Sony CDP-CE275, CDP-CE375 Service manual

CDP-CE275/CE375

SERVICE MANUAL

Ver 1.0 2001.04

Photo: CDP-CE375

US Model

Canadian Model

CDP-CE275/CE375

AEP Model

UK Model

E Model

CDP-CE375

Australian Model

CDP-CE275/CE375

Model Name Using Similar Mechanism CDP-CE345

CD Mechanism Type CDM59-5BD27

Base Unit Name BU-5BD27

Optical Pick-up Name PXR-104X

Compact disc player

Laser Semiconductor laser ( λ = 780 nm)

Emission duration : continuous

Frequency response 2 Hz to 20 kHz ± 0.5 dB

Dynamic range More than 93 dB

Harmonic distortion Less than 0.0045%

Outputs

Jack Maximum Load

type output level impedance

ANALOG Phono 2 V Over 10

OUT jacks (at 50 kilohms) kilohms

DIGITAL Optical –18 dBm Wave

OUT output length:

(OPTICAL) connector 660 nm

PHONES Stereo 10 mW 32 ohms

(CDP-CE375 phone

only) jack

SPECIFICATIONS

General

Power requirements 120 V AC, 60 Hz

Power consumption 11 W

Dimensions (approx.) 430 x 110 x 400 mm

(w/h/d) (17 x 4 3/8 x 15 3/4 in.)

incl. projecting parts

Mass (approx.) 5 kg (11 lbs 1 oz)

Supplied accessories

Audio cord (2 phono plugs – 2 phono plugs) (1)

Remote commander (remote) (1) (CDP-CE375 only)

R6 (size AA) batteries (2) (CDP-CE375 only)

Design and specifications are subject to change without notice.

9-873-822-11

2001D0900-1

© 2001. 4

COMPACT DISC PLAYER

Sony Corporation

Audio Entertainment Group

General Engineering Dept.

CDP-CE275/CE375

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY ......................................................... 5

4. DIAGRAMS

4-1. Note for Printed Wiring Boards

and Schematic Diagrams ................................................ 11

4-2. Printed Wiring Board – BD Board – ............................. 12

4-3. Schematic Diagram – BD Board – ................................ 13

4-4. Printed Wiring Boards – JUNCTION/SENSOR/

LOADING MOTOR Boards –........................................ 14

4-5. Schematic Diagram – JUNCTION/SENSOR/

LOADING MOTOR Boards –........................................ 15

4-6. Printed Wiring Board – MAIN Board – ........................ 16

4-7. Schematic Diagram – MAIN Board –........................... 17

4-8. Printed Wiring Boards – PANEL Section – .................. 18

4-9. Schematic Diagram – PANEL Section –....................... 19

4-10. IC Pin Function Description ........................................... 22

5. EXPLODED VIEWS ................................................ 26

6. ELECTRICAL PARTS LIST ............................... 31

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

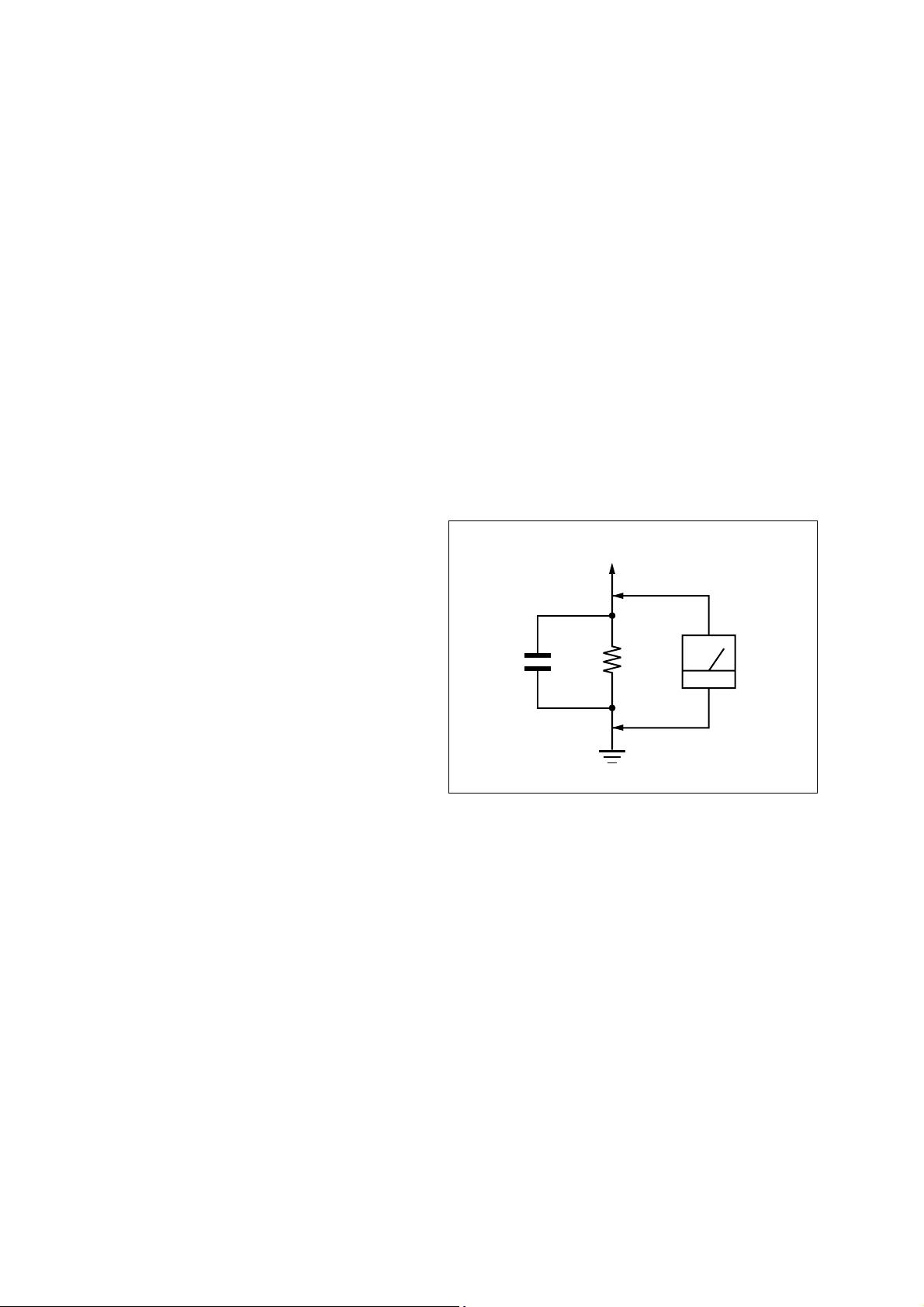

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the man ufacturers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are e xamples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

voltmeter

(0.75 V)

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMA TIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

2

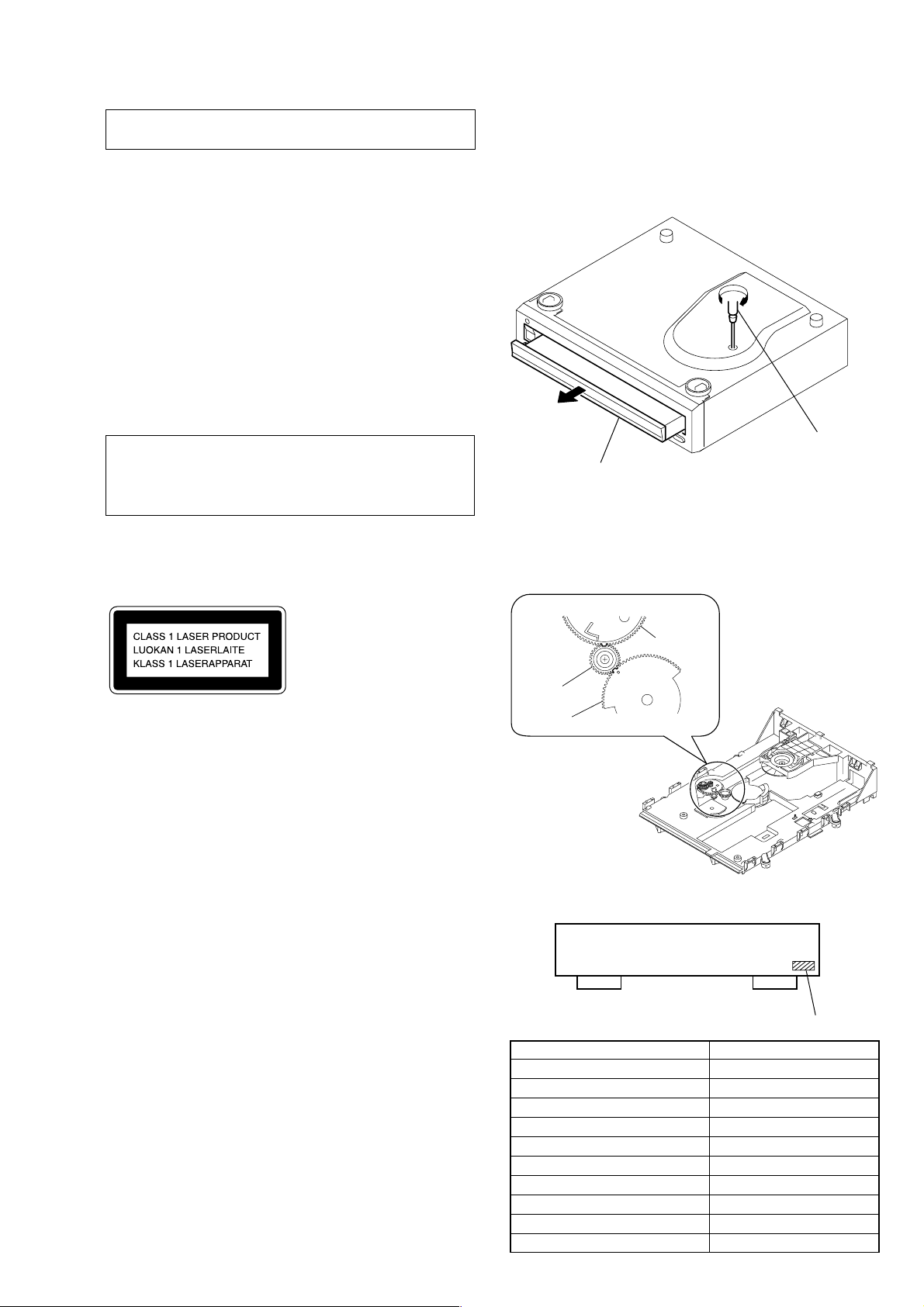

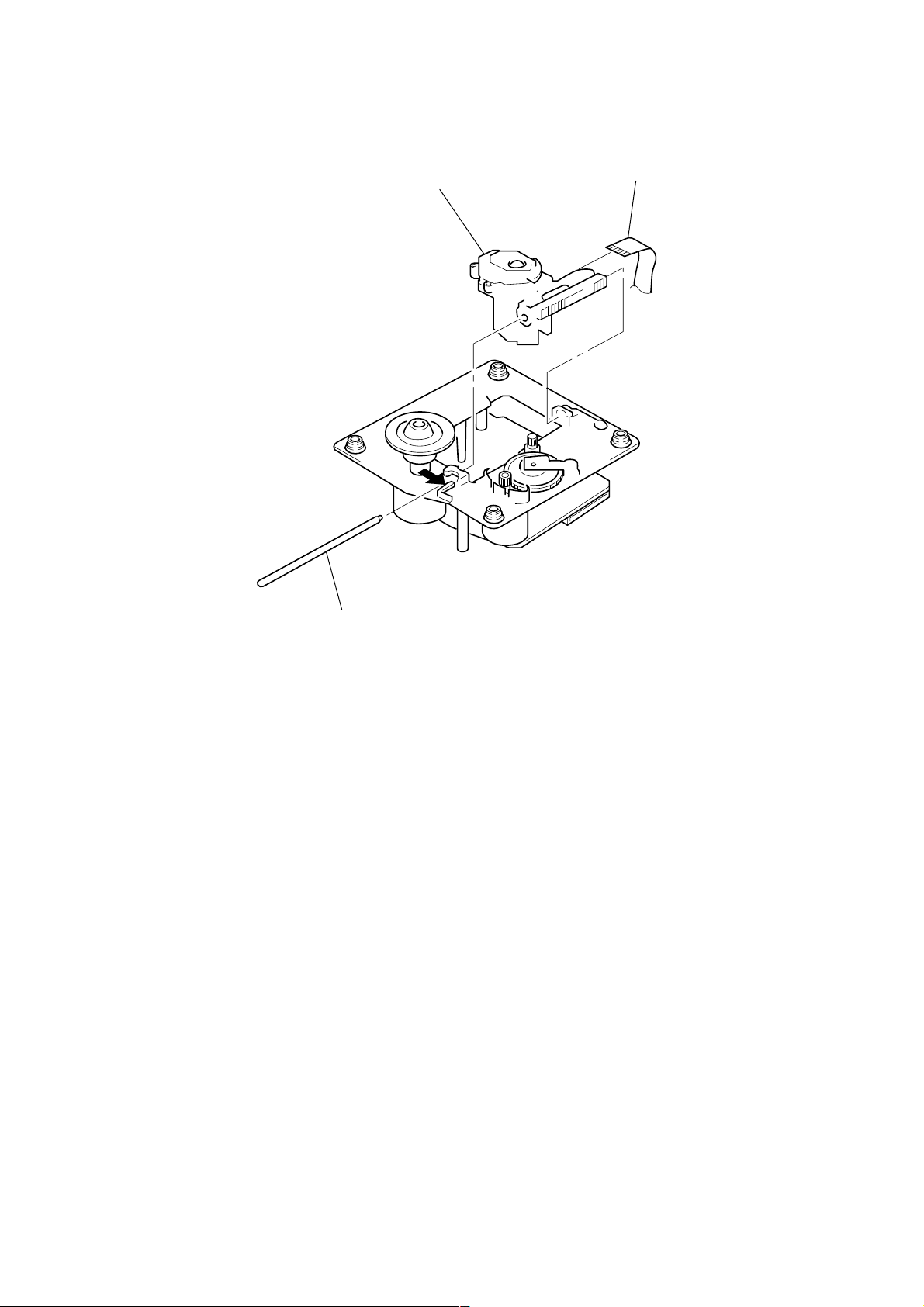

SECTION 1

table

tapering driver

*To close the disc table, turn the tapering

driver in the reverse direction (to IN direction).

gear (U/D)

gear (RV)

gear, swing

SERVICING NOTES

CDP-CE275/CE375

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

HOW T O OPEN THE DISC T ABLE WHEN PO WER

SWITCH TURNS OFF

Insert a tapering driver into the aperture of the unit bottom, and

turn it in the direction of the arrow (to OUT direction).

NOTE FOR MAIN GEAR INSTALLATION

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

MODEL IDENTIFICATION

– BACK PANEL –

Part No.

Model Part No.

CDP-CE275: US model 4-233-719-0s

CDP-CE275: Canadian model 4-233-719-1s

CDP-CE275: Australian model 4-233-719-2s

CDP-CE375: US model 4-233-718-0s

CDP-CE375: Canadian model 4-233-718-1s

CDP-CE375: AEP model 4-233-718-2s

CDP-CE375: UK model 4-233-718-3s

CDP-CE375: Australian model 4-233-718-4s

CDP-CE375: E model 4-233-718-5s

CDP-CE375: Singapore model 4-233-718-6s

3

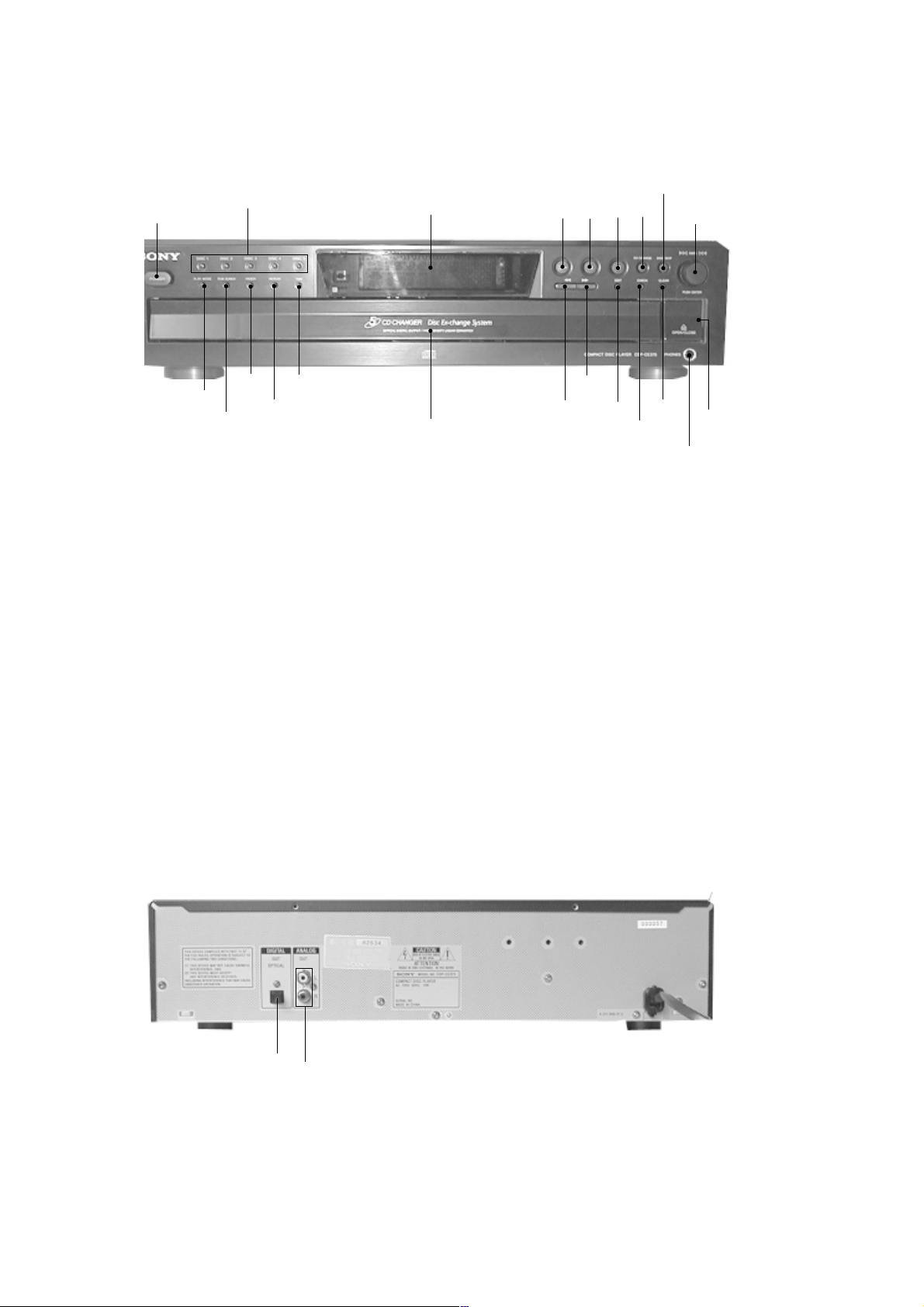

CDP-CE275/CE375

• LOCATION OF CONTROLS

– Front panel –

SECTION 2

GENERAL

1

2

w;

ws

wa

1 POWER button

2 DISC1 – DISC5 button

3 Fluorescent indicator tube display

4 H button

5 X button

6 x button

7 EX-CHANGE button

8 DISC SKIP button

9 l AMS L control

0 A OPEN/CLOSE button

qa PHONES jack

ql

qk

3

qj

qs CLEAR button

qd CHECK button

qf EDIT button

qg M button

qh m button

qj Disc table

qk TIME button

ql REPEAT button

w; FADER button

wa PEAK SEARCH button

ws PLAY MODE button

4

qh

5

qg

6

qf

7

qd

8

qs

9

0

qa

– Rear panel –

1

1 DIGITAL OUT OPTICAL connector

2 ANALOG OUT

4

2

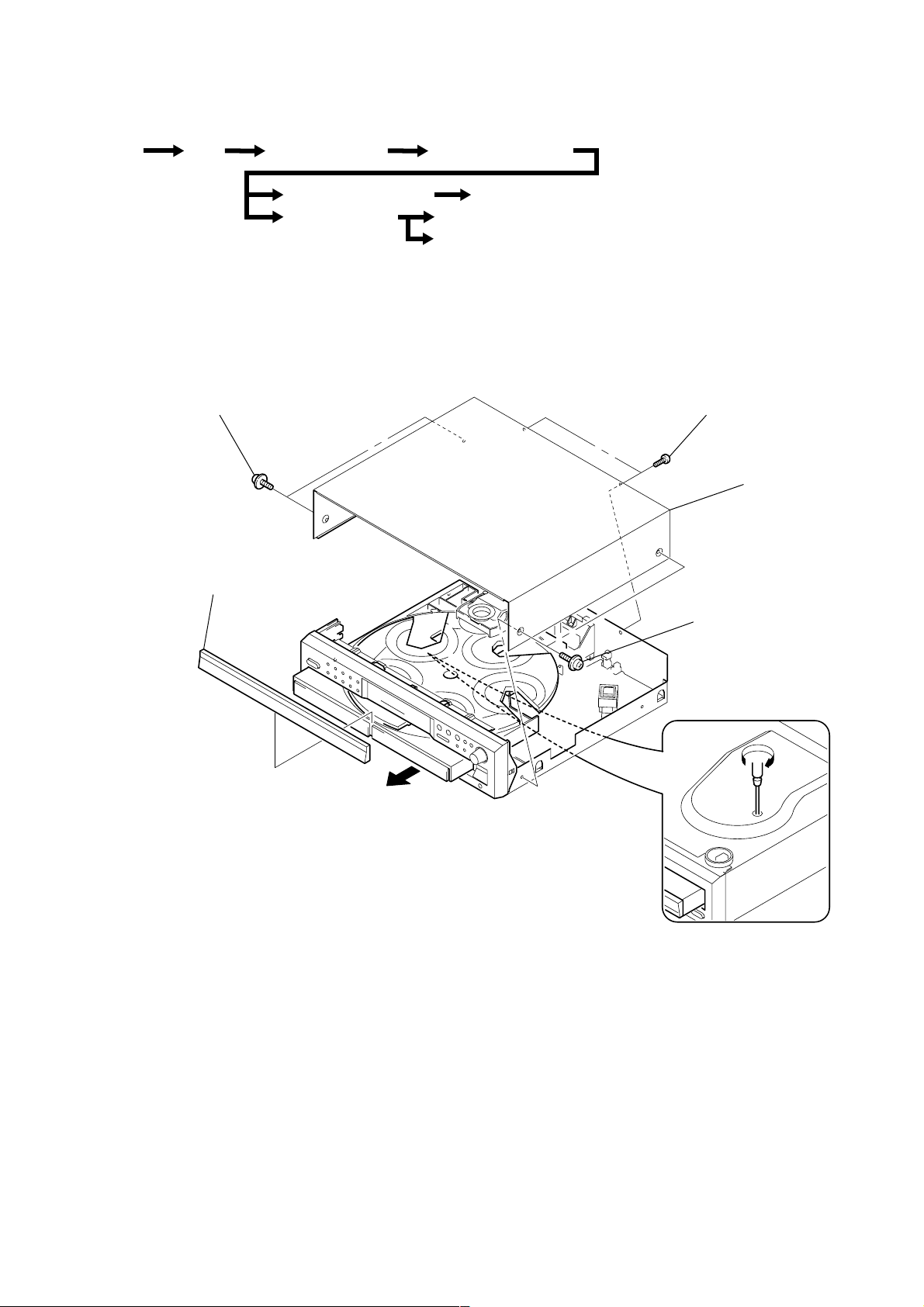

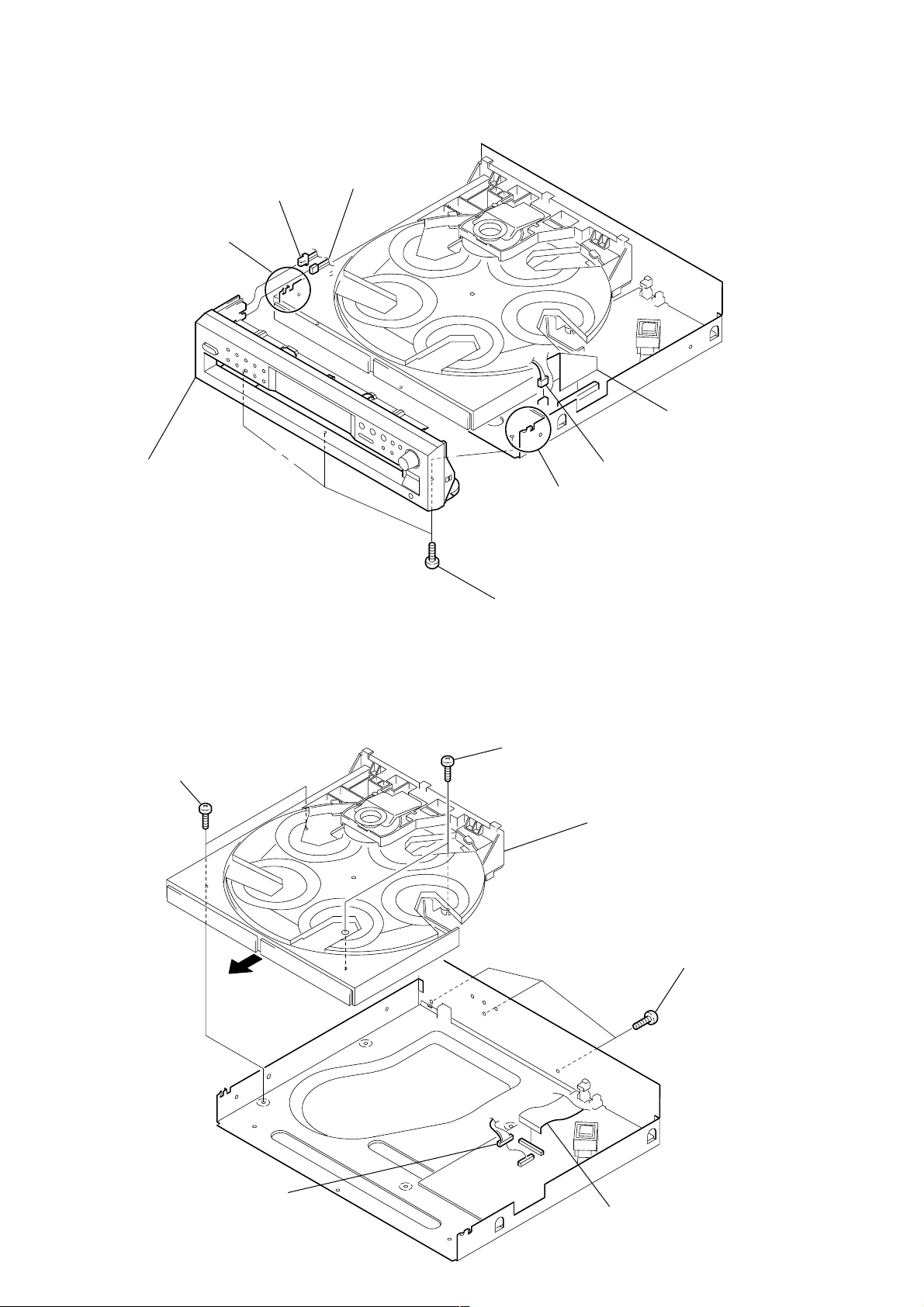

• The equipment can be removed using the following procedure.

CDP-CE275/CE375

SECTION 3

DISASSEMBLY

Set Case Front Panel Assy

Base Unit (BU-5BD27) Optical Pick-up

Tray, Table Assy

Note: Follow the disassembly procedure in the numerical order given.

CD Mechanism Block

Sensor Board

Jnuction Board, Loading Motor Board

3-1. CASE

two screws

2

(case 3TP2)

7

panel, loading

3

two screws

(BVTP 3x8)

4

case

6

1

two screws

(case 3TP2)

5

5

CDP-CE275/CE375

3-2. FRONT PANEL ASSY

7 claw

8 front panel assy

1 CN601

2 CN602

3 CN301

4 CN351

6 claw

5 three screws

(BVTP 3x8)

3-3. CD MECHANISM BLOCK (CDM59-5BD27)

4 two screws

(BVTP 3x8)

5 tray

6 two screws

(BVTP 3x8)

7 CDM59-5BD27

3 three screws

(BVTP 3x8)

2 CN311

1 CN302

6

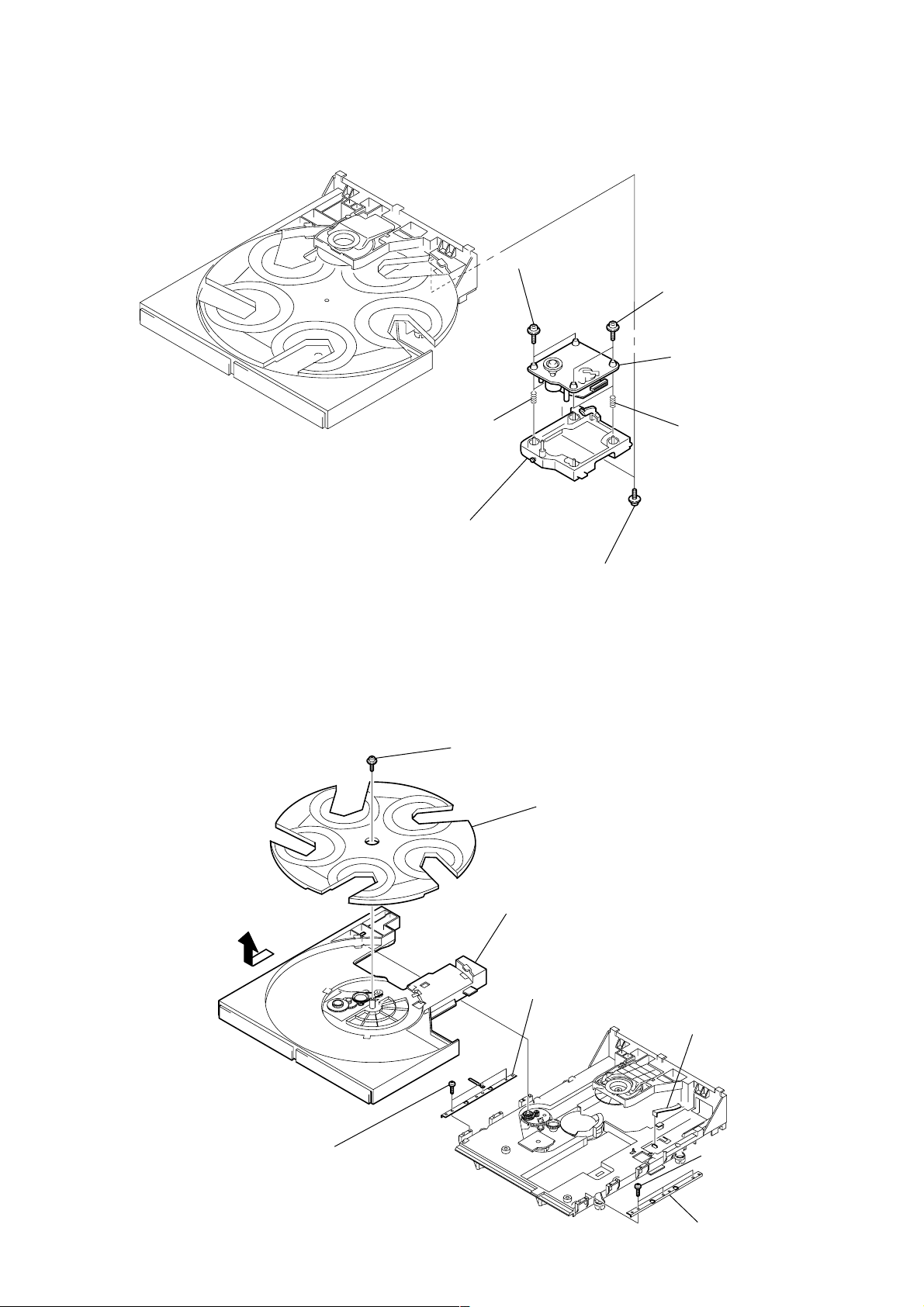

3-4. BASE UNIT (BU-5BD27)

P

3 two screws

(+PTPWHM 2.6),

floating

CDP-CE275/CE375

2 two screws

(+PTPWHM 2.6), floating

7 base unit (BU-5BD27)

3-5. TRA Y , T ABLE ASSY

6 spring (932),

compression

4 holder (BU) assy

8 screw

(+PTPWHM 2.6), floating

5 spring (932),

compression

1 two screws

(+PTPWHM 2.6), floating

9 tray

5

1 two screws

(M 2.6), +BTTP

7 table assy

2 bracket (guide)

6 CN15

3 three screws

(M 2.6), +BTT

4 bracket (guide)

7

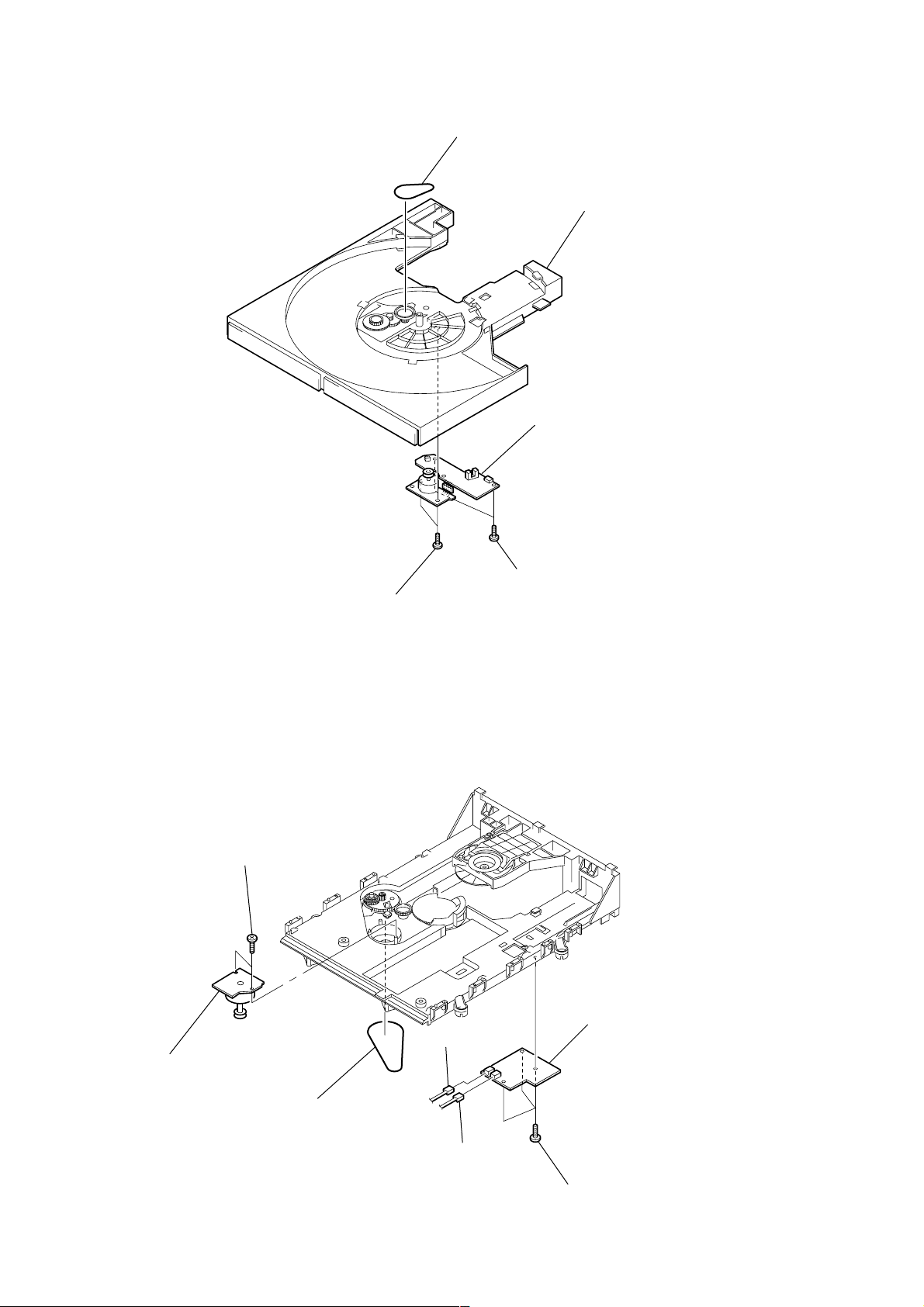

CDP-CE275/CE375

d

d

3-6. SENSOR BOARD

1 belt (rotary)

table assy

4 SENSOR boar

3 two screws

3-7. JUNCTION BO ARD , LO ADING MOTOR BOARD

6 two screws

(M 2.6), +BTTP

7 LOADING MOTOR board

2 two screws

(M 2.6), +BTTP

(M 2.6), +BTTP

4 JUNCTION boar

2 CN13

5 belt (loading)

1 CN14

3 three screws

(M 2.6), +BTTP

8

3-8. OPTICAL PICK-UP

r

CDP-CE275/CE375

2 shaft, sled

3 optical pick-up

1

4 connecto

9

CDP-CE275/CE375

MEMO

10

SECTION 4

d

DIAGRAMS

CDP-CE275/CE375

4-1. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• Indication of transistor

Q

B

CE

These are omitted.

Q

B

CE

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• A: B+ Line

• B: B– Line

: internal component.

under no-signal conditions.

no mark : CD PLAY

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

J : CD PLAY

c : DIGITAL OUT

4

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro

spécifié.

W or less unless otherwise

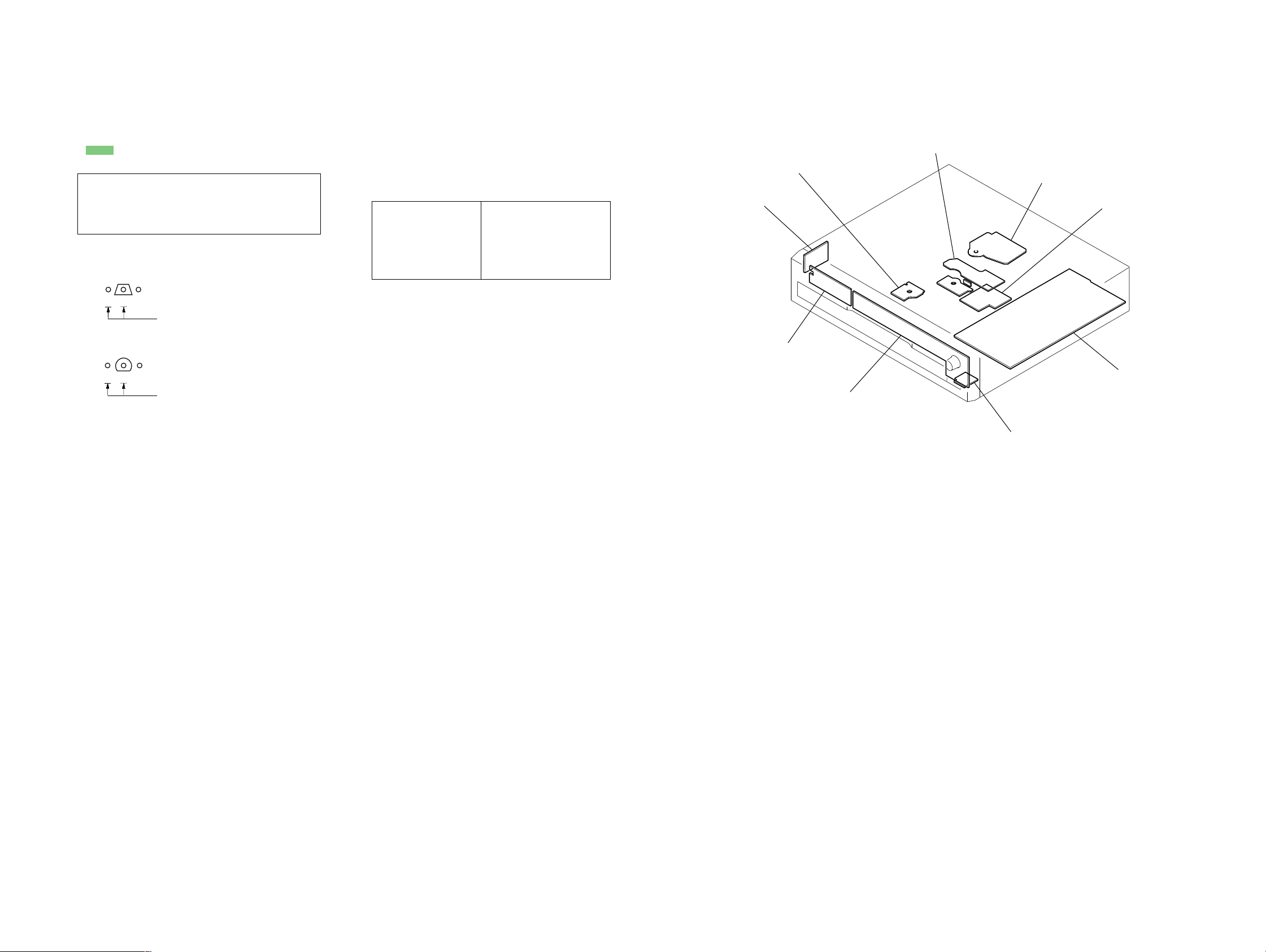

• Circuit Boards Location

LOADING MOTOR board

POWER SW board

KEY board

SENSOR board

BD board

JUNCTION board

MAIN boar

DISPLAY board

HEADPHONE board

1111

Loading...

Loading...