Sony CDPCE-545 Service manual

CDP-CE545

SERVICE MANUAL

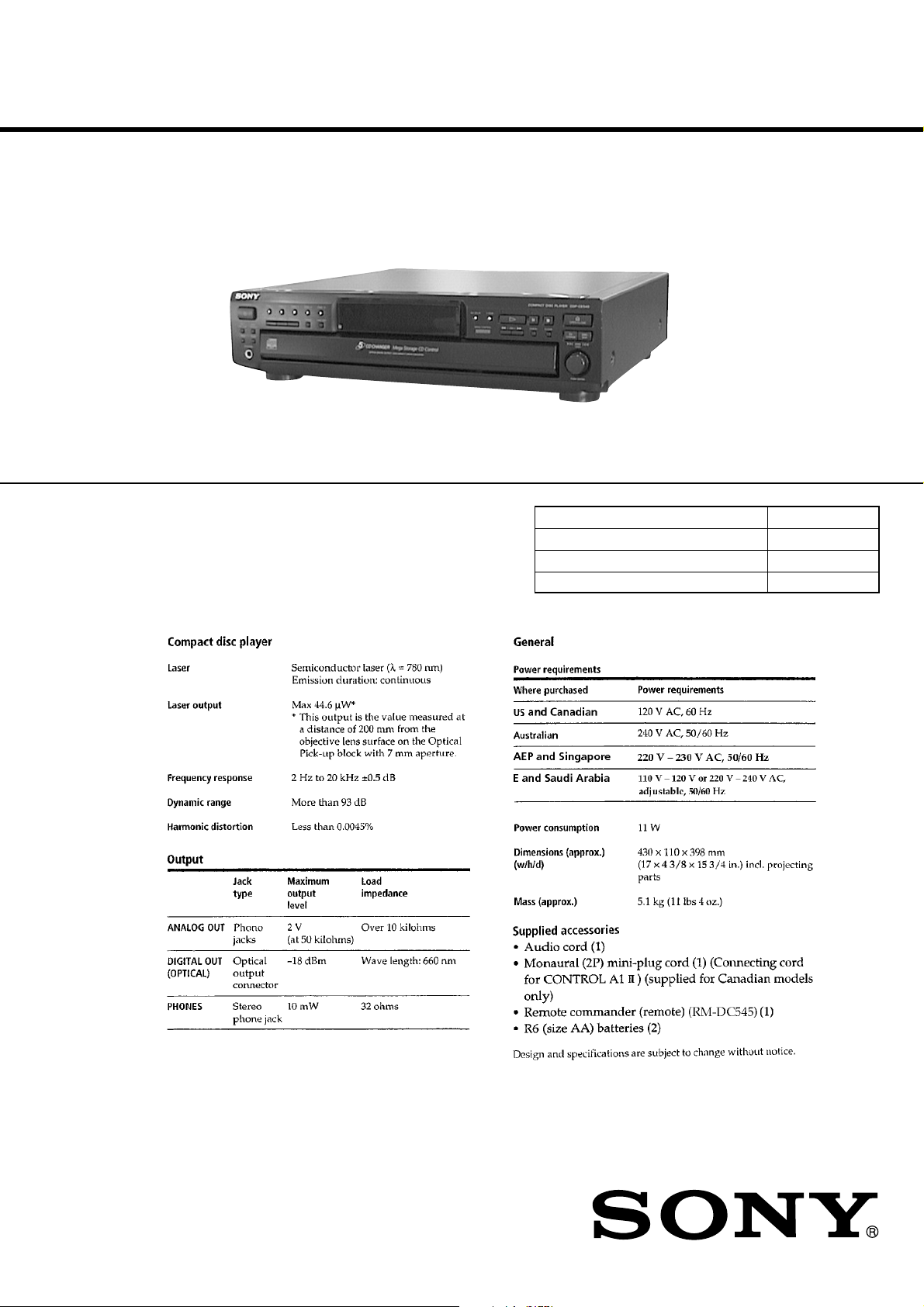

SPECIFICATIONS

US Model

Canadian Model

AEP Model

E Model

Australian Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM59-5BD32A

Base Unit Name BU-5BD32A

Optical Pick-Up Name KSS-213BA/F-NP

COMPACT DISC PLAYER

TABLE OF CONTENTS

1. SERVICEING NOTES ............................................ 3

2. GENERAL ................................................................... 6

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

3. DISASSEMBLY ......................................................... 7

4. TEST MODE.............................................................. 12

5. ELECTRICAL CHECKING .................................. 16

6. DIAGRAMS

6-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 19

6-2. Printed Wiring Board – BD Board – ............................. 20

6-3. Schematic Diagram – BD Board – ................................ 21

6-4. Printed Wiring Boards – JUNCTION/SENSOR/

LOADING MOTOR Boards –........................................ 22

6-5. Schematic Diagram – JUNCTION/SENSOR/

LOADING MOTOR Boards –........................................ 23

6-6. Printed Wiring Board – MAIN Board – ........................ 24

6-7. Schematic Diagram – MAIN Board – ........................... 25

6-8. Printed Wiring Boards – PANEL Section – .................. 26

6-9. Schematic Diag ram – PANEL Section –....................... 27

6-10. IC Pin Function Description ........................................... 32

7. EXPLODED VIEWS ................................................ 36

8. ELECTRICAL PARTS LIST ............................... 42

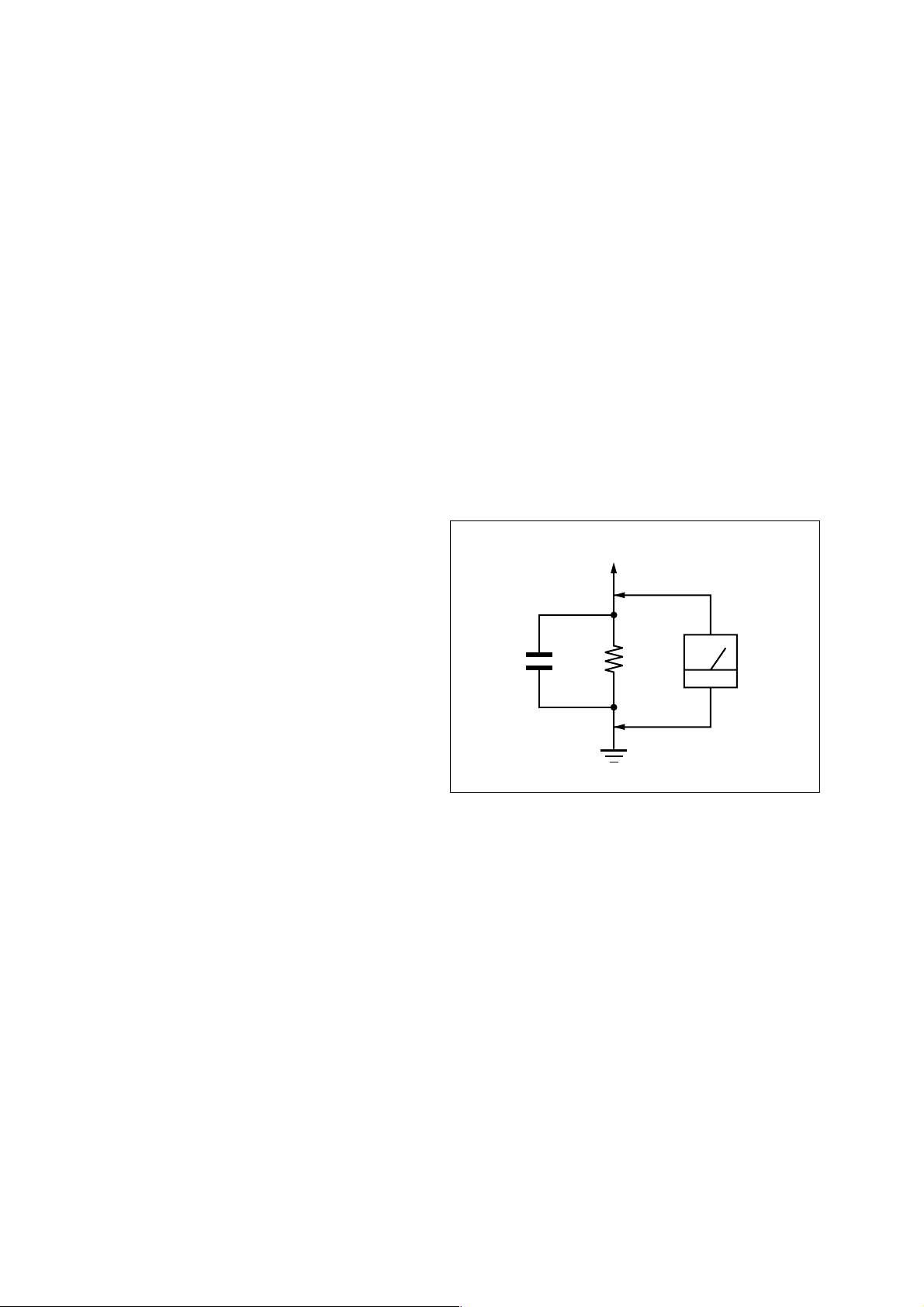

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15 µF

1.5 k

Ω

AC

voltmeter

(0.75 V)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

2

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

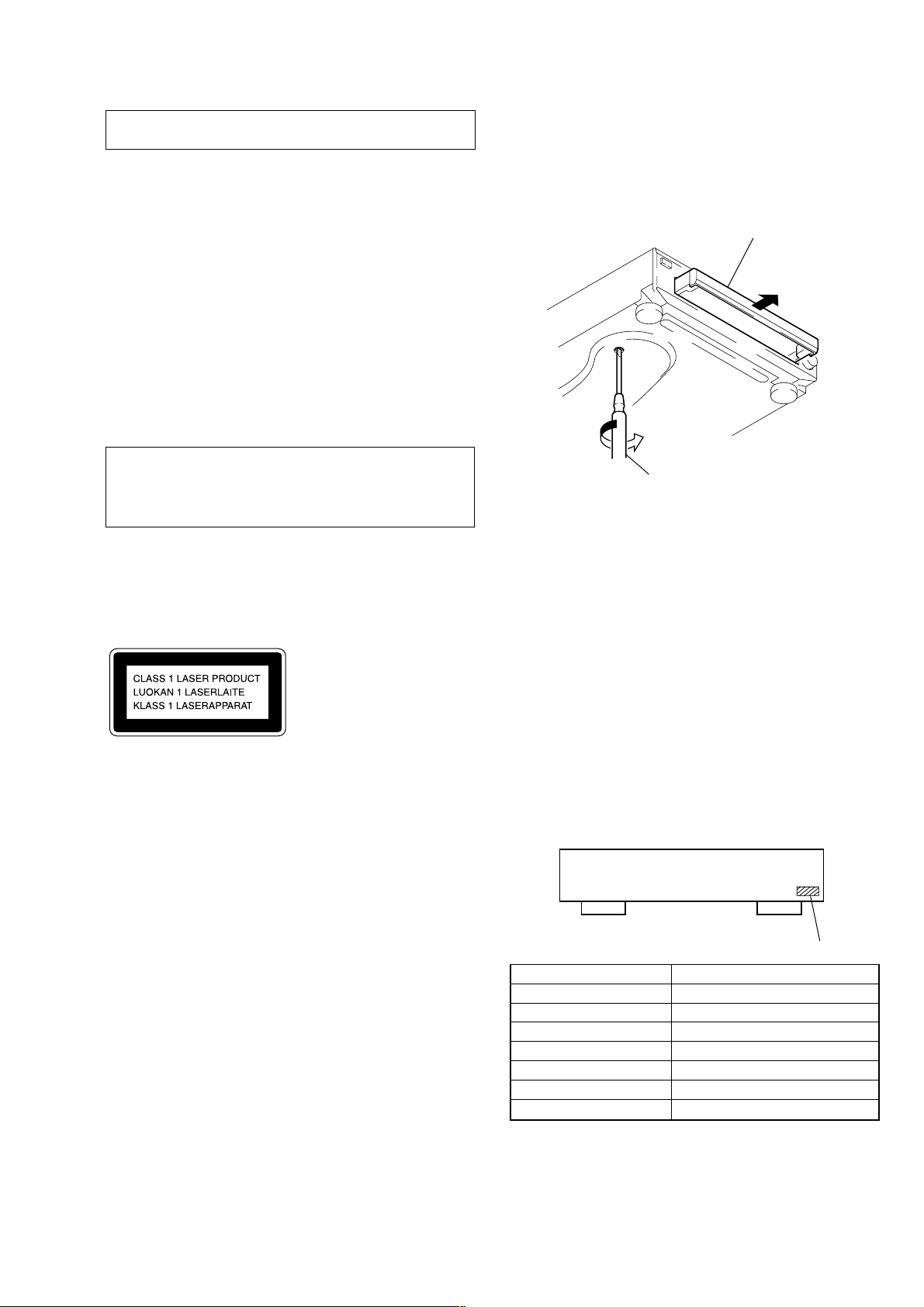

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

HOW T O OPEN THE DISC T ABLE WHEN PO WER

SWITCH TURNS OFF

Insert a tapering driver into the aperture of the unit bottom, and

turn it in the direction of the arrow (to OUT direction).

table

tapering driver

*To close the disc table, turn the tapering

driver in the reverse direction (to IN direction).

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

MODEL IDENTIFICATION

– BACK PANEL –

Part No.

Model Part No.

US model 4-224-879-0s

Canadian model 4-224-879-1s

AEP model 4-224-879-2s

Australian model 4-224-879-3s

E model 4-224-879-4s

Singapore model 4-224-879-5s

Saudi Arabia model 4-224-879-6s

3

SHIPMENT MODE

Performed when returning the unit to the customer.

Custom File Erases all custom files and initializes settings.

Procedure:

1. Remove the discs from all trays.

2. While pressing the DISK SKIP button and PROGRAM button, press the POWER button to turn ON the power.

3. “NO DISC” is displayed, indicating that the mode has ended.

Note:“NO DISC” may be displayed even if there are discs on the

trays.

CD-TEXT TEST DISC

This unit is able to display the TEXT data (character information) written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:4-989-366-01) is used for checking the display.

To check, perform the following procedure.

Checking Method:

1. Set the test disc on a free tray, and chuck the disc.

2. Press the B button and play back the disc.

3. The following will be displayed on the fluorescent indicator tube.

Display : 1kHz/0 dB/ L&R

4. Rotate l AMS L knob to switch the track. The text data of each track will be displayed.

For details of the displayed contents for each track, refer to “Table 1 : CD-TEXT TEST DISC TEXT Data Contents” and “Table 2 : CDTEXT TEST DISC Recorded Contents and Display”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling it. For

details, refer to “Table 2 : CD-TEXT DISC Recorded Contents and Display”.

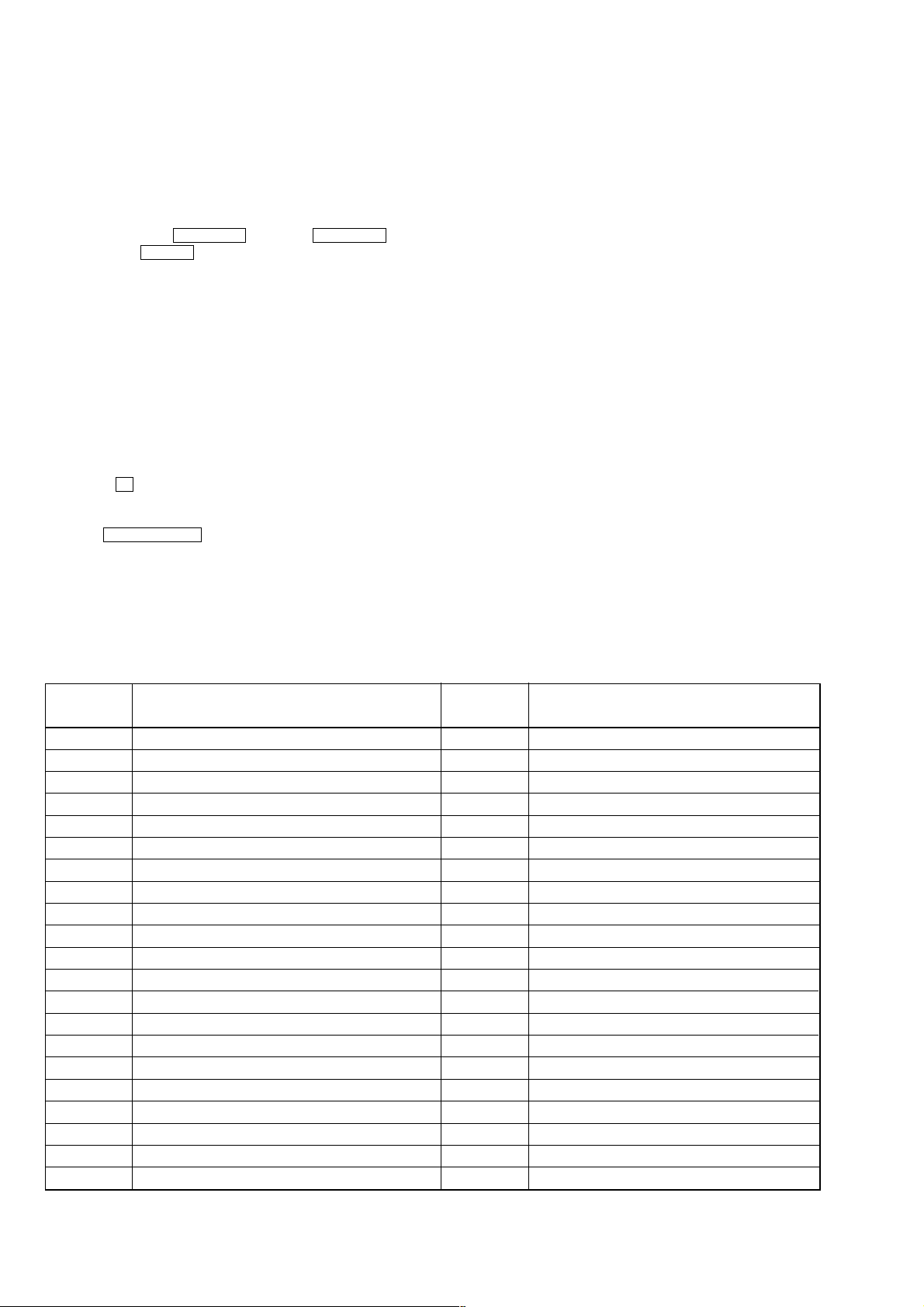

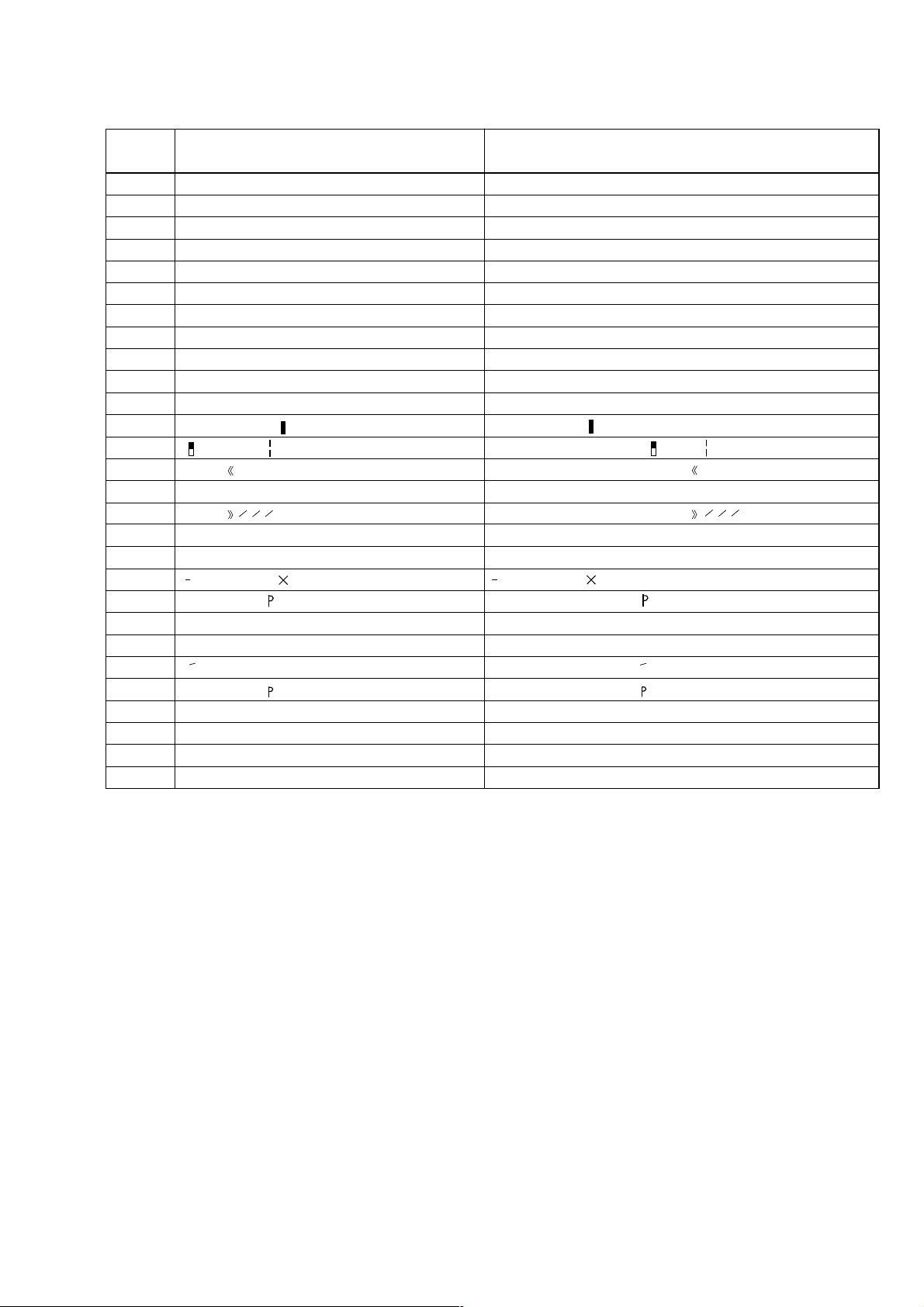

Table 1 : CD-TEXT TEST DISC TEXT Data Contents (TRACKS No. 1 to 41:Normal Characters)

TRACK

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Displayed Contents

1kHz/0dB/L&R

20Hz/0dB/L&R

40Hz/0dB/L&R

100Hz/0dB/L&R

200Hz/0dB/L&R

500Hz/0dB/L&R

1kHz/0dB/L&R

5kHz/0dB/L&R

7kHz/0dB/L&R

10kHz/0dB/L&R

16kHz/0dB/L&R

18kHz/0dB/L&R

20kHz/0dB/L&R

1kHz/0dB/L&R

1kHz/-1dB/L&R

1kHz/-3dB/L&R

1kHz/-6dB/L&R

1kHz/-10dB/L&R

1kHz/-20dB/L&R

1kHz/-60dB/L&R

1kHz/-80dB/L&R

TRACK

No.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Displayed Contents

1kHz/-90dB/L&R

Infinity Zero w/o emphasis//L&R

Infinity Zero with emphasis//L&R

400Hz+7kHz(4:1)/0dB/L&R

400Hz+7kHz(4:1)/-10dB/L&R

19kHz+20kHz(1:1)/0dB/L&R

19kHz+20kHz(1:1)/-10dB/L&R

100Hz/0dB/L*

1kHz/0dB/L*

10kHz/0dB/L*

20kHz/0dB/L*

100Hz/0dB/R*

1kHz/0dB/R*

10kHz/0dB/R*

20kHz/0dB/R*

100Hz Squer Wave//L&R

1kHz Squer Wave//L&R

1kHz w/emphasis/-0.37dB/L&R

5kHz w/emphasis/-4.53dB/L&R

16kHz w/emphasis/-9.04dB/L&R

Note : The contents of Track No. 1 to 41 are the same as those of the current TEST DISC-their titles are displayed.

4

Table 2: CD-TEXT TEST DISC Recorded Contents and Display

(In this unit, some special characters cannot be displayed. This is no a fault.)

TRACK

No.

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

to

99

Recorded contents Display

! ” # $ % & ´ (21h to 27h)1kHz 0dB L&R

( ) + , – . / (28h to 2Fh)

*

01234567 (30h to 37h)

8 9 : ; < = > ? (38h to 3Fh)

@A B CD E F G (40h to 47h)

H I J K L M NO (48h to 4Fh)

P QR S T U VW (50h to 57h)

X Y Z [ ¥ ] ^ _ (58h to 5Fh)

a b c d e f g (60h to 57h)

′

h i j k l m n o (68h to 6Fh)

p q r s t u v w (70h to 77h)

xyz{ I }

~

(78h to 7Fh)

i¢£¤¥ § (A0h to A7h) 8859-1

¬

9 C ª

•±23

1

º ¿ (B8h to BFh)

†

–

PR

µ ¶ • (B0h to B7h)

′

14123

(A8h to AFh)

4

АБВГДЕЖЗ (C0h to C7h)

ИЙКЛМНОП (C8h to CFh)

DСТУФХЦ

ШЩЪЫЬY

˙

(D0h to C7h)

Я (D8h to DFh)

абвгдежз (E0h to E7h)

ийклмноп (E8h to FFh)

∂ стуфхц÷ (F0h to F7h)

шщъыьy

ÿ (F8h to FFh)

´

No.66

No.67

to

No.99

T All the same

T All the same

T All the same

T All the same

T All the same

T All the same

T All the same

X Y Z [ \ ] ^ _ (58····

X a b c d e f g (60····

T All the same

T All the same

′

–

(78····

¢£¥ are not displayed

–

(A8···· 9 C ª¬PR are not displayed

•23

1

¿ (B8···· †

º are not displayed

xyz{I}

i ¤ § (A0····

±µ(B0····

а б в г Д ЕЖЗ (C0····

ийклмноп(C8····

DСтуфOЦ

Ш щ ъ ы ь Y ß (D8····

(D0····

is not displayed

T All the same

T All the same

ñòóôoö÷ (F0····∂ is not displayed

ø ù ú û ü y y (F8····

is not displayed

T All the same

T All the same

to

T All the same

¶• are not displayed

14123

4

5

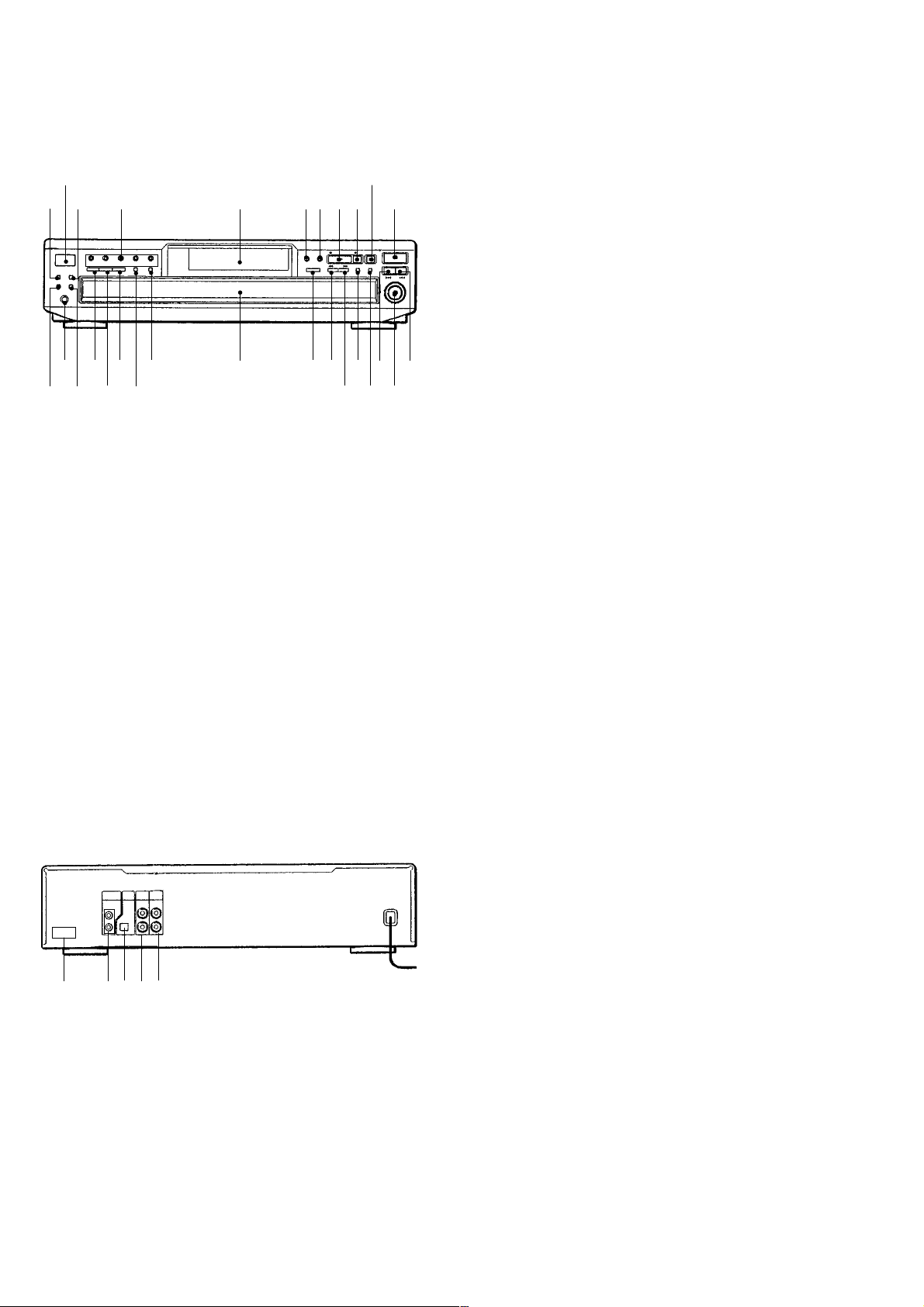

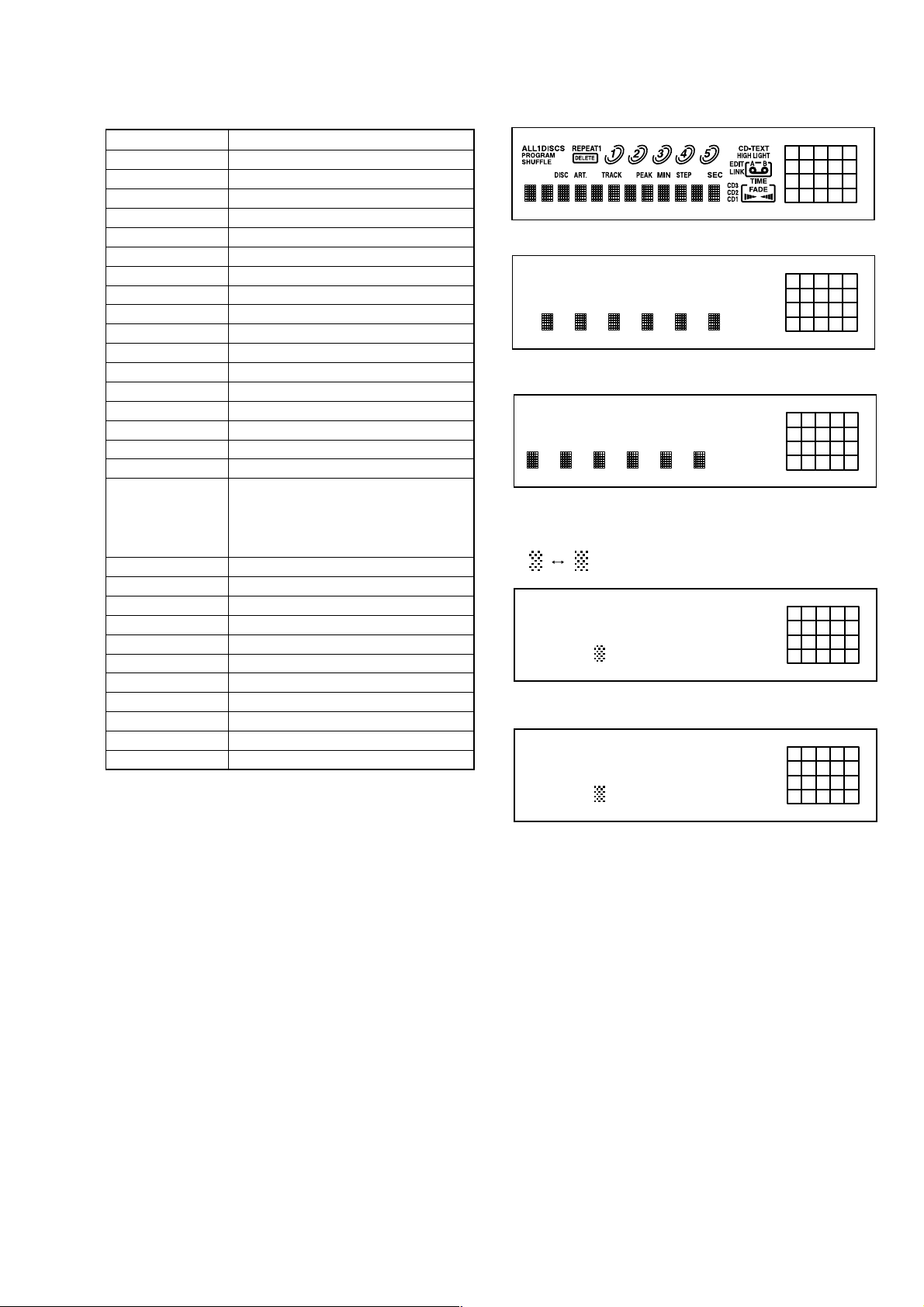

• LOCATION OF CONTROLS

SECTION 2

GENERAL

– Front panel –

2

3

wg

wf

4

ws

1

wk wh

1 EDIT/TIME FADE button

0

5

wawd

w;

6

89 qa7

qh

qk

qlwj

qj

qf qs

qg

qd

2 POWER button

3 PEAK SEARCH button

4 DISC1–DISC5 button

5 Fluorescent indicator tube display

6 NO DELAY button

7 X-FADE button

8 H button

9 X button

0 x button

qa A OPEN/CLOSE button

qs DISC SKIP button

qd l AMS L control

qf EX-CHANGE button

qg CLEAR button

qh CHECK button

qj M button

qk m button

ql MEGA CONTROL button

w; Disc table

wa TIME TEXT button

ws REPEAT button

wd PROGRAM button

wf SHUFFLE button

wg CONTINUE button

wh FADER button

wj PHONES jack

wk MENU button

– Rear panel –

1

342

6

1 Voltage selector switch (E and Saudi Arabia models only)

2 CONTROL A1I I jack

3 DIGITAL OUT OPTICAL connector

4 2ND CD jack

5 ANALOG OUT jack

5

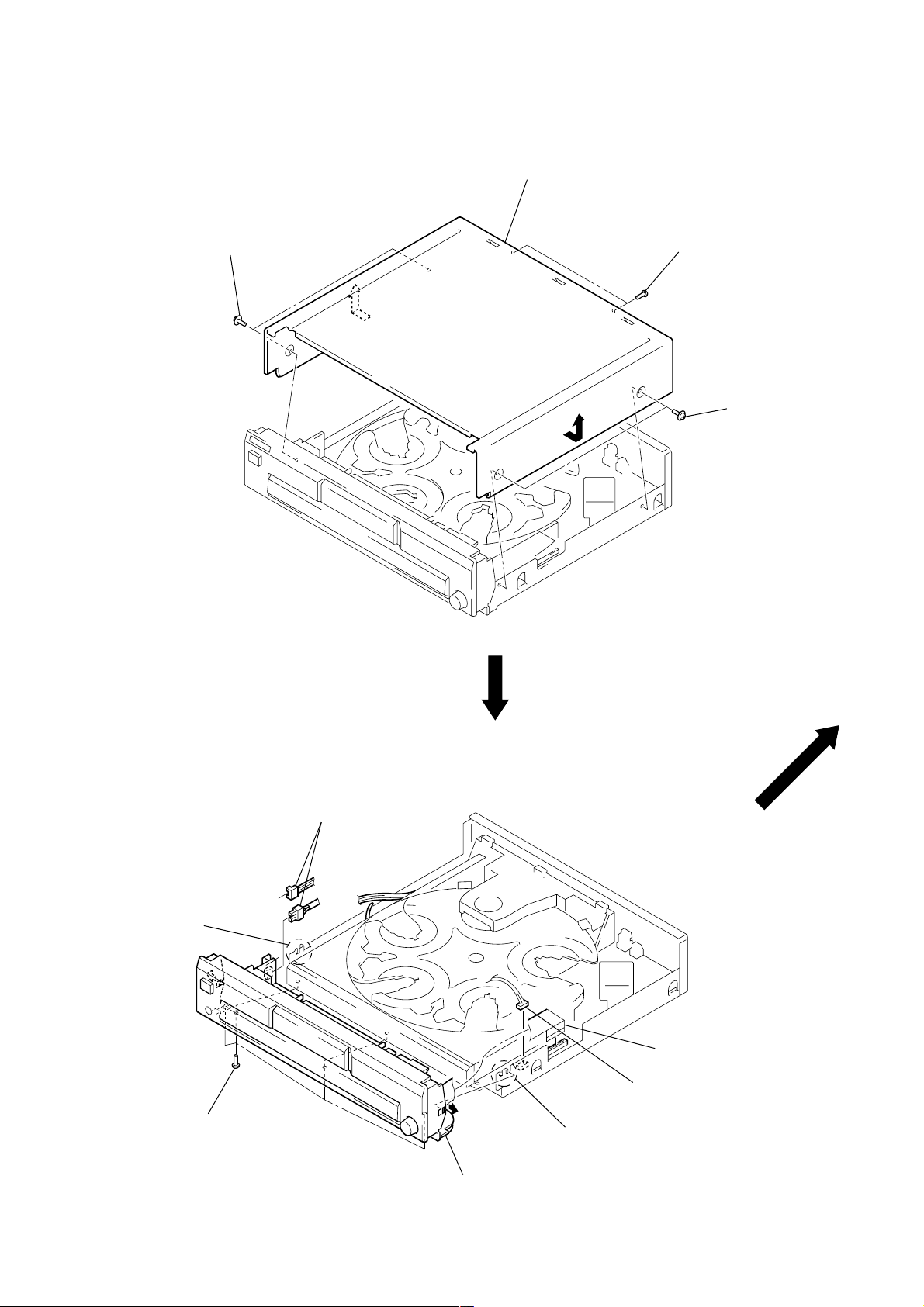

SECTION 3

)

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER (409537)

3 cover (409537)

1 two screws

(case3 TP2)

2 two screws

(BVTP3 × 8)

1 two screws

(case3 TP2

FRONT PANEL SECTION

4 claw

3 four screws

(BVTP3 × 8)

2 two connectors

(CN601, 602)

4 claw

5 front panel section

1 wire (flat type) (19 core

(CN301)

2 connectors

(CN351)

7

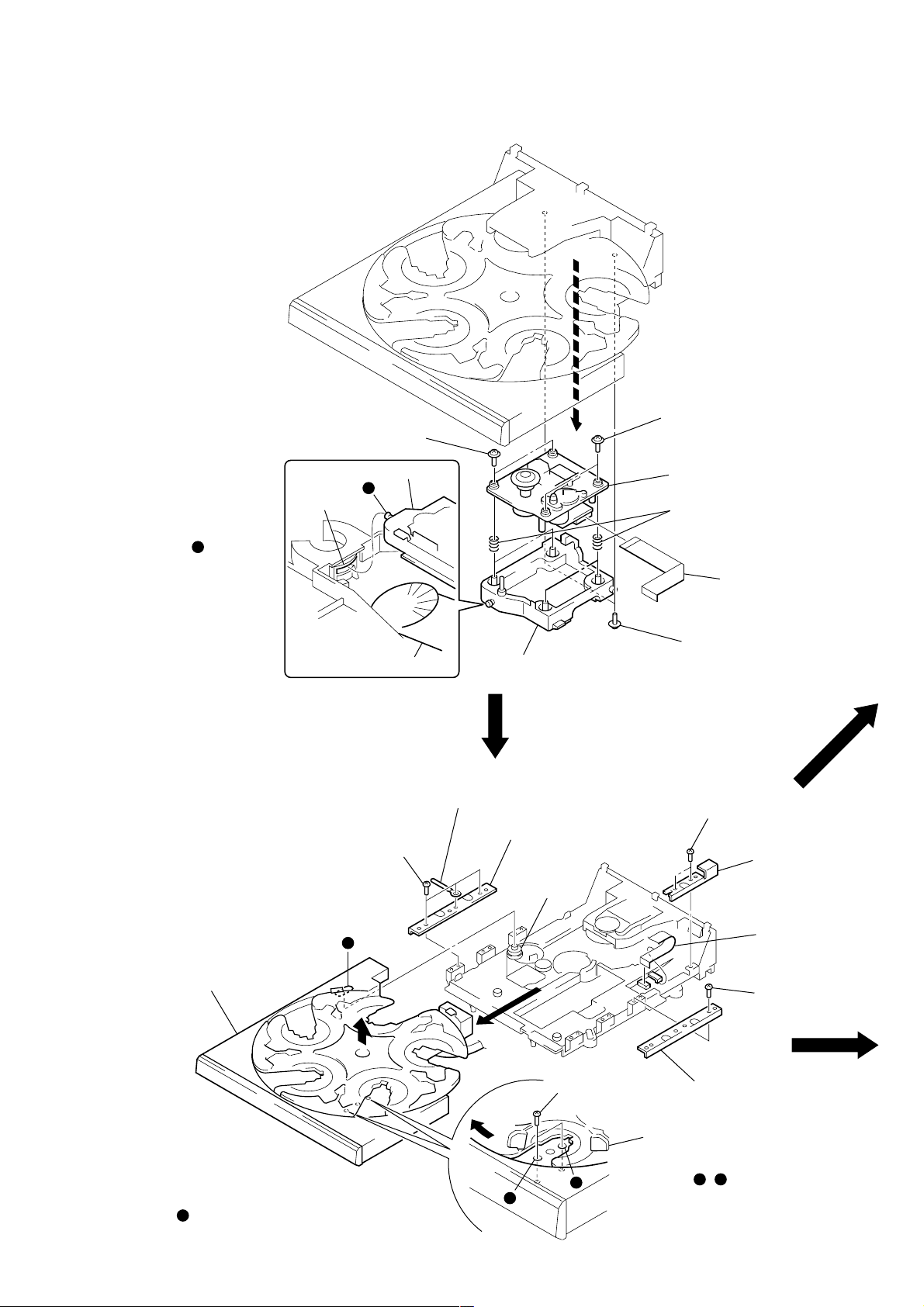

CD MECHANISM DECK (CDM59-5BD32A)

5 screw

(BVTP3 × 8)

4 Slide the tray until the screw

that fixes the table ass’y can be

seen through around hole

in the table ass’y.

3 three screws

a

a

(BVTP3 × 8)

9 CD mechanism deck

(CDM59-5BD32A)

2 three screws

(BVTP3 × 8)

6

7 wire (flat type) (21 core)

(CN302)

MAIN BOARD

5 MAIN board

8 connector

(CN311)

1 Insert a tapering driver from the bottom of the chassis,

and turn it in the direction of the arrow until the base unit

goes down to the lowest position.

3 two screws

(PTTWH3 × 6)

2 two screws

(BVTP3 × 8)

1 three screws

(BVTP3 × 8)

4 two PC board holders

8

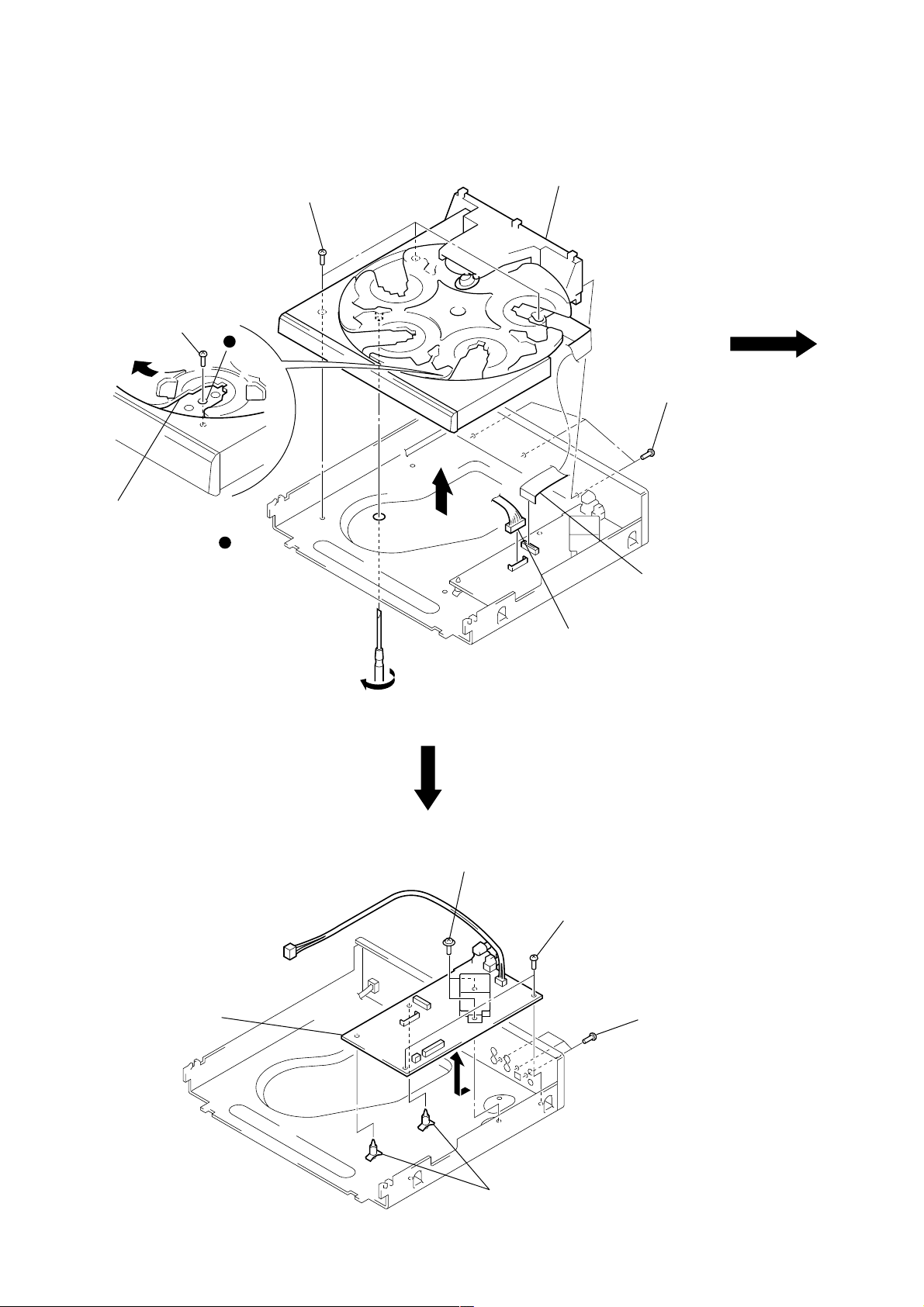

BASE UNIT (BU-5BD32A)

4 two screws

(PTPWH M2.6)

4 two screws

(PTPWH M2.6)

5 base unit (BU-5BD32A)

1 wire (flat type) (21 core)

(CN101)

6 four compression springs (932)

3

2 two screws

(PTPWH M2.6)

7 holder (BU) ass’y

lever (lifter)

BU section

Note: When installing the BU

on the chassis, set the

lever (lifter) in free

position, the gear (U/D)

in UP position, and insert

the shaft into the

groove of gear (U/D).

gear (U/D)

b

b

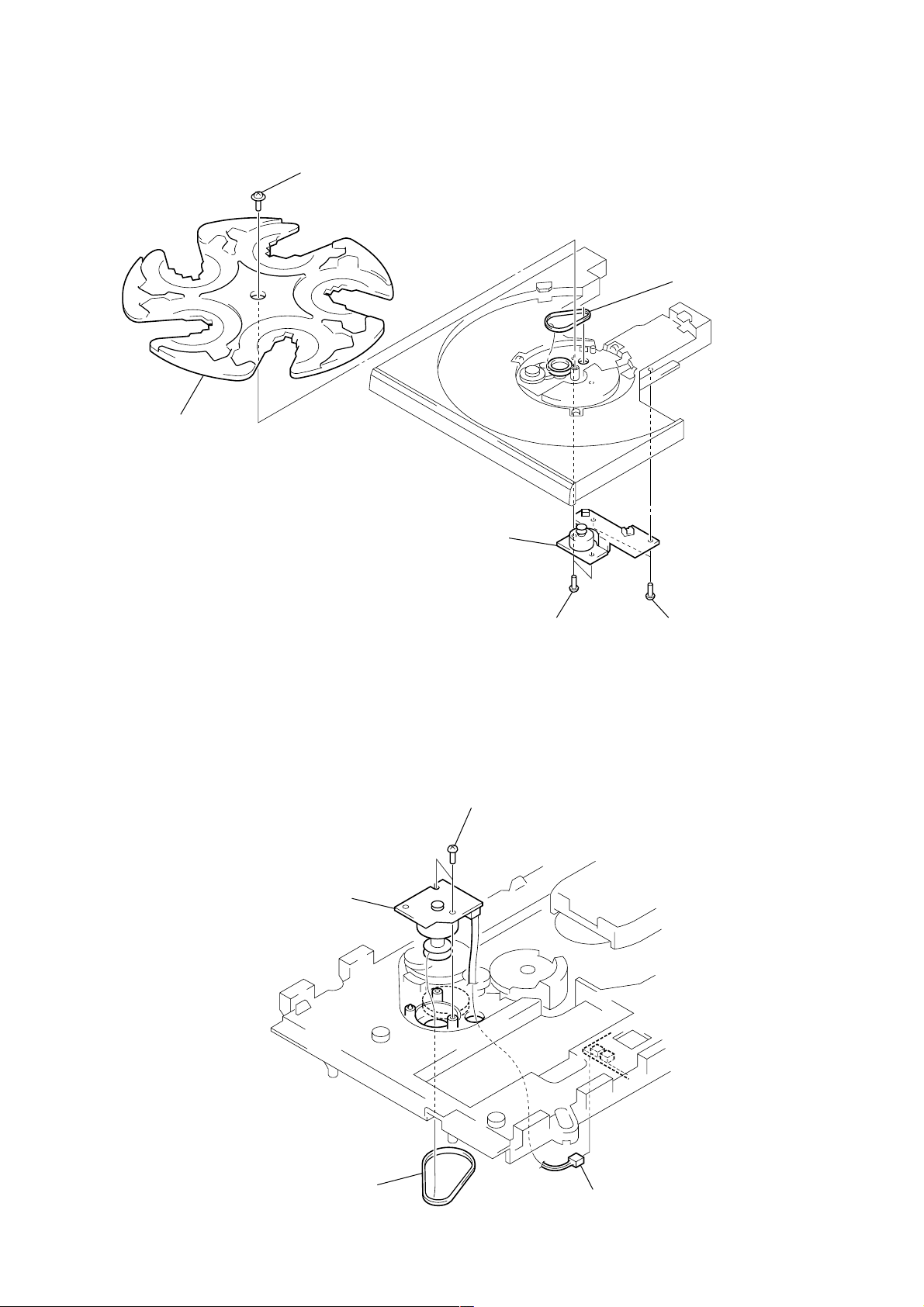

TABLE ASS’Y

Note: When installing the table ass’y

on the chassis ass’y, engage

the gear (loading C) with the groove

by looking into the gear through

a hole in the table ass’y.

qs table ass’y

e

9 three screws

(BTTP M2.6)

e

q; clamp

3

qa bracket (guide)

gear

(loading C)

2 two screws

(BTTP M2.6)

c

d

7 two screws

(BTTP M2.6)

6 bracket (guide)

1 Slide the tray until the screw

that fixes the bracket (guide)

can be seen through a round

c

hole , in the table ass’y.

d

8 bracket (guide 2)

4 wire (flat type)

(6 core) (CN15)

5 screw

(BTTP M2.6)

9

TRAY, BELT (ROTARY), SENSOR BOARD

)

1 screw

(PTPWH M2.6)

2 tray

3 belt (rotary)

5 SENSOR board

BELT (LOADING ), LOADING MOTOR BOARD

4 LOADING MOTOR board

4 two screws

(BTTP M2.6)

3 two screws

(BTTP M2.6)

4 two screws

(BTTP M2.6

10

1 belt (loading)

2 connector

(CN13)

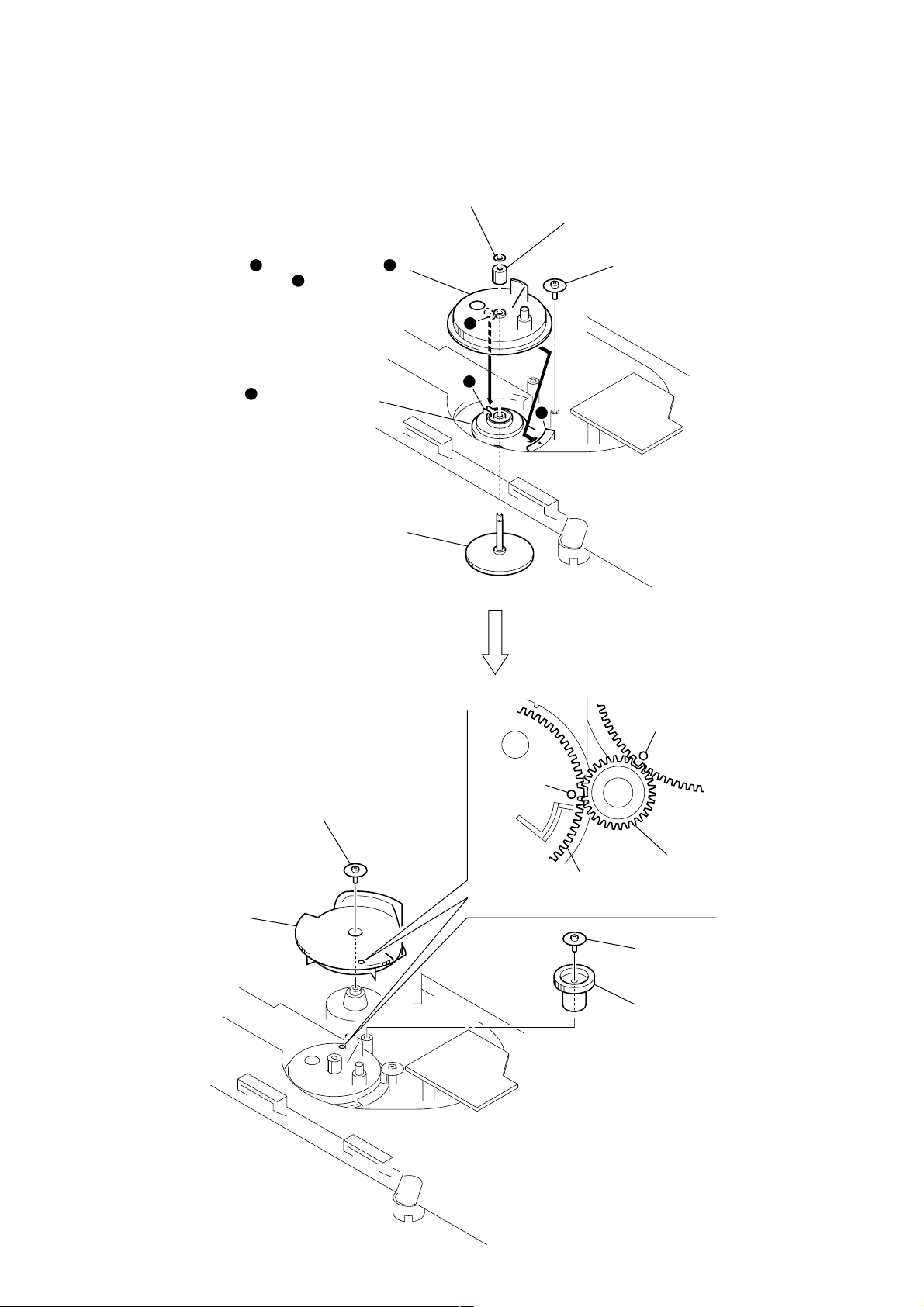

ADJUSTING PHASE OF SWING GEAR AND GEAR (U/D)

7 gear (U/D)

8 screw

(PTPWH M2.6)

q; screw

(PTPWH M2.6)

circle mark

circle mark

swing gear

gear (RV)

Fig. A

9 gear (RV)

Note: Align swing gear, a circle mark

on the gear (U/D), and the teeth

of gear (RV) to the position

showing in the Fig. A.

Note: Follow the assembly procedure in the numerical order given.

5 stopper washer (FR)

3 Let the swing gear through under the

chassis and engage its dowel

with the groove of rotary encoder.

h

f

g

g

4 Push fully the shaft of shaft gear and

align the hole shape of gear (loading B).

6 screw

(PTPWH M2.6)

2 Install the rotary encoder so that

its groove comes to the position

shown in the figure.

f

1 Insert the shaft gear up to the

position where its shaft comes

out by 5 mm.

f

h

11

SECTION 4

r

TEST MODE

ADJ MODE

NOTE:This mode cannot be performed without a general remote com-

mander.

1. Chuck the CD first, and then turn OFF the power.

2. Short-circuit the test point TP1 (ADJ) of the MAIN boar d and

ground with a lead wire.

3. Press the

The CD is playback automatically and the ADJ mode is set.

4. To exit the mode, press the

power.

• Prohibits high speed search during accessing

• Ignores even if GFS becomes “L”

ADJ Mode Special Function Table

PROGRAM

CONTINUE

SHUFFLE

FADER RFCK → GFS → Error rate display

[POWER] button to turn ON the power.

[POWER] button to turn OFF the

Button Function

Auto gain display

(Focus, Tracking and Sledding)

Servo average display 1

(VC, FE and RF)

Servo average display 2

(TE and Traverse)

FLUORESCENT INDICATOR TUBE, LED ALL LIT,

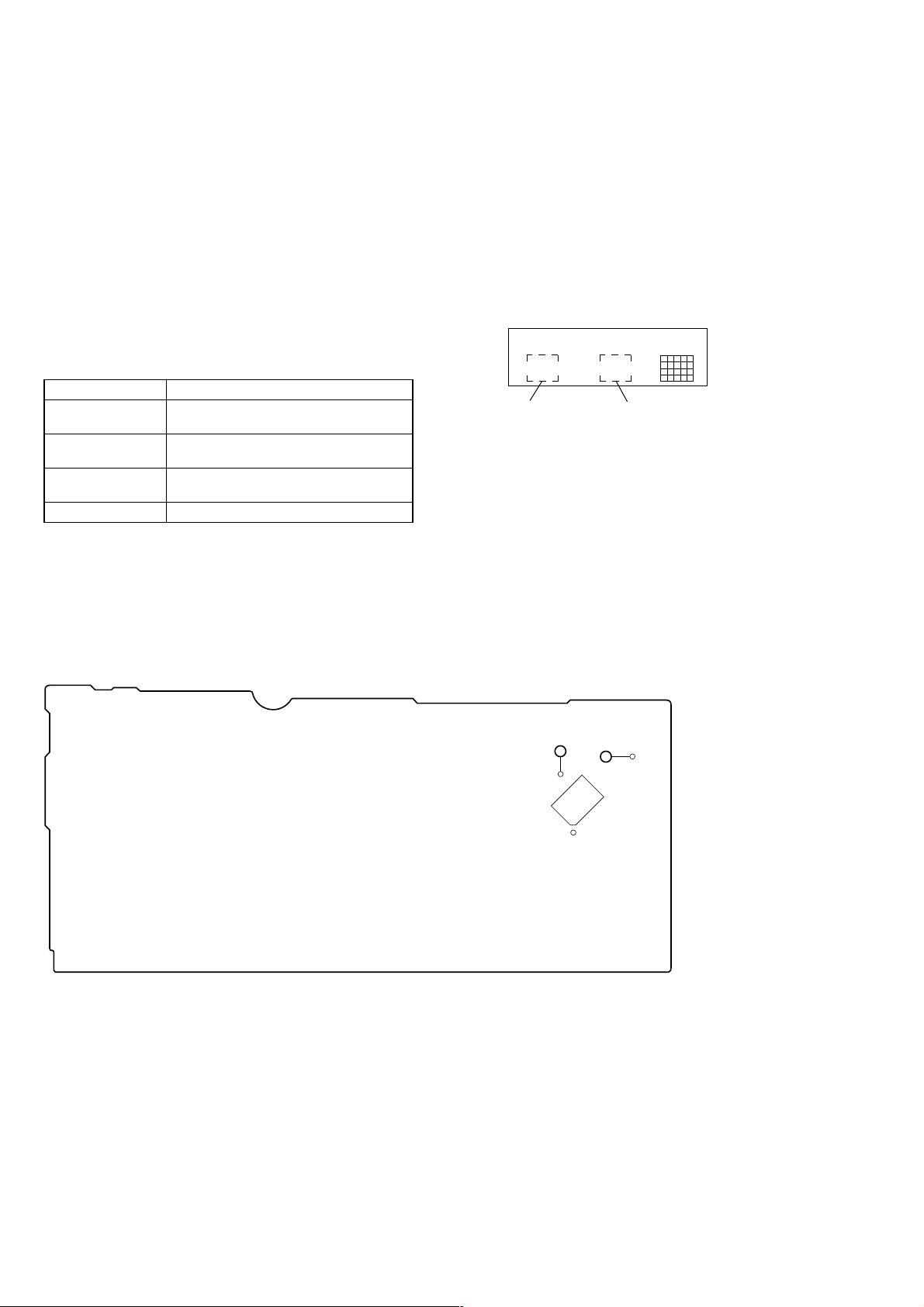

AND KEY CHECK MODE

1. Short-circuit the test TP2 (AFADJ) of the MAIN board and

ground with a lead wire.

2. Press the

The whole fluorescent indicator tube lights up.

Nothing will be displayed when the S-RAM (IC302) is faulty

or improperly soldered.

3. All buttons have individual button numbers.

When a button is pressed, the button number is counted up

and displayed.

[POWER] button to turn ON the power.

10

Count up display Displays button numbe

When remote controller signals are received, “RM **” will be

displayed.

(** are the numbers corresponding to the remote controller

buttons.)

When using the remote controller, switch the

to CD1.

4. To exit the mode, press the [POWER] button to turn OFF the

power.

[CD1/2/3] switch

Checking Location:

– MAIN BOARD (Conductor Side) –

TP1

(ADJ)

JW28

IC301

(GND)

TP2

(AFADJ)

JW26

12

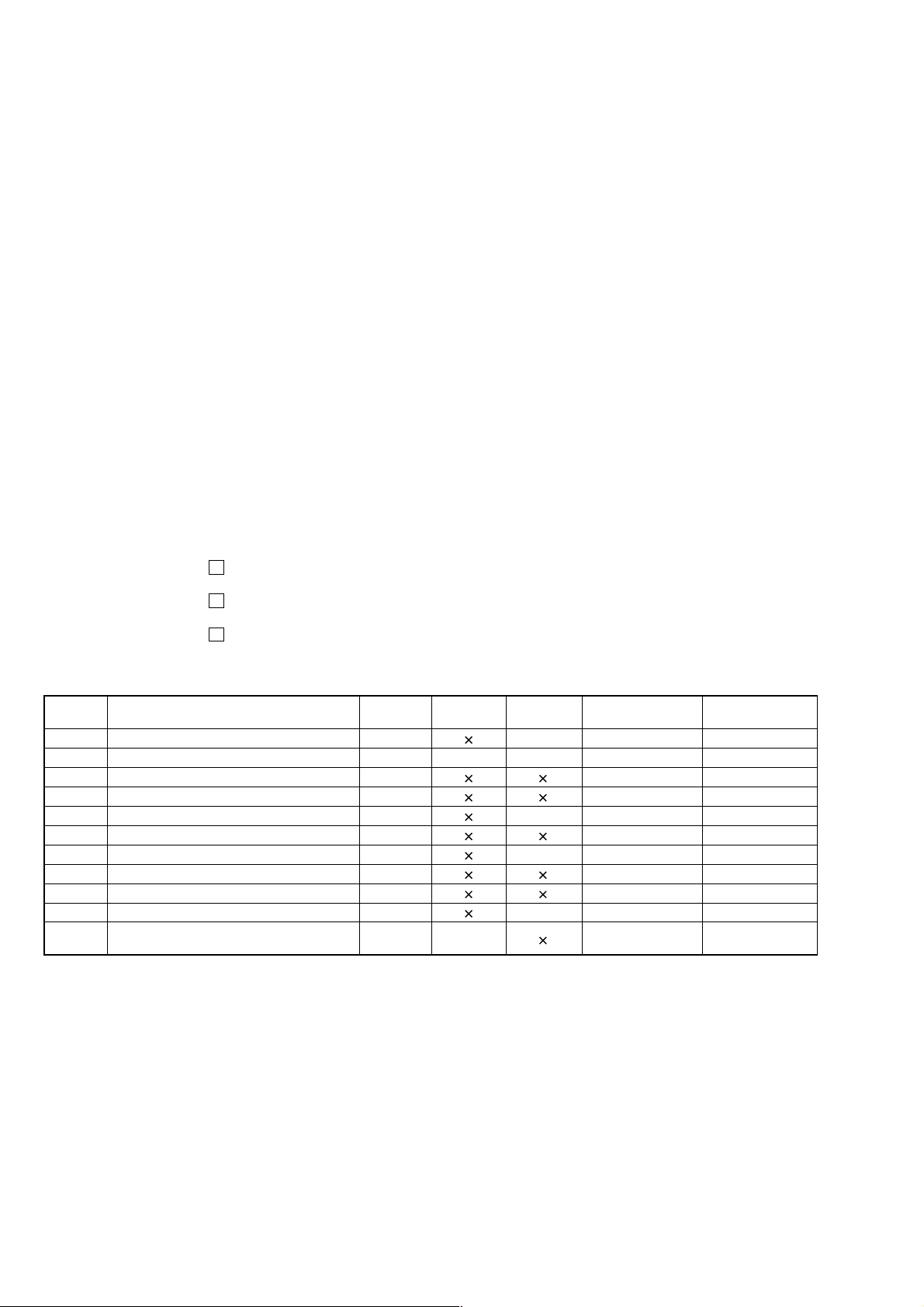

Buttons and Corresponding Button Numbers

12345

678910

11 12 13 14 15

16 17 18 19 20

All lit

Partial lighting 1

Button Button Number or Display

CONTINUE 2

SHUFFLE 1

PROGRAM 0

REPEAT 9

MENU 5

DISC1 14

DISC2 13

DISC3 12

DISC4 11

DISC5 10

H (PLAY) Partial lighting 1 (Grid check)

X (PAUSE) 26

x (STOP) Partial lighting 2 (Segment check)

EX-CHANGE 17

DISC SKIP 16

A OPEN/CLOSE All lit (LED lighting)

AMS (button) 30

When rotated clockwise: The music calendar

AMS (knob)

MEGA CONTROL 22

X-FADE 28

NO DELAY 29

CLEAR 18

CHECK 19

M 20

m 21

PEAK SEARCH 3

EDIT/TIME FADE 4

TIME/TEXT 8

FADER 6

numerals light up in ascending order.

When rotated counterclockwise: The music

calendar numerals light up in descending

order.

Partial lighting 2

Light altemately

R

Light altemately

r

R

Light altemately

r

13

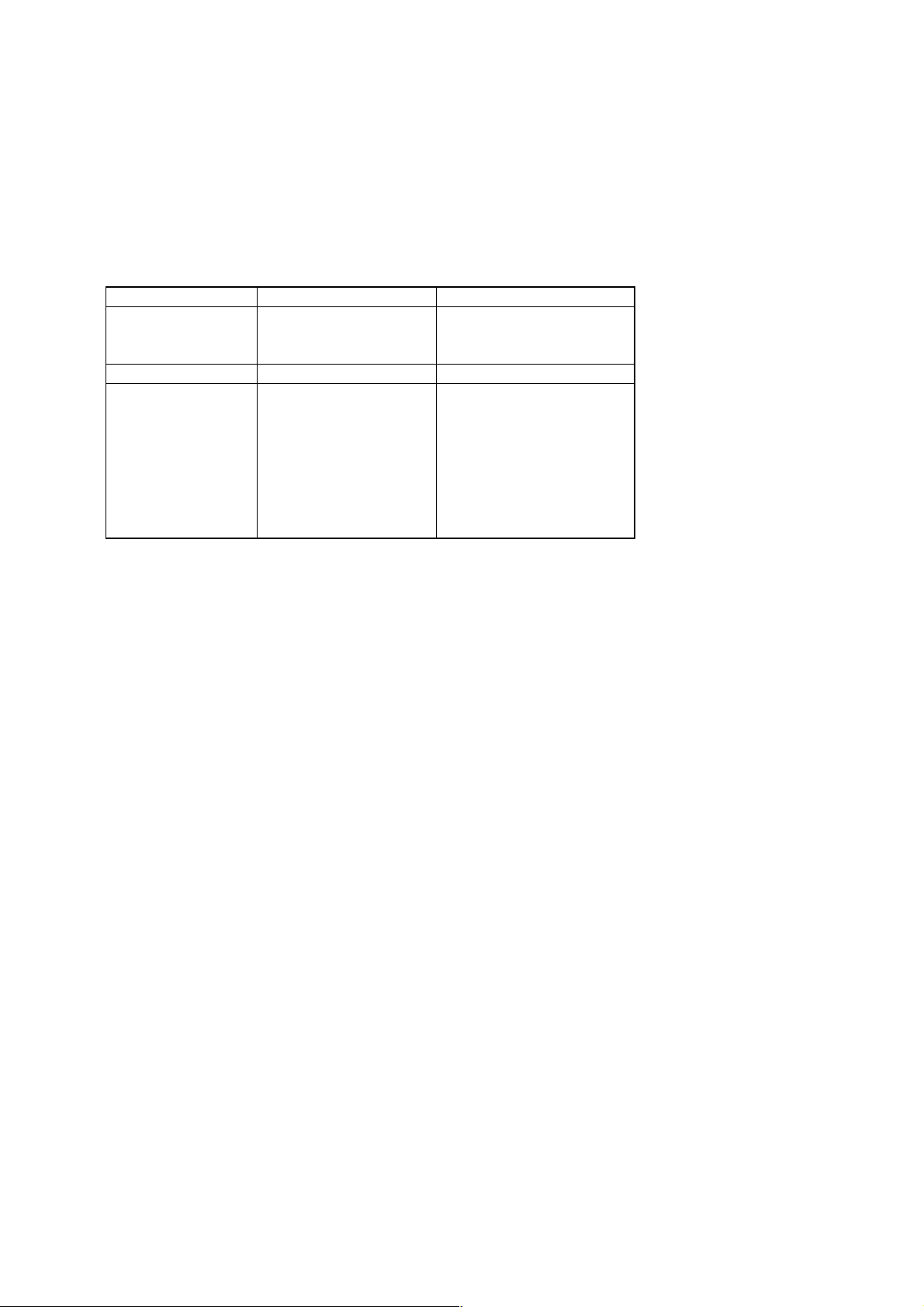

AGING MODE

For the aging mode, three modes of all mode, disc table mode, and loading mode are available.

This set has the Aging mode for operation check of the mechanism deck.

• If a failure occurred

The aging operation stops and a faulty status is displayed on the fluorescent indicator tube.

• If no failure occurs

The aging operation continues repeatedly.

Note: Do not use the test disc when performing aging.

Aging will not be performed properly if discs with tracks shorter than 4 seconds are used.

Aging method 1

(When using the aging remote controller (J-2501-123-A):

1. Set the remote controller [CD1/2/3] switch to CD1.

2. Press the [POWER] button and turn ON the power.

3. Set discs on all trays.

(More than two discs if five are not available.)

4. Press the [AGING START] button of the aging remote controller.

5. Aging starts and the fluorescent indicator tube will display the following.

6. To exit the mode, press the [POWER] button to turn OFF the power.

Aging method 2

(When no aging remote controller):

1. Press the [POWER] button and turn ON the power.

2. Set discs on all trays.

(More than two discs if five are not available.)

3. All mode:

Press the [CONTINUE], x and [CHECK] buttons at the same time.

Disc table mode:

Press the [CONTINUE], x and [DISC SKIP] buttons at the same time.

Loading mode:

Press the [CONTINUE], x and [EX-CHANGE] buttons at the same time.

4. Aging starts, and the fluorescent indicator tube will display the following.

5. To exit the mode, press the

[POWER] button to turn OFF the power.

Code No. Status All mode

0 CLOSE (Tray closed) a a A-0 NG 0

1 TOC reading aa a A-1 NG 1

2 Access to last track a A-2 NG 2

3 Play of last track (3 sec) a Counter display NG 3

4 EX OPEN (Tray opened while chucking) a a A-4 NG 4

5 EX SKIP (Disc tray rotated) a A-5 NG 5

6 EX CLOSE (Tray closed) a a A-6 NG 6

7 Access to first track a A-7 NG 7

8 Play of first track (3 sec) a Counter display NG 8

9 OPEN (tray opened) a a A-9 NG 9

DISC SKIP (Disc tray rotated,

A

and next disc was selected)

aa A-A NG A

Disc table Loading Display in Display in

mode mode Normal operation case of failure

The discs are selected in the order of DISC 1 → DISC 2 → DISC 3 → DISC 4 → DISC 5 → DISC 1....Empty trays are skipped.

14

MECHANISM DECK CHECK MODE

For the mechanism deck check mode, two modes of disc table mode and loading mode are available.

In the mechanism deck check mode, the disc table turning time and the loading time in each section are measured and displayed.

1. Disc table mode:

Press the [POWER] switch while pressing [CHECK], [ OPEN/CLOSE] and [REPEAT] buttons simultaneously.

Loading mode:

Press the

Display contents

(

time measurement

[POWER] switch while pressing [CHECK], [ OPEN/CLOSE] and [TIME] buttons simultaneously.

Mode Check command Display

Disc table mode 0: Right one turn R 12.5 L ––.–

Table turning 1: Left one Turn R 12.5 L 10.2

Table mode

Loading time

(

measuremnet

)

2: Measurement end R12.5 L 10.2

3: Undefined

4: Star position START ––.–

5: Open → Close CLOSE 10.2

6: Close → BU up BU UP 0.7

7: BU up → EX open EX OPEN 6.2

)

8: EX open → EX close EX CLOSE 10.3

9: EX close → BU down BU DOWN 1.2

A: BU down → Open OPEN 9.3

FF: Measurement end CLOSE 10.2

A

A

15

Loading...

Loading...