EN TRANSLATION OF THE ORIGINAL INSTALLATION AND OPERATING MANUAL

Garage door operator

S 9050 base / S 9050 base+

S 9060 base / S 9060 base+

S 9080 base / S 9080 base+

S 9110 base / S 9110 base+

Download the current manual:

base-plus_46900V001_192019_0-DRE_Rev-E_EN

Dear customer,

Congratulations on your purchase of a product of SOMMER

Antriebs- und Funktechnik GmbH.

This product has been developed and manufactured under

high standards of quality and with reference to ISO 9001.

Our passion for the product is just as important to us as

the needs and requirements of our customers. We place

particular emphasis on the safety and reliability of our products.

Read this installation and operating manual carefully and

follow all instructions. This will ensure that you can install

and operate the product safely and optimally. If you have

any questions, please contact your specialist retailer or

installer.

Our products are intended for use by persons of all genders, even where this is not specifically stated.

Warranty

The warranty complies with statutory requirements.

7KHFRQWDFWSHUVRQIRUZDUUDQWLHVLVWKHTXDOL¿HGGHDOHU

The warranty is only valid in the country in which the operator was purchased. There is no warranty for consumables

such as batteries, accumulators and fuses as well as light

bulbs. This also applies for wear parts. The operator is only

designed for a limited frequency of use. More frequent use

leads to increased wear.

Contact data

If you require after-sales service, spare parts or accessories,

SOHDVHFRQWDFW\RXUTXDOL¿HGVSHFLDOLVWUHWDLOHURULQVWDOOHU

Feedback on this Installation and Operating Manual

We have tried to make the Installation and Operating Manual as easy as possible to follow. If you have any suggestions as to how we could improve it or if you think more

information is needed, please send your suggestions to us:

+49 (0) 7021 8001-403

doku@sommer.eu

Service

If you require service, please contact us on our service hotline (fee required) or see our web site:

+49 (0) 900 1800-150

(0.14 euros/minute from landline telephones

in Germany, mobile prices may vary)

www.sommer.eu/de/kundendienst.html

Copyright and proprietary rights

The manufacturer retains the copyright for this Installation and Operating manual. No part of this Installation and

Operating Manual may be reproduced in any form or processed, copied, or distributed using electronic systems

without the written permission of SOMMER Antriebs- und

Funktechnik GmbH. Violations of the above stipulations

will lead to damage claims. All brands mentioned in this

Installation and Operating Manual are the property of their

respective manufacturer and hereby recognised as such.

Table of contents

1. About this Installation and Operating Manual 4

1.1 Storage and circulation of the Installation and

Operating Manual 4

1.2 Important for translations 4

1.3 Description of the product type 4

1.4 Target groups of the Installation and Operating

Manual 4

1.5 Explanation of symbols and notes 4

1.6 Special warning symbols and mandatory signs 5

1.7 Information regarding the depiction of text 5

1.8 Intended use of the operator 5

1.9 Improper use of the operator 6

1.10 Qualifications of personnel 6

1.11 Information for the user 7

2. General safety instructions 8

2.1 Basic safety instructions for operation 8

2.2 Additional safety information for the radio

remote control 9

2.3 Notes and information on operation and radio

remote control 9

2.4 Simplified Declaration of Conformity for radio

systems 9

3. Description of function and product 10

3.1 The operator and its mode of operation 10

3.2 Safety equipment 10

3.3 Product designation 11

3.4 Explanation of tool symbols 11

3.5 Scope of delivery 12

3.6 Dimensions 13

3.7 Technical data 13

3.8 Overview of connection options 14

4. Tools and protective equipment 15

4.1 Required tools and personal protective

equipment 15

5. Declaration of Installation 15

6. Installation 16

6.1 Important notes and information 16

6.2 Preparing for installation 17

6.3 Installing the drive system 18

6.4 Installation on the door 20

7. Removing and fastening covers 24

7.1 Cover of the motor carriage 24

7.2 Cover of the ceiling control unit 24

8. Electrical connection 26

8.1 Connection to a power outlet 26

9. Initial operation 27

9.1 Important notes and information 27

9.2 Carrying out automatic initial operation 27

Table of contents

9.3 Carrying out manual initial operation 29

9.4 Detecting obstacles during the force

programming run 29

9.5 Mechanical adjustment of the end positions 30

9.6 Attaching information sign and warning signs 31

10. Connections and special functions

of the motor carriage 32

10.1 Motor carriage circuit board 32

10.2 Connection options on the motor carriage 33

10.3 Reducing the illumination power of LEDs 34

10.4 Explanation of the radio channels 34

10.5 Programming the transmitter 34

10.6 Information on Memo 35

10.7 Cancelling programming mode 35

10.8 Deleting a transmitter button from the radio

channel 35

10.9 Deleting transmitter completely from

the receiver 35

10.10 Deleting a radio channel in the receiver 35

10.11 Deleting all radio channels in the receiver 36

10.12 Programming a second handheld transmitter

by radio (HFL) 36

10.13 Carrying out a reset 36

10.14 Setting the DIP switches on the motor carriage 37

10.15 Setting automatic closing function – defining

basic values 37

10.16 Setting the lighting function 38

10.17 Setting partial opening 38

10.18 Deleting partial opening 38

10.19 Wicket door safety device 38

10.20 Connecting the safety contact strip 39

10.21 12 V output 39

10.22 SOMlink 39

13. Operation 49

13.1 Important notes and information 49

13.2 Handover to the user 49

13.3 Operating modes of door movement 50

13.4 Obstacle detection 50

13.5 Power-saving mode 50

13.6 In the event of a power failure 51

13.7 Function of the emergency release 51

14. Maintenance and care 52

14.1 Important notes and information 52

14.2 Maintenance schedule 53

14.3 Care 53

15. Troubleshooting 54

15.1 Important notes and information 54

15.2 Preparing for troubleshooting 55

15.3 Time sequences of operator lighting in normal

mode and in case of faults 56

15.4 Troubleshooting table 57

15.5 Replacing the motor carriage 58

16. Taking out of operation, storage and

disassembly 59

16.1 Important notes and information 59

16.2 Taking out of operation and disassembly 59

16.3 Storage 59

16.4 Disposal of waste 59

17. Short instructions for installation 61

18. Connection diagrams and functions

of the DIP switches for base/base+ 64

11. Connections and special functions

of the ceiling control unit 40

11.1 Ceiling control unit circuit board 40

11.2 Connection options of the ceiling control unit 41

11.3 Setting the DIP switches on the ceiling

control unit 42

11.4 Button 2 for partial opening 42

11.5 Photocell and frame photocell 43

11.6 Wallstation 44

11.7 Conex 44

11.8 Output OC 45

11.9 Relay 45

11.10 Installing and removing the accumulator 45

12. Function test and final test 47

12.1 Testing obstacle detection 47

12.2 Handover of the door system 48

3

1. About this Installation and Operating Manual

1.1 Storage and circulation of

the Installation and Operating Manual

Read this Installation and Operating Manual carefully and

completely before installation, commissioning and operation and also before removal. Observe all warnings and

safety instructions.

Keep this installation and operating manual accessible

to all users at all times at the place of use. A replacement

for the installation and operating manual can be downloaded from SOMMER at:

www.sommer.eu

During the transfer or resale of the operator to third parties, the following documents must be passed on to

the new owner:

• EC Declaration of Conformity

• handover protocol and inspection book

• this Installation and Operating Manual

• proof of regular maintenance, testing and care

• documents recording retrofitting and repairs

1.2 Important for translations

The original installation and operating manual was written

in German. The other available languages are translations of the German version. You can get the original

installation and operating manual by scanning

the QR code.

• unloading and in-house transport

• unpacking and installation

• initial operation

• setting

• usage

• maintenance, testing and care

• troubleshooting and repairs

• disassembly and disposal

1.5 Explanation of symbols and notes

The warnings in this installation and operating manual

are structured as follows.

Signal word

Type and source of hazard

Consequences of the hazard

` Preventing/avoiding the hazard

Hazard

symbol

The hazard symbol indicates the hazard. The signal word

is linked to a hazard symbol. The hazard is classified into

three classes depending on its danger:

DANGER

WARNING

CAUTION

There are three different classifications of hazards.

http://som4.me/orig-base-plus-reve

For other language versions, see:

www.sommer.eu

1.3 Description of the product type

The operator has been constructed according to the technological state-of-the-art and recognised technical regulations and is subject to the EC Machinery Directive

2006/42/EC.

The operator is fitted with a radio receiver. Optionally

available accessories are also described. The version

can vary depending on the type. This means the use of

accessories can vary.

1.4 Target groups of the Installation and

Operating Manual

The Installation and Operating Manual must be read and

observed by everyone assigned with one of the following

tasks or using the device:

DANGER

Describes an immediate danger that leads

to serious injury or death.

Describes the consequences of the danger to

you or other persons.

` Follow the instructions for avoiding or pre-

venting the danger.

WARNING

Describes a potential danger that may lead

to fatal or serious injury.

Describes the possible consequences of

the danger to you or other persons.

` Follow the instructions for avoiding or pre-

venting the danger.

CAUTION

Describes a potential danger of a hazardous

situation.

Describes the possible consequences of

the danger to you or other persons.

` Follow the instructions for avoiding or pre-

venting the danger.

4

1 A

1. About this Installation and Operating Manual

The following symbols are used for notes and information:

NOTE

• Describes additional information and useful notes for

correct use of the operator without endangering persons.

If this information is not observed, property damage or

faults in the operator or door may occur.

INFORMATION

• Describes additional information and useful tips.

Functions for optimum usage of the operator are

described.

The following symbols are used in the figures and text.

Continue reading the Installation and Operating

Manual for more information

Disconnect the operator from the mains voltage

Connect the operator to the mains voltage

Factory setting, as-delivered state depending

on version

Connection to a WiFi-enabled device via SOMlink

Operator components must be disposed of

properly

Old accumulators and batteries must be disposed

of properly

1.6 Special warning symbols and

mandatory signs

To specify the source of danger more precisely,

the following symbols are used together with the abovementioned hazard symbols and signal words. Follow

the instructions to prevent a potential hazard.

Danger due to electric current!

Danger of falling!

Danger due to falling parts!

Danger due to optical radiation!

The following mandatory signs are used for the respective actions. The requirements described must be complied with.

Wear personal safety glasses

Wear a personal safety helmet

Wear personal safety gloves

1.7 Information regarding the depiction

of text

1. Stands for directions for an action

Stands for the results of the action

Lists are shown as a list of actions:"6.1 Important notes

and information"

• List 1

• List 2

1, A Item number in the figure refers to a number

in the text

Important text items, for example in directions for actions,

are emphasised in bold type.

References to other chapters or sections are in bold and

set in "quotation marks".

1.8 Intended use of the operator

The operator is intended exclusively to open and close

doors. Any other use does not constitute intended use.

The manufacturer accepts no liability for damage resulting from use other than intended use. The user bears

the sole responsibility for any risk involved. It also voids

the warranty.

Any changes to the operator must be made with original

SOMMER accessories only and only to the extent

described. For more information on accessories, see:

Danger of entrapment!

Danger of crushing and shearing!

Danger of tripping and falling!

https://downloads.sommer.eu/

5

1. About this Installation and Operating Manual

Doors automated with this operator must comply with all

valid international and domestic standards, directives and

regulations in their current version. These include

EN 12604 and EN 13241-1.

The operator may only be used:

• in combination with door types in the reference list

which can be found at:

http://som4.me/cgdo

• if the EC Declaration of Conformity has been issued for

the door system

• if the CE mark and the type plate for the door system

have been attached to the door

• if the handover protocol and the inspection book have

been completed and are available

• if the installation and operating manuals for the operator

and the door are present

• as specified in this Installation and Operating Manual

• in good technical condition

• with an awareness of the safety hazards and risks

involved and by trained users.

After installation of the operator, the person responsible

for the installation of the operator must complete an

EC Declaration of Conformity for the door system in

accordance with Machinery Directive 2006/42/EC and

apply the CE mark and a type plate to the door system.

This also applies if the operator is retrofitted to a manually operated door. In addition, a handover protocol and

an inspection book must be completed.

The following are available:

• EC Declaration of Conformity

• handover protocol for the operator

http://som4.me/konform

1.9 Improper use of the operator

Any other use or additional use that has not been

described in Chapter 1.8 constitutes improper use. The

user bears the sole responsibility for any risk involved.

The manufacturer's warranty will be voided by:

• damage caused by other use and improper use

• use with defective parts

• unauthorised modifications to the operator

• modifications and non-approved programming of

the operator and its components

The door must not be part of a fire protection system,

an escape route or an emergency exit that automatically

closes the door in the event of fire. Installation of the

operator will prevent automatic closing.

Observe the local building regulations.

The operator may not be used in:

• areas with explosion hazard

• very salty air

• aggressive atmosphere, including chlorine

1.10 Qualifications of personnel

4XDOL¿HGVSHFLDOLVWIRULQVWDOODWLRQFRPPLVVLRQLQJ

and disassembly

This Installation and Operating Manual must be read and

complied with by a qualified specialist who installs or

performs maintenance on the operator.

Work on the electrical system and live parts may only be

performed by a trained electrician in accordance with

EN 50110-1.

The installation, initial operation and disassembly of

the operator may only be performed by a qualified spe

cialist. A qualified specialist is a person commissioned

by the installer.

The qualified specialist must be familiar with the following

standards:

• EN 13241-1 Doors and gates – Product standard

• EN 12604 Doors and gates – Mechanical aspects

– Requirements and test methods

• EN 12453:

2017 (Plc)

When all work has been completed, the qualified

specialist must:

• issue an EC Declaration of Conformity

• attach the CE mark and the type plate to the door system.

Safety in use of power-operated doors

Instructing the user and handing over documents

The qualified specialist must instruct the user:

• on the operation of the operator and its dangers

• on the handling of the manual emergency release

• on regular maintenance, testing and care which

the user can carry out

The qualified specialist must inform the user which work

may only be carried out by a qualified

specialist:

-

6

1. About this Installation and Operating Manual

• installation of accessories

• settings

• regular maintenance, testing and care

• troubleshooting

1.11 Information for the user

The user must ensure that the CE mark and the type

plate have been attached to the door system.

The following documents for the door system must be

handed over to the user:

• EC Declaration of Conformity

• handover protocol and inspection book

• the installation and operating manuals for the operator

and the door

The user is responsible for:

• keeping this Installation and Operating Manual

accessible at all times at the place of use

• ensuring compliance with the intended use of

the operator

• ensuring that operator is in good condition

• instructing all users on how to use the operator,

the associated risks and the emergency release

• operation

• regular maintenance, testing and care

• troubleshooting

The operator must not be used by persons with restricted

physical, sensory or mental capacity or who lack experience and knowledge. All users must be specially

instructed and have read and understood the Installation

and Operating Manual.

Children must never play with or use the operator, even

under supervision. Children must be kept clear of the

operator. Handheld transmitters or other command

devices must never be given to children. Handheld transmitters must be safely stored and protected against unintended and unauthorised use.

The user must ensure compliance with the accident prevention regulations and the applicable standards.

The guideline "Technical regulations for workplaces

ASR A1.7" of the German committee for workplaces

(ASTA) is applicable for commercial use. The guidelines

described must be observed and complied with. In other

countries, the user must comply with the applicable

national regulations.

7

2. General safety instructions

2.1 Basic safety instructions for operation

Follow the basic safety instructions listed below.

Danger if not observed!

If safety instructions are not observed, serious injury or

death may result.

` All safety instructions must be complied with.

Danger due to electric current!

&RQWDFWZLWKOLYHSDUWVPD\UHVXOWLQHOHFWULFFXUUHQWÀRZing through the body. Electric shock, burns or death will

result.

` Installation, testing and replacement of electrical com-

ponents must be carried out by a trained electrician.

` Disconnect the mains plug before working on

the operator.

` If an accumulator is connected, disconnect it from

the control unit.

` Check that the operator is not live.

` Secure the operator against being switched back on.

Danger due to use of the operator with incorrect

settings or when it is in need of repair!

If the operator is used despite incorrect settings or if it

is in need of repair, severe injury or death may result.

` The operator may only be used with the required set-

tings and in the proper condition.

` You must have faults repaired professionally without

delay.

Danger of hazardous substances!

Improper storage, use or disposal of accumulators,

batteries and operator components are dangerous

for the health of humans and animals. Serious injury or

death may result.

` Accumulators and batteries must be stored out of

the reach of children and animals.

` Keep accumulators and batteries away from chemical,

PHFKDQLFDODQGWKHUPDOLQÀXHQFHV

` Do not recharge old accumulators and batteries.

` Components of the operator as well as old accumula-

tors and batteries must not be disposed of with house-

hold waste. They must be disposed of properly.

Danger for trapped persons!

Persons may be trapped inside the garage. If trapped

persons cannot free themselves, severe injury or death

may result.

` Check the function of the emergency release at monthly

intervals, particularly from inside in the door CLOSE

end position and if necessary, also from outside.

` You must have faults repaired professionally without

delay.

Danger due to projecting parts!

Parts must not project into public roads or footpaths.

This also applies while the door is moving. Persons and

animals may be seriously injured.

` Keep public roads and footpaths clear of projecting

parts.

Danger due to falling parts of doors!

Actuating the emergency release can lead to uncontrolled door movement if:

• Springs are weakened or broken.

• The door has not been optimally weight-balanced.

Falling parts may cause a hazard. Severe injuries or

death may result.

` Check the weight balance of the door at regular

intervals.

` Pay attention to the movement of the door when

the emergency release is actuated.

` Keep clear of the movement area of the door.

Danger of entrapment!

Persons or animals in the movement area of the door

may be trapped and pulled along with the door. Severe

injuries or death may result.

` Keep clear of the movement area of the door.

Danger of crushing and shearing!

If the door moves and there are persons or animals

in the movement area, crushing and shearing injuries

may be caused by the mechanism and safety edges of

the door.

` Only use the operator when you have a direct view of

the door.

` All danger zones must be visible during the entire door

operation.

` Always keep the moving door in sight.

` Keep persons and animals clear of the range of move-

ment of the door.

` Never put your hand near the door when it is moving

or near moving parts. In particular, do not reach into

the moving push arm.

` Do not reach into the ceiling suspension unit when

the motor carriage is running along the track.

` Do not drive through the door until it has opened com-

pletely.

` Store the handheld transmitter so that unauthorised

or accidental operation, e.g., by children or animals,

is impossible.

` Never stand under the opened door.

Danger due to optical radiation!

Looking into an LED at short range for an extended

period may cause optical glare. This may temporarily

reduce vision. This may cause serious or fatal accidents.

` Never look directly into an LED.

Risk of eye injury!

&KLSVÀ\LQJZKHQGULOOLQJPD\FDXVHVHULRXVLQMXULHVWR

eyes and hands.

` Wear safety glasses when drilling.

Risk of injury in the head region

Impact with suspended objects may cause serious

abrasions and cuts.

` You must wear a safety helmet when installing

suspended parts.

8

2. General safety instructions

Risk of injury to hands!

Rough metal parts may cause abrasions and cuts when

picked up or touched.

` Wear safety gloves when deburring or performing

similar work.

2.2 Additional safety information for

the radio remote control

Follow the basic safety instructions listed below.

Danger of crushing and shearing!

If the door is not visible and the radio control is operated, crushing and shearing injuries to persons or animals may be caused by the mechanism and safety

edges of the door.

` In particular when operating control elements such as

the radio remote control, all danger zones must be vis-

ible during the entire door operation.

` Always keep the moving door in sight.

` Keep persons and animals clear of the range of move-

ment of the door.

` Never put your hand near the door when it is moving

or near moving parts.

` Do not drive through the door until it has opened com-

pletely.

` Store the handheld transmitter so that unauthorised

or accidental operation, e.g., by children or animals,

is impossible.

` Never stand under the opened door.

• Dispose of all components in accordance with local and

national regulations to avoid environmental damage.

INFORMATION

• All components that have been taken out of

service, old accumulators and operator batteries

must not be disposed of with household waste.

Dispose of components which are no longer

in use, old accumulators and batteries properly.

You must observe the local and national

regulations.

2.4 Simplified Declaration of Conformity

for radio systems

SOMMER Antriebs- und Funktechnik GmbH hereby

declares that the radio system (base and base+) complies

with Directive 2014/53/EU. You can see the full text of

the EU Declaration of Conformity for the radio system at:

http://som4.me/konform-funk

2.3 Notes and information on operation

and radio remote control

The user of the radio system is not protected against

interference due to other telecommunications equipment

or devices. This includes radio-controlled systems that

are licensed to operate in the same frequency range.

If significant interference occurs, please contact your

appropriate telecommunications office which has radio

interference measuring equipment or radio location

equipment.

NOTE

• The motor carriage is supplied with safety low voltage

via the chain and the track.

The use of oil or grease will greatly reduce the conductivity of the chain, track and motor carriage. This may

result in faults due to inadequate electrical contact.

The chain and track are maintenance-free and must

not be oiled or greased.

• Objects in the movement area of the door may be

jammed and damaged.

Objects must not be in the range of movement of

the door.

• If the door is not in view and the radio remote control

is actuated, objects in the movement area of the door

may be jammed and damaged.

Objects must not be in the range of movement of

the door.

9

3. Description of function and product

3.1 The operator and its mode of operation

Fig. Door structure with operator, using the example of a sectional door

Sectional doors and other door types can be opened and

closed with the electrically powered operator and its

available accessories. The operator can be controlled

with a handheld transmitter.

The track is mounted on the ceiling and the lintel above

the garage door. The motor carriage is attached to

the door by a push arm. The motor carriage moves along

the track on a spring-mounted chain and opens or closes

the door.

The handheld transmitter can be stored in a holder

in the garage or in the vehicle.

3.2 Safety equipment

The operator stops and reverses slightly if it encounters

an obstacle. This prevents injury and damage to property.

The door will be partially or completely opened, depending on the setting.

In the event of a power failure, the door can be opened

from the inside via an emergency release handle or from

the outside with a Bowden wire or emergency release

lock.

10

3. Description of function and product

3.3 Product designation

Fig. Motor carriage with type plate and device specifications

The type plate includes:

• type designation

• item Number

• date of manufacture with month and year

• serial number

In case of questions or service, please supply the type

designation, the date of manufacture and the serial number.

3.4 Explanation of tool symbols

Tool symbols

These symbols refer to the use of tools required for

installation.

Phillips screwdriver

Metal drill 5 mm

Masonry drill 10 mm

Fork wrench 17 mm

Ratchet wrench 10/13/17 mm

Other symbols

Drilling depth

“clic ”

Audible engaging or clicking noise

11

3. Description of function and product

3.5 Scope of delivery

2.2

3

1

2.1

17

4

2

5

6

10

11

12

15

7

10

9

8

16

14

13

11

12

18

19

21

20

22

23

24

Fig. Scope of delivery

1) Ceiling control unit

2) Track, pre-assembled with 1x limit stop, chain and

motor carriage

2.1) Isolator, included with the track

2.2) Limit stop, pre-assembled on the track

3) Connecting sleeve, 2x

4) Track, 2x

5) Plug-in unit, pre-assembled

6) Ceiling holder, 2-part

7) Perforated strip, angled, 2x

8) Screw M8 x 20 mm, 2x

9) Hexagonal nut, self-locking M8, 2x

10) S10 plug, 4x

11) Washer, 4x

12) Screw 8 x 60 mm, 4x

14) Hexagonal nut, self-locking M10

15) Hexagonal head screw M10 x 100 mm

16) Emergency release handle

17) Push arm, straight

18) Bolt lock 10 mm, 2x

19) Bolt 10 x 34.5 mm, 2x

20) Door bracket

21) Combination self-tapping screw, 4x

22) Handheld transmitter, preprogrammed, channel 1

pulse sequence, with CR 2032, 3 V lithium battery

23) Information sticker for garage interior

24) Installation and Operating Manual

When unpacking, make sure that all parts are included

in the packages. The actual scope of delivery may vary

depending on the specific version.

13) Lintel bracket, 2x

12

3. Description of function and product

3.6 Dimensions

3.554

257

30

< 22,5

325

272

111

< 2.750

< 215

246

7

144

3

84

1.200

141

170

Fig. Dimensions (all dimensions are in mm)

3.7 Technical data

S 9050 base/

base+

Rated voltage

Rated frequency 50/60Hz

Rating

Memory positions in radio receiver

Duty cycle

Operating temperature –25 ºC … +65 ºC

Emission value according to

operating environment

IP protection class IP21

IP-code II

Max. travel length 2750 mm

Max. travel length incl. extension

Max. speed*

Max. pull and pushing force 500 N 600 N 800 N 1,100 N

Rated pull force 150 N 180 N 240 N 330 N

Max. current consumption 0.8 A 0.8 A 0.9 A 0.9 A

Rated current consumption** 0.7 A 0.8 A 0.8 A 0.8 A

Max. power consumption 195 W 205 W 185 W 175 W

Rated power consumption** 130 W 150 W 170 W 165 W

Power consumption

in power-saving mode

Max. door weight* 80 kg approx. 120 kg approx. 160 kg approx. 200 kg

Sectional doors

Max. door

width/door

height***

Max. no. of spaces 2 30 50 30

* Depending on door and the operating conditions

** Values apply without lighting, Lumi

*** Reference value, depending on the door construction

One piece doors

Up-and-over doors

Side-opening

sectional doors/

Side-opening doors

+

3,800 mm

(1x 1,096 mm

180 mm/s 240 mm/s 210 mm/s 180 mm/s

3,000 mm/

2,500 mm

3,000 mm/

2,750 mm

3,000 mm/

2,050 mm

2,500 mm

(3,000 mm

2,300 mm

)

)/

S 9060 base/

base+

AC 220–240 V

3 cycles or 4 minutes

40

S3 = 40 %

< 59 dB(A) – operator only

4,900 mm

(2x 1,096 mm

<3 W base/<1 W base+

4,500 mm/

2,500 mm

4,500 mm/

2,750 mm

4,500 mm/

2,050 mm

2,500 mm/

(4,500 mm

2,500 mm

)

)/

S 9080 base/

base+

6,000 mm

(3x 1,096 mm

6,000 mm/

2,500 mm

6,000 mm/

2,750 mm

6,000 mm/

2,050 mm

2,500 mm

(5,750 mm

2,750 mm

)/

S 9110 base/

base+

7,100 mm

)

(4x 1,096 mm

8,000 mm/

2,500 mm

8,000 mm/

2,750 mm

8,000 mm/

2,050 mm

2,500 mm

(6,850 mm

3,000 mm

)

)/

13

3. Description of function and product

3.8 Overview of connection options

Only SOMMER accessories may be used. Observe

the corresponding instructions.

Accessories may only be installed and adjusted by qualified specialists. The use of accessories can vary depending on the type.

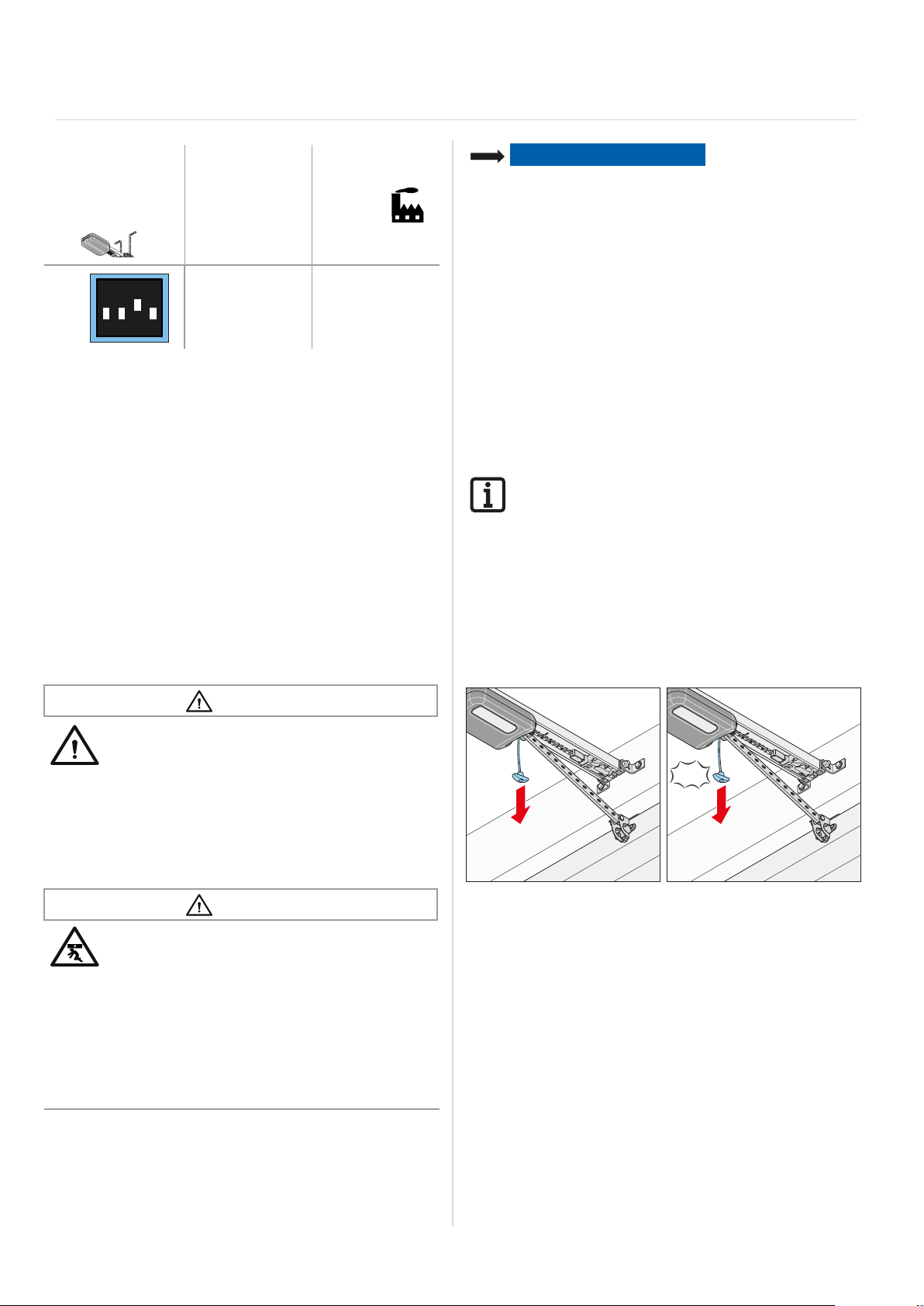

Motor carriage base base+

LED 3 6

Lock Ɣ

Memo Ɣ

USART Ɣ Ɣ

Senso Ɣ

Buzzer Ɣ Ɣ

Laser Ɣ

Motion Ɣ

For OSE/8k2 Ɣ

Wicket door contact Ɣ Ɣ

Output 12 V, 100 mA Ɣ

DIP switches 4 4

Ceiling control unit base base+

Accumulator Ɣ

Keypad (Conex connection) Ɣ Ɣ

Relay/Output OC Ɣ Ɣ

+

Lumi

Pulse button Ɣ Ɣ

Button 2 (partial opening) Ɣ

Warning light 24 V, 25 W Ɣ Ɣ

2-/4-wire photocell Ɣ Ɣ

Output DC 24 V Ɣ Ɣ

DIP switches 4

Wallstation Ɣ Ɣ

Ɣ Ɣ

Door types and accessories

Door type Accessories

One piece door No accessories

required

Sectional door

with single track

Sectional door

with double track

Sectional

overhead door

Up-and-over door Curved arm*

Side-opening

door, side-opening

sectional door

* Accessories not included in the scope of delivery

** The standard fitting can also be used depending on

the installation type. Custom fittings are not included

in the scope of delivery.

6HFWLRQDOGRRU¿WWLQJ

with curved push arm*

6HFWLRQDOGRRU¿WWLQJ

without curved push

arm**

No accessories

required

Side-opening/side-

VHFWLRQDOGRRU¿WWLQJ

A SOMlink is also available as an accessory. For more

information on accessories, see:

https://downloads.sommer.eu/

14

4. Tools and protective

equipment

5. Declaration of Installation

4.1 Required tools and personal

protective equipment

10 mm

13 mm

17 mm

5 mm

17 mm

Fig. Recommended tools and personal protective equipment for

installation

You will require the tools shown above to assemble and

install the operator. Lay out the required tools beforehand

to ensure fast and safe installation.

Wear your personal protective equipment. This includes

safety glasses, safety gloves and a safety helmet.

10 mm

Declaration of Installation

for installation of an incomplete machine in accordance with

the Machinery Directive 2006/42/EC, Annex II, Part 1 B

SOMMER Antriebs- und Funktechnik GmbH

Hans-Böckler-Straße 21-27

D-73230 Kirchheim/Teck

Germany

hereby declares that the control units

S 9050 base; S 9060 base; S 9080 base; S 9110 base;

S 9050 base+ S 9060 base+; S 9080 base+; S 9110 base+;

S 9050 pro; S 9060 pro; S 9080 pro; S 9110 pro; S 9050

pro+; S 9060 pro+; S 9080 pro+; S 9110 pro+

have been developed, designed and manufactured in conformity

with the:

• Machinery Directive 2006/42/EC

• Low Voltage Directive 2014/35/EU

• Electromagnetic Compatibility Directive 2014/30/EU

• RoHS Directive 2011/65/EU.

The following standards were applied:

EN ISO 13849-1,

PL "C" Cat. 2

EN 60335-1,

where applicable

EN 61000-6-3 Electromagnetic compatibility (EMC) –

EN 61000-6-2 Electromagnetic compatibility (EMC) –

EN 60335-2-95 General safety requirements for household

EN 60335-2-103 General safety requirements for household

The following requirements of Annex 1 of the Machinery Directive

2006/42/EC are met: 1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.2, 1.2.3, 1.2.4,

1.2.5, 1.2.6, 1.3.1, 1.3.2, 1.3.4, 1.3.7, 1.5.1, 1.5.4, 1.5.6, 1.5.14,

1.6.1, 1.6.2, 1.6.3, 1.7.1, 1.7.3, 1.7.4

The special technical documentation was prepared in accord-

ance with Annex VII Part B and will be submitted to regulators

electronically on request.

The operator may only be used:

• In combination with door types in the reference list, which can

EHIRXQGXQGHU&HUWL¿FDWLRQV

www.sommer.eu

The incomplete machine is intended for installation in

DGRRUV\VWHPRQO\WRIRUPDFRPSOHWHPDFKLQHDVGH¿QHG

by the Machinery Directive 2006/42/EC. The door system

may only be put into operation after it has been established

that the complete system complies with the regulations of

the above EC Directives.

The undersigned is responsible for compilation of the technical

documents.

Kirchheim/Teck,

20.04.2016

Safety of machines – Safety-related parts

of controls

– Part 1: General design guidelines

Safety of electrical appliances/operators for

doors

interference

interference resistance

and similar electrical appliances

– Part 2: Particular requirements for

operators for vertically moving garage

doors for residential use

and similar electrical appliances

– Part 2: Special requirements for operators

for gates, doors and windows

i.V.

Jochen Lude

Responsible for documents

15

6. Installation

6.1 Important notes and information

In particular, please observe and comply with the following

warnings, notes and information to ensure safe installation.

DANGER

Danger if not observed!

If warnings are not observed, serious injury or

death may result.

` All warnings must be complied with.

WARNING

Danger of falling!

Unsafe or defective ladders may tip and cause

serious or fatal accidents.

` Use only a non-slip, stable ladder.

` Ensure that ladders are safely positioned.

Danger for trapped persons!

Persons may be trapped inside the garage.

If trapped persons cannot free themselves,

severe injury or death may result.

` Check the function of the emergency release

at monthly intervals, particularly from inside

in the door CLOSE end position and if necessary, also from outside.

` If there is no second entrance to the garage,

you must have a release lock or a Bowden

wire for unlocking from the outside installed.

This can be used to free persons who cannot

free themselves.

Danger due to projecting parts!

Door leaves or other parts must not project

into roads or public footpaths. This also applies

while the door is moving. This may cause serious injury or death to persons or animals.

` Keep public roads and footpaths clear of

projecting parts.

Danger due to falling parts of doors!

If a door is incorrectly balanced, springs may

break suddenly. Falling door parts may cause

serious injury or death.

Check:

` The stability of the door.

` That the door does not bend, rotate or twist

when you open or close it.

` That the door runs smoothly in the tracks.

Danger due to falling ceiling and wall parts!

The operator cannot be installed correctly if

ceiling and walls are unstable or if unsuitable

mounting materials are used. Persons or animals may be struck by falling parts of the wall,

ceiling or operator. Severe injuries or death

may result.

` You must test the stability of the ceiling and

the walls.

` Use only permissible mounting materials

appropriate for the supporting surface.

Danger of entrapment!

Loose clothing or long hair may be trapped by

moving parts of the door. Severe injuries or

death may result.

` Keep clear of the moving door.

` $OZD\VZHDUWLJKW¿WWLQJFORWKLQJ

` Wear a hairnet if you have long hair.

Danger of crushing and shearing!

If the door moves and there are persons or

animals in the movement area, crushing and

shearing injuries may be caused by the mechanism and safety edges of the door.

` Only use the operator when you have a direct

view of the door.

` All danger zones must be visible during

the entire door operation.

` Always keep the moving door in sight.

` Keep persons and animals clear of the range

of movement of the door.

` Never put your hand near the door when it

is moving or near moving parts. In particular,

do not reach into the moving push arm.

` Do not reach into the ceiling suspension unit

when the motor carriage is running along

the track.

` Do not drive through the door until it has

opened completely.

` Never stand under the opened door.

Danger of tripping and falling!

Unsafely positioned parts such as packaging,

operator parts or tools may cause trips or falls.

` Keep the installation area free of unneces-

sary items.

` Place all parts where no-one is likely to trip or

fall over them.

` The general workplace guidelines must be

observed.

16

6. Installation

Risk of eye injury!

&KLSVÀ\LQJZKHQGULOOLQJPD\FDXVHVHULRXV

injuries to eyes and hands.

` Wear safety glasses when drilling.

Risk of injury in the head region

Impact with suspended objects may cause

serious abrasions and cuts.

` You must wear a safety helmet when

installing suspended parts.

CAUTION

Risk of injury to hands!

Rough metal parts may cause abrasions and

cuts when picked up or touched.

` Wear safety gloves when deburring or per-

forming similar work.

NOTE

• If the ceiling and walls are not stable, parts of the ceiling and wall or the operator may fall. Objects may be

damaged.

Ceiling and walls must be stable.

• To prevent damage to the door or operator, use only

approved mounting materials such as wall plugs or

screws.

The mounting material must be suitable for the material of the ceiling and walls. This applies particularly for

prefabricated garages.

6.2 Preparing for installation

Before installation, you must check whether the operator

is suitable for the door, see also Chapter "3.7 Technical

data".

Removal of actuation parts

Disabling mechanical locks

The mechanical lock on a door with an operator must be

removed or disabled if it is not compatible with the operator.

NOTE

• If locks or other locking systems are installed on

a mechanical door, they may block the operator.

This may cause faults or damage to the operator.

• Before the installation of the operator, all mechanical

locking systems must be disabled.

Checking the mechanism and weight balance

WARNING

Danger due to falling parts of doors or

complete door panels!

:LUHVVSULQJVHWVDQGRWKHU¿WWLQJVFDQEH

damaged and break. The complete door panel

can fall.

Persons or animals may be struck by falling

parts of the door or the complete door panel.

Severe injuries or death may result.

Before installation, a TXDOL¿HGVSHFLDOLVW must

check and, if necessary, adjust the following:

` :LUHVVSULQJVHWVDQGRWKHU¿WWLQJVRI

the door.

` The weight balance of the door.

WARNING

Danger of entrapment!

If the force setting is too high, persons or animals in the movement area of the door may be

trapped and pulled along with the door. Severe

injuries or death may result.

` The force setting is relevant to safety and

must be carried out by a TXDOL¿HGVSHFLDOLVW.

` You must proceed with extreme caution if you

check and if necessary adjust the force setting.

WARNING

Danger of entrapment!

Persons or animals may be trapped by straps

or cords and pulled into the movement zone of

the door. Severe injuries or death may result.

` Remove straps and cords used for mechani-

cal actuation of the door.

Before installation, remove:

• manual locking on door

• all cords or straps necessary to operate the door

by hand.

NOTE

• If the weight compensation of the door is incorrectly

adjusted, the operator may be damaged.

ņ The door must be stable.

ņ It must not bend, rotate or twist when opening and

closing.

ņ The door must move easily in its tracks.

1. Check the mechanisms of the door, such as cables,

spring sets and other fittings.

17

6. Installation

¹⁄ ¹⁄

¹⁄

Fig. 2

2. Open the door halfway.

The door must remain in this position.

The door must be moved easily by hand and must

be balanced.

If the door moves upwards or downwards by itself,

the weight balance of the door must be adjusted.

Emergency release

In a garage without a separate entrance (e.g. wicket

doors), the operator's emergency release must be operable from outside. The emergency release must also be

routed to be accessible from the outside. This can be

done with a Bowden wire or a release lock.

INFORMATION

• The emergency release must be easy to operate

in all necessary positions.

• In particular, unlocking must be possible in door

CLOSE.

¹⁄

6.3 Installing the drive system

The operator may only be installed if the installation

requirements and dimensions below are correct.

NOTE

• Specify the position for mounting the operator on

the door. Manually open and close the door several

times. The door must be moved easily.

A manual movement force of 150 N is applicable for

private garage doors and 260 N for commercial doors.

The value is applicable for the entire life of the door.

The door must also be maintained and inspected

DVVSHFL¿HGE\WKHGRRUPDQXIDFWXUHU

INFORMATION

• Before installation, check whether the garage is

suitable for the operating temperature indicated

on the motor carriage.

Fig. 1

CAUTION! Risk of injury to hands

Rough metal parts may cause abrasions and cuts when

picked up or touched.

` You must wear safety gloves when working with rough

metal parts.

18

1. Open the package.

Place the two cartons in the package beside the

tracks and open them.

Check the entire contents against the scope of delivery, see Chapter "3.5 Scope of delivery".

“clic”

“clic”

Fig. 2

6. Installation

2. Remove the two connecting sleeves beside the motor

carriage and attach to the track on the left and right.

Fig. 3

3. Attach a track to each of the connecting sleeves.

Fig. 6

6. Plug the plug-in unit onto the opposite side of the track.

90°

Fig. 4

4. Plug in the ceiling control unit to the track behind the

limit stop.

Lay the chain over the limit stop.

90°

90°

Fig. 5

5. Rotate the chain 90° and insert it into the chain holder

of the ceiling control unit.

Rotate the chain back 90°.

90°

Fig. 7

NOTE

• The chain must be parallel to the track to prevent

damage to the operator.

7. Rotate the chain 90° and insert it into the chain holder

of the plug-in unit.

Rotate the chain back 90°.

The entire chain is attached.

10 mm 17 mm 17 mm

Fig. 8 Fig. 9

8. Tension the chain to the mark on the plug-in unit, see

arrow in the detailed view.

9. Screw the two header brackets to the plug-in unit with

bolt and nut.

19

B

ACK

H

INTEN

6. Installation

100-700 mm

Fig. 10 Fig. 11

13 mm

10. Turn the track to install the ceiling bracket.

The distance between the ceiling control unit and

the ceiling holder should be approx. 100–700 mm.

Place the ceiling holder on the track and slide into

one another.

NOTE

• Depending on the door construction, the installation

situation and the installation type, it should be checked

whether a second ceiling suspension unit is necessary.

11. Fasten the perforated strips to the ceiling holder

on the right and left. Also observe the distances for

installation to the ceiling or lintel.

The track is prepared for the remainder of

the installation.

For further installation, see Chapter "6.4 Installation on

the door".

6.4 Installation on the door

X

65 mm

min. 35 mm

Fig. 1.1 Highest running point for one piece and up-and-over doors

5 -

X

35 mm

min.

Fig. 1.2 Highest running point for a sectional door

INFORMATION

• The distance may be reduced if a door handle is

attached to the middle of the door. The door

must be able to run freely.

65 mm

5 -

X

X

1. Measure the highest running point of the door "X"

depending on the door type:

Open the door and measure the closest distance

(min. 35 mm) between the top edge of the door and

the ceiling.

The distance between "X" and the bottom edge of

the track must be at least 5 mm and no more than

65 mm.

If the distance between the ceiling and the bottom

edge of the track is greater than 245 mm, extend

the ceiling holder with additional perforated strips.

max. 30°

Fig. 2

2. The push arm must be at a max. angle of 30° with

the door closed.

20

70 mm 70 mm

100 mm

700 mm

6. Installation

13 mm

½½½

Fig. 3 Fig. 4

½

21 mm

3. Close the door.

Select the lintel or ceiling for installation. Measure

the centre of the door at the front and mark the position on the door and the lintel or ceiling.

4. Mark points 70 mm to the right and left of the centre

of the door at the same height on the lintel or ceiling.

min.

15 mm

65 mm

15 mm

½½½

15

½

10 mm

30 mm

Fig. 7

7. Close the door.

Insert the wall plug into the lintel or ceiling. Lift the track

at the front.

Screw the lintel fitting at the front to the lintel or ceiling

with two screws and the washers. Tighten the screws.

The track is attached to the lintel or ceiling.

X

X

Fig. 5 Fig. 6

NOTE

• Cover the operator during drilling to prevent dirt from

entering the operator unit and damaging it.

INFORMATION

• If installing on the ceiling, space the drill holes

15 mm apart if possible. This reduces the tilting

angle of the mounting bracket.

• The drilling depth must be considered with respect

to the ceiling and wall thickness, particularly with

prefabricated garages. It may be necessary to

reduce the hole depth.

• Only use permissible mounting materials

appropriate for the supporting surface.

5. Drill two holes (Ø 10 × 65 mm deep) in the ceiling or

lintel.

6. Open the door.

Transfer the mark from the centre of the door to

the ceiling at the rear.

Fig. 8

NOTE

• The operator must always be installed parallel to

the tracks of the door to prevent damage to the operator and the tracks.

8. Align the operator parallel to the tracks of the door.

10 mm

65 mm

13 mm

Fig. 9 Fig. 10

9. Align the tracks parallel to the centre of the door at

the rear.

Align the ceiling bracket.

21

6. Installation

The distance between the ceiling control unit and

the ceiling holder should be approx. 100–700 mm.

The ceiling bracket should be installed in this area.

Check the alignment of the track with a spirit level.

10. Mark the holes for the ceiling holder on the ceiling.

Drill two holes (Ø 10 × 65 mm deep).

Insert the wall plugs.

Insert two screws with washers and screw the perforated strip to the ceiling.

Tighten the screws.

The track is attached to the ceiling.

Fig. 11

NOTE

• The emergency release handle may cause damage,

e.g. scratches on the vehicle.

7KHGLVWDQFHEHWZHHQWKHJDUDJHÀRRUDQGWKHHPHUgency release cord must be less than 1.8 m.

The emergency release handle must be at least 50 mm

IURPPRYLQJDQG¿[HGSDUWVWKURXJKRXWLWVFRPSOHWH

movement range.

12. Attach the emergency release handle:

Thread the cord through the emergency release handle. Tie a double knot in the cord at an appropriate

point. Pull the emergency release handle over the double knot. If necessary, shorten the cord or lengthen

it with suitable materials.

CAUTION! Risk of injury to hands

Rough metal parts may cause abrasions and cuts when

picked up or touched.

` 7KHSURMHFWLQJSHUIRUDWHGVWULSVPXVWEHVDZQRႇDQG

deburred to prevent injury.

` Wear safety gloves when deburring.

11. The projecting perforated strips must be shortened.

< 1,8 m

2x

Fig. 12

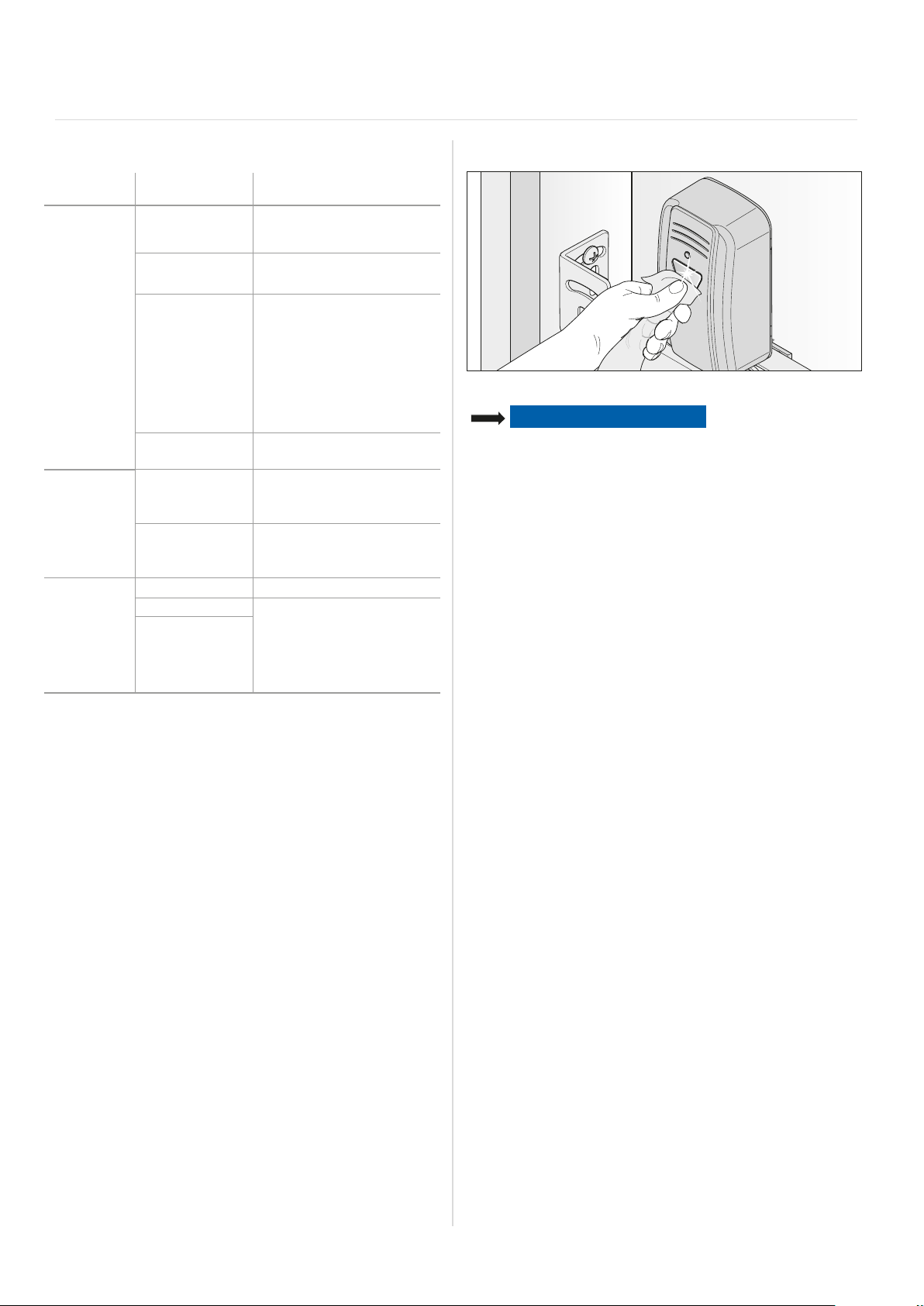

WARNING! Danger of entrapment

Persons or animals in the movement area of the door

may be trapped in a loop of the emergency release cord

and the door may be accidentally unlocked. Severe

injuries or death may result.

` The emergency release handle which is included must

be used.

Fig. 13

13. Pull the emergency release cord once to unlock

the motor carriage.

Slide the motor carriage forward to the door.

5 mm

Fig. 14 Fig. 15

WARNING! Risk of injury in the head region

Impact with suspended objects may cause serious

abrasions and cuts.

` You must wear a safety helmet when installing

suspended parts.

14. Plug the push arm into the door bracket. Insert

the bolt and slide on the security pin.

Plug the push arm into the motor carriage at the front.

Also insert the bolt here and slide on the security pin.

15. Align the door bracket with the centre of the door.

22

6. Installation

Mark the position of the holes and drill them

(Ø 5 mm). Fix the door bracket to the door with

the hexagon bolts.

The push arm is attached to the motor carriage and

the door.

Fig. 16

NOTE

• The door must not rub against the operator or tracks.

This could damage the operator or tracks.

7KHRSHUDWRUPXVWEHRႇVHW

16. Open the door completely by hand.

If the door rubs against the operator or the tracks,

the operator must be offset.

The limit stop moves automatically with the motor

carriage.

Open the door fully for this. The motor carriage

moves against the limit stop to the door OPEN end

position until a click noise is heard.

The door OPEN end position is set.

¹⁄

¹⁄

“clic ”

Fig. 18 Fig. 19

18. Move door to centre position.

The motor carriage moves with it.

19. Pull the emergency release cord.

The motor carriage is locked.

The door can only be moved by the operator.

20. Check to make sure no part of the door projects into

public footpaths or roads.

WARNING! Danger due to projecting parts

Parts must not project into public roads or footpaths.

This also applies while the door is moving. Persons and

animals may be seriously injured.

` Keep public roads and footpaths clear of projecting

parts.

Fig. 17

NOTE

• Do not push the door all the way to the mechanical

stop. This is because otherwise, the operator will pull

the door against the mechanical stop. This will apply

tension to the door and it may be damaged.

A clearance of 30 mm is required.

INFORMATION

• The limit stop can be subsequently pushed

under the chain and screwed into the track.

Then screw the limit stop tightly to the track at

the respective spot.

17. Tighten the screw on the limit stop with a Phillips

screwdriver without changing its position.

Check the door OPEN end position:

Installation of the operator is complete.

23

7. Removing and fastening covers

7.1 Cover of the motor carriage

In particular, observe the warnings below.

WARNING

Danger due to optical radiation!

Looking into an LED at short range for an

extended period may cause optical glare.

This may temporarily reduce vision. This may

cause serious or fatal accidents.

` Never look directly into an LED.

WARNING

Danger due to hot surfaces!

After frequent operation, parts of the motor carriage or the control unit may become hot. If the

cover is removed and hot parts are touched,

they may cause burns.

` Allow the operator to cool down before

removing the cover.

Removing the cover

7.2 Cover of the ceiling control unit

In particular, observe the warnings below.

DANGER

Danger due to electric current!

Contact with live parts may result in electric

FXUUHQWÀRZLQJWKURXJKWKHERG\(OHFWULFVKRFN

burns or death will result.

` All work on electrical components must be

carried out by a trained electrician.

` Before performing work on the operator, includ-

ing the connection of accessories, it must be

disconnected from the power supply.

` If an accumulator is connected, disconnect

it from the control unit.

` Check that the operator is not live.

` Secure the operator against being switched

back on.

WARNING

Danger due to hot surfaces!

After frequent operation, parts of the motor

carriage or the control unit may become hot.

If the cover is removed and hot parts are

touched, they may cause burns.

` Allow the operator to cool down before

removing the cover.

Fig. 1

1. Press on the cover lock at the back of the motor carriage and remove the cover.

Installing the cover

“clic”

Fig. 1

1. Insert the cover from the front and lock it to the motor

carriage at the back.

Unscrewing cover

1. Disconnect the operator from the mains voltage.

Check that the operator is disconnected from

the power supply.

Fig. 2

NOTE

• If there is an accumulator in the cover of the ceiling

control unit, remove the cover carefully. The accumulator is loose in the cover.

Disconnect the accumulator plug from the circuit board.

2. Unscrew and remove the cover from the ceiling

control unit.

24

7. Removing and fastening covers

Fig. 3

3. If an accumulator is used, unscrew the cover carefully.

Disconnect the accumulator from the circuit board.

Remove the cover with the disconnected accumulator, see Chapter "11.10 Installing and removing

the accumulator".

Installing the cover

1. After working on the ceiling control unit, replace

the cover in reverse order.

2. Connect the operator to the mains voltage.

Check that the power supply is connected.

The operator is supplied with mains voltage.

25

8. Electrical connection

< 1100 mm

8.1 Connection to a power outlet

A power outlet is required for the electrical connection of

the operator.

A power outlet must be installed by a trained electrician.

The power outlet must be protected by a fuse. Local and

national regulations must be observed (e.g. VDE).

In particular, observe the warnings below.

DANGER

Danger due to electric current!

Contact with live parts may result in electric

FXUUHQWÀRZLQJWKURXJKWKHERG\(OHFWULFVKRFN

burns or death will result.

` All work on electrical components must be

carried out by a trained electrician.

` Before inserting the mains power plug for

WKH¿UVWWLPHHQVXUHWKDWWKHYROWDJHRI

the power source matches the voltage listed

on the operator type plate.

` Do not connect the power supply until

installation is complete.

` Disconnect the mains plug before working on

the operator.

` If an accumulator is connected, disconnect

it from the control unit.

` Check that the operator is not live.

` Secure the operator against being switched

back on.

The power cord is about 1.2 m long. The power cord

supplied must not be shortened or extended. Note that

the distance between the ceiling control unit and

the power outlet must not exceed 1.1 m.

The power outlet must be installed as follows:

• Within easy reach of the ceiling control unit power cord.

• Easily visible and clear of obstacles.

NOTE

• Do not connect the ceiling control unit to the power

supply until the installation is complete to prevent

damage to the operator.

INFORMATION

• All devices to be connected externally must have

safe isolation of the contacts from the mains voltage supply in accordance with IEC 60364-4-41.

Wiring for external devices must be installed

in accordance with IEC 60364-4-41.

$OOHOHFWULFDOZLULQJPXVWEH¿UPO\VHFXUHGWR

prevent displacement.

Fig. Distance between ceiling control unit and power outlet

26

9. Initial operation

9.1 Important notes and information

In particular, observe the warnings below.

WARNING

Danger of entrapment!

If the force setting is too high, persons or animals in the movement area of the door may be

trapped and pulled along with the door. Severe

injuries or death may result.

` The force setting is relevant to safety and

must be carried out by a TXDOL¿HGVSHFLDOLVW.

` You must proceed with extreme caution if you

check and if necessary adjust the force setting.

` Please note that the operator may only be

operated if a non-hazardous force value has

been set.

` Select the force setting low enough to elimi-

nate any danger of injury by the closing force.

Danger of crushing and shearing!

If the door moves and there are persons or

animals in the movement area, crushing and

shearing injuries may be caused by the mechanism and safety edges of the door.

` Only use the operator when you have a direct

view of the door.

` All danger zones must be visible during

the entire door operation.

` Always keep the moving door in sight.

` Keep persons and animals clear of the range

of movement of the door.

` Never put your hand near the door when it

is moving or near moving parts. In particular,

do not reach into the moving push arm.

` Do not reach into the ceiling suspension unit

when the motor carriage is running along

the track.

` Do not drive through the door until it has

opened completely.

` Never stand under the opened door.

Danger due to optical radiation!

Looking into an LED at short range for an

extended period may cause optical glare.

This may temporarily reduce vision. This may

cause serious or fatal accidents.

` Never look directly into an LED.

NOTE

• In the case of a door without lintel or without lintel

panel, programming should be carried out as described

in Chapter "9.3 Carrying out manual initial opera-

tion". Otherwise, the operator may be damaged.

• Do not use a metal object to set the DIP switches,

because this may damage the DIP switches or

the circuit board.

Use a suitable tool to set the DIP switches, such as

DÀDWWKLQSODVWLFREMHFW

• Objects in the movement area of the door may be

jammed and damaged.

Objects must not be in the range of movement of

the door.

INFORMATION

• The control unit detects a short-circuit between

chain and track and then switches the operator off.

• If a photocell is used, it must not be actuated

when starting the programming.

If a photocell is used as a frame photocell, move

the door to the centre position.

9.2 Carrying out automatic initial

operation

Before initial operation, read this chapter with special

care to ensure that you can make the adjustments to

the operator safely and optimally.

WARNING

Danger of entrapment!

If the force setting is too high, persons or animals in the movement area of the door may be

trapped and pulled along with the door. Severe

injuries or death may result.

` The force setting is relevant to safety and

must be carried out by a TXDOL¿HGVSHFLDOLVW.

` You must proceed with extreme caution if you

check and if necessary adjust the force setting.

` Please note that the operator may only be

operated if a non-hazardous force value has

been set.

` Select the force setting low enough to

eliminate any danger of injury caused by

the closing force.

INFORMATION

• During initial operation:

ņ Stay in the garage, particularly when

programming.

ņ Obstacle recognition is not yet coordinated to

the door and is in the programming phase.

• Programming can be carried out via a handheld

transmitter or an external button.

• The limit stop can also be retrofitted.

27

9. Initial operation

For compliance with EN 13241-1, before initial operation,

the door type must be selected and set on the motor

carriage with the DIP switch.

The factory setting of the DIP switches on the motor carriage is "OFF," which is then applicable for sectional

doors. The motor carriage has an automatic force setting.

The motor carriage memorises the required force during

the door OPEN and CLOSE movements and stores it

when the end position has been reached.

RADIO

4

3

2

1

ON

RESET

RADIO

4

3

2

1

ON

RESET

Fig. 1

1. Open the cover of the motor carriage. Set the

DIP switches on the motor carriage depending on

the door.

RADIO

4

3

2

1

ON

RESET

2

1

RESET

Fig. 2.1

STATUS

7KHVWDWXV/('RIWKHPRWRUFDUULDJHÀDVKHVJUHHQ

¹⁄

¹⁄

Fig. 3

3. After the operator has been connected to the voltage

supply, its first movement after a pulse is always door

OPEN.

On the preprogrammed handheld transmitter, press

button 1 briefly; see also the separate instructions for

the "Handheld transmitter."

The motor carriage moves slowly to the door OPEN

end position and automaticallyVZLWFKHVRႇDW

the limit stop.

Fig. 2

2. Compare the existing power supply with the type

plate.

Connect the operator with the mains voltage.

28

rt

sw

STATUS

BUZZER

SENSO

MEMO

Fig. 3.1

The operator lighting blinks.

Fig. 4

9. Initial operation

4. Press button 1 on the handheld transmitter again

briefly.

The motor carriage moves slowly in the door

CLOSE direction.

The operator lighting blinks.

7KHPRWRUFDUULDJHVZLWFKHVRႇautomatically

when it reaches the factory-set closing force at

the door CLOSE end position.

7KHRSHUDWRUOLJKWLQJEOLQNVLQDGLႇHUHQWVHTXHQFH

Fig. 5

5. Press button 1 on the handheld transmitter briefly

(<1 second) to save the end position.

7KHRSHUDWRUOLJKWLQJEOLQNVEULHÀ\LQDIDVW

sequence.

The operator automatically starts its

programming process

≈2x

Fig. 5.1

The motor carriage moves automatically to the door

OPEN end position again and programs the required

operating force.

The motor carriage automatically moves to the door

CLOSE end position.

If necessary, the motor carriage moves over the path

several times for programming with a greater door

weight.

The motor carriage automaticallyPRYHVEULHÀ\LQ

the door OPEN direction to program the soft run.

The door automatically returns to the door CLOSE

end position.

The motor carriage automatically moves to the door

OPEN end position.

The LEDs of the operator lighting remain steady.

6. The function of the emergency release must be

checked in the door CLOSE end position. Unlocking

must be possible.

Operator is programmed and ready for use.

INFORMATION

• The motor carriage stops if the door is difficult to

move. The door mechanism must be checked;

see Chapter "9.3 Carrying out manual initial

operation".

• It may be necessary to adjust the end positions;

see Chapter "9.5 Mechanical adjustment of

the end positions".

• The force setting must be checked after installation of the operator; see Chapter "12.1 Testing

obstacle detection".

9.3 Carrying out manual initial operation

In the case of doors without lintel or without lintel panel,

programming should be carried out manually. To do this,

carry out steps 1.–3. In Chapter "9.2 Carrying out

automatic initial operation" and then the steps below:

1. Press button 1 on the handheld transmitter briefly.

The door begins to move towards the door CLOSE

end position.

2. Before the door reaches the door CLOSE end posi-

tion, press button 1 on the handheld transmitter again

briefly.

The door stops.

3. To approach the desired end position for door

CLOSE, press and hold button 1 on the handheld

transmitter until the motor carriage moves briefly.

Release button 1 on the handheld transmitter.

4. The process can be repeated until the desired end

position is reached.

5. Press button 1 on the handheld transmitter briefly

(<1 second) to save the door CLOSE end position.

6. The door then starts the programming process; see

Chapter "9.2 Carrying out automatic initial oper-

ation", section "The operator automatically starts

its programming process".

9.4 Detecting obstacles during the force

programming run

If the door detects an obstacle during its first door CLOSE

movement and the force programming runs cannot be

completed, the door stops.

NOTE

• Check the movement range, mechanism, spring

tension and the weight balance to prevent damage to

the door system.

1. Press and hold button 1 on the handheld transmitter.

The motor carriagePRYHVEULHÀ\ and then moves

continuously in the door CLOSE direction until

the desired end position has been reached.

2. Release button 1 on the handheld transmitter.

3. Fine adjustment:

Press and hold button 1 on the transmitter until

the motor carriage moves briefly.

29

9. Initial operation

Release button 1 on the handheld transmitter.

3.1 The process can be repeated until the desired end

position is reached.

Press button 1 on the handheld transmitter briefly

(< 1 second) to save the door CLOSE end position.

The motor carriage starts the automatic force

programming runs for the door OPEN end position.

The door starts the automatic force programming

runs for the door CLOSE end position.

If an obstacle is detected again, the motor carriage stops

and reverses a short distance.

1. Press and hold button 1 on the handheld transmitter.

The motor carriage starts without jerking, because

the end position of the door is already saved.

The motor carriage moves to the end position.

2. Release button 1 on the handheld transmitter.

3. Press button 1 on the handheld transmitter briefly.

Automatic force programming runs start again.

On completion of the force programming runs,

the motor carriage automatically moves to

the door OPEN end position.

The LEDs of the operator lighting remain steady.

4. The function of the emergency release must be

checked in the door CLOSE end position. Unlocking

must be possible.

Operator is programmed and ready for use.

9.5 Mechanical adjustment of the end

positions

Increasing the closing pressure of the end

position for door CLOSE

Fig. 1

1. Loosen the screw on the limit stop and move

the limit stop a few millimetres towards door CLOSE.

Re-tighten the screw.

2. The function of the emergency release must be

checked in the door CLOSE end position. Unlocking

must be possible.

Reducing the closing pressure of the end

position for door CLOSE

30

Fig. 1

1. Loosen the screw on the limit stop and move the limit

stop a few millimetres towards door OPEN. Re-tighten

the screw.

NOTE

• Do not push the door all the way to the mechanical

stop. This is because otherwise, the operator will pull

the door against the mechanical stop. This will apply

tension to the door and it may be damaged.

A clearance of about 30 mm is required.

9. Initial operation

9.6 Attaching information sign and

warning signs

Fig. 1.1 Attach sticker near the stationary control or control unit

Fig. 1.2 Attach sticker on door panel

1. Attach the warning signs and information sign at

a cleaned and degreased point:

• far from moving parts

• near the stationary control or control unit

• at eye level at a highly visible section of the door leaf

2. Carry out obstacle detection, see Chapter

"12.1 Testing obstacle detection".

Initial operation is complete.

31

10. Connections and special functions of the motor carriage

10.1 Motor carriage circuit board

MAGNET

2

1

gn

OSE

8K2

CH1

CH2

CH3

CH4

STATUS

wh

10

SENSO

LASER

MOTION

9 8

BUZZER

15

17

16

14

RADIO

4

3

2

1

ON

RESET

br

+12V

+12V

13 12

11

Fig. Motor carriage circuit board, complete version*

Overview of connection options

1 LED, CH 1–4, red

Display for radio channel

2 MAGNET slot*, green, 2-pin

Lock terminal

LIMIT

ws

gn

ws

+

-

rt

sw

SOMMER

Antriebs- u.

Funktechnik GmbH

LW-A

MEMO

USART

7

6

PCXXXXXXX

10 LASER slot*, white, 2-pin

Parking position laser terminal

11 MOTION slot*, white, 3-pin

Terminal for movement sensor

435

3 LIMIT slot, blue, 2-pin

Limit switch terminal (OPEN)

12.1 Terminal for safety contact strip 8k2*

12.2 Terminal for OSE safety contact strip*

4 Circuit board label 13 Terminal for wicket door safety device

potential-free

5 LEDs, operator lighting 12/13 Terminal DC12 V, max. 100 mA

6 MEMO slot*

14 Status LED, green

Memo terminal

7 USART slot

15 Reset button, green

Interface