Page 1

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

SERVICE MANUAL

MICROFILM

SPECIFICATIONS

h

VIDEO CAMERA RECORDER

— Continued on next page —

Video camera recorder

System

Video recording system

2 Rotary heads

Helical scanning FM system

Audio recording system

Rotary heads, FM system

Video signal

NTSC color, EIA standards

Usable cassette

8mm video format cassette

CCD-TR315/TR416/TR416PK

CCD-TRV16/TRV16PK

: standard 8

CCD-TR516/TR516PK/TR716

CCD-TRV36/TRV36PK/TRV43/TRV46/

TRV46PK : Hi8

Recording / Playback time

(using 120 min. cassette)

SP mode: 2 hours

LP mode: 4 hours

Fastforward/rewind time

(using 120 min. cassette)

Approx. 5 min.

Image device

1/4 inch CCD (Charge Coupled Device)

CCD-TR315/TR416/TR416PK/TR516/

TR516PK

CCD-TRV16/TRV16PK/TRV36/

TRV36PK : Approx. 270,000 pixels

(Effective : approx 250,000 pixels)

CCD-TR716

CCD-TRV34/TRV46/TRV46PK :

Approx. 320,000 pixels

(Effective : approx 200,000 pixels)

Viewfinder

Electronic viewfinder

CCD-TR315/TRV series : Monochrome

CCD-TR416/TR416PK/TR516/

TR516PK/TR716 : Color

Lens

Combined power zoom lens

Filter diameter 1 7/16 in. (37 mm)

CCD-TR315/TR416:US,CND

CCD-TRV16/TRV16PK

: 18 x (Optical), 180 x (Digital)

CCD-TR416:BR/TR416PK

: 18 x (Optical), 220 x (Digital)

CCD-TR516/TR516PK/TR716

CCD-TRV36/TRV36PK/TRV43/TRV46/

TRV46PK

: 18 x (Optical), 330 x (Digital)

Focal distance

3/16 - 8 in. (4.1 - 37.8 mm)

When converted to a 35 mm still camera

CCD-TR315/TR416/TR416PK/TR516/

TR516PK

CCD-TRV16/TRV16PK/TRV36/

TRV36PK

: 1 9/16 - 28 in. (39.4 - 709 mm)

CCD-TR716

CCD-TRV43/TRV46/TRV46PK

: 1 7/8 - 33 1/2 in. (47.2 - 850 mm)

Photo : CCD-TR516

Photo : CCD-TRV46

H

VIDEO CAMERA RECORDER

CCD-TR315/TR416/TR416PK

CCD-TRV16/TRV16PK

CCD-TR516/TR516PK/TR716

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

Color temperature

Auto

Minimum illumination

0.4 lux at F 1.4

0 lux (in NightShot mode)*

Illumination range

0.4 lux to 100,000 lux

Recommended illumination

More than 100 lux

* Object invisible for the dark can be

shot with infrared lighting.

LCD screen (TRV series only)

Picture

2.5 inches measured diagonally

2 x 1 1/2 in.(50.3 x 37.4 mm)

On-screen display

TN LCD/TFT active matrix method

Total dot number

61,380 (279 x 220)

For MECHANISM ADJUSTMENTS, refer to

the “8mm Video MECHANICAL ADJUSTMENT

MANUAL VII” (9-973-801-11).

B MECHANISM

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/

Ver 1.3 2001. 12

TRV46/TRV46PK

RMT-708

US Model

Canadian Model

CCD-TR416/TR516/TR716

CCD-TRV16/TRV36/TRV43/TRV46

E Model

CCD-TR315/TR416PK/TR516PK

CCD-TRV16/TRV16PK/TRV36PK/

TRV46/TRV46PK

Hong Kong Model

CCD-TRV16/TRV46

Taiwan Model

CCD-TRV16

Brazilian Model

CCD-TR315/TR416

CCD-TRV16

NTSC

Page 2

Input and output connectors

Video output

Phono jack, 1 Vp-p, 75 ohms, unbalanced

Audio output

Monaural, Phone jack, 327 mV

(at output impedance 47 kilohms)

impedance less than 2.2 kilohms

RFU DC OUT

Special minijack, DC 5V

Earphone jack (TRV series only)

Monaural minijack (ø 3.5 mm)

LANC control jack

Stereo mini-minijack (ø 2.5 mm)

MIC jack

Mini jack, 0.388mV low impedance with

2.5 to 3.0 V DC, output impedance 6.8

kilohms (ø 3.5 mm) : Monaural type

Speaker (TRV series only)

Dynamic speaker

General

Power requirements

7.2 V (battery pack)

8.4 V (AC power adaptor)

Averege power consumption(when

using the battery pack)

During camera recording

CCD-TR416/TR416PK/TR516/

TR516PK : 2.4 W

CCD-TR315/TR716 : 2.5 W

During camera recording using

LCD

CCD-TRV16/TRV16PK/TRV36/

TRV36PK : 3.1 W

CCD-TRV43/TRV46/TRV46PK : 3.2 W

Viewfinder

CCD-TRV16/TRV16PK/TRV36/

TRV36PK : 2.5 W

CCD-TRV43/TRV46/TRV46PK : 2.6 W

Operating temperature

32°FC to 104°F (C0°C to 40°C)

Storage temperature

-4°FC to 140°F (-20°C to +60°C)

Dimentions (Approx.)

4 1/4 x 4 1/4 x 7 5/8 in.

107 x 107 x 193 mm)(w/h/d)

Mass (Approx.)

CCD-TR315/TR716 : 1 lb 11 oz (790 g)

CCD-TR416/TR416PK/TR516/

TR516PK : 1 lb 11 oz (780 g)

CCD-TRV16/TRV16PK/TRV36/

TRV36PK : 1 lb 14 oz (870 g)

CCD-TRV43/TRV46/TRV46PK

: 1 lb 15 oz (880 g)

excluding the battery pack, lithium

battery, cassette and shoulder strap

2 lb 3 oz (1 kg)

including the battery pack NP-F330,

lithium battery CR2025, cassette and

shoulder strap

Microphone

Monaural type

Supplied accessories

See page 4.

AC power adaptor

Power requirements

100 -240 V AC, 50/60 Hz

Power consumption

23 W

Output voltage

DC OUT: 8.4 V, 1.5 A in operating mode

Operating temperature

32°F to 104°F(0°C to 40°C)

Storage temperature

-4°F to +140°F(-20°C to +60°C)

Dimentions (Approx.)

5 x 1 9/16 x 2 1/2 in. (125 x 39 x 62

mm)(w/h/d) excluding projecting parts

Mass (Approx.)

9.8 oz (280 g) excluding power cord

Design and specifications are subject to

change without notice.

• Abbreviation

Canadian model is abbreviated as CND.

Brazilian model is abbreviated as BR.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are “pinched”

or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to

the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend

their replacement.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÉCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÉCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

Page 3

Remark

CCD-

TRV36PK

E

B/W¬¬G330X¬510GG

CCD-

TRV36

US,CND

B/W¬¬G330X¬510GG

CCD-

TRV16PK

E

B/WGG¬180XG510GG

CCD-

TRV16

US,CND,E,

HK,BR,TW

B/WGG¬180XG510GG

CCD-

TR716

US,CND

Color¬¬G330X¬510P¬G

CCD-

TR516PKEColor¬¬G330X¬510GG

¬ : with SE-80/81board SE451,452,IC451

¬ : with VC-215board IC751

2.5 inch : TRV series only

2.5 inch

2.5 inch

2.5 inch

2.5 inch

G

G

Canadian model is abbreviated as CND.

Brazilian model is abbreviated as BR.

• Abbreviation

Hong Kong model is abbreviated as HK.

Taiwan model is abbreviated as TW.

CCD-

TR516

US,CND

Color¬¬G330X¬510GG

CCD-

TR416PKEColorGG¬220XG510GG

BR

ColorGG¬220XG510GG

CCD-

TR416

US,CND

ColorGG¬180XG510GG

CCD-

TR315

Model

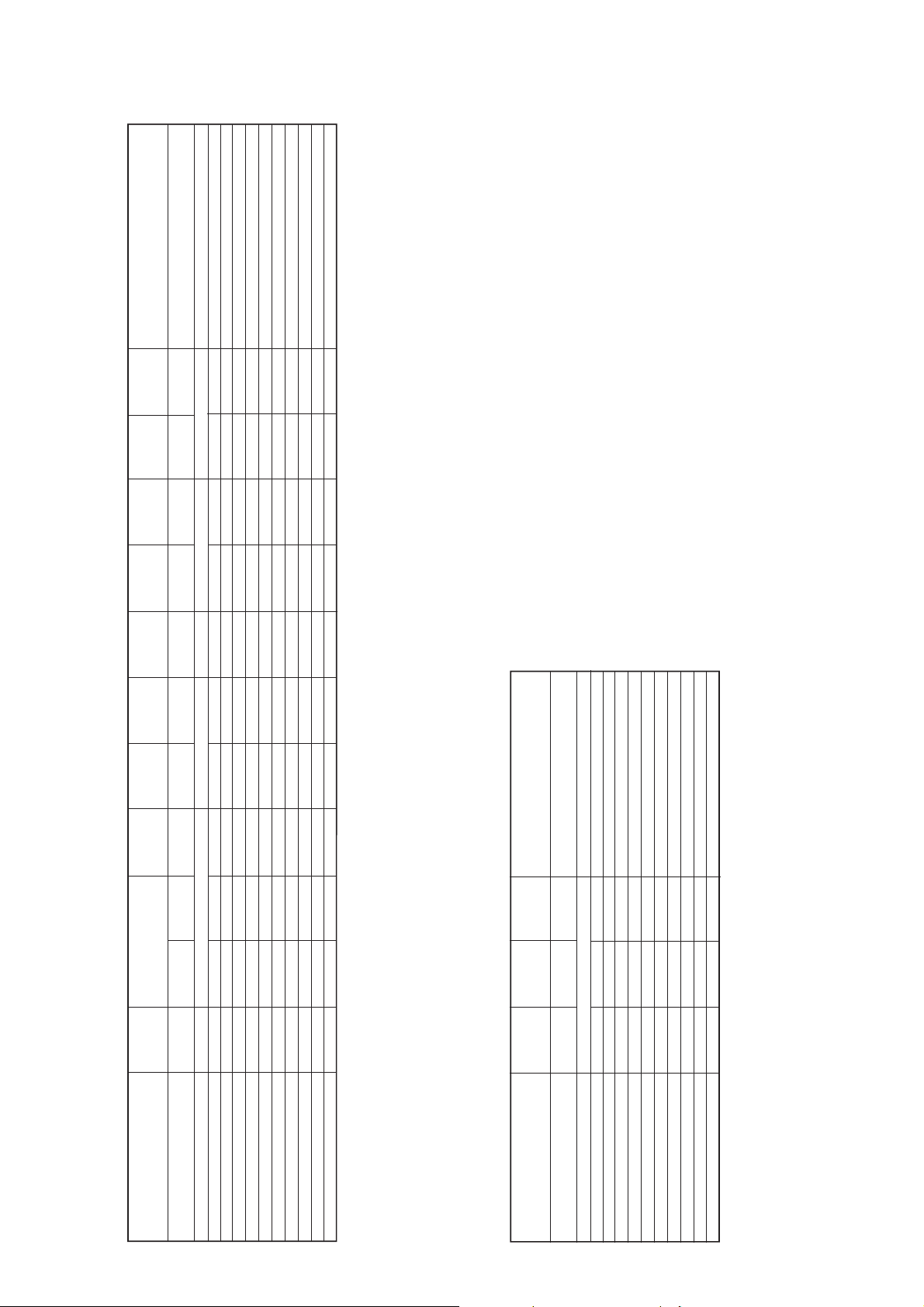

Table for difference of function

TYPE E TYPE G TYPE C TYPE D TYPE F TYPE A

E,BR

B/WGG¬180XG510GG

Destination

Classification

View finder

Remote commander (RMT-708)

Hi8

Standard 8

Lens (Digital ZOOM)

Video light

CCD

Steadyshot

Laser Link

G

G

G

G

G

LCD panel

Remark

CCD-

TRV46PK

E

B/W¬¬G330x¬510P¬¬

CCD-

TRV46

CCD-

TRV43

Model

TYPE B

US,CND,E,HKB/W¬¬G330x¬510P¬¬

US,CND

B/W¬¬G330x¬510P¬¬

Destination

Classification

View finder

Remote commander (RMT-708)

Hi8

Standard 8

Lens (Digital ZOOM)

Video light

CCD

¬ : with SE-80/81board SE451,452,IC451

¬ : with VC-215board IC751

2.5 inch : TRV series only

2.5 inch

2.5 inch

2.5 inch

Steadyshot

Laser Link

LCD panel

– 3 –

Page 4

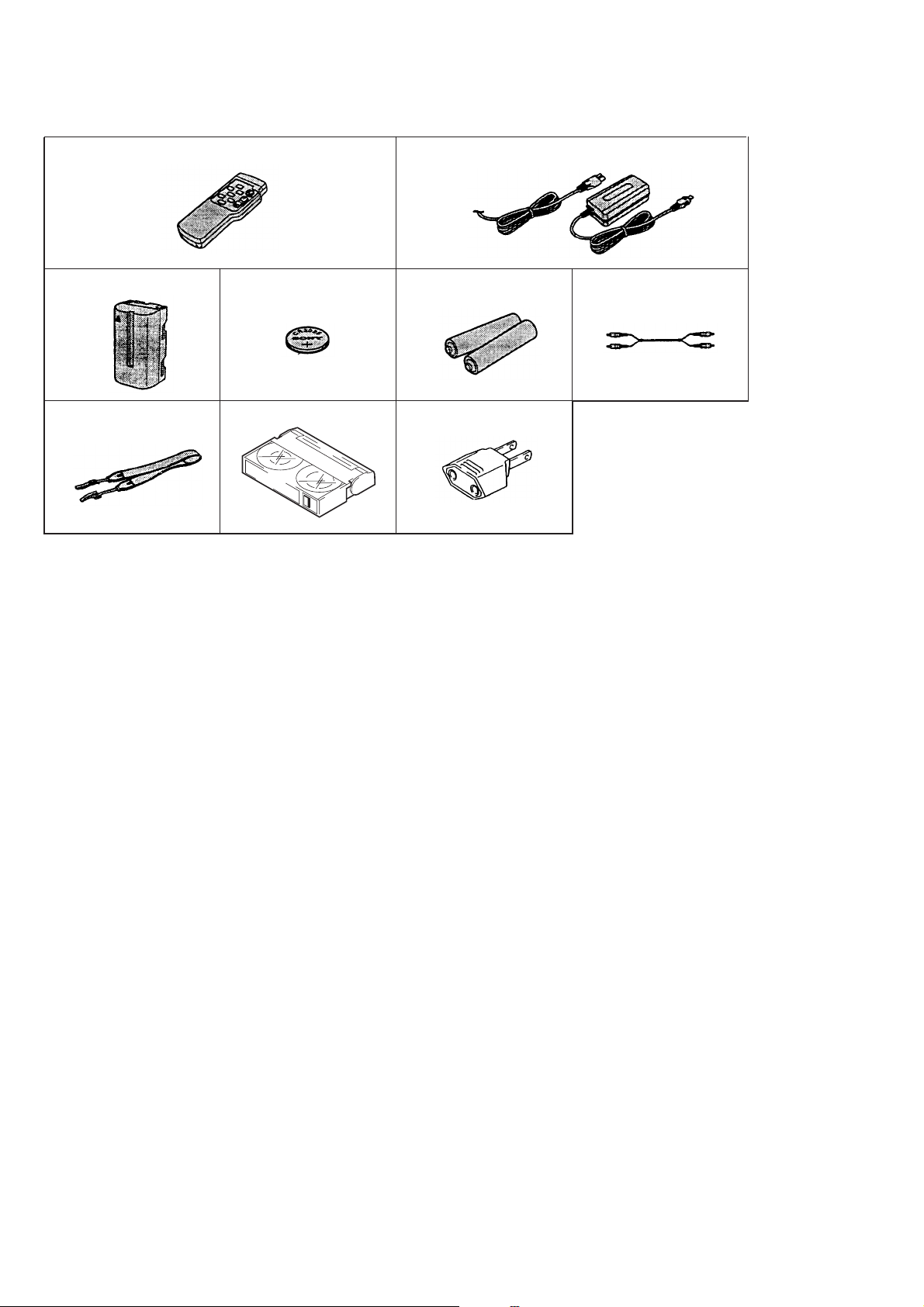

Supplied accessories

1

3

7

1 RMT-708 Wireless Remote Commander (1)

CCD-TR516/TR516PK/TR716

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

2 AC-L10A/L10B/L10C AC power adaptor

4

8

2

5

9

7 Shoulder strap (1)

8 Video P6-15P HB tape

CCD-TR416: US/TR516: US/TR716:US

CCD-TRV16:US/TRV36:US/TRV43:US/TRV46:US

6

3 NP-F330 Battery pack (1)

4 CR2025 Lithium Battery (1)

The lithium battery is already installed in your camcorder.

5 Size AA (R6) battery for Remote Commander

(2)

CCD-TR516/TR516PK/TR716

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

6 A / V connecting cable (1)

9 2 pin conversion adaptor (1)

CCD-TR315//TR416PK/TR516PK

CCD-TRV16:E,BR,HK,TW/TRV16PK/TRV36PK/

TRV46:E,HK/TRV46PK

• Abbreviation

Brazilian model is abbreviated as BR.

Hong Kong model is abbreviated as HK.

Taiwan model is abbreviated as TW.

– 4 –

Page 5

SERVICE NOTE

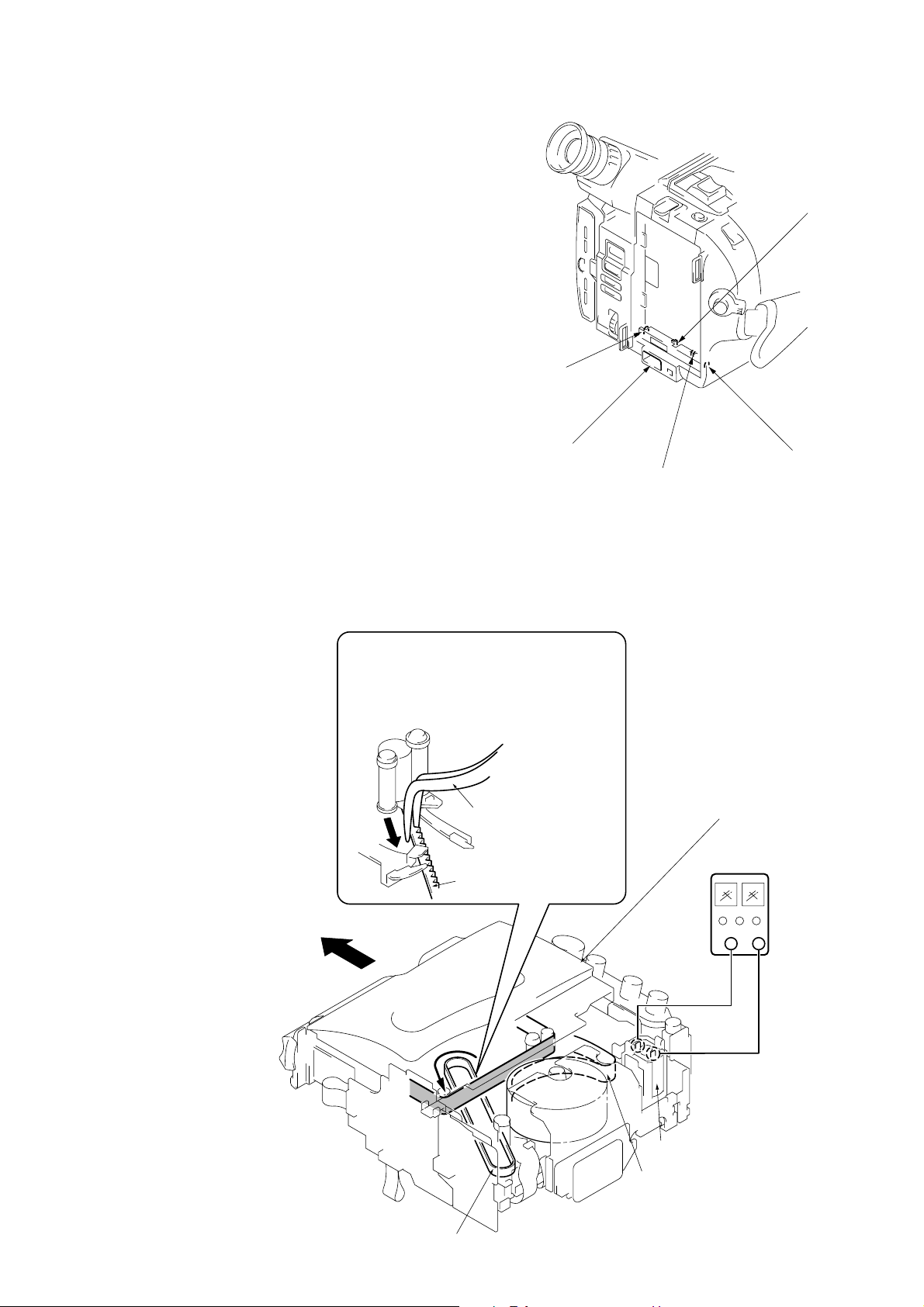

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied (8.4V) to the

battery terminal using the service power cord (J-6082-223-A), the

power is shut off so that the unit cannot operate.

This following three methods are available to prevent this. Take

note of which to use during repairs.

Method 1.

Connect the servicing remote commander RM-95 (J-6082-053-B)

to the LANC jack, and set the remote commander switch to the

“ADJ” side.

Method 2.

Press the battery switch of the battery terminal using adhesive tape,

etc.

Method 3.

Use the DC IN terminal. (Use the AC power adaptor.)

Battery terminal

Battery switch

‘

DC IN terminal

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to 2-1. to remove the front panel block.

2 Refer to 2-4. to remove the cabinet (R) assembly.

3 Refer to 2-6. to remove the battery panel block.

4 Refer to 2-7. to remove the cabinet (L) block.

5 Add +5V from the DC POWER SUPPLY and unload with a

pressing the cassette lid.

6

Pull the timing belt in the direction of arrow A

with a pinsette while pressing the cassette lid

(take care not to damage) to adjust the

bending of a tape.

A

Pinsette

Timing belt

Battery SIG terminal

Press the cassette lid not to rise the

cassette compartment

[DC power supply]

Battery terminal

(+5V)

’

7

Let go your hold the cassette

lid and rise the cassette

compartment to take out a cassette.

Timing belt

– 5 –

+

Loading motor

Adjust the bending of a tape

–

Page 6

SELF-DIAGNOSIS FUNCTION

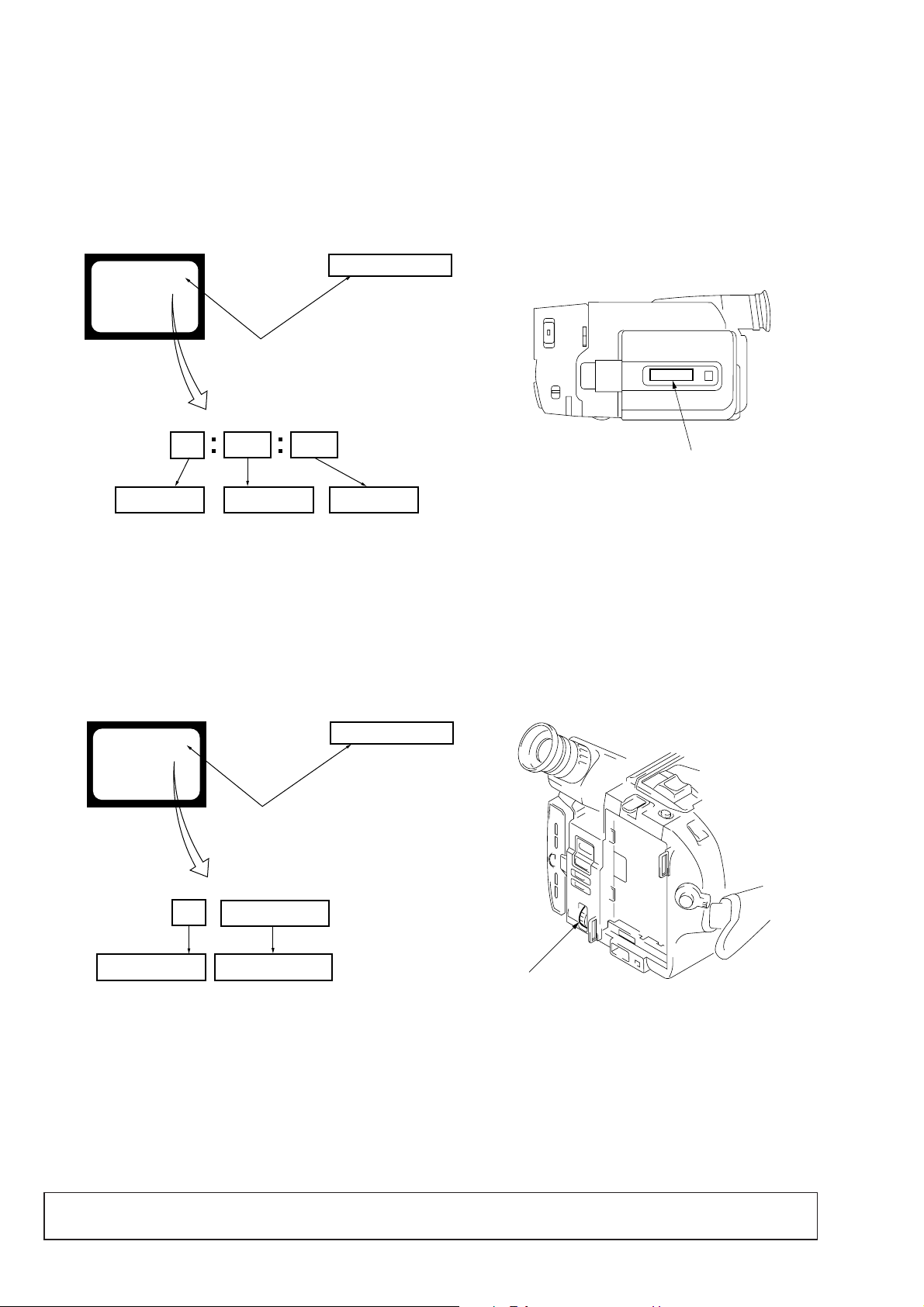

1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis function starts working, and displays on the viewfinder or Display window what to do. This function consists of two display; selfdiagnosis display and service mode display .

Details of the self-diagnosis functions are provided in the Instruction manual.

Viewfinder

C : 3 1 : 1 1

Blinks at 3.2 Hz

C

Repairede by :

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service engineer

3 1 1 1

Block

Indicates the appropriate step to be taken

E. g.

31 ... Reload the tape.

32 ... Turn on power again.

Display window

C : 3 1 : 1 1

Detailed Code

2. Self-diagnosis display

When problems occur while the unit is operating, the counter of the

viewfinder or Display window shows a 4-digit display consisting

of an alphabet and numbers, which blinks at 3.2 Hz. This 5-character display indicates the “repaired by:”, “block” in which the problem occurred, and “detailed code” of the problem.

Refer to page7

Self-diagnosis Code table

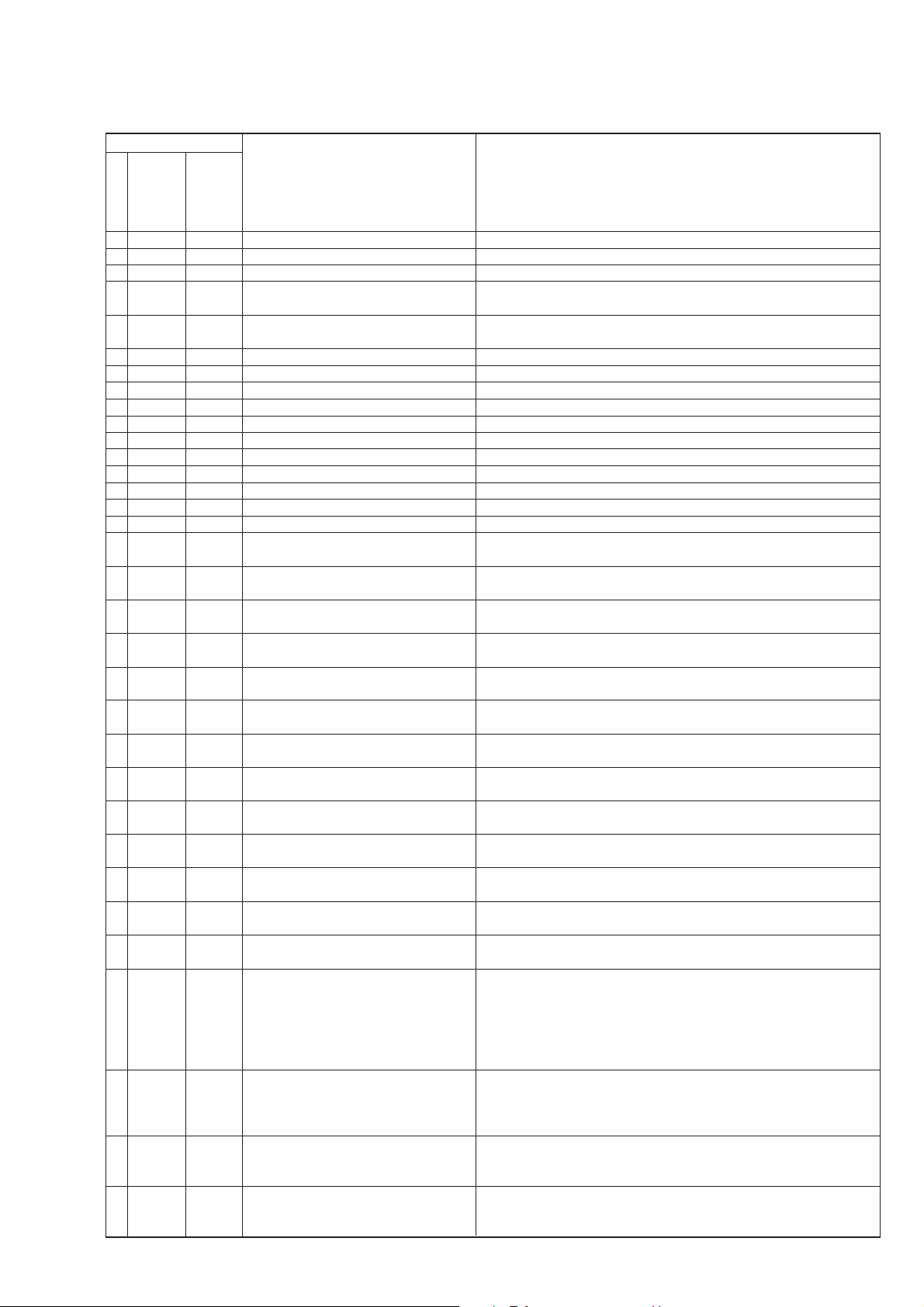

3. Service Mode Display

The service mode display shows up to six self-diagnosis codes shown in the past.

Display window

3-1. Display Method

While pressing the “STOP” key, set the switch from OFF to “VTR or PLAYER”, and continue pressing the “STOP” key for 5 seconds

continuously. The service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

3-2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

C : 3 1 : 1 1

Self-diagnosis codes

Display window

3 C : 3 1 : 1 1

Control dial

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The self-diagnosis display data will be backed up by the coin-type lithium battery . When this coin-type lithium battery is

disconnected, the self-diagnosis data will be lost by initialization.

– 6 –

Page 7

4. Self-diagnosis Code Table

Self-diagnosis Code

Block

Function

Repaired by:

C

21

C

22

C

23

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

32

C

32

C

32

C

32

C

32

C

32

C

32

C

32

C

32

C

32

C

32

C

32

C

32

E

61

E

61

E

62

E

62

Detailed

Code

00

00

00

10

11

20

21

22

23

30

31

40

41

42

43

44

10

11

20

21

22

23

30

31

40

41

42

43

44

00

10

00

01

Condensation.

Video head is dirty.

Non-standard battery is used.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading.

S reel side tape slacking when unloading.

T reel fault

S reel fault

FG fault when starting capstan

FG fault during normal capstan operations

FG fault when starting drum

PG fault when starting drum

FG fault during normal drum operations

PG fault during normal drum operations

Phase fault during normal drum operations

LOAD direction loading motor time-out

UNLOAD direction loading motor time-

out

T reel side tape slacking when unloading.

S reel side tape slacking when unloading.

T reel fault

S reel fault

FG fault when starting capstan

FG fault during normal capstan operations

FG fault when starting drum

PG fault when starting drum

FG fault during normal drum operations

PG fault during normal drum operations

Phase fault during normal drum operations

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Handshake correction function does not

work well.(With pitch angular velocity

sensor output stopped)

Handshake correction function does not

work well.(With yaw angular v elocity

sensor output stopped)

Symptom/State Correction

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Use the InfoLITHIUM battery.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Remove the battery or power cable, connect, and perform operations

from the beginning.

Inspect the lens block focus reset sensor (Pin !ª of CN551 of VC-215

board) when focusing is performed when the focus dial is rotated in the

focus manual mode and the focus motor drive circuit (IC552 of VC-215

board) when the focusing is not performed.

Note : Use the remote commander RM-95 only for the model without

the focus dial.

Inspect the lens block zoom reset sensor (Pin @¡ of CN551 of VC-215

board) when zooming is performed when the zoom lens is operated and

the zoom motor drive circuit (IC552 of VC215 boar d) when zooming is

not performed.

Inspect yaw angular velocity sensor (SE451 of SE-80/81 board)

peripheral circuits.

Inspect pitch angular velocity sensor (SE452 of SE-80/81 board)

peripheral circuits.

– 7 –

Page 8

TABLE OF CONTENTS

SERVICE NOTE

1. Power Supply During Repairs ................................................ 5

2. To Take out a Cassette when not Eject (Force Eject)..............5

Self-Diagnosis Function

1. Self-diagnosis function ............................................................ 6

2. Self-diagnosis Display............................................................. 6

3. Service Mode Display .............................................................6

3-1. Display Method................................................................ 6

3-2. Switching of Backup No..................................................6

3-3. End of Display ................................................................. 6

4. Self-diagnosis Code Table ....................................................... 7

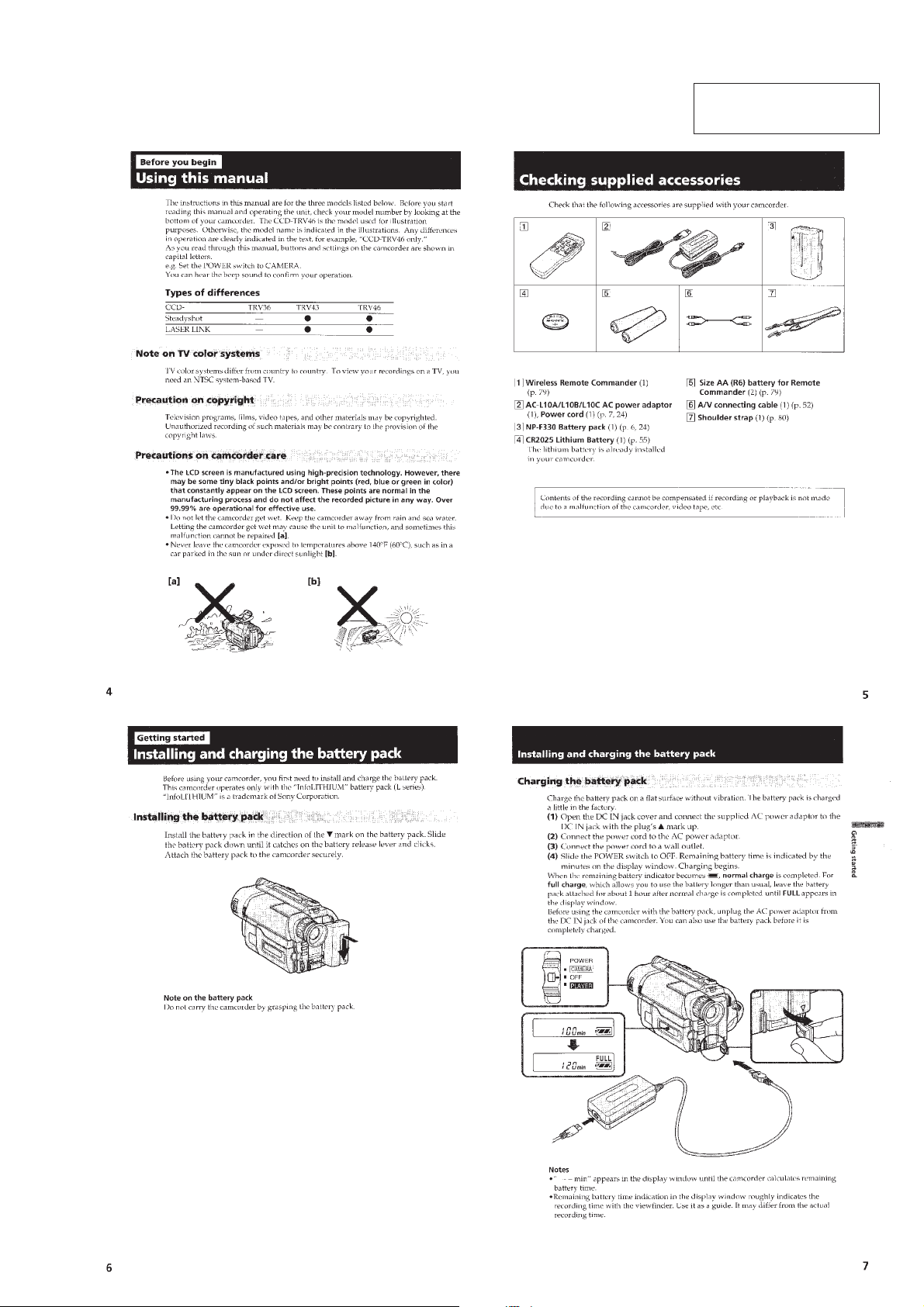

1. GENERAL

This section is extacked from instruction manual of

CCD-TRV36/TRV43/TRV46.

Using this manual ......................................................................1-1

Checking supplied accessories .................................................. 1-1

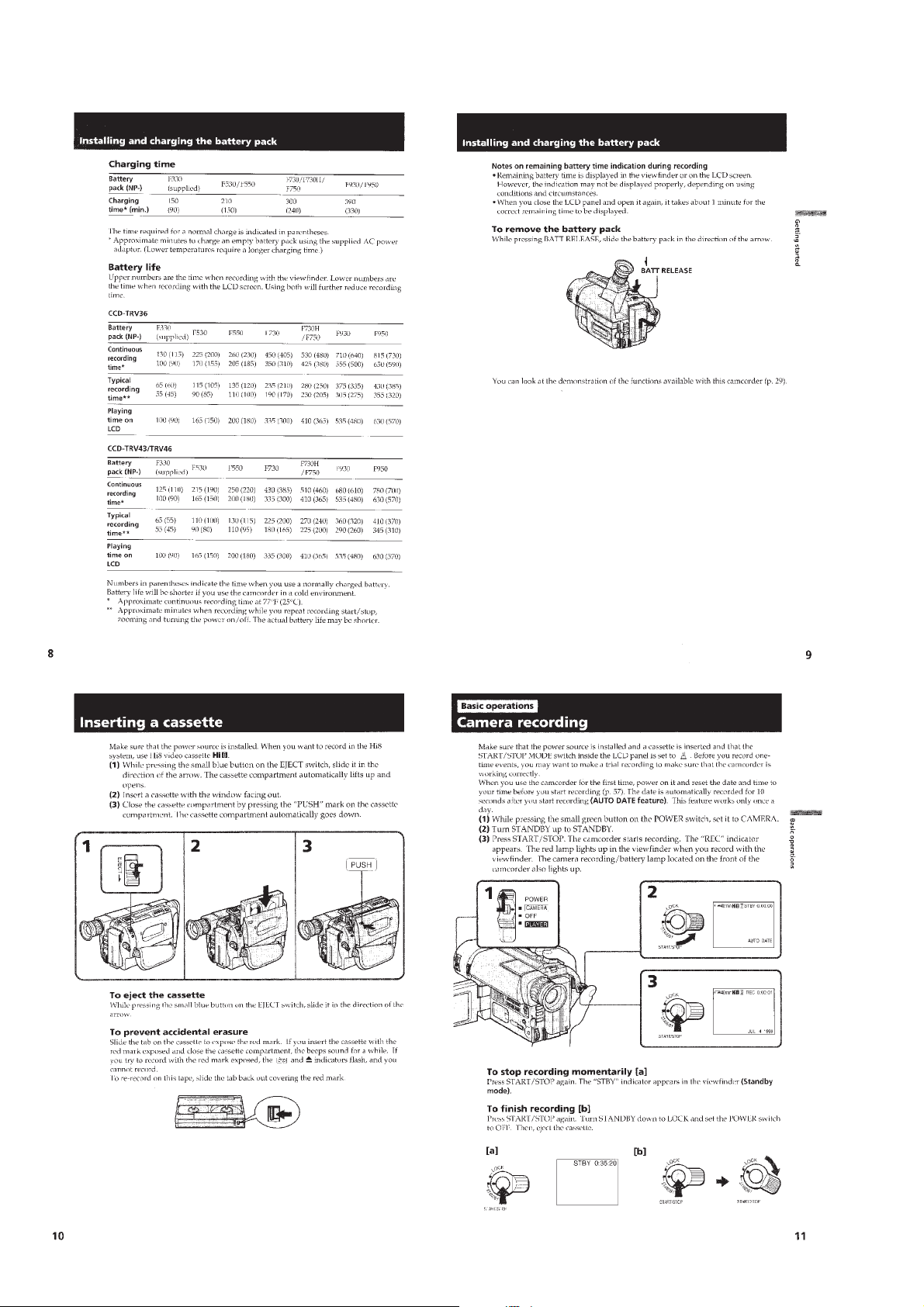

Installing and Charging the battery pack................................... 1-1

Inserting a cassette.....................................................................1-2

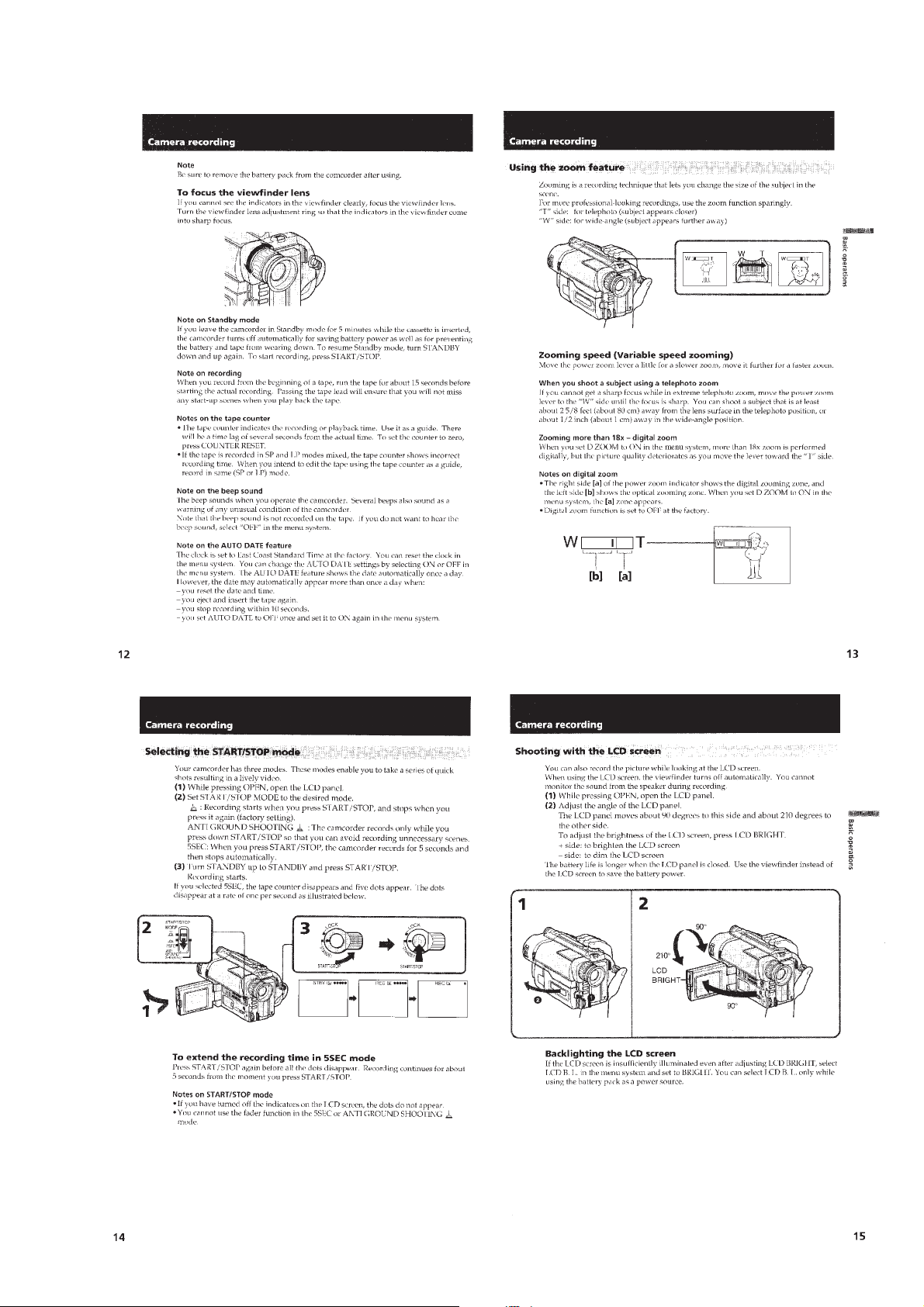

Camera recording ......................................................................1-2

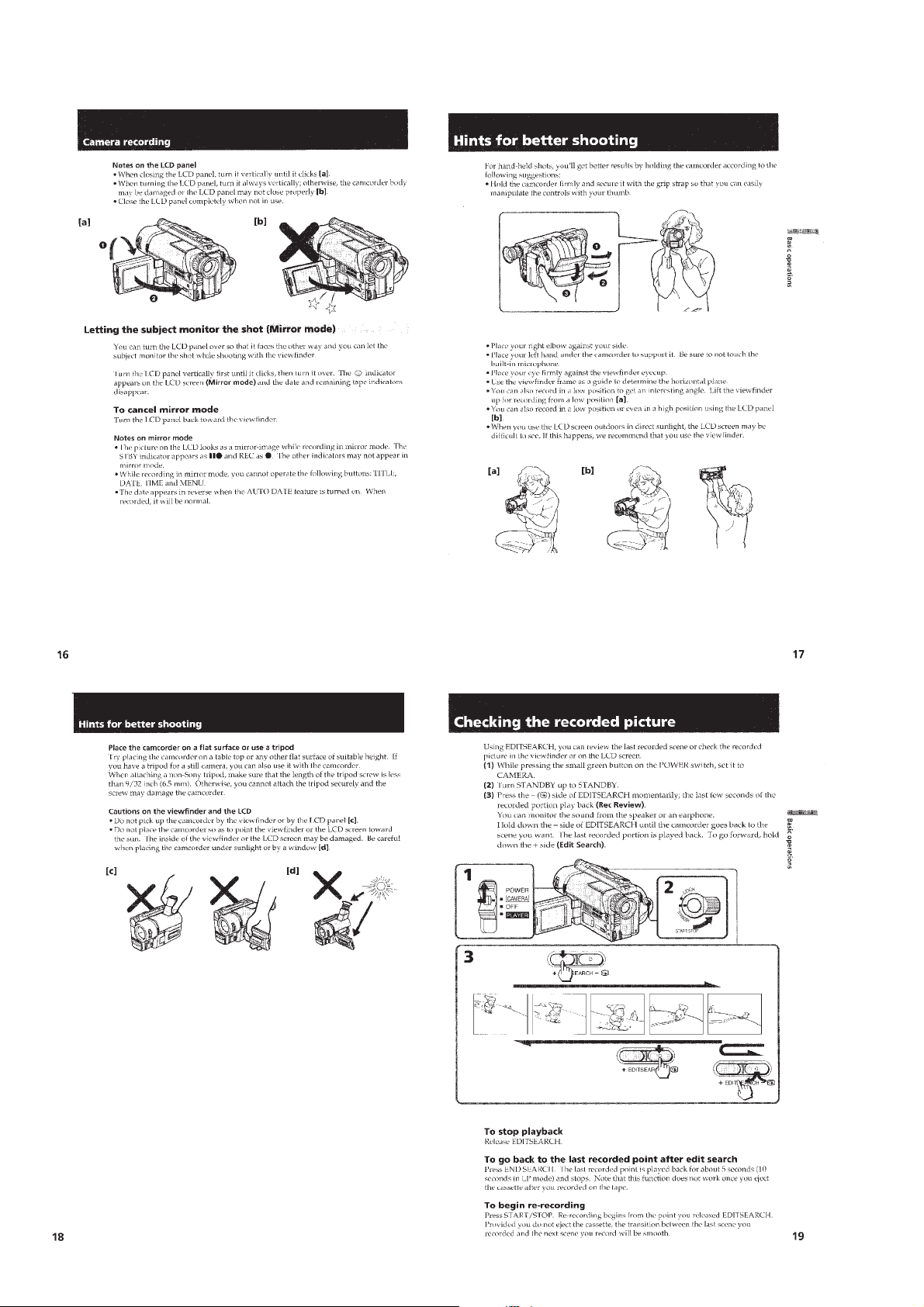

Hints for better Shooting ........................................................... 1-4

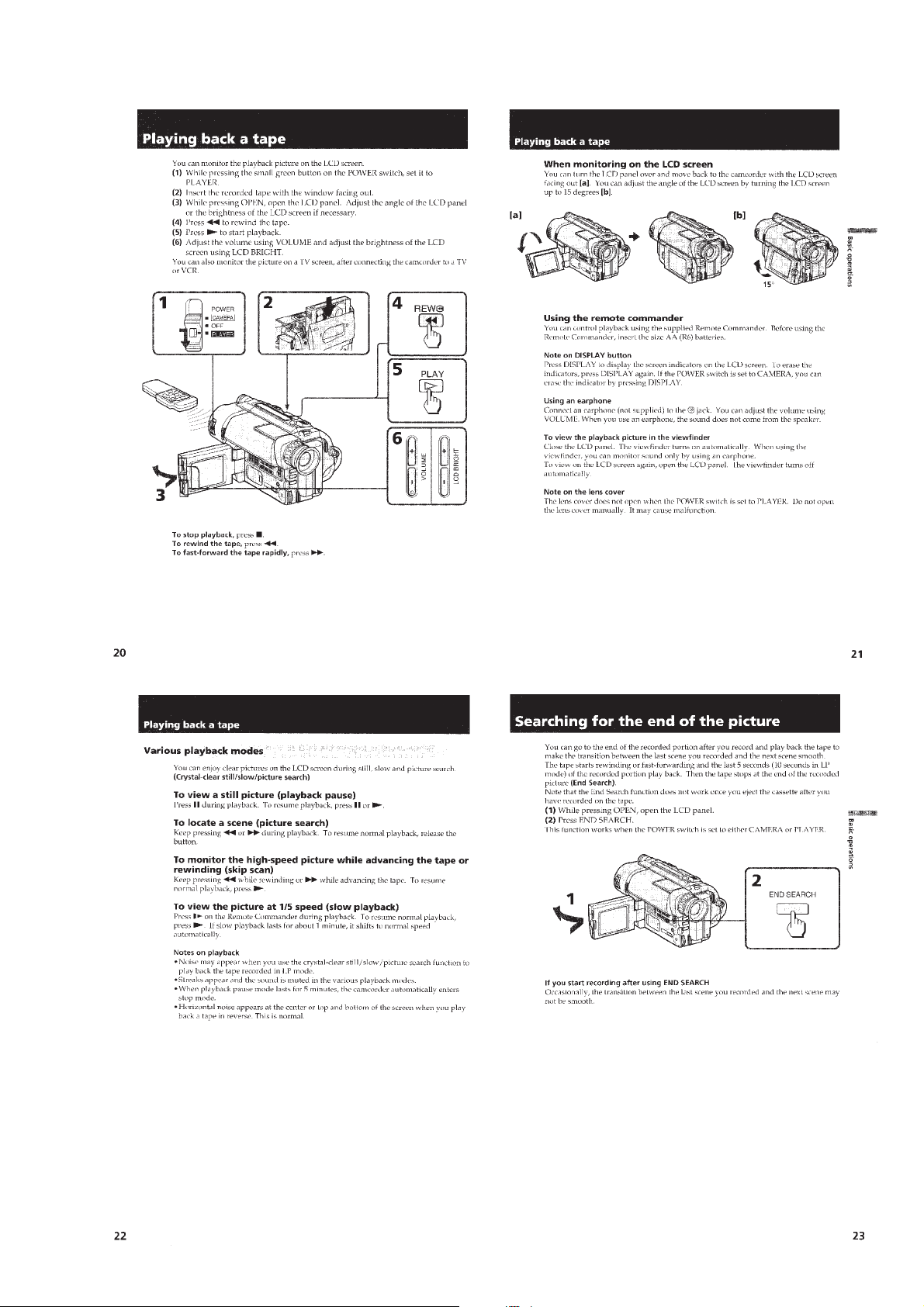

Checking the recorded picture...................................................1-4

Playing back a tape ....................................................................1-5

Searching for the end of the picture ..........................................1-5

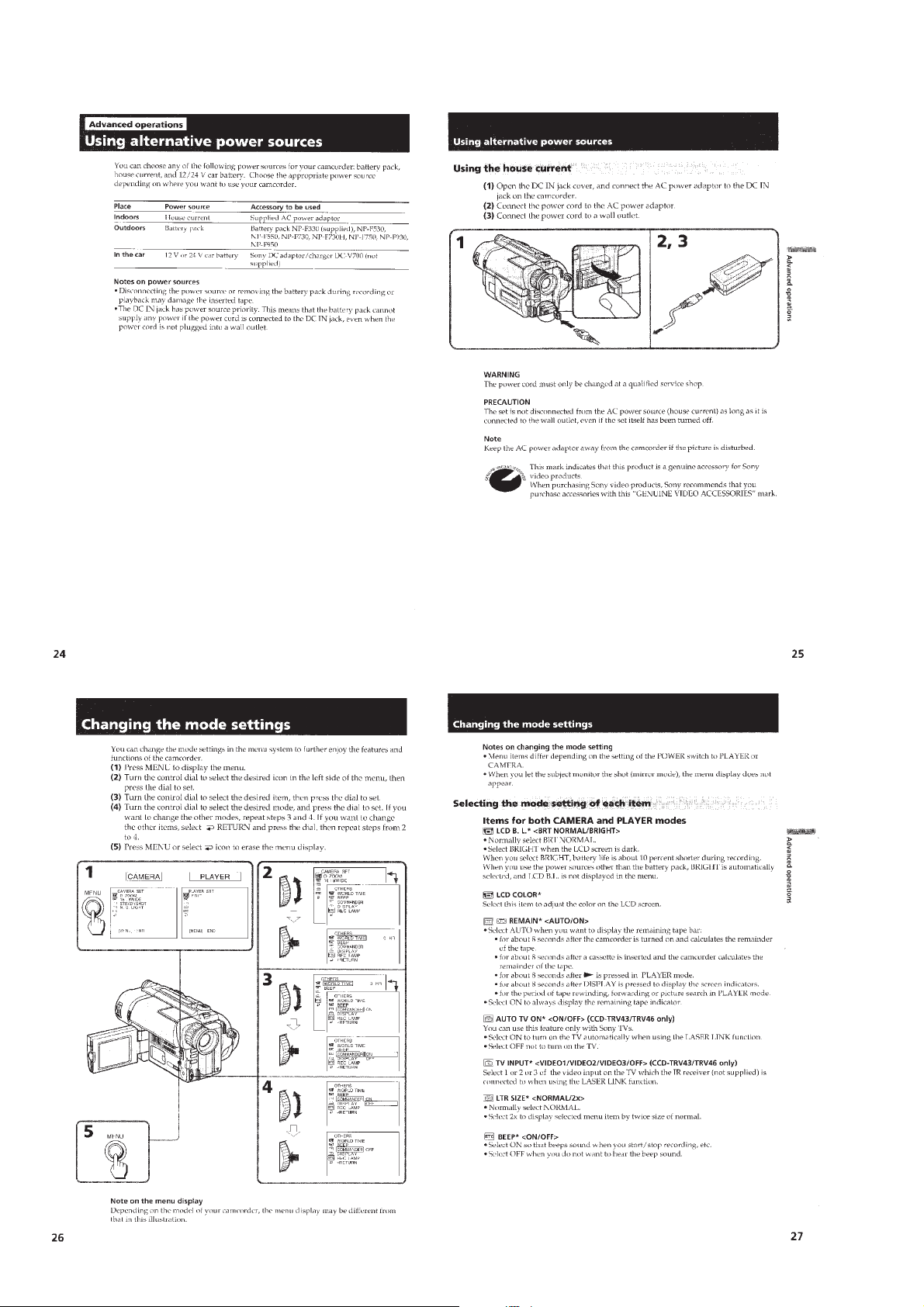

Using alternative power sources................................................ 1-6

Changing the mode settings ......................................................1-6

Shooting with backlighting .......................................................1-7

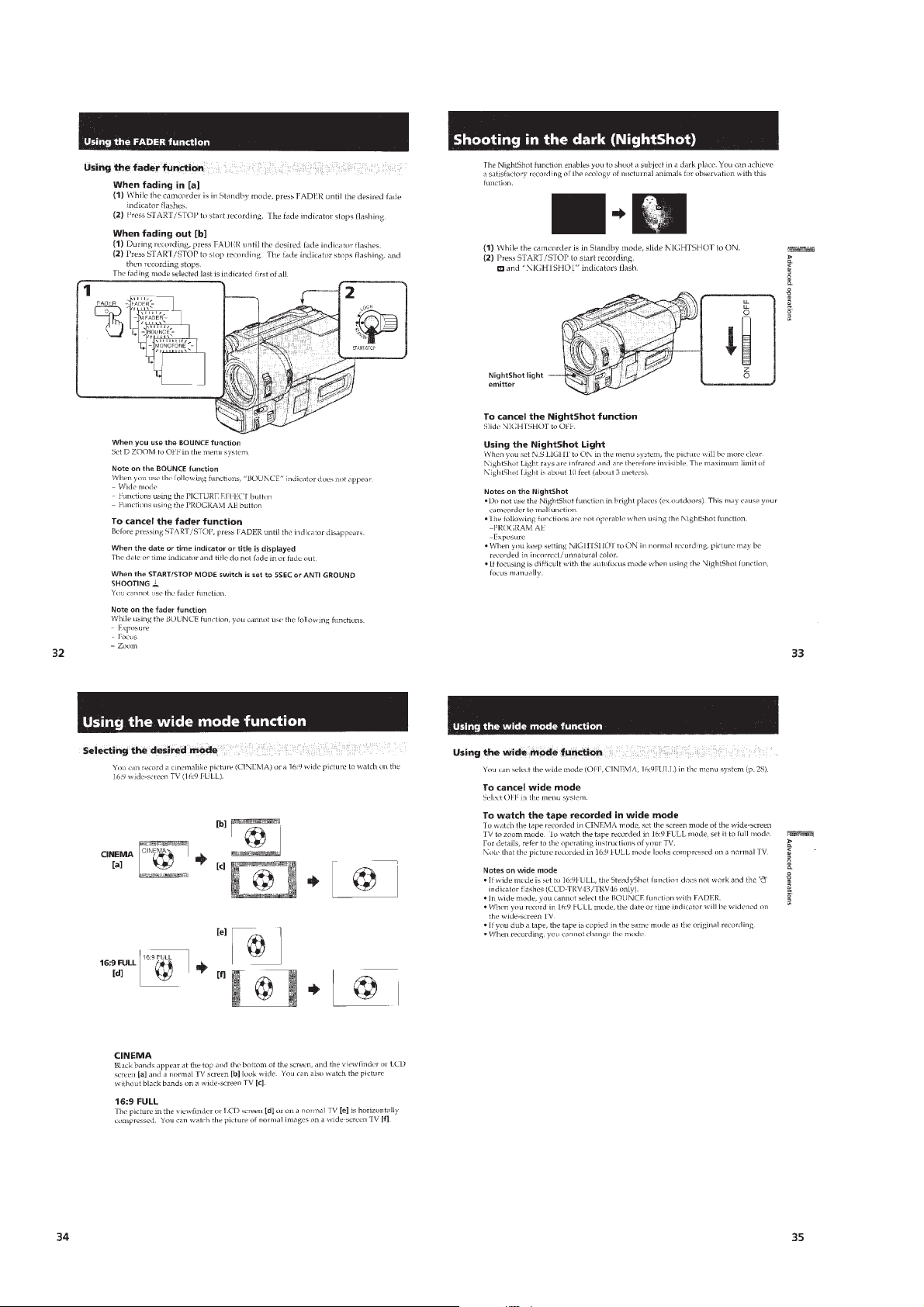

Using the FADER function .......................................................1-7

Shooting in the dark (NightShot) ..............................................1-8

Using the wide mode function...................................................1-8

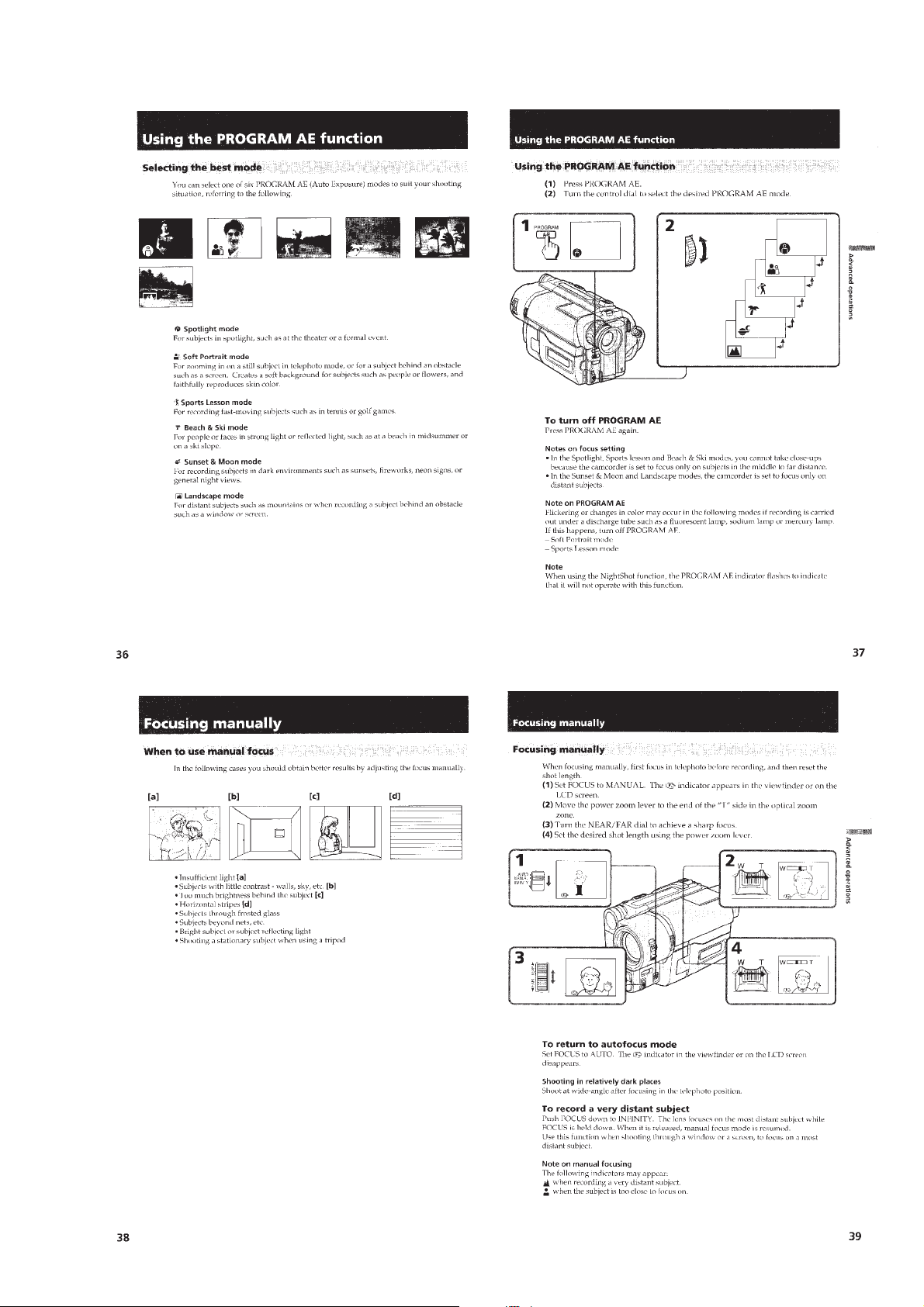

Using the PROGRAM AE function........................................... 1-9

Focusing manually.....................................................................1-9

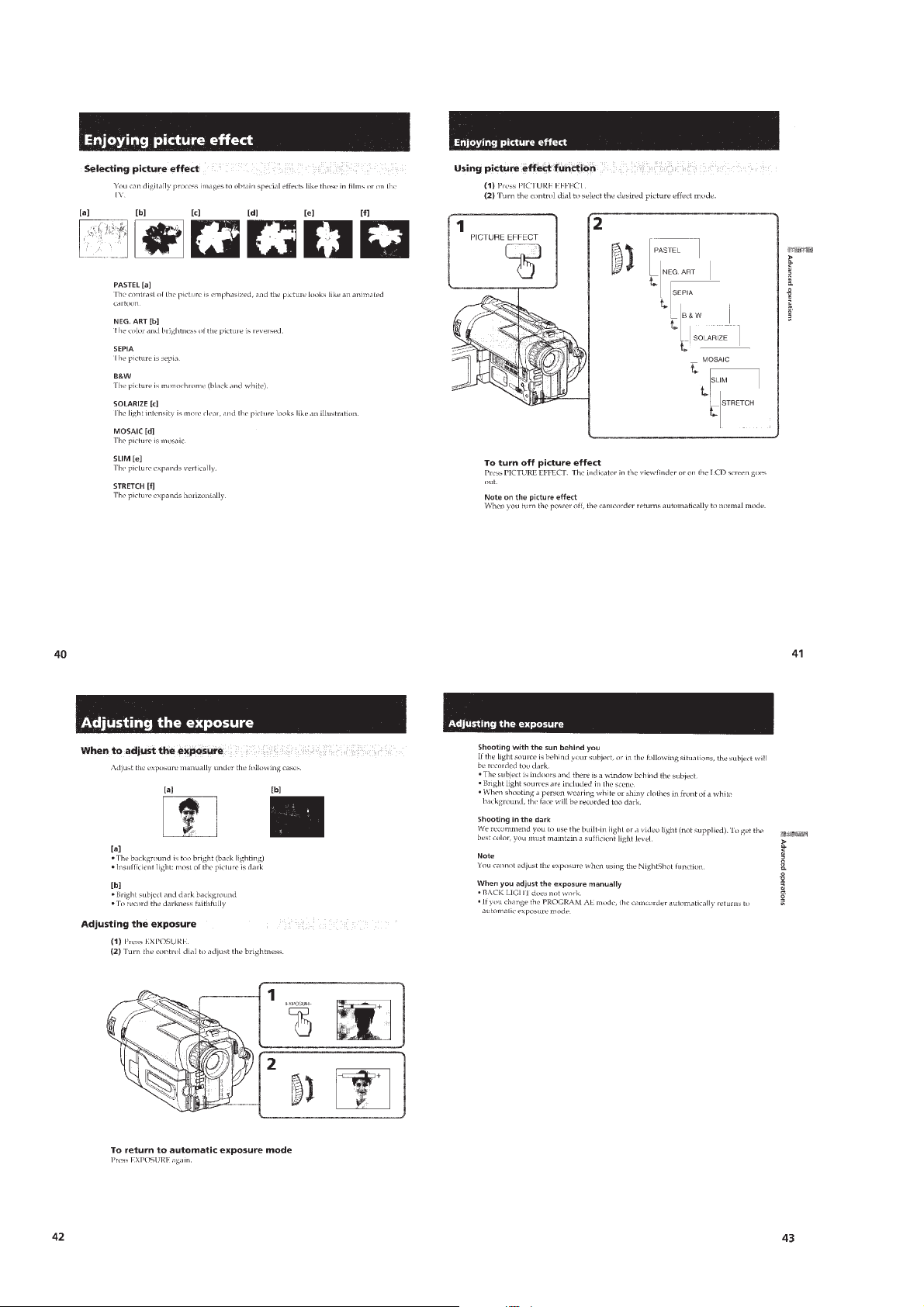

Enjoying picture effect ............................................................ 1-10

Adjusting the exposure ............................................................1-10

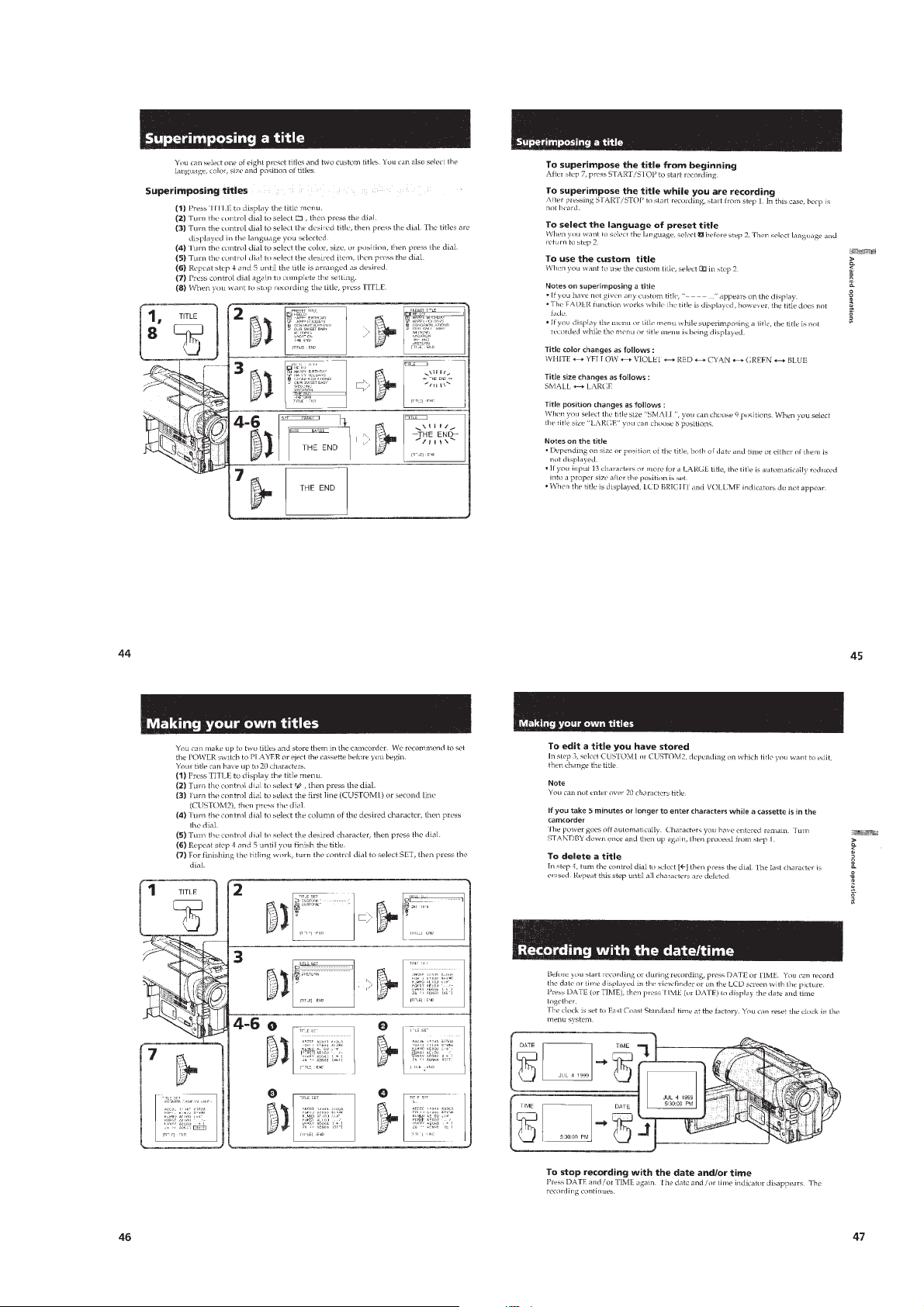

Superimposing a title ...............................................................1-11

Making your own titles............................................................1-11

Recording with the date/time...................................................1-11

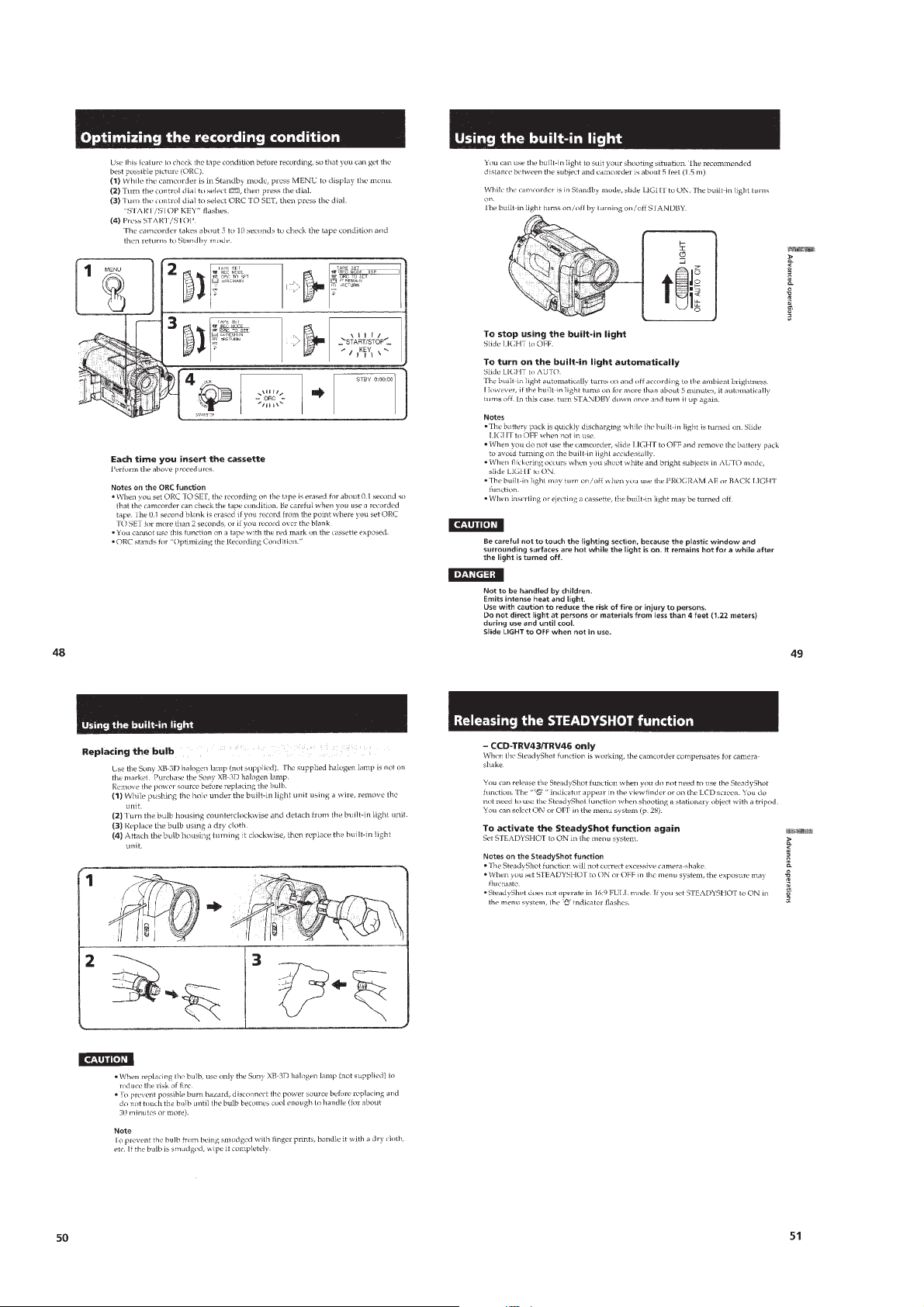

Optimizing the recording condition.........................................1-12

Using the built-in light.............................................................1-12

Releasing the STEADYSHOT function ..................................1-12

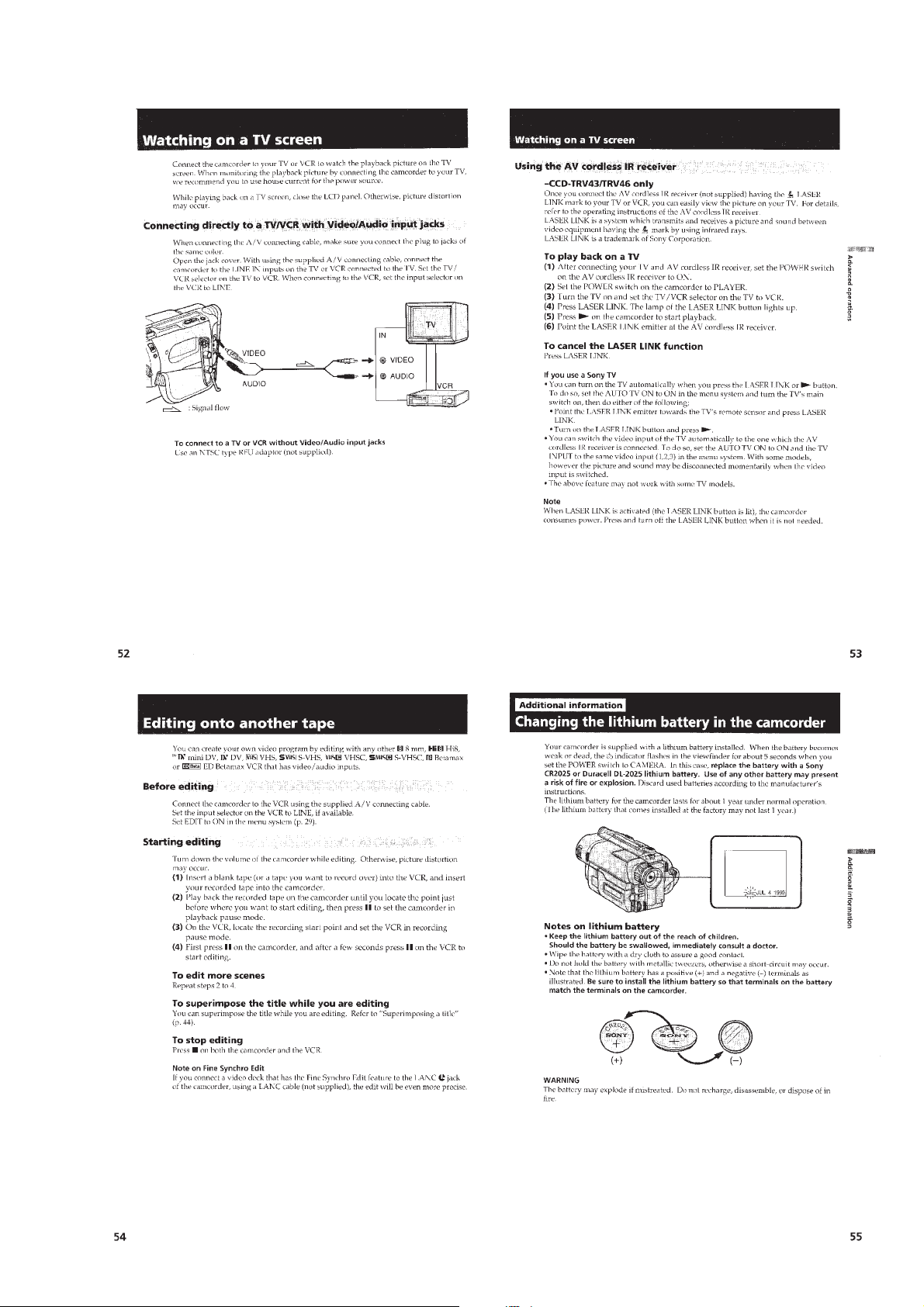

Watching on a TV screen......................................................... 1-13

Editing onto another tape.........................................................1-13

Changing the lithium battery in the camcoder ........................1-13

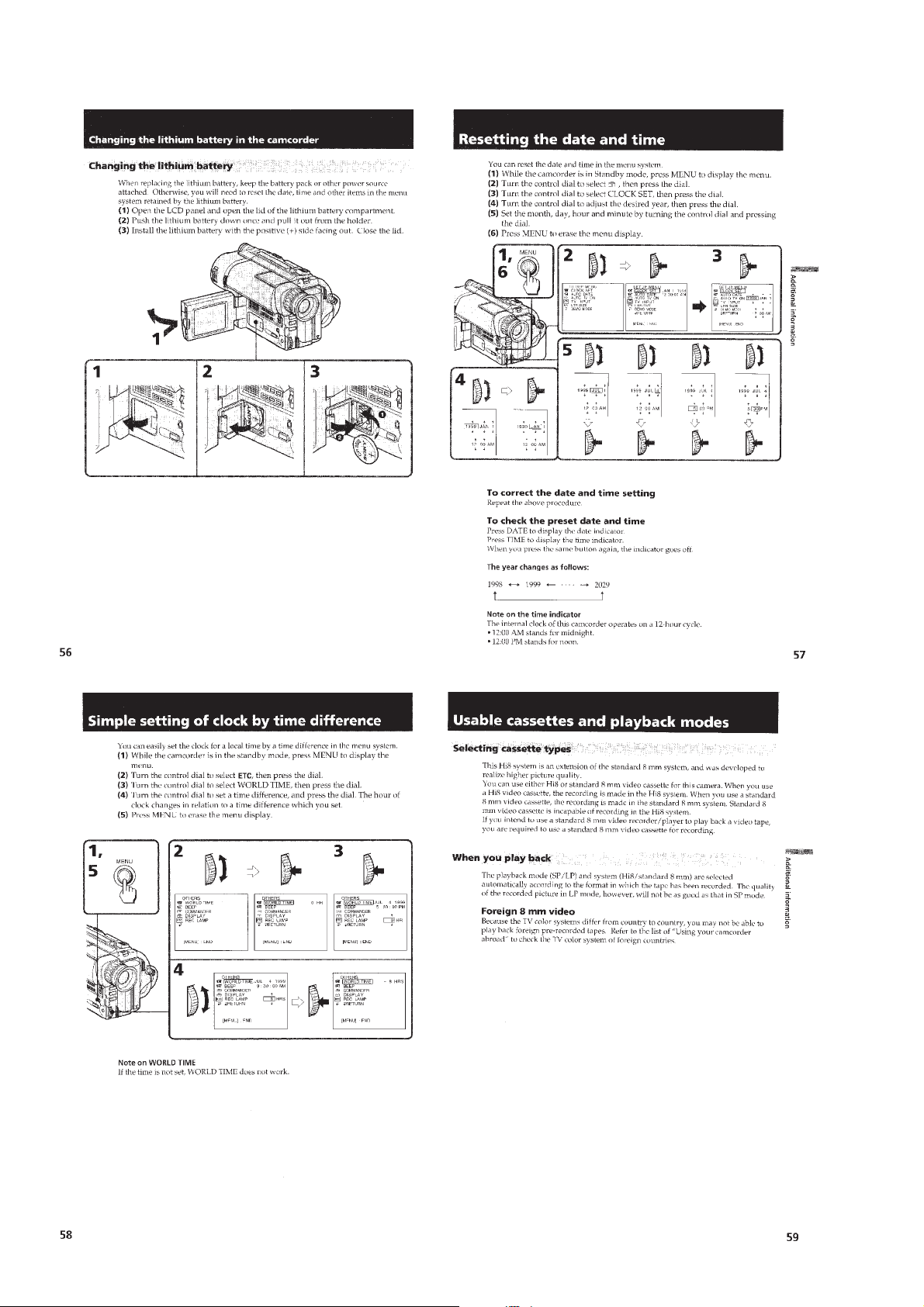

Resetting the date and time......................................................1-14

Simple setting of clock by time difference..............................1-14

Usable cassettes and playback modes .....................................1-14

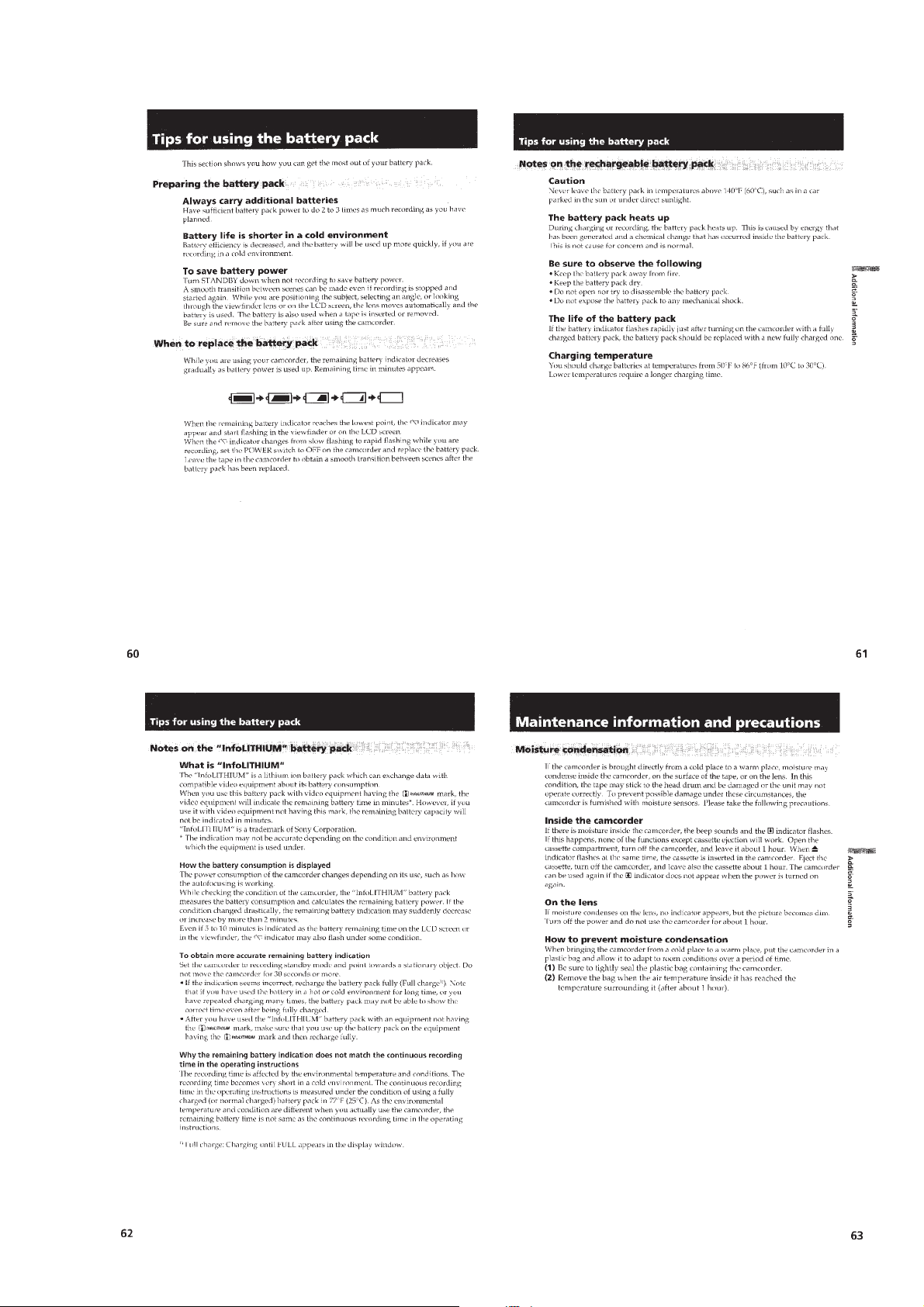

Tips for using the battery pack ................................................1-15

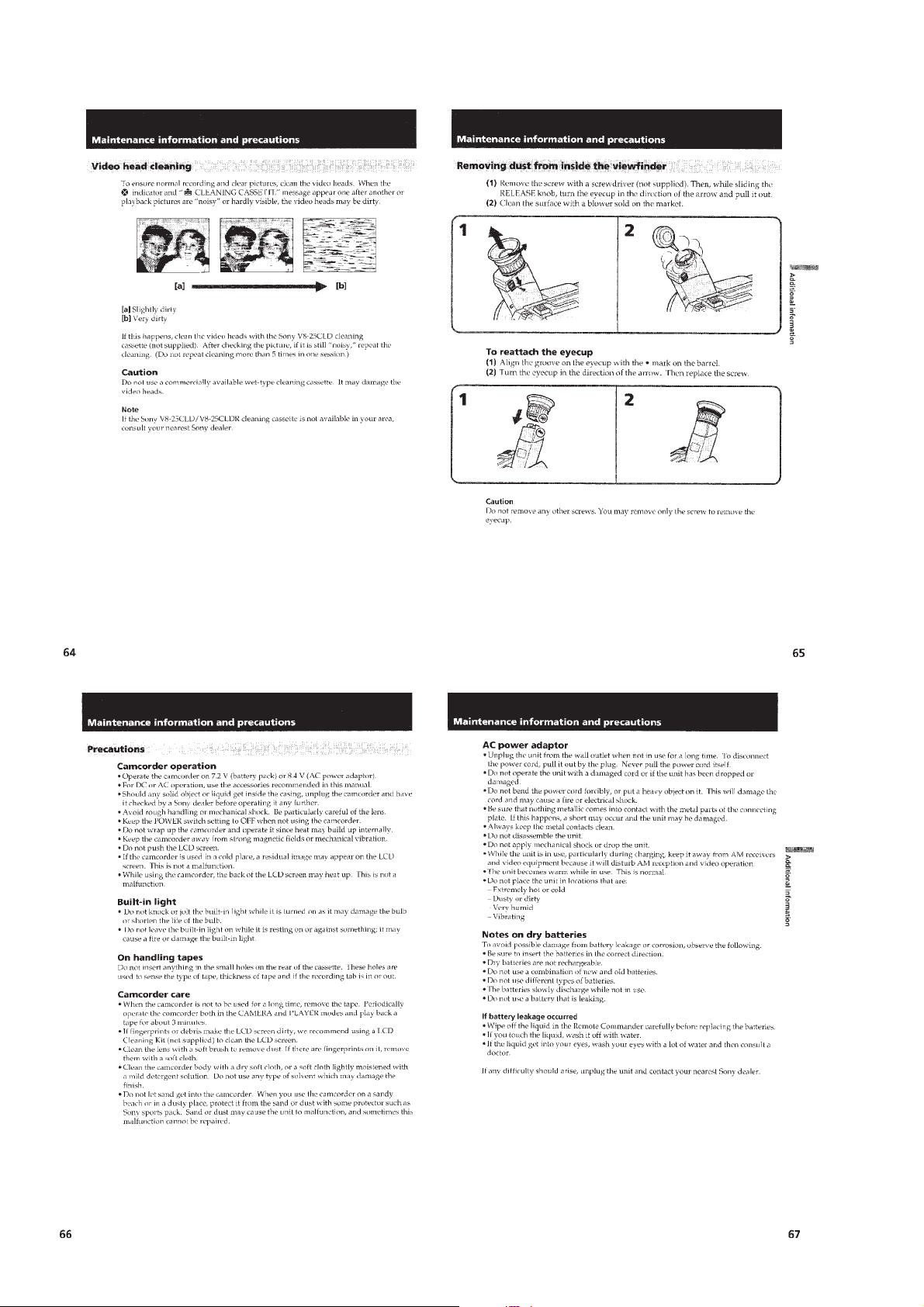

Maintenance information and precautions ..............................1-15

Using your camcorder abroad .................................................1-17

Truoble check ..........................................................................1-17

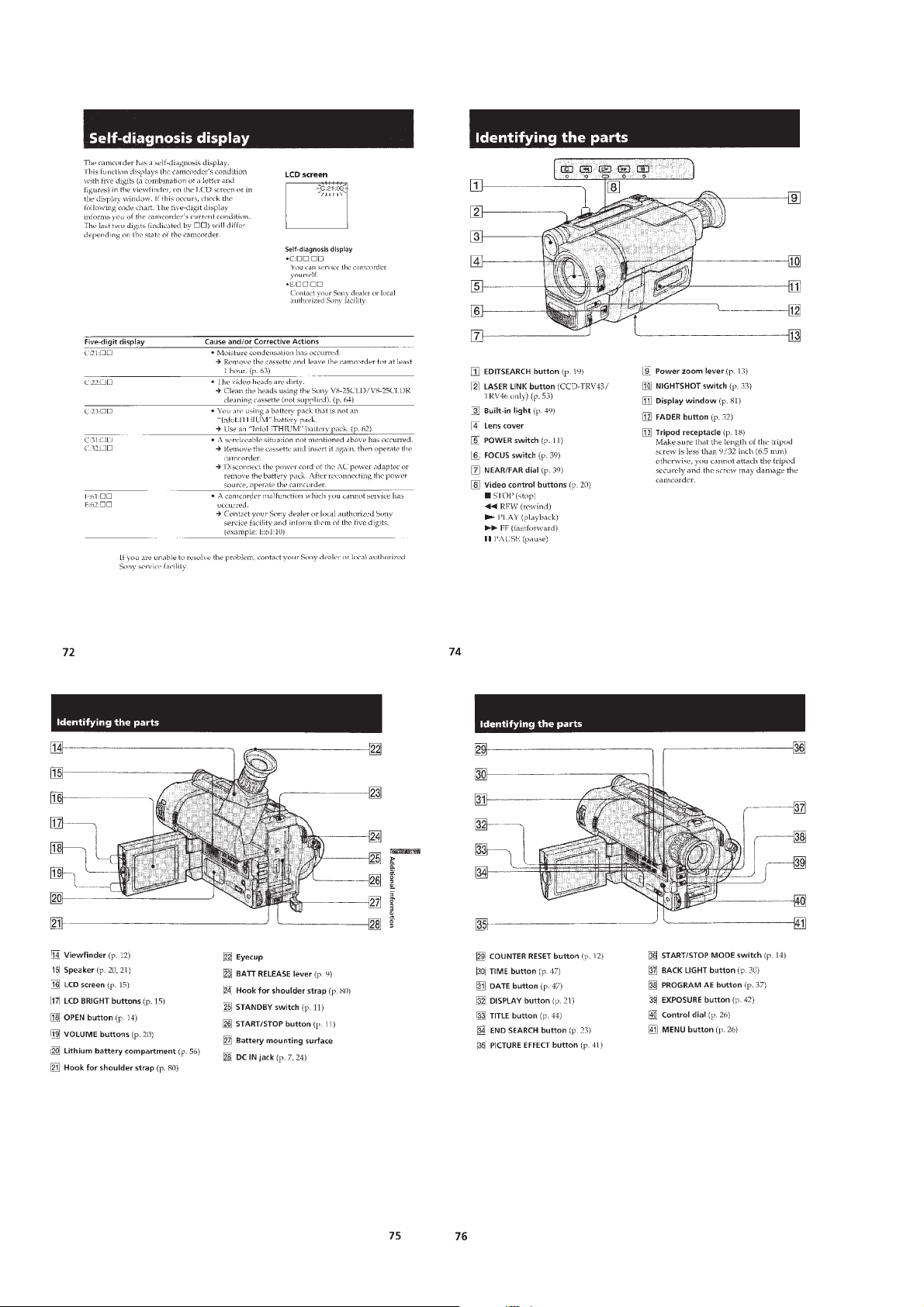

Self-diagnosis display..............................................................1-18

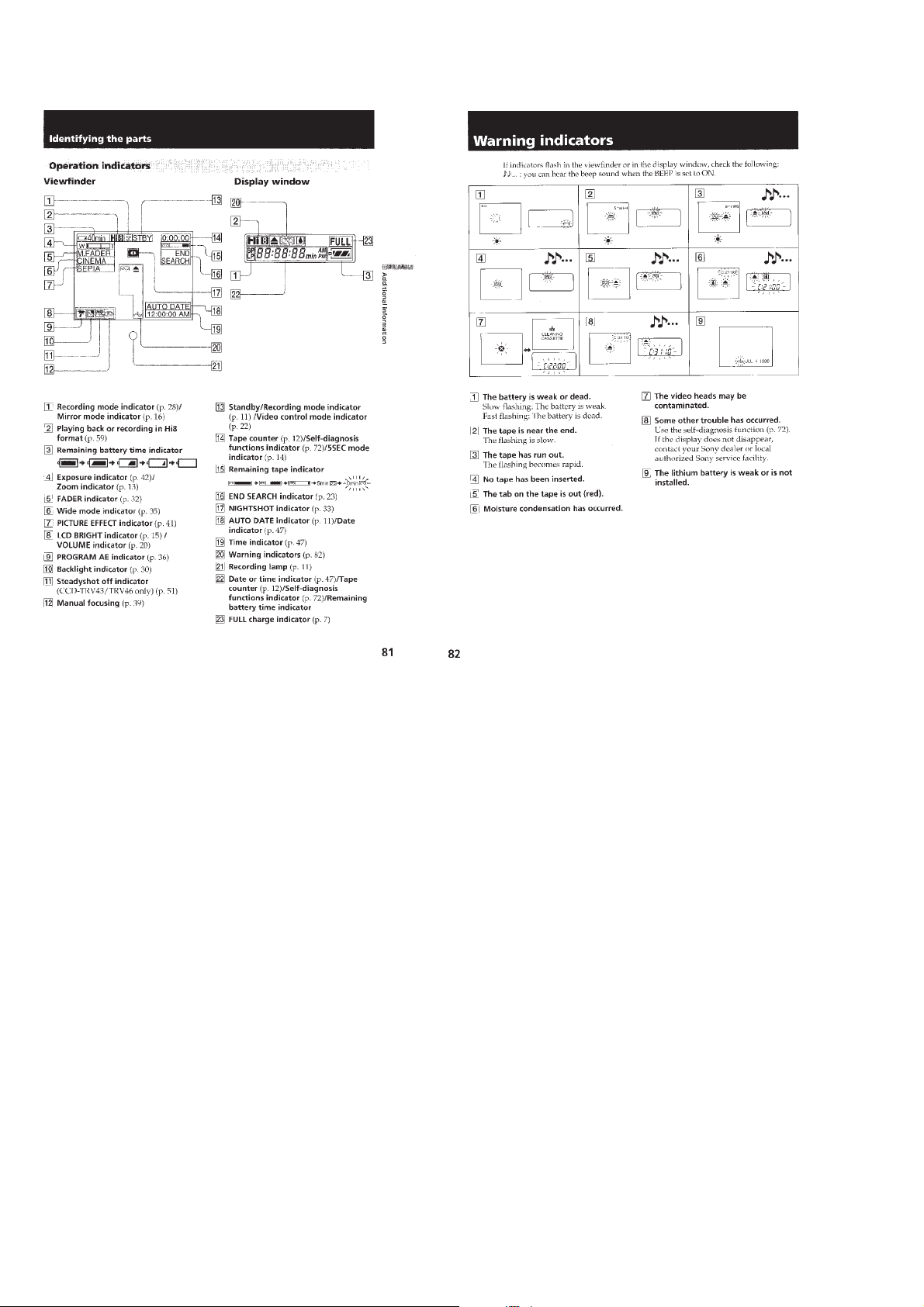

Identifying the parts.................................................................1-18

Warning Indicators ..................................................................1-20

2. DISASSEMBLY

2-1. Removal of Front Panel Block and Video Light Block....2-1

2-2. Removal of LB-54, VF-119 and

VF-120 Boards (Color View Finder Models) ..................2-2

2-3. Removal of VF-99 Board and

CRT Assembly (B/W View Finder Models).....................2-2

2-4. Removal of Cabinet (R) Block.........................................2-3

2-5. Removal of Cassette Lid Assembly ................................. 2-3

2-6. Remo v al of Battery Panel Block ..........................................2-3

2-7. Removal of Cabinet (L) Block .........................................2-4

2-8. Removal of Control Switch Block (FK-8500) .................2-4

2-9. Removal of Zoom Lens Block and VL-20/21 Board .......2-4

2-10. Removal of DD-117 and PJ-90/91 Boards.......................2-4

2-11. Removal of VC-215 abd SE-80/81 Boards ......................2-5

2-12. Removal of View Finder Block ........................................2-5

2-13. Removal of TR Cover, CF-60 Board and

Display Panel (TR series) ................................................2-6

2-14. Removal of IR Cover, CF-61 Board

and LCD Panel (TRV series)............................................2-6

2-15. Service Position ...............................................................2-7

2-16. Circuit Boards Location ...................................................2-8

2-17. Flexible Boards and Flat Cables Location .......................2-8

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram ....................................................3-1

3-2. Camera/Video 1 Block Diagram ......................................3-5

3-3. VTR/Camera Control Block Diagram .............................3-9

3-4. Servo Block Diagram .....................................................3-12

3-5. Mode Control Block Diagram........................................3-15

3-6. Audio Block Diagram....................................................3-19

3-7. LCD Bloc k Diagram (TRV model) ....................................3-23

3-8. Color EVF Block Diagram (Color EVF model)............3-26

3-9. B/W EVF Block Diagram (B/W EVF model) ...............3-29

3-10. Power Block Diagram ....................................................3-33

– 8 –

Page 9

4. PRINTED WIRING BOARDS AND SCHEMATIC

DIAGRAMS

4-1. Frame Schematic Diagram (1) ...........................................4-1

• Frame Schematic Diagram (2) ........................................4-4

4-2. Printed Wiring Boards and Schematic Diagrams...............4-7

• CD-210/211 (CCD Imager) Board ..................................4-8

• VC-215 (Camera, Y/C Processor, IN/OUT,

REC/PB Head Amp, Servo/System Control, Servo,

Audio, IR Transmitter, Mode Control) Board ............... 4-10

• VC-215 (Camera 1) Board ............................................4-17

• VC-215 (Camera 2) Board ............................................4-19

• VC-215 (Y/C Processor) Board ....................................4-23

• VC-215 (IN/OUT) Board ..............................................4-27

• VC-215 (REC/PB Head Amp) Board............................4-31

• VC-215 (Servo/System Control) Board ........................ 4-35

• VC-215 (Servo) Board ..................................................4-38

• VC-215 (Audio) Board ..................................................4-41

• VL-20/21 (Video Light) Board (Video Light model)....4-45

• VC-215 (IR Transmitter) Board ....................................4-46

• VC-215 (Mode Control) Board .....................................4-49

• SE-80/81 (Steady Shot) Board ......................................4-52

• PJ-90/91 (AV OUT) Board............................................4-55

• MA-345/346 (Mic, Laser Link) Board ..........................4-59

• CF-60 (Control (TR Series)) Board ...............................4-65

• CF-61 (Control (TRV Series)) Board ............................4-72

• Control Switch Block (FK-8500/SS-8500) ...................4-79

• PD-107 (RGB Decorder, LCD Drive,

Back Light, LCD (TRV Series)) Board .........................4-81

• PD-107 (RGB Decorder (TRV Series)) Board ..............4-83

• PD-107 (LCD Drive (TRV Series)) Board ....................4-86

• PD-107 (Back Light (TRV Series)) Board ....................4-89

• PD-107 (LCD (TRV Series)) Board ..............................4-90

• VF-99 (B/W EVF (B/W EVF Model)) Board ...............4-92

• VF-119 (COLOR EVF (COLOR EVF Model)) Board ......4-95

• VF-120 (COLOR EVF (COLOR EVF Model)) Board ....4-100

• LB-54 (Back Light (Color EVF model)) Board ..........4-102

• DD-117 (Power) Board ...............................................4-109

5. ADJUSTMENTS

5-1. CAMERA SECTION ADJUSTMENTS .......................... 5-1

1-1. Preparations before Adjustment (Camera Section) ..........5-1

1-1-1. List of Service Tools .................................................5-1

1-1-2. Preparations ...............................................................5-2

1-1-3. Precautions ................................................................5-5

1. Setting the Switch .....................................................5-5

2. Adjusting Procedure ..................................................5-5

3. Subject .......................................................................5-5

1-1-4. Adjusting Remote Commander .................................5-6

1. Using the adjusting remote commander....................5-6

2. Precautions upon using the adjusting

remote commander....................................................5-6

1-1-5. Data Processing .........................................................5-7

1-2. Initialization of D, E, F Page Data....................................5-8

1. Initialization the D, E, F Page Data...........................5-8

2. Modification of D, E, F Page Data...........................5-8

3. D Page Table .............................................................5-9

4. F Page Table ............................................................5-10

5. E Page Table............................................................5-12

1-3. Camera System Adjustments .......................................... 5-14

1. G-CAM flip Adjustment .........................................5-14

2. Hall Adjustment ......................................................5-15

3. Flange Back Adjustment .........................................5-16

3-1. Flange Back Adjustment (1) ...................................5-16

3-2. Flange Back Adjustment (2) ...................................5-16

4. Flange Back Check .................................................5-17

5. Picture Frame Setting ..............................................5-17

6. Color Reproduction Adjustment .............................5-18

7. IRIS IN/OUT Adjustment .......................................5-19

8. MAX GAIN Adjustment .........................................5-19

9. Auto White Balance Standard Data Input ...............5-20

10. Auto White Balance Adjustment.............................5-20

11. White Balance Check ..............................................5-21

12. Angular Velocity Sensor Sensitivity Check ............5-22

1-4. Color Electronic Viewfinder System Adjustments

(CCD-TR416/TR416PK/TR516/TR516PK/TR716)......5-23

1. EVF Initial Data Input.............................................5-23

2. VCO Adjustment (VF-119 board)...........................5-24

3. Bright Adjustment (VF-119 board).........................5-24

4. Contrast Adjustment (VF-119 board) .....................5-25

5. Backlight Consumption Current Adjustment

(VF-120 board) .......................................................5-25

1-5. Monochrome Electronic Viewfinder

System Adjustments .......................................................5-26

1-5-1. Horizontal Slant Check ...........................................5-26

1-5-2. Centering Adjustment ............................................. 5-26

1-5-3. Focus Adjustment ....................................................5-26

1-5-4. Aberration Adjustment ............................................5-27

1-5-5. Horizontal Amplitude Adjustment (VF-99 board) ..5-27

1-5-6. Vertical Amplitude Adjustment (VF-99 board).......5-28

1-5-7. Brightness Adjustments (VF-99 board) ..................5-28

1-5-8. Horizontal Amplitude, V ertical Amplitude,

Focus Check ............................................................5-28

1-6. LCD System Adjustment (TRV Series)..........................5-29

1. LCD initial data input ............................................. 5-29

2. VCO adjustment (PD-107 board) ...........................5-30

3. D range adjustment (PD-107 board) .......................5-30

4. Bright adjustment (PD-107 board) ..........................5-31

5. Contrast adjustment (PD-107 board) ......................5-31

6. V-COM adjustment (PD-107 board).......................5-32

7. Color adjustment (PD-107 board) ...........................5-32

8. V-COM adjustment (PD-107 board).......................5-33

9. White balance adjustment (PD-107 board) .............5-33

– 9 –

Page 10

5-2. MECHANICAL SECTION ADJUSTMENT .................5-34

2-1. Operating without a Cassette..........................................5-34

2-2. Tape path Adjustment .....................................................5-34

1. Preparations for adjustments ...................................5-34

5-3. VIDEO SECTION ADJUSTMENTS .............................5-35

3-1. Preparations before Adjustment......................................5-35

3-1-1. Equipments to be Used ...........................................5-35

3-1-2. Precautions on Adjusting ........................................5-36

3-1-3. Adjusting Connectors ..............................................5-36

3-1-4. Connecting the Equipments ....................................5-37

3-1-5. Alignment Tape .......................................................5-37

3-1-6. Output Level and Impedance ..................................5-39

3-1-7. Recording Mode (Standard 8/Hi8) switching

(Hi8 model) .............................................................5-39

3-1-8. Service Mode ..........................................................5-39

1. Test mode setting.....................................................5-39

2. Emergency memory address ...................................5-40

2-1. EMG CODE (Emergency Code).............................5-40

2-2. MSW Codes ............................................................ 5-41

3. Bit value discrimination ..........................................5-42

4. Switch check (1) ......................................................5-42

5. Switch check (2) ......................................................5-43

6. Headphone jack check ............................................5-43

7. Input/output selection check ...................................5-43

8. LED, LCD (display window) check........................5-44

9. Record of use check ................................................5-44

3-2. System Control System Adjustment ...............................5-45

1. Initialization of D, E, F Page Data .......................... 5-45

2. Battery End Adjustment (VC-215 board) ...............5-45

3-3. Servo System Adjustments .............................................5-46

1. CAP FG Offset Adjustment (VC-215 board).......... 5-46

2. Switching Position Adjustment (VC-215 board) ....5-46

3-4. Video System Adjustments .............................................. 5-47

1. 28 MHz Origin Oscillation Adjustment

(VC-215 board) .......................................................5-47

2. AFC f0 Adjustment (VC-215 board) ......................5-48

3. Filter f0 Adjustment (VC-215 board)...................... 5-48

4. Y OUT Level Adjustment (VC-215 board).............5-49

5. C OUT Level Adjustment (VC-215 board) .............5-49

6. RP Filter f0 Adjustment (VC-215 board)................5-50

7. Hi8 REC Y Current Adjustment (VC-215 board)

(CCD-TR516/TR516PK/TR716 CCD-TRV36/

TRV36PK/TRV43/TRV46/TRV46PK) ...................5-51

8. Standerd8 REC Y Current Adjustment

(VC-215 board) (CCD-TR315/TR416/TR416PK

CCD-TRV16/TRV16PK) ........................................5-52

9. Hi8 REC L Level Adjustment (VC-215 board)

(CCD-TR516/TR516PK/TR716 CCD-TRV36/

TRV36PK/TRV43/TRV46/TRV46PK) ...................5-53

10. Standerd8 REC L Level Adjustment

(VC-215 board) (CCD-TR315/TR416/TR416PK

CCD-TRV16/TRV16PK) ........................................5-54

11. REC C Current Adjustment (VC-215 board).......... 5-55

3-5. IR Transmitter Adjustments

(CCD-TR V43/TRV46/TRV46PK) ..........................5-56

1. IR Video Carrier Frequency Adjustment

(VC-215 board) .......................................................5-56

2. IR Video Deviation Adjustment (VC-215 board)....5-56

3. IR Audio Deviation Adjustment (VC-215 board) ...5-57

3-6. Monaural Audio System Adjustment ...............................5-58

1. 1.5 MHz Deviation Adjustment (VC-215 board) ....5-59

2. BPF Adjustment (VC-215 board) ...........................5-59

3-7. Arrangement Diagram for Adjustment Parts ...................5-60

6. REPAIR PARTS LIST

6-1. Exploded V iews .................................................................6-1

6-1-1. Remote Commander and Cassette Lid Assembly....6-1

6-1-2. Cabinet (L) and Battery Panel Assembly .................6-2

6-1-3. Front Panel Block Assembly ....................................6-3

6-1-4. Cabinet (R) Block Assembly (TR series) ................6-4

6-1-5. Cabinet (R) Block Assembly (TRV series) ..............6-5

6-1-6. Main Boards Block Assembly .................................6-6

6-1-7. Clolor EVF Block Assembly

(CCD-TR416/TR416PK/TR516/TR516PK/TR716) .....6-7

6-1-8. B/W EVF Block Assembly

(CCD-TR315 and TRV series).................................6-8

6-1-9. LCD Block Assembly (TRV series).........................6-9

6-1-10. Zoom Lens Block Assembly..................................6-10

6-1-11. Cassette Compartment Assembly .......................... 6-11

6-1-12. LS Chassis Assembly.............................................6-12

6-1-13. Mechanism Chassis Assembly...............................6-13

6-2. Electrical Parts List ..........................................................6-14

– 10 –

Page 11

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

SECTION 1

GENERAL

This section is extracted

from instruction manual of

CCD-TRV36/TRV43/TRV46.

1-1

Page 12

1-2

Page 13

1-3

Page 14

1-4

Page 15

1-5

Page 16

1-6

Page 17

1-7

Page 18

1-8

Page 19

1-9

Page 20

1-10

Page 21

1-11

Page 22

1-12

Page 23

1-13

Page 24

1-14

Page 25

1-15

Page 26

1-16

Page 27

1-17

Page 28

1-18

Page 29

1-19

Page 30

1-20

E

Page 31

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

k

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

SECTION 2

DISASSEMBLY

The equipment can be removed using the following procedure.

VIDEO CAMERA RECORDER

2-1. FRONT PANEL BLOCK

VIDEO LIGHT BLOCK

(Video light models only)

2-4. CABINET (R) BLOCK

2-5. CASSETTE LID ASSEMBLY

2-6. BATTERY PANEL BLOCK

2-7. CABINET (L) BLOCK

2-9. ZOOM LENS BLOCK

VL-21/22 BOARD

2-11. VC-215 & SE-80/81 BOARDS

2-2. LB-54/VF-119 & 120 BOARDS

(Color view finder models only)

2-3. CRT/VF-99 BOARD

(B/W view finder models only)

2-12. VIEW FINDER BLOCK

2-8. CONTROL SWITCH BLOCK

(FK-8500)

NOTE : Follow the disassembly procedure in the numerical order given.

2-5. CASSETTE LID ASSEMBLY

2-13. CONTROL SWITCH BLOCK (MF-8500)

TR COVER (TR series)

CF-60 BOARD (TR series)

LCD BLOCK (TR series)

2-14. IR COVER (TRV series)

CF-61 BOARD (TRV series)

LCD PANEL (TRV series)

2-10. DD-117 & PJ-90/91 BOARDS

2-1. REMOVAL OF FRONT PANEL BLOCK AND VIDEO LIGHT BLOCK

—Video light models—

CCD-TR516/TR516PK/TR716

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

1

Two screws (M2 x 4)

3

Screw (M2 x 4)

Claw

4

Screw (M 2x 4)

7

5

Two screws (M2 x 4)

FP-56 flexible board

CN303, 18P

2

Cabinet (LT)

6

Front panel block

8

Video light block

Two claws

—No video light models—

CCD-TR315/TR416/TR416PK

CCD-TRV16/TRV16PK

1

Two screws (M2x4)

5

Two screws (M2 x 4)

Claw

2

Cabinet (N)

3

Screw (M2x4)

6

Front panel bloc

4

Screw (M2x4)

7

FP-56 flexible board

CN303, 18P

2-1

Page 32

d

d

2-2. REMOVAL OF LB-54, VF-119 AND VF-120 BOARDS

(Color view finder model CCD-TR416/TR416PK/TR516/TR516PK/TR716)

1

Tilt-up the EVF block to the direction of arrow

3

Remove the EVF rear cabinet assembly

to the direction of arrow

B

.

!£

2

Two screws (M2 x 3)

B

A

VF-119 board

A

.

!™

LCD cushion (1)

!¡

LCX024AK-5

CN5402, 16P

Four claws

Three claws

5

FP-57 flexible board

CN5401,20P

9

LB-54 board

4

Flexible retainer sheet

!º

Back light cushion

Turn the cushion (Sponge rubber)

face to the LB-54 board side for

()

installation.

6

FP-57 flexible boar

CN5301,8P

2-3. REMOVAL OF VF-99 AND CRT ASSEMBLY

(B/W view finder model CCD-TR315 and TRV series)

1

Tilt-up the EVF block to the direction of arrow

3

Remove the EVF rear cabinet assembly

to the direction of arrow

2

Three screws (M2 x 3)

A

.

B

.

B

7

VF light interception sheet

7

CRT assembly

4

VF electrostatic sheet

6

CRT holder assmebly

8

VF-120 board

A

2-2

8

VF-99 boar

5

Flexible flat cable(FFC-235)

CN5803,4P

Page 33

2-4. REMOVAL OF CABINET (R) BLOCK

1

Two screws

(M2 x 4)

6

Harness

(PD-108)

2

Two screws

(M2 x 4)

5

Flat cable (FFC-257F)

CN911, 45P

4

Cabinet (R) block

3

Three screws

(M2 x 4)

IR knob

Pin

2

Battery panel block

3

Connector

CN801, 7P

1

Two screws (M2 x 4)

Note : Be sure to that the pin of the Lens assembly is put into the

hole of the IR knob when attaching.

5

Flat cable (FFC-257F)

CN911, 45P

2

Two screws

(M2 x 4)

3

Three screws

(M2 x 4)

Pin

(TRV series) (TR series)

1

4

Cabinet (R) block

IR knob

Two screws

(M2 x 4)

2-5. REMOVAL OF CASSETTE LID ASSEMBLY 2-6. REMOVAL OF BATTERY PANEL BLOCK

1

Two screws (M2x4)

2

Cassette lid assembly

2-3

Page 34

d

)

2-7. REMOVAL OF CABINET (L) BLOCK 2-8. REMOVAL OF CONTROL SWITCH BLOCK

Function Key Switch (FK-8500)

2

Cabinet (L) block

Screwdriver(

1

Remove the Function key switch in

the direction of arrow with pushing

-

)

the claw.

3

Flexible connector

CN934,12P

1

Screw (M2 x 3)

2-9. REMOVAL OF ZOOM LENS BLOCK AND

VL-21/22 BOARD

—Video light models—

CCD-TR516/TR516PK/TR716

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

—No video light models—

CCD-TR315/TR416/TR416PK

CCD-TRV16/TRV16PK

7

Two screws

(M2 x 3)

8

Shoe bracket

2

Flexible connector

CN935, 10P

Two claws

Two claws

2-10. REMO V AL OF DD-117 AND PJ-90/91 BO ARDS

1

Three screws (M2 x 3)

CN931, 70P

3

FP-621 flexible boar

CN101, 12P

5

FP-623 flexible board

6

CN501, 16P

Lens flexible board

CN551, 23P

0

VL-21/22 board

9

Screw (M2 x 3)

No video light

models

3

Screw (M2 x 3)

CN909

4

Zoom lens block

2

Screw (M2 x 3

1

Screw (M2 x 3)

!¡

FP-58 flexible board

(VC side)CN909, 4P

(VL side)CN151, 4P

Video light models

2

DD-117 board

5

PJ-90/91 board

4

Two screws (M2 x 4)

2-4

Page 35

2-11. REMO VAL OF VC-215 AND SE-80/81 BO ARDS

1

2

Flexible board

CN001, 16P

from video head

3

Flexible board

CN905, 10P

from drum motor

4

FP-248 flexible board

CN905, 12P

5

FP-221 flexible board

CN908, 15P

FP-220 flexible board

CN901, 8P from loading motor

!¡

VC-215 board

9

Two screws (M2 x 3)

6

FP-56 flexible board

CN916, 18P

0

Screw (M2x3)

7

FP-621 flexible board

CN902, 12P

8

FP-620 flexible board

(VC side) CN904, 10P

(SE side) CN650, 10P

!£

SE-80/81 board

!™

Four screws (M2x3)

2-12. REMOVAL OF VIEW FINDER BLOCK

—Color view finder—

CCD-TR416/TR416PK/TR516/TR516PK/TR716

2

VF flexible retainer sheet

4

Tapping screw

1

FP-57 flexible board

CN007, 20P

3

Tapping screw

5

VF base assembly

7

Three tapping

screws

—B/W view finder—

CCD-TR315 and TRV series

2

VF flexible retainer sheet

4

Tapping screw

1

Flat cable (FFC-235)

CN008, 4P

CCD-TR716 & TRV series

3

Tapping screw

5

VF base assembly

7

Three tapping

screws

6

Tilt-up the EVF block to

the direction of arrow.

2-5

6

Tilt-up the EVF block to

the direction of arrow.

Page 36

b

b

2-13. REMOVAL OF TR COVER, CF-60 BOARD AND DISPLAY PANEL ...(TR series)

!∞

4

FP-57 flexible board...(Color EVF type only)

CN007, 20P

Flat cable (FFC-235)...(B/W EVF type only)

CN008, 4P

6

Two tapping screws

5

Flat cable (FFC-257S)

CN001, 50P

8

Tapping screw

1

Flexible connector

CN002, 8P

2

Two tapping screws

!¢

LCD holder

Liquid crystal display panel

!™

!¡

Two tapping

screws

Hole

7

Three tapping screws

3

Control switch block (MF-8500)

CF-60 board

!£

CN009

0

Two tapping screws

Phase adjustment

S024

S015

!¶

Claw

9

TR cover assembly

Link plate spring

!§

IR kno

2-14. REMOVAL OF IR COVER, CF-61 BOARD AND LCD PANEL...(TRV series)

!¶

LCD panel

Hole

!¡

Three tapping screws

!§

Four tapping

screws

5

Flat cable (FFC-257S)

CN001, 45P

0

CF-61 board

9

Five tapping screws

1

Flexible connector

CN002, 8P

2

Two tapping screws

Phase adjustment

S024

4

Flat cable (FFC-235)

CN008, 4P

!™

Two tapping

screws

CN008

6

Harness

7

Harness (PD-108)

8

Three tapping screws

3

Control switch block (MF-8500)

Claw

!£

IR cover assembly

!∞

Link plate spring

!¢

IR kno

2-6

Page 37

CPC-7 jig (J-6082-382-A)

VC-215 board : CN910, 16P

VC-215 board

Screw (M2x3)

Cabinet (R) block

PJ-90 board

Front panel block

Cabinet (L) block

DD-117 board

Battry panel block

Control switch block

(FK-8500)

Extension cord 70P (J-6082-439-A)

DD-117 board : CN931 — VC-215 board : CN915

k

2-15. SER VICE POSITION

Preparation : Refer to previous section “DISASSEMBLY”, and con-

nect as shown in the figure after each parts has been

removed.

—TR series—

—TRV series—

Extension cord 70P (J-6082-439-A)

DD-117 board : CN931 — VC-215 board : CN915

Control switch block

(FK-8500)

Battry panel block

DD-117 board

Cabinet (L) block

CPC-7 jig (J-6082-382-A)

VC-215 board : CN910, 16P

VC-215 board

Screw (M2 x 3)

Cabinet (R) block

LCD panel bloc

PJ-91 board

Front panel block

2-7

Page 38

y

2-16. CIRCUIT BOARDS LOCATION

Color EVF models only

LB-54...

VF-119...

(Color EVF)

DD-117

(Power)

Color EVF models only

(Back light)

VF-120...

(Color EVF)

CF-60...

(Control)

Color EVF models only

TR series only

TR516/TR516PK/TR716

VL-21...

VL-22...

TRV36/TRV36PK/TRV43/

TRV46/TRV46PK

(Video light)

PJ-90...

PJ-91...

(AV Out)

TR series

TRV series

VF-99...

B/W EVF models only

(B/W EVF)

CD-210...

CD-211...

(CCD imager)

TR series only

TRV series only

PD-107...

TRV series only

RGB decoder, LCD,

LCD drive, Back light

VC-215

Camera, Y/C prosessor, IN/OUT,

REC.PB head amp, Servo/System control,

Servo, Audio, IR transmitter, Mode control

MA-345...

MA-346...

(Mic, Laser link)

TR series

TRV series

CF-61...

TRV series only

(Control)

2-17. FLEXIBLE BOARDS AND FLAT CABLES LOCATION

FP-57...

Color EVF models only

Stand-by, Start/Stop

(SS-8500)

Back light...

Color EVF models only

Zoom lens

FP-623

FP-58...

Video light models only

FP-355

Flat cable (FFC-235)...

FP-356

SE-80...

SE-81...

(Steady shot)

B/W EVF models only

TR716 only

TRV series only

FP-680

Flat cable (FFC-257F)

FP-621

FP-56

FP-249

FP-248

FP-221

Function key

(FK-8500)

Capstan motor

2-8

E

Video head

Drum motor

FP-220

FP-620...

FP-642...

TRV series onl

Manual forcus

(MF-8500)

TR716 & TRV series only

Page 39

SECTION 3

BLOCK DIAGRAMS

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3-1. OVERALL BLOCK DIAGRAM

( TR716 only )

(VIDEO LIGHT MODEL)

(TR MODEL TR516/TR516PK/TR716)

(TRV MODEL TRV36/TRV36PK/TRV43/TRV46/TRV46PK)

VIDEO

LIGHT

4-69

SELECT

( TRV MODEL )

TR MODEL : CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

TRV MODEL : CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

COLOR EVF MODEL : CCD-TR416/TR416PK/TR516/TR516PK/TR716

B/W EVF MODEL : CCD-TR315

STEADY SHOT MODEL : CCD-TRV43/TRV46/TRV46PK

IR TRANSMITTER MODEL : CCD-TRV43/TRV46/TRV46PK

REMOTE COMMANDER MODEL : CCD-TR516/TR516PK/TR716

VIDEO LIGHT MODEL : CCD-TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

I/O L

I/O R

3.1V

3.1V

3-1 3-2

3-3

3-4

Page 40

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3-2. CAMERA/VIDEO 1 BLOCK DIAGRAM

1.3Vp-p

H

IC401

7

CAMERA REC

H

IC502

CAMERA REC

0.3Vp-p

CAMERA REC

0.4Vp-p

H

IC202

16

1.3Vp-p

26

CAMERA REC

H

IC202

0.5Vp-p

13

CAMERA REC

H

IC001

3

IC001

0.3Vp-p

2V

5 21

TRIG : IC001

CAMERA REC

2V

IC001

44 48

3Vp-p

,

3.1

7Vp-p

H

IC401

3 4

TR MODEL : CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

TRV MODEL : CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

COLOR EVF MODEL : CCD-TR416/TR416PK/TR516/TR516PK/TR716

B/W EVF MODEL : CCD-TR315

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

IC401

CAMERA REC

3.2Vp-p

0.14usec

IC502

—

3.1

2 10

PB

IC202

0.4Vp-p

V

40

PB

V

IC001

0.4Vp-p

17

PB

0.4Vp-p

H

IC502

36

7Vp-p

H

,

1 2

CAMERA REC

14.32 MHz

IC501

2.3Vp-p

11 12,

3.1

CAMERA REC

28.636 MHz

IC501

2.3Vp-p

5

CAMERA REC

3Vp-p

H

IC501

44

PB

IC001

0.4Vp-p

V

11

PB

0.4Vp-p

IC001

H

7

CAMERA REC

4.12 MHz

Q001

7Vp-p

C

CAMERA REC

IC001

2.9Vp-p

21

2V

CAMERA REC

3Vp-p

IC501

V

45

H

IC151 62

1.6Vp-p

H

IC151

0.46Vp-p

3

CAMERA REC

H

IC202

6

CAMERA REC

3.58 MHz

IC202

0.84Vp-p

3.1Vp-p

66

CAMERA REC

IC202

CAMERA REC

3Vp-p

H

IC201

20

0.34Vp-p

H

3

CAMERA REC

H

IC202

0.9Vp-p

33

CAMERA REC

V

IC201

3Vp-p

19

3-5

IC151 29

0.32Vp-p

H

IC151

H

2.1Vp-p

5

CAMERA REC

0.18Vp-p

H

IC202

26

CAMERA REC

H

IC202

0.18Vp-p

23

CAMERA REC

IC202

3Vp-p

V

81

CAMERA REC

7.16 MHz

IC201

3.2Vp-p

8

3.1

PB

3Vp-p

H

IC202

80

3-6 3-7

3-8

Page 41

3-3. VTR/CAMERA CONTROL BLOCK DIAGRAM

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

710 only

3.1V

1.7Vp-p

20 MHz

IC402 1

3.1V

IC402

3Vp-p

70

13usec

3.1V

IC402

3Vp-p

4V

48

3.1V

3.1V

TR MODEL : CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

TRV MODEL : CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

COLOR EVF MODEL : CCD-TR416/TR416PK/TR516/TR516PK/TR716

STEADY SHOT MODEL : CCD-TRV43/TRV46/TRV46PK

3Vp-p

2V

IC402

47

3.1V

3.1V

3.1V

3.1V

3-9

3-10

3-11

Page 42

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3-4. SERVO BLOCK DIAGRAM

2.8msec

IC402

3Vp-p

3Vp-p

116

IC402

13usec

69

506 kHz

IC801 64

0.76Vp-p

3.1V

1.2Vp-p

5.6msec

IC451 1 2 29,,

3.1V

2V

IC402

3Vp-p

117

1.2msec

IC402

3Vp-p

115

3Vp-p

13usec

IC402

68

507 kHz

IC801 4

0.76Vp-p

3-12

3-13 3-14

Page 43

3-5. MODE CONTROL BLOCK DIAGRAM

SELECT

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

(TRV MODEL)

1.5Vp-p

20 MHz

IC604 41

2.6Vp-p

32 kHz

IC604 52

TRV

TR MODEL : CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

TRV MODEL : CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

REMOTE COMMANDER MODEL : CCD-TR516/TR516PK/TR716

VIDEO LIGHT MODEL : CCD-TR516/TR516PK/TR716

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

CCD-TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3.1V

3-15 3-16

3-17

(VIDEO LIGHT MODEL)

(VIDEO LIGHT MODEL)

(TR MODEL TR516/TR516PK/TR716)

(TRV MODEL TRV36/TRV36PK/TRV43/TRV46/TRV46PK)

VIDEO

LIGHT

3-18

Page 44

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3-6. AUDIO BLOCK DIAGRAM

CAMERA REC

V

IC301

IC751

22

0.09usec

IC751

0.7Vp-p

0.34Vp-p

16

3.1V

0.5Vp-p

H

IC751

41

PB

0.4Vp-p

V

IC301

24

IC751

0.5Vp-p

15

0.25Vp-p

3.58 MHz

IC751 7

0.36Vp-p

29

2usec

0.09usec

CAMERA REC

3.58 MHz

IC301 32

0.26Vp-p

CAMERA REC

2V

IC301

TR716 only

3.1V

TR MODEL : CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

TRV MODEL : CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

IR TRANSMITTER MODEL : CCD-TRV43/TRV46/TRV46PK

2.9Vp-p

21

3-19

3-20 3-21

3-22

Page 45

3-7. LCD BLOCK DIAGRAM

(TRV MODEL)

H

IC5502

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

H

16

4.7Vp-p

IC5502

2H

IC5502

20

4.2Vp-p

0.7Vp-p

13

3.1V

3.1V

H

IC5502

2H

IC5502

22

4.2Vp-p

2H

4.2Vp-p

IC5502

0.44Vp-p

8

H

IC5502

0.2Vp-p

9

H

IC5502

0.2Vp-p

10

Approx.5.8MHz : 4.1Vp-p

IC5601 26

IC5602

DAC AMP

IN+

OUT1

3

1

FRPT

FRPV

IC5601 37

H

4.7Vp-p

3.1V

24

IC5601 24

4.7Vp-p

Approx.2.9 MHz

H

5601 4

4.7Vp-p

15

VGL

COM

11

FRPT

FRPV

12

3-23

IC4601/5601

20msec

34

4.7Vp-p

3-24

TRV MODEL : CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3.1V

3-25

Page 46

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3-8. COLOR EVF BLOCK DIAGRAM

(COLOR EVF MODEL)

FP-57 (FLEXIBLE

IC5401

7.5Vp-p

2H

IC5401

7.2Vp-p

2H

20

3.1V

22

LCD902

3.1V

3.1V

IC5301

7.6Vp-p

2H

IC5401

24

3.1V

12Vp-p

H

15

2.4Vp-p

H

IC5301

4

3.1V

3.1V

3.1V

IC5401

V

IC5404

3Vp-p

H

14

3Vp-p

45

IC5404

3.4Vp-p

1.84 MHz

IC5404 23 24

,

7.852 kHz

IC5404 20 21

3Vp-p

,

11.06 MHz

IC5404 41

3Vp-p

H

22

2.7Vp-p

IC5404

3Vp-p

V

18

COLOR EVF MODEL : CCD-TR416/TR416PK/TR516/TR516PK/TR716

3-26

3-27 3-28

Page 47

3-9. B/W EVF BLOCK DIAGRAM

B/W EVF MODEL

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

T901/T902

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

B/W EVF MODEL : CCD-TR315

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

H

IC901

IC901

2.2Vp-p

13

H

1Vp-p

11

3-29 3-30

3-31

3-32

Page 48

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3-10. POWER BLOCK DIAGRAM

(VIDEO LIGHT MODEL)

(TR MODEL TR516/TR516PK/TR716)

(TRV MODEL TRV36/TRV36PK/TRV43/TRV46/TRV46PK)

VIDEO

3.1V

3.1V

J

3.1V

3.1V

3.1V

3.1V

3.1V

3.1V

20

20

3.1V

3.1V

3.1V

3.1V

3.1V

3.1V

TR MODEL : CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

TRV MODEL : CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

COLOR EVF MODEL : CCD-TR416/TR416PK/TR516/TR516PK/TR716

B/W EVF MODEL : CCD-TR315

STEADY SHOT MODEL : CCD-TRV43/TRV46/TRV46PK

IR TRANSMITTER MODEL : CCD-TRV43/TRV46/TRV46PK

3.1V

3.1V

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

3.1V

4. 75VMT

3.1V

3.1V

3.1V

TR716 only

3-33

3-34

3-35

3-36 E

Page 49

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1)

SECTION 4

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

(TR MODEL)

(COLOR EVF MODEL)

(B/W EVF MODEL)

(TR710 ONLY)

4-1

4-2

4-3

FRAME

Page 50

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

FRAME SCHEMATIC DIAGRAM (2)

FRAME

4-4

4-5 4-6

Page 51

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

• For printed wiring boards.

• b : Pattern from the side which enable seeing.

(The other layer's patterns are not indicated.)

• Circled numbers refer to waveforms.

• Through hole is omitted.

• There are few cases that the part printed on diagram isn’t

mounted in this model.

• Chip parts.

Transistor Diode

C

Q

BE

132

5 46

5 64

Q

Q

312

312

54

21

Q

Q

534

3

21

3213

21

• For schematic diagrams.

• All capacitors are in µF unless otherwise noted. pF: µµF.

50 V or less are not indicated e xcept for electrolytics and tantalums.

• Chip resistor are 1/16W unless otherwise noted.

kΩ : 1000Ω, MΩ : 1000kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum capacitor, because

it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

TA A 2520

Kinds of capacitor

• Constants of resistors, capasitors, ICs and etc with XX indicate

tha they are not used. In such cases, the unused circuits may be

indicated.

• Parts with differ according to the model/destination. Refer to

the mount table for each function.

• All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

• Signal name

XEDIT n EDIT PB/XREC n PB/REC

• 2 : non flammable resistor.

• 1 : fusible resistor.

• H : panel designation.

• A :B+ Line

• B :B– Line

• J : IN/OUT direction of (+, –) B LINE.

• C :adjustment for repair.

• Circled numbers refer to w aveforms.

The components identified by

mark !or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

When indicating parts by reference number, please include the

board name.

22U 10UH

(

Â

Temperature

chracteristics

Â

External dimensions (mm)

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

• Measuring conditions voltage value and waveform.

• The object is color bar chart of pattern box.

• Voltages and dc between ground and measurement points.

Readings are taken with a digital multimeter (DC 10MΩ).

• Voltages variations may be noted due to normal production

tolerances.

1.Connection

Pattern box

Lens reference plane

surface lmaging surface

of CCD imager

(IC401 on CD-197/198 board)

2.Adjust the distance so that the output waveform of Fig. a and the

Fig. b can be obtain.

H

Yellow

Cyan

B

A

Fig. a (Video output terminal output waveform)

Electron beam

scanned frame

Cyan

White

Green

Yellow

Fig. b (Picture on monitor TV)

1.5m

White

Green

A=B

Red

Magenta

Magenta

Red

B

Blue

Blue

A

CRT picture frame

CD-210/211 (CCD IMAGER) PRINTED WIRING BOARD

– Ref No. CD-210 BOARD: 4,000 series, CD-211 BOARD: 9,000 series –

CD-210/211 BOARD (SIDE B)

C

B

3

1

2

A

09

CD-210/

CD-211 BOARD

C401 A-3

C403 B-3

C405 A-3

C406 A-3

C407 B-3

CN401 B-4

IC401 A-1

L401 B-1

Q402 B-3

R401 A-3

R404 B-3

R405 A-3

R406 B-4

1234

• For Printed Wiring Boards.

There are few cases that the part isn't mounted in this model is

printed on this diagram.

• Chip transistor

C

Q

BE

VF-99...

(B/W EVF)

TRV series only

CF-61...

(Control)

CD-210/211 BOARD (SIDE A)

1-672-4581-672-464-

B/W EVF models only

CD-210...

TR series only

CD-211...

TRV series only

(CCD imager)

PD-107...

TRV series only

RGB decoder, LCD,

LCD drive, Back light

TR716 only

SE-80...

SE-81...

TRV series only

(Steady shot)

11

11 21

CD-210/211 BOARD

CAMERA REC

1

H

IC401

,

1 2

2

H

IC401

,

3 4

3

7Vp-p

7Vp-p

Note on the CCD imager replacement

• The CCD imager is not mounted for the already mounted

CD-210/211 board supplied as the repair parts.

When replacing the CD-210/211 board, remove the CCD imager from the old board and install on the new board.

• Perform all adjustments of the camera block when the CCD

imager has been replaced.

• Handle the CCD imager with attention such as MOS IC as it

may be broken by static electricity in the structure.

Also, prevent the receiving light section from dust attached

and strong light.

Refer to page 3 as for “Table for difference

of functions” of models and classification.

4-7

4-8

H

IC401

1.3Vp-p

7

4-9

CCD IMAGER

CD-210/211

Page 52

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716

VC-215 BOARD (SIDE B)

123456789

A

B

C

D

E

F

G

09

1-672-456-

11 21

27

26

25

6

5

1

2

4

3

52

51

50

61

60

59

57

58

CCD-TRV16/TRV16PK/TRV36/TRV36PK/TRV43/TRV46/TRV46PK

VC-215 BOARD

(SIDE B)

C002 A-5

C003 A-5

C008 A-4

C011 B-5

C012 B-5

C013 B-6

C014 B-6

C015 B-5

C016 B-5

C017 B-5

C019 B-5

C020 B-6

C022 B-5

C025 B-6

C038 B-6

C040 B-6

C042 B-5

C043 B-5

C048 B-6

C050 C-6

C051 B-5

C054 B-5

C056 B-5

C058 B-6

C060 C-5

C066 B-6

C067 C-6

C068 C-6

C069 C-5

C070 C-6

C072 C-6

C074 C-6

C076 C-5

C080 C-5

C083 C-5

C086 C-4

C087 C-4

C090 C-6

C152 D-8

C157 E-8

C158 E-8

C159 C-8

C174 D-8

C175 D-8

C176 D-8

C182 D-8

C183 D-8

C190 D-8

C191 C-7

C192 C-7

C202 D-3

C203 D-3

C205 E-4

C206 D-4

C207 D-3

C208 D-3

C209 D-6

C210 D-6

C211 E-3

C212 D-3

C213 D-5

C217 D-4

C218 D-4

• For Printed Wiring Boards.

• This board is four-layer print board. However, the patterns of

layers 2 to 3 have not been included in the diagram.

C227 D-5

C229 E-5

C232 D-3

C233 D-5

C234 D-5

C235 D-3

C236 D-3

C239 E-4

C241 E-3

C243 F-3

C244 F-3

C246 D-4

C247 D-4

C249 E-4

C252 F-3

C301 B-9

C302 C-9

C348 F-7

C371 E-8

C372 E-7

C378 F-7

C380 E-7

C381 E-7

C382 F-8

C383 E-8

C384 E-8

C385 E-8

C386 F-8

C387 F-8

C388 E-8

C402 C-1

C451 A-3

C452 A-3

C453 A-3

C454 A-3

C455 A-3

C456 A-4

C457 A-3

C458 A-4

C459 A-4

C460 A-4

C461 A-3

C462 A-4

C463 A-3

C464 B-3

C465 B-4

C466 B-3

C467 B-3

C468 B-3

C469 B-4

C470 B-4

C471 B-4

C473 A-1

C474 A-2

C475 A-2

C476 A-2

C477 A-2

C478 A-2

C479 A-2

C479 A-2

C480 A-2

C481 A-1

C483 A-2

C484 A-2

C485 A-1

C504 E-6

C505 E-6

C506 E-7

C507 E-6

C508 F-5

C509 E-6

C510 E-6

C514 E-5

C515 E-5

C553 G-6

C554 G-7

C556 G-7

C557 G-5

C558 G-5

C559 F-7

C563 F-6

C564 F-6

C566 G-7

C569 G-6

C572 F-6

C607 E-2

C610 F-2

C611 F-2

C613 E-1

C625 E-2

C626 E-2

C627 F-2

C630 F-3

C634 F-3

C636 F-2

C704 F-7

C714 F-8

C715 F-8

C751 B-7

C752 A-7

C753 A-7

C754 A-7

C755 A-7

C756 A-7

C758 A-8

C759 B-7

C760 B-7

C761 B-8

C762 B-8

C763 B-8

C764 B-8

C765 A-8

C766 A-8

C767 B-8

C768 B-8

C769 A-8

C770 A-8

C771 B-8

C772 A-8

C773 B-8

C774 A-8

C775 A-8

C776 B-9

C777 A-9

C778 B-9

C781 B-8

CN904 A-9

CN910 D-1

D001 C-4

D201 D-3

D202 D-3

D371 E-8

D502 F-5

D604 F-2

D608 F-1

D609 F-2

D610 E-2

D611 E-2

D612 E-2

FB204 F-3

FB205 F-3

FB503 E-5

FB504 E-5

IC152 C-8

IC201 E-4

IC204 F-4

IC371 E-7

IC401 C-2

IC451 A-4

IC452 A-2

IC501 E-6

IC552 G-6

IC602 E-2

IC603 F-1

IC751 B-8

L002 B-4

L003 B-4

L007 C-6

L008 C-6

L010 C-6

L011 C-6

L015 C-5

L019 B-6

L152 D-8

L204 D-4

L205 D-6

L206 D-3

L552 F-7

L602 E-3

L701 F-7

L702 F-7

L704 F-8

L751 B-8

L752 B-8

L753 B-8

Q003 A-5

Q004 A-6

Q005 A-5

Q006 A-5

Q007 A-6

Q008 B-6

Q009 B-6

Q010 B-5

Q011 B-5

Q012 B-5

Q016 B-5

Q017 B-6

Q018 C-5

Q019 C-6

Q021 B-6

Q023 C-6

Q025 C-6

Q026 C-6

Q030 C-5

Q031 C-5

Q032 C-7

Q038 C-5

Q039 C-5

Q041 B-5

Q042 C-4

Q151 D-8

Q204 D-5

Q205 E-5

Q208 D-6

Q217 D-4

Q303 C-9

Q306 B-9

Q307 C-9

Q451 B-3

Q454 A-1

Q455 A-1

Q551 G-7

Q607 F-2

Q619 E-3

Q705 F-7

Q901 D-2

R001 A-6

R002 A-6

R008 A-4

R009 A-5

R010 B-6

R011 B-5

R012 B-5

R013 B-6

R014 B-4

R015 B-5

R016 B-6

R017 B-6

R018 B-5

R019 B-5

R020 B-4

R021 B-5

R022 C-5

R023 B-6

R025 B-6

R029 B-5

R031 B-5

R040 B-5

R041 B-5

R042 B-5

R047 B-5

R048 B-5

R049 B-6

R050 B-6

R051 B-6

R056 B-6

R058 B-6

R066 B-6

R067 C-6

R068 C-6

R069 C-6

R070 C-6

R076 C-6

R077 C-6

R078 C-6

R079 C-6

R080 C-6

R083 C-5

R084 C-5

R087 C-5

R088 C-5

R089 C-5

R090 C-5

R094 C-5

R095 D-7

R105 C-6

R106 C-6

R109 B-4

R110 B-4

R112 C-7

R152 D-8

R154 D-8

R157 D-8

R179 D-8

R180 D-8

R183 E-8

R184 E-7

R185 D-7

R186 D-7

R188 D-8

R189 C-7

R190 C-8

R202 D-3

R203 D-4

R204 D-3

R205 D-3

R206 D-4

R208 D-3

R210 D-3

R211 D-3

R212 D-5

R214 E-5

R215 D-5

R216 D-5

R217 E-4

R223 D-3

R224 D-3

R226 D-4

R240 D-4

R244 D-3

R245 D-4

R246 D-3

R247 D-3

R248 E-3

R249 E-3

R250 F-3

R254 D-2

R255 E-5

R257 D-4

R260 D-3

R261 E-4

R262 D-4

R263 E-6

R264 E-4

R265 E-4

R266 E-4

R267 D-4

R304 B-9

R305 C-9

R306 B-9

R307 C-9

R312 C-9

R324 B-9

R326 C-9

R327 C-9

R371 E-8

R372 E-8

R373 D-9

R374 E-8

R376 E-8

R377 E-8

R378 E-8

R379 E-7

R382 E-8

R383 E-8

R384 E-7

R385 F-8

R386 F-8

R388 E-8

R389 E-8

R403 C-2

R404 C-3

R415 B-2

R416 B-2

R417 B-2

R418 B-2

R426 C-2

R427 B-2

R428 B-2

R429 B-2

R430 B-2

R432 C-2

R433 C-2

R434 C-2

R435 B-2

R442 B-2

R443 C-2

R452 A-3

R453 A-3

R454 A-3

R455 A-3

R456 A-3

R457 A-3

R459 A-3

R460 A-3

R461 A-3

R462 A-3

R463 A-3

R467 A-2

R468 A-2

R469 A-2

R470 A-2

R471 A-2

R472 A-2

R473 A-1

R475 A-1

R477 A-2

R479 A-2

R480 A-2

R481 A-2

R482 A-2

R483 A-1

R484 A-1

R485 A-1

R486 B-1

R487 A-1

R504 E-6

R508 E-5

R510 E-5

R511 E-5

R512 F-5

R527 E-5

R530 F-7

R535 E-5

R536 E-5

R537 E-6

R552 G-6

R555 G-7

R563 G-5

R564 G-6

R566 G-5

R567 G-6

R570 F-5

R579 G-6

R582 G-6

R584 G-7

R603 F-2

R604 F-2

R608 F-2

R612 E-1

R618 F-1

R619 F-1

R620 F-1

R621 F-1

R622 F-2

R624 F-1

R625 F-2

R627 F-2

R628 F-2

R629 F-1

R630 F-2

R631 G-2

R632 G-1

R633 E-2

R634 E-2

R635 E-2

R636 E-2

R637 G-2

R638 G-2

R639 G-2

R640 F-2

R641 F-3

R642 G-2

R643 F-2

R644 G-2

CCD-TR315/TR416/TR416PK/TR516/TR516PK/TR716