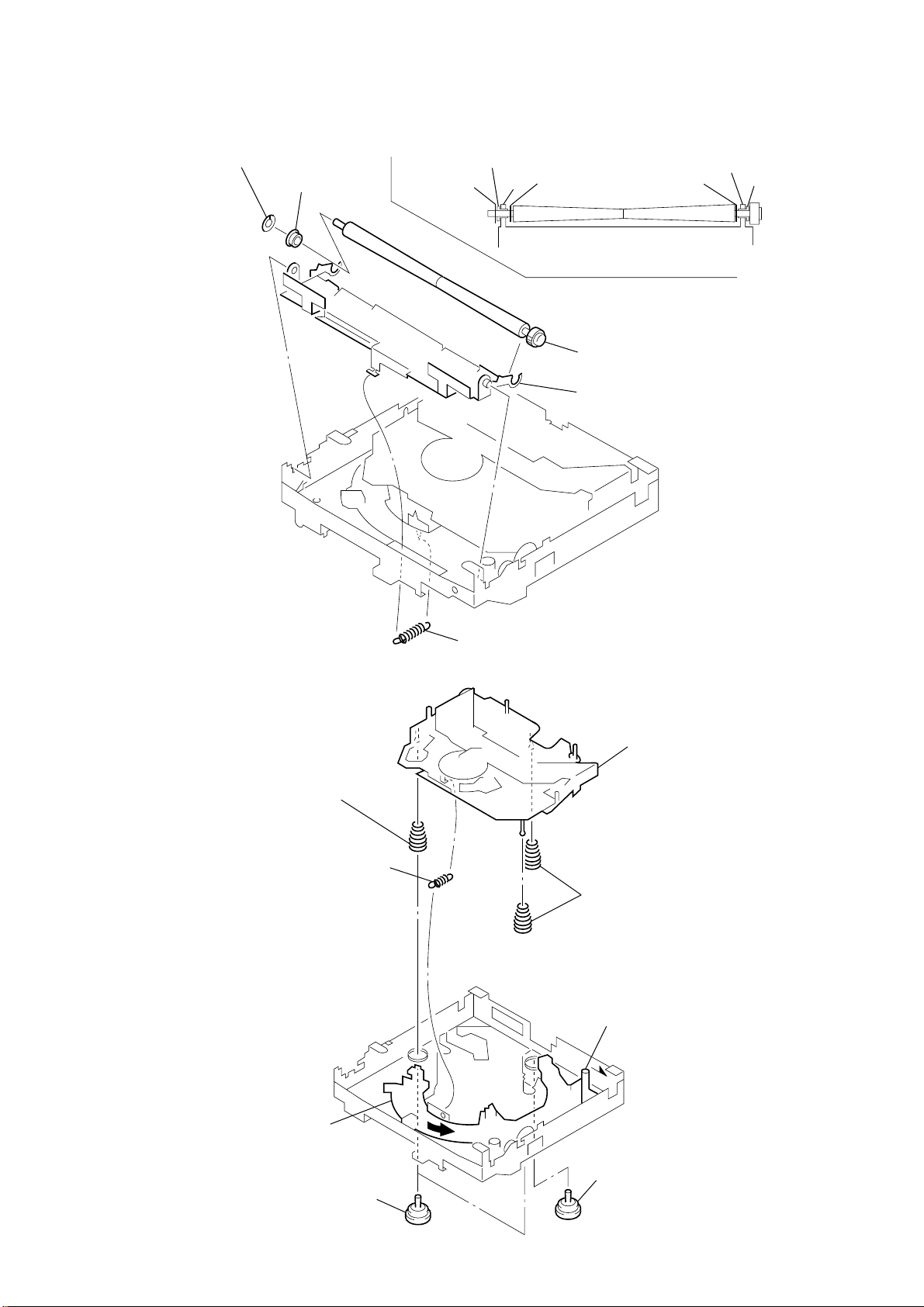

4-4. CD MECHANISM SECTION (2)

(MG-393X-121//K)

CDX-CA650X/CA660X/CA690X

157

158

162

163

154

D

160

165

151

156

157

164

155

153

161

D

159

152

152

152

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 3-040-025-01 ARM, CHUCKING

152 3-040-031-01 DAMPER (T)

153 3-040-056-01 LEVER (D)

154 3-040-024-01 RETAINER (DISC)

155 3-040-053-01 RING, LOADING

156 3-040-026-01 SPRING (CH), TENSION

157 3-040-032-01 SPRING (FL), COMPRESSION

158 3-040-033-01 SPRING (KF1), TENSION

159 A-3307-422-A CHASSIS (M) COMPLETE ASSY

160 3-040-059-01 SPRING (TR), TENSION

161 3-040-057-01 LEVER (LOCK)

162 3-040-058-01 GEAR (MDL)

163 3-040-052-01 WHEEL (U), WORM

164 3-040-051-01 LEVER (TR)

165 3-040-054-01 WHEEL (LW), WORM

33

Page 34

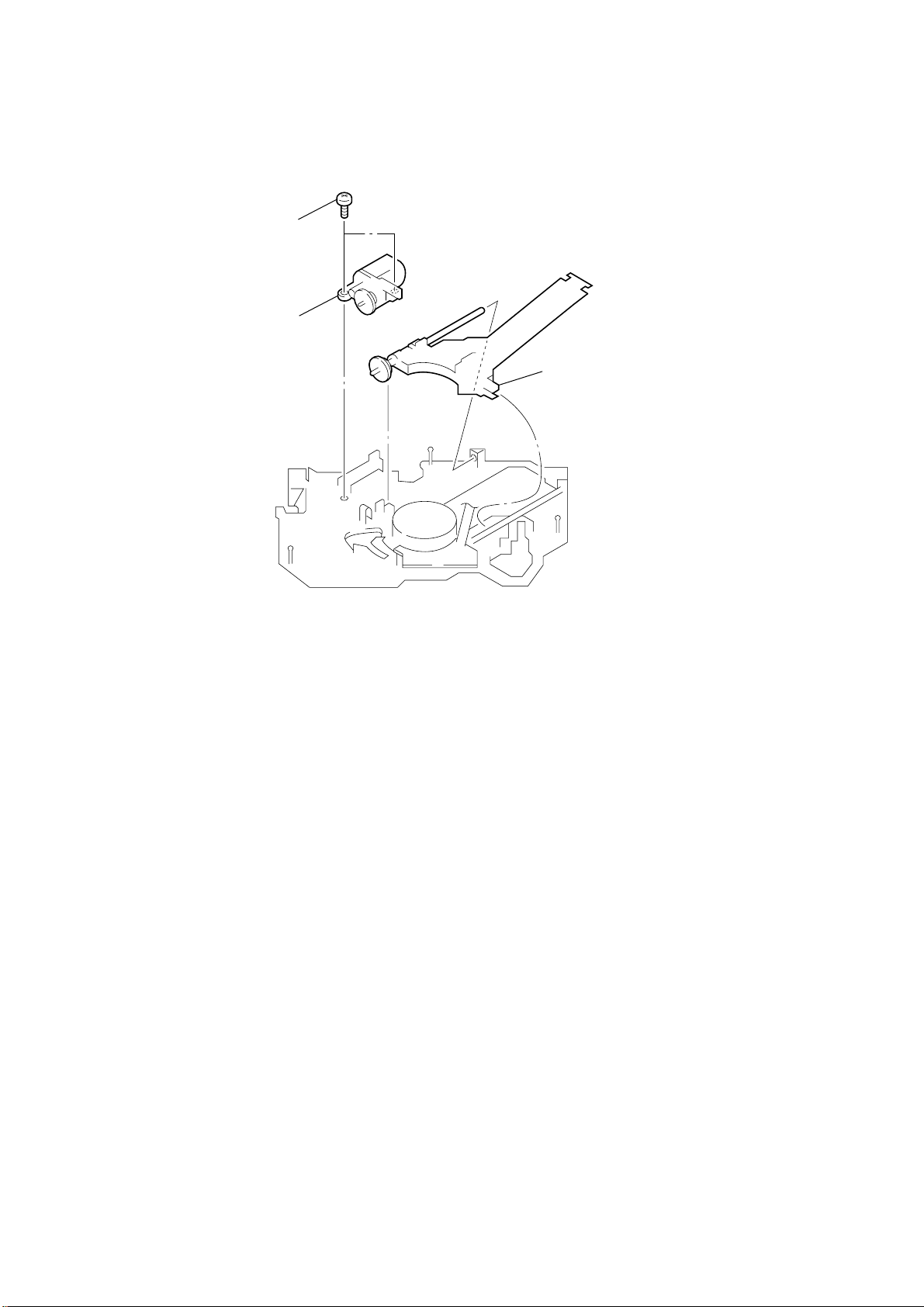

CDX-CA650X/CA660X/CA690X

4-5. CD MECHANISM SECTION (3)

(MG-393X-121//K)

207

201

M901

209

206

208

210

#8

211

202

M902

205

#8

203

#10

204

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

201 X-3378-480-1 CHASSIS (OP) ASSY (including M901)

202 3-040-029-01 SPRING (SL), TORSION

203 3-040-045-01 BASE (DRIVING)

204 3-040-194-01 GEAR (MIDWAY)

205 A-3301-983-A SHAFT (FEED) ASSY

206 1-676-707-11 PICK-UP FLEXIBLE BOARD

207 1-677-182-11 MOTOR FLEXIBLE BOARD

* 208 1-676-708-11 SL SW BOARD

209 3-909-607-01 SCREW

0 210 8-820-103-03 PICK-UP, OPTICAL KSS-720A/K1RP

211 3-040-030-01 SPRING (FEED), PLATE

M902 A-3301-985-A MOTOR ASSY, SLED (SLED)

Les composants identifiés par une

marque 0 sont critiques pour

la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

34

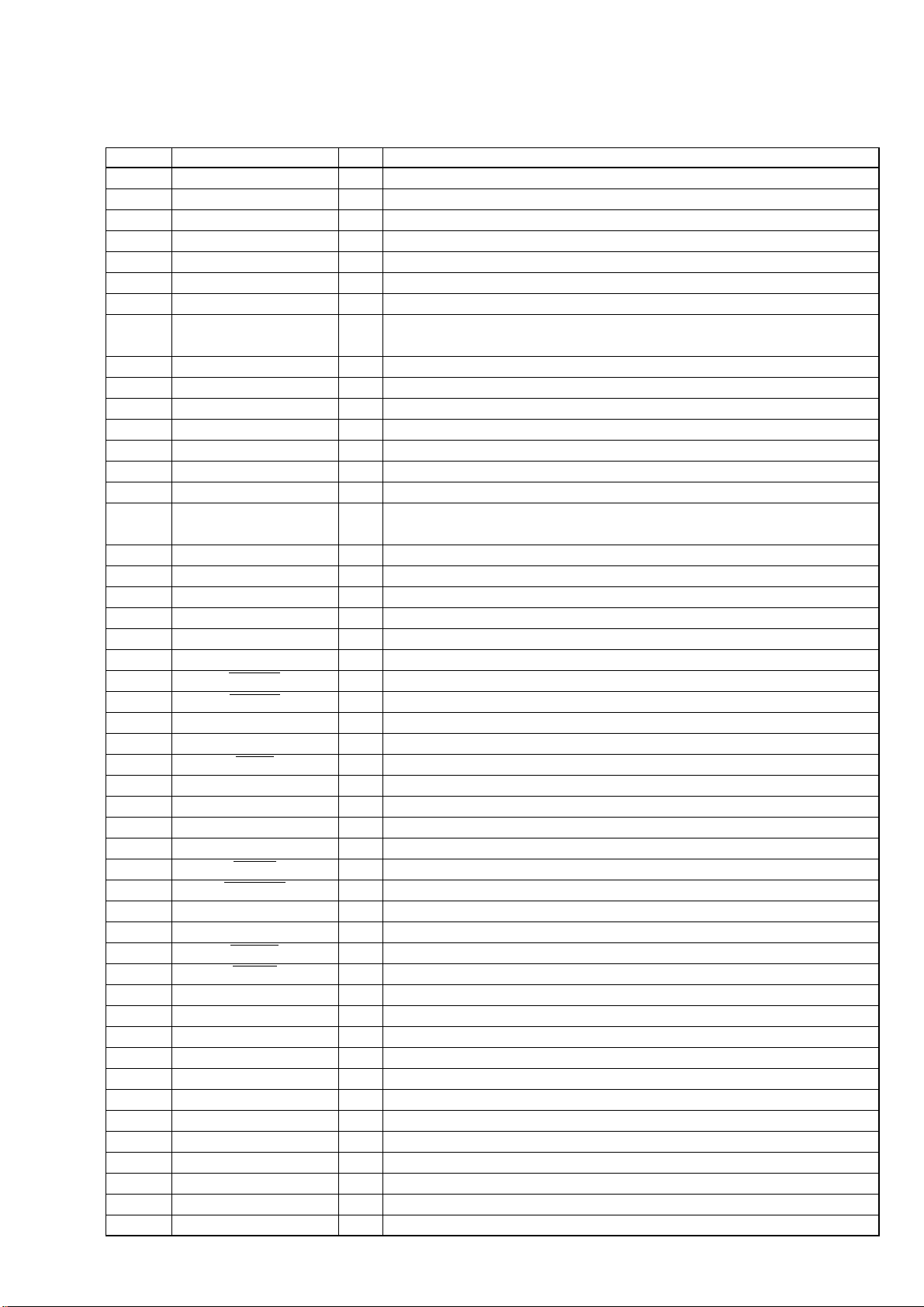

Page 35

CDX-CA650X/CA660X/CA690X

SECTION 5

ELECTRICAL PARTS LIST

DISPLAY

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

DISPLAY BOARD

**************

1-694-787-11 CONDUCTIVE BOARD, CONNECTION

* 3-224-306-01 PLATE (LCD), GROUND

* 3-224-307-01 SHEET (DIFFUSION)

< CAPACITOR >

C531 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C532 1-115-467-11 CERAMIC CHIP 0.22uF 10% 10V

C533 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C534 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C535 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C536 1-162-963-11 CERAMIC CHIP 680PF 10% 50V

< CONNECTOR >

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

LSW506 1-771-476-11 SWITCH, KEYBOARD (WITH LED)

LSW507 1-771-883-11 SWITCH, TACTILE (WITH LED) (SOUND)

LSW508 1-771-476-11 SWITCH, KEYBOARD (WITH LED) (ENTER)

LSW509 1-771-883-11 SWITCH, TACTILE (WITH LED) (DSPL)

LSW510 1-771-883-11 SWITCH, TACTILE (WITH LED) (LIST)

LSW513 1-771-476-11 SWITCH, KEYBOARD (WITH LED) (SOURCE)

LSW514 1-771-883-11 SWITCH, TACTILE (WITH LED) (MODE)

LSW515 1-771-500-21 SWITCH, KEYBOARD (WITH LED) (EQ7)

LSW516 1-771-500-21 SWITCH, KEYBOARD (WITH LED) (POS)

LSW517 1-771-883-11 SWITCH, TACTILE (WITH LED) (6)

LSW518 1-771-883-11 SWITCH, TACTILE (WITH LED) (5)

LSW519 1-771-883-11 SWITCH, TACTILE (WITH LED) (4)

LSW520 1-771-883-11 SWITCH, TACTILE (WITH LED) (3)

LSW521 1-771-883-11 SWITCH, TACTILE (WITH LED) (2/SHUF)

LSW522 1-771-883-11 SWITCH, TACTILE (WITH LED) (1/REP)

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiques pour

la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

(., SEEK –, m)

CN501 1-794-065-12 PLUG, CONNECTOR 14P

< DIODE >

D501 8-719-056-93 DIODE UDZ-TE-17-18B

D502 8-719-068-68 DIODE SDZ6V2WA

D503 8-719-069-56 DIODE UDZS-TE17-6.2B

D504 8-719-069-54 DIODE UDZS-TE17-5.1B

< IC >

IC501 8-759-826-21 IC LC75874W

IC502 8-749-017-35 IC KSM-401N

< LIQUID CRYSTAL DISPLAY >

LCD500 1-804-294-11 DISPLAY PANEL, LIQUID CRYSTAL

< DIODE >

LED510 8-719-078-19 LED LWA673-R1S2 (LCD BACK LIGHT)

LED511 8-719-078-19 LED LWA673-R1S2 (LCD BACK LIGHT)

LED512 8-719-078-19 LED LWA673-R1S2 (LCD BACK LIGHT)

LED513 8-719-078-19 LED LWA673-R1S2 (LCD BACK LIGHT)

< SWITCH >

LSW501 1-771-883-11 SWITCH, TACTILE (WITH LED) (OFF)

LSW502 1-771-476-11 SWITCH, KEYBOARD (WITH LED) (MENU)

LSW503 1-771-476-11 SWITCH, KEYBOARD (WITH LED)

(DISC/PRESET +)

LSW504 1-771-476-11 SWITCH, KEYBOARD (WITH LED)

(DISC/PRESET –)

LSW505 1-771-476-11 SWITCH, KEYBOARD (WITH LED)

(>, SEEK +, M)

< RESISTOR >

R501 1-216-819-11 METAL CHIP 680 5% 1/16W

R502 1-216-819-11 METAL CHIP 680 5% 1/16W

R503 1-216-819-11 METAL CHIP 680 5% 1/16W

R504 1-216-821-11 METAL CHIP 1K 5% 1/16W

R505 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R506 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R507 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R508 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R509 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R510 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R514 1-216-819-11 METAL CHIP 680 5% 1/16W

R515 1-216-819-11 METAL CHIP 680 5% 1/16W

R516 1-216-819-11 METAL CHIP 680 5% 1/16W

R517 1-216-821-11 METAL CHIP 1K 5% 1/16W

R518 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R519 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R520 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R521 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R522 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R523 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R524 1-216-864-11 SHORT 0

R525 1-216-817-11 METAL CHIP 470 5% 1/16W

R526 1-216-817-11 METAL CHIP 470 5% 1/16W

R527 1-216-817-11 METAL CHIP 470 5% 1/16W

R528 1-216-817-11 METAL CHIP 470 5% 1/16W

R532 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R533 1-216-815-11 METAL CHIP 330 5% 1/16W

35

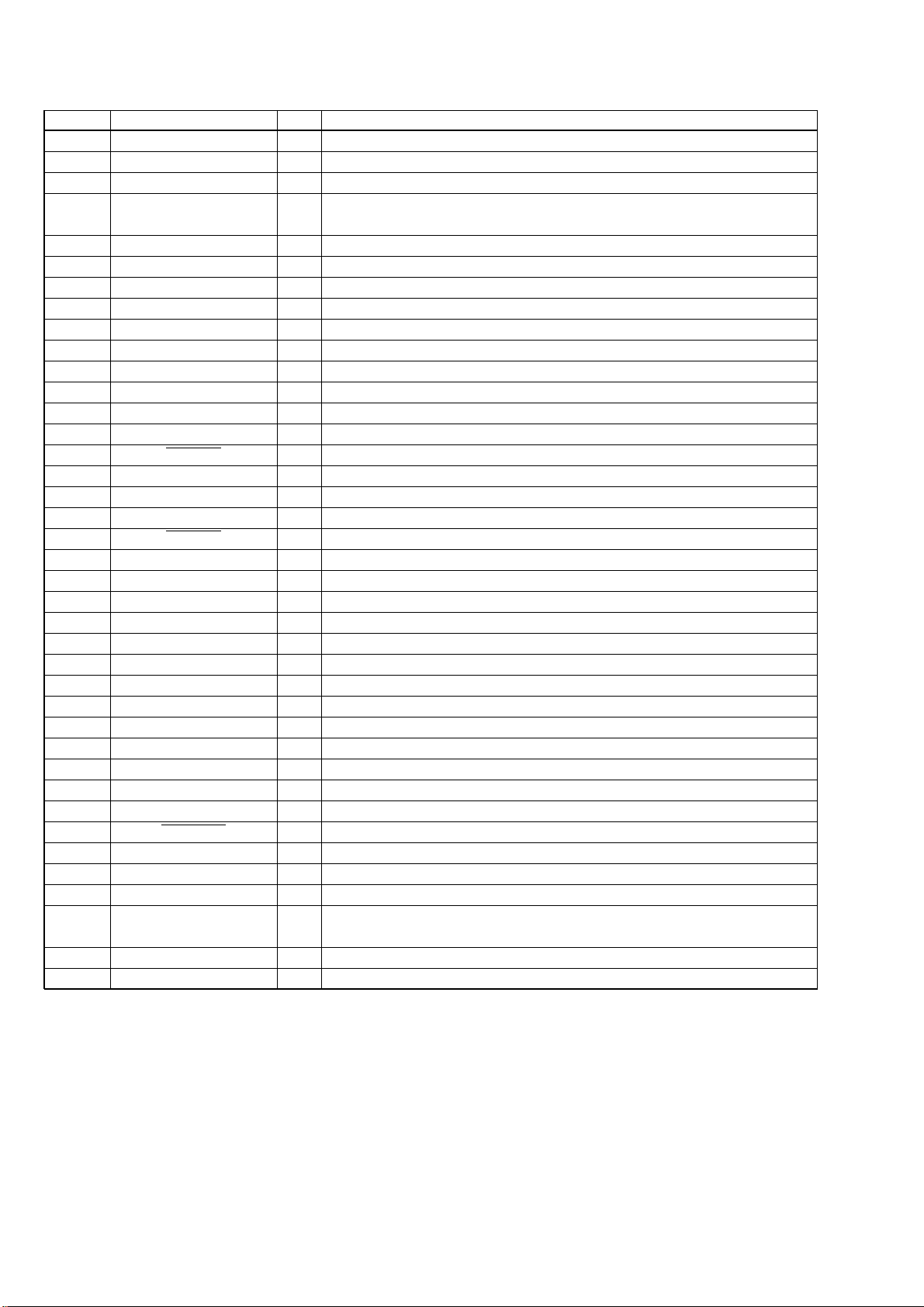

Page 36

CDX-CA650X/CA660X/CA690X

DISPLAY IN SELF SW

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R534 1-216-857-11 METAL CHIP 1M 5% 1/16W

R535 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R536 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R537 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R538 1-216-841-11 METAL CHIP 47K 5% 1/16W

R539 1-216-821-11 METAL CHIP 1K 5% 1/16W

R540 1-216-821-11 METAL CHIP 1K 5% 1/16W

R541 1-216-821-11 METAL CHIP 1K 5% 1/16W

R542 1-216-818-11 METAL CHIP 560 5% 1/16W

R543 1-216-818-11 METAL CHIP 560 5% 1/16W

R544 1-216-864-11 SHORT 0

R545 1-216-864-11 SHORT 0

R546 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R547 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R548 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R549 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R550 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R551 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R552 1-216-818-11 METAL CHIP 560 5% 1/16W

R553 1-216-818-11 METAL CHIP 560 5% 1/16W

R554 1-216-817-11 METAL CHIP 470 5% 1/16W

R555 1-216-817-11 METAL CHIP 470 5% 1/16W

R556 1-216-817-11 METAL CHIP 470 5% 1/16W

R557 1-216-817-11 METAL CHIP 470 5% 1/16W

< ROTARY ENCODER >

RE501 1-418-818-21 ENCODER, ROTARY

*************************************************************

* 1-676-709-11 IN SELF SW BOARD

****************

< SWITCH >

SW2 1-529-566-41 SWITCH, PUSH (1 KEY) (SELF)

SW3 1-529-566-41 SWITCH, PUSH (1 KEY) (DISC IN)

*************************************************************

MAIN

C121 1-124-233-11 ELECT 10uF 20% 16V

(CA660X)

C122 1-124-233-11 ELECT 10uF 20% 16V

C123 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C131 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C132 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C133 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

(CA660X)

C143 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

(CA660X)

C201 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C211 1-124-233-11 ELECT 10uF 20% 16V

(CA660X)

C212 1-124-233-11 ELECT 10uF 20% 16V

C213 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C221 1-124-233-11 ELECT 10uF 20% 16V

(CA660X)

C222 1-124-233-11 ELECT 10uF 20% 16V

C223 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C231 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C232 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C233 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

(CA660X)

C243 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

(CA660X)

C311 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

(CA660X)

C312 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

(CA660X)

C321 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

(CA660X)

C322 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

(CA660X)

C402 1-124-259-11 ELECT 4.7uF 20% 16V

(CA650X/CA690X)

C402 1-126-163-11 ELECT 4.7uF 20% 50V

(CA660X)

C403 1-124-233-11 ELECT 10uF 20% 16V

* A-3283-087-A MAIN BOARD, COMPLETE (CA660X)

* A-3283-091-A MAIN BOARD, COMPLETE (CA690X)

A-3283-156-A MAIN BOARD, COMPLETE (CA650X)

*********************

* 3-019-565-01 BRACKET (IC)

* 3-041-261-01 BRACKET (TR)

3-226-766-01 HEAT SINK (MAIN)

* 3-224-313-01 HEAT SINK (REG)

7-685-535-19 SCREW +BTP 2.6X10 TYPE 2 N-S

7-685-793-09 SCREW +PTT 2.6X8 (S)

7-685-795-09 SCREW +PTT 2.6X12 (S)

< CAPACITOR >

C101 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C111 1-124-233-11 ELECT 10uF 20% 16V

C112 1-124-233-11 ELECT 10uF 20% 16V

C113 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

(CA660X)

C404 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C405 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C430 1-124-233-11 ELECT 10uF 20% 16V

(CA660X)

C433 1-126-382-11 ELECT 100uF 20% 16V

(CA660X)

C435 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C440 1-124-233-11 ELECT 10uF 20% 16V

(CA660X)

C443 1-126-382-11 ELECT 100uF 20% 16V

(CA660X)

C445 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C453 1-126-382-11 ELECT 100uF 20% 16V

(CA660X)

C455 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C463 1-126-382-11 ELECT 100uF 20% 16V

(CA660X)

C465 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C471 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

36

Page 37

CDX-CA650X/CA660X/CA690X

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C476 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C479 1-128-057-11 ELECT 330uF 20% 6.3V

(CA660X)

C601 1-162-918-11 CERAMIC CHIP 18PF 5% 50V

C602 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C603 1-126-382-11 ELECT 100uF 20% 16V

C925 1-124-233-11 ELECT 10uF 20% 16V

(CA660X)

C926 1-126-157-11 ELECT 10uF 20% 16V

C927 1-126-157-11 ELECT 10uF 20% 16V

C928 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C929 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C604 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C605 1-126-382-11 ELECT 100uF 20% 16V

C606 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C607 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C608 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C610 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C611 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C612 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C701 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C702 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C703 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C704 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C705 1-126-176-11 ELECT 220uF 20% 10V

C706 1-124-233-11 ELECT 10uF 20% 16V

C708 1-126-153-11 ELECT 22uF 20% 6.3V

C709 1-126-176-11 ELECT 220uF 20% 10V

C710 1-126-153-11 ELECT 22uF 20% 6.3V

C801 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C804 1-162-918-11 CERAMIC CHIP 18PF 5% 50V

C805 1-162-918-11 CERAMIC CHIP 18PF 5% 50V

C806 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C809 1-128-647-11 DOUBLE LAYERS 0.1F 5.5V

C810 1-124-584-00 ELECT 100uF 20% 10V

C811 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C812 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C813 1-124-119-00 ELECT 330uF 20% 16V

C814 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C815 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C816 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C865 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C869 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C905 1-124-465-00 ELECT 0.47uF 20% 50V

(CA660X)

C905 1-126-160-11 ELECT 1uF 20% 50V

(CA650X/CA690X)

C906 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C907 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C912 1-124-233-11 ELECT 10uF 20% 16V

C914 1-135-473-21 ELECT 3300uF 20% 16V

C915 1-110-563-11 CERAMIC CHIP 0.068uF 10% 16V

C916 1-124-589-11 ELECT 47uF 20% 16V

C917 1-126-157-11 ELECT 10uF 20% 16V

C919 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C921 1-126-153-11 ELECT 22uF 20% 6.3V

C922 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C924 1-164-156-11 CERAMIC CHIP 0.1uF 25V

(CA660X)

C930 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C931 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

(CA660X)

C932 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C933 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C934 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

(CA650X/CA690X)

< CONNECTOR >

CNJ801 1-580-907-31 PLUG, CONNECTOR (BUS CONTROL IN)

CNP701 1-764-617-12 PIN, CONNECTOR (PC BOARD) 30P

CNP802 1-569-907-11 SOCKET, CONNECTOR 12P

CNP902 1-774-701-11 PIN, CONNECTOR 16P

< JACK >

CNP801 1-764-270-21 JACK, STEREO MINIATURE (DIA.3.5)

(REMOTE IN)

< DIODE >

D601 8-719-056-65 DIODE 1SS372-TE85L

D801 8-719-988-61 DIODE 1SS355TE-17

D802 8-719-988-61 DIODE 1SS355TE-17

D803 8-719-109-93 DIODE MTZJ-T-77-6.2B

D804 8-719-110-49 DIODE MTZJ-T-77-18B

D805 8-719-058-24 DIODE RB501V-40TE-17

D806 8-719-056-93 DIODE UDZ-TE-17-18B

D807 8-719-056-93 DIODE UDZ-TE-17-18B

D809 8-719-109-97 DIODE MTZJ-T-77-6.8B

D811 8-719-978-33 DIODE UDZS-TE17-6.8B

D812 8-719-978-33 DIODE UDZS-TE17-6.8B

D813 8-719-978-33 DIODE UDZS-TE17-6.8B

D814 8-719-978-33 DIODE UDZS-TE17-6.8B

D815 8-719-109-97 DIODE MTZJ-T-77-6.8B

D816 8-719-978-33 DIODE UDZS-TE17-6.8B

D817 8-719-109-97 DIODE MTZJ-T-77-6.8B

D818 8-719-978-33 DIODE UDZS-TE17-6.8B

D901 8-719-991-33 DIODE 1SS133T-77

D902 8-719-200-82 DIODE 11ES2-TA1B

D906 8-719-978-33 DIODE UDZS-TE17-6.8B

D907 8-719-200-82 DIODE 11ES2-TA1B

D908 8-719-988-61 DIODE 1SS355TE-17

D909 1-216-864-11 SHORT 0

D911 8-719-079-97 DIODE CRZ22(TE85L.SONY)

D912 8-719-079-97 DIODE CRZ22(TE85L.SONY)

D913 8-719-079-97 DIODE CRZ22(TE85L.SONY)

D914 8-719-079-97 DIODE CRZ22(TE85L.SONY)

D915 8-719-079-97 DIODE CRZ22(TE85L.SONY)

D916 8-719-079-97 DIODE CRZ22(TE85L.SONY)

37

Page 38

CDX-CA650X/CA660X/CA690X

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

D917 8-719-079-97 DIODE CRZ22(TE85L.SONY)

D918 8-719-079-97 DIODE CRZ22(TE85L.SONY)

D919 8-719-200-82 DIODE 11ES2-TA1B

D920 8-719-049-38 DIODE 1N5404TU

D931 8-719-056-84 DIODE UDZS-TE17-7.5B

JR703 1-216-864-11 SHORT 0

JR704 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

JR801 1-216-864-11 SHORT 0

JR802 1-216-864-11 SHORT 0

JR803 1-216-864-11 SHORT 0

D932 8-719-978-33 DIODE UDZS-TE17-6.8B

D933 8-719-056-88 DIODE UDZ-TE-17-11B (CA660X)

D934 1-216-864-11 SHORT 0 (CA650X/CA690X)

D934 8-719-978-33 DIODE UDZS-TE17-6.8B (CA660X)

D935 1-216-864-11 SHORT 0 (CA650X/CA690X)

D935 8-719-988-61 DIODE 1SS355TE-17 (CA660X)

D941 8-719-109-89 DIODE MTZJ-T-77-5.6B

< IC >

IC301 8-759-909-71 IC BA4558F-E2 (CA660X)

IC302 8-759-909-71 IC BA4558F-E2 (CA660X)

IC401 8-759-827-13 IC TDA7406T

IC404 8-759-827-14 IC TA8268AH

IC405 8-759-909-71 IC BA4558F-E2 (CA660X)

IC406 8-759-909-71 IC BA4558F-E2 (CA660X)

IC431 8-759-593-97 IC NJM2160AM-TE2 (CA660X)

IC441 8-759-593-97 IC NJM2160AM-TE2 (CA660X)

IC801 6-800-079-01 IC MN101C49KTG1

IC802 8-759-682-69 IC XC61CN4302MR

IC803 8-759-449-89 IC BA8270F-E2

IC901 8-759-661-47 IC BA4908-V3

< JUMPER RESISTOR >

JR101 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR102 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR103 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR104 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR105 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR106 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR107 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR108 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR201 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR202 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR203 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR204 1-216-864-11 SHORT 0 (CA650X/CA690X)

JR301 1-216-864-11 SHORT 0

JR302 1-216-864-11 SHORT 0 (CA660X)

JR303 1-216-864-11 SHORT 0 (CA660X)

JR804 1-216-864-11 SHORT 0

JR805 1-216-864-11 SHORT 0

JR806 1-216-864-11 SHORT 0

JR901 1-216-864-11 SHORT 0

< COIL >

L900 1-419-476-31 COIL, CHOKE 250uH

< JACK >

PJ401 1-794-068-11 JACK, PIN 6P (AUDIO OUT FRONT/REAR,

BUS AUDIO IN)

PJ601 1-793-598-11 JACK (ANTENNA)

< TRANSISTOR >

Q101 8-729-920-21 TRANSISTOR DTC314TK-T-146

Q102 8-729-920-21 TRANSISTOR DTC314TK-T-146

Q201 8-729-920-21 TRANSISTOR DTC314TK-T-146

Q202 8-729-920-21 TRANSISTOR DTC314TK-T-146

Q801 8-729-027-31 TRANSISTOR DTA124EKA-T146

Q803 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q901 8-729-049-40 TRANSISTOR STC2412G

Q902 8-729-049-40 TRANSISTOR STC2412G

Q905 8-729-049-43 TRANSISTOR STB1132Y

Q906 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q907 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q908 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q909 8-729-027-31 TRANSISTOR DTA124EKA-T146

Q910 8-729-021-82 TRANSISTOR 2SD2396K

Q911 8-729-052-35 TRANSISTOR STD1664

Q912 1-801-806-11 TRANSISTOR DTC144EK-T146

Q913 8-729-901-04 TRANSISTOR DTA114EK-T146

Q914 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q915 8-729-027-31 TRANSISTOR DTA124EKA-T146

Q922 8-729-052-35 TRANSISTOR STD1664 (CA660X)

Q923 8-729-901-00 TRANSISTOR DTC124EKA-T146 (CA660X)

Q924 8-729-027-31 TRANSISTOR DTA124EKA-T146 (CA660X)

< RESISTOR >

JR304 1-216-864-11 SHORT 0 (CA660X)

JR401 1-216-864-11 SHORT 0 (CA660X)

JR403 1-216-864-11 SHORT 0 (CA660X)

JR404 1-216-864-11 SHORT 0 (CA660X)

JR411 1-216-864-11 SHORT 0

JR412 1-216-864-11 SHORT 0

JR413 1-216-864-11 SHORT 0 (CA660X)

JR490 1-216-864-11 SHORT 0

JR602 1-216-864-11 SHORT 0

JR701 1-216-864-11 SHORT 0

JR702 1-216-864-11 SHORT 0

38

R111 1-216-813-11 METAL CHIP 220 5% 1/16W

R112 1-218-725-11 RES-CHIP 24K 5% 1/16W

(CA660X)

R113 1-202-926-11 RES-CHIP 36K 5% 1/16W

(CA660X)

R114 1-216-864-11 SHORT 0

R115 1-216-841-11 METAL CHIP 47K 5% 1/16W

R116 1-216-844-11 METAL CHIP 82K 5% 1/16W

(CA660X)

R117 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

Page 39

CDX-CA650X/CA660X/CA690X

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R118 1-216-864-11 SHORT 0

R119 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R121 1-216-813-11 METAL CHIP 220 5% 1/16W

R122 1-218-725-11 RES-CHIP 24K 5% 1/16W

(CA660X)

R123 1-202-926-11 RES-CHIP 36K 5% 1/16W

(CA660X)

R124 1-216-864-11 SHORT 0

R125 1-216-841-11 METAL CHIP 47K 5% 1/16W

R126 1-216-844-11 METAL CHIP 82K 5% 1/16W

(CA660X)

R127 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R128 1-216-864-11 SHORT 0

R129 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R131 1-216-833-11 METAL CHIP 10K 5% 1/16W

R132 1-216-821-11 METAL CHIP 1K 5% 1/16W

R133 1-216-847-11 METAL CHIP 150K 5% 1/16W

(CA660X)

R134 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R143 1-216-847-11 METAL CHIP 150K 5% 1/16W

(CA660X)

R144 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R211 1-216-813-11 METAL CHIP 220 5% 1/16W

R212 1-218-725-11 RES-CHIP 24K 5% 1/16W

(CA660X)

R213 1-202-926-11 RES-CHIP 36K 5% 1/16W

(CA660X)

R214 1-216-864-11 SHORT 0

R215 1-216-841-11 METAL CHIP 47K 5% 1/16W

R216 1-216-844-11 METAL CHIP 82K 5% 1/16W

(CA660X)

R217 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R218 1-216-864-11 SHORT 0

R219 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R221 1-216-813-11 METAL CHIP 220 5% 1/16W

R222 1-218-725-11 RES-CHIP 24K 5% 1/16W

(CA660X)

R223 1-202-926-11 RES-CHIP 36K 5% 1/16W

(CA660X)

R224 1-216-864-11 SHORT 0

R225 1-216-841-11 METAL CHIP 47K 5% 1/16W

R226 1-216-844-11 METAL CHIP 82K 5% 1/16W

(CA660X)

R227 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R228 1-216-864-11 SHORT 0

R229 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R231 1-216-833-11 METAL CHIP 10K 5% 1/16W

R232 1-216-821-11 METAL CHIP 1K 5% 1/16W

R233 1-216-847-11 METAL CHIP 150K 5% 1/16W

(CA660X)

R234 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R243 1-216-847-11 METAL CHIP 150K 5% 1/16W

(CA660X)

R244 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R301 1-410-841-11 METAL CHIP 4.7K 5% 1/16W

(CA660X)

R302 1-410-841-11 METAL CHIP 4.7K 5% 1/16W

(CA660X)

R311 1-216-846-11 METAL CHIP 120K 5% 1/16W

(CA660X)

R312 1-216-840-11 METAL CHIP 39K 5% 1/16W

(CA660X)

R313 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R314 1-216-846-11 METAL CHIP 120K 5% 1/16W

(CA660X)

R315 1-216-840-11 METAL CHIP 39K 5% 1/16W

(CA660X)

R316 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R321 1-216-846-11 METAL CHIP 120K 5% 1/16W

(CA660X)

R322 1-216-840-11 METAL CHIP 39K 5% 1/16W

(CA660X)

R323 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R324 1-216-846-11 METAL CHIP 120K 5% 1/16W

(CA660X)

R325 1-216-840-11 METAL CHIP 39K 5% 1/16W

(CA660X)

R326 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA660X)

R401 1-216-821-11 METAL CHIP 1K 5% 1/16W

R402 1-216-833-11 METAL CHIP 10K 5% 1/16W

R403 1-216-841-11 METAL CHIP 47K 5% 1/16W

R404 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R601 1-216-864-11 SHORT 0

R602 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R604 1-216-845-11 METAL CHIP 100K 5% 1/16W

R608 1-216-809-11 METAL CHIP 100 5% 1/16W

R609 1-216-809-11 METAL CHIP 100 5% 1/16W

R610 1-216-864-11 SHORT 0

R611 1-216-841-11 METAL CHIP 47K 5% 1/16W

R701 1-216-841-11 METAL CHIP 47K 5% 1/16W

R702 1-216-864-11 SHORT 0

R703 1-216-864-11 SHORT 0

R801 1-216-837-11 METAL CHIP 22K 5% 1/16W

R802 1-216-813-11 METAL CHIP 220 5% 1/16W

R803 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R804 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R805 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

39

Page 40

CDX-CA650X/CA660X/CA690X

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R806 1-216-809-11 METAL CHIP 100 5% 1/16W

R807 1-216-809-11 METAL CHIP 100 5% 1/16W

R808 1-216-841-11 METAL CHIP 47K 5% 1/16W

R810 1-216-809-11 METAL CHIP 100 5% 1/16W

R811 1-216-809-11 METAL CHIP 100 5% 1/16W

R812 1-216-809-11 METAL CHIP 100 5% 1/16W

R813 1-216-809-11 METAL CHIP 100 5% 1/16W

R814 1-216-845-11 METAL CHIP 100K 5% 1/16W

R815 1-216-809-11 METAL CHIP 100 5% 1/16W

R816 1-216-821-11 METAL CHIP 1K 5% 1/16W

R817 1-216-809-11 METAL CHIP 100 5% 1/16W

R818 1-216-809-11 METAL CHIP 100 5% 1/16W

R819 1-216-821-11 METAL CHIP 1K 5% 1/16W

R820 1-216-821-11 METAL CHIP 1K 5% 1/16W

R821 1-216-845-11 METAL CHIP 100K 5% 1/16W

R910 1-216-841-11 METAL CHIP 47K 5% 1/16W

R911 1-216-833-11 METAL CHIP 10K 5% 1/16W

R912 1-216-833-11 METAL CHIP 10K 5% 1/16W

R913 1-216-073-00 METAL CHIP 10K 5% 1/10W

R914 1-216-836-11 METAL CHIP 18K 5% 1/16W

(CA660X)

R914 1-216-841-11 METAL CHIP 47K 5% 1/16W

(CA650X/CA690X)

R915 1-216-838-11 METAL CHIP 27K 5% 1/16W

(CA660X)

R915 1-216-841-11 METAL CHIP 47K 5% 1/16W

(CA650X/CA690X)

R916 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

(CA650X/CA690X)

R916 1-216-835-11 METAL CHIP 15K 5% 1/16W

(CA660X)

R822 1-216-845-11 METAL CHIP 100K 5% 1/16W

R823 1-216-845-11 METAL CHIP 100K 5% 1/16W

R825 1-216-675-00 METAL CHIP 10K 0.5% 1/10W

R826 1-216-675-00 METAL CHIP 10K 0.5% 1/10W

R827 1-216-837-11 METAL CHIP 22K 5% 1/16W

R828 1-216-821-11 METAL CHIP 1K 5% 1/16W

R830 1-216-809-11 METAL CHIP 100 5% 1/16W

R831 1-216-809-11 METAL CHIP 100 5% 1/16W

R834 1-216-809-11 METAL CHIP 100 5% 1/16W

R835 1-216-809-11 METAL CHIP 100 5% 1/16W

R836 1-216-675-00 METAL CHIP 10K 0.5% 1/10W

R839 1-216-849-11 METAL CHIP 220K 5% 1/16W

R840 1-216-849-11 METAL CHIP 220K 5% 1/16W

R841 1-216-849-11 METAL CHIP 220K 5% 1/16W

R842 1-216-833-11 METAL CHIP 10K 5% 1/16W

R843 1-247-807-31 CARBON 100 5% 1/4W

R844 1-247-807-31 CARBON 100 5% 1/4W

R845 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA650X/CA690X)

R846 1-216-864-11 SHORT 0 (CA660X)

R851 1-216-845-11 METAL CHIP 100K 5% 1/16W

(CA690X)

R852 1-216-864-11 SHORT 0 (CA650X/CA660X)

R853 1-216-841-11 METAL CHIP 47K 5% 1/16W

(CA690X)

R854 1-249-417-11 CARBON 1K 5% 1/4W

R855 1-216-864-11 SHORT 0

R856 1-216-821-11 METAL CHIP 1K 5% 1/16W

R917 1-216-845-11 METAL CHIP 100K 5% 1/16W

R919 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R920 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R921 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R922 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R923 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R924 1-216-809-11 METAL CHIP 100 5% 1/16W

R925 1-216-845-11 METAL CHIP 100K 5% 1/16W

R926 1-216-059-00 METAL CHIP 2.7K 5% 1/10W

R927 1-216-073-00 METAL CHIP 10K 5% 1/10W

R928 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R930 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R934 1-249-400-11 CARBON 39 5% 1/4W

R935 1-249-400-11 CARBON 39 5% 1/4W

R936 1-249-400-11 CARBON 39 5% 1/4W

R937 1-249-400-11 CARBON 39 5% 1/4W

R940 1-216-833-11 METAL CHIP 10K 5% 1/16W

(CA660X)

< SWITCH >

S901 1-762-638-21 SWITCH, TACTILE (RESET)

S902 1-771-540-11 SWITCH, PUSH (1 KEY) (NOSE DET)

SW802 1-571-478-11 SWITCH, SLIDE (FREQUENCY SELECT)

(CA690X)

< THERMISTOR (POSITIVE) >

TH900 1-801-792-21 THERMISTOR, POSITIVE

R857 1-216-833-11 METAL CHIP 10K 5% 1/16W

R861 1-216-845-11 METAL CHIP 100K 5% 1/16W

R862 1-216-845-11 METAL CHIP 100K 5% 1/16W

R863 1-216-833-11 METAL CHIP 10K 5% 1/16W

R864 1-216-833-11 METAL CHIP 10K 5% 1/16W

R901 1-216-833-11 METAL CHIP 10K 5% 1/16W

R906 1-216-805-11 METAL CHIP 47 5% 1/16W

R907 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R908 1-216-864-11 SHORT 0

R909 1-216-821-11 METAL CHIP 1K 5% 1/16W

40

< TUNER >

TU601 A-3220-738-A TUNER UNIT (TUX-020)

< VIBRATOR >

X801 1-781-822-21 VIBRATOR, CERAMIC (18.432MHz)

X802 1-567-098-41 VIBRATOR, CRYSTAL (32.768kHz)

*************************************************************

Page 41

CDX-CA650X/CA660X/CA690X

RELAY

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-679-988-11 RELAY BOARD

************

< CONNECTOR >

CNP902 1-794-064-12 SOCKET, CONNECTOR 14P

CNP903 1-792-173-11 CABLE, FLAT (FFC) 12P

< DIODE >

LED905 8-719-078-39 LED CL-170SR-CD-T (CD WINDOW)

< SWITCH >

LSW916 1-771-883-11 SWITCH, TACTILE (WITH LED) (Z)

< RESISTOR >

R930 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R931 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

R932 1-216-823-11 METAL CHIP 1.5K 5% 1/16W

*************************************************************

* A-3283-048-A SERVO BOARD, COMPLETE

**********************

C35 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C36 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C37 1-126-393-11 ELECT CHIP 33uF 20% 10V

C38 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C39 1-126-391-11 ELECT CHIP 47uF 20% 6.3V

C41 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C43 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C44 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

< CONNECTOR >

CN1 1-764-616-12 HOUSING, CONNECTOR (PC BOARD) 30P

CN2 1-794-153-21 CONNECTOR, FPC (ZIF) 16P

CN3 1-770-347-21 CONNECTOR, FPC 6P

< JUMPER RESISTOR >

FB1 1-216-864-11 SHORT 0

FB2 1-216-864-11 SHORT 0

FB3 1-216-864-11 SHORT 0

FB4 1-216-864-11 SHORT 0

FB6 1-216-864-11 SHORT 0

FB7 1-216-864-11 SHORT 0

SERVO

< CAPACITOR >

C1 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C3 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C4 1-104-609-11 ELECT CHIP 100uF 20% 4V

C5 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C6 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C7 1-126-394-11 ELECT CHIP 10uF 20% 16V

C8 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C9 1-162-924-11 CERAMIC CHIP 56PF 5% 50V

C10 1-162-924-11 CERAMIC CHIP 56PF 5% 50V

C11 1-162-909-11 CERAMIC CHIP 4PF 0.25PF 50V

C13 1-162-916-11 CERAMIC CHIP 12PF 5% 50V

C14 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C15 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C16 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C17 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C18 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C19 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C20 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C21 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C22 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C23 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C24 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C25 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C26 1-126-391-11 ELECT CHIP 47uF 20% 6.3V

C27 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C28 1-126-391-11 ELECT CHIP 47uF 20% 6.3V

C29 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C30 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C31 1-126-391-11 ELECT CHIP 47uF 20% 6.3V

C34 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

< IC >

IC1 8-759-699-98 IC uPD63711GC-8EU

IC2 8-759-658-87 IC BA5810FP-E2

< TRANSISTOR >

Q1 8-729-904-87 TRANSISTOR 2SB1197K-T-146-R

< RESISTOR >

R3 1-216-797-11 METAL CHIP 10 5% 1/16W

R5 1-218-344-11 RES-CHIP 7.5K 5% 1/16W

R6 1-216-837-11 METAL CHIP 22K 5% 1/16W

R7 1-216-839-11 METAL CHIP 33K 5% 1/16W

R8 1-216-833-11 METAL CHIP 10K 5% 1/16W

R9 1-216-840-11 METAL CHIP 39K 5% 1/16W

R10 1-216-835-11 METAL CHIP 15K 5% 1/16W

R12 1-216-837-11 METAL CHIP 22K 5% 1/16W

R14 1-216-841-11 METAL CHIP 47K 5% 1/16W

R15 1-216-841-11 METAL CHIP 47K 5% 1/16W

R17 1-216-809-11 METAL CHIP 100 5% 1/16W

R18 1-216-809-11 METAL CHIP 100 5% 1/16W

R19 1-216-809-11 METAL CHIP 100 5% 1/16W

R20 1-216-809-11 METAL CHIP 100 5% 1/16W

R21 1-216-821-11 METAL CHIP 1K 5% 1/16W

R22 1-216-821-11 METAL CHIP 1K 5% 1/16W

R24 1-216-864-11 SHORT 0

R25 1-216-864-11 SHORT 0

R26 1-216-797-11 METAL CHIP 10 5% 1/16W

R29 1-216-833-11 METAL CHIP 10K 5% 1/16W

R30 1-216-833-11 METAL CHIP 10K 5% 1/16W

41

Page 42

CDX-CA650X/CA660X/CA690X

SERVO

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

SW1 1-762-944-12 SWITCH, DETECTION (SMALL TYPE) (DOWN)

X1 1-781-759-21 VIBRATOR, CERAMIC (CHIP TYPE)

*************************************************************

* 1-676-708-11 SL SW BOARD

CN13 1-770-347-21 CONNECTOR, FPC 6P

SW4 1-529-565-41 SWITCH, PUSH (1 KEY) (LIMIT)

*************************************************************

9 1-776-207-82 CORD (WITH CONNECTOR) (POWER)

201 X-3378-480-1 CHASSIS (OP) ASSY (including M901)

206 1-676-707-11 PICK-UP FLEXIBLE BOARD

207 1-677-182-11 MOTOR FLEXIBLE BOARD

0 210 8-820-103-03 PICK-UP, OPTICAL KSS-720A/K1RP

F901 1-532-877-11 FUSE (BLADE TYPE) (AUTO FUSE) 10A

M902 A-3301-985-A MOTOR ASSY, SLED (SLED)

M903 A-3315-039-A MOTOR SUB ASSY, LO (LOADING)

*************************************************************

SL SW

< SWITCH >

< VIBRATOR >

************

< CONNECTOR >

< SWITCH >

MISCELLANEOUS