Somat SPC-30S, SP-30 Installation Manual

OPERATION/INSTRUCTION MANUAL

AND

GENERAL INFORMATION

165 Independence Court, Lancaster, PA 17601

Telephone 717-397-5100 Fax 717-291-0877

1-800-23-SOMAT (1-800-237-6628)

SAFETY

INSTRUCTIONS

READ THE MANUAL COMPLETELY BEFORE ATTEMPTING TO OPERATE THE UNIT.

HIGH VOLTAGE! DO NOT PERFORM ANY REPAIRS TO MOTORS OR CONTROL SYSTEMS WITHOUT TURNING OFF THE MAIN POWER.

ALWAYS TURN THE MAIN POWER OFF AND LET ALL MOTORS COME TO A STANDSTILL BEFORE DOING ANY MAINTENANCE ADJUSTMENTS OR CLEANING OF THE UNIT.

BEFORE STARTING, BE SURE ALL PERSONNEL ARE CLEAR OF MOVING PARTS.

KNOW LOCATION AND FUNCTIONS OF ALL START/STOP BUTTONS AND SAFETY SWITCHES.

DURING PERIODIC MAINTENANCE, CHECK ALL SAFETY SWITCHES TO BE SURE THEY ARE OPERATING PROPERLY.

DO NOT REMOVE OR ALTER GUARDS.

DO NOT REMOVE SAFETY LABELS. IF LABELS ARE MISSING OR DESTROYED, CONTACT FACTORY FOR REPLACEMENT.

DO NOT OBSTRUCT ELECTRICAL PANELS OR PUSH BUTTONS.

GOOD HOUSEKEEPING IS THE MOST IMPORTANT SAFETY PROCEDURE.

IMPORTANT

The Instruction Manual is important to the proper operation and maintenance of your SOMAT® System. It should be readily available to those who are responsible for the operation and performance of

the SOMAT® equipment.

Due to the high cost of preparing replacement manuals, a charge will be made for duplicate manuals beyond those furnished with the original shipment.

For ordering duplicate manuals, please contact:

SERVICE DEPARTMENT

SOMAT COMPANY

165 Independence Court, Lancaster, PA 17601 USA Telephone 717-397-5100, Fax 717-291-0877 1-800-23-SOMAT (1-800-237-6628)

Internet: www.somatcompany.com Parts: parts@somatcompany.com

SOMAT COMPANY

LIMITED WARRANTY

SOMAT COMPANY warrants each new product manufactured by it to be free from defects in material and workmanship under normal use and service, which does not include normal wear of parts, ("normal use and service", with respect to Pulpers, Presses, water Hydra-Extractors, Waste Handling and Processing Systems, shall mean the handling only of waste items of the types listed in the SOMAT® Quotation or Sales Order therefore and within the LIMITATIONS THEREIN set forth), its obligation under this warranty being limited to repairing or replacing any part or parts thereof, free of charge INCLUSIVE of labor to remove and replace, f.o.b. factory from which shipped, which shall, within one year from initial start-up of the SOMAT® System or from date of original installation of the product if not a system, or eighteen months from date of shipment, whichever shall first occur, be returned to SOMAT® at the factory from which shipped, with transportation charges prepaid, and which SOMAT's examination shall disclose to its satisfaction to have been thus defective. This warranty shall not apply to any product or part which shall have been repaired or altered by any person not employed or retained by SOMAT®, so as in the judgment of SOMAT® to affect its operation and reliability, nor which has been installed, operated, or maintained contrary to SOMAT® OPERATION or PREVENTIVE MAINTENANCE INSTRUCTION MANUALS or to other written instructions or drawings approved by SOMAT®, nor which has been subject to misuse, negligence, or accident. This warranty shall not apply should the SOMAT® System be initially started up without a duly authorized SOMAT® representative present.

EXCEPT AS HEREIN EXPRESSLY STATED, NO WARRANTY, EXPRESS, IMPLIED OR BY LAW, (INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), IS MADE BY SOMAT; AND IN ANY EVENT SOMAT’S LIABILITY, WHETHER IN CONTRACT, TORT, STRICT LIABILITY, OR UNDER ANY WARRANTY, OR OTHERWISE, SHALL NOT EXCEED THE PURCHASE PRICE RECEIVED BY IT AND SHALL IN NO EVENT INCLUDE ANY CONSEQUENTIAL, INCIDENTAL, PUNITIVE OR OTHER SPECIAL DAMAGES.

NO CHANGE IN THIS WARRANTY AND LIMITATION OF LIABILITY AND NO SUBSTITUTE THEREFORE (WHETHER INCORPORATED IN A PURCHASE ORDER OR OTHERWISE) SHALL BE EFFECTIVE UNLESS SPECIFICALLY SET FORTH IN A WRITTEN INSTRUMENT SIGNED BY AN OFFICER OF SOMAT®.

rev. 08/01/00

GENERAL DESCRIPTION

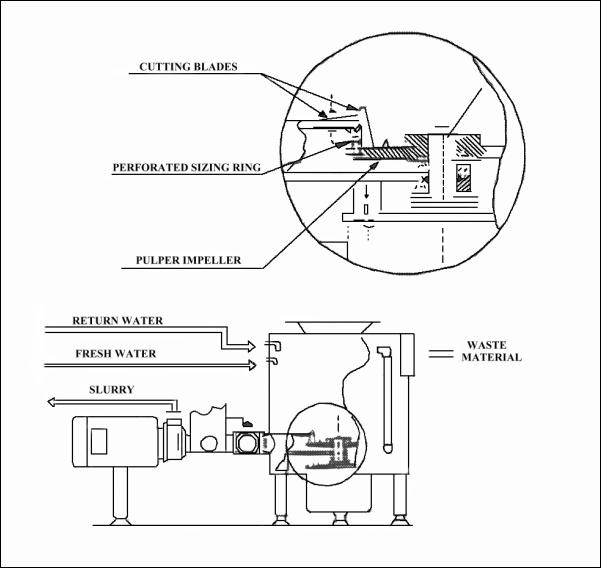

The SOMAT® system prepares solid waste materials for disposal by transforming the materials, with water, into a pulp. This transformation takes place in a unit called a Pulper which is designed to pulp all forms of paper, plastic, foil, and food waste. The waste material is fed manually or automatically to the Pulper. The continual down flow of water and the rotation of the Pulper impeller create a strong vortex action which pulls the waste down against the cutting blades of the impeller. The resultant slurry is then forced through a perforated stainless steel Sizing Ring surrounding the impeller.

Items such as tin cans, silverware, nails, bolts and other non-palpable objects which may be inadvertently fed into the Pulper are separated out of centrifugal force and gravity and are caught in the junk box within the Pulper. This junk box should be emptied manually during cleanup.

TYPICAL PULPER

The SOMAT® System is designed to pump the mixture of macerated solids and water, called a slurry, to the HydraExtractor® where the slurry is reduced to a semi-dry pump. Within the Hydra-Extractor®, the slurry is carried by a helicoid screw within a perforated tubular screen. The water passes through the screen and is pumped back to the pulping unit. The solids continue up the helicoid screw to a compression chamber or plug area where additional water is removed by extrusion. The solids in this area are called the plug. This plug is broken up at the Hydra-Extractor® discharge opening by a cutter and the pulp then falls out of the discharge chute. This system is capable of reducing the volume of average non-compacted waste by approximately 80 percent.

TYPICAL HYDRA-

EXTRACTOR®

The system is powered by electric motors with the associated controls housed in Som-A-Trols (electric control panels). Since, in the course of operation, some water is absorbed by the pulp, fresh make-up water is supplied to the Pulper automatically through a solenoid valve which responds to a water level sensor.

In addition to the basic system as discussed to this point, numerous additional items of equipment may or may not be required to comprise a specific system. The inside rear cover of this manual is provided with a pocket which contains Installation Drawings. These drawings show the equipment comprising your system.

DEFINITIONS – GENERAL

1.Pulper - SOMAT® device that contains an impeller and security ring to grind solid waste. The resultant mixture of waste particles and water is called slurry.

2.Hydra-Extractor® - Inclined screw-type press for removing transport water from pulp.

3.Slurry - A water solution containing a low percentage of suspended solids.

4.Pulp - Semi-dry solid from which transport water has been extracted.

5.Som-A-Trol® - Electrical control panel, including motor starters and sequencing controls for automatic operation of the SOMAT® system.

6.Slurry Pump - Specially designed pump used to transport slurry from a SOMAT® Pulper to Hydra-Extractor®.

7.Return Pump - Specially designed pump used to return water from Hydra-Extractor® to SOMAT® Pulpers.

8.Water Level Control - a pressure-sensitive device that automatically controls the water level in the SOMAT® Pulper.

9.Chemical Additive Pump - A proportioning type Additive pump that adds defoaming, deodorizer, and/or buffering solutions to the process water.

*10. Pulp Screw Conveyor - Transport screw used for conveying pulp to a point remote

from Hydra-Extractor®.

*11. Distributing Type Pulp Screw Conveyor - Transport screw with discharge ports throughout its length for even distribution in large haul-away containers.

*12. Water economizing tank. Reservoir for return water used in large systems.

*Optional equipment which may not be furnished with your Pulping System.

DEFINITIONS – COMPONENTS

SOMAT® PULPER:

1.Tank - Pulping or grinding chamber of the SOMAT® Pulper.

2.Impeller - Rotating metal plate with Cutting Blades and Tungsten Carbide teeth which defiber and pulp the waste, and along with the Security Ring provides a shearing action for non-fibrous waste.

3.Security Ring - Perforated stainless steel ring surrounding the impeller through which all slurry must pass after waste is pulped. Dimensions of Security Ring holes controls particle size of materials leaving the Pulper.

4.Junk Box - Chamber in bottom of tank that segregates non-pulpable materials from tank.

HYDRA-EXTRACTOR®:

1.Screw - Vertical helix which lifts and compresses solids from the slurry and permits water to drain off by gravity.

2.Screen - Mesh screen that surrounds the screw, through which water drains off.

3.Plug - Mass of pulp extending beyond last helix of the screw. The force required to extrude the plug squeezes additional water from pulp.

4.Brush - Nylon brush attached to edge of screw helix which serves to clean the screen.

5.Plug Cutter - Adjustable portion of Hydra-Extractor® screw which controls moisture content of the pulp.

GENERAL:

1.Throttling Valve - Full ported valve used to control water flow.

2.Timer - Electrical device used to automatically shut down the SOMAT® System at a predetermined time.

3.Fresh Water Solenoid - Electric valve used to control fresh water make-up to the SOMAT® System.

4.Motor Operated Valve - (MOV) Electric valve used to control return water flow in the system.

OPERATING INSTRUCTIONS

TYPICAL STARTUP AND OPERATING PROCEDURE - The following startup procedures must be followed prior to operating the System:

1. Close drain valve on the Pulper.

2Check to ensure that the main power switch of the SOM-A-TROL® panels is in the "ON" position.

3.Unlock the Pulper "STOP' button. Turn "EMPTY-RUN" Selector Switch to the "RUN" position if so equipped. The Pulper will begin to fill with water. When the water has reached the prescribed level, press the Pulper "START" button and wait until there is a continuous flow of return water. Then begin feeding waste to the Pulper either manually or by starting waste down the flushed trough, if so equipped.

Waste Feeding Instructions - Best results are obtained if the Pulper is fed waste at a UNIFORM RATE. Under normal conditions, waste may be fed to the Pulper as long as a strong vortex is maintained in the tank. If waste is fed too fast the vortex will diminish to a point where it will no longer pull the material into the impeller for efficient grinding.

Do not "starve" the Pulper. If no waste is available for disposal, TURN THE PULPER OFF. Don't "slug" the Pulper for short periods of time with excessive feeding. Overloading interferes with the grinding process and takes longer to dispose of a given quantity of waste than if the machine is fed at a

UNIFORM RATE.

When shutting down the Pulper for short periods, it is not necessary to run the Pulper until all the waste has been pumped out of the tank. Run the Pulper for a few minutes to thin down the slurry and then shut off the machine.

SHUTDOWN PROCEDURES - The following shutdown procedures must be followed prior to performing necessary cleaning and maintenance duties.

1.Allow the Pulper to operate approximately fifteen minutes after the last waste has been fed.

2.With the Pulper still running, turn the Selector Switch to the "EMPTY" position, if so equipped, permitting the system to be pumped down automatically. The Pulper will stop when the shutdown timer has timed out.

3.Press the "STOP" button and engage the locking attachment. Turn off the electrical power at both the Pulper and Hydra-Extractor®.

4.Open the drain valve on the Pulper.

5.Refer to the applicable Pulper and Hydra-Extractor® maintenance sections of this manual for daily, weekly and long term shutdown cleaning procedures and maintenance instructions.

SPECIAL OPERATING CONDITIONS - While applications vary widely the following conditions could occur and should be watched for:

A.Overfeeding - The SOMAT® Pulper is designed as a continuous process machine. In general, the feed rate should not exceed one tenth of the rated

hourly capacity in any six minute period. Exceeding this will cause the machine to bog down and operate under its rated capacity.

B.Foaming - this is caused by contaminants in the water, or by certain materials in the

waste, such as glue in corrugated cardboard. Add a defoamer, such as Somat® Neutro Plus, or any of a number of commercial preparations.

C.Corrosion - If the water and/or the waste is acidic or alkaline, use a buffering agent to neutralize the water. Regular testing is recommended, since rapid corrosion due to acidic or alkaline conditions can result in costly repairs.

D.Freezing - All equipment and piping should be protected from freezing. Insulation and heating cable are often used where equipment is exposed.

E.Non-Pulpables - The SOMAT® Pulper is designed to handle a limited amount of non-

pulpable material. The lighter items are eventually ground and the heavier material is discharged into the junk box. However, the SOMAT® Pulper is not designed to handle heavy masonry materials or tramp iron and other materials of this nature. Such items will break away the cutting teeth and seriously reduce the machine's ability to handle material of any kind.

OPERATING INSTRUCTIONS

Occasionally, the amounts of non-pulpables may become excessive and, due to their slower processing rate, create a material build-up in the Pulper tank. Safely stop the Pulper, scoop out the non-pulpable matter, and then re-start the Pulper.

F.Wear - Moving parts, and their mating surfaces, will wear with service, especially those which are part of cutting mechanisms. Your routine maintenance and inspection, as described in the applicable component sections, will disclose which parts are wearing and provide an indication as to when replacement will be necessary. The maintenance plan should include pre-ordering of spare parts and scheduled replacement.

CLEANING INSTRUCTIONS

After feeding waste to the SOMAT® System has been completed for the day, the equipment should be thoroughly cleaned. The cleaning operation requires only a few minutes daily and, if properly done, will keep the machine free of odor and at top-operating efficiency. A regular cleaning program will eliminate costly maintenance and unsatisfactory operation.

CLEANING THE PULPER:

With the system properly shut down, in accordance with the System "Shutdown Procedures", perform the following:

TURN THE MAIN POWER

OFF BEFORE DOING ANY

MAINTENANCE OR

CLEANING.

1. Clean the Junk Box of non-pulpable material

CAUTION

THERE MAY BE BROKEN GLASS PRESENT

IN THE PULPER

2.Wash the interior of the Pulper shell with a hose, suitable brush, detergent and deodorant or other cleaning solution. Exercise particular care in cleaning the underside of the upper shell flange.

3.Wipe down the equipment exterior.

4.Close the drain valve. The Pulper is now ready to be started as soon as the Som-A- Trol® panel is turned on.

5.Remove the standpipe by unthreading the vertical 12” nipple from the elbow near the base of the pulper tank. Clean the standpipe and nipple by suitable means. Reinstall the standpipe.

CLEANING THE HYDRA-EXTRACTOR®:

1.With high pressure hose, wash down screens and interior walls of Hydra-Extractor® housing. If necessary, a long-handled brush can be used.

B.Long Term Shut Down Procedure - If the Pulper is to remain idle for a relatively long period (four weeks or more), special procedures should be taken to protect the equipment. These procedures are as follows:

1.Perform the daily cleaning procedure, then circulate a solution of a cleaning and disinfecting agent through the lines to combat bacteria growth and odor.

2.Remove the impeller from the Pulper, (refer to Pulper Maintenance Section). Do not remove the mechanical seal. Using a hose and brush, thoroughly clean the mechanical seal, slurry chamber, and the underside of the impeller.

CLEANING COMPOUNDS

The ideal cleaning compounds available for use with SOMAT® equipment, combine four important functions: detergency, disinfection, pH buffering and odor counter action.

In order to help our customers overcome the problem of selecting chemicals for use with their SOMAT® System, we offer the chemicals that we believe will best meet their needs.

We offer:

SOMAT® NEUTRO PLUS (72000)

Designed for use in the SOMAT® System to keep it clean, to deodorize, and to reduce grease build-up. This is an industrial strength product. The surfactants in this detergent/deodorant are bio-degradable.

SOMAT® DEFOAMER (73000)

A neutral, liquid silicone emulsion specifically designed for suppressing and controlling undesirable foam. This is an industrial strength product. The surfactants in this defoamer are bio-degradable.

Dilution: Five (5) parts water to one (1) part defoamer.

Please direct all orders, whether by mail or by phone, to our SERVICE DEPARTMENT. If you have any questions, please feel free to contact us at this office.

CAUTION – CORROSION

In isolated cases, depending on local water supply characteristics and operating conditions, the

mild steel components in the SOMAT® System can be subject to corrosion.

This condition is generally associated with food service machines. Corrosion may occur in steel piping, pulping tanks, fittings, and pump parts. Corrosion works very rapidly and the pitting of metal parts can cause early failure, requiring extensive repairs.

Acid corrosion is caused by low pH level in the system water, but it can be easily controlled by the addition of commercial grade soda ash. Soda ash is readily available and costs only a few cents a pound in bulk lots.

Alkaline Corrosion is caused by high pH level in the system water. While damages done by this condition does not occur as quickly as that of Acid corrosion, neutralizing agents should be added to the system to help eliminate potential corrosion problems. The proper pH level of the system water should be maintained at a minimum of 7.0 and not over 8.5. The pH level can be determined by a simple test using litmus paper indicators.

GENERAL TEST AND TREATMENT PROCEDURE

1.After the system is in operation under normal load conditions, dip litmus test paper in grinder slurry (or return water from Hydra-Extractor® and determine whether the liquid is acid or alkaline.

2.Neutral water is neither acidic nor alkaline and will have a pH of 7.0. An acid liquid will have a pH of less than 7.0, as is indicated by the color change of the litmus paper.

3.If the liquid is neutral (a pH of 7.0) no treatment is required.

NOTE: SOMAT Company cannot be responsible for failure due to corrosion resulting from improper water conditions.

ILLUSTRATED PARTS BREAKDOWN

PURPOSE:

The Illustrated Parts Breakdown in each section provides information on components, assemblies and detail parts for identification, determination of needed replacement parts and an illustration of assembly and disassembly relationships.

GROUP ASSEMBLY PARTS LIST:

The Group Assembly Parts List consists of those components, assemblies and detail parts which comprise the specific piece of equipment. Each assembly listed is followed immediately by its detail parts, properly indented thereunder to show their relationship to the assembly; for example, a part listed under indenture "2" is a component of the assembly listed under indenture "1" immediately above it. Items used to attach parts or assemblies to each other designated "(ATTACHING PARTS)" and are listed immediately following the item or items they attach: The symbol ---*--- denotes the end of attaching parts. The quantity required or "REQ" column lists the quantity of the item required in one assembly of which it is a component. It is, therefore, not necessarily the total quantity of the part required in the complete equipment. Items indicated by an asterisk (*) in the "REQ" column are recommended spare parts to be kept on hand by the customer. The term "Ref", if required, denotes that the assembly has been previously listed in the breakdown and at that point reflected the quantity required. The 5-digit numbers shown in parenthesis (00000) are SOMAT® part numbers and should be used when ordering parts.

PARTS ORDERING INFORMATION:

Include the following information when ordering parts.

1.The correct, complete description of the part required (see Group Assembly Parts List.)

2.The serial number of the unit on which the part is to be used.

3.Complete shipping instructions.

The above information will help expedite the delivery of your needed parts.

When ordering spare or replacement parts, direct the above information to:

SERVICE DEPARTMENT

SOMAT COMPANY

165 Independence Court, Lancaster, PA 17601 Telephone 717-397-5100 * Fax 771-291-0877 1-800-23-SOMAT (1-800-237-6628)

SPC-30S PULPER

DESCRIPTION

GENERAL - The SOMAT® Pulper:

The main body of the Pulper is composed of the shell weldment and the slurry chamber, Figure 1 (A). A drive motor (B) is mounted to the underside of the slurry chamber weldment. The drive shaft is fitted with a mechanical seal (C) that prevents slurry liquid from leaking into the drive motor. Above the mechanical seal an impeller assembly (D) is keyed to the drive shaft. The impeller is surrounded by a perforated stainless steel sizing ring (E). This ring controls the particle size of the solids entering the slurry chamber. A stainless steel junk box (F) is located inside the Pulper shell. The entire Pulper assembly is supported by stainless steel legs (G) with threaded adjustable feet.

FIGURE 1. TYPICAL PULPER GENERAL ARRANGEMENT

PERIODIC MAINTENANCE AND INSPECTION

These procedures consist primarily of regularly scheduled cleaning and inspections. The time intervals cited are based on normal use of the SOMAT® unit; approximately six hours per day, seven days per week. Equipment operating more than this or in severe service will require more frequent inspection/maintenance.

Particular attention should be paid to cutting blades and grinding teeth as these will sustain the highest degree of wear. Continued adherence to these inspections will provide adequate lead time when ordering spare parts, thereby minimizing unnecessary and costly equipment downtime.

PREVENTIVE MAINTENANCE INSPECTION SCHEDULE

|

DAILY |

WEEKLY |

MONTHLY |

QUARTERLY |

|

|

|

|

|

1. GENERAL |

|

|

|

|

|

|

|

|

|

a. Check shell and slurry |

|

|

|

|

chamber for wear. |

|

|

X |

|

b. Check exterior finish for |

|

|

X |

|

corrosion. |

|

|

|

|

c. Check airline for leaks and |

|

X |

|

|

clogs. |

|

|

|

|

d. Check standpipe for leaks and |

|

X |

|

|

clogs. |

|

|

|

|

2. IMPELLERS |

|

|

|

|

a. Check impeller blades for |

|

X |

|

|

wear. |

|

|

|

|

b. Check stationary blades for |

|

X |

|

|

wear. |

|

|

|

|

c. Check impeller teeth for wear. |

|

X |

|

|

|

|

|

|

|

d. Check security ring for wear. |

|

X |

|

|

|

|

|

|

|

3. DRIVE

a. |

Check seal for leakage. |

X |

|

|

|

|

|

|

|

|

|

b. |

Check bearings for noise and |

|

|

|

X |

|

wear. |

|

|

|

|

|

|

|

|

|

|

TROUBLE SHOOTING AND ANALYSIS

The following table provides probable causes and appropriate corrective action relative to system malfunctions.

SYMPTOM |

POSSIBLE CAUSE |

CORRECTIVE ACTION |

|

Not enough |

1. |

Water make up |

1. Open valve. |

water in Pulper. |

|

shut-off valve |

|

|

|

closed. |

2. Straighten the line to remove kinks, bends or |

|

|

|

|

|

2. |

Obstructed air line |

pinches. Blow high pressure air or water through |

|

|

from air pump to |

the line from pump end to rid the obstruction or |

|

|

Pulper shell |

replace with new line. Clean the standpipe (see |

|

|

(pinched, kinked or |

section 5) of internal buildup. |

|

|

blocked). |

3. The pressure switch controls the circuit to the |

|

|

|

|

|

|

|

solenoid valve. Too low a pressure setting would |

|

3. |

Misadjusted |

tend to hold the solenoid valve closed too long |

|

|

pressure switch. |

preventing water from entering the Pulper. Adjust |

|

|

|

the pressure switch to correct the problem. |

4.Check for loose electrical connections. If the valve plunger is stuck or the coil is burned out, replace with a new valve.

4.Faulty operation of solenoid valve (see equipment

schematic for |

5. Remove strainer from fresh water line. Clean |

location). |

housing interior and clean strainer element with a |

|

stiff bristled brush and replace. |

5.Plugged Strainer (see equipment schematic for location).

SYMPTOM |

POSSIBLE CAUSE |

|

CORRECTIVE ACTION |

||

|

|

|

|

|

|

Too much water |

1. |

Leakage from air |

1. |

Tighten air line connections. Check for leakage |

|

in Pulper. |

|

line. |

|

through splits or cuts in the |

line; if present, replace |

|

|

|

|

the line. |

|

|

2. |

Misadjusted |

2. |

The pressure switch controls the circuit to the |

|

|

|

pressure switch. |

|

solenoid valve. Too high a pressure setting would |

|

|

|

|

|

tend to hold the solenoid valve open too long |

|

|

|

|

|

letting too much water into the Pulper. Adjust the |

|

|

|

|

|

pressure switch to correct the problem. |

|

|

3. |

Faulty operation |

3. Repair or replace solenoid valve. |

||

|

|

|

|

||

|

|

at valve. (see |

|

|

|

|

|

equipment |

|

|

|

|

|

schematic for |

|

|

|

|

|

location.) |

4. |

If pump fails there is no back pressure on the |

|

|

|

|

|||

|

4. |

Air pump failure. |

|

switch contacts that hold the |

solenoid open. |

|

|

|

|

Replace pump. |

|

|

5. |

Overflow fitting and |

5. Clean fitting and line. |

|

|

|

|

|

|

||

|

|

line clogged. |

|

|

|

|

|

|

|

|

|

SYMPTOM |

|

POSSIBLE CAUSE |

|

CORRECTIVE ACTION |

|

|

|

|

|

Pulper operates but |

1. |

Plugging of sizing ring. |

1. |

Check stationary blades and ears. If dull, |

pulping rate is low. |

|

|

|

replace. Refer to Pulper maintenance |

|

|

|

|

section. Check water level control - it |

|

|

|

|

may be adjusted too low. See previous |

|

2. |

Worn or missing |

|

section. |

|

2. |

Refer to Pulper maintenance section for |

||

|

|

impeller blades. |

||

|

3. |

Worn or missing |

|

replacement procedure. |

|

3. |

Adjust or replace blades in accordance |

||

|

|

stationary blades. |

||

|

|

|

|

with Pulper maintenance section of |

|

4. |

Excessive foaming. |

|

manual. |

|

4. Add a defoamer or any other suitable |

|||

|

|

|

||

|

5. |

Sluggish vortex due to: |

|

commercial preparation. (See Section 5.) |

|

5. |

(See below) |

||

|

|

a. Too little water in |

||

|

|

|

a. See Previous section. |

|

|

|

Pulper. |

|

|

|

|

b. Overload of waste. |

|

b. Revise waste feeding rate (see |

|

|

|

|

|

|

6. |

Clogged or worn pump. |

|

Feeding Instructions, Section 4). |

|

6. See pump section for require |

|||

|

|

|

||

|

|

|

|

corrective action. |

|

7. |

Clogged slurry lines. |

7. Check individual cleanouts for loss of |

|

|

|

|

||

|

|

|

|

pressure to locate blockage. Remove |

|

|

|

|

blockage. |

|

|

|

|

|

SYMPTOM |

|

POSSIBLE CAUSE |

CORRECTIVE ACTION |

|

|

|

|

Pulper stops |

1. |

Overloaded by feeding. |

1. Revise the waste feeding rate; see Waste |

frequently. |

|

|

Feeding Instructions, Section 4. |

|

2. |

Rotation of impeller |

2. Inspect cutter blades and impeller for |

|

|

restricted by buildup of |

breakage. Follow repair and replacement |

|

|

foreign material |

instructions as specified in The Pulper |

|

|

around circumference |

Maintenance Section. |

|

|

or underneath of |

If necessary, remove impeller in accordance |

|

|

impeller. |

|

|

|

|

with Component Removal and Replacement |

|

|

|

in the Pulper Maintenance Section. |

|

|

|

Thoroughly clean away debris from the |

|

|

|

impeller and sizing ring. |

|

|

|

3. Check electrical wiring diagram (supplied |

|

3. |

Incorrect or defective |

with the system equipment) for proper |

|

|

fuses or thermal |

amperage requirements. Replace incorrect or |

|

|

overloads. |

defective parts as specified. |

|

|

|

|

Loading...

Loading...